Page 1

SUBWOOFER

NS-SW300/NS-SW200

SERVICE MANUAL

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifi cally Yamaha Products, are already known

and understood by the users, and have therefore not been restated.

WARNING:

IMPORTANT:

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifi cations are, therefore, inevitable and specifi cations

are subject to change without notice or obligation to retrofi t. Should any discrepancy appear to exist, please contact the distributor's

Service Division.

WARNING:

IMPORTANT:

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specifi ed. For these reasons, we advise

all Yamaha product owners that any service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

The presentation or sale of this manual to any individual or fi rm does not constitute authorization, certifi cation or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL ............................................2

FRONT PANELS ............................................................. 3

REAR PANELS ...........................................................4–8

SPECIFICATIONS /

INTERNAL VIEW .......................................................... 11

SERVICE PRECAUTIONS /

DISASSEMBLY PROCEDURES /

参考仕様

................................... 8–10

サービス時の注意事項

分解手順

........... 13–16

.....12

IMPORTANT NOTICE

BLOCK DIAGRAMS ................................................17–18

WIRING DIAGRAMS .....................................................19

PRINTED CIRCUIT BOARDS .................................20–27

PIN CONNECTION DIAGRAMS ...................................28

SCHEMATIC DIAGRAMS ....................................... 29–30

REPLACEMENT PARTS LIST ................................ 31–45

NS-SW300/NS-SW200

101279

Copyright (c) Yamaha Corporation All rights reserved.

This manual is copyrighted by Yamaha and may not be copied or

redistributed either in print or electronically without permission.

P.O.Box 1, Hamamatsu, Japan

'13.12

Page 2

NS-SW300/NS-SW200

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked ⚠ and

must be replaced with parts having specifications equal to those

originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

• Meter impedance should be equivalent to 1500 ohms shunted

by 0.15 μF.

For U model

“CAUTION”

NS-SW300 “F1: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE 6A, 125V FUSE.”

NS-SW200 “F1: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE 3A, 125V FUSE.”

For C model

CAUTION

NS-SW300 F1: REPLACE WITH SAME TYPE 6A, 125V FUSE.

NS-SW200 F1: REPLACE WITH SAME TYPE 3A, 125V FUSE.

ATTENTION

NS-SW300 F1: UTILISER UN FUSIBLE DE RECHANGE DE MÉME TYPE DE 6A, 125V.

NS-SW200 F1: UTILISER UN FUSIBLE DE RECHANGE DE MÉME TYPE DE 3A, 125V.

WALL

OUTLET

• Leakage current must not exceed 0.5mA.

• Be sure to test for leakage with the AC plug in both polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive

harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or

expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

About lead free solder /

All of the P.C.B.s installed in this unit and solder joints are

soldered using the lead free solder.

Among some types of lead free solder currently available,

it is recommended to use one of the following types for

the repair work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

NS-SW300/NS-SW200

Caution:

As the melting point temperature of the lead free solder

is about 30°C to 40°C (50°F to 70°F) higher than that of

the lead solder, be sure to use a soldering iron suitable

to each solder.

無鉛ハンダについて

本機に搭載されているすべての基板およびハンダ付けに

よる接合部は無鉛ハンダでハンダ付けされています。

無鉛ハンダにはいくつかの種類がありますが、修理時に

は下記のような無鉛ハンダの使用を推奨します。

Sn+Ag+Cu(錫+銀+銅)

Sn+Cu(錫 + 銅)

Sn+Zn+Bi(錫 + 亜鉛 + ビスマス)

注意:

無鉛ハンダの融点温度は通常の鉛入りハンダに比べ 30 〜

40℃程度高くなっていますので、それぞれのハンダに合っ

たハンダごてをご使用ください。

2

Page 3

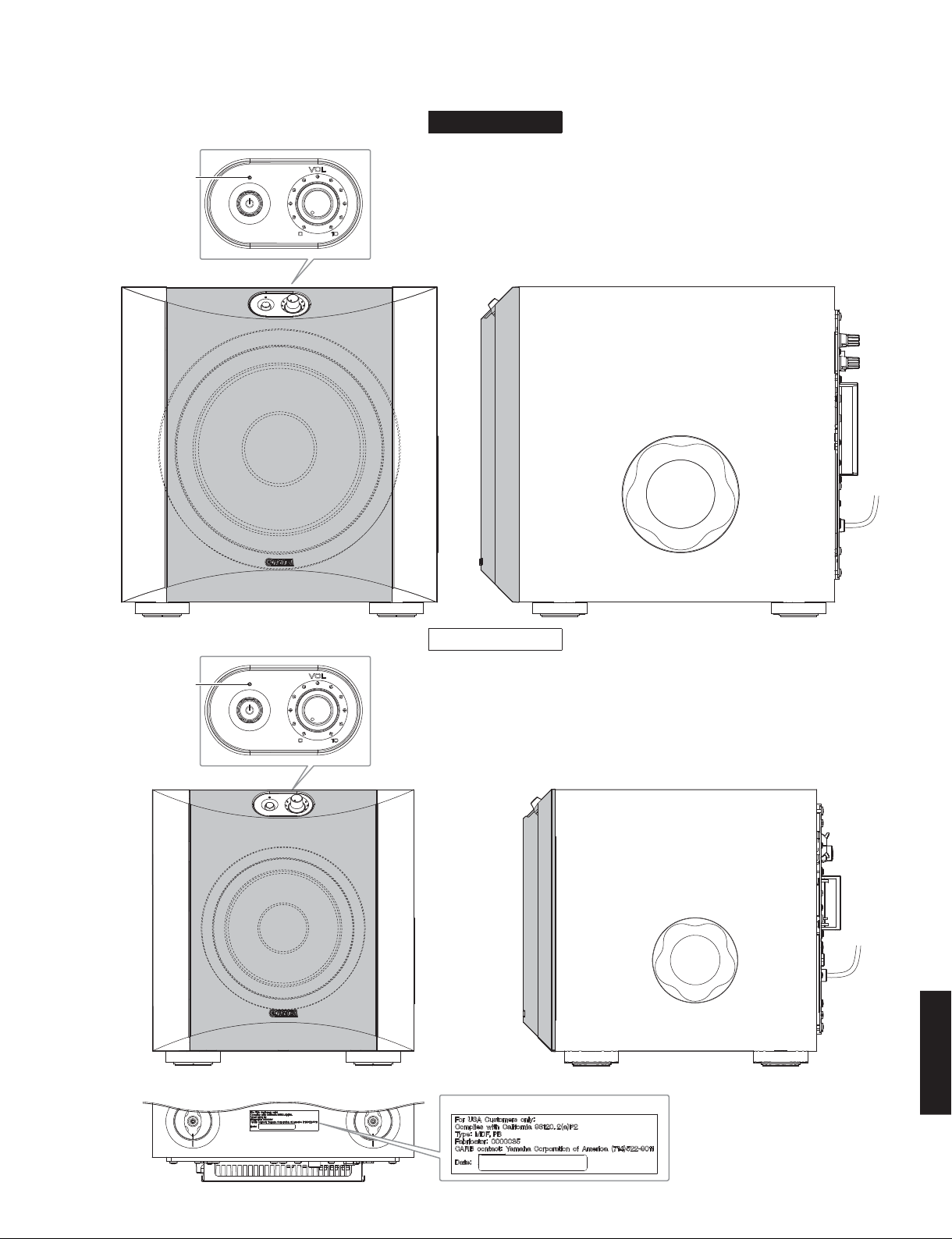

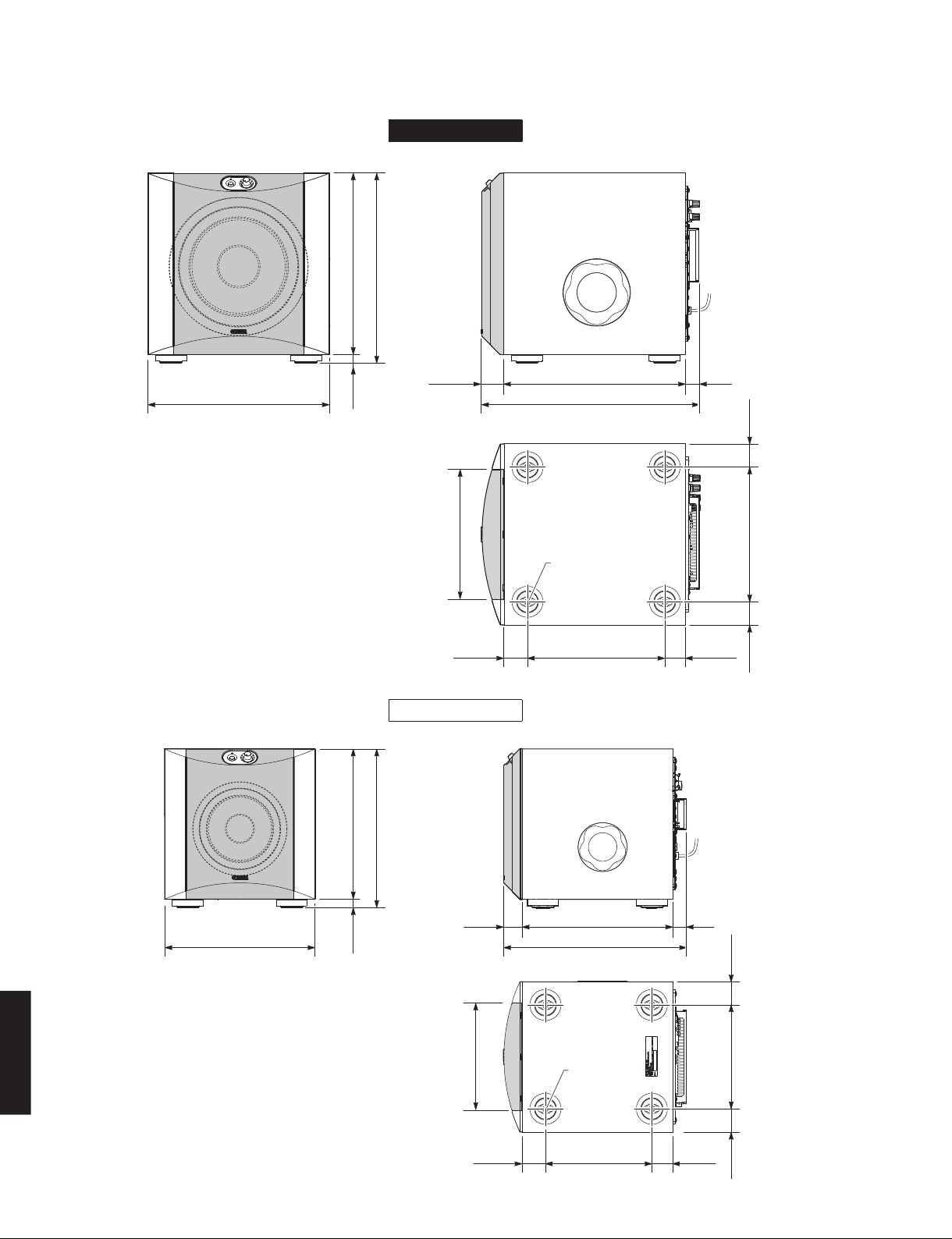

■ FRONT PANELS

NS-SW300

Indicator

インジケーター

Front view Side view

NS-SW300/NS-SW200

Indicator

インジケーター

Front view

Bottom view

NS-SW200

Side view

NS-SW300/NS-SW200

U model

3

Page 4

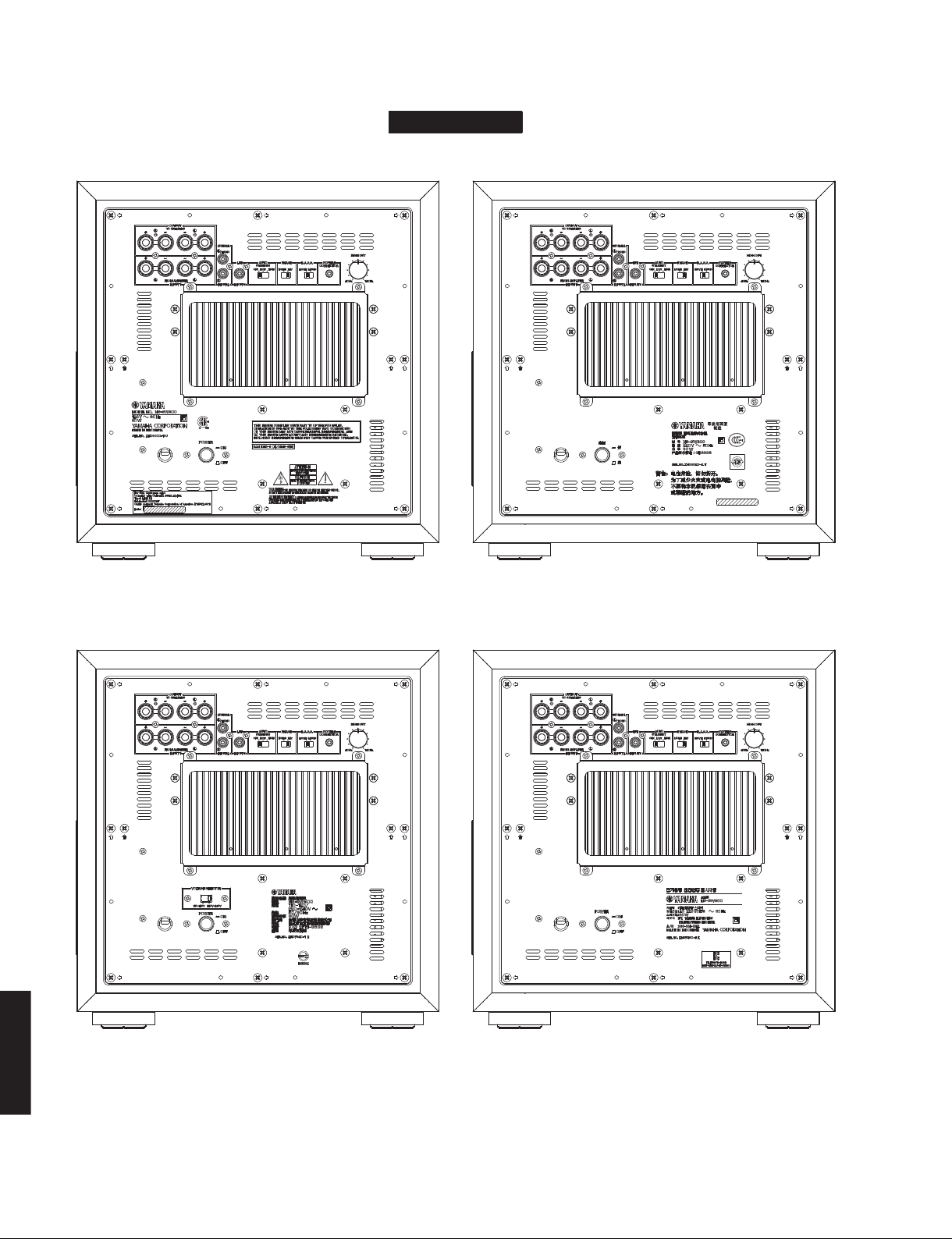

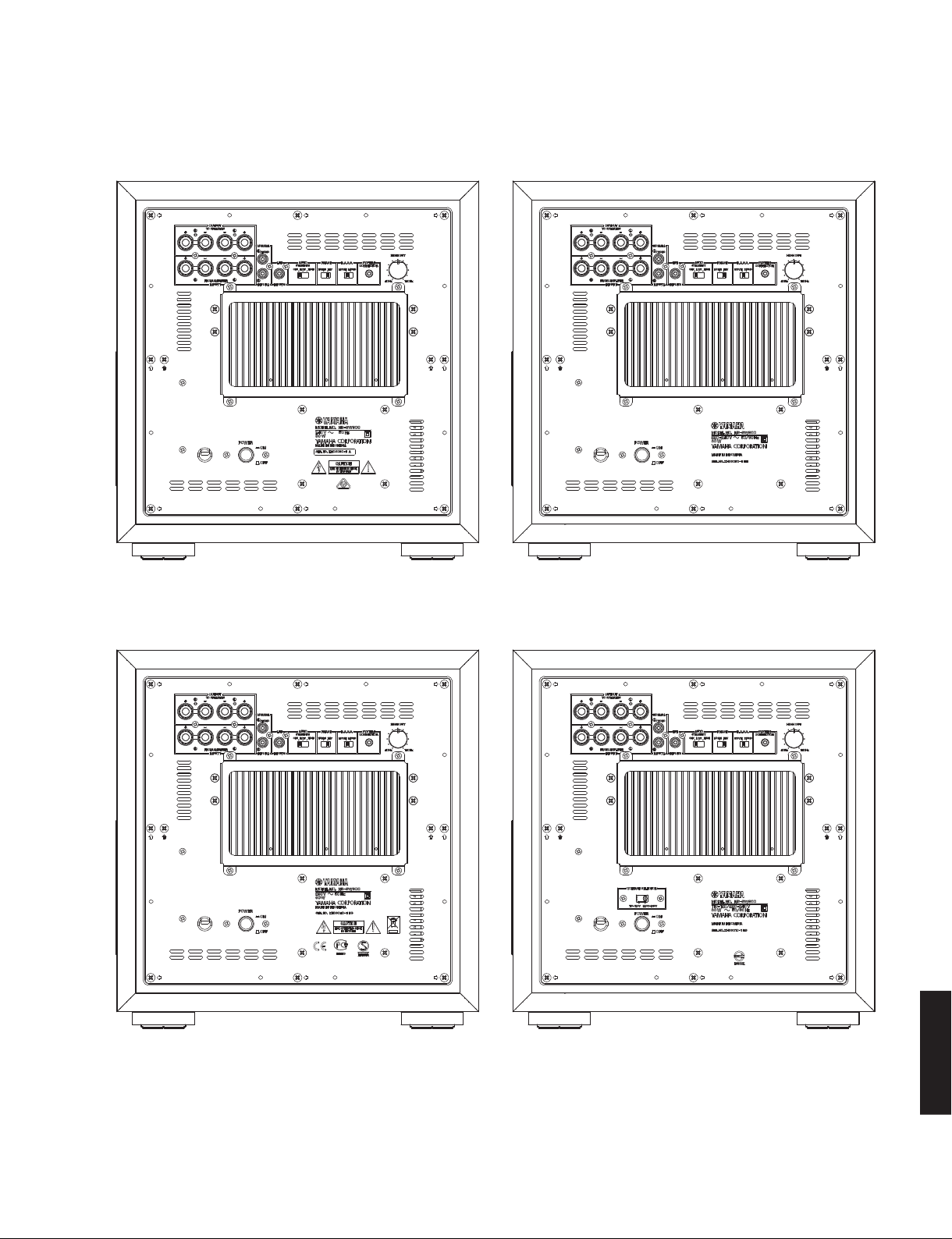

NS-SW300/NS-SW200

■ REAR PANELS

NS-SW300

U model

T model

R model

K model

NS-SW300/NS-SW200

4

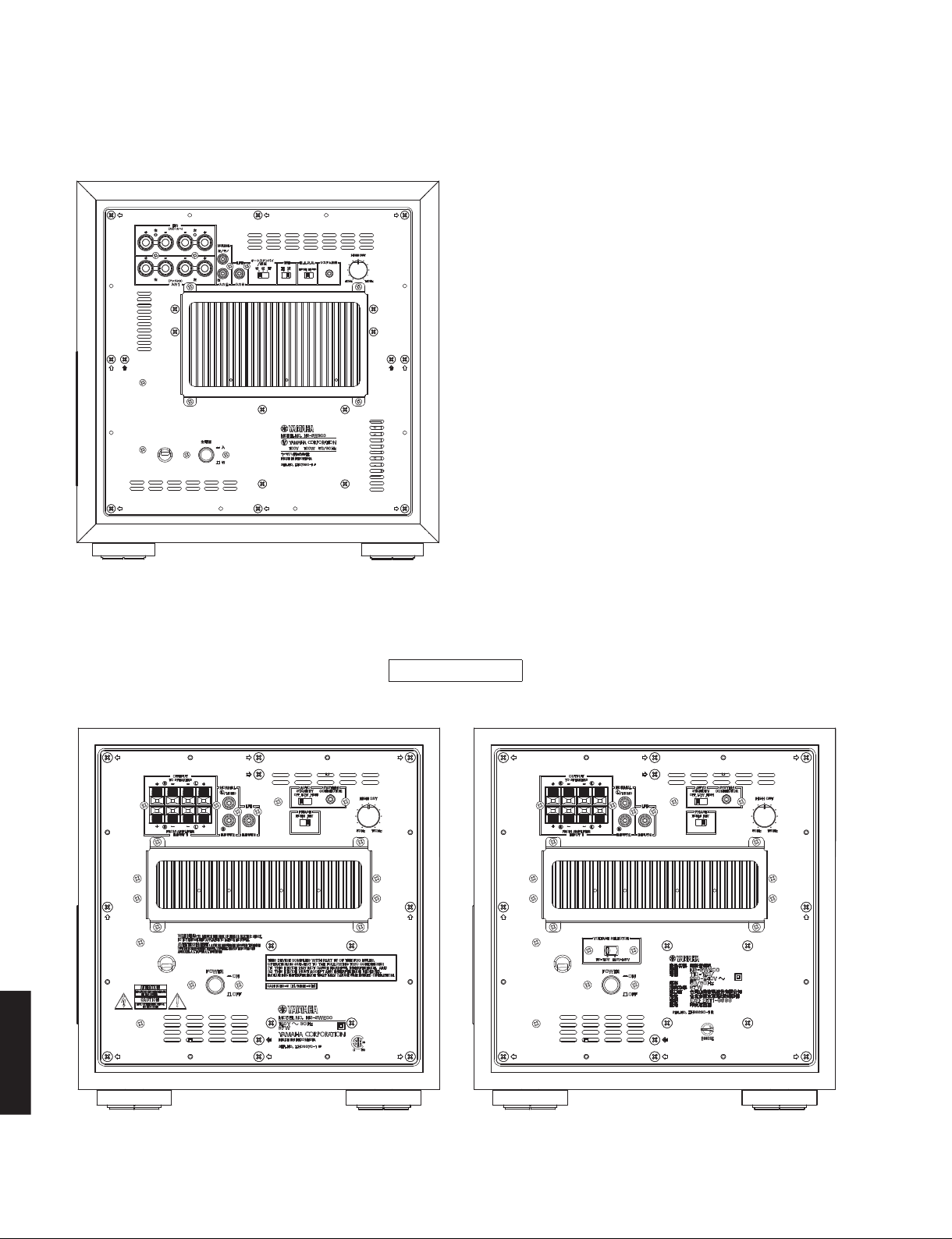

Page 5

A model L, H models

NS-SW300/NS-SW200

B, G models

S model

NS-SW300/NS-SW200

5

Page 6

NS-SW300/NS-SW200

J model

NS-SW200

U model R model

NS-SW300/NS-SW200

6

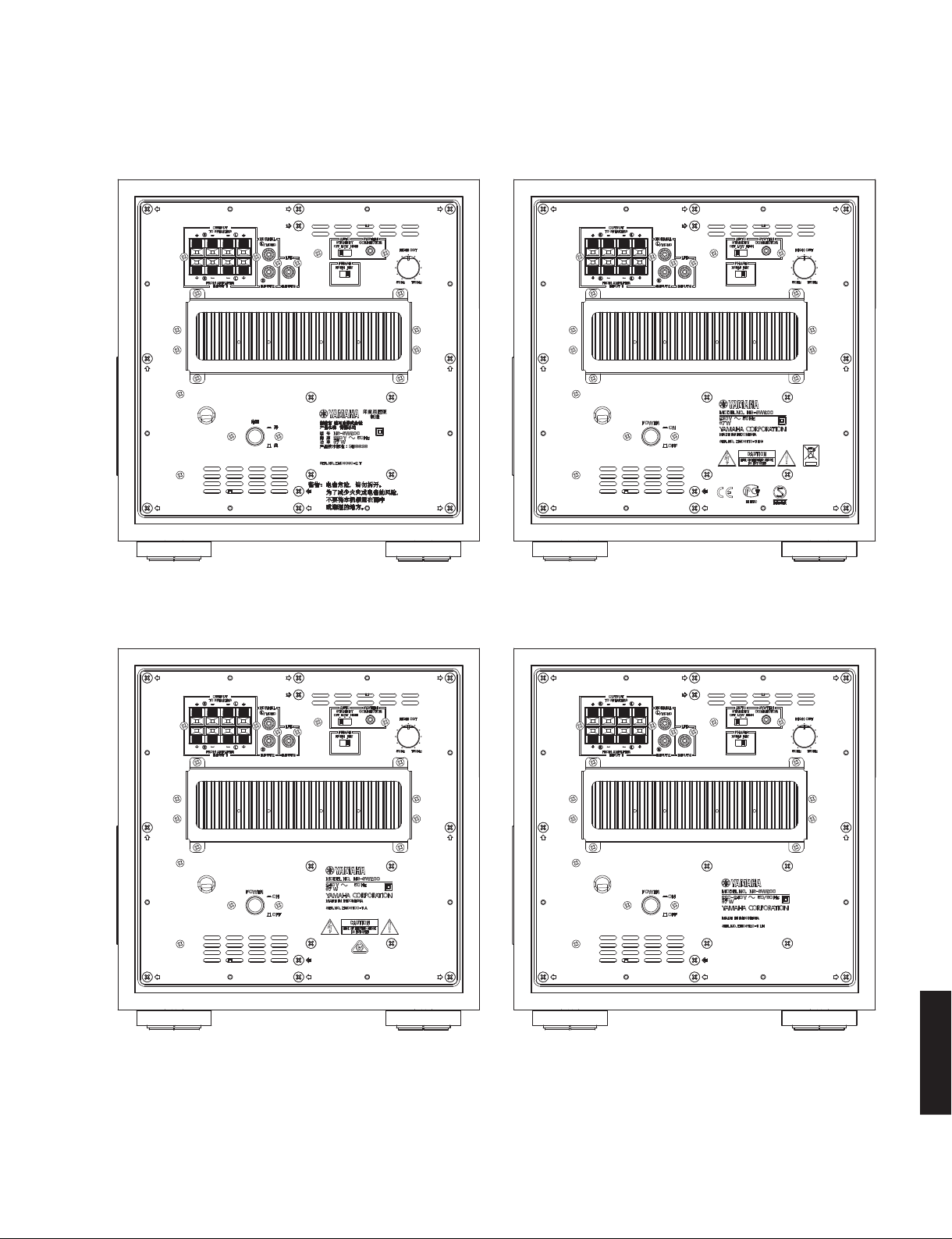

Page 7

T model B, G models

NS-SW300/NS-SW200

A model

L, H models

NS-SW300/NS-SW200

7

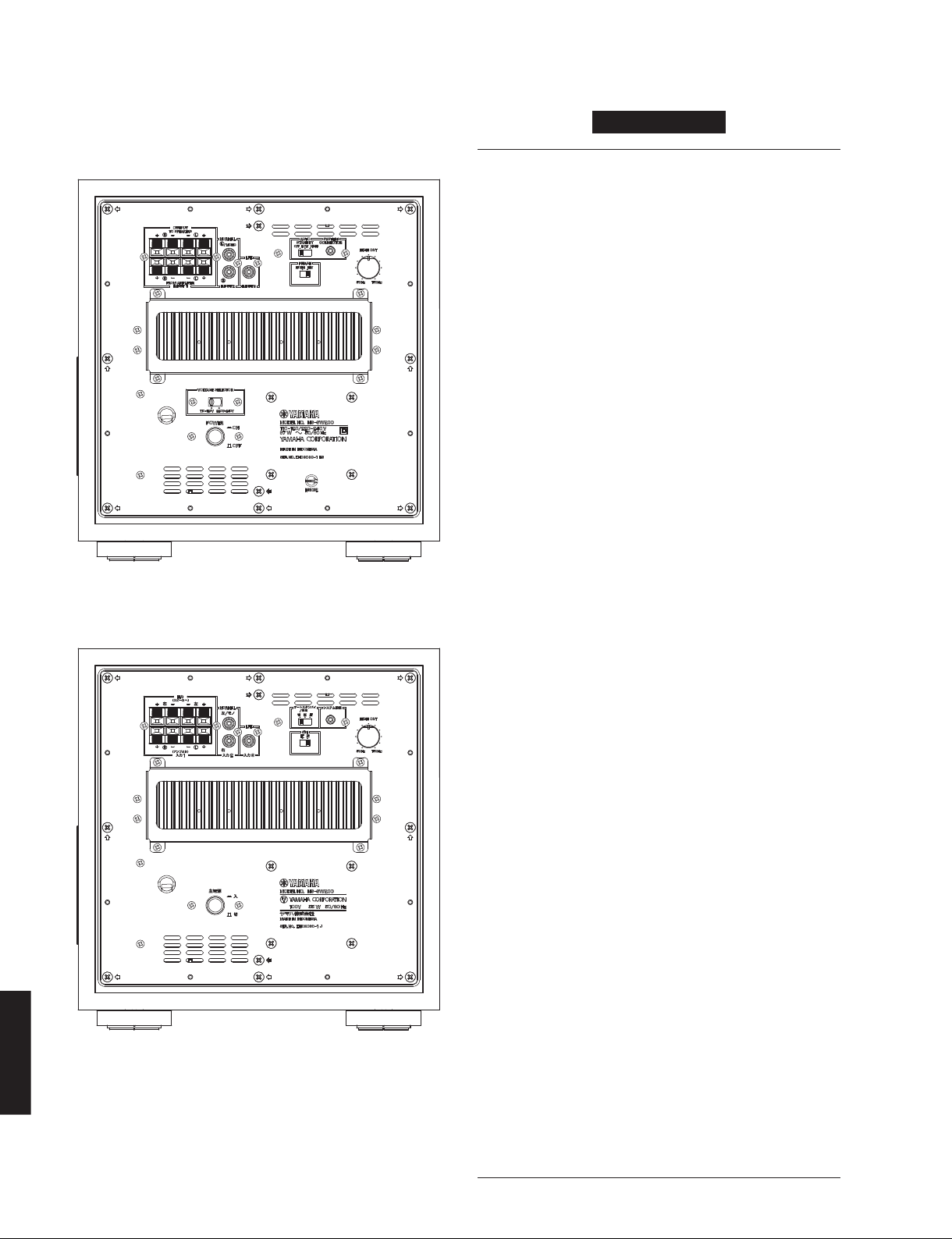

Page 8

NS-SW300/NS-SW200

■ SPECIFICATIONS /

参考仕様

NS-SW300

S model

J model

NS-SW300/NS-SW200

Type /

型式

......................... Advanced Yamaha Active Servo Technology II

PWM Digital Drive High Efficient Amplifier

Output Power /出力 (100 Hz, 5 ohms, 10 % T.H.D.)

.........................................................................................250 W

Input Sensitivity /

INPUT (SP) ......................................................................... 1.5 V

INPUT (PJ) ....................................................................... 60 mV

Input Impedance /

INPUT (SP) ................................................................2.2 k-ohms

INPUT (PJ) .................................................................12 k-ohms

Frequency Response /

..........................................................................20 Hz to 160 Hz

Driver /

スピーカーユニット

SUBWOOFER ........................... 25 cm (9-7/8") cone woofer x 1

Input Section /

INPUT1 ............................................................ Speaker terminal

INPUT2, 3 .............................................................. RCA pin jack

Operation Section /

Front panel .................................................... STANDBY/ON key

Rear panel ................................................POWER ON/OFF key

Power Supply /

U model ........................................................... AC 120 V, 60 Hz

R, S models ...........................AC 110–120/220–240 V, 50/60 Hz

T model ............................................................ AC 220 V, 50 Hz

K model ............................................................ AC 220 V, 60 Hz

A model ............................................................ AC 240 V, 50 Hz

B, G models ..................................................... AC 230 V, 50 Hz

L, H models ......................................... AC 220–240 V, 50/60 Hz

J model ....................................................... AC 100 V, 50/60 Hz

Power Consumption /

U, R, T, K, A, B, G, L, S, H models ..................................... 80 W

J model ............................................................................ 100 W

Standby Power Consumption /

...............................................................................0.3 W or less

Dimensions /

...................... 350 x 366 x 420 mm (13-3/4" x 14-3/8" x 16-1/2")

Weight /

Finish /

Accessories /

質量

...................................................................... 18.0 kg (39.7 lbs.)

仕上げ

B, G models .................................................... WH (White color)

R, T, K, G, L, S, H models .............................. RW (Brown color)

R, T, K, A, B, G, L, S, H, J models .....................BL (Black color)

U, R, T, K, A, B, G, L, S, H models ......... PN (Piano black color)

System control cable (5 m) ....................................................x 1

Subwoofer cable (5 m) (J model) ..........................................x 1

入力感度

入力インピーダンス

入力部

電源

外形寸法

付属品

(50 Hz, 250 W/5 ohms, L+R)

再生周波数帯域

Magnetic shielding type /

操作部

VOLUME control

Indicator (Green, Red)

AUTO STANDBY (HIGH / LOW / OFF) switch

PHASE (NORM / REV) switch

B.A.S.S. (MOVIE / MUSIC) switch

HIGH CUT control switch

VOLTAGE SELECTOR switch (R, S models)

消費電力

待機消費電力

(W x H x D)

防磁型

8

Page 9

NS-SW200

NS-SW300/NS-SW200

Type /

型式

......................... Advanced Yamaha Active Servo Technology II

PWM Digital Drive High Efficient Amplifier

Output Power /出力 (100 Hz, 5 ohms, 10 % T.H.D.)

.........................................................................................130 W

Input Sensitivity /

入力感度

(50 Hz, 130 W/5 ohms, L+R)

INPUT (SP) ......................................................................... 1.2 V

INPUT (PJ) ....................................................................... 50 mV

Input Impedance /

入力インピーダンス

INPUT (SP) ................................................................2.2 k-ohms

INPUT (PJ) .................................................................12 k-ohms

Frequency Response /

再生周波数帯域

..........................................................................28 Hz to 200 Hz

Driver /

スピーカーユニット

.................................................. 20 cm (7-7/8") cone woofer x 1

Input Section /

Magnetic shielding type /

入力部

防磁型

INPUT1 ............................................................ Speaker terminal

INPUT2, 3 .............................................................. RCA pin jack

Operation Section /

操作部

Front panel .................................................... STANDBY/ON key

VOLUME control

Indicator (Green, Red)

Rear panel ................................................POWER ON/OFF key

AUTO STANDBY (HIGH / LOW / OFF) switch

PHASE (NORM / REV) switch

HIGH CUT control switch

VOLTAGE SELECTOR switch (R, S models)

Power Supply /

電源

U model ........................................................... AC 120 V, 60 Hz

R, S models ...........................AC 110–120/220–240 V, 50/60 Hz

T model ............................................................ AC 220 V, 50 Hz

A model ............................................................ AC 240 V, 50 Hz

B, G models ..................................................... AC 230 V, 50 Hz

L, H models ......................................... AC 220–240 V, 50/60 Hz

J model ....................................................... AC 100 V, 50/60 Hz

Power Consumption /

消費電力

U, R, T, A, B, G, L, S, H models ......................................... 67 W

J model .............................................................................. 55 W

Standby Power Consumption /

待機消費電力

...............................................................................0.3 W or less

Dimensions /

外形寸法

(W x H x D)

............................ 290 x 306 x 351 mm (11-3/8" x 12" x 13-7/8")

Weight /

質量

...................................................................... 11.2 kg (24.7 lbs.)

Finish /

仕上げ

B, G, S models ................................................ WH (White color)

R, T, G, L, S, H models ................................... RW (Brown color)

R, T, A, B, G, L, S, H, J models .........................BL (Black color)

U, R, T, A, B, G, L, H models ................. PN (Piano black color)

Accessories /

付属品

System control cable (5 m) ....................................................x 1

Subwoofer cable (5 m) (J model) ..........................................x 1

* Specifications are subject to change without notice due to

product improvements.

※ 参考仕様および外観は予告なく変更されることがあります。

U .......................U.S.A. model

R ....................General model

T .................... Chinese model

K .....................Korean model

A ................Australian model

B ......................British model

G .................European model

L .................Singapore model

S ..................Brazilian model

H ..........................Thai model

J .................. Japanese model

NS-SW300/NS-SW200

9

Page 10

NS-SW300/NS-SW200

• DIMENSIONS /

Front view Side view

寸法図

350 (13-3/4")

366 (14-3/8")

350 (13-3/4")

16

(5/8")

NS-SW300

44

(1-3/4")

Bottom view

250 (9-7/8")

350 (13-3/4")

420 (16-1/2")

ø 60

26

(1")

45

(1-3/4")

260 (10-1/4")

Unit: mm (inch)

単位:mm(インチ)

45

(1-3/4")

265 (10-3/8")

40

(1-5/8")

45

(1-3/4")

NS-SW200

Front view

306 (12")

290 (11-3/8")

290 (11-3/8")

16

(5/8")

(1-3/8")

NS-SW300/NS-SW200

Side view

35

Bottom view

207 (8-1/8")

290 (11-3/8")

351 (13-7/8")

ø 60

26

(1")

45

(1-3/4")

200 (7-7/8")

10

Unit: mm (inch)

単位:mm(インチ)

45

(1-3/4")

205 (8-1/8")

40

(1-5/8")

45

(1-3/4")

Page 11

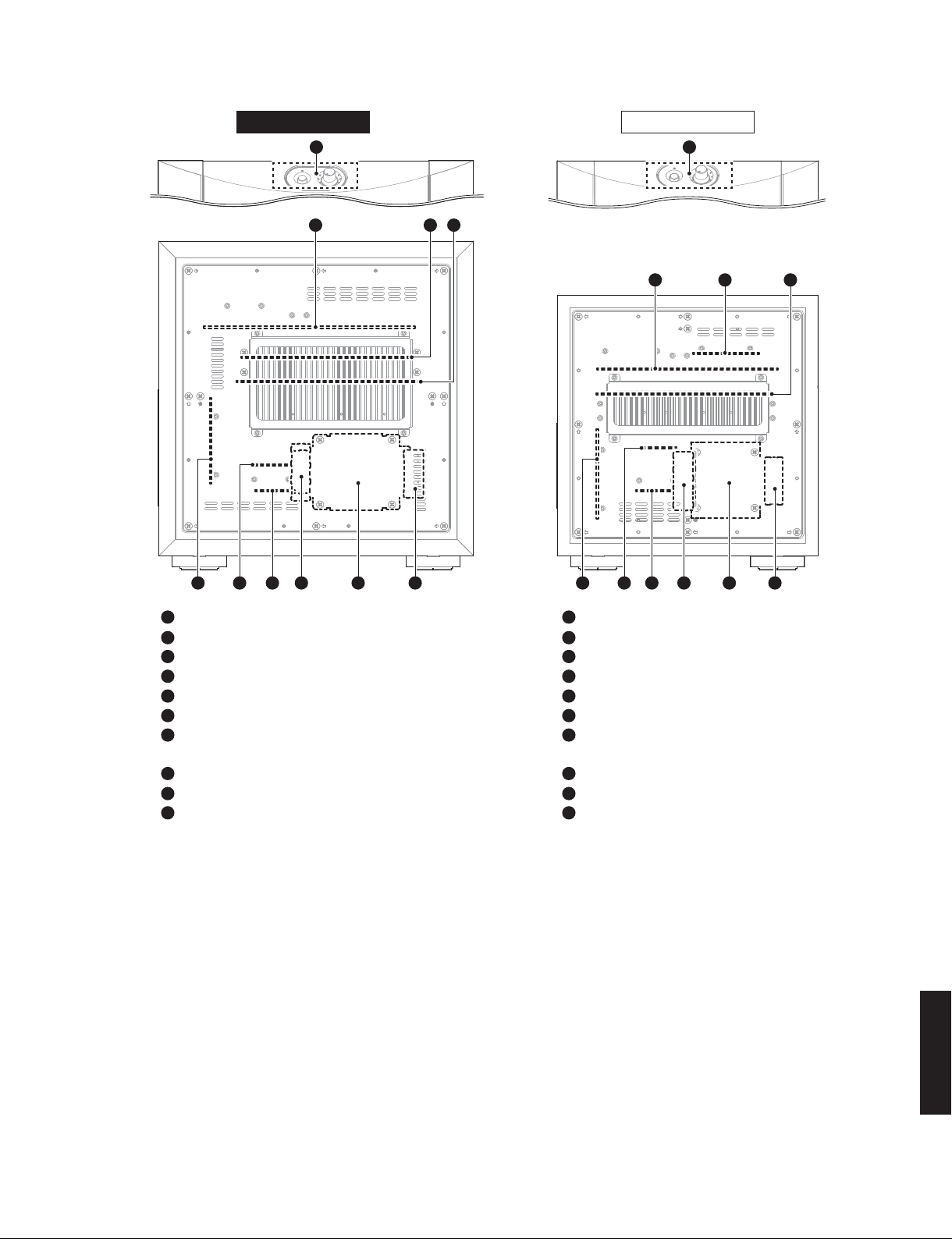

■ INTERNAL VIEW

NS-SW300 NS-SW200

Front view Front view

NS-SW300/NS-SW200

11

Rear view

10 9 6 587 10 9 6 587

1

MAIN (4) P.C.B.

2

MAIN (3) P.C.B.

3

MAIN (6) P.C.B.

4

MAIN (1) P.C.B.

5

MAIN (8) P.C.B.

6

POWER TRANSFORMER

7

MAIN (9) P.C.B. (U, T, K, A, B, G, L, H, J models)

2

MAIN (10) P.C.B. (R, S models)

8

MAIN (5) P.C.B.

9

MAIN (11) P.C.B. (R, S models)

10

MAIN (2) P.C.B.

344

Rear view

1

MAIN (4) P.C.B.

2

MAIN (3) P.C.B.

3

MAIN (8) P.C.B.

4

MAIN (1) P.C.B.

5

MAIN (6) P.C.B.

6

POWER TRANSFORMER

7

MAIN (7) P.C.B. (U, T, A, B, G, L, H, J models)

MAIN (9) P.C.B. (R, S models)

8

MAIN (5) P.C.B.

9

MAIN (10) P.C.B. (R, S models)

10

MAIN (2) P.C.B.

2

3

11

NS-SW300/NS-SW200

Page 12

NS-SW300/NS-SW200

■ SERVICE PRECAUTIONS /

サービス時の注意事項

Safety measures

• Some internal parts in this product contain high voltages

and are dangerous.

Be sure to take safety measures during servicing, such

as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous

even after the power is turned off because an electric

charge remains and a high voltage continues to exist

there.

Before starting any repair work, connect a discharging

resistor (5 k-ohms/10 W) to the terminals of each

capacitor indicated below to discharge electricity.

The time required for discharging is about 30 seconds

per each.

C85 and C86 on MAIN (1) P.C.B.

For details, refer to “PRINTED CIRCUIT BOARDS”.

安全対策

・ この製品の内部には高電圧部分があり危険です。修理

の際は、絶縁性の手袋を使用するなどの安全対策を

行ってください。

・ 下記のコンデンサには電源を OFF にした後も電荷が残

り、高電圧が維持されており危険です。

修理作業前に放電用抵抗(5k Ω /10W)を下記の各コ

ンデンサの端子間に接続して放電してください。

放電所用時間は各々約 30 秒間です。

MAIN(1)P.C.B. の C85、C86

詳しくは “PRINTEDCIRCUITBOARDS” を参照してくだ

さい。

NS-SW300/NS-SW200

12

Page 13

NS-SW300/NS-SW200

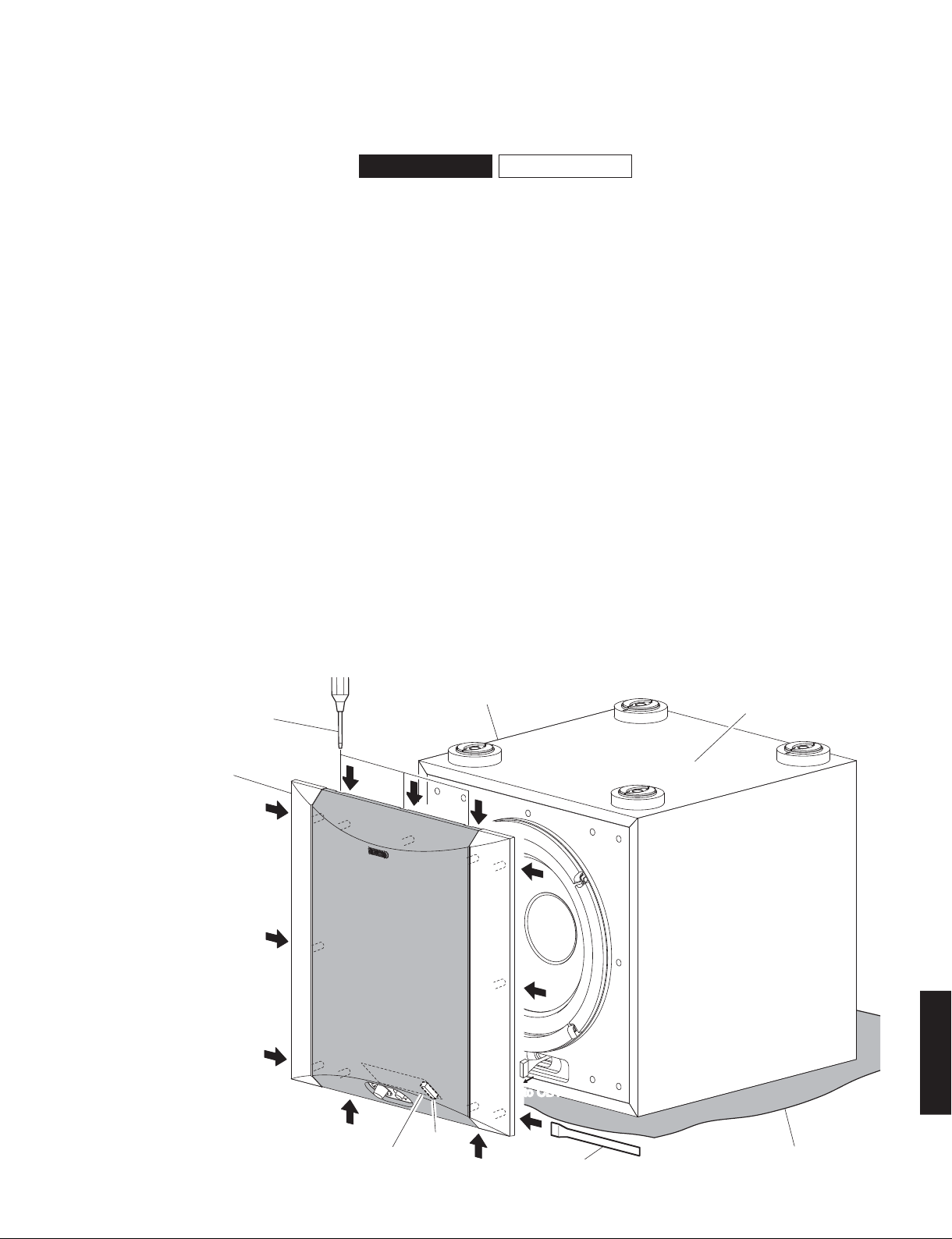

■ DISASSEMBLY PROCEDURES /

(Remove parts in the order as numbered.)

Disconnect the power cable from the AC outlet.

NS-SW300 NS-SW200

Disassembly procedures of the NS-SW300 and NSSW200 are almost the same. For that reason, we

explain disassembly procedure of the NS-SW300 as a

representative here.

1. Removal of Front Grille Assembly

a. Spread a rubber sheet and cloth for protection of this

unit against any damage and place this unit on cloth

with its bottom side facing up. (Fig. 1)

* The front grille assembly is fixed to the cabinet

assembly with dowels at 11 locations.

As a flatblade screwdriver is used for removal, use

special care not to cause damage to the cabinet

assembly.

b. First, insert a flatblade screwdriver at 3 dowel positions

and push up the front grille assembly. (Fig. 1)

c. Next, using the metalblade or the like, push the front

grille assembly upward until it comes off. (Fig. 1)

d. Remove CB1. (Fig. 1)

e. Remove the front grille assembly. (Fig. 1)

Notes:

• Removing the front grille assembly with the flatblade

screwdriver only without using the metalblade or the

like may cause damage to the front grille assembly.

• When installing the front grille assembly, apply quick-

drying bond or the like to dowels and then fit them

into dowel holes for secure installation. (The front

grille assembly will come off easily if its dowels are

fitted into dowel holes without applying quick-drying

bond or the like.)

Flatblade screwdriver

マイナスドライバー

Cabinet assembly

キャビネット Ass'y

分解手順

( 番号順に部品を取り外してください。)

AC 電源コンセントから、電源コードを抜いてください。

NS-SW300 と NS-SW200 の分解手順はほぼ同じです。そ

のため、ここでは代表として NS-SW300 の分解手順で説

明します。

1. フロントグリル Ass'y の外し方

a. 本機に傷などが付かないようにゴムシートと布を敷

き、本機を底面が上になるように置きます。(Fig.1)

※ フロントグリル Ass'y は 11 箇所のダボでキャビ

ネット Ass'y に固定されています。

取り外しの際、キャビネット Ass'y に傷が付かない

よう十分注意してください。

b. 最初にマイナスドライバーを 3 箇所のダボ位置へ差し

込み、フロントグリル Ass'y を押し上げます。(Fig.1)

c. 次にヘラ等を使い、フロントグリル Ass'y が外れるま

で徐々に上面ヘ押し上げていきます。(Fig.1)

d. CB1 を外します。(Fig.1)

e. フロントグリル Ass'y を外します。(Fig.1)

注意:

・ フロントグリル Ass'y を外す際、ヘラ等を使わずマイ

ナスドライバーだけを使って外すと、フロントグリル

Ass'y が破損する場合があります。

・ フロントグリル Ass'y を取り付ける場合、フロントグ

リル Ass'y のダボに速乾ボンドなどを塗って取り付け

ます。(ダボへ速乾ボンドなどを塗らずに差し込んだ

場合、フロントグリル Ass'y は容易に外れてしまいま

す。)

Bottom side

底面

Front grille assembly

フロントグリル Ass'y

MAIN (4) P.C.B.

CB1

Fig. 1

to CB1

Metalblade

ヘラ

NS-SW300/NS-SW200

Rubber sheet and cloth

ゴムシートと布

13

Page 14

NS-SW300/NS-SW200

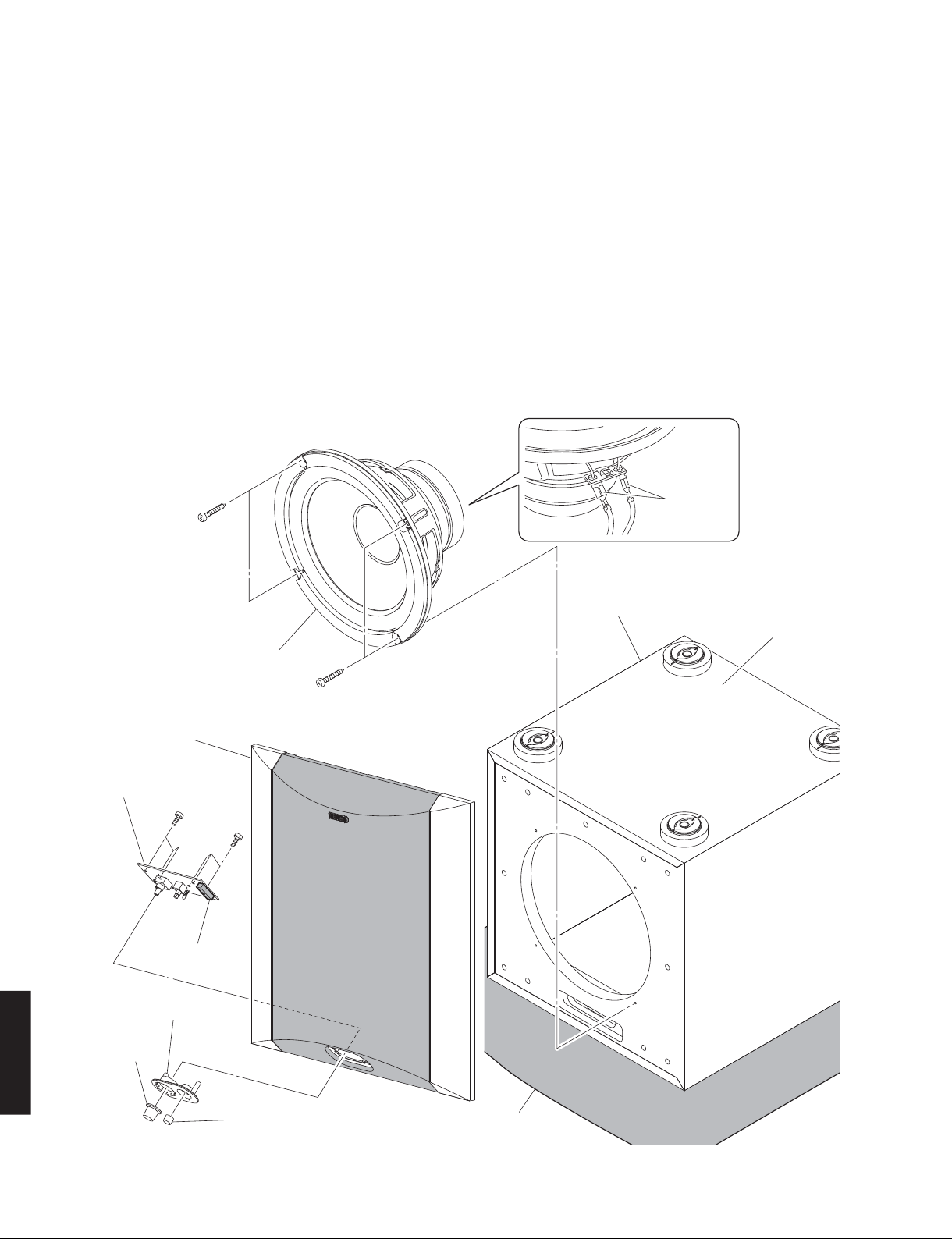

2. Removal of Front Panel

a. Remove the VOLUME knob and POWER knob. (Fig. 2)

b. Remove 6 screws (①). (Fig. 2)

c. Remove the front panel together with the MAIN (4)

P.C.B. (Fig. 2)

3. Removal of Driver

a. Remove 4 screws (②) and then pull out the driver.

(Fig. 2)

b. Disconnect the connector connected to the terminal

of the driver. (Fig. 2)

c. Remove the driver. (Fig. 2)

②

2. フロントパネルの外し方

a. VOLUME つまみと POWER つまみを外します。(Fig.2)

b. ①のネジ 6 本を外します。(Fig.2)

c. フロントパネルと MAIN(4)P.C.B. を一緒に外します。

(Fig.2)

3. スピーカーユニットの外し方

a. ②のネジ 4 本を外し、スピーカーユニットを引き出し

ます。(Fig.2)

b. スピーカーユニットの端子に接続されているコネク

ターを外します。(Fig.2)

c. スピーカーユニットを外します。(Fig.2)

Connectors

コネクター

Front grille assembly

フロントグリル Ass'y

MAIN (4) P.C.B.

Front panel

フロントパネル

VOLUME knob

VOLUME つまみ

スピーカーユ ニット

Driver

①

①

CB1

②

Cabinet assembly

キャビネット Ass'y

Bottom side

底面

NS-SW300/NS-SW200

POWER knob

POWER つまみ

Rubber sheet and cloth

ゴムシートと布

Fig. 2

14

Page 15

NS-SW300/NS-SW200

4. Removal of Rear Panel Assembly

a. Remove the bushing (Font panel side). (Fig. 3)

b. Remove 8 screws (③). (Fig. 3)

* Screws (③) are identified with arrow marks (

c. Pull out the rear panel assembly. (Fig. 3)

d. Remove 2 screws (④). (Fig. 3)

* Screws (④) are identified with arrow marks (

e. Remove the bushing (cover assembly side). (Fig. 3)

f. Remove the cover assembly. (Fig. 3)

g. Remove CB6. (Fig. 3)

h. Remove the rear panel assembly. (Fig. 3)

Bushing (Cover assembly side)

ブッシュ(カバー Ass'y 側)

Cover assembly

カバー Ass'y

Rear panel assembly

リヤパネル Ass'y

4. リアパネル Ass'y の外し方

a. ブッシュ(フロントパネル側)を外します。(Fig.3)

b. ③のネジ 8 本を外します。(Fig.3)

)

※ 取り外す③のネジには矢印(

ます。

c. リアパネル Ass'y を引き出します。(Fig.3)

)

d. ④のネジ 2 本を外します。(Fig.3)

※ 取り外す④のネジには矢印(

ます。

e. ブッシュ(カバー Ass'y 側)を外します。(Fig.3)

f. カバー Ass'y を外します。(Fig.3)

g. CB6 を外します。(Fig.3)

h. リアパネル Ass'y を外します。(Fig.3)

to DRIVER

)が印刷されてい

)が印刷されてい

③

④

CB6

④

③

to CB6

W1

MAIN (1) P.C.B.

Fig. 3

to CB1

Bushing (Front panel side)

ブッシュ(フロントパネル 側)

Rubber sheet and cloth

ゴムシートと布

* The old bushing, once removed, cannot be reused

as it may cause air leakage.

Be sure to install a new one for its replacement.

※外した古いブッシュは、空気漏れの原因となる

恐れがあるため、再利用できません。

新しいものに交換してください。

NS-SW300/NS-SW200

15

Page 16

NS-SW300/NS-SW200

When checking the P.C.B.:

• Spread the rubber sheet and cloth. Then place this

unit on the cloth and check it. (Fig. 4)

• Reconnect all cables (connectors) that have been

disconnected.

* The old bushing, once removed, cannot be reused

as it may cause air leakage.

Be sure to install a new one for its replacement.

※外した古いブッシュは、空気漏れの原因となる

恐れがあるため、再利用できません。

新しいものに交換してください。

P.C.B. をチェックする場合には:

・ ゴムシートと布を敷き、その上に本機を置いてチェッ

クします。(Fig.4)

・ 外したケーブル(コネクター)をすべて接続します。

Rear panel assembly

リヤパネル Ass'y

Rubber sheet and cloth

ゴムシートと布

Fig. 4

NS-SW300/NS-SW200

16

Page 17

ABCDEFGH I J

1

■ BLOCK DIAGRAMS

NS-SW300/NS-SW200

NS-SW300

IC9B

+

2

L

-

3

+

1

-

2

INPUT 1

+

6

5

IC6B

+

775

IC6A

+

-

6

2

3

IC7A

+

R

-

L.P.F

12dB/oct

+

L

-

OUTPUT

3

+

R

HIGH CUT

VR1

-

VR2

5

6

5

6

IC7B

+

-

IC8B

+

-

1

7

7

PHASE

NORM

REV

3

2

IC8A

+

-

1

SW3

IC10B

6

+

-

7

B.A.S.S

8

MOVIE

MUSIC

3

2

IC10A

+

-

1

Q25-Q32

Pre Drive

-

+

Q33A,Q33C

Power Drive

A.N.I.C

H.P.F

12dB/oct

Q11,12,14,15

Limitter

Q17,19,22,24

SW1

L/

INPUT 2

MONO

R

IC9A

INPUT 3

4

LFE

6

5

7

+

AUTO STANDBY

SW2

OFF

LOW

HIGH

OFF

LOW

HIGH

IC5

Music

Sensor

8

IC1

4

Timer

6

7

3

+

Q6,8,9,13

Protection

AUTO STANDBY CIRCUIT

5

Protection

+12

C61

C62

-12

D6

D7

+

+

+B

-B

IC2

Regulator

IC3

C85

C86

C51

C52

Power

transformer

D21

+

Power

Supply

+

D10

+

Power

Supply

+

+B

Q43C,Q45A

PS Amplifier

Q43A,Q45C

PS Amplifier

-B

RY2F1

RY1

DRIVER

SUBWOOFER

R180

0.1

Protection

POWER

ON/OFF

SW5

AC IN

(U, T, K, A, B, G, L, H, J models)

RY2

D14

Sub-Power

Supply

SYSTEM

CONNECTOR

DCIN

STATUS

Indicator

D1

Q2,4

R

G

Control

SW6

STANDBY/ON

IC4

Regulator Regulator

(R, S models)

6

MAIN

• See page 29 →

SCHEMATIC DIAGRAM

T1

Sub-

transformer

7

17

Page 18

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW200

1

+B

Q43C,Q45A

PS Amplifier

Q43A,Q45C

PS Amplifier

-B

RY1

DRIVER

SUBWOOFER

R180

0.1

7

SW1

PHASE

REV

NORM

IC8A

3

+

1

-

2

Q25-Q32

Pre Drive

-

Q33A,Q33C

Power Drive

+

A.N.I.C

Q11,12,14,15

Limitter

IC9B

+

2

L

-

5

+

7

-

6

INPUT 1

+

R

-

+

L

-

OUTPUT

3

+

R

2

3

IC6A

+

1

L.P.F

12dB/oct

IC6B

5

+

-

6

HIGH CUT

VR1

IC7A

7

2

-

1

+

3

IC7B

5

6

7

+

-

IC8B

5

7

+

-

6

VR1

VOLUME

H.P.F

12dB/oct

-

Q40,42

L/

MONO

INPUT 2

R

IC9A

INPUT 3

4

LFE

2

-

1

+

3

AUTO STANDBY

SW2

OFF

LOW

HIGH

OFF

LOW

IC5

Music

Sensor

8

IC1

4

Timer

6

7

3

+

HIGH

AUTO STANDBY CIRCUIT

5

Q17,19

Protection

+15

C61

C62

-15

D41

+

+

Q51

Regulator

Q52

C85

C86

Q22,24

Protection

POWER

Power

transformer

RY2F1

ON/OFF

SW5

D21

+

Power

Supply

+

AC IN

T2

Sub-

transformer

T1

SYSTEM

CONNECTOR

DCIN

STATUS

Indicator

D1

(U, T, A, B, G, L, H, J models)

RY2

Q2,4

R

G

Control

SW6

IC4

Regulator Regulator

STANDBY/ON

Q16,18,20,21

(R, S models)

D14

Sub-Power

Supply

6

MAIN

• See page 30 →

SCHEMATIC DIAGRAM

7

18

Page 19

ABCDEFGH I J

1

■ WIRING DIAGRAMS

• OVERALL ASSEMBLY

2

3

CB6

PN1

CB3

W4

W3W1

CB4

CB5

MAIN (1)

W8A1

W8A2

W8A3

W7A1

W7A2

W7A3

Side viewRear view

MAIN (3)

to MAIN (4)

(CB1)

to DRIVER

MAIN (6)

W5

MAIN (2) MAIN (2)

W3

W1

MAIN (8)

W1

CB6

to MAIN (4)

(CB1)

W4

CB3

CB5

NS-SW300/NS-SW200

NS-SW200NS-SW300

Side viewRear view

CB4

W2

to DRIVER

CB2

MAIN (3)

MAIN (1)

W5

4

W7B1

W7B2

W7B3

W8B1

W8B2

W8B3

POWER

TRANSFORMER

MAIN (11)

R, S models

POWER

TRANSFORMER

MAIN (10)

R, S models

MAIN (2)

MAIN (2)

MAIN (8)

5

MAIN (10)MAIN (9)

R, S modelsU, T, K, A, B, G, L, H, J models

MAIN (5)

MAIN (6)

R, S models

MAIN (5)

MAIN (7)MAIN (9)

U, T, A, B, G, L, H, J models

Power cable Power cable

100 mm

6

(3-7/8")

Cord Stopper Cord Stopper

120 mm

(4-3/4")

7

19

Page 20

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW300

1

■ PRINTED CIRCUIT BOARDS

MAIN (3) (Side A)

SP

SPRYON

MAIN (6)

(CB4)

140Hz40Hz

HIGH CUT

MAIN (1) (Side A)

SIG2

SGNDE2LIMT

+12

W4

-12

OCDET

2

SW

SIG

+5V

VOL

SGND

WH

SP-

CB6

NF

RE

SP+

W7A1

RE

BL

W7A2

3

RE

W7A3

DRIVER

SUBWOOFER

SYSTEM

CONNECTOR

MUSICMOVIEREVNORM

B.A.S.S.

JK1

W1

MAIN (4)

ACRYON

+5V

W3

ASE

-12

+12

BASW

SGND

SIG1

MAIN (6)

MAIN (8)

(W7B1, W7B2, W7B3)

PHASE

HIGH

4

5 k-ohms

10 W

MAIN (2) (Side A)

5 k-ohms

10 W

T, K, B, G, L, H models

SUB-

TRANSFORMER

MAIN (9) (W11B, W12B)

(U, T, K, A, B, G, L, H, J models)

MAIN (10) (W11B, W12B)

(R, S models)

T, K, B, G, L, H models

• Semiconductor Location

Ref no. Location

D14 D5

D21 B3

LFE

INPUT3 /

AUTO

STANDBY

LOW

OFF

D31 D3

D32 D3

D33 D3

D34 E3

D35 E3

D36 D3

D37 D3

D38 D3

D39 D3

D40 D3

IC4 C6

Q30 E2

Q31 D2

Q32 E2

Q33A F4

Q33C C4

Q35A C3

Q35C E2

Q40 E4

Q42 F3

Q43A E4

Q43C C4

Q45A D4

Q45C E4

Q50 B2

INPUT2 /

NORMAL

+--+

TO SPEAKERS

INPUT1 / OUTPUT

FROM AMPLIFIER/

RL

L / MONO / R

WH

W11A

W9A

W10A

OR

GY

BE

W12A

MAIN (5)

(W9B, W10B)

AC IN

5

R, S models

U, T, K, A, B, G, L, H, J models

IC4

E2

+5V

6

Safety measures

• Some internal parts in this product contain high voltages and are dangerous. Be sure to take safety measures during servicing, such

as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous even after the power is turned off because an electric charge remains and a

high voltage continues to exist there. Before starting any repair work, connect a discharging resistor (5 k-ohms/10 W) to the terminals

of each capacitor indicated below to discharge electricity. The time required for discharging is about 30 seconds per each.

C85, C86 on MAIN (1) P.C.B.

安全対策

・ この製品の内部には高電圧部分があり危険です。修理の際は、絶縁性の手袋を使用するなどの安全対策を行ってください。

7

・ 下記のコンデンサには電源を OFF にした後も電荷が残り、高電圧が維持されており危険です。修理作業前に放電用抵抗

(5k Ω /10W)を下記の各コンデンサの端子間に接続して放電してください。放電所用時間は各々約 30 秒間です。

MAIN(1)P.C.B. の C85、C86

MAIN (6)

(CB5)

ACRYON

W5

-12D

(CB1)

(CB3)

+12D

ASE

LEDR

LEDG

20

Page 21

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW300

1

MAIN (3) (Side B)

MAIN (1) (Side B)

85

IC6

14

2

14

IC11

85

3

4

T, K, B, G, L, H models

MAIN (2) (Side B)

• Semiconductor Location

Ref no. Location

5

R, S models

D3 I4

D4 I4

D5 H2

D8 A2

D9 A3

D15 C5

D17 C5

D19 C6

D22 E3

D23 D2

6

D24 D2

D25 E3

D27 C3

D28 C3

D29 D3

D30 D3

D42 B2

Ref no. Location

D43 A2

D44 A2

D46 I6

D47 I6

IC1 I5

IC5 H5

IC6 I2

IC8 I4

IC9 I7

IC11 E2

Q1 I4

Q2 H3

Q3 H5

Q4 H3

Q16 C5

Q18 C5

Q20 C5

Ref no. Location

Q21 C5

Q23 C6

Q25 E3

Q26 E3

Q27 D2

Q28 E3

Q29 E3

Q37 C2

Q38 D2

Q39 F3

Q41 F3

Q44 B2

Q46 I6

Q47 I6

Q48 I6

Q49 A2

85

14

4

IC5

58

IC8

T, K, B, G, L, H models

1

4

1

IC1

58

4

1

IC9

58

7

21

Page 22

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW300

1

MAIN (6) (Side A)MAIN (4) (Side A)

ASE

+5V

MAIN (3)

(W3)

ACRYON

SIG2

SGNDE2LIMT

+12

CB4

-12

STATUS

indicator

2

VOLUME

(Standby/On)

3

MAIN (5) (Side A)

VOL

SGND

SIG

-12D

+12D

+5V

CB1

SW

ASE

LEDG

LEDR

MAIN (3)

(W1)

• Semiconductor Location

SIG1

SGND

+12

-12

BASW

CB3

Ref no. Location

D1 C2

POWER

ON

D10 I3

IC2 I3

IC3 I3

SP

SPRYON

OCDET

MAIN (1)

(W4)

E2

ACRYON

+5V

CB5

MAIN (2)

(W5)

U, R, A, S, J models

T, K, B, G, L, H models

BE

W8B1

IC3

IC2

W8B2

W8B3

BL

BE

OFF

4

W10B

W9B

T, K, B, G, L, H models

T, K, B, G, L, H models

MAIN (2)

(W9A, W10A)

5

MAIN (8) (Side A)MAIN (9) (Side A) MAIN (8) (Side A)MAIN (10) (Side A) MAIN (11) (Side A)

R, S models R, S modelsU, T, K, A, B, G, L, H, J models

W11B W12B

MAIN (2)

(W11A, W12A)

WH

6

BE

W8B3 W8B2 W8B1 W7B3 W7B2 W7B1

BE

BL

BE

RE

BL

RE

MAIN (1)

(W7A1, W7A2, W7A3)

MAIN (2)

(W11A, W12A)

WH

YE

BR

GR

BE

BE

W11B

W14B

W16B

W13B

W12B

W15B

W8B3 W8B2 W8B1 W7B3 W7B2 W7B1

BE

BL

BE

RE

BL

RE

MAIN (1)

(W7A1, W7A2, W7A3)

BR

W16A

VOLTAGE

SELECTOR

7

W13A

GR

W14AW15A

YE

BE

220-240V110-120V

22

Page 23

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW300

1

MAIN (6) (Side B)MAIN (4) (Side B)

2

5

4

IC7

1

8

• Semiconductor Location

Ref no. Location

D6 I3

D7 J3

D11 I3

D12 G3

D13 G3

Ref no. Location

D16 G3

D18 F3

D20 H2

IC7 C2

IC10 F3

Ref no. Location

Q5 F3

Q6 I3

Q7 E3

Q8 I3

Q9 I2

Ref no. Location

Q10 F3

Q11 G3

Q12 G3

Q13 I3

Q14 G3

Ref no. Location

Q15 G3

Q17 I3

Q19 H3

Q22 H2

Q24 H2

3

4

MAIN (5) (Side B)

T, K, B, G, L, H models

T, K, B, G, L, H models

14

IC10

85

T, K, B, G, L, H models

5

MAIN (8) (Side B)MAIN (9) (Side B) MAIN (8) (Side B)MAIN (10) (Side B) MAIN (11) (Side B)

6

7

23

Page 24

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW200

1

MAIN (3) (Side A)

MAIN (1) (Side A)

2

3

4

5

6

DRIVER

SUBWOOFER

• Semiconductor Location

Ref no. Location

D14 D5

D21 F3

D31 E3

D32 E3

D33 E3

D34 D3

D35 D3

D36 D3

D37 D2

D40 D2

IC4 C5

Q30 C3

Q31 D3

Q32 C3

RE

SP+

CB6

NF

WH

SP-

MAIN (2) (Side A)

Ref no. Location

Q33A C2

Q33C E2

Q35A E3

Q35C D3

Q40 D2

Q42 D2

Q43A C2

Q43C E2

Q45A E2

Q45C D2

Q50 F3

Q51 I5

Q52 I5

U, T, A, B, G, L, H, J models

T, B, G, L, H models

W4

W4

E2

SP

-15

PDET

OCDET

SPRYON

R, S models

+15

LIMT

SGND

SIG2

T, B, G, L, H models

IC4

W5

E2

+5V

ACRYON

SUB-

TRANSFORMER

WH

W11A

W9A

W10A

OR

GY

BE

W12A

W2

5 k-ohms

10 W

MAIN (7) (W11B, W12B)

(U, T, A, B, G, L, H, J models)

MAIN (9) (W11B, W12B)

(R, S models)

MAIN (5)

(W9B, W10B)

AC IN

W7A3

W7A2

W7A1

5 k-ohms

10 W

RE

BL

RE

MAIN (6)

(W7B1, W7B2, W7B3)

-B2

+B2

GND

HIGH CUT

PHASE

T, B, G, L, H models

U, R, A, S, J models

LFE

INPUT3 /

INPUT2 /

NORMAL

+--+

TO SPEAKERS

INPUT1 / OUTPUT

FROM AMPLIFIER/

RL

150Hz50Hz

REVNORM

L / MONO / R

VOL

SGND

SIG

-15D

W1

+15D

+5V

SW

ASE

LEDG

LEDR

MAIN (4)

(CB1)

W3

IN2

SW

+15

ASE

LED_R

LED_G

ACRYON

MAIN (8)

(CB3)

U, R, A, S, J models

T, B, G, L, H models

CB5

E2

+5V

ACRYON

E2

SP

-15

+15

LIMT

SIG2

SGND

CB2

PDET

OCDET

SPRYON

Safety measures

• Some internal parts in this product contain high voltages and are dangerous. Be sure to take safety measures during servicing, such

as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous even after the power is turned off because an electric charge remains and a

-B2

GND

+B2

high voltage continues to exist there. Before starting any repair work, connect a discharging resistor (5 k-ohms/10 W) to the terminals

of each capacitor indicated below to discharge electricity. The time required for discharging is about 30 seconds per each.

C85, C86 on MAIN (1) P.C.B.

安全対策

・ この製品の内部には高電圧部分があり危険です。修理の際は、絶縁性の手袋を使用するなどの安全対策を行ってください。

7

・ 下記のコンデンサには電源を OFF にした後も電荷が残り、高電圧が維持されており危険です。修理作業前に放電用抵抗

(5k Ω /10W)を下記の各コンデンサの端子間に接続して放電してください。放電所用時間は各々約 30 秒間です。

MAIN(1)P.C.B. の C85、C86

24

Page 25

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW200

1

MAIN (3) (Side B)

MAIN (1) (Side B)

4

5

IC6

1

8

2

8

1

IC8

5

T, B, G, L, H models

3

58

IC11

41

4

8

1

IC9

5

4

4

T, B, G, L, H models

MAIN (2) (Side B)

• Semiconductor Location

R, S models

5

Ref no. Location

D8 F3

D9 F2

D12 I3

D13 I3

D15 C5

D16 I4

D17 C5

D18 I4

D19 C5

D20 I5

D22 B3

D23 C3

6

D24 C3

D25 B2

D27 E2

D28 E2

D29 C2

D30 C2

D41 F3

Ref no. Location

D42 E3

D43 F3

D44 F3

D48 I5

D49 I6

D50 I6

D51 H6

D52 H6

D53 I5

IC6 H2

IC8 H2

IC9 H4

IC11 B3

Q11 I3

Q12 I3

Q14 I3

Q15 I3

Q16 C5

Q17 I4

Ref no. Location

Q18 C5

Q19 I4

Q20 C5

Q21 C5

Q22 I5

Q23 C6

Q24 I4

Q25 B2

Q26 B3

Q27 C3

Q28 B3

Q29 B2

Q37 D3

Q38 C3

Q39 B3

Q41 B3

Q44 E3

Q49 E3

7

25

Page 26

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW200

1

MAIN (8) (Side A)MAIN (4) (Side A) MAIN (5) (Side A)

POWER

W9B

ON

OFF

MAIN (2)

(W9A, W10A)

ACRYON

LED_G

LED_R

MAIN (3)

(W3)

IN2

+15

SW

ASE

CB3

2

VOLUME

STATUS

indicator

(Standby/On)

CB1

VOL

SGND

SIG

-12D

+12D

+5V

SW

ASE

LEDG

LEDR

MAIN (3)

W10B

(W1)

3

• Semiconductor Location

Ref no. Location

D1 C2

AUTO

STANDBY

LOW

OFF

HIGH

SYSTEM

CONNECTOR

JK1

4

MAIN (6) (Side A) MAIN (6) (Side A)MAIN (9) (Side A)MAIN (7) (Side A) MAIN (10) (Side A)

WH

BR

GR

YE

BE

BE

R, S models R, S modelsU, T, A, B, G, L, H, J models

GR

W7B3

RE

W11B

W14B

W16B

W13B

W12B

W15B

W7B3

BL

W7B2

W7B2

RE

W7B1

W7B1

(W7A1, W7A2, W7A3)

MAIN (1)

YE

BE

BR

W14AW15A

W16A

W13A

VOLTAGE

SELECTOR

220-240V110-120V

5

RE

MAIN (2)

(W11A, W12A)

WH

W11B

W7B3

W7B2

BL

MAIN (2)

(W11A, W12A)

6

RE

W7B1

BE

W12B

MAIN (1)

(W7A1, W7A2, W7A3)

7

26

Page 27

ABCDEFGH I J

NS-SW300/NS-SW200

NS-SW200

1

MAIN (5) (Side B)

MAIN (8) (Side B)MAIN (4) (Side B)

2

4

5

IC7

8

1

3

• Semiconductor Location

Ref no. Location

D3 I4

D4 I4

D5 I3

4

D46 H3

D47 H3

Ref no. Location

IC1 I3

IC5 H3

IC7 C3

Q1 I4

Q2 I3

Ref no. Location

Q3 I3

Q4 I3

Q46 H3

Q47 H3

Q48 H3

14

IC5

85

58

IC1

41

MAIN (6) (Side B) MAIN (6) (Side B)MAIN (9) (Side B)MAIN (7) (Side B) MAIN (10) (Side B)

5

6

7

27

Page 28

NS-SW300/NS-SW200

■ PIN CONNECTION DIAGRAMS

• ICs

KIA78S05P-AT/P NJM4580E NJM78M12FA NJM79M12FANJM555MD

NJM2904M (TE3)

8

1

3

• Diodes

D3SBA60-71011SS355VMTE-17 D5SBA60 EL02ZLF-H5K RR264M-400TR

Anode

Cathode

S2L20U

Anode

+

TFZGTR10B

TFZGTR15B

4

1

8

4

1

3: IN

2: COM

1: OUT

3: COM

2: IN

1: OUT

S1NB60 1.0A 600V

Anode

–

AC

AC

–

AC

AC

+

Cathode

Cathode

Anode

AC

AC

–

+

UDZV5.1B

UDZV5.6B

UDZV6.2B

Anode

UDZV6.8B

UDZV24B

Anode

Cathode

Cathode

• Transistors

2SA949 2SA1162-Y (TE85R, F) 2SA1312-GR,BL 2SA1837

C

E

C

B

BF422 BF423ZL1G

E

C

B

E

C

B

E

B

KTA1046-Y-U/PFY KTA1266 Y AT KTC2026 STD01P STD01N STD03P STD03N

C

B

B

B

C

E

2SC4793

E

E

C

B

Cathode

B

C

E

2SC2712-Y (TE85R, F) 2SC3324-GR,BL

C

E

B

1

2

3

B

C

E

4

1

5

C

B

2

3

4

5

E

1

2

3

4

5

2SD2704 K

C

B

1

2

3

4

E

5

28

Page 29

A

BCDEFGH I J K

L MN

SCHEMATIC DIAGRAMS

NS-SW300

NS-SW300/NS-SW200

MAIN 1/2

1

STATUS indicator

MAIN (3)

LED_R

MAIN(3) MAIN(1)

INPUT1

TE1

s1

FROM

OUTPUT/

INPUT1

AMPLIFIER

L/R

TO

SPEAKERS

2

INPUT2

PJ1

RJ-1060-01-Z500

L/MONO

R31MR8

1M

R12

R14

R15

R17

2.2K

2.2K

2.2K

R10

12K

R16

12K

INPUT2/

R18

R19

2.2K

10/50

4.7K

4.7K

C4

R21

100K

R22

100K

R23

100K

R24

100K

C139

no_use

C8

R28

220P(SL)

R215

0

NORMAL

LOW CUT

C7

0.22

47K

)

1000P(B

R

R1

100K

PJ2

INPUT3/

3

LFE

SYSTEM

CONNECTOR

LFE

MSP-241V1-10-GI

R2

G

J10

0

no_use

JK1

LGY6501-0600

R4

100K

DCIN

PUP

ASE

100K

R6

12K

R11

12K

C1

10/50

4.2

10

4.2

0

220P(SL)

NJM4580E(TE2)

2

0

0

3

C2

no_use

C129

0.1/50(F)

R9

C3

R20

33K

0

IC9

IC9

1

8

V+

11.9

+12D

4

0

Q46

C5

AUTO STANDBY

CIRCUIT

AUTO

STANDBY

5

The voltages are measured

with AUTO STANDBY OFF.

電圧はオートスタンバイOFFで測定

12

OFF

AUTO STANDBY

OFF LOW HIGH

0.047/16

D2704(K)

R30

100

SSSU124900

SW2

L

H

MUSIC SENSOR

(J,U,T,K,A,B,G,L,H]

C12

220P(SL)

R33

3.3K

NJM4580E(TE2)

0

6

IC9

0

V-

5

4

0.1/50(F)

-12.2

C130

3.3K

-12D

)

2

C10

C14

100P(SL

0.22

R29

R31

100K

C141

B.A.S.S.

Q47

R13

47K

-0.5

C137

0.1/16

C11

LEDR

LED_R

R41

0

7

10K

R38

3.3K

NJM4580E(TE2)

5

0

0

6

4

-12.2

R34

10K

7

0

V-

R40

22K

C131

0.1/50(F)

-12D

NORM

MUSIC

MOVIE

B.A.S.S

11.9

11.9

C116

220P(SL)

11.9

-0.5

R35

R36

R37

1K

1.5K

C14

3.3K

2.7K

LED_G

R32

R193

0.6

5.0

V+

2

0

100P(SL)

2.8

3

C15

0.01(B)

A1312-GR,BL(TE8

LEDG

1.9

A1312-GR,BL(TE8

100/16

C20

0.033/100

R44

39K

NJM4580E(TE2)

6

0

IC6

IC6

5

0

V-

4

C21

-12.2

10/50

-12D

PHASE

REV

REV

C17

MUSIC

MOVIE

11.9

10K

D46

1SS355VM

1000P(B)

8

IC5

IC5

NJM2904M

0.1

NOM

REV

NOM

R42

100K

SW3

8

6

4

3

1

7

SSSF121900

C22

10/50

C18

R43

56K

3.7

R47

6.8K

1

OPE AMP

5.0

R46

5.0

Q1

R45

560

10/50

Q48

A1312-GR,BL(TE8

L.P.F

C24

7

0

10/50

R52

3.3K

PHASE SW

SW1

8

6

4

3

1

SSSF121900

7

5

2

R194

4.7K

R195

4.7K

6.2

D47

R51

2.2K

NJM2904M

3.6

6

IC5

2.8

5

4

10K

R50

4.4 4.0 3.7

47K

1SS355VMD41SS355VM

C25

10/50

5

C26

10/50

2

R217

100

+12

UDZV6.2B

R53

390K

V-

D3

R27

3.3K

R26

100K

H.P.F

R55

10K

s40

C30

R56

10K

R60

0.1/50(F)

CONTROL

1SS355VM

C2712-Y(TE85R,F

R58

10K

C27

0.1/16

R59

10K

C29

0

7

1/50

R61

(R,S)

HIGH CUT

40 to 140Hz

HIGH CUT

VR1

10KSX2

R64

10K

2

0

IC8

0

3

8

NJM4580E(TE2)

V+

10K

C132

+12D

D5

0.7

Q2

R63

4.7K

TIMER

VCC+5V

R65

1

M

NJM555M

R66

1.7

Q3

R62

10K

0

100K

VCC+5V

OUT

3.3K

C13

0.82

C32

0

1IC8

10/50

R5

1.0

+12D

+12

R68

1K

4.3

R69

10K

0

Q4

3.7

VCC

DISTHCONT

5.0

NJM555M

IC1

1234

GND

TRIG

0

10

C33

C2712-Y(TE85R,F

R39

SW

5.0

5.0

0

C34

C16

R57

100K

A1162-Y(TE85R,F

C37

10/50

3.7

5678

OUT

RES

3.7

5.0

330/16

C35

0.01(B)

+12D

C19

10/50

11.9

8

0

V+

3

IC6

0

2

NJM4580E(TE2)

0.12

R70

100

-12D

R7

1.0

ACRYON

J2

L1

no_use

3.3

C40

0.022

C39

0.01(B)

220/16

0

1

SGND

+12

-12

ASE

+5V

R48

8.2K

R49

10K

W3 CB3

0

0

11.9

11.9

-12.2

0

5.0

3.7

C23

10/50

18

PHI

R, S modelsU, T, K, A, B, G, L, H, J models

6

7

8

CAPACITOR

REMARKS

NONOMARK

MARK

P

RESISTOR

REMARKS

NO MARK

NOTICE

ELECTROLYTIC CAPACITOR

PARTS NAME

TANTALUM CAPACITOR

CERAMIC CAPACITOR

TUBULAR CAPACITORCERAMIC

POLYESTER FILM CAPACITOR

POLYSTYRENE FILM CAPACITOR

MICA CAPACITOR

POLYPROPYLENE FILM CAPACITOR

SEMICONDUCTIVE CERAMIC CAPACITOR

PARTS NAME

FILM RESISTOR

CARBON

FILM RESISTOR

CARBON

OXIDE FILM RESISTOR

METAL

FILM RESISTOR

METAL

PLATE RESISTOR

METAL

PROOF CARBON FILM RESISTOR

FIRE

MOLDED RESISTOR

CEMENT

VARIABLE RESISTOR

SEMI

(P=5)

(P=10)

CHIP RESISTOR

(model)

JAPAN

J

U.S.A

U

C

CANADA

GENERAL

R

CHINA

T

KOREA

K

AUSTRALIA

A

B BRITISH

G

EUROPE

L

SINGAPORE

SOUTH EUROPEE

V TAIWAN

F RUSSIAN

P LATIN AMERICA

S BRAZIL

H THAI

MAIN (8)

MAIN (9)

REREBL

MAIN[8]

MAIN[9]

BE

W12B

W7B1

W7B2

BEBEBL

W7B3

W8B1

W8B2

WH

W11B

W8B3

W11A

W12A

W9A

W10A

TE3

TE2

MAIN (8)

MAIN (10)

MAIN(10)

MAIN (11)

RE

BL

W7B2

W7B1

MAIN[8]

T2T2

BE

BE

W15B

s39

W12B

s34

W13A

CB11

s17

GR

W13B

s38

W14A

YE

110-120V

41

5

6

220-240V

VOLTAGE

SELECTOR

MAIN (5)

POWER

REBEBL

W7B3

BR

s37

s38

W16B

s39

s36

W15A

2

3

CB12

F2

s17

s18

ON

OFF

BE

W8B2

W8B1

YE

s36

W11B

W14B

s37

W16A

BRGRBE

s27

SW4

MAIN[11]

MAIN(5)

PS4E-A-040-NP

1500P/250

W8B3

W8A1

W8A2

AC27.4

W8A3

WH

s33

WH

W11A

s33

BE

W12A

s34

GY

W9A

SW5

C36

W9B

W10B

OR

W10A

LED_G

MAIN(6)

1GIS1GIS

SGND

no_use

BASWBASW

+12

+12

-12

-12

ASE

+5V

ACRYON

-17.0

Q17

C2712-Y(TE85R,F

PDET

16.8

-17.0

D6

D7

RR264M-400TR

BE

C41

0.82

BL

C42

0.82

BE

C43

s10

G5

s9

MAIN(2)

CB7 CB8

F1

s3

TE3 IPS-5007

TE2 IPS-5007

R109

PROTECTION

C44

9

SGND

SW

+12D

-12D

J3

R74

L2

10K

11.9

R72

33K

11.9

Q5

-12.2

LIMITER

R113

-17.0

68K

-16.4

Q19

A1312-GR,BL(TE8

10K

-15.4

1.1

R114

R73

10K

R75

10K

10/50

C47

R76

27K

C45

10/50

RR264M-400TR

POWER

SUPPLY

S1NB60-7101

D10

-17.8

0.01/275

DLS9D1-O(M)0.15

AC8.9

W1

LEDR

LEDG

1.9

ASE

SW

5.0

+5V

5.0

+12D

11.9

-12.2

-12D

SIG

SGND

VOL

011

PHL

B.A.S.S

0

A1312-GR,BL(TE8

12.0

R78

47K

Q7

R77

100K

+12

10

R89

Q11

C2712-Y(TE85R,F

0

0

0

0

Q12

A1162-Y(TE85R,F

-12

11.9

10K

R117

C70

1.6

R118

4.7K

10K

Q6

0

0

C2712-Y(TE85R,F

C2712-Y(TE85R,F

0.1

R79

10K

R81

1.0

17.8

1.0

C46

RY2

C51

C52

R82

T1

s2

SUB-

TRANSFORMER

CB1

LEDR

LEDG

ASE

SW

+5V

+12D

-12D

SIG

SGND

VOL

R83

15K

R80

100K

)

D2704(K

J9

D13

0

1SS355VM

D12

0

1SS355VM

R125

100K

0

Q22

10/5

-2.5

R84

47K

3.63.6

Q8

0

0

17.8

C125

470/25

470/25

C126

-17.8

100P(SL)

C49

0.27

R87

15K

C50

0.39

R85

330K

-12.0

R88

47K

11.9

R96

100

R97

100

-12.2

1.4

1.4

D2704(K)

D2704(K)

3.6

1SS355VM

R90

47K

3.6

3.6

0

C55

220/16

IC2

NJM78M12FA

IN

COM

0.01(B)

0.01(B)

COM

IN

NJM79M12FA

IC3

MAIN (2)

C53

C54

AC INAC IN

1259-7SDRGVW/S5

D1

RED

0

31

GR

1.9

R208

100

C134

100K

R209

C133

C135

2.2

A.N.I.C

NJM4580E(TE2)

5

0

IC10

s7

6

0

C56

Q24

D11

R91

R92

OUT

OUT

s35

s35

C59

0.12

R98

R93

15K

15K

C60

0.18

0

Q10

0

0

R127

0

R95

D2704(K)

Q14

C2712-Y(TE85R,F

000

C65

R101

100K

C66

R102

100K

0

Q15

A1162-Y(TE85R,F

10K

R128

R131

100K

22

R129

470K

0

C73

22/50

R132

R94

11.9

22K

Q9

A1312-GR,BL(TE8

10K

0.7

Q13

10K

C2712-Y(TE85R,F

+12

11.9

C127

0.01(B)

REGULATOR

C61

100/16

C62

100/16

C128

0.01(B)

-12.2

-12

SUB

POWER SUPPLY

0

C57

0.01/100

S1NB60-7101

2

R204

4.7K

C140

100P(SL)

-12

0

2

IC7

0

3

100P(SL)

NJM4580E(TE2)

R100

7

0

1K

C63

330K

D18

1SS355VM

47/16

R10647R112

47/16

D16

1SS355VM

R134

470K

1.4

D20

1SS355VM

C79

220K

100/16

R99

10

D15

s19

4.0

9.8

D14

4.0

(Standby/On)

STANDBY/ON

SW6

V-

C31

0

4

1

47/16

VOLUME

C58

10/50

C67

+12

R104

s20

C64

470

+12

R107

3.6

0.7

R105

Q18

s26

10/50

s23

0

0

100K

R111

R122

470

R103

Q16

s24

R108

D17

s21

10/50

0.82

00

SPPH130400

VR2

DUMMY

MIN MIN

5KAX2

DUMMY

100

R207

11.9

8

V+

IC10

IC10

2

4

-12.2

V-

R116

10K

10K

C68

10/50

R123

470

10K

J4

s25

R110

R115

s28

s28

s22

MAIN (4)

MAIN(4)

C136

2.2

R206

100

47/16

+12

C138

V+

5

8

0

IC7

6

C143

0

R214

100K

+12

NJM4580E(TE2)3

0

1

-12

+12

-12

47P(CH)

100

R124

SIG2

+12

-12

OCDET

SPRYON

s9

C69

G1

SP

s10

R216

100

IHP

4BC

AC99.4

MAIN (6)

REGULATOR

KIA78S05P-AT/P

IN

9.8

COM

s24

Q20

9.8

D19

RY2

s24

Q21

1SS355VM

1.2

s32

R119

C71

1000/25

J5

no_use

Q23

C2712-Y(TE85R,F

R120

R121

s31

s30

MAIN (1)

7

0

NJM4580E(TE2)

9

11.9

-12.2

-2.5

1.4

1

W4

PDET

W7A1

RE

BL

W7A2

RE

W7A3

ACRYON

+5V

CB5

13

5.0

0.7

W5

+5V

IC4

DLS9D1-O(M)0.15

R126

0

ACRYON

OUT

5.0

C72

10/50

R130

68

0.7

R136

C80

10/100

GND1

A1312-GR,BL(TE8

C81

s8

0.6 0.6

Q25

0.1 0.1

-68.0 -67.9

0

J7

A1312-GR,BL(TE8

R133

3.9K

-68.0

D22

100/16

C77

G4

0.1/250

0.1/250

J6

s11

PHI

C78

s10

0.01(B)

D5SBA60

-68.8

s12

1SS355VM

-68.0

Q26

-68.5

C2712-Y(TE85R,F

220

R135

C82

10/100

GND1

+12

-12

PN1

POWER

SUPPLY

D21

C83

G3

no_use

G8 s9

C76

SIG2

DNGSDNGS

LIMTLIMT

+12

-12

OCDET

SP

SPRYON

E2E2

JG-11-T

C74

C75

L3

E2

E2

10

560

68.0

Q27

0.6

PRE DRIVE

R137

10

Q29

100

R138

A1312-GR,BL(TE8

-67.9

C87

0.027/100

33

R140

C2712-Y(TE85R,F

220

R139

R141

GND1

GND3

RR264M-400TR

D8

45.0

D9

RR264M-400TR

s4

C85

C86

s4

-B

5 k-ohms

-67.9

J8

C84

no_use

s6

Q28

-68.5

s5

-67.9

68.8

68.6

68.0

67.567.5

C88

P

1000P/200

-67.3

-67.3

-68.0

KTA1266(Y)

10K

G6

R211

22

45.0

+B

10 W

C113

C114

+B

330/100

GND3

330/100

-B

RY1

OSA-SH-224DM3M

54

23

GND2

R180

SP+

NF

SP-

3P0.1

CB6

VHI

RE

13

WH

SUBWOOFER

D23

D24

R142

R185

R186

R187

Q30

R190

D43

UDZV6.8B

5 k-ohms

1SS355VM

Q31

39K

39K

39K

39K

Q32

-67.9

-67.9

G2

JG-11-T

A949(O/Y)

44.0

10K

44.0

R191

25.6

10K

20.6

D44

10 W

330

R143

1SS355VM

68.1

C89

-1.0

220

R144

GND2

Q50

44.0

44.0

44.0

UDZV24B

A1837

Q35AQ35C

68.0

820

R210

R148

G

C90

10/100

R188

BF423ZL1

1.1

R145

2.2

0.4

R147

10/100

0.4

R146

2.2

-1.0

STD03P

BF422

R189

C91

10/100

R149

-68.1

-68.7

C4793

RR264M-400TR

5.0

Q44

100

R213

44.0

A1312-GR,BL(TE8

Q49

10K

R192

A1312-GR,BL(TE8

R153

68.668.6

27

Q37

68.8

A1312-GR,BL(TE8

39K

39K

Q33C

4.8

STD03N

2.2

39K

39K

R86

0

R152

3.9K

R150

3P0.15

R151

3P0.15

0

-4.8

Q33A

C3324-GR,BL(TE8

-68.8

Q38

R154

-68.7

27

C92

P

1000P/200

R155

330K

D42

5.0 23.4

1.4

22K

R212

C48

4.7K

Q40

68.7

0

R157

1.2K

23.4

39K

0.1

R156

0.9

0.7

Q39

0.1

0.7

330/100

C2712-Y(TE85R,F

10K

R159

R158

10K

BF422

C96

0.022/100

C94

no_use

GND3

G7

no_use

D25

UDZV24B

RY1

Q41

C2712-Y(TE85R,F

C95

0.1

68.8

68.7

Q42

BF423ZL1G

-2.5

C99

39K

R161

C100

C97

0.022/100

39K

R184

10

R160

C98

1

6

OSA-SH-224DM3M

R163

5.6K

R165

5.6K

47/63

47/63

R166

5.6K

R164

5.6K

R162

150K

R167

100

0.47

100K

1000P/100

5.8 5.3

D27

RR264M-400TR

5.8

C101

D28

0

0.01/100

0

D29

C102

0.01/100

-5.8

D30

RR264M-400TR

NJM4580E(TE2)

C103

7

0

R168

68.8

22

R170

D31

2P1

R174

68.5

EL02ZLF-H5K

D32

68.2

EL02ZLF-H5K

D33

68.6

Q43C

C4793

68.6

4.8

EL02ZLF-H5K

HS1

PS AMPLIFIER

UDZV5.6B

UDZV5.6B

-4.8

Q43A

A1837

-5.4-5.8

IC11

4

-12.2

R169

10K

Destination Part List

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| sXX | LOC | J | U | RS | TK | A | BGLH |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s1 | TE1 | VC31370 | VC31370 | V481140 | V481140 | VC31370 | V481140 |

| | | LTS0810-1002FM| LTS0810-1002FM|LTS0810-1009-FM|LTS0810-1009-FM| LTS0810-1002FM|LTS0810-1009-FM|

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s2 | T1 | YC636A0 | YC637A0 | YC638A0 | YC639A0 | YC639A0 | YC639A0 |

| | | YC636 | YC637 | YC638 | YC639 | YC639 | YC639 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s3 | F1 | WG41050 | WG41050 | KB00079 | KB00075 | KB00075 | KB00075 |

| | | 6A125V | 6A125V | T4AL250V | T2AL250V | T2AL250V | T2AL250V |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s4 | C85 | V609250 | V609250 | ZH86010 | V609250 | V609250 | V609250 |

| | C86 | 8200/80 | 8200/80 | 9000/90 | 8200/80 | 8200/80 | 8200/80 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s5 | C84 | X | X | X | WB54020 | X | WB54020 |

| | | | | | 0.1/250 | | 0.1/250 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s6 | J8 | X | X | X | VN50000 | X | VN50000 |

| | | | | | JIS C 3101 | | JIS C 3101 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s7 | C56 | X | X | X | US06210 | X | US06210 |

| | | | | | 100P(SL) | | 100P(SL) |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s8 | C81 | US06247 | US06247 | US06247 | US06322 | US06247 | US06322 |

| | | 470P(SL) | 470P(SL) | 470P(SL) | 2200P(B) | 470P(SL) | 2200P(B) |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s9 | G8,G5 | X | X | X | V723510 | X | V723510 |

| | G1 | | | | JG-11-T | | JG-11-T |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s10 | C43 | X | X | X | US06410 | X | US06410 |

| | C69 | | | | 0.01(B) | | 0.01(B) |

| | C78 | | | | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s11 | L3 | X | X | X | V511780 | X | V511780 |

| | | | | | B-10 | | B-10 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s12 | J6 | VN50000 | VN50000 | VN50000 | X | VN50000 | X |

| | | JIS C 3101 | JIS C 3101 | JIS C 3101 | | JIS C 3101 | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s17 | CB12 | X | X | WN07770 | X | X | X |

| | CB11 | | | PFC5000-0202F | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s18 | F2 | X | X | KB00075 | X | X | X |

| | | | | T2AL250V | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s19 | D15 | X | X | WR89730 | X | X | X |

| | | | | RR264M-400TR | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s20 | R104 | X | X | VC74380 | X | X | X |

| | | | | 1P33 | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s21 | J4 | VN50000 | VN50000 | X | VN50000 | VN50000 | VN50000 |

| | | JIS C 3101 | JIS C 3101 | | JIS C 3101 | JIS C 3101 | JIS C 3101 |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s22 | D17 | X | X | WY16320 | X | X | X |

| | | | | UDZV5.1B | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s23 | R105 | X | X | RD35810 | X | X | X |

| | | | | 100K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s24 | Q16 | X | X | VJ92720 | X | X | X |

| | Q21 | | |A1162-Y(TE85R,F| | | |

| | Q20 | | | | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s25 | R108 | X | X | RD35747 | X | X | X |

| | | | | 47K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s26 | Q18 | X | X | VJ92710 | X | X | X |

| | | | |C2712-Y(TE85R,F| | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s27 | SW4 | X | X | WC90670 | X | X | X |

| | | | | SDKPA40300 | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s28 | R115 | X | X | RD35710 | X | X | X |

| | R110 | | | 10K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s30 | R121 | X | X | RD35682 | X | X | X |

| | | | | 8.2K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s31 | R120 | X | X | RD35712 | X | X | X |

| | | | | 12K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s32 | R119 | X | X | RD35610 | X | X | X |

| | | | | 1K | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s33 | W11A | MH19618 | MH19618 | MH19614 | MH19620 | MH19618 | MH19620 |

| | W11B |1P 180MM WHT M-|1P 180MM WHT M-|1P 140MM WHT M-|1P 200MM WHT M-|1P 180MM WHT M-|1P 200MM WHT M-|

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s34 | W12A | MH16618 | MH16618 | MH16614 | MH16620 | MH16618 | MH16620 |

| | W12B |1P 180MM BLU M-|1P 180MM BLU M-|1P 140MM BLU M-|1P 200MM BLU M-|1P 180MM BLU M-|1P 200MM BLU M-|

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s35 | C53 | X | X | WJ61020 | X | X | X |

| | C54 | | | 0.01/100 | | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s36 | W14B | X | X | MH14614 | X | X | X |

| | W14A | | |1P 140MM YEL M-| | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s37 | W16B | X | X | MH11614 | X | X | X |

| | W16A | | |1P 140MM BRN M-| | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s38 | W13B | X | X | MH15614 | X | X | X |

| | W13A | | |1P 140MM GRE M-| | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s39 | W15A | X | X | MH16614 | X | X | X |

| | W15B | | |1P 140MM BLU M-| | | |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

| s40 | C30 | X | X | X | US06110 | X | US06110 |

| | | | | | 10P(CH) | | 10P(CH) |

+--------+---------------+---------------+---------------+---------------+---------------+---------------+---------------+

-68.7

22

R171

D35

EL02ZLF-H5K

-68.8

5

0

6

0

V-

C104

10/50

HS2

D34

-68.2-68.5

EL02ZLF-H5K

D36

EL02ZLF-H5K

C105

0.039/100

C106

0.95UH

TP2

C107

R172

0.18

C108

L4

R173

4.7

C109

0.18

R175

no_use

0.22

4.7/250

4.7/250

0.22

2P1

R176

22K

R177

10K

C110

R178

220

R179

220

C111

Q45A

STD03P

68.6 4.8

L5

120UH

L6

120UH

-68.7

Q45C

STD03N

TP1

NJM4580E(TE2)

1

0

IC11

11.9

V+ 8

68.8

S2L20U-5002P7.5

S2L20U-5002P7.5

S2L20U-5002P7.5

S2L20U-5002P7.5

-4.8

-68.8

3

0

2

0

C112

10/50

+12-12

WJ36210

STD03P

D39

4.8

D40

D37

-4.8

D38

WJ36220

STD03N

WK19290

Safety measures

• Some internal parts in this product contain high voltages and are dangerous. Be sure to take safety measures during servicing, such as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous even after the power is turned off because an electric charge remains and a high voltage continues to exist there.

Before starting any repair work, connect a discharging resistor (5 k-ohms/10 W) to the terminals of each capacitor indicated below to discharge electricity.

The time required for discharging is about 30 seconds per each.

C85, C86 on MAIN (1) P.C.B.

安全対策

・ この製品の内部には高電圧部分があり危険です。修理の際は、絶縁性の手袋を使用するなどの安全対策を行ってください。

・ 下記のコンデンサには電源を OFF にした後も電荷が残り、高電圧が維持されており危険です。修理作業前に放電用抵抗(5kΩ/10W)を

下記の各コンデンサの端子間に接続して放電してください。放電所用時間は各々約 30 秒間です。

MAIN(1)P.C.B. の C85、C86

DRIVER

10

★ All voltages are measured with a 10MΩ/V DC electronic voltmeter.

★ Components having special characteristics are marked ⚠ and must be replaced

with parts having specifications equal to those originally installed.

★ Schematic diagram is subject to change without notice.

●電圧は、内部抵抗 10MΩの電圧計で測定したものです。

●⚠印のある部品は、安全性確保部品を示しています。部品の交換が必要な場合、

パーツリストに記載されている部品を使用してください。

●本回路図は標準回路図です。改良のため予告なく変更することがあります。

Threshold

Trigger

Reset

Discharge

GND

IC1: NJM555M

Timer

8

V+

6

2

4

7

1

Control Voltage

5

3

Output

IC2: NJM78M12FA

Voltage regulator

INPUT

OUTPUT

COMMON

IC3: NJM79M12FA

Voltage regulator

COMMON

OUTPUT

INPUT

IC4: KIA78S05P-AT/P

Three terminal positive voltage regulator

Q14

Q1

Z1

Q16

R11 R10 R9

R1

Q2 Q7

Q3 Q5

Q4 Q6

R2

Q8

R3

R4

C1

Q9

Q10

Q11

Q12

3 INPUT

IC5: NJM2904M (TE3)

Q13

R8

R7

1

OUTPUT

R6 R5

2

COMMON

Single supply dual operational amplifier

1

A

2

3

B

8

7

6

54

1. A OUTPUT

2. A-INPUT

3. A+INPUT

4. GND

5. B+INPUT

6. B-INPUT

7. B OUTPUT

8. V

+

IC6–11: NJM4580E

Dual operational amplifier

V+

8

–INPUT

+INPUT

2, 6

3, 5

V–

4

1, 7

OUTPUT

29

Page 30

A

BCDEFGH I J KLMN

NS-SW300/NS-SW200

NS-SW200

MAIN 2/2

1

MAIN (3)

STATUS indicator

1259-7SDRGVW/S5

MAIN(3) MAIN(1)