Page 1

YASKAWA AC Drive A1000 Option

120 Vac Digital Input

Installation Manual

Type: DI-101

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end

user receives this manual.

E(G)

HC H1 H2 DM+ DM- IG R+ R- S+ S-

M3 M6 M4

V+ AC V- A1 A2 A3 FM AM AC MP RP AC

S1 S2 S3 S4 S5 S6 S7 S8 SN

S1 S2 S3 S4 S5 S6 S7 S8 SN

MANUAL NO. TOEP YEAOPT 07

SC SP

M1 M2 M5

MA MB MC

Page 2

Copyright © 2011 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of Yaskawa. No patent liability is assumed with respect to the use of the

information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality

products, the information contained in this manual is subject to change without notice. Every precaution has

been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

2 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 OPTION COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 10

6 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 3

Page 4

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS

OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses,

or claims arising from misapplication of its products.

◆ Applicable Documentation

The following manuals are available for the option and drive:

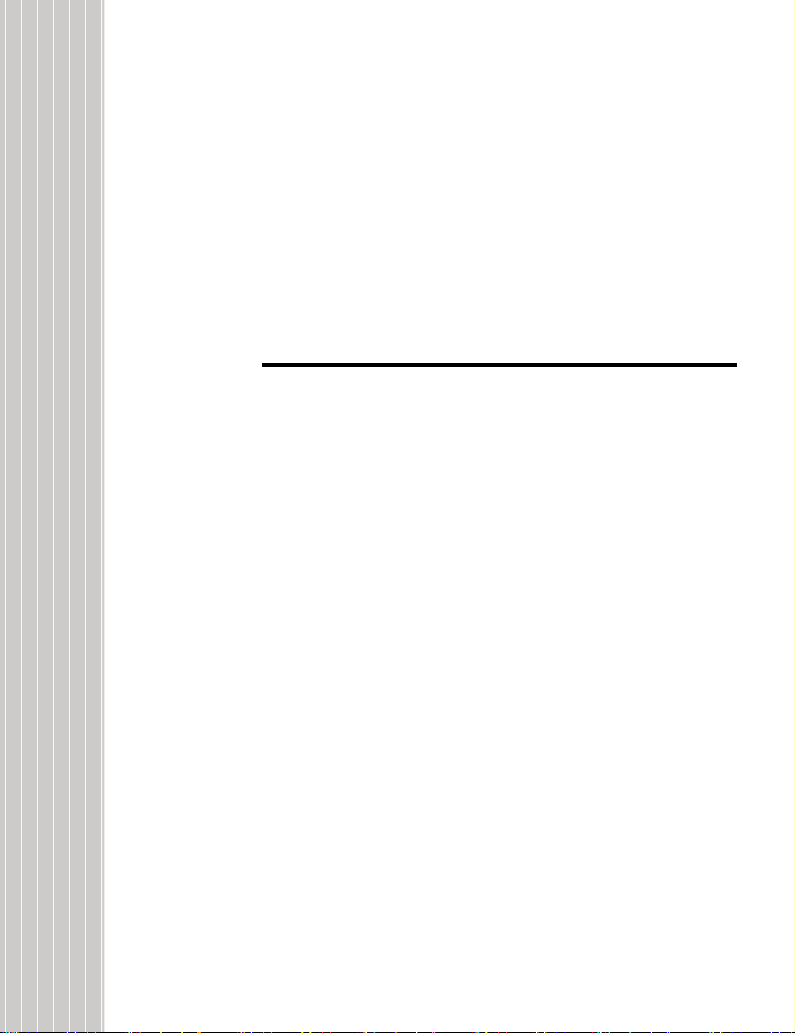

Option

Yaskawa AC Drive -A1000 Option

DI-101 120 Vac Interface

Installation Manual

Manual No: TOEP YEAOPT 07

Read this manual first.

The installation manual is packaged with the

DI-101 120 Vac Interface Option and contains

installation procedures and precautions.

Yaskawa Drive

Yaskawa AC Drive

A1000-Series

Quick Start Guide

Yaskawa AC Drive

A1000-Series

Technical Manual

4 YASKAWA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

The drive manuals cover basic installation,

wiring, operation procedures, functions,

troubleshooting, and maintenance information.

The manuals also include important

information about parameter settings and drive

tuning. Access these sites to obtain Yaskawa

instruction manuals:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

For questions, contact your local Yaskawa sales

office or the nearest Yaskawa representative.

Page 5

1 Preface and Safety

DANGER

W ARNING

CAUTION

NOTICE

◆ Terms

Note: Indicates supplemental information that is not related to safety messages.

Drive: Yaskawa AC Drive A1000-Series

Option: Yaskawa AC Drive A1000-Series Option Digital Input DI-101

◆ Registered Trademarks

Trademarks are the property of their respective owners.

◆ Supplemental Safety Information

Read and understand this manual before installing, operating, or servicing this option. Install

the option according to this manual and local codes.

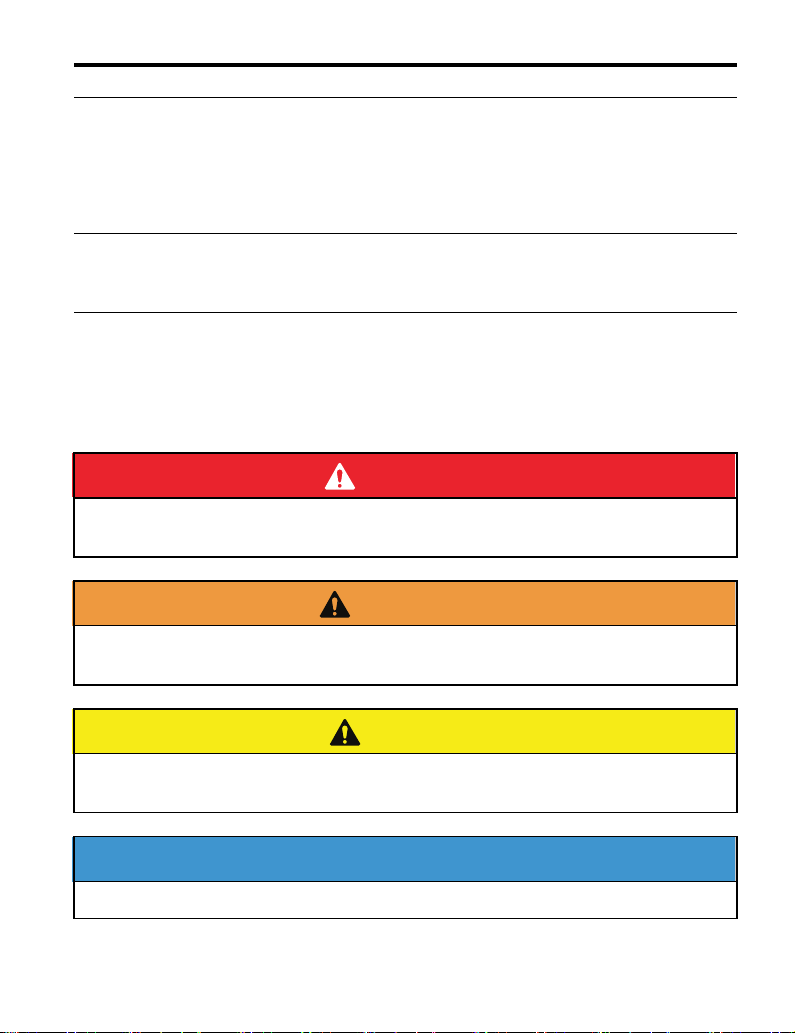

The following conventions indicate safety messages in this manual. Failure to heed these

messages could cause fatal injury or damage products and related equipment and systems.

Indicates a hazardous situation, which, if not avoided, will result in death or serious

injury.

Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate injury.

Indicates an equipment damage message.

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 5

Page 6

1 Preface and Safety

DANGER

NOTICE

■ General Safety

General Precautions

• The diagrams in this book may include options and drives without covers or safety shields to

illustrate details. Be sure to reinstall covers or shields before operating any devices. Use the option

according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and

may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering new copies of the manual, contact a Yaskawa representative or the nearest Yaskawa

sales office and provide the manual number shown on the front cover.

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting

from failure to heed the warnings in this manual.

Do not modify the drive or option circuitry.

Failure to comply could result in damage to the drive or option and will void warranty.

Yaskawa is not responsible for any modification of the product made by the user. This

product must not be modified.

Do not expose the drive or option to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the drive or option.

Do not pack the drive in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

6 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 7

2 Product Overview

2 Product Overview

◆ About this Product

The DI-101 option has eight optically isolated input terminals that can be used to connect

external 120 Vac control circuitry to the A1000 drive. The DI-101 option mounts directly to

the A1000 control board terminals (S1 to S8 and SN). This option makes it possible to

control the A1000 digital inputs with 120 Vac.

This manual explains the handling, installation and specifications of this product.

◆ Applicable Models

The option can be used with the drive models in Table 1.

Tab le 1 Applicable Models

Drive Series Drive Model Number

A1000 All models (excluding A1000 HHP models)

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 7

Page 8

3 Receiving

S1 S2 S3 S4 S5 S6 S7 S8 SN

MANUAL

3 Receiving

Please perform the following tasks upon receiving the option:

• Inspect the option for damage. Contact the shipper immediately if the option appears

damaged upon receipt.

• Verify receipt of the correct model by checking the model number printed on the option

packaging. (Refer to Figure 1 on page 9 for more information)

• Contact your supplier if you have received the wrong model or the option does not

function properly.

◆ DI-101 Option Package Contents

Description:

–

Quantity: 11

PCB 120 V Interface Card

UTC000450,RB

Installation Manual

◆ Tools Required for Installation

• A Phillips screwdriver (M3 metric / #1, #2 U.S. standard size) is required to install the

option.

• A straight-edge screwdriver (blade depth: 0.4 mm, width: 2.5 mm) is required to wire the

option terminal block.

Note: Tools required to prepare option cables for wiring are not listed in this manual.

8 YASKAWA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 9

4 Option Components

A

B

C

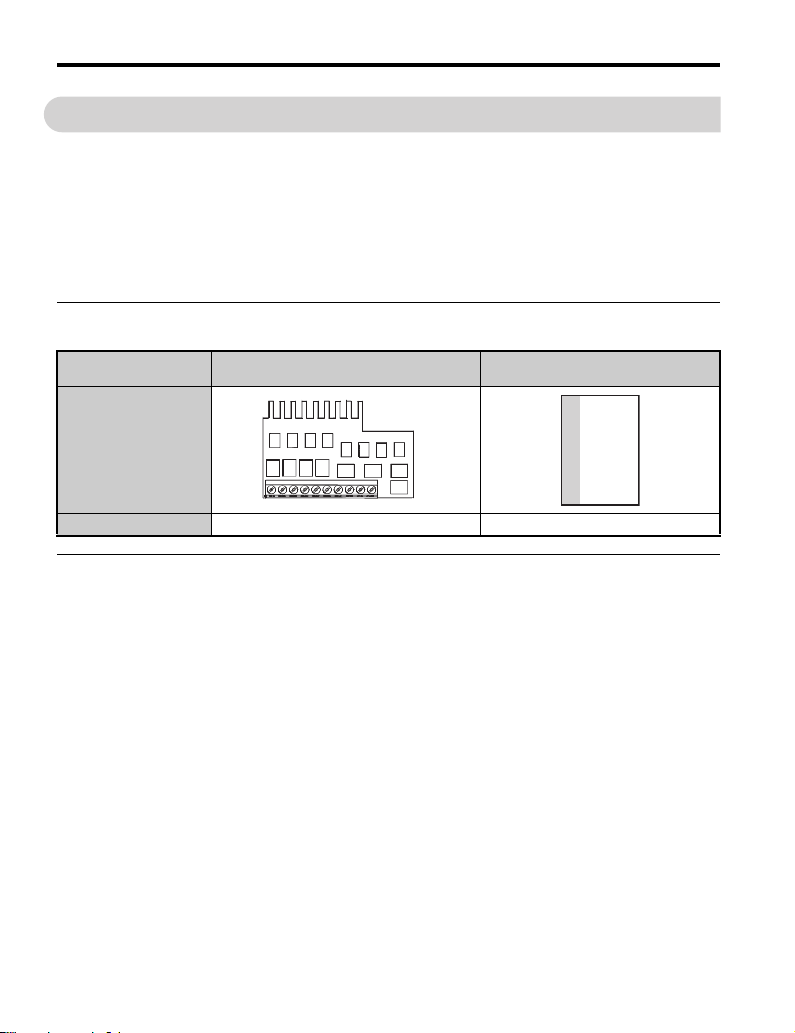

4 Option Components

◆ DI-101 Option

Figure 1

A – DI-101 120 V Interface Card

B – Option terminals (to drive)

C – Option terminal block (to control wiring)

Figure 1 DI-101 Option

◆ Option Terminal Block TB1

An 10-position terminal block is provided for the connection of 120 Vac and common signal

control wires.

Tab le 2 Option Terminal Functions

Terminal Functions

DI-101 Option Terminal Block Ter mi nal Signal Function Description

S1 Forward Run / Stop <1>

S2 Reverse Run / Stop <1>

S3 Multi-function Input <1>

S4 Multi-function Input <1>

S5 Multi-function Input <1>

S6 Multi-function Input <1>

S7 Multi-function Input <1>

S8 Multi-function Input <1>

X2 Common Control Input Common

X2 Common (spare) Control Input Common

<1> Terminal functions S1 to S8 may change based on drive programming.

Forward Run when closed,

stop when open (H1-01)

Reverse Run when closed,

stop when open (H1-02)

Multi-function contact inputs

(H1-03 to H1-08)

Signal

Level

120 Vac

±10 %

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 9

Page 10

5 Installation Procedure

W ARNING

5 Installation Procedure

◆ Section Safety

DANGER

Electric Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply will result in death or serious injury.

Disconnect all power to the drive and wait at least the amount of time specified on the

drive front cover safety label. After all indicators are off, measure the DC bus voltage to

confirm safe level, and check for unsafe voltages. The internal capacitor remains charged

after the power supply is turned off.

Electrical Shock Hazard

Do not remove the front covers of the drive while the power is on.

Failure to comply could result in death or serious injury.

The diagrams in this section may include options and drives without covers or safety

shields to show details. Be sure to reinstall covers or shields before operating any devices.

Use the option according to the instructions described in this manual.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized

personnel familiar with installation, adjustment, and maintenance of this product.

Do not touch circuit boards while the power to the drive is on.

Failure to comply could result in death or serious injury.

10 YASKAWA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 11

5 Installation Procedure

NOTICE

W ARNING

Do not use damaged wires, place excessive on wiring, or damage the wire insulation.

Failure to comply could result in death or serious injury.

Fire Hazard

Tighten all terminal screws to the specified tightening torque.

Loose electrical connections could result in death or serious injury by fire due to

overheating of electrical connections.

Damage to Equipment

Observe proper electrostatic discharge (ESD) procedures when handling the option,

drive, and circuit boards.

Failure to comply may result in ESD damage to circuitry.

Never shut the power off while the drive is running or outputting voltage.

Failure to comply may cause the application to operate incorrectly or damage the drive.

Do not operate damaged equipment.

Failure to comply may cause further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

Do not use unshielded cable for control wiring.

Failure to comply may cause electrical interference resulting in poor system performance.

Use shielded twisted-pair wires and ground the shield to the ground terminal of the drive.

Properly connect all pins and connectors.

Failure to comply may prevent proper operation and possibly damage equipment.

Check wiring to ensure that all connections are correct after installing the option

and connecting any other devices.

Failure to comply may result in damage to the option.

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 11

Page 12

5 Installation Procedure

A

◆ Prior to Installing the Option

Prior to installing the option, wire the drive, make the necessary connections to the drive

terminals, and verify that the drive functions normally. Refer to the Quick Start Guide

packaged with the drive for information on wiring and connecting the drive.

Figure 2 is an exploded view of the drive with the option and related components for

reference.

Figure 2

E

D

C

A – A1000 Drive D – Terminal Cover

B – DI-101 Option E – A1000 TB1 - Digital Input Terminal Block,

C – Cover Screw

Figure 2 Drive Components with Option

12 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

B

Insertion Point for DI-101 Option

Page 13

5 Installation Procedure

D

C

◆ Installing the Option

Refer to the following instructions to install the option.

1. Shut off power to the drive, wait the appropriate amount of time for voltage to

dissipate. Remove the terminal cover screw (C) then remove the terminal cover (D).

Refer to the Quick Start Guide packaged with the drive for directions on removing

the cover. Cover removal varies depending on drive size.

DANGER! Electrical Shock Hazard. Disconnect all power to the drive and wait at least the amount of time

specified on the drive front cover safety label. After all indicators are off, measure the DC bus voltage to

confirm safe level, and check for unsafe voltages before servicing to prevent electric shock. The internal

capacitor remains charged even after the power supply is turned off.

NOTICE: Damage to Equipment. Observe proper electrostatic discharge procedures (ESD) when handling

the option, drive, and circuit boards. Failure to comply may result in ESD damage to circuitry.

Figure 3

Figure 3 Terminal Cover Removal

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 13

Page 14

5 Installation Procedure

TB1

2. Loosen terminals S1 to S8 and SN on the A1000 drive digital Input terminal block

Figure 4

TB1.

Figure 4 Loosen Drive Control Terminals TB1 S1 to S8 and SN

3. Remove the DI-101 option from the ESD bag.

NOTICE: When handling printed circuit boards (PCB) always use electrostatic discharge (ESD) protection.

Keep the boards in the ESD bag as long as you can. Do not lay the board on any surfaces without the ESD

protection. When handling, always hold the board from the edges and do not touch the components. Before

installing this option, a technically qualified individual, familiar with this type of equipment and the hazards

involved, should read this entire installation guide.

14 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 15

5 Installation Procedure

4. Insert the DI-101 option (B) into the A1000 drive control terminals TB1, S1 to S8

and SN at the insertion point (E).

Refer to Figure 6 for the proper placement of the option terminals into the drive TB1

terminals. Secure the DI-101 option by tightening the TB1 terminals S1 to S8 and

SN. Refer to Wire Gauges, Tightening Torques, and Crimp Terminals on

Figure 5

page 20 to confirm that the proper tightening torque is applied to each terminal.

E

B

Figure 5 DI-101 Option Insertion into TB1

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 15

Page 16

5 Installation Procedure

DI-101

Option

A1000 Drive Terminals

Terminal Block

TB1

Wire Jumper

MA MB MC

M1 M2 M5

M3 M6 M4

E(G)

HC H1 H2 DM+ DM- IG R+ R- S+ S-

SC SP

V+ AC V- A1 A2 A3 FM AM AC MP RP AC

S1 S2 S3 S4 S5 S6 S7 S8 SN

S1 S2 S3 S4 S5 S6 S7 S8 SN

Figure 6

Figure 6 DI-101 Option to Drive Connection

5. Ensure the factory installed wire jumper is present between TB1 terminals SC to SP.

If no wire jumper is present, prepare and install a jumper according to Figure 7.

Route the customer-supplied option wiring through one of the cable glands on the

A1000 drive bottom conduit bracket.

16 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 17

5 Installation Procedure

S1S2 S3S4 X2X2S8S7S6S5

DI-101 Option Terminal Block

Preparing wire ends:

Screwdriver blade size

about 5.5 mm (7/32”)

When not using

crimped insulated

sleeves

Strip wire insulation about 5.5 mm

and lightly twist the end with fingers,

keeping the ends from fraying.

Customer-supplied

120 Vac control circuit wires

(do not solder ends)

Loosen the screws and

insert the wire into the

opening on each terminal.

Blade depth of

0.4 mm or less

Blade width of

2.5 mm or less

6. Prepare the external 120 Vac control circuit wires (customer supplied) for terminals

Figure 7

S1 to S8 and X2 on the DI-101 option as shown in Figure 7.

Figure 7 Preparing Cable Wiring

7. Connect the customer wiring to the DI-101 option terminal block. Refer to Figure 8

for a wiring diagram example showing customer interface circuitry.

Refer to Wire Gauges, Tightening Torques, and Crimp Terminals on page 20 to

confirm that the proper tightening torque is applied to each terminal. Take particular

precaution to ensure each wire is properly connected and wire insulation is not

accidentally pinched into electrical terminals.

WARNING! Fire Hazard. Tighten terminal screws to the specified tightening torque. Loose electrical

connections could result in death or serious injury by fire due to overheating. Tightening screws beyond the

specified tightening torque may cause erroneous operation, damage the terminal block, or cause a fire.

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 17

Page 18

5 Installation Procedure

Figure 8

Customer Supplied Circuit

FWD

REV

S3

S4

S5

S6

S7

S8

120 Vac

X1

TB1

S1

S2

S3

S4

S5

S6

S7

S8

X2

X2

DI-101

120 Vac Interface

Option

Opto-Coupler

x8

3 mm Isolation

J2

Yaskawa A1000

AC Drive

S1

S1 Forward Run/Stop

S2

S2 Reverse Run/Stop

S3

S3 External fault

S4

S4 Fault reset

S5

S5 Multi-step speed 1

S6

S6 Multi-step speed 2

S7 Jog reference

S7

S8

S8 External baseblock

SN

Figure 8 Wiring Diagram Example

To ensure accurate control, use a stable 120 Vac power supply for the DI-101 input voltage

source.

18 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 19

8. Replace terminal cover (D) and secure screw (C).

C

D

Figure 9

5 Installation Procedure

Figure 9 Replace the Terminal Cover

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 19

Page 20

5 Installation Procedure

d1

d2

6 mm

L

◆ Wire Gauges, Tightening Torques, and Crimp Terminals

■ Wire Gauges and Tightening Torques

Wire gauge and torque specifications are listed in Table 3.

Tab le 3 Wire Gauges and Tightening Torques

Ter mi nal

signal

S1 to S8

and X2

Screw

Size

M2

Tightening

Torque

N.m (in.lb)

0.22 to 0.25

(1.95 to 2.21)

(24 to 17 AWG)

(24 to 16 AWG)

■ Crimp Terminals

Yaskawa recommends using CRIMPFOX 6 by Phoenix Contact or equivalent crimp

terminals with the specifications listed in Table 4 for simplier and more reliable wiring.

Wire Gauge

2

mm

0.25 (24 AWG) AI 0.25 - 6YE 10.5 (13/32) 0.8 (1/32) 2 (5/64)

0.34 (22 AWG) AI 0.34 - 6TQ 10.5 (13/32) 0.8 (1/32) 2 (5/64)

0.5 (20 AWG) AI 0.5 - 6WH 14 (9/16) 1.1 (3/64) 2.5 (3/32)

Bare Cable Crimp Terminals

Applicable

Gauges mm

Stranded wire:

0.25 to 1.0

Solid wire:

0.25 to 1.5

Recomm.

2

Gauge mm

0.75

(18 AWG)

Applicable

2

Gauges mm

0.25 to 0.5

(24 to 20 AWG)

Tab le 4 Crimp Terminal Sizes

Phoenix Contact

Model

L

mm (in)

Recomm.

2

Gauge mm

(20 AWG)

d1

mm (in)

0.5

2

Stranded

or solid

d2

mm (in)

Wire

Typ e

wire

20 YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 21

6 Troubleshooting

6 Troubleshooting

Troubleshooting tips are provided below. Verify these points if the drive performance is not

as expected after installing the option:

• Verify all wire connections are tight.

• Verify all DI-101 PCB Fingers are fully inserted into the A1000 TB1 drive terminals and

the terminals are fully tightened.

• Verify the factory installed wire jumper is installed between A1000

TB1 terminals SC to SP.

• Verify the signal is present at the DI-101 option input terminals by using an AC voltmeter

to measure for a 120 Vac input signal is present on any activated terminals S1 thru S8 with

respect to the X2 terminal.

• Verify the digital input is recognized by the drive by viewing Input Terminal Status

monitor parameter U1-10.

• Verify the drive Multi-Function Digital Input parameters (H1-01 through H1-08) of the

drive are set correctly for the expected S1 to S8 input terminal behavior.

Preventing Noise Interference

Take the following steps to prevent erroneous operation caused by conducted electrical noise

interference:

• Use shielded wire for the signal lines less than 24 V.

• Limit the length of I/O signal wiring to less than 50 m (164 ft.).

• Use seperate conduits or cable tray separation for 120 Vac control wiring, DC signal and

other I/O wiring, main circuit power lines.

• Use noise suppression on relay coils.

• Ensure adequate system and drive grounding.

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 21

Page 22

7 Specifications

MANUAL NO. TOEP YEAOPT 07

Published in USA May 2011 11-5

Date of publication

Date of original publication

Revision number

1

7 Specifications

Tab le 5 Option Specifications

Specification Data

Inputs 8 Digital Inputs , +2 Neutral Common

Input Impedance 10 Kohms

On-State Voltage 93 to 132 Vac (110/120 Vac +10 % / -15 %)

On-State Current, Nominal 12.5 mA @ 120 Vac

Off-State Voltage, Maximum 19 Vac

Off-State Leakage Current, Maximum 4.0 mA

Operating Frequency 57 to 63 Hz (+/- 15 %)

On-State Response Time, Maximum 50 ms

Off-State Response Time, Maximum 50 ms

Terminal Wiring 16 AWG to 26 AWG

Area of Use Indoors

Operating Temperature -10 to +60 degrees C

Storage Temperature

Humidity 95% Relative Humidity or less (non condensing)

Revision History

Revision dates and manual numbers are located on the bottom of the back cover.

-20 to +85 degrees C

(short-term temperature during transport)

Date of

Publication

May 2011 −−First edition

Revision

Number

Section Revised Content

22 YASKAWA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual

Page 23

7 Specifications

YAS KA WA TOEP YEAOPT 07 A1000 Option DI-101 120 Vac Interface Installation Manual 23

Page 24

YASKAWA AC Drive-A1000 Option

DI-101 120 Vac Interface Option

Installation Manual

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: 81-930-25-3844 Fax: 81-930-25-4369

http://www.yaskawa.co.jp

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4502 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brasil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstrasse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

http://www.yaskawa.co.uk

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Yeoungdungpo-gu, Seoul, 150-877, Korea

Phone: 82-2-784-7844

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, 17F, Harbour Ring Plaza, Shanghai, 200001, China

Phone: 86-21-5385-2200

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone: 886-2-2502-5003

Fax: 55-11-5581-8795

Fax: 44-1236-458182

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

YASKAWA AMERICA, INC.

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be

sure to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2011 YASKAWA AMERICA, INC. All rights reserved.

MANUAL NO. TOEP YEAOPT 07

Published in USA May 2011 11-5

Loading...

Loading...