Yamaha YFM400FA User Manual

YFM4FAT

YFM400FAT

5TE2-AE2

SUPPLEMENTARY

SERVICE MANUAL

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

YFM4FAT/YFM400FAT. For complete service information procedures it is necessary to use this

Supplementary Service Manual together with the following manual.

YFM4FAR/YFM400FAR SERVICE MANUAL: 5TE2-AE1

YFM4FAT/YFM400FAT

SUPPLEMENTARY

SERVICE MANUAL

©2004 by Yamaha Motor Co., Ltd.

First edition, June 2004

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on

Yamaha machine has a basic understanding of the mechanical ideas and the procedures of

machine repair. Repairs attempted by anyone without this knowledge are likely to render the

machine unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized Yamaha

dealers and will appear in future editions of this manual where applicable.

OTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death

to the machine operator, a bystander or a person inspecting or repairing the

machine.

A CAUTION indicates special precautions that must be taken to avoid

damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

EB002000

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”)

1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page.

2nd title 2: This title indicates the section of the chapter and only appears on the first page of each

section. It is located in the upper left corner of the page.

3rd title 3: This title indicates a sub-section that is followed by step-by-step procedures

accompanied by corresponding illustrations.

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram 4 is provided for removal and disassembly jobs.

2. Numbers 5 are given in the order of the jobs in the exploded diagram. A number that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

6

. The meanings of the symbol marks are given on the next page.

4. A job instruction chart 7 accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more information, the step-by-step format supplements 8 are given in addition

to the exploded diagram and the job instruction chart.

12

GEN

INFO

34

SPEC

CHK

ENG

ADJ

56

COOL

78

CARB

EB003000

ILLUSTRATED SYMBOLS

Illustrated symbols 1 to 0 are printed on the

top right of each page and indicate the subject

of each chapter.

General information

1

Specifications

2

Periodic checks and adjustments

3

Engine

4

Cooling system

5

Carburetion

6

Drive train

7

Chassis

8

Electrical

9

Troubleshooting

0

DRIV

90

–+

ELEC

AB

CD

EF

T

.

R

.

GH

CHAS

TRBL

SHTG

Illustrated symbols A to H are used to identify

the specifications appearing in the text.

Can be serviced with engine mounted

A

Filling fluid

B

Lubricant

C

Special tool

D

Torque

E

Wear limit, clearance

F

Engine speed

G

, V, A

Ω

H

IJK

LS

G

M

M

New

E

LMN

B

OP

LT

Illustrated symbols I to N in the exploded

diagrams indicate the types of lubricants and

lubrication points.

Apply engine oil

I

Apply gear oil

J

Apply molybdenum disulfide oil

K

Apply wheel bearing grease

L

Apply lithium-soap-based grease

M

Apply molybdenum disulfide grease

N

Illustrated symbols O to P in the exploded

diagrams indicate where to apply a locking

agent O and when to install a new part P.

®

Apply the locking agent (LOCTITE

O

Replace

P

)

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS ..................................................................1

MAINTENANCE SPECIFICATIONS .........................................................3

ENGINE ................................................................................................3

CHASSIS ..............................................................................................4

ELECTRICAL ........................................................................................6

CABLE ROUTING .....................................................................................7

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION .....................................................................................18

PERIODIC MAINTENANCE/LUBRICATION ...........................................18

SEAT, CARRIERS, FENDERS AND FUEL TANK ..................................20

FRONT CARRIER, FRONT BUMPER AND FRONT FENDER ..........20

CHASSIS .................................................................................................22

ADJUSTING THE REAR BRAKE .......................................................22

CHECKING THE BRAKE FLUID LEVEL ............................................24

CHECKING THE REAR BRAKE PADS ..............................................25

CHECKING THE BRAKE HOSES ......................................................25

BLEEDING THE HYDRAULIC BRAKE SYSTEM ...............................26

ADJUSTING THE SELECT LEVER CONTROL CABLE

AND SHIFT ROD ................................................................................27

CHECKING THE FINAL GEAR OIL LEVEL ........................................29

CHECKING THE CONSTANT VELOCITY JOINT DUST BOOTS ......29

ADJUSTING THE REAR SHOCK ABSORBERS ...............................30

............................................................................................1

..................................................18

ENGINE

DRIVE TRAIN

..........................................................................................................31

CRANKCASE ..........................................................................................31

STARTER MOTOR, TIMING CHAIN AND OIL FILTER .....................31

CRANKCASE ......................................................................................34

INSTALLING THE SHIFT LEVER .......................................................35

TRANSMISSION .....................................................................................36

CHECKING THE STOPPER LEVER AND STOPPER WHEEL .........38

MIDDLE GEAR ........................................................................................39

MIDDLE DRIVEN SHAFT ...................................................................39

.................................................................................................41

TROUBLESHOOTING ............................................................................41

FRONT CONSTANT VELOCITY JOINTS

AND DIFFERENTIAL GEAR ..................................................................44

MEASURING AND ADJUSTING THE DIFFERENTIAL

GEAR LASH ........................................................................................44

REAR CONSTANT VELOCITY JOINTS, FINAL DRIVE GEAR

AND DRIVE SHAFT ...............................................................................46

ASSEMBLING THE REAR CONSTANT VELOCITY JOINTS ............51

DISASSEMBLING THE FINAL DRIVE GEAR ....................................52

CHECKING THE DRIVE SHAFT/UNIVERSAL JOINT YOKE ............52

CHECKING THE FINAL DRIVE GEAR ...............................................53

REPLACING THE FINAL DRIVE ROLLER BEARING .......................53

REPLACING THE FINAL DRIVE PINION GEAR AND BEARING ......54

POSITIONING THE FINAL DRIVE PINION GEAR .............................56

MEASUREMENT AND ADJUSTING THE FINAL GEAR LASH .........57

ASSEMBLING THE FINAL DRIVE GEAR ..........................................60

CHASSIS ........................................................................................................62

FRONT AND REAR WHEELS ................................................................62

REAR WHEELS ..................................................................................62

INSTALLING THE REAR BRAKE DISC .............................................64

INSTALLING THE REAR WHEEL HUBS ...........................................64

REAR BRAKE .........................................................................................65

REAR BRAKE PADS ..........................................................................65

REPLACING THE REAR BRAKE PADS ............................................66

REAR BRAKE MASTER CYLINDER ..................................................68

CHECKING THE MASTER CYLINDER ..............................................71

ASSEMBLING THE REAR BRAKE MASTER CYLINDER .................71

INSTALLING THE REAR BRAKE MASTER CYLINDER ....................72

REAR BRAKE CALIPER .....................................................................74

DISASSEMBLING THE REAR BRAKE CALIPER ..............................76

CHECKING THE REAR BRAKE CALIPER ........................................76

ASSEMBLING THE REAR BRAKE CALIPER ....................................77

INSTALLING THE REAR BRAKE CALIPER ......................................78

STEERING SYSTEM ..............................................................................80

STEERING STEM ...............................................................................80

FRONT ARMS AND FRONT SHOCK ABSORBERS .............................82

REAR KNUCKLES AND STABILIZER ....................................................84

CHECKING THE REAR KNUCKLES ..................................................85

CHECKING THE STABILIZER ...........................................................85

REAR ARMS AND REAR SHOCK ABSORBERS ..................................86

CHECKING THE REAR ARMS ...........................................................87

INSTALLING THE REAR ARMS AND REAR SHOCK ABSORBERS ....87

ELECTRICAL .................................................................................................88

ELECTRICAL COMPONENTS ...............................................................88

CHECKING THE SWITCHES .................................................................89

CHECKING THE SWITCH CONTINUITY ...........................................89

SIGNAL SYSTEM ...................................................................................91

CIRCUIT DIAGRAM ............................................................................91

CHECKING THE SIGNAL SYSTEM ...................................................93

YFM4FAT/YFM400FAT WIRING DIAGRAM

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard

Model code: 1P11, 1P14 (for USA)

1P12 (for CDN)

1P13 (for Oceania)

Dimensions:

Overall length 1,993 mm (78.5 in)

Overall width 1,093 mm (43.0 in)

Overall height 1,120 mm (44.1 in)

Seat height 830 mm (32.7 in)

Wheelbase 1,233 mm (48.5 in)

Minimum ground clearance 245 mm (9.7 in)

Minimum turning radius 3,000 mm (118.1 in)

Basic weight:

With oil and full fuel tank 279 kg (615 lb) (for USA and CDN)

283 kg (624 lb) (for Oceania)

Oil capacity:

Engine oil

Periodic oil change 2.30 L (2.02 Imp qt, 2.43 US qt)

With oil filter replacement 2.40 L (2.11 Imp qt, 2.54 US qt)

Total amount 2.60 L (2.29 Imp qt, 2.75 US qt)

Final gear case oil

Periodic oil change 0.16 L (0.14 Imp qt, 0.17 US qt)

Total amount 0.18 L (0.16 Imp qt, 0.19 US qt)

Differential gear case oil

Periodic oil change 0.35 L (0.31 Imp qt, 0.37 US qt)

Total amount 0.40 L (0.35 Imp qt, 0.42 US qt)

Radiator capacity (including all routes) 1.32 L (1.16 Imp qt, 1.40 US qt)

Chassis:

Frame type Steel tube frame

Caster angle 2.5°

Camber angle 1°

Kingpin angle 11°

Kingpin offset 0 mm (0 in)

Trail 8.5 mm (0.33 in)

Tread (STD) front 850 mm (33.46 in)

rear 839 mm (33.03 in)

Toe-in 0 ~ 10 mm (0 ~ 0.39 in)

SPEC

– 1 –

GENERAL SPECIFICATIONS

Item Standard

Tires:

Type Tubeless

Size front AT25 × 8–12

rear AT25 × 10–12

Manufacturer front MAXXIS (for USA and CDN)

CHENG SHIN (for Oceania)

rear MAXXIS (for USA and CDN)

CHENG SHIN (for Oceania)

Model front M911Y (for USA and CDN)

C828 (for Oceania)

rear M912Y (for USA and CDN)

C828 (for Oceania)

Brakes:

Front brake type Dual disc brake

operation Right hand operation

Rear brake type Single disc brake

operation Left hand and right foot operation

Suspension:

Front suspension Double wishbone

Rear suspension Double wishbone

Bulb wattage × quantity:

Headlight 12 V 30 W/30 W × 2

Tail/brake light 12 V 5 W/21 W × 1

Meter light 14 V 3 W × 1

Indicator lights

Neutral 12 V 1.7 W × 1

Reverse 12 V 1.7 W × 1

Park 12 V 1.7 W × 1

Coolant temperature 12 V 1.7 W × 1

Four-wheel drive 12 V 1.7 W × 1

SPEC

– 2 –

MAINTENANCE SPECIFICATIONS

SPEC

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

Carburetor:

I. D. mark 5TEC 00 ---Main jet (M.J) #132.5 ---Main air jet (M.A.J) #50 ---Jet needle (J.N) 5EP13-55-3 ---Needle jet (N.J) P-0M ---Pilot air jet (P.A.J.1) #80 ---Pilot air jet (P.A.J.2) 1.3 ---Pilot outlet (P.O) 0.95 ---Pilot jet (P.J) #17.5 ---Bypass 1 (B.P.1) 0.8 ---Bypass 2 (B.P.2) 0.8 ---Bypass 3 (B.P.3) 0.8 ---Pilot screw (P.S.) 2-1/2 turns out ---Valve seat size (V.S) 2.0 ---Starter jet (G.S.1) #75 ---Starter jet (G.S.2) 0.9 ---Throttle valve size (Th.V) #90 ---Float height (F.H) 13 mm (0.51 in) ---Fuel level (F.L) 4.0 ~ 5.0 mm (0.16 ~ 0.20 in) ---Engine idle speed 1,450 ~ 1,550 r/min ---Intake vacuum 33.3 kPa (250 mmHg, 9.84 inHg) ----

Tightening torques

Part to be tightened

Shift lever 2 assembly Bolt M6 1 14 1.4 10

Shift lever cover Bolt M6 4 10 1.0 7.2

Stopper lever Bolt M6 1 10 1.0 7.2

Stopper lever shaft Bolt M6 1 10 1.0 7.2

Park switch — M10 1 20 2.0 14

Part

name

Thread

size

Q’ty

Tightening torque

Nm m · kg ft · lb

Remarks

– 3 –

MAINTENANCE SPECIFICATIONS

CHASSIS

Item Standard Limit

Front suspension:

Shock absorber travel 99 mm (3.90 in) ---Spring free length 285 mm (11.22 in) ---Spring fitting length 231.9 mm (9.13 in) ---Spring rate (K1) 15 N/mm

(1.53 kg/mm, 85.68 lb/in)

Stroke (K1) 0 ~ 99 mm (0 ~ 3.90 in) ---Optional spring No ----

Rear suspension:

Shock absorber travel 95 mm (3.74 in) ---Spring free length 277.9 mm (10.94 in) ---Spring fitting length 247.9 mm (9.76 in) ---Spring rate (K1) 27 N/mm

(2.75 kg/mm, 153.99 lb/in)

Stroke (K1) 0 ~ 95 mm (0 ~ 3.74 in) ---Optional spring No ----

Rear disc brake:

Type Single ---Disc outside diameter × thickness 220.0 × 3.5 mm (8.66 ~ 0.14 in) ---Pad thickness inner 5.0 mm (0.20 in) 1 mm

Pad thickness outer 5.0 mm (0.20 in) 1 mm

Master cylinder inside diameter 14 mm (0.55 in) ---Caliper cylinder inside diameter 32.03 mm (1.26 in) ---Brake fluid type DOT 4 ----

Brake lever and brake pedal:

Brake lever free play (pivot) front 0 mm (0 in) ----

rear 0.5 ~ 2.0 mm (0.02 ~ 0.08 in) ---Brake pedal height 67 ~ 77 mm (2.64 ~ 3.03 in) ---Throttle lever free play 3 ~ 5 mm (0.12 ~ 0.20 in) ----

SPEC

----

----

(0.04 in)

(0.04 in)

– 4 –

Tightening torques

MAINTENANCE SPECIFICATIONS

SPEC

Part to be tightened

Thread

size

Tightening torque

Remarks

Nm m · kg ft · lb

Rear shock absorber and sub-frame M10 45 4.5 32

Rear shock absorber and rear lower arm M10 45 4.5 32

Rear upper arm and sub-frame M10 45 4.5 32

Rear lower arm and sub-frame M10 45 4.5 32

LS

LS

Rear upper arm and rear knuckle M10 45 4.5 32

Rear lower arm and rear knuckle M10 45 4.5 32

Stabilizer and sub-frame M8 30 3.0 22

Stabilizer joint and stabilizer M10 56 5.6 40

Stabilizer joint and rear lower arm M10 56 5.6 40

Frame and sub-frame (front lower) M12 82 8.2 59

Frame and sub-frame (rear upper) M10 48 4.8 35

Final drive gear case and sub-frame M10 45 4.5 32

Trailer hitch and sub-frame M10 40 4.0 29

Brake disc guard and steering knuckle M6 7 0.7 5.1

Front lower arm and protector M6 7 0.7 5.1

Steering stem, pitman arm and frame M14 190 19.0 140

Fuel tank and frame M6 10 1.0 7.2

Front wheel and wheel hub M10 55 5.5 40

Rear axle and wheel hub M20 260 26.0 190 Stake

Rear knuckle and brake caliper M8 30 3.0 22

Brake disc guard and rear knuckle M6 7 0.7 5.1

Rear brake disc and wheel hub M8 30 3.0 22

LT

Front brake pipe joint and frame M6 7 0.7 5.1

Brake hose holder and steering knuckle M6 7 0.7 5.1

Brake hose holder and front upper arm M6 7 0.7 5.1

Rear brake hose union bolt M10 30 3.0 22

Rear brake pad holding bolt M10 17 1.7 12

LT

Rear brake master cylinder M8 23 2.3 17

Rear brake master cylinder bracket M8 30 3.0 22

Rear brake master cylinder cover M6 7 0.7 5.1

Rear brake pipe nut M10 19 1.9 13

Rear brake pipe joint and frame M6 7 0.7 5.1

Final drive gear case filler bolt M14 23 2.3 17

Final drive gear case drain bolt M14 23 2.3 17

Final drive gear case and bearing housing M10 40 4.0 29

Final drive gear case and bearing housing M8 23 2.3 17

Bearing retainer (final drive pinion gear) M75 115 11.5 85 Left-hand

threads

Universal joint yoke (final drive pinion gear) M14 97 9.7 70

Ring gear stopper M8 16 1.6 11

Air duct assembly 1 and frame M6 7 0.7 5.1

Engine skid plate and frame M6 7 0.7 5.1

Final gear case skid plate and sub-frame M6 7 0.7 5.1

– 5 –

MAINTENANCE SPECIFICATIONS

ELECTRICAL

Item Standard Limit

C.D.I.:

Magneto model/manufacturer F4T464/MITSUBISHI ---Pickup coil resistance/color 459 ~ 561 Ω at 20 °C (68 °F)/

White/Red – White/Green

Rotor rotation direction sensing coil resistance/color

C.D.I. unit model/manufacturer F8T40376/MITSUBISHI ----

0.086 ~ 0.105 Ω at 20 °C (68 °F)/

Red – White/Blue

SPEC

----

----

– 6 –

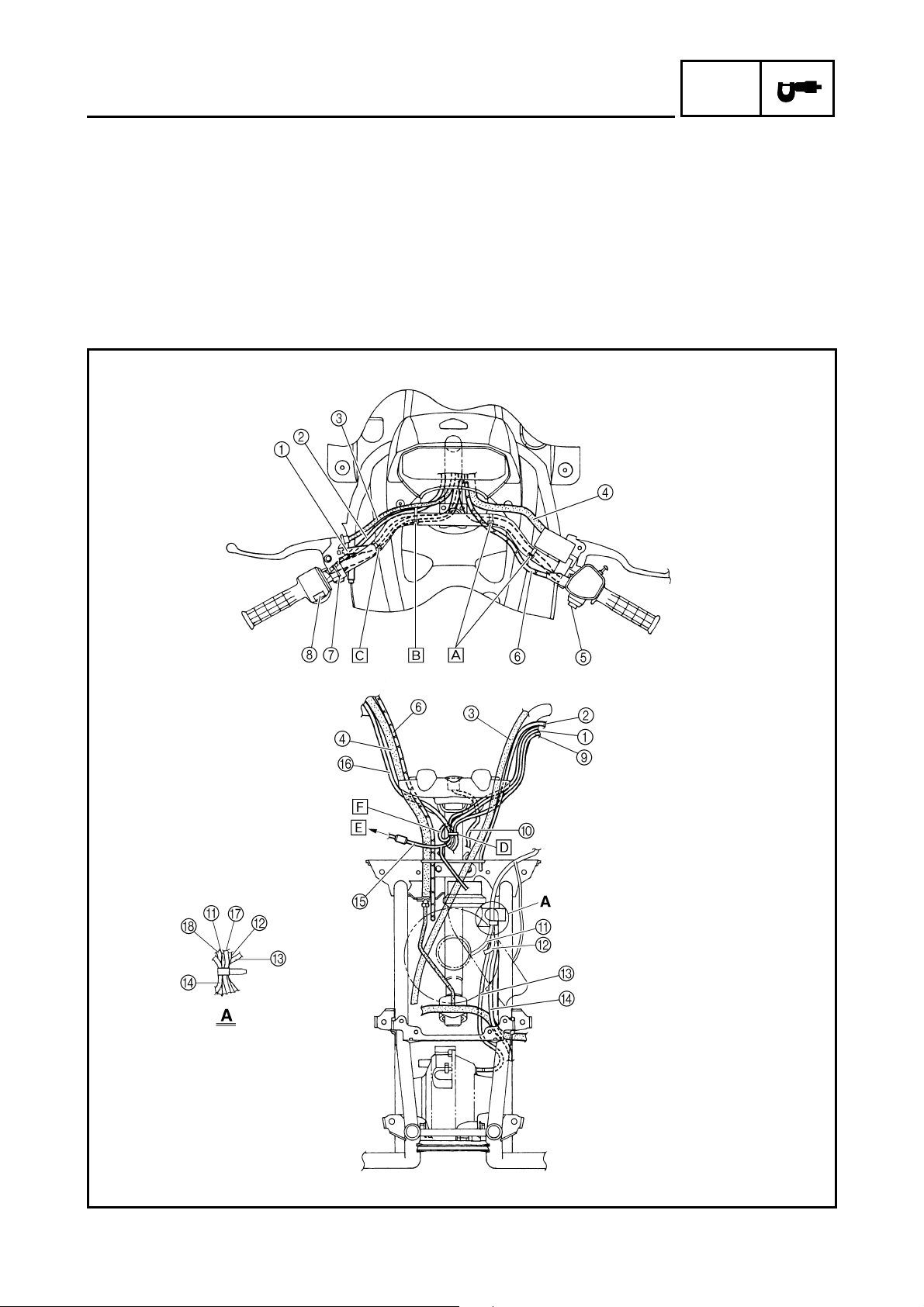

CABLE ROUTING

1 Rear brake switch lead

2 Starter cable

3 Rear brake cable

4 Front brake hose

5 On-command four-wheel drive switch

6 Throttle cable

7 Horn switch (for Oceania)

8 Handlebar switch

9 Handlebar switch lead

CABLE ROUTING

0 Main switch lead

A Fan motor lead

B Fan motor breather hose

C Differential gear case breather hose

D Sub-wire harness

E Horn switch lead (for Oceania)

F On-command four-wheel drive switch lead

G Coolant reservoir hose

H Coolant reservoir breather hose

SPEC

– 7 –

CABLE ROUTING

SPEC

È Fasten the on-command four-wheel drive switch

lead behind the handlebar with the plastic

bands.

É Fasten the starter cable, handlebar switch lead,

rear brake switch lead, and horn switch lead (for

Oceania) behind the handlebar with a plastic

band.

Ê Fasten the handlebar switch lead, rear brake

switch lead, and horn switch lead (for Oceania)

behind the handlebar with a plastic band.

Ë Fasten the handlebar switch lead, rear brake

switch lead, on-command four-wheel drive

switch lead, and horn switch lead (for Oceania)

with a plastic band.

Ì To wire harness

Í Loop the horn switch lead (for Oceania) around

the plastic band as shown.

– 8 –

CABLE ROUTING

SPEC

1 Sub-wire harness

2 Headlight leads

3 Auxiliary DC jack lead

4 Meter light coupler

5 Indicator light assembly couplers

6 Differential gear case breather hose

7 Coolant reservoir breather hose

8 Fan motor breather hose

9 Speedometer cable

È Fasten the wire harness with a plastic band.

É Fasten the auxiliary DC jack lead with a plastic

holder.

– 9 –

CABLE ROUTING

SPEC

1 Starter cable

2 Fuel tank breather hose

3 Cylinder head breather hose

4 Fuel hose

5 Carburetor drain hose

6 Coolant reservoir breather hose

7 Radiator outlet hose

8 Coolant reservoir hose

9 Sub-wire harness

0 Differential gear case breather hose

A Thermo switch (radiator)

B Speedometer cable

C Horn (for Oceania)

– 10 –

È Insert the fuel tank breather hose into the hole of

the handlebar cover.

É Fasten the sub-wire harness and differential

gear case breather hose with a plastic band.

Ê Fasten the sub-wire harness, differential gear

case breather hose, coolant reservoir hose,

coolant reservoir breather hose, fan motor lead

and fan motor breather hose with a plastic band.

Ë 11.5 ~ 12.5 mm (0.45 ~ 0.49 in)

CABLE ROUTING

SPEC

– 11 –

CABLE ROUTING

SPEC

1 Cylinder head breather hose

2 Final drive gear case breather hose

3 Wire harness

4 Starter motor lead

5 Negative battery lead

6 Rear brake hose

7 Rectifier/regulator

8 Air filter case check hose

9 Water pump breather hose

0 Speedometer cable

A Radiator outlet hose

B Starter cable

C Float chamber air vent hose

D Cylinder head breather hose

E Fuel hose

F A.C. magneto lead

G Neutral switch/park switch/reverse switch leads

H Rectifier/regulator lead

I Neutral switch

J Park switch

K Reverse switch

– 12 –

CABLE ROUTING

SPEC

È Fasten the wire harness with a plastic band.

É Fasten the starter motor lead, wire harness,

negative battery lead, final drive gear case

breather hose, rectifier/regulator lead, neutral

switch/park switch/reverse switch leads, and

A.C. magneto lead with a plastic band.

Ê Fasten the wire harness and starter motor lead

with a plastic band.

Ë Fasten the neutral switch/park switch/reverse

switch leads, A.C. magneto lead, rectifier/regulator lead, negative battery lead, and final drive

gear case breather hose with a plastic band.

Ì 10 ~ 30°

Í 35 ~ 45°

– 13 –

CABLE ROUTING

SPEC

1 Throttle cable

2 Radiator inlet hose

3 Spark plug lead

4 Main switch

5 Wire harness

6 Rear brake light switch lead

7 Rear brake fluid reservoir hose

8 Select lever control cable

9 Rear brake cable

0 Rear brake hose

A Rear brake pipe

È Fasten the radiator inlet hose and spark plug

lead with a plastic band.

É Fasten the select lever control cable with a plas-

tic holder.

Ê Fasten the radiator inlet hose with a plastic

holder.

Ë Fasten the select lever control cable and rear

brake light switch lead with the plastic bands.

Ì Fasten the rear brake hose with a plastic holder.

Í 15 ~ 45 mm (0.59 ~ 1.77 in)

– 14 –

CABLE ROUTING

SPEC

1 Final drive gear case breather hose

2 Rectifier/regulator lead

3 Rear brake hose

4 Rear brake pipe

È Fasten the final drive gear case breather hose,

rectifier/regulator lead, and rear brake hose with

a plastic band.

É Fasten the brake pipe with the plastic bands.

Ê Fasten the brake hose with the plastic bands.

– 15 –

1 Front brake hose

2 Float chamber air vent hose

3 Throttle cable

4 Wire harness

5 Final drive gear case breather hose

6 Starter cable

7 Rear brake cable

CABLE ROUTING

SPEC

– 16 –

CABLE ROUTING

SPEC

1 Battery

2 Negative battery lead

3 Tail/brake light lead

4 CDI unit

5 Positive battery lead

È Fasten the negative battery lead with the plastic

holders.

É For CDN

Ê For Oceania

– 17 –

INTRODUCTION/

PERIODIC MAINTENANCE/LUBRICATION

EB300000

CHK

ADJ

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjustments.

These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation

and a longer service life. The need for costly overhaul work will be greatly reduced. This information

applies to vehicles already in service as well as to new vehicles that are being prepared for sale. All

service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION

NOTE:

• For ATVs not equipped with an odometer or an hour meter, follow the month maintenance intervals.

• For ATVs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance

intervals. However, keep in mind that if the ATV isn’t used for a long period of time, the month

maintenance intervals should be followed.

INITIAL EVERY

month136612

km

(mi)

hours 20 75 150 150 300

320

(200)

1,200

(750)

(More often in wet or dusty areas.)

2,400

(1,500)

Every 20–40 hours

2,400

(1,500)

4,800

(3,000)

ITEM ROUTINE

Valves*

Cooling system

Spark plug

Air filter element

Carburetor*

Crankcase breather

system*

Exhaust system*

Fuel line*

Engine oil

Engine oil filter cartridge

Engine oil strainer*

Final gear oil

Differential gear oil

Front brake*

Rear brake*

Select lever safety

system cable*

Whichever

comes first

• Check valve clearance.

• Adjust if necessary.

• Check coolant leakage.

• Repair if necessary.

• Replace coolant every 24 months.

• Check condition.

• Adjust gap and clean.

• Replace if necessary.

• Clean.

• Replace if necessary.

• Check starter (choke).

• Adjust engine idling speed.

• Check breather hose for cracks or damage.

• Replace if necessary.

• Check for leakage.

• Tighten if necessary.

• Replace gasket(s) if necessary.

• Check fuel hose for cracks or damage.

• Replace if necessary.

• Replace. (Warm engine before draining.)

• Replace.

• Clean.

• Check for oil leakage.

• Replace every 12 months.

• Check operation/fluid leakage. (See NOTE page 19.)

• Correct if necessary.

• Check operation/fluid leakage. (See NOTE page 19.)

• Adjust if necessary.

• Check operation.

• Adjust if necessary.

– 18 –

ITEM ROUTINE

V-belt*

Wheels*

Wheel bearing*

Front and rear

suspension*

Steering system*

Rear upper and

lower knuckle pivots*

Drive shaft universal

joint*

Engine mount*

Front and rear axle

boots*

Stabilizer bushes*

Fittings and fasteners*

Lights and switches*

PERIODIC MAINTENANCE/LUBRICATION

INITIAL EVERY

Whichever

comes first

• Check operation.

• Check for cracks or damage.

• Check balance/damage/runout.

• Repair if necessary.

• Check bearing assemblies for looseness/damage.

• Replace if damaged.

• Check operation.

• Correct if necessary.

• Check operation./Replace if damaged.

• Check toe-in./Adjust if necessary.

• Lubricate with lithium-soap-based grease.

• Lubricate with lithium-soap-based grease.

• Check for cracks or damage.

• Check operation.

• Replace if damaged.

• Check for cracks or damage.

• Check all chassis fittings and fasteners.

• Correct if necessary.

• Check operation.

• Adjust headlight beams.

month136612

km

(mi)

hours 20 75 150 150 300

320

(200)

1,200

(750)

CHK

ADJ

2,400

(1,500)

2,400

(1,500)

4,800

(3,000)

* Since these items require special tools, data and technical skills, have a Yamaha dealer perform the ser-

vice.

NOTE:

• Recommended brake fluid: DOT 4

• Brake fluid replacement:

1. When disassembling the master cylinder or caliper, replace the brake fluid. Normally check the

brake fluid level and add fluid as required.

2. On the inner parts of the master cylinder and caliper, replace the oil seals every two years.

3. Replace the brake hoses every four years, or if cracked or damaged.

WARNING

Indicates a potential hazard that could result in serious injury or death.

– 19 –

SEAT, CARRIERS, FENDERS AND FUEL TANK

SEAT, CARRIERS, FENDERS AND FUEL TANK

FRONT CARRIER, FRONT BUMPER AND FRONT FENDER

CHK

ADJ

Order Job/Part Q’ty Remarks

Removing the front carrier, front

bumper and front fender

Seat and fuel tank side panels Refer to “SEAT AND SIDE PANELS” in

1 Front carrier 1

2 Front fender panel 1

3 Engine skid plate 1

4 Front bumper 1

5 Front bumper cover 2

6 Headlight coupler 2 Disconnect.

7 Main switch coupler 1 Disconnect.

8 Handlebar cover 1

9 Fuel tank cover 1

Remove the parts in the order below.

chapter 3. (Manual No.: 5TE2-AE1)

– 20 –

SEAT, CARRIERS, FENDERS AND FUEL TANK

CHK

ADJ

Order Job/Part Q’ty Remarks

10 Auxiliary DC jack connector 2 Disconnect.

11 Indicator light assembly coupler/meter

light coupler

12 Sub-wire harness 1 coupler 1 Disconnect.

13 Speedometer cable 1 Disconnect.

14 Fan motor breather hose 1

15 Coolant reservoir breather hose 1

16 Differential gear case breather hose 1

17 Front fender 1

3 Disconnect.

For installation, reverse the removal procedure.

– 21 –

ADJUSTING THE REAR BRAKE

CHASSIS

ADJUSTING THE REAR BRAKE

WARNING

Always adjust both the brake pedal and the

rear brake lever whenever adjusting the

rear brake.

1. Check:

• rear brake lever free play a

Out of specification → Adjust.

Rear brake lever free play

0.5 ~ 2.0 mm (0.02 ~ 0.08 in)

CHK

ADJ

2. Check:

• rear brake pedal height a

Out of specification → Adjust.

Rear brake pedal height

67 ~ 77 mm (2.64 ~ 3.03 in)

Brake pedal

1

Footrest bracket

2

3. Adjust:

• rear brake lever free play

• rear brake pedal height

▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

a. Loosen the locknut (handlebar) 1 and fully

screw in the brake lever cable adjuster (handlebar) 2.

b. Remove the rear brake master cylinder

cover 3.

– 22 –

Loading...

Loading...