Page 1

YASKAWA AC Drive-J1000 Option

RS-485

MEMOBUS/Modbus

Interface

Technical Manual

Type SI-485/J

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

J1000オプションユニット

MEMOBUS

オプションユニット

取扱説明書

形式 SI-485/J

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

J1000

MANUAL NO. TOBP C730600 33A

通信

Page 2

This Page Intentionally Blank

Page 3

Contents

1 PREFACE AND SAFETY . . . . . . .5

2 RECEIVING . . . . . . . . . . . . . . . . . . 9

3 PRODUCT OVERVIEW . . . . . . . .10

4 OPTION COMPONENTS. . . . . . .11

5 INSTALLATION PROCEDURE . .14

6 RELATED DRIVE PARAMETERS . . .21

7 TROUBLESHOOTING. . . . . . . . .24

8 SPECIFICATIONS . . . . . . . . . . . .26

9 YASKAWA LOCATIONS. . . . . . . 28

10 REVISION HISTORY . . . . . . . . .29

TOBPC73060033A RS-485 Interface Technical Manual 3

Page 4

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any

means, mechanical, electronic, photocopying, recording, or

otherwise, without the prior written permission of Yaskawa. No

patent liability is assumed with respect to the use of the

information contained herein. Moreover, because Yaskawa is

constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this

manual. Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

4 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 5

1 Preface and Safety

J1000

1 Preface and Safety

◆ Applicable Documentation

The following manuals are available for the RS-485 Interface

Option:

Option Unit

Yaskawa AC Drive - RS-485

MEMOBUS/Modbus Interface Option

Technical Manual

Read this manual first.

The Technical Manual is packaged with the

RS-485 Interface Option and contains a basic

overview of wiring, settings, functions, and

fault diagnoses.

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 5

Page 6

1 Preface and Safety

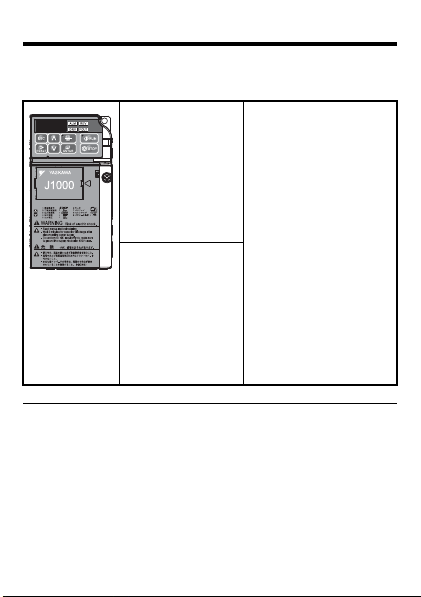

Yaskawa Drive

U.S. and Europe:

Yaskawa AC Drive

J1000 Quick Start

Guide

Other Areas:

Yaskawa AC Drive

J1000 Installation &

Start-Up Manual

Yaskawa AC DriveJ1000

Technical Manual

To obtain instruction

manuals for Yaskawa

products access these

sites:

U.S.: http://

www.yaskawa.com

Europe: http://

www.yaskawa.eu.com

Japan: http://www.emechatronics.com

Other areas: contact a

Yaskawa representative.

For questions, contact the

local Yaskawa sales

office or the nearest

Yaskawa representative.

◆ Terms

Note: Indicates a supplement or precaution that

does not cause drive damage.

Drive: Yaskawa AC Drive - J1000 Series

Option:

6 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Yaskawa AC Drive - J1000 RS-485 MEMOBUS/

Modbus Interface

Page 7

1 Preface and Safety

DANGER

W ARNING

◆ Registered Trademarks

• Company names and product names listed in this manual are

registered trademarks of those companies.

◆ Supplemental Safety Information

Read and understand this manual before installing, operating, or

servicing this option unit. The option unit must be installed

according to this manual and local codes.

The following conventions are used to indicate safety messages in

this manual. Failure to heed these messages could result in serious

or possibly even fatal injury or damage to the products or to related

equipment and systems.

Indicates a hazardous situation, which, if not avoided, will

result in death or serious injury.

Indicates a hazardous situation, which, if not avoided, could

result in death or serious injury.

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 7

Page 8

1 Preface and Safety

CAUTION

NOTICE

Indicates a hazardous situation, which, if not avoided, could

result in minor or moderate injury.

Indicates an equipment damage message.

8 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 9

2 Receiving

Blade width

3.0 mm max.

0.6 mm max.

Blade thickness

2 Receiving

◆ Receiving

Confirm the packaging after receiving the RS-485 Interface

Option. If the wrong model is received or the RS-485 Interface

Option does not function properly, contact your supplier.

Components packaged with the option:

• The RS-485 MEMOBUS/Modbus Interface (SI-485/J)

• Technical manual

◆ Tool Requirements

Use a flat-blade screwdriver with the dimensions below for

installation (See page 12) or removal (See page 13) of the option

cover and RS-485 Interface Option.

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 9

Page 10

3 Product Overview

3 Product Overview

◆ About this product

The RS-485 MEMOBUS/Modbus Interface is used to connect the

drive to a network using the MEMOBUS protocol.

By installing this option unit, the user can operate the drive with a

PLC or some other type of control device.

• Drive operation

• Monitor drive operational status

• Change drive parameter settings

◆ Applicable Models

The RS-485 Interface Option is used with these Yaskawa drive

models.

Drive Drive Software Version <1>

CIMR-JABA ≥1010

<1> See “PRG” on the drive nameplate for software version

number.

10 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 11

4 Option Components

4 Option Components

A

BC

A – DIP Switch

S2

B–Terminal

Block

C–Option

Model

Number

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 11

DE

D – Drive

Connector

E – Connection

Tab s

Page 12

4 Option Components

◆ Dimensions

The installed Option Interface adds 23.8 mm (0.94 in) to the total

depth of the drive.

8.8(0.35)

12 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

15(0.59)

mm(in)

Page 13

4 Option Components

S– S+ IG R– R+

Top View

Bottom View

◆ Terminal Block

Ter min al Name Description

1 R+ Receive (+)

2 R- Receive (-)

3 IG Shield Ground

4 S+ Send (+)

5S-Send (-)

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 13

Page 14

5 Installation Procedure

DANGER

NOTICE

5 Installation Procedure

◆ Section Safety

Electrical Shock Hazard

Disconnect all power to the drive, before servicing.

Failure to comply will result in death or serious injury.

Wait at least one minute after all indicators are off. The drive

has internal capacitors that remain charged even after main

power supply is disconnected. The drive charge LED will

extinguish when the DC bus voltage is below 50 Vdc. Measure

drive DC bus voltage to confirm safe level.

Damage to Equipment

Properly connect the connectors.

Failure to comply may prevent proper operation and possibly

damage equipment.

14 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 15

5 Installation Procedure

◆ Attaching the Interface Option

1. Insert a flat-blade screwdriver into the

opening as shown in the diagram below to

remove the option cover from the drive.

2. Insert the connector on the back of the

interface into the CN5 port and click into

place.

Note: The RS-485 Interface Option has three additional

connection tabs that must also click into place to

properly mount the option.

Flat-blade

screwdriver

CN5 port

Connection

tabs

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 15

Page 16

5 Installation Procedure

Underside of

Interface Option

Flat-blade

screwdriver

◆ Removing the Interface Option

1. Insert a flat-blade screwdriver into the

small opening between the drive and the

Interface Option, and gently apply

pressure to the connection tabs as shown.

16 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 17

5 Installation Procedure

Drive

SI-485/J

S2

DIP Switch

ON

R+

R–

IG

S+

S–

R+

R–

IG

S+

S–

PLC

◆ Connecting Peripheral Devices to the

RS-485 Interface Option

PLC (Master)

Drive Drive Drive

◆ Wiring Diagram

■ RS-485 Communications (2-wire)

Single Drive Wiring

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 17

Page 18

5 Installation Procedure

Drive

SI-485/J

S2

DIP Switch

ON

R+

R–

IG

S+

S–

Drive

SI-485/J

S2

R+

R–

IG

S+

S–

Drive

SI-485/J

S2

R+

R–

IG

S+

S–

R+

R–

IG

S+

S–

PLC

DIP Switch

OFF

DIP Switch

OFF

Multiple Drive Wiring

Note: • Set termination resistor switch S2, located

18 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

on the SI-485/J Option Interface to the ON

position for the end drive on the network.

• Set parameter H5-07 = 1 for each drive on

the network that is using RS-485

communications.

Page 19

5 Installation Procedure

Drive

SI-485/J

S2

DIP Switch

ON

PLC

R+

R–

IG

S+

S–

R+

R–

IG

S+

S–

■ RS-422 Communications (4-wire)

Single Drive Wiring

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 19

Page 20

5 Installation Procedure

R+

R–

IG

S+

S–

PLC

Drive

SI-485/J

DIP Switch

OFF

S2

R+

R–

IG

S+

S–

Drive

SI-485/J

S2

R+

R–

IG

S+

S–

Drive

SI-485/J

S2

R+

R–

IG

S+

S–

DIP Switch

OFF

DIP Switch

ON

Multiple Drive Wiring

Note: • Set termination resistor switch S2, located

20 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

on the SI-485/J Option Interface to the ON

position for the end drive on the network.

• Set parameter H5-07 = 0 for each drive on

the network that is using RS-422

communications.

Page 21

6 Related Drive Parameters

6 Related Drive Parameters

No. Name Description Default

Selects the frequency

reference input source.

Frequency

b1-01

Reference

Selection 1

Run Command

b1-02

Selection 1

Drive Slave

H5-01

Address

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 21

0: Operator - Digital preset

speed d1-01 to d1-17.

1 : Terminals - Analog input

terminal A1 or A2.

2: MEMOBUS/Modbus

communications

3: Option PCB

Selects the run command

input source.

0: Operator - RUN and

STOP keys on the digital

operator.

1 : Digital input terminals

2: MEMOBUS

communications

Selects drive slave number

(address) for MEMOBUS/

Modbus terminals R+, R-,

S+, S-. Cycle power for the

setting to take effect.

1

1

1F

Page 22

6 Related Drive Parameters

No. Name Description Default

Selects the baud rate for

MEMOBUS/Modbus

terminals R+, R-, S+ and S-.

Cycle power for the setting

Communication

H5-02

Speed Selection

Communication

H5-03

Parity Selection

Stopping

Method After

H5-04

Communication

Error

22 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

to take effect.

0: 1200 bps

1: 2400 bps

2: 4800 bps

3: 9600 bps

4: 19200 bps

5: 38400 bps

Selects the communication

parity for MEMOBUS/

Modbus terminals R+, R-,

S+ and S-. Cycle power for

the setting to take effect.

0: No parity

1: Even parity

2: Odd parity

Selects the stopping method

when a communication

time-out fault (CE) is

detected.

0: Ramp to stop

1: Coast to stop

2: Fast-stop

3: Alarm only

3

0

3

Page 23

6 Related Drive Parameters

No. Name Description Default

Drive Transmit

H5-06

Wait Time

RTS Control

H5-07

Selection

Run Command

H5-12

Method

Selection

MEMOBUS/

Modbus

frequency

H5-13

reference and

frequency

monitor unit

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 23

Set the wait time between

receiving and sending data.

Selects “request to send”

(RTS) control:

0: Disabled - RTS is always

on.

1: Enabled - RTS turns on

only when sending.

0 : FWD/STOP, REV/STOP

Method

1: RUN/STOP, FWD/REV

Method

0: 0.1 Hz / 1

1: o1-03 based

2: 100% / 30000

3: 0.1% / 1

10 ms

1

0

0

Page 24

7 Troubleshooting

7 Troubleshooting

Problems with the option interface may trigger an operator error.

Refer to the J1000 Technical Manual for all other errors.

◆ Fault

LED Operator

Display

MEMOBUS/Modbus Communication

CE

Error

Cause Possible solutions

Data not received

within the CE

detection time

limit set in

parameter H5-09.

This is possibly

due to noise or a

improperly

connected

communication

cable.

24 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

⇒Check for improper wiring or loose

cables.

⇒Make sure the unit is properly grounded.

⇒Reconnect leads running to the main

circuit in the drive.

⇒Make sure the DIP switch for terminal

resistance is set appropriately.

Minor Fault Name

Page 25

7 Troubleshooting

LED Operator

Display

Run Command Selection Error

oPE05

The Run command selection parameter b102 is set to 3 but no option unit is installed.

Cause Possible solutions

Frequency

reference is

assigned to an

option (b1-01 = 2)

that is not

connected to the

drive.

The Run command

is assigned to an

option (b1-02 = 2)

that is not

connected to the

drive.

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 25

⇒Make sure that parameters b1-01 and b102 are set properly.

⇒Reconnect the option unit to the drive.

Minor Fault Name

Page 26

8 Specifications

8 Specifications

◆ Option Specifications

Item Specification

Model

Number

Storage/

Installation

Area

Ambient

Temperature

Humidity 95% RH or less with no condensation

Storage

Temperature

Altitude 1000 m or less

26 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

SI-485/J

Indoors (an area free from oil mist and dust)

-10 to +50°C

-20 to +60°C allowed for short-term transport of

the product

Page 27

8 Specifications

◆ Network Specifications

Item Specification

Interface RS-422, RS-485

Communication

Speeds Available

Communication

Parameters

Protocol MEMOBUS/Modbus (using RTU mode only)

Maximum

Number of

Slaves

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 27

Data length 8 bit (fixed)

Parity

Stop bit 1 bit (fixed)

31 drives (using RS-485)

1.2; 2.4; 4.8; 9.6;

19.2; 38.4 kbps

Select even, odd, or

none

Page 28

9 Yaskawa Locations

(Address revision No.: 10-10-6)

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: 81-930-25-3844 Fax: 81-930-25-4369

http://www.yaskawa.co.jp

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4502 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brasil

Phone: 55-11-3585-1100

Fax: 55-11-5581-8795

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstrasse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

Fax: 44-1236-458182

http://www.yaskawa.co.uk

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Yeoungdungpo-gu, Seoul, 150-877, Korea

Phone: 82-2-784-7844

Fax: 82-2-784-8495

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

Fax: 65-6289-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, 17F, Harbour Ring Plaza, Shanghai, 200001, China

Phone: 86-21-5385-2200

Fax: 86-21-5385-3299

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

Fax: 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone: 886-2-2502-5003

Fax: 886-2-2505-1280

9 Yaskawa Locations

28 YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Manual

Page 29

10 Revision History

MANUAL NO. TOBP C730600 33A

Published in Japan December 2008 08-1

Date of

publication

Date of original

publication

Revision

number

1

123

4

10 Revision History

The revision dates and numbers of the revised manuals are given

on the bottom of the back cover.

Date of

Publication

January 2008 – – First edition

December 2008 Chapter 5

April 2010 Chapter 9 Revision: Address

September 2010 Chapter 9 Revision: Address

July 2011

YASKAWA ELECTRIC TOBPC73060033A RS-485 Interface Technical Ma nual 29

Rev.

Section Revised Content

No.

Correction:

Wiring diagram of RS-422

communications (4-wire)

Front cover,

back cover

Revision: Format

Page 30

YASKAWA AC Drive-J1000 Option

RS-485

MEMOBUS/Modbus

Interface

Technical Manual

J1000オプションユニット

MEMOBUS

オプションユニット

取扱説明書

Any inquiries related to the product can be directed to the address listed at chapter 9.

この製品に関するお問い合わせ先については,9章お問い合わせ先をご覧ください。

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure to

follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2008-2011 YASKAWA ELECTRIC CORPORATION. All rights reserved.

本製品の最終使用者が軍事関係であったり,用途が兵器などの製造用である場合には,「外国為替及び外国貿易法」の定める輸出規制の対象となることがあります

ので,輸出される際には十分な審査及び必要な輸出手続きをお取りください。

製品改良のため,定格,仕様,寸法などの一部を予告なしに変更することがあります。

通信

YASKAWA ELECTRIC CORPORATION

MANUAL NO. TOBP C730600 33A

Published in Japan July 2011 08-1

4 -0

Loading...

Loading...