Page 1

2001

WaveRunner

GP760

OWNER’S/OPERATOR’S

READ THIS MANUAL

CAREFULLY BEFORE OPERATION!

MANUAL

GP7-F8199-75

Page 2

Page 3

EJU00270

CAUTION:

To the owner/operator

Thank you for choosing a Yamaha water-

craft.

This Owner’s/Operator’s Manual contains

information you will need for proper operation, maintenance, and care. A thorough

understanding of these simple instructions

will help you to obtain maximum enjoyment

from your new Yamaha. If you have any

questions about the operation or maintenance of your watercraft, please consult a

Yamaha dealer.

Because Yamaha has a policy of continuing product improvement, this product may

not be exactly as described in this Owner’s/

Operator’s Manual. Specifications are subject to change without notice.

This manual should be considered a permanent part of this watercraft and should

remain with it even if the watercraft is subsequently sold.

E

Important manual information:

In this manual, information of particular

importance is distinguished in the following

ways:

The Safety Alert Symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions

could result in severe injury or death to

the machine operator, passenger(s), a

bystander, or a person inspecting or

repairing the watercraft.

A CAUTION indicates special precautions that must be taken to avoid damage

to the watercraft.

NOTE:

A NOTE provides key information to make

procedures easier or clearer.

EJU00272

WaveRunner GP760

OWNER’S/OPERATOR’S MANUAL

©2000 by Yamaha Motor Co., Ltd.

1st Edition, August 2000

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in USA

Page 4

Page 5

EJU00273

CONTENTS

GENERAL AND SAFETY

INFORMATION

E

1

FEATURE AND FUNCTIONS

OPERATION

MAINTENANCE AND CARE

TROUBLESHOOTING AND

EMERGENCY PROCEDURES

2

3

4

5

APPENDIX

READ THIS OWNER’S/OPERATOR’S MANUAL CAREFULLY

BEFORE OPERATING YOUR WATERCRAFT.

6

Page 6

Page 7

EJU00274

GENERAL AND

SAFETY

E

INFORMATION

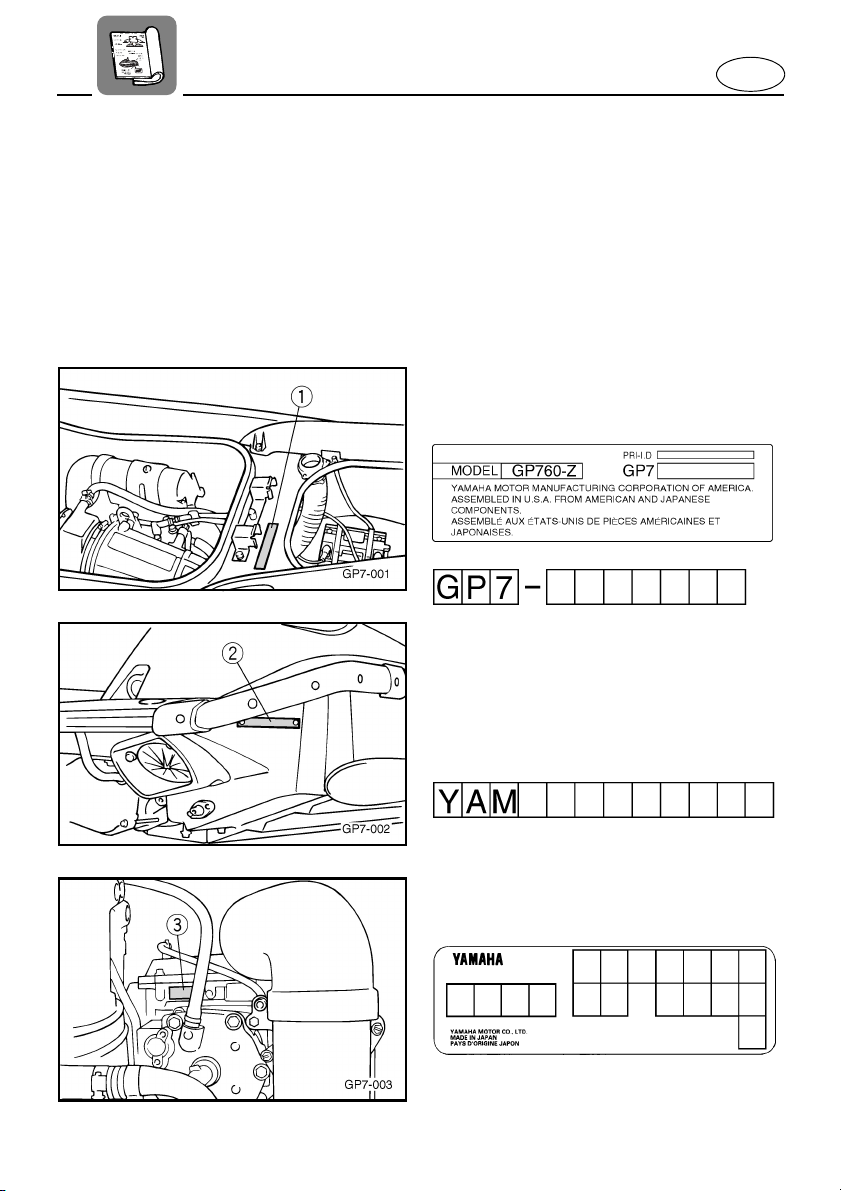

Identification numbers

Primary Identification (PRI-ID) number .. 1-1

Hull Identification Number (HIN).............1-1

Engine serial number..............................1-1

Emission control information

Approval label of Emission control

certificate.................................................1-2

Important labels

Label location..........................................1-3

Warning labels ........................................1-4

Caution labels .........................................1-7

Other labels.............................................1-8

Safety information

Limitations on who may operate the

watercraft.................................................1-9

Cruising limitations................................1-10

Operation requirements........................1-11

Hazard information ...............................1-13

Watercraft characteristics .....................1-14

Safe boating rules

Enjoy your watercraft responsibly

.............................1-1

.................1-2

........................................1-3

.............................. 1-9

..................................1-15

.......1-15

1

Page 8

E

EJU00699

Identification numbers

Record your Primary Identification (PRIID) number, Hull Identification Number (HIN)

and engine serial number in the spaces provided, to assist you in ordering spare parts

from a Yamaha dealer. Also record and keep

these ID numbers in a separate place in

case your watercraft is stolen.

EJU00700

Primary Identification (PRI-ID)

number

The PRI-ID number is stamped on a label

attached to the deck under the seats.

EJU00701

Hull Identification Number

(HIN)

The HIN is stamped on a plate 2

attached to the stern.

EJU00288a

Engine serial number

The engine serial number is stamped on

a label 3 attached to the engine unit.

1-1

1

Page 9

E

EJU00631a

Emission control

information

This engine conforms to the U.S. Environmental Protection Agency (EPA) regulations

for marine SI engines for the year 2001.

Approval label of Emission

control certificate

This label is attached to the electrical box.

1 Emission control information label

1-2

Page 10

EJU00293

Label location

E

Important labels

1-3

Page 11

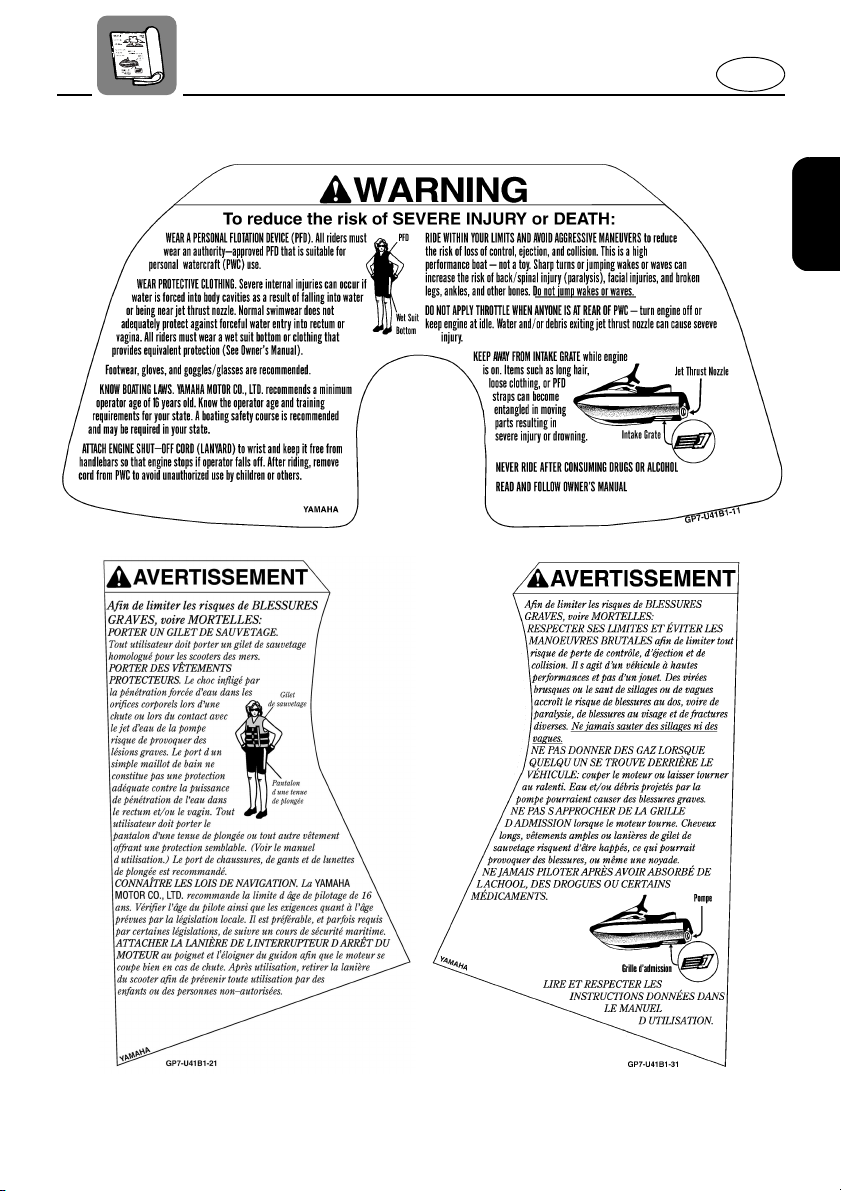

Warning labels

1

23

E

1-4

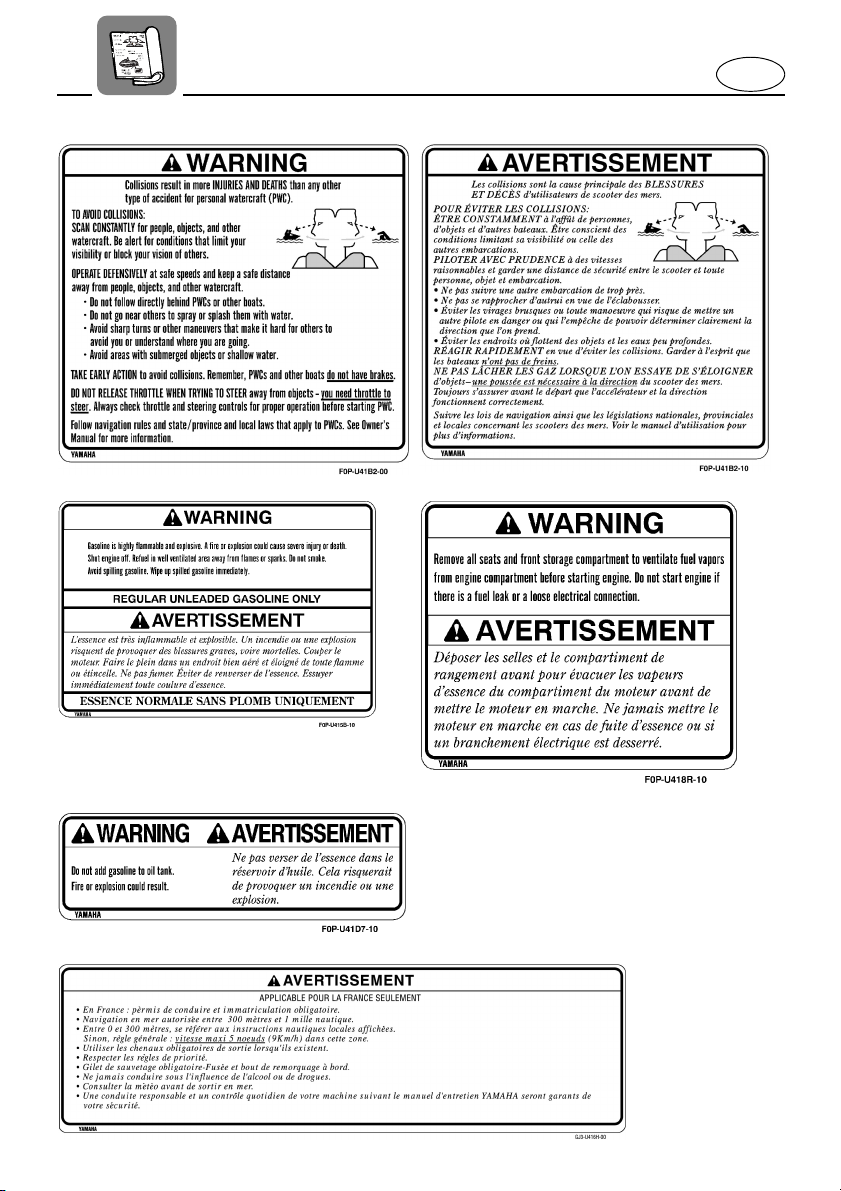

Page 12

E

45

67

8

9

1-5

Page 13

E

0A

B

C

D

1-6

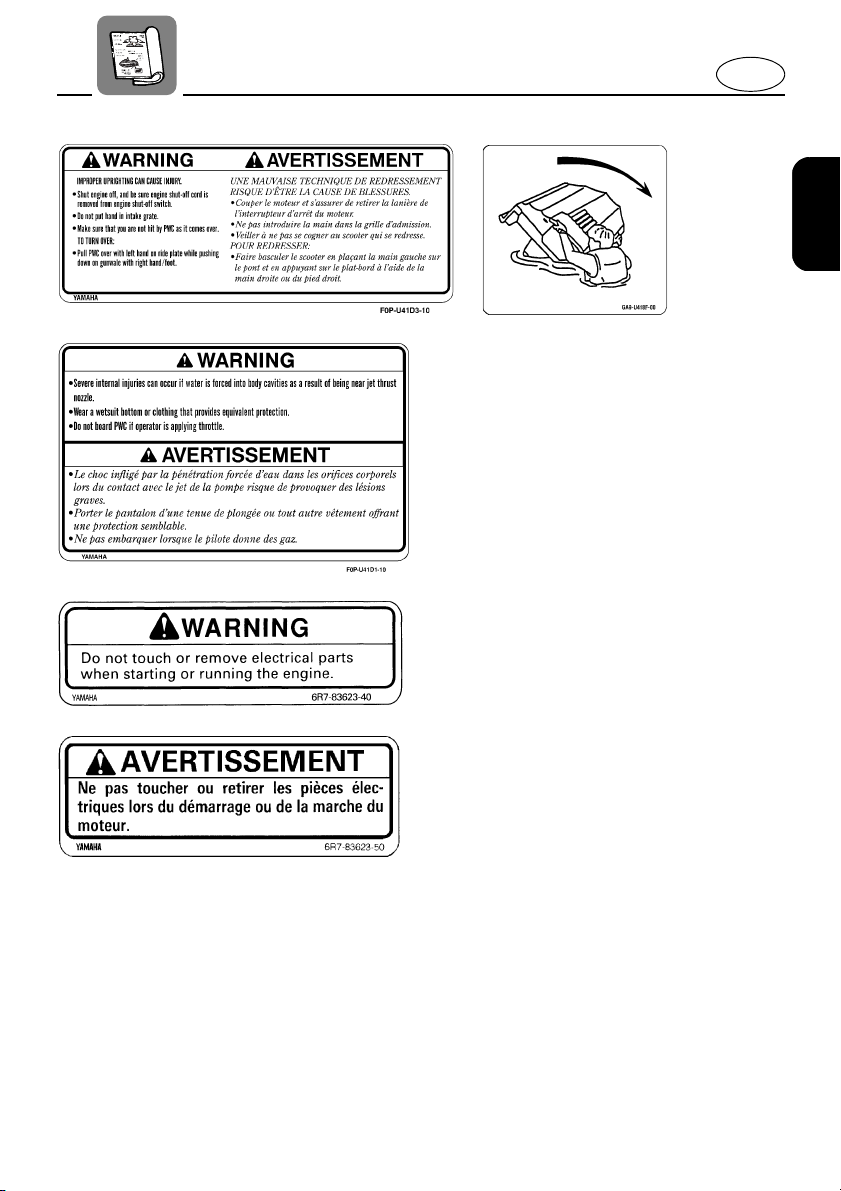

Page 14

E

Caution labels

EF

G

HI

1-7

Page 15

E

Other labels

J

K

L

MN

O

1-8

Page 16

E

EJU00961

Safety information

The safe use and operation of this

watercraft is dependent upon the use of

proper riding techniques, as well as upon

the common sense, good judgment, and

expertise of the operator. Before using

this watercraft, make sure that its use is

permitted under local laws, by-laws and

regulations and always operate the

watercraft in full conformity with any

requirements and limitations imposed.

Every operator should know the following requirements before riding the watercraft.

● Before operating the watercraft, read this

Owner’s/Operator’s Manual, the Riding

Practice Guide, and all warning and cau-

tion labels on the watercraft. These mate-

rials should give you an understanding of

the watercraft and its operation.

● Never allow anyone to operate this water-

craft until they too have read this Owner’s/

Operator’s Manual, the Riding Practice

Guide and all warning and caution labels.

EJU00298

Limitations on who may

operate the watercraft

● Yamaha recommends a minimum opera-

tor age of 16 years old.

Adults must supervise use by minors.

Know your local operator age and training

requirements.

● This watercraft is designed to carry the

operator and one passenger. Never

exceed the maximum load limit or allow

more than 2 persons to ride the watercraft

at one time.

Maximum load: 160 kg (353 lb)

Load is the total weight of cargo, operator and passenger.

● Do not operate the watercraft with a pas-

senger on board until you have considerable practice and experience riding alone.

Operating the watercraft with a passenger

requires more skill. Take the time to

become accustomed to the handling

characteristics of the watercraft before

trying any difficult maneuvers.

1-9

Page 17

E

EJU00613

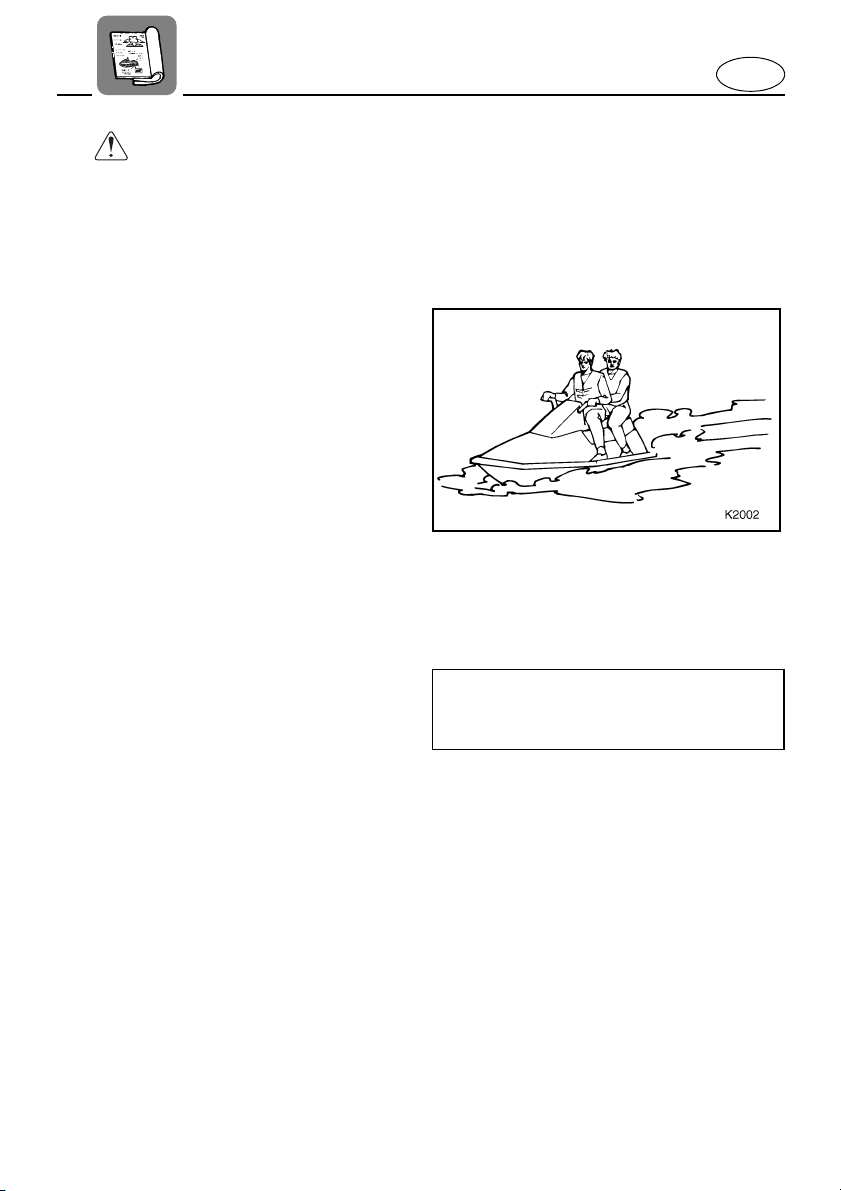

Cruising limitations

● Scan constantly for people, objects, and

other watercraft. Be alert for conditions

that limit your visibility or block your vision

of others.

● Operate defensively at safe speeds and

keep a safe distance away from people,

objects, and other watercraft.

● Do not follow directly behind watercraft or

other boats.

● Do not go near others to spray or splash

them with water.

● Avoid sharp turns or other maneuvers

that make it hard for others to avoid you or

understand where you are going.

● Avoid areas with submerged objects or

shallow water.

● Ride within your limits and avoid aggres-

sive maneuvers to reduce the risk of loss

of control, ejection, and collision.

● This is a high performance boat—not a

toy. Sharp turns or jumping wakes or

waves can increase the risk of back/spinal

injury (paralysis), facial injuries, and bro-

ken legs, ankles and other bones. Do not

jump wakes or waves.

● Do not operate the watercraft in rough

water, bad weather or when visibility is

poor; this may lead to an accident causing injury or death. Be alert to the possibility of adverse weather. Take note of

weather forecasts and the prevailing

weather conditions before setting out on

your watercraft.

● As with any water sport, you should not

ride your watercraft without someone else

near by. If you ride further than swimming

distance from shore, you should ride by

another boat or watercraft, but make sure

you stay a safe distance away. It’s good

common sense!

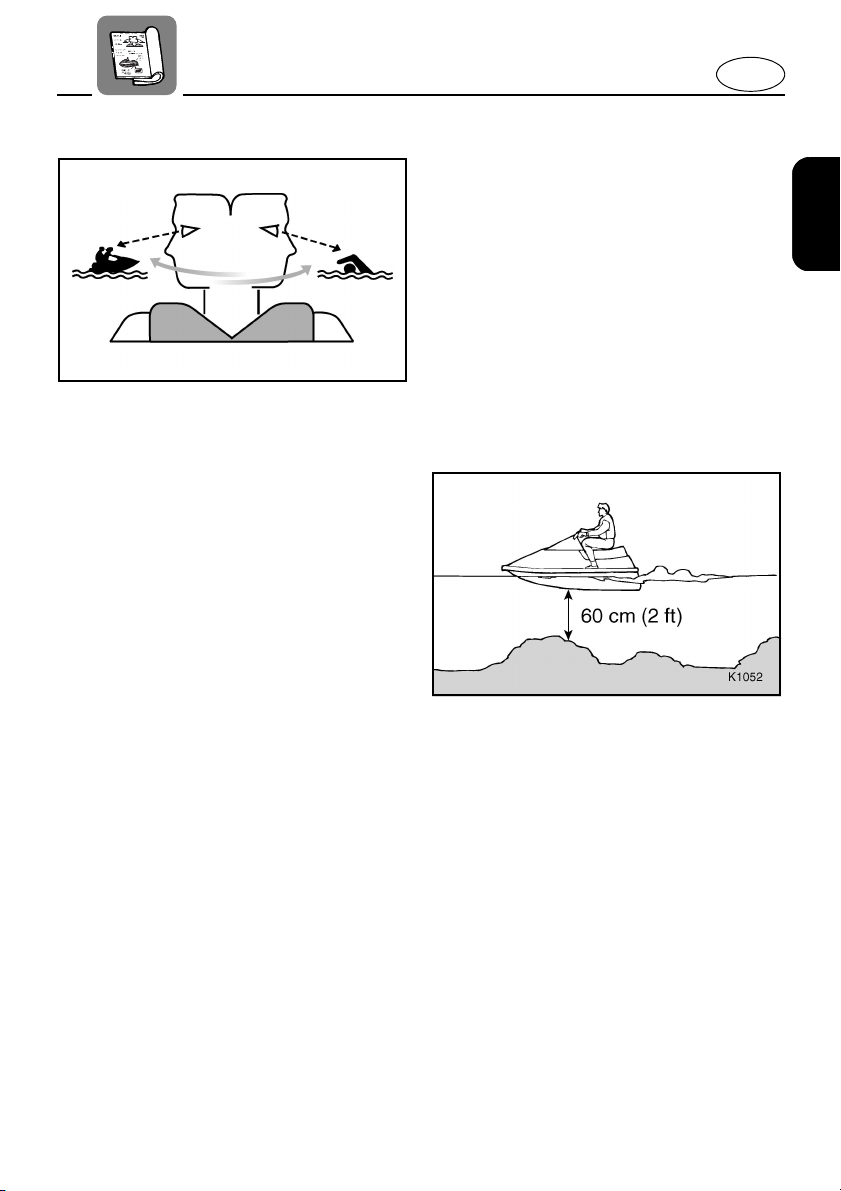

● Never operate in water that is less than

60 cm (2 ft) deep, otherwise you increase

your chance of hitting a submerged

object, which could result in injury.

1-10

Page 18

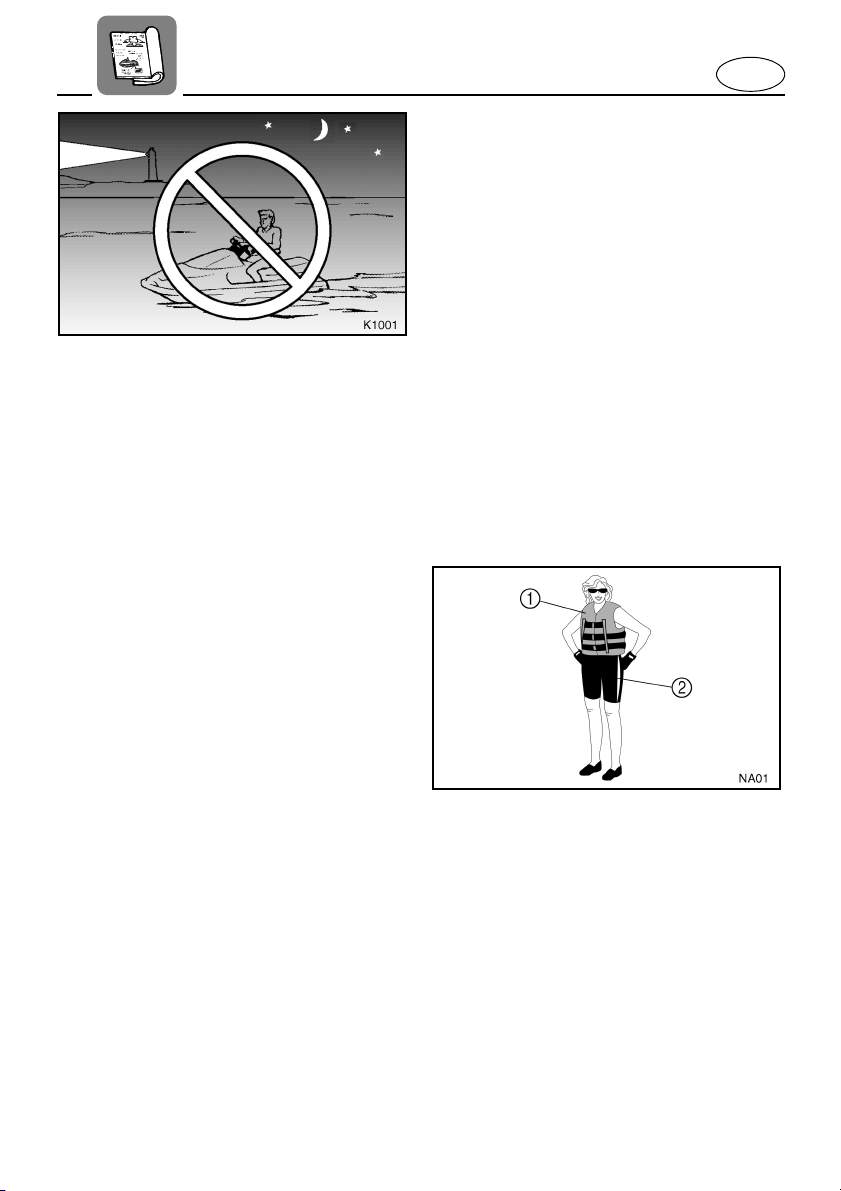

● This watercraft is not equipped with light-

ing required for night operation. Do not

operate the watercraft after sunset or

before dawn, otherwise you increase the

risk of colliding with another boat, which

could result in severe injury or death.

E

EJU00735a

Operation requirements

● All riders must wear a personal flotation

device (PFD) that is approved by the

appropriate authorities and suitable for

personal watercraft use.

● Wear protective clothing. Severe internal

injuries can occur if water is forced into

body cavities as a result of falling into

water or being near the jet thrust nozzle.

Normal swimwear does not adequately

protect against forceful water entry into

rectum or vagina. All riders must wear a

wetsuit bottom or clothing that provides

equivalent protection. Such clothing

includes thick, tightly woven, sturdy and

snug-fitting apparel such as denim, but

does not include spandex or similar fabrics, like those used in bicycle shorts.

1 Authority-approved PFD

2 Wetsuit bottom

● Eye protection is recommended to keep

wind, water, and glare from the sun out of

your eyes while you operate your watercraft. Restraining straps for eyewear are

made which are designed to float should

your eyewear fall in the water.

Footwear and gloves are recommended.

1-11

Page 19

● You must decide whether to wear a hel-

met while you ride for recreation. You

should know that a helmet could help pro-

tect you in certain kinds of accidents and

that it could injure you in others.

A helmet is designed to provide some

head protection. Although helmets cannot

protect against all foreseeable impacts, a

helmet might reduce your injuries in a col-

lision with a boat or other obstacle.

A helmet may have potential safety haz-

ards, as well. Falling into the water could

risk the chance of the helmet catching

water, commonly known as “bucketing,”

and the resulting strain on your neck

could cause choking, severe and perma-

nent neck injuries, or death. A helmet

could also increase the risk of an accident

if it reduces your vision or hearing, or if it

distracts you or increases your fatigue.

How should you decide if a helmet’s

potential safety benefits outweigh its

potential risks for you? Consider your par-

ticular riding conditions. Consider factors

such as your riding environment and your

riding style and ability. Also consider the

likelihood of traffic congestion, and the

water surface conditions. If you decide to

wear a helmet based upon your riding cir-

cumstances, choose one carefully. Look

for a helmet designed for personal water-

craft use, if possible. If you will be engag-

ing in closed-course competition, follow

the helmet requirements of the sanction-

ing organization.

E

● NEVER operate the watercraft after con-

suming alcohol or taking other drugs.

● For reasons of safety and proper care of

the watercraft, always perform the preoperation checks listed on page 3-5

before operating the watercraft.

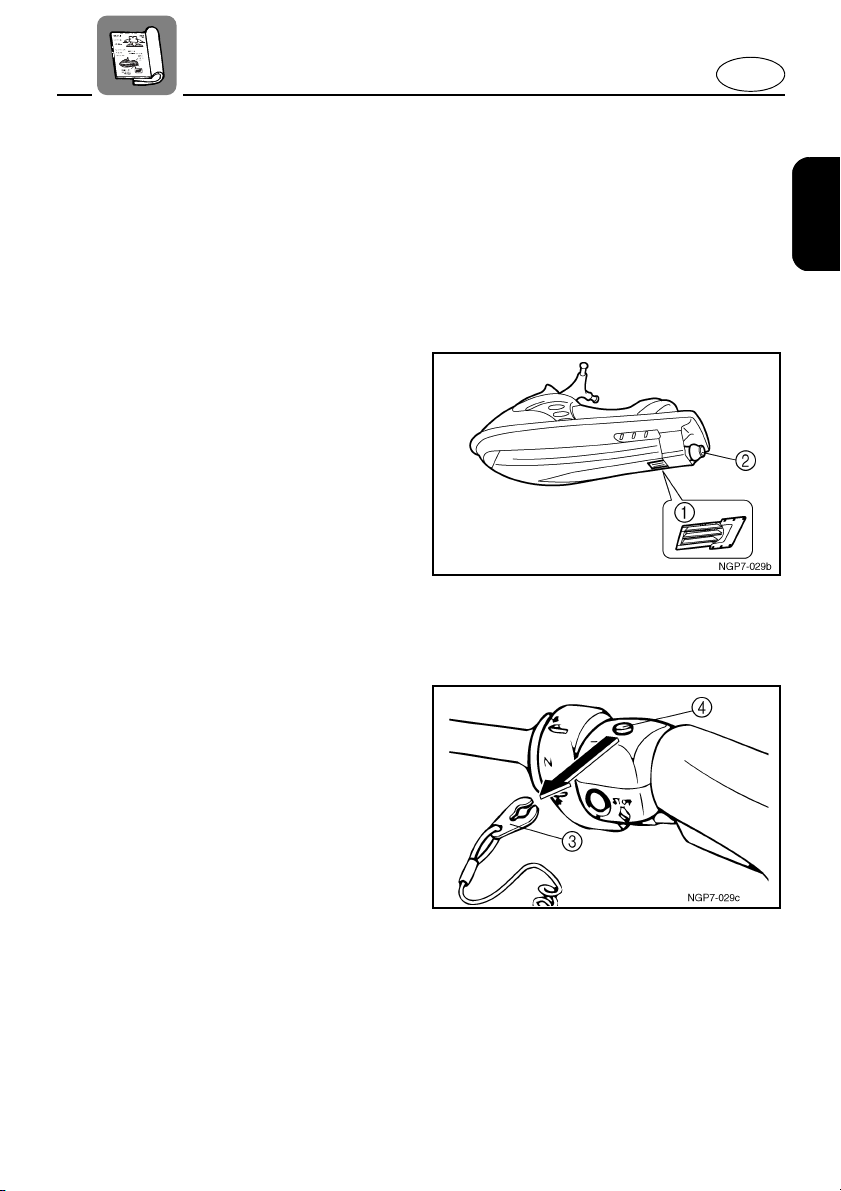

● The operator and passenger should

always keep both feet in the footwell when

the watercraft is in motion. Lifting your

feet increases your chances of losing your

balance, and your feet being hit by objects

outside the watercraft. Do not give a ride

to a child whose feet cannot reach the

floor of the footwell.

● Passenger should firmly hold on to the

operator.

● Always consult your doctor on whether it

is safe for you to ride this watercraft if you

are pregnant or in poor health.

1-12

Page 20

E

● Do not attempt to modify this watercraft!

Modifications to your watercraft may

reduce safety and reliability, and render

the watercraft unsafe or illegal for use.

● Attach the engine shut-off cord (lanyard)

to wrist and keep it free from the handle-

bars so that the engine stops if the opera-

tor falls off. After riding, remove the

engine shut-off cord from the watercraft to

avoid accidental starting or unauthorized

use by children or others.

● Scan carefully for swimmers and stay

away from swimming areas. Swimmers

are hard to see and you could acciden-

tally hit someone in the water.

● Avoid being hit by another boat! You

should always take the responsibility to

watch for traffic; other boaters may not be

watching for you. If they do not see you,

or you maneuver more quickly than other

boaters expect, you risk a collision.

● Maintain a safe distance from other boats

or watercraft, and also watch for boats’ ski

ropes or fishing lines. Obey the “Safe

boating rules” and be sure to check

behind you before making a turn. (See

Safe boating rules on page 1-15.)

EJU00313

Hazard information

● When transporting or storing your water-

craft, always place the fuel cock knob in

the “OFF” position, otherwise gasoline

may overflow from the carburetor.

● Never start the engine or let it run for any

length of time in an enclosed area.

Exhaust fumes contain carbon monoxide,

a colorless, odorless gas that may cause

loss of consciousness and death within a

short time. Always operate the watercraft

in an open area.

1-13

Page 21

E

EJU00315a

Watercraft characteristics

● Jet thrust turns the watercraft. Releasing

the throttle completely produces only min-

imum thrust. If you are traveling at speeds

above trolling, you will have rapidly

decreasing ability to steer without throttle.

You may still have some turning ability

immediately after releasing the throttle,

but once the engine slows down, the

watercraft will no longer respond to han-

dlebar input until you open the throttle

again or you reach a trolling speed. Prac-

tice turning in an open area without

obstructions until you have a good feel for

this maneuver.

● This watercraft are water-jet propelled.

The jet pump is directly connected to the

engine. This means that jet thrust will pro-

duce some movement whenever the

engine is running. There is no “neutral”

position.

● Keep away from intake grate 1 while the

engine is on. Items such as long hair,

loose clothing, or PFD straps can become

entangled in moving parts resulting in

severe injury or drowning.

● Never insert any object into the jet thrust

nozzle 2 while the engine is running.

Severe injury or death could result from

coming in contact with the rotating parts

of the jet pump.

● Stop the engine and remove the clip 3

from the engine shut-off switch 4 before

removing any debris or weeds, which may

have collected around the jet intake.

1-14

Page 22

E

EJU00319

Safe boating rules

Your Yamaha watercraft is legally considered a powerboat. Operation of the watercraft must be in accordance with the rules

and regulations governing the waterway on

which it is used.

EJU00322

Enjoy your watercraft

responsibly

You share the areas you enjoy when

riding your watercraft with others and with

nature. So your enjoyment includes a

responsibility to treat these other people,

and the lands, waters, and wildlife with

respect and courtesy.

Whenever and wherever you ride, think of

yourself as the guest of those around you.

Remember, for example, that the sound of

your watercraft may be music to you, but it

could be just noise to others. And the exciting splash of your wake can make waves

others won’t enjoy. Avoid riding close to

shoreline homes and waterfowl nesting

areas or other wildlife areas, and keep a

respectful distance from fishermen, other

boats, swimmers, and populated beaches.

When travel in areas like these is unavoidable, ride slowly and obey all laws.

Remember that pollution can be harmful

to the environment. Do not refuel or add oil

where a spill could cause damage to nature.

Remove your watercraft from the water and

move it away from the shoreline before refueling. And keep your surroundings pleasant

for the people and wildlife that share the

waterways: don’t litter!

When you ride responsibly, with respect

and courtesy for others, you help ensure

that our waterways stay open for the enjoyment of a variety of recreational opportunities.

1-15

Page 23

EJU00326

FEATURES AND

FUNCTIONS

E

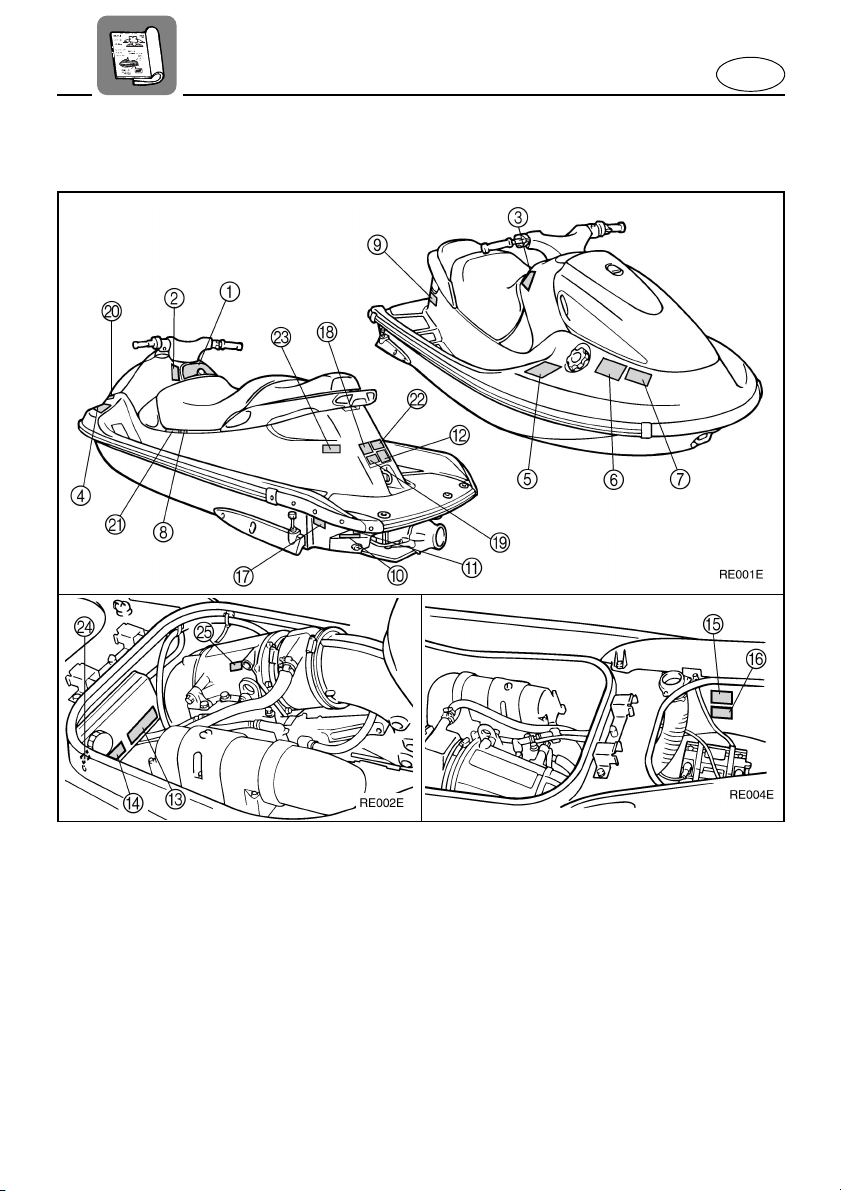

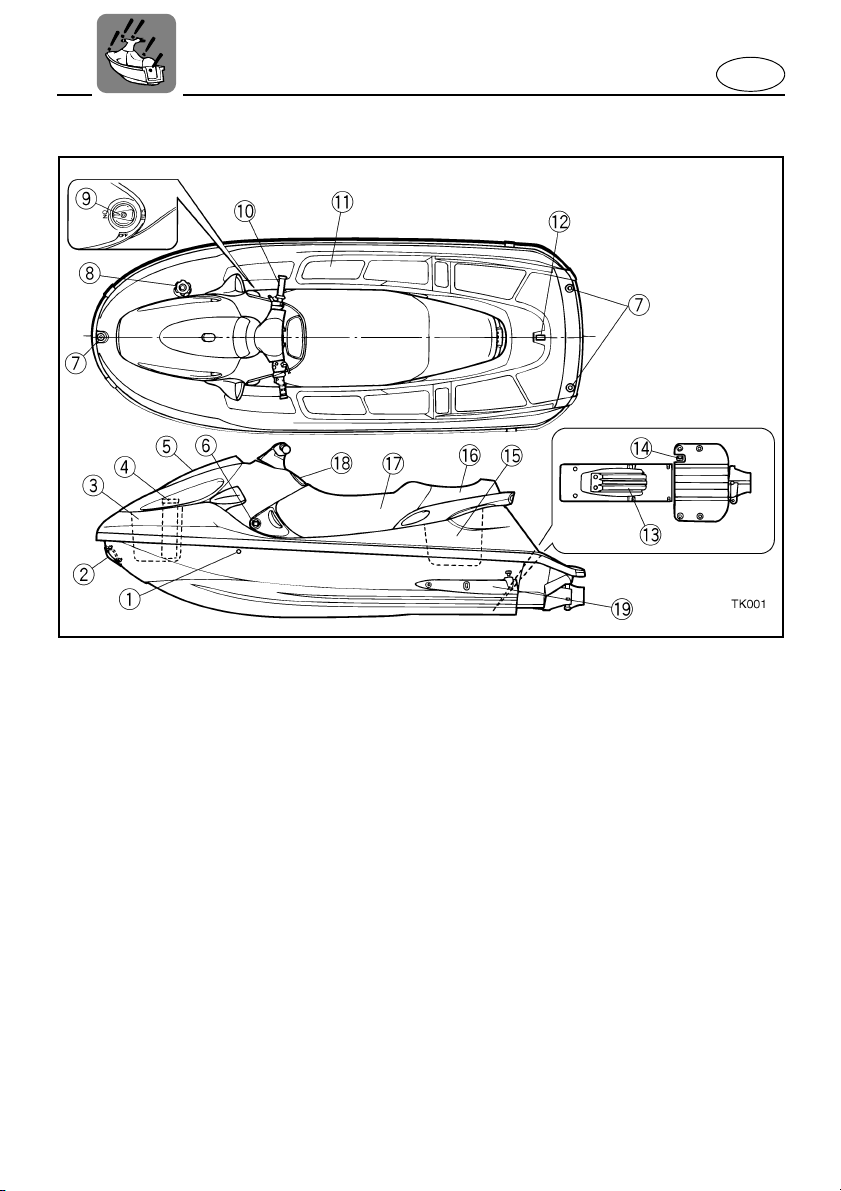

Location of main components

Operation of controls and other

functions

Rear seat.................................................2-4

Front seat ................................................2-5

Hood........................................................ 2-6

Fuel tank filler cap...................................2-6

Fuel cock knob........................................2-7

Engine stop switch..................................2-8

Engine shut-off switch............................. 2-8

Choke knob.............................................2-8

Throttle lever ...........................................2-9

Start switch..............................................2-9

Cooling water pilot outlet ......................2-10

Steering system ....................................2-10

Quick Shift Trim System (QSTS)

selector..................................................2-11

Engine overheat warning system......... 2-13

Handgrip................................................2-14

Multifunction meter................................2-15

PADLOC (Programmable digital locking

ignition)..................................................2-16

Tachometer...........................................2-18

Speedometer ........................................2-19

Fuel meter.............................................2-19

Engine oil meter....................................2-20

Clock .....................................................2-20

Hour meter ............................................2-21

Trip timer ...............................................2-21

Tripmeter...............................................2-22

Fuel warning indicator...........................2-22

Oil warning indicator .............................2-23

Engine overheat warning indicator....... 2-23

Battery warning indicator ......................2-24

Storage compartments .........................2-25

Yamaha Adjustable Sponson

(Y.A.S.)..................................................2-27

....................................................2-4

...............2-1

2

Page 24

EJU00327

Location of main components

Cooling water pilot outlet

1

Use to verify cooling water flow.

Bow eye

2

Use to attach rope for transporting, mooring or

towing the watercraft in an emergency.

Front storage compartment

3

Fire extinguisher container

4

Use to store the fire extinguisher.

Hood

5

Choke knob

6

Use to start a cold engine.

Rope hole

7

Rope attachment point for transporting, and

mooring.

Fuel tank filler cap

8

Fuel cock knob

9

Use to select either normal or reserve fuel flow

from the fuel tank to the carburetors, or to shut

off fuel flow.

Handlebars

0

Use to control direction.

Footwell

A

Use to place feet for balance.

Cleat

B

Use to attach a rope for mooring.

Intake grate

C

Prevents debris from getting into the jet pump.

Speed sensor

D

Seat storage compartment

E

Rear seat

F

Front seat

G

Glove compartment

H

Yamaha Adjustable Sponson (Y.A.S.)

I

Changes maneuvering characteristic by

adjusting the sponson angle.

2-1

E

Page 25

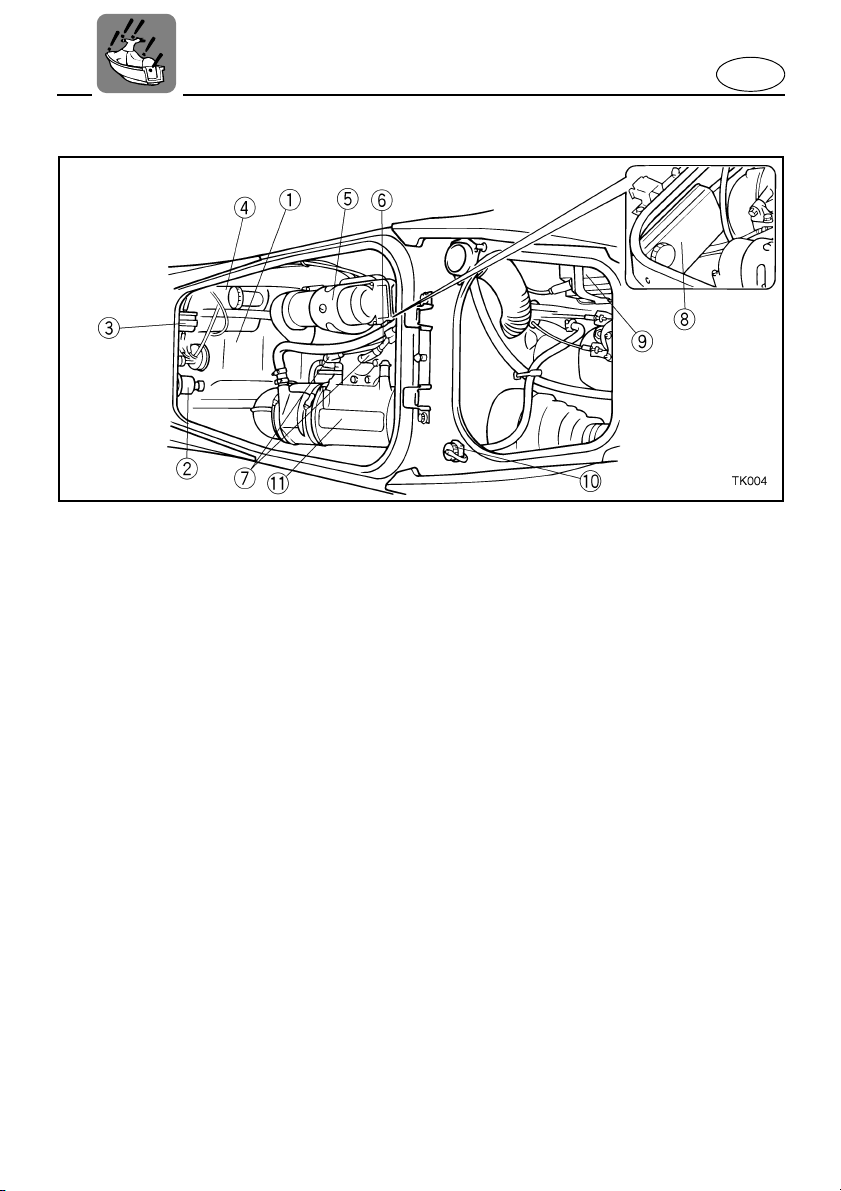

Engine shut-off cord (lanyard)

1

Attach to wrist so that the engine stops if the

operator falls off the watercraft.

Engine stop switch

2

Push to stop the engine normally.

Engine shut-off switch

3

Remove the clip to stop the engine and disable it from starting.

Clip

4

Insert into the engine shut-off switch to enable

starting of the engine.

Remove to stop the engine or prevent accidental starting of the engine or unauthorized

use of the watercraft.

Quick Shift Trim System (QSTS) selector

5

Use to select the trim angle of the watercraft.

Start switch

6

Push to start the engine.

Multifunction meter

7

Use to check watercraft operation.

Throttle lever

8

Use to accelerate and decelerate.

Stern drain plugs

9

Use to drain water in the bilge when the watercraft is on dry land.

Jet thrust nozzle

0

Changes the direction of jet thrust according

to handlebar position.

E

2-2

Page 26

Fuel tank

1

Water separator

2

Traps water from the breather hose to the fuel

tank.

Fuel filter

3

Oil tank

4

Silencer

5

Prevents water from getting into the engine

and reduces air intake noise.

Spark plug lead

6

Spark plugs/Spark plug caps

7

Electrical box

8

Protects electrical components from water.

Battery

9

Flush hose connector

0

Use to flush the engine cooling water passages.

Muffler

A

E

2-3

Page 27

E

EJU00328

Operation of controls and

other functions

EJU00335a

Rear seat

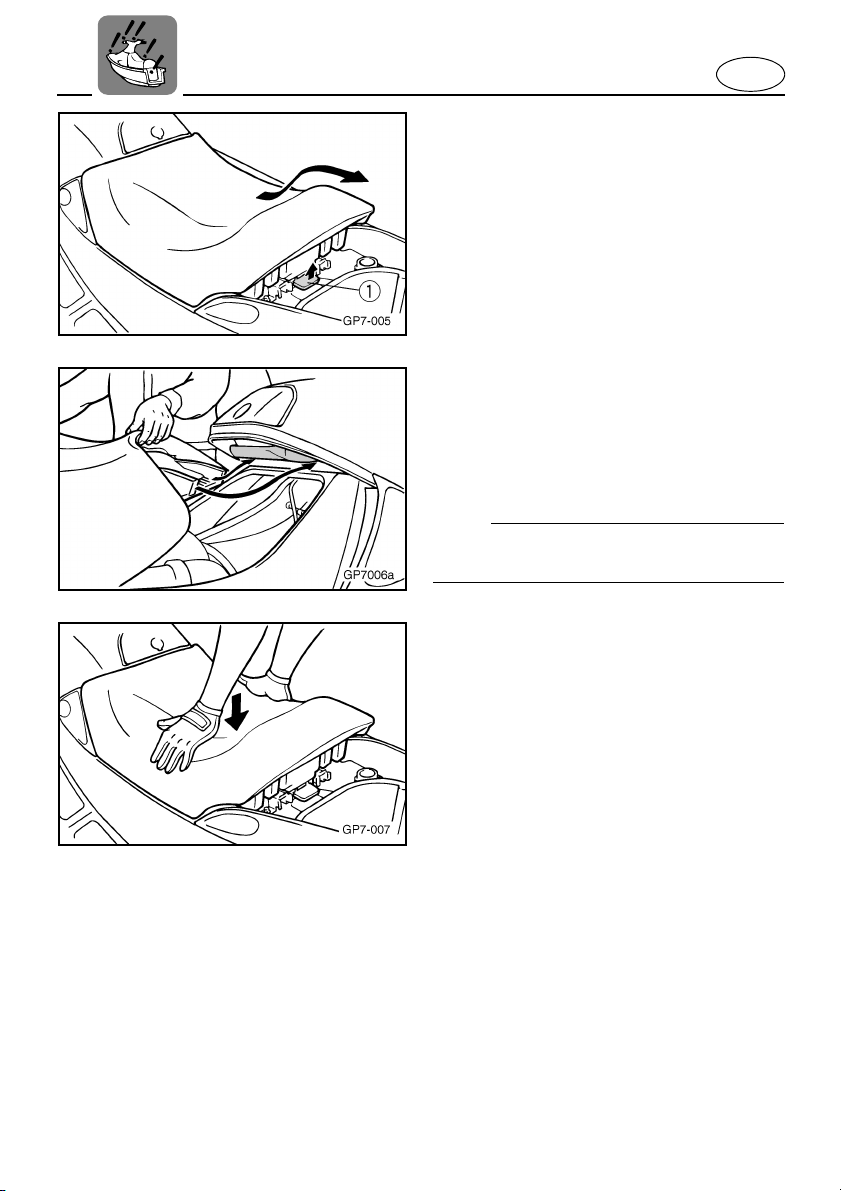

To remove the rear seat:

Pull the rear seat latch 1 up, and then

pull the seat off.

To install the rear seat:

Insert the projections on the front of the

seat into the stays on the deck, and then

push the rear of the seat down to lock it in

place securely.

2-4

Page 28

E

EJU00714

Front seat

To remove the front seat:

1. Remove the rear seat.

2. Pull the front seat latch 1 up, and then

pull the seat off.

To install the front seat:

1. Insert the projections on the front of the

seat into the stays on the deck, and then

push the rear of the seat down to lock it

in place.

2. Install the rear seat.

NOTE:

Make sure that the seats are properly

secured before operating the watercraft.

2-5

Page 29

E

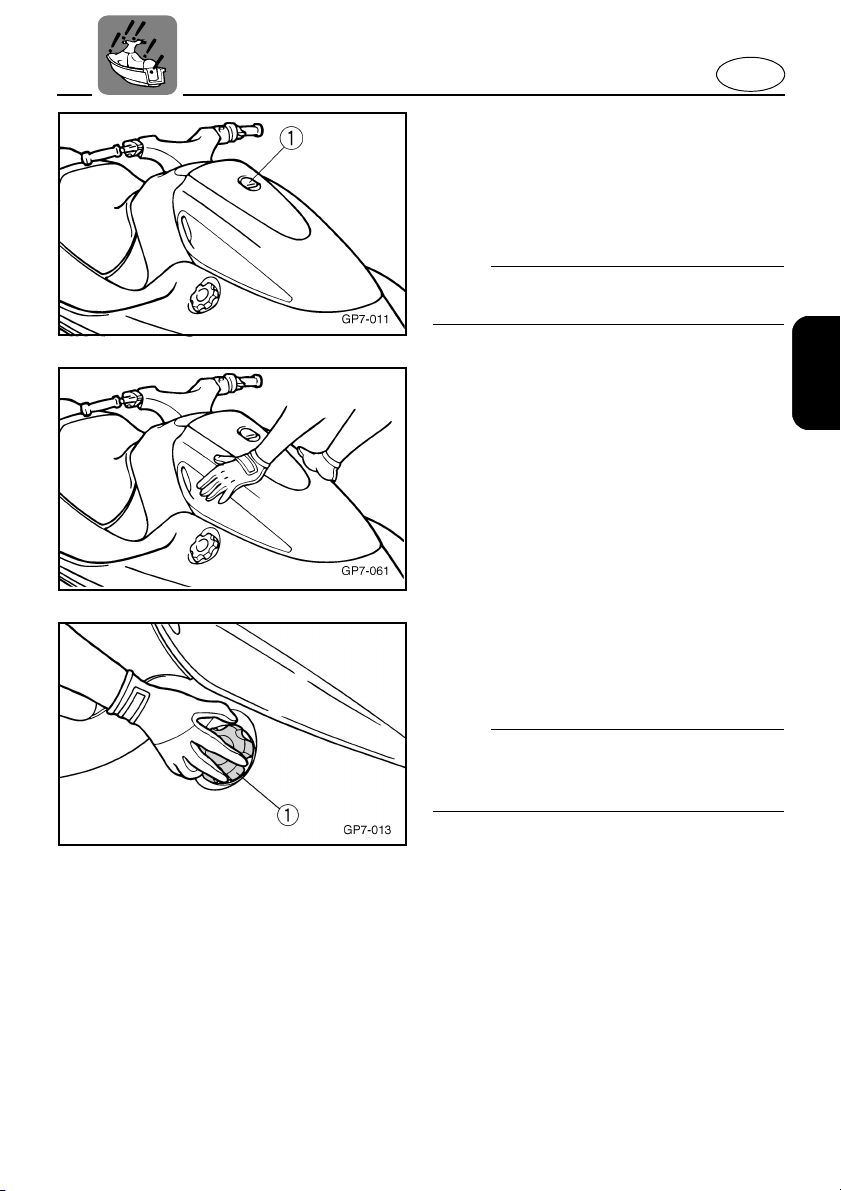

EJU00703

Hood

To open the hood, pull the latch 1 up,

and then lift the hood up.

To close the hood, push the hood down to

lock it in place.

NOTE:

Make sure that the hood is properly secured

before operating the watercraft.

EJU00347

Fuel tank filler cap

To remove the fuel tank filler cap 1, turn it

counterclockwise.

NOTE:

Make sure that the fuel tank filler cap is

properly secured before operating the watercraft.

2-6

Page 30

E

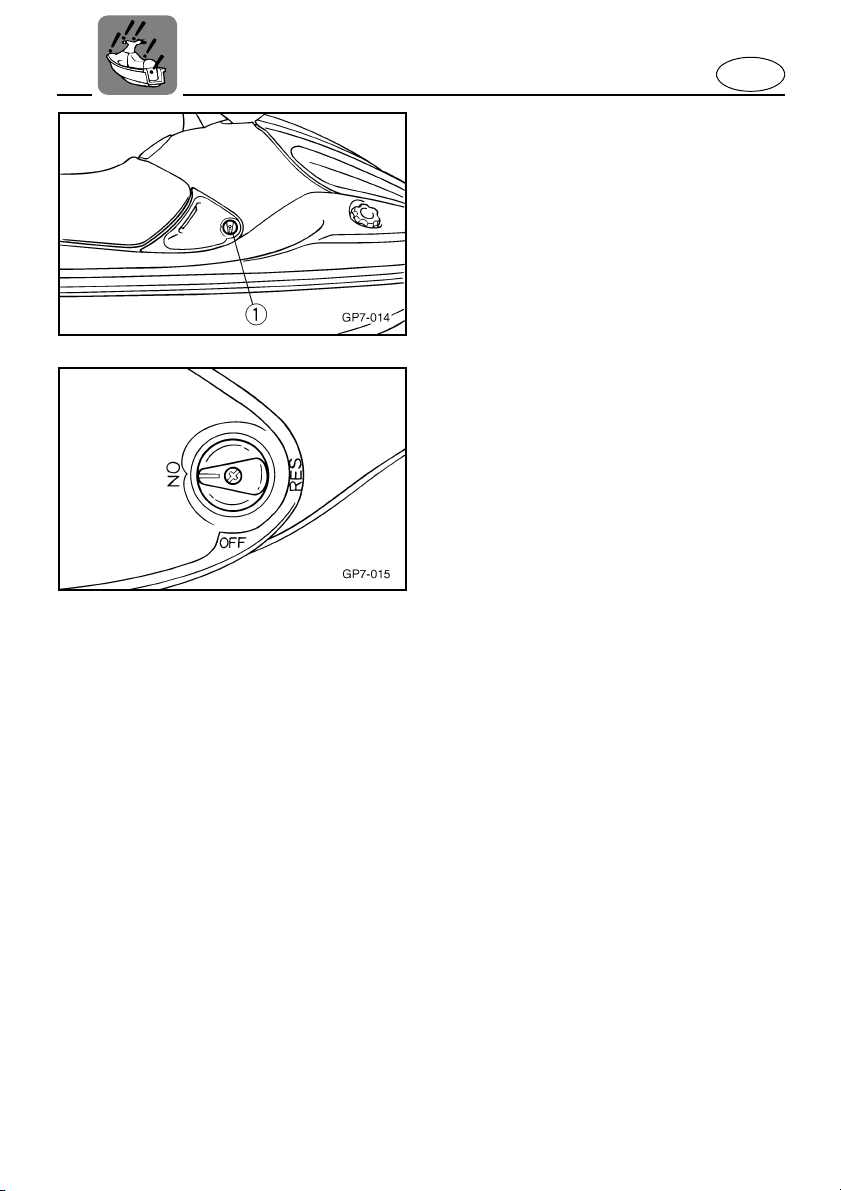

EJU00704

Fuel cock knob

The fuel cock supplies fuel from the fuel

tank to the carburetors.

The fuel cock knob 1 positions are

explained as follows and are shown in the

illustration.

OFF:

With the fuel cock knob in this position,

fuel does not flow. Always turn the fuel cock

knob to this position when the engine is not

running.

ON:

With the fuel cock knob in this position,

fuel flows to the carburetors. Turn the fuel

cock knob to this position when starting the

engine and operating the watercraft.

RES:

This indicates reserve. With the fuel cock

knob in this position, the fuel reserve is

made available. Turn the fuel cock knob to

this position if you run out of fuel while operating the watercraft. When this occurs,

refuel as soon as possible and be sure to

turn the fuel cock knob back to “ON”!

2-7

Page 31

E

EJU00705

Engine stop switch

Push this switch 1 (red button) to stop

the engine normally.

EJU00706

Engine shut-off switch

Insert the clip 1, on the end of the engine

shut-off cord 2, under the engine shut-off

switch 3 (black button). The engine will stop

automatically when the clip is removed from

the switch, such as if the operator falls off

the watercraft.

WARNING

● Always attach the engine shut-off cord

to your wrist and the clip to the engine

shut-off switch BEFORE starting the

engine.

● To prevent accidental starting of the

engine or unauthorized use by chil-

dren or others, always remove the clip

from the shut-off switch when the

engine is not running.

EJU00350

Choke knob

Starting a cold engine requires a richer

air-fuel mixture, which is supplied by the

choke.

Pull the knob 1 out to turn the choke on.

Push the knob in to turn the choke off.

2-8

Page 32

E

EJU00351

Throttle lever

Squeeze the throttle lever 1 to increase

engine speed.

Release the throttle lever to decrease

engine speed or to return it to the idle position.

EJU00353

Start switch

Push the start switch 1 (green button) to

start the engine.

NOTE:

● The engine will not start when the clip is

removed from the engine shut-off switch.

● The engine will not start if the “LOCK”

mode of the multifunction meter has been

selected. (See page 2-16 for “PADLOC”

mode selection procedures.)

2-9

Page 33

E

EJU00354

Cooling water pilot outlet

This watercraft is equipped with a cooling

water pilot outlet.

When the engine is running, cooling

water is circulated in the engine, and then it

is discharged from the pilot outlet.

To check for proper operation of the cool-

ing system, check that water is being discharged from the pilot outlet. If water is not

being discharged from the outlet, cooling

water may not be circulating in the engine.

When this occurs, stop the engine and check

for the cause. (See pages 2-13 and 5-4 for

further instructions.)

NOTE:

If the cooling water passages are dry, it will

take about 20 seconds for the water to reach

the outlet after the engine is started.

EJU00356

Steering system

Your watercraft can be steered by turning

the handlebars 1 the same direction you

wish to travel.

When the handlebars are turned, the

angle of the jet thrust nozzle 2 is changed,

and the direction of the watercraft is

changed accordingly. Since the strength of

the jet thrust determines the speed and

direction of a turn, the throttle must always

be open when attempting a turn, except at

trolling speed.

2-10

Page 34

E

EJU00360a

Quick Shift Trim System

(QSTS) selector

The QSTS selector 1 is located at the

left handlebar grip and is used to adjust the

trim angle of the watercraft.

Operating the QSTS selector changes the

angle of the jet thrust nozzle vertically. This

changes the trim angle of the watercraft.

There are 5 positions: 2 bow down posi-

tions A and B, neutral “N,” and 2 bow up

positions C and D.

To change the trim angle:

1. Reduce engine speed to 3,000 r/min or

less.

2. Squeeze the shift lock lever 2, and then

turn the QSTS selector to the desired

position.

3. Release the shift lock lever to lock the

QSTS selector.

CAUTION:

Do not turn the QSTS selector while

operating the watercraft at full throttle,

otherwise damage could occur to the

QSTS.

The neutral “N” position will provide good

performance for most operating conditions.

To enhance particular types of perfor-

mance, select bow down or bow up.

2-11

Page 35

E

Bow down

Turn the grip to A or B and the bow will

go down while the watercraft is on plane.

Bow down puts more of the bow in the

water. This gives the watercraft more “hook,”

which enhances turning performance. This

position will also help the watercraft get up

on plane more quickly.

At higher speeds, however, the watercraft

will have greater tendency to “bow steer”

and follow waves and wakes in the water.

Fuel economy and maximum speed are also

reduced.

Bow up

Turn the grip to C or D and the bow will

go up while the watercraft is on plane.

Bow up puts less of the bow in the water.

There is less water resistance, so straightahead acceleration when on plane and top

speed are enhanced.

In some conditions, however, the watercraft may tend to “porpoise” (hop in the

water). If the watercraft is porpoising,

choose neutral or bow down.

2-12

Page 36

E

EJU00366

Engine overheat warning

system

This model is equipped with an engine

overheat warning system.

If the engine starts to overheat, the warning light, the indicator for the water temperature symbol, and “W.TEMP” display begin to

blink. The buzzer sounds, and the engine

speed will be limited to about 3,000 r/min.

When this occurs, check for water discharge at the cooling water pilot outlet. If

there is no discharge of water, reduce the

engine speed and beach the watercraft, and

then check the intake grate and impeller for

clogging.

WARNING

Before attempting to remove weeds or

debris from the intake grate or impeller,

shut the engine off and remove the clip

from the engine shut-off switch. Severe

injury or death could result from coming

in contact with the rotating parts of the

jet pump.

CAUTION:

If you cannot locate and correct the

cause of the overheating, consult a

Yamaha dealer. Continuing to operate at

higher speeds could result in severe

engine damage.

NOTE:

Press any button on the multifunction meter

to stop the buzzer.

2-13

Page 37

E

EJU00367a

Handgrip

The handgrip 1 provides a handhold for

boarding the watercraft.

CAUTION:

Do not use to tow objects, lift watercraft,

or attach tie downs, otherwise damage

could occur.

2-14

Page 38

E

EJU00698b

Multifunction meter

This meter contains following functions for

help and convenience in operating the

watercraft.

1 “MODE” button

2 “SET” button

3 “CODE” setting buttons

4 Tachometer

5 Speedometer

6 Fuel meter

7 Engine oil meter

8 Display for Clock, Hour meter, Trip meter and

Trip timer

9 Warning light

0 Display for PADLOC and direction of warning

indicator

A Battery warning indicator

B Overheat warning indicator

C Fuel warning indicator

D Oil warning indicator

CAUTION:

● Do not run the engine at full throttle or

more than 15 seconds to check the

meter for operation on land. The

engine could overheat.

● Use the specified resistor-type spark

plugs and caps, otherwise the meter

may function erratically.

NOTE:

The demonstration mode display starts

showing after the engine starts. Then all displays light up and the buzzer sounds twice.

The meter will operate normally after a few

seconds. The current display will continue to

operate for 30 seconds after the engine

stops.

2-15

Page 39

E

EJU00711a

PADLOC (Programmable

digital locking ignition)

This feature is provided to deter unauthorized use.

The function allows you to choose either

“START” or “LOCK” mode, as the situation

requires, much as you would use an ignition

key in a motor vehicle. If you have previously

chosen “LOCK” mode, the engine will not

start unless the right code is put in to select

“START” mode.

NOTE:

If you do not use the PADLOC system, it is

unnecessary to perform the initial setting of

the PADLOC. In this case, the “START”

mode is automatically selected.

PADLOC initial setting

1. Disconnect the blue connector 1 behind

the front storage compartment.

2. After the warning light turns on, press

the “MODE” button for at least 3 seconds

until the display shows “COdE.” You are

ready to set your code.

2-16

Page 40

E

3. Select your four-letter code by pressing

the “A/SET,” “B,” or “C” buttons in a

desired sequence.

NOTE:

If you do not press a button for more than

10 seconds, the display automatically turns

off. This cancels the process of setting a

code.

4. After code setting is complete, the

buzzer will sound 3 times and the display

will show “SET.” Lastly, the display turns

off and the warning light turns on again.

After the meter has displayed this

sequence, connect the blue connector

again.

NOTE:

● Your own code is kept even if the battery

terminal is disconnected.

● If you forget your own code, or if you want

to change the code, do this initial setting

procedure again from the beginning.

Selecting “PADLOC” mode

Selecting the desired mode can only be

done after the initial setting has been done

and while the display is not lit.

1. Press the “MODE” button until the meter

displays the current mode, “START” or

“LOCK.”

2. With “START” or “LOCK” displayed,

press the “MODE” button continuously

for about 3 seconds until the display

changes to “COdE.”

2-17

Page 41

E

3. Enter your four-letter code by pressing

the “A/SET,” “B,” or “C” buttons in the

right sequence.

NOTE:

If you do not press a button for more than

10 seconds, the display automatically turns

off. This cancels the process of selecting the

mode.

4. If the code entered is correct, the mode

will change from the previous mode to

either “START” or “LOCK.” Then the

mode display and buzzer will operate for

2 seconds.

NOTE:

● Once you select a mode, the mode will

not change unless you perform this mode

selection sequence again.

● If the wrong code is entered, the mode

display shows “ERROR” for 2 seconds

and the buzzer will sound 5 times. Then

the display returns to “COdE.”

EJU00383

Tachometer

The engine speed (r/min) is displayed by

segments. Each segment indicates a 200 r/min

increment.

2-18

Page 42

E

EJU00384

Speedometer

This meter shows the watercraft speed in

kilometer per hour (km/h).

EJU00386a

Fuel meter

The fuel meter is provided for convenient

fuel level checking while operating the

watercraft.

The fuel meter has 4 segments which

show the amount of fuel remaining in the

fuel tank.

NOTE:

The indication of the segments differs

depending on your operating condition. Use

the meter as a reference.

2-19

Page 43

E

EJU00387a

Engine oil meter

The engine oil meter is provided for convenient oil level checking while operating the

watercraft.

The engine oil meter has 3 segments

which show the amount of oil remaining in

the oil tank.

NOTE:

The indication of the segments differs

depending on your operating condition. Use

the meter as a reference.

EJU00388aa

Clock

A 12-hour clock is provided in this meter.

To show the clock, press the “MODE” button until the display shows “CLOCK.”

1. When the display shows “CLOCK,” press

the mode button for at least 3 seconds.

2. The buzzer will sound once. The hour

display and “SET” start blinking. Then

press the “A/SET” button until the

desired hour is displayed.

3. Press the “MODE” button again.

4. The buzzer will sound once. The minute

display and “SET” start blinking. Then

press the “A/SET” button until the

desired minute is displayed.

5. Press the “MODE” button again.

2-20

Page 44

E

6. The buzzer will sound twice. The warn-

ing light and “SET” blink for 2 seconds.

Then the display turns to “CLOCK” and

shows the time.

NOTE:

If the battery terminal is disconnected, the

clock will be reset to 12:00.

EJU00390

Hour meter

The hour meter is provided to make it

easy to follow the maintenance schedule.

The meter shows how many hours of

engine operation have elapsed since the

watercraft was new.

To show the hour meter, press the

“MODE” button until the display shows

“HOUR.M.”

EJU00659a

Trip timer

The trip timer is provided for counting the

time traveled on a given trip.

To show the trip timer, press the “MODE”

button until the display shows “TRIP.T.”

1 Minutes

2 Seconds

1. When the display shows “TRIP.T,” press

the “A/SET” button to start counting. The

buzzer will sound once.

2. Press the “A/SET” button again to stop

counting. The buzzer will sound once.

3. Press “MODE” button for at least

2 seconds to set the time back to 00:00.

The buzzer will sound twice. The time

display and “TRIP.T” blink for 2 seconds.

Now it is ready to start counting.

2-21

Page 45

E

EJU00712

Trip m et e r

A tripmeter is provided for measuring the

approximate distance traveled.

To show the tripmeter, press the “MODE”

button until the display shows “TRIP.” After

showing “TRIP,” the display turns to “.KM.”

1. When the display shows “.KM,” press the

“MODE” button for at least 2 seconds.

2. The buzzer will sound twice. The warn-

ing light and “.KM” blink for 2 seconds,

and “000” is displayed. Now the meter

will start to measure the distance you

travel.

3. When the tripmeter begins measuring

the distance traveled, the “.” to the left of

“KM” on the display will blink.

NOTE:

Measured distance may vary depending on

the water surface conditions, and wind direction. The measured distance should be used

for a reference.

EJU00716

Fuel warning indicator

If the fuel remaining in the tank drops to

about 12 L (3.2 US gal, 2.6 Imp gal), the

lowest fuel level segment, the fuel warning

indicator, “FUEL” and the warning light

begin to blink. The buzzer also starts sounding intermittently.

2-22

Page 46

E

EJU00717a

Oil warning indicator

If the oil remaining in the tank drops to

about 1.2 L (0.31 US gal, 0.26 Imp gal) or

the oil filter is clogged, the lowest oil level

segment, the oil warning indicator, “OIL” and

the warning light begin to blink. The buzzer

also starts sounding intermittently.

If the oil warning indicator begins to blink,

refill with engine oil as soon as possible.

NOTE:

If the warning indicator blinks with adequate

oil in the tank, check the oil filter for clogging.

EJU00003n

Engine overheat warning

indicator

If the engine starts to overheat, the overheat warning indicator, “W.TEMP” and the

warning light begin to blink. The buzzer also

starts sounding.

Refer to “Engine overheat warning system” on page 2-13.

2-23

Page 47

E

EJU00719

Battery warning indicator

If the battery voltage becomes less than

11.5 volts, the battery warning indicator,

“VOLT” and the warning light begin to blink.

The buzzer also starts sounding.

If this happens during operation, beach

the watercraft. Then recharge the battery

and have the charging system inspected by

a Yamaha dealer.

2-24

Page 48

E

EJU00672a

Storage compartments

A front storage compartment, a glove

compartment, and a seat storage compartment are provided.

NOTE:

● Make sure that the storage compartments

are properly secured before operating the

watercraft.

● The storage compartments are not

designed to be waterproof. If you carry

objects that must be kept dry, such as the

manuals, put them in a waterproof bag.

Front storage compartment

The front storage compartment 2 is

located at the bow.

To open the front storage compartment,

pull the hood latch 1 up, and then open the

hood.

To close the front storage compartment,

push down on the rear of the hood until it

latches securely.

NOTE:

The front storage compartment can be

removed to access the engine compartment.

Front storage compartment:

Capacity: 16.5 L (4.4 US gal, 3.6 Imp gal)

Load limit: 5 kg (11 lb)

2-25

Page 49

E

Glove compartment

A glove compartment 4 is located in front

of the seat.

To open the glove compartment, push the

latch 3, and then lift up the lid.

To close the glove compartment, push the

lid down until it locks securely.

Glove compartment:

Capacity: 1 L (0.26 US gal, 0.22 Imp gal)

Load limit: 1 kg (2.2 lb)

Seat storage compartment

The seat storage compartment 5 is

located under the rear seat.

To open the seat storage compartment,

remove the rear seat. (See page 2-4 for rear

seat.)

Seat storage compartment:

Capacity: 21.2 L (5.6 US gal, 4.7 Imp gal)

Load limit: 9 kg (19.8 lb)

2-26

Page 50

E

EJU00409*

Yamaha Adjustable Sponson

(Y.A.S.)

The sponsons 1 have adjustable positioning to allow the operator to enhance

either straight-line performance or turning

performance according to the preference

and operating conditions.

Adjusting to upward A:

There will be less water resistance in this

position, so straight-ahead acceleration

when on plane and top speed will be

enhanced.

Adjusting to downward B:

This position will give the water vehicle

more “hook” which will enhance turning performance.

2-27

Page 51

EJU00410

E

OPERATION

Fuel and oil

Gasoline ..................................................3-1

Filling the fuel tank ..................................3-3

2-stroke engine oil................................... 3-3

Filling the oil tank ....................................3-4

Pre-operation checks

Pre-operation check list ..........................3-5

Pre-operation check points.....................3-6

Operation

Engine break-in.....................................3-13

Starting the engine................................3-15

Stopping the engine..............................3-18

Leaving the watercraft ..........................3-18

Operating your watercraft

Getting to know your watercraft............3-19

Learning to operate your watercraft .....3-19

Riding watercraft with a passenger......3-20

Starting the watercraft...........................3-21

Boarding and starting in deep water ....3-23

Capsized watercraft..............................3-25

Turning the watercraft........................... 3-27

Stopping the watercraft.........................3-29

Beaching the watercraft........................3-30

Docking the watercraft..........................3-30

Rough water operation ......................... 3-30

Post-operation checks

................................................3-1

............................... 3-5

.................................................3-13

.....................3-19

..........................3-31

3

Transporting

...........................................3-33

Page 52

E

EJU00411a

Fuel and oil

This engine uses Yamaha’s oil injection

system, which provides superior lubrication

by ensuring the proper oil ratio for all operating conditions. No fuel premixing is necessary except during the engine break-in

period. Simply pour gasoline into the fuel

tank and oil into the oil tank.

Gasoline

WARNING

GASOLINE AND ITS VAPORS ARE

HIGHLY FLAMMABLE AND EXPLOSIVE!

● Do not smoke when refueling, and

keep away from sparks, flames, or

other sources of ignition.

● Stop engine before refueling.

● Refuel in a well-ventilated area. Do not

stand or sit on the watercraft while

refueling in case of fire.

● Take care not to spill gasoline. If gaso-

line spills, wipe it up immediately with

dry rags. Always properly dispose of

gasoline-soaked rags.

● Avoid overfilling the fuel tank. Stop fill-

ing when the fuel level just reaches the

bottom of the filler tube. Do not fill up

the filler tube because fuel expands as

it warms up and could overflow.

● Tighten the filler cap securely after

refueling.

● If you should swallow some gasoline,

inhale a lot of gasoline vapor, or get

gasoline in your eyes, get immediate

medical attention.

● If any gasoline spills onto your skin,

immediately wash with soap and

water. Change clothing if gasoline

spills on it.

3-1

Page 53

E

CAUTION:

Use only fresh gasoline that has been

stored in clean containers.

Recommended gasoline:

Regular unleaded gasoline with

a minimum octane rating of

86 (Pump octane number) = (R+M)/2

90 (Research octane number)

Gasohol

There are two types of gasohol: gasohol

containing ethanol and that containing methanol.

Gasohol containing ethanol can be used

if ethanol content does not exceed 10 % and

the fuel meets minimum octane ratings.

Gasohol containing methanol is not recommended by Yamaha because it can

cause fuel system damage or engine performance problems.

3-2

Page 54

E

EJU00724a

Filling the fuel tank

CAUTION:

Be careful when refueling. Avoid getting

water or other contaminants in the fuel

tank. Contaminated fuel can cause poor

running or engine damage.

1. Remove the rear and front seats to watch

the fuel level. (See pages 2-4 to 2-5 for

seat removal and installation procedures.)

2. Open the fuel tank filler cap, and slowly

add fuel to the fuel tank.

3. Stop filling when the fuel just reaches the

top of the fuel tank visible under the

engine oil tank.

Fuel tank capacity:

Total: 50 L (13.2 US gal, 11 Imp gal)

Reserve: 8.8 L (2.32 US gal, 1.94 Imp gal)

EJU00324a

2-stroke engine oil

Recommended engine oil:

YAMALUBE 2-W

If YAMALUBE 2-W is not available,

another 2-stroke engine oil with an NMMAcertified TC-W3 rating may be used.

3-3

Page 55

E

EJU00419a

Filling the oil tank

WARNING

● Do not add gasoline to the oil tank.

Fire or explosion could result.

● Oil in the bilge is a serious fire hazard.

Wipe up any spilled oil immediately.

CAUTION:

Do not allow the oil tank to become completely empty. If the oil tank becomes

empty the oil injection pump must be

bled to ensure proper oil flow, otherwise

engine damage may occur. If bleeding of

the oil pump is necessary, have a

Yamaha dealer bleed it.

1. Remove the rear and front seats to

access the oil filler cap. (See pages 2-4

and 2-5 for seat removal and installation

procedures.)

2. Open the oil tank filler cap, and very

slowly add engine oil to the oil tank

watching the oil level.

3. Stop pouring when the oil just reaches

the bottom of the filler tube.

Oil tank capacity:

4 L (1.06 US gal, 0.88 Imp gal)

3-4

Page 56

E

EJU00422

Pre-operation checks

Pre-operation check list

Before operating this watercraft, perform the checks in the following check list. See the

accompanying text in this chapter for details on how to perform the checks.

WARNING

If any item in the pre-operation check list is not working properly, have it inspected

and repaired before operating the watercraft, otherwise an accident could occur.

ITEM ROUTINE PAGE

Engine compartment Remove all seats and front storage compart-

ment to ventilate engine compartment. Check for

fuel vapors or loose electrical connections

Bilge Check for water and fuel residue and remove if

necessary

Throttle Check that the throttle lever springs back 3-10

Steering system Check for proper steering system operation 3-10

Fuel and oil Check fuel and oil level and add if necessary

Check hoses and tanks for leakage

Water separator Check for water and drain if necessary 3-7

Battery Check electrolyte level and battery condition 3-8

Hood Check the hood for securely 2-6

Front and rear seats Check that the seats are properly secured 2-4, 2-5

Hull/Deck Check the hull and deck for cracks or other dam-

age

Jet unit Check for debris and remove if necessary 3-11

Fire extinguisher Check the condition and replace if necessary 3-9

Engine shut-off cord Check condition and replace is frayed or broken 3-11

Switches Check the start switch, engine stop switch and

engine shut-off switch for proper operation when

the watercraft is in the water

Cooling water pilot outlet Check that water is discharged while the engine

is running and the watercraft is in the water

Multifunction meter Check for warning indications and proper opera-

tion

3-6

3-7

3-6

—

3-12

3-12

3-12

NOTE:

Pre-operation checks should be made thoroughly each time the watercraft is used. This procedure can be completed in a short time. It is worth the time spent to assure safety and reliability.

3-5

Page 57

E

EJU00426

Pre-operation check points

Engine compartment

Ventilate the engine compartment before

each use.

To ventilate the engine compartment,

remove all seats and front storage compartment. (See pages 2-4 to 2-5 for front and

rear seat, and 2-25 for front storage compartment.) Allow the engine compartment to

remain open for a few minutes to allow any

fuel vapors to escape. Also, check for loose

electrical connections.

WARNING

Failure to ventilate the engine compartment could result in fire or explosion. Do

not start the engine if there is a fuel leak

or a loose electrical connection.

EJU00427-30a

Fuel and oil systems

Check the fuel system for leakage, cracks

or malfunctions before each use. (See page

4-9 for check points and correct procedures.)

1. Remove the fuel tank filler cap to release

any pressure that might have built up in

the fuel tank.

2. Remove the rear and front seats. (See

pages 2-4 to 2-5 for seat removal and

installation procedures.)

3. Check the fuel and oil levels in the tanks

and replenish if necessary. (See page 3-3

for filling instructions.)

3-6

Page 58

E

EJU00432a

Water separator

Check the water separator 1 for water.

Normally the water separator is empty. The

water separator retains any water entering

through the fuel tank breather hose if the

watercraft is capsized.

If water remains in the water separator,

drain it by removing the drain screw 2.

Install the drain screw again after draining

the water separator.

EJU00433a

Bilge

Check for moisture and fuel residue in the

bilge.

Excessive water in the bilge can splash

into the carburetor and engine which could

cause engine damage.

To remove water from the bilge:

1. Remove the stern drain plugs.

2. Raise the bow of the watercraft until the

water drains.

3. After the water has drained, wipe the

bilge with dry rags to make sure that the

bilge is thoroughly dry.

4. Install the drain plugs.

CAUTION:

● Make sure that the stern drain plugs

are tightened securely before launch-

ing the watercraft.

● Clean any foreign materials, such as

dirt or sand, from the drain plug

threads before installing the drain

plugs.

3-7

Page 59

E

EJU00435a

Battery

Check the battery condition and the electrolyte level.

Check that the battery leads are tightened

securely and there is no corrosion on the

battery terminals.

WARNING

The battery must always be fully charged

and in good condition. Loss of battery

power may leave you stranded. Never

operate the watercraft if the battery does

not have sufficient power to start the

engine or if it shows any other signs of

decreased power.

Make sure that the breather hose is properly connected and that it is not damaged or

obstructed.

Make sure that the battery is securely

held in place.

1 Positive (+): Red lead

2 Negative (–): Black lead

3 Breather hose

3-8

Page 60

F0P03010

E

EJU00728

Fire extinguisher

Check that there is a full fire extinguisher

on board. The fire extinguisher container 1

is located in the front storage compartment.

To open the fire extinguisher container

cap 2 turn it counterclockwise.

After inserting the fire extinguisher make

sure that the container cap is tightened

securely.

NOTE:

● See the instructions supplied by the fire

extinguisher manufacturer for checking

the fire extinguisher. Always keep the

extinguisher in the fire extinguisher con-

tainer.

● Always carry a fire extinguisher on board.

A fire extinguisher is not standard equip-

ment with this watercraft. If you do not

have one, contact a Yamaha dealer or a

fire extinguisher dealer to obtain one

meeting the proper specifications.

3-9

Page 61

E

EJU00447

Throttle

Squeeze and release the throttle lever

several times to make sure that there is no

hesitation in its travel. It should be smooth

over the complete range, and spring back to

the idle position when released.

WARNING

Before starting the engine, always check

the operation of the throttle lever. It

should move smoothly through its full

range of operation, and should spring

back to the idle position when released.

EJU00448

Steering system

Check for looseness in the handlebars.

Turn them as far as possible to the right

and left to make sure that operation is

smooth and unrestricted throughout the

whole range. Make sure that the jet thrust

nozzle also changes directions as the handlebars are turned, and that there is no free

play between the handlebars and the jet

thrust nozzle.

3-10

Page 62

E

EJU00451a

Jet unit

Carefully check the jet intake for weeds,

debris, or anything else that might restrict

the intake of water. If the intake is clogged,

cavitation could occur, reducing jet thrust,

and possibly damaging the jet pump.

In some cases, the engine may overheat

because of lack of cooling water, and damage to the engine could result. Engine cooling water is fed to the engine by the jet

pump. (See page 5-4 for jet intake cleaning

procedures.)

WARNING

● Keep away from intake grate while

engine is on. Items such as long hair,

loose clothing, or PFD straps can

become entangled in moving parts

resulting in severe injury or drowning.

● Stop the engine and remove the clip

from the engine shut-off switch before

removing any debris or weeds, which

may have collected around the jet

intake.

EJU00004n

Engine shut-off cord (lanyard)

Check that the engine shut-off cord is not

frayed or broken. If the cord is damaged,

replace it; never try to repair it or tie it

together.

3-11

Page 63

E

EJU00452a

Switches

Check the start switch 1, the engine stop

switch 2, and the engine shut-off switch 3

for proper operation.

To check these switches place the watercraft in the water to provide adequate cooling.

Start the engine, and then pull the engine

shut-off cord 5 to remove the clip 4 from the

engine shut-off switch. Verify that the engine

stops immediately. (See pages 3-15 to 3-18

for information on proper operation of the

start switch, the engine stop switch and the

engine shut-off switch.)

EJU00453

Cooling water pilot outlet

Check that water comes out from the outlet while the engine is running and the

watercraft is in the water.

EJU00454

Multifunction meter

Check the operation of the multifunction

meter. (See pages 2-15 to 2-24 for operation

of the meter.)

3-12

Page 64

E

EJU00676a

Operation

WARNING

Before operating your watercraft,

become familiar with all controls. Consult your Yamaha dealer about any control or function you do not fully

understand. Failure to understand how

controls work could cause an accident or

prevent you from avoiding an accident.

CAUTION:

Make sure that stern drain plugs are

securely tightened before launching the

watercraft.

EJU00459

Engine break-in

The engine break-in period is essential to

allow the various components of the engine

to wear and polish themselves to the correct

operating clearances. This ensures proper

performance and promotes longer component life.

CAUTION:

● For the first tankful of operation, pre-

mix a 50:1 mixture of fuel and oil (in

addition to the oil in the oil tank).

● After break-in, use straight gasoline

for normal operation.

1. Launch the watercraft and start the

engine. (See pages 3-15 to 3-18 for

engine starting procedures.)

2. Run the engine at the lowest possible

speed for 5 minutes.

3-13

Page 65

E

3. Gradually open the throttle to 3/4 or less.

4. Continue operation at 3/4 throttle or less

until the first tankful of fuel has been

used.

5. Fill the tank with straight gasoline, and

then proceed with normal operation.

CAUTION:

Failure to follow the engine break-in procedure properly can result in severe

damage to the engine.

3-14

Page 66

E

EJU00645a

Starting the engine

WARNING

Never start the engine or let it run for any

length of time in an enclosed area.

Exhaust fumes contain carbon monoxide, a colorless, odorless gas that may

cause loss of consciousness and death

within a short time. Always operate the

watercraft in an open area.

1. Launch the watercraft in water free from

weeds and debris and at least 60 cm

(2 ft) deep.

WARNING

Never operate in water that is less than

60 cm (2 ft) deep, otherwise you increase

your chance of hitting a submerged

object, which could result in injury.

CAUTION:

Never operate in water that is less than

60 cm (2 ft) deep, otherwise pebbles or

sand could be sucked into the jet intake,

causing impeller damage or engine overheating.

3-15

Page 67

E

2. Turn the fuel cock knob to the “ON” posi-

tion.

NOTE:

Before starting the watercraft, after it has

been sitting, remove the fuel tank filler cap

to release any built-up pressure in the tank

due to fuel expansion.

3. Attach the clip 1 to the engine shut-off

switch 2. Also, attach the engine shutoff cord 3 to your left wrist.

WARNING

Check that the engine shut-off cord is not

frayed or broken, and keep it free from

the handlebars so the engine stops if the

operator falls off. The engine shut-off

cord may not pull free if wrapped around

the handlebars when the operator falls

off, allowing the watercraft to continue to

run and cause an accident.

NOTE:

It is not possible to start the engine with the

clip removed from the engine shut-off

switch.

4. Pull and hold the choke knob all the way

out to start a cold engine.

NOTE:

The choke should not be used when the

engine is warm.

3-16

Page 68

E

5. If the “LOCK” mode was chosen previ-

ously, choose the “START” mode before

starting the engine. (See pages 2-16 to

2-17 for selecting “PADLOC” mode.)

NOTE:

● If the initial setting of the PADLOC has not

been done, the “START” mode is auto-

matically selected.

● If you have previously chosen “LOCK”

mode, the engine will not start unless the

correct code is entered. This selects the

“START” mode.

6. While lightly squeezing the throttle lever,

push the start switch (green button).

WARNING

On this watercraft, the engine is connected directly to the jet pump. Starting

the engine immediately generates some

thrust. Apply only enough throttle to

keep the engine running.

7. Release the start switch as soon as the

engine starts to run.

CAUTION:

● Never push the start switch while the

engine is running.

● Do not operate the start switch for

more than 5 seconds, otherwise the

battery will be discharged and the

engine will not start. Also, the starter

motor may be damaged. If the engine

does not start in 5 seconds, release

the start switch, wait 15 seconds, and

try again.

8. After the engine has warmed up, push

the choke knob in to its original position.

NOTE:

If the choke knob is left pulled out, the

engine will stall.

3-17

Page 69

E

EJU00463a

Stopping the engine

To stop the engine, release the throttle

lever, and then push the engine stop switch

(red button).

WARNING

You need throttle to steer. Shutting off

the engine can cause you to hit an obstacle you are attempting to avoid. A collision could result in severe injury or

death.

EJU00005n

Leaving the watercraft

If leaving the watercraft, choose the

“LOCK” mode on the multifunction meter by

setting PADLOC, and remove the engine

shut-off cord to reduce the chance of accidental starting or unauthorized use by children or others.

To set the mode, see PADLOC under Multifunction meter.

3-18

Page 70

E

EJU00674

Operating your watercraft

Getting to know your

watercraft

Operating your watercraft requires skills

acquired through practice over a period of

time. Take the time to learn the basic techniques well before attempting more difficult

maneuvers.

Operating your new watercraft can be a

very enjoyable activity, providing you with

hours of pleasure. However, it is essential to

familiarize yourself with the operation of the

watercraft to achieve the skill level necessary to enjoy riding safely. Before operating

this watercraft, read this Owner’s/Operator’s

Manual, the Riding Practice Guide, and all

warning and caution labels on the watercraft. Pay particular attention to the safety

information on pages 1-9 to 1-14. These

materials should give you an understanding

of the watercraft and its operation.

Remember: This watercraft is designed to

carry the operator and one passenger.

Never exceed the maximum load limit or

allow more than 2 persons to ride the watercraft at one time.

Maximum load: 160 kg (353 lb)

Load is the total weight of cargo, operator and passenger.

EJU00474

Learning to operate your

watercraft

Before operating the watercraft, always

perform the pre-operation checks listed on

page 3-3. The short time spent checking the

watercraft will reward you with added safety

and reliability.

Check all local laws before operating your

watercraft.

Operate defensively at safe speeds and

keep a safe distance away from people,

objects, and other watercraft. Select a wide

area to learn in, where you have good visibility and light boat traffic.

Use the buddy system—operate with

someone nearby. Scan constantly for people, objects, and other watercraft. Be alert

for conditions that limit your visibility or block

your vision of others.

Attach the engine shut-off cord (lanyard)

to your wrist and keep it free from the handlebars so that the engine stops if the operator falls off.

Wear a personal flotation device (PFD).

All riders must wear an authority-approved

PFD that is suitable for personal watercraft

use.

3-19

Page 71

E

Wear protective clothing. Severe internal

injuries can occur if water is forced into body

cavities as result of falling into the water or

being near the jet thrust nozzle. Normal

swimwear does not adequately protect

against forceful water entry into rectum and

vagina. All riders must wear a wetsuit bottom or clothing that provides equivalent protection.

Such clothing includes thick, tightly

woven, sturdy and snug-fitting apparel such

as denim, but does not include spandex or

similar fabrics like those used in bicycle

shorts. A full wetsuit can also protect against

hypothermia (subnormal body temperature)

and abrasions.

Footwear and gloves are recommended.

Eye protection is recommended to keep

wind, water, and glare from the sun out of

your eyes while you operate your watercraft.

Restraining straps for eyewear are made

which are designed to float should your eyewear fall in the water.

You should grip the handlebars firmly and

keep both feet on the floor of the footwell. Do

not attempt to ride with passengers until

your operating skills are fully developed.

The passenger must always wear an

authority-approved PFD and a wetsuit bottom or equivalent.

WARNING

Do not apply throttle when anyone is at

rear of watercraft. Turn engine off or keep

engine at idle. Water and/or debris exiting the jet thrust nozzle can cause severe

injury. The passenger should not attempt

to board the watercraft if the operator is

applying throttle.

Do not give a ride to a child whose feet

cannot reach the floor of the footwell. The

passenger should hold on firmly to the operator and keep both feet in the footwell.

WARNING

When a passenger is on board, make

sure that he or she is holding on firmly

and has his or her feet in the footwell

before you start to accelerate.

EJU00736

Riding watercraft with a

passenger

When a passenger is on board with the

operator, the watercraft handles differently,

and is not as easy to maneuver, so operating it requires a higher degree of skill.

Before attempting to operate the watercraft

with a passenger on board, the operator

must practice operating the watercraft alone

enough to be able to acquire the necessary

skills.

3-20

Page 72

E

EJU00484

Starting the watercraft

WARNING

● Scan constantly for people, objects

and other watercraft. Be alert for conditions that limit your visibility or block

your vision of others.

● Operate defensively at safe speeds

and keep a safe distance away from

people, objects, and other watercraft.

● Do not follow directly behind water-

craft or other boats. Do not go near

others to spray or splash them with

water. Avoid sharp turns or other

maneuvers that make it hard for others

to avoid you or understand where you

are going. Avoid areas with submerged objects or shallow water.

● Take early action to avoid collisions.

Remember watercraft and other boats

do not have brakes. Do not release the

throttle when trying to steer away from

objects—you need throttle to steer.

● Practice reboarding in shallow water

before riding in deep water.

3-21

Page 73

E

EJU00486a

Starting and boarding in shallow

water

1. Do not start the engine in less than

60 cm (2 ft) of water. Put the watercraft

in water that is deep enough, and then

board the watercraft from the side or the

rear.

2. Attach the engine shut-off cord to your

left wrist, and then install the clip to the

engine shut-off switch.

3. Grip the handlebars with both hands,

place both feet on the floor of the footwell, start the engine, and start off.

Starting from a dock

1. Board the watercraft from the side.

2. Attach the engine shut-off cord to your

left wrist, and then install the clip to the

engine shut-off switch.

3. Push the watercraft away from the dock,

grip the handlebars with both hands,

place both feet on the floor of the footwell, start the engine, and start off.

3-22

Page 74

E

EJU00490a

Boarding and starting in deep

water

WARNING

● Operator and passenger should prac-

tice getting on board in shallow water

before riding in deep water. Boarding

in deep water requires more skill.

● The fatigue and exposure that could

result after unsuccessful attempts to

get back on the watercraft may

increase the risk of injuries and drowning.

Boarding alone

1. Swim to the rear of the watercraft and

place both hands on the boarding platform, pull yourself up, and then grasp the

handgrip with one hand.

2. Pull yourself up to a kneeling position on

the platform, and then move to the seat

and sit astride.

3. Attach the engine shut-off cord to your

wrist, and then install the clip to the

engine shut-off switch.

4. Grip the handlebars firmly with both

hands, place both feet in footwell, start

the engine, and look in all directions

before starting off.

WARNING

Before starting off, make sure that there

are no boats, obstructions, or swimmers

around you.

3-23

Page 75

E

EJU00737a

Boarding with a passenger

WARNING

Severe internal injuries can occur if

water is forced into body cavities as a

result of being near the jet thrust nozzle.

Do not apply throttle until the passenger

is seated with his or her feet on the floor

of the footwell and is holding on to the

operator.

1. Climb on board as noted in the previous

section, and sit astride the seat. Attach

the engine shut-off cord to your wrist,

and then install the clip to the engine

shut-off switch.

2. Have the passenger move to the rear of

the watercraft.

3. Have the passenger get on board and sit

on the seat.

NOTE:

When a passenger is getting on board, both

the passenger and the operator should try to

balance the watercraft.

4. The operator should check to see that

the passenger has his or her feet on the

floor of the footwell and that he or she is

securely holding on to the operator.

5. Start the engine, look in all directions,

and then accelerate to planing speed.

WARNING

Before starting off, make sure that there

are no boats, obstructions, or swimmers

around you.

3-24

Page 76

E

NOTE:

The heavier the total weight of the operator

and passengers, the more difficult it will be

to balance the watercraft. Do not operate the

watercraft when the total weight exceeds

160 kg (353 lb) including any cargo. If it is

difficult to balance the vehicle at a standstill,

proceed as follows:

1. The passenger must steady the watercraft while the operator is boarding. The

operator pulls himself up onto the platform into a seating position, then balances the vehicle.

2. Attach the lanyard to your left wrist, then

install the clip on the lanyard to the

engine shut-off switch. Start the engine

and keep it at idle.

3. The passenger pulls himself up on the

platform, kneels down, then crawls onto

the seat as the watercraft accelerates.

4. The watercraft can now be accelerated

to planing speed, then the operator can

reduce the throttle to the desired running

speed.

EJU00677a

Capsized watercraft

If the watercraft capsizes, follow the procedures below carefully to prevent damage

or injury.

WARNING

IMPROPER UPRIGHTING CAN CAUSE

INJURY:

● Shut engine off, and be sure engine

shut-off cord is removed from the

engine shut-off switch.

● Do not put hand in intake grate.

● Watch so you are not hit by the water-

craft as it comes over.

3-25

Page 77

E

CAUTION:

Be sure to remove the clip from the shutoff switch, otherwise the engine will

overheat and engine damage may occur.

1. Shut the engine off by removing the clip

from the engine shut-off switch.

2. Swim to the rear of the watercraft. Pull

the watercraft over with left hand on ride

plate while pushing down on the gunwale with your right hand/foot.

NOTE:

If the port side of the capsized watercraft is

tilting upward, first tilt the watercraft so the

port side is down by using your weight to

press down on the rub rail.

CAUTION:

Do not turn the watercraft over counterclockwise, otherwise water may leak into

the carburetor and engine and cause

damage.

3. Start the engine, and then head for

shore to inspect the engine for water

damage.

CAUTION:

If the watercraft has been capsized for

5 minutes or more, air may have entered

the oil injection system. Leave the engine

off, or operate only at trolling speed, for

10 minutes after the watercraft has been

turned right-side up. This will allow any

air to bleed off.

3-26

Page 78

E

EJU00499

Turning the watercraft

Steering control depends on the combination of handlebar position and the amount

of throttle.

Water sucked in through the intake grate