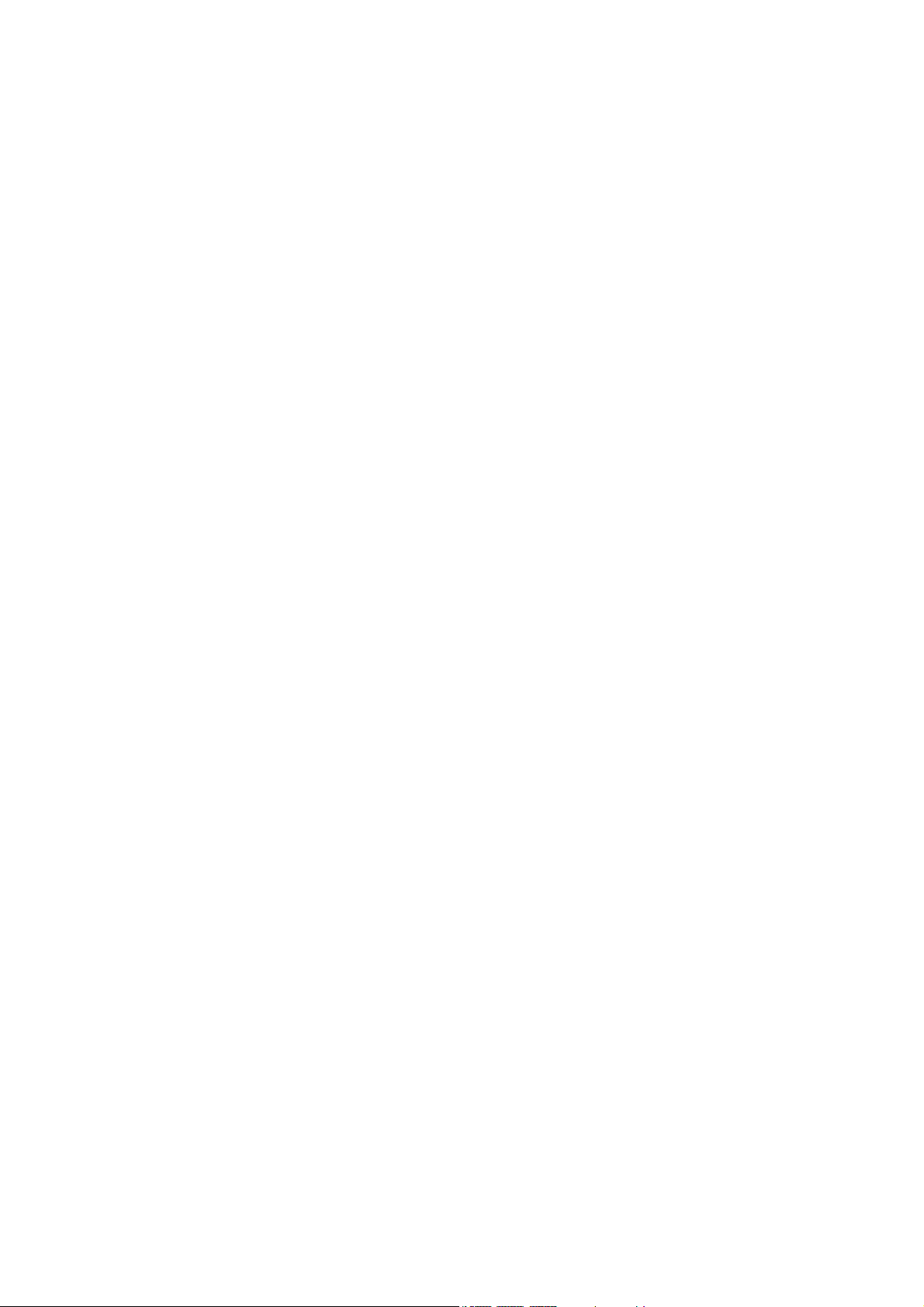

Yamaha XZ550RJ SERVICE MANUAL

YAMAHA

XZ550RJ

SERVICE MANUAL

11H-28197-10

1

FEATURES

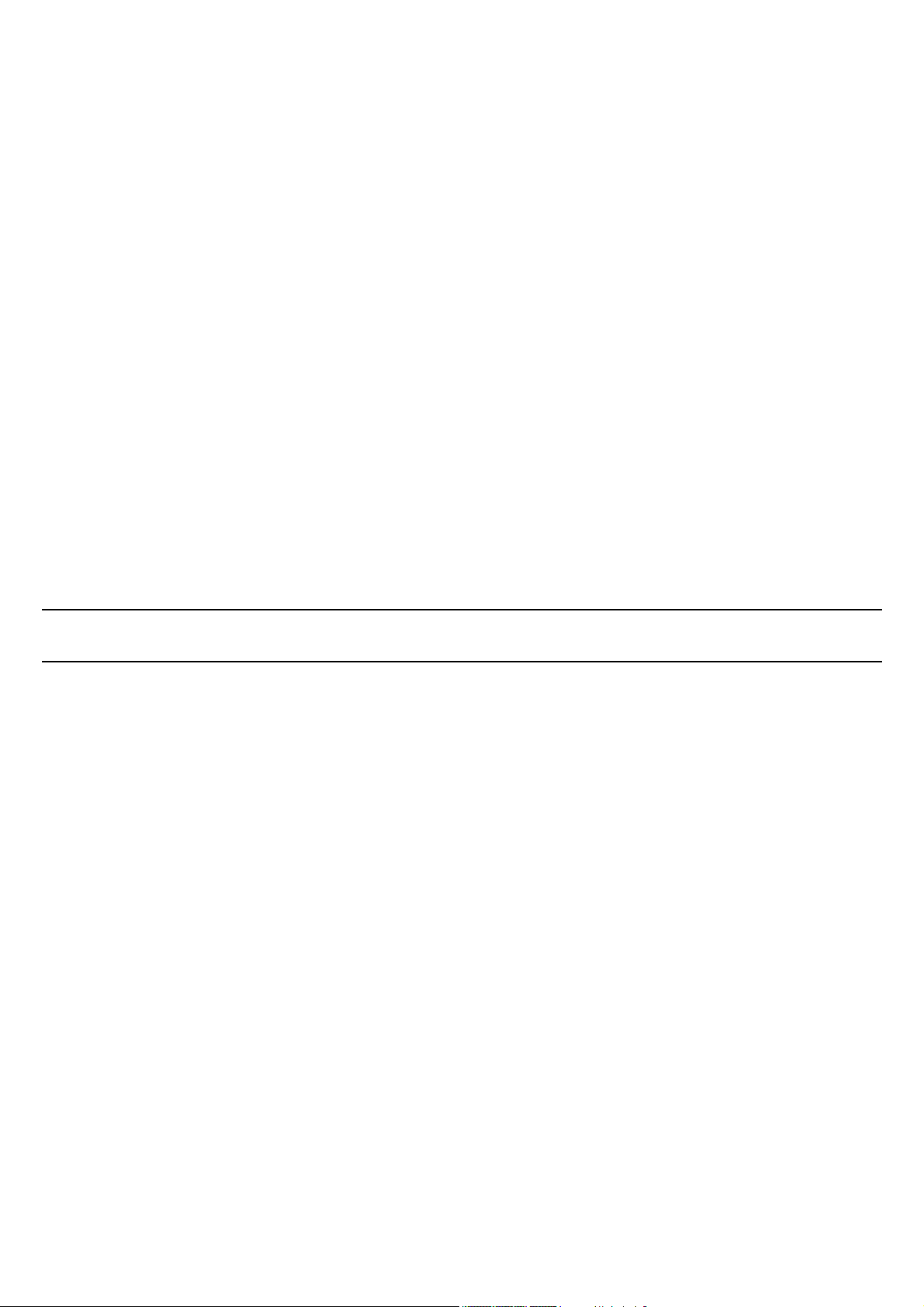

XZ550RJ

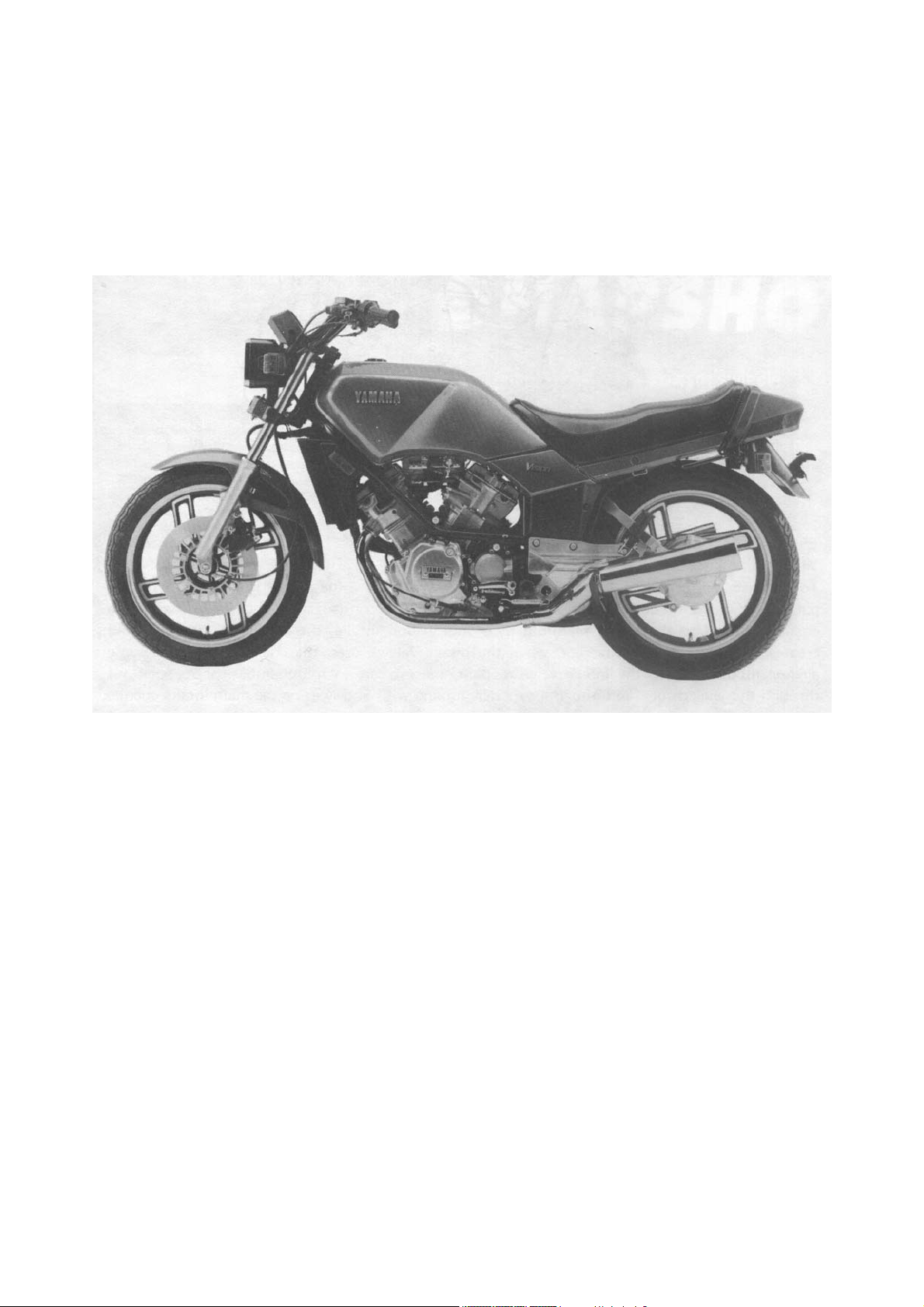

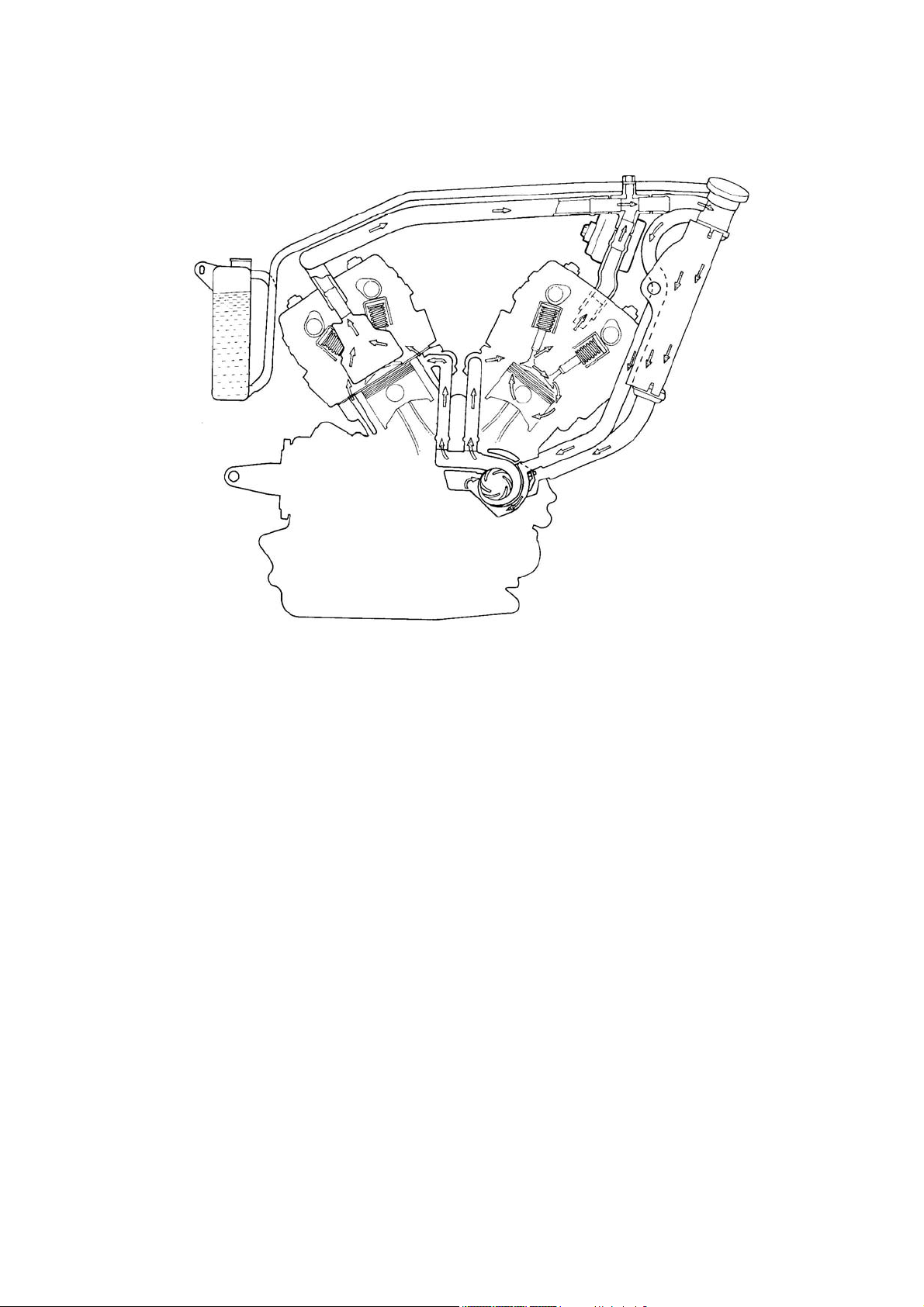

Liquid-cooled V-Twin

The 70° V-Twin engine is liquid-cooled to maintain the best operating temperature range. The cooling system

features an aluminum-corrugate radiator which is extremely light and exhibits excellent heat-dissipating characteristics. An automatically activated electric fan pulls air through the radiator in heavy-traffic situations. The

system has an automotive-type expansion and recovery tank which makes airspace in the radiator unnecessary and virtually eliminates coolant loss on even the hottest days. A thermostatic valve mounted in the engine

block provides quick warmups and stable coolant temperature.

2

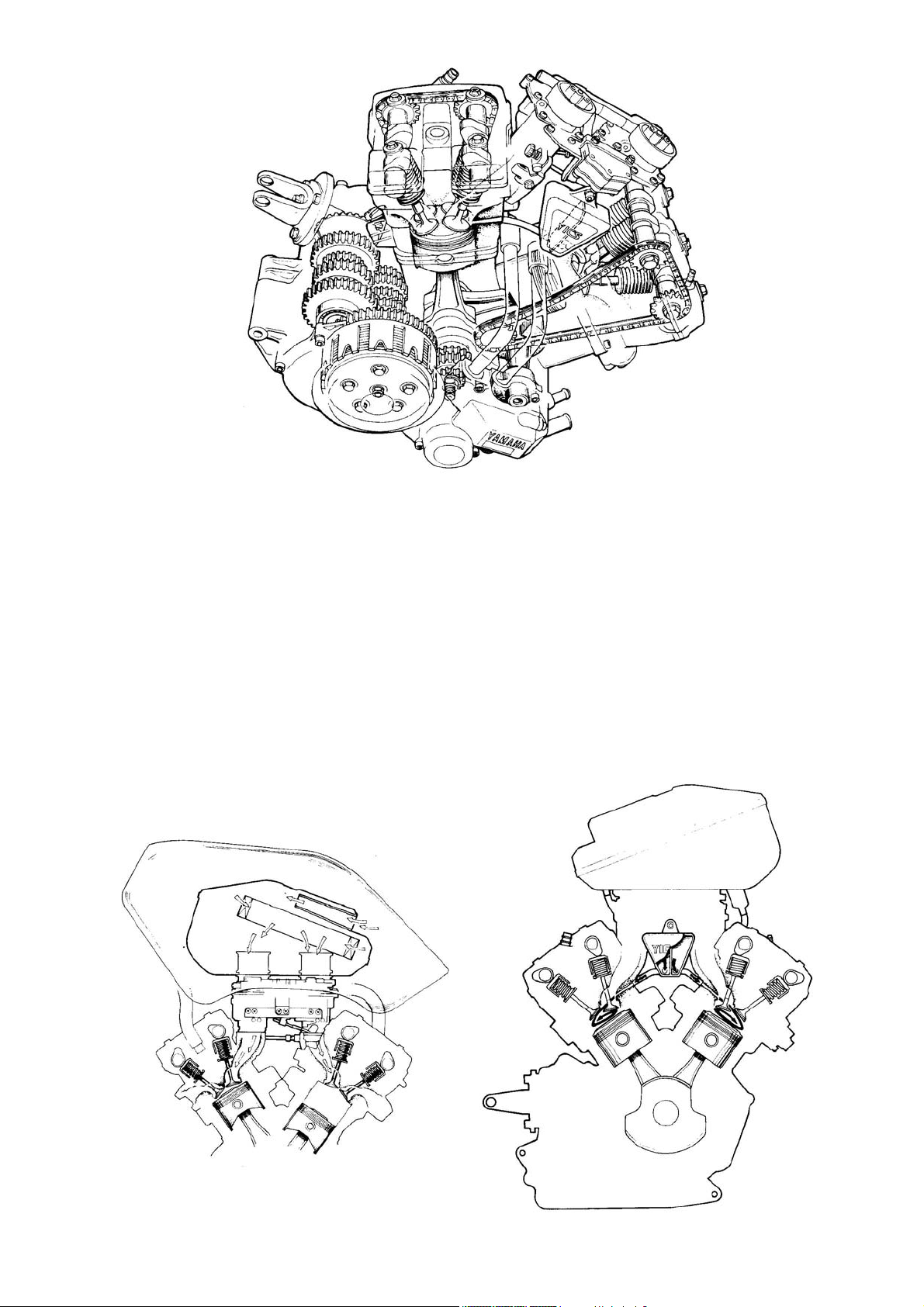

YICS

To increase fuel economy through more efficient combustion, the engine is equipped with the patented Yamaha Induction Control System (YICS). In this configuration, the YICS consists of a chamber linked to the intake manifold by a tube. Upon intake, the vacuum in the manifold creates a vacuum in the chamber; when the

intake valve closes, the chamber draws in some air-fuel mixture. When the intake valve reopens, the mixture

in the chamber shoots back out through the angled tube and into the cylinder, mixing with and swirling the

main intake charge. The swirling charge is then compressed and ignited, burning more completely and producing more power than that of a conventional engine.

INTAKE SYSTEM AND YICS

3

LIQUID COOLING SYSTEM

Downdraft carb

The induction system on this motorcycle features downdraft carburetion. The 34 mm (1.34 in) Venturis are

positioned so that the incoming air takes a virtually straight path through the carbs and the intake manifolds to

the combustion chambers; intake efficiency is remarkably high. An accelerator pump is installed in the carburetor assembly to eliminate hesitation when the throttle is opened at low engine speeds. A fuel pump delivers

gas from the tank to the float bowls, and a regulator sends excess fuel through a circuit back to the fuel pump

inlet.

DOHC 4-valve heads

Each cylinder head has dual overhead camshafts, and each camshaft acts directly on top of the valves; there

are no pushrods or rocker arms. Both heads have four valves, two intake and two exhaust, instead of one intake and one exhaust valve. By using two slightly smaller valves in place of each large valve, port area is significantly increased. This provides a much greater volume of mixture and exhaust flow. In addition, the smaller,

lighter valves are easier to control at high engine speeds; the valves can follow the cam profiles more closely

to resist "floating" and allow a 9,500 r/min red line.

4

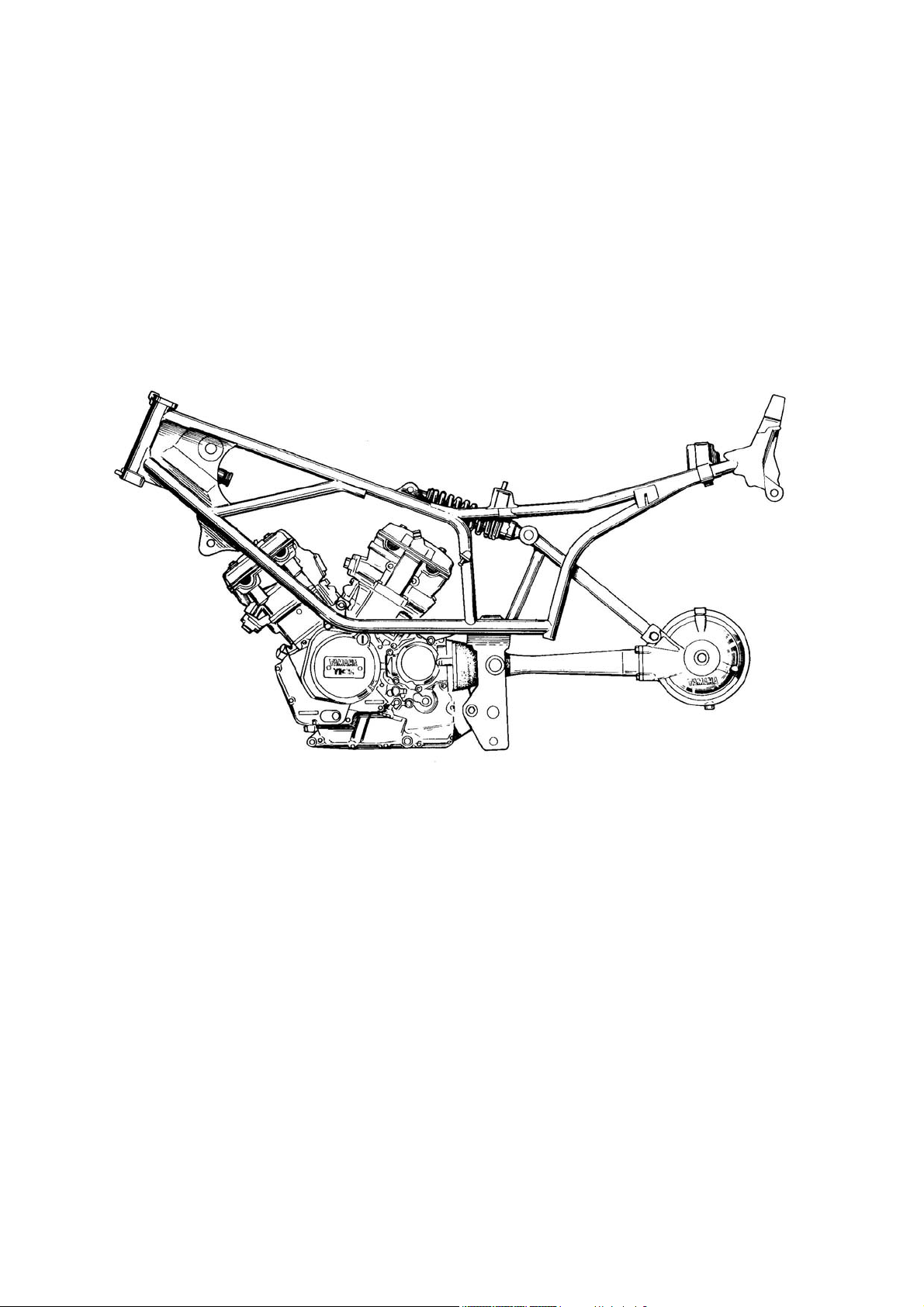

Chassis bits

The "hang-support" frame on this motorcycle allows a lower engine placement and center of gravity while providing excellent rigidity for precise handling. Cornering clearance is also enhanced. The trailing-axle front suspension performs superbly. The axle placement helps to maintain a short wheelbase, allowing quick, sporty

handling. Yamaha's proven Monoshock rear suspension provides the excellent handling and comfort characteristics for which it is famous. The spring preload is adjustable to five settings.

FRAME AND MONOCROSS SUSPENSION SYSTEM

5

NOTICE

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to put an entire mechanic's education into one manual, so it is assumed that

persons using this book to perform maintenance and repairs on Yamaha motorcycles have a hasic understanding of the mechanical concepts and procedures inherent to motorcycle repair technology. Without such

knowledge, attempted repairs or service to this model may render it unfit to use and/or unsafe.

This model has been designed and manufactured to perform within certain specifications in regard to performance and emissions. Proper service with the correct tools is necessary to ensure that the motorcycle will operate as designed. If there is any question about a service procedure, it is imperative that you contact a Yamaha

dealer for any service information changes that apply to this model. This policy is intended to provide the customer with the most satisfaction from his motorcycle and to conform with federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by Yamaha. Modifications and significant changes in specifications or procedures will be forwarded to all Authorized Yamaha dealers and will, where applicable, appear in future editions of this manual.

NOTE:

This Service Manual contains information regarding periodic maintenance to the emission control system for

the XZ550RJ. Please read this material carefully.

Particularly important information is distinguished in this manual by the following notations:

NOTE: A NOTE provides key information to make procedures easier or clearer.

CAUTION: A CAUTION indicates special procedures that must be followed to avoid damage to the motorcy-

cle.

WARNING: A WARNING indicates special procedures that must be followed to avoid injury to a motorcycle

operator or person inspecting or repairing the motorcycle.

SERVICE DEPT.

INTERNATIONAL DIVISION

YAMAHA MOTOR CO., LTD.

6

CHAPTER 1. GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION………………………………………………………………………………..... 8

Frame serial number……………………………………………………………………………………….. 8

Engine serial number………………………………………………………………………………………. 8

Vehicle identification number…………………………………………………………………………….. 8

SPECIAL TOOLS……………………………………………………………………………………………………... 9

For tune-up…………………………………………………………………………………………………… 9

For engine service………………………………………………………………………………………….. 9

For chassis service…………………………………………………………………………………………. 12

For middle gear service……………………………………………………………………………………. 12

For shaft drive service……………………………………………………………………………………... 13

For electrical components………………………………………………………………………………… 13

7

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

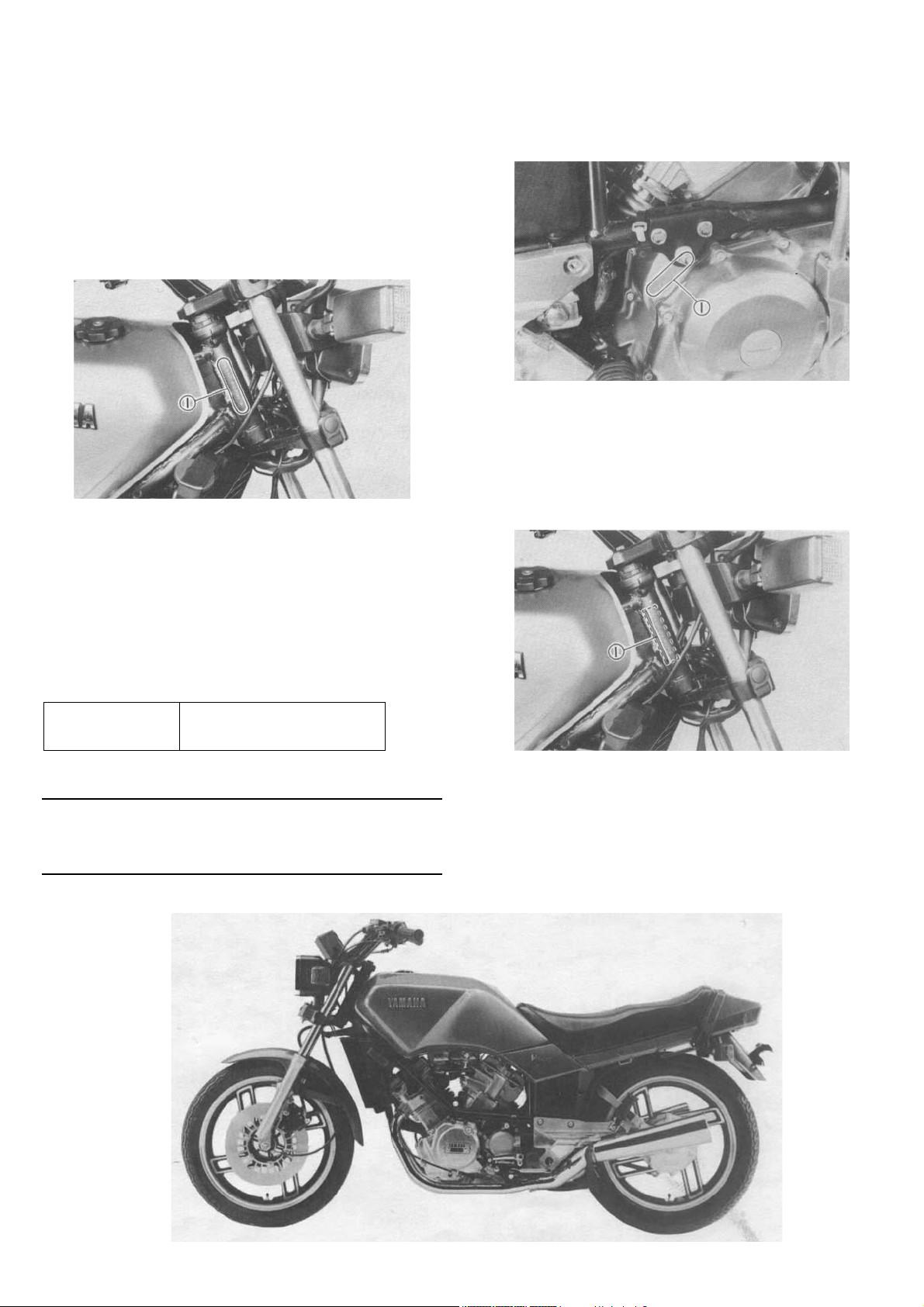

Frame serial number

The frame serial number is stamped into the right

side of the steering head pipe.

1. Frame serial number

Engine serial number The engine serial number is stamped into the elevated part of the right rear section of the engine.

Starting serial number:

XZ550RJ

11H-000101

NOTE

The first three digits of these numbers are for model

identification; the remaining digits are the unit production number.

1. Engine serial number

Vehicle identification number The vehicle identification number is on the left side of the steering head pipe.

1. Vehicle identification number

8

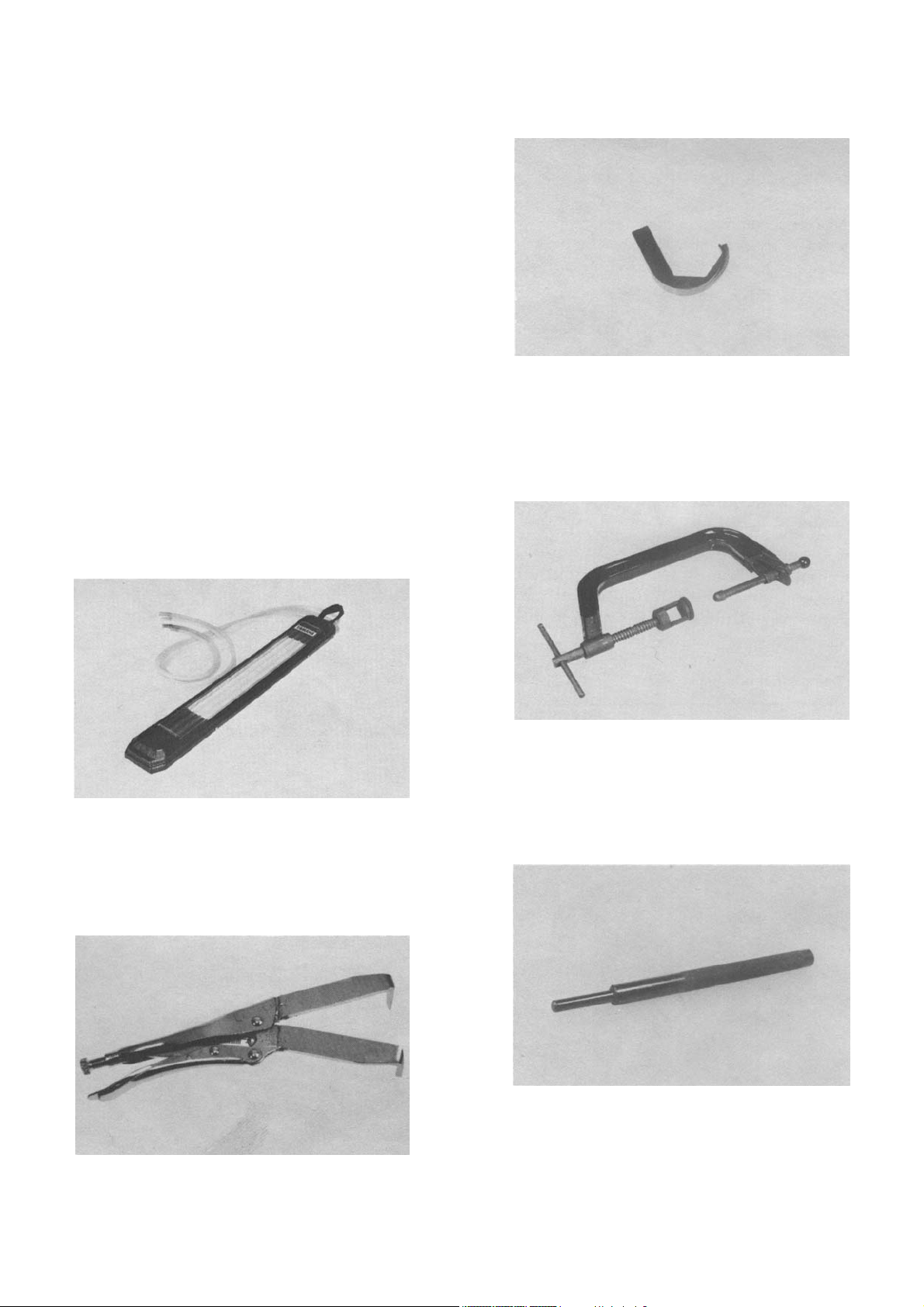

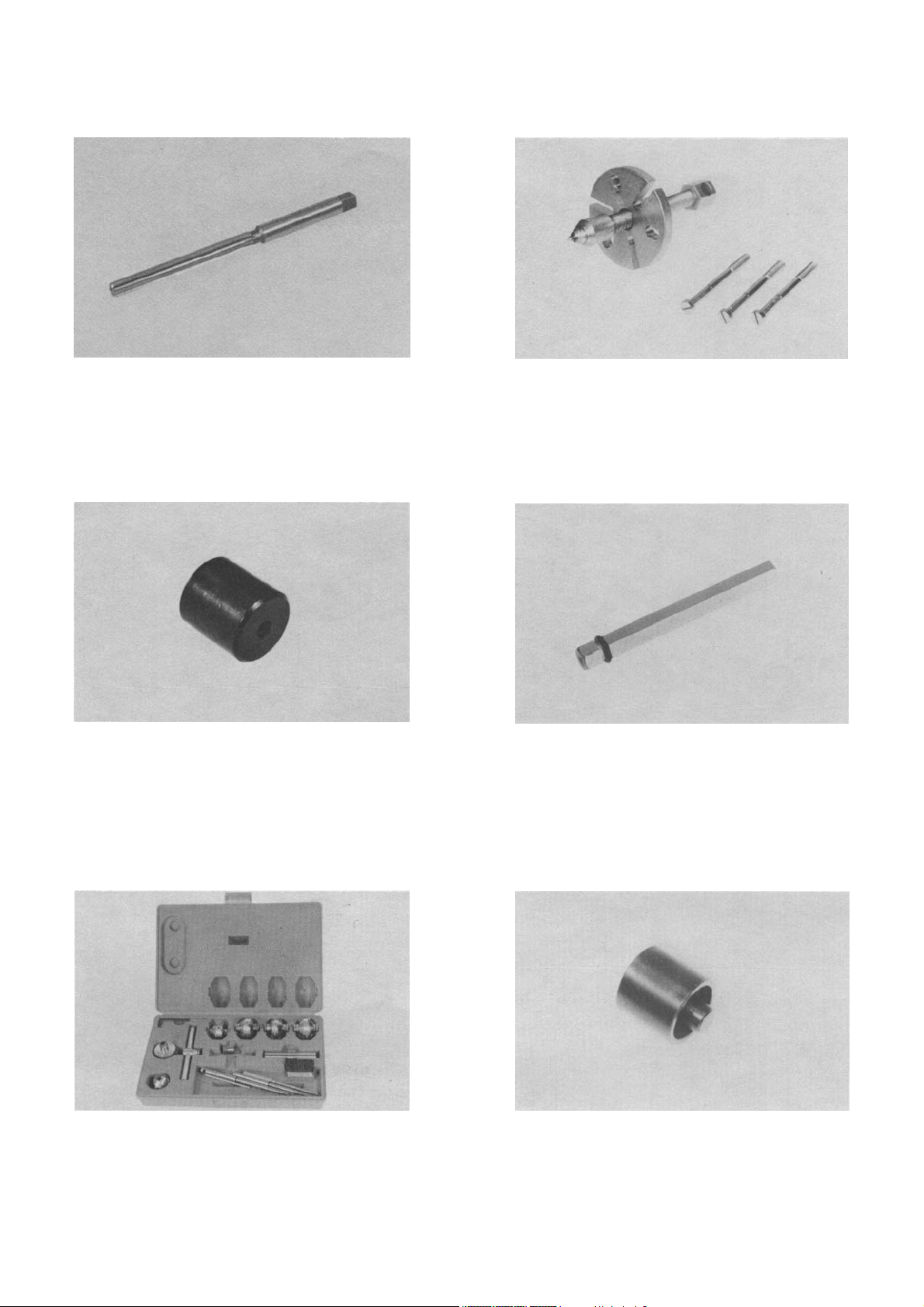

SPECIAL TOOLS The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques.

For tune-up Inductive tachometer (P/N YU-08036)

Inductive timing light (P/N YU-08037)

Fuel level gauge (P/N YM-01312)

Cooling system tester (P/N YU-24460)

Compression gauge (P/N YU-33223)

Compression gauge

12 mm (0.47 in) adapter (P/N YU-33223-3)

Vacuum gauge (P/N YU-08030)

Tappet adjusting tool (P/N YM-28899)

This tool is necessary to replace valve adjusting

pads.

Valve spring compressor

(P/N YM-04019)

This gauge is needed for carburetor synchronization

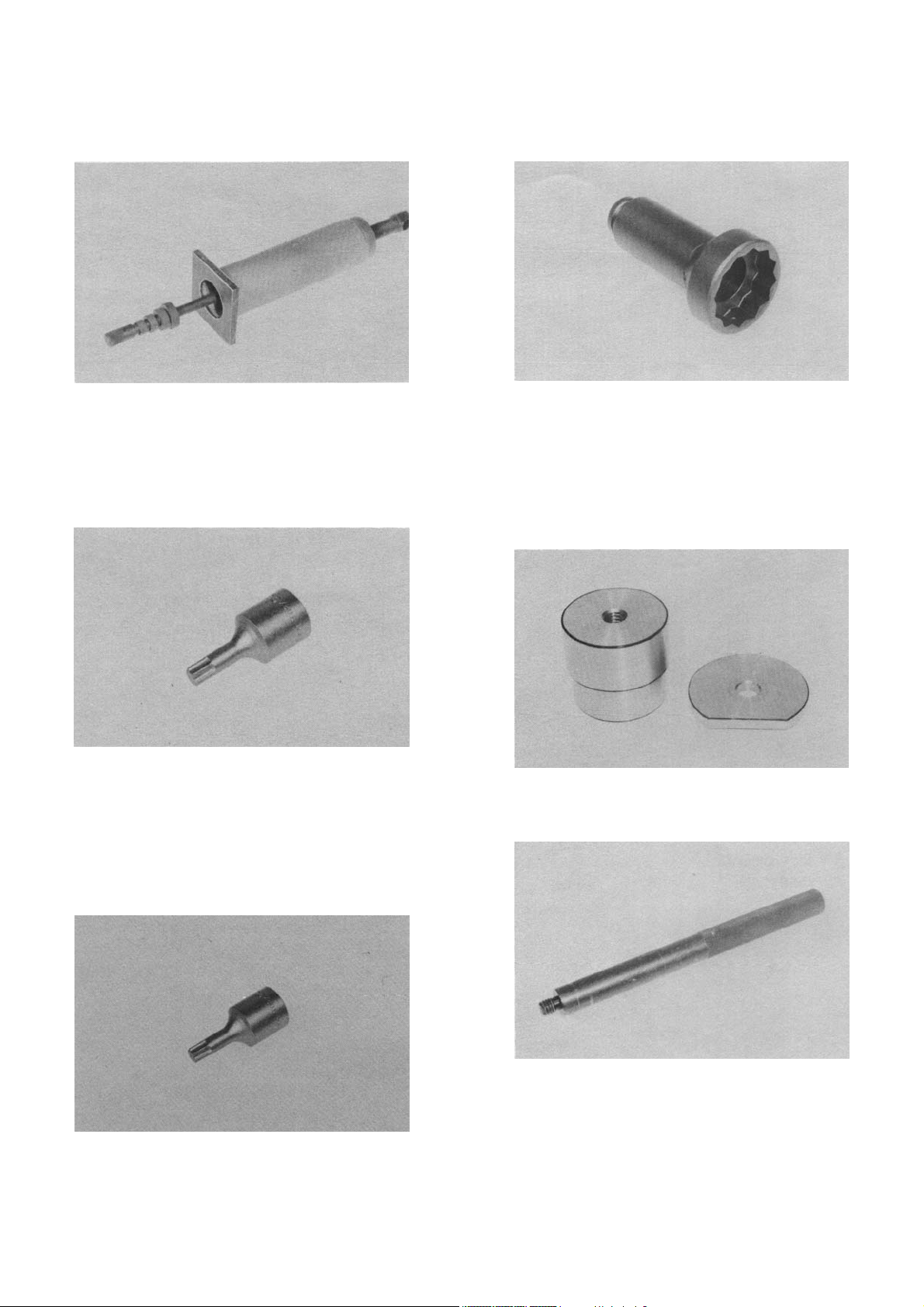

For engine service

Universal clutch holder

(P/N YM-91042)

This tool is used to hold the clutch when removing

or installing the clutch boss locknut

This tool must be used for removing and installing

the valve assemblies

Vavle guide remover

(P/N YM-04064)

This must be used to remove the valve guides

9

Valve guide reamer

(P/N YM-04066)

Flywheel puller

(P/N YU-33270)

This must be used when replacing the valve guide.

Valve guide installer

(P/N YM-04065)

This tool is needed for proper installation of the

valve guides.

Valve seat cutter set

(P/N YM-91043)

This tool is used for removing the flywheel

8mm (0,3 in) wrench adapter

(P/N YM-28897)

This tool is used to loosen or tighten the cylinder

head securing nut.

Water pump seal installer

(P/N YM-33221)

This tool is needed to resurface the valve seat.

This tool is needed for proper installation of the water pump seal.

10

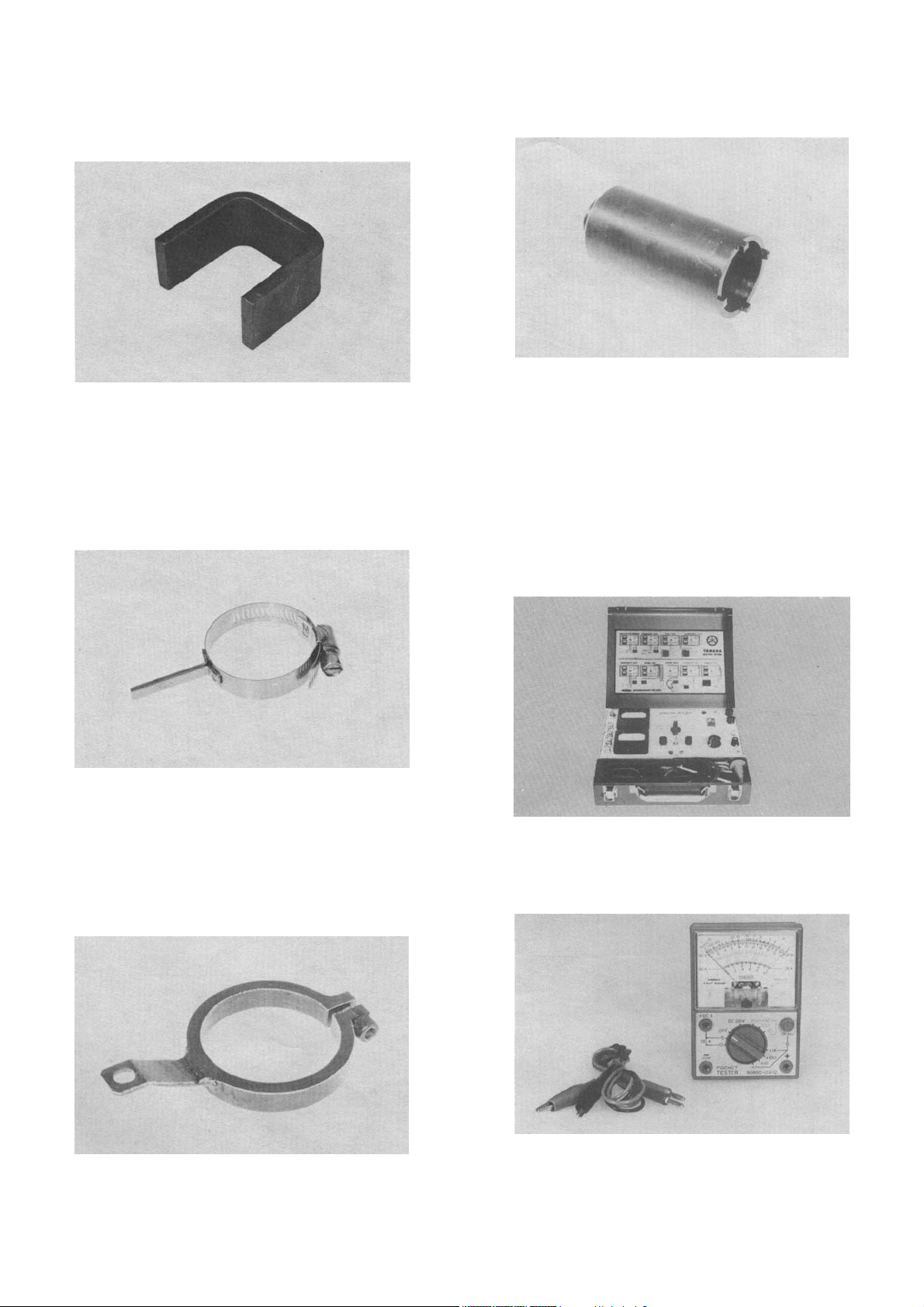

Piston pin puller

(P/N YU-01304)

46 mm (1.8 in) offset wrench

(P/N YM-04045A)

This tool is used to remove the piston pin.

#30 Torx driver

(P/N YU-29843-6)

This tool is used to loosen or tighten the drive axle

bearing stopper bolt

#25 Torx driver

(P/N YU-29843-4)

This tool is used to loosen and tighten the primary

drive gear/balancer drive gear securing nut.

Plain bearing driver/installer

(P/N YM-28898)

Handle (P/N YM-04058-1)

This tool is used to loosen or tighten the shift cam

segment securing bolt

These tools are used for removing and installing the

crankshaft plain bearing.

11

Plastigauge set “Green”

(P/N YU-33210)

This gauge is needed when measuring clearance

for connecting rod bearing.

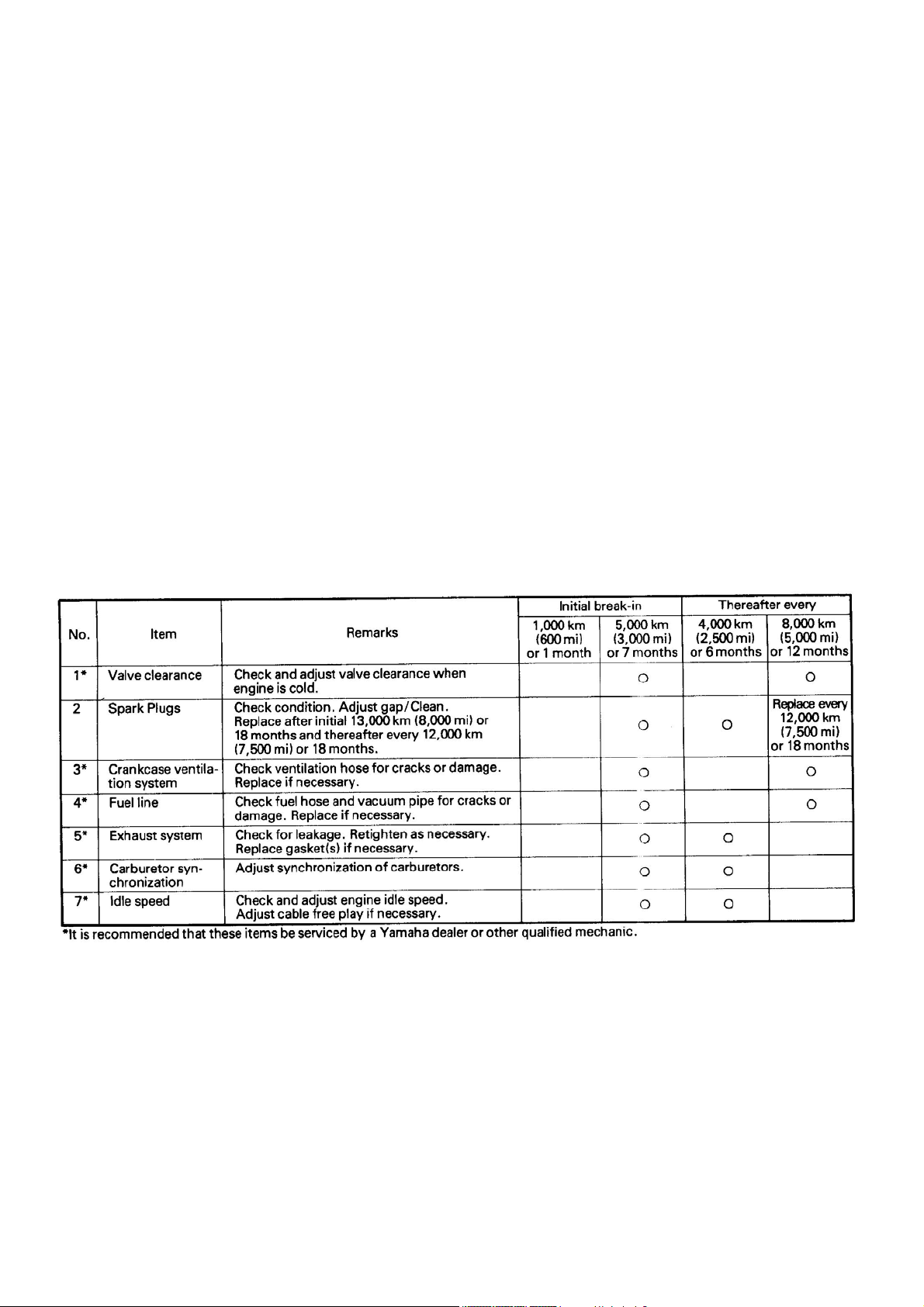

For chassis service

T-handle (P/N YU-01268) and damper rod holder

(P/N YM-33256)

For middle gear service

Universal joint holder

(P/N YM-04062)

This tool is used when adjusting gear lash, in the

middle gear.

Middle drive gear holder

(P/N YM-33222)

This tool is used to loosen and tighten the fron fork

cylinder holding bolt

Front fork cap socket (19mm) (0.75 in))

(P/N YM-01298)

This tool is needed when loosening and tightening

the front fork cap bolt

This tool is needed when measuring gear back lash.

Dial indicator

(P/N YU-03097)

These tools are used when measuring gear lash for

middle gear.

12

For shaft drive service

Damper spring compressor

(P/N YM-04011)

This tool is needed to disassemble and reassemble

the middle gear damper.

Final drive gear lash tool

(P/N YM-01230)

Bearing retainer wrench

(P/N YM-33214)

This tool is used to loosen or tighten the bearing

retainer.

For electrical components

The uses of these tools are described in Chapter 6.

Electro tester

(P/N YU-03021)

This tool is needed when measuring gear lash for

final gear.

Ring gear holder

(P/N YM-01254)

This tool is needed when measuring gear lash.

Pocket tester

(P/N YU-03112)

13

CHAPTER 2.

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION…………………………………………………………………………………………………….. 15

MAINTENANCE INTERVALS CHARTS…………………………………………………………………………. 15

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM………………………………………………… 15

GENERAL MAINTENANCE/LUBRICATION……………………………………………………………………. 16

ENGINE………………………………………………………………………………………………………………. 17

Valve clearance adjustment………………………………………………………………………………… 17

Spark plug……………………………………………………………………………………………………… 23

Crankcase ventilation system……………………………………………………………………………… 23

Fuel line………………………………………………………………………………………………………… 23

Exhaust system………………………………………………………………………………………………. 23

Carburetor synchronization………………………………………………………………………………… 23

Idle speed……………………………………………………………………………………………………… 24

Engine oil………………………………………………………………………………………………………. 24

Coolant…………………………………………………………………………………………………………. 25

Clutch adjustment……………………………………………………………………………………………. 26

Checking ignition timing……………………………………………………………………………………. 27

Compression pressure measurement……………………………………………………………………. 27

CHASSIS…………………………………………………………………………………………………………….. 28

Final gear oil…………………………………………………………………………………………………… 28

Air filter…………………………………………………………………………………………………………. 28

Front and rear brake…………………………………………………………………………………………. 29

Brake light switch adjustment……………………………………………………………………………… 30

Front brake pad……………………………………………………………………………………………….. 30

Rear brake shoe………………………………………………………………………………………………. 31

Brake fluid……………………………………………………………………………………………………… 31

Cable inspection and lubrication………………………………………………………………………….. 31

Brake and change pedals/brake and clutch levers…………………………………………………….. 31

Centerstand and sidestand.................................………………………………………………………… 31

Front fork oil change………………………………………………………………………………………… 32

Rear shock absorber adjustment…………………………………………………………………………. 33

Steering head adjustment………………………………………………………………………………….. 33

Wheel bearings………………………………………………………………………………………………. 33

Front wheel……………………………………………………………………………………………………. 34

Rear wheel…………………………………………………………………………………………………….. 34

Fuel cock………………………………………………………………………………………………………. 34

Tubeless tires and aluminum wheels…………………………………………………………………….. 35

ELECTRICAL……………………………………………………………………………………………………….. 35

Battery………………………………………………………………………………………………………….. 35

Headlight……………………………………………………………………………………………………….. 36

Fuse……………………………………………………………………………………………………………... 37

14

INTRODUCTION

This chapter includes all information necessary to

perform recommended inspections and adjustments. These preventive maintenance procedures,

if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly

overhaul work will be greatly reduced. This information applies to vehicles already in service and to

new vehicles that are being prepared for sale. All

service technicians should be familiar with this entire chapter.

PERIODIC INSPECTIONS AND ADJUSTMENTS

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

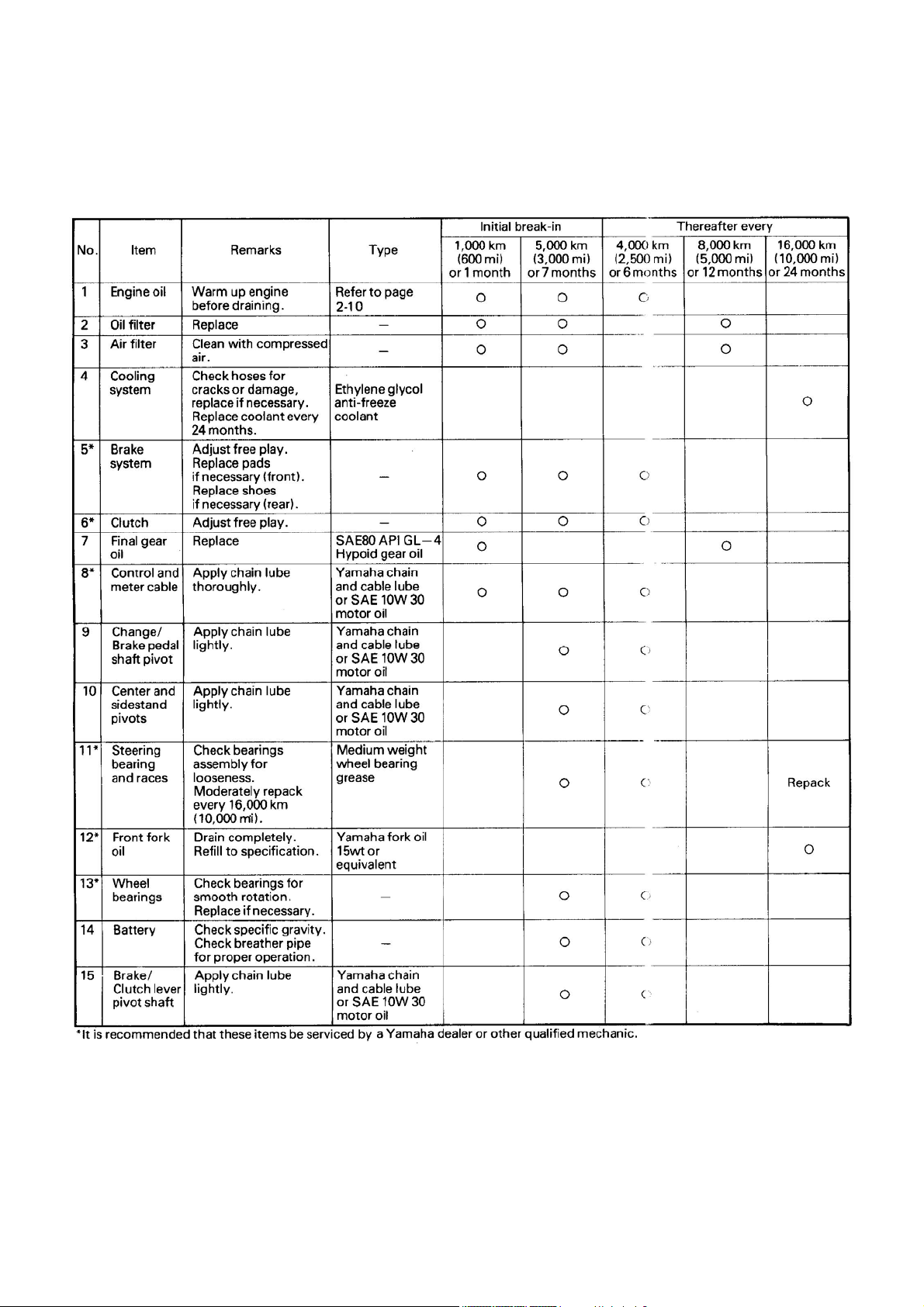

MAINTENANCE INTERVALS CHARTS

Proper periodic maintenance is important. Especially important are the maintenance services related to emissions control. These controls not only

function to ensure cleaner air but are also vital to

proper engine operation and maximum performance. In the following maintenance tables, the services related to emissions control are grouped separately.

15

GENERAL MAINTENANCE/LUBRICATION

16

ENGINE

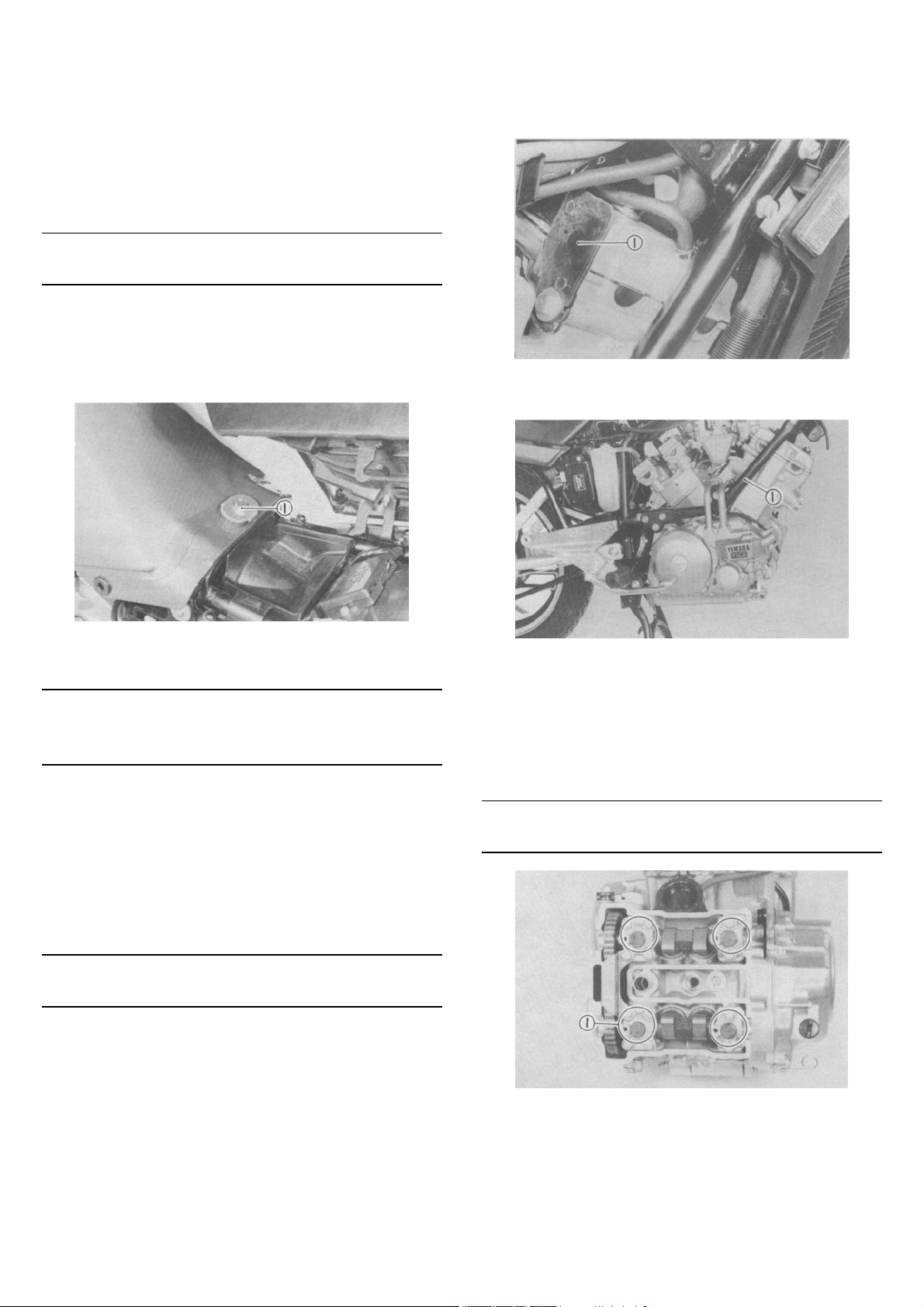

Valve clearance adjustment

Adjust the valve clearance as follows:

NOTE:

Valve clearance must be measured when the engine is cool to the touch.

1. Remove the seat, and remove the side covers, fuel tank, air filter assembly, and crankcase ventilation pipes.

1. Air baffle plate

1. Fuel tank holding bolt

CAUTION:

After removing the air filter assembly, cover the

carburetors with a clean rag to prevent dust or

any foreign materials from entering.

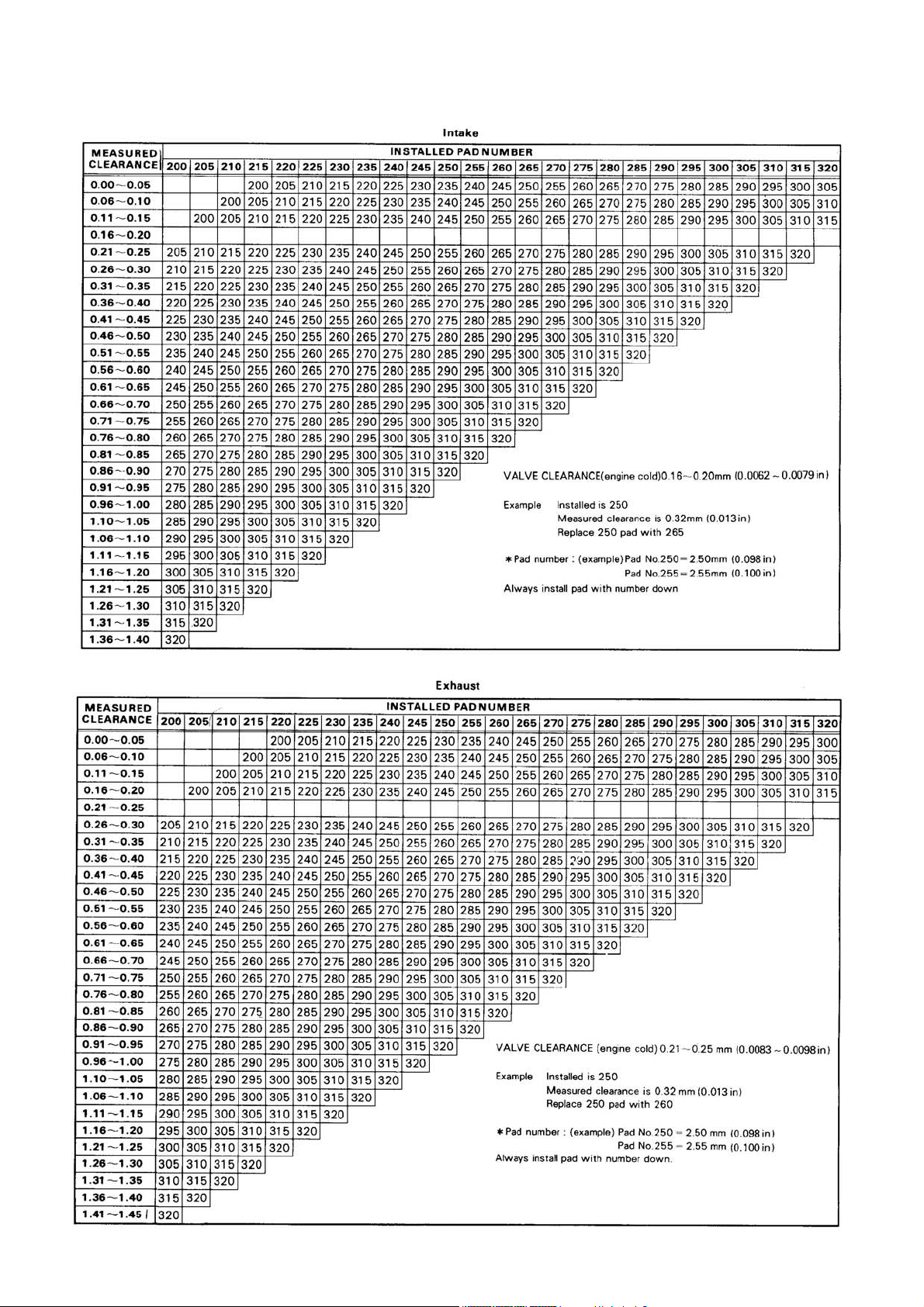

2. Remove the radiator cover and the radiator

securing bolts. Gently and firmly push the

left side of the radiator assembly towards the

front wheel. The right side of the radiator and

connected pipes should remain in place.

NOTE:

It is not necessary to completely remove the radiator

from the motorcycle.

3. Remove the air baffle plate from behind the

front cylinder and remove the right side

frame tube.

1. Down tube frame

4. Disconnect the spark plug cap from each

cylinder head.

5. Remove the cylinder head covers.

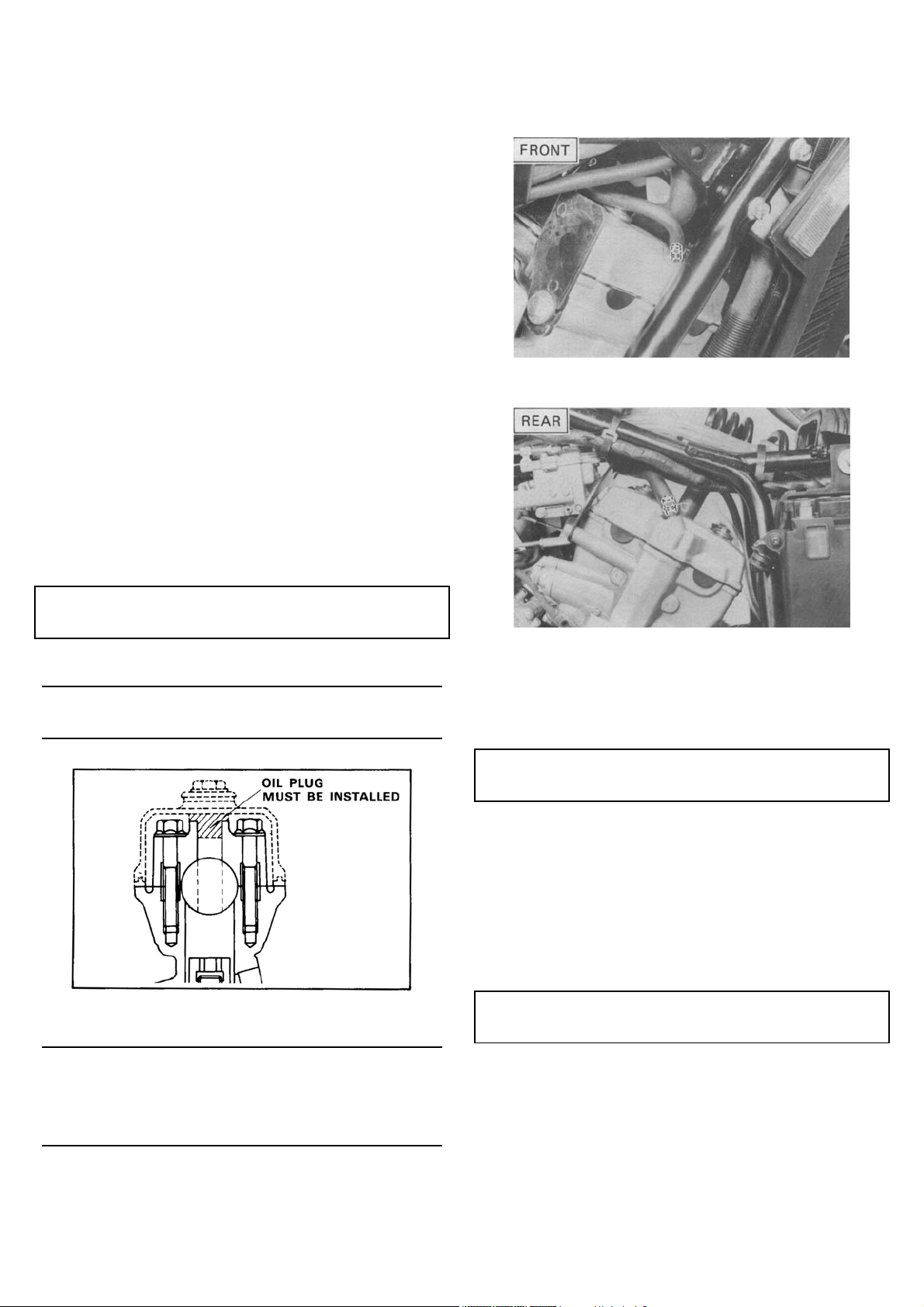

NOTE:

Be careful so that the oil plugs on the camshaft caps

are not lost.

1. Oil plug

6. Remove the emblem plate and timing plug

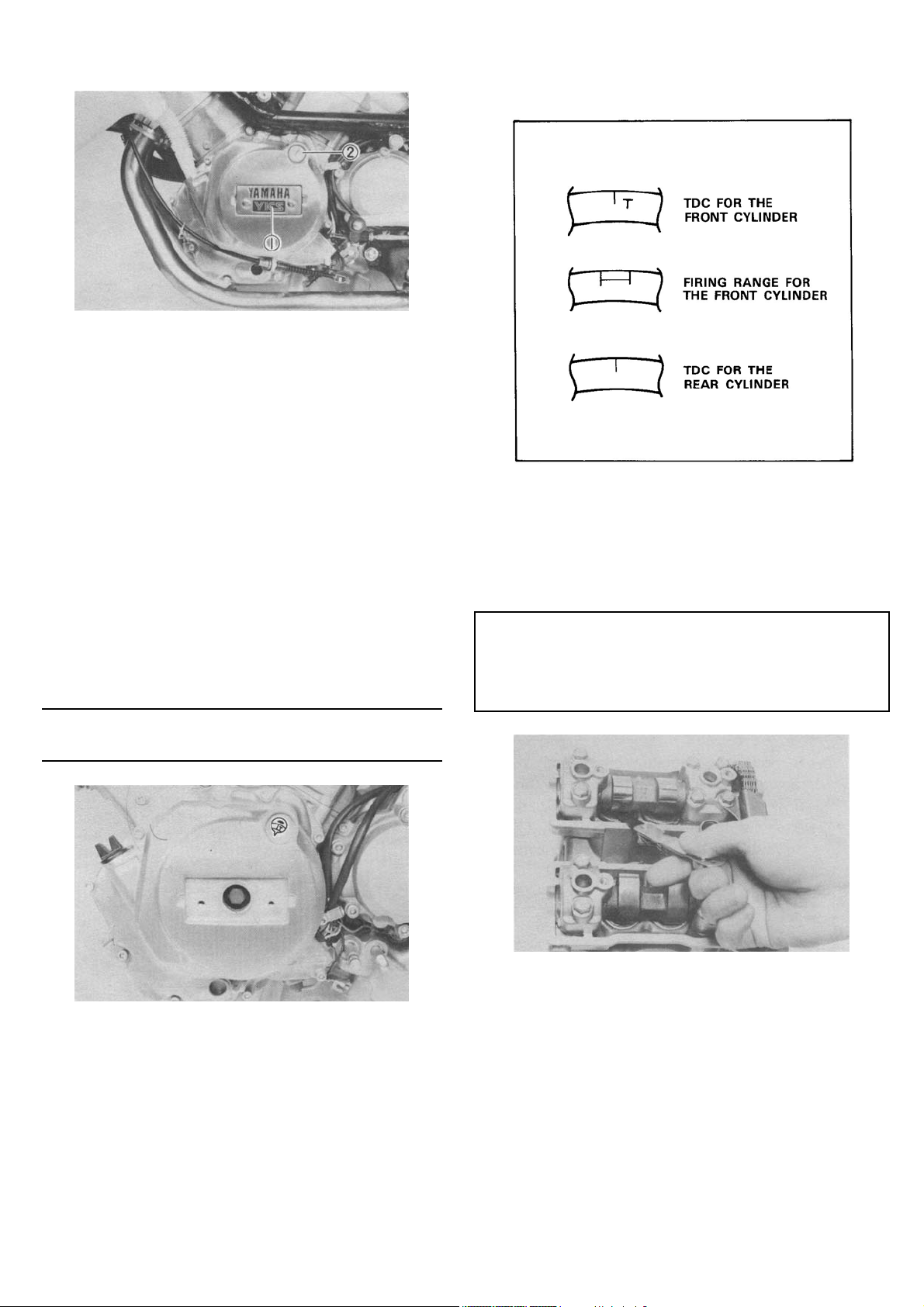

from the left-side crankcase.

17

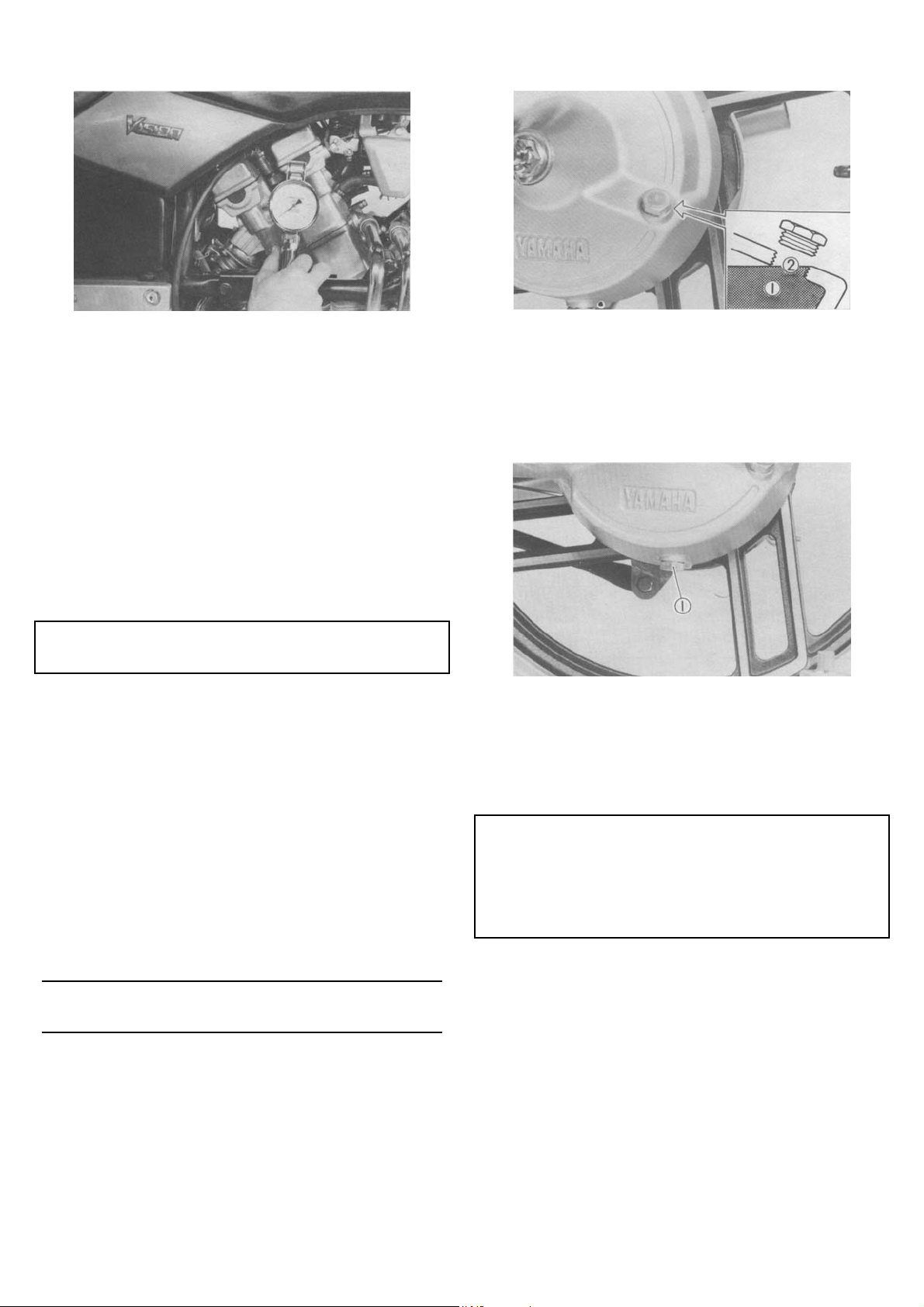

The flywheel is marked as follows:

1. Emblem plate 2. Timing plug

7. Align the "T" mark (for the front cylin-der)Vpn

the flywheel with the stationary pointer on

the crankcase cover. The pointer can be

viewed through the timing window in the

crankcase cover. When the "T" mark is

aligned with the stationary pointer, the piston

is at Top Dead Center (TDC). Valve clearance should be checked and adjusted when

the piston is at TDC on the compression

stroke. The piston is at TDC on compression

when there is free play in both valve adjusters.

NOTE:

The crankshaft should be turned counterclockwise,

as viewed from the left side of the motorcycle.

8. Use a feeler gauge to determine the clearance. If clearance is incorrect, record the

measured amount of clearance. This must

be measured carefully.

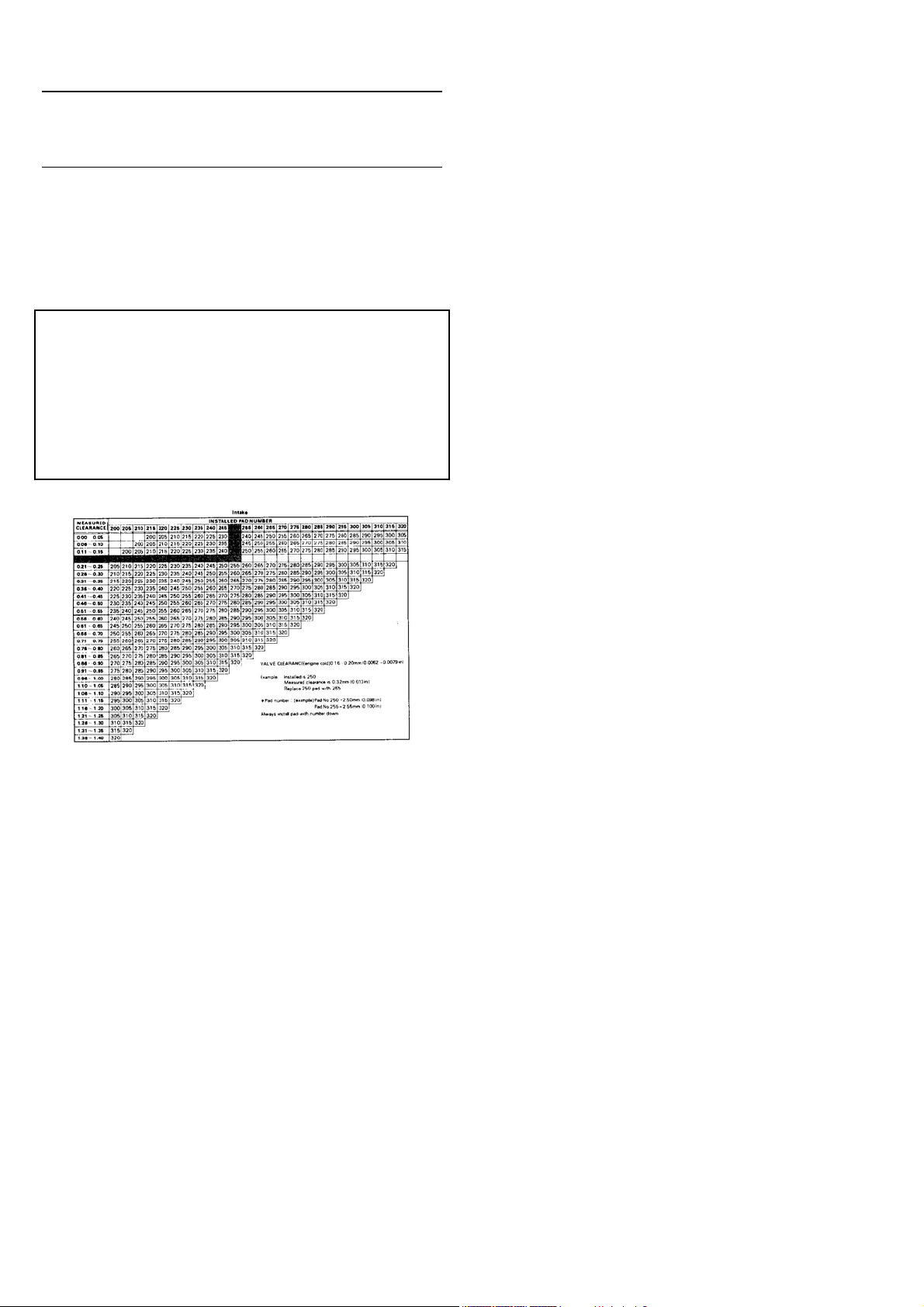

Intake valve (cold):

0.11 ~0.15mm (0.0043 -0.0059 in)

Exhaust valve (cold):

0.16 ~ 0.20mm (0.0063 ~ 0.0079 in)

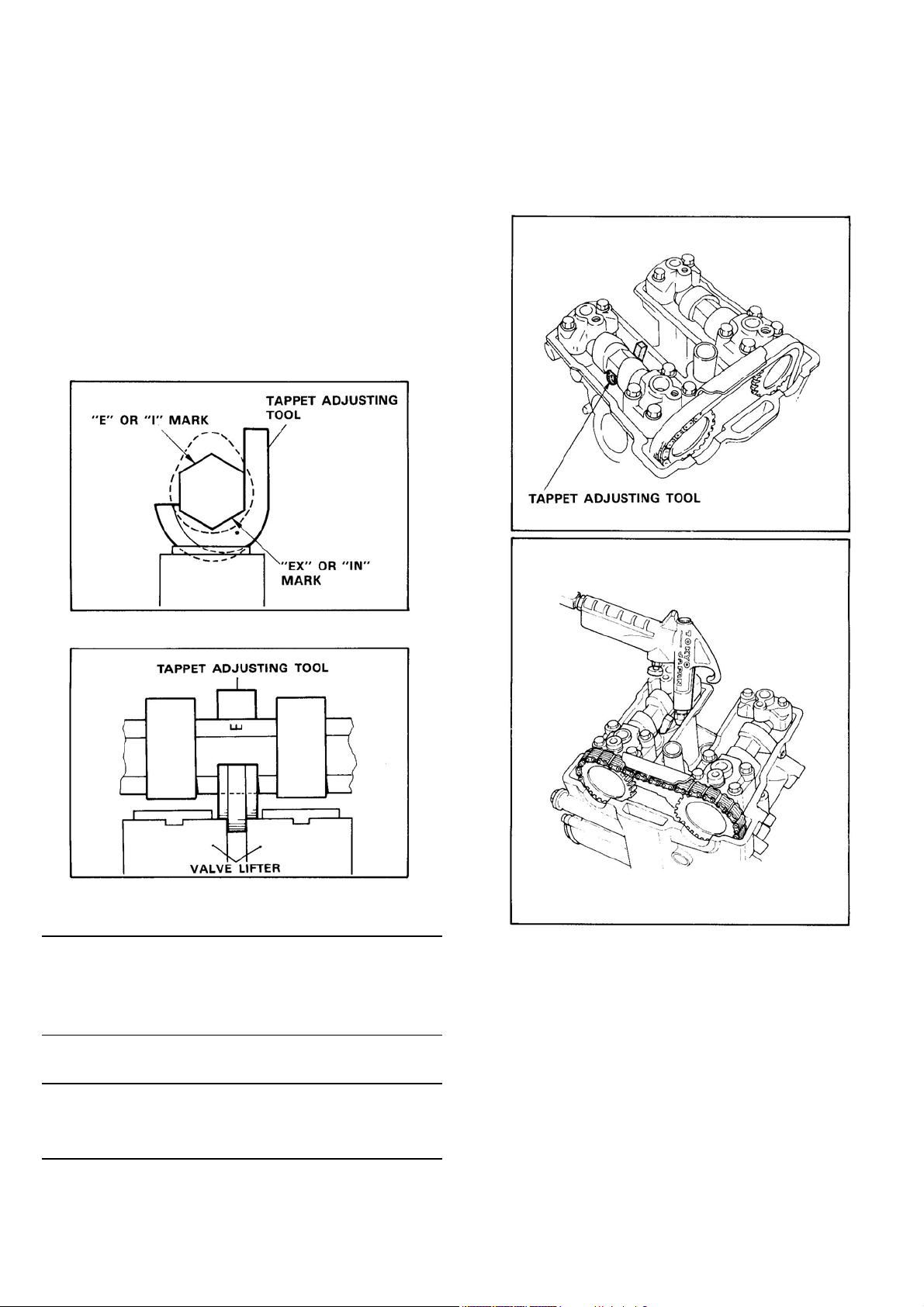

9. Valve clearance is adjusted by replacing the

adjusting pad on the top of the valve lifter.

Adjusting pads are available in 25 thicknesses, ranging from No. 200 (2.00 mm

(0.079 in)) to No. 320 (3.20 mm (0.130 in) >

in steps of 0.05 mm (0.002 in). The thickness of each pad is marked on the pad face

that contacts the valve lifter (not the cam).

Adjustment of the valve clearance is accomplished as follows:

18

a. There is a slot in each valve lifter. The slots

must be positioned opposite of each other on

the exhaust and intake side before the tappet

adjusting tool is installed.

b. Turn the crankshaft until the camshaft identi-

fication mark (IN or EX) faces upward. Place

the tappet adjusting tool under the camshaft

with the tool match mark (•) and camshaft

I.D. mark aligned.

c. Turn the crankshaft until the lobe of the tool

depresses the valve lifters.

d. Remove the pads from the lifters. There is a

slot in each lifter. Use an air gun or a small

screwdriver and a magnetic rod to remove

the pads. Note the numbers on the pads.

WARNING:

When turning the crankshaft, exercise care so

that the tappet adjusting tool does not contact

the mating surface of the cylinder head and the

cylinder head cover.

NOTE:

When installing the tappet adjusting tool onto the

camshaft, be careful so that the lobe of the tool

does not ride on the pad.

e. Proper pad selection is made as follows:

(Use appropriate chart for exhaust or intake

valves.)

1) Find number of original (installed) pad

number on chart. Read down on chart.

2) Find measured valve clearance (from

step 1) on chart. Read across.

19

NOTE:

The new pad number is to be used as a guide only.

Verify the correctness of this choice in the following

step(s).

3) At the intersection of installed pad

number (down) and measured clearance (across) is a new pad number.

EXAMPLE:

Intake valve, installed pad:

No.250 (read down)

Measured clearance:

0.32mm (0.013 in) (read across)

New pad number: No.270

(intersection of down & across)

20

21

10. Install the new pad in the lifter. Install the

pad with the number down.

11. Turn the crankshaft to remove the adjusting

tool from the camshaft.

12. Turn the crankshaft to rotate cam several rotations. This will set the pad in the lifter.

13. Recheck the valve clearance. If the clearance is incorrect, repeat the proceeding

steps until the proper clearance is obtained.

14. To assemble the motorcycle, reverse the

disassembly procedures. Pay close attention

to installation of the cylinder head cover.

15. Rotate the crankshaft approximately 290 degrees counterclockwise to TDC for the rear

cylinder. Repeat the steps above, and

check/adjust the valve clearance.

Inspect the head cover gasket. If damaged,

replace the gasket.

16. Install the head covers, and torque the bolts

to specification.

Tightening torque:

10 Nm (1.0 m-kg, 7.2ft-lb)

WARNING:

When installing the cylinder head cover, make

sure all cam caps are covered with oil plugs.

NOTE:

The cylinder head cover should be so installed that

the smaller crankcase ventilation pipe fitting hole is

toward the front cylinder, and the larger one is toward the rear side.

17. Install the air baffle plate and radiator.

Tighten the radiator securing bolts to specification.

Tightening torque:

7 Nm (0.7m-kg, 5.1 ft-lb)

18. Install the radiator cover and air filter assembly. Connect the crankcase ventilation

pipes.

19. Install the fuel tank and connect the fuel and

vacuum pipe lines. Tighten the fuel tank holding bolt to specification.

Tightening torque:

15 Nm (1.5m-kg, 11 ft-lb)

22

Spark plug

1. Check electrode condition and wear, insulator color, and electrode gap.

2. Clean the spark plug with spark plug cleaner

if necessary. Use a wire gauge to adjust the

plug gap to specification.

3. If the electrode becomes too worn, replace

the spark plug.

4. When installing the plug, always clean the

gasket surface, wipe off any grime that might

be present on the surface of the spark plug,

and torque the spark plug properly.

Standard spark plug:

D8EA (NGK) or

X24ES-U(NIPPON DENSO)

Spark plug gap:

0.6-0.7 mm (0.024-0.028 in)

Spark plug tightening torque:

20 Nm (2.0 m-kg, 14 ft-lb)

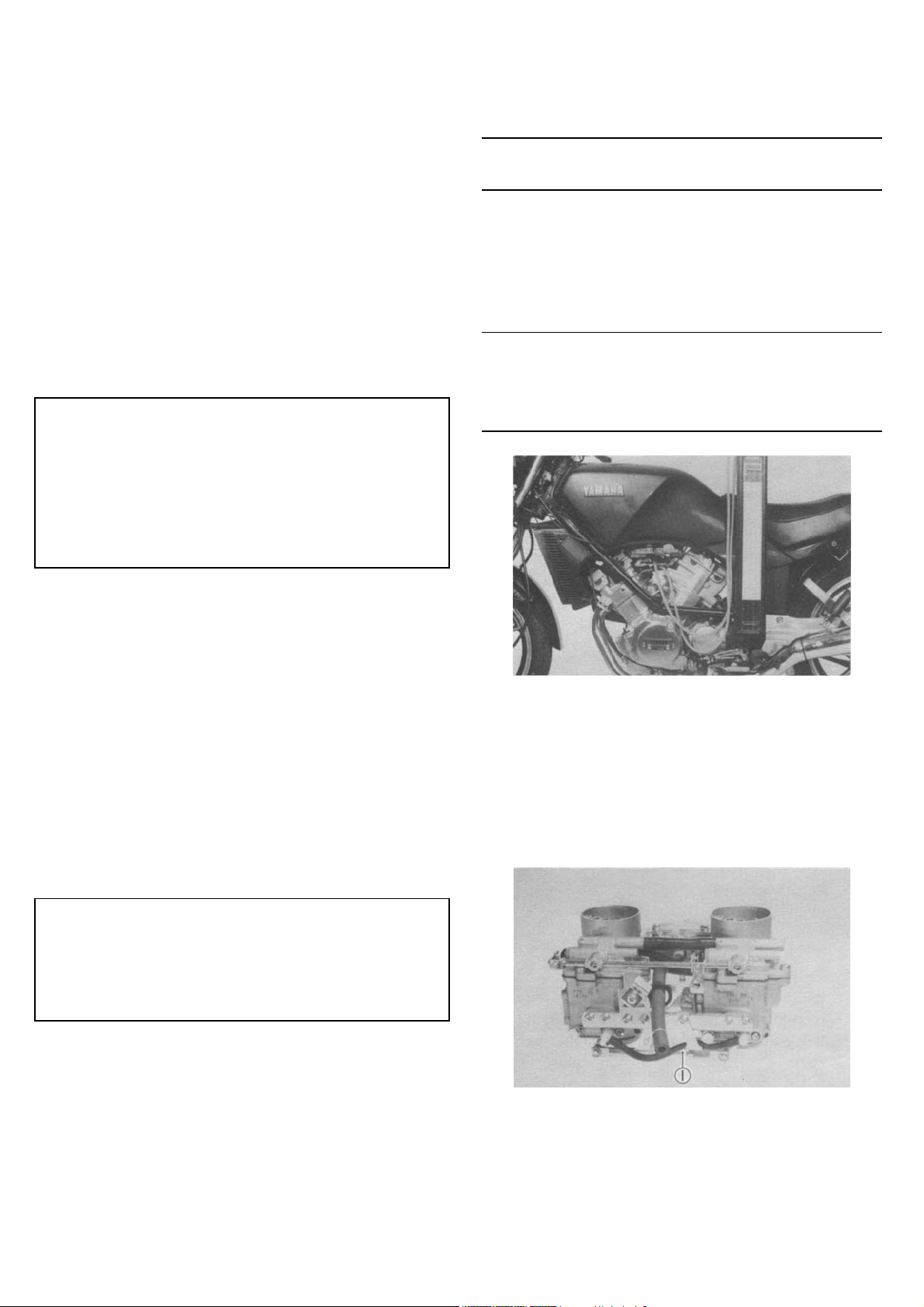

NOTE:

Valve clearance must be set properly before synchronizing the carburetors.

1. Remove the vacuum lines from each carburetor joint, and install the vacuum gauge

lines to each carburetor joint.

NOTE:

The front cylinder carburetor joint has two vacuum

lines coming out of it. Disconnect the smaller diameter line, and leave the larger line in place on the

carburetor joint.

Crankcase ventilation system Check the ventilation pipe from the cylinder head cover on the each cylinder to the air filter assembly for cracks or damage; replace if necessary.

Fuel line

Check the fuel hoses and vacuum lines for cracks or

damage; replace if necessary.

Exhaust system

1. Retighten the exhaust pipe flange bolts and

muffler clamp bolts.

Tightening torque:

Exhaust pipe flange bolt

10 Nm (1.0 m-kg, 7.2 ft-lb)

Muffler clamp bolt

20 Nm (2.0 m-kg, 14 ft-lb)

2. Turn the fuel cock to the "PRI" position.

3. Start the engine, and let it warm up.

4. Read the vacuum gauge. The readings for

each carburetor should be the same. If not,

adjust the synchronizing rod until the readings are the same.

2. Replace the exhaust pipe gasket(s) and/ or

muffler gasket(s) if necessary.

Carburetor synchronization Carburetors must be adjusted to open and close simultaneously. Adjust as follows:

1. Synchronizing rod

5. Reconnect the vacuum lines.

23

Idle speed

1. Start the engine, and warm it up for a few

minutes.

2. Set the engine idle speed to the specified

level by adjusting the throttle stop screw on

the rear cylinder carburetor. Turning the

throttle stop screw in (clockwise) increases

the engine speed; turning it out (counterclockwise) decreases the engine speed. Use

a tachometer for checking and adjusting the

engine speed.

Engine idle: 1,300 ± 50 r/min

Engine oil

Recommended oil

Use Yamalube 4-cycle oil or SAE 20W40 SE motor

oil if the temperature does not go below 5°C (40°F).

Use SAE 10W30SE motor oil if the temperature

does not go above 15°C (60° F).

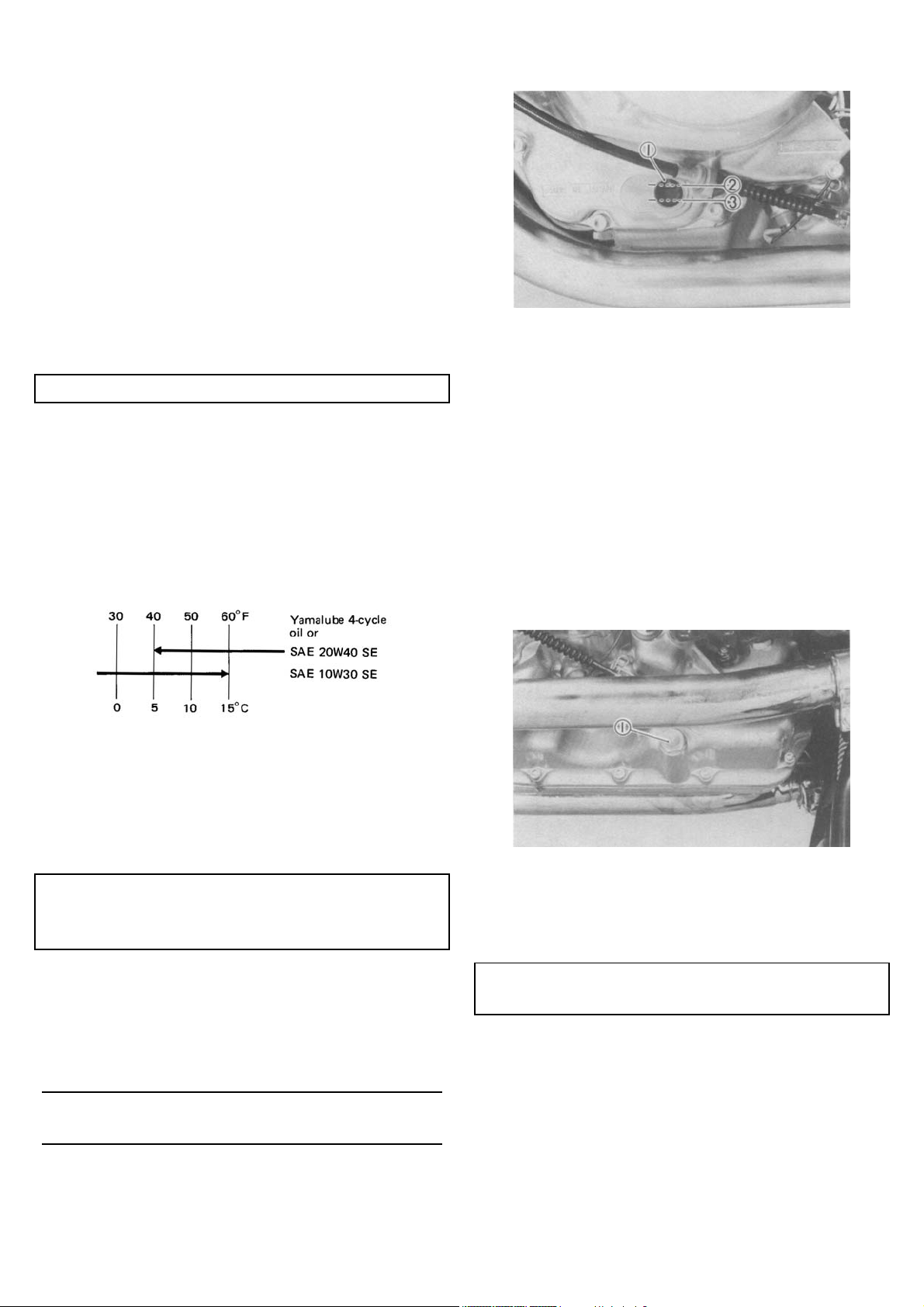

1. Level window 2. Maximum mark 3. Minimum mark

3. The oil level should be between the maximum and minimum marks. If the level is

lower, add sufficient oil to raise it to the

proper level.

Oil change (without changing the filter)

1. Start the engine and stop after a few minutes

of warm-up.

2. Place an oil pan under the engine and remove the oil filler cap.

3. Remove the drain plug and drain the oil.

Oil level measurement

1. Place the motorcycle on its center-stand.

Warm up the engine for several minutes.

NOTE:

Be sure the motorcycle is positioned straight up

when checking the oil level; a slight tilt toward the

side can produce false readings.

2. With the engine stopped, check the oil level

through the level window located at the

lower part of the left side crankcase cover.

NOTE:

Wait a few minutes until the oil level settles before

checking.

1. Engine drain plug

4. Reinstall the drain plug (make sure it is

tight).

Drain plug torque:

43 Nm (4.3 m-kg, 31.0 ft-lb)

24

5. Add 2.4 L (2.1 Imp qt, 2.5 US qt) of engine

oil through the oil filler hole. Reinstall the oil

filler cap.

CAUTION:

Take care not to allow foreign material to enter

the crankcase.

6. Start the engine, and let it warm up. During

warm-up, check for oil leakage. If oil leaks,

stop the engine immediately, and check for

the cause.

7. Stop the engine and check the oil level.

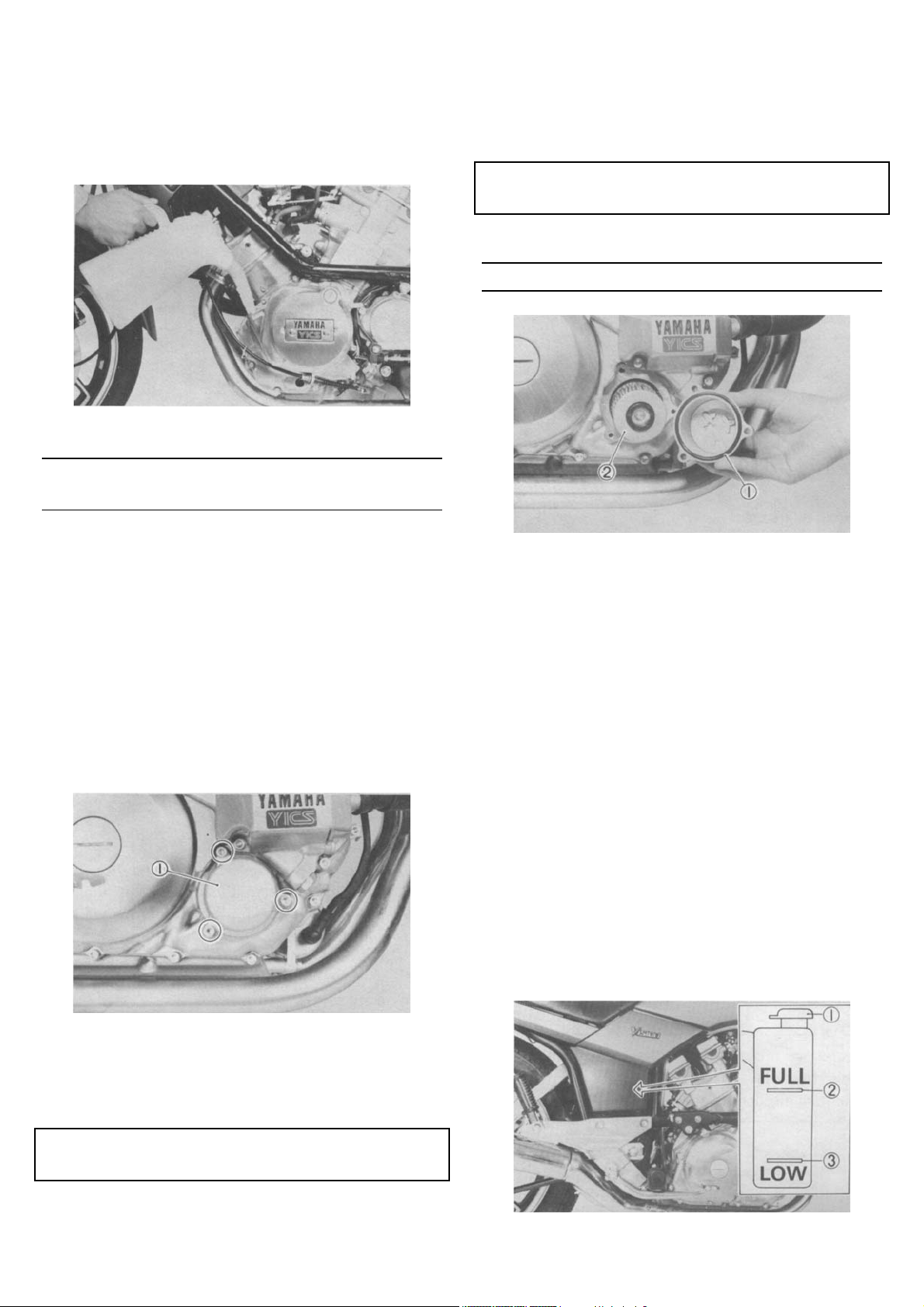

Oil and filter change

1. Remove the drain plug and drain the oil.

2. Remove the oil filter bolt and filter element

1. Oil filter cover

3. Reinstall the drain plug (make sure it is

tight).

4. Install the new oil filter element, new O-ring,

and filter cover; tighten the oil filter bolt.

Oil filter bolt:

10 Nm 1.0 m-kg, 7.2ft-lb)

NOTE:

Make sure the O-ring is positioned properly.

1. Proper O-ring position 2. Oil filter element

5. Add. 2.7 L (2.4 Imp qt, 2.9 US qt) of engine

oil through the oil filler. Reinstall the oil filler

cap.

6. After the replacement of engine oil and/or oil

filter, be sure to check for the oil level and

any oil leakage. The oil level indicator light

should go off after the oil is filled.

Coolant Check the coolant level in the reservoir tank when the engine is cold. The coolant level is satisfactory if it is between the FULL and LOW level on the tank. The coolant level will vary with engine temperature. However, if the level is on or below the LOW level, add tap water (soft water) until the "FULL" level is reached. Change the coolant every two years. (See "COOLING SYSTEM" for more detail.)

Drain plug torque:

43 Nm (4.3 m-kg, 31.0 ft-lb)

1. Coolant reservoir tank cap 2. Full level 3. Low level

25

WARNING:

Do not remove the radiator cap when the engine

is hot.

CAUTION:

Hard water or salt water is harmful to the engine

parts.

You may use boiled water or distilled water if

you can't get soft water.

Reservoir tank capacity:

Total:

0.35 L(0.3 Impqt, 0.4 US qt)

From LOW to FULL level:

0.25 L(0.2 Impqt, 0.3 US qt)

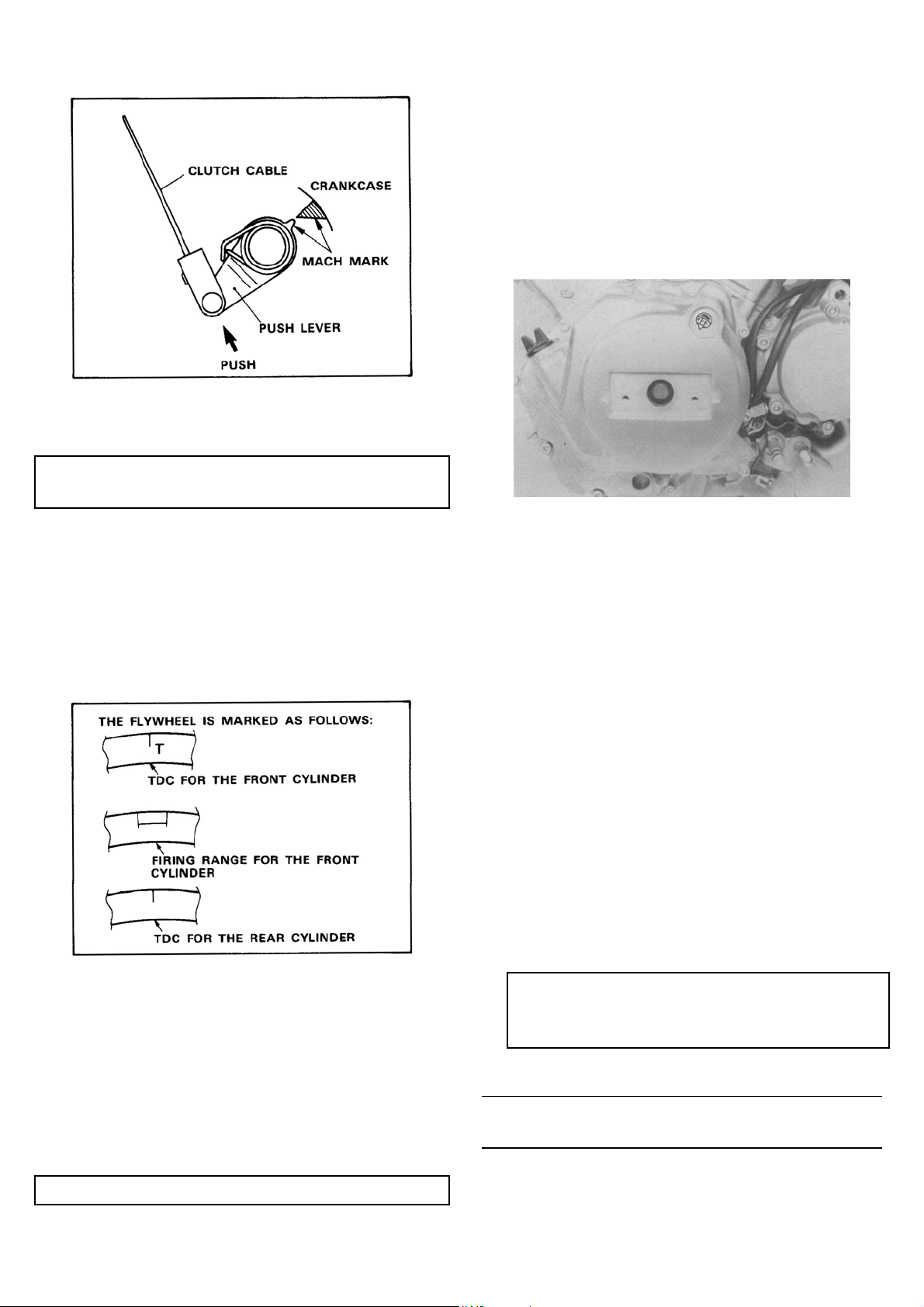

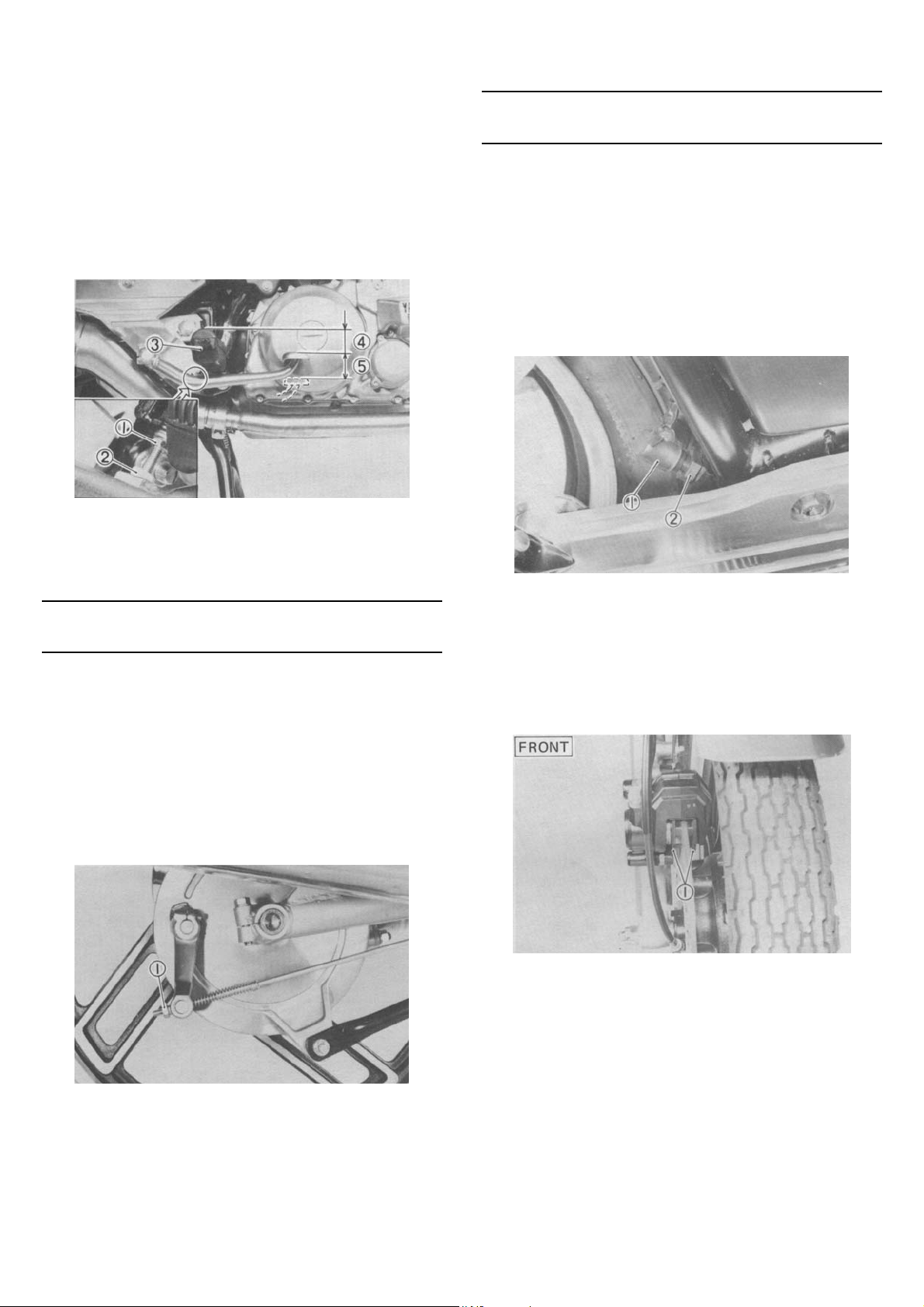

Clutch adjustment Free play adjustment

1. Loosen the clutch lever adjuster lock-nut.

2. Turn the cable adjuster either in or out until

proper lever free play is attained. Tighten the

locknut.

Mechanism adjustment

1. Fully loosen the cable inner wire lengthadjuster locknut and screw in the adjuster

until tight.

2. Turn the handle lever adjuster in.

3. Remove the clutch adjuster plug from the

right side crankcase cover.

1. Clutch adjuster plug

4. Loosen the adjuster lock nut on the pressure plate.

1. Locknut 2. Adjuster a. 2~3 mm (0.08-0.12 in)

Clutch lever free play:

2 ~3 mm (0.08 ~0.12 in)

NOTE:

The above procedure provides for maximum cable

free play to allow for proper clutch actuating mechanism adjustment.

1. Adjuster 2. Locknut

5. Move the push lever toward the front with

your finger until it stops. With the push lever

in this position, back out the adjusting screw,

and as illustrated, align the mark on the end

of the push lever with the mark (protuberance) on the crankcase.

26

6. Tighten the adjuster lockout.

Tightening torque:

8 Nm (0.8 m-kg, 5.8ft-lb)

7. Adjust the clutch lever free play.

Checking ignition timing Check the ignition timing with a timing light by observing the stationary pointer and the marks stamped on the flywheel.

1. Remove the emblem plate and timing plug

from the left side crankcase cover.

2. Connect the timing light to the front (#1) cyl-

inder spark plug wire.

3. Start the engine, and keep the engine running at the specified speed. Use a tachometer to check the engine speed.

Engine Speed: 1,300 ± 50 r/min

4. The stationary pointer (in the timing window)

should be within the firing range shown on

the flywheel. If the pointer is not within the

range or if it is not steady, check the flywheel

and/or pickup assembly for tightness and/or

damage. (See Chapter 7, "ELECTRICAL" for

further information.)

5. Reinstall the generator cover.

Compression pressure measurement

Insufficient compression pressure will result in performance loss and may indicate leaking valves or

worn or damaged piston rings.

1. Make sure the valve clearance is correct.

2. Warm up the engine for 2 ~ 3 minutes; stop

the engine.

3. Remove both spark plugs.

4. Install a compression gauge.

5. Turn over the engine with the electric starter

(make sure the battery is fully charged) with

the throttle wide open until the pressure indicated on the gauge does not increase further. The compression should be within the

specified levels.

Compression pressure (at seal level):

Standard: 980 kPa (10 kg/cm2, 142 psi)

Minimum: 882 kPa (9 kg/cm2, 128 psi)

Maximum: 1,079 kPa (11 kg/cm2,156 psi)

WARNING:

When cranking the engine, ground the spark

plug wires to prevent sparking.

27

6. If the pressure is too low, squirt a few drops

of oil into the cylinder being measured.

Measure compression again. If there is a

higher reading than before (without oil), the

piston rings may be worn or damaged. If the

pressure remains the same after measuring

with the oil, one or both rings and valves

may be the source of the problem.

7. Check both cylinders. Compression pressure

should not vary more than the specified

value from one cylinder to the other.

Difference between each cylinder:

Less than 98 kPa (1.0 kg/cm2, 14 psi)

CHASSIS

Final gear oil

Oil level measurement

1. Place the motorcycle on a level place, and

place it on its centerstand. The engine

should be cool (at atmospheric temperature).

2. Remove the oil filler cap and check the oil

level. If it is not up to the brim of the filler

hole, add oil.

CAUTION:

Take care not to allow foreign material to enter

the final gear case.

1. Final gear oil 2. Correct oil level

Gear oil replacement

1. Place an oil pan under the final gear case.

2. Remove the final gear oil filler cap and the

drain plug; drain the oil.

1. Final gear drain plug

3. Reinstall and tighten the final gear drain

plug.

4. Fill the gear case to the specified level.

Oil capacity: 0.20 L (0.18 Imp qt, 0.21 US qt)

Recommended oil: SAE 80 API "GL-4"

Hypoid gear oil

If desired, an SAE 80W90 Hypoid gear oil may be

used for all conditions.

5. Reinstall the filler cap securely.

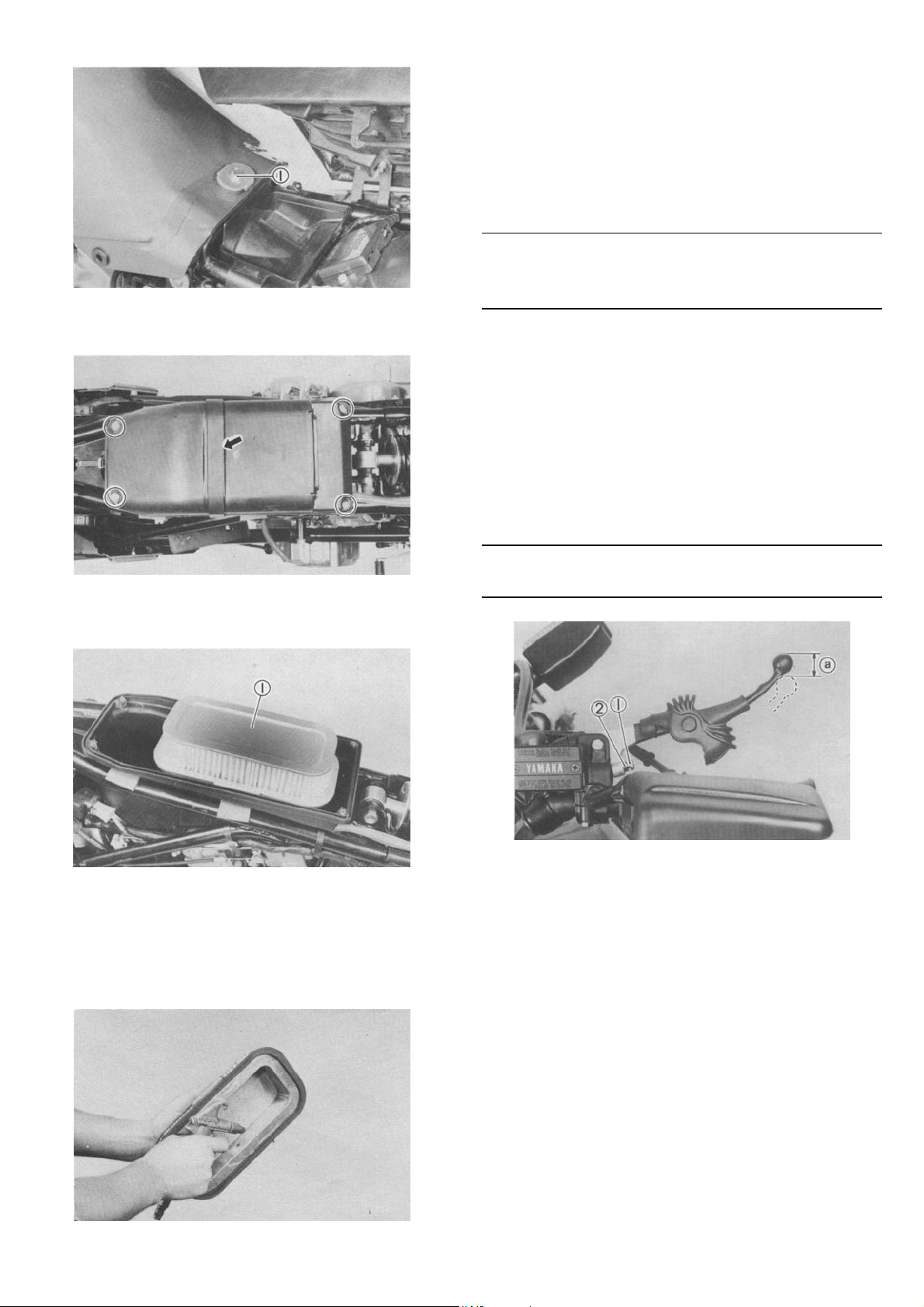

Air filter

1. Turn the fuel cock lever to "RES". Remove

the fuel pipes from the fuel cock.

2. Remove the sidecovers.

3. Open the seat and remove the fuel tank

holding bolt.

28

1. Fuel tank holding bolt

4. Remove the band and air filter case cover by

removing the four screws.

7. Reassemble by reversing the removal procedure. Check whether the element is

seated completely against the case.

8. The air filter element should be cleaned at

the specified intervals.

CAUTION:

The engine should never be run without the air

cleaner element installed; excessive piston

and/or cylinder wear may result.

Front and rear brake

Front brake lever free play adjustment. The brake

can be adjusted by simply adjusting the free play of

the brake lever. The piston in the caliper moves

forward as a brake pad wears out, automatically

adjusting the clearance between the brake pads and

brake disc.

CAUTION:

5. Pull out the element.

1. Air filter element

6. Tap the element lightly to remove most of

the dust and dirt; then blow out the remaining dirt with compressed air from the inner

surface of the element. If element is damaged, replace it.

Proper lever free play is essential to avoid excessive brake drag.

1. Adjuster 2. Locknut @ 5~8mm (0.2~0.3 in)

1. Loosen the adjuster locknut on the brake

lever.

2. Turn the adjuster so that the brake lever

movement at the lever end is 5 ~ 8mm (0.2 ~

0.3 in) before the adjuster contacts the master cylinder piston.

3. After adjusting, tighten the locknut.

29

Rear brake pedal height adjustment

1. Loosen the adjuster locknut (for pedal

height).

2. By turning the adjuster bolt clockwise or

counterclockwise, adjust the brake pedal position so that its top end is flush with the top

of the footrest.

3. Secure the adjuster locknut.

WARNING:

Check the operation of the brake light after adjusting the rear brake.

Brake light switch adjustment

The brake light switch is operated by the movement

of the brake pedal. To adjust, hold the switch body

with your hand so it does not rotate and turn the

adjusting nut. Proper adjustment is achieved when

the brake light comes on slightly before the brake

begins to take effect.

1. Adjuster bolt 3. Footrest

(for pedal height) 4. Pedal height 20mm (0.8 in)

2. Locknut 5. Free play 15 -25 mm (0.6 ~1.0 in)

WARNING:

After adjusting the pedal height, the brake-pedal

free play should be adjusted.

Free play

1. The rear brake should be adjusted to suit the

rider's preference, but free play at the end of

the brake pedal should be 15 ~25mm (0.6 ~

1.0 in). To adjust, turn the adjuster on the

brake rod clockwise to reduce play; turn the

adjuster counterclockwise to increase play.

1. Main body 2. Adjusting nut

Front brake pad

To check, examine the pads in the front brake. If

any pad is worn to the wear limit, replace both pads

in the caliper.

1. Wear indicator

1. Adjuster

30

Loading...

Loading...