Yale GP80VX, GLP80VX, GDP80VX, GP90VX, GLP90VX Repair Manual

...

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/GDP100VX, GP/GLP/

GDP110VX, GP/GLP/GDP120VX (J813)

SERVICE MANUAL CONTENTS

PART

SECTION

FRAME............................................................................................................................ 524262274 0100 YRM 1243 05/14

OPERATOR'S CAB........................................................................................................ 524306203 0100 YRM 1290 04/14

GM 4.3L V-6 ENGINES................................................................................................... 524265337 0600 YRM 1251 05/14

KUBOTA ENGINE REPAIR............................................................................................ 550048607 0600 YRM 1557 03/13

KUBOTA DIESEL 3.6L ENGINE.................................................................................... 550055279 0600 YRM 1579 01/14

COOLING SYSTEM........................................................................................................ 524223757 0700 YRM 1123 03/13

LPG FUEL SYSTEM GM 4.3L ENGINE WITH PSI........................................................ 550043871 0900 YRM 1556 04/14

GASOLINE FUEL SYSTEM............................................................................................ 550048401 0900 YRM 1570 09/13

1 AND 2 SP PS TRANSMISSION REPAIR.................................................................... 550048681 1300 YRM 1569 08/13

DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 524262278 1400 YRM 1246 12/13

DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 550055280 1400 YRM 1582 12/13

STEERING AXLE............................................................................................................ 524223764 1600 YRM 1133 07/13

WET BRAKES - NMHG.................................................................................................. 550064329 1800 YRM 1597 12/13

HYDRAULIC GEAR PUMP............................................................................................. 524223766 1900 YRM 1136 04/14

HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14

MAIN CONTROL VALVE................................................................................................ 524223767 2000 YRM 1137 04/14

CYLINDER REPAIR (MAST S/N A551, A555, A559, A661, A662, A663, A66, B507,

B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515,

C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND

E564)..........................................................................................................................

HIGH VOLTAGE SWITCH (HVS) IGNITION.................................................................. 524208014 2200 YRM 1097 05/14

WIRE HARNESS REPAIR.............................................................................................. 524223769 2200 YRM 1128 12/14

USER INTERFACE......................................................................................................... 524223770 2200 YRM 1130 12/14

USER INTERFACE......................................................................................................... 524223771 2200 YRM 1131 12/14

ELECTRICAL SYSTEM.................................................................................................. 524223772 2200 YRM 1142 04/14

MAST REPAIRS (S/N A513, A514, A613, A614, A702, A703, A704, A705, A706,

A707, A751, A752, B513, B514, B586, B587, B588, B589, B590, B591, B749,

B750, B751, B752, B753, B754)................................................................................ 524265342 4000 YRM 1250 02/14

METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13

CALIBRATION PROCEDURES...................................................................................... 524223780 8000 YRM 1134 12/14

DIAGRAMS AND SCHEMATICS.................................................................................... 550055283 8000 YRM 1585 04/14

PERIODIC MAINTENANCE............................................................................................ 550068685 8000 YRM 1604 12/13

CAPACITIES AND SPECIFICATIONS........................................................................... 550068693 8000 YRM 1605 07/14

DIAGRAMS AND SCHEMATICS.................................................................................... 550096331 8000 YRM 1689 04/14

DIAGNOSTIC TROUBLESHOOTING MANUAL............................................................ 524221866 9000 YRM 1112 12/14

NUMBER

524223768 2100 YRM 1139 02/14

YRM

NUMBER

REV

DATE

9000 YRM 1112 ON CD

PART NO. 550069027 (12/14)

SAFETY PRECAUTIONS

MAINTENANCE AND REPAIR

• The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the

product. Updated technical service information may be available from your local authorized Yale® dealer.

Service Manuals provide general guidelines for maintenance and service and are intended for use by

trained and experienced technicians. Failure to properly maintain equipment or to follow instructions contained in the Service Manual could result in damage to the products, personal injury, property damage or

death.

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the

load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the

weight of the load.

• Do not lift heavy parts by hand, use a lifting mechanism.

• Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift

trucks. Disconnect the battery ground cable on internal combustion lift trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK

ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

• Keep the unit clean and the working area clean and orderly.

• Use the correct tools for the job.

• Keep the tools clean and in good condition.

• Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the

specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit

needs repairs.

• Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable.

Be sure to follow the necessary safety precautions when handling these fuels and when working on these

fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area.

Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury and property damage.

On the lift truck, the WARNING symbol and word are on orange background. The CAUTION symbol and word are on yellow background.

Table of Contents

TABLE OF CONTENTS

General ..................................................................................................................................................................... 1

Description ................................................................................................................................................................2

Hood, Seat, and Side Covers Replacement ............................................................................................................. 4

Remove ................................................................................................................................................................ 4

Install .................................................................................................................................................................... 4

Steering Column ..................................................................................................................................................... 12

Description ..........................................................................................................................................................12

Steering Column Repair ..................................................................................................................................... 12

Remove ..........................................................................................................................................................12

Disassemble ...................................................................................................................................................13

Clean ..............................................................................................................................................................16

Inspect ............................................................................................................................................................16

Assemble ....................................................................................................................................................... 16

Install ..............................................................................................................................................................16

LPG Tank and Bracket Replacement ..................................................................................................................... 17

Counterweight Replacement .................................................................................................................................. 17

Remove .............................................................................................................................................................. 17

Install .................................................................................................................................................................. 20

Tow Pin ...............................................................................................................................................................24

Remove and Install For Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/

GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813)................ 24

Remove and Install For Lift Truck Models GLC55SVX (GC/GLC80XVBCS, GC/

GLC100VXBCS; GC/GLC120SVX; and GC/GLC120VXPRS) (E818, F818) and GLP/

GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/

GDP080, 090, 100, 110, 120VX) (J813)......................................................................................................... 24

Overhead Guard Replacement ...............................................................................................................................25

Remove .............................................................................................................................................................. 25

Install .................................................................................................................................................................. 25

LED Tail, Backup, and Brake Lights, Replace ....................................................................................................26

Operator Restraint System Replacement ............................................................................................................... 26

Description ..........................................................................................................................................................26

Engine Replacement .............................................................................................................................................. 28

Remove Engine Only ..........................................................................................................................................28

Install Engine only .............................................................................................................................................. 56

Remove Engine and Transmission .....................................................................................................................60

Install Engine and Transmission .........................................................................................................................65

Electronic Throttle Replacement .............................................................................................................................69

Cummins 4.5L Diesel Engine With Electronic Throttle .......................................................................................69

Remove ..........................................................................................................................................................69

Install ..............................................................................................................................................................69

Pull Actuator Linkage Adjustment .................................................................................................................. 74

Low Idle Adjustment .......................................................................................................................................75

Throttle Pedal and Cable Adjustment ..................................................................................................................... 75

Cummins 4.5L Diesel Engine with Basic Power Shift Transmission .................................................................. 75

Kubota 3.6L Diesel Engine .................................................................................................................................75

Exhaust System Repair .......................................................................................................................................... 78

GM 4.3L Engine for Lift Truck Models and GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100,

120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818)..................................78

Cummins 4.5L Diesel Engine for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5,

GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813)..................................78

©2014 Yale Materials Handling Corp.

i

Table of Contents

TABLE OF CONTENTS (Continued)

Remove ..........................................................................................................................................................78

Inspect ............................................................................................................................................................78

Install ..............................................................................................................................................................78

Cummins QSB 3.3L Engine for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5,

GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (G813)................................. 80

Remove ..........................................................................................................................................................80

Inspect ............................................................................................................................................................82

Install ..............................................................................................................................................................82

Kubota Diesel Engine for Lift Truck Models and Equipped with Kubota 3.6L Diesel Engine

GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/

GDP080, 090, 100, 110, 120VX) (H813).............................................................................................................82

Remove ..........................................................................................................................................................82

Inspect ............................................................................................................................................................84

Install ..............................................................................................................................................................84

Kubota Diesel Engine for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/

GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (J813).......................................... 84

Remove ..........................................................................................................................................................84

Inspect ............................................................................................................................................................87

Diesel Particulate Filter .................................................................................................................................. 89

Disassemble .............................................................................................................................................. 89

CLEAN AND INSPECT ..............................................................................................................................90

Assembly ................................................................................................................................................... 91

Install ..............................................................................................................................................................91

Cooling System .......................................................................................................................................................92

Description ..........................................................................................................................................................92

Hydraulic Filter Assembly Repair ............................................................................................................................93

Remove .............................................................................................................................................................. 93

Disassemble .......................................................................................................................................................93

Clean .................................................................................................................................................................. 94

Inspect ................................................................................................................................................................94

Assemble ............................................................................................................................................................94

Install .................................................................................................................................................................. 94

Fuel and Hydraulic Tanks Repair ........................................................................................................................... 94

Inspect ................................................................................................................................................................94

Clean .................................................................................................................................................................. 95

Steam Method of Cleaning .............................................................................................................................95

Chemical Solution Method of Cleaning .......................................................................................................... 96

Additional Preparations for Repair ......................................................................................................................96

Small Leaks, Repair ........................................................................................................................................... 96

Large Leaks, Repair ........................................................................................................................................... 96

Preparations for Use After Repair ...................................................................................................................... 96

Safety Labels .......................................................................................................................................................... 97

This section is for the following models:

GLC40, 45, 55VX; GLC55SVX (GC/GLC080, 100, 120VX; GC/GLC080,

100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) [E818, F818];

GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX

(GP/GLP/GDP080, 090, 100, 110, 120VX) [F813, G813, H813, J813]

ii

0100 YRM 1243 General

General

If additional engine repairs are necessary for lift trucks

WARNING

The lift truck must be put on blocks for some

types of maintenance and repairs. The removal of

the following assemblies will cause large changes

in the center of gravity: mast, drive axle, engine

and transmission, and counterweight. When the

lift truck is put on blocks, put additional blocks in

the following positions to maintain stability:

• Before removing the mast and drive axle,

put blocks under the counterweight so the

lift truck cannot fall backward.

• Before removing the counterweight, put

blocks under the mast assembly so the lift

truck cannot fall forward.

The surface must be solid, even, and level when

the lift truck is put on blocks. Make sure any

blocks used to support the lift truck are solid,

one-piece units. See the procedure How to Put Lift

Truck on Blocks in the Operating Manual or the

Periodic Maintenance section for your lift truck.

covered in this manual see:

• GM 4.3L V-6 Engines 0600YRM1251

• Kubota Diesel 3.8L Engines 0600YRM1557

• Kubota Diesel 3.6L Engine 0600YRM1579

If additional transmission repairs are necessary for lift

trucks covered in this manual see:

• Powershift Transmission 1300YRM1129

• Powershift Transmission 1300YRM1529

• One and Two Speed Transmissions

1300YRM1569

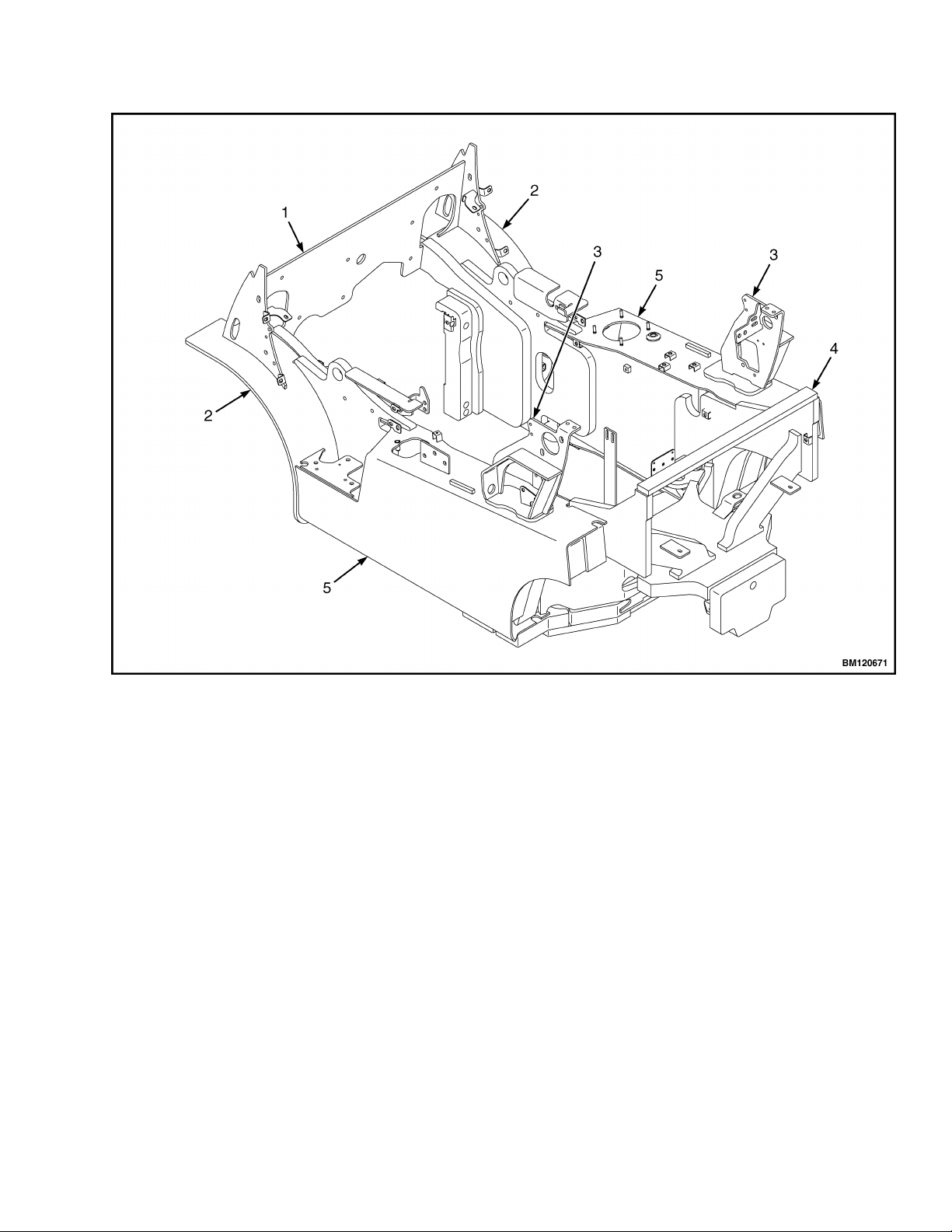

This section contains the description of the frame (see

Figure 1 or Figure 2) and connected parts.

Procedures for removing and installing the

counterweight, hood, overhead guard, engine and

transmission, and exhaust system are found in this

section. Checks for the operator restraint system and

procedures for the repair of tanks and installation of

safety labels are also included.

1

Description 0100 YRM 1243

Description

The frame is one weldment and includes the hydraulic

tank and fuel tank for gasoline or diesel fuel. See Figure 1 or Figure 2.

There is a counterweight for each capacity of lift truck.

The counterweights are similar in appearance, but are

different weights. See Table 2.

The muffler is fastened to the frame inside the counterweight.

The overhead guard, cowl, and hood are installed on

the frame. The hood is connected to the frame with

hinges. Two gas-controlled springs provide assistance when raising the hood and hold the hood in the

open position. The floor plate and side covers can be

removed for access to the engine, transmission, and

other components.

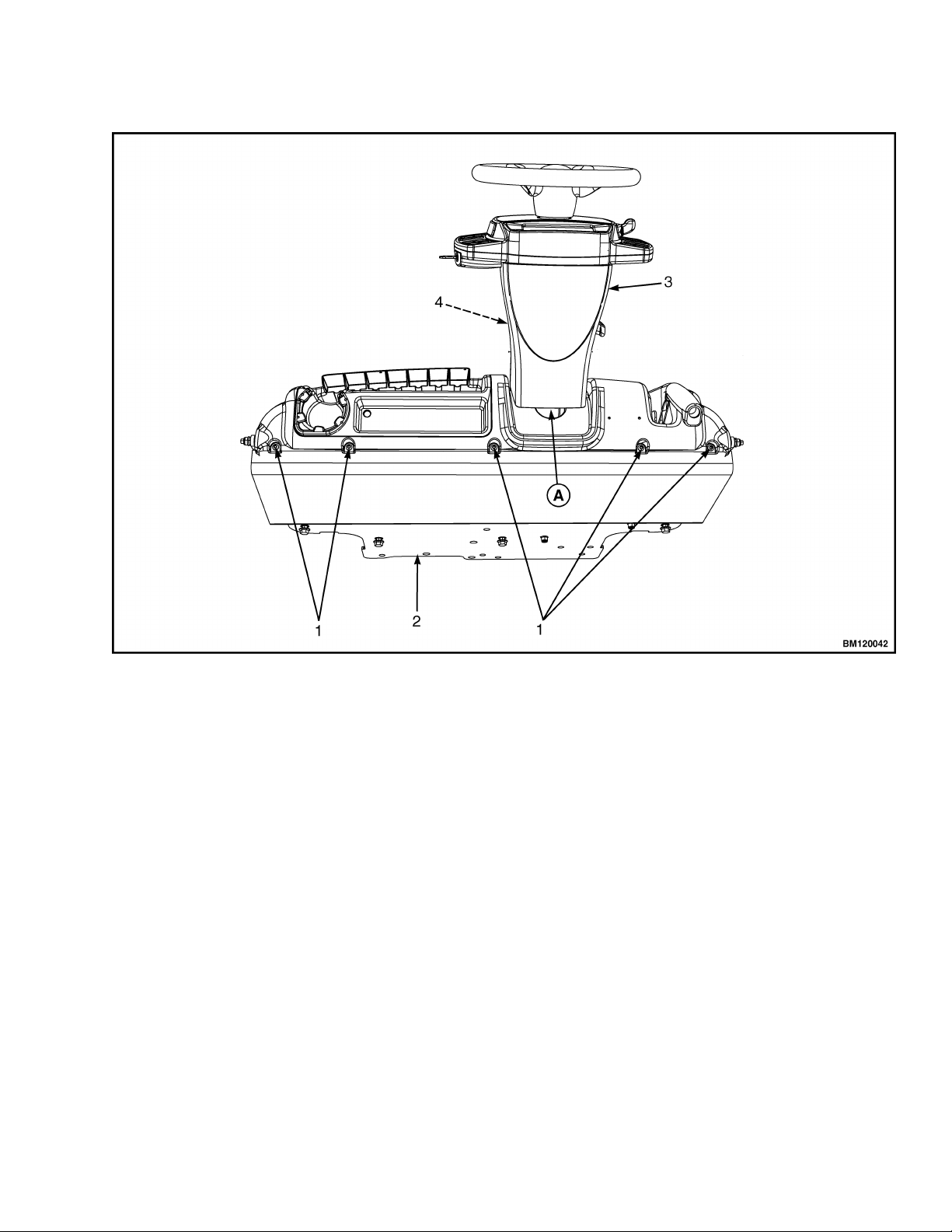

1. COWL PLATE

2. FENDERS

3. HOOD MOUNTS

2

4. COUNTERWEIGHT MOUNTS

5. HYDRAULIC TANK

6. FUEL TANK (GAS OR DIESEL)

Figure 1. Frame for Lift Trucks with Single Hydraulic Tank

0100 YRM 1243 Description

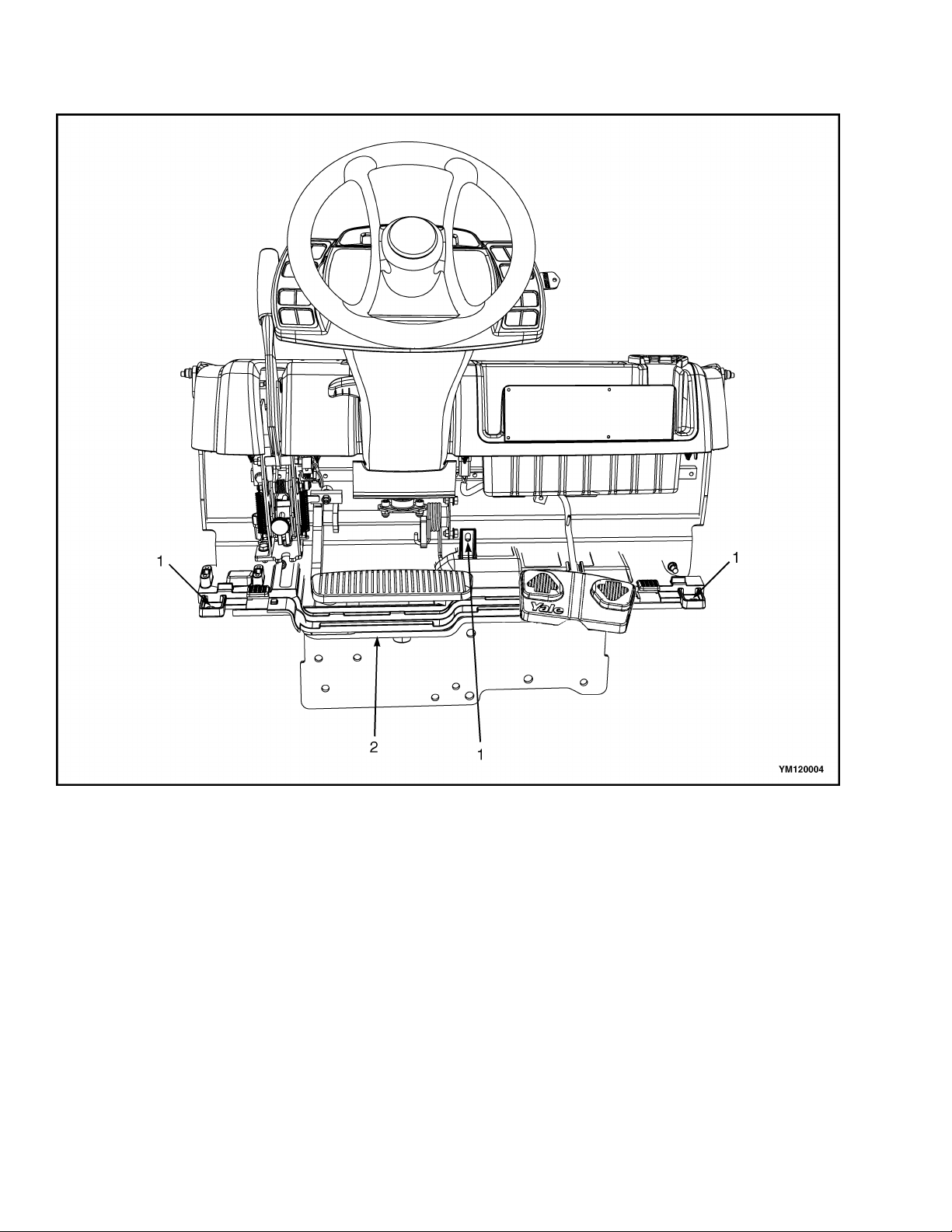

1. COWL PLATE

2. FENDERS

3. HOOD MOUNTS

4. COUNTERWEIGHT MOUNTS

5. HYDRAULIC TANKS

Figure 2. Frame for Lift Trucks with Dual Hydraulic Tanks

3

Hood, Seat, and Side Covers Replacement 0100 YRM 1243

Hood, Seat, and Side Covers Replacement

REMOVE

1. Slide seat to the closest position to steering col-

umn.

2. Fully tilt steering column forward.

3. If your truck is equipped with an LPG tank, swing

tank off to the side.

4. Raise latch on the left, front corner of hood to un-

latch and lift up hood. See Figure 3.

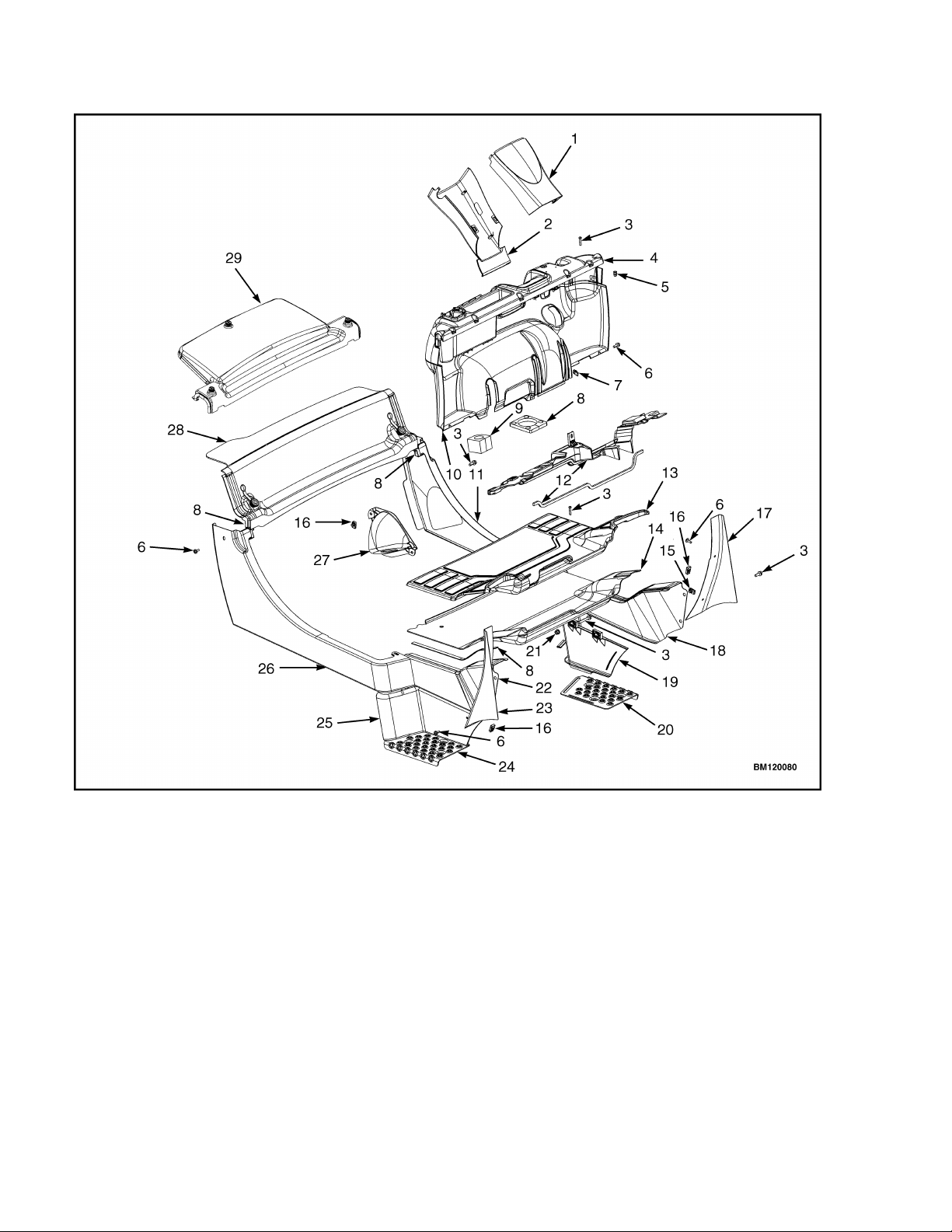

5. Remove floor mat and floor plate. See Figure 4.

6. Remove two capscrews holding left and right rear

side covers to the frame. Remove rear side covers from frame. See Figure 4.

7. Remove two capscrews holding left and right

fender covers to front overhead guard leg. Remove covers. See Figure 4.

8. Remove four capscrews holding left and right

front side covers to frame. Remove covers.

9. Fully lower the steering column.

10. Remove upper steering column cover by pulling

up on upper steering column cover to release

latches (one on either side), and pulling cover

away from steering column. See Figure 5.

CAUTION

When removing the seat from the hood, DO NOT

use an impact wrench to remove the capscrews.

Damage can be caused to the threads on the

screws and in the holes.

15. If seat is to be removed, and truck is equipped

with a non-swivel seat, remove seat wire harness

from seat wire harness brackets that are attached

to the underside of hood. Remove the cable clips

from the seat wire harness. If truck is equipped

with a swivel seat, remove seat wire harness from

seat wire harness bracket attached to underside

of hood and behind the seat. See Figure 3.

16. Remove four capscrews and washers holding

seat to the hood. Lift seat off the hood. Pull seat

wire harness through hood. See Figure 3.

17. Remove capscrews and washers at top of the gas

springs. Remove gas springs from hood.

18. Remove hinge screws, located in the rear of the

hood.

19. Lift hood from the truck. See Figure 3.

INSTALL

1. Place hood onto the lift truck frame.

11. Remove five fasteners (see Figure 5) securing

dash to the top of cowl. Remove four clips, located underneath dash, that attach dash to the kick

panel. Lift to remove dash.

12. Lift kick panel to remove it from truck. See Fig-

ure 4.

13. Remove three capscrews holding the seal plate.

Remove seal plate. See Figure 6.

14. Disconnect seat wire harness connector. See Fig-

ure 3.

4

2. Install hinge screws, located in the rear of the

hood, and tighten to 38 N•m (28 lbf ft). See Figure 3.

3. Align top holes in the gas springs with holes in

hood. There are two sets of holes used to install

the gas springs to hood, based on the type of seat

installed on lift truck. One set is for installing the

cylinder end of the gas springs and the other set

is for attaching the rod end of the gas springs. Install capscrews and washers to attach gas

springs to the hood. Refer to Figure 7 and Table 1

for correct holes used to connect the rod end of

the cylinder, depending on the type of seat installed on the lift truck. Tighten capscrews to

19.2 N•m (170 lbf in).

0100 YRM 1243 Hood, Seat, and Side Covers Replacement

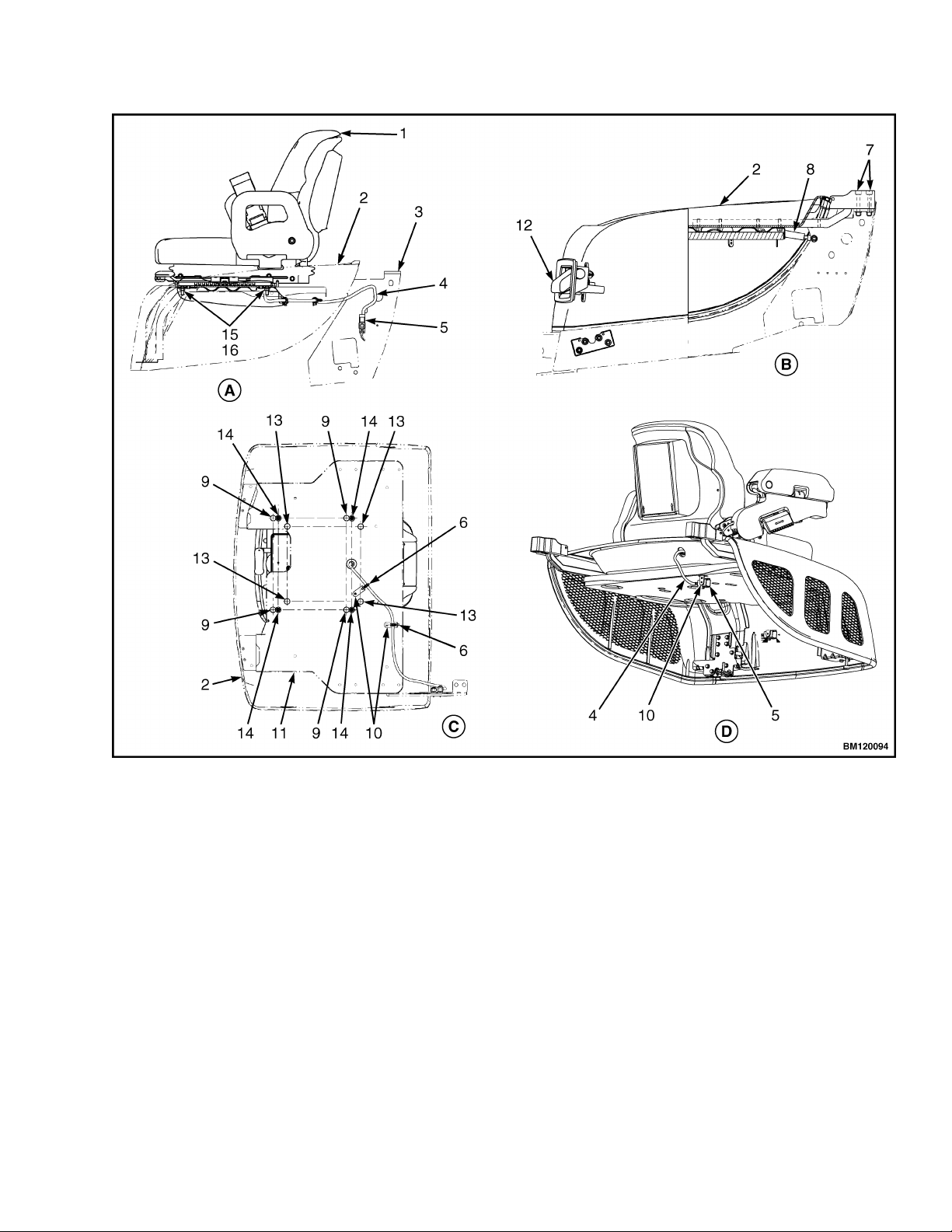

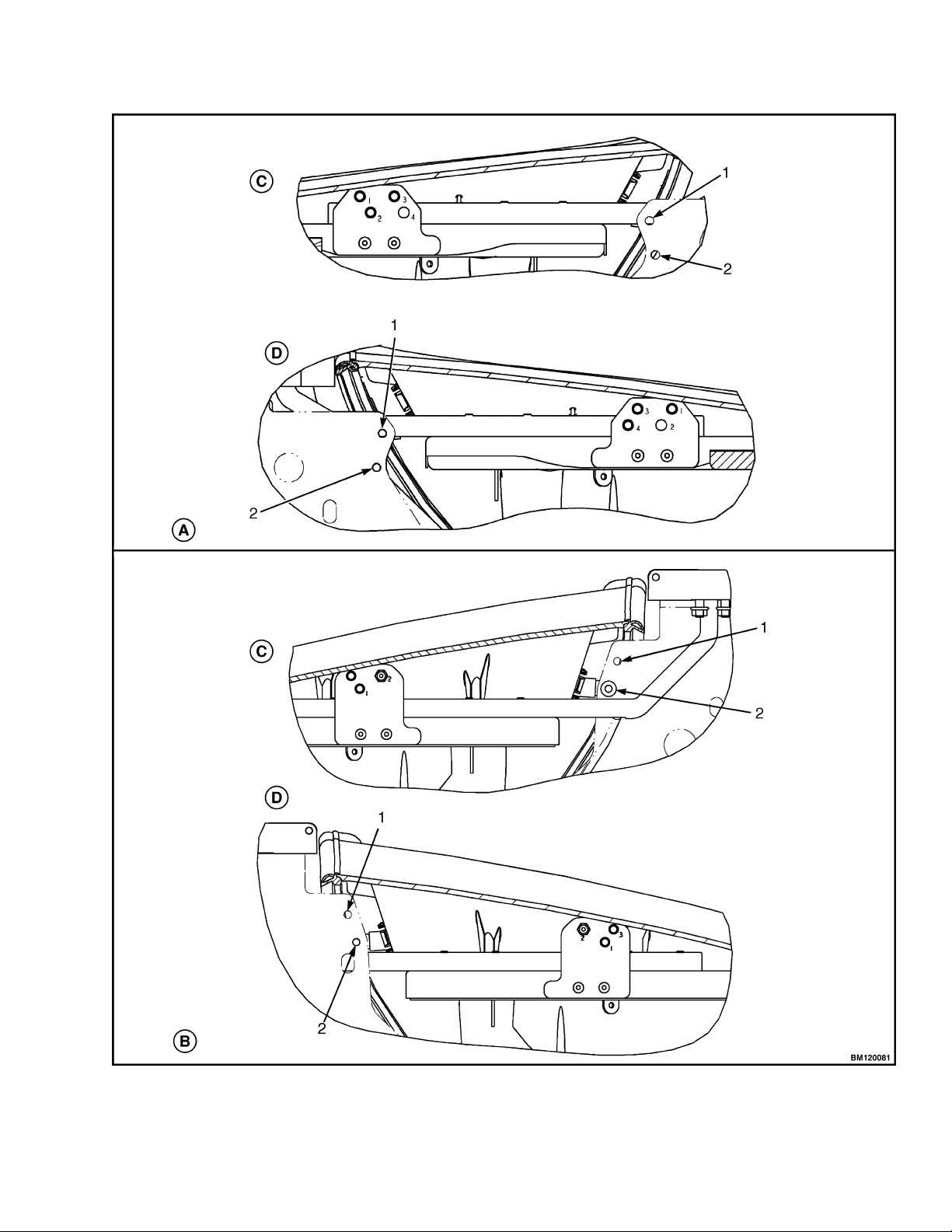

NOTE: SWIVEL SEAT AND VENTED HOOD ARE OPTIONAL FEATURES.

A. SIDE VIEW OF HOOD AND SEAT

B. SIDE VIEW OF HOOD

1. SEAT

2. HOOD

3. FRAME

4. SEAT WIRE HARNESS

5. SEAT WIRE HARNESS CONNECTOR

6. CABLE CLIPS

7. HINGE SCREWS

8. GAS SPRING

9. ATTACHMENT HOLES ATTACHING HOOD TO

SEAT (SEMI-SUSPENSION)

Figure 3. Hood and Seat Arrangement

C. BOTTOM VIEW OF HOOD

D. SIDE VIEW OF VENTED HOOD WITH SWIVEL

SEAT

10. SEAT WIRE HARNESS BRACKETS

11. SEAT LINER

12. HOOD LATCH

13. ATTACHMENT HOLES ATTACHING HOOD TO

SEAT (NON-SUSPENSION)

14. ATTACHMENT HOLES ATTACHING HOOD TO

SEAT (FULL SUSPENSION)

15. SPACER

16. FLANGE NUT

5

Hood, Seat, and Side Covers Replacement 0100 YRM 1243

1. UPPER STEERING COLUMN COVER

2. LOWER STEERING COLUMN COVER

3. CAPSCREW

4. DASH ASSEMBLY

5. INSERT

6. SCREW

7. CLIP

8. SEAL

9. GROMMET

10. KICK PANEL

11. LEFT REAR SIDE COVER

12. SEAL PLATE ASSEMBLY

13. FLOOR MAT

14. FLOOR PLATE

15. CLIP NUT

16. FOLDOVER NUT

17. LEFT FENDER COVER

18. LEFT FRONT SIDE COVER

Figure 4. Side Covers, Floor Plate, and Cowl Components

6

19. LEFT PANEL

20. LEFT STEP PLATE

21. LOCK NUT

22. RIGHT FRONT SIDE COVER

23. RIGHT FENDER COVER

24. RIGHT STEP PLATE

25. RIGHT PANEL

26. RIGHT REAR SIDE COVER

27. SPLASH SHIELD

28. RADIATOR COVER GLC40, 45, 55VX;

GLC55SVX; (GC/GLC080, 100, 120VX; GC/

GLC080, 100VXBCS; GC/GLC120SVX; GC/

GLC120VXPRS) (E818, F818)

29. RADIATOR COVER (GLP/GDP40VX5/VX6; GLP/

GDP45SVX5, GLP/GDP45VX6; GLP/

GDP50-55VX (GP/GLP/GDP080, 090, 100, 110,

120VX) (F813, G813, H813, J813)

0100 YRM 1243 Hood, Seat, and Side Covers Replacement

NOTE: TOP VIEW OF DASH SHOWN.

A. INDICATES TO PULL UP TO UNLATCH

1. ALLEN SCREWS

2. COWL

Figure 5. Remove Dash From Cowl

3. UPPER STEERING COLUMN COVER

4. LOWER STEERING COLUMN COVER

7

Hood, Seat, and Side Covers Replacement 0100 YRM 1243

1. CAPSCREWS 2. SEAL PLATE

Figure 6. Remove Seal Plate From Dash

8

0100 YRM 1243 Hood, Seat, and Side Covers Replacement

Figure 7. Gas Spring Installation

9

Hood, Seat, and Side Covers Replacement 0100 YRM 1243

Legend for Figure 7

NOTE: SEE TABLE 1 FOR HOLES TO USE TO ATTACH ROD END OF GAS SPRING.

A. GLC40, 45, 55VX; GLC55SVX; (GC/GLC080,

100, 120VX; GC/GLC080, 100VXBCS; GC/

GLC120SVX; GC/GLC120VXPRS) (E818, F818)

B. GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/

GDP45VX6; GLP/GDP50-55VX (GP/GLP/

GDP080, 090, 100, 110, 120VX) (F813, G813,

H813, J813)

1. MOUNTING LOCATION FOR CYLINDER END OF GAS SPRING FOR NON-SUSPENSION SEAT

2. MOUNTING LOCATION FOR CYLINDER END OF GAS SPRING FOR SEMI OR FULL SUSPENSION SEAT

Table 1. Gas Spring Installation, Holes for Installing Rod Ends (See Figure 7)

Counterweight

Type

Standard

Counterweight

GLC40, 45, 50, 55VX

(GC/GLC080, 100,

120VX) (E818, F818)

Standard

Counterweight GLP/

GDP40VX5/VX6;

GLP/GDP45SVX5,

GLP/GDP45VX6;

GLP/GDP50-55VX

(GP/GLP/GDP080,

090, 100, 110,

120VX) (F813, G813,

H813, J813)

BCS and PRS

Counterweights

GLC55SVX (GC/

GLC080,

100VXBCS, GC/

GLC120SVX; GC/

GLC120VXPRS)

(E818, F818)

Full or Semi Suspension Seat Non-Suspension Seat

Left Side Right Side Left Side Right Side

3 3 1 1

2 2 1 1

2 4 2 4

C. LEFT SIDE

D. RIGHT SIDE

10

0100 YRM 1243 Steering Column

4. Install latch striker in highest slot position. Check

that latch striker is in center of jaws of hood latch

when hood closes. Open and close hood to ensure that center pin strikes hood latch properly

and that the stop screw contacts the frame. A

properly closed hood MUST click twice on the

hood latch. If the hood latch does not close properly, loosen capscrews on the back of center pin

and adjust center pin up or down as required for

correct alignment. See Figure 8.

5. Push down until hood just touches rubber

bumper. Make sure latch striker is still in center of

hood latch. Open hood and tighten capscrews for

latch.

6. Check operation of hood latch. Have an operator

sit in seat. Make sure hood is fully closed (two

clicks). Also check that hood touches rubber

bumper. If necessary, repeat Step 5.

CAUTION

When installing the seat to the hood, DO NOT use

an impact wrench to install the capscrews. Damage can be caused to the threads on the screws

and in the holes.

7. Place seat on the hood and thread seat wire har-

ness through the hole in the hood. See Figure 3.

8. Align holes in the seat with the holes in hood. In-

sert washers and capscrews. Tighten capscrews

to 18 N•m (159 lbf in).

9. If truck is equipped with a non-swivel seat, tie ca-

ble clips to seat wire harness and insert harness

into seat wire harness brackets under hood. If

truck is equipped with a swivel seat, secure seat

harness to bracket. See Figure 3.

10. Install seal plate using three capscrews. See Fig-

ure 6.

1. HOOD

2. HOOD LATCH

Figure 8. Hood Latch Adjustment

11. Install kick panel onto truck. See Figure 4.

12. Install dash to top of cowl. See Figure 5. Install

four clips to attach dash to kick panel.

13. Install upper steering column cover to dash.

14. Using four capscrews, install left and right front

side covers to frame. See Figure 4.

15. Using two capscrews, install left and right fender

covers to front of overhead guard legs.

16. Using two capscrews, install left and right rear

side covers to frame. See Figure 4.

17. Install floor mat and floor plate.

18. If truck is equipped with an LPG tank, swing LPG

tank into position on back of counterweight.

19. Adjust the steering column and seat positions.

3. CENTER PIN

4. CAPSCREW

11

Steering Column 0100 YRM 1243

Steering Column

DESCRIPTION

This section describes the repair procedures for the

steering column. The steering column assembly

mounts to the cowl inside the operator compartment

and is the mechanical connection between the steering wheel and the steering control unit. The steering

column includes the steering wheel, housing, bracket

and lower shaft. For lift trucks with gas and LPG engines, bolts and bushings attach the steering column

to the cowl standoffs. For lift trucks with diesel engines, bolts, bushings and isolators attach the steering column to the cowl standoffs. See Figure 9.

STEERING COLUMN REPAIR

Remove

1. Put blocks on each side (front and back) of tires

to prevent lift truck from moving.

WARNING

Disconnect the battery before removing any covers to avoid injury to personnel.

2. Attach a tag on battery connector or negative bat-

tery cable stating, DO NOT CONNECT BATTERY. Move steering column to most FORWARD

position.

CAUTION

If a puller tool is used to remove steering wheel

from steering column, be careful not to damage

horn wires.

NOTE: This procedure is for removal of all compo-

nents of steering column assembly. Not all components are removed for a repair procedure. Do only

those steps of procedure necessary to remove required component.

NOTE: Tag wires prior to disconnect.

3. Remove horn button assembly and disconnect

electrical wires. Remove large hex nut and steering wheel from steering column. See Figure 10.

4. Remove steering column covers. Remove floor

mats and floor plate. See section Hood, Seat, and

Side Covers Replacement.

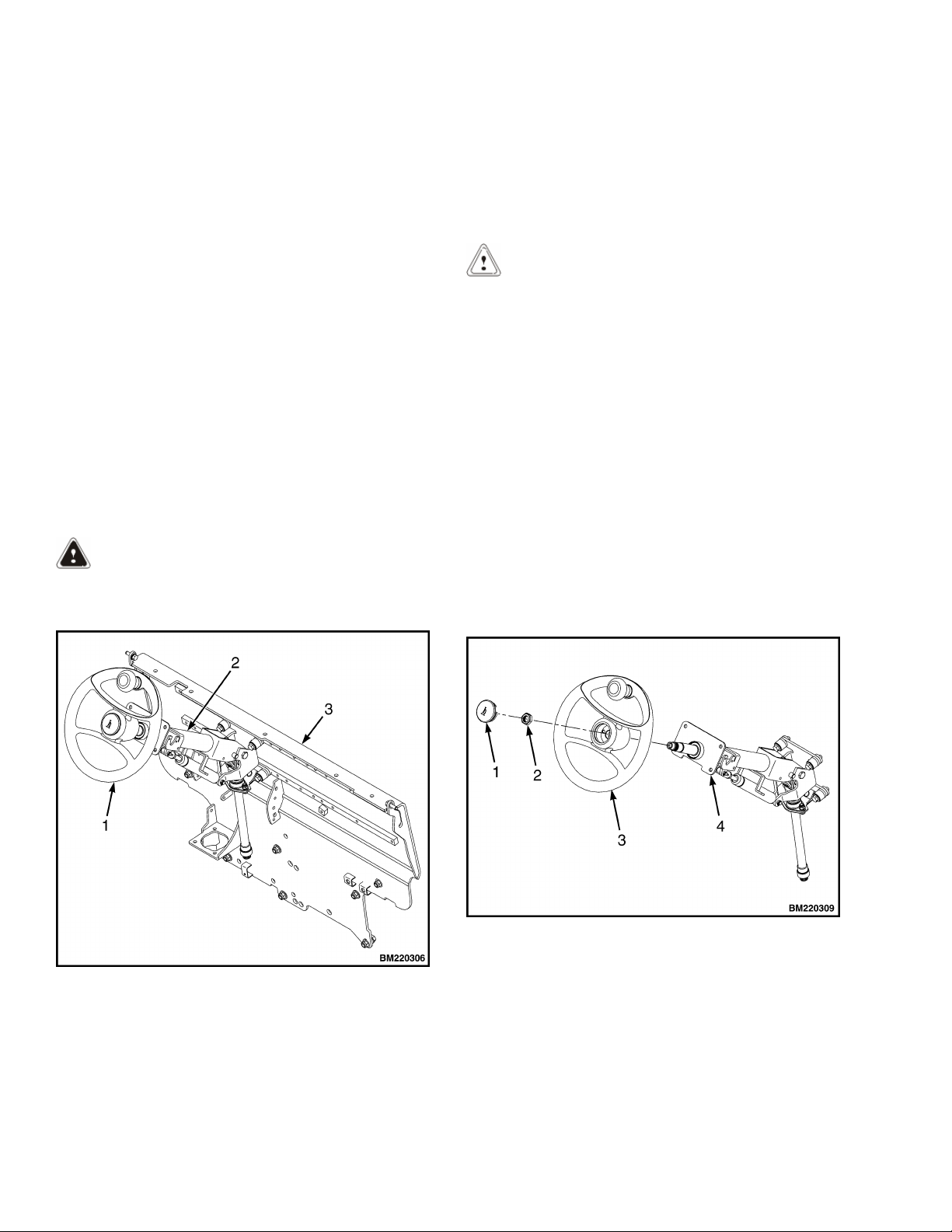

NOTE: DIESEL SHOWN, LPG AND GAS SIMILAR.

1. STEERING WHEEL

2. STEERING COLUMN

3. COWL

Figure 9. Steering Column and Cowl

12

1. HORN BUTTON

2. HEX NUT

3. STEERING WHEEL

4. STEERING COLUMN

Figure 10. Steering Wheel Remove/Install

0100 YRM 1243 Steering Column

NOTE: Perform Step 5 for lift trucks equipped with

gas or LPG engines.

5. Remove four capscrews, four bushings and steer-

ing column from cowl standoffs. See Figure 11.

NOTE: Perform Step 6 for lift trucks equipped with

diesel engines.

6. Remove four capscrews, four bushings, four iso-

lators, steering column and four isolators from

cowl standoffs. See Figure 11.

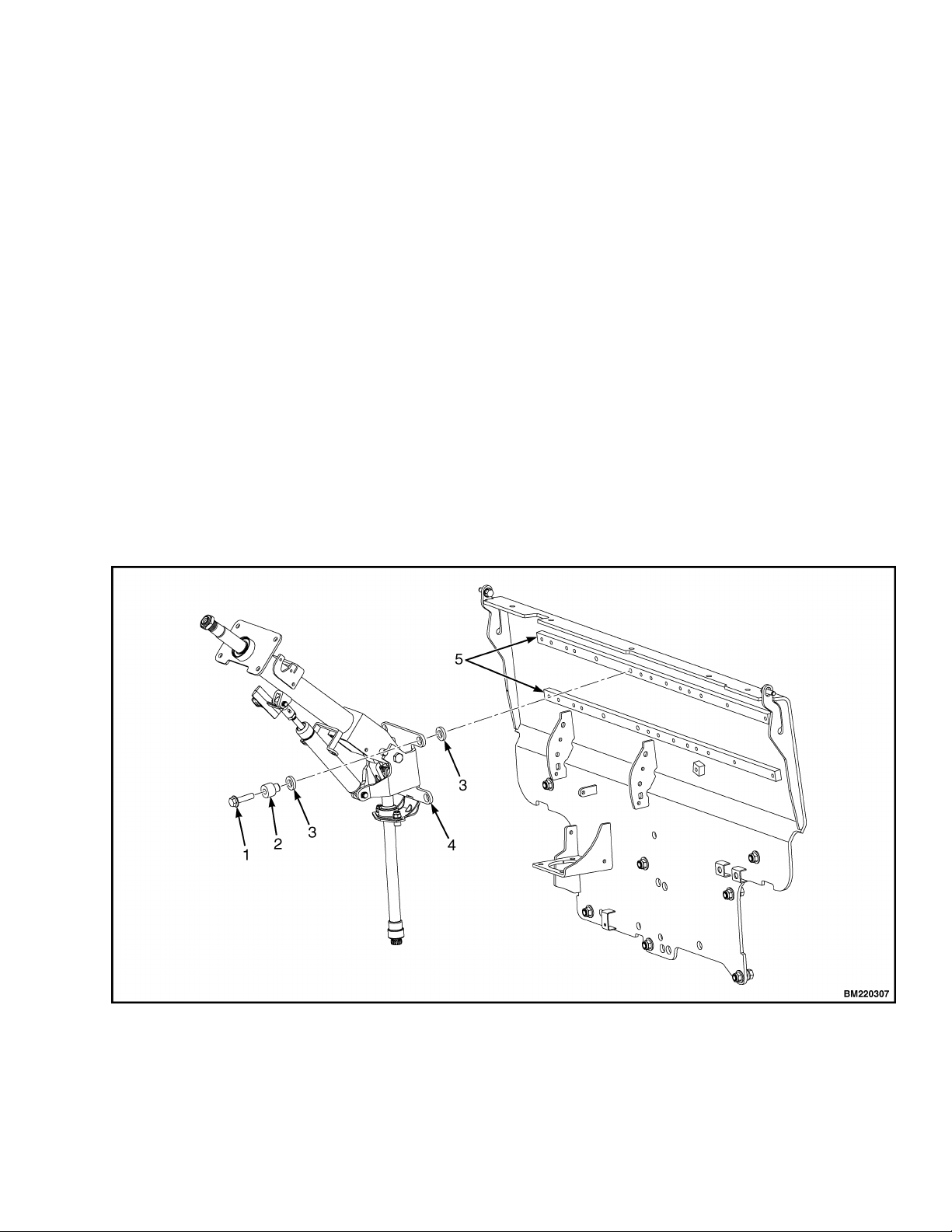

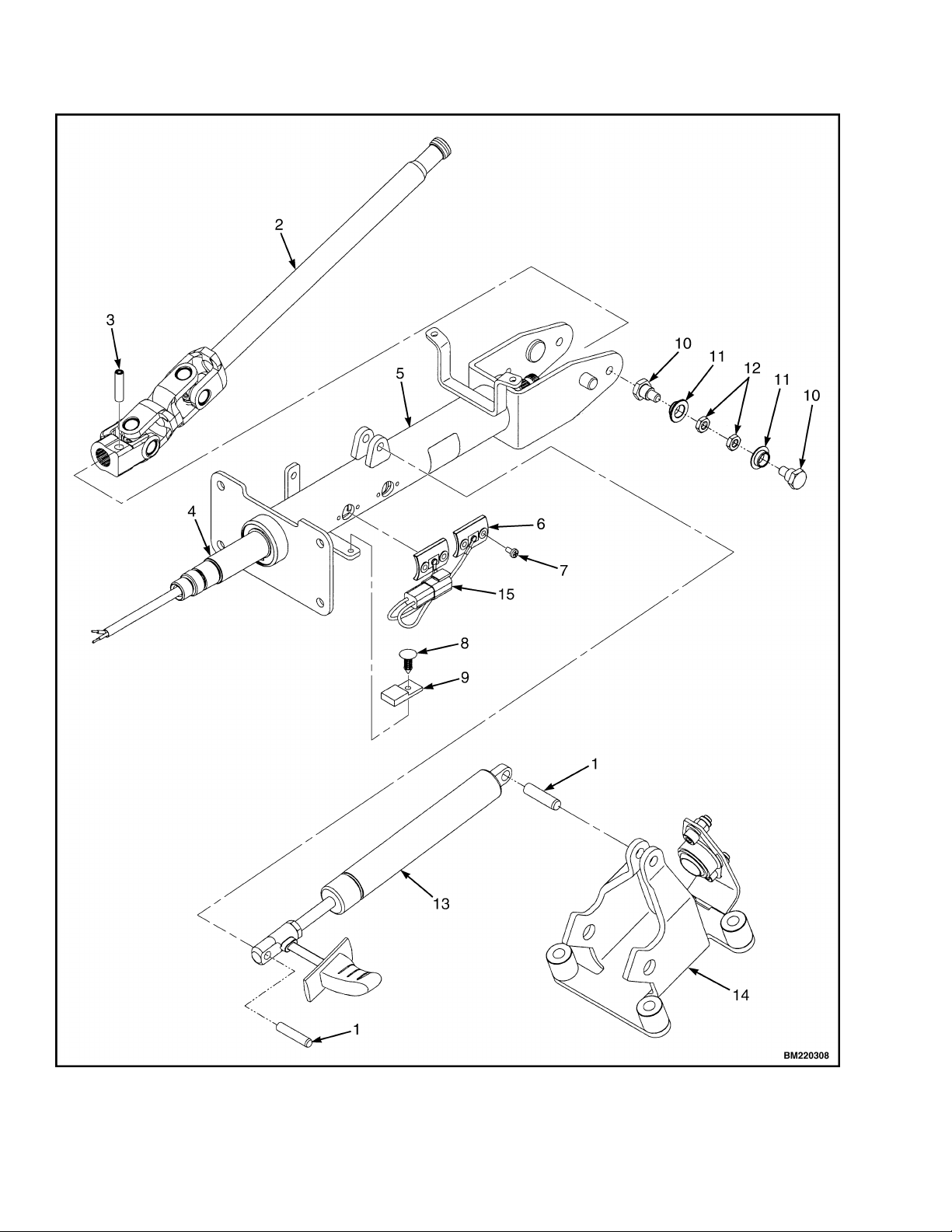

Disassemble

1. Remove two pins and gas spring from housing.

See Figure 12, for lift trucks manufactured before

January, 2012.

See Figure 13, for lift trucks manufactured after

January, 2012.

2. Remove two pivot bolts, two bushings, two nuts

and bracket from housing.

See Figure 12, for lift trucks manufactured before

January, 2012.

See Figure 13, for lift trucks manufactured after

January, 2012.

3. Remove split pin and lower shaft from upper

shaft.

See Figure 12, for lift trucks manufactured before

January, 2012.

See Figure 13, for lift trucks manufactured after

January, 2012.

4. Remove connector from connector bracket. Re-

move connector bracket, fastener, four screws

and two horn contacts from housing.

See Figure 12, for lift trucks manufactured before

January, 2012.

See Figure 13, for lift trucks manufactured after

January, 2012.

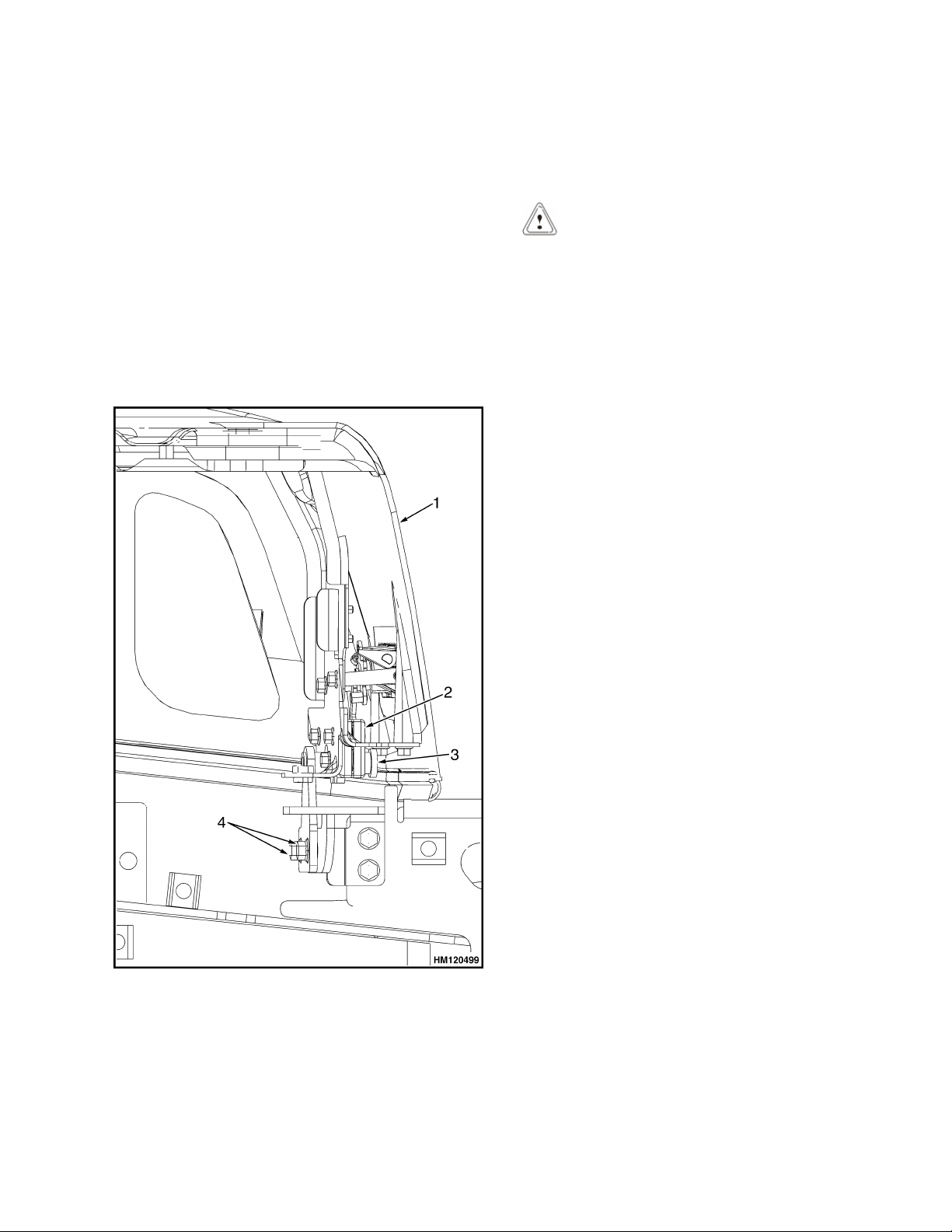

1. CAPSCREW

2. BUSHING

3. ISOLATOR

4. STEERING COLUMN

5. COWL STANDOFF

Figure 11. Steering Column Remove/Install

13

Steering Column 0100 YRM 1243

14

Figure 12. Steering Column Assembly, Lift Trucks Manufactured Before January, 2012

Loading...

Loading...