Yamaha RCX142 User Manual

User’s Manual

ENGLISH

E

YAMAHA 4-AXIS ROBOT CONTROLLER

E92-Ver. 1.09

RCX142

1

2

Introduction

Our sincere thanks for your purchase of this YAMAHA robot controller.

This manual explains how to install and operate the robot controller. Be sure to read this

manual carefully as well as related manuals and comply with their instructions for using

the YAMAHA robot controllers safely and correctly.

Refer to the "Programming Manual" for detailed information on robot programs.

2

2

Safety precautions (Be sure to read before using)

Before using the YAMAHA robot controller, be sure to read this manual and related manuals, and follow their instructions to use the robot controller safely and correctly.

Warning and caution items listed in this manual relate to YAMAHA robot controllers.

When this robot controller is used in a robot controller system, please take appropriate

safety measures as required by the user’s individual system.

This manual classifies safety caution items and operating points into the following le vels,

along with symbols for signal words “WARNING”, “CAUTION” and “NOTE”.

w

WARNING

"WARNING" indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

c

CAUTION

"CAUTION" indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury or damage to the equipment or software.

n

NOTE

Explains key points in the operation in a simple and clear manner.

Note that the items classified into “CAUTION” might result in serious injury depending

on the situation or environmental conditions. So always comply with CAUTION and

WARNING instructions since these are essential to maintain safety.

Keep this manual carefully so that the operator can refer to it when needed. Also make

sure that this manual reaches the end user.

When installing the RCX142 series robot controller, please take into account all the instructions and precautions described in Chapter 3, "Installation".

3

2

[System design safety points]

w

WARNING

• Refer to this manual for details on the operating status of the robot controller and

to related instruction manuals. Design and configure the system including the

robot controller so that it will always work safely.

• The robot controller has an emergency stop terminal to trigger emergency stop.

Using this terminal, prepare a physical interlock circuit so that the system

including the robot controller will work safely.

c

CAUTION

• Do not bundle control lines or communication cables together or in close contact with the

robot controller main circuit or power lines. As a general rule, separate them by at least

100mm. Noise in the main circuit or power lines may cause faulty operation or malfunctions.

• Data (programs, point data, etc.) stored in the robot controller is not guaranteed to be

unchanged, so be sure to back it up onto an external storage device.

[Installation safety points]

w

WARNING

• Securely install the connectors into the robot controller, and when wiring the

connectors, make the crimp, press-contact or solder connections correctly using

the tool specified by the manufacturer.

• Always shut off all phases of the power supply externally before starting

installation or wiring work. Failure to shut off all phases could lead to electrical

shocks or product damage.

c

CAUTION

• Use the robot controller within the environment specifications listed in this manual.

Using the controller in an environment outside the specification range could lead to electrical

shocks, fires, malfunctions, product damage or lower performance.

•Tighten the screws on the robot controller firmly to make secure connections.

•Never directly touch the conductive sections or electronic components other than the rotary

switches and DIP switches on the outside panel of the robot controller.

• Securely attach each connector cable connector into the receptacles or sockets. Poor

connections will cause faulty operation or malfunctions.

[Wiring safety points]

w

WARNING

• Always shut off all phases of the power supply externally before starting

installation or wiring work. Failure to shut off all phases could lead to electrical

shocks or product damage.

• Always attach the terminal cover (supplied) before turning on the power to the

robot controller after installation and wiring work are complete. Failure to attach

the terminal cover could lead to fire, electrical shock, product damage or

malfunctions.

c

CAUTION

•Tighten the terminal screws within the specified torque ranges. A loose terminal screw could

lead to short-circuit, faulty operation or malfunctions. However, if the terminal screw is too

tight, short-circuit, faulty operation or malfunctions could also occur due to screw damage.

• Make sure that no foreign matter such as cutting chips or wire scraps do not enter the robot

controller.

•Always store the cables connected to the robot controller in a conduit or clamp them securely

in place. If the cables are not stored in a conduit or properly clamped, excessive play or

movement or mistakenly pulling on the cable might damage the connector or cables, and poor

cable contact may lead to faulty operation or malfunctions.

•When disconnecting the cable, detach by gripping the connector itself and not by tugging on

the cable. Loosen the screws on the connector (if fastened with the screws), and then

disconnect the cable. Detaching by pulling on the cable itself may damage the connector or

cables, and poor cable contact may lead to faulty operation or malfunctions.

4

2

[Start-up and maintenance safety points]

w

WARNING

• Only personnel trained in safety and robot operation may operate it.

• Never allow anyone to enter the robot movement range when the robot controller

is turned on. Serious accidents including fatal injury or death might otherwise

result.

• This robot controller is not designed to be explosion-proof. Do not use it in

locations exposed to inflammable gases, gasoline or solvent that could cause

explosion or fire.

• Do not touch any electrical terminal while power is supplied to the robot

controller. This might cause electrical shocks, faulty operation or malfunctions.

• Always shut off all phases of the power supply externally before cleaning or

tightening the terminal screws. Failure to shut off all phases could lead to

electrical shocks, product damage or malfunctions. A loose screw could lead to

parts dropping out, short circuits or malfunctions. If the screw is too tight, short

circuits or malfunctions could also occur due to screw damage.

• Never disassemble or modify the robot controller. This may lead to breakdowns,

malfunctions, injury or fire.

• Always shut off all phases of the power supply externally before installing or

removing an option board. Failure to shut off all phases could lead to breakdowns

or malfunctions.

• When using ferrite cores for noise elimination, fit them to the power cable as close

to the robot controller as possible to prevent faulty operation or malfunctions due

to noise.

• When performing maintenance of the robot controller under instructions from the

YAMAHA or YAMAHA sales dealer, turn off the robot controller and wait for at least

30 minutes. Some components in the robot controller may be hot or still retain a

high voltage shortly after operation, so burns or electrical shocks may occur if

those parts are touched.

[Precautions for disposal]

c

CAUTION

• When disposing of absolute batteries used in this product, comply with local regulations or

contact our sales office.

•When disposing of this product (except for absolute batteries), discard it as industrial waste.

[Other precautions]

c

CAUTION

• Please note that the state of California USA has legal restrictions on the handling of

manganese dioxide lithium batteries. See the following website for more information:

http://www.dtsc.ca.gov/hazardouswaste/perchlorate

This manual does not constitute a concession of rights or a guarantee of

industrial rights. Please acknowledge that we bear no liability whatsoever

for conflicts with industrial rights arising from the contents of this manual.

2008 YAMAHA MOTOR CO., LTD.

5

2

Before using the robot controller

(Be sure to read the following notes.)

Please be sure to perform the following tasks before using the robot controller.

Failing to perform these tasks will require absolute reset for setting the origin position

each time the power is turned on or may cause abnormal operation (vibration, noise).

[1] When connecting the power supply to the robot controller

Always make a secure connection to the ground terminal on the robot controller to

ensure safety and prevent malfunctions due to noise.

[2] When connecting the battery cable to the robot controller

The absolute battery is fully charged when the robot controller is shipped to the

customer. Ho wever , it is left disconnected to prev ent battery discharge. After installing

the controller, always be sure to connect the absolute battery while referring to “9.

Connecting the absolute battery” in Chapter 3 before connecting the robot cables.

An error (relating to absolute settings) is always issued if the robot controller power is

turned on without connecting the absolute batteries, so the origin position cannot be

detected. This means the robot connected to this controller cannot be used with absolute

specifications.

[3] When connecting robot cables to the robot controller

Be sure to keep robot cables separate from the robot controller power connection

lines and other equipment power lines. Using in close contact with lines carrying

power may cause malfunctions or abnormal operation.

Reference

Absolute reset is always required when

the robot controller power is first

turned on after connecting the robot

cable to the robot controller. Perform

absolute reset while referring to “11.8

Absolute reset” in Chapter 4,

“Operation”.

Absolute reset is also required after the

robot cable was disconnected from the

robot controller and then reconnected.

Reference

Refer to “4. Connecting to the power”

in Chapter 3, “Installation”.

6

2

Overview of the RCX series

The YAMAHA RCX series robot controllers were developed based on years of

YAMAHA experience and proven achievements in robotics and electronics. These

controllers are specifically designed to operate YAMAHA industrial robots efficiently

and accurately.

Despite their compact size, the RCX series controllers operate efficiently as multi-axis

controllers with a variety of functions.

Major features and functions are:

1. Multi-task function

Up to 8 tasks* can be run simultaneously in a specified priority. (Low priority tasks

are halted while high priority tasks are run.)

I/O parallel processing and interrupt processing are also available, so that operational

efficiency of the total robot system including peripheral units is greatly improved.

(*: Refer to the programming manual for more details on multi-tasking.)

2. Robot language

The RCX series controller comes with a BASIC-like high-level robot language that

conforms to the industrial robot programming language SLIM*1. This robot language

allows easy programming ev en of comple x mov ements such as multi-task operations

and uses a compiling method*2 for rapid execution of programs.

(*1: Standard Language for Industrial Manipulators)

(*2: This compiling method checks the syntax in a robot language program, conv erts

it into intermediate codes, and creates an execution file (object file) before actuall y

performing the program.)

3. Movement command

• Arch motion

Spatial movement during pick-and-place work can be freely set according to the

work environment. This is effective in reducing cycle time.

• Three-dimensional CP control

Allows three-dimensional interpolation control of linear and circular movements.

4. Maintenance

Software servo control provides unit standardization. This allo ws connection to most

YAMAHA robot models and simplifies maintenance.

5. CE marking*

As a YAMAHA robot series product, the RCX series robot controller is designed to

conform to machinery directives, low-voltage directives and EMC (Electromagnetic

compatibility) directives. In this case, the robot controller is set to operate under SAFE

mode. (* For CE marking compatibility, see the CE marking supplement man ual.)

This manual explains how to handle and operate the YAMAHA robot controllers correctly

and effectively, as well as I/O interface connections.

Read this manual carefully before installing and using the robot controller. Also refer to

the separate “Programming Manual” and “Robot User's Manual” as needed.

i

Contents

Chapter 1 Safety

1. Safety .........................................................................................1-1

1.1 Safety precautions during robot operation ........................................... 1-2

1.2 Safety precautions during maintenance ............................................... 1-2

1.3 Motor overload precautions ................................................................ 1-2

1.4 Warning labels.................................................................................... 1-3

1.5 Warning marks.................................................................................... 1-3

2. Warranty ...................................................................................1-4

3. Operating environment .............................................................1-5

Chapter 2 System overview

1. System overview ........................................................................2-1

1.1 Main system configuration .................................................................. 2-1

1.2 Axis definition for the RCX142 series .................................................. 2-3

2. Part names and functions...........................................................2-4

2.1 RCX142 (Maximum number of axes: 4 axes) ....................................... 2-4

2.2 RCX142-T ........................................................................................... 2-4

3. Controller system ......................................................................2-5

3.1 RCX142 .............................................................................................. 2-5

3.2 RCX142-T ........................................................................................... 2-6

4. Optional devices........................................................................ 2-7

4.1 MPB programming box ....................................................................... 2-7

4.2 Expansion I/O board ........................................................................... 2-7

4.3 Regenerative unit ................................................................................ 2-7

5. Basic sequence from installation to operation ...........................2-8

Chapter 3 Installation

1. Unpacking .................................................................................3-1

1.1 Packing box ........................................................................................ 3-1

1.2 Unpacking .......................................................................................... 3-1

2. Installing the robot controller.................................................... 3-2

2.1 Installation .......................................................................................... 3-2

2.2 Installation methods ............................................................................ 3-3

3. Connector names....................................................................... 3-5

4. Connecting to the power ...........................................................3-6

4.1 AC200 to 230V single-phase specifications......................................... 3-6

4.2 Power capacity ................................................................................... 3-6

4.3 Installing an external leakage breaker ................................................. 3-8

4.4 Installing a circuit protector ................................................................ 3-8

4.5 Installing a current control switch ....................................................... 3-8

5. Connecting the robot cables ......................................................3-9

ii

6. Connecting the MPB programming box ...................................3-10

7. I/O connections....................................................................... 3-11

8. Connecting a host computer.................................................... 3-12

9. Connecting the absolute battery ..............................................3-13

10. Replacing the absolute battery ................................................ 3-16

11. Connecting a regenerative unit ................................................3-17

12. Precautions for cable routing and installation .........................3-18

12.1 Wiring methods ................................................................................ 3-18

12.2 Precautions for installation ................................................................ 3-19

12.3 Methods of preventing malfunctions ................................................. 3-19

13. Checking the robot controller operation .................................3-20

13.1 Cable connection.............................................................................. 3-20

13.2 Emergency stop input signal connection ........................................... 3-21

13.3 Operation check ............................................................................... 3-22

Chapter 4 Operation

1. Operation overview................................................................... 4-1

2. The RCX robot controller ..........................................................4-2

2.1 Part names .......................................................................................... 4-2

2.2 Main functions .................................................................................... 4-2

3. MPB programming box ..............................................................4-3

3.1 Part names .......................................................................................... 4-3

3.2 Main functions .................................................................................... 4-4

3.3 Connection to the robot controller ...................................................... 4-5

4. Turning power on and off .......................................................... 4-6

5. Operation keys ..........................................................................4-7

5.1 MPB screen......................................................................................... 4-7

5.2 Operation key layout .......................................................................... 4-8

5.3 Basic key operation............................................................................. 4-9

5.4 Function keys.................................................................................... 4-10

5.5 Control keys ...................................................................................... 4-12

5.6 Data keys .......................................................................................... 4-14

5.7 Other keys ........................................................................................ 4-14

6. Emergency stop .......................................................................4-15

6.1 Emergency stop reset ........................................................................ 4-16

7. Mode configuration .................................................................4-18

7.1 Basic operation modes ...................................................................... 4-18

7.2 Other operation modes ..................................................................... 4-19

7.3 Mode hierarchy ................................................................................. 4-20

8. “SERVICE” mode .....................................................................4-24

8.1 Operation device .............................................................................. 4-24

8.2 Prohibition of “AUTO” mode operation ............................................ 4-24

8.3 Hold-to-Run function ........................................................................ 4-24

8.4 Limitations on robot operating speed ................................................ 4-24

iii

9. “AUTO” mode......................................................................... 4-25

9.1 Automatic operation ......................................................................... 4-27

9.2 Stopping the program........................................................................ 4-28

9.3 Resetting the program ....................................................................... 4-29

9.4 Switching task display ....................................................................... 4-32

9.5 Switching the program ...................................................................... 4-33

9.6 Changing the automatic movement speed......................................... 4-34

9.7 Executing the point trace................................................................... 4-34

9.7.1 PTP motion mode ........................................................................................... 4-36

9.7.2 ARCH motion mode ....................................................................................... 4-38

9.7.3 Linear interpolation motion mode ................................................................... 4-40

9.8 Direct command execution............................................................... 4-42

9.9 Break point ....................................................................................... 4-43

9.9.1 Setting break points ........................................................................................ 4-43

9.9.2 Deleting break points ...................................................................................... 4-44

9.10 Executing a step ................................................................................ 4-45

9.11 Skipping a step.................................................................................. 4-45

9.12 Executing the next step ..................................................................... 4-45

10. “PROGRAM” mode .................................................................4-46

10.1 Scrolling a program listing ................................................................ 4-47

10.2 Program editing ................................................................................ 4-48

10.2.1 Cursor movement ........................................................................................... 4-50

10.2.2 Insert/Overwrite mode switching .................................................................... 4-50

10.2.3 Inserting a line ................................................................................................ 4-51

10.2.4 Deleting a character ....................................................................................... 4-51

10.2.5 Deleting a line ................................................................................................ 4-52

10.2.6 User function key display ............................................................................... 4-52

10.2.7 Quitting program editing ................................................................................ 4-53

10.2.8 Specifying the copy/cut lines .......................................................................... 4-53

10.2.9 Copying the selected lines .............................................................................. 4-53

10.2.10 Cutting the selected lines ................................................................................ 4-54

10.2.11 Pasting the data ............................................................................................... 4-54

10.2.12 Backspace ...................................................................................................... 4-54

10.2.13 Line jump ....................................................................................................... 4-55

10.2.14 Searching a character string ............................................................................ 4-56

10.3 Directory .......................................................................................... 4-57

10.3.1 Cursor movement ........................................................................................... 4-58

10.3.2 Registering a new program name ....................................................................4-58

10.3.3 Directory information display ......................................................................... 4-59

10.3.4 Copying a program ......................................................................................... 4-60

10.3.5 Erasing a program ........................................................................................... 4-61

10.3.6 Renaming a program ...................................................................................... 4-62

10.3.7 Changing the program attribute ...................................................................... 4-63

10.3.8 Displaying object program information ........................................................... 4-63

10.3.9 Creating a sample program automatically ....................................................... 4-64

10.4 Compiling ......................................................................................... 4-66

10.5 Line jump and character string search ............................................... 4-67

10.6 Registering user function keys ........................................................... 4-67

10.7 Resetting an error in the selected program ........................................ 4-70

iv

11.“MANUAL” mode ................................................................... 4-71

11.1 Manual movement ............................................................................ 4-74

11.2 Displaying and editing point data ..................................................... 4-77

11.2.1 Point data input and editing ............................................................................4-78

11.2.1.1 Restoring point data ........................................................................................ 4-79

11.2.2 Point data input by teaching ........................................................................... 4-80

11.2.3 Point data input by direct teaching.................................................................. 4-84

11.2.4 Point jump display ..........................................................................................4-84

11.2.5 Copying point data ......................................................................................... 4-85

11.2.6 Erasing point data ........................................................................................... 4-86

11.2.7 Point data trace ............................................................................................... 4-87

11.2.8 Point comment input and editing ....................................................................4-88

11.2.8.1 Point comment input and editing ..................................................................... 4-89

11.2.8.2 Point data input by teaching ............................................................................4-89

11.2.8.3 Jump to a point comment ................................................................................ 4-90

11.2.8.4 Copying a point comment ............................................................................... 4-91

11.2.8.5 Erasing point comments ................................................................................... 4-92

11.2.8.6 Point comment search ..................................................................................... 4-93

11.2.9 Point data error reset ....................................................................................... 4-94

11.3 Displaying, editing and setting pallet definitions ............................... 4-95

11.3.1 Editing pallet definitions ................................................................................. 4-97

11.3.1.1 Point setting in pallet definition ....................................................................... 4-98

11.3.1.1.1 Editing the point in pallet definition ................................................................... 4-99

11.3.1.1.2 Setting the point in pallet definition by teaching ................................................ 4-99

11.3.2 Pallet definition by teaching ..........................................................................4-100

11.3.3 Copying a pallet definition ............................................................................ 4-102

11.3.4 Deleting a pallet definition ........................................................................... 4-103

11.4 Changing the manual movement speed .......................................... 4-104

11.5 Displaying, editing and setting shift coordinates.............................. 4-105

11.5.1 Editing shift coordinates ................................................................................4-108

11.5.1.1 Restoring shift coordinates .............................................................................4-109

11.5.2 Editing the shift coordinate range ..................................................................4-109

11.5.2.1 Restoring a shift coordinate range ..................................................................4-111

11.5.3 Shift coordinate setting method 1 .................................................................. 4-111

11.5.4 Shift coordinate setting method 2 .................................................................. 4-113

11.6 Displaying, editing and setting hand definitions .............................. 4-115

11.6.1 Editing hand definitions ................................................................................ 4-121

11.6.1.1 Restoring hand definitions ............................................................................. 4-122

11.6.2 Hand definition setting method 1 .................................................................. 4-122

11.7 Changing the display units .............................................................. 4-124

11.8 Absolute reset ................................................................................. 4-125

11.8.1 Checking absolute reset ................................................................................ 4-126

11.8.2 Absolute reset on each axis ........................................................................... 4-127

11.8.3 Absolute reset on all axes ............................................................................. 4-132

11.9 Setting the standard coordinates...................................................... 4-136

11.9.1 Setting the standard coordinates by 4-point teaching .................................... 4-139

11.9.2 Setting the standard coordinate by 3-point teaching ...................................... 4-141

11.9.3 Setting the standard coordinates by simple teaching ..................................... 4-143

11.10 Executing the user function keys ..................................................... 4-145

12. “SYSTEM” mode ....................................................................4-146

12.1 Parameters ...................................................................................... 4-148

12.1.1 Robot parameters .......................................................................................... 4-150

12.1.2 Axis parameters ............................................................................................ 4-155

12.1.3 Other parameters ..........................................................................................4-171

12.1.4 Parameters for option boards......................................................................... 4-181

12.1.4.1 Option DIO setting ........................................................................................4-182

12.1.4.2 Serial I/O setting ............................................................................................4-183

12.1.4.3 Setting the network parameters ......................................................................4-185

v

12.2 Communication parameters ............................................................ 4-187

12.3 OPTION parameters ....................................................................... 4-193

12.3.1 Setting the area check output ........................................................................4-194

12.3.2 Setting the “SERVICE” mode ......................................................................... 4-199

12.3.2.1 Saving the “SERVICE” mode parameters ........................................................ 4-204

12.3.2.2 Help display in “SERVICE” mode................................................................... 4-204

12.3.3 SIO settings ................................................................................................... 4-205

12.3.4 Double-carrier setting ................................................................................... 4-208

12.3.4.1 Before using a double-carrier ........................................................................ 4-208

12.3.4.2 Setting the double-carrier parameters ............................................................ 4-209

12.4 Initialization.................................................................................... 4-212

12.4.1 Initializing the parameters ............................................................................. 4-213

12.4.2 Initializing the memory .................................................................................4-214

12.4.3 Initializing the communication parameters ................................................... 4-215

12.4.4 Clock setting .................................................................................................4-216

12.4.5 System generation ......................................................................................... 4-217

12.5 Self diagnosis .................................................................................. 4-218

12.5.1 Controller check ........................................................................................... 4-218

12.5.2 Error history display ...................................................................................... 4-219

12.5.3 Displaying the total operation time ............................................................... 4-220

12.5.4 System error details display ........................................................................... 4-220

12.6 Backup processes............................................................................ 4-221

12.6.1 Internal flash ROM ....................................................................................... 4-221

12.6.1.1 Loading files ..................................................................................................4-222

12.6.1.2 Saving files .................................................................................................... 4-223

12.6.1.3 Initializing the files ........................................................................................ 4-223

13. “MONITOR” mode ............................................................... 4-224

14. “UTILITY” mode....................................................................4-227

14.1 Canceling emergency stop; Motor power and servo on/off .............. 4-228

14.1.1 Canceling emergency stop ............................................................................4-228

14.1.2 Motor power and servo on/off ....................................................................... 4-229

14.2 Enabling/disabling the sequence execution flag .............................. 4-230

14.3 Changing the arm type .................................................................... 4-231

14.4 Resetting the output ports................................................................ 4-232

14.5 Changing the execution level .......................................................... 4-233

14.5.1 Changing the execution level ........................................................................ 4-234

14.5.2 Displaying the Help message ........................................................................4-235

14.6 Changing the access level (operation level) ..................................... 4-236

14.6.1 Entering the password ...................................................................................4-236

14.6.2 Changing the access level .............................................................................4-237

14.6.3 Displaying the Help message ........................................................................4-237

Chapter 5 Two-robot setting

1. Explanation of two-robot setting................................................5-1

1.1 Two-robot setting ................................................................................ 5-1

1.2 System configuration example ............................................................ 5-2

2. Operations and data when using the two-robot setting .............5-3

2.1 "AUTO" mode..................................................................................... 5-3

2.1.1 Changing the automatic movement speed ........................................................ 5-3

2.1.2 Executing the point trace .................................................................................. 5-4

2.2 "MANUAL" mode ............................................................................... 5-5

2.2.1 Current position ................................................................................................5-5

2.2.2 Manual movement ............................................................................................ 5-6

2.2.3 Point data ......................................................................................................... 5-8

vi

2.2.3.1 Point data input by teaching .............................................................................. 5-9

2.2.3.2 Input by point data direct teaching .................................................................. 5-10

2.2.4 Pallet definition ............................................................................................... 5-10

2.2.4.1 Setting the point in pallet definition by teaching ..............................................5-11

2.2.4.2 Pallet definition by teaching............................................................................. 5-11

2.2.5 Changing the manual movement speed .......................................................... 5-12

2.2.6 Shift coordinates ............................................................................................. 5-13

2.2.6.1 Shift coordinates setting method 1 ...................................................................5-15

2.2.6.2 Shift coordinates setting method 2 ...................................................................5-16

2.2.7 Hand definition .............................................................................................. 5-17

2.2.7.1 Hand definition setting method 1 .................................................................... 5-17

2.2.8 Absolute reset ................................................................................................. 5-19

2.2.8.1 Checking absolute reset status ......................................................................... 5-19

2.2.8.2 Absolute reset on each axis (Mark Method) ..................................................... 5-20

2.2.8.3 Absolute reset on each axis (Stroke end method / sensor method).................... 5-21

2.2.8.4 Absolute reset on all axes ................................................................................ 5-22

2.3 "SYSTEM" mode ................................................................................ 5-24

2.3.1 "SYSTEM" mode initial screen format .............................................................. 5-24

2.3.2 Robot parameters screen format ...................................................................... 5-25

2.3.3 Axis parameters screen format ........................................................................ 5-25

2.3.4 Setting the area check output ..........................................................................5-26

2.3.5 Double-carrier collision prevention ................................................................ 5-27

2.4 Error message displays ...................................................................... 5-31

3. Programming ...........................................................................5-32

3.1 Robot languages used in the two-robot setting .................................. 5-32

Chapter 6 Parallel I/O interface

1. Standard I/O interface overview ...............................................6-1

1.1 Power supply ...................................................................................... 6-1

1.2 Connector I/O signals ......................................................................... 6-2

1.3 Connector pin numbers ...................................................................... 6-3

1.4 Typical input signal connection .......................................................... 6-4

1.5 Typical output signal connection ........................................................ 6-5

1.5.1 Dedicated outputs ............................................................................................ 6-5

1.5.2 General-purpose outputs .................................................................................. 6-6

1.6 Dedicated input signal description ...................................................... 6-7

1.7 Dedicated output signal description .................................................... 6-9

1.8 Dedicated I/O signal timing chart ..................................................... 6-11

1.8.1 Controller power ON, servo ON and emergency stop..................................... 6-11

1.8.2 Absolute reset ................................................................................................. 6-12

1.8.3 Switching to AUTO mode, program reset and execution ................................. 6-13

1.8.4 Stopping due to program interlocks ................................................................ 6-14

1.9 General-purpose I/O signals.............................................................. 6-15

1.9.1 General-purpose input signals ........................................................................ 6-15

1.9.2 General-purpose output signals ...................................................................... 6-15

1.9.3 General-purpose output signal reset (off) ......................................................... 6-15

2. Option I/O interface overview ................................................6-16

2.1 ID settings ......................................................................................... 6-17

2.2 Power supply .................................................................................... 6-17

2.3 Connector I/O signals ....................................................................... 6-18

2.4 Connector pin numbers .................................................................... 6-19

2.5 Typical input signal connection ........................................................ 6-20

2.6 Typical output signal connection ...................................................... 6-20

2.7 General-purpose I/O signals.............................................................. 6-20

vii

2.7.1 General-purpose input signals ........................................................................ 6-20

2.7.2 General-purpose output signals ...................................................................... 6-20

2.7.3 General-purpose output signal reset (off) ......................................................... 6-21

3. Ratings .....................................................................................6-22

4. Caution items ..........................................................................6-23

Chapter 7 SAFETY I/O interface

1. SAFETY I/O interface overview .................................................7-1

1.1 Power ................................................................................................. 7-1

1.2 Connector I/O signals ......................................................................... 7-1

1.3 Connector terminal numbers............................................................... 7-2

1.4 Emergency stop input signal connections ............................................ 7-3

1.4.1 RCX142 ............................................................................................................ 7-3

1.4.2 RCX142-T .........................................................................................................7-6

1.5 Dedicated input signal connections .................................................... 7-9

1.6 Input signal description ..................................................................... 7-10

Chapter 8 RS-232C interface

1. Communication overview.......................................................... 8-1

2. Communication function overview............................................8-2

3. Communication specifications ...................................................8-3

3.1 Connector ........................................................................................... 8-3

3.2 Transmission mode and communication parameters ........................... 8-4

3.3 Communication flow control .............................................................. 8-5

3.3.1 Flow control during transmit .............................................................................8-5

3.3.2 Flow control during receive .............................................................................. 8-5

3.4 Other caution items ............................................................................ 8-6

3.5 Character code table ........................................................................... 8-8

3.6 Connecting to a PC ............................................................................. 8-9

Chapter 9 Specifications

1. Controller basic specifications ...................................................9-1

1.1 RCX142 basic specifications ............................................................... 9-1

1.2 RCX142-T basic specifications ............................................................ 9-2

2. Controller basic functions..........................................................9-3

3. Robot controller external view ..................................................9-4

3.1 RCX142 external view ........................................................................ 9-4

3.2 RCX142-T external view ..................................................................... 9-5

4. MPB basic specifications and external view...............................9-6

Chapter 10 Troubleshooting

1. Error Messages......................................................................... 10-1

1.1 Robot controller error messages ........................................................ 10-1

[ 0] Warnings and messages .......................................................................................... 10-3

[ 1] Warnings (error history entry).................................................................................. 10-5

[ 2] Robot operating area errors..................................................................................... 10-5

viii

[ 3] Program file operating errors................................................................................... 10-9

[ 4] Data entry and edit errors ..................................................................................... 10-11

[ 5] Robot language syntax (compiling) errors ............................................................. 10-11

[ 6] Robot language execution errors .......................................................................... 10-19

[ 9] Memory errors ......................................................................................................10-24

[10] System setting or hardware errors ......................................................................... 10-26

[12] I/O and option board errors .................................................................................. 10-28

[13] MPB errors ........................................................................................................... 10-32

[14] RS-232C communication errors ............................................................................10-33

[15] Memory card errors .............................................................................................. 10-35

[17] Motor control errors.............................................................................................. 10-37

[21] Major software errors ............................................................................................ 10-44

[22] Major hardware errors .......................................................................................... 10-45

1.2 MPB Error Messages........................................................................ 10-49

2. Troubleshooting .....................................................................10-51

2.1 When trouble occurs ...................................................................... 10-51

2.2 Acquiring error information ............................................................ 10-52

2.2.1 Acquiring information from the MPB ............................................................ 10-52

2.2.2 Acquiring information from the RS-232C ...................................................... 10-52

2.3 Troubleshooting checkpoints........................................................... 10-53

Chapter 1 Safety

Contents

1. Safety ............................................................................................... 1-1

1.1 Safety precautions during robot operation ............................................... 1-2

1.2 Safety precautions during maintenance ................................................... 1-2

1.3 Motor overload precautions .................................................................... 1-2

1.4 Warning labels ........................................................................................1-3

1.5 Warning marks ........................................................................................ 1-3

2. Warranty .......................................................................................... 1-4

3. Operating environment .................................................................... 1-5

MEMO

1-1

1

Safety

1. Safety

Please observe all safety rules and cautions to ensure safe and correct use of the YAMAHA robot.

Also, bear in mind that not all safety items can be listed in detail, so that accurate judgment by the

operator or service personnel is essential for operating the robot and controller safely.

Industrial robots are highly programmable, mechanical devices that provide a large deg ree

of freedom for performing various manipulative tasks. To ensure safe and correct of

YAMAHA industrial robots, carefully read this manual and FOLLOW THE WARNINGS,

CAUTIONS AND INSTRUCTIONS in this chapter. Failure to take necessary safety

measures or mishandling may result in trouble or damage to the robot and injury to

personnel (robot operator or service personnel) including fatal accidents.

Particularly important safety items and operation points are identified in this manual by

the following symbols and signal words.

w

WARNING

"WARNING" indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

c

CAUTION

"CAUTION" indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury or damage to the equipment or software.

n

NOTE

Explains key points in the operation in a simple and clear manner.

To install, operate or adjust the YAMAHA robot or controller safely and correctly, always

follow the instructions explained in this manual by using either of the following methods.

1. Install, operate or adjust the robot or controller while referring to the contents of this

manual.

2. Install, operate or adjust the robot or controller while vie wing the contents of the CDROM version manual on your computer screen.

3. Install, operate or adjust the robot or controller while referring to a printout of the

necessary pages from the CD-ROM version manual.

1-2

Safety

1

1. Safety

1.1 Safety precautions during robot operation

a. The robot must be operated by a person who has received the proper training on safety

and operation from YAMAHA or an authorized YAMAHA sales dealer.

b. During operation of the robot, be sure to stay out of the work area of the robot

manipulator. Install a safeguard enclosure to keep others away from the work area or

provide a gate interlock using an area sensor that triggers emergency stop when someone

enters the work area.

c. This robot controller is not designed to be explosion-proof. Do not use the controller

and robot in locations exposed to inflammable gases, gasoline or solvent that could

cause explosion or fire.

1.2 Safety precautions during maintenance

a. Never disassemble the robot or controller . In cases where you hav e to replace or repair

parts used in the robot or controller, first consult with us and then follo w the instructions

we provide.

b. Before beginning maintenance for the robot or controller, be sure to turn off the power

to the controller. Even after turning off the controller, there are some parts in the

controller which are still hot or at a high voltage. Always wait for at least 30 minutes

after the controller is turned off.

1.3 Motor overload precautions

Since abnormal operation (such as overload) of the motor is detected by software, the

controller parameters must be set correctly to match the motor type used in the robot

connected to the controller.

Prior to shipping, the controller parameters are preset to match the robot model to be

used. However, please check the robot model again when connecting it to the controller.

If any abnormality is found during operation, stop the controller and contact us for

corrective action.

1-3

1

Safety

1. Safety

1.4 Warning labels

The warning labels shown below are af fix ed to the controller. To use the YAMAHA robot

and controller safely and correctly , be sure to observ e the instructions and caution on the

labels.

a. “Electric Hazard” label

!

CAUTION

ELECTRIC HAZARD

■ This label warns you of possible electrical shock. Do not touch the terminal strip and

connectors to avoid electrical shock.

b. “Read Instruction Manual” label

READ INSTRUCTION

MANUAL

■ This label means that important information you must kno w is described in the manual.

When in particular connecting a power supply to the robot controller, read this manual

carefully and follow the instructions. Connectors have a particular orientation, so insert

each connector in the correct direction.

1.5 Warning marks

The following warning marks are shown on the controller. To use the YAMAHA robot

and controller safely and correctly, be sure to observe the instructions and caution of the

marks.

a. “Electric Hazard” mark

■ This mark warns you of possible electrical shock. Do not touch the terminal block and

connectors to avoid electrical shock.

b. “CAUTION” mark

!

■ This mark indicates that important information you must know is descr ibed in the

manual.

When in particular connecting a power supply to the robot controller, read this

manual carefully and follow its instructions. Connectors have a particular

orientation, so insert each connector in the correct direction.

1-4

Safety

1

2. Warranty

The YAMAHA robot and/or related product you have purchased are warranted against the defects or

malfunctions as described below.

Warranty description:

If a failure or breakdown occurs due to defects in materials or workmanship in the genuine

parts constituting this YAMAHA robot and/or related product within the warranty period,

then YAMAHA will repair or replace those parts free of charge (hereafter called "warranty

repair").

Warranty Period:

The warranty period ends when any of the following applies:

(1) After 18 months (one and a half year) have elapsed from the date of shipment

(2) After one year has elapsed from the date of installation

(3) After 2,400 hours of operation

Exceptions to the Warranty:

This warranty will not apply in the following cases:

(1) Fatigue arising due to the passage of time, natural wear and tear occurring during

operation (natural fading of painted or plated surfaces, deterioration of parts subject

to wear, etc.)

(2) Minor natural phenomena that do not affect the capabilities of the robot and/or

related product (noise from computers, motors, etc.).

(3) Programs, point data and other internal data that were changed or created by the

user.

Failures resulting from the following causes are not covered by warranty repair.

1) Damage due to earthquakes, storms, floods, thunderbolt, fire or any other natural or

man-made disasters.

2) Troubles caused by procedures prohibited in this manual.

3) Modifications to the robot and/or related product not approved by YAMAHA or

YAMAHA sales representatives.

4) Use of any other than genuine parts and specified grease and lubricants.

5) Incorrect or inadequate maintenance and inspection.

6) Repairs by other than authorized dealers.

YAMAHA MOTOR CO., LTD. MAKES NO OTHER EXPRESS OR IMPLIED

WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR ANY PARTICULAR PURPOSE. THE WARRANTY SET FORTH

ABOVE IS EXCLUSIVE AND IS IN LIEU OF ALL EXPRESSED OR IMPLIED

WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, OR WARRANTIES ARISING FROM A COURSE

OF DEALING OR USAGE OF TRADE.

YAMAHA MOTOR CO., LTD. SOLE LIABILITY SHALL BE FOR THE DELIVERY

OF THE EQUIPMENT AND Y AMAHA MO T OR CO., LTD. SHALL NOT BE LIABLE

FOR ANY CONSEQUENTIAL DAMAGES (WHETHER ARISING FROM

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY). YAMAHA

MOTOR CO., LTD. MAKES NO WARRANTY WHATSOEVER WITH REGARD TO

ACCESSORIES OR PARTS NOT SUPPLIED BY YAMAHA MOTOR CO., LTD.

1-5

1

Safety

3. Operating environment

Operating temperature

The ambient temperature should be maintained within a range of 0 to 40°C during

operation. This is the range in which continuous operation of the robot controller is

guaranteed according to the initial specifications. If the robot controller is installed in a

narrow space, then heat generated from the controller itself and from peripheral equipment

may drive the temperature above the allowable operating temperature range. This may

result in thermal runaway or malfunctions and may lower component performance along

with shortening their useful service life. So be sure to install the controller in locations

with a vent having a natural air flow . If this pr oves insuff icient, provide forced air-cooling.

Storage temperature

The controller should be stored in a location at an ambient temperature between -10 and

+65°C when not being used. If the robot controller is stored in a location at high

temperatures for extended periods, deterioration of the electronic components may occur

and the memory backup time may decrease.

Operating humidity

The ambient humidity of the robot controller should be 35% to 85% RH (no condensation)

in order to guarantee continuous operation within the initial specifications. Installing the

robot controller inside an air-conditioned or cooled housing is recommended when the

ambient humidity is higher than 85% or when condensation occurs.

Storage humidity

The controller should be stored in a location at an ambient humidity below 95% RH (no

condensation) when not being used. If the robot controller is stored in a location at high

humidity for an extended period of time, rust may form on the electronic components.

Vibration and shock

Do not apply excessive shocks to the robot controller. Install the robot controller in a

location that is not subject to vibrations.

Atmosphere (gas, etc.)

Do not install the robot controller in locations where conductive dust particles, hydrogen

sulfide gas or sulfurous acid gas are present. Such an atmosphere may cause the components

to erode or poor installation. If such dust particles or gases are generated at the current

location, then installing the robot controller in an air-conditioned or cooled housing is

recommended.

Installation location

Always install the robot controller indoors, at a height of less than 1000 meters above sea

level.

This robot controller is neither dust-proof nor water-proof. Do not install it in locations

exposed to oil mist, cutting fluids or cleaning agents.

1-6

MEMO

Chapter 2 System overview

Contents

1. System overview .............................................................................. 2-1

1.1 Main system configuration ...................................................................... 2-1

1.2 Axis definition for the RCX142 series ...................................................... 2-3

2. Part names and functions ................................................................. 2-4

2.1 RCX142 (Maximum number of axes: 4 axes) ........................................... 2-4

2.2 RCX142-T ............................................................................................... 2-4

3. Controller system ............................................................................. 2-5

3.1 RCX142 .................................................................................................. 2-5

3.2 RCX142-T ............................................................................................... 2-6

4. Optional devices .............................................................................. 2-7

4.1 MPB programming box ........................................................................... 2-7

4.2 Expansion I/O board ............................................................................... 2-7

4.3 Regenerative unit .................................................................................... 2-7

5. Basic sequence from installation to operation .................................. 2-8

MEMO

2-1

2

System overview

1. System overview

The RCX series controllers are designed for use with a SCARA robot or Cartesian robot, mainly for

assembly and pick-and-place applications. Applications also include various inspection instruments,

sealers and spray equipment utilizing linear and circular interpolation functions.

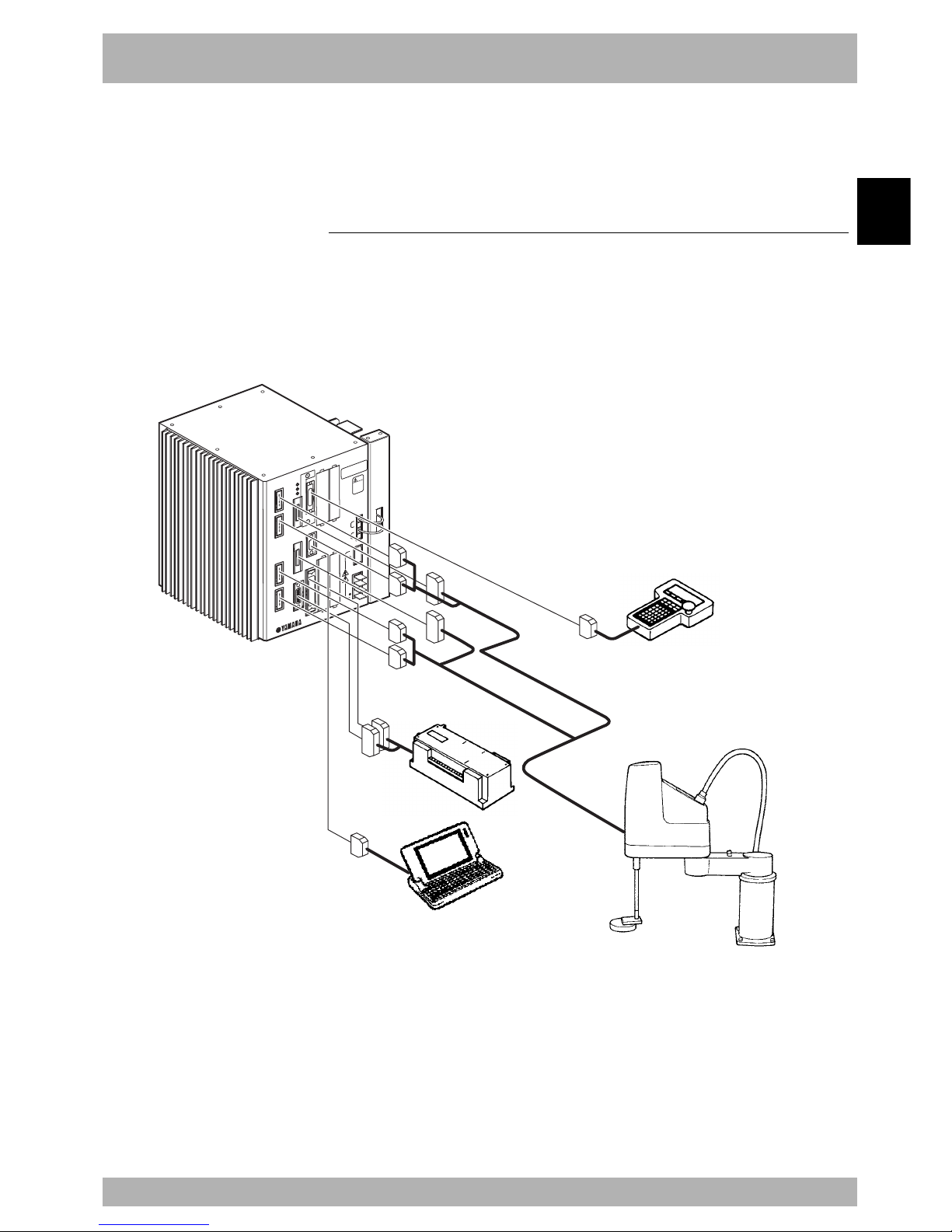

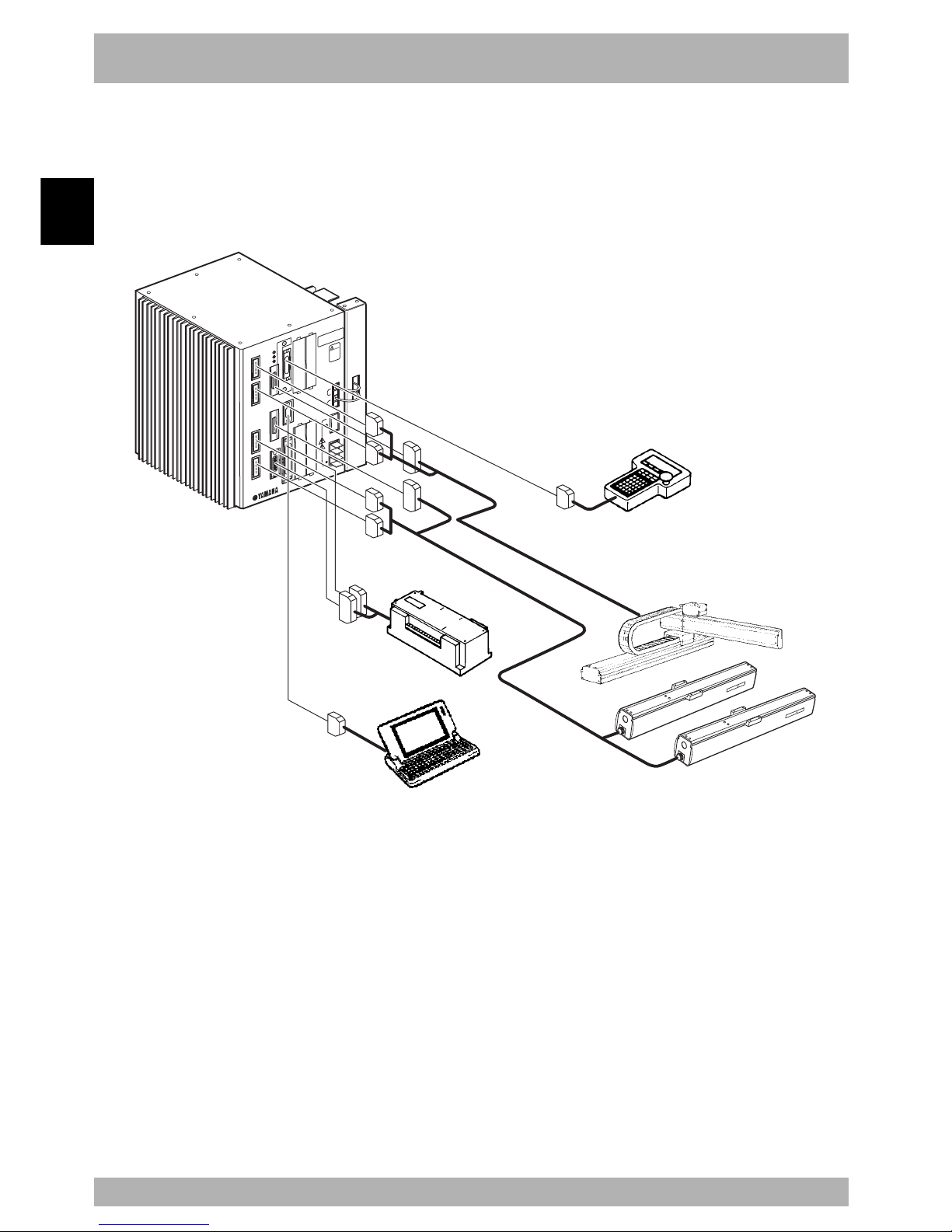

1.1 Main system configuration

Configuration 1: System for controlling one robot

Example :YK500X

All the axes on the robot controller are used as the main robot axes.

Fig. 2-1-1 System for controlling one robot

RCX142

MOTO

R

XM

YM

ZM

RM

PWR

SRV

ERR

SAFETY

MPB

COM

STD.DI

O

RGEN

AC

IN

P

N

L

N

ROB

I/O

XY

ROB

I/O

ZR

OP.1 OP.3

OP.2 OP.4

2

00-

2

30V~

50-60Hz

MAX.2500VA

M

O

DEL.

SER. NO.

M

ANUF

A

CTURED

F

A

CT

O

RY AUT

O

M

ATION EQUIPMENT MAD

E

IN JAPAN

注意

CAUTION

取扱説明書参照

READ INSTRUCTION

MANUAL

BATT

ZR

XY

PC

PLC

MPB

YAMAHA robot

2-2

System overview

2

1. System overview

Configuration 2: System for controlling one robot and auxiliary axes

Example: MXYx+T9+T9

Axes 1 and 2 on the robot controller are used as the main robot axes and

axes 3 and 4 are used as the main auxiliary axes.

Fig. 2-1-2 System for controlling one robot and auxiliary axes

RCX142

MOTO

R

XM

YM

ZM

RM

PWR

SRV

ERR

SAFETY

MPB

COM

S

T

D.DI

O

RGEN

ACIN

P

N

L

N

ROB

I/O

XY

ROB

I/O

ZR

OP.1 OP.3

OP.2 OP.4

2

00-2

30V~

50-60Hz

MAX.2500VA

M

ODEL.

SER. NO.

MANUF

A

CTURED

FACTOR

Y

AUTO

M

ATION EQ

UIPMENT

MADE IN JAPAN

注

意

CAUTION

取扱説明書参照

READ INSTRUCTION

MANUAL

BATT

ZR

XY

PLC

MPB

PC

YAMAHA robot

2-3

2

System overview

1. System overview

1.2 Axis definition for the RCX142 series

Axis definitions for the YAMAHA RCX142 series robot controller are shown below.

Robot

controller (RC)

Main robot axis (M?)

Main robot auxiliary axis (m?)

Sub robot axis (S?)

Sub robot auxiliary axis (s?)

Main robot (MR)

Sub robot (SR)

Main group (MG)

Subgroup (SG)

Robot controller ................ Indicates the entire robot controller and controls a

maximum of 4 axes.

The letters “RC” are displayed on the MPB.

Main group ........................ Indicates the main robot and main auxiliary axes and has a

maximum of 4 axes.

The letters “MG” are displayed on the MPB.

Main robot ......................... Indicates the robot name specified as a main robot, and

includes all axes of the main robot.

The letters “MR” are displayed on the MPB.

Main robot axes................. Indicate the axes composing the main robot.

These can be moved with the robot language MOVE

command.

The letters “M?” are displayed on the MPB. (?=1 to 4)

Main auxiliary axes ........... Are the single axes composing the main group.

These cannot be moved with the robot language MOVE

command. Use the DRIVE command to move these axes.

The letters “m?” are displayed on the MPB. (?=1 to 4)

Sub group .......................... Indicates the sub robot and sub auxiliary axes, and has a

maximum of 2 axes.

The letters “SG” are displayed on the MPB.

Sub robot ........................... Indicates the robot name specified as a sub robot, and

includes all axes of the sub robot.

The letters “SR” are displayed on the MPB.

Sub robot axes ................... Indicate the axes composing the sub robot.

These can be moved with the robot language MOVE2

command.

The letters “S?” are displayed on the MPB. (?=1 to 2)

These cannot be moved with the robot language MOVE2

command. Use the DRIVE2 command to move these axes.

The letters “s?” are displayed on the MPB. (?=1 to 2)

Only the main robot axes are usually specified. Auxiliary ax es and sub group settings ar e

for options made at the time of shipment.

2-4

System overview

2

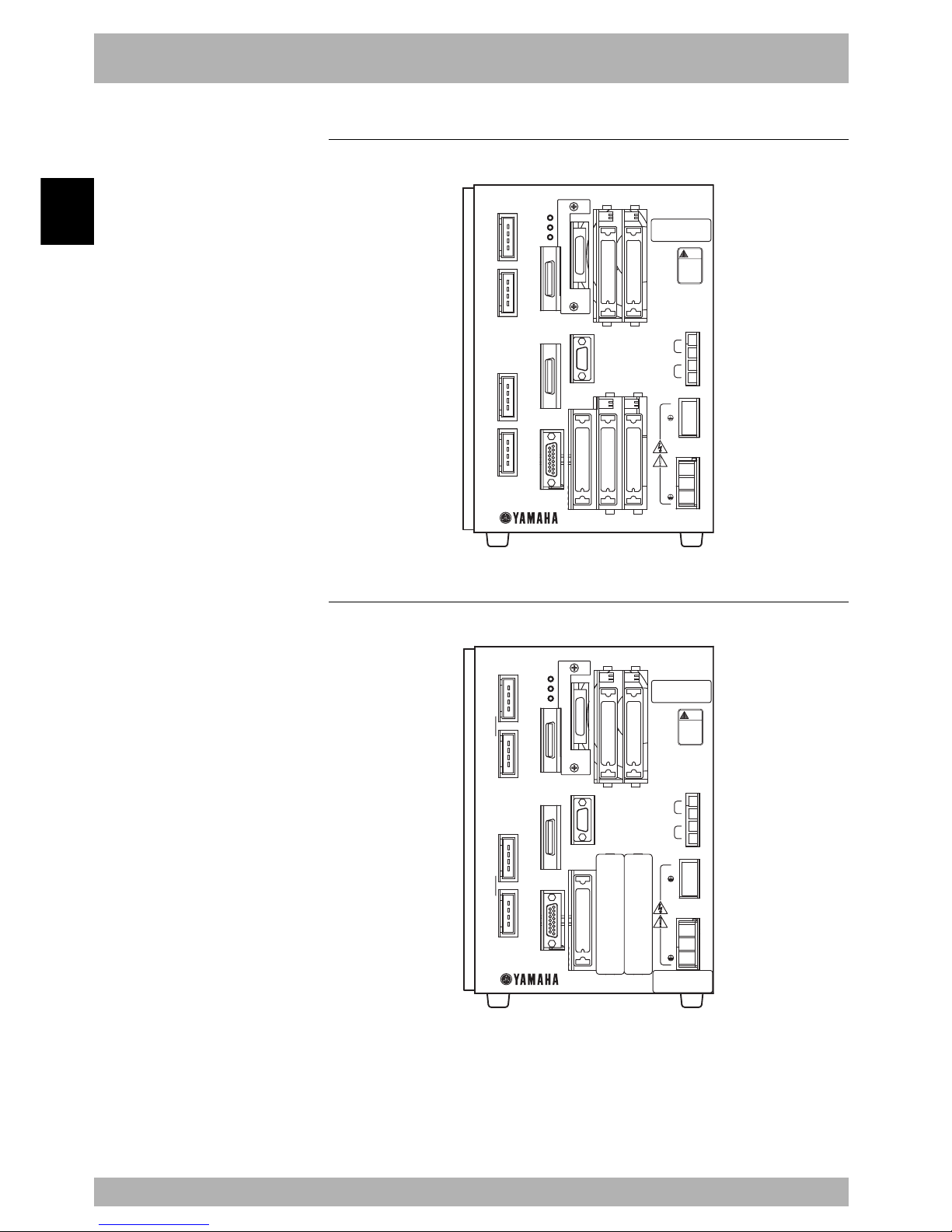

2. Part names and functions

2.1 RCX142 (Maximum number of axes: 4 axes)

Fig. 2-2-1

RCX142

MOTOR

XM

YM

ZM

RM

PWR

SRV

ERR

SAFETY

MPB

COM

STD.DIO

RGEN

ACIN

P

N

L

N

ROB

I/O

XY

ROB

I/O

ZR

OP.1 OP.3

OP.2 OP.4

200-230V~

50-60Hz

MAX.2500VA

BATT

ZR

XY

MODEL.

SER. NO.

MANUFACTURED

FACTORY AUTOMATION EQUIPMENT MADE IN JAPAN

注意

CAUTION

取扱説明書参照

READ INSTRUCTION

MANUAL

2.2 RCX142-T

Fig. 2-2-2

MOTOR

XM

YM

ZM

RM

PWR

SRV

ERR

SAFETY

COM

STD.DIO

RGEN

ACIN

P

N

L

N

ROB

I/O

XY

ROB

I/O

ZR

OP.1 OP.3

OP.2 OP.4

BATT

ZR

XY

注意

CAUTION

取扱説明書参照

READ INSTRUCTION

MANUAL

MODEL.

SER. NO.

MANUFACTURED

FACTORY AUTOMATION EQUIPMENT MADE IN JAPAN

RCX142T

RCX142

200-230V~

50-60Hz

MAX.300VA

Loading...

Loading...