Page 1

OWNER’S MANUAL

MANUEL DU PROPRIÉTAIRE

USO E MANUTENZIONE

INSTRUKTIONSBOK

OMISTAJAN KÄSIKIRJA

EIERHÅNDBOK

E

F

I

S

SF

N

E

F

I

S

SF

N

Read this manual carefully before operating this vehicle.

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

Leggere attentamente questo manuale prima di utilizzare questo veicolo.

Läs den här instruktionsboken noga innan snöskotern används.

Lue tämä käsikirja huolellisesti ennen moottorikelkan käyttöä.

Les denne håndboken nøye før du tar kjøretøyet i bruk.

SR10ARLG

SR10ALLG

SR1ASD37G

SR1ASD46G

SR10AXLG

SR1AMS41G

SR10AM53G

SR1AMS53G

SR1AML53G

SR10AM62G

SR1AML62G

8KS-F8199-S1

Page 2

Original instructions

Notice originale

Istruzioni originali

Bruksanvisning i original

Alkuperäiset ohjeet

Opprinnelige instruksjoner

PRINTED IN U.S.A.

Page 3

Read this manual carefully

before operating this vehicle.

OWNER’S MANUAL

SR10ARLG

SR10ALLG

SR1ASD37G

SR1ASD46G

SR10AXLG

SR1AMS41G

SR10AM53G

SR1AMS53G

SR1AML53G

SR10AM62G

SR1AML62G

8KS-F8199-S1-E0

Page 4

Read this manual carefully before operating this vehicle. This manual

should stay with this vehicle if it is sold.

EC Declaration of Conformity

conforming to Directive 2006/42/EC

We, YAMAHA MOTOR CO., LTD. 2500 Shingai, Iwata, Japan,

declare in sole responsibility, that the product

SRV10RL(SR10ARL) (4UF8KN50 GT000001–)

SRV10LL(SR10ALL) (4UF8KP40 GT000001–)

SRV10MS53(SR1AMS53) (4UF8KS40 GT000001–)

SRV10ML62(SR1AML62) (4UF8KU40 GT000001–)

SRV10M53(SR10AM53) (4UF8KG40 GT000001–)

SRV10MS41(SR1AMS41) (4UF8LK20 GT000001–)

to which this declaration applies, conforms to the essential health and safety

requirements of Directive 2006/42/EC

SRV10SD37(SR1ASD37) (4UF8LJ20 GT000001–)

SRV10XL(SR10AXL) (4UF8LH20 GT000001–)

SRV10ML53(SR1AML53) (4UF8LL20 GT000001–)

SRV10M62(SR10AM62) (4UF8LM20 GT000001–)

SRV10SD46(SR1ASD46) (4UF8LN20 GT000001–)

(Make, model)

(

If applicable

)

and to the other relevant Directive of EEC

2004/108/EC

(

Title and/or number and date of issue of the other Directives of EEC

(

If applicable

)

To effect correct application of the essential health and safety requirements

stated in the Directives of EEC, the following-standards and/or technical

specifications were consulted:

)

– – – – – –

(

Title and/or number and date of issue of standards and/or specifications

)

Authorized Representative

YAMAHA MOTOR EUROPE N.V.

Koolhovenlaan 101, 1119 NC Schiphol-Rijk, The Netherlands

Signature

Akihiro Tsuzuki

General Manager

Engineering Div., RV Business Unit

Business Development Operations

Date of Issue

13 January, 2015

Page 5

Table of Contents

Foreword ...................................................... 2

General Information.................................3-14

Snowmobile Identification ............................3

Control Locations ......................................... 3

Gasoline-Oil .................................................4

Engine Break-In ...........................................4

Drive Belt Break-In ....................................... 5

Cold Drive-Away Function ............................5

Speedometer/Tachometer/Digital Gauge.....5

Diagnostic Codes.........................................7

Handlebar Tilt (Mountain Models) ................8

Handlebar Tilt (SR10 Models)...................... 8

Exhaust System ...........................................8

Air-Intake Silencer........................................8

Cooling System ............................................ 9

Battery.......................................................... 9

Jump-Starting...............................................9

Drive Clutch and Driven Clutch..................10

Drive Clutch/Driven Clutch Alignment ........11

Fuel Pump ..................................................11

Shock Absorbers (Rebuildable Gas) ..........11

Track/Track Studs ....................................... 11

Paddle Track (On Equipped Models)..........12

Reverse Operation ..................................... 12

Access Panel/Hood ....................................13

Removable Seat......................................... 13

Towing ........................................................ 14

Operating Instructions ...........................15-18

Starting and Stopping Engine .................... 15

Braking .......................................................16

Emergency Stopping..................................17

Throttle/Ignition Monitor Switch.................. 17

Varying Altitude Operation .........................18

Lubrication .............................................19-20

Chain Case ................................................ 19

Rear Suspension........................................ 20

Maintenance ..........................................21-42

Periodic Maintenance Checklist .................21

Fuel System ............................................... 22

Checking Engine Oil Level ......................... 22

Changing Engine Oil/Filter.........................22

Coolant Level ............................................. 24

Spark Plugs ................................................24

Checking/Adjusting Valve Clearance .........25

Battery........................................................25

Fuses .........................................................27

Brake System .............................................28

Burnishing Brake Pads............................... 30

Chain Tension ............................................ 31

Drive Belt.................................................... 31

Track Tension .............................................33

Track Alignment.......................................... 34

Suspension ................................................35

Adjusting Skid Frame Rear Shock (Limited

Models)...................................................37

Adjusting Rear Spring Pre-Load ................ 37

Lights..........................................................38

Ski Wear Bars ............................................ 39

Adjusting Ski Stance ..................................40

Single Wear Bar .........................................40

Dual Wear Bar............................................ 41

Rail Wear Strips ......................................... 41

Performance Tips ..................................43-44

Preparation for Storage ..............................45

Preparation after Storage ...........................46

Snowmobile Safety Rules...........................47

Page 6

Reference Information

Write the appropriate information for your Yamaha Snowmobile in the spaces below.

Always use these numbers when referring to your snowmobile.

Model: _________________________________________________

Date of Purchase: ________________________________________

Vehicle Identification Number: _______________________________

Engine Serial Number: _____________________________________

Your Yamaha Dealer: _____________________________________

Address: _______________________________________________

Phone: _________________________________________________

WARNING

A snowmobile is a very high performance vehicle. Because it does accelerate rapidly and is capable of very high speeds, it should not be operated by a

novice or an inexperienced operator. Never accelerate rapidly or drive at

high speed beyond the limits of visibility or without being totally familiar

with the terrain and what lies in front of you. Obey speed limits and never

operate at speeds that do not allow adequate maneuvering and stopping distances. Read and study the entire Operator’s Manual and Safety Handbook.

Failure to follow this warning could result in personal injury to yourself or

others.

Personal Injury

• To avoid injury to yourself and others, NEVER operate the snowmobile without first reading and understanding this manual and the Snowmobile Safety

Handbook; then follow the instructions and heed the warnings given.

• USE COMMON SENSE.

• DON’T DRINK and DRIVE.

• STAY IN CONTROL at ALL TIMES.

• TELL YOUR FRIENDS. If you see a friend operating a snowmobile recklessly, at excessive speeds, while intoxicated, or in other unsafe ways, don’t

wait until it is too late to warn of the consequences of snowmobile misuse.

Such conduct endangers everyone. TAKE AN ACTIVE ROLE IN THE

SAFETY OF YOURSELF AND OTHERS.

Parts and Accessories

When in need of replacement parts, oil, or accessories for your Yamaha Snowmobile, be sure to only use GENUINE YAMAHA PARTS, OIL, AND ACCESSORIES. Only genuine Yamaha parts, oil, and accessories are engineered to meet the

standards and requirements of your Yamaha Snowmobile. For a complete list of

accessories, refer to the current Yamaha Accessory Catalog. To aid in service and

maintenance procedures on these snowmobiles, an Illustrated Parts Manual and a

Service Manual are available through your local Yamaha Snowmobile dealer.

1

Page 7

Foreword

Congratulations! You have chosen a quality Yamaha Snowmobile designed and

assembled to give dependable service. Be sure, as the owner/operator of a Yamaha

Snowmobile, to become thoroughly familiar with its basic operation, maintenance,

and off-season storage procedures. Read this manual and the accompanying Snowmobile Safety Handbook before operating the snowmobile to learn safe and proper

use of your new Yamaha Snowmobile. Always operate the snowmobile within your

level of skill and current terrain conditions.

The Operator’s Manual, Snowmobile Safety Handbook, and Snowmobile Decals display the words Warning, Caution, and Note to emphasize important information. The

symbol WARNING identifies personal safety-related information. Be sure to follow the directive because it deals with the possibility of serious personal injury or

even death. A CAUTION identifies unsafe practices which may result in snowmobile-related damage. Follow the directive because it deals with the possibility of damaging part or parts of the snowmobile. The symbol

supplementary information worthy of particular attention.

This manual covers operator-related maintenance, operating instructions, and off season storage instructions. If major repair or service is ever required, contact an authorized Yamaha Snowmobile dealer for professional service.

At the time of publication, all information and illustrations were technically correct.

Some illustrations used in this manual are used for clarity purposes only and are not

designed to depict actual conditions. Because Yamaha constantly refines and

improves its products, no retroactive obligation is incurred.

This Operator’s Manual should be considered a permanent part of the snowmobile

and must remain with the snowmobile at the time of resale. If the snowmobile

changes ownership more than once, contact your yamaha.

Every Yamaha Snowmobile meets or exceeds the standards of the Snowmobile

Safety and Certification Committee and displays the SSCC decal. Yamaha endorses

and encourages the safe use of all snowmobiles. Always wear a helmet and eye protection. Drive with caution, observe all state and local regulations, and respect the

rights of others. ISMA members like Yamaha do their part to improve trails, sponsor

events, and generally support the sport of snowmobiling. As a member of the National Snowmobile Foundation, Yamaha promotes snowmobiling through education,

charity, and research programs.

© 2015 Yamaha

NOTE: identifies

2

Page 8

General Information

VIN

Accessory Outlet

Emergency Stop Switch

Reverse Switch

Throttle Lever

Ignition Switch

Heated Shield Outlet

(if equipped)

Brake Lever Lock

Brake Lever

Headlight Dimmer Switch

Thumb Warmer/

Handlebar Warmer Switches

Seat Warmer Switch (if equipped)

Tether Switch (if equipped)

Accessory Outlet

Emergency Stop Switch

Reverse Switch

Throttle Lever

Ignition Switch

Brake Lever Lock

Brake Lever

Headlight Dimmer Switch

Thumb Warmer/

Handlebar Warmer Switches

Seat Warmer Switch (if equipped)

Snowmobile Identification

The snowmobile has two important identification numbers. The Vehicle Identification Number (VIN) is stamped into the

tunnel near the right-side footrest and on

a decal beneath the seat. The decal also

displays pertinent production information. The Engine Serial Number (ESN) is

stamped into the crankcase of the engine.

0726-383

SR10 Models

These numbers are required by the dealer

to complete warranty claims properly. No

warranty will be allowed by Yamaha Inc.

if the engine serial number or VIN is

removed or mutilated in any way.

Always provide the snowmobile name,

VIN, and ESN when contacting an authorized Yamaha Snowmobile dealer for

parts, service, accessories, or warranty. If

the complete engine must be replaced,

ask the dealer to notify Yamaha for correct registration information.

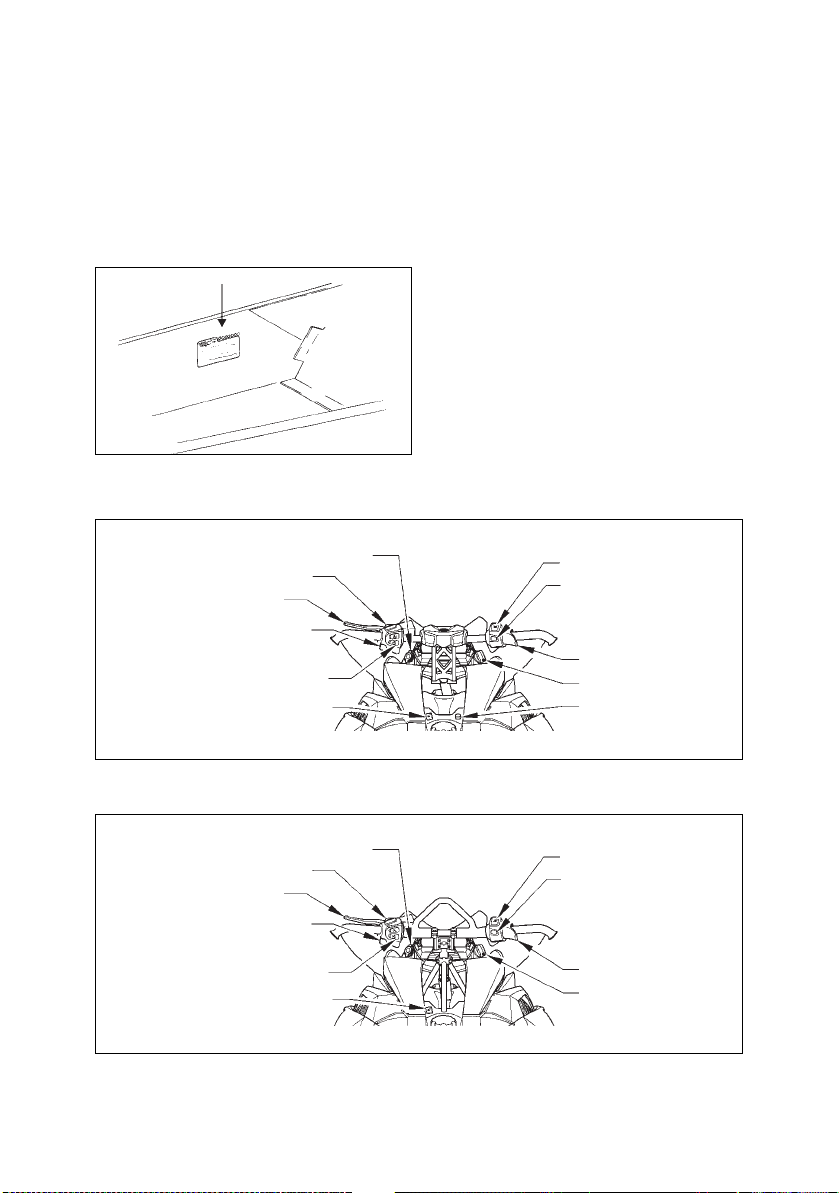

Control Locations

Shown are the typical control locations

for Yamaha snowmobiles. Location of a

specific control will vary according to

model.

3

SR10 Long Track Models

0749-256

0749-257

Page 9

Gasoline-Oil

Accessory Outlet

Emergency Stop Switch

Reverse Switch

Throttle Lever

Ignition Switch

Heated Shield Outlet

Brake Lever Lock

Brake Lever

Headlight Dimmer Switch

Thumb Warmer/

Handlebar Warmer Switches

Seat Warmer Switch

Recommended Gasoline

The recommended gasoline to use in

these snowmobiles is RON 95 octane

regular unleaded. In many areas, oxygenates are added to the gasoline. Oxygenated gasolines containing up to 10%

ethanol are acceptable gasolines.

When using ethanol blended gasoline, it is

not necessary to add a gasoline antifreeze

since ethanol will prevent the accumulation of moisture in the fuel system.

Recommended Engine Oil

The recommended oil to use is SemiSynthetic Yamalube 0W-30 oil.

CAUTION

Any oil used in place of the recommended oil could cause serious

engine damage

After 800 km (500 miles) of operating,

the engine oil must changed and the oil

filter replaced. The engine oil should be

changed every 4000 km (2500 miles)

before prolonged storage and the oil filter

should be changed every 20,000 km

(12,500 miles).

Filling Gas Tank

Since gasoline expands as its temperature

increases, the gas tank must be filled to

its rated capacity only. Expansion room

must be maintained in the tank particularly if the tank is filled with cold gasoline and then moved to a warm area.

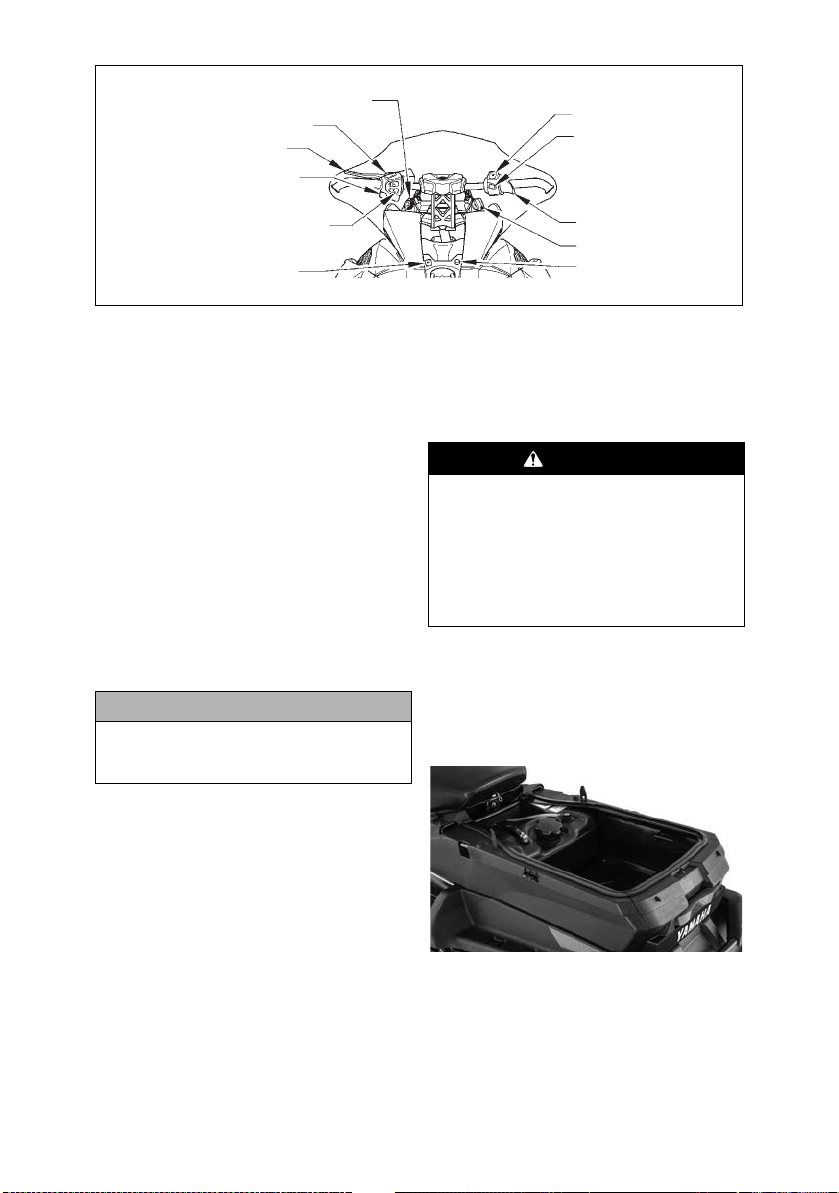

SR10SD46 Models

Also, if the snowmobile is to remain on a

trailer after filling the gas tank, the bed of

the trailer must be maintained level to

prevent gasoline from draining out

through the gas tank vent hose.

Always fill the gas tank in a well-ventilated area. Never add gasoline to

the snowmobile gas tank near any

open flames or with the engine running. DO NOT SMOKE while filling

the gas tank. Do not sit on the snowmobile without first installing the gas

tank cap.

The SR10SD46 features a 15.9 L (4.2 US

gallon) auxiliary gas tank. A separate gas

tank cap is located beneath the cowling

just behind the operator seat. The auxiliary tank is plumbed directly into the

main gas tank.

Engine Break-In

The engine (when new or rebuilt)

requires a short break-in period before

the engine is subjected to heavy load conditions.

0749-258

WARNING

YM-126

4

Page 10

This engine does not require any pre-

Upper Left

Button

Lower Left

Button

Upper Right

Button

Lower Right

Button

A B C D

G

H

G

F

E

mixed fuel during the break-in period.

There is never a more important period in

the life of the engine than the first 500

km (300 miles).

Since the engine is brand new, do not put

an excessive load on it for the first 500

km (300 miles). The various parts in the

engine wear and polish themselves to the

correct operating clearances. During this

period, prolonged full throttle operation

or any condition that might result in

engine overheating must be avoided.

Operating your snowmobile for the first

time: Start the engine and let it idle for 15

minutes.

0-160 km (0–100 miles): Avoid prolonged operation above 6000 RPM.

160-500 km (100–300 miles): Avoid prolonged operation above 8000 RPM.

500 km (300 miles) and beyond: The

snowmobile can now be operated normally.

NOTE: After 800 km (500 miles) of

operation, the engine oil must be

changed and the oil filter replaced.

If any engine trouble should occur

during the engine break-in period,

immediately have a Yamaha dealer

check the snowmobile.

Drive Belt Break-In

Drive belts require a break-in period of 40

km (25 miles). Drive the snowmobile for

40 km (25 miles) at 3/4 throttle or less. By

revving the engine up and down (but not

exceeding 100 km/h [60 mph]), the

exposed cord on the side of a new belt will

be worn down. This will allow the drive

belt to gain its optimum flexibility and

will extend drive belt life.

NOTE: Before starting the snowmobile in extremely cold temperatures, the drive belt should be

removed and warmed up to room

temperature. Once the drive belt is

at room temperature, install the

drive belt.

CAUTION

Never run the engine with the drive

belt removed. Excessive revving of

the engine could result in serious

engine damage and drive clutch

failure.

Cold Drive-Away Function

There is a “cold drive-away” function

incorporated within the engine.

NOTE: When cold-starting the

engine, the coolant temperature

warning icon will illuminate and the

LOW TEMP display on the readout

screen will begin to flash. With the

engine in this temperature range,

the RPM “limit” of the engine will

be below drive system engagement

speed. As the engine warms, the

coolant temperature warning icon

will begin to flash, the TEMP display will continue to flash, and the

RPM “limit” of the engine will

increase allowing the snowmobile

to move without full-throttle operation. When the engine reaches

proper operating temperature, the

coolant temperature warning icon

and the LOW TEMP display will go

out.

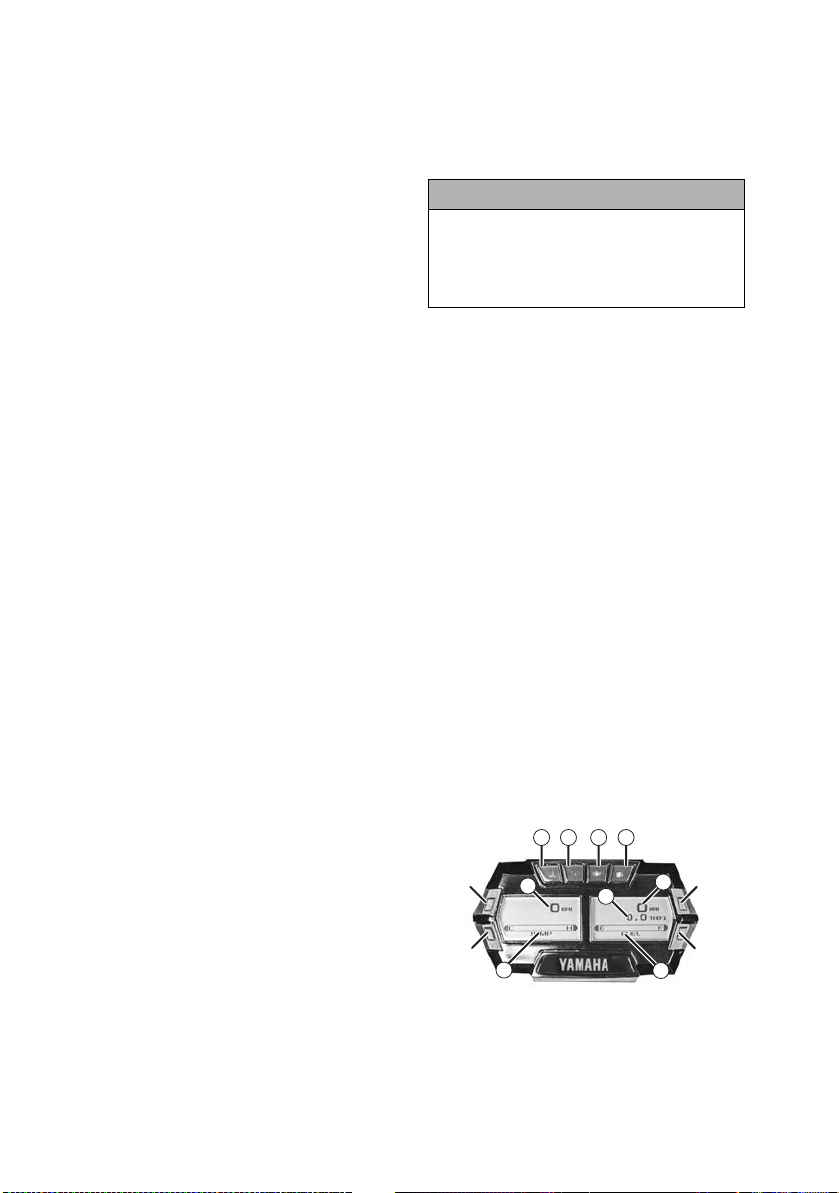

Speedometer/Tachometer/ Digital Gauge

5

CWI-050A

Page 11

A. Coolant Temperature Indicator

The indicator and LOW TEMP display

will cease to flash when the engine

reaches proper operating temperature.

If the coolant temperature rises too far

above proper operating temperature, the

indicator will flash a warning (alert) and

the engine will “surge” to alert the operator. If the coolant temperature rises to a

critical point above proper operating temperature, the indicator will cease flashing

and will remain constantly illuminated.

NOTE: If the indicator is con-

stantly on, the engine will shut off

if vehicle speed is reduced to 1.5

km-h (0.9 MPH) or slower.

CAUTION

If the indicator is illuminated, stop the

engine immediately and allow it to

cool down. If unable to either determine or remedy the problem, take the

snowmobile to an authorized Yamaha

Snowmobile dealer for service. If not

under warranty, this service is at the

discretion and expense of the snowmobile owner.

B. High Beam Indicator

The indicator is on whenever the high

beam mode is selected by the headlight

switch.

C. Oil Pressure Indicator

The indicator relates to engine oil pressure, not the oil level; however, if the oil

level is low, it may affect oil pressure. If

oil pressure is lost, check the oil level

(see page 22).

If the indicator does not go out or if the

engine does not start, take the snowmobile to an authorized Yamaha Snowmobile dealer. If not under warranty, this

service is at the discretion and expense of

the snowmobile owner.

D. Low Fuel Indicator

The indicator illuminates whenever the

gas in the gas tank is low.

E. Coolant Temperature/Battery

Voltage/Intake Air Temperature

This bar display shows coolant temperature, battery voltage, and intake air temperature. Press the Lower Left Button to

change which parameter is being displayed. Press and hold the Lower Left

Button to see the actual values associated

with the mode selected.

F. Fuel Level Display

This display shows the approximate

amount of gas remaining in the gas tank.

G. RPM/Speed/Clock/Altimeter

Press the Upper Left Button to cycle the

left screen between RPM and speed.

NOTE: When RPM is displayed on

the left screen, the right screen will

display speed, clock, or altimeter.

When speed is displayed on the

left screen, the right screen will

display RPM, clock, or altimeter.

Press the Upper Right Button to cycle the

right screen between speed, RPM, clock,

and altimeter.

Press and hold the Upper Button on the

speed-side of the gauge to shift the gauge

between standard (MPH/miles/fahrenheit) and metric (km/h/kilometers/celsius) modes.

Press and hold the Upper Button on the

RPM-side of the gauge to view maximum RPM. This value is reset each time

the ignition key is turned off.

With the clock mode selected by pressing

the Upper Right Button, press and hold

the Upper Right Button to set the clock.

The option of selecting the 12-hour or

24-hour clock is available; press the

either Left Button to alternate between

the two modes. Next, press the Lower

Right Button to set the clock. Press either

Left Button to set the hours; then press

the Lower Right Button to set the minutes. Press either Left Button to set the

minutes. When the proper time has been

set, press the Lower Right Button to

return to the main gauge display.

6

Page 12

With the altimeter mode selected by

pressing the Upper Right Button, press

and hold the Upper Right Button to set

the current altitude by using either Left

Button. When the proper altitude has

been set, press the Lower Right Button to

return to the main gauge display.

H. Engine Hour Meter/Odometer/

Trip Meter/Clock

This display shows engine hours, odometer, trip meter, or clock. Press the Lower

Right Button to change which parameter

is being displayed. The Engine Hour

Meter and Odometer cannot be reset. To

reset the trip meter, select the Trip Meter;

then press and hold the Lower Right Button until the trip meter display reads 0.

NOTE: The clock can only be dis-

played in this position if it is not

already being displayed in the main

right screen. To set the clock when

the clock is in this position, press

and hold the Lower Right Button;

then use the procedure found in G.

Diagnostic Codes

Diagnostic codes are activated by the

ECM and may be displayed on the readout screen for a number of reasons.

If a code is displayed while the engine is

running, the ECM is receiving input that

is outside of its established parameters. If

a code has been activated, take the snowmobile to an authorized Yamaha Snowmobile dealer for service. If not under

warranty, this service is at the discretion

and expense of the snowmobile owner.

Refer to the following chart for diagnostic codes.

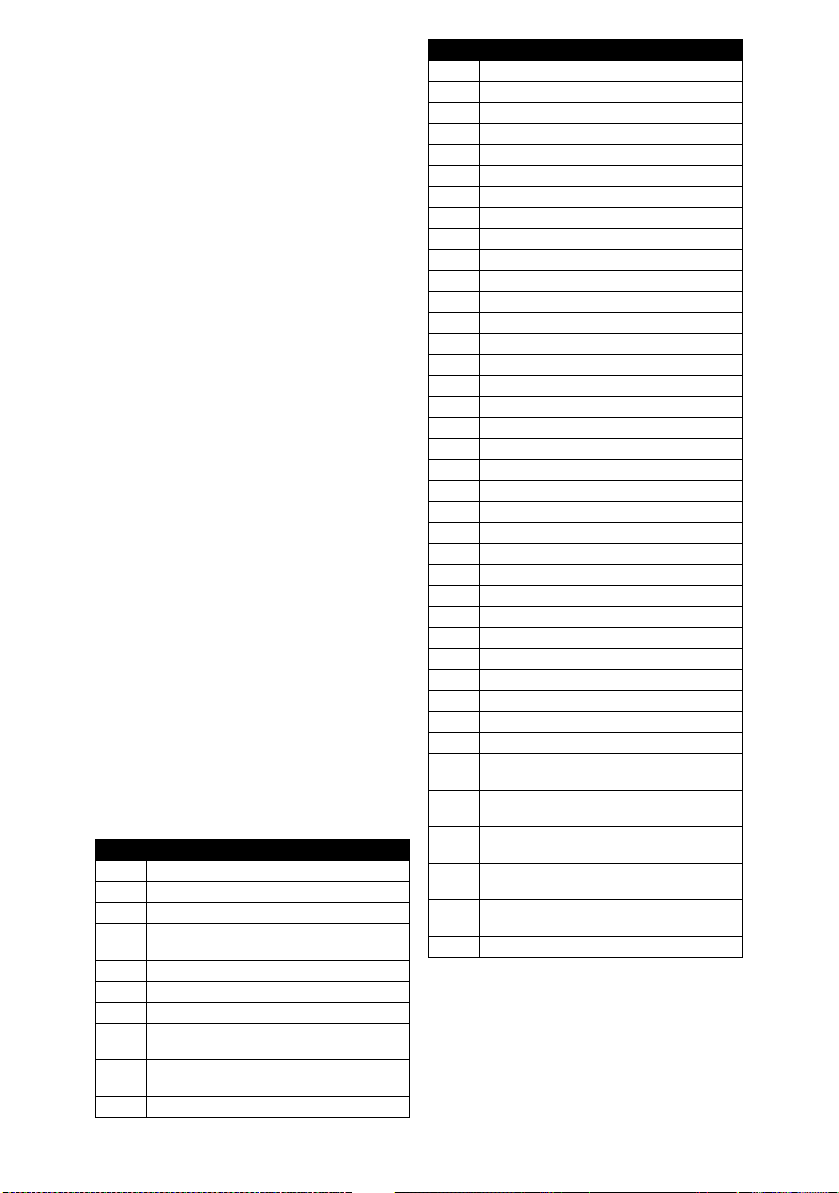

Code Trouble

P0031 O2 Heater Control Circuit Low

P0032 O2 Heater Control Circuit High

P0107 Manifold absolute pressure circuit low

P0108 Manifold absolute pressure circuit

high

P0112 Intake air temp sensor circuit low

P0113 Intake air temp sensor circuit high

P0115 Engine coolant temp sensor 1 circuit

P0117 Engine coolant temp sensor 1 circuit

low

P0118 Engine coolant temp sensor 1 circuit

high

P0120 Throttle position sensor circuit

Code Trouble

P0122 Throttle position sensor circuit low

P0123 Throttle position sensor circuit high

P0130 O2 sensor circuit

P0131 O2 sensor circuit low

P0132 O2 sensor circuit high

P0171 System too lean

P0172 System too rich

P0201 Injector circuit/open - cylinder 1

P0202 Injector circuit/open - cylinder 2

P0203 Injector circuit/open - cylinder 3

P0217 Engine coolant over temp condition

P0261 Cylinder 1 injector circuit low

P0264 Cylinder 2 injector circuit low

P0267 Cylinder 3 injector circuit low

P0508 Idle air control system circuit low

P0509 Idle air control system circuit high

P0511 Idle air control circuit

P0522 Engine oil pressure sensor circuit low

P0523 Engine oil pressure sensor circuit high

P0562 System voltage low

P0563 System voltage high

P0780 Shift Error

P1315 Crankshaft Position out of sync

P1338 Crankshaft spike detected

P1339 Crankshaft tooth not detected

P1685 Main relay open circuit

P1686 Main relay circuit low

P1688 Reverse relay open circuit

P1689 Reverse relay circuit low

P1691 Forward relay open circuit

P1692 Forward relay circuit low

P1694 Headlight relay open circuit

P1695 Headlight relay circuit low

P2228 Barometric pressure sensor A circuit

low

P2229 Barometric pressure sensor A circuit

high

P2300 Ignition coil A primary control circuit

low

P2303 Ignition coil B primary control circuit

low

P2306 Ignition coil C primary control circuit

low

U0155 Lost communication with the ECM

7

Page 13

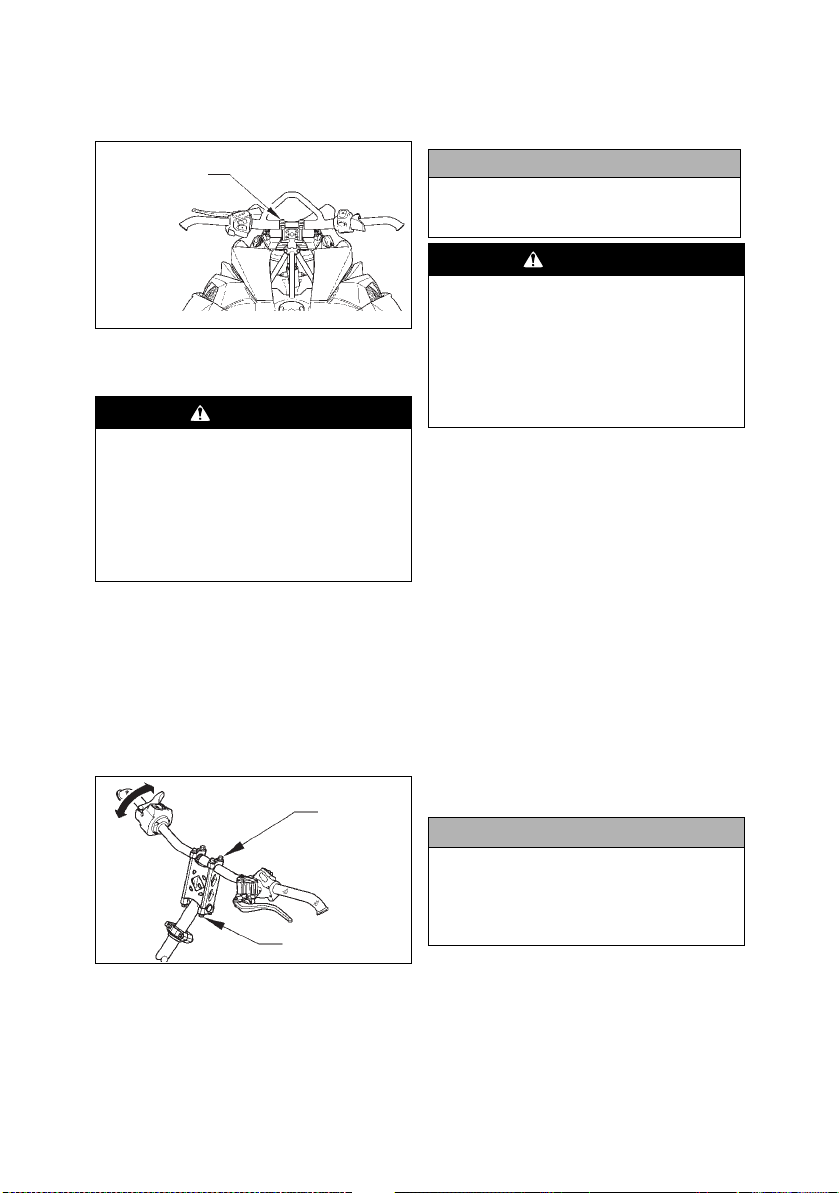

Handlebar Tilt

Cap Screws

Cap Screws

(Mountain Models)

1. Loosen the four cap screws and tilt

the handlebar to the desired position.

2. Adjust the handlebar to operator’s

desired position, tighten the cap

screws evenly to 2.0 kg-m (15 ft-lb),

and check steering for maximum

right/left turning capabilities.

Machine Screws

0748-905

2. Tighten the four cap screws evenly

to 15 ft-lb.

WARNING

Tighten the cap screws according

to specifications to prevent unexpected “movement” of the handlebar during operation over rough

terrain. DO NOT position handlebar

so steering (maximum right/left

turning capabilities) or throttle and

brake controls are affected.

Handlebar Tilt (SR10 Models)

The handlebar can be adjusted to the

operator’s preference. To adjust the handlebar, use the following procedure:

1. Remove the handlebar cover; then

loosen the eight cap screws securing

the handlebar caps to the riser and the

riser to the steering post.

CAUTION

Do not rotate the handlebar to a

position that allows air to enter the

brake system.

WARNING

Tighten cap screws according to

specifications to prevent unexpected “movement” of the handlebar during operation over rough

terrain. DO NOT position the handlebar so steering (maximum right/

left turning capabilities) or throttle

and brake controls are affected.

Exhaust System

The exhaust system is designed to reduce

noise and to improve the total performance of the engine. If any exhaust system component is removed from the

engine and the engine is run, severe

engine damage will result.

Air-Intake Silencer

Used in conjunction with the fuel intake

system is a specially designed air-intake

silencer. The purpose of the silencer is to

quiet the intake of fresh air. Since the fuel

intake system is calibrated with the airintake silencer in place, the engine must

never be run with the silencer removed.

Performance will not be improved if the

air-intake silencer is removed. In contrast, severe engine damage will occur.

CAUTION

These snowmobiles are not

designed to be operated in dusty

conditions. Operating the snowmobile in dusty conditions will result

in severe engine damage.

0747-828

8

Page 14

Cooling System

These snowmobiles are equipped with a

closed liquid cooling system for engine

cooling. The cooling system should be

inspected daily for leakage and damage.

Also, the coolant level should be checked

daily. If leakage or damage is detected,

take the snowmobile to an authorized

Yamaha Snowmobile dealer for service.

If not under warranty, this service is at

the discretion and expense of the snowmobile owner.

When filling the cooling system, use an

ethylene glycol-based coolant/water mixture which will satisfy the coldest anticipated weather conditions of your area in

accordance with the coolant manufacturer’s recommendations.

NOTE: If operating on ice or hard-

packed snow conditions, it is recommended that Ice Scratchers be

installed to reduce wear strip wear

and engine overheating.

For checking/filling cooling system, refer

to Coolant Level sub-section in the Maintenance section.

Battery

It is extremely important that the battery

be maintained at full charge at all times

and that the battery connections be clean

and tight. If charging the battery becomes

necessary, refer to Battery sub-section in

the Maintenance section.

CAUTION

Always turn the ignition switch key

to the OFF position when the snowmobile is not being used. Leaving

the ignition switch in the ON position will result in discharging the

battery and possible damage to the

battery.

Jump-Starting

NOTE: Yamaha does not recom-

mend jump-starting a snowmobile

with a dead battery but rather to

remove the battery, service it, and

correctly charge it; however, in an

emergency, it may be necessary to

jump-start a snowmobile. If so, use

the following procedure to carefully and safely complete this procedure.

WARNING

Improper handling or connecting of

a battery may result in severe injury

including acid burns, electrical

burns, or blindness as a result of an

explosion. Always remove rings

and watches. Any time service is

performed on a battery, the following must be observed: keep sparks,

open flame, cigarettes, or any other

flame away. Always wear safety

glasses. Protect skin and clothing

when handling a battery. When servicing a battery in an enclosed

space, keep the area well-ventilated.

NOTE: To access the battery, the

seat must be removed.

1. For the snowmobile to be jumpstarted, slide any terminal boots away.

2. Inspect the battery for any signs of

electrolyte leaks, loose terminals, or

bulging sides. Leaking or bulging

battery cases may indicate a frozen

or shorted battery.

WARNING

If any of these conditions exist, DO

NOT attempt to jump-start, boost, or

charge the battery. An explosion

could occur causing serious injury.

9

Page 15

3. Inspect the snowmobile to be used for

jump-starting to determine if voltage

and ground polarity are compatible.

The vehicle must have a 12-volt DC,

negative ground electrical system.

CAUTION

Always make sure the electrical

systems are of the same voltage

and ground polarity prior to connecting jumper cables. If not,

severe electrical damage may

occur.

4. Move the vehicle to be used for the

jump-start close enough to ensure

the jumper cables easily reach; then

set and lock the brakes, shut off all

electrical accessories, and turn the

ignition switch OFF.

NOTE: Make sure all switches on

the snowmobile to be jump-started

are turned OFF.

5. Disconnect all external accessories

such as cell phones, GPS units, and

radios on both vehicles.

CAUTION

Failure to disconnect electronic

accessories during jump-starting

may cause system damage due to

power spikes.

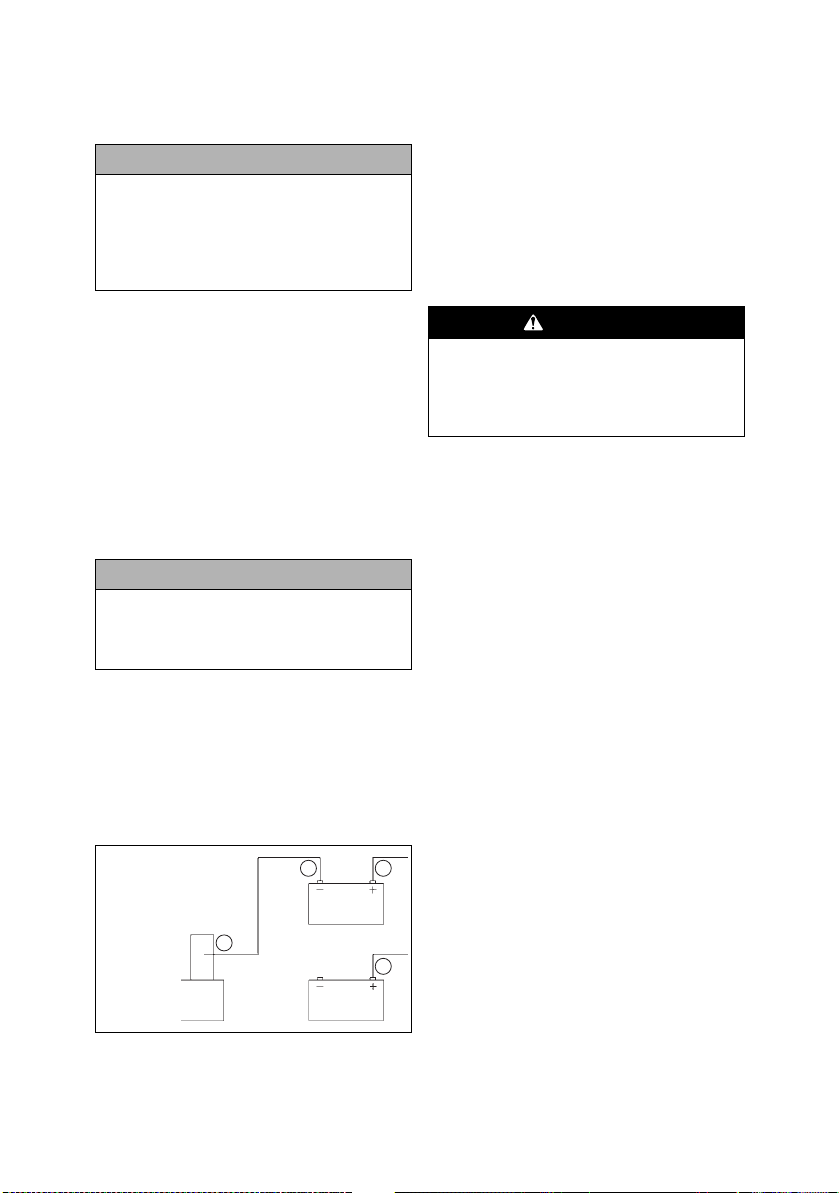

6. Attach one clamp of the positive

(red) cable to the positive (+) terminal (1) of the dead battery (C) being

careful not to touch any metal with

the other clamp; then attach the

other clamp of the positive (red)

cable to the positive (+) terminal (2)

of the good battery (B).

A. Unpainted Surface on Engine

B. Good Battery

C. Dead Battery

4

A

23

B

1

C

0744-527

NOTE: Some jumper cables may

be the same color but the clamps or

ends will be color-coded red and

black.

7. Attach one clamp of the negative

jumper cable (black) to the negative

(-) terminal (3) of the good battery

(B); then attach the other clamp of

the negative (black) jumper cable (4)

to an unpainted metal surface (A) on

the engine or frame well away from

the dead battery and fuel system

components.

WARNING

Never make the final connection to a

battery as a spark could ignite hydrogen gases causing an explosion of the

battery resulting in acid burns or

blindness.

8. Stand well away from the dead battery and start the vehicle with the

good battery. Allow the vehicle to

run for several minutes applying

some charge to the dead battery.

9. Start the snowmobile with the dead

battery and allow it to run for several

minutes before disconnecting the

jumper cables.

10. Remove the jumper cables in opposite order of hook-up (4, 3, 2, 1). Be

careful not to short cables against

bare metal.

NOTE: Have the battery and elec-

trical system checked prior to

operating the snowmobile again.

Drive Clutch and Driven Clutch

The drive clutch and driven clutch do not

require lubrication; therefore, no special

maintenance is required by the snowmobile owner except for periodical cleaning.

However, the drive clutch and driven

clutch should be disassembled, cleaned,

and inspected by an authorized Yamaha

Snowmobile dealer after every 4000 km

(2500 miles) or seasonally, whichever

occurs first. This service is at the discretion

and expense of the snowmobile owner.

10

Page 16

When operating the snowmobile at high

altitudes, it may be necessary to change

certain component parts of the drive

clutch and/or the driven clutch. See an

authorized Yamaha Snowmobile dealer

for further information.

CAUTION

DO NOT attempt to service the drive

clutch and driven clutch. The drive

clutch and driven clutch must be serviced by an authorized Yamaha

Snowmobile dealer only.

Drive Clutch/Driven Clutch Alignment

The alignment between the drive clutch

and driven clutch is set at the factory.

Normally, no adjustment is necessary as

long as neither the drive clutch nor the

driven clutch is removed or disassembled. However, if premature drive belt

wear is experienced or if the drive belt

turns over, the drive clutch/driven clutch

alignment must be checked. Take the

snowmobile to an authorized Yamaha

Snowmobile dealer for this service. If not

under warranty, this service is at the discretion and expense of the snowmobile

owner.

Fuel Pump

The fuel pump is designed to provide

adequate amount of gas to the

at all throttle settings. If a fuel delivery

problem is suspected, take the snowmobile to an authorized Yamaha Snowmobile dealer. If not under warranty, this

service is at the discretion and expense of

the snowmobile owner.

injectors

Shock Absorbers (Rebuildable Gas)

Each shock absorber should be visibly

checked weekly for fluid leakage, cracks or

breaks in the body/reservoir, or a bent shaft.

If any one of these conditions is detected,

replacement or service is necessary. Take the

snowmobile to an authorized Yamaha

Snowmobile dealer for this service. If not

under warranty, this service is at the discretion and expense of the snowmobile owner.

NOTE: When the snowmobile is

operated in extremely cold

weather (-23°C/-10°F or colder), a

small amount of leakage may be

present. Unless the leakage is

excessive, replacement is not necessary.

NOTE: The frequency of servic-

ing rebuildable shock absorbers

will vary according to the types of

conditions and terrain the snowmobile has been subjected to. If

riding quality deteriorates (or

seems to be deteriorating), take the

snowmobile to an authorized

Yamaha Snowmobile dealer for

shock absorber evaluation and/or

servicing. This service is at the discretion and expense of the snowmobile owner.

Track/Track Studs

Accelerated wear strip and track clip

wear caused by operating on ice or hardpacked snow conditions is NOT covered

under Yamaha warranty policy.

NOTE: If regularly operating on

ice or hard-packed snow conditions, Performance Wear Strips

may be installed at the expense of

the snowmobile owner.

In general, track life will be shortened

when studs are installed. Drilling stud

holes into the drive track will cut the

internal fibers weakening the track.

Avoid spinning the drive track. Studs

may catch on an object and pull out of the

track leaving tears and damage around

the already weakened area. To minimize

possible damage, consult your stud manufacturer for installation and stud pattern

recommendations. Yamaha does not recommend studding a track.

11

Page 17

Paddle Track (On Equipped

Reverse Switch Button

Models)

These models are equipped with a Power

Claw style track which is specially

designed for use in powder snow riding

conditions. When the Power Claw track

is operated in hard-packed snow conditions, it will run slightly slower than a

standard track and it will accelerate wear

strip wear. To decrease the amount of

wear strip wear, slower speeds must be

maintained when operating on hardpacked trails. Accelerated wear strip

wear caused by operating a Power Claw

track on hard-packed snow conditions is

NOT covered under Yamaha warranty

policy.

NOTE: If operating on ice or hard-

packed snow conditions, it is recommended that Ice Scratchers be

installed to reduce wear strip wear

and engine overheating.

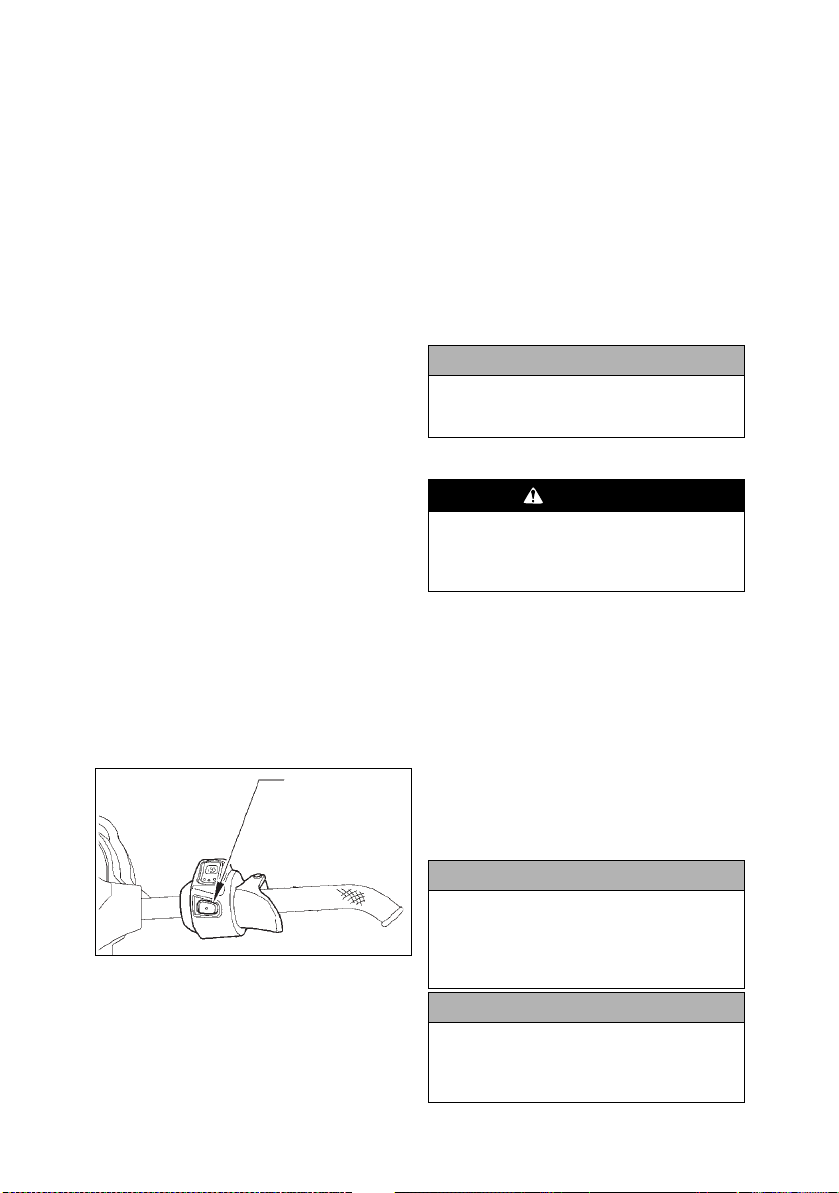

Reverse Operation

The electrical reverse function offers the

operator the convenience of being able to

back up the snowmobile rather than having

to turn the snowmobile around by hand.

This feature, under most situations, should

not be used to free a stuck snowmobile as

it will tend to dig the skis deeper into the

snow. Always use minimal speed when

operating in reverse and come to a complete stop before shifting from either forward to reverse or reverse to forward.

Shifting Into Reverse

1. Always warm up the engine for 2-3

minutes prior to shifting into reverse.

2. With the engine at idle (under 2500

RPM) and the snowmobile at a complete stop, press and release the

reverse switch button.

NOTE: The snowmobile must be

at a complete stop and the engine

running under 2500 RPM before the

system will allow shifting.

3. When reverse is engaged, a reverse

icon will illuminate on the deluxe

digital gauge and a reverse alarm

will sound.

CAUTION

Never shift into reverse while the

snowmobile is moving forward as it

is hard on the drive system.

Operating in Reverse

WARNING

Use caution and minimal speed

when operating the snowmobile in

reverse. Be sure the button is in the

desired position.

1. When shifting into reverse, always

wait for the reverse icon to illuminate and the reverse alarm to sound

before backing up.

NOTE: The reverse function is cancelled whenever the engine is shut

off.

2. After shifting from reverse to forward (or from forward to reverse),

apply the throttle slowly and evenly

to allow the driven pulley to engage

properly.

741-438A

NOTE: Correct drive belt tension

(deflection) is important for the

reverse function to operate properly. If the belt is too tight, difficulty

in engaging reverse will be experienced.

CAUTION

After reversing in deep powder

snow conditions, make sure the

snowflap does not become “caught

up” in the track. Track and/or snowflap damage may occur.

CAUTION

If the snowmobile is equipped with

ice scratchers, the scratchers must

be disengaged or component damage will occur.

12

Page 18

Access Panel/Hood

Torx Head Screw

To remove the access panel and hood, use

the following procedure:

1. Remove the hairpin clip from the pin

located at the front of the access

panel. Remove the thumb screw

securing the front left access panel

to the front fascia. Move the panel

up and off the pin; then swing the

panel all the way out and unhinge

the panel from the lower console.

2. Remove the torx-head screws securing the hood (located on the underside

of the hood above the front tube of the

upper A-arm); then remove the torxhead screws from the top-side of the

hood securing the hood to the upper

console and the torx-head screws

from under the nosepiece of the hood.

Torx Head Screw

Removable Seat

To remove the seat, remove the torx-head

screw from the underside of the seat; then

lift on the back of the seat and move it up

and rearward to remove it.

CAUTION

Prior to removing the seat, lift the

rear of the seat and disconnect the

seat heater harness connector.

0747-739

To install the seat, route the front tab on

the seat through the seat-base hold-down

bracket; then install the seat and secure

using the torx-head screw.

Torx Head Screws

Torx Head Screw

0747-830

3. Remove the intake panel below the

gauge; then locate the hood harness

connector (located in front of the

speedometer) and unplug the connector; then move the hood slightly

forward and remove the hood.

To install the access panel and hood, use

the following procedure:

1. Position the hood onto the snowmobile and connect the hood harness

connector making sure the harness

does not become pinched.

2. Secure the hood with torx-head

screws and tighten securely.

3. Install the access panel onto the

lower console; then close the access

panel and secure with the hairpin

clip. Install the intake panel.

13

SNO-273

NOTE: Prior to lowering and

securing the seat, connect the seat

heater harness connector.

NOTE: On SR10SD46 models,

pull back on the seat retainer pin

and remove the seat. Make sure to

disconnect the seat heater harness.

Page 19

0748-419

Towing

If the snowmobile is to be towed by

another snowmobile, do not tow using

the loops in the skis. The tow rope should

be attached to the spindles.

14

Page 20

Starting and Stopping Engine

High Brake Fluid Mark

Low Brake Fluid Mark

It is imperative that the brake system be

checked for wear and proper operation.

After the engine has been started, check

the headlights (high and low beam), taillight, and brakelight to be sure they are

working properly and adjusted correctly.

Make sure all lights are clean to provide

maximum illumination. The headlight

and taillight must be clean and must be

illuminated whenever the engine is running.

Engine startup at ambient temperature below minus 30 °C is not guaranteed.

Manual emergency startup of engine

is not provided.

1. Test the operation of the brake sys-

2. With the brake fluid reservoir in a

Operating Instructions

WARNING

WARNING

tem by compressing the brake lever.

The brake lever must feel firm when

compressed; then while holding the

brake lever in the compressed position, measure the distance between

the brake lever and the handlebar.

The distance must be greater than

2.54 cm (1 in.).

1 in.

0745-816

level position and the cover

removed, check the fluid level. The

brake fluid level must be at the high

brake fluid mark in the reservoir.

0745-817

3. If the brake fluid is below the high

brake fluid mark, add Yamaha

approved DOT 4 brake fluid until

the fluid is at the recommended

level. Install and secure the reservoir

cover. Do not allow moisture to contaminate the brake system.

CAUTION

Brake fluid is highly corrosive. Do

not spill brake fluid on any surface

of the snowmobile.

WARNING

Do not overfill the brake fluid reservoir. Overfilling the reservoir may

cause the brake system to hydraulically lock. Use only Yamaha

approved brake fluid.

WARNING

Do not start the engine if the brake

system is not functioning properly.

Service the brake system or have it

properly repaired prior to operating

the snowmobile. Serious personal

injury or even death may occur if the

brake system is not operating properly.

4. Test the throttle control lever by

completely compressing and releasing it several times. The lever

MUST return to the idle position

quickly and completely.

CAUTION

Always check the coolant level

before starting the engine.

5. Move the emergency stop switch to

the UP or RUN position.

15

Page 21

6. Insert key into ignition switch; then

rotate key to the RUN position.

NOTE: Rotate the key to the START

position; then when the engine starts,

release the key.

CAUTION

Do not continuously run the starter

for more than 5 seconds at a time.

NOTE: When the engine starts,

allow it to warm up properly. Idle the

engine several minutes until the

engine has reached normal operating temperature. Do not idle the

engine for excessively long periods

of time.

7. There is a “cold drive-away” function

incorporated within the engine. This

function is active until the engine

reaches operating temperature.

8. Flooding — If the engine does not

start but seems ready to start, engage

the brake lever lock; then compress

the throttle control lever fully and try

to start the engine. When the engine

starts, release the throttle control lever

immediately. After the warm-up,

release the brake lever lock.

9. To shut off the engine, turn the ignition key to the OFF position or push

the emergency stop switch to the

DOWN position.

CAUTION

Always turn the ignition switch key to

the OFF position when the snowmobile is not being used. Leaving the

ignition switch in the ON position will

result in discharging the battery and

possible damage to the battery.

Braking

The following items are items that the

operator must be familiar with when

operating this snowmobile and its

hydraulic brake system. Important additional information on the proper maintenance of the brake system is found in the

Maintenance section.

1. Use the brakes wisely. Each time the

brakes are applied in all hydraulic

brake systems (including automotive

applications), heat is transferred to the

brake fluid. The amount of heat transferred during high speed stops and/or

repetitive use may be high enough to

boil the brake fluid and cause the

brakes to either fade or may cause an

unexpected loss of brakes. If this

occurs, the brake fluid requires a cooldown period before the brakes will

again function properly.

This cool-down period will vary

depending upon the ambient air temperature and the temperature of the

brake fluid. If loss of brakes has

occurred because of high fluid temperatures, do not operate the snowmobile

until the cool-down period has expired

and brake lever firmness has returned.

WARNING

Excessive, repetitive use of the

hydraulic brake for high speed

stops will cause overheating of the

brake fluid and premature brake

pad wear which will result in an

unexpected loss of brakes.

2. Be sure to maintain the brake fluid at

the proper level and take care not to

get any moisture in the system as

moisture in the brake fluid lowers the

boiling point. If the brake fluid is ever

boiled (by high speed stops or repetitive use) or if moisture is allowed to

enter the system, it must be changed.

Never substitute or mix different types

or grades of brake fluid.

WARNING

Use only Yamaha approved DOT 4

brake fluid. Never substitute or mix

different types or grades of brake

fluid. Brake loss can result. Check

brake fluid level and pad wear

before each use. Brake loss can

result in severe injury or even

death.

3. Never ride the brake. Even maintaining minimal pressure on the

brake lever will cause the brake pads

to drag on the disc and may overheat

the brake fluid.

16

Page 22

4. The brake lever lock is not a parking

brake and should not be applied for

periods exceeding 5 minutes.

NEVER OPERATE THE SNOWMOBILE WITH THE BRAKE

LEVER LOCK ENGAGED.

WARNING

The brake lever lock is not a parking

brake and should not be applied for

periods exceeding 5 minutes. The

brake lever lock maintains the brake

lever in the compressed position

and maintains pressure against the

brake disc; however, after a period

of time, the pressure applied to the

brake disc may relax below the

amount required to hold the snowmobile stationary.

5. Pumping the brake lever is permissible; however, if pumping the brake

lever more than twice is necessary to

obtain the necessary stopping power,

immediately take the snowmobile to

an authorized Yamaha Snowmobile

dealer for service. If not under warranty, this service is at the discretion

and expense of the snowmobile

owner.

6. When new brake pads are installed,

a “burnishing” process is required.

Emergency Stopping

There are several methods of stopping or

slowing the snowmobile under a variety

of situations. Identified in the following

chart are the ways a snowmobile may be

brought to a stop and the effectiveness

under normal conditions.

Item Function

Emergency Stop

Switch

Throttle/Ignition

Monitor Switch

Ignition Switch interrupts ignition circuit

Brake slows the drive system

Tether interrupts ignition circuit

interrupts ignition circuit

interrupts ignition circuit

Throttle/Ignition Monitor Switch

The throttle control is equipped with a

monitor switch for safety purposes which

will stop the engine when a loss of return

spring force occurs. If ice forms in the

throttle system or if there is some other

malfunction of the throttle system resulting in a loss of return spring force, the

monitor switch will stop the engine when

the throttle control lever is released.

WARNING

If any malfunction of the throttle

system occurs (such as freezing in

fluffy snow) and the monitor switch

does not shut off the engine, press

down on the emergency stop switch

IMMEDIATELY to stop the engine.

DO NOT start the engine until the

malfunction in the throttle system

has been located and corrected.

If the snowmobile engine stops abruptly

when the throttle control lever is released

and the activation of the monitor switch

is suspected, use the following procedure:

1. Rotate the ignition key to the OFF

position.

2. Remove ice and snow from the

throttle system and wait 5-10 minutes for the engine heat to thaw ice

from the throttle system.

3. Test the throttle control lever by

compressing and releasing it several

times. The lever MUST return to the

idle position quickly and completely.

17

Page 23

NOTE: If the throttle control lever

operates properly and the engine

does not start, compress the throttle lever slightly (approximately 1/8

throttle) and try starting the

engine. If the engine now starts

and stops when the throttle lever is

released, take the snowmobile to

an authorized Yamaha Snowmobile

dealer for service. If not under warranty, this service is at the discretion and expense of the

snowmobile owner.

WARNING

If the throttle control lever does not

work properly, DO NOT ATTEMPT

TO START THE ENGINE.

4. If the throttle control lever operates

properly, rotate the ignition key to

the RUN position and go through

normal starting procedures.

NOTE: If the throttle control lever

operates properly and the engine

does not start, a malfunctioning

monitor switch may be the problem.

Take the snowmobile to an authorized Yamaha Snowmobile dealer for

service. If not under warranty, this

service is at the discretion and

expense of the snowmobile owner.

However, if a dire emergency exists

wherein the engine must be started,

disconnect the throttle monitor

switch located in the right-side handlebar control.

NOTE: If disconnection of the

throttle monitor switch is needed to

start the engine, take the snowmobile to an authorized Yamaha Snowmobile dealer for service as soon as

possible. If not under warranty, this

service is at the discretion and

expense of the snowmobile owner.

WARNING

Under no circumstances should

disconnection of the throttle control

wiring harness be used as a substitute for the monitor switch during

normal operation of the snowmobile. Personal injury and damage

could occur if the throttle system

malfunctions or if the operator is

unable to stop the engine in an

emergency. If the snowmobile must

be operated with a disconnected

throttle control wiring harness,

EXTREME CAUTION MUST BE

TAKEN. NEVER EXCEED 10 MPH

WITH THE THROTTLE CONTROL

WIRING HARNESS DISCONNECTED.

NOTE: The monitor switch is now

bypassed. All other ignition/electrical features (ignition switch, emergency stop switch, headlight,

taillight, and brakelight) will operate

properly.

Varying Altitude Operation

Operating a snowmobile at varying altitudes requires changes in performance

components. These changes affect drive

train components. Have a Yamaha dealer

perform altitude-related service.

NOTE: Just as important as cali-

brating the snowmobile for higher

altitudes is recalibrating the snowmobile when going to lower altitudes.

NOTE: Drive train changes can be

made by the snowmobile owner if

qualified to do so. If the owner

does not feel qualified, take the

snowmobile to an authorized

Yamaha Snowmobile dealer for this

service. This service is at the discretion and expense of the snowmobile owner

.

18

Page 24

Wire Harness

Detent Block

Spring

Shift Actuator

Extension

Screw

(Qty 3)

Lubrication

Chain Case

Checking Lubricant Level

NOTE: The snowmobile must be

on a level surface for this procedure.

1. Check the lubricant level in the

chain case by using the sight glass.

Full Level

0746-115

NOTE: The correct level is when

the lubricant is at least halfway up

in the sight glass.

NOTE: Adding lubricant can be

done by the snowmobile owner if

qualified to do so. If the owner

does not feel qualified, take the

snowmobile to an authorized

Yamaha Snowmobile dealer for this

service. This service is at the discretion and expense of the snowmobile owner

2. If the lubricant level is low, remove

the three screws securing the shift

actuator to the chain case, disconnect the actuator wiring harness, and

remove the actuator w/extension,

detent, and spring; then add appropriate amount of Synthetic Chain

Lube through the shift actuator

opening. When the lubricant is halfway up the sight glass, install the

shift actuator w/extension, detent,

and spring and connect the actuator

wiring harness. Tighten screws to

0.4 kg-m (36 in.-lb).

.

0748-259

CAUTION

When installing the shift actuator,

rotate the actuator back and forth

to properly align it with the extension gear. Failure to do so could

cause component damage.

3. Start the engine and verify proper

reverse and forward operation by shifting in and out of reverse three times.

NOTE: If excessive build-up of

moisture or discolored oil is

detected in the chain case, it may

be necessary to replace the lube.

Replacing Lubricant

NOTE: Replacing the lubricant

can be done by the snowmobile

owner if qualified to do so. If the

owner does not feel qualified, take

the snowmobile to an authorized

Yamaha Snowmobile dealer for this

service. This service is at the discretion and expense of the snowmobile owner

NOTE: The side panels, hood,

and exhaust resonator must be

removed for this procedure.

1. Place a drain pan under the chain

case; then loosen the eleven screws

securing the chain case cover/oil tank

assembly to the chain case housing

starting with the bottom screws first.

NOTE: It is critical that the snow-

mobile is on a level surface to

ensure the lubricant drains properly and completely.

NOTE: Inspect the chain case

cover seal for nicks or damage.

.

19

Page 25

2. When the lubricant has completely

drained from the case and the chain

case is cleaned of old oil, install the

chain case cover. Tighten the cap

screws to 1.65 kg-m (12 ft-lb).

3. Remove the three screws securing

the shift actuator to the chain case,

disconnect the actuator wiring harness, and remove the actuator w/

extension, detent, and spring. Pour

the recommended chain lubricant

through the shift actuator opening

until the lubricant is at least halfway

up in the sight glass; then install the

shift actuator w/extension, detent,

and spring and connect the actuator

wiring harness.

NOTE: Make sure the reverse

sensor wire is routed up so the

wires do not become pinched

between the actuator and the case.

CAUTION

When installing the shift actuator,

rotate the actuator back and forth

to properly align it with the extension gear. Failure to do so could

cause component damage.

4. Install and secure the exhaust resonator.

5. Start the engine and verify proper

reverse and forward operation by

shifting in and out of reverse three

times.

CAUTION

The correct lubricant to use in the

chain case is Synthetic Chain Lube.

Any substitute may cause serious

damage to the drive system.

Rear Suspension

This procedure should be done every 40

operating hours.

NOTE: Yamaha recommends that

All-Temp Grease be used for this

procedure.

1. Using Handlebar Stand or Steering

Post Stand or a suitable substitute,

lay the snowmobile on its left side.

2. Lubricate all grease fittings with alltemperature grease.

20

Page 26

Maintenance

Periodic Maintenance Checklist

Item Interval Page Remarks

Brake System Daily 28 Check for binding, leakage, and proper operation;

Cooling System - Liquid Daily 9,24 Check for leakage, damage, obstructions, coolant

Engine Oil Daily 22 Check oil level and for signs of leakage

Engine Oil - Initial 800 km

Engine Oil - After Initial 4000 km

Engine Oil Filter - Initial 800 km

Engine Oil Filter - After Initial 20000 km

Battery Daily 9,25 Check for proper charge and tight connections

Stop Switch Daily — Check for proper operation

Hoses Daily — Check for damage, leakage, and wear

Headlight & Taillight/Brake-

light

Steering System Daily — Check for proper operation, tightness of bolts, and

Throttle Control System Daily 17 Check for binding, sticking, proper operation,

Drive Belt Daily

Ski Wear Bars Daily 39 Check for wear and damage

Electrical Wiring Weekly — Check for wear, damage, and tight connections

Exhaust System Weekly 8 Check for damage, leakage, and obstructions

Nuts, Bolts, Fasteners Weekly — Check tightness

Shock Absorbers Weekly 11,35 Check for fluid leakage and damage and air pres-

Spark Plugs 4000 km

Valve Clearance 40000 km

Crankcase Breather System Seasonal — Check breather hose for cracks or damage and

Suspension Weekly 35 Check for damage, loose components, and proper

Track Tension/Alignment Weekly 33,34 Check/adjust as necessary

Wear Strips Weekly 41 Check for wear and damage

Wires & Cables Weekly — Check for wear, damage, and fraying

Fuel System - Tank, Pump, &

Ven t H ose

Chain Case Daily 19 Check lube level and for leakage

Chain Case - Lubricant Seasonal 19 Replace

Drive Chain Tension - Initial 500 km

Drive Chain Tension - After

Initial

Heat Exchangers Monthly — Check for wear, leakage, and damage

Drive Clutch/Driven Clutch 4000 km

Rear Suspension Monthly 20 Grease

(500 Mi)

(2500 Mi)

(500 Mi)

(12500 Mi)

Daily 38-39 Check for proper operation and cleanliness

Monthly

(2500 Mi)/

Seasonal

(25000 Mi)

Weekly — Check for damage, wear, obstructions, and leak-

(300 Mi)

800 km

(500 Mi)

(2500 Mi)/

Seasonal

lever firmness, travel, caliper, disc, and pads

level

22 Change oil

22 Change oil

22 Change filter

22 Change filter

binding

throttle cable tension, and wear

31 Check for wear, cracks, and fraying

Check length and width dimensions

sure (Fox Air Shocks)

24 Check center electrode insulator color, carbon,

and gap

25 Check/adjust

replace as necessary

adjustment

age

31 Check tension and adjust as necessary

31 Check tension and adjust as necessary

10,11 Check for damage, binding, and wear/remove

drive belt, clean drive clutch/driven clutch

21

Page 27

The longevity and safety of the snowmobile can be increased by making periodic

checks of the items in the preceding

checklist.

If, at any time, abnormal noises, vibrations, or improper working conditions of

any component of this snowmobile are

detected, DO NOT OPERATE THE

SNOWMOBILE. Take the snowmobile

to an authorized Yamaha Snowmobile

dealer for inspection and adjustment or

repair. If not under warranty, this service

is at the discretion and expense of the

snowmobile owner.

The snowmobile should be taken to an

authorized Yamaha Snowmobile dealer at

the end of each snowmobiling season for

general inspection and for off-season

storage servicing. This inspection and

servicing is at the expense of the snowmobile owner.

Fuel System

WARNING

Whenever any maintenance or

inspection is made on the fuel system in which there may be fuel leakage, there should be no welding,

smoking, open flames, etc., in the

area.

Gasoline Additives

Fuel de-icer can be used for all models.

Yamaha Fuel Stabilizer should also be

added to the last tank of gasoline before

storage.

Fuel Pickup Valves

If ever there is a restricted fuel flow and a

pickup valve is suspected, take the snowmobile to an authorized Yamaha Snowmobile dealer for this service. If not under

warranty, this service is at the discretion

and expense of the snowmobile owner.

Checking Engine Oil Level

NOTE: The snowmobile must be

on a level surface for this procedure.

CAUTION

If the engine and oil are not at operating temperature, the oil will not

read correctly on the oil level stick.

1. Start the engine and let it idle and

warm up until the fan on the radiator

turns on, or if the snowmobile was

operated, allow the engine to idle for

approximately 30 seconds.

CAUTION

Immediately after the engine is

started, check that the oil pressure

warning light goes out.

2. Shut the engine off; then allow the

engine to cool. Remove the oil level

stick from the oil tank and verify it is

within the “NORMAL” range on the

stick.

SNO-482

3. If step 1 and 2 was followed and the

oil level is not within the “NORMAL” range, add the recommended

engine oil.

NOTE: Care must be taken not to

over-fill the oil tank.

Changing Engine Oil/Filter

Fuel Pickup Valves

WARNING

Engine oil is extremely hot immediately after the engine is turned off.

Burning could occur if oil contacts

skin or clothing.

NOTE: Recycle or properly dis-

pose of the used engine oil.

0747-833

22

Page 28

NOTE: The access panels and

Torx-Head Screws

Oil Drain Plug

hood must be removed for this procedure.

1. Park the snowmobile on a level surface; then start the engine and let it

idle and warm up until the fan on the

radiator turns on, or if the snowmobile was operated, allow the engine

to idle for approximately 30 seconds. Shut the engine off.

2. Remove the torx-head screws and

the rear access plate from beneath

the snowmobile.

3. Place a drain pan beneath the engine oil

drain screw; then remove the screw and

allow the oil to drain completely.

XM125A

4. Using Oil Filter Wrench, loosen (but

do not remove) the oil filter and allow

the oil to drain from the filter into the

drain pan; then remove the filter.

5. Apply a light coat of fresh engine oil

to the seal of the new oil filter.

6. Install the new oil filter by turning the

oil filter by hand until the seal has contacted the oil filter mounting surface;

then tighten the oil filter to 1.7 kg-m

(12 ft-lb).

7. Install the engine oil drain screw

with a new gasket. Tighten the screw

to 1.0 kg-m (7.2 ft-lb).

8. Remove the four torx-head screws

securing the right-side footrest to the

tunnel and the support; then with a

drain pan in position, remove the

drain plug from the oil tank.

746-121A

NOTE: To aid in draining the oil

from the tank, position a funnel

between the tank and the opening

of the tunnel running board.

9. After the oil has drained completely,

install the drain plug with a new Oring and tighten to 2.2 kg-m (16 ft-lb).

10. Pour 2.8 L (3 US quarts) of engine

oil into the oil tank.

11. Without starting the engine, place

the handlebar emergency stop

switch to the RUN position and the

ignition switch to the ON position.

The Oil Pressure Warning Icon

should illuminate.

NOTE: If the warning icon does not

illuminate, take the snowmobile to an

authorized Yamaha Snowmobile

dealer for service. If not under warranty, this service is at the discretion

and expense of the snowmobile

owner.

12. If the warning icon illuminates

(from step 11), start the engine. The

warning icon should go out within

five seconds. If it does, proceed to

step 13.

NOTE: If the warning icon does

not go out, shut the engine off

immediately and repeat step 11;

then place the ignition switch to

the ON position and repeat step 12.

If the warning icon does not go out,

take the snowmobile to an authorized Yamaha Snowmobile dealer

for service. If not under warranty,

this service is at the discretion and

expense of the snowmobile owner.

23

Page 29

13. Shut the engine off; then allow the

Full Level

engine to cool. Remove the oil level

stick from the oil tank and verify it is

within the “NORMAL” range on the

stick.

SNO-482

NOTE: If the oil and engine are

not at operating temperature, the

oil level may read too low. Always

make sure the engine is at operating temperature before checking

the oil.

14. Install the access plate and torx-head

screws beneath the snowmobile; then

install the hood and access panels.

Coolant Level

NOTE: Use a good quality, ethyl-

ene glycol-based, automotive-type

coolant.

WARNING

Always check the coolant level with

the engine cold.

Locate the filler neck located above the

resonator; then remove the coolant cap

from the filler neck. Verify that the coolant

is at the bottom of the tab in the filler neck.

Full Level

0747-547

Locate the coolant tank above the drive

clutch; then remove the plug from the

coolant tank. Add coolant to the full level

on the tank. Install the plug.

0747-766

CAUTION

If the coolant is below the neck and

if coolant has been added, immediately inspect for leakage and/or

damage. If leakage or damage is

detected, take the snowmobile to

an authorized Yamaha Snowmobile

dealer for service. If not under warranty, this service is at the discretion and expense of the

snowmobile owner.

Spark Plugs

NOTE: Always use the recom-

mended spark plugs in the engine.

See the appropriate specifications

sheet for correct spark plug gap.

CAUTION

If adjusting spark plug gap is necessary, do not use the center electrode as a leverage point. Damage

to the plug may occur.

1. Disconnect the main harness from the

ignition coils; then remove the ignition

coils from the cylinder head cover.

2. Remove the three spark plugs.

NOTE: Prior to installing the

spark plugs, check the gap

between the electrode and ground

strap. The clearance should be 0.7-

0.8 mm (0.028-0.031 in.).

3. Install new spark plugs. Tighten to

1.3 kg-m (9.4 ft-lb).

4. Install the ignition coils onto the cylinder head cover making sure they

are fully seated. Connect the main

harness to the ignition coils.

5. Install the hood and access panels.

24

Page 30

Checking/Adjusting Valve

Lock Nuts

Battery Bracket

Clearance

After 40,000 km (25,000 miles), valve

clearance should be checked and adjusted

as necessary.

NOTE: Take the snowmobile to an

authorized Yamaha Snowmobile

dealer for inspection and service.

This service is at the discretion

and expense of the snowmobile

owner.

CAUTION

It is critical that the checking/

adjusting valve clearance be done

at the recommended intervals or

severe engine damage may occur.

Battery

These sealed batteries after being in service require regular cleaning and charging in order to deliver peak performance

and maximum service life. The following

procedure is recommended for cleaning

and maintaining sealed batteries. Always

read and follow instructions provided

with battery chargers and battery products.

NOTE: Battery maintenance may

be done by the snowmobile owner

if qualified to do so. If the owner

does not feel qualified, take the

snowmobile to an authorized

Yamaha Snowmobile dealer for this

service. This service is at the discretion and expense of the snowmobile owner.

WARNING

Battery posts, terminals, and

related accessories contain lead

and lead compounds, chemicals

known to the state of California to

cause cancer and reproductive

harm. Wash hands after handling.

1. Remove the torx-head screw from

the rear underside of the seat; then

remove the seat.

CAUTION

Make sure to disconnect the seat

heater harness connector prior to

removing the seat.

2. Remove the negative battery cable

and ground wire; then remove the

positive cable.

NOTE: For installing purposes

prior to removing the battery, note

the routing and securing locations

of the cables and harness wires.

3. Remove the two screws and lock

nuts securing the battery bracket/

solenoid to the seat-base; then move

the bracket up and out of the way

and remove the battery.

WARNING

Improper handling or connecting of

a battery may result in severe injury

including acid burns, electrical

burns, or blindness as a result of an

explosion. Always remove rings

and watches. Any time service is

performed on a battery, the following must be observed: keep sparks,

open flame, cigarettes, or any other

flame away. Always wear safety

glasses. Protect skin and clothing

when handling a battery. When servicing a battery in an enclosed

space, keep the area well-ventilated.

25

0747-528

WARNING

Avoid spillage and contact with

skin, eyes, and clothing.

CAUTION

Do not charge the battery while it is

in the snowmobile with the battery

terminals connected.

4. Thoroughly wash the battery with soap

and water; then using a wire brush,

clean the battery posts and cable ends

removing all corrosive buildup.

Replace damaged cables or cable ends.

Page 31

NOTE: If battery posts or cable

ends have a build-up of white/

green powder residue, apply water

and baking soda to neutralize acid;

then flush off with warm soapy

water.

CAUTION

Do not remove seal strip on a

sealed battery.

WARNING

Battery acid is harmful if it contacts

eyes, skin, or clothing. Care must

be taken whenever handling a battery.

5. Using a multimeter, test the battery

voltage. The meter must read no less

than 12.5 DC Volts for a fully

charged battery.

NOTE: At this point if the meter

reads as specified, the battery may

be returned to service (see step 9).

6. If the meter reads less than specified

voltage, charge the battery using the

following guidelines.

A. When using an automatic battery

charger, always follow the charger manufacturer’s instructions.

B. When using a constant-current

battery charger, use the following Battery Charging Chart.

CAUTION

Never exceed the standard charging rate.

WARNING

An overheated battery could