Page 1

(Starter Motor & Disc Brake)

5P41

OWNER'S MANUAL

5P4-E8199-E0

PRINTED IN INDIA

5P41- FAZER

2Y16(OM-01)-234-10-05

Starter Motor & Disc BrakeStarter Motor & Disc Brake

Page 2

WARNING

PLEASE READ THISMANUAL CAREFULLYAND COMPLETELYBEFORE OPERATING THIS MOTORCYCLE.

OWNER'S MANUAL

YAMAHA MOTOR INDIA PVT. LIMITED

All rights reserved. Any reprinting or

unauthorised use without the written

permission of

YAMAHA MOTOR LIMITED is

expressly prohibited.

INDIA PVT.

TAKE NECESSARY PRECAUTIONS DURING RUNNING-IN PERIOD.

Page 3

INTRODUCTION

Congratulations on your purchase of the FAZER. This motorcycle has been produced using the latest technology

in our modern plant, to provide you a happy, enjoyable and safe riding for many thousand kilometers and years. It

represents the high degree of craftsmanship and reliability that have made YAMAHA a leader in these fields.

This Owner's Manual will give you an understanding of the operation, inspection and basic maintenance of this

Motorcycle. To ensure a long trouble free performance, please take due care and ensure proper maintenance of

your Motorcycle as recommended in this Owner's Manual. Always demand only YAMAHA Genuine Spare Parts

and Yamalube oil. If you have any queries regarding the operation or maintenance of your Motorcycle, please

consult your YAMAHA DEALER who will be too happy to help you.

This Owner's Manual also includes the GREEN BOOK containing Guidelines, DO's and DON'Ts to be followed by

the Owner/ User of the Motorcycle for keeping Environment Clean and Green. You are requested to please read

the GREEN BOOK carefully.

We Provide

At Your Caring Service,

YAMAHA MOTOR INDIA PVT. LTD.

19/6, Mathura Road,

Faridabad-121006 (India)

fazer5p41.pmd 10/1/2005, 12:57 PM1

Page 4

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION ! BECOME ALERT ! YOUR SAFETY

IS INVOLVED !

Failure to follow WARNING instructions could result in severe injury to the

Motorcycle operator, a bystander or a person inspecting or repairing the Motorcycle.

CAUTION :

NOTE :

fazer5p41.pmd 10/1/2005, 12:57 PM2

A CAUTION indicates special precautions that must be taken to avoid damage to

the Motorcycle.

A NOTE provides key information to make procedures easier or clearer.

NOTE :

• This manual should be considered a permanent part of this Motorcycle and

should remain with it even if the Motorcycle is subsequently sold.

• YAMAHA continually seeks advancements in product design and quality.

Therefore, while this manual contains the most current product information

available at the time of printing, there may be minor discrepancies between

your Motorcycle and this manual. If there is any question concerning this

manual, please consult your YAMAHA dealer.

Page 5

1

ROAD SAFETY TIPS ....................................... 1-1

2

DESCRIPTION ................................................ 2-1

Left view ........................................................ 2-1

Right view ...................................................... 2-2

Controls/Instruments ................................... 2-3

3

INSTRUMENT AND CONTROL

FUNCTIONS .................................................... 3-1

Main switch cum steering lock ..................... 3-1

Speedometer ................................................ 3-2

Tachometer ................................................... 3-2

Indicator lights .............................................. 3-2

Handlebar switches/Kill Switch/ .................. 3-3

Starter Switch

Clutch lever ................................................... 3-4

Shift pedal ..................................................... 3-4

Front brake lever ........................................... 3-4

Rear brake pedal .......................................... 3-5

Fuel tank cap ................................................ 3-5

Fuel ............................................................... 3-6

Fuel cock ....................................................... 3-6

Starter Lever .................................................. 3-7

Kick starter .................................................... 3-8

TABLE OF CONTENTS

Seat ............................................................... 3-8

Storage compartment................................... 3-9

Rear shock absorber adjustment ............... 3-9

Handle Seat, Stay Lock................................. 3-10

4

PRE-OPERATION CHECKS ........................... 4-1

Pre-operation check list ............................... 4-1

5

OPERATION AND IMPORTANT RIDING

POINTS ............................................................ 5-1

Starting and warming up a

cold engine ................................................... 5-1

Starting a warm engine ................................ 5-2

Shifting .......................................................... 5-2

Tips for reducing fuel consumption ............. 5-3

Running-in .................................................... 5-3

Parking .......................................................... 5-4

6

PERIODIC MAINTENANCE AND MINOR

REPAIR ............................................................ 6-1

Tool kit ........................................................... 6-1

Preventive maintenance schedule .............. 6-3

Panel removal and installation .................... 6-5

Spark plug inspection .................................. 6-7

Engine Oil ..................................................... 6-8

fazer5p41.pmd 10/1/2005, 12:57 PM3

Page 6

TABLE OF CONTENTS

Air filter ........................................................... 6-10

Carburetor adjustment ................................. 6-11

Idle speed adjustment ................................. 6-12

Throttle cable free play adjustment ............. 6-12

Valve clearance adjustment ......................... 6-13

Tyres .............................................................. 6-13

Wheels .......................................................... 6-15

Clutch lever free play adjustment ................ 6-16

Rear brake adjustment ................................ 6-17

Brake light switch adjustment ..................... 6-17

Checking front & rear brake shoes .............. 6-18

Checking brake fluid level ............................ 6-18

Drive chain slack check ................................ 6-19

Drive chain slack adjustment ...................... 6-20

Drive chain lubrication .................................. 6-22

Cable inspection and lubrication ................. 6-22

Throttle cable and grip lubrication ............... 6-22

Brake and shift pedal lubrication ................. 6-23

Brake and clutch lever lubrication ................ 6-23

Center and sidestand lubrication ................ 6-23

Front fork inspection ..................................... 6-24

Steering inspection....................................... 6-24

Wheel bearings ............................................ 6-25

Battery ........................................................... 6-25

Fuse replacement ........................................ 6-27

Headlight bulb replacement ........................ 6-28

Turn signal and taillight bulb

replacement .................................................. 6-29

Front wheel removal ..................................... 6-29

Front wheel installation ................................ 6-30

Rear wheel removal ..................................... 6-31

Rear wheel installation ................................ 6-33

Troubleshooting ........................................... 6-33

Troubleshooting chart .................................. 6-34

7

CLEANING & STORAGE ................................. 7-1

A. Cleaning ................................................... 7-1

B. Storage ...................................................... 7-2

8

SPECIFICATIONS ........................................... 8-1

9

CUSTOMER INFORMATION ........................... 9-1

Key identification number ............................. 9-1

Frame serial number ................................... 9-1

Engine serial number .................................. 9-1

10

DETACHMENTS

Pre-delivery inspection .............................. 10-1

Installation ................................................. 10-5

GREEN BOOK

fazer5p41.pmd 10/1/2005, 12:57 PM4

Page 7

ROAD SAFETY TIPS

SAFE RIDING

1. Before riding, you should learn to ride your motorcycle properly and all the control functions should be known

to you.

2. Remember that there are no legal “rights” when it comes to survival as far as Motorcyclists are

concerned. The fact that you may be well within your rights is no guarantee that you will avoid a collision with

a bigger vehicle whose driver fails to see you. Always ride defensively and take nothing on road for granted.

3. Develop the ability to react swiftly to any unexpected road hazards or emergencies giving yourself time to

spare for appropriate response.

4. Develop the ability to get the most out of your Motorcycle, But at the same time get to know its

capabilities and limitations.

5. Right thoughtfully, planning your route well in advance.

6. Give proper Signals and use Horn and Headlights judiciously.

7. Don’t ride in another motorist’s blind spot.

8. Always make pre-ride safety checks before you start the Engine.

SAFE BRAKING

Use the basic methods of braking effectively.

1. Engine Brake : When the Throttle is released, compression backs up and acts as the Engine Brake.

If the riding condition allows, reduce speed by shifting the Gear down.

2. Front and Rear Brakes : It is important to apply equal force to the Front and Rear Brakes simultaneously.

CAUTION :

• Use Front and Rear Brakes simultaneously.

• Be sure not to disengage the clutch while braking.

• While riding downhill always use Engine as a Brake and never ride in Neutral Gear.

• While riding down hill do not switch off ignition while Engine is in gear.

fazer5p41.pmd 10/1/2005, 12:57 PM5

1-1

Page 8

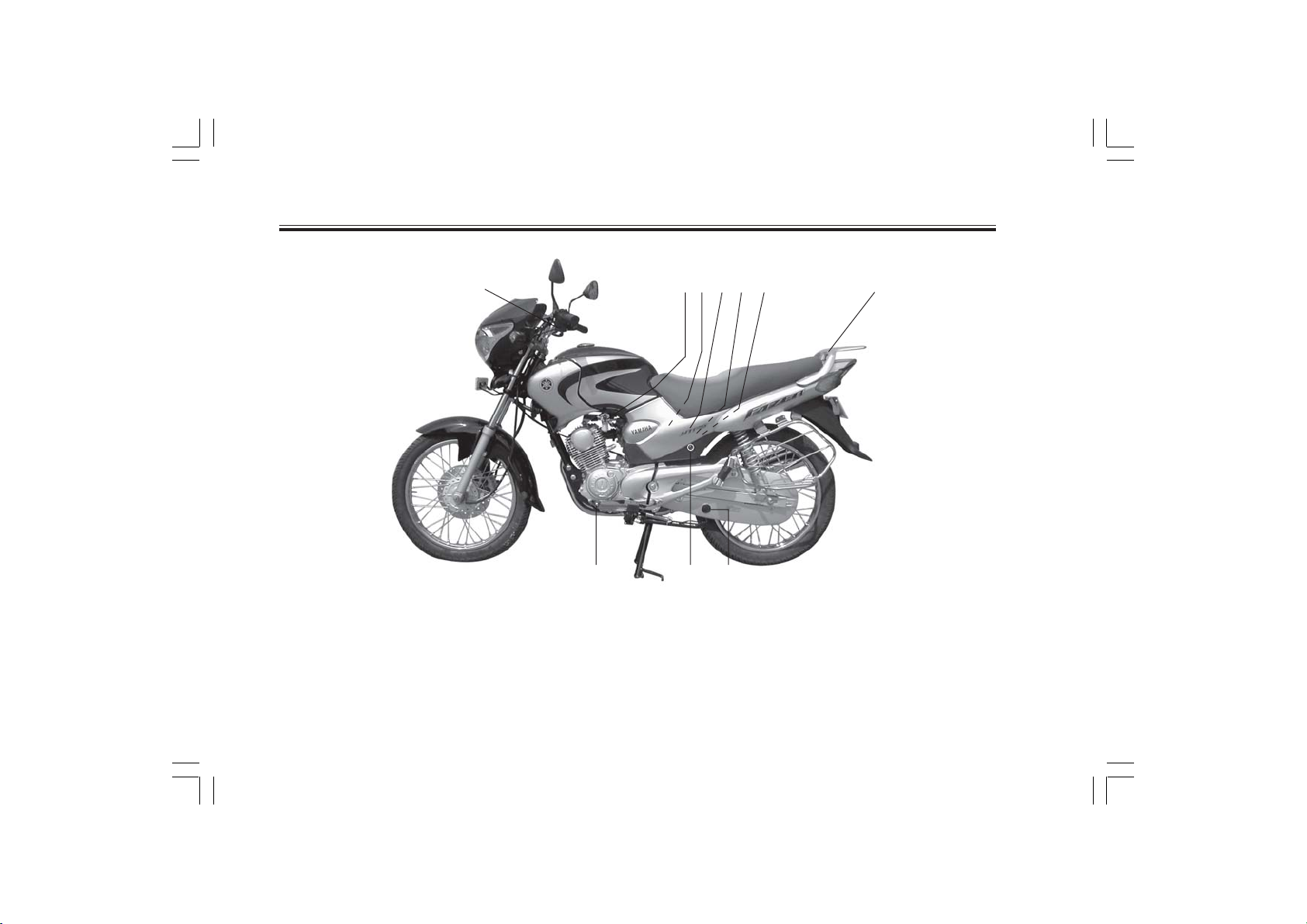

DESCRIPTION

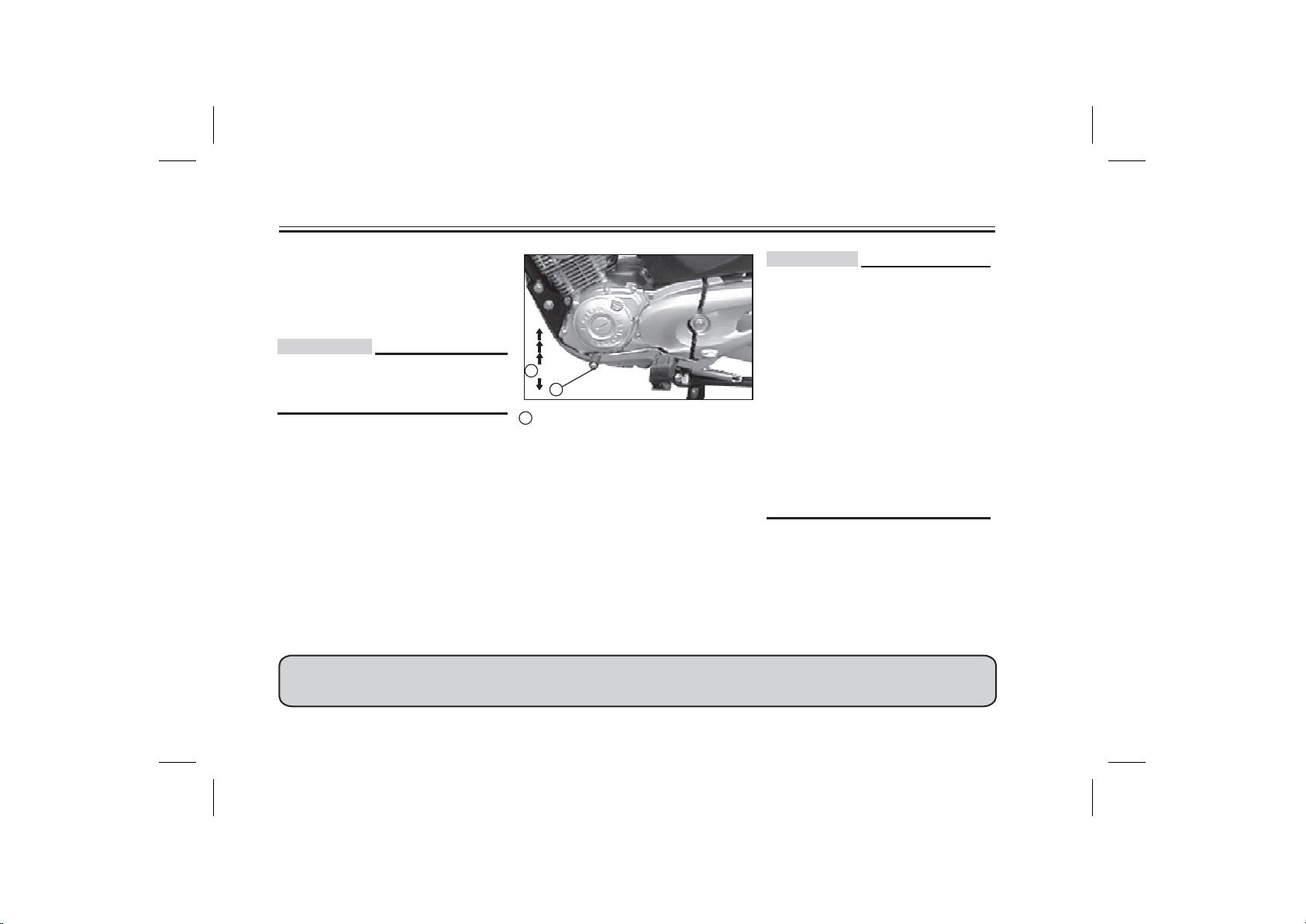

Left view

2

STANDARD VEHICLE

10

1. Fuel cock (page 3-6)

2. Starter Lever (page 3-7)

3. Fuse (page 6-27)

4. Battery (page 6-25)

5. Storage Compartment (page 3-9)

6543 7

1

89

6. Toolkit (page 6-1)

7. Handle Seat (page 3-10)

8. Drive chain free play check window (page 6-19)

9. Side panel (L.H.) lock (page 6-5)

10. Shift pedal (page 3-4)

fazer5p41.pmd 10/1/2005, 12:57 PM6

2-1

Page 9

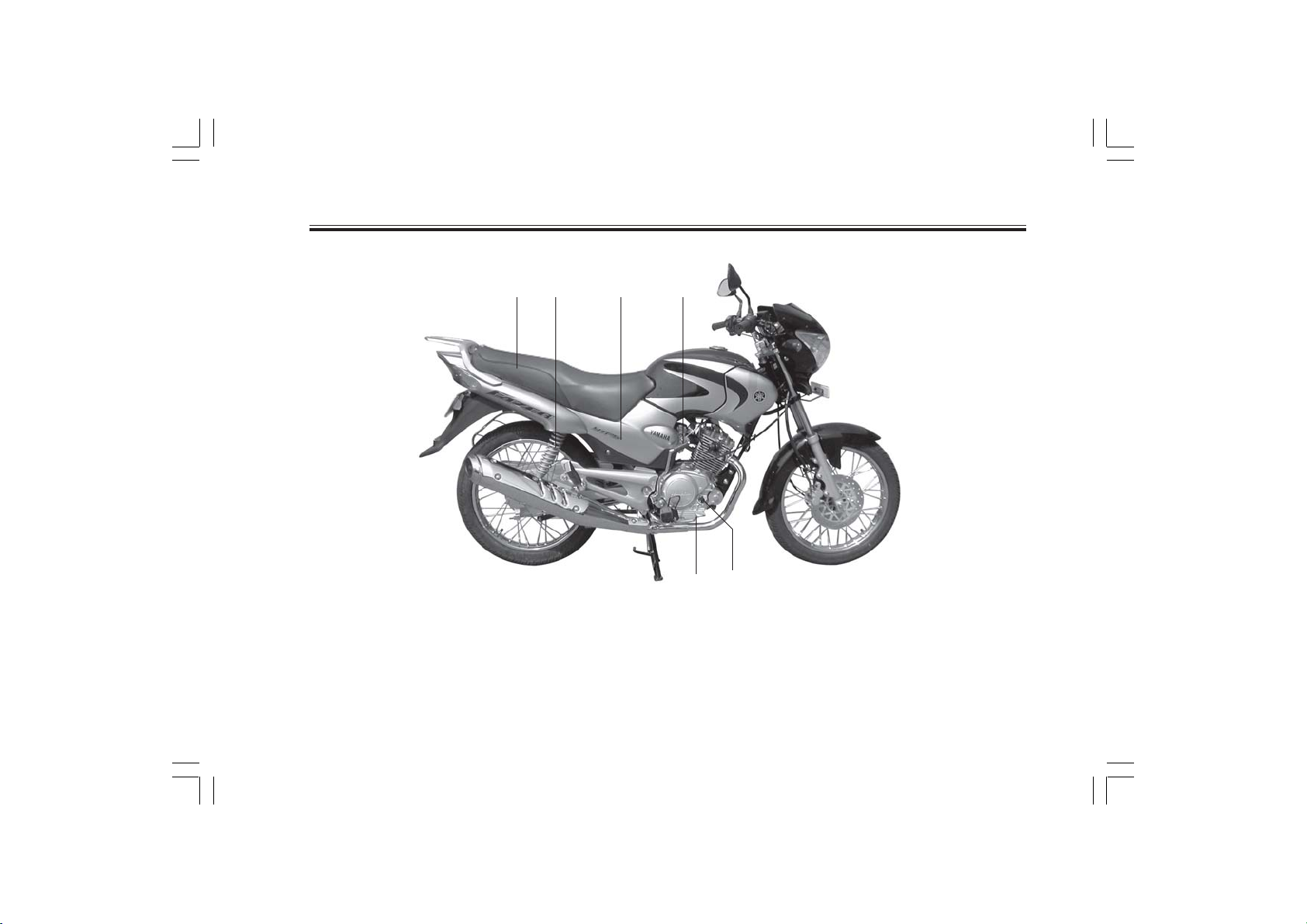

Right view

STANDARD VEHICLE

DESCRIPTION

11 12 1314

15

16

11. Rear shock absorber (page 3-9)

12. Air filter (page 6-10)

13. Kick starter (page 3-8)

fazer5p41.pmd 10/1/2005, 12:57 PM7

14. Seat (page 3-8)

15. Engine oil filler cap (page 6-8)

16. Rear brake pedal (page 3-5,6-17)

2-2

Page 10

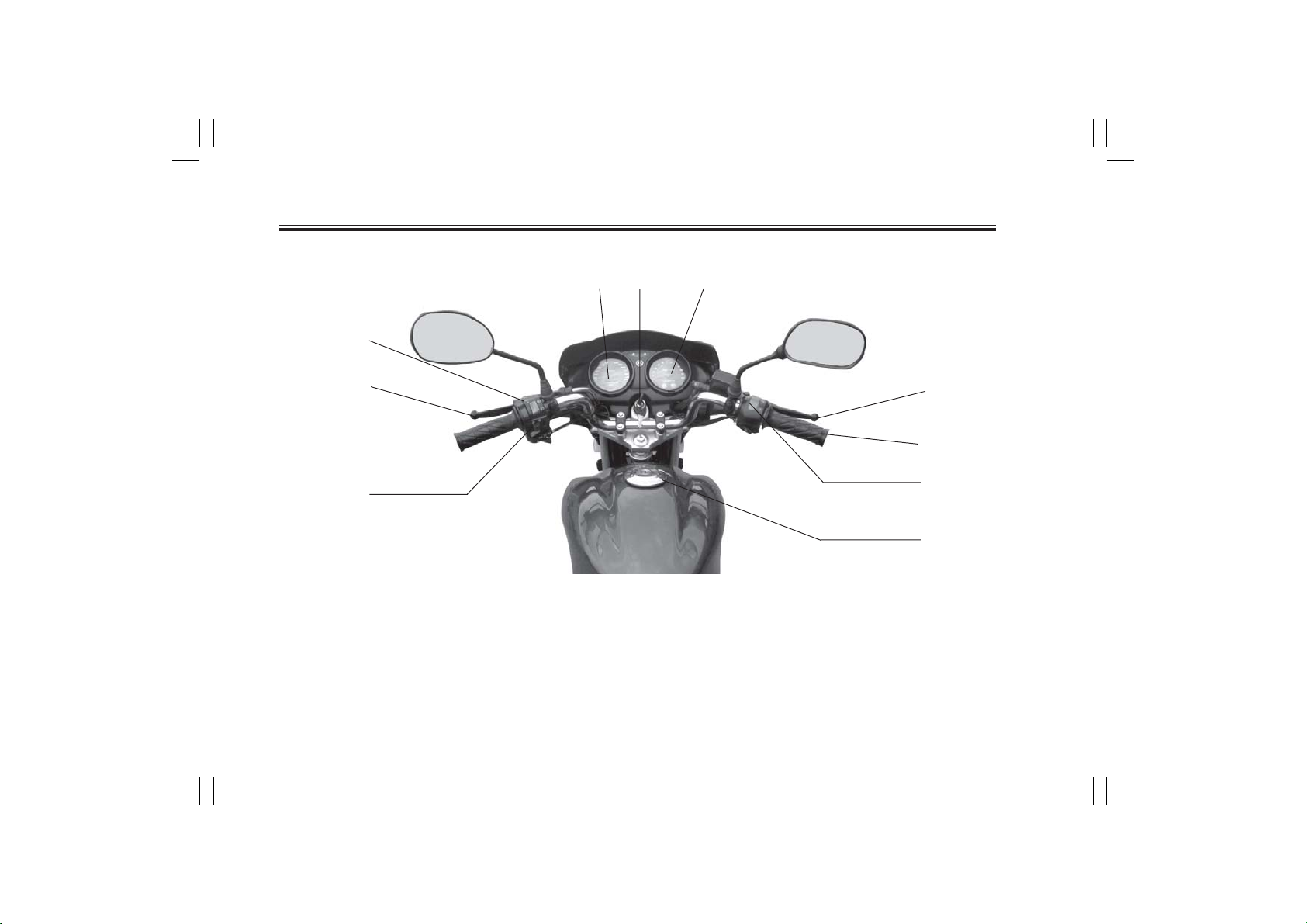

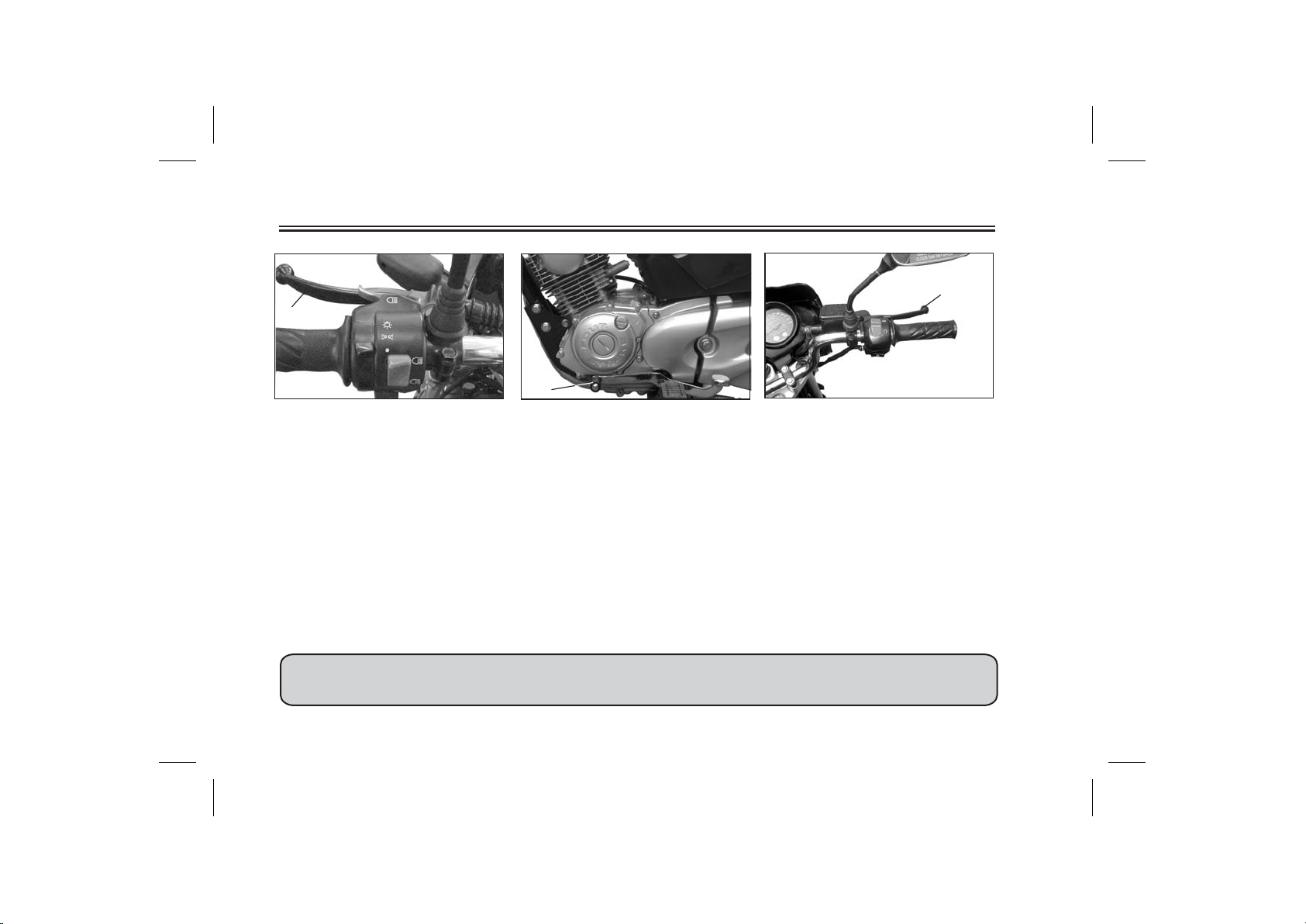

DESCRIPTION

Controls / Instruments

19 20 21

18

17

25

STANDARD VEHICLE

17. Clutch Lever (page 3-4, 6-16)

18. Left Hand Switch (page 3-3)

19. Speedometer (page 3-2)

20. Main switch Cum Steering Lock (Page 3-1)

21. Tachometer (page 3-2)

22

23

26

24

22. Front Brake Lever (page 3-4, 6-16)

23. Throttle Grip (page6-12)

24. Fuel Tank Cap (page 3-5)

25. Turn Indicator Switch (page 3-2)

26. Starter/Kill Switch (page 3-3)

fazer5p41.pmd 10/1/2005, 12:57 PM8

2-3

Page 11

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

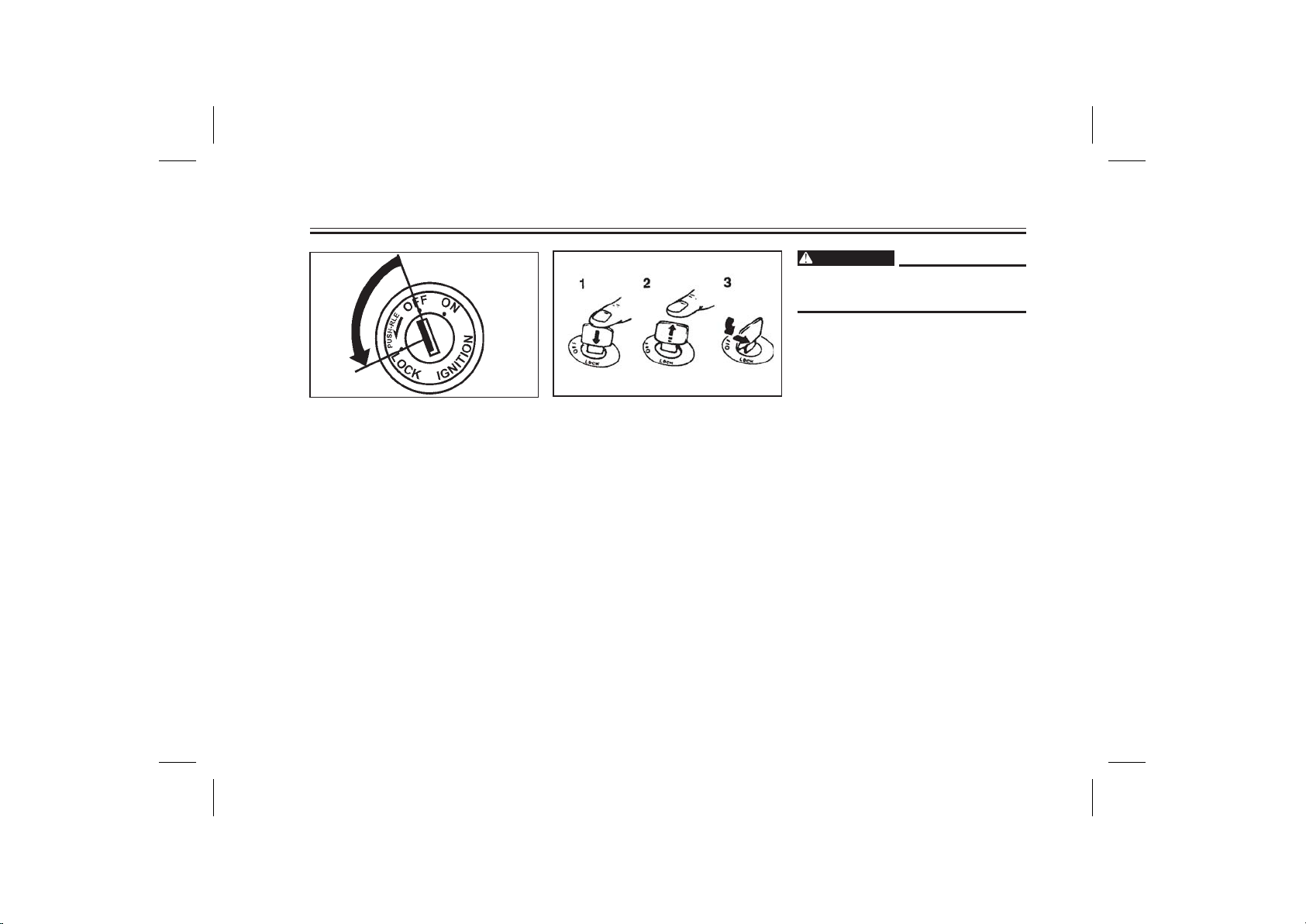

INSTRUMENT AND CONTROL FUNCTIONS

WARNING

Never turn the key to "LOCK" when

the Motorcycle is moving.

Main switch cum steering

lock

The main switch controls the ignition

and lighting systems. Its operation is

described below.

ON:

Electrical circuits are switched on.

The engine can be started. The key

cannot be removed in this position.

OFF:

Engine will be shut off. All electrical

circuits are switched off. The key can

be removed in this position.

D:\Chapt3.cdr

Saturday,October01,20051:01:01PM

1. Push

2. Release

3. Turn

LOCK:

The steering is locked in this position

and all electrical circuits are switched

off.

The key can be removed in this

position.

To lock the steering, turn the handlebars all the way to the left or right. With

the key at "OFF", push it into the main

switch and release it, turn it counterclockwise to "LOCK" and remove it.To

release the lock, turn the key to

"OFF".

3-1

1

Page 12

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

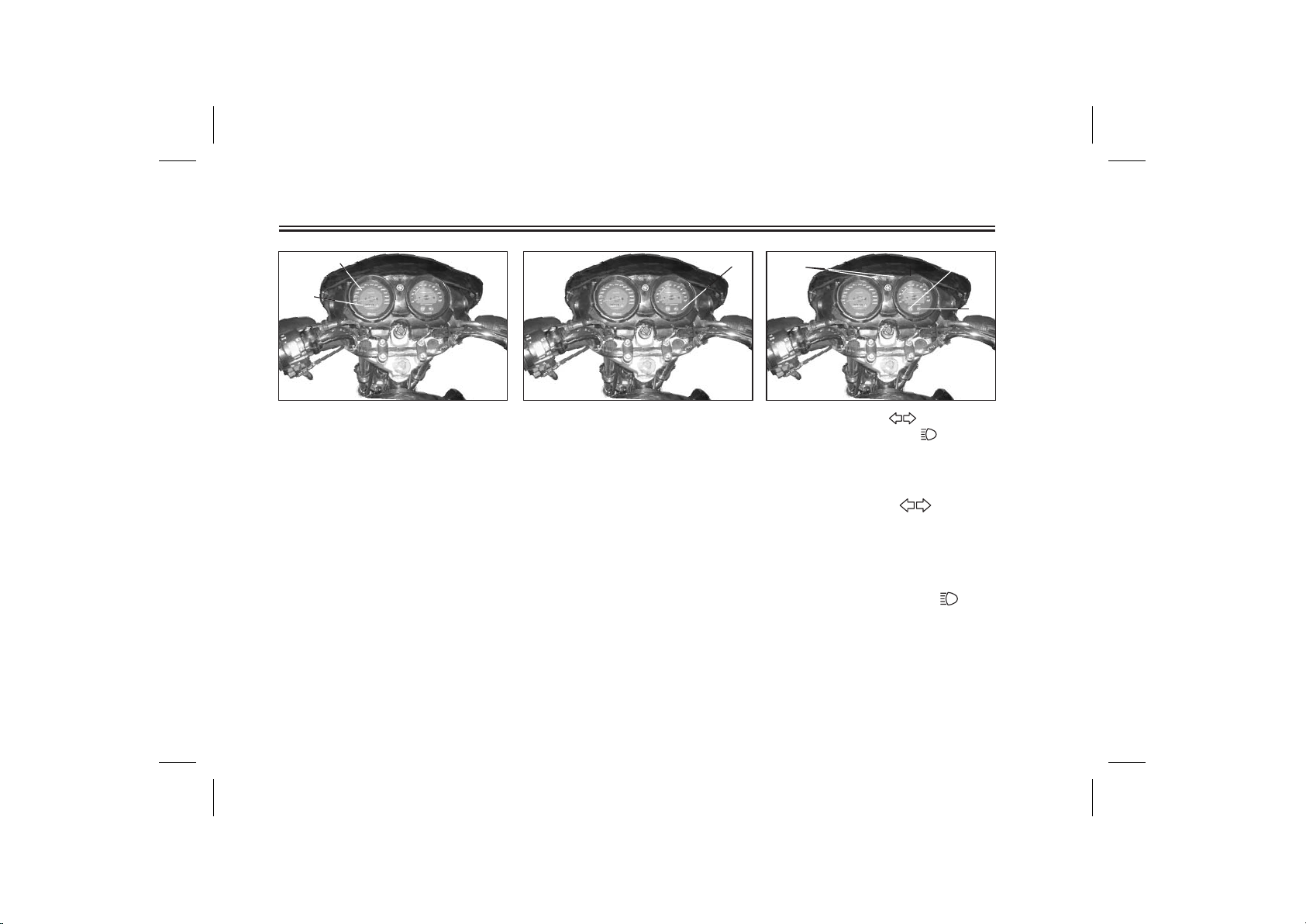

INSTRUMENT AND CONTROL FUNCTIONS

1

2

1. Speedometer

2. Odometer

Speedometer

The speedometer shows riding

speed.

This speedometer is equipped with

an odometer.

1

1. Tachometer

Tachometer

The Tachometer Indicates Engine

Speed (RPM) and is Pulse Operated.

1

3

2

1. Turn indicator light “ ”

2. High beam indicator light “ ”

3. Neutral indicator light “N”

Indicator lights

Turn indicator light " "

The indicator flashes when the turn

switch is moved to the left or right. .

Neutral indicator light "N"

This indicator comes on when the

transmission is in neutral.

High beam indicator light" "

This indicator comes on when the

headlight high beam is used.

D:\Chapt3.cdr

Saturday,October01,20051:01:01PM

3-2

2

Page 13

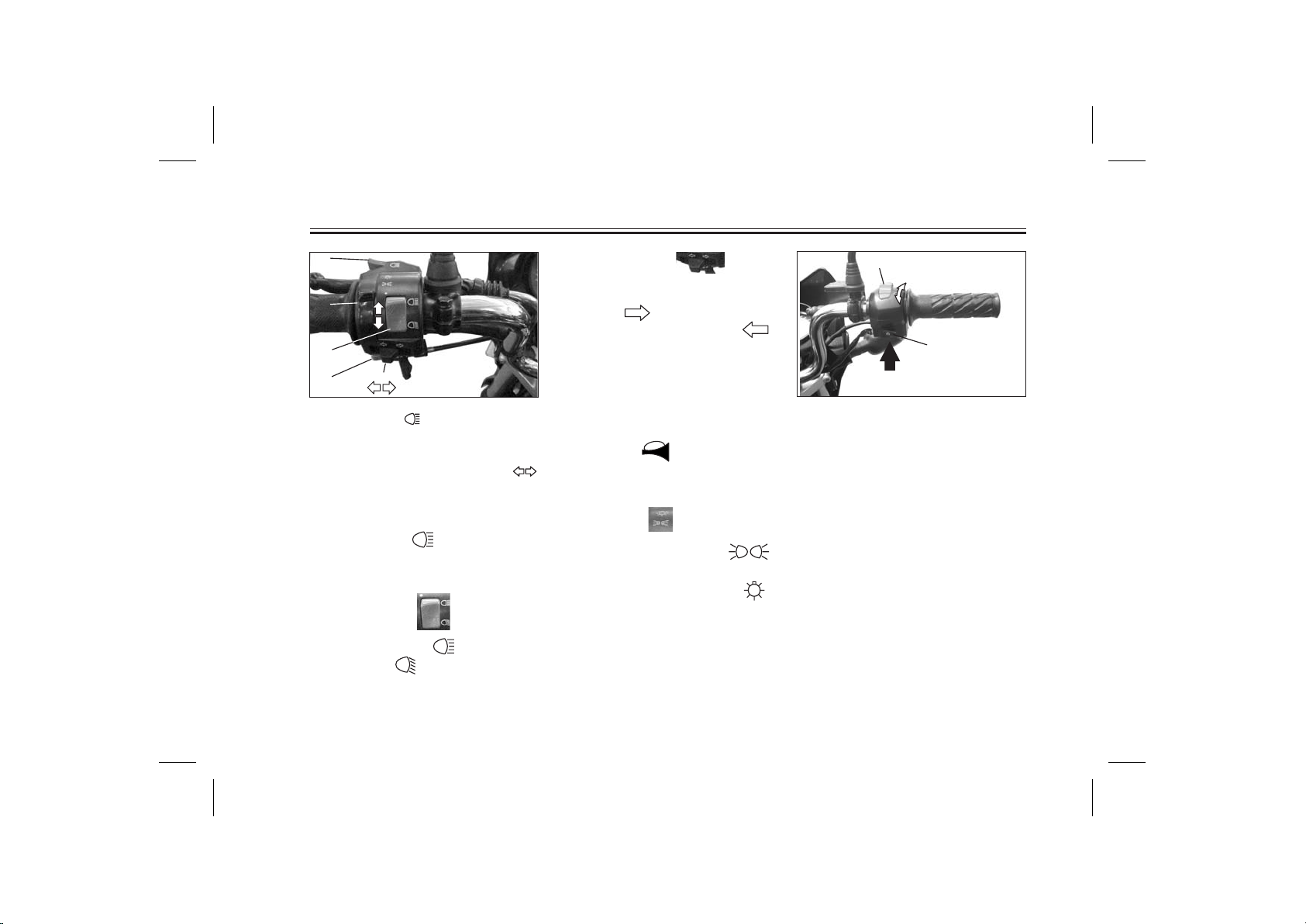

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

1

3

2

5

1. PassSwitch " "

2. Dimmer Switch

3. Light switch

4. Turn signal cum cancellation switch“ “

5. Horn switch

4

Handlebar switches

Pass switch ""

Press the switch to operate the

Passing Light.

Dimmer switch

Turn the switch to" " for the high

beam and to " " for the low beam.

Turn signal switch

To signal a right-hand turn, push the

switch to " ". To signal a lefthand turn, push the switch to " ".

Once the switch is released it will

return to the center position. To

cancel the signal, push the switch in

after it has returned to the center

position.

Horn switch " "

Press the switch to sound the horn.

Lights switch

Turning the light switch to " ",

turns on the meter light and tail-light.

Turning the light switch to “ ",

turns the headlight on also.

2

OFF

ON

1

Press

1. Starter Switch

2. Kill Switch

Starter Switch

Press the button to start the bike.

Vehicle should be in

1) Neutral Position

2) If in Gear clutch lever to be

pressed

Kill Switch

Kill switch is an emergency switch to

cut "OFF" engine & should always

be in "ON" positon at the time of

starting the vehicle.

D:\Chapt3.cdr

Saturday,October01,20051:01:01PM

3-3

3

Page 14

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

1

1

1

1

1. Clutch lever

Clutch lever

The clutch lever is located on the left

handlebar. Pull the clutch lever to

the handlebar to disengage the

clutch, and release the lever to

engage the clutch. The lever should

be pulled rapidly and released slowly

for smooth clutch operation.

D:\Chapt3.cdr

Saturday,October01,20051:01:02PM

1. Shift pedal

Shift pedal

The shift pedal is located on the left

side of the engine and is used in

combination with the clutch when

1. Front brake lever

Front brake lever

The front brake lever is located on

the right handlebar. Pull it toward the

handlebar to apply the front brake.

shifting.

Use your toe or heel to shift up and

your toe to shift down.

USE BOTH BRAKES SIMULTANEOUSLY

3-4

4

Page 15

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

NOTE :

This tank cap cannot be closed

unless the key is in the lock. The key

cannot be removed if the cap is not

locked properly.

1 Rear brake pedal

Rear brake pedal

The rear brake pedal is on the right

side of the Motorcycle. Press down on

the brake pedal to apply the rear

brake.

D:\Chapt3.cdr

Saturday,October01,20051:01:03PM

1

1

1. Open

Fuel tank cap

TO OPEN:

Insert the key and turn it 1/4 turn

clockwise. The lock will be released

and the cap can be opened.

TO CLOSE:

Push the tank cap into position with

the key inserted. To remove the key,

turn it counterclockwise to the

original position.

Ensure the arrow on fuel tank is

towards the Front of the bike when

inserting Fuel Tank Cap in Fuel

Tank.

3-5

5

WARNING

WARNING

Be sure the cap is properly

installed and locked in place

before riding the Motorcycle.

1

1. Arrow

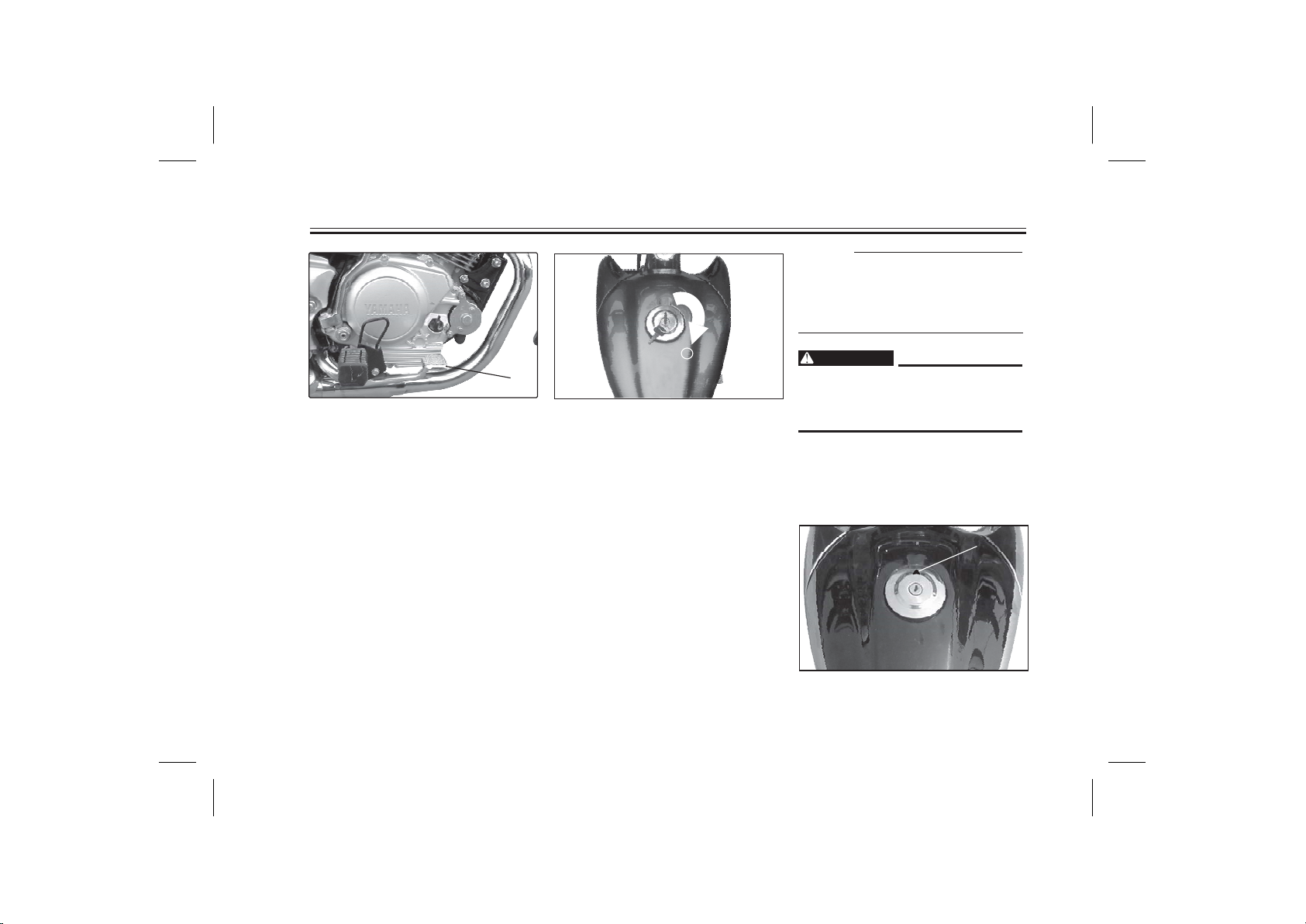

Page 16

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

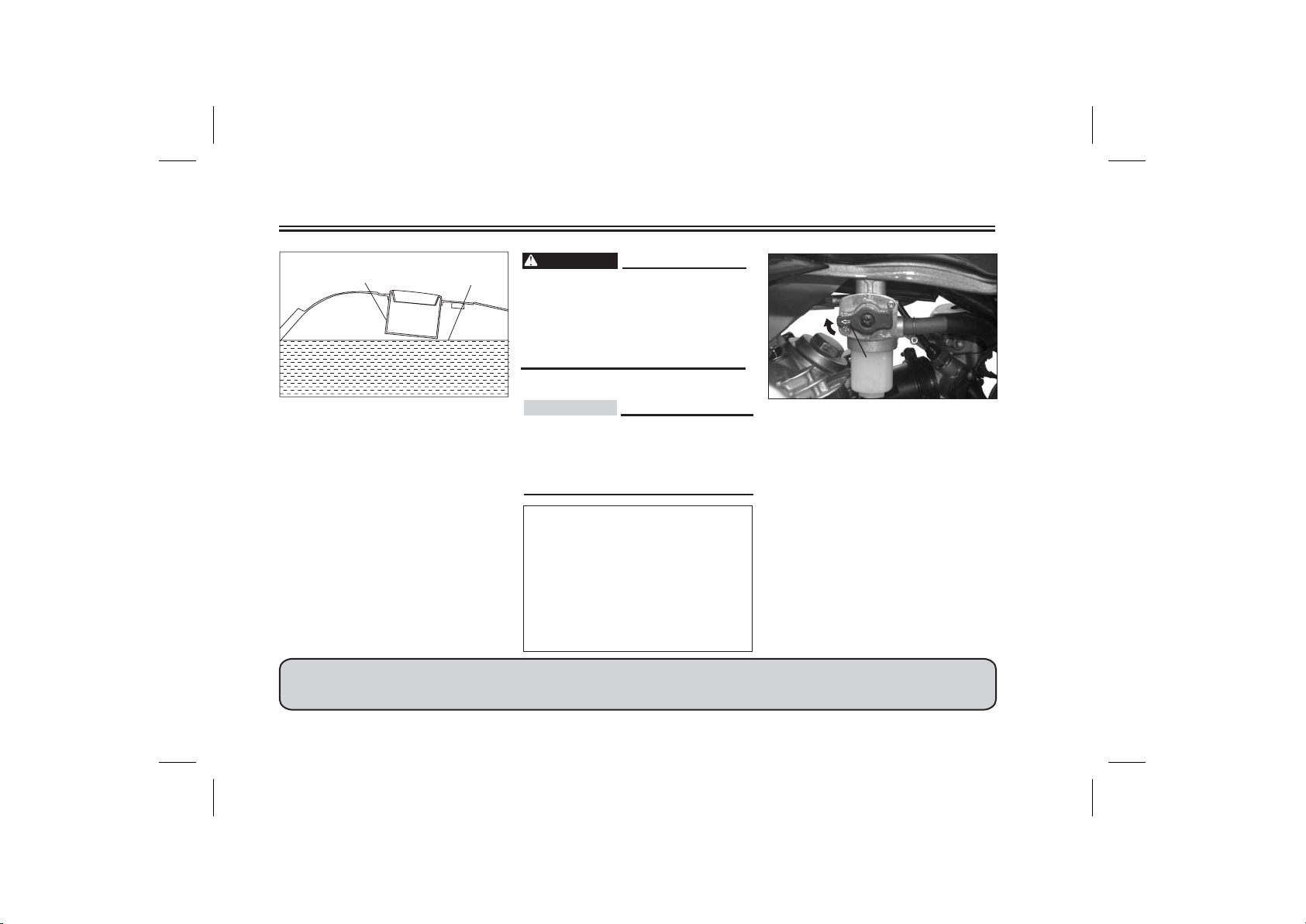

1

1. Filler tube

2. Fuel level

2

Fuel

Make sure there is sufficient fuel in the

tank. Fill the fuel tank to the bottom of

the filler tube as shown in the

illustration.

IT IS A GOOD PRACTICE TO RETURN THE FUEL COCK LEVER TO

"Off" POSITION WHEN ENGINE IS NOT RUNNING

WARNING

Do not overfill the fuel tank. Avoid

spilling fuel on the hot engine. Do

not fill the fuel tank above the

bottom of the filler tube to avoid

Spillage

CAUTION :

Always wipe off spilled fuel

immediately with a dry and clean

soft cloth. Fuel may deteriorate

painted surfaces or plastic parts.

Recommended Fuel :

Regular gasoline (Petrol)

Fuel tank capacity :

Total :

13.0 L

Reserve :

1.2 L

OFF

1

1. Arrow mark

Fuel cock

The fuel cock supplies fuel from the

tank to the carburetor while filtering it

also.

The fuel cock has three positions,

which should be set as shown in the

illustrations.

OFF: With the fuel cock in this

position, fuel will not flow.

Always set the fuel cock to this

position when the engine is not

running.

D:\Chapt3.cdr

Saturday,October01,20051:01:04PM

3-6

6

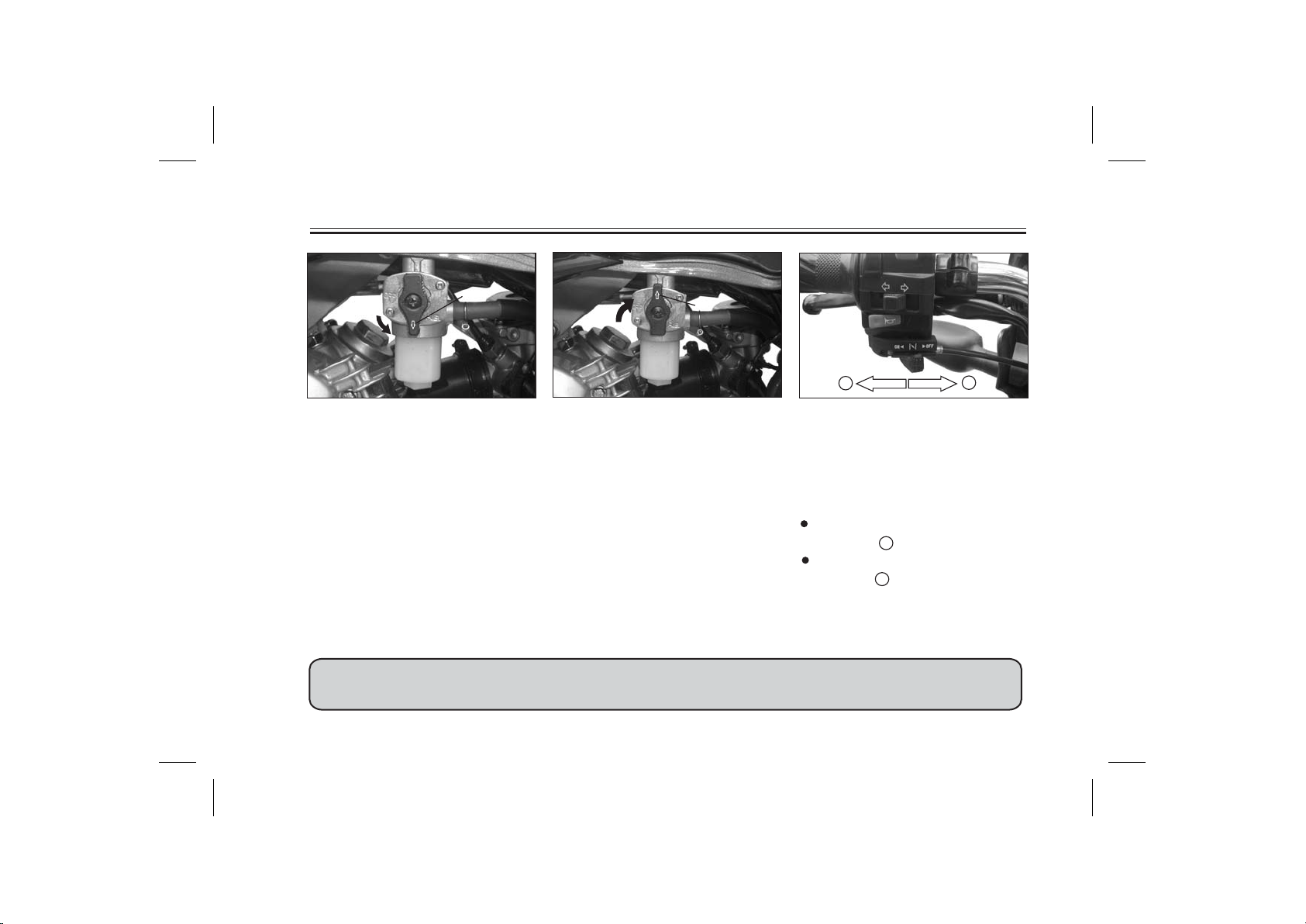

Page 17

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

1

ON

1. Arrow mark

ON: With the fuel cock in this

position, fuel flows to the

carburettor. Set the fuel cock to

this position when starting the

engine and while riding.

RES

1. Arrow mark

1

RES: This indicates reserve. If you

run out of fuel while riding, set

the fuel cock to this position.

Fill the tank at the first

opportunity. Be sure to set the

fuel cock back to "ON" after

refueling

NEVER MIX OIL IN PETROL

3-7

a

1. Starter lever

b

Starter lever

Starting a cold engine requires a

richer air-fuel mixture. A separate

starter circuit supplies this mixture.

Move the Starter Lever in

Direction a to Turn on theStarter

Move the Starter Lever in

Direction b to TurnOff the Starter

D:\Chapt3.cdr

Saturday,October01,20051:01:04PM

7

Page 18

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

2

1

1. Kick starter

Kick-starter

Raise the right Pillion footrest, and

rotate the kick starter away from the

engine. Push the starter down

lightly with your foot Kick until the

gears engage, then kick smoothly and

forcefully to start the engine. This

model has a primary-coupled kick

starter so the engine can be started in

any gear if the clutch is disengaged.

However, shifting to neutral before

starting is recommended.

D:\Chapt3.cdr

Saturday,October01,20051:01:05PM

1. Seat Holder

2. Projection

To install

Insert the projection on the rear of

seat in to seat holder. Then push

down on front of the seat and tighten

the bolts on the left and right hand

side of the seat.

kick

1. Open (Bolt - 1 No.)

2. Open (Bolt - 1 No.)

Opening of Seat

To remove

Open side panels as per instructions

on page 6-5.

Remove the two bolts 1 and 2 as

shown in figure. Lift the front of the

seat and slide forward to remove.

ALWAYS USE A HELMET WHILE RIDING FOR YOUR SAFETY

3-8

8

1

Page 19

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

1

1. Storage compartment

Storage compartment

The storage compartment is located

inside the L.H. Side Cover

INSTRUMENT AND CONTROL FUNCTIONS

1

b

2

a

1. Spring preload adjusting ring

2. Position indicator

Rear shock absorber

adjustment

Each shock absorber is equipped

with a spring preload adjusting ring.

Adjust spring preload as follows.

Turn the adjusting ring in direction a

to increase spring preload and in

direction b to decrease spring

preload. Make sure that the

appropriate notch in the adjusting

ring is aligned with the position

indicator on the rear shock absorber.

Stan-

Soft

Adjusting

Position

(Depends upon rider's requirement)

12345

dard

Hard

WARNING

Always adjust each shock

absorber to the same setting.

Uneven adjustment can cause poor

handling and loss ofstability.

D:\Chapt3.cdr

Saturday,October01,20051:01:06PM

3-9

9

Page 20

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

INSTRUMENT AND CONTROL FUNCTIONS

1

1

1. HandleSeat

D:\Chapt3.cdr

Saturday,October01,20051:01:06PM

1. Stay Lock on Saree Guard

Stay Lock

For mounting Helmet Lock

3-10

10

Page 21

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

Owners are personally responsible for their vehicle's condition. Your Motorcycle's vital functions can start to

deteriorate quickly and unexpectedly- even if it remains unused (for instance, if it is exposed to the elements). Any

damage. fluid leak or loss of tyre pressure could have serious consequence Therefore' it is very important that, in

addition to a thorough visual inspection, you check the following points before each ride.

PRE-OPERATION CHECKS

PRE - OPERATION CHECK LIST

ITEM CHECKS

Front brake

Rear brake

Clutch

Throttle grip and housing

Engine oil

Drive chain

Wheels and tyres

CHAPT4_5_6.cdr

Saturday,October01,20051:02:21PM

• Check operation, condition and free play.

• Adjust if necessary.

• If necessry, add recommended brake fluid to specified level.

• If soft or spongy, have YAMAHA dealer bleed hydraulic system.

• Check fluid level in reservoir.

• Check hydraulic system for leakage.

• Check operation, condition and free play.

• Adjust if necessary.

• Check operation, condition and free play.

• Adjust if necessary.

• Check for smooth operation.

• Lubricate if necessary.

• Check oil level.

• Fill with oil if necessary.

• Check chain slack and condition.

• Lubricate if necessary.

• Adjust if necessary.

• Check tyre pressure, wear, damage and spoke tightness.

• Tighten spokes if necessary.

4-1

1

PAGE

3-4, 6-18

3-5, 6-17

3-4, 6-16

6-12, 6-22

6-8 ~ 6-9

6-19 ~ 6-20

6-13 ~ 6-15

Page 22

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PRE-OPERATION CHECKS

ITEM CHECKS

Control and meter cable

Brake and shift pedal shafts

Brake and clutch lever pivots

Center and sidestand pivot

Chassis fasteners

Fuel Tank

Lights, signals and switches

Battery

• Check for smooth operation.

• Lubricate if necessary.

• Check for smooth operation.

• Lubricate if necessary.

• Check for smooth operation.

• Lubricate if necessary.

• Check for smooth operation.

• Lubricate if necessary.

• Make sure that all nuts, bolts, and screws are properly tightened.

• Tighten if necessary.

• Check fuel level.

• Fill with fuel if necessary.

• Check for proper operation.

• Check fluid level.

• Fill with distilled water if necessary.

PAGE

6-22

6-23

6-23

6-23

-

3-5 ~ 3-6

3-3, 6-28 ~ 6-29

6-25 ~ 6-26

WARNING

If any item in the Pre-Operation Check is not working properly, have it inspected and repaired before operating

the Motorcycle.

IF WAITING AT TRAFFIC SIGNAL IS FOR LONG, SWITCH OFF THE ENGINE

TO PROTECT THE ENVIRONMENT AND TO LOWER FUEL CONSUMPTION

CHAPT4_5_6.cdr

Saturday,October01,20051:02:21PM

4-2

2

Page 23

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

OPERATION AND IMPORTANT RIDING POINTS

WARNING

1. Before riding this Motorcycle,

become thoroughly familiar

with all operating controls and

their functions. Consult a

YAMAHA dealer regarding any

control or function that you do

not thoroughly understand.

2. Never start your engine or let it

run for any length of time in a

closed area. The exhaust fumes

are poisonous and can cause

loss of consciousness.

Always operate your

Motorcycle in an area with

adequate ventilation.

3. Before starting out, always be

sure the side stand is up.

Failure to retract the side stand

completely can result in a

serious accident when you try

to turn a corner.

Starting and warming up a

cold engine

1. Turnthe fuel cock to "ON"

2. Turnthe main switch to "ON."

3. Shift the transmission into

neutral.

NOTE :

When the transmission is in neutral,

the neutral indicator light should be on.

If the light does not comeon, aska YMI

dealer to inspect it.

4 Fully open the Starter Lever and

completely close the throttle grip.

5. Kick the kick starter to start the

engine.

6. After starting the Engine, turn back

the Starter Lever to the Warmingup Position (About Half way)

7. After Warming-up the Engine,

turn off the Starter Lever

completely.

NOTE :

For better engine performance

always warm up the engine. before

take off. Never open throttle fully

when engine is cold, otherwise

engine tends to stop.

NOTE :

The engine is warm when it

responds normally to the throttle

with the Starter Lever in “OFF”

direction.

CHAPT4_5_6.cdr

Saturday,October01,20051:02:21PM

5-1

3

Page 24

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

OPERATION AND IMPORTANT RIDING POINTS

Starting a warm engine.

The Starter Lever may not be required

when the engine is warm.

CAUTION :

See the "Running-in" section prior

to operating the Motorcycle for the

first time.

NEVER RIDE MOTORCYCLE WITH CLUTCH PARTIALLY ENGAGED.

4

3

2

N

1

a

a. Shift pedal

N. Neutral, 1,2,3,4 Gear Shift Patterns

Shifting

The transmission lets you control the

amount of power you have available

at a given speed for starting,

accelerating, climbing hills, etc. The

use of the shift pedal is shown in the

illustration.

To shift into neutral, depress the shift

pedal repeatedly until it reaches the

end of its travel, then raise the pedal

slightly.

CAUTION :

• Do not ride downhill with

Ignition Switch in “OFF”

Position & in NeutralGear.

• Always ride motor cycle with

Ignition Switch in “ON”

Position & in NeutralGear.

• Always use the clutch when

changing gears. The engine,

transmission, and driveline are

not designed to withstand the

shock of forced shifting and

can be damaged by shifting

without using the clutch.

CHAPT4_5_6.cdr

Saturday,October01,20051:02:23PM

5-2

4

Page 25

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

OPERATION AND IMPORTANT RIDING POINTS

Tips for reducing fuel

consumption

Your Motorcycle's fuel consumption

depends to a large extent on your

riding style. The following tips can

help reduce fuel consumption:

1. Warmup the engine before riding.

2. Move the starter Lever to “Off” as

soon as possible.

3. Shift up swiftly and avoid high

engine speeds during

acceleration.

4. Do not double-clutch or rev the

engine while shifting down and

avoid high engine speeds with no

load on the engine.

5. Turn off the engine instead of

letting it idle for an extended

length of time, i.e. in traffic jams, at

traffic lights or rail- road crossings.

6. Do not drive with excessive load

on the Motorcycle.

7. Plan your routein advance.

8. Avoid frequent braking.

9. Always maintain your tyre

pressure as per recommendation

10. Get your motorcycle serviced

periodically after every 2000 kms.

Running-in

There is never a more important

period in the life of your Motorcycle

than the period between zero and

1,000 km. For this reason we ask that

you carefully read the following

material. Because the engine is brand

new, you must not put an excessive

load on it for the first 1,000 km. The

various parts in the engine wear and

polish themselves to the correct

operating clearances. During this

period, prolonged full throttle

operation, or any condition which

might result in excessive heating of

the engine, must be avoided.

CAUTION :

Be sure to replace the engine oil as

per recommended schedule.

1,000 km and below :

Avoid prolonged full-throttle

operation. Vary speedoccasionally.

CAUTION :

If any engine trouble should occur

during the "Running-in" period,

consult YAMAHA dealer

immediately.

CHAPT4_5_6.cdr

Saturday,October01,20051:02:23PM

5-3

5

Page 26

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

OPERATION AND IMPORTANT RIDING POINTS

Parking

When parking the Motorcycle, stop

the engine and remove the ignition

key. Turn the fuel cock to "OFF"

whenever stopping the engine.

WARNING

The exhaust system is hot. Park

the Motorcycle in a place where

pedestrians or children are not

likely to touch the Motorcycle. Do

not park the Motorcycle on a slope

or soft ground; the Motorcycle

may overturn.

CONSTANT THROTTLE OPENING FOR VERY LONG DISTANCE

CHAPT4_5_6.cdr

Saturday,October01,20051:02:23PM

IT IS NOT RECOMMENDED TO RIDE THE MOTORCYCLE WITH

5-4

6

Page 27

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Periodic inspection, adjustment and

lubrication will keep your Motorcycle

in the safest and most efficient

condition possible. Safety is an

obligation of the Motorcycle owner.

The maintenance and lubrication

schedule chart should be considered

strictly as a guide to general

maintenance and lubrication

intervals. YOU MUST TAKE INTO

CONSIDERATION THAT

WEATHER, TERRAIN,

GEOGRAPHICAL LOCATIONS,

AND A VARIETY OF INDIVIDUAL

USES ALL TEND TO DEMAND

THAT EACH OWNER ALTER THIS

TIME SCHEDULE TO SHORTER

INTERVALS TO MATCH THE

ENVIRONMENT. The most important points of Motorcycle inspection,

adjustment, and lubrication are

explained in the following pages.

WARNING

If you are not familiar with

Motorcycle service, this work

should be done by a YAMAHA

dealer.

1

1. Tool kit

Tool kit

The service information included in

this manual is intended to provide

you, the owner, with the necessary

information for completing some of

your own preventive maintenance

and minor repairs. The tools

provided in the owner's tool kit are to

assist you in the performance of

periodic maintenance. However,

some other tools such as a torque

wrench are also necessary to

perform the maintenance correctly.

CHAPT4_5_6.cdr

Saturday,October01,20051:02:24PM

6-1

7

Page 28

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

NOTE :

If you do not have necessary tools

required during a service operation,

take your Motorcycle to a YAMAHA

dealer for service.

WARNING

Modifications to this Motorcycle

not approved by YAMAHA may

cause loss of performance, and

render it unsafe for use. Consult

a YAMAHA dealer before

attempting any changes.

CHAPT4_5_6.cdr

Saturday,October01,20051:02:24PM

KEEP YOUR MOTORCYCLE TUNED IN PERFECT CONDITION

6-2

8

Page 29

Colorprofile:Disabled

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

ITEM OPERATIONSNO

VALVES

1

2

SPARK PLUG

3

CARBURETOR

1. TPS (Throttle Position Sensor)

AIR FILTER

4

*

5

FUEL LINE

FUEL FILTER

6

7

ENGINE OIL

ENGLINE OIL FILTER SCREEN

8

9

BRAKE REAR

10

BRAKE SHOES-REAR

BRAKE FLUID LEVEL

11

BRAKE DISC

12

13

BRAKE PADS

MASTER CYLINDER & CALIPER

14

15

FRONT BRAKE

PREVENTIVE MAINTENANCE SCHEDULE

Check valve clearances, adjust if necessary.

Check condition, gap;

Clean and reset if necessary.

Check idle speed, Starter lever operation.

2. BS (Butterfly Slide) Valve Screws

CAUTION :

1. Do not Tamper/Adjust with TPS(fig-1)

2. Do not Open BS(Butterfly slide) ValveScrews (fig-2)

Clean, inspect & lubricate. (replace if necessary)

Check fuel hose, for cracks or damage.

Replace if necessary.

Check for free flow of petrol, cleanliness of filter bowl,

replace if necessary.

Replace with recommended oil - Yamalube SG Grade

(Warm engine before draining)

Wash with petrol

Check operation./ Adjust if necessary.

Grease the brake cam.

Check for wear, replace if necessary.

Check Level Refill if necessary

Check for scoring marks on disc Face and Run out

Check for wear

Check for leakage

Check operation, fluid level and vehicle fluid leakage

Replace Brake Pads

DURING SERVICE DAYS OR KMS

WHICHEVE OCCURS FIRST

30 DAYS OR

500~700 KMS

90 DAYS OR

2500~2700 KMS

180 DAYS OR

4500~5000 KMS

REPLACE EVERY 10,000 km

WHENEVER WORN TO THE LIMIT

AFTER

2000 KMS

CHAPT4_5_6.cdr

Wednesday,October19,200510:32:41AM

6-3

9

Page 30

Colorprofile:Disabled

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

S.NO

16

CLUTCH

17

REAR ARM PIVOT

18

WHEELS

19

WHEEL BEARING

20

STEERING BEARING

21

FRONT FORKS

REAR SHOCK

22

ABSORBER

23

DRIVE CHAIN

NUTS, BOLTS AND

24

FASTENERS

CENTERSTAND AND

25

SIDE STAND

26

BATTERY

CONTROL CABLES

-THROTTLE

27

-CLUTCH

-FRONT BRAKE

ITEM

PREVENTIVE MAINTENANCE SCHEDULE

OPERATION

Check alignment marks on Push Lever and

Crankcase L.H. Adjust if necessary

Check Rear Arm assembly for looseness.

Tighten with specified Torque if necessary

Check runout, spoke tightness, damage;

Correct it, if necessary.

Check Bearing assembly for looseness, damage;

Replace if necessary.

Check Bearing assembly for looseness;

Correct if necessary.

Check operation/oil leakage. Repair if necessary.

Check operation/oil leakage.

Replace if necessary.

Check Chain slack, alignment. Adjust if necessary.

Clean periodically.

Check all Chassis fittings and fasteners for looseness.

Tighten as per specification.

Check operation and lubricate if necessary.

Check electrolyte level and top it up if necessary.

Check specific gravity and charge if required.

Check breather pipe for blockage and routing.

Check operation, free play, cable damage

Readjust or replace as required.

Repack grease

Repack grease

Relace oil

30 DAYS OR

500~700 KMS

DURING SERVICE DAYS OR KMS

WHICHEVE OCCURS FIRST

90 DAYS OR

2500~2700 KMS

180 DAYS OR

4500~5000 KMS

EVERY 10,000 KMS

EVERY 10,000 KM

EVERY 10,000 KM

EVERY MONTH

AFTER

2000 KMS

*

IT IS RECOMMENDED THAT THE ABOVE BE SERVICED BY AUTHORIZED YAMAHA DEALER.

*

SERVICE MORE FREQUENTLY WHEN THE VEHICLE IS DRIVEN IN DUSTY AREAS.

CHAPT4_5_6.cdr

Wednesday,October19,200510:32:42AM

6-4

10

Page 31

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

1. Panel A

Panel removal and installation

The panels illustrated need to be

removed to perform some of the

maintenance described in this

manual. Refer to this section each

time a panel has to be removed or

reinstalled.

2. Panel B

2

3

1

2

1. Lug

2. Panel A

3. Lug

Removal of Panel A

Unlock the panel.

Pull the lug 1 towards you to remove

it from the fuel tank.

Slide the panel A towards the Front

of the motorcycle for removing the

lug 3 to free the panel.

CHAPT6_A.cdr

Saturday,October01,20051:03:40PM

6-5

1

Page 32

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

1. Lug

2. Lug

3. Lug

3

Removal of Panel B

Loosen screw completely and follow

the same procedure as for

removing panel A.

2

1

1. Lug

2. Lug

Installation of Panel A

Slide the panel towards the Rear of

the motorcycle for inserting the lug

"2" in the slot given in the frame.

Insert and push the lug "1" in the

fuel tank ensuring proper seating.

After proper seating of the panel A,

lock it.

6-6

3

2

1. Lug.

2. Lug

3. Lug

1

Installation of Panel B

Follow the same procedure as given

for installation of panel A and tighten

the screw for locking.

CHAPT6_A.cdr

Saturday,October01,20051:03:40PM

2

Page 33

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

A

A. Spark plug gap

Spark plug inspection

The spark plug is an important engine

component and is easy to inspect.

The condition of the spark plug can

indicate the condition of the engine.

The ideal color on the white insulator

around the center electrode is a

medium-to-light tan color for a

Motorcycle that is being ridden

PERIODIC MAINTENANCE AND MINOR REPAIR

normally. Do not attempt to diagnose

any problems yourself. Instead, take

the Motorcycle to a YAMAHA dealer.

You should periodically remove and

inspect the spark plug because heat

and deposits will cause the spark plug

to slowly break down and erode. If

electrode erosion becomes excessive, or if carbon and other deposits

are excessive, you should replace the

spark plug with the specified plug.

Specified spark plug:

CR7HSA (NGK)

Before installing the spark plug,

measure the electrode gap with a wire

thickness gauge; adjust the gap to

specification as necessary.

A.- Spark plug gap: 0.6-0.7 mm

When installing the plug, always

clean the gasket surface and use a

new gasket. Wipe off any grime from

the threads and tighten the spark plug

to the specified torque.

Tightening torque:

Spark plug:

12 ft-lb (1.75 m-kg)

NOTE :

If a torque wrench is not available

when you are installing a spark plug,

a good estimate of the correct

torque is 1/4 to 1/2 turn past finger

using a box spanner.

ALWAYS USE ONLY THE STANDARD RECOMMENDED MAKE AND TYPE OF

CHAPT6_A.cdr

Saturday,October01,20051:03:41PM

SPARK PLUG

6-7

3

Page 34

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

112

1. Engine oil filler cap

Engine oil

1. Oil level measurement

a. Place the Motorcycle on the

centerstand. Warm up the engine

for several minutes.

NOTE :

Be sure the Motorcycle is positioned

straight up when checking the oil

level with the rear wheel off the

ground. A slight tilt toward the side

can result in false readings.

CHAPT6_A.cdr

Saturday,October01,20051:03:41PM

1. Maximum level

2. Minimum level

NOTE :

Wait a few minutes until the oil level

settles before checking.

B. Unscrew the dipstick and rest it

1. Dipstick

2. Engine oil replacement

a. Warm up the engine for a few

minutes.

b. Stop the engine. Place an oil pan

under the engine and remove the

dipstick.

on the threads of the oil filler hole.

The oil level should be between

the minimum and maximum mark

on the dip- stick. If the level is low,

add oil to raise it to the specified

level.

ALWAYS CHANGE ENGINE OIL AT RECOMMENDED INTERVALS

FOR OPTIMUM ENGINE PERFORMANCE AND ENGINE LIFE

6-8

4

Page 35

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

1 . Engine oil drain plug

c. Remove the drain plug and drain

the oil.

d. Reinstall the drain plug and

tighten it to the specified

torque.

ALWAYS USE ONLY THE RECOMMENDED GRADE OF ENGINE OIL

Tightening torque:

Drain plug:

14.5 It-lb (2.0 m-kg)

e. Fill engine with oil and install

the dipstick.

Recommended oil:

YAMALUBE 4-stroke motor oil

(20W40 type SG).

Oil quantity:

Total amount:

1.2 L

Periodic oil change:

1.0 L

f. Start the engine and warm up

for a few minutes. While

warming up, check for oil leakage. If oil leakage is found, stop

the engine immediately and

check for the cause.

CHAPT6_A.cdr

Saturday,October01,20051:03:41PM

6-9

5

Page 36

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

2

1

1

2

1

2

1. Air filter case cover

2. Screw(4 Nos)

Air filter

The air filter should be cleaned at

the specified intervals. It should be

cleaned more frequently when riding

in unusually wet or dusty areas.

1. Remove panel B. (See page 6-6

for removal and installation

procedures.)

2. Remove the air filter case fitting

screws and the air filter case

cover.

CHAPT6_A.cdr

Saturday,October01,20051:03:42PM

1. Air filter element

2. Lockable SpringWire

3. Remove the air filter from the

case.

4. Unlock the spring wire.

6-10

6

1. Air filter element

2. Frame

5. Remove the air filter elements

from the frame and clean them

with solvent (kerosene). After

cleaning, remove the remaining

solvent (kerosene) by squeezing

the elements.

6. Apply recommended oil to the

entire surface of the each element

and squeeze out the excess oil.

They should be wet but not

dripping.

Recommended oil:

YAMALUBE 20W40 Type SG

Page 37

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR`

7. Pull the air filter elements over

the frame and install the air filter

in the case.

8. Install the SpringWire

9. Install the air filter case cover

and panel

CAUTION :

• Make sure the air filter is

properly seated in the air filter

case.

• The engine should never be run

without the air filter installed.

Excessive piston and/or

cylinder wear may result.

• Dirty Element Air Cleaner

causes excessive fuel

consumption and loss of

power.

Clean Element Air Cleaner after

•

every 2000 Kms.

• The Element Air Cleaner should

be cleaned and lubricated more

frequently (every 1000 kms), if

Motorcycle is operated in very

dusty (e.g. unpaved, dust laden

roads) conditions.

Carburetor adjustment

The carburetor is a vital part of the

engine and requires very sophisticated adjustments. Most adjustments should be left to a YAMAHA

dealer who has the professional

knowledge and experience to do so.

However, the following may be

serviced by the owner as part of

routine maintenance.

CAUTION :

The carburetor was set at the

YAMAHA factory after many

tests. If the settings are changed,

poor engine performance and

damage may result.

CHAPT6_A.cdr

Saturday,October01,20051:03:42PM

6-11

7

Page 38

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Idle speed adjustment

NOTE :

A diagnostic tachometer must be

used for this procedure.

1. Attach the tachometer. Start the

engine and warm it up for a few

minutes at approximately 1,300

to 1,500 r/min. Occasionally rev

the engine to 4,000 to 5,000

r/min. The engine is warm when it

quickly responds to the throttle.

1

a

b

1. Throttle stop screw

2. Set the idle to the specified

engine speed by adjusting the

throttle stop screw. Turn the

screw in direction a to increase

engine speed and in direction b

to decrease engine speed.

Standard idle speed:

1,300 ~ 1,500 r/min

NOTE :

If the specified idle speed cannot be

obtained by performing the above

adjustment, consult a

dealer.

YAMAHA

Throttle cable free play

adjustment

NOTE :

Before checking the throttle cable

free play, the engine idling speed

should be adjusted.

Adjust the throttle cable by turning

the adjusting nut so that specified

free play at the throttle grip is

obtained.

Free play:

3 ~ 7mm

CAUTION :

1. Do not Tamper/Adjust with TPS

(Throttle Position Sensor)

2. Do not Open BS (Butterfly Slide)

ValveScrews.

Please refer Page 6.3

CHAPT6_A.cdr

Saturday,October01,20051:03:43PM

6-12

8

Page 39

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

b

3

a

2

1. Free play

2. Locknut

3. Adjusting nut

1. Loosen the locknut.

2. Turn the adjusting nut in direction

b to increase free play and in

direction a to decrease free play.

3. Tightenthe locknut.

KEEP RECOMMENDED TYRE PRESSURE IN BOTH THE TYRES

Valve clearance adjustment

The correct valve clearance

changes with use, resulting in

improper fuel/air supply or engine

noise. To prevent this, the valve

clearance must be adjusted

regularly. This adjustment however,

should be left to a YAMAHA dealer.

1. Tread depth

2. Side wall

Tyres

To ensure maximum performance,

long service and safe operation,

note the following:

1. Tyre air pressure

Always check and adjust the tyre

pressure before operating the

Motorcycle.

CHAPT6_A.cdr

Saturday,October01,20051:03:43PM

6-13

9

Page 40

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

WARNING

Tyre inflation pressure should be

checked and adjusted when the

temperature of the tyre equals the

ambient air temperature. Tyre

inflation pressure must be adjusted according to total weight of

cargo, rider, passenger, and

accessories (fairing, saddlebags,

etc. approved for this model), and

vehicle speed.

Maximum load* 153 kg

Front RearCold tyre pressure:

Single Rider

With Pillion Rider

25 psi

(1.75kg/cm )

25 psi

(1.75kg/cm )

32 psi

2

(2.25kg/cm )

32 psi

2

(2.25kg/cm )

WARNING

Proper loading of your Motorcycle

is important for several characteristics of your Motorcycle, such as

handling, braking, performance

and safety. Do not carry loosely

packed items that can shift.

Securely pack your heaviest items

close to the center of the Motorcycle, and distribute the weight

evenly from side to side. Properly

adjust the suspension for your

load, and check the condition and

pressure of your tyres. NEVER

OVERLOAD YOUR

MOTORCYCLE. Make sure the

total weight of the cargo, rider,

passenger, and accessories

2

(fairing, saddlebags, etc.

2

approved for this model) does not

exceed the maximum load of the

Motorcycle. Operation of an overloaded Motorcycle could cause

tyre damage, an accident, or even

injury.

2. Tyre inspection

Always check the tyres before

operating the Motorcycle. If a tyre

tread shows crosswise lines

(minimum tread depth), if the tyre

has a nail or glass fragments in it,

or if the side wall is cracked,

contact a dealer

YAMAHA

immediately and have the tyre

Front tyre size:

2.75-18” 4PR

Rear tyre size:

3.00-18” 6PR

Minimum tyre

tread depth :

1.0 mm

(front and rear)

Chapt6_b.cdr

Saturday,October01,20051:04:43PM

6-14

1

Page 41

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

WARNING

1. It is dangerous to ride with a

worn-out tyre. When a tyre

tread begins to show lines,

have a YAMAHA dealer replace

the tyre immediately.

Wheels

To ensure maximum performance,

long service, and safe operation,

note the following:

1. Always inspect the wheels before

a ride. Check for cracks, bends or

warpage of the wheel. Be sure the

spokes are tight and undamaged.

If any abnormal condition exists in

a wheel, consult a YAMAHA

dealer. Do not attempt even small

repairs to the wheel. If a wheel is

deformed or cracked, it must be

replaced.

2. Tyres and wheels should be

balanced whenever either one is

changed or replaced. Failure to

have a wheel balanced can result

in poor performance, adverse

handling characteristics, and

shortened tyre life.

3. Ride at moderate speeds after

changing a tyre since the tyre

surface must first be broken in for

it to develop its optimal

characteristics.

Chapt6_b.cdr

Saturday,October01,20051:04:43PM

6-15

2

Page 42

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

2

a

b

1. Locknut

2. Adjusting Bolt

3. Free play (10~15 mm)

Clutch lever free play

adjustment

The clutch lever free play should be

adjusted to 10 ~ 15 mm. If the free

play is incorrect, adjust as follows.

1 . Loosen thelocknut.

2. Turn the adjusting bolt at the

clutch lever in direction b to

increase free play or in direction a

to decrease free play.

3. Tightenthe locknut.

NOTE :

If proper adjustment cannot be

obtained or the clutch does not work

correctly, ask a dealer to

YAMAHA

inspect the internal clutch

mechanism.

3

1

Chapt6_b.cdr

Saturday,October01,20051:04:44PM

6-16

3

Page 43

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

INSTRUCTION 1

1. Adjusting Nut

Rear brake adjustment

The rear brake pedal free play

should be adjusted to 20 ~ 30 mm

(Instruction 2, a ) at the brake pedal

end. Turn the adjusting nut in

direction a to increase free play and

in direction b to decrease free play.

INSTRUCTION 2

a. Freeplay

WARNING

• When it is impossible to make

the proper adjustment, ask a

YAMAHA dealer.

• Check the operation of the

brake light after adjusting the

rear brake.

6-17

2

1

1. Brake light switch

2. Adjusting nut

b

a

Brake light switch adjustment

The rear brake light switch is activated by the brake pedal and is

properly adjusted when the brake

light comes on just before braking

takes effect. To adjust the rear

brake light switch, hold the switch

body so it does not rotate while

turning the adjusting nut.

Turn the adjusting nut in direction a

to make the brake light come on

earlier.

Turn the adjusting nut in direction b

to make the brake light come on

later.

Chapt6_b.cdr

Saturday,October01,20051:04:45PM

4

Page 44

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1. Brake pad wear indicator groove (x3)

Checking the front brake

pads

Each front brake pad is provided

with wear indicator grooves, which

allow you to check the brake pad

wear without having to disassemble

the brake. to check the brake pad

wear, check the wear indicator

grooves. If brake pad has worn to

the point that the wear indicator

grooves have almost disappeared,

have a YAMAHA dealer replace the

brake pads as a set.

2

1

1. Wear limit line

2. Wear indicator

Checking the rear brake

shoes

The rear brake is provided with a

wear indicator; which allows you to

check the brake shoe wear without

having to disassemble the brake.

To check the brake shoe wear,

check the position of the wear

indicator while applying the brake. If

a brake shoe has worn to thepoint

that the wear indicator reaches the

wear limit line, have a YAMAHA

dealer replace the brake shoes as a

set.

1

1. Minimum Level Mark

Checking the brake fluid

level

Insufficient brake fluid may allow air

to enter th brake system, possibly

causing it to become ineffective.

Before riding, check that the brake

fluid is above the minimum level mark

and replenish if necessary. A low

brake fluid level may indicate worn

brake pads and/or brake system

leakage. If the brakefluid levelis low,

be sure to check the brake pads for

wear and the brake system for

leakage.

Chapt6_b.cdr

Saturday,October01,20051:04:45PM

6-18

5

Page 45

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Observe these precautions :

• When checking the fluid level,

make sure that the top of the brake

fluid reservoir is level.

• Use only the recommended quality

brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking

performance

Recommended brake fluid :

DOT 3 Brake Fluid

• Refill with the same type of brake

fluid. Mixing fluids may result in

a harmful chemical reaction and

lead to poor braking

performance.

• Be careful that water does not enter

the brake fluid reservoir when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapour lock.

• Brake fluid may deteriorate painted

surfaces or plastic parts. Always

clean up spilled fluid immediately.

• As the brakepads wear, it isnormal

or the brake fluid level to gradually

go down, However, if the brake fluid

level goes down suddenly, have

YAMAHA dealer checkthe cause.

Changing the brake fluid

Have a YAMAHA dealer check the

brake fluid at the intervals specified in

the periodic maintenance. In

addition, have the oil seals of the

brake master cylinder and caliper as

well as the brake hose replaced at the

intervals listed below or

they are damaged or leaking.

• Oil Seals : Replace every two

years.

• Brake Hose : Replace every four

years.

• Brake Fluid : Replace every two

years or in case of severe operating

conditions replace every year.

whenever

20~30

mm

Drive chain slack check

Spin the wheel several times and

find the tightest position of the chain.

Check and/or adjust the chain slack

while it's in this tightest position.

Inspect the drive chain when the

Motorcycle is on the centerstand.

Check the slack at the position

shown in the illustration. Normal

slack is approximately 20 ~ 30 mm.

If the slack exceeds 30 mm, adjust.

Chapt6_b.cdr

Saturday,October01,20051:04:46PM

6-19

6

Page 46

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1. Chain joint

If the chain is disassembled, be sure

the chain lock is placed in the

correct direction when installing.

3

2

1

1. Adjusting nut

2. Cotter pin

3. Axle nut

Drive chain slack adjustment

1. Loosen the rear brake pedal

free play adjusting nut.

2. Remove the cotter pin from

the axle nut.

3. Loosen the axle nut.

1

a

b

2

1. Locknut

2. Adjusting Nut

4. Loosen the chain adjusting

locknuts on each chain puller. To

tighten the chain, turn the chain

adjusting nut in direction b to

loosen the chain, turn the chain

adjusting nut in direction a and

push the wheel forward. Turn each

chain adjusting nut exactly the

same amount to maintain correct

axle alignment. There are marks

on each chain puller. Use these

marks to align the rear wheel.

Chapt6_b.cdr

Saturday,October01,20051:04:47PM

6.20

7

Page 47

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

CAUTION :

•

Maintain chain slackness

within specified limits as per

specifications.

• To maintain correct axle

alignment, Ensure the notch

on the adjuster is on the same

Mark on Left and Right Side.

5. After adjusting, be sure to tighten

each chain adjusting locknut.

Then tighten the axle nut to the

specified torque.

Tightening torque:

Axle nut:

65 ft-lb (9.05 m-kg)

7 Adjust the free play in the

brake pedal.

WARNING

Check the operation of the brake

light after adjusting the rear

brake.

1. Cotter pin

6. Insert a new cotter pin into the

axle nut and bend the end of the

cotter pin as shown. If the notch in

the axle nut and the cotter pin

hole do not match, tighten the nut

slightly to align them.

WARNING

Always use a new cotter pin on

the axle nut.

Chapt6_b.cdr

Saturday,October01,20051:04:47PM

6-21

8

Page 48

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Drive chain lubrication

The chain consists of many parts

which work with each other. If the

chain is not maintained properly, it

will wear out quickly. Therefore, the

chain must be serviced regularly.

This service is especially necessary

when riding in dusty areas.

1. The drive chain should be

lubricated every 5,000 km.

2. To clean the chain thoroughly,

remove it from the Motorcycle,

dip it in solvent, and clean out as

much dirt as possible. Then, take

the chain out of the solvent to dry

it, and then dip the chain in oil of

20W40. Remove the chain and

hang it on a peg for a while till the

excess oil drips down completely.

Then using a clean cloth wipe the

chain.

Cable inspection and

lubrication

WARNING

Damage to the outer housing of

cables may lead to internal rusting

and interfere with the cable

movement. Replace damaged

cables as soon as possible to

prevent unsafe conditions.

Lubricate the cables with anticorrosive oil at cable ends. If a

cable does not operate smoothly,

ask a YAMAHA dealer to replace it.

Recommended lubricant:

YAMALUBE 20W40 Type SG

Throttle cable and grip

lubrication

The throttle twist grip assembly

should be greased at the time that

the cable is lubricated, since the

grip must be removed to get at the

end of the throttle cable. After

removing the screws, hold the end

of the cable up in the air and put in

several drops of lubricant. With the

throttle grip disassembled, coat the

metal surface of the grip assembly

with a suitable all purpose grease.

Chapt6_b.cdr

Saturday,October01,20051:04:47PM

6-22

9

Page 49

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Brake and shift pedal

lubrication

Lubricate the pivoting parts.

Chapt6_b.cdr

Saturday,October01,20051:04:48PM

Brake and Clutch Lever

Greasing

Grease the pivoting parts.

Recommended Grease :

MULTIPURPOSE

6-23

10

Center and sidestand

lubrication

Lubricate the pivoting and mating

joints.

Check to see that the center and

sidestand move up and down

smoothly.

WARNING

If the center and/or sidestand does

not move smoothly, consult a

YAMAHA dealer.

Page 50

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Front fork inspection

WARNING

Securely support the Motorcycle

so there is no danger of it falling

over.

1. Visual check

Check for scratches or damage

on the inner tube and excessive

oil leakage from the front fork.

2. Operation check

Place the Motorcycle on a level

place.

a. Hold the Motorcycle in an

upright position and apply the

front brake.

b. Push down hard on the

handlebars several times and

check if the fork rebounds

smoothly.

CAUTION :

If any damage or unsmooth

movement is found with the front

fork, consult a YAMAHA dealer.

Steering inspection

Periodically inspect the condition of

the steering. Worn out or loose

steering bearings may be dangerous. Place a stand under the engine

to raise the front wheel off the

ground. Hold the lower end of the

front forks and try to move them

forward and backward. If any free

play can be felt, ask a YAMAHA

dealer to inspect and adjust the

steering. Inspection is easier if the

front wheel is removed.

Chapt6_b.cdr

Saturday,October01,20051:04:48PM

6-24

11

Page 51

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

WARNING

Securely support the Motorcycle

so there is no danger of it falling

over.

Wheel bearings

If there is play in the front or rear

wheel hub or if the wheel does not

turn smoothly, have a YAMAHA

dealer inspect the wheel bearings.

1

MAX

MIN

2

1. Maximum level mark

2. Minimum level mark

Battery

1. Battery is located inside the

L.H. side panel (for removal &

installation of L.H. side panel

please refer page 6-5)

2. Open the lid.

3. Check the level of the battery

electrolyte and make sure that

the terminals are tight.

Top up with distilled water if the

electrolyte level is low.

Chapt6_c.cdr

Saturday,October01,20051:05:28PM

6-25

1

Page 52

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

CAUTION :

When inspecting the battery, be

sure the breather hose is routed

correctly. If the breather hose is

positioned in such a way as to

cause battery electrolyte or gas to

exit onto the frame, structural and

cosmetic damage to the

Motorcycle can occur.

Battery electrolyte is poisonous

and dangerous, causing severe

burns, etc. It contains sulfuric

acid. Avoid contact with skin, eyes

or clothing.

ENSURE THAT BATTERY ELECTROLYTE LEVEL IS MAINTAINED BETWEEN

MAX . AND MIN. MARKS. IF REQUIRED, ADD DISTILLED WATER ONLY

Antidote:

EXTERNAL: Flush with water.

INTERNAL: Drink large quantities

of water or milk. Follow with milk of

magnesia, beaten egg, or

vegetable oil. Call a physician

immediately. EYES: Flush with

water for 15 minutes and get

prompt medical attention.

Batteries produce explosive

gases. Keep sparks, flame,

cigarettes etc., away. Ventilate

when charging or using in an

enclosed space. Always shield

your eyes when working near

batteries. KEEP OUT OF REACH

OF CHILDREN.

Replenishing the battery fluid

A poorly maintained battery will

corrode and discharge quickly. The

battery fluid should be checked at

least once a month. The level should

be between the minimum level and

maximum level marks. Use only

distilled water if refilling is necessary.

CAUTION :

Normal tap water contains

minerals which are harmful to a

battery; therefore, refill only with

distilled water.

WARNING

Take care not to spill battery fluid

on the chain. Battery fluid may

weaken the chain causing shorter

chain life and possibly result in an

accident

Chapt6_c.cdr

Saturday,October01,20051:05:28PM

6-26

2

Page 53

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Battery storage

1. When the Motorcycle will not be

used for a month or longer,

remove the battery, fully charge it

and store it in a cool, dry place.

Completely recharge the battery

before reinstallation.

2. If the battery will be stored for

longer than two months, check

the specific gravity of the fluid at

least once a month and fully

recharge the battery when it is too

low.

3.Always make sure the

connections are correct when

putting the battery back in the

motorcycle. Make sure the

breather hose is properly

connected and is not damaged or

obstructed.

1

1. Main fuse

Fuse replacement

The fuse is located behind panel A.

(See page 6-6 for panel removal and

installation procedures.)

If the fuse is blown, turn off the main

switch and the switch of the circuit in

question. Install a new fuse of proper

amperage. Turn on the switches and

see if the electrical device operates.

If the fuse immediately blows again,

consult a YAMAHA dealer.

CAUTION :

Do not use fuse of higher

amperage rating than those

recommended. Substitution of a

fuse of improper rating can cause

extensive electrical system

damage and possibly a fire.

Specified fuse: 10A

Chapt6_c.cdr

Saturday,October01,20051:05:29PM

6-27

3

Page 54

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

1. Screw - 2 Nos.

2. Bolt - 1

(LH & RH)

No.

Headlight bulb replacement

If the headlight bulb burns out,

replace the bulb as follows:

1. Remove the two screws from

theHead Light Cowling "1"..

2. Loosen the Bolt "2" below the

Headlight Cowling.

3. Slide Headlight forward..

Chapt6_c.cdr

Saturday,October01,20051:05:29PM

2

1

1

1. Bulb holder - 2 Nos.

. Remove the defective bulb from

4

the bulb holder whichever is

fused.

6-28

4

1. Bulb 2 Nos. (LH & RH)

WARNING

Keep flammable products and

your hands away from the bulb

while it is on, as it is hot. Do not

touch the bulb untilit cools down.

5. Put a new bulb into position and

secure it in place with the bulb

holder.

6. Install the HeadLight Assy.

7. If the headlight beam adjustment

is necessary, ask a YAMAHA

dealer to make adjustment.

Page 55

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

1. Indicator Screw (1 No.)

Turn signal and taillight

bulb replacement

1. Remove the screwand the lense.

2. Push the bulb inward and turn it

counterclockwise.

3. Place a new bulb in the socket.

Push the bulb inward and turn it

clockwise until it engages into the

socket.

4. Install the lenseand the screw.

PERIODIC MAINTENANCE AND MINOR REPAIR

Front wheel removal

1

1

1

1. Integral Tail lamp

with Indicators

CAUTION :

Do not over-tighten the screws as

the lense may break.

Screws Nos)

(2

WARNING

• It is advisable to have a

YAMAHA dealer service the

wheel.

• Securely support the

Motorcycle so there is no

danger of it falling over.

Chapt6_c.cdr

Saturday,October01,20051:05:30PM

6-29

5

Page 56

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

1

1

1. Nut

2. Speedometer Cable

1. Place the Motorcycle on the

centerstand.

2. Loosen the Speedometer cable

Nut '1', & pull the cable '2' out from

the Front Wheel

Chapt6_c.cdr

Saturday,October01,20051:05:31PM

2

1. Cotter Pin

2. Axle Nut

3. Remove the cotter pin '1' and axle

nut '2'.

4. Remove the Axle.

5. Remove the wheel, make sure

the Motorcycle is properly

supported.

6. Remove the FrontWheel

6-30

6

Page 57

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

1. Stopper

Front wheel installation

When installing the front wheel,

reverse the removal procedure.

Pay attention to the following points:

1. Make sure the slot in the gear

meter assembly fits over the

stopper on the front fork outer

tube.

2. Make sure the axle nut is properly

torqued and a new cotter pin is

installed.

WARNING

Always use a new cotter pin.

Axle nut torque:

33 ft-lb (4.55 m-kg)

Rear wheel removal

WARNING

• It is advisable to have a

YAMAHA dealer service the

wheel.

• Securely support the

Motorcycle so there is no

danger of it falling over.

Chapt6_c.cdr

Saturday,October01,20051:05:32PM

6-31

7

Page 58

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

1. Nut

2. Cotter pin

3. Tension bar

1. Place the Motorcycle on the

centerstand.

2. Remove the cotter pin and nut.

Then remove the tension bar

from the brake shoe plate.

Chapt6_c.cdr

Saturday,October01,20051:05:33PM

1. Axle nut

2. Cotter pin

3. Brake rod

4. Brake adjusting nut

1. Rear axle

5. Pull out the rear axle.

6. Remove the wheel assembly.

3. Remove the brake adjusting nut

and brake rod from the brake cam

lever.

4. Remove the axle nut cotter pin

and the axle nut.

ALWAYS USE YAMAHA GENUINE SPARE PARTS

6-32

8

Page 59

Colorprofile:GenericCMYKprinterprofile

CompositeDefaultscreen

PERIODIC MAINTENANCE AND MINOR REPAIR

Rear wheel installation

1. Install the rear wheel and the

axle.

2. Install the axlenut.

3. Insert the brake rod into the

brake cam lever and install the

brake free play adjusting nut.

4. Install the tension bar onto the

brake shoe plate and tighten the

tension bar nut to the specified

tightening torque.

5. Take the Motorcycle off the

centerstand.

6. Tighten the axle nut to the

specified tightening torque.

Then install a new cotter pin.

Specified torque:

Tension bar nut:

14 ft-lb (1.9 m kg)

Axle nut:

65 ft-lb (9.05 m kg)

WARNING

Always use a new cotter pin.

7. Adjust the rear brake pedal free

play.(See page 6-17.)

WARNING

Check the operation ofthe brake

light after adjusting therear brake.

Troubleshooting

Although YAMAHA Motorcycles

receive a rigid inspection before

shipment from the factory, trouble

may occur during operation. Any

problem in the fuel, compression, or

ignition systems can cause poor

starting and loss of power. The

troubleshooting chart describes a

quick, easy procedure for making

checks. If your Motorcycle requires

any repair, bring it to a YAMAHA

dealer. The skilled technicians at a

YAMAHA dealership have the tools,

experience, and know-how to

properly service your Motorcycle.