Page 1

YASKAWA AC Drive - V1000 Option

1000 Hz High Frequency

Custom Software

Supplement

Software No. VSV90503X

To properly use the product, read this manual thoroughly

and retain for easy reference, inspection, and maintenance.

Ensure the end user receives this manual.

MANUAL NO. EZZ020793

Page 2

This Page Intentionally Blank

Copyright 2008 YASKAWA ELECTRIC CORPORATION. All rights reserved.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or tra nsmitted, in any form or by any

means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability

is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its

high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication

2 YASKAWA ELECTRIC EZZ020793 V1000 High Frequency Custom Software Supplement

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 MODIFICATIONS FROM STANDARD SOFTWARE . . . . . . .9

4 MODIFIED PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . .10

5 NEW AND MODIFIED SOFTWARE FUNCTIONS . . . . . . . . 13

6 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Refer to the V1000 Technical Manual for content not described in this document.

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 3

Page 4

This Page Intentionally Blank

4 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Page 5

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESSED OR IMPLIED,

IS OFFERED. Yaskawa assumes no liability for any personal injury, property damage,

losses, or claims arising from misapplication of its products.

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 5

Page 6

1 Preface and Safety

◆ Applicable Documentation

The following manuals are available for the V1000 1000 Hz Drive:

Option Supplement

Yaskawa AC Drive -V1000 1000 Hz High Frequency Custom Software Supplement

SUPPLEMENT

Manual No: EZZ020793

Read this manual first.This supplement is an addendum to V1000 Quick Start Guide and

Technical

Manual. It lists the effect of this custom software on the parameters in the drive and function

descriptions in the manual.

To obtain the supplement access this site:

U.S.: http://www.yaskawa.com

Yaskawa Drive

To obtain instruction manuals for Yaskawa products

access these sites:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

Other areas: contact a Yaskawa representative.

For questions, contact the local Yaskawa sales office or

the nearest Yaskawa representative.

STOP

V1000

ᵄᢙᜰ

ᱜォㅒォㆬᛯ

ജᵄᢙ

ജ㔚ᵹ

ജ㔚

ࡕ࠾࠲

ࡌࡈࠔࠗ

࠶࠻ࠕ࠶ࡊ

ࡄࡔ࠲⸳ቯ

ࠝ࠻࠴ࡘ࠾ࡦࠣ

ߌ߇㧚ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ෂޓ㒾

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ߎߣޕ

ಽએౝߪࡈࡠࡦ࠻ࠞࡃࠍ

ㅢ㔚߅ࠃ߮㔚Ḯㆤᢿᓟ

5

ᄖߐߥߎߣޕ

⚖ࠗࡦࡃ࠲ߩ႐วߪޔ㔚Ḯߩᕈὐ߇ធ

400V

ߐࠇߡࠆߎߣࠍ⏕ߔࠆߎߣޕ㧔ޓޓኻᔕ㧕

Yaskawa AC Drive-V1000

Quick Start Guide

(Hz)

(Hz)

(A)

(V)

Yaskawa AC Drive-V1000

Technical Manual

6 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Page 7

1 Preface and Safety

◆ Supplemental Safety Information

Read and understand this manual and the V1000 Quick Start Guide before installing,

operating, or servicing this option unit. The drive must be installed according to the V1000

Quick Start Guide and local codes. Observe all cautions and warnings in this document and

the standard drive technical manuals.

Refer to the V1000 Quick Start Guide and the V1000 Technical Manual for safety

information and installation and start-up instructions.

This document is a supplement to the standard drive technical manual. It describes the

effects on the drive parameters and functions with the software installed.

• Custom software is provided to add functionality to a standard AC drive to enhance or

enable use in a specific application.

• The software is loaded to the flash ROM area of the control board, and replaces the

standard drive software.

◆ Obtaining Support

When seeking support for a drive with custom software, it is imperative to provide the

unique part number shown on the drive nameplate. The software is flashed to the control

board memory and the operation of parameters, functions, and monitors are different than

the standard drive software, as described herein.

Refer to Yaskawa office locations listed on the back cover of this supplement.

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 7

Page 8

2 Product Overview

2 Product Overview

◆ About This Product

This custom software is designed for high frequency motor applications. The drive's

maximum output frequency can be set up to 1000 Hz. Non-applicable drive functions are

deleted in order to optimize CPU processing time for this software.

◆ Applicable Models

The 1000 Hz Option is available in these drive models in Table 1.

Table 1 Applicable Models

Drive Software Version <1>

CIMR-VUBAA = 503

CIMR-VUBBA = 503

CIMR-VUBFA = 503

<1> See “PRG” on the drive nameplate for the software version number.

8 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Page 9

3 Modifications from Standard Software

3 Modifications from Standard Software

Changed Item High Frequency Software Standard Software

Applicable Drive Models All All

Maximum Output Frequency 1000 Hz 400 Hz

Carrier Frequency

Drive Current Rating Fixed at Heavy Duty (HD) ratings Depends on C6-01

Drive Overload Rating Fixed at 150%/1 min. (C6-01 fixed) Depends on C6-01

Control Mode Fixed at V/f (A1-02 fixed) V/f, OLV, OLV for PM

DriveWorksEZ (DWEZ) No Available

Communication Option Kits No Available

Frequency Setting Resolution Fixed at 0.1 Hz

Frequency reference and output

frequency display units.

Torque Compensation

On-Delay Compensation

Stall Prevention Level During

Acceleration (L3-02)

Deleted Functions

<1> MEMOBUS/Modbus frequency reference can be set by 0.1 Hz. For 1000 Hz reference, 10000 (2710Hex) must be

set to 0002Hex MEMOBUS/Modbus register.

<2> Also applies to register data via MEMOBUS/Modbus RTU communication.

Max: 7 kHz

C6-02: 2, B, C, F

o1-03 parameter (same as b5-20)

0: 0.1 Hz

1: 0.01 (Max frequency 100%)

<1> <2>

2: Deleted

3: User Defined (o1-10 and o1-11)

Enabled only at low speeds.

Refer to New and Modified Software

Functions on page 13.

Enabled only at low speeds. Addition of OnDelay Compensation Selection parameter

S1-01

Refer to New and Modified Software

Functions on page 13.

Maximum setting: 170% Maximum setting: 150%

• All OLV and OLV for PM specific

parameters

• All OLV and OLV for PM specific

monitors

• Estimation type Speed Search

• High Slip Braking (HSB)

• Auto-Tuning

•KEB

• Overexcitation Deceleration

Refer to Modified Parameters on page 10.

Max: 15 kHz

C6-02: 1 ~ A, F

0.01 Hz (less than 100 Hz)

0.1 Hz (above 10 Hz)

o1-03 parameter (same as b5-20)

0: 0.1 Hz

1: 0.01 (Max frequency 100%)

2: RPM

3: User Defined (o1-10 and o1-11)

Constant throughout the entire

frequency range.

Enabled throughout the entire

frequency range.

-

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 9

Page 10

4 Modified Parameters

4 Modified Parameters

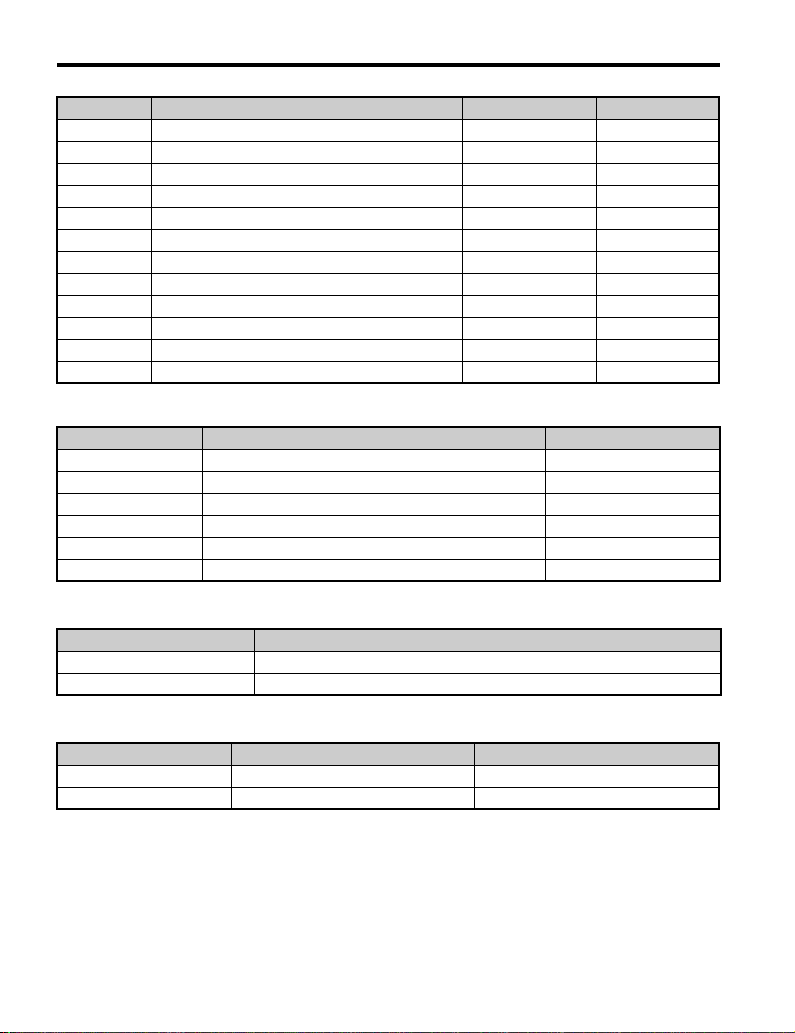

Table 2 Deleted Parameters from Standard Software

Parameter Name

A1-06 Application Preset

b3-06 Output Current 1 during Speed Search (Estimation Type)

b3-10 Speed Search Detection Compensation Gain (Estimation Type)

b3-24 Speed Search Method Selection

b8-01 ~ b8-19 Energy Saving Control Parameters

C6-01 Normal/Heavy Duty Selection

E3-01 Motor 2 Control Method Selection

L2-06 ~ L2-11 KEB Parameters

L3-11 ov Suppression Function Selection

n3-01 ~ n3-23 High Slip Braking/Overexcitation Deceleration Parameters

T1-01 ~ T1-08 Motor Tuning Parameters

Table 3 Deleted Multi-function Digital Inputs (H1 Group)

Setting Function

65 KEB Ride-thru 1 (N.C.)

66 KEB Ride-thru 1 (N.O.)

68 HSB (High Slip Braking)

7A KEB Ride-thru 2 (N.C.)

7B KEB Ride-thru 2 (N.O.)

Table 4 Deleted Multi-function Digital Outputs (H2 Group)

Setting Function

4A KEB Operation

Table 5 Modified Parameter Setting Ranges

Parameter Name Setting Range

A1-02 Control Method Selection 0

b4-01 Timer Function On-Delay Time 0.0 ~ 3000.0 s

b4-02 Timer Function Off-Delay Time 0.0 ~ 3000.0 s

b5-20 PID Setpoint Scaling 0, 1, 3

H6-01 Pulse Train Input Terminal RP Function Selection 0, 1, 2

L3-02 Stall Prevention Level during Acceleration 0 ~ 170%

10 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Page 11

4 Modified Parameters

Parameter Name Setting Range

L3-04 Stall Prevention Selection during Deceleration 0 ~ 3

o1-03 Digital Operator Display Selection 0, 1, 3

Table 6 Parameters with Modified Defaults

Parameter Name Setting Range Default Note

b2-04 DC Injection Braking Time at Stop 0.0 ~ 10.0 0.0 s Previous default: 0.5

n1-01 Hunting Prevention Selection 0, 1 0 (off) Previous default: 1 (on)

Tab l e 7 N e w P aramet e r

Parameter Name Setting Range Default Note

S1-01 On-Delay Compensation Selection 0, 1 1 0: Disabled, 1: Enabled

Table 8 Parameters with Modified Upper Limits

Parameter Name Setting Range Default

b5-19 PID Setpoint Value 0.0 ~ 1000.0 0.0 Hz

C1-11 Accel/Decel Time Switching Frequency 0.0 ~ 1000.0 0.0 Hz

d1-01 Frequency Reference 1 0.0 ~ 1000.0 0.0 Hz

d1-02 Frequency Reference 2 0.0 ~ 1000.0 0.0 Hz

d1-03 Frequency Reference 3 0.0 ~ 1000.0 0.0 Hz

d1-04 Frequency Reference 4 0.0 ~ 1000.0 0.0 Hz

d1-05 Frequency Reference 5 0.0 ~ 1000.0 0.0 Hz

d1-06 Frequency Reference 6 0.0 ~ 1000.0 0.0 Hz

d1-07 Frequency Reference 7 0.0 ~ 1000.0 0.0 Hz

d1-08 Frequency Reference 8 0.0 ~ 1000.0 0.0 Hz

d1-09 Frequency Reference 9 0.0 ~ 1000.0 0.0 Hz

d1-10 Frequency Reference 10 0.0 ~ 1000.0 0.0 Hz

d1-11 Frequency Reference 11 0.0 ~ 1000.0 0.0 Hz

d1-12 Frequency Reference 12 0.0 ~ 1000.0 0.0 Hz

d1-13 Frequency Reference 13 0.0 ~ 1000.0 0.0 Hz

d1-14 Frequency Reference 14 0.0 ~ 1000.0 0.0 Hz

d1-15 Frequency Reference 15 0.0 ~ 1000.0 0.0 Hz

d1-16 Frequency Reference 16 0.0 ~ 1000.0 0.0 Hz

d1-17 Jog Frequency Reference 0.0 ~ 1000.0 0.0 Hz

d3-01 Jump Frequency 1 0.0 ~ 1000.0 0.0 Hz

d3-02 Jump Frequency 2 0.0 ~ 1000.0 0.0 Hz

d3-03 Jump Frequency 3 0.0 ~ 1000.0 0.0 Hz

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 11

Page 12

4 Modified Parameters

Parameter Name Setting Range Default

E1-04 Maximum Output Frequency 0.0 ~ 1000.0 60.0 Hz

E1-06 Base Frequency 0.0 ~ 1000.0 60.0 Hz

E1-07 Mid Output Frequency 0.0 ~ 1000.0 3.0 Hz

E1-09 Minimum Output Frequency 0.0 ~ 1000.0 1.5 Hz

E1-11 Mid Output Frequency 2 0.0 ~ 1000.0 0.0 Hz

E3-04 Motor 2 Maximum Output Frequency 0.0 ~ 1000.0 60.0 Hz

E3-06 Motor 2 Base Frequency 0.0 ~ 1000.0 60.0 Hz

E3-07 Motor 2 Mid Output Frequency 0.0 ~ 1000.0 3.0 Hz

E3-09 Motor 2 Minimum Output Frequency 0.0 ~ 1000.0 1.5 Hz

E3-11 Motor 2 Mid Output Frequency 2 0.0 ~ 1000.0 0.0 Hz

L4-01 Speed Agreement Detection Level 0.0 ~ 1000.0 0.0 Hz

L4-03 Speed Agreement Detection Level (+/-) -999.9 ~ 999.9 0.0 Hz

Table 9 Modified Monitors

Parameter Name Setting Range

U1-01 Frequency Reference 0.0 ~ 1000.0 Hz

U1-02 Output Frequency 0.0 ~ 1000.0 Hz

U1-16 Output Frequency after Soft Start 0.0 ~ 1000.0 Hz

U2-03 Frequency Reference at Previous Fault 0.0 ~ 1000.0 Hz

U2-04 Output Frequency at Previous Fault 0.0 ~ 1000.0 Hz

U4-14 Peak Hold Output Frequency 0.0 ~ 1000.0 Hz

Table 10 Deleted Monitors

Parameter Name

U1-05 Motor Speed

U1-09 Torque Reference

Table 11 MEMOBUS/Modbus Communication Data

Register Name Data

2H Frequency Reference Setting upper limit 40000 to FFFFH

3EH Output Frequency RPM Deleted

12 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Page 13

5 New and Modified Software Functions

5 New and Modified Software Functions

◆ Carrier Frequency

• The carrier frequency upper limit changed from 15.0 kHz to 7.0 kHz and two new patterns

were added. See Figure 1.

• The carrier frequency selection parameter (C6-02) has been modified according to

Ta bl e 1 2.

• Refer to Application Notes on page 15 for more information.

Table 12 Carrier Frequency Selection Parameter (C6-02) Settings

C6-02

Carrier

Frequency

Selection

2 5.0 5.0 0 Same as standard

B 7.0 1.0 12 New setting

C 7.0 1.0 8 New setting

F 2.0 2.0 0 Same as standard

Figure 1

Carrier

Frequency

C6-03

Carrier

Frequency

Upper Limit

Parameter C6-02 = C

C6-04

Carrier

Frequency

Lower Limit

C6-05

Carrier Frequency

Proportional Gain

Carrier

Frequency

Note

Parameter C6-02 = B

7.0 kHz

1.0 kHz

62 Hz

437 Hz

E1-04

Figure 1 Additional Carrier Frequency Patterns

Output

Frequency

7.0 kHz

1.0 kHz

42 Hz

292 Hz

E1-04

Output

Frequency

◆ Torque Compensation

High speed motors typically have very low impedance compared to standard 60/120 Hz

motors. These high speed/low impedance motors saturate easily and may cause hunting and

oscillation when a high V/f pattern is applied, especially at high frequencies. Therefore,

Torque Compensation Gain (C4-01) is modified to limit voltage boost above 120 Hz and

eliminate voltage boost above 160 Hz as shown in Figure 2.

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 13

Page 14

5 New and Modified Software Functions

Figure 2

C4-01

Output

0

120 Hz

Figure 2 Torque Compensation Gain

160 Hz

Frequency

(Fout)

◆ On-Delay Compensation

High speed motors typically operate at low V/f ratios compared to standard 60/120 Hz

motors, and On-Delay Compensation settings may adversely affect the motor voltage and

cause hunting and oscillation. Therefore, On-Delay Compensation Gain is modified to

reduce its effectiveness above 120 Hz as shown in Figure 3.

Note: When S1-01 = 0, On-Delay Compensation is disabled at all frequencies.

Figure 3

1.00

Output

0

120 Hz

Figure 3 On-Delay Compensation Gain

14 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

160 Hz

Frequency

(Fout)

Page 15

6 Application Notes

6 Application Notes

◆ Using an Output Reactor

If drive oL2 faults occur and a typical drive overload is not suspected, an output reactor or a

larger drive may be required to eliminate oL2 faults. High-speed motors typically have very

low impedance, which may result in excessive peak motor current, increased motor

temperature, low speed cogging, or increased torque ripple.

It may be necessary to use an output reactor to add impedance to the system and reduce the

peak ripple current and eliminate nuisance oL2 faults. To confirm that excessive peak

current caused by low motor impedance is causing the oL2 fault, measure the output current

using an oscilloscope or chart recorder with a clamp-on amp meter.

Generally, the peak of the motor current waveform should not exceed 100% continuous

drive HD nameplate / 2.5. This value may vary slightly by drive model. Refer to Figure 4

for an example of peak current measurement.

When using a reactor to reduce peak current, consult with the reactor manufacturer to select

a reactor that will smooth out the current waveform and also prevent a large voltage drop.

Proper reactor selection is critical in high speed applications because the reactor impedance

is directly proportional to the output frequency, which is usually given at 60 Hz. Example; a

reactor operating at 600 Hz will have 10 times the impedance and result in 10 times the

voltage drop at rated load.

Using a larger capacity drive to allow for the additional peak current may also solve the oL2

overload trip problem. The decision to employ an output reactor or increase drive capacity is

made on a case-by-case basis.

Figure 4

Figure 4 Measuring Peak Current

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 15

Page 16

6 Application Notes

◆ Fine Tuning the Carrier Frequency

It is important to optimize the carrier frequency to improve the motor current waveform.

This will improve motor speed stability and torque performance and also limit hunting and

oscillation at higher speeds.

Use one of the following setting recommendations to fine tune the carrier frequency for

optimum motor performance:

1. For a flat 7.0 kHz across the speed range: Set C6-02 = “F” with C6-03 = “7.0”, C6-04 =

“7.0”, and C6-05 = “0”. The 7.0 kHz across the output frequency range keeps the carrier

frequency as high as possible.

2. To create a ramped carrier frequency pattern to keep the output frequency and

carrier frequency at a constant ratio:

• Set C6-02 = “F” to build a custom pattern.

• Set C6-03 = “7.0 kHz” so the motor will run at 7.0 kHz at top speed.

• Set C6-04 = “1.0 kHz” so the carrier frequency will be ramped for the greatest output

frequency range.

• Solve the following formula for C6-05:

C6-05 = [7000 Hz / (2 x E1-04)]

The C6-05 setting range is 7 ~ 99, however a setting lower than 7 disables the ramp

function and C6-03 is used across the output frequency range. For motors with output

frequencies greater than 500 Hz, use C6-05 = 7.

• Solve for corner output frequencies A and B

A Hz = [1000 Hz / (2 x C6-05)]

B Hz = [7000 Hz / (2 x C6-05)]

Figure 5

Carrier

Frequency

(Fc)

Parameter C6-02 = F

C6-03 =

7.0 kHz

C6-04 =

1.0 kHz

16 YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement

Fc = 2 x C6-05 x Fout

A Hz

Figure 5 Carrier Frequency

B Hz

E1-04

Output

Frequency

(Fout)

Page 17

6 Application Notes

◆ Precautions for High Frequency/Low Impedance Motors

High frequency motors exhibit different characteristics than standard 60/120 Hz maximum

frequency motors. The low impedance associated with these high frequency motors often

requires manually programming a custom V/f pattern into the E1 parameter group to obtain

proper performance and rated power from the drive-motor combination.

The low impedance may also cause excessive motor current. In addition to considering the

use of an output reactor, it may be advantageous to oversize the drive to accommodate the

high peak current that may result from the low impedance motor. Using a drive that is at

least one or two models larger than the motor FLA may also help eliminate the oL2 faults.

Compatibility between the drive, motor, and the reactor is best accomplished via testing and

observation of the motor current waveform with an oscilloscope. Refer to Using an Output

Reactor on page 15.

◆ Revision History

The revision dates and the numbers of the revised manuals appear on the bottom of the back

cover.

MANUAL NO.ޓTOBP C730600 28A

Published in Japan May 2008 07-12

Date of

publication

Revision No. Publication Date Software No. Revised Content

First Version 2007.11.09 VSV905030 -

<1> 2008.03.06 VSV905030 Cover addition

<2> 2008.05.06 VSV905030 English addition

<3> 2008.06.03 VSV905030 YEA revision, changed document number

1

Revision number

Date of original

publication

YASKAWA ELECTRIC EZZ020793 1000 Hz High Frequency Custom Software Supplement 17

Page 18

YASKAWA AC Drive - V1000 Option

1000 Hz High Frequency Custom Software

Supplement

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, S aitama 358–8555,Japan

Phone: 81-4-2962-5696 Fa x: 81-4-2962-6138

YASKAWA ELECTRIC AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: 1-847-887-7000) Fax: 1-8 47-887-7370

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL COMÉRCIO LTDA.

Avenda Fagundes Filho, 620 Bairro Saud e, São Paulo, SP 04304–000, Brasil

Phone: 55-11-3585-1100 Fax: 55-11-5581-8795

http://www.yaskawa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Haupstrausse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49- 6196-569-398

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000 Fax: 44-1236-458182

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Youngdungpo-Ku, Seoul, 150-877, Korea

Phone: 82-2-784-7844 Fax: 82-2- 784-8495

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003 Fax: 65-6289-3003

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, Room 1702-1707, Harbour Ring Plaza, Shanghai, 200001,China

Phone: 86-21-5385-2200 Fax: 86- 21-5385-3299

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011A, Tower W3 Oriental Plaza, No. 1 East Chang An Ave., Dong Cheng District, Beijing, 100738,China

Phone: 86-10-8518-4086 Fax: 86- 10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, Taiwan

Phone: 886-2-2502-5003 Fax: 886- 2-2505-1280

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems

Foreign Trade Regulations. Therefore, be sure to follow all procedures and submit all relevant documentation according to any and all rules,

regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2008 YASKAWA ELECTRIC CORPORATION. All rights reserved.

or the manufacture thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and

MANUAL NO. EZZ020793

Published in U.S.A. June 2008 08-06

08-06-YEA

3 -0

Loading...

Loading...