Yamaha XS650 1974-1980 Service Manual 07 anhaenge

CHAPTER 7. APPENDICES

7-1.

7-2.

7-3.

7-4.

7-5.

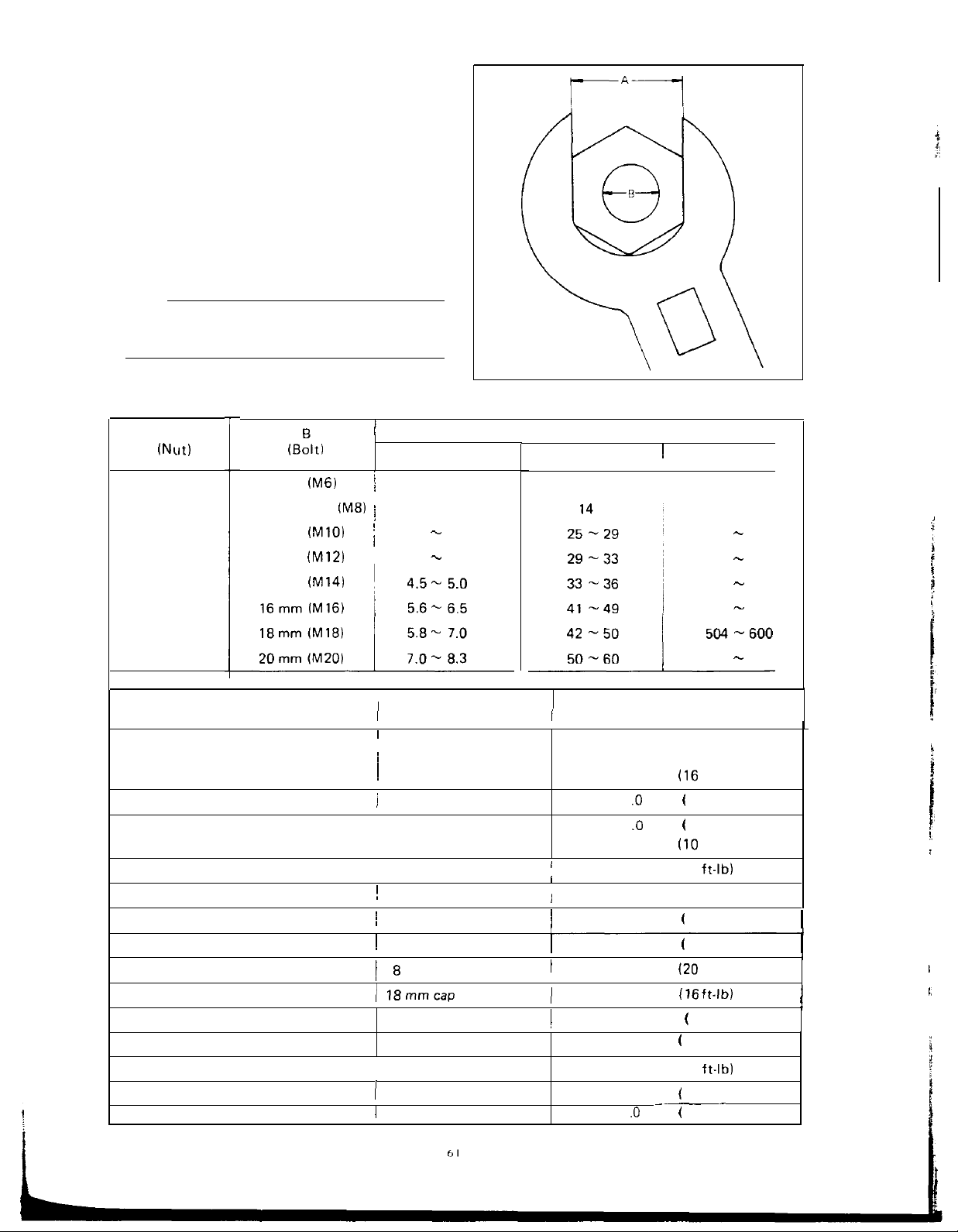

TORQUE SPECIFICATION

Torque Specifications

CONVERSION TABLE

Metric to Inch System

Inch to Metric System

Definition of Terms

SPEClFlCATlON.........

A. General

B.

Engine

C.

Chassis..

D. Electrical

CABLE ROUTING DIAGRAM

CIRCUIT DIAGRAM

...................................................................

.......................................................

........................................................

......................................................

...............................................................

...............................................

................................................

................................................

..................................................

...............................................................

...............................................

..........................................

...... 64

.........................................

..6 1

61

.63

.63

.63

.63

64

64

...66

..70

.72

..7 4

7-1.

TORQUE SPECIFICATION

The following torque specifications must be

adhered to on every machine. When applying

torque to multi-secured fastener components,

the several studs should be tightened in

gradual stages and in a pattern that will avoid

warpage

to the item being secured. Torque

settings are for dry, clean threads. Torquing

should always be done to the nut, never the

bolt head.

NOTE:

Certain items with other than standard thread

pitches

may require differing torque.

Torque Specifications

A

l-

INut)

10mm

12mm

14 mm

17 mm

19mm

22 mm

24 mm

27 mm

Part to be tightened

Ia

(Bk

6 mm (M6)

8mm fM8)

10mm

12mm

14mm

(Ml01

(Ml21

(Ml41

Engine:

Cylinder head and cylinder

head cover

Cylinder head

Cylinder head cover side

Spark plug

Generator

Stator

coil

Governer

Valve clearance adjustment nut

Cam chain tensioner cover

Pump cover

Strainer cover

I

m-kg

i

I

;

i

I

I

~

~ 8 mm bolt

)

6 mm bolt

6 mm crown nut

~ 12 mm nut

~ 6 mm pan headscrew

~ 6mmbolt

/ 8

/ 18mmcap

1.0

2.0

3.5

-

4.0

4.0

-

4.5

Thread dia. and

part name

10mm

nut

8 mm crown nut

l

14 mm

mm nut

6 mm pan head screw

6mmbolt

Standard tightening torque

ft-lb

7

I

I

/

I

/

I

I

I

2.2 m-kg

!

~

175

300

350 - 400

400 - 440

480 - 570

600 - 700

Tightening

3.8 m-kg (27 ft-lb)

2.2 m-kg

1 .O m-kg ( 7 ft-lb)

1 .O m-kg ( 7 ft-lb)

1.5 m-kg

2.0 m-kg (14

4.0 m-kg (29 ft-lb)

1.0 m-kg ( 7 ft-lb)

0.8 m-kg ((6 ft-lb)

2.7 m-kg

1 .O m-kg ( 7 ft-lb)

1.0

m-kg ((7

torque

(16

ft-lb)

(10

ft-lb)

ft.lb)

(20

ft-lb)

(16 f t.lb)

ft-lb)

in-lb

85

-

350

1

1

i

I

I

I

I

1,

Drain plug

Filter

cover

Oil filter

i 30 mm bolt

1

6mmbolt

1

16

mmbolt

4.4 m-kg (32

1.0

m-kg ((7

_~___

1 .Om-kg 1(7

ft.lb)

ft-lb)

ft-lb)

I

Delivery pipe

I

Exhaust

1

Crankcase 1 and 2

Crankcase

Kick crank

1

Clutch spring

Primary drive gear

Clutch boss

Drive sprocket

Change pedal

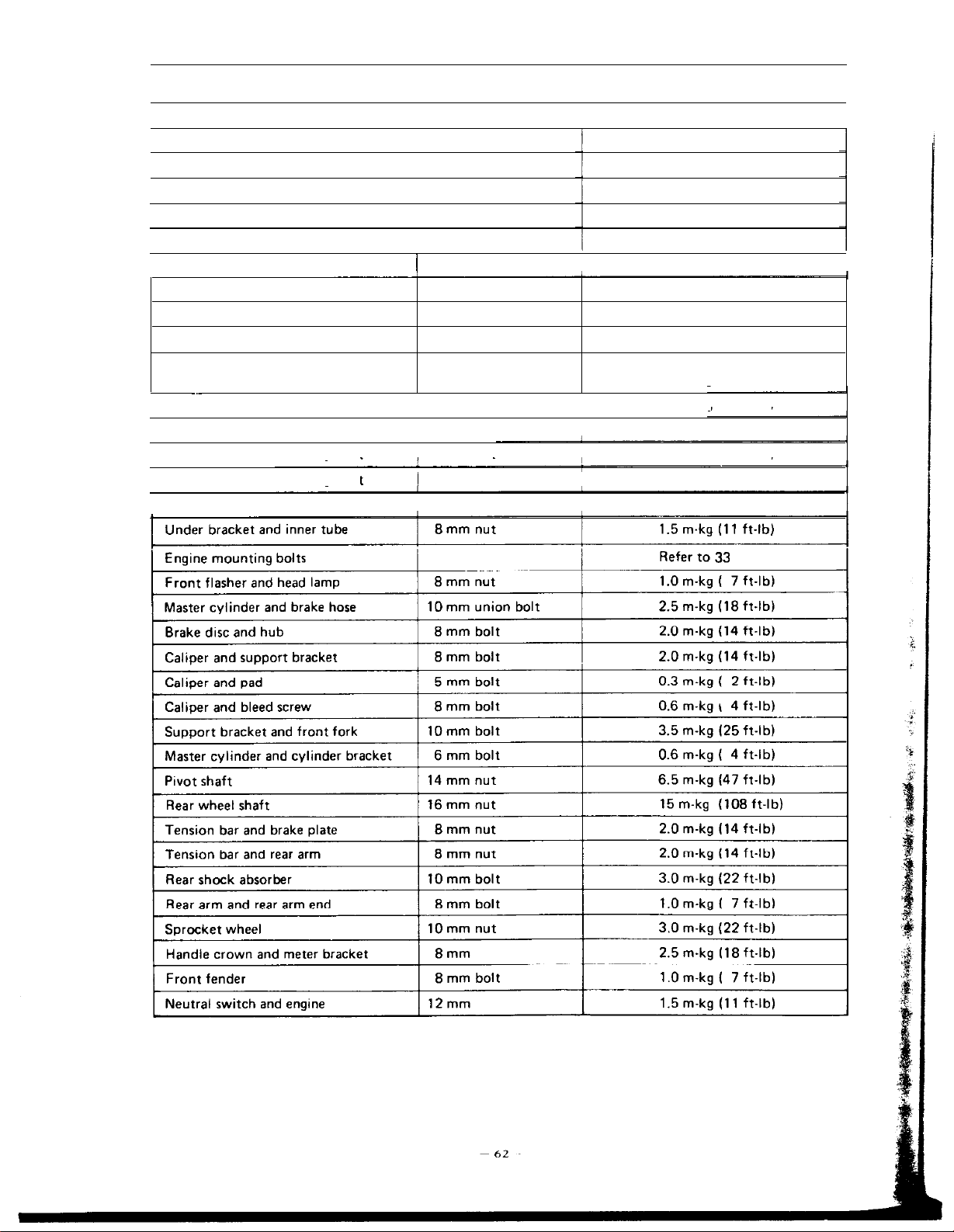

Chassis:

Front wheel shaft

Outer tube and axle holder

i-

Handle crown and inner tube

r

1

Handle crown and

1

Handle crown and steering shaft

I

Handle crown and handle holder

Part to be tightened

pipe

cover

boss

~~

steering

shaft

Thread dia. and

I

/

10 mm union bolt

/

8mm

1

8 mm bolt/nut

1

6 mm bolt

1

8 mm bolt

/

14 mm nut

1

8mm nut

/

8mm nut

I

8mmnut

/

/

part name

nut

6 mm screw

18 mm nut

22 mm nut

6 mm bolt

14 mm nut

14 mm bolt

8 mm bolt

I

I

I

I

I

I

I

I

Tightening torque

2.2 m-kg (16 ft-lb)

1.5 m-kg

2.2 m-kg (16 ft-lb)

1 .O m-kg (7 ft-lb)

2.0 m-kg (14 ft-lb)

1 .O m-kg (7 ft-lb)

9.0 m-kg (65 ft-lb)

6.5 m-kg (47 ft-lb)

5.0 m-kg (36 ft-lb)

1 .O m-kg (7 ft-lb)

8.5 m-kg

1.5 m-kg

1 .O m-kg

1.0 m-kg (7 ft-lb)

5.5 m-kg (40 ft-lb)

2.5 m-kg (18 ft-lb)

(11

ft-lb)

(61

ft-lb)

(1

1 ft-lb)

(7 ft-lb)

I

I

I

I

I

I

I

I

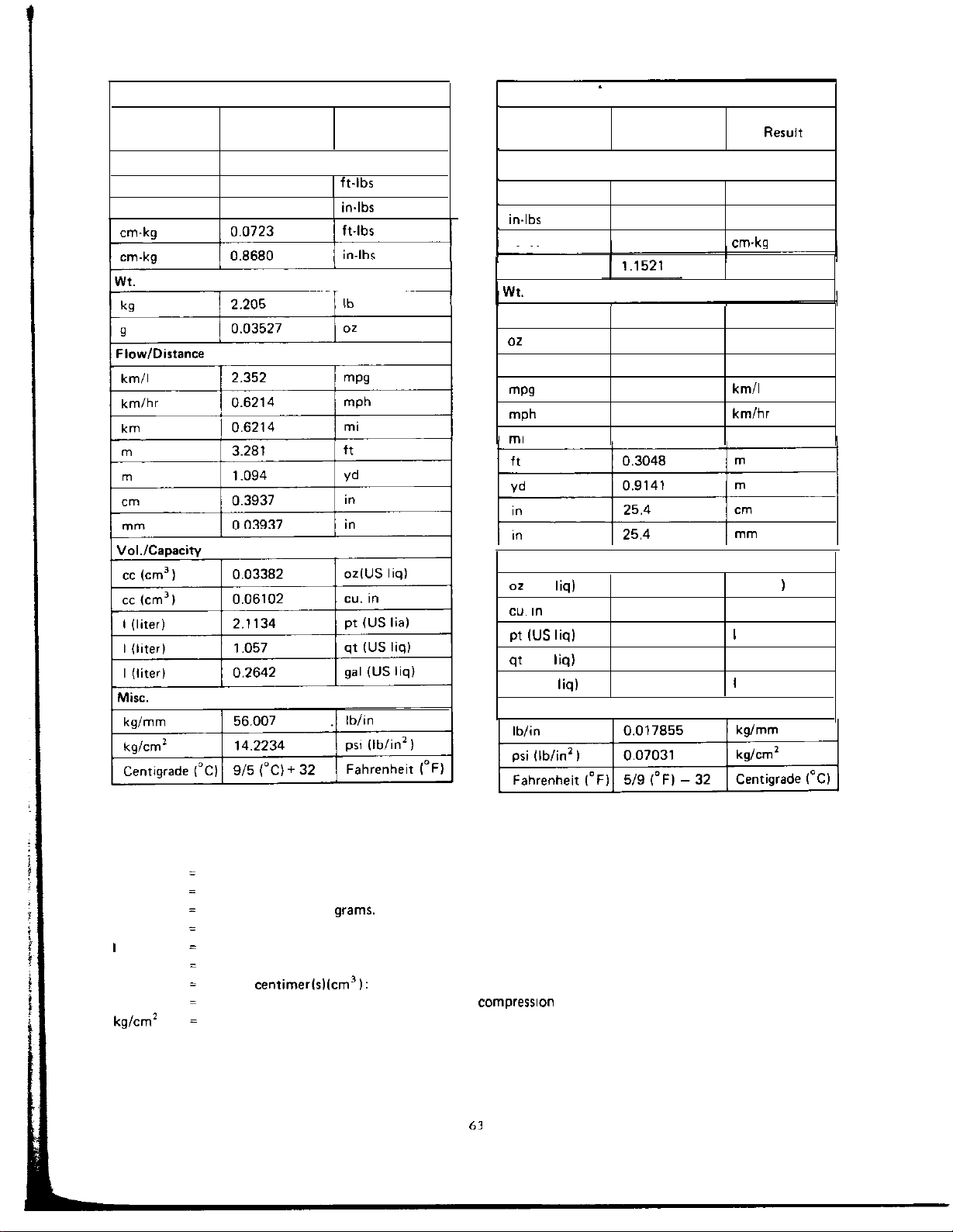

7-2.

CONVERSION TABLE

Known

Torque

m-kg

m-kg

Metric to Inch System

Multiplier

(Rounded

7.233

86.80

off)

ft.lbr

iwlbs

Result

Known

Torque

ft-lbs

in.lbs

ft.lbr

in-lbs

Wt.

lb

oz

Flow/Distance

mpg

mph

rn

Inch Metric System

Multiplier

(Rounded off)

0.13826

0.01152

13.831

0.4535

28.352

0.4252

1.609

1.609

Result

m-kg

m-kg

cm.kg

cm-kg

kg

g

km/l

kmlhr

km

Definition

m-kg

g

kg

km

I

km/l

cc

kg/mm

kg/cm’

of Terms:

Meter-kilograms: Usually torque.

Gram(s).

Kilogram(s): 1,000

Kilometer(s).

Liter(s).

Kilometer(s) per liter: Mileage.

Cubic centimer(s) (cm3): Volume or capacity.

Kilogram(s) per millimeter: Usually spring

Kilogram(s) per square centimeter: Pressure.

grams.

Vol./Capacity

oz

(US liq)

cu.

I”

pt

IUS

qt

(US

gal (US

Misc.

cqmpress~pn

liq)

liq)

liq)

rate,

29.57

16.387

0.4732

0.9461

3.765

cc (cm”

cc (cm”)

I

(liter)

I (liter)

I

(liter)

I

63

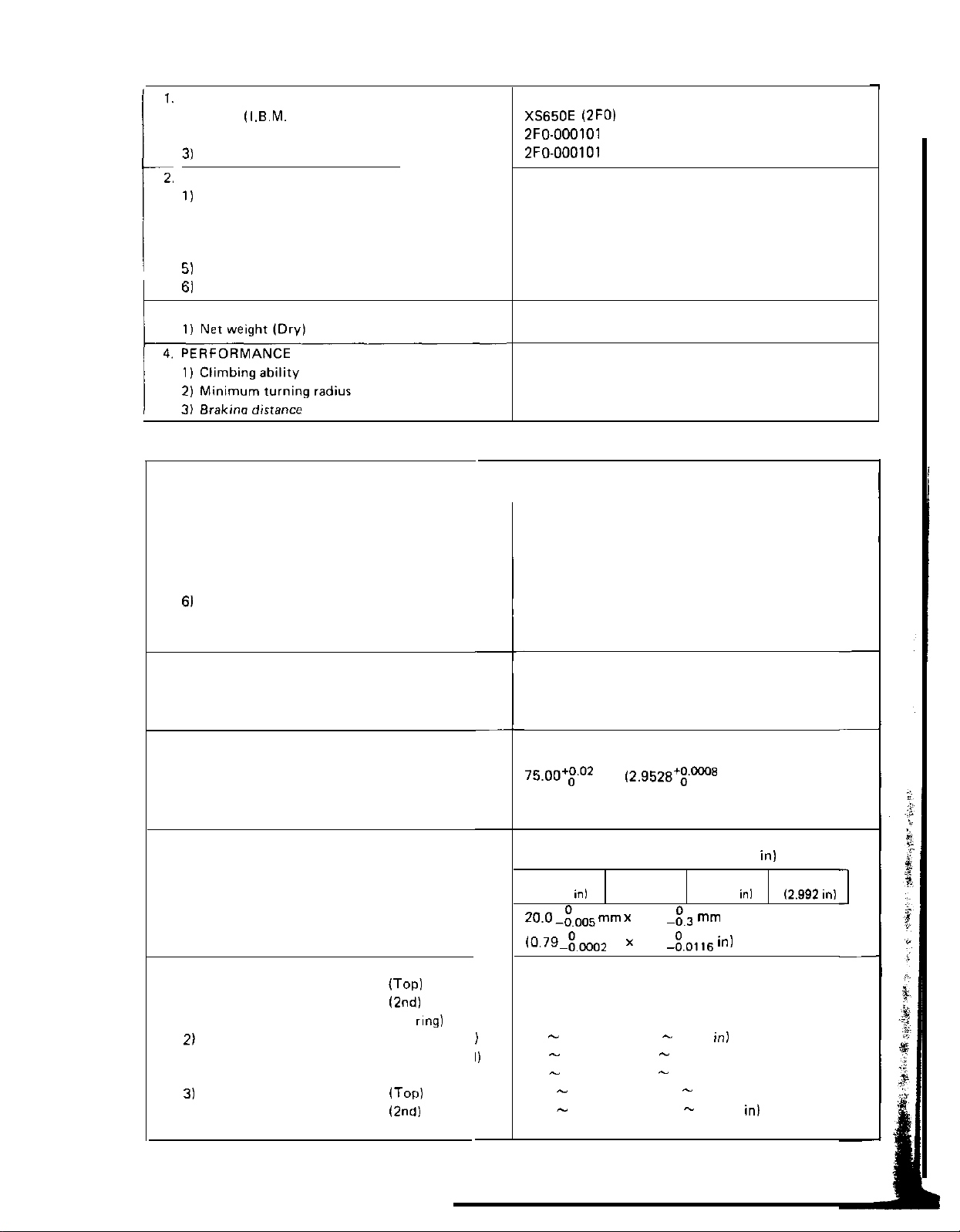

7.3. SPECIFICATION

A. General

MODEL

1.

1) Model

2) Frame I.D. and starting number

3)

Engine I.D. and starting number

DIMENSION

2.

1)

Overall length

21 Overall width

3) Overall height

4) Seat height

1

51

Wheelbase

61

Minimum ground clearance

3. WEIGHT

Engine

B.

1.

DESCRIPTION

1)

Engine type

2)

Engine model

3) Displacement

4) Bore

5) Compression ratio

61

Starting

7)

Ignition system

8) Lubrication system

2.

CYLINDER HEAD

1)

Combustion chamber volume (with

2)

Combustion chamber type

3) Head gasket thickness

3.

CYLINDER

1)

Material

2)

Bore size

3)

Taper limit

4) Out of round limit

4. PISTON

1)

Piston skirt clearance

21 Piston oversize

3)

Piston pin outside diameter x length

5.

PISTON RING

1)

Piston ring design

2) Ring end gap

3)

Ring groove side clearance

(I.B.M.

x

stroke

system

No.)

N-7Y)

ITOP)

(2nd)

(Oil

ring)

(Installed. top

(Installed. 2nd

(Installed, oil)

(TOP)

(2nd)

XS650E

2FO-000101

ZFO-000101

2,180 mm (85.8 in)

1,160 mm (45.7 in)

1,435 mm (56.5

212 kg (467

26°

2,500 mm (98.4

14 m @ 50 km/h (45.9 ft @ 31

Air cooled, 4-stroke. SOHC

incline

2F0

653 cc (39.85 cu.in)

75

8.5 :: 1

Kick and electric starter

Battery ignition

Wet sump

44.18 cc (2.696

Dome +

1.2 mm (0.047 in)

Aluminum alloy with cast iron sleeve

75.00f~.02

0.05 mm (0.002 in)

0.01 mm (0.0004 in)

0.050

20.0_~,005mm x

(0.79mg,M)02 in x 2.40

Barrel ring 1.2 mm (0.047 in)

Taper ring 1.5 mm (0.059 in)

With expander 2.8 mm (0.110 in)

0.2

0.2 - 0.4 mm (0.008 - 0.016 in)

0.3

0.04

0.03

(2FO)

835 mm (32.9

815 mm (32.1 in)

150

mm( 5.9 in)

x

74 mm (2.953 x 2.913

Squish

~

0.055 mm (0.0020~ 0.0022

75.25 mm 75.50 mm 75.75 mm

12.963

inl

-

0.4 mm 10.008 - 0.016

-

0.9 mm (0.012 - 0.036 in)

-

0.08 mm (0.0016 - 0.0031 in)

-

0.07 mm (0.0012 - 0.0028

in)

in)

lb)

in)

cu.in)

mm

(2.9528+~Ooo8

12.972 in, 12.982

61.0

& mm

-to115 in)

mi/h)

twin.

parallel forward

in)

in)

in)

in,

in)

in1

76.00 mm

l2.992

in1

Loading...

Loading...