Page 1

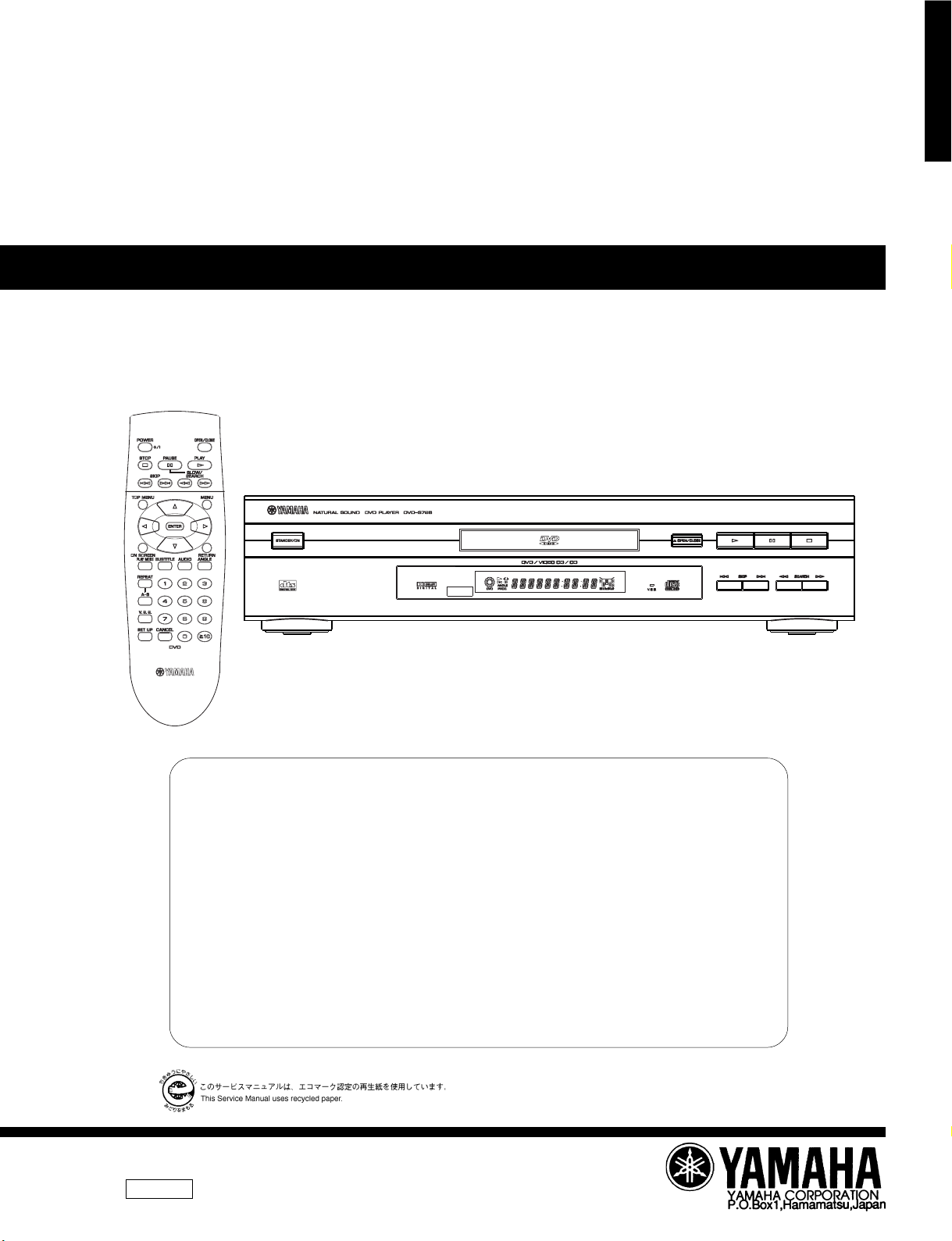

DVD-S796/DV-S5270

DVD-S796/S5270

DVD PLAYER

DVD-S796/DV-S5270

SERVICE MANUAL

SERV ICE M A N UAL

100711

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherant to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact

the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumu-

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that all service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

lated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

Page 2

CONTENTS

SECTION 1

DVD-S796/DV-S5270

SPECIFICATIONS ................................................................ 1-1

LOCALE MANAGEMENT INFORMATION ......................... 1-1

TO SERVICE PERSONNEL ................................................ 1-2

PREVENTION OF ESD TO ES DEVICES.........................1-3

PRECAUTION OF LASER DIODE......................................1-4

HANDILNG PRECAUTIONS FOR TRAVERSE DECK......1-4

REAR PANELS ..................................................................... 1-5

OPTICAL PICKUP SELF-DIAGNOSIS AND REPLACEMENT PROCEDURE ...

SELF-DIAGNOSIS FUNCTION AND SERVICE MODES ............

SERVICE PRECAUTIONS ................................................... 1-9

SERVICE TOOLS AND EQUIPMENT ................................ 1-9

OPERATING INSTRUCTIONS ..........................................1-10

SECTION 2

ASSEMBLING AND DISASSEMBLING THE CASING AND CHECKING

C. B. A.s

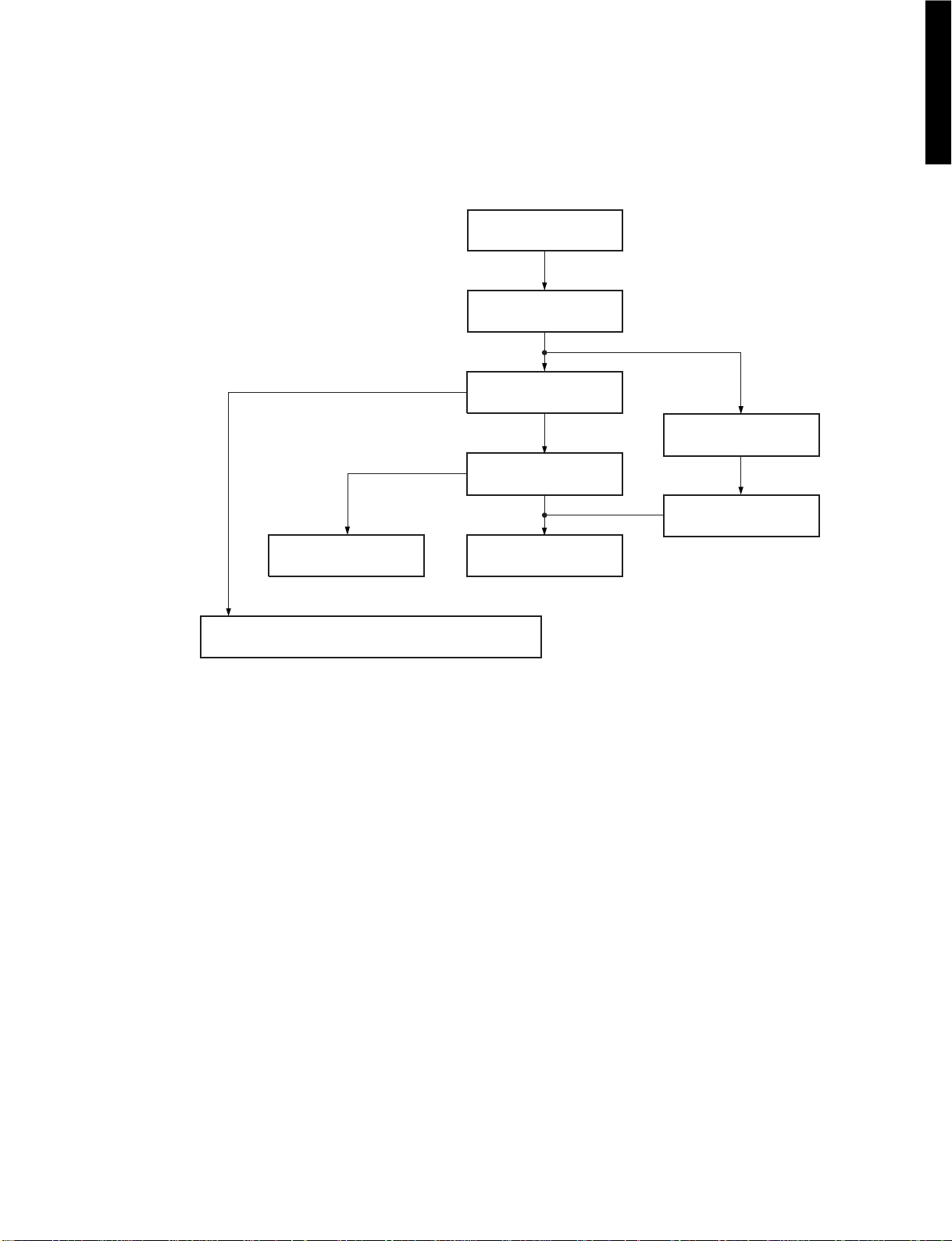

1.Disassembly Procedure .................................................2-1

2.Casing Parts and C.B.A. Positions .............................. 2-2

3.Service Positions ............................................................ 2-2

4.Disassembling the Top Cover ....................................... 2-3

5.Disassembling the Tray ................................................. 2-3

6.Disassembling the Front Panel ..................................... 2-3

7.Disassembling the Loading Base Unit .........................2-4

8.Checking the Module C.B.A. ......................................... 2-4

9.Disassembling the Rear Panel ..................................... 2-4

10.Checking the Power Supply C.B.A............................... 2-5

11.Checking the Mother C.B.A. ......................................... 2-5

12 Checking the Power Switch C.B.A. .............................. 2-5

13.Checking the Front Switch C.B.A. ................................ 2-5

ASSEMBLING AND DISASSEMBLING THE OPTICAL PICKUP

1.Handling the Optical Pickup .......................................... 2-6

2.Disassembly Procedure .................................................2-6

3.Lubricating the Loading Base Unit ............................... 2-7

4.Static Electricity Countermeasures ............................... 2-8

5.Disassembling the Clamp Base Unit ............................ 2-9

6.Disassembling the Clamper Weight, Clamper Yoke,

Magnet and Clamper .....................................................2-9

7.Disassembling the Traverse Unit .................................. 2-9

8.Disassembling the Stepping Motor Unit ..................... 2-10

9.Disassembling the Optical Pickup Unit ...................... 2-10

10.Disassembling the Nut Unit......................................... 2-11

11.Disassembling the Sub-Shaft Preload Spring ........... 2-11

12.Assembling the Optical Pickup ...................................2-11

13.Disassembling the Spindle Motor Unit ....................... 2-12

14.Optical Pickup Tilt Adjustment .................................... 2-13

15.Disassembling the Intermediate Chassis ...................2-15

16.Disassembling the Vertical Cam and Drive Gear ..... 2-15

17.

Disassembling the Pulley Gear and Deceleration Gear ....

18.Disassembling the Mechanism Loading C.B.A. ......... 2-15

19.

Lubricating the Optical Pickup and Peripheral parts .....

ELECTRICAL CONFIRMATION

1.Video Output (Luminance Signal) Confirmation ........2-17

2.Video Output (Chrominance Signal) Confirmation ....2-17

3.

Video Component Signal (CB) Output Confirmation .

1-6

1-7

2-15

2-16

2-18

SECTION 3

ABBREVIATIONS ................................................................. 3-1

BLOCK DIAGRAM

1.OVERALL BLOCK DIAGRAM ....................................... 3-3

2.SERVO BLOCK DIAGRAM ...........................................3-4

3.VIDEO BLOCK DIAGRAM (FOR U, A, R MODELS) .3-5

4.VIDEO BLOCK DIAGRAM (FOR G, B MODEL) ......... 3-6

5.AUDIO BLOCK DIAGRAM ............................................ 3-7

INTERCONNECTION DIAGRAM

1.U, A, R MODELS ........................................................... 3-8

2.G, B MODELS ................................................................ 3-9

SCHEMATIC DIAGRAM

1.POWER SUPPLY SCHEMATIC DIAGRAM (FOR U MODEL) ......

2.

POWER SUPPLY SCHEMATIC DIAGRAM (FOR G, B, A MODELS) .....

3.POWER SUPPLY SCHEMATIC DIAGRAM (FOR R MODEL) ......

4.

ADSC (MODULE C.B.A. 1/6) SCHEMATIC DIAGRAM .....

5.AV DECODER (MODULE C.B.A. 2/6)

SCHEMATIC DIAGRAM (FOR U MODEL) .....................................

6.AV DECODER (MODULE C.B.A 2/6)

SCHEMATIC DIAGRAM (FOR G, B, A, R MODELS) ..........

7.

AUDIO (MODULE C.B.A. 3/6) SCHEMATIC DIAGRAM

8.

FEP (MODULE C.B.A. 4/6) SCHEMATIC DIAGRAM ....

9.

CPU (MODULE C.B.A. 5/6) SCHEMATIC DIAGRAM ........

10.

ODC (MODULE C.B.A. 6/6) SCHEMATIC DIAGRAM...

11.VIDEO OUT (MOTHER C.B.A. 1/4)

SCHEMATIC DIAGRAM (FOR U, A, R MODELS) ... 3-20

12.VIDEO OUT (MOTHER C.B.A 1/4)

SCHEMATIC DIAGRAM (FOR G, B MODELS) ........ 3-21

13.AUDIO OUT1 (MOTHER C.B.A. 2/4) SCHEMATIC DIAGRAM

14.

AUDIO OUT2 (MOTHER C.B.A. 3/4) SCHEMATIC DIAGRAM.

15.

OPERATION (MOTHER C.B.A. 4/4) SCHEMATIC DIAGRAM ......

16.

FRONT SW AND POWER SW SCHEMATIC DIAGRAM ..

17.

SCART SCHEMATIC DIAGRAM (FOR G, B MODELS) ...

CIRCUIT BOARD DIAGRAM

1.POWER SUPPLY C.B.A. (FOR U MODEL) .............. 3-27

2.POWER SUPPLY C.B.A. (FOR G, B, A MODELS) ..........

3.POWER SUPPLY C.B.A. (FOR R MODEL) .............. 3-29

4.MODULE C.B.A. ........................................................... 3-30

5.MOTHER C.B.A. ........................................................... 3-32

6.FRONT SW AND POWER SW C.B.A. ......................3-33

7.SCART C.B.A. (FOR G, B MODELS) ........................ 3-34

SECTION 4

EXPLODED VIEWS & REPLACEMENT PARTS LIST

1.Electrical Replacement Parts List ............................... 4-11

2.Casing Parts & Mechanism Section ........................... 4-13

3.Loading Mechanism Section .......................................4-15

4.Traverse Section ..........................................................4-17

5.Remote Control Transmitter ........................................ 4-18

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-22

3-23

3-24

3-25

3-26

3-28

Page 3

SECTION 1

SPECIFICATIONS

Power requlrements: For U model

AC 120V,60Hz

For G, B, A models

AC 220 – 240V, 50Hz

For R model

AC 110 – 240V, 50/60Hz

Power consumption: For U model

14W

(approx. 2W when set to the standly

mode)

For G, B, A, R models

14W

(approx. 4W when set to the standby

mode)

DVD-S796/DV-S5270

DVD-S796/S5270

Signal system: For U model

NTSC

For G, B, A, R models

PAL 625/50, PAL 525/60

Weight: 7lbs. 4oz (3.3kg)

Dimensions: 17-1/8” (W) ✕ 10-7/8” (D) ✕ 3-7/8” (H)

[435 (W) ✕ 276 (D) ✕ 99 (H) mm]

Operating temperature range: +50° to +35°C (+41° to +95°F)

Operating humidity range: 5 to 90% (no condensation)

Discs played:

(1) DVD-VIDEO disc

5” (12cm) single-sided, single-layer

5” (12cm) single-sided, double-layer

5” (12cm) double-sided, single-layer

3” (8cm) single-sided, single-layer

3” (8cm) single-sided, double-layer

3” (8cm) double-sided, single-layer

(2) Compact disc (CD-DA, VIDEO CD)

5” (12cm) disc

3” (8cm) disc

S-video output:

Y output level: 1Vp-p (75Ω)

C output level: 0.286Vp-p (75Ω)

Output connector: S terminal (1 system)

Video output:

Output level: 1Vp-p (75Ω)

Output connector: Pin jack (1 system)

Compact video output:

For U, A, R models only

Y output level: 1Vp-p (75Ω), green

PB output level: 0.7Vp-p (75Ω), blue

PR output level: 0.7Vp-p (75Ω), red

Output connector: Pin jack

Audio output:

Output level: 2 Vrms (1kHz, 0dB)

Output connector: Pin jack

Mixed output: 1 system

Subwoofer output: 1 system

Audio signal output characteristics:

(1) Frequency response:

DVD (linear audio):

2Hz to 22kHz (48kHz sampling)

2Hz to 44kHz (96kHz sampling)

CD audio:

2Hz to 20kHz (EIAJ)

(2) S/N ratio:

CD audio: 115dB (EIAJ)

(3) Dynamic range:

DVD (linear audio): 102dB

CD audio: 98dB (EIAJ)

(4) Total harmonic distortion:

CD audio: 0.0025% (EIAJ)

Digital audio output:

Optical digital output: Optical connector

Pickup: Wave length: 655nm

Laser power: CLASS II

Laser output: Max. 1.0 mW (Continuous)

Color: DVD-S796BU Black

DV-S5270BU Black

DVD-S796BG Black

DVD-S796TG Titanium

DVD-S796GG Gold

DVD-S796BB Black

DVD-S796BA Black

DVD-S796GR Gold

Specifications are subject to change without notice.

Weight and dimensions are approximate.

U ........ U.S .A. mo del G ........ E uropean model

R ........Asian model B ........ United Kindom model

A ........ Australlan model

Manufactured under license from Dolby Laboratories Licensing Corporation. “Dolby” and the double-D symbol are

trademarks of Dolby Laboratories Licensing Corporation.

LOCALE MANAGEMENT INFORMATION

Locale Management Information: This DVD player is designed and manufactured to respond to the Locale

Management information that is recorded on a DVD disc. If the Locale number described on the DVD disc

does not correspond to the Locale number of this DVD player, this DVD player cannot play this disc.

(See page1-3, REGION CODE.)

This product incorporates copyright protection technology that is protected by method claims of certain

U.S. patents and other intellectual property rights owned by Macrovision Corporation and other rights

owners. Use of this copyright protection techology must be authorized by Macrovision Corporation,

and is intended for home and other limited viewing uses only unless otherwise authorized by Macrovision

Corporation. Reverse engineering or disassembly is prohibited.

1 - 1

Page 4

TO SERVICE PERSONNEL

1. Critical Components Information

DVD-S796/DV-S5270

Components having special characteristics are marked

and must be replaced with parts having specifications equal

to those originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both polarites.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic

and/or plastic (where applicable) components may also contain traces of chemicals found by the

California Health and Welfare Agency (and possibly other entities) to cause cancer and/or birth defects

or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH

FOR ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale

solder fumes or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your

hands before handling food.

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible

radiation, which may cause eye damage. To protect your eyes and skin from laser radiation, the following

precautions must be used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than

30cm away from the laser pick-up unit at all times. Do not stare the laser beam at any time.

2) Do not attempt readjustment, disassemble or repair of the laser pick-up, unless notes elsewhere in this

manual.

3) CAUTION : Use of controls, adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Laser Emitting conditions:

1) When the Top Cover is removed, and POWER SW is turned to the "ON" position, the laser component

will emit a beam for several seconds to detect if a disc is present. During this time (5-10sec.) the laser

may radiate through the lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is set, you will not be exposed to

any laser emissions.

2) The laser power level can be adjusted with VR on pick-up PWB, however, this level has been set by

the factory prior to shipping from the factory. Do not adjust this laser level control unless instruction

is provided elsewhere in this manual.

Adjustment of this control can increase the laser emission level from the device.

Laser Diode Properties

Material : GaAlAs Laser output : Max.6mW

Wavelength : 660~676nm ANSI Class : Class 1

Emission duration : Continuous

* This output is the value measured at a distance of about 200mm from the objective lens surface on the Optical

Pick-up Block,

1 - 2

Page 5

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASER-SÄTEILYLLE. ÄLÄ KATUO SÄTEESEEN.

VARNING! : OSYNIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

➁ G, B models

➀ G, B models

CLASS 1 LASER PRODUCT

PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically

Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor “chip”

components. The following techniques are used to help reduce the incidence of component damage caused by electro static discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your body by touching

a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent

electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only a anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can generate

electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement ES

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES divice, touch the protective material to the chassis or

circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of

your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

DVD-S796/DV-S5270

DVD-S796/S5270

There are special components used in this equipment which are important for safety.

These parts are marked by in the schematic diagrams, exploded views and replacement parts list. It is

essential that these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or

other hazards. Do not modify the original design without permission of manufacturer.

REGION CODE

IMPORTANT SAFETY NOTICE

1

4

2

2

5

6

5

5

2

3

4

1 - 3

Page 6

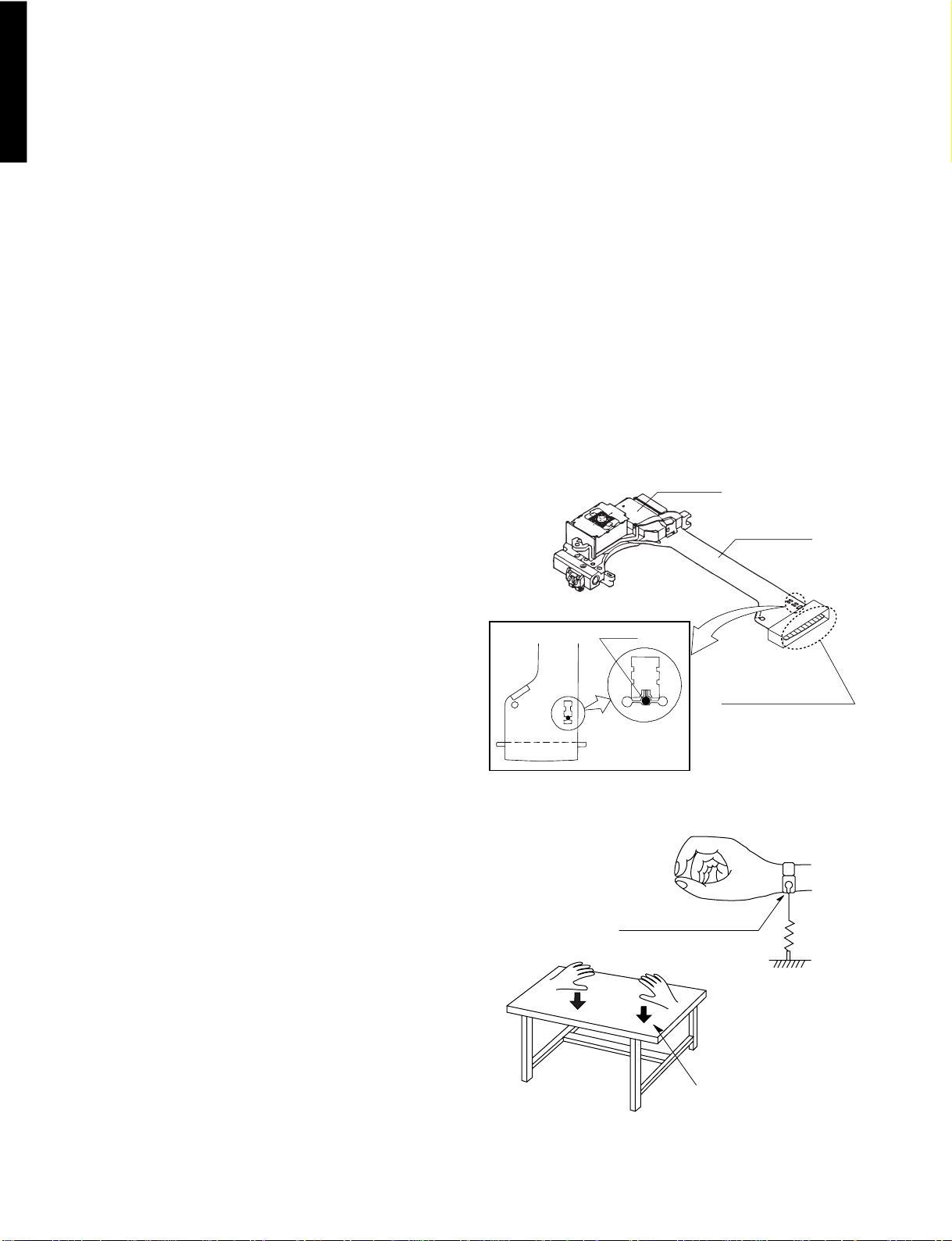

PRECAUTION OF LASER DIODE

CAUTION:

DVD-S796/DV-S5270

This unit utilizes a class II laser. Visible laser radiation is emitted from the optical pickup lens when the

unit is truned on:

1. Do not look directly into the pickup lens.

2. Do not use optical instruments to look at the pickup lens.

3. Do not adjust the preset variable resistor on the optical pickup.

4. Do not disassemble the optical pickup unit.

5. If the optical pickup is replaced, use the manufactures specified replacement pickup only.

6. Use of control or adjustment or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

HANDLING PRECAUTIONS FOR TRAVERSE DECK

The laser diode in the optical pickup may break down due to

potential difference caused by static electricity of clothes or

human body.

So be careful of electrostatic breakdown during repair of the

optical pickup.

Pickup unit

Handling of optical pickup

1. Do not subject the optical pickup to static electricity

as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode,

an antistatic shorting pin is inserted into the

flexible board (FPC Board).

When removing or connecting the short pin,

finish the job in as short times as possible.

3. Be careful not to apply excessive stress to the

flexible board (FPC Board).

4. Do not turn the variable resistor (Laser power adjustment).

It has already been adjusted.

Grounding for electrostatic breakdown prevention

1. Human body grounding.

Use the antistatic wrist strap to discharge the static

electricity from your body.

2. Work table grounding.

Put a conductive material (sheet) or steel on the area

where the optical pickup is placed and ground the sheet.

Solder

(Magnified view)

Wrist strap

(Anti-static bracelet)

Flexible Cable

Use a clip or other item

to ground the unit.

1M

Caution:

The static electricity of your clothes will not be grounded

through the wrist strap. So take care not to let your clothes

touch the optical pickup.

Iron plate or some metals

to conduct electricity

1 - 4

Page 7

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

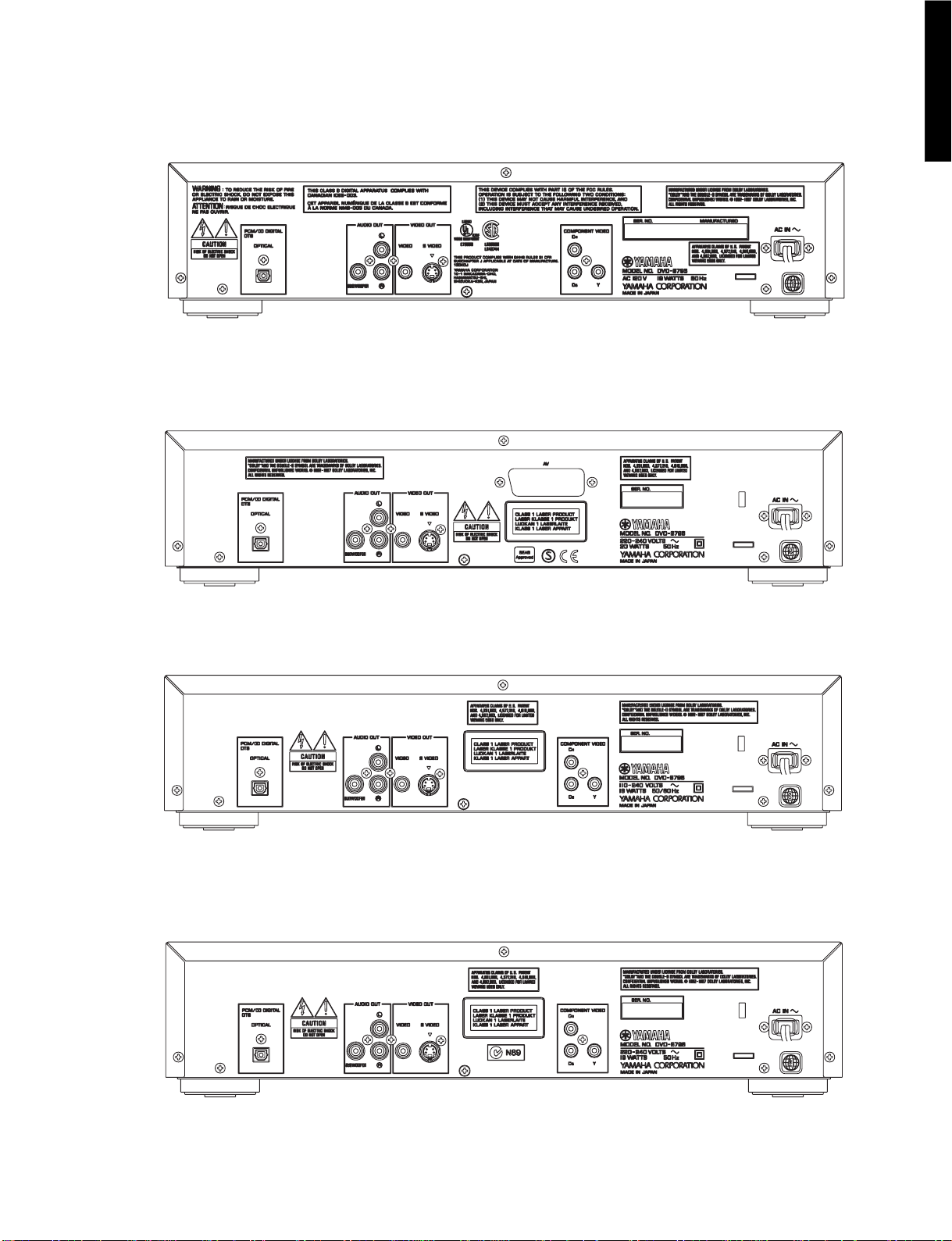

REAR PANELS

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

U model

N3

N3

N3

G, B models

N3N3N3

DVD-S796/DV-S5270

DVD-S796/S5270

N3

N3

N3

N3

N3

N3

N3

N3

R model

N3

A model

N3

N3

N3

N3

N3

N3N3N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

N3

1 - 5

Page 8

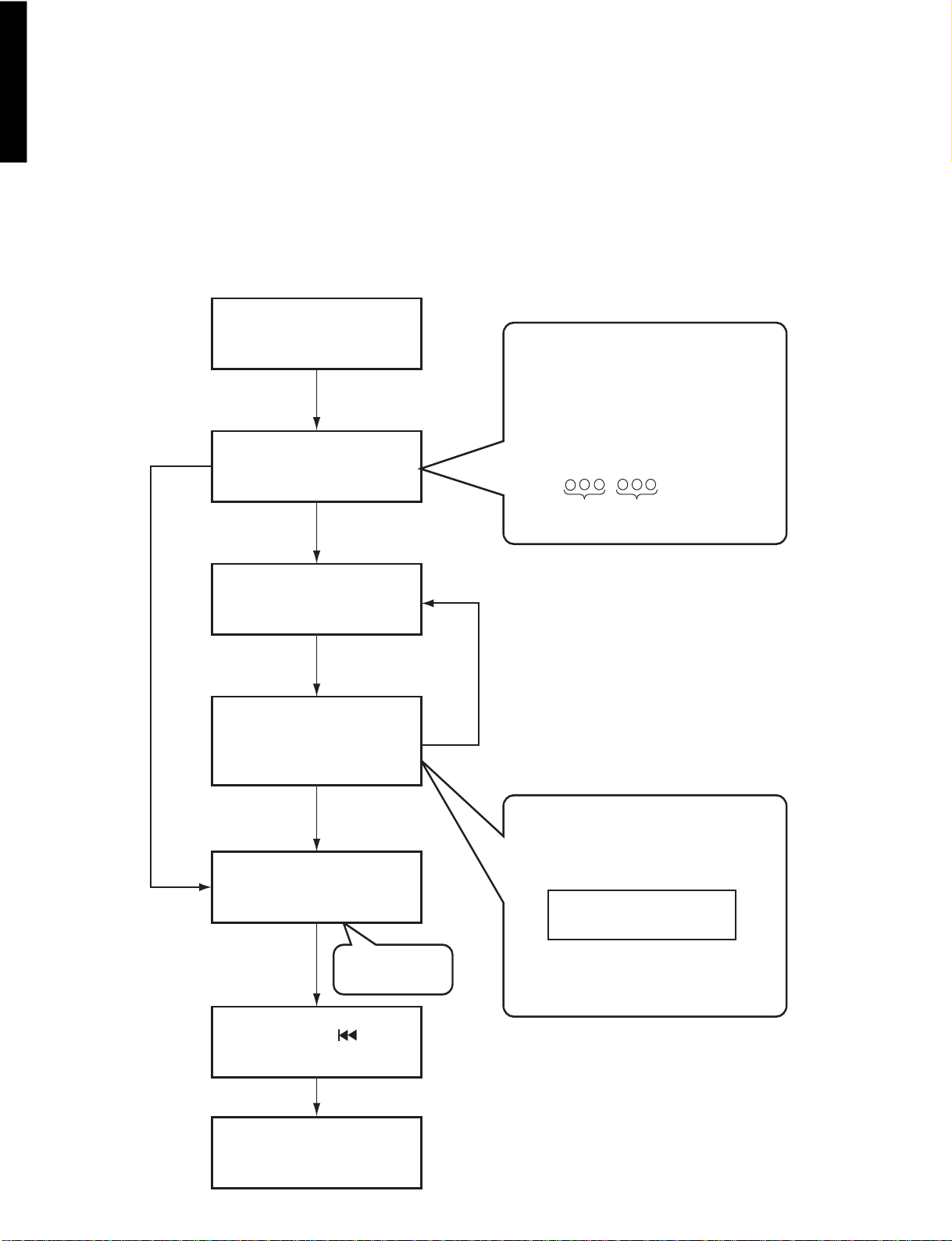

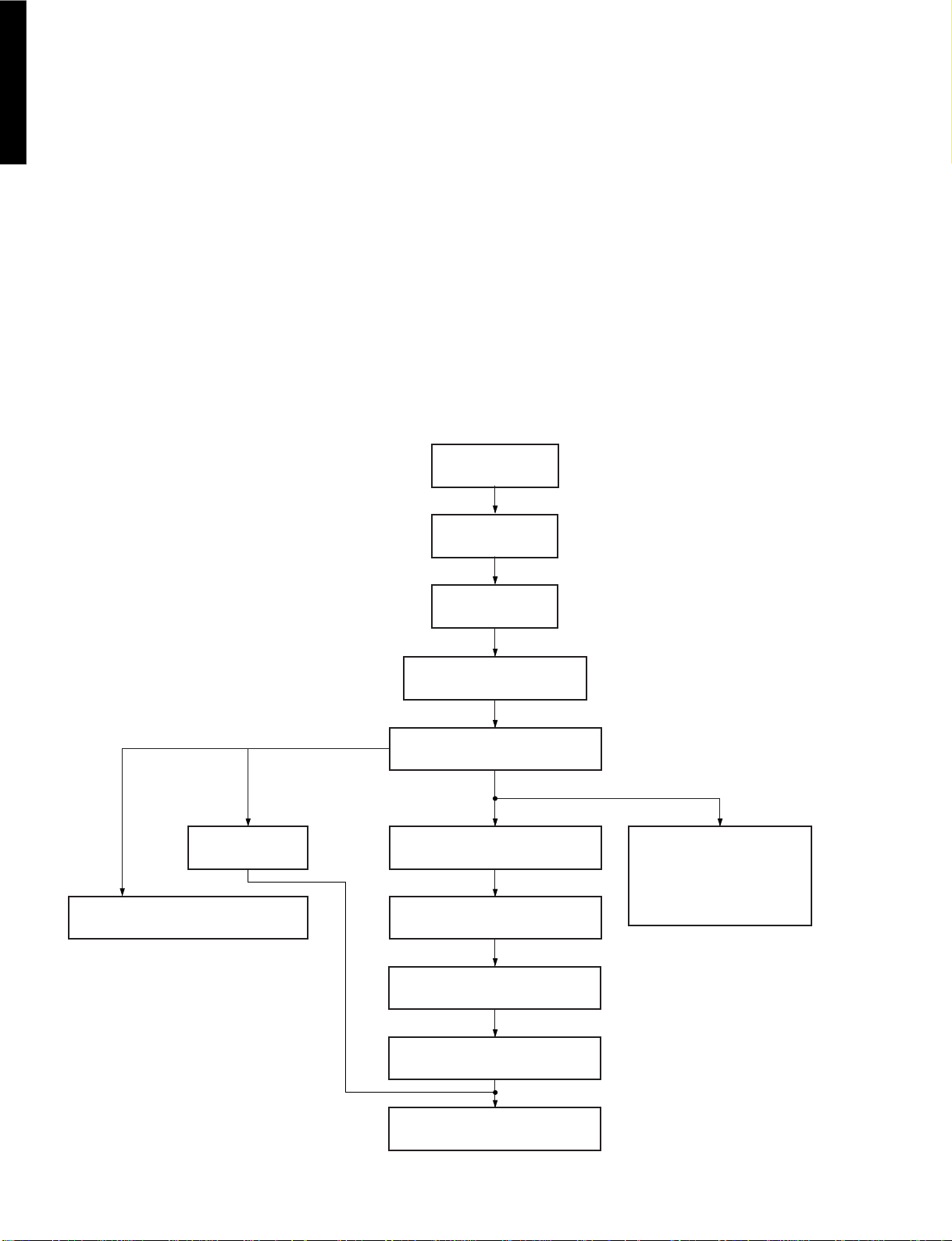

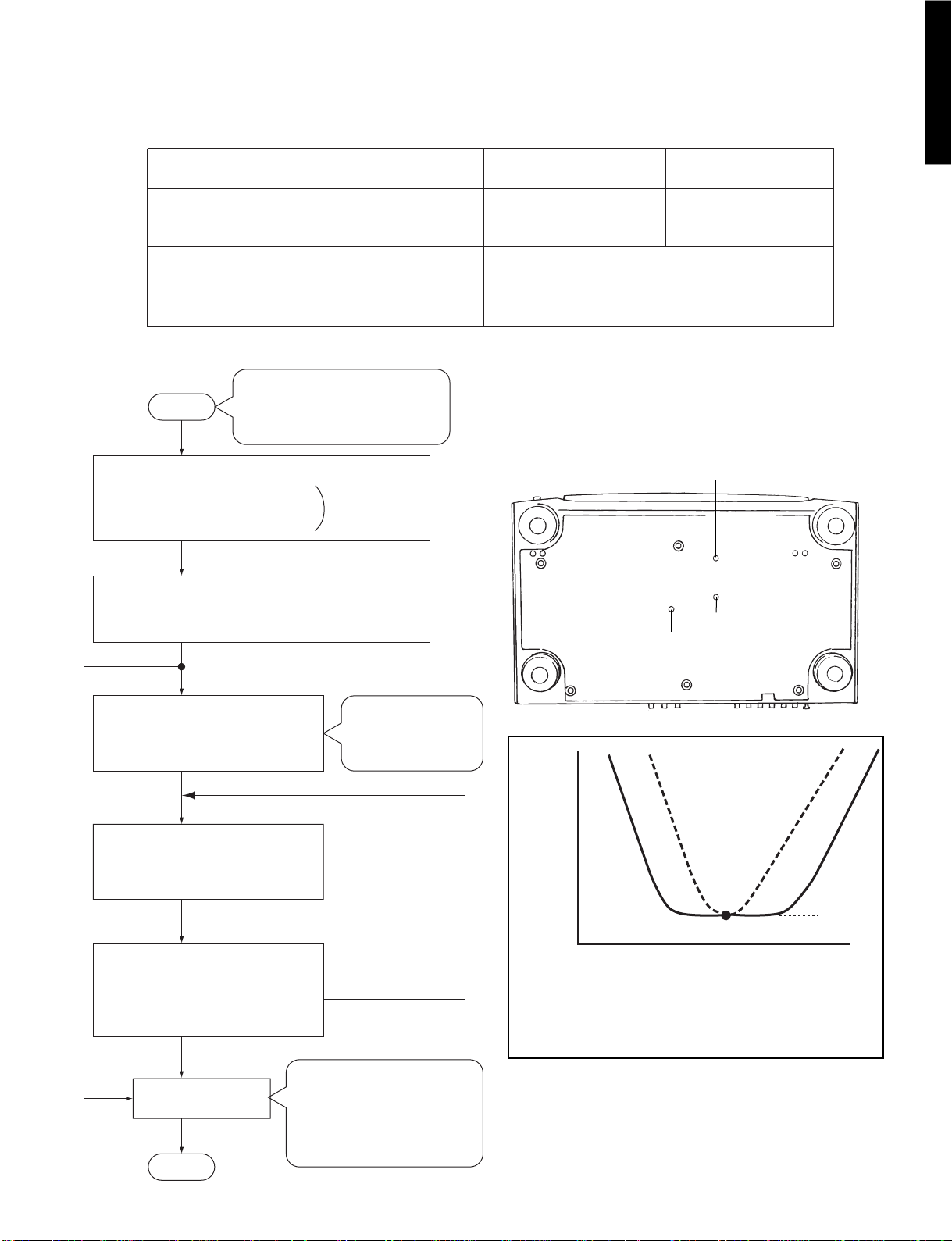

OPTICAL PICKUP SELF-DIAGNOSIS AND REPLACEMENT PROCEDURE

The optical pickup self-diagnosis function and tilt adjustment check function have been newly added to this player. When repairing, use the following procedure for effective Self-diagnosis and tilt adjustment.

DVD-S796/DV-S5270

Be sure to use the self-diagnosis function before replacing the optical pickup when “NO DISC” is displayed. As a guideline, you

should replace the optical pickup when the value of the laser drive current is more than 50.

Note

Press the power button to turn on the power, and check the value before the unit warms up (within three minutes).

• Use the self diagnosis function below

when "NO DISC" is displayed or unit

doesn't read a disc, before replacing

the OPU.

"NO DISC" is displayed,

unit does not play smoothly, etc.

• Use the optical pickup self-diagnosis function.

Method: With no disc in the player.

• Press the "ON SCREEN" button on the

remote control unit while pressing the

"STILL/PAUSE" and "OPEN/CLOSE"

button on the player.

Value is

50 or less

Check the laser drive current.

Value is

more than 50

Replace the optical pickup

(Refer to Assembling and

Disassembling the Optical

Pickup, page 2-1.)

Check the laser drive

current after replacement.

• Write the present value into

the unit if it is 40 or less.

Do the optical pickup

tilt adjustment.

(Refer to Optical Pickup

Tilt Adjustment, page 2-13.)

Display content

LD

Factory

preset value

Replace with a new optical pickup if the present

value is more than 40.

Cause:

Damage due to static electricity during replacement.

Method: With no disc in the player.

• Press the "ON SCREEN" button on the

remote control unit while pressing the

"PAUSE" and "OPEN/CLOSE"

button on the player.

• Write the present value into

the played if it is 40 or less.

Present value

Use the tilt

adjustment

check function.

Initialize the player.

Press Pause and and

Open/Close buttons on unit

simultaneously.

End

(Refer to Handling After

Completing Repairs, page 1-9.)

Writing method:

• Press the "PAUSE" button on the remote

control unit while pressing the "PAUSE" and

"OPEN/CLOSE" button on the player.

1 - 6

Page 9

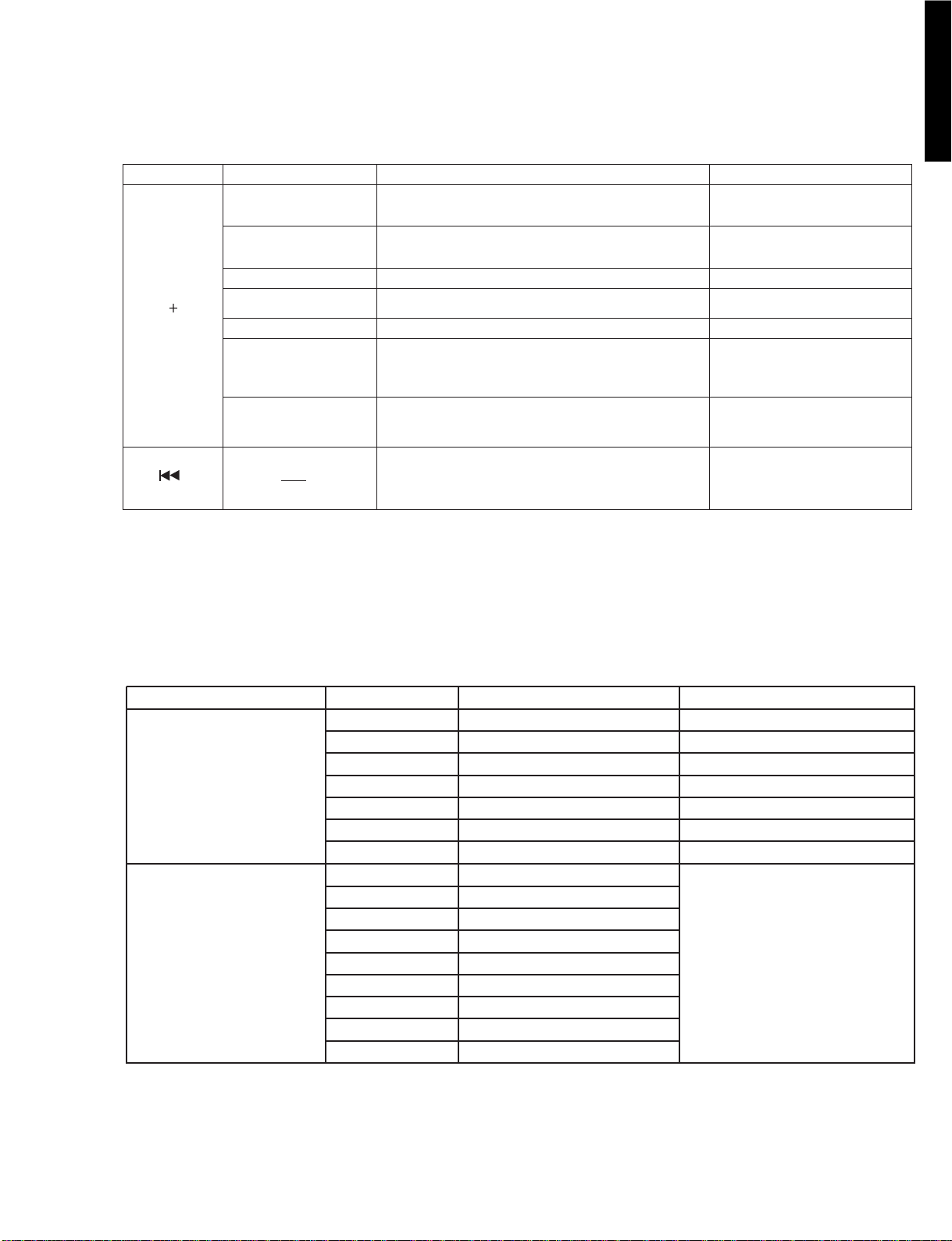

SELF-DIAGNOSIS FUNCTION AND SERVICE MODES

This unit incorporates a convenient self-diagnosis function for use in troubleshooting.

Display method Display

Diagnosis

Checkpoints

Service numbers displayed

during use.

Press the "0" button on the

remote control unit while pressing

the "STILL/PAUSE" and

"OPEN/CLOSE" button on the

player.

U11

H01

H02

H03

H04

H05

H06

F0**

F1**

F2**

F3**

F4**

F5**

F6**

F7**

F8**

Focus error

Tray loading error

Spindle servo error

Traverse error

Tracking servo error

Seek error

Power supply error

Disc format error

Disc code error

Decoder LSI error

SDRAM error

IC2001,IC2511,IC5201,pickup

IC2001,IC2511 loading motor

Spindle motor, IC2501,IC2001

Stepping motor,IC2511,IC2001

IC2001,IC2501,IC5201,pickup,disc

Stepping motor,IC2511,IC2001

IC1021,IC1121,IC1151,IC6001

If this type of error occurs,refer to

Examples of Repairs Using Error

Codes, in page 1-8.

IIC BUS error

DSC

ECC error

Microprocessor error

Microprocessor error

1. Service Mode Table

The service mode can be activated by pressing various button combinations on the player and remote control unit.

Player buttons

PAUSE

OPEN/CLOSE

STILL/PAUSE

SKIP

OPEN/CLOSE

Remote control unit button

0

5

6

7

9

ON SCREEN

STILL/PAUSE

Displaying the UHF display F_ _ _

Tilt adjustment

(JIT 070 to JIT 090 is normal range for a good pickup head.)

Checking the region numbers and broadcast system

Checking the program version

Lighting Confirmation Function of Display Tube

Checking the laser drive current

Writing the laser drive current value after replacing

the optical pickup (do not use for anything other than

optical pickup replacement)

Initializing the DVD player

(restoring factory preset settings)

Use when replaceing a microprocessor, microprocessor

peripheral parts, or C. B. A.

Application

Refer to Self-Diagnosis Function

(UHF Display)

Refer to Optical Pickup Tilt

Adjustment, in page 2-13.

Check the IC6302

FLASH ROM program.

Refer to Optical Pickup SelfDiagnosis and Replacement,

in page 1-6.

Procedure.

Refer to Initializing the DVD

Player, in page 1-9.

DVD-S796/DV-S5270

DVD-S796/S5270

Note

,in page 1-7.

2. Self-Diagnosis Function (UHF Display)

1 - 7

Page 10

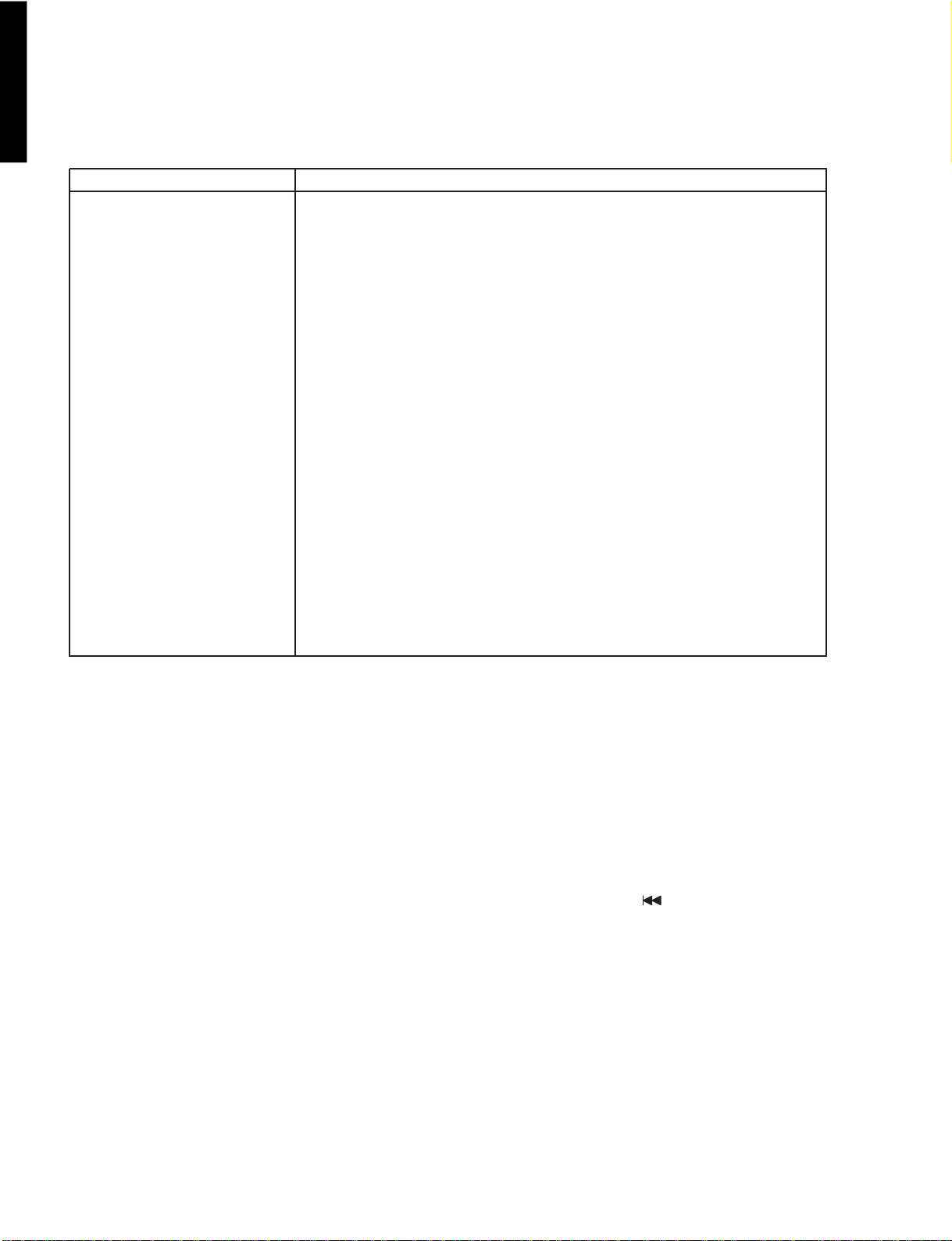

3. Examples of Repairs Using Error Code

DVD-S796/DV-S5270

Refer to this section when carrying out repairs.

Error display

F0**

F103

F4FF

F500

F501

F502

F504

F505

F506

F600

F601

F602

F603

F610

F611

F612

F620

F621

F700

F701

F702

F880

F890

F891

F8A0

F893

F894

Malfunction example

Disc, IC7001

Disc, IC7001

IC6001

Optical pickup, IC2001, IC5201, IC2511, IC2501

IC2001, IC6201

IC2501, IC2511, IC2001, IC5202

IC5202, IC2001

Disc, IC2501, IC2511, IC5202, IC2001

Disc, Optical pickup, IC2001

Disc, IC7001, IC5202, IC2001

Disc, IC7001

Disc, IC5202, IC2001

Disc, IC5202, IC2001

IC7001

IC7001, IC5202, IC2001

IC7001, IC15202,IC2001

Laser drive circuit

Laser drive circuit

IC6201

IC6201

IC6201

IC6201

IC6201

IC6201

IC6201

IC6302

IC6303

4. Sales Demonstration Lock Function

This function prevents discs from being lost when the unit is used for sales demonstrations, by disabling the disc eject function.

“LOCKED” is displayed on the unit, and ordinary operation is disabled.

4-1. Setting Method

The sales demonstration lock function is set by simultaneously pressing the “POWER” button of DVD Player on the remote

control unit and the “STOP” button on the main unit. (“LOCKED” is displayed when the lock function is engaged.)

4-2. Release Method

The function can be released using the same procedure as for setting. If the remote control unit is not at hand, the function can be

released by using the same method as for player initialization (pressing the “PAUSE”, “SKIP

buttons simultaneously).

” and “OPEN/CLOSE”

1 - 8

Page 11

SERVICE PRECAUTIONS

1. Initializing the DVD Player

Initialize the DVD player whenever you replace a microprocessor, microprocessor peripheral parts, module C.B.A or mother C.B.A.

1-1. Precautions

The customer settings will return to factory preset settings when the player is initialized. Make a note of the settings and reset

them after initializing.

• When resetting, see the Initial Setting in the Operating Instructions.

1-2. Initialization Method

The player will be initialized (return to the factory preset condition) when you press the “PAUSE”, “SKIP “ and “OPEN/CLOSE”

buttons simultaneously. When the DVD player is initialized, “All Clear” appears on screen, it also displays “INITIALIZED”.

2. Handling After Completing Repairs

Use the following procedure to secure the traverse unit in the standby position.

2-1. Method

With the power turned on:

1. Press the “OPEN/CLOSE” button to close the tray.

2. Press the “POWER” button to turn off the power.

3. Disconnect the power plug from the outlet.

DVD-S796/DV-S5270

DVD-S796/S5270

2-2. Precautions

Do not disconnect the power plug from the outlet with the tray still open, then close the tray manually. If you were to do so, the

traverse unit would not go to the upper (standby) position, and the player could not be transported.

SERVICE TOOLS AND EQUIPMENT

1. Service Tools and Equipment Table

Application

General

Tilt adjustment

Inspection

Others

Confirmation

Electrical adjustment

General

Static electricity countermeasures

DVD test disc

Hex wrench

Adjustment table

Extension cables (Power supply C.B.A. to mother C.B.A.)

Extension cable (module C.B.A. to mother C.B.A.)

Screw lock

Grease

Lubricant

Grease

CD test disc

VCD test disc

Oscilloscope

Probe

AV cable

TV monitor

General tools (Screwdriver, etc.)

Soldering iron (with ESD countermeasure)

Anti-static wrist strap

Conductive material (conductive sheet)

Name Number

DVDT-S15 (AAX07320) or DVDT-S01 (TX946080)

JZS0100 (TX946380) , 1.2mm

JGS0099 (TX946360)

JGS0098 (TX946370) × 2

RZZ0L01 (TX946400)

JGS0091 (TX946260)

JGS0092 (TX946270)

JZS0648 (TX946410)

JGS0101 (TX946390)

SZZP1054C (TX946090)

PVCD_K06 (TX946090)

VJA0658 (MX605190)

2. Storing and Handling Test Discs

Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness.

Place them into their case after use and store them verically. Store discs in a cool place where they are not exposed to direct

sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped from being placed on a surface made of glass, etc. If this

happens, use a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

1 - 9

Page 12

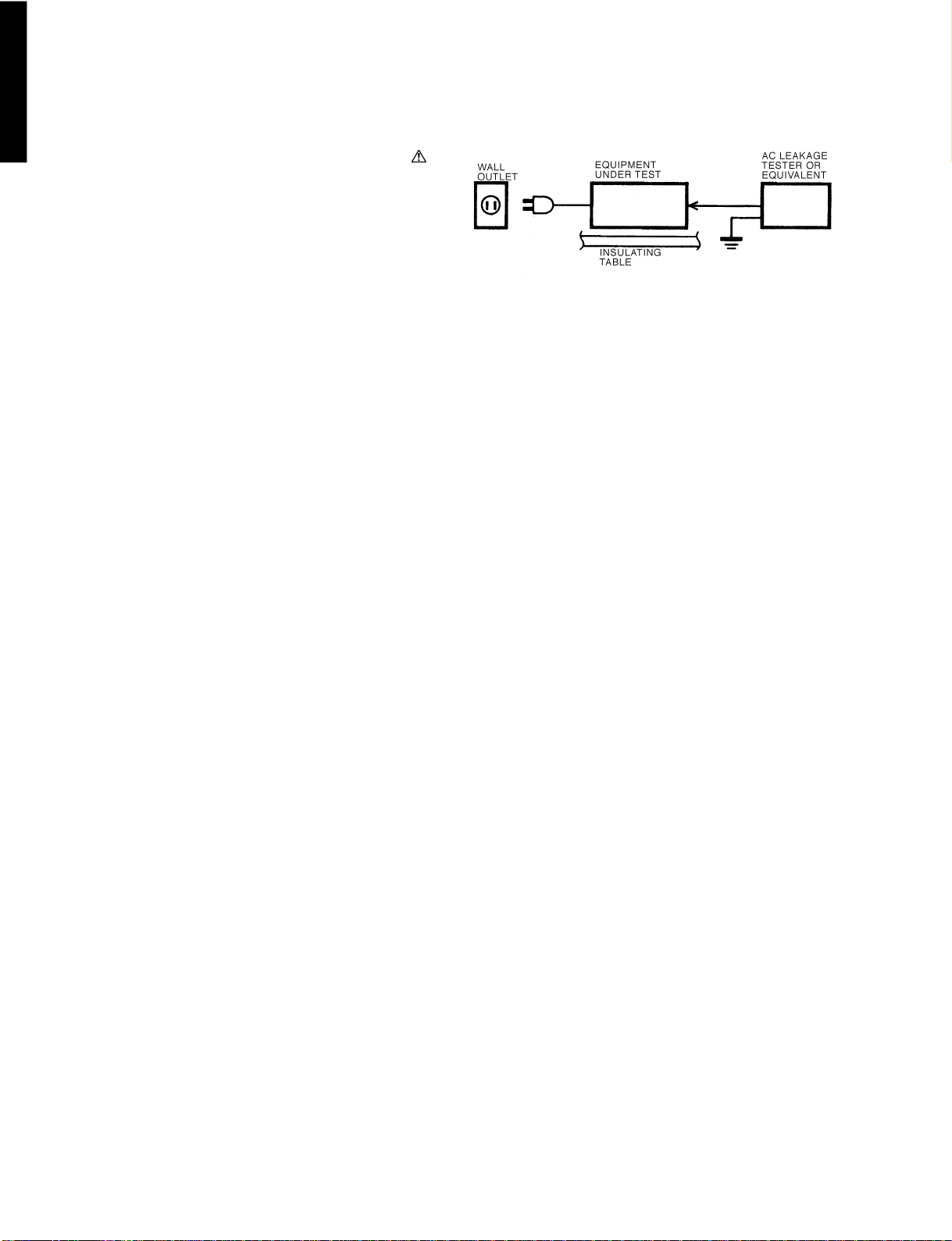

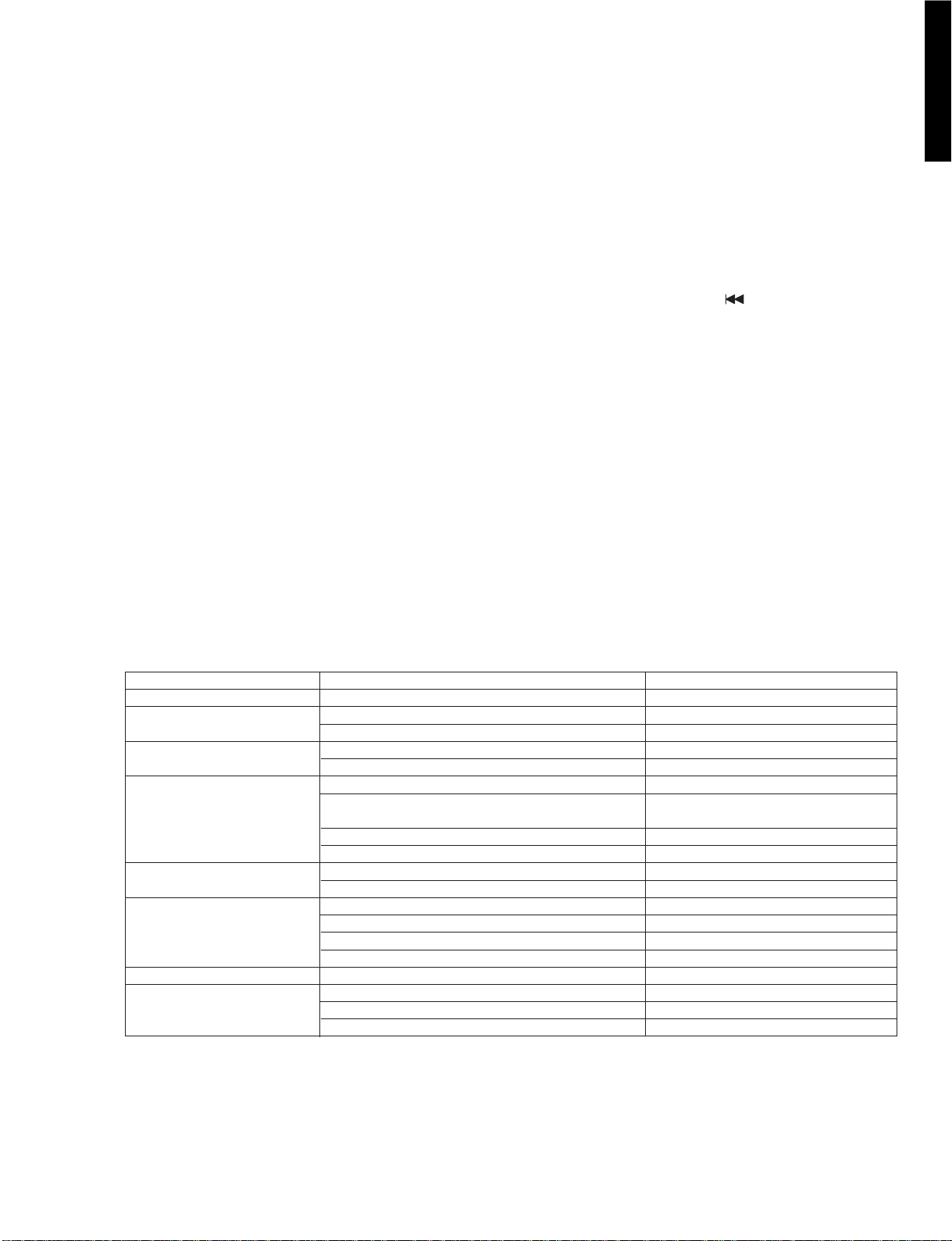

OPERATING INSTRUCTIONS

>

=

Control reference guide

DVD-S796/DV-S5270

1

NATURAL SOUND DVD PLAYER

STANDBY/ON

11

ANGLE

PROG.

DVD

17 18 19 20 21 22

Player

1

Standby/On button (STANDBY/ON) .......................14

Press to switch the unit from on to standby mode or vice versa.

In standby mode, the unit is still consuming a small amount of

power.

2

Disc tray ....................................................................14

3

Disc tray open/close button ( OPEN/CLOSE) ..... 14

4

Play button ( ) .......................................................14

5

Pause button ( ) ....................................................16

6

Stop button ( ) .......................................................15

7

FL display

8

Virtual Surround Sound indicator (V.S.S.)............. 21

9

Skip button ( SKIP ) .................................... 16

10

Search button ( SEARCH ) .........................17

11

12

13

14

15

16

Rotates during play.

Rotates fast clockwise or counter clockwise during

rapid advance (reverse).

Rotates slowly clockwise or counter clockwise

during slow-motion play.

Illuminates in the stop mode.

Illuminates during playback.

Flashes when the RESUME function is ON.

Illuminates during repeat play.

Illuminates in the still picture (pause) mode.

Elapsed playing time from the start of the title/track

during play.

Audio channel information recorded in the disc being

played back (e.g. 2ch or 5.1ch).

Surround (left)

Front (left)

D I G I T A L

DVD / VIDEO CD / CD

V.S.S.

87 9 10

15 1612 1314

Owner's Manual Page

DVD VCD

Center

Surround (right)

Subwoofer

Front (right)

32 4 5 6

f OPEN/CLOSE

:

SKIP

;

96kHz 24bit

Buttons such as function in exactly

1

the same way as the buttons on the

player.

1

C

POWER

SEARCH

D

6

5

9

STOP

∫

SKIP

TOP MENU

H /I

PAUSE

;

OPEN/CLOSE

PLAY

1

SLOW/

SEARCH

6:9 5

MENU

23

24

ENTER

25

26

27

28

29

30

31

17

A DVD is loaded.

18

It is possible to switch the angle.

19

Illuminates during program play.

20

Title/chapter number

21

Track number

VCD

CD

DVD

PLAY MODE

SUBTITLE

REPEAT

A-B

V.S.S.

CANCEL

SET UP

Linear PCM of 96 kHz sampling is being played.

22

Linear PCM of 24 bit is being played.

RETURNON SCREEN

AUDIO ANGLE

123

456

789

0S10

DVD

VCD

CD

Remote control

Owner's Manual Page

23

Top menu button (TOP MENU) ...................................... 14

24

Cursol button ( , , , ) /Enter button (ENTER) .. 14

25

On screen button (ON SCREEN) ................................... 25

26

Play mode button (PLAY MODE) ...................................23

27

Subtitle button (SUBTITLE)............................................ 20

28

Repeat button (REPEAT) ................................................ 22

29

A-B repeat button (A-B) .................................................. 22

30

Virtual Surround Sound button (V.S.S.)........................ 21

31

Setup buttons (SET UP) .................................................28

32

Slow/Search buttons ( , SLOW/SEARCH) ........17

33

Menu button (MENU) ......................................................14

34

Return button (RETURN) ................................................ 14

35

Angle button (ANGLE) .................................................... 20

36

Audio button (AUDIO)..................................................... 19

37

Numeric buttons (1-9, 0, 10) ........................................ 14

• To select a 2-digit number

Example: To select track 23

Press [ 10], then [2] and [3].

38

Cancel button (CANCEL)................................................ 23

>

=

3

4

32

33

34

35

36

37

38

1 - 10

Page 13

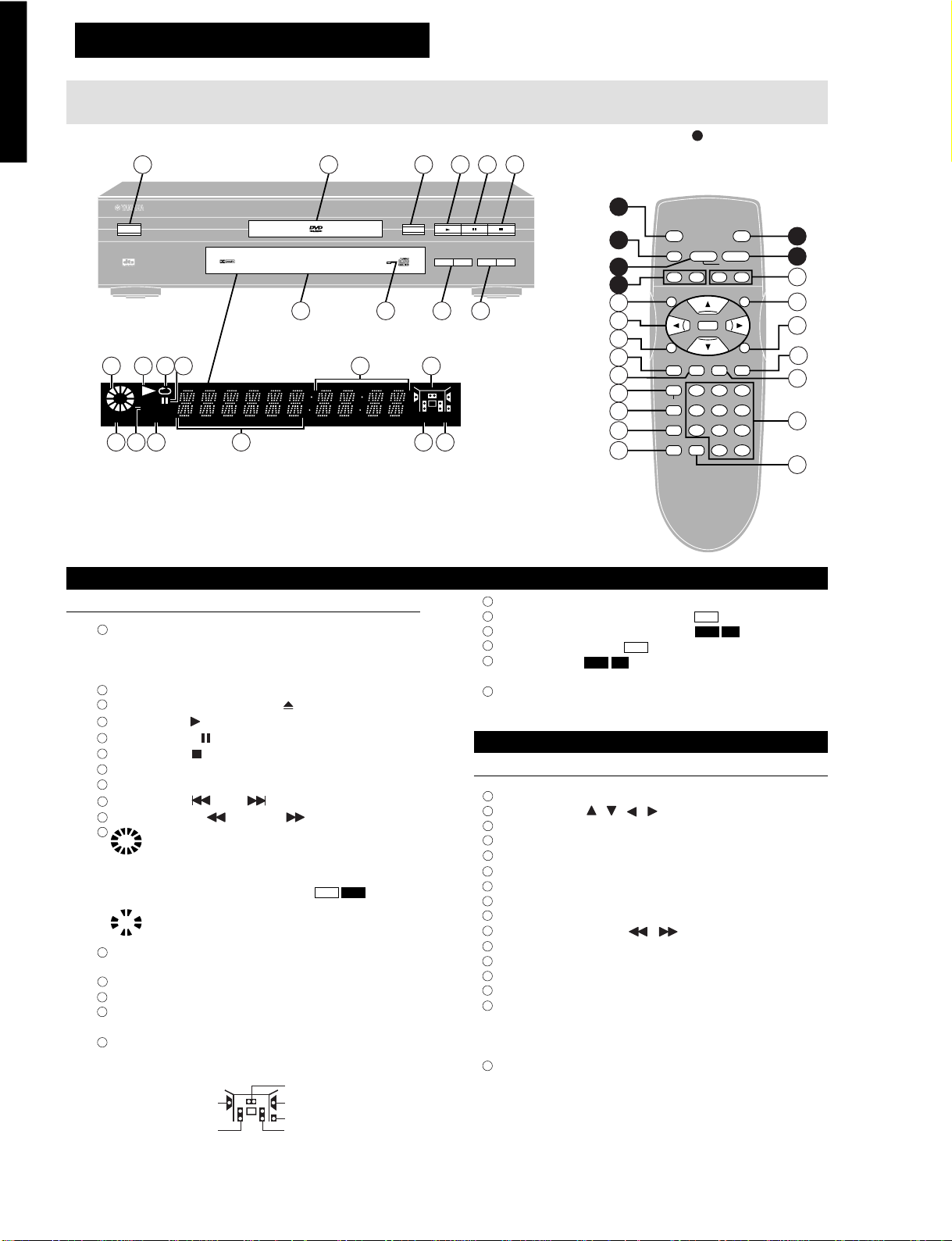

SECTION 2

ASSEMBLING AND DISASSEMBLING THE CASING AND CHECKING C.B.A.s

1. Disassembly Procedure

When servicing the unit, use the following procedure to disassemble the casing and inside parts for internal inspection.

Top cover

Tray

Front panel

Rear panel

DVD-S796/DV-

S5270

Mechanism unit

Module C.B.A.

Mother C.B.A.

Front SW C.B.A. and Power SW C.B.A.

Power Supply

C.B.A.

2 - 1

Page 14

S5270

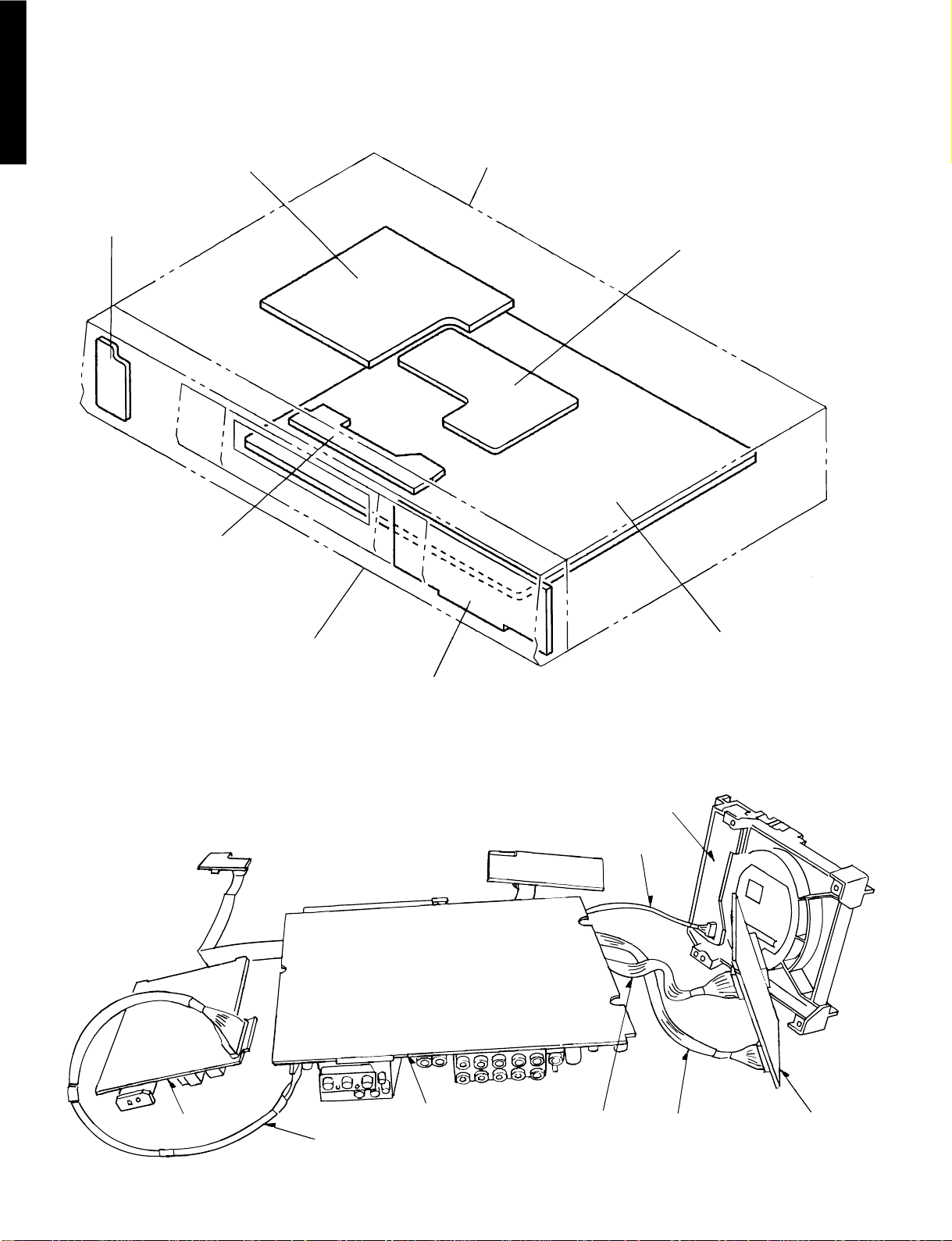

2. Casing Parts and C.B.A. Positions

DVD-S796/DV-

Power supply C.B.A.

Top cover

Power SW C.B.A.

Mechanism Loading C.B.A.

Front panel

Module C.B.A.

Mother C.B.A.

Front SW C.B.A.

3. Service Positions

Note

To inspect the loading base unit, position the left side upward (as viewed from the front).

Power supply C.B.A.

Mother C.B.A.

TX946360

AAX16590

Mechanism

Loading C.B.A.

AAX16600

AAX16610

Module C.B.A.

2 - 2

Page 15

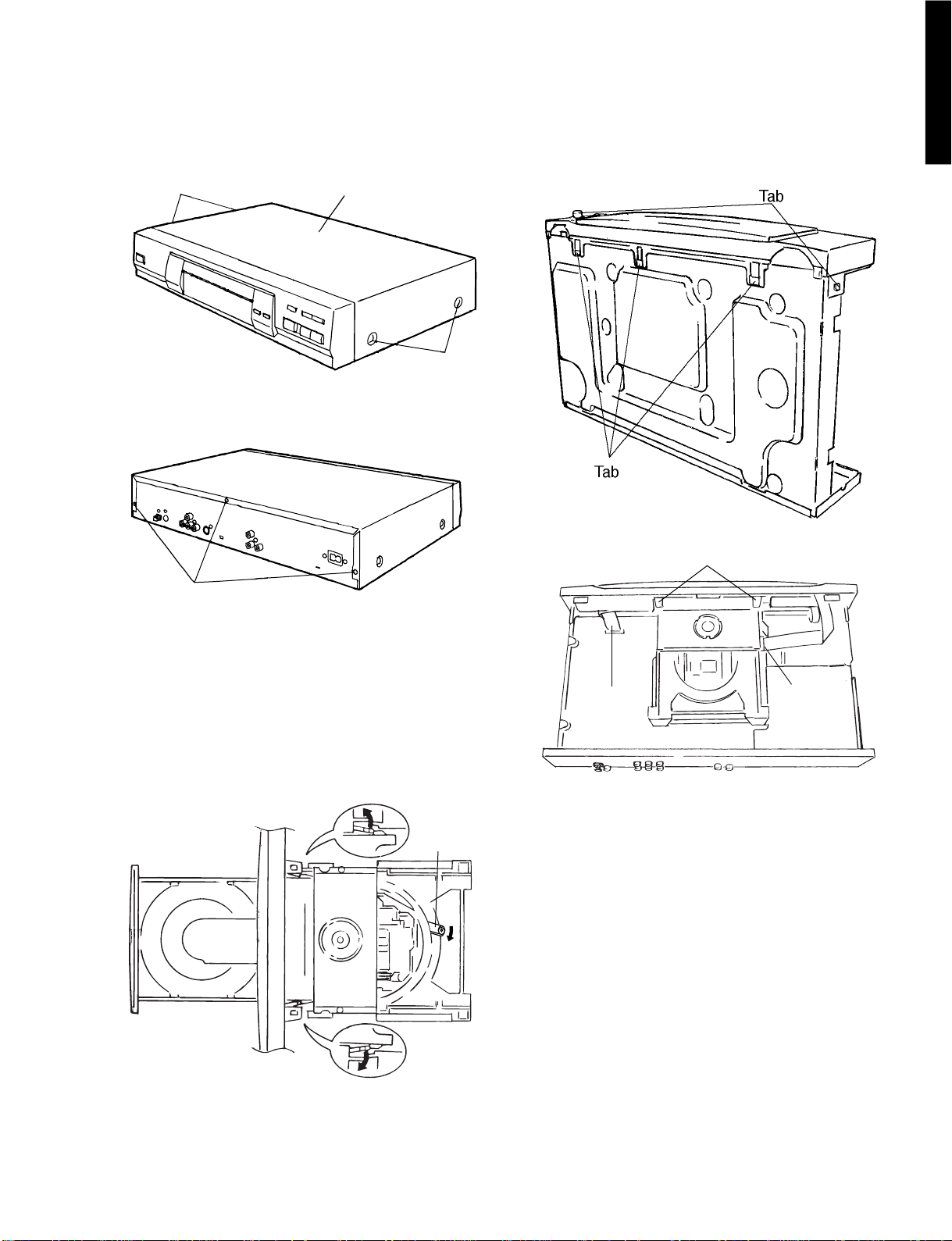

4. Disassembling the Top Cover

1. Remove the 4 screws.

Screw

2. Remove the 3 screws.

Top Cover

Screw

DVD-S796/DV-

S5270

6. Disassembling the Front Panel

1. Release the 3 tabs on the bottom.

2. Release the 2 tabs on the left and right.

SERV ICE M A N UAL

Screw

5. Disassembling the Tray

1. Turn the lever clockwise.

2. Move the tray in the direction of the arrow until it locks.

3. Release the tab locks on the left and right, then pull out

the tray.

Tab

Lever

3. Release the 2 tabs.

4. Disconnect the 2 flexible cables

Tab

Flexible

cable

.

Flexible

cable

Tab

2 - 3

Page 16

S5270

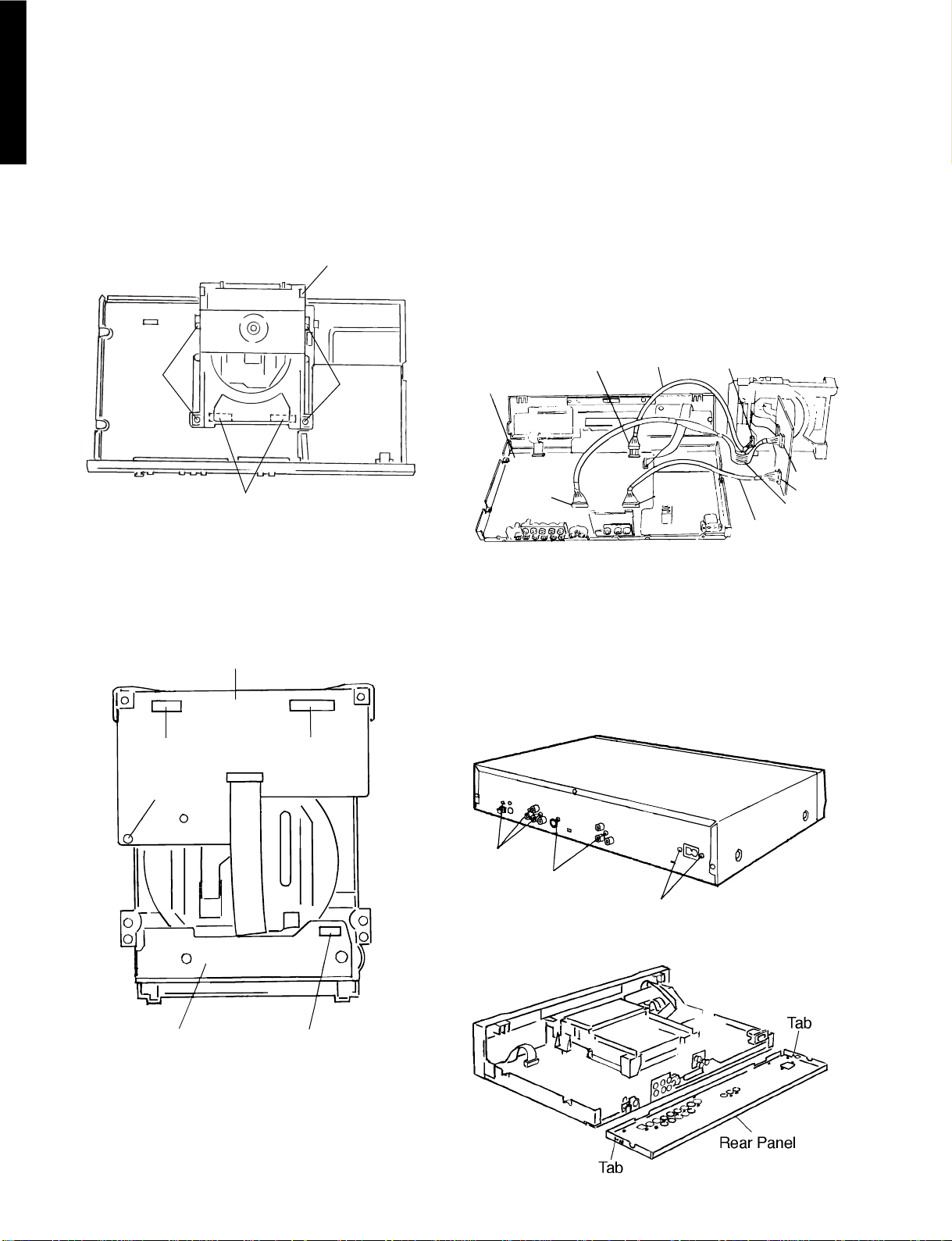

7. Disassembling the Loading

DVD-S796/DV-

Base Unit

1. Remove the 4 screws.

2. Pull out the loading base unit vertically.

Note

There is a danger of damaging the connectors.

Screw

Connector

Loading Base Unit

Screw

2. Connect the module C.B.A. to the mother C.B.A.

extension cables for inspection.

• Extension cable: AAX16590 (VUC8026)

• Extension cable: AAX16610 (JGS0116)

Mother C.B.A. Module C.B.A.

PP4201-PS4201

PP3201-PS3201

3. Connect the mechanism loading C.B.A. to the mother

C.B.A. with the extension cables for inspection.

• Extension cable: AAX16600 (VUC8027)

Mother C.B.A. Mechanism Loading C.B.A.

PP2591-PS2591

Mother C.B.A.

PP4201

PP2591

AAX16600

PP3201

PS2591

PS4201

PS3201

AAX16590

AAX16610

8. Checking the Module C.B.A.

1. Remove the screw.

Module C.B.A.

PS4201 PS3201

Screw

Note

Be sure to initialize the player whenever you replace a

C.B.A. (Refer to section 1-9, Initializing the DVD Player.)

9. Disassembling the Rear Panel

1. Remove all of the screws connected to the rear panel.

(The number of screws varies according to the model).

Screw

Screw

Screw

2. Release the two tabs on the left and right.

Loading C.B.A.

PS2591Mechanism

2 - 4

Page 17

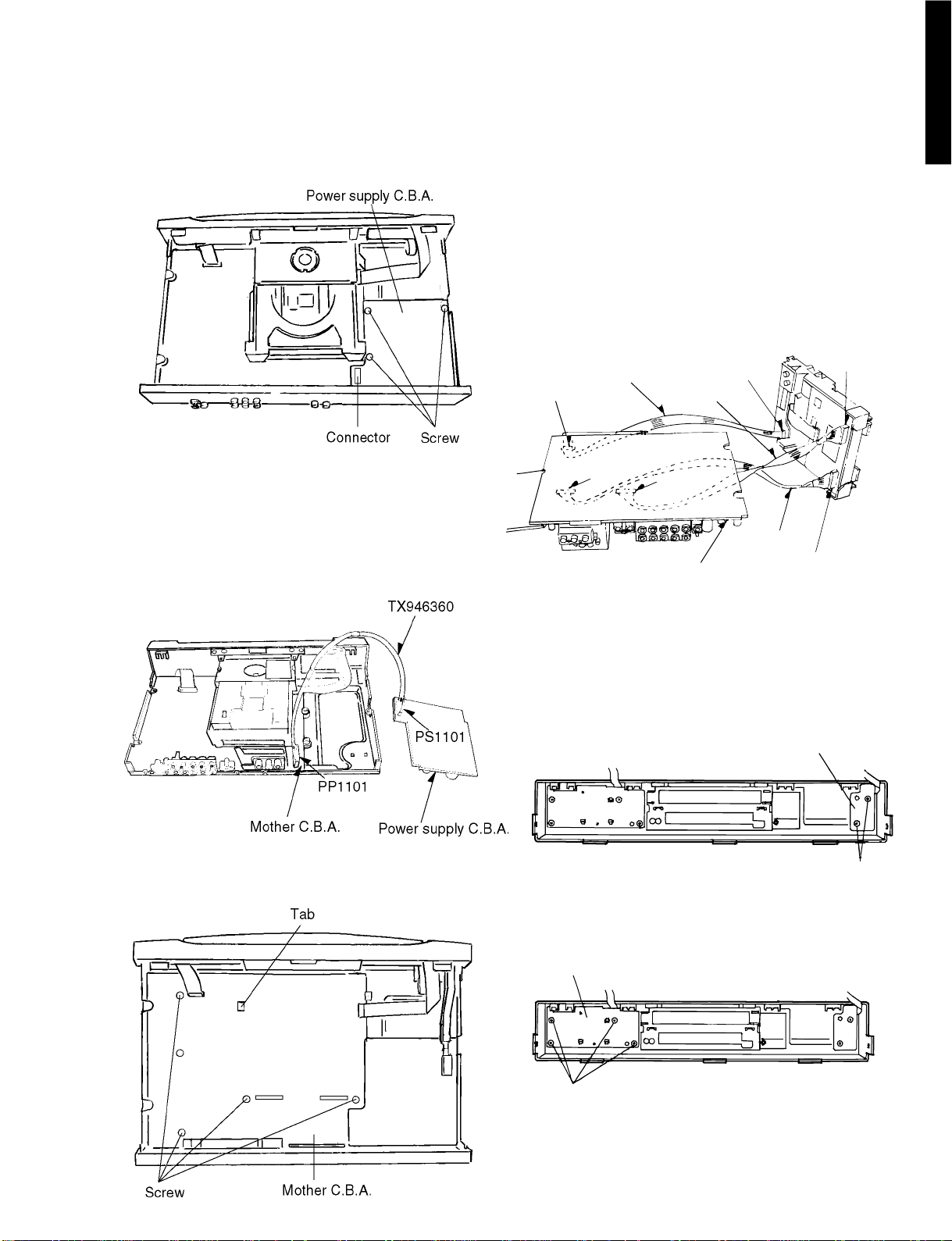

10. Checking the Power Supply

PP2591

PP3201

PP4201

AAX16600

AAX16590

PS2591

PS4201

PS3201

AAX16610

Mother C.B.A.

Screw

Front SW C.B.A.

C.B.A.

1. Remove the 3 screws.

DVD-S796/DV-

S5270

3. Checked by connecting the module C.B.A. and the mother

C.B.A. with the extension cables.

• Extension cable: AAX16590 (VUC8026)

• Extension cable: AAX16610 (JGS0116)

Module C.B.A. Mother C.B.A.

PS3201-PP3201

PS4201-PP4201

4. Checked by connecting the mechanism loading C.B.A.

and the mother C.B.A. with the extension cables.

• Extension cable: AAX16600 (VUC8027)

Mechanism loading C.B.A. Mother C.B.A.

PS2951-PP2591

2. Carefully pull out the power supply C.B.A.

Note

There is a danger of damaging the connectors.

3. Connect the power supply C.B.A. and the mother C.B.A.

with the extension cable for inspection.

•

Extension cable: TX946360 (JGS0099) (connects the power

supply C.B.A. PS1101 and the mother C.B.A. PP1101)

11. Checking the Mother C.B.A.

1. Remove the 4 screws.

2. Release the tab.

Note

Be sure to intialize the player whenever you replace a

C.B.A. (Refer to section 1-9, initializing the DVD player.)

12.

Checking the Power Switch C.B.A.

1. Remove the 4 screws.

Power SW C.B.A.

Screw

13.

Checking the Front Switch C.B.A.

1. Remove the 9 screws.

2 - 5

Page 18

S5270

ASSEMBLING AND DISASSEMBLING THE OPTICAL PICKUP (MECHANICAL PARTS)

The optical pickup can be damaged by static electricity from your body. Be sure to take static electricity countermeasures when

working around the optical pickup.

DVD-S796/DV-

1. Handling the Optical Pickup

The optical pickup can be damaged by static electricity from your body. Be sure to take static electricity countermeasures when

working around the optical pickup.

1. The optical pickup is an extremely high-precision mechanism. Do not subject it to strong impact.

2. To preserve the quality of the optical pickup replacement parts during transport and installation, the terminals of the laser

diode are short-circuited. After replacing the parts, use the proper procedure to return the laser diode to its original condition.

(Refer to page 2-11, Assembling the Optical Pickup.)

3. Testers cannot be used to check the laser diode of the optical pickup. The power supply inside the tester can easily damage

the laser diode.

4. Take care when handling the flexible cable because excessive force can cause it to break.

5. You cannot adjust the semifixed resistor for laser power adjustment. Do not turn it.

2. Disassembly Procedure

Use the following procedure to replace major parts.

For the assembly procedure, follow the flow chart in reverse.

Top cover

Pulley gear

Tray

Front panel

Mechanism unit

Clamp base unit

Static electricity

countermeasures

Traverse unitMechanism Loading C.B.A.

Intermediate chassis

Clamper weight

Clamper yoke

Magnet

Clamper

Vertical cam, Drive gear

Deceleration gear

2 - 6

Page 19

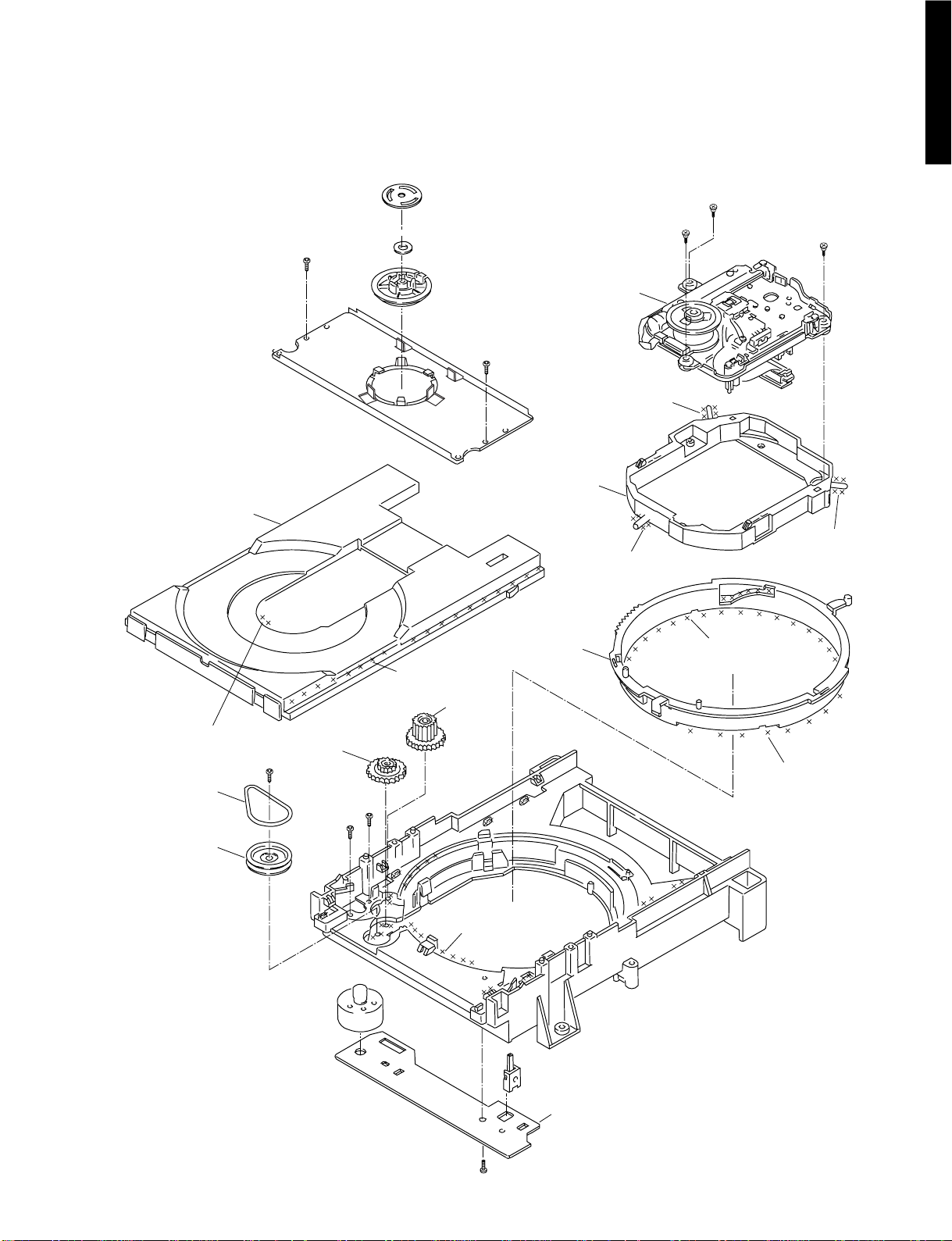

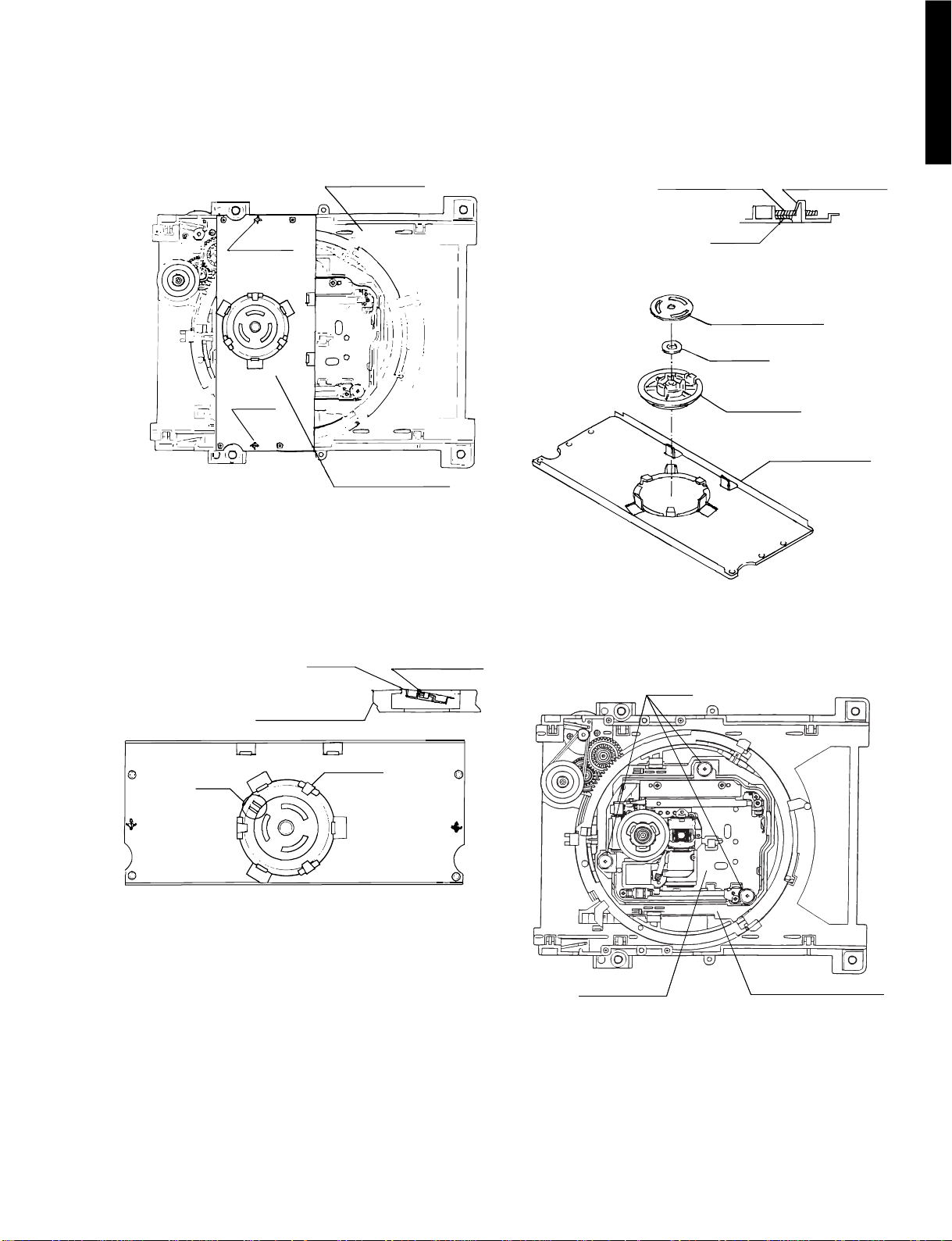

3. Lubricating the Loading Base Unit

Grease EM-30LG

(TX946270)

0.01g

Grease EM-30LG

(TX946270)

0.01g

Grease EM-30LG

(TX946270)

0.01g

Grease EM-30LG

(TX946270)

0.01g

Grease EM-30LG

(TX946270)

0.01g

Grease EM-30LG

(TX946270)

0.02g

Grease EM-30LG

(TX946270)

0.02g

Grease EM-30LG

(TX946270)

0.01g

Intermediate

chassis

Traverse unit

Vertical cam

drive gear

Drive gear

Deceleration

gear

Belt

Tray

Pulley gear

Mechanism Loading C.B.A.

When replacing parts, Iubricate the parts maked “XXX” in the diagram

DVD-S796/DV-

S5270

2 - 7

Page 20

S5270

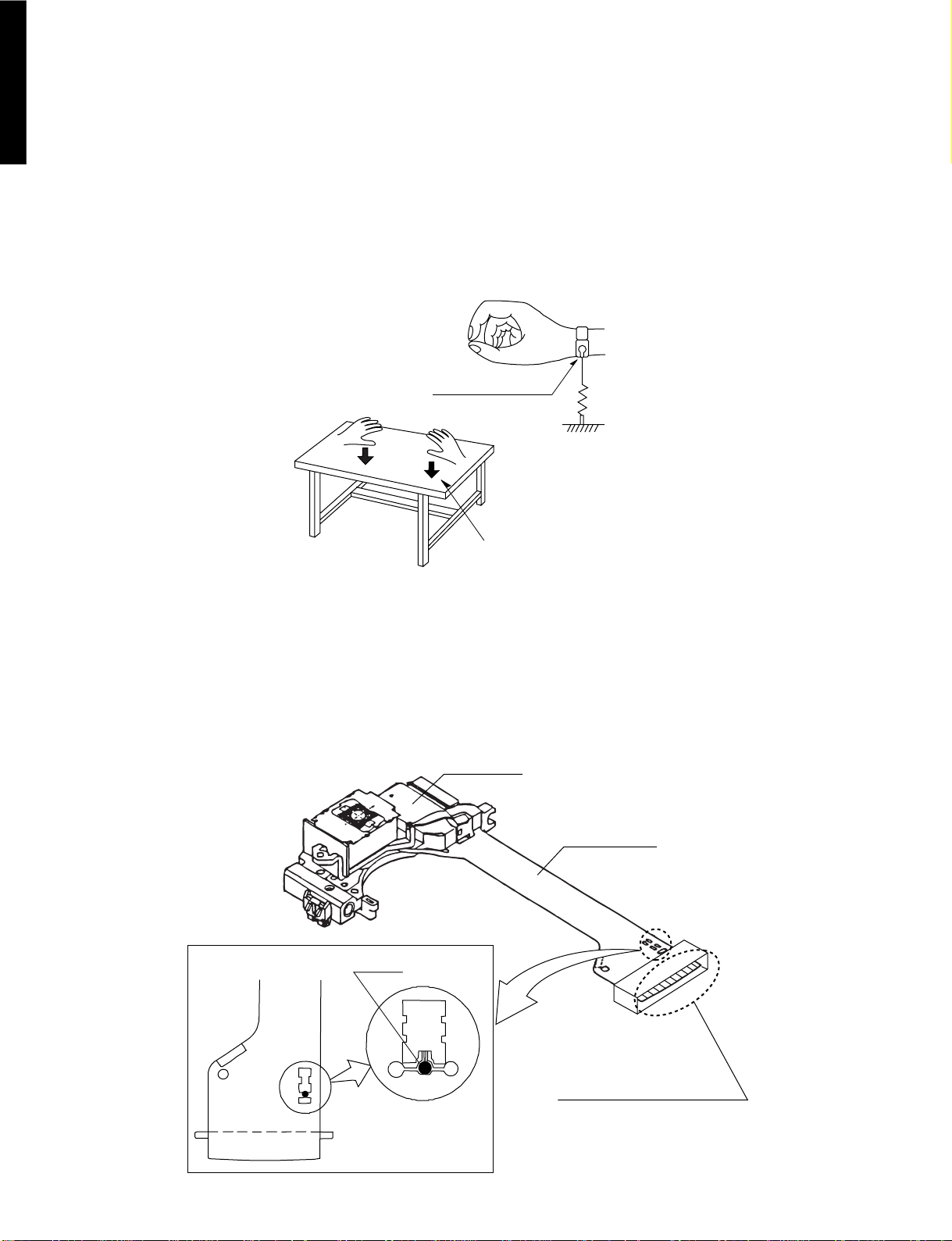

4. Static Electricity Countermeasures

DVD-S796/DV-

The laser diode inside the traverse unit (optical pickup) can be damaged by static electricity from your body. Be sure to take static

electricity countermeasures when working around the optical pickup.

4-1. Static Electricity Countermeasure Methods

1. Ground yourself

Use an anti-static wrist strap to discharge static electricity from your body.

2. Ground the workbench

Lay a conductive material (sheet) or steel sheet on the surface where the traverse unit (optical pickup) is to be placed, then

ground the sheet.

Anti-static wrist strip

1M

Conductive material

(sheet) or steel sheet

4-2. Short-circuit the laser diode

Solder the land in the flexible cable of the optical pickup.

Notes

• Be sure to do this before disconnecting the flexible cable of the optical pickup from the module C.B.A.

• Use an anti-static soldering iron to short-circuit and unshort-circuit laser diode.

(Recommended soldering iron: Hakko with ESD countermeasure)

• After you have finished repairing the laser diode, follow the correct procedure to remove the solder from the short-circuit

location. (Refer to page 2-7, Assembling and Disassembling the Optical Pickup (Mechanical Parts).)

Pickup unit

Flexible cable

Solder

(Magnified view)

2 - 8

Use a clip or other item to

ground the unit.

Page 21

5.

Disassembling the Clamp Base Unit

1. Remove the 2 screws.

Loading base

2. Release the 3 tabs on the clamper.

Clamper weight

DVD-S796/DV-

S5270

3-clamper tabs

Screw

Screw

Clamp base unit

6. Disassembling the Clamper

Weight, Clamper Yoke, Magnet

and Clamper

1. Remove the tab, and pull out the clamper.

Clamper unitTab

Magnet

Clamper weight

Magnet

Clamper

Clamper base

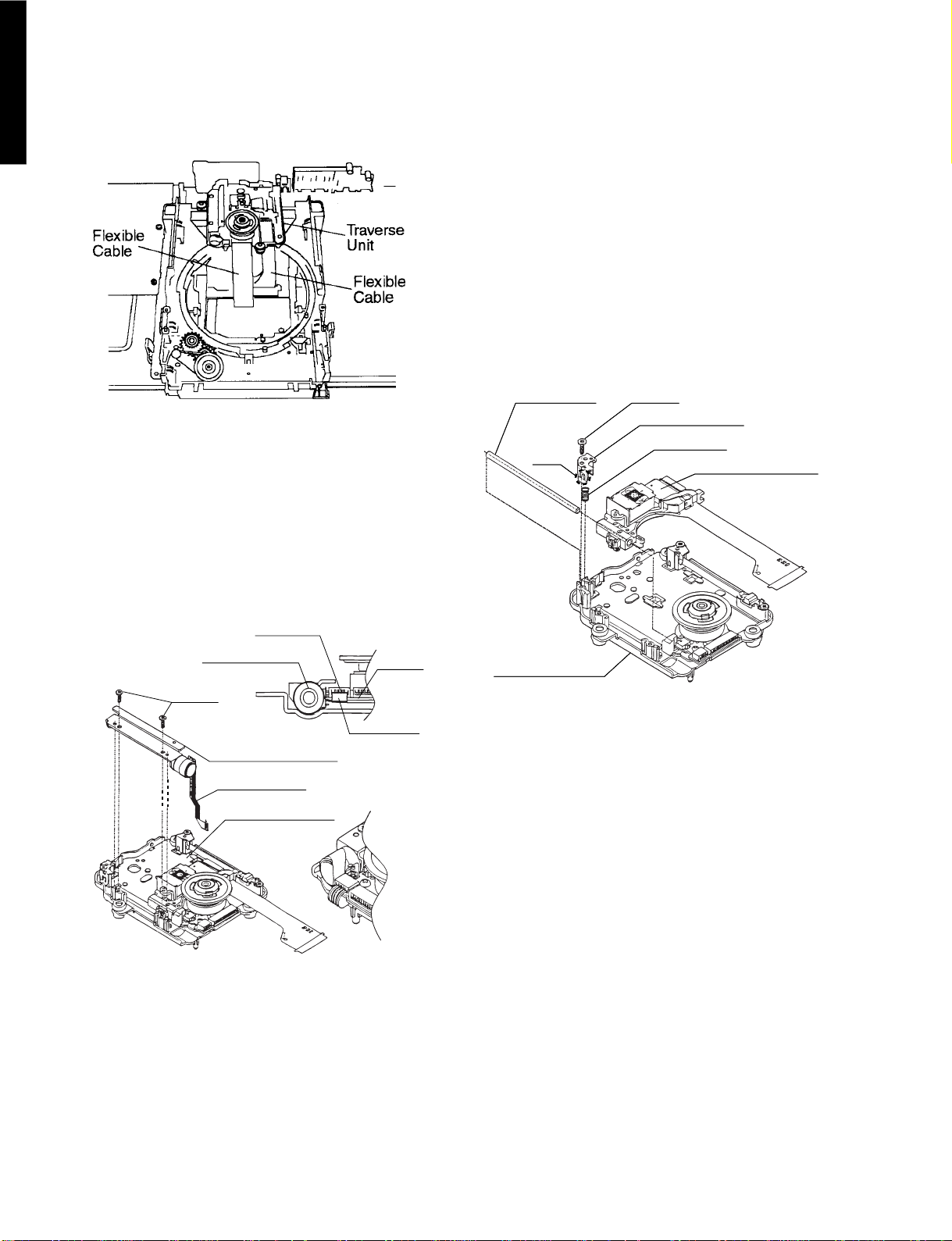

7. Disassembling the Traverse

Unit

1. Remove the 3 screws.

Tab

Clamper base

Stopper

Screw

Screw

Intermediate chassis

Traverse unit

Traverse unit

Note

Be sure to take static electricity counterneasures before

disconnecting the flexible cable. (Refer to page 2-8,

Static Electricity Countermeasures.)

Intermediate chassis

2 - 9

Page 22

S5270

2. Disconnect the 2 flexible cables.

DVD-S796/DV-

8. Disassembling the Stepping

1. Disconnect the flexible cable.

2. Remove the 2 screws.

Note

Take care when handling the flexible cable bacause it can be

broken by excessive force.

Motor Unit

9. Disassembling the Optical

Pickup Unit

1. Remove the hook of the FPC holder, then remove the FPC

holder itself.

2. Remove the screw.

3. Release the tab, then remove spring holder 1.

Note

Be sure not to lose the spring.

4. Remove the guide shaft.

Note

Be sure to adjust the optical pickup tilt after replacing the

optical pickup.

(Refer to page 2-13, Optical Pickup Tilt Adjustment.)

Screw

Guide shaft

Guide shaft

Tab

Tab

Screw

Spring holder 1

Spring holder 1

Tilt spring

Tilt spring

Optical pickup unit

Optical pickup unit

Stepping motor

Screw

Stepping motor unit

Flexible cable

Traverse chassis

Connector

C.B.A

Motor FPC

Traverse chassis

Traverse chassis

2 - 10

Page 23

DVD-S796/DV-

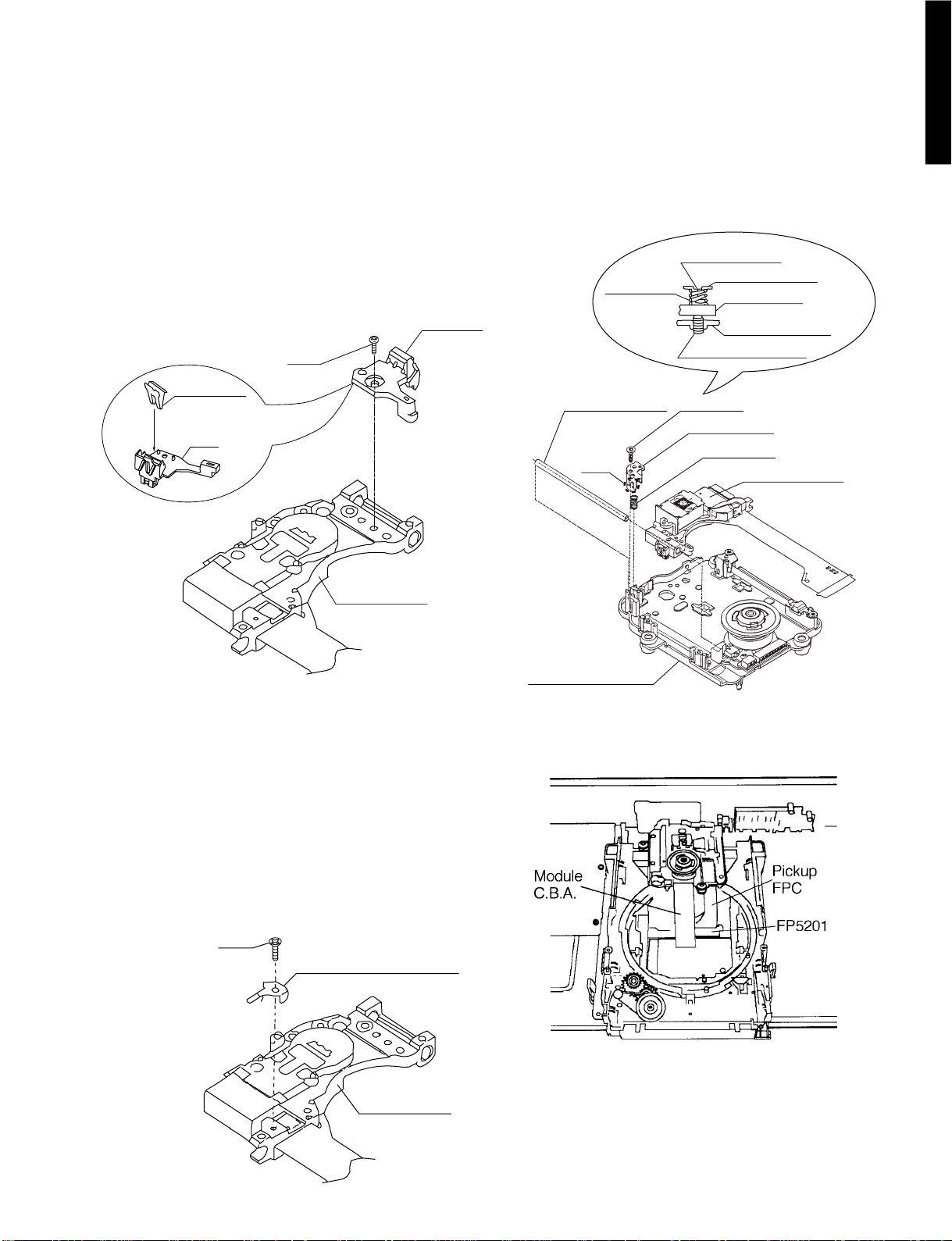

10. Disassembling the Nut Unit

1. Remove the screw.

Notes

• The nut unit is not part of the optical pickup.

Before replacing the optical pickup, remove the nut

unit for use with the new optical pickup.

• After installation, use screw lock to lock the screw in

position.

• When reassembling, use screw lock to lock the screw

in position after attaching it.

11. Disassembling the Sub-Shaft

Preload Spring

1. Remove the screw.

Notes

• Handle the sub-shaft preload spring carefully because

the shape of the tip is easily deformed.

• The sub-shaft preload spring is not part of the optical

pickup. Before replacing the optical pickup, remove

the sub-shaft preload spring for use with the new

optical pickup.

• After installation, use screw lock to lock the screw in

position.

12. Assembling the Optical Pickup

1. Install the optical pickup.

Note

Take care not to attach the tilt spring and guide shaft in

the wrong order.

Nut spring

Nut

screw

Nut unit

Optical pickup

(Rear surface)

Spring holder 1

Traverse chassis

Adjustment screw

Tilt spring

Guide shaft

Protruding part

Optical pickup unit

Tilt spring

Spring holder 1

Screw

Guide shaft

Tab

Traverse chassis

Screw

Sub-shaft preload spring

(Rear surface)

Optical pickup

2. Insert the pickup FPC into connector FP5201 on the module

C.B.A.

S5270

2 - 11

Page 24

S5270

3. Remove the solder from the pickup FPC’s soldered short-circuit

DVD-S796/DV-

Open the circuit after short-circuiting it.

4. Adjust the optical pickup tilt after removing the solder.

(Refer to page 2-13, Optical Pickup Tilt Adjustment.)

5. If installing a new pickup, write the new head current

into memory as shown on page 1-6.

Do this first after turning on the unit with NO disc and

while the unit is cold (within the first 3 minutes of power

ON), or the jitter reading will not be accurate for the new

pickup head.

Remove the solder.

(Magnified view)

Solder removal

direction

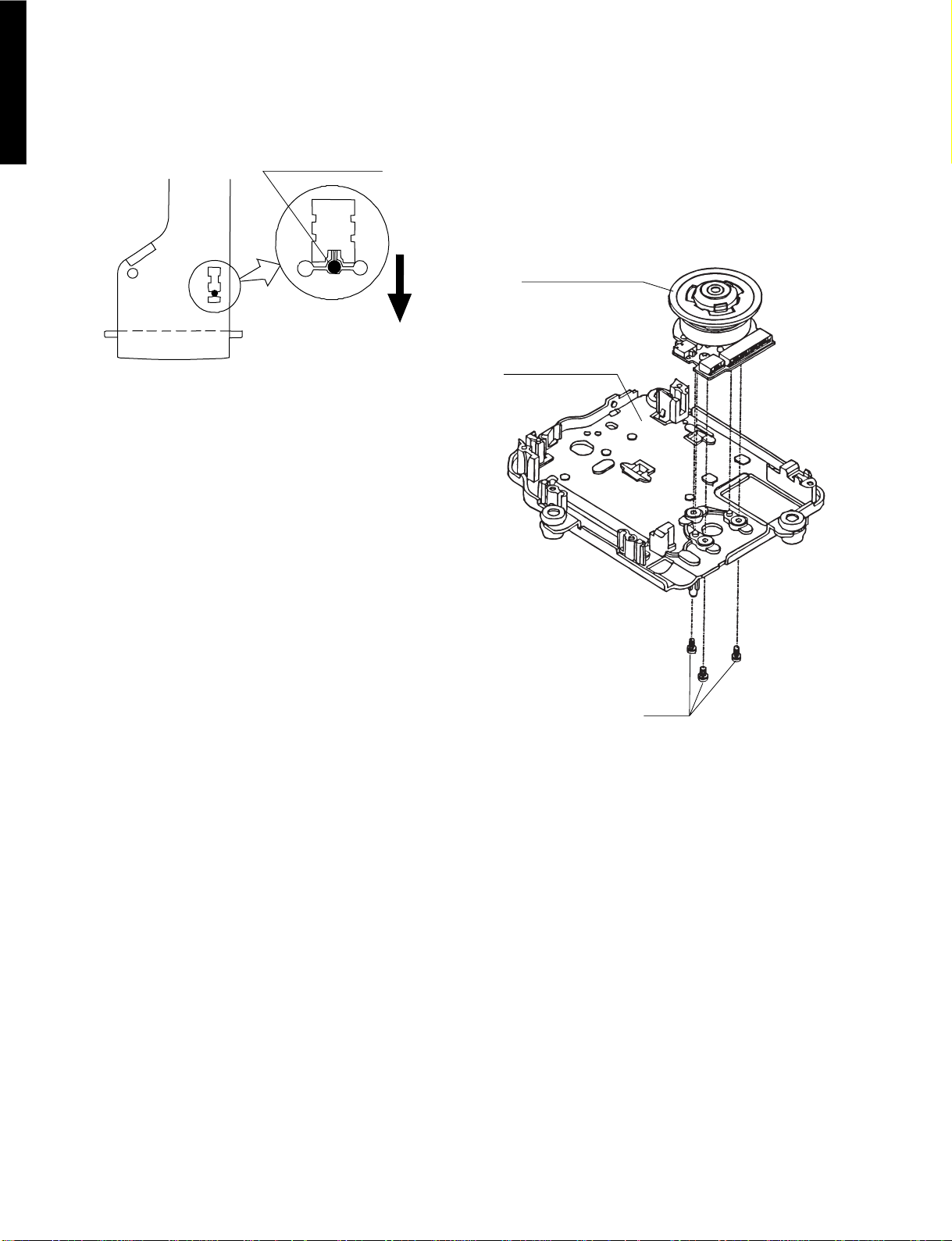

13. Disassembling the Spring

Motor Unit

1. Remove the three screws.

Note

Be sure to adjust the optical pickup tilt after replacing

the spindle motor unit.

Spindle motor unit

Traverse chassis

Screw

2 - 12

Page 25

14. Optical Pickup Tilt Adjustment

DVD-S796/DV-

S5270

Measurement point

Main unit

service display

Measuring equipment, tools

Hex wrench (part number: TX946380), 1.2mm

Screw lock (part number: TX946400)

Replaced the optical pickup.

•

Replaced the spindle motor.

STEP7

STEP1

Start with Power ON and in play.

OP/PAUSE" button: main unit

"ST

"OPEN/CLOSE" button: main unit

"5" button: remote control unit

STEP2

Main unit display

Check to see that "JIT xxx" is displayed.

Present jitter value.

•

• Replaced the peripheral parts

of the optical pickup, etc.

Adjustment point Mode Disc

Tangential adjustment screw

Tilt adjustment screw

Press

simultaneously

T1 (inner periphery) play

T2 (outer periphery) play

Adjustment value

(JIT 070 to 090 is normal.)

Adjust to the minimum jitter value.

DVDT-S15 (AAX07320)

or

DVDT-S01 (TX946080)

(070 = 7% and 090 = 9% jitter.)

Tangential adjustment screw

Tilt adjustment screw 1

Tilt adjustment screw 2

STEP3

Play test disc title 1

(inner periphery)

Tangential adjustment screw

Adjust to the minimum jitter value.

STEP4

Play test disc title 43

(outer periphery)

Tilt adjustment screw 1

Adjust to the minimum jitter value.

STEP5

Play test disc title 43

(outer periphery)

Tilt adjustment screw 2

Adjust to the minim

(070 to 090 is normal.)

STEP6

NG

Check condition

after adjustment

STEP7

um jitter value.

OK

Do steps 3-5

from the bottom

of the main unit

using a hex wrench.

Repeat adjusting tilt

adjustment screws

1 and 2 alternately ,

two or three times.

Play the disc to make sure

there is no picture

degradation in the inner,

middle and outer

peripheries, and no audio

skipping.

Change in

jitter value

•

Jitter value depends on the model:

(1) If the jitter value changes like A,

the optimum point is easy to find

(2) If the jitter value changes like B,

BA

set the optimum point near the middle.

Optimum

point

Adjustment angle

2 - 13

Page 26

S5270

DVD-S796/DV-

STEP7

Pull out the traverse unit.

(Refer to disassembly procedure

in this manual.)

STEP8

Lock the adjustment screw in

position using screw lock

(part number: TX946400).

STEP9

Assemble the main unit.

STEP10

Follow procedure

for handling

after repairs

are completed.

STEP6

Remove in the order

of top cover, tray

and clamper base.

With the power supply turned on:

1. Use the OPEN/CLOSE

button to close the tray.

2. Use the POWER button

to turn off the power.

3. Disconnect the power plug

from the outlet.

Screw lock

(0.02 g)

Screw lock

(0.02 g)

Adjustment screws

Screw lock

(0.02 g)

Traverse unit

(rear side)

End

Notes

•

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, adjust if there is a noticeable

degradation in picture quality.

•

Optical adjustments cannot be made inside the optical pickup.

•

Adjustment is generally unnecessary after replacing the traverse unit.

2 - 14

Page 27

DVD-S796/DV-

S5270

15. Disassembling the

Intermediate Chassis

1. Push the stopper downward, then rotate it until it contacts

the vertical cam.

2. Release the 2 tabs.

Stopper

Loading base

Vertical cam

Intermediate

chassis

Tabs

Contact

position

16. Disassembling the Vertical

Cam and Drive Gear

1. Rotate the vertical cam until it reaches the contact position.

2. Lift the vertical cam straight upward to pull it out.

2. Remove the Drive gear.

17. Disassembling the Pulley Gear

and Deceleration Gear

1. Remove the screw.

2. Remove the pulley gear.

3. Remove the belt.

4. Remove the deceleration gear.

Drive gear

Deceleration gear

Pulley gear

Belt Screw

Deceleration gear

Belt

Pulley gear

Drive gear

18. Disassembling the Mechanism

Loading C.B.A.

1. Remove the 2 screws.

Loading base

Vertical cam

Assembly guide

Double switch

Drive gear Contact position

2. Remove the 2 screws.

3. Release the 2 tabs.

(Rear surface)

Tab

2 - 15

Screw

Screw

Screw

Screw

Tab

Mechanism Loading C.B.A.Screw

Page 28

S5270

19. Lubricating the Optical Pickup and Peripheral Parts

DVD-S796/DV-

When replacing parts, lubricate the parts marked “xxx” in the diagram.

Spindle motor unit

Froil 946P

(part number. TX946410)

0.01g

MC grease PD No. 10

(part number. TX946390)

0.04g

(gearshaft opening)

Screw lock

Three-Bond 1401C

(0.02g)

(part number. TX946400)

MC grease PD No. 10

(part number. TX946390)

Screw lock

Three-Bond 1401C

(0.02g)

(part number. TX946400)

0.04g

Stepping motor unit

Screw lock

Three-Bond 1401C

(0.02g) (part number. TX946400)

2 - 16

Page 29

DVD-S796/DV-

ELECTRICAL CONFIRMATION

1. Video Output (Luminance Signal) Confirmation

Do this confirmation after replacing a C.B.A.

Measurement point

Video output terminal

Measuring equipment, tools Confirmation value

Screwdriver, Oscilloscope

200mV/div, 10 usec/div

Purpose: To maintain video signal output compatibility.

1. Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2. Confirm that the luminance signal (Y+S) level is 1000 mVp-p±30 mV.

30mV

PLAY (Title 46): DVDT-S15

PLAY (Title 10): DVDT-S01

Mode Disc

Color bar 75%

S5270

DVDT-S15 (AAX07320)

or

DVDT-S01 (TX946080)

1000mVp-p±30mV

2. Video Output (Chrominance Signal) Confirmation

Do this confirmation after replacing a C.B.A.

Measurement point

Video output terminal

Measuring equipment, tools

Screwdriver, Oscilloscope

200mV/div, 10 usec/div

Purpose: To maintain video signal output compatibility.

1. Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2. Confirm that the chrominance signal (C) level is 621 mVp-p

621mV

PLAY (Title 46): DVDT-S15

PLAY (Title 10): DVDT-S01

±13 mV.

Mode Disc

Color bar 75%

Confirmation value

621mVp-p±13mV

DVDT-S15 (AAX07320)

or

DVDT-S01 (TX946080)

2 - 17

Page 30

S5270

3. Video Component Signal (CB) Output Confirmation

DVD-S796/DV-

Do this confirmation after replacing a C.B.A.

Purpose: To maintain video signal output compatibility.

1. Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2. Apply the trigger at the Y output terminal signal.

Confirm that the video component signal (CB) level is 525 mVp-p

3.

For B, A, G Models

Measurement point Mode Disc

Video output terminal

Measuring equipment, tools

Screwdriver, Oscilloscope

100mV/div, 10 usec/div

(Y) (CB) Output terminal

Color bar 75%

PLAY (Title 46): DVDT-S15

PLAY (Title 10): DVDT-S01

DVDT-S15 (AAX07320)

or

DVDT-S01 (TX946080)

Confirmation value

525mVp-p±11mV (B, A, G Models)

486mVp-p±10mV (U Model)

±11 mV (B, A, G Models) /486mVp-p±10 mV(U Model).

For U Model

486mV

±

10mV

2 - 18

Page 31

SECTION 3

ABBREVIATIONS

INITIAL/LOGO

A A0~UP ADDRESS

ACLK AUDIO CLOCK

AD0–UP ADDRESS BUS

ADATA AUDIO PES PACKET DATA

ALE ADDRESS LATCH ENABLE

AMUTE AUDIO MUTE

AREQ AUDIO PES PACKET REQUEST

ARE AUDIO RF

ASI SERVO AMP INVERTED INPUT

ASO SERVO AMP OUTPUT

ASYNC AUDIO WORD DISTINCTION SYNC

B BCK BIT CLOCK (PCM)

BCKIN BIT CLOCK INPUT

BDO BLACK DROP OUT

BLKCK SUB CODE BLOCK CLOCK

BOTTOM CAP. FOR BOTTOM HOLD

BYP BYPATH

BYTCK BYTE CLOCK

C CAV CONSTANT AUGULAS VELOCITY

CBDO CAP. BLACK DROP OUT

CD COMPACT DISC

CDSCK CD SERIAL DATA CLOCK

CDSRDATA CD SERIAL DATA

CDRF CD RF (EFM) SIGNAL

CDV COMPACT DISC-VIDEO

CHNDATA CHANNEL DATA

CKSL SYSTEM CLOCK SELECT

CLV CONSTANT LINEAR VELOCITY

COFTR CAP. OFF TRACK

CPA CPU ADDRESS

CPCS CPU CHIP SELECT

CPDT CPU DATA

CPUADR CPU ADDRESS LATCH

CPUADT CPU ADDRESS DATA BUS

CPUIRQ CPU INTERRUPT REQUEST

CPRD CPU READ ENABLE

CPWR CPU WRITE ENABLE

CS CHIP SELECT

CSYNCIN COMPOSITE SYNC IN

CSYNCOUT COMPOSITE SYNC OUT

D DACCK D/A CONVERTER CLOCK

DEEMP DEEMPHASIS BIT ON/OFF

DEMPH DEEMPHASIS SWITCHING

DIG0~UP FL DIGIT OUTPUT

DIN DATA INPUT

DMSRCK DM SERIAL DATA READ CLOCK

DMUTE DIGITAL MUTE CONTROL

DO DROP OUT

DOUT0–UP DATA OUTPUT

DRF DATA SLICE RF (BIAS)

DRPOUT DROP OUT SIGNAL

DREQ DATA REQUEST

DRESP DATA RESPONSE

DSC DIGITAL SERVO CONTROLLER

DSLF DATA SLICE LOOP FILTER

DVD DIGITAL VIDEO DISC

ABBREVIATIONS

INITIAL/LOGO ABBREVIATIONS

E EC ERROR TORQUE CONTROL

ECR ERROR TORQUE CONTROL

REFERENCE

ENCSEL ENCODER SELECT

ETMCLK EXTERNAL M CLOCK (81MHz/40.5MHz)

ETSCLK ETSCLK EXTERNAL S CLOCK (54MHz)

F FBALFCLK FOCUS BALANCEFRAME CLOCK

FE FOCUS ERROR

FFI FOCUS ERROR AMP INVERTED INPUT

FEO FOCUS ERROR AMP OUTPUT

FG FREQUENCY GENERATOR

FSC FREQUENCY SUB CARRIER

FSCK FS (384 OVER SAMPLING) CLOCK

G GND COMMON GROUNDING (EARTH)

H HA0–UP HOST ADDRESS

HD0–UP HOST DATA

HINT HOST INTERRUPT

HRXW HOST READ/WRITE

I IECOUT IEC958 FORMAT DATA OUTPUT

IPFRAG INTERPORATION FLAG

IREF I (CURRENT) REFERENCE

ISEL INTERFACE MODE SELECT

L LDONL LASER DIODE CONTROL

LPC LASER POWER CONTROL

LRCK L CH/R CH DISTINCTION CLOCK

M MA0–UP MEMORY ADDRESS

MCK MEMORY CLOCK

MCKI MEMORY CLOCK INPUT

MCLK MEMORY SERIAL COMMAND CLOCK

MDQ0–UP MEMORY SERIAL COMMAND DATA

MDQM MEMORY DATA INPUT/OUTPUT

MLD MEMORY DATA I/O MASK

MPEG MEMORY SERIAL COMMAND LOAD

MOTION PICTURE IMAGE CODING

EXPERT GROUP

O ODC OPTICAL DISC CONTROLLER

OFTR OFF TRACKING

OSCI OSCILLATOR INPUT

OSCO OSCILLATOR OUTPUT

OSD ON SCREEN DISPLAY

P P1~UP PORT

PCD CD TRACKING PHASE DIFFERENCE

PCK PLL CLOCK

PDVD DVD TRACKING PHASE DIFFERENCE

PEAK CAP. FOR PEAK HOLD

PLLCLKPLLO CHANNEL PLL CLOCK

K PLL LOCK

PWMCTL PWM OUTPUT CONTROL

PWMDA PULSE WAVE MOTOR DRIVE A

PWMOA, B PULSE WAVE MOTOR OUT A, B

DVD-S796/DV-

S5270

3 - 1

Page 32

S5270

INITIAL/LOGO

R RE READ ENABLE

DVD-S796/DV-

S SBI0, 1 SERIAL DATA INPUT

T TE TRACKING ERROR

ABBREVIATIONS

RFENV RF ENVELOPE

RFO RF PHASE DIFFERENCE OUTPUT

RS (CD-ROM) REGISTER SELECT

RSEL PF POLARITY SELECT

RST RESET

RSV RESERVE

SBO0 SERIAL DATA OUTPUT

SBT0, 1 SERIAL CLOCK

SCK SERIAL DATA CLOCK

SCKR AUDIO SERIAL CLOCK RECEIVER

SCL SERIAL CLOCK

SCLK SERIAL CLOCK

SDA SERIAL DATA

SEG0–UP FL SEGMENT OUTPUT

SELCLK SELECT CLOCK

SEN SERIAL PORT ENABLE

SIN1, 2 SERIAL DATA IN

SOUT1, 2 SERIAL DATA OUT

SPDI SERIAL PORT DATA INPUT

SPDO SERIAL PORT DATA OUTPUT

SPEN SERIAL PORT R/W ENABLE

SPRCLK SERIAL PORT READ CLOCK

SPWCLK SERIAL PORT WRITE CLOCK

SQCK SUB CODE Q CLOCK

SQCX SUB CODE Q DATA READ CLOCK

SRDATA SERIAL DATA

SRMADR SRAM ADDRESS BUS

SRMDT0–7 SRAM DATA BUS 0–7

SS START/STOP

STAT STATUS

STCLK STREAM DATA CLOCK

STD0–UP STREAM DATA

STENABLE STREAM DATA INPUT ENABLE

STSEL STREAM DATA POLARITY SELECT

STVALID STREAM DATA VALIDITY

SUBC SUB CODE SERIAL

SBCK SUB CODE CLOCK

SUBQ SUB CODE Q DATA

SYSCLK SYSTEM CLOCK

TIBAL BALANCE CONTROL

TID BALANCE OUTPUT 1

TIN BALANCE INPUT

TIP BALANCE INPUT

TIS BALANCE OUTPUT 2

TPSN OP AMP INPUT

TPSO OP AMP OUTPUT

TPSP OP AMP INVERTED INPUT

TRCRS TRACK CROSS SIGNAL

TRON TRACKING ON

TRSON TRAVERSE SERVO ON

INITIAL/LOGO ABBREVIATIONS

V VBLANK V BLANKING

VCC COLLECTOR POWER SUPPLY

VOLTAGE

VCDCONT VIDEO CD CONTROL (TRACKING

BALANCE)

VDD DRAIN POWER SUPPLY VOLTAGE

VFB VIDEO FEED BACK

VREF VOLTAGE REFERENCE

VSS SOURCE POWER SUPPLY VOLTAGE

W WAIT BUS CYCLE WAIT

WDCK WORD CLOCK

WEH WRITE ENABLE HIGH

WSR WORD SELECT RECEIVER

XX X' TAL

XALE X ADDRESS LATCH ENABLE

XAREQ X AUDIO DATA REQUEST

XCDROM X CD ROM CHIP SELECT

XCS X CHIP SELECT

XCSYNC X COMPOSITE SYNC

XDS X DATA STROBE

XHSYNCO X HORIZONTAL SYNC OUTPUT

XHINT XH INTERRUPT REQUEST

XI X' TAL OSCILLATOR INPUT

XINT X INTERRUPT

XMW X MEMORY WRITE ENABLE

XO X' TAL OSCILLATOR OUTPUT

XRE X READ ENABLE

XSRMCE X SRAM CHIP ENABLE

XSRMOE X SRAM OUTPUT ENABLE

XSRMWE X SRAM WRITE ENABLE

XVCS X V-DEC CHIP SELECT

XVDS X V-DEC CONTROL BUS STROBE

XVSYNCO X VERTICAL SYNC OUTPUT

3 - 2

Page 33

BLOCK DIAGRAM

1. OVERALL BLOCK DIAGRAM

-

B,G,A,R ONLY

3 - 3

Page 34

2. SERVO BLOCK DIAGRAM

3 - 4

Page 35

3. VIDEO BLOCK DIAGRAM (FOR U, A, R MODELS)

U, A, R, MODELS

3 - 5

PB

PR

Page 36

4. VIDEO BLOCK DIAGRAM (FOR G, B MODELS)

G, B MODELS

3 - 6

Page 37

5. AUDIO BLOCK DIAGRAM

3 - 7

Page 38

INTER CONNECTION DIAGRAM

1. U, A, R MODELS

U, A, R, MODELS

3 - 8

Page 39

2. G, B MODELS

G, B MODELS

3 - 9

Page 40

SCHEMATIC DIAGRAM

1. POWER SUPPLY SCHEMATIC DIAGRAM (FOR U MODEL)

U MODEL

3.8

4.9

5.1 5.1

0

-8.6

0

10.2

(9.7)

4.9

0

0

4.9

0

0

2.6

1.2

9.0

9.0

10.1

0

-0.5

0

0.6

0

0.1

0.2

-0.2

0

0

10.2

1.1

5.2

4.0

2.9

2.5

0

3 - 10

Page 41

2. POWER SUPPLY SCHEMATIC DIAGRAM (FOR G, B, A MODELS)

G, B, A MODELS

3.8

4.9

5.1 5.1

-8.6

0

0

10.2

(9.7)

4.9

0

0

4.9

0

0

2.6

1.2

9.0

9.0

10.1

0

-0.5

0

0.6

0

0.1

0.2

-0.2

0

0

10.2

1.1

5.2

4.0

2.9

2.5

0

3 - 11

Page 42

3. POWER SUPPLY SCHEMATIC DIAGRAM (FOR R MODEL)

R MODEL

3.8

4.9

0

-8.6

0

4.9

10.2

(9.7)

4.9

5.1

2.6

1.2

0

0

5.1

0

9.0

9.0

0

10.2

0

1.1

1.1

5.2

4.0

2.9

2.5

0

3 - 12

Page 43

4. ADSC SECTION (MODULE C.B.A. (1/6)) SCHEMATIC DIAGRAM

1.6(1.7)

1.7 9.0

1.7

1.7

1.6(1.7)

1.7

1.6(0)

1.7

2.0(1.7)

2.0(1.8)

1.7

1.9(1.7)

1.9(1.5)

0(3.3)

5.1(5.0)

2.4(2.6)

0.5(2.4)

0.5(2.4)

0.5(2.7)

0

0

5.0(0)

5.0(0)

0

0

9.0

7.4(5.0)

7.1(3.4)

7.0(3.7)

6.7(4.8)

1.7(7.4)

1.6(7.4)

1.5(7.4)

IC2001

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

5.1(2.9)

5.1(2.9)

5.1(0.8)

9.0

5.1(0)

9.0

5.1(0)

0(0.6)

0(3.3)

1.7(1.6)

2.7(1.4)

1.7(0)

3.3

5.0

1

2.2

0.2

2.8

1.6

3.3

0

0

0

1.5

1.6

1.6

0

0

1.7

3.3

1.6

1.6

1.7

2.8

1.7

3.3

1.6

1.5

1.5

1.5

1.6

1.6

0

1.7

1.5

3.3

1.7

0

1.5

34

33

32

31

30

29

28

27

26

25

24

23

22

21

0.4

1.7

0

0

1.7

3.3

2.2

1.5

0

0

2.2

2.2

0

1.2

1.7

3.3

2.2

1.5

1.7

1.5

1.7

1.8

48

47

46

45

44

43

42

41

3.3

0

1.6

1.4

2.1

0

1.7

1.6

2.0

0

62

61

0

3.3

0

3.3

82

81

0

0

3.3

0

64

63

0

0

0

3.3

84

83

3.2

0

3.3

3.3

3.3

0

66

65

0

0

0

0

86

85

3.3

3.3

0

0

1.5

3.0

0

0

68

67

0

3.3

1.7

0

88

87

3.1

3.3

3.2

3.3

50

49

0

0

0.4

0

70

69

1.4

0

1.4

0

90

89

3.1

3.3

3.1

3.3

1.2

1.7

52

51

0

0

1.6

1.5

72

71

0

0

0

0

92

91

0

0

0

0

1.6

1.7

1.6

1.7

54

53

0

0

3.3

1.4

74

73

0

0

0

0

94

93

0.1

0

0

0

36

35

1.6

0

1.6

0

56

55

0

0

0

3.3

76

75

1.6

3.3

1.6

0

96

95

2.5

0

2.5

0

2.2

0.2

38

37

3.3

1.7

3.3

1.7

58

57

2.5

0

3.0

0

78

77

1.6

1.6

1.6

1.6

98

97

1.6

1.7

1.8

1.4

0

1.5

0

1.5

40

39

1.7

0

1.7

1.7

60

59

0

0

0

3.0

80

79

0

1.6

1.6

1.6

100

99

1.7

1.6

2.2

1.4

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

0

3 - 13

Page 44

5. AV DECORDER SECTION (MODULE C.B.A. (2/6)) SCHEMATIC DIAGRAM (FOR U MODEL)

U MODEL

3.3

1.3

00

5.1(5.0)

1.7(0)

3.1(3.3)

000

3.3(0)

1.2(0)

3.0(3.3)

0

0

2.8(0)

2.6(0)

2.8(2.6)

2.9(2.7)

0

3.3

2.8(3.1)

2.8(3.1)

2.8(3.3)

3.3

2.6

3.3

3.3

0(2.5)

2.9(3.3)

3.1(3.3)

0

2.6(2.5)

0

2.7(3.3)

2.8(2.5)

2.9(3.3)

2.9(0)

3.3

3.3

1.8

2.6(3.3)

3.2(3.3)

2.6(0)

3.2(3.3)

0

0(1.4)

000

0

0

1.0(0)

1.3

1.2(0)

5.1(5.0)

2.6

0

1.0(1.2)

IC3001

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

STOP

PLAY

3.3

5.0

15

1

3.3

3.3

21

0

0

41

3.1

0

61

3.1

3.3

81

3.3

3.3

102

101

1.1

1.3

122

121

0.6

0.6

142

141

0

0

162

161

2.6

2.6

182

181

2.8

2.6

202

201

0

0

0

0

1.2

0

0

0

1.1

0

25

24

23

22

0

0

0

0

0

0

0

0

45

44

43

42

2.9

0

2.7

2.8

3.3

0

3.3

3.3

65

64

63

62

3.2

3.1

1.8

3.1

3.3

3.3

1.8

3.3

85

84

83

82

1.6

0

3.3

0

0

1.7

3.3

3.3

105

104

103

1.8

1.8

0

0

0

1.8

0.2

0

125

124

123

0

0.4

2.4

0.6

0

0.4

0

0.6

145

144

143

0

3.1

3.3

0

0

3.1

3.3

0

165

164

163

2.8

2.7

0

2.8

2.5

2.6

0

2.7

185

184

183

0

3.3

1.7

0

1.6

3.3

1.6

0

205

204

203

3.3

0

1.2

1.8

0

0

1.4

0

3.3

1.2

1.0

0

1.2

3.3

2.0

1.0

0

1.1

29

30

28

27

26

46

2.9

66

3.1

3.3

86

1.8

106

126

0.6

0.6

146

1.8

1.8

166

3.3

3.3

186

206

0

3.3

3.3

3.3

0

0

3.3

3.3

0

0

49

50

48

47

3.1

3.1

3.3

2.9

3.3

3.3

3.3

0

0

69

70

68

67

3.2

0

0

3.2

3.3

0

0

3.3

89

90

88

87

1.6

1.6

1.4

1.8

0

107

0

0

127

0.6

0.6

147

167

3.0

2.5

187

0

3.3

0

207

0.9

0

1.2

0

0

1.6

1.7

1.4

110

109

108

1.6

3.3

1.8

0

1.6

3.3

0

0

130

129

128

3.3

0.4

2.3

3.3

0.4

2.3

150

149

148

0

0

0

0

0

0

0

0

170

169

168

2.8

0

2.8

2.5

0

2.5

190

189

188

3.3

2.6

1.8

0

3.3

2.2

1.8

208

0

0

1.8

3.2

3.3

3.3

1.8

3.2

3.3

3.3

34

32

33

31

3.3

3.3

1.5

3.1

3.3

3.3

1.5

3.3

54

52

53

51

3.1

0

3.3

3.1

3.3

0

3.3

0

74

72

73

71

3.3

3.3

3.3

1.6

3.3

3.3

3.3

1.6

94

92

93

91

3.3

111

3.3

3.3

131

1.3

1.3

151

171

3.1

2.6

191

3.3

3.3

0

0

0

0

0

0

0

114

112

113

0

3.3

0.6

0

3.3

0

134

132

133

0.4

1.3

2.2

0

2.2

0.5

154

152

153

0

0

0

0

0

0

0

0

174

172

173

1.8

3.3

0

1.8

2.5

3.3

194

193

192

0

3.2

0

3.3

3.3

1.9

14

12

13

11

9

10

8

7

6

5

4

3

2

18

16

17

19

0

0

0

0

35

36

3.0

3.0

3.3

3.3

55

56

3.1

3.1

3.3

3.3

75

76

3.3

0

0

3.3

95

96

0

0

0

3.3

115

116

0

1.0

0

1.0

135

136

0

0

0

0

155

156

0

3.3

0

3.3

175

176

2.9

0

2.6

0

195

196

0

3.1

3.2

3.3

20

0

0

0

0

0

0

0

0

38

37

39

40

3.0

2.9

1.8

2.8

0

3.3

1.8

3.3

58

57

59

60

0

3.2

3.2

3.1

0

3.3

3.3

3.3

78

77

79

80

0

3.3

1.8

0

3.3

3.3

1.8

3.3

97

98

99

100

0

3.3

1.6

3.3

1.5

3.3

3.3

3.3

117

118

119

120

1.0

2.3

0.6

3.3

0

0

0.6

3.3

137

138

139

140

0

0

0

0