Page 1

Digital Output Option Card

DO-02C

Part Number: DO-02C.

Applicability: F7, G7, GPD515/G5, G5HHP.

Introduction: The Digital Output option board is mounted

on the drive’s control board. When installed, the DO-02C

option card provides the user with two sets of Form-C

relay contacts, the output from which is selected by the

programming of the drive’s parameters.

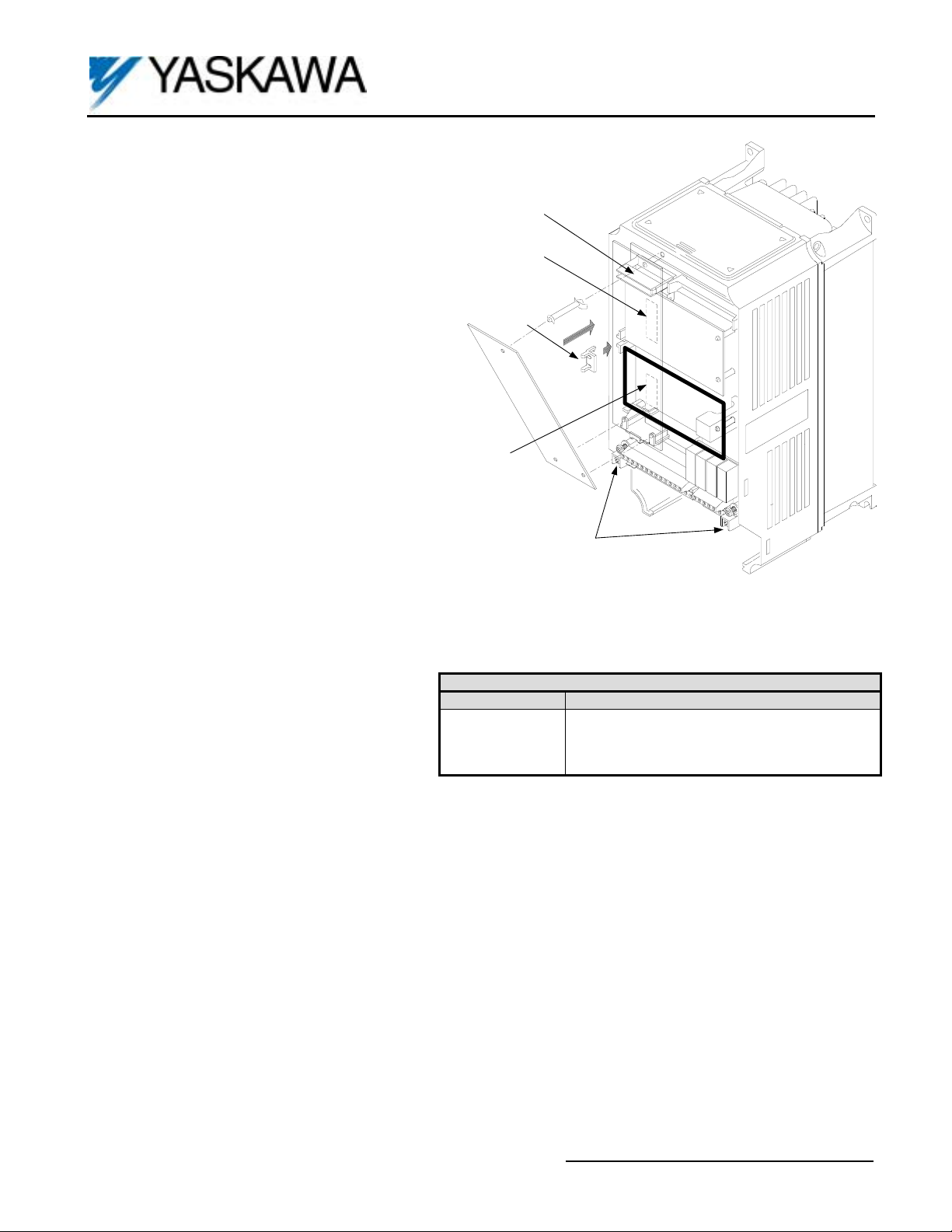

4CN

Option Card A

2CN

Option Card C

Receiving: All equipment is tested against defect at the

factory. Report any damages or shortages evident when

the equipment is received to the commercial carrier who

Option Clip

transported the equipment.

Warning: Hazardous voltage can cause severe injury or

death. Lock all power sources feeding the drive in the

“OFF” position.

Caution: This option card uses CMOS IC chips. Use

proper electrostatic discharge (ESD) protective

3CN

Option Card D

procedures when handling the card to prevent I.C.

damage or erratic drive operation.

Important:

a) If this option is being installed in a drive with the

Grounding Terminal

speed feedback option card, that card may need

to be temporarily removed to allow access to

connector 3CN on the drive’s control board and

terminal block TD on the option card.

Figure 1. DO-02C Option Card Installation

b) Before installing this option, a technically

qualified individual, who is familiar with this type of equipment and the hazards involved, should read this entire

installation guide.

Installation and Wiring:

1. Disconnect all electrical power to drive.

2. Remove the drive front cover.

3. Check that the “CHARGE” indicator lamp inside

drive is off.

4. Use a voltmeter to verify voltage at incoming

power terminals (L1, L2, L3) has been

Table 1. Specifications

Output Method Available Outputs

2 Channels (independent)

Relay Contact

Control voltage input (from drive): 24VDC (Isolated)

Form C (1A-1B)

250VAC, 1A or lower

30VDC, 1A or lower

disconnected.

5. Option Card Installation: See Figure 1. Position the option card above the control board’s 3CN connector and gently

press the card into place.

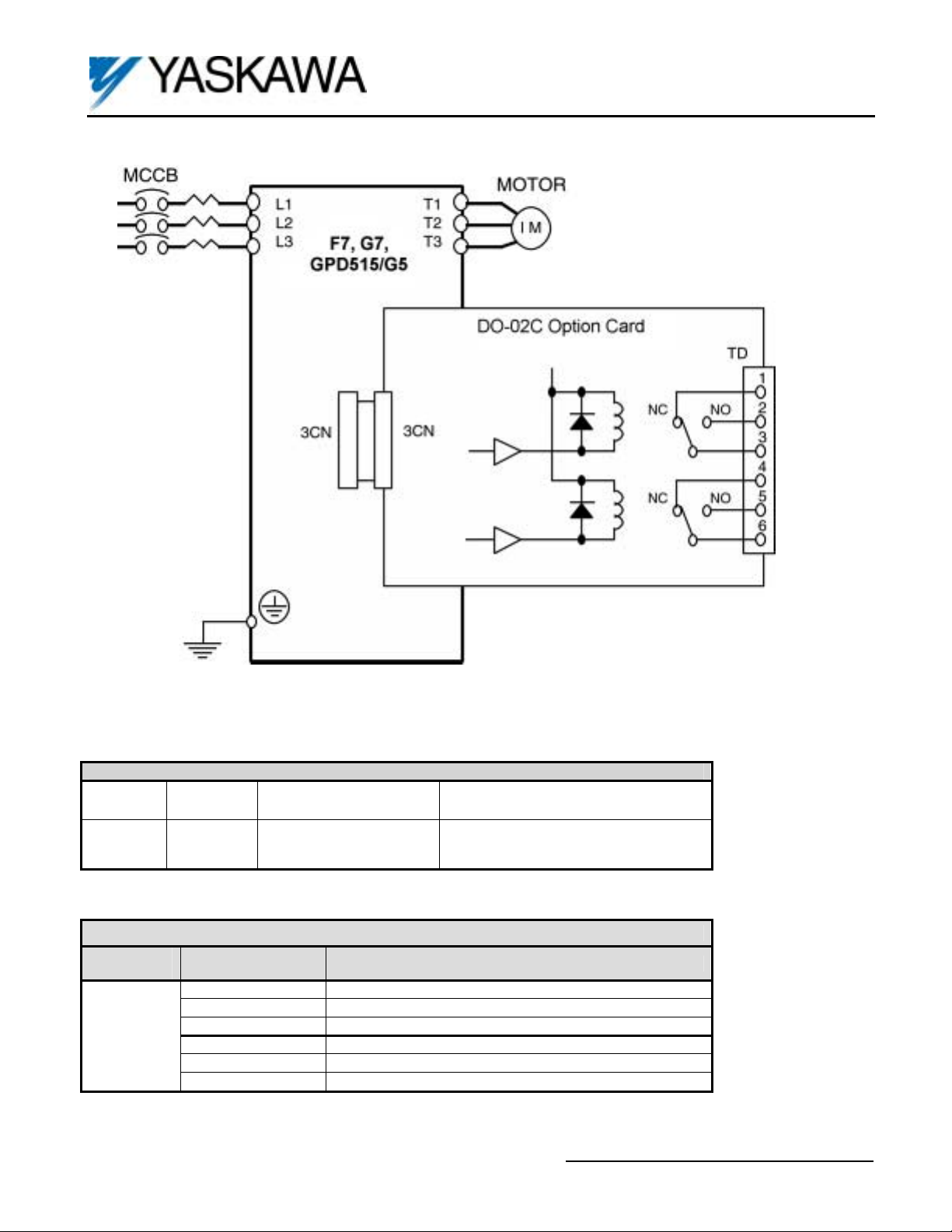

6. Wiring: Refer to Figure 2 and Tables 2 and 3. Make wire connections between the DO-02C card and the drive as well as

all peripheral devices. Observe the following:

a) Keep DO-02C (i.e. control circuit) wiring separate from main circuit input/output wiring. A separate metallic grounded

conduit with only the option card’s wiring running through it is preferred.

b) To prevent erroneous operation caused by noise interference, use shielded cable for control signal wiring, and limit

the distance to 50m (165 feet) or less.

c) Refer to the drive technical manual for additional information on use of shielded cable.

7. Adjustment. None; however, drive parameters must be programmed. Parameter F5-01 controls terminals TD1-TD3 and

parameter F5-02 controls terminals TD4-TD6. See Table 4.

8. Reinstall and secure the drive’s front cover.

9. Place this instruction sheet with the drive’s technical manual.

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.57, Page 1 of 3

Date: 07/01/04, Rev: 04-07

Page 2

Digital Output Option Card

DO-02C

Terminal

Symbol

TD M3

Terminal

Block

TD

Terminal

Screw

Pin Number Function

Figure 2. DO-02C Interconnection Diagram

Table 2. Terminal and Wire Specifications

Clamping Torque

Lb-in (N-m)

4.2 to 5.3

(0.5 to 0.6)

Table 3. DO-02C Terminal Functions

1 No. 1 output, Normally closed (NC) contact

2 No. 1 output, Normally open (NO) contact

3 No. 1 output, Common terminal

4 No. 2 output, Normally closed (NC) contact

5 No. 2 output, Normally open (NO) contact

6 No. 2 output, Common terminal

Wire range

AWG (mm

26 to 16

(Stranded: 0.14 to 1.5)

(Solid: 0.14 to 1.5)

2

)

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.57, Page 2 of 3

Date: 07/01/04, Rev: 04-07

Page 3

Digital Output Option Card

DO-02C

Table 4. DO-02C Output Selection

F5-01

and

F5-02

Setting

During Run 1

0

(ON: Run command with voltage output. Includes Decel and DC injection)

1 Zero Speed (ON: Fout < E1-09) X X X X X

2 Fref/Fout Agree 1 (ON: Fref = Fout, detection width L4-02) X X X X X

3 Fref/L4-01 Agree 1 (ON: Fref = Fout = ±L4-01, detection width L4-02) X X X X X

4

Frequency Detection 1 (ON: +L4-01 ≥ Fout ≥ - L4-01, detection width L4-02)

5

Frequency Detection 2 (ON: Fout ≥ +L4-01 or Fout ≤ -L4-01, detection width L4-02)

6 Inverter Ready (ON: No fault and not in programming mode) X X X X X

DC Bus Undervoltage (UV1, UV2)

7

(ON: DC bus below L2-05 or loss of pre-charge contactor answerback)

8 Baseblock 1 N.O. (ON: Baseblock function is active) X X X X X

9 Operator Reference (ON: Frequency reference source is from operator) X X X X X

A Local/Remote Operation (ON: Start/stop source is from operator) X X X X X

B Torque Detection 1 N.O. (ON: Current is greater/lower than L6-02 for L6-03 time) X X X X X

C Loss of Frequency Reference (Function enabled when L4-05 = 1) X X X X X

D Braking Resistor Fault (ON: Resistor overheat or braking transistor fault) X X X X X

E Fault (ON: Fault occurred other than CPF00 and CPF01) X X X X X

F Not Used (Set for use as remote I/O when drive has network communication link) X X X X X

10 Alarm (ON: Alarm occurring) X X X X X

11 Fault Reset Command Active (keypad, terminal, network) X X X X X

12 Timer Function Output (See parameter group B4) X X X X X

13 Fref/Fout Agree 2 (detection width L4-04) X X X X X

14 Fref/Fout Agree 2 (ON: Fref = Fout = L4-03, detection width L4-04) X X X X X

15

Frequency Detection 3 (ON: Fout ≤ L4-03, detection width L4-04)

16

Frequency Detection 4 (ON: Fout ≥ L4-03, detection width L4-04)

17 Torque Detection 1 N.C. (OFF: Current is greater/lower than L6-02 for L6-03 time) X X X X X

18 Torque Detection 2 N.O. (OFF: Current is greater/lower than L6-05 for L6-06 time) X X X X X

19 Torque Detection 2 N.C. (OFF: Current is greater/lower than L6-05 for L6-06 time) X X X X X

1A Reverse Direction (ON: Motor rotation is in reverse due to run command or Fref) X X X X X

1B Baseblock 2 N.C. (OFF: Baseblock function is active) X X X X X

1C

1D Regenerative operation (ON: During regenerative operation.) - - - X X

1E Automatic Fault Restart (ON: Automatic fault restart function is active. See L5-01) X X X X X

1F Motor Overload OL1 Alarm (ON: 90% or greater OL1 detection level) X X X X X

20 OH Alarm (ON: Heatsink temperature is greater than L8-02) X X X X X

30 Torque Limit (ON: Torque limit function active) - - X X X

31 Speed Limit During Speed Control (ON: Speed limit function active) - - - X X

32

33 Zero Servo Complete (ON: Zero servo function is within the b9-02 detection width) - - - X -

37

38

(1) Available in the G7 only.

(2) Not available in the GPD515/G5.

Motor 2 Selection

(ON: Motor 2 selected using a digital input (H1-XX) programmed for “16”)

(2)

Speed Limit During Torque Control (ON: Speed limit function active)

During Run 2 (ON: Run command with voltage output. Does not include baseblock,

DC injection, or initial excitation)

Drive Enable

(2)

(ON: Drive Enable selected using a digital input (H1-XX) programmed for “6A”)

Function

Control Mode (A1-02)

0: V/F

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

- - - X X

X X X X X

X X X X X

2: OLV

1: V/F PG

3: FV

(1)

4: OLV2

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.57, Page 3 of 3

Date: 07/01/04, Rev: 04-07

Loading...

Loading...