Page 1

|-1Т-Т1121^^И

ШЁжтлл^

Page 2

A WARNING

The engine exhaust from this product

contains chemicais known to the

State of Caiifornia to cause cancer, birth

defects or other reproductive harm.

YAMAHA

PW80T

OWNER'S SERVICE MANUAL

©2004 by Yamaha Motor Corporation, U.S.A.

1st Edition, April 2004

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation

U.S.A. is expressly prohibited.

Printed in Japan.

P/N. LIT-11626-18-30

LIT-CALIF-65-01

Page 3

NOTICE

Some data in this manual may become outdated due to improvements made to this model in

the future. If there is any question you have regarding this manual or your machine, please con

sult your Yamaha dealer.

INTRODUCTION

Congratulations on your purchase of the Yamaha PW80.

This model represents the product of many years of Yamaha experience in the production of fine

sporting, touring, and pacesetting racing machines. You can now appreciate the high degrees

of craftsmanship and reliability that have made Yamaha a leader in these fields. This manual will

provide you with a good basic understanding of the features, operation, and basic maintenance

and inspection items of this vehicle. If you have any questions regarding the operation or main

tenance of your machine, please consult your Yamaha dealer.

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

^ SAFETY IS INVOLVED!

A WARNING

NOTE:

Failure to follow WARNING instructions could result in severe injury or

death to the machine operator, a bystander, or a person inspecting or repair

ing the machine.

A CAUTION indicates special precautions that must be taken to avoid

damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

Page 4

A WARNING

READ THIS MANUAL CAREFULLY FOR INSTRUCTIONS ON HOW TO

PROPERLY OPERATE THIS MACHINE.

ADULT INSTRUCTION AND SUPERVISION ARE REQUIRED.

THIS MODEL IS PROVIDED WITH A POWER REDUCTION PLATE FOR THE BE

GINNING RIDER. DO NOT REMOVE THESE ITEMS UNTILTHE ADULT SUPERVISIOR HAS JUDGED THE RIDER TO BE PROFICIENT.

WEIGHT OF THE RIDER SHOULD NOT EXCEED 40 kg (88 lb).

ALWAYS WEAR A HELMET AND SUITABLE PROTECTIVE CLOTHING

WHEN RIDING.

DO NOT TOUCH ANY MOVING PARTS OR HEATED AREAS.

ALWAYS PERFORM PRE-OPERATION CHECKS. REFER TO PAGE 5.

THIS MACHINE IS DESIGNED TO CARRY THE OPERATOR ONLY. NO

PASSENGERS.

THIS MACHINE IS DESIGNED FOR OFF-ROAD USE ONLY. IT IS NOT

SUITABLE FOR ON-ROAD USE.

IMPORTANT NOTICE

This machine is designed for off-road use only by young operators under adult instruction

and supervision. It is illegal for this machine to be operated on any public street, road, or

highway. Off-road use on public lands may be illegal. Please check local regulations before

riding.

A SAFETY INFORMATION

GASOLINE IS HIGHLY FLAMMABLE:

* Always turn off the engine when refueling.

* Take care not to spill on the engine or exhaust pipe/muffler, when refuel

ing.

* Never refuel while smoking or in the vicinity of an open flame.

If you should swallow some gasoline or inhale a lot of gasoline vapor, or

allow some gasoline to get in your eye(s), see your doctor immediately. If

any gasoline spills on your skin or clothing, immediately wash it with soap

and water, and change your clothes.

Always turn off the engine before leaving the machine unattended. When

parking the machine, note the following:

* The engine and exhaust pipe(s)/muffler(s) may be hot. Park the machine

in a place where pedestrians or children are not likely to touch the

machine.

* Do not park the machine on a slope or soft ground; the machine may over

turn.

When transporting the machine in another vehicle, be sure it is kept upright

and that the fuel cock is turned to the "OFF". If it should lean over, gasoline

may leak out of the carburetor or fuel tank.

5.

Never start your engine or let it run for any length of time in a closed area.

The exhaust fumes are poisonous and may cause loss of consciousness and

death within a short time. Always operate your machine in an area with ade

quate ventilation.

Always wear a helmet, gloves, boots, trousers, and jacket for motocross

6.

riding.

Page 5

FOR THE PARENTS

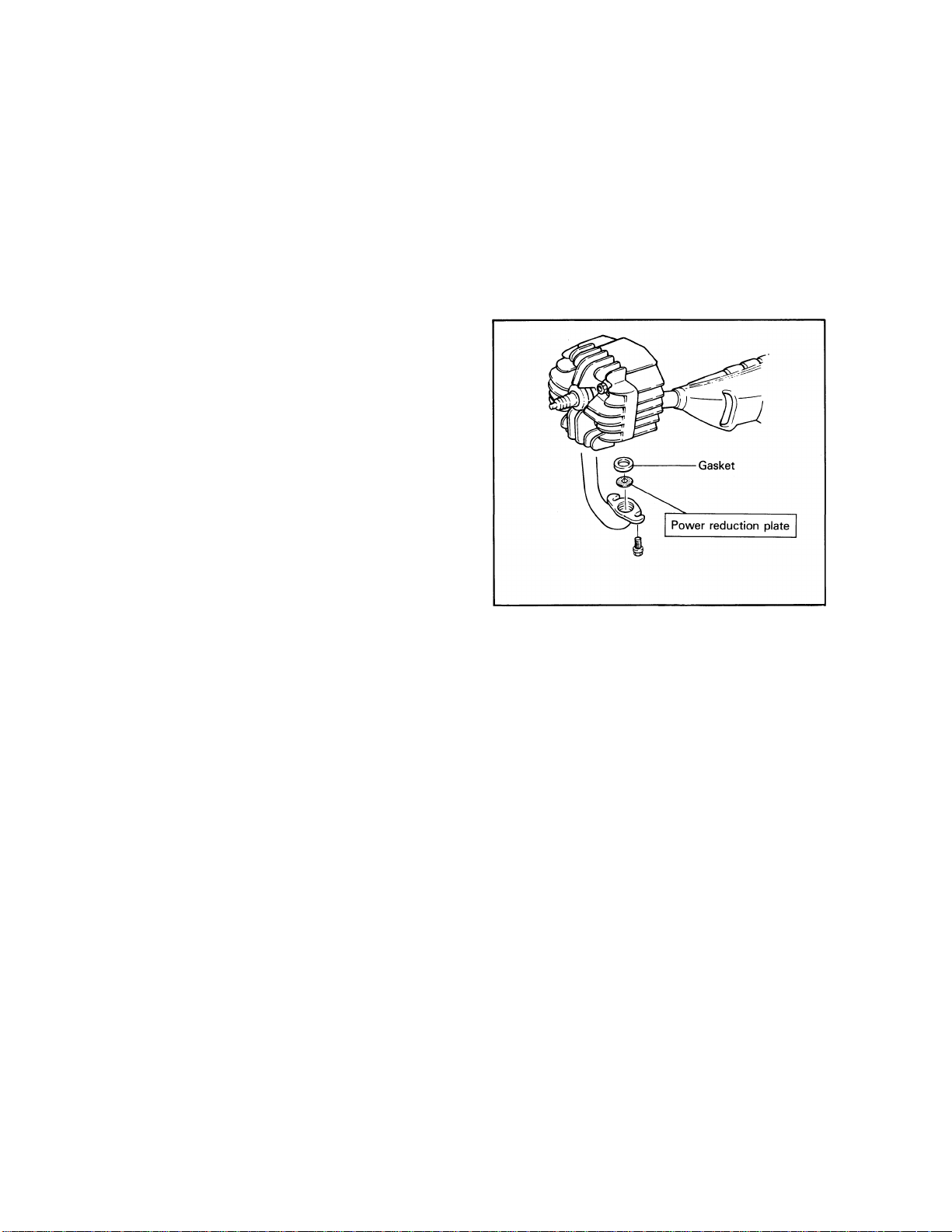

Since this model is intended for beginning riders, it is equipped with an safety device

that let you limit the operating speed of the machine; the power reduction plate. It limits

the output of the engine.

As your child's riding skills improve, you can remove the power reduction plate. Since

removal of this plate will result in a significant increase in power.

Please use this safety device to match the machine's output to your child's riding skills.

• A power reduction plate is provided in the

cylinder exhaust port. Removal of this plate

adds to the vehicle output power.

Page 6

OFF-ROAD MOTORCYCLE LIMITED WARRANTY

Yamaha Motor Corporation, U.S.A. hereby warrants

that each new Yamaha off-road motorcycle purchas

ed from an authorized Yamaha motorcycle dealer in the

continental United States will be free from defects in

material and workmanship for the period of time stated

herein, subject to certain stated limitations.

THE PERIOD OF WARRANTY for Yamaha off-road

motorcycles shall be ninety (90) days from the date

of purchase, with no mileage limitation.

MODELS EXCLUDED FROM WARRANTY include

those machines used for non-Yamaha-authorized ren

ting, leasing, or other commercial purposes.

DURING THE PERIOD OF WARRANTY any authorized

Yamaha motorcycle dealer will, free of charge, repair

or replace, at Yamaha's option, any part adjudged

defective by Yamaha due to faulty workmanship or

material from the factory. Parts used in warranty

repairs will be warranted for the balance of the pro

duct's warranty period. All parts replaced under war

ranty become property of Yamaha Motor Corporation

U.S.A.

GENERAL EXCLUSIONS from this warranty shall

include any failures caused by:

a. Competition or racing use (except TY models used

for sanctioned trials).

b. Installation of parts or accessories that are not

qualitatively equivalent to genuine Yamaha parts.

c. Abnormal strain, neglect, or abuse.

d. Lack of proper maintenance.

e. Accident or collision damage.

f. Modification to original parts.

g. Damage due to improper transportation.

YAMAHA MOTOR CORPORATION, U.S.A.

SPECIFIC EXCLUSIONS from this warranty shall

include parts replaced due to normal wear or routine

maintenance.

THE CUSTOMER'S RESPONSIBILITY under this war

ranty shall be to:

1. Operate and maintain the motorcycle as specified

in the appropriate Owner's Manual, and

2. Give notice to an authorized Yamaha motorcycle

dealer of any and all apparent defects within ten

(10) days after discovery, and make the machine

available at that time for inspection and repairs at

such dealer's place of business.

WARRANTY TRANSFER: To transfer the warranty

from the original purchaser to any subsequent pur

chaser, it is imperative that the machine be inspected

and registered for warranty by an authorized Yamaha

motorcycle dealer. In order for this warranty to remain

in effect, this inspection and registration must take

place within ten (10) days after transfer. An inspec

tion and registration fee will be charged for this service.

YAMAHA MOTOR CORPORATION, U.S.A. MAKES NO

OTHER WARRANTY OF ANY KIND, EXPRESSED OR

IMPLIED. ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH EXCEED THE

OBLIGATIONS AND TIME LIMITS STATED IN THIS

WARRANTY ARE HEREBY DISCLAIMED BY YAMAHA

MOTOR CORPORATION, U.S.A. AND EXCLUDED

FROM THIS WARRANTY.

SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. ALSO

EXCLUDED FROM THIS WARRANTY ARE ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES

INCLUDING LOSS OF USE. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

YAMAHA MOTOR CORPORATION, U.S.A.

P. O. Box 6555

Cypress, California 90630

WARRANTY QUESTIONS AND ANSWERS CUSTOMER SERVICE

Q. What costs are my responsibility during the warranty period?

A. The customer's responsibility includes all costs of normal maintenance services, non

warranty repairs, accident and collision damage, and oil, oil filters, air filters, spark

plugs, and brake shoes or pads.

Q. What are some examples of "abnormal" strain, neglect, or abuse?

A. These terms are general and overlap each other in areas. Specific examples include:

Running the machine out of oil; sustained high-rpm, full-throttle use; operating the

machine with a broken or damaged part which causes another part to fail; damage

or failure due to improper or careless transporation and or tie down; and so on. If

you have any specific questions on operation or maintenance, please contact your

dealer for advice.

Q. Does the warranty cover incidental costs such as towing or transportation due to

a failure?

A. No. The warranty is limited to repair of the machine itself.

Q. May I perform any or all of the recommended maintenance shown in the Owner's

Manual instead of having the dealer do them?

A. Yes, if you are a qualified mechanic and follow the procedures specified in the Owner's

and Service Manual. We do recommend, however, that items requiring special tools

or equipment be done by a Yamaha motorcycle dealer.

Q. Will the warranty be void or cancelled if I do not operate or maintain my new

motorcycle exactly as specified in the Owner's Manual?

A. No. The warranty on a new motorcycle cannot be "voided" or "cancelled." However,

if a particular failure is caused by operation or maintenance other than as shown

in the Owner's Manual, that failure may not be covered under warranty.

Q. What responsibility does my dealer have under this warranty?

A. Each Yamaha motorcycle dealer is expected to:

1. Completely set up every new machine before sale.

2. Explain the operation, maintenance, and warranty requirements to your satisfation at the time of sale, and upon your request at any later date.

In addition, each Yamaha motorcycle dealer is held responsible for his setup, service

and warranty repair work.

Q. Is the warranty transferable to second owners?

A. Yes. The remainder of the existing warranty can be transferred upon request. The

unit has to be inspected and re-registered by an authorized Yamaha motorcycle dealer

for the warranty coverage to remain effective.

If your machine requires warranty service, you must take it to any authorized

Yamaha motorcycle dealer within the continental United States. Be sure to

bring your warranty registration identification or other valid proof of the

original date of purchase. If a question or problem arises regarding warranty,

first contact the owner of the dealership. Since all warranty matters are

handled at the dealer level, this person is in the best position to help you.

If you are still not satisfied and require additional assistance, please write:

YAMAHA MOTOR CORPORATION U.S.A.

CUSTOMER RELATIONS DEPARTMENT

When contacting Yamaha Motor Corporation, U.S.A. don't forget to include

any important information such as names, addresses, model, V.I.N. (frame

number), dates, and receipts.

The federal government requires each manufacturer of a motor vehicle to

maintain a complete, up-to-date list of all first purchasers against the

possibility of a safety-related defect and recall. This list is compiled from

the purchase registrations sent to Yamaha Motor Corporation, U.S.A. by the

selling dealer at the time of your purchase.

If you should move after you have purchased your new motorcycle, please

advise us of your new address by sending a postcard listing your motorcycle

model name, V.I.N. (frame number), dealer number (or dealer's name) as it is

shown on your warranty identification, your name and new mailing address.

Mail to :

YAMAHA MOTOR CORPORATION, U.S.A.

This will ensure that Yamaha Motor Corporation, U.S.A. has an up-to-date

registration record in accordance with federal law.

P.O. Box 6555

Cypress, California 90630

CHANGE OF ADDRESS

WARRANTY DEPARTMENT

P.O. Box 6555

Cypress, California 90630

Page 7

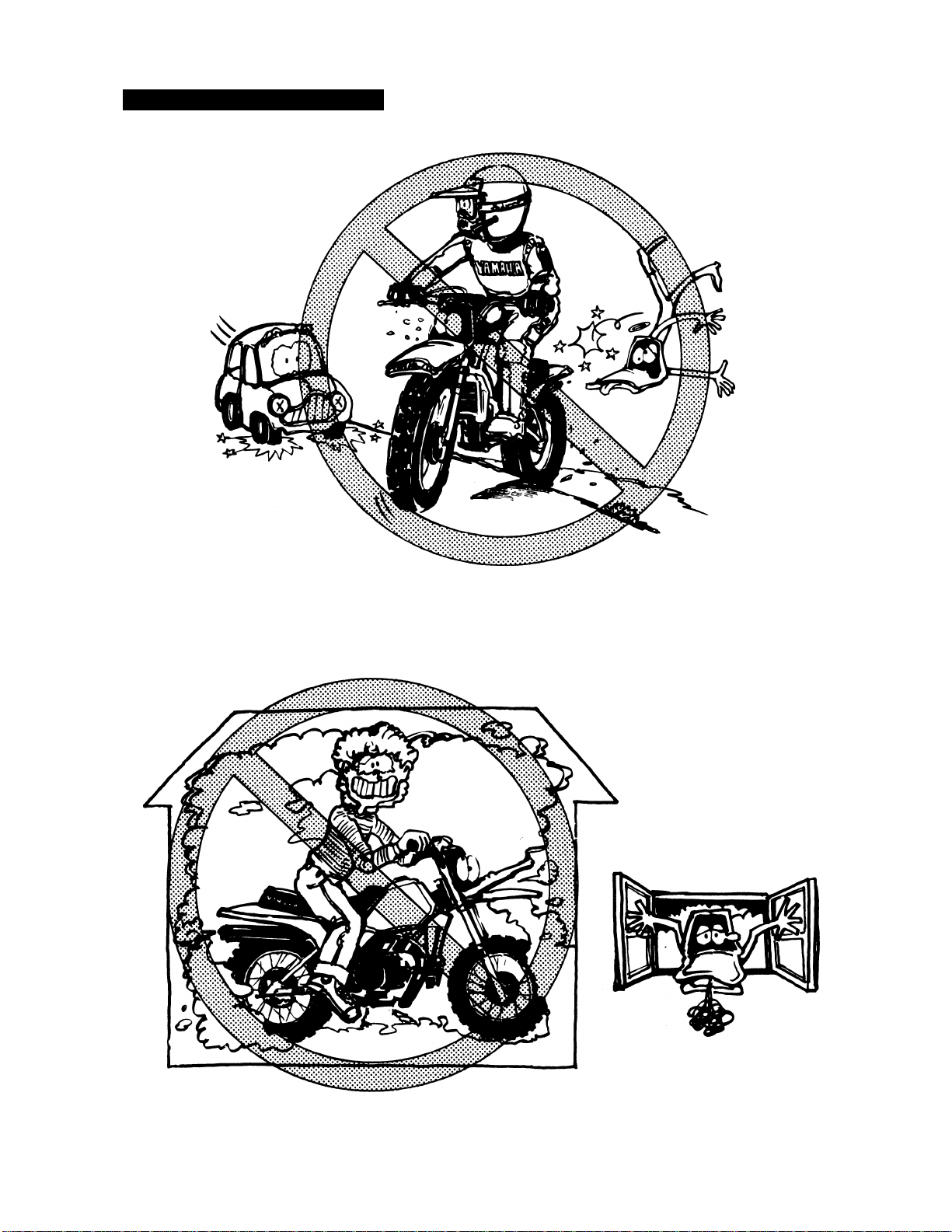

A SAFETY INFORMATION

1. Don't ride it on the street.

2. Don't run the engine inside a building.

Page 8

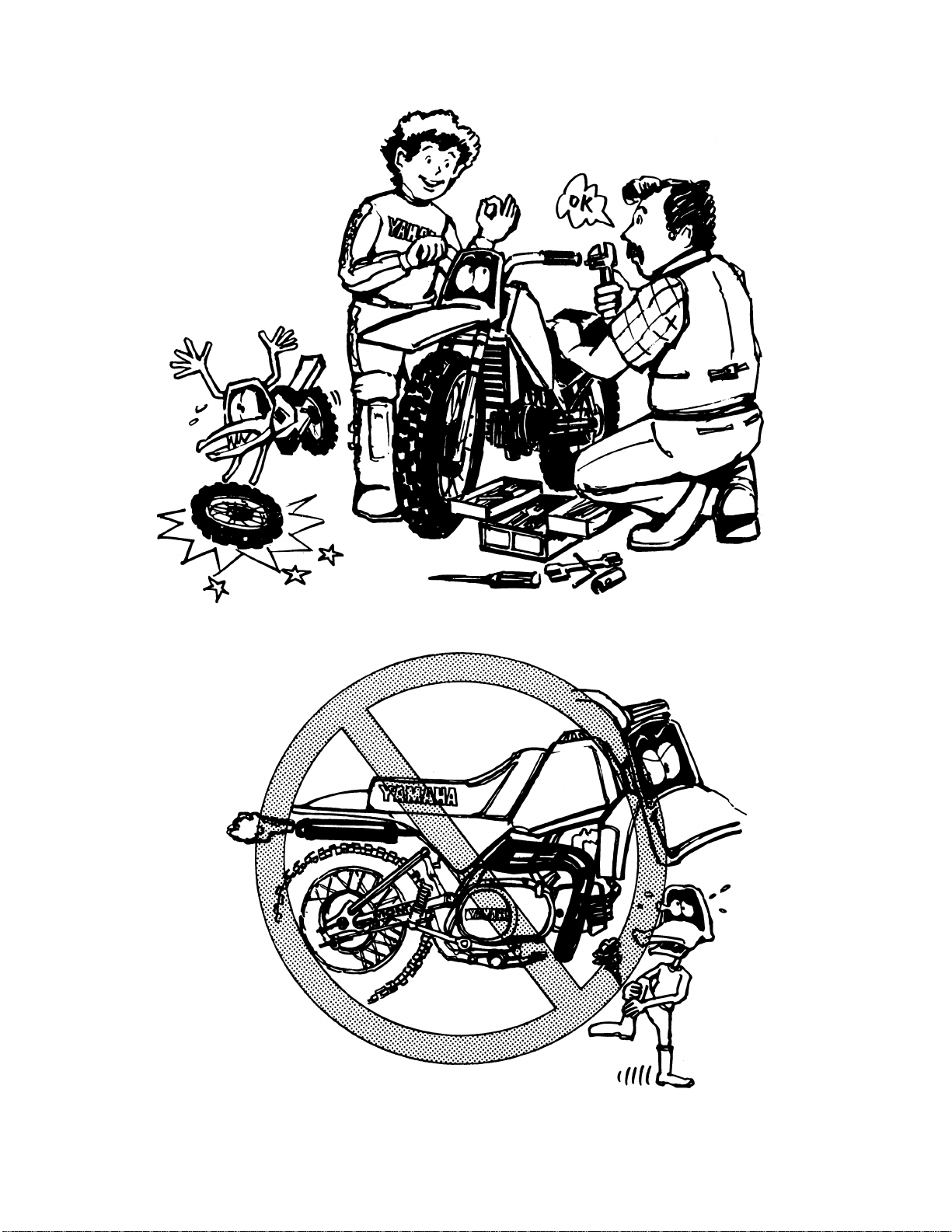

3. This is a one-seater motorbike. Don't give any person a ride.

4. Let's learn how to ride properly. Ask your parents for any question.

Page 9

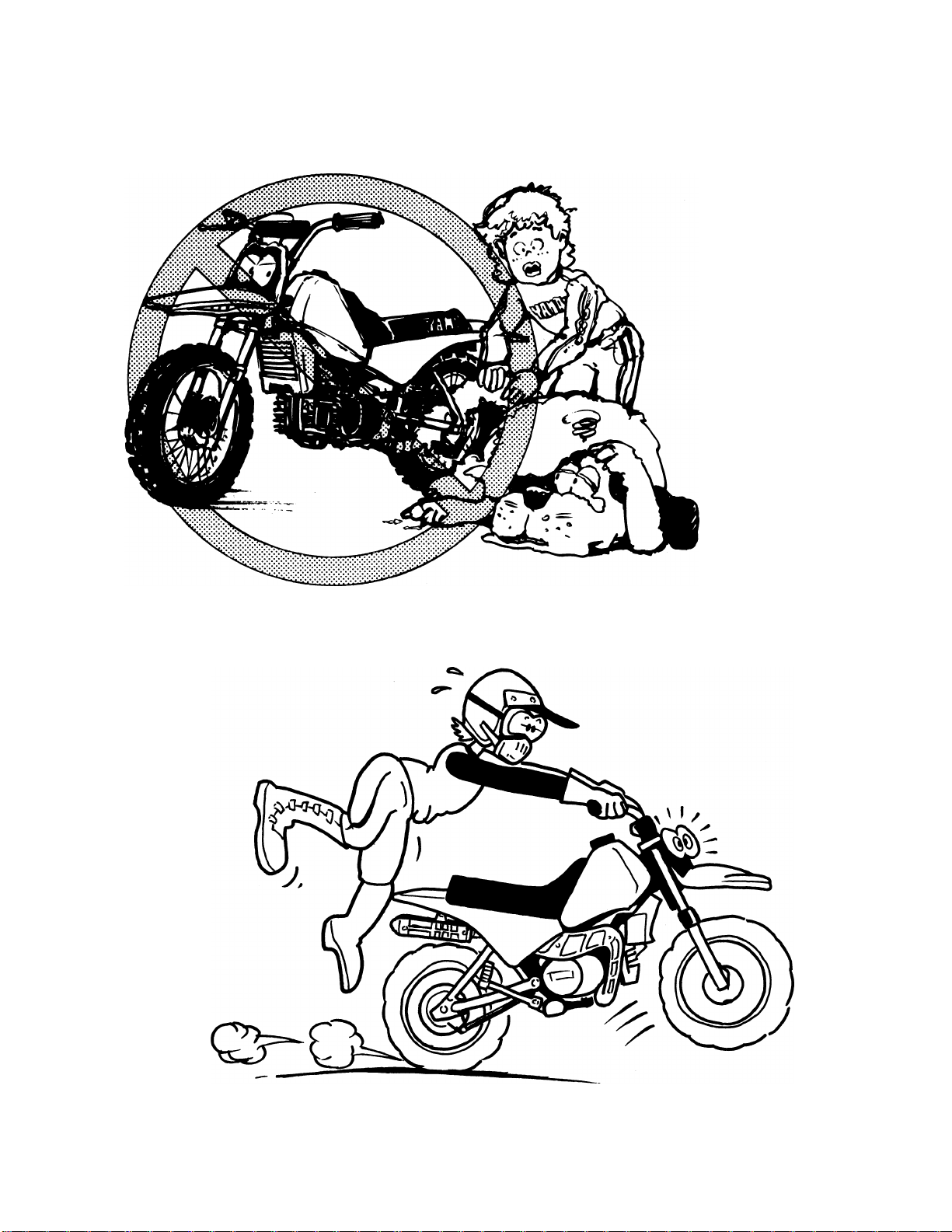

5. When riding the machine, be sure to wear a helmet as illustrated.

Long sleeved trainer

Motocross pants

Boots

Helmet

Goggles

Mouth guard

Gloves

6. When going for riding, be sure to be with your family. Never go alone.

Page 10

7. Before riding the machine, ask your parents to check the machine very carefully.

8. Don't touch the areas shown below, or you'll get burnt in the hand.

Page 11

9. Don't touch rotating or moving parts.

10. Before starting the engine, be sure to shift the transmission into neutral.

Page 12

CONTENTS

GENERAL INFORMATION.........................................................................................................................1

DESCRIPTION....................................................................................................................................1

MACHINE IDENTIFICATION .............................................................................................................1

CONTROL FUNCTIONS ....................................................................................................................2

FUEL AND OIL....................................................................................................................................3

PRE-OPERATION CHECKS...............................................................................................................5

STARTING AND OPERATION ..........................................................................................................6

PERIODIC MAINTENANCE AND ADJUSTMENT .. .

MAINTENANCE AND LUBRICATION SCHEDULE CHART

SPECIAL TOOLS .............................................................................................................................. 8

ADJUSTMENT...................................................................................................................................10

MAINTENANCE AND MINOR REPAIRS..................................................................................................19

PREPARATION FOR SERVICE.......................................................................................................19

ENGINE..............................................................................................................................................19

CHASSIS ......................................................................................................................................... 31

MISCELLANEOUS................................................................................................................................... 37

ELECTRICAL COMPONENTS AND WIRING DIAGRAM...............................................................37

TROUBLESHOOTING......................................................................................................................40

CLEANING AND STORAGE ...........................................................................................................41

SPECIFICATIONS.............................................................................................................................42

CABLE ROUTING.............................................................................................................................50

NOISE REGULATION............................................................................................................................... 52

MAINTENANCE RECORD ........................................................................................................................52

...................

............................................................

............................................................

7

7

Page 13

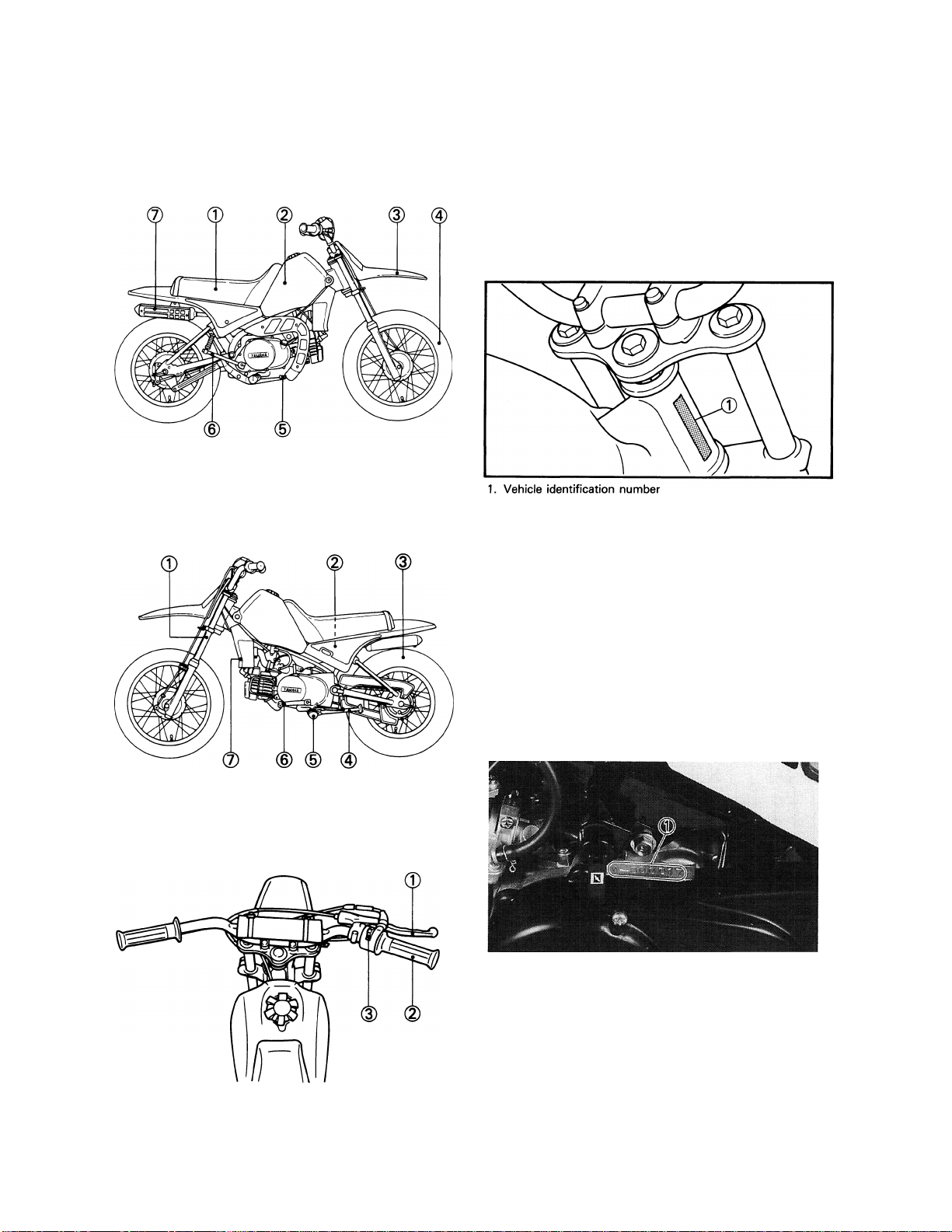

GENERAL INFORMATION

1. Seat

2. Fuel tank

3. Front fender

4. Front wheel

DESCRIPTION

5. Brake pedal

6. Kick starter

7. Muffler

MACHINE

IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is stamped

into the steering head pipe.

NOTE:

The vehicle identification number is used to

identify your machine and may be used to

register your machine with the licensing

authority in your state.

--------------------------------------

1. Front fork

2. Monocross suspension

3. Rear wheel

4. Sidestand

1. Front brake lever

2. Throttle grip

3. "ENGINE STOP" switch

ENGINE SERIAL NUMBER

The engine serial number is stamped on the left

side of the engine on top of the crankcase.

5. Footrest

6. Shift pedal

7. Air filter

1. Engine serial number

NOTE:

The first digits of these numbers are for model

identifications; the remaining digits are the unit

production number.

Keep a record of these numbers for reference

when ordering parts from a Yamaha dealer.

-1-

Page 14

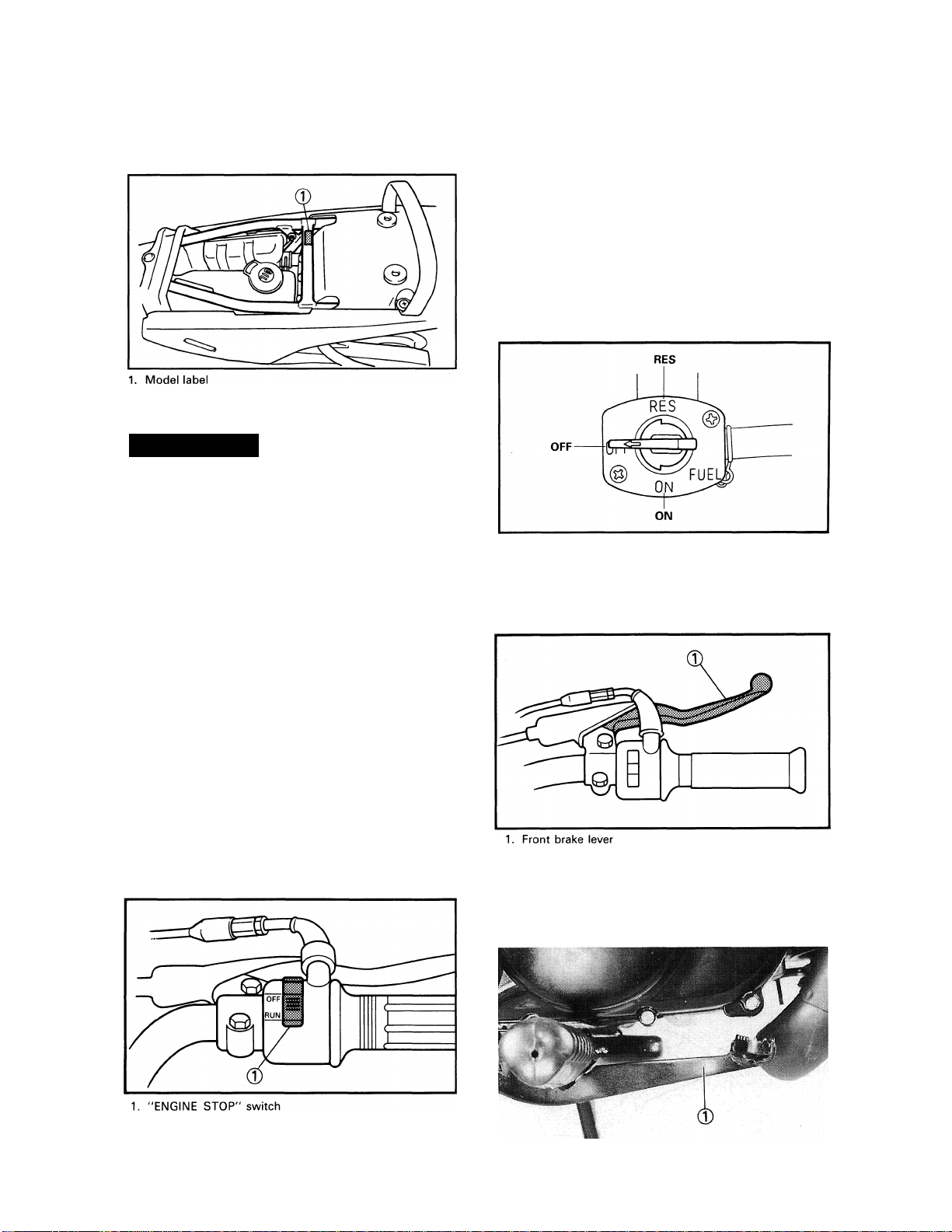

MODEL LABEL

The model label (T) is affixed to the frame

under the rider's seat. This information will

be needed to order spare parts.

CONTROL FUNCTIONS

A WARNING

Before riding this machine, become tho

roughly familiar with all operating controls

and their function.

Consult a Yamaha dealer or other qualified

mechanic regarding any control or func

tion you do not thoroughly understand.

I— NOTICE:

This machine is designed strictly for

competition use only. It is not equipped

with highway approved lighting. Off

road use on public land may be illegal.

--------------------------------------------

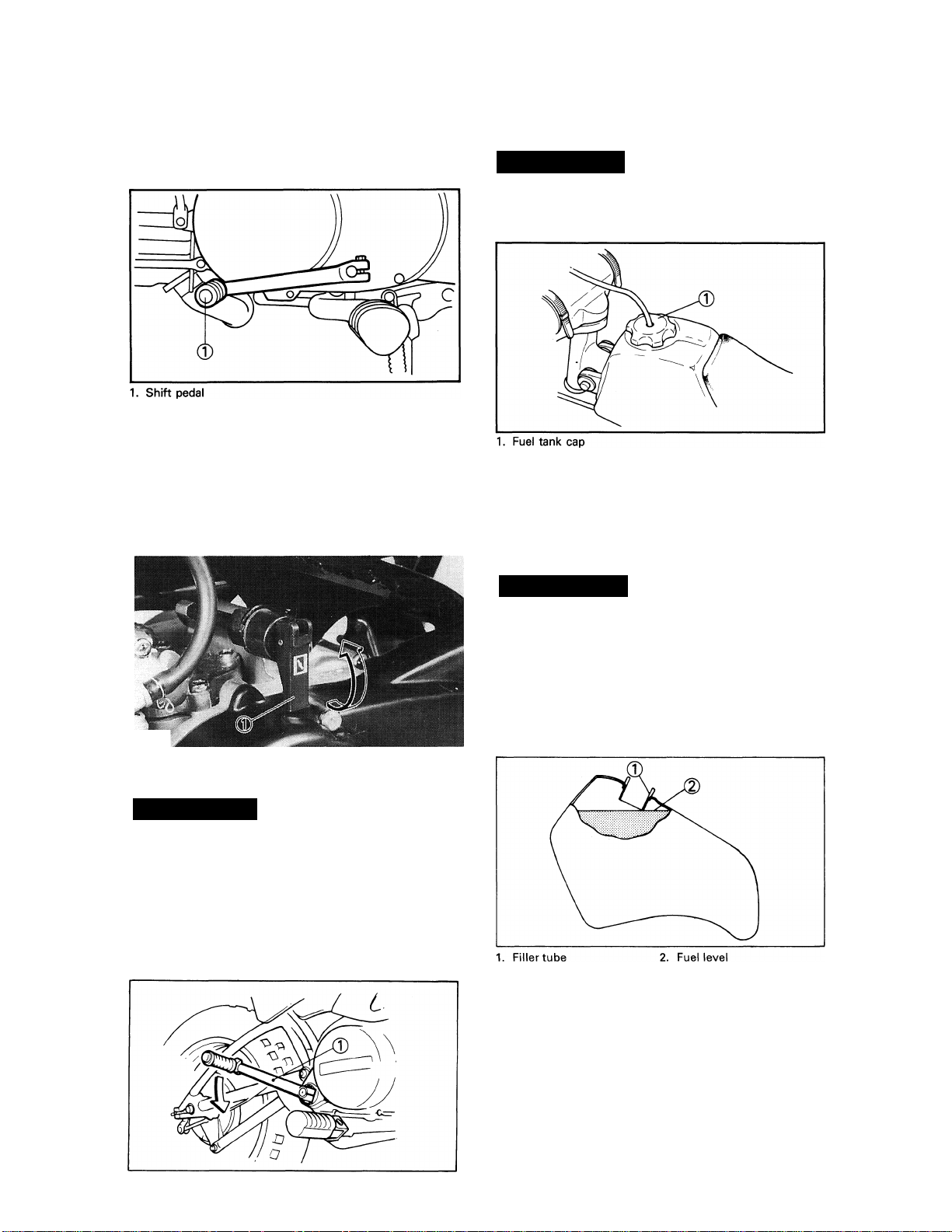

OFF: With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

RES: This indicates reserve. If you run out of

fuel while riding, move the lever to this

position. FILL THE TANK AT THE

FIRST OPPORTUNITY. BE SURE TO

SET THE LEVER TO "ON" AFTER

REFUELING.

FRONT BRAKE LEVER

The front brake lever is located on the right

handlebar, pull it toward the handlebar to ac

tivate the front brake.

"ENGINE STOP" SWITCH

Make sure that the engine stop switch is posi

tioned to "RUN". The engine switch has been

equipped to ensure safety in an emergency

such when the machine is upset or trouble

takes place in the throttle system. The engine

will not start or run when the engine stop

switch is turned to "OFF".

FUEL COCK

The fuel cock supplies fuel from the tank to car

buretor while filtering the fuel. The fuel cock

has the three positions;

REAR BRAKE PEDAL

The rear brake pedal is on the right side of the

machine. Press down on the brake pedal to ac

tivate the rear brake.

1. Rear brake pedal

2-

Page 15

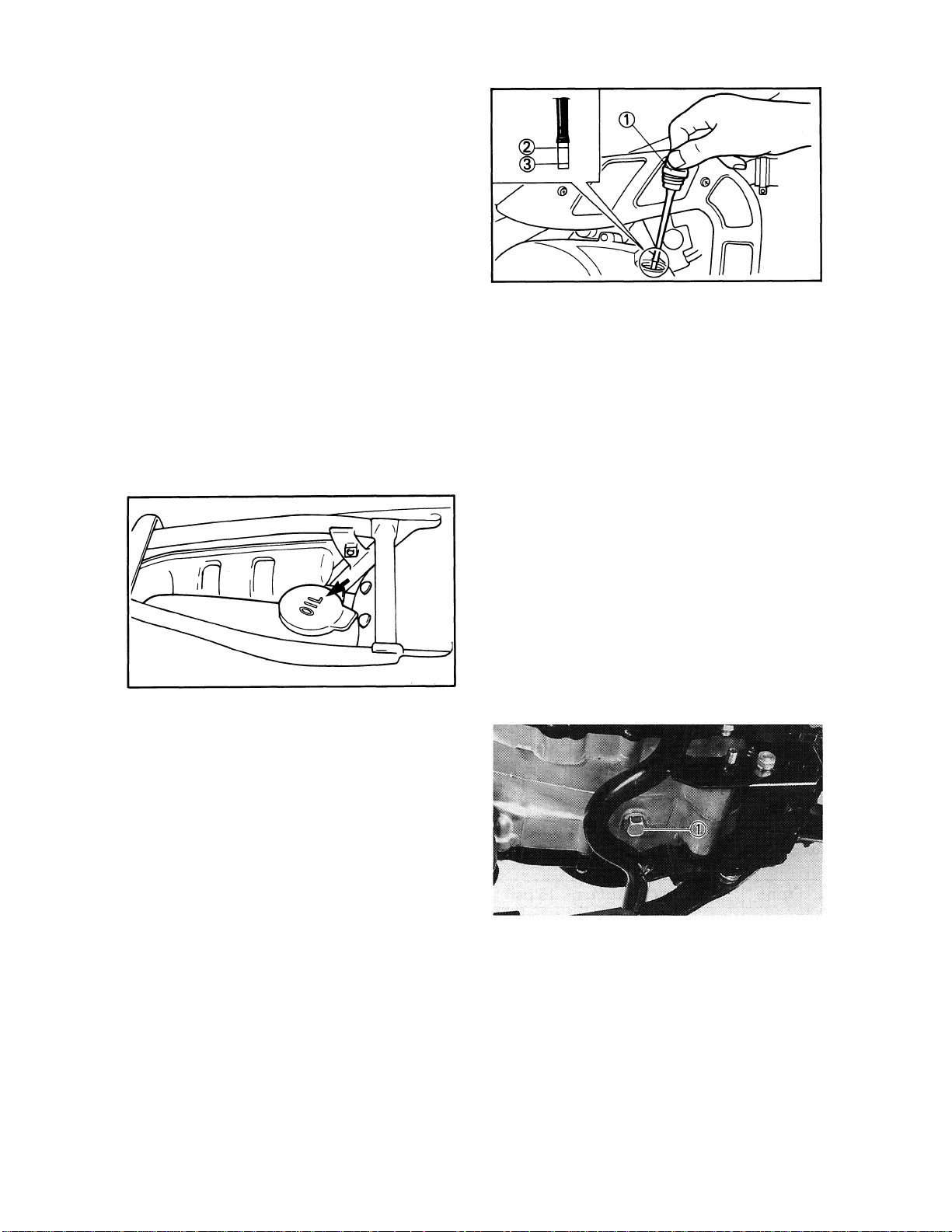

SHIFT PEDAL

The gear ratios of the constant mesh 3-speed

transmission are ideally spaced. The gears can

be shifted by using the shift pedal on the left

side of the engine.

STARTER LEVER (CHOKE)

When cold, the engine requires a richer air/fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter lever, sup

plies this mixture.

Pull the lever out to open the circuit (for star

ting) and push the lever in to close the circuit.

FUEL TANK CAP

Remove the fuel tank cap by turning counter

clockwise.

▲ warning

Do not overfill the fuel tank. Avoid spill

ing fuel on the hot engine.

FUEL AND OIL

FUEL

Use regular gasoline. Always use fresh, name

brand gasoline.

1. Starter lever

KICK STARTER

▲WARNING

Before starting the engine, be sure to

shift the transmission into neutral.

Rotate the kick starter 0 away from the en

gine. Push the starter down lightly with your

foot until the gears engage, then kick

smoothly and forcefully to start the engine.

▲ warning

Do not overfill the fuel tank. Avoid spill

ing fuel on the hot engine. Do not fill the

fuel tank above the bottom of the filler

tube as shown in the illustration or it may

overflow when the fuel heats up later and

expands.

Recommended fuel:

UNLEADED GASOLINE ONLY

Fuel tank capacity:

Total:

4.9 L (1.08 Imp gal, 1.29 US gal)

Reserve:

1.0 L (0.22 Imp gal, 0.26 US gal)

1. Kickstarter

-3-

Page 16

Your Yamaha engine has been designed to use

regular unleaded gasoline with a pump octane

number ([R + M]/2) of 86 or higher, or research

octane number of 91 or higher. If knocking or

pinging occurs, use a different brand of gaso

line or premium unleaded fuel. Unleaded fuel

will give you longer spark plug life and reduced

maintenance cost.

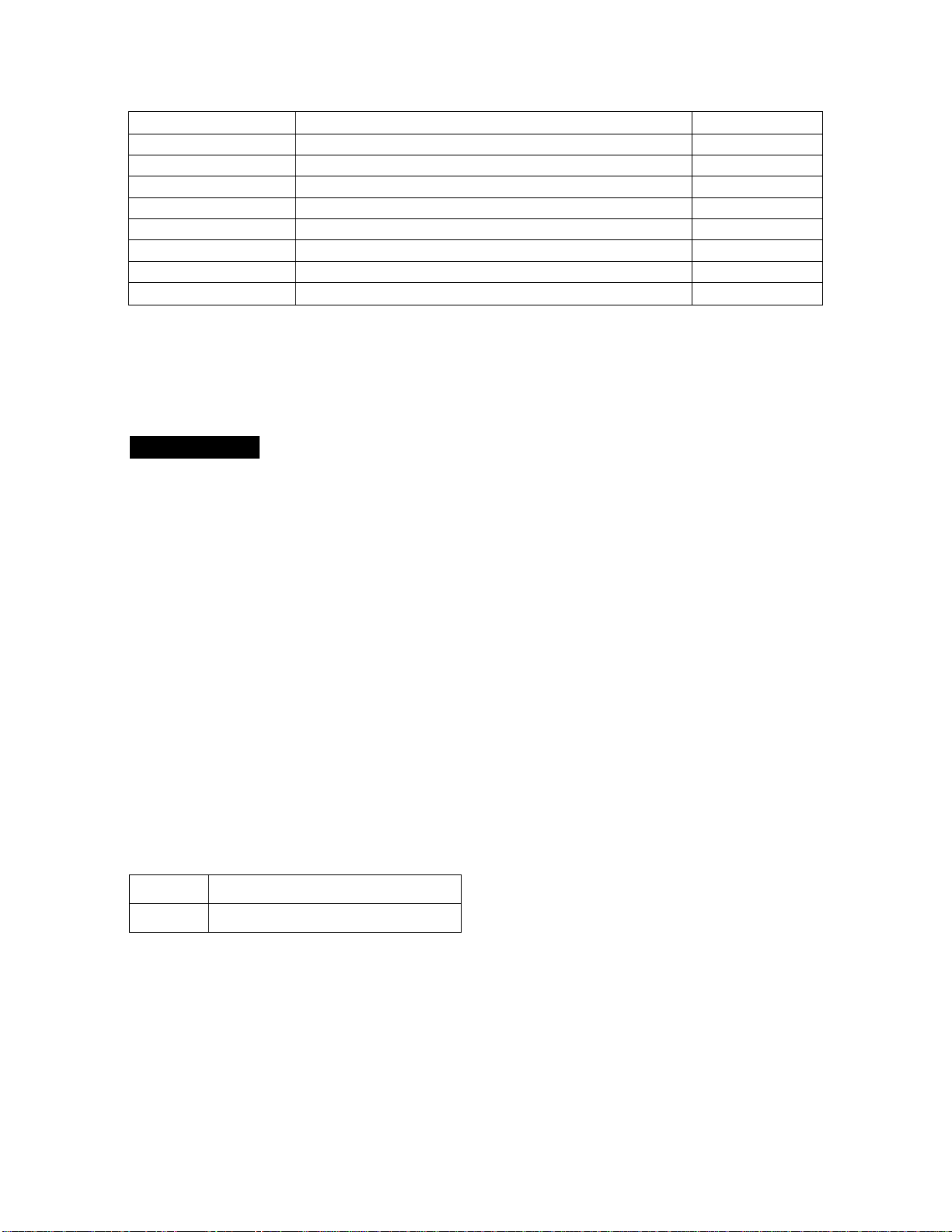

ENGINE OIL (OIL TANK)

Make sure there is sufficient engine oil in the

oil tank. If necessary add oil.

Recommended oil:

Yamalube 2-S or air-cooled

2-stroke engine oil

Oil tank capacity:

0.95 L (0.84 Imp qt, 1.00 US qt)

1. Dip stick

2. Maximum level

3. Minimum level

Recommended oil

Yamalube 4 (10W30)

or SAE 10W30 type SE motor oil

Oil capacity:

Total amount:

0.75 L (0.66 Imp qt, 0.79 US qt)

Periodic oil change:

0.65 L (0.57 Imp qt, 0.69 US qt)

The dip stick has a Minimum and Maximum

mark, and the oil level should be between the

two. If the level is lower, then and sufficient

oil to raise it to the proper level.

On the bottom of the engine there is a drain

plug. Remove it and drain all the transmission

oil out. Reinstall the drain plug (make sure it

is tight). Add oil through the dip stick hole.

TRANSMISSION OIL

The only servicing for you to do is to check and

fill the transmission lubricating oil. The trans

mission dip stick is located right above the kick

starter. To check the level, warm the engine

up for several minutes, screw the dip stick com

pletely out and then just rest the stick in the

hole.

NOTE:

When checking transmission oil level with the

dip stick, let the unscrewed dip stick just rest

on the case threads. Also, be sure the machine

is positioned straight up.

------------------------------------------

1. Drain plug

Drain plug torque:

20 Nm (2.0m*kg, 14fHb)

NOTE: ______________________________

Do not add any chemical additives. Transmis

sion oil also lubricates the clatch and additives

could cause the clutch to slip.

-4-

Page 17

PRE-OPERATION CHECKS

Item

Brake

Transmission oil

Drive chain

Spark plug

Throttle Check for proper throttle cable operation

Air filter

Wheels and tires

Fittings/fasteners

Check operation/adjustment

Change oil as required

Check alignment/ adjustment/ lubrication

Check color/condition

Foam type — must be clean and damp w/oil always 11^12

Check pressure/runout/spoke tightness/bead stopper/axle nuts

Check all — tighten as necessary

NOTE:______________________________________________________________________

Pre-operation checks should be made each time the machine is used. Such an inspection can

be thoroughly accomplished in a very short time; and the added safety it assures is more than

worth the time involved.

Routine Page

5, 14

4

15

10

5, 12

5, 16,31 ~ 34

5, 46, 47, 49

A WARNING

If any item in the PRE-OPERATION CHECK is not working properly, have it inspected

and repaired before operating the machine.

BRAKE (FRONT AND REAR)

Check for correct play in the brake lever and

pedal and make sure they are working proper

ly. Check the brakes at tow speed shortly after

starting out. If the play is correct, make an

adjustment.

WHEEL

Check the wheel runout and damage, and

check the tightness of spokes.

TIRES

Check the tire pressure and check the tires for

wear.

Front

Rear

100 kPa (1.0 kgf/cm^ 15 psi)

100 kPa (1.0 kgf/cm', 15 psi)

THROTTLE GRIP

Turn the throttle grip to see that it operates pro

perly and that the play is normal. Make certain

the throttle springs are closed when released.

"ENGINE STOP" SWITCH

Start the engine and make sure the "ENGINE

STOP" switch functions properly.

FITTINGS/FASTENERS

Always check the tightness of chassis fittings

and fasteners before a ride. Use the chart on

page 46, 47 and 49 to find the correct torque.

-5-

Page 18

STARTING AND

OPERATION

CAUTION:

Prior to operating the machine, perform

steps listed in pre-operation check list.

A WARNING

Never start your engine or let it run for any

length of time in a closed area. The ex

haust fumes are poisonous and can cause

loss of consciousness and death within a

short time. Always operate your machine

in an area with adequate ventilation.

STARTING A COLD ENGINE

AWARNING

Before starting the engine, be sure to

shift the transmission into neutral.

1. Turn the fuel cock to "ON".

2. Operate the starter (choke) and complete

ly close the throttle grip.

3. Slide the "ENGINE STOP" switch to the

"RUN".

4. Kick the kick starter with full strength to

start the engine.

5. After the engine starts, warm up for one

or two minutes. Make sure the starter

(choke) is returned to the original position

before riding.

STARTING A WARM ENGINE

To start a warm engine, refer to the "Starting

a cold engine" section. The starter (choke)

should not be used. The throttle should be

opened slightly.

CAUTION:

See "Break-in Section" prior to operating

engine for the first time.

WARMING UP

To get maximum engine life, always "warm

up" the engine before starting off. Never ac

celerate hard with a cold engine! To see

whether or not the engine is warm, see if it

responds to throttle normally with the starter

(choke) turned off.

A WARNING

Before starting off, be sure to turn up or

remove the side stand.

Failure to retract the side stand completely

can result in a serious accident when you

try to turn a corner.

ENGINE BREAK-IN

1. Prior to starting, fill fuel tank with gasoline

and oil tank with specified oil.

2. Allow engine to warm up. Check engine

idling speed. Check operating controls

and engine stop switch operation.

3. Operate machine is lower gears at

moderate throttle setting for 3 — 5 min

utes. Check spark plug condition.

4.

Allow engine to cool. Repeat procedure,

running for 5 minutes. Very briefly, shift

to higher gears and check full throttle

response. Check spark plug condition.

5.

Allow engine to cool. Repeat procedure,

running for 5 minutes. Full throttle and

higher gears may be used, but avoid sus

tained full throttle operation. Check spark

plug condition.

6.

Allow engine to cool. Remove top end

and inspect. Remove "high" spots on

piston with No. 600 grit, wet sandpaper.

Clean, and carefully reassemble.

7.

Check entire unit for loose or misadjusted

fittings/controls/fasteners.

8.

Re-start engine and check through entire

operating range thoroughly. Stop. Check

spark plug condition. Re-start. After 10 ~

15 minutes operation, machine is ready

to ride.

-6-

Page 19

PERIODIC MAINTENANCE AND

ADJUSTMENT

MAINTENANCE AND LUBRICATION SCHEDULE CHART

The maintenance and lubrication schedule chart should be considered strictly as a guide to general

maintenance and lubrication intervals. You must take into consideration that weather, terrain,

geographical locations, and a variety of individual uses all tend to demand that each owner alter

this time schedule to match his environment. For example, if the machine is continually operated

in an area of high humidity then all parts must be lubricated much more frequently that shown

on the chart to avoid rust and damage. If you are in doubt as to how closely you can follow these

time recommendations, check with the Yamaha dealer in your area.

Lubrication intervals

Item

Transmission oil change

Drive chain

Con trol cables All apply thoroughly

Throttle grip and housing App ly lig htly

Brake pe dal shaft

Stand sh aft pivot

Front forks

Steering ball race

Wheel bearings Do not over-p ack yearly or...

Warm en gine before draining

Lub e/Adjust as req uired

Rem ove/ Clea n / Lube/ Adjust

App ly lig htly

App ly lig htly

Drain completely

Inspect thoroughly / Pack

moderately

Rem arks

Yam alub e 4-cycle oil or SAE 10W30

type SE motor oil

Yam alub e Chain and Cable L ube or

SAE 10W 30 m otor oil

Yam aha Cable Lub e or WD-40

Yam aha Cable Lub e or WD-40

Yam aha Cable Lub e or WD-40

Yam aha Cable Lub e or WD-40

Yam aha fork oil 20 wt or equivalent

Medium-weight wh eel bearin g grease

Medium-weight wh eel bearin g grease

Periodic maintenance intervals

Item

Brake sy stem (com plete)

Clutch

Spa rk plug

Spa rk arrester

Wheels and tires

Fittings and fasten ers

Drive chain

Air filter Wet type — clean / Replace as required (No .2)

Fue l cock

Ignition timing

Autolube pum p

Carburetor ad justm ent Chec k / operation / Timings

Carburetor overhaul

Cylinder compression Preventive maintenance check

Dec arbonize e ngin e

Che ck / Adjust as required — repair as required

Che ck / Adjust as required

Inspect / Clean or replace as requ ired

Clean

Pressure / Runout / Spoke — tension

Tighten before eac h trip and / or

Ten sion / Alig nment (No.1)

Clean / F lush tank as require d

Adjust / Clean or replac e as required

Che ck / Adjust / Air bleeding

Clean / R epair as required / Refit / Adjust

Includes exhaust s ystem

Rem arks

Typ e

Initial (hour)

10 20 40

O

O O

See service notes

o

o

The reafter

every (hour)

80 4 0 80 160

O

o o

o o

o

o

o

o

o o

o

o O o

Initial (hour)

10 20 40 80 40 80 160

o o O

o o o

O o o o

O o o o

o o o o

o o o o

o o o o

o o o

o o o o

o o o o

o o

o

o o o o

o o

The reafter

every (hour)

o

o

o

o

SERVICE NOTES:_____________________________________________________________

No. 1. DRIVE CHAIN: In addition to tension and alignment, chain must be lubricated every 0.5-1.0

hour. If unit is subjected to extremely hard usage and wet weather riding, chain must

be checked constantly. See "Lubrication Intervals" for additional details.

No. 2. AIR FILTER: Remove and clean filter every 20 - 40 hours.

-7-

Page 20

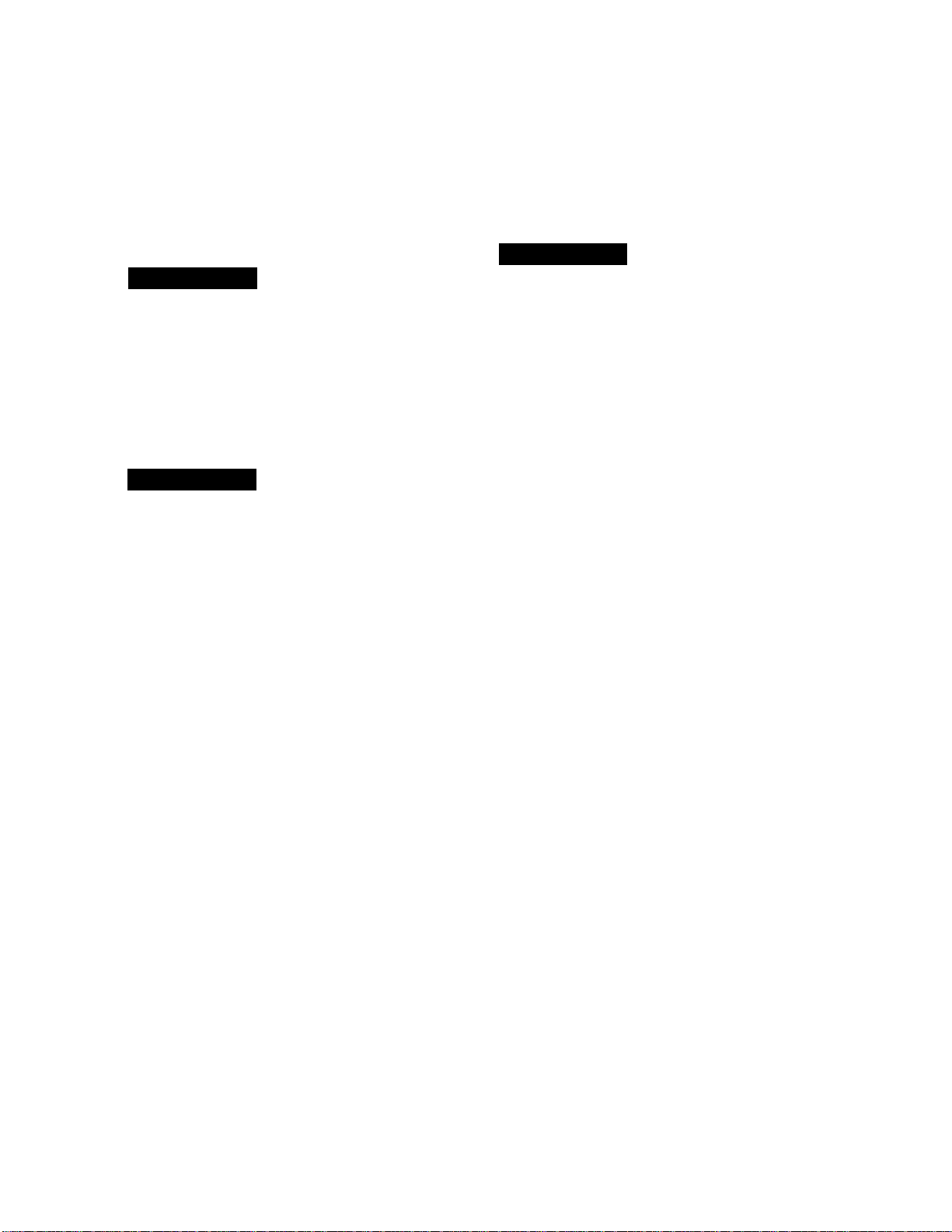

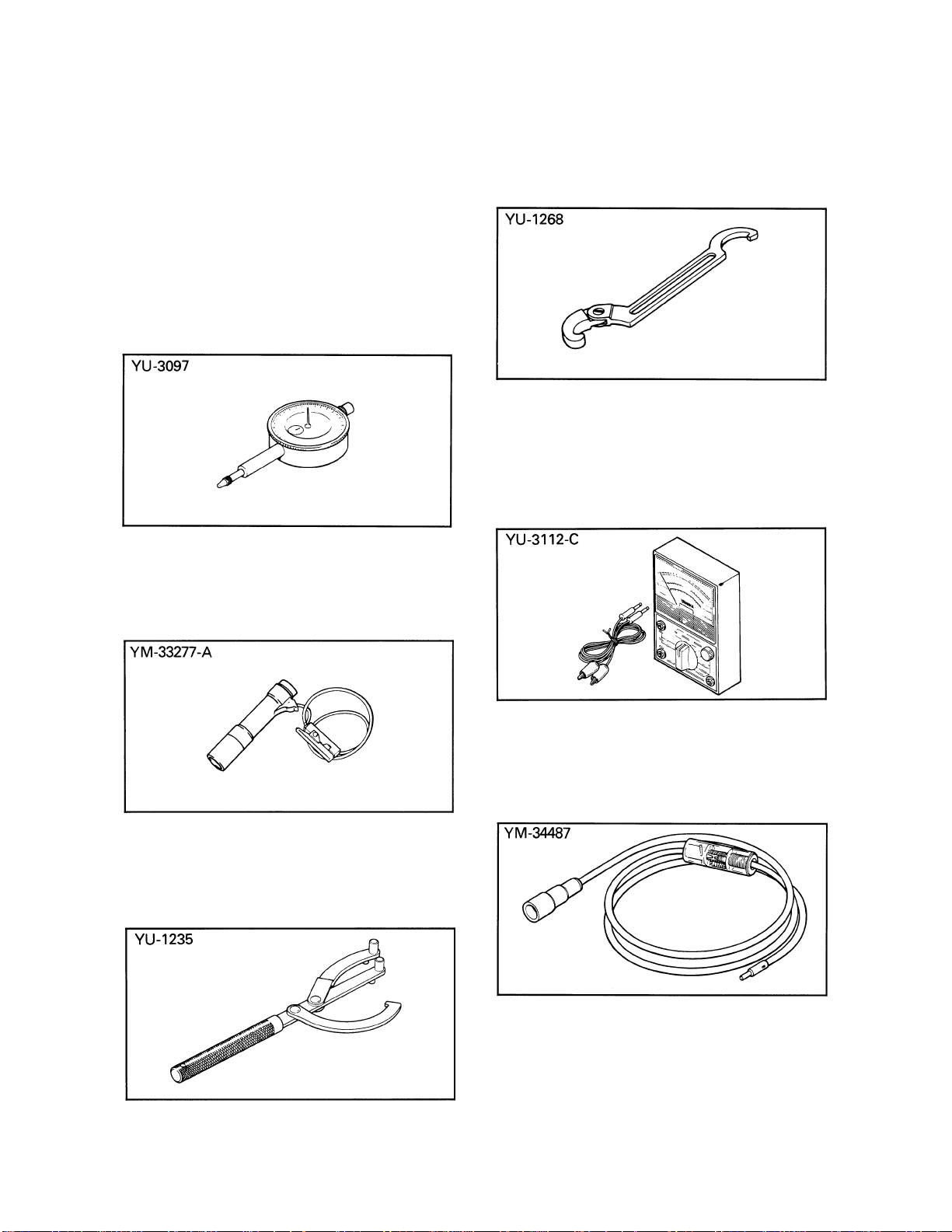

SPECIAL TOOLS

The following special tools are required to per

form maintenance, adjustments, and repairs on

your machine. These tools can be obtained

through your Yamaha dealer.

FOR ENGINE SERVICE

1. Dial Gauge

P/N. YU-3097

This tool is used for adjusting the oil pump

stroke.

FOR CHASSIS SERVICE

1. Ring Nut Wrench

P/N. YU-1268

This tool is used to loosen or tighten the steer

ing ring nut.

FOR ELECTRICAL SERVICE

1. Yamaha Pocket Tester

P/N. YU-3112-C

Use this tool to inspect the coil resistance, out

put voltage and amperage.

2. Inductive Timing Light

P/N. YM-33277-A

This tool is necessary for checking the ignition

timing.

3. Rotor Holding Tool

P/N. YU-1235

This tool is used when loosening or tightening

the flywheel magneto securing nut.

2. Dynamic Spark Tester

P/N. YM-34487

This instrument is necessary for checking the

ignition system components.

Page 21

LUBRICATION

-9-

Page 22

ADJUSTMENT

A WARNING

The engine, exhaust pipe(s), and muffler(s)

will be very hot after the engine has been

run. Be careful not to touch them or to

allow any clothing item to contact them

during inspection or repair.

SPARK PLU^

Standard spark plug:

BP6HS (NGK) or W20FP

(DENSO)

1. Measure the electrode gap with a wire

thickness gauge.

This situation is quite common during the

engine break-in period. However, use the

standard plug. If the insulator tip shows

a very light tan or white color or is actually

pure white or if the electrodes show signs

of melting, then a spark plug with a col

der heat range is required.

NOTE:

If a torque wrench is not available when you

are installing a spark plug, a good estimate of

the correct torque is 1 /4 to 1 /2 turns past finger

tight. Have the spark plug torqued to the cor

rect value as soon as possible with a torque

wrench.

______________________________

IGNITION TIMING CHECKING

1. Ignition timing is checked with Inductive

Timing Light by observing the position of

the stationary punch mark on the stator

and the punch mark on the rotor.

Adjustment can be made by bending the

side electrode.

Electrode gap:

0.6-0.7 mm (0.024-0.028 in)

When installing the plug, always, clean

the gasket surface and use a new gasket.

Wipe off any grime from the threads and

torque the spark plug properly.

Spark plug torque:

25 Nm (2.5 m-kg, 18 ft lb)

2. The insulator must be a medium-to-light

tan color. If not, check carburetion, igni

tion timing and gas-oil mixing ratio.

If the porcelain is a very dark brown or

black color, then a plug with a hotter heat

range may be required.

1. Punch mark

^ Using a Inductive Timing Light, check to

see that the stationary punch mark and

punch mark on the flywheel magneto are

aligned.

a. Remove the crankcase cover (L).

b. Connect the timing light to the spark plug

lead.

c. Start the engine and keep it running at the

specified speed. Use a tachometer for

checking.

2. Stationary punch mark

■10-

Page 23

d. While running the engine at the specified

speed, check to see that the stationary

punch mark is aligned with the punch

mark. If the marks are out of alignment,

check to see that the woodruff key is

broken or flywheel assembly is out of

alignment.

Ignition timing: 20.6°/4,000 r/min

AIR FILTER CLEANING

The most critical aspect of routine maintenance

on a racing machine is proper air filter mainte

nance. The air filter on a motocross must be

serviced after every practice session and moto

to ensure maximum engine performance and

life. For convenience, many racers prepare two

or three spare air filters ahead of time and simp

ly switch filters between practices and motos.

Follow these instructions to service foam air

filters correctly:

3. Using uncontaminated cleaning solvent,

thoroughly wash the filter element; wash

it gently to avoid damage.

4. Squeeze the solvent from the filter ele

ment.

1. Remove the cleaner case cap.

2. Pull out the element and guide from the

cleaner case cap.

CAUTION:

Do not twist or wring the filter element,

as it can easily be torn or otherwise dam

aged.

5. Using liquid dishwashing detergent and

water, again wash the air filter element.

Rinse the element with water, squeeze it,

and allow the element to dry completely.

6 Pour a liberal amount of high-quality,

foam-air-filter oil into a plastic bag. Put

the filter element in the bag and thorough

ly work the oil into the element.

-11

Page 24

Recommended oil: Foam-air-filter oil

If for any reason you should use another

type, use air cooled 2-stroke engine oil.

CAUTiON:

Never use motor oil on a foam air filter ele

ment. Motor oil will not remain suspend

ed in the filter element.

7. Remove the filter element from the plastic

bag and squeeze out the excess oil.

Again, avoid twisting or wringing the air

filter element. The element should be

damp, but not dripping, with oil.

CAUTiON:

Never operate the engine with the air filter

element removed. This will allow un

filtered air to enter, causing rapid wear and

possible engine damage. Additionally,

operation without the filter element will

affect carburetor jetting with subsequent

poor performance and possible engine

overheating.

THROTTLE CABLE ADJUSTMENT

Check the play in turning direction of throttle

grip. The play should be 3~5 mm (0.12 — 0.20

in) at grip flange, loosen the lock nut and turn

the cable adjuster to make the necessary ad

justment. Tighten the lock nut.

8. Reinstall the filter in the machine, and

make sure the sealing surface of the filter

is seated properly. Complete reassembly

of the machine, and check all the fittings

for tightness.

NOTE:

Each time filter element maintenance is per

formed, check the air inlet to the filter case for

obstructions. Check the air cleaner joint rub

ber to the carburetor and manifold fittings for

an air-tight seal. Tighten all fittings thoroughly

to avoid the possibility of unfiltered air enter

ing the engine.

--------------------------------------

IDLE SPEED ADJUSTMENT

1. Turn the pilot air screw in until lightly

seated.

2. Back out 1 and 1 /2 turns. Start the engine

and warm it up.

1. Pilot air screw

Pilot air screw:

1-1/2 turns out

3. Turn the throttle stop screw until idle is

at desired r/min.

-12-

Page 25

4. Turn the pilot air screw in or out until the

idle speed is at the highest possible r/min.

5. Turn the throttle stop screw in or out un

til idle speed is at desired r/min.

Idle speed:

1,650—1,750 r/min

1. Throttle stop screw

If the engine, when warm, hesitates after

adjusting as described, turn the idle air

mixture screw in or out in 1/4 turn in

crements until the problem is eliminate.

NOTE: --------------------------------------------------

Pilot air and throttle stop screws should be ad

justed so that engine response from idle posi

tion is rapid and without hesitation.

AUTOLUBE PUMP

1. Cable adjustment

a. Remove the grommet from the oil pump

cover.

b. Start the engine.

c. When the throttle cable becomes tight

and the engine begins to run faster, hold

the throttle grip steady and check to see

that the match mark on the adjust pulley

is aligned with the pump case mark. If

not, loosen the pump cable locknut and

make adjustment by turning the adjuster.

1. Adjuster

Lock nut

NOTE:-

After adjusting, be sure to tighten the lock nut

completely.

2. Air bleeding

The oil pump just be bled after the oil pipe

or oil pump is reinstalled.

a. Remove the oil pump cover.

b. Remove the bleeder bolt.

c. When the bleeder bolt is removed, oil con

taining air bubbles flows out. Let the oil

flow out until air bubbles completely

disappear, and reinstall the bleeder bolt.

NOTE:

______________________________

• Place a rag or oil can under the engine.

• Add the Autolube oil to the oil tank before

bleeding.

• Thoroughly clean the engine exterior of oil.

3. Minimum plunger stroke adjustment

a. Set the dial gauge as illustrated, and

check to see if the plunger stroke is cor

rect while keeping the engine idling.

1. Set position

3. Pump case mark

2. Mark

-13-

Page 26

b. To adjust the plunger stroke, first loosen

the lock nut.

c. Turn the adjusting bolt in or out for pro

per adjustment.

Turning the adjusting bolt clockwise de

creases the plunger stroke; while turning

counterclockwise increases the plunger

stroke.

d. When the correct stroke is attained,

tighten the lock nut.

Free play (a):

10-20 mm (0.39 - 0.79 in)

Minimum stroke

Maximum stroke

0.40 - 0.45 mm

(0.016^0.0l8in)

1.00 ~ 1.10 mm

(0.039 «^0.043 in)

FRONT BRAKE ADJUSTMENT

Front brake cable free play can be adjusted

to suit rider preference, but a minimum

free play of 10 ~ 20 mm (0.39 ~ 0.79 in)

should be maintained. Free play can be ad

justed at handlebar lever and brake shoe

plate.

1. Loosen the lock nut on the brake lever

holder and then, fully turn the adjuster in.

2. Loosen the lock nut on the shoe plate and

turn the adjuster in or out until proper ad

justment is achieved.

3. Unless the shoe plate adjuster helps bring

a proper play, turn the lever holder ad

juster.

4. Tighten the lock nuts.

REAR BRAKE ADJUSTMENT

The rear brake should be adjusted so the end

of the brake pedal moves 20 ~ 30 mm (0.8 ~ 1.2

in). To adjust, turn the adjuster on the brake

rod clockwise to reduce play; turn the adjuster

counterclockwise to increase play.

Free play (a):

10-20 mm (0.39 - 0.79 in)

-14-

Page 27

DRIVE CHAIN SLACK CHECK

NOTE:

Before checking and/or adjusting, rotate rear

wheel through several revolutions and check

tension several times to find the tightest point.

Adjust chain tension with rear wheel in this

"tight chain" position.

Elevate the rear wheel by placing the suit

able stand under the engine.

Then measure the play at the bottom of the

chain at a point midway between the drive and

driven sprockets.

________________________

3. Adjusting nut

4. After adjusting, be sure to tighten the

rear wheel axle nut.

Tightening torque:

60 Nm (6.0 m • kg, 43 ft • lb)

5. Also tighten the lock nuts against the

rear arm.

The normal vertical deflection is approximate

ly 40~53 mm (1.6~2.1 in). If the chain deflection

is not as specified, adjust the chain tension.

Drive chain slack (a):

40 ~ 53 mm (1.6 ~ 2.1 in)

DRIVE CHAIN SLACK ADJUSTMENT

CAUTION:

Too small chain slack will overload the en

gine and other vital parts; keep the slack

within the specified limits.

1. Loosen the rear brake rod adjuster.

2. Loosen the rear wheel axle nut and

lock nuts.

3. To tighten chain, turn chain puller adjust

ing nut clockwise. Too loosen chain, turn

adjusting nuts counterclockwise and

push wheel forward. Turn each adjusting

nut exactly the same amount to maintain

correct axle alignment. (There are marks

on each side of rear arm and on each

chain puller; use them to check for proper

alignment.)

Tightening torque:

7 Nm (0.7 m-kg, 5.1 ft-lb)

6. In the final step, adjust the play in the

brake pedal.

DRIVE CHAIN LUBRICATION

The chain consists of many parts which work

against each other. If the chain is not maintain

ed properly, it will wear out rapidly. Form the

habit of periodically servicing the chain. This

service is especially necessary when driving in

dusty conditions.

1. Use any of the many brands of spray type

chain lubricant. First, remove dirt and

mud from the chain with a brush or cloth

and then spray the lubricant between both

rows of side plates and on all center

rollers.

2. To clean the entire chain, first remove the

chain from the machine, dip it in solvent

and clean out as much dirt as possible.

Then take the chain out of the solvent and

dry it. After drying, lubricate the chain to

prevent the formation of rust.

-15-

Page 28

TIRE PRESSURE CHECK

Improper tire pressure affects the smoothness

of the tire, traction, handling and the life of the

tires. Always maintain the correct tire pressure.

Tire pressure:

Front 100 kPa (1.0 kgf/cm^, 15 psi)

Rear 100 kPad.O kgf/cmM5psi)

CHECK THE SPOKES

If the spokes are loose or bent, tighten or

replace them. They should be checked before

each use.

STEERING HEAD INSPECTION

Periodically inspect the condition of the steer

ing. Worn out or loose steering bearings may

be dangerous.

Place a suitable stand under the engine to hold

the front wheel of the machine off the ground;

then hold the lower end of the front fork and

try to move forward and backward.

1. Steering shaft bolt

2. Ring Nut Wrench

CAUTION: ___________________

Forks must swing from lock to lock

without binding or catching.

3. Tighten the steering shaft bolt.

Tightening torque:

42 Nm (4.2 m *kg, 30ft‘lb)

NOTE:---------------------------------------------------

Steering head disassembly must be perform

ed by a Yamaha dealer or other qualified

mechanic.

FRONT FORK OIL CHANGE

A WARNING

1. Fork oil leakage can cause loss of

stability and safe handling. Have any

problem corrected before operating

the machine.

2. Support the machine securely so there is no danger of it falling over.

STEERING HEAD ADJUSTMENT

1. To adjust, loosen the steering shaft bolt.

2. Use the Ring Nut Wrench to tighten the

ring nut.

1. Elevate the front wheel by placing a

suitable stand under the engine.

2. Remove the brake cable clamp.

1. Brake cable clamp

-16-

Page 29

3. Remove the number plate.

NOTE:

Select the weight oil that suits local conditions

and your preference (lighter for less damping;

heavier for more damping).

11. After filling, slowly pump the outer tube

______________________________

up and down to distribute the oil.

4. Remove the handlebar.

5. Remove the front wheel. (Refer to page

32.)

6. Remove the cap bolt from the inner tube.

7. Loosen the pinch bolt.

8. Remove the front fork.

9. Drain the fork oil.

10. Installing the front fork on the machine.

Bring up the front fork to the correct po

sition and partially tighten the underbrack

et pinch bolt.

Pour specified amount of oil into the in

ner tube through the upper end opening.

NOTE:

Adjust the oil levels in both right and left front

forks so they are even.

12. Inspect 0-ring on fork cap bolt and

1. Cap bolt

13. Install the front wheel. (Refer to page 32.)

14. Install the handlebar.

___________^__________________

replace if damaged.

Install the fork cap bolt and torque to

specification.

Fork cap bolt torque:

40 Nm (4.0 m • kg, 29 ft • lb)

2. 0-ring

Handle holder upper torque:

13 Nm (1.3 m.kg, 9.4 ft-lb)

Recommended oil:

Yamaha fork oil 15 wt or equivalent

Capacity per leg:

60 cm^ (2.1 Imp oz, 20 US oz)

Pinch bolt torque:

33 Nm (3.3 m-kg, 24 ft-lb)

15. Install the number plate and the brake ca

ble clamp.

REAR SHOCK ABSORBER (MONOCROSS

SUSPENSION "DE CARBON" SYSTEM)

A WARNING

This shock absorber contains highly com

pressed nitrogen gas.

Read and understand the following infor

mation before handling the shock ab

sorber. The manufacturer cannot be held

responsible for property damage or per

sonal injury that may result from improper

handling.

-17-

Page 30

1. Do not tamper with or attempt to

open the cylinder assembly. Injury

may result.

2. Do not subject shock absorber to an

open flame or other high heat. This

may cause the unit to explode due to

excessive gas pressure.

3. Do not deform or damage the cylinder

in any way. Cylinder damage will

result in poor damping performance.

4. Handle it with great care, for a score

or scratch in the piston rod sliding

portion will cause oil leakage.

NOTES ON DISPOSAL

(YAMAHA DEALERS ONLY)

Gas pressure must be released before disposal

of shock absorber. To do so, drill a 2 ~ 3 mm

(0.08 ~ 0.12 in) hole ® through the cylinder

wall at a point 10 ~ 15 mm (0.4 ~ 0.6 in) (a)

above the bottom of the cylinder.

2. Remove the spring guide.

NOTE: ______________________________

While compressing the spring, remove the

spring guide.

3. To stiffen the spring preload, install the

circlip into the groove (a). To soften the

spring preload, install the circlip into

the groove ®.

NOTE: ______________________________

Do not spread the circlip too much.

CAUTiOM;

Wear eye protection to prevent eye

damage from escaping gas and/or metal

chips.

A WARNING

To dispose of a damage or wornout shock

absorber, take the unit to your Yamaha

dealer for this disposal procedure.

REAR SHOCK ABSORBER SPRING PRE

LOAD ADJUSTMENT

1. Remove the rear shock absorber.

(Refer to page 34.)

Standard installation position.

Groove (g)

4. Install the spring guide.

NOTE:

_________________

While compressing the spring, install the

spring guide.

5. Install the rear shock absorber.

(Refer to page 35.)

■18-

Page 31

MAINTENANCE AND MINOR

REPAIRS

PREPARATION FOR

SERVICE

1. Before servicing the machine, be sure to

clean machine exteriors.

2. Place the removed parts, always on a tray

in the order of removal.

3. When replacing parts, always use genuine

Yamaha parts to maintain better perfor

mance, durability and safety.

4. All gaskets and seals should be replaced

when an engine is overhauled. All gasket

surfaces must be cleaned.

5. Properly oil all mating engine and trans

mission parts during assembly.

6. All circlips should be inspected before

assembly. Replace distorted circlips.

7. Always replace cotter pins and piston pin

clips after one use.

8. When installing parts, apply grease or oil

to them, as required, and following the

torque chart. (Refer to "Maintenance and

Lubrication Schedule Chart.")

9. For assembly, reverse the procedure for

removal.

ENGINE

CARBURETOR

-19-

1. Turn fuel cock lever to the "OFF".

2. Disconnect the fuel hose and oil delivery

pipe.

3. Loosen the carburetor joint screw and air

cleaner joint screw.

Page 32

4. Rotate the carburetor, remove the mix

ing chamber top, and carburetor assem

bly.

1. Carburetor

5. Remove the float chamber body and main

jet.

Standard main jet: #125

2. Mixing chamber top

Inspection

1. Examine carburetor body and fuel

passages. If contaminated, wash car

buretor in petroleum based solvent. Do

not use caustic carburetor cleaning solu

tions. Blow out all passages and jets with

compressed air.

2. Examine condition of floats. If floats are

leaking or damaged, they should be

replaced.

3. Inspect inlet needle valve and seat for

wear or contamination. Replace these

components as a set.

r- IMPORTANT;

--------------------------------------

The Carburetor has been set for

normal sea level conditions. The

standard setting is the result of exten

sive testing and does not usuaiiy re

quire changing. However, under condi

tions of high atmospheric pressure or

heavy ioad (deep sand or mud) the

standard main jet should be replaced

with another main jet. if the carburetor

requires any other setting changes to

suit iocai conditions of aititude, weath

er, etc., the change must be made with

great care. Improper carburetor setting

changes wiil cause poor engine perfor

mance and possibie engine damage.

Please consult a Yamaha dealer or other

qualified mechanic about any carbure

tor setting changes before actuaiiy go

ing about them.

Adjustment

1. Float height

a. Checking

Hold the carburetor in an upside down

position. Incline the carburetor at

60°~70° (so that the end of the float

valve does not hang down of float

weight), and measure the distance from

the mating surface of the float chamber

(gasket removed) and carburetor to the

top of the float using a gauge.

Float height:

20.8 - 22.8 mm (0.82 - 0.90 in)

Level with carburetor base

-20-

Page 33

b. Adjustment

CAUTION:

L The valve stopper controls the movement

of the valve. Check the valve stopper

height.

Check the needle valve and valve seat for

wear before adjustment.

Make the adjustment by bending the tang

on the float arm.

2. Jet needle

The mid-range air/fuel supply is affected

by the position of the needle in the nee

dle jet. If it is necessary to alter the mid

range air/fuel mixture characteristics of

the machine, the jet needle position may

be changed. Move the jet needle up for

a leaner condition or toward the bottom

position for a richer condition.

Jet needle type: 3E3

Clip position: No. 3 Groove

Valve stopper height (a):

7.4~7.8 mm (0.291 -0.307 in)

If the valve stopper height is not within

specification, replace the valve stopper.

tolerance, replace reed valve.

Reed valve bending limit:

0.2 mm (0.008 in)

Inspection

1. Inspect rubber intake manifold for signs

of weathering, checking or other deterio

ration.

2. Inspect reed petals for signs of fatigue and

cracks. Reed petals should fit flush or

nearly flush against neoprene seats. If in

doubt as to sealing ability, apply suction

to carburetor side of assembly. Leakage

should be slight to moderate.

5. Manifold:

Check the distortion of manifold surface.

If the distortion is out of limit, resurface

it on the #600 wet sandpaper.

Distortion limit: 0.1 mm (0.004 in)

-21-

Page 34

MUFFLER

With the carburetor removed, proceed as

follows:

^WARNING

Be sure the exhaust pipe and muffler are cool before cleaning the spark arrester.

Removal

1. Remove the two nuts and remove seat.

2. Remove the three bolts from the side

cover assembly and two bands.

1. Muffler

a. Using a rounded scraper, remove ex

cess carbon deposits from manifold

area of exhaust pipe.

b. Check muffler gasket condition. The

gasket seat is located around the

cylinder exhaust port.

2. Spark arrester cleaning

a. Remove the bolt ®.

b. Remove the tailpipe (2) by pulling out

of the muffler.

c. Use a wire brush to remove any car

bon deposits from the spark arrester

portion of the tailpipe (2).

d. Tap the tailpipe (2) lightly and remove

the carbon deposits from the outside

portion of the tailpipe.

e. Insert the tailpipe into the muffler

and align the bolt hole.

f. Install the bolt ® and tighten it.

3. Remove the muffler mounting bolts from

the cylinder and remove the silencer

mounting bolts.

Maintenance

^WARNING

•Always let the exhaust system cool prior

to touching exhaust components.

•Do not start the engine when cleaning

the exhaust system.

----------------

------------------------------------------------------------------------------------------------------------------------------------------------^22-

Tightening torque:

8 Nm (0.8 m-kg, 5.8 ft-lb)

1. Bolt

a. Tailpipe

TOP END

Removal

1. Remove spark plug cap and spark plug.

2. Remove the cylinder head securing nuts

(4 nuts).

Remove cylinder head and gasket.

Page 35

NOTE:

Break each nut loose (1/4 turn) prior to remov

ing.

_________________________

Maintenance

Cylinder head

1. Using a rounded scraper, remove car

bon deposits from combustion chamber.

Take care to avoid damaging the spark

plug threads. Do not use a sharp instru

ment. Avoid scratching the metal sur

face.

3. With the piston at top dead center, raise

the cylinder until the cylinder skirts clear

crankcase. Stuff a clean shop rag into

crankcase cavity, around rod, to prevent

dirt and other foreign particles from enter

ing. Remove cylinder.

4. Remove the piston pin clip from the

piston. Push the piston pin out from op

posite side. Remove the piston.

NOTE:

If the pin hangs up, use a piston pin puller. Do

not hammer on pin as damage to rod, piston

and bearing will result.

------------------------------------------

2. Place the head on a surface plate. There

should be no warpage. Correct by resur

facing. Place 400 ~ 600 grit wet emery

sandpaper on surface plate and re-sur

face head using a figure-eight sanding

pattern. Rotate head several times to

avoid removing too much material from

one side.

3. Clean the spark plug gasket mating sur

face throughly.

Cylinder

1. Using a rounded scraper, remove carbon

deposits from exhaust port.

■=!-23-

Page 36

2. Check cylinder bore. Using a cylinder

hone, remove any scoring. Hone lightly,

using smooth stones. Hone no more than

required to avoid excess piston clearance.

center and bottom just above exhaust

port. Compare minimum and maximum

measurements. If over tolerance and not

correctable by honing, rebore to next

oversize.

Piston

1. Using a scraper, remove carbon deposits

from piston crown.

2. Break a used piston ring in two. File end

square. De-burr edges to avoid scratching

ring groove and clean carbon deposits

from ring grooves.

3.

Using 400 ~ 600 grit wet sandpaper, lightly

sand score marks and lacquer deposits

from sides of piston. Sand in a crisscross

pattern. Do not sand excessively.

Piston outside diameter measurement

2.

Using an outside micrometer, measure

piston diameter. The measuring point is

at right-angles to the piston pin holes,

about 5 mm (0.2 in) from the bottom of

the piston skirts.

Make a correct calculation of the piston

clearance using the following formula.

• PISTON CLEARANCE

= Minimum Cylinder Diameter

- Maximum Piston Diameter

Piston clearance

1. Cylinder bore measurement

Using a cylinder gauge set to standard

bore size, measure the cylinder. Measure

front-to-rear and side-to-side at top.

EXAMPLE:

PISTON CLEARANCE

= 47.000 mm-46.965 mm = 0.035 mm

(1.8504 in-1.8490 in = 0.0014 in)

Norminal piston clearance

0.033-0.038 mm (0.0013-0.0015 in)

-24-

Page 37

If beyond tolerance replace piston or rebore

cylinder as required.

Piston rings

1. Remove ring from piston.

2. Insert ring into cylinder. Push down ap

proximately 20 mm (0.79 in) using piston

crown to maintain right-angle to bore.

Measure installed end gap. If beyond

tolerance, replace.

Ring end gap installed (top and 2nd):

0.15-0.35 mm (0.006-0.014 in)

3. With rings installed in grooves, insert

feeler gauge between ring and groove. If

beyond tolerance, replace ring and/or

piston as required.

Ring groove clearance:

0.020-0.060 mm (0.0008-0.0024 in)

NOTE:

New rings require break-in. Follow first portion

of new machine break-in procedure.

Piston pin bearing and connecting rod

1. Check the pin for signs of wear. If any

2. Check the pin and bearing for signs of

3. Check the bearing cage for excessive

4. Apply a light film of oil to pin and bear

5. Mount the dial gauge at right angles to

------------------------------------------

wear is evident, replace pin and bearing.

heat discoloration. If excessive (heavily

blued), replace both.

wear. Check the rollers for signs of flat

spots. If found, replace pin and bearing.

ing surfaces. Install in connecting rod

small end. Check for play. There should

be no noticeable vertical play. If play ex

ists, check connecting rod small end

diameter for wear. Replace pin and bear

ing or all as required.

connecting rod small end holding the bot

tom of rod toward the dial indicator, rock

top of rod and measure axial play.

Holding cylinder towards light, check for

4.

full seating of ring around bore. If not fully

seated, check cylinder. If cylinder is not

out-of-round, replace piston ring.

During installation, make sure ring ends

5.

are properly fitted around ring locating pin

in piston groove. Apply liberal coating of

two-stroke oil to ring.

Connecting rod axial play:

1.0 mm (0.04 in)

-25-

Page 38

6. Remove the dial gauge and slide the con

necting rod to one side. Insert a feeler

gauge between the side of the connec

ting rod big end and the crank wheel.

Measure clearance.

Connecting rod/crank side clearance:

0.30-0.80 mm (0.012-0.031 in)

7. If any of the above measurements exceed

tolerance, crankshaft repair is required.

Take the machine to your authorized

dealer.

8. During reassembly apply a liberal coating

of two-stroke oil to the piston pin and

bearing. Apply several drops of oil to the

connecting rod big end. Apply several

drops of oil into each crankshaft bearings

oil delivery hole.

CLUTCH

Removal

1. Remove the kick starter.

2. Remove the pan head screws holding the

case cover in place and remove the cover.

Note the position of the dowel pins.

NOTE:

Drain transmission oil before removing cover.

------------------------------------------

ft

3. Using the Rotor Holder, remove the

clutch securing nut and lock washer. Re

move the clutch boss and driven gear

(clutch housing).

-26-

Page 39

1. Rotor Holder

4. Remove the circlip, pressure plate, clutch

plates, friction plates, one-way clutch,

and clutch boss from the clutch housing.

Inspection

1. Measure each clutch spring and off

spring. If beyond tolerance, replace.

NOTE:

------------------------------------------

For optimum performance, if any plate requires

replacement, it is advisable to replace the en

tire set.

4. Check each clutch plate for signs of heat

damage and warpage. Place on surface

plate (plate glass is acceptable) and use

feeler gauge.

Clutch plate warp allowance:

0.1 mm (0.004 in)

^

OFF spring free length

Clutch spring free length

New

30.5 mm

(1.20 In)

12.9 mm

(0.51 in)

Minimum

28.5 mm

(1.12 in)

11.9 mm

(0.47 in)

2. Check the plates for signs of warpage and

heat damage, replace as required.

3. Measure the friction plates at three or four

points. If their minimum thickness ex

ceeds tolerance, replace.

Friction plate

thickness

New

3.0 mm

(0.118 In)

Wear limit

2.7 mm

(0.106 in)

Checking the ball

5.

Check balls for excessive wear or damage.

If such wear is found, replace balls.

Checking the ratchet mechanism

Check for damage or wear on each pawl

and dog. If damaged or worn to excess,

replace it. Check the pawl-spring for

damage and tension. If damaged or

fatigued to excess, replace it.

-27-

Page 40

7. Measure the gap between the friction

plate and pressure plate with a thickness

gauge.

If the gap is found incorrect, it should be

properly adjusted by changing the

thickness of the clutch plate.

Thickness:

1.2, 1.4 or 1.6 mm

(0.047, 0.055, 0.063 in)

Clutch adjustment gap (a):

1.40-1.75 mm (0.055-0.069 in)

KICK STARTER

Removal

1. Unhook the kick spring from its post in

the crankcase. Allow it to relax. Then

remove the kick axle assembly by rotating

the shaft counterclockwise and then pull

ing out the entire assembly. Check the

gear teeth for wear and breakage.

Inspection

1. The kick clip friction force is 0.9 — 1.5 kg

(2.0-3.3 lb).

If above pressure is too strong, spring

wear and kick starter slipping will result.

If it is too weak, the same slippage will

occur particularly at low temperatures. Do

not try to bend the clip.

2. Check the clip for damage and wear, and

determine whether or not, it should be

replaced.

-28-

Page 41

Reassembly

1. While keeping the kick stopper upwards,

engage the kick axle return spring with the

slot on the end of the kick axle.

And hook the spring to the spring hook.

Check whether the kick starter acts cor

rectly and whether it returns to its home

position.

2. After installing the kick assembly be sure

to check whether it operates smoothly or

not.

Inspection

1. Check the shift shaft for bends.

If bent excessively replace it.

2. Check the shift lever and the return spring

for fatigue.

If fatigued excessively, replace it.

3. Check the stopper lever for wear. If worn

to excess, replace it.

SHIFTER

NOTE:

Shifter maintenance should be performed with

clutch assembly removed.

------------------------------------------

Removal

1. Remove the shift lever assembly and stop

per lever.

4. After installation of the shift shaft, check

the clearances A and A' (between the

prongs of shift lever 1 and shift drum pins)

are equal.

1. Stopper lever

Installation

1. Before installation, grease the shift shaft

oil seal.

2. Be sure to install the stopper lever first,

and then shift shaft assembly.

-29-

Page 42

CRANKCASE

®=3»y

KICK STARTER

-30-

Page 43

CHASSIS

FRONT WHEEL

REAR WHEEL

0 16Nm (1.6m-kg,11ft lb)

0 16Nm (1.6m kg,1in ibf

07Nm (0.7m-kg,5.1ft-lb)

g) \ 7Nm (0.7m-kg,5.1ft-lb)

25Nm (2.5m-kg,18ft lb)

0: Tightening torque

0: Apply grease

0 7Nm (0.7m kg,5.1ft-lb)

60Nm (6.0m-kg,43ft-lb)

-31

Page 44

FRONT WHEEL Removal

1. Elevate the front wheel by placing a

suitable stand under the engine.

2. Remove the brake cable: Loosen all ca

ble adjuster screws and remove cable

from handle lever holder. Then remove

cable from cam lever at front brake shoe

plate.

3. Remove the axle nut ® and the wash

er®.

REAR WHEEL Removal

1. Elevate the rear wheel by placing a

suitable stand under the engine.

2. Remove the tension bar and the brake rod

from the brake shoe plate. The tension bar

can be removed by removing the cotter

pin and nut from the tension bar bolt. The

brake rod can be removed by removing

the adjuster.

3.

Disconnect the drive chain.

Loosen the lock nuts and chain slack

4.

adjusting nuts on both sides.

Remove the axle nut and washer.

5.

4. Turn and pull out the front wheel axle; the

wheel assembly can now be removed.

Installation

When installing front wheel, reverse the

removal procedure taking the following steps:

1. Check for proper engagement of the boss

on the outer fork tube with the locating

slot on the brake shoe plate.

2. Tighten the axle nut.

Axle nut torque:

35 Nm (3.5 m -kg, 25 ft lb)

1. Adjuster

2. Brake rod

3. Tension bar

4. Lock nut

5. Adjusting nut

6. Axle nut

Washer

6. The rear wheel assembly can be removed

from the machine by pulling the wheel

axle.

Installation

The rear wheel can be installed by reversing

the removal procedure. Take the following

steps.

1. When connecting the chain, make certain

closed end of master link clip is facing

direction of rotation.

-32-

2. Be sure to adjust the chain slack. (Refer

to "Drive chain slack adjustment".)

Page 45

3. Tighten the axle nut and tension bar

nut.

Axle nut torque:

60 Nm (6.0 m*kg, 43 ft»lb)

Tension bar nut:

16 Nm (1.6 m*kg, 11 ft*lb)

4. Insert the new cotter pin into the ten

sion bar bolt.

A WARNING

Always use a new cotter pin.

4. Starting opposite the valve stem on one

side, use two round-ended tire irons to

work the bead off the rim.

NOTE:

Use a tire removal lubricant and be careful not

to pinch the tube vyith the tire irons.

5. Remove the valve stem from its hole and

6. If the tire is to be changed, remove the

____

_____________________

remove the tube.

second bead from the rim using the tire

irons and tire lubricant.

5. Bend the end of the cotter pin.

BRAKE SHOE INSPECTION

Measure the outside diameter of the brake shoe

set with slide calipers.

If they measure less than replacement limit,

replace them. Smooth out any rough spots on

shoe surface with sandpaper.

Brake shoe diameter

Replacement limit

Front

95 mm

(3.74 in)

92 mm

(3.62 in)

Rear

110 mm

(4.33 in)

107 mm

(4.21 in)

BRAKE DRUM INSPECTION

Check the inner surface of the brake drum and

remove any scratches with emery cloth.

Remove any oil with a cloth dipped in solvent.

If damage is more extensive, have a Yamaha

dealer or other qualified mechanic replace the

wheel hub.

TIRE

Removal and repair

1. Remove the wheel from the machine.

2. Remove the lock nut from valve stem and

release as much air as possible from the

tire.

3. Push both tire beads away from the edges

of the rim.

Inspection

1. Use a cloth to check for nails or other

sharp objects in the tire.

CAUTION:

_____________________

Always use a cloth to avoid cutting your

hand.

2. Check for faults in the side wall. If there

is any fault, the tire should be replaced

as a damaged tire may burst at high

speeds, which is extremely dangerous.

3. Inflate the tube with air and check the

valve stem and the tube for damage and

leakage, replace as required. Some leaks

can be patched in an emergency, but it

is best to replace tube.

Reassembly

1. Install one tire bead on the rim using tire

irons and lubricant and then install the

tube.

2. Inflate tube with air to about one-third the

specified pressure. Hit the outer cir

cumference of the tire with a soft ham

mer to make certain the tube is hot caught

between tire and rim. Release air from

tube.

Inspect rim band and replace if damaged.

3.

4.

Install second tire bead starting opposite

the valve stem using the irons and tire

mounting lubricant.

5.

Inflate tire to approximately 294 kPa (3

kgf/cm^, 42 psi) and then reduce pres

sure to specified setting.

-33-

Page 46

CAUTION:

_____________________

Check the valve stem; it must be pointing

directly at center of wheel hub. If angled

in any direction, release air and adjust tube

position.

REPLACING WHEEL BEARINGS

If the bearings allow excessive play in the wheel

or if they do not turn smoothly have your dealer

replace the wheel bearings.

CHECKING RIM

1. Check for cracks, bends or warpage of

rim. If a rim is deformed or cracked, it

must be replaced.

2. Check the wheel run-out.

If deflection exceeds tolerance, check

wheel bearing or replace wheel as

required.

2. Turn the fuel cock to “OFF" and discon

nect the fuel pipe.

3. Remove the fuel tank mounting bolt and

holding band from fuel tank. Lift rear of

the fuel tank up and pull back to clear

frame mounts. Remove tank.

Rim run-out limits;

Vertical — 2.0 mm (0.08 in)

Lateral — 2.0 mm (0.08 in)

REAR SHOCK ABSORBER

(MONOCROSS SUSPENSION)

Removal

1. Remove the seat and side cover assembly.

4. Elevate rear wheel by placing a suitable

stand under the engine.

5. Remove the cotter pin and remove the pin

from the frame.

6. Remove the cotter pin and remove the pin

from the swingarm.

-34-

Page 47

7. Remove the rear shock absorber from the

machine. (To remove, pull the rear shock

backward while lifting up the frame.)

8. When reassembling, reverse the removal

procedure taking care of the following

points:

a. Always use new cotter pins.

b. Apply the molybdenum disulfide

grease on the pins.

SWINGARM INSPECTION

1. With shock absorber removed, grasp the

ends of the swingarm and move them

from right to left to check for free play.

Swingarm free play: 1.0 mm (0.04 in)

LUBRICATION OF LEVER, PEDALS, ETC.

1. Lubricate the pivoting parts of the brake

lever with Yamaha Chain and Cable Lube

or SAE 10W30 motor oil.

2. Lubricate the shaft of the brake pedal with

lithium base grease.

-35-

Page 48

CABLE INSPECTION AND LUBRICATION

1. Damage to the outer housing of the vari

ous cables, may cause corrosion and

often free movement will be obstructed.

An unsafe condition may result so replace

as soon as possible.

2. If the inner cables do not operate smooth

ly, lubricate or ask a Yamaha dealer or

other qualified mechanic to replace them.