Yamaha CRXM-170 Service manual

STANDBY/ON

1 2 3 4

5 6 7 8

9 0

AUX 2AUX 1 TAPE CD

BAND PRESET TUNER

FUNCTION/

FM MODE

INFO/TEXT AUTO TUNE

TIMER DIMMER

VOLUME

+

–

SLEEP

MUTE

CD/DAB RECEIVER

CRX-M170

SERV ICE MA NUA L

ENTER

CRX-M170

REPEAT A-B PROG CLEAR

RANDOM TIME

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherant to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact

the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumu-

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that all service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

lated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL.....................................2–3

PREVENTION OF ELECTRO STATIC DISCHARGE

REAR PANEL ...............................................................4

SPECIFICATIONS.........................................................5

INTERNAL VIEW .......................................................... 6

DISASSEMBLY PROCEDURES ..............................6–8

MAINTENANCE FLOW CHART (CD) .........................9

.....4

IMPORTANT NOTICE

MAINTENANCE FLOW CHART (TUNER) .................. 9

WIRING DIAGRAM .....................................................10

PRINTED CIRCUIT BOARD ................................11–13

BLOCK DIAGRAM ...................................................... 14

SCHEMATIC DIAGRAM.......................................15–17

REMOTE CONTROL ..................................................19

PARTS LIST..........................................................20–21

100975

© 2005 YAMAHA CORPORATION. All rights reseved.

This manual is copyrighted by YAMAHA and may not be copied or

redistributed either in print or electronically without permission.

’05.09

CRX-M170

■ TO SERVICE PERSONNEL

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

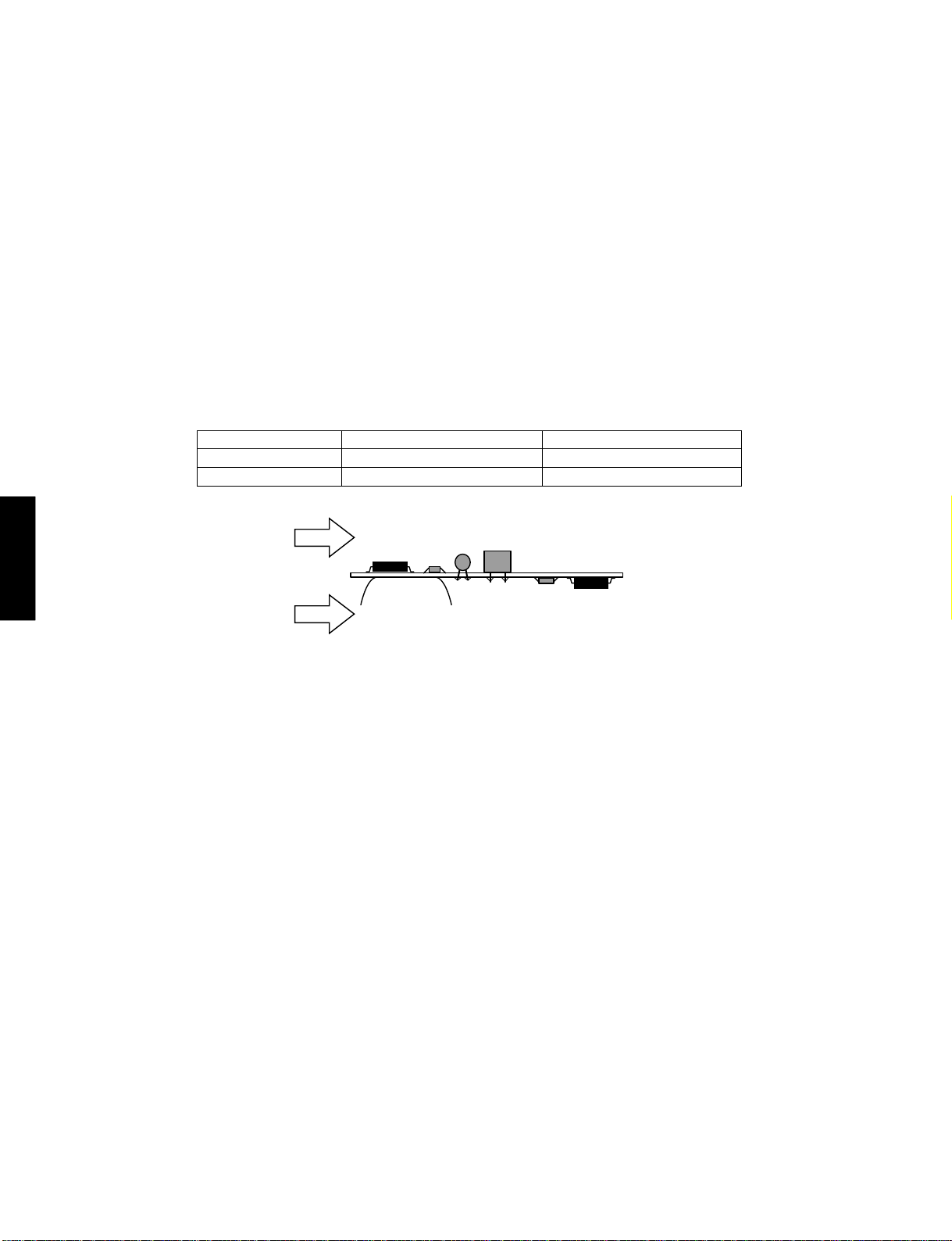

About Lead Free Solder

The P.C.B.s installed in this unit are soldered using the following solder.

SIDEA SIDEB

MAINP.C.B. LeadFreeSolder LeadFreeSolder

POWERP.C.B. − LeadFreeSolder

Side A

CRX-M170

Among some types of lead free solder currently available, it is recommended to use one of the following types for the repair

work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

1. As the melting point temperature of the lead free solder is about 30°C to 40°C (50°F to 70°F) higher than that of the lead

solder, be sure to use a soldering iron suitable to each solder.

2. If lead solder must be used, be sure to remove lead free solder from each terminal section of the parts to be replaced and from

the area around it completely before soldering, or make sure that the lead free solder and lead solder melt together fully.

Side B

SMT REFLOW Process

Solder Dip

MI FLOW Process

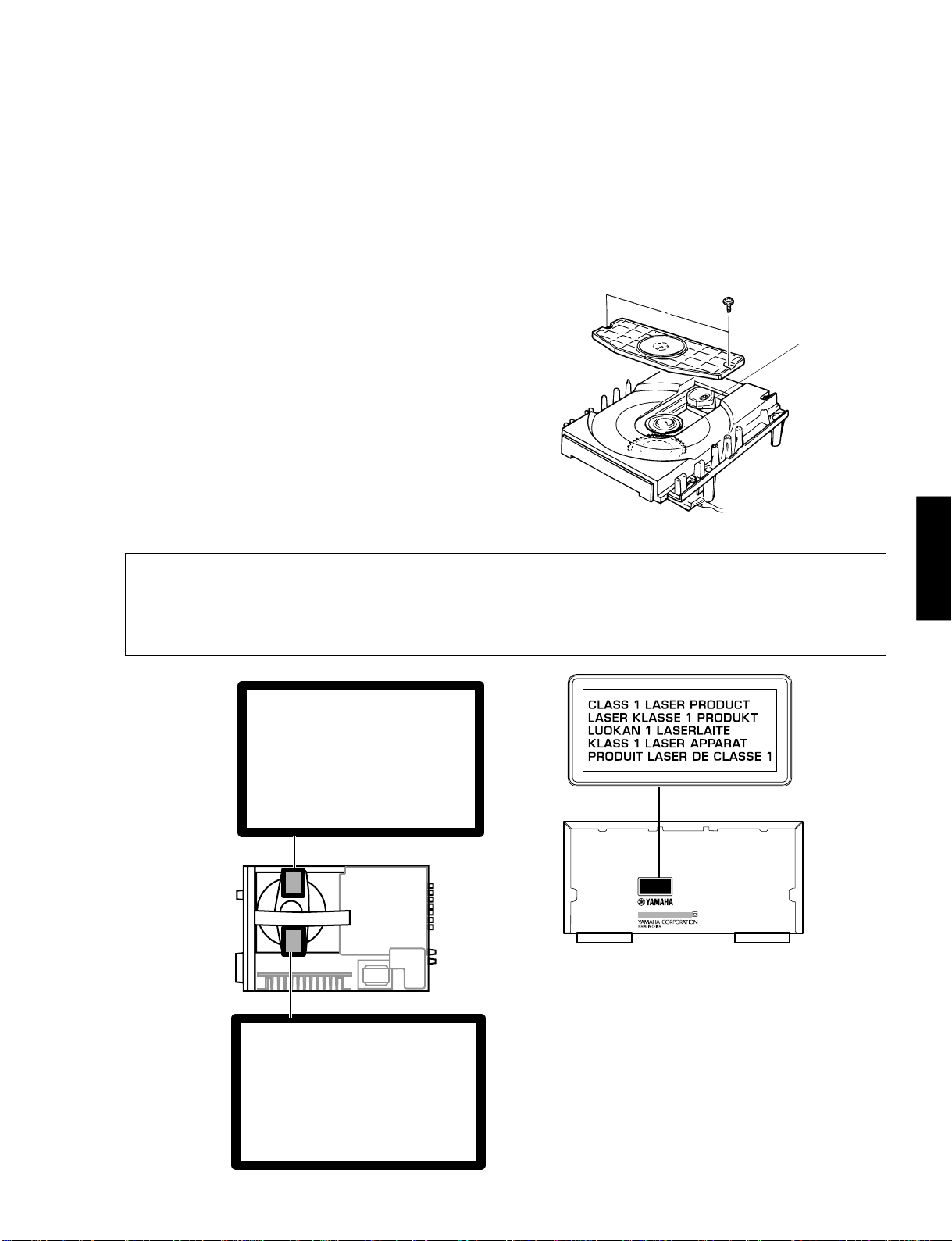

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must

be used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION : Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

2

CRX-M170

Laser Emitting conditions:

1) When the Top Cover is removed, and the “STANDBY/ON” SW is turned to the "ON" position, the laser component will

emit a beam for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through

the lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is set, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB. However, this level has been set by the factory

prior to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this

manual. Adjustment of this control can increase the laser emission level from the device.

Laser Diode Properties

● Material : GaAlAs

● Wavelength : 789 nm

● Emission Duration : Continuous

● Laser Output : max. 44.6 µW*

* This output is the value measured at a distance of about

200 mm from the objective lens surface on the Optical

Pick-up Block.

Optical Pick-up

When checking the laser diode emission, keep your eyes more

than 30 cm away from the objective lens.

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASER-SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING! : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED, AVOID EXPOSURE TO

BEAM.

VORSICHT! UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GE÷FFNET UND WENN SICHERHEITSVER RIEGELUNG ‹BERBR‹CKT IST . NICHT DEM STRAHL

AUSSETZEN!.

VARNING - OSYNLING LASERSTR≈LNING NƒR DENNA DEL ƒR

÷PPNAD OCH SPƒRR ƒR URK OPPLAD. STR≈LEN ƒR

FARLIG.

CLASS 1 LASER PRODUCT

LASER KLASSE 1 PRODUKT

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

PRODUIT LASER DE CLASSE 1

MODEL NO. RDX-E700

CRX-M170

ADVARSEL - USYNLIG LASERSTR≈LING VED ≈BNING, N≈R

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION.

UNDG≈ UDS∆TTELSE FOR STR≈KING.

VAROITUS! - SUOJAKOTEL OA EI SAA AVATA. LAITE SISƒLTƒƒ

LASERDIODIN, JOKA LƒHETTƒƒ (NƒKYMƒ T÷NTƒ)

SILMILLE VAARALLISTA LASERSƒTEILYƒ.

ADVARSEL - USYNLING LASERBESTR≈LING N≈R DENNE DELEN ER

≈PEN OG SIKKERHETSSPERREN ER UTKOBLET.

UNNG≈ UTSETTELSE FOR STR≈LING.

3

CRX-M170

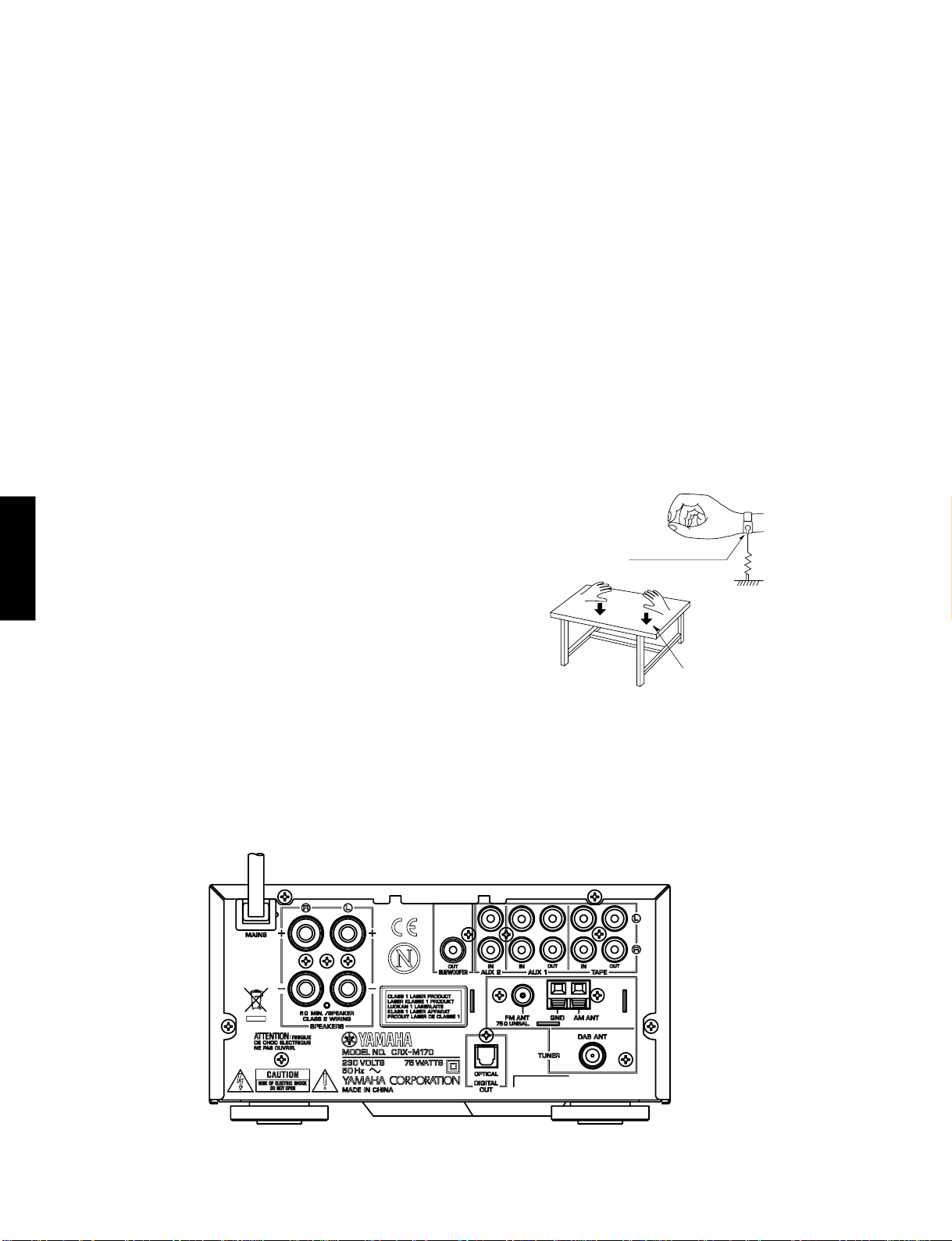

■ PREVENTION OF ELECTRO STATIC DISCHARGE

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically

Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor “chip”

components. The following techniques should be used to help reduce the incidence of component damage caused by electro static discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your body by touching

a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent

electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can generate

electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement ES

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES divice, touch the protective material to the chassis or

circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of

your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

Grounding for electrostatic breakdown prevention

1. Human body grounding.

Use the antistatic wrist strap to discharge the static

electricity from your body.

2. Work table grounding.

Put a conductive material (sheet) or steel sheet on the area

where the optical pickup is placed and ground the sheet.

Anti-static wrist strip

1M-ohms

CRX-M170

Caution:

The static electricity of your clothes will not be grounded

through the wrist strap. So take care not to let your clothes

touch the optical pickup.

■ REAR PANEL

Conductive material

(sheet) or steel sheet

4

■ SPECIFICATIONS

DAB (Digital Audio Broadcasting), also known as digital

radio, is a new way of radio broadcasting. DAB is

broadcast using digital signals instead of analog signals,

resulting in near CD-quality sound. Analog signals (i.e.

AM/FM) are susceptible to interference (i.e. distortion and

noise) caused by electrical equipment, weather conditions,

tall buildings, mountains, etc.; digital signals are not.

Thus, with DAB, there is virtually interference-free

reception and no hiss or crackle.

CRX-M170

■ AUDIO SECTION

Minimum RMS Output Power Per Channel

1 kHz, 0.1% THD, 6 ohms . . . . . . . . . . . . . . . . . . .25 W + 25 W

Input Sensitivity/Impedance

Tape, AUX 1, AUX 2 . . . . . . . . . . . . . . . . 300 mV/47 k-ohms

Output Level

REC OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280 mV

SUB WOOFER (50Hz) . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 V

Headphone Jack Rated Output

CD, etc. (32 ohms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 V

Frequency Response

CD, etc (20Hz to 20kHz) . . . . . . . . . . . . . . . . . . . . . . ±0.5 dB

Total Harmonic Distortion

CD, etc. 1 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03%

Signal to Noise Ratio (IHF-A-Network)

CD, etc. (300 mV, Input Shorted) . . . . . . . . . . . . . . . . .98 dB

Tone Control Characteristics

BASS Boost/cut . . . . . . . . . . . . . . . . . . ±10 dB (100 Hz)

TREBLE Boost/cut . . . . . . . . . . . . . . . . . . ±10 dB (10 kHz)

■ FM SECTION

Tuning Range (50 kHz steps) . . . . . . . . . 87.50 to 108.00 MHz

Signal to Noise Ratio (Mono) . . . . . . . . . . . . . . . . . . . . . .65 dB

Sensitivity (S/N 30 dB) . . . . . . . . . . . . . . . . . . . . . . . . 1.0 µV/m

■ AM SECTION

Tuning Range (9 kHz steps) . . . . . . . . . . . . . . .531 to 1629kHz

Signal to Noise Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 dB

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600 µV/m

■ GENERAL

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . AC 230V, 50 Hz

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 W

Standby Power Consumption . . . . . . . . . . . . . . . . . . . . .0.9 W

Dimensions (W x H x D) . . . . . . . . . . . . . .215 x 110 x 359 mm

(8-7/16" x 4-5/16" x 14-1/8")

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 kg (9 lbs. 11 oz)

Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Silver color

Accessories . . . . . . . . . . . . . . . . . . . . . . AM loop antenna x 1

Indoor FM antenna x 1

Indoor DAB antenna x 1

Remote Control x 1

Battery (size "AAA", "R03", "UM-4") x 2

* Specifications subject to change without notice.

B ....... British model

CRX-M170

■ DAB SECTION

Tuning Range (BAND

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 ohms (nominal)

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .– 96 dBm

Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 dB typ.

Audio Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stereo, 2.0 Vp-p

Digital Out . . . . . . . . . . . . . . . . . . . . . . 24 bit/48 kHz resolution

III

) . . . . . . . . . . . . 174 MHz to 240 MHz

■ CD PLAYER SECTION

Signal to Noise Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 dB

Total Harmonic Distortion . . . . . . . . . . . . . . . . . . . . . . 0.007%

Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 dB

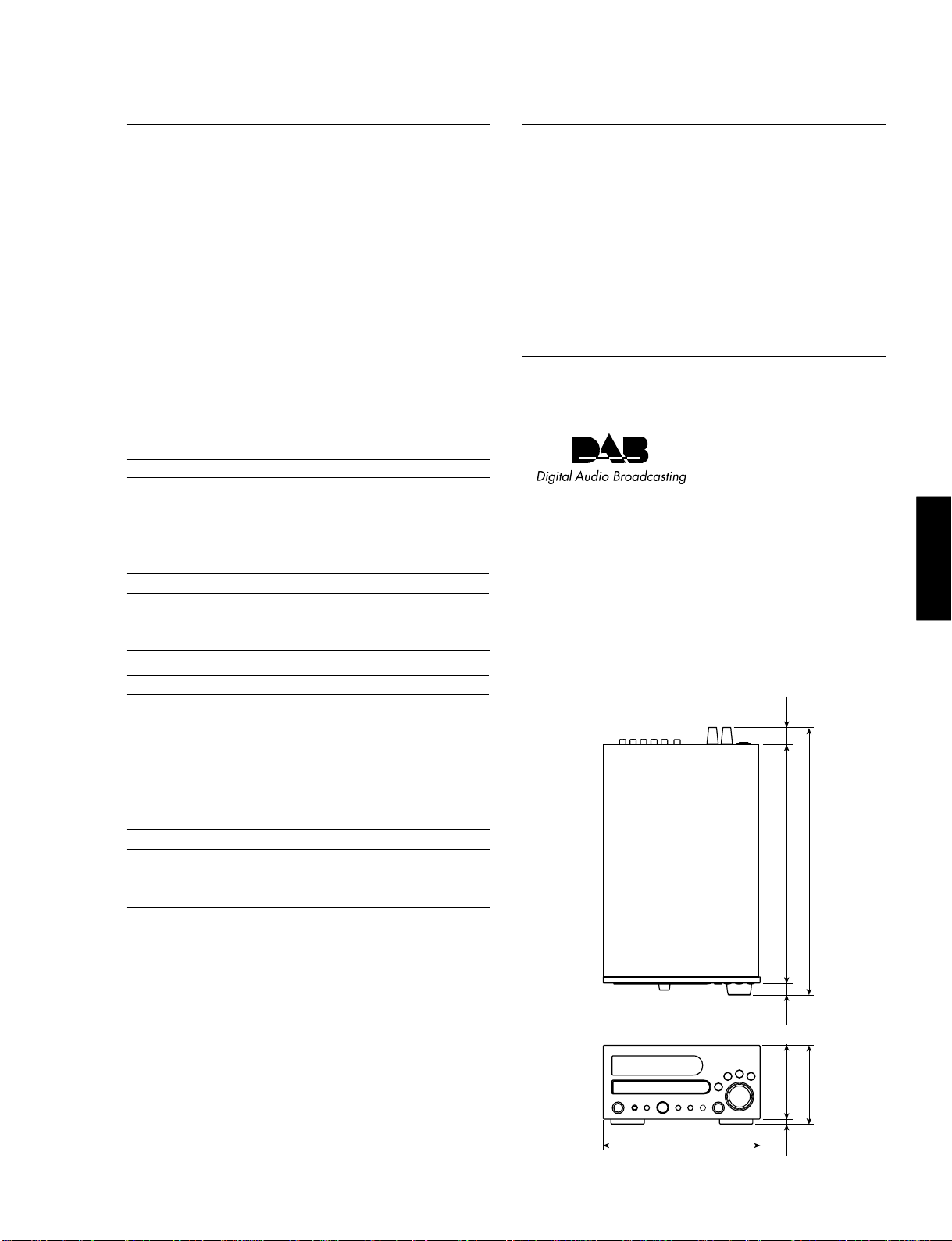

● DIMENSIONS

Unit : mm (inch)

215 (8-7/16")

22

(7/8")

359 (14-1/8")

17

(11/16")

101 (4") 320 (12-5/8")9

110 (4-5/16")

(3/8")

5

CRX-M170

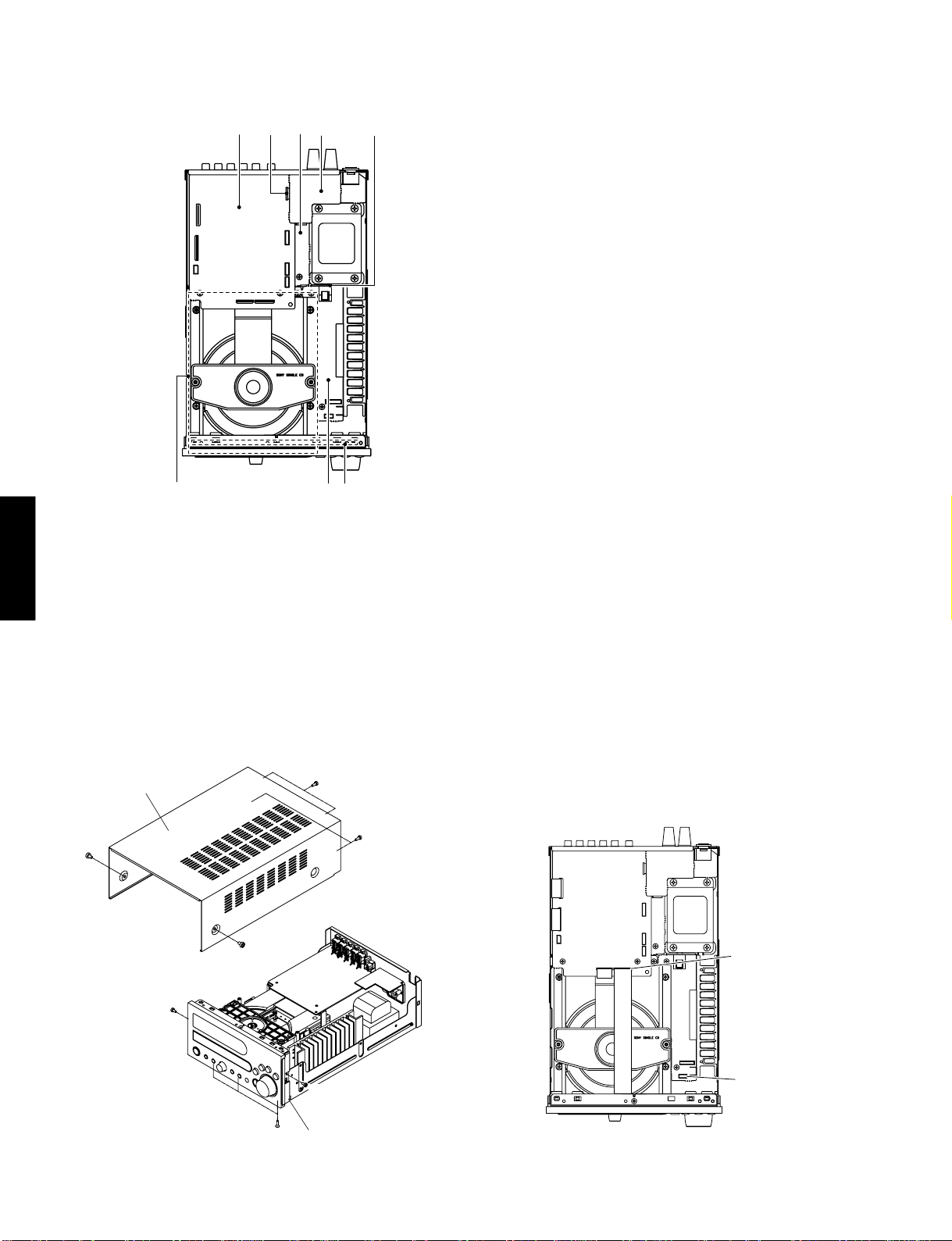

■ INTERNAL VIEW

wer tq

q MAIN P.C.B.

w POWER (6) P.C.B.

e POWER (1) P.C.B.

r POWER (4) P.C.B.

t POWER (5) P.C.B.

y CD MECHANISM UNIT

u POWER (2) P.C.B.

i POWER (3) P.C.B.

■ DISASSEMBLY PROCEDURES

CRX-M170

• Remove parts in disassembly order as numbered.

• Disconnect the power cable from the AC outlet.

1. Removal of Top Cover

a. Remove 2 screws ( q ) and 4 screws ( w ). (Fig. 1)

b. Slide the Top Cover rearward to remove it. (Fig. 1)

T op Cover

q

uiy

w

2. Removal of Front Panel Unit

a. Disconnect the connectors (WF14 and CN16).

(Fig. 2)

b. Remove 2 screws ( e ) and 3 screws ( r ), and then

remove the Front Panel Unit. (Fig. 1)

w

q

e

e

Front Panel Unit

r

Fig. 1 Fig. 2

6

WF14

CN16

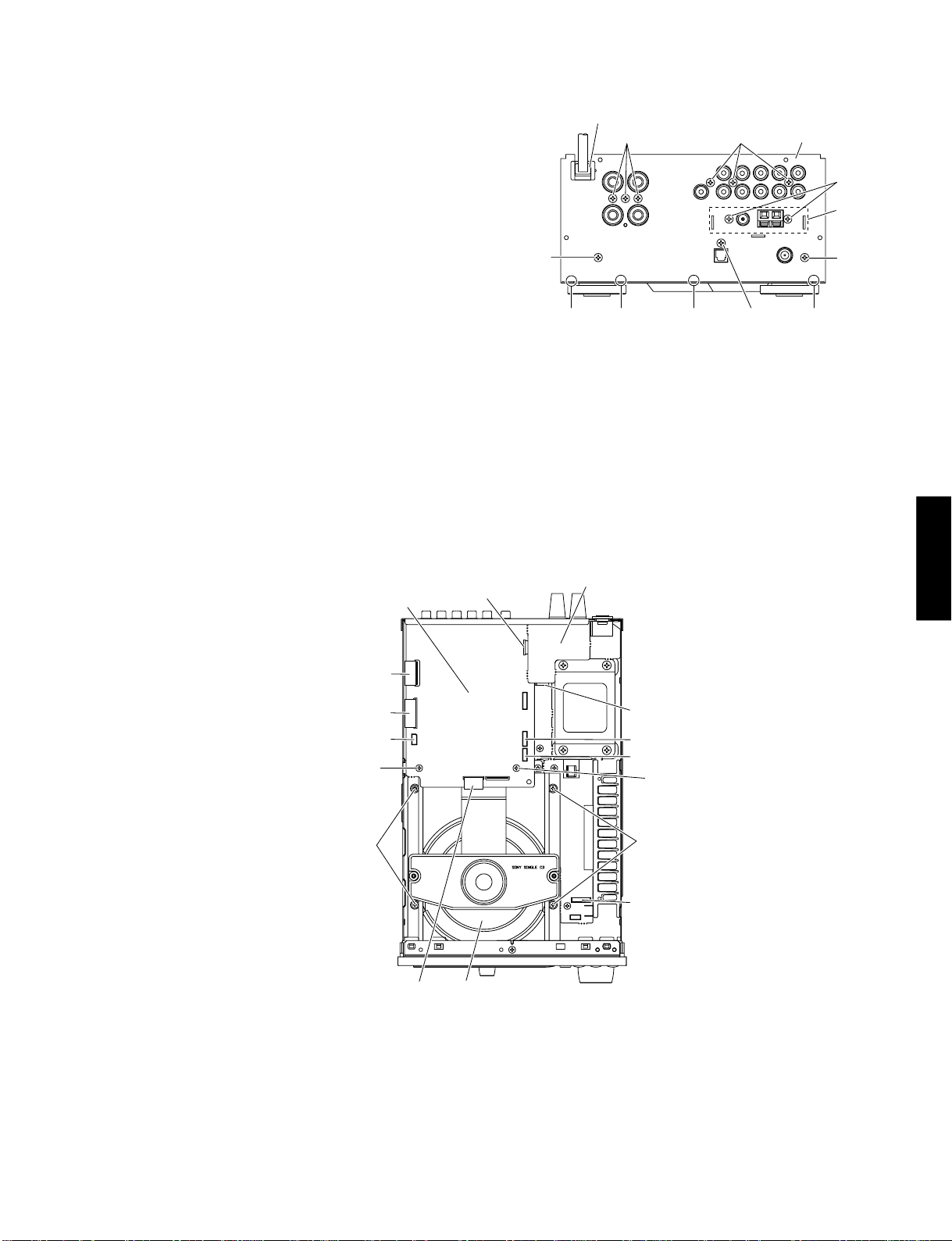

3. Removal of Rear Panel and Tuner Module

t

y

tt

y

uiiii

Tuner

Module

Rear Panel

Cord Stopper

a. Remove the Cord Stopper. (Fig. 3)

b.

Remove 8 screws ( t ), 2 screws ( y ), 1 screw ( u )

and 4 screws ( i ). (Fig. 3)

c. Remove the Rear Panel. (Fig. 3)

d. Disconnect the connector (WF20). (Fig. 4)

e. Remove the Tuner Module. (Fig. 3)

4. Removal of Main, Power (4) and Power (6) P.C.B.s

a. Remove the Rear Panel.

b. Disconnect the connectors (WF12, WF15, CN10,

CN11, CN13, CN18 and CN19). (Fig. 4)

c. Remove 2 screws (

o ) and then remove the Main,

Power (4) and Power (6) P.C.B.s. (Fig. 4)

5. Removal of CD Mechanism Unit

a. Remove the Front Panel Unit.

b. Disconnect the connectors (WF12, CN10 and CN11).

(Fig. 4)

c. Remove 4 screws (

!0 ). (Fig. 4)

d. Remove the CD Mechanism Unit. (Fig. 4)

CRX-M170

Fig. 3

CRX-M170

Main P.C.B.

WF20

WF15

CN13

o

!0

WF12

Power (6) P.C.B.

CD Mechanism Unit

Fig. 4

Power (4) P.C.B.

CN19

CN11

CN10

o

!0

CN18

7

Loading...

Loading...