CDX-396/496

COMPACT DISC PLAYER

CDX-396/496

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherant to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact

the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumu-

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

■

CONTENTS

TO SERVICE PERSONNEL ....................................... 1-2

FRONT PANELS ............................................................ 3

REAR PANELS .............................................................. 4

SPECIFICATIONS .......................................................... 5

INTERNAL VIEW ........................................................... 5

DISASSEMBLY PROCEDURES ............................... 6, 7

STANDARD OPERATION CHART ........................... 7, 8

TEST MODE ............................................................... 8, 9

ERROR MESSAGE................................................ 10, 11

injury, destruction of expensive components and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that all service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

lated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

IMPORTANT NOTICE

CDX-396/496

DISPLAY DATA ........................................................... 12

IC DATA .................................................................. 13-16

BLOCK DIAGRAM ....................................................... 17

PRINTED CIRCUIT BOARD ................................... 18-21

IC BLOCK .................................................................... 22

WAVEFORMS .............................................................. 23

SCHEMATIC DIAGRAM .............................................. 24

PARTS LIST ............................................................ 25-37

REMOTE CONTROL TRANSMITTER......................... 38

100707

CDX-396/496

■

TO SERVICE PERSONNEL

1. Critical Components Information.

Components having special characteristics are marked

and must be replaced with parts having specifications equal

to those originally installed.

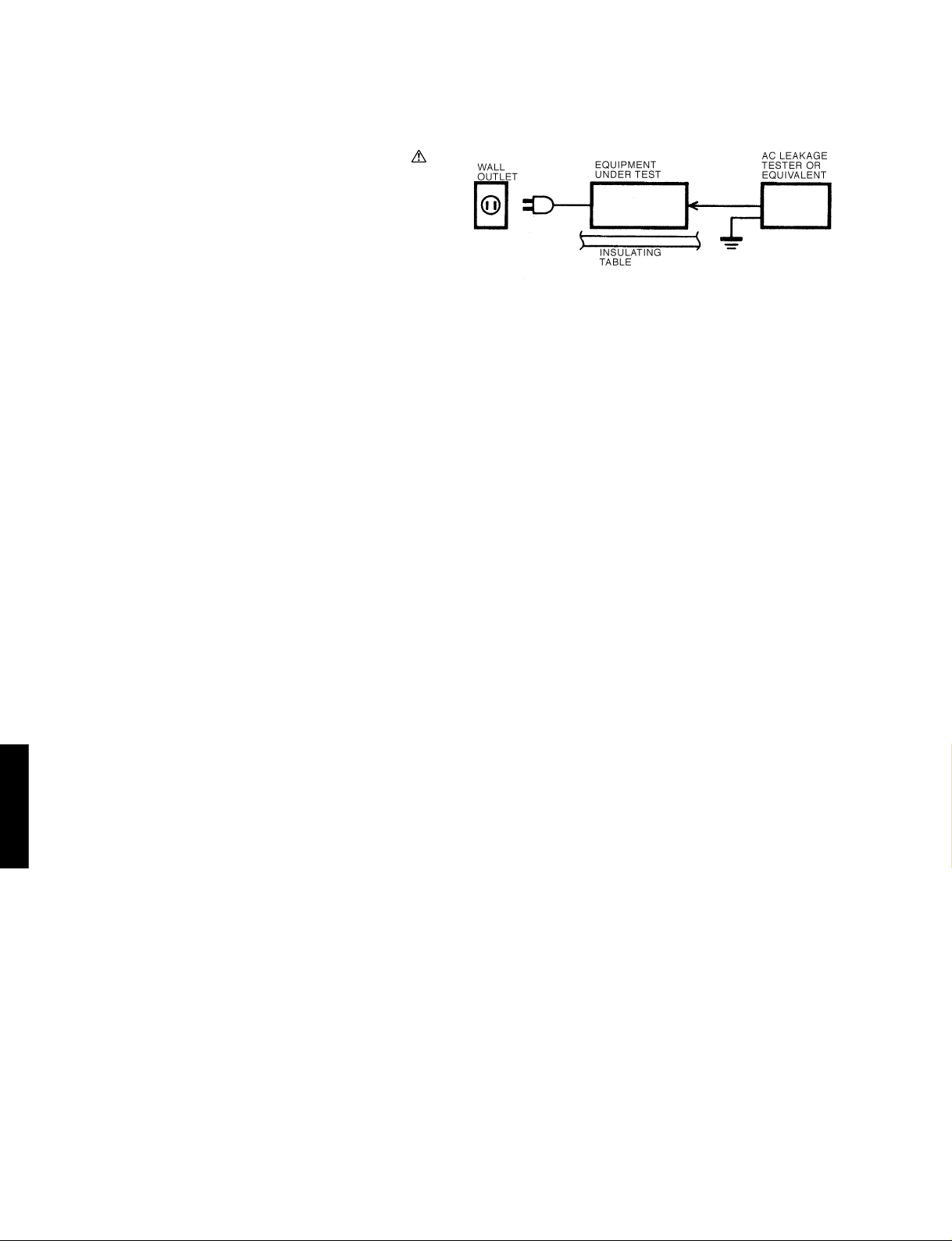

2. Leakage Current Measurement (For 120V Models Only).

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

CAUTION: USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

THE COMPACT DISC PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY

QUALIFIED SERVICE PERSONNEL.

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs a laser. Therefore, be sure to carefully

follow the instructions below when servicing .

1. Laser Diode Properties

● Material : GaAlAs

● Wavelength : 780 nm

● Emission Duration : Continuous

● Laser Output : max. 44.6 µW*

* This output is the value measured at a distance of

WARNING: CHEMICAL CONTENT NOTICE!

CDX-396/496

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic

and/or plastic (where applicable) components may also contain traces of chemicals found by the

California Health and Welfare Agency (and possibly other entities) to cause cancer and/or birth defects

or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH

FOR ANY REASON WHATSOEVER!

2. When checking the laser diode emission, keep your

eyes more than 30 cm away from the objective lens.

about 200 mm from the objective lens surface on

the Optical Pick-up Block.

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale

solder fumes or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your

hands before handling food.

1

➀ G, B models

CLASS 1 LASER PRODUCT

➁ R, G, B model

CDX-396/496

English

➀

THIS PRINTING (SEE POSITION SHOWN IN THE ILLUSTRATION) INFORMS THE USER THAT THE APPARATUS

CONTAINS A LASER COMPONENT.

➁ THIS LABEL (SEE POSITION SHOWN IN THE ILLUSTRATION) WARNS THAT ANY FURTHER PROCEDURE WILL

BRING THE USER INTO EXPOSURE WITH THE LASER BEAM.

CAUTION : USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Swedish

DENNA MÄRKNING (SE FIGUR) UPPLYSER OM ATT DET I APPARATEN INGÅR EN LASERKOMPONENT AV TYP

➀

KLASS 1.

➁ VARNINGSMÄRKNING (SE FIGUR) FÖR STRÅLNING. INGREPP I APPARATEN BÖR ENDAST FÖRETAGAS AV

FACKMAN MED KÅNNEDOM OM LASER. APPARATEN INNEHÄLLER EN LASERKOMPONENT SOM AVGER

STRÅLNING ÖVERSTIGANDE GRÄNSEN FÖR LASERKLASS 1.

VARNING : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD: BETRAKTA EJ STRÅLEN.

Danish

DETTE MÆRKAT ER ANBRAGT SOM VIST I ILLUSTRATIONEN FOR AT ADVARE BRUGEREN OM AT APPARATET

➀

INDEHOLDER EN LASERKOMPONENT.

➁ DETTE MÆRKAT OM LASEREN ER ANBRAGT PÅ APPARATET SOM EN OPLYSNING OM AT APPARATET

INDEHOLDER ET LASERKOMPONENT.

ADVARSEL : INDGREB BOR KUN FORETAGES AF EN FAGMAND DA DER ER RISIKO FOR RADIOAKTIV

STRÅLING.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING.

UNDGÅ UDSAETTELSE FOR STRÅLING.

CDX-396/496

Finnish

VARO! :

AVATTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

2

CDX-396/496

■

FRONT PANELS

CDX-396

CDX-496

CDX-396

CDX-396/496

CDX-496

OUTPUT LEVEL

+

-

39

3

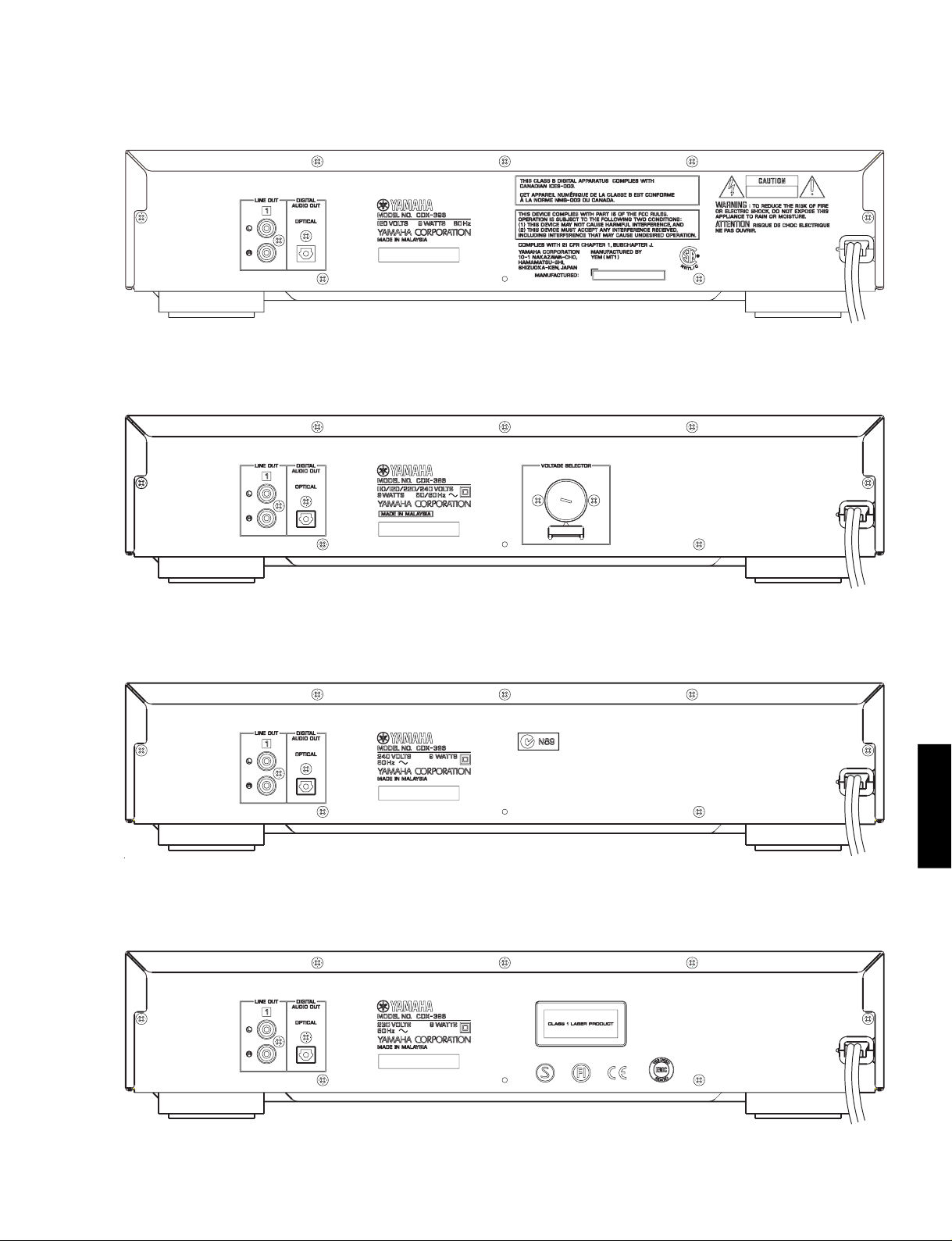

■

240V

120V

110V

REAR PANELS

U, C models

R model

CDX-396/496

A model

G, B models

120V

220V

110

V

240V

CDX-396/496

4

CDX-396/496

■

SPECIFICATIONS

Output Level

1kHz, 0dB 2.0 ± 0.5Vrms

Signal to Noise Ratio (EIAJ) 105dB

Dynamic Range 95dB

Harmonic Distortion+Noise (1kHz) 0.003%

Frequency Response

2Hz — 20kHz ±0.5dB

Power Requirements

U, C models (CDX-396 ONLY) 120V AC 60Hz

B, G models 230V AC 50Hz

A model (CDX-396 ONLY) 240V AC 50Hz

R model 110/120/220/240V AC 50/60Hz

Power Consumption 9W

Dimensions (W x H x D) 435 x 96 x 277mm

Weight 3.7kg (7 lbs 11 oz)

Finish

CDX-396

CDX-396BL Black color

CDX-396TI Titanium color

CDX-496

CDX-496BL Black color

CDX-496TI Titanium color

Accessories Pin plug cord

*Specifications are subject to change without notice.

U ................... U. S. A. model

C ................Canadian model

A .............. Australian model

(17-1/8" x 3-3/4" x 10-7/8")

Remote control transmitter

(Dry-cell : x 2: Size “AA”, R06)

B .................... British model

G ............... European model

R .................. General model

● DIMENSION

435(17-1/8")

6

(1/4")

277

261.5

(10-7/8")

(10-5/16")

5.5

(3/16")

80

96

(3-1/18")

(3-3/4")

16

(5/8")

Unit : mm (inch)

■

INTERNAL VIEW

CDX-396/496

1 MAIN P.C.B. (3)

2 MAIN P.C.B. (6)

3 MAIN P.C.B. (1)

4 MAIN P.C.B. (4)

5 CD MECHANISM UNIT

6 MAIN P.C.B. (2)

7 MAIN P.C.B. (5) (CDX-496 ONLY)

5 6 7

5

2

1

4

4

1

3

3

3

CD Mchanism

Unit

Front Panel

Top Cover

Lid

■

CB200

CB101

PJ100

CB1

CB2

CB3

CB301

CB100

CB202

CB203

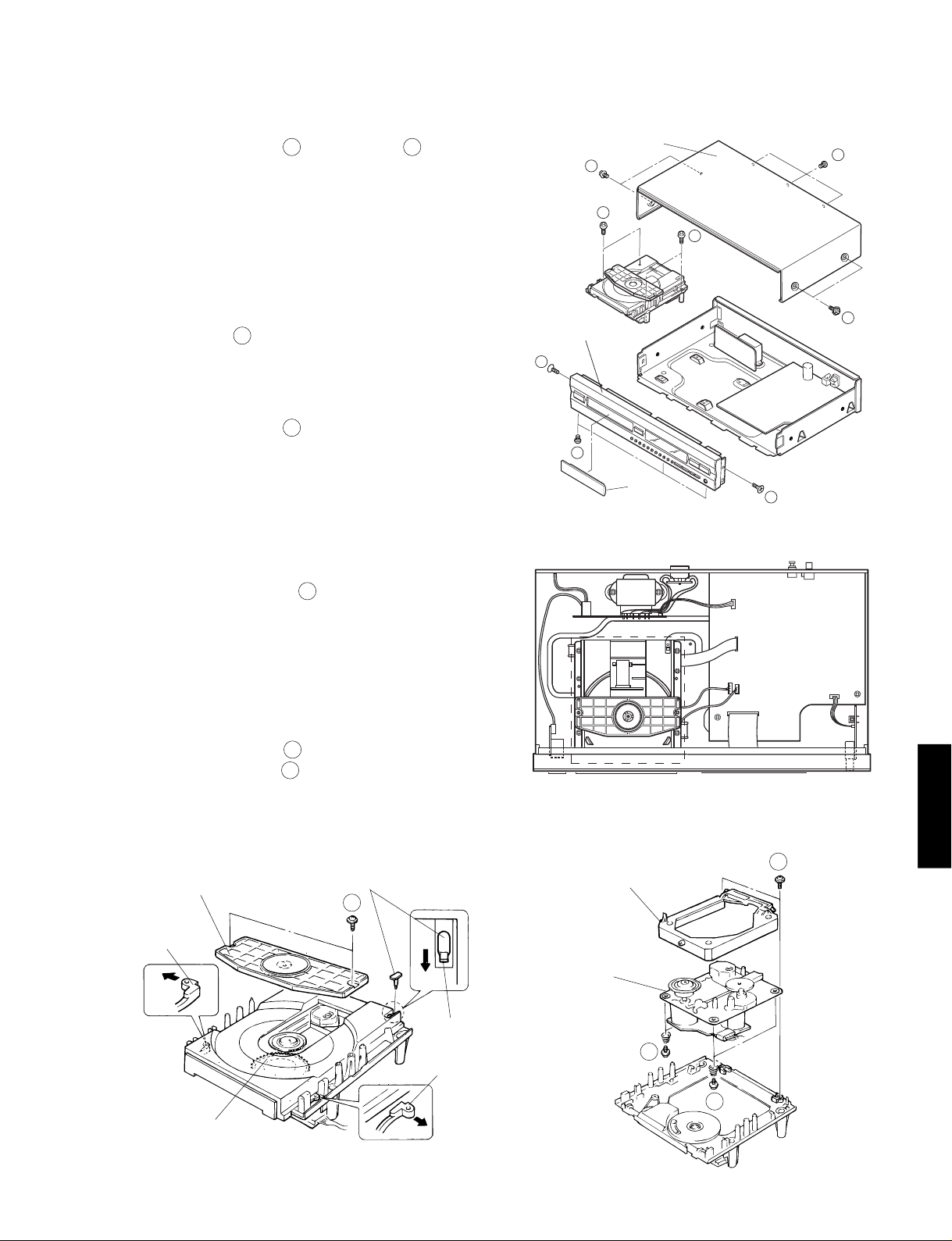

DISASSEMBLY PROCEDURES

1. Removal of Top Cover

a. Remove 4 screws ( 1 ) and 3 screws

(2)

in Fig. 1.

b. Lift the Top Cover at the rear and move it rear-ward.

2. Removal of Front Panel

a. Press the OPEN/CLOSE key and open the tray.

Then remove the Lid attached to the front edge of

the tray in Fig. 2.

Press the OPEN/CLOSE key and close the tray,

then unplug the power cord.

b. Remove 2 connectors (CB202, CB301) in Fig. 2.

c.

Remove a connector (CB100) in Fig. 2. (CDX-496

only)

d. Remove 5 ( 3 ) screws in Fig. 1.

e.

Remove 2 hooks and then pull the Front Panel for-

ward.

3. Removal of CD Mechanism Unit

a. Remove 3 connectors (CB1, CB2, CB3) in Fig. 2.

b. Remove 4 screws ( 4 ) in Fig. 1.

CDX-396/496

(Remove parts in disassembly order as numbered.)

4. Removal of Tray Unit

a. Remove 2 screws ( 5 ) and then remove the

Chucking Unit in Fig. 3.

b. Remove 1 hook and then remove the Stopper Pin

in Fig. 3.

c. Rotate the Drive Gear and then open the Tray Unit

in Fig. 3.

d. Detach the Stoppers on both sides and then pull

out the Tray in Fig. 3.

5. Removal of Pick-up Head

a. Remove 2 screws ( 6 ) in Fig. 4.

b. Remove 4 screws ( 7 ) and then remove the Drive

Unit in Fig. 4.

c. Remove the gear A in Fig. 5.

d. Pull out the Sled Shaft in Fig. 5.

e. Remove the Pick-up Head.

Chucking Unit

Stopper

Stopper Pin

5

Sub Chassis (S)

Drive Unit

3

Fig. 1

CDX-396/496

Fig. 2

6

Drive Gear

Hook

Stopper

Fig. 3 Fig. 4

7

7

6

CDX-396/496

Pick-up Head Gear A

Check that the disc table height is as specified below.

Sled Shaft

Stopper

■

STANDARD OPERATION CHART

POWER ON If a disc is not loaded, "0:00" appears in the time indicator.

Press OPEN/CLOSE key.

Forced feed return operation

Clamp down operation

"

OPEN

"TRV" signal is output until detection of LIMIT switch.

Disc Table

19.4 ± 0.2mm

Fig. 5

" appears in the TIME indicator.

CDX-396/496

Tray open

Load a disc.

Press PLAY key or push the tray.

Tray closed

Disc mechanism unit clamped up.

Feed inward switch reached.

Tracking offset auto ADJ

Laser ON

Focus offset auto ADJ

Disc scan

Focus gain rough ADJ

Focus search operation

Focus lock servo ON

Spindle motor accelerated.

Tracking servo ON

Stop after detection of LOADING switch.

Proceeds to next step after detection of LOADING switch.

if FLSW = L (IC300, 23 pin)

Proceeds To Next Step.

LDON = H (IC1, 5 pin)

FLOCK = H → L (IC300, 18 pin)

TLOCK = H → L (IC300, 19 pin)

Spindle servo ON

VCO lock

Feed servo ON

A

7

CDX-396/496

Tracking gain rough ADJ

- * Data f etch cycle -

After searching the beginning, PLAY starts.

- PLAY -

MUTE ON

TRACK search

MUTE ON

Spindle motor stop

: MUTE OFF = H → L (Q201 Collector)

0:00 appears in the time indicator.

Tracking balance ADJ (only tray OPEN/CLOSE)

Focus balance ADJ

Focus gain ADJ

Tracking gain ADJ

* TOC READ

TRACK NO. 1 is searched.

Set to SEARCH by means of , key.

After searching the beginning, MUTE is cancelled.

- PLAY -

Press the STOP key.

Laser OFF

Forced feed return

- STOP -

: MUTE ON = L → H

: MUTE OFF = H → L

0:00 appears in the time indicator.

: LDON = H → L (IC1, 5 pin)

A

■

TEST MODE

(1) Turning ON the POWER while pressing the keys "PLAY/PAUSE" and "STOP" will set to the TEST mode.

(When the TEST mode is set, all indicators light for 1 second.)

CDX-396/496

8

CDX-396/496

(2) Shown below are the panel key and remote control transmitter functions in the TEST mode.

● Function List of Panel keys Note) "Traverse servo" means the same as "feed servo".

PANEL KEY

OPEN/CLOSE

(SKIP/SEARCH)

(SKIP/SEARCH)

+10

1

2

3

4

5

6

7

8

9

0

Tray open/close.

FOON, TRON, SPON, TVON(FEON).

All stop. (Focus, spindle, feed, laser, tray, etc.) Initializes FL display

Inner circumference traverse servo.

Outer circumference traverse servo.

Rotating the mode of coefficients. (Coefficient mode --- Coefficient setting --- product mode)

Pressing twice will set to the product mode.

Returns to product mode.

Auto adjustment mode 1 (TR-off set, FO-off set, FO-rough gain adjustment)

Auto adjustment mode 2 (TR-balance, TR-rough gain adjustment)

Auto adjustment mode 3 (FO-fine gain, TR-fine gain, FO-balance adjustment)

1 TRACK KICK (–) continuously (Coefficient set up mode : address down)

1 TRACK KICK (+) continuously (Coefficient set up mode : address up)

30 TRACK KICK (–) continuously (Coefficient set up mode : upper digit down)

30 TRACK KICK (+) continuously (Coefficient set up mode : upper digit up)

150 TRACK KICK (–) continuously (Coefficient set up mode : lower digit down)

150 TRACK KICK (+) continuously (Coefficient set up mode : lower digit up)

FUNCTION

● Function List of Remote Control Transmitter

CODE

01

02

04

05

06

07

08

0A

0B

0C

0D

0F

10

11

12

13

14

15

CDX-396/496

16

17

18

19

1A

1B

1E

55

56

57

58

5D

KEY

OPEN/CLOSE

REPEAT

TIME

INDEX

PROG

CLEAR

SPACE

0

1

2

3

4

5

6

7

8

9

+10

RANDOM

DIMMER

TAPE

SYNCHRO

PEAK

CUSTOM CODE = (79)x

FUNCTION

Tray open/close.

PLAY (FOON, TRON, TVON(FEON), SPON)

Inner circumference traverse servo.

Inner 10 tracks kick continuously.

Outer 10 tracks kick continuously.

Outer circumference traverse servo.

FOON, TROF (Enter focus search if focus servo is off.)

Checks FL display. (88 8888 --- goes out --- All lamps.)

FOON, TROF, TVOF(FEOF) (Enter focus search if focus servo is off.)

Rotates or accelerates spindle.

Decelerates spindle. (checking EFM pattern and reflected STAT)

FOOF, TROF, TVOF(EFOF)

150 TRACK KICK (+) continuously (Coefficient set up mode : lower digit up)

Returns to product mode. (tray inoperative.)

Auto adjustment mode 1 (TR-off set, FO-off set, FO-rough gain adjustment)

Auto adjustment mode 2 (TR-balance, TR-rough gain adjustment)

Auto adjustment mode 3 (FO-fine gain, TR-fine gain, FO-balance adjustment)

1 TRACK KICK (–) continuously (Coefficient set up mode : address down)

1 TRACK KICK (+) continuously (Coefficient set up mode : address up)

30 TRACK KICK (–) continuously (Coefficient set up mode : upper digit down)

30 TRACK KICK (+) continuously (Coefficient set up mode : upper digit up)

150 TRACK KICK (–) continuously (Coefficient set up mode : lower digit down)

Rotating the mode of coefficients.

SPON (Spindle servo on.)

Checks FL display. (All lamps --- 88 8888 --- goes out.)

FOON, TROF, TVOF(EFOF) (Enter focus search if focus servo is off.)

All stop. (Focus, spindle, traverse, laser, tray, etc.)

Spindle free (off)

TV(Feed) REV

-

9

CDX-396/496

■

ERROR MESSAGE

(1) When operation is terminated in an abnormal condition (stop or open), pressing STOP on the remote control while

pressing STOP on the panel will set to the error message display enable mode.

(2) Shown below is an example of display. ("E-73" as an example)

(3) This function stays effective till the power is turned OFF. (It is cleared at OFF.)

(4) Listed in the table below are error messages.

● Error Messages List

ERROR MESSAGES

E–X0

E–X1

E–71

E–72

E–73

E–94

E––5

E–X7

E–X8

Er r

Data cannot be read after finishing search.

Data cannot be read during PLAY(X=0), PAUSE(X=3), or SCAN(X=2).

At the start, tracking servo is not effective.

At the start, spindle servo PLL is not effective.

At the start, data cannot be read.

Close switch does not work with tray closed.

Open switch does not work with tray open.

Traverse(Feed) inner switch does not work.

Recovery action fails after focus drop.

MN35511AL does not give response of SENSE, with resetting by the

DESCRIPTION

unit’s microcomputer.

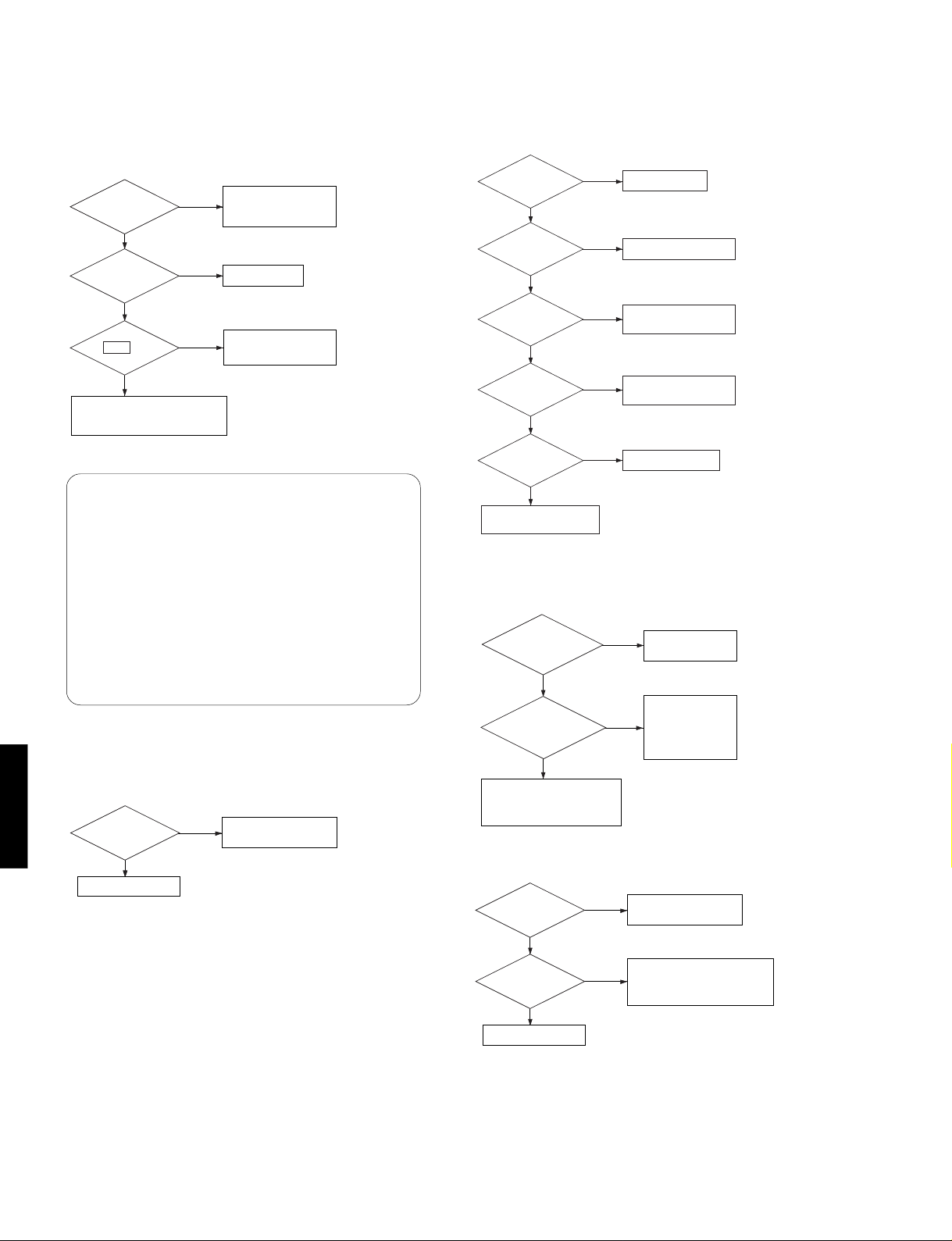

1) Error Code Troubleshooting

Error code X0 , X1 , 73 ...... Data cannot be read.

Is disc dirty or

scratched?

NO

Pick-up position

Within disc range

Pick-up defective, Spindle system

defective (Motor fails to run, etc.).

YES

Outermost

(on mirror

surface)

Check by using

another disc.

TRACKING

servo defective.

FEED servo defective.

*No. for each state

(meaning of "X")

PLAY X="0"

SCAN X="2"

PAUSE X="3"

PEAK SEARCH X="4"

SEARCH X="5"

START X="7"

STOP X="8"

LOADING X="9"

OPEN X="-"

NO DISC X="C"

Error codes 94 , – 5 ..... Poor tray loading operation.

Does tray

operate when

OPEN/CLOSE key is

pressed?

NO

Motor defective.

Control IC (IC2) defective.

Microcomputer defective.

Loading switch defective.

YES

Poor Microcomputer

defective.

CDX-396/496

Error code X7 ............. FEED operation defective.

(Limit switch fails)

Is forced

feed operation

available in TEST

mode?

NO

FEED servo defective.

Microcomputer defective.

Y...Outward

T...Inward

Feed limit switch

YES

defective.

Microcomputer defective.

Error code X8 ............ Focus drops.

Is disc dirty or

scratched?

NO

Pick-up position

Within disc range

FOCUS servo defective.

Pick-up defective.

YES

Outermost

(on mirror

surface)

Check by using

another disc.

TRACKING servo

defective.

FEED servo defective.

10

CDX-396/496

2) Troubleshooting from System Malfunctions

a) Tray fails to come out/go in.

Tray starts to

move but stops.

Is output

available at LOADING

terminal?

FLSW = L

Limit switch defective.

FEED servo system defective.

Microcomputer, IC1 or IC3 defective.

When tray fails to close completely

(when it stops midway)

[Corrective measure]

1) Turn ON the power and open the tray.

* If it failed to open (head and tray contacting each other),

open it after removing the chucking unit.

2) Turn OFF the power and force the tray to go in fully and

close.

3) With the power turned ON, open and close the tray to

check if the tray close completely.

b) No sound generated, Sound cut during play.

( but time display advances properly)

MUTING applied.

CDX-396/496

IC3 or IC200 defective.

c) Operates as if no disc loaded. (although loaded)

Does tray

YES

NO

YES

NO

YES

NO

Poor mechanism

operation.

Wire caught.

Loose gear, etc.

Motor defective.

Microcomputer or

LOADING IC (IC2)

defective.

load properly?

YES

Is pick-up at

innermost position?

YES

Is FOCUS

lock done?

YES

Does spindle

motor run?

YES

Is EFMI signal

normal?

YES

IC3 defective.

Microcomputer defective.

NO

Poor tray loading.

NO

Feed limit switch defective.

NO

NO

NO

FOCUS servo

system defective.

Spindle servo

system defective.

Jitter defective.

d) Sound skips.

(Time display fails to advance properly)

Is disc dirty,

scratched or

warped?

NO

Is disc or disc

stabilizer in contact with

mechanism?

NO

Tracking servo system defective.

FEED servo system defective.

FOCUS servo system defective.

YES

MUTING circuit defective.

Microcomputer defective.

NO

NO

Pick-up defective.

e) No search provided. (Sound skipped after search)

Is disc dirty,

scratched or

warped?

NO

Is TER

waveform normal?

NO

IC3 defective.

YES

YES

YES

Check by using a

known good disc.

Poor mechanism

YES

accuracy.

Floating rubber/

spring deformed.

Pick-up connector

assembly caught.

Check by using a

known good disc.

Tracking servo system defective.

FEED servo system defective.

FOCUS servo system defective.

Pick-up defective.

11

■

PROGRAM

RANDOM

DISPLAY DATA

V401 : 9-MT-133GK

PATTERN AREA

CDX-396/496

1

PIN CONNECTION

1

F1

19

NC

2F13NP4

20NC21

P1222P11

PIN NO.

CONNECTION

PIN NO.

CONNECTION

NOTE 1) F1, F2 ..........Filament

2) NP ............... No pin

3) NC ...............No connection

4) P1~P10 .......Datum Line

5) 1G~9G.........Grid

GRID ASSIGNMENT

9G

5

8G

23

P10

35

6

76G85G94G103G112G121G13NC14NC15NC16NC17NC18

7G

24

25P826P727P628P529P430P331P232P133NP34F235

P9

NC

F2

CDX-396/496

ANODE CONNECTION

P1

PROGRAM

P2

RANDOM

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

9G

A

B

SPACE

—

—

1

2

3

4

7G

7G

a

b

c

d

e

f

g

—

5

6

—

—

a

b

c

d

e

f

g

—

7

8

—

—

6G

TOTAL

REMAIN

—

—

—

—

—

—

9

10

11

—

5G

a

b

c

d

e

f

g

—

12

INDEX

—

—

4G

13

14

3G

a

b

c

d

e

f

g

—

—

—

a

b

c

d

e

f

g

:

15

PEAK

—

—

2G

16

17

1G

a

b

c

d

e

f

g

—

—

—

SINGLE

FULL

REPEAT

B1

B2

B3

B4

B5

S1

18

19

20

12

CDX-396/496

■

IC DATA

IC3 : MN35511AL

Signal Processor Controller (SPC) & D/A Converter

VDDX2X1

VSS

60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41

XSEL

CRC

FLAG

PCK/RESY

EFM

AVSS2

AVDD2

VCOF

PLLF

DSLF

DRF

IREF

ARF

WVEL

PLAY/TRVSTOP

TOFS

60

VDD

57

VSS

4

DVDD1

5

DVSS1

18

/RST

71

/TEST

32

FE

33

RFFNV

TRCRS

VDET

BDO

/RFDET

OPT

TE

34

37

35

39

38

36

CDX-396/496

CLVS/FLAG6

DEMPO

SUBC

SBCK2

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

SBCK

CLDCK

LDON

BDO

/RFDET

TRCRS

OFT

VDET

RFENV

TE

FE

TBAL

FBAL

VREF

FOD

TRD

KICK

ECS

ECM

PC

TVD

TRV

BLKCK

CRC

IOSEL

DIGITAL DE-EMPHASIS

PEM

(L)

SDATI

8 TIMES

OVER SAMPLING

DIGITAL FILTER

DO

DAC

61

VCOF2

62

AVSS1

63

OUT1C

64

OUT1D

65

OUT2D

66

OUT2C

67

AVDD1

68

DEMP0

69

CK384

70

IOSEL

71

/TEST

72

SBCK2

73

SUBC

74

SBCK

75

/CLDCK

76

IPFLAG

SDATI

LRCKI

BCKI

77

78

79

80

SMCK/FCLK

VCOF

CK384

VCO

1 2 2 4 5 6 7 8 91011121314151617181920

TX

DVSS1

DRF

MCLK

IREF

MDATA

DSLF

MLD

PLLF

SENSE

/FLOCK

EFM

PCK/RESY

BLKCK

/TLOCK

AVDD

SQCK

SUBQ

AVSS

SUBQ

SUBCODE

BUFFER

DMUTE

SQCK

MDATA

BCLK

MCLK

LRCK

MLD

DVDD1

SRDATA

ARF

DSL.PLL VCO

STAT

/RST

SMCK/FCLK

CLVS/FLAG6

DEMP1/TEST2

STATX1X2

17 58 59 56 19 49 69 8 7 9 44 46 45 47 48 52 53 67 62 15 14 20 68 73 72 74 75 13 55 70 78 80 79 77

XSEL

TIMING

GENERATOR

PITCH CONTROL

EFM DEMODULATION

SYNC INTERPOLATION

SUBCODE DEMODULATION

CIRC ERROR CORRECTION

DEINTERLEAVE

16K

SRAM

A/D CONVERTER

MICRO COMPUTER

INTERFACE

SERVO

CPU

INPUT PORT

OUTPUT

PORT

D/A

CONVERTER

INTERPOLATION

SOFT MUTING

DIGITAL

ATTENUATION

PEAK DETECT

AUTO CUE

CLV

SERVO

DIGITAL

AUDIO

INTERFACE

SERVO

LRCKI

BCKI

PLL VCO2

DEMP1/TEST2

PEM

(R)

61

VSOF2

13

TIMING GENERATOR

10 43 41 40 11 12 30 31 28 27 22 25 42 29 26 21 16 1 3

WVEL

SENSE

TOFS

LDON

/FLOCK

FBAL

/TLOCK

TBAL

FOD

TRD

TVD

ECS

KICK

VREF

TRV

DMUTE

PLAY/TRVSTOP

BCLK

23 24 6 76 54 51 63 64 66 65 50

2

PC

LRCK

SRDATA

ECM

TX

FLAG

IPFLAG

AVSS2

OUT1C

OUT1D

OUT2C

AVDO2

OUT2D

.oNNIPEMANO/INOITCNUF.oNNIPEMANO/INOITCNUF

1KLCBCN14SFOTCN

2KCRLCN24YALPCN

3RDRSCN34LEVWCN

41DDVD

51SSVDDNG54FERII tnerrucecnerefeR

6XTO langisecafretnioidualatigiD64FERDILSDrofsaiB

7KLCMIkcolcUPC74FLSDO/ILSDrofretlifpooL

8ATADMIatadUPC84FLLPO/ILLProfretlifpooL

9DLMI langisdaolUPC94FOCV

01ESNESOlangisesneS052DDVA

11KCOLF/O langiswardovressucoF152SSVADNG

21KCOLT/O langiswardovresgnikcarT25MFECN

31KCKLBO kcolckcolbedoc-buS35KCPCN

41KCQSI kcolcQedoc-buS45GALFCN

51QBUSO langisedocQedoc-buS55CRCCN

61ETUMDIlangisetuM65LESXDNG

71TATSOlangissutatS75SSVDNG

81TSR/IlangisteseR851XI noitallicolatsyrC

91KLCF/KCMSCN952XO noitallicolatsyrC

026GALF/SVLCCN06DDV

12VRTO langisdeefdecrofesrevarT162FOCVDNG

22DVTO langisevirdesrevarT261SSVADNG

32CPCN36C1TUOO langisC1MEP

42MCEO langisevirddecrofeldnipS46D1TUOO langisD1MEP

52SCEO langisevirdeldnipS56D2TUOO langisD2MEP

62KCIKOeslupkciK66C2TUOO langisC2MEP

72DRTO langisevirdgnikcarT761DDVA

82DOFO langisevirdsucoF86OPMEDlangistcetedsisahpme-eD

92FERVO egatloVecnerefeR96483KCOCN

03LABFO langisecnalabsucoF07LESOI)H(tcelesedoM

13LABTO langisecnalabgnikcarT17TSET/)H(tesedomtseT

23EFI langisrorresucoF272KCBSCN

33ETI langisrorregnikcarT37CBUSCN

43VNEFRI langisepolevneFR47KCBSCN

53TEDVDNG57KCDLC/CN

63TFOI langiskcart-ffO67GALFPICN

73SRCRTI langisesolcgnikcarT77IPMEDDNG

83TEDFR/I tcetedlangisFR87ITADSCN

930DBI tcetedtodkcalB97IKCRLCN

04NODLO langisNOresaL08IKCBCN

+

V5

44FRAIlangisFR

+

+

+

+

CDX-396/496

V5

V5

V5

CDX-396/496

V5

14

CDX-396/496

IC300 : uPD78043FGF-072

System Control

P95/FIP7

P96/FIP8

P97/FIP9

P100/FIP10

P101/FIP11

P102/FIP12

P103/FIP13

P104/FIP14

P105/FIP15

LOAD

V

P106/FIP16

P107/FIP17

P110/FIP18

P111/FIP19

P112/FIP20

P113/FIP21

CDX-396/496

P94/FIP6

P93/FIP5

P92/FIP4

P91/FIP3

P90/FIP2

P81/FIP1

P80/FIP0

P27/SCK0

P26/SO0/SB1

P25/SI0/SB0

P24/BUSY

P23/STB

P22/SCK1

P21/SO1

P17/ANI7

P16/ANI6

P15/ANI5

P14/ANI4

TO0/P30

TI0/INTP0/P00

TO1/P31

TI1/P33

TO2/P32

TI2/P34

CI0/INTP3/P03

SI0/SB0/P25

SO0/SB1/P26

SCK0/P27

SI1/P20

SO1/P21

SCK1/P22

STB/P23

BUSY/P24

ANI0/P10-

ANI7/P17

INTP0/TI0/P00

INTP3/CI0/P03

P20/SI1

RESET

AV

AV

AV

DD

V

P74

P73

AV

SS

DD

SS

REF

-

80 78 7679 77 75 73 7174 72 70 68 6669 67 65

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 27 2926 28 30 32 3431 33 35 37 3936 38 40

REF

AV

P04/XT1

78K/0

CPU CORE

RAM

EVENT

COUNTER1

SS

X1

V

XT2

PROM

P13/ANI3

16-bit TIMER/

EVENT COUNTER

8-bit TIMER/

8-bit TIMER/

EVENT COUNTER2

WATCHDOG TIMER

WATCH TIMER

6-bit UP/DOWN

COUNTER

SERIAL

INTERFACE0

SERIAL

INTERFACE1

A/D CONVERTER

INTERRUPT

CONTROL

P12/ANI2

P11/ANI1

DD

AV

P10/ANI0

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

X2

P37

P34/TI2

P33/TI1

P35/PCL

P36/BUZ

FIP

CONTROLLER/

DRIVER

PORT0

PORT1

PORT2

PORT3

PORT7

PORT8

PORT9

PORT10

PORT11

PORT12

P114/FIP22

P115/FIP23

P116/FIP24

P117/FIP25

P120/FIP26

P121/FIP27

P122/FIP28

P123/FIP29

P124/FIP30

P125/FIP31

P126/FIP32

P127/FIP33

V

DD

P70

P71

P72

V

PP

P00/INTP0/TI0

P01/INTP1

P02/INTP2

P03/INTP3/CI0

P30/TO0

P31/TO1

P32/TO2

P00

P01-P03

P04

P10-P17

P20-P27

P30-P37

P70-P74

P80, P81

P90-P97

P100-P107

P110-P117

P120-P127

FIP0-FIP33

V

LOAD

15

BUZ/P36

PCL/P35

BUZZER OUTPUT

CLOCK OUTPUT

CONTROL

RESET

SYSTEM

CONTROL

VPPVSSV

DD

X1

X2

XT1/P04

XT2

CDX-396/496

NIP

.oN

16PIF/49P7GO

25PIF/39P6GO 241OT/13PSLC/NPOO langisesolc/nepoyarT

34PIF/29P5GO 340OT/03PFERSO ecnereferybdnatS

43PIF/19P4GO 440IC/3PTNI/30PWSLCI hctiwsnepoyarT

52PIF/09P3GO 542PTNI/20PWSPOI hctiwsesolcyarT

61PIF/18P2GO 641PTNI/10PKCKLBI kcolckcolbedoc-buS

70PIF/08P1GO 740IT/0PTNI/00PMERI rosneslortnocetomeR

8DDV

90KCS/72PKCQSO )KCQS(kcolclaireS9427PO

110BS/0IS/52PQBUSI )QBUS(atadF/IlaireS1507PO

21YSUB/42PESNESI langisesneS25DDV

31BTS/32PDLMO langistcelespihc11553NM3533PIF/721PO

411KCS/22PKLCMO kcolclaireS4523PIF/621PO

511OS/12PATADMOatadlaireS5513PIF/521PO

611IS/02PCN6503PIF/421PO

71TESERTESER/I langisteseR7592PIF/321P3KI

8147PKCOLF/I langiskcolsucoF8582PIF/221P2KI

9137PKCOLT/I langiskcolgnikcarT9572PIF/121P1KI

02SSVADNGDNG0662PIF/021P0KI

127INA/71PTSRNM/I langisteseR1652PIF/711PO

226INA/61PETUMD/IlangisetuM2642PIF/611PO

325INA/51PWSLFI hctiwstimildeeF3632PIF/511PO

424INA/41PRREO )H(galftcetedrorrE4622PIF/411PO

523INA/31PETUMO langisetumgolanA5612PIF/311P21PO

622INA/21PCN6602PIF/211P11PO

721INA/11PFFODEEFO langisffoovresdeeF7691PIF/111P01PO

820INA/01PLRTCGO langislortnocniaG8681PIF/011P9PO

92DDVADDVA

03FERVAFERVADNG0761PIF/601P7PO

131TX/40P694/693I )H:694,L:693(tcetedledoM17DAOLV–V02

232TXCN2751PIF/501P6PO 6langistnemgesLF

33SSVDNGDNG3741PIF/401P4DK/5PO

431X1X)zHM0.5(rotallicsO4731PIF/301P3DK/4PO

532X2X)zHM0.5(rotallicsO5721PIF/201P2DK/3PO

6373P3NOM

73ZUB/63P2NOM7701PIF/001P0DK/1PO

83LCP/53P1NOM879PIF/79P)LotdexiF(

932IT/43PADSCN978PIF/69P9GO

041IT/33PLCSCN087PIF/59P8GO

EMAN

ECIVEDTIUCRICECIVEDTIUCRIC

O/INOITCNUF

+

V5

+

V5

7-1slangisdirgLF

)HotdexiF(

NIP

.oN

142OT/23PYBDNATSO langisybdnatS

84)PPV(CIDNGDNG

9671PIF/701P8PO

6711PIF/101P1DK/2PO

EMAN

O/INOITCNUF

+

V5

)LotdexiF(011BS/0OS/62PTATSI langissutatS0517PO

)LotdexiF(

3-0slangisnruteryeK

)LotdexiF(

21-7slangistnemgesLF

/5-1slangistnemgesLF

4-0slangisnacsyeK

9,8slangisdirgLF

CDX-396/496

16

■

BLOCK DIAGRAM

17

CDX-396/496

ABCDE FGHI J

2

■

PRINTED CIRCUIT BOARD

(Foil side)

MAIN P.C.B.(1)

OPTICAL PICK-UP

KSM-213CCM

SPDL+

SPDL-

FEED+

FEED-

GND

To : MAIN (3)

3

W210

AC

GNDACF1

#1

F2

TRK-

FCS+VRGNDCAEVC

FCS-

TRK+PDLDFBDVCC

1528

FL SW

#2

IC2

141

4

36 19

LOADING+

LOADING-

OPEN

#3

GND

CLOSE

+5V

GND

K2

K0

G2

G4

G6

G8

P1

P3

P5

P7

P9

P11

F2

REM

K3

K1

G1

G3

G5

G7

G9

P2

P4

P6

P8

P10

P12

F1

#301

To : MAIN (2)

• Semiconductor Location

IC1

118

5

DIGITAL

AUDIO OUT

OPTICAL

16 1

9

24

25

8

4

1

58

40

41

CDX-496

ONLY

80

1

65

IC300

41

40

64

6

21

20

1

LINE OUT

60

IC3

61

80

CDX-496 ONLY

1

4

7

W100

58

1

4

58

GND

L

R

To : MAIN (5)

Ref. No. Location

D100

D101

D200

D201

D202

D203

D204

D205

D206

D207

D208

D209

D210

D211

D212

D213

D214

D215

D216

D250

Q1

Q3

Q4

Q100

Q101

Q102

Q103

Q201

Q202

Q203

Q204

Q250

Q300

Q301

IC1

IC2

IC3

IC101

IC105

IC300

IC301

F6

F7

D3

D4

C4

D2

D3

D3

D3

D3

D3

D3

C3

C3

C3

D3

D3

C3

C3

D4

E3

F4

F3

C6

C7

C6

C7

D3

C4

C4

D3

D3

F5

G3

E4

F3

E5

D6

G6

G4

F5

18

ABCDE FGHI J

YE OR

BL

BR RE

OR

BE

WH

BR RE YE BL

MAIN P.C.B.(6)

MAIN P.C.B.(3)

F2

F1

AC

GND

AC

F2

F1

AC

GND

AC

BE

WH

R MODEL ONLY

CDX-496 ONLY

CDX-496 ONLY

CDX-496 ONLY

CDX-496 ONLY

CDX-396 ONLY

CDX-396 ONLY

AC

IN

MAIN P.C.B.(3)

MAIN P.C.B.(5)

MAIN P.C.B.(4)

MAIN P.C.B.(2)

AC

IN

(EXCEPT R MODEL)

W200

WH

BE

POWER

PHONES

L

R

GND

W100

To : MAIN (1)

J17

J18

SW418 SW417 SW415 SW315 SW406

+-

OUTPUT LEVEL

(STOP) (PLAY)

STOP/SEARCH

OPEN/CLOSE

F1

P12

P10P8P6P4P2G9G7G5G3G1K1K3REM

F2

P11P9P7P5P3P1G8G6G4G2K0K2GND

+5

To : MAIN (1)

To :

MAIN (1)

SKIP/

SEARCH

98

35 32 21 12 4 1

+1012+10/31/42/53/64/75/86/97/10

Ref. No. Location

D300

D301

D302

D303

D304

U300

F2

E3

E3

F3

D3

H2

• Semiconductor Location

To :

MAIN (1)

110V

120V

220V

240V

1

■

PRINTED CIRCUIT BOARD

(Foil side)

2

3

4

5

6

7

20

CDX-396/496

+-+-+-+-+-+

-

+-+-+-+

-

+

-

+

-

+

-

+

-

+

+

-

-

+

-

16 10 12 11 18 17 14 13 19 1

4

5

3

6

28 26 25 24

Standby

Band gap

V

CC/VREF

Reset Circuit

1.25V

SW

Thermal

Protection

Circuit

ININ+

OUT

VREF

222720

15

21897232

IN2+

CH4 SW

IN2-

IN4

IN3

IN1

IN5

SVCC

PGND2

PGND1

STANDBY

D2-

D4-

D3-

D1-

D5-

D2+

D4+

D3+

D1+

D5+

PVCC3

PVCC1

PVCC2

■ IC BLOCK

IC1 : AN8882SB

Digital Servo Head Amp

OUT

3T

6

ADD

Amp.

ADD

Amp.

36

A

ADD

35

Amp.

C

34

B

ADD

33

Amp.

D

32

Amp.

F

31

Amp.

E

GCA

GCA

18321

LDON

TVREF2

EQCTL

GCA

GCA

BCA

BCA

T

TFL

ARF

CEA

NRFDET

9

8

7

RF-A GC

RFDET

AC

BCA

BCA

V

REF2

30

232425

AL

FB

FTEO

GCTRL

TEOUT

IC101, 102 : NJM2068D-D

Dual OP-Amp

1

OUT

1

2

–IN

+IN

–V

1

1

CC

–+

–+

3

4

IC2 : AN8785SB

PU Driver

RFC

CAGC

17

10

FL TCTL

29

28

AL

TEN

TB

EQCTL

ENV DET

STANDBY

11

4195

V

CC2

CC1

V

RFOUT

12

13

CBDO

BDO

14

BDO

15

OFTR

GND

COFTR

16

OFTR

26

FEN

27

FEOUT

V

REF2

22

V

REF2

20

V

REF1

2

LD

1

PD

IC105 : BA15218

Dual OP-Amp

8

7

6

5

+V

OUT

–IN

+IN

CC

1

OUT1

-IN1

2

2

2

2

+IN1

GND

1

+

3

4

8

VCC

OUT2

7

6

-IN2

-

2

+

+IN2

5

IC200 : M5290P

Constant-Voltage Tracking Supply with Reset

VCC

REFERENCE

REGULA TOR

GND

9

ON/OFF

CONTROL

10

—VCC

ON/OFF

Other ICs

IC3: See page 13.

IC300: See page 15.

22

C+

E—

16 15 12 7

14 13

3

1

E—

NC

CURRENT

CONTROL

CURRENT

CURRENT

CONTROL

CONTROL

+

PROTECTION

+

4

2

C—

NC

OUTPUT

(—

OUTPUT

(+5V)

5

5V)

IC301 : S-24001ADP

EEPROM

DELA Y

REFERENCE

11

IN

8

RESET OUT

DELA Y

CIRCUIT

BAL. ADJ.

6

6

SCL

SDA

A2

A1

A0

START/STOP

DEVICE ADDRESS

D

IN

DET

COMPARATOR

LOAD

SERIAL CLOCK

CONTROL

COMP

LOAD

INC

R/W

ADDRESS

COUNTER

Y–DECODER

D

OUT

HIGH VOLTAGE GENERATOR

DATA REGISTER

E2PROM

X–DECODER

SELECTOR

DATA OUTPUT

ACK OUTPUT

CONTROL

5

3

2

1

V

CC

8

4

GND

WAVEFORMS

CDX-396/496

Point A (EFM : Pin10 of IC1)

V : 0.2V/div H : 0.5 usec/div

AC range 1 : 1 probe

Point C (Pin35 of IC300)

V : 2V/div H : 0.2 usec/div

DC range 1 : 1 probe

Point B (Pin59 of IC3)

V : 1V/div H : 50 nsec/div

DC range 1 : 1 probe

0V

Point D (CH1 : Pin1 of IC200)

Point E (CH2 : Pin8 of IC200)

V : 5V/div H : 2 sec/div

DC range1 1 : probe

0V

0V

0V

-10V

With the POWER switch

turned ON, connect the

power cord to the AC outlet.

This waveform is not available by pushing the

power swich ON and OFF.

Disconnect the power cord

from the AC outlet.

23

ABCDEFGH I

■

SCHEMATIC DIAGRAM

J

LINE AMP & LPF

1

6

7

0

0

0

5

4

-5.7

2.5

2.5

2.4

2.4

2.4

2.5

2.50.1

3.8

0

4.5

3.8

1.8

2.2

2.5

2.5

2.8

1.9

0

2.8

1.8

2.4

2

2.3

2.8

2.4

0

2.5

2.5

5.5

3

2.4

2.5

0

2.5

5.5

2.5

2.5

2.2

2.8

2.4

5.5

0

2.4

2.4

5.5

2.6

2.5

3.3

0

PU DRIVER

4

5

PIN CONNECTION DIAGRAM OF

2.4

4.9

2.4

0

2.9

3.0

2.4

2.4

0

0

3.0

0.1

0

DIGITAL SERVO

HEAD AMP

0

4.9

0

4.8

0

2.4

2.3

2.3

2.4

2.4

002.4

0

2.5

1.3

A

2.4

0

2.4

2.4

2.4

1.9

1.3

1.9

2.4

2.5

1.8

4.9

4.9

0

0

0

0

2.3

2.4

4.9

0

0

2.4

2.4

2.4

0

2.3

0

SPC & DAC

B

2.5

2.5

2.5

2.5

5.1

4.9

2.5

2.4

4.9

4.8

EEPROM

CDX—496 ONLY

4.9

0

00

4.9

0

0

4.8

4.8

2.5

0

0

4.9

0

0

4.9

0

4.9

0

0

0

0

2.3

4.8

000

SYSTEM

4.9

2.1

4.9

0

000

C

CONTROL

~~~~~

-12

~~~

~

-18.1

-21.4

2.4

5.6

8

3

0

1

2

0

4.8

4.8

0

~

4.8

0

0

0

0

4.9

0

4.9

2.4

0

4.9

0

0

0

0

POWER SUPPLY

5.5

0

0

4.9

0

4.8

0

0

0

4.9

0

4.9

4.9

0

~

4.8

4.8

4.9

~

~

~

~

~

~

~

-3.2

~

~

~

4.9

4.3

4.3

3.8

POWER SUPPLY

E

4.9

0

10.1

6.1

0

MUTE CONTROL

5.0

5.0

4.3

0

-5.0

6.9

0

D

-11.5

-11.5

-5.7

00

1.2

5.6

-5.7

0

10

9.4

9.4

10

1.3

-5.0

-11.5

-11.5

-0.210.2

-0.2

10.2

-0.2

10.2

-0.2

10.2

10.1

-0.2

-0.2

10

-0.2

10

-0.2

TRANSISTORS, DIODES AND ICS.

2SA933S(Q,R)

2SC1740S(R,S)

NJM2068D

S-24C01ADP

POWER SUPPLY

-25.6

-22.1

-25.6

-19.0

-20.3

B

C

E

2SB544(E,F,G)

2SC2878(A,B)

M5290P

8

4

1

9

-21.3

-16.9

-21.3

-22.1

-11.5

8

0

3

5.6

1

2

0

0

6

0

7

5

0

-5.7

0

4

AC18.0

AC

GND

AC

F1

F2

AC3.5

MUTING

0

0

0

0

10.0

-10.9

-11.5

0

-5.0

-5.0

0

0

-5.0

-5.0

0

LINE

OUT

CDX—496 ONLY

HEADPHONE

AMP

9.3

8

9.0

0

3

1

2

0

0

PHONES

6

0

7

5

0

-10.5

0

4

DIGITAL

AUDIO OUT

OPTICAL

(CDX—496)

<U,C,A,G> (CDX—396)

1

15

1

19

1

40 25

65 80

8

14

CDX—496

18

(X = Not used.)

S2 C220—222 FI32410 VS74170 VS74170

~

4160

40

CDX—396 ONLY

~

~

~

~

21

24

1

~

~

~

~

~

-16.8

-16.8

CDX—396

~~~

~~~~~~~~~

~

~~~~~~~

-18.1

-16.8

-16.8

S2 C220—222 VY67500 VS74170 VS74170 VS74170

(X = Not used.)

REMOTE

* All voltages are measured with a 10M /DC electric volt meter.

* Components having special characteristics are marked and

CDX—496 ONLY

SENSOR

E

C

6

B

2SB1565(E,F)

2SD2394(E,F)

IT2

HSS104

Cathade

E

C

B

Anode

16

AN8285SB

28

AN8882SB

36

MN35511PIC-28043TH2

61

7

1

2

3

BA15218

8

1

4

80

120

uPD78043FGF-072

41

64

must be replaced with parts having specifications equal to those

originally installed.

* Schematic diagram is subject to change without notice.

24

■ WARNING

PA RTS LIST

■

ELECTRICAL PARTS

Components having special characteristics are marked and must be

replaced with parts having specifications equal to those originally installed.

● Carbon resistors (1/6W or 1/4W) are not included in the ELECTRICAL PARTS

List. For the part Nos. of the carbon resistors, refer to the last page.

ABBREVIATIONS IN THIS LIST ARE AS FOLLOWS :

CDX-396/496

C.A.EL.CHP : CHIP ALUMI. ELECTROLYTIC CAP

C.CE : CERAMIC CAP

C.CE.ARRAY : CERAMIC CAP ARRAY

C.CE.CHP : CHIP CERAMIC CAP

C.CE.ML : MULTILAYER CERAMIC CAP

C.CE.M.CHP : CHIP MULTILAYER CERAMIC CAP

C.CE.SAFTY : RECOGNIZED CERAMIC CAP

C.CE.TUBLR : CERAMIC TUBULAR CAP

C.CE.SMI : SEMI CONDUCTIVE CERAMIC CAP

C.EL : ELECTROLYTIC CAP

C.MICA : MICA CAP

C.ML.FLM : MULTILAYER FILM CAP

C.MP : METALLIZED PAPER CAP

C.MYLAR : MYLAR FILM CAP

C.MYLAR.ML : MULTILAYER MYLAR FILM CAP

C.PAPER : PAPER CAPACITOR

C.PLS : POLYSTYRENE FILM CAP

C.POL : POLYESTER FILM CAP

C.POLY : POLYETHYLENE FILM CAP

C.PP : POLYPROPYLENE FILM CAP

C.TNTL : TANTALUM CAP

C.TNTL.CHP : CHIP TANTALUM CAP

C.TRIM : TRIMMER CAP

CN : CONNECTOR

CN.BS.PIN : CONNECTOR, BASE PIN

CN.CANNON : CONNECTOR, CANNON

CN.DIN : CONNECTOR, DIN

CN.FLAT : CONNECTOR, FLAT CABLE

CN.POST : CONNECTOR, BASE POST

COIL.MX.AM : COIL, AM MIX

COIL.AT.FM : COIL, FM ANTENNA

COIL.DT.FM : COIL, FM DETECT

COIL.MX.FM : COIL, FM MIX

COIL.OUTPT : OUTPUT COIL

DIOD.ARRAY : DIODE ARRAY

DIODE.BRG : DIODE BRIDGE

DIODE.CHP : CHIP DIODE

DIODE.VAR : VARACTOR DIODE

DIOD.Z.CHP : CHIP ZENER DIODE

DIODE.ZENR : ZENER DIODE

DSCR.CE : CERAMIC DISCRIMINATOR

FER.BEAD : FERRITE BEADS

FER.CORE : FERRITE CORE

FET.CHP : CHIP FET

FL.DSPLY : FLUORESCENT DISPLAY

FLTR.CE : CERAMIC FILTER

FLTR.COMB : COMB FILTER MODULE

FLTR.LC.RF : LC FILTER ,EMI

GND.MTL : GROUND PLATE

GND.TERM : GROUND TERMINAL

HOLDER.FUS : FUSE HOLDER

IC.PRTCT : IC PROTECTOR

JUMPER.CN : JUMPER CONNECTOR

JUMPER.TST : JUMPER, TEST POINT

L.DTCT : LIGHT DETECTING MODULE

L.EMIT : LIGHT EMITTING MODULE

LED.DSPLY : LED DISPLAY

LED.INFRD : LED, INFRARED

MODUL.RF : MODULATOR, RF

PHOT.CPL : PHOTO COUPLER

PHOT.INTR : PHOTO INTERRUPTER

PHOT.RFLCT : PHOTO REFLECTOR

PIN.TEST : PIN, TEST POINT

PLST.RIVET : PLASTIC RIVET

R.ARRAY : RESISTOR ARRAY

R.CAR : CARBON RESISTOR

R.CAR.CHP : CHIP RESISTOR

R.CAR.FP : FLAME PROOF CARBON RESISTOR

R.FUS : FUSABLE RESISTOR

R.MTL.CHP : CHIP METAL FILM RESISTOR

R.MTL.FLM : METAL FILM RESISTOR

R.MTL.OXD : METAL OXIDE FILM RESISTOR

R.MTL.PLAT : METAL PLATE RESISTOR

RSNR.CE : CERAMIC RESONATOR

RSNR.CRYS : CRYSTAL RESONATOR

R.TW.CEM : TWIN CEMENT FIXED RESISTOR

R.WW : WIRE WOUND RESISTOR

SCR.BND.HD : BIND HEAD B-TITE SCREW

SCR.BW.HD : BW HEAD TAPPING SCREW

SCR.CUP : CUP TITE SCREW

SCR.TERM : SCREW TERMINAL

SCR.TR : SCREW, TRANSISTOR

SUPRT.PCB : SUPPORT, P.C.B.

SURG.PRTCT : SURGE PROTECTOR

SW.TACT : TACT SWITCH

SW.LEAF : LEAF SWITCH

SW.LEVER : LEVER SWITCH

SW.MICRO : MICRO SWITCH

SW.PUSH : PUSH SWITCH

SW.RT.ENC : ROTARY ENCODER

SW.RT.MTR : ROTARY SWITCH WITH MOTOR

SW.RT : ROTARY SWITCH

SW.SLIDE : SLIDE SWITCH

TERM.SP : SPEAKER TERMINAL

TERM.WRAP : WRAPPING TERMINAL

THRMST.CHP : CHIP THERMISTOR

TR.CHP : CHIP TRANSISTOR

TR.DGT : DIGITAL TRANSISTOR

TR.DGT.CHP : CHIP DIGITAL TRANSISTOR

TRANS : TRANSFORMER

TRANS.PULS : PULSE TRANSFORMER

TRANS.PWR : POWER TRANSFORMER ASS’y

TUNER.AM : TUNER PACK, AM

TUNER.FM : TUNER PACK, FM

TUNER.PK : FRONT-END TUNER PACK

VR : ROTARY POTENTIOMETER

VR.MTR : POTENTIOMETER WITH MOTOR

VR.SW : POTENTIOMETER WITH ROTARY SW

VR.SLIDE : SLIDE POTENTIOMETER

VR.TRIM : TRIMMER POTENTIOMETER

CDX-396/496

Note) Those parts marked with “#” are not included in the P.C.B. ass'y.

25

CDX-396/496

CDX-396 MAIN P.C.B.

Schm

Ref. PART NO. Description

* V5003700 P.C.B. MAIN(UC)

* V5003800 P.C.B. MAIN(R)

* V5003900 P.C.B. MAIN(A)

* V5004000 P.C.B. MAIN(BG)

CB1 V2731000 CN.FMN 16P

CB2 VB390200 CN.BS.PIN 6P

CB3 VB390100 CN.BS.PIN 5P

CB101 VT707200 L.EMIT TOTX178

CB200 VK024900 CN.BS.PIN 5P

CB201 Vi878300 CN.BS.PIN 5P

CB202 VP245600 CN 2P

CB203 VG879900 CN.BS.PIN 2P

CB300 VU283000 CN.BS.PIN 30P

CB301 VU273000 CN.BS.PIN 30P

C1 VJ599100 C.CE.TUBLR 0.1uF 50V

C3 UA654470 C.MYLAR 0.047uF 50V

C4 UR818100 C.EL 100uF 6.3V

C5 UR818100 C.EL 100uF 6.3V

C6 UR866100 C.EL 1uF 50V

C7 VJ599100 C.CE.TUBLR 0.1uF 50V

C8 VJ599100 C.CE.TUBLR 0.1uF 50V

C9 UA953100 C.MYLAR 1000pF 50V

C10 VJ599100 C.CE.TUBLR 0.1uF 50V

C11 VF466700 C.CE.TUBLR 47pF 50V

C12 UA655100 C.MYLAR 0.1uF 50V

C13 VG278400 C.CE.TUBLR 220pF 50V

C14 UN865470 C.EL 0.47uF 50V

C15 UA655100 C.MYLAR 0.1uF 50V

C16 UA953120 C.MYLAR 1200pF 50V

C17 UA953270 C.MYLAR 2700pF 50V

C18 UN866470 C.EL 4.7uF 50V

C19 UR837470 C.EL 47uF 16V

C20 VJ599100 C.CE.TUBLR 0.1uF 50V

C21 UR818100 C.EL 100uF 6.3V

* C22 V4749000 C.EL 150uF 6.3V

C23 VF467000 C.CE.TUBLR 1000pF 50V

CDX-396/496

C24 VJ599100 C.CE.TUBLR 0.1uF 50V

C25 UR818100 C.EL 100uF 6.3V

C26 UR818100 C.EL 100uF 6.3V

C27 UR838100 C.EL 100uF 16V

* C28 V4749000 C.EL 150uF 6.3V

C29 UA953330 C.MYLAR 3300pF 50V

C30 UA655100 C.MYLAR 0.1uF 50V

C31 VG278700 C.CE.TUBLR 390pF 50V

C32 UA655100 C.MYLAR 0.1uF 50V

C33 VJ599100 C.CE.TUBLR 0.1uF 50V

C34 UA954120 C.MYLAR 0.012uF 50V

* C35 V4749000 C.EL 150uF 6.3V

C36 UA655100 C.MYLAR 0.1uF 50V

* C37 UN865220 C.EL 0.22uF 50V

C38 UA655100 C.MYLAR 0.1uF 50V

C39 VJ599100 C.CE.TUBLR 0.1uF 50V

C42 VJ599100 C.CE.TUBLR 0.1uF 50V

New Parts

*

26

Schm

Ref. PART NO. Description

C43 VA761400 C.CE 47pF 50V

C44 VA761400 C.CE 47pF 50V

C46 UR866100 C.EL 1uF 50V

C47 UR866100 C.EL 1uF 50V

C48 UR866100 C.EL 1uF 50V

C49 UR866100 C.EL 1uF 50V

C50 UR818470 C.EL 470uF 6.3V

C51 VJ599100 C.CE.TUBLR 0.1uF 50V

C54 VJ599100 C.CE.TUBLR 0.1uF 50V

C55 UR818100 C.EL 100uF 6.3V

C56 UR818100 C.EL 100uF 6.3V

C60 VJ599100 C.CE.TUBLR 0.1uF 50V

C62 VJ599100 C.CE.TUBLR 0.1uF 50V

C63 VJ599100 C.CE.TUBLR 0.1uF 50V

C100 UA952100 C.MYLAR 100pF 50V

* C101 V4850700 C.MYLAR 560pF 50V

* C102 V4850700 C.MYLAR 560pF 50V

C103 UA952100 C.MYLAR 100pF 50V

C104 UA954180 C.MYLAR 0.018uF 50V

C105 V2680700 C.MYLAR 3300pF 50V

C106 V2680700 C.MYLAR 3300pF 50V

C107 UA954180 C.MYLAR 0.018uF 50V

C108 VG287300 C.EL 22uF 50V

C109 VG287300 C.EL 22uF 50V

C118 VJ599100 C.CE.TUBLR 0.1uF 50V

C119 UA953100 C.MYLAR 1000pF 50V

C120 UA953100 C.MYLAR 1000pF 50V

C124 UR818100 C.EL 100uF 6.3V

C125 UR818100 C.EL 100uF 6.3V

C126 UR818100 C.EL 100uF 6.3V

C127 UR818100 C.EL 100uF 6.3V

C200 VJ599100 C.CE.TUBLR 0.1uF 50V

C201 UR866470 C.EL 4.7uF 50V

C202 UR866470 C.EL 4.7uF 50V

C203 UR865680 C.EL 0.68uF 50V

C204 UR818100 C.EL 100uF 6.3V

C205 UR818100 C.EL 100uF 6.3V

C206 UR866470 C.EL 4.7uF 50V

C207 UR739470 C.EL 4700uF 16V

C208 UR818100 C.EL 100uF 6.3V

C209 UR838220 C.EL 220uF 16V

C210 VG287900 C.EL 470uF 16V

C211 VG288300 C.EL 4700uF 16V

C212 UR828100 C.EL 100uF 10V

C213 UR866470 C.EL 4.7uF 50V

C214 UR866470 C.EL 4.7uF 50V

C215 FG644100 C.CE 0.01uF 50V

C216 FG644100 C.CE 0.01uF 50V

C217 UR867470 C.EL 47uF 50V

C218 FG644100 C.CE 0.01uF 50V

C219 UR868100 C.EL 100uF 50V

C220 VS741700 C.CE.SAFTY 0.01uF 275V

C221 VS741700 C.CE.SAFTY 0.01uF 275V

New Parts

*

CDX-396 MAIN P.C.B.

CDX-396/496

Schm

Ref. PART NO. Description

C222 VS741700 C.CE.SAFTY 0.01uF 275V

C300 VJ599100 C.CE.TUBLR 0.1uF 50V

C301 UR818100 C.EL 100uF 6.3V

C302 VG278700 C.CE.TUBLR 390pF 50V

C303 VG278700 C.CE.TUBLR 390pF 50V

C304 VG278700 C.CE.TUBLR 390pF 50V

C305 VG278700 C.CE.TUBLR 390pF 50V

C306 UM388100 C.EL 100uF 10V

C401 VG279100 C.CE.TUBLR 1200pF 16V

D200 VD631600 DIODE 1SS133,176,HSS104

D201 VD631600 DIODE 1SS133,176,HSS104

D202 VG438000 DIODE.ZENR MTZJ6.2B 6.2V

* D203 VG437000 DIODE.ZENR MTZJ4.7A 4.7V

D204 VS997800 DIODE 1T2

D205 VG437400 DIODE.ZENR MTZJ5.1B 5.1V

D206 VG442200 DIODE.ZENR MTZJ22C 22V

D207 VS997800 DIODE 1T2

D208 VS997800 DIODE 1T2

D209 VS997800 DIODE 1T2

D210 VS997800 DIODE 1T2

D211 VS997800 DIODE 1T2

D212 VS997800 DIODE 1T2

D213 VS997800 DIODE 1T2

D214 VS997800 DIODE 1T2

D215 VS997800 DIODE 1T2

D216 VS997800 DIODE 1T2

D217 VS997800 DIODE 1T2

* D250 VG438500 DIODE.ZENR MTZJ7.5A 7.5V

D300 VD631600 DIODE 1SS133,176,HSS104

D301 VD631600 DIODE 1SS133,176,HSS104

D302 VD631600 DIODE 1SS133,176,HSS104

D303 VD631600 DIODE 1SS133,176,HSS104

D304 VD631600 DIODE 1SS133,176,HSS104

HS201 VA119100 HEAT.SINK

HS202 VA119100 HEAT.SINK

* IC1 XW249A00 IC AN8882SB

* IC2 XW244A00 IC AN8785SB

* IC3 XW915A00 IC MN35511AL

IC101 XA987A00 IC NJM2068D-D

IC102 XA987A00 IC NJM2068D-D

IC200 XD201A00 IC M5290P

* IC300 XY240A00 IC.CPU UPD78043FGF-072

L201 VV900900 FLTR 3071-012-0

* PJ100 V4925100 JACK.PIN 2P

Q1 iB054430 TR 2SB544 D,E,F,G

Q3 iC287820 TR 2SC2878 A,B

Q4 iC287820 TR 2SC2878 A,B

Q100 iC287820 TR 2SC2878 A,B

Q101 iC287820 TR 2SC2878 A,B

Q102 iC287820 TR 2SC2878 A,B

Q103 iC287820 TR 2SC2878 A,B

Q201 iA093320 TR 2SA933S Q,R

Q202 VS883300 TR 2SB1565 E,F

New Parts

*

Schm

Ref. PART NO. Description

Q203 VS883400 TR 2SD2394 E,F

Q204 iA093320 TR 2SA933S Q,R

Q250 iA093320 TR 2SA933S Q,R

Q300 iA093320 TR 2SA933S Q,R

Q301 iC174020 TR 2SC1740S R,S

R203 HV755100 R.CAR.FP 100

1/4W

R206 HV755100 R.CAR.FP 100 1/4W

R208 Vi868300 R.FUS 0.68 1/6W

R217 HV755150 R.CAR.FP 150 1/4W

R401 Vi868300 R.FUS 0.68 1/6W

SW200 VZ364100 SW.PUSH SDDLD1-A2-F-1

SW201 VL908000 VOLT.SELCT ESE-370(R)

SW300 VG392900 SW.TACT SKHVAA

SW301 VG392900 SW.TACT SKHVAA

SW302 VG392900 SW.TACT SKHVAA

SW303 VG392900 SW.TACT SKHVAA

SW304 VG392900 SW.TACT SKHVAA

SW305 VG392900 SW.TACT SKHVAA

SW307 VG392900 SW.TACT SKHVAA

SW308 VG392900 SW.TACT SKHVAA

SW310 VG392900 SW.TACT SKHVAA

SW311 VG392900 SW.TACT SKHVAA

SW313 VG392900 SW.TACT SKHVAA

SW314 VG392900 SW.TACT SKHVAA

SW406 VG392900 SW.TACT SKHVAA

SW415 VG392900 SW.TACT SKHVAA

SW416 VG392900 SW.TACT SKHVAA

SW417 VG392900 SW.TACT SKHVAA

* T200 XW858A00 TRANS.PWR (UC)

* T200 XW859A00 TRANS.PWR (R)

* T200 XW860A00 TRANS.PWR (A)

* T200 XW861A00 TRANS.PWR (BG)

U300 V2856200 L.DTCT PIC-28043TH2

V300 VR061600 FL.DSPLY 9-MT-133GK

XL1 VJ719800 RSNR.CRYS 16.9344MHz

XL300 VU763600 RSNR.CE 5MHz

V3750100 PIN L=50(R)

VQ948800 SHEET.FL GD

VZ156000 SPACER.FL t4x5x23

New Parts

*

CDX-396/496

27

CDX-396/496

CDX-496 MAIN P.C.B.

Schm

Ref. PART NO. Description

* V5004200 P.C.B. MAIN(R)

* V5004300 P.C.B. MAIN(BG)

CB1 V2731000 CN.FMN 16P

CB2 VB390200 CN.BS.PIN 6P

CB3 VB390100 CN.BS.PIN 5P

CB100 VK024700 CN.BS.PIN 3P

CB101 VT707200 L.EMIT TOTX178

CB102 Vi878100 CN.BS.PIN 3P

CB200 VK024900 CN.BS.PIN 5P

CB201 Vi878300 CN.BS.PIN 5P

CB202 VP245600 CN 2P

CB203 VG879900 CN.BS.PIN 2P

CB300 VU283000 CN.BS.PIN 30P

CB301 VU273000 CN.BS.PIN 30P

C1 VJ599100 C.CE.TUBLR 0.1uF 50V

C3 UA654470 C.MYLAR 0.047uF 50V

C4 UR818100 C.EL 100uF 6.3V

C5 UR818100 C.EL 100uF 6.3V

C6 UR866100 C.EL 1uF 50V

C7 VJ599100 C.CE.TUBLR 0.1uF 50V

C8 VJ599100 C.CE.TUBLR 0.1uF 50V

C9 UA953100 C.MYLAR 1000pF 50V

C10 VJ599100 C.CE.TUBLR 0.1uF 50V

C11 VF466700 C.CE.TUBLR 47pF 50V

C12 UA655100 C.MYLAR 0.1uF 50V

C13 VG278400 C.CE.TUBLR 220pF 50V

C14 UN865470 C.EL 0.47uF 50V

C15 UA655100 C.MYLAR 0.1uF 50V

C16 UA953120 C.MYLAR 1200pF 50V

C17 UA953270 C.MYLAR 2700pF 50V

C18 UN866470 C.EL 4.7uF 50V

C19 UR837470 C.EL 47uF 16V

C20 VJ599100 C.CE.TUBLR 0.1uF 50V

C21 UR818100 C.EL 100uF 6.3V

* C22 V4749000 C.EL 150uF 6.3V

C23 VF467000 C.CE.TUBLR 1000pF 50V

CDX-396/496

C24 VJ599100 C.CE.TUBLR 0.1uF 50V

C25 UR818100 C.EL 100uF 6.3V

C26 UR818100 C.EL 100uF 6.3V

C27 UR838100 C.EL 100uF 16V

* C28 V4749000 C.EL 150uF 6.3V

C29 UA953330 C.MYLAR 3300pF 50V

C30 UA655100 C.MYLAR 0.1uF 50V

C31 VG278700 C.CE.TUBLR 390pF 50V

C32 UA655100 C.MYLAR 0.1uF 50V

C33 VJ599100 C.CE.TUBLR 0.1uF 50V

C34 UA954120 C.MYLAR 0.012uF 50V

* C35 V4749000 C.EL 150uF 6.3V

C36 UA655100 C.MYLAR 0.1uF 50V

* C37 UN865220 C.EL 0.22uF 50V

C38 UA655100 C.MYLAR 0.1uF 50V

C39 VJ599100 C.CE.TUBLR 0.1uF 50V

C42 VJ599100 C.CE.TUBLR 0.1uF 50V

* New Parts * New Parts

Schm

Ref. PART NO. Description

C43 VA761400 C.CE 47pF 50V

C44 VA761400 C.CE 47pF 50V

C46 UR866100 C.EL 1uF 50V

C47 UR866100 C.EL 1uF 50V

C48 UR866100 C.EL 1uF 50V

C49 UR866100 C.EL 1uF 50V

C50 UR818470 C.EL 470uF 6.3V

C51 VJ599100 C.CE.TUBLR 0.1uF 50V

C54 VJ599100 C.CE.TUBLR 0.1uF 50V

C55 UR818100 C.EL 100uF 6.3V

C56 UR818100 C.EL 100uF 6.3V

C60 VJ599100 C.CE.TUBLR 0.1uF 50V

C62 VJ599100 C.CE.TUBLR 0.1uF 50V

C63 VJ599100 C.CE.TUBLR 0.1uF 50V

C100 UA952100 C.MYLAR 100pF 50V

* C101 V4850700 C.MYLAR 560pF 50V

* C102 V4850700 C.MYLAR 560pF 50V

C103 UA952100 C.MYLAR 100pF 50V

C104 UA954180 C.MYLAR 0.018uF 50V

C105 V2680700 C.MYLAR 3300pF 50V

C106 V2680700 C.MYLAR 3300pF 50V

C107 UA954180 C.MYLAR 0.018uF 50V

C108 VG287300 C.EL 22uF 50V

C109 VG287300 C.EL 22uF 50V

C110 UR837100 C.EL 10uF 16V

C111 UR837100 C.EL 10uF 16V

C112 UR838330 C.EL 330uF 16V

C113 VJ599000 C.CE.TUBLR 0.047uF 16V

C114 VG277700 C.CE.TUBLR 68pF 50V

C115 VG277700 C.CE.TUBLR 68pF 50V

C116 VJ599000 C.CE.TUBLR 0.047uF 16V

C117 UR838330 C.EL 330uF 16V

C118 VJ599100 C.CE.TUBLR 0.1uF 50V

C119 UA953100 C.MYLAR 1000pF 50V

C120 UA953100 C.MYLAR 1000pF 50V

C124 UR818100 C.EL 100uF 6.3V

C125 UR818100 C.EL 100uF 6.3V

C126 UR818100 C.EL 100uF 6.3V

C127 UR818100 C.EL 100uF 6.3V

C200 VJ599100 C.CE.TUBLR 0.1uF 50V

C201 UR866470 C.EL 4.7uF 50V

C202 UR866470 C.EL 4.7uF 50V

C203 UR865680 C.EL 0.68uF 50V

C204 UR818100 C.EL 100uF 6.3V

C205 UR818100 C.EL 100uF 6.3V

C206 UR866470 C.EL 4.7uF 50V

C207 UR739470 C.EL 4700uF 16V

C208 UR818100 C.EL 100uF 6.3V

C209 UR838220 C.EL 220uF 16V

C210 VG287900 C.EL 470uF 16V

C211 VG288300 C.EL 4700uF 16V

C212 UR828100 C.EL 100uF 10V

C213 UR866470 C.EL 4.7uF 50V

28

CDX-496 MAIN P.C.B.

CDX-396/496

Schm

Ref. PART NO. Description

C214 UR866470 C.EL 4.7uF 50V

C215 FG644100 C.CE 0.01uF 50V

C216 FG644100 C.CE 0.01uF 50V

C217 UR867470 C.EL 47uF 50V

C218 FG644100 C.CE 0.01uF 50V

C219 UR868100 C.EL 100uF 50V

C220 VS741700 C.CE.SAFTY 0.01uF 275V

C221 VS741700 C.CE.SAFTY 0.01uF 275V

C222 VS741700 C.CE.SAFTY 0.01uF 275V

C300 VJ599100 C.CE.TUBLR 0.1uF 50V

C301 UR818100 C.EL 100uF 6.3V

C302 VG278700 C.CE.TUBLR 390pF 50V

C303 VG278700 C.CE.TUBLR 390pF 50V

C304 VG278700 C.CE.TUBLR 390pF 50V

C305 VG278700 C.CE.TUBLR 390pF 50V

C306 UM388100 C.EL 100uF 10V

C307 VJ599100 C.CE.TUBLR 0.1uF 50V

C401 VG279100 C.CE.TUBLR 1200pF 16V

D100 VD631600 DIODE 1SS133,176,HSS104

D101 VD631600 DIODE 1SS133,176,HSS104

D200 VD631600 DIODE 1SS133,176,HSS104

D201 VD631600 DIODE 1SS133,176,HSS104

D202 VG438000 DIODE.ZENR MTZJ6.2B 6.2V

* D203 VG437000 DIODE.ZENR MTZJ4.7A 4.7V

D204 VS997800 DIODE 1T2

D205 VG437400 DIODE.ZENR MTZJ5.1B 5.1V

D206 VG442200 DIODE.ZENR MTZJ22C 22V

D207 VS997800 DIODE 1T2

D208 VS997800 DIODE 1T2

D209 VS997800 DIODE 1T2

D210 VS997800 DIODE 1T2

D211 VS997800 DIODE 1T2

D212 VS997800 DIODE 1T2

D213 VS997800 DIODE 1T2

D214 VS997800 DIODE 1T2

D215 VS997800 DIODE 1T2

D216 VS997800 DIODE 1T2

D217 VS997800 DIODE 1T2

* D250 VG438500 DIODE.ZENR MTZJ7.5A 7.5V

D300 VD631600 DIODE 1SS133,176,HSS104

D301 VD631600 DIODE 1SS133,176,HSS104

D302 VD631600 DIODE 1SS133,176,HSS104

D303 VD631600 DIODE 1SS133,176,HSS104

D304 VD631600 DIODE 1SS133,176,HSS104

HS201 VA119100 HEAT.SINK

HS202 VA119100 HEAT.SINK

* IC1 XW249A00 IC AN8882SB

* IC2 XW244A00 IC AN8785SB

* IC3 XW915A00 IC MN35511AL

IC101 XA987A00 IC NJM2068D-D

IC102 XA987A00 IC NJM2068D-D

IC105 Xi249A00 IC BA15218

IC200 XD201A00 IC M5290P

* IC300 XY240A00 IC CPU UPD78043FGF-072

* New Parts

Schm

Ref. PART NO. Description

IC301 XS070A00 IC

S-24C01ADP EEPROM

JK100 V2700900 JACK.PHONE JY-6317-03-030GD

L201 VV900900 FLTR 3071-012-0

* PJ100 V4925200 JACK.PIN 2P

Q1 iB054430 TR 2SB544 D,E,F,G

Q3 iC287820 TR 2SC2878 A,B

Q4 iC287820 TR 2SC2878 A,B

Q100 iC287820 TR 2SC2878 A,B

Q101 iC287820 TR 2SC2878 A,B

Q102 iC287820 TR 2SC2878 A,B

Q103 iC287820 TR 2SC2878 A,B

Q201 iA093320 TR 2SA933S Q,R

Q202 VS883300 TR 2SB1565 E,F

Q203 VS883400 TR 2SD2394 E,F

Q204 iA093320 TR 2SA933S Q,R

Q250 iA093320 TR 2SA933S Q,R

Q300 iA093320 TR 2SA933S Q,R

Q301 iC174020 TR 2SC1740S R,S

R118 HV755120 R.CAR.FP 120 1/4W

R125 HV755120 R.CAR.FP 120 1/4W

R203 HV755100 R.CAR.FP 100 1/4W

R206 HV755100 R.CAR.FP 100 1/4W

R208 Vi868300 R.FUS 0.68 1/6W

R217 HV755150 R.CAR.FP 150 1/4W

R401 Vi868300 R.FUS 0.68 1/6W

SW200 VZ364100 SW.PUSH SDDLD1-A2-F-1

SW201 VL908000 VOLT.SELCT ESE-370(R)

SW300 VG392900 SW.TACT SKHVAA

SW301 VG392900 SW.TACT SKHVAA

SW302 VG392900 SW.TACT SKHVAA

SW303 VG392900 SW.TACT SKHVAA

SW304 VG392900 SW.TACT SKHVAA

SW305 VG392900 SW.TACT SKHVAA

SW306 VG392900 SW.TACT SKHVAA

SW307 VG392900 SW.TACT SKHVAA

SW308 VG392900 SW.TACT SKHVAA

SW309 VG392900 SW.TACT SKHVAA

SW310 VG392900 SW.TACT SKHVAA

SW311 VG392900 SW.TACT SKHVAA

SW312 VG392900 SW.TACT SKHVAA

SW313 VG392900 SW.TACT SKHVAA

SW314 VG392900 SW.TACT SKHVAA

SW315 VG392900 SW.TACT SKHVAA

SW316 VG392900 SW.TACT SKHVAA

SW317 VG392900 SW.TACT SKHVAA

* T200 XW859A00 TRANS.PWR (R)

* T200 XW861A00 TRANS.PWR (BG)

U300 V2856200 L.DTCT PIC-28043TH2

V300 VR061600 FL.DSPLY 9-MT-133GK

XL1 VJ719800 RSNR.CRYS 16.9344MHz

XL300 VU763600 RSNR.CE 5MHz

V3750100 PIN L=50(R)

VQ948800 SHEET.FL GD

VZ156000 SPACER.FL t4x5x23

VN008600 SCR.TERM 8.3x13

New Parts

*

CDX-396/496

29

ABCDE

CDX-396/496

1

2

3

■

CDX-396 EXPLODED VIEW

60

23

69

50

5

69

63

R model only

8

9

63

2

63

60

2

(3)

67

62

13

14

21

62

11

(6)

64

21

36

63

71

37

4

200

200-1

2

(4)

70

20

1-40

55

35

2

(1)

5

1-23

1-20

66

1-31

1-40

2

(2)

6

1-25

27

1-40

61

1-3

28

27

61

1-40

63

1-26

26

7

1-22

66

1-27

30

CDX-396

■

MECHANICAL PARTS

Ref.

No. PART NO. Description Remarks Markets

1-3 MF130100 FLEXIBLE FLAT CABLE 30P 100mm

* 1-20 V4200600 FRONT PANEL BL

* 1-20 V4200700 FRONT PANEL TI

* 1-22 V4210400 WINDOW PANEL,LID

1-23 VZ494400 BUTTON 11x22 BL

1-23 VZ494500 BUTTON 11x22 TI

* 1-25 V4201400 BUTTON BL

* 1-25 V4201500 BUTTON TI

* 1-26 V4201200 BUTTON,4P BL

* 1-26 V4201300 BUTTON,4P TI

* 1-27 V4201000 BUTTON BL

* 1-27 V4201100 BUTTON TI

* 1-31 V4201600 SUPPORT,PANEL

1-40 EP630290 BIND HEAD P-TITE SCREW 3x6 FCRM3-BL

* 2 V5003700 P.C.B.ASS'Y MAIN (UC)

* 2 V5003800 P.C.B.ASS'Y MAIN (R)

* 2 V5003900 P.C.B.ASS'Y MAIN (A)

* 2 V5004000 P.C.B.ASS'Y MAIN (BG)

5 VZ573200 CD MECHANISM UNIT KSL-2130CCM

8 V2296800 POWER CORD ASS'Y (A)

8 V2363800 POWER CORD ASS'Y (UC)

8 VN363700 POWER CORD ASS'Y (G)

8 VV437300 POWER CORD ASS'Y (B)

8 VZ542500 POWER CORD ASS'Y (R)

9 V2438700 CORD STOPPER #10P1

11 V2017700 CONNECTOR,FLAT CABLE 16P 280mm

* 13 MF706120 IDC CABLE ASS'Y 6P 120mm

14 MF705120 IDC CABLE ASS'Y 5P 120mm

20 VZ151800 CHASSIS,MAIN ALL

* 21 V4410100 REAR PANEL (UC)

* 21 V4410200 REAR PANEL (R)

* 21 V4410300 REAR PANEL (BG)

* 21 V4410400 REAR PANEL (A)

23 VZ151900 TOP COVER BL

23 VZ152000 TOP COVER TI

* 26 V4200800 LID,CDX BL

* 26 V4200900 LID,CDX TI

27 VQ780300 LEG D60xH16

28 VS037900 SHEET,TRAY B

35 VU981200 SUPPORT,P.C.B.No.3596

36 VS257300 PLATE,R (R)

37 VZ262200 SUPPORT PU

50 VU590000 BINDING TIE CBTD001B

55 V2113100 SPACER

60 21991500 PW HEAD S-TITE SCREW 4x8-10 FCRM3-BL BL

60 VH313200 BW HEAD S-TITE SCREW 4x8-10 FNM3-BL TI

61 EP600250 BIND HEAD B-TITE SCREW 3x8 ZMC2-Y

62 EP630640 BIND HEAD P-TITE SCREW 3x20 FCRM3-BL

63 VN413300 BIND HEAD BONDING B-T.SCREW 3x8 MFZN2-BL

64 EP600140 BIND HEAD B-TITE SCREW 3x10 MFZN2-BL (R)

66 EP630400 FLAT HEAD B-TITE SCREW 3x6 FCRM3-BL

67 V2728500 BIND HEAD S-TITE SCREW 4x7 MFZN2-BL

69 EP600830 BIND HEAD B-TITE SCREW 3x8 FCRM3-BL

New Parts

*

31

CDX-396

Ref.

No. PART NO. Description Remarks Markets

70 V2128100 PW HEAD S-TITE SCREW 3x12-8 MFZN2-Y

71 VT669300 PW HEAD B-TITE SCREW 3x8-8 MFC2

ACCESSORIES

* 200 V4925800 REMOTE CONTROL TRANSMITTER

* 200-1 AAX13340 LID BLJYE 60050001

VS381600 PIN-PLUG CORD 2P 1.0m

BATTERY,MANGANESE SUM-3,AA,R06

CDX-396/496

New Parts

*

32

ABCDE

CDX-396/496

CDX-396/496

1

2

3

■

CDX-496 EXPLODED VIEW

60

23

69

50

5

69

63

63

R model only

2

(6)

64

21

36

63

71

8

9

63

60

2

(3)

37

67

62

13

14

21

62

11

4

5

CDX-396/496

1-20

6

63

66

1-23

26

200-1

2

(4)

1-40

1-21

200

1-40

2

(1)

70

20

27

61

2

(2)

1-40

1-3

28

66

69

1-31

1-40

55

35

27

2

(5)

61

7

1-22

33

CDX-496

■

MECHANICAL PARTS

Ref.

No. PART NO. Description Remarks Markets

1-3 MF130100 FLEXIBLE FLAT CABLE 30P 100mm

* 1-20 V4241800 FRONT PANEL BL

* 1-20 V4241900 FRONT PANEL TI

* 1-21 V4211000 PANEL,SUB BL

* 1-21 V4211100 PANEL,SUB TI

* 1-22 V4316800 WINDOW PANEL,LID

1-23 VZ494400 BUTTON 11x22 BL

1-23 VZ494500 BUTTON 11x22 TI

1-31 V2668300 SUPPORT,HP

1-40 EP630290 BIND HEAD P-TITE SCREW 3x6 FCRM3-BL

* 2 V5004200 P.C.B.ASS'Y MAIN (R)

* 2 V5004300 P.C.B.ASS'Y MAIN (BG)

5 VZ573200 CD MECHANISM UNIT KSL-2130CCM

8 VN363700 POWER CORD ASS'Y (G)

8 VV437300 POWER CORD ASS'Y (B)

8 VZ542500 POWER CORD ASS'Y (R)

9 V2438700 CORD STOPPER #10P1

11 V2017700 CONNECTOR,FLAT CABLE 16P 280mm

* 13 MF706120 IDC CABLE ASS'Y 6P 120mm

14 MF705120 IDC CABLE ASS'Y 5P 120mm

20 VZ151800 CHASSIS,MAIN ALL

* 21 V4410600 REAR PANEL (R)

* 21 V4410700 REAR PANEL (BG)

23 VZ151900 TOP COVER BL

23 VZ152000 TOP COVER TI

* 26 V4200800 LID,CDX BL

* 26 V4200900 LID,CDX TI

27 VQ780300 LEG D60xH16

28 VS037900 SHEET,TRAY B

35 VU981200 SUPPORT,P.C.B.No.3596

36 VS257300 PLATE,R (R)

37 VZ262200 SUPPORT PU

50 VU590000 BINDING TIE CBTD001B

55 V2113100 SPACER

60 21991500 PW HEAD S-TITE SCREW 4x8-10 FCRM3-BL BL

60 VH313200 BW HEAD S-TITE SCREW 4x8-10 FNM3-BL TI

61 EP600250 BIND HEAD B-TITE SCREW 3x8 ZMC2-Y

62 EP630640 BIND HEAD P-TITE SCREW 3x20 FCRM3-BL

63 VN413300 BIND HEAD BONDING B-T.SCREW 3x8 MFZN2-BL

64 EP600140 BIND HEAD B-TITE SCREW 3x10 MFZN2-BL (R)

66 EP630400 FLAT HEAD B-TITE SCREW 3x6 FCRM3-BL

67 V2728500 BIND HEAD S-TITE SCREW 4x7 MFZN2-BL

69 EP600830 BIND HEAD B-TITE SCREW 3x8 FCRM3-BL

70 V2128100 PW HEAD S-TITE SCREW 3x12-8 MFZN2-Y

71 VT669300 PW HEAD B-TITE SCREW 3x8-8 MFC2

34

ACCESSORIES

* 200 V4925900 REMOTE CONTROL TRANSMITTER

200-1 AAX13340 LID BLJYE 60050001

VS381600 PIN-PLUG CORD 2P 1.0m

BATTERY,MANGANESE SUM-3,AA,R06

New Parts

*

ABCDE

COMMON

1

2

3

■

EXPLODED VIEW

(CD Mechanism Unit)

4

Stopper

5

6

* The stopper is not supplied with the tray as a spare part.

7

35

When replacing the tray, keep the removed stopper and reuse it.

Should it be lost and a new one be necessary, order service part 18 Main Chassis (S) and remove the stopper

only from it and use it as a spare part.

■

MECHANICAL PARTS

Ref.

No. PART NO. Description Remarks Markets

VZ573200 CD MECHANISM UNIT KSL-2130CCM

1 CX680620 TRAY (C) 2130 264629001

3 CX675250 GEAR COVER (S) 262554401

4 CX675210 TRAY GEAR (S) 262553501

5 AX619150 CHUCKING PLATE (S) 262554601

6 EX602890 BW HEAD P-TITE SCREW 2.6x7 262629401

7 BX602660 CHUCKING YOKE (S) 262553701

8 NX610570 MAGNET ASS'Y 145249321

9 CX675240 DAMPER (S) 262554102

10 NX636010 CHUCKING PULLEY 264629101

11 AX624650 SUB CHASSIS ASS'Y (S) 264628801

12 AX624640 COIL, SPRING (F) 264723601

13 AX624630 COIL, SPRING (R) 262723501

14 AX624660 WASHER 2130 264628901

15 EX604270 P-TITE SCREW 2.6x10 768513511

16 AX624620 INSULATOR 262723401

18 AX619160 MAIN CHASSIS (S), OUTSERT 262555206

19 VH554700 BW HEAD P-TITE SCREW 2.6x16 331950151

20 CX675270 DRIVE GEAR (S) 262554701

21 CX675260 CONTROL CAM (S) 262554504

22 KX604780 LEAF SWITCH 169266711

23 LX608390 CONNECTOR PIN 5P 156472111

24 NX613050 PWB, LOADING (S) 164052311

25 JX601470 LOADING MOTOR ASS'Y X26251171

26 CX675200 CENTER GEAR (S) 262527402

27 CX675220 LOADING PULLEY (S) 262553602

28 CX610840 BELT, LOADING MOTOR 365338700

29 EX602880 SCREW 2.6x2.5 262527901

CDX-396/496

COMMON

(CD Mechanism Unit)

New Parts

*

CDX-396/496

36

ABCDE

CDX-396/496

1

2

3

■

EXPLODED VIEW

10

(Drive Unit)

COMMON

9

4

5

Ref.

No. PART NO. Description Remarks Markets

6