FZ6-ST

FZ6-STC

SUPPLEMENTARY

SERVICE MANUAL

LIT-11616-18-43

5VX-28197-11

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

FZ6-ST/FZ6-STC. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

FZ6-SS/FZ6-SSC SERVICE MANUAL: LIT-11616-17-50 (5VX-28197-10)

EAS00010

FZ6-ST/ FZ6-STC

SUPPLEMENTARY

SERVICE MANUAL

© 2004 by Yamaha Motor

Corporation, U.S.A.

First edition, August 2004

All rights reserved. Any reproduction

or unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

P/ N LIT-11616-18-43

EAS00002

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard

to performance and emissions. Proper service with the correct tools is necessary to ensure that the

vehicle will operate as designed. If there is any question about a service procedure, it is imperative

that you contact a Yamaha dealer for any service information changes that apply to this model. This

policy is intended to provide the customer with the most satisfaction from his vehicle and to conform

to federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

• This Service Manual contains information regarding periodic maintenance to the emission control

system. Please read this material carefully.

• Designs and specifications are subject to change without notice.

EAS00040

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death

to the motorcycle operator, a bystander or a person checking or repairing the

motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the motorcycle.

A NOTE provides key information to make procedures easier or clearer.

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

each page indicate the current chapter.

Refer to “SYMBOLS”.

Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s)

appears.

Sub-section titles appear in smaller print than the section title.

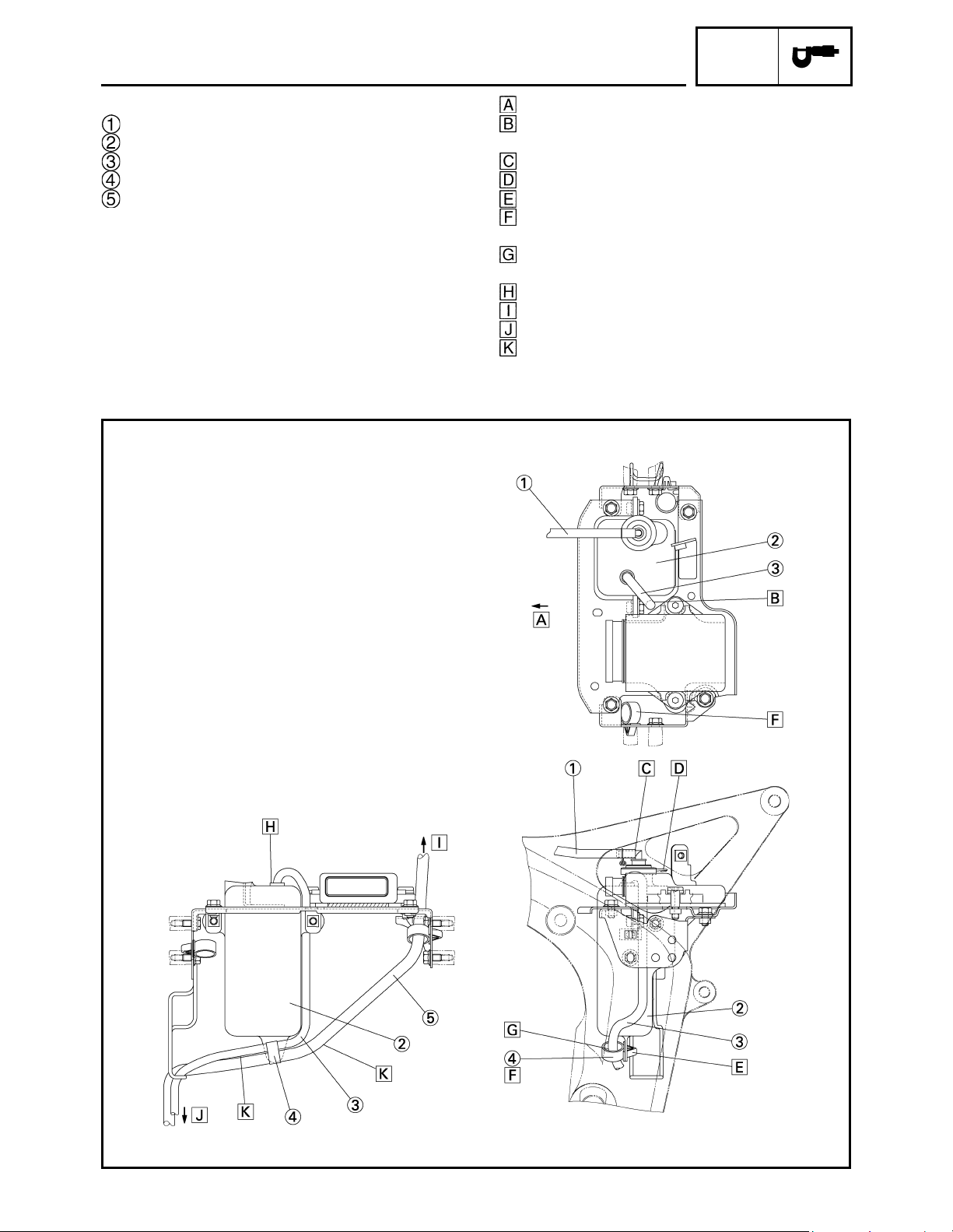

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section.

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

disassembly step.

Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

Jobs requiring more information (such as special tools and technical data) are described

sequentially.

EAS00008

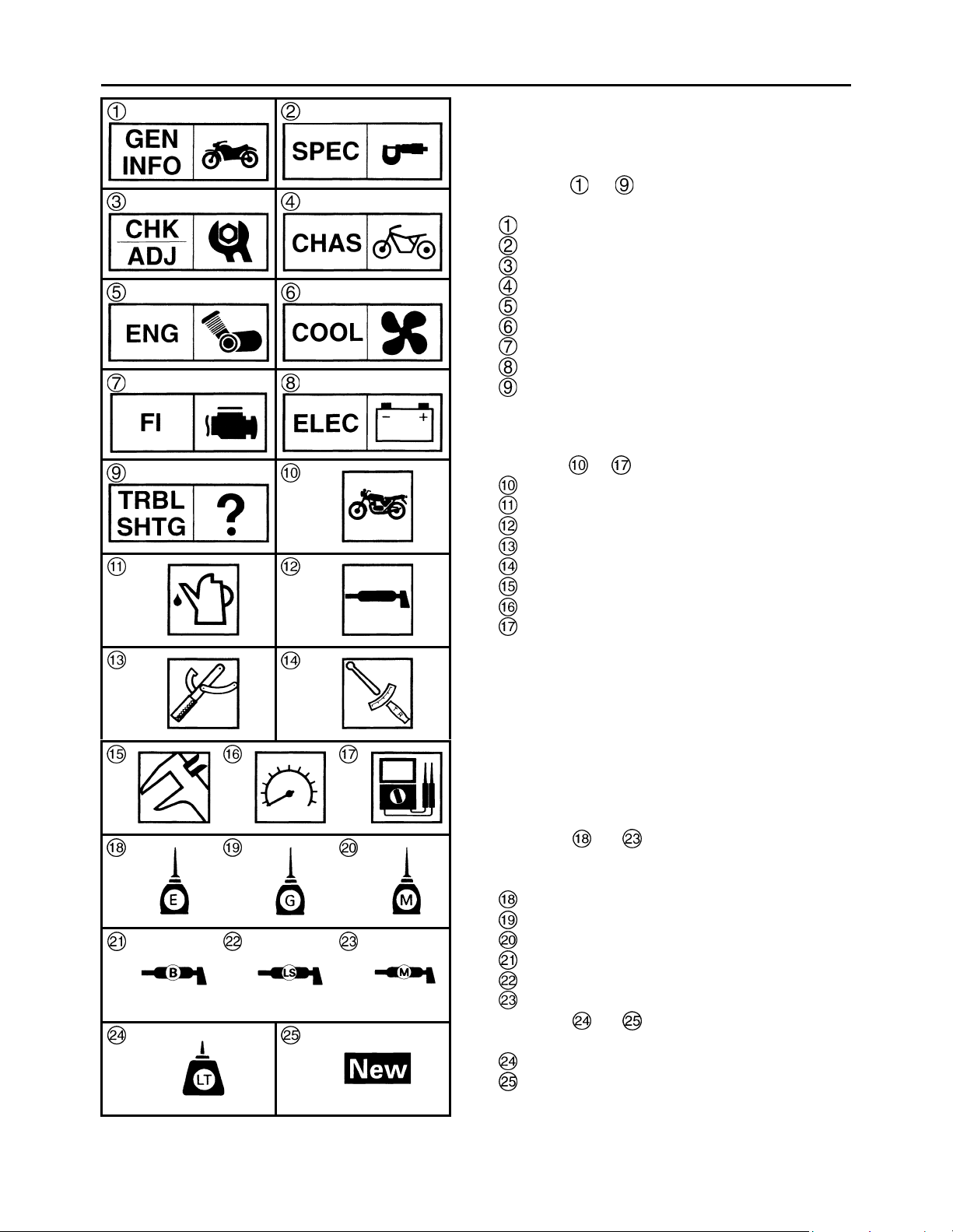

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols to indicate the subject of each

chapter.

General information

Specifications

Periodic checks and adjustments

Chassis

Engine

Cooling system

Fuel injection system

Electrical system

Troubleshooting

Symbols to indicate the following.

Serviceable with engine mounted

Filling fluid

Lubricant

Special tool

Tightening torque

Wear limit, clearance

Engine speed

Electrical data

Symbols to in the exploded diagrams

indicate the types of lubricants and lubrication

points.

Engine oil

Gear oil

Molybdenum-disulfide oil

Wheel-bearing grease

Lithium-soap- based grease

Molybdenum-disulfide grease

Symbols to in the exploded diagrams

indicate the following.

Apply locking agent (LOCTITE

®

)

Replace the part

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHASSIS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ENGINE TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . 2

CHASSIS TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . 2

CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHASSIS

SWINGARM AND DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHECKING THE DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ENGINE

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INSTALLING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CONNECTING RODS AND PISTONS . . . . . . . . . . . . . . . . . . . . . . . . 18

REMOVING THE CONNECTING RODS AND PISTONS . . . . . . . 19

CHECKING THE BIG END BEARINGS. . . . . . . . . . . . . . . . . . . . . 20

INSTALLING THE CONNECTING ROD AND PISTON . . . . . . . . . 24

GENERAL SPECIFICATIONS / ENGINE SPECIFICATIONS /

CHASSIS SPECIFICATIONS / ELECTRICAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard Limit

Model code

ENGINE SPECIFICATIONS

Item Standard Limit

Piston

Diameter D 65.475 ~ 65.490 mm (2.5778 ~ 2.5783

5VX8 (USA except for CAL)

5VX9 (CAL)

in)

SPEC

•

• •

• •

•

•

• •

Height H 5 mm (0.20 in) •

CHASSIS SPECIFICATIONS

Item Standard Limit

Drive chain

Model (manufacturer) 50V4 (DAIDO) •

Link quantity 118 •

Drive chain slack 45 ~ 55 mm (1.77 ~ 2.17 in) •

Maximum 15-link section •

• • 239.3 mm

ELECTRICAL SPECIFICATIONS

Item Standard Limit

Ignition system

T.C.I. unit model (manufacturer) F8T812 (MITSUBISHI) (USA) •

F8T813 (MITSUBISHI) (CAL) •

Starting circuit cut-off relay

Model (manufacture) G8R-30Y-V3 (OMRON) •

Coil resistance 162 ~ 198 Ω •

• •

• •

• •

• •

(9.42 in)

• •

• •

• •

• •

1

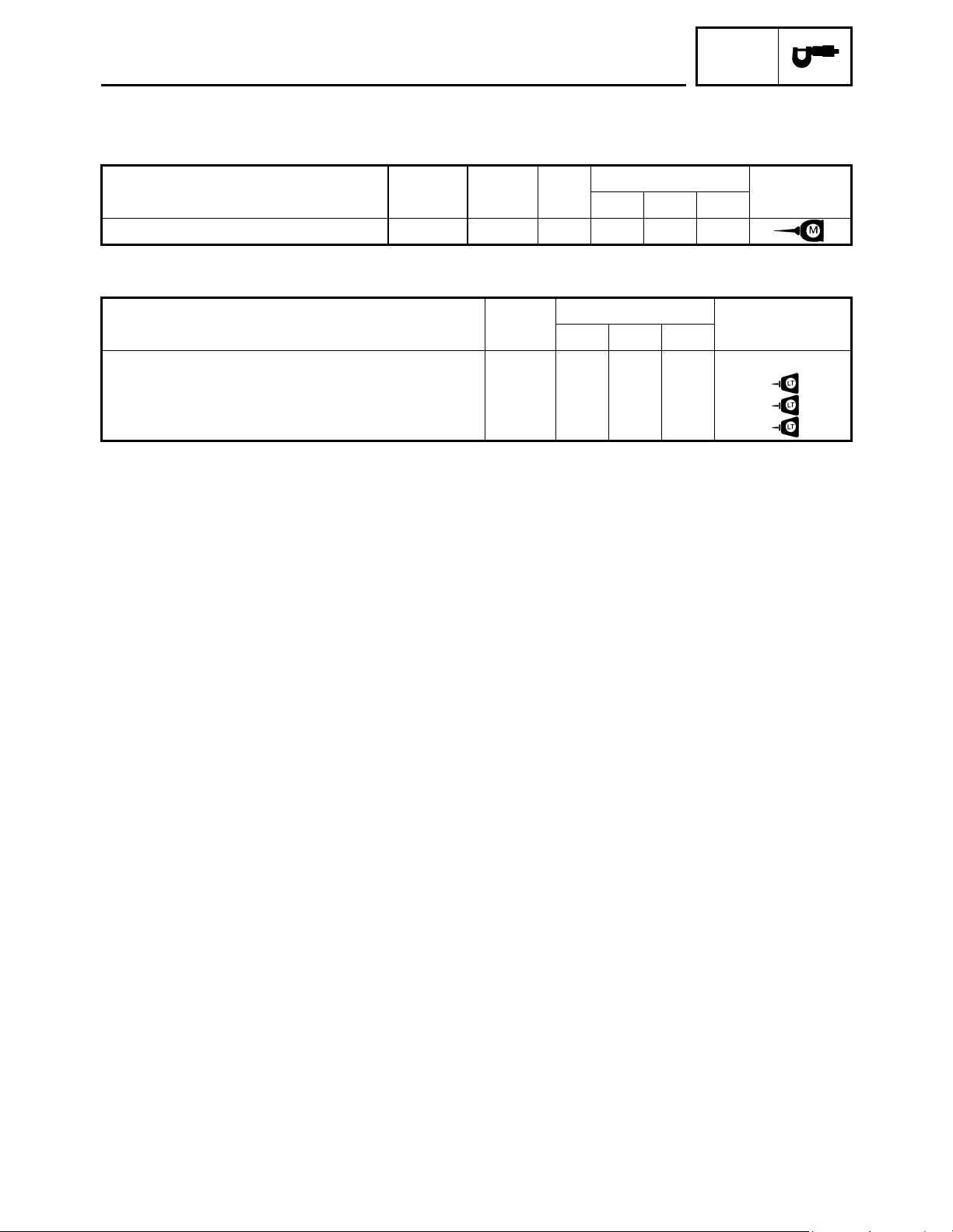

TIGHTENING TORQUES

ENGINE TIGHTENING TORQUES

TIGHTENING TORQUES

SPEC

Item Fastener

Connecting rod caps Bolt M7 8

CHASSIS TIGHTENING TORQUES

Item

Pivot shaft and frame M18 125 12.5 90

Sidestand switch nut M5 4 0.4 2.9

Shift rod and shift arm bolt M6 10 1.0 7.2

Footrest bracket and footrest cover plate M5 7 0.7 5.1

Thread

size

Thread

Q’ty

size

Tightening torque

Nm m•kg ft•lb

15+120°

Tightening torque

Nm m•kg ft•lb

1.5+120°

Remarks

11+120°

Remarks

2

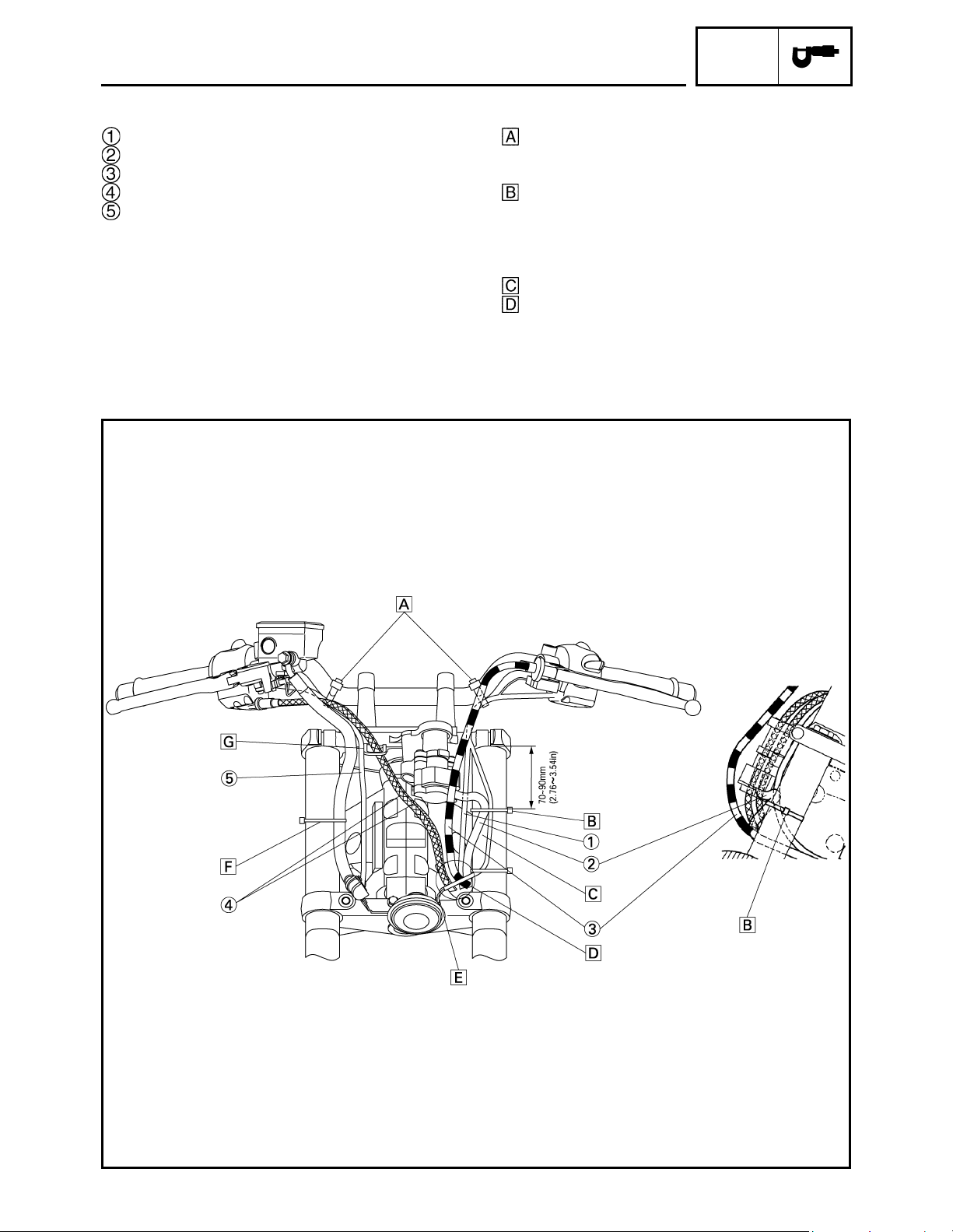

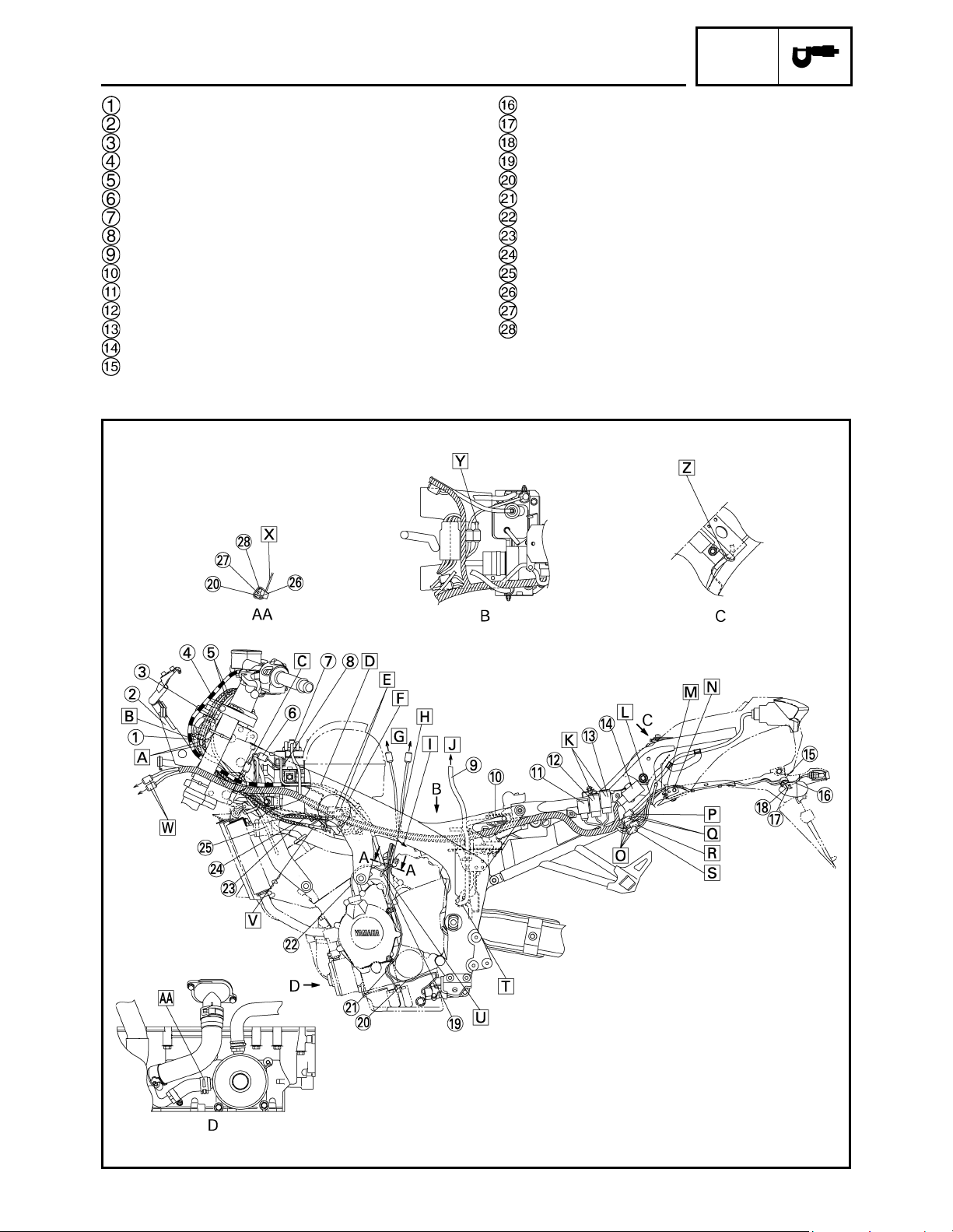

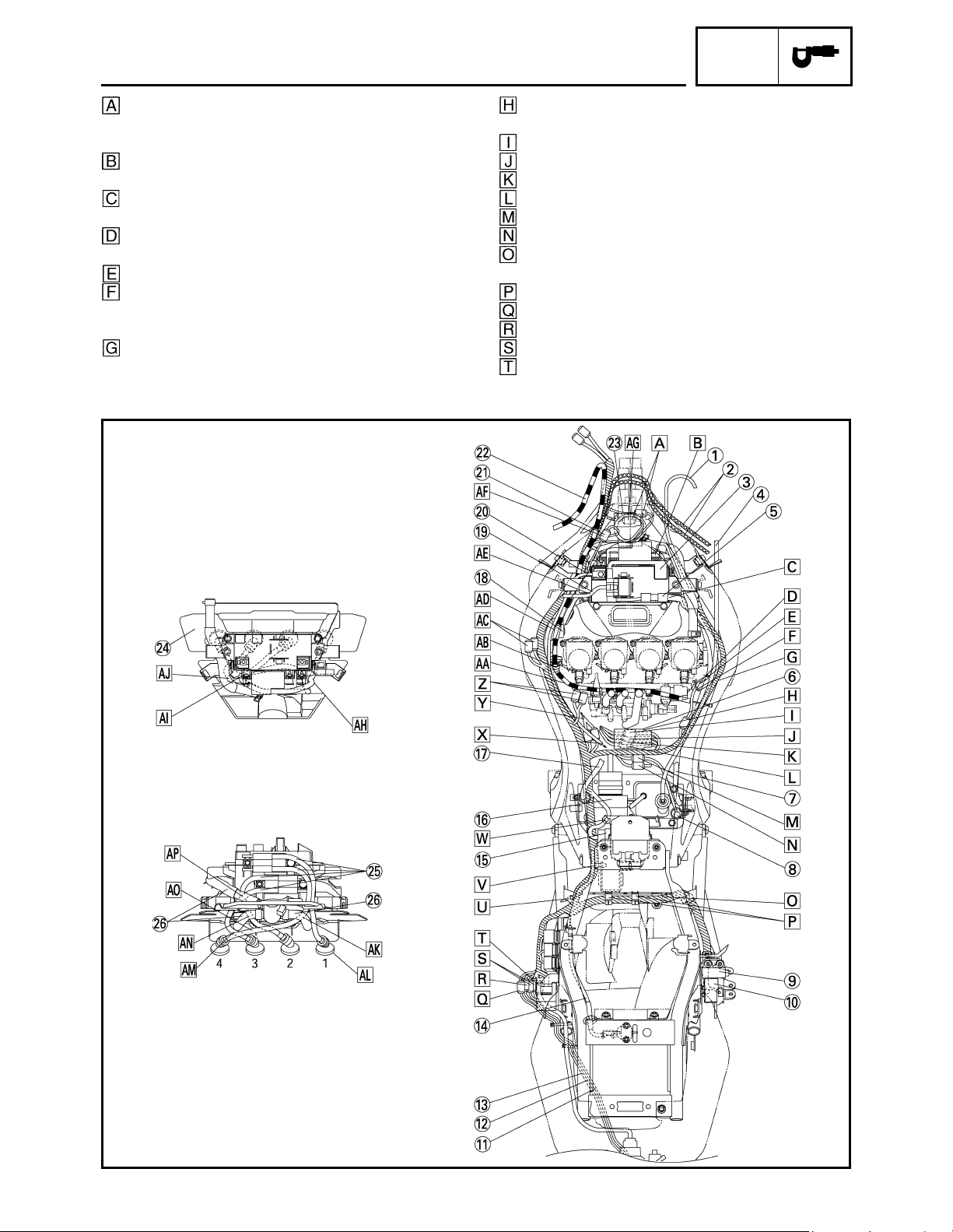

CABLE ROUTING

Left handlebar switch lead

Main switch lead

Clutch cable

Throttle cables

Right handlebar switch lead

CABLE ROUTING

Clamp the right and left handlebar switch leads

and handlebars. Point the tip of the clamp

downward in front of the handlebars.

Clamp the horn lead and main switch lead

(upper side only) to the inner tube. Point the

binding section to the outside of the vehicle

body and cut the tip down to the length of 1 to 5

mm (0.04 to 0.20 in).

Route the horn lead by the headmost side.

Pass the throttle cables, wire harness lead,

clutch cable, main switch and immobilizer lead

and left handlebar switch lead in order through

the frame hole from the inner side of the vehicle.

SPEC

3

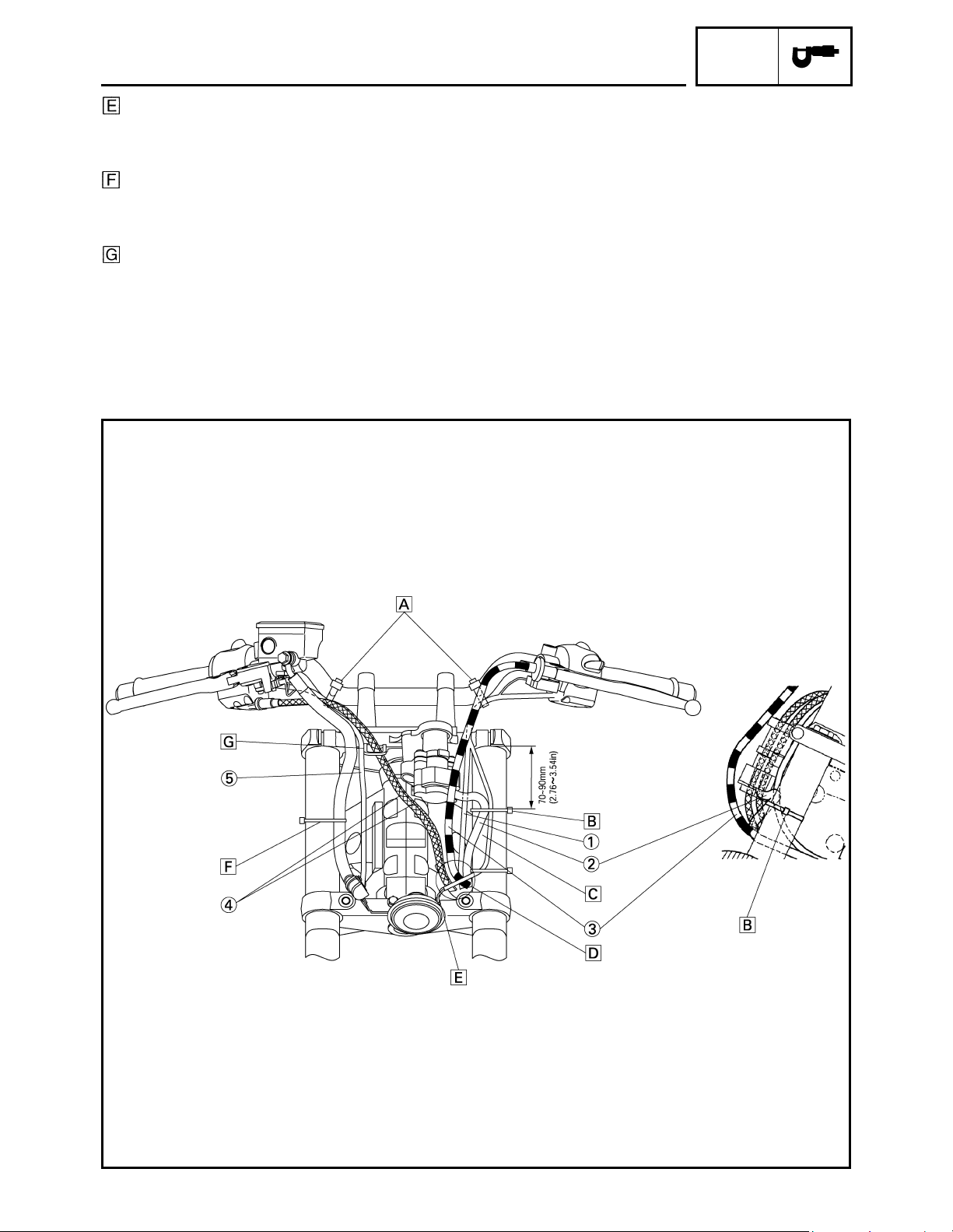

Point the lead, which comes from the terminal,

to the front side of the vehicle body. There

should be no slack of leads between the band

and terminals.

Clamp the brake hose to the inner tube. Point

the binding section to the outside of the vehicle

body and cut the tip down to the length of 1 to 5

mm (0.04 to 0.20 in).

Pass the throttle cables through the wire guide.

Route the right handlebar switch lead by the outside of the wire guide.

CABLE ROUTING

SPEC

4

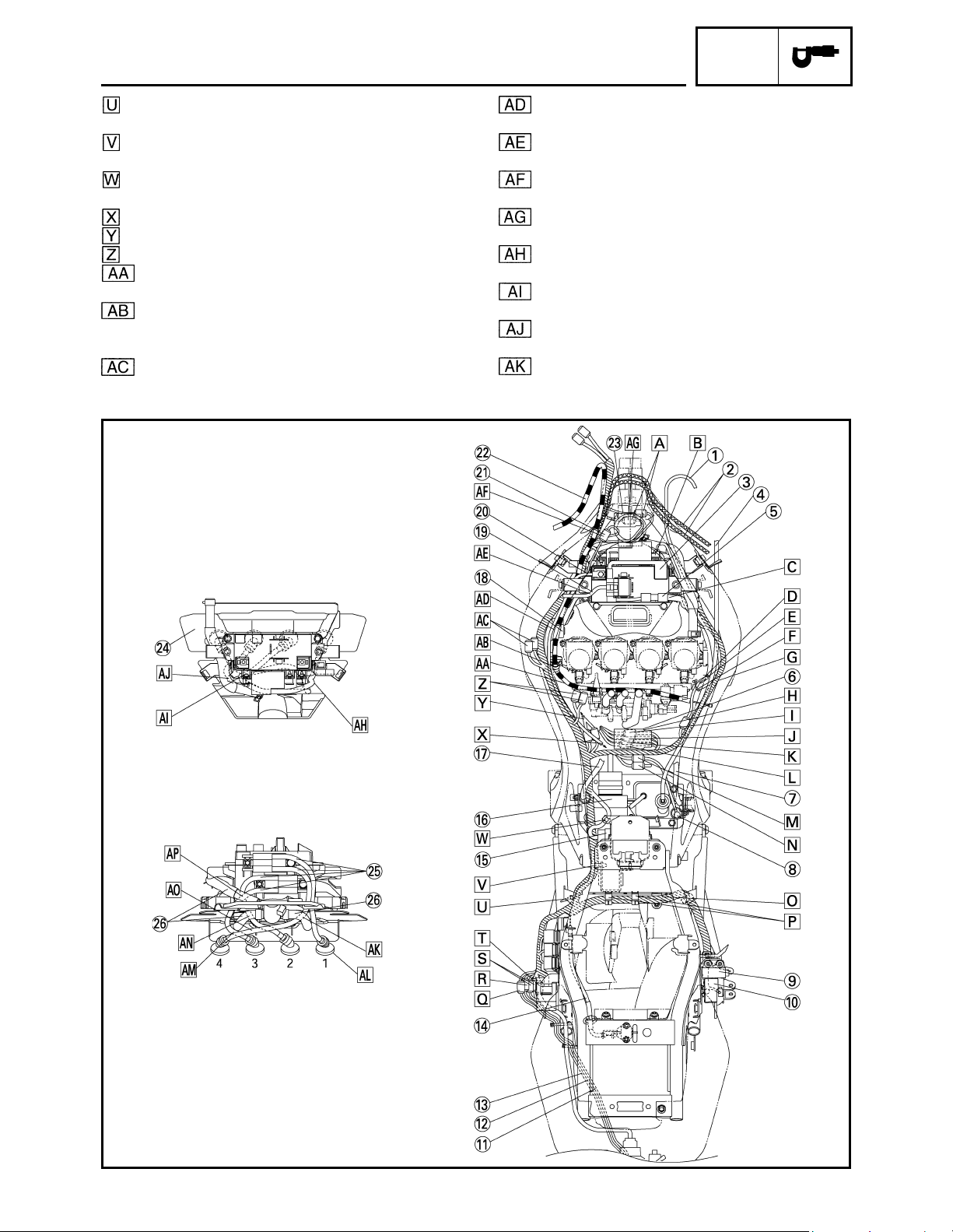

CABLE ROUTING

SPEC

Main switch lead

Stay assembly

Left handlebar switch lead

Clutch cable

Throttle cables

Battery negative lead coupler

Starter relay lead

Battery negative lead

Fuel tank drain hose

Rectifier/regulator

Turn signal relay

Radiator fan motor relay

Dimmer relay

Starting circuit cut-off relay

Clamp

License plate light lead

Rear turn signal light lead (right)

Rear turn signal light lead (left)

Speed sensor lead

Sidestand switch lead

Oil level switch lead

A.C. magneto lead

Throttle cable (return side)

Throttle cable (pull side)

Radiator fan motor lead

Oil level gauge lead

A. C. magneto lead

Speed sensor lead

5

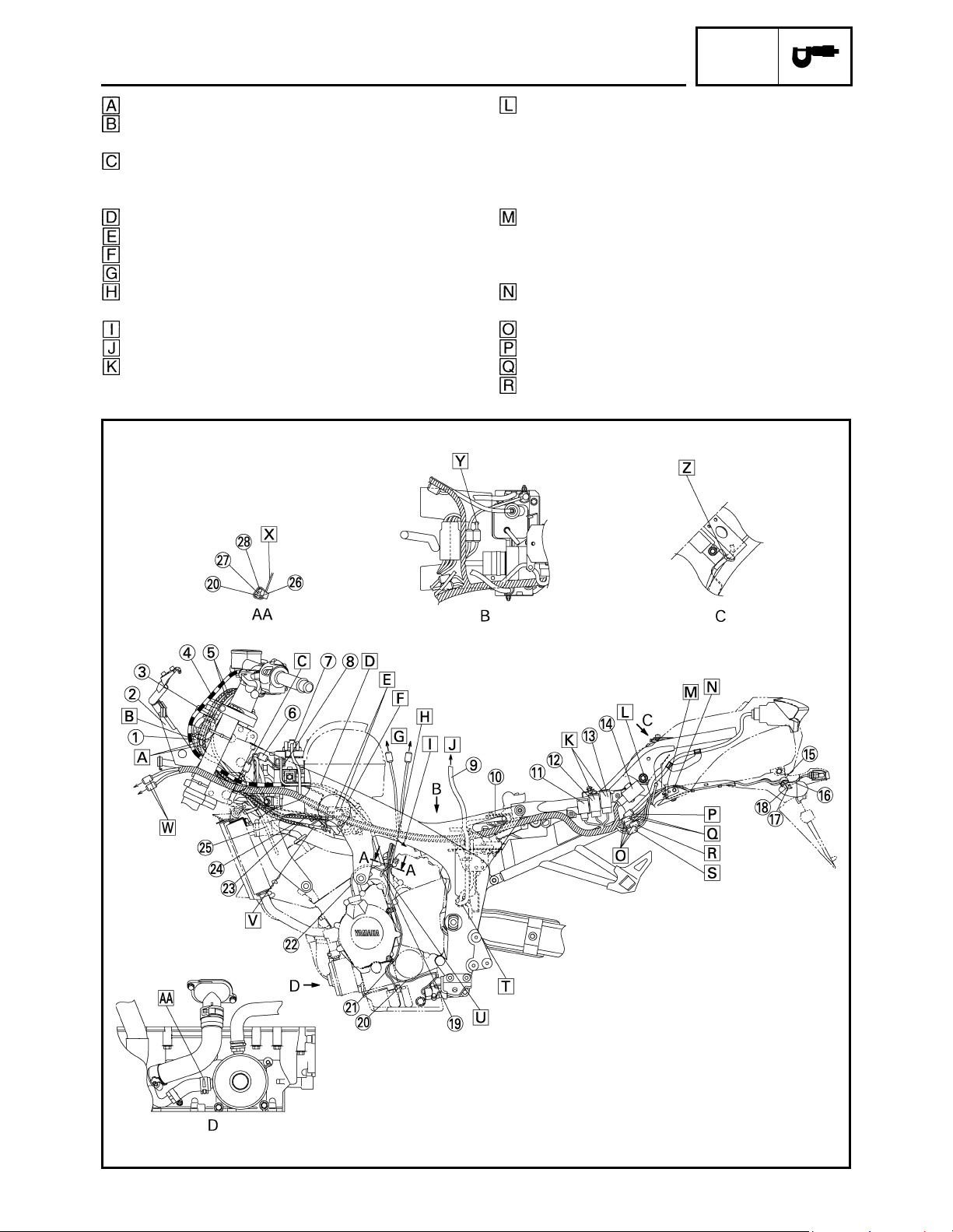

CABLE ROUTING

SPEC

Route the throttle cables above the stay assy 1.

Route the main switch lead above the clutch

cable.

Line up the left handlebar switch lead coupler

and fan motor lead coupler behind the head

pipe.

Route the clutch cable over the wire harness.

To the main switch.

Place three couplers on the flange of the cover.

To the fuel pump.

Clamp four wire leads. There should be no

excessive slack on the wire leads.

To the engine.

To the fuel tank.

Either installation position can be accepted, but

make sure that the leads are not crossed.

Clamp the rear turn signal light lead and license

plate light lead to the frame. Hook the clamp to

the bracket. Pull out the lead sufficiently to the

frame side and route it along with the side of the

back stay. Cut the tip of the clamp to be between

1 and 5 mm (0.04 and 0.20 in) upward.

Clamp the rear turn signal light lead and license

plate light lead to the frame. Cut the tip of the

clamp to be between 1 and 5 mm (0.04 and 0.20

in).

Gap between the lead and muffler should be 10

mm (0.39 in) or more.

Coupler should not run on the relay assembly.

To the tail/brake light.

To the license plate light.

To the rear turn signal light. (right)

6

CABLE ROUTING

SPEC

To the rear turn signal light (left)

Pass the fuel tank drain hose through the clamp

located under the coolant reservoir tank.

Route it behind the starter motor lead.

Point the bend-R section of the throttle cable

(pull side) to the inner side horizontally. It is also

possible to visually check the bend-R section.

To the headlight lead.

Point the tip of the clamp to the inner side of the

vehicle body.

Make sure to pass the neutral switch lead

through the hole of the flap.

Clamp the seat lock wire to the frame as shown

in the illustration. Secure the clamp to the weld

of the cross member with the frame. Position the

binding section in front of the vehicle body and

cut the tip to be between 1 and 5 mm (0.04 and

0.20 in).

Install the clamp with its ends facing between

the downward or forward position.

7

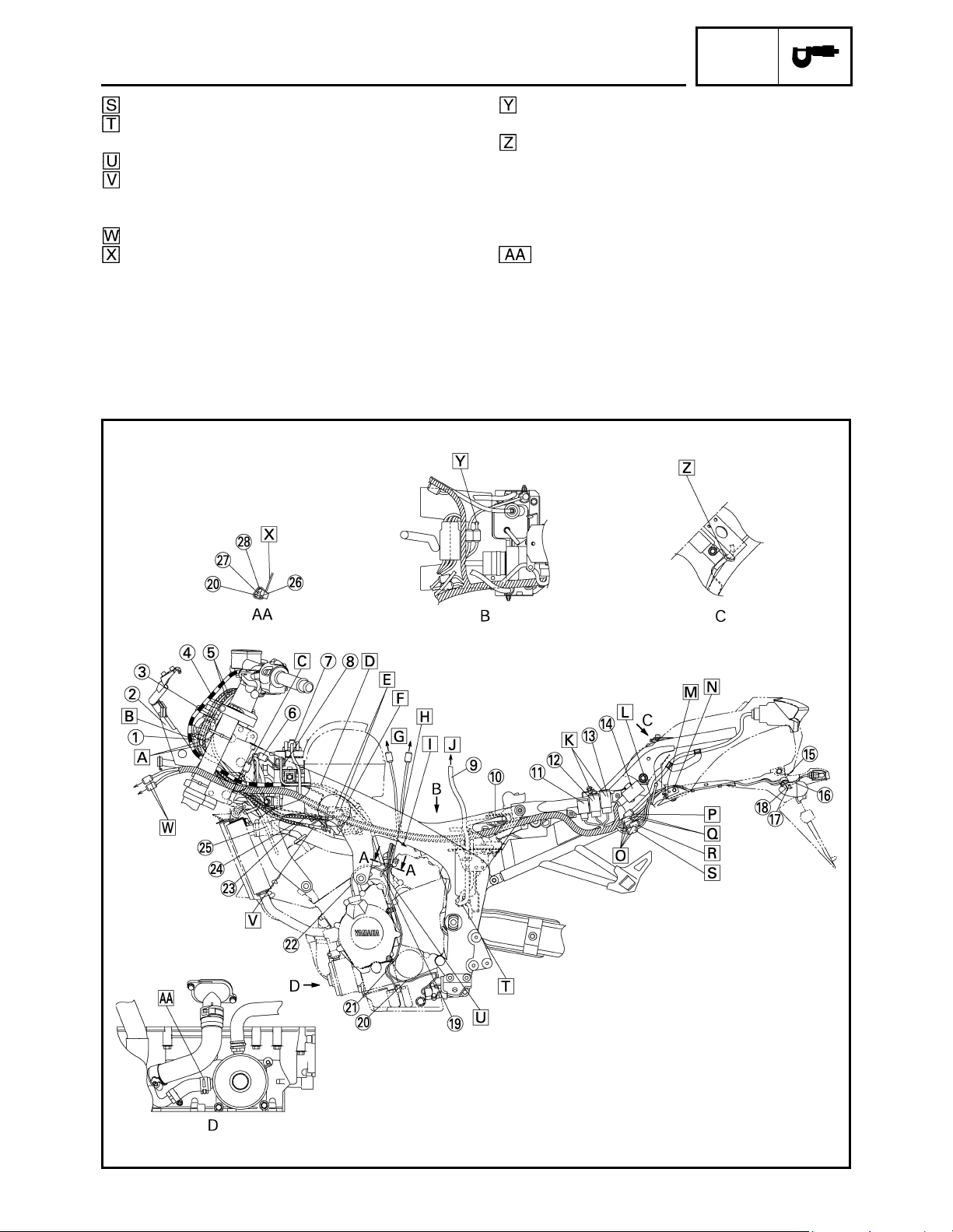

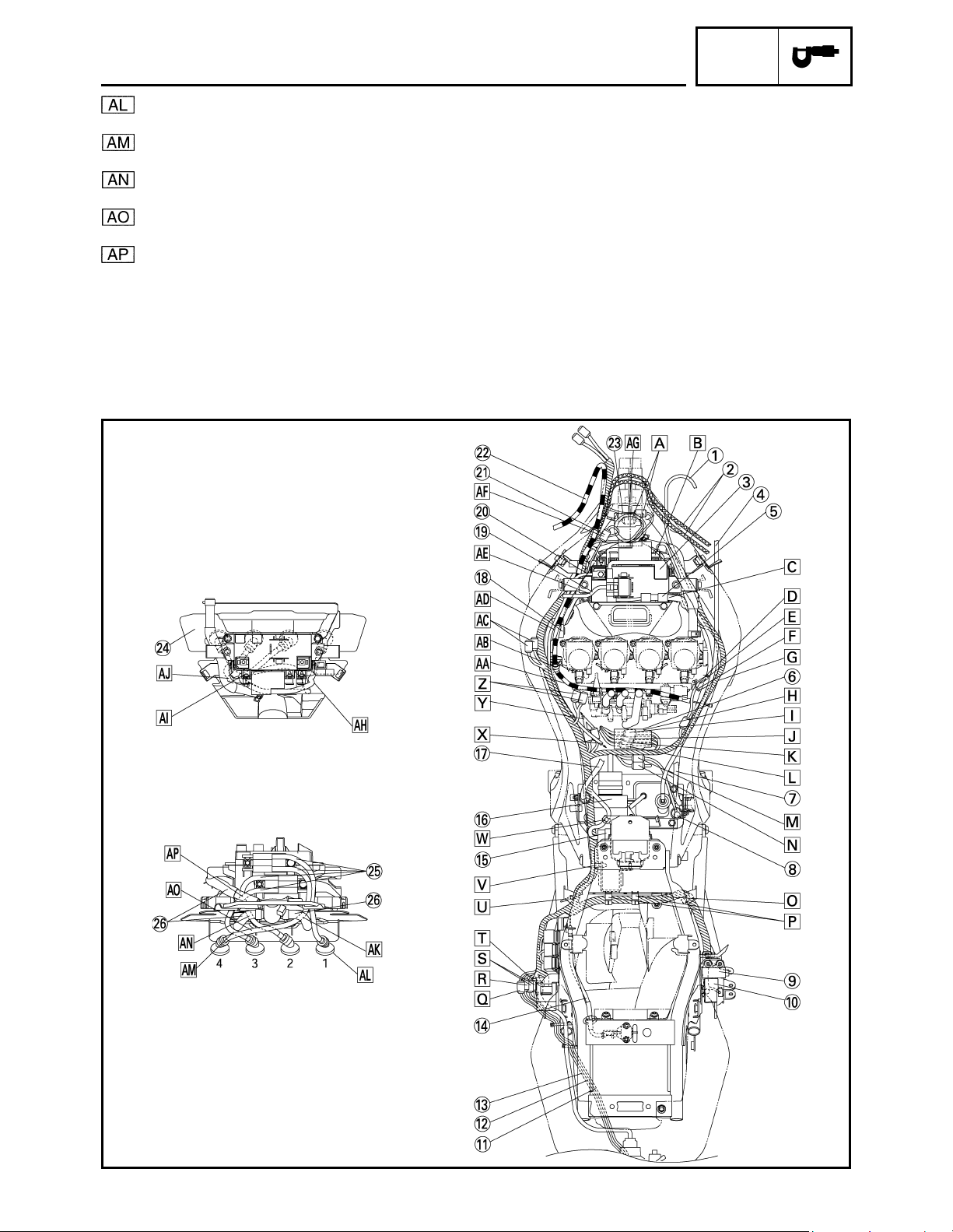

CABLE ROUTING

SPEC

Right handlebar switch lead

Throttle cables

Battery positive lead

Coolant reservoir tank hose

Battery cover

Connecter cover

Fuel tank breather hose

Brake fluid reservoir hose

Lean angle cut-off switch

Fuse box

Rear turn signal light lead (right)

License plate light lead

Rear turn signal light lead (left)

Seat lock cable

Rectifier/regulator

E.C.U

Fuel tank drain hose

Cover

Starter relay lead

Battery negative lead

Battery negative lead coupler

Clutch cable

Connecter cover

Cover 2

Spark plug lead

Air cut-off valve hose

8

CABLE ROUTING

SPEC

Either right or left side arrangement for the left

handlebar switch lead coupler and radiator fan

motor coupler can be accepted.

Point the L-shape terminal to the front side of

the vehicle.

Hook the starter motor lead to the alternate

pawls on the battery cover.

Route the crankshaft position sensor lead above

the starter motor leads.

To the crankshaft position sensor.

Clamp the starter motor lead and crankshaft

position sensor lead. Point the projected part of

the tip to the inner side of the vehicle.

Pass the radiator hose, coolant reservoir hose,

wire harness and starter motor lead in order

through the lower side of the vehicle.

Set the 4-pin coupler in the connector cover

after wiring it.

To the sidestand switch.

To the speed sensor.

To the A.C. magneto.

To the oil level switch.

To the tail/brake light switch.

To the neutral switch.

Push the wire harness in the groove of the mud

guard.

Point the opening section of the clamp upward.

To the rear turn signal (right)

To the rear turn signal (left)

To the license plate light.

To the tail/brake light.

9

CABLE ROUTING

SPEC

Point the tip of the clamp to the outside of the

vehicle.

Insert the enwinding clamp of the wire harness

into the hole of the rear frame.

Attach the rectifier/regulator lead to the clamp of

the rectifier bracket.

To the engine ground.

To the fuel injection.

To the fuel pump.

Route the clutch cable under the fuel injection

lead.

Pass the clutch cables through the clamp, and

then install the clamp to the cover. Position of

the clamp is forward of the cable stopper.

To the main switch.

Plate the adjuster of the clutch cable above

the cover.

Route the starter relay lead outside of the

main switch.

Press the battery negative lead into the space

between the ribs of the frame.

After connecting the coupler of the connector

cover position it inside.

Pass the spark plug leads #1 and #4 through

the slit of the cover 2.

Pass the spark plug lead #2 through the inner

hole of the cover 2.

Pass the spark plug lead #3 through the outer

hole of the cover 2.

Route the spark plug lead #4 behind the air

cut-off valve hose.

10

Point the spark plug caps of #1 to #4 to the

direc-tion as shown in the illustration.

Route the spark plug lead #3 under the air

cut-off valve hose.

Route the spark plug lead #2 behind the air

cut-off valve hose.

Route the spark plug lead #4 by the front side

of the spark plug leads #2 and #3.

Route the spark plug leads #2 and #3 behind

the air cut-off valve hose.

CABLE ROUTING

SPEC

11

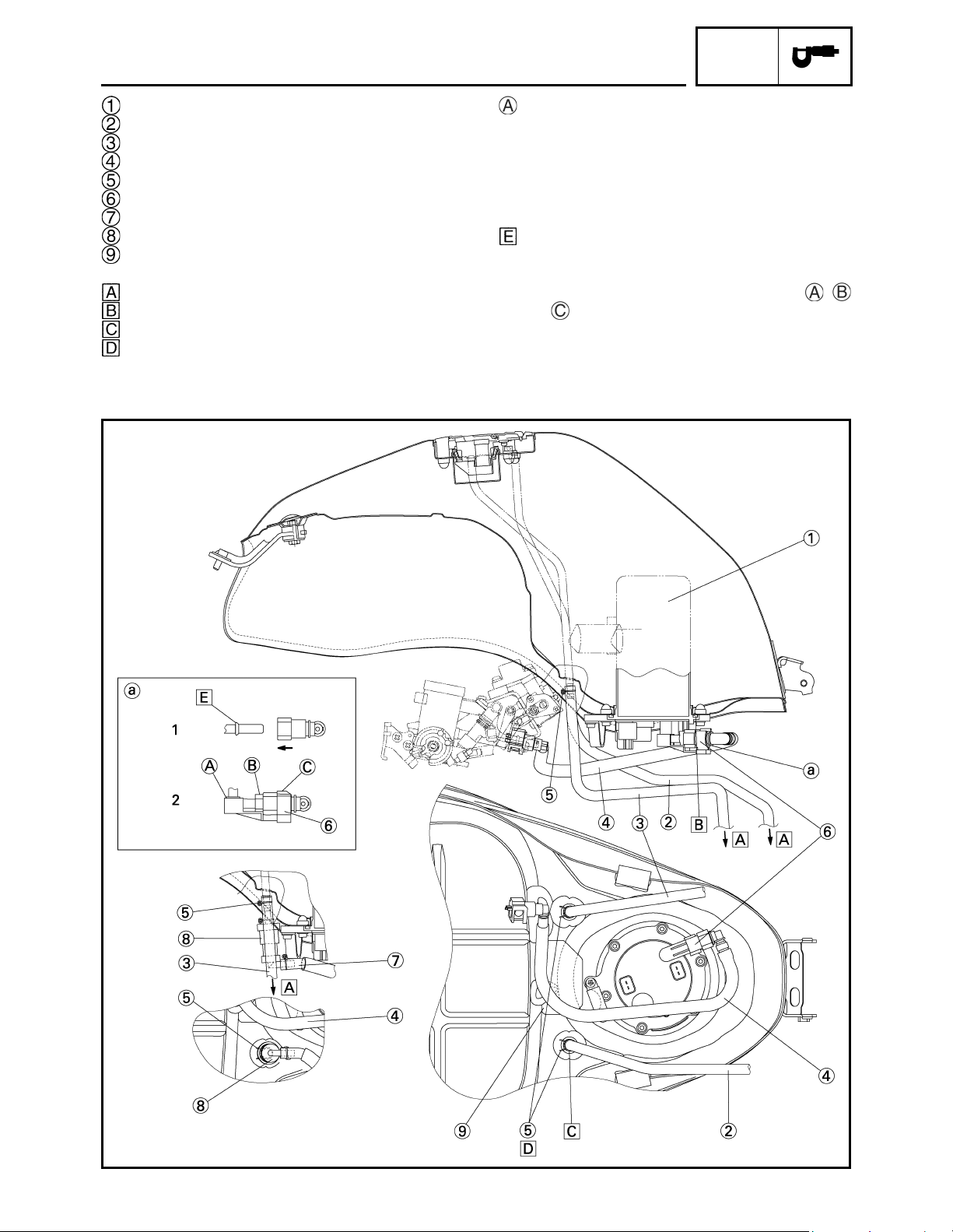

CABLE ROUTING

SPEC

Fuel pump assembly

Fuel tank breather hose (except for CAL)

Fuel tank drain hose

Fuel hose

Clip

Clamp

Charge hose (for CAL)

Roll over valve (for CAL)

Fuel tank protector

Air opening.

Install the O-ring with its lip pointed upward.

Fuel tank breather hose has a white point mark.

Point the knob of clip front side.

Fuel piping connector attachment directions.

(fuel pump side)

1. It is inserted until it makes a click sound the connector, and it checks that a connector does not

fail out. It takes care that a foreign substance

does not enter into a seal portion. (Working

gloves should not be used at the time of work.)

It prevents that this portion falls out.

2. The clamp is attached from the bottom after the

work of “1”.

It checks being completely equipped with ,

and section.

12

CABLE ROUTING

SPEC

except for CAL

Coolant breather hose

Coolant reservoir tank

Coolant reservoir tank hose

Clamp

Fuel tank drain hose

Front side.

Pass the coolant reservoir tank hose hangs

down downward from back of the bolt.

Insert this portion securely.

Spittle is turned back.

Insert the clamp certainly.

It may open and close to direction of which. All

notches gear at the time of attachment.

Pass the coolant reservoir tank hose inside of

the clamp.

Insert in certainly.

To the fuel tank drain tube.

Air opening.

There should be no slacking of the hose when it

is routed.

13

SWINGARM AND DRIVE CHAIN

EAS00709

CHASSIS

SWINGARM AND DRIVE CHAIN

CHECKING THE DRIVE CHAIN

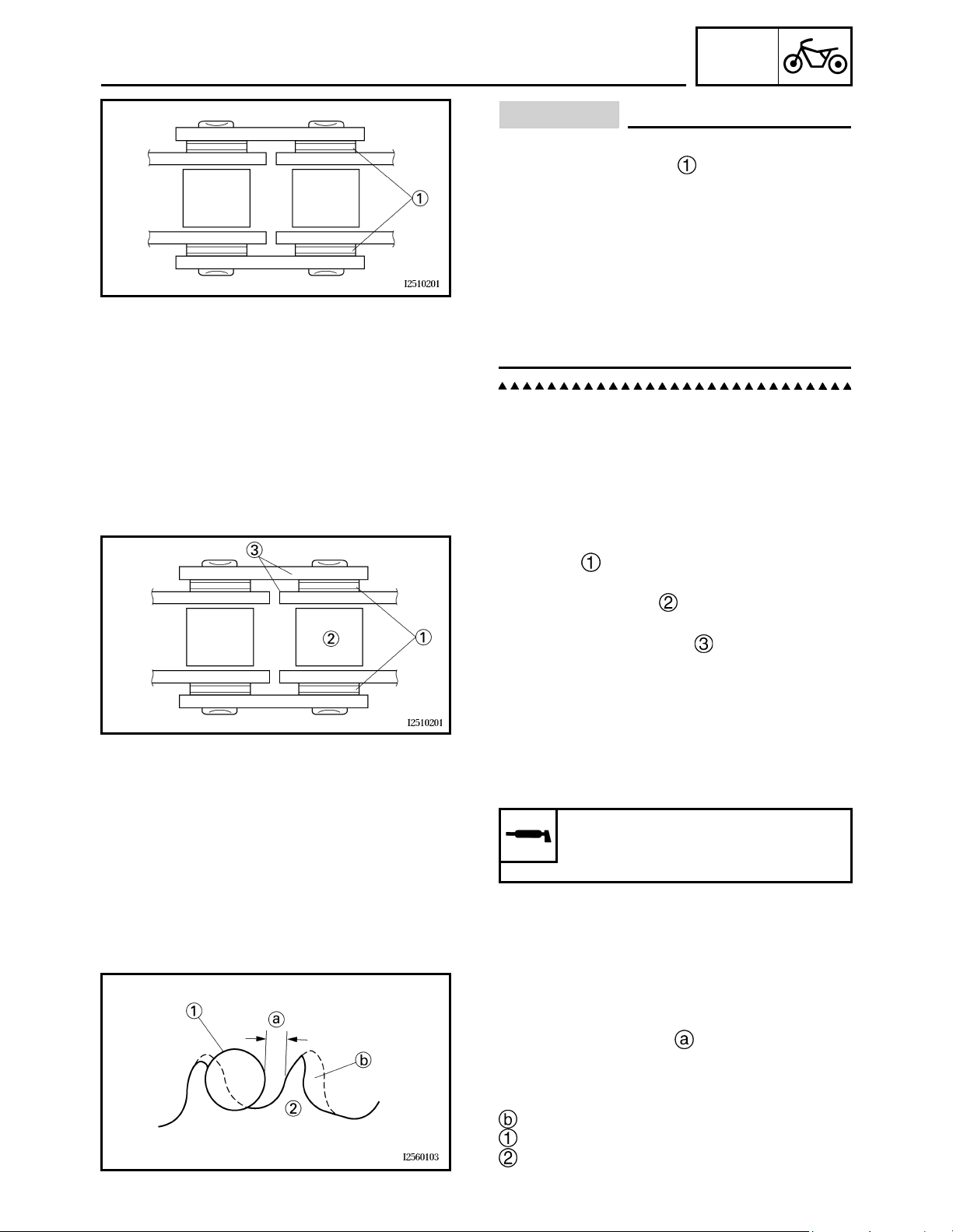

1. Measure:

• Measure the dimension between 15-links

on the inner side and outer side of the

roller and calculate the dimension between

pin centers.

• Dimension between pin centers = (Inner

dimension + Outer dimension )/2

• 15-link section of the drive chain

Out of specification → Replace the drive

chain, front drive sprocket and rear drive

sprocket as a set.

15-link drive chain section limit

(maximum)

239.3 mm (9.42 in)

CHAS

NOTE:NOTE:

• While measuring the 15-link section, push

down on the drive chain to increase its tension.

• Perform this measurement at two or three different places.

2. Check:

• drive chain

Stiffness → Clean and lubricate or replace.

3. Clean:

• drive chain

a. Wipe the drive chain with a clean cloth.

b. Put the drive chain in kerosene and remove

any remaining dirt.

c. Remove the drive chain from the kerosene

and completely dry it.

14

SWINGARM AND DRIVE CHAIN

CAUTION:

This motorcycle has a drive chain with

small rubber O-rings between the drive

chain side plates. Never use high-pressure

water or air, steam, gasoline, certain solvents (e.g., benzine), or a coarse brush to

clean the drive chain. High-pressure methods could force dirt or water into the drive

chain's internals, and solvents will deteriorate the O-rings. A coarse brush can also

damage the O-rings. Therefore, use only

kerosine to clean the drive chain.

CHAS

4. Check:

•O-rings

Damage → Replace the drive chain.

• drive chain rollers

Damage/ wear → Replace the drive chain.

• drive chain side plates

Damage/ wear → Replace the drive chain.

Cracks → Replace the drive chain and

make sure that the battery breather hose is

properly routed away from the drive chain

and below the swingarm.

5. Lubricate:

• drive chain

Recommended lubricant

Engine oil or chain lubricant

suitable for O-ring chains

6. Check:

• drive sprocket

• rear wheel sprocket

More than 1 / 4 tooth wear → Replace the

drive chain sprockets as a set.

Bent teeth → Replace the drive chain

sprockets as a set.

Correct

Drive chain roller

Drive chain sprocket

15

ENGINE

EAS00192

ENG

ENGINE

ENGINE

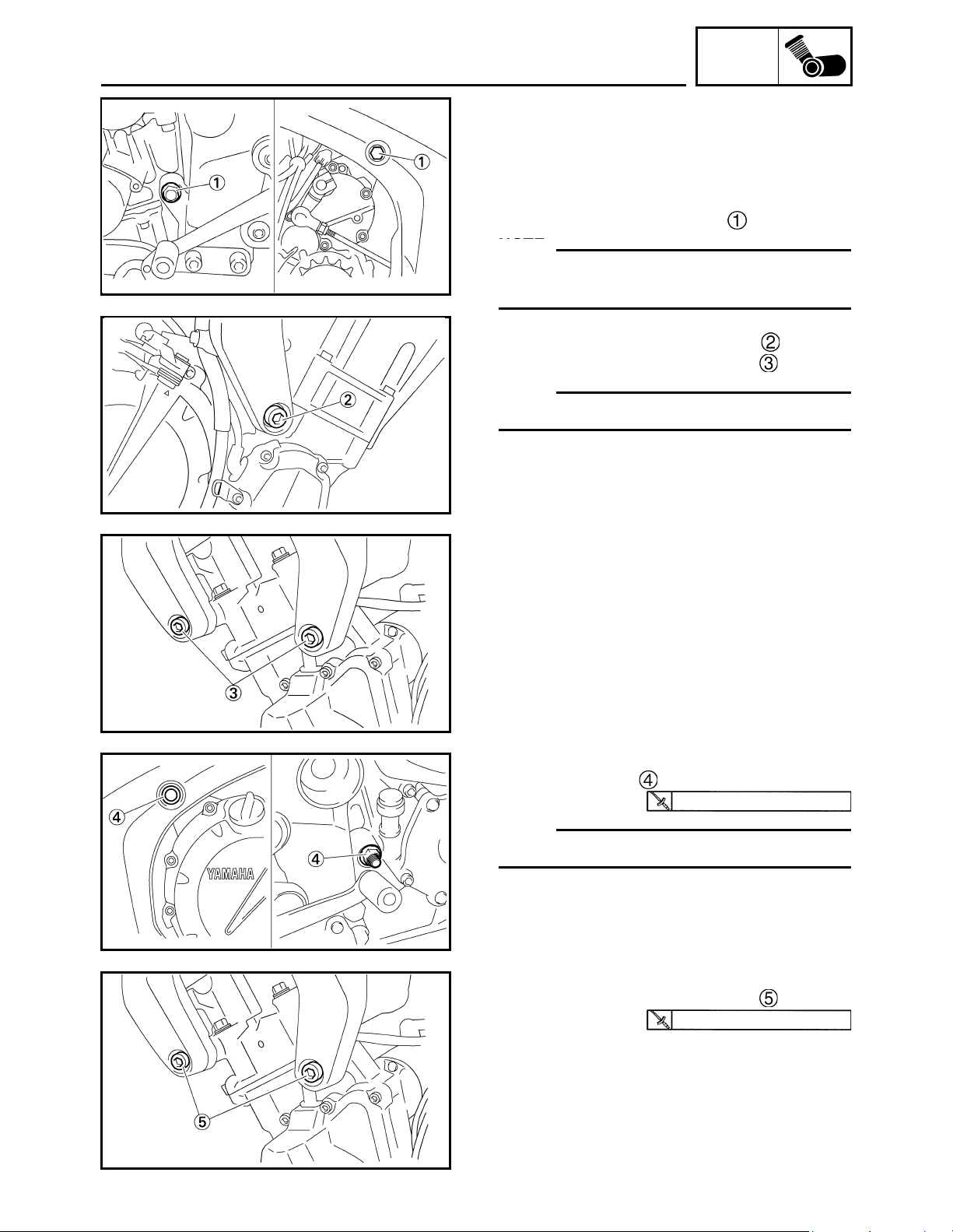

INSTALLING THE ENGINE

1. Install:

• rear engine mounting bolts

NOTE:NOTE:

Lubricate the rear engine mounting bolt

threads with lithium-soap-based grease.

2. Install:

• right front engine mounting bolt

• left front engine mounting bolts

NOTE:NOTE:

Do not fully tighten the bolts.

3. Tighten:

• self-locking nut

55 Nm (5.5 m•kg, 40 ft•lb)

NOTE:NOTE:

First tighten the lower self-locking nut.

4. Tighten

• left front engine mounting bolts

55 Nm (5.5 m•kg, 40 ft•lb)

16

ENGINE

5. Tighten

• right front engine mounting bolts

6. Install:

• shift arm bolt

NOTE:NOTE:

• Before installing, make sure to align the

punch mark of the shift shaft with the

punch mark of the shift arm.

• Align the bottom edge of the shift pedal with

the mark on the frame-to-swingarm bracket.

ENG

55 Nm (5.5 m•kg, 40 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

17

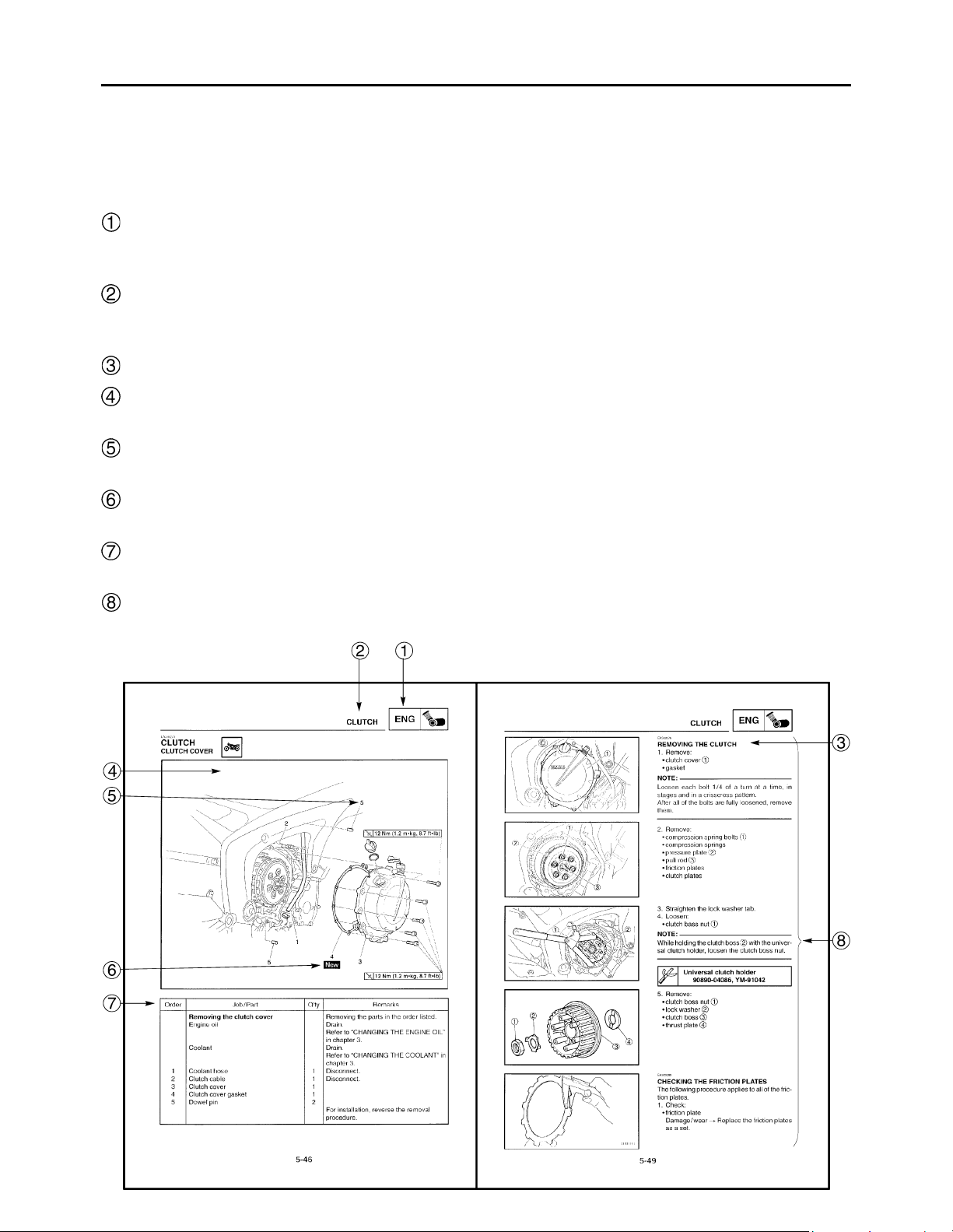

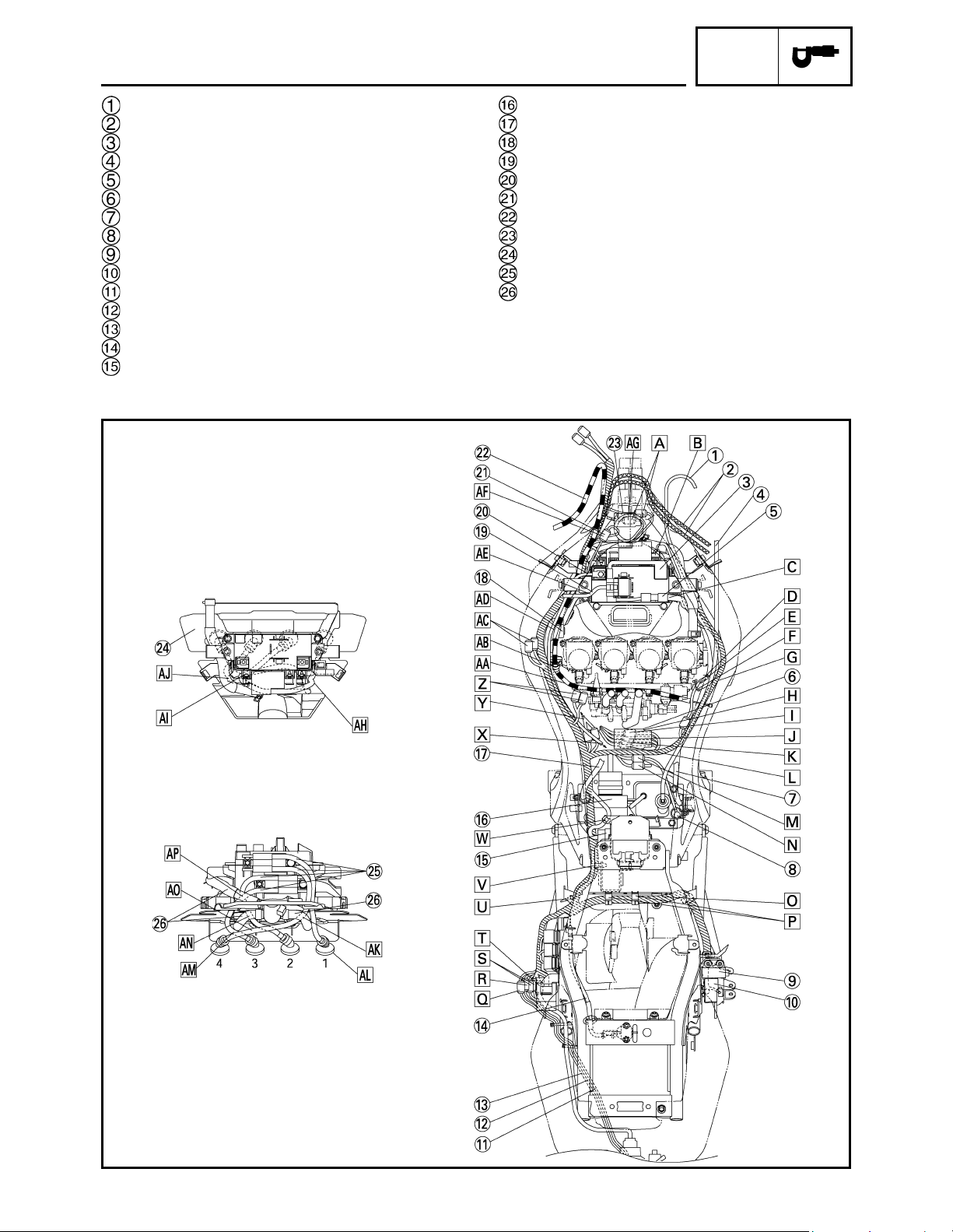

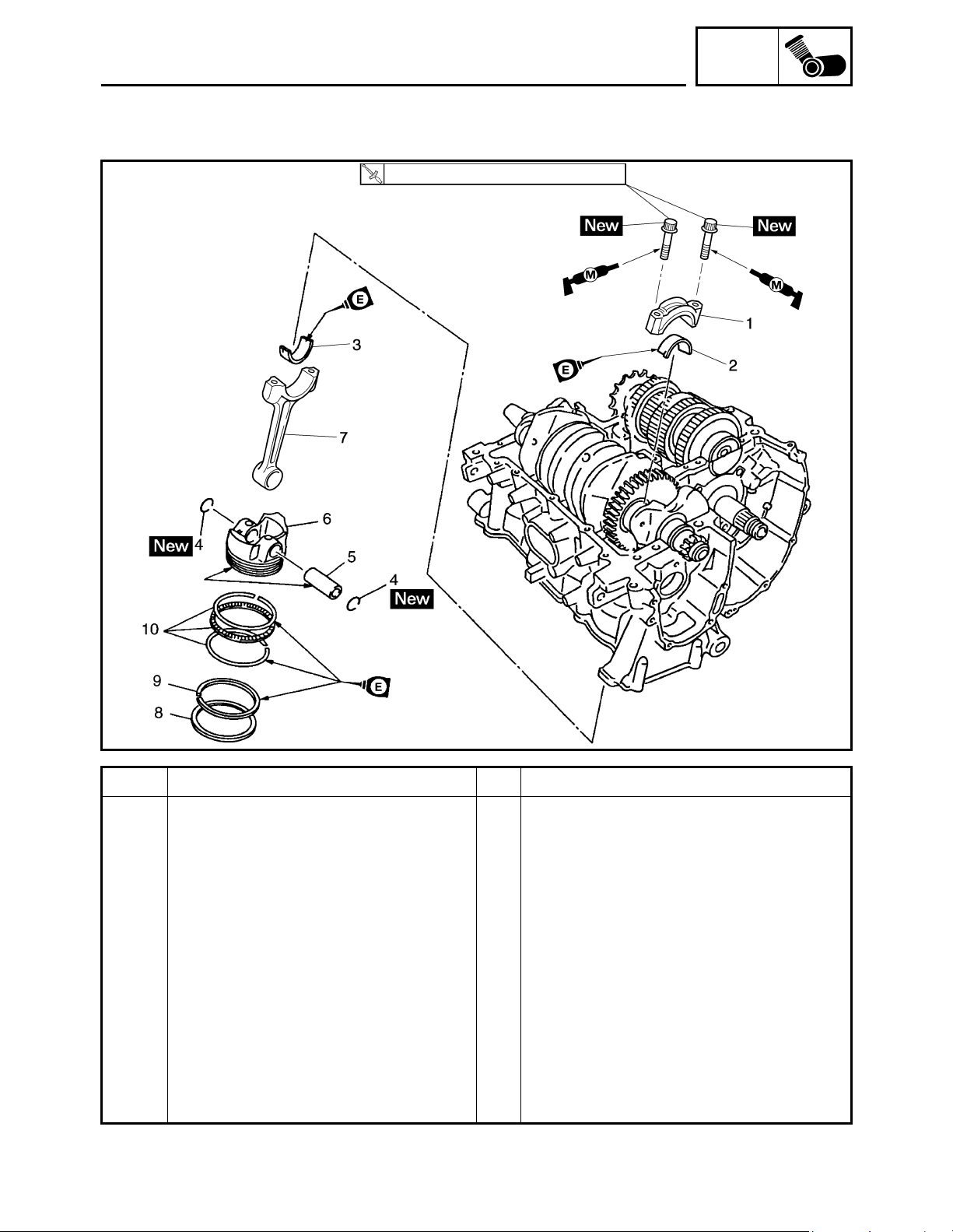

CONNECTING RODS AND PISTONS

EAS00252

CONNECTING RODS AND PISTONS

15Nm (1.5 m•kg, 11ft•lb) + 120°

ENG

Order Job / Part Q'ty Remar ks

Removing the connecting rods and

pistons

Lower crankcase Refer to “CRANKCASE”.

1 Connecting rod cap 4

2 Big end lower bearing 4

3 Big end upper bearing 4

4 Piston pin clip 8

5 Piston pin 4

6Piston 4

7 Connecting rod 4

8 Top ring 4

92nd ring 4

10 Oil ring 4

Remove the parts in the order listed.

For installation, reverse the removal

procedure.

18

CONNECTING RODS AND PISTONS

EAS00393

REMOVING THE CONNECTING RODS AND

PISTONS

The following procedure applies to all of the

connecting rods and pistons.

1. Remove:

• connecting rod cap

• big end bearings

NOTE:NOTE:

Identify the position of each big end bearing so

that it can be reinstalled in its original place.

ENG

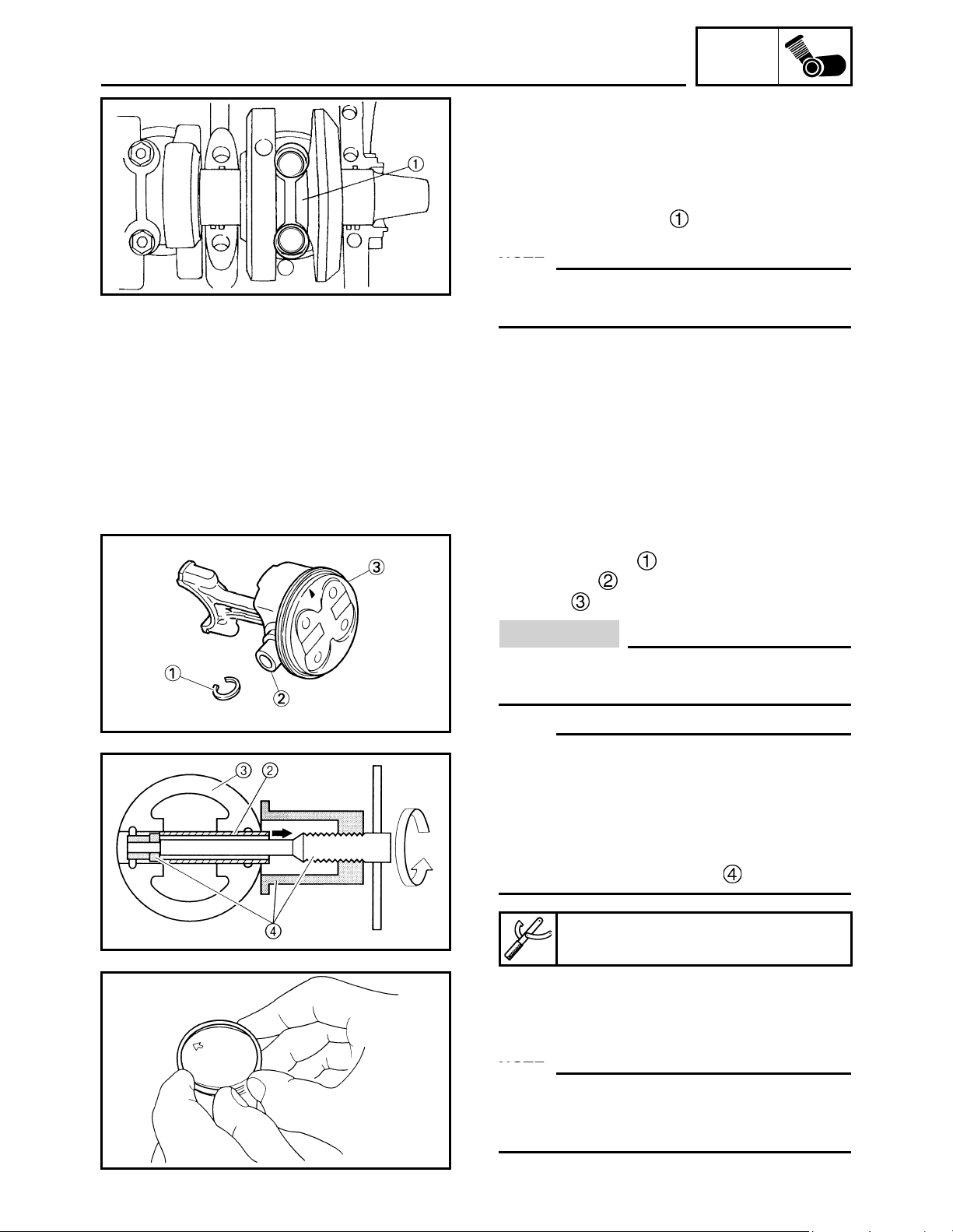

2. Remove:

• piston pin clips

• piston pin

•piston

CAUTION:

Do not use a hammer to drive the piston

pin out.

NOTE:NOTE:

• For reference during installation, put identification marks on the piston crown.

• Before removing the piston pin, deburr the

piston pin clip groove and the piston pin bore

area. If both areas are deburred and the piston pin is still difficult to remove, remove it

with the piston pin puller set .

Piston pin puller set

90890-01304, YU-01304

3. Remove:

• top ring

•2nd ring

•oil ring

NOTE:NOTE:

When removing a piston ring, open the end

gap with your fingers and lift the other side of

the ring over the piston crown.

19

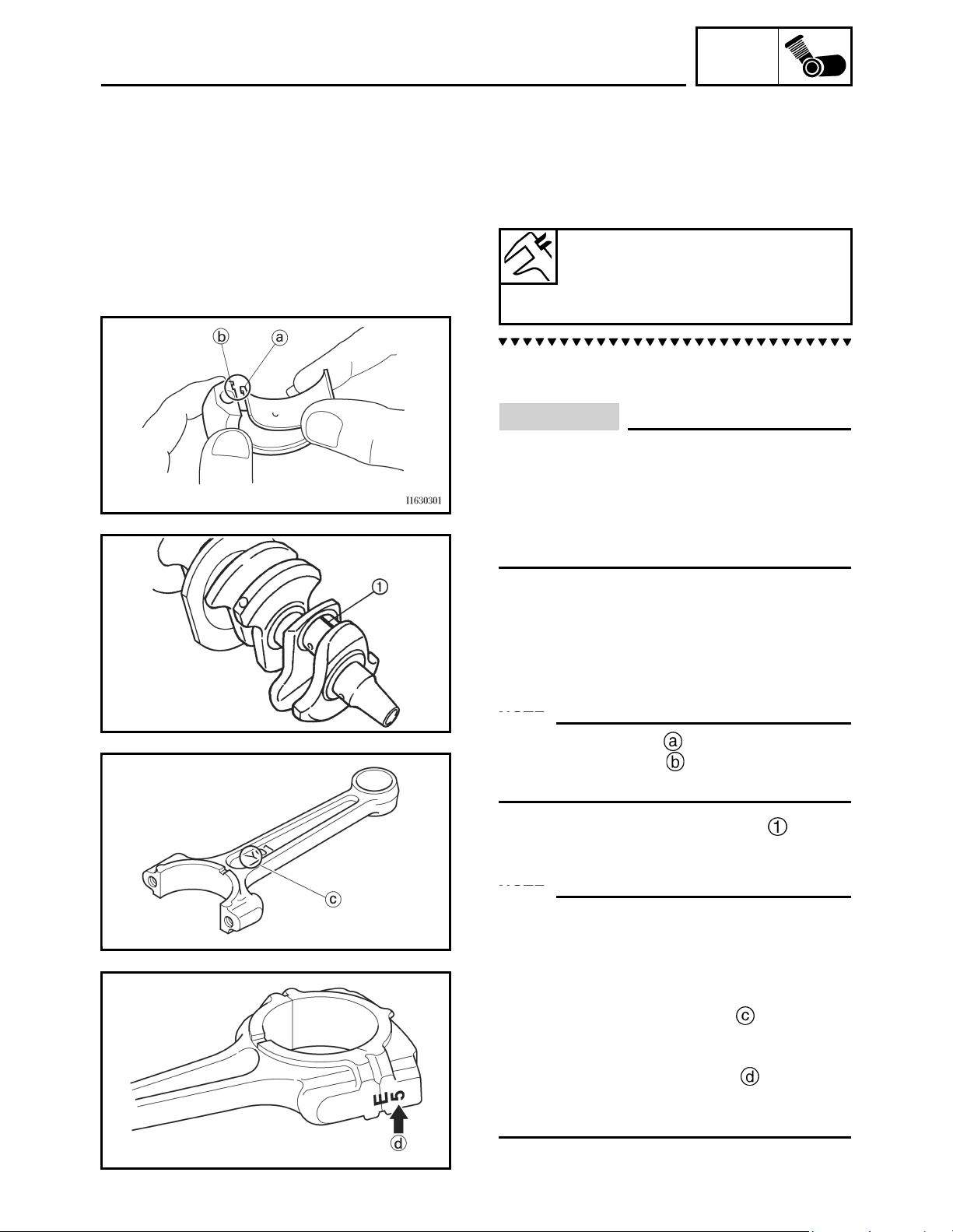

CONNECTING RODS AND PISTONS

CHECKING THE BIG END BEARINGS

1. Measure:

• crankshaft-pin-to-big-end-bearing clearance

Out of specification → Replace the big end

bearings.

Crankshaft-pin-to-big-end-bearing

clearance

0.028 ~ 0.052 mm

(0.0011 ~ 0.0020 in)

The following procedure applies to all of the

connecting rods.

CAUTION:

Do not interchange the big end bearings

and connecting rods. To obtain the correct

crankshaft-pin-to-big-end-bearing clearance and prevent engine damage, the big

end bearings must be installed in their original positions.

ENG

a. Clean the big end bearings, crankshaft

pins, and the inside of the connecting rod

halves.

b. Install the big end upper bearing into the

connecting rod and the big end lower bearing into the connecting rod cap.

NOTE:NOTE:

Align the projections on the big end bearings with the notches in the connecting rod

and connecting rod cap.

®

c. Put a piece of Plastigauge

crankshaft pin.

d. Assemble the connecting rod halves.

NOTE:NOTE:

• Do not move the connecting rod or crankshaft

until the clearance measurement has been

completed.

• Lubricate the bolt threads and seats with

molybdenum disulfide grease.

• Make sure that the “Y” mark on the connecting rod faces towards the left side of the

crankshaft.

• Make sure that the characters on both the

connecting rod and connecting rod cap are

aligned.

on the

20

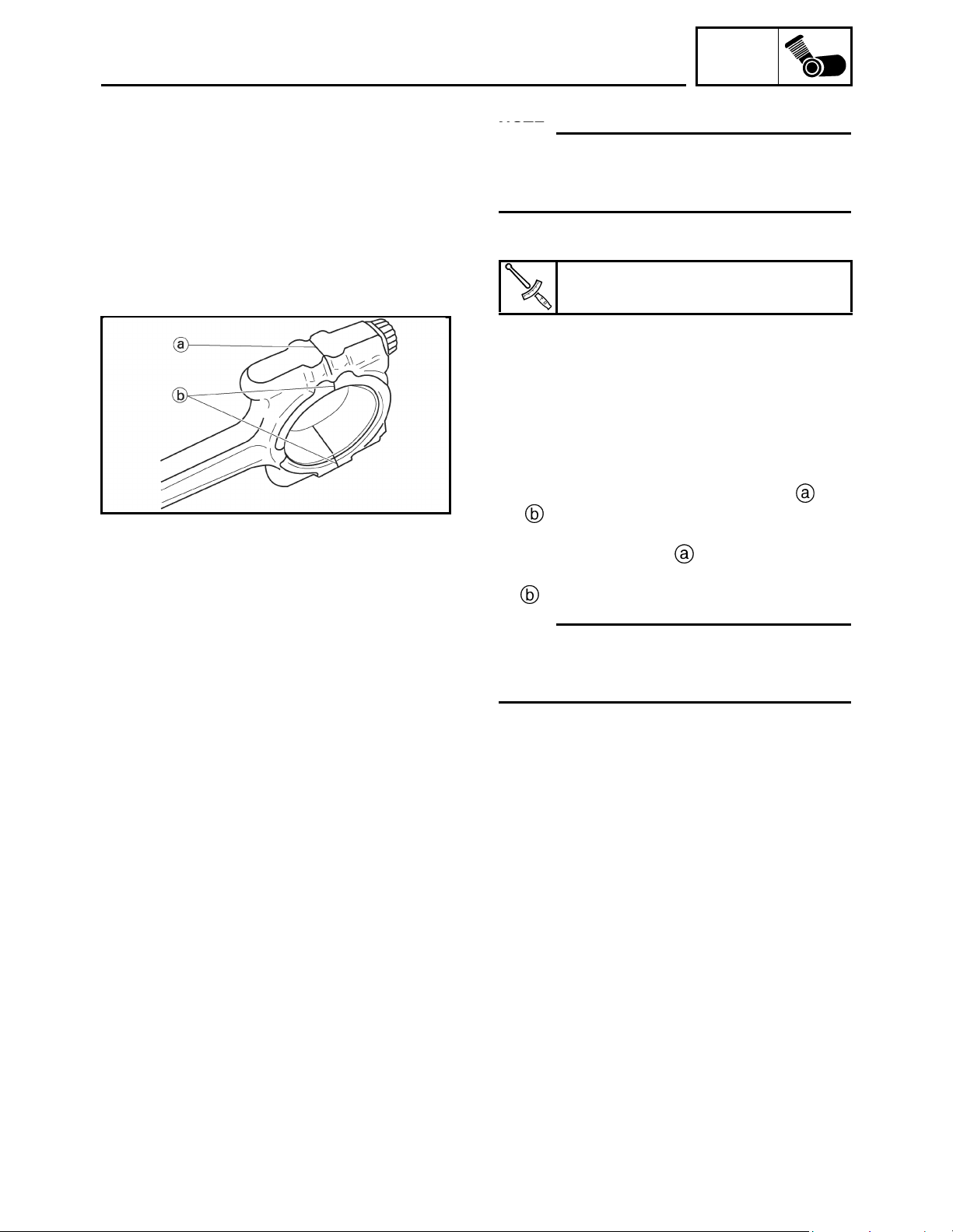

CONNECTING RODS AND PISTONS

e. Tighten the connecting rod bolts.

NOTE:NOTE:

Install by carrying out the following procedures

in order to assemble in the most suitable condition.

• connecting rod bolts

Connecting rod bolt

24.5 Nm (2.5 m•kg, 17.7 ft•lb)

f. Replace the connecting rod bolts with new

ones.

g. Clean the connecting rod bolts.

h. After installing the big end bearing, assem-

ble the connecting rod and connecting rod

cap once using a single unit of the connect-

ing rod.

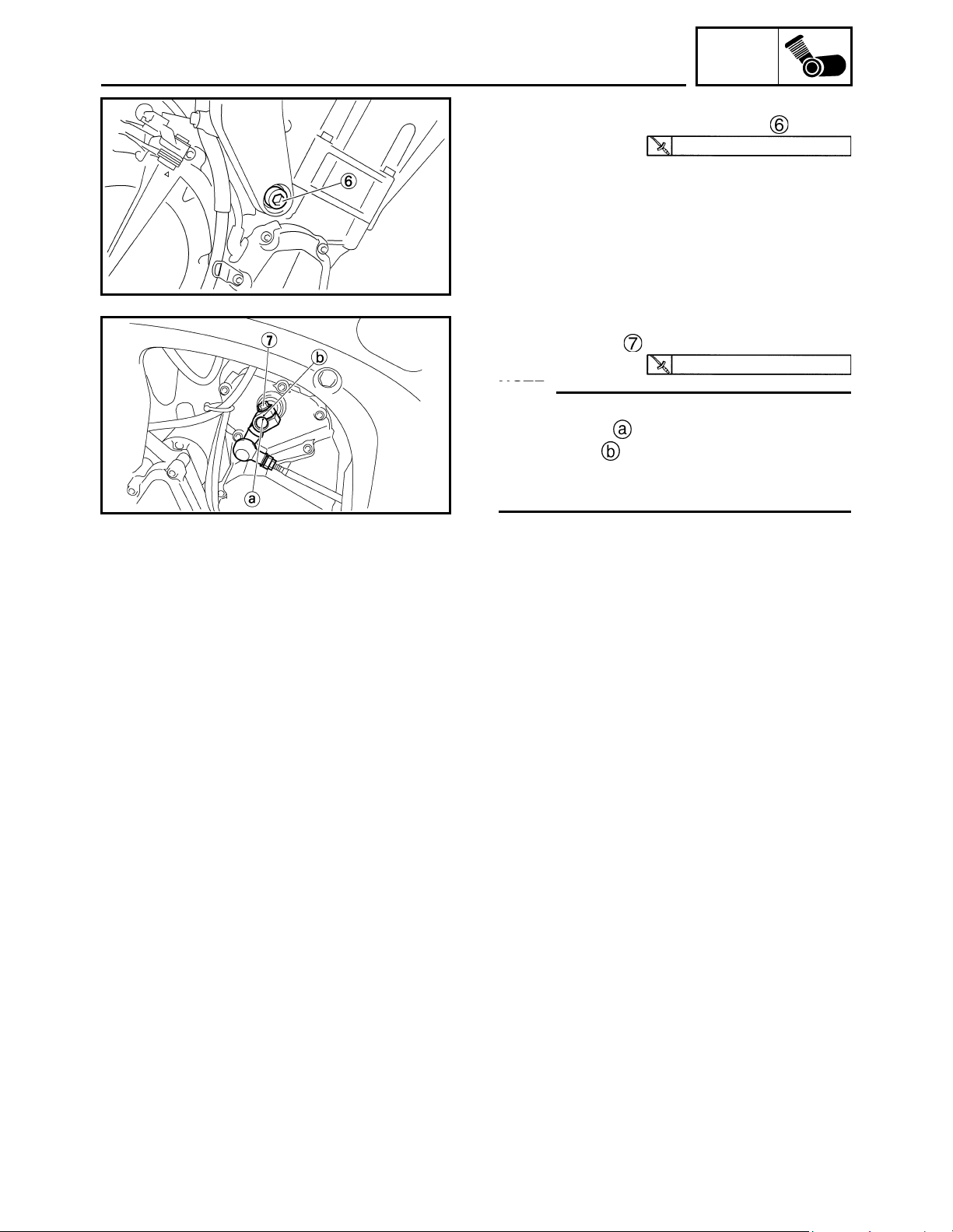

i. Tighten the connecting rod bolt while

checking that the sections shown and

are flush with each other by touching

the surface.

• Side machined face

• Thrusting faces (4 places at front and rear)

ENG

NOTE:NOTE:

To install the big end bearing, care should be

taken not to install it at an angle and the position should not be out of alignment.

j. Loosen the connecting rod bolt, remove the

connecting rod and connecting rod cap and

install these parts to the crankshaft with the

big end bearing kept in the current condi-

tion.

21

CONNECTING RODS AND PISTONS

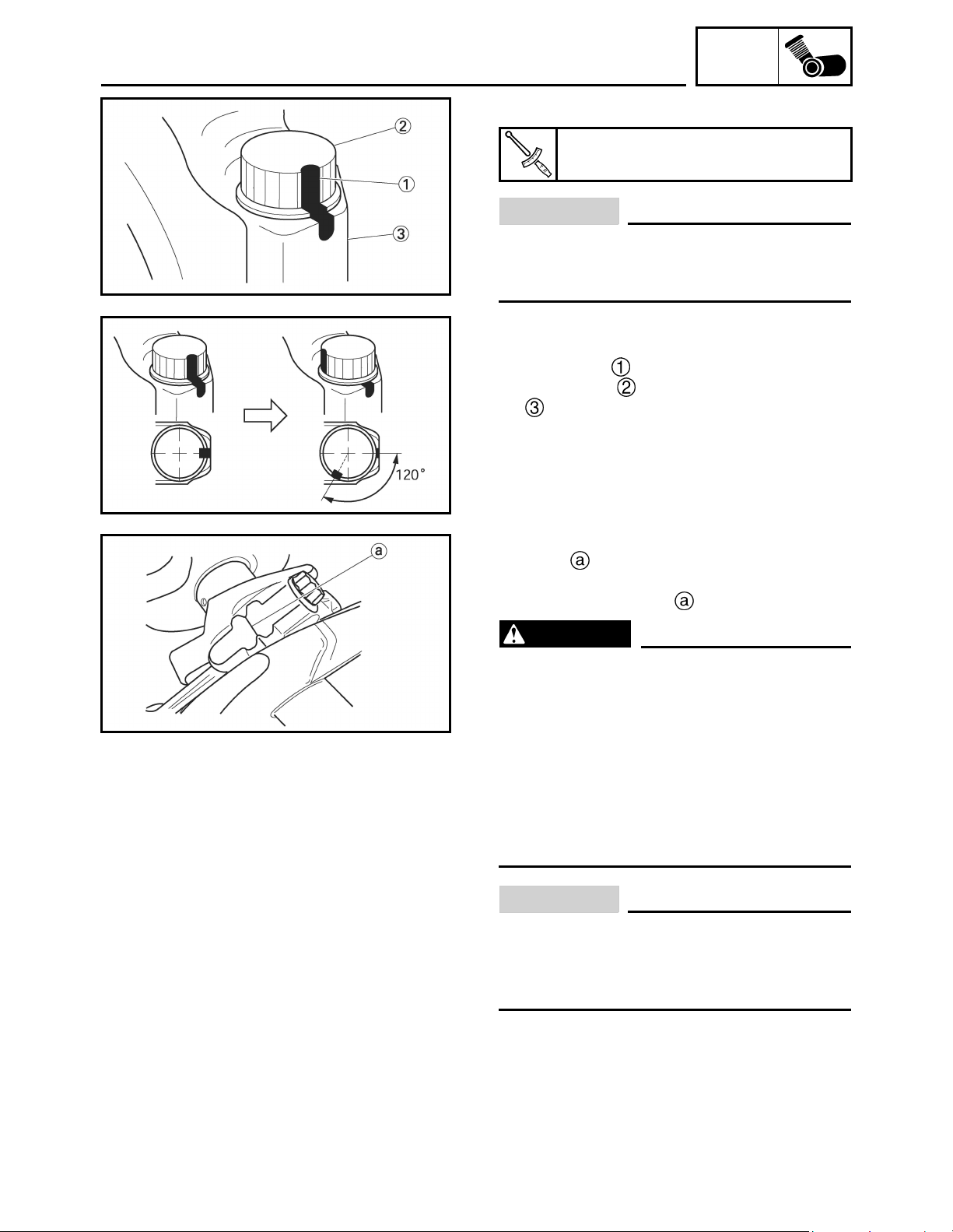

k. Tighten the connecting rod bolts.

Connecting rod bolt

15 Nm (1.5 m•kg, 11 ft•lb) + 120°

CAUTION:

Tighten the connecting rod bolts using the

plastic-region tightening angle method.

Always install new bolts.

l. Clean the connecting rod bolts.

m. Tighten the connecting rod bolts.

n. Put a mark on the corner of the connect-

ing rod bolt and the connecting rod cap

o. Tighten the bolt further to reach the speci-

fied angle (120°).

ENG

p. After the installation, check that the section

show is flush with each other by touch-

ing the surface.

• Side machined face

WARNING

• When the bolt is tightened more than the

specified angle, do not loosen the bolt and

then retighten it.

Replace the bolt with a new one and perform the procedure again.

• If they are not flush with each other,

remove the connecting rod bolt and big

end bearing and restart from step "e". In

this case, make sure to replace the connecting rod bolt.

CAUTION:

• Do not use a torque wrench to tighten the

nut to the specified angle.

• Tighten the bolt until it is at the specified

angles.

22

CONNECTING RODS AND PISTONS

q. Remove the connecting rod and big end

bearings.

Refer to "REMOVING THE CONNECTING

RODS AND PISTONS".

r. Measure the compressed Plastigauge

width on the crankshaft pin.

If the crankshaft-pin-to-big-end-bearing

clearance is out of specification, select

replacement big end bearings.

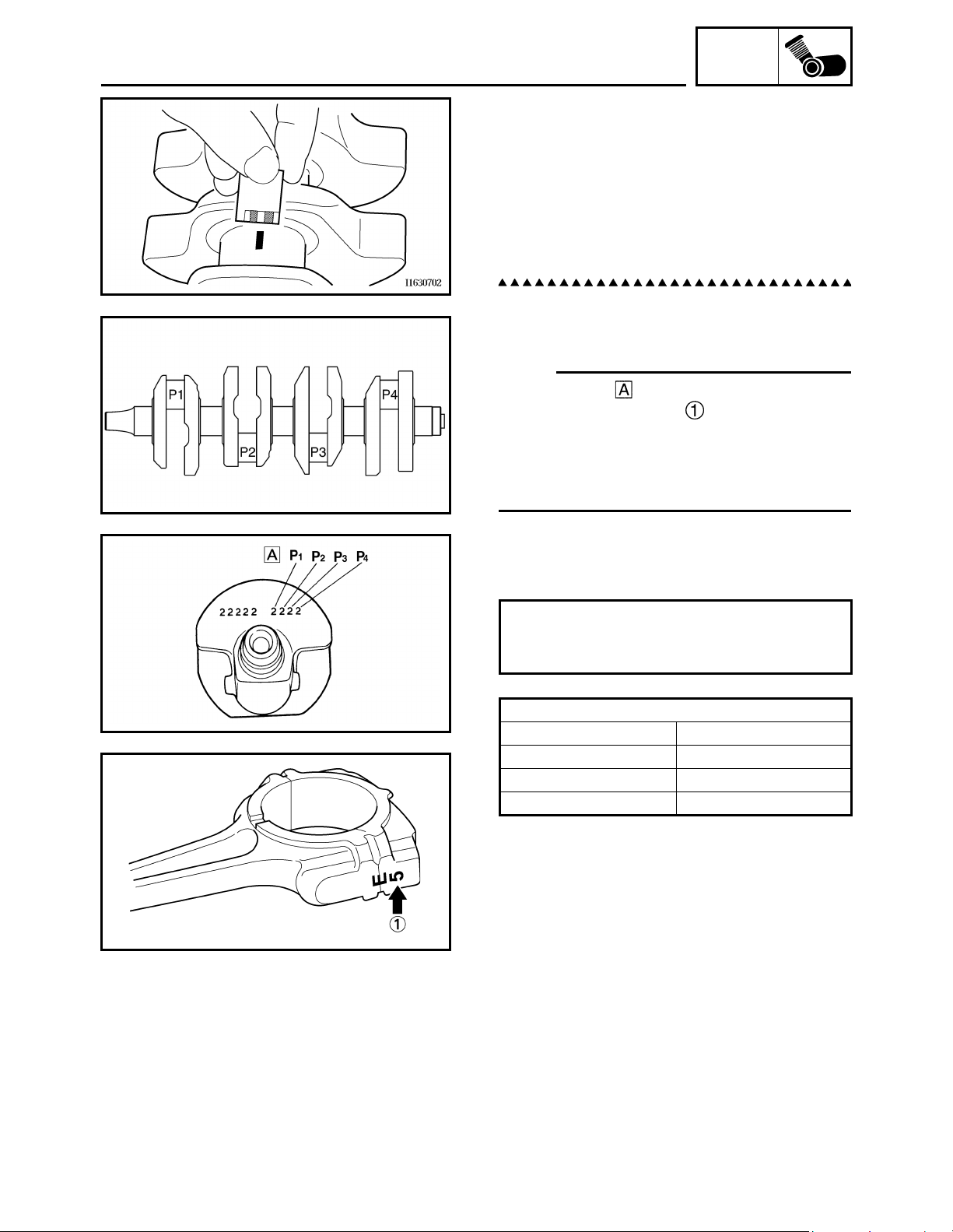

2. Select:

• big end bearings (P1 ~ P4)

NOTE:NOTE:

• The numbers stamped into the crankshaft

web and the numbers on the connecting

rods are used to determine the replacement

big end bearing sizes.

• “P1” ~ “P4” refer to the bearings shown in the

crankshaft illustration.

ENG

®

For example, if the connecting rod “P

crankshaft web “P

respectively, then the bearing size for “P

“P1” (connecting rod) – “P1”

(crankshaft) =

5 – 2 = 3 (brown)

BIG END BEARING COLOR CODE

1Blue

2Black

3Brown

4 Green

” numbers are “5” and "2"

1

” and the

1

1

” is:

23

CONNECTING RODS AND PISTONS

INSTALLING THE CONNECTING ROD AND

PISTON

The following procedure applies to all of the

connecting rods and pistons.

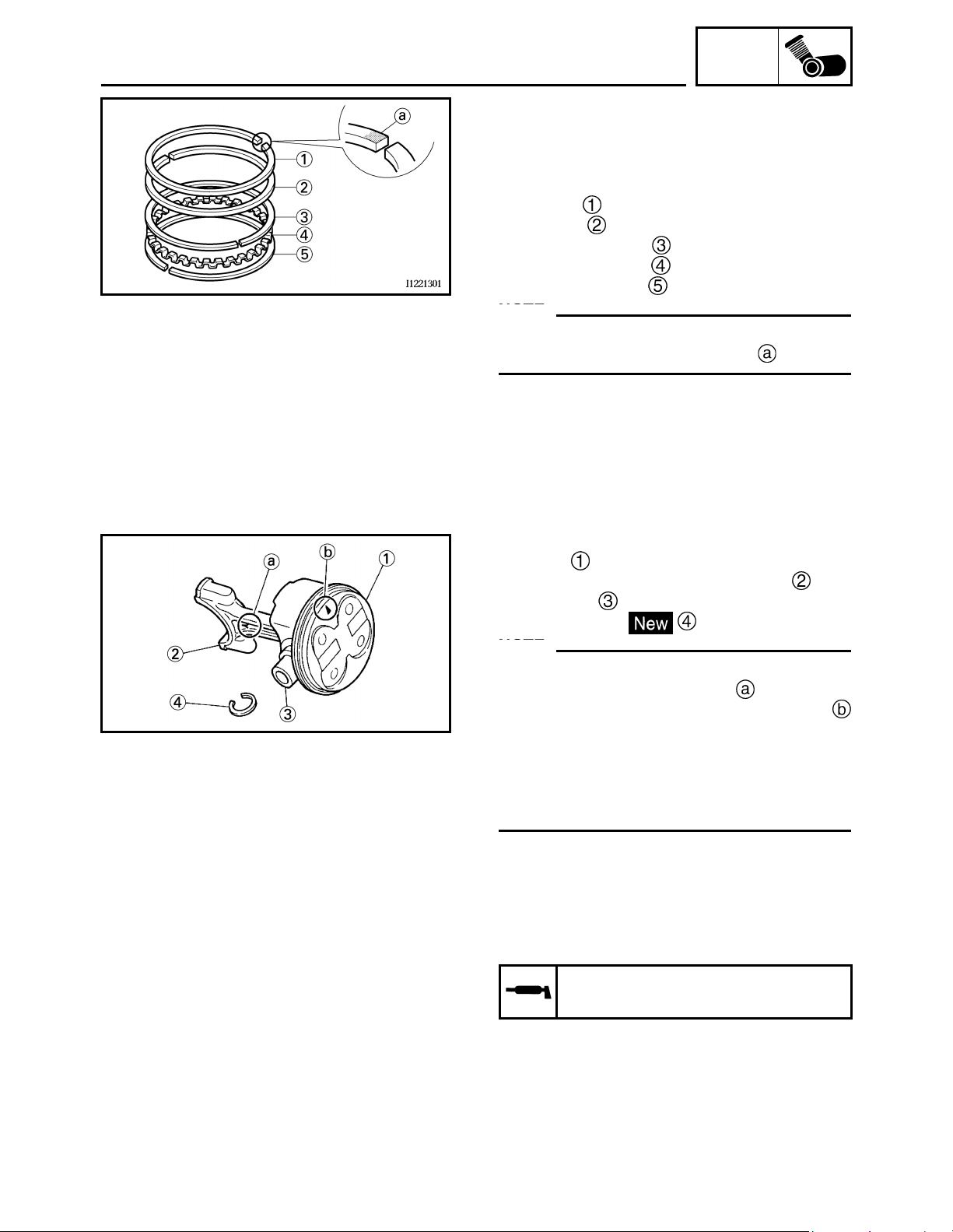

1. Install:

• top ring

• 2nd ring

• upper oil ring rail

• oil ring expander

• lower oil ring rail

NOTE:NOTE:

Be sure to install the piston rings so that the

manufacturer's marks or numbers face up.

ENG

2. Install:

•piston

(onto the respective connecting rod )

• piston pin

• piston pin clip

NOTE:NOTE:

• Apply engine oil onto the piston pin.

• Make sure that the “Y” mark on the connecting rod faces left when the arrow mark

on the piston is pointing up. Refer to the illustration.

• Reinstall each piston into its original cylinder

(numbering order starting from the left: #1 to

#4).

3. Lubricate:

•piston

• piston rings

• cylinder

(with the recommended lubricant)

Recommended lubricant

Engine oil

24

Loading...

Loading...