YZF-R6T

YZF-R6TC

SUPPLEMENTARY

SERVICE MANUAL

LIT-11616-18-45

5SL-28197-12

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

YZF-R6T / YZF-R6TC. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

YZF-R6R / YZF-R6SR / YZF-R6RC / YZF-R6SRC SERVICE MANUAL:

LIT-11616-16-45 (5SL-28197-10)

YZF-R6S / YZF-R6SC SUPPLEMENTARY SERVICE MANUAL: LIT-11616-17-46 (5SL-28197-11)

EAS00001

YZF-R6T / YZF-R6TC

SUPPLEMENTARY

SERVICE MANUAL

©2004 by Yamaha Motor

Corporation, U.S.A.

First edition, September 2004

All rights reserved. Any reproduction

or unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

P / N LIT-11616-18-45

EAS00030

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to

render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard

to performance and emissions. Proper service with the correct tools is necessary to ensure that the

vehicle will operate as designed. If there is any question about a service procedure, it is imperative

that you contact a Yamaha dealer for any service information changes that apply to this model. This

policy is intended to provide the customer with the most satisfaction from his vehicle and to conform

to federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

• This Service Manual contains information regarding periodic maintenance to the emission control

system. Please read this material carefully.

• Designs and specifications are subject to change without notice.

EAS00040

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death

to the motorcycle operator, a bystander or a person checking or repairing the

motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the motorcycle.

A NOTE provides key information to make procedures easier or clearer.

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

each page indicate the current chapter.

Refer to “SYMBOLS”.

Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s)

appears.

Sub-section titles appear in smaller print than the section title.

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section.

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

disassembly step.

Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

Jobs requiring more information (such as special tools and technical data) are described

sequentially.

EAS00008

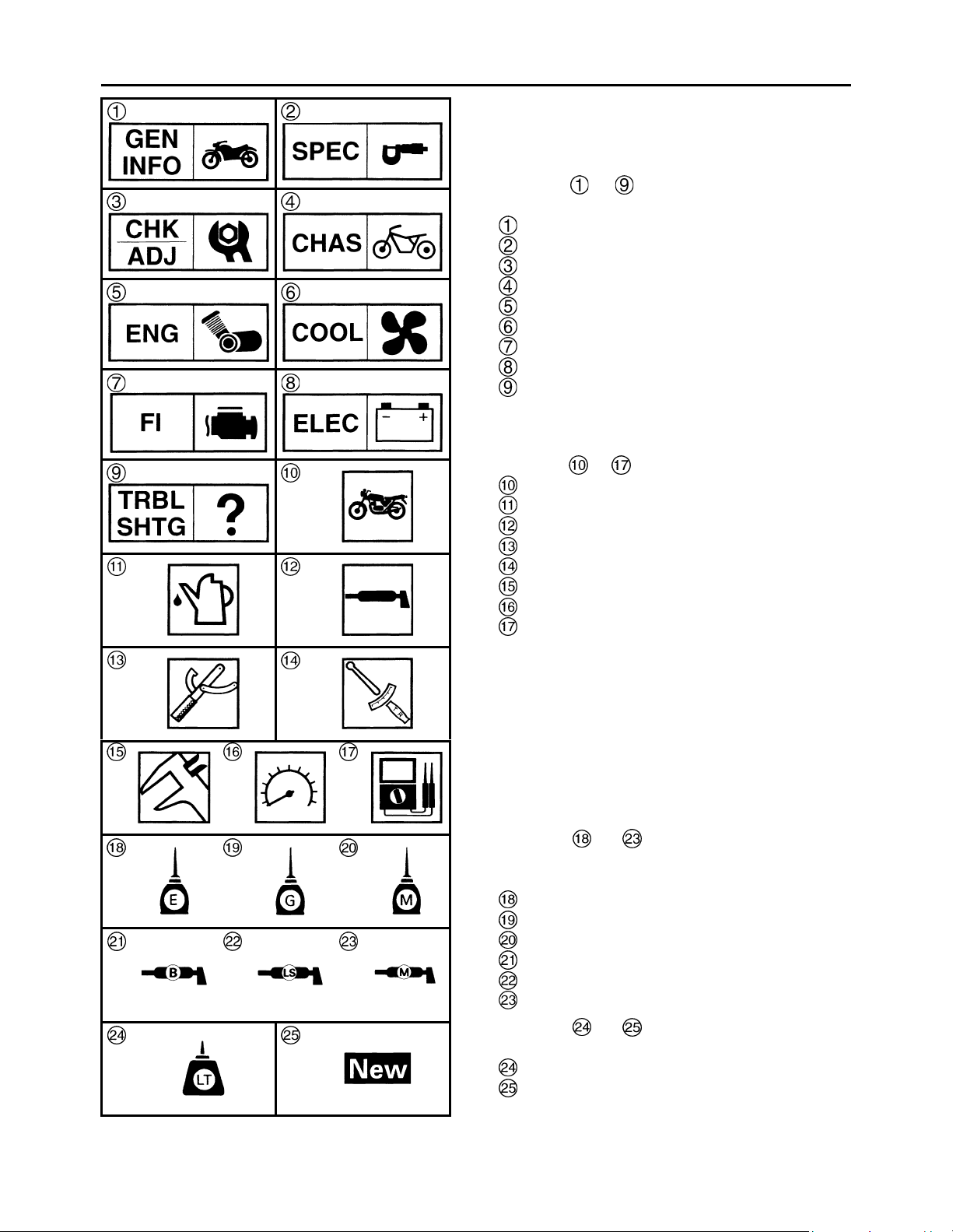

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols to indicate the subject of each

chapter.

General information

Specifications

Periodic checks and adjustments

Chassis

Engine

Cooling system

Fuel injection system

Electrical system

Troubleshooting

Symbols to indicate the following.

Serviceable with engine mounted

Filling fluid

Lubricant

Special tool

Tightening torque

Wear limit, clearance

Engine speed

Electrical data

Symbols to in the exploded diagrams

indicate the types of lubricants and lubrication

points.

Engine oil

Gear oil

Molybdenum-disulfide oil

Wheel-bearing grease

Lithium-soap-based grease

Molybdenum-disulfide grease

Symbols to in the exploded diagrams

indicate the following.

Apply locking agent (LOCTITE

®

)

Replace the part

CONTENTS

GENERAL INFORMATION

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ENGINE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHASSIS SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TIGHTENING TORQUES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ENGINE TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . 5

CHASSIS TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . 5

CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PERIODIC CHECKS AND ADJUSTMENTS

BLEEDING THE HYDRAULIC BRAKE SYSTEM . . . . . . . . . . . . . . 20

ADJUSTING THE FRONT FORK LEGS. . . . . . . . . . . . . . . . . . . . . 22

CHASSIS

FRONT WHEEL AND BRAKE DISCS. . . . . . . . . . . . . . . . . . . . . . . . . 24

FRONT AND REAR BRAKES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FRONT BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FRONT BRAKE MASTER CYLINDER . . . . . . . . . . . . . . . . . . . . . . 26

FRONT BRAKE CALIPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ASSEMBLING AND INSTALLING THE FRONT BRAKE MASTER

CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

FRONT FORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DISASSEMBLING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . 36

CHECKING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . 37

ASSEMBLING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . 38

SWINGARM AND DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

CHECKING THE DRIVE CHAIN. . . . . . . . . . . . . . . . . . . . . . . . . . . 43

COOLING SYSTEM

RADIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ELECTRICAL SYSTEM

ELECTRIC STARTING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

YZF-R6T / YZF-R6TC WIRING DIAGRAM

GEN

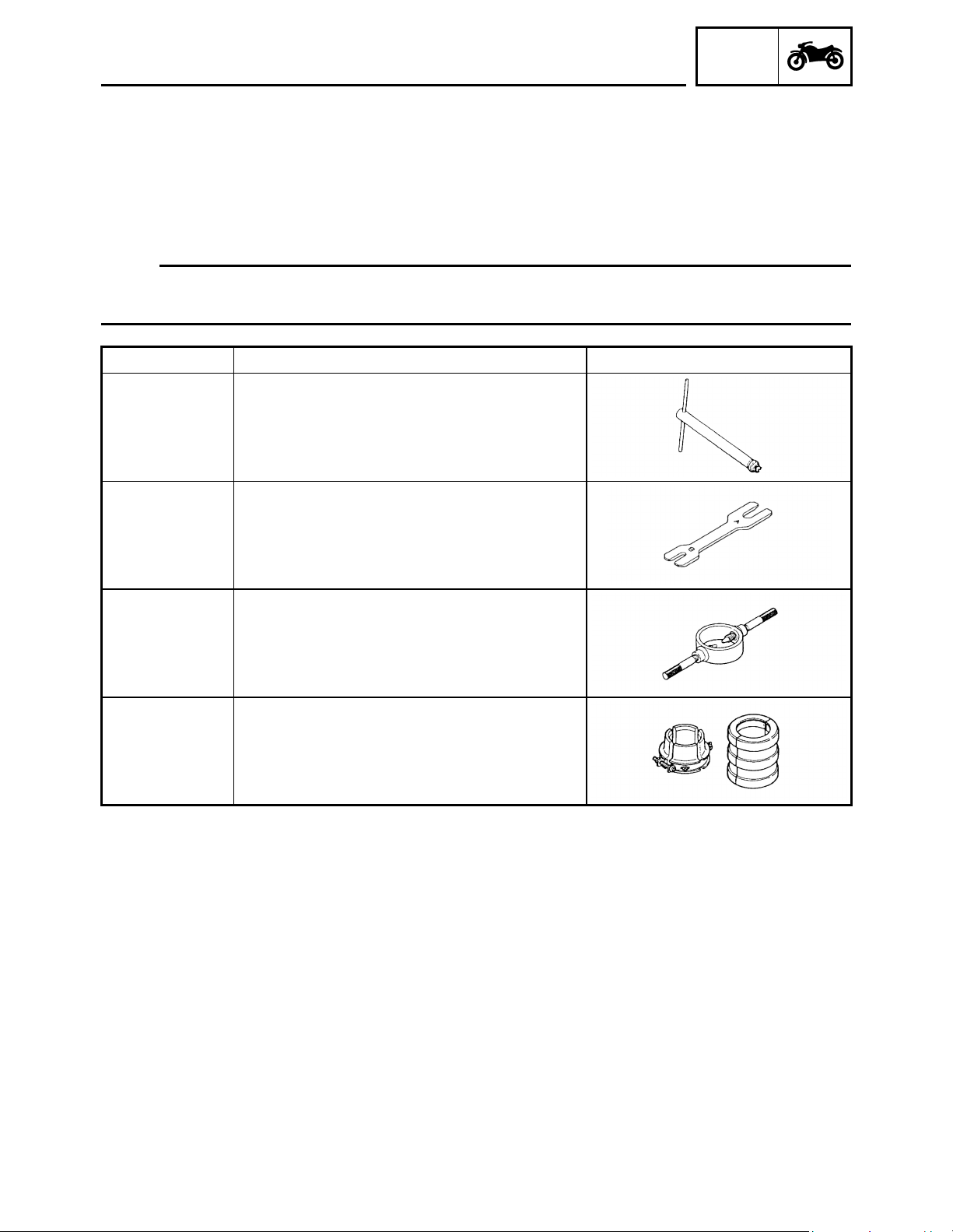

SPECIAL TOOLS

EAS00027

INFO

GENERAL INFORMATION

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly. Use

only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers or both may differ depending on the

country. When placing an order, refer to the list provided below to avoid any mistakes.

NOTE:

• For U.S.A. and Canada, use part number starting with “YM-”, “YU-”, or “ACC-”.

• For others, use part number starting with “90890-”.

Tool No. Tool name / Function Illustration

Damper rod holder

90890-01423

YM-01423

90890-01434

YM-01434

90890-01441

YM-01441

90890-01442

YM-01442

This tool is used to hold the damper rod

assembly when loosening or tightening the

damper rod assembly bolt.

Rod holder

This tool is used to support the damper

adjusting rod.

Fork spring compressor

This tool is used to disassemble or assemble

the front fork legs.

Fork seal driver

This tool is used to install the front fork’s oil

seal and dust seal.

1

GENERAL SPECIFICATIONS / ENGINE SPECIFICATIONS

SPEC

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard Limit

Model code 5SLR (USA except for CAL) •

5SLS (CAL)

Dimensions

Overall length 2,045 mm (80.5 in) •

Overall width

Overall height 1,105 mm (43.5 in) •

Seat height 830 mm (32.7 in) •

Wheelbase 1,385 mm (54.5 in) •

Minimum ground clearance 145 mm (5.7 in) •

Minimum turning radius 3,800 mm (149.6 in) •

Weight

Wet (with oil and a full fuel tank) 183 kg (404 lb) (USA except for CAL) •

Maximum load (except motorcycle) 192 kg (423 lb) (USA except for CAL) •

690 mm (27.2 in)

184 kg (406 lb) (CAL) •

191 kg (421 lb) (CAL) •

• •

• •

• •

•

• •

• •

• •

• •

• •

• •

• •

• •

• •

ENGINE SPECIFICATIONS

Item Standard Limit

Throttle bodies

Model (manufacturer)

ID mark 5SLM 30 (5SLR), 5SLS 40 (5SLS) •

× quantity 40EIS (MIKUNI) × 4• • •

• •

2

CHASSIS SPECIFICATIONS

SPEC

CHASSIS SPECIFICATIONS

Item Standard Limit

Frame

Caster angle 24.5° •

Trail 95 mm (3.74 in) •

Front tire

Size 120 / 70 ZR17 M / C (55W) • • •

Model (manufacturer) Pilot POWER C (MICHELIN) •

D218FM (DUNLOP)

Rear tire

Model (manufacturer) Pilot POWER (MICHELIN) •

D218M (DUNLOP)

Tire pressure (cold)

0 ~ 90 kg (0 ~ 198 lb) 290 kPa (2.9 kgf / cm

90 ~ 192 kg (198 ~ 426 lb) 290 kPa (2.9 kgf / cm

(USA except for CAL)

90 ~ 191 kg (198 ~ 423 lb) (CAL) 290 kPa (2.9 kgf / cm

High-speed riding 290 kPa (2.9 kgf / cm

Front brakes

Brake lever free play 6.7 ~ 18.1 mm (0.26 ~ 0.71 in) •

Brake discs

Diameter

Min. thickness •

× thickness 310 × 4.5 mm (12.20 × 0.18 in) • • •

• • 4.0 mm

Master cylinder inside diameter 16 mm (0.63 in) •

Rear brake

Brake pedal freeplay 4.3 ~ 9.0 mm (0.17 ~ 0.35 in) •

2

, 2.9 bar, 41.3 psi) • • •

2

, 2.9 bar, 41.3 psi) • • •

2

, 2.9 bar, 41.3 psi) • • •

2

, 2.9 bar, 41.3 psi) • • •

• •

• •

• •

• •

• •

(0.16 in)

• •

• •

3

CHASSIS SPECIFICATIONS /

ELECTRICAL SPECIFICATIONS

Item Standard Limit

Front suspension

Spring

Free length 248.8 mm (9.80 in) 243.8 mm

Installed length 244.3 mm (9.62 in) •

Spring rate (K1) 8.8 N / mm (0.90 kg / mm, 50.22 lb / in) •

Spring stroke (K1) 0 ~ 120 mm (0 ~ 4.7244 in) •

Inner tube outer diameter 41 mm (1.61 in) •

Fork oil

Quantity (each front fork leg) 0.475 L (0.418 lmp qt, 0.502 US qt) •

Level (from the top of the outer tube,

with the outer tube fully compressed,

and without the fork spring)

Spring preload adjusting positions

Minimum 8 •

Standard 7 •

Maximum 0 •

Rebound damping adjusting positions

Minimum* 10 •

Standard* 6 •

Maximum* 1 •

Compression damping adjusting

positions

Minimum* 13 •

Standard* 6 •

Maximum* 1 •

*from the fully turned-in position

Rear suspension

Spring

Free length 167.5 mm (6.59 in) •

Installed length 157.5 mm (6.2 in) •

Spring rate (K1) 103 N / mm (10.5 kg / mm, 587.83 lb / in) •

Drive chain

Maximum 15-link section •

92 mm (3.62 in) •

• • 239.3 mm

SPEC

(9.60 in)

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

(9.42 in)

ELECTRICAL SPECIFICATIONS

Item Standard Limit

Ignition system

CDI unit model (manufacturer) F8T828 (MITSUBISHI) •

Fuses (amperage

Radiator fan motor fuse 15 A

× quantity)

× 2• • •

4

• •

TIGHTENING TORQUES

ENGINE TIGHTENING TORQUES

TIGHTENING TORQUES

SPEC

Item Fastener

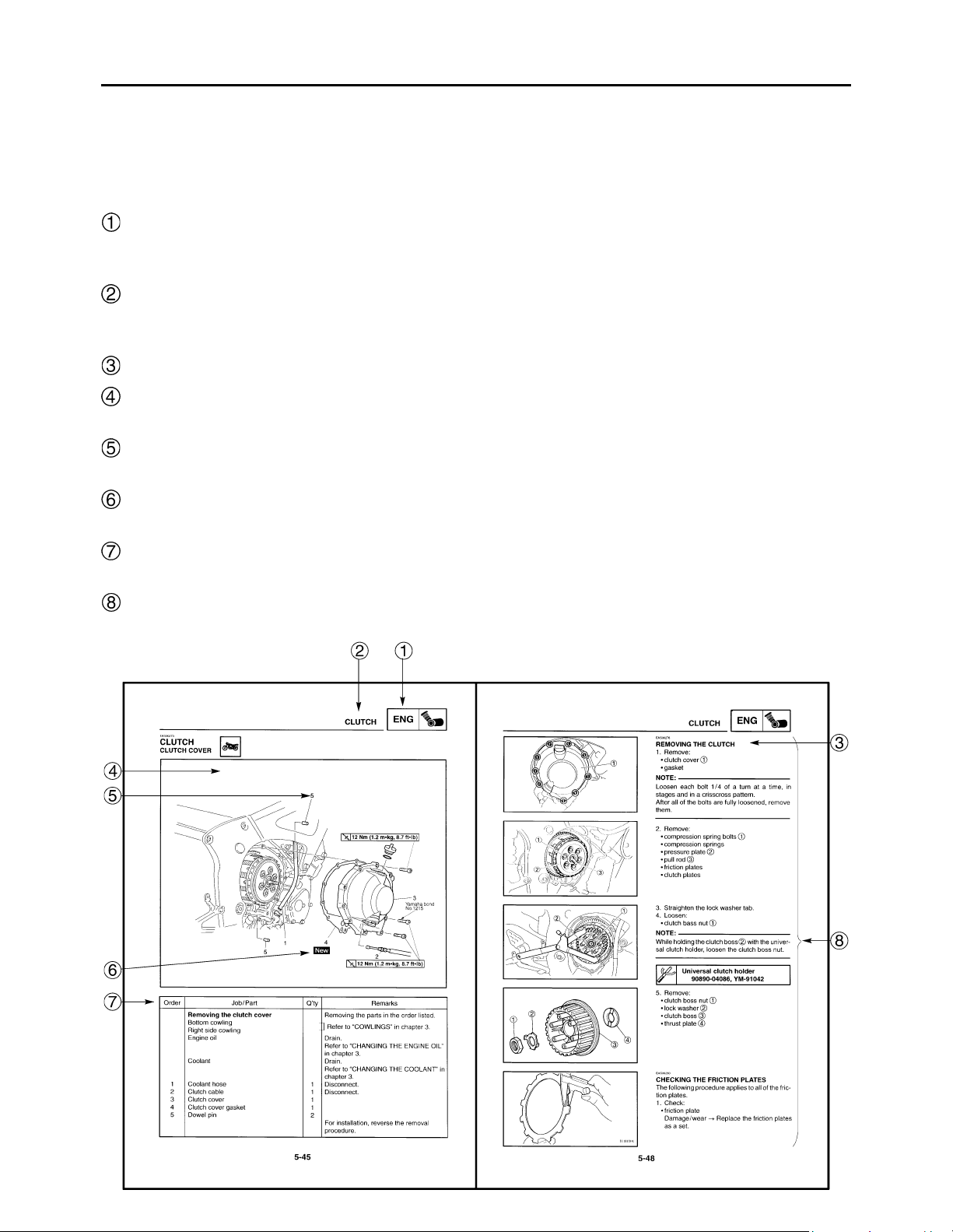

Clutch boss Nut M20 1 90 9.0 65 Use a lock

Cylinder identification sensor Bolt M6 1 7.5 0.75 5.4

CHASSIS TIGHTENING TORQUES

Item

Handlebar and front fork M8 32 3.2 2.3

Front fender and front fork M6 6 0.6 4.3

Rear brake master cylinder and footrest bracket M8 13 1.3 9.4

Front brake caliper and front fork M10 35 3.5 25

Front master cylinder bleed screw M8 6 0.6 4.3

Brake caliper bleed screw M8 5 0.5 3.6

Front wheel axle pinch bolt M8 21 2.1 15 See NOTE

Thread

size

Thread

NOTE:NOTE:

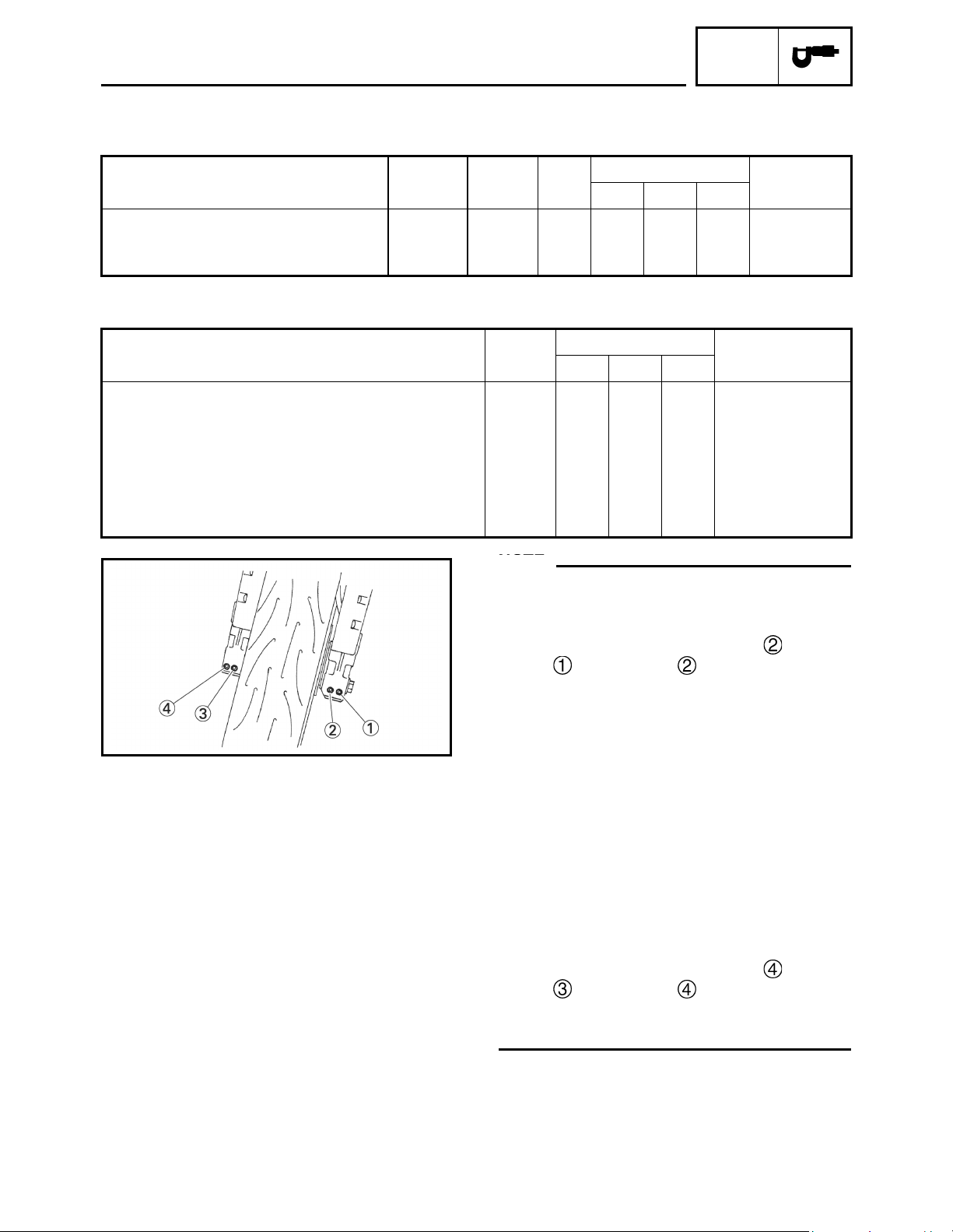

1. Insert the front wheel axle from the right

2. In the order from the pinch bolt → pinch

3. Check that the end face of the axle head

4. In the order from the pinch bolt → pinch

Q’ty

size

side and tighten it with the flange bolt from

the left side to 91 Nm (9.1 m•kg, 66 ft•lb).

bolt → pinch bolt , tighten each bolt to

21 Nm (2.1 m•kg, 15 ft•lb) without performing temporary tightening.

and the end face of the fork side are flushmounted. If they are out of alignment, make

sure to fit them by adding the external force

by hand or with a plastic hammer, etc.

If the end face of the axle is not parallel to

the end face of the fork, align them so that

one point of the axle circumference is positioned on the end face of the fork.

At this stage, it can be accepted if the end

face of the axle becomes partially concave

to the end face of the fork.

bolt → pinch bolt , tighten each bolt to

21 Nm (2.1 m•kg, 15 ft•lb) without performing temporary tightening.

Tightening torque

Remarks

Nm m•kg ft•lb

washer

Yamaha bond No.1215

Tightening torque

Remarks

Nm m•kg ft•lb

5

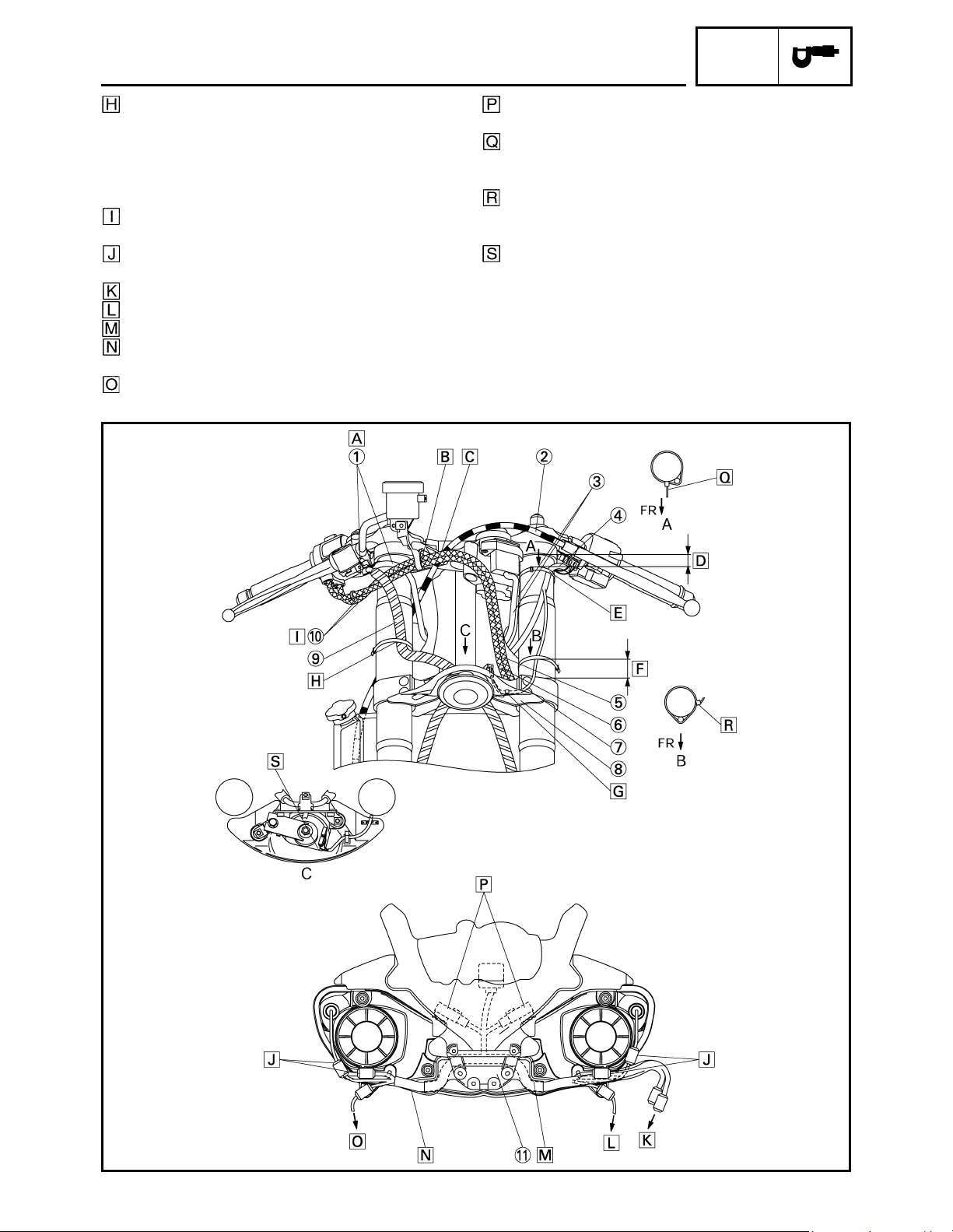

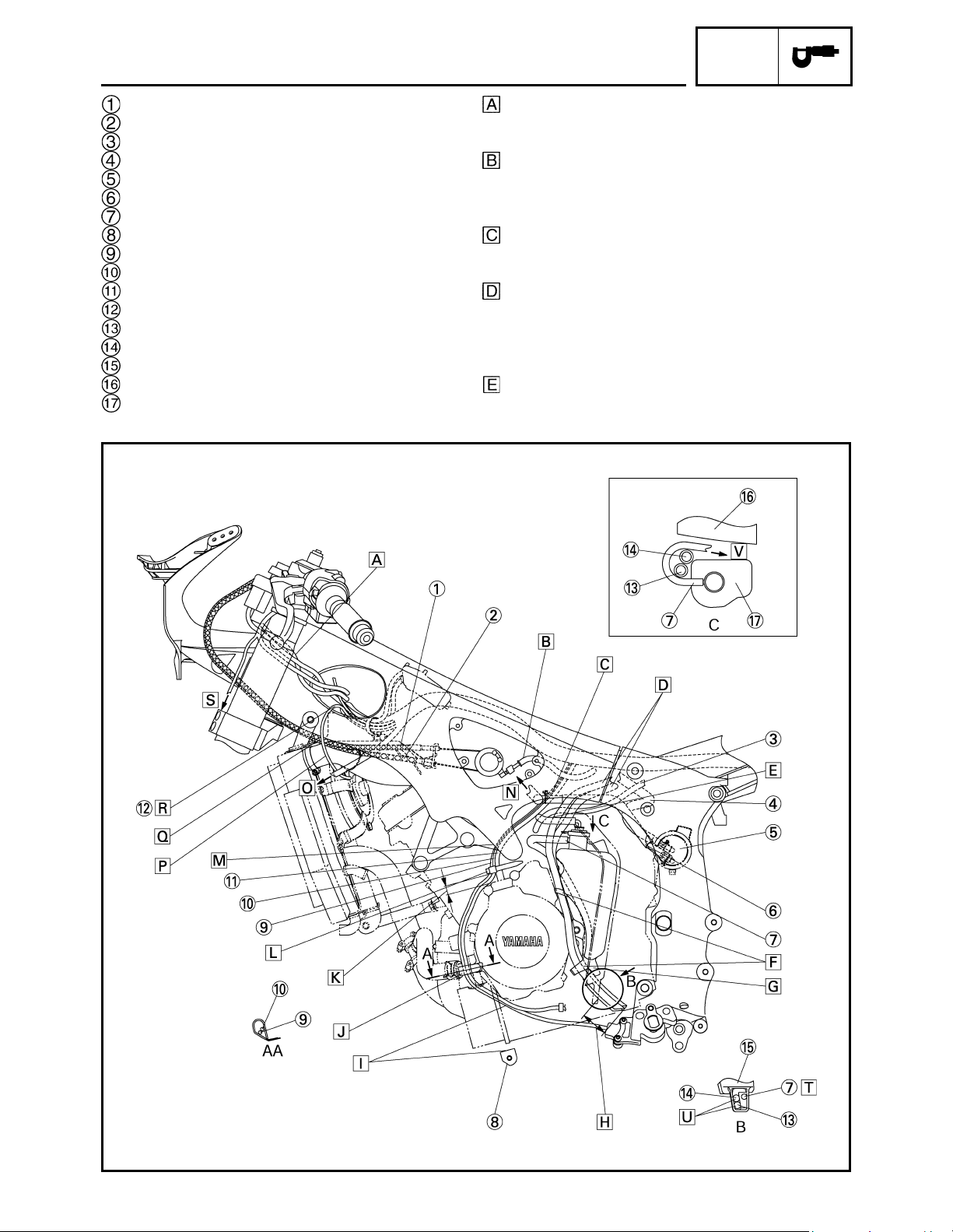

CABLE ROUTING

Right handlebar switch lead

Clutch cable

Main switch lead

Left handlebar switch lead

Throttle cable (return side)

Throttle cable (pull side)

Horn lead

Steering cover

Front brake hose

Throttle cables

Joint

CABLE ROUTING

Pass the right handlebar switch lead inside the

front brake hoses and over the throttle cables.

Install the throttle cables to the hook so that the

pulling side of the throttle cables is routed downward.

Pass the clutch cable through the guide.

Plastic locking tie shall be positioned at 15 mm

(0.59 in) below from the upper bracket.

Clamp the left handlebar switch lead to the front fork

with the plastic locking tie and cut the tip of the tie.

Clamp it to the protector section.

Clamping position should be 10 mm (0.39 in) or

lower from the top end of the under bracket.

Attach the horn lead to the hook on the steering

cover.

SPEC

6

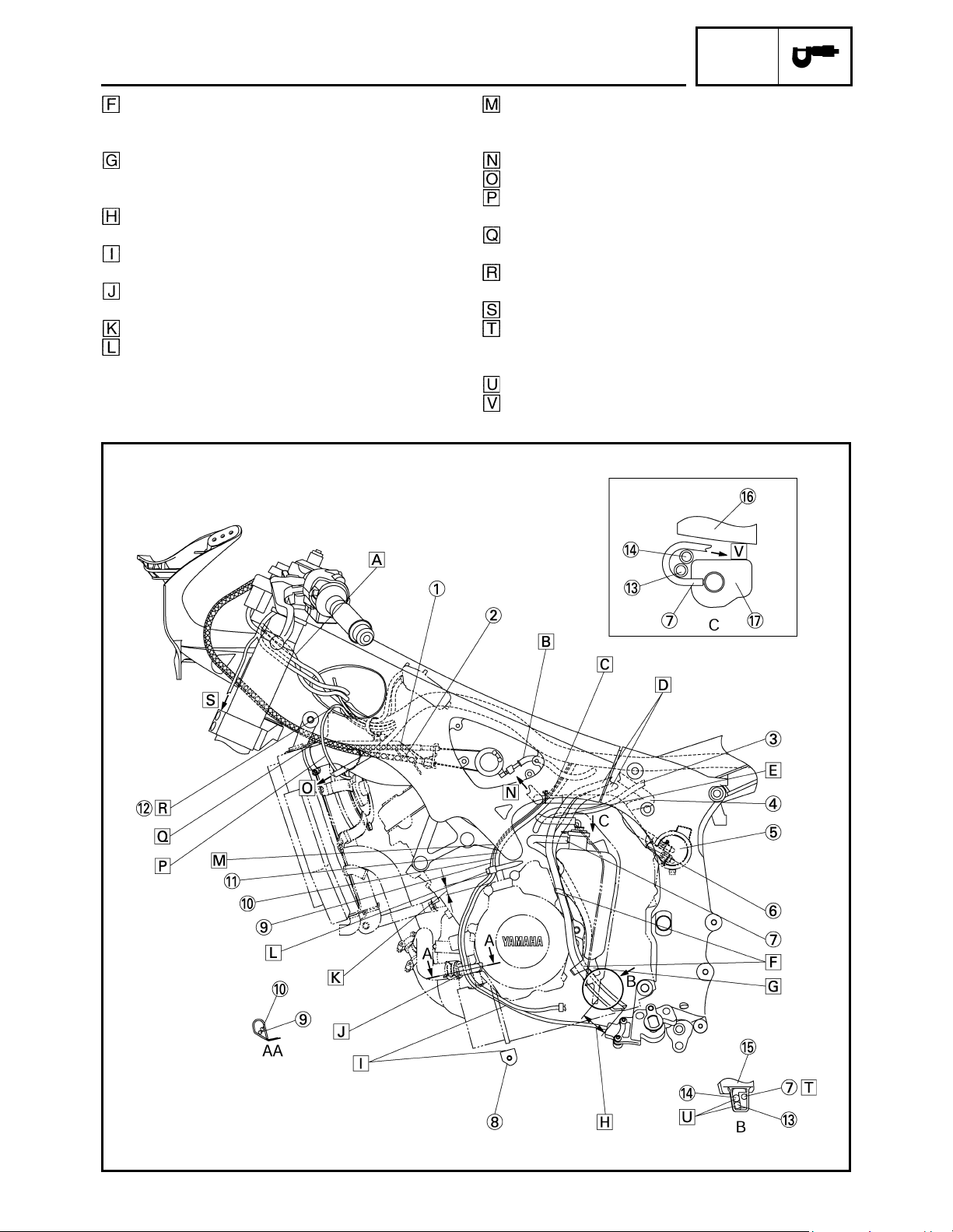

CABLE ROUTING

SPEC

Clamp it at the position of 50 mm (1.97 in) to 65

mm (2.56 in) from the upper face of the under

bracket with the plastic locking tie. Cut the surplus

part of the clamp tip leaving 2 mm (0.08 in) to 4

mm (0.16 in). Point the tip of the clamp to the outside of vehicle.

Pass the throttle cables inside the front brake

hoses.

Set in the coupler between the headlight’s hollow

section and the duct.

To the wire harness

To the front turn signal light (right)

Set the sub wire harness in the joint.

Do not catch the sub wire harness when the duct

is assembled.

To the front turn signal light (left)

Install the relay to the rib of the headlight.

(Location for the left and right relays is alternative.)

Point the tip of the plastic locking tie to the front

side of the vehicle. Cut the tip leaving 2 ~ 10 mm

(0.08 ~ 0.39 in).

Point the tip of the plastic locking tie to the outside

of the vehicle. Cut the tip leaving 2 ~ 10 mm (0.08

~ 0.39 in).

Attach the horn lead pointing to the front side of

the vehicle.

7

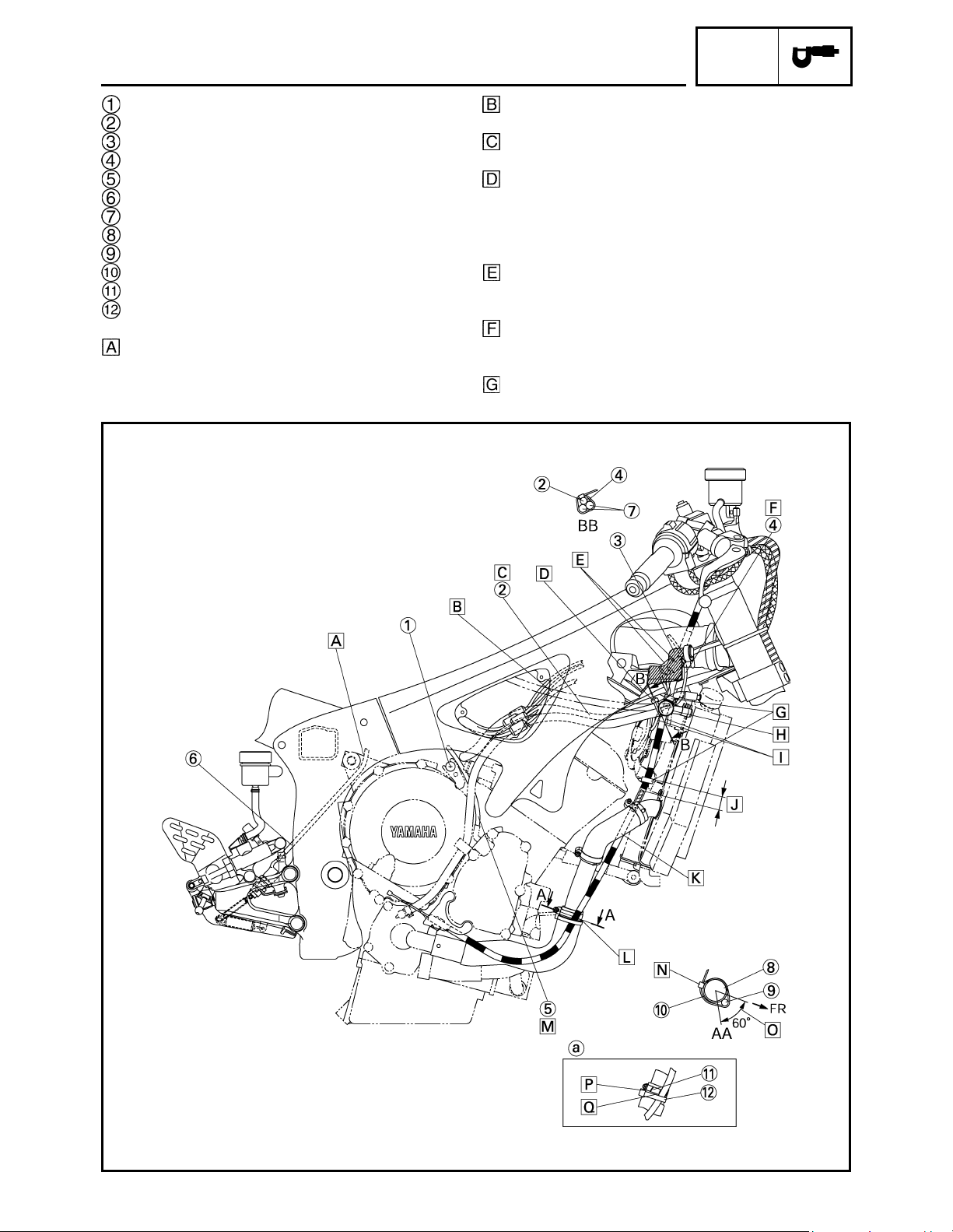

CABLE ROUTING

SPEC

Throttle stop screw

Coolant reservoir tank hose

Cover 8

Radiator fan motor lead (right)

Pickup coil lead

Rear tail / brake light switch lead

Radiator return hose

Coolant hose

Clutch cable

Coolant hose protector

Hose clamp assembly

Hose clamp

Pass the rear tail / brake light switch lead outside of

rear engine mount bolt.

Pass the ignition coil lead outside of the radiator

hose.

Pass the coolant reservoir tank hose under the

frame and right side of the throttle body.

The tip of the clamp should be pointed to the

inside above the vehicle. Items to be clamped here

are the radiator fan motor lead (right), coolant reservoir tank hose and radiator return hoses (2

hoses).

Coupler should be placed within the shaded area

of the cover 8. (Extrusion below the shaded area is

prohibited.)

Radiator fan motor lead (right) should be entered

into the inside of the vehicle through the frame

hole.

Clamp the clutch cable.

8

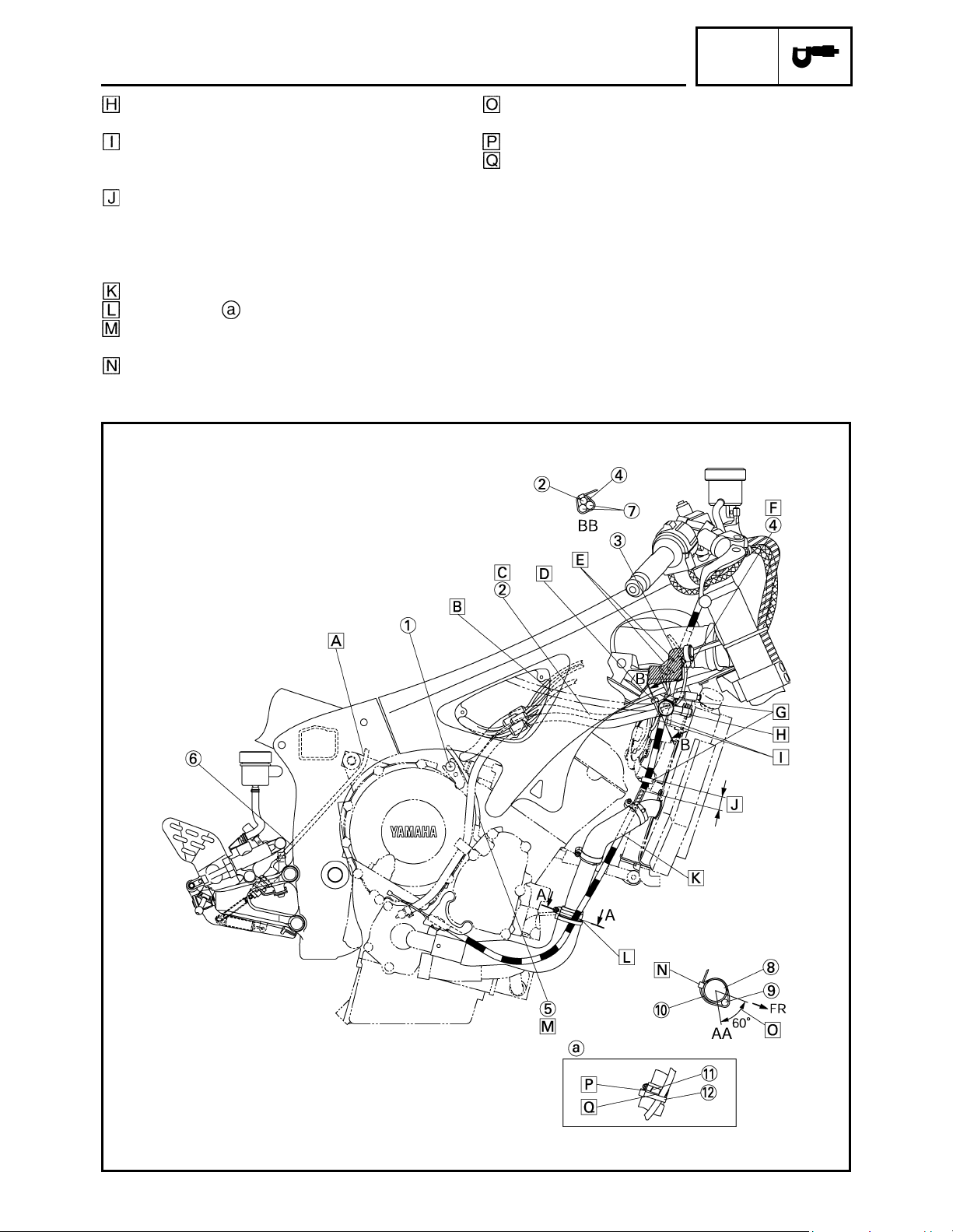

CABLE ROUTING

SPEC

Route the radiator fan motor lead (right) by the outside of the clutch cable.

Route the radiator fan motor lead (right) and clutch

cable by the inner side of the coolant reservoir

tank hose and radiator return hoses (2 hoses).

The punch mark starting point should be lower

than the clamp’s top end.

However, the aiming position of the punch mark

starting point should be 5 mm (0.20 in) below the

clamp’s bottom end.

Pass the clutch cable inside of the radiator hose.

Assemble as “ ” shown below when clamping.

Pass the pickup coil lead over the throttle stop

cable.

Tip of the plastic locking tie shall be pointed to the

inner side at the rear part of the vehicle.

Clamp the clutch cable so that it is positioned in

this range.

Put and apply the hose clamp to it.

Clamp the clutch cable by routing the upper end of

the clamp along with the bottom end of the hose

clamp assembly.

9

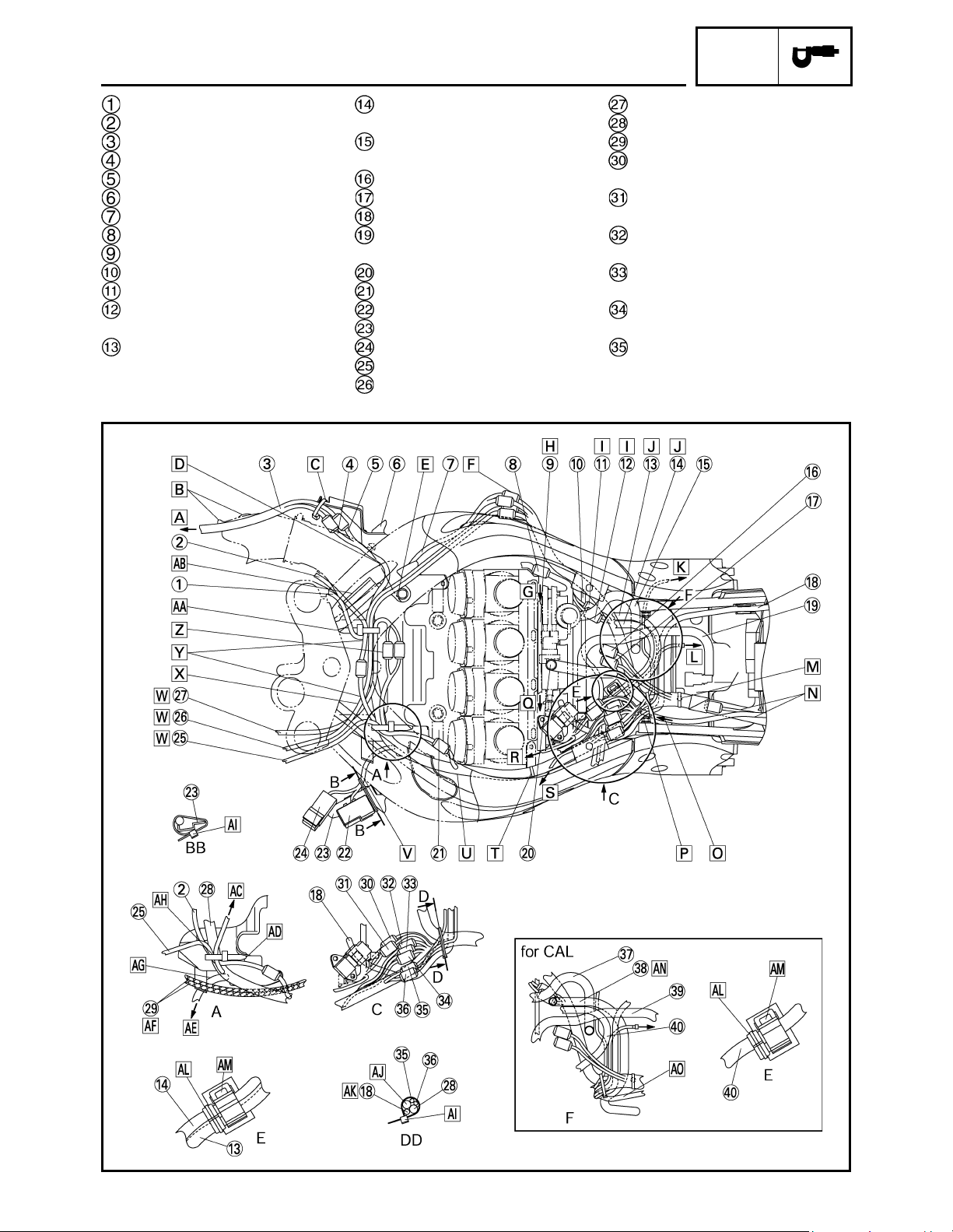

CABLE ROUTING

SPEC

Throttle cable (return side)

Throttle cable (pull side)

Starter motor lead

Canister hose (for CAL)

Canister (for CAL)

Balance hose (for CAL)

Coolant reservoir tank breather hose

Bracket 2

Sidestand switch lead

Oil level switch lead

A.C. magneto lead

Radiator fan motor lead (left)

Fuel tank breather hose

Fuel tank drain hose

Coolant reservoir tank cover

Drive sprocket cover

Coolant reservoir tank

Pass the main switch lead under the left handlebar

switch lead and then to the right side of the vehicle.

Pass the throttle stop cable by the left side of the

side stand switch lead, oil level switch lead, A.C.

magneto lead and then to the right side of the vehicle.

Route the A.C. magneto lead, sidestand switch

lead and oil level switch lead so that they pass the

inner side of the barance pipe 3. (for CAL)

Pass the fuel tank drain hose and fuel tank

breather hose inside of the coolant reservoir tank

breather hose, coolant reservoir tank hose and

wire harness and then route it by the out side of

the starter motor lead.

Pass the coolant reservoir tank hose outside of the

fuel tank drain hose and fuel tank breather hose.

10

CABLE ROUTING

SPEC

Pass the fuel tank drain hose, fuel tank breather

hose through the clamp of the coolant reservoir

tank.

Pass the coolant reservoir tank breather hose

through the clamp of under the coolant reservoir

tank.

Projection allowance from the coolant reservoir

tank cover shall be 30 to 50 mm (1.18 ~ 1.97 in).

Pass the oil level switch lead and sidestand switch

lead over the bracket 2.

Pass the oil level switch lead, and sidestand switch

lead through the clamp.

5 ~ 45 mm (0.20 ~ 1.77 in).

Clamp the A.C. magneto lead, oil level switch lead

and sidestand switch lead.

Pass the sidestand switch lead, oil level switch

lead and A.C. magneto lead between the engine

stay and the engine.

To the throttle body

To the radiator fan motor relay and fuse box

Route the radiator fan motor lead (left) by the outside of the radiator inlet hose.

Pass the throttle cable between the guide of the

cover 2 and the frame.

Pass the radiator fan motor lead (left) through the

hole of the frame to the inner side of the vehicle.

To the horn

Pass the coolant reservoir tank breather hose

through the hole of the coolant reservoir tank

cover.

Order of ups and downs means no object.

Route it below the coolant reservoir tank.

11

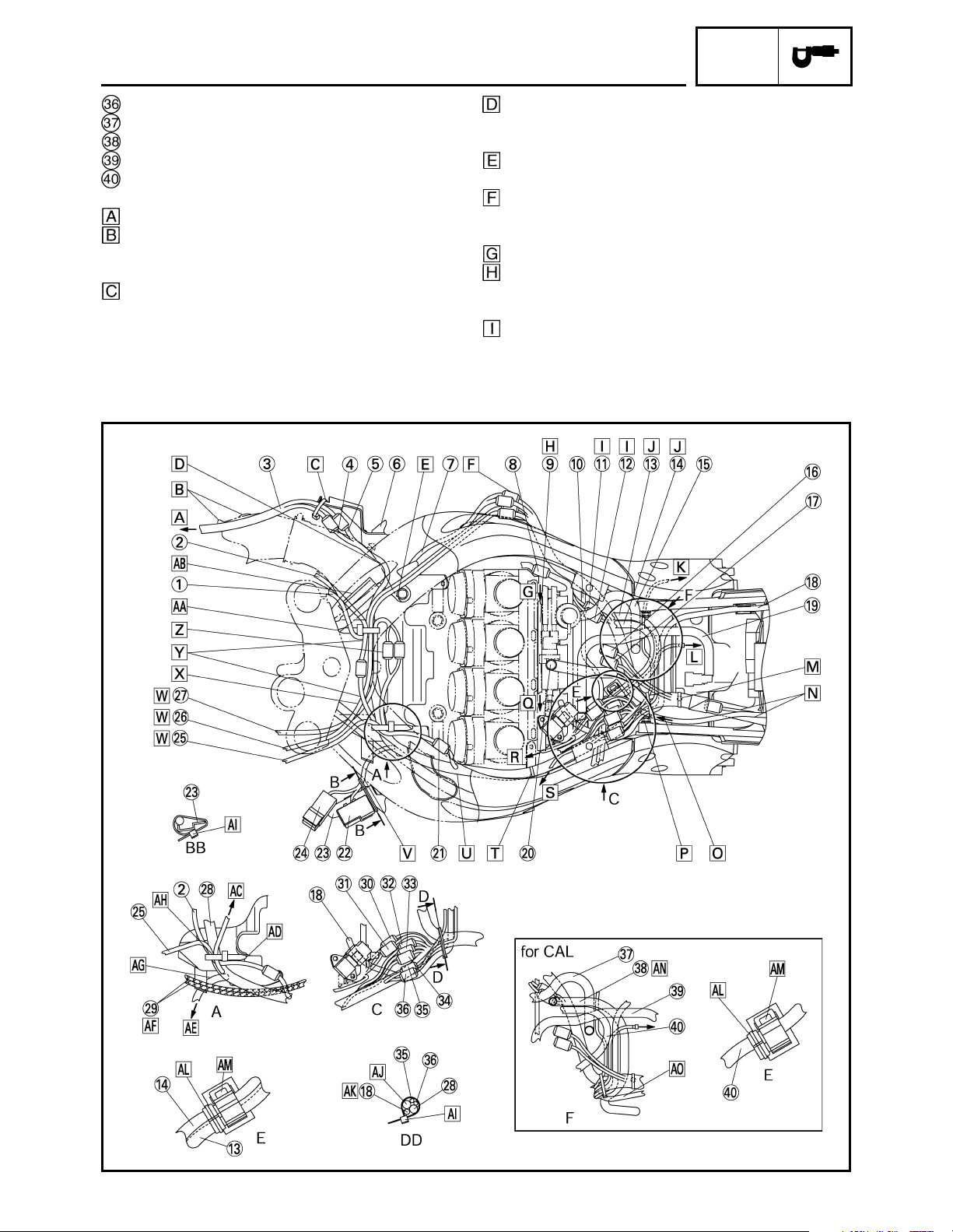

CABLE ROUTING

SPEC

Right handlebar switch lead

Radiator fan motor lead (right)

Sub wire harness

Headlight lead

Meter lead

Cover 8

Ignition coil lead

Throttle position sensor coupler

Coolant reservoir tank hose

Throttle stop cable

Speed sensor lead coupler

Crankshaft position sensor lead

coupler

Fuel tank breather hose (except

for CAL)

Fuel tank drain hose (except for

CAL)

Fuel hose (return side, except

for CAL)

Fuel pump 2 coupler

Fuel pump 1 coupler

Starter motor lead

Fuel hose (feed side, except for

CAL)

Crankcase breather hose

Throttle air vent hose

Fuse box

Cover 7

Radiator fan motor relay

Radiator fan motor lead (left)

Left handlebar switch lead

Main switch lead

Wire harness

Throttle cables

Throttle sub-lead 1 (white 6

poles)

Throttle sub-lead 2 (black 6

poles)

Oil level switch lead coupler

(white 1 pole)

Sidestand switch lead coupler

(blue 2 poles)

A.C. magneto lead coupler

(white 3 poles)

Rear tail / brake light switch lead

coupler (brown 2 poles)

12

CABLE ROUTING

SPEC

Neutral switch lead coupler (connector 1 pole)

Fuel hose (return side, for CAL)

Canister hose (for CAL)

Fuel hose (feed side, for CAL)

Fuel tank drain hose (for CAL)

To the headlight

Make sure not to drop the headlight sub wire harness beneath the projection of the duct. Check it

when installing the side cowling.

Clamp the plastic locking tie to the cover 8. Place

the coupler at the rear side of the vehicle against

the plastic locking tie. Point the tip of the plastic

locking tie to the downward in the inner side of the

vehicle.

Route the headlight and meter leads under the

frame’s lower part from the hollow section of the

cover 2.

Pass the left and right handlebar switch leads outside of the air filter case air vent hose.

Connect the couplers (4 units) at the frame side

hole. Do not catch each lead and wire harness

when the cover 8 is attached.

From the radiator

Pass the coolant reservoir tank hose through forward the starter motor lead and speed sensor

lead.

Pass the speed sensor lead coupler and crankshaft position sensor lead coupler over the throttle

stop cable.

13

Loading...

Loading...