Page 1

VARISPEED-686SS5

YASKAWA

INSTRUCTION MANUAL

SUPER-ENERGY SAVING VARIABLE SPEED DRIVE (VS-686SS5)

MODEL: CIMR-SSA

200V CLASS 0.4 to 75kW (1.2 to 110kVA)

400V CLASS 0.4 to 300kW (1.4 to 460kVA)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

REFERENCE

VARISPEED-686SS5 DESCRIPTIVE MANUAL FOR CONSTANTS (TOE-S686-15.2)

YA S K A WA

MANUAL NO. TOE-S686-15B

Page 2

PREFACE

The VS-686SS5 inverter is intented for use only with YASKAWA’s SS motor drive.

This instruction manual describes installation, maintenance and inspection,

troubleshooting, and specifications of the VS-686SS5. Read this instruction manual

thoroughly before operation.

YASKAWA ELECTRIC CORPORATION

General Precautions

S Some drawings inthis manual are shown with the protective cover or shields removed, in order to

describe detail with more clarity. Make sure all covers and shields are replaced before operating

this product.

S This manual may be modified when necessary because of improvement of the product, modifica-

tion, or changes in specifications.

Such modifications are denoted by a revised manual No.

S To order a copy of this manual, if your copy has been damaged or lost, contact your YASKAWA

representative.

S YASKAWA is not responsible for any modification of the product made by the user,since that will

void your guarantee.

3

Page 3

NOTES FOR SAFE OPERATION

Read this instruction manual thoroughly before installation, operation, maintenance or inspection of

the VS-686SS5. In this manual, NOTES FOR SAFE OPERATION are classified as “WARNING”

or “CAUTION.”

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

to personnel.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to personnel and damage to equipment.

It may also be used to alert against unsafe practices.

Even items described in

case, follow these important notes.

NOTE

: These are steps to be taken to insure proper operation.

CAUTION

may result in a vital accident in some situations. In either

4

Page 4

NOTES FOR SAFE OPERATION

NOTES ON USE

WARNING

The SS5 motor is a synchronous motor equipped with a built-in, high performance magnet as a rotor.

The SS5 motor terminals continue to produce high voltage whenever the motor is rotating even if

inverter power is OFF. Observe the following when hadling the inverter.

S

Make sure the motor is stopped when carrying out maintenance, inspection or wiring.

S

Connect a low-voltage manual starter to the inverter output side when the motor is rotated

by the load even if the inverter power is OFF.

CAUTION

S

If using a motor with a PG, be sure to confirm the safety and adjust the PG zero-pulse be-

fore starting any operation.

Failure to observe this caution may cause the torque to be insufficient, which may result in the

following motor malfunctions:

• The motor is pulled in the direction of the load.

• The motor rotates in reverse.

• The motor does not rotate.

• The motor suddenly accelerates.

S

Before starting operation, be sure to set the motor constants according to the motor name-

plate values.

Failure to observe this caution may cause torque insufficiency, which result in motor malfunctions:

• The motor is pulled in the direction of the load.

• The motor rotates in reverse direction.

• The motor does not rotate.

• The motor is suddenly accelerated.

RECEIVING

CAUTION

(Ref. page)

S

Do not install or operate any inverter which is damaged or has missing

parts.

Failure to observe this caution may result in personal injury or equipment damage. 14

5

Page 5

INSTALLATION

CAUTION

S Lift the cabinet by the base. When moving the unit, never lift by the front

cover.

Otherwise, the main unit may be dropped causing damage to the unit. 16..........

S Mount the inverter on nonflammable material (i.e. metal).

Failure to observe this caution can result in a fire. 16............................

S When mounting units in an enclosure, install a fan or other cooling device

to keep the intake air temperature below 45_C.

Overheating may cause a fire or damage to the unit. 16........................

WIRING

WARNING

(Ref. page)

S Only commence wiringafter verifying that thepower supply is turnedOFF.

Failure to observe this warning can result in an electric shock or a fire. 20.........

S Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electric shock or a fire. 20.........

S When wiring the emergency stop circuit, check the wiring thoroughly

before operation.

Failure to observe this warning can result in personal injury. 20.................

S Make sure to ground the ground terminal .

(Ground resistance

200V class: 100Ω or less, 400V class: 10Ω or less)

Failure to observe this warning can result in an electric shock or a fire. 24.........

(Ref. page)

6

Page 6

NOTES FOR SAFE OPERATION

CAUTION

S Do not connect the other type of motor (i.e. induction motor). The

VS-686SS5 inverter is exclusive-use for SS5 motor drive.

Failure to observe this caution can result in inverter damage. 20.................

S Verify that the inverter rated voltage coincides with the AC power supply

voltage.

Failure to observe this caution can result in personal injury or a fire. 20...........

S Do not perform a withstand voltage test of the inverter.

It may cause semi-conductor elements to be damaged. 20......................

S To connect a braking resistor, braking resistor unit or braking unit, follow

the procedures described in APPENDIX 3.

Improper connection may cause a fire. 20..................................

S Tighten terminal screws to the specified tightening torque.

Failure to observe this caution can result in a fire. 20..........................

(Ref. page)

S Never connect the AC main circuit power supply to output terminals U, V

and W.

The inverter will be damaged and invalidate the guarantee. 24.................

S (Standard connection)

Be sure to connect the motor leads to the correct output terminals:

Motor lead U to output terminal U,

Motor lead V to output terminal V, and

Motor lead W to output terminal W.

Failure to observe this caution may cause the motor to run unusual way such as in

reverse. 24...........................................................

S With the standard connection for the output terminals, the motor rotates

counterclockwise as viewed from the load side in a forward operation.

To rotate the motor clockwise in a forward operation, connect the output

terminals as refered in Appendix 6. 24...................................

7

Page 7

OPERATION

WARNING

S Only turn ON the input power supply after replacingthe front cover. Do not

remove the cover while current is flowing.

Failure to observe this warning can result in an electric shock. 38................

S When the retry function (L5-02) is selected, do not approach the inverter

or the load, since it may restart suddenly after being stopped.

(Construct machine system, so as to assure safety for personnel, even if the

inverter should restart.)

Failure to observe this warning can result in personal injury. 38.................

S Since the stop button can be disabled by a function setting, install a sepa-

rate emergency stop switch.

Failure to observe this warning can result in personal injury. 38.................

S If an alarm is reset with the operation signal ON, the inverter restarts auto-

matically. Only reset the alarm after verifying that the operation signal is

OFF.

Failure to observe this warning can result in personal injury. 38.................

(Ref. page)

S When adjusting PG zero-pulse, disconnect the motor from the machine.

The motor rotates automatically during adjustment. 49....................

S When PG zero-pulse adjustment is completed, “End” is displayed on the

digital operator. Do not touch it until it has come to a complete stop.

The motor starts and stops repeatedly when adjustments are made. 49.......

CAUTION

S Never touch the heatsink or discharging resistor since the temperature is

very high.

Failure to observe this caution can result in harmful burns to the body. 3 8.........

S Since it is easy to change operation speed from low to high speed, verify

the safe working range of the motor and machine before operation.

Failure to observe this caution can result in personal injury and machine damage. 38..

S Install a holding brake separately if necessary.

Always construct the external sequence to confirm that the holding

brake is activated in the event of an emergency, a power failure, or an

abnormality in the inverter occuring.

Failure to observe this caution can result in personal injury. 38..................

(Ref. page)

S If using with an elevator, take safety measures on the machine’s side to

prevent the elevator from dropping.

Failure to observe this caution may result in personal injury. 38.................

S Do not change signals during operation.

The machine or the inverter may be damaged. 38.............................

8

Page 8

NOTES FOR SAFE OPERATION

CAUTION

S All the constants of the inverter have been preset at the factory. Do not

change the settings unnecessarily.

The inverter may be damaged. For supply voltage, follow Par. 4.2. 38............

S Be sure to set the motor constants in accordance with the values listed on

the motor nameplate values. 38........................................

Failure to observe this caution may cause the torque to be insufficient, which

may result in the following motor malfunctions:

• The motor is pulled in the direction of the load.

• The motor rotates in reverse.

• The motor does not rotate.

• The motor suddenly accelerates.

S

Besure to set themotorconstants before the initialoperation and after

replacement of the motor. Reconfirm the motor constants after they

have been set.

Failure to observe this caution may result in motor malfunctions such as

sudden acceleration. 44..............................................

(Ref. page)

S In the following cases when under flux vector control, be sure to adjust

the PG zero-pulse as described in 4.3 (3) (e) PG Zero-pulse Adjustment: 44..

• Before initial operation.

• After replacing the motor.

• After replacing the PG.

S Verify that digital operator STOP LED is ON before checking motor speed

detection. 48........................................................

S Verify that nothing is caught on the shaft or coupling. 48...................

S If the constant b1-06 is set to 1 and the run command is ON, the motor will

start immediately if the following operations are done. Confirm the safety if such operation is required.

•

The operation mode is switched from LOCAL to REMOTE.

•

The power supply is turned ON.

Failure to observe this caution may result in personal injury. 71.................

S Confirm safety. 49....................................................

• Is the motor disconnected from the machine?

• Is the lock key disconnected from the machine?

• Are there any persons or objects near the motor shaft?

• Has the motor come to a complete stop?

9

Page 9

MAINTENANCE AND INSPECTION

WARNING

S Never touch high-voltage terminals in the inverter.

Failure to observe this warning can result in an electric shock. 65................

S Replace all protective covers before powering up the inverter. To remove

the cover, make sure to shut OFF the molded-case circuit breaker.

Failure to observe this warning can result in an electric shock. 65................

S Perform maintenance or inspection only after verifying that the CHARGE

LED goes OFF, after the main circuit power supply is turned OFF.

The capacitors are still charged and can be dangerous. 65......................

S Only authorized personnel should be permitted to perform maintenance,

inspections or parts replacement.

[Remove all metal objects (watches, bracelets, etc.) before operation.]

(Use tools which are insulated against electrical shock.)

Failure to observe this warning can result in an electric shock. 65................

(Ref. page)

CAUTION

(Ref. page)

S The control PC board employs CMOS ICs. Do not touch the CMOS ele-

ments.

They are easily damaged by static electricity. 65.............................

S Do not connect or disconnect wires or connectors while power is applied

to the circuit.

Failure to observe this caution can result in personal injury. 65..................

OTHERS

WARNING

S Never modify the product.

Failure to observe this warning can result in an electrical shock or personal injury and will invalidate the guarantee.

10

Page 10

NOTES FOR SAFE OPERATION

WARNING LABEL

A warning label is displayed on the front cover of the inverter, as shown below. Follow these instructions when handling the inverter.

Warning Label

Model CIMR-SSA23P7

WarningLabel

WARNING

May cause injury or electric shock.

Please follow the instructions in the manual before

installation or operation.

Disconnect all power before opening front cover of unit.

Wait 1 minute until DC Bus capacitors discharge.

Use proper grounding techniques.

Make sure that the motor has stopped and voltage

between terminals U-V, U-W, and V-W is “0 volt” before

maintenance, inspection, or wiring.

11

Page 11

CONTENTS

NOTES FOR SAFE OPERATION 4......................................

1 RECEIVING 14.....................................................

1.1 INSPECTION CHECKPOINTS 14............................................

1.2 IDENTIFYING THE PARTS 15...............................................

2 INSTALLATION 16...................................................

2.1 REMOVING AND REPLACING THE DIGITAL OPERATOR 16...................

2.2 REMOVING AND REPLACING THE FRONT COVER 17........................

2.3 CHOOSING A LOCATION TO MOUNT THE INVERTER 18......................

2.4 CLEARANCES 19.........................................................

3 WIRING 20.........................................................

3.1 CONNECTION WITH PERIPHERAL UNITS 21................................

3.2 CONNECTION DIAGRAM 22................................................

3.3 WIRING THE MAIN CIRCUIT 24.............................................

3.4 WIRING THE CONTROL CIRCUIT 36........................................

3.5 WIRING INSPECTION 37...................................................

4 OPERATION 38.....................................................

4.1 TEST RUN CHECKPOINTS 39..............................................

4.2 SETTING THE LINE VOLTAGE USING JUMPER

4.3 TEST RUN 40.............................................................

(FOR 400V CLASS 18.5kW AND ABOVE) 39..................................

5 SETTING OPERATION CONDITIONS 56...............................

5.1 DIGITAL OPERATOR KEY DESCRIPTION 56.................................

5.2 DIGITAL OPERATOR MODE SELECTION 57..................................

5.3 DRIVE MODE 58..........................................................

5.4 INITIALIZE MODE 61......................................................

5.5 PROGRAM MODE 63......................................................

5.6 MODIFIED CONSTANTS MODE 64..........................................

6 MAINTENANCE AND INSPECTION 65................................

6.1 PERIODIC INSPECTION 66.................................................

6.2 PARTS REPLACEMENT SCHEDULE (GUIDELINES) 66........................

7 TROUBLESHOOTING 67............................................

7.1 FAULT DIAGNOSIS AND CORRECTIVE ACTIONS 67..........................

7.2 MOTOR FAULTS AND CORRECTIVE ACTIONS 71............................

APPENDIX 1 SPECIFICATIONS 72......................................

APPENDIX 2 DIMENSIONS (mm) 74....................................

200 V/400 V Class Inverters of 15 kW and Lower 74...................................

200 V/400 V Class Inverters of 18.5 kW and Higher 74.................................

Mounting Dimensions for 400 V Class Inverters of 220 to 300 kW 74.....................

APPENDIX 3 TYPICAL CONNECTION DIAGRAM 76......................

3.1 BRAKING RESISTOR UNIT 76..............................................

3.2 BRAKING UNIT AND BRAKING RESISTOR UNIT 77...........................

3.3 THREE BRAKING UNITS IN PARALLEL 80...................................

3.4 WITH CONTACT OUTPUT, OPEN COLLECTOR OUTPUT 83...................

12

APPENDIX 4 CONSTANTS LIST 84....................................

Page 12

APPENDIX 5 ERROR PROCESSING IN PG ZERO-PULSE

ADJUSTMENT 90.........................................

APPENDIX 6 ROTATION DIRECTION OF MOTOR 92.....................

APPENDIX 7 ZDEV CAUSES AND CORRECTIVE ACTIONS LIST 93........

Revision History

13

Page 13

1 RECEIVING

S

Do not install or operate any inverter which is damaged or has missing

parts.

Failure to observe this caution may result in personal injury or equipment damage.

This chapter describes how to verify the inverter after delivery to the user.

1.1 INSPECTION CHECKPOINTS

(1)

Receiving Checkpoints

Table 1 Checkpoints

Checkpoints Description

Does the inverter model number correspond with

the purchase order?

Are any parts damaged?

Ishardwareproperly seatedand securelytightened?

Was an instruction manual received? VS-686SS5 instruction manual (No.: TOE-S686-15)

CAUTION

Check the model number on the nameplate on the side of the

VS-686SS5.

Visuallycheck the exterior and verify that there was no damage during

transport.

Remove inverter front cover.

Check all visible hardware with appropriate tools.

If any of the above checkpoints are not satisfactory, contact your YASKAWA representative.

(2)

Checking the Nameplate Data

(a)

Nameplate Data

Example of Japan domestic standard model CIMR-SSA2018 (200VAC 18.5kW)

Inverter Model

Input Spec.

Output Spec.

Lot No.

Serial No.

MODEL : CIMR− SSA2018 SPEC : 20180A

INPUT :

OUTPUT : AC 3PH 0− 230 V 30kVA 80A

LOT NO : MASS : 28kg

SER NO :

YASKAWA ELECTRIC CORPORATION

AC 3PH 200− 220 V 50Hz

200− 230 V 60Hz

JAPAN

Inverter Spec.

Mass

14

Page 14

(b)

Model Designation

Inverter

VS-686SS5 Series

1 RECEIVING

CIMR − SS A 2 0P4

Symbol

A

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

D 200 VDC class

E 400 VDC class

(c)

Specification Designation

Symbol

2 3-phase 200 V class

4 3-phase 400 V class

Symbol Max. applicable motor output

0P4 0.4kW

0P7

to

300

* For special specifications, a spec. sheet No. appears on the nameplate.

Specifications

Japan domestic standard

Voltage

Voltage

0.75kW

to

300kW

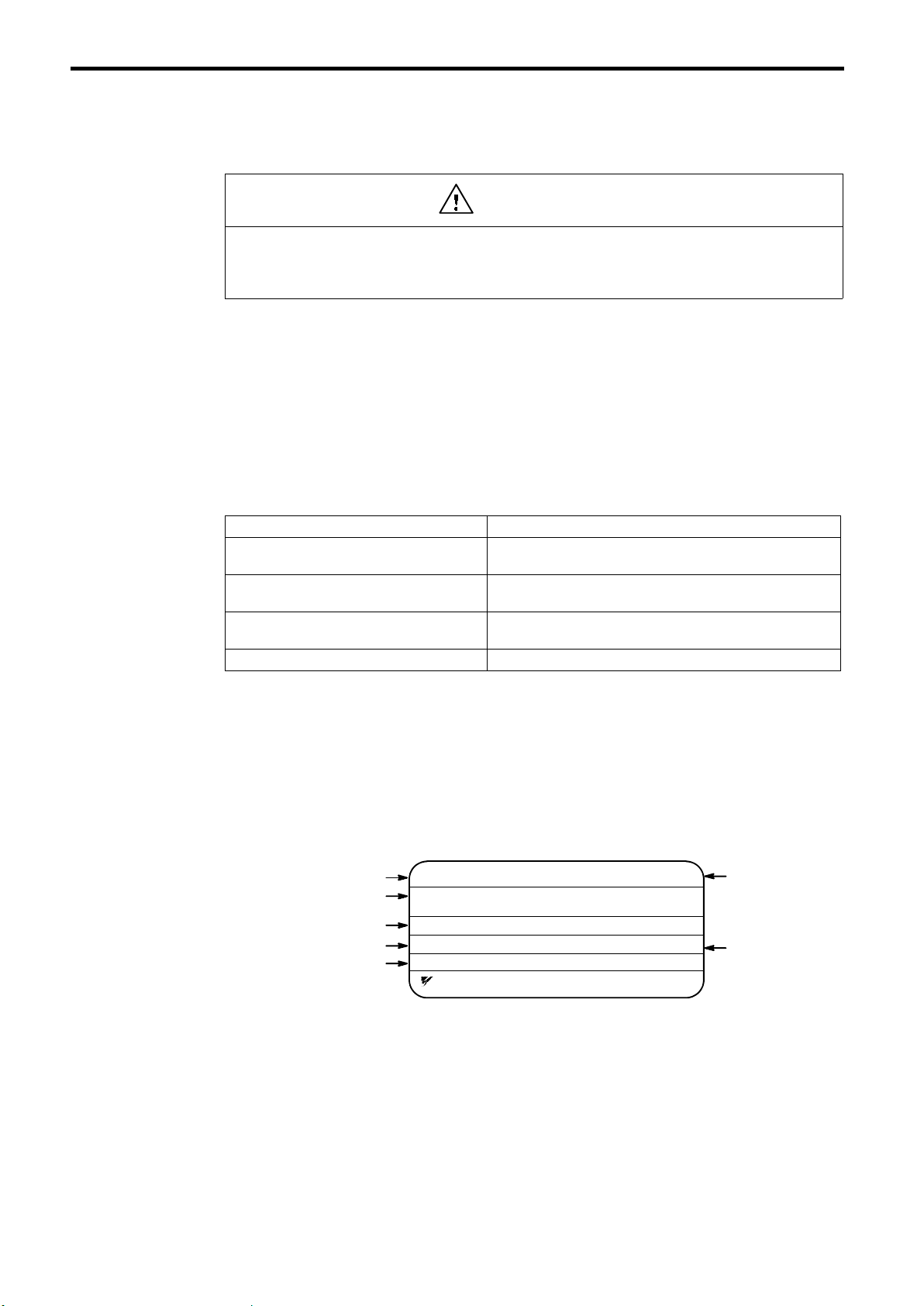

1.2 IDENTIFYING THE PARTS

2 0P4 1 A *

Symbol Max. applicable motor output

0P4 0.4kW

0P7

to

300

Revision symbol

Symbol

0 Open chassis type

1

Enclosed wall-mounted

type (NEMA 1)

0.75kW

to

300kW

Enclosure

Protective Cover (top/bottom)

4-Mounting Holes

Front Cover

Digital Operator

JVOP-132

Heatsink

Fig.1Configuration of VS-686SS5 (Model CIMR-SSA20P4)

15

Page 15

2 INSTALLATION

CAUTION

S

Lift the cabinet by the base. When moving the unit, never lift by the front cover.

Otherwise, the main unit may be dropped causing damage to the unit.

S

Mount the inverter on nonflammable material (i.e. metal).

Failure to observe this caution can result in a fire.

S

When mounting units in an enclosure, install a fan or other cooling device to keep the intake air temperature below 45_C.

Overheating may cause a fire or damage to the unit.

This chapter describes the configuration, location and space when mounting the VS-686SS5.

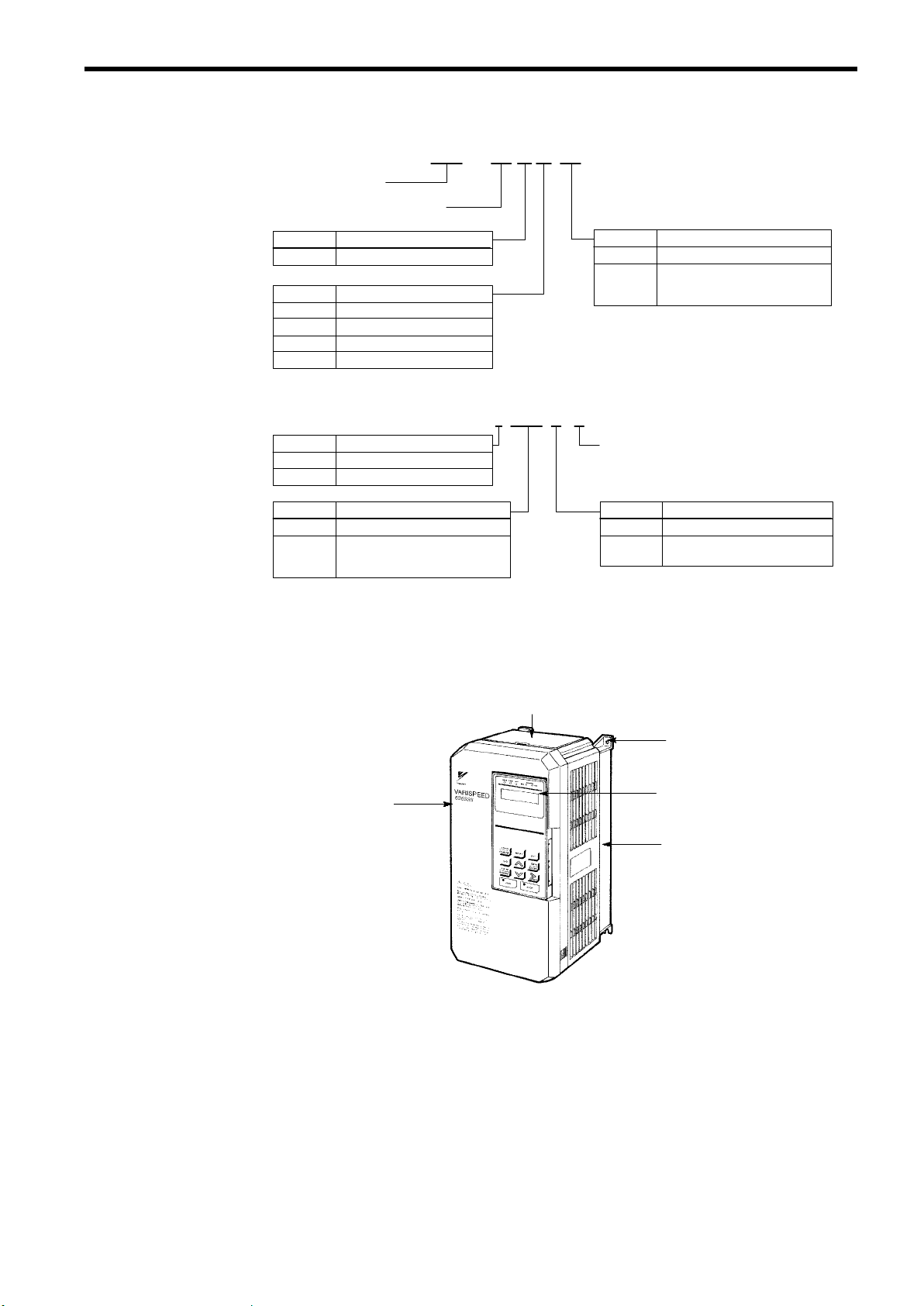

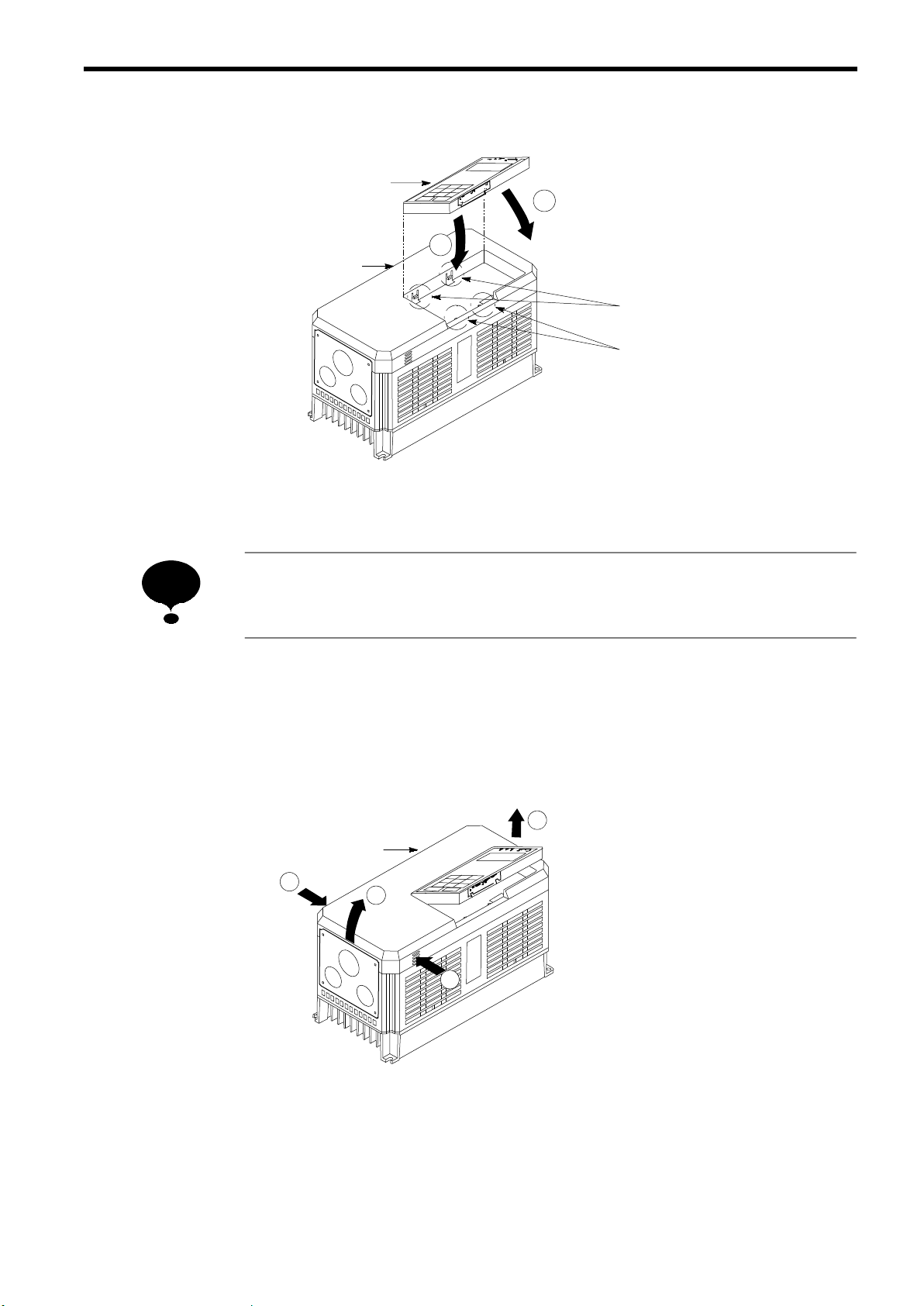

2.1 REMOVING AND REPLACING THE DIGITAL OPERATOR

Remove and replace the digital operator as follows.

(1)

Removing the Digital Operator

Front Cover

Digital Operator

Fig.2Removing the Digital Operator

Push the digital operator lever in the direction

2

1

shown by arrow 1 and lift the digital operator

in the direction shown by arrow 2 to remove

the digital operator from the front cover.

16

Page 16

(2)

Replacing the Digital Operator

Digital Operator

1

Front Cover

Fig.3Replacing the Digital Operator

2 INSTALLATION

Engage the digital operator on claws A in the

direction shown byarrow 1 and then on claws

2

B in the direction shown by arrow 2 to lock

the digital operator.

Claws A

Claws B

NOTE

Never fit the digital operator in any other direction or by any other method.

The digital operator will not be connected to the inverter.

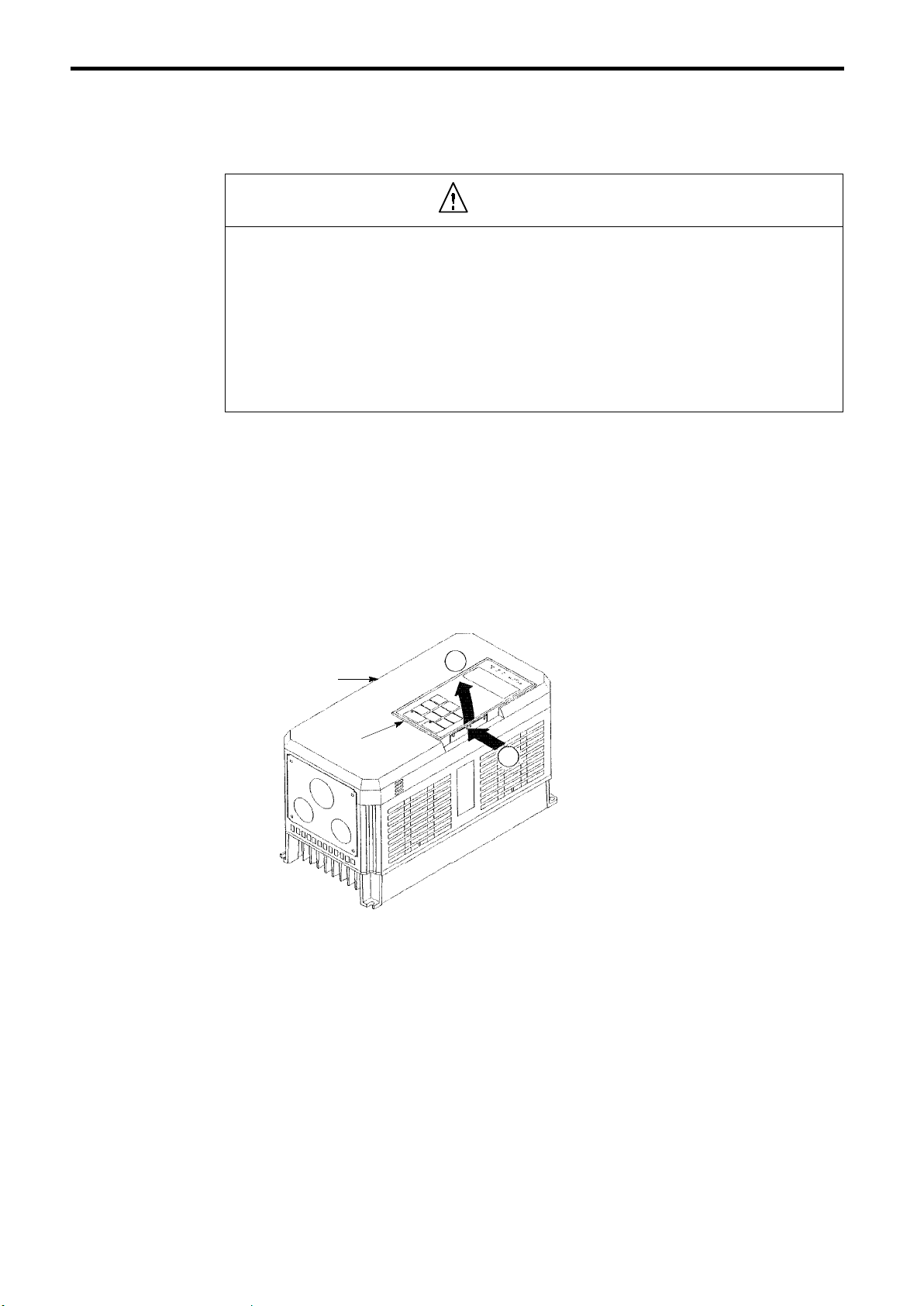

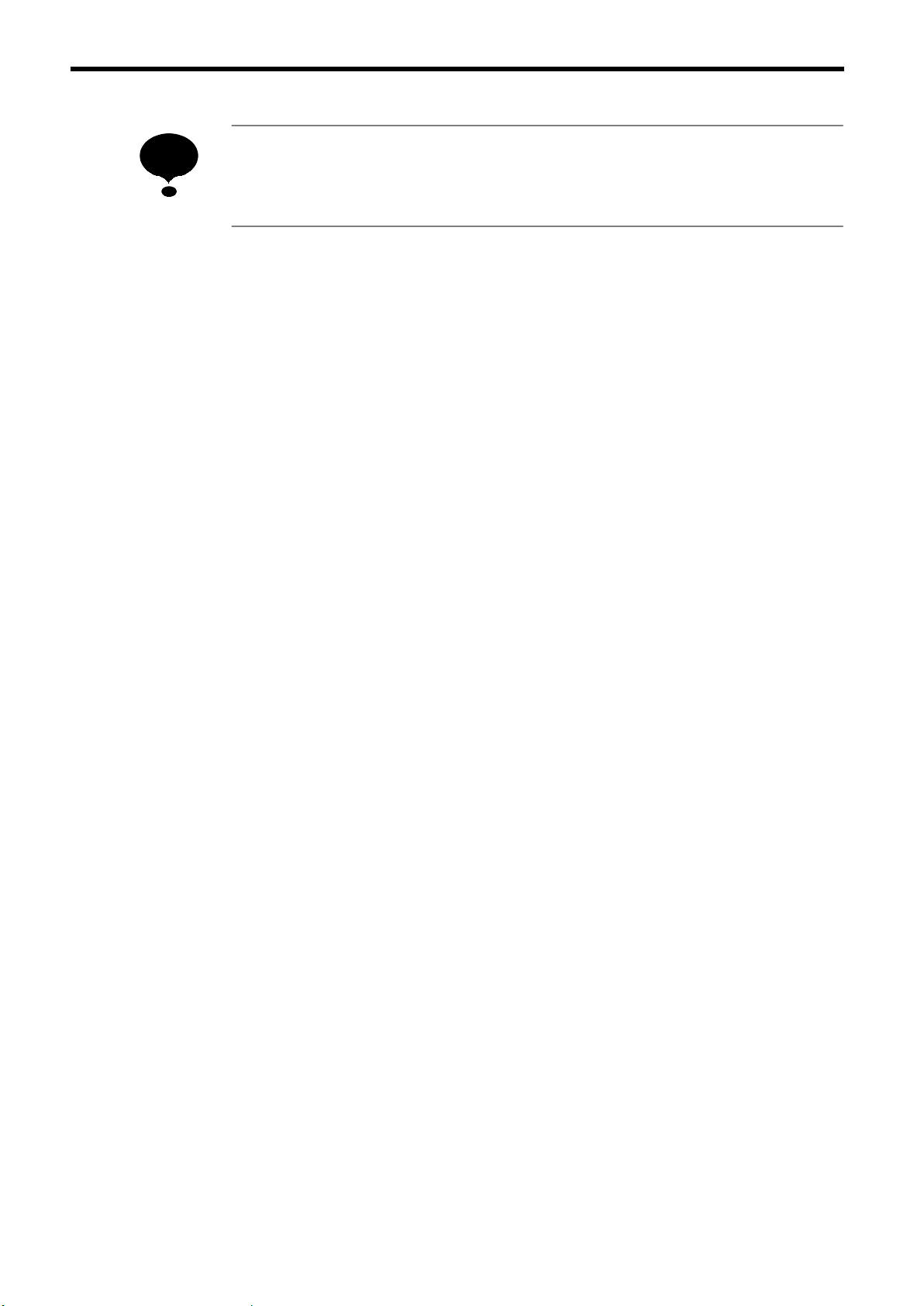

2.2 REMOVING AND REPLACING THE FRONT COVER

To remove the front cover, first move the digital operator in the direction shown by arrow 1. (See Par.

2.1.) Then squeeze the cover in the direction shown by arrows 2 on both sides and lift in the direction

shown by arrow 3.

1

Front Cover

2

3

2

Fig.4Removing and Replacing the Front Cover

17

Page 17

NOTE

Do not replace the front cover with the digital operator connected. The digital operator will not

be connected to the inverter. Replace the front cover first and then install the digital operator

on the cover. See Par. 2.1 for replacing the digital operator.

2.3 CHOOSING A LOCATION TO MOUNT THE INVERTER

To ensure proper performance and long operating life, follow the recommendations below when

choosing a location for installing the VS-686SS5. Make sure the inverter is protected from the

following conditions:

V Extreme cold and heat.

Use only within ambient temperature range: -10_ C to +40_C

V Rain, moisture. (For enclosed wall-mounted type)

V Oil sprays, splashes

V Salt spray.

V Direct sunlight. (Avoid using outdoors.)

V Corrosive gases or liquids.

V Dust or metallic particles in the air. (For enclosed wall-mounted type)

V Physical shock, vibration.

V Magnetic noise. (Example: welding machines, power devices, etc.)

V High humidity.

V Radioactive materials.

V Combustibles: thinners, solvents, etc.

18

Page 18

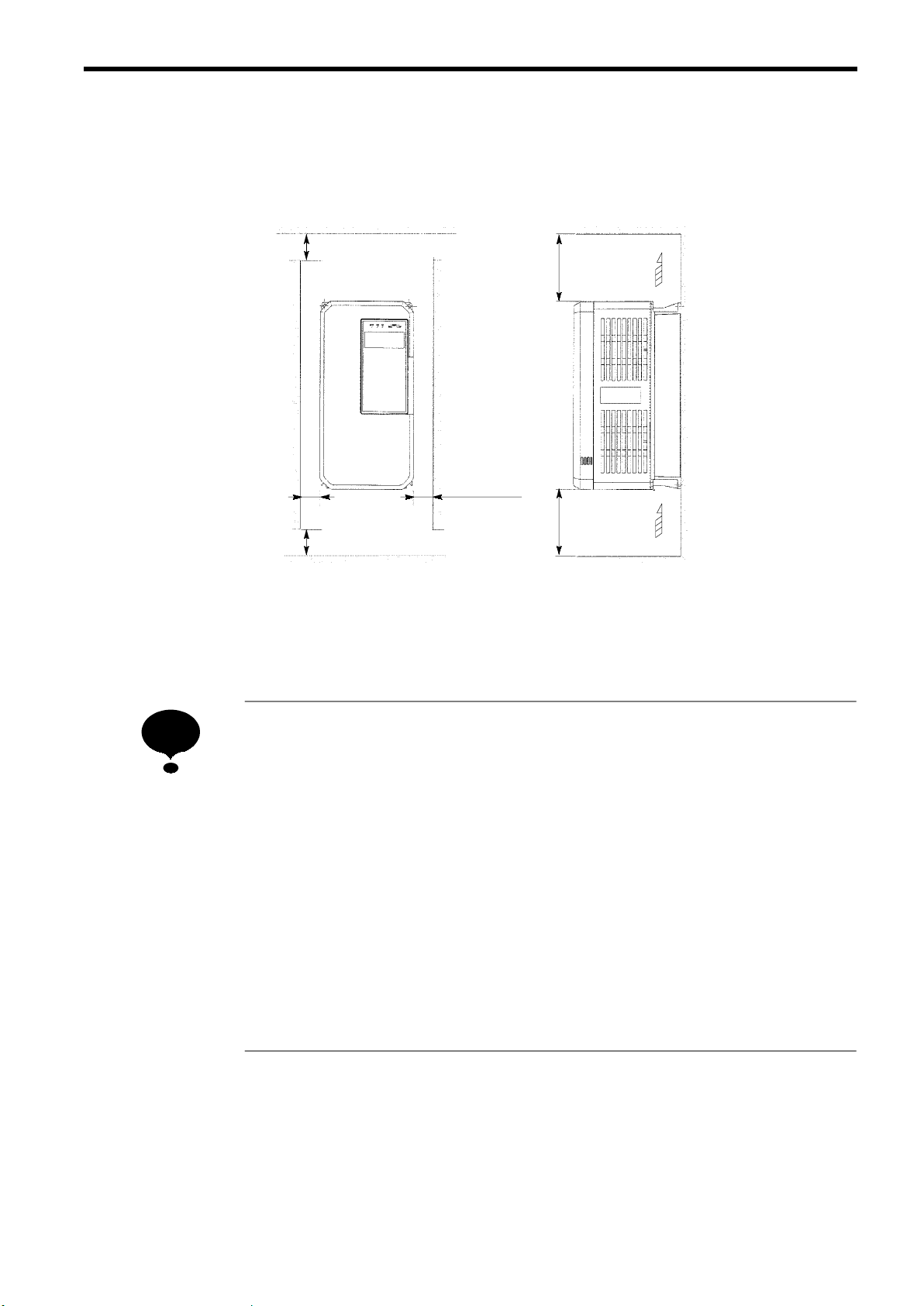

2.4 CLEARANCES

Install the VS-686SS5 vertically and allow sufficient clearances for effective cooling as shown in Fig.

5.

2 INSTALLATION

50 mm or more

*

30 mm or more

*

50 mm or more

(a) Front View

Fig.5Clearances

Air

120 mm or more

30 mm or more

120 mm or more

Air

(b) Side View

NOTE

1. The clearances required at top/bottom and both sides are common in open chassis type

(IP00) and enclosed wall-mounted type (IP20).

2. Remove the top and bottom covers to use the open chassis type of 15kW or less.

3. When installing the models of 30kW or more equipped with eyebolts, extra spacing will

be required on either side. For detailed dimensions, contact your YASKAWA representative.

4. For the external dimensions and mounting dimensions, refer to APPENDIX 2 “DIMEN-

SIONS.”

5. Allowable intake air temperature to the inverter:

Open chassis type : -10_C to +45_C

Enclosed wall-mounted type : -10_C to +40_C

6. Ensure sufficient space for the sections at the upper and lower parts marked with ∗ in order

to permit the flow of intake/exhaust air to/from the inverter.

19

Page 19

3 WIRING

S

S

S

S

S

WARNING

Only commence wiring after verifying that the power supply is turned OFF.

Failure to observe this warning can result in an electric shock or a fire.

Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electric shock or a fire.

When wiring the emergency stop circuit, check the wiring thoroughly before operation.

Failure to observe this warning can result in personal injury.

CAUTION

Do not connect the other type of motor (i.e. induction motor). The VS-686SS5 inverter is

exclusive-use for SS5 motor drive.

Failure to observe this caution can result in inverter damage.

Verify that the inverter rated voltage coincides with the AC power supply voltage.

Failure to observe this caution can result in personal injury or a fire.

S

Do not perform a withstand voltage test of the inverter.

It may cause semi-conductor elements to be damaged.

S

To connect a braking resistor, braking resistor unit or braking unit, follow the procedures

described in APPENDIX 3.

Improper connection may cause a fire.

S

Tighten terminal screws to the specified tightening torque.

Failure to observe this caution can result in a fire.

This chapter describes the main circuit wiring and the control circuit wiring of the VS-686SS5.

20

Page 20

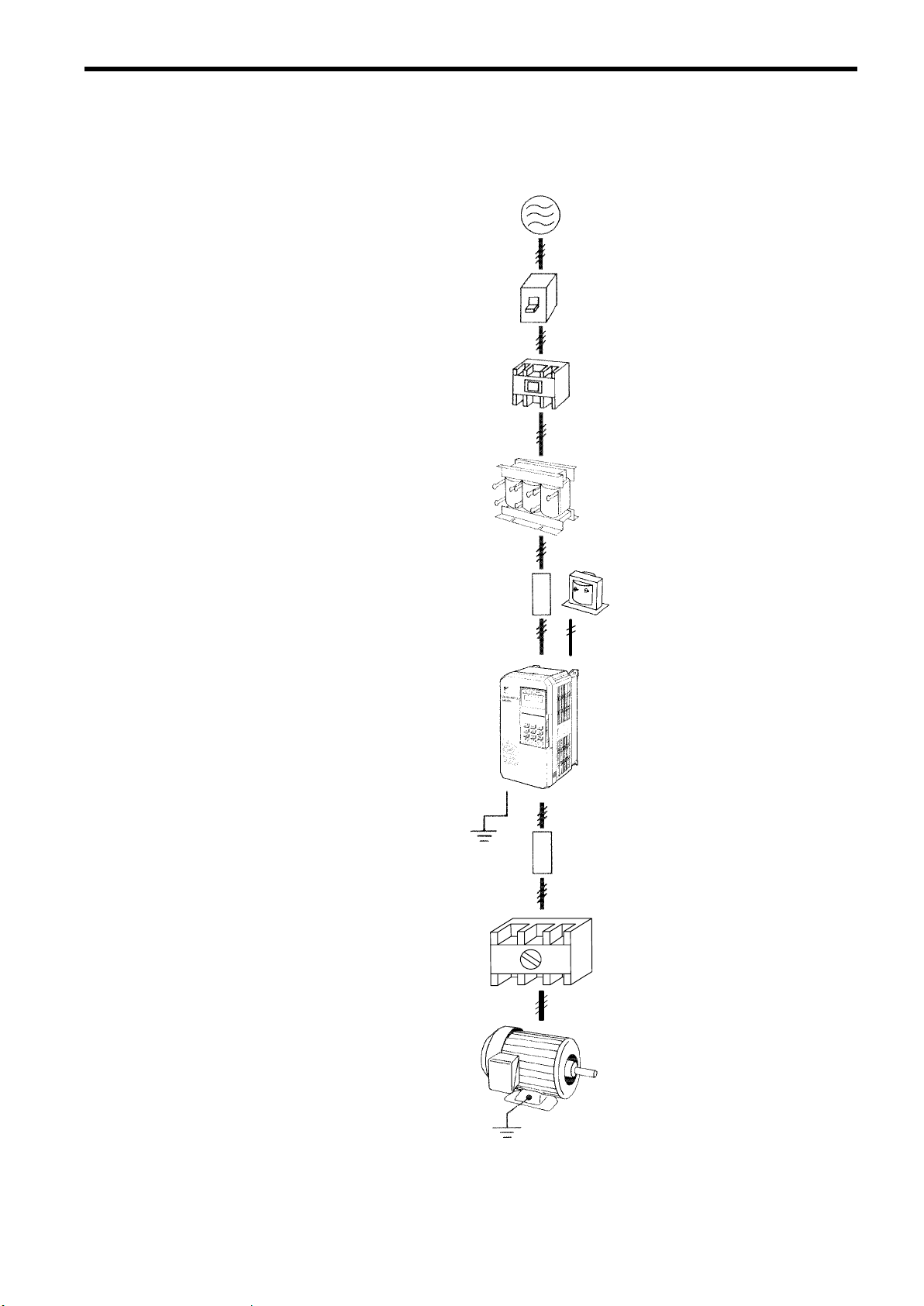

3.1 CONNECTION WITH PERIPHERAL UNITS

The following shows standard connection of the VS-686SS5 with peripheral units.

Power Supply

Molded-case Circuit

Breaker or Ground

Fault Interrupter

Magnetic Contactor

AC Reactor

3 WIRING

Input Noise Filter

VS-686SS5

Output Noise Filter

Low-voltage Manual

Starter

(Used when the motor

is rotated by the load.)

DC Reactor

Grounding

Motor

Grounding

Fig.6Connection with Peripheral Units

21

Page 21

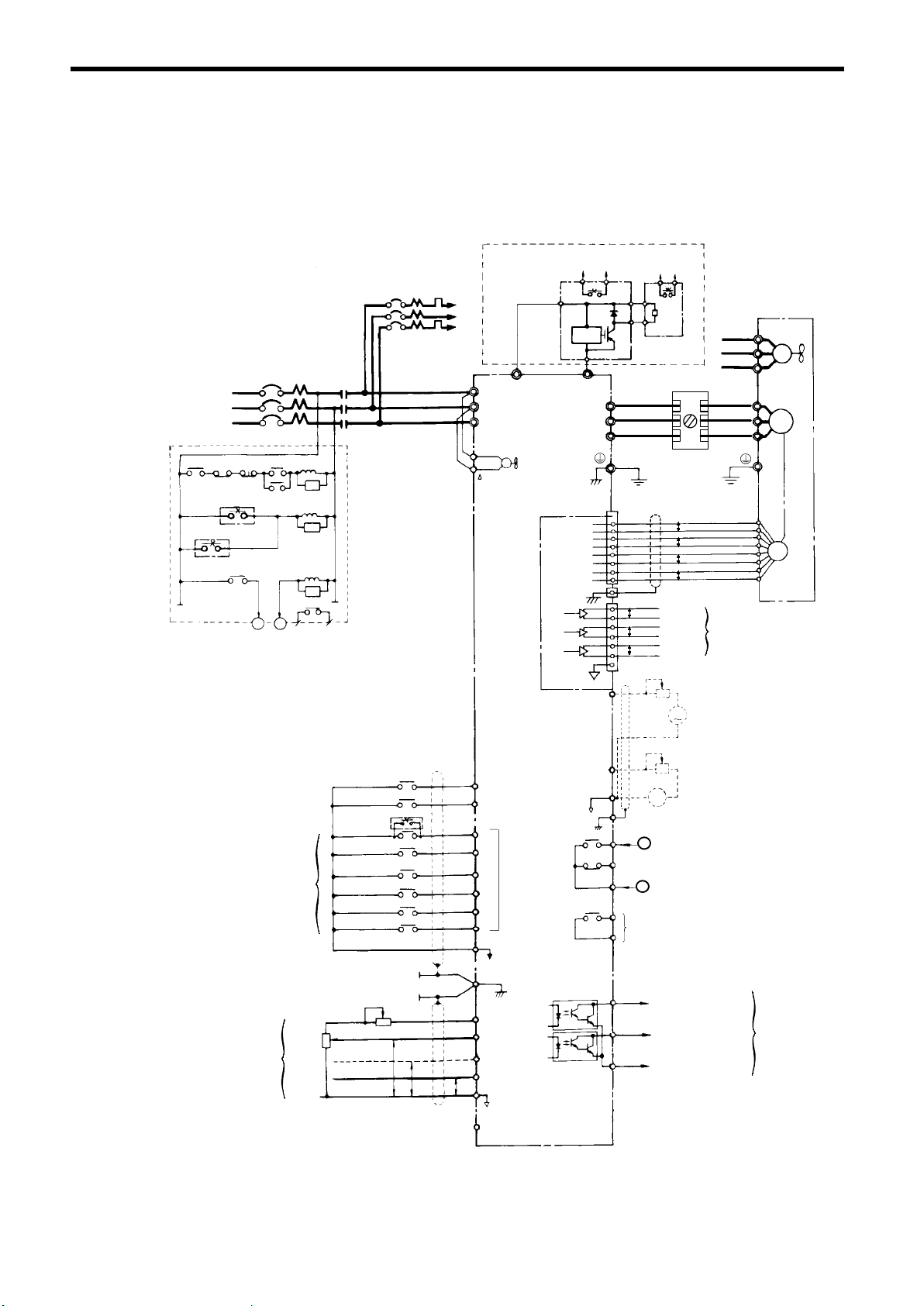

3.2 CONNECTION DIAGRAM

Below is a connection diagram of the main circuit and control circuit. The example shows the models

CIMR-SSA2018 to -SSA2075 (200V class 18.5 to 75kW). Using the digital operator, the motor can

be operated by wiring the main circuit only.

2MCCB

3-Phase

Power Supply

200 to 230V

50/60 Hz

2MCCB

Overload Relay Trip

Contact of Braking Resistor Unit

Overload Relay Trip Contact of

Motor Cooling Fan

1

R

S

T

THRX

12

2

MC

OFF

1MCCB

ON MC

MC

20

18

SA

THRX

SA

TRX

SA

TRX

Fault

Contact

MC

Overload Relay

Trip Contact

Braking Unit

R1

S1

T1

¨ 3

R

S

T

VS-686SS5

Cooling Fan

r

M

¨

PG-X2

3

Level

Detector

©

(E)

4

©

U

V

W

1

2

4

5

6

7

8

9

1

2

3

4

5

6

7

12

¨

P

©

B

Braking Resistor

Unit

Low-voltage Manual Starter

Ground (100 Ω or less)

TA1

P

P

P

TA3

TA2

P

P

P

P

Shielded Wire

Pulse A

Pulse B

Pulse Z

Motor

R1

S1

T1

FV

FW

Fan

IM

Cooling

FU

U

V

M

W

D

F

A

H

B

PG

I

C

J

Pulse Monitor Output

External Speed Reference

Factory

Setting

2kΩ

Forward

Run/Stop

Reverse

Run/Stop

External

Fault

Fault Reset

Multi-step Speed Setting 1

(Master/Aux Change)

Multi-step Speed

Setting 2

Jog Reference

External

Baseblock

34

2kΩ

0 to +10 V

4 to 20mA

0 to +10 V

P

P

0V

1 Forward Run

when CLOSED

2 Reverse Run

when CLOSED

3

4

5

Multi-function

Contact Input

6

7

8

Sequence Common

11

Terminal (0V)

12 Shield Sheath

Connection

Terminal

15 Speed Setting Power

Supply +15 V 20 mA

13 Master Speed Ref.

0 to 10V (20kΩ)

14 Master Speed Ref.

4 to 20mA (250Ω)

16 Multi-function Analog

Input 0 to 10V (20kΩ)

P

17

(Aux. Speed Ref. at Factory

Setting)

0V

33 Speed Setting Power

Supply -15V 20mA

23

21

22

−

(12)

18

18

19

20

20

9

Multi-function Contact Output

250 VAC 1 A or less

10

30 VDC 1 A or less

(Signal during Running at Factory Setting)

25

26

27

Multi-function Analog Monitor 2

+

-10 to +10 V 2mA

A

(Output Current at Factory Setting

−

0 to +10 V)

Frequency Meter Calibration Resistor

RV30YN20S 20kΩ

Multi-function Analog Monitor 1

-10 to +10 V 2mA

+

(Rotation Speed at Factory Setting

N

0 to +10 V)

Fault Contact Output

Contact Capacity:

250 VAC 1A or less

30 VDC 1A or less

Open Collector 1

(Zero Speed Signal at

Factory Setting)

Open Collector 2

(Speed Agree Signal

at Factory Setting)

Multi-function

Output Common

Multi-function

Open Collector

Output

48 V 50 mA or

less

22

7 Connection Diagram

Fig.

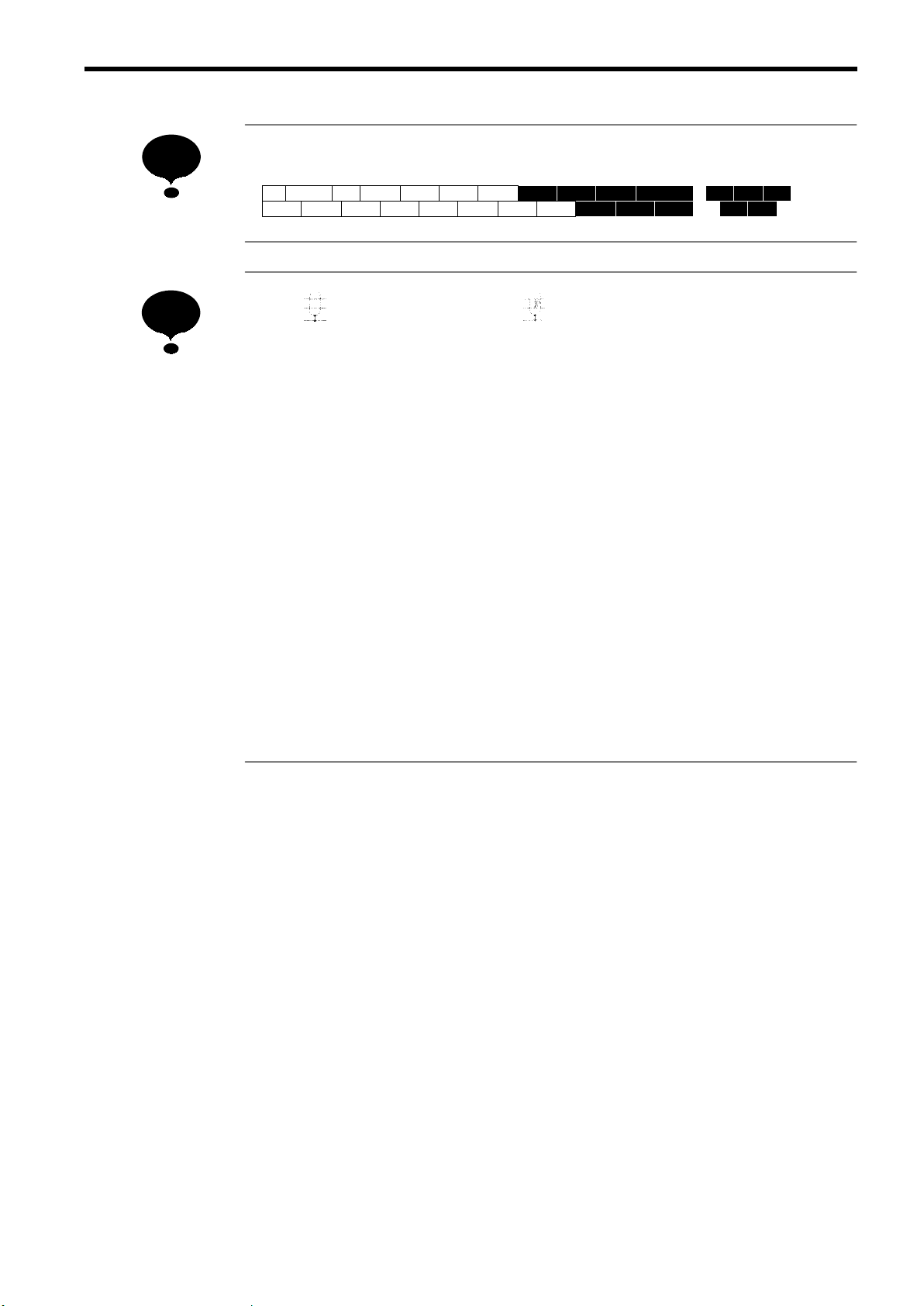

Page 22

3 WIRING

NOTE

NOTE

Layout of control circuit terminals

123 4567 8

1.

13 14 15 16 17

indicates shielded wires and indicates twisted-pair shielded wires.

25 26 27 33 18 19 2011 12(G)

21 22 23 9 10

2. Either control circuit terminal 13 or 14 can be used. (For simultaneous inputs, the two

signals are added internally.)

3. Control circuit terminal 15/33 of +15 V/-15 V has a maximum output current capacity of

20 mA.

4. Multi-function analog output should be used for monitoring meters (e.g. output frequency

meter) and should not be used for feedback control system. Use analog monitor cards

(Model AO-12) for the control system, for a more accurate signal.

5. When using a braking resistor unit, set the constant L3-01 to “0” (overvoltage prevention

level is “disabled”). If it is not changed, the motor may not stop within the set decel time.

6. When using model ERF braking resistor (inverter-mounted type), set the constant L8-01

to “01” (braking resistor protection selection to “enabled”). If it is not changed, the braking resistor cannot be protected.

7. When installing a DC reactor (optional for models of 15kW or below), remove the short-

circuit bar between ¨1 and ¨2 terminals and connect a DC reactor with the terminals.

8. The models of 200V 30 to 75kW or 400V 55 to 160kW cannot be connected with DC pow-

er supply.

9. Once external baseblock signal is turned ON, do not release until a motor stops.

23

Page 23

3.3 WIRING THE MAIN CIRCUIT

S Make sure to ground the ground terminal .

(Ground resistance 200V class: 100Ω or less, 400V class: 10Ω or less)

Failure to observe this warning can result in an electric shock or a fire.

S Never connect the AC main circuit power supply to output terminals U, V and W.

The inverter will be damaged and invalidate the guarantee.

S (Standard connection)

Be sure to connect the motor leads to the correct output terminals:

Motor lead U to output terminal U,

Motor lead V to output terminal V, and

Motor lead W to output terminal W.

Failure to observe this caution may cause the motor to run unusual way such as in reverse.

S With the standard connection for the output terminals, the motor rotates counterclock-

wise as viewed from the load side in a forward operation. To rotate the motor clockwise

in a forward operation, connect the output terminals as refered in Appendix 6.

WARNING

CAUTION

(1) Wiring Precautions for Main Circuit Input

(a) Installation of Molded-case Circuit Breaker (MCCB)

Make sure to connect MCCBs or fuses between the AC main circuit power supply and

VS-686SS5 input terminals R, S and T to protect wiring.

(b) Installation of Ground Fault Interrupter

When connecting a ground fault interrupter to input terminals R, S and T, select one that

is not affected by high frequency.

Examples: NV series by Mitsubishi Electric Co., Ltd. (manufactured in or after1988),

EG, SG series by Fuji Electric Co., Ltd. (manufactured in or after 1984)

24

Page 24

3 WIRING

(c) Installation of Magnetic Contactor

Inverter can be used without a magnetic contactor (MC) installed at the power supply side.

When the main circuit power supply is shut OFF in the sequence, a magnetic contactor (MC)

can be used instead of a molded-case circuit breaker (MCCB). However, when a magnetic

contactor is switched OFF at the primary side, regenerative braking does not function and

the motor coasts to a stop.

S The load cannot be operated/stopped by opening/closing the magnetic contactor at the

power supply side.

S When using a brakingresistor unit, use a sequencer to break power supply side on over-

load relay trip contact. If the inverter malfunctions, the braking resistor unit may be

burned out.

(d) Terminal Block Connection Sequence

Input power supply phases can be connected to any terminal regardless of the order of R,

S and T on the terminal block.

(e) Installation of Reactor

When connecting an inverter (200V/400V 15kW or less) to a large capacity power supply

transformer (600kVA or more), or when switching a phase advancing capacitor, excessive peak current flows in the input power supply circuit, which may damage the converter

section. In such cases, install a DC reactor (optional) between inverter ¨1 and ¨2 terminals or an AC reactor (optional) on the input side. Installation of a reactor is effective for

improvement of power factor on the power supply side.

(f) Installation of Surge Suppressor

For inductive loads (magnetic contactors, magnetic relays, magnetic valves, solenoids,

magnetic brakes, etc.) connected near the inverter, use a surge suppressor simultaneously.

(g) Prohibition of Installation of Phase Advancing Capacitor

If a phase advancing capacitor or surge suppressor is connected in order to improve the

power factor, it may become overheated and damaged by inverter high harmonic components. Also, the inverter may malfunction because of overcurrent.

(h) Using Input Noise Filters

Noise filters can reduce a higher harmonics noise leaking from the drive unit to the power

line.

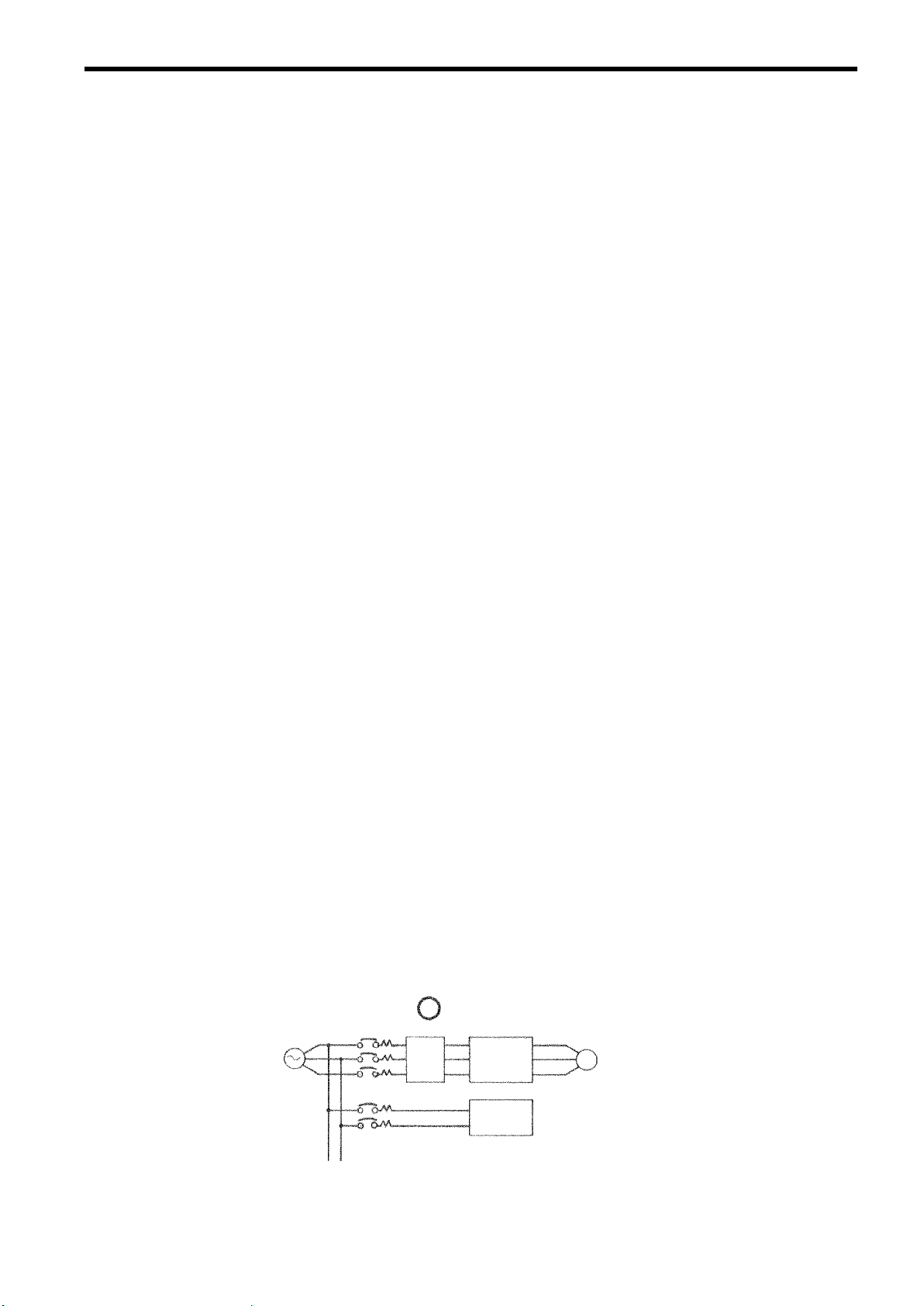

S Example 1

Power

Supply

MCCB

MCCB

Noise

Filter

VS-686SS5

Other

Control

Device

Fig. 8 Using Input Noise Filter (Example 1)

Use an exclusive noise filter

specified for the inverter.

M

25

Page 25

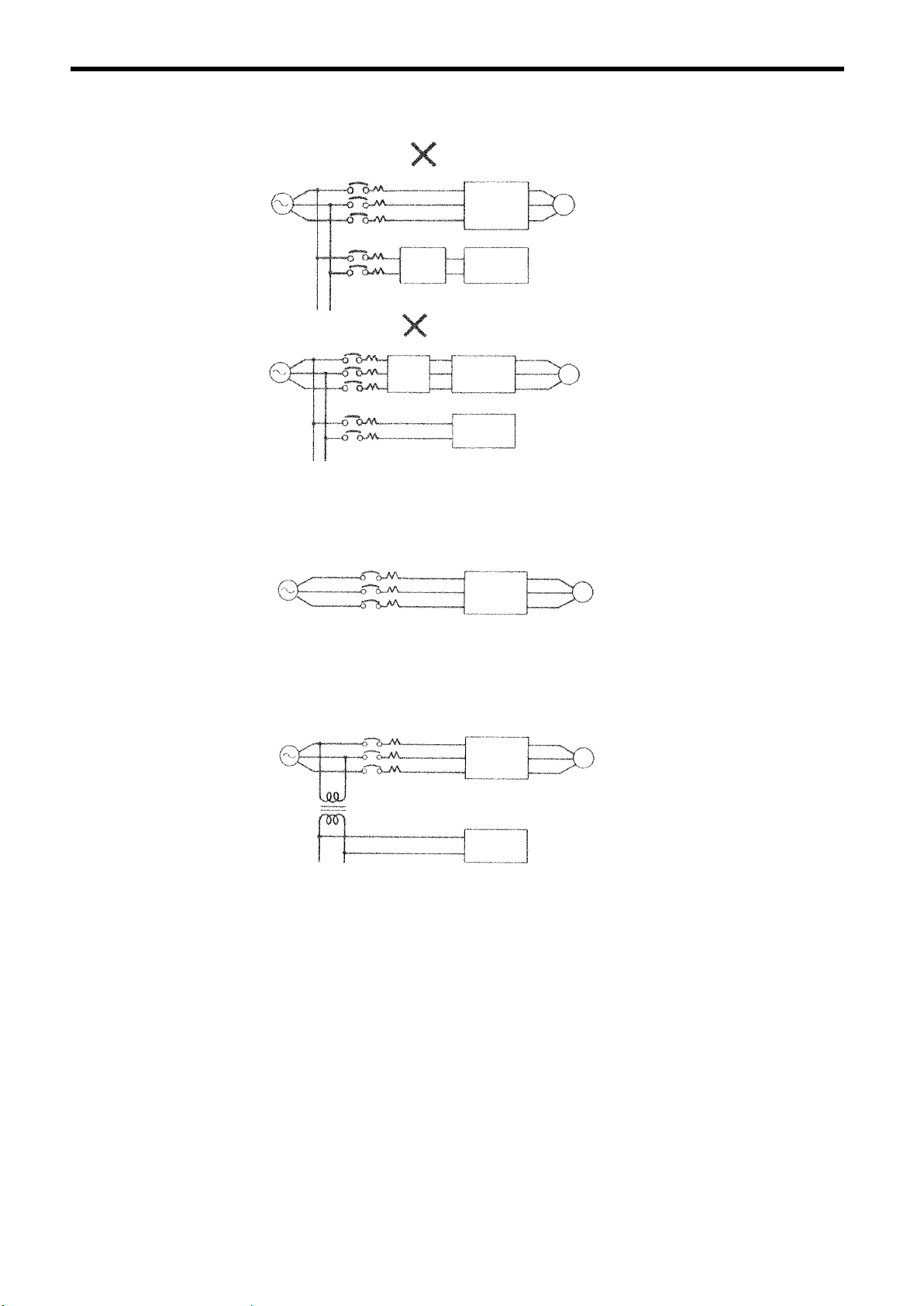

S Example 2

Power

Supply

Power

Supply

MCCB

MCCB

MCCB

MCCB

General

Noise

Filter

General

Noise

Filter

VS-686SS5

Other

Control

Device

VS-686SS5

Other

Control

Device

Fig. 9 Using Input Noise Filter (Example 2)

S Example 3

Power

Supply

MCCB

VS-686SS5

A general-purpose noise

filter will not effective.

M

M

When one inverter is installed

on one power line, a noise fil-

M

ter is not required.

Fig. 10 Using Input Noise Filter (Example 3)

S Example 4

Power

Supply

MCCB

Isolating Transformer

VS-686SS5

Other

Control

Device

Fig. 11 Using Input Noise Filter (Example 4)

By installing an isolating trans-

former on the power side of

M

another control device, the

same result as with installing a

noise filter is achieved.

26

Page 26

(2) Wiring Precautions for Main Circuit Output

(a) Connection of Terminal Block and Load

Connect output terminals U, V and W to motor lead wires U, V and W. For standard connections, be sure to connect the motor leads to the correct output terminals: motor lead U to

output terminal U, motor lead V to output terminal V, and motor lead W to output terminal

W.

With the standard connection for the output terminals, the motor rotates counterclockwise

as viewed from the load side in a forward operation. To rotate the motor clockwise in a forward operation, connect the output terminals as refered in Appendix 6.

(b) Strict Prohibition of Connection of Input Power Supply to Output Terminals

3 WIRING

Never connect the input

power supply to output terminals U, V and W.

(c) Installation of Low-voltage Manual Starter

Make sure to connect a low-voltage manual starter to the inverter output side when the motor is rotated by the load even if the inverter power supply is OFF. Turn OFF the starter before performing maintenance/inspection or wiring.

Example: LB series of AICUT manufactured by Aisei

(d) Strict Prohibition of Short Circuiting or Grounding of Output Circuit

Never touch the output circuit directly or put the output line in contact with the inverter case.

Otherwise, it may cause an electric shock or grounding. In addition, never short circuit the

output line.

(e) Prohibition of Connection of Phase Advancing Capacitor or LC/RC Line Filter

Never connect a phase advancing capacitor or LC/RC line filter to the output circuit.

(f) Avoidance of Installation of Magnetic Starter

Do not connect a magnetic starter or magnetic contactor to the output circuit. If the load

is connected while the inverter is running, the inverter overcurrent protective circuit operates because of inrush current.

(g) Installation of Thermal Overload Relay

An electronic overload protective function is incorporated into the inverter. When using

a thermal overload relay, set inverter constant L1-01 to 0 (motor protection selection: disabled).

27

Page 27

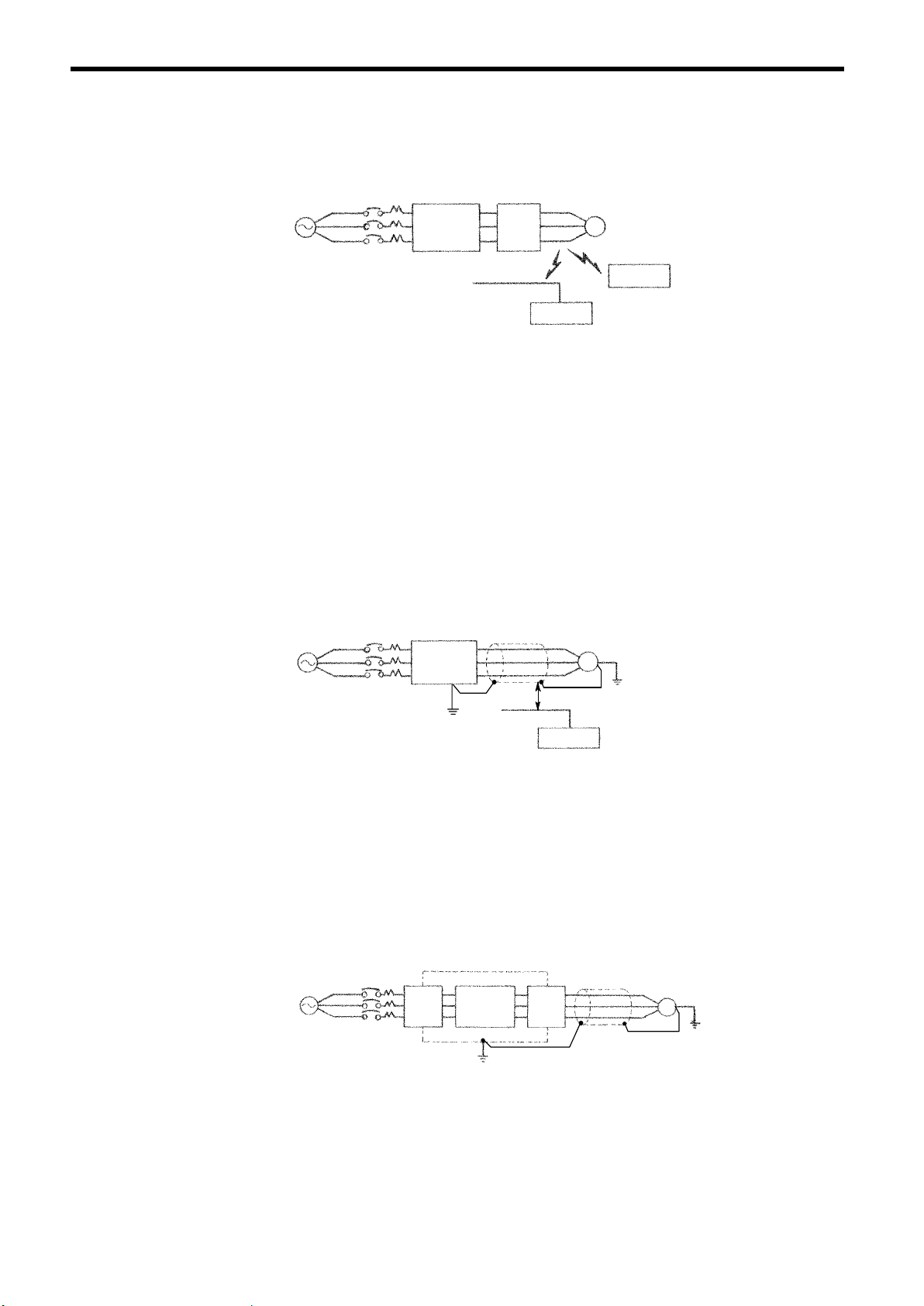

(h) Using Output Noise Filters

By installing a noise filter on the output side of the inverter, radio frequency interference

(RFI) and inductive noise are reduced.

Power

Supply

MCCB

VS-686SS5

Noise

Filter

Inductive

Noise

Signal Line

Control

Device

M

RFI Noise

AM Radio

Fig. 12 Using Output Noise Filter

Inductive noise: Noise coming on the signal line due to electromagnetic inductance can

cause malfunctioning of a control device.

RFI noise: Higher harmonics waves from the inverter or cable can interfere with radio

receiver.

(i) Countermeasures Against Inductive Noise

As described previously,a noise filter can be used to prevent inductive noise fromgenerated

on the output side. Alternatively, cables can be routed through a grounded metal pipe to

prevent inductive noise. Keeping the metal pipe at least 30 cm away from the signal line

considerably reduces inductive noise.

Power

Supply

MCCB

VS-686SS5

Metal Pipe

M

30 cm min.

Signal Line

Control

Device

Fig. 13 Countermeasures Against Inductive Noise

(j) Countermeasures Against RFI Noise

RFI noise is generated form the inverter as well as from the input andoutput lines. To reduce

RFI noise, install noise filters on both input and output sides, and also install in a totally enclosed steel box. The cable between the inverter and the motor should be as short as possible.

Power

Supply

MCCB

Noise

Filter

Steel Box

VS-686SS5

Noise

Filter

Metal Pipe

M

Fig. 14 Countermeasures Against RFI Noise

28

Page 28

3 WIRING

(k) Wiring Distance between Inverter and Motor

If the total wiring distance between inverter and motor is excessively long and the inverter

carrier frequency (main transistor switching frequency) is high, harmonic leakage current

from the cable will adversely affect the inverter and peripheral devices.

Consider the wiring distance between inverter and motor when increasing the carrier frequency value. Carrier frequency can be set by constant C6-02.

Table 2 Wiring Distance between Inverter and Motor

Wiring Distance between

Inverter and Motor

(Set value of constant C6-02)

(3) Grounding

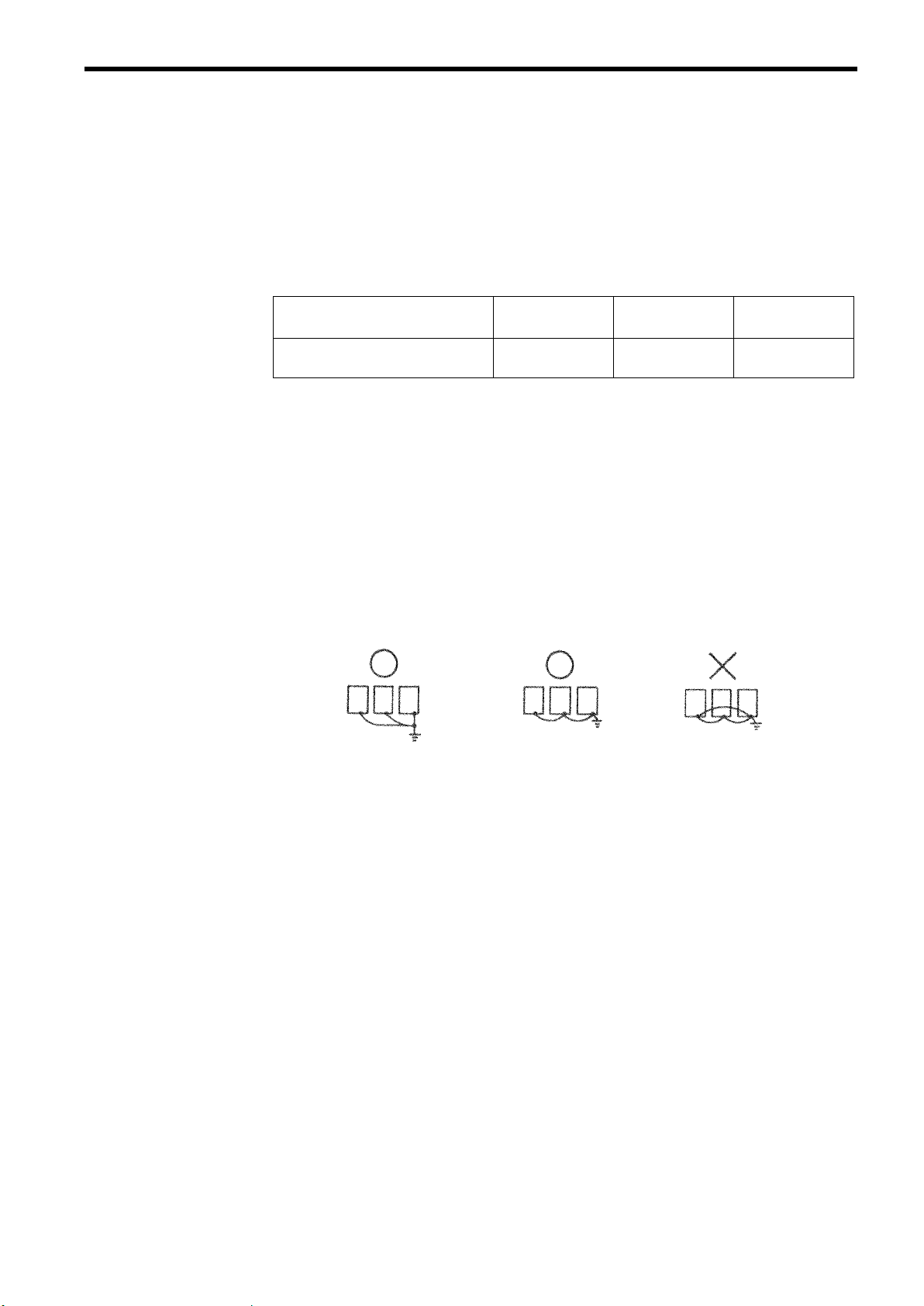

S Ground resistance

S Never ground the inverter in common with welding machines, motors, or other large-

S Use the ground wires described in Table5 or 6 and keep the length as short as possible.

S When using several inverter units side by side, ground the units as shown in Fig. 15,

Up to 50m From 50m to 100m More than 100m

Carrier Frequency

12kHz or less

(Max. 12)

8kHz or less

(Max. 8)

200V class : 100Ω or less, 400 V class : 1 0Ω or less.

current electrical equipment.

(a) or (b). Do not loop the ground wires as shown in (c).

(a) Acceptable

(b) Acceptable

(c) Not Acceptable

4kHz or less

(Max. 4)

Fig. 15 Grounding of Three Inverter Units

29

Page 29

(4) Functions of Main Circuit Terminals

Max

Applicable

0

kW11to15kW

18

22kW30

kW

pppp y

p

C

C

C

u

g

(

)

DC

bus

terminals

DC

bus

terminals

g

Braking

unit

(¨1

and¨2

•

Braking

unit

provided)

Max

Applicable

0

kW

18

kW

160kW18

300

kW

g

C

Braking

unit

(

)

•

DC

bus

terminals

(¨1©)

(¨1and¨2

Braking

unit

(¨3

©

)

(¨2

terminal

not

Cooling

fan

power

Cooling

fan

power

supply

p

r-200:200to230VAC

input

The following table outlines the functions of the main circuit terminals. Wire according to each

terminal function.

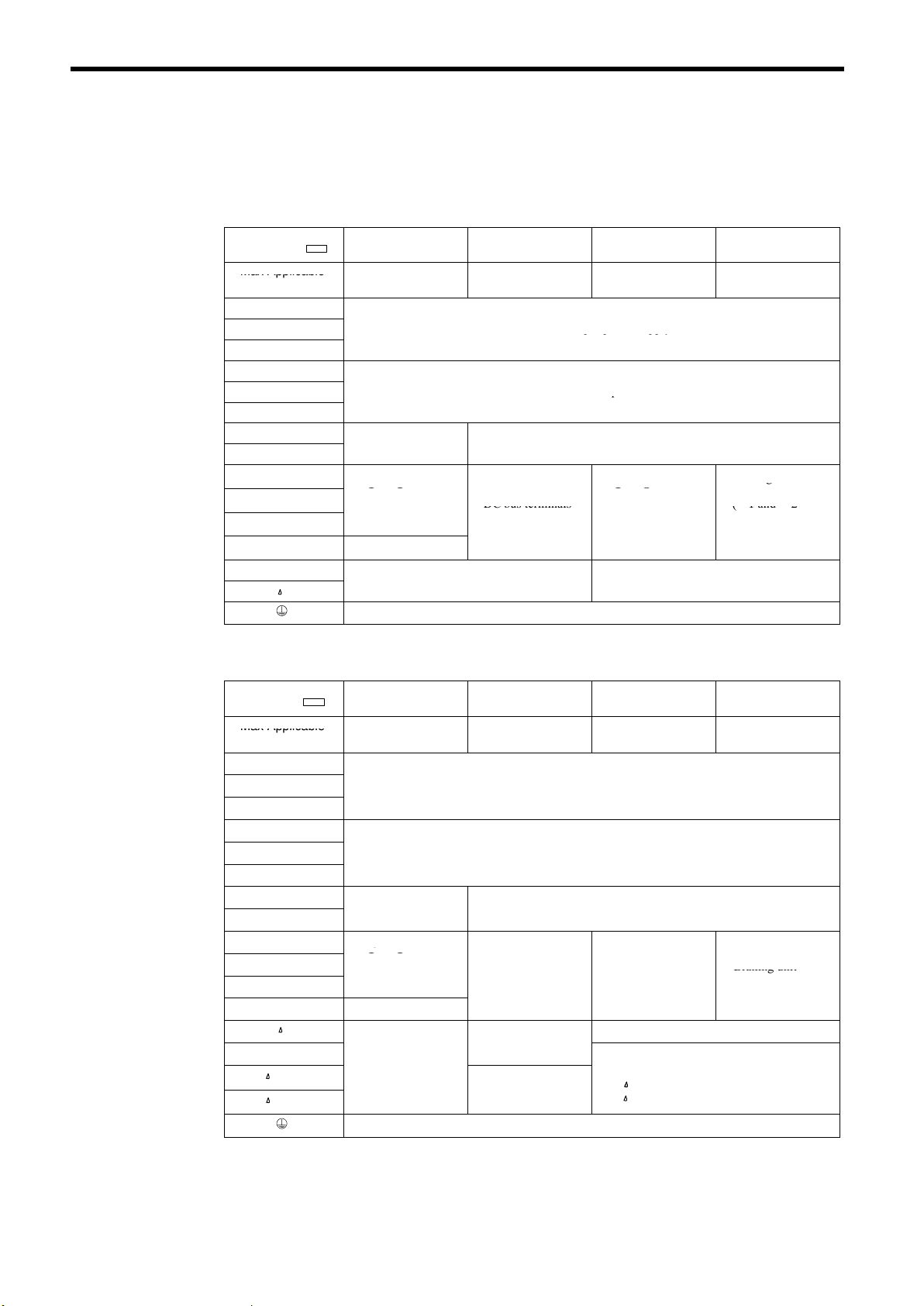

Table 3 200V Class Terminal Functions

Models

CIMR-SSA

Max Applicable

Motor Output

R (L1)

S (L2)

T (L3)

U (T1)

V (T2)

W (T3)

B1

B2

©

¨ 1

¨ 2

¨ 3

r

20P4 to 27P5 201 1 to 2015 2018 to 2022 2030 to 2075

.4 to 7.5

Braking resistor unit

• DC reactor

(¨1-¨2)

• DC bus terminals

(¨1-©)

• DC reactor • DC bus terminals

(¨ 1-¨ 2)

• DC bus terminals

(¨ 1-© )

• Brakin

(¨3-©)

Ground terminal (Ground resistance : 100Ω or less)

Table 4 400V Class Terminal Functions

.5 to

Main circuit input power supply

Inverter output

(¨1-©)

• Braking unit

unit

(¨3-©)

Cooling fan power supply

to 75

• Braking unit

¨3-©

(¨1 and ¨2

terminals not

provided) *

Models

CIMR-SSA

Max Applicable

Motor Output

R (L1)

S (L2)

T (L3)

U (T1)

V (T2)

W (T3)

B1

B2

©

¨ 1

¨ 2

¨ 3

r

200

400

40P4 to 4015 4018 to 4045 4055 to 4160 4220 to 4300

.4 to15

Braking resistor unit

• DC reactor

(¨1-¨2)

• DC bus terminals

(¨1-©)

.5 to 45

Main circuit input power supply

Inverter output

• DC bus terminals

(¨1-©)

• Braking unit

-

-

Coolingfanpower

supply

Ground terminal (Ground resistance : 10Ω or less)

55 to

• Brakin

• Cooling fan power supply

unit

(¨3-© )

terminals not

provided)

(Control power supply)

r - 200 : 200 to 230 VAC in

r - 400 : 380 to 460 VAC input

*

5to

• DC bus terminals

¨1-©

• Braking unit

(¨3-© )

provided)

ut

* The models of 200V 30 to 75kW or 400V 55 to 160kW cannot be connected with DC power

supply. Terminal ¨3 is for exclusive use for connecting a braking unit. Do not connect DC

power supply to terminal ¨3.

30

Page 30

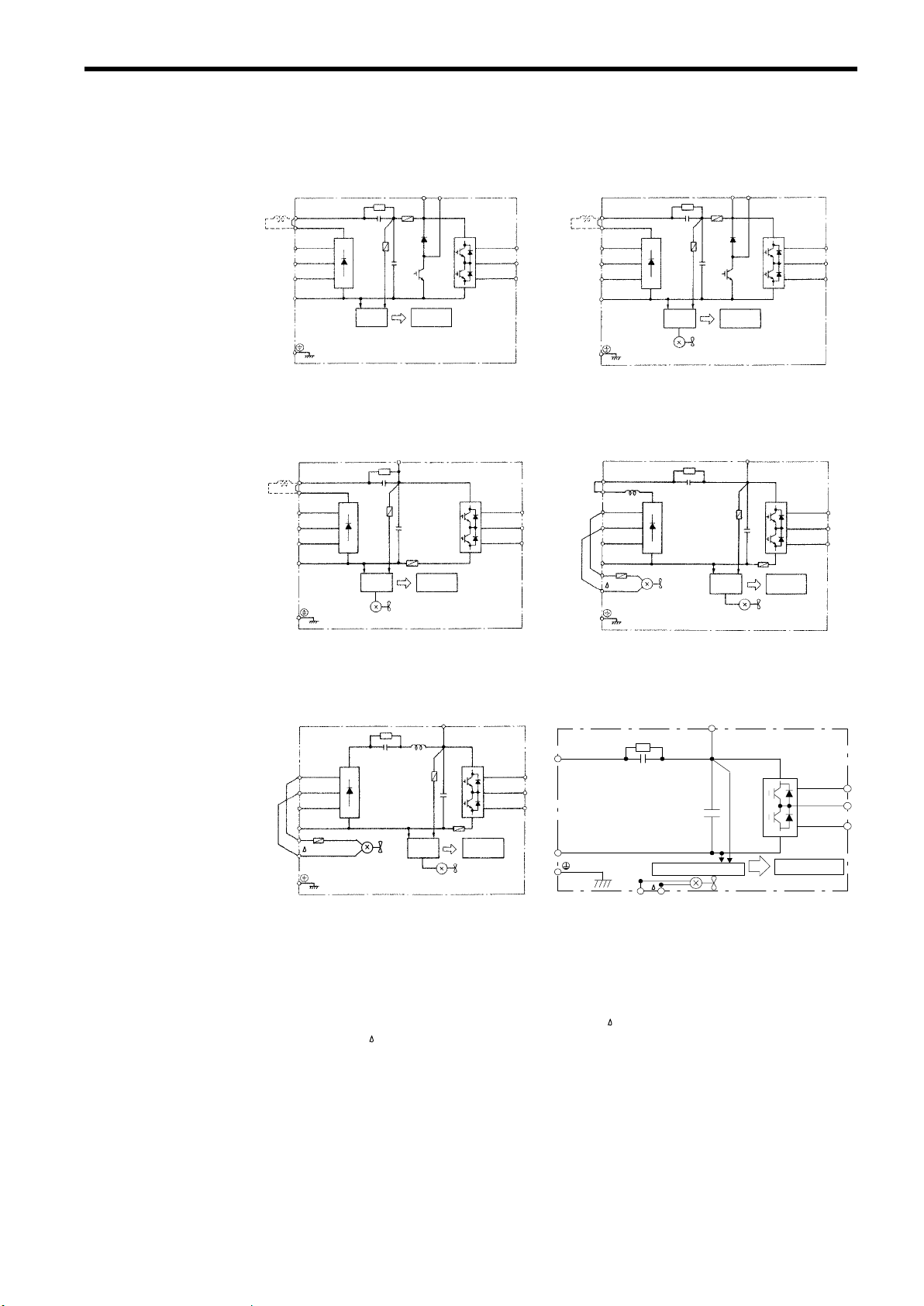

(5) Main Circuit Configuration

200V Class

CIMR-SSA20P4 to 21P5 CIMR-SSA22P2 to 27P5

+

Control

Circuit

B2B1

U(T1)

V(T2)

W(T3)

(DCL

Option)

:1

:2

¨1

¨2

R(L1)

S(L2)

T(L3)

©

(DCL

Option)

:1

:2

¨1

¨2

R(L1)

S(L2)

T(L3)

©

Power

Supply

(RCC)

CIMR-SSA2011 to 2015 CIMR-SSA2018 to 2022

¨3 ¨3

(T1)

U

(T2)

V

(T3)

W

Power

Supply

+

(RCC)

Cooling Fan

Control

Circuit

:3

:1

¨1

¨2

R

S

T

©

r

Cooling Fan

(DCL

Option)

:1

:2

¨1

¨2

R(L1)

S(L2)

T(L3)

©

Power

Supply

+

(RCC)

Cooling Fan

Power

Supply

(RCC)

Control

Circuit

B2B1

+

Control

Circuit

Internal

Cooling Fan

3 WIRING

U(T1)

V(T2)

W(T3)

U

V

W

CIMR-SSA2030 to 2075 CIMR-SSAD030*4to D045

¨3

¨1

:1

R

S

T

©

r

Cooling Fan

Power

Supply

+

(RCC)

Control

Circuit

Internal

Cooling Fan

U

V

W

©

Power Supply (RCC)

r

*1: The wiring has been completed at the factory prior to shipping.

*2: When installing aDCreactor(option) on models of 15kW or below,removetheshort-circuit

bar between ¨1 and ¨2 terminals and connect a DC reactor with the terminals.

*3: The wiring has been completed at the factory prior to shipping. When using main circuit

power supply as DC input, remove the wirings of R - r and S ply to r and

.

and connect AC power sup-

*4: The CIMR-SSD030 motor is under development.

¨3

+

Cooling Fan

U

V

W

Control Circuit

31

Page 31

400V Class

CIMR-SSA40P4 to 41P5 CIMR-SSA42P2 to 4015

+

Control

Circuit

B2B1

U(T1)

V(T2)

W(T3)

(DCL

Option)

:2

:1

¨1

¨2

R(L1)

S(L2)

T(L3)

©

Power

Supply

+

(RCC)

Cooling Fan

(DCL

Option)

:1

:2

¨1

¨2

R(L1)

S(L2)

T(L3)

©

Power

Supply

(RCC)

CIMR-SSA4018 to 4045 CIMR-SSA4055 to 4160

Power

Supply

(RCC)

¨3

+

Control

Circuit

Internal

Cooling Fan

U

V

W

:1

R

S

T

©

r

200

400

Cooling Fan

)

Power

Supply

:1

:3

¨1

¨2

©

r

R

S

T

Cooling Fan

Control

Circuit

(RCC

B2B1

¨3

+

Control

Circuit

Internal

Cooling Fan

U(T1)

V(T2)

W(T3)

U

V

W

CIMR-SSA4220 to 4300 CIMR-SSAE075*4to E110

Power

Supply

(RCC)

¨3

+

Control

Circuit

¨1

U

V

W

©

r

200 400

:3

¨1

R

S

T

©

r

200

400

Cooling Fan

*1: The wiring has been completed at the factory prior to shipping.

*2: When installing a DC reactor (option) on models of 15 kW or below,removetheshort-circuit

bar between ¨1 and ¨2 terminals and connect a DC reactor with the terminals.

*3: The wiring has been completed at the factory prior to shipping. When using main circuit

power supply as DC input, correct the wirings as follows.

• CIMR-SSA4018 to 4045

Remove the wirings of R - r and S -

and connect AC power supply to r and .

• CIMR-SSA4220 to 4300

Remove the wirings of R - r and S -

400 and connect AC power supply to r and 400.

*4: The CIMR-SSAE075 motor is under development.

¨3

+

Power Supply (RCC)

Cooling Fan

Control

Circuit

U

V

W

32

Page 32

(6) Parts Required for Wiring

SSA20P4

M4

2to5.5

SSA20P7

M4

2to5.5

SSA22P2

M4

3.5to5.5

SSA23P7

M4

5.5

q

wireorequivalent

Select wires or closed-loop connectors to be used for wiring from Tables 5, 6 and 7.

Table 5 200V Class Wire Size

3 WIRING

Circuit

Main

Control

Model

CIMR-

SSA21P5

SSA25P5

SSA27P5

SSA2011

SSA2015

SSA2018

SSA2022

SSA2030

SSA2037

SSA2045

SSA2055

SSA2075

Common to all

models

Terminal Symbol

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M8 30

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5 to 5.5

R, S, T, U, V, W M10 38 to 100

© , ¨ 3

r, M4 0.5 to 5.5

R, S, T, U, V, W M10 38 to 100

© , ¨ 3

r, M4 0.5 to 5.5

R, S, T, U, V, W M10 60 to 100

© , ¨ 3

r, M4 0.5 to 5.5

R, S, T, U, V, W M10 100

© , ¨ 3

r, M4 0.5 to 5.5

R, S, T, U, V, W M12 100 to 200

© , ¨ 3

r, M4 0.5 to 5.5

1to33 M3.5 0.5 to 2

Terminal

Screw

Wire Size *

mm

M4

M5

M5

M6

M6 8

M8

M8

M8

M8 22

M8

M8 22

M8

M8 22

M8

M8 30

M8

M8 50

2 to 5.5

3.5 to 5.5

5.5 to 8

5.5 to 8

2

8

8

22

8

30

14

38

14

Wire Type

Power cable:

600V vinyl sheathed

wire or e

uivalent

Twisted shielded wire

* Wire size is determined using 75_C temperature-rated copper wire.

When connecting a braking resistor unit or a braking unit, select wire size referring to the

instructions of braking resistor unit and braking unit (manual No.: TOE-C726-2).

33

Page 33

Table 6 400V Class Wire Size

SSA40P4

M4

2to5.5

SSA40P7

M4

2to5.5

SSA41P5

M4

2to5.5

SSA42P2

M4

2to5.5

SSA45P5

M4

3.5to5.5

SSA47P5

M5

5.5

SSA4018

SSA4022

SSA4030

Power

cable:

Main

SSA4037

600V

vinyl

sheathed

q

SSA4045

Circuit

Model

CIMR-

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

Terminal Symbol

Terminal

Screw

Wire Size *

2

mm

Wire Type

Main

Control

SSA43P7

SSA4011

SSA4015

SSA4018

SSA4022

SSA4030

SSA4037

SSA4045

SSA4055

SSA4075

SSA4110

SSA4160

SSA4220

SSA4300

Common to all

models

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W M5 8to14

R, S, T, © , ¨ 1,¨ 2, B1, B2, U, V, W M5 8to14

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M6 14

r, M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W M6 22

r, M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 2, ¨ 3, U, V, W

r, M4 0.5 to 5.5

R, S, T, U, V, W M10 38 to 100

© , ¨ 3

r , 200, 400 M4 0.5 to 5.5

R, S, T, U, V, W M10 38 to 100

© , ¨ 3

r , 200, 400 M4 0.5 to 5.5

R, S, T, U, V, W M10 60 to 100

© , ¨ 3

r , 200, 400 M4 0.5 to 5.5

R, S, T, U, V, W M12 100 to 200

© , ¨ 3

r , 200, 400 M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 3, U, V, W M16

r , 200, 400 M4 0.5 to 5.5

R, S, T, © , ¨ 1,¨ 3, U, V, W M16

r , 200, 400 M4 0.5 to 5.5

1to33 M3.5 0.5 to 2

M4

M6 8

M6 8

M8 8

M8 8

M8

M8

M8

M8

M8 22

M8

M8 22

M8

M8 30

M8

M8 50

M8 60

M8 60

2 to 5.5

3.5 to 5.5

22

8

30

14

50

14

325 or

200 × 2P

250 × 2P or

325 × 2P

Power cable:

600V vinyl sheathed

wire or equivalent

Twisted shielded wire

* Wire size is determined using 75_C temperature-rated copper wire.

When connecting a braking resistor unit or a braking unit, select wire size referring to the

instructions of braking resistor unit and braking unit (manual No.: TOE-C726-2).

34

Page 34

Table 7 Closed-Loop Connectors

5

5

5

5

5

325

Wire Size mm

0.

0.7

1.2

3.5/5.

30 / 38 M8 38 - 8

0/60

100

100 100 - 12

150 M12 150 - 12

200 200 - 12

2

2 M5 2-5

8 M6 8-6

14

22

80

Terminal Screw Closed-Loop Connectors

M3.5 1.25 - 3.5

M4 1.25 - 4

M3.5 1.25 - 3.5

M4 1.25 - 4

M3.5 1.25 - 3.5

M4 1.25 - 4

M3.5 2 - 3.5

M4 2-4

M6 2-6

M8 2-8

M4 5.5 - 4

M5 5.5 - 5

M6 5.5 - 6

M8 5.5 - 8

M5 8-5

M8 8-8

M6 14 - 6

M8 14 - 8

M6 22 - 6

M8 22 - 8

M8 60 - 8

M10 60 - 10

M10

M12 × 2

M16 325 - 16

3 WIRING

80 - 10

100 - 10

325 - 12

NOTE

When determining wire size, consider voltage drop. Select a wire size so that voltage drop will

be less than 2% of the normal rated voltage. Voltage drop is calculated by the following equation:

Phase-to-phase voltage drop (V)

=√ 3¢wire resistance (Ω/km)¢wiring distance (m)¢current (A)¢10

-3

35

Page 35

3.4 WIRING THE CONTROL CIRCUIT

S

u

c

inputs

(H1 01

to

H1 06)

u

S

n

u

Master

speed

reference

I

n

)

Cl

Contact

capacity:

S

25

d

d

Closedatzero speed

level

(b2 01)

or

u

t

Cl

Open

collector

output

26

Speed

agree

detection

¦

48V50mAor

less

p

y

p()

Fault

when

open

between

terminals

19

and20250VAC1Aorless

2mAor

less

The following table outlines the functions of the control circuit terminals. Wire according to each terminal function.

(1) Functions of Control Circuit Terminals

Table 8 Control Circuit Terminals

Classifi-

Terminal Signal Function Description Signal Level

cation

Forward run/stop Forward run when closed, stop when open

1

Reverse run/stop Reverse run when closed, stop when open

2

ignal

ut

ce Inp

uen

eq

nal

ut Sig

Inp

nalog

A

nal

Sig

ut

tp

u

nce

que

Se

utput

gOul

AnalogSignal

External fault input

3

Fault reset input Reset when closed

4

Master/Auxiliary change

5

(Multi-step speed reference 1)

Multi-step speed reference 2 Effective when closed

6

Jog reference Jog run when closed

7

External baseblock Inv. output stop when closed

8

0V for sequence input

11

+15 V

15

Power supply output

-15 V

33

Power supply output

13

Master speed reference

14

Multi-function analog input

16

Common terminal for control circuit

17

Connection to shield sheath of signal

12

lead or optional unit grounding

9

During running(NOcontact

10

Zero spee

Speed agree detection

26

Open collector output common

27

18

Fault contact output (NO/NC contact)

19

20

Rotation speedometer output 0 to +10 V/100% rotation speed

21

Common

22

Current monitor 5 V/inverter rated current

23

etection

Fault when closed, normal state when

open

Auxiliary speed reference when closed

For analog command +15 V power supply

For analog command -15 V power supply

-10 to +10 V/-100% to +100%

0 to +10 V/100%

4 to 20 mA/100%, -10 to +10 V/-100% to +100%, 0 to +10 V/100%

-10 to +10V/-100% to +100%

0 to +10 V/100%

osedwhen running

Closed at zero-speed level (b2-01) or

below

osedwhenthe speedreachesto

2 Hz of set speed.

Fault when closed between terminals 18 and 20

Fault when o

en between terminals 19 and 20

Multi-function contact

inputs (H1-01 to H1-06)

Auxiliary analog input

(H3-05)

Multi-function output

Multi-function analog

monitor 1 (H4-01,H4-02)

Multi-function analog

monitor 2 (H4-04,H4-05)

Photo-coupler insulation

Input : +24 VDC 8 mA

+15 V

(Allowable current 20 mA max.)

-15 V

(Allowable current 20 mA max.)

-10 to +10 V (20 kΩ),

0 to +10 V (20 kΩ)

4 to 20mA (250Ω)

-10 to +10V (20kΩ),

0 to +10V (20kΩ)

Dry contact

Contact capacity:

250 VAC 1 A or less

30 VDC 1 A or less

Open collector output

48 V 50 mA or less *

Dry contact

Contact capacity:

250 VAC 1 A or less

30 VDC 1 A or less

0to¦10 V Max. ¦5%

2 mA or less

36

* When an inductive load such as a relay coil is driven, insert a fly-wheel diode as shown in the following figure.

External Power

Supply

48 V or less

11 12(G)

123 4567 8

13 14 15 16 17

Coil

50 mA or less

25 26 27 33 18 19 20

Fig. 16 Control Circuit Terminal Arrangement

Fly-wheel Diode

Fly-wheel diode rating should be of

rated circuit voltage/current value or

over.

21 22 23 9 10

Page 36

(2) Precautions on Control Circuit Wiring

S Separate control circuit wires 1 to 33 from main circuit wires R, S, T, B1, B2, U, V,

W,©,¨1,¨2,¨3 and other power cables to prevent erroneous operation caused by

noise interference.

S Separate the wiring of control circuit terminals 9, 10, 18, 19 and 20 (contact output)

from those of terminals 1 to 8, 21, 22, 23, 25, 26, 27, 33 and 11 to 17.

S Use twisted shielded or twisted-pair shielded wire for the control circuit line and con-

nect the shield sheath to the inverter terminal 12. See Fig. 17. Wiring distance should

be less than 50 m.

Shield Sheath Armor

3 WIRING

To inverter shield

sheath terminal 12

Fig. 17 Shielded Wire Termination

3.5 WIRING INSPECTION

After completing of installation and wiring, check for the following items. Never use control circuit

buzzer check.

V Wiring is proper.

V Wire clippings or screws are not left in the unit.

V Screws are securely tightened.

V Bare wire in the terminal does not contact other terminals.

Insulate these parts

with insulating tape.

Never connect.

37

Page 37

4 OPERATION

S

Only turn ON the input power supply after replacing the front cover. Do not remove the

cover while current is flowing.

Failure to observe this warning can result in an electric shock.

S

When the retry function (L5-02) is selected, do not approach the inverter or the load, since

it may restart suddenly after being stopped.

(Construct machine system, so as to assure safety for personnel, even if the inverter should restart.) Failure to observe this warning can result in personal injury.

S

Since the stop button can be disabled by a function setting, install a separate emergency

stop switch.

Failure to observe this warning can result in personal injury.

S

If an alarm is reset with the operation signal ON, the inverter restarts automatically. Only

reset the alarm after verifying that the operation signal is OFF.

Failure to observe this warning can result in personal injury.

WARNING

CAUTION

S

Never touch the heatsink or discharging resistor since the temperature is very high.

Failure to observe this caution can result in harmful burns to the body.

S

Since it is easy to change operation speed from low to high speed, verify the safe working

range of the motor and machine before operation.

Failure to observe this caution can result in personal injury and machine damage.

S

Install a holding brake separately if necessary.

Always construct the external sequence to confirm that the holding brake is activated

in the event of an emergency, a power failure, or an abnormality in the inverter occuring.

Failure to observe this caution can result in personal injury.

S

If using with an elevator, take safety measures on the machine’s side to prevent the ele-

vator from dropping.

Failure to observe this caution can result in personal injury.

S

Do not change signals during operation.

The machine or the inverter may be damaged.

S

All the constants of the inverter have been preset at the factory. Do not change the

settings unnecessarily.

The inverter may be damaged. For supply voltage, follow Par. 4.2.

S

Be sure to set the motor constants in accordance with the values listed on the motor name-

plate.

Failure to observe this caution may cause the torque to be insufficient, which may result in the

following motor malfunctions:

• The motor is pulled in the direction of the load.

• The motor rotates in reverse.

• The motor does not rotate.

• The motor suddenly accelerates.

38

Page 38

4.1 TEST RUN CHECKPOINTS

Check the following items before a test run.

V Wiring and terminal connections are correct.

V No short circuit caused by wire clippings.

V Screw-type terminals are securely tightened.

V Motor is securely mounted.

4.2 SETTING THE LINE VOLTAGE USING JUMPER (FOR 400V CLASS 18.5kW AND ABOVE)

Insert the jumper at the appropriate location corresponding to the input line voltage. (See Fig. 18.)

It has been preset at the factory to 440V.

23CN 24CN 25CN 26CN 22CN FU2

4 OPERATION

Fig.

TB2

20CN

r

18

Line Voltage Jumper (For 400V Class 18.5kW to 45kW)

400/415V

380V 440V 460V

21CN

39

Page 39

4.3 TEST RUN

(1) Digital Operator Display at Power ON

When the system is ready for operation, turn ON the power supply. Verify that the inverter

powers up properly. If any problems are found, turn OFF the power supply immediately.

The digital operator display illuminates as shown below when turning the power supply ON.

Refer tp Section 5 for operation method of digital operator.

DRIVE FWD REV REMOTE

DIGITAL OPERATOR

JVOP-132

LOCAL

REMOTE

JOG

SEQ REF

DRIVE

PRGM

Mode Indicator LED :

DRIVE/REMOTE (SEQ, REF) LED ON

Display Section :

Displays frequency reference

(corresponding to analog reference value)

DSPL

DATA

ENTER

40

Fig.

FWD

REV

RUN STOP

19

Digital Operator Display at Power ON

RESET

Operation Indicator LED :

STOP LED ON

Page 40

4 OPERATION

(2) OPERATION MODE SELECTION

The VS-686SS5 has two operation modes, LOCAL and REMOTE, as described below. These

two modes can be selected by the digital operator “LOCAL/REMOTE” key only while the

operation is stopped. The selected operation mode can be verified by observing the digital

operator SEQ and REF LEDs (both LEDs light in REMOTE mode).

The operation mode at power ON is set to REMOTE (run by control circuit terminals 13 and

14 speed reference and run command from a control circuit terminal) prior to shipment. Multifunction contact inputs from control circuit terminals 3 to 8 are enabled in both operation

modes LOCAL/REMOTE.

LOCAL

REMOTE

Both speed reference and run command are set by the digital operator. SEQ and REF LEDs

go OFF.

Master speed reference and run command can be selected by setting constants b1-01 and

b1-02. The factory setting is “1” (command from control circuit terminal).

Table 9 Reference Selection in REMOTE Mode

Constant No. Name Remarks

0 : Master speed reference from digital operator (d1-01)

(Digital operator REF LED is OFF.)

1 : Master speed reference from control circuit terminals 13 and 14

(Digital operator REF LED is ON.)

b1-01 Speed reference selection

b1-02 Run command selection

2 : Not used.

3 : Master speed reference set by transmission option (CP-916 B/G,

216 I/F)

(Digital operator REF LED is ON.)

4 : Master speed reference set by personal computer (CP-717).

(Digital operator REF LED is ON.)

0 : Run command from digital operator

(Digital operator SEQ LED is OFF.)

1 : Run command from control circuit terminal

(Digital operator SEQ LED is ON.)

2 : Not used.

3 : Run command from transmission option (CP-916 B/G, 216 I/F)

(Digital operator SEQ LED is ON.)

4 : Run command set by personal computer (CP-717).

(Digital operator SEQ LED is ON.)

DRIVE FWD REV REMOTE

SEQ REF

ON, OFF or blinking

41

Page 41

(3) Setting and Verification before Operation

NOTE

When setting up the VS-686SS5, make sure to follow the procedures below. Mistakes in setup order may cause values to be written over resulting in poor operation.

STEP 1 Control method setting (Page 43)

STEP 2 Constant torque/variable torque motor settings (Pages 44 to 47)

STEP 3 Motor capacity selection (Pages 44 to 47)

STEP 4 Nameplate value setting (Pages 44 to 47)

The VS-686SS5 is equipped with two current vector control methods (with or without PG).

Either method can be easily selected by using the digital operator to meet user application

needs. Open loop vector control is set at the factory prior to shipment. In the following cases,

follow the procedures below to set and verify the control method and motor related constants.

S When conducting initial operation of the VS-686SS5.

S When replacing either motor or inverter

S When replacing PG

Setting and verification

before operation

Initial operation?

Motor or inverter replaced?

No

Yes

Select control method.

(Refer to page 43.)

Set motor related

constants.

(Refer to page 44.)

With PG?

Yes

• Verify motor speed detection.

(Refer to page 48.)

• Adjust PG zero-pulse.

(Refer to page 49 and 50.)

End

No

PG replaced?

No

Yes

• Verify motor speed detection.

(Refer to page 48.)

• Adjust PG zero-pulse.

(Refer to page 49 and 50.)

42

Page 42

4 OPERATION

(a) Control Method Selection

The following procedures show how to change the control method from open loop vector

to flux vector.

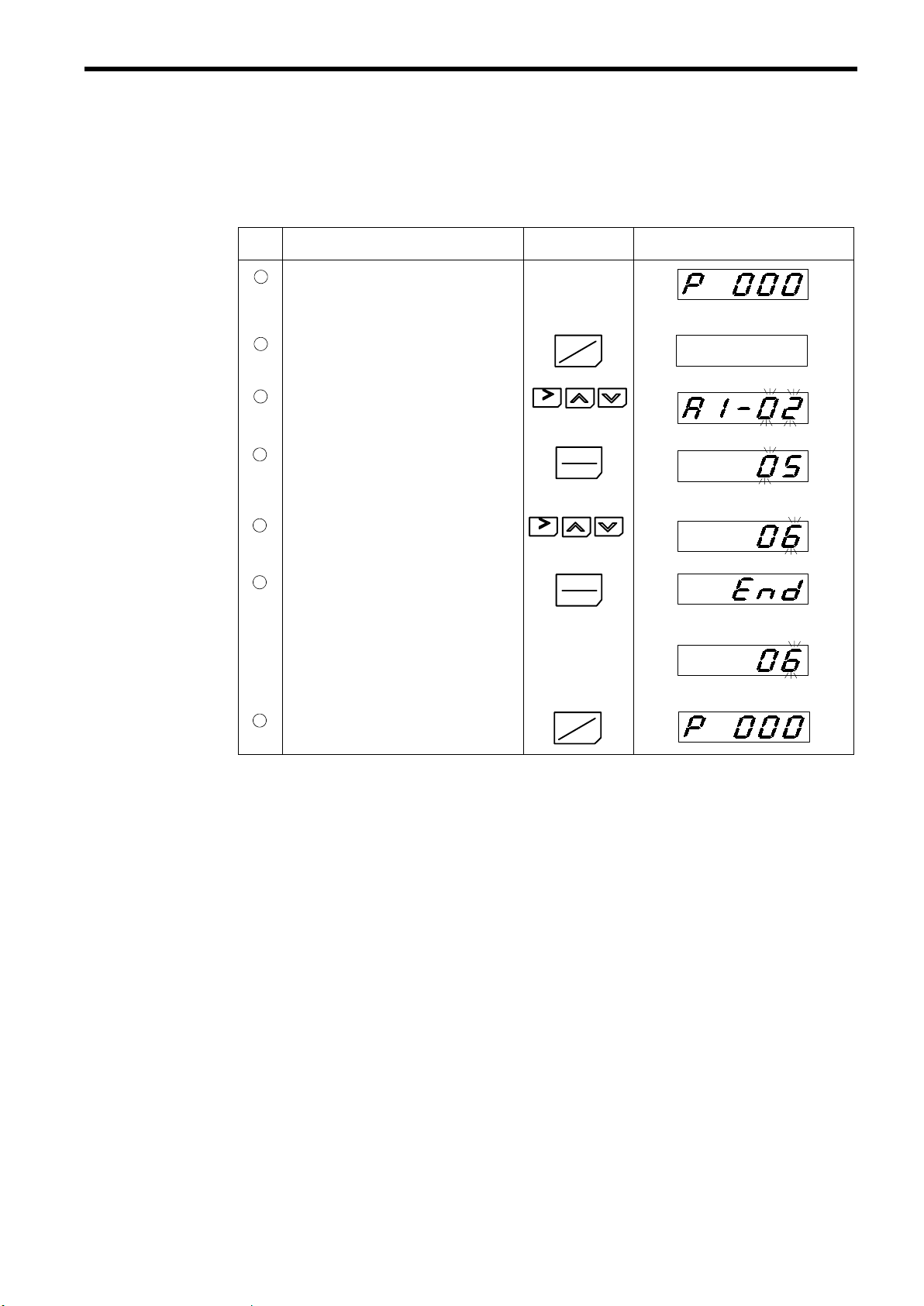

Table 10 Control Method Selection/Change

Step Description Key Sequence Digital Operator Display

Power ON

1

• Displays speed reference value.

REMOTE LEDs (SEQ, REF) ON

G

Control method selection

2

• Move to program mode.

3

4

5

6

7

• Move to control method selection

• Verify the set value.

• Change to flux vector.

• Write-in the value.

Return to drive mode.

(A1-02).

RESET

RESET

DRIVE

PRGM

DATA

ENTER

DATA

ENTER

DRIVE

PRGM

Constant No. display

(Initial setting: open loop vector)

Displays for 0.5 seconds.

Setting completed.

G

43

Page 43

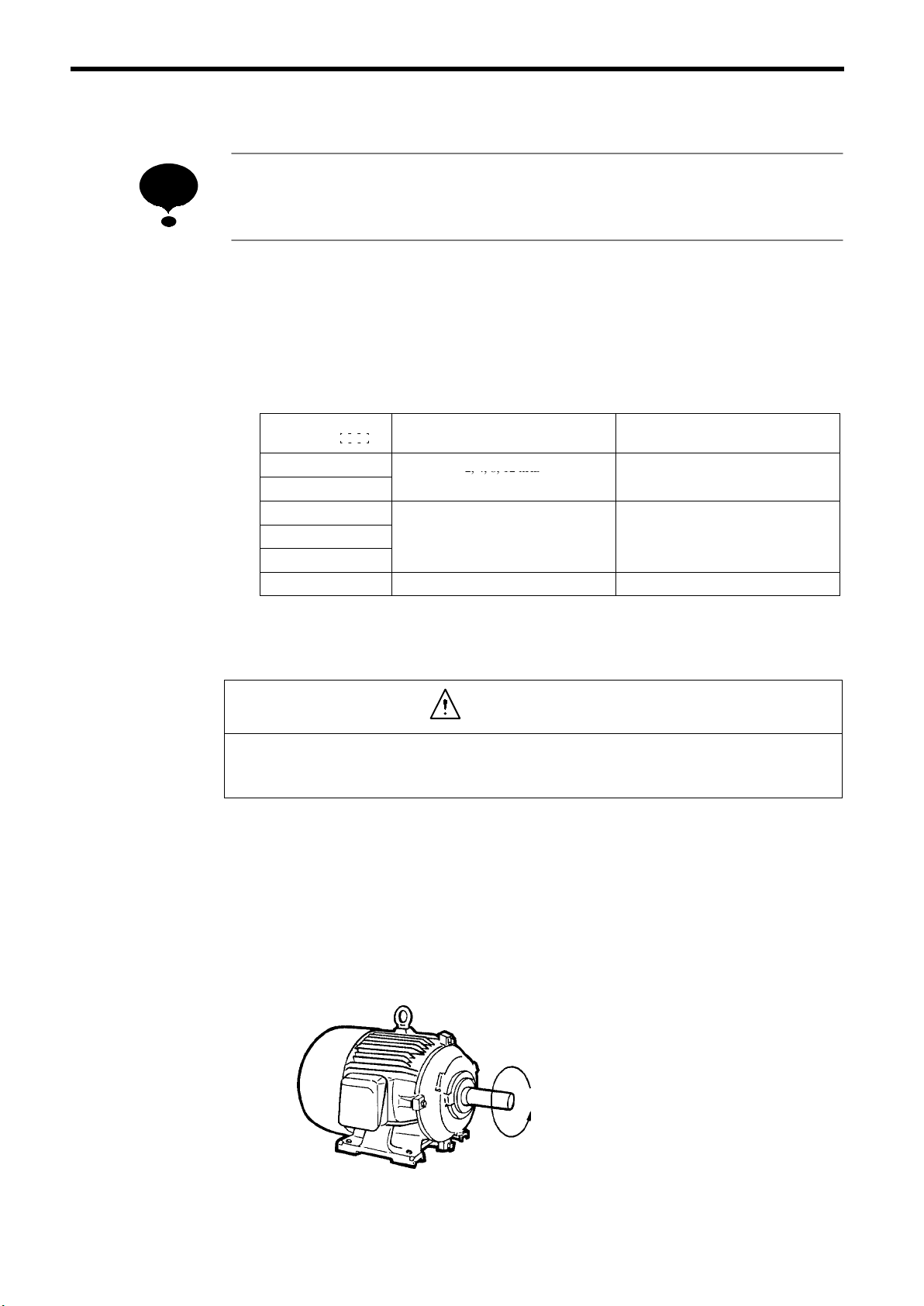

(b) Setting Motor Constants

CAUTION

S Be sure to set the motor constants before the initial operation and after replacement of the

motor. Reconfirm the motor constants after they have been set.

Failure to observe this caution may result in motor malfunctions such as sudden acceleration.

S In the following cases when under flux vector control, be sure to adjust the PG zero-pulse

as described in 4.3 (3) (e) PG Zero-pulse Adjustment:

• Before initial operation.

• After replacing the motor.

• After replacing the PG.

Set the motor constants in accordance with the values listed on the motor nameplate.

If the open loop vector control is selected, set

the motor constants in the order shown in

Table 11.

If the flux vector control is selected, set the

motor constants in the order shown in Table

12.

If the setting of the motor capacity selection

(E1-02) is changed, the motor constants will

Main Nameplate

VARISPEED-686SS5

3-PHASE PERMANENT MAGNET MOTOR

TYPE

PROTECTION

kW V

E1-03

E1-03

INS. COOLANT TEMP. ALTITUDE

STD

BRG NO

SER NO YEAR

YASKAWA ELECTRIC CORPORATION

Hz

POLES E1-05

COOLING

RATING A

E1-04

E1-04

MASS

r/min

E1-06, 07

E1-07

kg

JAPAN

m_C

return to their initial values.

Fig. 20 Example of Motor Nameplate

Table 11 Motor Constants Setup for Open Loop Vector Control

Constant

No.

A1-01 Constant access level 4

A1-02 Control method selection 5 5: Open loop vector control

E1-02 Motor capacity selection See remarks. Refer to Table A-6 Motor Capacity Selection List in Appendix

Name Set Value

(On Nameplate)

Remarks Checked

4.

PARAMETER

R

1

E1-09

Ld

E1-10

Lq

E1-11

E1-13

Ke

nθ

C2-12, 13

Ki

C3-02

Kt

C3-03

Si

B3-03

E1-03 Motor rated voltage (V) If two values for (V) are shown on the nameplate, set E1-03 to

the value in the lower row.

E1-04 Motor rated current (A) If two values for (A) are shown on the nameplate, set E1-04 to

the value in the lower row.

E1-05 Number of motor poles (POLES) If (POLES) is not shown on the nameplate, set E1-05 to 6.

E1-06 Motor max. speed (r/min) or (min-1) If two values are shown for (r/min) or (min-1), set E1-06 to the

value in the upper row.

E1-07 Motor base speed (r/min) or (min-1) If two values are shown for (r/min) or (min-1), set E1-07 to the

value in the lower row.

E1-08 Motor min. speed 10% of the base

Initial setting: 10% of base speed.

speed or higher

E1-09 Motor armature resistance (R1)

E1-10 Motor d-axis inductance (Ld)

44

Page 44

4 OPERATION

Constant

No.

E1-11 Motor q-axis inductance (Lq)

E1-13 Induced voltage (Ke)

C2-12 Leading phase compensation

Name

(On Nameplate)

(∆θ)

amount

E1-14 Variable torque/constant torque

selection

See remarks. If the motor model starts with SSR, E1-14 = 0.

If the motor model starts with SST, E1-14 = 1.

Table 12 Motor Constants Setup for Flux Vector Control

Constant

No.

A1-01 Constant access level 4

A1-02 Control method selection 6 6: Flux vector control

E1-02 Motor capacity selection See remarks. Refer to Table A-6 Motor Capacity Selection List in Appendix

E1-03 Motor rated voltage (V) If two values for (V) are shown on the nameplate, set E1-03 to

Name Set Value

(On Nameplate)

Remarks Checked

4.

the value in the lower row.

CheckedRemarksSet Value

E1-04 Motor rated current (A) If two values for (A) are shown on the nameplate, set E1-04 to

the value in the lower row.

E1-05 Number of motor poles (POLES) If (POLES) is not shown on the nameplate, set E1-05 to 6.

E1-06 Motor max. speed (r/min) or (min-1) If two values are shown for (r/min) or (min-1), set E1-06 to the

value in the upper row.

E1-07 Motor base speed (r/min) or (min-1) If two values are shown for (r/min) or (min-1), set E1-07 to the

value in the upper row.

E1-08 Motor min. speed Any value

Initial setting: 30 min

-1

between 0 and

the base speed

E1-09 Motor armature resistance (R1)

E1-10 Motor d-axis inductance (Ld)

E1-11 Motor q-axis inductance (Lq)

E1-13 Induced voltage (Ke)

C2-13 PG zero-pulse compensation

(∆θ) If the PG zero-pulse is adjusted, the set value of C2-13 changes.

amount

E1-14 Variable torque/constant torque

1

selection

Motor speed detection check

Check if the motor speed is detected correctly as explained in

4.3 (3) (d).

PG zero-pulse adjustment

Adjust the PG zero-pulse as explained in 4.3 (3) (e).

45

Page 45

The following procedures show how to change variable torque motor selection to

constant torque motor selection and set the motor related constants.

Table 13 Motor Related Constants Setting

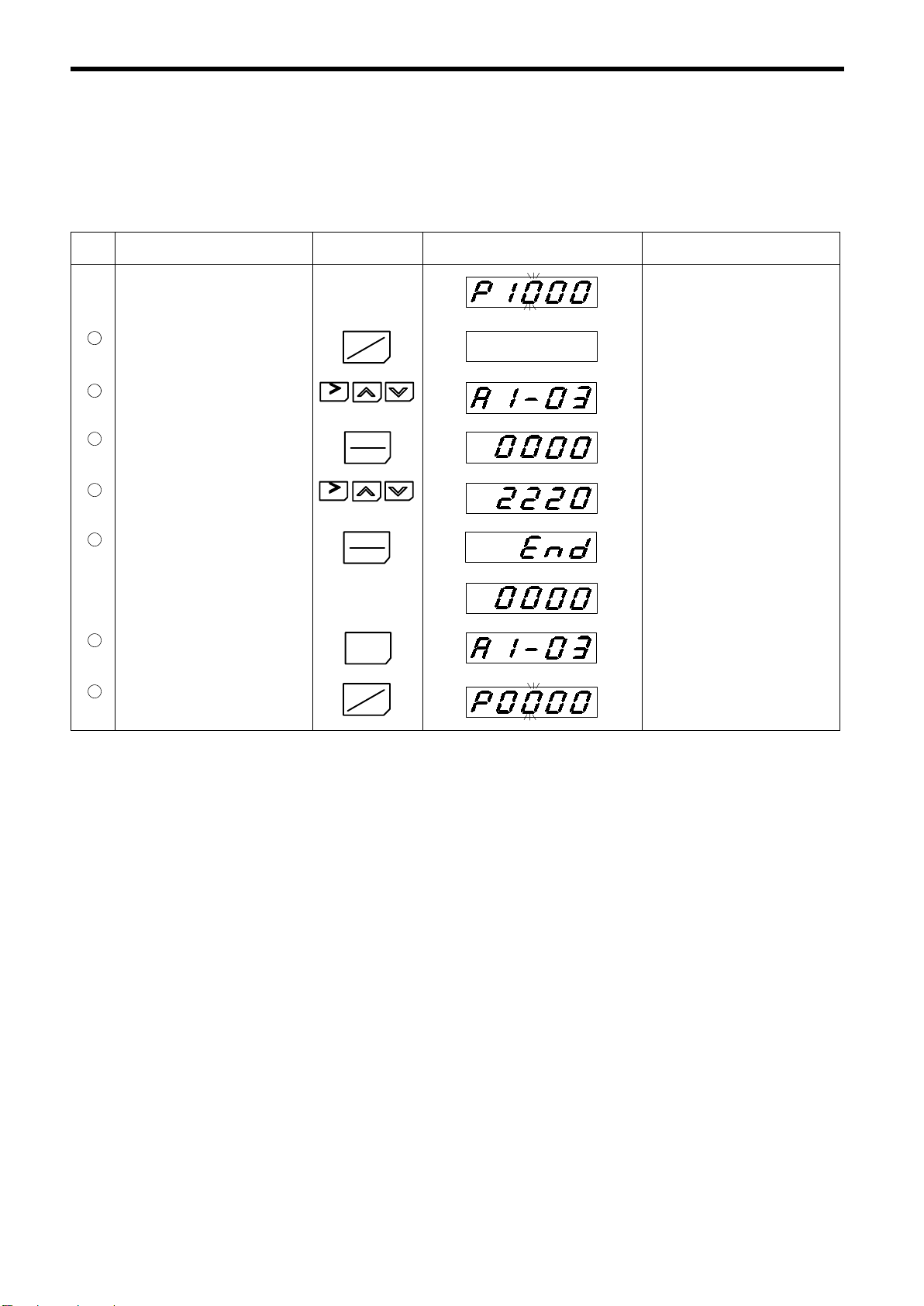

Step Description Key Sequence Digital Operator Display

Power ON

1

• Displays speed reference value.

REMOTE LEDs

G

(SEQ, REF) ON.

Move to program mode.

2

When inputting the values other than motor

nameplate values, execute steps

low.

3

4

5

6

7

• Move to access level (A1-01).

• Verify the set value.

• Change to ADVANCED.

• Write-in the value.

• Return to constant No. display.

to be-

7

3

RESET

RESET

DRIVE

PRGM

DATA

ENTER

DATA

ENTER

DSPL

Constant No. display

Displays for 0.5 seconds.

Setting completed.

Variable torque/constant torque motor selection

8

• Move to variable torque/constant torque

motor selection (E1-14).

9

10

11

12

• Verify the set value.

• Select constant torque motor.

• Write-in the value.

• Return to constant No. display.

RESET

DATA

ENTER