Yamaha YP30G, YP20G Owner's Manual

OWNER’S MANUAL

Read this manual carefully before operating this machine.

YP20G

070009301

YP30G

9CB-F8199-70

Read this manual carefully before operating this machine. This manual

should stay with this machine if it is sold.

INTRODUCTION

Congratulations on your purchase of your new Yamaha.

This manual will provide you with a good basic understanding of the operation and

maintenance of this machine.

If you have any questions regarding the operation or maintenance of your machine,

please consult a Yamaha dealer.

YP20G/YP30G

OWNER’S MANUAL

© 2015 by Yamaha Motor Powered

Products Co., Ltd.

1st Edition, January 2015

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Powered

Products Co., Ltd.

is expressly prohibited.

Printed in China

IMPORTANT MANUAL

INFORMATION

Particularly important information is distinguished in this manual by the following

notations.

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

WARNING

A WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

NOTICE

A NOTICE indicates special precautions that must be taken to avoid damage to the machine or other property.

TIP

A TIP provides key information to make

procedures easier or clearer.

WARNING

PL EASE READ AND UNDERSTAND

THIS MANUAL COMPLETELY BEFORE

OPERATING THE MACHINE.

TIP

9 Yamaha continually seeks advance-

ments in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your machine and this manual. If

there is any question concerning this

manual, please consult a Yamaha

dealer.

9 This manual should be considered a

permanent part of this machine and

should remain wi t h this machine

when resold.

* Product and specifications are subject to

change without notice.

CONTENTS

SAFETY INFORMATION ...................... 1

Exhaust fumes are poisonous ............1

Fuel is highly flammable and

poisonous ...........................................1

Engine and muffler may be hot .......... 1

LOCATION OF IMPORTANT

LABELS ................................................ 3

DESCRIPTION ...................................... 4

CONTROL FUNCTION ......................... 5

Oil warning light (Red)........................ 5

Engine switch ..................................... 5

Throttle lever ...................................... 5

Fuel cock lever ................................... 6

Choke lever ........................................ 6

Recoil starter ...................................... 6

PREPARATION ..................................... 7

Fuel .................................................... 7

Engine oil ...........................................8

Water hose installation .......................9

Water priming ...................................10

PRE-OPERATION CHECK .................11

Pre-operation check ......................... 11

OPERATION ....................................... 12

Preparation for operation.................. 12

Water priming ...................................12

Starting the engine ........................... 13

Stopping the engine ......................... 14

Drain water after use ........................15

High altitude operation .................... 15

PERIODIC MAINTENANCE ................ 16

Maintenance chart ........................... 16

Spark plug inspection ....................... 17

Carburetor adjustment ..................... 18

Water leakage check ........................ 18

Engine oil replacement ..................... 18

Air filter ............................................. 20

Fuel cock .......................................... 21

Fuel tank filter ................................... 22

Muffler screen and spark arrester .... 22

Troubleshooting ................................ 24

STORAGE ...........................................27

Drain the fuel .................................... 27

Engine .............................................. 29

SPECIFICATIONS ............................... 30

Dimensions ...................................... 30

Engine .............................................. 30

Pump ................................................ 30

CONSUMER INFORMATION.............. 31

Identification number records ........... 31

Machine identification ....................... 31

EXHAUST EMISSION CONTROL

SYSTEM AND COMPONENTS .......... 32

WIRING DIAGRAM ............................. 33

RUBBER MOUNT INSTALLATION .... 34

745-013

745-014

745-016

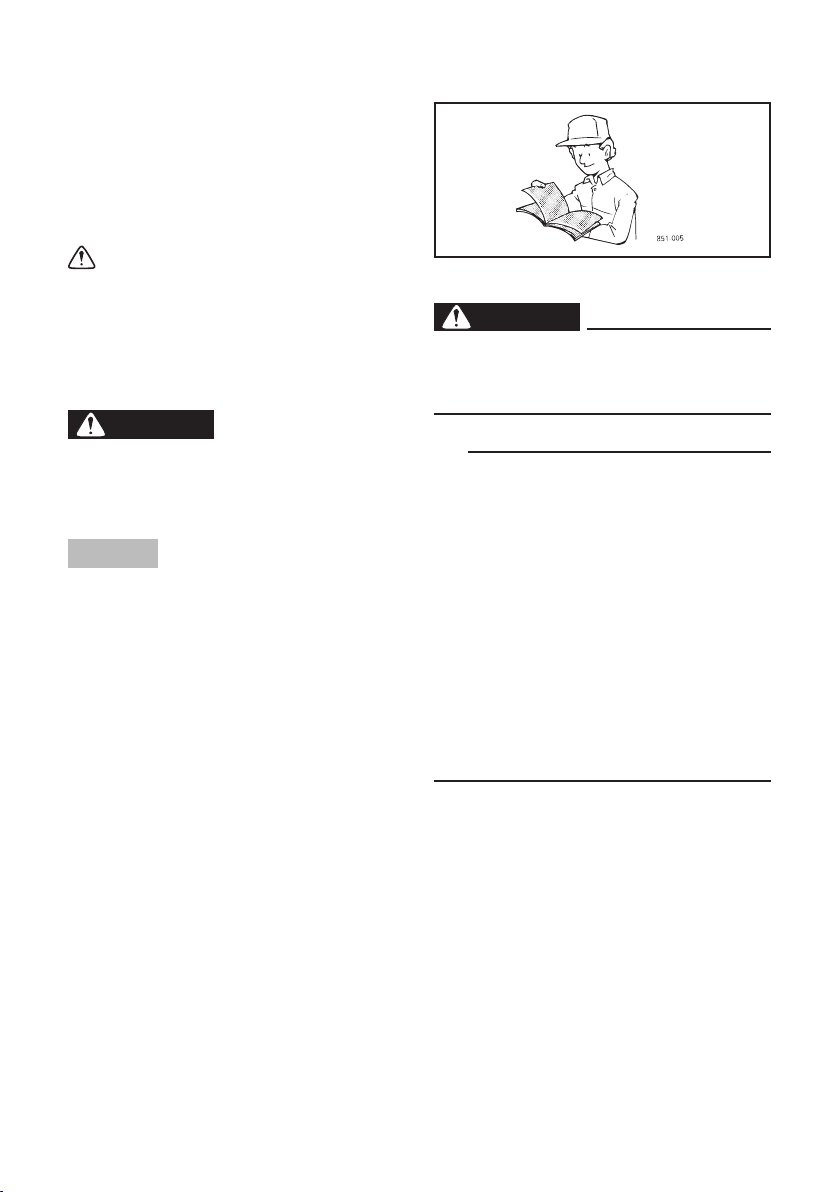

SAFETY INFORMATION

Exhaust fumes are poisonous

9 Using a water pump indoors CAN KILL YOU IN

MINUTES. Engine exhaust contains carbon monoxide. This is a poison you cannot see or smell.

9 NEVER use inside a home or garage, EVEN IF

doors and windows are open.

9 Only use OUTSIDE and far away from windows,

doors, and vents.

Fuel is highly flammable and poisonous

9 Always turn off the engine when refuelling.

9 Never refuel while smoking or in the vicinity of an

open flame.

9 Take care not to spill any fuel on the engine or

muffler when refuelling.

9 Do not leave the water pump inside the vehicle or

in the trunk.

9 If you swallow any fuel, inhale fuel vapor, or allow

any to get in your eye(s), see your doctor immediately. If any fuel spills on your skin or clothing,

immediately wash with soap and water and

change your clothes.

9 When operating or transporting the water pump,

be sure it is kept upright. If it tilts, fuel may leak

from the carburetor or fuel tank.

745-015

745-017

745-018

Engine and muffler may be hot

9 Place the water pump in a place where pedestri-

ans or children are not likely to touch the water

pump.

9 Do not place any flammable materials near the

exhaust outlet during operation.

– 1 –

745-019a

745-020

9 In order to prevent overheating, ensure adequate

airflow by keeping the machine at least 1 m (3 ft)

from objects or other equipment.

9 Do not operate the engine with a dust cover or

other objects covering it.

9 When covering the water pump, be sure to do so

only after the engine and muffler have completely

cooled down.

– 2 –

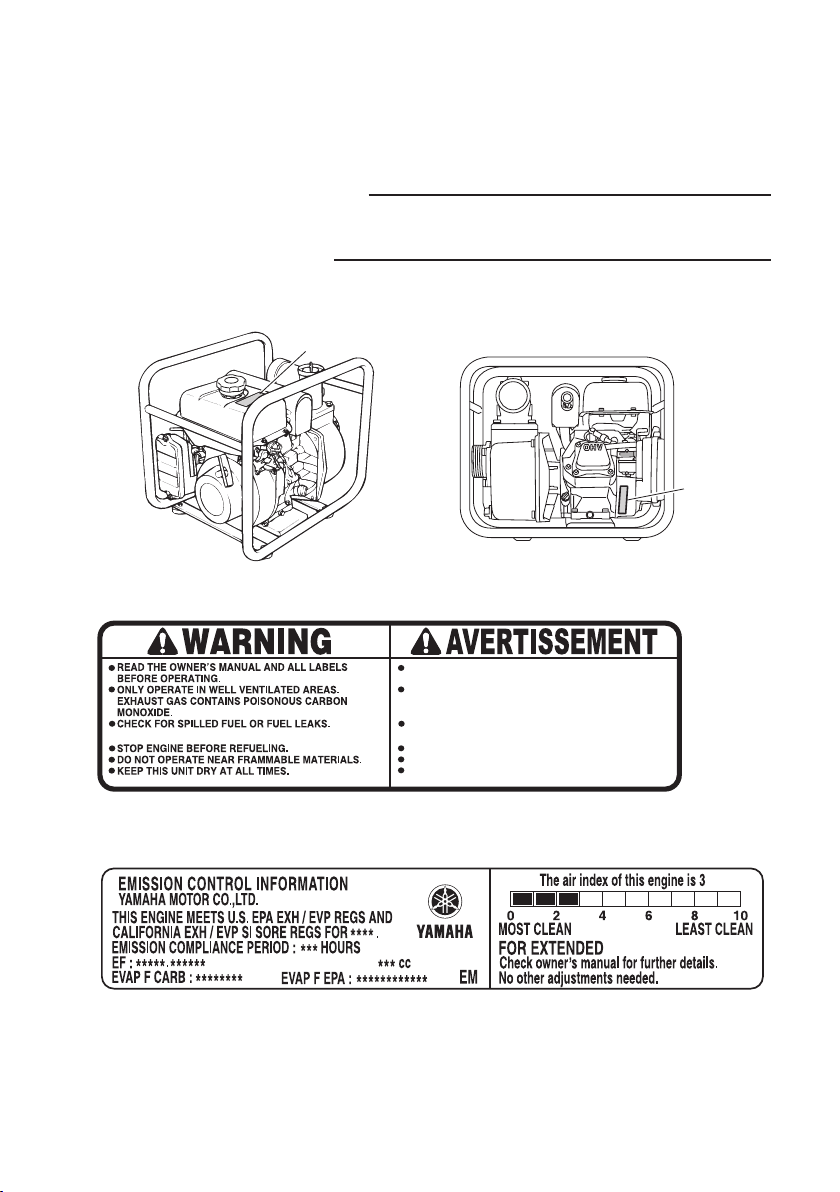

LOCATION OF IMPORTANT LABELS

Please read the following labels carefully before operating this water pump.

TIP

Maintain or replace safety and instruction labels, as

necessary.

1

2

792-016

1

LISEZ LE MANUEL DU PROPRIÉTAIRE ET TOUTES LES

ÉTIQUETTES AVANT L'UTILISATION.

NE FAITES FONCTIONNER QUE DANS DES LIEUX BIEN AÉRÉS.

LES GAZ D'ÉCHAPPEMENT CONTIENNENT DU MONOXYDE DE

CARBONE NOCIF.

VÉRIFIEZ QU'IL N'Y A PAS DE FUITES DE CARBURANT OU DE

CARBURANT RENVERSÉ.

ARRÊTEZ LE MOTEUR AVANT DE FAIRE LE PLEIN.

NE PAS UTILISER PRÈS DE MATÉRIAUX INFLAMMABLES.

GARDEZ L'APPAREIL AU SEC EN TOUTES CIRCONSTANCES.

7CN-F4162-60

2

DISPLACEMENT :

– 3 –

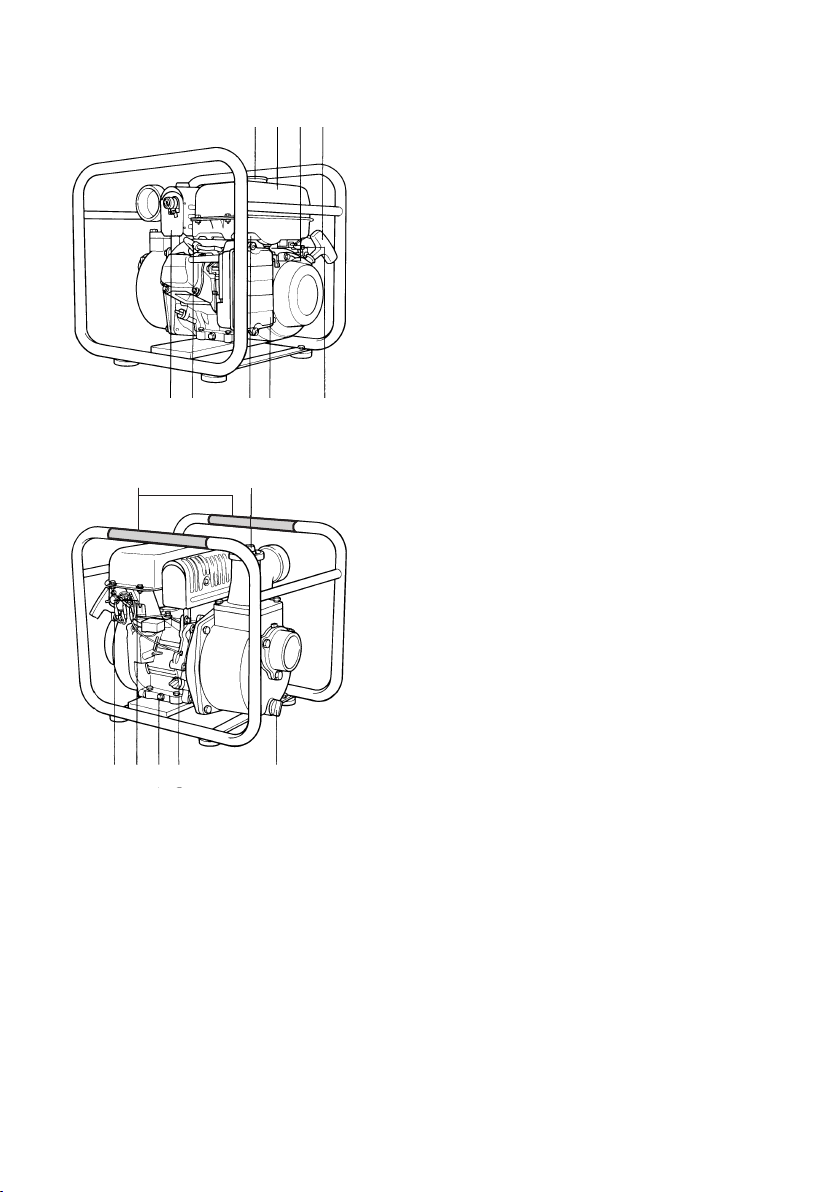

4321

1 Fuel tank cap

2 Fuel tank

3 Fuel cock

4 Recoil starter

5 Throttle lever

6 Air filter case cover

7 Choke lever

8 Spark plug

9 Muffler

0 Priming plug

q Water drain plug

56789

0y

w Oil filler cap

e Oil drain bolt

r Engine switch

t Oil warning light

y Carrying handle

DESCRIPTION

t r e w q

– 4 –

CONTROL FUNCTION

Oil warning light (Red)

When the oil level falls below the lower level, the oil

warning light comes on and then the engine stops

automatically. Unless you refill with oil, the engine will

not start again.

TIP

If the engine stalls or does not start, turn the engine

switch to “ON” (ON) and then pull the recoil starter. If

the oil warning light flickers for a few seconds, the

engine oil is insufficient. Add oil and restart.

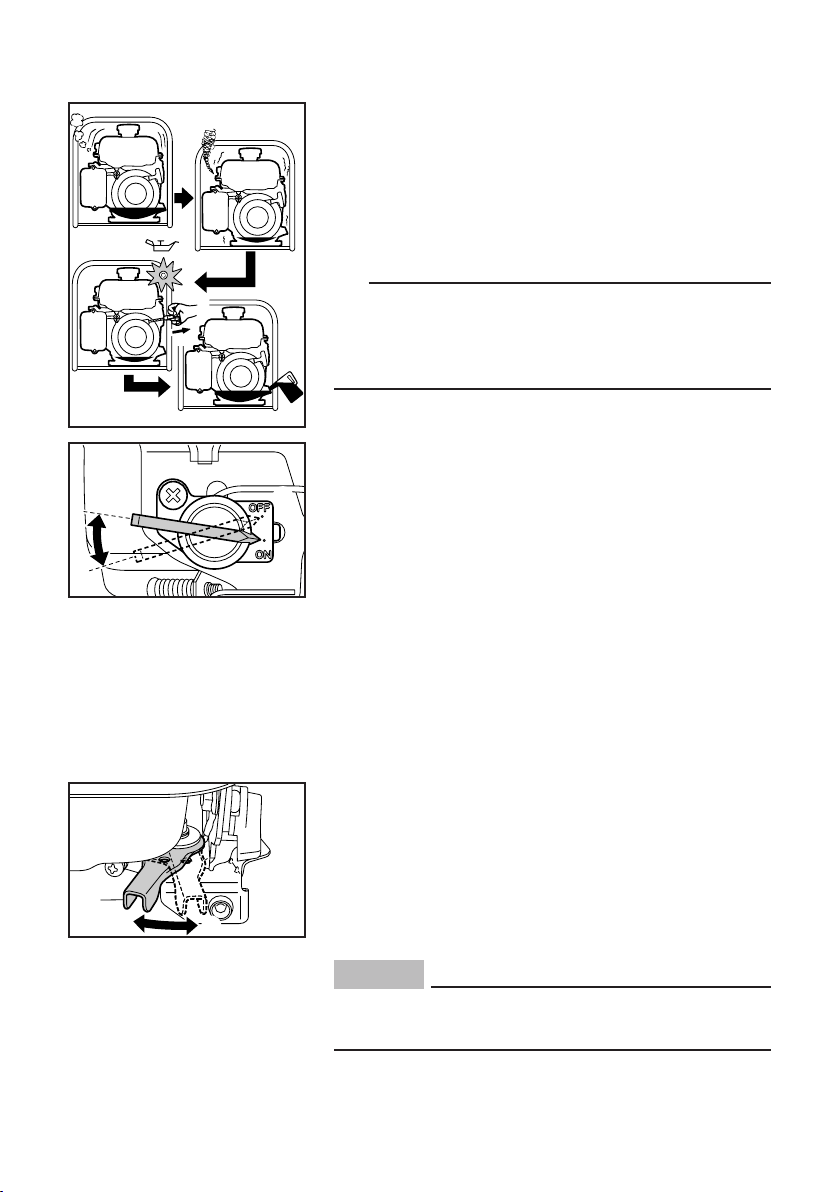

Engine switch

The engine switch controls the ignition system.

2

1 “ON” (ON)

Ignition circuit is switched on.

The engine can be started.

1

2 “OFF” (OFF)

Ignition circuit is switched off.

The engine will not run.

Throttle lever

The throttle lever controls the engine speed. Move the

throttle lever in direction 2 to increase engine speed.

Move the throttle lever in direction 1 to decrease

engine speed.

a

1

2

a Throttle lever

NOTICE

Always check throttle operation before starting the

engine.

– 5 –

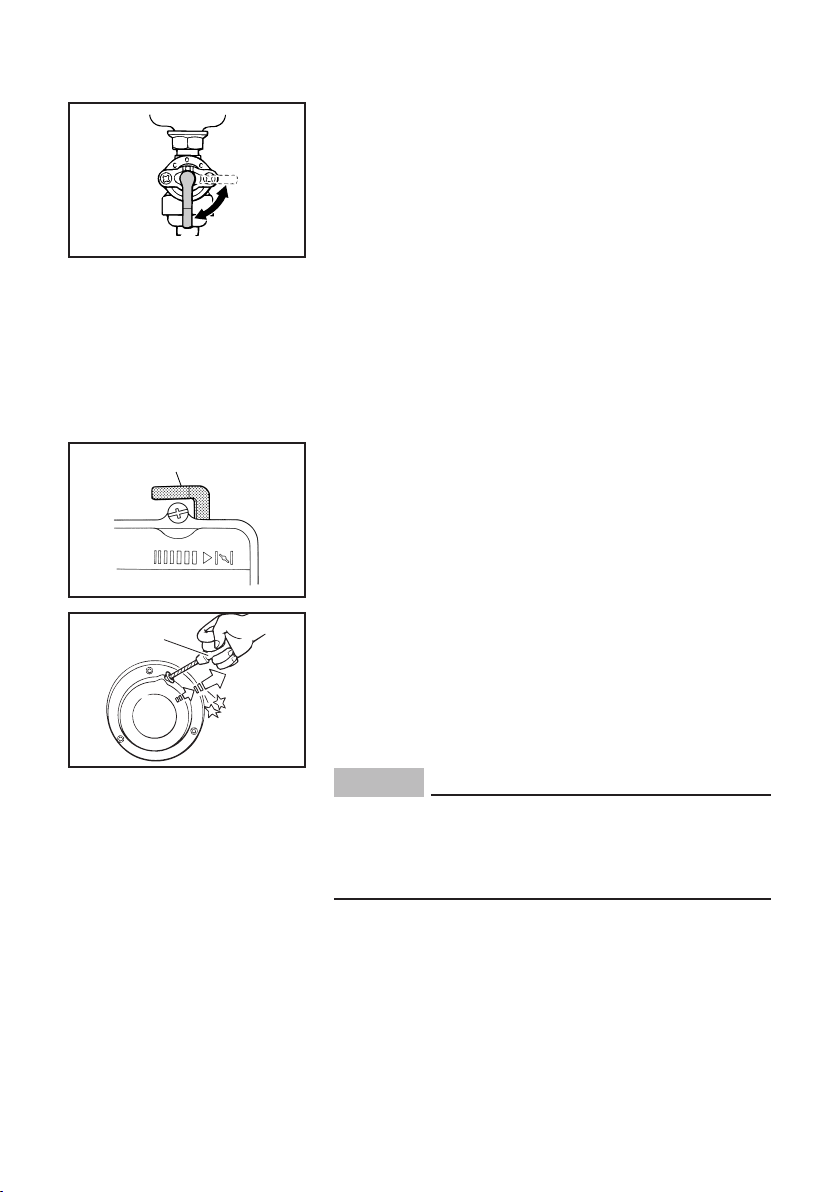

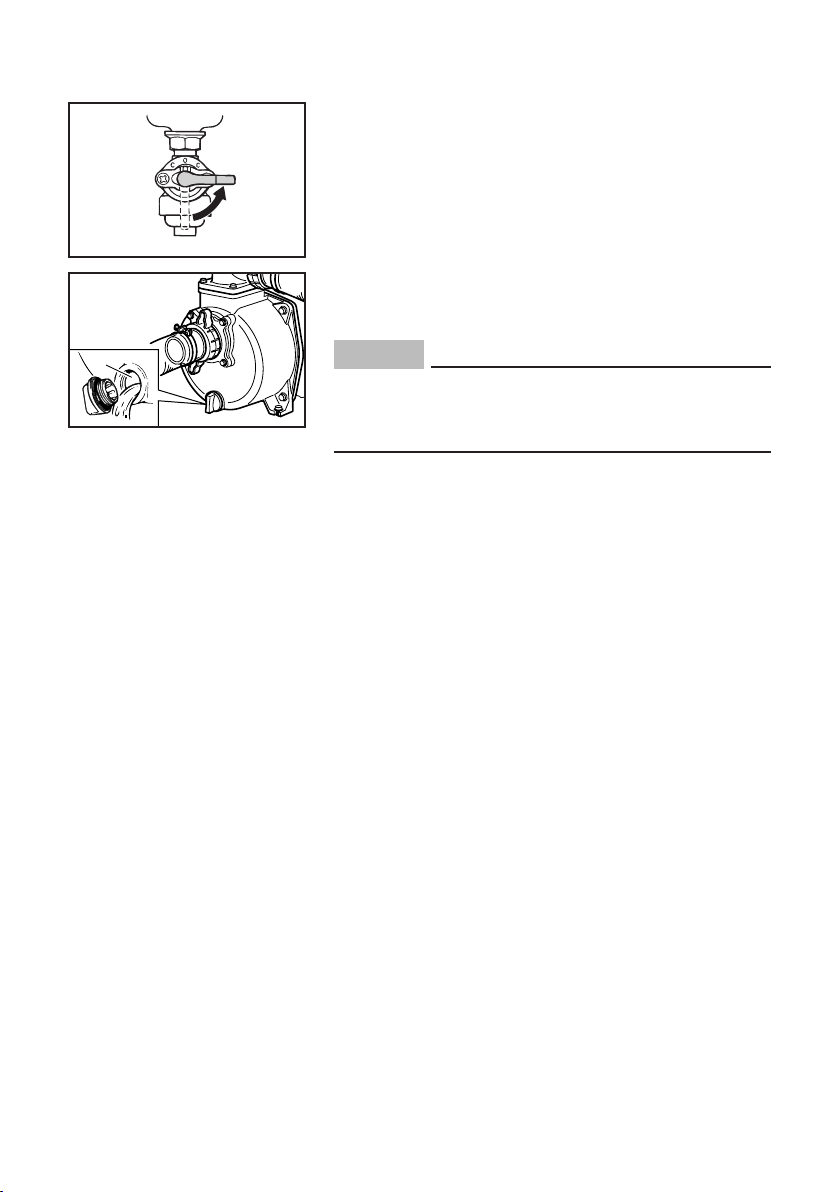

Fuel cock lever

The fuel cock supplies fuel from the fuel tank to the

carburetor.

2

1

The fuel cock has two positions.

1 ON

With the lever in this position, fuel flows to the carburetor. Normal using is done with the lever in this position.

2 OFF

With the lever in this position, fuel will not flow. Always

turn the lever to this position when the engine is not

running.

1

Choke lever

Starting a cold engine requires a richer air-fuel mixture, which is supplied by the choke lever.

1 Choke lever

1

Recoil starter

The recoil starter is used to start the engine.

Pull the recoil starter slowly until it is engaged, then

pull it briskly.

704-010

1 Recoil starter handle

NOTICE

9 Pull the recoil starter handle straight.

9 Return the recoil starter handle slowly.

9 Do not touch the recoil starter handle while the

water pump is operating.

– 6 –

PREPARATION

WARNING

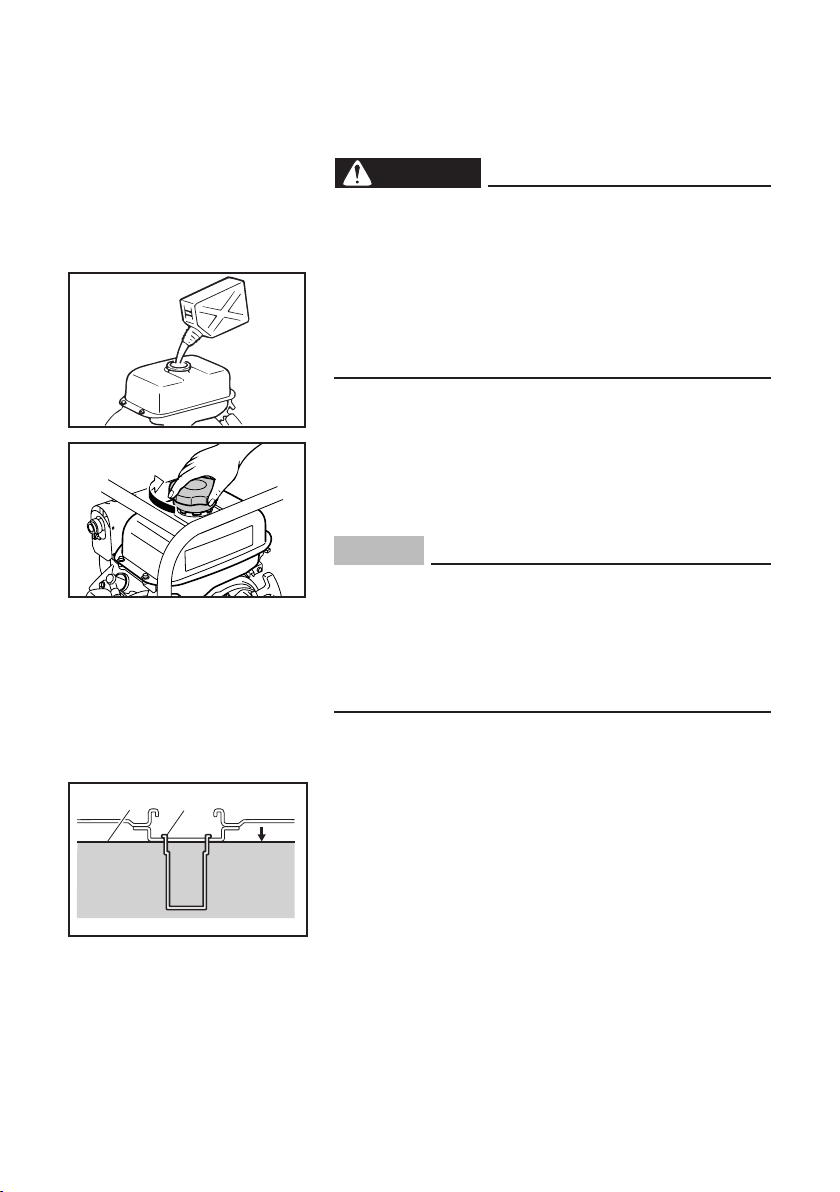

Fuel

9 Fuel is hig h ly flammable and poisonous.

Check “SAFETY INFORMATION” (See page 1)

carefully before filling.

9 Do not overfill the fuel tank, otherwise it may

overflow when the fuel warms up and expands.

9 Wipe up any spilled fuel immediately.

9 After fill the fuel, make sure the fuel tank cap is

tightened securely.

707-041

1. Stop the engine.

2. Place the water pump on a level surface.

3. Remove the fuel tank cap.

4. Check the fuel level.

5. If low, fill the tank with fuel.

NOTICE

9 Immediately wipe off spilled fuel with a clean,

dry, soft cloth, since fuel may deteriorate paint-

ed surfaces or plastic parts.

9 Use only unleaded gasoline. The use of leaded

gasoline will cause severe damage to internal

engine parts.

1

2

707-037

Make sure there is sufficient fuel in the tank.

When refueling, be sure to fill the tank up to the bottom edge of the fuel tank filter.

1 Fuel level

2 Fuel tank filter

Your Yamaha engine has been designed to use regular

unleaded gasoline with a pump octane number ((R +

M)/2) of 86 or higher, or research octane number of 91

or higher.

– 7 –

Recommended fuel:

Unleaded gasoline

Fuel tank capacity:

Total:

4.0 L (1.06 US gal, 0.88 Imp gal)

Engine oil

NOTICE

The water pump has been shipped without engine

oil. Do not start the engine until you have filled it

with the sufficient engine oil.

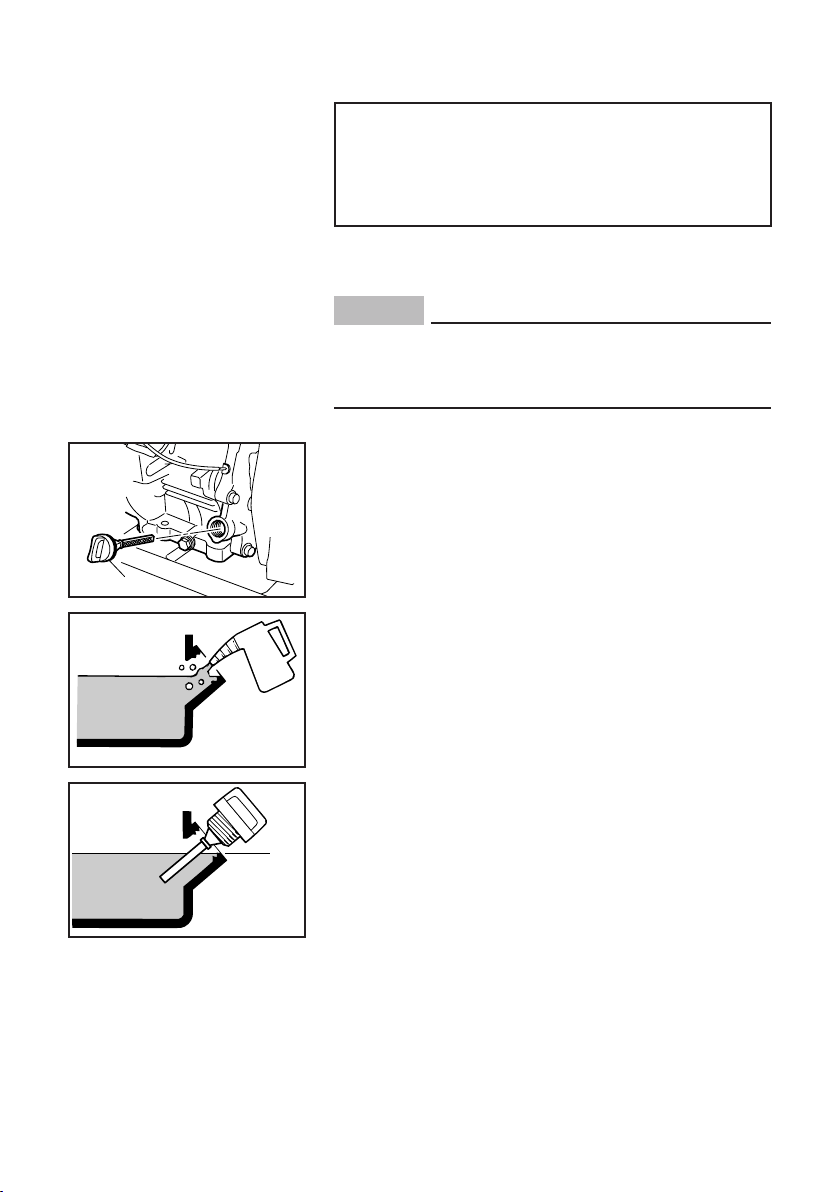

1. Place the water pump on a level surface.

2. Remove the oil filler cap.

1 Oil filler cap

1

3. Fill the specified amount of the recommended

engine oil, and then install and tighten the oil filler

cap.

700-006

2

700-110

2 Correct level

– 8 –

0˚C

å

YAMALUBE 4 (10W-40)

ç

SAE #20

32˚F

25˚C

80˚F

Recommended engine oil:

å YAMALUBE 4 (10W-40),

SAE 10W-30 or 10W-40

∫ SAE #30

ç SAE #20

∂ SAE 10W

Recommended engine oil grade:

API Service SE type or higher

Engine oil quantity:

0.6 L (0.63 US qt, 0.53 Imp qt)

1

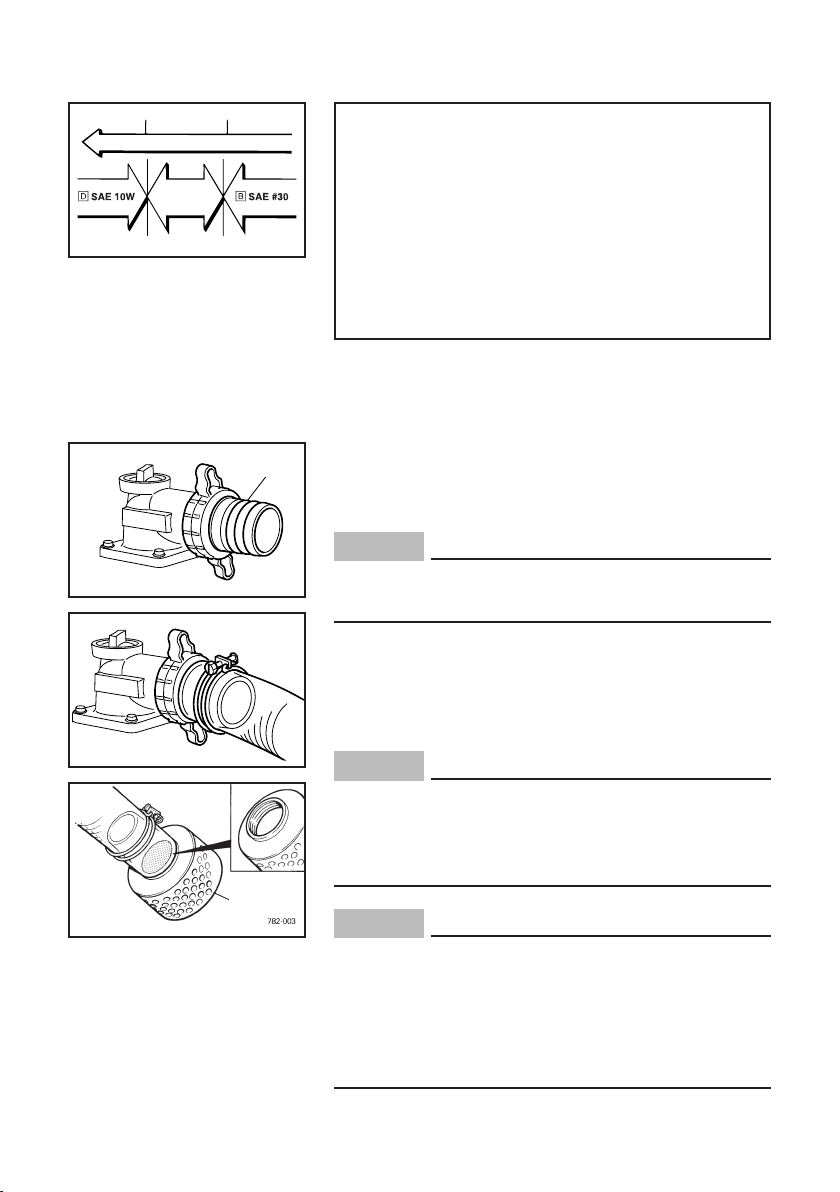

1. Install the hose joint to the pump.

1 Hose joint

NOTICE

Water hose installation

When installing the joint to the pump, be sure the

gasket is in place.

2. Connect the hoses on the joints with clamp.

3. Connect the strainer on the inlet hose end.

2 Strainer

NOTICE

9 Be sure the hoses are installed securely or air

leak will occur and water will not be drawn up.

9 Be sure the strainer is installed or pump dam-

age may occur.

2

NOTICE

Install the strainer

A) 50 mm (2 in) suction port diameter for YP20G

or

B) 80 mm (3 in) suction port diameter for YP30G

both with filtering perforations 8 mm (0.31 in) or

less in diameter.

– 9 –

Water priming

Make sure the water is at pump casing upper level.

Add water as necessary.

1

1 Upper level

NOTICE

Be sure the pump is filled up with water before

starting the engine or mechanical seal damage will

occur.

TIP

9 Place the water pump on a secure, flat and level

surface as near to the water to be pumped as possible.

9 The higher the water pump is from the water sur-

face (more suction head), the longer it will take to

prime and the lesser pump output (discharge

head) will be.

– 10 –

PRE-OPERATION CHECK

WARNING

If any item in the Pre-operation check is not working properly, have it inspected and repaired before

operating the water pump.

The condition of a water pump is the owner’s responsibility. Vital components can start to deteriorate quickly

and unexpectedly, even if the water pump is unused.

TIP

Pre-operation checks should be made each time the

water pump is used.

Pre-operation check

Fuel (See page 7)

9 Check fuel level in fuel tank.

9 Refuel if necessary.

Fuel line

9 Check fuel hose for crack or damage.

9 Replace if necessary.

Engine oil (See page 8)

9 Check oil level in engine.

9 If necessary, add recommended oil to specified

level.

9 Check water pump for oil leakage.

The point where abnormality was recognized by

use

9 Check operation.

9 If necessary, consult a Yamaha dealer.

– 11 –

OPERATION

WARNING

Never operate the water pump in a closed area or it

may cause unconsciousness and death within a

short time. Operate the engine in a well ventilated

area.

NOTICE

The water pump has been shipped without engine

oil. Do not start the engine until you have filled it

with the sufficient engine oil.

Preparation for operation

Choose the best location for the water pump to perform the pumping job. Place the pump on a flat, level

surface as near as possible to the water to be pumped.

Connect the hoses properly (See page 9).

Pumping performance is affected by various factors

including the length of the hoses and the vertical

height from the water surface to the pump (suction

head) and from the pump to the end of the discharge

hose (discharge head). As the height of the pump from

the water surface increases the time necessary to

prime the pump will increase and the discharge from

the pump will decrease. Do not exceed maximum Total

head and Suction head specifications for your water

pump (See page 30).

Water priming

Before starting the engine, make sure water is at the

pump casing upper level.

1

Add clean water as necessary.

1 Upper level

NOTICE

Be sure the pump is filled up with water before

starting the engine or mechanical seal damage will

occur.

– 12 –

Starting the engine

NOTICE

Be sure the pump is filled up with water before

starting the engine.

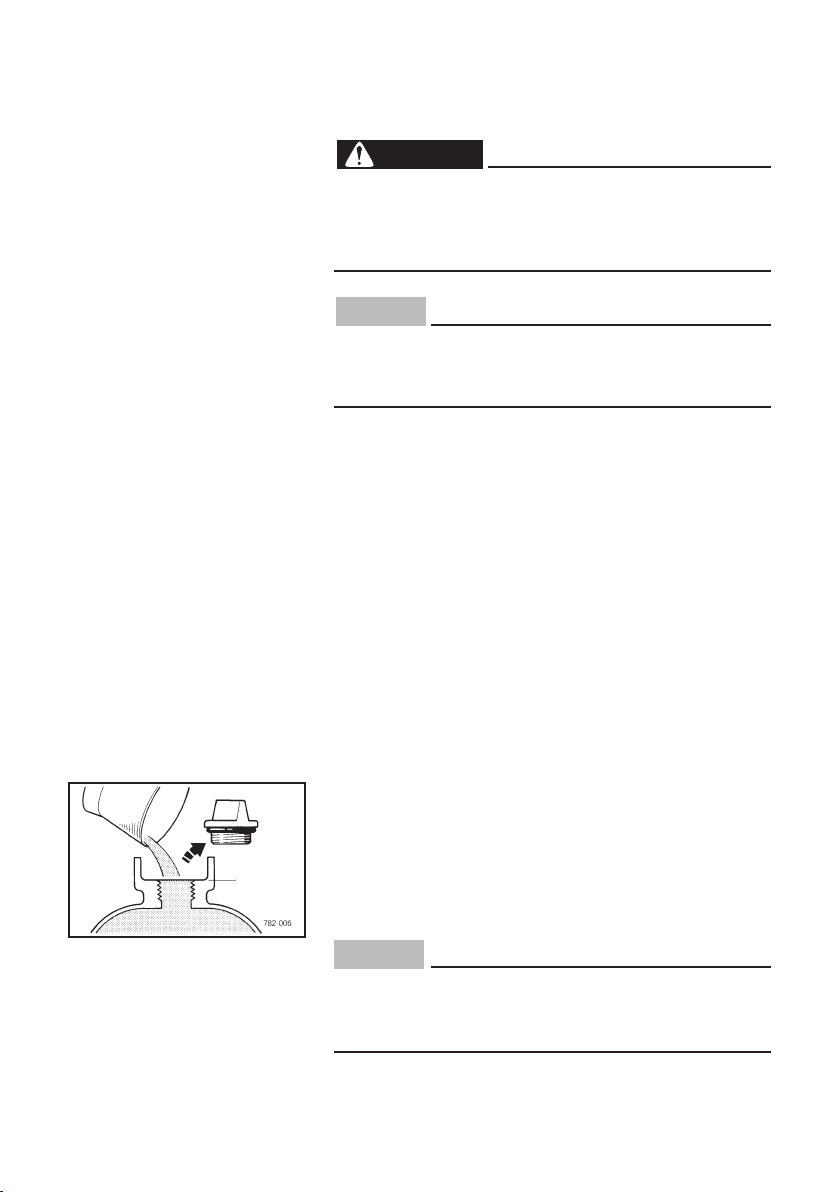

1. Turn the fuel cock lever to the ON.

1 ON

1

705-037

2. Turn the engine switch to the “ON” (ON).

2 “ON” (ON)

2

1

3. Turn the choke lever to the “1”.

3

3 Choke lever

TIP

The choke is not required to start a warm engine.

Turn the choke lever to the operating position.

4. Move the throttle lever slightly to right.

– 13 –

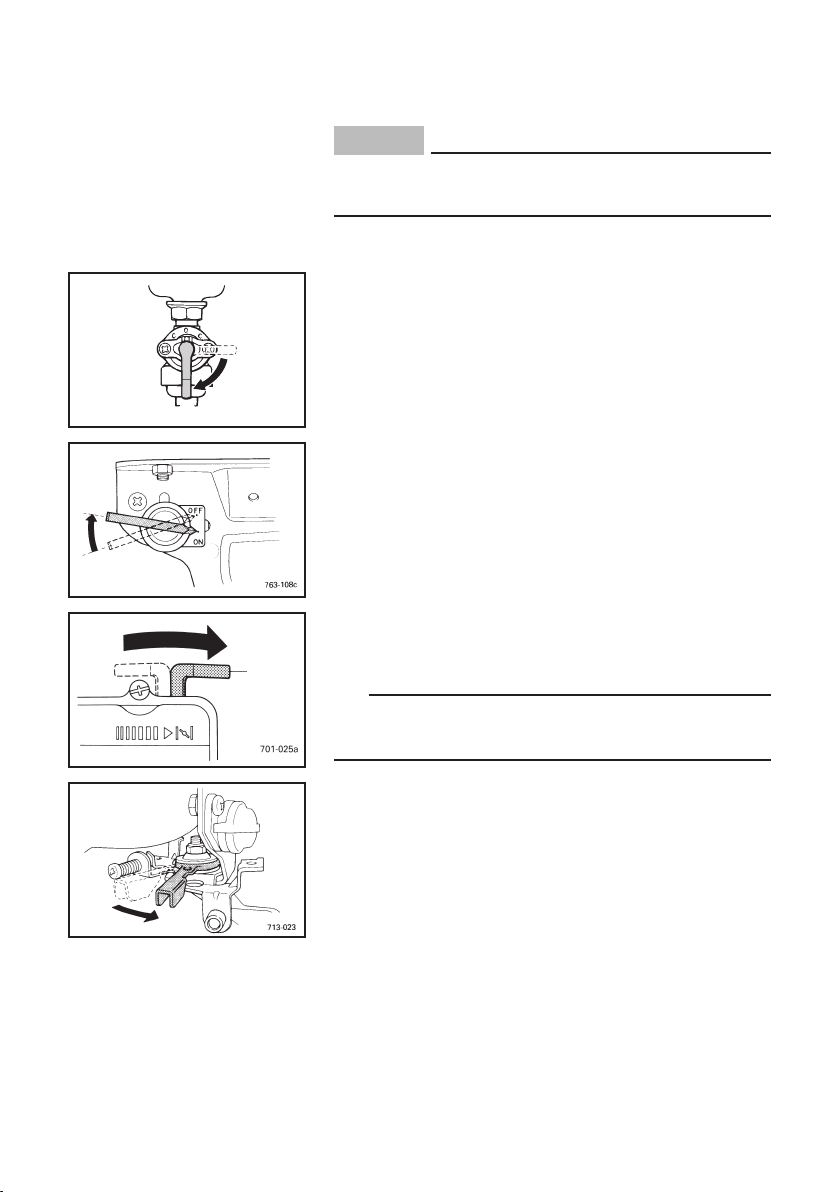

5. Pull the recoil starter slowly until it is engaged,

WARNING

then pull it briskly.

704-010

the recoil starter handle can be drawn back quickly

by the engine kickback.

TIP

Grasp the carrying handle firmly to prevent the water

pump from falling over when pulling the recoil starter.

6. After the engine starts, warm up the engine until

the engine does not stop when the choke lever is

Be careful to use the recoil starter. In rare cases,

4

returned to the original position.

4 Original position

7. Set the throttle lever in desired position.

5 Increase engine speed

6 Decrease engine speed

6

5

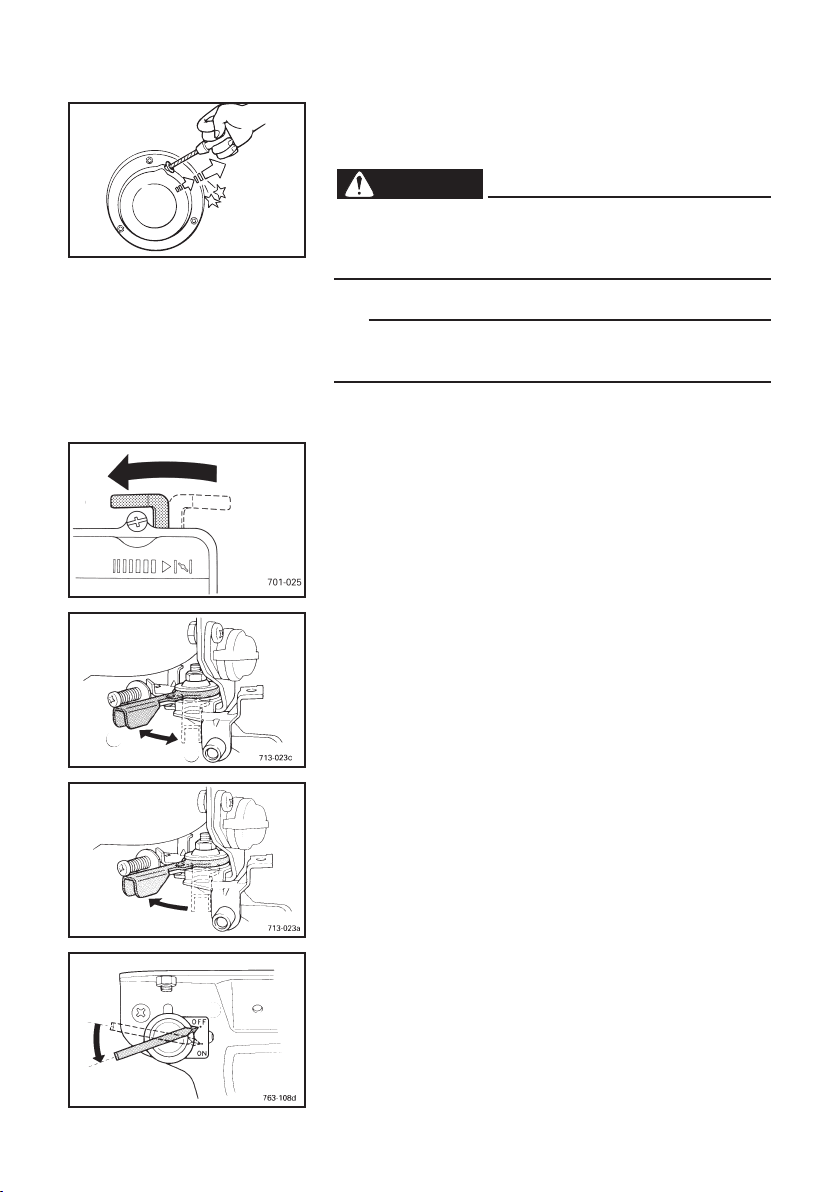

Stopping the engine

1. Move the throttle lever fully to left.

2. Turn the engine switch to the “OFF” (OFF).

1

1 “OFF” (OFF)

– 14 –

3. Turn the fuel cock lever to the OFF.

2 OFF

2

705-038

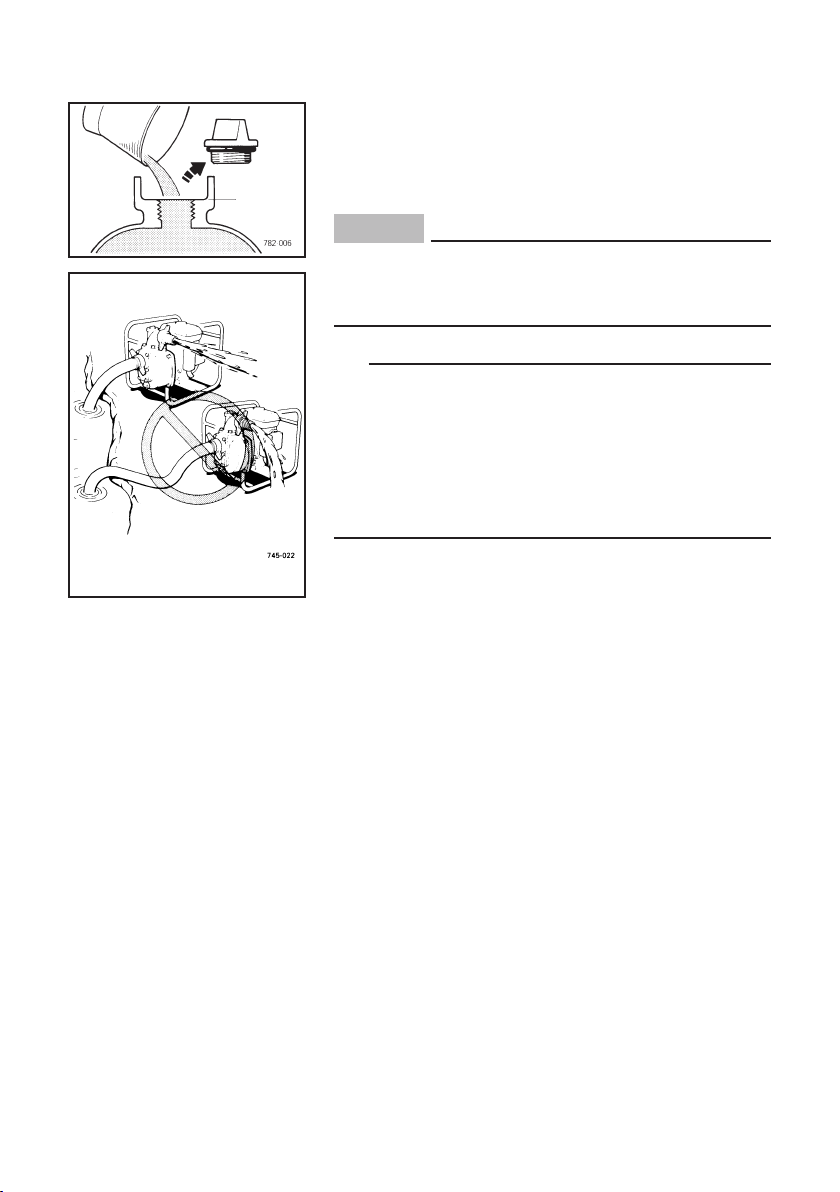

Drain water after use

After use, open the drain plug to drain remaining water

from the casing.

1

NOTICE

Unless the casing is drained before storage, the

pump can be severely damaged by freezing water

if temperatures drop to 0 °C (32 °F) or below.

1 Drain port

High altitude operation

This engine may require a high altitude carburetor kit

to ensure correct engine operation at altitudes above

4000 ft. (1219 meters). If you operate your engine at

altitudes above 4000 ft. (1219 meters) consistently,

have your local Yamaha dealer perform the necessary

carburetor modification. This engine should be operated in its original configuration below 4000 ft. (1219

meters) as damage may occur if high altitude carburetor kit is installed and operated below 4000 ft. (1219

meters).

– 15 –

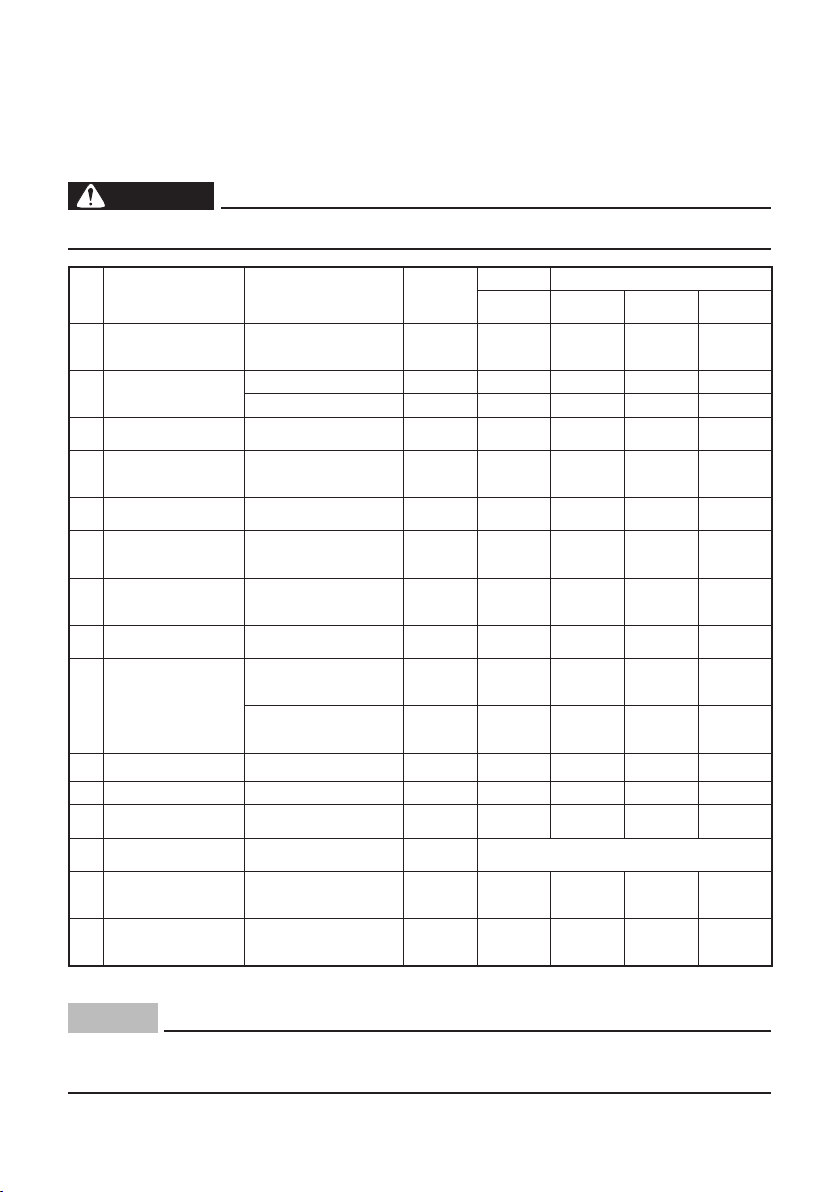

PERIODIC MAINTENANCE

Maintenance chart

Regular maintenance is most important for best performance and safe operation.

WARNING

Stop the engine before starting maintenance work.

No. Item Remarks

**

1.

Spark plug

2. Engine oil

**

3.

Air filter

4. Fuel tank filter

**

5.*

Valve clearance

6. Fuel line

**

Crankcase

7.*

breather system

**

8.*

Idle speed

**

9.

Exhaust system

**

10.

Choke lever

11.* Cooling system Check fan damage.

12. Starting system

**

13.*

Decarbonization

14. Water pump

15.* Fittings/Fasteners

* : It is recommended that these items be serviced by a Yamaha dealer.

** : Related to emission control system.

Check condition,

adjust gap and clean.

Replace if necessary.

Check oil level.

Replace.

Clean.

Replace if necessary.

Clean fuel cock and

fuel tank filter.

Replace if necessary.

Check and adjust

when engine is cold.

Check fuel hose for

cracks or damage.

Replace if necessary.

Check breather hose

for cracks or damage.

Replace if necessary.

Check and adjust

engine idle speed.

Check for leakage.

Retighten or

replace gasket if necessary.

Check muffler screen and

spark arrester. Clean or

replace if necessary.

Check choke operation.

Check recoil starter

operation.

More frequently if

necessary.

Check for leakage.

Retighten or replace

O-ring and/or gasket.

Check all fittings and

fasteners.

Correct if necessary.

Pre-opera-

tion check

(daily)

7

7

7

7

7

7

Initial Every

1 month or

20 Hr

3 month or

50 Hr

7

7 7

7

After every 500 Hrs.

6 month or

100 Hr

7

7

7

12 month or

300 Hr

7

7

7

7

NOTICE

Use only Yamaha specified genuine parts for replacement. Ask an authorized

Yamaha dealer for further attention.

– 16 –

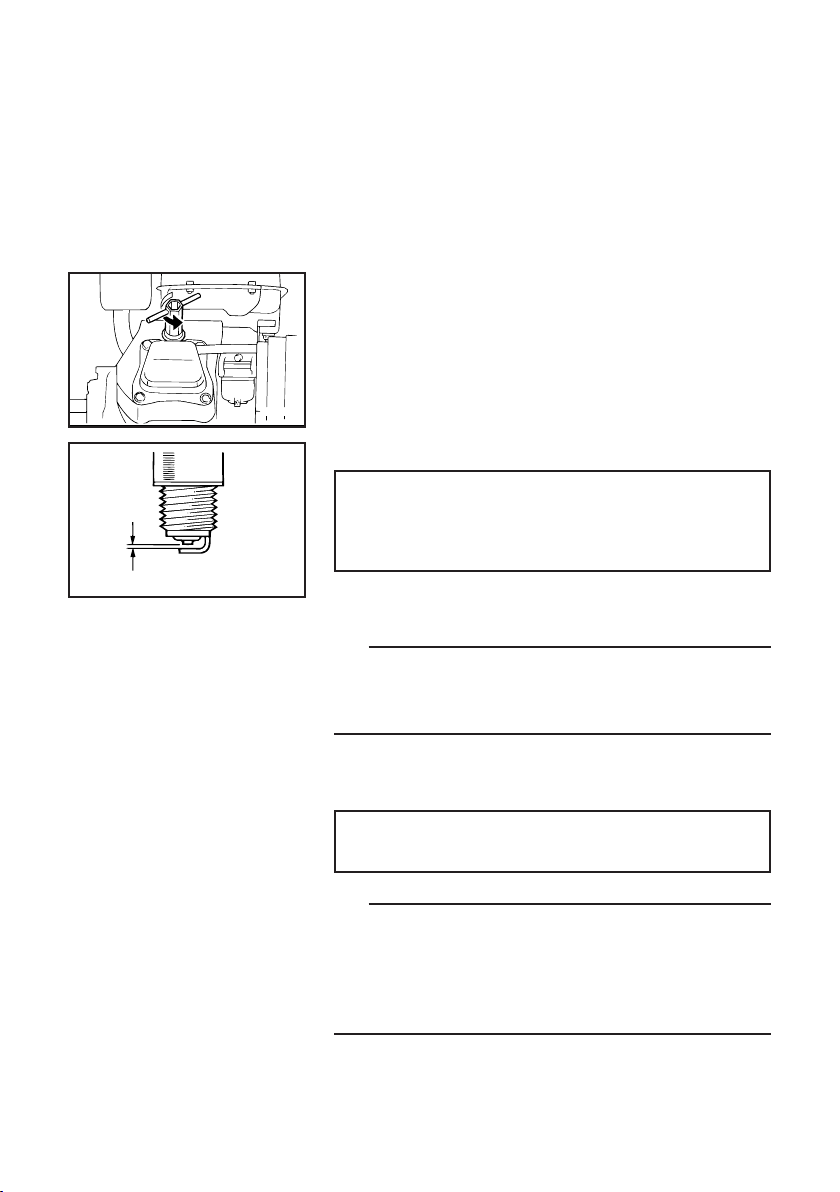

Spark plug inspection

The spark plug is an important engine component,

which should be checked periodically.

1. Remove the spark plug cap and the spark plug.

2. Check for discoloration and remove the carbon.

The porcelain insulator around the center elec-

trode of spark plug should be a medium-to-light

760-005a

a

760-001a

tan color.

3. Check the spark plug type and gap.

Standard spark plug:

BPR4ES (NGK)

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

a Gap

TIP

The spark plug gap should be measured with a wire

thickness gauge and, if necessary, adjusted to specification.

4. Install the spark plug, and then tighten it.

Spark plug tightening torque:

20 Nm (2.0 m·kgf, 14 ft·lbf)

TIP

If a torque wrench is not available when installing a

spark plug, a good estimate of the correct torque is

1/4–1/2 turn past finger tight. However, the spark plug

should be tightened to the specified torque as soon as

possible.

5. Install the spark plug cap.

– 17 –

Carburetor adjustment

The carburetor is a vital part of the engine. Adjusting

should be left to a Yamaha dealer with the professional

knowledge, specialized data, and equipment to do so

properly.

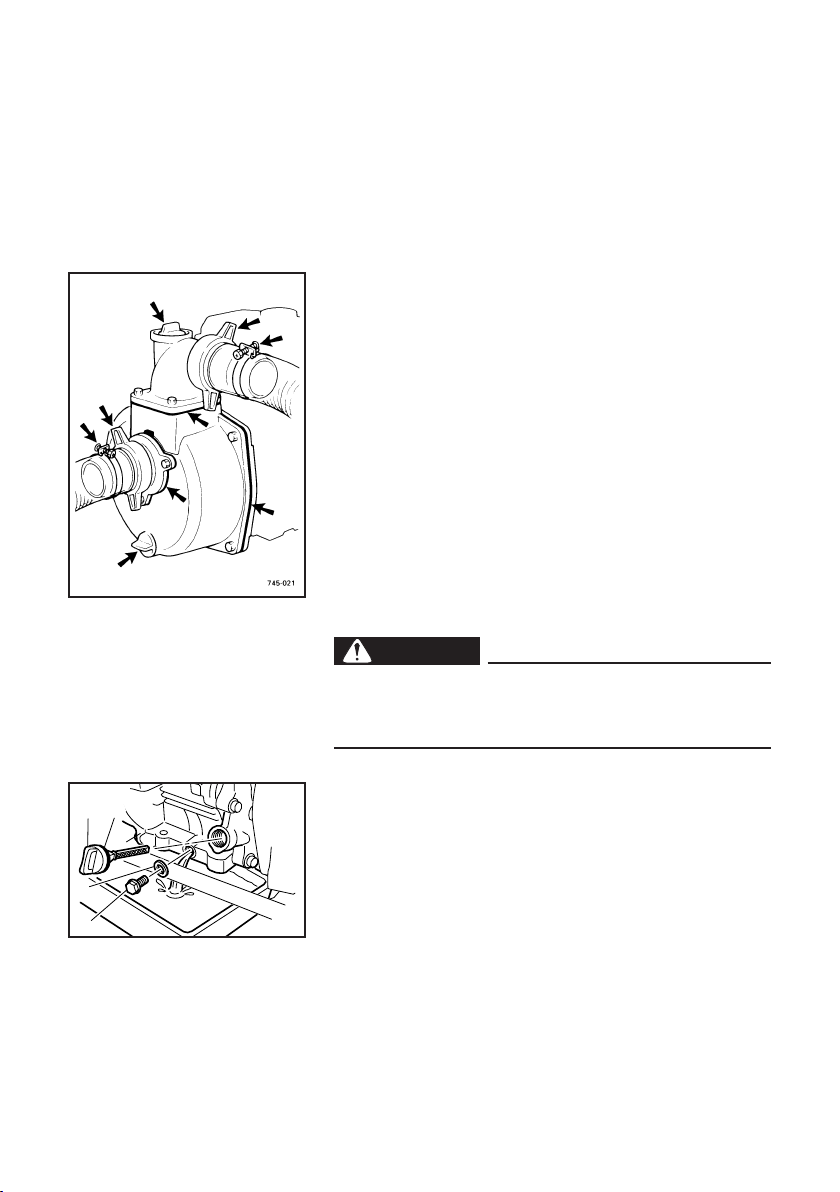

Water leakage check

Check for water leakage from water pump.

Retighten the bolts, plugs, band, and hose joints.

Replace O-rings and/or gaskets if necessary.

Engine oil replacement

WARNING

Avoid draining the engine oil immediately after

stopping the engine. The oil is hot and should be

handled with care to avoid burns.

3

1. Place the water pump on a level surface and warm

4

1

up the engine for several minutes. Then stop the

engine and turn the fuel cock lever to OFF.

2. Remove the oil filler cap.

2

1 Oil filler cap

3. Place an oil pan under the engine. Remove the oil

drain bolt and the gasket so that the oil can be

completely drained.

2 Oil drain bolt

3 Gasket

4 O-ring

– 18 –

4. Check the oil drain bolt, the oil filler cap and the

O-ring. Replace them if damaged.

5. Install a new gasket and the oil drain bolt and then

tighten the bolt.

Oil drain bolt tightening torque:

17 Nm (1.7 m·kgf, 12 ft·lbf)

6. Add engine oil to the correct level.

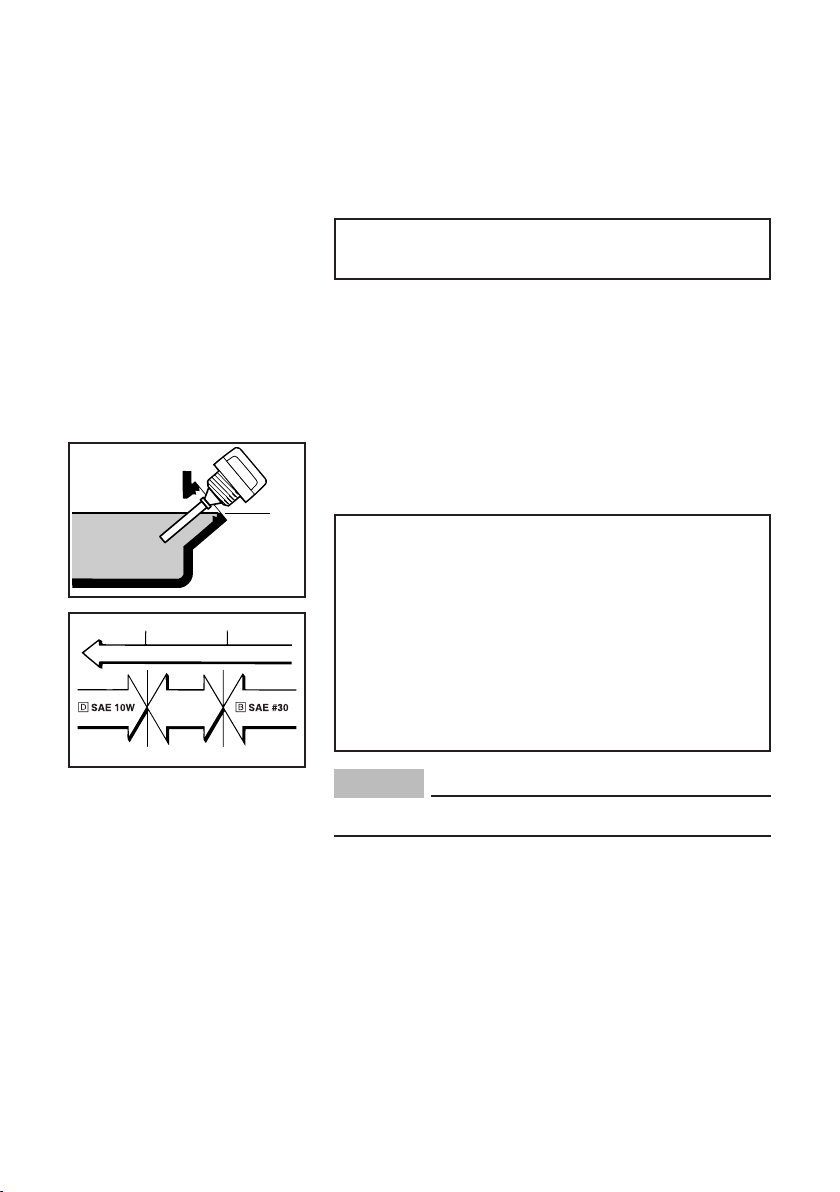

0˚C

å

YAMALUBE 4 (10W-40)

ç

SAE #20

32˚F

25˚C

80˚F

5

700-110

5 Correct level

Recommended engine oil:

å YAMALUBE 4 (10W-40),

SAE 10W-30 or 10W-40

∫ SAE #30

ç SAE #20

∂ SAE 10W

Recommended engine oil grade:

API Service SE type or higher

Engine oil quantity:

0.6 L (0.63 US qt, 0.53 Imp qt)

NOTICE

Be sure no foreign material enters the crankcase.

7. Install the oil filler cap.

– 19 –

Loading...

Loading...