Page 1

STAGEPAS 500

SERVICE MANUAL

SpeakerSpeaker Mixer

CONTENTS(目次)

SPECIFICATIONS(総合仕様) ............................................... 3

PANEL LAYOUT(パネルレイアウト) .................................. 4

DIMENSIONS(寸法図)......................................................... 4

CIRCUIT BOARD LAYOUT(ユニットレイアウト) .............. 5

DISASSEMBLY PROCEDURE(分解手順) ........................... 6

LSI PIN DESCRIPTION(LSI端子機能表)............................ 16

IC BLOCK DIAGRAM(ICブロック図)................................. 18

CIRCUIT BOARDS(シート基板図)..................................... 19

INSPECTIONS(検査) ......................................................... 27

ADJUSTMENT OF AMPLIFIER UNIT

(アンプユニットの調整)..................................................... 30

FACTORY SETTING(出荷時の設定).................................. 30

TROUBLE SHOOTING(トラブルシューティング)............ 31

PARTS LIST

BLOCK DIAGRAM(ブロックダイアグラム)

CIRCUIT DIAGRAM(回路図)

011840

PA

200612-155400

HAMAMATSU, JAPAN

Copyright (c) Yamaha Corporation. All rights reserved. PDF ’07.01

1

Page 2

STAGEPAS 500

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that basic

service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the users,

and have therefore not been restated.

WARNING : Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components and failure of the product to perform as specified. For these reasons, we advise

all Yamaha product owners that all service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

IMPORTANT : This presentation or sale of this manual to any individual or firm does not constitute authorization certification,

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and changes in

specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the

distributor’s Service Division.

WARNING : Static discharges can destroy expensive components. Discharge any static electricity your body may have accumulated

by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to this bus.)

IMPORTANT : Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where applicable)

components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly other entities) to cause

cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/

flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance

with the following code:

GREEN-AND-YELLOW

BLUE

BROWN

: EARTH

: NEUTRAL

: LIVE

As the colours of the wires in the mains lead of this apparatus may not

correspond with the coloured markings identifying the terminals in your plug

proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to the

terminal in the plug which is marked by the letter E or by the safety earth

symbol or colored GREEN or GREEN-and-YELLOW.

The wire which is coloured BLUE must be connected to the terminal which is

marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal which is

marked with the letter L or coloured RED.

WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those

originally installed.

印の部品は、安全を維持するために重要な部品です。交換する場合は、安全のために必ず指定の部品をご使用ください。

2

Page 3

STAGEPAS 500

SPECIFICATIONS

General Specifications

Maximum Output Power

250 W+250 W (±10 %)/4 Ω @10 % THD at 1 kHz (SPEAKER L/R)

200 W+200 W/4 Ω @1 % THD at 1 kHz (SPEAKER L/R)

Maximum Output Level

116 dB (1 m)

Frequency Response (Nominal output level @ 1 kHz)

-3 dB, 0 dB, +1 dB @20 Hz–20 kHz (MUSIC/SPEECH=MUSIC)

(MONITOR OUT)

-3 dB, 0 dB, +1 dB @80 Hz–20 kHz (MUSIC/SPEECH=SPEECH)

(REC OUT)

-3 dB, 0 dB, +1 dB @20 Hz–20 kHz, 1 W Output

(MUSIC/SPEECH=MUSIC, without Speaker EQ)

(SPEAKERS L/R)

Total Harmonic Distortion

0.5 % @20 Hz, 1 kHz, 20 kHz, +14 dBu GAIN=nominal

(MONITOR OUT, REC OUT)

Hum & Noise (Equivalent Input Noise, Rs=150 Ω, MIC/LINE=MIC)

-106 dBu (CH1/2)

-112 dBu (CH3/4)

-65 dBu Residual output noise (SPEAKERS L/R)

Crosstalk (1 kHz)

-70 dB between input channels

Phantom V oltage

+15 V (CH1–4)

LIMIT/COMP switch

ON=Comp, OFF=Limit (CH1/2)

Power Consumption

65 W

Weight

24 kg (Speaker x 2 + Powered Mixer)

Stereo Input Channel Equalization

±15 dB

HIGH 10 kHz shelving

LOW 100 Hz shelving

Accessories

Power Cable, Speaker Cable, Owner’s Manual

Option

Microphone

総合仕様

一般仕様

最大出力

250W+250W(±10%)/4Ω@10%THDat1kHz(SPEAKERSL/R)

≧200W+200W/4Ω@1%THDat1kHz(SPEAKERSL/R)

最大出力音圧レベル

116dB(軸上1m)

周波数特性(ノミナル出力レベル @1kHz)

-3dB,0dB,+1dB@20Hz〜20kHz(MUSIC/SPEECH=MUSIC)

(MONITOROUT)

-3dB,0dB,+1dB@80Hz〜20kHz(MUSIC/SPEECH=SPEECH)

(RECOUT)

-3dB,0dB,+1dB@20Hz〜20kHz,1W出力

(MUSIC/SPEECH=MUSIC,スピーカEQを除く)

(SPEAKERSL/R)

全高調波歪率

≦0.5%@20Hz,1kHz,20kHz+14dBuGAIN=すべてノミナル

(MONITOROUT,RECOUT)

ハム&ノイズ(入力換算ノイズ,Rs=150Ω,MIC/LINEスイッチ=MIC)

≦-106dBu(CH1/2)

≦-112dBu(CH3/4)

≦-65dBu残留ノイズ(SPEAKERSL/R)

クロストーク(1kHz)

≦-70dB入出力間

ファンタム電源

+15V(CH1-4)

LIMIT/COMP スイッチ

ON=コンプレッサー,OFF=リミッター(CH1/2)

消費電力

65W

質量

24kg(スピーカ2台+ミキサー)

入力チャンネルイコライザー特性

最大可変幅(±15dB)

HIGH:10kHzシェルビングタイプ

LOW:100Hzシェルビングタイプ

付属品

電源ケーブル、スピーカケーブル、取扱説明書、保証書

オプション

マイク

Speakers (500S)

Enclosure

2 way bass-reflex type, Polypropylene, Black

Crossover Frequency

4.0 kHz (LF: 12 dB/oct, HF: 12 dB/oct)

Frequency Range

55 Hz–20 kHz (-10 dB)

Speaker Unit

LF: 10" (25 cm) Cone

HF: 1" (2.54 cm) Compression Driver

スピーカ(500S)

エンクロージャー

2-wayバスレフ型,ポリプロピレン,黒

クロスオーバー周波数

4.0kHz(LF:12dB/oct,HF:12dB/oct)

再生周波数帯域

55Hz〜20kHz(-10dB)

スピーカユニット

LF:10"(25cm)コーン

HF:1"(2.54cm)コンプレッションドライバー

3

Page 4

STAGEPAS 500

PANEL LAYOUT(パネルレイアウト)

9/107/85/64321MASTER

q [AC IN] jack ([ACIN]端子)

w [POWER] switch ([POWER]スイッチ)

e [SPEAKERS L/R] jacks

(for included speakers (500S) only)

([SPEAKERSL/R]端子(付属のスピーカ(500S)専用))

r [REC OUT L/R] jacks ([RECOUTL/R]端子)

t [MONITOR OUT L(MONO)/R] jacks

([MONITOROUTL(MONO)/R]端子)

y Channel input jacks (CH 1 to 4)

(チャンネル入力端子(CH1から4))

u Stereo channel input jacks (CH 5/6, 7/8, 9/10)

(ステレオチャンネル入力端子(CH5/6、7/8、9/10))

i [MIC/LINE] switches ([MIC/LINE]スイッチ)

o [PHANTOM] switch ([PHANTOM]切り替えスイッチ)

DIMENSIONS(寸法図)

Speaker

(スピーカ部)

544.5

!0 [LIMIT/COMP] switches ([LIMIT/COMP]スイッチ)

!1 Equalizer [HIGH]/[LOW] (EQ(イコライザー))

!2 [REVERB] switches ([REVERB]スイッチ)

!3 [REVERB] control ([REVERB]コントロール)

!4 [LEVEL] controls ([LEVEL]コントロール)

!5 [MASTER LEVEL] control

([MASTERLEVEL]コントロール)

!6 [SPEECH/MUSIC] switch

([SPEECH/MUSIC]スイッチ)

!7 [MONITOR OUT] control

([MONITOROUT]コントロール)

!8 [LEVEL] meter ([LEVEL]メーター)

!9 [POWER] indicator ([POWER]インジケーター)

Mixer

(ミキサー部)

9/107/85/64321MASTER

330

111.5

Unit: mm

152

2-M8 x 25

175

342 298

120

(単位)

4

Page 5

CIRCUIT BOARD LAYOUT(ユニットレイアウト)

Front view Right side view

Speaker HF <Tweeter>

NETWORK

(スピーカHF <ツィーター>)

NETWORK

DSP

STAGEPAS 500

POWER

CONTROL1 (1/3)

CONTROL2 (2/3)

CONTROL3 (3/3)

AMP

CONTROL1 (1/3)

Speaker LF <Woofer>

(スピーカLF <ウーファー>)

Rear view

POWER

JACK

CONTROL2 (2/3)

DSP

CONTROL3 (3/3)

JACK

AMP

5

Page 6

STAGEPAS 500

DISASSEMBLY PROCEDURE

1. Front Grille Assembly

(Time required: About 1 minute)

1-1 Remove the four (4) scre ws marked [190]. The front

grille assembly can then be removed. (Fig. 1)

2. Speaker LF (Woofer)

(Time required: About 2 minutes)

2-1

Remove the front grille assemb ly. (See procedure 1)

2-2 Remove the eight (8) screws marked [170A]. The

speaker LF (woofer) can then be removed. (Fig. 1)

2-3 Remove the wire LF (red/black) attached to the

speaker LF (woofer). (Photo 1)

3. Front Cabinet Unit, Rear Cabinet Unit

(Time required: About 2 minutes)

3-1 Remove the fourteen (14) screws marked [150A].

The front cabinet unit and rear cabinet unit can then

be separated. (Fig. 1, Fig. 2)

3-2 Remove the wire LF (red/black) attached to the

speaker LF (woofer). (Photo 1)

3-3 Remove the wire HF (yellow/blue) attached to the

speaker HF (tweeter). (Photo 2)

* T ake care not to open the fr ont cabinet unit and

rear cabinet unit too wide or the speaker LF

(woofer) terminal and speaker HF (tweeter)

terminal may be damaged.

(分解手順)

1. フロントグリル Ass'y(所要時間:約1 分)

1-1 [190]のネジ4本を外して、フロントグリルAss'yを

外します。(図 1)

2. スピーカLF(ウーファー)(所要時間:約2分)

2-1 フロントグリルAss'y を外します。(1 項参照)

2-2 [170A]のネジ 8 本を外して、スピーカLF (ウー

ファー)を外します。(図 1)

2-3 スピーカLF(ウーファー)に取り付けられている

束線 LF(赤/黒)を外します。(写真 1)

3. フロントキャビネット部、リアキャビ ネット部

3-1 [150A]のネジ14本を外して、フロントキャビネッ

ト部、リアキャビネット部を別けます。(図1、図2)

3-2 スピーカLF(ウーファー)に取り付けられている

束線 LF(赤/黒)を外します。(写真 1)

3-3 スピーカHF(ツィーター)に取り付けられている

束線 HF(黄/青)を外します。(写真 2)

※ フロントキャビネット部とリアキャビネット部を

開きすぎて、スピーカLF(ウーファー)端子、ス

ピーカHF(ツィーター)端子を傷めないように注

意してください。

(所要時間:約2 分)

<Front view>

Front cabinet unit

(フロントキャビネット部)

[190]

Front grille assembly

(フロントグリルAss'y)

[170A]

[190]

[170A]: BindHeadTappingScrew-P(Pタイト+ BIND)

5.0X18BLCR3(WJ559700)

[190]: BindHeadTappingScrew-P(Pタイト+BIND)

4.0X12NI-BL(WJ329500)

[170A]

[170A]

Fig.1 (図1)

<Rear view>

[190]

Speaker LF (Woofer)

(スピーカLF (ウーファー))

[170A]

[190]

[150A]

[150A]

[150A]

[150A]

[150A]

[150A]: BindHeadTappingScrew-A(Aタイト+ BIND)

5.0X45NI-BL(WJ329900)

Rear cabinet unit

(リアキャビネット部)

[150A]

[150A]

[150A]

Fig.2 (図2)

6

Page 7

Speaker LF (Woofer)

Wire HF (Blue)

(束線HF(青))

Wire HF (Yellow)

(束線HF(黄))

Speaker HF (Tweeter)

(スピーカHF(ツィーター))

(スピーカLF(ウーファー))

STAGEPAS 500

Wire LF (Red)

(束線LF(赤))

Wire LF (Black)

(束線LF(黒))

Photo 1 (写真 1) Photo 2 (写真 2)

4. Speaker HF (Tweeter)

(Time required: About 3 minutes)

4-1 Separate the front cabinet unit and rear cabinet unit.

(See procedure 3)

4-2 Remove the two (2) screws marked [140]. The

speaker HF (tweeter) can then be removed from

the front cabinet unit. (Photo 3)

5. Network Assembly, NETWORK Circuit Board

5-1 Separate the front cabinet unit and rear cabinet unit.

(See procedure 3)

5-2 Remove the SP connector assembly from the

network assembly. (Photo 4)

5-3 Remove the four (4) screws marked [30]. The

network assembly can then be removed from the

rear cabinet unit. (Photo 4)

5-4 Remove the four (4) screws marked [N40]. The

NETWORK circuit board can then be removed.

(Photo 4-1)

(Time required: About 4 minutes)

4. スピーカHF(ツィーター)(所要時間:約3分)

4-1 フロントキャビネット部、リアキャビネット部を

別けます。(3 項参照)

4-2

[140]のネジ2 本を外して、フロントキャビネット部

からスピーカHF(ツィーター)を外します。(写真3)

5. ネットワークAss'y、NETWORKシート

(所要時間:約 4 分)

5-1 フロントキャビネット部、リアキャビネット部を

別けます。(3 項参照)

5-2 ネットワーク Ass'y からSP 束線を外します。

(写真 4)

5-3 [30]のネジ4本を外して、リアキャビネット部から

ネットワーク Ass'y を外します。(写真 4)

5-4

[N40]のネジ4本を外して、NETWORK シートを外

します。(写真 4-1)

Network assembly

(ネットワークAss'y)

SP connector assembly

(SP束線)

<Rear view>

Speaker HF

(Tweeter)

(スピーカHF

(ツィーター))

[140]: BindHeadTappingScrew-B(Bタイト+BIND)

4.0X20NI-BL(WJ329100)

Front cabinet unit

(フロントキャビネット部)

[140]

Photo 3 (写真 3)

Rear cabinet unit

(リアキャビネット部)

[30]

[30]

[30]: BindHeadTappingScrew-B(Bタイト+ BIND)

3.0X10NI-BL(WJ329200)

Photo 4 (写真 4)

Network Assembly (ネットワークAssy)

●

NETWORK

[N40]

[N40]: PanHeadTappingScrew-B(Bタイト+ PAN)

3.0X8CR3(WJ329000)

[N40]

Photo 4-1 (写真 4-1)

7

Page 8

STAGEPAS 500

6. Mixer Assembly, Cover Mold Assembly

(Time required: About 1 minute)

6-1 Rotate the two (2) straight slots on the fastener

heads with a coin driver or minus driver until each

straight slot is in alignment with the “OPEN” position.

The mixer assembly or cover mold assembly can

then be removed. (Photo 5)

7. JACK Circuit Board

(Time required: About 1 minute)

7-1 Remove the mixer assembly or cover mold

assembly. (See procedure 6)

7-2 Remove the three (3) screws marked [50A]. The

mount bracket assembly can then be removed

together with the JACK circuit board. (Photo 6)

7-3 Remove the SP connector assembly from the J ACK

circuit board. (Photo 6-1)

7-4 Remove the hexagonal nut marked [210a]. The

JACK circuit board can then be removed from the

mount bracket assembly. (Photo 6-1)

Coin driver or minus driver

(コインドライバーまたは

マイナスドライバー)

6. ミキサー Ass'y、カバーモールドAss'y

(所要時間:約 1 分)

6-1 コインドライバーまたはマイナスドライバーで、

ファスナーヘッドのマイナス形溝 2 箇所を

OPENの位置まで回して、ミキサーAss'yまたは

カバーモールドAss'y を外します。(写真 5)

7. JACKシート(所要時間:約1 分)

7-1 ミキサーAss'yまたはカバーモールドAss'yを外し

ます。(6 項参照)

7-2 [50A]のネジ 3 本を外して、JACK シートと共にマ

ウントブラケット Ass'y を外します。(写真 6)

7-3 JACK シートから SP束線を外します。(写真 6-1)

7-4 [210a]の特殊六角ナット1個を外して、マウントブ

ラケット Ass'y からJACK シートを外します。

(写真 6-1)

Fastner head

(ファスナーヘッド)

Fastner head

(ファスナーヘッド)

Fastner head

(ファスナーヘッド)

Mount bracket assembly

(マウントブラケットAss'y)

Fastner head

(ファスナーヘッド)

Fastner head

(ファスナーヘッド)

Mixer assembly

(ミキサーAss'y)

[210a]

Cover mold assembly

(カバーモールドAss'y)

Photo 5 (写真 5)

Mount bracket assembly

(マウントブラケットAss'y)

JACK

[50A]: BindHeadTappingScrew-P(P タイト+BIND)

[50A]

4.0X12NI-BL(WJ329500)

Photo 6 (写真 6)

8

SP connector assembly

(SP束線)

[210a]: HexagonalNut(特殊六角ナット)M15.0BL

Photo 6-1 (写真 6-1)

Page 9

STAGEPAS 500

Shield bracket 2 (シールドブラケット2)

[380]

[380]

8. Rear Case

(Time required: About 2 minutes)

8-1 Remove the mixer assembly. (See procedure 6)

8-2 Remove the eight (8) screws marked [400]. The rear

case can then be removed from the mixer assemb ly.

(Photo 7)

9. Shield Bracket 2

(Time required: About 2 minutes)

9-1 Remove the mixer assembly. (See procedure 6)

9-2 Remove the rear case. (See procedure 8)

9-3 Remove the four (4) screws marked [380]. The

shield bracket 2 can then be removed. (Photo 8)

10. POWER Circuit Board

(Time required: About 3 minutes)

10-1 Remove the mixer assembly. (See procedure 6)

10-2 Remove the rear case. (See procedure 8)

10-3 Remove the shield bracket 2. (See procedure 9)

10-4

Remove the six (6) scre ws marked [290]. The PO WER

circuit board can then be removed. (Photo 9)

● Mixer Assembly (ミキサーAssy)

[400]

8. リアケース(所要時間:約 2 分)

8-1 ミキサー Ass'y を外します。(6 項参照)

8-2 [400]のネジ8本を外して、ミキサーAss'y からリア

ケースを外します。(写真 7)

9. シールドブラケット 2(所要時間:約2 分)

9-1 ミキサー Ass'y を外します。(6 項参照)

9-2 リアケースを外します。(8 項参照)

9-3 [380]のネジ4本を外して、シールドブラケット2を

外します。(写真 8)

10. POWER シート(所要時間:約 3 分)

10-1 ミキサー Ass'y を外します。(6 項参照)

10-2 リアケースを外します。(8 項参照)

10-3 シールドブラケット 2 を外します。(9 項参照)

10-4 [290]のネジ 6 本を外して、POWER シートを外し

ます。(写真 9)

Rear case (リアケース)

[400]: HexagonalTappingScrew-B(六角ネジ Bタイト)

3.0X8NI-BL(AAX62010)

[400]

Photo 7 (写真 7)

POWER

[290]:PanHeadTappingScrew-B(Bタイト+ PAN)3.0X8CR3(WJ329000)

[380]: BindHeadTappingScrew-B(Bタイト+BIND)

3.0X8CR3(AAX61980)

Photo 8 (写真 8)

[290]

[290]

Photo 9 (写真 9)

9

Page 10

STAGEPAS 500

ト

11. DSP Circuit Board

(Time required: About 2 minutes)

11-1 Remove the mixer assembly. (See procedure 6)

11-2 Remove the rear case. (See procedure 8)

11-3 Remove the shield bracket 2. (See procedure 9)

11-4 Remove the DSP circuit board from the connectors

CN27 and CN33 of the CONTROL2 (2/3) circuit

board. (Photo 10)

CONTROL2 (2/3)

[CN33]

[CN27]

11. DS P シート(所要時間:約 2分)

11-1 ミキサー Ass'y を外します。(6 項参照)

11-2 リアケースを外します。(8 項参照)

11-3 シールドブラケット 2 を外します。(9 項参照)

11-4 CONTROL2(2/3)シートのCN27とCN33のコネク

ターから DSP シートを外します。(写真 10)

[CN32]

DSP

[CN28]

Photo 10 (写真 10)

12.

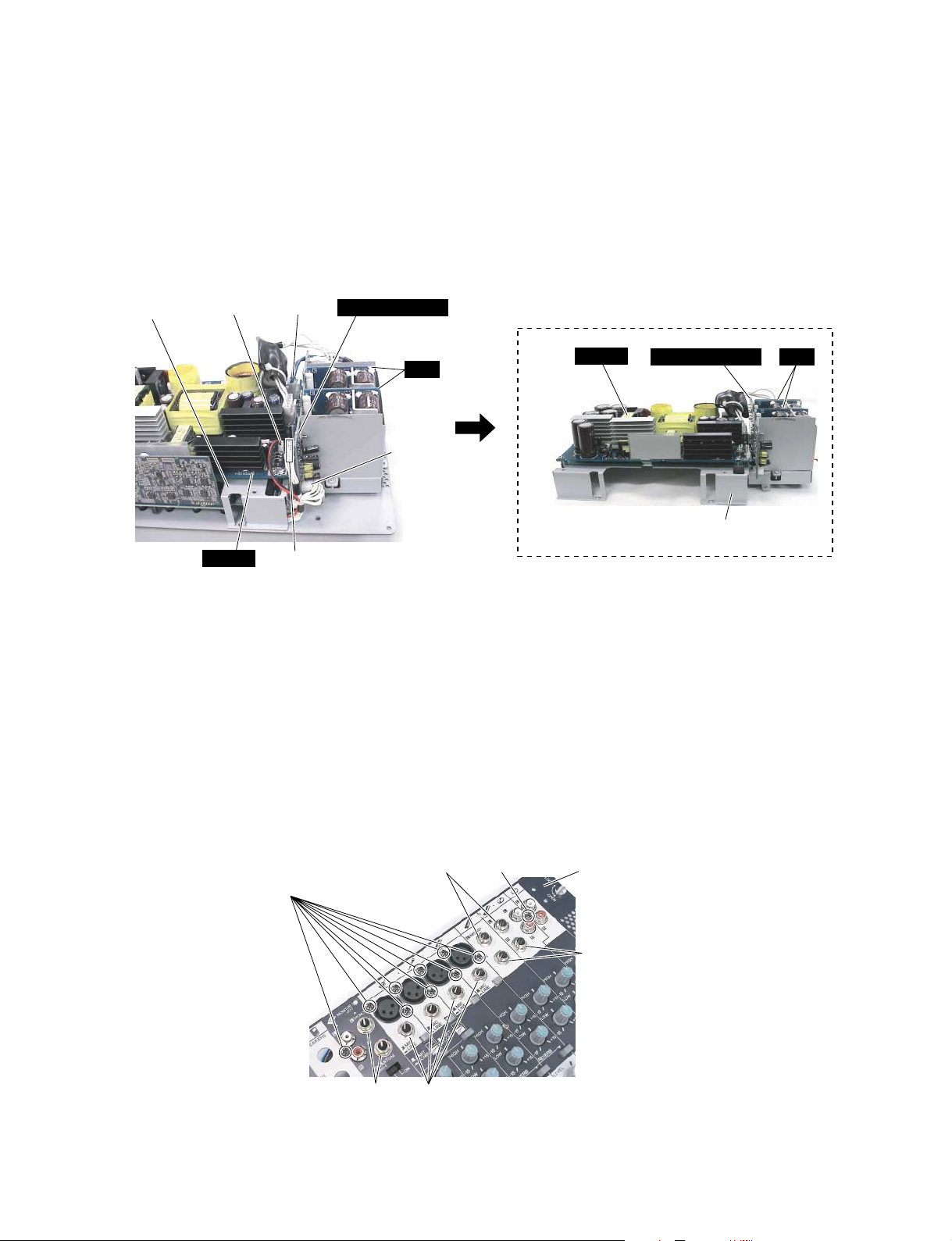

AMP Circuit Board, CONTROL3 (3/3) Circuit Board

(Time required: About 4 min utes)

12-1 Remove the mixer assembly. (See procedure 6)

12-2 Remove the rear case. (See procedure 8)

12-3 Remove the shield bracket 2. (See procedure 9)

12-4 Remove the two (2) hexagonal nuts mark ed [240aA]

from the panel printing side. (Photo 11)

12-5 Remove the two (2) screws marked [270]. The

phone bracket can then be removed together with

the AMP circuit board and CONTROL3 (3/3) circuit

board. (Photo 12)

12-6 Remove the two (2) screws marked [260A]. The

AMP circuit board and CONTROL3 (3/3) circuit

board can then be removed from the phone brack et.

(Photo 13)

12-7 Remove the screw marked [260B]. The AMP circuit

board A can then be removed from the CONTROL3

(3/3) circuit board. (Photo 13)

12-8 Remove the screw marked [260C]. The AMP circuit

board B can then be removed from the CONTROL3

(3/3) circuit board. (Photo 13)

Panel assembly

(パネルAss'y)

12. AMP シート、CONTROL3(3/3)シート

(所要時間:約 4 分)

12-1 ミキサー Ass'y を外します。(6 項参照)

12-2 リアケースを外します。(8 項参照)

12-3 シールドブラケット 2 を外します。(9 項参照)

12-4 パネル印刷面から[240aA]の特殊六角ナット2個を

外します。(写真 11)

12-5 [270]のネジ2本を外して、A M P シート、

CONTROL3(3/3)シートと共にホーンブラケット

を外します。(写真 12)

12-6 [260A]のネジ2本を外して、ホーンブラケットから

AMP シートとCONTROL3 (3/3)シートを外しま

す。(写真 13)

12-7 [260B]のネジ1本を外して、CONTROL3(3/3)シー

トからAMP シートA を外します。(写真 13 )

12-8 [260C]のネジ1本を外して、CONTROL3(3/3)シー

トからAMP シートB を外します。(写真 13)

CONTROL3 (3/3)

10

[240aA]

[240aA]:HexagonalNut(特殊六角ナット)M15.0BL

Photo 11 (写真 11)

[270]

Phone bracket (ホーンブラケッ

[270]: BindHeadTappingScrew-B(Bタイト+BIND)

3.0X8CR3(AAX61980)

AMP

[270]

)

Photo 12 (写真 12)

Page 11

STAGEPAS 500

Panel assembly

(パネルAss'y)

[240aB]

[170B]

[170B]

1

2

3

4

5

6

[P30]

[260B] [260C] [260A][260A]

CONTROL3 (3/3)

AMP

B

Phone bracket

(ホーンブラケット)

[260A],[260B],[260C]:BindHeadTappingScrew-B(Bタイト+ BIND)3.0X8CR3(AAX61980)

Photo 13 (写真 13)

13. Shield Bracket 1 Assembly

(Time required: About 4 minutes)

13-1 Remove the mixer assembly. (See procedure 6)

13-2 Remove the rear case. (See procedure 8)

13-3 Remove the two (2) each screws marked [P30]. The

two (2) handles can then be removed. (Photo 14,

Photo15, Photo16)

13-4 Remove the six (6) screws marked [170B] and two

(2) hexagonal nuts marked [240aB] from the panel

printing side. (Photo 17)

13-5 Remove the shield bracket 2. (See procedure 9)

A

AMP

13. シールドブラケット 1Ass'y

(所要時間:約 4 分)

13-1 ミキサー Ass'y を外します。(6 項参照)

13-2 リアケースを外します。(8 項参照)

13-3 [P30]のネジを 2 本づつ外して、ハンドルを2 本外

します。(写真 14、写真15、写真 16)

13-4 パネル印刷面から[170B]のネジ6 本、[240aB]の特

殊六角ナット 2 個を外します。(写真 17)

13-5 シールドブラケット 2 を外します。(9 項参照)

[P30]

[P30]:BindHeadScrew(小ネジ+BIND)M3.0X8CR3

(AAX61910)

Photo 14 (写真 14)

Handle (ハンドル)

Photo 16 (写真 16)

[P30]:BindHeadScrew(小ネジ+BIND)M3.0X8CR3

(AAX61910)

Photo 15 (写真 15)

[170B]: BindHeadTappingScrew-B(B タイト+ BIND)

3.0X10NI-BL(WJ329200)

[240aB]: HexagonalNut(特殊六角ナット)M15.0BL

Photo 17 (写真 17)

11

Page 12

STAGEPAS 500

13-6

Disconnect the connectors CN801, CN802 and

CN803 of the POWER circuit board and the connector

CN542 of the CONTROL3 (3/3) circuit board. The

shield bracket 1 assembly (including AMP circuit

board, CONTROL3 (3/3) circuit board and POWER

circuit board) can then be removed. (Photo 18)

* When installing the shield bracket 1 assembly,

tighten the screws marked [170B] in numerical

order (①→⑥ ). (Photo 17)

Shield bracket 1

(シールドブラケット1)

[CN803]

POWER

[CN801]

[CN802]

CONTROL3 (3/3)

AMP

[CN542]

Photo 18 (写真 18)

13-6 POWER シートの CN801、CN802、CN803 と

CONTROL3(3/3)シートのCN542のコネクターを

抜いて、シールドブラケット1Ass'y(AMPシート、

CONTROL3(3/3)シート、POWERシートを含みま

す。)を外します。(写真 18)

※ シールドブラケット 1 Ass'y を取り付ける際は、

[170B]のネジを①→⑥の順に締めます。(写真17)

●

Shield Bracket 1 Assembl y (シールドブラケット1Ass'y)

POWER

CONTROL3 (3/3)

Shield bracket 1

(シールドブラケット1)

AMP

14. CONTROL1 (1/3) Circuit Board

(Time required: About 8 minutes)

14-1 Remove the mixer assembly. (See procedure 6)

14-2 Remove the rear case. (See procedure 8)

14-3 Remove the shield bracket 2. (See procedure 9)

14-4 Remove the

(See procedure 13)

14-5 Remove the ten (10) hexagonal nuts marked [140a],

ten (10) flat washers marked [140b] and ten (10)

screws marked [150B] from the panel printing side.

(Photo 19)

shield bracket 1 assembly

[150B]

.

[140a], [140b]

14. CONTROL1(1/3)シート(所要時間:約8分)

14-1 ミキサー Ass'y を外します。(6 項参照)

14-2 リアケースを外します。(8 項参照)

14-3 シールドブラケット 2 を外します。(9 項参照)

14-4 シールドブラケット 1Ass'y を外します。

(13 項参照)

14-5 パネル印刷面から[140a]の特殊六角ナット 1 0 個、

[140b]の特殊平座金 10 個、[150B]のネジ 10本を外

します。(写真 19)

[150B]

Panel assembly

(パネルAss'y)

[140a], [140b]

12

[140a], [140b][140a], [140b]

[140a]:HexagonalNut(特殊六角ナット)M11.0

[140b]:FlatWasher(特殊平座金)M9.2

[150B]:BindHeadTappingScrew-B(Bタイト+ BIND )3.0X10NI-BL(WJ329200)

Photo 19 (写真 19)

Page 13

STAGEPAS 500

14-6 Remove the CONTROL1 (1/3) circuit board from

the connectors CN21 and CN26 of the CONTROL2

(2/3) circuit board. (Photo 20)

*

The four (4) push buttons marked [120] and four

(4) push spacers marked [130] are not parts of

the CONTROL1 (1/3) circuit board. When

replacing the CONTROL1 (1/3) circuit board, be

sure to remove these parts and attach them to

the new CONTROL1 (1/3) cir cuit boar d. (Photo 21)

CONTROL1 (1/3)

[CN25]

[CN26]

[CN22]

[CN21]

CONTROL2 (2/3)

Photo 20 (写真 20)

14-6

CONTROL2(2/3)シートのCN21、CN26のコネクター

からCONTROL1(1/3)シートを外します。(写真 20)

※ [120]のプッシュボタン4 個と[130]のプッシュス

ペーサ4個は、CONTROL1(1/3)シートの構成部品

ではありません。CONTROL1(1/3)シートを交換す

る際には必ずこれらを取り外し、新しい

CONTROL1 (1/3)シートに取り付けてください。

(写真 21)

[120]: Push button

(プッシュボタン)

[130]: Push spacer

(プッシュスペーサ)

CONTROL1 (1/3)

Photo 21 (写真 21)

15. CONTROL2 (2/3) Circuit Board

(Time required: About 9 minutes)

15-1 Remove the mixer assembly. (See procedure 6)

15-2 Remove the rear case. (See procedure 8)

15-3 Remove the shield bracket 2. (See procedure 9)

15-4 Remove the DSP circuit board. (See procedure 11)

15-5 Remove the shield bracket 1 assembly.

(See procedure 13)

15-6 Remove the CONTROL1 (1/3) circuit board.

(See procedure 14)

15-7 Remove the sev en (7) volume knobs (white) marked

[80] and the volume knob (red) marked [90] from

the panel printing side. (Photo 22)

[90]: Volume knob (Red)

(ノブVR(赤))

[80]: Volume knob (White)

(ノブVR(白))

15. CONTROL2(2/3)シート(所要時間:約 9 分)

15-1 ミキサー Ass'y を外します。(6 項参照)

15-2 リアケースを外します。(8 項参照)

15-3 シールドブラケット 2 を外します。(9 項参照)

15-4 DSP シートを外します。(11 項参照)

15-5 シールドブラケット 1Ass'y を外します。

(13 項参照)

15-6 CONTROL1(1/3)シートを外します。(14 項参照)

15-7 パネル印刷面から[80]のノブVR(白)7個、[90]の

ノブVR(赤)1 個を外します。(写真 22)

Panel assembly

(パネルAss'y)

Photo 22 (写真 22)

13

Page 14

STAGEPAS 500

15-8 Remove the five (5) screws marked [110]. The

CONTROL2 (2/3) circuit board can then be

removed. (Photo 23)

* The following parts are not parts of the

CONTROL2 (2/3) circuit board. When replacing

the CONTROL2 (2/3) circuit board, be sure to

remove these parts and attach them to the new

CONTROL2 (2/3) circuit board. (Photo 24)

• [40]: Push buttons 7 pcs.

• [50B]: Volume knob (S) (white) 1 pc.

• [60]: Volume knobs (S) (green) 14 pcs.

• [70]: Volume knob (S) (blue) 1 pc.

[110]

[110]: BindHeadScrew(小ネジ+BIND)

M3.0X8CR3(AAX61910)

CONTROL2 (2/3)

[110]

Photo 23 (写真 23)

15-8 [110]のネジ 5 本を外して、CONTROL2(2/3)シー

トを外します。(写真 23)

※ 以下の各部品は、CONTROL2(2/3)シートの構成部

品ではありません。CONTROL2(2/3)シートを交換

する際には必ずこれらを取り外し、新しい

CONTROL2 (2/3)シートに取り付けてください。

(写真 24)

・[40]: プッシュボタン 7 個

・[50B]: ノブ VR(S)(白) 1個

・[60]: ノブ VR( S)(緑) 14個

・[70]: ノブ VR( S)(青) 1個

[50B]: Volume knob (S) (White)

(ノブVR(S)(白))

[40]: Push button

(プッシュボタン)

CONTROL2 (2/3)

[70]: Volume knob (S) (Blue) (ノブVR(S)(青))

[40]: Push button (プッシュボタン)

[60]: Volume knob (S) (Green)

(ノブVR(S)(緑))

Photo 24 (写真 24)

16. Power Switch, AC Inlet

(Time required: About 5 minutes)

16-1 Remove the mixer assembly. (See procedure 6)

16-2 Remove the rear case. (See procedure 8)

16-3 Remove the shield bracket 2. (See procedure 9)

16-4 Remove the shield bracket 1 assembly.

(See procedure 13)

16-5 Remove the two (2) connector assemblies

(connector assembly (1P) and connector assembly

(2P)) and earth wire soldered to the power switch

and AC inlet. (Fig. 3)

16-6

Remove the pow er switch by pressing its claws. (Fig. 4)

16-7 Remove the AC inlet by pressing its claws. (Fig. 5)

17. Fan (Time required: About 5 minutes)

17-1 Remove the mixer assembly. (See procedure 6)

17-2 Remove the rear case. (See procedure 8)

17-3 Remove the shield bracket 2. (See procedure 9)

17-4 Remove the shield bracket 1 assembly.

(See procedure 13)

17-5 Remove the four (4) screws marked [210]. The fan

can then be removed from the shield bracket 1

assembly. (Photo 25)

* The fan is fixed with two-sided tape. Apply

power little by little to remove the fan.

16. 電源スイッチ、ACインレット

(所要時間:約5分)

16-1 ミキサー Ass'y を外します。(6 項参照)

16-2 リアケースを外します。(8 項参照)

16-3 シールドブラケット 2 を外します。(9 項参照)

16-4 シールドブラケット 1Ass'y を外します。

(13 項参照)

16-5 電源スイッチとACインレットに半田付けされてい

る束線2本(束線1P,束線2P)とアース線を外しま

す。(図 3)

16-6 電源スイッチのツメを押して外します。(図 4)

16-7 AC インレットのツメを押して外します。(図 5)

17. ファン(所要時間:約 5分)

17-1 ミキサー Ass'y を外します。(6 項参照)

17-2 リアケースを外します。(8 項参照)

17-3 シールドブラケット 2 を外します。(9 項参照)

17-4 シールドブラケット 1Ass'y を外します。

(13 項参照)

17-5 [210]のネジ 4 本を外して、シールドブラケット 1

Ass'y からファンを外します。(写真 25)

※ ファンは両面テープで固定されていますので、軽

く力を加えて外してください。

14

Page 15

y

Fig.3 (図3)

AC inlet

(ACインレット)

Connector assembly (1P) (brown)

(束線 1P (茶))

Connector assembly (2P)

(束線 2P)

(brown)

(茶)

(blue)

(青)

Panel (パネル)

Earth wire (green)

(アース線 (緑))

Power switch

(電源スイッチ)

Soldering (半田付け)

Soldering

(半田付け)

Power switch

(電源スイッチ)

Panel (パネル)

Claw (ツメ)

Claw (ツメ)

AC inlet

(ACインレット)

Claw (ツメ)

Panel (パネル)

Claw

(ツメ)

STAGEPAS 500

Fig.4 (図4)

Fig.5 (図5)

[210]

Fan (ファン)

[210]:BindHeadTappingScrew-B(Bタイト+ BIND)3.0X20NI-BL(WK008800)

Photo 25 (写真 25)

[210]

Shield bracket 1 assembly

(シールドブラケット1Ass'

)

15

Page 16

STAGEPAS 500

LSI PIN DESCRIPTION

(LSI端子機能表)

YMW767-VTZ (X6055A00) CPU (SWL01B)

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

TESTN

PLLBPN

PLLV

CIN

PLLVss

TRSTN

TMS

TCK

TDO

ICN

ECSN

EWRN/PD5

ERDN/PD4

EA3/PD3

EA2/PD2

EA1/PD1

EA0/PD0

IOV

ED0/PC0

ED1/PC1

ED2/PC2

ED3/PC3

ED4/PC4

ED5/PC5

ED6/PC6

ED7/PC7

IRQ0N/PH0

TxD0

RxD0

TxD1/PG2

RxD1/PH1

SCLK1/PH2

SDO

SDI/PH3

BCLK

WCLK/SYO

SYSCLK/PG3

IOV

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7/SYI

Vss

TDI

XI

XO

Vss

V

Vss

Vss

V

Vss

I/O FUNCTIONNAME

I

I

DD

-

-

-

Ground

Input for TEST

PLL bypass select

PLL Power supply +2.5 V

Capacitor terminal for PLL

PLL Ground

I

I

I

JTAG input

I

O

I

O

-

DD

I

I

I

I

JTAG output

Crystal oscillator

Crystal oscillator

Ground

Power supply +2.5 V

Hardware reset

CPU I/F chip select

CPU I/F write enable / Port D

CPU I/F read enable / Port D

I

I

I

CPU I/F address bus / Port D

I

-

DD

Power supply +3.3 V

I/O

I/O

I/O

I/O

I/O

CPU I/F data bus / Port C

I/O

I/O

I/O

I

O

I

O

I

I

O

I

O

O

O

-

-

DD

-

DD

Ground

Interrupt input / Port H

Serial output

Serial input

Serial output / Port G

Serial input / Port H

External synchronization clock / Port H

Serial output

Serial input / Port H

Bit clock output

Word clock output

Clock output / Port G

Ground

Power supply +2.5 V

Power supply +3.3 V

I/O

I/O

I/O

I/O

I/O

I/O port A

I/O

I/O

I/O

-

Ground

I/O

I/O

I/O

I/O

I/O

I/O port B

I/O

I/O

I/O

PIN

NO.

Vss

65

IOV

66

67

LBN/LWRN/PF6

68

UBN/UWRN/PF7

69

RDN/PF4

70

MD00

71

MD08

72

MD01

73

MD09

74

MD02

75

MD10

76

MD03

77

Vss

78

MD11

79

MD04

80

MD12

81

MD05

82

MD13

83

MD06

84

MD14

85

MD07

86

MD15

87

WRN/PF5

88

Vss

89

V

90

IOV

91

MA17

92

MA16

93

MA15

94

MA14

95

MA13

96

MA12

97

MA11

98

MA10

99

MA09

100

MA08

101

MA07

102

MA06

103

MA05

104

Vss

105

MA04

106

MA03

107

MA02

108

MA01

109

CS0N/PG0

110

MA18

111

MA19

112

MA21/PF1

113

MA22/PF2

114

MA20

115

MA23/PF3

116

CSIN/PG1

117

MA00/PF0

118

Vss

119

V

120

IOV

121

CS2N/PE0

122

CS3N/PE1

123

CS4N/CASN/PE2

124

CS5N/PE3

125

CS50RDN/PE4

126

CS51WRN/PE5

127

CS52WRN/PE6

128

CS53WRN/RASN/PE7

DSP: IC1007

I/O FUNCTIONNAME

-

-

DD

O

O

O

Ground

Power supply +3.3 V

External memory lower-byte enable / Port F

External memory upper-byte enable / Port F

External memory read enable / Port F

I/O

I/O

I/O

I/O

External memory data bus

I/O

I/O

I/O

-

Ground

I/O

I/O

I/O

I/O

I/O

External memory data bus

I/O

I/O

I/O

I/O

O

-

-

DD

-

DD

Ground

Power supply +2.5 V

Power supply +3.3 V

O

O

O

O

O

O

O

External memory address bus

O

O

O

O

O

O

-

Ground

O

O

O

External memory address bus

O

O

O

O

O

O

O

O

O

O

-

-

DD

-

DD

External memory chip select / Port G

External memory address bus

External memory address bus / Port F

External memory address bus

External memory address bus / Port F

External memory chip select / Port G

External memory address bus / Port F

Ground

Power supply +2.5 V

Power supply +3.3 V

O

O

O

O

O

External memory chip select / Port E

O

O

O

16

Page 17

STAGEPAS 500

AK5381VT (X8575A00) ADC (Analog to Digital Converter)

PIN

NO.

1

2

3

4

5

6

7

8

NAME

AINR

AINL

CKS1

VCOM

AGND

VA

VD

DGND

I/O

FUNCTION

I

I

I

O

-

-

-

-

Rch Analog input pin

Lch Analog input pin

Mode select 1 pin

Common voltage output pin

Analog ground

Analog power supply +5V

Digital power supply +3.3V

Digital ground

PIN

NO.

9

10

11

12

13

14

15

16

NAME

SDTO

LRCK

MCLK

SCLK

PDN

DIF

CKS2

CKS0

I/O

I/O

PCM1742EK (X8574A00) DAC (Digital to Analog Converter)

PIN

NO.

1

2

3

4

5

6

7

8

NAME

BCK

DATA

LRCK

DGND

DD

V

Vcc

OUTL

V

VOUTR

I/O

I

Audio data bit clock input

I

Audio data digital input

I

L-channel and R-channel audio-data latch-enable input

-

Digital ground

-

Digital power supply +3.3V

-

Analog power supply +5V

O

Analog output for L-channel

O

Analog output for R-channel

FUNCTION

PIN

NAME

NO.

9

AGND

10

Vco

11

ZEROR/ZEROA

12

ZEROL/NA

13

MD

14

MC

15

ML

16

SCK

M

DSP: IC1004

DAC1A: IC401

I/O

O

Audio serial data output pin

FUNCTION

Output channel clock pin

I

Master clock input pin

Audio serial data clock pin

I

I

I

I

I/O

-

-

O

O

I

I

I

I

Power down mode pin

Audio interface format pin

Mode select 2 pin

Mode select 0 pin

DSP: IC1008

DAC1A: IC401

FUNCTION

Analog ground

Common voltage decoupling

Zero-flag output for R-channel/Zero-flag output for L-/R-channel

Zero-flag output for L-channel/No assign

Mode control data input

Mode control clock input

Mode control latch input

System clock input

17

Page 18

STAGEPAS 500

IC BLOCK DIAGRAM

FA3641N (X8570A00) PWM Control

POWER: IC803

7

REF

1

RTRch

2

FB

GND

3

4

IS(+)/IS(-)

LB1407-E LF (AAX68710) AC/DC Voltage Level Meter

CONTROL2 (2/3): IC604

1

Vcc

2

Rch

3

Vref

+

4

IN

--

5

IN

6

OUT

7

GND

7

8

CS

7

REF

6

VCC

5

OUT

2

FB

14

D7

13

D6

12

D5

11

D4

+

10

9

8

8

IN

D3

--

IN

D2

D1

(ICブロック図)

0.82V~0.68V

OSC

RM RT

1 3

2

–

–

8.5V~7.9V

4V

5.83 kΩ

-COM

7

+

+

+

0.24V

R7

5V VCC

ENB

5V REF

3.0V

+

–

Dmax

70%

+

–

Vref

1

3

4

5

VCCCS

68

6.5 A

0.9mA

–

–

–

PWM

+

–

+

IS +RT

D7

14

R6

4.12 kΩ

-COM

6

+

0.8V

15.5V

UVLO

15.5V

+

–

R

S

D6

13

16.5V/9V

ENB

FF

QB

Q

12, 11, 10, 9

R1

1 kΩ

-COM

1

+

+

–

OUTPUT

D1Vcc Rch

8

5

OUT

GND

4

NJM2068M-D TE1 (AAX62750) Dual Operational Amplifier

CONTROL1 (1/3):

CONTROL2 (2/3):

CONTROL3 (3/3):

DSP:

Output A

Inverting

Input A

Non-Inverting

Input A

-DC Voltage Supply

IC101, 201, 501, 701, 704

IC102, 104-106, 108, 202,

203, 205, 206, 302, 402,

502, 503, 702, 703, 901,

902

IC541, 542

IC103, 107, 204, 603, 1009,

1011

1

2

3

4-V

+V

+-

+-

18

+DC Voltage

8

Supply

7

Output B

Inverting

6

Input B

Non-Inverting

5

Input B

OUT

7

6

GND

µPC494GS-T2-A (X8569A00)

Switching Regulator

POWER: IC802

Non-Inv.

Inv.

Ref

Output

Vcc C

2

E2E

GND

1

C

1

Input

Input

Out

16 15 14 13 12 11 10 9

+

ERROR

AMP

2

ERROR

AMP

+

1

1 2 3 4 5 6 7 8

Non-Inv.

Inv.

Input

Input

Control

–

REFERENCE

REGULATOR

0.1V

Dead-

Time

Control

OSCILLATOR

CTR

T

–

Feed-

Back

Page 19

STAGEPAS 500

CIRCUIT BOARDS

AMP Circuit Board (4200-30) ...................................................................26

CONTROL1 (1/3) Circuit Board (6486-30) ...............................................24

CONTROL2 (2/3) Circuit Board (6486-30) ......................................... 22/23

CONTROL3 (3/3) Circuit Board (6486-30) ...............................................25

DSP Circuit Board (1043-40) ....................................................................19

JACK Circuit Board (5254B-30) ...............................................................25

NETWORK Circuit Board (5254A-30) ......................................................26

POWER Circuit Board (8146-40) ........................................................ 20/21

Note: See parts list for details of circuit board component parts.

注: シートの部品詳細はパーツリストをご参照ください。

DSP Circuit Board

not installed

(シート基板図)

* 1

* 1

to CONTROL2 (2/3)-CN33 to CONTROL2 (2/3)-CN27

Component side(部品側)

* 2

+

C1012

–

* 2

C1013

444608

Pattern side(パターン側)

19

Page 20

STAGEPAS 500

to CONTROL3 (3/3)-CN541

to FAN

to POWER switch

AC IN

to CONTROL2 (2/3)-CN1

POWER Circuit Board

20

Component side(部品側)

444598 (J, U, C), 444744 (B, H, O)

Page 21

POWER Circuit Board

STAGEPAS 500

444598 (J, U, C), 444744 (B, H, O)

Pattern side(パターン側)

21

Page 22

STAGEPAS 500

LIMITER

MONITOR OUT

REVERB

REVERB

HIGH

LOW

REVERB

HIGH

LOW

REVERB

HIGH

LOW

REVERB

HIGH

LOW

HIGH

LOW LOW

HIGHHIGH

LOW

+6

+3

0

-6

-20

POWER

SPEECH

MUSIC

LEVEL

MASTER

LEVEL

CH1

LEVEL

CH2

LEVEL

CH3

LEVEL

CH4

LEVEL

CH5/6

LEVEL LEVEL

CH7/8 CH9/10

to DSP-CN32

to CONTROL1 (1/3)-CN22

to POWER-CN802

to CONTROL1 (1/3)-CN25

to DSP-CN28

to CONTROL3 (3/3)-CN542

LIMIT

COMP

LIMIT

COMP

CONTROL2 (2/3) Circuit Board

22

Component side(部品側)

444603

Page 23

CONTROL2 (2/3) Circuit Board

STAGEPAS 500

444603

Pattern side(パターン側)

23

Page 24

STAGEPAS 500

to CONTROL2 (2/3)-CN26

to CONTROL2 (2/3)-CN21

L

R

R

L(MONO)

R

R

R

R

L(MONO)

L

L

L

REC OUT

MONITOR

OUT

CH1

CH2

CH3

CH4

CH5/6

CH7/8

CH9/10

MIC

LINE

MIC

LINE

MIC

LINE

MIC

LINE

PHANTOM

CH1-4

OFF ON

CONTROL1 (1/3) Circuit Board

24

Component side(部品側) Pattern side(パターン側)

444603

Page 25

SPEAKER

INPUT

to NETWORK-CN8

CONTROL3 (3/3) Circuit Board

to CONTROL2 (2/3)-CN24

to AMP-1100 (L ch)

to AMP-1101 (L ch)

STAGEPAS 500

to AMP-1101 (R ch)

to AMP-1100 (R ch)

R

SPEAKERS

L

to POWER-CN804

Component side(部品側)

JACK Circuit Board

Pattern side(パターン側)

CONTROL3 (3/3): 444603

JACK: 445546

Component side(部品側)

25

Page 26

STAGEPAS 500

AMP Circuit Board

to CONTROL3 (3/3)-CN544 (L ch)

CONTROL3 (3/3)-CN546 (R ch)

to CONTROL3 (3/3)-CN543 (L ch)

CONTROL3 (3/3)-CN545 (R ch)

Component side(部品側)

NETWORK Circuit Board

to JACK-CN15

Pattern side(パターン側)

to Speaker HF

to Speaker LF

26

(TWEETER)

(WOOFER)

Component side(部品側)

AMP: 444611

NETWORK: 445546

Page 27

STAGEPAS 500

)

INSPECTIONS

(検査)

1. Test Conditions(試験条件)

Measuring Voitage(測定電圧): AC 100 V 50/60 Hz (J)

AC 120 V 60 Hz (U, C)

AC 230 V 50 Hz (B, H)

AC 220 V 50 Hz (O)

Load(負荷):4 Ω

Input(入力): 1 KHz

MASTER LEVEL VR(マスターレベルVR): MAX.

Tone-control VR(トーンコントロール VR): HIGH, LOW = All channel Center.

REVERB SW(リバーブSW): All channel OFF.

REVERB level(リバーブレベルVR):MIN.

SPEECH/MUSIC SW(スピーチ/ ミュージックSW): MUSIC

LIMIT/COMP SW(リミット/ コンプSW): LIMIT

USE MEASUREMENT FILTER: DIN-Audio

PHANTOM SW(ファンタムSW):OFF

NOTE:

q Use a low pass filter (20 KHz) to measure noise at the SP jack (SPEAKERS).

(SP端子(SPEAKERS)でノイズを測定する場合は、ローパスフィルター(20KHz)を使用してくださ い。)

w The sleeve of the SPEAKERS Lch is the hot terminal. So, pay attention not to let it

contact GND.

(SPEAKERSLchは、スリーブ側がホット端子となりますので、アースに接触しない

様注意してください。)

Sleeve

(スリーブ)

Tip

(チップ

2. Electric Characteristic(電気特性)

No.

1

OUTPUT POWER

(定格出力)

2

T. H. D.

(歪率)

ITEM

(項目)

INPUT CONDITIONS

(入力条件)

INPUT1-SW=LINE

INPUT1-LEVEL=NOMINBAL

INPUT1-SW=LINE

INPUT1-LEVEL=MAX.

INPUT1-SW=LINE

INPUT1-LEVEL=MAX.

OUTPUT CONDITIONS

(出力条件)

SP OUT: L, R

1 %THD OUTPUT

(1%歪 出力)

20-20KHz FILTER

SP OUT: L, R

50 W OUTPUT

(50W 出力)

MONITOR OUT: L, R

+14 dBu OUTPUT

(Load: 10 kΩ)

NOMINAL

(標準値)

210 W

0.5 %

0.1 %

LIMIT

(限界値)

>200 W

<1 %

<0.5 %

27

Page 28

STAGEPAS 500

No.

3

INPUT SENSITIVITY

(入力感度)

4

LIMIT/COMP SW

(リミット/コンプスイッチ)

5

FREQUENCY

RESPONSE

(周波数特性)

6

TONE-CONTROL

CHARACTERISTIC

(トーンコントロール特性)

ITEM

(項目)

INPUT CONDITIONS

(入力条件)

INPUT 1, 2, 3, 4 (Each)

INPUT=XLR

INPUT-SW=LINE

INPUT-LEVEL=MAX.

INPUT 1, 2, 3, 4 (Each)

INPUT=XLR

INPUT-SW=MIC

INPUT-LEVEL=MAX.

INPUT 1, 2, 3, 4 (Each)

INPUT=PHONE

INPUT-SW=LINE

INPUT-LEVEL=MAX.

INPUT 5 and 6, 7 and 8

(Each pair)

INPUT=PHONE, RCA

INPUT-LEVEL=MAX.

INPUT 9 and 10 (Each)

INPUT=RCA

INPUT-LEVEL=MAX.

INPUT 1, 2

INPUT=PHONE

INPUT-SW=LINE

INPUT-LEVEL=MAX.

LIMIT/COMP SW=COMP

INPUT: 60 Hz

1, 2, 3, 4 (Each)

INPUT=XLR

INPUT-SW=LINE 10 KHz

INPUT-LEVEL=MAX.

INPUT: 60 Hz

5 and 6, 7 and 8,

9 and 10 (Each pair)

INPUT=PHONE, RCA 10 KHz

INPUT-LEVEL=MAX.

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

LOW=MIN.

REF: 30 Hz, LOW VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

LOW=MAX.

REF: 30 Hz, LOW VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

HIGH=MIN.

REF: 30 KHz, HIGH VR CENTER

INPUT 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

(Each)

HIGH=MAX.

REF: 30 KHz, HIGH VR CENTER

INPUT1

HIGH, LOW VR CENTER

SPEECH/MUSIC=SPEECH

REF: 80 Hz, MUSIC MODE

OUTPUT CONDITIONS

(出力条件)

SP OUT: L, R

REF: 200 W OUTPUT

MONITOR OUT: L

+4 dBu OUTPUT

(Load: 10 kΩ)

MONITOR OUT: L

+4 dBu OUTPUT

(Load: 10 kΩ)

L

L, R

REC OUT: L, R

-10 dBV OUTPUT

(Load: 10 kΩ)

MONITOR OUT: L

+4 dBu OUTPUT

(Load: 10 kΩ)

SP OUT: L, R

REF: 1 KHz, 1W OUTPUT

(基準:1KHz,1W出力)

SP OUT: L, R

REF: 1 KHz, 1W OUTPUT

(基準:1KHz,1W出力)

REF: 300 mV RECOUT

(基準:300mVRECOUT 出力)

(Load: 10 kΩ)

NOMINAL

(標準値)

-23 dBu

-30 dBu

-60 dBu

-20 dBu

-20 dBu

-20 dBu

-25 dBu

+5.0 dB

+1 dB

+5.0 dB

+1 dB

-15.0 dB

+15.0 dB

-15.0 dB

+15.0 dB

-3.0 dB

LIMIT

(限界値)

-23 dBu±2 dB

-30 dBu±2 dB

-60 dBu±2 dB

-20 dBu±2 dB

-20 dBu±2 dB

-20 dBu±2 dB

-24 dBu±2 dB

+4.0±2 dB

+1±2 dB

+4.0±2 dB

+1±2 dB

-15.0±2 dB

+15.0±2 dB

-15.0±2 dB

+15.0±2 dB

-3.0±2 dB

28

Page 29

STAGEPAS 500

No.

7

CROSSTALK

(クロストーク)

8

SIGNAL TO NOISE

RATIO

(信号雑音比)

9

RESIDUAL NOISE

(残留雑音)

10

PHANTOM VOLTAGE

(ファンタム電源)

11

LEVEL METER

INDICATION

(レベルメーター表示)

12

POWER CONSUMPTION

(消費電力)

(NOTE): 0 dBu=0.775 V

ITEM

(項目)

INPUT CONDITIONS

(入力条件)

INPUT 1, 2, 3, 4, 5, 6, 7, 8 to

Adjacent INPUT

(隣接CH 間)

HIGH, LOW VR CENTER

INPUT SHORT

(入力短絡)

INPUT-SW=LINE

MASTER-LEVEL=MIN.

SW-MIC

INPUT=XLR

INPUT IMPEDANCE=150 Ω

PHANTOM SW=ON

INPUT1

OUTPUT CONDITIONS

(出力条件)

SP OUT:

REF: 1 KHz, 200 W OUTPUT

(基準:1KHz,200W出力)

(MEASURE WITH 20 KHz LPF)

SP OUT: SP OUT

REF: 100 W OUTPUT MONITOR

(基準:100W 出力) OUT

SP OUT

SP OUT

(MEASURE WITH 20 KHz LPF AES17)

CH1-4 XLR w-q

e-q

SP OUT:

REF: LEVEL METER=“0”

(LEVELMETER0が表示)

SP OUT:

REF: 25 W OUTPUT

NOMINAL

(標準値)

75 dB

53dB

95dB

-54 dBu

-70 dBu

15V

22 dBu

90 W

3. ● Overload Protection(過負荷保護回路動作)

The product shall be set to 25 W output on SP OUT.

When + and - of SP OUT short-circuit, the product should stop the output and should blink POWER LED.

*

Cycle power (turn off and then on the POWER switch) to return to normal operation.

(SPOUTに25Wを出力させ、SPOUTの+と−をショートさせた時、SPOUTの出力が無くなり、POWER表示LED

が点滅することを確認します。)

(※POWERスイッチを OFF し、再度ONにすれば正常動作へ復帰します。)

LIMIT

(限界値)

>70 dB

>50 dB

>90 dB

<-50 dBu

<-65 dBu

15V±1V

22 dBu±2 dB

<93 W

● DC Detection Circuit Protection(DC検出保護回路動作)

When DC is detected in AMP output, the power latch circuit is activated to turn off the power. In this case, it is

impossible to turn on the power until the power switch is turned off to discharge the capacitors C806 to C809. (It will

take about 10 minutes to discharge.)

(AMP出力に DC を検出した場合は、電源のラッチ回路が動作し、電源をOFF します。この場合は、POWERスイッ

チを OFF し、C806〜 C809のコンデンサーが放電されるまでは電源が入りません。(約10 分位かかります。))

● Temperature Elevation Protection(温度上昇保護回路動作)

When the temperature of the TH803 (temperature of the heat sink) is 70 ˚C or more, the protection circuit is activated

to turn off the output. The output will be automatically turned on when the temperature comes down.

(TH803の温度(放熱板の温度)が 70℃以上になると、保護回路が働き、出力をOFF します。温度が下がると自動

復帰します。)

● POWER Circuit Board

TH803

PartoftheTH803

(TH803 の部分)

29

Page 30

STAGEPAS 500

4. Limiter Indication(リミッタ−表示の確認)

The product shall be set to 32 dBu output on SP OUT.

Then, LIMITER LED(RED) should light on and all LEDs of LEVEL meter should light on.

(SPOUT に 32dBuを出力させた時、LIMITER 表示LED(赤色)が点灯し(一瞬でも可)、LEVEL 表示 LEDが全て

点灯することを確認します。)

ADJUSTMENT OF AMPLIFIER UNIT(アンプユニットの調整)

1. Connect a 4 Ω of dummy resistor to the SPEAKERS

jacks.

2. After turning on the power, wait more than 60

seconds until performance is stabilized. Then, adjust

the trimmer potentiometer to make the voltage

across the dummy resistor ±3 mV or less.

● AMP Circuit Board

Partofthetrimmerpotentiometer

(半固定ボリウムの部分)

FACTORY SETTING(出荷時の設定)

1. SPEAKERS端子に4Ωのダミー抵抗を接続します。

2. 電源ON 後、60秒以上経過して動作が安定してか

ら、ダミー抵抗の両端電圧が±3mV以下となるよ

うに、半固定ボリウムを調整します。

・POWERswitch(POWER スイッチ): OFF

・MASTERLEVELvolume(MASTERLEVELボリューム):MIN.

・LEVELCH1-10volume(LEVELCH1-10 ボリューム):MIN.

・SPEECH/MUSICswitch(SPEECH/MUSIC スイッチ): MUSIC

・REVERBswitch(REVERB スイッチ): OFF

・LIMIT/COMPswitch(LIMIT/COMPスイッチ): LIMIT

・REVERBvolume(REVERBボリューム):MIN.

・MONITOROUTvolume(MONITOROUT ボリューム):MIN.

・EqualizerHIGH,LOWvolume(イコライザーHIGH,LOW ボリューム): CENTER

・MIC/LINEswitch(MIC/LINEスイッチ): MIC

・PHANTOMswitch(PHANTOMスイッチ): OFF

30

Page 31

STAGEPAS 500

TROUBLE SHOOTING

∗∗

∗ Points marked by “A” to “L” in the figure of circuit board are the points to be checked as indicated by the

∗∗

same marks in the flowchart on the next page or after.

※ 基板図の

POWER Circuit Board

to CONTROL2

A〜L

D,

(2/3)-CN1

は、次ページからのフローチャートにおけるチェックポイントを示しています。

E , F

(トラブルシューティング)

B,C

AC IN

A

CONTROL3 (3/3) Circuit Board

Component side(部品側)

J

J

L

I

K

H

G

Component side(部品側)

31

Page 32

STAGEPAS 500

● Trouble Shooting (POWER circuit board)

Note: Check and repair must be done carefully, otherwise the electrical shock may be caused.

[注意:感電するおそれがありますので、注意して作業を行ってください。]

START

< Fuse: Primary >

< Power Supply: +VB >

[無負荷]

< Power Supply: -VB >

No Load

< Power Supply: +15 V >

< Power Supply: +5 V >

A

F801 (Fuse)

OPEN ?

B

<+VB> about +44 V(DC)

C

<-VB> about -44 V(DC)

D

about +15 V (DC)

?

E

CN802: 3 pin

about +5 V (DC)

?

No

CN804: 1 pin

?

Yes

CN804: 3 pin

?

Yes

CN802: 2 pin

Yes

Yes

Yes

No

No

No

No

Check

IC804,D816-819

and peripheral

IC804,D816-819

及び周辺の確認

< Power Circuit Board >

Check

IC806 and peripheral

IC806及び周辺の確認

Check

< Power Supply: -15 V >

Connect the circuit boards. ("CONTROL3 (3/3): CN804-CN541", "AMP (L ch)", "AMP (R ch)")

"CONTROL3(3/3)シート:CN804-CN541"、"AMP(Lch)シート"、"AMP(Rch)シート"を接続

< L ch: VDR >

[AMPシート]

GND: 2124 820/50V (+)

< R ch: VDR >

[AMPシート]

GND: 2124 820/50V (+)

F

CN802: 1 pin

about -15 V (DC)

?

Yes

*Discharge [ 放電]: +VB,-VB

820 3W

PGND

discharge 1 minute [1分間放電]

G

<VDR> about -35 V (DC)

H

<VDR> about -35 V (DC)

+VB (-VB)

CN543: 3 pin

?

Yes

CN545: 3 pin

?

Yes

1

No

*Disconnect AC plug from the wall outlet

before discharging electricity.

[放電を行なう前にACプラグをコンセントから

抜いてください。]

IC805,D816-819

and peripheral

IC805,D816-819

及び周辺の確認

Check

Q556,D543,R594,R595

No

Q556,D543,R594,R595

の確認

Check

Q557,D544,R596,R597

No

Q557,D544,R596,R597

の確認

< CONTROL3 (3/3) Circuit Board >

2

32

Page 33

1

< FAN >

Connect the circuit boards("CONTROL1 (1/3)", "DSP", "CONTROL2 (2/3):CN542-CN24") and a fan.

< Signal Path >

"CONTROL1(1/3)シート"、"DSPシート"、"CONTROL2(2/3)シート:CN542-CN24"及びFANを接続

< Power LED >

STAGEPAS 500

K

Q545:

Base = 0.6 V (DC)

Replace the AMP circuit boards.

AMPシートの交換

Check

R564–566, 568,569,572,573

R580–583, 598

Q541–545, 548

C561

R564〜566,568,569,572,573

R580〜583,598

Q541〜545,548

C561の確認

?

( Q545: OFF )

( Q545: ON )

Yes

< AMP:Operate Mode>

Power LED=BLINKING

?

I

Power LED = ON

?

Yes

No

No

CN544: 11 pin

(CN546: 11 pin)

OUTPUT OK

?

Yes

[点滅]

No

[点灯]

( Q549: OFF )

J

Yes

POWER switch: OFF ON

No

No

Q548: ON

Power LED=BLINKING

?

( Q549: ON )

Remove the AMP circuit boards.

AMPシートを外す

No

Power LED = ON

?

Replace the AMP circuit boards.

AMPシートの交換

No

Check

R577–579, 584–587

Q550–553

C563, 564

R577〜579,584〜587

Q550〜553

C563,564の確認

Q548:

Base = 0 V

?

[点滅]

Yes

[点灯]

Yes

Q548:OFF

Yes

L

< CONTROL3 (3/3) Circuit Board >

2

Replace the POWER circuit board.

POWERシートの交換

Check

R563,567,570,571,574–576, 535

Q546,547,558,559

C559,562,

D541,542

R563,567,570,571,574〜576,535

Q546,547,558,559

C559,562,

D541,542の確認

END

33

Page 34

PARTS LIST

CONTENTS

OVERALL ASSEMBLY

MIXER ASSEMBLY

ELECTRICAL PARTS

Notes : DESTINATION ABBREVIATIONS

A : Australian model

B : British model

C : Canadian model

D : German model

E : European model

F : French model

H : North European model

I : Indonesian model

J : Japanese model

K : Korean model

(目次)

(総組立)

(ミキサー Ass'y)

(電気部品)

..................................... 2

............................. 5

.............................. 8-26

M : South African model

O : Chinese model

Q : South-east Asia model

T : Taiwan model

U : U.S.A. model

V : General export model (110V)

W: General export model (220V)

N,X: General export model

Y : Export model

WARNING

Components having special characteristics are marked and must be replaced with parts having

specifi cation equal to those originally installed.

印の部品は、安全を維持するために重要な部品です。交換する場合は、安全のために必ず指定の部品を

ご使用ください。

• The numbers “QTY” show quantities for each unit.

• The parts with “--” in “PART NO.” are not available as spare parts.

• This mark “ } ” in the REMARKS column means these parts are interchangeable.

• The second letter of the shaded (

• The second letter of the shaded (

•

部品価格ランクは、変更になることがあります。

•

QTY 欄に記されている数字は、各ユニット当たりの使用個数です。

•

PARTNO. が--の部品は、サービス用部品として準備されておりません。

•

REMARKS 欄の「

•

網掛けの付いた PARTNO.の 2 番目の文字は「ゼロ」ではなく、「オー」です。

•

網掛けの付いた PARTNO.の 2 番目の文字は「イチ」ではなく、「アイ」です。

}

」マークの部品は、併用部品です。

) part number is O, not zero.

) part number is I, not one.

Page 35

STAGEPAS 500

OVERALL ASSEMBLY

Rear cabinet unit

(リアキャビネット部)

Rear cabinet assembly

(リアキャビネットAss'y)

10

R30

R40

Bracket fastner 1 assembly

(ブラケットファスナー1Ass'y)

60

F10

R20

(総組立)

F40

F30

F20

R10

R30

R70

∗

[With mixer]

Mixer assembly:

See page 5.

70

Bracket fastner 2 assembly

(ブラケットファスナー2Ass'y)

80

B10

B40

B30

B20

B,H models

only

230

210

240

J,B,H,O

models

(ミキサーAss'y)

90

M20

250

U,C models

250

[Blank]

Cover mold assembly

(カバーモールドAss'y)

130~140mm

100

250

J,B,H,O

models

240

B,H models

only

260

U,C models

only

40

M10

250

U,C models

Mount bracket assembly

(マウントブラケットAss'y)

210a

50

110 d

110

110c

110b

110 a

R60

N20

180a

220

R50

Network assembly

20

(ネットワークAss'y)

180c

180b

180c

180f

180

(フロントグリルAss'y)

Front grille assembly

N10

N60

N50

30

190

N30

180b

180d

N40

180c

180e

R40

160

170

2

200

150

130

120b

120e

120d

Either mixer assembly or cover mold assembly is attached.

∗

ミキサー Assy ま たは カバーモールド Assy のどちらかが取り付けられています。

∗

120c

140

120b

120d

120c

120a

120

Front cabinet assembly

(フロントキャビネットAss'y)

Front cabinet unit

(フロントキャビネット部)

Page 36

STAGEPAS 500

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

REF NO.

10

20

30

40

50

60

70

80

90

100

100

100

100

110

110a

110b

110c

110d

120

120a

120b

120c

120d

120e

130

140

150

160

170

180

180a

180b

180c

180d

180e

180f

190

200

210

210a

220

230

240

250

250

260

PART NO.

--

--

--

--

--

WJ326600

--

WJ329200

-WJ329500

WJ327500

WJ329500

WJ327600

WJ329500

--

--

--

-WJ365000

WJ362500

WJ492800

WJ492600

WJ492700

WJ325800

WJ325900

WJ326000

WJ326100

WJ326400

WJ326500

X8440A00

WJ329100

WJ329900

X8439A00

WJ559700

WJ325100

WJ325200

WJ325600

WJ559200

WJ325400

WJ325300

WJ325500

WJ329500

WJ327400

WJ328300

--

-WJ339300

--

--

--

--

DESCRIPTION

OVERALL ASSEMBLY

Overall Assembly

Overall Assembly

Overall Assembly

Overall Assembly

Overall Assembly

Rear Cabinet Assembly

Network Assembly

Bind Head Tapping Screw-B 3.0X10 NI-BL

Mount Bracket Assembly

Bind Head Tapping Screw-P 4.0X12 NI-BL

Bracket Fastner 1 Assembly

Bind Head Tapping Screw-P 4.0X12 NI-BL

Bracket Fastner 2 Assembly

Bind Head Tapping Screw-P 4.0X12 NI-BL

Mixer Assembly

Mixer Assembly

Mixer Assembly

Mixer Assembly

Cover Mold Assembly

Cover Mold

Fastner Head

Flat Washer D9.5

Ret-Ring E4

Front Cabinet Assembly

Front Cabinet

Cushion 7.0X540

Cushion 7.0X345

Damping Material C FELT SIDE

Damping Material D FELT TOP

Speaker HF

Bind Head Tapping Screw-B 4.0X20 NI-BL

Bind Head Tapping Screw-A 5.0X45 NI-BL

Speaker LF

Bind Head Tapping Screw-P 5.0X18 BL CR3

Front Grille Assembly

Front Grille

Cushion Grille A

Cushion Grille B

Logo Badge

Cushion Badge

Bush Nut

Bind Head Tapping Screw-P 4.0X12 NI-BL

Cushion Bush 10X20X0.9

Circuit Board JACK

Hexagonal Nut M15.0 BL

Cushion 40X400X2

Wing Bolt M6.0X10 CR3

Label, WEEE

Label, SERIAL

Label, SERIAL

Label, SERIAL

部品名

総組立

総組立

総組立

総組立

総組立

総組立

リアキャビネットAssy

ネットワークAssy

Bタイト+BIND

マウントB Assy

Pタイト+BIND

ブラケットF1 Assy

Pタイト+BIND

ブラケットF2 Assy

Pタイト+BIND

ミキサーAssy

ミキサーAssy

ミキサーAssy

ミキサーAssy

カバーモールドAssy

カバーモールド

ファスナーヘッド

特殊平座金

リング

フロントC Assy

フロントキャビネット

ガスケット

ガスケット

吸音材C

吸音材D

スピーカHF

Bタイト+BIND

Aタイト+BIND

スピーカLF

Pタイト+BIND

フロントグリルAssy

フロントグリル

クッショングリルA

クッショングリルB

ロゴバッジ

クッション バッジ

ブッシュナット

Pタイト+BIND

クッション

JACKシート

特殊六角ナット

クッション

ちょうボルト

WEEEマークラベル

ラベル

ラベル

ラベル

STAGEPAS 500

J 440373

U,C 440374

B 440377

H 440378

O 440380

J

U,C

B,H

O

TWEETER 445977 2

WOOFER 442206 2

YAMAHA 441149 2

WITH NUT 445546 2

B,H 428263 3

J,B,H,O 082706 3

U,C 417569 3

U,C 450046

REMARKS

QTY

410798 8

425629 6

425629 4

425629 4

442772

413462 2

411068 2

411064 2

441144 2

446799 4

446798 4

446998 16

446999 2

410796 4

447892 28

448357 16

441151 2

446797 4

450793 8

445103 2

031814 4

425629 8

331850 2

429166 2

448348 2

RANK

2

2

2

2

2

2

2

2

*

*

*

*

*

*

*

*

*

*

*

*

*

WJ326600

R10

WJ326800

R20

WJ326200

R30

WJ326300

R40

WJ326400

R50

WJ286100

R60

WJ285700

R70

WJ327300

N10

WJ329800

N20

WJ328600

N30

WJ328700

N40

WJ329000

N50

N60

: New Parts RANK: Japan only

Rear Cabinet Assembly

Rear Cabinet

Damping Material A FELT REAR

Damping Material B FELT SIDE

Damping Material C FELT SIDE

Misc Bolt

Flange Nut M12.0 CR3

Connector Assembly SP VH-VH 2P-550

Network Assembly

--

Circuit Board NETWORK

Holder C Network

Holder D Network

Pan Head Tapping Screw-B 3.0X8 CR3

Cushion 40X160X2

--

Cushion 40X90X2

--

リアキャビネットAssy

リアキャビネット

吸音材A

吸音材B

吸音材C

特殊ボルト

フランジナットM12

SP束線

ネットワークAssy

NETWORKシート

ネットワーク固定金具C

ネットワーク固定金具D

Bタイト+PAN

クッション

クッション

441145

446996

446997 6

446998 2

410784 2

410781 2

448139

445546

370892

370893

410791 4

404676

431397

3

Page 37

STAGEPAS 500

*

*

*

*

*

*

*

*

*

*

*

*

*

REF NO.

M10

M20

F10

F20

F30

F40

B10

B20

B30

B40

PART NO.

-WJ329600

WJ559600

WJ327500

WJ327700

WJ328000

WJ327900

WJ328200

WJ327600

WJ327800

WJ328000

WJ327900

WJ328200

WG261700

AAX69550

WG261800

WG262000

WH221600

AAX69560

WJ329300

DESCRIPTION

Mount Bracket Assembly

Mount Bracket

Cushion 20X20X2

Bracket Fastner 1 Assembly

Fastner 1 Bracket

Spring

Spacer

Flat Head Screw M3.0X8 NI-BL

Bracket Fastner 2 Assembly

Fastner 2 Bracket

Spring

Spacer

Flat Head Screw M3.0X8 NI-BL

ACCESSORIES

AC Cord J

Label Caution

AC Cord U

AC Cord E

AC Cord BS

AC Cord O (CHN)

Speaker Cable

部品名

マウントB Assy

マウントブラケット

クッション

ブラケットF1 Assy

ファスナー1ブラケット

バネ

スペーサー

小ネジ+FLAT

ブラケットF2 Assy

ファスナー2ブラケット

バネ

スペーサー

小ネジ+FLAT

付属品

電源ケーブル

ラベル

電源ケーブル

電源ケーブル

電源ケーブル

電源ケーブル

スピーカーケーブル

J 414427 08

J 415042

U,C 369532 08

H 417976 08

B 417977 12

O 414426 12

REMARKS

451344

450795 2

439681

411059

416617 2

415242 2

441147

411059

416617 2

415242 2

416441 2

QTY

RANK

: New Parts RANK: Japan only

*

• AC Cord (J model)

(電源ケーブル)

150±5 mm

Label (J only)

(ラベル(Jのみ))

4

Page 38

STAGEPAS 500

MIXER ASSEMBLY

P50

P40

P20

P14

150

400

170

30

P110

P80

P110

P70

AC-IN connector assembly

P70

(ACインレットAss'y)

Rear view

P70f

P70c

P90

P120

P70e

P70f

P70b

P70a

AC-IN connector assembly

(ACインレットAss'y)

P70b

P70a

P12

P100

P12

P14

P70d

P70c

P70e

P70d

180

(ミキサー

P60

P11

80

90

10

Panel assembly

(パネルAss'y)

190

P20

P11

310

P10

450

Ass'y

20

P30

P15

P13

P14

240a

290

320

365

310

369

368

)

120

240

364

140a

132

220

380

130

140b

131

260

364

366

270

360

364

365

250

260

370

140

70

50

60

420

40

390

430

410

100

330

110

300

420

340

350

210

350

200

200a

160

161

200a

161

361

280

367

430

362

363

364

440

362

365

410

5

Page 39

STAGEPAS 500

REF NO.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

PART NO.

10

10

10

20

AAX61760

30

AAX61840

40

V9664700

50

V9665200

60

V9665300

70

V9665400

80

WA009900

90

WA010000

100

WJ336600

110

AAX61910

120

V9664800

130

AAX61920

131

132

140

WJ336500

140a

140b

150

WJ329200

160

161

170

WJ329200

180

190

200

WJ344200

200a

210

WK008800

220

240

WJ336700

240a

250

WJ337100

260

AAX61980

270

AAX61980

280

WJ336200

280

WJ336300

290

WJ329000

300

WJ336900

310

320

330

340

350

AAX63240

360

361

362

363

364

365

366

367

368

369

370

380

AAX61980

390

WJ362300

390

WJ362400

400

AAX62010

410

WJ586400

420

WJ586500

430

WJ586600

440

: New Parts RANK: Japan only

DESCRIPTION

MIXER ASSEMBLY

Mixer Assembly

--

Mixer Assembly

--

Mixer Assembly

--

Mixer Assembly

--

Panel Assembly

--

Panel Assembly

--

Panel Assembly

--

Spacer L16

Hexagonal Screw M3.0X8 NI-BL

Push Button Milky/D-Gray

Volume Knob White/Gray S

Volume Knob Green/Gray S

Volume Knob Blue/Gray S

Volume Knob White/M-Gray

Volume Knob Red/M-Gray

Circuit Board CONTROL2 (2/3)

Bind Head Screw M3.0X8 CR3

Push Button White/D-Gray

Push Spacer

Cushion, SW

--

Deco Sheet

--

Circuit Board CONTROL1 (1/3)

Hexagonal Nut M11.0

--

Flat Washer M9.2

--

Bind Head Tapping Screw-B 3.0X10 NI-BL

Shield Bracket 1

--

Cushion 5X5XD3.2

--

Bind Head Tapping Screw-B 3.0X10 NI-BL

Shield Plate, POWER

--

Insulation Sheet, POWER

--

Fan 7015M12F ND4 LF

Cushion 6X55

--

Bind Head Tapping Screw-B 3.0X20 NI-BL

Phone Bracket

--

Circuit Board CONTROL3 (3/3)

Hexagonal Nut M15.0 BL

--

Circuit Board AMP

Bind Head Tapping Screw-B 3.0X8 CR3

Bind Head Tapping Screw-B 3.0X8 CR3

Circuit Board POWER

Circuit Board POWER

Pan Head Tapping Screw-B 3.0X8 CR3

Circuit Board DSP

Insulation Sheet, DSP

--

Shield Bracket 3

--

Ferrite Core TFCM-16-8-16

--

Insulator

--

Cord Holder SKB-1M WH

Shield Bracket 2

--

Mold Edge Guard L10

--

Mold Edge Guard L20

--

Cushion 5X58

--

Cushion 5X5XD3.2

--

Cushion 5X15

--

Cushion 5X10

--

Cushion 5X30

--

Cushion 5X110

--

Cushion 5X40

--

Insulation Sheet 50X100X0.5

--

Bind Head Tapping Screw-B 3.0X8 CR3

Rear Case

Rear Case

Hexagonal Tapping Screw-B 3.0X8 NI-BL

Connector Assembly EH 8P 80L

Connector Assembly PH 8P 80L

Connector Assembly VH 5P 145L

Cushion 40X90X2

--

部品名

ミキサーAssy

ミキサーAssy

ミキサーAssy

ミキサーAssy

ミキサーAssy

パネルAssy

パネルAssy

パネルAssy

スペーサー

六角ネジ

プッシュボタン

ノブVR(S)

ノブVR(S)

ノブVR(S)

ノブVR

ノブVR

CONTROL2シート

小ネジ+BIND

プッシュボタン

プッシュスペーサ

クッション SW

デコシート

CONTROL1シート

特殊六角ナット

特殊平座金

Bタイト+BIND

シールドブラケット1

クッション

Bタイト+BIND

シールド板 POWER

絶縁板シート POWER

ファン

クッション

Bタイト+BIND

ホーンブラケット

CONTROL3シート

特殊六角ナット

AMPシート

Bタイト+BIND

Bタイト+BIND

POWERシート

POWERシート

Bタイト+PAN

DSPシート

絶縁板シート DSP

シールドブラケット3

フェライトコア

絶縁材

インシュロックタイ

シールドブラケット2

モールドエッジガード

モールドエッジガード

クッション

クッション

クッション

クッション

クッション

クッション

クッション

絶縁板シート

Bタイト+BIND

リアケース

リアケース

六角ネジBタイト

束線 8P

束線 8P

束線 5P

クッション

STAGEPAS 500

J

U,C

B,H

O

J,U,C

B,H

O

SPEECH/MUSIC,LIMIT/COMP, 7 01

REVERB 410350

REVERB 410354 01

HIGH,LOW 410355 14 01

MONITOR OUT 410356 01

LEVEL (CH1-4,5/6,7/8,9/10) 7 01

LEVEL (MASTER) 410359 01

MIC/LINE 410353 4 01

WITH NUT 444603

J,U,C 444598

B,H,O 444744

J,B,H,O 439472

U,C 446640

REMARKS

QTY

411063 5

411066 5

410358

444603

410792 5

411147 4

450515

450517

444603

410798 10

450622

451406 2

410798 6

447998

449424

445184

448356 4

448355 4

439640

444611 2

410797 4

410797 2

410791 6

444608

447994 2

447118

353161

391242

080558 3

450623

451340

37 1112 2

451405 2

451406 4

448474 3

448475

448471

448473

448472

447966 3

410797 4

411067 8

446691

446692

446693

431397

RANK

10

10

2

6

Page 40

STAGEPAS 500

*

*

*

*

*

*

*

*

*

*

REF NO.

450

P10

P10

P10

P11

P12

P13

P14

P15

P20

P30

P40

P50

P60

P70

P70a

P70b

P70c

P70d

P70e

P70f

P80

P90

P100

P110

P120

PART NO.

--

--

--

-WJ362600

WJ362700

WJ362800

--

--

--

--

-WJ362900

AAX61910

WJ492800

WJ492600

WJ492700

-WJ614300

AAX61860

WJ586700

-WJ586800

-AAX61870

AAX61880

AAX61890

AAX63240

--