Page 1

DX100

1 of 764

MAINTENANCE MANUAL

FOR EUROPEAN STANDARD

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN- INSTRUCTIONS

DX100 INSTRUCTIONS FOR EUROPEAN STANDARD

DX100 OPERATOR’S MANUAL

DX100 MAINTENANCE MANUAL FOR EUROPEAN STANDARD

The DX100 operator’s manual above correspond to specific usage.

Be sure to use the appropriate manual.

Part Number: 171768-1CD

Revision: 0

MANUAL NO.

RE-CHO-A109

2

Page 2

DX100 European

2 of 764

Standard Maintenance

171768-1CD

Copyright © 2014, Yaskawa America, Inc. All Rights Reserved.

ii

RE-CHO-A109

Page 3

171768-1CD

MANDATORY

CAUTION

3 of 764

DX100 European

Standard Maintenance

• This instruction manual is intended to explain mainly on the

mechanical part of the DX100 for the application to the actual

operation and for proper maintenance and inspection. It describes

on safety and handling, details on specifications, necessary items

on maintenance and inspection, to explain operating instructions

and maintenance procedures. Be sure to read and understand this

instruction manual thoroughly before installing and operating the

manipulator.

• General items related to safety are listed in Section 1: Safety of the

DX100 Instructions. To ensure correct and safe operation, carefully

read the DX100 Instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers

or shields removed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications.

• If such modification is made, the manual number will also be

revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product's warranty.

iii

RE-CHO-A109

Page 4

DX100 European

DANGER

WARNING

CAUTION

MANDATORY

PROHIBITED

NOTE

4 of 764

Standard Maintenance

Notes for Safe Operation

Read this manual carefully before maintenance or inspection of the

DX100.

In this manual, the Notes for Safe Operation are classified as “DANGER”,

“WARNING,” “CAUTION,” “MANDATORY,” or “PROHIBITED.”

171768-1CD

Indicates an imminent hazardous

situation which, if not avoided,

could result in death or serious

injury to personnel.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury to personnel.

Indicates a potentially hazardous

situation which, if not avoided,

could result in minor or moderate

injury to personnel and damage to

equipment. It may also be used to

alert against unsafe practices.

Always be sure to follow explicitly

the items listed under this

heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations. At any rate, be sure to follow these important items.

To ensure safe and efficient operation at all times, be sure

to follow all instructions, even if not designated as

“DANGER”, “WARNING” and “CAUTION”.

iv

RE-CHO-A109

Page 5

171768-1CD

WARNING

TURN

5 of 764

DX100 European

Standard Maintenance

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning on the power for the DX100.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operations.

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation. Always press an emergency stop button

immediately if there is a problem.

The emergency stop button is located on the right side of the

programming pendant.

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– Be sure to use a lockout device to the safeguarding when going

inside. Also, display the sign that the operation is being

performed inside the safeguarding and make sure no one closes

the safeguarding.

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons on the programming

pendant.

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

Figure 1: Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Figure 2: Release of Emergency Stop

v

RE-CHO-A109

Page 6

DX100 European

CAUTION

6 of 764

Standard Maintenance

171768-1CD

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the cabinet

of the DX100 after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX100 Instructions before operating the manipulator:

Definition of Terms Used Often in This Manual

The MOTOMAN manipulator is the YASKAWA industrial robot product.

The manipulator usually consists of the controller, the programming

pendant, and manipulator cables.

In this manual, the equipment is designated as follows:.

Equipment Manual Designation

DX100 Controller DX100

DX100 Programming Pendant Programming Pendant

Cable between the manipulator and the

controller

Manipulator cable

vi

RE-CHO-A109

Page 7

171768-1CD

PAGE

GO BACK

PAGE

GO BACK

7 of 764

DX100 European

Standard Maintenance

Descriptions of the programming pendant keys, buttons, and displays are

shown as follows:

Equipment Manual Designation

Programming

Pendant

Character

Keys

Symbol Keys The keys which have a symbol printed on them

Axis Keys

Numeric Keys

Keys pressed

simultaneously

Displays The menu displayed in the programming

The keys which have characters printed on

them are denoted with [ ].

ex. [ENTER]

are not denoted with [ ] but depicted with a

small picture.

ex. page key

The cursor key is an exception, and a picture is

not shown.

“Axis Keys” and “Numeric Keys” are generic

names for the keys for axis operation and

number input.

When two keys are to be pressed

simultaneously, the keys are shown with a “+”

sign between them.

ex. [SHIFT]+[COORD]

pendant is denoted with { }.

ex. {JOB}

Description of the Operation Procedure

In the explanation of the operation procedure, the expression “Select • • •”

means that the cursor is moved to the object item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or brand names for each company or

corporation. The indications of (R) and TM are omitted.

vii

RE-CHO-A109

Page 8

DX100 European

X81

PROGRAMMING PENDANT

PROPERLY.

CHECK ALL THE DOOR LOCKS

NJ3005-1

kVA

kVA

ERDR-

Average

Peak

NJ3053-1

Kammerfeldstr. 1, D-85391 Allershausen

Motoman

2-1 Kurosaki Shiroishi Yahatanishi-Ku Kitakyushu-City Fukuoka 806-0004 Japan

YASKAWA Electric corporation

Robot Serial No.

Robot Order No.

Robot Type

Type

Date/Signature

Serial No.

AC 400/415/440 V

Power Supply

Part No.

Motoman DX100

with power ON.

WARNING

Do not open the door

High Voltage

with power ON.

WARNING

High Voltage

Do not open the door

8 of 764

Standard Maintenance

Explanation of Warning Labels

• The label described below is attached to the manipulator.

Observe the precautions on the warning labels.

Failure to observe this caution may result in injury or damage to

equipment.

Refer to the manipulator manual for the warning label location.

Figure 3: Warning Labels

171768-1CD

DANGER

• The following warning labels are attached to DX100.

Observe the precautions on the warning labels.

Failure to observe this warning may result in injury or damage to

equipment.

Figure 4: Warning Label Location

viii

RE-CHO-A109

Page 9

171768-1CD

9 of 764

DX100 European

Standard Maintenance

Table of Contents

Table of Contents

1 Equipment Configuration ................................................................................................................ 1-1

1.1 Arrangement of Units and Circuit Boards .......................................................................... 1-1

1.1.1 Arrangement......................................................................................................... 1-1

1.1.1.1 Small-Capacity DX100 Controller............................................................ 1-1

1.1.1.2 Medium and Large-Capacity DX100 Controller....................................... 1-2

1.2 Power Flow ........................................................................................................................ 1-3

1.3 Signal Flow ........................................................................................................................ 1-4

2 Security System .............................................................................................................................. 2-1

2.1 Protection Through Security Mode Settings ...................................................................... 2-1

2.1.1 Security Mode ...................................................................................................... 2-1

2.1.1.1 Changing the Security Mode ................................................................... 2-6

2.1.2 User ID .................................................................................................................2-8

2.1.2.1 Changing a User ID................................................................................. 2-8

3 Inspections...................................................................................................................................... 3-1

3.1 Regular Inspections ........................................................................................................... 3-1

3.2 DX100 Inspections............................................................................................................. 3-2

3.2.1 Checking if the Doors are Firmly Closed .............................................................. 3-2

3.2.2 Checking for Gaps or Damage in the Sealed Construction Section..................... 3-2

3.3 Cooling Fan Inspections ................................................................................................... 3-3

3.4 Emergency Stop Button Inspections.................................................................................. 3-4

3.5 Enable Switch Inspections.................................................................................................3-4

3.6 Battery Inspections ............................................................................................................ 3-5

3.7 Power Supply Voltage Confirmation .................................................................................. 3-5

3.8 Open Phase Check............................................................................................................ 3-6

4 Preparation before Replacing Parts................................................................................................ 4-1

4.1 Creating a Check Program ................................................................................................ 4-3

ix

RE-CHO-A109

Page 10

171768-1CD

10 of 764

DX100 European

Standard Maintenance

5 Replacing Parts............................................................................................................................... 5-1

5.1 Replacing DX100 Parts...................................................................................................... 5-1

5.1.1 Replacing Parts of the CPU Unit .......................................................................... 5-2

5.1.1.1 Replacing the Battery ..............................................................................5-3

5.1.1.2 Replacing the Control Circuit Board (JANCD-YCP01-E)......................... 5-3

5.1.1.3 Replacing the CPS Unit (JZNC-YPS01-E) .............................................. 5-5

5.1.1.4 Replacing the Robot I/F Board (JANCD-YIF01-oE) ................................ 5-6

5.1.1.5 Replacing the I/O Unit (JZNC-YIU02-E) .................................................. 5-8

5.1.1.6 Replacing the Power Supply Contactor Unit (JZRCR-YPU01-o) ..........5-10

5.1.1.7 Replacing the Brake Control Board (JANCD-YBK01-1E)...................... 5-11

5.1.1.8 Replacing the Machine Safety Unit (JZNC-YSU01-1E)......................... 5-12

5.1.2 Replacing the SERVOPACK .............................................................................. 5-14

5.1.3 Replacing the Converter ..................................................................................... 5-18

5.1.4 Replacing the Major Axes Control Circuit Board (SRDA-EAXA01A).................. 5-22

Table of Contents

5.1.5 Checking and Replacing Fuses.......................................................................... 5-23

5.1.5.1 Power Supply Contactor Unit ................................................................ 5-23

5.1.5.2 I/O Unit .................................................................................................. 5-24

5.1.5.3 Machine Safety Unit .............................................................................. 5-25

5.1.5.4 Brake Control Board.............................................................................. 5-26

5.1.6 Interior Circulation Fan ....................................................................................... 5-27

5.1.6.1 Replacing the Interior Circulation Fan ................................................... 5-27

5.1.6.2 Replacing the Backside Duct Fan ......................................................... 5-28

5.2 DX100 Parts List .............................................................................................................. 5-29

5.3 Supplied Parts List ........................................................................................................... 5-31

5.4 Recommended Spare Parts............................................................................................. 5-32

6 Operations After Replacing Parts.................................................................................................... 6-1

6.1 Home Position Calibration .................................................................................................6-2

6.1.1 Home Position Calibration .................................................................................... 6-2

6.1.2 Calibrating Operation............................................................................................ 6-4

6.1.2.1 Registering All Axes at One Time............................................................ 6-4

6.1.2.2 Registering Individual Axes ..................................................................... 6-5

6.1.2.3 Changing the Absolute Data ................................................................... 6-7

6.1.2.4 Clearing Absolute Data............................................................................ 6-7

6.1.3 Manipulator Home Position................................................................................... 6-9

6.2 Position Deviation Check Using the Check Program....................................................... 6-10

6.3 Checking of the Check Program ...................................................................................... 6-11

6.3.1 Motion of the Check Program ............................................................................. 6-11

6.3.2 Checking of the Check Program......................................................................... 6-11

6.3.3 Home Position Data Correction .......................................................................... 6-12

x

RE-CHO-A109

Page 11

171768-1CD

11 of 764

DX100 European

Standard Maintenance

6.4 Setting the Second Home Position (Check Point) ................................ 6-13

6.4.1 Purpose of Position Check Operation ................................................................ 6-15

6.4.2 Procedure for the Second Home Position Setting (Check Point) ....................... 6-17

6.4.3 Procedure after the Alarm .................................................................................. 6-18

7 System Diagnosis ........................................................................................................................... 7-1

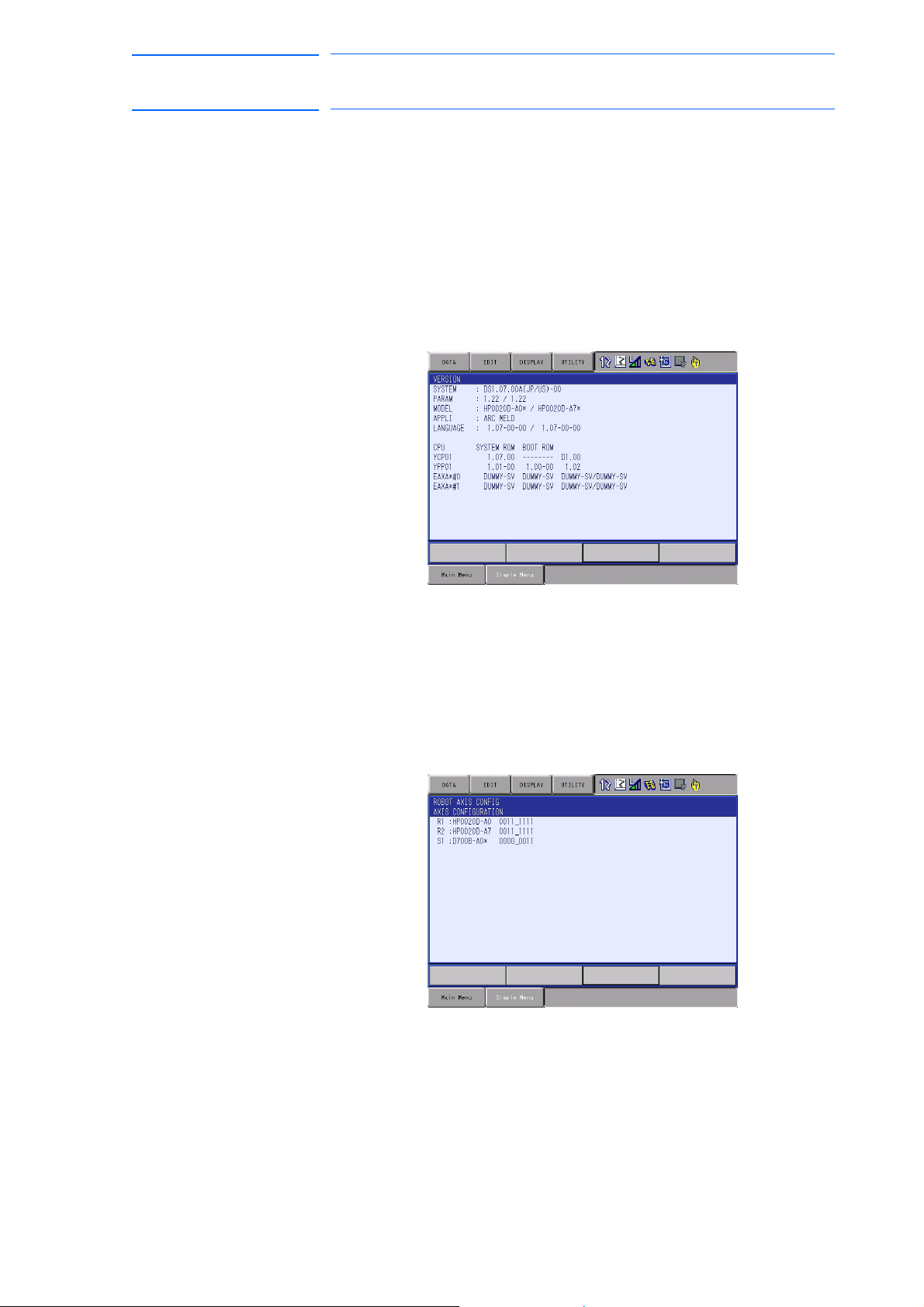

7.1 System Version.................................................................................................................. 7-1

7.2 Manipulator Model ............................................................................................................. 7-1

7.3 Input/Output Status............................................................................................................ 7-2

7.3.1 Universal Input ..................................................................................................... 7-2

7.3.1.1 Universal Input Window........................................................................... 7-2

7.3.1.2 Universal Input Simple Window............................................................... 7-2

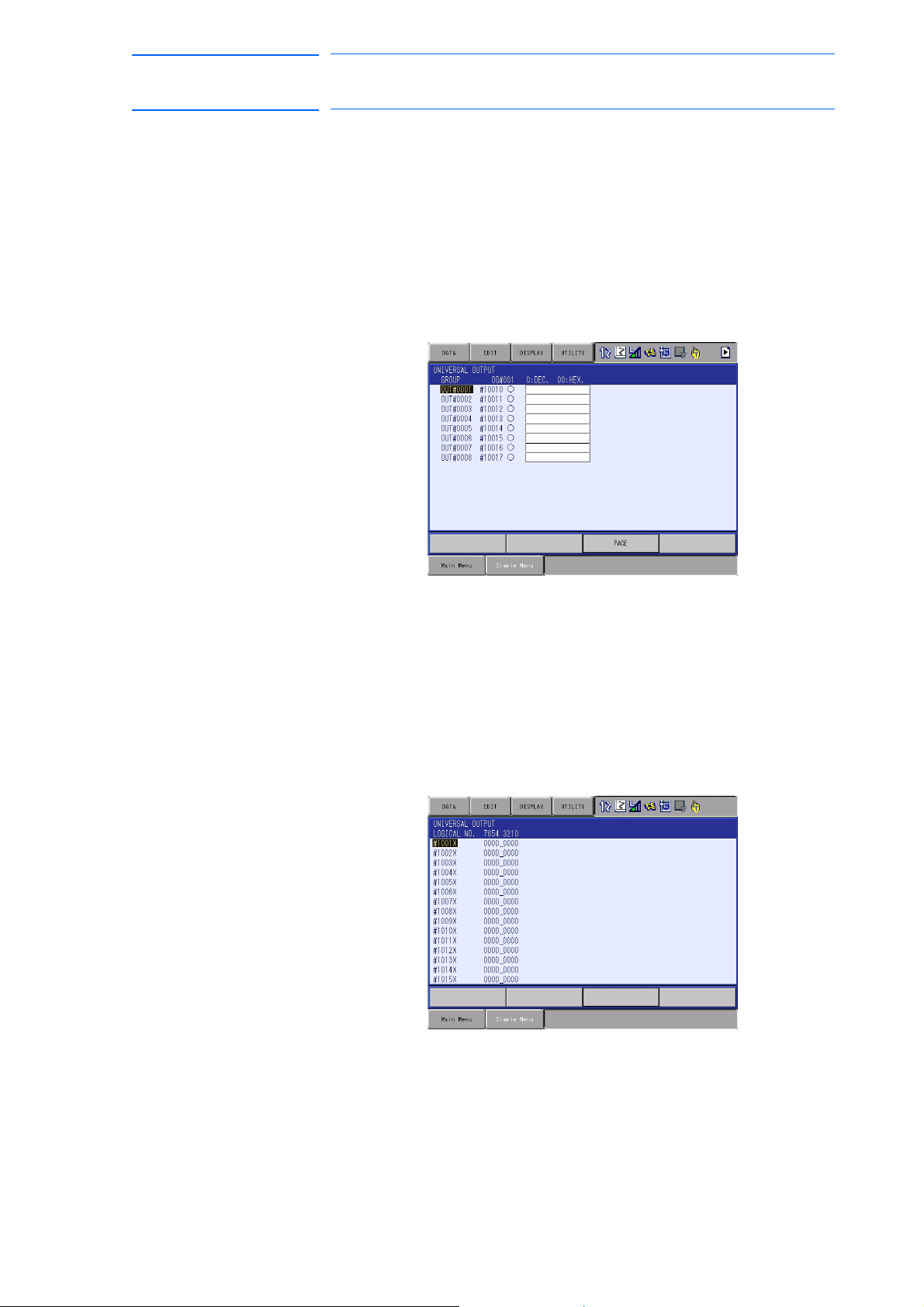

7.3.2 Universal Output................................................................................................... 7-3

7.3.2.1 Universal Output Window........................................................................ 7-3

7.3.2.2 Universal Output Simple Window............................................................ 7-3

7.3.2.3 Modifying the Output Status .................................................................... 7-4

Table of Contents

7.3.3 Specific Input ........................................................................................................ 7-5

7.3.3.1 Specific Input Window ............................................................................. 7-5

7.3.3.2 Specific Input Simple Window ................................................................. 7-5

7.3.4 Specific Output ..................................................................................................... 7-6

7.3.4.1 Specific Output Window .......................................................................... 7-6

7.3.4.2 Specific Output Simple Window .............................................................. 7-6

7.3.5 RIN Input .............................................................................................................. 7-7

7.3.5.1 RIN Input Window ................................................................................... 7-7

7.3.6 Signal Number Search ......................................................................................... 7-7

7.3.6.1 Direct Search on the Universal/Specified Input/Output Window ............. 7-8

7.3.6.2 Search from the Menu............................................................................. 7-9

7.3.7 Relay Number Search ........................................................................................ 7-10

7.3.7.1 Direct Search on the Universal/Specified Input/Output Window ........... 7-10

7.3.7.2 Search from the Menu........................................................................... 7-11

7.3.8 Modification of the Signal Name......................................................................... 7-12

7.3.8.1 Direct Modification on the Universal/Specified Input/Output Window ... 7-12

7.3.8.2 Modification from the Menu ................................................................... 7-13

7.4 System Monitoring Time Display ..................................................................................... 7-14

7.4.1 System Monitoring Time Display Window .......................................................... 7-14

7.4.2 Individual Window of the System Monitoring Time Display ................................ 7-15

7.4.3 Clearing the System Monitoring Time Display.................................................... 7-16

xi

RE-CHO-A109

Page 12

DX100 European

12 of 764

Standard Maintenance

7.5 Alarm History ...................................................................................................................7-17

7.5.1 Alarm History Window ........................................................................................ 7-17

7.5.2 Clearing the Alarm History.................................................................................. 7-18

7.6 I/O Message History ........................................................................................................7-19

7.6.1 I/O Message History Window ............................................................................. 7-19

7.6.1.1 Search ................................................................................................... 7-19

7.6.2 Clearing the I/O Message History....................................................................... 7-20

7.7 Position Data When Power is Turned ON/OFF ............................................................... 7-21

7.7.1 Power ON/OFF Position Window ....................................................................... 7-21

7.8 Current Position ............................................................................................................... 7-22

7.8.1 Current Position Window .................................................................................... 7-22

7.9 Servo Monitoring.............................................................................................................. 7-23

Table of Contents

171768-1CD

7.9.1 Servo Monitor Window........................................................................................ 7-23

7.9.1.1 Changing the Monitor Items .................................................................. 7-23

7.9.1.2 Clearing Maximum Torque Data............................................................ 7-25

8 Alarm............................................................................................................................................... 8-1

8.1 Outline of Alarm ................................................................................................................. 8-1

8.2 Alarm Display..................................................................................................................... 8-2

8.2.1 Displaying and Releasing Alarm........................................................................... 8-2

8.2.1.1 Releasing Alarms .................................................................................... 8-2

8.2.2 Special Alarm Display........................................................................................... 8-3

8.3 Display of Alarm Details..................................................................................................... 8-5

8.3.1 Parameter ............................................................................................................. 8-5

8.3.2 Display of Alarm Detail Window........................................................................... 8-5

8.3.3 Transition of Alarm Detail Window........................................................................ 8-7

8.4 Alarm Message List ........................................................................................................... 8-8

9 Error ............................................................................................................................................... 9-1

9.1 Error Message List............................................................................................................. 9-1

9.1.1 System and General Operation ............................................................................9-2

9.1.2 Editing................................................................................................................... 9-6

9.1.3 Job Defined Data .................................................................................................. 9-7

9.1.4 External Memory Equipment .............................................................................. 9-11

9.1.5 Concurrent I/O .................................................................................................... 9-16

9.1.6 Maintenance Mode ............................................................................................. 9-18

xii

RE-CHO-A109

Page 13

171768-1CD

13 of 764

DX100 European

Standard Maintenance

9.2 Particular Error Message ................................................................................................. 9-20

9.2.1 Message............................................................................................................. 9-20

9.2.1.1 Fatal Error ............................................................................................. 9-20

9.2.1.2 Application Transaction Error ................................................................ 9-20

9.2.1.3 Other Errors .......................................................................................... 9-21

9.2.2 When the Error is Indicated ................................................................................ 9-22

9.2.2.1 Fatal Error ............................................................................................. 9-22

9.2.2.2 Application Transaction Error ................................................................ 9-22

9.2.2.3 Other Errors .......................................................................................... 9-22

10 LED Indicator on Circuit Board .................................................................................................. 10-1

10.1 LED Indicator on YCP 01 Circuit Board......................................................................... 10-1

10.2 LED Indicator on Robot I/F Circuit Board ...................................................................... 10-2

10.3 7 SEG-LED Indicator ..................................................................................................... 10-3

10.3.0.1 7 SEG-LED Indicator Status (1-digit indication)

10.3.0.2 7 SEG-LED Indicator Status (4 digit-indication)

Table of Contents

of Each Unit at Error Occurrence ........................................................ 10-4

of Each Unit at Error Occurrence ....................................................... 10-5

11 Trouble Shooting When Alarm is not Displayed ......................................................................... 11-1

xiii

RE-CHO-A109

Page 14

DX100 European

JZRCR-YPU01-1

Interior circulation fan:

4715MS-22T-B5A-B00

194E-A40-1753-6G

JANCD-YIF01-1E

JZNC-YPS01-E

JZNC-YRK01-1E

JZNC-YIU02-E

JZNC-YSU01-1E

Backside duct fan:

4715MS-22T-B5A-B00

A

A

A-A’ Section

Inside View of Door

Front View

Inside the Controller

Back View

(without cover)

Power supply

contractor unit

CPS Unit

CPU Unit

Machine safety unit

Robot I/F board

I/O Unit

Main power switch

(-X18)

Robot system

input terminal

block

SERVOPACK:

Refer to the

following table.

JANCD-YBK01-1E

Brake control board

14 of 764

Standard Maintenance

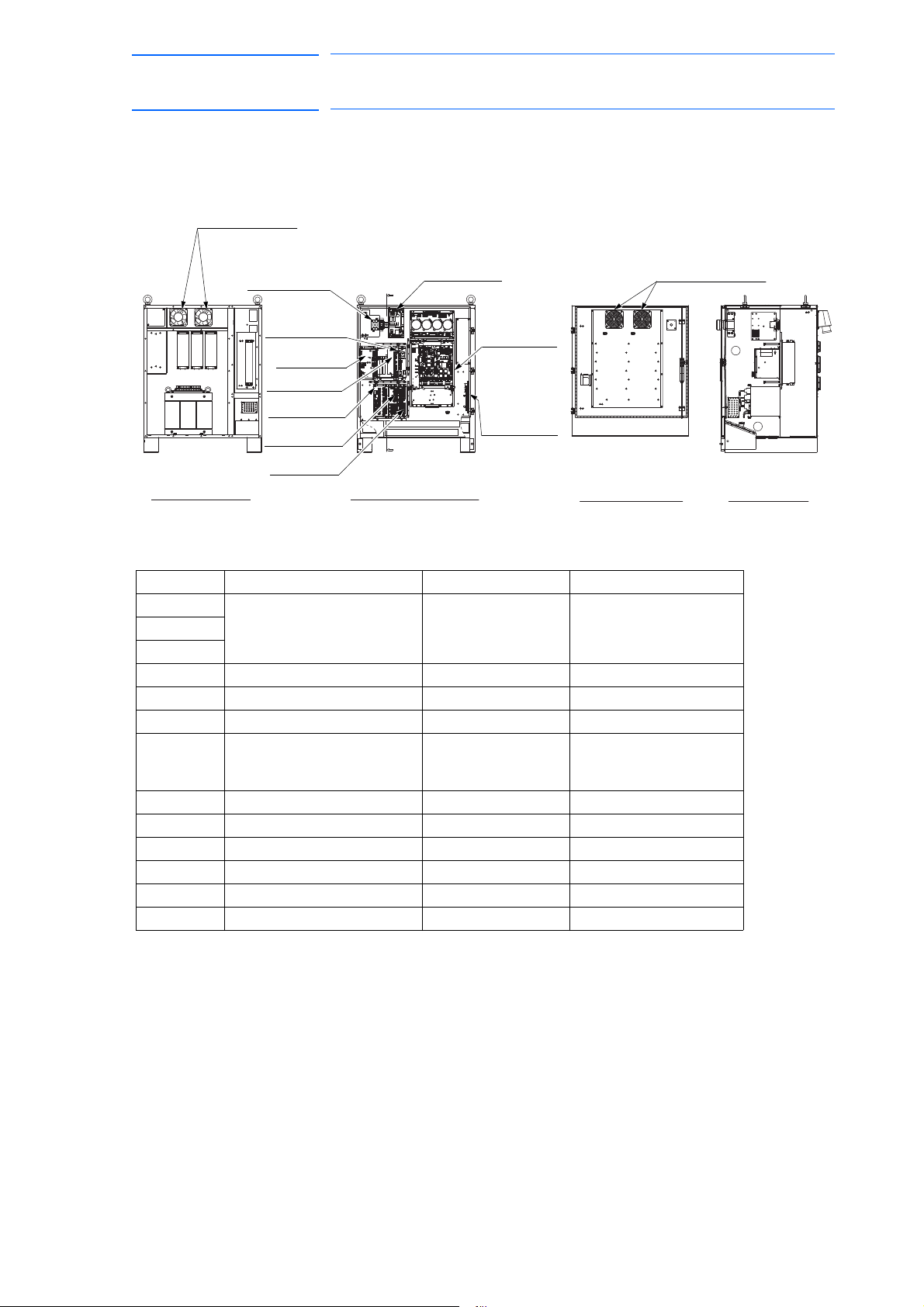

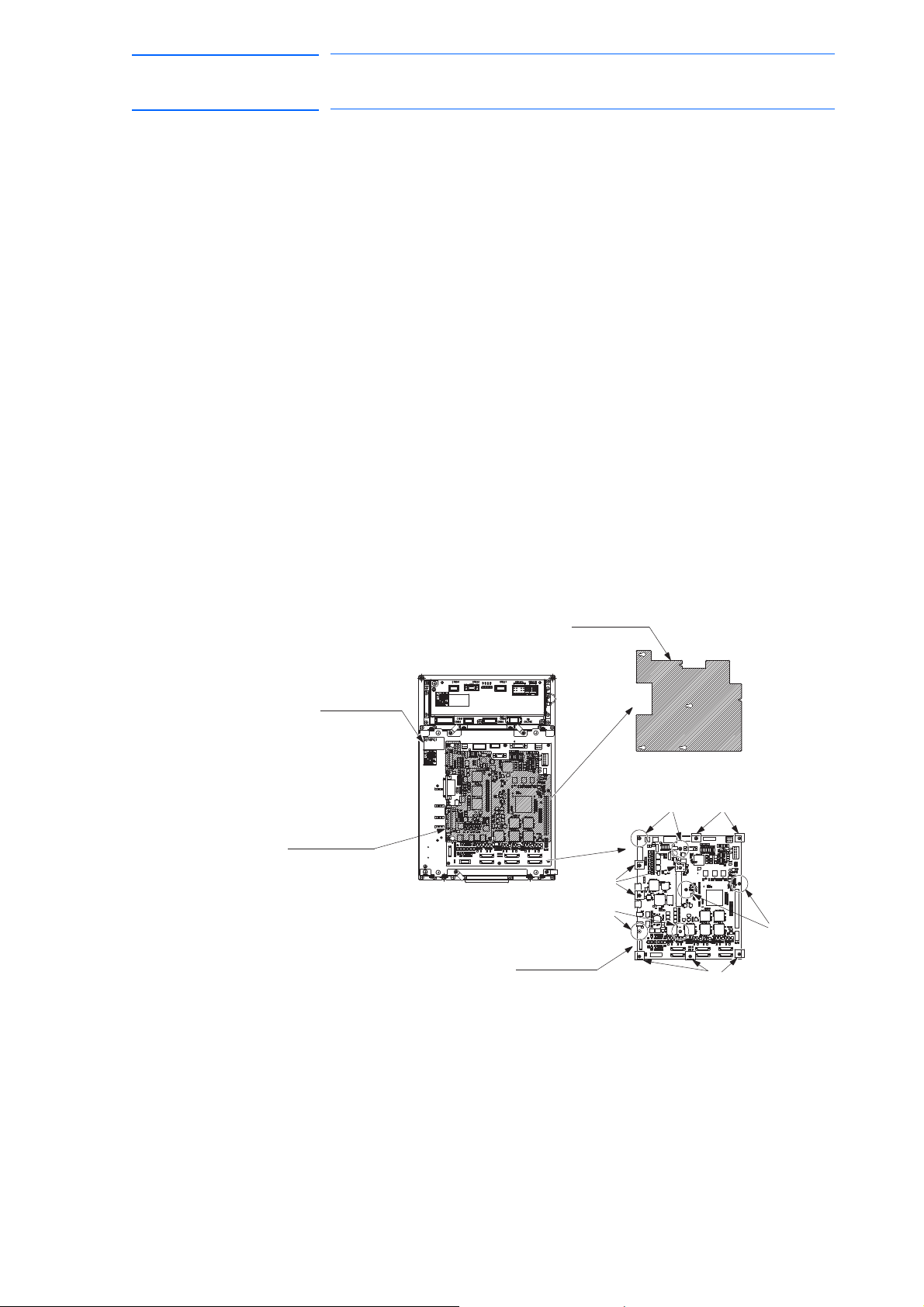

1 Equipment Configuration

1.1 Arrangement of Units and Circuit Boards

1 Equipment Configuration

The DX100 is comprised of individual units and modules (circuit boards).

Malfunctioning components can generally be easily repaired after a failure

by replacing a unit or a module. This section explains the configuration of

the DX100 equipment.

1.1 Arrangement of Units and Circuit Boards

1.1.1 Arrangement

The arrangements of units and circuit boards in small-capacity, mediumcapacity, and large-capacity DX100s are shown.

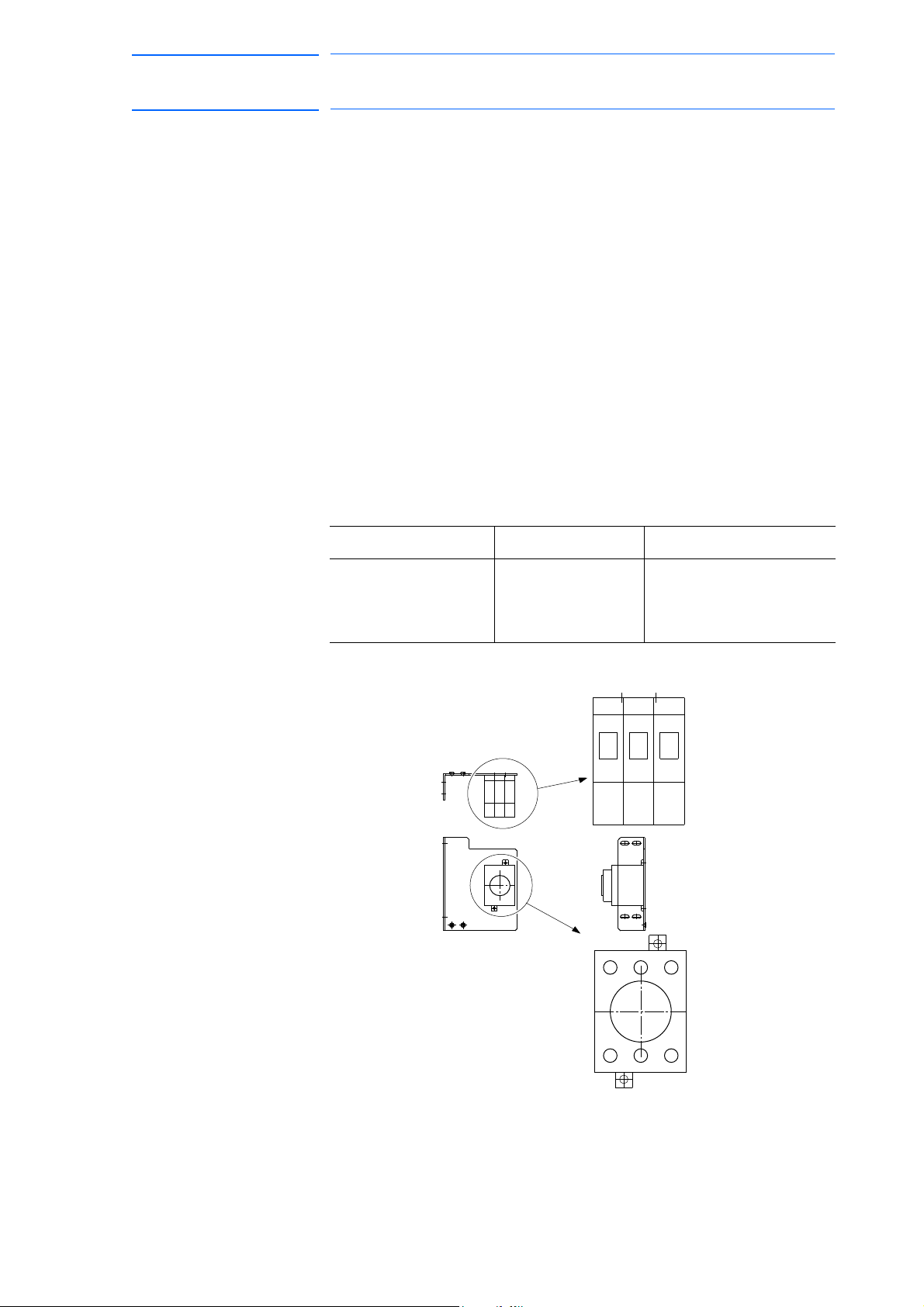

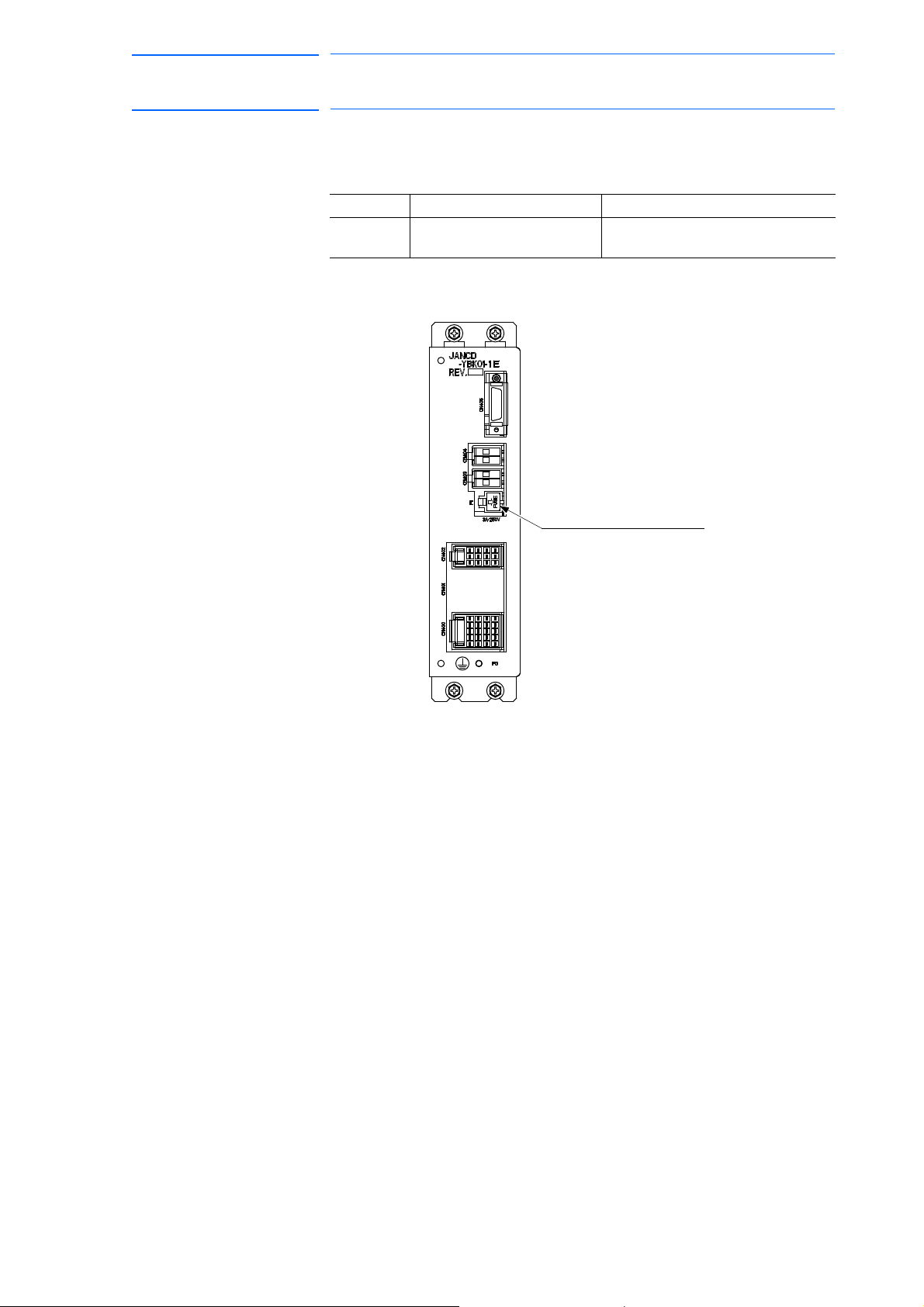

1.1.1.1 Small-Capacity DX100 Controller

Fig. 1-1: Configuration of Small Capacity DX100

171768-1CD

Model DX100 SERVOPACK (Converter Integrated)

MH5L ERDR-MH00005-E02 JZRCR-YSV01-11

MH5

MH6 ERDR-MH00006-E02 JZRCR-YSV02-11

MA1400 ERDR-MA01400-E02

JZRCR-YSV02-11

ERDR-MA01400-E04

(without JANCD-YEW01-E)

VA1400 ERDR-VA01400-E02

JZRCR-YSV02-31

ERDR-VA01400-E04

(without JANCD-YEW01-E)

MA1900 ERDR-MA01900-E02

ERDR-MA01900-E04

(without JANCD-YEW01-E)

HP20D ERDR-HP0020D-E02 JZRCR-YSV03-11

HP20D-6

HP20RD

JZRCR-YSV03-11

1-1

RE-CHO-A109

Page 15

171768-1CD

4715MS-22T-B5A-B00

A

A

JZRCR-YPU01-1

A-A’ Section

Inside View of Door

Front View

Inside the Controller

Power supply

contactor unit

(-X18)

Robot system

input terminal

block

SERVOPACK:

Refer to the

following table.

Interior circulation fan:

4715MS-22T-B5A-B00

194E-A40-1753-6G

JANCD-YIF01-1E

JZNC-YPS01-E

JZNC-YRK01-1E

JANCD-YBK01-1E

JZNC-YIU02-E

JZNC-YSU01-1E

Back View

(without cover)

Backside duct fan:

Main power switch

CPS Unit

CPU Unit

Machine safety unit

Robot I/F board

I/O Unit

Brake control board

15 of 764

DX100 European

Standard Maintenance

1 Equipment Configuration

1.1 Arrangement of Units and Circuit Boards

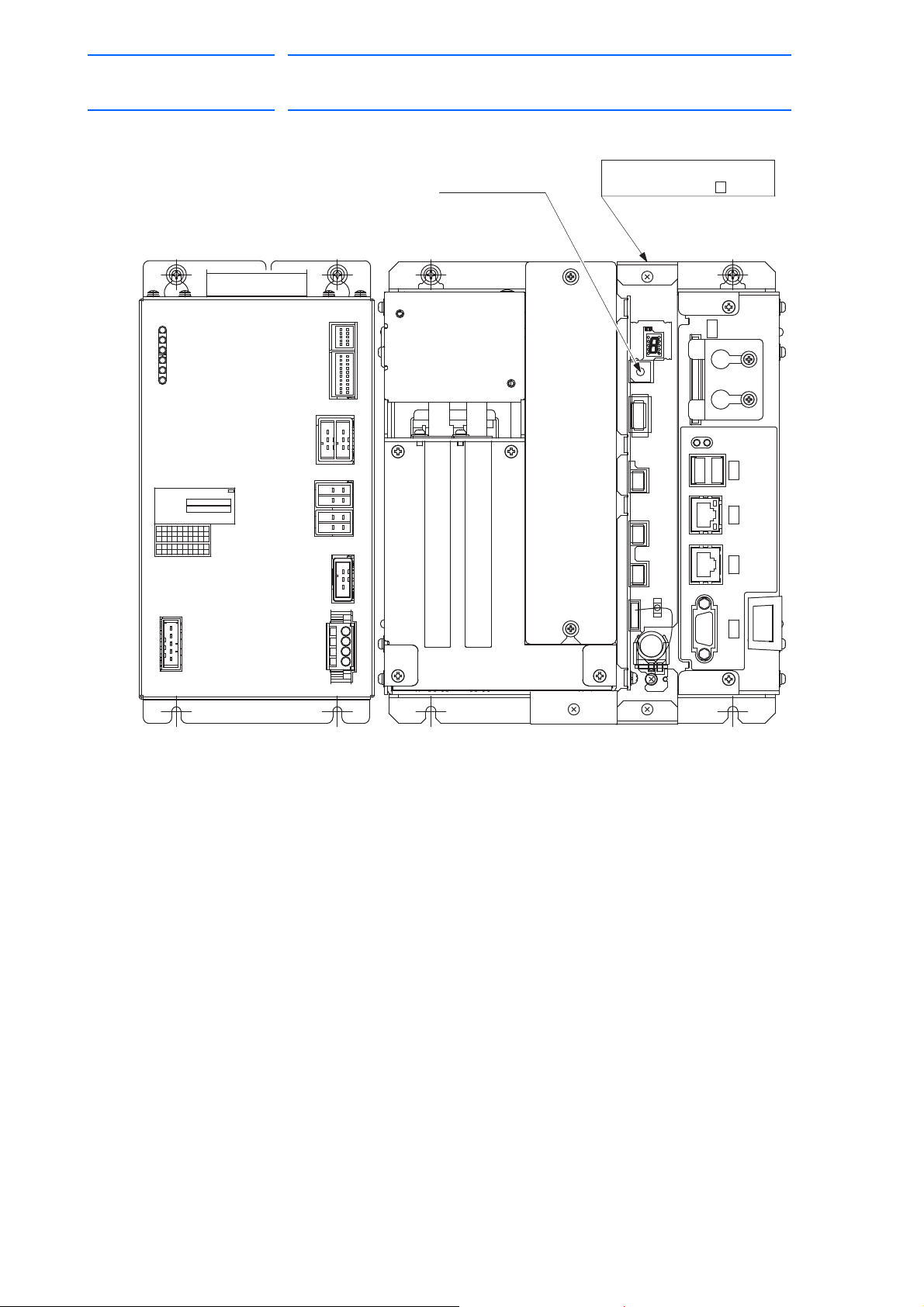

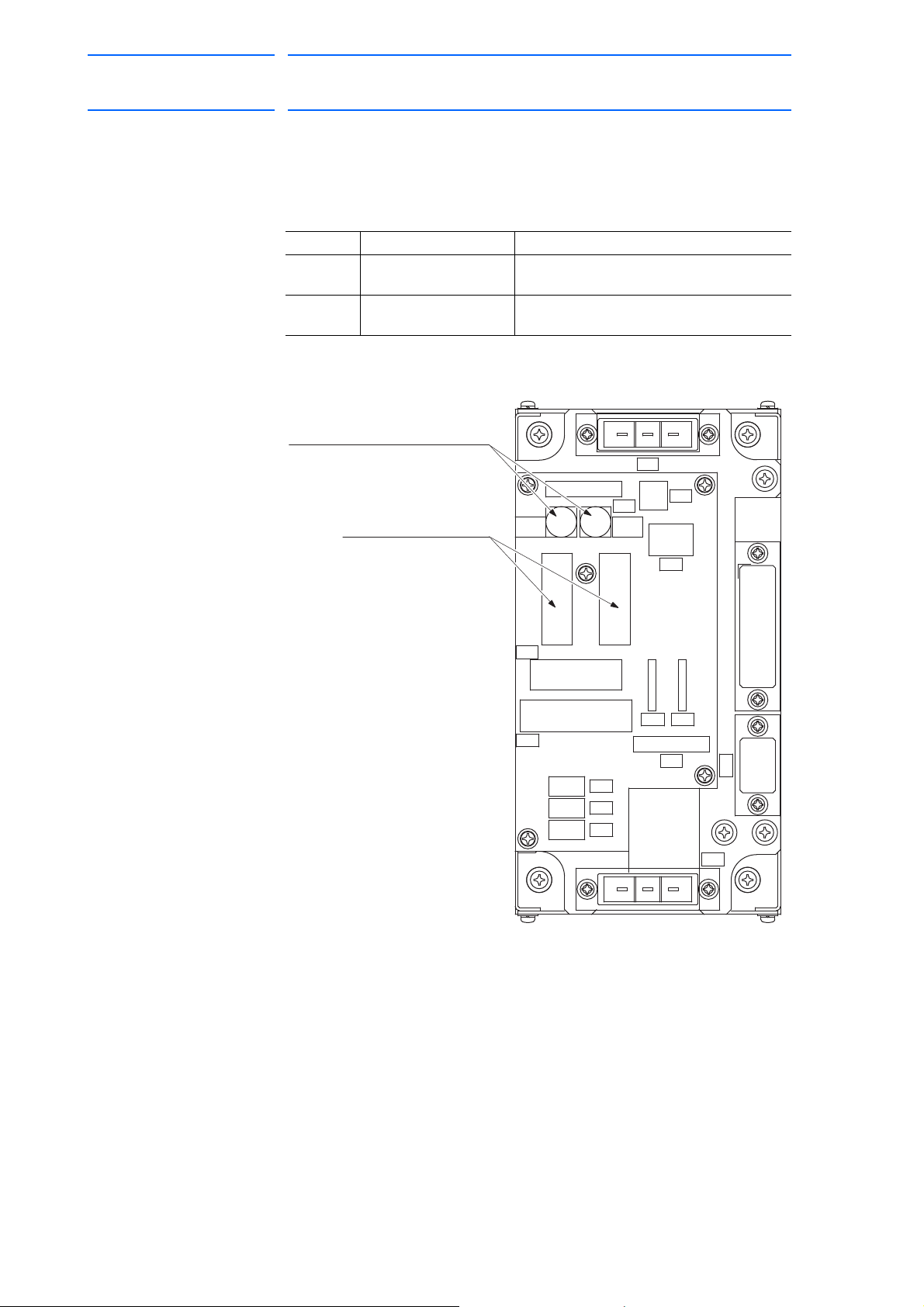

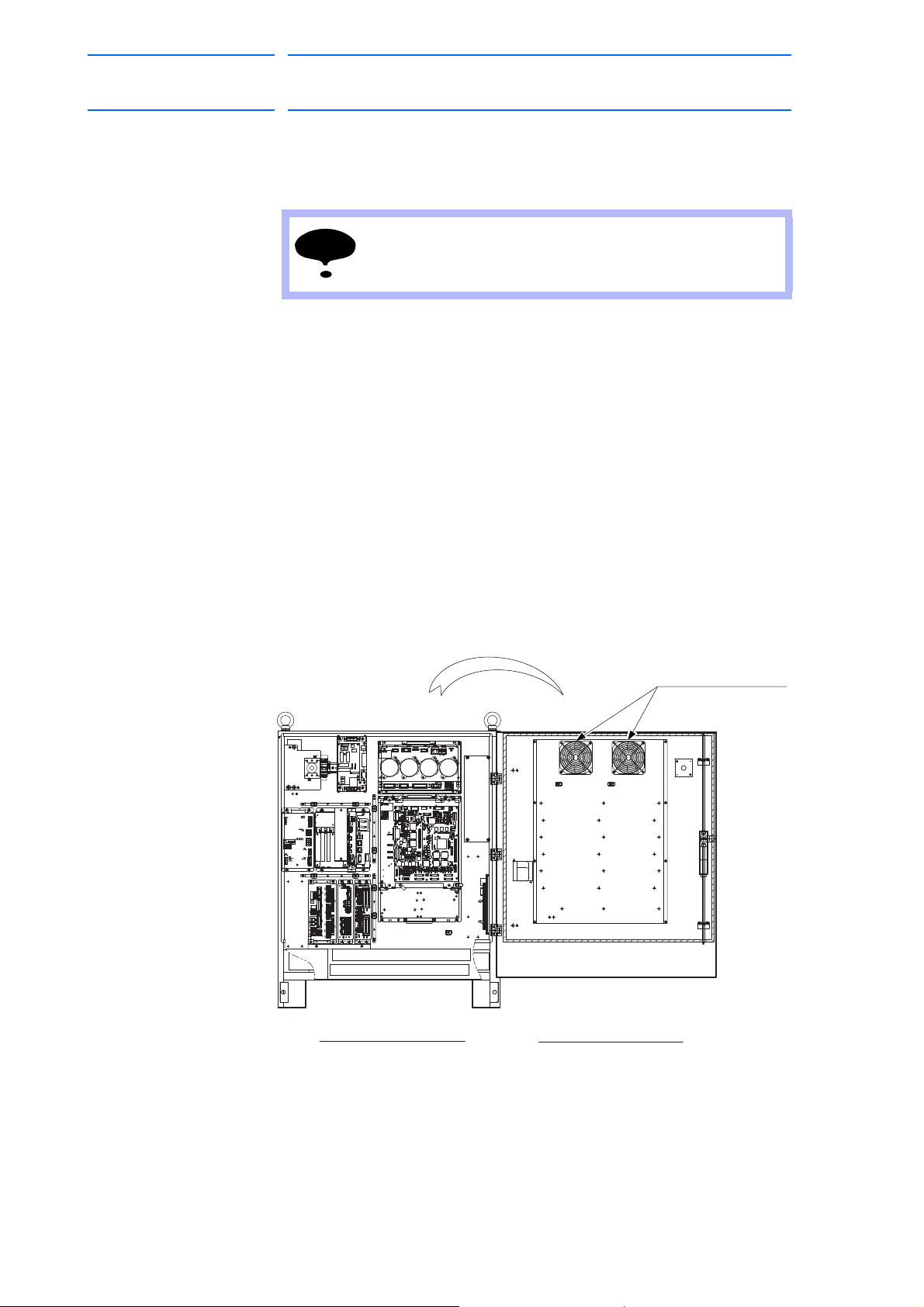

1.1.1.2 Medium and Large-Capacity DX100 Controller

Fig. 1-2: Configuration of Medium and Large Capacity DX100

Model DX100 SERVOPACK Converter

MH50 ERDR-MH00050-E02 JZRCR-YSV04-11 SRDA-COA30A01A-E

MH50-20

MH50-35

MS80 ERDR-MS00080-E02 JZRCR-YSV05-11 SRDA-COA30A01A-E

VS50 ERDR-VS00050-E02 JZRCR-YSV05-41 SRDA-COA30A01A-E

SIA50D ERDR-SIA050D-E02 JZRCR-YSV05-41 SRDA-COA30A01A-E

MA1800 ERDR-MA01800-E02

ES165D ERDR-ES0165D-E02 JZRCR-YSV06-11 SRDA-COA30A01A-E

ES200D ERDR-ES0200D-E02 JZRCR-YSV06-11 SRDA-COA30A01A-E

ES165RD ERDR-ES165RD-E02 JZRCR-YSV06-11 SRDA-COA30A01A-E

ES200RD ERDR-ES200RD-E02 JZRCR-YSV06-11 SRDA-COA30A01A-E

HP165D ERDR-HP0165D-E02 JZRCR-YSV06-11 SRDA-COA30A01A-E

UP350D ERDR-UP0350D-E02 JZRCR-YSV07-11 SRDA-COA30A01A-E

JZRCR-YSV08-11 SRDA-COA30A01A-E

ERDR-MA01800-E04

(without JANCD-YEW01-E)

1-2

RE-CHO-A109

Page 16

DX100 European

(2.5A)4FU

(2.5A)3FU

(10A)

(10A)

2FU

1FU

(SRDA-EAXA01A)

DC24V

(Brake)

DC24V

DC24V

DC24V

DC24V

DC24V

(SRDA-COA )

(JZNC-YPS01-E)

(JZNC-YRK01-1E)

(JZNC-YIU02-E)

(JZNC-YSU01-1E)

(JANCD-YBK01-1E)

Power supply contactor unit (JZRCR-YPU01-1)

X81

(+24V1)

CN209

(+24V3)

CN400

+24V2)

CN584

CN583

CN584

CN583

CN584

CN583

CN584

CN583

CN584

CN583

CN404

(+24VU)

(+24V3)

CN403

(+24V1)

(+24V1

/

CN510

CN508

CN509

AMP6

AMP5

AMP4

AMP3

AMP2

CN551

CN556CN552

CN555

CN554

AMP1

CN584

CN583

+24VU)

(+24V2

/

(+24V2)

CN304

CN303

CN305

(+24V1/+24V2)

CN200

(+24V2)

CN158

+24V2 )

(+24V1/

CN5

CN2

CN1

Control circuit board

BACK BOARD

JANCD-YBB01

BATTERY

CN110

JANCD-YIF01- E

CNBUS

ROBOT I/F BOARD

JANCD-YCP01-E

CN1A/1B

(+5V)

+24V2 )

(+24V1/

CN157

CN154

(AC200V IN)

CN151

(+24V3)

CN153

CN155

(+24V2)

CN156

CN159

CN604

CN603

CN606

CN602

2KM

2KM1KM

10A

AC250V

1KM

E

E

E

CN582

CN582

CN582

CN582

CN582

CN582

-G1

-G3

-G4

E

-G2

- AE2

- AE3

- AE1

- AE7

- AE4

- AE5

- TP1

- AE6

- TA1

- TA2

- TA3

- TA4

- TA5

- TA6

L2(S)

L1(R)

PE

L3(T)

-X4

1

2

CN601

3

2

4

1

3

- Q1M

6

5

2

4

1

3

- FS1

6

5

L1’

L2’

- V1

L3’

L1

L2

L3

u

v

- T1

w

U

V

W

3 phase

400 VAC 50/60 Hz

Filter

CPS Unit

Backside duct fan

Interior circulation fan

CPU Unit

Machine safety unit

Programming pendant

Brake control board

Major axes control circuit board

Converter

Manipulator

SERVOPACK

I O Unit

SGDR-FBA A

24V(IN)

5V(OUT)

Brake

Power

Brake

Power

Brake

Power

Brake

Power

Brake

Power

Brake

Power

T-axis motor

B-axis motor

R-axis motor

U-axis motor

L-axis motor

S-axis motor

16 of 764

Standard Maintenance

171768-1CD

1 Equipment Configuration

1.2 Power Flow

1.2 Power Flow

1-3

RE-CHO-A109

Page 17

(SRDA-EAXA01A)

(SRDA- )

(SRDA-COA )

(JANCD-YBK01-1E)

(JZNC-YSU01-1E)

(JZNC-YRK01-1E)

(JZNC-YPS01-E)

Power supply contactor unit (JZRCR-YPU01-1)

(JZRCR-YPP01-

)

I/O=8/8

I

/

O=8/8

I

/

O=12/12

I

/

O=12/12

(JZNC-YIU02-E)

CN607

CN608

RY1 RY2

CN602

1KM

CN601

2KM

CN203CN202

CN209

CN216

CN212

CN211

CN210

CN214

CN208

- X18

CN103

(RS232C)

CN101

(RS422)

CN102

(RS232C)

CN105

(LAN:PP)

(LAN:Ethernet)

CN104

CN581

CN581

CN581

CN581

CN581

CN405

CN402

SHOCK.LAMP

OT

X81

CN512

CN518

CN517

CN516

CN515

CN511

CN513

AMP6

AMP5

AMP4

AMP3

AMP2

AMP1

CN581

CN553

CN507

CN502

CN504

CN506

CN501

CN503

CN505

CN508

(I/O I/F)

CN300

CN309

CN308

CN307

CN306

CN5

CN2

CN1

Control circuit board

BACK BOARD

JANCD-YBB01

BATTERY

CN110

CN113

JANCD-YIF01- E

CN114

CNBUS

ROBOT I/F BOARD

JANCD-YCP01-E

CN1A/1B

CN159

- AE2

- AE3

- AE1

- AE7

- AE4

- AE5

- TP1

- AE6

- TA1

- TA2

- TA3

- TA4

- TA5

- TA6

CPS Unit

I/O Unit

Terminal resistor

(Universal I/O)

(Robot system input terminal block)

Machine safety unit

Terminal resistor

(P.P.

Emergency stop signal)

(Specified I/O)

(Lump)

(External axis overrun)

(Emergency stop signal)

(Overrun)

CPU Unit

Brake control board

Programming pendant

Manipulator

S-axis

motor

L-axis

motor

U-axis

motor

R-axis

motor

B-axis

motor

T-axis

motor

(Optional )

Major axes control circuit board

SERVOPACK

Converter

Terminal resistor

(Shock sensor)

17 of 764

171768-1CD

DX100 European

Standard Maintenance

1 Equipment Configuration

1.3 Signal Flow

1.3 Signal Flow

1-4

RE-CHO-A109

Page 18

DX100 European

18 of 764

Standard Maintenance

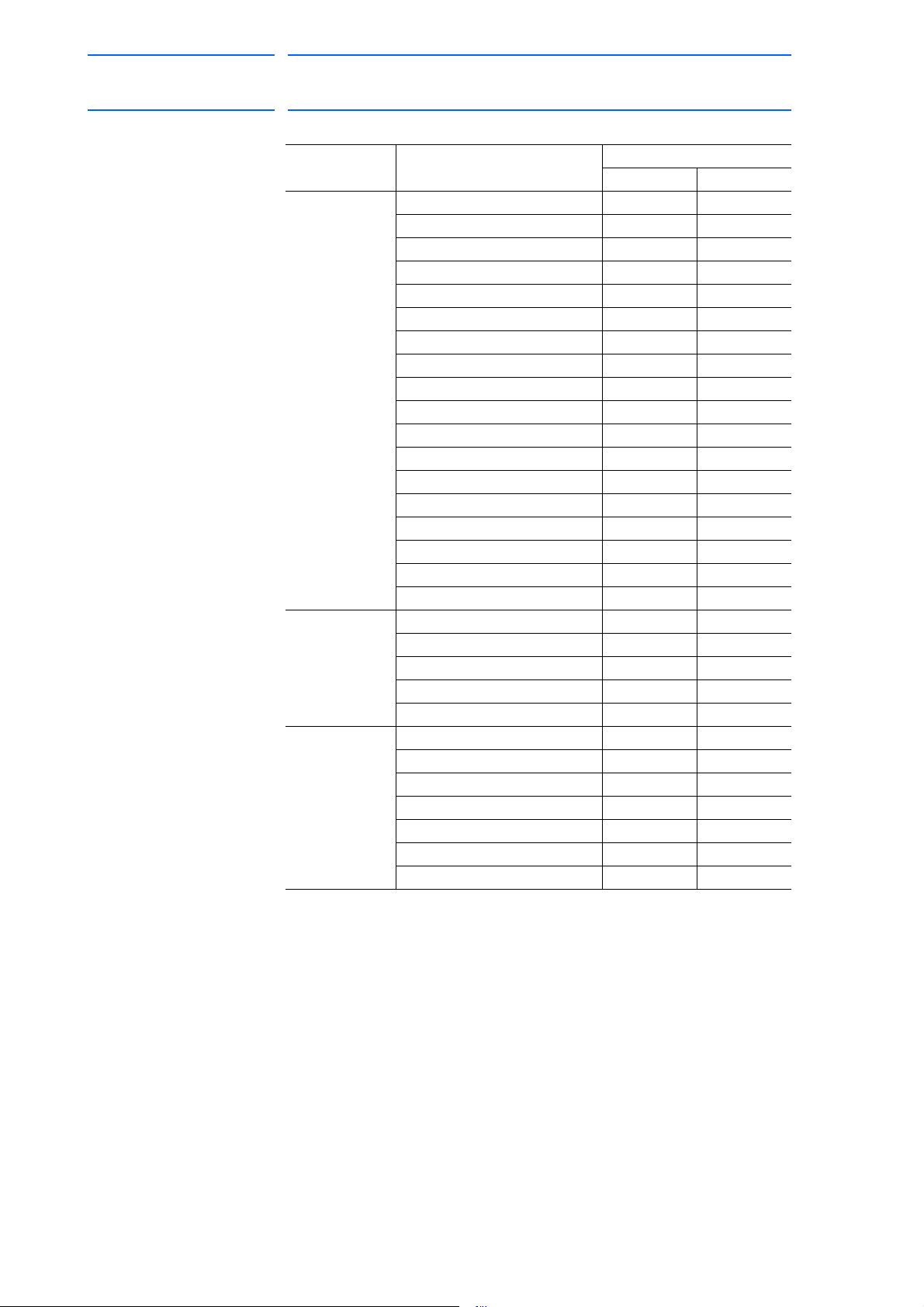

2 Security System

2.1 Protection Through Security Mode Settings

2 Security System

2.1 Protection Through Security Mode Settings

The DX100 modes setting are protected by a security system. The system

allows operation and modification of settings according to operator

clearance. Be sure operators have the correct level of training for each

level to which they are granted access.

2.1.1 Security Mode

There are three security modes. Editing mode and management mode

require a user ID. The user ID consists of numbers and letters, and

contains no less than 4 and no more than 8 characters. (Significant

numbers and signs: “0 to 9”, “-”, “.”.

171768-1CD

Security Mode Explanation

Operation Mode This mode allows basic operation of the robot (stopping,

starting, etc.) for people operating the robot work on the

line.

Editing Mode This mode allows the operator to teach and edit jobs and

robot settings.

Management

Mode

This mode allows those authorized to set up and maintain

robot system: parameters, system time and modifying user

IDs.

2-1

RE-CHO-A109

Page 19

171768-1CD

19 of 764

DX100 European

Standard Maintenance

2 Security System

2.1 Protection Through Security Mode Settings

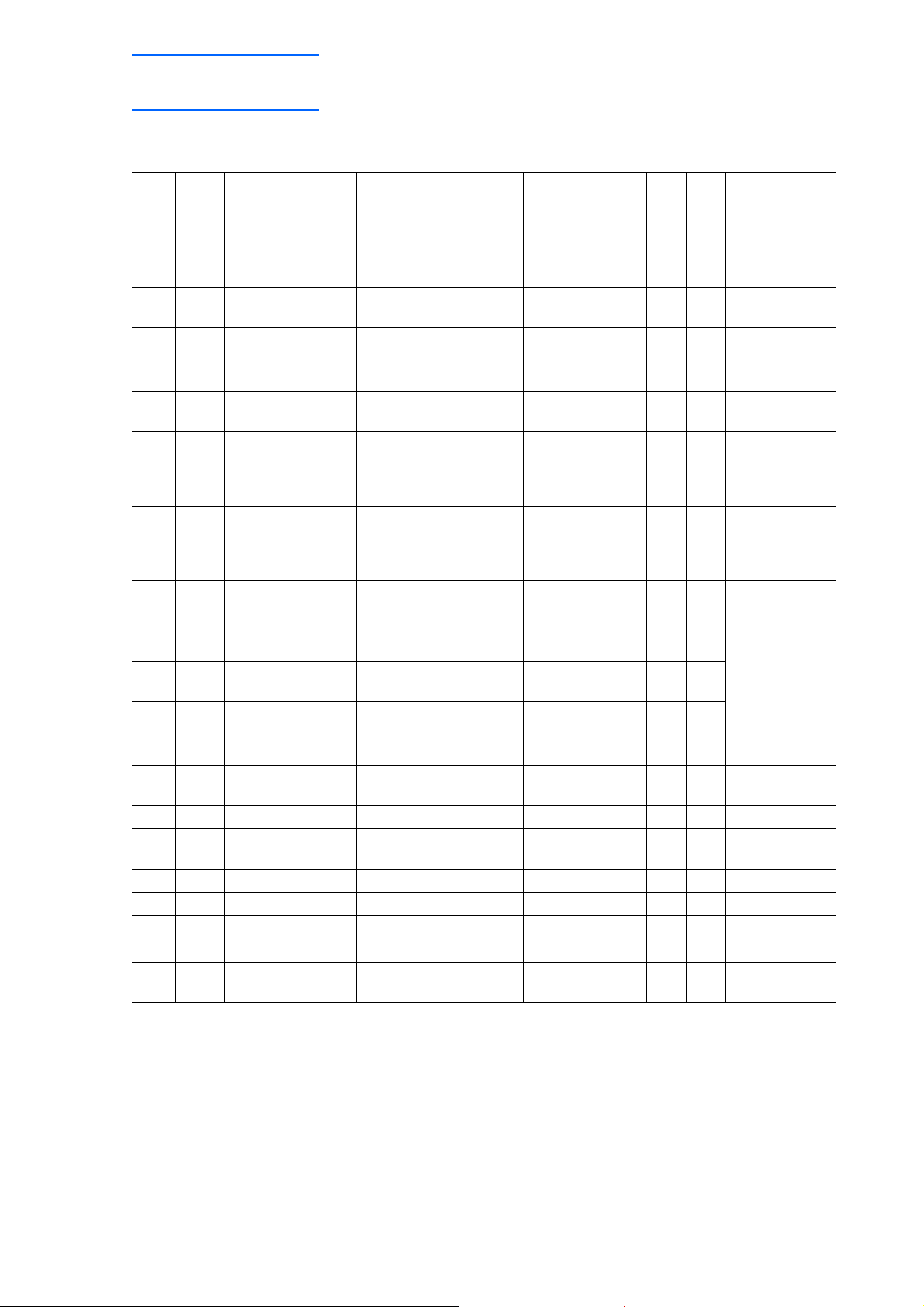

Table 2-1: Menu & Security Mode (Sheet 1 of 4)

Main Menu Sub Menu Allowed Security Mode

DISPLAY EDIT

JOB JOB Operation Edit

SELECT JOB Operation Operation

CREATE NEW JOB

MASTER JOB Operation Edit

JOB CAPACITY Operation -

RES. START (JOB)

RES. STATUS

CYCLE Operation Operation

VARIABLE BYTE Operation Edit

INTEGER Operation Edit

DOUBLE Operation Edit

REAL Operation Edit

STRING Operation Edit

POSITION (ROBOT) Operation Edit

POSITION (BASE) Operation Edit

POSITION (ST) Operation Edit

LOCAL VARIABLE Operation -

IN/OUT EXTERNAL INPUT Operation Edit

EXTERNAL OUTPUT Operation Edit

UNIVERSAL INPUT Operation Operation

UNIVERSAL OUTPUT Operation Operation

SPECIFIC INPUT Operation -

SPECIFIC OUTPUT Operation -

RIN Operation -

CPRIN Operation -

REGISTER Operation Management

AUXILIARY RELAY Operation -

CONTROL INPUT Operation -

PSEUDO INPUT SIG Operation Management

NETWORK INPUT Operation -

NETWORK OUTPUT Operation -

ANALOG OUTPUT Operation -

SV POWER STATUS Operation -

LADDER PROGRAM Management Management

I/O ALARM Management Management

I/O MESSAGE Management Management

1)

1)

2)

Edit Edit

Edit Edit

Operation -

2-2

RE-CHO-A109

Page 20

DX100 European

20 of 764

Standard Maintenance

171768-1CD

2 Security System

2.1 Protection Through Security Mode Settings

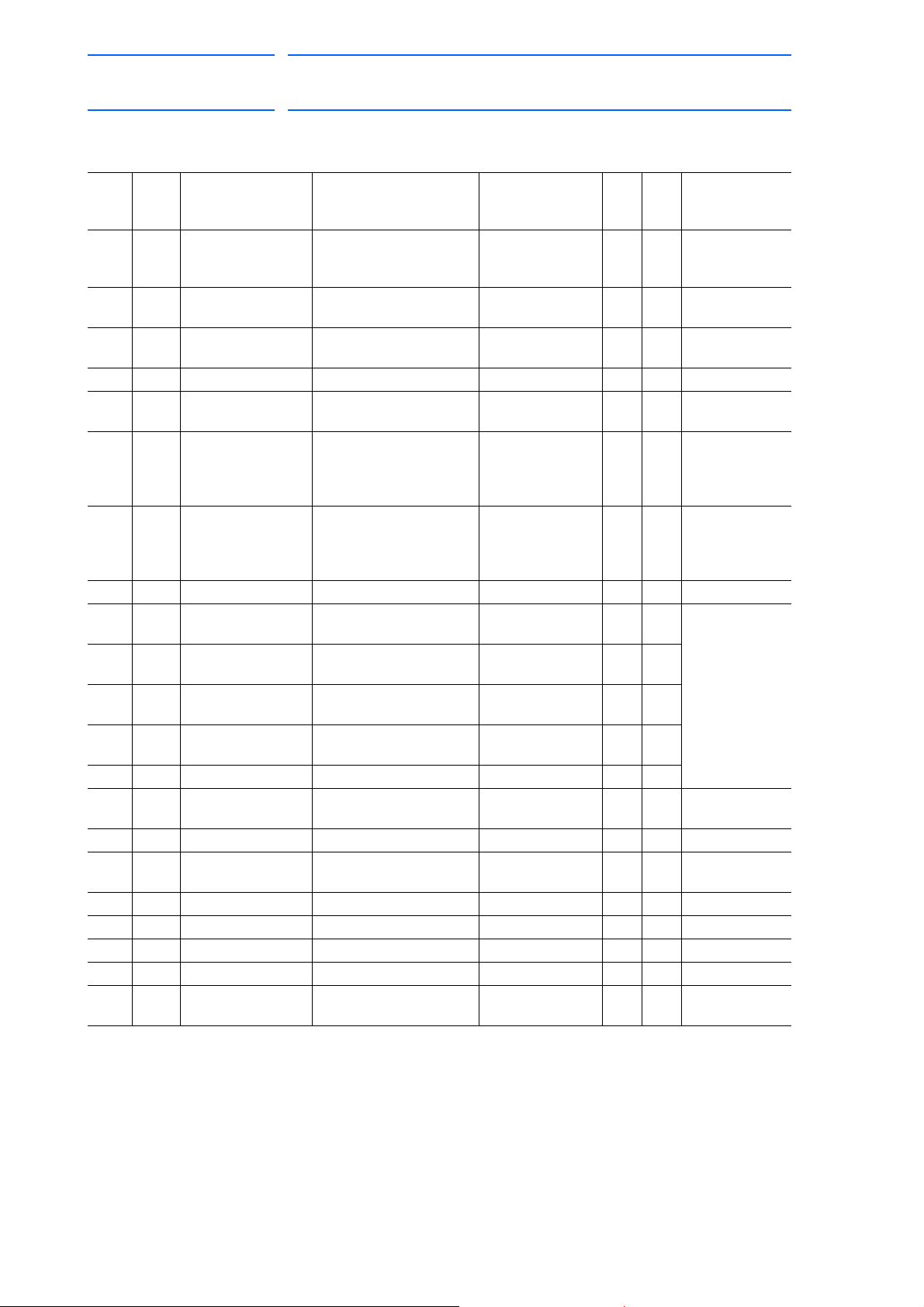

Table 2-1: Menu & Security Mode (Sheet 2 of 4)

Main Menu Sub Menu Allowed Security Mode

DISPLAY EDIT

ROBOT CURRENT POSITION Operation -

COMMAND POSITION Operation -

SERVO MONITOR Management -

WORK HOME POS Operation Edit

SECOND HOME POS Operation Edit

DROP AMOUNT Management Management

POWER ON/OFF POS Operation -

TOOL Edit Edit

INTERFERENCE Management Management

SHOCK SENS LEVEL Operation Edit

USER COORDINATE Edit Edit

HOME POSITION Management Management

MANIPULATOR TYPE Management -

ANALOG MONITOR Management Management

OVERRUN&S-SENSOR

LIMIT RELEASE

ARM CONTROL

SHIFT VALUE Operation -

SYSTEM INFO VERSION Operation -

MONITORING TIME Operation Management

ALARM HISTORY Operation Management

I/O MSG HISTORY Operation Management

SECURITY Operation Operation

EX.MEMORY LOAD Edit -

SAVE Operation -

VERIFY Operation -

DELETE Operation -

DEVICE Operation Operation

FOLDER Edit Management

INITIALIZE

1)

1)

1)

1)

Edit Edit

Edit Edit

Management Management

Operation -

2-3

RE-CHO-A109

Page 21

171768-1CD

21 of 764

DX100 European

Standard Maintenance

2 Security System

2.1 Protection Through Security Mode Settings

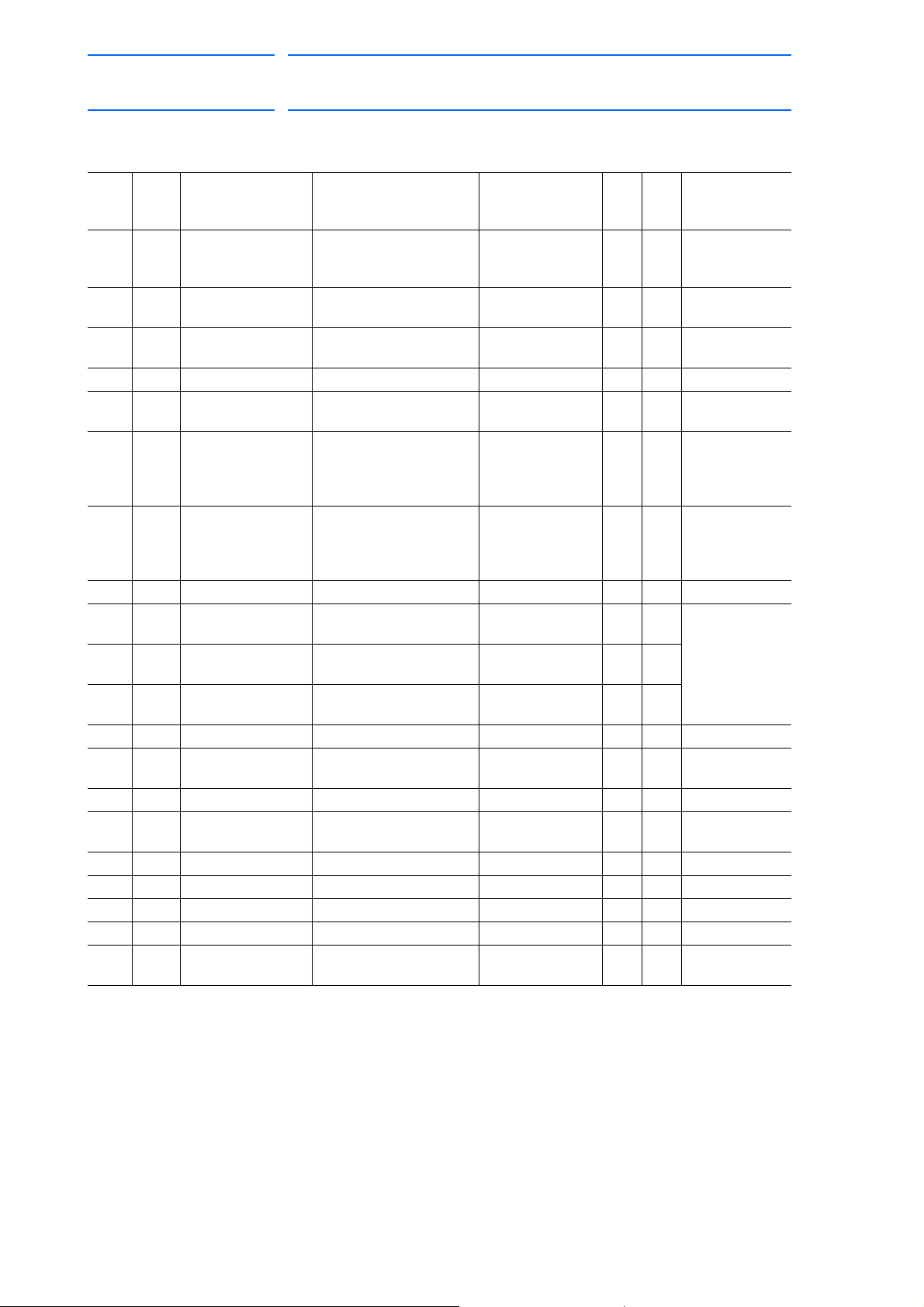

Table 2-1: Menu & Security Mode (Sheet 3 of 4)

Main Menu Sub Menu Allowed Security Mode

DISPLAY EDIT

PARAMETER S1CxG Management Management

S2C Management Management

S3C Management Management

S4C Management Management

A1P Management Management

A2P Management Management

A3P Management Management

A4P Management Management

A5P Management Management

A6P Management Management

A7P Management Management

A8P Management Management

RS Management Management

S1E Management Management

S2E Management Management

S3E Management Management

S4E Management Management

S5E Management Management

S6E Management Management

S7E Management Management

S8E Management Management

SETUP TEACHING COND. Edit Edit

OPERATE COND. Management Management

OPERATE ENABLE Management Management

FUNCTION ENABLE Management Management

JOG COND. Management Management

PLAYBACK COND. Management Management

FUNCTION COND. Management Management

DATE/TIME Management Management

DISPLAY

SETUP

GRP COMBINATION

RESERVE JOB NAME Edit Edit

USER ID Edit Edit

SET SPEED Management Management

KEY ALLOCATION Management Management

JOG KEY ALLOC. Edit Management

RES. START (CNCT) Management Management

AUTO BACK SET Management Management

WRONG DATA LOG Edit Management

ENERGY SAVING FUNCTION Edit Management

CHANGE FONT Operation Operation

CHANGE BUTTON Operation Operation

INITIALIZE LAYOUT Operation Operation

CHANGE WINDOW PATTERN Operation Operation

2)

Management Management

2-4

RE-CHO-A109

Page 22

DX100 European

22 of 764

Standard Maintenance

171768-1CD

2 Security System

2.1 Protection Through Security Mode Settings

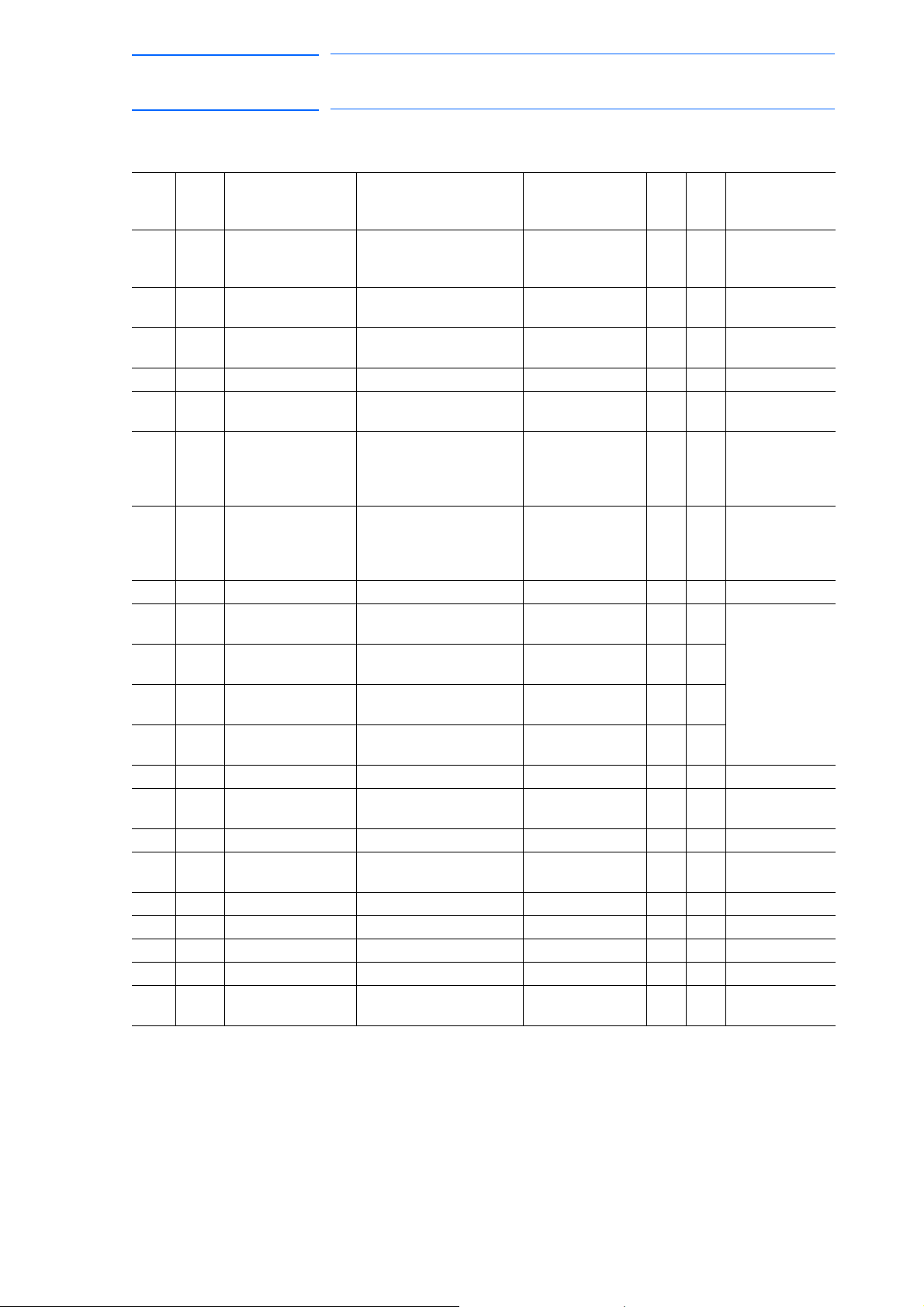

Table 2-1: Menu & Security Mode (Sheet 4 of 4)

Main Menu Sub Menu Allowed Security Mode

DISPLAY EDIT

ARC WELDING ARC START COND. Operation Edit

ARC END COND. Operation Edit

ARC AUX COND. Operation Edit

POWER SOURCE COND. Operation Edit

ARC WELD DIAG. Operation Edit

WEAVING Operation Edit

ARC MONITOR Operation Edit

ARC MONITOR (SAMPL) Operation -

HANDLING HANDLING DIAGNOSIS Operation Edit

SPOT

WELDING

SPOT

WELDING

(MOTOR GUN)

GENERAL WEAVING Operation Edit

COMMON TO

ALL

APPLICATIONS

1 Displayed in the teach mode only.

2 Displayed in the play mode only.

WELD DIAGNOSIS Operation Edit

I/O ALLOCATION Management Management

GUN CONDITION Management Management

SPOT POWER SOURCE

COND.

APPLICATION CONDITION

SETTING

WELD DIAGNOSIS Operation Edit

GUN PRESSURE Edit Edit

PRESSURE Edit Edit

I/O ALLOCATION Management Management

GUN CONDITION Management Management

CLEARANCE SETTING Operation Edit

SPOT POWER SOURCE

COND.

TIP INSTALLATION Operation Management

APPLICATION SETTING Management Management

GENERAL DIAG. Operation Edit

I/O VARIABLE CUSTOMIZE Operation Operation

Management Management

Management Management

Management Management

2-5

RE-CHO-A109

Page 23

171768-1CD

23 of 764

DX100 European

Standard Maintenance

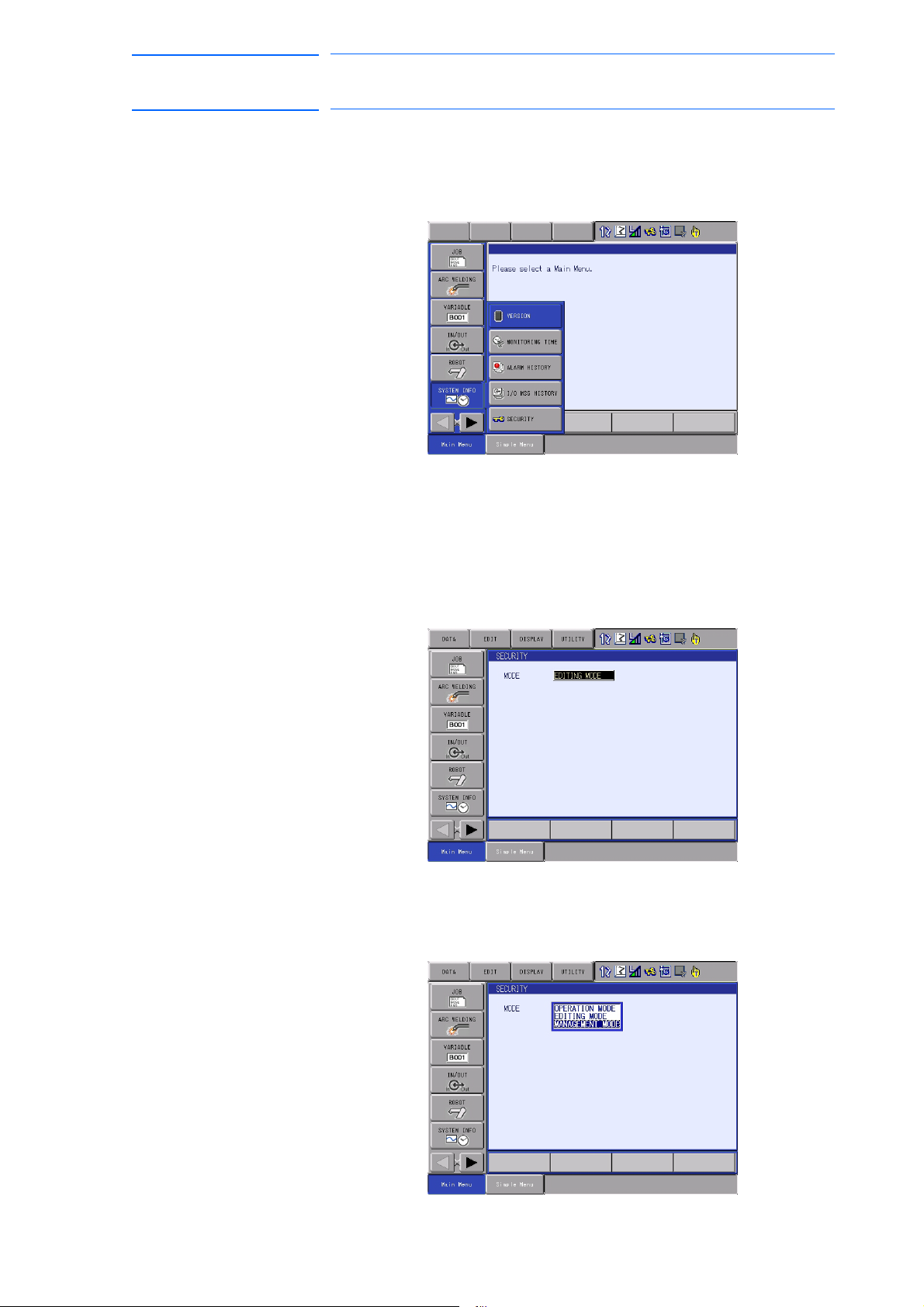

2.1.1.1 Changing the Security Mode

2 Security System

2.1 Protection Through Security Mode Settings

1. Select {SYSTEM INFO} under the main menu.

– The sub menu appears.

– Note: Icons for the main menu such as arc welding system differ

depending on the system being used.

2. Select {SECURITY}.

– The selection window of security mode appears.

3. Press [SELECT] and select “SEC

URITY MODE”

2-6

RE-CHO-A109

Page 24

DX100 European

SUPPLE-

MENT

24 of 764

Standard Maintenance

171768-1CD

2 Security System

2.1 Protection Through Security Mode Settings

4. Input the user ID.

– The user ID input window appears.

At the factory, the following below user ID number is preset.

• Editing Mode:[00000000]

Management Mode:[99999999]

5. Press [ENTER].

– The input user ID is compared with the user ID of the selected

security mode. When the correct user ID is entered, the security

mode is changed.

2-7

RE-CHO-A109

Page 25

171768-1CD

25 of 764

DX100 European

Standard Maintenance

2.1.2 User ID

2.1.2.1 Changing a User ID

2 Security System

2.1 Protection Through Security Mode Settings

User ID is requested when Editing Mode or Management Mode is

operated.

User ID must be between 4 characters and 8, and they must be numbers

and symbols. (“0 to 9”,“-” and “.”)

In order to change the user ID, the DX100 must be in Editing Mode or

Management Mode. Higher security modes can make changes the user

ID of to lower security modes.

1. Select {SETUP} under the main menu.

– The sub menu appears.

2. Select {USER ID}.

– The USER ID window appears.

2-8

RE-CHO-A109

Page 26

DX100 European

26 of 764

Standard Maintenance

171768-1CD

2 Security System

2.1 Protection Through Security Mode Settings

3. Select the desired ID.

– The character input line appears, a

no. (4 to 8 digits)” is shown.

4. Input current ID and press [ENTER].

– When the correct user ID is entered, a new ID is requested to be

in

put. “Input new ID no.(4 to 8 digits)” appears.

nd the message “Input current ID

5. Input new ID and press [ENTER].

– User ID is changed.

2-9

RE-CHO-A109

Page 27

171768-1CD

WARNING

27 of 764

DX100 European

Standard Maintenance

3 Inspections

3.1 Regular Inspections

3 Inspections

3.1 Regular Inspections

• Do not touch the cooling fan or other equipment while the power is

turned ON.

Failure to observe this caution may result in electric shock or injury.

Carry out the following inspections.

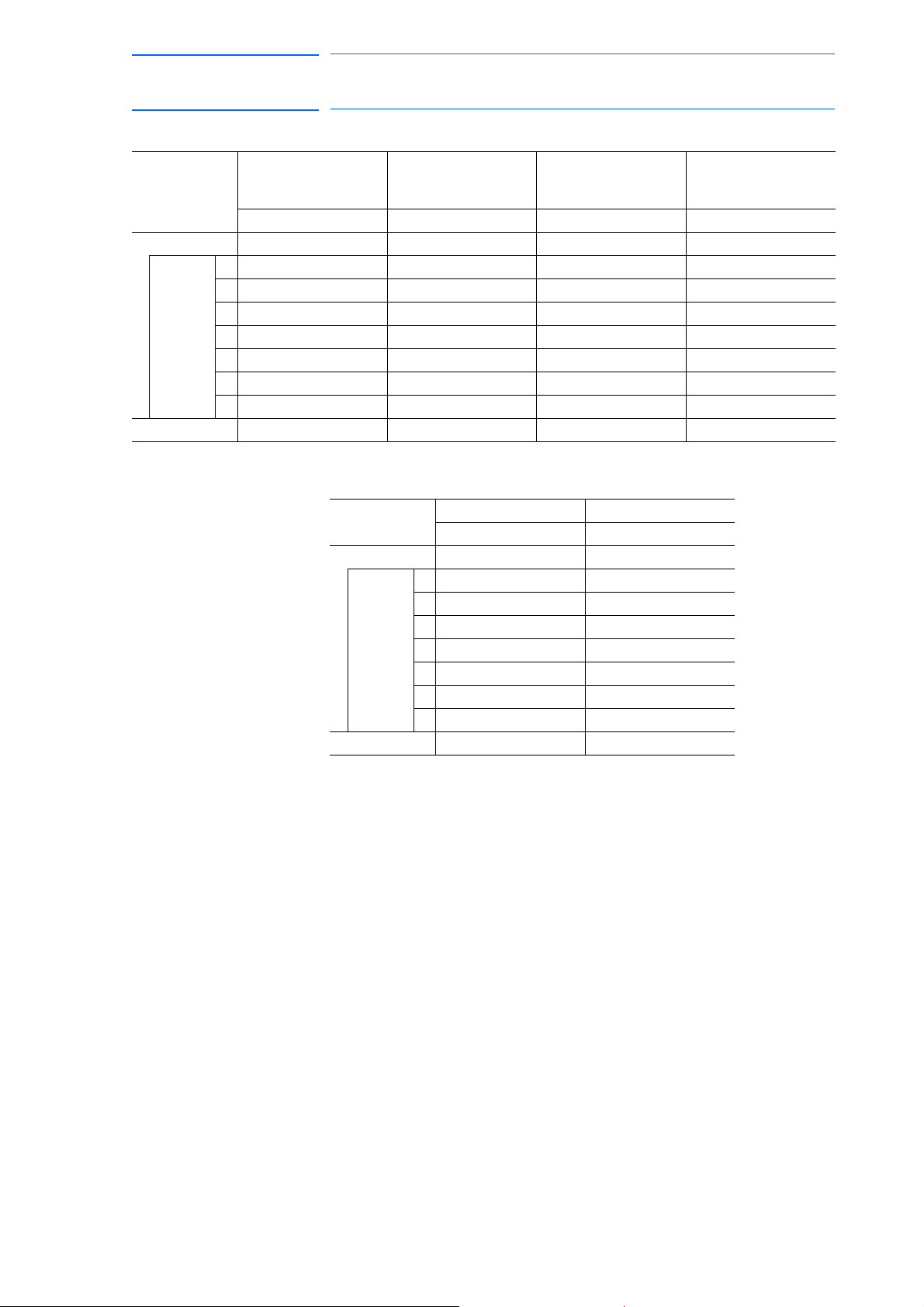

Inspection

Equipment

DX100 Controller Check that the doors

Interior circulation

fan and backside

duct fan

Emergency stop

button

Enable switch Check operation As required In teach mode

Battery Confirm battery

Power Supply Check power supply

Inspection Item Inspection

Frequency

Daily

are completely

closed

Check for gaps or

damage to the

sealed construction

Check operation As required While power ON

Check operation As required While servo ON

alarm or message is

displayed or not

voltage is normal

Monthly

As required

As required

Comments

Lead Cables for

main power switch

Check falling out,

loosing or breaking

of the lead cables

Check the correlate

voltage

3-1

As required

RE-CHO-A109

Page 28

DX100 European

X81

PROGRAMMING PENDANT

PROPERLY.

CHECK ALL THE DOOR LOCKS

NJ3005-1

kVA

kVA

ERDR-

Average

Peak

NJ3053-1

Kammerfeldstr. 1, D-85391 Allershausen

Motoman

2-1 Kurosaki Shiroishi Yahatanishi-Ku Kitakyushu-City Fukuoka 806-0004 Japan

YASKAWA Electric corporation

Robot Serial No.

Robot Order No.

Robot Type

Type

Date/Signature

Serial No.

AC 400/415/440 V

Power Supply

Part No.

Motoman DX100

with power ON.

WARNING

Do not open the door

High Voltage

X81

PROGRAMMING PENDANT

PROGRAMMING PENDANT

Main power switch

Door lock

X 8 1

28 of 764

Standard Maintenance

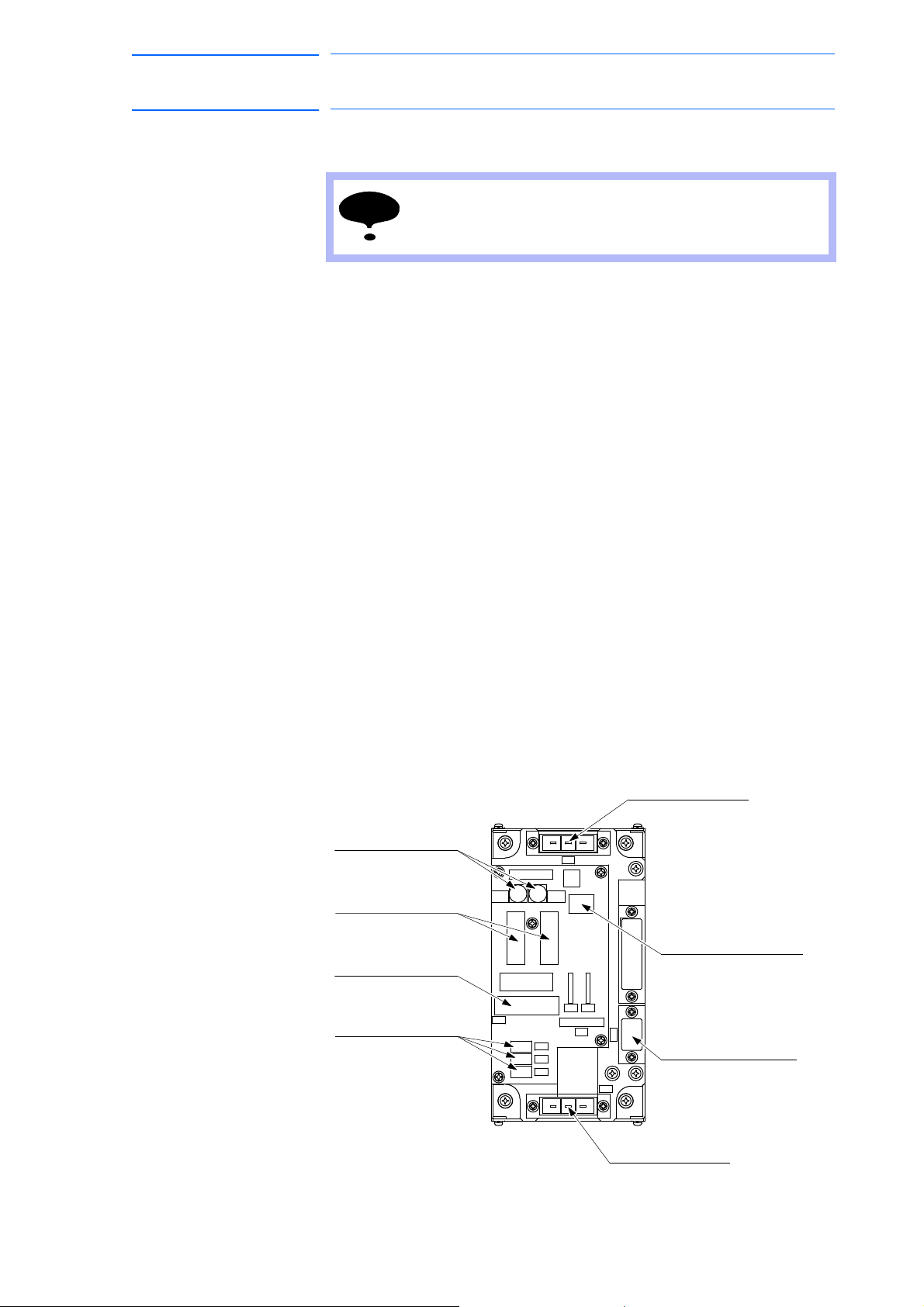

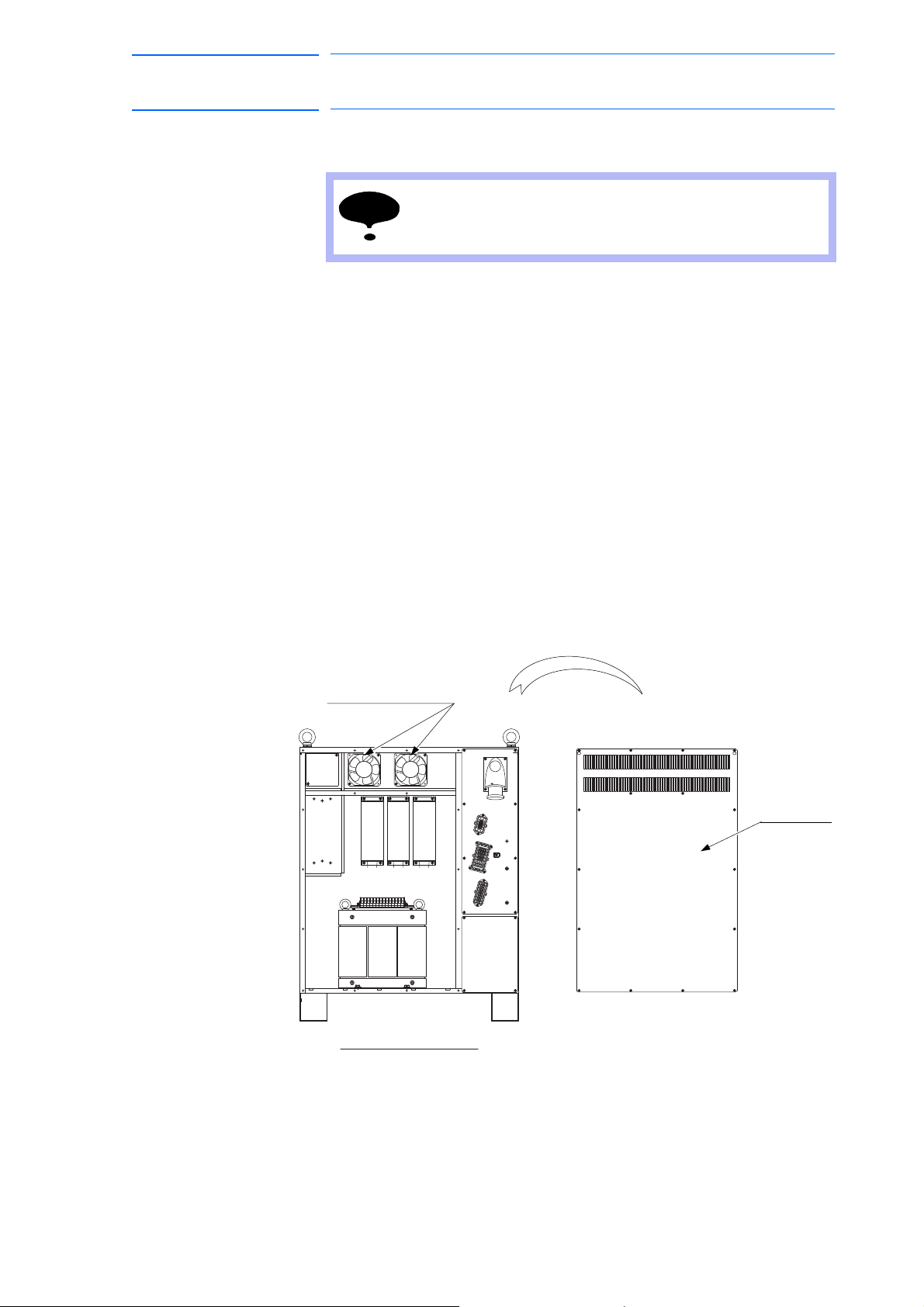

3.2.1 Checking if the Doors are Firmly Closed

171768-1CD

3 Inspections

3.2 DX100 Inspections

3.2 DX100 Inspections

• The DX100 has a fully sealed construction, designed to keep

external air containing oil mist out of the DX100.

Be sure to keep the DX100 doors fully closed at all times, even when

the controller is not operating.

• When opening or closing the doors for maintenance, use the specific

key for this operation after the main power is turned OFF with the

main power switch. (CW: Open, CCW: Close)

Make sure to push the door and turn the door-lock with the specific

key to open or close the door. When closing the door, turn the door

lock until it clicks.

Fig. 3-1: DX100 Front View

3.2.2 Checking for Gaps or Damage in the Sealed Construction Section

• Open the door and check that the seal around the door is

undamaged.

• Check that the inside of the DX100 is not stained badly. If it is,

determine the cause, take measures and immediately clean it.

• Firmly lock each door and check that no excessive gaps exist around

the edge of the door.

3-2

RE-CHO-A109

Page 29

171768-1CD

NOTE

Air intake

Air outlet

Backside duct fan

Interior circulation fan

29 of 764

DX100 European

Standard Maintenance

3 Inspections

3.3 Cooling Fan Inspections

3.3 Cooling Fan Inspections

Inspect the cooling fans as required. A defective fan can cause the DX100

to malfunction because of excessive high temperatures inside.

The interior circulation fan and backside duct fan normally operate while

the power is turned ON. Check if the fans are operating correctly by visual

inspection and by feeling air moving into the air inlet and from the outlet.

Fig. 3-2: Cooling Fan Construction

When the message of the “Cooling fan in YPS power supply

stopped. Exchange fan” is displayed, it may be caused by

the error occurrence at the cooling fan (JZNC-YZU01-E)

inside CPU unit (JZNC-YPS01-E).

When the message of the “Cooling fan in YPS unit stopped,

replace cooling fan” is displayed, carry out an inspection

and the replacement of the cooling fan in the CPS unit

(JZNC-YPS01-E) as soon as possible.

3-3

RE-CHO-A109

Page 30

DX100 European

NOTE

REMOTE

TEACH

PLAY

SERVO

ON

READY

SERVO ON

Blinking

30 of 764

Standard Maintenance

3 Inspections

3.4 Emergency Stop Button Inspections

3.4 Emergency Stop Button Inspections

The emergency stop button is located on the programming pendant.

Before operating the manipulator, confirm the servo power is OFF by

pressing the emergency stop button after the servo ON

3.5 Enable Switch Inspections

The programing pendant is equipped with a three-position enable switch.

Perform the following operation to confirm the enable switch operates.

1. Set the mode switch with key on the programming pendant to

"TEACH."

Mode switch with key

171768-1CD

2. Press [SERVO ON READY] on the programming pendant. The

[SERVO ON] lamp blinks.

3. When the enable switch is grasped lightly, the servo power is turned

ON.

When the enable switch is grasped fir

mly or released, the servo power

is turned OFF.

If the [SERVO ON] lamp does not light in previous operation

(2), check the following:

• The emergency stop button on the programming pendant

is being pressed.

• The emergency stop signal is input from external.

• If a major alarm is occurring.

3-4

RE-CHO-A109

Page 31

171768-1CD

Main power switch part

in the controller

135

24 6

31 of 764

DX100 European

Standard Maintenance

3 Inspections

3.6 Battery Inspections

3.6 Battery Inspections

The DX100 has a battery that backs up the important program files for

user data in the CMOS memory.

A battery alarm indicates when a battery has expired and must be

replaced. The programming pendant display and the message “Memory

battery weak” appears at the bottom of the display.

Please confirm that the above mentioned message is NOT indicated when

inspecting.

The way to replace the battery is described in section 5.1.1.1 “Replacing

the Battery” on page 5-3.

3.7 Power Supply Voltage Confirmation

Check the voltage of the 1, 3, 5 terminal of the main power switch (-Q1M)

with a voltmeter.

Table 3-1: Power Supply Voltage Confirmation

Measuring Items Terminals Correct Value

Correlate voltage Between

1 and 3(R-S),

3 and 5(S-T),

1 and 5(R-T)

400/415/440V

(+10%, -15%)

Fig. 3-3: Main Power Switch

3-5

RE-CHO-A109

Page 32

DX100 European

L1

L2

L3

2(U)

4(V)

6(W)

AC400/415/440V input

Transformer (-T1)

AC400-415-440V/200V

1KM

2KM

-X4

PE

1(R) 3(S) 5(T)

L1 L2 L3

L1’ L2’ L3’

CN555

Filter

(-V1)

Main Power Switch

(-Q1M)

Circuit protector

(-FS1)

Power supply

contactor unit

(-AE2)

Converter (-TP1)

32 of 764

Standard Maintenance

171768-1CD

3 Inspections

3.8 Open Phase Check

3.8 Open Phase Check

Table 3-2: Open Phase Check List

Check Item Contents

Lead Cable Check Confirm if the lead cable for the power supply is wired as

shown in the following without any falling out, looseness

or breaking from the connecting part.

Input Power

Supply Check

Main power switch

(-Q1M) Check

Check the open phase voltage of input power supply with

an electric tester.

(Normal value: 400/415/440 V

+10%, -15%)

AC

Turn ON the main power switch and check the open

phase voltage of terminals 2, 4, and 6 of the main power

switch (-Q1M) with a voltmeter. If abnormal, replace the

main power switch (-Q1M).

3-6

RE-CHO-A109

Page 33

171768-1CD

WARNING

33 of 764

DX100 European

Standard Maintenance

4 Preparation before Replacing Parts

4 Preparation before Replacing Parts

• Before operating the manipulator, check that the SERVO ON

lamp turns OFF when the emergency stop button on the

programming pendant is pressed.

Injury or damage to machinery may result if the manipulator cannot be

stopped in case of an emergency.

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– Be sure to use a lockout device to the safeguarding when going

inside. Also, display the sign that the operation is being

performed inside the safeguarding and make sure no one closes

the safeguarding.

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no persons are present in the P-point maximum

envelope of the manipulator and that you are in a safe location

before:

– Turning ON the DX100 power.

– Moving the manipulator with the programming pendant

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation.Always press the emergency stop button

immediately if there are problems.

Emergency stop buttons are located at the upper right corner of the

front door of the DX100 and on the upper right of the programming

pendant.

4-1

RE-CHO-A109

Page 34

DX100 European

CAUTION

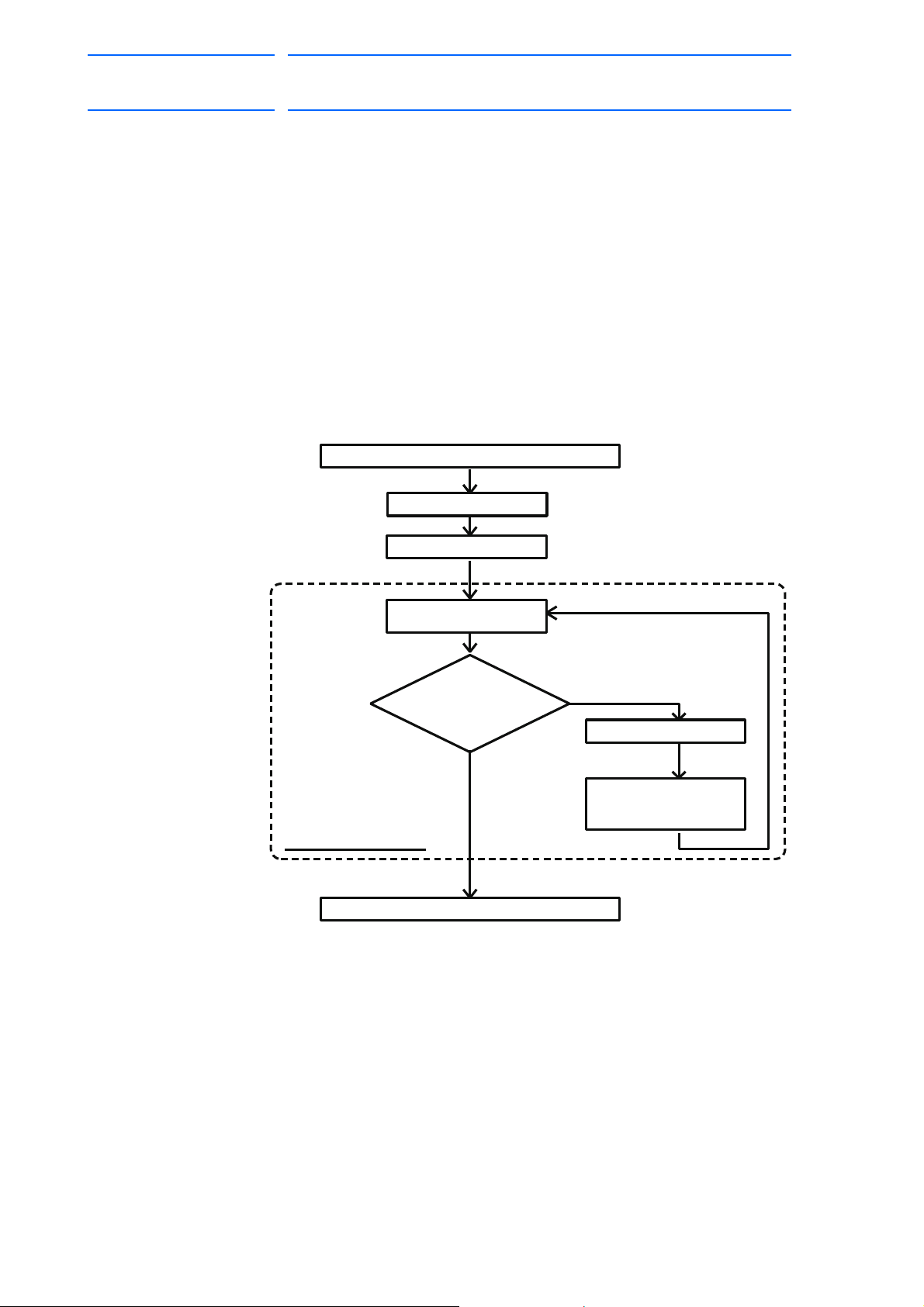

Start

Creating a check program

Position deviation check

using the check program

Replacing parts

Home position

calibration

OK?

End

: Chapter 4

: Chapter 5

: Chapter 6

Yes

No

34 of 764

Standard Maintenance

171768-1CD

4 Preparation before Replacing Parts

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

– Always return the programming pendant to the hook on the

DX100 cabinet after use.

The programming pendant can be damaged if it is left in the P-point

maximum envelope of the manipulator, on the floor, or near fixtures.

The following flowchart shows the operations for replacing parts.

This chapter describes how to create a check program as a preparation

for replacing parts. The check program is a program to check the position

deviation. If positions are deviated, home position calibration is required.

For the calibration, this program data is used to correct the home position

data. In the following cases particularly, the home position calibration

using the check program is needed. Be sure to create a check program

referring to section 4.1 “Creating a Check Program” on page 4-3.

4-2

RE-CHO-A109

Page 35

171768-1CD

35 of 764

DX100 European

Standard Maintenance

4 Preparation before Replacing Parts

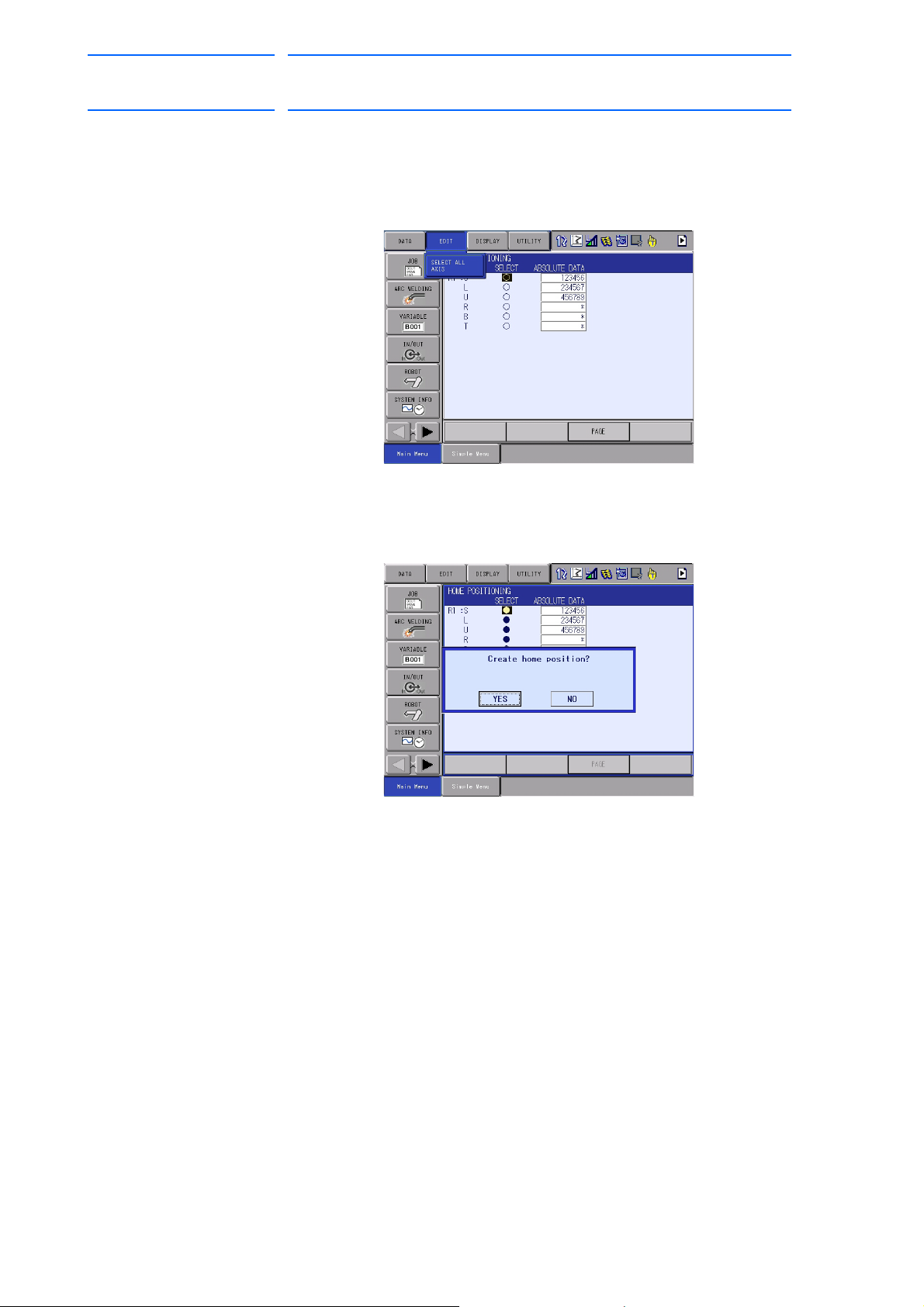

4.1 Creating a Check Program

• Change in the combination of the manipulator and DX100

• Replacement of the motor or absolute encoder

• Clearing stored memory (by replacement of the robot I/F board

(JANCD-YIF01-E), weak battery, etc.)

• Home position deviation caused by hitting the manipulator against a

workpiece, etc.

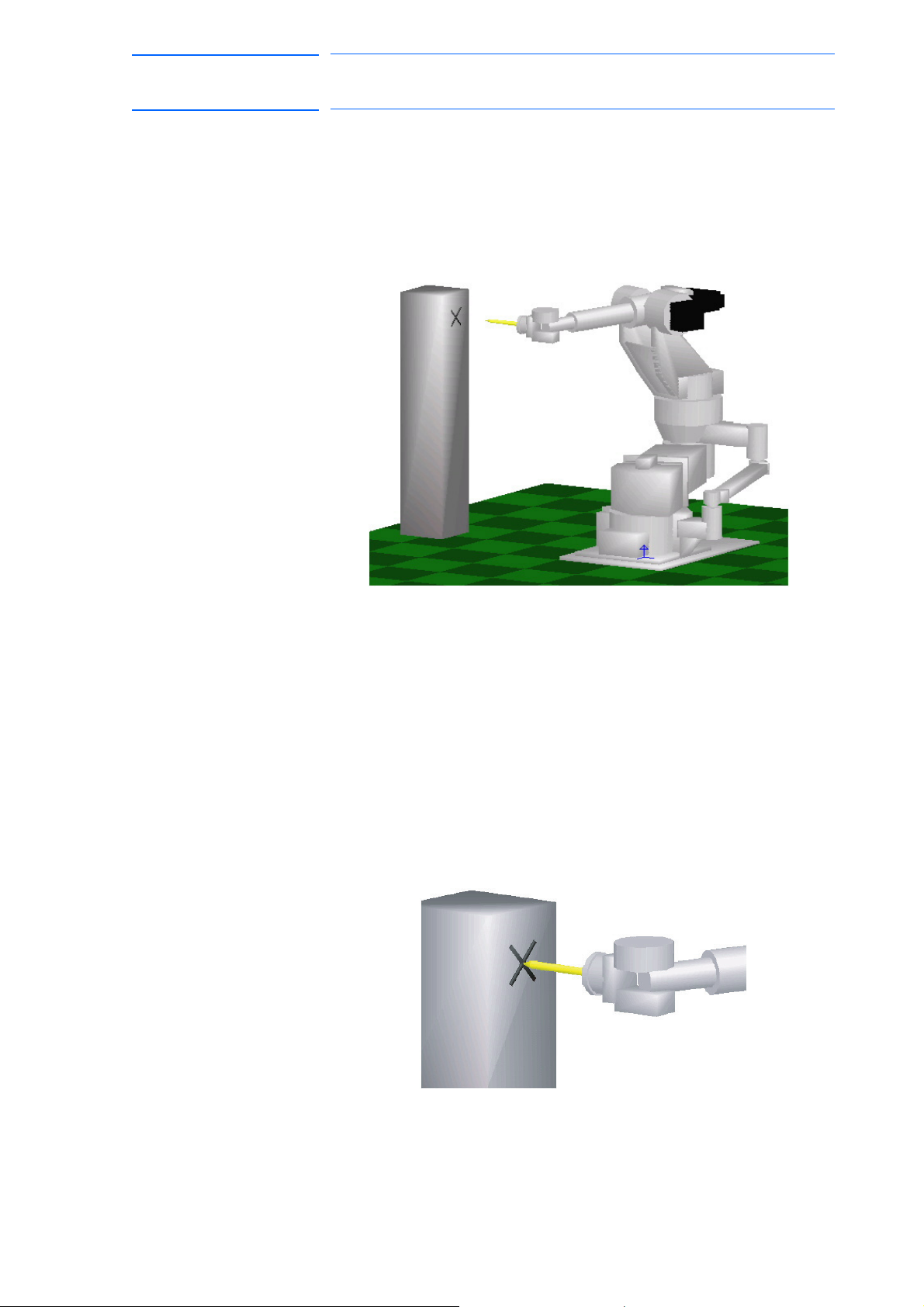

4.1 Creating a Check Program

To check position deviation whenever necessary, create a program in

which a check point is taught (the job for the check point). In the job for the

check point, teach two points; one as a check point and the other as the

point to approach the check point. This program checks for any deviation

between the tool tip position and the check point.

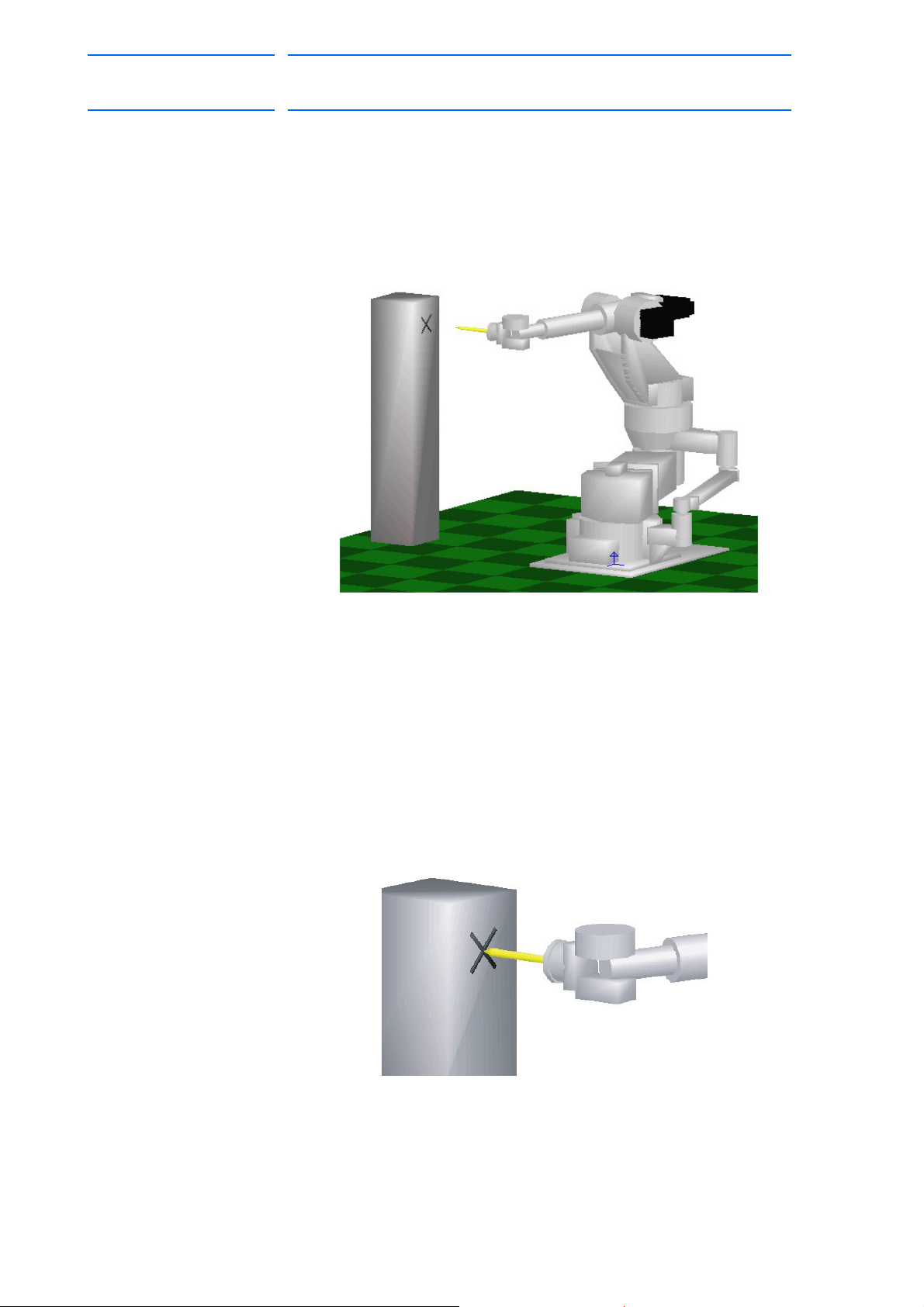

Fig. 4-1: <Enlarged View>

4-3

RE-CHO-A109

Page 36

DX100 European

WARNING

WARNING

36 of 764

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5Replacing Parts

5.1 Replacing DX100 Parts

• Turn OFF the power supply before opening the DX100 doors.

Failure to observe this warning may result in electric shock.

• After turning OFF the power supply, wait at least five minutes before

Failure to observe this warning may result in electric shock.

171768-1CD

replacing a SREVOPACK (including the converter) or CPS unit. Do

not touch any terminals during this period.

• To prevent anyone inadvertently turning ON the power supply

during maintenance, put up a warning sign such as “DO NOT TURN

ON THE POWER” at the primary power supply (knife switch, wiring

circuit breaker, etc.) and at the DX100 and related controllers and

use accepted lockout/tagout procedures.

Failure to observe this caution may result in electric shock or injury.

• Do not touch the regeneration resistors. They are very hot.

Failure to observe this caution may result in burn injuries.

• After maintenance is completed, carefully check that no tools are

left inside the DX100 and that the doors are securely closed.

Failure to observe this caution may result in electric shock or injury.

5-1

RE-CHO-A109

Page 37

171768-1CD

CPS Unit

CPU Unit

VUTSRQPNM

L

KJHGFEDC

BA

30

292827261425242322

21

20

19181716151312

11

10

0908070605040302

01

MADE IN JAPAN

Fuji Electric Hi-Tech Corp.

DATE

NO.

POWER SUPPLY

CPS-520F

VUTSRQPNM

L

KJHGFEDC

BA

30

292827261425242322

21

20

19181716151312

11

10

0908070605040302

01

CN154

(+24V1/+24V2)

CN158

(+5V)

CN155

(+24V1/+24V2)

(+24V2)

CN156/157

(+24V3)

CN153

(REMOTE)

CN152

SOURCE

OHT

INPUT

FAN

+24V

+5V

P-ON

50/60Hz

(AC IN)

CN151

200-240V AC

3.4A-2.8A

CN107

CN106

CN105

CN104

CN103

Ground connecting terminal

+24V1/+24V2 Power supply

output connector

(CN154/CN155)

+24V3 Power supply

output connector

(CN153)

(CN152)

+24V2 Power supply output connector

(CN156/CN157)

Connector 1 for connecting with CPU (CN158)

Connector 2 for connecting with CPU(CN159)

AC power supply

input connector

(CN151)

JANCD-YIF01- E

Robot I/F board

JANCD-YCP01-E

Control circuit board

Specified PCI slot for

sensor board X1

Battery

(CN113)

Drive I/F (communication with EAXA)

(CN114)

IO I/F (communication with YIU)

LED

(CN103)

Serial Port (RS232C)

(CN104)

For LAN

(CN106)

USB

(CN105)

For programming pendant

(CN107)

PCI Slot X2

Monitor, alarm display LED

Compact flash

Remote control connector

CN159

(ALM)

37 of 764

DX100 European

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

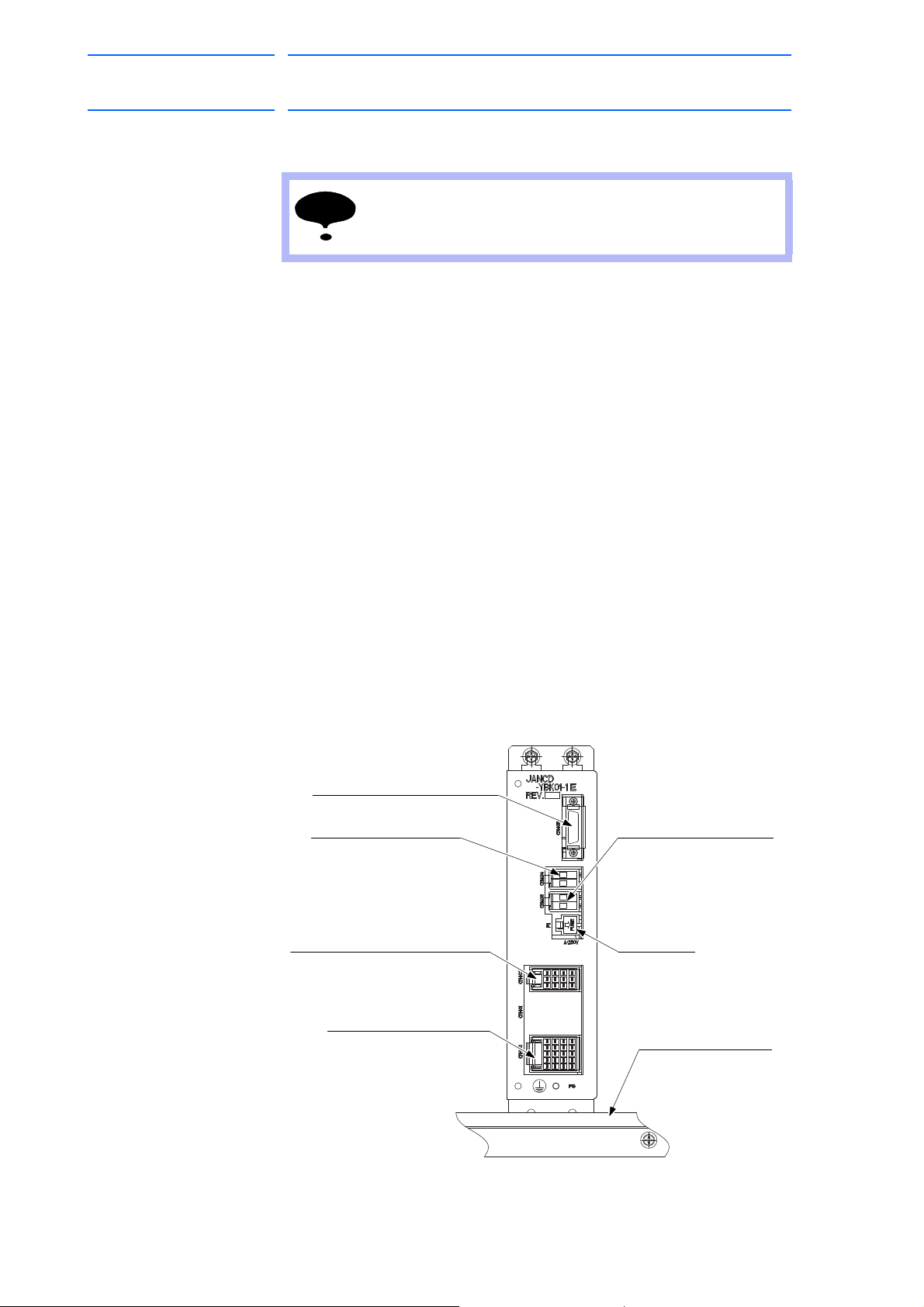

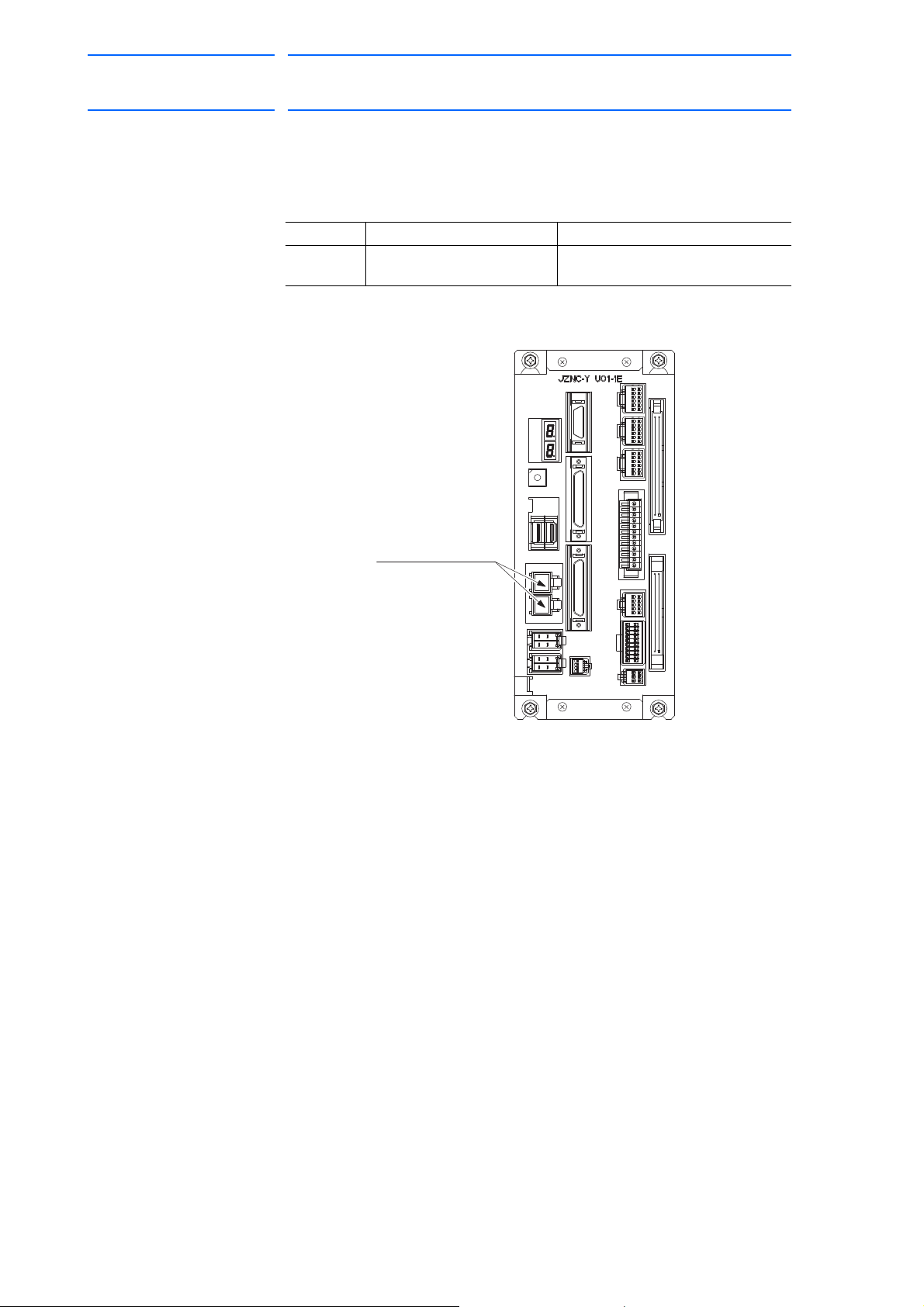

5.1.1 Replacing Parts of the CPU Unit

CPU unit (JZNC-YRK01-1E) is comprised of the rack for the various circuit

boards, control circuit board (JANCD-YCP01-E) and robot I/F board

(JANCD-YIF01-E). CPS unit (JZNC-YPS01-E) is a separated unit and it

is arranged to the left side of CPU unit.

Fig. 5-1: Configuration of CPU rack and CPS unit (JZNC-YRK01-1E,

JZNC-YPS01-E)

5-2

RE-CHO-A109

Page 38

DX100 European

NOTE

38 of 764

Standard Maintenance

5.1.1.1 Replacing the Battery

The battery must be replaced as soon as the message “Memory battery

weak” appears at the programming pendant display.

Replace the battery within two hours after the main power switch is turned

OFF.

Replacement Procedure

1. Loosen the screws on the battery connector holder and slide it to the

2. Remove the battery connector (CN110/BAT) on the robot I/F board

3. Mount a new battery on the robot I/F board and connect the connector

4. Slide the battery connector holder to the left and fix it with the screws.

5. Please confirm that the above mentioned message is not indicated at

171768-1CD

5 Replacing Parts

5.1 Replacing DX100 Parts

right.

(JANCD-YIF01-E) and loosen the fixing screws below the battery to

remove the battery.

110/BAT).

(CN

the

programming pendant display after battery replacement.

5.1.1.2 Replacing the Control Circ

Turn OFF the power before replacing a circuit board.

Replacement Procedure

1. Disconnect all cables connected to the circuit board.

2. Remove screws fixing the circuit board from upper and lower side.

(

one part at each side)

3. Pull out the circuit board from the rack.

4. Remove the Compact Flash from the removed circuit board and insert

the

Although the CMOS memory is backed up by a super

capacitor, the battery must be replaced as soon as the

message “Memory battery weak” appears.

The job data and other data may be lost if the message

“Memory battery weak” appears and the main power switch

is turned OFF for more than two hours.

uit Board (JANCD-YCP01-E)

Compact Flash into a new circuit board.

5. Mount the new circuit board to the rack.

6. Tighten upper and lower screws.

7. Connect all disconnected cables.

5-3

RE-CHO-A109

Page 39

171768-1CD

ABCDEFGHJK

LMNPQRSTUV

YYYY-MM

CPS-520F

POWER SUPPLY

NO.

DATE

Fuji Electric Hi-Tech Corp.

MADE IN JAPAN

C90AD XXXXX

010203040506070809 10

111213 151617181920

2122232425142627282930

ABCDEFGHJK

LMNPQRSTUV

(CN107)

Compact flash

JANCD-YCP01-E

Control circuit board

CN154

(+24V1/+24V2)

CN159

CN158

(+5V)

CN155

(+24V1/+24V2)

(+24V2)

CN156/157

(+24V3)

CN153

(REMOTE)

CN152

(ALM)

INPUT

50/60Hz

(AC IN)

CN151

200-240V AC

3.4A-2.8A

SOURCE

OHT

FAN

+24V

+5V

P-ON

CN103CN104CN105CN106

CN107

39 of 764

DX100 European

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5-4

RE-CHO-A109

Page 40

DX100 European

WARNING

ABCDEFGHJK

LMNPQRSTUV

YYYY-MM

CPS-520F

POWER SUPPLY

NO.

DATE

Fuji Electric Hi-Tech Corp.

MADE IN JAPAN

C90AD XXXXX

01020304050607080910

111213 151617181920

2122232425142627282930

ABCDEFGHJK

LMNPQRSTUV

CN154

(+24V1/+24V2)

CN159

CN158

(+5V)

CN155

(+24V1/+24V2)

(+24V2)

CN156/157

(+24V3)

CN153

(REMOTE)

CN152

(ALM)

INPUT

50/60Hz

(AC IN)

CN151

200-240V AC

3.4A-2.8A

SOURCE

OHT

FAN

+24V

+5V

P-ON

CN103CN104CN105CN106

CN107

JZNC-YPS01-E

CPS UNIT

40 of 764

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5.1.1.3 Replacing the CPS Unit (JZNC-YPS01-E)

• After turning OFF the power supply, wait at least five minutes before

replacing a control power supply. Do not touch any terminals during

this period. Confirm all monitor lights are turned OFF.

Failure to observe this caution may result in electric shock or injury.

Replacement Procedure

1. Disconnect all cables connected to the CPS unit.

2. Loosen the upper and lower side screws (four places) fixing the CPS

unit to the controller.

3. Hold the body of the CPS unit, then pull and remove the CPS unit from

the c

ontroller.

171768-1CD

4. Hook the new CPS unit to the screws (four places).

5. Tighten the upper and lower side screws (four places) to fix the CPS

un

it.

6. Connect all the disconnected cables.

5-5

RE-CHO-A109

Page 41

171768-1CD

NOTE

41 of 764

DX100 European

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5.1.1.4 Replacing the Robot I/F Board (JANCD-YIF01-

• Turn OFF the power before replacing the robot I/F

board.

• Be sure to back up robot data before replacing the robot

I/F board since the robot I/F board contains important

data such as robot jobs and parameters.

• There are some versions which require maker mode

operations after replacing the robot I/F board.

Contact your Yaskawa representative for maker mode

operations.

Replacement Procedure

1. Back up the robot data.

Insert a CF card for backup to the programming pendant, and start the

system in maintenance mode.

Select {EX.MEMORY} {SAVE} "CMOS" to save the CMOS data.

Backup all the individual data for safe.

E)

2. Turn OFF the power after making backup.

3. Disconnect all cables on the robot I/F board.

4. Remove two screws fixing the robot I/F board and rack.

5. Pull out the robot I/F board from the rack.

6. Insert new robot I/F board into the slot of the rack.

7. Tighten upper and lower screws of the robot I/F board.

8. Connect all the cables disconnected in step 3.

9. Set the rotary switch as the same value as the original I/F board.

10. Start up the system in maintenance mode and insert the CF card with

the ba

cked up data in procedure 1 to the programming pendant.

Change the mode from security mode to management mode. Select

{EX.MEMORY} {LOAD} "CMOS" to start loading the data. After

ading, the state returns to the state as before the replacement.

lo

5-6

RE-CHO-A109

Page 42

DX100 European

ABCDEFGHJK

LMNPQRSTUV

YYYY-MM

CPS-520F

POWER SUPPLY

NO.

DATE

Fuji Electric Hi-Tech Corp.

MADE IN JAPAN

C90AD XXXXX

010203040506070809 10

111213 151617181920

2122232425142627282930

ABCDEFGHJK

LMNPQRSTUV

Rotary switch

JANCD-YIF01- E

Robot I/F board

CN154

(+24V1/+24V2)

CN159

CN158

(+5V)

CN155

(+24V1/+24V2)

(+24V2)

CN156/157

(+24V3)

CN153

(REMOTE)

CN152

(ALM)

SOURCE

OHT

INPUT

FAN

+24V

+5V

P-ON

50/60Hz

(AC IN)

CN151

200-240V AC

3.4A-2.8A

CN103CN104CN105CN106

CN107

42 of 764

Standard Maintenance

171768-1CD

5 Replacing Parts

5.1 Replacing DX100 Parts

5-7

RE-CHO-A109

Page 43

171768-1CD

NOTE

43 of 764

DX100 European

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5.1.1.5 Replacing the I/O Unit (JZNC-YIU0

Turn OFF the power before replacing the I/O unit.

Replacement Procedure

1. Disconnect all the cables connected to the I/O unit.

(Disconnect the ground wire screwed to the front side of the unit.)

2. Loosen the upper screws (two places) fixing the I/O unit.

3. Hold and pull the I/O unit, then remove it from the controller.

4. Insert the lower part flange of the new I/O unit into the fixing jig, and

mo

unt it to the controller.

5. Tighten the upper side screws (two places) to fix the I/O unit.

6. Connect all the disconnected cables.

(Connect the ground wire firmly.)

7. If CN300 has a termination connector (CBL-YRC020), install it at the

right of

CN300 in the new I/O unit.

2-E)

8. Set the rotary switch to the same value as the removed unit’s rotary

sw

itch.

5-8

RE-CHO-A109

Page 44

DX100 European

3.15

F1, F2

(CN301)

(CN303)

(CN304)

(CN309)

Digital I/O connector

Digital I/O connector

(CN300)

(CN302)

(CN305)

D1:24V2IN LED

(CN306)

(CN307)

Digital I/O connector

(CN308)

Digital I/O connector

Communication switch

Rotary switch

D2:FUSE CUT LED

Panel IO connector

Universal input connector

Power supply protective

fuse 3.15 A/250 V

For switching external

power supply

Power supply output connector

Power supply input connector

Fixing jig for the flange

44 of 764

Standard Maintenance

171768-1CD

5 Replacing Parts

5.1 Replacing DX100 Parts

Fig. 5-2: I/O Unit JZNC-YIU02-E

5-9

RE-CHO-A109

Page 45

171768-1CD

NOTE

A01

2FU FU

A01

1

CN601

SVMX2SVMX1

CN606

CN612

CN608

CN602

CN603

CN604

CN605

3FU 2.5A

4FU 2.5A

SVMX2

SVMX1

CN603

CN604

CN605

CN612

CN606

NCM

CN607

CN611

3FU4FU

1FU2FU

CN610

CN601

CN609CN608

CN602

(CN608)

(CN607)

Main power input connectors

Converter output connectors

AC control power supply

connectors

AC cooling fan connectors

GP25(2.5A 250V)

Fuse for AC cooling fan

(4FU),(3FU)

0218010P(10A 250V)

AC control power supply fuse

Brake interlock output connectors

Contactor control input connectors

(CN602)

(2FU),(1FU)

(CN606)

(CN605,CN604,CN603)

(CN601)

45 of 764

DX100 European

Standard Maintenance

5 Replacing Parts

5.1 Replacing DX100 Parts

5.1.1.6 Replacing the Power Supply Contactor Unit (JZRCR-YPU01-

Turn OFF the power before replacing the unit.

Replacement Procedure

1. Disconnect all the cables connected to the power supply contactor

unit.

*The following connectors are not necessarily disconnected since they

are to connected inside the unit.

CN610, CN611, CN612

(Disconnect the ground wire screwed to the front side of the unit.)

2. Loosen upper and lower side screws (four places) fixing the power

supply contactor unit to the controller.

3. Hold and pull the power supply contactor unit, then remove it from the

contr

oller.

*Do not hold the board only, but hold it together with the unit because it

may cause damage to the board or personal injury.

)

4. Hook the new power supply contactor unit to the screws in the

contr

oller (4 places).

*Do not hold the board only, but hold it together with the unit because it

may cause damage to the board or personal injury.

5. Tighten the upper and lower side screws (four

power supply contactor unit.

6. Connect all the disconnected cables.

(Connect the ground wire firmly.)

Fig. 5-3: Configuration of Power Supply Contactor Unit (JZRCR-YPU01-1)

places) firmly to fix the

5-10

RE-CHO-A109

Page 46

DX100 European

NOTE

3.15

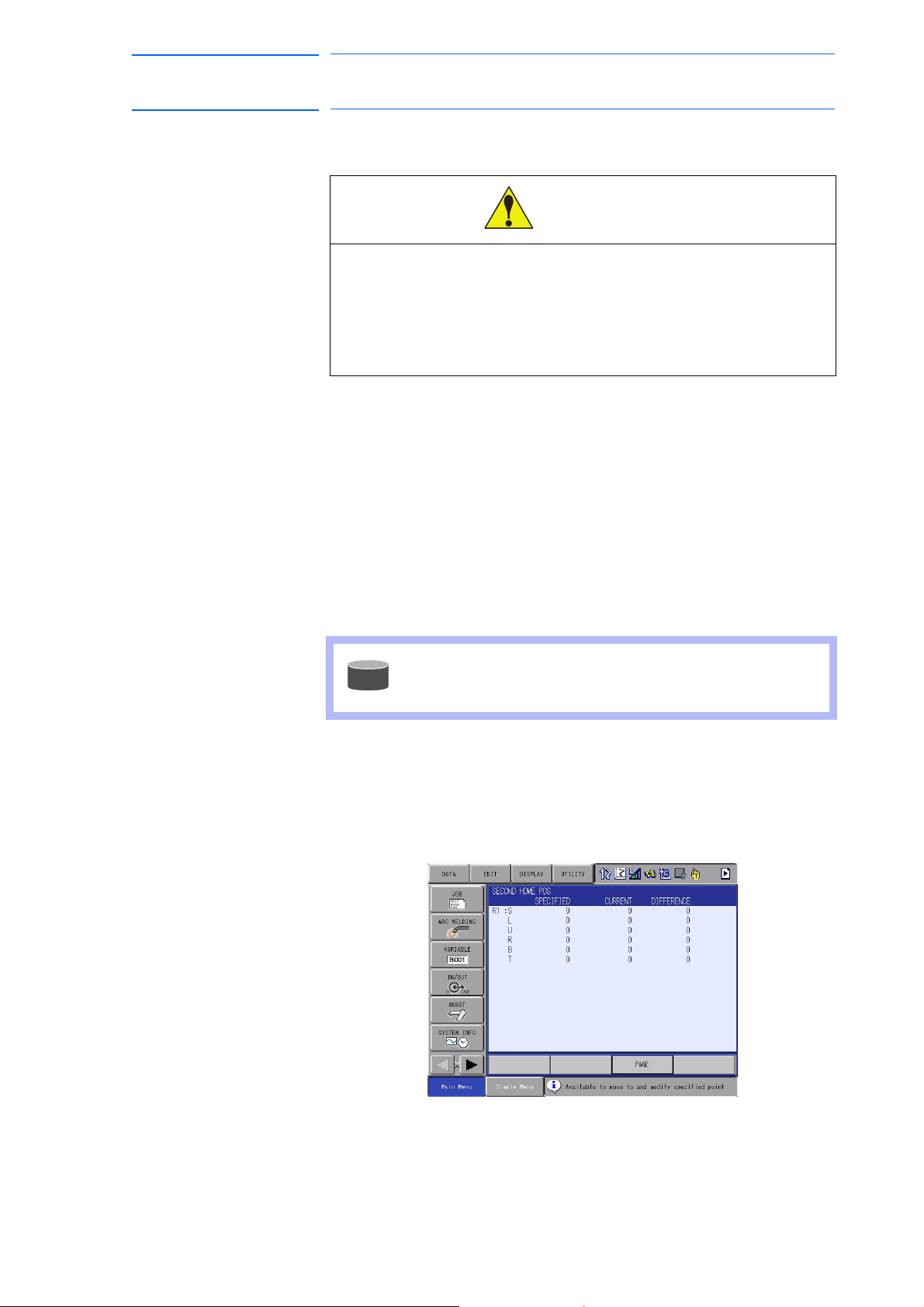

F1: Fuse