Yamaha DVDC-961 Service Manual

DVD AUDIO/VIDEO SA-CD PLAYER

DVD-C961

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL ...................................... 2–3

PREVENTION OF ELECTROSTATIC DISCHARGE .... 4

LOCALE MANAGEMENT INFORMATION ................... 4

FRONT PANEL .............................................................. 5

REAR PANEL ................................................................ 5

REMOTE CONTROL PANEL ........................................ 5

SPECIFICATIONS...................................................... 6–7

INTERNAL VIEW ........................................................... 7

101068

2007 All rights reserved.

This manual is copyrighted by YAMAHA and may not be copied or

redistributed either in print or electronically without permission.

DVD-C961

REPAIR NOTES............................................................. 7

DISASSEMBLY PROCEDURES ............................... 8–9

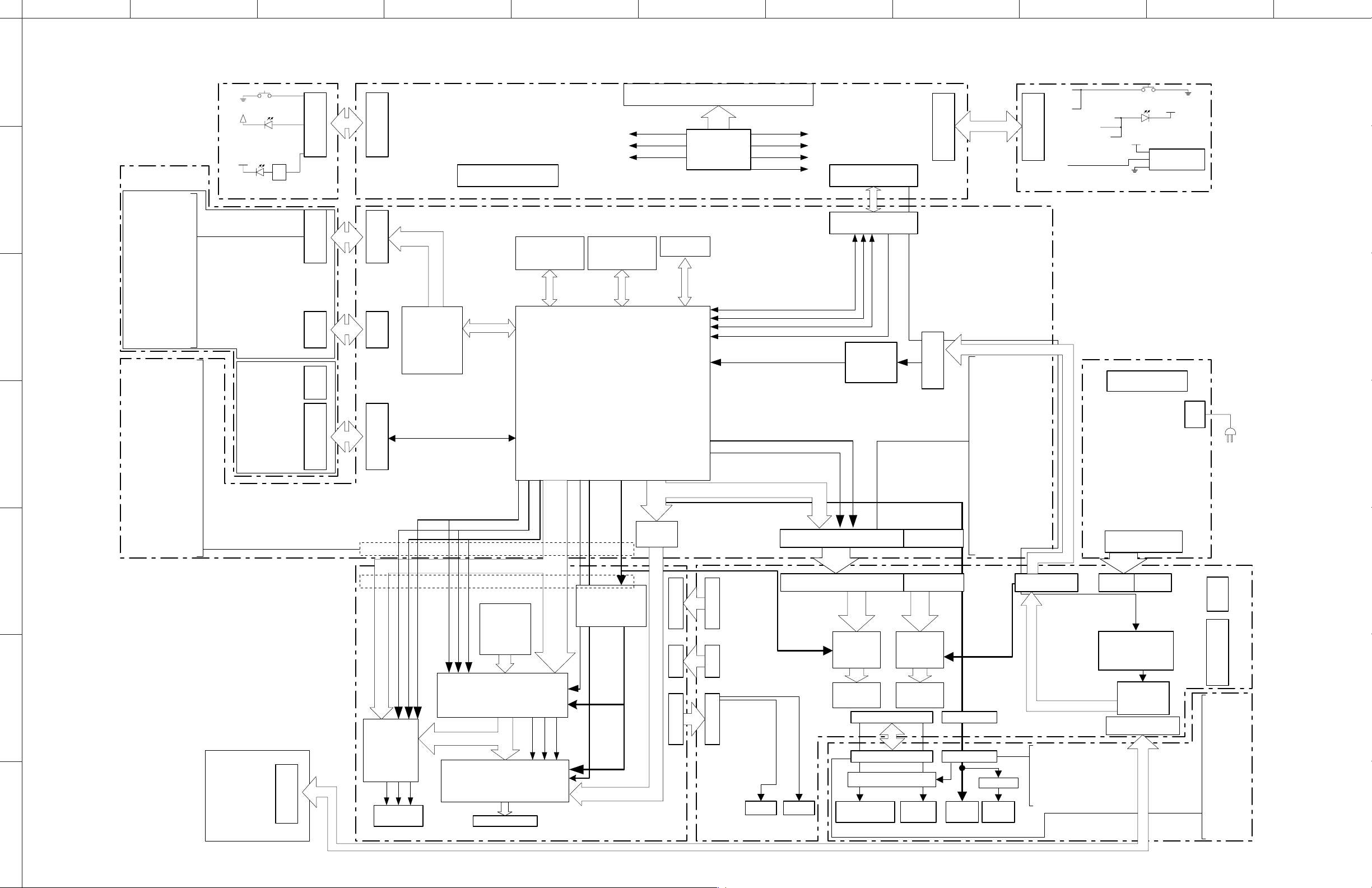

BLOCK DIAGRAM....................................................... 10

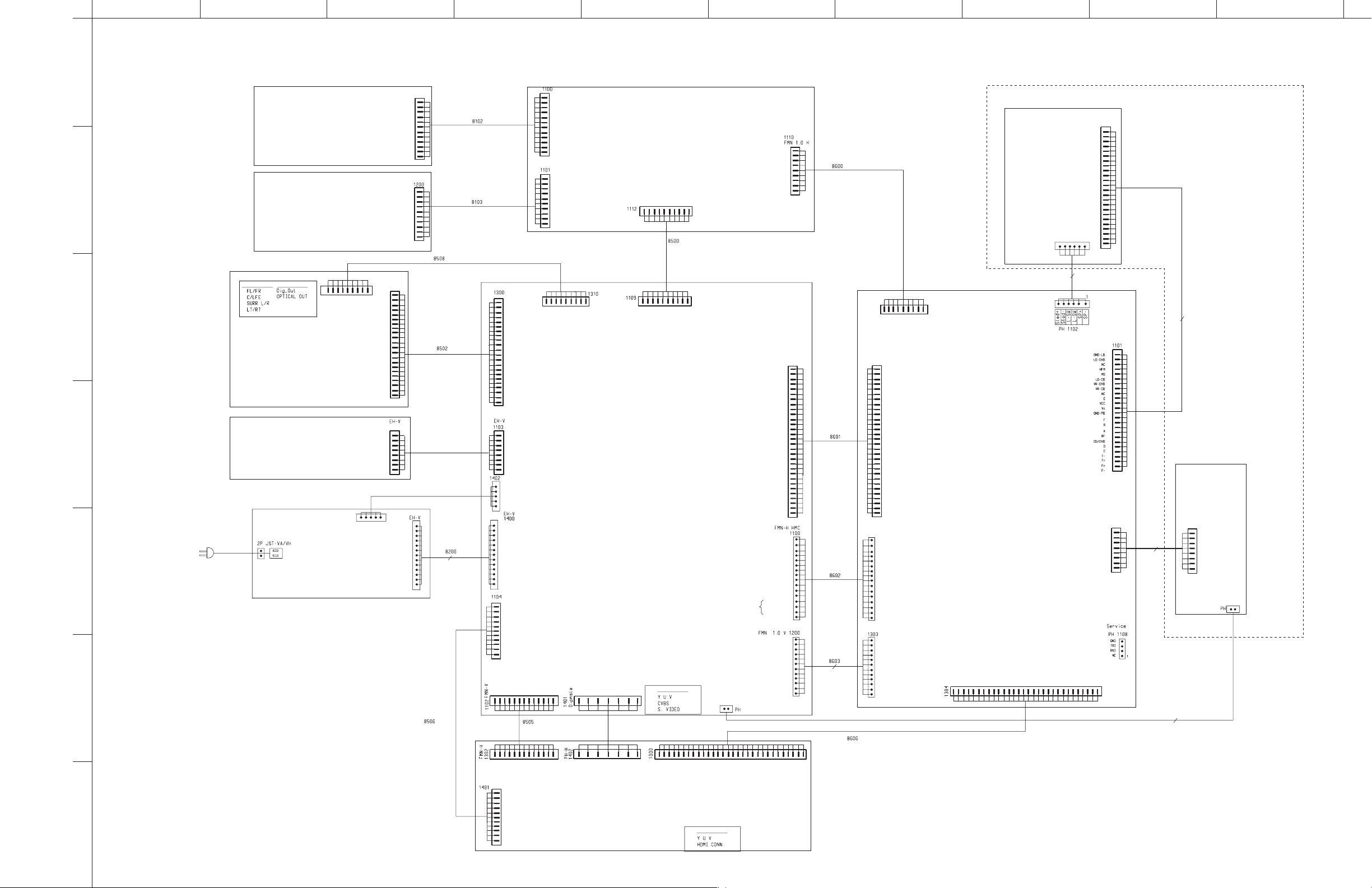

WIRING DIAGRAM ...................................................... 11

PRINTED CIRCUIT BOARDS................................ 12–22

SCHEMATIC DIAGRAMS...................................... 23–38

REPLACEMENT PARTS LIST .............................. 40–41

P.O.Box 1, Hamamatsu, Japan

'07.09

DVD-C961

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are

marked s and must be replaced with parts having

specifications equal to those originally installed.

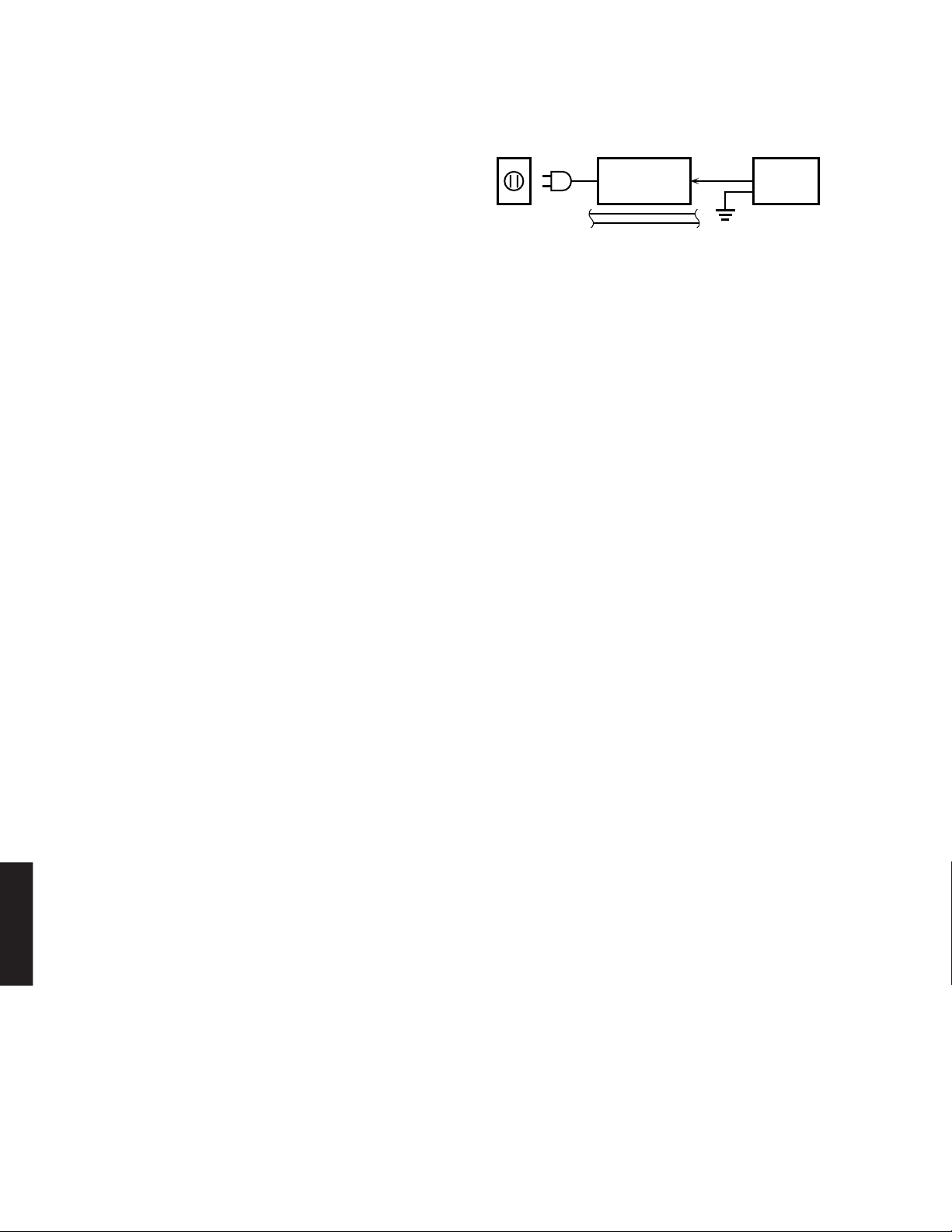

2. Leakage Current Measurement (For 120V Models

Only)

When service has been completed, it is imperative to

verify that all exposed conductive surfaces are properly insulated from supply circuits.

● Meter impedance should be equivalent to 1500 ohms

shunted by 0.15µF.

WALL

OUTLET

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive

harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

About lead free solder

All of the P.C.B.s installed in this unit and solder joints are soldered using the lead free solder.

Among some types of lead free solder currently available, it is recommended to use one of the following types for the repair

work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder is about 30°C to 40°C (50°F to 70°F) higher than that of the lead

solder, be sure to use a soldering iron suitable to each solder.

DVD-C961

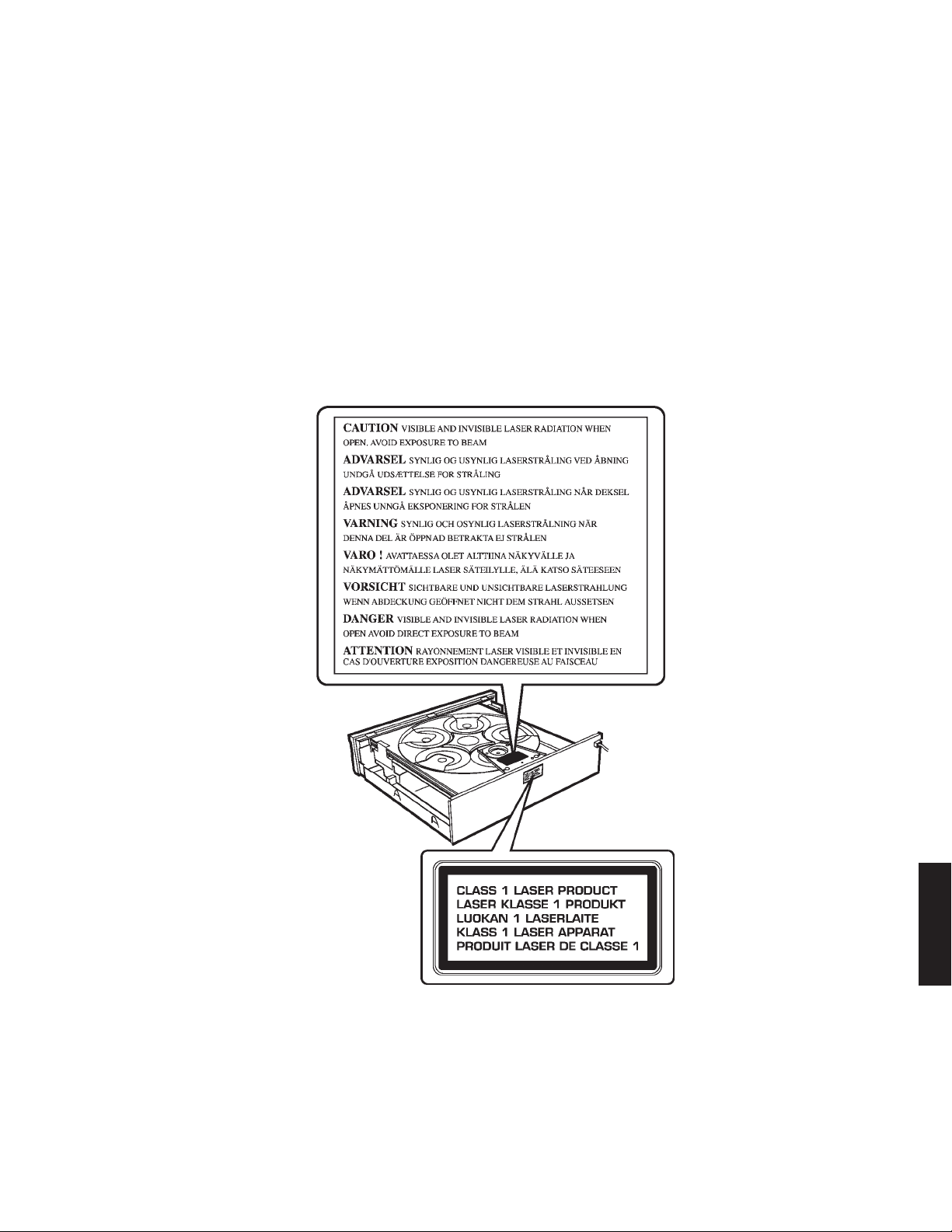

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must be

used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION : Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

2

DVD-C961

Laser Emitting conditions:

1) When the Top Cover is removed, and the STANDBY/ON SW is turned to the "ON" position, the laser component will emit

a beam for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through the

lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is loaded, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB, however, this level has been set by the factory

prior to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this

manual. Adjustment of this control can increase the laser emission level from the device.

Laser Diode Properties

Type: Semiconductor laser GaAlAs

Wave length: 650 nm (DVD)

780 nm (VCD/CD)

Output power: 7 mW (DVD/VCD/CD)

Beam divergence: 60 degrees

Warning for power supply

The primary side of the power supply carries live mains voltage when the pla yer is connected to the mains e ven when

the player is switched off !

This primary area is not shielded so it is possible to touch copper tracks and/or components when servicing the player.

Service personnel have to take precautions to prevent touching this area or components in this area.

Note:

The screws on the DVD mechanism may never be touched, removed or re-adjusted.

Handle the DVD mechanism with care when the unit has to be exchanged!

The DVD mechanism is very sensitive for dropping or giving shocks.

DVD-C961

3

DVD-C961

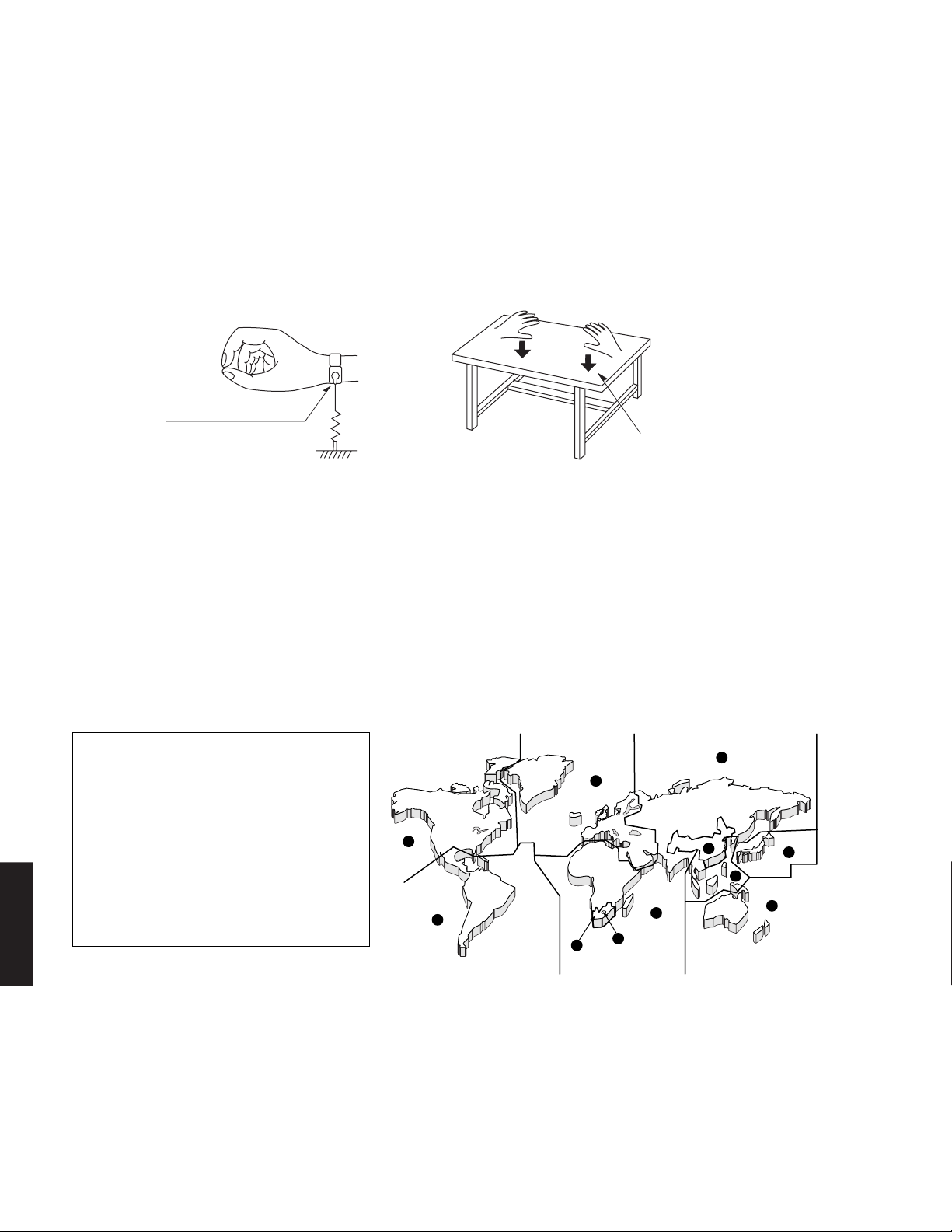

■ PREVENTION OF ELECTROSTATIC DISCHARGE

The laser diode in the DVD mechanism may be damaged due to static electricity from clothes or the human body. Use caution

to prevent electrostatic damage when servicing or handling the DVD-mechanism.

1. Grounding for electrostatic damage prevention

Some devices, such as the DVD player, use an optical pickup (laser diode) that will be damaged by static electricity in the

working environment. Only attempt service after ensuring that all grounding procedures have been completed.

1. Worktable grounding

Put a grounded conductive material (sheet) or iron sheet on the area where the optical pickup is placed.

2. Human body grounding

Use an anti-static wrist strap to discharge the static electricity from your body.

2. Handling Precautions for DVD mechanism

1. Handle the DVD mechanism gently, as it is an extremely high-precision assembly.

2. The flexible cable lines may break if an excessive force is applied to it. Use caution when handling the cable.

3. The semi-fixed resistor for laser power adjustment should not be adjusted. Do not turn the resistor.

■ LOCALE MANAGEMENT INFORMATION

Locale Management Information : This DVD player is designed and manufactured to respond to the Locale

Management Information that is recorded on a DVD disc. If the Locale number described on the DVD disc does not

correspond to the Locale number of this DVD player, this DVD player cannot play this disc.

This product incorporates copyright protection technology that is protected by method

claims of certain U.S. patents and other

intellectual property rights owned by

Macrovision Corporation and other rights

owners. Use of this copyright protection

technology must be authorized by Macrovision

Corporation, and is intended for home and

other limited viewing uses only unless otherwise authorized by Macrovision Corporation. Reverse engineering or disassembly

is prohibited.

DVD-C961

Anti-static wrist strap

1M-ohms

Conductive material

(sheet) or steel sheet

5

2

1

4

2

5

5

6

3

2

4

4

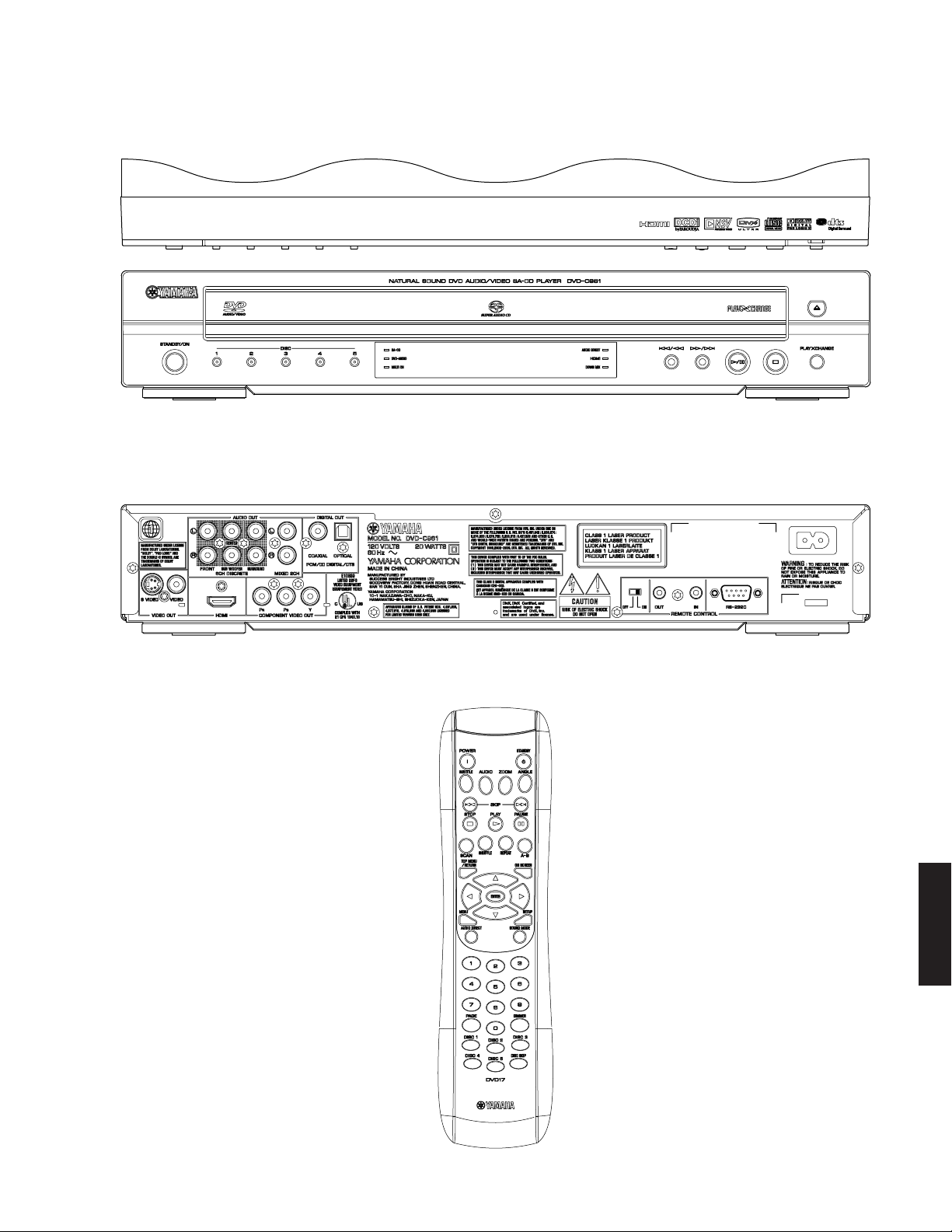

■ FRONT PANEL

U model

■ REAR PANEL

U model

DVD-C961

■ REMOTE CONTROL PANEL

DVD-C961

5

DVD-C961

■ SPECIFICATIONS

PLAYBACK SYSTEM

DVD-video, VR (video recording) format (DVD-RW)

DVD-audio

DVD-R, DVD-RW

DVD+R, DVD+RW, DVD+R DL

Video CD, SVCD

SA-CD multi-channel and SA-CD stereo

CD

Picture CD

CD-R, CD-RW

MP3 (ISO 9660) fs 16, 22.05, 24, 32, 44.1, 48 kHz /

WMA fs 44.1 kHz, 62 kbps to 192 kbps

DivX

JPEG 3072 x 2048 pixels or less

VIDEO PERFORMANCE

Video (CVBS) output 1 Vpp into 75 ohms

S-video output Y: 1 Vpp into 75 ohms

Component video output Y: 1 Vpp into 75 ohms

Black level shift On/Off

AUDIO FORMAT

Digital Dolby Digital, DTS, MPEG

Full decoding of Dolby Digital and DTS multi-channel sound

Analog stereo sound

Dolby surround compatible downmix from Dolby Digital multichannel sound

Dolby Pro Logic II

3D sound for virtual 5.1 channel sound on 2 speakers

AUDIO PERFORMANCE

DA converter 24 bits, 192 kHz

Signal to noise (1 kHz) 105 dB

Dynamic range (1 kHz) 100 dB

DVD fs 96 kHz 2 Hz to 44 kHz

SVCD fs 48 kH z 2 Hz to 22 kHz

DVD-C961

CD/VCD fs 44.1 kH z 2 H z to 20 k Hz

Distortion and noise (1 kHz)

TV STANDARD

Number of lines PAL: 625, NTSC: 525

Vertical frequency PAL: 50 Hz, NTSC: 60 H z

Playback Multistandard (PAL/NTSC)

HDMI video output 480 p/60 Hz, 576 p/50 Hz, 720 p/60 Hz,

CONNECTIONS

Video output RCA/Phono x 1 (yellow)

S-video output Mini DIN, 4 pins x 1

96, 128, 256 kbps (CBR only)

(CBR only) /

fs 48 kHz, 128 kbps to 192 kbps

(CBR only)

®

C: 0.3 Vpp into 75 ohms

PB/CB PR/CR: 0.7 Vpp into 75 ohms

Compressed digital

PCM fs 44.1, 48, 96 kHz /

16, 20, 24 bits

MP3 (ISO 9660) fs 16, 22.05, 24, 32, 44.1, 48 kHz /

24, 32, 56, 64, 96, 128, 256 kbps

WMA 32 kbps to 192 kbps,

mono, stereo

fs 48 kHz 2 Hz to 22 kHz

fs 44.1 kHz 2 Hz to 20 kHz

0.0035 %

1080 i/60 Hz, 1080 p/60 Hz

Component video output

Y output RCA/Phono x 1 (green)

PB output RCA/Phono x 1 (blue)

output RCA/Phono x 1 (red)

P

R

2-channel audio output (L+R)

RCA/Phono x 1 pair (white/red)

6-channel audio output

Audio front L/R RCA/Phono x 1 pair (white/red)

Audio surround L/R

RCA/Phono x 1 pair (white/red)

Audio center RCA/Phono x 1 (black)

Audio subwoofer RCA/Phono x 1 (black)

Digital output

Coaxial RCA/Phono x 1

IEC60958 for CDDA / LPCM, IEC61937

for MPEG2, Dolby Digital, DTS

Optical RCA/Phono x 1

IEC60958 for CDDA / LPCM, IEC61937

for MPEG2, Dolby Digital, DTS

HDMI (Ver. 1.1) Type A x 1

IEC60958 for CDDA / LPCM, IEC61937

for MPEG2, Dolby Digital, DTS

PCM (PPCM) multi / 2ch (DVD-audio),

PCM multi / 2ch (SA-CD)

Remote control

Input ø3.5 mm mini jack x 1

Output ø3.5 mm mini jack x 1

RS-232C D-sub 9 P

GENERAL

Dimensions (W x D x H) 435 x 425 x 75 mm

(17-1/8" x 16-3/4" x 2-15/16")

Weight Approx. 5.5 kg (12 lbs. 2 oz.)

Finish Black color

Power supply AC 120 V, 60 Hz

Power consumption Approx. 20 W

Standby power consumption Less than 0.5 W

ACCESSORIES

Remote control x 1

Battery (R6, AA, UM-3) x 2

Power cable (1.5 m) x 1

Audio/Video pin cable (1.5 m) x 1

* Specifications are subject to change without prior notice.

U ........ U.S.A. model

Manufactured under license from

Dolby Laboratories. “Dolby”, “Pro

Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

“DTS” and “DTS Digital Surround”

are registered trademarks of DTS,

Inc.

“DCDi” is a trademark of Faroudja,

a division of Genesis Microchip, Inc.

6

DVD-C961

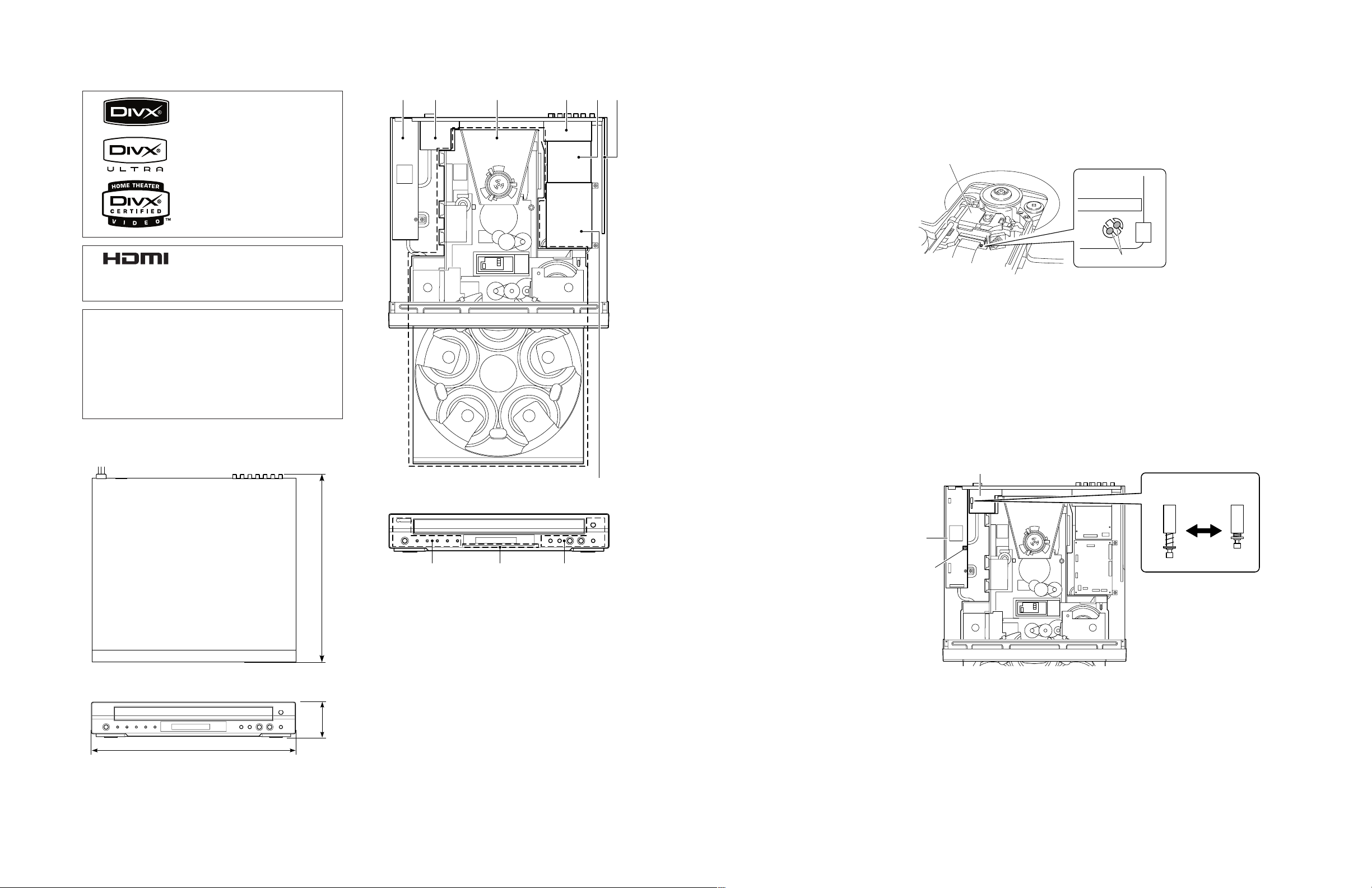

Power supply unit

Front side

RS232C P.C.B.

OK NG

Top view

Switch (Ref. No. 1107)

Potentiometer (Ref. No. VR1)

DivX, DivX Ultra Certified, and associated logos are trademarks of

DivX, Inc. and are used under license.

HDMI, the HDMI logo and High

Definition Multimedia Interface are

trademarks or registered trademarks of HDMI Licensing LLC.

This product incorporates copyright protection technology

that is protected by method claims of certain U.S. patents

and other intellectual property rights owned by Macrovision

Corporation and other rights owners. Use of this copyright

protection technology must be authorized by Macrovision

Corporation, and is intended for home and other limited

viewing uses only unless otherwise authorized by

Macrovision Corporation. Reverse engineering or disassembly is prohibited.

• DIMENSIONS

■ INTERNAL VIEW

1 2 3 4 5 6

■ REPAIR NOTES

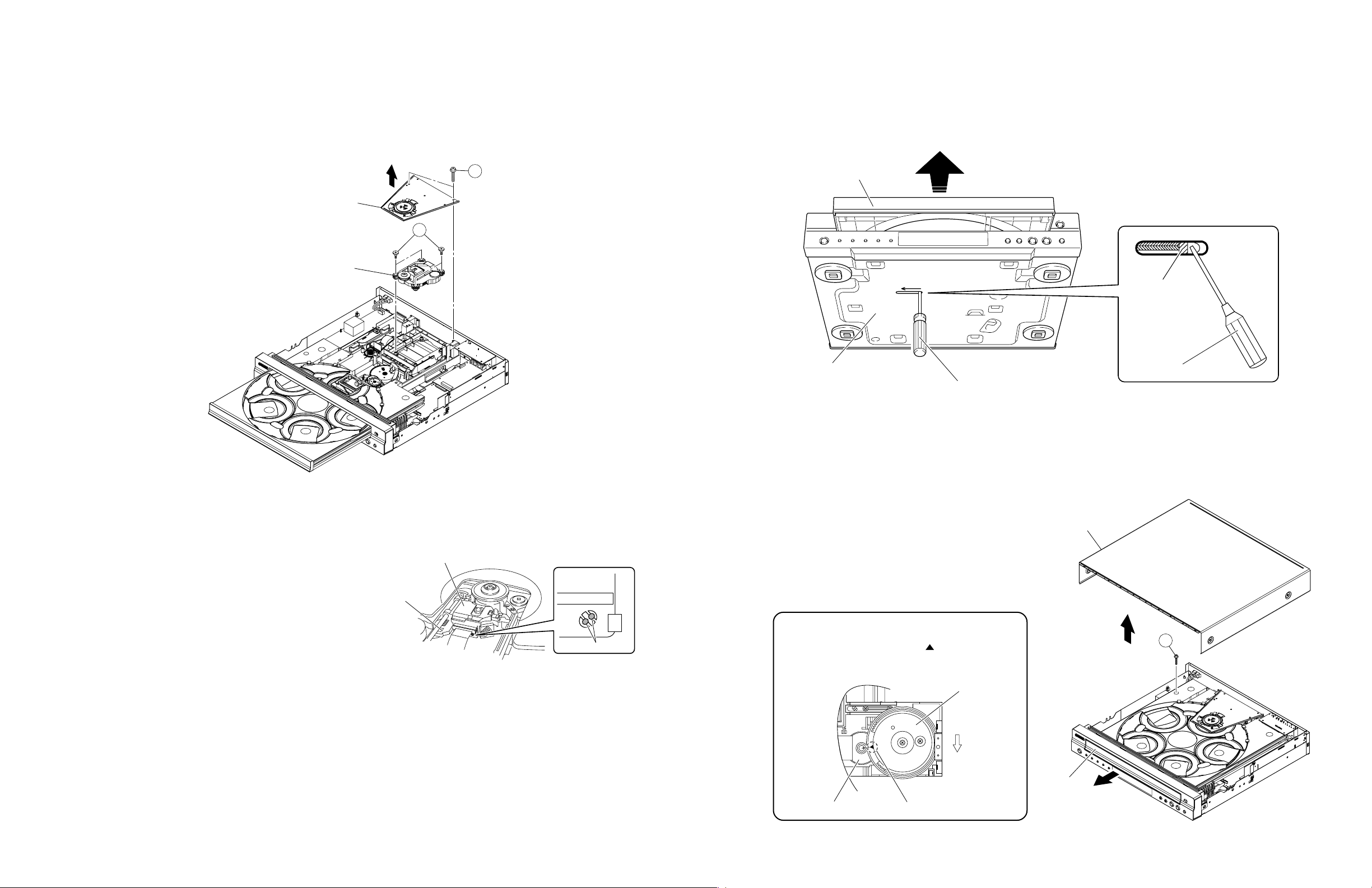

1. DVD 5-disc changer module

• When installing a new traverse unit, remove the solder from the shorted point of P.C.B. using an electrostatic

shielding soldering iron. (Fig. 1)

Traverse unit

Solder

Fig. 1

2. Power supply unit

• The power supply unit has to be replaced in case of failure.

• Never touch the potentiometer (Ref. No. VR1) installed to the power supply unit. (Fig. 2)

3. P.C.B. assembly

• When a failure has occurred in the P.C.B. assembly, replace each P.C.B..

• Never touch the switch (Ref. No. 1107) installed to the RS232C P.C.B.. (Fig. 2)

435 (17-1/8")

425 (16-3/4")

75

Unit: mm (inch)

1

POWER SUPPLY UNIT

2

RS232C P.C.B.

3

DVD 5-DISC CHANGER MODULE

4

FRONT (4) P.C.B.

5

HDMI P.C.B.

6

AV P.C.B.

7

MONO P.C.B.

8

(2-15/16")

FRONT (2) P.C.B.

9

FRONT (1) P.C.B.

0

FRONT (3) P.C.B.

7

8 9 0

Fig. 2

7

DVD-C961

View A

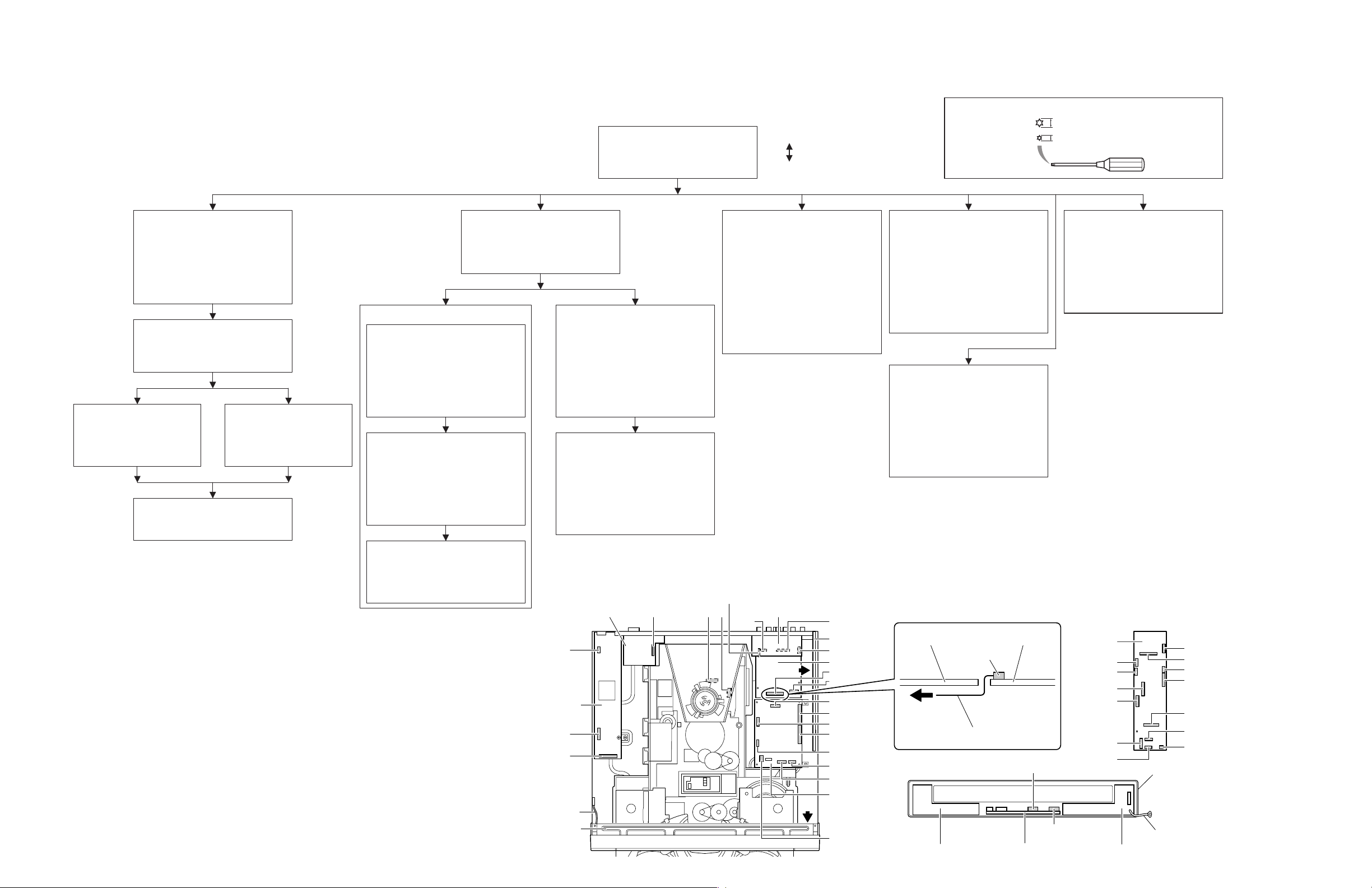

■ DISASSEMBLY PROCEDURES

See replacement parts list for item numbers.

Front Panel Ass'y [101]

➝ Remove 2 screws.

[257] (

➝ Unlock front panel from frame by

➝ Remove 1105, 1109 and ground lead.

Bracket Front

➝ Remove 4 screws. [252]

➝ Remove bracket front.

FRONT (2) P.C.B. [1200]

➝ Remove 1100 (FRONT).

(Fig. 1)

➝ Remove 3 screws. [252]

➝ Remove P.C.B..

FRONT (1) P.C.B. [1200]

➝ Remove 2 screws. [251]

➝ Remove P.C.B..

Bracket front to bottom frame.

releasing successively 4 snaps.

(2 on the side and 2 on the bottom.)

(Fig. 1)

(Bracket front to front panel.)

FRONT (3) P.C.B. [1200]

➝ Remove 1101 (FRONT).

(Fig. 1)

➝ Remove 5 screws. [252]

➝ Remove P.C.B..

When disassembling, use the special screw driver with tip shape in figure.

2.7 mm

T10

Top Cover [240]

➝ Remove 7 screws. [257]

(4 on side and 3 rear side.)

➝

Lift top cover from rear side to remove.

Preventive Measure for Laser Diode

➝ Remove 2 screws (1). (Fig. 2)

)

DVD 5-Disc Changer Module

Tray Ass'y

➝ Remove stopper screw (3). on the

tray. (Fig. 5)

(See "Removal of tray ass'y".)

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Gently pull the tray out.

Traverse Unit

➝ Remove 4 screws (2).

(Traverse unit to CM unit.)

*

Use the phillips screwdriver to

remove screws marked (

➝ Remove A and B.

(Fig. 1)

➝ Remove traverse unit.

➝ Remove clamper ass’y. (Fig. 2)

➝ Solder the lands of the optical pick

up. (Fig. 2)

MONO P.C.B. [1300]

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Remove 1101 (MONO), 1102 (MONO),

1104 (MONO), 1105, 1301, 1303, 1304

and 1305. (Fig. 1)

➝ Remove 4 screws. [257]

(P.C.B. to bottom frame.)

➝ Remove P.C.B..

HDMI P.C.B. [1800]

➝ Remove 1302, 1401 and 1402. (Fig. 1)

➝ Remove 2 screws. [252]

(P.C.B. to rear panel.)

2

).

➝ Remove screw. [257]

(P.C.B. to rear panel.)

➝ Remove 2 screws. [257]

(P.C.B. to bottom frame.)

➝ Remove P.C.B..

AV P.C.B. [1500]

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Remove 1100 (AV), 1101 (AV), 1102

(AV), 1103 (AV), 1104 (AV), 1109,

1200, 1300, 1310, 1400, 1401, 1402

and 1460. (Fig. 1)

➝ Remove screw. [252]

(P.C.B. to rear panel.)

➝ Remove screw. [268 (3 x 4)]

(P.C.B. to bottom frame.)

➝ Remove P.C.B..

Mounting

Dismounting

Power Supply Unit [1000]

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Remove CN1, CNA and CNB. (Fig.

1)

➝ Remove 2 screws. [257]

(P.C.B. to bottom frame.)

➝ Release 2 spacers locking.

(P.C.B. to bottom frame.)

➝ Remove power supply unit.

RS232C P.C.B. [1700]

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Remove screw. [257]

(P.C.B. to rear panel.)

➝ Remove 2 jack screws.

(P.C.B. to rear panel.)

➝ Remove 1103 (RS232C). (Fig. 1)

➝ Remove P.C.B..

1.7 mm

T6

FRONT (4) P.C.B. [1200]

➝ Open tray. (Fig. 4)

(See "How to manually open the tray

ass'y".)

➝ Remove 5 screws. [252]

(P.C.B. to rear panel.)

➝ Remove 1500 and 1503.

(Fig. 1)

➝ Remove P.C.B..

CM Unit

➝ Remove 1101 (MONO), 1102 (MONO),

1305 and 1460.

➝ Remove 5 screws. [257]

➝ Remove CM unit.

Power supply unit

• Cable Connections

RS232C P.C.B.

CN1

CNA

CNB

1103 (RS232C)

1302 (HDMI)

AB

FRONT (4) P.C.B.

View B

15001503

AV P.C.B.

1401 (HDMI)

HDMI P.C.B.

1000

1402

1303

1301

1101 (MONO)

1304

1102 (MONO)

1105

AV P.C.B.

1000

To 1304

(MONO P.C.B.)

Flexible flat cable (30P 180mm)

• View A

HDMI P.C.B.

1101 (FRONT)

AV P.C.B.

1200

1104 (AV)

1103 (AV)

1401

1100 (AV)

1109

• View B

1102 (AV)

1101 (AV)

1310

1300

1400

1402

1460

Front panel ass'y

1104 (MONO)

MONO P.C.B.

Ground lead

Bracket front

8

View A

1305

Fig. 1

1100 (FRONT)

FRONT (2) P.C.B.FRONT (1) P.C.B.FRONT (3) P.C.B.

Ground lead

DVD-C961

Gear/L0

Front panel

Gear/L01

Marking

• Precaution for installation of the tray ass'y.

On tray ass’y setting.

Check the direction of marking " " on gear according

to this drawing.

b. c.

Top cover

Tray ass'y

a.

3

Tray ass'y

Flatblade screwdriver

Flatblade screwdriver

Bottom side

Slider

• Preventive measure for laser diode from electrostatic breakdown

When replacing the MONO P.C.B. or DVD 5-disc changer module, solder between lands of the optical pick up P.C.B. to

protect the laser diode against electrostatic breakdown.

Use the phillips screwdriver to remove screws (2). (Fig. 2)

*

1

Clamper ass'y

2 *

Traverse unit

• How to manually open the tray ass’y

a. Move the slider in the direction indicated with a flatblade screwdriver until the tray is ejected.

b. Gently pull the tray ass’y out.

Fig. 4

Notes

• Use an anti-static soldering iron to short-circuit and

unshort-circuit laser diode.

• After you have finished repairing, remove the

solder from the short-circuit location.

• When installing a new traverse unit, remove the

solder from the shorted point of P.C.B. using an

electrostatic shielding soldering iron.

Fig. 2

Traverse unit

Optical pick up

• Removal of tray ass’y

* The tray ass’y cannot be supplied independently. The tray ass’y is contained in DVD 5-disc changer module and

supplied as a DVD 5-disc changer module.

a. Remove the top cover.

b. Open tray (see “How to manually open the tray

ass’y”).

c. Remove screw (3).

d. Remove the tray ass’y.

Solder

Fig. 3

Fig. 5

9

ABCDEFGHI J

DVD-C961

1

■ BLOCK DIAGRAM

Keys

+5V STBY

+5V STBY

DVD 5-DISC

2

3

4

CHANGER MODULE

1

GND

2

LD_DVD

3

NC

4

HFM

5

MD

6

LD_CD

7

VR_DVD

8

VR_CD

9

NC

10

E

11

VCC

12

VC

13

GND

14

F

15

B

(KHM313AAA)

16

A

TRAVERSE UNIT

17

RF

18

CD/DVD

19

D

20

C

21

T-

22

T+

23

F+

24

F-

1

GND

2

SDA

3

SCL

4

GND

5

27M

6

GND

7

YUV(0)

8

GND

9

YUV(1)

10

GND

11

YUV(2)

12

+12VD

13

YUV(3)

14

+5V

15

YUV(4)

16

+3V3

17

YUV(5)

18

+3V3

19

YUV(6)

20

GND

21

YUV(7)

22

GND

23

MCLK

24

GND

25

VSYN

26

GND

27

SPDIF_OUT

28

GND

29

INT

30

HSYN

FRONT (2) P.C.B.

1

2

3

4

5

6

(SD5.5)

CM UNIT

MONO P.C.B.

(SD6.3)

5

6

1

RC_IN

2

IR_SW

3

RESET

4

+5V_STBY

5

SCL

6

SDA

7

GND

7

RS232C P.C.B.

8

STBY_CTRL

B02

DISC1-5_Y

7300

SCL/SDA

SPSP+

LIMIT

GND

SLEDSLED+

12GND

+12V

1

IRQ

2

SCL

3

SDA

4

NC

5

GND

6

+8V

7

+8V

8

GND

1103

8P EH V to AV

1300

12P 1.0 FFC H

to AV_1460

1304

1000

1100

1

B02

GND

2

Disc5_Y

3

Disc4_Y

4

Disc3_Y

5

Disc2_Y

6

Disc1_Y

7

12P 1.0 FFC H8P 1.0 FFC H

+5VL

8

+5V_STBY

9

SDA_uP

10

GND

11

SCL_uP

12

H

24P 0.5 FFC

1101

7111

MOTOR

DRIVER

6P PH V

1102

1305

MM1646XH

I2C

8-bit ITU601

412

50 49 32

Video DAC

ADV7320

37 38 39

7202

Component video

YUV

1003 1002

7100

20-bit YCbCr

7405

IR_SW

RC6_IN

RESET

+5VL

123456789

10P 1.0 FFC V to AV

1112

to AV_1109

27M

HSYNC

VSYNC

30P 1.0 FFC H

30P 1.0 FFC H

7101

SDRAM

MT48LC2M32

Faroudja

FLi2310L

HDMI Tx

Sil9030CTU-7

HDMI OUT

GND

-24V

+12VL

7302

DDR SDRAM

4M x 16

7112

125 119 118

P_VSYNC

P_CLK

66

21

+5V_STBY

STBY_CTRL

10

8-bit ITU601

47

P_HSYNC

42

7100

STDBY_CTRL

DISC1Y_5Y

FRONT (1) P.C.B.

7303 7301

Flash

2M x 8

MT1389B

I2C

Buffer

74LVC125

IO

Expander

PCF8574T

7201

Video Reset

HDMI Reset

I2C

SPDIF/I2S

HDMI P.C.B. AV P.C.B. FRONT (4) P.C.B.

RESET

10

21

Microprocessor

2-6

7101

E2PROM

I2C

11P 1.0 FFC V13P 1.0 FFC V 7P PH H

1305

1402

1302

VFD

111

102

103

104

I2S_0_1_2_3

11P 1.0 FFC V13P 1.0 FFC V 7P PH H

1104

10

11

1401

1102

10

11

12

13

1101

22

R6C_OUT

23

24

26-28

SCL

SDA

B01-03

VINTRQ

SDA

SCL

GND

RC6_OUT

123456789

9P 1.0 FFC V

1110

9P 1.0 FFC V

1105

RC6

Front_I2C_DAT

Front_I2C_CLK

Front_I2C_IRQ#

3.3V

S0

S1

Regulator

STDBY_CTRL

1104

SPDIF

1

GND

2

PCM_MCLK

3

GND

4

SD3

5

SD2

6

SD1

7

SD0

8

GND

9

PCM_LRCLK

PCM_SCLK

GND

1301

1101

30P 1.0 FFC H

30P 1.0 FFC V

I2S_1

7200

6-Ch DAC

CS4360

7300

_2_3

1303

12P 1.0 FFC V

1200

12P 1.0 FFC V

I2S

7201

2-Ch DAC

AK4385

7300

_0

Pre-AMP Pre-AMP

1

GND

2

DPDET

3

DLINE3

4

DLINE2

5

DLINE1

6

+5VID

7

GND

8

CVBS

9

GND

C

GND

Y

GND

S-Video CVBS

1107 1107

1300

22P 1.0 FFC V 9P 1.0 FFC V

1500

22P 1.0 FFC V 9P 1.0 FFC V

7502-7516

Mute circuit

1502

5.1 CH

Analog audio

1501 7600 1600

MIXED 2CH

L/R

VIDEO OUT AUDIO OUT DIGITAL OUT

10P 1.0 FFC H

1

2

3

16P 1.0 FFC V

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

GND

2

PCM_LR

3

GND

4

PCM_LsRs

5

GND

6

PCM_Clfe

7

GND

8

PCM_Cs

9

GND

10

SCL

11

SDA

12

RESET

MUTE/SPDIF

MUTE

OPTICAL COAXIAL

1200

GND

P50

NC/L2

SCART1/L3

SCART2/L3

AV_MUTE

VGND

Y

VGND

C

VGND

CVBS

VGND

G_Y

VGND

B_U

VGND

R_V

GND

PCMSCLK

PCMDATA_L0

GND

PCMCLK

PCMLRCLK

GND

SPDIF_OUT

GND

SPDIF_PCM_Data_IN

GND

MIC_DET

16P 1.0 FFC H

SPI

1310

1503

5601

Buffer

B01

1

GND

2

B03

3

LED_Progressiv

4

LED_HDMI

5

LED_Downmix

6

+5VL

7

10P 1.0 FFC H

+5V_STBY

8

IR

9

GND

10

1100

1

GND

2

GND

3

+1V8 _senses

4

+1V8

5

+1V8

6

+5VL

7

+5VL

8

+5VL

9

GND

10

+8V

11

GND

12

STDBY_CTRL

13

DAC_STB

14

SCL

15

SDA

16

GND

1

MUTE_SLR

2

MUTE_LFE_CE

3

MUTE

4

MUTE_TVLR

5

GND

6

MUTE_FLR

7

SPDIF_OUT

8

GND

9

+5VD

Keys

+5VL

+5V STBY

7102

IR

FRONT (3) P.C.B.

CN3

to AV_1402

5PEH V to AV

12345

GND

+5VL

+12VL

+5V_STBY

CN4

-24V

POWER SUPPLY UNIT

+5V_XM

GND

+5VL

+5VL

GND

+12VL

GND

-12VL

STBY_CTRL

POWER_DN

+12VL

GND

+5V_STBY

12345678910111213

CN1

1111

13P PH V

1400

13P PH 5P EH V

STDBY_CTRL

1

2

3

4

5

Power Switching

Circuit

Regulator

8P EH V to RS232C

1402

+5VL

+12VL

GND

+5V_STBY

-24V

SUPPLY

UNIT_CN3

to POWER

1460

1109

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

AC IN

to SD5.5

2P PH V

to DVD 5-DISC

to FRONT (1)

10P 1.0 FFC V

to FRONT (1)_1112

RT

GND

GND

GND

LT

GND

SURR_R

GND

GND

GND

SURR_L

GND

LEF

GND

GND

GND

CE

GND

FR

GND

GND

FL

MODULE

CHANGER

10

ABCDEFGH I J

1

■ WIRING DIAGRAM

2

FMN 1.0 H

1300

I2C_CLK

12

GND_D

11

I2C_DATA

10

+5VSTDBY

9

8

+5VL

7

FRONT (2) P.C.B. FRONT (1) P.C.B.

FRONT (3) P.C.B.

DISC1_Y

DISC2_Y

DISC3_Y

DISC4_Y

DISC5_Y

GND_B

KEY_B02

KEY_B01

GND_B

KEY_B03

LED_PROGRESSIVE

LED_HDMI

LED_DOWNMIX

+5VL

+5VSTBY

GND_D

6

5

4

3

2

1

FMN SM 1.0 H

1

2

3

4

5

6

7

8

9

IR

10

12P, 280mm

10P, 340mm

FMN 1.0 H

FMN SM 1.0 H

I2C_CLK (from MCU)

12

11

GND_D

10

I2C_DATA (from MCU)

+5VSTDBY

9

+5VL

8

DISC1_Y

7

DISC2_Y

6

DISC3_Y

5

DISC4_Y

4

DISC5_Y

3

GND_B

2

KEY_B02

1

10

KEY_B01

9

GND_B

8

KEY_B03

LED_PROGRESSIVE

7

6

LED_HDMI

LED_DOWNMIX

5

4

+5VL

3

+5VSTBY

2

IR (from IR eye)

GND_D

1

FMN SM 1.0 H

+5Vstdby

STDBY_CTRL

+12VL

10

9

876

+5VL

-24V

GND_D

5

RC6_IN (from RS232 board)

IR_SW (from RS232)

RESET

mute_uP

1

432

10P, 560mm

INTRQ

I2C_DATA

I2C_CLK

GND_D

1KHZ ( not used )

RC6_OUT

STDBY_CTRL

GND_D

DVD-C961

DVD 5-DISC CHANGER MODULE

TRAVERSE UNIT

KHM313

1

2

3

4

5

6

7

8

NC

9

9P, 340mm

1109

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

-12VL

9P, 180mm

FMN-22-V

1

RT

2

GND

3

GND

4

GND

LT

5

GND

6

SURR_R

7

GND

8

9

GND

GND

10

SURR_L

11

12

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

GND_D

DPDDETN

2

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

+5VL

+12VL

GND

+5Vstby

-24V

+5V_XM

GND

+5V_VL

+5V_VL

GND

+12VL

GND

-12VL

STBY_CTRL

Power_DN

+12VL

GND

+5V_STBY

1

GND

SCLK

2

LRCLK

3

4

GND

LR_PCM

5

6

SLR_PCM

7

SubCen_PCM

8

Cs_PCM

9

GND

MCLK

10

11

GND

DLINE2

DLINE3

4

3

GND

LFE

GND

GND

GND

CE

GND

FR

GND

GND

FL

RC6_IN

RC6_OUT

RESET

+5VStdby

I2C_CLK

I2C_DATA

GND

STDBY_CTRL

V_GND

DLINE1

+5VA

5

6

7

22P, 180mm

8P, 480mm

5P, 560mm

CN1

1

GND

2

3

4

GND

5

6

7

GND

8

13P, 560mm

9

10

11

GND

12

13

V/CVBS

V_GND

8

9

U/C1Y

10

1

2

MUTE_SLR

MUTE_LFE_CE

V_GND

11

12

3

MUTE

V_GND

456

GND

MUTE_FLR

MUTE_TVLR

7

SPDIF_OUT

FMN SM 1.0 H

8

9

GND

+5VD

AV P.C.B. MONO P.C.B.

1102

3

+12VL

+5Vstdby

STDBY_CTRL

4

567

8

9

-24V

+5VL

IR_SW

GND_D

RESET

RC6_IN

mute_uP

FMN 1.0 V

1101

1

GND

P50

2

NC / Line 2

3

SCART1/Line3

4

5

SCART0/Line3

6

AV_MUTE

7

Y_REF

Y

8

9

C_REF

10

C

11

CVBS_REF

CVBS

12

G_REF

13

G_Y

14

B_REF

15

B_U

R_REF

PCMSCLK

PCMDATA_LO

PCMCLK

PCMLRCLK

SPDIF_out

SPDIF_PCM_Data_MIC_IN

Mic_det

+1V8_Sense

STDBY_CTRL

DAC_STDBY

To control

SCL-DAC

DAC

SDA-DAC

AK4382A

16

17

R_V

18

GND

19

20

21

GND

22

23

24

25

GND

26

GND

27

28

GND

29

30

GND

GND

+1V8

+1V8

+5VL

+5VL

+5VL

GND

+8V

GND

GND

30P, 180mm

16

15

14

13

12

11

10

9

8

16P, 140mm

7

6

5

4

3

2

1

7

8

9

STDBY_CTRL

VolB ( not used )

VolA ( not used )

SFW30R-2STE 1

1301

1

GND

P50

2

NC / Line 2

3

SCART1/Line3

4

SCART0/Line3

5

6

AV_MUTE

Y_REF

7

8

Y

C_REF

9

10

C

11

CVBS_REF

CVBS

12

G_REF

13

G_Y

14

B_REF

15

B_U

16

17

R_REF

R_V

18

GND

19

20

PCMSCLK

PCMDATA_LO

21

GND

22

PCMCLK

23

24

PCMLRCLK

GND

25

26

SPDIF_out

27

GND

28

SPDIF_PCM_Data_MIC_IN

GND

29

Mic_det

30

FMN-V SM

1104

GND

1

2

GND

3

+8V

+1V8

4

+1V8

5

6

+5VL

+5VL

7

+5VL

8

9

GND

+8V

10

11

GND

12

STDBY_CTRL

13

Strobe

VSCK

14

VSDA

15

16

GND

6

RC6_OUT (front)

SFW12S-2STE 1

1

+5VL

1

CEC

2

GND_D

3

+3V3

4

GND_D

5

+3V3

6

Interface connections

+12V_Power

Video Signal

7

GND

+12V

1

2

PCM_Data_LR

PCM_Data_sLR

PCM_Data_Sub/Cen

PCM_Data_EX_sLR (op)

I2C_CLK

I2C_DATA

DAC_RST

1460

GND

2

3

GND

4

GND

5

6

7

GND

GND

12P, 180mm

8

9

10

11

12

1

GND

2

PCM_Data_LR

3

GND

4

PCM_Data_sLR

GND

5

6

PCM_Data_Sub/Cen

7

GND

8

PCM_Data_EX_sLR (op)

9

GND

10

I2C_CLK

11

I2C_DATA

12

DAC_RST

432

5

1KHZ ( not used )

GND_D

I2C_CLK

I2C_DATA

1

INTRQ

1105

FMN 1.0 V

SFW30R-2STE 1

(SD 6.3)

I2C_DATA

GND

27M

I2C_CLK

GND

1

4

3

5

GND

6

VDATA0

789

GND

GND

VDATA1

10

VDATA2

11

GND

12

VDATA3

NC

13

14

VDATA4

NC

15

161718

NC

VDATA5

Interface connection

Audio Signal Dig Aud Sig

3

FRONT (4) P.C.B.

1503

7

8

9

MUTE

MUTE_SLR

MUTE_LFE_CE

6

GND

MUTE_FLR

MUTE_TVLR

12345

GND

+5VD

SPDIF_OUT

SURR_R

SURR_L

FMN-22-V

RT

GND

GND

GND

LT

GND

GND

GND

GND

GND

LFE

GND

GND

GND

CE

GND

FR

GND

GND

FL

1500

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1103

1

RC6_IN

2

CN3

RC6_OUT

RESET

+5VStdby

I2C_CLK

I2C_DATA

STDBY_CTRL

1

2

345

GND

+5VL

+12VL

GND

+5Vstby

-24V

3

4

5

6

7

8

+5V_XM

+5V_VL

+5V_VL

+12VL

STBY_CTRL

Power_DN

+12VL

+5V_STBY

4

5

RS232C P.C.B.

CN4

POWER SUPPLY UNIT

6

11P, 100mm 13P, 220mm 7P, 80mm

VDATA6

19220

GND

VDATA7

21

6P

24P

SFW24R-2STE 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CM UNIT

1305

SFW8R-2STE 1

1

IRQ

2

SCL

3

SDA

NC

4

5

GND

6

NC

NC

7

GND

8

GND

NC

GND

SPDIFOUT

HDMI_IRQ

NC

NC30GND

GND

27

28

29

25

26

24

23

22

30

8P

(SD 5.5)

2P

1

IRQ

2

SCL

3

SDA

NC

4

5

GND

NC

6

NC

7

GND

8

GND

+12V

1

2

30P, 180mm

5

6

4

3

DLINE3

DLINE2

DPDDETN

1

GND

SCLK

2

LRCLK

3

GND

4

LR_PCM

5

SLR_PCM

6

SubCen_PCM

7

Cs_PCM

8

GND

9

MCLK

10

GND

11

DLINE1

+5VA

7

8

V/CVBS

AV_GND

9

10

U/C

AV_GND

111213

Y

AV_GND

2

CEC

3

GND_D

4

+3V3

5

GND_D

+3V3

1

+5VL

AV_GND 13

7

6

1

+12V_Power

HDMI P.C.B.

Interface connection

Video Signal

1

2

GND_D

7

11

DVD-C961

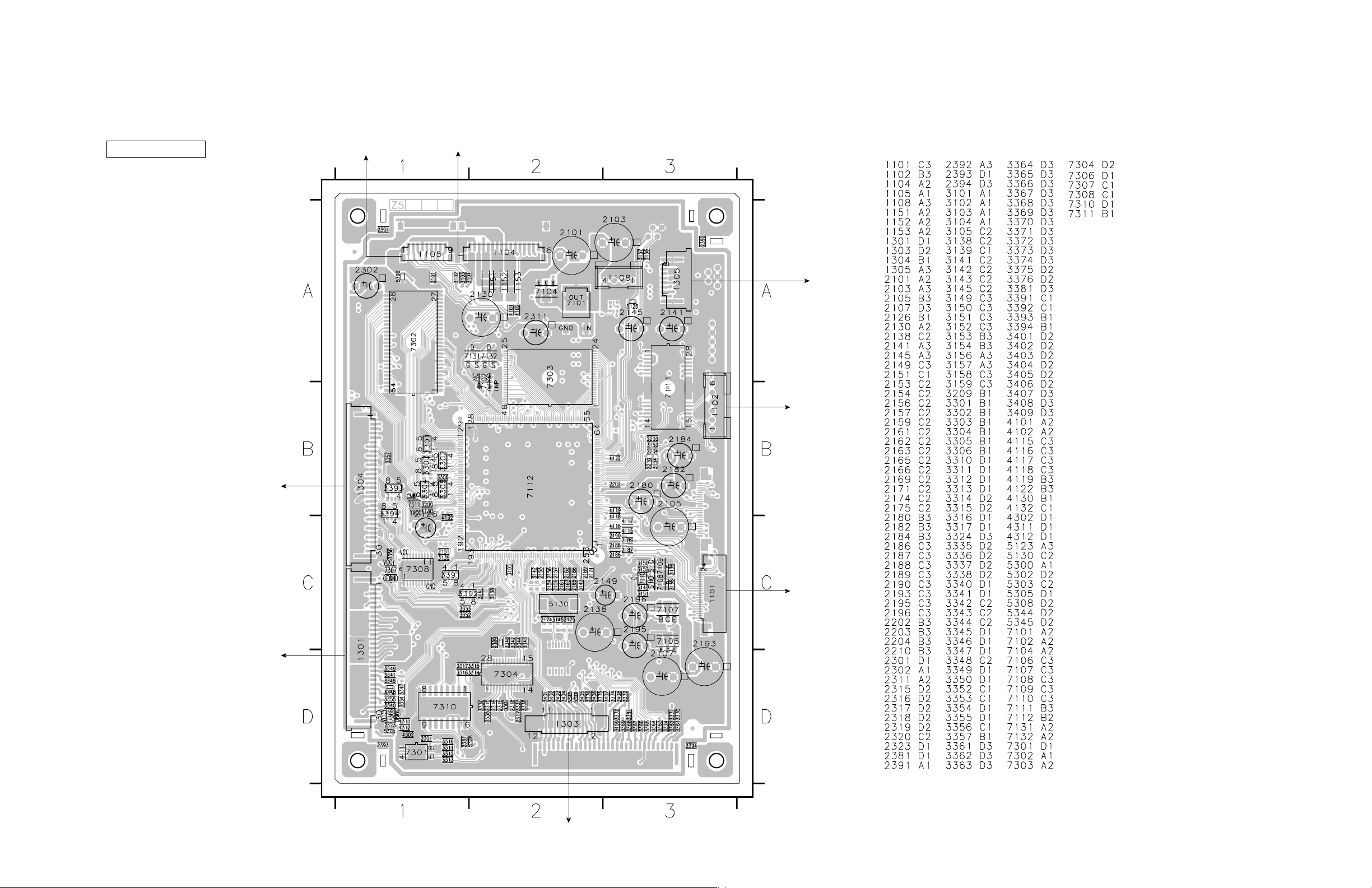

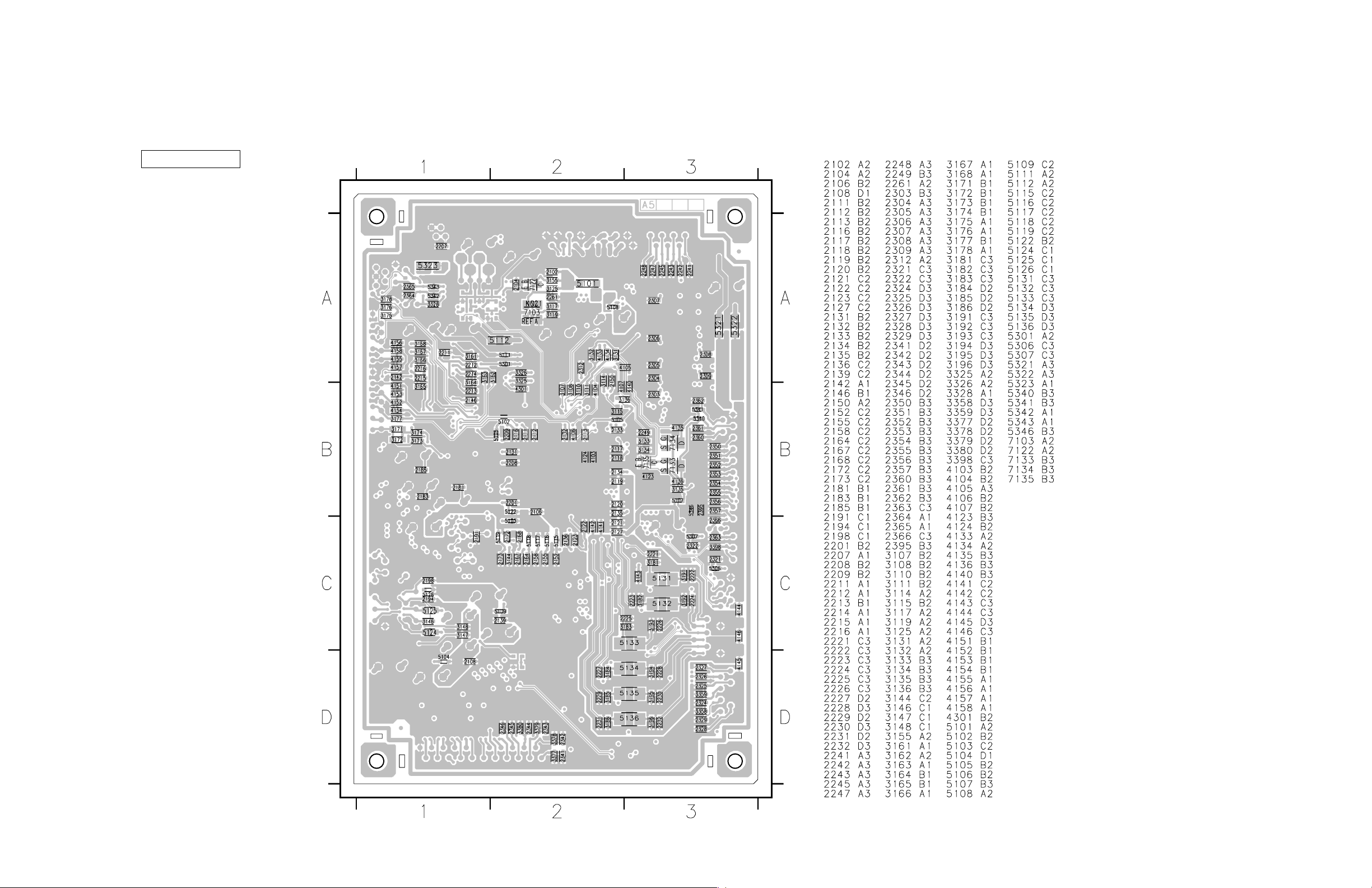

■ PRINTED CIRCUIT BOARDS

FOR INFORMATION ONLY (NO REPLACEMENT COMPONENT PARTS WILL BE AVAILABLE)

AV

MONO P.C.B.

(Top view)

FRONT (1)

(1110)

(1100)

The first digit of a component indicates the component type.

1xxx : Connector 3xxx : Resistor 5xxx : Coil 7xxx : IC, Transistor, FET

2xxx : Capacitor 4xxx : SMD jumper 6xxx : Diode 9xxx : Wire jumper

(1000)

HDMI

(1101)

AV

DVD 5-DISC CHANGER MODULE

KHM313

TRAVERSE UNIT

KHM313

TRAVERSE UNIT

12

AV

(1200)

MONO P.C.B.

(Bottom view)

DVD-C961

The first digit of a component indicates the component type.

1xxx : Connector 3xxx : Resistor 5xxx : Coil 7xxx : IC, Transistor, FET

2xxx : Capacitor 4xxx : SMD jumper 6xxx : Diode 9xxx : Wire jumper

13

Loading...

Loading...