Yanmar 3TNV82A, 4TNV1006T Troubleshooting Manual

TROUBLESHOOTING

Gehl Form No. 50950006, AP1210

MANUAL

ELECTRONIC CONTROL

3TNV82A

3TNV82A-B

3TNV84

3TNV84T

3TNV84T-B

3TNV88

3TNV88-B

3TNV88-U

4TNV84

4TNV84T

4TNV84T-Z

4TNV88

4TNV88-B

4TNV88-U

4TNV94L

4TNV98

4TNV98-Z

4TNV98-E

4TNV98T

4TNV98T-Z

4TNV106

4TNV106T

California

Proposition 65 Warning

California

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the state of

California to cause cancer, birth

defects, and other reproductive harm.

Battery posts, terminals, and related

accessories contain lead and lead

compounds, chemicals known to the

state of California to cause cancer and

reproductive harm.

Wash hands after handling.

TNV DI Service Manual

Section 1

FAILURE DIAGNOSIS

Page

DTCs (Diagnostic Trouble Codes) General Description.................. 1-3

DTC Code List........................................................................... 1-3

Description Items....................................................................... 1-7

Analog Input Related Failures................................................... 1-8

Pulse Sensor Related Failures................................................ 1-60

Contact Output Related Failures............................................. 1-66

Contact Input Related Failures.............................................. 1-100

Actuators etc.......................................................................... 1-114

E-ECU Internal and Communication Errors........................... 1-122

Method and Procedure of Failure Diagnosis............................... 1-133

Description Items................................................................... 1-133

Analog Input Related Failures............................................... 1-136

Pulse Sensor Related Failures.............................................. 1-164

Contact Output Related Failures........................................... 1-170

Contact Input Related Failures.............................................. 1-187

Actuator Related Failures...................................................... 1-193

ECU Internal and Communication Errors.............................. 1-197

FAILURE INDICATOR LAMP FLASHING PATTERN........... 1-207

Using the Failure Indicator for Failure Diagnosis ........................ 1-208

Flashing Patterns of the Failure Indicator.............................. 1-208

Factor Analysis............................................................................ 1-210

2G-Type Eco-Governor Speed-Fluctuation Factor Analysis. 1-210

2G-Type Eco-Governor Engine

Stalling/Start-Up Inability Factor Analysis.............................. 1-213

2G-Type Eco-Governor Black Smoke Factor Analysis.......... 1-216

Special Service Tools.................................................................. 1-218

Troubleshooting By Measuring Compression Pressure.............. 1-219

Compression Pressure Measurement Method...................... 1-219

Quick Reference Table For Troubleshooting .............................. 1-222

TNV DI Service Manual

1-1

FAILURE DIAGNOSIS

This Page Intentionally Left Blank

1-2

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

FAILURE DIAGNOSIS

DTCS (DIAGNOSTIC TROUBLE CODES) GENERAL DESCRIPTION

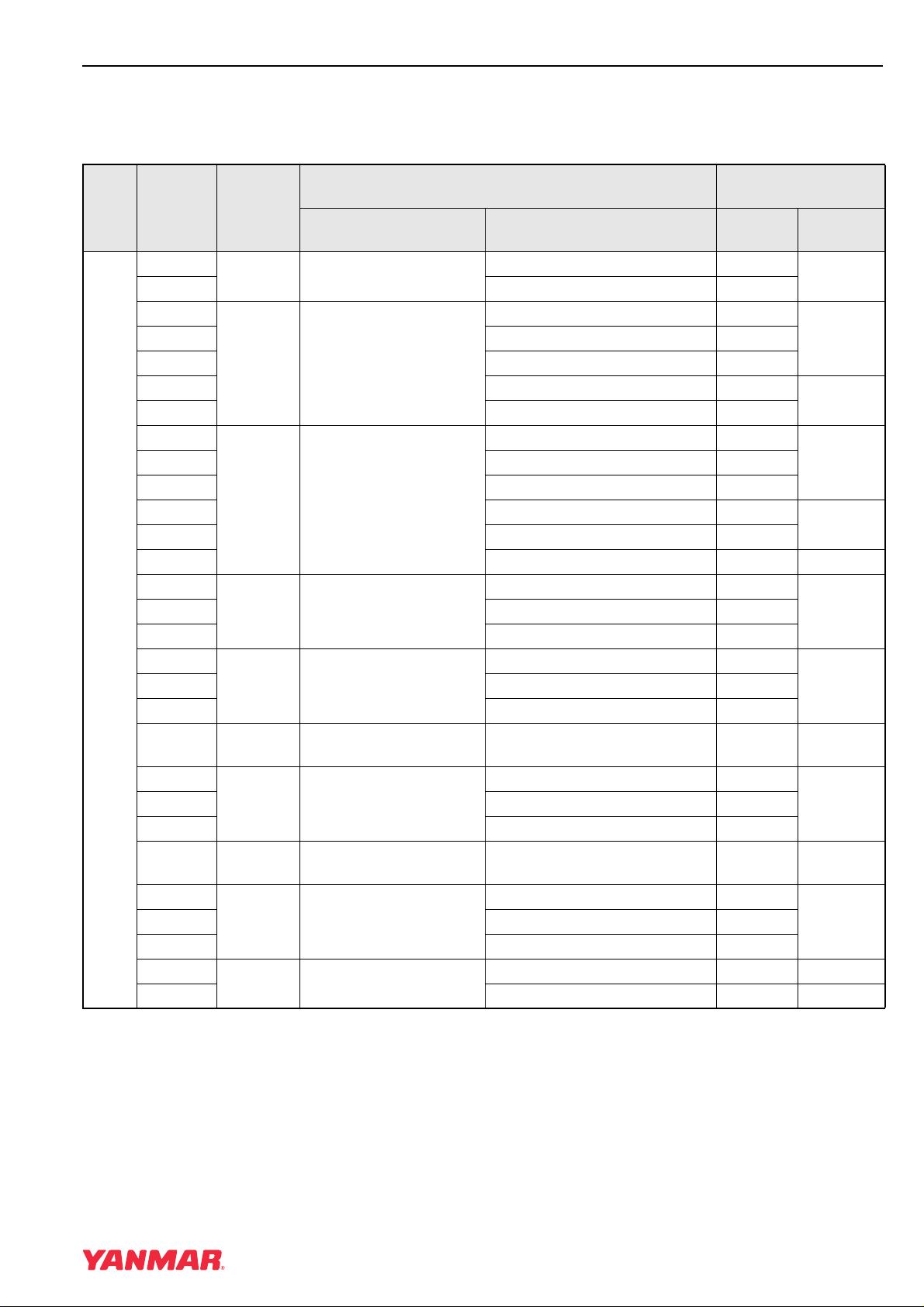

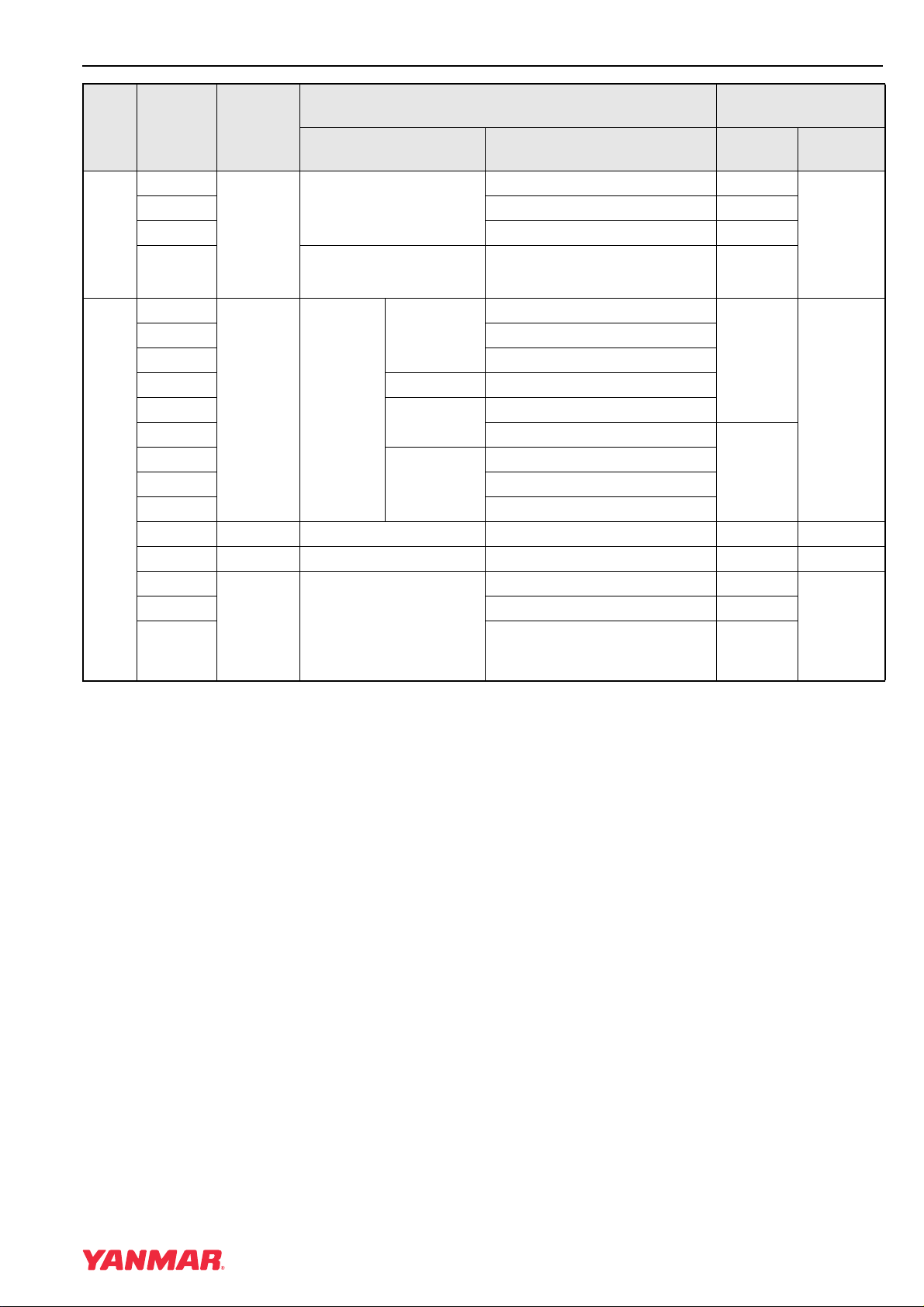

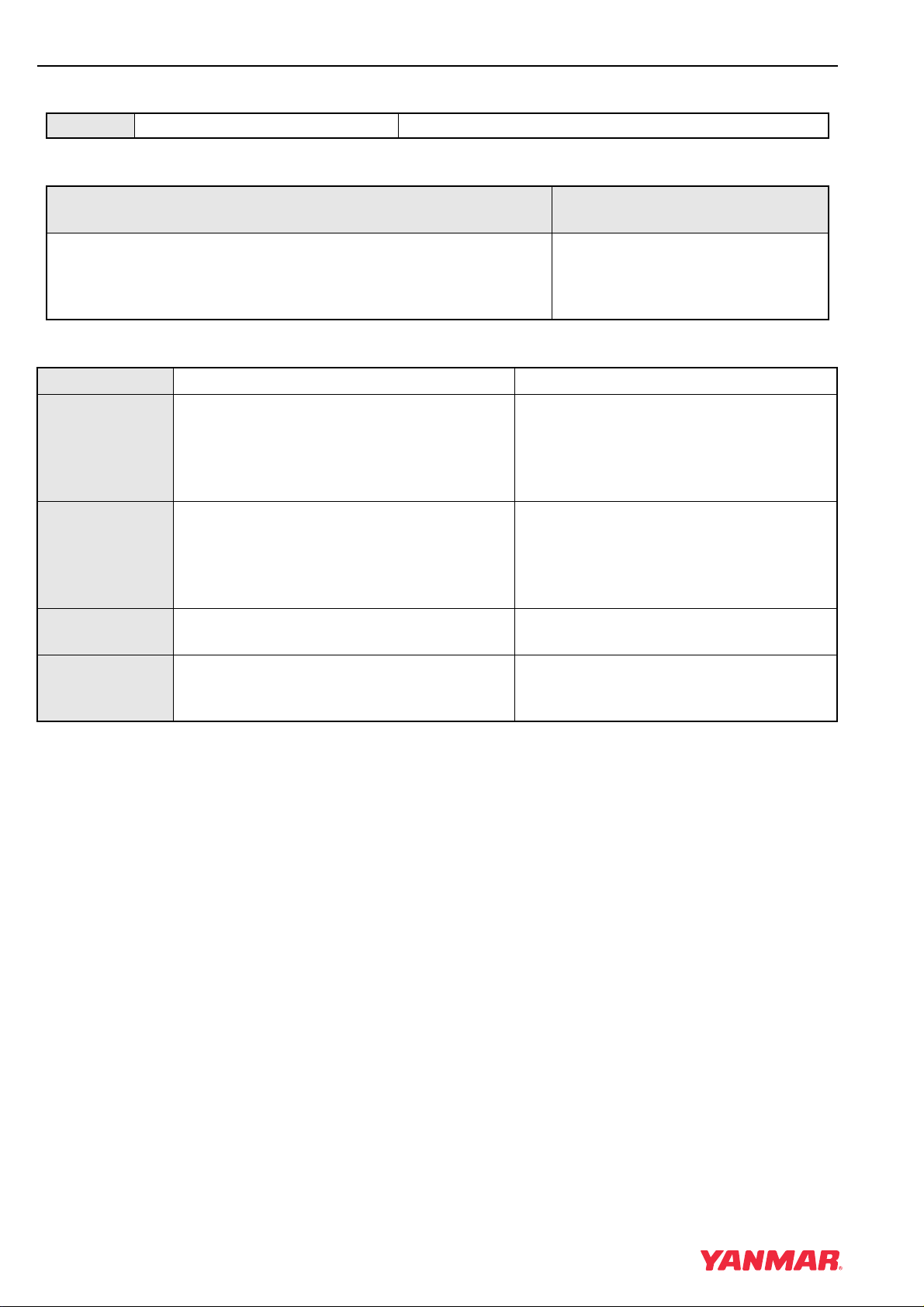

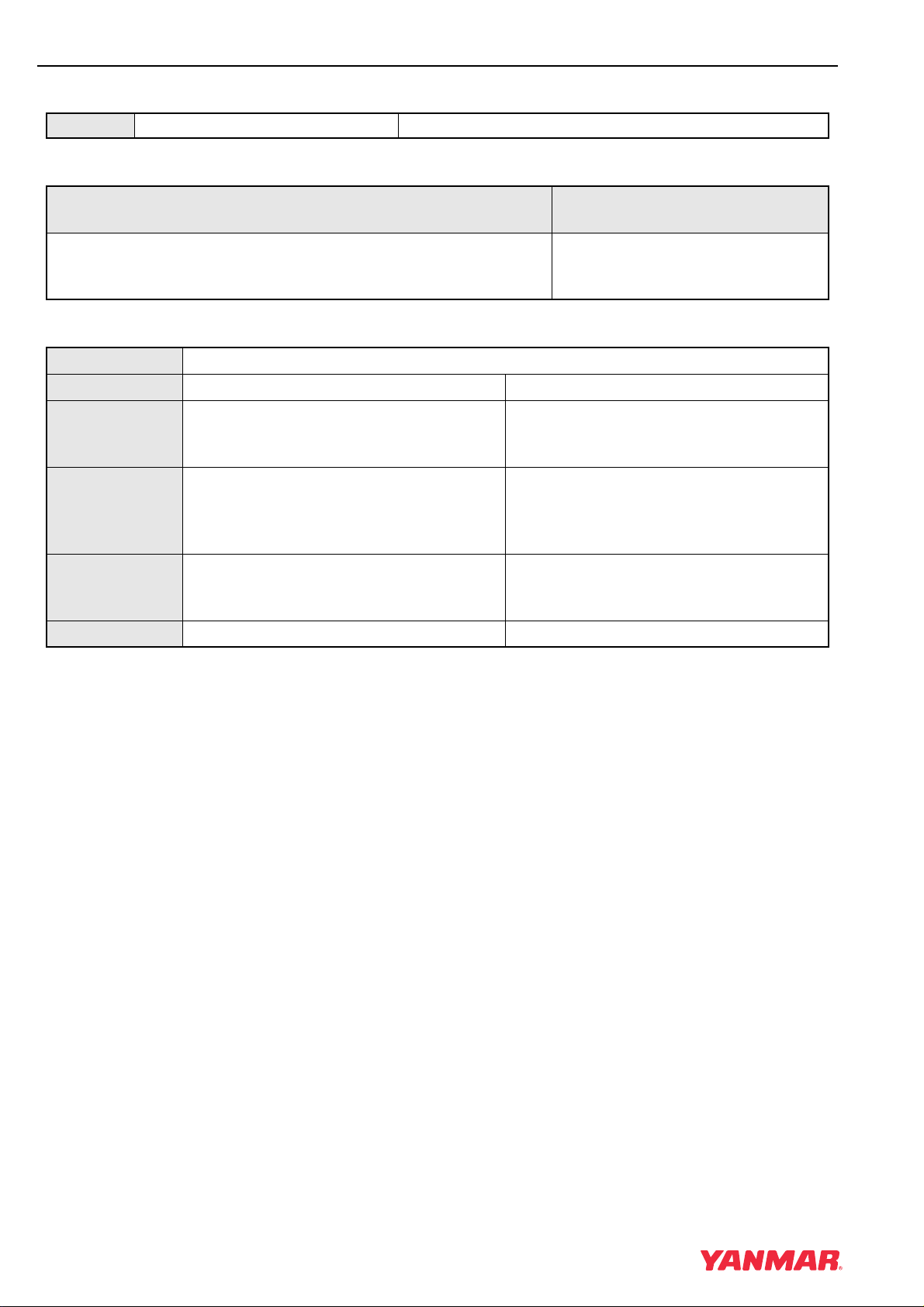

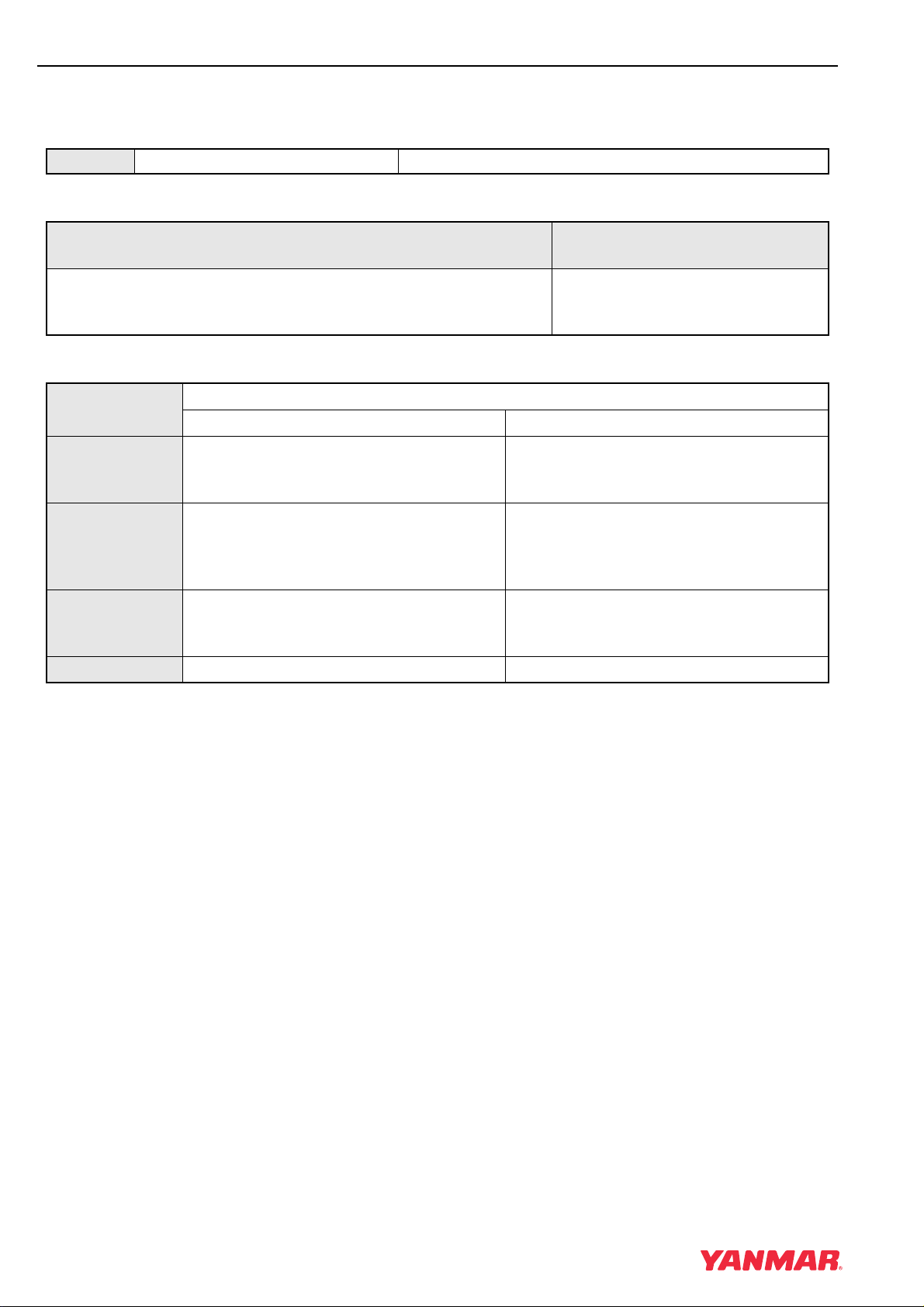

DTC Code List

Clas

sifica

tion

Analog Input Related Failures

DTC

P1202/4

P1203/3 Error (high voltage) P.1-10

P0122/4

P0124/2 Intermittent failure P.1-16

P1125/1 Error (foot pedal-close position) P.1-18

P1126/0 Error (foot pedal-open position) P.1-20

P0222/4

P0224/2 Intermittent failure P.1-26

P1225/1 Error (foot pedal-close position) P.1-28

P1226/0 Error (foot pedal-open position) P.1-30

P1227/8 Error (pulse communication) P.1-32 P.1-152

P0222/4

P0224/2 Intermittent failure P.1-38

P0668/4

P1644/2 Intermittent failure P.1-42

P0634/0 2-5

P0117/4

P0119/2 Intermittent failure P.1-49

P0217/0 3-6

P0642/4

P1644/2 Intermittent failure P.1-55

P0562/1

P0563/0 Error (High Voltage) P.1-58 P.1-58

Lamp

Flashing

Patterns

Area Status Overview

7 Rack position sensor

5 Accelerator sensor

1-8 Spare accelerator sensor

1-9

4-1

4

2-4 SENSOR 5V

2-3 Power supply Voltage

Atmospheric pressure

sensor

ECU Temperature

Sensor

ECU Temperature Rise

Alarm

Cooling water

temperature sensor

Cooling Water

Temperature Rise Alarm

Error Item

Error (low voltage) P.1-8

Error (low voltage) P.1-12

Error (low voltage) P.1-22

Error (low voltage) P.1-34

Error (low voltage) P.1-40

Error (Low Voltage) P.1-45

Error (low voltage) P.1-53

Error (Low Voltage) P.1-56 P.1-56

Referenced page

number

Diagnosis

P.1-43 P.1-154

P.1-51 P.1-156

Failure

P.1-136

P.1-140P1203/3 Error (high voltage) P.1-14

P.1-144

P.1-148P0223/3 Error (high voltage) P.1-24

P.1-144

P.1-148P0223/3 Error (high voltage) P.1-36

P.1-154P0669/3 Error (high voltage) P.1-41

P.1-156P0118/3 Error (High Voltage) P.1-47

P.1-160P0643/3 Error (High Voltage) P.1-54

TNV DI Service Manual

1-3

FAILURE DIAGNOSIS

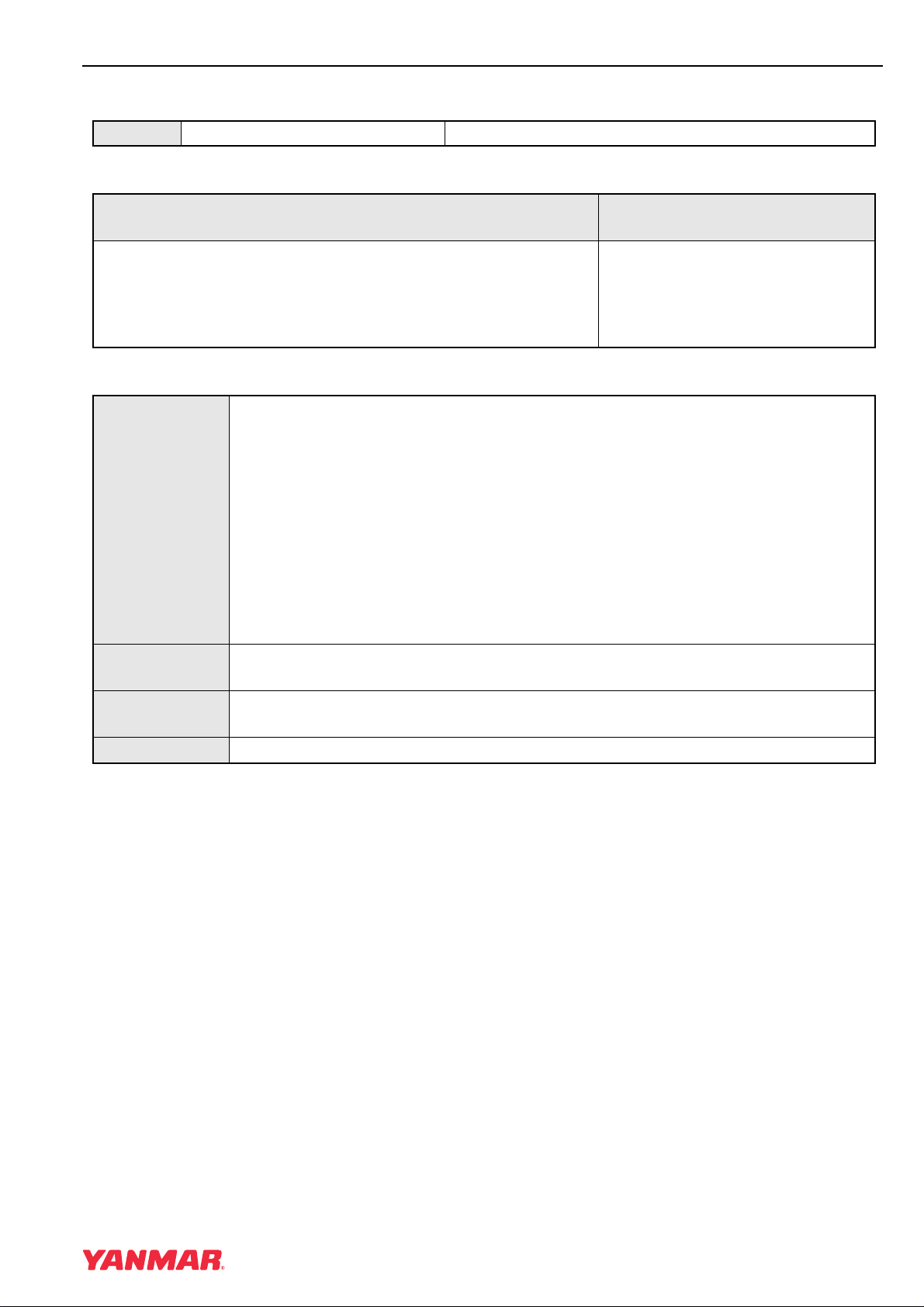

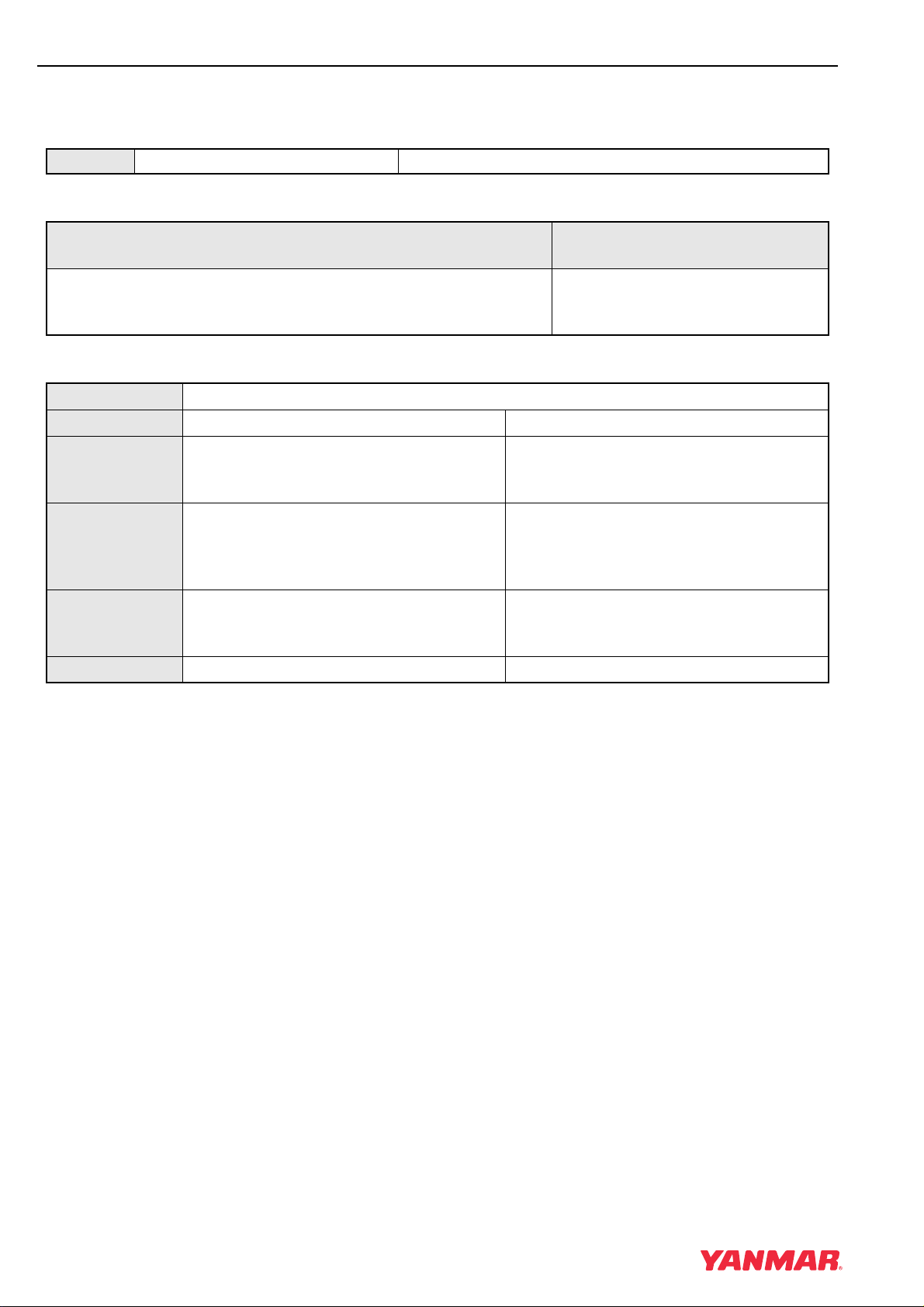

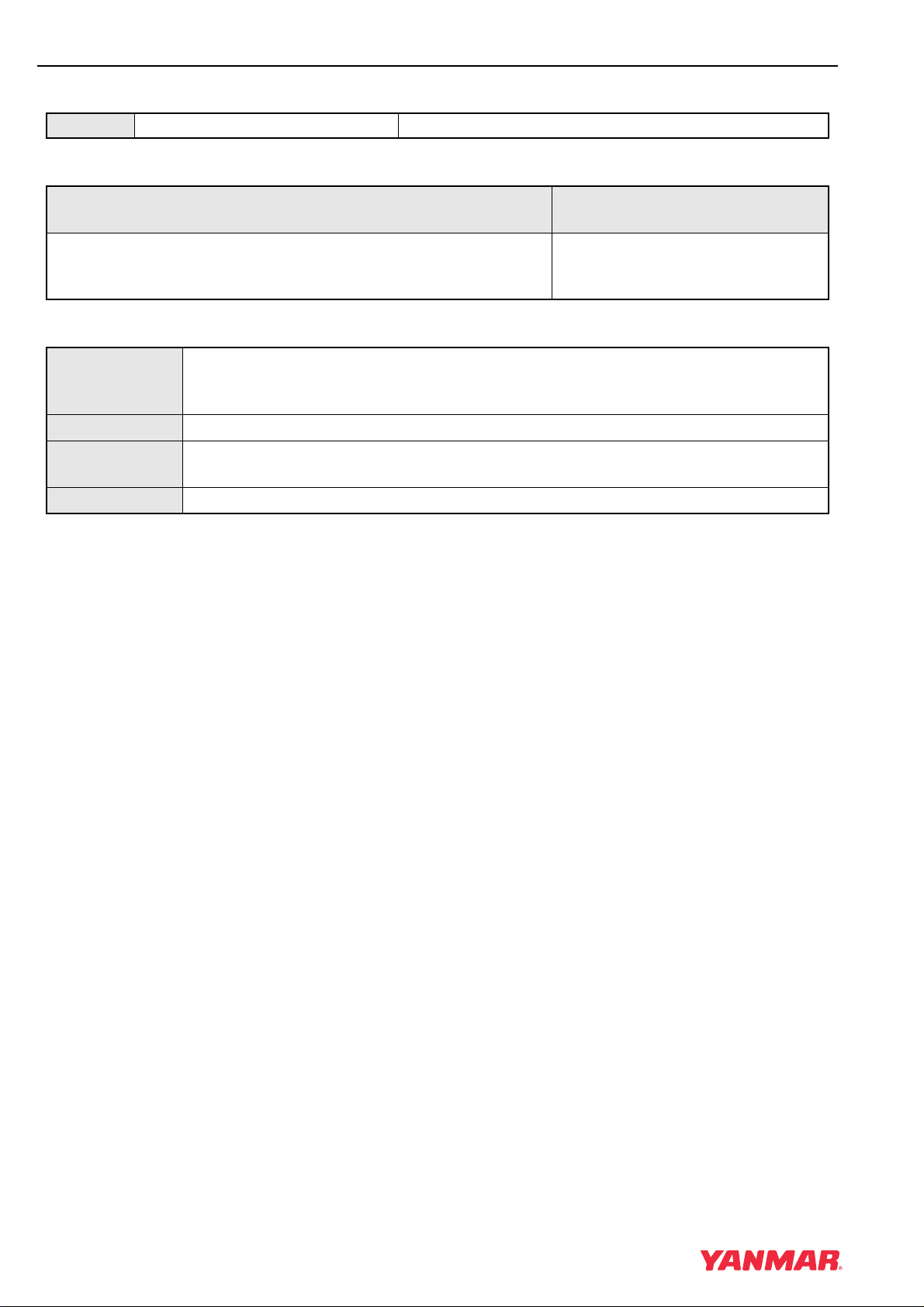

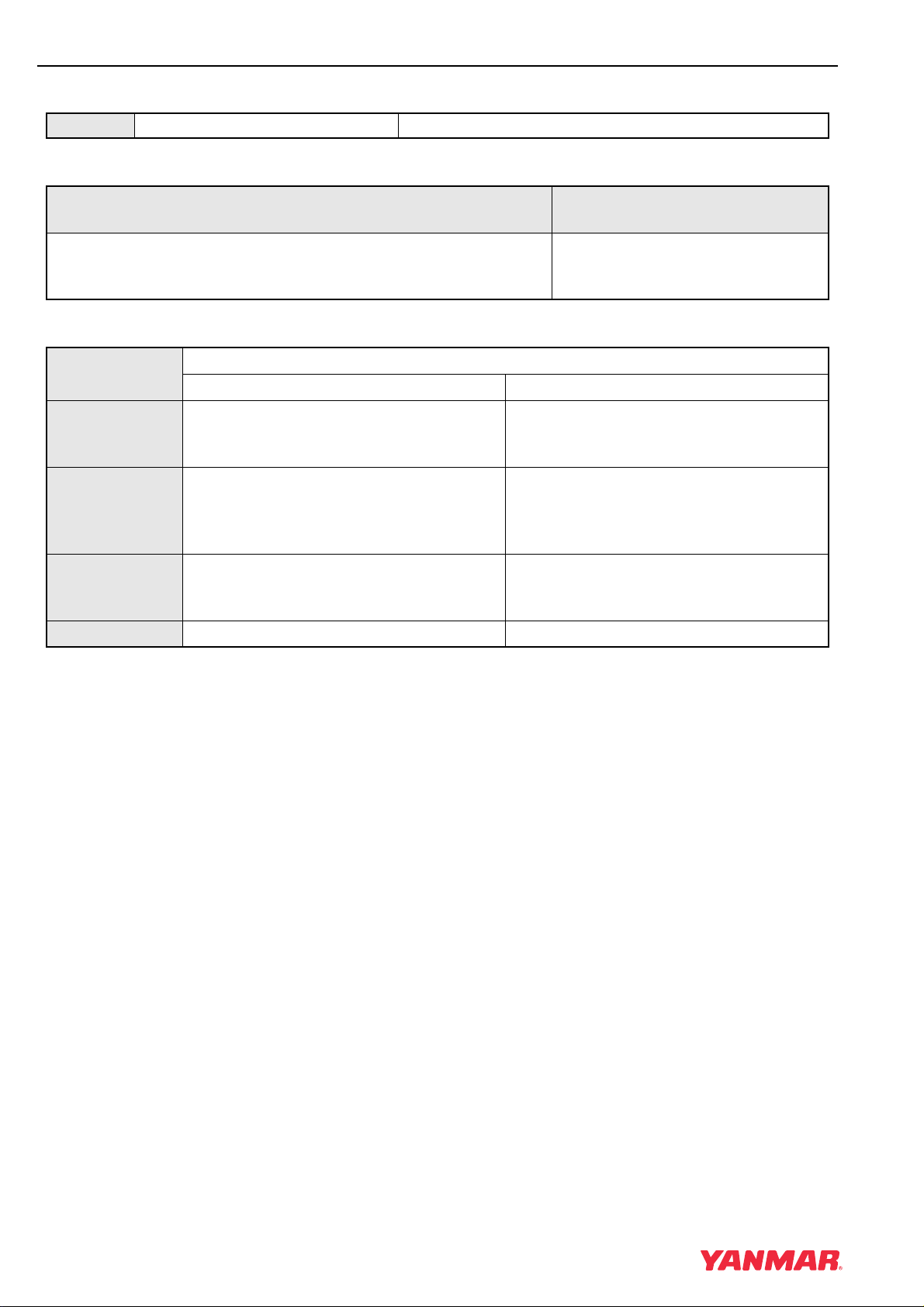

DTCs (Diagnostic Trouble Codes) General Description

Clas

sifica

tion

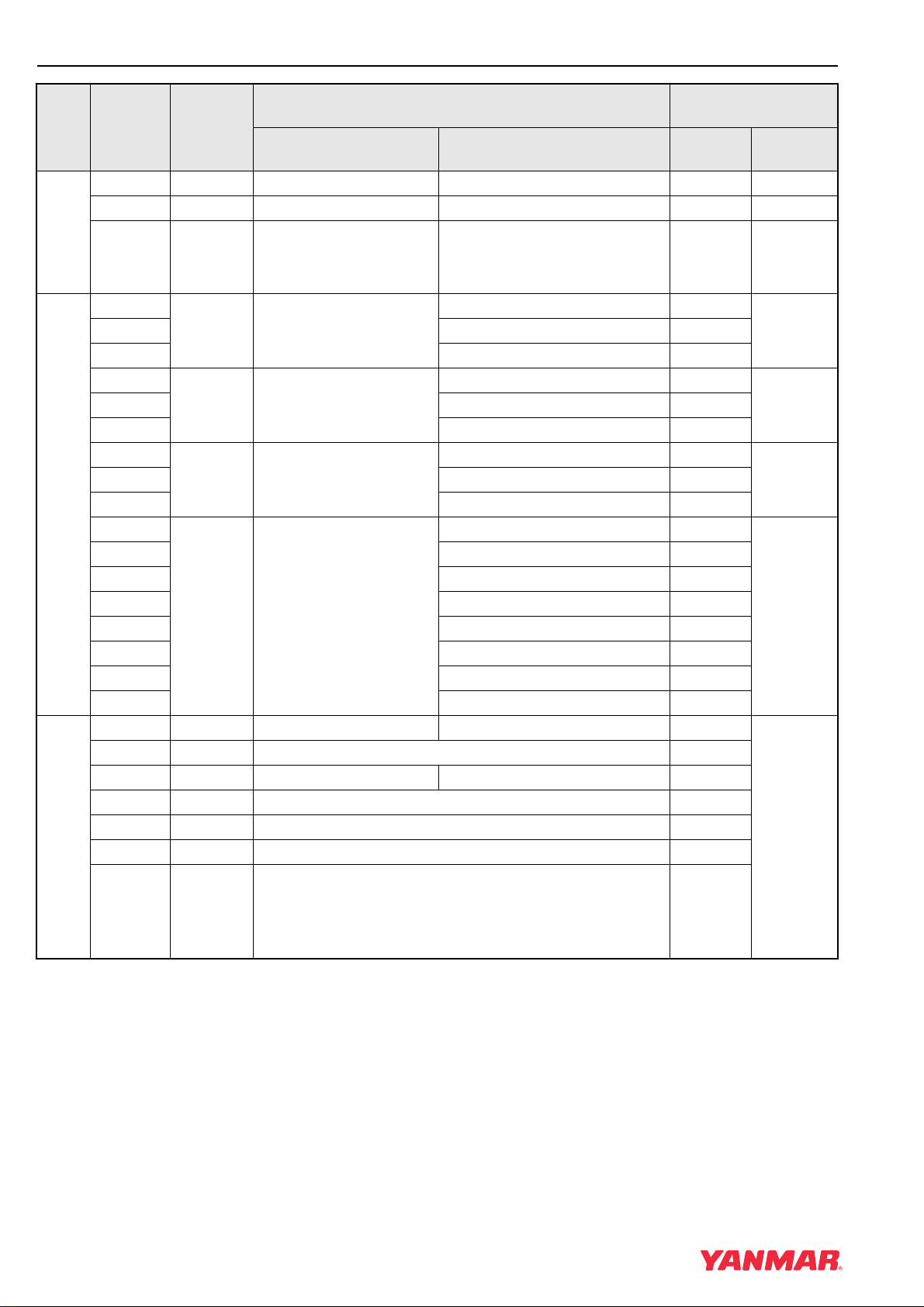

Pulse Sensors

Contact Output Related Failures

Lamp

DTC

P0340/4 6 Speed Sensor Error P.1-60 P.1-164

P1340/4 1-1 Spare speed sensor Error P.1-62 P.1-167

P0219/0 9 Overspeed Error P.1-64 P.1-64

P1222/4

P1224/2 Intermittent failure P.1-70

P1232/4

P1234/2 Intermittent failure P.1-76

P1242/4

P1244/2 Intermittent failure P.1-82

P1402/4

P1403/3 Error B (Step Motor A-Phase) P.1-86

P1412/4 Error A (Step Motor B-Phase) P.1-88

P1413/3 Error B (Step Motor B-Phase) P.1-90

P1422/4 Error A (Step Motor C-Phase) P.1-92

P1423/3 Error B (Step Motor C-Phase) P.1-94

P1432/4 Error A (Step Motor D-Phase) P.1-96

P1433/3 Error B (Step Motor D-Phase) P.1-98

P1192/4 2-1 Oil pressure switch Error P.1-100

P1198/1 3-1 Oil Pressure Descend Error P.1-102

P1562/4 2-2 Charge switch Error P.1-104

P1568/1 3-2 Charge Alarm P.1-106

P1217/0 3-3 Abnormal Water Temperature P.1-108

P1101/0 3-4 Air cleaner Clogging Alarm P.1-110

Flashing

Patterns

1-7 Rack actuator Relay

1-5 Start Assist Relay

1-4 CSD solenoid valve

1-3 EGR valve

Area Status Overview

Error Item

Error A P.1-66

Error A P.1-72

Error A P.1-78

Error A (Step Motor A-Phase) P.1-84

Referenced page

number

Failure

Diagnosis

P.1-170P1223/3 Error B P.1-68

P.1-174P1233/3 Error B P.1-74

P.1-178P1243/3 Error B P.1-80

P.1-182

P.1-187

Contact Input Related Failures

1-4

P1151/0 3-5 Oil-water separator Alarm P.1-112

TNV DI Service Manual

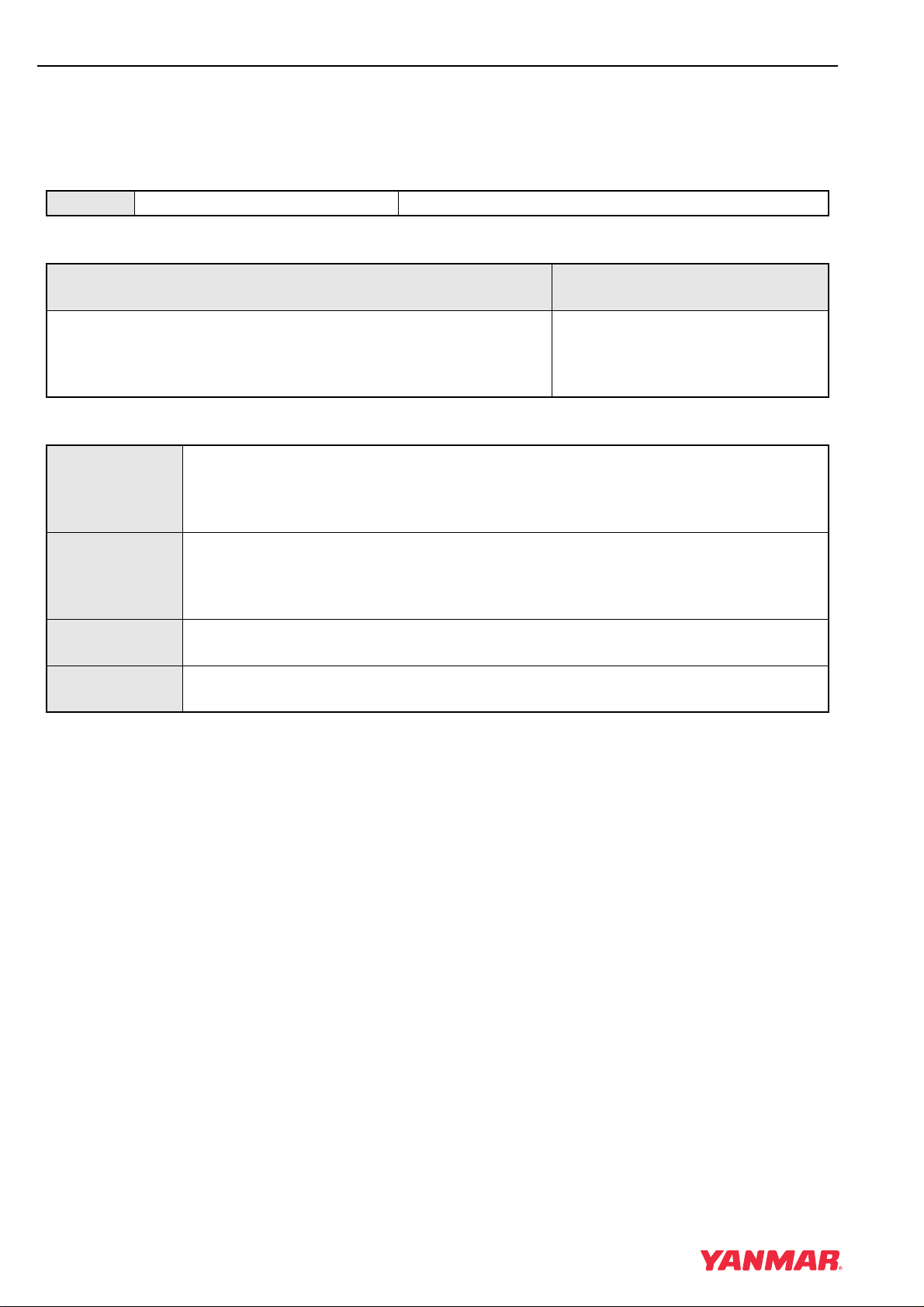

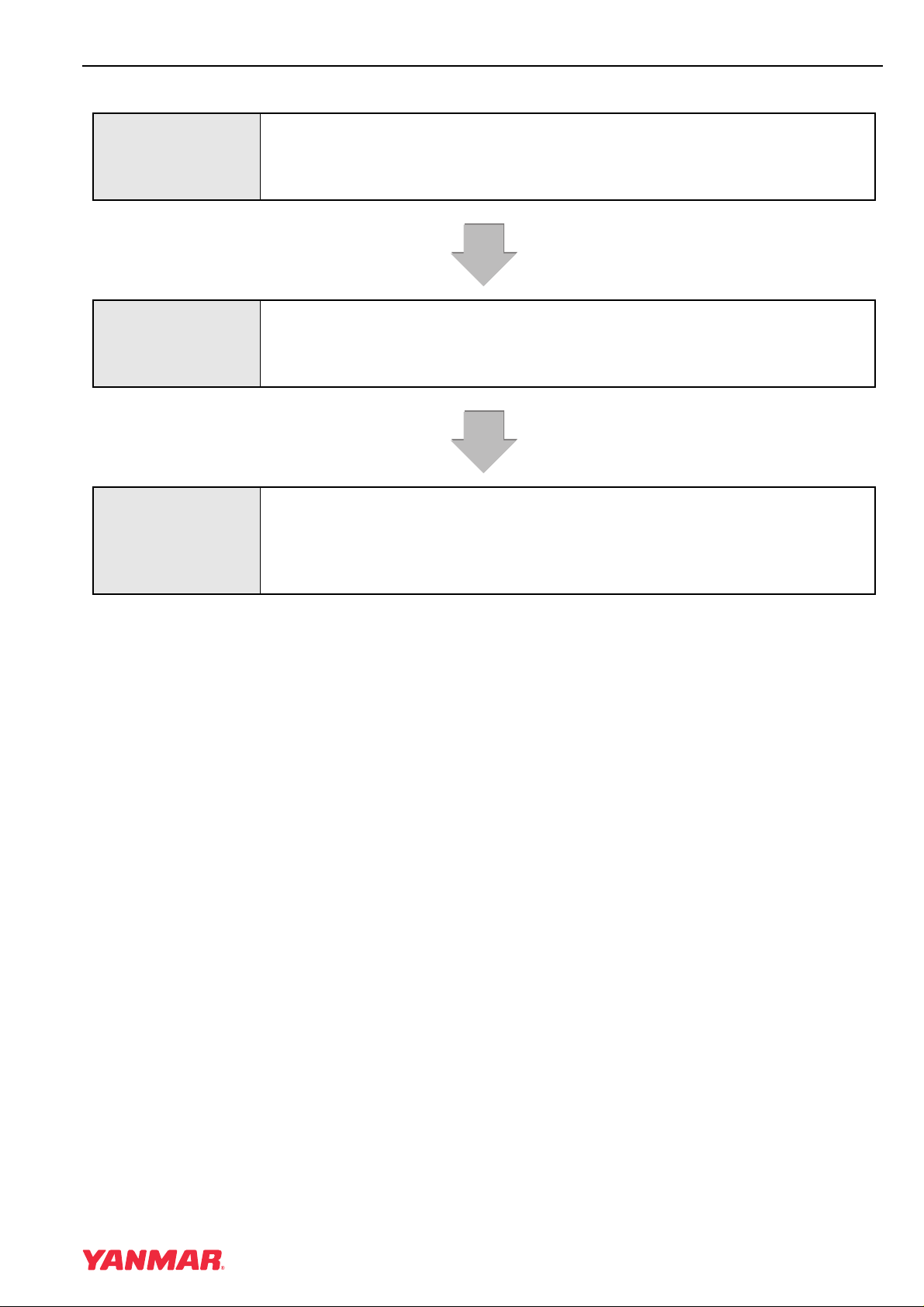

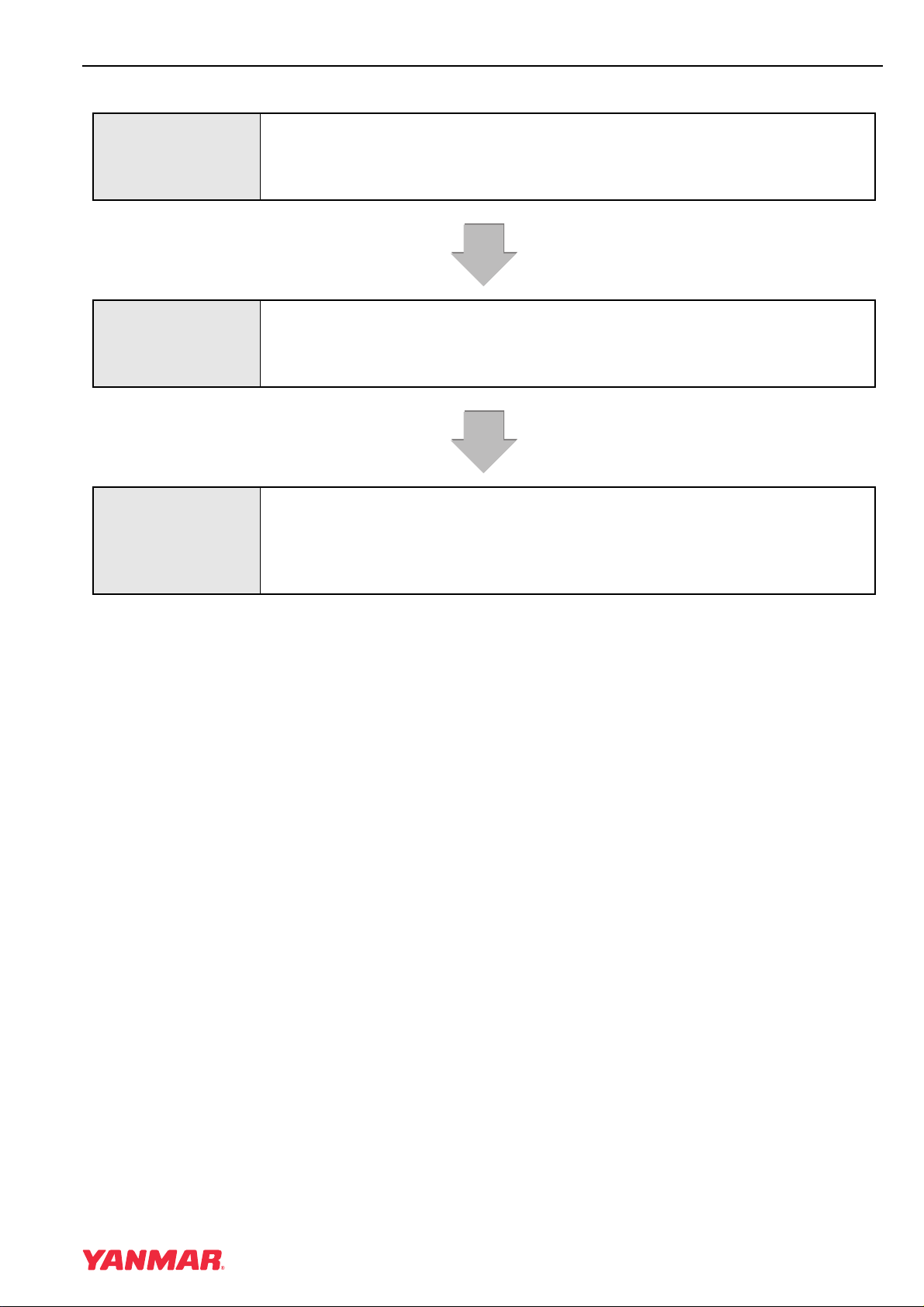

DTCs (Diagnostic Trouble Codes) General Description

FAILURE DIAGNOSIS

Clas

sifica

tion

DTC

P1212/4

P1213/3 Error (high current) P.1-116

P1211/7 Mechanical failure P.1-118

P1214/2 Engine Error P.1-120

Actuator Errors

P0605/12

P1605/2 Error (Checksum B)

P1606/2 Error (Checksum C)

P1620/12 Map format Error

P1601/2

P0601/12 Error (read/write error)

P1610/12

P1611/12 Error B

P1612/12 Error C

P0686/4 1-6 Main relay Error P.1-124 P.1-199

U0001/12 1-2 CAN Communication Error P.1-126 P.1-203

U0167/12

U1167/8 Error (pulse communication) P.1-130

U0426/2 Error (System) P.1-132

ECU inside and Communication Related Failures

Lamp

Flashing

Patterns

Rack actuator

8

4-1

4-2 Immobilizer

ECU

Internal

Error Item

Area Status Overview

Error (low current) P.1-114

Error (Checksum A)

Flash ROM

EEPROM

Sub CPU

Error (Checksum)

Error A

Error (CAN communication) P.1-128

Referenced page

number

P.1-122

P.1-123

Failure

Diagnosis

P.1-193

P.1-197

P.1-205

TNV DI Service Manual

1-5

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

This Page Intentionally Left Blank

1-6

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

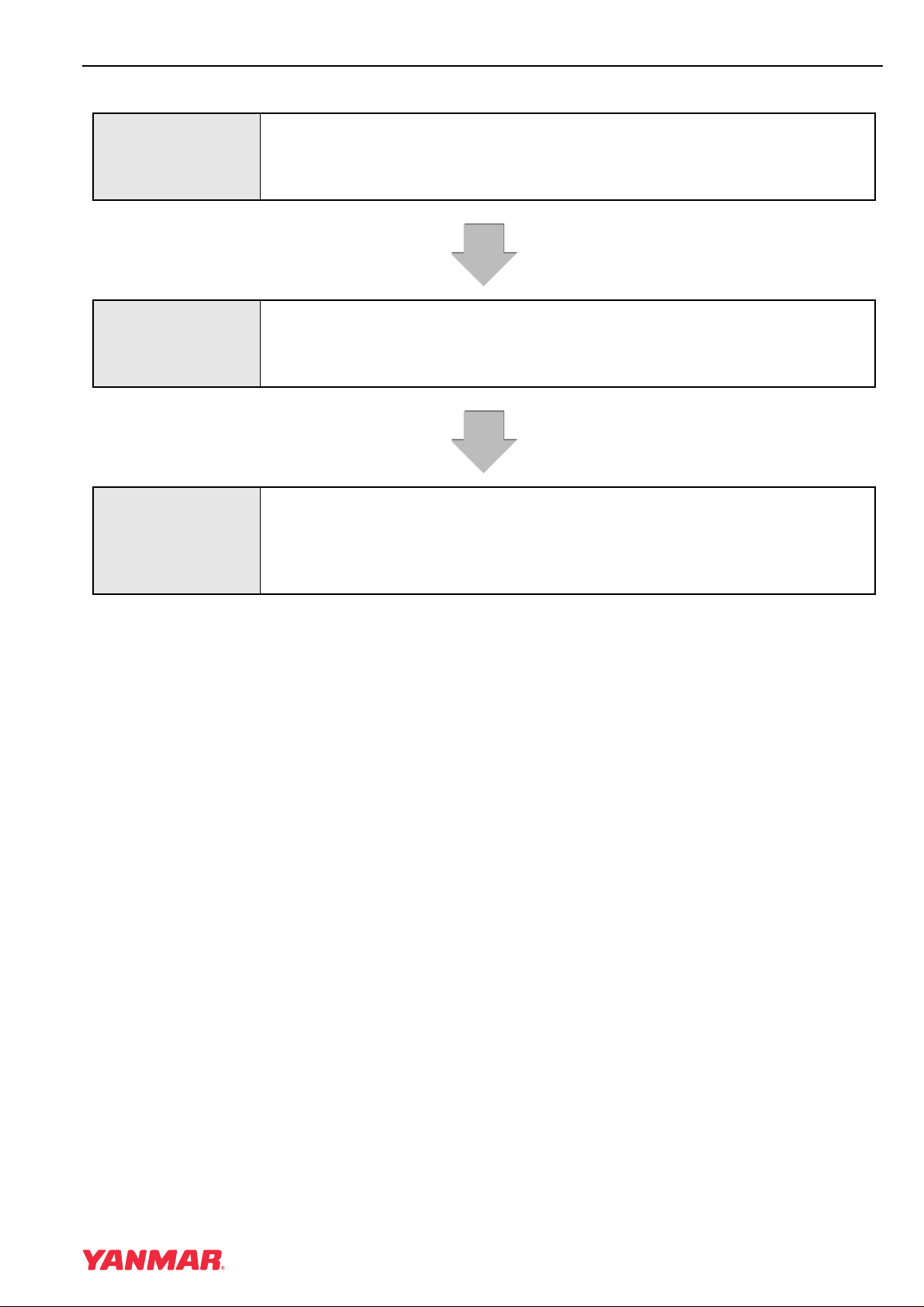

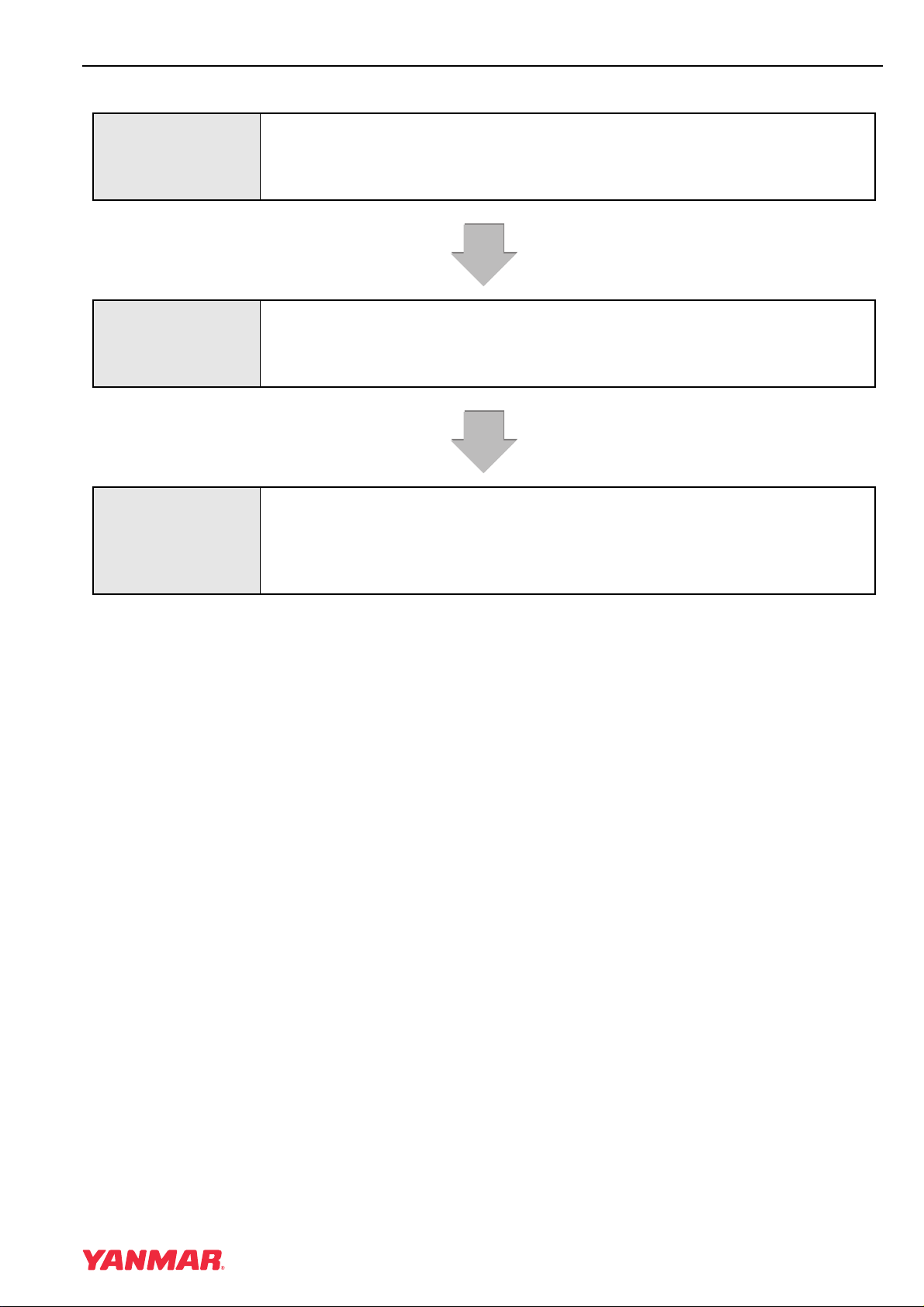

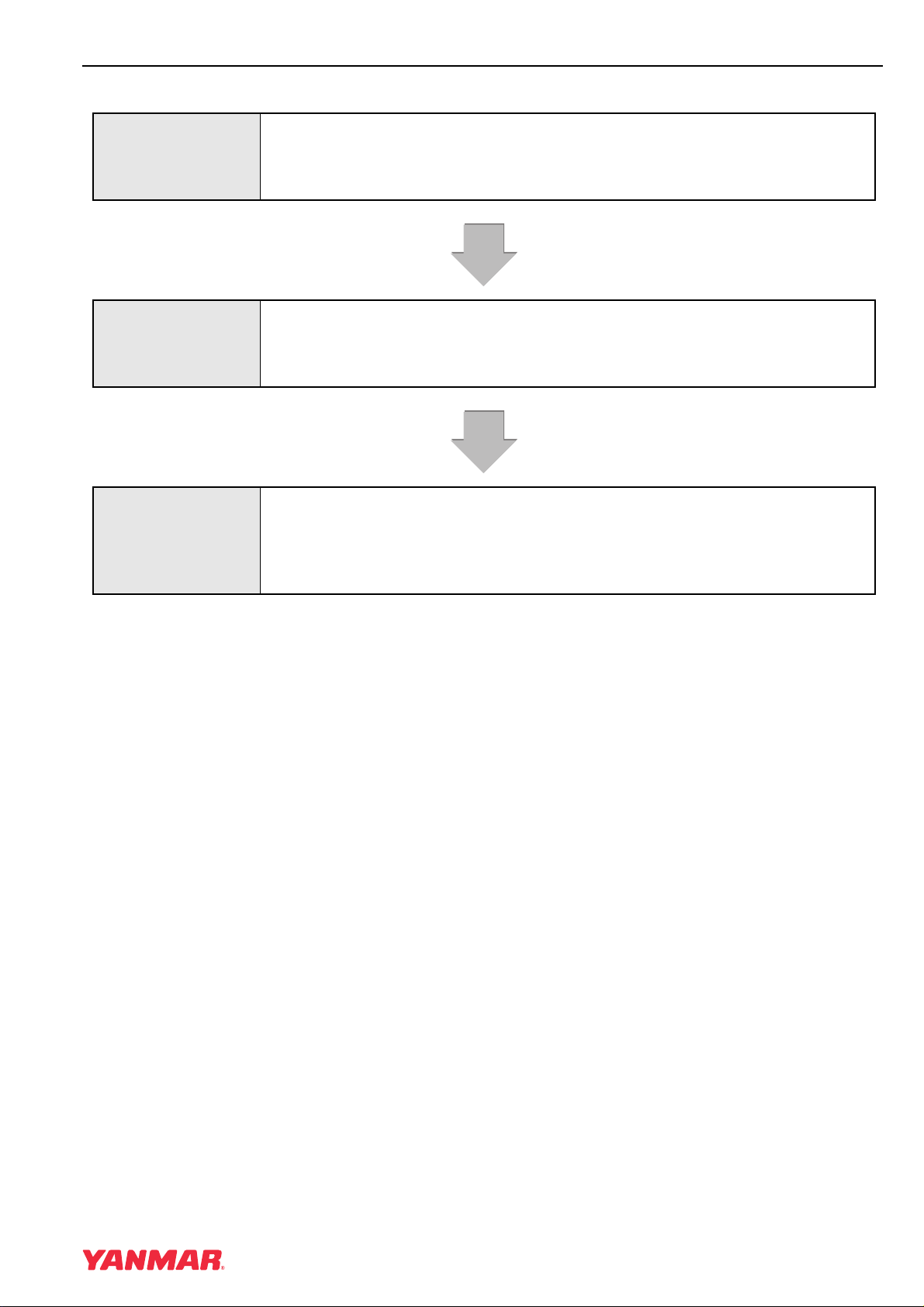

Description Items

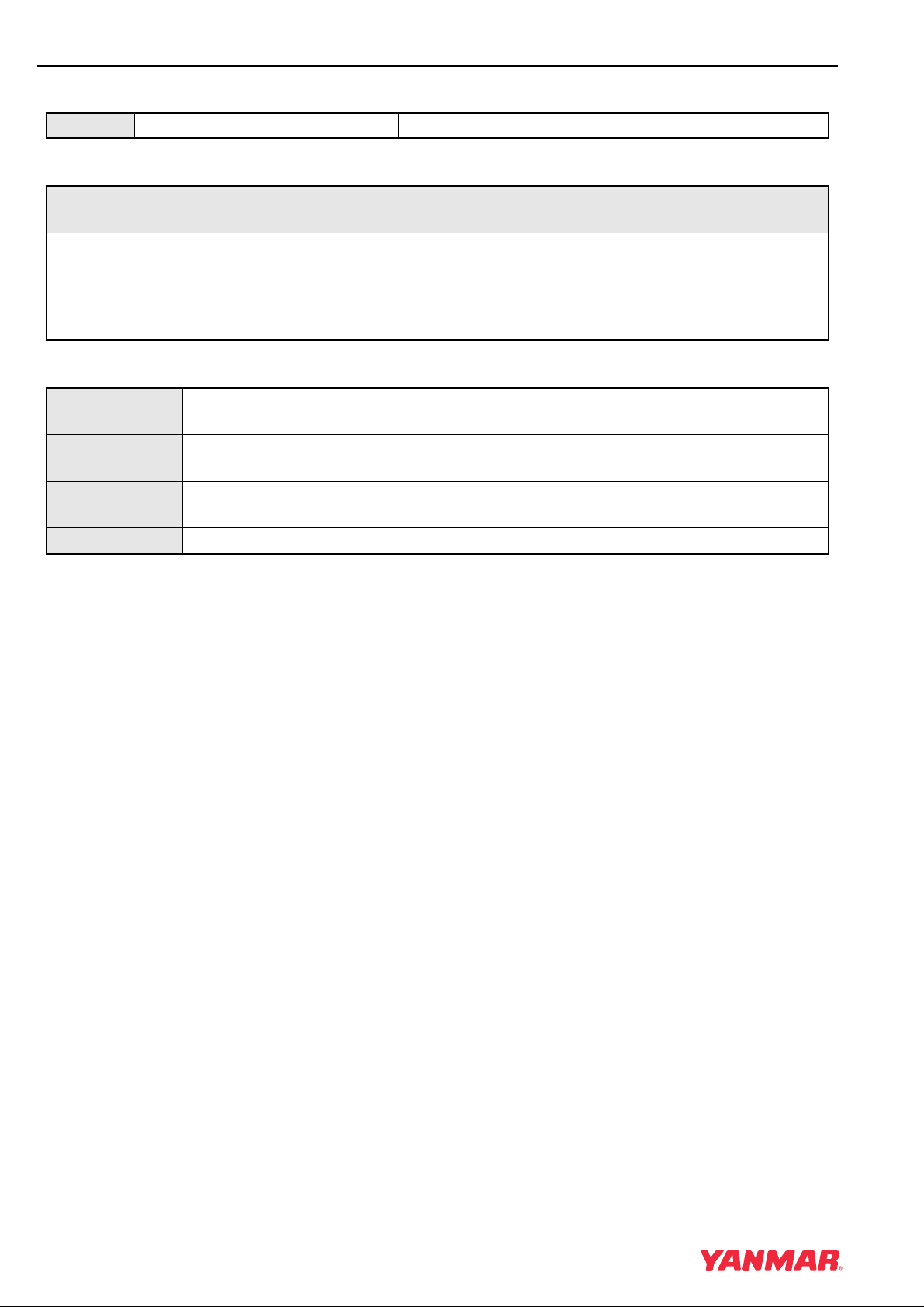

DTC Code Number DTC Name

DTC Detecting Conditions

FAILURE DIAGNOSIS

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Precondition for Error detection

2. Error detecting Condition

3. Indicates the pattern in which the failure lamp flashes when the

DTC is output. (For detailed information on various flashing

patterns, see Annex).

This column shows what parts or

items should be checked to identify

the cause of the error.

For details, see "<Diagnosis

Description>."

Check points

Movement at Error occurrence

Error Mode [Operation Continuation] / [Run Under Restrictions] / [Stop Immediately]:

The engine operation after detecting the error is described.

*

[Operation Continuation]:After detecting the error, the system lets the engine

continue to run without any restrictions.

[Run Under Restrictions]:The system lets the engine continue to run but restricts the

High idle speed, engine power, and/or other performance

factors as appropriate.

[Stop Immediately]: The system stops the engine immediately after detecting the

error.When any error is detected before starting the engine, the

starter will not rotate.

Run restricted? Yes/No.: If Yes, this field details how the engine run is restricted when the error has

occurred.

Recovery

Conditions

Yes/No.: If Yes, this field describes what conditions must be true for the error mode

to be reset.

Remarks This field describes some notes on safety precautions and so on, as appropriate.

Estimation of Failure cause/Error condition

Provides descriptive information on possible points of failure, possible direct causes (such as a disconnected sensor

wire), or possible system abnormalities that has indirectly caused the failure (such as abnormally high cooling water

temperature), as can be estimated from the output DTC.

Note: Indicates failures that might be related with the output DTC.

Diagnosis Description

Describes methods or procedures of failure d iagnosis.

* After sucessful recovery by the replaceme nt of ECU, sensor or actuato r , make sure that installing

the previous parts will reproduce the same error.

TNV DI Service Manual

1-7

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

Analog Input Related Failures

Rack position sensor

(1) P1202/4: Failure with Rack Position Sensor (Low Voltage)

DTC P1202/4 Rack Position Sensor Error (Low Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. The sensor voltage lower limit and below [at E-ECU activation,

engine running]

3. Seven flashes.

Connector

Harness

Rack position sensor

E-ECU

Check points

Movement at Error occurrence

Error Mode [Run Under Restrictions]:

The engine continues to run in on-error engine control mode.

If any error is detected at E-ECU activation, it takes 1 - 10 seconds from the starter

begins to rotate until the engine starts.

Run restricted? Yes: • The High idle speed is restricted to one of the following, whichever smaller:

• 80% of the pre-error High idle speed

• 150% of the Low idle speed

• The fuel injection rate is restricted.

Recovery

No.

Conditions

Remarks The High and Low idle speeds must be equal to those specified in the engine

specifications.

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The rack position sensor's signal wires ma y be disconnected or short-circuited with GND .

• The SENSOR 12V wire may be disconnected or short-circuited with GND (*NOTE).

• The SENSOR GND wire may be short-circuited with POWER SUPPLY (*NOTE).

*NOTE) If the SENSOR 12V wire is short-circuited wi th GND or SE NSOR GND wire is shor t-circuited with

POWER SUPPLY, the E-ECU's po wer supply line fuse 10A might be blo wn.With this fuse b lown, the

E-ECU may fail to detect/ind icate the error, and to store the error history .

The rack position sensor may be faulty.

• Output defect of the r ack position signal by a disconnection or a short circuit of the inner wiring

• The E-ECU internal circuitry may be faulty.

1-8

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

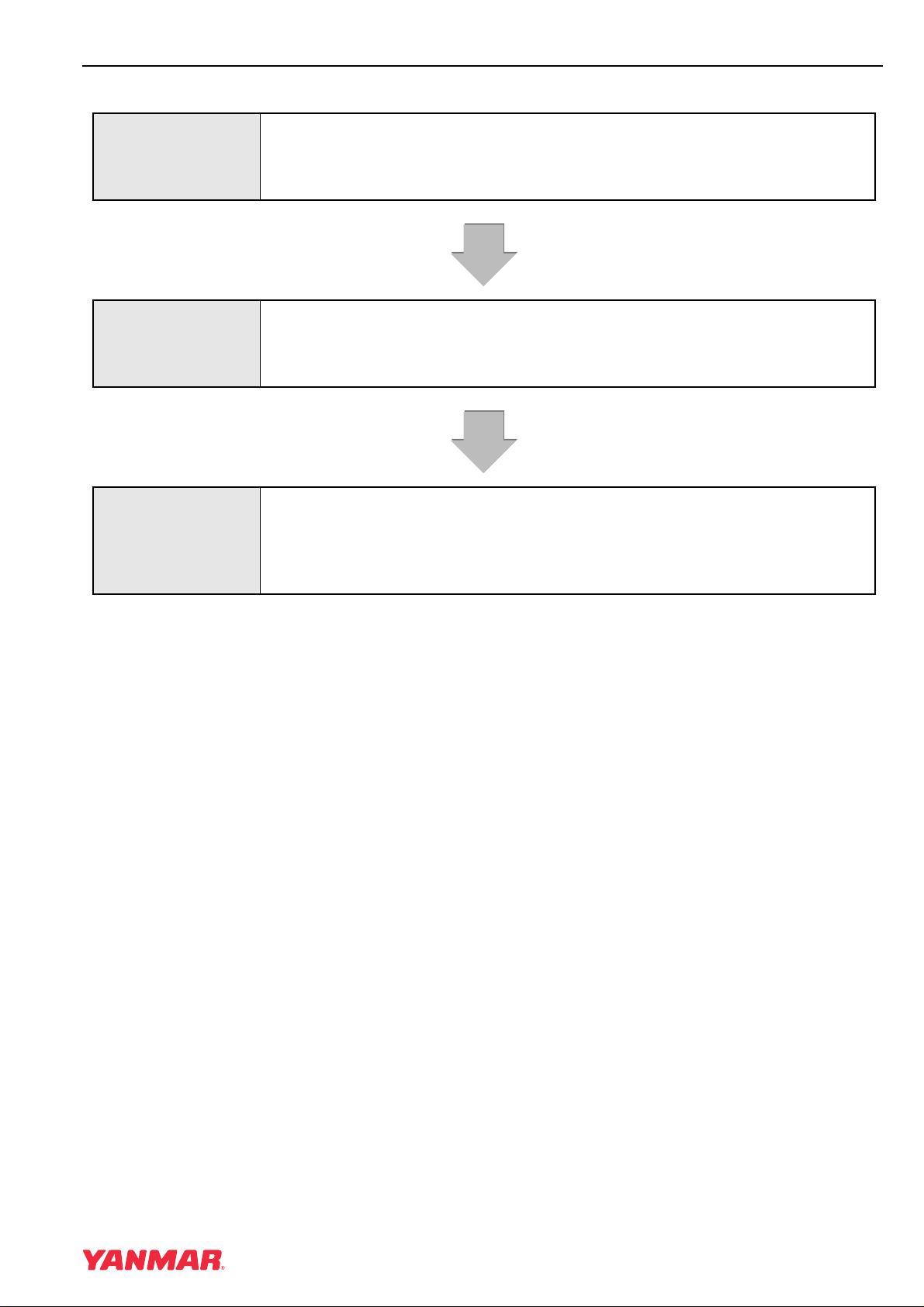

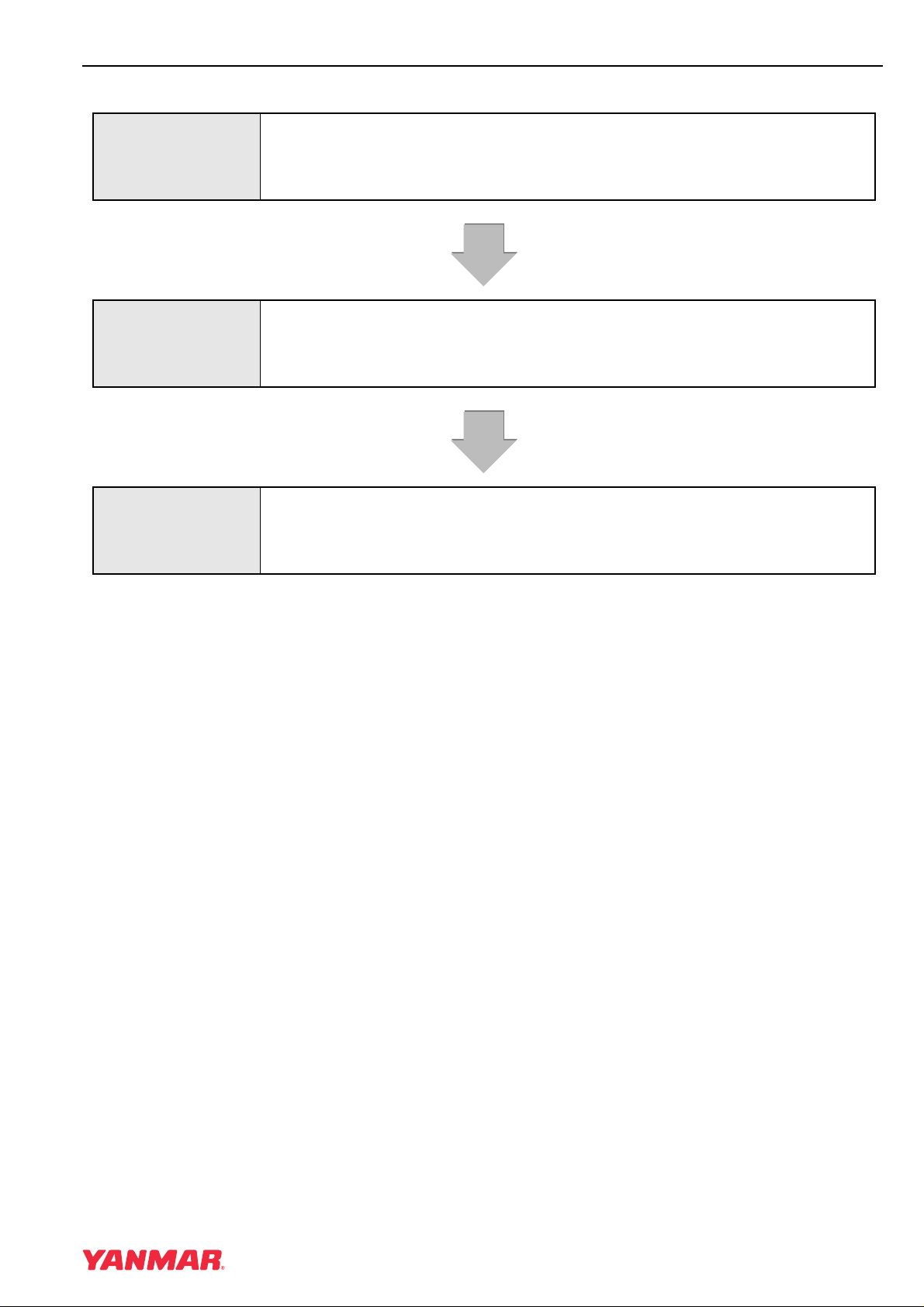

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage (AD value).

*For details of the method and the procedure of diagnosis, see P.1-136

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the rack actuator is correctly inserted.

• Check that the wiring of the rack actuator is not disconnected or the insulation

of the wiring is not peeled.

• Check the input voltage of the rack position sensor (voltage of the sensor 12V

line).

• Check the harness for correct continuity.

*For details of the method and the procedure of diagnosis, see P.1-136

TNV DI Service Manual

1-9

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(2) P1203/3: Failure with Rack Position Sensor (High Voltage)

DTC P1202/3 Failure with Rack Position Sensor (High Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. The sensor voltage upper limit and above [at E-ECU activation,

engine running]

3. Seven flashes.

Movement at Error occurrence

Detection at the engine start Detection at the engine running

Error Mode [Run Under Restrictions]:

Start the engine in on-error engine control

mode.

It takes 1 to 10 seconds from the starter’s

rotation to the engine start.

Run restricted? Yes: • The High idle is restricted to one of

the following, whichever smaller:

• 80% of the pre-error High idle speed

• 150% of the Low idle speed

• The fuel injection rate is restricted.

Recovery

No. No.

Conditions

Remarks The High and Low idle speeds must be

equal to those specified in the engine

specifications.

Check points

Connector

Harness rack position sensor

Rack actuator

E-ECU

[Stop Immediately]:

The engine stops running.

Yes: The rack actuator relay is turned

OFF, and the rack position is forcibly

set to the engine stop position.

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The SENSOR GND wire may be disconnected.

• The rack position sensor signal wire ma y be short-circuited with POWER SUPPLY .

• The rack actuator wiring ma y be short-circuited with GND (with engine running).

• The rack position sensor may be faulty.

• Output defect of the r ack position signal by a disconnection or a short circuit of the inner wiring

• The rack actuator may be faulty.

• The rack actuator inner wiring ma y be short-circuited with GND (with engine running).

• The E-ECU internal circuitry may be faulty.

1-10

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

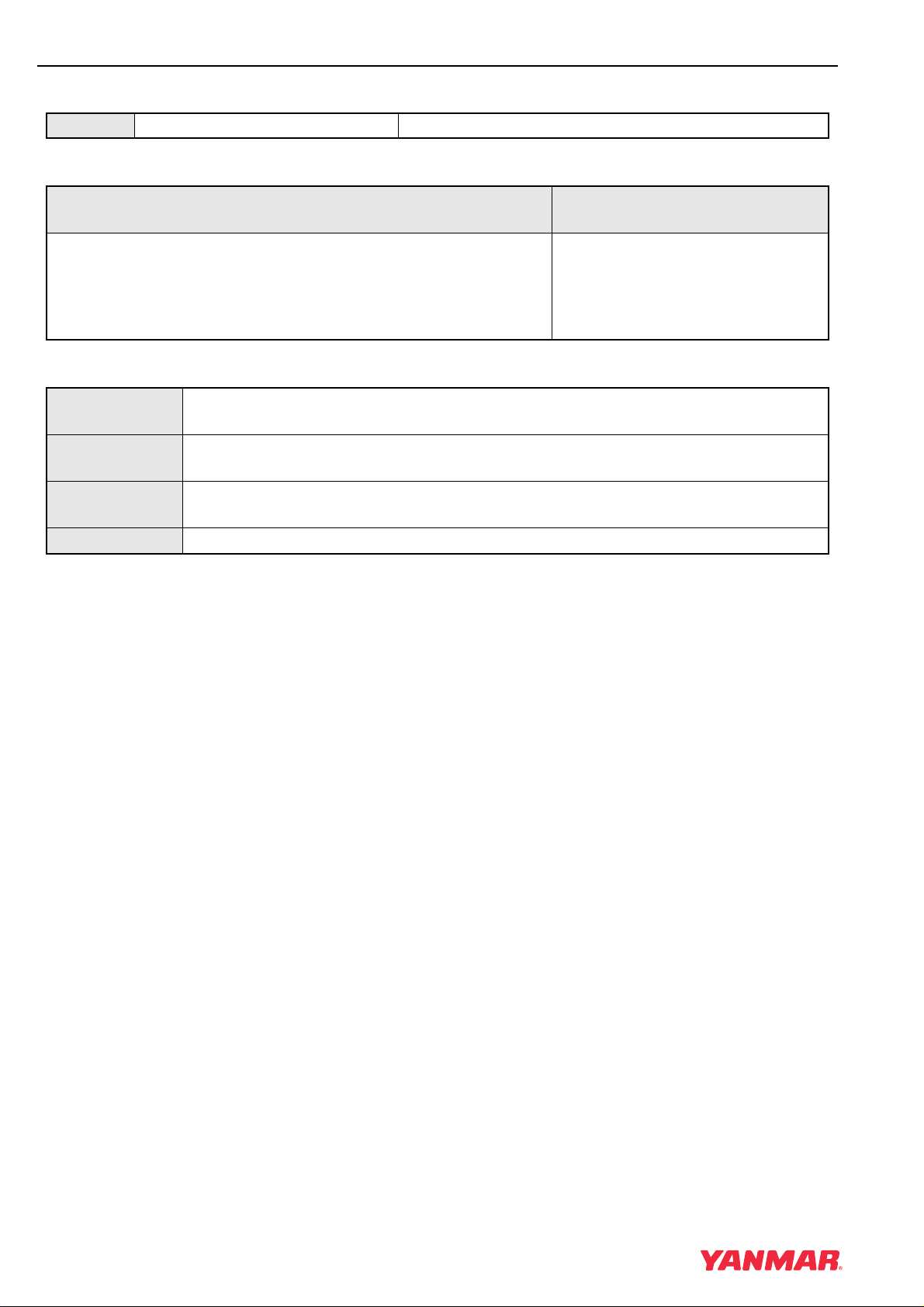

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage (AD value).

*For details of the method and the procedure of diagnosis, see P.1-136

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the rack actuator is correctly inserted.

• Check that the wiring of the rack actuator is not disconnected or the insulation

of the wiring is not peeled.

• Check the input voltage of the rack position sensor (voltage of the sensor 12V

line).

• Check the harness for correct continuity.

*For details of the method and the procedure of diagnosis, see P.1-136

TNV DI Service Manual

1-11

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

Accelerator sensor

(1) P0122/4: Accelerator Sensor Error (Low Voltage)

DTC P0122/4 Accelerator Sensor Error (Low Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. Sensor voltage 0.2 [V] or lower.

3. Five flashes.

Movement at Error occurrence

Spare Accelerator Sensor Function

Unavailable Available

Error Mode [Run Under Restrictions]:

The engine runs at a constant rotational

speed.

Run restricted? Yes: The target speed is set to the "on-

error target speed (standard value:

1500[min

-1

])" or “pre-error target

speed”.

Recovery

Conditions

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Remarks

Check points

Harness

Accelerator sensor

[Stop Immediately]:

The engine continues to run using the

spare accelerator sensor instead.

No.

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The accelerator sensor's signal wires ma y be disconnected or short-circuited with GND .

• The SENSOR 5V wire may be disconnected o r short-circuited with GND.

• The SENSOR GND wire may be short-circuited with POWER SUPPLY (*NOTE).

*NOTE) If the SENSOR GND wire is short-circuited with PO WER SUPPL Y , the E-ECU's po wer supply line fuse

10A might be blown.With this fuse blown, the E-ECU may fail to detect/indicate the error , and to store

the error history.

• The accelerator sensor may be faulty.

• Sensor output defect by a disconnection of the accelerator sensor inner wiring or a sliding resistance

increase

• The E-ECU internal circuitry may be faulty.

1-12

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

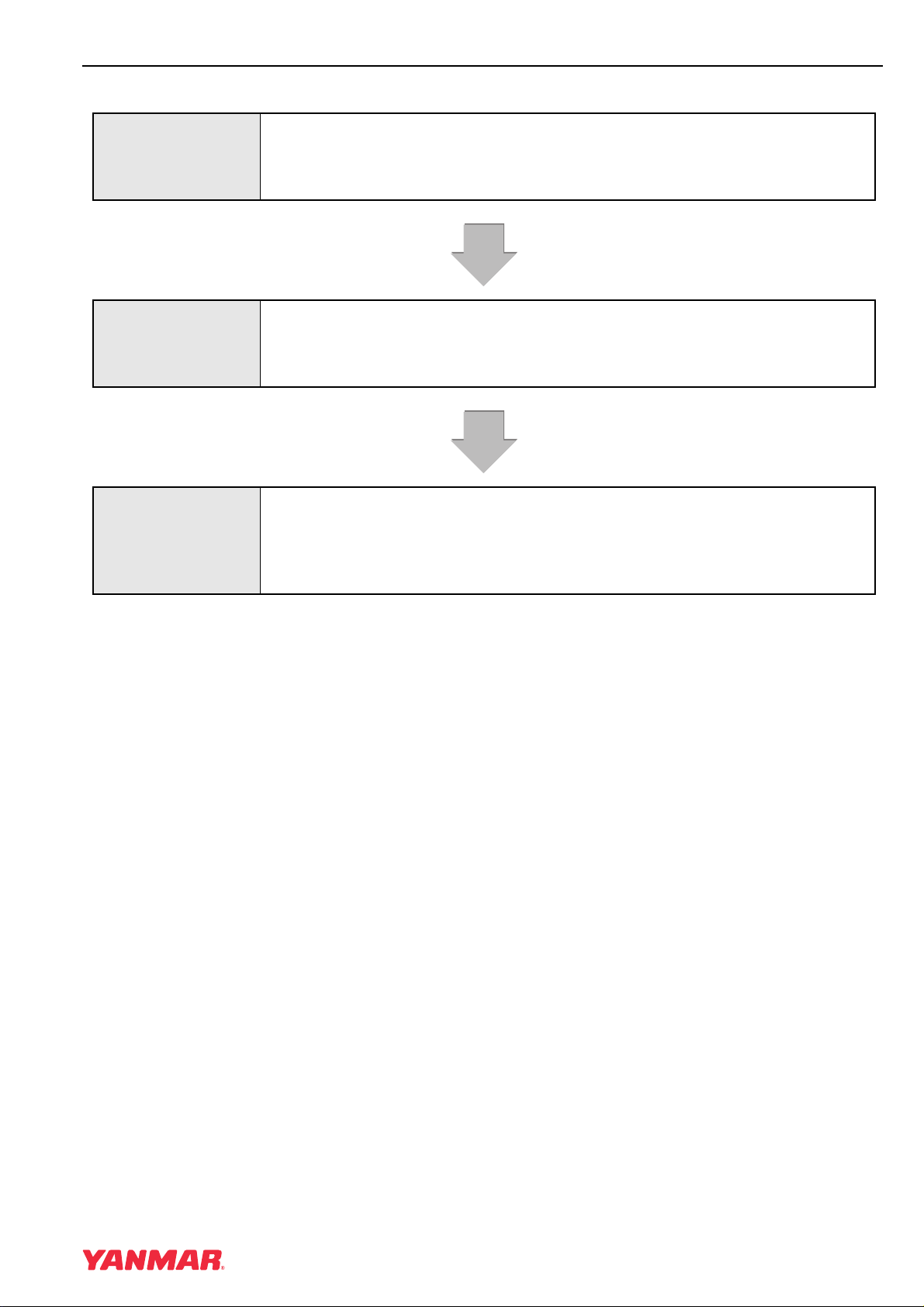

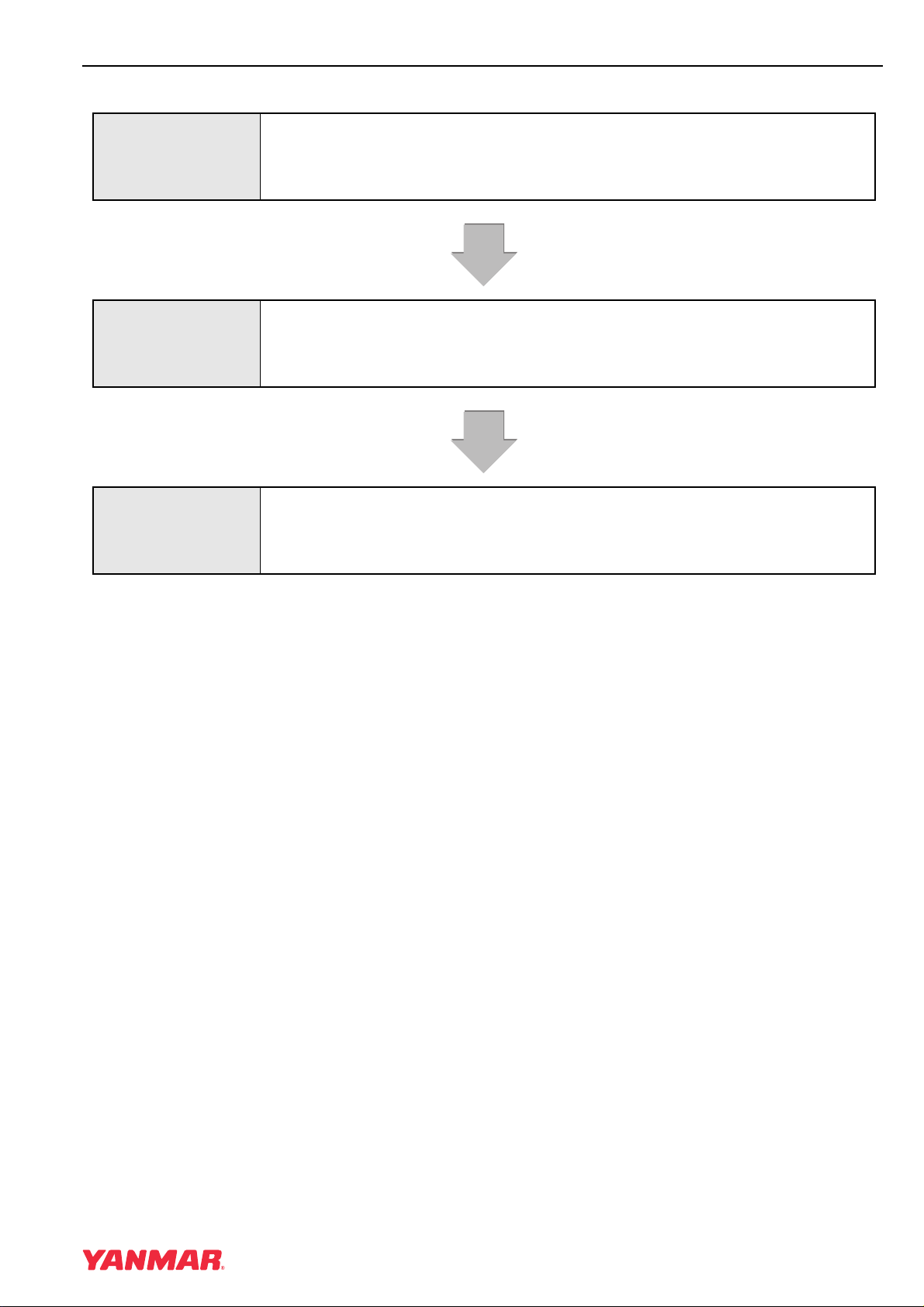

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-140

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the accelerator sensor is correctly inserted.

• Check that the wiring of the accelerator sensor is not disconnected or the

insulation of the wiring is not peeled.

• Check the resistance value of the accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-140

TNV DI Service Manual

1-13

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(2) P0123/3: Accelerator Sensor Error (High Voltage)

DTC P0123/3 Accelerator Sensor Error (High Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. Sensor voltage 4.6 [V] or higher.

3. Five flashes.

Movement at Error occurrence

Spare Accelerator Sensor Function

Unavailable Available

Error Mode [Run Under Restrictions]:

The engine runs at a constant rotational

speed.

Run restricted? Yes: The target speed is set to the "on-

error target speed (standard value:

-1

1500[min

])" or “pre-error target

speed”.

Recovery

Conditions

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Remarks

Check points

Harness

Accelerator sensor

[Stop Immediately]:

The engine continues to run using the

spare accelerator sensor instead.

No.

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The SENSOR GND wire may be disconnected.

• The sensor signal wire may be short-circuited with POWER SUPPLY.

• The accelerator sensor may be faulty.

• Sensor output defect by a short circuit with pow er supply of the accelerator sensor inner wiring

• The E-ECU internal circuitry may be faulty.

1-14

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-140

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the accelerator sensor is correctly inserted.

• Check that the wiring of the accelerator sensor is not disconnected or the

insulation of the wiring is not peeled.

• Check the resistance value of the accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-140

TNV DI Service Manual

1-15

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(3) P0124/2: Intermittent Failure with Accelerator Sensor

DTC P0124/2 Intermittent Failure with Accelerator Sensor

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Engine running.

2. Unconfirmed error detected 10 times.

3: Does not flash.

Connector

Harness

Accelerator sensor

Check points

Movement at Error occurrence

Error Mode [Run Under Restrictions]:

After detecting the error, the system lets the engine continue to run without any

restrictions.

Run restricted? No.

Recovery

No.

Conditions

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• Accelerator sensor signal wire ma y be disconnected, or short-circuited with GND or power supply.

• Sensor 5V wire may be disconnected, or short-circuited with GND or power supply.

• Sensor GND wire may be disconnected.

• The accelerator sensor may be faulty.

• Inner wiring may be disconnected or short-circuited

1-16

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-140

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the accelerator sensor is correctly inserted.

• Check that the wiring of the accelerator sensor is not disconnected or the

insulation of the wiring is not peeled.

• Check the resistance value of the accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-140

TNV DI Service Manual

1-17

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(4) P0123/1: Accelerator Sensor Error (foot pedal-close position)

DTC P1125/1 Accelerator Sensor Error (foot pedal-close position)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. With sensor voltage at or below 0.65[V], foot pedal Normally

Harness

Foot pedal

Check points

Open switch detected being ON or foot pedal Normally Closed

Switch detected being OFF.

3. Five flashes.

Movement at Error occurrence

Error Mode [Run Under Restrictions]:

The engine runs at a constant rotational speed.

Run restricted? Yes: The target speed is set to the "on-error target speed (standard value: 1500[min-1])"

or “pre-error target speed”.

Recovery

No.

Conditions

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The wiring for the f oot pedal Normally Closed switch ma y be disconnected.

• The wiring for the f oot pedal Normally Open switch ma y be short-circuited with GND .

• The foot pedal may be faulty.

• The foot pedal inner wiring ma y be disconnected or short-circuited with GND .

• The E-ECU internal circuitry may be faulty.

1-18

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check that the foot pedal movement is correctly recognized.

*For details of the method and the procedure of diagnosis, see P.1-144

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the foot pedal is correctly inserted.

• Check that the wiring of the foot pedal is not disconnected or the insulation of

the wiring is not peeled.

• Check the foot pedal for correct continuity.

• Check the harness for correct continuity.

*For details of the method and the procedure of diagnosis, see P.1-144

TNV DI Service Manual

1-19

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(5) P1126/0: Accelerator Sensor Error (foot pedal-open position)

DTC P1126/0 Accelerator Sensor Error (foot pedal-open position)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. With sensor voltage 1.1[V] and above, foot pedal Normally Open

Harness

Foot pedal

Check points

switch detected being OFF or foot pedal Normally Closed

Switch detected being ON.

3. Five flashes.

Movement at Error occurrence

Error Mode [Run Under Restrictions]:

The engine runs at a constant rotational speed.

Run restricted? Yes: The target speed is set to the "on-error target speed (standard value: 1500[min-1])"

or “pre-error target speed”.

Recovery

No.

Conditions

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The wiring for the f oot pedal Normally Open switch ma y be disconnected.

• The wiring for the fo ot pedal Normally Closed switch ma y be short-circuited with GND .

• The foot pedal may be faulty.

• The inner wiring may be disconnected or short-circuited with GND .

• The E-ECU internal circuitry may be faulty.

1-20

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check that the foot pedal movement is correctly recognized.

*For details of the method and the procedure of diagnosis, see P.1-144

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the foot pedal is correctly inserted.

• Check that the wiring of the foot pedal is not disconnected or the insulation of

the wiring is not peeled.

• Check the foot pedal for correct continuity.

• Check the harness for correct continuity.

*For details of the method and the procedure of diagnosis, see P.1-144

TNV DI Service Manual

1-21

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

Spare accelerator sensor (option)

(1) P0222/4: Failure with Spare Accelerator Sensor (Low Voltage)

DTC P0222/4 Failure with Spare Accelerator Se nsor (Low Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. Sensor voltage 0.2 [V] or lower.

Harness

Spare accelerator sensor

Check points

3. One flash followed by eight flashes

Movement at Error occurrence

Error detection of main accelerator sensor

Unavailable Available

Error Mode [Run As Is]:

The engine continues to run using the

main accelerator sensor.

[Run Under Restrictions]:

The engine runs at a constant rotational

speed.

Run restricted? No. Yes: The target speed is set to the "on-

error target speed (standard value:

1500[min

-1

])" or “pre-error target

speed”.

Recovery

Conditions

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The spare accelerator sensor's signal wires may be disconnected or short-circuited with GND .

• The SENSOR 5V wire may be disconnected o r short-circuited with GND.

• The SENSOR GND wire may be short-circuited with POWER SUPPLY (*NOTE).

*NOTE) If the SENSOR GND wire is short-circuited with PO WER SUPPL Y , the E-ECU's po wer supply line fuse

10A might be blown.With this fuse blown, the E-ECU may fail to detect/indicate the error , and to store

the error history.

• The spare accelerator sensor may be faulty.

• Sensor output defect by a disconnection of the spare accelerator sensor inner wiring or a sliding

resistance increase

• The E-ECU internal circuitry may be faulty.

1-22

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-148

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the spare accelerator sensor is correctly inserted.

• Check that the wiring of the spare accelerator sensor is not disconnect ed or the

insulation of the wiring is not peeled.

• Check the resistance value of the spare accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the spare accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-148

TNV DI Service Manual

1-23

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(2) P0223/3: Spare Accelerator Sensor Error (High Voltage)

DTC P0223/3 Spare Accelerator Sensor Error (High Voltage)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. Sensor voltage 4.6 [V] or higher.

Harness

Spare accelerator sensor

Check points

3. One flash followed by eight flashes

Movement at Error occurrence

Error detection of main accelerator sensor

Unavailable Available

Error Mode [Run As Is]:

The engine continues to run using the

main accelerator sensor.

[Run Under Restrictions]:

The engine runs at a constant rotational

speed.

Run restricted? No. Yes: The target speed is set to the "on-

error target speed (standard value:

-1

1500[min

])" or “pre-error target

speed”.

Recovery

Conditions

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Yes: This error will be automatically reset

when a normal voltage (0.2 to

4.6[V]) is input.

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The SENSOR GND wire may be disconnected.

• The sensor signal wire may be short-circuited with POWER SUPPLY.

• The spare accelerator sensor may be faulty.

• Sensor output defect by a short circuit with power supply of the spare accelerator sensor inner wiring

• The E-ECU internal circuitry may be faulty.

1-24

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-148

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the spare accelerator sensor is correctly inserted.

• Check that the wiring of the spare accelerator sensor is not disconnect ed or the

insulation of the wiring is not peeled.

• Check the resistance value of the spare accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the spare accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-148

TNV DI Service Manual

1-25

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(3) P0224/2: Intermittent Failure with Spare Accelerator Sensor

DTC P0224/2 Intermittent Failure with Spare Accelerator Sensor

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Engine running.

2. Unconfirmed error detected 10 times.

3: Does not flash.

Connector

Harness

Spare accelerator sensor

Check points

Movement at Error occurrence

Error Mode [Run As Is]:

After detecting the error, the system lets the engine continue to run without any

restrictions.

Run restricted? No.

Recovery

No.

Conditions

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• Spare accelerator sensor signal wire may be disconnected or short-circuited with GND or power supply.

• Sensor 5V wire may be disconnected, or short-circuited with GND or power supply.

• Sensor GND wire may be disconnected.

• The spare accelerator sensor may be faulty.

• Spare accelerator sensor wiring may be disconnected or short-circuited.

1-26

TNV DI Service Manual

DTCs (Diagnostic Trouble Codes) General Description

Diagnosis Description

FAILURE DIAGNOSIS

1) Initial diagnosis

with the diagnosis

tool

2) Check of

connectors/wiring

3) Failure Diagnostic

Work

• Check the fault indication.

• Check the sensor voltage.

*For details of the method and the procedure of diagnosis, see P.1-148

• Before beginning your work, be sure to turn off the key switch.

• Check that the connector of the spare accelerator sensor is correctly inserted.

• Check that the wiring of the spare accelerator sensor is not disconnect ed or the

insulation of the wiring is not peeled.

• Check the resistance value of the spare accelerator sensor.

• Check the harness for correct continuity.

• Check the output voltage of the spare accelerator sensor.

*For details of the method and the procedure of diagnosis, see P.1-148

TNV DI Service Manual

1-27

FAILURE DIAGNOSIS

DTCs (Diagnostic Trouble Codes) General Description

(4) P1225/1: Spare Accelerator Sensor Error (foot pedal-close position)

DTC P1225/1

Spare Accelerator Sensor Error (foot peda l-close

position)

DTC Detecting Conditions

1 - Precondition; 2 - Detecting condition(s);

3 - Flashing pattern of failure indicator

1. Key switch ON.

2. With sensor voltage at or below 0.65[V], foot pedal Normally

Harness

Foot pedal

Check points

Open switch detected being ON or foot pedal Normally Closed

Switch detected being OFF.

3. One flash followed by eight flashes

Movement at Error occurrence

Error detection of main accelerator sensor

Unavailable Available

Error Mode [Run As Is]:

The engine continues to run using the

main accelerator sensor.

[Run Under Restrictions]:

The engine runs at a constant rotational

speed.

Run restricted? No. Yes: The target speed is set to the "on-

error target speed (standard value:

1500[min

-1

])" or “pre-error target

speed”.

Recovery

No. No.

Conditions

Remarks

Estimation of Failure cause/Error condition

• The connector may not be properly connected.

• Wiring defect of the harness

• The wiring for the f oot pedal Normally Closed switch ma y be disconnected.

• The wiring for the f oot pedal Normally Open switch ma y be short-circuited with GND .

• The foot pedal may be faulty.

• The inner wiring may be disconnected or short-circuited with GND .

• The E-ECU internal circuitry may be faulty.

1-28

TNV DI Service Manual

Loading...

Loading...