Page 1

1987 - 1990

Downloaded from www.ScooterTime.net

MOTORCYCLE

SERVICE MANUAL

Model : CE50T, CG50A, CG50U, CG50W

2YT281972000

*2YT281972000*

Page 2

CE50T

Downloaded from www.ScooterTime.net

SERVICE MANUAL

©1986 by Yamaha Motor Co., Ltd.

1st Edition, November 1986

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Page 3

3

Downloaded from www.ScooterTime.net

Page 4

NOTICE

Downloaded from www.ScooterTime.net

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and

their qualified mechanics. It is not possible to put an entire mechanic's education into one manual,

so it is assumed that persons using this book to perform maintenance and repairs on Yamaha scooter

have a basic understanding of the mechanical concepts and procedures inherent in scooter repair tech-

nology. Without: such knowledge, attempted repairs or service to this model may render it unfit to

use and/or unsafe.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by Yamaha.

Modifications and significant changes in specifications or procedures will be forwarded to all Autho-

rized Yamaha dealers and will, where applicable, appear in future editions of this manual.

TECHNICAL PUBLICATIONS

SERVICE DIVISION

MOTORCYCLES OPERATIONS

YAMAHA MOTOR CO., LTD.

HOW TO USE THiS MANUAL

PARTICULARLY iMPORTANT iNFORMATiON

This material is distinguished by the following notation.

D

NOTE: A NOTE provides key information to make procedureseasier or clearer.

ili ii i iiil ACAUTIONindicatesspecialproceduresthatmustbefollowedtoavoid

damage to the scooter.

A WARNING indicatesspecial procedures that must be followed to avoid injury

to a scooter operator or person inspecting or repairingthe scooter.

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The informa-

tion has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of afaulty component will precede an arrow symbol and the course

of action required will follow the symbol, e.g.,

• Bearings

Pitting/Damage_ Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying cor-

rect disassembly and assembly procedures.

Page 5

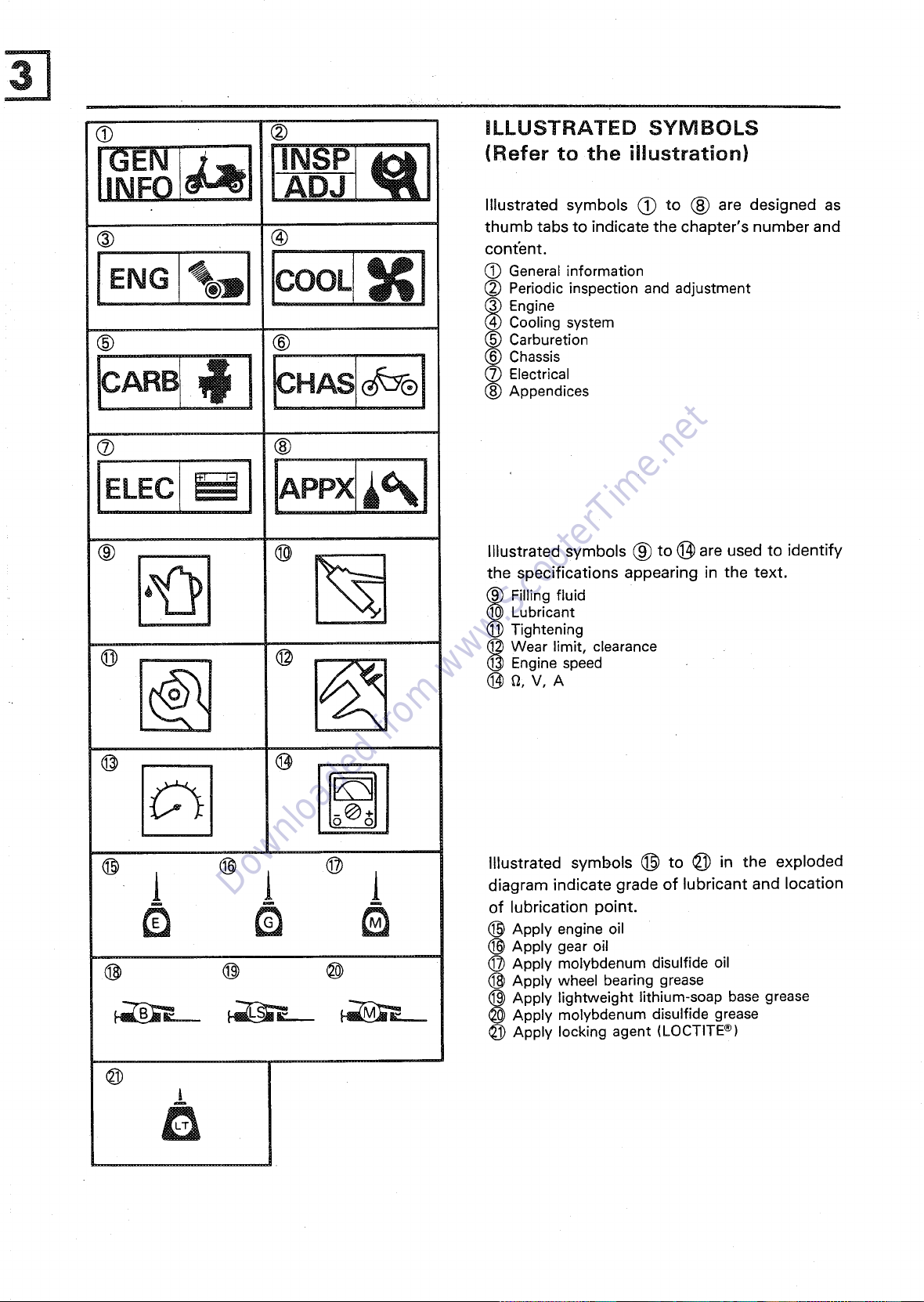

(9 ® iLLUSTRATED SYMBOLS

Downloaded from www.ScooterTime.net

IGENINFO (Refer to the illustration)

Illustrated symbols (_) to _) are designed as

thumb tabs to indicate the chapter's number and

(_ (_) content.

ENG OOL Periodic inspection and adjustment

(_ (_) _ Carburetion

ICARB[ ]_ 1 _"AS1_I _(_)_; pter'nCdl'ces

® ®

® ® _ Illustrated symbols (_ to (_) are used to identify

%_JDI IC _i General information

_ EngineCooling system

Chassis

@

6_ _ the specifications appearing in the text.

(_) Filling fluid

(_ Lubricant

(_) Tightening

_Wear limit, clearance(_) (_) -- Engine speed

@ @

® ®

.,1 _ j diagram indicate grade of lubricant and location

- _ = of lubrication point.

_ _ ® Apply engine o,1

@ (_ (_ @(_Apply molybdenum disulfide oilApply wheel bearing grease

_ _ _ _L_.._ _(_))Apply lightweight lithium-soap base grease

@

Illustrated symbols (_ to (_ in the exploded

® Apply gear oil

Apply molybdenum disulfide grease

Apply locking agent (LOCTITE ®)

®

l

m

i

Page 6

INDEX

Downloaded from www.ScooterTime.net

GENERAL,NFORMAT,ON

ENGINE OVERHAUL '_'%_

ENG _

CARBURETION

CARB_,

CHASSIS CHAS_

L..,-.-----J

ELECTRICAL ELEC_

APPENDICES APPX_

Page 7

i

Downloaded from www.ScooterTime.net

!

i

i

1

p,

Page 8

GEN

Downloaded from www.ScooterTime.net

CHAPTER 1

GENERAL INFORMATNON

SCOOTER IDENTIFICATION ....................................... B-3

VEHICLE IDENTIFICATION NUMBER .............................. B-3

ENGINE SERIAL NUMBER ....................................... B-3

IMPORTANT INFORMATION ...................................... B-3

ALl. REPLACEMENT PARTS ..................................... B-3

GASKETS, OIL SEALS, AND O-RINGS ............................ B-3

LOCK WASHER/PLATES AND COTTER PINS ..................... B-3

BEARINGS AND OIL SEALS ..................................... B-4

CIRCLIPS ...................................................... B-4

SPECIAL TOOLS .................................................. B-4

FOR TUNE-UP .................................................. B-4

FOR ENGINE SERVICE .......................................... B-4

FOR CHASSIS SERVICE ......................................... B-5

FOR ELECTRICAL COMPONENTS ................................ B-5

m

Page 9

Downloaded from www.ScooterTime.net

Page 10

INFO

Downloaded from www.ScooterTime.net

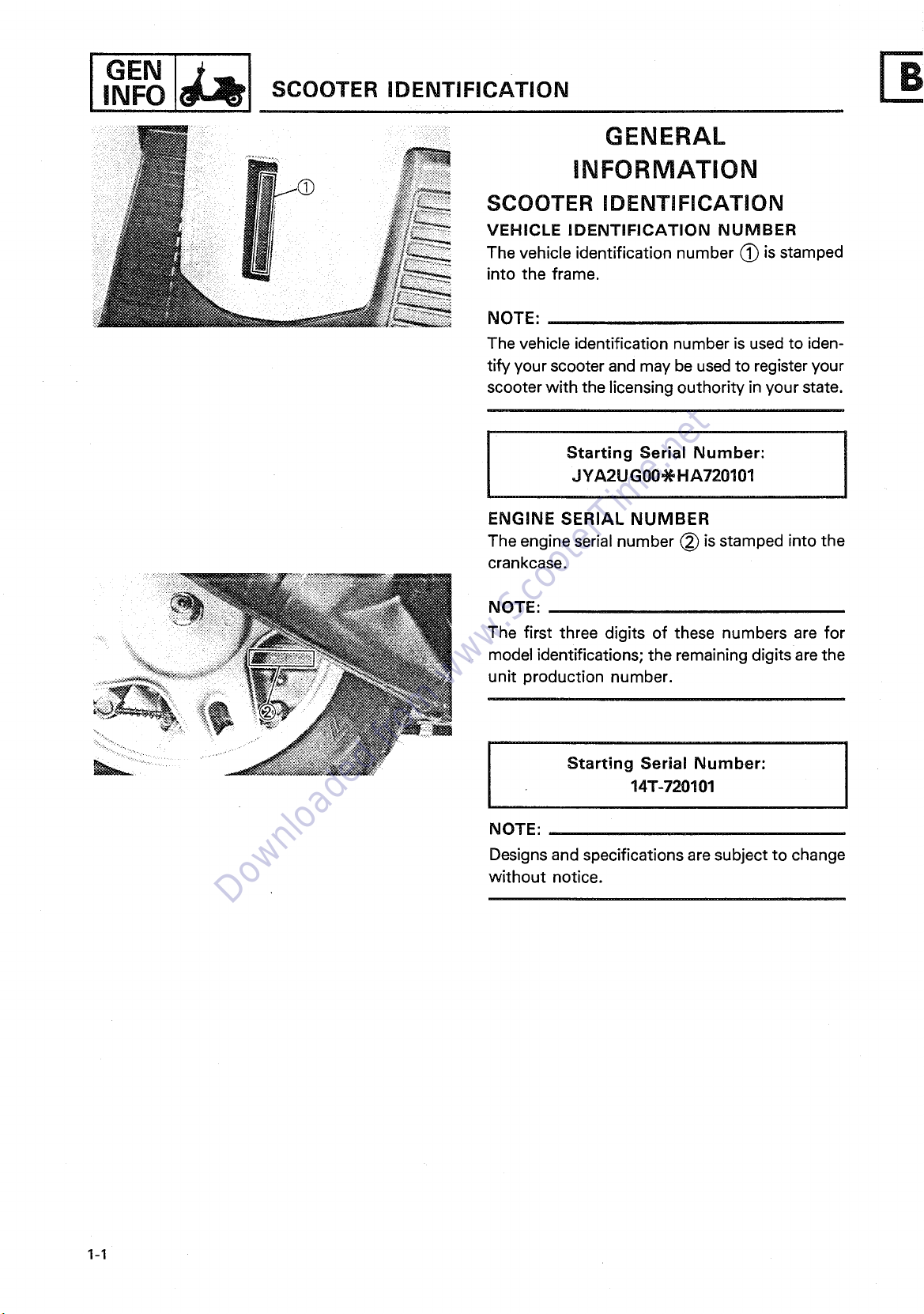

SCOOTER IDENTIFICATION

GENERAL

INFORMATION

SCOOTER IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number (~ is stamped

into the frame.

NOTE:

The vehicle identification number is used to iden-

tify your scooter and may be used to register your

scooter with the licensing outhority in your state.

Starting Serial Number:

JYA2U G00-~ H A720101

ENGINE SERIAL NUMBER

The engine serial number (~ is stamped into the

crankcase.

NOTE:

The first three digits of these numbers are for

model identifications; the remaining digits are the

unit production number.

Starting Serial Number:

14T-720101

NOTE:

Designs and specifications are subject to change

without notice.

1-1

Page 11

IMPORTANT INFORMATION INFO

Downloaded from www.ScooterTime.net

I°E"

IMPORTANT INFORMATION

ALL REPLACEMENT PARTS

1. Use only genuine Yamaha parts for all

replacements. Use oiland/or grease recom-

mended by Yamaha for assembly and adjust-

ment. Other brands may be similar in func-

tion and appearance, but inferior in quality.

GASKETS, OIL SEALS, AND O-RINGS

1. All gaskets, seals, and O-rings should be

replaced when an engine is overhauled. All

gasket surfaces, oil seal lips and O-rings must

be cleaned.

2. Properly oil all mating parts and bearings dur-

ing reassembly. Apply grease to the oil seal

lips.

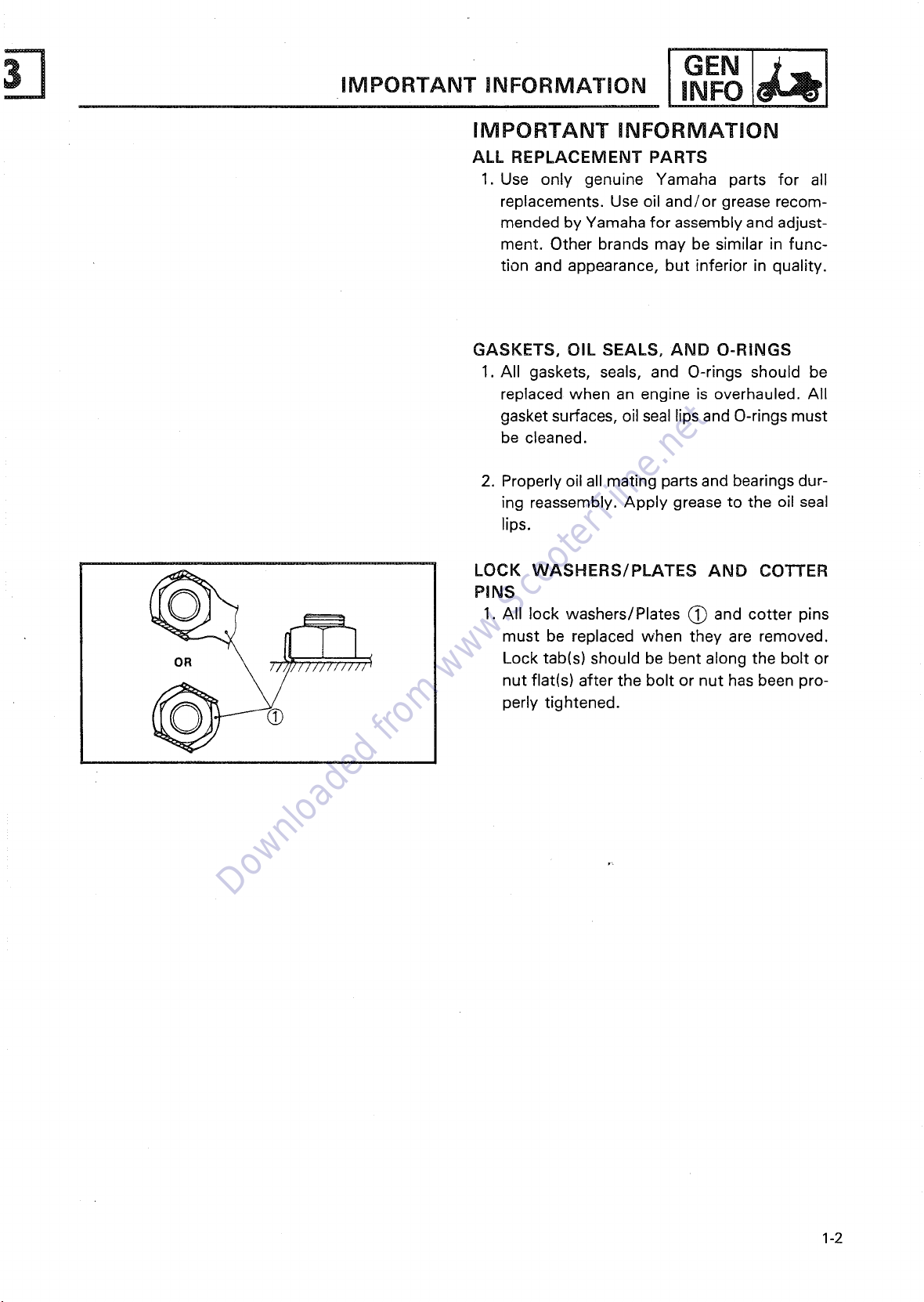

LOCK WASHERS/PLATES AND COTTER

PINS

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been pro-

perly tightened.

1. All lock washers/Plates (_ and cotter pins

1-2

Page 12

INFO iMPORTANT iNFORMATiON

Downloaded from www.ScooterTime.net

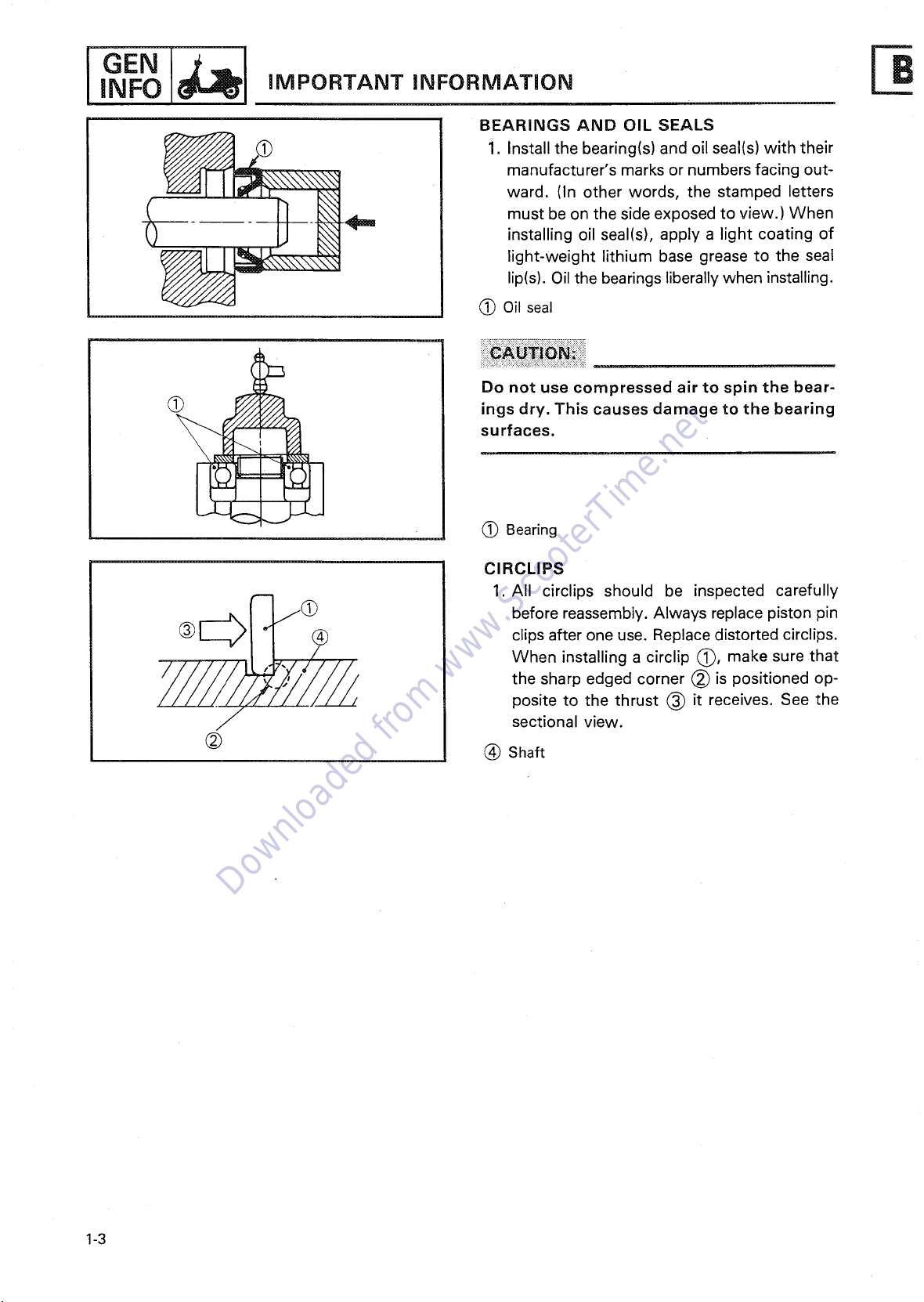

BEARINGS AND OIL SEALS

manufacturer's marks or numbers facing out-

ward. (In other words, the stamped letters

__) _ must be on the side exposed to view.) When

(_ ings dry. This causes damage to the bearing

_/._/7_/_////_ When installing a cirelip (_, make sure th at

/J sectional view.

installing oil seal(s), apply a light coating of

i. Install the bearing(s) and oil seal(s) with their

lip(s). Oil the bearings liberally when installing.

light-weight lithium base grease to the seal

(_ Oil seal

Do not use compressed air to spin the bear-

surfaces.

(_ Bearing

CIRCLIPS

1. All circlips should be inspected carefully

clips after one use. Replace distorted circlips.

e orereas ereoaceO ton

the sharp edged corner (_ is positioned op-

posite to the thrust (_) it receives. See the

(_) (_) Shaft

1-3

Page 13

3

Downloaded from www.ScooterTime.net

GEN

I

SPECIAL TOOLS I

SPECIAL TOOLS

The proper special tools are necessary for com-

plete and accurate tune-up and assembly. Using

the correct special tool will help prevent damage

caused by the use of improper tools or improvis-

ed techniques.

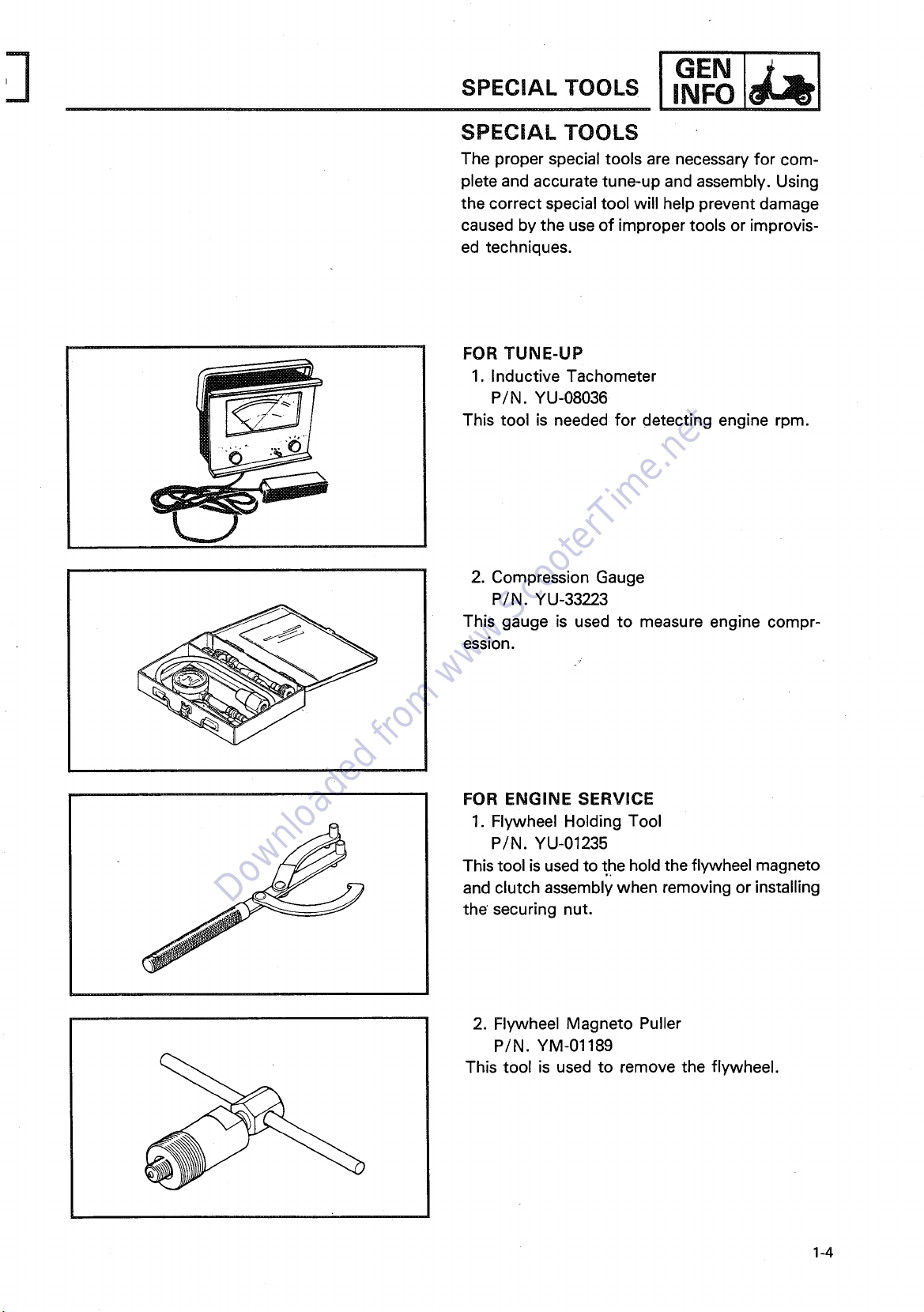

FOR TUNE-UP

1. Inductive Tachometer

P/N. YU-08036

This tool is needed for detecting engine rpm.

2. Compression Gauge

P/N. YU-33223

This gauge is used to measure engine compr-

ession.

FOR ENGINE SERVICE

1. Flywheel Holding Tool

P/N. YU-01235

This tool is used to the hold the flywheel magneto

and clutch assembly when removing or installing

the securing nut.

2. Flywheel Magneto Puller

P/N.

YM-01189

This tool is used to remove the flywheel.

1-4

Page 14

I GEN

Downloaded from www.ScooterTime.net

SPECIAL TOOLS

i ............. ir

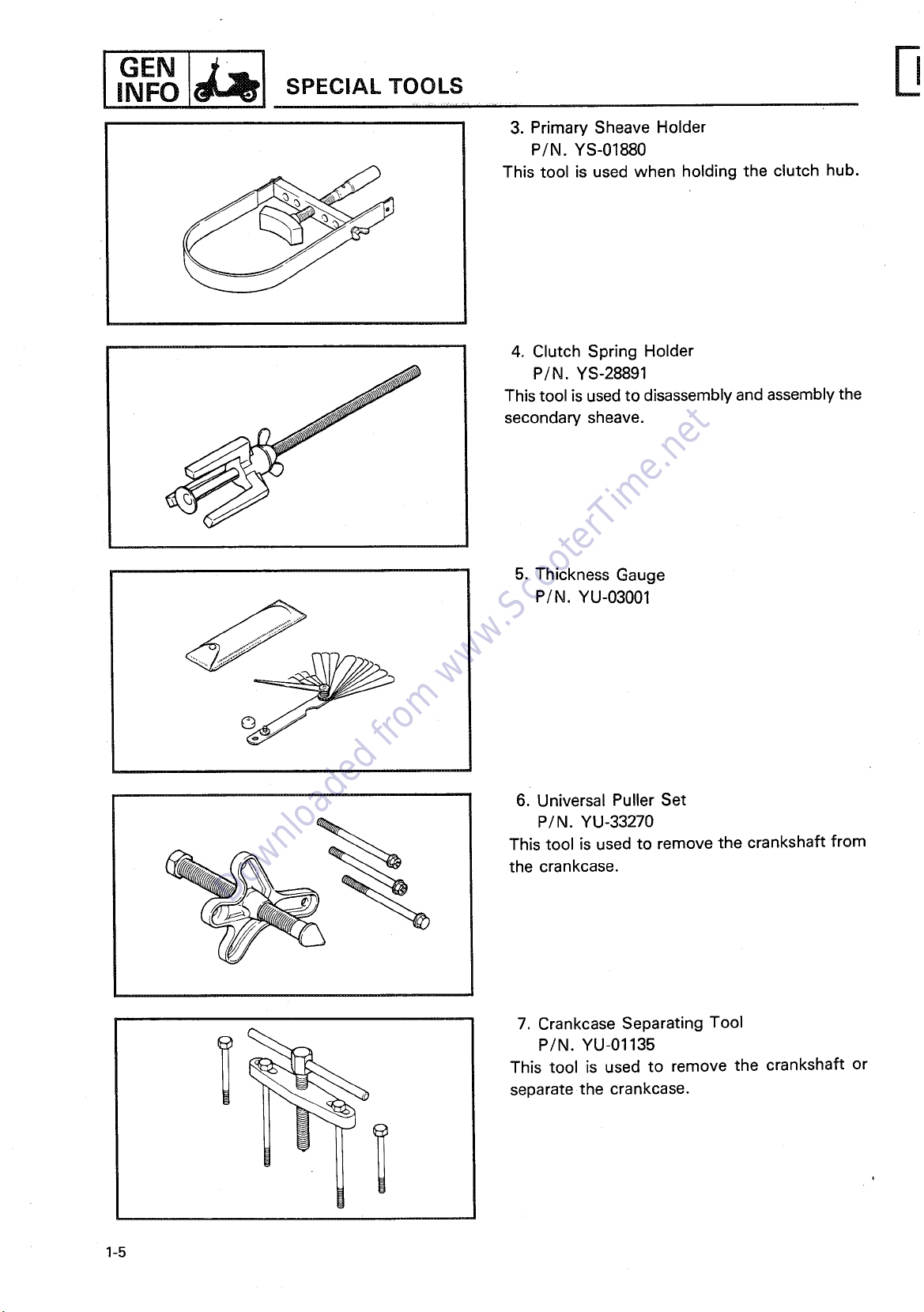

3. Primary Sheave Holder

P/N.

YS-01880

This tool is used when holding the clutch hub.

4. Clutch Spring Holder

P/N.

YS-28891

This tool is used to disassembly and assembly the

secondary sheave.

P

5.

Thickness Gauge

P/N. YU-03001

6.

Universal Puller Set

P/N. YU-33270

This tool is used to remove the crankshaft from

the crankcase.

7. Crankcase Separating Tool

P/N. YU-01135

This tool is used to remove the crankshaft or

separate the crankcase.

1-5

Page 15

I

Downloaded from www.ScooterTime.net

GEN

SPECIAL TOOLS I

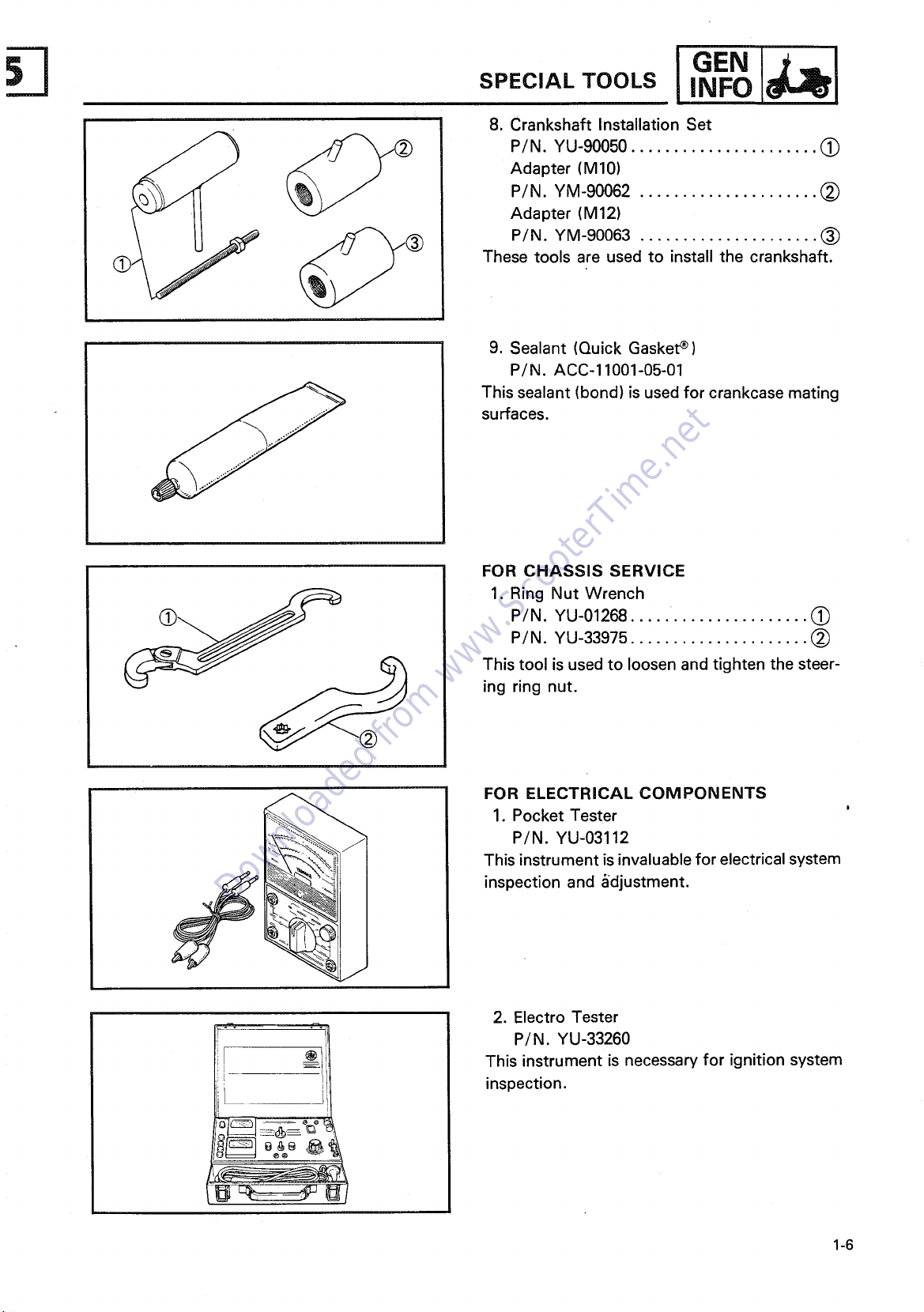

8. Crankshaft Installation Set

P/N. YU-90050 ...................... (~)

Adapter (M10)

P/N. YM-90062 ..................... (~

Adapter (M12)

P/N. YM-90063 ..................... ~)

These tools are used to install the crankshaft.

9. Sealant (Quick Gasket ~)

P/N. ACC-11001-05-01

This sealant (bond) is used for crankcase mating

surfaces.

,.Fol l

@

!J

FOR CHASSIS SERVICE

1. Ring Nut Wrench

P/N. YU-01268 (~

P/N. YU-33975 ..................... (~

This tool is used to loosen and tighten the steer-

ing ring nut.

FOR ELECTRICAL COMPONENTS

1. Pocket Tester

P/N. YU-03112

This instrument is invaluable for electrical system

inspection and §djustment.

2. Electro Tester

P/N. YU-33260

This instrument is necessary for ignition system

inspection.

1-6

Page 16

INSP

Downloaded from www.ScooterTime.net

CHAPTER 2

PERiODiC iNSPECTiONS AND ADJUSTMENTS

INTRODUCTION ................................................. C-3

PERIODIC MAINTENANCE/LUBRICATION INTERVALS ............ C-3

TAIL COVER ..................................................... C-3

REMOVAL .................................................... C-3

INSTALLATION ................................................ C-4

FRONT FENDER, FRONT PANEL AND FOOTREST BOARD ......... C-4

REMOVAL .................................................... C-4

INSTALLATION ................................................ C°5

HANDLEBAR COVERS ........................................... C-5

REMOVAL ..................................................... C-5

INSTALLATION ................................................ C-5

ENGINE .......................................................... C-5

ENGINE IDLE SPEED ADJUSTMENT ............................. C-5

THROTTLE CABLE FREE PLAY ADJUSTMENT ................... C-6

AUTOLUBE PUMP CABLE ADJUSTMENT ........................ C-6

AUTOLUBE PUMP AIR BLEEDING ............................... C°7

AIR CLEANER ELEMENT CLEANING ............................. C-8

FUEL COCK CLEANING ........................................ C-8

COMPRESSION PRESSURE MEASUREMENT ..................... C-9

ENGINE OIL LEVEL INSPECTION ................................ C-10

TRANSMISSION OIL REPLACEMENT .... ........................ C-10

FUEL LINE INSPECTION ........................................ C-11

CHASSIS ........................................................ C-11

FRONT BRAKE LEVER FREE PLAY CHECK ....................... C-11

REAR BRAKE LEVER FREE PLAY CHECK ....................... C-11

FRONT AND REAR BRAKE LINING INSPECTION ................ C-12

TIRE AND WHEEL INSPECTION ................................. C-12

STEERING ADJUSTMENT ...................................... C-12

ELECTRICAL ..................................................... C-13

BATTERY ..................................................... C-13

FUSE INSPECTION ............................................. C-14

SPARK PLUG INSPECTION ..................................... C-14

HEADLIGHT BEAM ADJUSTMENT .............................. C-15

IGNITION TIMING ......................................... ..... C-15

Page 17

Downloaded from www.ScooterTime.net

Page 18

ADJ LUBRICATION iNTERVALS

Downloaded from www.ScooterTime.net

I INSPli 1 INTRODUCTION/PERIODIC MAINTENANCE/ B

PERIODIC INSPECTIONS AND ADJUSTMENTS

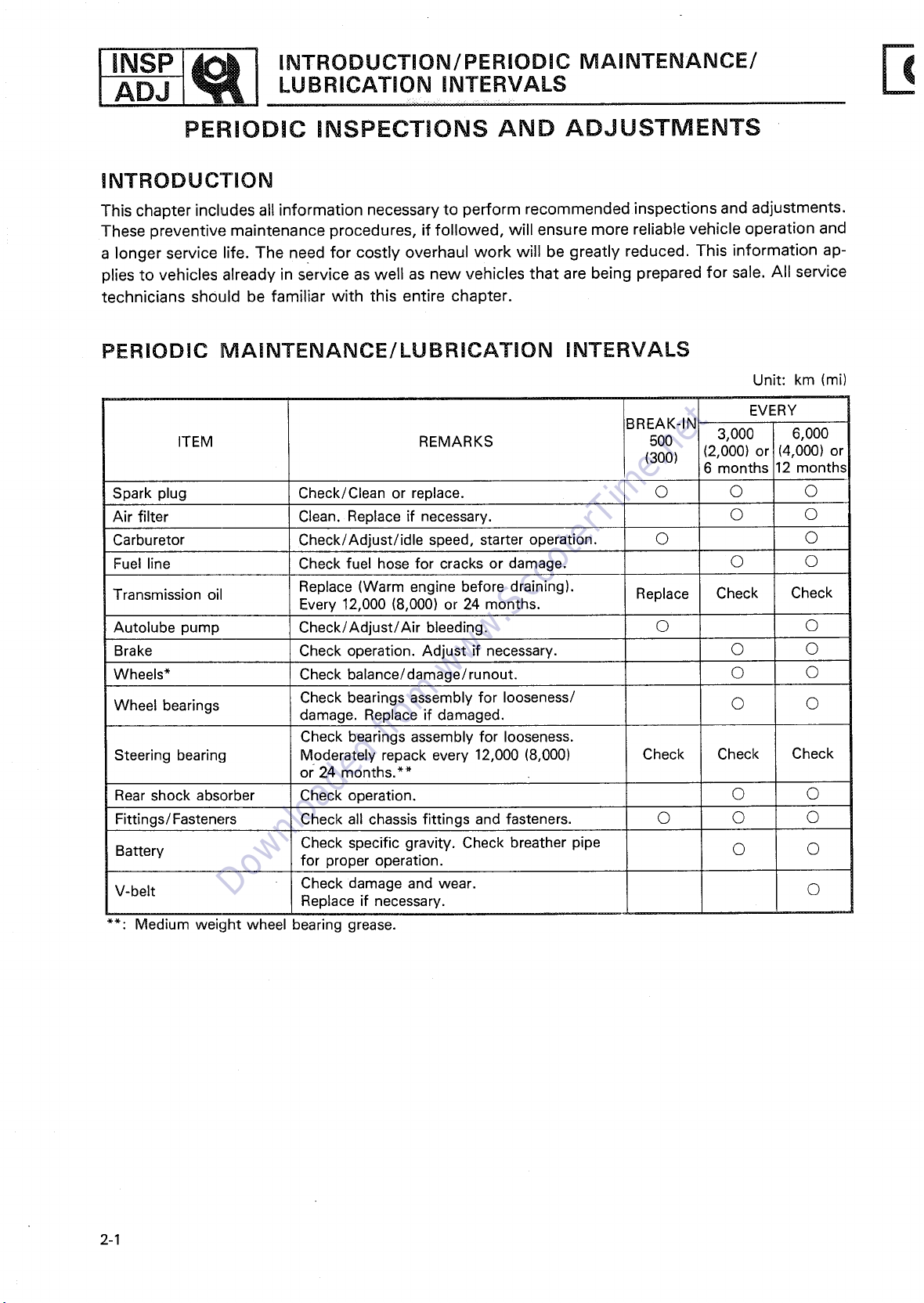

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments.

These preventiw, • maintenance procedures, if followed, will ensure more reliable vehicle operation and

a longer service life. The need for costly overhaul work will be greatly reduced. This information ap-

plies to vehicles already in service as well as new vehicles that are being prepared for sale. All service

technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

Unit: km (mi)

BREAK-IN

ITEM REMARKS 500 3,000 6,000

(300) (2,000) or (4,000) or

Spark plug Check/Clean or replace. O © O

Air filter Clean. Replace if necessary. O ©

Carburetor Check/Adjust/idle speed, starter operation. © ©

Fuel line Check fuel hose for cracks or damage. O O

Transmission oil Replace (Warm engine before draining). Replace Check Check

Autolube pump Check/Adjust/Air bleeding. O O

Brake Check operation. Adjust if necessary. O O

Wheels* Check balance/damage/runout. O O

Wheel bearings damage. Replace if damaged.

Steering bearing Moderately repack every 12,000 (8,000) Check Check Check

Rear shock absorber Check operation. O O

Fittings/Fasteners Check all chassis fittings and fasteners. O O O

Battery for proper operation.

Every 12,000 (8,000) or 24 months.

Check bearings assembly for looseness/ O O

Check bearings assembly for looseness.

or 24 months.**

Check specific gravity. Check breather pipe O O

EVERY

6 months 12 months

V-belt Check damage and wear. O

**: Medium weight wheel bearing grease.

2-1

Replace if necessary.

Page 19

TAIL COVER ADJ

Downloaded from www.ScooterTime.net

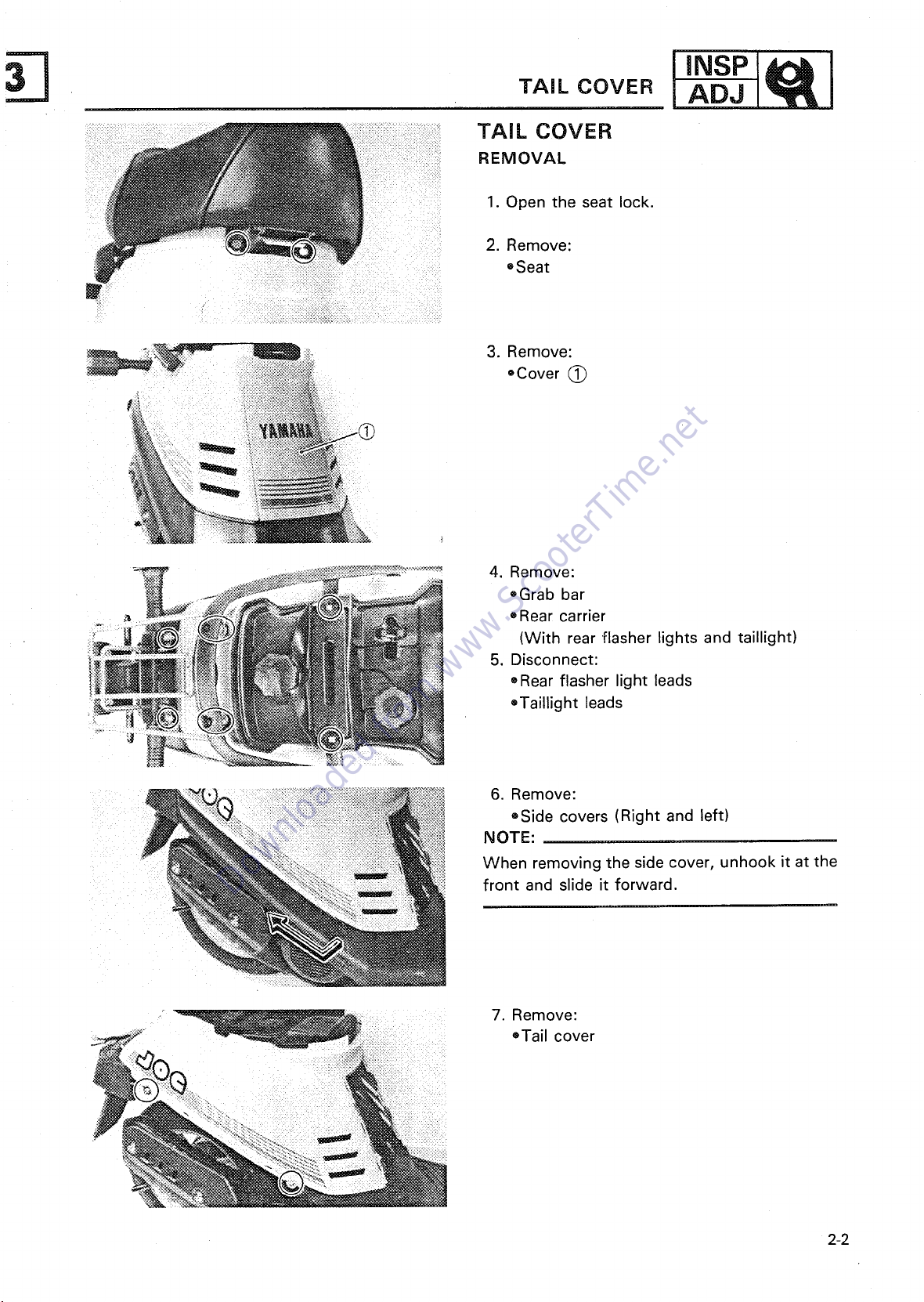

TAIL COVER

REMOVAL

1. Open the seat lock.

2. Remove:

=Seat

3. Remove:

-Cover (_

4. Remove:

,Grab bar

_ , Rear carrier

(With rear flasher lights and taillight)

5. Disconnect:

,Rear flasher light leads

•Taillight leads

6. Remove:

®Side covers (Right and left)

NOTE:

When removing the side cover, unhook it at the

front and slide it forward.

7. Remove:

=Tail cover

: !!

2-2

Page 20

INSP E

Downloaded from www.ScooterTime.net

ADJ _1 TA'LCOVER

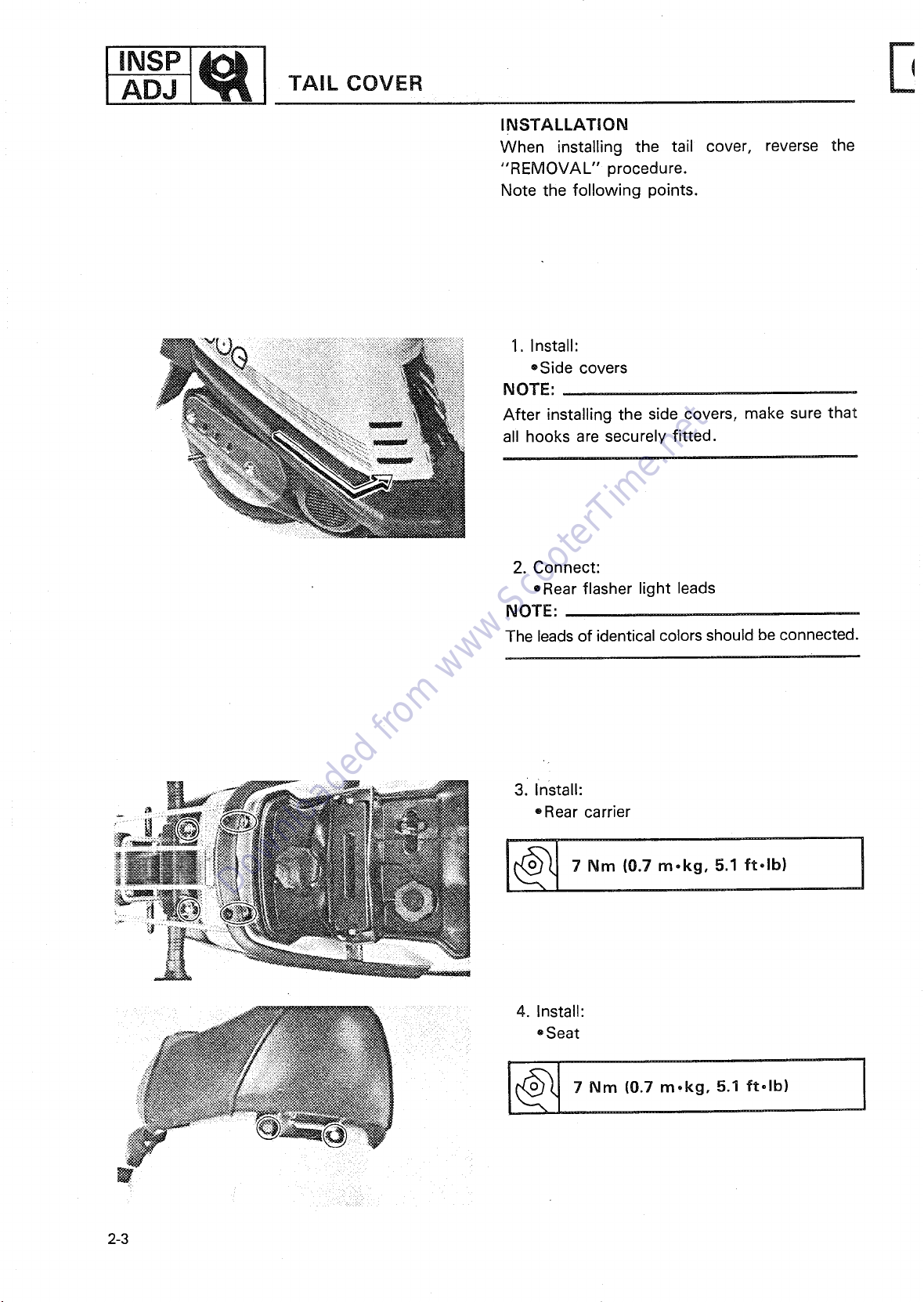

INSTALLATION

When installing the tail cover, reverse the

"REMOVAL" procedure.

Note the following points.

1. Install:

®Side covers

NOTE:

After installing the side covers, make sure that

all hooks are securely fitted.

2. Connect:

eRear flasher light leads

NOTE:

The leadsof identical colors should beconnected.

31install:

i_J_. ®Rear carrier

i__i 7Nm (0.7 m,kg, 5.1 ft-lb)

4. Install:

eSeat

!_ 7 Nm (0.7 5.1 ft,lb)

2-3

m,kg,

Page 21

I FRONT FENDER, FRONT PANEL INSP

Downloaded from www.ScooterTime.net

- i

AND FOOTREST BOARD ADJ

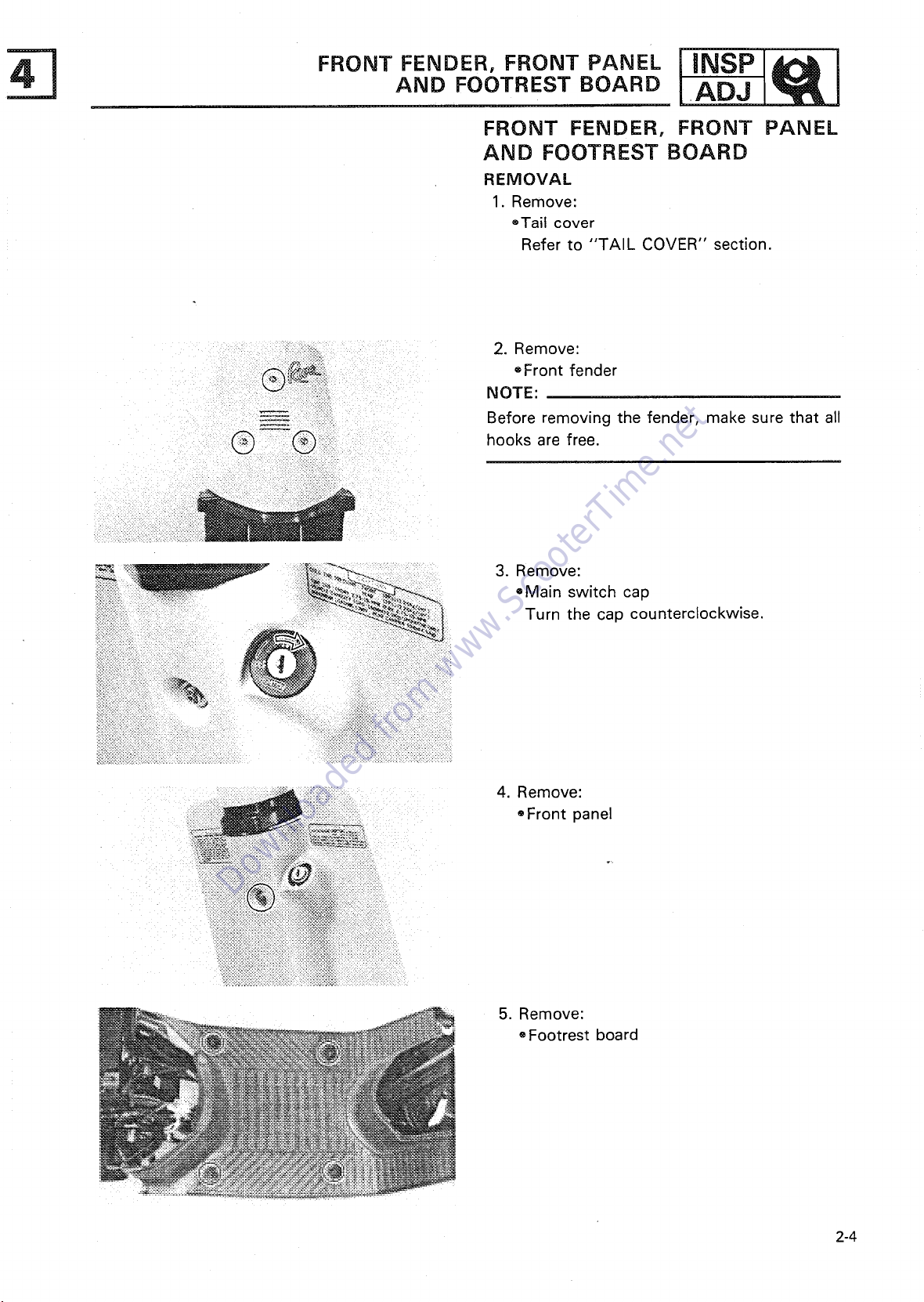

FRONT FENDER, FRONT PANEL AND FOOTREST BOARD

REMOVAL

1. Remove:

-Tail cover

Refer to "TAIL COVER" section.

2. Remove:

®Front fender

_, NOTE:

@ i:Q::!i hooks are free.

_N % - -_ - 3. Remove:

_iiiii:iiii___" ,Main switch cap

i:iiii!i!ilii_ii Turn the cap counterclockwise.

!_-::

Before removing the fender, make sure that all

4. Remove:

®Front panel

5. Remove:

, Footrest board

2-4

Page 22

I INSP

Downloaded from www.ScooterTime.net

FRONT FENDER, FRONT PANEL

AND FOOTREST BOARD/HANDLEBAR COVERS

I

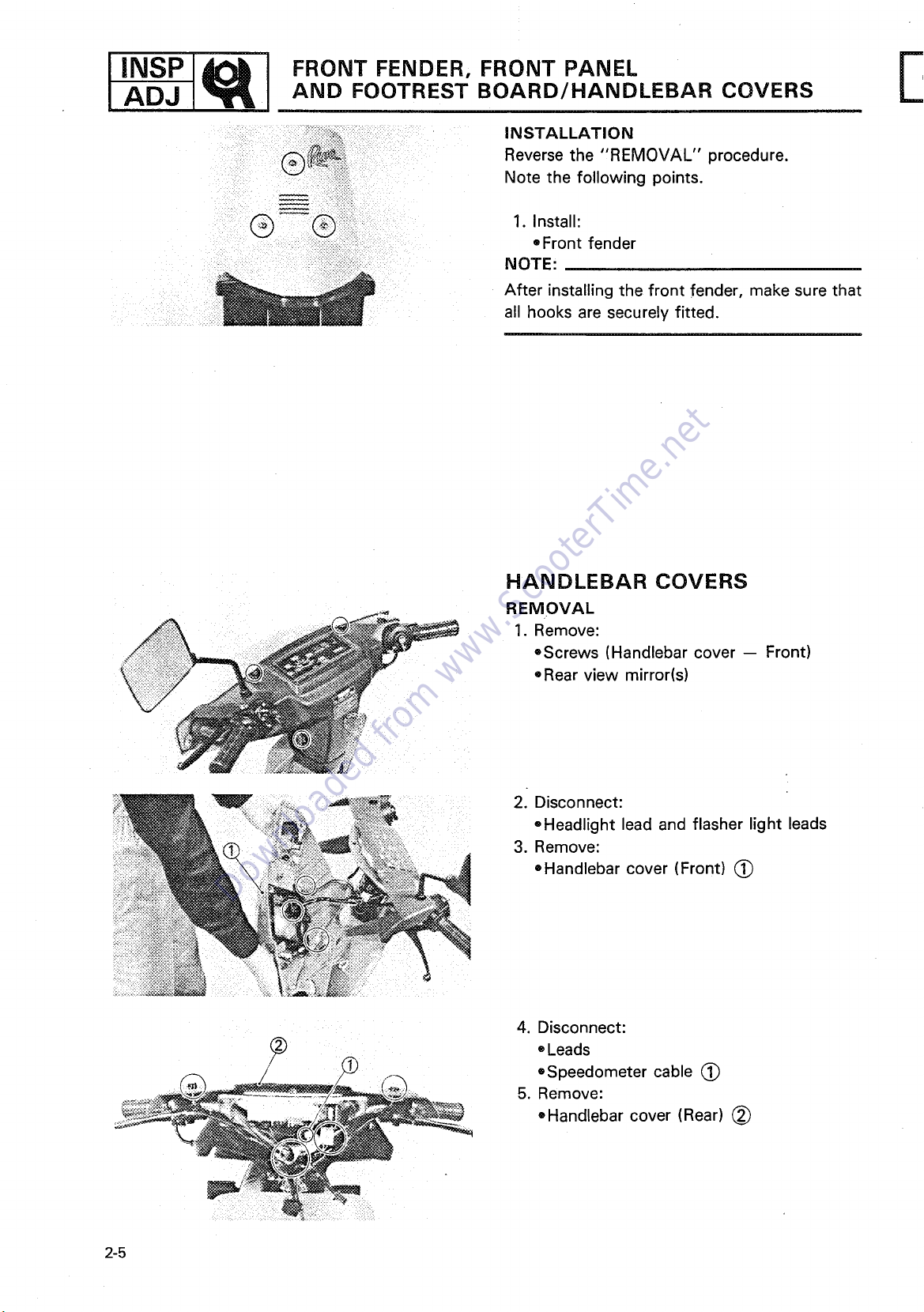

NSTALLATION

Reverse the "REMOVAL" procedure.

Note the following points,

1. Install:

® Front fender

NOTE:

After installing the front fender, make sure that

all hooks are securely fitted.

E

HANDLEBAR COVERS

REMOVAL

1. Remove:

=Screws (Handlebar cover -- Front)

=Rear view mirror(s)

2. Disconnect:

-Headlight lead and flasher light leads

3. Remove:

-Handlebar cover (Front) (~

4. Disconnect:

® Leads

-Speedometer cable (~

5. Remove:

®Handlebar cover (Rear) (~

2-5

Page 23

ENGINE iDLE SPEED ADJUSTMENT I ADJ

Downloaded from www.ScooterTime.net

INSTALLATION

1. Install:

oHandlebar cover (Rear) (~)

2. Connect:

• Leads

oSpeedometer cable (~)

NOTE:

Position the cables as shown.

Front brake cable

(~) Throttle cable

(~) Rear brake cable

I

3. Connect:

eHeadlight lead and flasher ]~ght leads

4. Install:

® Handlebar cover (Front)

®Rear view mirror(s)

ENGINE

ENGINE iDLE SPEED ADJUSTMENT

1. Remove:

• Tail cover,.

Refer to "TAIL COVER" section.

2. Start the engine and warm it up before check-

ing the idle speed.

NOTE:

A warm engine is defined as one which had been

operated for about 3 minutes at 3,000 r/min with

no load.

2-6

Page 24

I INSP

Downloaded from www.ScooterTime.net

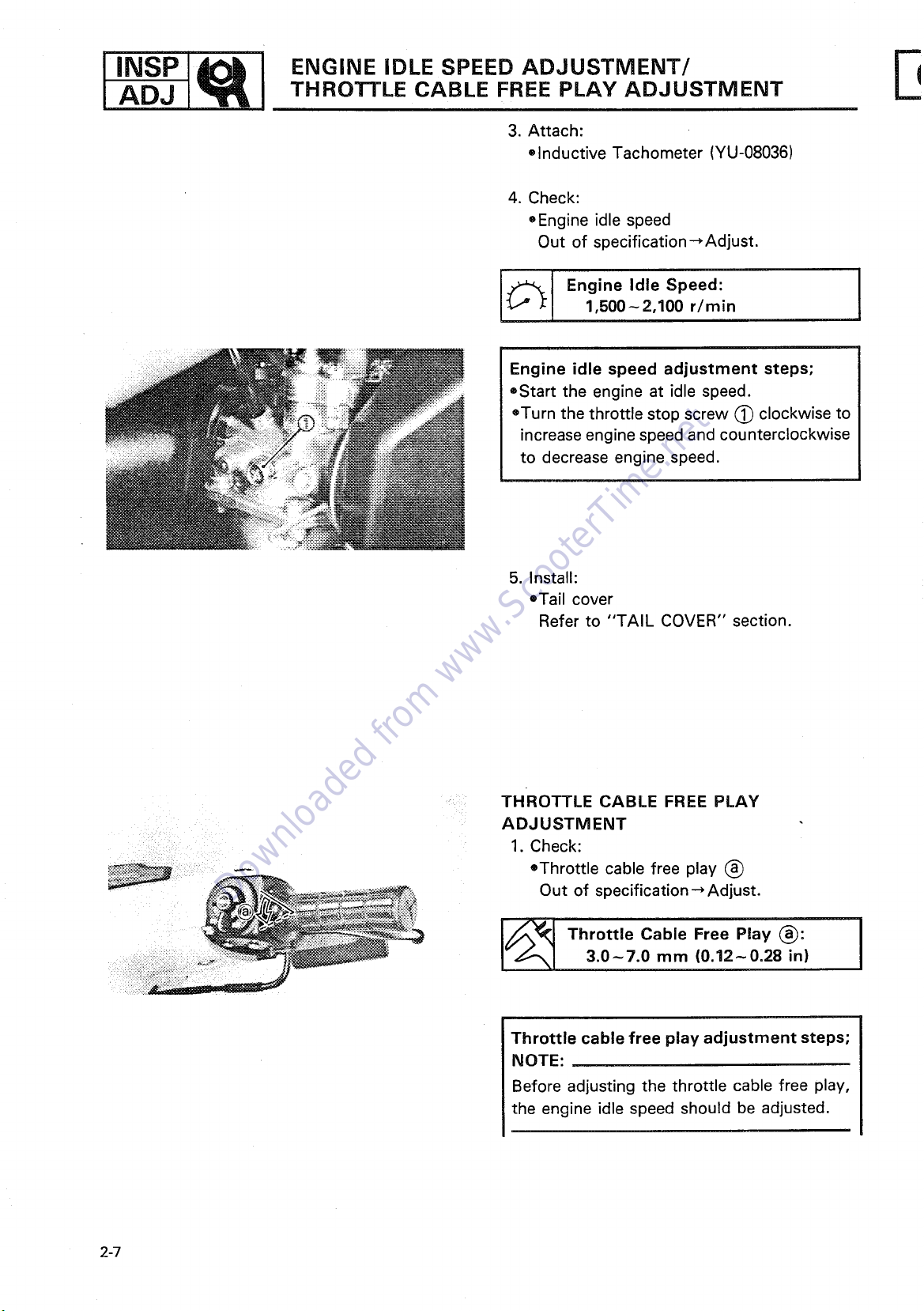

ENGINE IDLE SPEED ADJUSTMENT/

THROTTLE CABLE FREE PLAY ADJUSTMENT

3. Attach:

®Inductive Tachometer (YU-08036)

4. Check:

eEngine idle speed

Out of specification-*Adjust.

Engine Idle Speed:

1,500-2,100 r/rnin

Engine idle speed adjustment steps;

®Start the engine at idle speed.

eTurn the throttle stop screw (~ clockwise to

increase engine speed and counterclockwise

to decrease engine speed.

E

5. Install:

eTail cover

Refer to "TAIL COVER" section.

THROTTLE CABLE FREE PLAY

ADJUSTMENT

1. Check:

*Throttle cable free play (~

Out of specification-*Adjust.

[~ Throttle Cable Free Play (~):

3.0-7.0 mm (0.12-0.28 in)

Throttle cable free play adjustment steps;

NOTE:

Before adjusting the throttle cable free play,

the engine idle speed should be adjusted.

2-7

Page 25

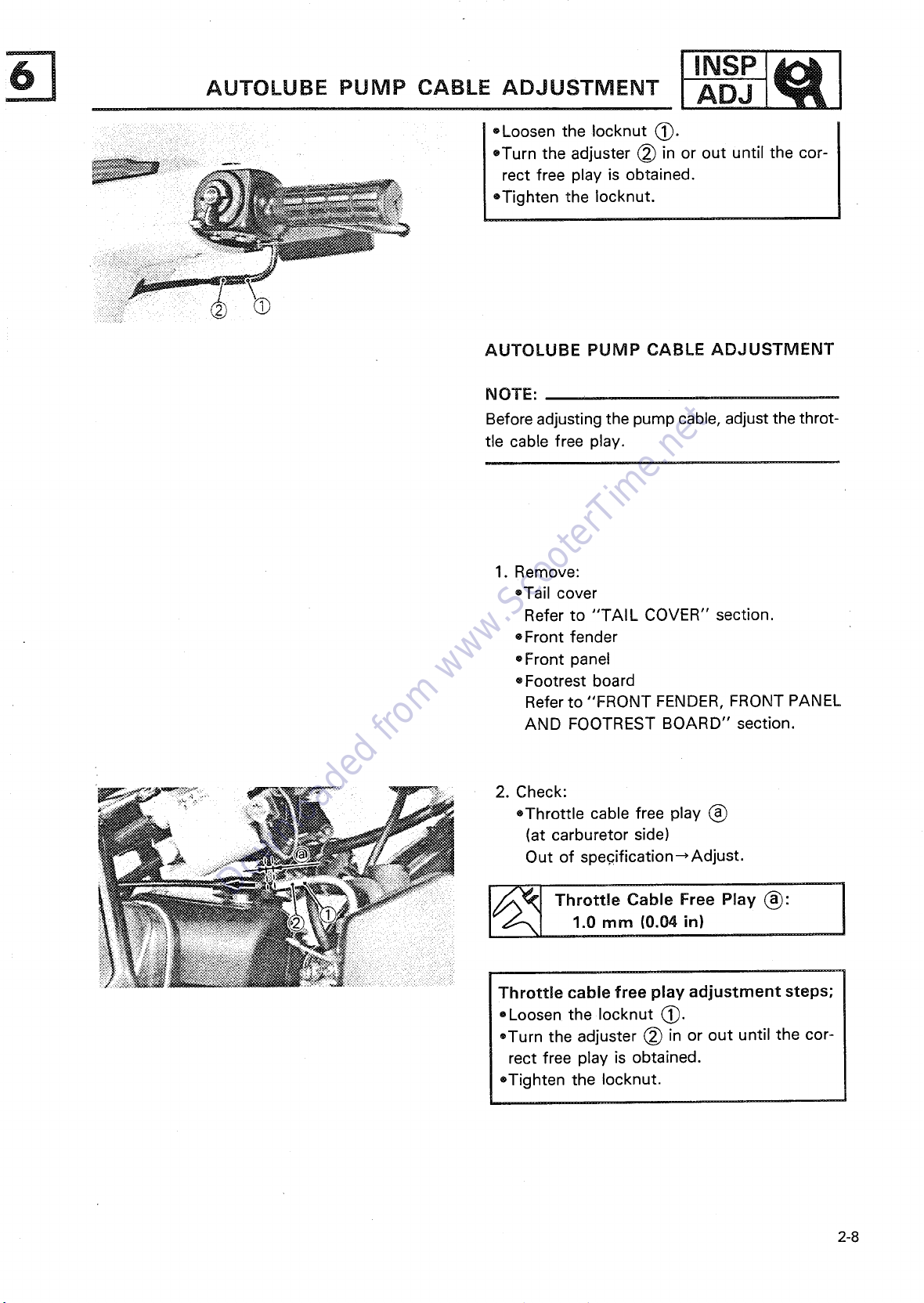

AUTOLUBE PUMP CABLE ADJUSTMENT ADJ

Downloaded from www.ScooterTime.net

=Loosen the Iocknut (_.

oTurn the adjuster (_ in or out until the cor-

!_:__...... rect free play is obtained.

=Tighten the Iocknut.

AUTOLUBE PUMP CABLE ADJUSTMENT

NOTE:

Beforeadjustingthe pumpcable, adjustthe throt-

tle cable free play.

1. Remove:

=Tail cover

Refer to "TAIL COVER" section.

* Front fender

=Front panel

eFootrest board

Refer to "FRONT FENDER, FRONT PANEL

AND FOOTREST BOARD" section.

2. Check:

*Throttle cable free play (_

(at carburetor side)

Out of specification_Adjust.

..... 1.0 mm (0.04 in)

J_ Thrott,eCableFreePlay(_):

Throttle cable free play adjustment steps;

=Loosen the Iocknut (_.

=Turn the adjuster _ in or out until the cor-

rect free play is obtained.

=Tighten the Iocknut.

2-8

Page 26

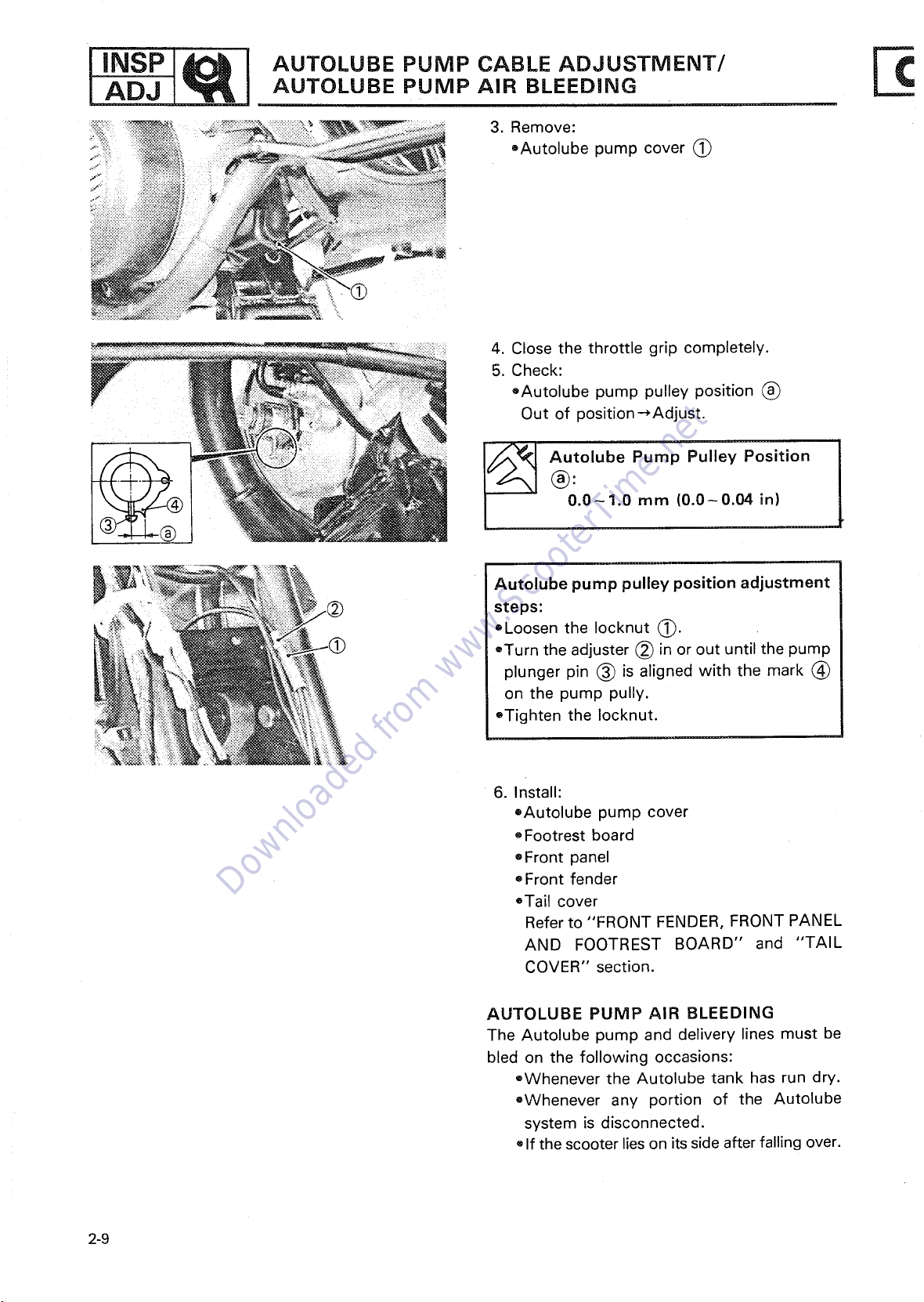

4. Close the throttle grip completely.

Downloaded from www.ScooterTime.net

5. Check:

®Autolube pump pulley position (_

Out of position-*Adjust.

®:

0.0-1.0 mm (0.0-0.04 in)

_ Autolube Pump Pulley Position

Autolube pump pulley position adjustment

steps:

oLoosen the Iocknut _.

®Turnthe adjuster (_ in or out until the pump

plunger pin (_ is aligned with the mark _)

on the pump pully.

eTighten the Iocknut.

6. Install:

oAutolube pump cover

oFootrest board

®Front panel

• Front fender

eTail cover

Refer to "FRONT FENDER, FRONT PANEL

AND FOOTREST BOARD" and "TAIL

COVER" section.

AUTOLUBE PUMP AIR BLEEDING

The Autolube pump and delivery lines must be

bled on the following occasions:

•,Whenever the Autolube tank has run dry.

oWhenever any portion of the Autolube

system is disconnected.

oIf the scooter lieson its sideafter falling over.

2-9

Page 27

__ AUTOLUBE PUMP AIR BLEEDING ADJ

Downloaded from www.ScooterTime.net

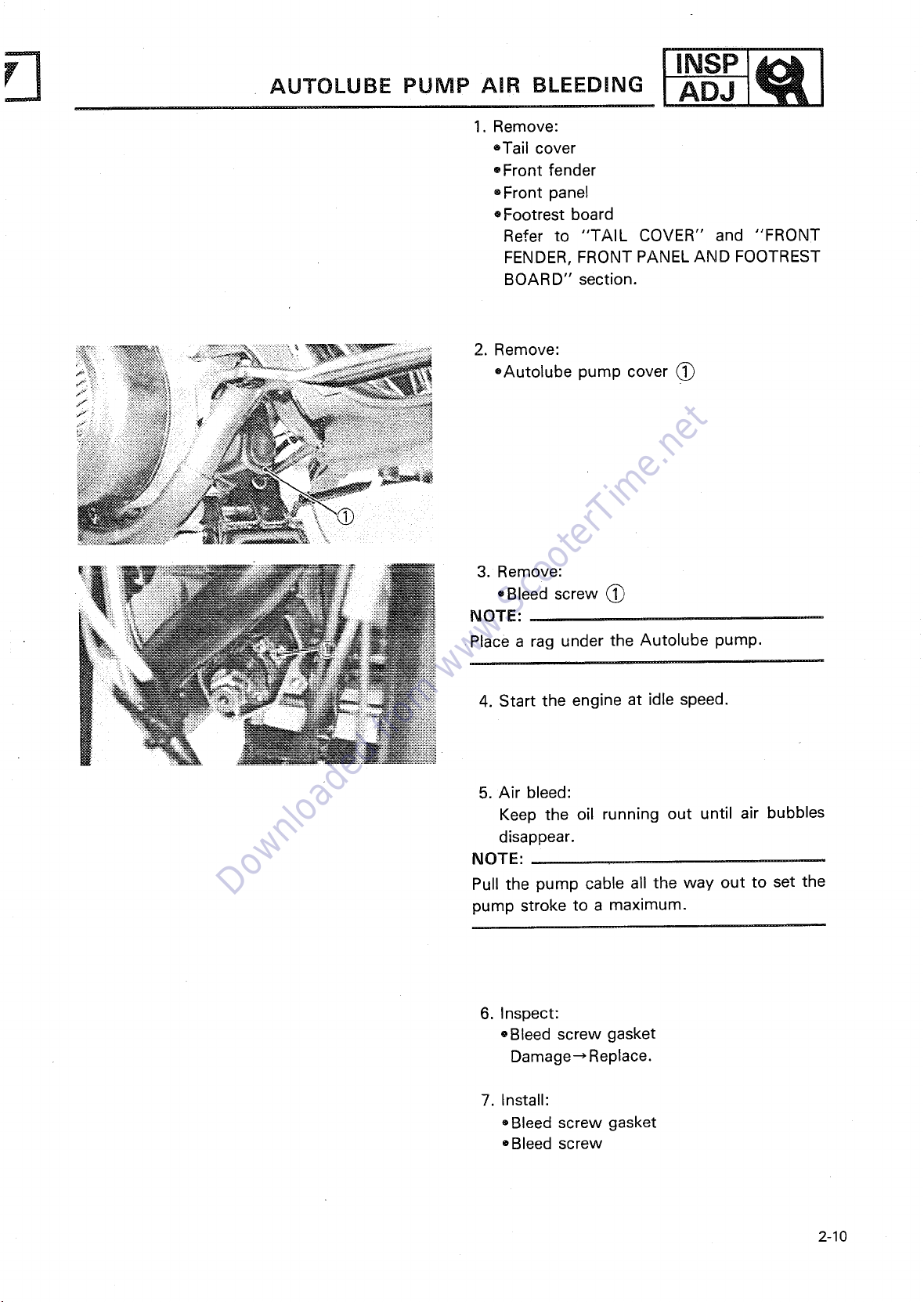

1. Remove:

=Tail cover

®Front fender

-Front panel

• Footrest board

Refer to "TAIL COVER" and "FRONT

FENDER, FRONT PANELAND FOOTREST

BOARD" section.

2. Remove:

®Autolube pump cover

J

I,.sPl l

3. Remove:

• Bleed screw @

NOTE:

Place a rag under the Autolube pump.

4. Start the engine at idle speed.

5. Air bleed:

Keep the oil running out until air bubbles

disappear.

NOTE:

Pull the pump cable all the way out to set the

pump stroke to a maximum.

6. Inspect:

®Bleed screw gasket

Damage_Replace.

7. Install:

•,Bleed screw gasket

• Bleed screw

2-10

Page 28

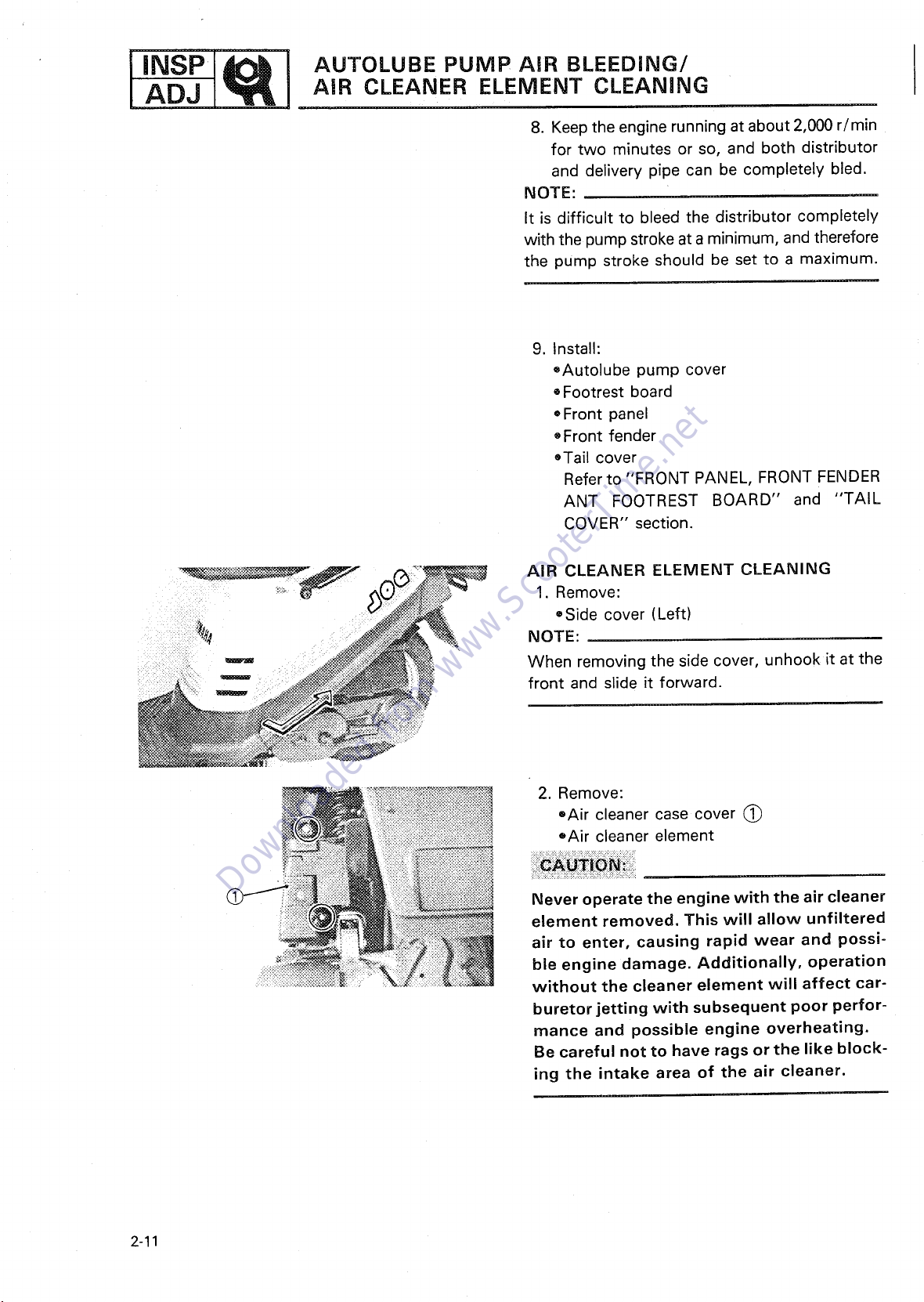

ADJ AiR CLEANER ELEMENT CLEANING

Downloaded from www.ScooterTime.net

t INSP AUTOLUBE PUMP AiR BLEEDING/

8. Keep the enginerunningat about2,000 r/min

for two minutes or so, and both distributor

and delivery pipe can be completely bled.

NOTE:

It is difficult to bleed the distributor completely

with the pump strokeat aminimum, and therefore

the pump stroke should be set to a maximum.

9. Install:

eAutolube pump cover

• Footrest board

®Front panel

Front fender

oTail cover

Refer to "FRONT PANEL, FRONT FENDER

ANT FOOTREST BOARD" and "TAIL

COVER" section.

AIR CLEANER ELEMENT CLEANING

1. Remove:

®Side cover (Left)

;_ NOTE:

When removing the side cover, unhook it at the

front and slide it forward.

2. Remove:

®Air cleaner case cover (_

eAir cleaner element

i i : i_iii i:i i_i!i !_i!i i_ ! i

Never operate the engine with the air cleaner

element removed. This will allow unfiltered

air to enter, causing rapid wear and possi-

ble engine damage. Additionally, operation

without the cleaner element will affect car-

buretor jetting with subsequent poor perfor-

mance and possible engine overheating.

Be careful not to have rags or the like block-

ing the intake area of the air cleaner.

2-11

Page 29

;'='8 I AiR CLEANER ELEMENT CLEANHNG/ INSP

Downloaded from www.ScooterTime.net

FUEL COCK CLEANING ADJ

3. Clean:

oAir cleaner element

Air cleaner element cleaning steps:

oWash the element gently, but thoroughly in

solvent.

Never use low flash point solvents such as

gasoline to clean the element. Such sol-

vent may lead to a fire or explosion.

oSqueezethe excess solvent out of the element

and let dry.

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Do not twist the element when squeezing

the element.

4. Inspect:

oElement

Damage-_ Replace.

5. Apply:

oFoam-air-filter oil or SAE 10W30 type SE

motor oil

Onto the element.

6. Squeeze out the excess oil.

NOTE:

The element should be wet but not dripping.

7. Install:

oAir cleaner element

®Air cleaner case cover

®Side coyer (Left)

FUEL COCK CLEANING

1. Remove:

-Tail cover

Refer to "TAIL COVER" section.

2-12

Page 30

ADJ FUEL COCK CLEANHNG

Downloaded from www.ScooterTime.net

I,NsP E

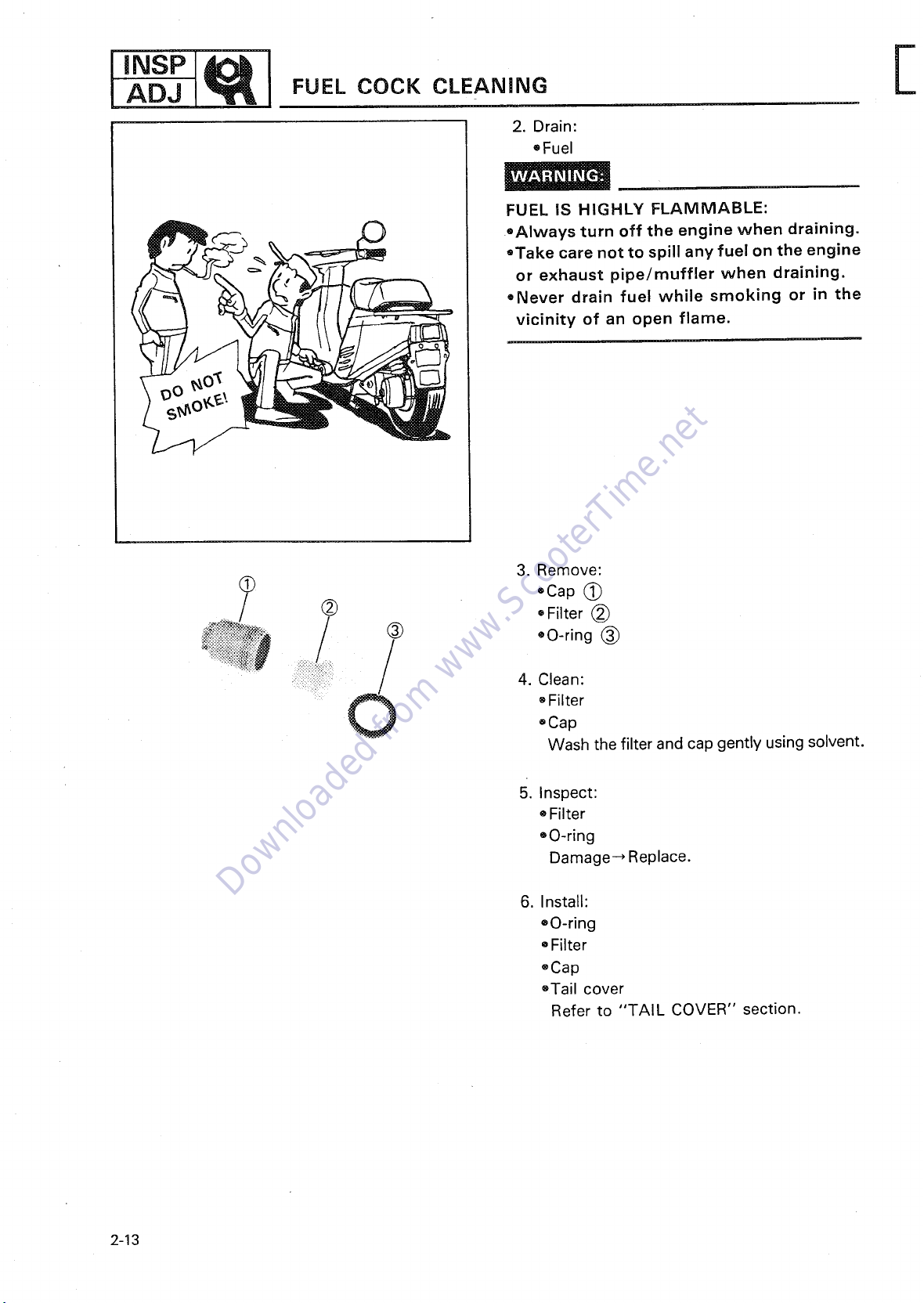

2. Drain:

=Fuel

FUEL IS HIGHLY FLAMMABLE:

__ _k,_ ®Always turn off the engine when draining.

==_£ or exhaust pipe/muffler when draining.

' =_ { " oNever drain fuel while smoking or in the

(_ *Cap (_

_,_/ (_) ®Filter (_

_*_'!_ii!_iiii_ _:::_ 4. Clean:

=Take care not to spill any fuel on the engine

vicinity of an open flame.

3. Remove:

Filter

oCap

Wash the filter and cap gently using solvent.

2-13

5. Inspect:

• Filter

oO-ring

Damage--* Replace.

6. Install:

®O-ring

Filter

oCap

oTail cover

Refer to "TAIL COVER" section.

Page 31

COMPRESSION PRESSURE MEASUREMENT ADJ

Downloaded from www.ScooterTime.net

• ;!i...... COMPRESSION PRESSURE

Insufficient compression pressure will result in

performance loss and may indicate worn or

__4 A damaged piston rings.

1. Remove:

®Cover (_

2. Warm up engine for serveral minutes, then

stop the engine.

........_ 3. Remove:

I eSpark plugs

4. Connect:

®Compression Gauge (YU-33223) (_

INSP

_ "" ::::::::........ • Compression

_..._:_::,. 5. Measure:

NOTE:

Start the starter motor and throttle valve wide-

open until the pressure indicated on gauge can

riseno further. Compression should be within the

specified levels.

Compression Pressure (at sea level):

Standard ....... 800 kPa (8.0 kg/cm 2,

Minimum ...... 640 kPa (6.4 kg/cm 2,

When cranking engine, ground spark plug

wires to prevent sparking.

Compression test steps (below minimum

levels):

oSquirt a few drops of oil into cylinder.

eMeasure compression again.

114 psi)

91 psi)

Reading Diagnosis

Higher than piston and piston

without oil

Same as ring(s), valve(s) and

without oil

Compression test steps (above standard

levels):

eCheck cylinder head or piston crown for car-

bon deposits.

®Worn cylinder,

rings

®Defective piston,

cylinder head gasket

2-14

Page 32

IiNSPADJ J_l ENGINE OIL LEVEL INSPECTION

Downloaded from www.ScooterTime.net

ENGINE OiL LEVEL INSPECTION

1. Place the scooter on the level place.

NOTE:

Be sure the scooter is positioned stratight up and

on both wheels when inspecting the oil level,

":":%_{iii_ 2. Inspect:

...... ":<_ oEngine oil level

__:_-_ .... "............- 0il level low-,Add sufficient oil by the

" _ following inspection steps.

(_) "OIL" indicator light

_3N _0-_ _$E ONLY

Engine oil level visual inspection steps:

position.

ITurn main switch to "_" I

l

does not :ome on. comes on.

I "OlL"indicatorlight I I "OlL"indicatorlight I

+

"ON" position.

I urn main switch to

I

"OIL" indicator light _ i"OIL" indicator light I

does not come on. ?1 iomeson i

e,ec-1en0ineo"'eve'"e'ec-I Su 0'eat'he°"'lI trical circuit, trical circuit are OK.

I

2-15

Page 33

ENGINE OiL LEVEL iNSPECTiON/ l lNSPI_I_ ITRANSMISSION OiL REPLACEMENT ADJ

Downloaded from www.ScooterTime.net

_ Recommended Oil:

NOTE:

Install the oil tank filler cap (_ and push it fully

into the filler.

Always use the same type of engine oil; mix-

ing oils may result in a h_rmful chemical

reaction and lead to poor performance.

Yamalube 2 or Air Cooled 2

Stroke Engine Oil

Oil Capacity:

Total:

0.8 L (0.7 Imp qt, 0.84 US qt)

TRANSMISSION OIL REPLACEMENT

1. Warm up the engine at idle speed, then stop

it.

2. Place the oil pan under the drain hole.

3. Remove:

oDrain bolt (_

Drain the transmission oil.

oOil filler plug

2-16

Page 34

ADJ FUEL LiNE iNSPECTiON

Downloaded from www.ScooterTime.net

t INSPt_ I TRANSMISSION OIL REPLACEMENT/

4. Inspect:

®Gasket (Drain bolt)

• O-ring (Oil filler plug)

Damage_ Replace.

5. Install:

• Gasket

Drain bolt

I_ Drain Bolt:

6. Fill:

•Transmission case

___ Transmission Oil:

NOTE:

Wipe off any oil split on the crankcase, tire or

wheel.

7. Install:

•Oil filler plug

18 Nm (1.8 m.kg, 13 ft.lb)

Yamalube 4 or SAE 10W30 Type

SE Motor Oil

Capacity:

0.1 L (0.09 Imp qt, 0.11 US qt)

FUEL LINE INSPECTION

1. Remove:

eTail cover

Refer to "TAIL COVER" section.

2-17

Page 35

REAR BRAKE LEVER FREE PLAY CHECK ADJ

Downloaded from www.ScooterTime.net

F.ONTB LEVE.F.EEP.AC.ECK/I,.SP[ I

_ 2. Inspect:

oFuel pipe (_

Cracks/Damage -_Replace.

3. Install:

oTail cover

Refer to "TAIL COVER" section.

FRONT BRAKE LEVER FREE PLAY CHECK

1. Check:

oFront brake lever free play

CHASSIS

Out of specification-_Adjust.

,0- 0 l

Front brake lever free p|a¥ adjustment

steps:

oTurn the adjuster (_ in or out until the cor-

rect free play is obtained.

REAR BRAKE LEVER FREE PLAY CHECK

1. Check:

®Rear brake lever free play (_

Out of sP,ecification_ Adjust.

'_ 10-20 mm (0.4-0.8 in)

Rear brake lever free play adjustment

steps;

®Turnthe adjuster (_ in or out until the cor-

rect free play is obtained.

2-18

Page 36

ADJ TIRE AND WHEEL iNSPECTION

Downloaded from www.ScooterTime.net

I INSP I (i_ FRONT AND REAR BRAKE LNNING INSPECTION/ l

[] _. FRONT AND REAR BRAKE LINING

) 1. Activate the brake lever.

2. Inspect:

-_; ®Wear indicator (_

Indicator at wear limit line (_Replace

brake shoes.

!

_; TiRE AND WHEEL INSPECTION

1. Measure:

®Air pressure

Out of specification-_Adjust.

Cold tire

Front 125 kPa (1.25 kg/crn 2, 18 psi)

Rear 225 kPa (2.25 kg/crn 2, 32 psi)

Proper loading of your scooter is important

for the handling, braking, and other perfor-

mance and safety characteristics of your

scooter. Do not carry loosely packed items

that can shift. Securely pack your heaviest

items close to the center of the scooter, and

destribute the weight evenly from side to

side. And check the condition and pressure

of your tires. NEVER OVERLOAD YOUR

SCOOTER. Make sure the total weight to the

cargo, rider, passenger, and accessories (fair-

ing, saddlebags, etc. if approved for this

model) does not exceed the maximum load

of the scooter. Operation of an overloaded

scooter could cause tire damage, an acci-

dent, or even injury.

pressure

2-19

Page 37

" STEERING ADJUSTMENT ADJ

Downloaded from www.ScooterTime.net

2. Inspect:

'_._=q _ oTire surface

__, _:._\1 Wear/Damage/Cracks/Road hazards--*

"-" +Aluminum wheels

Damage/Bends--* Replace.

Never attempt even small repairs to the

wheel.

__._ ii. Replace.

Ride conservatively after installing a tire to

allow it to seat itself properly on the rim.

(]_) 3. Measure:

(_ _ Minimum Tire Tread Depth:

®Tire tread depth

Out of specification_Replace.

(front and rear)

0.8 mm (0.03 in)

(_) Tread depth

Wear indicator

Side wall

STEERING ADJUSTMENT

1. Place the scooter on its centerstand, then

elevate the front wheel.

2-20

Page 38

INSP

Downloaded from www.ScooterTime.net

STEERING ADJUSTMENT/BATTERY

2. Check:

=Steering assembly bearings

Grasp the bottom of the forks and gently

rock the rock assembly back and forth.

Looseness-*Adjust.

Steering head adjustment steps:

=Remove the front fender and front panel.

Refer to "FRONT FENDER, FRONT PANEL

AND FOOTREST BOARD" section.

=Tighten the ring nut ~ to specification us-

ing the Ring Nut Wrench (YU-33975).

Ring Nut (~:

30 Nm (3.0 m okg, 22 ftolb)

NOTE:

Set the torque wrench to the ring nut wrench

so that they form right angle.

*Move the handlebar up and down, and/or

back and forth. If handlebar free play is ex-

cess, tighten the bolt (~ to specification.

Bolt (~:

60 Nm (6.0 m-kg, 43 ft-lb)

=Install the front fender and front panel.

ELECTRICAL

BATTERY

1. Check:

= Fluid level

Incorrect-* Refill.

Fluid level should be between upper and

lower level marks.

(~ Upper level

(~) Lower level

iiii!!ii i ii i iiiii!iii!!i

Refill with distilled water only; tap water

contains minerals harmful to a battery.

2-21

Page 39

BATTER*L'NSP1 IAOJ

Downloaded from www.ScooterTime.net

2. inspect:

• Breather hose

Obstruction_ Remove.

Damage-* Replace.

3. Inspect:

®Battery

Replace the battery if:

Battery voltage will not riseto a specific value

or bubbles fail to rise even after many hours

of charging.

®Sulfation of one or more cells occurs, as in-

dicated by the plates turning white, or an ac-

cumulation of material exists in the bottom

of the cell.

®Specific gravity readings after a long, slow

charge indicate one cell to be lower than the

rest.

®Warpage or buckling of plates or insulators

• is evident.

®Specific gravity:

Less than 1.280-*Recharge battery.

Charging Current:

_ 4. Measure:

0.4 amps/10 hrs

Specific Gravity:

1.280 at 20°C (68°F)

2-22

Page 40

I INSP

Downloaded from www.ScooterTime.net

ADJ l( l BATTERY/FUSE INSPECTION

Always charge a new battery before using

it to ensure maximum performance.

Battery electrolyte is dangerous; it contains

sulfuric acid and therefore is poisonous and

highly caustic.

__,=== Always follow these preventive measures:

_\_J--_ 9/ -SKIN-- Flush with water.

____= '_ "_ can cause servere burns or permanent eye

oAvoid bodily contact with electrolyte as it

injury.

=Wear protective eye gear when handling or

working near batteries.

Antidote (EXTERNAL):

®EYES--Flush with water for 15 minutes and

get immediate medical attention.

Antidote (INTERNAL):

eDrink large quantities of water or milk

follow with milk of magnesia) beaten egg,

or vegetable oil. Get immediate medical

attention.

Batteries also generate explosive hydrogen

gas, therefore you should always follow

these preventive measures:

eCharge batteries in a well-ventilated area.

®Keep batteries away from fire, sparks, or

open flames (e.g., welding equipment,

lighted cigarettes, etc.)

=DO NOT SMOKE when charging or handl-

ing batteries.

KEEP BATTERIES AND ELECTROLYTE OUT

OF REACH OF CHILDREN.

FUSE INSPECTION

1. Open the seat lock.

2-23

Page 41

FUSE iNSPECTION/SPARK PLUG iNSPECTiON ADJ

Downloaded from www.ScooterTime.net

2. Inspect:

eFuse C)

Defective--* Replace.

Blown fuse procedure steps:

=Turn off ignition and the circuit.

=Install a new fuse of proper amperage.

=Turn on switches to verify operation of elec-

trical device.

®If fuse blowsimmediately again, check circuit

in question.

Do not use fuses of higher amperage rating

than recommended. Extensive electrical

system damage and fire could result from

substitution of a fuse of impcoper amperage:

i =Cover @

_i_:_- =Spark plug,

0 H_

" --?: i

Description Amperage Quantity

Main 7A 1

SPARK PLUG INSPECTION

1. Remove:

2. Inspect:

=Electrode _)

Wear/Damage--, Replace.

=Insulator (_

Abnormal Color_ Replace.

@ @ Standard Spark Plug:

"

BPR6HS (N.G.K.)

2-24

Page 42

I INSP

Downloaded from www.ScooterTime.net

SPARK PLUG INSPECTION/

HEADLIGHT BEAM ADJUSTMENT/IGNITION TIMING

3. Measure:

ePlug gap (~

Out of specification--* Regap.

Use a Wire Gauge or Feeler Gauge.

I~ Spark Plug Gap (~: ]

0.9-1.0 mm (0.035-0.039 in)

4. Clean the plug with a spark plug cleaner if

necessary.

5. Tighten:

Before installing a spark plug, clean the gasket

and plug surfaces.

NOTE:

Finger,tighten the spark plug before torquing to

specification.

Spark Plug:

20 Nm (2.0 m-kg, 14 ft.ib)

HEADLIGHT BEAM ADJUSTMENT

1. Adjust:

• Headlight (Vertically)

Vertical adjustment

Higher Loosen the adjusters (~)

Lower Tighten the adjusters (~)

• Headlight (Horizontal)

Horizontal adjustment

Right the adjuster (~)

Left

Loosen the adjuster (~) or tighten

Loosen the adjuster (~) or tighten

the adjuster (~)

IGNITION TIMING

Adjustment free.

2-25

Page 43

Downloaded from www.ScooterTime.net

Page 44

CHAPTER 3

Downloaded from www.ScooterTime.net

ENGINE OVERHAUL

I ENG

ri

ENGINE REMOVAL .

PREPARATION FOR REMOVAL ................................. D-3

TAIL COVER .................................................. D-3

FRONT FENDER, FRONT PANEL AND FOOTREST BOARD ........ D-3

CARBURETOR ................................................. D-3

CABLES, LEADS AND PIPES ................................... D-4

ENGINE REMOVAL ............................................. D-4

DISASSEMBLY

MUFFLER ..................................................... D-5

CYLINDER HEAD .............................................. D-5

CYLINDER .................................................... D-6

PISTON PIN AND PISTON ...................................... D-6

PRIMARY AND SECONDARY SHEAVE ........................... D-6

STARTER SYSTEM ............................................ D-7

C.D.I. MAGNETO .............................................. D-8

AUTOLUBE PUMP ............................................. D-8

TRANSMISSION ............................................... D-8

CRANKCASE AND CRANKSHAFT ............................... D-9

INSPECTION AND REPAIR ....................................... D-10

CYLINDER HEAD .............................................. D-10

CYLINDER AND PISTON ....................................... D-10

PISTON PIN AND PISTON PIN BEARING ........................ D-12

AUTOLUBE PUMP ............................................. D-12

CRANKSHAFT ................................................. D-12

TRANSMISSION ............................................... D-13

PRIMARY SHEAVE ................... ~ ......................... D-13

SECONDARY SHEAVE ......................................... D-13

V-BELT ....................................................... D-15

STARTER CLUTCH AND GEARS ................................ D-15

............................................. D-3

.................................................. D-5

ENGINE ASSEMBLY AND ADJUSTMENT

CRANKSHAFT AND CRANKCASE ............................... D-16

TRANSMISSION ............................................... E-1

AUTOLUBE PUMP ............................................. E-3

C.D.I. MAGNETO .............................................. E-4

STARTER SYSTEM ............................................ E-5

PRIMARY AND SECONDARY SHEAVE ........................... E-6

PISTON PIN AND PISTON ...................................... E-8

CYLINDER AND CYLINDER HEAD ............................... E-9

MUFFLER ..................................................... E-10

REMOUNTING ENGINE ......................................... E-10

......................... D-16

Page 45

Downloaded from www.ScooterTime.net

Page 46

ENG %-j]

Downloaded from www.ScooterTime.net

ENGINE REMOVAL

ENGINE OVERHAUL

ENGINE REMOVAL

NOTE:

It is necessary to remove the engine in order to

remove the following components.

oCylinder head

• Cylinder

• Piston

®CDI magneto

®Starter motor

®Primary and secondary sheave

PREPARATION FOR REMOVAL

1. Remove all dirt, mud, dust and foreign

material before removal and disassembly.

2. Use proper tools and cleaning equipment.

Refer to "CHAPTER 1. GENERAL INFOR-

MATION-SPECIAL TOOLS" section.

NOTE:

When disassembling the engine, keep mated parts

together. This includes gears, cylinder, piston and

other parts that have been " mated" through nor-

mal wear. Mated parts must be reused as an

assembly or replaced.

3-1

Page 47

ENGINE REMOVAL

Downloaded from www.ScooterTime.net

.

During engine disassembly, clean all parts and

place them in trays in the order of

disassembly. This will speed up assembly time

and help assure that all parts are correctly

reinstalled in the engine.

.

Drain the transmission oil completely.

Refer to "CHAPTER 2.--TRANSMISSION

OIL REPLACEMENT" section.

I E.o I, .l

TAIL COVER

1. Remove:

.Seat

• Tail cover

• Rear carrier

Refer to "CHAPTER 2.--TAIL COVER"

section.

FRONT FENDER, FRONT PANEL AND FOOTREST BOARD

1. Remove:

® Front fender

® Front panel

= Footrest board

Refer to "CHAPTER 2.--FRONT FENDER,

FRONT PANEL AND FOOTREST BOARD"

section.

CARBURETOR

1. Remove:

-Air cleaner case

3-2

Page 48

[ENO EOO,NE.EMOVA, Fi

Downloaded from www.ScooterTime.net

2. Remove:

oFuel pipe (_

oOil delivery pipe (_)

®Vacuum pipe (_)

®Auto choke unit lead

3. Remove:

_, ®Carburetor top cover

oCarburetor

NOTE:

Cover the carburetor with a clean rag to prevent

dirt or foreign matter into the carburetor.

i 1. Remove:

_i CABLES, LEADS AND PIPES

i

-Autolube pump cover @

2. Remove:

oOil pump cable (_

oOil pipe (_)

NOTE:

Plug the oil pipe so the oil will not run out of the

oil tank.

3. Remove:

• Battery negative lead (_

3-3

Page 49

4 ENGINE REMOVAL ENG %_

Downloaded from www.ScooterTime.net

4. Remove:

®Spark plug cap

5. Remove:

.Earth lead (_

]

6. Remove:

• Rear brake cable (_

7. Disconnect:

• C.D.I. magneto leads

• Starter motor leads

+,

ENGINE REMOVAL

1. Remove:

• Air shroud (_

3-4

Page 50

[ENG ENGINEREMOVAL/DISASSEMBLY

Downloaded from www.ScooterTime.net

2. Remove:

oEngine mounting bolts

3. Remove:

®Engine

Lift up the frame and remove the engine.

4. Place the frame on a suitable stand.

DISASSEMBLY

MUFFLER

1. Remove:

oExhaust pipe

3-5

Page 51

O'SASSEMB'IEN°

Downloaded from www.ScooterTime.net

2. Remove:

`"Muffler

CYLINDER HEAD

1. Remove:

`"Fan cover

2. Remove:

" _::_:_ ®Air shroud

3. Remove:

(_,

........::: : _ ,,Cylinder head (_

®Cylinder head gasket

NOTE:

`"Before loosening the cylinder head, loosen the

spark plug _).

• The cylinder head holding nuts should beloosen-

ed 1/2 turn each time, and remove.

3-6

Page 52

O,SASSEMBL* E

Downloaded from www.ScooterTime.net

CYLINDER

1. Remove:

• Cylinder (_

i_ • Cylinder gasket

2. Remove:

®Carburetor joint (_

oReed valve assembly

PISTON PIN AND PISTON

1. Remove:

®Piston pin clip (_

NOTE:

Before removing the piston pin clip, cover the

crankcase with a cleanrag so you will not acciden-

tally drop the clip into the crankcase.

2. Remove:

oPiston pin (_

®Piston (_)

®Piston pin bearing

NOTE:

Before removing the piston pin, deburr the clip

groove and pin hole area. If the piston pin groove

is deburred and piston pin is still difficult to

remove, use Piston Pin Puller (YU-01304).

Do not use a hammer to drive the piston pin

out.

3-7

Page 53

PRIMARY AND SECONDARY SHEAVE

Downloaded from www.ScooterTime.net

1. Remove:

*Crankcase cover (Left)

*Dowel pins

2. Remove:

*Fan (_

;i4_! '- __ 3. Remove:

*Nut @ (Primary sheave)

NOTE:

--...... the C.D.I. magneto using Flywheel Holding Tool

_ (YU-01235). •

- *Conical spring washer (_

_._,. *Primary fixed sheave _)

"_'_, ,,V-Belt

When loosening the nut (primary sheave), hold

4. Remove:

*One-way clutch (_

3-8

Page 54

_ !_:._ STARTER SYSTEM

Downloaded from www.ScooterTime.net

/ ';_-_-:_ ........ 1 Remove:

3-9

• Starter clutch assembly (_

2. Remove:

-Plate (_ (Idle gear)

Page 55

q

Downloaded from www.ScooterTime.net

O,SASSEMB. ! I' .1

j ii

.Z ; !;;~!!

3. Remove:

eStarter wheel gear (~)

® Bearing (~

®Washers (~

oldie gear (~)

4. Remove:

®Stay (~

oCollar (~)

5. Remove:

oStarter motor (~

6. Remove:

®Kick crank (~

7. Remove:

oKick torsion spring (~

3-10

Page 56

9. Remove:

Downloaded from www.ScooterTime.net

oCirclip (_

oPlain washer (_

C.D.I. MAGNETO

1. Remove:

...._ oNut (_ (C.D.I. magneto)

Use Flywheel Holding Tool (YU-01235) (_).

._ ii;_ 2. Remove:

3-11

_- __..9 ®C.D.I. magneto

Use Flywheel Magneto Puller (YM-01189)

oWoodruff key

Page 57

O'SASSEMB'IE"Ot

Downloaded from www.ScooterTime.net

_ 3. Remove:

eStator assembly (_

4. Remove:

®Gasket @

AUTOLUBE PUMP

1. Remove:

*Autolube pump @

2. Remove:

®Circlip (_

*Shim (_)

-,Wave washer. (_)

\. ®Pump drive gear @

_0\ 0 "Pin @

TRANSMISSION

1. Remove:

• Rear wheel

oBrake shoe plate

3-12

Page 58

ENGr

Downloaded from www.ScooterTime.net

DISASSEMBLY

I-q

2. Unhook:

= Spring (Centerstand)

3, Remove:

• Clip (~

• Centerstand

4. Remove:

• Transmission case cover (~

• Gasket (~)

®

~ii!ii~:~ :~!!~:ii ~:~¸:: ! ~~:~ / ~ !iii~i~i~ii~ ~ii~ O

...... ....

5. Remove:

=Main axle (~

• Drive axle (~

-Washer (~ (Main axle)

• Washer (~ (Drive axle)

6. Remove:

®Oil seal

oCirclip (~

7. Remove:

• Secondary sheave axle (~

3-13

Page 59

O,SASSEMOLY[ENOL

Downloaded from www.ScooterTime.net

_zi;ili_:__- CRANKCASE AND CRANKSHAFT

: : eOil seal stopper (_)

"'_ 2. Remove:

1. Remove:

®Circlip (_)

oScrews (Crankcase)

NOTE:

Loosen each screw 1/4 turn, and remove them

after all are loosened.

_, 3. Attach:

_ _i__:i: _:.....

_:?. _

oCrankcase Separating Tool (YU-01135) (_

_ NOTE:

Fully tighten the-tool holding bolts, but make sure

the tool body is parallel with the case. If

necessary, one screw may be backed out slight-

ly to level tool body.

4. Remove:

eCrankcase (Left)

"::"- i ":""!: i. :: • "

Use soft hammer to tap on the case half. Tap

only on reinforced portions of case. Do not

tap on gasket mating surface. Work slowly

and carefully. Make sure the case halves

separate evenly. If one end "hangs up", take

As pressure isapplied, alternately tap on the

engine mounting bosses.

3-14

Page 60

[ENoI

Downloaded from www.ScooterTime.net

DISASSEMBLY/INSPECTION AND REPAIR

pressure off the push screw, realign,

start

over. If the cases do not

check

Do not force.

NOTE:

Use the following bolts available on the market.

Lenght: 160 mm (6.3 in)

Thread: 6 mm (0.24 in)

for a remaining case screw or fitting.

5. Remove:

= Crankshaft

Use Universal Puller Set (YU-33270) (~.

Pitch: 1.25 mm

and

separate,

INSPECTION AND REPAIR

CYLINDER HEAD

1. Remove:

=Carbon deposits

Use a rounded scraper (~.

NOTE:

Take care to avoid damaging the spark plug

threads. Do not use a sharp instrument. Avoid

scratching the aluminum.

2. Inspect:

=Cylinder head warpage

Out of specification ~ Re-su rface.

Warpage measurement and re-surface-

ment steps:

=Attach a straight edge and a thickness gauge

on the cylinder head.

=Measure the warpage limit.

3-15

Page 61

oq .osONANO.EPA..IE"OI .l

Downloaded from www.ScooterTime.net

/ 1. Eliminate:

-_ _ ( /

_ Warpage Limit:

olf the warpage is out of specification, reface

the cylinder head.

oPlace a 400-600 grit wet sandpaper on the

surface plate, and re-surface the head using

a figure-eight sanding pattern.

NOTE:

Rotate the head several times to avoid remov-

ing too much material from one side.

CYLINDER AND PISTON

0.02 mm (0.0008 in)

From the piston crown and ring grooves.

< \ ._. .,. 2. Eliminate:

-_/_ 1 _ -Carbon deposits

-- _ NOTE:

_ _ Sand in a crisscross pattern. Do not sand exces-

i+:_ ,!+++,

®Score marks and lacquer deposits

From the sides of piston.

Use a 600-800 grit wet sandpaper.

3. Inspect: +'

• Piston wall

Wear/Scratches/Damage_ Replace.

sively.

4. Eliminate:

®Carbon deposits

Use a rounded scraper (_.

3-16

Page 62

5. Inspect:

Downloaded from www.ScooterTime.net

oCylinder wall

Wear/Scratches -_Rebore or replace.

6. Measure:

i_± ®Piston-to-cylinder clearance

::_ ......... _ (_ Piston-to-cylinder clearance measurement

steps:

First step:

:_ D_ Bore Gauge.

.-,_ r___-,.__ ...... Measure the cylinder bore "C" in parallel to and

/

_- _ at right angles to the crankshaft. Then, find the

--_._--_ --=_" average of the measurements.

®Measure the cylinder bore "'C" with a Cylinder

NOTE:

_ Standard Wear Limit

Cylinder bore 40.00-40.02 mm 40.50 mm

"C" (1.575-1.583 in) (1.594 in)

Taper "'T"

Out of round 0.01 turn

"'R" (0.0004 in)

C= Maximum D

T=(Maximum Dz or D2) -

(Maximum Ds or D6)

R=(Maximum D1, D3 or Ds) -

(Minimum D2, D4 or D6)

elf out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

0.05 mm

(0.0019 in)

_/ ®Measure the piston skirt diameter "P" with

__ 2nd step:

307,000

3-17

a micrometer.

Page 63

INSPECTION AND REPAIR ENG]

Downloaded from www.ScooterTime.net

_._ Piston Size P

Standard

Oversize 1 40.25 mm (1.585 in)

Oversize 2 40.50 mm (1.594 in)

elf out of specification, replace piston and

piston rings as a set.

3rd step:

• Calculate the piston-to-cylinder clearance with

following formula:

Piston-to-cylinder Clearance =

Cylinder bore "C"-

Piston skirt diameter "P"

olf out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

40.05- 40,07 mm

(1.577 - 1.578 in)

_ Piston-to-cylinder Clearance:

.... i;:i 7. Measure:

oEnd gap

_:i ___ Standard Limit

Top ring (0.006 - 0.012 in) (0.028 in)

2nd ring (0.006-0.012 in) (0.028 in)

Measuring Point 20 mm (0.8 in)

0.034-0.047 mm

(0.0013- 0.0018 in)

Limit: 0.1 mm (0.004 in)

Out of specification--* Replace rings as a set.

Use a Feeler Gauge (_.

0.15-0.30 mm 0.70 mm

0.15-0.30 mm 0.70 mm

3-18

Page 64

,°SPEOT,ONANO.EPA,.

Downloaded from www.ScooterTime.net

8. Oversize piston ring size:

Ring size is stamped on top of the ring.

Oversize piston ring

Oversize 1 25

Oversize 2 50

PISTON PIN AND PISTON PIN BEARING

1. Apply:

e2 cycle oil

To the piston pin and bearing.

2. Install:

oPiston pin

®Piston pin bearing

Into the small end of the connecting rod.

3. Check:

/ There should be no noticeable for the play.

__. _]]_ .Free play

_.¢_/ for wear/Replace the pin and/or connecting

(___j_ Into the piston pin hole.

Freeplay exists_ Inspect the connecting rod

rod as required.

4. Install:

oPiston

5. Check:

oFree play (when the piston pin is in place in

the piston)

There should be no noticeable for the play.

Free play exists--* Replace piston pin and/or

piston.

6. Inspect:

oPiston pin and bearing

Signs of heat discoloration-_Replace.

pin

3-19

Page 65

'OSPEOT'ONAOO"EPA'"IENo

Downloaded from www.ScooterTime.net

AUTOLUBE PUMP

Wear or an internal malfunction may cause pump

output to vary from the factory setting. This situa-

tion is, however, extremely rare. If improper out-

put is suspected, inspect the following:

1. Inspect:

®Delivery line

Obstructions_ Blow out.

cO-ring

Wear/Damage _ Replace.

2. Inspect:

_ ®Autolube pump drive gear teeth (_.._ I_ oAutolube pump driven gear teeth (_

_i_?!i:!_!i!_ Pitting/Wear/Damage--* Replace.

F CRANKSHAFT

-= =- 1. Measure:

eRunout limit "C"

oSmall end free play limit "'F"

Out of Specification_Replace.

_Connecting rod big end side clearance "D"

Use V-Blocks, Dial Gauge and thickness

gauge.

Runout Limit "'C":

Connecting Rod Big End Side

Clearance "D":

Small End Free Play:

2. Inspect:

oBearings (Crankshaft)

Spin the bearing inner race.

Excessive play/Roughness_ Replace.

Pitting /Damage_ Replace.

0.03 mm (0.0012 in)

0.2-0,5 mm (0.008-0.02 in)

0.4-0.8 mm (0.015-0.031 in)

3-20

Page 66

[ENG ,NSPEOT,OOAND.EPA,.

Downloaded from www.ScooterTime.net

TRANSMISSION

m

_,_,:;_ .Primary drive gear teeth (_

_,_ 4_ ,_i_,,/ . Primary driven gear teeth (_)

,_;_;_!_#_, _,_,/'_ *Secondary drive gear teeth

/ / ......... _i .Secondary driven gear teeth _)

@/ ®/ Burrs/Chips/Roughness/Wear_ Replace.

_i!!i_i Spin the bearing inner race.

(_) Pitting/Damage--* Replace.

.... • Primary sliding sheave (_

1. Inspect:

2. Inspect:

• Drive gear bearing (_

• Main axle bearing (_)

QSecondary sheave axle bearing (_)

Excessive play/Roughness-* Replace.

1. Inspect:

PRIMARY SHEAVE

®Primary fixed sheave (_

• Collar (_)

Wear/Cracks/Scratch/Damage--* Replace.

®

2. Check:

®Free movement

Insert the collar into the primary sliding

sheave, and check for free movement.

..... Stick or excessiveplay-* Replacethe sheave

or collar.

__:_;__<;_.-....... SECONDA RY SH EAVE

_:_;;_.... Disassembly

1. Attach:

_--_ _ ,Primary Sheave Holder (YS-01880) (_)

•Socket Wrench (41 mm) (_

:, _., _ _Clutch securing nut

,oose :

_i_i_:.:. :.

Do not remove the clutch securing nut yet.

3-21

Page 67

3q ,osPEoT,oNAOO.EPA,.lENOI' .i

Downloaded from www.ScooterTime.net

3. Attach:

oClutch Spring Holder (YS-28891) (_

NOTE:

Use the following bolt (_ available on the

market.

Thread: 10 mm (0.39 in)

Pitch: 1.25 mm

4. Remove:

®Clutch securing nut (_

5. Remove:

®Clutch spring (_

...._-_[_,, ®Spring seat (_

(_ . __ ®Clutch assembly @

.-::5*"

6. Remove:

,Guide pins @

7. Remove:

oSecondary sliding sheave (_

Inspection

(_ 1. Inspect:

............... oSecondary sliding sheave (_)

%

i_ Scratch/Crack/Damage--* Replace as a set.

_Secondary fixed sheave (_

3-22

Page 68

F ~

Downloaded from www.ScooterTime.net

y

,' If l! !f

2. Inspect:

oTorque cam groove (~)

oGuide pin (~

Wear/Damage-*Replace as a set.

®Oil seals (~

oO-rings (~)

Damage-* Replace.

3. Measure:

®Clutch spring free length (~

Out of specification-* Replace.

Clutch Spring Free Length:

109.6 mm (4.31 in)

< Limit > :

94.0 mm (3.70 in)

4. Inspect:

®Clutch housing inner surface

Oil/Scratches-* Remove.

Oil

Scratches

5. Measure:

oClutch housing inside diameter (~)

Ouf of specification-*Replace.

Clutch Housing Inside Diameter:

<Wear

Use a rag soaked in lacquer

thinner or solvent.

Use an emery cloth

(lightly and evenly polishing).

105.0 mm (4.13 in)

Limit> :

105.4 mm (4.15 in)

r

6. Inspect:

oClutch shoes

Glazed parts-* Sand with coarse sandpaper.

NOTE:

After using the sand paper, clean of the polished

particles with cloth.

3-23

Page 69

INSPECTION AND REPAIR

Downloaded from www.ScooterTime.net

7. Measure:

oClutch shoe thickness (~

Out of specification-* Replace.

Clutch Shoe Thickness:

4.0 mm (0.16 in)

<Wear Limit> :

2.5 mm (0.10 in)

Assembly

When assemblying the secondary sheave, reverse

the disassembly procedure. Note the following

points.

1. Apply:

+BEL-RAY Assembly Lube ®

(to the inside of the sliding sheave)

I ENG

,!:,.~ .... ~+~iii,si= ~. .......

~; ++.

+.;+!:i:~!

2. Install:

• Sliding sheave

NOTE:

Be careful so that the oil seal lips are not turned

over when installing the sheave.

3. Apply:

eBEL-RAY Assembly Lube ®

(to the torque cam grooves and O-rings)

4. Check:

• Sliding sheave

Unsmooth operation-* Repair.

3-24

Page 70

5. Install:

Downloaded from www.ScooterTime.net

®Clutch securing nut

Use Clutch Spring Holder (_) (YS-28891).

_z,_,_._ ......... 6. Tighten:

oCtutch securing nut

Use Sheave Holder (_ (YS-01880) and

Wrench (41 mm).

[_ 50 Nm (5.0 m,kg, 36 ft°lb)

V-BELT

1. Inspect:

oV-belt

Crack/Wear-_ Replace.

NOTE:

Replace the V-belt smeared with a lot of oil or

grease.

2. Measure:

oV-belt width (_

Out of specification_Replace.

15.0 mm 10.59 in)

13.5 mm (0.53 in)

Push the dowel pin to arrow direction.

Unsmooth operation-_Replacce starter

clutch assembly.

3-25

/

a

I <Wear Limit>:

_ V-Belt Width:

STARTER CLUTCH AND GEARS

1. Inspect:

-Starter clutch

Page 71

,osooAoo.EPA,.!ENOI I

Downloaded from www.ScooterTime.net

2. Inspect:

oStarter wheel gear teeth (_

oldie gear teeth (_)

Burrs/Chips/Roughness/Wear-* Replace.

3. Inspect:

_Z(_ oBearing (_) (Starter wheel gear)

_ ®Kick gear teeth (_

(_ Burrs/Chips/Roughness/Wear-* Replace.

/

; /

Pitting/Damage--* Replace.

4. Inspect:

oKick pinion gear teeth (_)

5. Inspect:

oMating dogs (Kick pinion gear and one-way

clutch)

Rounded edges/Damage_ Replace.

6. Measure:

eClip tension (Kick pinion gear)

Out of spedification-*Replace.

f,]_ _ :_ Use a spring balance.

Standard Tension:

250- 300 g (8.83- 10.6 oz)

3-26

Page 72

ENGINE ASSEMBLY AND ADJUSTMENT

Downloaded from www.ScooterTime.net

ENGINE ASSEMBLY AND ADJUSTMENT

CRANKSHAFT AND CRANKCASE

i!!i,!!iii!~!i!ii~!!ii:i!i:ii!!i!i:i~i~i~i!i:i~i!~ii!~i:i~i!~!i~i!ii~!~:~!~i~i~!!i~iii~i~ii

To protect the crankshaft against scratches

or to facilitate the operation of the

installation.

Apply the grease to the oil seal lips, and app-

ly the engine oil to each bearing.

1. Attach:

oCrankshaft Installing Tool

(YU-90050 (~, YM-90062 (~)

2. Install:

® Crankshaft

To left crankcase.

NOTE:

Hold the connecting rod at top dead center with

one hand while turning the nut of the Installing

Tool with the other. Operate the Installing Tool

until the crankshaft bottoms against the bearing.

3. Apply:

®Sealant (Quick Gasket ® )

(ACC-11001-30-00)

To the mating surfaces of both case halves.

4. Install:

®Dowel pins (~)

oSpacer (~)

5. Install:

®Right crankcase

Use crankshaft Installing Tool (YU-90050

(~, YM-90063 (~)).

3-27

Page 73

NOTE:

Downloaded from www.ScooterTime.net

Tighten the crankcase holding screws in stage,

using a crisscross pattern.

7. Check:

oCrankshaft operation

Unsmooth operation-* Repair.

8. Install:

®Oil seal stopper plate (_

®Circlip (_)

Screw (Oil Seal Stopper Plate):

13 Nm (1.3 m=kg, 9.4 ft.lb)

3-28

Page 74

m

Downloaded from www.ScooterTime.net

E.oIIEOO,NEASSEMB,ANOAOJOSTMENT

CRANKSHAFT A: 37.90-37.95 mm

0 Oil seal F (1.492-1.494 in)

Crank (Right) D: 0.2-0.5 mm

@ Crank pin (0.008-0.020 in)

Bearing F: 0.4-0.8 mm

Connecting rod (0.015-0.031 in)

_ Bearing __ C: 0.03mm(0.oe12in)

_ Crank ([.eft)

(_) Oil seal

(_ Bearing _D

!

®

3-29

Page 75

q Eoo.NEAssEMB,YAooAOJOSTMEOTIENOI'..

Downloaded from www.ScooterTime.net

TRANSMISSION

J, 1. Apply:

o10W30 Type SE Motor oil

(to transmission case cover bearing)

2. Install:

®Secondary sheave axle (_

(to transmission case cover)

3. Install:

®Circlip @

®Oil seal

NOTE:

i_i_i Apply lithium soap base grease onto the oil seal

_,_i . % lips.

4. Apply:

®10W30 type SE Motor oil

(to main axle bearing and drive axle bearing)

_ '_{_...... 5. Install:

®Drive axle (_

®Main axle (_)

,Washer (_) (Main axle)

(_) ,Washer @ (Drive axle)

3-30

Page 76

ENG _ ENGINEASSEMBLYAND ADJUSTMENT

Downloaded from www.ScooterTime.net

7. Install:

_.....:_:'_::_!..... i_ii_ii: (_ *Transmission case cover (_

_iii:_;_;_ !ilili;__ _ Screw (Case cover):

ii;_ili!! 'i _ 8 Nm (0.8 m,kg, 5.8 ft,lb)

8. Install:

i:._i_ ' * Centerstand

9. Install:

*Brake shoe plate @

18 Nm (1.8 m°kg, 13 ft,lb)

-t SoeP'ate':

10. Install:

*Plain washer (_

®Rearwheel (_)

(_ *Plain washer _)

t I_LI 93 Nm (9"3 m'kg" 67 ft'ib) I

®Nut @

3-31

Page 77

TRANSMISSION

Downloaded from www.ScooterTime.net

Bearing

Oil seal

Drive axle

(_ Bearing

q_) Main axle

(_) Plain washer

_ econdary sheave axleBearing

(_ Circlip

(_ Oil seal

EOO,NEASSEMBLANOAOJUSTM OT "OJ

G

3-32

Page 78

3-33

Downloaded from www.ScooterTime.net

Page 79

o oo,oE AooAOJOSTMENTIE"OI I

Downloaded from www.ScooterTime.net

AUTOLUBE PUMP

(_ Autolube pump

(_ Pin

(_ Circlip

@ Shim

(_) Wave washer

(_) Pump drive gear

(_ Circlip

3-34

Page 80

[ ENG '_®_D] ENGINE ASSEMBLY AND ADJUSTMENT h

Downloaded from www.ScooterTime.net

C.D.I. MAGNETO

1. Install:

eGasket (_

• ,.,_*'_

, .:.:z,.:.,

2. Pass the C.D.I. magneto lead through the

crankcase hole.

'"_ 3. Install:

_ 8 Nm (0.8 m,kg, 5.8 ftolb)

_.......... ®Woodruff key

_, *C.D.I. magneto

_" _:_._, 5. Tighten:

,i:_ ®Nut (C.D.I. magneto)

_ 4. Install:

eStator assembly (_)

!_ Screw (Stat°r Assemb'y): I

• Plain washer

,_Spring washer

_Nut

NOTE:

When installing the C.D.I. magneto, make sure

the woodruff key is properly seated in the key way

of the crankshaft. Apply a light coating of lithium

soap base grease to the tapered portion of the

crankshaft end.

Use Flywheel Holding Tool (YU-01235) (_.

43 Nm 14.3 m°kg, 31 ft°lb)

...... 141 I

3-35

Page 81

EOO,OEASSEMBLANOAOJOSTMEOT

Downloaded from www.ScooterTime.net

C.D.I. MAGNETO

(_ Fan

(_ C.D.I. magneto

Stator assembly

Gasket

(_ Woodruff key

[8Nm(08___.kg,5.8ft._b)}

• >%'--.

43 Nm 14.3mokg, 31 ft-lb) ! __._

8 Nm 10.8m,kg, 5.8 ft,lb)

I

I

3-36

Page 82

ENG _ ENGINEASSEMBLYANDADJUSTMENT [

Downloaded from www.ScooterTime.net

STARTER SYSTEM

1. Install:

oCollar (_

• Kick shaft (_)

@

3-37

4. Install:

• Kick torsion spring (_

NOTE:

Set the kick torsion spring to the spring hook.

Page 83

_=_ ENGINE ASSEMBLY AND ADJUSTMENT ENG

Downloaded from www.ScooterTime.net

_. 6. Install:

oStarter motor (_

8 Nm 10.8 m,kg, 5.8 ft-lb)

NOTE:

Apply lithium soap base grease to the O-ring of

(_ the starter motor.

7. Install"

®Stay (_

:' ............."............. oCollar (_)

8 Nm 10.8 m okg, 5.8 ftolb)

, :_._:_..,.'_., _,:;'&:-"_,_':: ,::!:i::':_!:!"_ i_i:::_:_

@_:!_i_: :_:_"_(-_ -Apply lithium soap base grease to the bearing

_: _'_ "-:;:'._'_t............ 8. Install:

" _:: ,-_i:_,, :i_.... * Plain washers (_

.......:_::_i:{:;:_i-_-_::;:_;___ "Starter wheel gear (_

_=-_) -Apply Yamalube 2 cycle oil to the idle gear (_.

ii:i 9., sta,"

.:..:.:,._ ®Plate (_D(Idle gear)

I _ Screw ('die Gear Plate):

10. Install:

8 Nm (0.8 m okg, 5.8 ft-lb)

eStarter clutch assembly (_

3-38

Page 84

ENG

Downloaded from www.ScooterTime.net

STARTER SYSTEM

(~) Kick shaft

(~) Kick torsion spring

(~) Kick crank

@ Idle gear

~ ollar

Stay

ENGINE ASSEMBLY AND ADJUSTMENT

(~) Bearing

Starter wheel gear

(~) Starter clutch assembly

(~ Kick pinion gear

0 Nm (1.0 mokg. 7.2 ft°lb) I

/ ~J

/

/ ~ ~

®

"~v / ~ /

® @

(~

I °kg' 5"8 ft°lb) I

I CLIP STANDARD TENSION:

A 250-300 g (8.83-10.6 oz)

3-39

Page 85

Eoo,oEASSEMBLANOAOUSTMEOTE"OI'. I

Downloaded from www.ScooterTime.net

PRIMARY AND SECONDARY SHEAVE

1. Install"

-Secondary sheave assembly

=Clutch housing (_

i

2. Tighten:

• Nut (Secondary sheave)

Use Sheave Holder (_ (YS-01880).

[_40 Nm (4.0 m,kg, 29 ftolb) ]

3. Install:

cO-ring

I 4. Apply:

• Lithium soap base grease

L>

......:_;- ..,_::-_,,_,:-:,:_:_-:_.......,, .,,_::; 5. Install:

iiiiiiii_iii_i_iiii -Primary sheave assembly (_

_i::!!ii_iiiii_iiii i_i -Collar (_

_;;!_:!:_!_:ililili_i!_iii_i_i _ - Shim (_ .,

6. Install:

_V-belt

Place the V-belt around the secondary

sheave, andcompress the secondary sheave

spring hard so that the V-belt moves toward

the clutch hub.

NOTE:

The V-belt must be installed with the arrow

': frontward.

3-40

Page 86

I ENG ENGINE ASSENIBLY AND ADJUSTMENT E

Downloaded from www.ScooterTime.net

7. Install:

ePrimary fixed sheave (_

®One-way clutch (_)

• Conical spring washer @

oNut

_ ::_ -- _;_ 8. Tighten:

®Nut (primary sheave) (_

30 Nm (3.0 m,kg, 22 ft,lb)

NOTE:

When tightening the nut (primary sheave), hold

the C.D.I. magneto using Flywheel Holding Tool

(YU-01235).

9. install:

oFan (_

[_ Screw (Fan): ]ii_ 8 Nm (0.8 m-kg, 5.8 ft-lb)

10. Install:

®Dowel pins

oCrankcase cover (Left)

8 Nm (0.8 m,kg, 5.8 ft,lb)

Screw (Crankcase Cover): ]

3-41

Page 87

q EooNEAssEMB.,AooAOJOSTMEOT[ENOl

Downloaded from www.ScooterTime.net

PRIMARY AND SECONDARY SHEAVE

Secondary fixed sheave (_) Clutch assembly

(_ Oil seal (_ Clutch housing

(_ Secondary sliding sheave (_ O-ring

(_ O-ring O Primary sheave assembly

(_) Oil seal (_ V-belt

(_) Spring seat (_ Primary fixed sheave

(_ Clutch spring (_) One-way clutch

*Apply BEL-RAY Assembly Lube®

CLUTCH SPRING FREE LENGTH LIMIT:

A

94.0 rnrn (3.70 in)

CLUTCH HOUSING WEAR LIMIT:

B

105,4 mrn (4.15 in)

CLUTCH SHOE WEAR LIMIT: /_" _ • ,

C 2.5mm (0.10 in) _ / 150 Nm (5.0 m kg, 36ft.lb) I

VBELT_,L,_,T /_% /

O135mm(0.53_nl __ / /_

_r///%: _ / / ®

@

t e

3-42

Page 88

I ENG ENGINE ASSEMBLY AND ADJUSTMENT

Downloaded from www.ScooterTime.net

PISTON PIN AND PISTON

1. Apply:

oYamalube 2 cycle oil

To the piston pin, bearing, piston ring

grooves and piston skirt areas.

2. Install:

• Small end bearing

• Piston

Piston pin

®Piston pin clip

NOTE:

=The arrow (_ on the piston must point to the

front of the engine.

-Before installing the piston pin clip, cover the

crankcase with aclean towel or rag so you will

not accidentally drop the pin clip and material

into the crankcase.

®Always use a new piston pin clip.

3-43

Page 89

ENGINE ASSEMBLY AND ADJUSTMENT ENG

Downloaded from www.ScooterTime.net

PISTON PIN AND PISTON

(_ Piston ring (1st, 2nd)

(_) Piston

(_ Piston pin clip

@ Piston pin

_ Piston pin clipSmall end bearing

PISTON RING SIDE CLEARANCE:

A 0.03-0.05 mm (0.0012-0.0020 in)

< LIMIT>: 0.10 mm (0.004 in)

B 0.015-0.03 mm (0.006- 0.012 in)

<LIMIT>: 0.7 mm (0.028 in)

I

.®

3-44

Page 90

_i CYLINDER AND CYLINDER HEAD

Downloaded from www.ScooterTime.net

_; 1. Install:

®Cylinder gasket (New gasket)

2. Offset the piston ring end gaps as shown.

(_ 1st ring

_) 2nd ring

NOTE:

oBe sure to check the manufacturer's marks or

numbers stamped on the rings are on the top

side of the rings.

oBefore installing the cylinder, apply a liberal

coating of 2-stroke to the pisotn rings.

3. Install:

• Reed valve

oCarburetor joint (_

B°'t (Carburet°rJ°int): I

;_i_;_J 4. Install:

• Cylinder (_

;_ NOTE:

Install the cylinder with one hand while compress-

ing the piston rings with the other hand.

5. Pass the oil delivery pipe as shown,

8 Nm (0.8 m okg, 5.8 ft.lb)

3-45

Page 91

ENGINE

Downloaded from www.ScooterTime.net

ASSEMB'YA.OIA.OSTME°T IENO

eCylinder head gasket (New gasket)

7. Install:

oCylinder head (~

oSpark plug (~

NOTE:

Tighten the cylinder head holding nuts in stage,

using a crisscross pattern.

~, 4:. ,~, ~:.

Q

Cylinder Head Holding

10 Nm (1.0 m.kg, 7.2 ftolb)

Spark Plug:

20 Nm (2.0 m°kg, 14 ftolb)

8. Install:

eAir shroud

Bolt (Air Shroud):

l~

8 Nm (0.8 m-kg, 5.8 ft.lb)

Nuts:

9.

Install:

® Fan cover

Screw (Fan cover):

l~

8 Nm (0.8 m.kg, 5.8 ft.lb)

3-46

Page 92

[ ENGI &~] ENGINE ASSEMBLY AND

Downloaded from www.ScooterTime.net

CYLINDER AND CYLINDER HEAD

(~) Spark plug

(~) Cylinder head

® Gasket

@ Cylinder

® Gasket

ADJUSTMENT

120 Nm (2.0 14 l~

®

m.kg, ft-lb) A

• C

PISTON TO CYLINDER CLEARANCE:

0.034-0.047 mm (0.0013-0.0018 in)

CYLINDER HEAD WARPAGE LIMIT:

0.02 mm (0.0008 in)

SPARK PLUG:

BPR6HS (N.G.K,)

GAP: 0.9-1.0 mm (0.035-0.039 in)

@

®

3-47

Page 93

ENGINE ASSEMBLY AND ADJUSTMENT

Downloaded from www.ScooterTime.net

MUFFLER

1. Install:

®Muffler

Bolt (Muffler):

27 Nm (2.7 m.kg, 19 ft.lb)

Bolt (Exhaust pipe):

8 Nrn (0.8 m.kg, 5.8 ftolb)

I ENG

i~!?i~:i!i:~i;:~i)!::

!iiiiiiiiiiii~i

REMOUNTING ENGINE

When remounting the engine, reverse the removal

procedure.

1. Install:

®Engine mounting bolts

These bolts should be temporarily secured.

2. Tighten:

oEngine mounting bolts

Bolt

~--]:

42 Nm (4.2 rn.kg, 30 ft.lb)

Bolt r-~:

17 Nm (1:7 m°kg, 12 ft-lb)

3.

Install:

® Carburetor

®Carburetor top together with throttle valve

NOTE:

When installing the throttle valve into the car-

buretor, align the groove (~ of the throttle valve

with the projection (~) of the carburetor.

3-48

Page 94

ENG ENGINE ASSEMBLY AND ADJUSTMENT

Downloaded from www.ScooterTime.net

4. Air bleeding:

®Autolube pump

Referto "CHAPTER 2--AUTOLUBE PUMP

AIR BLEEDING" section.

5. Apply:

• Transmission oil

Refer to "CHAPTER 2--TRANSMISSION

OIL REPLACEMENT" section.

6. Adjust:

,Brake lever free play

Refer to "CHAPTER 2--BRAKE LEVER

FREE PLAY ADJUSTMENT" section.

•Autolube pump cable

Refer to "CHAPTER 2--AUTOLUBE PUMP

CABLE ADJUSTMENT" section.

• Throttle cable free play

Refer to "THROTTLE CABLE FREE PLAY

ADJUSTMENT" section.

3-49

Page 95

Downloaded from www.ScooterTime.net

Page 96

CHAPTER 4

Downloaded from www.ScooterTime.net

CARBURETION

AUTO CHOKE SYSTEM .......................................... F-3

CONSTITUENTS ................................................ F-3

WIRING SCHEMATIC .......................................... F-3

OPERATION ................................................... F-3

CARBURETOR ................................................... F-4

SECTION VIEW ................................................ F-5

REMOVAL .................................................... F-5

DISASSEMBLY ................................................ F-5

INSPECTION .................................................. F-6

ASSEMBLY ................................................... F-7

INSTALLATION ................................................ F-7

AUTO CHOKE UNIT CHECK .................................... F-8

REED VALVE ........................... . ........................ F-8

REMOVAL .................................................... F-8

INSPECTION .................................................. F-8

INSTALLATION ................................................ F-9

Page 97

Downloaded from www.ScooterTime.net

Page 98

AUTO CHOKE SYSTEM

Downloaded from www.ScooterTime.net

CARBURETION

AUTO CHOKE SYSTEM

CONSTITUENTS The electric auto-choke consists of the Positive Temperature Coefficient (P.T.C.) thermistor, wax element and starter plunger.

~ P.T.C. thermistor

Wax element

O-ring

(~) Starter plunger

r-i

®

I P.T.C.

When electric current flows in this thermistor, it

begins to be heated up to a specified temperature.

This specified temperature is then reained.

I Wax