Page 1

DSD 406 / DSD 412

Technical Manual

MagneTek

Page 2

a

3/21/96

© 1996 by

MagneTek, Inc.

New Berlin, Wisconsin

All rights reserved. No part of this publication may be reproduced or used in any form by any means – graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems – without written

permission of the publisher.

MicroTrac, DSD, PAC and MagneTek are trademarks of MagneTek, Inc.

The following table shows all pages that have been revised since the first issue

of this manual.

Revision Affected Pages

Date

4/15/94 Initial

3/21/96 Overall revision

Revision

History

Related

Documents List

The following publications provide additional information on the DSD 406 / 412

drives. Each is available from MagneTek.

● PCDU Guide TM 6305

Additional copies of this manual can also be ordered by specifying the

DSD 406 / 412 Product Guide (TM 6107).

Page 3

Warranty

i

Warranty

3/21/96

Warranty

Standard products manufactured by MagneTek are warranted to be free from

defects in workmanship and material for a period of one year from date of

shipment and any products which are defective in workmanship or material will

be repaired or replaced, at MagneTek's option, at no charge to the Buyer. Final

determination as to whether a product is actually defective rests with MagneTek.

The obligation of MagneTek hereunder shall be limited solely to repair or

replace, at MagneTek's discretion, products that fall within the foregoing

limitations, and shall be conditioned upon receipt by MagneTek of written notice

of any alleged defects or deficiency promptly after discovery and within the

warranty period, and in the case of components or units purchased by

MagneTek, the obligations of MagneTek shall not exceed the settlement that

MagneTek is able to obtain from the supplier thereof. No products shall be

returned to MagneTek without its prior consent. Products which MagneTek

consents to have returned shall be shipped prepaid f.o.b. MagneTek's factory .

MagneTek cannot assume responsibility or accept invoices for unauthorized

repairs to its components, even though defective. The life of the products of

MagneTek depends, to a large extent, upon the usage thereof, and MAGNETEK

MAKES NO WARRANTY AS TO FITNESS OF ITS PRODUCTS FOR THE

SPECIFIC APPLICATIONS BY THE BUYER NOR AS TO PERIOD OF

SERVICE UNLESS MAGNETEK SPECIFICALLY AGREES OTHERWISE

IN WRITING AFTER THE PROPOSED USAGE HAS BEEN MADE

KNOWN TO IT.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE AND BUYER HEREBY

WAIVES ANY AND ALL CLAIMS THEREFORE.

IN NO EVENT SHALL MAGNETEK BE LIABLE FOR LOSS OF PROFIT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES WHETHER

ARISING OUT OF WARRANTY, BREACH OF CONTRACT OR TOR T.

Limitation

of Liability

Page 4

Manual Contents

ii

Table of Contents

3/21/96

Table of

Contents

Page

Introduction ........................................................................................................ 1

How To Use This Manual ............................................................................. 1

Controls and Indicators ................................................................................. 1

Safety Statements .......................................................................................... 2

How To Contact MagneTek .......................................................................... 2

DSD Drive Description ................................................................................. 3

System Considerations .................................................................................. 5

Installation and Start-Up .................................................................................. 9

Pre-Installation Considerations ..................................................................... 9

Physical Installation ...................................................................................... 9

Electrical Hook-Up ..................................................................................... 14

Use of An Analog Tachometer ................................................................... 20

Pre-Power Check ......................................................................................... 20

Drive Start-Up ............................................................................................. 21

Operation .......................................................................................................... 23

Controls and Indicators ............................................................................... 23

Start-Up Operation ...................................................................................... 25

General Operation........................................................................................ 26

Parameter Functions .................................................................................... 28

Monitor Functions ....................................................................................... 30

Upload/Download of Program/Parameters ................................................. 31

Upload/Download Introduction and Definitions......................................... 31

General Upload/Download Procedures....................................................... 33

Error Handling/Reporting ........................................................................... 45

Non-Volatile “Ram”-Access ....................................................................... 51

Load Defaults Function ............................................................................... 53

Self-Tune (PCU Parameter Measurement) ................................................. 54

Maintenance ..................................................................................................... 57

Preventive Maintenance .............................................................................. 57

Power Conversion Unit Diagnostics............................................................ 58

Troubleshooting Guide................................................................................. 61

Replacing Fuse(s)......................................................................................... 77

Replacing DSD Drive Control PCB............................................................ 79

Replacing the Fan......................................................................................... 81

Replacing the Power Supply........................................................................ 85

Replacing the DSD Armature Interface PCB.............................................. 87

Spare Parts List ............................................................................................... 89

Glossary ............................................................................................................ 95

Index .............................................................................................................. 104

Page 5

List of Tables

Table

Number Title Page

1 Drive Ratings and Specifications.................................................... 5

2 # Function Code Descriptions........................................................ 27

3 Troubleshooting Guide .................................................................. 61

4 Connectors on Drive Control PCB................................................. 79

5 230 Volt Drives Spare Parts............................................................ 89

6 460 Volt Drives Spare Parts ........................................................... 91

7 Burden Resistor .............................................................................. 93

8 Power Range Resistor..................................................................... 94

Manual Contents

iii

List of Illustrations

3/21/96

List of

Illustrations

Figure

Number Title Page

1 Typical MicroTrac DSD System Diagram..................................... 7

2 Dimensions and Mounting Holes

DSD 406/412 1-60 Hp Versions..................................................... 10

3 Dimensions and Mounting Holes

DSD 406/412 75-125 Hp Versions................................................. 11

3.1 Dimensions and Mounting Holes

DSD 412 150-200 Hp Versions...................................................... 13

4 Shield Sheath Termination ............................................................ 16

5 Basic Connections for DSD Power Cube –

Ratings up to 206 Amps................................................................. 17

6 Connections to TB3 and TB1 DSD Power Cube –

Ratings up to 206 Amps................................................................. 18

7 Grounding of Multiple Units.......................................................... 19

8 Operator Controls and Indicators................................................... 23

9 DSD 406/412 to IBM PC Compatible Comp. Inter. Diagram...... 31

10 DSD Drive Fuse Replacement....................................................... 76

11 DSD Drive Control PCB................................................................ 78

12 Replacing DSD Fan........................................................................ 66

13 DSD Power Supply Replacement.................................................. 84

14 DSD Armature Interface PCB Replacement ................................. 86

Page 6

1

Introduction

1

How To Use This Manual

3/21/96

MagneTek has made this product guide an easy to use reference. To help you

use this manual, we have provided the following guides:

● The top of each page has an identification of the section. For example, notice

that at the top of this page appears. This identifies

the page as part of Section 1, Introduction. There are four sections in this

manual: Introduction, Installation and Start-Up, Operation and Maintenance.

● Each section is organized into one or more major subject headings. These are

the main topics covered in that section. You will recognize major subject

headings by their distinctive appearances. The next line illustrates an

example:

This is an example of a major subject heading from Section 3.

Each major subject heading may have one or more minor topics that are

covered. The next line illustrates an example:

This is a minor topic covered under “Controls and Indicators.”

Each minor topic may have one or more descriptive headings. These identify

items covered within the minor topic. The next line illustrates an example:

This is a descriptive heading covered under “Status LEDs.”

At the bottom of each page is the name of the first major subject heading

covered on that page. The page number and revision date are also included.

For example, at the bottom of this page, the information indicates that “How

to Use This Manual” is the first major subject heading. The revision date

indicates the last date the page was changed in any way .

Using the information on the top of the page to find the section, the bottom of

the page to find the major subject heading and the left margin to find the

minor topics and descriptive headings, you can easily page through the

manual to find the information you need.

A table of contents and index are also included. The Table of Contents can be

used to locate sections and major topics. The Index is helpful in locating

specific terms or topics. A glossary is provided to define terms which may be

unfamiliar.

How To Use

This Manual

Controls and

Indicators

Status LEDs

Ready

1

Introduction

Page 7

1

Introduction

2

Safety Statements

3/21/96

Safety

Statements

How To Contact

MagneTek

In addition to notes, the following types of precautionary statements appear in

this manual.

IMPORTANT

A statement of conditions which should be observed during drive

setup or operation to ensure dependable service.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults or degraded drive system

performance.

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or serious equipment damage.

For additional information, contact any MagneTek Representative, or

Authorized Distributor, or contact the DSD Technical Support Staff at:

MagneTek, Inc.

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939 (414) 782-0200

FAX: (414) 782-1283

Page 8

1

Introduction

3

DSD Drive Description

3/21/96

DSD Drive

Description

Regeneration

Capability

Flexibility

Control

Accuracy

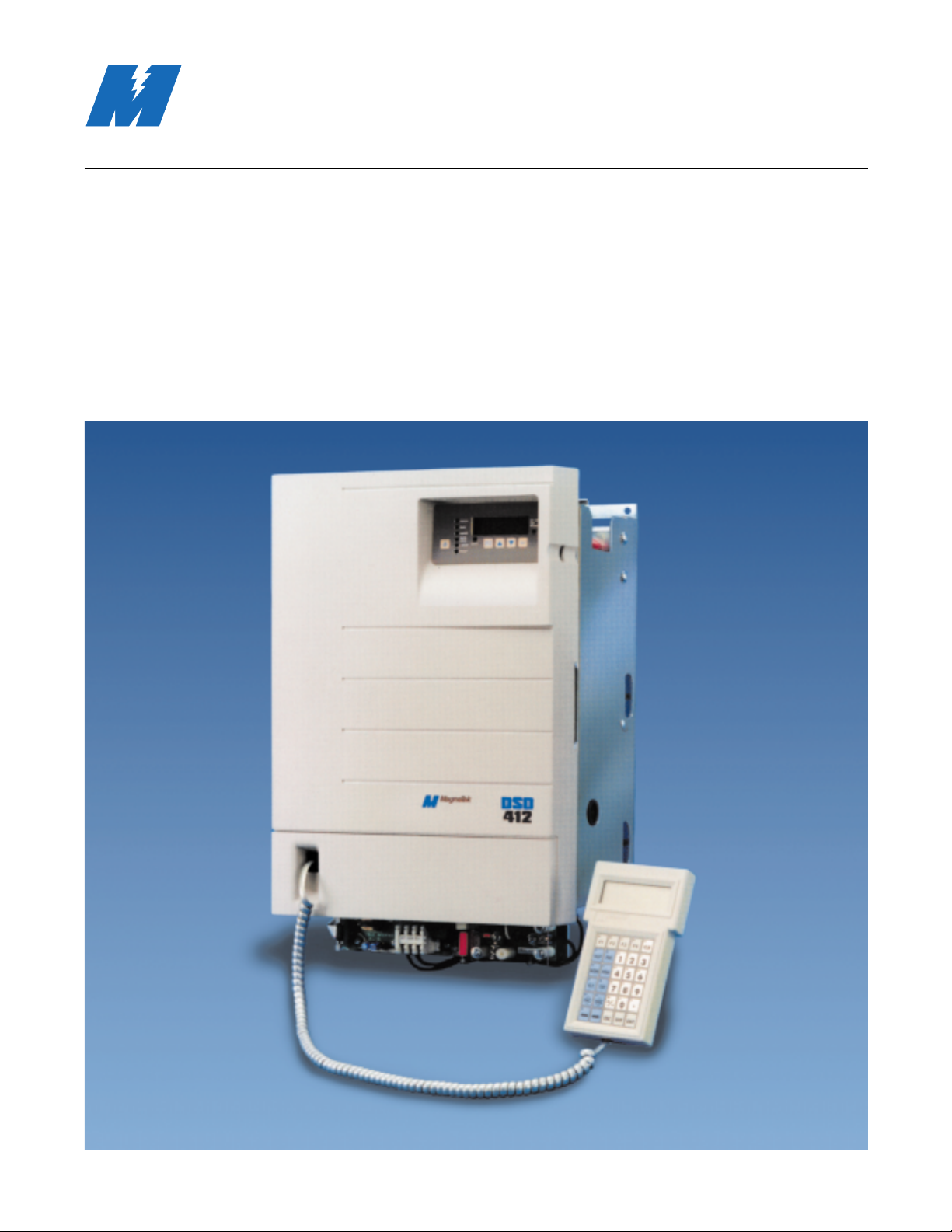

The MicroTrac®DSD is a complete digital system drive which provides

individual drive and system control in one compact package. This manual

describes two basic configurations, the DSD 406 (6SCR) Nonregenerative and

the DSD 412 (12SCR) Regenerative. All descriptions pertain to both

configurations unless specifically noted.

The nature of an electric motor is such that, if more torque is applied to the

motor by the load than is applied to the load by the motor, the motor will act as

an electrical generator, producing an electrical current. This phenomenon, called

regeneration, occurs anytime the speed of the motor is above the reference (or

preset) speed, sometimes referred to as an “overhauling load” condition. A

regenerative drive, such as the DSD 412, has the capability to feed the electrical

power generated by the motor back into the supply mains. Also referred to as

four-quadrant operation, it is this capability which requires that the DSD 412

contain a total of 12 SCRs, rather than the six included in the two-quadrant,

Nonregenerative DSD 406.

The drive uses two microprocessors, one for the Power Conversion Unit

circuitry , one for the Drive Control Unit circuitry, and is totally software

configurable to the application through a high level language. This provides

complete flexibility without having to make hardware adjustments. Interface to

other equipment is provided with Local Input/Output (I/O) or a high speed Local

Area Network. Use of the MicroTrac Local Area Network (LAN) means that a

single coaxial cable eliminates multiple conductor cables and provides high

noise immunity .

Extensive diagnostics and setup capability are provided through two

Control/Display Units. The Standard Control/Display Unit (SCDU) is mounted

on the Drive Control PCB and consists of a 4-1/2 digit numeric LED display ,

four push buttons and LEDs. The SCDU can be used for all setup functions and

many diagnostics. The Portable Control/Display Unit (PCDU) is an optional

hand-held device that can be plugged into any DSD drive and used for all the

same functions as the SCDU plus some advanced diagnostics. The PCDU has

two lines of sixteen alphanumeric characters and a thirty-key keypad.

The distributed control architecture of the DSD systems means that each drive

performs its own regulation calculations synchronized to a common high

accuracy crystal master. Thus even minute crystal drift will not affect multiple

drive tracking. This allows a DSD system to maintain the drift between sections

at 0.00% steady state. The fully digital nature of the regulation means that an

individual drive can maintain a 0.00% average difference between set and actual

speed from no-load to full-load when using digital tachometer speed feedback.

Digital setup and performance assure exact process line and finished product

duplication shift to shift and month to month.

Page 9

1

Introduction

4

DSD Drive Description

3/21/96

Useability

Characteristics

Speeds, tensions, ratios, draws, limits, ranges, alarms, and other control

parameters can be set as percentages or exact numerical values. Parameters are

entered and displayed in common understandable units. The drive can be

completely setup prior to actual running and changes can be made during

operation. Keypad entry of changed parameters, protected memory , and factory

default values allow the operator to modify data with minimum risk to the

process.

The DSD is available for general use as a complete panel mounted enclosed

drive (NEMA 1 or NEMA 12).

Authorized system integrators can also purchase the drive as a power cube. The

power cube is designed for mounting in a cabinet; space allowances for air

circulation, additional components, outgoing terminals, and wire bends must be

provided.

The enclosed drive consists of the DSD power cube mounted on a panel with a

skirted NEMA 1 or NEMA 12 enclosure, with added fused control transformer

for 115V supply, armature loop contactor, and field wiring terminals. An input

circuit breaker with through-the-door operator is available as an option.

The DSD drive is designed to be connected to a three wire ungrounded power

system, or a four wire grounded or ungrounded power system.

All DSD drives are programmed using MagneTek's PAC language. The drive

programming consists of two portions; the standard control programs shared by

all DSD drives and the application specific programming which defines how the

drive operates in the particular application. The latter portion of DSD drive

programs are developed based on the PAC language, wherein different drive

functions are represented by interconnected graphical symbols, called PAC

blocks, much like an electronic schematic. This provides the ability to quickly

modify programs, along with an assurance of program repeatability and stability .

PAC Language

Programming

Page 10

Ratings Protective Features

● 3.3 - 206 Amps

● 3 Phase, 48-62 Hz

● 1.0 Service Factor

● 150% full load current for one

minute

● 200% full load current for 10

seconds

Basic Drive Specifications

● Full-wave six-pulse SCR control

● Regulation (of set speed) to

0.00% with digital tachometer

speed feedback

● Current regulated shunt field

● Capable of constant HP

operation (requires tachometer)

● Self-adapting to incoming line

power of 230 or 460 VAC.

Service Conditions

● Line voltage 230 or 460 Vac, 3

phase, ±10% of nominal setting

● 115 volt, 1 phase control power

from separate source

● Frequency 48-62 Hz

● Incoming line impedance range

2%-10% of rated

● Operating Temperature 0-45° C

(55° C max at DSD chassis)

● Altitude to 3300 feet above sea

level

● Relative Humidity 95%

(noncondensing)

1

Introduction

5

System Considerations

3/21/96

System

Considerations

In order to operate in a system application, the DSD drive may be used with

other MagneTek devices with which it will communicate by means of the

MicroTrac Local Area Network (LAN). Refer to Figure 1 for a typical DSD

System.

Each of the following remote devices (board or assembly) is described in detail

in a separate User Reference Sheet.

● Remote Display Controller LAN Node PCB (RDC) – This board provides

a means for the DSD system to have system operating parameters displayed

● Programmed memory protection

● Self-protected control power

supply

● Fast phase-back of current

before loop contactor opens

● Contact interlock for E-Stop

● I

2

t motor overload protection

● AC line current limiting fuses

● DC bus fuse (DSD 412 only)

● Instantaneous over-current

protection

● Phase loss protection

● Input line monitoring

● Phase sequence insensitive

● dv/dt protection (snubbers)

● 1400 Peak Reverse Voltage

thyristors

● Field current economizer and

loss protection

● Tachometer monitoring and loss

protection

● Heat sink thermostat

● Automatic test of power circuit

upon power-up

● Control power supply loss

detection

● Isolated I/O and grounded

electronics

Table 1. Drive Ratings and Specifications

Page 11

1

Introduction

6

3/21/96

System Considerations

at locations remote from the DSD drive. The RDC communicates with the

drive through the LAN. A single RDC can support up to 31 Remote Display

Units (RDUs). By means of a Portable Control/Display Unit (PCDU), the

RDC allows the selected display for each RDU to be changed at anytime.

● Remote Display Unit (RDU) – Designed for mounting in a panel cutout, the

RDU provides a two-line LED display (16 character alphanumeric, and 5-1/2

digit numeric). It constitutes a terminal with the information on its display

transmitted to it by a Remote Display Controller LAN Node PCB (RDC).

● Remote Keyboard Assembly – Designed for mounting on a panel with or

near a Remote Display Unit (RDU), the Remote Keyboard allows initiation

of RDU display changes without the need for a Portable Control/Display

Unit (PCDU) plugged into the Remote Display Controller LAN Node PCB

(RDC).

● Remote I/O [Input/Output] Controller LAN Node PCB (RIO) – This

board provides a means for the DSD system to have inputs or outputs at

locations remote from the DSD drive. The RIO communicates with the

drive through the LAN. A single RIO can support up to 6 Remote I/O

boards, using any combination of the following three available types.

● Remote Logic I/O PCB (LOGIO) – This board provides isolated and non

isolated remote logic signal input/output capability for the DSD system. It is

connected to a Remote I/O Controller LAN Node PCB (RIO) for

communication with the DSD drive.

● Remote Analog I/O PCB (ANIO) – This board provides isolated and non

isolated remote analog signal input/output capability for the DSD system. It

is connected to a Remote I/O Controller LAN Node PCB (RIO) for

communication with the DSD drive.

● Remote Thumbwheel Switch I/O PCB (TWIO) – This board provides

remote thumbwheel switch input/output capability for the DSD system. It

can support up to 9 Thumbwheel Switch Assemblies. This board is

connected to a Remote I/O Controller LAN Node PCB (RIO) for

communication with the DSD drive.

● Remote Programmable Logic Controller (PLC) Interface – Available for

PLCs from many major manufacturers. It allows bi-directional

communication via the MicroTrac LAN between DSD drives and the PLC.

Both logic and numeric data can be transferred.

● Remote Power Supply – The Remote Power Supply produces control level

voltages for use by a Remote LAN Node PCB or a Remote Display Unit.

● Remote Serial Communication Controller LAN Node PCB (RSC) – This

board provides a means for the DSD system to have input from or output to

other equipment that uses RS-232 serial communication. The RSC

communicates with the DSD drive through the LAN.

Page 12

1

Introduction

7

3/21/96

System Considerations

Figure 1. Typical MicroTrac DSD System Diagram

MicroTrac

Drive

DRIVE

CONTROL

UNIT

93 Ohm

Terminator

93 Ohm

Terminator

INPUT/OUTPUT

REMOTE

CONTROLLER

PCB (RIO)

MicroTrac

Drive

DRIVE

CONTROL

LOCAL

I/O

PROGRAMMABLE

LOGIC

CONTROLLER (PLC)

UNIT

REMOTE

PLC

INTERFACE

LOCAL

I/O

RG 62/U Coaxial Cable

2.5 million bits/second

REMOTE

COMMUNICATIONS

CONTROLLER

PCB (RSC)

MicroTrac

CONTROL

RS-232

Drive

DRIVE

UNIT

LOCAL

I/O

REMOTE

DISPLAY

CONTROLLER

PCB (RDC)

RS-485

PCDU

DISPLAY #1

8 ISOLATED LOGIC

REMOTE

LOGIC

INPUT/OUTPUT

PCB

(LOGIO)

REMOTE

ANALOG

INPUT/OUTPUT

PCB

(ANIO)

REMOTE

THUMBWHEEL

INPUT/OUTPUT

PCB

(TWIO)

UP TO 6 REMOTE INPUT/OUTPUT PCBS

I/O MODULES

7 NON-ISOLATED

LOGIC OUTPUTS

16 NON-ISOLATED

LOGIC INPUTS

2 NON-ISOLATED

ANALOG OUTPUTS

4 ISOLATED ANALOG

I/O MODULES

4 NON-ISOLATED

ANALOG OUTPUTS

4 NON-ISOLATED

ANALOG INPUTS

PERSONAL

COMPUTER

UP TO 9 BANKS OF

6 DIGITS

+188888

8 8 8 8 8 8

+188888

THUMB

WHEELS

UP TO 31 REMOTE

DISPLAY UNITS

REMOTE

DISPLAY

UNIT (RDU)

DISPLAY #2

MESSAGE

DISPLAY #3

DISPLAY #4

KEYBOARD

123DC

456DN

7

89

+

-

•

0

NE

KEYBOARD

SELECT

ENABLE

LA-8

Page 13

2

Installation and Start-Up

9

3/21/96

Pre-Installation Considerations

Pre-Installation

Considerations

Receipt of

Shipment

Unpacking

Re-Packing

Physical

Installation

The “Installation and Start-Up” section describes and illustrates the following:

● How to select the site to install your DSD drive.

● How to mount your DSD drive.

● How to connect your DSD drive to incoming power and the motor .

● How to start-up the system after it is installed.

The DSD drive is air cooled. The lowest HP rated units are cooled by

convection; all other units are equipped with a fan to ensure adequate air flow .

Select a site for installing the drive which is clean and well ventilated.

Maintenance will be minimized if the drive is located in a clean atmosphere. The

standard drive is designed for vertical mounting.

All equipment is fully tested at the factory . Any damage or shortages evident

when the equipment is received must be reported immediately to the commercial

carrier who transported the equipment. Assistance, if required, is available from

your MagneTek representative. Always refer to the order number, equipment

description, and serial number when contacting MagneTek.

For long periods of storage, equipment should be covered to prevent corrosion

and should be placed in a clean, dry location. If possible, equipment should be

stored in its original crating. Periodic inspection should be made to ensure that

the equipment is dry and that no condensation has accumulated. The equipment

warranty does not cover damage due to improper storage.

Remove the protective shipping material from around the equipment. Remove

all packing material. Unbolt the equipment from its crate. Inspect for loose

wiring. Make sure that all contact wedges and other shipping devices have been

removed.

The drive should be bolted in a crate which provides at least 2 inches clearance.

The drive should then be wrapped in polyethylene and covered with wax

impregnated double walled # 350 corrugation and crated. Assistance, if

required, is available from your MagneTek representative.

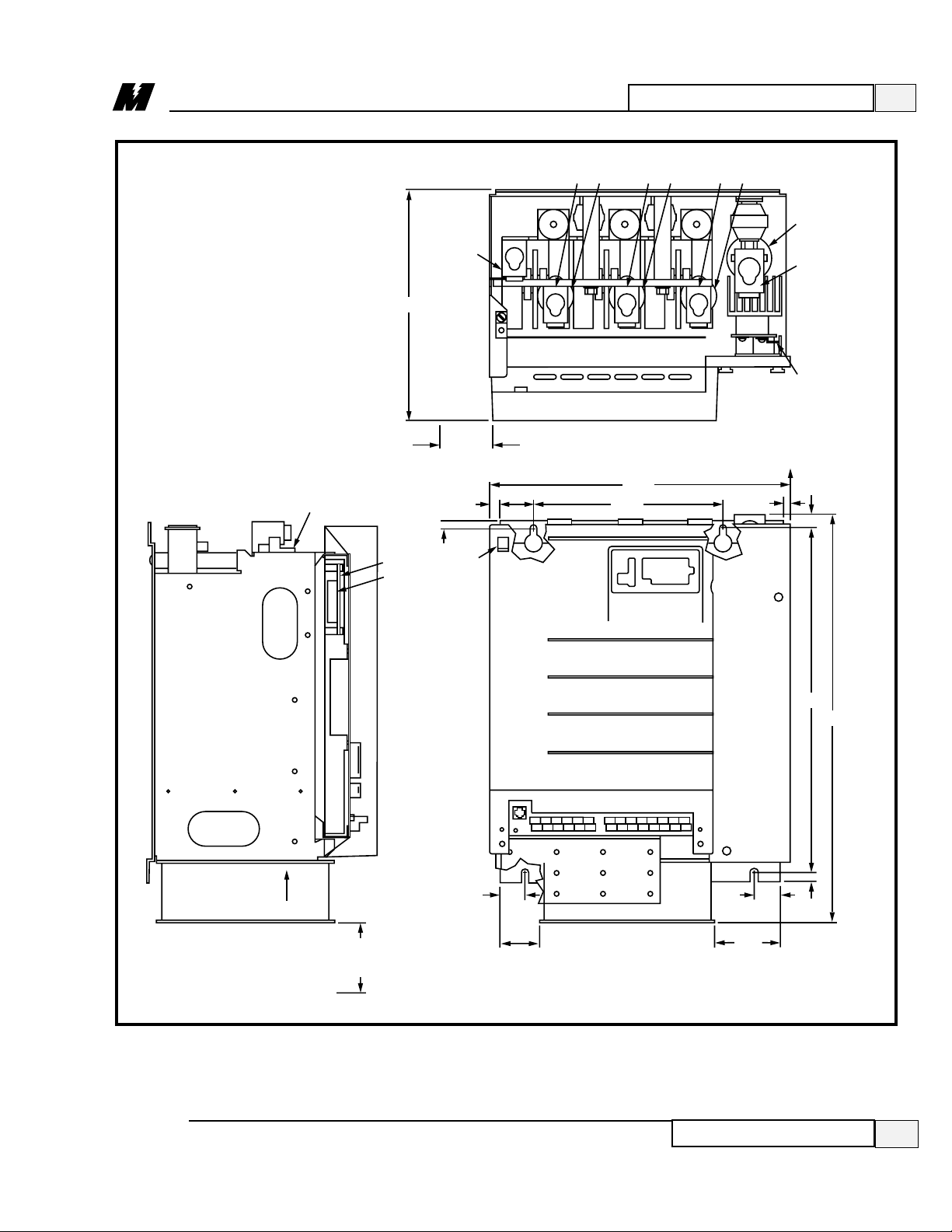

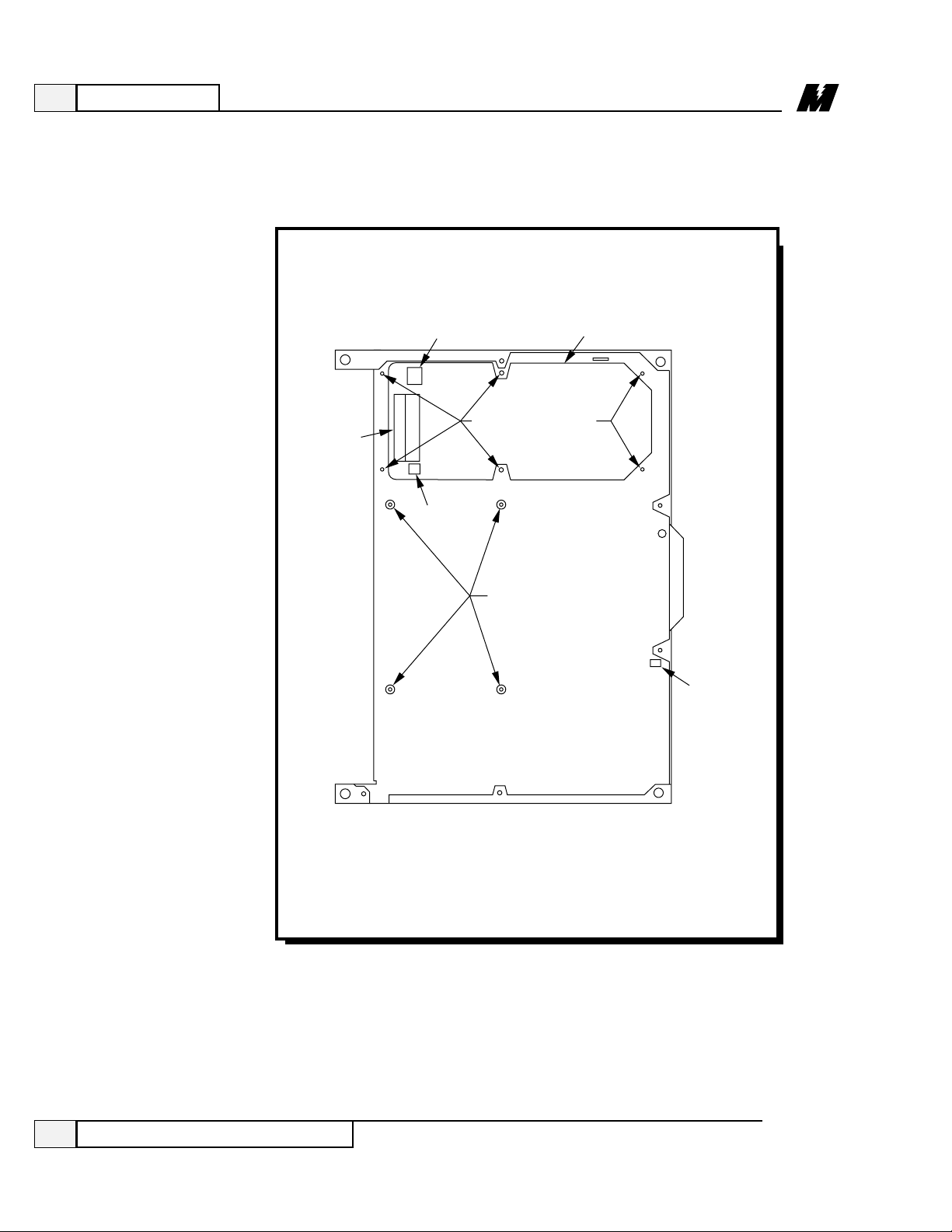

Attach the drive to a cabinet panel or other vertical structure using the mounting

holes provided at the back of the drive (refer to Figure 2, 3 or 3.1 for dimensions

and mounting hole locations). Allow six inches top and bottom and two inches

at sides for free air circulation. For either style, hinged door swing-out clearance

is the same as the width dimension. Ensure that the unit is level.

Storage

CAUTION

The DSD Drive Control PCB has electrostatic sensitive

components. You must follow Electrostatic Discharge (ESD)

procedures to protect the components.

Page 14

4/15/94

2

Installation and Start-Up

10

Physical Installation

Figure 2. Dimensions and Mounting Holes

DSD 406/412

1-60 Hp Versions

MIN. DOOR

SWING

CLEARANCE

2.00

(APPROX. 6.75"

ABOVE MTG. SURFACE)

9.75

0.50

0.31

12.25

11.25

ARM.

NEG.

GND.

L3

L2

L1

NEG GND L1 L2 L3 POS

ARM.

POS.

0.31

FAN (WHEN SUPPLIED)

AIR

FLOW

A4

TB3

MOTOR

FIELD

CONNECTIONS

8

7

6

5

4

3

2

1

TB3

8

7

6

5

4

3

2

1

S3

J3

17.12

19.87

A1

TB1

TB4

2.44

J2

TB1

TB4

F2(–)

FAN (WHEN SUPPLIED)

11.25

3" MINIMUM CLEARANCE REQUIRED

0.50

LA-4

Page 15

2

Installation and Start-Up

11

Physical Installation

3/21/96

Figure 3. Dimensions and Mounting Holes

DSD 406/412

75 - 125 Hp Versions

0.31

GND

A4

TB3

MIN. DOOR SWING

WITH MATING DB9

CONNECTOR IN J1

8

7

6

5

4

3

2

1

J3

21.06

GND

2.69

0.38

0.94

18.06

F1 F2 F3 F4

12.00

11.25

ARM (–) L1 L2 L3

GND

TB3

8

7

6

5

4

3

2

1

11.00

13.06

0.44

ARM (+)

S3

FAN

AIR FLOW

13.88

A1

J2

TB1

TB4

FAN

MOTOR FIELD

CONNECTIONS

0.31

A3

0.38

4.00

ALLOW APPROX. 4" BELOW FAN FOR SERVICING

OF FAN, AND UNRESTRICTED AIR INTAKE.

AC1

07

0.38

1.25

LA-4A

Page 16

2

Installation and Start-Up

12

Physical Installation

3/21/96

Page 17

2

Installation and Start-Up

13

Physical Installation

3/21/96

Figure 3.1. Dimensions and Mounting Holes

DSD 412

150-200 Hp Versions

4.00 MINIMUM

CLEARANCE

REQUIRED

AIR FLOW

1.94

2.13

FAN

FAN

3.50

1.69

23.49

19.50

0.50

A4

TB3

17.09

10.75

0.505

0.83

12.50 MIN.

WIRE BEND

ALLOWANCE

1.94

0.58

2.38 MIN.

DOOR SWING

0.438

12.93

GND

ARM (–)

GND

UNPLUG TB3

FROM HEADER

WHILE

INSTALLING

WIRES.

LA-100

TB1

A1

J2

8

7

6

5

4

3

2

1

(TERMINAL BLOCK QTY PER DRIVE SPECIFICATION)

L1 F1 L2 F2 L3 F3

F4

ARM(+)

MOTOR

FIELD

CONNECTIONS

GND

Page 18

2

Installation and Start-Up

14

Electrical Hook-Up

3/21/96

Ensure that wire size and disconnect devices conform to the installation

contractor’s drawings and to all applicable codes.

● Although the three phase input power line is fuse protected internal to the

drive, it is recommended to provide branch circuit protection by means of a

circuit breaker in accordance with the National Electrical Code, local codes

and with a rating of not less than 5,000 rms Symmetrical Amperes and 600

Volts for 2 to 25 Hp rated drives or 10,000 rms Symmetrical Amperes and

600 volts for 30 to 60 Hp rated drives.

● Electronic overload protection is provided as part of the standard DSD

product. It si electronically timed and will shut down the drive along a

time/output current curve which provides shutdown at 60 seconds at 150%

or 10 seconds at 200% of rated output current. An overload relay may be

added external to the drive in accordance with the National Electrical Code

and local codes for additional protection.

● Main Circuit Input/Output Wire Sizing:

L1-3

: Using 600V vinyl-sheathed wire per the following table.

Electrical

Hook-Up

Recommended Wire Gauge (Copper Only)

Torque

Drive Hp

60°C 75°C

(in-lbs)

214 1435

314 1435

514 1435

7 8 10 40 - 35 *

10 8 10 40 - 35 *

15 6 8 45 - 40 *

20 6 8 45 - 40 *

25 4 4 45

30 4 4 45

40 1 150

50 1 150

60 1/0 180

75 3/0 250

100 3/0 250

125 250 MCM 325

150 600 MCM 375

200 600 MCM 375

* Torque per wire gauge.

Page 19

2

Installation and Start-Up

15

Electrical Hook-Up

3/21/96

ARM (–): Using 600V vinyl-sheathed wire per the following table.

ARM (+): Using 600V vinyl-sheathed wire per the following table.

● Field Current Wire Sizing: The recommended conductor for field current

ratings between 10.0 Ampere and 16.0 Ampere is 12 AWG. The

recommended conductor for field current ratings below 10.0 AMpere is 14

AWG. use 600 V vinyl-sheathed 105°C wire or equivalent. The

recommended torques on the field lugs for 14-10 AWG is 25 in-lbs.

Recommended Wire Gauge (Copper Only)

Torque

Drive Hp

60°C 75°C 90°C

(in-lbs)

214 14 35

314 14 35

514 14 35

7 6 8 45 - 40 *

10 6 8 45 - 40 *

15 4 4 45

20 4 4 45

25 3 50

30 3 50

40 1/0 50

50 1/0 50

60 3/0 50

75 250 MCM 325

100 250 MCM 325

125 350 MCM 325

150 500 MCM 375

200 750 MCM 375

* Torque per wire gauge.

Recommended Wire Gauge (Copper Only)

Torque

Drive Hp

60°C 75°C 90°C

(in-lbs)

214 14 35

314 14 35

514 14 35

7 6 8 45 - 40 *

10 6 8 45 - 40 *

15 4 4 45

20 4 4 45

25 3 50

30 3 50

40 1/0 180

50 1/0 180

60 3/0 250

75 250 MCM 325

100 250 MCM 325

125 350 MCM 325

150 500 MCM 375

200 700 MCM 375

* Torque per wire gauge.

Page 20

2

Installation and Start-Up

16

Electrical Hook-Up

3/21/96

● If the DSD drive is being used in a system application, use a BNC "T"

connector to connect LAN (Local Area Network) coaxial cable to J3 on the

DSD Drive Control PCB.

● The coaxial cable must ultimately be terminated at both ends by a 93 ohm

termination resistor. (MagneTek part number 05P00034-0586)

Figure 4. Shield Sheath Termination

● GND: Recommended conductor size, 2 AWG 600 V vinyl-sheathed for

COPPER wire, 1/0 AWG 600 V vinyl-sheathed for ALUMINUM OR

COPPER CLAD ALUMINUM wire. Recommended torque on the GND

lug is 50 in-lbs.

● Control Wire Sizing:

TB1

: Recommended conductor size, 22-18 AWG 300 V 105°C

vinyl-sheathed wire. Recommended torque is 3.4 in-lbs.

TB3

: Recommended conductor size, < 12 AWG 300 V 105°C

vinyl-sheathed wire. Recommended torque is 5 in-lbs.

TB1

: Recommended conductor size, 14 AWG 300 V 105°C

vinyl-sheathed wire. Recommended torque is 3.4 in-lbs.

Observe the following when wiring:

● Separate the leads used for speed reference, feedback, and other low level

signals from those used for the motor armature, field and AC power.

Do not run these two groups in the same conduit or wire trough.

● Provide shielded and twisted leads as indicated on the Schematic and/or

Interconnection Diagrams. Connect all shields on shielded wire to system

common (not ground) on one end only . Twisted shielded pair wire should be

used for long runs. (Refer to Figure 4 for proper cable preparation.)

SHIELD SHEATH

OUTER JACKET

TO DSD

406/412

SIGNAL

TERMINALS

TO SHIELD

SHEATH

TERMINAL

CRIMP

CONNECTION

WRAP BOTH ENDS

OF SHEATH WITH

INSULATING TAPE

DO NOT

CONNECT

TO

EXTERNAL

CIRCUIT

LA-9

Page 21

2

Installation and Start-Up

17

Electrical Hook-Up

3/21/96

For a NEMA 1 or open panel mounted drive, refer to the equipment

Interconnection Diagram for detailed wiring information.

If only a power cube was ordered, the following connections need to be made

(refer to Figures 5 and 6 for location of terminating points on drives rated up to

330 Amps):

❏ On units rated at 206A armature current (206A Iarm) or less, connect the

three phases of the line from the load side of the isolation transformer or

input circuit breaker to fuses F1, F2, and F3 (marked L1, L2, and L3).

(Refer to Figure 5.) Phase rotation is not important.

Figure 5. Basic Connections for DSD Power Cube –

Ratings up to 206 Amps

WARNING

The external COAST STOP circuit shown on the

Schematic Diagram MUST BE WIRED to the drive as a

safety consideration in case of microprocessor failure.

3 PHASE 230-460 VAC INPUT POWER

FROM CIRCUIT BREAKER OR

ISOLATION TRANSFORMER.

PHASE ROTATION IS NOT IMPORTANT

GND

NEG

L1 L2 L3 POS

F2F1 F3

F4

(DSD

412

ONLY)

K1

DBR

K1

OR

OR

A2

MTR

ARM.

A1

K1

CONNECT TO

ONLY ONE

TERMINAL

PER

APPLICATION

CONNECT HERE

FOR DSD412

ONLY

ARMATURE INTERFACE PCB (A2)

(MOUNTED ON SCR BUS BARS)

TB5 (PART OF E5

SCR BUS BAR)

FIELD INTERFACE PCB (A3)

L2A

L1A

F1(+)

TB4

F1 F2

(+) (–)

MOTOR FIELD

FRONT VIEW OF POWER CUBE INTERIOR WITH SWING DOOR OPEN

F2(-)

AC

AC

+

2

1

–

2

(LOCATED UNDER

FIELD INTERFACE

CONNECT

HERE FOR

DSD406

ONLY

FIELD

CONTROL

MODULE

PCB)

LA-2

Page 22

2

Installation and Start-Up

18

Electrical Hook-Up

3/21/96

Figure 6. Connections to TB3 and TB1 DSD Power Cube –

Ratings up to 206 Amps

❏ On units rated at 206A or less, connect the motor field lead F1 (+) to

A3TB4(F1+), and motor field lead F2 (-) to Field Control Module (F2–).

(Refer to Figure 5.)

❏ On units rated at 206A Iarm or less, connect armature voltage sensing lead

(A1) to Armature Interface PCB(A2) TB5-2(+), and connect armature

voltage sensing lead (A2) to Armature Interface PCB TB5-1(–).

(Refer to Figure 5.)

❏ On units rated 206A Iarm or less, connect the motor armature A1 lead

through contactor N.O. contact to fuse F4 (in a DSD 412) or terminal E5 (in

a DSD 406). (Refer to Figure 5.)

❏ On units rated at 206A Iarm or less, connect the motor armature A2 lead

through armature contactor N.O. contact to terminal ‘NEG’. (Refer to

Figure 5.)

115 VAC LO

(NEUTRAL)

MOTOR

THERMOSTAT

MOTOR

LOOP

CONTACTOR

COAST

STOP

115 VAC HI

(HOT)

K1

DSD POWER SUPPLY PCB (A4)

TB3

8

7

6

5

4

3

2

1

DSD DRIVE CONTROL PCB (A1)

1

TBI

FRONT VIEW OF SWING OUT DOOR

4843

7

K1 AUX

42

84

LA-1

Page 23

❏ Connect 115 VAC control power to the DSD Power Supply PCB(A4), TB3-

1 (Hot) and (A4)TB3-7 (Neutral). This source must be rated at 250 VA or

greater. (Refer to Figure 6.)

❏ Connect the armature (motor loop) contactor coil to DSD Power Supply

PCB, (A4)TB3-4 and (A4)TB3-5. (Refer to Figure 6.)

❏ An auxiliary 10ma, 24VDC, low power, normally open (N.O.) contact from

the armature (motor loop) contactor must be connected to DSD Drive

Control PCB, (A1)TB1-48 and (A1)TB1-7, for the drive to operate.

(Refer to Figure 6.)

❏ The Coast Stop push button (maintained, 10ma, 24VDC, low power), MUST

BE CONNECTED to the DSD Power Supply PCB, (A4)TB3-3 and (A4)

TB3-6. (Refer to Figure 6.)

❏ Connect a grounding wire from the ground pole to the ground terminal

provided. The ground terminal is marked GND, and is located near the

power input and output terminals.

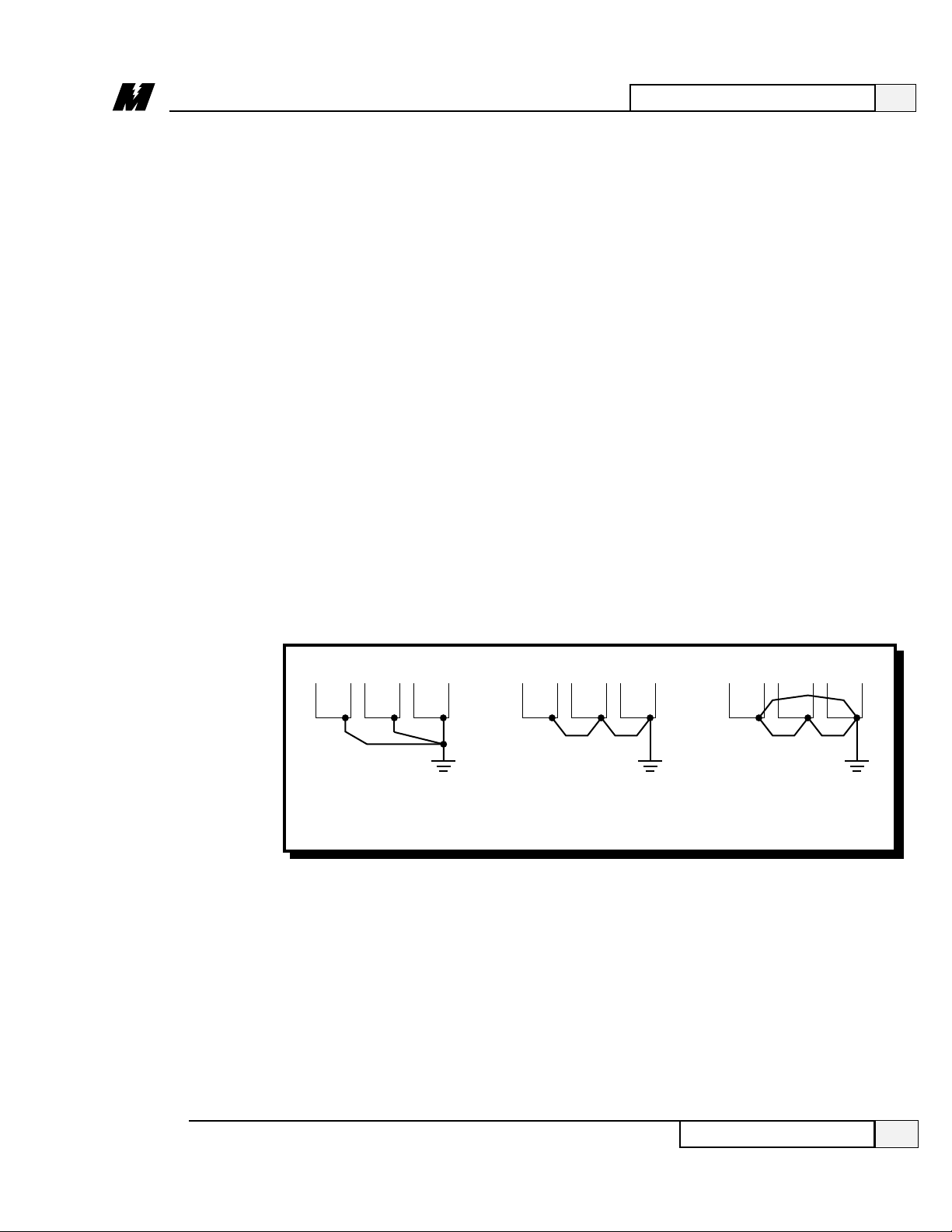

❏ Where several units are used side by side, all units should be grounded

directly to the ground pole. However, it is permissible to connect all the

ground terminals in series and ground only one unit to the ground pole (refer

to Figure 7). DO NOT FORM A LOOP WITH THE GROUND WIRES.

2

Installation and Start-Up

19

Electrical Hook-Up

3/21/96

❏ If dynamic braking resistors (DBR) are to be used, connect across motor

armature in series with loop contactor N.C. contact. (See Figure 5.)

Figure 7. Grounding of Multiple Units

CORRECT CORRECT NOT

ACCEPTABLE

GROUND

POLE

GROUND

POLE

GROUND

POLE

LA-10

Page 24

2

Installation and Start-Up

20

Using of An Analog Tachometer

3/21/96

❏ Inspect all equipment for signs of damage, loose connections, or other

related problem areas.

❏ Ensure the three phase line voltage is within +10% of the nominal input

voltage range of 230/460 VAC. Also verify that frequency is correct for the

drive system. Note that the drive is not sensitive to phase sequence. Input

power specifications are contained on the drive nameplate or the drive

system Schematic Diagram.

❏ Remove all shipping devices and relay wedges. Manually operate all

contactors and relays to ensure that they move freely .

Pre-Power

Check

CAUTION

To prevent damage to the drive, the following checks must be

performed before applying the input power.

IMPORTANT

In order to produce output to a motor, the power cube may also

need input and output signal connections for Local I/O. See

Schematic and/or Interconnection Diagrams for specific

connections.

The DSD 406 / 412 has provisions for an analog tachometer input at TB1

terminals 22 and 23. Either a DC or AC tachometer may be used as selected in

the PAC program. The hardware circuitry is designed for 75-120 volts DC or

50-85 volts AC of nominal input at rated top speed. For best performance, it is

recommended that a 50 volts per 1,000 rpm DC tachometer be used with 1750 or

2300 rpm motors.

If higher tachometer voltages are required, add an external resistor in series with

the tachometer wiring signal at terminal 23. Use 107 Kohms (±1%, 1/2 watt) for

each additional 100 volts expected signal. [ For example, add a 107 Kohm, 1%,

1/2 watt resistor in series with the tachometer wire at terminal 23 if a 100 volts

per 1,000 rpm DC tach is used with 1750 or 2300 rpm motors. ]

Use of An

Analog

Tachometer

CAUTION

The analog tachometer input channel may saturate if input

voltages exceed 150 volts DC or 106 volts AC at terminal 23.

This may cause loss of drive control and a drive speed runaway or component damage.

Page 25

2

Installation and Start-Up

21

Drive Start-Up

3/21/96

Drive Start-Up

❏ Ensure that all electrical connections are secure.

❏ Ensure that all transformers are connected for proper voltage according to

the drive system Schematic Diagram.

❏ Attach a DVM across the 115 VAC control power , at transformer T1

secondary terminals X1 and X2.

❏ Apply the three phase power and verify that the control power is between

103 VAC and 126 VAC as read on the DVM. Then press the RESET push

button on the front of the power cube, and observe the “Drive power-up

sequence” as described below .

NOTE: The "Drive Power-Up Sequence" is also described in the Operation

section of this manual under “Start-Up Operation”. If using upload/download

capabilities, please refer to DSD 406/412 Upload/Download procedure in the

Operation section.

❏ The “Drive Power-Up Sequence” can be observed by monitoring the

Standard Control/Display Unit (SCDU) on the front of the power cube.

❶ First, all of the segments on the digital LED display and all of the LEDs

will light for about one second.

❷ Then the LEDs and display extinguish and the drive will perform

internal checks.

❸ If the drive passes the self-test, then the READY LED will light and the

SCDU will display 'P-UP' to indicate a proper power-up.

Displays other than those mentioned above may occur. If abnormal display

conditions occur, the following actions maybe necessary to correct the situation:

● If no digits or LEDs ever light up, check for proper voltage between the 115

VAC control power lines, or for blown 115 VAC control power fuses, or for

a defective control voltage power supply in the power cube.

● If horizontal segment(s) of the SCDU display are lit, then one or more

phases of the three phase power are missing. Check the three phase power

fuses. See Section 3, Start-Up Operation, for more detailed information

about this test.

Page 26

2

Installation and Start-Up

22

Drive Start-Up

3/21/96

Parameter

Verification

● If the FAULT LED lights and a fault code appears on the SCDU, then refer

to the Fault/Error Codes List in Section 4, Maintenance, to see what caused

the fault and to find the correct solution. A fault code is the letter 'F'

followed by a number representing the fault. See Section 3, Operation, for

more detailed information about fault reporting and clearing.

● If the SCDU displays 'Prot', then the initial checks found that the protected

non-volatile RAM (NVRAM) has not been initialized. Move the NVRAM

PROTECTION switch to "OFF" in order to allow the CPU to initialize the

NVRAM with preprogrammed default values. Notice that the NVRAM

UNPROTECTED LED is now lit to indicate the NVRAM

PROTECTION switch position. Next, press the RESET push button. The

drive will go through its power up sequence again; however, this time it will

initialize the protected NVRAM. After the power up sequence has finished,

return the NVRAM PROTECTION switch to "ON" in order to assure

protection of this memory area. Notice that the NVRAM UNPROTECTED

LED is now turned off.

❏ On drives with fans, verify that the fans are working.

When the READY LED on the SCDU is lit, all the selectable parameter data

should be verified for the proper values as follows. See the PCDU Guide for

information on verifying and entering parameter values on a PCDU:

❏ VERIFY OR CHANGE EACH PARAMETER VALUE for the particular

application and motor involved.

❏ PCU DIAGNOSTICS (function # 998) should now be performed to verify

armature and field circuitry .

❏ SELF-TUNE (PCU Parameter Measurement) (function # 997) should be

performed before the drive is “RUN”. This gives the drive various motor

parameters essential for optimal operation. NVRAM protection must be off

to store parameters.

❏ SELF-TUNE SELECT (Function # *) should be turned on for optimal

operation. (* Check the PAC diagram for correct function number.)

❏ STORE PARAMETERS, (function # 994) so that power can be removed and

reapplied without losing the entered parameters. Remember that NVRAM

protection must be OFF to store parameters.

❏ Operate drive, using external control signal inputs shown on the system

schematic.

Page 27

3

Operation

23

3/21/96

Controls and Indicators

Controls and

Indicators

Pressing the reset button causes the drive to clear faults, or in some cases to reset

the drive, depending on the context.

To the right of the RESET button is a vertical strip of six light emitting diodes

(LEDs):

All status LEDs are under the control of the application specific software.

However, the following descriptions indicate typical uses for the LEDs. The

PAC diagram for this drive must be consulted to determine the actual meaning

for each LED.

Indicates that the drive is ready to operate.

DC loop contactor is closed and drive is controlling motor speed.

Drive is demanding armature current at or above the preset current limits.

RESET Button

Status LEDs

Ready

Run

Torque Limit

Figure 8. Operator Controls and Indicators

The “Operation” Section describes and illustrates the following:

● Operator’s controls and indicators.

● Steps you need to follow to start-up your DSD drive.

● Types of parameters that can be entered after start-up.

● Types of monitor functions available after start-up.

● Upload/Download of Programs or Parameters procedure.

● How to access error and fault lists and clear them.

● How to access non-volatile “RAM”.

● How to reload the default functions.

● Self-tuning feature.

The upper right corner of the power cube cover contains the operator controls

and indicators of the SCDU. Figure 8 identifies these operator components.

Although accessible with the cover in place, all of these components are part of

the DSD Drive Control PCB.

RESET

BUTTON

RUN (green)

READY (green)

SCDU

MEM

UNPROT

DOWN

NV RAM

PROTECTION

ENTER

E-STOP

(red)

FAULT (red)

OVERLOAD

(yellow)

TORQUE

LIMIT

(yellow)

+

DATA/FCTN

UP

LA-3

DATA

LED

DATA

PENDING

Page 28

3

Operation

24

Controls and Indicators

3/21/96

Standard

Control/Display

Unit (SCDU)

Non-Volatile

“RAM” Protection

Current exceeded safe levels for too long and drive was stopped to protect the

motor.

Drive contactor safety interlock is detected as open. Drive will not run when this

light is on.

Indicates that a declared drive fault exists. The Fault/Error Code List defines

what conditions the drive will recognize as faults.

IMPORTANT

Clearing a Fault from the Fault List is NOT THE SAME as

resetting the fault. Some faults are transient in nature and require

no further action after clearing the fault from the Fault List.

Others require some additional positive action to allow the drive

to continue to run. See the Fault/Error Code List for further

details.

The major part of the SCDU is a 4-1/2 digit numeric LED display . Each of its

four full digits can display the values of 0 to 9 plus limited alphabetic characters.

The so-called half digit can display only the value “1” and a plus or minus sign.

Below the numeric LED, is a single indicator and four push buttons. The four

push buttons (DATA/FCTN, ⇑[UP], ⇓ [DOWN], and ENTER) are used to

operate the SCDU.

Next to the numeric displays of the SCDU is a red LED labeled MEM

UNPROT. This LED is lit when the “protected” portion of the non-volatile

random access memory (NVRAM) can be written to. Protection of the NVRAM

is determined by the switch labeled NVRAM PROTECTION. When this

switch is in the "ON" position, the MEM UNPROT LED is off and the

protected portion of the NVRAM can not be written to. This prevents setup

parameters and other important constants from being accidentally erased or

changed. When these parameters need to be changed the switch can be moved

to the "OFF" position, removing the write protection and causing the MEM

UNPROT LED to be lit.

Fault

CAUTION

The NVRAM PROTECTION switch should be left in the

"ON" position to protect the NVRAM during the critical

power-up and power-down periods.

Overload

E-Stop

The optional Portable Control/Display Unit (PCDU) plugs into a telephone-style

jack at the bottom left of the DSD Drive Control PCB (accessible through a

cutout at the bottom left of the front cover). If your unit is equipped with this

option, refer to the PCDU guide provided with the unit for operating procedures.

Portable

Control/Display

Unit Connection

Page 29

3

Operation

25

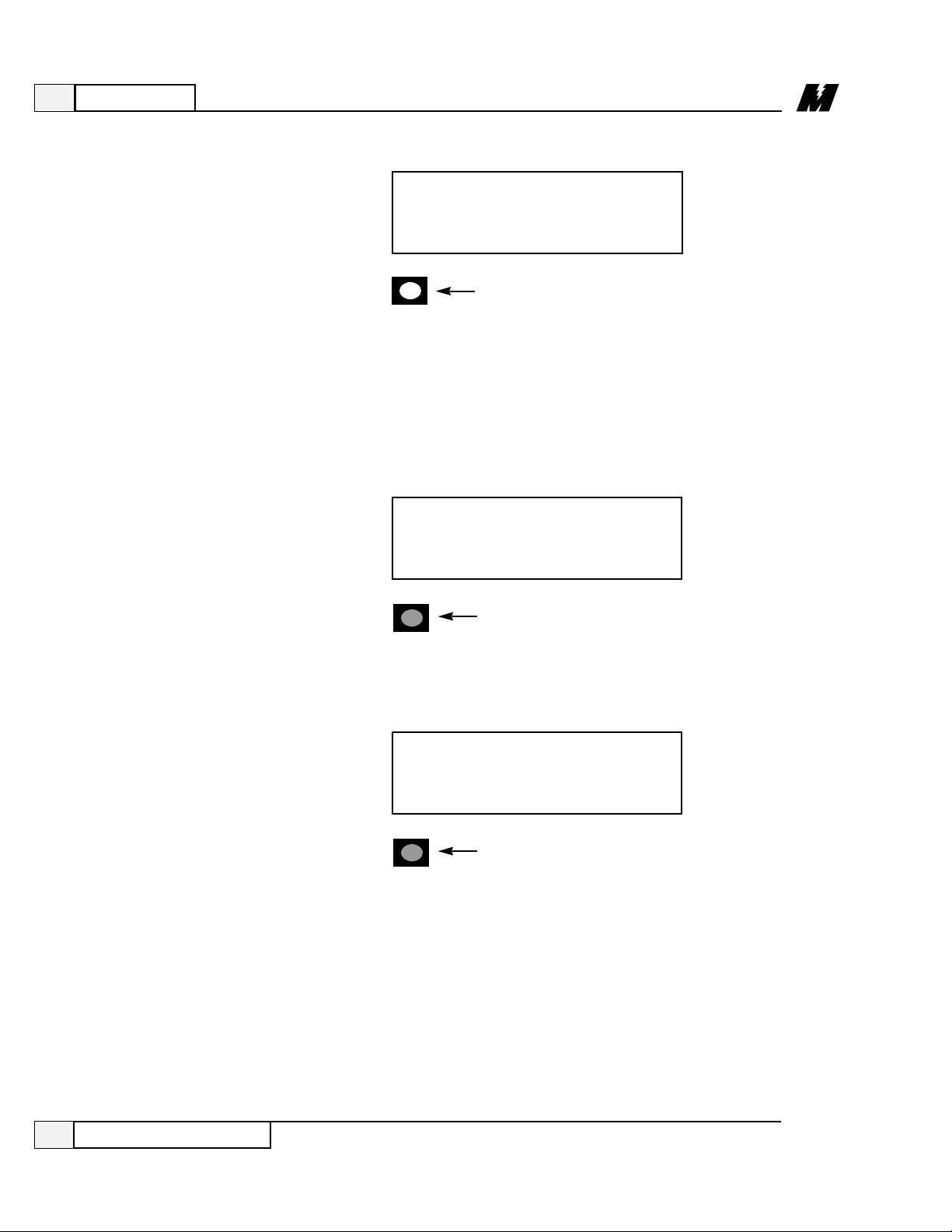

Start-Up Operation

3/21/96

Start-Up

Operation

❏ When power is first applied to the drive, all of the segments on the 4-1/2

digit display will turn on briefly in order to show that all are functioning:

❏ After this lamp test is completed, an internal check is made to determine if

the NVRAM chips have ever been used before, or if the EPROMs are the

same as before power-down. If not, the drive software will attempt to load

the defaults into the NVRAM chips. The SCDU displays the word ‘Prot’ if

the NVRAM PROTECTION switch is in the “ON” position; this prevents

NVRAM updates:

If the display shows ‘Prot’, it is necessary to move the NVRAM

PROTECTION switch to the "OFF" position and press the RESET button

in order to load defaults into NVRAM and restart the drive. Then set the

NVRAM PROTECTION switch back to "ON". This message will only

happen when the drive is powered up for the very first time or if the software

in the drive or the NVRAM chips are changed.

❏ After the LED lamp test has completed, the drive software will now perform

a fuse test on each of the three line fuses. If any power conversion fuse is

open, the SCDU will indicate this on its display as follows:

1.8.8.8.8.

-

.

.

prot

-

DATA

RED

Page 30

3

Operation

26

General Operation

3/21/96

If two fuses are blown, the SCDU display will be:

The drive will not operate unless all three line fuses are functional. If the SCDU

indicates a bad fuse, power must be removed from the drive, the fuse replaced

and power reapplied.

❏ After the drive has performed all three tests (lamp test, “RAM” test, and fuse

test), the SCDU displays one of two final messages. If there are any faults

present at this time, the SCDU will display a Fault code. The display will be

similar to:

where the leading ‘F’ indicates a fault and the 3 digits following the ‘F’

indicate the fault number. If however, there are no faults present, the SCDU

displays the normal power-up message:

General

Operation

This ‘P-UP’ display will remain on the SCDU until a key is pressed or a fault

occurs.

After the drive has powered up and the SCDU display is showing ‘P-UP’ or a

fault number, it can be used to enter new parameters, monitor drive operation,

and/or perform certain drive diagnostics. Every operation that the SCDU can

perform is called a ‘function’. There may be up to 1000 functions defined.

The function codes between # 000 and # 999 are grouped as follows:

- -

DATA

RED

OFF

DATA

f 102

OFF

DATA

p-up

Page 31

3

Operation

27

General Operation

3/21/96

All SCDU functions have at least 2 levels and some functions use 3 levels. The

data indicator below the lower left corner of the 4-1/2 digit display is used to

indicate which level of a particular function the SCDU is currently at. The top

level of the SCDU operation is called the "Function" level. The data indicator is

off when the SCDU is in the "Function" level. The ⇑or ⇓ keys are used to select

a function number to be accessed while at this level. The ⇑ key increments the

function number in the display while the ⇓ key decrements it. The SCDU will

ramp the displayed function number when the ⇑ or ⇓ key is pressed and held for

1/2 second or longer.

The DATA/FCTN key is used to toggle between the “Data” level and the

“Function” level. Press the DATA/FCTN key when the desired function

number is in the display . At this point, the SCDU leaves the "Function" level

and enters the "Data" level. Note that the data indicator is now GREEN. This

operation is consistent for every function on the SCDU, although the data

actually displayed while the indicator is GREEN is function-number specific.

Examples of every type of SCDU function are given in subsequent sections. All

function numbers are the same for both the SCDU and the PCDU (Portable

Control/Display Unit). (See the “PCDU Guide” for steps required for PCDU

function entry .) There are some functions, however, that can only be performed

with the PCDU. When such a function number is selected on the SCDU and the

DATA/FCTN key is pressed, the SCDU’s display will change to:

Function # Description

# 000 Reserved for the Fault Display/Clear Function

# 001 - 299 PAC dependent Parameter Mode (Settable Parameters)

# 600 - 799 PAC dependent Monitor Mode (View Only Values)

# 800 - 899 Reserved for Advanced Fault/Error Routines

# 900 - 999 Reserved for Diagnostic/Test Routines

Table 2. # Function Code Descriptions

Function

Levels

DATA/FCTN

Key

OFF

DATA

pcdv

Page 32

❏ Press the DA TA/FCTN key to enter the "Data" level for this function

number. The data indicator is GREEN to verify that the number being

shown is the current actual value for this parameter. For example, if function

# 040 is currently set for a value of 10.6, it will be displayed as follows:

❏ Use the ⇑ and ⇓ keys to ramp the number in the SCDU display to the desired

value. Note that the data indicator is RED to verify that the value being

displayed is NOT the actual value, but rather is in the process of being

changed. Each parameter has an upper and lower limit depending on the

PAC diagram. The following display will occur when the lower limit is

exceeded:

❶ Similarly, if the upper limit is exceeded, the SCDU displays:

GREEN

DATA

10.6

3

Operation

28

3/21/96

Parameter Functions

Parameter

Functions

SCDU functions # 001 through # 299 inclusive are used to modify and/or

display setup points that the drive needs for operation. Items that would

typically fall into this category are functions such as Accel Times, Regulator

Gains, Rated Speed and any other parameter that has been previously

programmed in the PAC diagram for the drive. The following steps show how

to modify a given parameter via the SCDU display .

❏ Use the ⇑ and ⇓ keys to select the function number (between # 001 and

# 299) to be accessed. The data indicator is turned off during this step.

In the example below , function # 040 is chosen:

OFF

DATA

40

DATA

RED

----

Page 33

3

Operation

29

3/21/96

Parameter Functions

❷ The SCDU display will increment from ‘10.6’ to ‘11.0’ if the ⇑

key is pressed 4 times:

❏ Press the ENTER key to transfer the value in the SCDU display to the actual

value used by the drive. Note that the data indicator will change back to

GREEN to indicate that this value is now the actual value for this parameter:

If the ENTER key is pressed while the display is indicating that the upper or

lower limit has been exceeded, the display will change to the appropriate

limit value and the LED will change to GREEN.

The DATA/FCTN key can be pressed any time before the ENTER key is

pressed, to cancel the changes and return to the initial value.

❏ Press the DA TA/FCTN key to put the SCDU back into the "Function" level.

As with the example above, the SCDU display will be:

DATA

RED

----

11.0

DATA

RED

GREEN

DATA

11.0

OFF

DATA

40

All changes made become active values upon pressing the ENTER key.

They remain active until the next reset, or until the drive is powered down.

Page 34

3

Operation

30

3/21/96

Monitor

Functions

Monitor Functions

Due to PAC programming considerations it may be possible to access a

value which cannot be changed. In this case the CDU function will proceed

as described until the ENTER key is pressed to change the value. In this

case the value will simply ignore any requested changes and remain the

same.

SCDU functions # 600 through # 799 inclusive are used to monitor those values

that cannot be directly changed by the operator. Items that would typically fall

into this category are Speed Feedback, Armature Current and Armature Voltage.

To view one of these values, it must have been previously programmed in the

PAC Diagram for the drive. The following steps show how to display a given

value on the SCDU display .

❏ Use the ⇑ and ⇓ keys to select the function number (between # 600 and

# 799) to be accessed. The data indicator is turned off during this step. For

example, if function # 604 is selected, the SCDU display will be:

❏ Press the DA TA/FCTN key to enter the "Data" level for this function

number. The data indicator is GREEN to indicate that actual data is

currently being viewed. If the data for function # 604 is currently at 20.94

for example, the SCDU display will change to:

OFF

DATA

604

When the drive is reset or powered up the value reverts to the value stored in

NVRAM. If changes are to be permanent, use function # 994 (described

later) to save the changed value in NVRAM.

GREEN

DATA

20.94

The SCDU’s display is updated immediately if the value for the selected

function changes.

NOTE: Values displayed with these function numbers cannot be modified.

Page 35

3

Operation

31

3/21/96

Upload/Download of Program/Parameters

Upload/

Download of

Programs or

Parameters

(T992)

In addition to the electrical connections, a serial communications

program must be used by the computer to access data through the

serial port. The serial port communications program must support Y

Modem Batch file transfer protocol (i.e. Qmodem).

Figure 9: DSD 406/412 to IBM PC Compatible

Computer Interconnect Diagram

The “Upload/Download of Programs or Parameters” Section describes

and illustrates the following:

● What is upload/download.

● General upload/download procedures.

● How to upload program into a new Flash ROM chip.

● How to upload a program.

● How to download a program.

● How to upload parameters.

● How to download parameters.

The DSD 406/412 have the ability to pass program and parameter

information between the drive’s memory and a computer with a serial

port. The direction of data flow is defined as Upload (from the

computer to the drive) or Download (from the drive to the computer).

Figure 9 shows the electrical connections required to connect the serial

port of the DSD 406/412 to the serial port (COM1 or COM2) of an IBM

PC compatible computer. The PC utilized must have a serial port and

disk drive.

ISOLATED

RS232 PORT

DB25 TO RJ12

CONVERTER

(P/N 46S03027-0010)

RJ12 CABLE

(P/N 05P00211-004)

9 TO 25 PIN

CONVERTER

(P/N 50210702)

IBM PC

COMPATIBLE

COM 1

Upload/

Download

Introduction

and Definitions

Page 36

3

Operation

32

3/21/96

The default data bit, stop bit and parity values of the drive are “8”, “1”

and “NO”, respectively. These settings can not be changed. The Y

Modem Batch file transfer is the only protocol available for

communicating with the DSD 406/412.

In uploading and downloading

files, the drive behaves like a

bulletin board service to the PC.

A file upload means that a file

is sent from the PC to the drive.

A file download means that a

file is sent from the drive to the

PC.

There are two file types associated with upload and download. The

PAC program file (i.e. the .PRG file) contains the executable

instructions that determine the application characteristics of the drive.

The parameter file is the file of all the parameter settings of a drive at

the time the .PAR file was captured.

● Program upload is the process of a computer sending a new

PAC program (i.e. the .PRG file) to a DSD 406/412 through the

drive’s serial port. This process may be required when, upon

application of power, the drive finds the PAC program loaded

into memory is invalid. This process may also be used when it is

desired to change the PAC program from what was previously

loaded. Some of the steps shown below are skipped when the

PAC program in memory is found to be invalid.

● Program download is the process of the DSD 406/412 drive

sending the PAC program (i.e. the .PRG file) through the drive’s

serial port to a computer. This process can be used for memory

backup.

● Parameter upload is the process of a computer sending all

settable parameters (i.e. the .PAR file) to a DSD 406/412 drive.

This process can be used to set up the drive with a set of tuned

constants.

Upload/Download of Program/Parameters

CAUTION

The communications software must be set up to match

the baud rate of the drive.

Communications Program Set-up

protocol: Y Modem Batch

parity: NO

data: 8

stop: 1

speed: 9600 or 19200

Page 37

3

Operation

33

3/21/96

General

Upload/

Download

Procedures

● Parameter download is the process of the DSD 406/412 drive

sending all of its settable parameter values (i.e. the .PAR file) to

a computer. This process can be used for memory backup. A

parameter download is the only data transfer process that can

occur while the drive is running a motor.

NOTE

The DSD 406 / 412 can not be running a motor while uploading

parameters or a program. It cannot also be running a motor if a

program download is occurring. The PAC program stops

execution during this time.

To perform an upload or download use function # 992. This will allow

you to upload or download PAC programs and parameters. The

following steps explaining how to perform these operations from the

Command/Display Unit, SCDU, resident on the drive:

❏ Check to verify the DATA PENDING light is “OFF”. If not,

press the DATA/FCTN key.

❏ Use the ⇑ and ⇓ keys to select function # 992. The display will

show the function number.

❏ Press the DATA/FCTN key. At this point the DATA/FCTN key,

the ⇑ key and the ⇓ key may be pressed.

● Press the DATA/FCTN key to return to the function entry

mode without performing any data transfers.

General Upload/Download Procedures

OFF

DATA

992

CAUTION

The NVRAM PROTECTION switch needs to be in the

“OFF” position to perform an upload.

The MEM UNPROT light will also need to be lit.

Page 38

3

Operation

34

3/21/96

● Press the ⇑ key to select an upload operation.

● Press the ⇓ key to select a download operation.

❏ Press the ENTER key to accept the Upload or Download

selection. At this point the DATA/FCTN key, the ⇑ key,

and the ⇓ key may be pressed.

● Press the DATA/FCTN key to return to the function entry

mode without performing any data transfers.

● Press the ⇑ key to select transfer of the program.

● Press the ⇓ key to select transfer of the parameters.

GREEN

DATA

pa(

GREEN

DATA

data

General Upload/Download Procedures

GREEN

DATA

send

GREEN

DATA

recv

❏ Press ENTER to accept the given action.

Page 39

3

Operation

35

3/21/96

The DSD 406/412 will automatically go into the upload/download

function # 992, on power up of a drive without DCU software or

replacement of a Flash ROM chip. The default baud rate of 19,200 will

be displayed.

❏ Use the ⇓ key to select the another baud rate if your terminal

does not support 19,200 baud. This will decrease the baud rate.

The ⇑ key is not applicable here since 19,200 is the maximum

baud rate.

❏ Press the ENTER key to accept the displayed baud rate. The

DSD 406/412 will begin to initiate transfer sequence.

A message will appear explaining that permanent storage memory is

being erased.

CAUTION

The communications software must be set up to match

the baud rate of the drive.

CAUTION

When the program transfer begins it must be completed.

eras

General Upload/Download Procedures

Upload

Procedure for a

New Flash ROM

Chip

WARNING

After putting in a new Flash ROM chip and

19,200 baud is not displayed on the SCDU,

contact MagneTek for assistance.

19200

Page 40

3

Operation

36

3/21/96

A message will appear explaining that the DSD 406/412 is attempting

to start the program transfer.

At this time, the DSD 406/412 is waiting to communicate with the PC.

You will see the LED’s on drive scroll upward to indicate it is ready to

upload. Y Modem protocol will be sent to the serial port in the form of

a ‘C’ character indicating that the transfer can start.

Initiate a Y Modem Batch file transfer from the PC (i.e. for Q modem

users, press the PgUp key for an upload and select the Y Modem batch

mode).

When transfer begins, a message will appear showing how much of the

transfer has already taken place. For a baud rate of 19,200, the transfer

will take approximately five minutes. The completion percentage

number counts as more data is transferred.

The LED’s will continue to scroll upward until the upload is complete.

When the upload finishes, the drive resets itself, runs an internal check,

and then executes the PAC program.

General Upload/Download Procedures

l0ad

GREEN

DATA

78

Page 41

3

Operation

37

3/21/96

❏ Press the DATA/FCTN key.

❏ Press the ⇑ key to select an upload operation.

❏ Press the ENTER key to accept the Upload selection.

❏ Press the ⇑ key to select transfer of the program.

❏ Use the DATA/FCTN key to exit out of the program upload

without performing any data transfers.

General Upload/Download Procedures

❏ Check to verify that the DATA PENDING light is “OFF”. If not,

press the DATA/FCTN key.

❏ Use the ⇑ and ⇓ keys to select function # 992. The display will

show the function number.

Program Upload

CAUTION

When the program transfer begins, it must be completed

because the existing program is erased.

OFF

DATA

992

GREEN

DATA

re(v

GREEN

DATA

pa(

Page 42

3

Operation

38

3/21/96

❏ Use the ⇓ key to select the another baud rate.

❏ Press the ENTER key to accept the displayed baud rate. The

DSD 406/412 will begin to initiate transfer sequence.

A message will appear explaining that permanent storage memory is

being erased.

A message will appear explaining that the DSD 406/412 is attempting

to start the program transfer.

General Upload/Download Procedures

❏ Press the ENTER key to accept the transfer of the program.

The current baud rate will be displayed.

19200

eras

l0ad

At this time, the DSD 406/412 is waiting to communicate with the PC.

You will see the LED’s on drive scroll upward to indicate it is ready to

upload. Y Modem protocol will be sent to the serial port in the form of

a ‘C’ character indicating that the transfer can start.

Initiate a Y Modem Batch file transfer from the PC (i.e. for Qmodem

users, press the PgUp key for an upload and select the Y Modem batch

mode).

CAUTION

The communications software must be set up to match

the baud rate of the drive.

Page 43

3

Operation

39

3/21/96

When transfer begins, a message will appear showing how much of the

transfer has already taken place. For a baud rate of 19,200, the transfer

will take approximately five minutes. The completion percentage

number counts as more data is transferred.

The LEDs will continue to scroll upward until the transfer is complete.

When the upload finishes, the drive resets itself, runs an internal check,

and then executes the PAC program.

❏ Check to verify that the DATA PENDING light is “OFF”. Press

the DATA/FCTN key.

❏ Use the ⇑ and ⇓ keys to select function # 992. The display will

show the function number.

❏ Press the DATA/FCTN key.

❏ Press the ENTER key to accept the Download selection.

General Upload/Download Procedures

Program

Download

GREEN

DATA

78

GREEN

DATA

send

OFF

DATA

992

Page 44

3

Operation

40

3/21/96

❏ Press the ⇑ key to select transfer of the program.

❏ Use the DATA/FCTN key to exit out of the program download

without performing any data transfers.

❏ Press the ENTER key to accept the transfer of the program.

The current baud rate will be displayed.

❏ Use the ⇓ key to select the another baud rate if your terminal

does not support 9,600 baud. The maximum baud rate for a

download is 9,600.

❏ Press the ENTER key to accept the displayed baud rate. The

DSD 406/412 will begin to initiate transfer sequence.

Initiate a Y Modem Batch file transfer from the PC (i.e. for Qmodem

users, press the PgDn key for a download and select the Y Modem

batch mode).

General Upload/Download Procedures

GREEN

DATA

pa(

CAUTION

File can not already exist in directory you are trying

to download to.

CAUTION

The maximum baud rate is different from a program

download.

9600

Page 45

3

Operation

41

3/21/96

❏ Check to verify the DATA PENDING light is “OFF”. If not,

press the DATA/FCTN key.

❏ Use the ⇑ and ⇓ keys to select function # 992. The display will

show the function number.

❏ Press the DATA/FCTN key.

❏ Press the ⇑ key to select an upload operation.

General Upload/Download Procedures

NOTE

The downloaded program is already named in the PAC program.

At this time, the DSD 406/412 is waiting to communicate with the PC.

When the transfer begins, a message will appear showing how much of

the transfer has taken place. The completion percentage number

counts as more data is transferred. This transfer should take ten

minutes at 9,600 baud.

GREEN

DATA

re(v

OFF

DATA

992

GREEN

DATA

78

Parameter

Upload

Page 46

3

Operation

42

3/21/96

❏ Use the DATA/FCTN key to exit out of the parameter upload

without performing any data transfers.

❏ Press ENTER to accept the transfer of the parameters.

The current baud rate will be displayed.

❏ Use the ⇓ key to select the another baud rate if your terminal

does not support 9,600 baud. The maximum baud rate for a

download is 9,600.

❏ Press the ENTER key to accept the displayed baud rate. The

DSD 406/412 will begin to initiate transfer sequence.

Initiate a Y Modem Batch file transfer from the PC (i.e. for Qmodem

users, press the PgUp key for an upload and select the Y Modem batch

mode).

At this time, the DSD 406/412 is waiting to communicate with the PC.

When the transfer begins, a message will appear showing how much of

General Upload/Download Procedures

9600

CAUTION

The communications software must be set up to match

the baud rate of the drive.