Page 1

TOE

-C

843-5a<.

June.

1961

YASNAC

OPERATOR'S

2QOOQ

MANUAL

%

YASKAWA

Electric

Mfg.

Co.,

Ltd.

Page 2

PftfFACE

This

manual

the

tors

and

tion

The

descriptions

the

basic

YASNAC

marked

YASNAC

the

machine-tool

is

primarily

descriptions

maintenance

functions

2000G.

t.

with

2000G,

refer

builder.

in

For

for

for

this

and

The

the

to

intended

programming,

YASNAC

manual

the

optional

optional

specifications

manual

the

to

give

2000G.

are

given

functions

functions

provided

opera¬

opera¬

as

of

are

for

your

to

by

Unless

are

otherwise

applied

examples

Code:

Least

•

Least

•

•

•

•

•

Function

Feed

Absolute

Fixed

Dimensions:

to

the

showninthis

EIA

code

Command

Input

Increment:

Zero

Original

in

specified,

description

is

employed.

Increment:

Selection:

Point:

(Zero

Point

MM

the

manual.

01

0.

G99

following

of

programming

Specification

mm

(mm/rev)

Return

Position);.ÿÿ-

rules

A

r-

Page 3

1.

INTRODUCTION

2.

PROGRAMMING

1

2.

TAPE

2.

1.

2.

1.2

1.3

2.

2.

1.4

2.

1.5

2.2

SEQUENCE

2.2.

2.2.2

2.3

MOVE

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

FORMAT

1

Tape

Address

Buffer

TV

Optional

1

4-Digit

3-Digit

COMMAND

Least

Least

Absolute

DIAMETER

Maximum

Format

and

Register

Check

NUMBER

(Tape

Block

Sequence

Sequence

Command

Input

and

Programmable

TAftU

Function

vertical

{"/"

Skip

Number

Number

Increment

Increment

Incremental

/RADIUS

or

CONTINTS

Characters

parity

code)

• •

..

.

.

Inputs

Switching*

Value

check)

•

1

1

1

1

3

•

•

4

4

4

5

5

5

5

5

5

6

7

7

2.4

RAPID

2.4.1

2.4.2

CUTTING

2.5

2.5.1

2.5.2

2.6

AUTOMATIC

2.6.1

2.6.2

MISCELLANEOUS

2.7

2.7.

2.7.2

2.7.3

2.7.4

SPINDLE-SPEED

2.8

2.8.

2.8.2

TOOL

2.9

2.9.

2.9.2

2.9.3

2.9.4

TRAVERSE

Rapid

Range

FEED

Feed

Feed

ACCELERATION

Acceleration

and

Manual

Acceleration

1

M

Codes

M

Codes

Other

Subprogram

S

-Digit

2

1

4-Digit*Command

S

FUNCTION

T

1

2-Digit

4-Digit+

T

Storage

Tool

Position

RATE

Traverse

of

Rapid

Function

Function

FUNCTIONS

for

for

M

Codes

FUNCTION

Command

(T-

Tool

of

Rate

Traverse

(F-

A

(F-function

B'

and

Deceleration

Feed

Deceleration

and

Stop

ON/OFF

Function

FUNCTION)

Offset

Offsets

.......

....

Rate

function

AND

of

(M98,

(S-FUNCTION)

Values

.

A)

B)

DECELERATION

of

of

(M-FUNCTION)

Functions

M99)t

••

..

.

Rapid

Cutting

•

.

.

Traverse

Feed

•

.

••

8

8

8

8

8

10

10

10

10

10

10

11

12

12

15

15

15

1C

16

16

16

17

Page 4

2.10

PREPARATORY

1

10.

2.

2.

10.2

10.3

2.

10.4

2.

2.

10.5

2.10.6

2.

10.7

10.

2.

10.9

2.

10.

2.

10.

2.

10.

2.

10.

2.

2.

10.

10.

2.

10.

2.

2.10.

10

11

12

13

14

15

16

17

8

List

Positioning

Linear

Circular

Dwell

Cornering

Radius

(G22,

Zero

Automatic

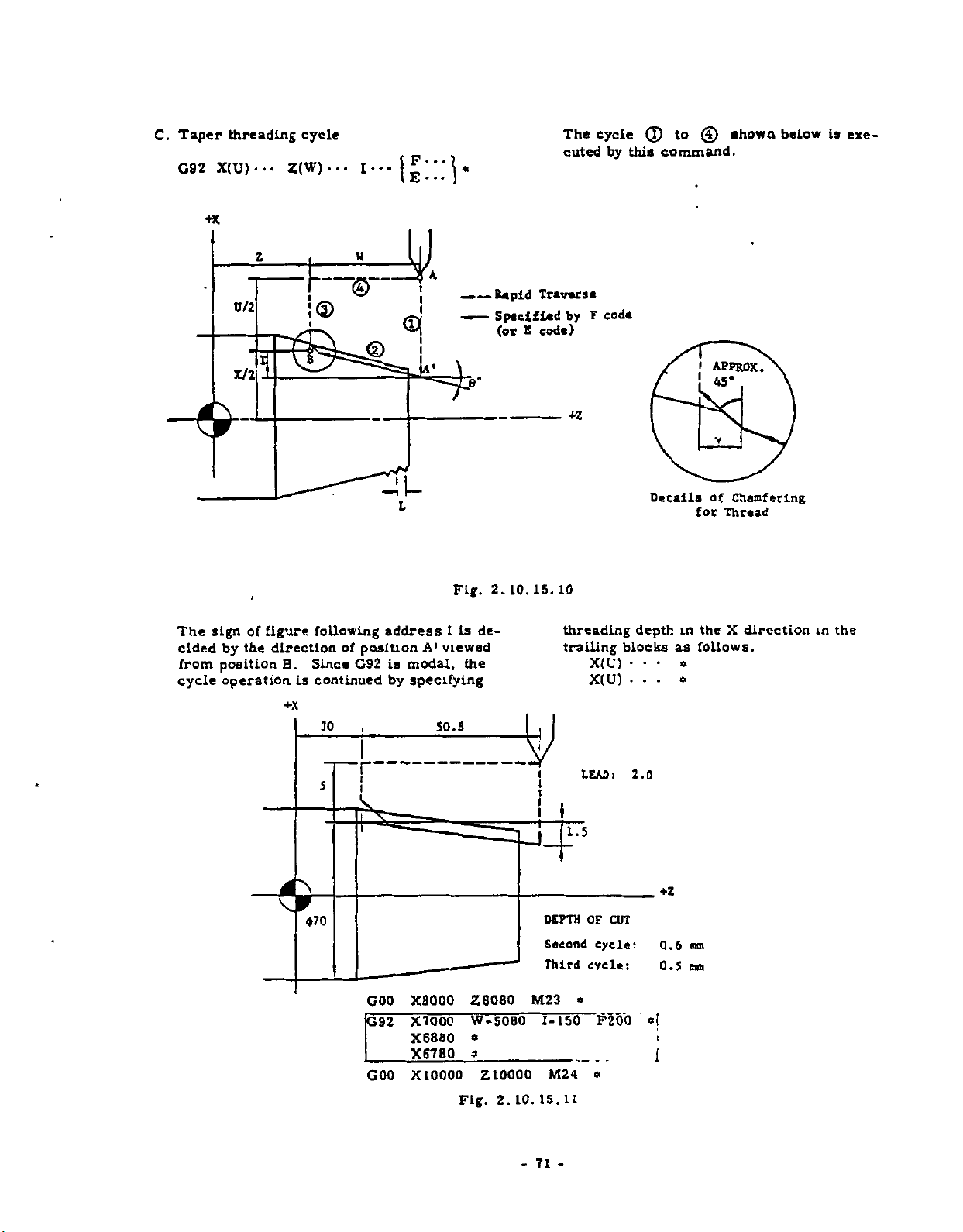

Threadcutting

Tip

Programming

Maximum

Multiple

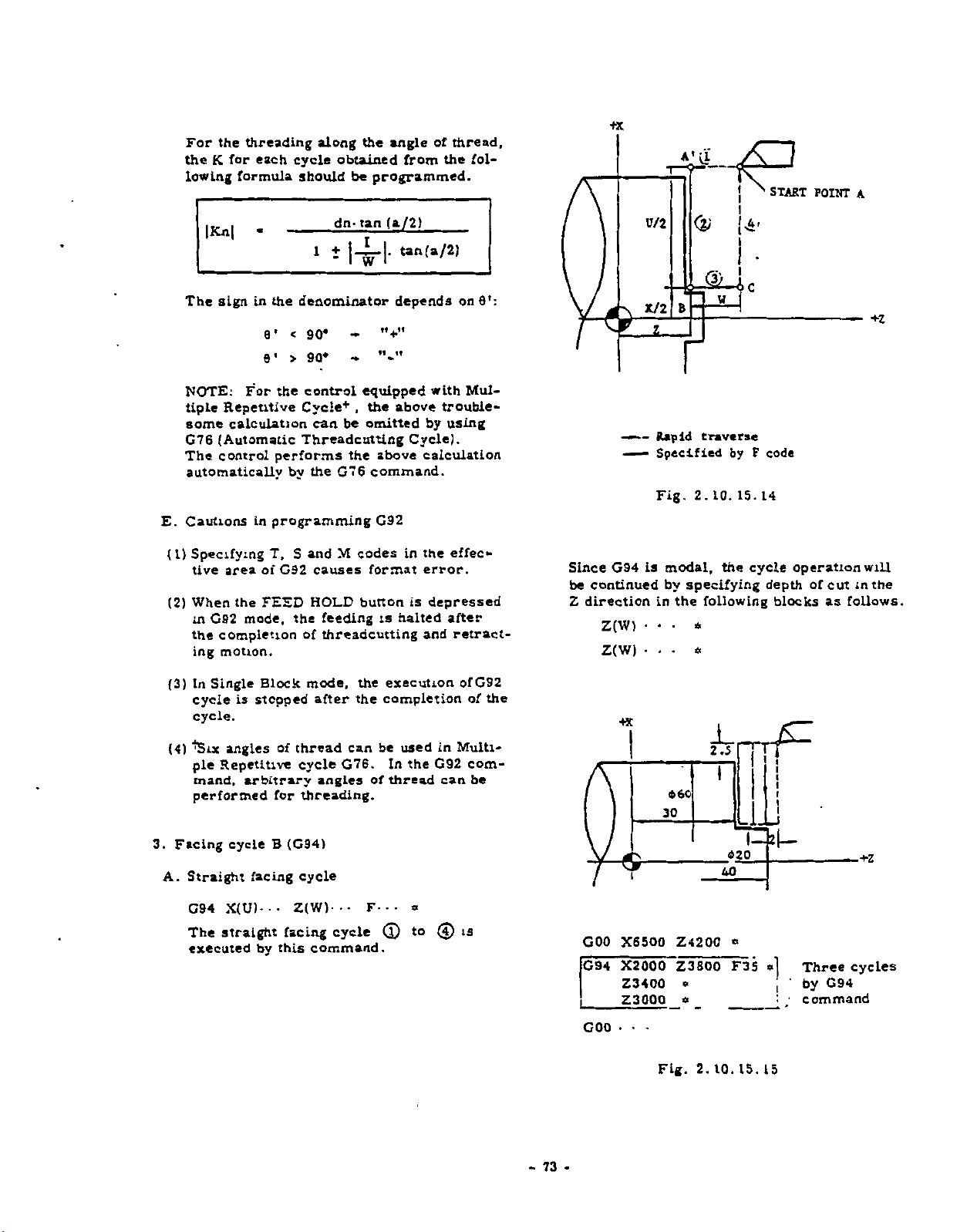

Canned

Constant

Feed

FUNCTIONS

of

Codes

G

(GOO)

Interpolation

Interpolation

(G04)

(Gil,

Programming

G23)

*

Return

Zero

Nose

Radius

Spindle-Speed

Repetitive

Cycles

Surface

Function

(G-FUNCTION)

G12)*

Check

(G27)

Return

(G32)

Compensation

of

Absolute

Cycles

(G90,

Speed

Designation

(G01)

(G02,

for

(G2

G92,

Control

G03)

Circular

•

.

8)

Zero

Setting

(G70

G94)

(G98,

Interpolation

(G40

through

Point

(G50)7

through

(G96,

G99)

(GSO)

G76)*

097)ÿ

044)7

..

.

.

19

19

21

21

22

24

•

25

27

28

29

29

.

34

44

45

46

65

76

78

PUNCHING

TAPI

NC

3.

1.2

2.2

TAPE

TAPE

1

1.

1.2

1.4

1.5

1.6

1.7

1.9

10

1.

1.

12

13

1.

1.14

CODE

List

ELA/1SO/A

Process

General

Precaution

Paper

Punching

Checking

HANDLING

Tape

Keeping

PANEL

POWER

Indicating

FUNCTION

ADDRESS

NUMBER

DATA

WR

AS

Sequential

ERS

EOB

START

RESET

Universal

TAPE

of

Tape

Tape

for

KEYS,

Keys

(Write)

(Address

(Erase),

(End

Key

Key

FEED

Code

uto-Select

Sheet

Program

Programming

in

•••ÿ

NC

NC

NC

Tape

Tape

Tape

of

of

Splicing

of

AND

ON/OFF

Lamps

Select

Select

Setting

Key

Search)

Search

INS

Block)

of

Display

and

Form

NC

LAMPS

Pushbuttons

Keys

Keys

Keys

(Insert),

SYSTEM

Keys

Key

Keys

•

Tape

•

and

and

_

QJ]

-

Display

Display

•

•••

•

and

ALT

NO.

Switches

.

1

Ti

(Alter),

•

-

-

-

•

•

and

-

-

1

3.

3.2

3.3

3.4

NC

4.

4.

TAPE

3.1.1

3.

PROGRAMMING

3.2.1

3.

3.2.3

NC

3.3.1

3.3.2

3.3.3

NC

3.4.1

3.4.2

OPERATOR'S

1

PUSHBUTTONS,

4.

4.

4.1.3

4.

4.

4.

4.

4.1.8

4.

4.

4.1.11

4.

4.

4.

79

79

79

80

80

80

81

81

82

82

82

82

83

83

83

85

85

85

85

86

86

86

87

87

87

87

87

88

88

88

88

Page 5

4.2

POWER

1

4.2.

4.2.2

4.2.3

ON/OFF

Turning

Turning

Remote

OPERATION

on

Power

off

Power

Turning

ON/OFF

Buttons

89

89

90

90

4.3

4.4

4.5

DISPLAY

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

4.3.13

4.3.14

4.3.15

4.3.16

STORING

PART

4.5.1

PROGRAM

4.5.2

4.5.3

4.

5.4

AND

WRITING

Display

Writing

Current

of

Command

Position

Incremental

Display

Writing

Writing

of

of

of

Parameter

Writing

Parameters

Operation

Setting

Alarm

Display

Address

TV

Current

TOOL

Function

and

of

Search

Check

Position

OFFSET

STORAGE

Storing

Part

Storing

Address

(Parameter

Part

Program

Part

Display

OF

COMMAND

Command

Data

Display

Value

Display

Tool

Offset

Tool

Offset

Incremental

Display

Display

Time

Status

Code

Input/Output

(Vertical

Parity

Display

VALUES

+

Program

Modification

Program

Tape

of

99)

No.

Data

Value

Value

.

•

Display

from

from

by

MDI

Value

Signals

Check)

Unlt't

FROM

from

Memory

DATA

Tool

of

NC

Tape*

NC

MDI1'

Offset

TAPE+-

Tape

NC

90

90

91

92

93

93

94

94

94

95

99

99

100

103

104

104

104

105

105

<

•

•

+

105

106

107

108

4.

4.7

4.8

'4.9

6

EDIT"

4.6.

4.6.2

4.6.3

PUNCHOUT

4.7.1

4.7.2

4.7.3

4.7.4

COLLATING

4.8.1

4.8.2

OUTLINE

1

Display

Editing

Outline

of

Stored

of

OPERATION*

Puncher

Tape

Punchout

Punchout

Outline

Collating

Collating

OF

of

OF

STORED

OPERATION

Stored

Edit

of

NC

Tool

of

Tape

of

Stored

Stored

of

Part

Program+

Part

Operation

+

Tape-*1

Offset

Data

PROGRAM

Program*

Offset

IN

Program*

t

Valued

Storing

Value

EDT

THE

and

AND

...

MODE*

Punching

OFFSET

Operation+

VALUE

108

108

109

111

112

112

113

114

•

•

114

114

•

114

115

116

HI

Page 6

5.

TAM

5.1

READER

TAPE

5.

1.1

5.

1.2

1.3

5.

COMPARTMENT

READER

TAPE

Tape

Tumble

FEED

Reader

Bo*

and

SYSTEM

No.

Switches

117

117

•

117

117

118

5.2

6.

PENDANT

6.

6.2

TAPE

1

SWITCHING

6.

6.

6.

6.

6.

6.

6.

6.

6.

6.

6.1.11

6.

6.

6.

6.

6.

6.

6.

OPERATION

6.2.1

6.2.2

REELS

CONTROL

1

1.

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.

1.12

1.

1.

1.

1.

1.

1.

MODE

CYCLE

FEED

SINGLE

EMERGENCY

HANDLE

HANDLE

HANDLE

JOG

10

FEEDRATE

ZERO

ZERO

13

G50

14

DISPLAY

15

DRY

16

OPTIONAL

17

OPTIONAL

18

MANUAL

Manual

G50

+

STATION

UNITS

SELECT

START

HOLD

BLOCK

Lever

RETURN

POSITION

RETURN

RUN

FOR

MANUAL

Zero

Return*

MACHINE

FOR

ON

THE

Switch

Pushbutton

Pushbutton

Switch

STOP

JOG

(Manual

X-Z

Lo-Hi

Dlal+

AXIS

&

OVERRIDE

Switch

Lamps

Switch'

LOCK*

Switch

/MACHINE

BLOCK

STOP

ABSOLUTE

Return

....

PENDANT

Pushbutton

Pulse

Select

Select

&

(Manual

for

SKIP

Switch

Switch

Switch-'-

ZERO

RETURN

CONTROL

Generator)

Switch*

Switch

JOG

FEEDRATE

Zero

and

X

LOCK*

Z

Switch

AND

STATION

Return)

axes

G50

Switch

RETURN

• •

•

118

119

119

120

120

120

120

120

121

121

121

121

121

•

123

123

123

123

123

124

124

124

•

125

125

126

7.

OPERATION

7.

7.2

7.3

7.4

7.5

7.6

.7.

7.8

7.9

7.

7.

INSPECTION

1

TURNING

MANUAL

PREPARATION

ABSOLUTE

PREPARATION

OPERATION

7

MANUAL

AUTOMATIC

MDI

PREPARATION

10

TURNING

11

PROCEDURE

BEFORE

ON

POWER

OPERATION

ZERO

IN

OPERATION

OPERATION

OPERATION

OFF

TURNING

FOR

PROGRAMMING

POINT

FOR

AREA

TAPE

AND

INTERRUPTING

INTERRUPTING

TURNING

FOR

POWER

CHECK

MEMORY

MDI

IN

OFF

l¥

ON

POWER

OF

OPERATION

MODE

AUTOMATIC

MODE

AUTOMATIC

POWER

+

OPERATION

OPERATION

127

127

127

128

128

129

129

130

130

•

130

•

131

131

Page 7

MAINTENANCE

8*

132

1

8.

8.2

8.3

8.4

8.5

APPENDIX-1

APPENDIX-2

ROUTINE

8.

1.1

1.2

8.

8.1.3

8.1.4

INSPECTION

Tape

Control

Servomotor

Battery

REPLACEMENT

POWER

8.3.

8.3.2

1

FUSES

Fuses

Fuses

OTHERS

8.4.1

8.4.2

TROUBLE

8.5.1

8.

5.2

8.5.3

8.5.4

Molded-Case

Power

CAUSES

On-Line

List

List

Before

INTERFACE

INTERFACE

SPEED

SCHEDULE

Reader

Panel

and

OF

BATTERY

of

Composite

of

Servo

Circuit

Receptacles

REMEDY

AND

Diagnostics

of

Alarm

of

Input

Maintenance

/Output

FOR

FOR

and

M-.

CONSTANT

CONTROL*

DC

Unit

Motor

Control

for

Breakers

for

Status

Signals

Call

S-.

for

Spindle

Power

and

X-

Maintenance

Codes

AND

Z-

(MCB)

and

T-CODE

SURFACE

Supply

axis

Tools

Remedies

Unit

•••

•

•

132

133

133

133

134

134

137

137

•

137

138

138

138

138

138

138

143

147

148

153

APPENDIX-3

LIST

OF

PARAMETERS

155

y

Page 8

Page 9

1.

INTRODUCTION

YASNAC

specifically

Incorporates

It

nology

upgrades

of

The

bined

offer

2.1

2.1.1

A

6313

Table

following

indicate

In

optional

improved

with

quick

TAPE

variable

is

2.1.1

TAPE

used

2000G

designed

the

every

basic

the

features

transistorized

the

optimum

response

FORMAT

FORMAT

block

for

shows

the

address

the

programmable

a

Is

microprocessor-based

for

turning

latest

design

format

YASNAC

the

feature,

functions

of

YASNAC

pulse

and

conforming

tape

characters

microelectronics

and

PWM

higher

2000G.

format.

number

applications.

which

widens

2000G.

servos

distribution

accuracy

2.

to

Numerals

Table

in

of

of

machining.

The

tects

industrial

greater

On-line

detection

reduces

CNC

tech¬

remarkably

the

scope

com¬

control

PROGRAMMING

B

JIS*

2.1.1

digits.

totally-enclosed,

all

components

environment.

the

of

downtime.

reliability.

source

control

diagnostics

the

dustproof

from

of

YASNAC

of

the

This,

trouble

enclosure

attack

also

2000G

and

by

rugged

assures

speeds

drastically

pro¬

the

The

dress

med,

#

Japanese

leading

codes.

but

EXAMPLE

(U)

X

Note:

zeros

Plus

minus

all

Industrial

+

I

A

decimal

can

signs

signs

.

4

TT

point

be

suppressed

need

must

Standard

3

must

be

not

programmed.

be

Down

Four

Sign

Address

omitted

be

all

for

program¬

ad¬

to

digits

decimal

third

of

integer

character:

in

actual

the

In

is

represented

gramming,

should

place

or

U

X

programming.

manual,

be

CR

used

EOB

by

(EIA

instead

an

)

code

asterisk

code)

of

in

mm

or

inches

a

in

or

the

program

)

(•*

.

LF/NL

asterisk

In

example

actual

(ISO

(ÿ»).

pro¬

code'

1

-

-

Page 10

Sequence

Items

Number

Least

Table

input

Increment

2.1.1

Tape

0.

Format

01

mm

Metric

N4

Inch+

001

mm

0.

0.001

inch

#

0.0001

inch

4

Preparatory

Command

Move

Radius

Arc

Designation

Feedrate

Threadcutting

Function

Tool

Spindle

-Speed

Miscellaneous

Dwell

Radius

Designation

Multiple

Repetitive

Cycles-ÿ

Function

Function

Function

Sequence

Depth

Retracting

Number

Cutting

Angle

for

of

of

X

Z

X

Z

mm/rev

e

r

me

h/

mm

/min

inch/min

Normal

Precise

G22,

G23

Number

Cut,

Value

of

Cycles

Thread

v_

'

X(U)+4.

Z(W)+4.

1+4.2

+

K

F2.2

F2.2

U3.3

R

+

4.2

+

D

4.2

4.

T2

S2

G2

2

2

F4

E2.4

M2

2

P4

04

D3

A2

X(U)+4.3

Z(W)+4.

1

+

K

+

3

F2.

F2.3*

T4"

"ÿ

S4

U3.3

+

R

+

D

4.3

4.3

T

4

4.3

3

3

X(U)+3.

Z(W)+3.

1+3.3

+

K

U3.3

R

+

+

D

3.

T2

S2

3.3

3.3

G2

3

3

3

Ft.

F3.2

FI.

El.

M2

04

D3

X(U)+3

Z(W)+

K

T

S4'

R

P

4

D

A2

1+3.4

+

4

4

6

4"

U3.3

+

+

3.4

3.4

3.4

4

.

3.

4

Repetition

of

End

Notes-

Functions

1.

Only

2.

cannot

tion

Least

3.

Feedrate

4.

revolution,

When

5.

Inch

6.

Metric

of

Block

the

of

input

F2.3"

input

Subprogram"

with

numbers

exceed

each

the

item.

increment

designated

is

which

is

available

is

selection.

are

digits

of

maximum

optional.

T

(0.01/0.

by

be

can

for

used

for

Inch/Metric

are

shown

programmable

001

either

switched

F

code.

control

the

is

2

-

mm)

mm

by

E2.4

switched

-

L4

*5

the

in

is

(inch)

code.

G

cannot

equipped

above

value.

switched

minute

per

(G'J8,

be

with

by

parameter

table.

Refer

used.

by

G99)

an

Some

the

to

parameter

or

mm

optional

setting.

L4

*1

of

descrip¬

(inch)

Inch/

them

setting.

per

Page 11

2.1.2

ADDRESS

AND

FUNCTION

CHARACTERS

Address

In

Table

Function

in

Table

characters

2.1.2.

characters

2.

1.2.2.

Address

Characters

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Note:

1.

Any

area

and

the

meanings

and

the

meanings

Angle

Unused

Unused

Depth

Precise

Feed

Preparatory

Unused

X-coordinate

of

multi

Unused

Z-coordinate

repetitive

Number

Miscellaneous

Sequence

Unused

Sequence

Sequence

Sequence

Radius

Spindle-speed

Tool

Incremental

Unused

Incremental

Absolute

Unused

Absolute

address

they

are

if

Table

of

thread

of

cutting

lead

function

repetitive

cycles,

of

repetitions

number

number

number

number

designation

function

X-coordinate

Z-coordinate

characters

programmed.

are

shown

are

shown

2.

1.2.

multiple

for

multiple

for

designation

lead

and

function

of

arc

center

cycles.

of

arc

center.

Amount

functions

start

for

designation

for

finish

of

function

X-coordmate,

Z-coordinate

defined

not

1

Address

Meanings

for

designation

(radius

Amount

of

of

subprogram

of

of

a

circular

Dwell

Characters

repetitive

repetitive

threadcutting

for

value).

of

Parameters

rounding

multiple

forjump

multiple

arc

time

above

cause

cycle

cycles

threadcutting

Parameters

rounding

of

multiple

repetitive

repetitive

for

G22

errors

G76

G70

and

to

cycle,

cycle

G23

in

significant

B:

O:

G76

Basic

Optional

Section

I

;

I

t

I

I

data

O

O

B

B

B

B

O

B

O

O

B

B

O

O

O

B

B

B

B

B

B

3

-

-

Page 12

EIA

Blank

BS

Tab

CR

SP

ER

UC

LC

able

T

ISO

NuL

BS

HT

LF/NL

;

CR

:

SP

I

<

%

<

)

2.

1.2.2

Error

data

Disregarded

Disregarded

Disregarded

End

Disregarded

Disregarded

Rewind

Disregarded

Disregarded

Control

Control

F

unction

Meanings

in

significant

area

of

of

block

stop

out

in

Characters

EIA

ISO

in

Remarks

2.

1.3

While

register,

the

the

tape

means,

loss

the

Buffer

EOB.

causes

ters

displayed.

into

read

by

buffer

Disregarded

•

)

etc.

Insignificant

EOB

•

Control

them.

NOTE:

or

two

case,

above

each

.

BUFFER

control

the

stored

and

tape

the

time

capacity

command

A

errors

The

buffer

capacity.

the

at

Out,

During

three

blocks

buffer

REGISTER

operates

block

next

reading

the

in

64

is

of

following

register

codes

data

Label

Control

nose

tip

capacity

of

buffer

into

operation

machining

characters

block

and

the

and

(SPACE,

the

from

state.

Skip

In

radius

are

read

the

with

data

is

register.

operation.

exceeding

alarm

characters

are

TAB,

start

codes

and

compensation,

ahead.

is

the

data

read

does

including

code

are

not

restricted

ALL

the

to

between

In

same

in

out

not

64

"14"

first

this

as

active

from

By

this

cause

charac¬

is

not

MARK,

the

0

to

a

to

0

/

Del

Notes:

1.

Characters

in

Information

2.

In

Tape

3.

parameter.

9

0

to

z

AtoZ

:

/

DEL

|

significant

ignored

is

code

Disregarded

Negative

9

Numerals

Address

Regarded

Optional

Disregarded

(Including

other

between

as

(ELA

than

data

area.

insignificant

or

ISOlcan

sign

characters

as

N

block

Mark)

All

the

above

Control

skip

Out

data.

be

cause

and

switched

Usually

used

not

error

Control

by

2.1.4

Number

in

check.

TV

number

ON/OFF

ameter.

characters

is

Ml3"

Check.)

2.1.5

block

A

quence

switch

SKIP

into

buffer

TV

CHECK

of

characters

SP

even

when

switching

block

A

causes

displayed.

OPTIONAL

with

"/"

number

is

on.

register

(TAPE

VERTICAL

in

is

code

programming.

of

TV

containing

error

(Refer

BLOCK

before

the

skipped

after

"/"

is

but

one

block

used

check

odd

the

and

the

to

SKIP

address

at

OPTIONAL

the

ignored.

PARITY

must

for

making

set

is

number

alarm

4.3.15

("/"

address

with

CODE)

for

N

N

CHECK)

even

be

the

par¬

of

code

TV

se¬

BLOCK

is

read

-4-

Page 13

SEQUENCE

2.2

2.2.

i

Sequence

and

block

order.

and

continuous

number

sequential

use

to

Sequence

Integers

The

N.

EXAMPLE

NO

Nl,

NOTE:

as

given

effective.

are

overlapped

after

stops

The

block

searched

block.

2.2.2

3-DIGIT

(SPECIAL

When

Workpiece

provided,

number.

workpiece.

of

2.3

MOVE

2.3.1

LEAST

4-

DIGIT

number

does

Therefore,

numbers,

are

acceptable.

number

from

leading

N001,

1.

When

sequence

a

sequence

reading

without

searching

by

three

The

COMMAND

NUMBER

SEQUENCE

a

is

reference

not

affect

sequential

overlapped

numbers.

is

represented

0001

to

9999

zeros

can

N0001

a

number

number,

When

address

number,

the

out

sequence

SEQUENCE

SPECIFICATION

Number

digits

forth

are

digit

COMMAND

NUMBER

number

the

machining

numbers,

numbers

But

it

is

recommendable

by

four

with

the

proceeding

be

suppressed.

All

correct

----

of

the

5

digits

search

block

number

address

the

address

latter

first

or

over

is

made

searched.

can

data

NUMBER

)

Designation

for

used

is

used

sequence

designation

for

option

INCREMENT

for

the

operation

dis¬

and

digit

is

digits

4

for

search

be

the

in

is

no

-

Notes:

axis

X

1.

2.

Inch/Metric

above

2.3.2

least

The

can

that

millimeters

be

must

Table

and

Z

X

Switching

0.0001

(Parameter

ameter

in

when

However,

0.001

content

For

the

of

•

•

•

•

inciv

No.

unit

the

"1,

mm

example,

following

0.01

Programming

Write

Programming

Program

is

shown

metric

LEAST

input

be

programmed

or

designated

2.3.2

axes

of

0.01

)

No.

88

0.001

of

the

in

"

tool

the

(or

of

parameter

operation

mm.

operation

editing

by

selection

based

INPUT

Increment

in

inches

by

Least

Metric

0.01

mm

mm/0.001

is

made

88).

"0,

is

"

mm

unit

offset

0.0001

0.01

in

for

operation

in

for

operation

operation

effective

is

value.

radius

machine.

INCREMENT

is

and

+

diameter.

Input

0.001

mm

by

When

programming

(or

01

0.

of

value

inch-)

No.

88.

mm

must

mode.

MDI

minimum

the

Is

represented

Values

.

Increment

0.001

inch

mm

parameter

the

contents

0.0001

(or

mm

can

regardless

increment

made

be

in

TAPE

MEMORY

in

EDT

in

(or

can

0.

be

for

for

Inch-

0.001

setting

be

inch-)

001

given

of

system,

in

mode.

mode

the

unit

in

Xaxis

0.0001

inch

inch/

of

par¬

made

inch

in

the

the

mode-.

.

and

'.

unit

The

unit

and

Two

The

the

them

the

X

Z

least

command

of

movement

is

represented

types

system

machine.

which

machine

Table

axis

axis

in

increment

of

be

to

used

The

depends

builder's

tool

1

2.3.

Least

Specification

00

1

mm/pulse

0.

0.002

mm/pulse

increment

which

millimeters

in

is

control

upon

is

the

machine

system

specified

specified

is

the

machine.

manual..

Command

A

0.0005

0.001

the

minimum

can

pulse.

per

available.

are

according

by

Refer

Increment

Specification

mm/pulse

mm/pulse

move

one

NOTES:

0.01

to

will

the

in

0.001

mm

move

-is

of

NC

will

commanded

•

Note

that

if

NC

times

that

ten

in

system,

of

if

the

state

memory-,

in

times

the

intended

the

or

is

stored

to

of

to

mental

ten

•

Note

under

stored

the

programmed

tape

control

machine

the

increment

the

that

one

set

dimensions.

system

contents

the

machine

of

tenth

incre¬

the

by

switched

tape

move

mm

is

by

dimensions.

When

the

the

\

least

pulse,

since

control,

stored

of

mm

of

stored

the

increment

command

the

the

the

O.OOt

program

figures

switching

machine

command

machine

mm’.

is

are

of

is

commanded

increment

will

value

will

punched

punched

increment

is

not

move.

is

move

out

0.002

retained

at

5

-

•

tape

gardless

•

If

0.001

whose

per

ever,

the

command

-

B

on

out

system.

to

the

re¬

Z

How

next

the

axis

mm

in

Page 14

2.3.3

of

Both

used

be

Absolute

•

and

X

EXAMPLE:

Incremental

•

and

U

EXAMPLE:

ABSOLUTE

absolute

the

Input

control.

is

for

Z.

X-

input

W.

U-

AND

INCREMENTAL

and

input

specified

Z-.

•

•

is

specified

.

W---

•

incremental

addresses

the

by

*

the

by

*

INPUTS

input

addresses

can

•

Absolute

in

used

EXAMPLE:

NOTE:

are

W

and

tive.

addresses

The

center

must

dimension.

input

one

When

used

and

block

.

X-

U-

•

addresses

In

and

I

be

specified

incremental

mixedly.

W-

--

-

Z-

•

•

X

block,

one

K

for

by

Input

s.

*

and

designation

U

the

the

incremental

or

latter

can

be

addresses

is

effec¬

of

arc-

Z

Address

X

Z

U

W

I

K

Note:

Increment

System

Absolute

Input

Incremental

Input

Incremental

Input

Designation

Refer

to

2.3.4

Table

Designation

Diameter

2.3.3

Position

(Note)

Position

Diameter

Radius

Move

tion

Move

tion

Distance

from

center

Distance

from

center

addresses

of

and

U

X

"DLAMETER/RADIUS

amount

(Note)

amount

starting

starting

_

depends

Switching.

Meaning

in

X

_

Z

in

_

in

X

in

Z

upon

axis

axis

in

in

axis

point

axis

point

direction

direction

X

axis

Z

axis

direction

direction

the

'*

direc-

direc¬

of

arc

arc

of

option.

to

to

END

POINT

X

W

START

POINT

(a)

+x

U/2

Fig.

2.3.3.

+x

I

6

END

POINT

ARC

CENTER

t

I

JL

'-START

(b)

POINT

-

Page 15

03/2

+X

Contents

Diameter

0:

Radius

1:

of

Parameter

designation

designation

+X

No.

70

Effective

the

}

X

addresses

and

U

only

for

X3/2

and

X

and

U

Note:

diameter,

in

the

values.

Fig.

2.3.4

When

RADIUS

can

U

radius.

and

of

parameter

02/2

X24

CU2tt/2

Ml

*1

11

Absolute

Z:

Incremental

W:

Since

X

2.3.

3.2

Incremental

DIAMETER/RADIUS

control

the

switching

used

be

and

the

actual

Absolute

for

The

No.

Input

Input

are

U

movement

Coordinate

Coordinate

equipped

is

option,

designation

switching

70.

designated

SWITCHING4-

the

W7

*3

with

addresses

of

is

made

Ml

by

the

the

half

is

Values

Values

DIAMETER/

X

diameter

both

the

setting

by

+2

values

of

and

and

(a)

(b)

Addresses

switching

2.3.5

X2

case

the

In

+x

*2

case

the

In

2,

W,

function.

MAXIMUM

U/2

*1

of

Diameter

U

Xl

2.3.4

are

K

Designation

not

Radius

of

Fig.

and

I

PROGRAMMABLE

Designation

+z

affected

VALUE

by

the

Table

Metric

Inch

2.3.5

Least

s.

Lea3ts\.

\

Input

Increment

\

Maximum

Command

Increment

01

mm

0.

001

0.

001

0.

0

1

000

.

Programmable

'

mm

inch

inch

Values

axis:

X

0.

Z

mm/pulse

001

axis:

mm/pulse

002

0.

(Specification

±8388.

£8388.

60

607

*330.260

£330.2601

-

Maximum

is

shown

(Addresses

A)

mm

mm

Inch

inch

7

-

programmable

below.

X,

axis:

X

0.0005

axis:

Z

0.001

(Specification

*4194.30

*4194,

£165.

*165.

value

Z,

U,

mm/pulse

mm/pulse

303

130

1300

W,

mm

mm

inch

inch

of

move

command

K)

and

I

B)

Page 16

In

Incremental

the

accumulative

imum

absolute

In

amount

not

exceed

The

machine

move

value

RAPID

2.4

2.4.1

programming,

programmable

programming.

of

each

the

axis

maximum

may

command

is

given.

over

TRAVERSE

RAPID

TRAVERSE

value

specified

not

must

value.

Input

programmable

properly

the

maximum

RATE

RATE

input

not

by

operate

exceed

values

values

the

and

the

inputs

value,

if

programming

the

and

max¬

move

must

2-5

2.5.1

code

G

function

code

G

CUTTING

FEED

of

D

commanded.

is

of

D

G99

G98

FEED

FUNCTION

must

group

groups

(F-FUNCTION

A

be

designated

Function

Designation

in

mm/rev.

Designation

in

mm/rev.

of

feedrate

of

feedrate

A)

before

F

Each

axis

GOO

(positioning)

(manual

rates

Two

able,

and

An

operator

functions

The

contents

0:

Rapid

Rapid

1:

Rapid

traverse

accidental

or

ation

newly

punched

2.4.2

Rapid

axis

traverse

independently

Step

rate

increment

moves

rapid

rapid

of

are

can

(Parameter

of

traverse

traverse

collision

the

dry

RANGE

of

rapid

(Specification

at

is

traverse)

set

with

switch

parameter

rate

run

tape.

OF

RAPID

rates

in

system)

the

rapid

commanded

is

traverse

parameter

Hi/Lo

01).

No.

rate

Hi

Lo

rate

used

Lo

is

the

when

is

performed

TRAVERSE

and

Hi

the

following

traverse

A

traverse

or

selected.

and

Lo

by

01:

No.

to

Single

are

Lo

of

RAPID

Hi

No.

means

prevent

Block

for

RATE

set

step.

7.

mm

rate

are

93

the

for

5

/min

and

of

test

when

mode

avail¬

94.

setting

an

oper¬

each

of

Note:

For

Function

F

Since

next

the

G98/G99

ignated

•

Metric

InchT

However,

stricted

again.

Feedrate

the

After

tool

per

digits

4

by

programmable

the

F

details,

the

Designation.

modal,

is

code

codeiscommanded.

F

is

switched

per

designation

spindle

over,

revolution

revolution

following

range

Table

2.

5.1.1

ormat

F2.2

F

by

1

the

.

the

Range

Feedrate

4

programming

spindle

FI

F9999

Fl

F39366

refer

the

of

F.

to

to

speed

code

F

(G99)

G99,

Table

of

F

of

to

code

can

the

code

of

as

the

feedrate

2.

10.

17

effective

is

However,

must

feedrate

commanded

be

5.

1.

code.

(G99)

Meaning

to

I

99.99

2.

F

0.01

mm/rev.

0001

to3.

0.

inch/rev.

is

shown

below

Feed

be

shows

re¬

until

when

des-

of

9366

Note:

The

maximum

ever,

upon

suitably

machine

Half

the

since

the

the

of

control

traverse

the

maximum

servo

according

builder's

tool

motor

above

with

to

value

the

rate

and

the

manual.

is

specification

100

is

traverse

machine,

the

machine.

available

kPPS.

rate

Refer

for

B.

How¬

depends

set

is

it

to

the

F

(mm/rev)

the

Note:

8

-

-

In

mental

of

the

case

system,

above

x

of

value.

S

(rpm)

specification

the

<

(mm/

restriction

B

4800

of

min)

incre¬

is

the

half

Page 17

Fig.

•

Feedrate

(am/

2.5.

99.99

F

rev)

per

0

1.

i

1

minute

4800

S

(rpn)

Restriction

Spindle

(G98)

an/mln

of

Speed

5000

Feedrate

and

Feedrate

•

must

axis

EXAMPLE

G99

G01

the

In

F

x

EXAMPLE

G98

G01

the

In

F

*

commands

be

l

S350

U10000

above

S

2.

*

700

*

2

X20000

above

700

mm/min

given

(rpm)

F20Q

case,

0

mm/rev.

mm/min

F700

case,

in

in

*

the

the

.

the

radius.

*

feedrate

x

—

«

feedrate

—

direction

rpm

350

is:

.

is:

of

the

X

The

feedrate

manded

after

shows

Metric

Inch*

Notes:

the

In

1.

system,

half

The

2.

by

the

to

NOTES:

•

command

A

alarm

•

Any

minus

commands.

operate

EXAMPLE

F-250

by

the

designation

the

programmable

Table

ormat

F

F4

F3.2

case

the

of

upper

servo

the

machine

code

properly.

4

digits

the

above

limit

"F0"

"15"

value

*

of

of

If

tool

per

foliowing

2.5.

1.2

Range

Feedrate

1

'F

F5400

F

1

F21259

specification

upper

values.

of

mechanical

and

tool

causes

will

should

specified,

•

•

•

-

minute

of

G98.

range

F

of

to

to

limit

feedrate

builder's

data

displayed.

be

not

Wrong

code

|

of

be

the

can

the

address

Tabie

of

(G98)

to

l

mm/

0.01

inch

of

B

feedrate

may

systems.

manual.

errors

specified

machine

com¬

be

2.5.

F

code.

Meanings

5400

min

to

212.

min

/

incremental

is

restricted

be

and

will

F

1.2

59

the

Refer

the

for

not

FEEDRATE

|

700

nm/min

+Z

2.

5.

Fig.

of

F

1

the

«

axes

«

U3000

above

500

X

*X

command

represent

are

1

(mm/min|

+

Z

axis

component

500

simultaneously

W4000

case,

4002

t

axis

mm/mli

400

Vaiues

terpolation

when

two

EXAMPLE

G98

GO

In

F

F

1.2

at

linear

the

FS00

the

component

300

[

mm/ratT

or

tangential

*

feedrate

aan/min

circular

feedrate

controlled.

is:

in¬

Fig.

9

-

-

5.

(a)

1.3

2.

Page 18

EXAMPLE

C99

G03

the

In

FiS-

2

S1000

U

•

above

(mm/rev)

200

*

\J

(rpm)

•

•

case,

0.2

mm/min

fx2

W.

V

r.00

*

I-

-

the

x

f*2

+

•

•

feedrate

1000

(rpm)

F20

is:

•

VELOCITY

Fig.

TIME

t

-

2.

I

6.

CENTER

+x

1

L-

2.5.2

Feedrate

FEED

commanded

functions

Table

Format

Metric

Note-

E

F-

2.6

Acceleration

and

without

No

code

cannot

function

AUTOMATIC

cutting

for

programming.

mm/mi

+z

FUNCTION

per

revolution

by

the

are

2.5.2

F2.3

change

B.

and

!

fx

fz

3~

in

format

the

as

same

code

F

Range

Feedrate

FI

F99999

in

used

be

ACCELERATION

of

to

inch

for

deceleration

automatically

are

feed

2.5.

1.3

Fig.

(F-F'JNCTICN)

metric

of

those

F2.

(G99

system

3.

of

F-

mode)

0.001

The

function

Meaning

to

mm/rev.

the

control

AND

DECELERATION

for

rapid

performed

(b)

is

other

99.999

with

traverse

2.6.2

the

In

matic

tential

.

•

•

ACCELERATION

OF

CUTTING

following

acceleration

curve.

Cutting

Threadcutting

Handle

(See

feed

(HANDLE

AND

FEED

operation,

and

Fig.

(G0I

(G32)

DECELERATION

the

pattern

deceleration

2.6.2.)

G03)

to

mode)

of

auto¬

of

is

expo¬

*1

A.

_

VELOCITY

MISCELLANEOUS

2.7

(M-FUNCTION)

miscellaneous

The

address

M

chine,

machine

M

cerned

2.7.1

code

codes

M

(MOO

except

tool

except

with

M

and

to

for

builder's

the

CODES

Fig.

two

M99)

several

for

control.

FOR

TIME

2.6.2

FUNCTIONS

function

digits.

determined

is

M

manual

following

the

STOP

is

specified

The

codes.

for

function

by

Refer

the

M

codes

with

of

ma¬

the

to

function

con¬

t

the

each

the

of

2.6.1

the

In

matic

(See

Fig.

Positioning

•

Manual

•

Manual

•

"Automatic

*

TAPE.

ACCELERATION

RAPID

following

TRAVERSE

operation,

acceleration

1.)

2.6.

(COO)

rapid

continuous

operation"

or

MDI

MEM

AND

deceleration

and

traverse

mode

DECELERATION

MANUAL

AND

the

pattern

(RAPID)

in

(JOG)

operation

this

feeding

means

FEED

auto¬

of

is

linear.

manual.

OF

in

-10-

.

MOO

This

(Program

operation*

after

have

The

program

CYCLE

.

M01

M01

stop

is

the

(Optional

M00

on.

M01

code,

commands

the

been

completed

START

performs

whenever

When

code

Stop)

whenitis

mode,

may

button.

Stop)

the

the

OPTIONAL

is

disregarded.

commanded

stops

in

the

and

continued

be

same

the

OPTIONAL

the

block

MOO

function

in

automatic

containing

signal

R

pressing

by

as

STOP

STOP

automatic

operation

is

program

switch

MOO

fed.-

the

switch

off,

is

.

Page 19

•

(End-of-Program)

M02

is

M02

manded

stops

code

commands

completed.

been

inmost

machine.

manual.

(End-of-Tape)

M30

•

is

M30

commanded

code

stops

commands

completed.

been

the

control

memory).

the

by

builder's

NOTES:

When

•

it

prevents

block

next

signal

output

refer

•

Whether

spindle

tions,

manual.

Whether

•

rewinds

the

following

(a)

Input

reset

(b)

Input

input)

Refer

to

Appendix

2.7.2

•

M23/M24

OFF)

M23

M24

usedatthe

in

automatic

the

in

cases,

Refer

commanded

in

the

in

is

Since

machine,

manual.

M01,

MOO,

the

of

information.

in

is

fed

coaes.

for

M

the

to

Appencix

MOO.

stop,

refer

the

the

to

control

tape

state.

signal

input!

signal

is

wired

mac.nine

the

i.

M

CODES

(Chamfering

•

Chamfering

.

•

•

Chamfering

•

• •

of

end

program.

operation#

automatic

block

the

Although

the

details

to

automatic

automatic

block

the

In

reset

the

refer

M02

control

addition

M01.M02

coolant

the

(or

of

is

of

containing

the

machine

at

the

containing

addition,

and

rewinds

details

to

or

from

to

For

l.

or

or

off

machine

is

automatically

memory)

control

the

wired

the

control

"ON"

for

tool

builder's

operation

the

control

are

end

operation#

operation

are

the

machine

M30

reading

The

the

the

timing

M30

some

tool

"ON"

for

or

FORON/OF=OF

threadcutting

with

ON

OFF

When

mode,

after

M02

is

determined

tool

builder’s

of

tape.

When

mode,

after

have

M30

cases,

most

in

the

tape

determined

tool

is

commanded.

ahead

may

other

decode

BCD

of

output,

cause

single

2-digit

builder's

reset

determined

is

not.

manual

or

(internal

not.

(rewind

"EQP"

"RWD"

FUNCTIONS

com¬

this

the

have

reset

by

this

the

(or

the

code

the

execu¬

or

and

ON/

the

by

When

of

threadcutting

fering

manded,

performed.

When

effect.

Canned

.

M51/M52

These

vided

tion7.

follows.

as

(a)

At

tioning)

the

coming

(b)

In

G03

effective,

block

of

The

control

operates

M5i:

M52.

M51

permits

tween

servo.

ceeds

the

pulse

circular

When

next

the

within

void

rounding

(positioning)

GOO

Error

of

mand

and

M51

supply

When

together

(GO

feed

endofthe

is

M23

thread

of

chamfering

power

For

Cycles.

(Error

codes

the

with

The

the

end

next

within

end

the

(Linear

smoothly

servo.

as

Error

Error

blocks

When

the

to

distribution

interpolation.

M52

is

block

allowable

the

Detection

M51

of

M52

is

turned

or

M51

with

to

l

block

commanded

cycle

is

performed.

supply

the

is

details,

Detection

available

are

Error

control

of

the

command,

block

after

the

of

the

and

the

control

regardless

Error

with

follows.

Detection

Detection

the

machine

regardless

is

M51

block

next

effect,

in

after

a

corner.

of

is

ON

or

M52.

are

modal.

on,

M52

is

the

move

G03),

it

containing

before

(or

G92

with

threadcutting

turned

refer

ON/OFF'*')

for

Detection

without

execution

execution

circular

in

the

range.

always

M51

commanded

becomes

the

the

control

the

lag

allowable

proceeds

Detection

OFF

ON

to

of

the

effect,

after

to

servo

control

the

lag

pulse

executed

regardless

When

is

command

them.

the

command

G76+),

M24

If

M23

on,

10.

to

2.

control

the

ON/OFF

option

of

GOO

proceeds

pulse

range.

G01,

of

interpolations)

to

of

the

ON

/OFF

smoothly

move

pulse

lag

the

control

the

completion

for

linear

proceeds

of

servo

is

of

the

effect.

in

of

effective

used

at

the

power

a

cutting

M52

in

cham¬

is

is

is

in

15

func¬

operates

(Posi¬

of

servo

G02

the

pulse

lag

of

and

to

the

com¬

block

at

com¬

not

pro¬

to

or

is

next

be¬

pro¬

of

to

comes

a-

state

the

k

CSU.'trERIN'*

H

11

-

"Automatic

TAPE,

MDt

-

operation"

or

MEM

means

mode

in

operation

manual.

this

in

Page 20

(£)

(2>

(GOD

•

M94/M95

These

Clamp

M94:

M95:

After

feedrates

the

parameter

rate

erse

(a)

Rapid

(b)

Cutting

(Feedrate

v

FEEDRATE

MINUTE

and

M94

turned

When

M94

move

the

fective

NOTE:

function

(Feedrate

GOO

GOi

2

•

codes

option

Traverse

Traverse

the

GOO

M95

on,

command

at

Note

is

.

X

W-3000

U4000

•

20

(Traverse

can

is

is

M94

are

decelerated

clamp

traverse

feedrate

per

PER!

(G98)i

I

are

M94

or

M95

block

the

that

effective

not

revolution:

per

Z-

• •

F30

M52

ON

/

o

OFF

/

2.

Fig.

Rate

used

be

supplied.

Rate

Rate

commanded,

the

while

is

ON.

(GOO)

specified

minute)

S'

J

TRAVERSE

LIMIT

r

2.

Fig.

modal.

is

effect.

in

commanded

is

a

in

containing

Traverse

the

•

M51

*

®

30

7.2.1

Clamp

when

Clamp

Clamp

to

limit

SWITCH

2.

7.

When

block,

in

*

*

_

/

ON/OFF)+

Traverse

ON

OFF

the

values

the

switch

by

SPEED

BY

PARAMETER

1.

RATE

ON

2

the

it

them.

Rate

the

G99

mm/rev).

following

set

for

G98

command

SPECIFIED

C&MP

power

together

becomes

Clamp

mode

Rate

trav¬

is

with

ef¬

by

•

M98/M99

These

For

the

Function.

NOTE:

M94/M95,

control

machine.

the

to

2.7.3

use

to

How

above

depends

machine

Table

M

code

M03

M04

M05

M08

M09

When

together

Spindle

running

Spindle

running

Spindle

Coolant

Coolant

theseMcodes

commands

completion

after

mined

by

builder's

2.7.4

sequence

The

part

block

following

Jump

This

quence

When

tion

and

which

command

returns

the

option

with

commands

the

the

(Subprogram

used

are

codes

M

refer

codes

details,

Above

M98/M99)

signals

and

OTHER

tool

2.

with

the

no

give

M

other

the

upon

builder's

1

Typical

7.

Meanings

forward

reverse

_

stop

on

off

move

executed

are

machine.

CODES

the

for

are

command,

move

of

manual.

SUBPROGRAM

of

is

program

can

to

be

block.

instruction:

number

the

P

command

operation

FUNCTION

operation

available

storage.

specify

performed

)

P

jumps

specified

to

the

will

function}'*'

for

to

2.7.4

(M23/M24,

are

effective

(-2

codes

M

machine.

manual.

Example

Machine

M03

switchable.

M

intermediated.

commanded

simultaneously

command

Refer

can

for

sequence

the

next.

•

•

•

to

the

by

is

omitted,

first

address

be

repeated.

jump

-digit

other

05

to

the

The

M99

block

the

Remarks

and

(stop)

whether

(M98,

be

(The

instruction.

Subprogram

M51/M52,

only

for

BCD

output)

than

codes

M

M04

must

in

the

are

machine

to

are

a

with

deter¬

Refer

of

the

M99)4'

altered

control

M98

supplied

and

number

previous

*

of

the

address

execu¬

the

of

the

the

the

the

not

be

block

M

or

tool

this

by

M99

of

se¬

P.

memory

or

-12-

Page 21

•

Jump

.

P

M98

quired

(main

program)

after

Address

the

Address

of

subprogram.

value

Instruction

..

L

.

to

.

.

M98

commandisused

jump

must

specifies

of

specifies

address

from

to

subprogram.

The

to

program)

the

first

of

and

completion

P

block

L

the

Subprogram:

*

when

the

executing

the

other

return

L

of

the

sequence

the

the

number

maximum

is

9999.

to

subprogram.

the

program

program

program

the

main

number

of

repetitions

programmable

After

is

(sub¬

program

of

the

com-

re-

pletion

command

The

L

each

Return

•

p

.

.

When

end

the

designated

returns

sequence

P.

of

specified

returns

command

execution

Block

.

M99

address

an

of

subprogram,

by

the

to

number

times

to

must

this

of

Instruction

*

is

P

address

the

of

block

is

designated

of

the

main

be

programmed

instruction.

from

commanded

return

P.

main

execution,

program,

Subprogram:

with

block

The

program

by

the

the

in

M99

can

program

whose

address

at

be

>

—

NOTE:

"Subprogram"

•

ified

by

consideration

editing

M98

•

•

Signals

chine

•

The

P

ory

the

ed.

should

When

•

addressPis

•

Addresses

Up

cannot

.

sequence

searched

is

and

first

Therefore,

the

to

four-digit

of

not

command.

M98

subprogram.

be

M98

of

execution

the

block

used.

be

sequence

not

and

P

N

N2

N3

N4

N5

N6

N7

N8

N9

N10

Nil

N12

simply

not

is

used

and

number

from

of

the

the

found,

N

number

(Main

1

PS1

P58

PH

means

Therefore,

required

a

subprogram.

in

are

M99

designated

first

the

of

program

sequence

same

number

it

designate

can

Program)

M98

LI

L3

M98

M99

M30

the

for

not

address

number

sequence

designated

causes

sequence

used

be

program

storing

to

fed

the

by

starts

number

error.

*

a

a

a

a

a

a

*

a

a

a

a

any

the

of

search¬

by

numbers.

for

Fig.

spec¬

special

and

ma¬

address

mem¬

from

the

se-

-*ÿ

2.7.4.

'

i

1

quence

suppressed.

•

The

sum

subprogram

capacity

Address

-

command.

•

remaining

The

gram

and

the

tor

during

•

•

P

Subprogram

•

MDl

in

Endless

•

command

button

first

the

2.7.4.2(a).

»

i

numbers

of

of

L

is

displayed

address

L

•

mode

program

in

is

depressed,

address

(Subprogram)

N51

N52

N53

N54

N55

N56

N57

N58

N59

N60

N61

N62

P7

and

the

characters

should

control.

the

cannot

the

•

number

L

operation

.

.

cannot

be

when

is

M98

.

can

a

main

of

M99

M99

leading

not

exceed

used

of

POS

on

set

of

a.

be

executed

be

made

program.

the

program

memory.

a

a

a

a

a

a

a

a

a

a

a

a

zeros

main

of

the

together

repetitions

key

the

address

repeating

by

by

When

Refer

can

program

memory

with

of

is

depressed

command

writing

using

the

returns

to

be

and

M99

subpro¬

indica¬

M98

M99

RESET

to

Fig.

-13-

Page 22

•

part

Some

be

can

times

WhenMcodes

storedinadvance

when

programs

In

need.

causing

which

Refer

rewind

and

to

frequently

are

executed

Fig.

{M02

2,

required

7.

or

4.

M30)

2

used

(b).

is

used,

dress.

are

commanded,

executed

the

When

program

M

as

a

main

returns

codes

the

program.

causing

following

the

to

internal

program

initial

ad¬

reset

is

Ml

M2

N29

N30

N31

N59

N60

N61

•

•

PI

• •

P31

L10

LIS

M98

M98

M30

*

*

*

150

Ml

M2