Yamaha XH-150 Service Manual

POWER AMPLIFIER

XH150

SERVICE MANUAL

011441

PA

19990210-140000

CONTENTS

SPECIFICATIONS ……………………………………………3/4

PANEL LAYOUT ……………………………………………… 5

DIMENSIONS ………………………………………………… 6

BLOCK DIAGRAM …………………………………………… 6

CIRCUIT BOARD LAYOUT & WRING …………………… 7

DISASSEMBLY PROCEDURE ……………………………… 8

IC BLOCK DIAGRAM ………………………………………… 12

CIRCUIT BOARDS …………………………………………… 13

INSPECTIONS ……………………………………………15/17

PARTS LIST

1.97K-9636 1.92K-173 Printed in Japan '99.2

XH150

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that

basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the

users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specified. For these reasons, we

advise all Yamaha product owners that all service required should be performed by an authorized Yamaha Retailer

or the appointed service representative.

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and

changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and /or plastic (where applicable)

components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly other entities) to

cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHA TSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to

solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

2

SPECIFICATIONS

•General Specifications

Power Output Level

20 Hz-20 kHz

THD+N= 0.1 %

Power Bandwidth Halfpower

THD+N

20 Hz-20 kHz, Half Power

Frequency Responce

Intermodulation Distortion

60 Hz:7 kHz,4:1,Half Power

Channel Separation

Half Power

ATT.max input 600 ohm shunt

Residual Noise Att,min 12.7 kHz LPF

IHF-A Network

S/N ratio

Slew Rate

Sensitivity(Att.max)Rated Power

Voltage GAIN Att.max

Input Impeddance

Controls Front Panel

Rear Panel

Connectors Input

Output

Indicators POWER

PROTECTION

CLIP

SLGNAL

Protection circuit

Fan Circuit

PC Limitter

Power Requirements

Idle Power Consumption

1/8 Power Consumption (32 ohm)

Maximum Power Consumption (32 ohm)

Dimentions (W

Weight

x H x

D)

150 W+150 W

RL= 64 ohm (100 V)

RL= 32 ohm (70 V)

10 Hz- 40 kHz (THD + N= 0.1 %)

0.1 %

0 dB,+0.5 dB,-1 dB F= 20 Hz-50 kHz

0.1 %

>/– 65 dB 20 Hz-20 kHz

</– -65 dB

</– -65 dB

100 dB

+/–

35 V/uS

+4 dBu (100 V)+1 dBu (70 V)

38.2 dB

30 kohm (balance) 15 kohm (unbalance)

POWER switch (push on/push off)

Attenuator (31position)

x

2

MODE switch(STEREO/BRIDGE/PARALLEL)

Filter switch LOW CUT

HIGH CUT

x

2 (-12 dB/oct)

x

2 (-6 dB/oct)

Barrier strip terminal

XLR-3-31 type

Barrier strip terminal

Green

x

2 (Red)

x

2 (Red)

x

2 (Green)

POWER switch on/off mute

DC detection

TEMP (heatsink temp>/–90˚C)

Low Speed (50˚C) Variable, High Speed (70˚C)

RL</–16 ohm

Japan model 100 V, 50/60 Hz

US and Canada model 120 V, 60 Hz

Europe model 230 V, 50/60 Hz

AT model 240 V, 50/60 Hz

45 W

350 W

850 W

x

480

132.0 x 319 mm

16 Kg

0 dB=0.775 V

Half power= 1/2 Power output level

XH150

3

XH150

4

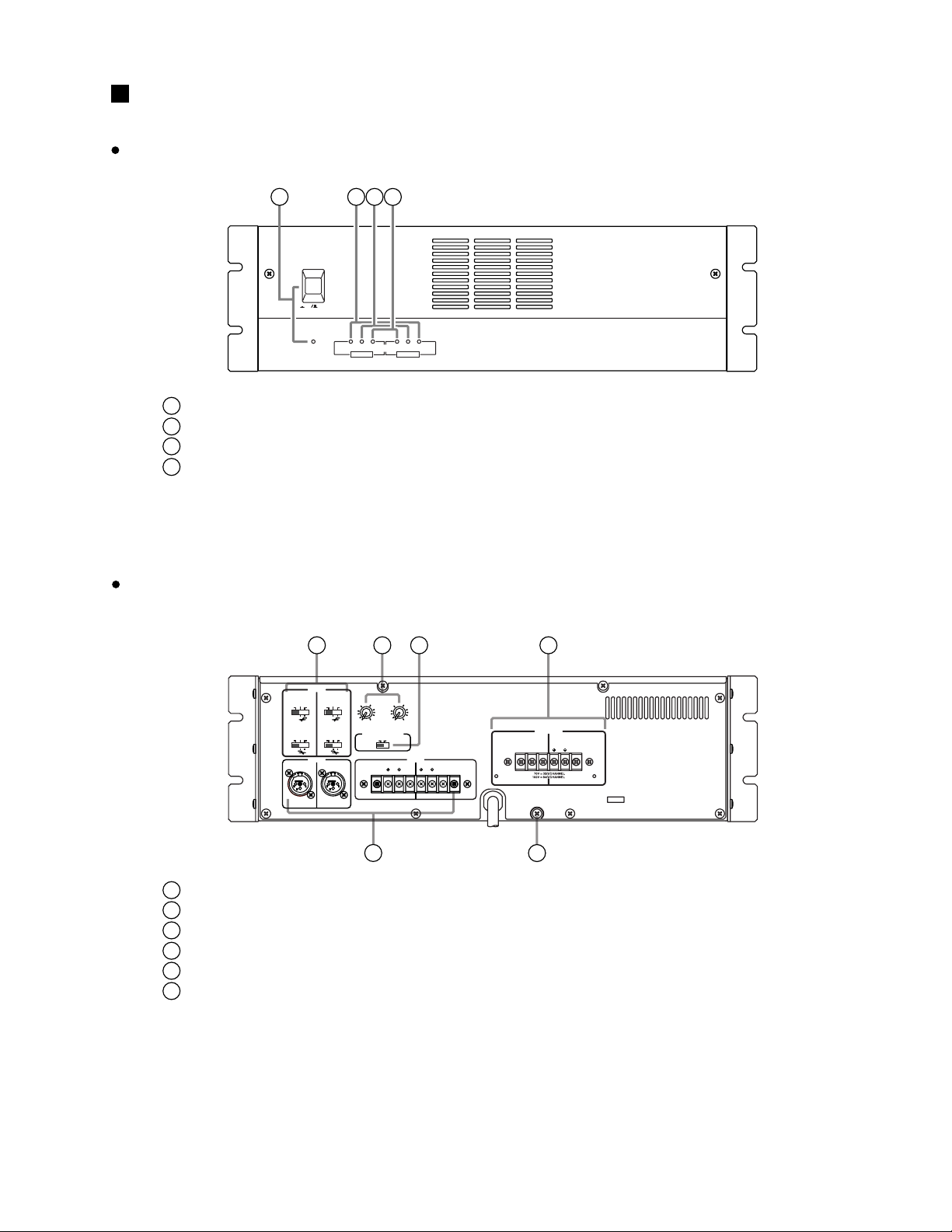

PANEL LAYOUT

Front Panel

XH150

1 2

ON OFF

1 POWER switch and indicator

2 SIGNAL indicators

3 CLIP indicators

4 PROTECTION indicator

Rear Panel

3

4

POWER

POWER SIGNAL CLIP SIGNALCLIPPROTECTION

CH A CH B

1 2 3

4

FILTER

CHANNEL B CHANNEL A

LOW CUT LOW CUT

40Hz

80Hz

OFF

OFF

HIGH CUT HIGH CUT

5kHz

10kHz

OFF

OFF

INPUT

CHANNEL B CHANNEL A

40Hz

80Hz

5kHz

10kHz

25

30

40

CHANNEL B CHANNEL A

15

20

10

25

6

30

3

0

00

–dB

OUTPUT VOLTAGE

70V

100V

CHANNEL B CHANNEL A

15

20

10

6

3

40

0

00

–dB

INPUT

GG

5

1 FILTER switches (CHANNEL A,B)

2 Volume controls (CHANNEL A,B)

3 OUTPUT VOLTAGE switch

4 SPEAKERS terminals (CHANNEL A,B)

5 INPUT terminals (CHANNEL A,B)

6 GND terminals

SPEAKERS

CHANNEL B CHANNEL A

6

5

XH150

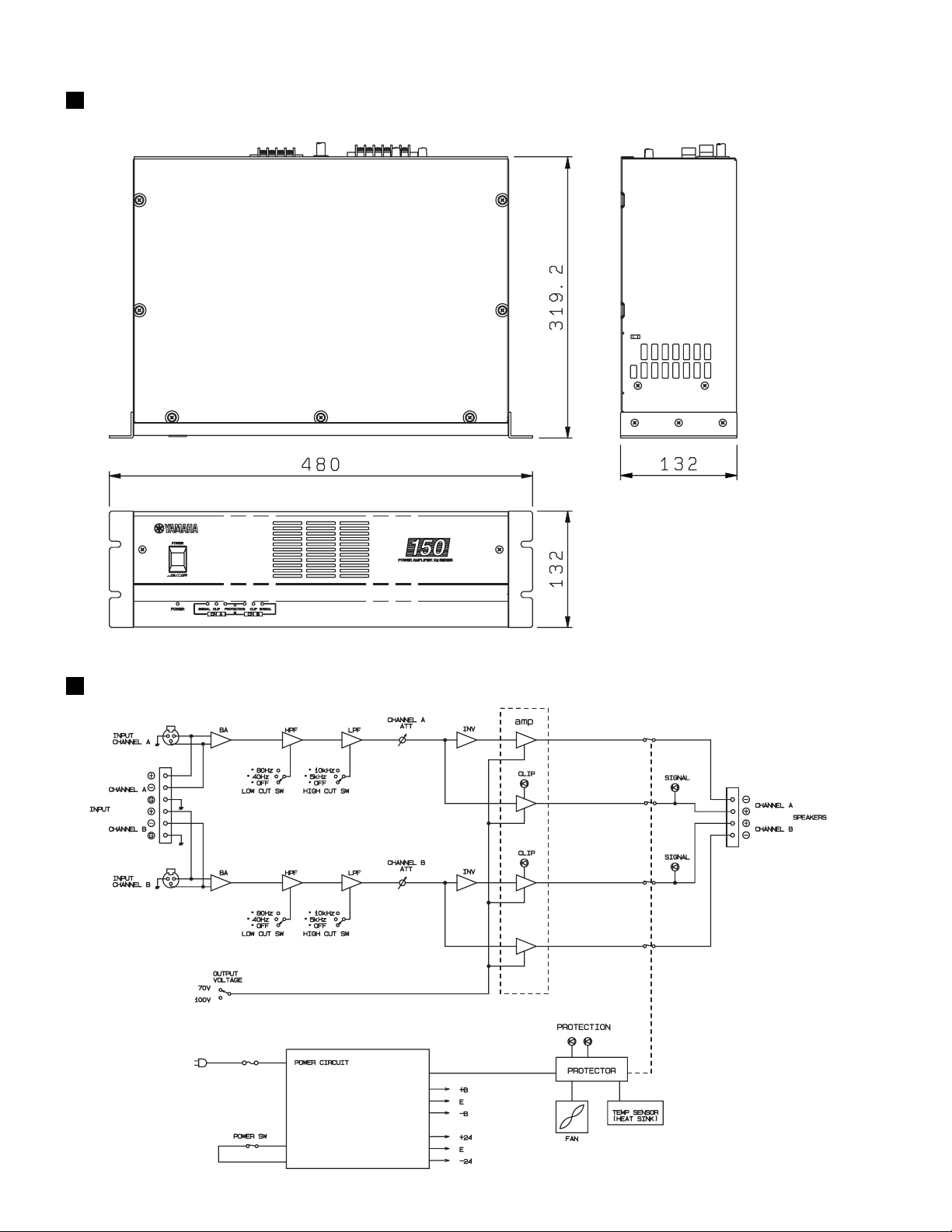

DIMENSIONS

BLOCK DIAGRAM

IC101 IC102 IC104 IC105

132

3

1

2

IC101 IC103 IC104 IC105

132

5

7

6

Unit: mm

PA7

KEC-92353

6

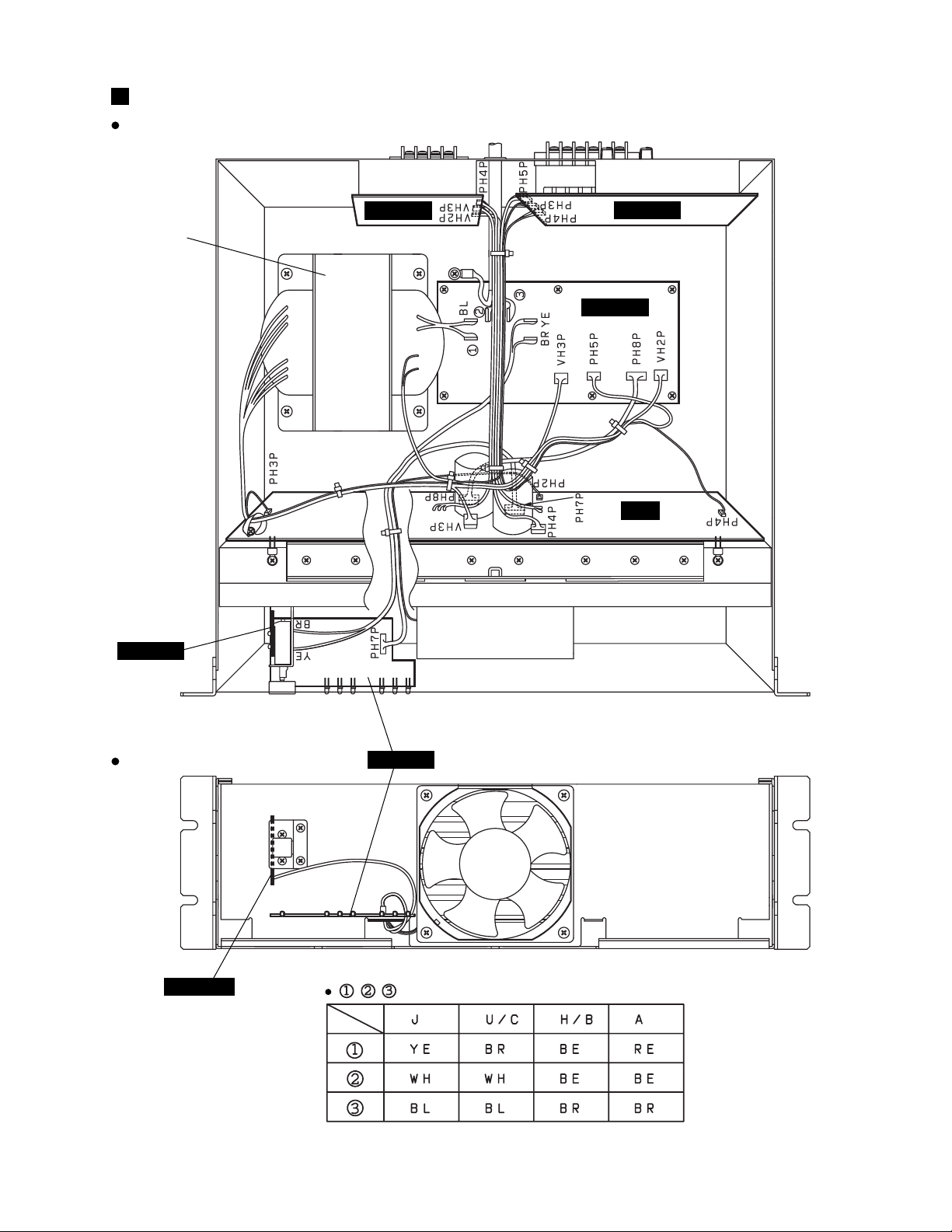

CIRCUIT BOARD LAYOUT & WIRING

Top View

XH150

Power

Transformer

SUB 4/5

SUB 5/5

SUB 2/5

SUB 1/5

PA7

Front View

SUB 4/5

SUB 3/5

Wire color

3NC2-V294100

7

XH150

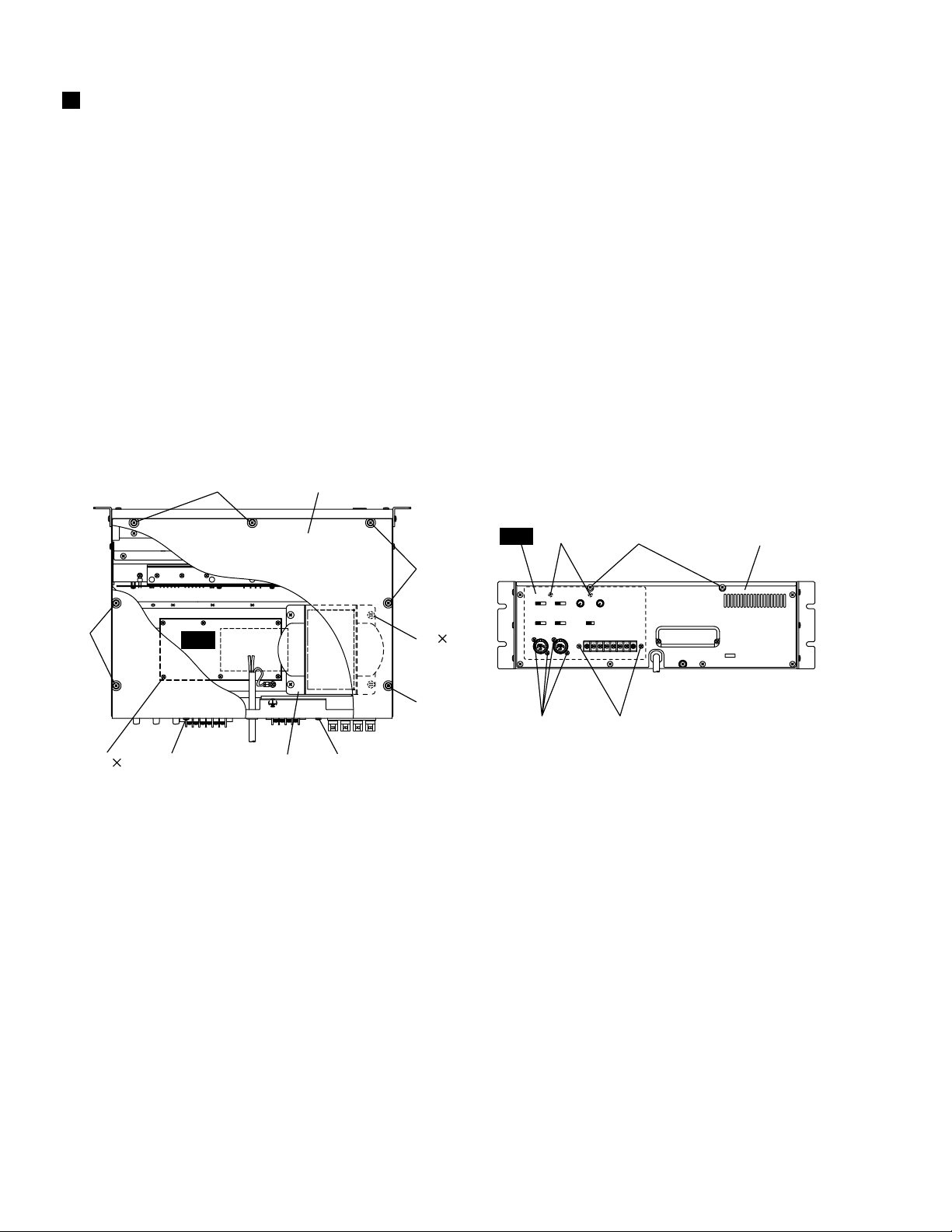

DISASSEMBLY PROCEDURE

1. Top Cover

1-1 Remove the nine (9) screws marked [410]. The top

cover can then be removed. (Fig. 1, 2)

2. Power Transformer

2-1 Remove the top cover. (See Procedure 1)

Remove the four (4) screws marked [70]. The power transformer

2-2

can then be removed. (Fig. 1)

3. SUB7 1/5 Circuit Board

3-1 Remove the top cover. (See Procedure 1)

3-2 Remove the six (6) screws marked [80a]. The SUB 1/5

circuit board can then be removed. (Fig. 1)

4. SUB 2/5 Circuit Board

4-1 Remove the top cover. (See Procedure 1)

4-2 Remove the six (6) screws marked [50a] and the two (2)

screws marked [50b]. The SUB 2/5 circuit board can then

be removed. (Fig. 2, 7)

[410]

[410]

[80a] 6 [410]

[70]: Bind Head Screw SP 5.0X10 MFZN2BL (VU688100)

[80]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[410]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

1/5

Power Transformer

Top cover

[410]

(Fig. 1) (Fig. 2)

[410]

[70] 4

[410]

[50b]

2/5

[50a] [50a]

[50]: Bind Head Screw A4.0X8 MFZN2BL (VP156800)

[410]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

[410]

Rear panel

8

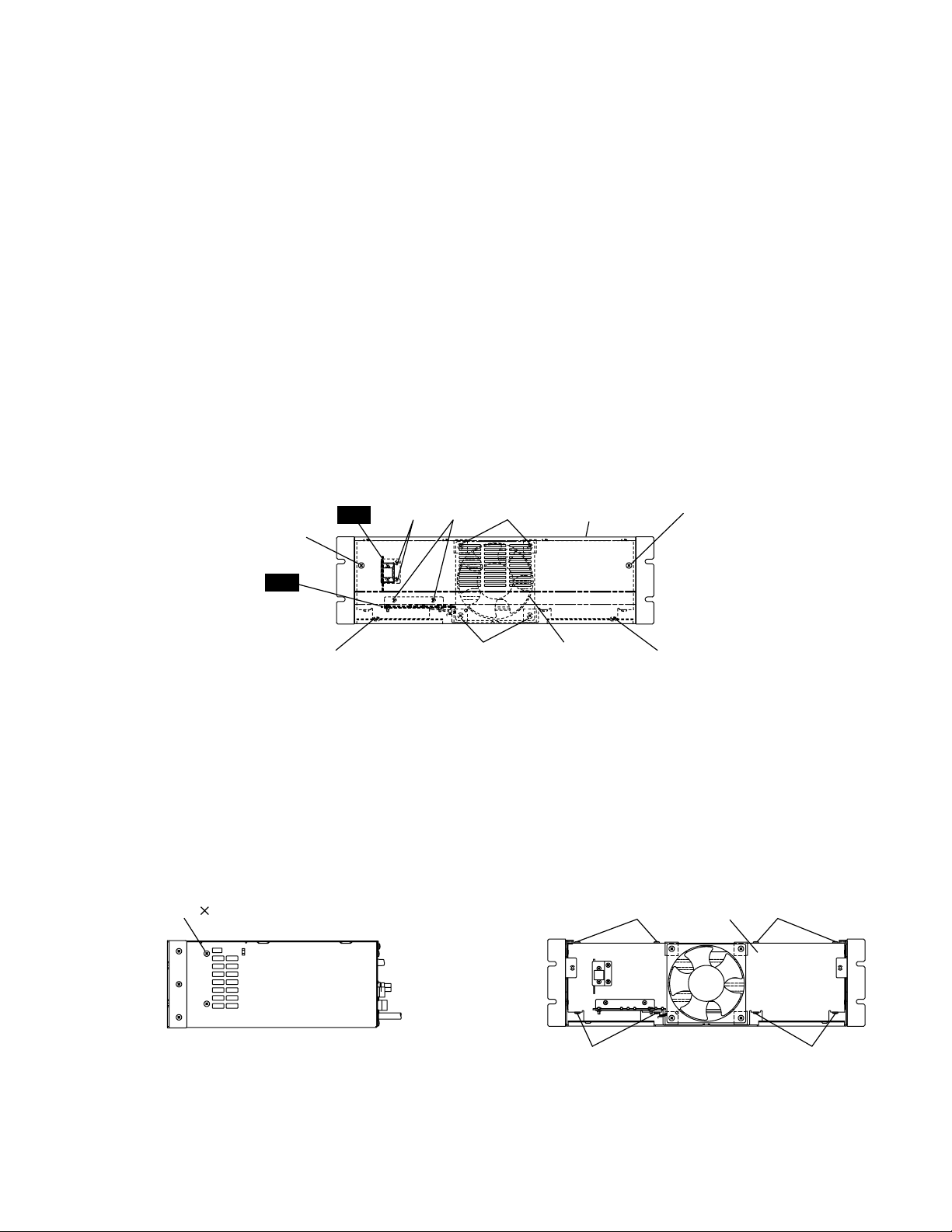

5. Panel Assembly

5-1 Remove the top cover. (See Procedure 1)

5-2

Remove the three (3) screws marked [380a] and the two (2)

screws marked [380b]. The panel assembly can then be removed.

(Fig. 3)

6. SUB 3/5 Circuit Board

6-1 Remove the top cover. (See Procedure 1)

6-2 Remove the panel assembly. (See Procedure 5)

6-3 Remove the two (2) screws marked [200]. The SUB 3/5

circuit board can then be removed. (Fig. 3)

7. SUB 4/5 Circuit Board

7-1 Remove the top cover. (See Procedure 1)

7-2 Remove the panel assembly. (See Procedure 5)

7-3 Remove the two (2) screws marked [220]. The SUB 4/5

circuit board can then be removed. (Fig. 3)

8. DC Fan

8-1 Remove the top cover. (See Procedure 1)

8-2 Remove the panel assembly. (See Procedure 5)

8-3 Remove the four (4) screws marked [150]. The DC fan

can then be removed. (Fig. 3)

XH150

4/5

[380a]

[200] [220] [150]

3/5

[380b] [380b]

[150]: Bind Head Screw 4.0X45 MFZN2BL (VB857700)

[200][220]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[380]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

9. PA7 Unit

9-1 Remove the top cover. (See Procedure 1)

9-2 Remove the panel assembly. (See Procedure 5)

9-3 Remove the four (4) screws marked [250]. The PA7

unit with the chassis can then be removed. (Fig. 4)

9-4 Remove the eight (8) screws marked [130]. The PA7

unit can then be removed. (Fig. 5)

[250] 4

[150]

(Fig. 3)

Front panel

DC Fan

[130]

[380a]

FAN Angle

[130]

[130] [130]

[250]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900) [130]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

(Fig. 4) (Fig. 5)

9

Loading...

Loading...