Yamaha XS650 1974-1980 Service Manual 02 wartung

CHAPTER 2.

PERIODIC INSPECTION AND ADJUSTMENT

2-1.

2-2.

2-3.

2-4.

2-5.

INTRODUCTION

MAINTENANCE INTERVAL CHARTS

A. PEPIODIC MAINTENANCE

B. LUBRICATION INTERVALS

ENGINE

..........................................................

A. Carburetor..

Air filten

B.

Engine/Transmission oil and filter

C.

D. Clutch adjustment

Cam chain adjustment

E.

F. Valve clearance adjustment

G. Crankcase ventilation system

H. Exhaust system

CHASSIS

Fuel petcock cleaning

A.

Fuel petcock disassembly

B.

Fuel hose

C.

Front brake

D.

Rear brake

E.

Wheels and tires

F.

Drivechain

G.

Front fork oil change

H.

Steering head

I.

Lubrication of cables, pivots, etc

J.

..............................................................9

.....................................................

...................................

.........................................

....

............................... ....

.4

.4

......6

.....................................................

........................................................

.....................................

..................................................

..............................................

...........................................

.........................................

. . 6

.7

.7

.8

.9

....................................................

..............................................

............................................

... 9

.9

...........................................................9

......................................................

.....................................................

...................................................

.......................................................

..............................................

.....................................................

......................................

10

..lO

10

11

.12

12

....I3

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . 13

Contact breaker point adjustment

A.

Contact breaker point maintenance

B.

lgnition timing

C.

Carbon brushes

D.

Battery

E.

Sparkplug

F.

Headlight

G.

....................................................................

..............................................................

................................................................

.....................................................

..................................................................

....................................

.....................................

.13

13

14

14

14

..... 15

15

5

6

8

9

-3-

CHAPTER 2.

PERIODIC INSPECTION AND ADJUSTMENT

2-1. INTRODUCTION

This chapter includes all information necessary to perform recommended inspection and adjustments, These

preventive maintenance procedures, if followed, will insure more reliable vehicle operation and a longer service

life. The need for costly overhaul work will be greatly reduced. This information applies not only to vehicles

already in service, but also to new vehicles that are being prepared for sale. Any service technician performing

preparation work should be familiar with this entire chapter.

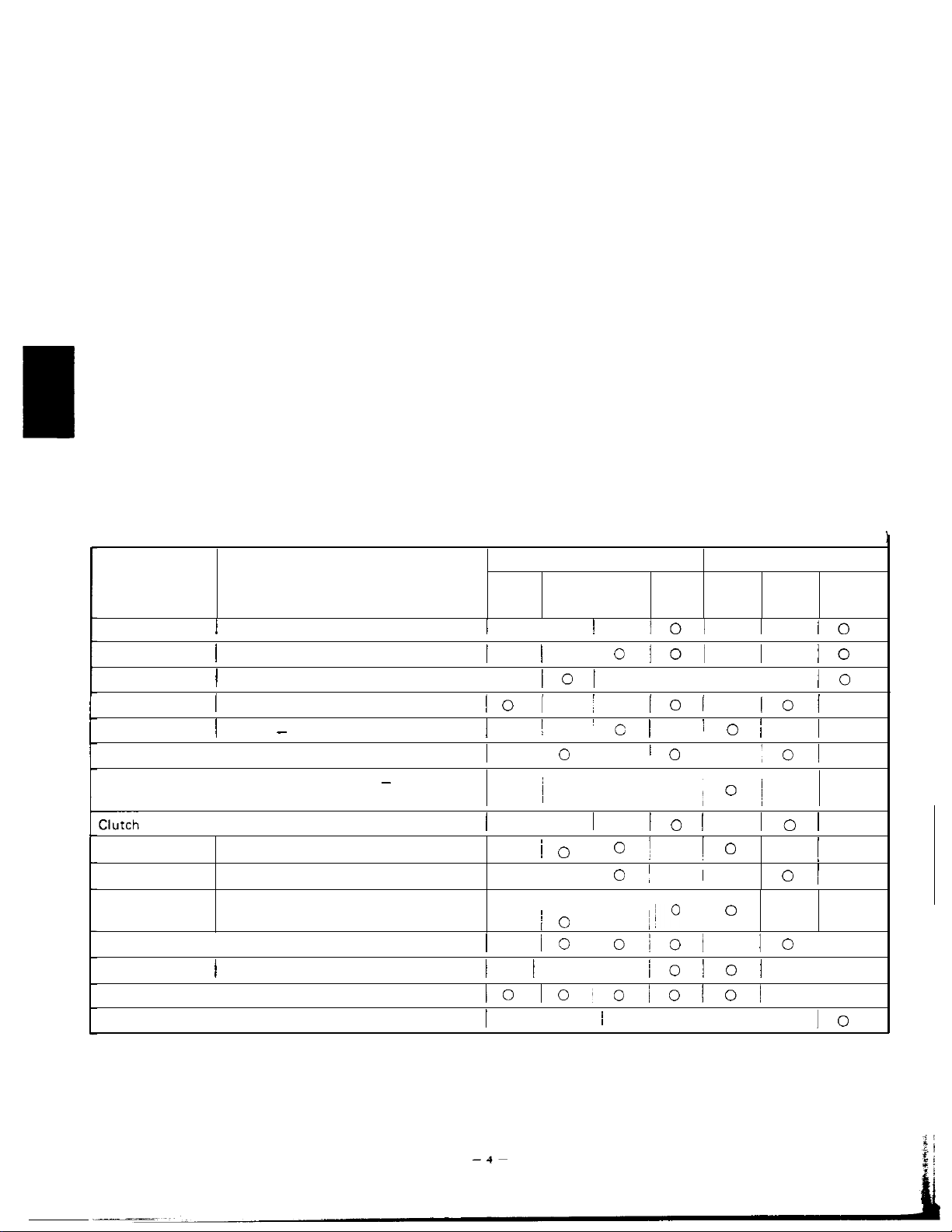

2-2. MAINTENANCE INTERVALS CHARTS

The following charts should be considered strictly as a guide to general maintenance and lubrication intervals.

You must take into consideration that weather, terrain, geographical location, and a variety of individual uses

all tend to alter this time schedule. For example, if the motorcycle is continually operated in an area of high

humidity, then all parts must be lubricated much more frequently than shown

caused by water to metal parts,

on the chart to avoid damage

A.PERIODIC

Periodic inspection,

cation will keep your motorcycle in the safest

Item

Cylinder

Valves

Cam chain

Spark

pluqs

Air filter

Carburetor

Brake system

(complete)

Wheel

andtires

Fuel petcocks

Battery

Ignition timing

Lights/Signals

Fittings/Fasteners

Generator

MAINTENANCE

adjustment and

1

Check

1

Check/Adjust valve clearance

(

Check/Adjust chain tension

I

inspect/Clean or replace as required

/

Dry type - Clean/Replace as required

| Check

Check/Adjust as required

required

/Adjust free

Checkpressure/Wear/Balance 0 ~

Clean/Flush tank as required

Top-up/Check specific gravity and

| Adjust/Clean

/

Check operation/Replace as required

| Tighten

brushes |

Check brush wear/Replace if necessary

lubri-

Remarks

compression

operation/Adjust as required

-

Repair as

play

pipe

or replace parts as required 1

before each trip and/or

and most efficient condition.Safety is an

ligation of the motorcycle owner.

initial Thereafter every

400 800 1,600

(250)

I

I

I

loI

1

I

I

0

0

/

0 ! 0 0

lo

1

(500)

(1,000) (2.000)

!

I

lo I

I

:

i

i

0

io

~breather

io

lo~o/olo/

:

‘0

0

I

0 0

0 011 ,oi0

I ~ I I I

3,200

IOI

0101

1,600

(1,000)

I

I

I I I

lo

1

0

0

~

o/oj

I

’ 0

I

0

;

/o/o

I 0 ;

I

I

I

0

(2.000)

IO

10

I 0 I

IO

I

ob-

Unit: km

3,200 6,400

(4,000)

lo

lo

lo

I

I

~

I

0 I

I

lo

(mi

6.

LUBRICATION INTERVALS

mission oil

Drive chain

,

a_:._ Y- ,-

Control/Meter

Oil filter element

Wheel bearings

Point cam

cation wicks

lubri-

Apply thoroughly

Do not over/

Yearly or . . .

Apply

very

lightly

Medium-weight

wheel bearing grease

Light-weight

machine oil

0 0 0

12,800

(8.000)

0

-5

2-3. ENGINE

A. Carburetor

1. Idle mixture

The idle mixture is set at the factory by

the use of special equipment. No attempt

should be made to change this adjustment

by the dealer.

1. Do not adjust

Throttle

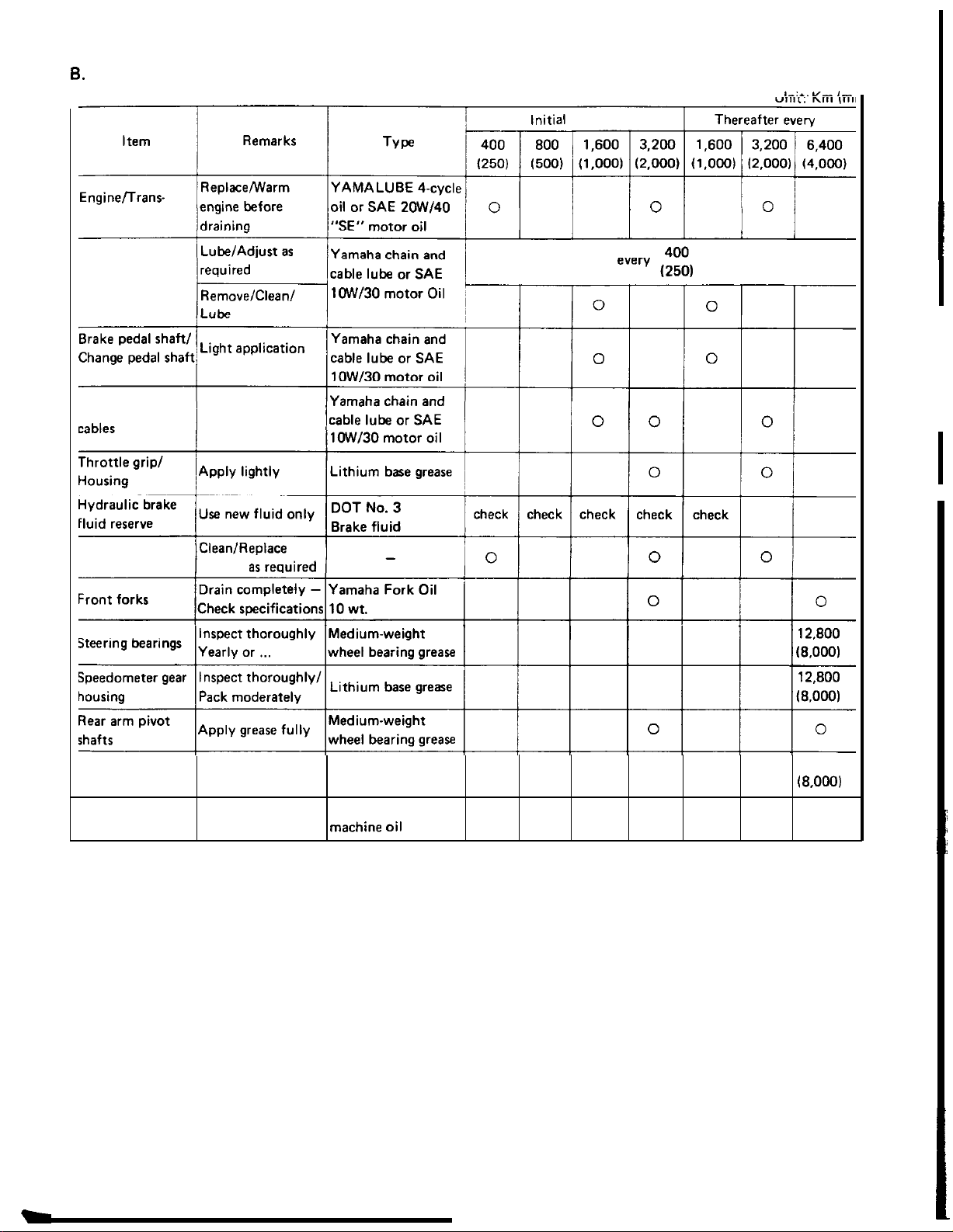

2.

Turn the throttle grip to see if it operates

properly and if the play is normal. Make

certain the throttle snaps closed when

released.

b. Install the attachment and set the vacuum

gauge.

c. Start motorcycle and allow it to warm up

for 2

-

3 minutes. The warm-up is complete when engine responds normally to

throttle opening.

d. Adjust damping valve on each vacuum

gauge until the needle flutters only

slightly. The gauge needles must respond

quickly to rapid opening of the throttle.

Both gauge will indicate the same reading

e.

if the carburetors are synchronized.

f.

Turn the synchronizing screw until the

gauge readings are the same.

1.

5 - 8 mm (0.2 - 0.3 in)

3. Synchronization

NOTE:

Ignition timing and valve clearances must

be set properly before synchronizing

carburetors.

Procedure:

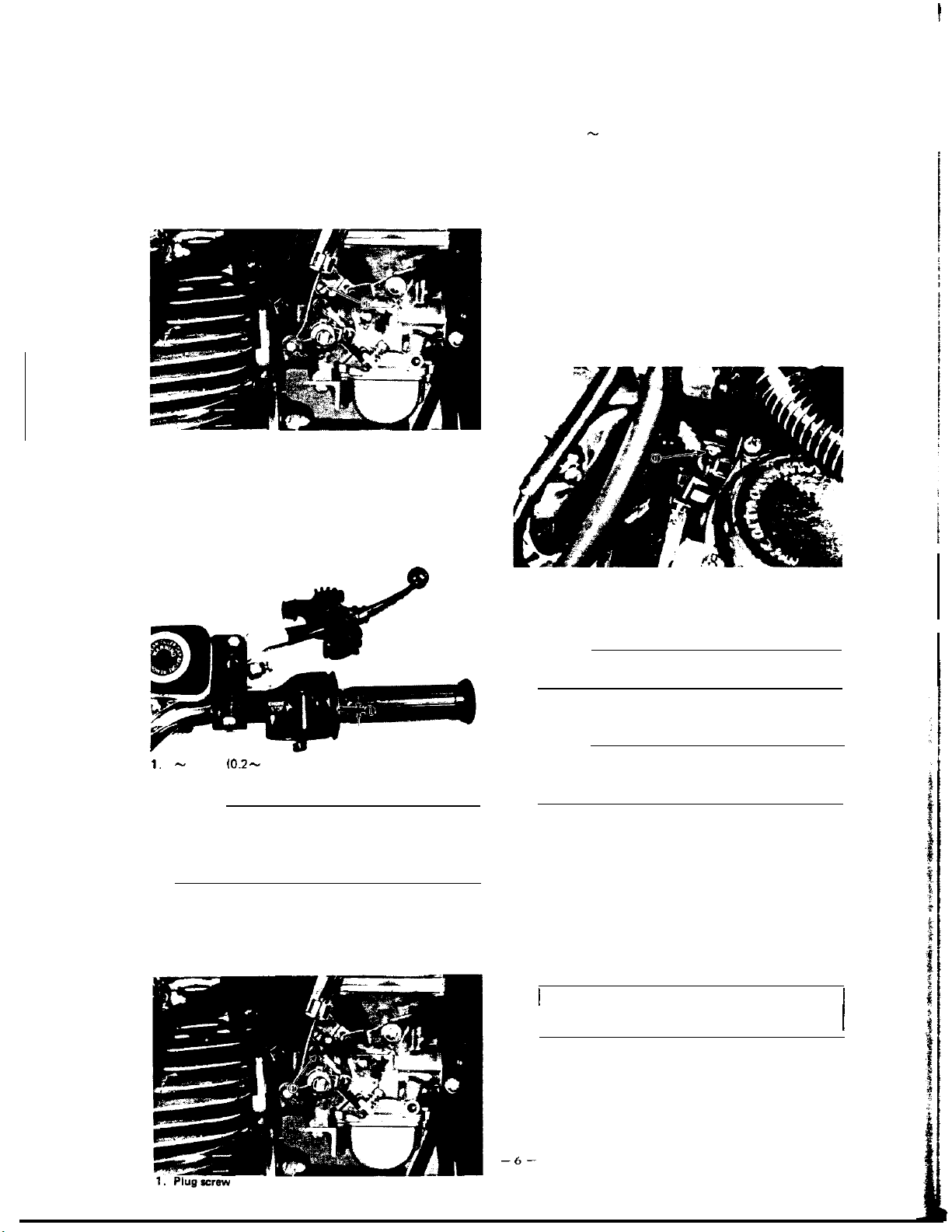

a. Turn fuel

petcocks

to “PRIME”, and

remove the plug screws for the adapter

attachment holes in the carburetor body.

1. Synchronizing screw

After adjustment, firmly tighten the plug

g.

screws.

NOTE:

Check gasket. Replace if damaged.

4. Idle speed adjustment.

NOTE:

Carburetors must be synchronized before

setting final idle speed.

a. Start the engine and warm it up for a few

minutes.

b. Set the engine idle speed to specified rpm

by turning the throttle stop screw in to

increase the engine speed and back off the

screw to decrease the engine speed.

Use a tachometer for checking and adjusting the engine speed.

I

Standard idle rpm:

1,200 rpm

I

-6-

Loading...

Loading...