Yanmar 6EY18LW, 6EY18ALW Service Manual

PROJECT GUIDE

MARINE AUXILIARY DIESEL ENGINE

MODEL 6EY18 Series

6EY18LW

6EY18ALW

Project Guide |

6EY18LW, 6EY18ALW |

Code No. 0GEY1-G00300 |

Marine Auxiliary Diesel Engine |

All Rights Reserved, Copyright

6EY18(A)LW |

46623 |

|

|

|

|

Marine Auxiliary Diesel Engine |

|

Page |

|

||

Contents |

|

1/3 |

|

|

|

00Introduction

01 Project Guide

02 Engine Model Name

03 Cylinder Layout and Operation Side

04 Direction of Rotation

05 Unit Conversion Table

06 Piping Symbols

01Outline

01 Major Specifications of Engine

02 Technical Data

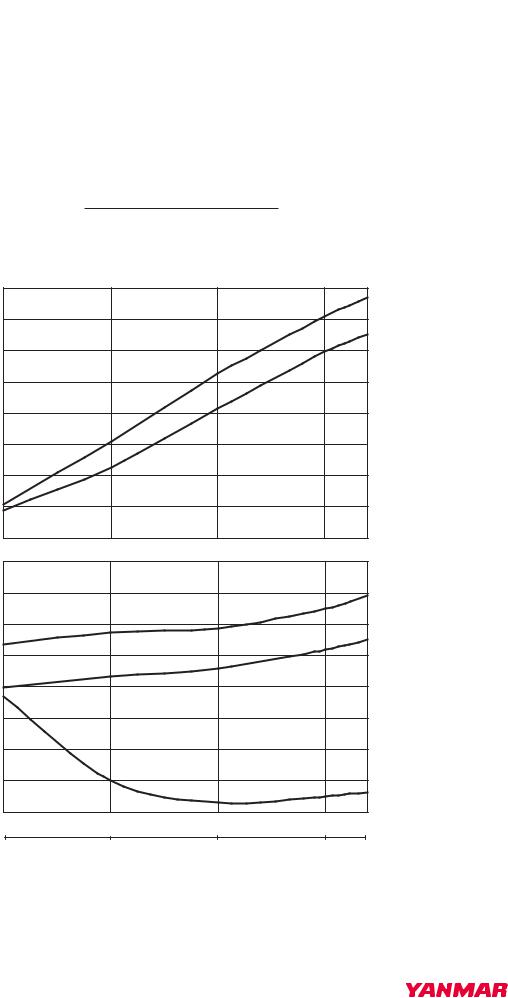

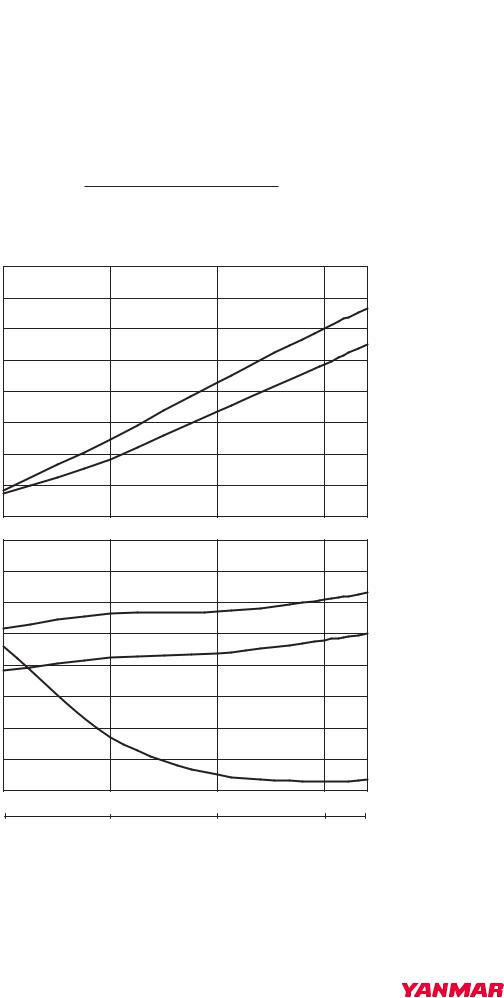

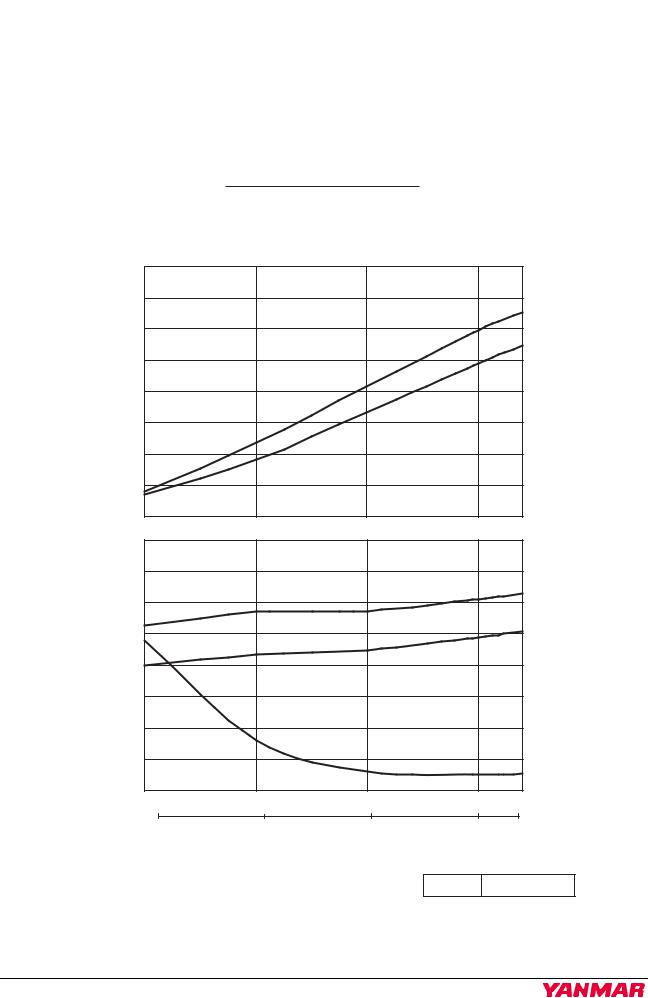

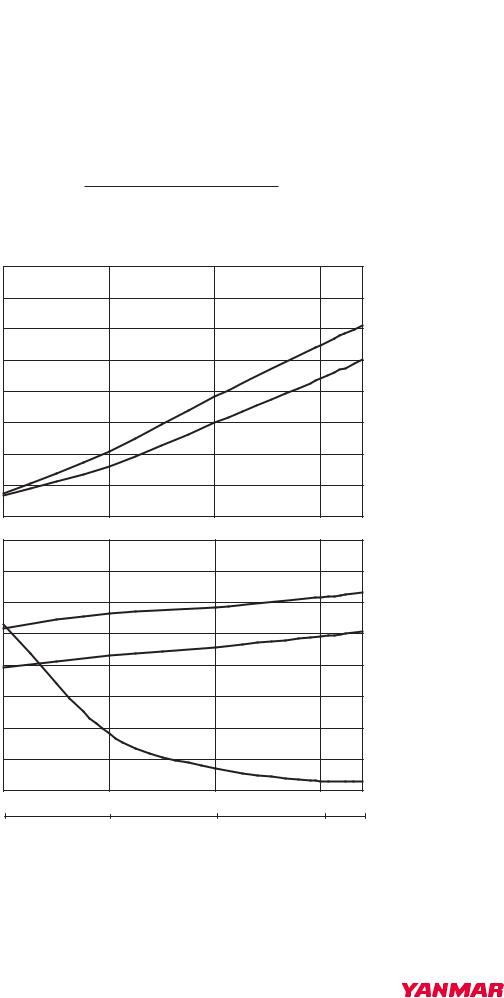

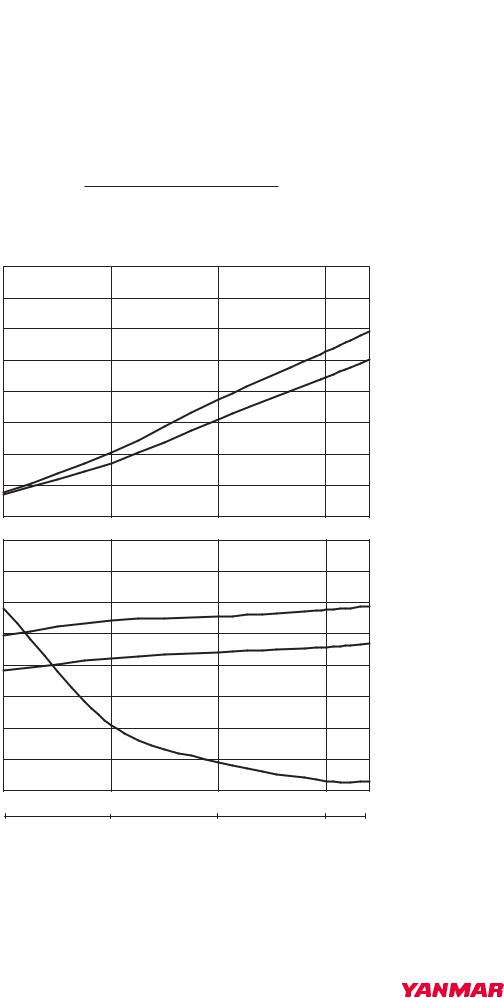

03 Engine Performance

04 Power and Specific Fuel Consumption

05 Heat Balance

06 Measurement of Noise

07 Exhaust Gas Emissions

08 Unbalance Forces and Unbalance Momentums

09 Equipment for Use with H.F.O. Low Load Operation

10 Inspection and Maintenance Intervals

02Engine Structure

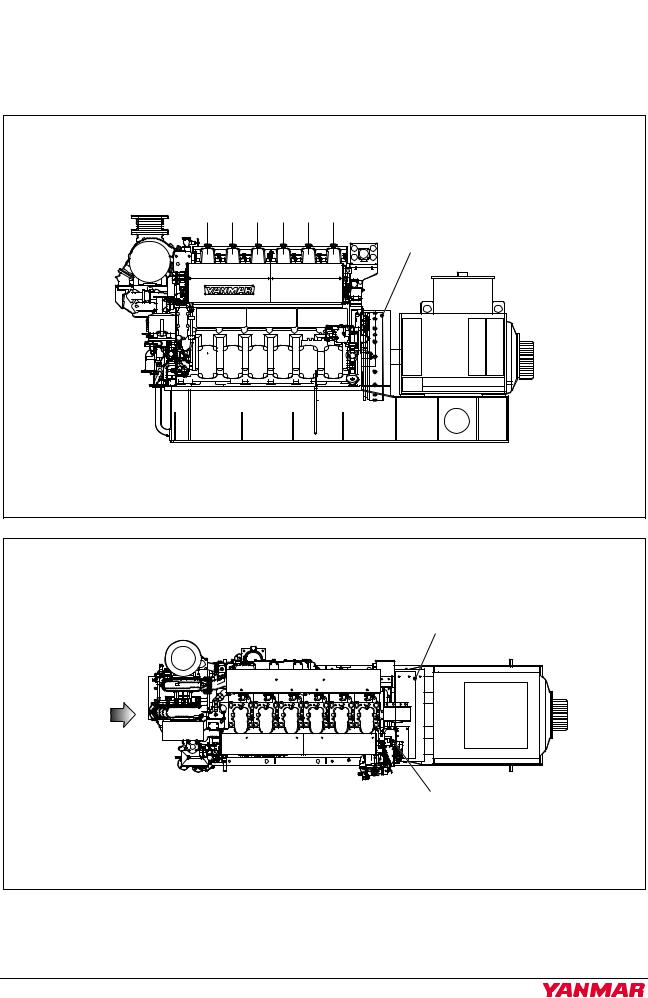

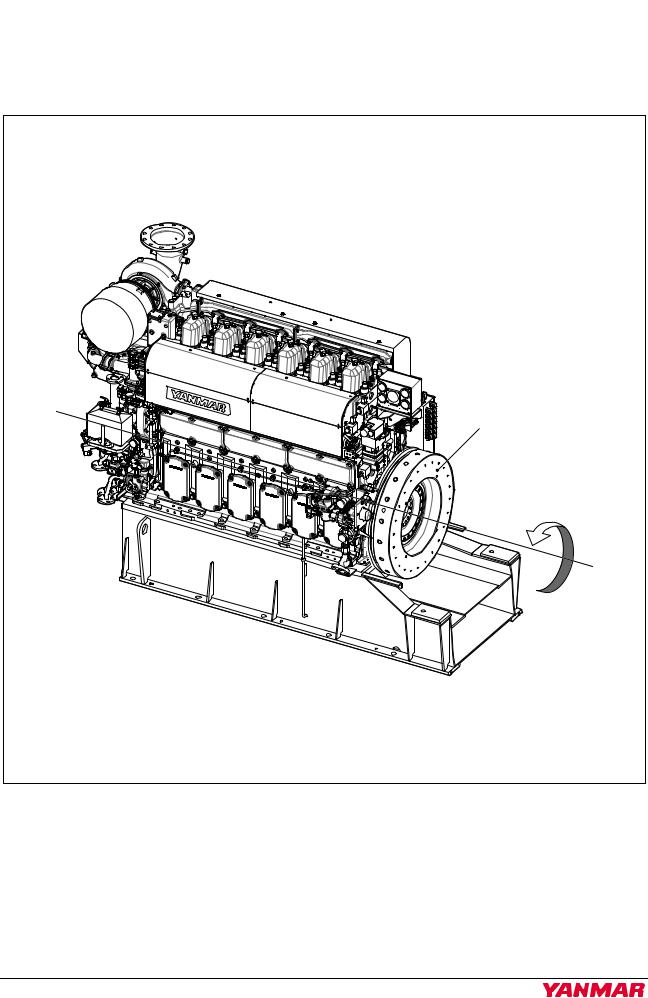

01 Engine External Appearance

02 Engine Sectional Drawings

03 Structural Outline

04 External Dimensions and Mass

05 Piping Connections

06 Disassembly and Maintenance Spaces

07 Mass and Dimensions of Major Parts

08 Material of Major Parts

09 Mass of Major Parts

6EY18(A)LW |

46623 |

|

|

|

|

Marine Auxiliary Diesel Engine |

|

Page |

|

||

Contents |

|

2/3 |

|

|

|

03Installation

01 Lifting Procedures

02 Layout of Generator Set

03 Installation of Generator Engine

04 Vibration Isolating Installation of Generator Engine

05 Crankshaft Deflection

10Air Charging and Exhaust System

01 Air Charging and Exhaust System

02 Turbocharger Compressor Water Cleaning Procedure

03 Turbocharger Turbine Cleaning Procedure

04 Selection of Exhaust Silencer

05 Exhaust Silencer

06 Rigging of Exhaust System

30Lubricating Oil System

01 Engine Lubricating Oil System

02 Priming Pump

03 Lubricating Oil Purification

04 Lubricating Oil Specifications

40Cooling Water System

01 Engine Cooling Water System

02 Inboard Cooling Water System

03 Warming Up System

04 Handling of Cooling Freshwater

50Fuel Oil System

01 Engine Fuel System

02 Fuel Supplying System

03 Fuel Pre-Treatment System

04 Fuel Quality Standard

05 Low-Sulfur Fuel

60Speed Control

01 Starting and Stopping Time Schedule

02 Governor

6EY18(A)LW |

46623 |

|

|

|

|

Marine Auxiliary Diesel Engine |

|

Page |

|

||

Contents |

|

3/3 |

|

|

|

70Starting and Control Air System

01 Starting and Control Air System

80Safety and Control Systems

01 Operation Data and Setting Values

02 Safety, Control and Monitoring

03 Communication with Generator Engine

04 Lubricating Oil Priming Pump Starter

81Generator

01 Drawing and Data

02 Coupling Type

03 Accessories

90Test

01 Shop Test Procedures of Generator Engine

91Spare Parts

01 Standard Spare Parts

02 Recommended Replacement Interval for Consumable Items

92Tools

01 Standard Tools

02 Special Tools

93Painting Colors and Name Plates 01 Painting Colors and Name Plates

99Storage Procedures

01 Long Storage Procedures

02 Maintenance after Installation

03 Starting after Long Term Storage

04 Storage Procedures for Spare Parts and Tools

00 Introduction

01 Project Guide

02 Engine Model Name

03 Cylinder Layout and Operation Side

04 Direction of Rotation

05 Unit Conversion Table

06 Piping Symbols

6EY18(A)LW

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Project Guide |

00-01-00 |

1/1 |

|

|

|

zThis project guide was prepared as reference when planning the implementation of a Yanmar marine auxiliary diesel engine. Accordingly, no details of engine accessories are included; they are decided separately based on the subsequent consultations.

zThe power of this engine is assured under the following atmospheric and standard operational conditions:

|

|

Standard condition |

Service condition |

|

|

|

|

Ambient temperature |

°C |

25 |

0-45 |

|

|

|

|

Atmospheric pressure |

kPa (mmHg) |

100 (750) |

− |

|

|

|

|

Relative humidity |

% |

30 |

85 or below |

|

|

|

|

Air cooler inlet water temp. |

°C |

25 |

38 or below |

|

|

|

|

zThe unit system used in this Project Guide is based on the international unit system (SI).

zDue to improvements to the product and other reasons, the descriptions in this Project Guide are subject to change without prior notice.

Please check the specifications, performance, etc. of the product by the delivery specifications, drawings of finished product, operation manual and individual consultations.

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Engine Model Name |

00-02-00 |

1/1 |

|

|

|

No. of cylinders

Name of engine series

Cylinder bore : cm

6 |

|

EY |

|

18 |

|

AL |

|

W |

|

|

|

|

|

|

|

|

|

Compliant with

IMO Tier 2 NOx regulations

AL : Marine Auxiliary (900, 1000 min-1)

L : Marine Auxiliary (720, 750 min-1)

041204-00E00

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Cylinder Layout and Operation Side |

00-03-00 |

1/1 |

|

|

|

Cylinder Numbers: No.1,2,...counted from the flywheel side (main PTO side)

6 |

5 |

4 |

3 |

2 |

1 |

|

|

|

|

|

Flywheel |

|

|

|

|

|

017732-01E00 |

(Operation side)

Operation side: right side viewed from the opposite side of the flywheel

Non-operation side (Exhaust manifold side)

|

|

|

|

|

|

|

Flywheel |

|

|

|

|

Engine |

|

|

|

View |

6 |

5 |

4 |

3 |

2 |

1 |

Generator |

|

|||||||

|

|

|

|

|

|

|

Governor |

Operation side (Fuel injection pump case side)

017733-00E01

(Viewed from top)

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Direction of Rotation |

00-04-00 |

1/1 |

|

|

|

Direction of Rotation: Counterclockwise viewed from flywheel side (Left Rotation).

Flywheel

017729-02E00

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Unit Conversion Table |

00-05-00 |

1/1 |

|

|

|

Conversion values between the international unit system (SI) and the metric unit system are shown below:

Force |

|

|

|

|

|

|

|

N |

kgf |

Conversion Examples |

|

1 |

0.101972 |

1 N = 0.101972 kgf |

|

|

|

1 kgf = 9.80665 N |

|

9.80665 |

1 |

||

|

|

|

|

Moment of Force, Torque |

|

|

|

|

|

|

|

N m |

kgf m |

|

|

|

|

|

|

1 |

0.101972 |

|

|

|

|

|

|

9.80665 |

1 |

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

Pa |

kgf/cm2 |

mAq |

mmHg |

1 |

1.019710-5 |

1.019710-4 |

7.50110-3 |

9.80665104 |

1 |

1.000010 |

7.356102 |

9.80665103 |

1.000010-1 |

1 |

7.35610 |

1.3332102 |

1.359510-3 |

1.359510-2 |

1 |

Work, Energy |

|

|

|

|

|

|

|

kW h |

J |

kcal |

kgf m |

|

|

|

|

1 |

3.600106 |

8.600102 |

3.671105 |

2.77810-7 |

1 |

2.38910-4 |

1.019710-1 |

1.16310-3 |

4.186103 |

1 |

4.269102 |

2.72410-6 |

9.80665 |

2.34310-3 |

1 |

Work Efficiency, Power |

|

|

|

|

|

|

|

kW |

PS |

|

|

|

|

|

|

1 |

1.3596 |

|

|

|

|

|

|

0.7355 |

1 |

|

|

|

|

|

|

6EY18(A)LW |

|

46623 |

Introduction |

No. |

Page |

Piping Symbols |

00-06-00 |

1/1 |

|

|

|

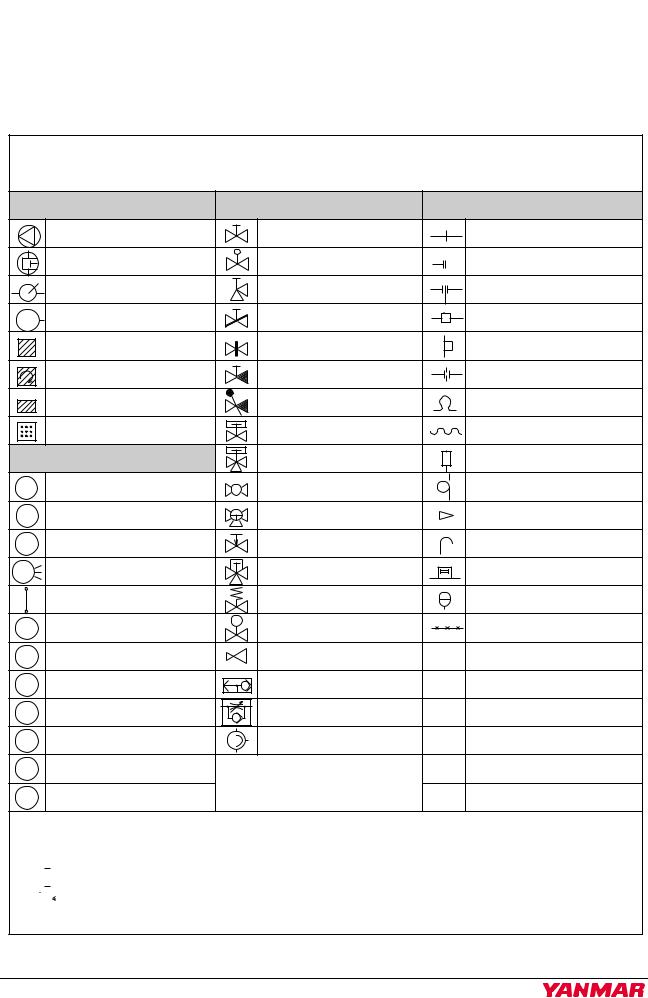

This Project Guide uses the following piping symbols.

Piping Diagram Codes

|

Equipment |

|

Valves |

|

Piping Parts |

|

Pump |

|

Globe valve |

|

Flange fitting |

|

Plunger pump |

|

Needle valve |

|

Shut-off valve |

|

Hand pump |

|

Angle valve |

|

Spectacle flange |

M |

Motor |

|

Butterfly valve |

|

Joint |

|

Strainer |

|

Sluice valve |

|

Boss |

|

Centrifugal strainer |

|

Screwed check valve |

|

Orifice |

AUTO |

Automatic backwash strainer |

|

Swing check valve |

|

Expansion joint |

|

|

|

|||

|

Porous plate strainer cylinder |

|

Piston valve |

|

Flexible pipe coupling |

|

Meter & Sensors |

|

Three-way piston valve |

|

Seal pot |

T |

Thermometer |

|

Cock |

|

Loop seal |

P |

Pressure gauge |

|

Three-way cock |

|

Reducer |

PD |

Differential pressure gauge |

|

Automatic pressure |

|

Air vent pipe |

|

regulating valve |

|

|||

P |

Oil signal |

|

Automatic temp. |

|

Safety plate |

|

regulating valve |

|

|||

|

Grazed level gauge |

|

Relief valve |

|

Accumulator |

PS |

Pressure switch |

S |

Solenoid valve |

|

Capillary tube |

|

|

||||

TS |

Temperature switch |

|

Pressure reducing valve |

CUT |

Copper pipe |

FS |

Float switch |

|

Duplex check valve |

STPG |

Carbon steel pipe |

|

for pressure tube |

||||

DPS |

Differential pressure SW |

|

Velocity regulating valve |

STKM |

Carbon steel pipe |

|

for high pressure tube |

||||

PT |

Pressure transmitter |

|

Flow volume regulating |

STS |

Machine structural |

|

valve |

carbon steel pipe |

|||

|

|

|

|

||

RB |

Resistance bulb |

|

|

O.D. |

Pipe outside diameter |

TC |

Thermocouple |

|

|

I.D. |

Pipe inner diameter |

Remark:

The black valve (globe valve, angle valve and needle valve) shows the constantly closed valve.

: Opened constantly

: Opened constantly

: Closed constantly

: Closed constantly

Piping parts marked with an asterisk ( ) are not included.

002887-01E00

01 Outline

01 Major Specifications of Engine

02 Technical Data

03 Engine Performance

04 Power and Specific Fuel Consumption

05 Heat Balance

06 Measurement of Noise

07 Exhaust Gas Emissions

08 Unbalance Forces and Unbalance Momentums

09Equipment for Use with H.F.O. Low Load Operation

10Inspection and Maintenance Intervals

6EY18(A)LW

6EY18(A)LW |

46623 |

|

|

Outline |

|

|

|

|

|

|

|

|

|

No. |

Page |

|

Major Specifications of Engine |

|

|

|

01-01-00 |

1/4 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Model 6EY18ALW (60 Hz, 900 min-1) |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Model Name |

|

|

|

|

|

6EY18ALW |

|

|

|

|

||

|

|

|

|

|

|

|||||||

Type |

|

|

|

Vertical water-cooled 4 cycle diesel engine |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. of Cylinders |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder Bore¯Stroke |

mm |

|

|

|

|

180×280 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Total Displacement |

l |

|

|

|

|

42.75 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating |

kW |

800 |

745 |

|

680 |

660 |

|

615 |

550 |

|

500 |

455 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Speed |

min-1 |

|

|

|

|

900 |

|

|

|

|

||

Brake Mean Effective |

MPa |

2.495 |

2.323 |

|

2.121 |

2.057 |

|

1.918 |

1.716 |

|

1.560 |

1.420 |

Pressure |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mean Piston Velocity |

m/s |

|

|

|

|

8.40 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Power of |

kWe |

750 |

680 |

|

620 |

600 |

|

560 |

500 |

|

450 |

400 |

Generating Equip. * |

|

|

|

|

|

|

|

|

|

|

|

|

kVA |

937.5 |

850 |

|

775 |

750 |

|

700 |

625 |

|

562.5 |

500 |

|

|

|

|

|

|

|

|

|

|

|

|||

Overload Rating |

|

|

10% Overload: within 60 min (every 12 hours) |

|

||||||||

|

|

|

|

|||||||||

Crankshaft Revolving Direction |

|

Counterclockwise (viewed from the flywheel side) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Firing Order |

|

|

|

|

|

1-4-2-6-3-5-1 |

|

|

|

|

||

|

|

|

|

|

||||||||

Operation Side |

|

|

Right side (viewed from the opposite side of the flywheel) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Combustion System |

|

|

|

|

|

Direct injection |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

Lubrication System |

|

|

|

|

Common bed incorporated sump |

|

|

|

||||

|

|

|

|

|

||||||||

Cooling System |

|

|

Freshwater and freshwater mixing dual cooling system |

|

||||||||

|

|

|

|

|

||||||||

Turbocharging System |

|

|

Exhaust gas turbine turbocharging with air cooler |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Starting System |

|

|

|

|

|

Air starter |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Turning System |

|

|

|

|

|

Turning bar |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Lubricating Oil |

|

|

|

|

|

SAE30 or 40 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Fuel Consumption |

g/kW•h |

190+5% |

189+5% |

|

188+5% |

190+5% |

|

188+5% |

188+5% |

|

189+5% |

191+5% |

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Lubricating Oil |

g/kW•h |

|

|

|

|

0.3-1.1 |

|

|

|

|

||

Consumption |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Engine Dry Weight |

kg |

|

|

|

|

6600 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

The specific fuel consumption shows the lower calorific value, 42.7 MJ/kg (10,200 kcal/kg), ISO3046/1, of a bare engine unit operated at 4/4 load and at rated speed and under the condition of complying with NOx emission regulation value (the tier 2 regulation) as required by IMO. When the engine-mounted lubricating oil pump is driven, 3 g/kW•h is added to the consumption and when the cooling water pump is driven, 1 g/kW•h is added to the consumption per one pump.

* The above generator capacity varies depending on actual generator efficiency.

6EY18(A)LW |

46623 |

|

|

Outline |

|

|

|

|

|

No. |

|

Page |

|

Major Specifications of Engine |

01-01-00 |

2/4 |

|||||||

|

|

|

|

|

|

|

|

|

|

2. Model 6EY18LW (60 Hz, 720 min-1) |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Model Name |

|

|

|

|

6EY18LW |

|

|

|

|

|

|

|

|

|

|

|

|||

Type |

|

|

|

Vertical water-cooled 4 cycle diesel engine |

|

|

|||

|

|

|

|

|

|

|

|

|

|

No. of Cylinders |

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder Bore¯Stroke |

mm |

|

|

|

180×280 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Displacement |

l |

|

|

|

42.75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating |

kW |

615 |

|

550 |

500 |

450 |

|

|

400 |

|

|

|

|

|

|

|

|

|

|

Rated Speed |

min-1 |

|

|

|

720 |

|

|

|

|

Brake Mean Effective |

MPa |

2.397 |

|

2.144 |

1.949 |

1.754 |

|

1.560 |

|

Pressure |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mean Piston Velocity |

m/s |

|

|

|

6.72 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power of |

kWe |

560 |

|

500 |

450 |

400 |

|

|

360 |

Generating Equip. * |

|

|

|

|

|

|

|

|

|

kVA |

700 |

|

625 |

562.5 |

500 |

|

|

450 |

|

|

|

|

|

|

|

|

|

|

|

Overload Rating |

|

|

|

10% Overload: within 60 min (every 12 hours) |

|

|

|||

|

|

|

|

|

|||||

Crankshaft Revolving Direction |

|

Counterclockwise (viewed from the flywheel side) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Firing Order |

|

|

|

|

1-4-2-6-3-5-1 |

|

|

|

|

|

|

|

|

|

|

||||

Operation Side |

|

|

Right side (viewed from the opposite side of the flywheel) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

Combustion System |

|

|

|

|

Direct injection |

|

|

|

|

|

|

|

|

|

|

|

|||

Lubrication System |

|

|

|

Common bed incorporated sump |

|

|

|||

|

|

|

|

|

|

||||

Cooling System |

|

|

Freshwater and freshwater mixing dual cooling system |

|

|

||||

|

|

|

|

|

|

|

|||

Turbocharging System |

|

|

|

Exhaust gas turbine turbocharging with air cooler |

|

|

|||

|

|

|

|

|

|

|

|

|

|

Starting System |

|

|

|

|

Air starter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turning System |

|

|

|

|

Turning bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil |

|

|

|

|

SAE30 or 40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Fuel Consumption |

g/kW•h |

191+5% |

|

190+5% |

189+5% |

189+5% |

|

190+5% |

|

|

|

|

|

|

|

|

|

|

|

Specific Lubricating Oil |

g/kW•h |

|

|

|

0.3-1.1 |

|

|

|

|

Consumption |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Dry Weight |

kg |

|

|

|

6600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The specific fuel consumption shows the lower calorific value, 42.7 MJ/kg (10,200 kcal/kg), ISO3046/1, of a bare engine unit operated at 4/4 load and at rated speed and under the condition of complying with NOx emission regulation value (the tier 2 regulation) as required by IMO. When the engine-mounted lubricating oil pump is driven, 3 g/kW•h is added to the consumption and when the cooling water pump is driven, 1 g/kW•h is added to the consumption per one pump.

* The above generator capacity varies depending on actual generator efficiency.

6EY18(A)LW |

46623 |

|

|

Outline |

|

|

|

|

|

|

|

|

|

No. |

Page |

|

Major Specifications of Engine |

|

|

|

01-01-00 |

3/4 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Model 6EY18ALW (50 Hz, 1000 min-1) |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Model Name |

|

|

|

|

|

6EY18ALW |

|

|

|

|

||

|

|

|

|

|

|

|||||||

Type |

|

|

|

Vertical water-cooled 4 cycle diesel engine |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. of Cylinders |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder Bore¯Stroke |

mm |

|

|

|

|

180×280 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Total Displacement |

l |

|

|

|

|

42.75 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating |

kW |

800 |

745 |

|

680 |

660 |

|

615 |

550 |

|

500 |

455 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Speed |

min-1 |

|

|

|

|

1000 |

|

|

|

|

||

Brake Mean Effective |

MPa |

2.246 |

2.091 |

|

1.909 |

1.851 |

|

1.726 |

1.544 |

|

1.403 |

1.277 |

Pressure |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mean Piston Velocity |

m/s |

|

|

|

|

9.33 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Power of |

kWe |

750 |

680 |

|

620 |

600 |

|

560 |

500 |

|

450 |

400 |

Generating Equip. * |

|

|

|

|

|

|

|

|

|

|

|

|

kVA |

937.5 |

850 |

|

775 |

750 |

|

700 |

625 |

|

562.5 |

500 |

|

|

|

|

|

|

|

|

|

|

|

|||

Overload Rating |

|

|

10% Overload: within 60 min (every 12 hours) |

|

||||||||

|

|

|

|

|||||||||

Crankshaft Revolving Direction |

|

Counterclockwise (viewed from the flywheel side) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Firing Order |

|

|

|

|

|

1-4-2-6-3-5-1 |

|

|

|

|

||

|

|

|

|

|

||||||||

Operation Side |

|

|

Right side (viewed from the opposite side of the flywheel) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Combustion System |

|

|

|

|

|

Direct injection |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

Lubrication System |

|

|

|

|

Common bed incorporated sump |

|

|

|

||||

|

|

|

|

|

||||||||

Cooling System |

|

|

Freshwater and freshwater mixing dual cooling system |

|

||||||||

|

|

|

|

|

||||||||

Turbocharging System |

|

|

Exhaust gas turbine turbocharging with air cooler |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Starting System |

|

|

|

|

|

Air starter |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Turning System |

|

|

|

|

|

Turning bar |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Lubricating Oil |

|

|

|

|

|

SAE30 or 40 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Fuel Consumption |

g/kW•h |

196+5% |

195+5% |

|

194+5% |

193+5% |

|

193+5% |

197+5% |

|

198+5% |

198+5% |

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Lubricating Oil |

g/kW•h |

|

|

|

|

0.3-1.1 |

|

|

|

|

||

Consumption |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Engine Dry Weight |

kg |

|

|

|

|

6600 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

The specific fuel consumption shows the lower calorific value, 42.7 MJ/kg (10,200 kcal/kg), ISO3046/1, of a bare engine unit operated at 4/4 load and at rated speed and under the condition of complying with NOx emission regulation value (the tier 2 regulation) as required by IMO. When the engine-mounted lubricating oil pump is driven, 3 g/kW•h is added to the consumption and when the cooling water pump is driven, 1 g/kW•h is added to the consumption per one pump.

* The above generator capacity varies depending on actual generator efficiency.

6EY18(A)LW |

46623 |

|

|

Outline |

|

|

|

|

|

No. |

|

Page |

|

Major Specifications of Engine |

01-01-00 |

4/4 |

|||||||

|

|

|

|

|

|

|

|

|

|

4. Model 6EY18LW (50 Hz, 750 min-1) |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Model Name |

|

|

|

|

6EY18LW |

|

|

|

|

|

|

|

|

|

|

|

|||

Type |

|

|

|

Vertical water-cooled 4 cycle diesel engine |

|

|

|||

|

|

|

|

|

|

|

|

|

|

No. of Cylinders |

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder Bore¯Stroke |

mm |

|

|

|

180×280 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Displacement |

l |

|

|

|

42.75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating |

kW |

615 |

|

550 |

500 |

450 |

|

|

400 |

|

|

|

|

|

|

|

|

|

|

Rated Speed |

min-1 |

|

|

|

750 |

|

|

|

|

Brake Mean Effective |

MPa |

2.302 |

|

2.058 |

1.871 |

1.684 |

|

1.497 |

|

Pressure |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mean Piston Velocity |

m/s |

|

|

|

7.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power of |

kWe |

560 |

|

500 |

450 |

400 |

|

|

360 |

Generating Equip. * |

|

|

|

|

|

|

|

|

|

kVA |

700 |

|

625 |

562.5 |

500 |

|

|

450 |

|

|

|

|

|

|

|

|

|

|

|

Overload Rating |

|

|

|

10% Overload: within 60 min (every 12 hours) |

|

|

|||

|

|

|

|

|

|||||

Crankshaft Revolving Direction |

|

Counterclockwise (viewed from the flywheel side) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Firing Order |

|

|

|

|

1-4-2-6-3-5-1 |

|

|

|

|

|

|

|

|

|

|

||||

Operation Side |

|

|

Right side (viewed from the opposite side of the flywheel) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

Combustion System |

|

|

|

|

Direct injection |

|

|

|

|

|

|

|

|

|

|

|

|||

Lubrication System |

|

|

|

Common bed incorporated sump |

|

|

|||

|

|

|

|

|

|

||||

Cooling System |

|

|

Freshwater and freshwater mixing dual cooling system |

|

|

||||

|

|

|

|

|

|

|

|||

Turbocharging System |

|

|

|

Exhaust gas turbine turbocharging with air cooler |

|

|

|||

|

|

|

|

|

|

|

|

|

|

Starting System |

|

|

|

|

Air starter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turning System |

|

|

|

|

Turning bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil |

|

|

|

|

SAE30 or 40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Fuel Consumption |

g/kW•h |

192+5% |

|

192+5% |

191+5% |

192+5% |

|

194+5% |

|

|

|

|

|

|

|

|

|

|

|

Specific Lubricating Oil |

g/kW•h |

|

|

|

0.3-1.1 |

|

|

|

|

Consumption |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Dry Weight |

kg |

|

|

|

6600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The specific fuel consumption shows the lower calorific value, 42.7 MJ/kg (10,200 kcal/kg), ISO3046/1, of a bare engine unit operated at 4/4 load and at rated speed and under the condition of complying with NOx emission regulation value (the tier 2 regulation) as required by IMO. When the engine-mounted lubricating oil pump is driven, 3 g/kW•h is added to the consumption and when the cooling water pump is driven, 1 g/kW•h is added to the consumption per one pump.

* The above generator capacity varies depending on actual generator efficiency.

6EY18(A)LW |

46623 |

|

|

|

Outline |

Technical Data (900 min-1) |

|

|

|

|

|

|

|

No. |

Page |

|||||||||||||

|

|

|

|

|

|

|

|

01-02-00 |

1/4 |

|

||||||||||||||

|

1. Model 6EY18ALW (900 min-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Pumps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling Water Pump (High temp) |

Centrifugal |

|

27 m3/h |

|

|

|

20 m |

|

|

|

|

Eng. mount |

|

|

|||||||||

|

Cooling Water Pump (Low temp) |

Centrifugal |

|

27 m3/h |

|

|

|

20 m |

|

|

|

|

Eng. mount |

|

|

|||||||||

|

Fuel Feed Pump for M.D.O. |

Gear type |

|

0.623 m3/h |

|

Refer to 50-02 |

|

|

|

Eng. mount |

|

|

||||||||||||

|

Fuel Supply Pump for H.F.O. |

Gear type |

|

- |

|

|

Refer to 50-02 |

|

|

|

|

Hull mount |

|

|

||||||||||

|

Lubricating Oil Pump |

Gear type |

|

21.4 m3/h |

|

|

0.80 MPa |

|

|

|

|

Eng. mount |

|

|

||||||||||

|

Lubricating Oil Priming Pump |

Gear type |

|

|

4 m3/h |

|

|

0.15 MPa |

|

|

|

|

Eng. mount |

|

|

|||||||||

|

Strainers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel Strainer (Eng. Inlet) |

Duplex change over, |

|

|

E.F. 35 μm |

|

|

|

|

Eng. mount |

|

|

||||||||||||

|

|

|

notch wire |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Fuel Strainer (For H.F.O. Circulate) |

Duplex change over, |

|

|

E.F. 10 μm |

|

|

|

|

|

Hull mount |

|

|

|||||||||||

|

automatic backwashing |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Fuel Strainer (For FCC) |

(Recommend) Fine Strainer |

|

|

E.F. 5 μm |

|

|

|

|

|

Hull mount |

|

|

|||||||||||

|

Lubricating Oil |

Common Bed |

Perforated Steel Plate |

|

|

- |

|

|

|

Assembled in common bed |

|

|||||||||||||

|

Primary Strainer |

Incorporated Sump |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Secondary Lubricating Oil Strainer |

Automatic backwashing |

|

35 μm (E.F. 30 μm) |

|

|

|

Eng. mount |

|

|

||||||||||||||

|

Coolers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Cooler |

Multi-tubular with fins |

|

|

|

8.7 m2 |

|

|

|

|

Eng. mount |

|

|

|||||||||||

|

Air Cooler |

|

Multi-tubular with plate fins |

|

|

|

24.6 m2 |

|

|

|

|

Eng. mount |

|

|

||||||||||

|

Temperature Regulating Valves |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

• Engine power: 745/800 kW |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Load 65% or above: 60°C±4°C |

|

|

|

|

|

|

|

|

||||

|

Freshwater Regulating Valve for |

Direct-action, wax-pellet, |

|

Load less than 65%: 85°C±4°C |

|

|

|

|

|

|

|

|

||||||||||||

|

|

• Engine power: 660/680 kW |

|

|

|

Eng. mount |

|

|

||||||||||||||||

|

High Temperature |

regulating at outlet |

|

Load 75% or above: 60°C±4°C |

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Load less than 75%: 85°C±4°C |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

• 445-615 kW |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

85°C±4°C |

|

|

|

|

|

|

|

|

|

|||

|

Lubricating Oil Temp. Regulating Valve |

Direct-action, wax-pellet |

|

|

|

50-65 |

|

|

|

|

Eng. mount |

|

|

|||||||||||

|

Tanks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Tank Capacity |

|

|

|

|

|

|

|

|

|

See 30-01-00 |

|

|

|

|

|

|

|

||||||

|

Engine Freshwater Holding Capacity |

|

|

|

|

|

|

|

|

|

|

145 l |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Starting Air Sump |

|

|

|

|

|

|

|

150 l× 1 Bottle, 2.94 MPa |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating Power |

kW |

|

800 |

|

745 |

|

680 |

|

660 |

|

615 |

|

|

550 |

|

500 |

455 |

|

|||||

|

Radiation |

Heat Radiation to L.O. (at 100% Load) |

MJ/h |

|

350.4 |

|

337.9 |

|

323.2 |

|

318.7 |

|

292.7 |

|

|

275.5 |

|

262.3 |

250.4 |

|

||||

|

Heat Radiation to Low Temp. C.W. |

MJ/h |

|

203.4 |

|

178.6 |

|

149.2 |

|

140.1 |

|

216.4 |

|

|

187.6 |

|

167.5 |

150.9 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

(at 100% Load) |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Heat |

Heat Radiation to High Temp. C.W. |

MJ/h |

|

785.3 |

|

714.4 |

|

630.6 |

|

604.8 |

|

567.0 |

|

|

461.2 |

|

384.0 |

319.1 |

|

||||

|

(at 100% Load) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Heat Radiation to Air (at 100% Load) |

MJ/h |

|

797.0 |

|

742.2 |

|

677.5 |

|

657.5 |

|

532.3 |

|

|

492.2 |

|

461.3 |

433.5 |

|

||||

|

Combustion Air Volume at 100% Load [25°C] |

m3/h |

|

4510 |

|

4320 |

|

4080 |

|

4060 |

|

3760 |

|

|

3600 |

|

3370 |

3100 |

|

|||||

|

Exh. Gas Volume at 100% Load [0°C] |

m3/h |

|

4060 |

|

3880 |

|

3730 |

|

3720 |

|

3480 |

|

|

3320 |

|

3090 |

2860 |

|

|||||

|

Eng. Room Ventilation Air Volume |

|

|

|

|

|

|

|

|

|

0.27-0.41 m3/min kW |

|

|

|

|

|||||||||

|

T/C Outlet Exh. Gas Temp. |

°C |

|

370 |

|

360 |

|

350 |

|

350 |

|

350 |

|

|

340 |

|

335 |

330 |

|

|||||

|

(at 100% Load, Ambient Temp. 25°C) |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Exh. Back Pressure at 100% Load |

|

|

|

|

|

|

|

|

|

|

3.43 kPa |

or below |

|

|

|

|

|

|

|

||||

|

Exhaust Pipe Diameter |

|

|

|

|

|

|

|

|

|

|

250 A or 300 A |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6EY18(A)LW |

46623 |

|

|

|

Outline |

Technical Data (720 min-1) |

|

|

|

|

No. |

Page |

||||||||||

|

|

|

|

|

|

01-02-00 |

2/4 |

|

||||||||||

|

2. Model 6EY18LW (720 min-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Pumps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling Water Pump (High temp) |

Centrifugal |

|

21 m3/h |

|

|

|

16 m |

|

|

Eng. mount |

|

||||||

|

Cooling Water Pump (Low temp) |

Centrifugal |

|

21 m3/h |

|

|

|

16 m |

|

|

Eng. mount |

|

||||||

|

Fuel Feed Pump for M.D.O. |

Gear type |

|

0.499 m3/h |

|

|

Refer to 50-02 |

|

|

Eng. mount |

|

|||||||

|

Fuel Supply Pump for H.F.O. |

Gear type |

|

- |

|

|

|

Refer to 50-02 |

|

|

Hull mount |

|

||||||

|

Lubricating Oil Pump |

Gear type |

|

27.3 m3/h |

|

|

0.80 MPa |

|

|

Eng. mount |

|

|||||||

|

Lubricating Oil Priming Pump |

Gear type |

|

4 m3/h |

|

|

0.15 MPa |

|

|

Eng. mount |

|

|||||||

|

Strainers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel Strainer (Eng. Inlet) |

Duplex change over, |

|

|

E.F. 35 μm |

|

|

Eng. mount |

|

|||||||||

|

|

notch wire |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Fuel Strainer (For H.F.O. Circulate) |

Duplex change over, |

|

|

E.F. 10 μm |

|

|

Hull mount |

|

|||||||||

|

automatic backwashing |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Fuel Strainer (For FCC) |

(Recommend) Fine Strainer |

|

|

E.F. 5 μm |

|

|

Hull mount |

|

|||||||||

|

Lubricating Oil |

Common Bed |

Perforated Steel Plate |

|

|

- |

|

Assembled in common bed |

|

|||||||||

|

Primary Strainer |

Incorporated Sump |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Secondary Lubricating Oil Strainer |

Automatic backwashing |

|

35 μm (E.F. 30 μm) |

|

|

Eng. mount |

|

||||||||||

|

Coolers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Cooler |

Multi-tubular with fins |

|

|

8.7 m2 |

|

|

Eng. mount |

|

|||||||||

|

Air Cooler |

|

Multi-tubular with plate fins |

|

24.6 m2 |

|

|

Eng. mount |

|

|||||||||

|

Temperature Regulating Valves |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

• 550-615 kW |

|

|

|

|

|

|

||

|

Freshwater Regulating Valve for |

Direct-action, wax-pellet, |

|

Load 75%±5% or above: 60°C±4°C |

|

|

Eng. mount |

|

||||||||||

|

|

Load less than 75%±5%: 85°C±4°C |

|

|

|

|||||||||||||

|

High Temperature |

regulating at outlet |

|

|

|

|

||||||||||||

|

|

• 400-500 kW |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

85°C±4°C |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Lubricating Oil Temp. Regulating Valve |

Direct-action, wax-pellet |

|

|

50-65°C |

|

|

Eng. mount |

|

|||||||||

|

Tanks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Tank Capacity |

|

|

|

|

|

|

|

See 30-01-00 |

|

|

|

|

|

||||

|

Engine Freshwater Holding Capacity |

|

|

|

|

|

|

|

|

145 l |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Starting Air Sump |

|

|

|

|

|

150 l× 1 Bottle, 2.94 MPa |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Continuous Rating Power |

kW |

|

615 |

|

550 |

|

500 |

|

450 |

|

400 |

|

|||||

|

Radiation |

Heat Radiation to L.O. (at 100% Load) |

MJ/h |

|

280.3 |

|

266.3 |

|

229.0 |

|

224.4 |

|

224.4 |

|

||||

|

Heat Radiation to Low Temp. C.W. |

MJ/h |

|

184.6 |

|

162.3 |

|

141.4 |

|

129.4 |

|

129.4 |

|

|||||

|

|

|

|

|

|

|

|

|||||||||||

|

|

(at 100% Load) |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat |

Heat Radiation to High Temp. C.W. |

MJ/h |

|

571.4 |

|

492.7 |

|

359.4 |

|

306.2 |

|

306.2 |

|

||||

|

(at 100% Load) |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Heat Radiation to Air (at 100% Load) |

MJ/h |

|

676.9 |

|

622.7 |

|

495.0 |

|

454.1 |

|

454.1 |

|

||||

|

Combustion Air Volume at 100% Load [25°C] |

m3/h |

|

4060 |

|

3760 |

|

3600 |

|

3370 |

|

3100 |

|

|||||

|

Exh. Gas Volume at 100% Load [0°C] |

m3/h |

|

3720 |

|

3480 |

|

3320 |

|

3090 |

|

2860 |

|

|||||

|

Eng. Room Ventilation Air Volume |

|

|

|

|

|

|

|

0.27-0.41 m3/min kW |

|

|

|||||||

|

T/C Outlet Exh. Gas Temp. |

°C |

|

335 |

|

335 |

|

300 |

|

300 |

|

300 |

|

|||||

|

(at 100% Load, Ambient Temp. 25°C) |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Exh. Back Pressure at 100% Load |

|

|

|

|

|

|

|

3.43 kPa or below |

|

|

|

|

|

||||

|

Exhaust Pipe Diameter |

|

|

|

|

|

|

|

|

250 A or 300 A |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6EY18(A)LW |

46623 |

|

|

|

Outline |

Technical Data (1000 min-1) |

|

|

|

|

|

|

|

No. |

Page |

||||||||||||

|

|

|

|

|

|

|

|

01-02-00 |

3/4 |

|

|||||||||||||

|

3. Model 6EY18ALW (1000 min-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Pumps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling Water Pump (High temp) |

Centrifugal |

|

29 m3/h |

|

|

|

23 m |

|

|

|

|

Eng. mount |

|

|

||||||||

|

Cooling Water Pump (Low temp) |

Centrifugal |

|

29 m3/h |

|

|

|

23 m |

|

|

|

|

Eng. mount |

|

|

||||||||

|

Fuel Feed Pump for M.D.O. |

Gear type |

|

0.692 m3/h |

|

Refer to 50-02 |

|

|

|

Eng. mount |

|

|

|||||||||||

|

Fuel Supply Pump for H.F.O. |

Gear type |

|

- |

|

|

Refer to 50-02 |

|

|

|

|

Hull mount |

|

|

|||||||||

|

Lubricating Oil Pump |

Gear type |

|

23.8 m3/h |

|

|

0.80 MPa |

|

|

|

|

Eng. mount |

|

|

|||||||||

|

Lubricating Oil Priming Pump |

Gear type |

|

|

4 m3/h |

|

|

0.15 MPa |

|

|

|

|

Eng. mount |

|

|

||||||||

|

Strainers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel Strainer (Eng. Inlet) |

Duplex change over, |

|

|

E.F. 35 μm |

|

|

|

|

Eng. mount |

|

|

|||||||||||

|

|

notch wire |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Fuel Strainer (For H.F.O. Circulate) |

Duplex change over, |

|

|

E.F. 10 μm |

|

|

|

|

|

Hull mount |

|

|

||||||||||

|

automatic backwashing |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Fuel Strainer (For FCC) |

(Recommend) Fine Strainer |

|

|

E.F. 5 μm |

|

|

|

|

|

Hull mount |

|

|

||||||||||

|

Lubricating Oil |

Common Bed |

Perforated Steel Plate |

|

|

- |

|

|

|

Assembled in common bed |

|

||||||||||||

|

Primary Strainer |

Incorporated Sump |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Secondary Lubricating Oil Strainer |

Automatic backwashing |

|

35 μm (E.F. 30 μm) |

|

|

|

Eng. mount |

|

|

|||||||||||||

|

Coolers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Cooler |

Multi-tubular with fins |

|

|

|

8.7 m2 |

|

|

|

|

Eng. mount |

|

|

||||||||||

|

Air Cooler |

|

Multi-tubular with plate fins |

|

|

|

24.6 m2 |

|

|

|

|

Eng. mount |

|

|

|||||||||

|

Temperature Regulating Valves |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

• Engine power: 745/800 kW |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Load 65% or above: 60°C±4°C |

|

|

|

|

|

|

|

|

||||

|

Freshwater Regulating Valve for |

Direct-action, wax-pellet, |

|

Load less than 65%: 85°C±4°C |

|

|

|

|

|

|

|

|

|||||||||||

|

|

• Engine power: 660/680 kW |

|

|

|

Eng. mount |

|

|

|||||||||||||||

|

High Temperature |

regulating at outlet |

|

Load 75% or above: 60°C±4°C |

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Load less than 75%: 85°C±4°C |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

• 445-615 kW |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

85°C±4°C |

|

|

|

|

|

|

|

|

|

|||

|

Lubricating Oil Temp. Regulating Valve |

Direct-action, wax-pellet |

|

|

|

50-65°C |

|

|

|

|

Eng. mount |

|

|

||||||||||

|

Tanks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating Oil Tank Capacity |

|

|

|

|

|

|

|

|

See 30-01-00 |

|

|

|

|

|

|

|

||||||

|

Engine Freshwater Holding Capacity |

|

|

|

|

|

|

|

|

|

145 l |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Starting Air Sump |

|

|

|

|

|

|

150 l× 1 Bottle, 2.94 MPa |

|

|

|

|

|||||||||||

|

Other Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Rating Power |

kW |

800 |

|

745 |

|

680 |

|

660 |

|

615 |

|

|

550 |

|

500 |

455 |

|

|||||

|

Radiation |

Heat Radiation to L.O. (at 100% Load) |

MJ/h |

350.4 |

|

337.9 |

|

323.2 |

|

318.7 |

|

292.7 |

|

|

275.5 |

|

262.3 |

250.4 |

|

||||

|

Heat Radiation to LowTemp. C.W. |

MJ/h |

203.4 |

|

178.6 |

|

149.2 |

|

140.1 |

|

216.4 |

|

|

187.6 |

|

167.5 |

150.9 |

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

(at 100% Load) |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Heat |

Heat Radiation to High Temp. C.W. |

MJ/h |

785.3 |

|

714.4 |

|

630.6 |

|

604.8 |

|

567.0 |

|

|

461.2 |

|

384.0 |

319.1 |

|

||||

|

(at 100% Load) |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Heat Radiation to Air (at 100% Load) |

MJ/h |

797.0 |

|

742.2 |

|

677.5 |

|

657.5 |

|

532.3 |

|

|

492.2 |

|

461.3 |

433.5 |

|

||||

|

Combustion Air Volume at 100% Load [25°C] |

m3/h |

4510 |

|

4320 |

|

4080 |

|

4060 |

|

3760 |

|

|

3600 |

|

3370 |

3100 |

|

|||||

|

Exh. Gas Volume at 100% Load [0°C] |

m3/h |

4060 |

|

3880 |

|

3730 |

|

3720 |

|

3480 |

|

|

3320 |

|

3090 |

2860 |

|

|||||

|

Eng. Room Ventilation Air Volume |

|

|

|

|

|

|

|

|

0.27-0.41 m3/min kW |

|

|

|

|

|||||||||

|

T/C Outlet Exh. Gas Temp. |

°C |

370 |

|

360 |

|

350 |

|

350 |

|

350 |

|

|

340 |

|

335 |

330 |

|

|||||

|

(at 100% Load, Ambient Temp. 25°C) |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Exh. Back Pressure at 100% Load |

|

|

|

|

|

|

|

|

|

3.43 kPa |

or below |

|

|

|

|

|

|

|

||||

|

Exhaust Pipe Diameter |

|

|

|

|

|

|

|

|

|

250 A or 300 A |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6EY18(A)LW |

46623 |

|

|

|

Outline |

Technical Data (750 min-1) |

|

|

|

|

No. |

Page |

||||||||||

|

|

|

|

|

|

01-02-00 |

4/4 |

|

||||||||||

|

4. Model 6EY18LW (750 min-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Pumps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling Water Pump (High temp) |

Centrifugal |

|

22 m3/h |

|

|

|

17 m |

|

|

Eng. mount |

|

||||||

|

Cooling Water Pump (Low temp) |

Centrifugal |

|

22 m3/h |

|

|

|

17 m |

|

|

Eng. mount |

|

||||||

|

Fuel Feed Pump for M.D.O. |

Gear type |

|

0.520 m3/h |

|

|

Refer to 50-02 |

|

|

Eng. mount |

|

|||||||

|

Fuel Supply Pump for H.F.O. |

Gear type |

|

- |

|

|

|

Refer to 50-02 |

|

|

Hull mount |

|

||||||

|

Lubricating Oil Pump |

Gear type |

|

21.2 m3/h |

|

|

0.80 MPa |

|

|

Eng. mount |

|

|||||||

|

Lubricating Oil Priming Pump |

Gear type |

|

4 m3/h |

|

|

0.15 MPa |

|

|