Yamaha PC-9500-N Service Manual

PC9500N/PC4800N

POWER AMPLIFIERS

SERVICE MANUAL

このサービスマニュアルはエコパルプ

(ECF:無塩素系漂白パルプ)を使用しています。

PC9500N

CONTENTS

SPECIFICATIONS ................................................ 3/4

PANEL LAYOUT .................................... 5

BLOCK DIAGRAM

WIRING ..................................................................... 8

DIMENSIONS .......................................................... 10

DISASSEMBLY PROCEDURE ............................ 11

LSI PIN DESCRIPTION .............................. 16

IC BLOCK DIAGRAM ................................. 17

CIRCUIT BOARDS ....................................... 19

INSPECTIONS ...................................................... 30/37

PARTS LIST

OVERALL CIRCUIT DIAGRAMS

(結線図)

(目次)

(

総合仕様

(パネルレイアウト)

(ブロックダイアグラム)

(

寸法図

(ICブロック図)

(シート基板図)

(検査)

)

)

(分解手順)

(LSI端子機能表)

(総回路図)

.............................. 6

011652

PA

PC9500N: 20020925-400000

PC4800N: 20020925-330000

HAMAMATSU, JAPAN

1.361K-3611 Printed in Japan 2002.9

1

PC9500N/PC4800N

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed

that basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the users, and have therefore not been restated.

WARNING : Failure to follow appropriate service and safety procedures when servicing this product may result in per-

IMPORTANT : This presentation or sale of this manual to any individual or firm does not constitute authorization certifi-

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable

and changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to

exist, please contact the distributor’s Service Division.

WARNING : Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT : Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power

sonal injury, destruction of expensive components and failure of the product to perform as specified. For

these reasons, we advise all Yamaha product owners that all service required should be performed by an

authorized Yamaha Retailer or the appointed service representative.

cation, recognition of any applicable technical capabilities, or establish a principal-agent relationship of

any form.

accumulated by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to

this bus.)

to the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT

SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN

ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

As the colours of the wires in the mains lead of this apparatus may

not correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:

The wire which is coloured GREEN and YELLOW must be

connected to the terminal in the plug which is marked by the letter E

or by the safety earth symbol or coloured GREEN and YELLOW.

The wire which is coloured BLUE must be connected to the terminal

which is marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the

terminal which is marked with the letter L or coloured RED.

* This applies only to products distributed by YAMAHA KEMBLE

MUSIC (U.K.) LTD.

WARNING

Components having special characteristics are marked and must be

replaced with parts having specification equal to those originally installed.

印の商品は、安全を維持するために重要な部品です。交換する場合は、

安全のために必ず指定の部品をご使用下さい。

2

PC9500N/PC4800N

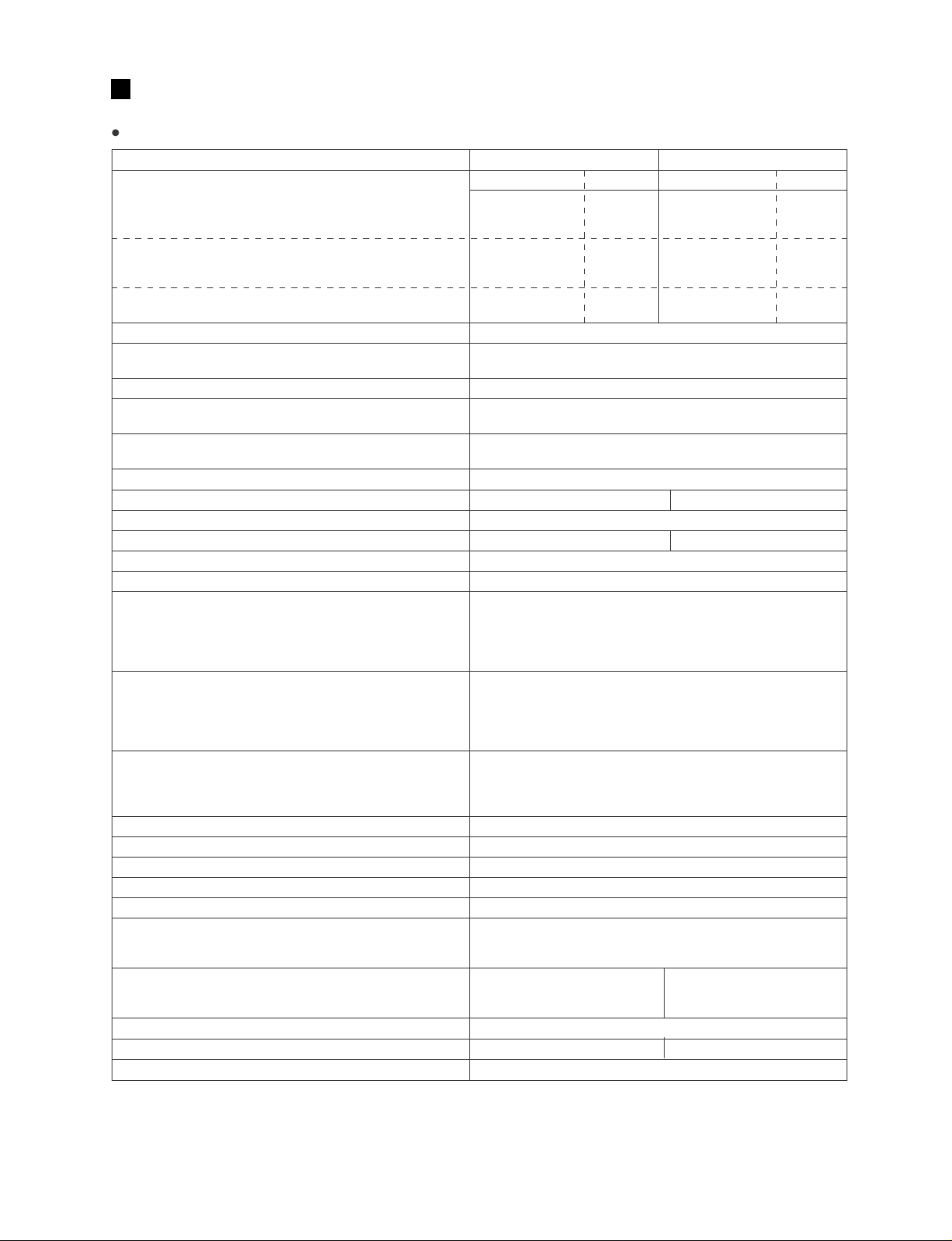

SPECIFICATIONS

(総合仕様)

General Specifications

PC9500N PC4800N

120 V (US)/ 240 V (A)

Power Output Level (Rated Power) 8Ω/STEREO 1000 W x 2 1050 W x 2 550 W x 2 500 W x 2

1 kHz 4Ω/STEREO 1600 W x 2 1650 W x 2 850 W x 2 800 W x 2

THD+N= 1% 8Ω/BRIDGE 3200 W x 1 3300 W x 1 1700 W x 1 1600 W x 1

20 Hz–20 kHz 4Ω/STEREO 1400 W x 2 1500 W x 2 725 W x 2 700 W x 2

THD+N= 0.1% 8Ω/BRIDGE 2800 W x 1 3000 W x 1 1450 W x 1 1400 W x 1

1 kHz 2Ω/STEREO 2300 W x 2 2300 W x 2 1200 W x 2 1200 W x 2

20mS nonclip 4Ω/BRIDGE 4600 W x 1 4600 W x 1 2400 W x 1 2400 W x 1

Power Bandwidth Half Power 10 Hz–40 kHz (THD+N= 0.5%)

Total Harmonic Distortion (THD + N)

20 Hz~20 kHz, Half Power

Frequency Response RL= 8Ω, Po= 1 W 0 dB, 0.5 dB, –1 dB f=20 Hz–50 kHz

Intermodulation distortion (IMD)

60 Hz:7 kHz, 4:1, Half Power

Channel Separation Half Power, RL= 8Ω, 1 kHz

Residual Noise Vol. min.

SN Ratio

Damping Factor RL=8Ω, 1f= 1 kHz ≥800

Sensitivity (Vol. max.) Rated Power into 8Ω +9 dB +6 dB

Voltage Gain (Vol. max.) 32 dB

Input Impedance 30 kΩ/Balanced, 15 kΩ/Unbalanced

Controls Front Panel POWER switch (ON/OFF)

Connectors Input XLR-3-31 type/ch

Indicators POWER/STAND-BY Green/Orange

Meters 10 points LED meter

Load protection POWER switch ON muting, DC detection,

Amp. protection Temp. detection (heatsink temp ≥ 90°C), VI limiter (RL ≤ 1 Ω)

Limiter Comp. : THD ≥ 0.5%

Cooling Dual Variable-speed fan

Power Requirements US & Canada 120 V, 60 Hz

Power Consumption Idling 55 W 40 W

Dimensions (W x H x D) 480 x 88 x 456 mm

Weight 13 kg 12.5 kg

Accessories

8Ω/STEREO 925 W x 2 950 W x 2 475 W x 2 450 W x 2

≤0.1%

≤0.1%

Vol. max., input 600Ω shunt

20 Hz~20 kHz (DIN AUDIO)

20 Hz~20 kHz (DIN AUDIO)

Rear Panel MODE switch (STEREO/BRIDGE/PARALLEL)

Output SPEAKON /ch, 5-way binding posts

NETWORK RJ45

POWER AC INLET

PROTECTION Red

TEMP Red (heatsink temp ≥ 85°C)

REMOTE Green

Europe 230 V, 50/60 Hz

Other 240 V, 50/60 Hz

1/8 output power, 4Ω 120 V 750 W 230/240 V 1100 W 120 V 450 W 230/240 V 600 W

Maximum output, 4

Ω

≥70 dB

≤ –70 dB

Volume (31 position) /ch

HPFswitch (ON/OFF) /ch

DIP switch (6P)

Euroblock connector (balance)/ch

Power cord, Security cover, Owner’s Manual, Euroblock connector (2)

0 dB=0.775 Vrms, Half Power=1/2 Power Output Level (Rated Power)

230 V (EU)

106 dB 103 dB

4500 W 2500 W

120 V (US)/ 240 V (A)

fc=40 Hz

230 V (EU)

For European Model

Purchaser/User information specified in EN55103-1 and EN55103-2.

Inrush Current: 20A (PC9500N) / 25A (PC4800N)

Conformed Environment: E1, E2, E3 and E4.

3

PC9500N/PC4800N

一般仕様

PC9500N PC4800N

出力レベル 8 Ω/STEREO 1000W ×2 500W×2

1kHz 4 Ω/STEREO 1500W ×2 750W×2

THD+N=1% 8Ω/BRIDGE 3000W×1 1500W ×1

8Ω/STEREO 900W×2 450W×2

20Hz〜20kHz 4Ω/STEREO 1300W ×2 650W ×2

THD+N=0.1% 8Ω/BRIDGE 2600W×1 1300W ×1

1kHz 2 Ω/STEREO 2200W ×2 1100W×2

20mSnonclip 4 Ω/BRIDGE 4400W×1 2200W ×1

出力帯域幅 HalfPower 10Hz〜40kHz(THD+N=0.5%)

全高調波歪率(THD +N)

20Hz 〜20kHz、HalfPower

周波数特性

混変調歪率

60Hz:7kHz、4:1、HalfPower

チャンネル間セパレーション

ボリューム.max. 入力600 Ωシャント

残留ノイズ ボリュームmin. 20Hz〜20kHz(DINAUDIO) ≦−70dB

SN比 20Hz 〜20kHz(DINAUDIO) 106dB 103dB

ダンピングファクター RL=8Ω、1f=1kHz ≧800

入力感度(ボリュームmax.)RatedPower 8 Ω +9dB +6dB

ボルテージゲイン(ボリュームmax.) 32dB

入力インピーダンス 30kΩ/バランス型、15k Ω/アンバランス型

コントロール フロントパネル POWERスイッチ:ON/OFF

コネクター INPUT XLR-3-31タイプ

インジケーター POWER/STAND-BY 緑/オレンジ

レベルメーター 10ポイントLED メーター

ロードプロテクション Powerスイッチオンミュート、DC 検出、

アンププロテクション 温度検出(ヒートシンク温度≧90℃)、VIリミッタ−(RL ≦1Ω)

リミッター コンプ:THD≧0.5%

クーリング 連続可変式ファン

電源 100V、50/60Hz

消費電力 無信号 55W 40W

最大外形寸法(W×H×D) 480×88×456mm

重量 13kg 12.5kg

付属品 電源コード(PC4800N)、セキュリティカバー、取扱説明書、

RL=

8Ω、Po=1W 0dB、+0.5dB、−1dB f=20Hz 〜50kHz

HalfPower RL=8Ω1kHz

リアパネル MODE スイッチ:STEREO/BRIDGE/PARALLEL

OUTPUT スピコン(チャンネル単位)、5ウェイバインディング・ポスト

NETWORK RJ45

POWER ACインレット(PC4800N)

PROTECTION 赤

TEMP 赤(ヒ−トシンク温度≧85℃)

REMOTE 緑

1/8出力、4 Ω 950W 500W

最大出力、4Ω 4500W 2500W

≦0.1%

≦0.1%

≧70dB

ボリューム:31ポジション(チャンネル単位)

HPFスイッチ:ON/OFF(チャンネル単位) fc=40Hz

DIPスイッチ(6P)

ユーロブロックコネクター(バランス)(チャンネル単位)

ユーロブロックコネクター(2 個)

0dB=0.775Vrms,HalfPower=1/2PowerOutputLevel(RatedPower)

4

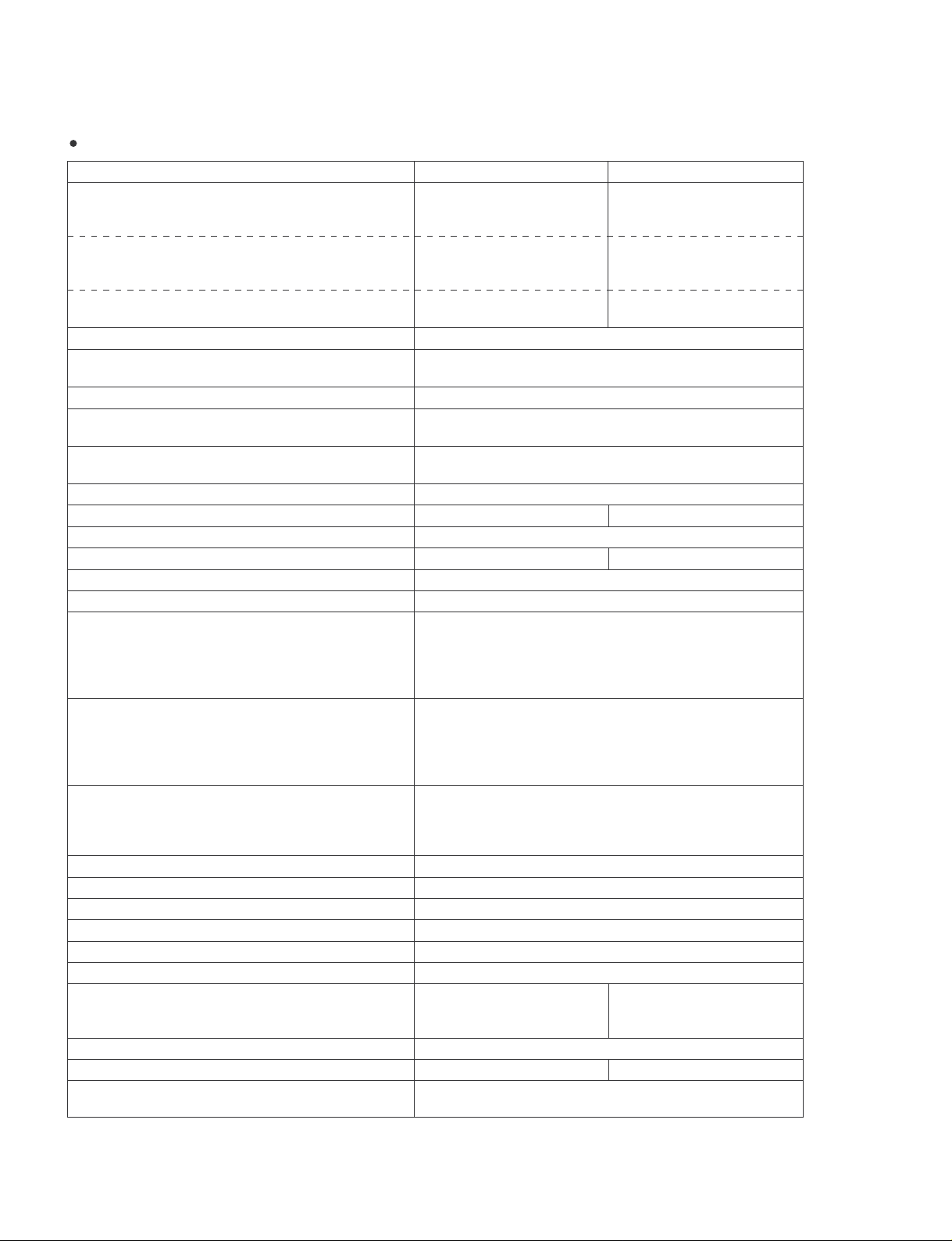

PC9500N/PC4800N

In case of PC9500N (J)

(PC9500N(J)の場合)

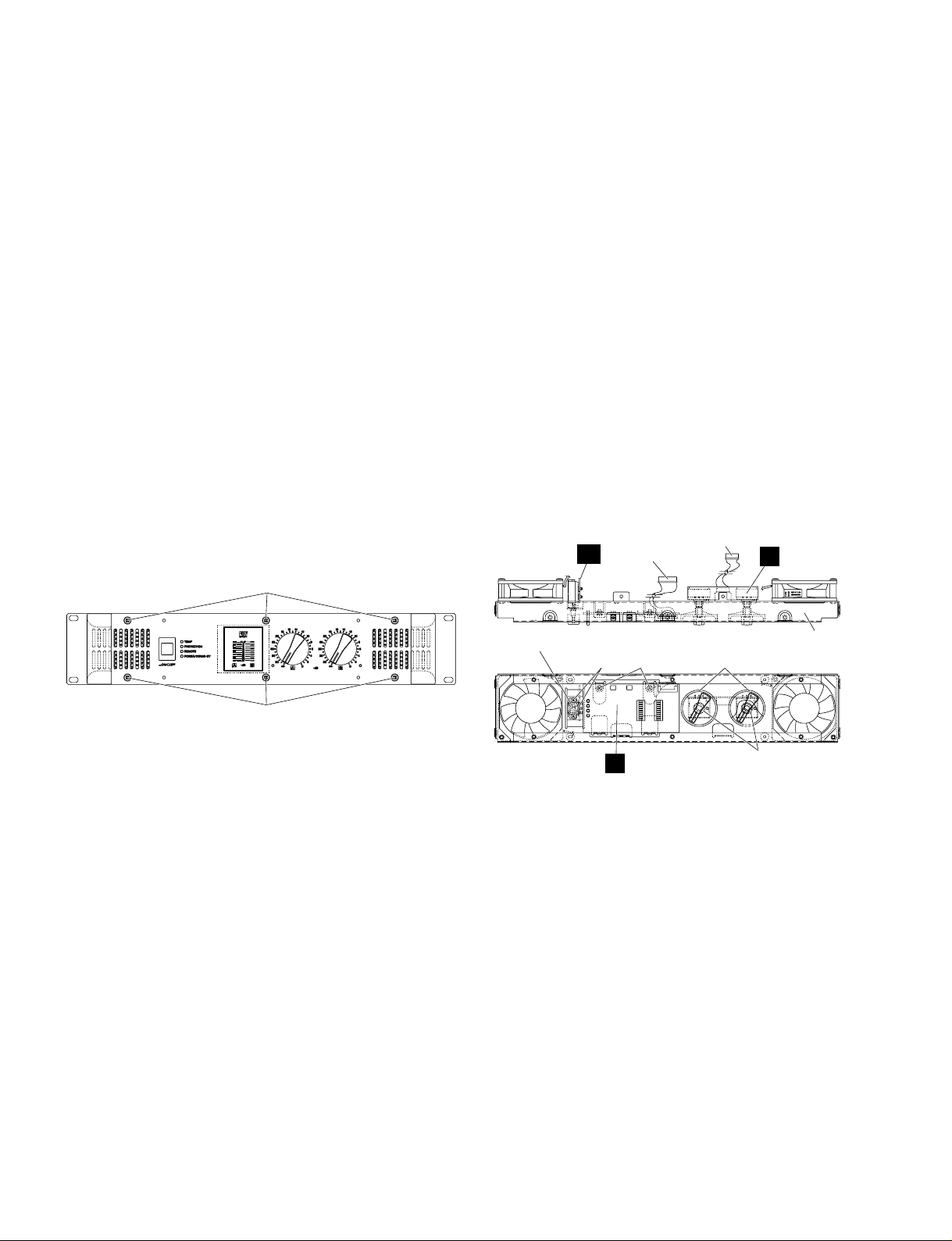

PANEL LAYOUT

Front Panel

(フロントパネル)

1

POWER/STAND-BY switch and indicator

2

REMOTE indicator

3

PROTECTION indicator

4

TEMP indicator

5

Level meters

6

Volume knobs

7

Air intakes

8

Security cover

(パネルレイアウト)

1

POWER/STAND-BYスイッチ、インジケーター

2

REMOTEインジケーター

3

PROTECTIONインジケーター

4

TEMPインジケーター

5

レベルメーター

6

ボリュームツマミ

7

吸気口

8

セキュリティカバー

Rear Panel

(リアパネル)

1

XLR inputs

2

MODE switch

3

HPF 40 switches

4

SPEAKERS jacks

5

DATA ports

6

AMP ID switch

7

Euroblock connector

8

AC inlet (only PC4800N)

9

GND terminals

1

XLR入力端子

2

MODEスイッチ

3

HPF40スイッチ

4

SPEAKERS端子

5

DATAポート

6

AMPIDスイッチ

7

ユーロブロックコネクター

8

ACインレット(PC4800N)

9

GND端子

5

PC9500N/PC4800N

N

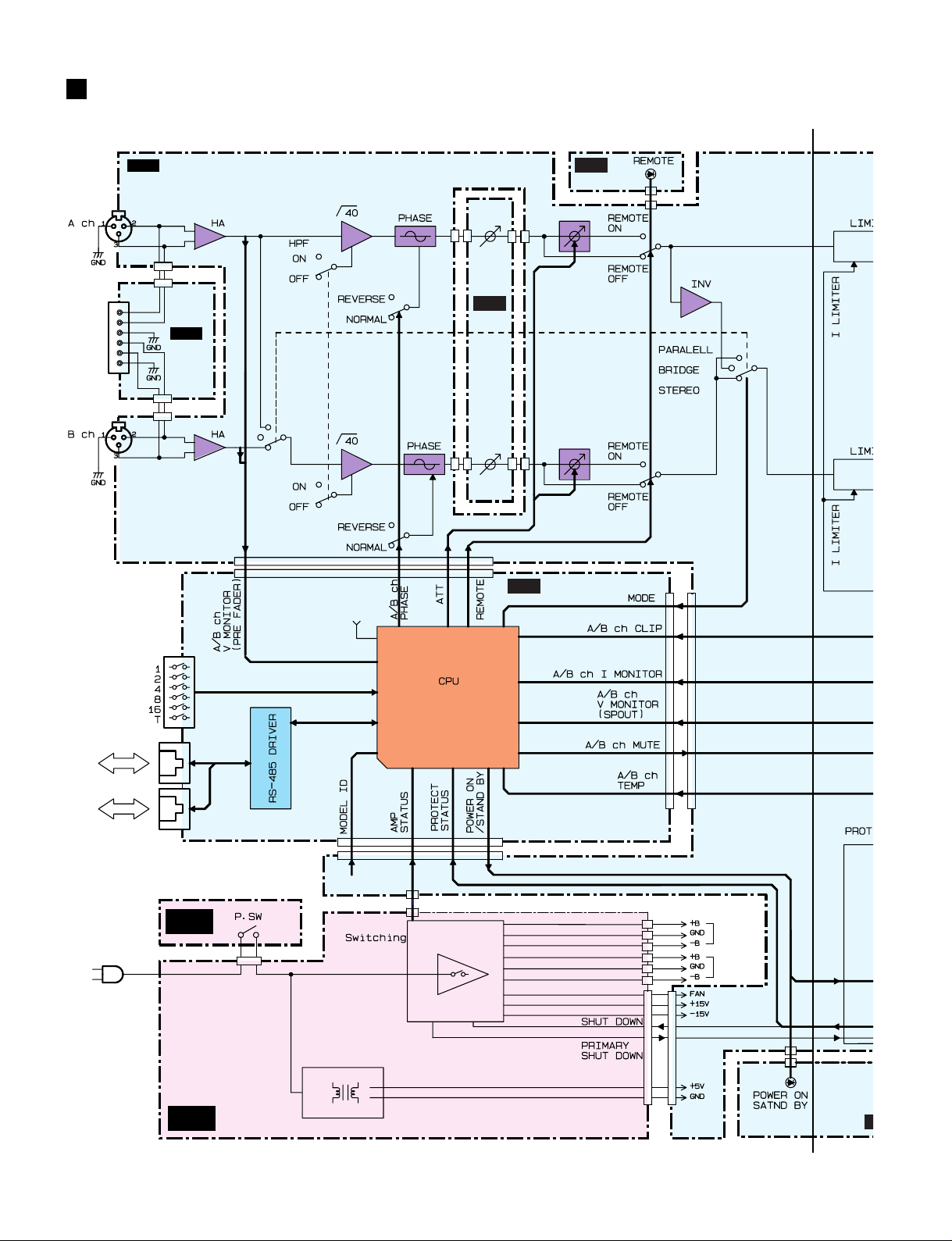

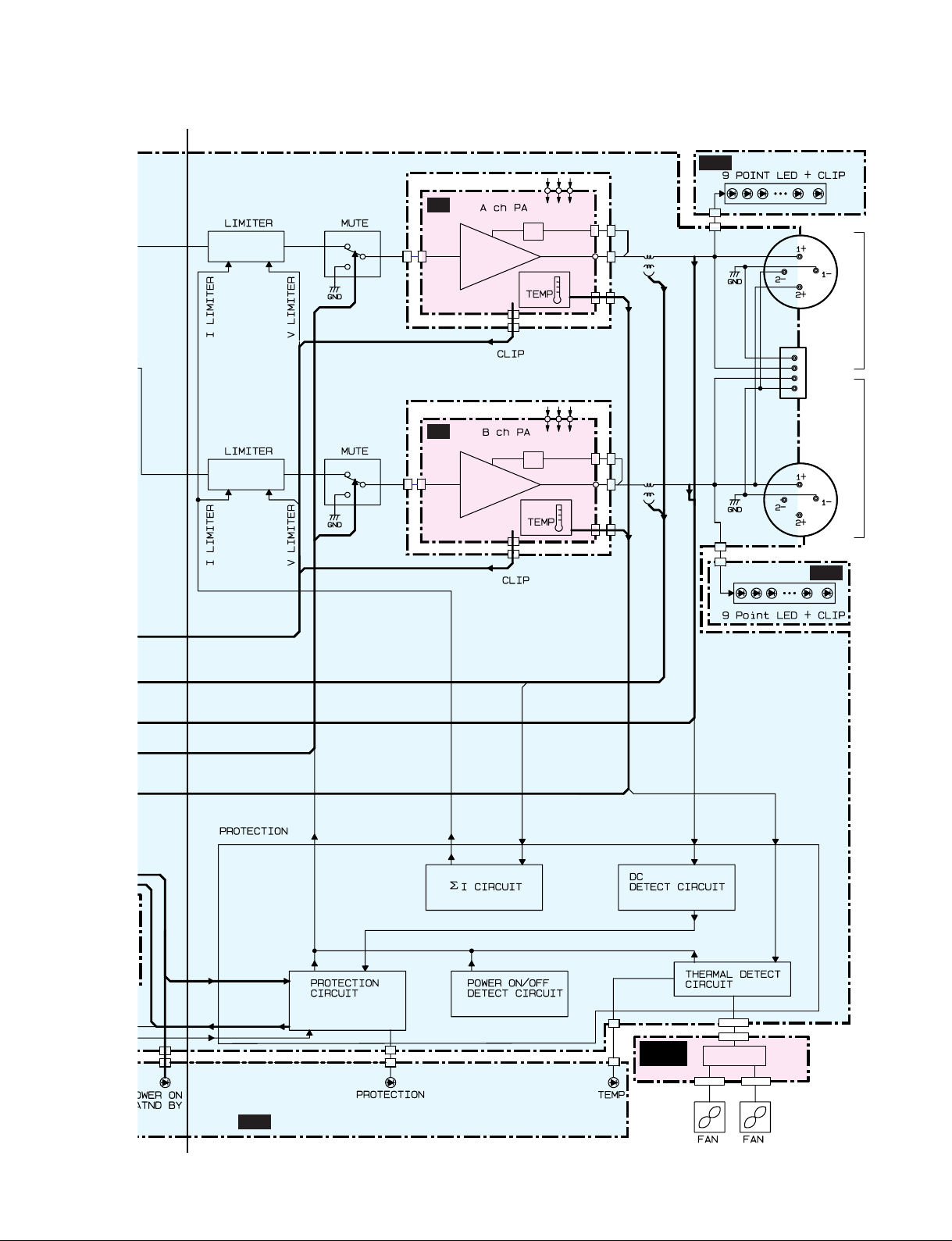

BLOCK DIAGRAM

IN 1/5

JK403

JK401

JK402

IC401

3

2

CN402-35P

CN401-35P

IN 5/5

CN401-35P

CN402-35P

IC401

5

6

1

7

INPUT

(ブロックダイアグラム)

SW401

-1/4

CN405-37P

*1

IC402-1/2

SW402-1/2

IC403-1/2

*1

SW402-2/2

IC402-2/2

*1

RY401

CN407-7P

CN406-7P

IN 3/5

A ATT

VR401

IC403-2/2

CN407-7P

B ATT

VR402

CN406-7P

RY402

CN407-7P

CN407-7P

CN406-7P

IN 2/5

A ATT

IC408 1/2

B ATT

IC408 2/2

LD704

CN701-11P

CN601-11P

RY403-1/2

RY403-2/2

IC406

SW401

-2/4

-3/4

-4/4

*1

A

JK801

JK802

SW801

PS10 2/2

PS5 2/2

Power Supply

CN801-37P

IC802

SW101

CN101-4P

CN801-37P

CN405-37P

Clock

6.4512M

91, 92

57~60

102

104

6

7

72

74

54 66 4

CN602-9P

CN102-9P

17 5

IC801

112P

IN 4/5

70, 69

93, 98

95, 96

10, 11

94, 99

CN801-37P

CN105-1P

CN106-1P

CN107-1P

CN108-1P

CN109-1P

CN110-1P

CN405-37P

YE

BL

BR

YE

BL

BR

to PA Ach

to PA Bch

CN701-11P

LD706

PS10 1/2

PS5 1/2

CN102-9P

CN602-9P

I

*1:IN 5/5

A'

6

PC9500N/PC4800N

A

IN 2/5

/4

/4

/4

401

SP602

1 1 +

2 +

2 -

SP601

SP603

IN 2/5

LD701

2

A ch

1

1

B ch

2

Q420

CN403

-3P

PA

CN201-3P

CN202-6P

CN603-6P

NF

IC201

+B -B GND

CN205-2P

CN202

-6P

RE

CN609-2P

CN605

-1P

CN603-6P

CN701-11P

CN601-11P

*1

Q418

CN404

-3P

PA

CN201-3P

CN202-6P

CN604-6P

NF

IC201

+B -B GND

CN205-2P

CN202

-6P

RE

CN610-2P

CN608-1P

CN604-6P

CN601-11P

CN701-11P

LD705

1-11P

706

LD703

CN601-11P

CN701-11P

CN701-11P

LD702

CN601-11P

PS10 1/2

PS5 1/2

CN104-2P

CN602-9P

CN102-9P

FAN DRIVE

Q115-117

CN103-2P

IN 2/5

A'

(A) (B)

38CA1-8821493

7

PC9500N/PC4800N

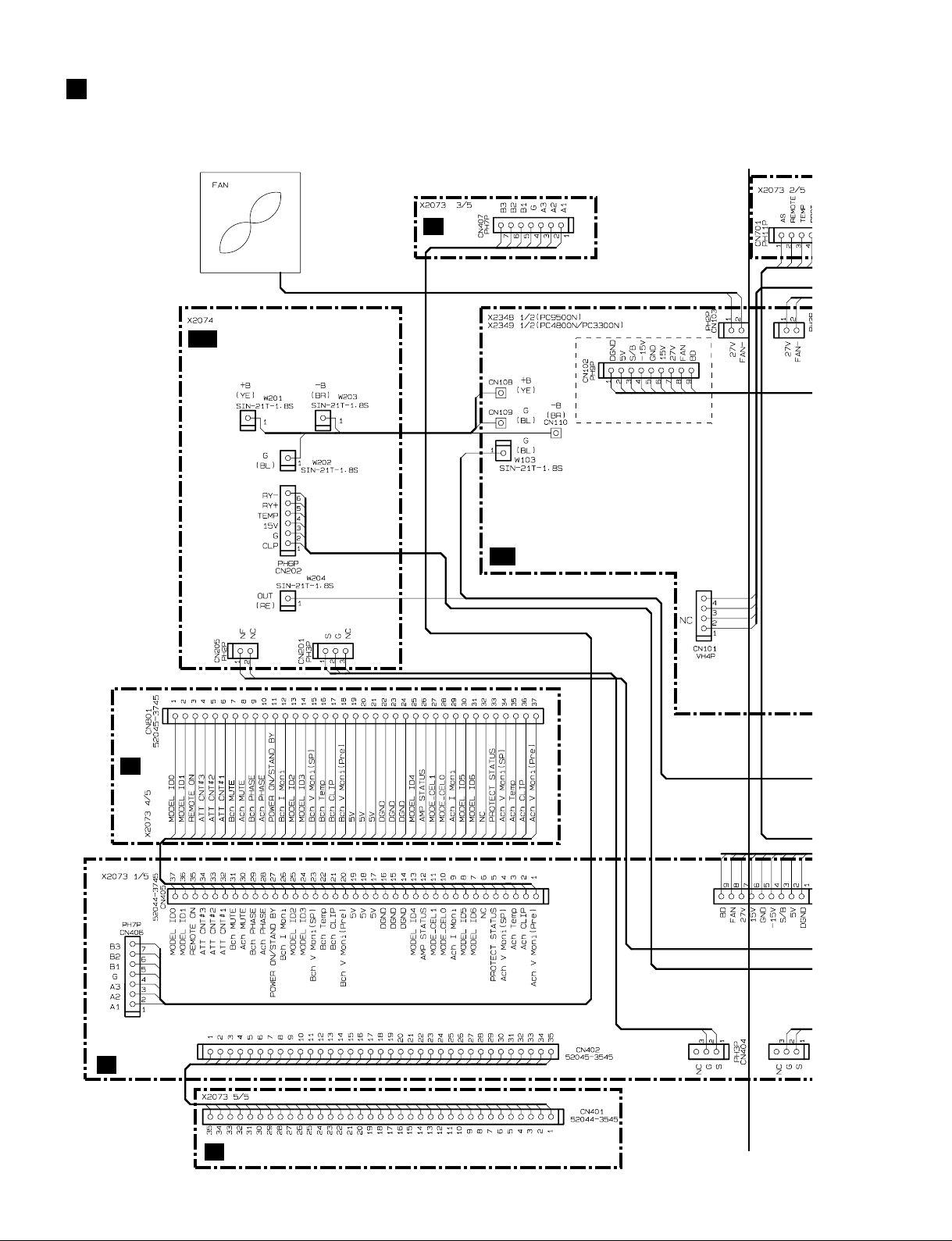

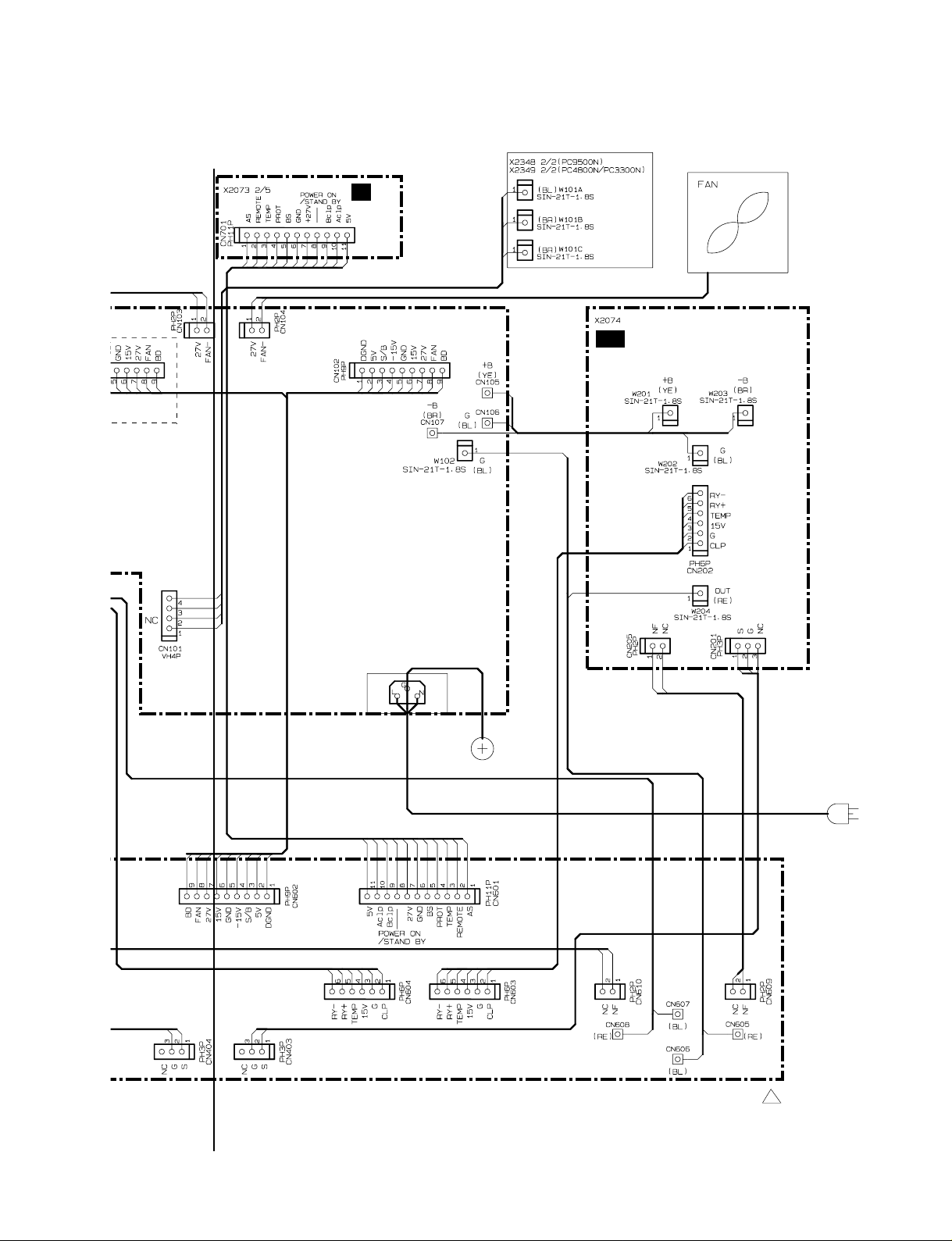

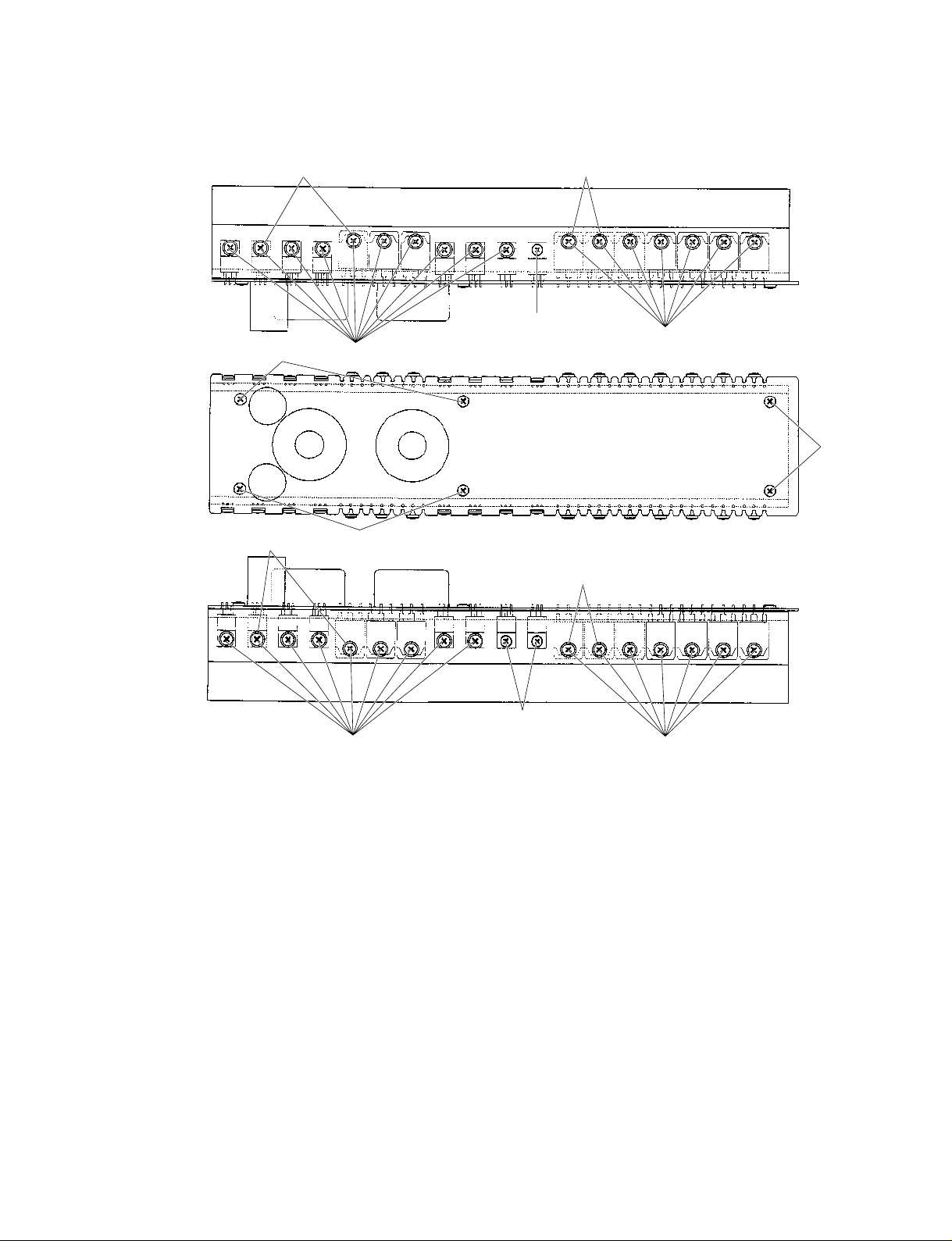

WIRING

(基板結線図)

B

IN 3/5

B ch

PA

PC4800N only

IN 4/5

PS

IN 1/5

IN 5/5

8

B'

0N only

PC9500N/PC4800N

B

IN 2/5

A ch

PA

38C99-8823966 2

B'

9

PC9500N/PC4800N

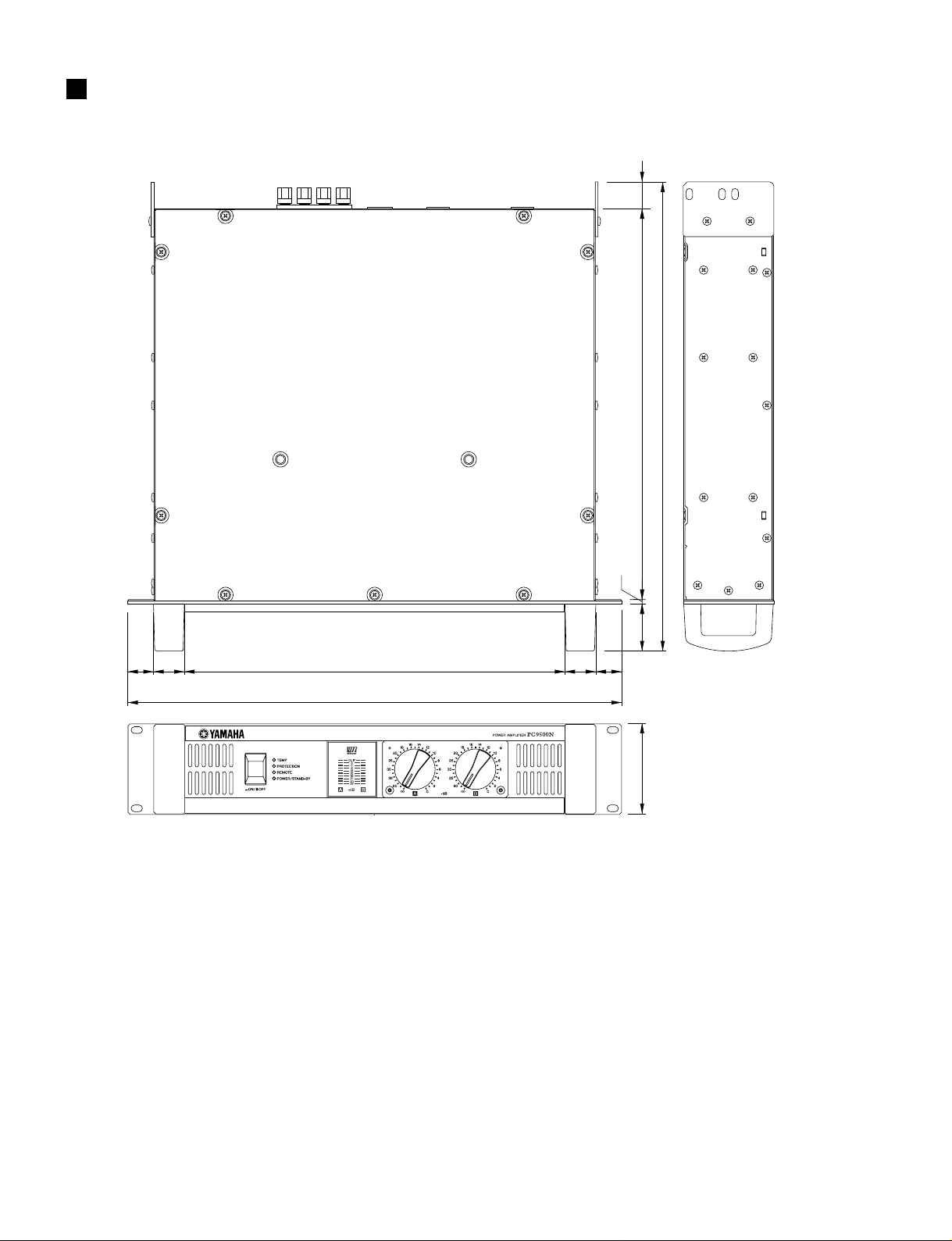

DIMENSIONS

(寸法図)

26

380

456

25 30 370 30 25

480

4

46

88

Units: mm

(単位)

10

PC9500N/PC4800N

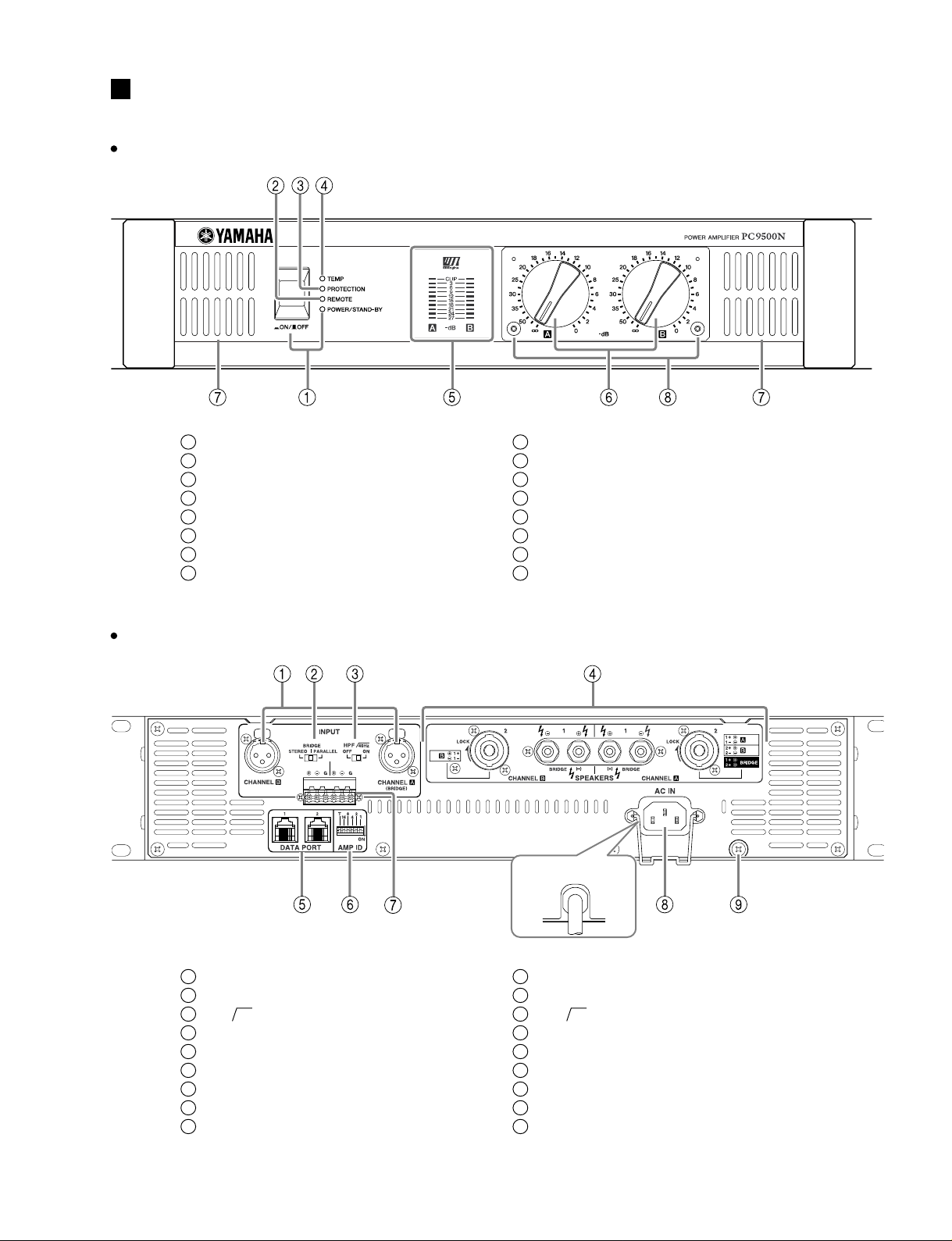

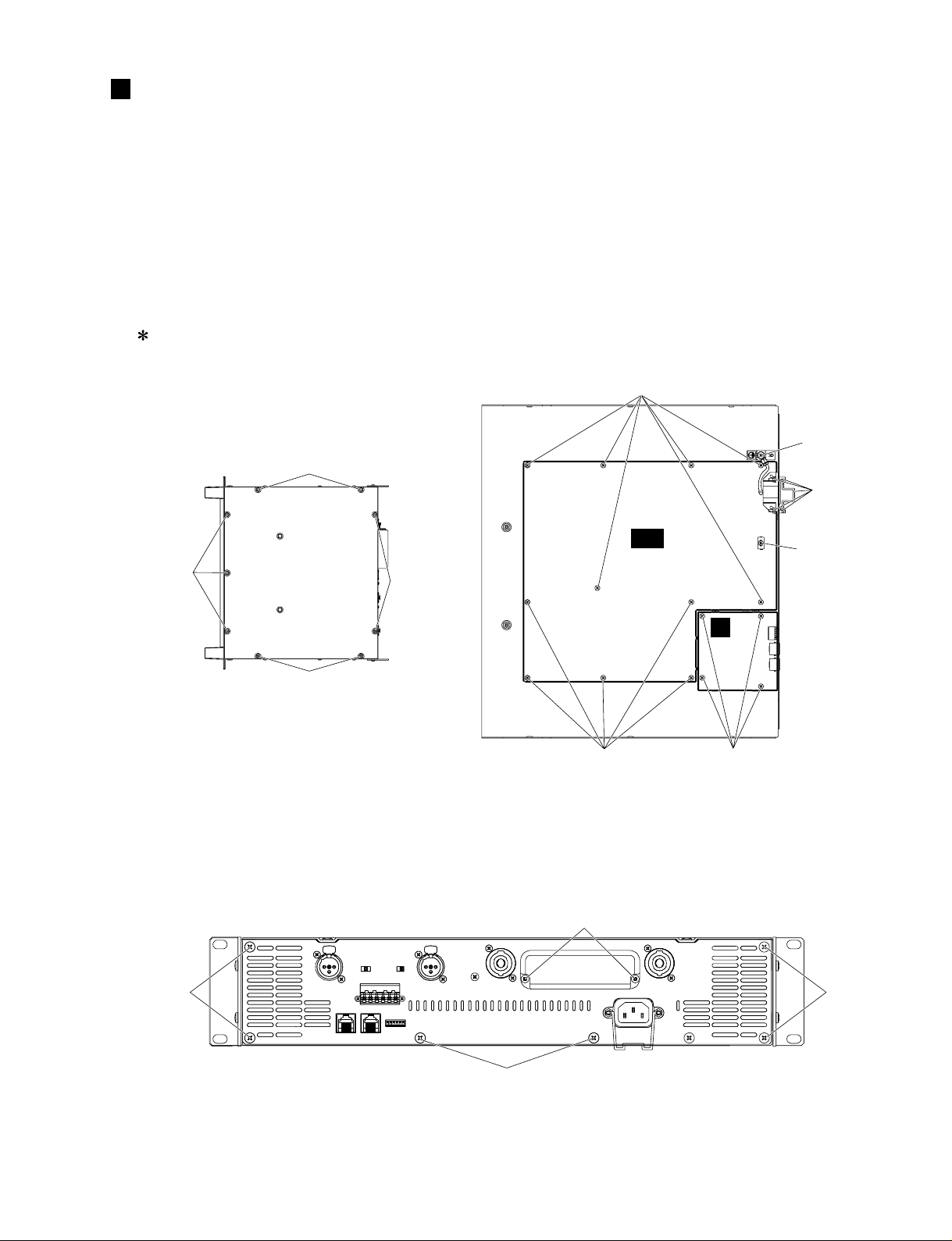

DISASSEMBLY PROCEDURE

(分解手順)

1. Top Cover (Time required: about 2 minutes)

1-1 Remove the nine (9) screws marked [260]. The top

cover can then be removed. (Fig. 1)

2. Rear Assembly (Time required: about 4 minutes)

2-1 Remove the top cover. (See Procedure 1.)

2-2 Remove the six (6) screws marked [220]. The rear

assembly can then be removed. (Fig. 2)

With PC9500N of the J specification, remove the

screw marked [70]. (Fig.1)

[260]

[260]

[260]

1. トップカバー(所要時間:約 2分)

1-1 [260]のネジ9本を外し、トップカバーを外します。

(Fig.1)

2. リア Assy(所要時間:約4分)

2-1 トップカバーを外します。(1項参照)

2-2 [220]のネジ6 本を外し、リア Assy を外します。

(Fig.2)

※PC9500N(J)仕向は[70]のネジを外します。(Fig.1)

[40b]

[70]

[65]

I/O Rock

PS 1/2

[90]

IN 4/5

[260]

[40b]

[40]: Bind Head Screw 3.0X4 MFZN2BL (VR139400)

[70]: Bind Head Screw 4.0X8 MFZN2BL A4.0X8 (VP156800)

[90]: Bind Head Screw 3.0X4 MFZN2BL (VR139400)

[260]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900)

+バインド小ネジ

+バインド小ネジ

+バインド小ネジ

ボンディングBタイト

Fig.1

[R310]

[220] [220]

[220]

[40a]

[220]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900)

[290]: Bind Head Screw 4.0X8 MFZN2BL (VP156800)

ボンディングBタイト

+バインド小ネジ

Fig.2

11

PC9500N/PC4800N

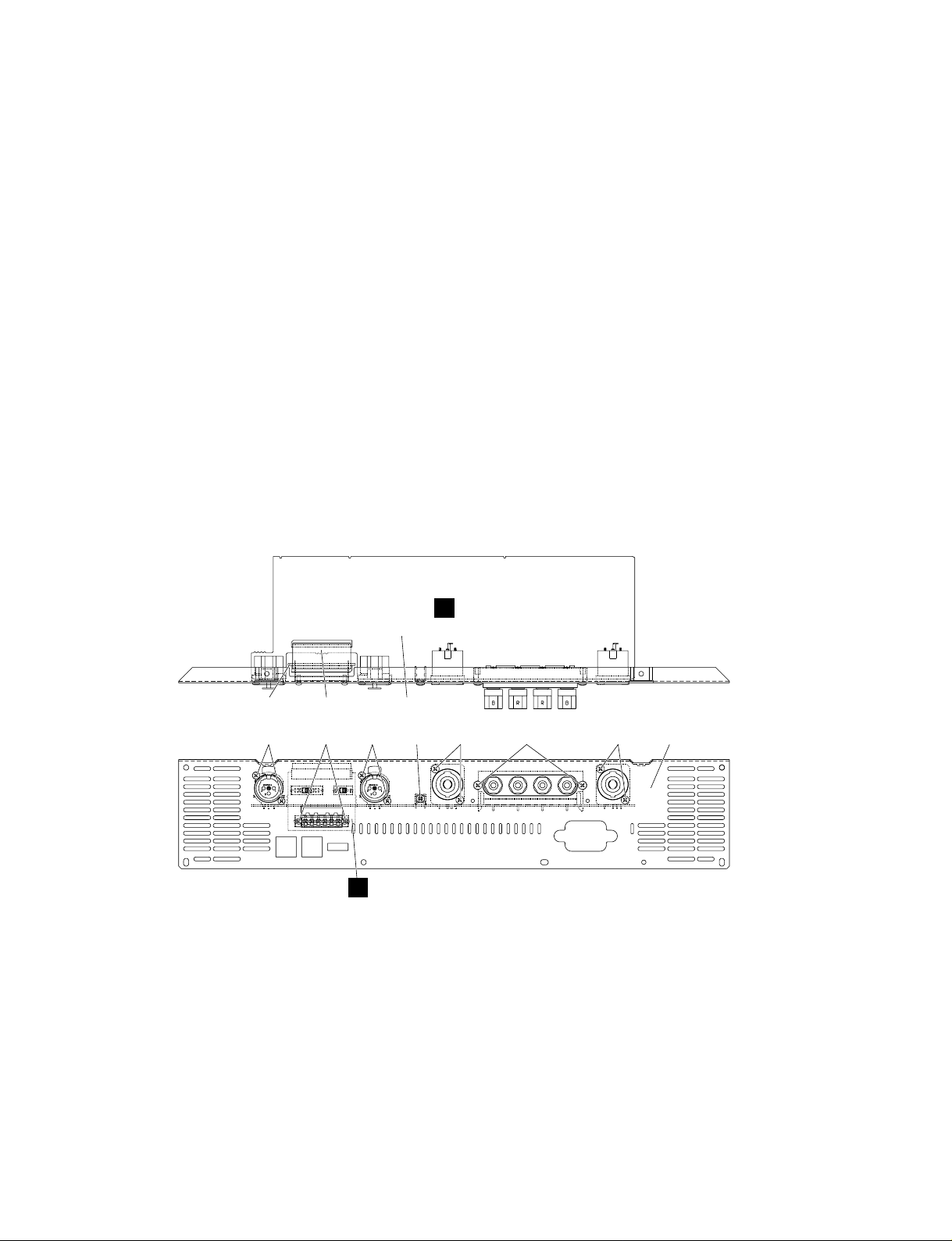

3. IN 1/5 Cir cuit Board (Time required: about 5 min utes)

3-1 Remove the top cover. (See Procedure 1.)

3-2 Remove the rear assembly. (See Procedure 2.)

3-3 Remove the two (2) screws marked [R310] and then

remove the SP terminal cover. (Fig. 2)

3-4 Remove the one (1) screw marked [R50] , two (2)

screws marked [R60] , four (4) scre ws marked [R70]

and four (4) screws marked [R75]. The IN 1/5 circuit

board can then be removed. (Fig. 3)

4. IN 4/5 Cir cuit Board (Time required: about 5 min utes)

4-1 Remove the top cover. (See Procedure 1.)

4-2 Remove the rear assembly. (See Procedure 2.)

4-3 Remove the four (4) screws marked [40a]. The IN 4/5

circuit board can then be removed. (Fig. 1)

5. IN 5/5 Circuit Board (Time required: about 3 minutes)

5-1 Remove the top cover. (See Procedure 1.)

5-2 Remove the two (2) screws marked [R40]. The IN 5/

5 circuit board can then be removed. (Fig. 3)

3. IN 1/5 シート(所要時間:約5分)

3-1 トップカバーを外します。(1項参照)

3-2 リア Assyを外します。(2項参照)

3-3 [R310]のネジ2本を外し、SPターミナルカバーを

外します。(Fig.2)

3-4 [R50]のネジ1本と、[R60]のネジ2本、[R70]のネジ4

本、[R75]のネジ4本を外し、IN1/5シートを外しま

す。(Fig.3)

4. IN 4/5 シート(所要時間:約5分)

4-1 トップカバーを外します。(1項参照)

4-2 リア Assyを外します。(2項参照)

4-3 [40a]のネジ4 本を外し、IN4/5シートを外します。

(Fig.1)

5. IN 5/5 シート(所要時間:約3分)

5-1 トップカバーを外します。(1項参照)

5-2 [R40]のネジ2 本を外し、IN5/5シートを外します。

(Fig.3)

IN 1/5

[R20a][R30][R20c]

[R70] [R70] [R50] [R75] [R75][R60] [R10]

[R40]

IN 5/5

[R40]: Pan Head Screw 2.6X6 MFZN2BL (VC990500)

[R50]: Bonding Tapping Screw-B 3.0X8 MFZN2BL (VN413300)

[R60]: Bind Head Tapping Screw-B 3.0X12 MFZN2BL (VQ074600)

[R70]: Bind Head Tapping Screw-B 2.6X8 MFZN2BL (VB096700)

[R75]: Flat Fillister H. Tapping 3.0X8 MFZN2BL (V9568800)

Fig.3

+ナベ小ネジ

ボンディングBタイト

+バインドBタイト

+バインドBタイト

+平頭Bタイト

6. Front Panel Assembly (Time required: about 4 minutes)

6-1 Remove the three (3) screws marked [190a] from

the side cover L, three (3) screws marked [190b]

from the side cover R and two (2) screws marked

[200]. The front panel assembly can then be

12

removed. (Fig. 4)

6. フロントパネル Assy(所要時間:約4分)

6-1 サイドカバーL[190a]のネジ3 本とサイドカバーR

[190b]のネジ3本を外し、[200]のネジ2本を外し、フ

ロントパネル Assyを外します。(Fig.4)

PC9500N/PC4800N

PS 1/2

IN 1/5

[190b]

Side Cover R

(サイドカバーR)

[170]

[170]

[190a]

[200]

Side Cover L

(サイドカバーL)

[F180]

[F30]

[F30] [F30]

[F30] Front cover

Front cover

[F180]

(フロントカバー)

(フロントカバー塗装上り)

[170]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900)

[190]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900)

[200]: Bind Head Screw 3.0X4 MFZN2BL (VR139400)

7. DC Fan (Time required: about 4 minutes)

7-1 Remove the top cover. (See Procedure 1.)

7-2 Remove the front panel assembly . (See Procedure 6.)

7-3 Remove the two (2) screws marked [F30] from the

DC fan and then remove the fan. Use the same for

both right and left fans. (Fig. 5)

8. Power Switch (Time required: about 8 minutes)

8-1 Remove the top cover. (See Procedure 1.)

8-2 Remove the front panel assembly . (See Procedure 6.)

8-3 Remove the DC fans. (See Procedure 7.)

8-4 Remove the four (4) screws marked [F180] and then

remove the two front covers. (Fig. 5)

8-5 Remove the six (6) screws marked [F150] and then

remove the front panel. (Fig. 6)

8-6 Remove the Power switch knob and the two (2)

screws marked [F40]. The power switch (PS 2/2

circuit board mount) can then be removed. (Fig. 6)

8-7 Remove the power switch from the PS 2/2 circuit

board.

ボンディングBタイト

ボンディングBタイト

+バインド小ネジ

Fig.4

7. DC ファン(所要時間:約4分)

7-1 トップカバーを外します。(1項参照)

7-2 フロントパネル Assyを外します。(6項参照)

7-3 DCファンの[F30]のネジ2本を外し、ファンを外し

ます。左右とも同じ方法で外せます。(Fig.5)

8. パワースイッチ(所要時間:約 8分)

8-1 トップカバーを外します。(1項参照)

8-2 フロントパネル Assyを外します。(6項参照)

8-3 DC ファンを外します。(7項参照)

8-4 [F180]のネジ4本を外し、フロントカバー及びフロ

ントカバー塗装上がりを 2ケ所外します。(Fig.5)

8-5 [F150]のネジ6本を外し、フロントパネルを外しま

す。(Fig.6)

8-6 PSWノブを外し、[F40]のネジ2本を外し、パワー

スイッチ(PS2/2シートにマウント)を外します。

(Fig.6)

8-7 PS2/2 シートからパワースイッチを外します。

[F30]: Bind Head Screw 4.0X30 MFZN2BL (VT229100)

[F180]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

Fig.5

+バインド小ネジ

+バインドBタイト

13

PC9500N/PC4800N

9. IN 2/5 Circuit Board (Time required: about 4 minutes)

9-1 Remove the top cover. (See Procedure 1.)

9-2 Remove the front panel assembly . (See Procedure 6.)

9-3 Remove the DC fans. (See Procedure 7.)

9-4 Remove the four (4) screws mark ed [F180] and then

remove the two front covers. (Fig. 5)

9-5 Remove the six (6) screws mark ed [F150] and then

remove the front panel. (Fig. 6)

9-6 Remove the two (2) scre ws marked [F70]. The IN 2/

5 circuit board can then be removed. (Fig. 6)

10. IN 3/5 Circuit Board (Time required: about 4 minutes)

10-1 Remove the top cover. (See Procedure 1.)

10-2 Remove the front panel assembly . (See Procedure 6.)

10-3 Remove the DC fans. (See Procedure 7.)

10-4 Remove the two front covers. (See Step 9-4.)

10-5 Remove the front panel. (See Step 9-5.)

10-6 Remove the two (2) knobs of attenuation A/B and

two (2) hexagonal nuts. The IN 3/5 circuit board can

then be removed. (Fig. 6)

[F150]

9. IN 2/5 シート(所要時間:約4分)

9-1 トップカバーを外します。(1項参照)

9-2 フロントパネル Assyを外します。(6項参照)

9-3 DC ファンを外します。(7項参照)

9-4 [F180]のネジ4本を外し、フロントカバー及びフロ

ントカバー塗装上がりを 2ケ所外します。(Fig.5)

9-5 [F150]のネジ6本を外し、フロントパネルを外しま

す。(Fig.6)

9-6 [F70]のネジ2本を外し、IN 2/5 シートを外しま

す。(Fig.6)

10. IN 3/5 シート(所要時間:約 4 分)

10-1 トップカバーを外します。(1項参照)

10-2 フロントパネル Assyを外します。(6 項参照)

10-3 DCファンを外します。(7項参照)

10-4 フロントカバー及びフロントカバー塗装上がりを2

ケ所外します。(9-4.項参照)

10-5 フロントパネルを外します。(9-5.項参照)

10-6 アッテネーターA/Bのツマミ2ケとVRの六角ナッ

ト2ケを外し、IN 3/5シートを外します。(Fig.6)

[F80]

IN 3/5

PS 2/2

[F60]

[F150]

[F40]: Bind Head Screw 3.0X6 MFZN2BL (EG330360)

[F70]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[F150]: Flat Head Screw 4.0X8 MFZN2BL (VA221200)

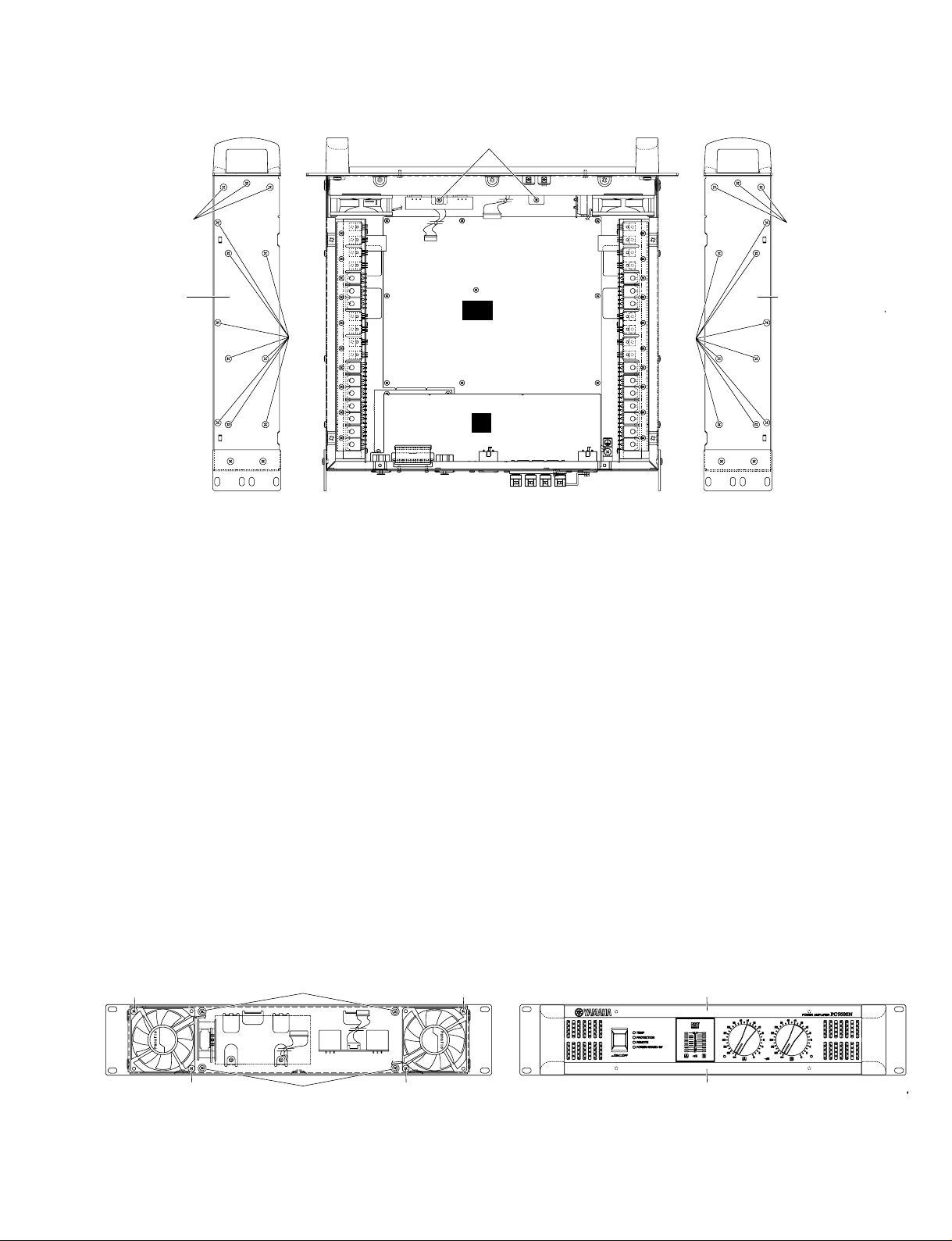

11. PA Unit (Time required: about 7 minutes)

11-1 Remove the rear assembly. (See Procedure 2.)

11-2 Remove the top cover. (See Procedure 1.)

11-3 Remove the nine (9) screws marked [170] and three

(3) screws marked [190]. The side co v er and PA unit

can then be removed. Use the same method f or both

A and B channels. (Fig. 4)

12. PA Circuit Board (Time required: about 11 minutes)

12-1 Remove the top cover. (See Procedure 1.)

12-2 Remove the PA unit. (See Procedure 11.)

12-3 Remove the screws fixing the pair transistor , FET and

diode marked [P70] (33 screws for PC9500N, 25

screws for PC4800N), three (3) screws mark ed [P76]

and six (6) screws marked [P40]. The PA circuit board

14

can then be removed. (Fig. 8)

Power Switch knob

(PSWノブ)

Fig.6

11. PA ユニット(所要時間:約 7 分)

11-1 リア Assyを外します。(2 項参照)

11-2 トップカバーを外します。(1項参照)

11-3 [170]のネジ9本と[190]のネジ 3 本を外し、サイド

12. PA シート(所要時間:約 11 分)

12-1 トップカバーを外します。(1項参照)

12-2 PA ユニットを外します。(11項参照)

12-3 ペアートランジスター、FET とダイオードの止め

[F10]

[F40]

(アッテネーターノブ)

[F70]

IN 2/5

+バインド小ネジ

+バインドBタイト

+皿小ネジ

Attenuation knob

Hexagonal nut

(六角ナット)

カバーを外し、PAユニットを外します。A,Bチャン

ネルとも同じ方法で外れます。(Fig.4)

ネジ[P70](PC9500N:33本、PC4800N:25 本)と

[P76]のネジ3 本、[P40]のネジ6本を外し、PAシー

トを外します。(Fig.7)

PC9500N/PC4800N

PA5: not installed

[P40]

PA5: not installed

PA5: not installed

[P76]

[P70]

[P70]

[P40]

[P40]

PA5: not installed

[P70]

[P40]: Bind Head Screw 3.0X6 MFZN2BL (EG330360)

[P70]: Bind Head Screw-SP 3.0X12 MFZN2Y (VB763800)

[P76]: Bind Head Screw-SP 2.6X8 MFZN2Y (EG320240)

13. PS Circuit Board

(Time required: about 8 minutes)

13-1 Remove the top cover. (See Procedure 1.)

13-2 Remove the front panel assembly . (See Procedure 6.)

13-3 Remove the rear assembly. (See Procedure 2.)

13-4 Remove the eleven (11) screws marked [40b], one

(1) screw marked [90] and one (1) screw marked

[70] and then release the I/O lock marked [65]. The

PS circuit board can then be removed. (Fig. 1)

[65]: PC9500N (J) is not used.

[P76]

[P70]

+バインド小ネジ

+バインド小ネジ

+バインド小ネジ

Fig.7

13. PS シート(所要時間:約 8 分)

13-1 トップカバーを外します。(1項参照)

13-2 フロントパネルAssyを外します。(6 項参照)

13-3 リアAssyを外します。(2 項参照)

13-4 [40b]のネジ11本と[90]のネジ1本と[70]のネジ1本

を外し、[65]のI/Oロックを外し、PSシートを外し

ます。(Fig.1)

[65]:PC9500N(J)は使用していません。

15

PC9500N/PC4800N

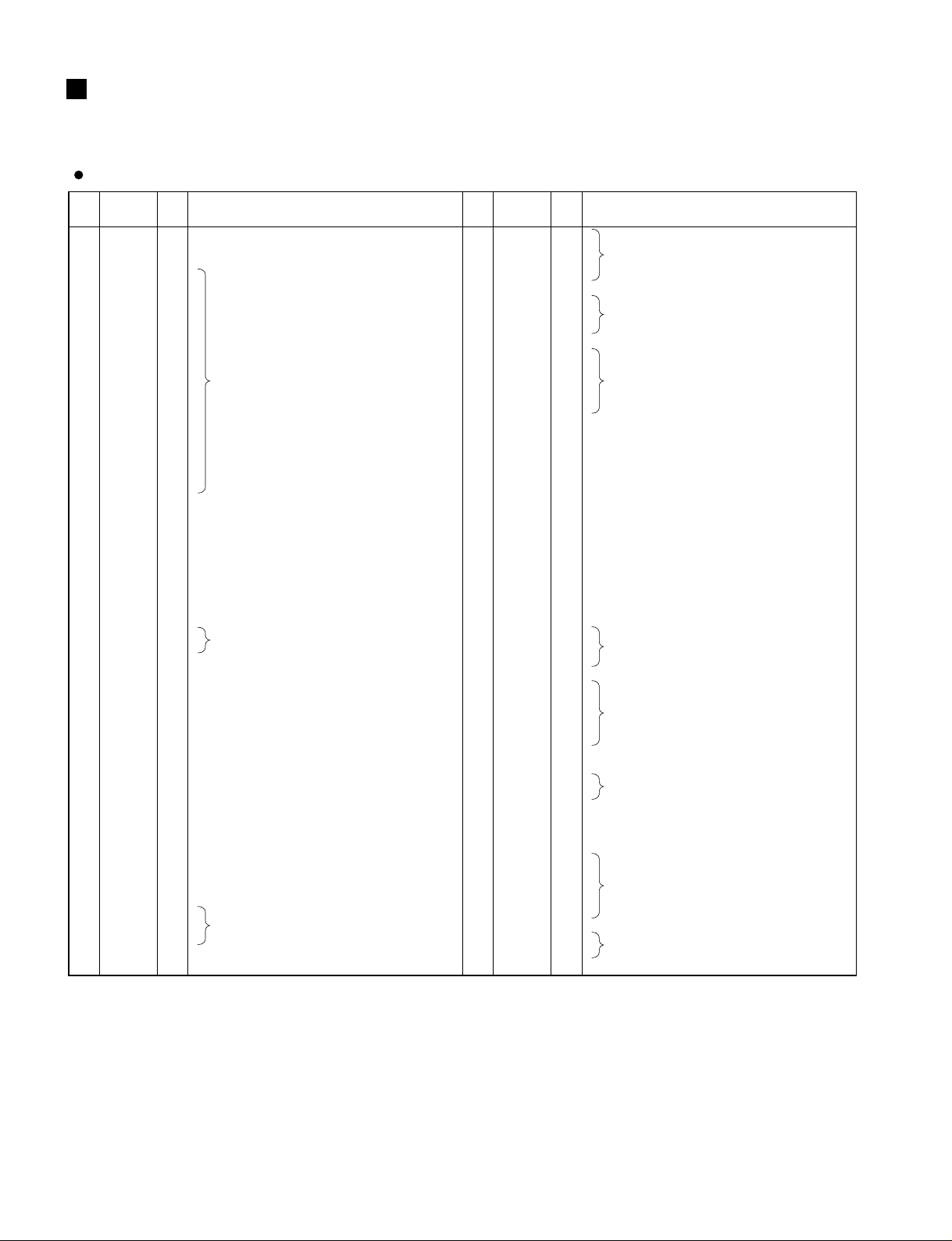

LSI PIN DESCRIPTION

(LSI端子機能表)

HD6437042AF28 (X2263100) CPU

PIN

NO.

1

TIOC4/DACK0/PE14

2

PE15

3

VSS

4

5

6

7

8

9

10

11

12

13

14

A10

15

A11

16

A12

17

A13

18

A14

19

A15

20

A16

21

VCC

22

A17

23

VSS

/RAS/PB2

24

/CASL/PB3

25

26

/CASH/PB4

27

VSS

28

/RDWR / PB5

A18//BACK/PB6

29

A19//BREQ/PB7

30

A20/PB8

31

A21/PB9

32

VSS

33

34

/RD

35

/WDTOVF

36

/WRH

VCC

37

/WRL

38

VSS

39

/CS1

40

/CS0

41

/IRQ3/TCLKD/PA9

42

TCLKC//IRQ2 /PA8

43

/CS3

44

/CS2

45

/IRQ1/PA5

46

TXD1

47

RXD1

48

/IRQ0/PA2

49

TXD0

50

RXD0

51

D15

52

D14

53

D13

54

VSS

55

D12

56

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

I/O FUNCTIONNAME

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

O

I/O

I/O

O

O

I/O

O

I/O

O

I/O

I/O

I/O

I/O

MTU I/O / DMA acknowledge / Port E

I

I

I

I

I

I

I

I

I

I

Port E

Ground

Address bus

Power supply

Address bus

Ground

Row address strobe / Port B

Column address strobe (low) / Port B

Column address strobe (high) / Port B

Ground

DRAM read / write / Port B

Address bus / Bus acknowledge / Port B

Address bus / Bus request / Port B

Address bus/ Port B

Ground

Read

Watch dog timer overflow

High write

Power supply

Low write

Ground

Chip select

Chip select

Interrupt request / Timer clock/ Port A

Timer clock / Interrupt request / Port A

Chip select

Chip select

Interrupt request / Port A

Data transmission

Data reception

Interrupt request / Port A

Data transmission

Data reception

Data bus

Ground

Data bus

PIN

NO.

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

PA15 / CK

84

PE0/DREQ0

85

PE1/DRAK0

86

87

88

89

90

PF0 / AN0

91

PF1 / AN1

92

PF2 / AN2

93

PF3 / AN3

94

PF4 / AN4

95

PF5 / AN5

96

97

PF6 / AN6

98

PF7 / AN7

99

100

101

102

103

104

105

106

107

108

109

110

111

112

D11

D10

D9

D8

VSS

D7

D6

D5

VCC

D4

D3

D2

D1

D0

VSS

XTAL

MD3

EXTAL

MD2

NMI

VCC

MD1

MD0

PLLVCC

PLLCAP

PLLVSS

/RES

PE2

PE3

PE4

VSS

AVSS

AVCC

VSS

PE5

VCC

PE6

PE7

PE8

PE9

PE10

VSS

PE11

PE12

/MRES

I/O FUNCTIONNAME

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

I/O

O

O

O

O

O

I/O

I/O

I/O

O

O

O

O

PC9500N IN10: IC801

PC4800N IN5: IC801

Data bus

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Ground

Data bus

Power supply

Data bus

Ground

Crystal oscillator

Mode control

Crystal oscillator

Mode control

Non-maskable interrupt request

Power supply

Mode control

Mode control

PLL Power supply

PLL capacitor

PLL Ground

Port A / Clock

Power on reset

Port E / DMA request

Port E / DMA acknowledge

Port E

Ground

Port F / Analog input

Analog ground

Port F / Analog input

Power supply

Ground

Port E

Power supply

Port E

Ground

Port E

Manual reset

16

PC9500N/PC4800N

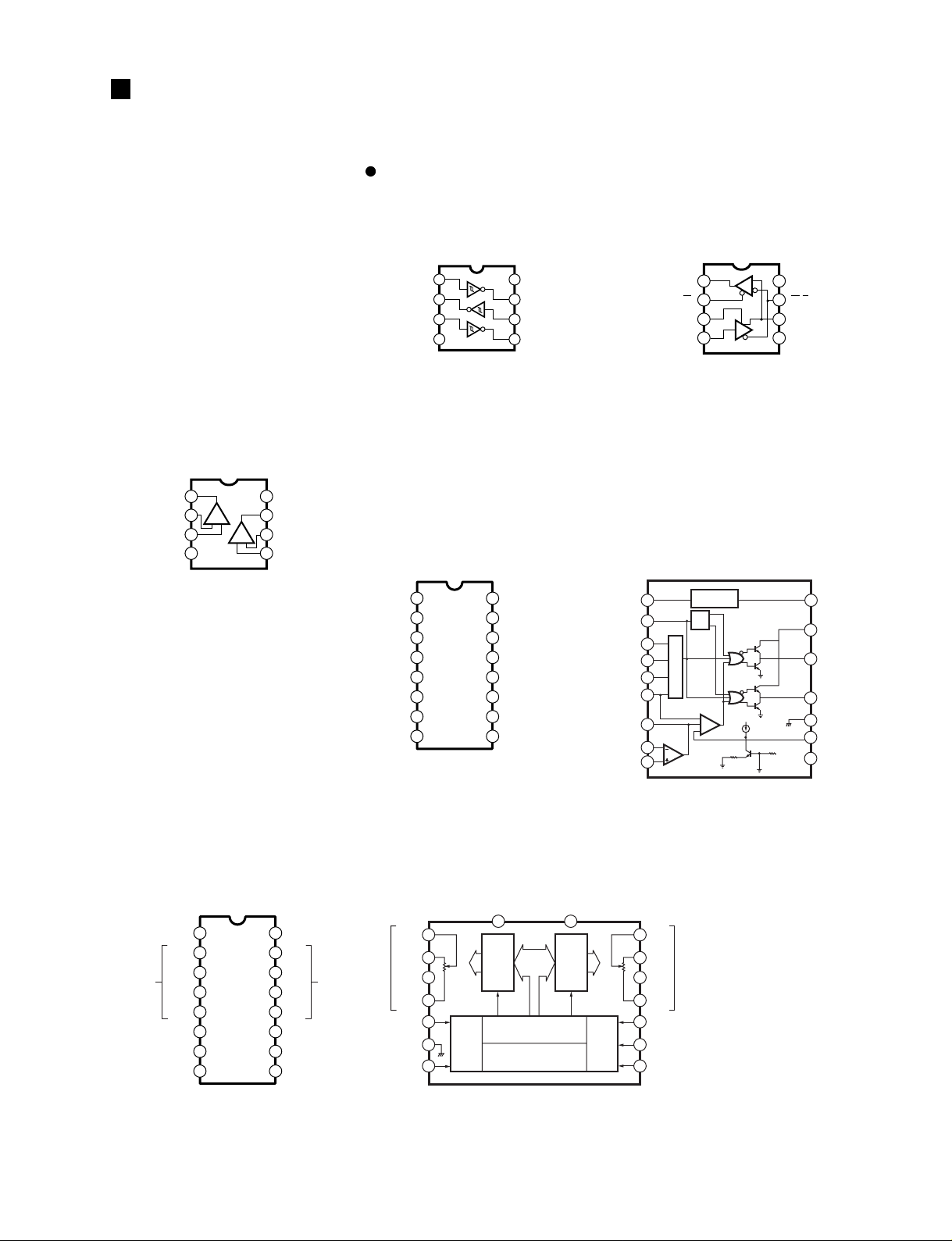

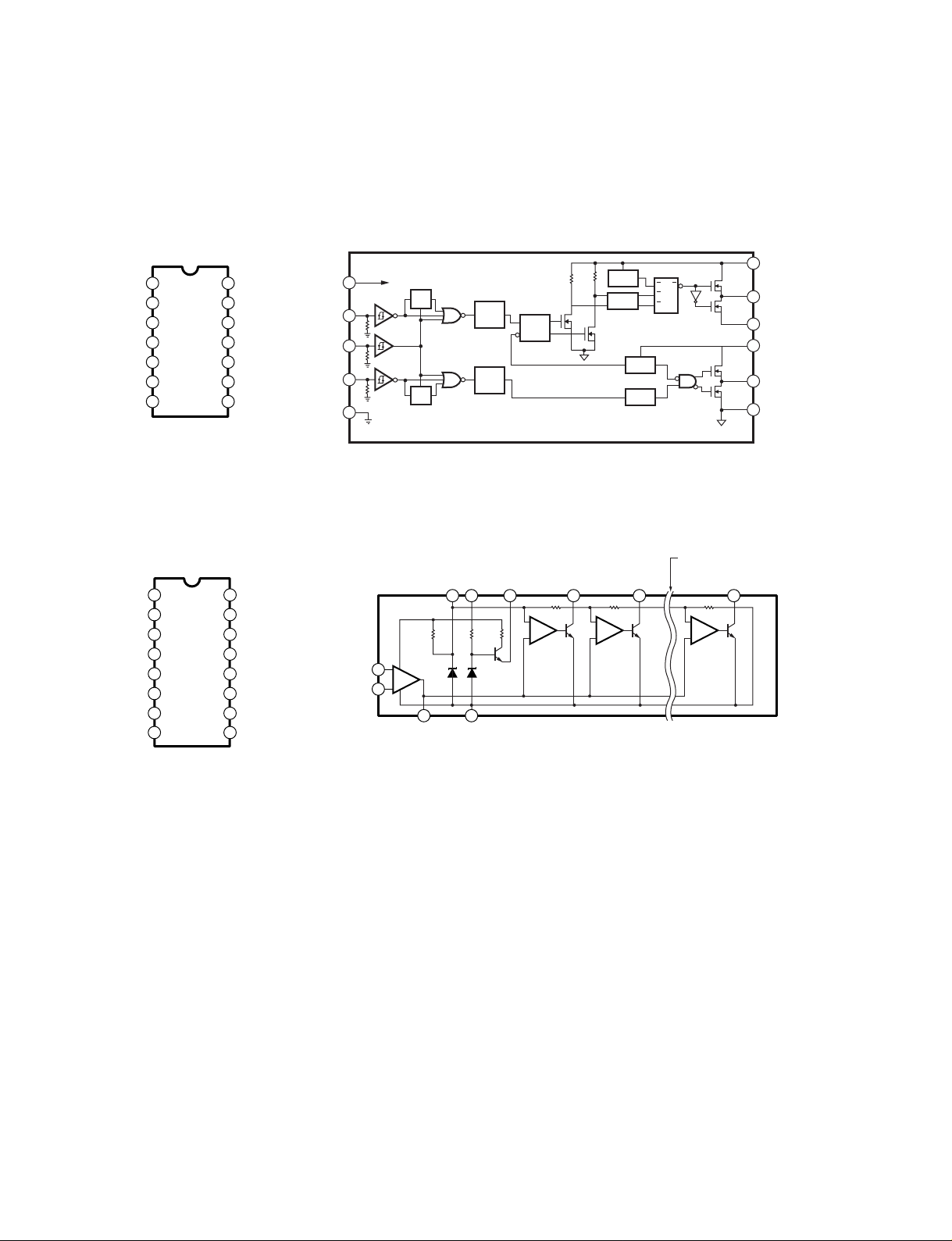

IC BLOCK DIAGRAM

●

NJM4558M(T1)

PC9500M IN10: IC601, IC602, IC603,

PC4800M IN5: IC601, IC602, IC603,

●

NJM2068MD-T1

PC9500M IN10: IC402, IC403, IC404,

PC4800M IN5: IC402, IC403, IC404,

●

M5238AFP

PC9500M IN10: IC401

PC4800M IN5: IC401

OP AMP

Output A

Inverting

Input A

Non-Inverting

Input A

Ground

(IG103520)

IC604, IC605, IC606

IC604, IC605, IC606

(XJ553A00)

IC405, IC406, IC407

IC405, IC406, IC407

(XL669A00)

1

2

+-

3

+-

4

8

7

6

5

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

(IC ブロック図)

TC7W14FU (XN883A00

PC9500M IN10: IC804

PC4800M IN5: IC804

INVERTER

1

2

3Y

2A

3

GND

4

●

SG3525AN

(X2383A00)

PC9500M PS10: IC101

PC4800M PS5: IC101

REGULATOR

81A

7

6

5

●

)

DS36276M

(X2155A00)

PC9500M IN10: IC802

PC4800M IN5: IC802

TRANSCEIVER

CC

Vcc

1Y

3A

2Y

1

RO

RE

DE

DI

R

2

3

D

4

V

8

DO/RI

7

6

DO/RI

GND

5

●

TC9413AP

(X2101A00)

PC9500M IN10: IC408

PC4800M IN5: IC408

VOLUME

1V

SS

2

OUT

3

IN

L-ch

A-GND

CS1

GND

4

NC

5

6

7

8

CK

IN

NC

A-GND

CS2

STB

DATA

DSCILLATDR

E/A

R-ch

REFERENCE

REGULATOR

FLIP/

FLOP

PWM

50µA

5K

+V

IN

13

V

C

A

B

11

OUTPUT A

14

OUTPUT B

GROUND

12

8

10

SOFT-START

SHUTDOWN

5K

1INV. INPUTN

2

N.I. INPUT

3

SYNC

OSC. OUTPUT

DISCHARGE

SOFT-START

DD

V

16

OUT

15

IN

14

13

12

11

10

R-ch

NC

A-GND

CS2

STB

9

DATA

4

5

C

T

6

R

T

7

8

2

OUT OUT

3

IN

L-ch

A-GND

GND

4

NC

5

6

CS1

CK

Level

7

circuit

8

16

15

14

13

12

11

10

9

Data latch

circuit

shift

REF

V

+V

IN

OUTPUT B

V

C

GROUND

OUTPUT A

SHUTDOWN

COMPENSATION

SS

V

1 16

L-ch

Shift register (13bit)

Strobe generation circuit

V

DD

R-ch

Data latch

circuit

V

OSC. OUTPUT

SYNC

DISCHARGE

COMPENSATION

INV. INPUTN

N.I. INPUT

Level

shift

circuit

16 15

REF

4

3

R

6

T

7

C

5

T

9

1

2

15

14

13

12

11

10

9

17

PC9500N/PC4800N

●

IR2110

(X2382A00)

PC9500M PS10: IC103,IC104

PC4800M PS5: IC103,IC104

DRIVER

1LC

2

COM

3

VCC

4

5

VS

6

VB

HC

7

6

UV

VDD

14

VSS

13

LIN

12

SD

11

HIN

10

9

VDD

8

9

Q

R

HIN

10

SD

11

14

LIN

VSS

15

S

S

Q

R

VDD/VCC

LEVEL

SHIFT

VDD/VCC

LEVEL

SHIFT

PULSE

PULSE

GEN

GEN

HV

LEVEL

SHIFT

DETECT

PULSE

FILTER

UV

DETECT

DELAY

R

Q

R

S

VB

7

HO

5

VS

3

CC

V

LO

1

COM

2

●

LB1409M

(X0654A00)

PC9500M IN10: IC701, IC702

PC4800M IN5: IC701, IC702

LED DRIVE

1VCC

2

Vref1

+

3

IN

V

–

4

V

IN

OUT

5

GND

6

D1

7

8D2

13, 12, 11, 10, 9, 8

R7(2.34K), R6(1.66K), R5(1.17K)

CC

16

Vref2

D9

15

D8

14

D7

13

D6

12

11

D5

D4

10

9

D3

+

3

VIN

–

4

V

IN

Vref 1 Vref 2V

5 6

OUT

2 1

R10

10K

GND

16 15

R20

5

D9

4.69K

R9

–

COM

+

98 1

3.31K

–

+

R8

COM

R4(830), R3(586), R2(414)

D8 D1

14 7

–

+

1K

R1

COM

18

PC9500N/PC4800N

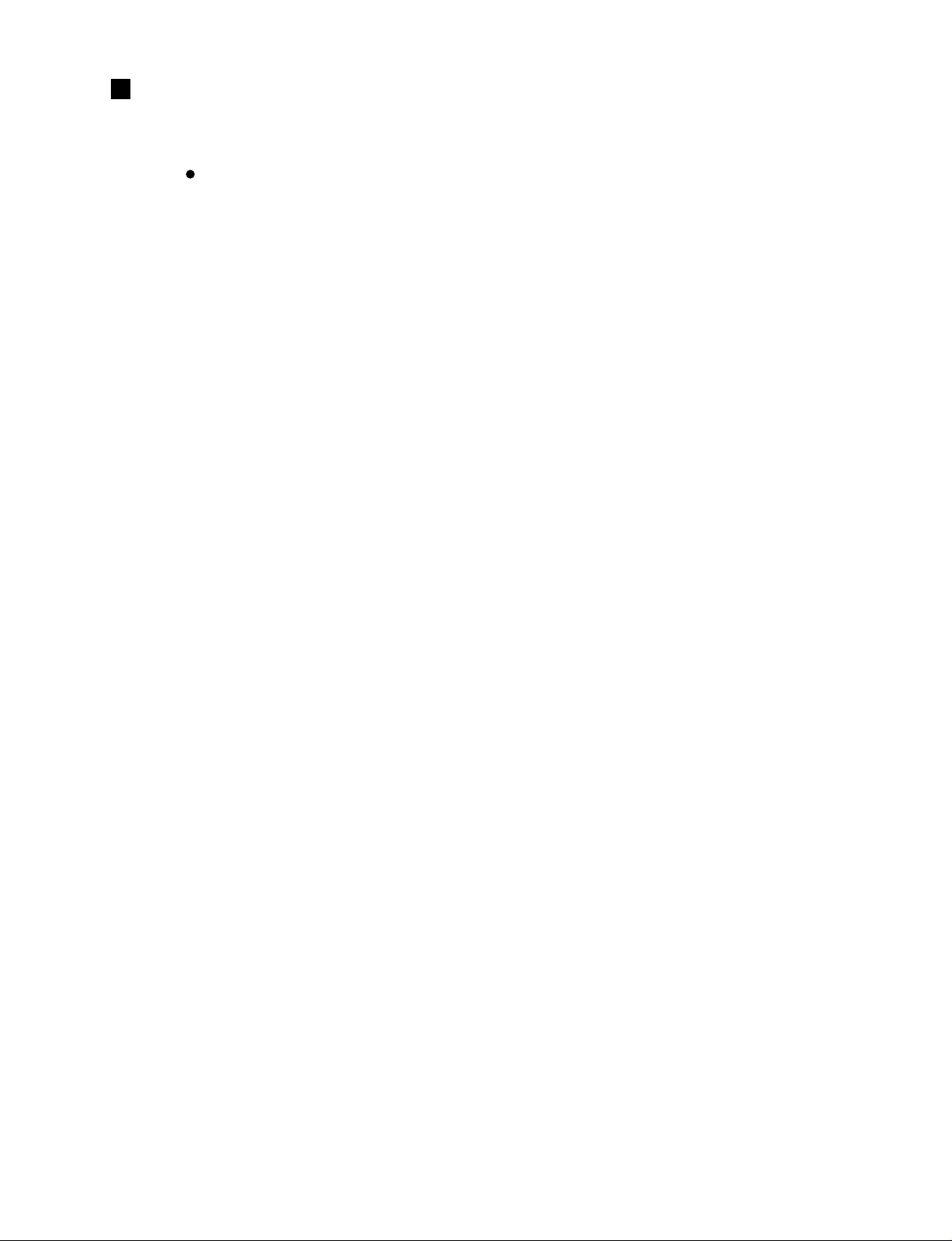

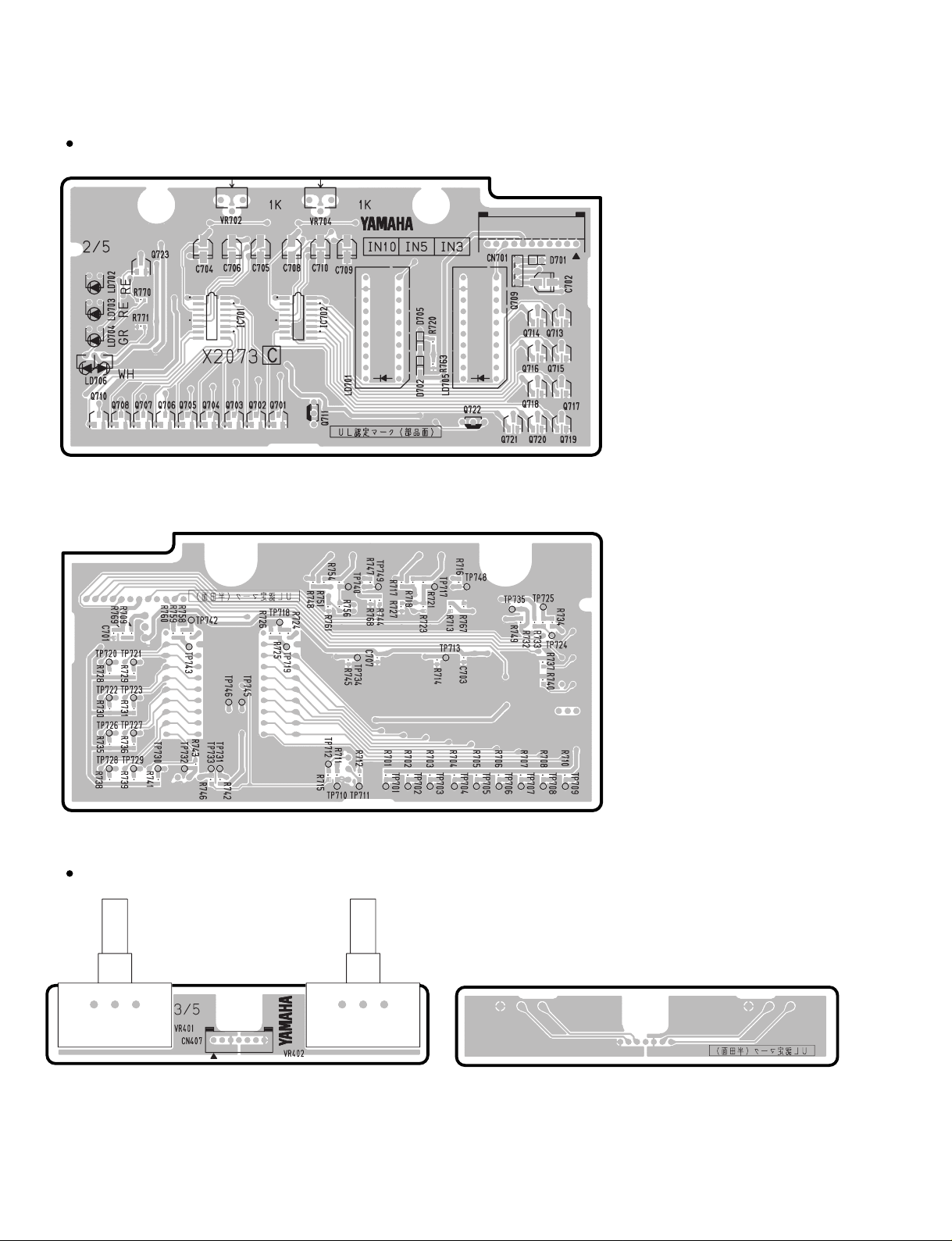

CIRCUIT BOARDS

CONTENTS

IN 1/5 Circuit Board (X2073C0)..................................................... 20

IN 2/5 Circuit Board (X2073C0)..................................................... 22

IN 3/5 Circuit Board (X2073C0)..................................................... 22

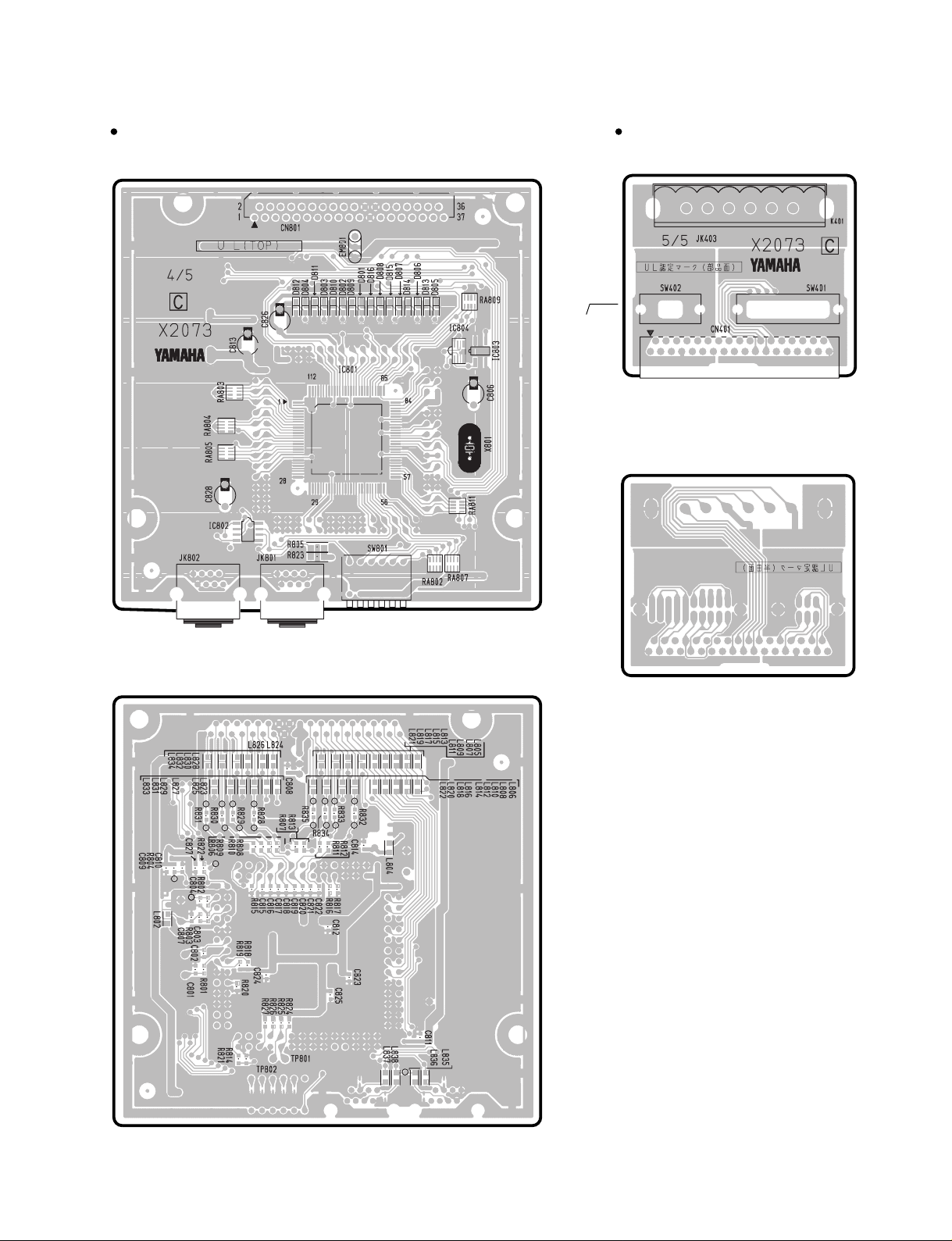

IN 4/5 Circuit Board (X2073C0)..................................................... 23

IN 5/5 Circuit Board (X2073C0)..................................................... 23

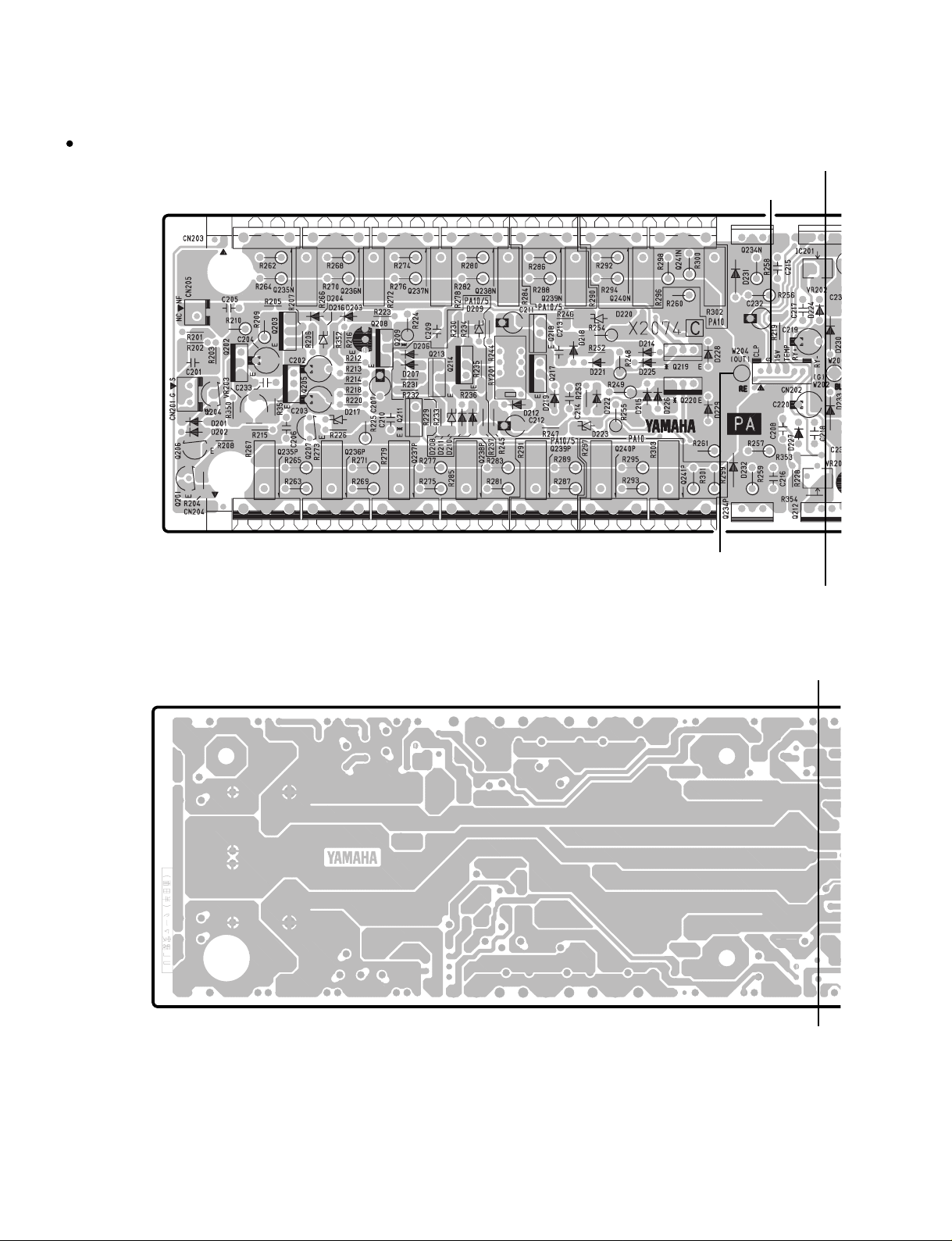

PA Circuit Board (X2074C0) ......................................................... 24

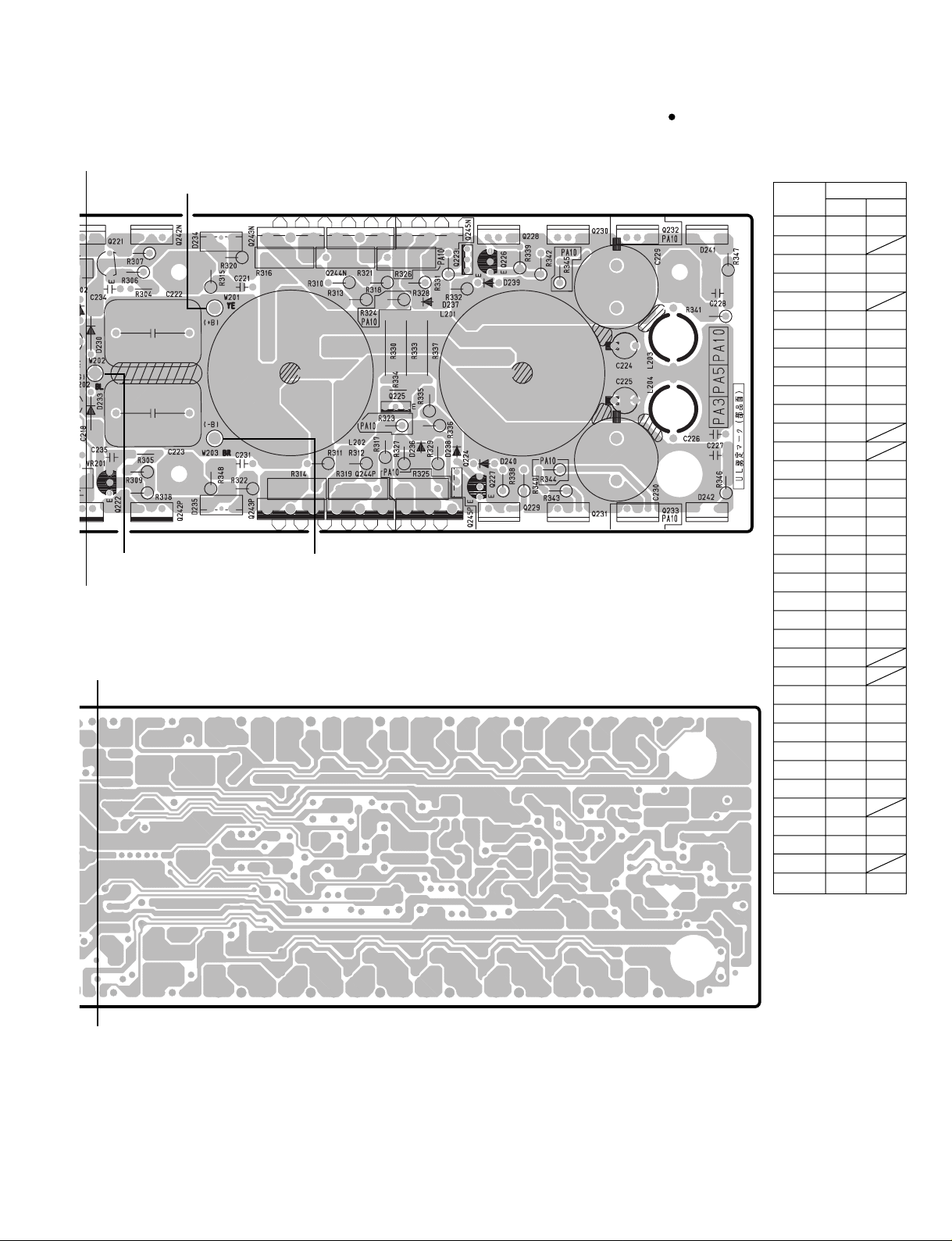

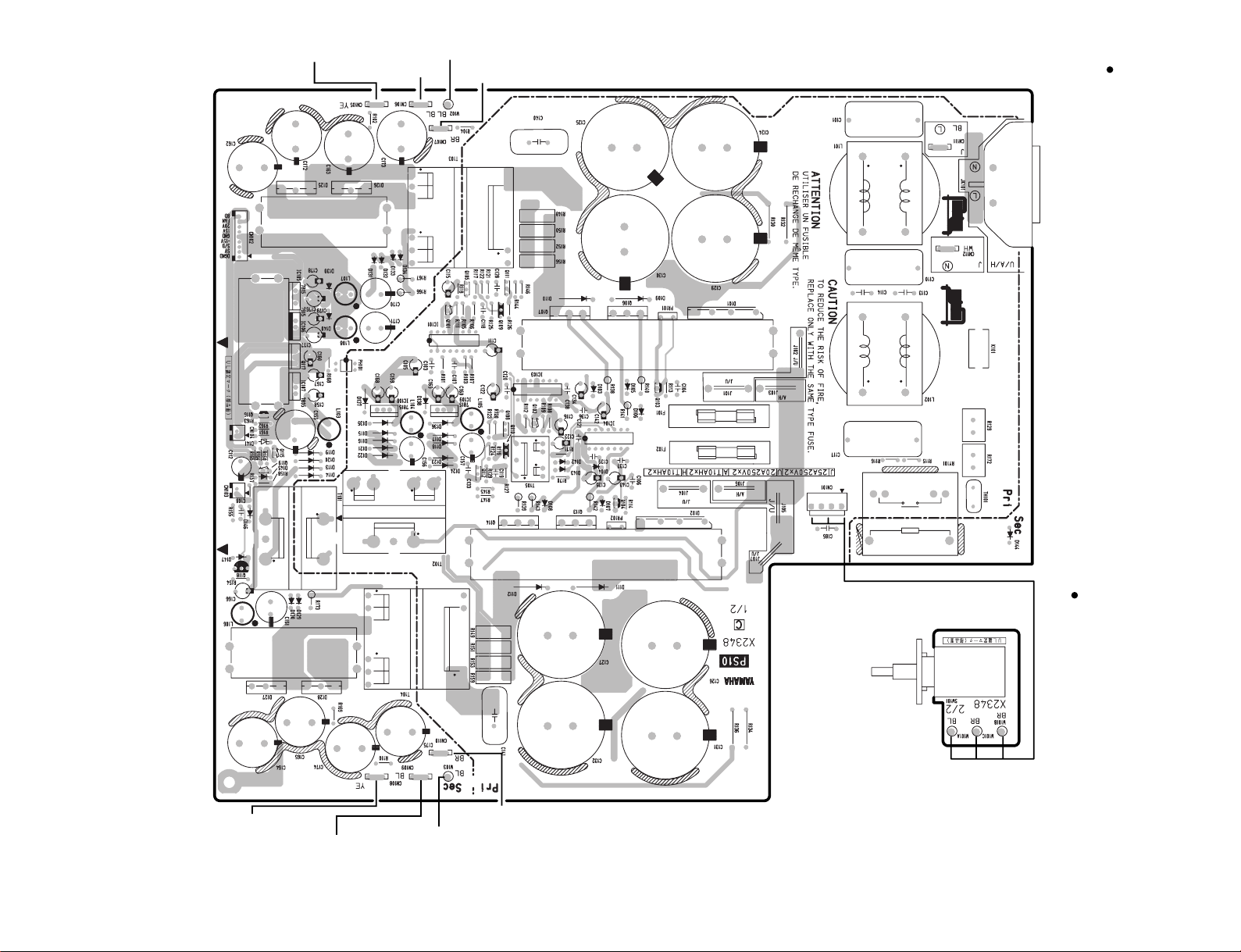

PS10 1/2 Circuit Board (X2348C0)................................................ 26

PS10 2/2 Circuit Board (X2348C0)................................................ 26

PS5 1/2 Circuit Board (X2349C0).................................................. 28

PS5 2/2 Circuit Board (X2349C0).................................................. 28

Note: See parts list for details of circuit board component parts.

注:シートの部品詳細はパーツリストをご参照下さい。

(目次)

(シート基板図)

19

PC9500N/PC4800N

f

o

IN 1/5 Circuit Board (PC9500N: IN10, PC4800N: IN5)

SPEAKERS

from PS-W102

from PS-W103

from PA ACH-CN205

from PA ACH-W204

A2 B2

--

OUTPUT

+

+

A

from PA BCH-W204

from PA ACH-CN205

GND

CN603: to PA ACH-CN202

CN601: to IN 2/5-CN701

CN604: t

CN602:

A'

B

20

B'

IN: 3NA-V848170

A

PA BCH-W204

ACH-CN205

B2 A

GND

PC9500N/PC4800N

B

from PA ACH-CN201

from PA BCH-CN201

CN402: to IN 5/5-CN401

CN406: to IN 3/5-CN407

CH-CN202

to IN 2/5-CN701

B

CN604: to PA BCH-CN202

CN602: from PS-CN102

A'

CN405: to IN 4/5-CN801

Component side

(部品側)

B'

IN: 3NA-V848170

Pattern side

(パターン側)

21

PC9500N/PC4800N

IN 2/5 Circuit Board

CN701: to IN 1/5-CN601

IN 3/5 Circuit Board

Component side

Pattern side

(パターン側)

(部品側)

22

CN407: to IN 1/5-CN406

Component side

(部品側)

Pattern side

(パターン側)

IN: 3NA-V848170

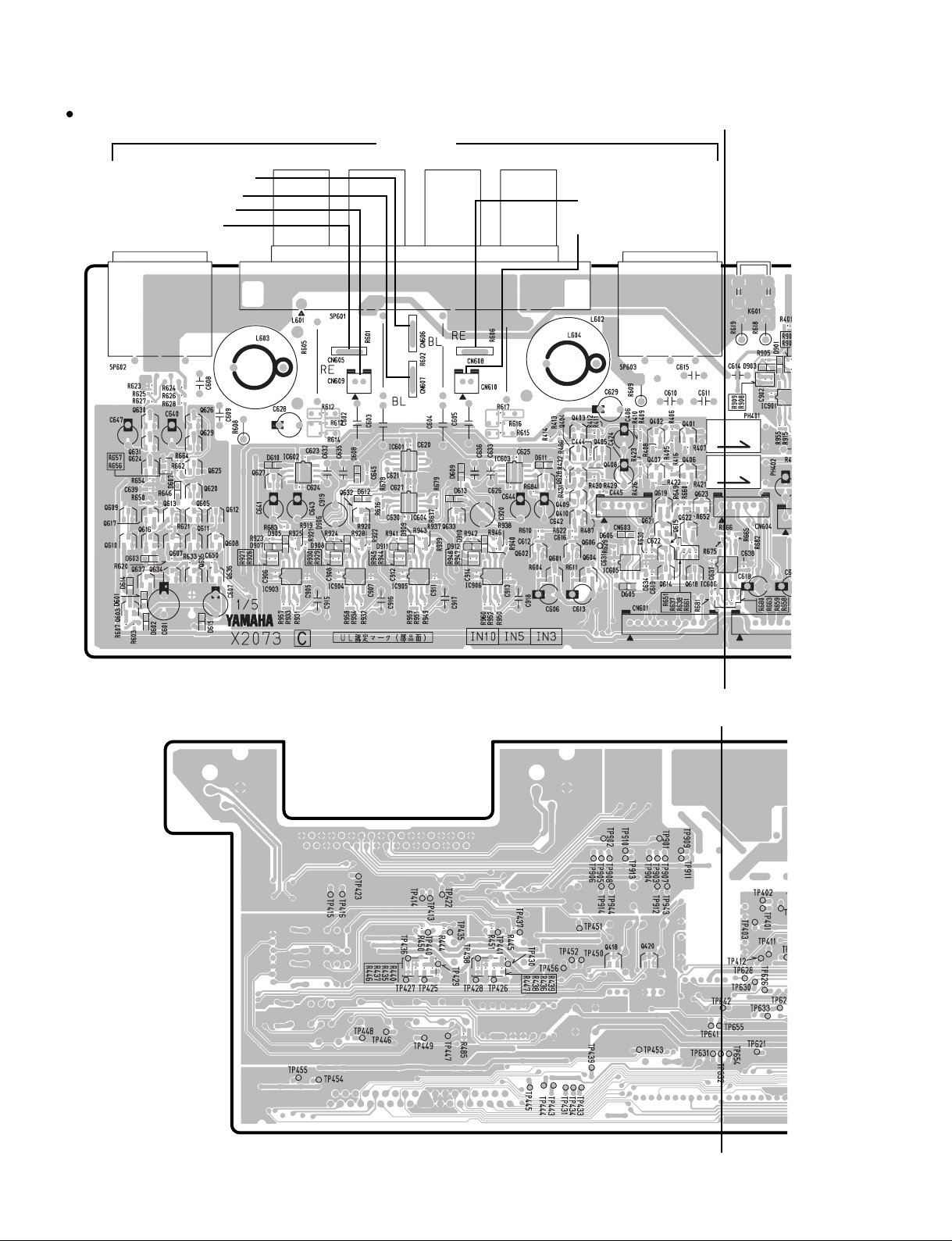

PC9500N/PC4800N

IN 4/5 Circuit Board

CN801: to IN 1/5-CN405

IN 5/5 Circuit Board

CHANNEL INPUT

HPF 40Hz BRIDGE

from IN 1/5-CN402

Component side

(部品側)

DATA PORT

AMP ID

Component side

(部品側)

Pattern side

(パターン側)

IN: 3NA-B848170

Pattern side

(パターン側)

23

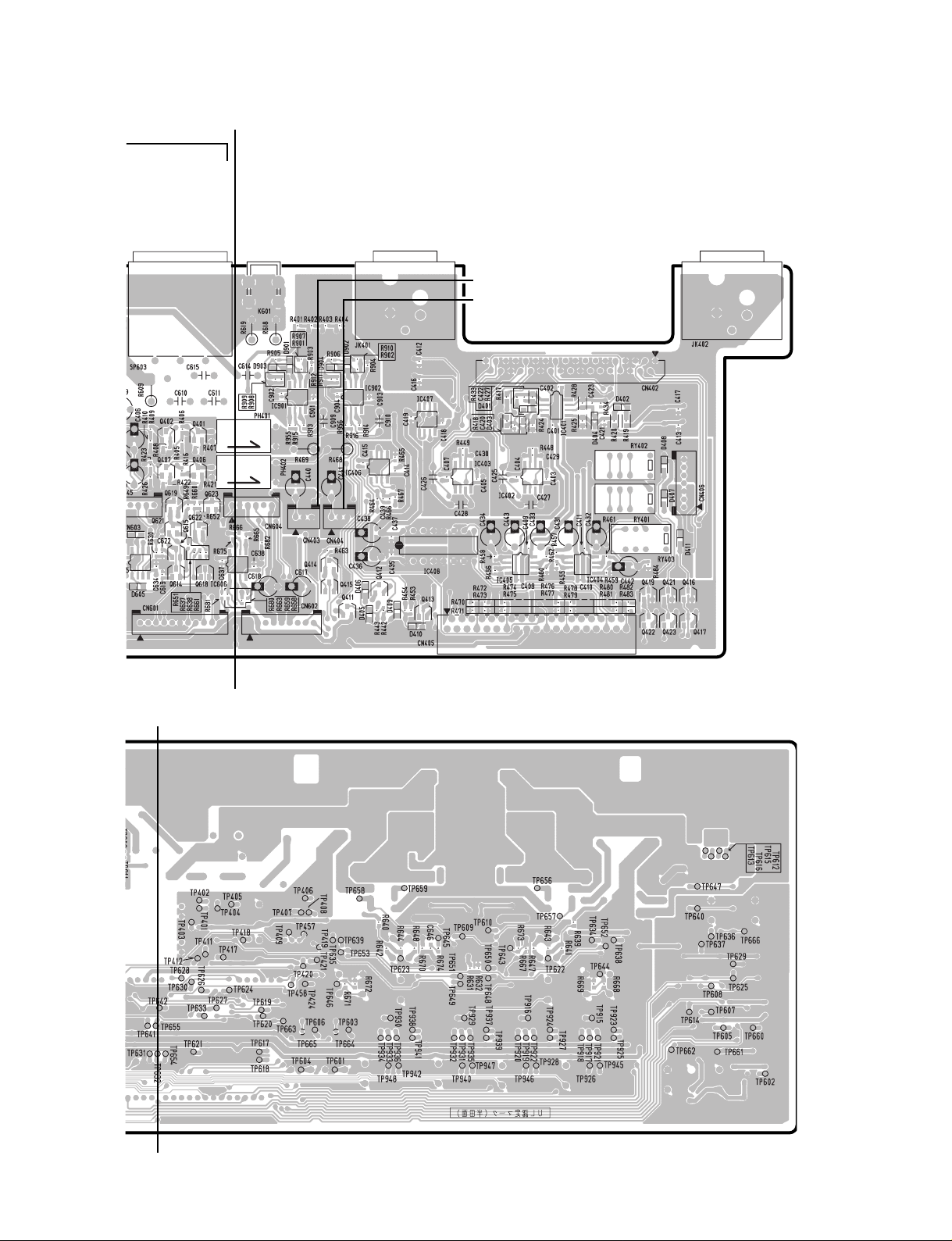

PC9500N/PC4800N

P

P

PA Circuit Board (PC9500N: PA10, PC4800N: PA5)

N.C

Q235N Q236N Q237N Q238N Q239N Q240N Q241N Q234N Q221N

PA ACH:

from IN 1/5

-CN609

PA BCH:

from IN1/5

-CN610

PA ACH:

from IN 1/5

-CN403

PA BCH:

from IN 1/5

-CN404

PA ACH: from IN 1/5-CN603

PA BCH: from IN 1/5-CN604

C

Q235P Q236P Q237P Q238P Q239P Q240P Q241P Q234P Q212

N.C

PA ACH: to IN 1/5-CN605

PA BCH: to IN 1/5-CN608

C'

D

24

D'

PA: 3LP-X2074A0

C

PA ACH: to PS-CN105

PA BCH: to PS-CN108

Q242N Q243N Q243N Q244N Q245N Q228 Q230 Q232 D241

Q242P Q243P Q243P Q244P Q245P Q229 Q231 Q233 D242

PA ACH: to PS-CN106

PA BCH: to PS-CN109

C'

D

PA ACH: to PS-CN107

PA BCH: to PS-CN110

Following semi-conductors

are installed for the PA unit.

(下記半導体はPAユニットで取付さ

れます。)

Component side(部品側)

PC9500N/PC4800N

Circuit board

ref.

PA10 PA5

D242

Q233

Q231

Q229

Q245P

Q244P

Q243P

D235

Q242P

Q212

Q234P

Q241P

Q240P

Q239P

Q238P

Q237P

Q236P

Q235P

Q235N

Q236N

Q237N

Q238N

Q239N

Q240N

Q241N

Q234N

IC201

Q242N

D234

Q243N

Q244N

Q245N

Q228

Q230

Q232

D241

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

D'

PA: 3LP-X2074A0

Pattern side

(パターン側)

25

26

AC IN

from PA ACH-W203

to IN 1/5-CN606

from PA ACH-W202

from PA ACH-W201

to IN10 1/5

-CN602

from FAN ACH

from FAN BCH

from PA BCH-W203

to IN10 1/5-CN607

from PA BCH-W201

POWER ON/OFF

from PA BCH-W202

PC9500N/PC4800N

PS10 1/2 Circuit Board (PC9500N)

Component side(部品側)

(PC9500N)

PS10 2/2 Circuit Board

PS10: 3LP-X2348A0

Component side(部品側)

Loading...

Loading...