Page 1

YASKAWA

VARISPEED-656DC5

INSTRUCTION MANUAL

PWM TRANSISTOR CONVERTER

MODEL: CIMR-D5A

200 to 230 V, 27 to 120 HP (20 to 90 kW)

380 to 460 V, 27 to 496 HP (20 to 370 kW)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

YA S K A WA

MANUAL NO. TOBP C710656 00C

Page 2

Copyright © 2004 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is

constantly striving to improve its high-quality products, the information contained in this

manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained

in this publication.

Page 3

PREFACE

• Some drawings in this manual are shown with the protective cover or shields removed, in order to describe

detail with more clarity. Make sure all covers and shields are replaced before operating this product.

• This manual may be modified when necessary because of improvement of the product, modification, or

changes in specifications.

Such modifications are denoted by a revised manual No.

• To order a copy of this manual, if your copy has been damaged or lost, contact your YASKAWA representative.

• YASKAWA is not responsible for any modification of the product made by the user, since that will void

your guarantee.

YASKAWA’s VARISPEED-656DC5 is a PWM transistor converter. This instruction man-

ual describes installation, maintenance and inspection, troubleshooting, and specifications of

the VS-656DC5. Read this instruction manual thoroughly before operation.

YASKAWA ELECTRIC CORPORATION

General Precautions

SAFETY INFORMATION

Read this instruction manual thoroughly before installation, operation, maintenance or

inspection of the VS-656DC5. In this manual, NOTES FOR SAFE OPERATION are classi-

fied as “WARNING” or “CAUTION.”

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury to personnel and damage to equipment.

It may also be used to alert against unsafe practices.

Even items described in may result in a vital accident in some situations.

In either case, follow these important notes.

CAUTION

NOTE

These are steps to be taken to insure proper operation.

iii

Page 4

NOTES FOR SAFE OPERATION

RECEIVING

CAUTION

(Ref. Page)

• Do not install or operate any VS-656DC5 which is damaged or has missing parts.

Failure to observe this caution may result in personal injury or equipment damage.

INSTALLATION

CAUTION

• Lift the cabinet by the base. When moving the VS-656DC5, never lift by the front

cover or the front panel.

Otherwise, the main unit may be dropped causing personal injury or damage to the VS656DC5.

• Mount the VS-656DC5 on nonflammable material (i.e. metal).

Failure to observe this caution may result in a fire.

• When mounting several Units in an enclosure, install a fan or other cooling device to

keep the intake air temperature below 45 °C.

Overheating may cause a fire or damage to the VS-656DC5.

E-3

(Ref. Page)

E-5

E-5

E-5

iv

Page 5

WIRING

WARNING

(Ref. Page)

• Only commence wiring after verifying that the power supply is tunred OFF.

Failure to observe this warning may result in an electric shock or a fire.

• Wiring should be performed only by qualified personnel.

Failure to observe this warning may result in an electric shock or a fire.

• Make sure to ground the ground terminal before connecting the other terminals.

(200 V class: Ground to 100 Ω or less, 400 V class: Ground to 10 Ω or less).

Failure to observe this warning may result in an electric shock or a fire.

CAUTION

• Verify that the VS-656DC5 rated voltage coincides with the AC power supply volt-

age.

Failure to observe this caution may result in personal injury or a fire.

E-11

E-11

E-11

(Ref. Page)

E-11

• Do not perform a withstand voltage test of the VS-656DC5.

Failure to observe this caution may result in damage to the semi-conductor elements.

• Connect the input AC reactor, harmonics filter reactor, and the harmonics filter

capacitor as described in this instruciton manual.

Failure to observe this caution may result in a fire.

• Verify that the rated voltage of the VS-656DC5 coincides with the rated voltage of

the Inverter to be connected.

Failure to observe this caution may result in a fire.

• Tighten terminal screws.

Failure to observe this caution may result in a fire.

E-11

E-11

E-11

E-11

v

Page 6

OPERATION

WARNING

(Ref. Page)

• Only turn ON the input power supply after attaching the front cover or the terminal

cover. Do not remove the cover while current is flowing.

Failure to observe this warning may result in an electric shock.

• Never operate the Digital Operator or other switches when your hand is wet.

Failure to observe this warning may result in an electric shock.

• Never touch the terminals while current is flowing, even if the VS-656DC5 stops.

Failure to observe this warning may result in an electric shock.

CAUTION

• Never touch the radiation fins (heatsink) or input reactor since the temperature is

very high.

Failure to observe this caution may result in harmful burns to the body.

• The VS-656DC5 is factory set to the suitable settings. Do not change the settings

unnecessarily.

E-30

E-30

E-30

(Ref. Page)

E-30

E-30

Failure to observe this caution may result in damage to the unit.

vi

Page 7

MAINTENANCE AND INSPECTION

WARNING

(Ref. Page)

• Never touch high-voltage terminals in the VS-656DC5.

Failure to observe this warning may result in an electric shock.

• Perform maintenance or inspection only after verifying that the CHARGE LED goes

OFF, after the main circuit power supply is turned OFF.

The capacitors are still charged and can be dangerous.

• Only authorized personnel should be permitted to perform maintenance, inspec-

tions, or parts replacement.

[Remove all metal objects (watches, bracelets, etc.) before operation.]

(Use tools which are insulated against electric shock.)

Failure to observe this warning may result in an electric shock.

CAUTION

• A CMOS IC is used in the control board. Handle the control board and CMOS IC

carefully. The CMOS IC can be destroyed by static electricity if touched directly.

E-39

E-39

E-39

(Ref. Page)

E-39

The CMOS IC may be destroyed by static electricity if touched directly.

• Do not change the wiring, or connect/disconnect the connectors while power is

applied to the circuit.

Failure to observe this caution may result in personal injury.

OTHERS

WARNING

• Never modify the product.

Failure to observe this warning may result in an electric shock or personal injury.

CAUTION

• Do not subject the VS-656DC5 to halogen gases, such as fiuorine, chlovine, bro-

mine, and iodine, at any time even during transportation or installation.

E-39

(Ref. Page)

E-39

(Ref. Page)

E-39

Otherwise, the VS-656DC5 can be damaged or interior parts burnt.

vii

Page 8

Warning Label Position

A warning label is displayed on the front cover of the VS-656DC5, as shown below. Follow

these instructions when handling the VS-656DC5.

Warning

Label

Warning Label

WARNING − Risk of electric shock.

Read manual before installing.

Wait 5 minutes for capacitor discharge after disconnecting

power supply.

Use proper grounding techniques.

AVERTISSMENT -

electrique.

Risque de decharge

Lisez le manuel avant installation.

Attendez 5 minutes apres la coupure de l’

alimentation electrique afin que les

condensateurs soient completement decharges.

Soyez a la masse par une bonne technique.

-

5

NPJT31393-1-0

viii

Page 9

WARRANTY INFORMATION

Warranty Period

This product is warranted for twelve months after being delivered to Yaskawa’s customer or

if applicable eighteen months from the date of shipment from Yaskawa’s factory, whichever

comes first.

Scope of Warranty

Inspections

Periodic inspections must be conducted by the customer. However, upon request, Yaskawa

or one of Yaskawa’s Service Centers can inspect the product for a fee. In this case, if after

conferring with the customer, a Yaskawa product is found to be defective due to Yaskawa

workmanship or materials and the defect occurs during the warranty period, then this fee

will be waived and the problem remedied free of charge.

Repairs

If a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and

the defect occurs during the warranty period, Yaskawa will provide a replacement, repair the

defective product, and provide shipping to and from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem with a

Yaskawa product is not due to defects in Yaskawa’s workmanship or materials, then the cus-

tomer will be responsible for the cost of any necessary repairs. Some problems that are out-

side the scope of this warranty are:

• Problems due to improper maintenance or handling, carelessness, or other reasons where

the customer is determined to be responsible.

• Problems due to additions or modifications made to a Yaskawa product without

Yaskawa’s understanding.

• Problems due to the use of a Yaskawa product under conditions that do not meet the rec-

ommended specifications.

• Problems caused by natural disaster or fire.

• Or other problems not due to defects in Yaskawa workmanship or materials.

Warranty service is only applicable within Japan.

However, after-sales service is available for customers outside of Japan for a reasonable fee.

Contact your local Yaskawa representative for more information.

Exceptions

Any inconvenience to the customer or damage to non-Yaskawa products due to Yaskawa's

defective products whether within or outside the warranty period are NOT covered by this

warranty.

ix

Page 10

RESTRICTIONS

• The VS-656DC5 was not designed or manufactured for use in devices or systems that

may directly affect or threaten human lives or health.

• Customers who intend to use the product described in this manual for devices or systems

relating to transportation, health care, space aviation, atomic or electric power, or under-

water use must contact their Yaskawa representatives or the nearest Yaskawa sales office

beforehand.

• This product has been manufactured under strict quality-control guidelines. However, if

this product is to be installed in any location where failure of this product could involve

or result in a life-and-death situation or loss of human life or in a facility where failure

may cause a serious accident or physical injury, safety devices must be installed to mini-

mize the likelihood of any accident.

x

Page 11

INSTRUCTIONS

Varispeed-656DC5

1 RECEIVING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

1.1 Checks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

1.2 Nameplate Information - - - - - - - - - - - - - - - - - - - - - - - - - - - E-3

2 INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-5

2.1 Checking Installation Site - - - - - - - - - - - - - - - - - - - - - - - - - E-5

2.2 Clearances - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-6

2.3 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-7

2.4 Removing/Attaching the Digital Operator - - - - - - - - - - - - - - E-9

2.5 Removing/Attaching the Front Cover - - - - - - - - - - - - - - - - E-10

3 WIRING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -E-11

3.1 Connection and Specifications of Peripheral Devices - - - - E-12

3.2 External Dimensions of Peripheral Devices - - - - - - - - - - - E-14

3.3 Interconnection Diagram with Varispeed G7 - - - - - - - - - - - E-18

3.4 Interconnection Diagram with VS-616G5 - - - - - - - - - - - - - E-20

3.5 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-22

3.6 WIRING MAIN CIRCUIT TERMINALS - - - - - - - - - - - - - - - E-24

3.7 EXTERNAL TERMINALS - - - - - - - - - - - - - - - - - - - - - - - - E-28

4 OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-30

4.1 Checkpoints before Turning ON the Power Supply - - - - - - E-30

4.2 Setting the Power Supply Voltage Jumper

(For 400 V Class VS-656DC5 with 22 kW or More) - - - - - E-31

4.3 Using the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - E-32

4.4 Power ON/OFF Sequence - - - - - - - - - - - - - - - - - - - - - - - E-38

E-1

Page 12

5 MAINTENANCE AND INSPECTION - - - - - - - - - - - - - - - - E-39

5.1 Maintenance Period - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-39

5.2 Daily Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-40

5.3 Periodic Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-40

5.4 PERIODIC MAINTENANCE OF PARTS - - - - - - - - - - - - - E-41

6 TROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - -E-42

6.1 Fault Detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-42

6.2 Minor Fault Detection - - - - - - - - - - - - - - - - - - - - - - - - - - - E-45

6.3 Operation Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-46

6.4 Informing the VS-656DC5 of a Peripheral Device Fault

to Stop the VS-656DC5 (External Fault Function) - - - - - - E-47

7 SPECIFICATIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E-48

Appendix A CONSTANTS LIST - - - - - - - - - - - - - - - - - - - - - E-50

A.1 Monitor Constant List - - - - - - - - - - - - - - - - - - - - - - - - - - E-50

A.2 Constant List Other Than Monitor Constants - - - - - - - - - - E-54

A.3 Multi-function I/O Terminals (H Constants) - - - - - - - - - - - E-57

Appendix B PRECAUTIONS ON VS-656DC5

APPLICATION - - - - - - - - - - - - - - - - - - - - - - - - E-58

E-2

Page 13

1 RECEIVING

• Do not install or operate any VS-656DC5 which is damaged or has missing parts.

Failure to observe this caution may result in personal injury or equipment damage.

This chapter describes how to verify the VS-656DC5 after delivery to the user.

1.1 Checks

he VS-656DC5 model number

Does t

correspond with the purchase order?

Are any parts damaged? Visually check the exterior and verify that there was no dam-

Are any screws or other components loose? Use a screwdriver or other tools to check for tightness.

1 RECEIVING

CAUTION

Table 1 Checks

Item Method

Check the model number on the nameplate on the side of the

VS-656DC5. (Refer to page E-4.)

age during transport.

If any of the above items are not satisfactory, contact your YASKAWA representative.

1.2 Nameplate Information

Nameplate Example

The following nameplate is an example for a standard domestic (Japan) VS-656DC5:

3-phase, 400 VAC, 30 kW, IEC IP00.

Converter Unit

model

Input Specification

Output Specification

LOT number

Serial No.

MODEL CIMR-D5A4030

INPUT

OUTPUT

SPEC

SER NO

AC3PH 380 - 460V 50Hz

DC660V 60A

40300A

YASKAWA ELECTRIC CORPORATION MADE IN JAPAN

380-460V 60Hz

Fig. 1 Nameplate

64A

MASS: 33kg

Converter

Unit

specifications

Mass

E-3

Page 14

VS-656DC5 Model Number and Specifications

CIMR − 5AD 4 030 0

Converter Unit

VS-656DC5 series

Symbol

A

Specifications

Japan standard model

2

4

Voltage Class

3-phase, 200 V

3-phase, 400 V

Symbol

Symbol

0

Symbol

015 to 300

* Protected so that parts of the human body cannot reach electrically

charged parts from the front when the VS-656DC5 is mounted in a control panel.

Fig. 2 VS-656DC5 Model Number and Specifications

Protective Structure

Open chassis (IEC IP00)*

Max. Applicable Inverter Output

15 to 300 kW

E-4

Page 15

2 INSTALLATION

• Lift the cabinet by the base. When moving the VS-656DC5, never lift by the front cover or the front

panel.

Otherwise, the main unit may be dropped causing personal injury or damage to the VS-656DC5.

• Mount the VS-656DC5 on nonflammable material (i.e. metal).

Failure to observe this caution may result in a fire.

• When mounting several Units in an enclosure, install a fan or other cooling device to keep the

intake air temperature below 45 °C.

Overheating may cause a fire or damage to the VS-656DC5.

2 INSTALLATION

CAUTION

This chapter describes the configuration, location, and space when mounting the VS-656DC5.

2.1 Checking Installation Site

Installation Site

Install the VS-656DC5 under the following conditions.

Type Ambient Operating Temperature Humidity

Open chassis

To ensure proper performance and long operating life, follow the recommendations below

when choosing a location for installing the VS-656DC5. Make sure the VS-656DC5 is pro-

tected from the following conditions:

• Extreme cold and heat

Use only within ambient temperature range: -10 °C to +45 °C

• Rain, moisture

• Oil sprays, splashes

• Salt spray

• Direct sunlight (Avoid using outdoors.)

• Corrosive gases or liquids

• Dust or metallic particles in the air

• Physical shock, vibration

• Magnetic noise (Example: welding machines, power devices, etc.)

• High humidity

• Radioactive materials

• Combustibles: thinners, solvents, etc.

-10 to + 45 °C 90 % RH or less (no condensation)

E-5

Page 16

Controlling the Ambient Temperature

To enhance the reliability of operation, the VS-656DC5 should be installed in an environ-

ment free from extreme temperature increases. If the VS-656DC5 is installed in an enclosed

environment, such as a box, use a cooling fan or air conditioner to maintain the internal air

temperature below 45 °C.

Protecting the VS-656DC5 from Foreign Matter

Place a cover over the VS-656DC5 during installation to shield it from metal powder pro-

duced by drilling.

Always remove the cover from the VS-656DC5 after completing installation. Otherwise,

ventilation will be reduced, causing the VS-656DC5 to overheat.

2.2 Clearances

Install the VS-656DC5 vertically and allow sufficient clearances for effective cooling as

shown in Fig. 3.

NOTE

50 mm or more

120 mm or more

30mm or more 30 mm

50 mm or more

(a) Front View (b) Side View

When installing the open chassis type of 200 V/400 V 30 kW or more, extra spacing will be required

on either side for eyebolts or main circuit wiring.

or more

Fig. 3 Clearances

120 mm or more

Air

Air

E-6

Page 17

2.3 Dimensions

Models of 200 V/400 V 15 kW or Less

The following figure shows a 200 V 15 kW model.

DRIVE FWD REV REMOTE

SEQ REF

U1 01 = 00.00 HZ

DIGITAL OPERATOR

JVOP - 130

LOCAL

MENU

REMOTE

JOG

FWD

REV

RUN STOP

2 INSTALLATION

ESC

DATA

ENTER

RESET

H1

H

W1

W

H2

4-d

Fig. 4 Dimensions of VS-656DC5

Models of 200 V/400 V 22 kW or More

The following figure shows a 200 V 22 kW model.

DRIVEFWD REV REMOTE

SEQ REF

U1 01 = 00.00HZ

DIGITAL OPERATOR

W1

W

JVOP - 130

LOCAL

MENU

ESC

REMOTE

DATA

JOG

ENTER

FWD

REV

RESET

RUN STOP

H1

H2

H

4-d

D

D

E-7

Page 18

Table 2 VS-656DC5 External Dimensions and Approx. Masses

Voltage

Class

VS-656DC5

Model

CIMR-

Open Chassis (IP00)

W H D W1 H1 H2 Approx.

D5A

200 V

Class

2015

2022 325 450 285 275 435 7.5 23 M6

250 380 225 236 365 7.5 11 M6

2037 425 725 350 320 700 12.5 47 M10

*

475 800 350 370 775 12.5 65 M10

575 925 400 445 895 15.0 135 M12

400 V

Class

2055

2075

4015 250 380 225 236 365 7.5 11 M6

4022 325 450 285 275 435 7.5 26 M6

4030 325 625 285 275 610 7.5 33 M6

4045 36 M6

4075 455 820 350 350 795 12.5 60 M10

4160 575 925 400 445 895 15.0 117 M12

4300

*

−

* Contact your YASKAWA representative.

Note: An attachment is required to mount the cooling fins (fin section) on

the outside of the control panel for 200 V/400 V class VS-656DC5 of

15 kW or less. Contact your YASKAWA representative for details.

For dimensional drawings for models with externally mounted cooling fins or other special requirements, contact your YASKAWA representative.

Mass

[kg]

Unit: mm

Mount-

ing

Hole d

E-8

Page 19

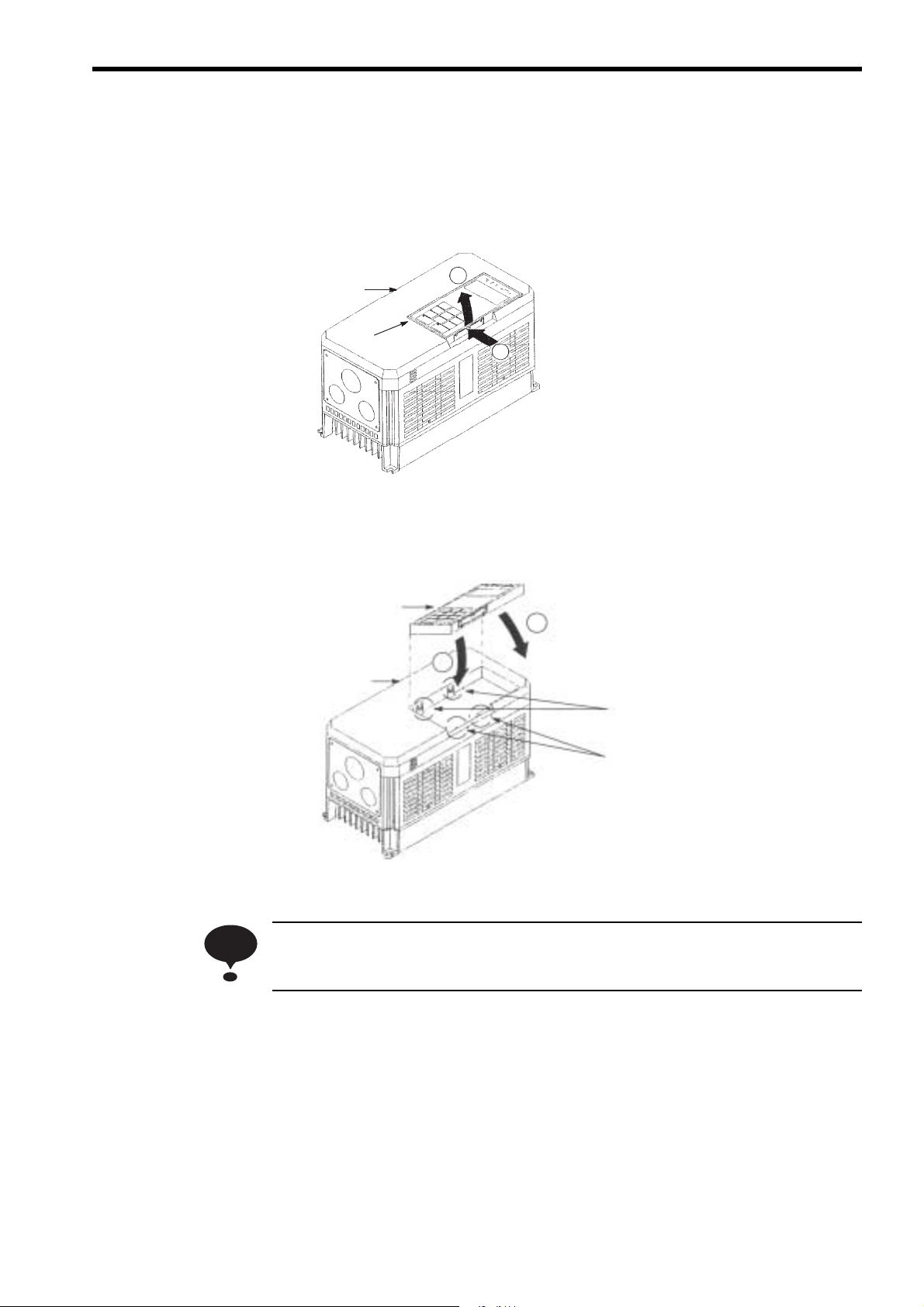

2.4 Removing/Attaching the Digital Operator

Remove and attach the Digital Operator as follows.

Removing the Digital Operator

2 INSTALLATION

Front cover

Digital Operator

2

1

Fig. 5 Removing the Digital Operator

Attaching the Digital Operator

Digital Operator

1

Front cover

Push the Digital Operator lever in the direction

shown by arrow 1 and lift the Digital Operator in

the direction shown by arrow 2 to remove the Digital

Operator from the front cover.

Attach the Digital Operator on claws A in

2

the direction shown by arrow 1 and then on

claws B in the direction shown by arrow 2, to

lock the Digital Operator.

Claws A

NOTE

Claws B

Fig. 6 Attaching the Digital Operator

Never attach the Digital Operator in any other direction or by any other method, as faulty contact may

result.

E-9

Page 20

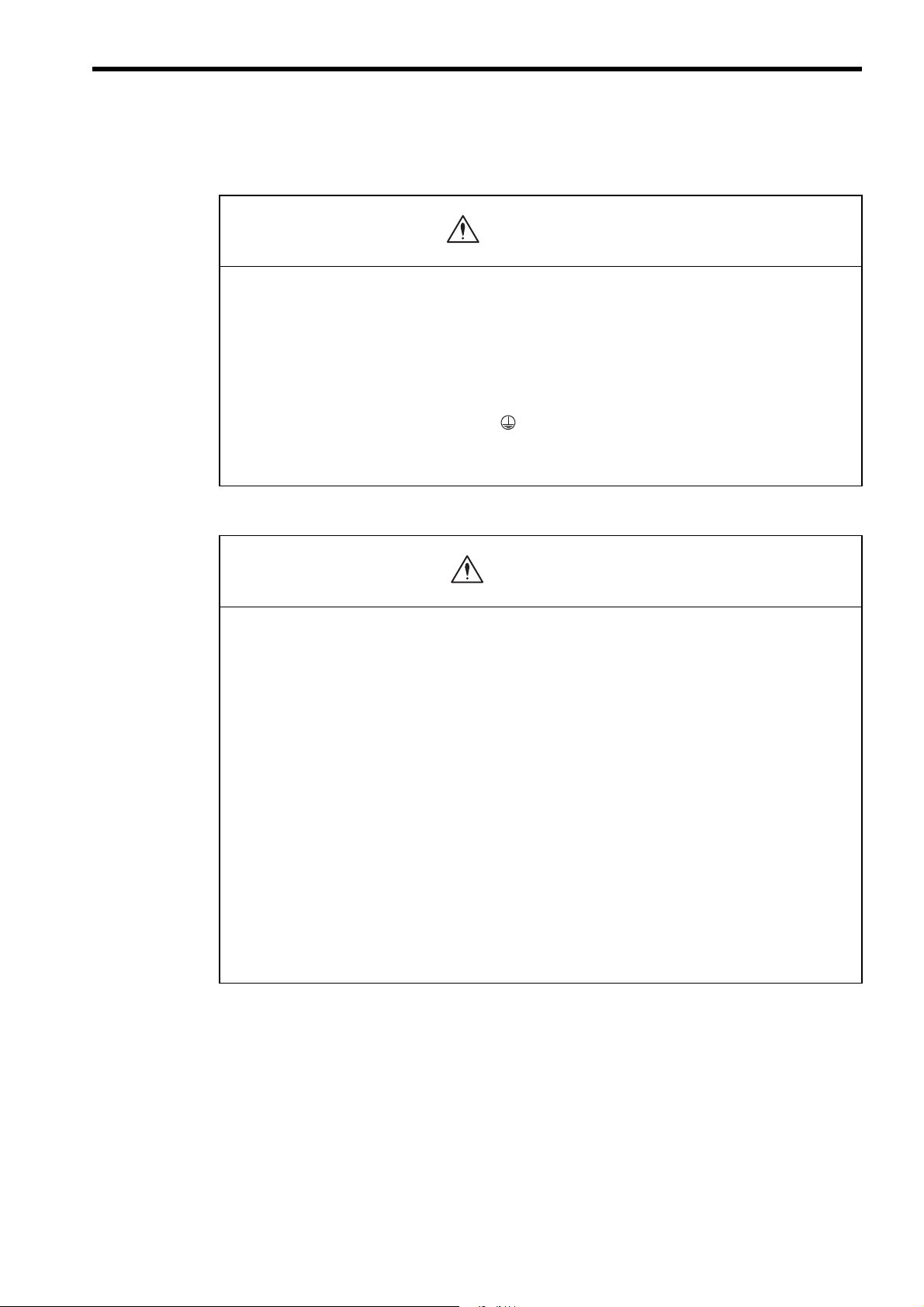

2.5 Removing/Attaching the Front Cover

Models of 15 kW or Less

To remove the front cover, first remove the Digital Operator in the direction shown by arrow

1. (Refer to 2.4 Removing/Attaching the Digital Operator.) Then squeeze the cover in the

direction shown by arrows 2 on both sides and lift in the direction shown by arrow 3.

Front cover

1

2

Fig. 7 Removing/Attaching the Front Cover (15 kW or Less)

3

2

Models of 22 kW or More

To remove the front cover, first remove the Digital Operator in the direction shown by arrow

1. (Refer to 2.4 Removing/Attaching the Digital Operator.)

Then loosen the four screws shown by arrow 2 and slide the front cover in the direction

shown by arrow 3.

2

3

2

NOTE

1

2

2

Fig. 8 Removing/Attaching the Front Cover (22 kW or More)

Do not attach the front cover with the Digital Operator connected, as faulty contact may result. Attach

the front cover first, and then attach the Digital Operator on the cover. Refer to 2.4 Removing/Attach-

ing the Digital Operator for attaching the Digital Operator.

E-10

Page 21

3 WIRING

• Only commence wiring after verifying that the power supply is tunred OFF.

Failure to observe this warning may result in an electric shock or a fire.

• Wiring should be performed only by qualified personnel.

Failure to observe this warning may result in an electric shock or a fire.

• Make sure to ground the ground terminal before connecting the other terminals.

(200 V class: Ground to 100 Ω or less, 400 V class: Ground to 10 Ω or less).

Failure to boserve this warning may result in an electric shock or a fire.

3 WIRING

WARNING

CAUTION

• Verify that the VS-656DC5 rated voltage coincides with the AC power supply voltage.

Failure to observe this caution may result in personal injury or a fire.

• Do not perform a withstand voltage test of the VS-656DC5.

Failure to observe this caution may result in damage to the semi-conductor elements.

• Connect the input AC reactor, harmonics filter reactor, and the harmonics filter capacitor as

described in this instruciton manual.

Failure to observe this caution may result in a fire.

• Verify that the rated voltage of the VS-656DC5 coincides with the rated voltage of the Inverter to be

connected.

Failure to observe this caution may result in a fire.

• Tighten terminal screws.

Failure to observe this caution may result in a fire.

E-11

Page 22

MCCB

3.1 Connection and Specifications of Peripheral Devices

Connection

PWM transistor converter

VS-656DC5

Input AC

*1

reactor

*3

U

X

R/L1

V

Y

S/L2

W

Z

T/L3

+

1

PWM

inverter

IM

Reactor

Capacitor

UVW

X Y Z

Harmonics

*1

filter

RUN-SB

STOP

External fault

Fault reset

Multi-function

contact input

External

base block

r/

1

/

*2

2

r1/

11

1/

21

t1/

31

36

+24V

35

1

2

3

4

5

6

7

8

11

Sequence common

Shielded sheath

12

connection terminal

Digital

Operator

JVOP-130

Multi-function

analog

monitor

E

Grounding

9

C RUN

10

250 VAC 1 A or less

30 VDC 1A or less

26

During MC

motion

37

25

C READY

27

18

Fault contact output

19

250 VAC 1 A or less

30 VDC 1A or less

20

21

23

22

+

+

Open-collector

output

48 VDC 50 mA or

less

Input power monitor

-

(-10 to +10V)

Input current monitor

-

(-10 to +10V)

Multi-function analog

output common

* 1. Be sure to attach the input AC reactor (reactor) and harmonics filter (capacitor).

* 2. For models CIMR-D5A2022 to -D5A2075 of the 200 V Class and CIMR- D5A4022 to

-D5A4300 of the 400 V Class, the wiring was done prior to shipment. Connections are not

needed for CIMR-D5A2015 and -D5A4015.

The terminals r/

and /2 in the above diagram are the terminal names for 200 V Class

1

VS-656DC5 with 37 to 75 kW. The terminal names are as follows respectively for each VS656DC5 capacity:

y 200 V Class 22 kW, 400 V Class 22 to 45 kW: /2, t/3

and 1/21, t/3 and t1/31 are

(/

2

connected respectively.)

y 400 V Class 75 and 160 kW: r/

, 400/2400

1

* 3. When a noise filter is attached on the VS-656DC5 power supply side, use a noise filter of the

reactor type (without a capacitor) such as finemet zero-phase reactor, and attach it behind the

MCCB at the power supply side. Do not use a capacitor-built-in type noise filter since the

harmonic components may overheat or damage the capacitor.

E-12

Page 23

Specifications of Peripheral Devices

VS-656DC5 Input AC Reactor (ACX) Harmonics Filter (LC Filter)

Voltage

Class

200 V Class

400 V Class

Applicable

Model

Rated Current

Arms

Inductance

CIMR-D5A

2015

64 1.32 30 0.35 100

2022 96 0.88 50 0.21 150

2037 160 0.53 80 0.13 200

2055

2075

*

224 0.38 120 0.09 300

300 0.28 160 0.07 400

4015 32 5.28 15 1.42 25

4022 48 3.52 20 1.06 40

4030 64 2.64 30 0.7 50

4045 96 1.76 50 0.42 75

4075 165 1.02 80 0.26 100

4160 300 0.57 150 0.15 200

*

4300

mH

3 WIRING

Reactor UZBA-B Capacitor

Rated

Current

InductancemHCapacity

µF

Arms

−

* Contact your YASKAWA representative.

Note: Be sure to use an input reactor and harmonics filter with specifica-

tions described in the above list.

E-13

Page 24

3.2 External Dimensions of Peripheral Devices

Input AC Reactor (Model UZBA-B)

Vol t-

age

Class

200 V

Class

400 V

Class

Applicable

Model

CIMR-D5A

DWG

No.

ABB1 C DEF G HI J KL M

2015 1 290 182 266

2022 1 310 222 286

2037 2 390 220 320

*

2055

2075

3* 390 220 300

2 450 240 375

4015 1 290 182 246

4022 3 330 162 230

4030 1 330 245 322.5

4045 2 455 240 330

4075 2 450 240 365

4160 2 575 330 445

*

4300

* Contact your YASKAWA representative.

DWG 1 DWG 2

2-M8: Eyebolts

6-M: Terminal

±10

280

±10

315

±10

375

±10

435

±10

435

±10

280

±10

330

±10

355

±10

435

±10

435

±10

525

Nameplate

Dimensinos in mm Approx.

150 145 255

150 180 270

150 180 380

200 180 320

200 200 430

150 145 255

170 130 270

150 210 300

200 200 430

200 200 430

200 270 530

240

275

330

395

390

240

290

310

390

390

470

±10

40 5 M10 25 12 M8 50 285

±10

50 6 M10 27.5 12 M10 65 395

±10

50 6 M12 26 15 M10 95 440

±10

50 6 M12 26 15 M12 120 665

±10

50 6 M12 25.5 14 M12 145 680

±10

40 5 M10 25 12 M6 50 275

±10

40 6 M10 20 12 M8 54 335

±10

50 6 M10 27.5 12 M8 100 525

±10

50 6 M12 25.5 14 M10 150 760

±10

50 6 M12 25.5 14 M10 155 690

±10

75 9 M12 36 15 M12 350 1120

−

2-M10: Eyebolts

6-M: Terminal

Mass

kg

Nameplate

Loss

W

X

U

Y

V

D

F

A (Max.)

Z

G

W

4-J: Mounting hole

C

H

E

X

U

B

B1 (Max.)

A (Max.)

L

K

Z

Y

V

W

C

G

D

F

4-J: Mount ing hole

H

E

B

B1 (Max.)

L

K

DWG 3

H

B1 (Max.)

φ25 Hole

E

B

Nameplate

Y

X

U

Z

V

D

F

A (Max.)

L

6-M:

Terminal

C

G

W

4-J: Mounting hole

K

E-14

Page 25

Harmonics Filter Reactor

3 WIRING

Voltage

Class

200 V

Class

400 V

Class

Applicable

Model

CIMRD5A

2015 2 130 88 119 105 50 70 130 − 22 3.2 M6 9 7 M5 3 45

2022 2 160 90 125 130 75 70 160 − 25 2.3 M6 10 7 M6 5 55

2037 2 180 100 155 150 75 80 180 − 25 2.3 M6 10 7 M8 8 75

2055

2075

4015 1 130 98 − 130 50 80 130 105 22 3.2 M6 9 7 M4 4 50

4022 2 160 90 115 130 75 70 160 − 25 2.3 M6 10 7 M5 5 50

4030 2 160 105 132.5 130 75 85 160 − 25 2.3 M6 10 7 M5 6 65

4045 2 180 100 145 150 75 80 180 − 25 2.3 M6 10 7 M6 8 90

4075 2 210 100 150 175 75 80 205 − 25 3.2 M6 10 7 M8 12 95

4160 2 240 126 198

4300

DWG

No.

ABB1CDEFGH I JKLM

*

2 180 100 155 150 75 80 180 − 25 2.3 M6 10 7 M10 8 90

2 210 100 170 175 75 80 205 − 25 3.2 M6 10 7 M10 12 100

±5

150 110 240 − 25 3.2 M8 8 10 M10 23 150

205

*

Dimensions in mm Approx.

Mass

kg

−

* Contact your YASKAWA representative.

DWG 1 DWG 2

U X V

U W Z

6-M: Terminal

6-M: Terminal

Nameplate

Loss

W

D

F

A

Details of

mounting hole

Nameplate

U

C

G

I

H

E

L

4-J: Mounting hole

K

B

Details of

mounting hole

V

X

W

C

Y

D

F

A

Z

4.5

H

E

L

K

B

B1

4-J: Mounting hole

E-15

Page 26

Harmonics Filter Capacitor

200 V Class

Applicable Model

CIMR-D5A

2015

80

P+10

Applicable Model

CIMR-D5A

60

Capacity

µF

100 0.4 1.8

67

φ4.5

70±1

φ4.5

30

φ4.5

Nameplate

Pitch 104 to 115 *

φ4.5

Capacity

µF

2022 150 160

2037 200 160

2055

2075

*

300 180

400 200

* Contact your YASKAWA representative.

32

Approx. Mass

kg

60

109.5

86

DIN rail

center line

(32.5)

Dimensions mmApprox.

HH1

107

107

127

147

32

90

(50)

7

±3

±3

±3

±3

Loss

W

DIN rail

center line

Mass

kg

1.2 2.7

1.2 3.6

1.4 5.4

1.6 7.2

Loss

W

Ground

terminal

E-16

170±2

190±2

205±3

94

25±1

60±2

6-6×8 Slotted hole

H (Max.)

H1

Page 27

400 V Class

3 WIRING

Applicable

Model

Capacity

µF

ABCDEFGH I

CIMR-D5A

4015

4022

4030

4045

4075

4160

4300

*

25

40

50

165±270

±270±2

165

±270±2

165

75 215

100

205

±2

200 305

400 −

* Contact your YASKAWA representative.

H

H

Name-

plate

Ground terminal

Dimensions in mm Approx.

Mass

Loss

W

kg

±2

135

155

155

185

I Bolt

150

150

150

190

G

±140±1

±140±1

±140±1

±1

C (Max.)

130±2100±330

130±2120±330

130±2120±330

±3

180

173±2150

4-7 dia. hole

±3

±3

270

B

±5

M5 1.3 2.4

±5

M5 1.6 3.6

±5

M5 1.5 4.8

2.3 7.2

2.5 9.6

4.5 19.2

F

E

t1.0

F

D

A

E-17

Page 28

3.3 Interconnection Diagram with Varispeed G7

3-phase

AC

Power

Supply

MCCB

Reactor

Capacitor

UVW

X Y Z

Harmonics

*3

filter

A

B

Input AC

*3, *8

reactor

X

*7

U

V

Y

W

Z

VS-656DC5

R/L1

S/L2

T/L3

*9, *10

*9, *10

Converter

r/

1

/

r1/

1/

t1/

2

11

21

31

C RUN

E

9

*6

A

*2

B

Grounding

*4

10

During MC

motion

26

*5

37

C READY

25

27

36

+24V

35

RUN-SB

1

2

STOP

3

External fault

Fault reset

4

5

Multifunction

6

contact

7

input

8

External baseblock

11

Sequence

common

12

Shielded sheath

connection

18

Fault contact

output

19

250 VAC 1 A or less

20

30 VDC 1 A or less

terminal

Multi-function

analog monitor

21

23

(Input power)

(Input current)

22

Inverter

Varispeed G7

1

R/L1

*1

S/L2

T/L3

r/

1

/

2

S1

FWD run command

S2

REV run command

S3

External fault

S4

Reset

S5

S6

S7

S8

Multifunction

S9

contact

input

S10

S11

S12

SC

Sequence common

Shielded sheath

E(G)

connection

terminal

Multi-function

analog input

+V

A1

A2

A3

AC

U/T1

V/T2

W/T3

AM

FM

AC

E(G)

MA

MB

MC

M2

P1

P2

PC

P3

C3

P4

C4

Grounding

Fault contact output

250 VAC 1 A or less

30 VDC 1 A or less

M1

Multi-function contact

output

250 VAC 1 A or less

30 VDC 1 A or less

IM

Multifunction

analog

AM

output

-10 to 10 V

FM

Multi-function

open-collector

output

48 VDC 50 mA

or less

Multi-function

analog output common

* 1. Do not connect a power supply to the Varispeed G7 AC power supply terminals R/L1, S/L2,

and T/L3.

* 2. For cooling fan terminals r/

and /2 of the Varispeed G7 200 V class 30 to 75 kW models,

1

remove the jumper wiring between r/1 and R/L1, and between /2 and S/L2. Then take the

power supply for r/

For cooling fan terminals r/

and /2 from the VS-656DC5 primary power supply line.

1

and 400/2 400 of the Varispeed G7 400 V Class 55 to 300

1

kW models, remove the jumper wiring between r/1 and R/L1, and between 400/2400 and

S/L2. Then take the power supply for r/1 and 400/2 400 from the VS-656DC5 primary

power supply line.

* 3. Be sure to use the specified AC reactor and harmonics filter for the VS-656DC5, to avoid

abnormal operations.

E-18

Page 29

* 4. Set up a sequence whereby the Varispeed G7 starts operation and then the VS-656DC5 starts

after the power supply is turned ON, and the power supply is turned OFF after the Varispeed

G7, the motor, and the VS-656DC5 are stopped in this order.

Operating the Varispeed G7 without starting the VS-656DC5, or turning OFF the power supply while the VS-656DC5 is running may cause the VS-656DC5 to malfunction.

* 5. Interlock with the Inverter. (Refer to Interlocking with Inverters in Appendix B PRECAU-

TIONS ON VS-656DC5 APPLICATION.)

* 6. For models CIMR-D5A2022 to -D5A2075 of the 200 V Class and CIMR- D5A4022 to -

D5A4300 of the 400 V Class, the wiring was done prior to shipment. Connections are not

needed for CIMR-D5A2015 and -D5A4015.

The terminals r/

and /2 in the above diagram are the terminal names for 200 V Class

1

VS-656DC5 with 37 to 75 kW. The terminal names are as follows respectively for each VS656DC5 capacity:

y 200 V Class 22 kW, 400 V Class 22 to 45 kW: /

, t/3

2

and 1/21, t/3 and t1/31 are

(/

2

connected respectively.)

y 400 V Class 75 and 160 kW: r/1, 400/2400

* 7. When a noise filter is attached on the VS-656DC5 power supply side, use a noise filter of the

reactor type (without a capacitor) such as finemet zero-phase reactor, and attach it behind the

MCCB at the power supply side. Do not use a capacitor-built-in type noise filter since the

harmonic components may overheat or damage the capacitor.

* 8. The wiring between the input AC reactor and the VS-656DC5 must be within 10 m.

* 9. The DC current bus bar wiring between the VS-656DC5 and the Inverter must be within 5 m.

* 10. If installing a circuit breaker or a magnetic contactor on the VS-656DC5 output (DC) side to

shut down the power supply in an emergency, observe the following precautions.

y Be sure to confirm that the charge lamps on the VS-656DC5 and the Inverter are not lit, and

then turn on the circuit breaker or contactor.If the circuit breaker or contactor is turned on

while power is supplied to the VS-656DC5 and the Inverter, an overcurrent may occur and

damage the circuit breaker or contactor.

y Be sure to confirm that the circuit breaker or contactor is turned on before the power is

turned on for the VS-656DC5.

Note: The standard type of Varispeed G7 models for all capacities can be connected to the VS-

656DC5.

3 WIRING

E-19

Page 30

3.4 Interconnection Diagram with VS-616G5

3-phase

AC

power

supply

MCCB

Reactor

Capacitor

UXVYW

Z

Harmonics

filter

A

B

Input AC

*3,*8

reactor

U

*7

X

V

Y

W

Z

Converter

VS-656DC5

R/L1

S/L2

T/L3

*9, *10

*9, *10

r/

1

/

*6

*3

2

r1/

11

1/

21

C RUN

t1/

31

During MC

motion

C READY

36

+24V

35

RUN-SB

1

STOP

2

External

3

fault

Fault reset

4

5

Multifunction

6

contact input

7

External baseblock

8

Sequence common

11

Shielded sheath

connection

12

terminal

Multi-function

analog monitor

E

9

10

26

37

25

27

18

19

20

21

23

22

A

*2

B

Grounding

*4

*5

Fault contact

output

250 VAC 1 A or less

30 VDC 1 A or less

(Input power)

(Input current)

Inverter

VS-616G5

1

R/L1

*1

S/L2

T/L3

r

1

FWD run command

2

REV run command

3

External fault

4

Reset

5

Multi-

6

function

7

contact

input

8

11

Sequence common

12

Shielded sheath

connection

terminal

15

13

Multifunction

14

analog

16

input

17

U/T1

V/T2

W/T3

21

22

(12)

Grounding

23

18

Fault contact output

19

250 VAC 1 A or less

20

30 VDC 1 A or less

Multi-function

contact output

9

250 VAC 1 A or less

10

30 VDC 1 A or less

25

26

27

Multi-function

output common

IM

AM

Multifunction

analog

output

-10 to 10 V

FM

Multi-function

open-collector

output

48 VDC 50 mA

or less

Multi-function

analog output common

* 1. Do not connect a power supply to the VS-616G5 AC power supply terminals R/L1, S/L2, and

T/L3.

* 2. For the VS-616G5 models provided with cooling fan terminals r and (200 V Class with 18.5

to 75 kW and 400 V Class with 18.5 to 300 kW), remove the jumper wiring between r and R/

L1, and between

and S/L2. Then take the power supply for r and from the VS-656DC5

primary power supply line. The VS-616G5, exclusive for DC input, has no jumper wiring.

The terminals r and in the above diagram are the terminal names for 200 V Class VS616G5 with 18.5 to 75 kW. These terminal names are as follows respectively for each VS616G5 capacity:

y 400 V Class 18.5 to 45 kW: r,

y 400 V Class 55 to 160 kW: r, 400

* 3. Be sure to use the specified AC reactor and harmonics filter for the VS-656DC5, to avoid

abnormal operations.

* 4. Set up a sequence whereby the VS-616G5 starts operation and then the VS-656DC5 starts

after the power supply is turned ON, and the power supply is turned OFF after the VS616G5, the motor, and the VS-656DC5 are stopped in this order.

Operating the VS-616G5 without starting the VS-656DC5, or turning OFF the power supply

while the VS-656DC5 is running may cause the VS-656DC5 to malfunction.

E-20

Page 31

* 5. Interlock with the Inverter. (Refer to Interlocking with Inverters in Appendix B PRECAU-

TIONS ON VS-656DC5 APPLICATION.)

* 6. For models CIMR-D5A2022 to -D5A2075 of the 200 V Class and CIMR- D5A4022 to -

D5A4300 of the 400 V Class, the wiring was done prior to shipment. Connections are not

needed for CIMR-D5A2015 and -D5A4015.

The terminals r/

and /2 in the above diagram are the terminal names for 200 V Class

1

VS-656DC5 with 37 to 75 kW. The terminal names are as follows respectively for each VS-

656DC5 capacity:

y 200 V Class 22 kW, 400 V Class 22 to 45 kW: /

, t/3

2

and 1/21, t/3 and t1/31 are

(/

2

connected respectively.)

y 400 V Class 75 and 160 kW: r/1, 400/2400

* 7. When a noise filter is attached on the VS-656DC5 power supply side, use a noise filter of the

reactor type (without a capacitor) such as finemet zero-phase reactor, and attach it behind the

MCCB at the power supply side. Do not use a capacitor-built-in type noise filter since the

harmonic components may overheat or damage the capacitor.

* 8. The wiring between the input AC reactor and the VS-656DC5 must be within 10 m.

* 9. The DC current bus bar wiring between the VS-656DC5 and the Inverter must be within 5 m.

* 10. If installing a circuit breaker or a magnetic contactor on the VS-656DC5 output (DC) side to

shut down the power supply in an emergency, observe the following precautions.

y Be sure to confirm that the charge lamps on the VS-656DC5 and the Inverter are not lit, and

then turn on the circuit breaker or contactor.If the circuit breaker or contactor is turned on

while power is supplied to the VS-656DC5 and the Inverter, an overcurrent may occur and

damage the circuit breaker or contactor.

y Be sure to confirm that the circuit breaker or contactor is turned on before the power is

turned on for the VS-656DC5.

Note: The standard type of VS-616G5 200 V Class with 0.4 to 22 kW, and the 400 V Class with

0.4 to 45 kW, 185 to 300 kW can be connected to the VS-656DC5.

For models of 200 V Class with 30 to 75 kW and 400 V Class with 55 to 160 kW, use the

VS-616G5 exclusive for DC input (CIMR0-G5AD and -G5AE).

The standard types of VS-616G5 200 V Class with 30 to 75 kW and 400 V Class with 55 to

160 kW cannot be connected to the VS-656DC5 since the DC input terminal 1 is not provided.

3 WIRING

E-21

Page 32

3.5 Wiring Precautions

The external interconnection wiring must be performed with following procedures. After

completing VS-656DC5 interconnections, be sure to check that the connections are correct.

Never use control circuit buzzer check.

Control Circuit Wiring

Separate control circuit wiring from main circuit wiring and other power cables.

Separate wiring for control circuit terminals from other control circuits or main circuit wir-

ings.

Wiring distance should be 50 m or less.

Insert the wire into the lower part of the terminal block and connect it tightly with a screw-

driver.

Screwdriver Blade Width

0.6 mm max.

5.5 mm

Wire sheath strip length must be 5.5 mm.

Fig. 9 Control Circuit Terminal Wiring

3.5 mm max.

Use twisted-pair shielded wire for the control circuit wire and connect the shielded sheath to

VS-656DC5 terminal E. (Refer to Fig. 10.)

Shielded sheath

Connect to shielded sheath

terminal E at VS-656DC5.

Fig. 10 Shielded Wire Termination

Armor

Do not connect here.

Insulate with tape.

E-22

Page 33

3 WIRING

Ground Wiring

Make sure to ground the ground terminal . (200 V class: Ground to 100 Ω or less, 400 V

class: Ground to 10

Do not share the ground wire with other devices, such as welding machines or power tools.

Separate the ground wires from the wirings for power tools.

Always use a ground wire that complies with technical standards on electrical equipment

and minimize the length of the ground wire.

When using more than one VS-656DC5, be careful not to loop the ground wire.

Ω or less).

OK

OK

NO!

Fig. 11 Ground Wiring

E-23

Page 34

3.6 WIRING MAIN CIRCUIT TERMINALS

Required Wire Size

Select wires to be used for wiring from the following table.

Circuit VS-656DC5

CIMR-D5A

Terminal

Symbol

Control Common to all models 1 to 12, 18

to 23,

25 to 27,

35 to 37

E (G)

* Wire size is determined by 75 °C temperature-rated copper wire, and

assuming external wiring of single 3-core wires at an ambient temperature of 30 °C.

Applicable Wire Sizes and Closed-loop Connectors

Select the appropriate wires and closed-loop connectors from Tab le s 3 to 5.

Table 3 200 V Class Wire Size

Inverter

Model

CIMR-

D5A2015

D5A2022 R/L1, S/L2, T/L3,

D5A2037 R/L1, S/L2, T/L3

Terminal Symbol Terminal

Screw

R/L1, S/L2, T/L3,

M8 8.2 to 10.2 14 to 30

, , ,

11, 1/ 21, t1/ 31

r1/

M4 1.2 to 1.4 2 to 5.5

M6 4.0 to 5.0 8

M8 8.2 to 10.2 30 to 70

, , ,

r1/

11, 1/ 21, t1/ 31

M4 1.2 to 1.4 2 to 5.5

M6 4.0 to 5.0 14

M10 18 to 23 50 to 100

, , ,

M10 18 to 23 50 to 70x2P

M10 18 to 23 22

11, 1/ 21, t1/ 31

r1/

M4 1.2 to 1.4 2.0 to 5.5

Terminal

Wire Size *

Screw

(AWG)

− Twisted wire

0.5 to 1.25

(20 to 16)

Single

0.5 to 1.25

(20 to 16)

M3.5 0.5 to 2

(20 to 14)

Tightening

Torque

Nxm

(1/0 to 2/0x2P)

2

mm

Possible

Wire Size

*1

mm2 (AWG)

(6 to 2)

(14 to 10)

(8)

(2 to 2/0)

(14 to 10)

(6)

(1/0 to 4/0)

(4)

(14 to 10)

Wire Type

• Twisted-pair shielded wires

• Shielded polyethylene-covered, vinyl

sheath cable (manufactured by Hitachi

Cable, Ltd. or equivalent)

Recom-

Wire Type

mended Wire

Size

2

(AWG)

mm

22

(4)

−

Power cable:

600 V vinyl

sheathed wire or

equivalent

8

(8)

38

(1)

−

14

(6)

80

(3/0)

30x2P

(2x2P)

22

(4)

−

E-24

Page 35

Table 3 200 V Class Wire Size (cont’d)

3 WIRING

Inverter

Model

CIMR-

D5A2055

D5A2075

Terminal Symbol Terminal

*2

R/L1, S/L2, T/L3

, , ,

11, 1/ 21, t1/ 31

r1/

R/L1, S/L2, T/L3

, , ,

11, 1/ 21, t1/ 31

r1/

Screw

Tightening

To rq u e

Nxm

Possible

Wire Size

mm2 (AWG)

M10 18 to 23 80 to 100

(3/0 to 4/0)

M10 18 to 23 30x2P to

70x2P

(2x2P to

2/0x2P)

M10 18 to 23 30

(2)

M4 1.2 to 1.4 2.0 to 5.5

(14 to 10)

M12 31.5 to 39.5 150 to 200

(300 to 400)

M12 31.5 to 39.5 38x2P to

100x2P

(1x2P to

4/0x2P)

M12 31.5 to 39.5 50

(1/0)

M4 1.2 to 1.4 2.0 to 5.5

(14 to 10)

*1

mended Wire

mm2 (AWG)

Recom-

Size

50x2P

(1/0x2P)

50x2P

(1/0x2P)

30

(2)

−

200

(400)

70x2P

(2/0x2P)

50

(1/0)

−

Wire Type

Power cable:

600 V vinyl

sheathed wire or

equivalent

* 1. Wire size is determined by 75 °C temperature-rated copper wire, and assuming external wir-

ing of single 3-core wires at an ambient temperature of 30 °C.

* 2. Contact your YASKAWA representative. (Under development)

Table 4 400 V Class Wire Size

Inverter

Model

CIMR-

Terminal Symbol Terminal

Screw

Tightening

Torque

Nxm

Possible

Wire Size

mm2 (AWG)

Recom-

*

mended Wire

Size

mm2 (AWG)

D5A4015 R/L1, S/L2, T/L3,

, , ,

r1/

11, 1/ 21, t1/ 31

M5 2 to 2.5 5.5 to 14

(10 to 6)

M4 1.2 to 1.4 2 to 5.5

8

(8)

−

(14 to 10)

D5A4022 R/L1, S/L2, T/L3,

, , ,

r1/

11, 1/ 21, t1/ 31

M6 4.0 to 5.0 8

(8)

M6 3.6 to 5.1 14 to 22

(6 to 4)

M4 1.2 to 1.4 2 to 5.5

8

(8)

14

(6)

−

(14 to 10)

M6 4.0 to 5.0 8

(8)

8

(8)

Wire Type

Power cable:

600 V vinyl

sheathed wire or

equivalent

E-25

Page 36

Table 4 400 V Class Wire Size (cont’d)

Inverter

Terminal Symbol Terminal

Model

CIMR-

D5A4030 R/L1, S/L2, T/L3,

, , ,

11, 1/ 21, t1/ 31

r1/

D5A4045 R/L1, S/L2, T/L3,

, , ,

11, 1/ 21, t1/ 31

r1/

D5A4075 R/L1, S/L2, T/L3

, , ,

r1/ 11, 1/ 21, t1/ 31

D5A4160 R/L1, S/L2, T/L3

, , ,

11, 1/ 21, t1/ 31

r1/

Screw

Tightening

To rq u e

Nxm

Possible

Wire Size

mm2 (AWG)

M8 8.2 to 10.2 14 to 70

(6 to 2/0)

M4 1.2 to 1.4 2 to 5.5

(14 to 10)

M6 4.0 to 5.0 8 to 14

(8 to 6)

M8 8.2 to 10.2 30 to 70

(2 to 2/0)

M4 1.2 to 1.4 2 to 5.5

(14 to 10)

M6 4.0 to 5.0 14

(6)

M10 18 to 23 50 to 100

(1/0 to 4/0)

M10 18 to 23 50 to 70x2P

(1/0 to 2/0x2P)

M8 9.0 to 11.0 22

(4)

M4 1.2 to 1.4 2.0 to 5.5

(14 to 10)

M12 31.5 to 39.5 150 to 200

(300 to 400)

M12 31.5 to 39.5 38x2P to

100x2P

(1x2P to

4/0x2P)

M8 9.0 to 11.0 50

(1/0)

M4 1.2 to 1.4 2.0 to 5.5

(14 to 10)

*

mended Wire

mm2 (AWG)

Recom-

Size

22

(4)

−

8

(8)

38

(1)

−

14

(6)

80

(3/0)

30x2P

(2x2P)

22

(4)

−

200

(400)

70x2P

(2/0x2P)

50

(1/0)

−

Wire Type

Power cable:

600 V vinyl

sheathed wire or

equivalent

* Wire size is determined by 75 °C temperature-rated copper wire, and assuming external wiring

of single 3-core wires at an ambient temperature of 30 °C.

E-26

Page 37

Closed-loop Connector Sizes

Table 5 Closed-loop Connector Sizes (JIS C 2805) (For 200 V/400 V Classes)

3 WIRING

Wire Size (mm

2

)

Terminal Screw Closed-loop Connector

0.5 M3.5

0.75

M4

1.25

2M42 to 4

M5 2 to 5

3.5 M4 3.5 to 4

M5 3.5 to 5

5.5 M4 5.5 to 4

M5 5.5 to 5

8M58 to 5

M6 8 to 6

14 M6 14 to 6

22 M8 22 to 8

38 M8 38 to 8

38 M10 38 to 10

60 60 to 10

80 80 to 10

100 100 to 10

100 M12 100 to 12

150 150 to 12

200 200 to 12

Size (mm

1.25 to 3.5

1.25 to 4

2

)

NOTE

Determine the wire size for the main circuit so that line voltage drop is within 2 % of the rated voltage.

Line voltage drop is calculated as follows:

(If there is a possibility of excessive voltage drop, use a larger wire suitable to the required length.)

Line voltage drop (V) = 3 × wire resistance (Ω/km) × wire length (m) × current (A) × 10

-3

E-27

Page 38

3.7 EXTERNAL TERMINALS

Main Circuit Terminal Functions

Table 6 Main Circuit Terminal Functions

Terminal Symbol Description

R/L1

S/L2

T/L3

,

r1/ 11

1/ 21

t1/ 31

r/ 1

/2

VS-656DC5

Main Circuit

Input

VS-656DC5

Main Circuit

Output

Power Supply

Voltage

Detection

Power Input

for FAN and

MC

Main circuit AC power supply input terminal for the VS-656DC5

Main circuit DC output terminal for the VS-656DC5

Detects the phase sequence and the voltage level.

Supplies power for the cooling fan and inrush current prevention MC of

the VS-656DC5.

• Connects to the Inverter’s DC power supply voltage input terminals.

Two terminals are provided for both and .

• Connect to the power side of the input reactor.

• Terminals may not be provided for some VS-656DC5s depending on

their capacities.

• The power supply voltage jumper in the VS-656DC5 must be set

depending on the voltage value to be supplied.

Control Circuit Terminal Functions

Table 7 Control Circuit Terminal Functions

Terminal Name

Sequence Input 1

*1

5 - 7

35

36

12

2

3

4

8

11

Signal Name Function Signal Level

RUN-SB

STOP

External Fault

Fault Reset

Multi-function

Contact Input

Ter minal

External Baseblock

Sequence Common

Photocoupler Internal

Common

+24-V Power Sup-

ply for Sequence

Shielded Sheath Wire

VS-656DC5 starts operation at

“Closed.” One-shot trigger inputs

are available: Once the data is input,

the VS-656DC5 keeps running even

at “Open.”

To start the VS-656DC5 operation,

set terminal 2 to “Closed

VS-656DC5 stops at “Open.”

−

*2

Set to “Unused” prior to shipment.

Constants H1-03 to H1-06 can be

used for the setting.

Baseblock at “Closed.”

−

−

−

−−

.”

*2

24 VDC 8 mA

Photocoupler

isolation

E-28

Page 39

Table 7 Control Circuit Terminal Functions (cont’d)

3 WIRING

Terminal Name

Photocoupler

*1

25 - 27

Output

26 - 37 Set to “MC Operating (MCON)”

Relay Output 18 - 20

19 - 20

9 - 10

Analog Output 21

23 Set to “Input current (Input Cur-

22

* 1. Indicates the terminal number of the control card.

* 2. The input signals excluding RUN-SB signal are status signals. (RUN-

SB signal is a rising trigger signal and held internally.) When RUNSB and fault reset signals are input, the input must be held at least 40

ms.

Signal Name Function Signal Level

Multi-function

Photocoupler

Set to “CREADY (Converter

Ready)” prior to shipment.

48 VDC 80

mA or less

Open-collector

Output

prior to shipment.

FAULT Output

(Transfer Contact)

Outputs when a fault is detected.

Terminal 18-20: Closed during fault

detection

Terminal 19-20: Open during fault

250 VAC 1 A

or less

30 VDC 1 A

or less

detection

Multi-function

Contact Output

Multi-function

Analog Output

Set to “During Converter Running

(During Run)” prior to shipment.

Set to “Input power (AC Side

Power)” prior to shipment.

-10 V to +10

VDC or less

rent)” prior to shipment.

Multi-function

−

Analog Common

E-29

Page 40

4 OPERATION

• Only turn ON the input power supply after attaching the front cover or the terminal cover. Do not

remove the cover while current is flowing.

Failure to observe this warning may result in an electric shock.

• Never operate the Digital Operator or other switches when your hand is wet.

Failure to observe this warning may result in an electric shock.

• Never touch the terminals while current is flowing, even if the VS-656DC5 stops.

Failure to observe this warning may result in an electric shock.

• Never touch the radiation fins (heatsink) or input reactor since the temperature is very high.

Failure to observe this caution may result in harmful burns to the body.

WARNING

CAUTION

• The VS-656DC5 is factory set to the suitable settings. Do not change the settings unnecessarily.

Failure to observe this caution may result in damage to the unit.

4.1 Checkpoints before Turning ON the Power Supply

Check the following before turning ON the power supply.

• Check that the power supply voltage is correct.

200 V class: 200 to 220 VAC, 50 Hz

200 to 230 VAC, 60 Hz

400 V class: 380 to 460 VAC, 50/60 Hz

• Make sure that the VS-656DC5 and the Inverter are connected correctly.

• Make sure that the phase sequence of the main circuit terminals (R/L1, S/L2, T/L3) and

the power supply voltage detection terminals (r1/ 11, 1/ 21, t1/ 31) are correct.

• Make sure that the VS-656DC5 control circuit terminals are connected to other control

devices correctly.

• Set the run command of the VS-656DC5 and the Inverter to OFF.

E-30

Page 41

4.2 Setting the Power Supply Voltage Jumper (For 400 V Class VS-656DC5 with 22 kW or More)

Set the power supply voltage jumper for 400 V class VS-656DC5 with 22 kW or more.

Insert the jumper into the voltage connector nearest to the actual power supply voltage.

Incorrect connector setting may negatively impact the performance and credibility of the

VS-656DC5.

The jumper is set to 440 V prior to shipment. If the power supply voltage other than 440 V

is to be used, use the following procedure to change the setting.

1. Turn OFF the power supply and wait for at least five minutes before removing the front

cover.

2. Remove the front cover.

3. Insert the jumper at the position for the voltage supplied to the VS-656DC5 (Refer to

Fig. 12).

4 OPERATION

4. Attach the front cover.

1 3 1 3 1 3 1 3

23CN 32CN 9CN 10CN 22CN

TB1

Fig. 12 Setting the Power Supply Voltage

(For 400 V Class VS-656DC5 with 22 kW)

1 4

DESIG

1 2 1 2 1 2 1 2

380V 440V

FU2

3PCB

400/415V

RATING : 600V

1.5A

CAT No.: ATML

-1/2

MAKER : COULD

460V

21CN

BU6/CO6

Jumper

E-31

Page 42

4.3 Using the Digital Operator

This section describes the component names and functions of the Digital Operator. The com-

ponent names and functions are shown in Fig. 13 and Key functions are described in Table

8.

DRIVE FWD REV REMOTE

SEQ REF

Output V Command

U1-01 = 330 V

DIGITAL OPERATOR

JVOP-130

LOCAL

REMOTE

JOG

FWD

REV

MENU

RUN STOP

ESC

DATA

ENTER

RESET

Operation Mode Display

DRIVE: Lit when in operation mode.

FWD: Not used.

REV: Not used.

SEQ: Lit when the run command from the

control circuit terminal is enabled.

REF: Not used.

Data Display

Tow-line LCD that displays data for monitoring,

user constants, and set values with characters

per line.

Keys

Execute operation such as setting user

constants, monitoring, etc.

Fig. 13 Digital Operator Component Names and Functions

E-32

Page 43

Table 8 Key Functions

Key Name Function

LOCAL

REMOTE

LOCAL/REMOTE Key Switches between operation (LOCAL) via the Digital

Operator and control circuit terminal (REMOTE) operation.

This Key can be enabled or disabled by setting a user

constant (o2-01).

MENU Key Displays menus.

MENU

4 OPERATION

ESC

JOG

FWD

REV

JOG Key Not used.

FWD/REV Key Not used.

pressed.

RESET Key Sets the number of digits for user constant settings.

ESC Key Returns to the status before the DATA/ENTER Key was

RESET

Also acts as the reset Key when a fault has occurred.

Increment Key Selects menu items, groups, functions, user constant

names, and increments set values.

Decrement Key Selects menu items, groups, functions, user constant

names, and decrements set values.

DATA

ENTER

RUN

DATA/ENTER Key Enters menu items, functions, constants, and set values

after they are set.

RUN Key Starts the VS-656DC5 operation when the VS-656DC5 is

in operation with the Digital Operator.

STOP Key Stops the VS-656DC5 operation when the VS-656DC5 is

STOP

in operation with the Digital Operator.

This Key can be enabled or disabled by setting a user

constant (o2-02) when operating from the control circuit

terminal.

Note: Except in diagrams, Keys are referred to using the Key names listed

in Table 8 .

E-33

Page 44

Modes

This section describes the VS-656DC5 monitor modes, switching between modes, and

accessing/setting user constants.

VS-656DC5 Modes

The VS-656DC5 user constants and monitoring functions have been organized in groups

called modes that make it easier to read and set user constants.

The VS-656DC5 is equipped with 4 modes, as shown in Ta b le 9.

Table 9 Modes

Mode Primary function(s)

Operation mode The VS-656DC5 can be run in this mode.

Use this mode when monitoring values such as DC voltage feedback or

power supply frequency, displaying fault information, or displaying the

fault history.

Initialize mode Use this mode when selecting the language displayed on the Digital Opera-

tor, selecting the access level for reading/setting user constants, or initializing the user constants.

The language to be displayed on the Digital Operator is set to English (A100 = 0) prior to shipment.

Programming mode Use this mode when reading/setting the user constants required for opera-

tion.

The program-mode functions are subdivided into the following groups:

• Application: Operation mode selection

• Tuning: Acceleration time, AVR, etc.

• Option: Settings for Optional Cards

• Terminal: Settings for sequential I/O and analog I/O

• Protection: Settings for the motor and VS-656DC5 protection functions

• Operator: Selection of the Digital Operator’s display and Key functions

Modified constants

mode

Use this mode to read/set user constants that have been changed from their

factory-set values.

E-34

Page 45

4 OPERATION

Switching Modes

Once the VS-656DC5 has been put into operation mode by pressing the Menu Key, the

Increment and Decrement Keys can be pressed to switch to other modes. Press the DATA/

ENTER Key to read/set the user constants in each mode.

Press the ESC Key to return to the mode display from the user constant display.

Press the DATA/ENTER Key twice to write a constant and then press the ESC Key to return

to the mode display. This is the most Basic operation, so you should remember it.

All modes/

constant status

MENU

x Operation mode

DC5 ∗ Main Menu ∗

Operation

x Initialize mode

DC5 ∗ Main Menu ∗

Initialize

x Programming mode

DC5 ∗ Main Menu ∗

Programming

x Modified constant mode

DC5 ∗ Main Menu ∗

Modified Consts

DATA

ENTER

ESC

DATA

ENTER

ESC

DATA

ENTER

ESC

DATA

ENTER

ESC

Power ON (o1-02 = 1)

Monitor (Output voltage reference)

Output V Command

U1-01 = 330V

Operator display

language selection

Select Language

English

Mode selection

Group b

Application

Displays constants changed

from factory settings.

None Modified

DATA

ENTER

ESC

DATA

ENTER

ESC

A1-00 = 1∗∗∗

English

Function b1

Sequence

(Mode Display)

IMPORTANT

Function

(Constant Reading)

Constant Display

(Constant Setting)

Fig. 14 Switching Modes

When running the VS-656DC5 after using Digital Operator, press the MENU Key to enter the opera-

tion mode and then press the DATA/ENTER Key from the operation mode display to bring up the

monitor display. Run commands cannot be received from any other display. (Monitor display in the

operation mode appears when the power is turned ON.)

E-35

Page 46

EXAMPLE

Setting a User Constant

The group level will be displayed when the DATA/ENTER Key is pressed at the program-

ming mode display.

Use the following procedure to set a constant.

Step Key

Digital Operator Display Remarks

Sequence

1

MENU

2

DC5 ∗ Main Menu ∗

Operation

DC5 ∗ Main Menu ∗

Programming

Press twice.

3

4 Changed to constant reading

5

6

7

8

9 Writes in the new setting.

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

Group b

Application

Function b1

Sequence

Reference Source

Operator

Run Source

Terminals

b1-02 = 1

Terminals

b1-02 = 0

Operator

Entry Accepted

(function) level.

After a few seconds, the Oper-

10

ESC

Run Source

Operator

Function b1

sequence

ator display is as shown on the

left.

IMPORTANT

The constant setting (drive mode is changed from Terminal to Operator with programming

mode) has been completed.

Operation Mode

Operation mode is the mode in which the VS-656DC5 can be operated.

Many user constants can't be changed when the VS-656DC5 is operating. Refer to A.1 Mon-

itor Constant List for details.

The following monitor displays are possible in operation mode: The AC power supply fre-

quency, current or voltage, as well as fault information and the fault history.

When running the VS-656DC5 after using Digital Operator, press the MENU Key to enter the

operation mode and then press the DATA/ENTER Key from the operation mode display to bring up the

monitor display. Run commands cannot be received from any other display. (Monitor display in the

operation mode appears when the power is turned ON.)

E-36

Page 47

Operations in Operation Mode

Key operations in operation mode are shown in Fig. 15.

4 OPERATION

All modes/

constants status

Operation Mode

DC5 * Main Menu *

Operation

MENU

DATA

ENTER

ESC

Power ON

(when o1-02 = 2)

DC voltage feedback display

Output V Feedback

U1-02 = 300V

Power supply side current display

Output Current

U1-03 = OA

Power supply frequency

(This item can be changed using o1-01.)

Input Frequency

U1-08=0.00Hz

Function selection U2 (fault trace)

Function U2

Fault Trace

Function selection U3 (fault history)

Function U3

Fault History

DATA

ENTER

ESC

DATA

ENTER

ESC

Power ON

(when o1-02 = 3)

Power ON

(when o1-02 = 4)

Example of fault trace contents

OC

Over Current

Example of fault history contents

Last Fault

Over Current

Function selection U1 (Monitor)

Function U1

Monitor

Fig. 15 Operations in Operation Mode

DATA

ENTER

ESC

Various monitors

Output V Command

U1-01=330V

E-37

Page 48

4.4 Power ON/OFF Sequence

Refer to Fig. 16 when building a power ON/OFF sequence for the VS-656DC5.

ON OFF

AC input power supply

VS-656DC5 READY OFF

(C-READY) RUN

VS-656DC5 run command STOP

(RUN-SB) RUN

VS-656DC5 run output STOP

(C-RUN)

VS-656DC5 stop signal

(STOP)

Inverter run command STOP

RUN

STOP

ON

RUN

ON

OFF

FWD

REV

RUN STOP

RESET

Fig. 16 Power Supply ON/OFF Sequence

Check the following when using the VS-656DC5.

• Run commands of the VS-656DC5 should be turned ON after turning ON the power

supply and then confirming that the VS-656DC5 is READY.

• Turn ON the run command of the Inverter after confirming that the VS-656DC5 is run-

ning.

• To stop the VS-656DC5, input the VS-656DC5 stop signal after confirming that the run

command of the Inverter is turned OFF and then the motor has stopped.

• Turn the power OFF after the run output of the VS-656DC5 is OFF.

E-38

Page 49

5 MAINTENANCE AND INSPECTION

WARNING

• Never touch high-voltage terminals in the VS-656DC5.

Failure to observe this warning may result in an electric shock.

• Perform maintenance or inspection only after verifying that the CHARGE LED goes OFF, after the

main circuit power supply is turned OFF.

The capacitors are still charged and can be dangerous.

• Only authorized personnel should be permitted to perform maintenance, inspections, or parts

replacement.

[Remove all metal objects (watches, bracelets, etc.) before operation.]

(Use tools which are insulated against electric shock.)

Failure to observe this warning may result in an electric shock.

5 MAINTENANCE AND INSPECTION

• Never modify the product.

Failure to observe this warning may result in an electric shock or personal injury.

• A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully. The

CMOS IC can be destroyed by static electricity if touched directly.

The CMOS IC may be destroyed by static electricity if touched directly.

• Do not change the wiring, or connect/disconnect the connectors while power is applied to the cir-

cuit.

Failure to observe this caution may result in personal injury.

• Do not subject the VS-656DC5 to halogen gases, such as fiuorine, chlovine, bromine, and iodine,

at any time even during transportation or installation.

Otherwise, the VS-656DC5 can be damaged or interior parts burnt.

5.1 Maintenance Period

CAUTION

The maintenance period of the VS-656DC5 is as follows.

Maintenance period: Within 18 months of shipping from the factory or within 12 months of

being delivered to the final user, whichever comes first.

E-39

Page 50

5.2 Daily Inspection

Check the following items with the system in operation.

• There should be no abnormal heat generation.

• The ambient temperature should not be too high.

• The cooling fan on the VS-656DC5 should be operating normally.

5.3 Periodic Inspection

Check the following items during periodic maintenance.

Always turn OFF the power supply before beginning inspection. Confirm that the LED

indicators on the front cover have all turned OFF, and then wait at least five minutes have

elapsed before beginning the inspection. Be sure not to touch terminals right after the power

has been turned OFF. Doing so may result in an electric shock.

Item Inspection Corrective Procedure

External terminals,

mounting bolts, connectors, etc.

Radiation Fin (Heatsink) Are the fins dirty or dusty? Clean off any dirt and dust with an air

PCBs Is there any conductive dirt or oil

Cooling fan Is there any abnormal noise or vibra-

Power elements Is there any dirt or dust on the ele-

Smoothing capacitor Are there any irregularities, such as

Table 10 Periodic Inspections

Are all screws and bolts tight? Tighten loose screws and bolts firmly.

Are connectors tight? Reconnect the loose connectors.

gun using dry air at a pressure of 39.2

4

to 58.8 × 104 Pa (4 to 6 kgxcm2).

10