Page 1

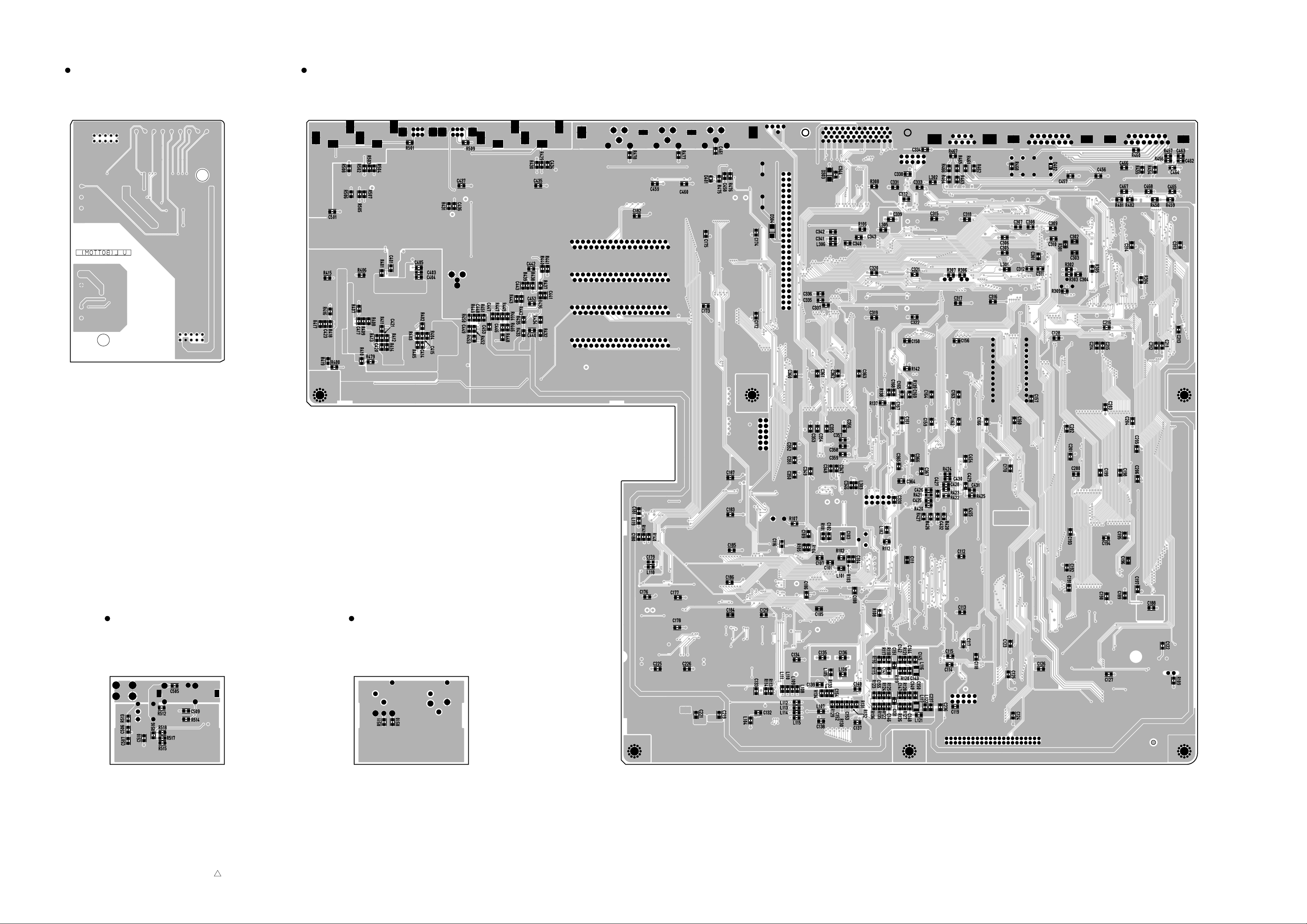

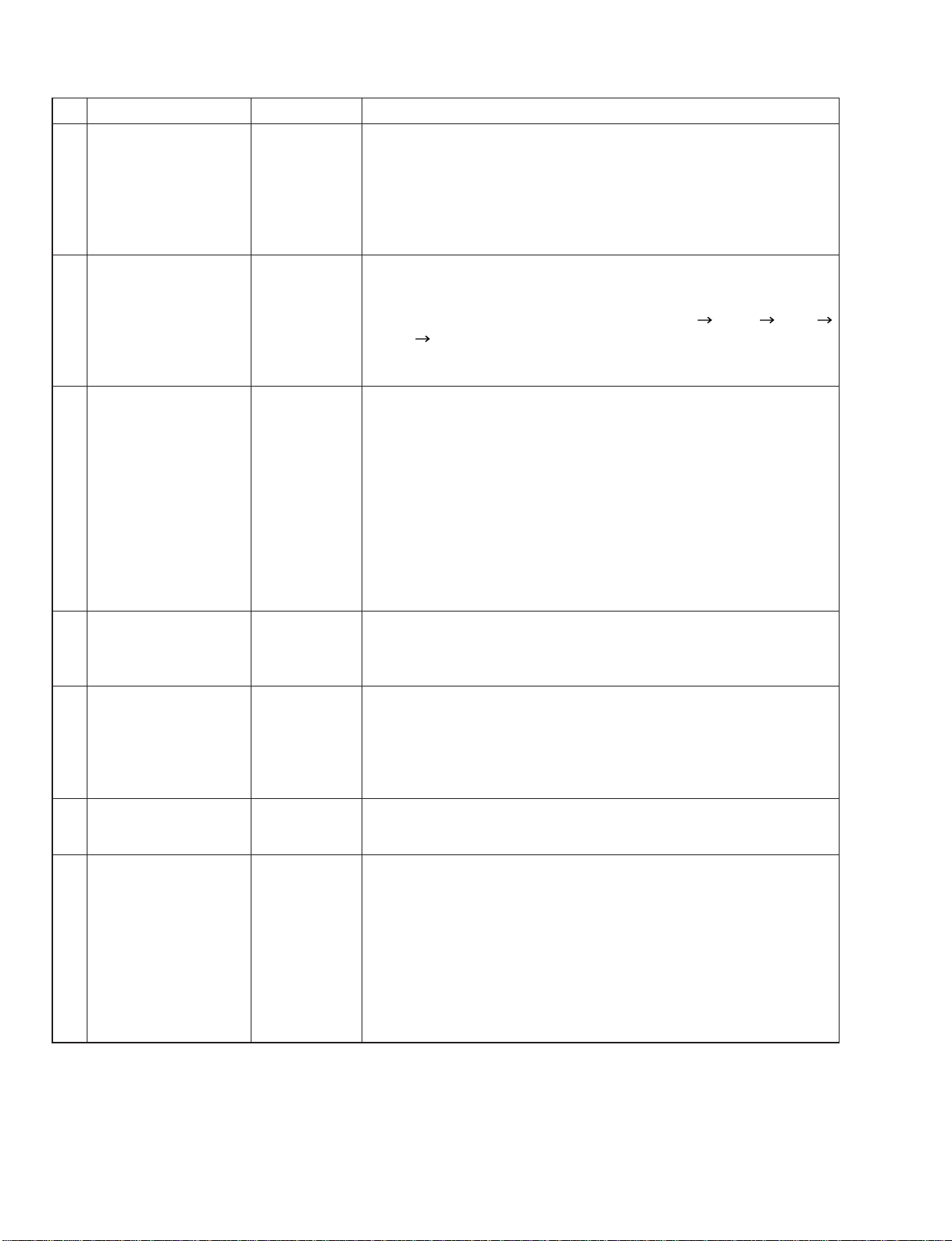

MAIN-A, MAIN-B, MAIN-C: 3NA-V312430-3

S-SYNC: 3NA-V519530-2

2

Pattern side Pattern side Pattern side

Pattern side

MAIN-A Circuit BoardS-SYNC Circuit Board

MAIN-B Circuit BoardMAIN-C Circuit Board

D24

36

Note: See parts list for details of circuit board component parts.

Page 2

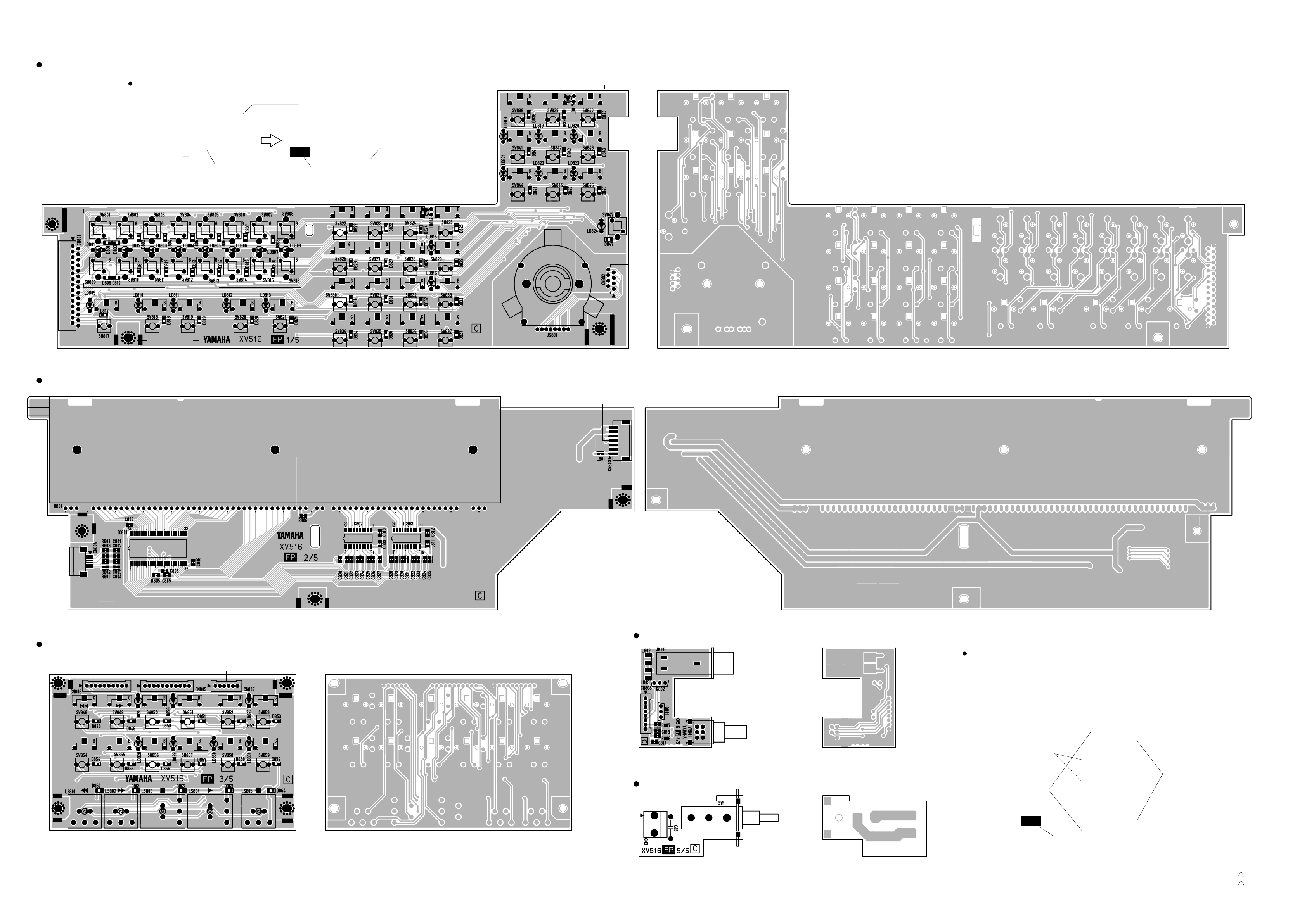

FP 1/5–5/5: 3NA-V312440-2

3NA-V312440-3

5

5

Pattern sideComponent side

Pattern sideComponent side

Component side Pattern side

Component side Pattern side

Pattern side

Component side

RECORD READY

12345678

897

564

231

0/-

1 234567 8

to SUB(PANEL)-CN705

to SUB(PANEL)-CN703

to PS2/2-CN8

Light touch switch

G=Glay

B=Black

Push button

(VT810300) or

(VT839000)

FP1/5 Circuit Board

FP2/5 Circuit Board

FP3/5 Circuit Board

Push Button installation

FP 4/5 Circuit Board

FP 5/5 Circuit Board

PHONES

PHONES

LEVEL

to MAIN A-CN108to PS 1/2-CN11

POWER

REHE

REPEAT

ROLL

BACK

AB

SET

AUTO

PUNCH

OUTIN

to SUB(PANEL)

-CN707

LAST REC

PROJECT SEARCH

RTN TO ZERO

Jog shuttle

(VR625800)

Jog cover

(V3287700)

Knob

FP

Jog Suttle

FP 1/5

to SUB(PANEL)

-CN706

to SUB(PANEL)

-CN708

SOLO/SELECT

AUTO

INPUT

PEAK

HOLD

ALL

INPUT

FORMAT CHASE

CANCEL ENTER LOCATE

JOG/

DATA

JOG ON

TIME DISPLAY

V.TRACK

SELECT

EDIT UNDO/

REDO

VARI

SPEED

UTILITY

SET

UP

CAP-

TURE

ABS/

REL

RE-

MAIN

to SUB(PANEL)-CN704

SHUTTLE/

CURSOR

LOC MEM STORE

LOC MEM RECALL

PROJECT SELECT

MONITOR SELECT

D24

37

Note: See parts list for details of circuit board component parts.

Page 3

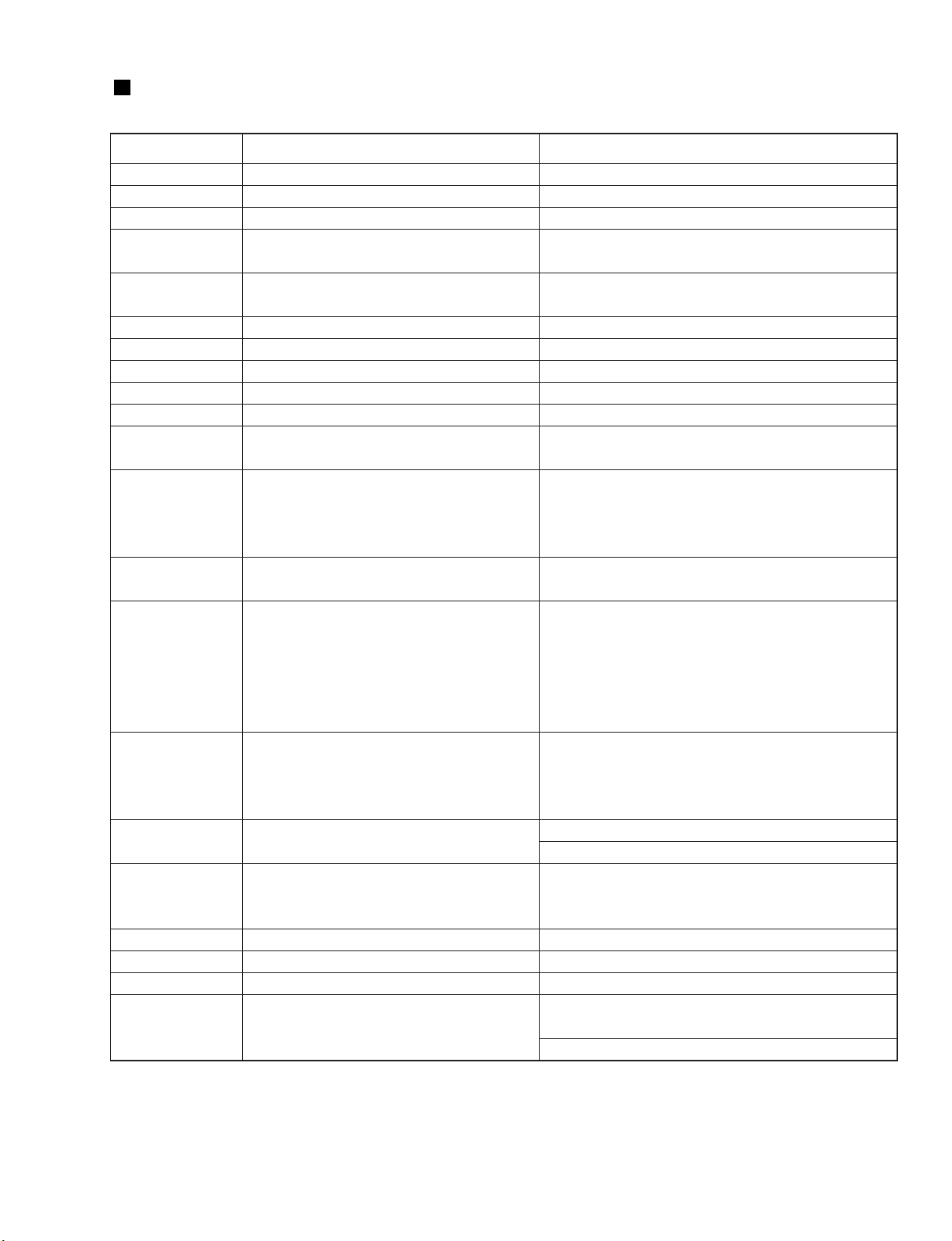

ERROR MESSAGES

D24

38

If the D24 displays an error message, follow the instructions below.

Message

Sync no comm

TC not read

WC not read

FILE ERROR

DEV CONT ERR

SCSI BREAK n

FIFO UO ERR n

INVALID COM n

PARITY ERR n

SCSI OUT n

SCSI ERR nn

MEDIA ERR nn

DRIVE ERR nn

REC ERROR

TOO SHORT

DISK FULL

FS DIFFER

RECCH NOTSEL

MO PROTECT

PROJ PROTECT

DATA FULL

Meaning

The slave machine is not connected properly.

The timecode source cannot be read properly.

The wordclock source cannot be read properly.

The MO disk data is not correct.

SCSI communication error. External device

connection.

SCSI communication error. Command break.

SCSI communication error. FIFO under/over.

SCSI communication error. Invalid command.

SCSI communication error. Parity error.

SCSI communication error. Time out.

SCSI error. SCSI error other than those listed

above.

Error due to media.

Error due to media or drive.

An incorrectly recorded track has been detected

and its contents may be distorted. This message

may appear after recording on a disk containing

heavily edited tracks and is due to the D24’s

disk drive not been able to keep up with the

excessive workload.

The interval between the points is too short.

There is no space available for storing sound

files.

Recording is not possible because the sampling

rate of the selected project is not the same as

the cur-rent D24 setting.

No tracks are selected for recording.

The disk is write protected.

The project is write protected.

There is no space available for storing project

management files.

Remedy

Check the connections to the slave machine.

Check the timecode settings.

Check the wordclock settings.

Follow the instructions on the display. If “TURN OFF”

is displayed, turn the D24 off and then on again.

Follow the instructions on the display.

Follow the instructions on the display.

Follow the instructions on the display.

Follow the instructions on the display.

Follow the instructions on the display.

Follow the instructions on the display.

Follow the instructions on the display.

Try the following:

1) Clean the media or disk drive head.

2) Physically reformat the disk. If the error persists,

change the media.

Reload the disk. If the error persists, change the media.

If that doesn’t fix it, the drive may be broken.

Press the [UNDO] button to undo the last recording,

reduce the number of tracks selected for simultaneous

recording, and try recording again. Temporarily

assigning unused virtual tracks to main tracks is another

way to reduce the D24’s workload.

For part editing, the minimum interval between the start

and end points is 15 ms. For punch in/out recording, the

minimum interval is 15 ms. Increase the interval as

necessary.

Retrieve some disk space by using the Optimize function.

Delete or erase an unwanted project.

Set the sampling rate on the D24 to match that of the

project.

Select a track for recording.

Turn off the write protection.

Turn off the write protection.

Retrieve some disk space by using the Optimize

function.

Delete or erase an unwanted project.

Page 4

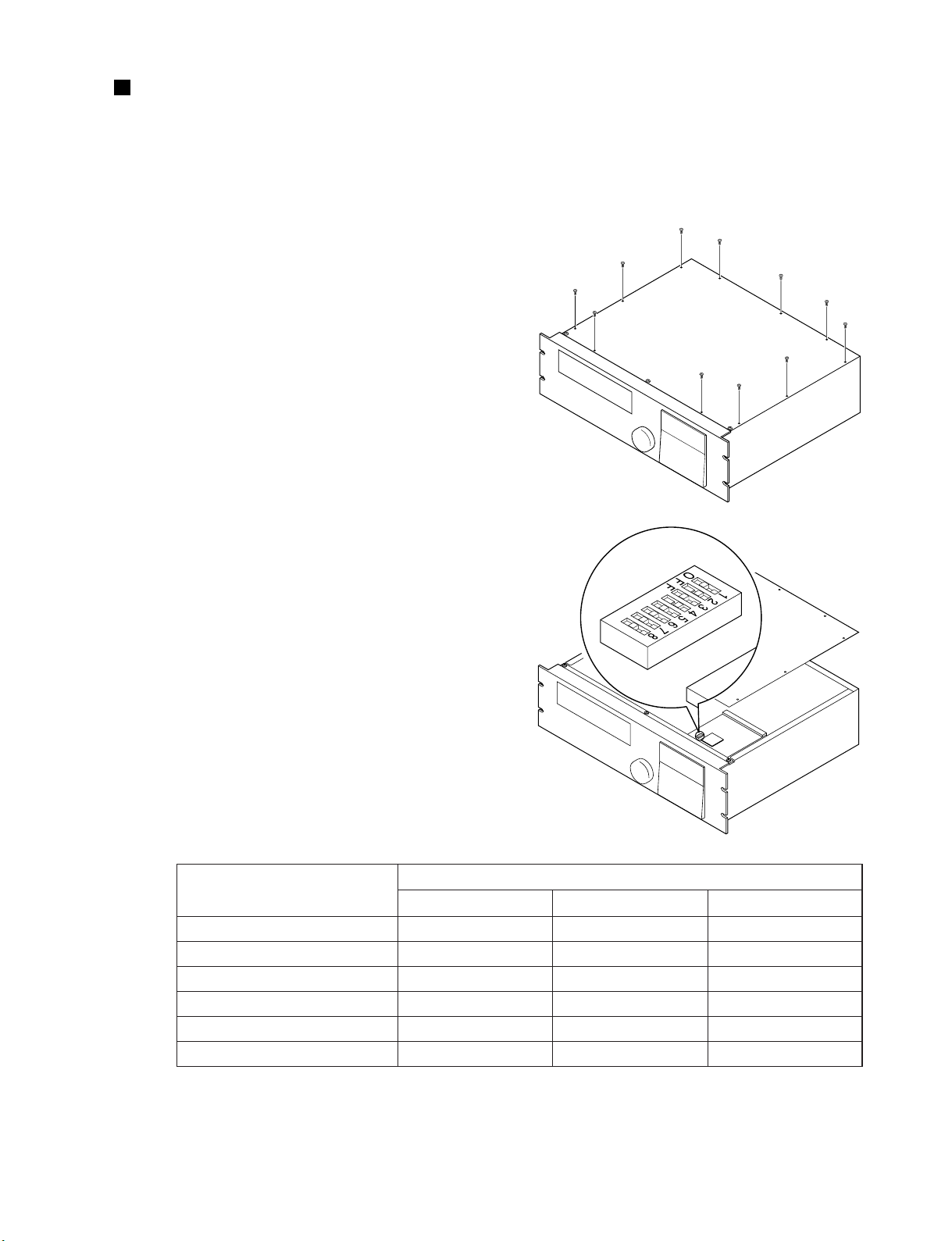

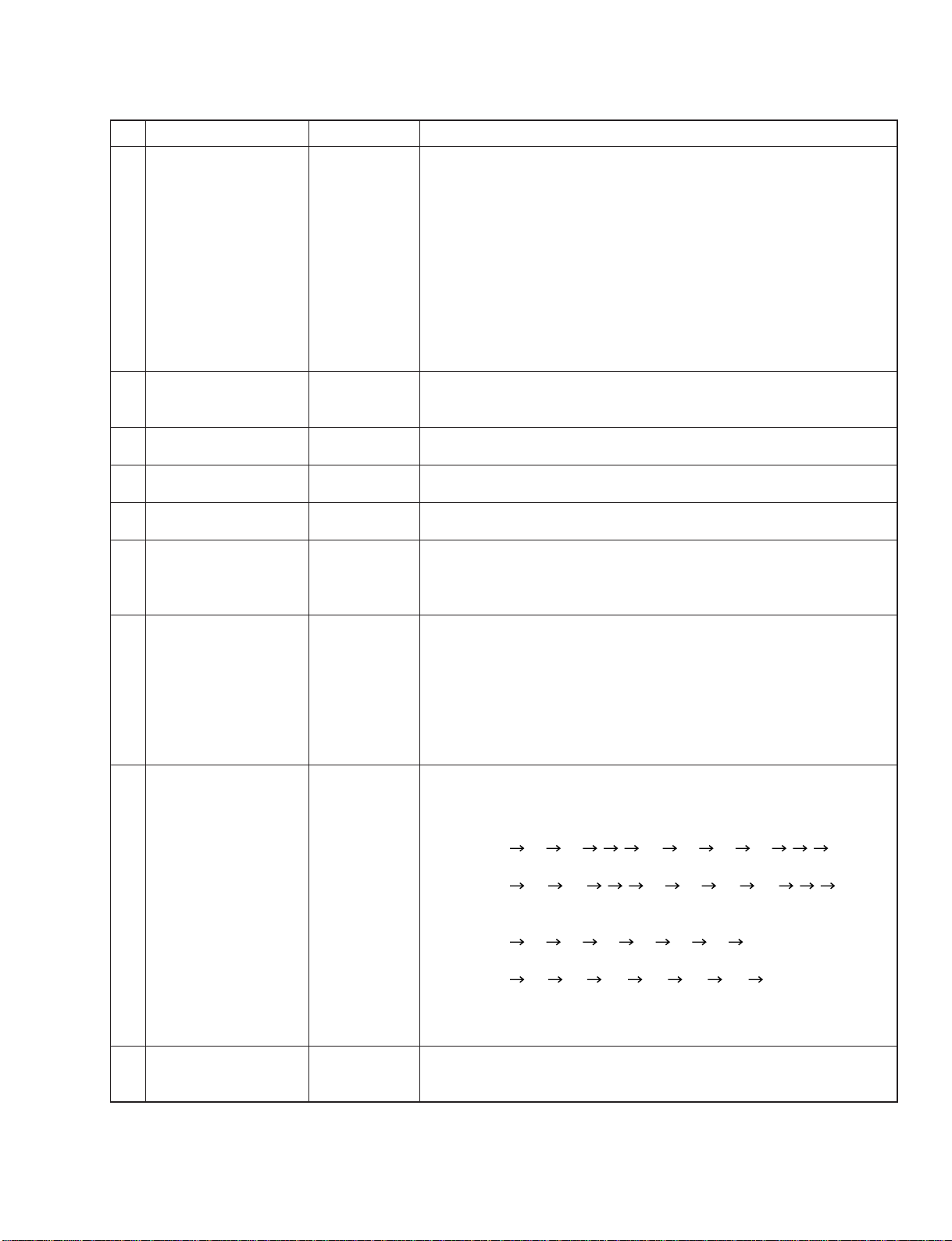

SETTING THE SCSI ID

D24

39

Setting the SCSI ID of the internal MO disk drive involves removing the D24’s top cover and setting the DIP

switch located on the MO drive’s circuit board.

1 Remove the top-cover fixing screws (11), as

shown here.

2 Remove the top cover.

3 Using a small flat-bladed screwdriver, or

something similar, set DIP switches 1 through 3,

as listed below, to achieve the required SCSI ID.

SCSI IDs 6 and 7 are not listed, since they are reserved for other purposes.

SCSI ID

5

4

3

2 (default)

1

0

DIP switch number

1

ON

ON

OFF

OFF

OFF

OFF

2

OFF

OFF

ON

ON

OFF

OFF

3

ON

OFF

ON

OFF

ON

OFF

Page 5

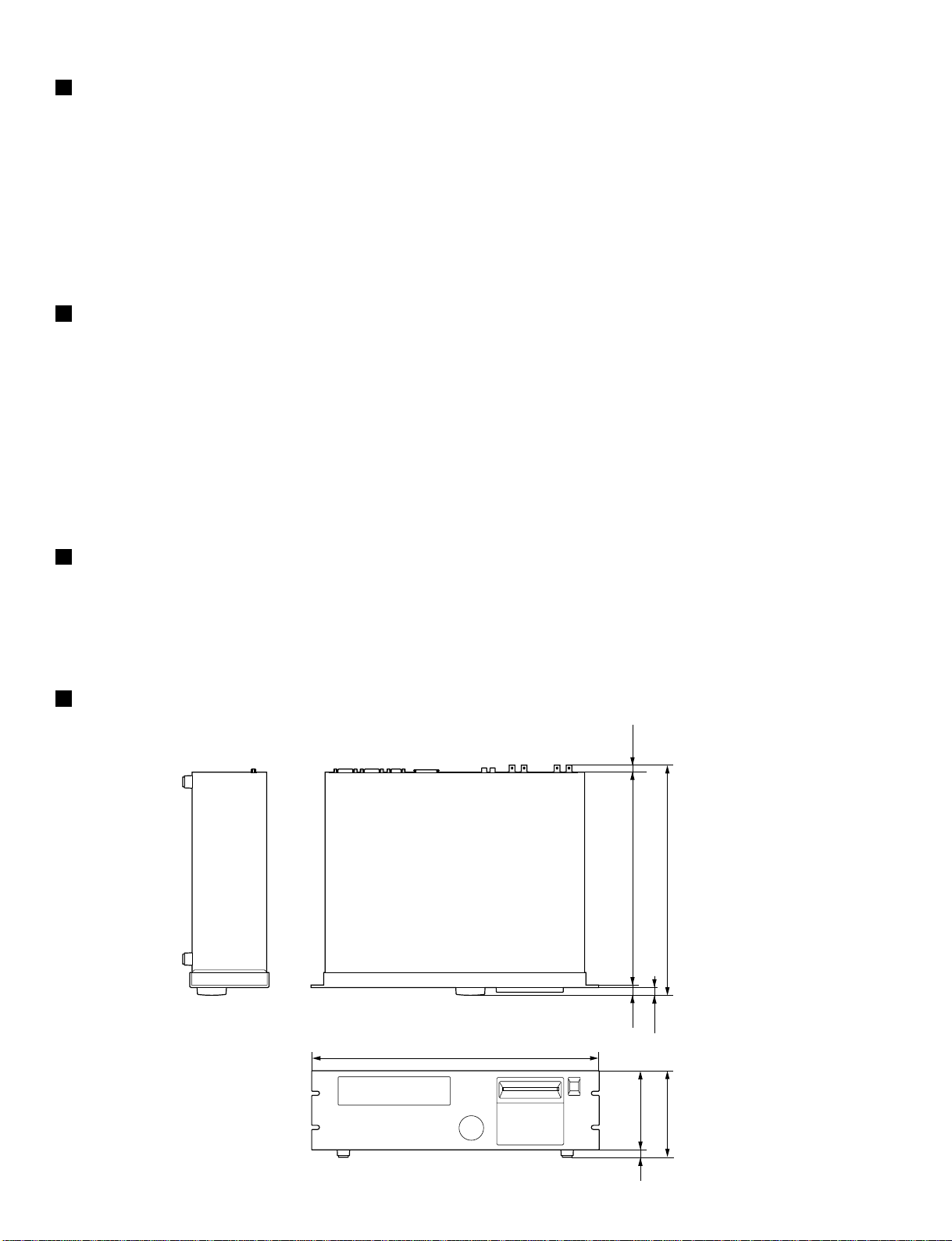

W: 480

Units: mm

12 132

12.9

4.1

H: 144 D: 383.9

355.1 11.8

D24

40

INITIALIZE

You can reset the D24 to its initial settings as follows.

1 Turn off the D24 Power switch.

2 While holding down the [RTN TO ZERO] button, turn on the D24 Power switch.

The D24 is initialized and “INITIALIZED” appears on the display.

CHECKING THE VERSION NUMBER

You can check the version number of the D24 system software as follows.

1 Turn off the D24 Power switch.

2 While holding down the [UTILITY] button, turn on the D24 Power switch.

The version number appears on the display.

UPDATING THE SYSTEM SOFTWARE

DIMENSIONS

See the Yamaha Professional Audio Web site at the address below for information on system updates.

<http://www.yamaha.co.jp/product/proaudio/homeenglish/>

Page 6

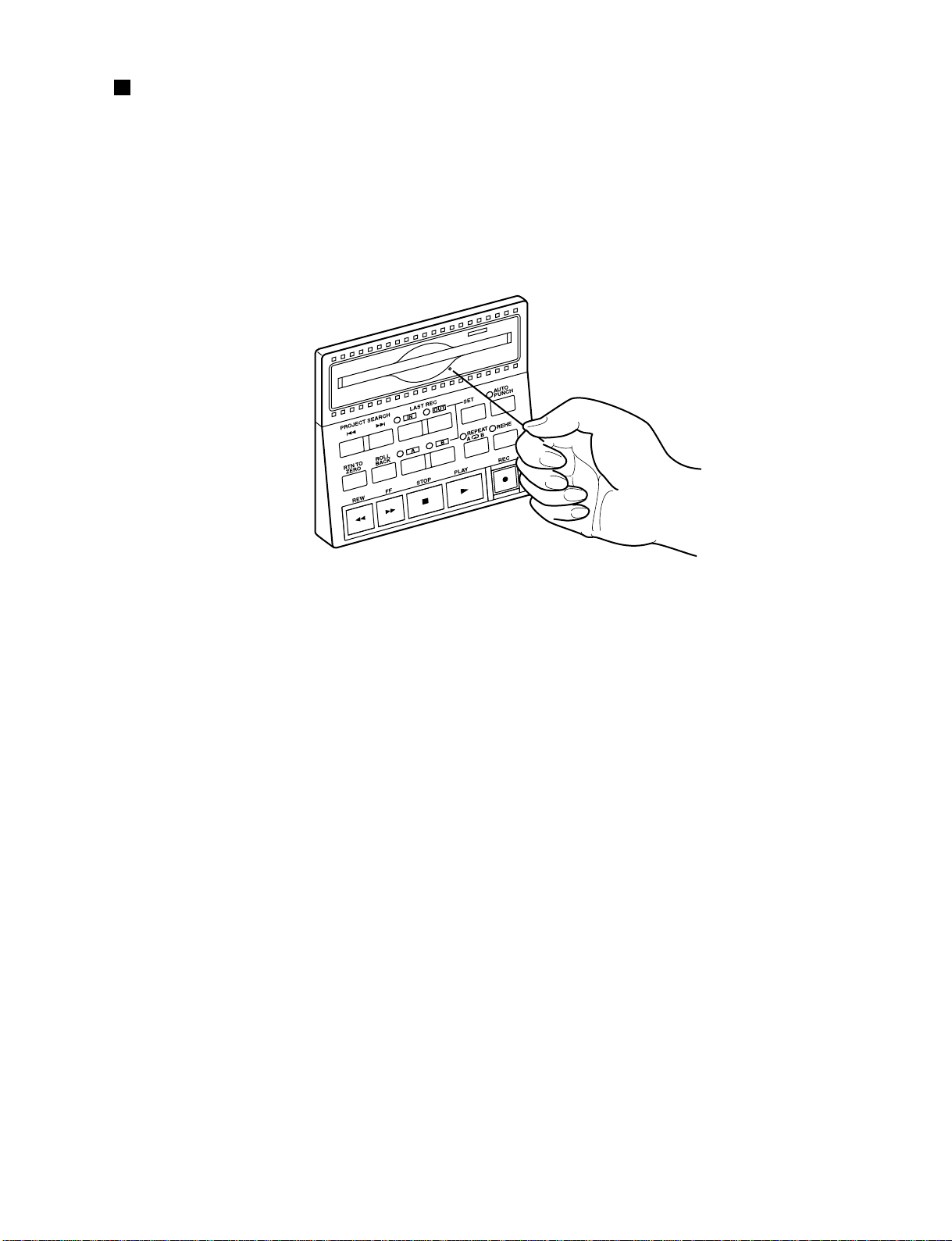

EJECTING TROUBLESOME DISKS (EMERGENCY USE)

D24

41

If the D24 is turned off inadvertently, or the disk loading mechanism fails, you may not be able to eject a disk in

the normal way. In this case, the disk can be ejected using the supplied disk eject tool. Note that this technique

should only be used as a last resort, as frequent use may lead to malfunction.

1 Turn off the D24 Power switch.

2 Insert the disk eject tool into the manual eject hole, as shown below, and push gently to eject the disk.

3 The disk ejects.

Page 7

D24

42

TEST PROGRAM

1. Measuring Conditions

• Unless specifically indicated, the unit is in the no MO DISC mode.

• All switches are set to OFF and the [PHONES LEVEL] is set to “0”

<Input Signal>

• With the MY8-AD card mounted in [SLOT 1], input a 1 kHz-10 dBmsine wave.

• Use the stereo plug to connect a 40 Ω load to the PHONES terminal.

2. Check Initial Operation of Main Circuit Board

With POWER ON, check that the CPU RUN indicator LEDs mounted on the MAIN-A circuit board are flashing.

GUI CPU & peripheral I/O: D101 (Red LED at front left side of main sheet.)

MEDIA CPU & peripheral I/O: D302 (Red LED at rear left side of main sheet.)

TIDSP & peripheral I/O: D301 (Green LED at rear left side of main sheet.)

3. Communication Inspection Between MAIN Circuit Board SUB Circuit Board

With POWER ON, check that OK is displayed on the fluorescent display tube.

Example:

4. Check ROM Version

Hold down the [Utility] key when turning on the power to display the ROM version in the fluorescent display tube.

(**.**is the version number)

5. Test Program

<Measuring Device>

Low-frequency oscillator, AC voltmeter, distortion meter, MY Card, SCSI compatible HDD (there are model restrictions),

device with VIDEO OUT, D24

<Preparations>

• Connect the inspection equipment (FAT D24) and main unit [TIME CODE IN/OUT] connector with a CANNON cable.

• Connect the inspection equipment (FAT D24) and main unit [SYNC IN/OUT] connector with D-SUB 15 PIN cable.

• Connect the [COAXIAL IN/OUT] connectors with RCA PIN cable.

• Connect the [MIDI IN/OUT] connectors with MIDI cable.

• Connect the D-SUB 9 PIN plug (Pin) connector for inspection to the [SERIAL I/O] connector. (Connect between 3

Pin 7 Pin and 2 Pin 8 Pin)

<Start>

Hold the [SETUP] key and turn on the power to enter the test program. The following will be displayed on the fluorescent

display tube.

(Due to MO mount processing, key entry is not accepted until

after normal operation has started, approximately 10 seconds.)

<Test Procedure>

Select test items: Use the keypad to enter the test item number. Press [ENTER] to execute the test.

Test result determination: The determination of each test item will be displayed as “OK” or “NG” in the fluorescent

tube display.

Interrupting the test: Press [CANCEL] to interrupt a test in progress. (If it is being used for test determination,

press [CANCEL] once again.)

YAMAHA D24, SCSI-IO OK ···

D24 V**.

**

00 DIAG RDY

Page 8

D24

43

00

01

02

03

04

05

06

07

08

Play output system

check

Software version

information

GUI-CPU peripheral

operation

TI-DSP peripheral

operation

Media CPU peripheral

operation

Fluorescent tube

display

Switch/LED display

JOG/SHUTTLE input

COAXIAL I/O (Status)

01 VNO G***

M*** U***

02 G-CPU

03 TI DSP

04 M-CPU

05 VFD

06 SW

***

07 JOG 00

SHU 00

08 COAX1

No. Test Item Display Test Functions and Judgment Criteria

When the Media CPU sine wave program (1 CH=500 Hz, 6 CH= 440 Hz -3

dB) starts there is output to the output CH lines for the 1 CH, 6 CH for

[PHONES], [SLOT 1– 4]. The output terminals for these are measured.

The determinations are as follows.

(1) Display on fluorescent tube display: [WC]INT, [FS]48K, [BIT]24,

[TC]MASTER.

(2) Level meter display: 1 TR, 6 TR both display -3 dB.

(3) PHONE OUT: Asound can be heard on the

headphones or by waveform

observation. (L=500 Hz, R=440 Hz

40 ΩLoad 2.5 Vp-p)

(4) SLOT OUT: Check output of MY Card.

Checks the version of the software that has been installed for use by the G

(GUI CPU), M (Media CPU) and U (Panel CPU). (Check by the number

displayed in the * * * section.)

Checks the operation of peripheral devices the GUI-CPU is controlling.

OK or NG is displayed.

Checks the operation of peripheral devices the TI-DSP is controlling.

OK or NG is displayed.

Checks the operation of peripheral devices the Media CPU is controlling.

OK or NG is displayed.

Checks that each segment of the fluorescent tube display lights in sequence.

After all segments have been lit, press the [ENTER] key. An OK will be

displayed. If an abnormality occurs, press [CANCEL]. A NG will be

displayed and the test will be interrupted.

Checks the operation of the front panel switches and the lighting of the LEDs.

When the key displayed in the *** section of the fluorescent tube display is

pushed, the name of the key for the next test will be displayed if there has

been proper operation. If the switch has an LED, it also checks that the LED

lights when the key is pushed. When the check for all switches has been

completed, an OK is displayed.

If there is an abnormality or if the test is to be interrupted, press the [REC]

key. A NG will be displayed and the test will be stopped.

Checks that each data display is displaced by the title operation of [JOG]

and [SHUTTLE].

(1) JOG data displacement value

In + direction (clockwise) hexadecimal display:

00 01 02 FF 00 01 02

In - direction (counterclockwise) hexadecimal display:

00 FF FE 01 02 FF FE

(2) SHUTTLE data displacement value

In + direction (clockwise) hexadecimal display:

00 01 02 03 04 05 06 07

In - direction (counterclockwise) hexadecimal display:

00 FF FE FD FC FB FA F9

After all data displacement values have been checked, press the [ENTER]

key and an OK is displayed. If there is an abnormality, press the [CANCEL]

key. A NG will be displayed and the test will be stopped.

Checks the sending and receiving of channel status signals.

If normal, an OK is displayed. If there is an abnormality, NG will be displayed

and the test will be stopped.

Test Items

Page 9

D24

44

09

10

11

12

13

14

15

System clock (FS)

detection

VARI SPEED

Variable operation

RTC operation, Date

registration

SERIAL I/O

REMOTE/SYNC I/O

VIDEO IN

TIME CODE OUT

09 FS

10 VARI

11 RTC

********

12 SERIAL

13 REMOTE

14 VIDEO

15 TC OUT

00:00:00:00

No. Test Item Display Test Functions and Judgment Criteria

Checks the result of the automatic measurement of the oscillating frequency of

the FS signals (44.1 kHz, 48.0 kHz) for the internal system clock generator.

First it measures the frequency of the 44.1 kHz signal, then the frequency

of the 48.0 kHz signal. If both frequencies are normal, an OK is displayed.

If there is an abnormality, a NG is displayed. In addition, it also checks that

“44.1 K” and “48 K” are lit in the FS area of the fluorescent display tube after

each signal frequency has been measured.

Automatically measures and checks the FS signals (44.1 kHz, 48.0 kHz)

oscillating frequencies at 5 step settings.

First it measures the frequency of the 44.1 kHz signal settings, then the frequency of

the 48.0 kHz signal settings at each of the 5 steps (-6.00% -3.00% 0.00%

+3.00% 6.00%), automatically makes the settings and measures the oscillating

frequency at each step. If both frequencies are normal, an OK is displayed.

If there is an abnormality, NG will be displayed and the test will be stopped.

Checks the date registration and operation of the Real Time Clock.

Date recording: Press the [CANCEL] key and all the data in the *** section

will be displayed as “0”. Use the keypad to enter the date in

AD format in the following sequence: year / month / day /

hour / minute / seconds. Press the [Enter] key to set. (In the

AD format, only the last two digits are entered. The entry for

May 6, 2000 at 15 minutes and 9 seconds past 3 o’clock

(3:15:09 PM) would appear as “000506151509”.

When the [ENTER] key is pushed and the date is registered, check that the

seconds display has started counting. When the [ENTER] key is pushed

again, an OK is displayed. If there is an abnormality, NG will be displayed

and the test will be stopped.

Checks that the SERIAL signal (RS-422) is being sent and received.

Prior to the test, connect the inspection connector (D-SUB 9 PIN) to the

[SERIAL IN/OUT] connector. If it is normal an OK is displayed. If there

is an abnormality, NG will be displayed and the test will be stopped

Checks that the SERIAL signal for REMOTE/SYNC (RS-485) is being

sent and received.

Prior to the test, connect a D-SUB 15 PIN cable to the inspection equipment

(FAT D24) and [SYNC IN/OUT] connector of the main unit. If it is normal,

an OK is displayed. If there is an abnormality, NG will be displayed and the

test will be stopped.

Checks the operation of the VIDEO vertical synchronization signal count function.

If it is normal, an OK is displayed. If there is an abnormality, NG will be

displayed and the test will be stopped.

Checks the output of the Time Code Generator.

Prior to the test, connect a CANNON cable to the inspection equipment (FAT

D24) and the [TIME CODE IN/OUT] connector on the main unit. When the

test is started, the receiving time data display on the fluorescent display tube

starts to count upward. When the test program for the inspection equipment

(FAT D24) is started and Test No. 16 is executed, the receiving time data on

the inspection equipment and the receiving time data on the main unit display

the same time and the counting up of the data is checked. The [ENTER] key

on the main unit is pushed. If the test is normal, an OK is displayed. If there is

an abnormality, NG will be displayed and the test will be stopped.

Page 10

D24

45

16

17

18

19

20

21

22

TIME CODE IN

SCSI operation

SLOT

Data initialize

EXIT

(Inspection

completed)

SYNC MASTER

SYNC SLAVE

16 TC IN

XLR

00:00:00:00

17 SCSI

18 BAY IO

SLOT 1 ENTER

19 INIT RDY

20 EXIT

21

SYNC-M ***

22

SYNC-S ***

No. Test Item Display Test Functions and Judgment Criteria

Checks the Time Code Reader input.

Prior to the test, connect a CANNON cable to the inspection equipment (FAT

D24) and the [TIME CODE IN/OUT] connector on the main unit. When the

test program is started on the inspection equipment (FAT D24) and Test No.

15 is executed, the receiving time data display on the fluorescent display tube

starts to count upward. The receiving time data on the inspection equipment

and the receiving time data on the main unit display the same time and the

counting up of the data is checked

Next, push the [ENTER] key on the main unit and the XLR display on the

fluorescent display tube will change to RMT. Also at this time, the receiving

time data on the inspection equipment and the receiving time data on the main

unit display the same time and the counting up of the data is checked.

Push the [ENTER] key one more time. If the test is normal, an OK is displayed.

If there is an abnormality, NG will be displayed and the test will be stopped.

Checks the internal and external SCSI operations.

Prior to the test, connect a SCSI cable to the HDD that is D24 operation

guaranteed (one that has been formatted in the normal mode). (The SCSI

ID is “0” or “1”.) If the test is normal, an OK is displayed. If there is an

abnormality, NG will be displayed and the test will be stopped.

Checks the connection of the SLOT for MY Card.

Prior to the test, mount MY SLOT CHECK CARD in [SLOT 1-4]. Press the

[ENTER] key and [SLOT 1] is checked. If it is normal, OK and GO TO

SLOT 2 will be displayed. The check then moves to [SLOT 2]. This same

process is also carried out for [SLOT 3] and [SLOT 4]. If all connections are

normal, an OK is displayed. If there is an abnormality, NG will be displayed

and the test will be stopped.

Initializes basic data with exception of date data.

Once this test is started, the RDY display section of the fluorescent display

tube will flash. Press the [ENTER] key to execute the initialization. To

interrupt the test, press [CANCEL]. A NG will be displayed and the test will

be stopped.

Removes unit from test mode and restores it to standard mode.

Press the [ENTER] key and if all test items have been completed, an OK will

be displayed. After a few seconds, the unit will be in the same mode as it is

after POWER ON. If one of the test items has not been completed, a NG will

be displayed. Press the [CANCEL] key to return to the test mode and execute

the incomplete tests.

Checks the output of the SYNC MASTER.

Prior to the test, connect a D-SUB 15 PIN cable to the inspection equipment

(FAT D24) and [SYNC IN/OUT] connector of the main unit. Start the test

program for the inspection equipment (FAT D24) is started and Test No. 22.

Each time the [ENTER] key is pushed on the main unit, the *** section display

on both the main unit and the inspection equipment will start to count up

simultaneously and can be checked.

Press the [CANCEL] key on the main unit. If the test is normal, an OK is displayed.

If there is an abnormality, NG will be displayed and the test will be stopped.

Checks the SYNC SLAVE input.

Prior to the test, connect a D-SUB 15 PIN cable to the inspection equipment

(FAT D24) and [SYNC IN/OUT] connector of the main unit. The test

program is started on the inspection equipment (FAT D24) and Test No. 21

is executed. Each time the [ENTER] key is pushed on the test equipment,

the *** section display on both the main unit and the inspection equipment

will start to count up simultaneously and can be checked.

Press the [CANCEL] key on the inspection equipment. If the test is normal, an

OK is displayed. If there is an abnormality, NG will be displayed and the test

will be stopped.

Page 11

D24

46

23

24

25

26

27

28

29

30

31

32

40

99

SYNC 8FS

EXT WORD CLOCK

IN

PHONE OUT-1

PHONE OUT-2

PHONE OUT-3

PHONE OUT-4

Switches SLOT input

COAXIAL INPUT

AES CH STATUS

COAXIAL CH

STATUS

Inspection support

mode

EXIT

(Forced termination)

23 SYNC-F

24 WC IN

25 OSC-1

26 OSC-2

27 OSC-3

28 OSC-4

29 SLOT

30 COAX

31 AES

C/S A100200

32 COAX

C/S 00000000

40

MASTER OK

No. Test Item Display Test Functions and Judgment Criteria

Checks the connection signal of the 8FS interrupt signal.

If the test is normal, an OK is displayed. If there is an abnormality, NG will

be displayed and the test will be stopped.

Checks the synchronizing function of the [WORD CLOCK INPUT] signal.

Displays the following on the fluorescent display tube for checking.

[LOCK]: Lights.

[WC] Column: EXT lights.

[FS] Column: 44.1 or 48 K lights. (input WORLD CLOCK frequency)

Push the [CANCEL] key. If the test is normal, an OK is displayed. If there

is an abnormality, NG will be displayed and the test will be stopped.

Check [PHONES] CH1/CH2 output.

Check the output from the [PHONES] by the sound in the headphones.

Check [PHONES] CH3/CH4 output.

Check the output from the [PHONES] by the sound in the headphones

Check [PHONES] CH5/CH6 output.

Check the output from the [PHONES] by the sound in the headphones

Check [PHONES] CH7/CH8 output.

Check the output from the [PHONES] by the sound in the headphones

Checks the input of [SLOT 1-4].

Each press of the [ENTER] key switches the [SLOT]. The absence or presence

of a signal is displayed at the level meter display of the fluorescent display tube

and a [PHONES] output sound can be heard.

After checking up to [SLOT 4], press the [ENTER] key once again. If the

test is normal, an OK is displayed. If there is an abnormality, NG will be

displayed and the test will be stopped.

Checks input signal of [COAXIAL INPUT].

Press the [ENTER] key. The absence or presence of a signal is displayed at

the level meter display of the fluorescent display tube and a [PHONES]

output sound can be heard. If the input is normal, an OK is displayed. If there

is an abnormality, NG will be displayed and the test will be stopped.

Checks the STATUS data of the AES CARD (MY-4) input signal.

Press the [ENTER] key. The flashing A100200 display on the fluorescent

display tube will stop and OK will be displayed. If no signal has been detected,

NG will be displayed and the test will be stopped.

Checks the STATUS data of the COAXIAL input signal.

Press the [ENTER] key. The flashing 00000000 display on the fluorescent

display tube will stop and OK will be displayed. If no signal has been detected,

NG will be displayed and the test will be stopped.

This mode has been provided for inspecting while linked to input and output

of the [TIME CODE INPUT/OUTPUT] etc. It receives the MIDI Program

change from the main unit subject to inspection and the corresponding test

items can be started. It can be ended by turning on the power again or by

pressing the [CANCEL] key.

Removes unit from test mode and restores it to standard mode.

Page 12

D24

47

YAMAHA [Digital Multitrack Recorder] Date: 18 Feb 1999

Model: D24

MIDI Implementation Chart

Version: 1.0

Function... Transmitted Recognized Remarks

Basic

Channel

Default

Changed

X

X

X

X

Mode

Default

Messages

Altered

X

X

**************

X

X

X

Note

Number True Voice

X

**************

X

X

Velocity

Note On

Note Off

X

X

X

X

After

Touch

Keys

Ch’s

X

X

X

X

Pitch bend X X

Control

Change

Prog

Change :True#

X

**************

X

XX

X

System Exclusive X O *1

System

Common

:Song Pos

:Song Sel

:Tune

X

X

X

X

X

X

System

Real Time

:Clock

:Commands

X

X

X

X

Aux

Messages

:Local ON/OFF

:All Notes OFF

:Active Sense

:Reset

X

X

X

X

X

X

X

X

Notes

MTC quarter frame messages are received in MTC Sync slave mode

MTC quarter frame messages are transmitted in MTC Sync master

mode.

*1: MMC

Mode 1: OMNI ON, POLY

Mode 3: OMNI OFF, POLY

Mode 2: OMNI ON, MONO

Mode 4: OMNI OFF, MONO

O: Yes

X: No

Page 13

CONTENTS

OVERALL ASSEMBLY······························································································································ 2

FRONT ASSEMBLY··································································································································4

POWER SUPPLY ASSEMBLY ················································································································· 5

ELECTRICAL PARTS ·························································································································6~17

PARTS LIST

WARNING

Components having special characteristics are marked and must be replaced with parts having

specification equal to those originally installed.

A: Australian model

B: British model

C: Canadian model

D: German model

E: European model

F: French model

H: North European model

I : Indonesian model

J: Japanese model

M: South African model

O: Chinese model

Q: South-east Asia model

T: Taiwan model

U: U.S.A. model

V: General export model (110 V)

W: General export model (220 V)

N,X:General export model

Y: Export model

Notes : DESTINATION ABBREVIATIONS

• The numbers in “ QTY ” show quantities for each unit.

• The parts with “ - - ” in “ PART NO. ” are not available as spare parts.

• The mark “ ” in the remarks column indicates that these parts are interchangeable.

• The second letter of the shaded ( ) part number is O, not zero.

• The second letter of the shaded ( ) part number is I, not one.

DIGITAL MULTITRACK RECORDER

Page 14

D24

2

OVERALL ASSEMBLY

650

600

660

710

680

210

370

380

390

350

200

180

160

190

720

140

310

210

300

130

150

120

440

440

430

540

270

550

500

800

250

240

340

10b

10

10c

10f

10d

10f

10e

10e

10g

10g

10a

10h

100

700

60

70

330

110

450

420

480

410

40

80

90

50

30

20

580

570

560

510

530

400

A

420

440

480

440

410

260

520

670

450a

450b

450c

300a

360c

360b

300b

360a

330

900

800

810

Power Supply

Assembly

(See page 5.)

Front Assembly

(See page 4.)

660

Page 15

3

D24

OVERALL ASSEMBLY

Overall Assembly

Overall Assembly

Overall Assembly

Overall Assembly

Circuit Board

Sub Assembly

Sub Assembly

Sub Assembly

Partition

Power Transformer

Power Transformer

Power Transformer

Bind Head Tapping Screw-B

Recorder Unit

Angle

Bind Head Screw

Bind Head Tapping Screw-B

Spacer

YGDI Angle

Bind Head Tapping Screw-B

Circuit Board

Bind Head Tapping Screw-B

Stay

Bind Head Tapping Screw-B

Side Panel

Bind Head Tapping Screw-B

Side Panel

Bind Head Tapping Screw-B

Rear Panel

Rear Panel

Rear Panel

Fan

Finger Guard

Fan Angle

Pan Head Screw

Bind Head Tapping Screw-B

Bind Head Screw

Bind Head Tapping Screw-B

Bind Head Tapping Screw-B

Circuit Board

Circuit Board

Bind Head Tapping Screw-B

Power Supply Assembly

Power Supply Assembly

Bind Head Tapping Screw-B

Connector Assembly

Ferrite Core

AC-IN Connector

Bind Head Tapping Screw-P

Cord Holder

Cord Holder

Bind Head Screw

Bind Head Screw

Circuit Board

Circuit Board

Circuit Board

Jack Socket

Pan Head Screw

Bind Head Tapping Screw-B

Bind Head Tapping Screw-B

Angle

Flat Head Tapping Screw-B

Front Assembly

Bind Head Tapping Screw-B

Bottom Assembly

Bottom Cover

Foot

Bind Head Tapping Screw-B

Bind Head Tapping Screw-B

DESCRIPTION

A

10

10

10

10a

10b

10b

10b

10c

10d

10e

10f

10g

10h

20

30

40

50

60

70

80

90

100

110

120

120

120

130

140

150

160

180

190

200

210

240

240

250

260

260

270

300

300a

300b

310

330

330

340

350

360a

360b

360c

370

380

390

400

410

420

430

440

450

450a

450b

450c

480

REF NO.

- -

- -

- -

- -

V5195300

- -

- -

- -

- XU676A00

XU677A00

XU678A00

VC688800

V3125400

V3103700

VP156600

VP157000

- -

- VC688800

V3268800

EP600190

- VC688800

V3101500

VC688800

V3101600

VC688800

V3101800

V3101900

V3102000

V3125300

VN003900

VM964700

VR116500

VP157000

VP156600

VP157000

VC688800

V3268200

V3268400

EP600190

V3117900

V3124900

VD831800

- VC362700

VL785200

VC161100

CB069250

CB069250

EG340360

VP156600

NX820720

NX820730

NX820740

VT362500

VT267800

VP157000

EP600190

V3103800

VP063700

- VC688800

V3496600

- CB651110

VS756600

VC688800

PART NO.

S-SYNC

UL CSA

CEE

A4.0X8 MFZN2BL

MCB3064SS

A3.0X6 MFZN2BL

A3.0X8 MFZN2BL

4.0X8 MFZN2BL

SUB(BAY)

3.0X8 MFZN2BL

4.0X8 MFZN2BL

LEFT

4.0X8 MFZN2BL

RIGHT

4.0X8 MFZN2BL

MMS-06E12DL

FG-06ULB

SP 4.0X25 MFZN2BL

3.0X8 MFZN2BL

3.0X6 ZMC2BL

3.0X8 MFZN2BL

4.0X8 MFZN2BL

PS 1/2

PS 1/2

3.0X8 MFZN2BL

4.0X12 MFZN2BL

ACIN ASSY 0

FR25/15/12-1400L

AC AC-P01CR02

3.0X12 ZMC2BL

BK-1

BK-1

4.0X8 MFZN2BL

3.0X6 MFZMC2BL

MAIN A

MAIN B

MAIN C

17L-003A3

2.6X6 MFNI33

3.0X8 MFZN2BL

3.0X8 MFZN2BL

4.0X10 MFZN2BL

4.0X8 MFZN2BL

TL-014

3.0X14 MFZN2B

4.0X8 MFZN2BL

D24 J,U,C,V,H,W,B

J (V309960)

U,C,V (V309970)

H,W (V309980)

B (V309990)

J (V325920)

U,C,V (V325930)

H,W,B (V325940)

(V310120)

J

U,C,V

H,W,B

(V413330)

(V310130)

(V310140)

J

U,C,V

H,W,B

J,U,C,V

H,W,B

J,U,C,V

H,W,B

AC IN (V325380)

J

U,C,V,H,W,B

(V311770)

(V310390)

REMARKS

4

2

4

4

2

2

4

8

3

3

3

4

4

5

4

2

2

11

12

4

6

2

2

6

2

4

5

4

4

11

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

01

01

01

01

01

01

01

01

05

09

01

01

01

01

01

01

01

04

03

01

01

01

01

01

01

01

01

01

01

01

02

01

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

KR Connector Assembly

KR Connector Assembly

Connector Assembly

FFC Cable

FFC Cable

Top Cover

Bind Head Tapping Screw-B

IF Plate

Bind Head Screw

Label

Label

Label

Label,Date Coad

Label,Date Coad

Holder

Holder

Ferrite Core

ACCESSORIES

MO Disk

Adapter, AC Cord

AC Cord

AC Cord

AC Cord

AC Cord

DESCRIPTION

500

510

520

530

540

550

560

570

580

590

600

650

660

670

680

700

700

710

720

720

800

810

900

REF NO.

- -

- -

- -

- -

- -

V3254300

- -

- V3261800

V3583900

V3116600

V3104000

VC688800

VZ678500

VP156900

- -

- -

- -

- -

- CB835590

CB825280

VC362700

- VQ240200

VT119800

VB927800

VB928000

VP204400

PART NO.

PSW ASSY

PS-MAIN ASSY

PH&PH 12P 500L

PH&PH 8P 160L

PH&PH 5P 250L

MO ASSY

6 160mm C&C 2mm

5 160mm C&C 2mm

MAIN TO MO D24

P=1.0-K-5-80

P=1.25-K-36-170

4.0X8 MFZN2BL

4.0X12 MFZN2BL

CAUTION A

CAUTION B

CAUTION C

TMS-20

CKN-05

FR25/15/12-1400L

RO-M640

KPR-25

J 7A 125V 3P 2.5m

CSA

VDE

BS 3

(V314570)

(V412780)

(V325400)

(V325410)

(V325420)

(VR78720)

(VR78550)

U,C,V (V332560)

H,W (V332570)

U,C,V (V333500)

U,C,V (VA03930)

H,W (CB07612)

U,C,V,H,W,B

(V360310)

J

J

U,C,V

H,W

B

REMARKS

4

11

4

8

2

QTY

RANK

*

*

*

*

*

01

05

01

01

01

04

06

06

08

08

10

*

:

New Parts RANK: Japan only

*

:

New Parts RANK: Japan only

Page 16

4

D24

FRONT ASSEMBLY

Front Assembly

Front Panel

Escutcheon, Power Switch

Window

Sub Chassis

Bind Head Screw

Hexagonal Nut

Circuit board

Circuit board

Circuit board

Circuit board

Circuit board

Bind Head Tapping Screw-B

Bind Head Tapping Screw-B

Sub Panel

Bind Head Tapping Screw-B

Bind Head Tapping Screw-B

Circuit Board

Bind Head Tapping Screw-B

Power Switch Knob

Knob

Bind Head Tapping Screw-B

Spacer

Adhesive Tape

FFC Cable

FFC Cable

FFC Cable

Connector Assembly

Cranp

JOG Cover

Cord Holder

Cushion

DESCRIPTION

10

20

30

40

60

70

110a

110b

110c

110d

110e

120

140

150

170

180

190

200

210

220

250

260

270

300

310

320

330

480

490

500

510

REF NO.

- V3114300

VL813000

V3114400

- VP156600

V2431400

NX820670

NX820680

NX820690

NX820700

NX820710

EP600190

EP600190

V3114900

EP600190

EP600190

V3268700

EP600190

VL812900

VQ920800

VC688800

- -

- V3583700

V3266100

V3583800

- CB825280

V3287700

CB069250

- -

PART NO.

3.0X6 MFZN2BL

9.0

FP 1/5

FP 2/5

FP 3/5

FP 4/5

FP 5/5

3.0X8 MFZN2BL

3.0X8 MFZN2BL

3.0X8 MFZN2BL

3.0X8 MFZN2BL

SUB(PANEL)

3.0X8 MFZN2BL

L GY /D GY

4.0X8 MFZN2BL

P=1.0-K-6-80 BNCD

P=1.25-K-8-80 BNCD

P=1.25-K-30-80 BNCD

PH&PH 7P 160L

CKN-05

BK-1

D24

(V311770)

(V311460)

POWER

PHONES LEVEL

(V413330)

(CB55090)

(VR92670)

(V453250)

REMARKS

2

3

5

4

4

2

2

2

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

03

01

01

01

01

01

01

01

03

03

01

01

03

01

*

:

New Parts RANK: Japan only

FRONT ASSEMBLY

110b

500

40

300

200

190

310

60

210

180

270

260

330

120

140

260

490

150

180

170

250

510

30

10

20

250

220

70

320

480

110e

110d

110a

110c

Page 17

D24

5

POWER SUPPLY ASSEMBLY

60

120

60

120

50

90

20

80

10

70

30

100

40

POWER SUPPLY ASSEMBLY

Power Supply Assembly

Power Supply Assembly

Heat Sink

Insulation Sheet

Heat Sink

Insulation Sheet

Circuit Board

Circuit Board

Bind Head Tapping Screw-B

TR holder (A)

Bind Head Tapping Screw-B

TR Holder (B)

Bind Head Tapping Screw-B

Spring Washer

DESCRIPTION

10

20

30

40

50

50

60

70

80

90

100

120

REF NO.

V3117900

V3124900

- -

V3115100

- V3115900

V3268300

V3268500

EP600190

- VP157000

- VP157000

03765160

PART NO.

A

B

B

PS 2/2

PS 2/2

3.0X8 MFZN2BL

3.0X8 MFZN2BL

3.0X8 MFZN2BL

#2 M3.0

D24

J,U,C,V

H,W,B

(V311500)

(V326940)

J,U,C,V

H,W,B

(V311560)

(V311600)

REMARKS

5

3

2

2

QTY

RANK

*

*

*

*

*

*

01

01

01

*

:

New Parts RANK: Japan only

Page 18

D24

6

ELECTRICAL PARTS

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Push Button

Push Button

Button

Spacer

Button

LED Spacer

Flat Head Screw

Hexagonal Nut

Capacitor

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Base Post Connector

Connector, FFC

Connector, FFC

Base Post

Connector, FFC

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Diode

Diode

IC

Transistor Array

Transistor Array

Phone Jack

Jog Shuttle

Chip Inductance

Chip Bead

DESCRIPTION

C45

C801

-803

C804

C805

C806

-812

C813

C814

C820

-835

CN9

CN801

CN802

CN803

CN804

CN805

CN806

CN807

CN808

D801

-864

IC801

IC802

IC803

JK106

JS801

L801

L802

REF NO.

NX820670

NX820680

NX820690

NX820700

NX820710

NX820720

NX820730

NX820740

V3268200

V3268400

V3268300

V3268500

V3268800

V3268700

V5195300

NX820670

NX820680

NX820690

NX820700

NX820710

VT810300

VT839000

V3117400

V3117500

V3259500

V3358580

VB939700

ES200030

VT575200

UB051470

UB051470

UB052100

UB052100

UB045100

UB045100

UB044220

UB044220

UB012220

UB012220

VG879900

VQ045900

VP682300

VR134400

VZ991900

VY921500

VY919900

VQ616000

VY917100

VT332900

VT332900

XT828A00

V3117600

V3117600

LB302070

VR625800

VS740100

VQ723100

PART NO.

FP 1/5

FP 2/5

FP 3/5

FP 4/5

FP 5/5

MAIN-A

MAIN-B

MAIN-C

PS 1/2

PS 1/2

PS 2/2

PS 2/2

SUB(BAY)

SUB(PANEL)

S-SYNC

FP 1/5

FP 2/5

FP 3/5

FP 4/5

FP 5/5

3.0X8 ZMC2BL

3.0 ZMC2BL

0.01 400V J.U.C.S

SL 47P 50V J

SL 47P 50V J

SL 100P 50V J

SL 100P 50V J

F 0.1 50V Z

F 0.1 50V Z

F 0.022 50V Z

F 0.022 50V Z

B 220P 50V K

B 220P 50V K

VA- 2P TE

52044 30P SE

52045 8P SE

PH- 7P SE

52207 6P SE

11P 250mm B&C 2mm

10P 250mm B&C 2mm

6P 250mm B&C 2mm

8P 450mm B&C 2mm

1SS355 TE-17

1SS355 TE-17

M66004FP

M54564FP

M54564FP

HLJ0544

SRGPHJ-A-3-1

BLM21B751S 2125

EXC CL3225U

D24

(XV516C0)

(XV516C0)

(XV516C0)

(XV516C0)

(XV516C0)

(XV515C0)

(XV515C0)

(XV515C0)

J,U,C,V (XV520B0)

H,W,B (XV620B0)

J,U,C,V (XV520B0)

H,W,B (XV620B0)

(XV517C0)

(XV517C0)

(XY230A0)

(XV516C0)

(XV516C0)

(XV516C0)

(XV516C0)

(XV516C0)

PEAK HOLD,AUTO INPUT,

ALL INPUT,FORMAT,CHASE,

PROJECT SELECT,UNDO/REDO,

LOC MEM(RECALL,STORE),

CUPTURE,ABS/REL,REMAIN,

VARI SPEED,UTILITY,SETUP,

V TRACKSELECT,EDIT,

LAST REC(IN,OUT,SET),

RTN TO ZERO,ROLL BACK,A,

B,REPEAT

1-9,0/-,CANCEL,LOCATE,

PROJECT SEARCH(FF,REW),

AUTO PUNCH,REHE

RECORD READY1-8,JOG ON

SOLO/SEL 1-8

FL DRIVER

PHONES

JOG/DATA SHUTTLE/CURSOR

REMARKS

25

17

9

8

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

03

03

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

01

02

01

01

07

03

07

03

01

ELECTRICAL PARTS

*

:

New Parts RANK: Japan only

Page 19

D24

7

Chip Bead

LED

LED

LED

LED

LED

LED

LED

LED

LED

LED

Push Switch

Push Switch

Push Switch

Push Switch

Push Switch

Transistor

Transistor

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Push Switch

Push Switch

Push Switch

Light Touch Switch

Light Touch Switch

Push Switch

Light Touch Switch

Light Touch Switch

Fluorescent display

Rotary Variable Resistor

Circuit Board

Circuit Board

Circuit Board

Terminal Plate

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

DESCRIPTION

L803

LD801

-808

LD809

-813

LD814

LD815

LD816

LD817

LD818

-831

LS801

LS802

LS803

LS804

LS805

Q801

Q802

R801

R802

-804

R805

R806

R807

R808

SW1

SW801

-816

SW817

-846

SW847

SW848

-859

U801

VR801

C101

C102

C103

C104

C105

-109

C110

C111

-119

C122

-129

C131

C132

C133

C134

-138

C139

-140

C143

C144

C145

C146

C147

C148

C149

C150

C151

-153

C154

C155

REF NO.

VQ723100

VU091400

VU091400

VT838500

VT838500

VT942200

VT838500

VT838500

VT942200

VT838500

VT838500

V3123700

V3266700

V3123800

V3266800

V3123900

VK432900

VK432900

RD257100

RD255470

RD255470

RD257270

RD257510

RD256470

RD256470

V3127000

V3123600

V3123600

VT513600

VT513600

V3123600

VT513600

VT513600

V3117800

V3123000

NX820720

NX820730

NX820740

VC719300

UB045100

UB051220

UB051220

UB012470

UB045100

UB045100

UF066100

UB045100

UB045100

UB045100

UB045100

UB215100

UB045100

UB044470

UB045100

UB045100

UB215100

UB215100

UB013100

UB013100

UB051470

UB215100

UB014220

UB013100

UB013100

UB051150

UB215100

UB215100

UB013100

UB013100

PART NO.

EXC CL3225U

SLZ-235B-08-T1 GR

SLZ-235B-08-T1 GR

SLZ-135B-08-T1 RE

SLZ-135B-08-T1 RE

SLP-135B-51 RE

SLZ-135B-08-T1 RE

SLZ-135B-08-T1 RE

SLP-135B-51 RE

SLZ-135B-08-T1 RE

SLZ-135B-08-T1 RE

UB-15SKP4Y

UB-15SKP4Y

UB-15RNKP4Y

UB-15RNKP4Y

UB-15SKP4R

2SD1915(F) S,T

2SD1915(F) S,T

10.0K 0.1 J

470.0 0.1 J

470.0 0.1 J

27.0K 0.1 J

51.0K 0.1 J

4.7K 0.1 J

4.7K 0.1 J

ESB92S23B J.U.C.S

SKECAF

SKECAF

EVQ 22C 05B

EVQ 22C 05B

SKECAF

EVQ 22C 05B

EVQ 22C 05B

BJ643GK

RK09L12B0 A10K X 2

MAIN-A

MAIN-B

MAIN-C

P-424

F 0.1 50V Z

SL 22P 50V J

SL 22P 50V J

B 470P 50V K

F 0.1 50V Z

F 0.1 50V Z

1 50V

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

B 0.1 25V K

F 0.1 50V Z

F 0.047 50V Z

F 0.1 50V Z

F 0.1 50V Z

B 0.1 25V K

B 0.1 25V K

B 1000P 50V K

B 1000P 50V K

SL 47P 50V J

B 0.1 25V K

B 0.022 50V K

B 1000P 50V K

B 1000P 50V K

SL 15P 50V J

B 0.1 25V K

B 0.1 25V K

B 1000P 50V K

B 1000P 50V K

RECORD READY/SOLO/SEL 1-8

PEAK HOLD, AUTO INPUT,

ALL INPUT, FORMAT, CHASE

PROJECT SELECT

LOC MEM RECALL

LOC MEM STORE

REMAIN

VARI SPEED, ....

....,REHA

REW

FF

STOP

PLAY

REC

POWER

RECORD READY/SOLO/SEL 1-8

MONITOR SELECT, ....

...., TIME DISOLAY

JOG ON

PROJECT SEARCH, ....

...., REHA

PHONES LEVEL

(XV515C0)

(XV515C0)

(XV515C0)

REMARKS

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 20

D24

8

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

DESCRIPTION

C156

-165

C166

C167

-169

C170

C171

C172

-179

C180

C181

-183

C184

-191

C192

C193

-206

C211

-216

C218

C219

C220

C221

C222

C223

C224

C225

C226

C236

C237

C301

C302

C303

C304

C305

-322

C330

-344

C345

C346

-367

C368

C401

C402

C403

-405

C406

C407

-412

C413

C414

C415

C416

C417

C418

C419

C420

C421

C422

C423

C424

C425

C426

C427

-429

C430

C431

C432

C433

C434

REF NO.

UB045100

UB045100

UB215100

UB051390

UB051390

UB045100

UF037100

UB045100

UB045100

UB013470

UB215100

UB215100

UB045100

UB045100

UB215100

UB045100

UB045100

UB045100

UB045100

UF037470

UB215100

UF018100

UB045100

UF037470

UF037470

UF018100

UB215100

UB215100

UB445330

UB215100

UB045100

UB051220

UB051220

UB012470

UB045100

UB045100

UB045100

UB045100

UF066220

UB045100

UB045100

UF017470

UB045100

UF037100

UB045100

UB045100

UF037470

UF047100

UF047100

UF037220

UB052180

UB051470

UF066100

UB051470

UF028100

UF037220

UB052180

UB051470

UF066100

UB051470

UF028100

UB045100

UB052510

UB045100

UB045100

UB013100

UB013100

UB045100

UF037100

UB051330

PART NO.

F 0.1 50V Z

F 0.1 50V Z

B 0.1 25V K

SL 39P 50V J

SL 39P 50V J

F 0.1 50V Z

10 16V

F 0.1 50V Z

F 0.1 50V Z

B 4700P 50V K

B 0.1 25V K

B 0.1 25V K

F 0.1 50V Z

F 0.1 50V Z

B 0.1 25V K

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

47 16V

B 0.1 25V K

100 6.3V

F 0.1 50V Z

47 16V

47 16V

100 6.3V

B 0.1 25V K

B 0.1 25V K

F 0.33 16V Z

B 0.1 25V K

F 0.1 50V Z

SL 22P 50V J

SL 22P 50V J

B 470P 50V K

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

F 0.1 50V Z

2.2 50V

F 0.1 50V Z

F 0.1 50V Z

47 6.3V

F 0.1 50V Z

10 16V

F 0.1 50V Z

F 0.1 50V Z

47 16V

10 25V

10 25V

22 16V

SL 180P 50V J

SL 47P 50V J

1 50V

SL 47P 50V J

100 10V

22 16V

SL 180P 50V J

SL 47P 50V J

1 50V

SL 47P 50V J

100 10V

F 0.1 50V Z

SL 510P 50V J

F 0.1 50V Z

F 0.1 50V Z

B 1000P 50V K

B 1000P 50V K

F 0.1 50V Z

10 16V

SL 33P 50V J

REMARKS

QTY

RANK

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 21

D24

9

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Electrolytic Cap. (chip)

Ceramic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap. (chip)

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Connector , FFC

Connector , FFC

Connector , FFC

Base Post

Base Post

Base Post

Base Post

Base Post

Connector Header

Base Post

Base Post

Pin Header

Pin Header

Pin Header

Pin Header

LED

LED

LED

Diode

Diode

Diode

Diode

Diode Array

Diode Array

Diode Array

Diode Array

Diode Array

Fuse

Fuse Holder

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

DESCRIPTION

C435

C436

C437

C438

C439

C440

C441

C442

C443

C444

C445

C446

-449

C450

C451

C452

-460

C461

C462

C463

C464

-467

C468

C501

C502

C503

C504

C505

C506

C507

C508

C509

C510

CN101

CN102

-105

CN106

CN108

CN109

CN110

CN111

CN301

CN502

CN503

CNGL1

-3

CNPGL

CNTI

D101

D301

D302

D303

D304

D401

D402

DA401

-406

DA409

-412

DA501

F301

F301

FB101

FB102

FB401

FB404

-409

FB414

-417

FB501

REF NO.

UB045100

UB052100

UB045100

UF037470

UF037470

UB052100

UB012680

UB045100

UB045100

UF037100

UF037470

UB012470

UB012470

UF037470

UF037470

UB045100

UB045100

UB215100

UB012330

UB012330

UB215100

UB215100

UB045100

UB045100

UF018100

UF047100

FG644100

UB044100

UB044100

UB052220

UF037220

UB045100

UB045100

VT006000

VQ048500

VQ048500

VR134300

VR134500

VR134500

VR134400

VR134200

VL536600

VR134300

VR134200

VQ623900

VQ623900

VT321500

VQ624000

VT439400

VR745300

VT439400

VS597600

VT532500

VT332900

VT332900

VD303900

VD303900

VD303900

VD303900

VD303900

KB003530

VP206500

VZ007300

VZ007300

VQ723100

VQ723100

VQ723100

VQ723100

VQ723100

VQ723100

PART NO.

F 0.1 50V Z

SL 100P 50V J

F 0.1 50V Z

47 16V

47 16V

SL 100P 50V J

B 680P 50V K

F 0.1 50V Z

F 0.1 50V Z

10 16V

47 16V

B 470P 50V K

B 470P 50V K

47 16V

47 16V

F 0.1 50V Z

F 0.1 50V Z

B 0.1 25V K

B 330P 50V K

B 330P 50V K

B 0.1 25V K

B 0.1 25V K

F 0.1 50V Z

F 0.1 50V Z

100 6.3V

10 25V

0.01 50V Z

F 0.01 50V Z

F 0.01 50V Z

SL 220P 50V J

22 16V

F 0.1 50V Z

F 0.1 50V Z

52207 5P SE

52045 36P TE

52045 36P TE

PH- 6P SE

PH- 8P SE

PH- 8P SE

PH- 7P SE

PH- 5P SE

HIF3FC-50PA2.54DSA

PH- 6P SE

PH- 5P SE

HIF3H-10PB-2.54DSA

HIF3H-10PB-2.54DSA

A3E 44P TE

HIF3H-12PB-2.54DSA

SLR-342VC3F RE

SLR-342MC3F GY

SLR-342VC3F RE

RB160L-40 TE25

1SR154-400

1SS355 TE-17

1SS355 TE-17

1SS226 TE85R

1SS226 TE85R

1SS226 TE85R

1SS226 TE85R

1SS226 TE85R

1.00A JU

EYF-52BC

FBMJ3216HM600-T

FBMJ3216HM600-T

EXC CL3225U 3

EXC CL3225U 3

EXC CL3225U 3

EXC CL3225U 3

EXC CL3225U 3

EXC CL3225U 3

REMARKS

QTY

RANK

*

*

*

*

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

02

02

01

03

01

03

03

04

03

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 22

D24

10

Chip Inductance

Terminal Plate

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

DESCRIPTION

-504

FG501

IC101

IC102

IC103

IC104

IC107

IC108

IC113

IC114

IC115

IC116

IC117

IC118

IC119

IC120

IC123

IC124

IC125

IC126

IC127

IC128

IC129

IC130

IC131

IC132

IC133

IC134

IC135

IC136

IC137

IC138

IC139

IC140

IC141

IC142

IC143

IC144

IC145

IC146

-150

IC151

IC152

IC156

IC156

IC157

IC157

IC158

IC159

IC160

IC301

IC302

IC303

IC304

IC305

IC306

IC307

IC308

IC308

IC309

IC309

IC316

IC316

IC317

IC318

IC319

IC320

IC321

IC321

IC322

REF NO.

VQ723100

VC719300

XV731A00

XM529A00

XV923A00

XV145A00

XC725A00

XV927A00

XV611A00

XL093A00

XV611A00

XV611A00

XH497A00

XV733A00

XV740A00

XV734A00

XG948E00

XC726A00

XC723A00

XH600A00

XV618A00

XH600A00

XC726A00

XN515A00

XN515A00

XD830A00

XD831A00

XP985A00

XC725A00

XD833A00

XV619A00

XH746A00

XH746A00

XC726A00

XD831A00

XD830A00

XG948E00

XM530A00

XV735A00

XD838A00

XD838A00

XQ962D00

XQ962D00

XV605A00

XW163A00

XV605A00

XW163A00

XC723A00

XH494A00

XS534A00

XV736A00

XV924A00

XV925A00

XK452A00

XV613A00

XV613A00

XP446A00

XV737A00

XV781A00

XV737A00

XV781A00

XV605A00

XW163A00

XV928A00

XU375A00

XV617A00

XU277A00

XV738A00

XV739A00

XV738A00

PART NO.

EXC CL3225U 3

P-424

HD6477042AF28

M51957BFP

MBM29F400BC-70PF

KM416C1200

SN74HC14NSR

EPM7032STC44-7

HD74HC245FPV

HD74HC08FPEL

HD74HC245FPV

HD74HC245FPV

YM6604

CY7C136-55NC

CRVP08

SN74HC151NSR

YM3436DK

SN74HC74NSR

SN74HCU04NSR

UPD71055GB-3B4

DS12887

UPD71055GB-3B4

SN74HC74NSR

SN74HC153NSR

SN74HC153NSR

SN74HC04NSR

SN74HC08NSR

SN74LS06NST-EL

SN74HC14NSR

SN74HC32NSR

ICS2008A

YM6029

YM6029

SN74HC74NSR

SN74HC08NSR

SN74HC04NSR

YM3436DK

YM3437C-F

SN74HC240NSR

SN74HC245NSR

SN74HC245NSR

YSS228E-F

YSS228E-F

CY7C024-15AC

IDT7024S15PF

CY7C024-15AC

IDT7024S15PF

SN74HCU04NSR

YM6067

NJM78M05DLA

HD6477043AF28

MBM29F400BC-70PF

MBM29F400BC-70PF

HD74AC32FPEL

HD74AC245FPV

HD74AC245FPV

HD74AC138FPEL

KM416C4100B-6

KM416C4100A-6

KM416C4100B-6

KM416C4100A-6

CY7C024-15AC

IDT7024S15PF

EPM7032STC44-7

UPD72611GF-3BA

BH9595FP-Y

TMS320C32PCM60

KM6164002A-15

CY7C1041-15VC

KM6164002A-15

CPU

RESET

FLASH MEMORY 4M

DRAM 16M

INVERTER

FPGA

TRANSCEIVER

AND

TRANSCEIVER

TRANSCEIVER

ACIA

DPRAM

GATE ARRAY

DATA SELECTOR

DIR2

D-FF

INVERTER

PIO

REAL TIME CLOCK

PIO

D-FF

DATA SELECTOR

DATA SELECTOR

INVERTER

AND

INVERTER

INVERTER

OR

T.C.READER/GENERATOR

DPB

DPB

D-FF

AND

INVERTER

DIR2

DIT2

INVERTER

BUFFER

BUFFER

DSP3

DSP3

SRAM 64K

SRAM 64K

INVERTER

PSC4

REGULATOR +5V

CPU

FLASH MEMORY 4M

FLASH MEMORY 4M

OR

TRANSCEIVER

TRANSCEIVER

DECODER

DRAM 64M

DRAM 64M

SRAM 64K

FPGA

SCSI CONTROLER

SCSI TERMINATOR

DSP

SRAM 4M

SRAM 4M

REMARKS

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

01

01

03

12

03

01

18

11

01

01

06

06

01

02

02

01

01

03

01

11

11

01

01

01

11

07

04

04

20

20

01

10

02

02

03

*

:

New Parts RANK: Japan only

Page 23

D24

11

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

IC

Photo Coupler

IC

IC

IC

IC

IC

IC

IC

IC

XLR Connector

XLR Connector

Pin Jack

Connector Socket

Connector Socket

Connector Socket

SCSI Connector

DIN Connector

BNC Connector

BNC Connector

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Chip Inductance

Coil

Transistor

Transistor

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

DESCRIPTION

IC322

IC323

IC401

IC402

IC403

IC404

IC405

IC406

IC407

IC408

IC409

IC410

IC411

IC412

IC413

IC414

IC415

IC416

IC417

IC418

IC419

IC420

IC421

IC422

IC423

IC424

IC501

JK10

JK11

JK12

JK101

JK102

JK103

JK104

JK105

JK106

-109

L101

L102

L104

-115

L116

L117

L118

L119

L121

L122

L301

L303

L305

L306

PT501

Q501

Q502

R101

R102

R103

R104

R105

R106

R107

R108

R109

R112

R113

R114

R115

R116

R117

R118

REF NO.

XV739A00

XV929A00

XS388A00

IG103520

IG103520

XQ138A00

XU069A00

XL106A00

XQ830A00

XV930A00

XU816A00

XD831A00

XD833A00

XQ138A00

XQ830A00

XQ138A00

XJ704A00

XN514A00

VN406200

XC725A00

XP985A00

XU073A00

XD831A00

XD831A00

XD655A00

XD833A00

XC723A00

VS133800

VS133700

VS166600

VT362400

VT362400

V3584100

VT890000

VI466400

VI552200

VI552200

VS740100

VS740100

VS740100

VS740100

VU374000

VU374000

VS740100

VS740100

VS740100

VS740100

VS740100

VS740100

VS740100

VS740100

VC548200

VV556500

VV556400

RD255220

RD255220

RD256330

RD256390

RD256150

RD257100

RD254220

RD257100

RD255470

RD257100

RD256330

RD255470

RD258100

RD258100

RD257150

VI197400

PART NO.

CY7C1041-15VC

EPM7032STC44-7

AK4321

NJM4558MT-1

NJM4558MT-1

NJM4556AMT1

LM1881M

HD74HC123AFPTR

LM311MX

SN75124NSR

SN75121NSR

SN74HC08NSR

SN74HC32NSR

NJM4556AMT1

LM311MX

NJM4556AMT1

SN75176BPS

SN74HC126NSR

HCPL-0600-500

SN74HC14NSR

SN74LS06NST-EL

SN75C1168NSR

SN74HC08NSR

SN74HC08NSR

TC74HC00AF

SN74HC32NSR

SN74HCU04NSR

NC3FAH1-0

NC3MAH

2P

17LE 15P SE

17LE 15P SE

17LE 9P SE

NHS050-022-BS2

3P YKF51-5046

YKS11-01P

YKS11-01P

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

ELJFA2R2 KF2

ELJFA2R2 KF2

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

BLM21B751S 2125

TC-1019-06 7mm

2SA1037K Q,R,S

2SC2412K Q,R,S

220.0 0.1 J

220.0 0.1 J

3.3K 0.1 J

3.9K 0.1 J

1.5K 0.1 J

10.0K 0.1 J

22.0 0.1 J

10.0K 0.1 J

470.0 0.1 J

10.0K 0.1 J

3.3K 0.1 J

470.0 0.1 J

100.0K 0.1 J

100.0K 0.1 J

15.0K 0.1 J

10.0K 0.1 J

FPGA

DAC

OP AMP

OP AMP

OP AMP

V SYNC.SEPARATOR

1SHOT

OP AMP

LINE RECEIVER

LINE DRIVER

AND

OR

OP AMP

OP AMP

OP AMP

LINE DRIVER

BUS BUFFER

INVERTER

INVERTER

LINE DRIVER

AND

AND

NAND

OR

INVERTER

TIME CODE INPUT

TIME CODE OUTPUT

COAXIAL OUTPUT/INPUT

REMOTE IN/SYNC IN

SYNC OUT

RERIAL I/O

SCSI

MIDI(IN,OUT,THRU)

WORD CLOCK INPUT/OUTPUT

VIDEO INPUT/OUTPUT

REMARKS

QTY

RANK

*

*

*

*

*

*

*

07

03

03

03

02

03

05

01

01

03

03

03

08

05

03

05

01

01

01

01

01

04

04

04

04

04

05

04

05

05

03

03

03

03

01

01

03

03

03

03

03

03

03

03

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 24

D24

12

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)

Carbon Resistor (chip)