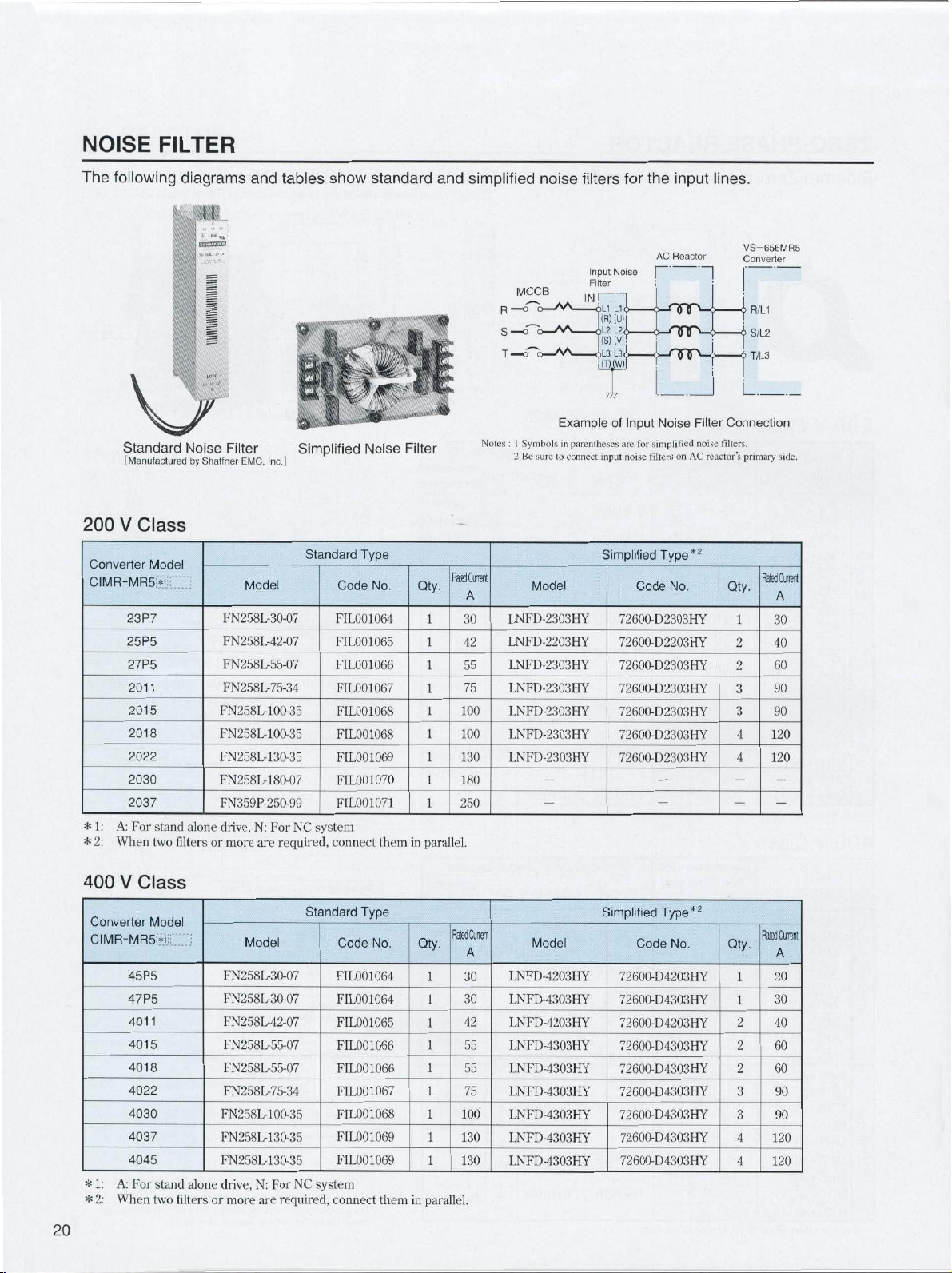

Page 1

YASKAWA

VECTOR-CONTROLLED

REGENERATIVE

FUNCTION

INVERTER

FOR

MACHINE

DRIVES

WITH

TOOLS

VARISPEED-626M5

STANDARD

WINDING

SELECTION

:

200V

400V

CLASS

CLASS

:

200V

400V

5/3HP

7.5/5HP

(3.7/2.2kW)

CLASS

CLASS

,1

TO

(5.5/3.7kW)

7.5/5HP

7.5/5HP

(5.5/3.7kW)

(5.5/3.7kW)

i!

50/40HP

TO

60/50HP

TO40/27HP

TO40/27HP

POWER

(37/30kW)

(45/37kW)

(30/20kW)

(30/20kW)

vt

j

"V

*

i

m

\«

i

[•1

1

6

V

YASKAWA

Certified

ISO9001

ISO14001

LITERATURE

for

and

no

JQA-0422

NO.

JQA-EM0498

JQA-EM0924

KAE-S626-7E

Page 2

Q

LU

LU

Q_

C/)

DC

<

>

K

P

-H|

!V

r'jt

LUTE

ijli

ui

..v

t

•T*

iRjfi

yAn&PBBD-zziMz

r

1/

'"Ns,

fj

>

•>.

r

vvsv

f

A*f%s

*

<Mh

1-,n

iflfr'~iiifn

;

ct

unit

ed£

Iring

jvj

,

f~

«ÿ***

V<

v

s

fi

mm

basi

itu*

Jrur

igh

Performance

ijuuJii/

?s*

pi’Oifa&s'dyir/

uusJ

1

4

-j

ii/J.

air/-,

T

:

t»

:-*.

t

:

j

,22,3a

;

r

:-.

i

Jujlt

r

»

>1>

TJT

i

ki

:hi)

kjf

cet

1

:

/

erfi,

r-

:-

JJJUIUJJJ

d

JJJ

rl

:

ne<j

its

?£

:

:-;

iUJl

-

:

rj

!

ifJjTii

JT

r

i

Reduce

•

impact

M3SOmm

Converter

power

regenerative

function

Vector

control

inverter

All

units

aligned

are

gle

converter

the

servo

fore,

the

designing

pact

quickly

MCompact

your

-

with

CIMR-MR5

—

CIMR-M5

(servo

drives

control

and

highly

and

tool

height

unitaswell

the

at

provides

does

easily

,

lightweight

machine

S?

H

S

JL

same

and

regenerates

panel

require

not

efficient

assembled.

book

height

power

can

size

fT

Id

#8

i

as

of

to

be

multi-axis

structure

“

\

rrr

J

lil

L

Servo

converter

350mm

both

their

standardized,

much

spindle

\

<v

I

ID

Mm

'

i

II

unit

(13.78").

the

power.

time.

drive

\

OBI]

feeding

for

and

spindle

motor

m

,

J

inverter)

There¬

A

can

E

i

in

c

D

S3

axes

A

sin¬

and

and

com¬

be

Precision

Highly

frequency

Gate

lated

reduced

torque

Servo

(Digital

n

ha

ME

Orientation

usingahigh

When

the

any

1:1,

can

be

Orientation

Reference

Orientation

Complete

Magnetic

Motor

accurate

PWM

Bipolar

by

suppressing

ripple.

performance

Processor).

Signal

need

time

resolution

motor

position

achieved

Signal

Signal

Signal

Sensor

Speed

Load

Factor

and

servo

speed

control

control

due

Transistor).

current

improved

is

Orientation

is

reduced

axis

orientation

without

0

0

encoder

and

adding

IQOOmin

SS-

ORIENTATION

to

the

performance

is

high

Rotational

distortion

by

load

using

any

0.73sec

achieved

speed

IGBTs

deviation

which

by

the

use

functions

position

a

orientation

axis

are

the

motor

options.

K

by

high

(Insu¬

causes

of

DSP

control

signal.

connected

encoder

ss:

is

The

reduced

optimum

to

design

structure.

well

are

achieved

highly

is

cooling

tained

tions.

The

machine

A

can

motor

in

size

and

Rapid

as

quick

reliable

capability

even

VS-626M5

be

assembled

has

been

further

weight

and

electro-magnetic

response

response

low

inertia.

because

adverse

conforms

using

cooling

is

the

improved

servo

at

in

meetimg

due

as

It

the

main¬

condi¬

to

CE

the

voltage

low

marking

VS-626M5.

£,

directives.

approval

of

M

twork

MApplicable

Only

one

spindle,

the

twisted

cise

nication.

(Applicable

and

pair

reliable

limited

with

our

standard

to

communication

the

cableisused.

for

analog

servo

with

units,

4Mbps

I/O

interface.)

wiring

network

cable

and

Transferring

high

required

is

the

speed

CNC.

YENET

to

A

practical

highly

is

serial

1200

connect

pre¬

commu¬

2

Page 3

VARISPEED

626M5

DRIVE

A

P

[-'

|!'-.:ible

*:

*:

•Applicable

lineups

Spindle

General

Tapping

MAG

Series

Milling

Liquid

Cooling

Machine

Built-in

Direct

Drive

Widely

used

VS-626M5

General-

purpose

Tapping

Series

MAG

Series

Liquid

Cooling

Built-in

Widely

Used*

Combination

Drive

Purpose

Series

and

Tools

Series

type

Range

Standard

Winding

Series

Single

Winding

Speed

High

Standard

Winding

of

VS-626MC5

all

for

general-purpose

from

VS-626M5

Series*

for

Compact

Tapping

Series

for

spindle

drive

Selection

Winding

Selection

Selection

inverter

kindsofmachine

to

Compact,

types

(Conforming

Compact,

duetoenhanced

Super

induction

high

at

V

200

400

200

200

200

200

induction

Induction

torque

(Conforming

Induction

tion

achieved.

available.

1.5

motor.

for

VS-626MC5(CHE-S626-8)

Voltage

200/400

200/400

200/400

and

tools

special

lightweight

provided.

are

low

low

inertia

motor

speeds

motor

achieved.

motor

also

available.

2

series

CE

to

inertia,

high

(torque

achieved.

with

CE

to

will

Single

2.2

markings.)

synchronous

accel/decel

motor.

liquid

"Shaft

markings.)

be

winding,

3.4

induction

Inertia

based).

"Shaft

through"

built

3.7

Spindle

motor.

performance.

is

High

through"

cooling

your

in

winding

5.5

motor.

approx.

structure.

are

Motor

Standard

Greatly

60%

torque

applicable

is

applicable.

spindle

selection

Continuous

6

reduced,

low

at

drive.

7.5

and

reduces

speeds

Compact,

High

and

Rating

11

winding

compared

as

an

high

kW

accel/decel

large

and

option.

high

speed,

speed,

speed

15

selection

with

output

low

series

18.5

time

our

high

vibra¬

are

20

Literature

KAE-S626-7

KAE-S626-7.3

25

22

No.

30

37

Type

Inverter

M5

Series

Specifications

For

A:

N:

For

Voltage

200V

2:

4:

400V

AC

Spindle

Output

A:

Standard

Wide

B:

J:

Base

Motor

04:

3.7/2.

to

45:

45/37kW

M5

Series

Designation

CIMR-M5

J

—

-

stand

alone

system

2kW

-

Motor

-

Constant

1150min

-

drive

Motor

NC

Class

class

class

Spindle

Characteristics

Range

Speed

Capacity

-

Power

1

UAASK

1:12

T

Enclosure

0:

Open

type

Externally

5:

type

Max.

Applicable

Motor

3P7:

3.7kW

to

45kW

045:

chassis

(with

(without

fan)

cooling

fan)

FZ

CIMR-MR5

Converter

Series

MR5

Specifications

Voltage

A:

N:

2:

4:

For

(Power

For

(Power

200V

400V

Stand

supply

NC

supply

Class

class

class

-

system

-

-

alone

drive

for

servo

unit

for

servo

(three-phase)

(three-phase)

not

unit

Terminal

Shaft

Mounting

provided)

provided)

Voltage

Blank:

E

S:

Oil

No

0:

Blank:

Flange

1:

3:

Foot

Encoder

Zero

Z:

Class

200V

class

400V

:

class

Box

Specifications

End

seal

provided

specification

Standard

Method

mounted

mounted

Specifications

point

provided

Specifications

(only

Enclosure

0:

Open

type

5:

Externally

type

Max.

Motor

3P7:

3.7kW

to

45kW

045:

flange-mounted)

for

chassis

(with

fan)

cooling

(without

Applicable

fan)

3

Page 4

I

RATINGS

STANDARD

Model

Rated

Output*

HP

Rated

mirv'

Output

Base

Continuous

Motor

Rotor

(GD74)

Rotor

Overload

Vibration

Noise

Ambient

Approx.

Model

Control

Speed

Speed

%

Overload

>

Approx.

Dimensions

inch

Model

Required

2

o

a

Power

Control

s

>

Control

o

o

Overload

Approx.

Dimensions

inch

Reactor

AC

4

kW

200V

30-minute

(50/-6ED

1

Continuous

Base

Speed

Maximum

Torque

Speed

Rating

Inertia

GD2

Capacity

Level

Temperature,

Mass

CIMR-M5D*T

Method

Control

Regulation

Capacity

Mass

Width

CIMR-MR5

Power

Supply

Power

Method

Capacity

Mass

No.

Code

Height

Depth

Width

Height

Depth

mm

mm

Range

Capacity

Supply

at

(At

Speed

power

AND

SERIES

(S2)

Rating

(S3)

Rating)

(S1)

Rating

Speed

N*m

•

lb

ft

kgf*m

•

lb

ft2

kg-m2

•

lb

ft2

kgf*m2

Humidity

lb

kg

kg

lb

i*3l

1

kVA

lb

supply)

I

kg

SPECIFICATIONS

FZ

11

15

11

10

7.5

of

30-minute

V5

or

less

95%Rh

68

PWM

inverter

maximum

to

’

maximum

%

30-minute

of

60s

13.78

12.60

19

(50/60Hz),

to

%

between

to

%

Control

200%

13.78

12.60

X010061

15

20

15

15

11

6000

70.0

51.7

7.14

1.614

0.069

6.478

0.276

207

94

2015

speed

27

5.91

350

320

2015

24

220V

%,

—15

220V

%,

—15

(120"

for1sof

5.91

350

320

0.083

7.902

0.332

rating

or

less

(Vector

motor

rating

12

(50/60Hz),

frequency

lines

(50/60Hz),

frequency

30-minute

27

12

150

X010062

19

25

18.5

20

15

95.0

70.6

9.74

1.970

(50%ED)

(Non-condensing)

238

108

2018

speed

or

less

(50%ED)

2018

30

:

current

04

5“

3.7“

3

2.2

14.0

10.4

1.43

0.209

0.009

0.831

0.036

71

32

23P7

23P7

7

(Voltage

(Voltage

X010057

06

7.5

5.5

5

3.7

8000

23.5

17.4

2.40

0.411

0.017

1.637

0.068

32

119

54

25P5 27P5

11

3.94

25P5

Three-phase,

9

to

5

0.617

0.026

2.492

0.104

104F,0

fluctuation

voltage

Single-phase

fluctuation

Power

120%

11

5

3.94

X010058

X010059

UAASKA-

08

10

7.5

7.5

5.5

35.0

25.8

3.57

0.759

0.033

120%

for

75dB(A)

to

130

59

Sine

wave

40min

0.2

for

120%

27P5

12

200V

:

+10

unbalanced

200V

:

+10

Regenerative

60s,

for

X010060

1500

47.7

35.8

4.87

3.061

0.132

60s

+40C,

150

2011

2011

(50/60Hz),

22

30

22

25

18.5

117.6

86.9

12.0

2.326

0.098

9.278

0.392

269

122

2022

control)

2022

36

230V

fluctuation

or

5

%

230V

fluctuation

conduction)

rating

X010063

less)

AASKJ-

U

30

40

30

30

22

182.3

134

18.6

6.122

0.259

24.54

1.036

80dB(A)

481

218

2030

35

16

7.84

2030

48

(60Hz)

:

(60Hz)

:±5%)

35

16

7.84

X010064

1150

4500

V10

±5%,

200

FZ

37

50

37

40

30

249.0

183.7

25.4

8.068

0.340

32.27

1.360

or

less

581

263

2037

57

26

300

11.76

2037

60

57

11.76

X010120

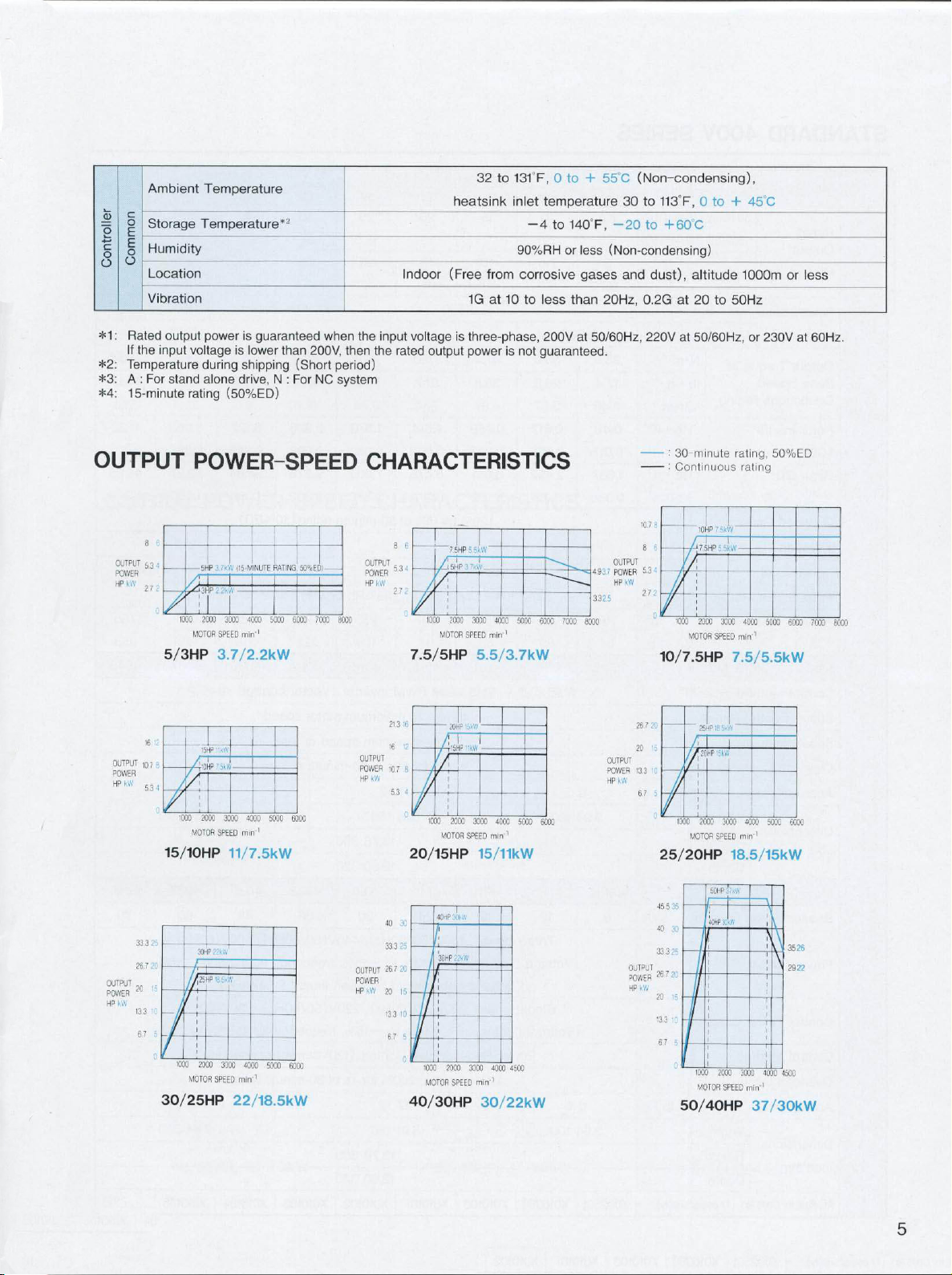

Page 5

§

E

2

E

o

Rated

*1

:

If

*2:

Temperature

A

*3:

1

*4:

5-minute

Ambient

Storage

Humidity

Location

Vibration

output

the

input

:

For

stand

Temperature

Temperature*2

power

during

alone

is

is

lower

shipping

drive,

(50%ED)

voltage

rating

guaranteed

than

(Short

For

N

:

when

200V,

NC

the

then

period)

system

input

the

Indoor

voltage

rated

(Free

output

32

heatsink

from

1G

at10to

three-phase,

is

power

to

is

131°F,

inlet

90%RH

0

temperature

-4

to

corrosive

less

200V

not

guaranteed.

55"C

to

+

30

-20

140F,

(Non-condensing)

or

less

gases

and

than

20Hz,

50/60Hz,

at

(Non-condensing),

F,

113

to

to

dust),

0.2G

220V

60

+

at

at

0

to

+

C

altitude

1000m

20to50Hz

50/60Hz,

45°C

230V

or

or

less

60Hz.

at

OUTPUT

8

OUTPUT

5.34

POWER

HP

kW

j

j

2

7":

5/3HP

•;

16

OUTPUT

to.7

POWER

kW

HP

4

5.3

15/10HP

25

33.3

26.7

OUTPUT

POWER

HP

KW

5

.'

i

5

67

1030

30/25HP

POWER-SPEED

-

1

50%ED|

IM'T

4000

min'1

4030

min

4000

min

'

5kW

1

RATI

5000

5030

5300

NG,

6000

6000

6000

7CCC

5HP

30CC

1000

2000

MOTOR

SPEED

3.7/2.2kW

15HP

-V’

-T4‘CHP

VH

/

1

2000

'C00

3030

MOTOR

SPEED

11/7.

3QHP

.

.

•

1

2300

3000

MOTOR

SPEED

22/18.5kW

;i5-N

CHARACTERISTICS

OUTPUT

POWER

HP

80CC

OUTPUT

POWER

kW

HP

OUTPUT

POWER

HP

KW

__

8

kW

-

3

21.3:6

16

107

5.3

40

33.3

267

20

133

67

6

J

7.5/5HP

12

6

4

20/15HP

30

25

20

15

10

40/30HP

10(10

MOTOR

'

1000

4CHP.

30rP.

r

1000

MOTOR

7

5HP

20CC

20HP

2CCC

MOTOR

T“

ktt

2300

SPEED

vi-W

--A.

300C

SPEED

7

SPEED

3000

.

40CG

5000

min'’

5.5/3.7kW

3000

4CO:

5000

min'1

15/11kW

4000

450C

min'1

30/22kW

6000

6000

7000

8000

4.93

3.325

OUTPUT

7

POWER

«W

HP

OUTPUT

POWER

HP

kW

OUTPUT

ROWER

HP

-

•

:

-

10.7

8

8

6

5.3

272

10/7.5HP

26.7

2C

20

'5

533

6.7

5

25/20HP

5

45

40

;

33.3

26.7

kW

20

133

67

30

minute

Continuous

[75HP

10CX)

200C

MOTOR

SPEED

If

25HP

1

-

20HP

1300

2CC0

MOTOR

SPEED

S0HP

36

W.

53

20

15

•:

i

0

1000

MOTOR

50/40HP

rating,

50%ED

rating

.

3000

40CC

SOOC

min'1

7.5/5.5kW

3000

4000

5CCC1

mirr1

18.5/15kW

\

2000

3000

4000

SPEED

min'1

37/30kW

\

H,,

3526

292

4500

6003

7000

8000

2

5

Page 6

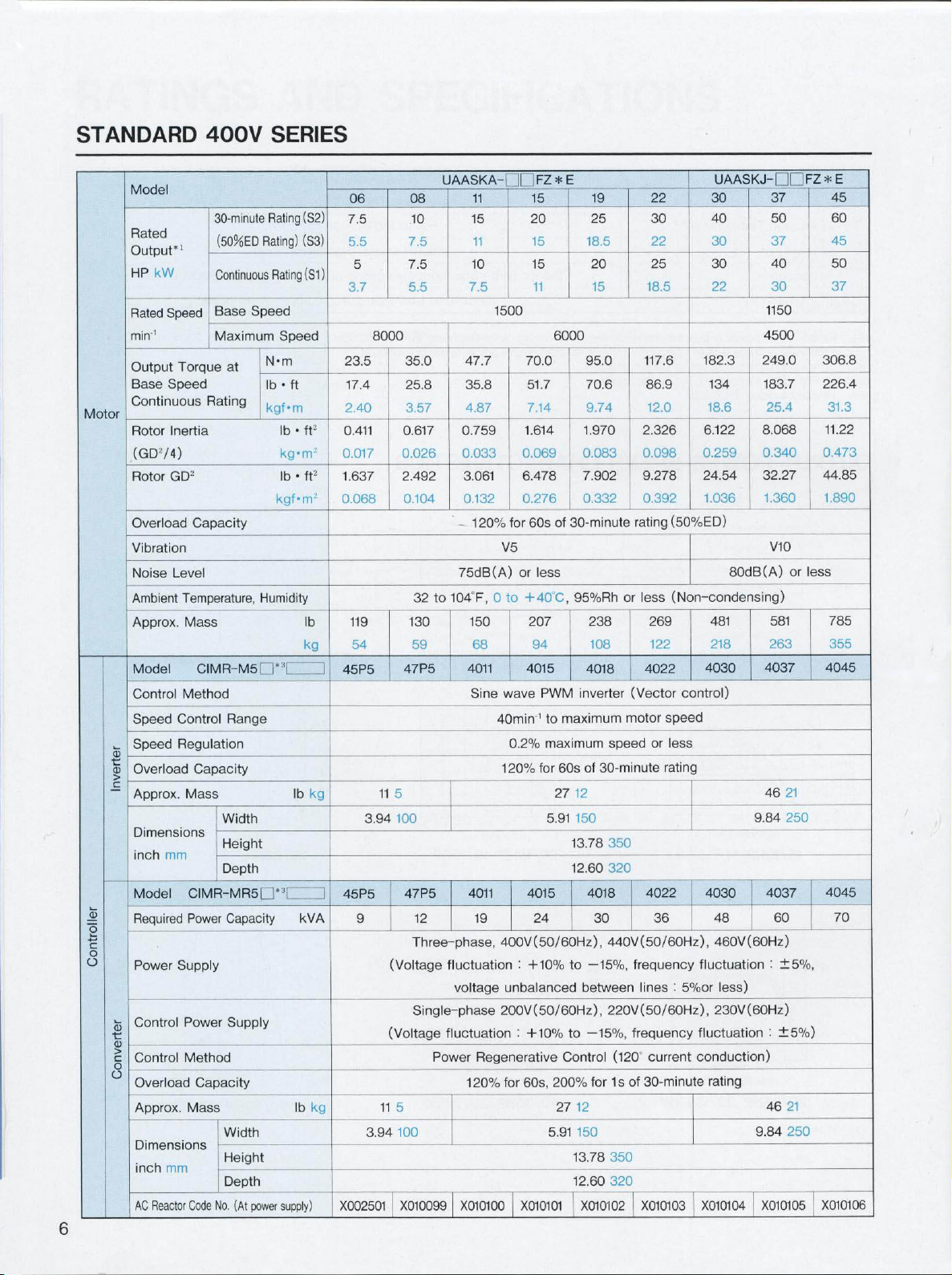

STANDARD

400V

SERIES

Motor

2

4-*

o

o

Model

Rated

Output'

HP

Rated

min''

Output

Base

Continuous

Rotor

(GD2/4)

Rotor

Overload

Vibration

Noise

Ambient

Approx.

Model

Control

Speed

Speed

G

%

Overload

>

Approx.

Dimensions

inch

Model

Required

Power

Control

G

%

>

Control

o

Overload

Approx.

Dimensions

inch

AC

1

kW

Speed

Torque

Speed

Inertia

GD2

Level

Temperature,

Mass

Method

Control

Regulation

Mass

mm

CIMR-MR5

Power

Supply

Power

Method

Mass

mm

Code

Reactor

30-minute

(50%ED

Continuous

Speed

Base

Maximum

at

Rating

Capacity

CIMR-M5D*'[

Range

Capacity

Width

Height

Depth

Capacity

Supply

Capacity

Width

Height

Depth

(At

power

No.

Rating

Rating)

Rating

Speed

N-m

•

lb

ft

kgf-m

•

lb

kg-m2

•

lb

kgf-m2

Humidity

lb

[H*3i

lb

supply)

(S2)

(S3)

(S1

ft2

ft2

lb

kg

kg

kVA

kg

)

23.5

0.411

0.017

1.637

0.068

]

45P5

I

45P5

X002501

06

7.5

5.5

5

3.7

17.4

2.40

119

54

9

8000

11

3.94

11

3.94

08

10

7.5

7.5

5.5

35.0

25.8

3.57

0.617

0.026

2.492

0.104

32

130

59

47P5

5

100

47P5

12

Three-phase,

(Voltage

Single-phase

(Voltage

5

100

X010099

UAASKA-

47.7

35.8

4.87

0.759

0.033

3.061

0.132

75dB(A)

to

104“F,

fluctuation

voltage

fluctuation

Power

120%

X010100

][

11

15

11

10

7.5

1500

1.614

0.069

6.478

0.276

for

120%

V5

or

0

to

150

68

4011

wave

Sine

40min''

0.2%

20%

1

4011

19

400V(50/60Hz),

:

unbalanced

200V(50/60Hz),

:

Regenerative

60s,

for

X010101

FZ

15

20

15

15

11

70.0

51.7

7.14

60s

less

+40C,

207

94

4015

PWM

to

maximum

for

5.91

4015

24

+10%

+10%

200%

5.91

E

*

19

25

18.5

20

15

6000

95.0

70.6

9.74

1.970

0.083

7.902

0.332

30-minute

of

95%Rh

238

108

4018

inverter

maximum

of

60s

27

12

150

13.78

12.60

4018

30

—15%,

to

between

—15%,

to

Control

for

12

27

13.78

12.60

X010102

22

30

22

25

18.5

117.6

86.9

12.0

2.326

0.098

9.278

0.392

(50%ED)

rating

(Non-condensing)

or

less

269

122

4022

(Vector

speed

motor

speed

or

less

30-minute

350

rating

320

4022

36

440V(50/60Hz),

frequency

:

lines

220V(50/60Hz),

frequency

(120

current

30-minute

of

1s

350

320

X010103

UAASKJ-I

30

40

30

30

22

182.3

134

18.6

6.122

0.259

24.54

1.036

481

218

4030

control)

4030

48

460V(60Hz)

fluctuation

less)

5%or

230V(60Hz)

fluctuation

conduction)

rating

X010104

80dB(A)

9.84

9.84

37

50

37

40

30

1150

4500

249.0

183.7

25.4

8.068

0.340

32.27

1.360

V10

or

581

263

4037

21

46

250

4037

60

:

±5%,

±5%)

:

46

21

250

X010105

FZ*E

45

60

45

50

37

306.8

226.4

31.3

11.22

0.473

44.85

1.890

less

785

355

4045

4045

70

X010106

6

Page 7

5;

§

E

2

E

o

:ÿ

:

Rated

*1

If

*2:

Temperature

A

*3:

Ambient

Storage

Humidity

Location

Vibration

output

the

input

:

For

stand

Temperature

Temperature*2

power

during

alone

is

is

lower

shipping

drive,

voltage

guaranteed

than

(Short

:

N

For

when

200V,

NC

the

then

period)

system

32

input

the

131'F,

to

Indoor

voltage

rated

0

output

+55C

to

(Free

from

1G

at10to

is

three-phase,

power

(Non-condensing),

-4

to

90%RH

corrosive

less

400V

is

not

guaranteed.

heatsink

140°F,

(Non-condensing)

or

less

gases

20Hz,

than

at

50/60Hz,

-20

or

temperature

inlet

to

+

dust),

0.2G

440V

C

60

altitude

at20to

50/60Hz,

at

30

to

113'F,

1000m

50Hz

or

460Vat60Hz.

0

to

+45’C

or

less

OUTPUT

6

8

-

OUTPUT

53ÿ

POWER

“W

HP

2J2

7.5/5HP

21

3

'

’2

16

OUTPUT

POWER

,o.7

8

KW

HP

4

5.3

20/15HP

40

25

33

3

20

26.7

OUTPUT

POWER

15

kW

20

HP

13.3

6.7

0

BOO

40/30HP

POWER-SPEED

L

.

-

7.5HP

•

;MV.

«HP

I

1000

2000

30CC

4000

5000

6000

7kW

5000

7000

6000

1000

MOTOR

'20HP

[l5HP

2000

MOTOR

SPEED

5.5/3.

'

llkV.

300C-

SPEED

min''

4000

min'1

15/11kW

40HP

/

L’Zk'.V

i3CHP

f

l

I

3000

2000

4000

W0T0H

SPEED

4500

min'1

30/22kW

CHARACTERISTICS

c

4.9

8000

3.3

OUTPUT

POWER

HP

2

5

OUTPUT

POWER

HP

107

8

,

53

W

2.7

26

20

13.3

kW

6.7

455

4C

33.3

I

„

-

2;

10/7.5HP

?0

7

-5

-

r

25/20HP

36

25

>V.

IQHP

&A

5

-/r75HP

u

n

1000

2000

3000

MOTOR

SPEED

'ÿÿÿÿ•

-?5HP

OHP'-h

w,

/n.

3000

1000

2000

MOTOR

SPEED

-.

hflHP

'

“Fn

*'A

40rtP

4000

min"'

7.5/5.5kW

h

4000

min’’

18.5/15kW

h

ffi7267

KW

HP

20

15

133

-

67

1000

2000

3000

4500

SPEED

min-’

4CC0

37/30kW

MOTOR

50/40HP

5000

5000

35

29

:

-

30-minute

:

Continuous

-

'2

16

OUTPUT

"

107

POWER

KW

HP

4

5.3

6000

7000

8000

o:

'000

MOTOR

15/10HP

25

33.3

20

26.7

OUTPUT

15

20

6000

POWER

KW

HP

13.3

/

ID

5

6.7

1000

MOTOR

30/25HP

SUP

45

60

40

53.4

45.5

40

333

02

OUTPUT

POWER

kW

HP

26

20

133

SQHP

•

(

7

-

15

1C

I

67

BOO

MOTOR

60/50HP

15HP

hjiip

2000

vHP

25HP

laxT

T

2000

SPEED

rating,

rating

"

3000

4000

min''

SPEED

11/7.

3000

4000

min''

SPEED

22/18.

\

-ff

i.

3000

400C

min'’

45/37kW

a

3

5kW

5000

40

26

35

45M

50%ED

6000

5kW

«

7

Page 8

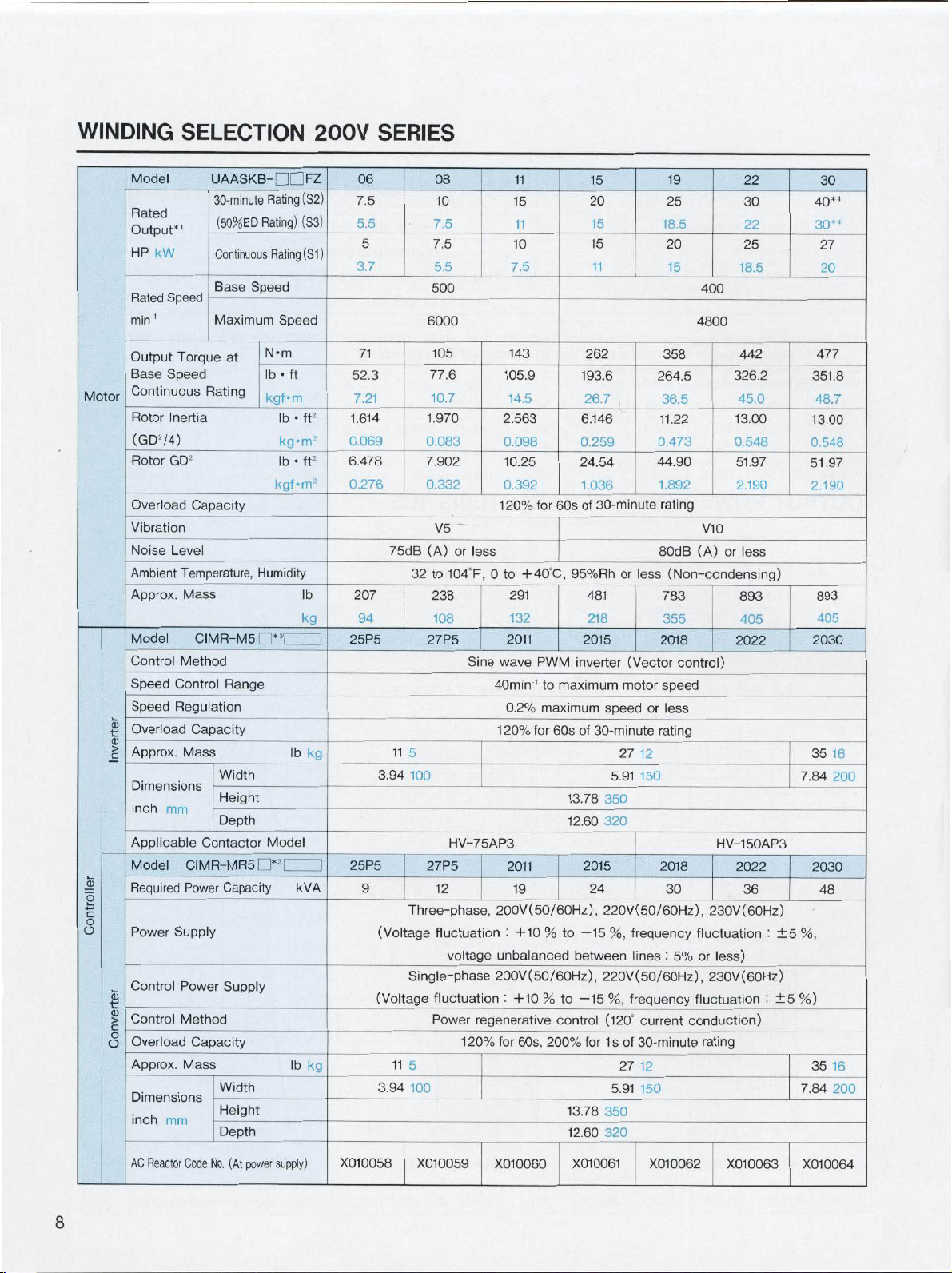

WINDING

SELECTION

200V

SERIES

Motor

2

o

o

Model

Rated

Output*

HP

Rated

min’’

Output

Base

Continuous

Rotor

(GD2/4)

Rotor

Overload

Vibration

Noise

Ambient

Approx.

Model

Control

Speed

Speed

a

Overload

s

>

Approx.

Dimensions

inch

Applicable

Model

Required

Power

Control

a>

%

Control

>

o

Overload

o

Approx.

Dimensions

inch

i

kW

Speed

Torque

Speed

Inertia

GD2

Capacity

Level

Temperature,

Mass

CIMR-M5D*3[

Method

Control

Regulation

Capacity

Mass

mm

Contactor

CIMR-MR5D*:,[

Power

Supply

Power

Method

Capacity

Mass

mm

UAASKB-DDFZ

(S2)

Speed

at

Humidity

Range

Capacity

Supply

Rating

Rating)

Rating

Speed

Nvn

•

lb

ft

kgf*m

•

lb

kg-m2

•

lb

kgf-m2

lb

Model

kVA

lb

(S3)

(S1)

ft2

ft2

lb

kg

kg

kg

30-minute

(50%ED

Continuous

Base

Maximum

Rating

Width

Height

Depth

Width

Height

Depth

06

7.5

5.5

5

3.7

71

52.3

7.21

1.614

0.069

6.478

0.276

207

94

25P5

25P5

9

75dB

32

11

5

3.94

Three-phase,

(Voltage

Single-phase

(Voltage

11

5

3.94

08

10

7.5

7.5

5.5

500

6000

105

77.6

10.7

1.970

0.083

7.902

0.332

V5

(A)

or

104

to

238

108

27P5

HV-75AP3

27P5

12

fluctuation

voltage

fluctuation

Power

1

11

15

11

10

7.5

143

105.9

14.5

2.563

0.098

10.25

0.392

120%

less

to

0

F,

+40”C,

291

132

2011

wave

Sine

40min'’

0.2%

120%

2011

19

200V(50/60Hz),

:

+10

unbalanced

200V(50/60Hz),

:

+10

regenerative

for

60s,

20%

60s

for

95%Rh

PWM

inverter

maximum

to

maximum

for

60s

13.78

12.60

to

%

between

to

%

control

200%

13.78

12.60

15

20

15

15

11

262

193.6

26.7

6.146

0.259

24.54

1.036

30-minute

of

or

less

481

218

2015

(Vector

motor

speed

of

30-minute

27

12

5.91

150

350

320

2015

24

220V(50/60Hz),

—15

frequency

%,

lines

220V(50/60Hz),

%,

for

(120°

1

s

of

27

5.91

350

320

frequency

current

30-minute

12

—15

19

25

18.5

20

15

400

4800

358

264.5

36.5

11.22

0.473

44.90

1.892

rating

V10

(A)

80dB

(Non-condensing)

783

355

2018

control)

speed

or

less

rating

HV-150AP3

2018

30

230V(60Hz)

fluctuation

:

5%

or

fluctuation

less)

230V(60Hz)

conduction)

rating

150

326.2

or

22

30

22

25

18.5

442

45.0

13.00

0.548

51.97

2.190

less

893

405

2022

2022

36

30

40*1

30’4

27

20

477

351.8

48.7

13.00

0.548

51.97

2.190

893

405

2030

35

16

7.84

200

2030

48

:

±5

%,

%)

:

±5

35

16

7.84

200

(At

Reactor

AC

Code

No.

power

supply)

X010058

X010059

X010060

X010061

X010062

X010063

X010064

8

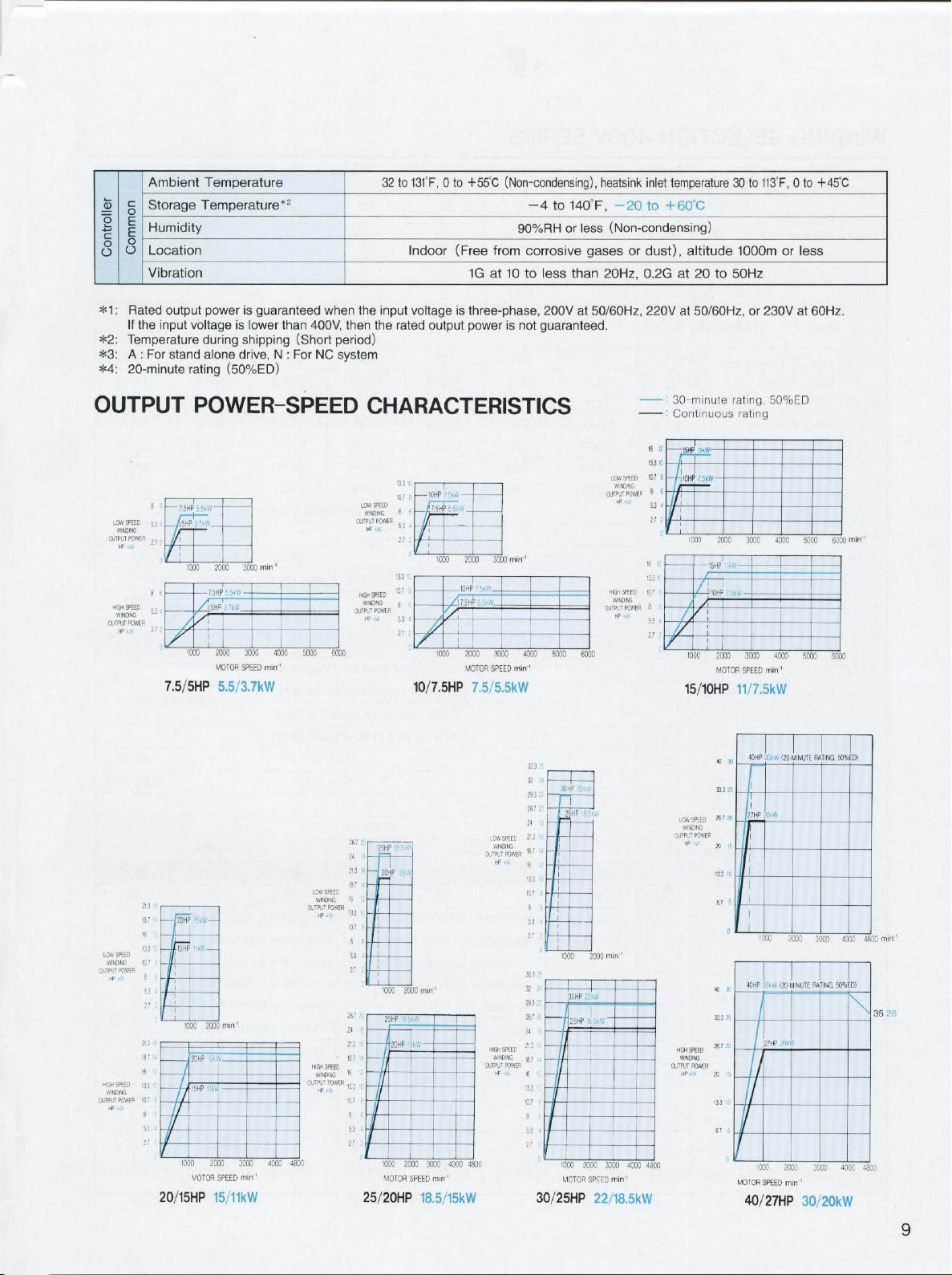

Page 9

c

5

O

1

E

ts

E

c

o

O

O

a

Rated

*1

:

If

*2:

Temperature

*3:

*4:

20-minute

Ambient

Storage

Humidity

Location

Vibration

the

For

:

A

output

input

stand

voltage

rating

Temperature

Temperature*2

power

is

guaranteed

is

lower

during

shipping

drive,

alone

N

(50%ED)

than

:

For

400V,

(Short

NC

when

period)

system

then

the

32

input

the

131“

to

Indoor

voltage

rated

0

F,

output

to

+55'C

(Free

from

1G

at

three-phase,

is

power

(Non-condensing),

-4

90%RH

corrosive

to

less

10

200V

is

not

guaranteed.

to

140F,-20

or

less

gases

than

at

heatsink

(Non-condensing)

20Hz,

50/60Hz,

or

inlet

to

dust),

0.2G

220V

H-60C

temperature

altitude

at

20to50Hz

at

50/60Hz,

30

to

1000m

or

113“F,

or

230V

0

less

at

to

60Hz.

+45"C

OUTPUT

i

—

SPEED

LOW

5.3

—p~

WINOING

OUTPUT

POWER

i

W

HP

fr

8

6

»'<3H

SEED

5:

WINDING

POWER

OUTPUT

HP

-ÿ4

7.5/5HP

213

187

[20HP

•

16

•33

107

53

27

16

21.3

4

187

16

.

133

3

107

8

4

53

27

20/15HP

-15HP

SPEED

LOW

WINOING

POWER

OUTPUT

HP

HIGHSPEED

WINDING

PO.VER

OUTPUT

HP

POWER-SPEED

,-MV

75HP

-

I

min

1000

•000

1-VA

ITV.

1000

2CH3

15HP

-

1000

MOTOR

3000

200C

-

75HP

3000

2000

MOTOR

SPEED

5.5/3.7kW

—

-

1

mm

200C

•

A

300C

200C

min

SPEED

’

15/11kW

min

40CC

4000

’

4500

5000

LOW

WINOING

OtTPL'T

if

HIGHSPEED

IMNOMG

0UPLT

HP

SPEED

POWER

•

POKIER

CHARACTERISTICS

IL

6000

A

267

T

18?

«

,33

*7

267

24

213

>6

133

107

24

6

52

27

SPEED

LOW

WINDING

POWER

OUTPUT

fW

If

HIGHSPEED

WWONG

ojmr

POWER

«W

H>

25HP

ih

20HP

57

6

6

1

53

27

1000

.1

2sHP

3

20HP

6

l

1000

MOTOR

25/20HP

133

137

113

10,7

'

'

V.

10HP

-

j-

1CC0

5

1000

10/7.5HP

min

200C

VA

-V,

3CCC1

200C

4000

min

SPEED

’

18.5/15kW

3000

2000

MV

I0HP

___

3000

2000

MOTOR

SPEED

7.5/5.5kW

.CW

SPEED

WINDING

XWT

if-

HIGH.

SPEED

WNC-NG

POWER

OUTPUT

HP

4800

POWER

min-'

4000

min

'

333

32

29.3

267

24

*2

187

16

13

K'

8

S3

2.7

313

32

24

292

.<

267

24

it

?2

|8?

16

•33

1C7

8

53

2.7

30/25HP

:t

-L

t

4

'

5000

30HP

25FP

'COO

/I25HP

100C

MOTOR

6000

1

2000

30HP

2000

SPEED

22/18.5kW

SPEED

LOW

MNCMQ

0UTAJ*

POWER

HP

HIGHSPEED

WINDING

POWER

OUTPUT

IP

rnin

•

f

V

3000

min0

-

4000

-

I6

H3

C7

8

K

113

lCr

3

5.3

2.7

480G

:

30-minute

:

Continuous

to

3

6

53

*

2

V

K

-

-

OUTPUT

MGH

OUTPUT

;'5HP

WW-

i

-llQHP

'tv.

1000

2000

-15HP

1

10HP

£

I00C

2000

MOTOR

15/10HP

40

333

7

SPEED

LOW

*

WINOING

POWER

•

/.

HP

X

33

67

40

i

333

26?

2C

SPEED

WINDING

POWER

HP

2C

133

6?

rating,

50%ED

rating

3000

4000

':r(,

3000

4000

min'1

SPEED

11/7.5kW

•

40HP

30

VW

27H»

X

it

F

I

5

IOOC

inti,

40HP

i“

27HP

’000

MOTOR

SPEED

40/27HP

500C

5000 5000

!20

MINUTE

2000

20-MINUTE

RATING.

vfJkW

3000

2000

min

’

30/20kW

5000

RATiNG.

3000

50%ED)

min'1

50%ED)

4000

40CC

4803

4800

min

.

35

9

Page 10

WINDING

SELECTION

400V

SERIES

Motor

2

4-»

o

Model

Rated

Output*

HP

Rated

min''

Output

Base

Continuous

Rotor

(GD2/4)

Rotor

Overload

Vibration

Noise

Ambient

Approx.

Model

Control

Speed

Speed

Overload

%

>

Approx.

Dimensions

inch

Applicable

Model

Required

Power

Control

a5

Control

>

o

Overload

Approx.

Dimensions

inch

U

AASKB-

I

kW

Speed

Torque

Speed

Rating

Inertia

GD2

Capacity

Level

Temperature,

Mass

CIMR-M5n*’

Method

Control

Regulation

Capacity

Mass

mm

Contactor

CIMR-MR5D*3[

Power

Supply

Power

Method

Capacity

Mass

mm

30-minute

(50%ED

Continuous

Base

Rating

Rating)

Rating

Speed

Maximum

N*m

at

lb

kgf-m

Humidity

Range

Width

Height

Depth

Model

Capacity

Supply

Width

Height

Depth

FZ*E

Speed

•

ft

•

lb

kg*m2

•

lb

kgf-m2

lb

kVA

lb

(S2)

(S3)

(S1

ft2

ft2

lb

kg

kg

kg

06

7.5

5.5

5

)

3.7

71

52.3

7.21

1.641

0.069

6.478

0.276

205

94

45P5

3.94

45P5

9

(Voltage

(Voltage

3.94

08

10

7.5

7.5

5.5

500

6000

105

77.6

10.7

1.970

0.083

7.902

0.332

V5

(A)

75dB

32

to

245

108

47P5

5

11

100

47P5

12

Three-phase,

fluctuation

Single-phase

fluctuation

Power

5

11

100

or

less

0

104

F,

Sine

40mim'

HV-75AP3

voltage

200V(50/60Hz),

regenerative

for

120%

11

15

11

10

7.5

143

105.9

14.5

2.568

0.098

10.25

0.392

120%

to

298

132

4011

wave

0.2%

120%

+

40C,

for

193.6

24.54

for

60s

95%Rh

PWM

inverter

maximum

to

maximum

of

60s

13.78

262

26.7

6.146

0.259

1.036

of

525

218

4015

12.60

4011

19

4015

400V(50/60Hz),

:

+10

to

—15

%

unbalanced

:

+10

%

between

to

—15

control

60s,

200%

for

13.78

12.60

15

20

15

15

11

18.5

358

264.5

36.5

11.22

0.473

44.90

1.892

30-minute

rating

80dB

or

less

581

355

4018

(Vector

motor

speed

speed

or

less

27

rating

12

150

30-minute

5.91

350

320

4018

24

440V(50/60Hz),

frequency

%,

lines

220V(50/60Hz),

%,

frequency

(120"

current

of

30-minute

1s

12

27

5.91

350

320

19

25

20

15

22

30

22

25

18.5

400

4800

442

326.2

45.0

13.00

0.548

51.97

2.190

V10

(A)

or

less

(Non-condensing)

893

405

4022

control)

HV-150AP3

4022

30

36

460V(60Hz)

:

:

5%

fluctuation

less)

or

230V(60Hz)

fluctuation

:

conduction)

rating

±5

±5

9.84

%,

%)

9.84

30

40.4

30*-1

27

20

525

387.2

53.6

13.00

0.548

51.97

2.190

893

405

4030

46

4030

48

46

16

21

250

10

AC

Reactor

Code

No.

(At

power

supply)

X002501

X010099

X010100

X010101

X010102

X010103

X010104

Page 11

output

voltage

during

stand

rating

Temperature

Temperature*2

power

is

guaranteed

is

lower

shipping

drive,

alone

N

(50%ED)

than

:

400V,

(Short

For

when

NC

the

then

period)

system

input

the

32

to

Indoor

voltage

rated

131‘F,

output

+55”C

0

to

(Free

1G

is

three-phase,

power

(Non-condensing),

-4

140

to

less

or

90%RH

from

corrosive

less

at10to

not

is

than

at

400V

guaranteed.

heatsink

inlet

F,

-20

to

+

(Non-condensing)

20Hz,

or

dust),

0.2G

440V

gases

50/60Hz,

temperature

C

60

altitude

at

20

to

50/60HZ,

at

113T,

30

to

1000m

50Hz

or

460Vat60Hz.

+45"C

0

to

or

less

Ambient

c

CD

Storage

o

1

E

Humidity

4=

E

c

o

o

o

Location

o

Vibration

*1

Rated

:

the

If

1

*2:

*3:

*4:

input

Temperature

For

:

A

20-minute

OUTPUT

6

6

SPEED

,w

PCW€R

534

„

8

2.72

—

‘

u'

6

LOW

OUTS-ER

HIGHSPEED

WINCING

OUTPUT

z

7.5/5HP

21.3

'f

187-4

'5

-j

'13

SPEED

LOW

107

WINCING

POWER

K>.w

WI1CING

POWER

«W

b

8

6

4

53

27

2

0

21316

18714

18

7

133

IC

7

IQ

9

6

4

53

27

2

20/15HP

OUTPLT

HtGHSPEEC

OUTPUT

75HP(okW-

/ÿ

1

1000

1000

2QHP

-15HP

1000

15HF

1000

POWER-SPEED

'

min

2000

3000

•

75HP

:kW

v,\

I

2000

30CC

4000

500C

OUTPUTPOWER

4800

6000

LOW

WINDING

HIGH

OUTPUT

MOTOR

5.5/3.7kW

|5KW—

li*

W

—

min

2000

’5kW-

"MV

2000

MOTOR

SPEED

15/11kW

SPEED

3000

min

min'1

1

4000

SPEED

H>«W

SPED

WINCING

POWER

kW

HP

CHARACTERISTICS

13310

-10HP

—

107

fi

SPEED

LOW

8

6

OUTPUT

OUTPUTPOWER

28’

2C

24

IB

?3l6

18?

14

'6

12

U3

:

107

8-

8

6

i

5.3

27

26.7

X

24

b

213

'fi

a

187

16

12

'33

10

107

0

8

6

4

53

;

27

25/20HP

WINDING

POWER

HIGHSPEED

WINDING

HP

KW

25HP,r..Wl

'23

HP

15'

1000

25Hf>

20HP

1000

MOTOR

i5H

27

2

oJ

•13

*37

£

8

’

4

53

27

2

0

10/7.5HP

t)

mm

2000

'

i-

'«VV

",

3000

2000

4000 4800

1

min

SPEED

18.5/15kW

*55kW

1000

2000

-10HP

VQBHP-

,

1000

2000

MOTOR

3000

'

1

<vV

.->ÿÿÿ

3000

SPEED

7.5/5.5kW

LCW

SPEED

WINCING

OUTPUT

SOWER

HP

.

HIGHSPEED

'WINCING

OUTPUT

kW

HP

min

min

POWER

'

4000

1

33

25

32

24

293

22

267

K

24

IE

213

IE

187

14

,g

133

«

1Q7

0

8

6

4

S3

27

2

O'

333

25

32

24

29.322

267

X

24

1i

213

>

'1

187

i

16

113

0

107

6

8

6

53

4

27

2

30/25HP

5000

30HP

'25HP

1000

30

25HP

1000

MOTOR

6000

•

SkVV

-B

mm

2000

HP

22kW

\

Wi

'8

3000

2000

SPEED

22/18.5kW

-

-

LOVSKED

WHONG

OUTPUTPOWER

HP

MV

10ft

SPEED

WINCING

POWER

OUTPUT

HF

A

’

4000

4800

1

min

30-minute

:

Continuous

-

B

,I5HP

11310

fi7

lOHP

8

6

4

13

I

17

7

;

16

133

,

1Q7

'

8

f

S3

4

w

15/10HP

LCW

SPEED

WINDING

OURT

POWER

V.

*>

-

NGH

SPEED

WWDWG

OUTPUT

POWER

HP

MV

rating,

rating

-W

1000

2000

15HP

:

10HP

/

1000

2000

MOTOR

11/7.5kW

4C

30

33

3

25

a?

20

15

133

to

;

67

4C

x

33

3

25

267

K

ij

20

ij

'33

67

5

0

50%ED

3000

-W

7

5kV.'

!

3000

min

SPEED

.

.

,\

40HR

27HP

A-v'v

I

I

I

J

1000

40HF

!

\w

27HP

20KW

1000

MOTOR

SPEED

40/27HP

4000

5000

4000

5000

’

,20-MINUTE

RATING

2000

3000

RATING.

20-MINUTE

1

2000

3000

1

min

30/20kW

6000

6000

50%EO)

4000

50%ED)

40CC

min'

4800

4800

min

'

35

26

11

Page 12

DIMENSIONS

AC

SPINDLE

MOTOR

(General-purpose

Series)

FOOT-MOUNTED

4-Z

TYPE

:

MTG

DIA.

Detail

HOLES

of

4

Shaft

f—

f—

m

JULl

QK

o

Kl

44°

M

Extension

TD

I

L

KD

a

A

4Note)

Jr'1

T

--

1

B

-

(Note)

,r°-

N-

j_F_

F

provided

7.5/5HP

and

SCREWS

)0

DEEP

XB

for

standard

5

5/3.7kW

models.

0

Note

:

Eyebolts

5/3HP

•

Only

for

Z>

-

w

motor

i—

are

3.7/2.2kW

5/3HP

w

.

N

not

3.7/2.2KW

D

i

i

3-m

SCREWS

0.394

10

s

DEEP

2-m

d

0.394

s

12

Standard

Winding

Selection

*1

*2

*3

Rated

Output

30-min

Rating

5*2

3.7

10

.;>

15

?Q

7

I

25

5

18

?!

10

30

S?

60*:1

45

7.5

5.0

10

7.5

15

20

15

25

3

18

30

40

2."

:

Dimensions

:

5/3-HP

:

60/50-HP

HP

kW

Continuous

Rating

h

5

3.7

7.5

Dÿ>

10

1

f.

15

11

20

15

25

18.5

30

403018.11

37

5_

3.7

7.5

5

i

.

10

5

7

15

11

20

i

:

25

18.5

27

2-'

of

(3.7/2.

2-kW)

(45/37-kW)

3#

1213

11.81

300

4'

10.28

261

11.14

28

'if

15.98

14.88

478

10.28

261

11.14

2S4

12.22

310.5

15.98

406

14.88

378

16.1

I""

16.1

409

the

A

l*'.o

6.14

7.72

,35

;

11,69

11.89

7.72

SB

ft

9.69

11.89

12.64

12.64

shaft

model

B

3.66

93

5.2

132

137

,

!

7.1

196

ft

207

402

196

246

302

321

321

extension

model

-U

C

3.94

100

3.94

|MU

4.41

1

ft

6.3

160

6.3

160

6

4

160

7.09

180

7.09

180

8,6

0.3

160

•'..8

loo

6.3

'-I

i

I

09

7

iso

8.86

22.4

8.86

225

8.86

225

is

15-minute

only

D

6.85

174

6.85

174

%

8.03

<

I

31

10.24

200

10.24

200

'4

ib6

%8

14.96

;s<

'

10.24

260

12.6

.

120

14.96

380

14.96

380

14.96

380

key

for

E

3.15

1

1

3.15

3.74

>

9

3.74

127

5

127

127

5.49

139.5

5.49

139.5

7.01

17s

127

5

127

127

5.49

139.5

7.01

178

7.01

178

7.01

178

and

the

F

1.97

"•f

3.5

so

2.76

70

3.5

89

3.5

so

1.13

105

5

127

5

127

7.01

78

1

,,,

3.5

89

4.13

105

as

5

127

6-12

1

55.5

6.87

174.5

6,87

174.5

keyway

rating

400V

G

H

0.35

"

0.35

¥8

0.39

10.59

269

10

0.39

10.59

|M

269

0.63

lo

13

0.63

411

16

0.63

13.43

341

16

0.63

16.02

16

407

0.64

16.02

lo7

In

19.88

0.83

•704

0.04

13.43

16

341

0.63

13.43

16

411

0.6)3

13.43

In

411

0.64

16.02

I"

407

19.88

405

°2f

19.88

505

ft

0,3

19.88

4o.>

are

/

continuous

series.

1.34

::

1.34

2.95

2,95

2,17

15

2.17

2.17

44

2.17

44

W

2795

2.17

45

2.17

4.'

2,17

217

2,95

75

2.95

7.4

based

J

i

;i

:

.1

>5

,

.>

75

rating.

KD

1.34

1.34

:

IS

If7

1.67

42.5

ft

m

2-4

o!

2.4

61

2.4

61

ft

If

IS

2

61

2.4

-.1

2.4

61

2.4

61

on

i

i

I

the

L

19.76

502

ff

23.23

frfK)

22.36

568

23.86

60..

2,28

ft?

35.49

899

?2?

22.46

508

23.86

not'.

26,.

3

nos

31.26

79

1

ft

ft

ft

standard

M

7

i

>

7.4

l:-:-

S.lili

220

11.42

700

11.42

2oo

11.42

700

%8

12.6

-.20

16.54

'If

1

1.12

2"(>

11.42

290

ft

16.54

420

16.54

120

16.54

420

I

N

4.92

l

8.11

206

,.M7

177

S3

,om

11.77

299

11.73

298

15.75

lou

01.73

425

8.78

224

‘ft

12.76

42

ft

16.73

124

is..;

16,5

18.3

In

model

1

.

R

6,1

i44i

7.64

194

8.66

220

10.59

2t.9

12.09

.107

12.72

323

13.58

345

15.28

17.28

149

17.5

1115

12.09

.4(6

ft

14.07

357.5

15.28

488

17.5

444.5

If5

ft

XB

1.77

1.77

2

7i'

2.76

7u

4.25

I

4.25

108

4.25

108

4.76

1.76

121

if

425

108

1.25

I

4.25

108

4.76

5.87

149

5.87

149

5.87

149

of

designed

In

inches

Shaft

Z

Kl

,ur

6,5

1

6f5

1..

°if

8.03

76

204

°i?

r

4

0.59

OS

»

I

4

0.59

9.84

15

250

0.59

9.84

15

27.0

0.75

12.6

lo

420

0.75

!§?

19

0.91

15,16

I

0.59

ft

15

9.84

0.59

2.4(

OS

15

0.59

SB

15

0.75

12.6

420

19

15.16

48.4

ft

15.16

ft

0.94

24

in

the

2.36

2

3.15

4.33

110

1.33

4.33

110

4.33

110

5.51

I

5.51

140

5.51

140

4.33

110

4.33

i

I

I

5.51

140

5.51

I

5.51

140

5.51

I

QK

Q

1.77

i

00

1.77

•

1

2.76

70

80

;.;>i

:

I

ft

to

3

54

'.,1

4.33

10

no

4.33

110

1.43

110

3.54

on

3.54

IX)

10

3.54

91'

to

I

I"

4.33

10

no

4.33

no

4.33

no

10

Japanese

QR

0.04

0.04

mi!

0.02

t»5

0.04

l

0.04

i

0.01

0.08

0.08

OO!

0.01

I

0.04

o

o

|

0.08

0.01

1

0.01

i

0.04

Industrial

Extension

T

S

0,28

...

1.1

0J28

28

Sn.

0.31

"i«»,

IS

paw

»

:».

....

.

s

"

60

r

oocw

48

l

S

mn

70

Standard.

8

0.35

"

0.35

o

0.35

9

059

10

0.13

11

0.43

!

°if

0.45

9

0.35

9

1

1.4!'

10

0.43

1

0.47

12

ft

0.17

12

fir

1.89

1.89

mm

*8

2.367llSw

2.™?=

‘f

1.89

2.17

2-76;??

2.76*“S»4

U

0.16

I

0.16

i2

0.22

5.5

0.22

5.5

033

I

0.2

6,

0.28

7

0.28

I

7

,

,.i

0.22

55

0.22

5,0

021

(,

0

28

7

1

0.3

.,

,

0.3

/.D

0.3

7.5

JIS

W

0.31

0.31

s

0.39

10

°i5,5

5

05

14

0.55

14

0.63

16

0.71

IS

0.71

18

0.79

20

0.55

11

0.55

i

l

0.63

16

0.71

0.79

20

<179

0.79

20

301

B1

d

0.63

16

(,S7

°-?,7

1.57

I"

1.57

lo

1.57

40

1.77

7

1

1.97

•

1.97

50

2.36

60

1.57

10

1.57

40

1.77

15

1.97

.40

no

2.36

60

ft

-1996.

mm

m

M6

M4

M5

M5

M5

M5

M5

M6

M6

M6

M5

M5

M5

M6

M6

M6

M6

Page 13

FLANGE-MOUNTED

TYPE

Standard

Winding

Selection

*1

*2

*3

y

4-Z

DIA.

Rated

30-min

Rating

1

1,1

if

7?

,fs

II

9

V

75

a

15

fS

&

s

40

30

:

Dimensions

:

5/3-HP

:

60/50-HP

ID

A

LB

(Note)

5/

_

“

:

MTG

HOLES

HP

Output

Continuous

ng

Rat

h

3J

E

15

n

2528

lf5

31,6

S

40

30

37

3lf

?7

75

ft

If

3,26

15

1

w

lf5

ft

a,

Iff

of

the

(3.7/2.2-kW)

(45/37-kW)

m

KL

L

'713

331,1

2i3?

303

shaft

model

KD

-t

A

ft

7.28

185

If?

Iff

to,:,

’I;13

W

15.75

400

‘0.43

UU3

,0.43

ft

15,75

400

17.77,

400

15.75

400

extension

model

_j

y

l

d

m

—

2

LB

3,,

1

7.09

180

1,00

Hftr

330

1.81

300

ft

ft-!”

13:l?

1

is

5-minute

only

fc

9603

9002

-00(0

for

,

..

key

LC

6.85

171

6.85

174

S8I

250

9.84

9J4

320

gg

ft

ft

lit

ft

ft

ft

"57

and

the

to

:

rating

400V

Note

LG

11,7

°if

“if?

°.63

ft

ft

ft

ft

ft

ft

ft

Of

°g

If

0.57

keyway

/

continuous

series.

:

Eyebolts

standard

LH

ll§

S3?

SSI

ss?

11.81

300

11.81

300

11.81

300

$

m

11.81

300

11.81

300

%6

77

ffl,

are

Detail

are

not

5/3HP

LL

LR

If?

w

,7

1

2.36

60

ft

|!U3

4.33

110

'IS1

If?

4.33

'ft

110

4.33

no

2ft

5.51

140

5.51

29,88

140

5.51

1ÿ

140

4.33

no

*»

4.33

no

‘fit?

4.33

21.97

110

5.51

If:'75

110

5.51

110

5.51

140

29.02

5.51

MO

basedonthe

rating.

of

Shaft

3

O

provided

3.7/2.2kWand

D

Z

0.43

Iff

0.43

Iff

38

0f

If?

ft

:,124

ft

0.59

15

w

'ft

°f

0.75

19

gg

°U?

Of*

ft1

0.59

ft

ft

ft

0.50

ft

0.75

as

19

14.96

ft

380

14.96

:se

1

'f1*’

standard

The

model

Extension

nx

for

17.32

17.32

ft

17.32

ft

W

7.5/5HP

I

1,1,3

'I5

m

as

110

440

as

as

110

model

is

not

5

KD

k3,4

l-'7

m

m

,„7

m

2.1

1

i

.'

fit

If

L„7

1.67

U',7

If

2.4

61

If

If

of

furnished

*'

D

w

S

5/3.

7k

W

models.

KL

Kl

W-

If?

6.85

171

If

8.03

204

71,1

S3!

ft

18295

gg

gg

221

131,1

,1.02

lift

ft

7,o

05,

ft,

lit

,3.0

If?

15,8

ft

,5,0

’if

designed

with

SCREWS

10

0.394

Q

2.36

60

2.36

.....

,,3

4.33

110

4.33

110

4.33

110

4.33

110

5.51

140

5.51

140

5.51

10

1

4.33

no

4.33no3.54

4.33

no

5.51

140

5.51

MO

5.51

140

5.51

140

in

the

eyebolts.

•

Only

DEEP

QK

QR

0.04

W

0.04

1.77

45

373

0.04

3.54

90

ft

3.54

0.04

...I

0.04

Iff

0.04

4.33

0,08

110

4.33

0.08

no

4.33

0.04

no

3.54

0.04

90

0.04

90

0.04

iff

4.33

0.,08

no

4.33

0.04

no

4.33

0.04

no

4.33

0.04

110

Japanese

for

motor

U

Shaft

S

i

1

126-Sra.

i,89

1.89

SHOOS

48

1.89

!!«*

48

2,z:=

2-36S

,,

2.76IIS

L89:;„..

'f

2.1?:P

2-Z«

2.7,7

i

2.Z6,=S

Industrial

5/3HP

3.7/2.2kW

w

2-m

0.394

S

Extension

T

'

°-8

028j0.16

0.31

0.35

0.35

0.35

0.39

10

0.43

,

0.43

047

0.35

0.35

~

039

H»

0.43

,U7

0.47

Standard,

SCREWS

10

DEEP

In

inches

U

W

u‘(i

n::!

0.31

0.39

055

°sf

022

0.55

5.5

0.55

0.22

0.24

0.63

6

0.28

0.71

0.28

0.71

03

0.79

„33

0.55

033

0.55

0.63

0.24

6116

|

of

°i72

n

03

079

079

9.3

B1

JIS

10

16

18

20

®

301

d

°if

0

f

ft

1.57

40

1

57

10

1.57

10

77

1

15

1.97

5II

60

1.57

Hi

1.57

40

1.77

45

'I?

If?

If?

If?

-1996.

mm

m

M6

M4

MS

M5

M5

M5

M5

M6

M6

M6

M5

M5

M5

M6

\16

M6

M6

13

Page 14

INVERTER

(VS-626M5)/

CONVERTER

(VS-656MR5)

Inverter

BB,

MS

vvi

w

Converter

D

W1

W

(Externally

x

Max.

\

4-d

X

5

Max.

4-d

/

ili

n

(t*

2.76

70

(Externally

llHlIlM

IP

2.76

70

fan-cooled

D1

fan-cooled

OTiMiiiifir

D1

_D_

f

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

For

stand

without

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

For

stand

fan)

:

3.94

5.91

7.87

11.81

3.94

5.91

9.84

alone

:

3.94

5.91

7.87

11.81

3.94

5.91

9.84

alone

W

100

150

200

:mn

100

150

250

fan)

W

100

150

200

300

100

150

250

H

13.78

350

13.78

350

13.78

350

13.78

13.78

350

13.78

350

13.78

350

drive,

N:

H

13.78

350

13.78

350

13.78

350 320

13.78

13.78

350

13.78

13.78

drive,

N:

D

12.6

320

12.6

320

12.6

320

12.6

12.6

320

12.6

320

12.6

320

For

D

12.6

320

12.6

320

12.6

12.6

12.6

320

12.6

320350

12.6

320

For

NC

NC

W1

2.95

75

3.94

100

5.91

150

9.84

2.95

_75_

3.94

100

7.87

200

system

W1

2.95

75

3.94

100

5.91

150

9.84

2.95

_75_

3.94

100

7.87

200

system

H1

12.99

330

12.99

330

12.99

330

12.99

12.99

330

12.99

330

12.99

330

H1

12.99

330

12.99

330

330

12.99

12.99

330

12.99

330

12.99

330

H2

0.39

1,0

0.39

10

0

ill

0.39

0.39

J0_

0.39

10

0.39

10

H2

0.39

10

0.39

10

0.39

_10_

0.39

111

0.39

ill

0.39

10

0.39

10

In

inches

Mass

In

Mass

mm

d

\15

M5

M5

M6

M5

M5

M5

inches

d

M5

M5

M5

M6

M5

M5

M5

D1

7.48

190

7.48

190

19

7

IB

190

7.48

7.48

190

7.48

190

7.48

190

D1

7.48

!

190

7.48

190

~

7.48

190

7.48

7.48

190

7.48

190

7.48

190

5.12

130

5.12

130

5.12

i

5.12

5.12

130

5.12

130

5.12

130

D2

5.12

130

5.12

130

5J2

130

5.12

5.12

130

5.12

130

5.12

13(1

lb

M

11

26.5

12

35.3

Jb_

w

57.3

11

5_

26.5

12

35.3

16

Approx.

kg

lb

11

5

26.5

12

35.3

16

57.3

11

26.5

12

35.3

16

Approx.

D2

without

type,

Air

Model

CIMR-M5;*

)

•:

Air

D2

D_

A:

*

type,

Air

Model

CIMR-MR5*

Air

D2

A:

*

14

Page 15

Inverter

a

o

©

in?,g,si

W1

w

Converter

o

0

CD

0

o

W1

VV

(Open

1

X

m!

'V

'

(Open

o

i

5

\

4

chassis

(

x

*Max.

4-d

*

x

T

d

3

9

r

70

chassis

[

Max.

70

type)

pi

type)

run

In

Model

CIMR-M5:*:

A:

*

Model

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

45

47P5

4011

4015