•

YAMAHA

SNOWMORlll

SUPPlEMENTARY

SERVICE

UAl

Frame serial number:

[

Engine serial number: S5433-036101 ~ SS433-049999

LIT

-12618-00-26

8J7-036101

~

8J7-049999 J

8J7-28197-10

CONTENTS

1980 EX440C

( )

1. NEW SERVI

2.

MAINTENANCE INTERVALS

3. SPECIFICATIONS ..........................

4.

SPECIAL

5.

WIRING

6. WIRE AND

CE

PROCEDURE

TOOLS ..................................

DIAGRAM

PIPE

....................................................................................

ROUTING

....

..........

DIAGRAM

..........

....

....

.. ..

........

....

..........

....

......

...........

..................

..

............................................................. 5

............................

......

....

....................

.............................

......

.. ..

..........................................

........... 3

..

2

11

12

13

-

1-

1980 EX440D

1.

(New

EX440D)

NEW

service procedure applied

SERVICE

PROCEDURE

to

the

1980

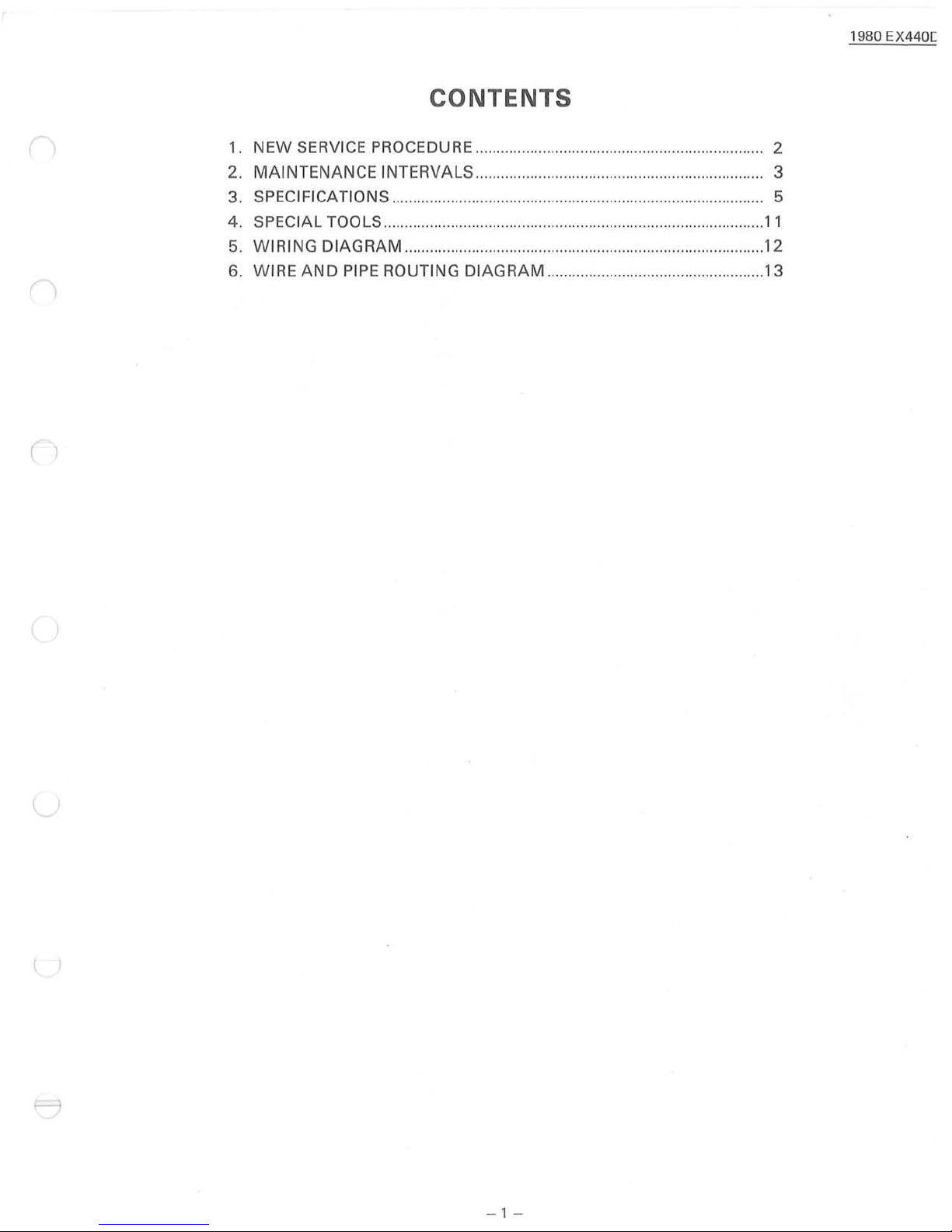

A. Ignition timing

1.

Remove the recoil starter assembly.

2. Remove the ri

screw

hol

Dial gauge stand

2. Insert dial gage w ith needle i

Dial gauge

Dial gauge needle

dial gauge stand i

e.

Tool name Tool No.

Tool name

ght

side spark plug and

90890-0

90890-01252

90890-03098

nto

spark plug

nto

Tool No.

1195

stand .

7. Check the marks on flywheel and pu lser

for a

li

gnment.

If

not aligned, adjust i

follows:

a.

Loosen the pulser set screws and

the pu lser until mark

achieved.

gnit

ion timing as

alignment

turn

( )

is

4. Rotate

at

Set the zero on dial gauge face

up exactly

Tighten set

to

flywhee l back and forth

indicator needle does

5. Start ing

counterclockwise

reads approx imate ly 3-1 / 2 needle

volutions

(B

6.

Slowly

dial gauge reads specifi

ing.

Ignition

1.6

magneto

top

-dead-center (T.D.C.)

secure dial gauge assembly . Rotate

at

.T.D.

C.)

.

turn flywheel

timing

± 0

.1

mm

flywheel

with

a dial gauge needle.

screw

(B.T.D.C.)

on dial gauge stand

T.D.C., rotate flywheel

before-top-dead

(0.060 ± 0.004

unti

to

not

go

unt

il dial gauge

clockwise until

ed

l piston is

to

line

be

sure

that

past zero.

re

-cente

ignition tim-

in)

~,

----

\

--------

not

be

----

--

---

aligned by this ad-

...&. \

NOTE:----

If the marks can

justment.

turn

the base (stator) assembly.

r

remove the flywheel rotor and

l )

-

2-

b.

Tight

en

the pulse r set screws.

8. Remove the

dial gauge and stand. Re-

place the spark plug and recoil starter.

Tightening torque

NOTE:

The timing light should

the marks

-------------------------

be used

on

the rotor and base are aligned

when both are replaced with n

marks

should align at any specified

to check if

ew

ones. The

timing

1980 EX440D

.

Spark plug :

Starter assembly:

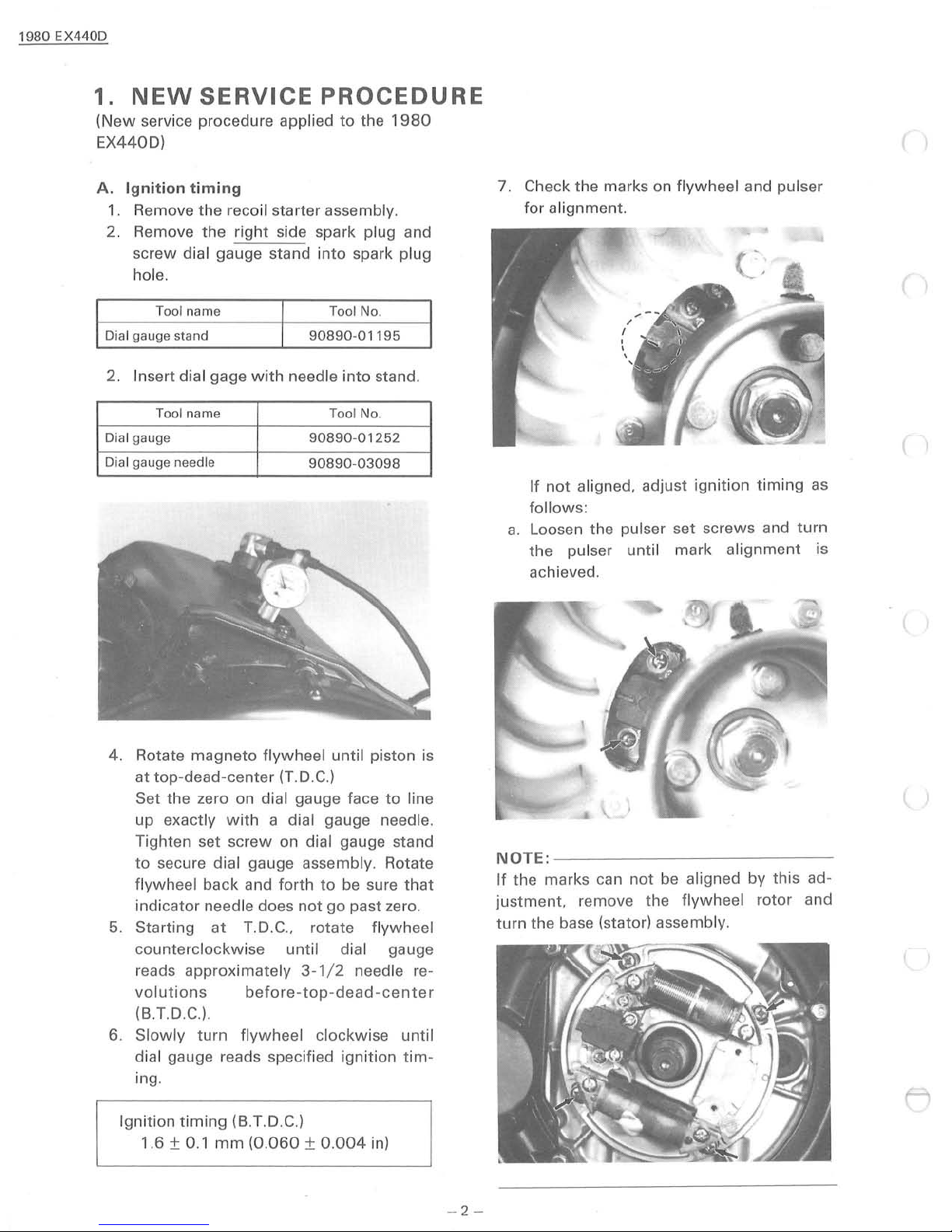

2.

MAINTENANCE

[

PERIODIC

(

ENGINE:

Tightness of bolts a

8ends. cracks and wear 0

Abnormal noi

Loose connection a

Loose con nection and breaks of oil pip

Loose connection and breaks of oil delivery pipe 0

Manua l rope starter system 0

Carburetor

Operation of starter jet 0

•

Mix

ing adjuster (pil

•

• Idling speed adjustment

Operation and adjustment

Ignition timing

Cylinder compressions

Muffler jo in

Cylinde r head/exhaus t pipe decarboni

Spark plug conditio

Tightening

DRIVE:

Tightness

Wear on slide runners

Pr

V-be lt 0

Secondary dri

Sheave distance

Sheave offset 0

Brake pad

Brake operation and adjustment 0

Guide wheel rubber

Wea r of drive track wheel sprocket 0

Drive track adjustment

Breaks in drive track 0

Be

Che

Drive

Dri

ts

of

of

imary dr ive system 0 0

wear

nds in front and rear axl

cking

of

cha

in adjustment

ve

chain

2.8

m-kg

(20

ft-I

b)

0.7

m-kg (5 ft-Ib)

INTERVAL

MAINTENANCE]

Check point

nd

nuts 0

se

nd

breaks of fuel and pulse pipes

es

ot screw) 0

of

oil pump 0

ze

n.

gap and cleaning 0 0

the cylinder he

bolts and nuts 0

ve

system 0

lock washe

oil

lev

el

ad"

es

rs

20 hrs. or

400

km

(250

mil

0

0

0

0

0 0

Every

40

hrs. or

800

(500m

0 0

0 0

0

0

0

0 0

0

0

km

i) (1

80

hrs. or

1

.600

km

.000m

0 a

i)

When

necessary

0

Seasonally

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-3-

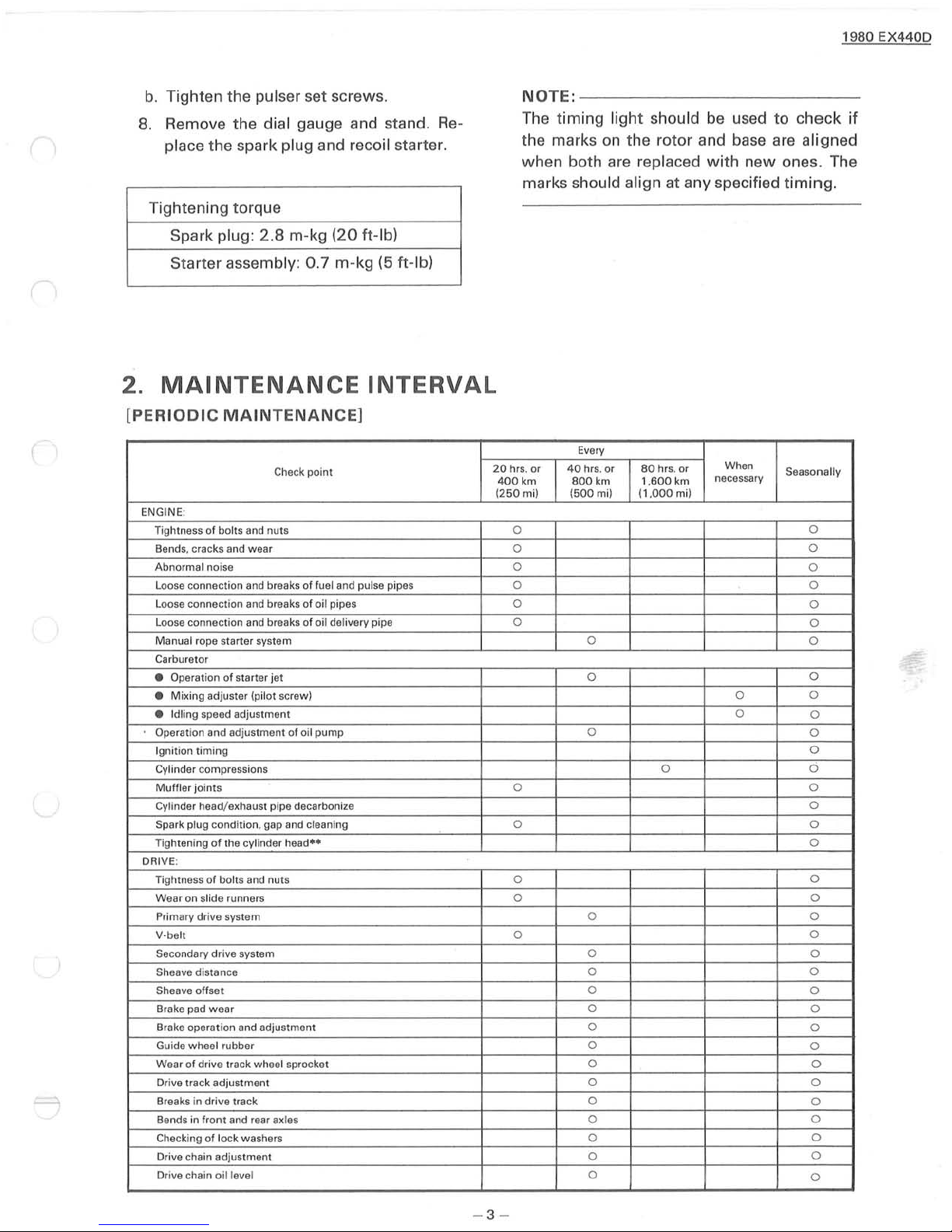

1980 EX440D

Every

km 1.

80 hrs.

600

km

(1.000mi)

40

20

Check point

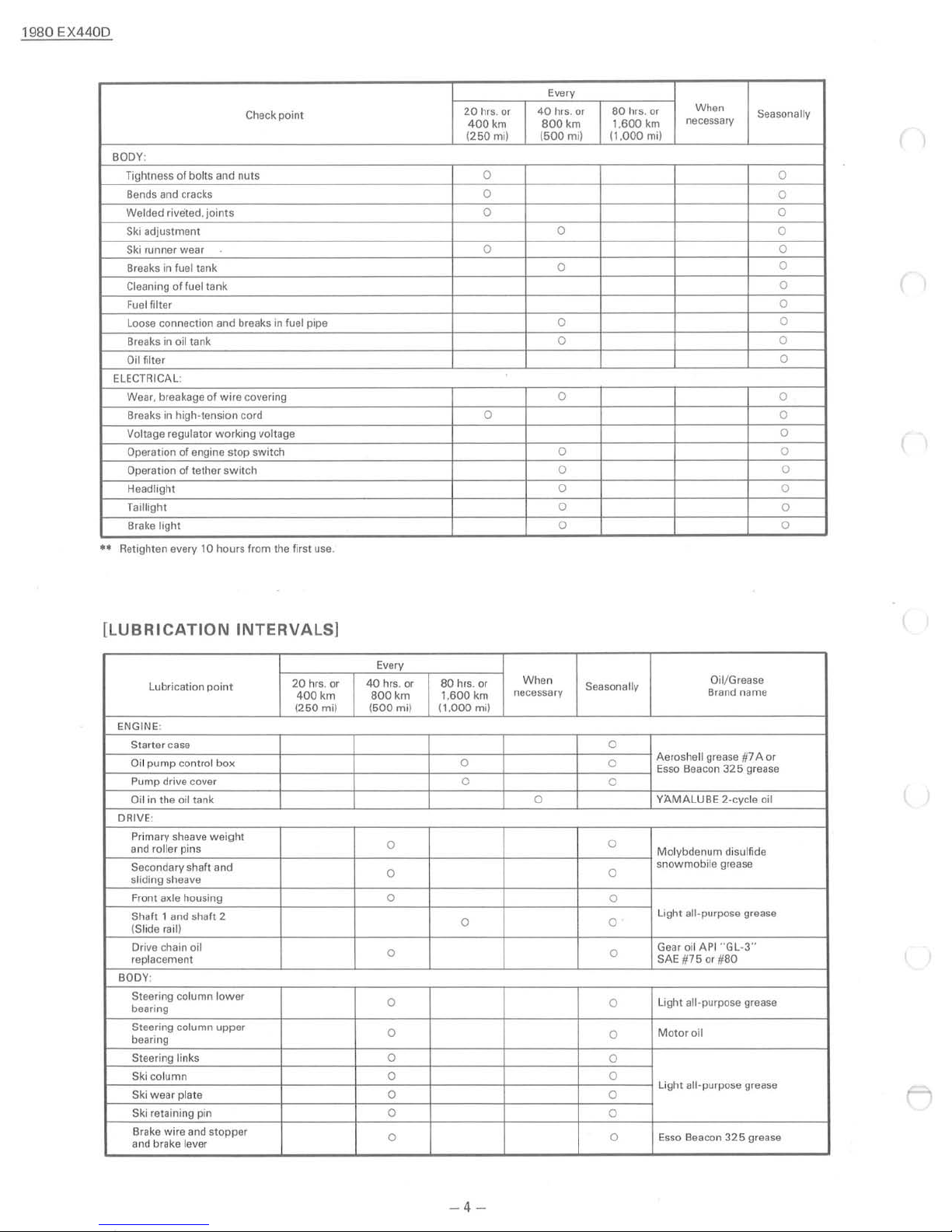

BODY:

Tightness of bolts and nuts 0 0

Bends and cracks

Welded riveted.

Ski

adjustment

Ski

runner wear 0 0

Breaks in fuel tank

Cleaning

Fuel

filter

Loose connection and breaks in fuel pipe

Breaks in oil tank

Oil filter

ELECTRICAL:

Wear. breakage

Breaks in high-tension cord

Vo

ltage regulato r

Operation

Operation of tether switch

Headlight

Taillight

Brake light 0 0

**

Retighten every

joints

of

fuel tank

of

wire

working

of

engine stop switch

10

hours from the first use.

covering

voltage

hrs. or

400

km

(250

mil

0

0 0

0 0

hrs. or

800

(500mi)

0

0

0

0

0

0 0

0

0 0

0

or

When

necessary

Seasonally

0

0

0

0

0

0

0

0

0

0

0

0

(

[LUBRICATION

Lubrication

ENGINE:

Starter

case 0

Oi

l pump control

Pump drive cover

Oi

l in the oil tank 0

DRIVE:

Pr

imary sheave

and roller pins

Secondary shaft and

sliding sheave

axle housing 0

Front

Shaft 1 and

(Slide rail)

ve

chain oil

Dri

replacement

BODY:

Steering column

bearing

Steering column upper

bearing

Steering links

Ski column 0 0

Ski wear plate 0

Ski

retaini ng pin

Brake wire and stopper

and brake

lever

INTERVALS]

point

box

weight

sha

ft 2

lower

20

400

(250

hrs. or

km

mil

Every

40

hrs. or

800

(500mi)

0

0

0

0

0

0

0

0

km

80

1.600

(1.0

hrs. or

km

00m

0

0

0

When

necessary Brand name

i)

Seasonally

0

0

0

0

0

O·

0

0

0

0

0

0

0

O

il/

Grease

Aeroshell grease #7 A or

Esso

Beacon

325

grease

YAMALUBE 2-cycle oil

Mo

lybdenum disulfide

snowmobile grease

Light all-purpose grease

Gear oil API "

SAE

Light all-purpose grease

Motor

Light all-p urpose grease

Esso

#75

or

oil

Beacon

GL-3"

#80

325

grease

l

-4-

Loading...

Loading...