Yale GLP20LX, GLP25LX, GDP20LX, GDP25LX Repair Manual

GLP20LX, GLP25LX, GDP20LX, GDP25LX (B974)

SERVICE MANUAL CONTENTS

PART

SECTION

FRAME............................................................................................................................ 550109110 0100 YRM 1766 12/14

YANMAR DIESEL ENGINES.......................................................................................... 524240453 0600 YRM 1205 12/14

PSI 2.4L ENGINE............................................................................................................ 550108890 0600 YRM 1755 12/14

COOLING SYSTEM........................................................................................................ 550109111 0700 YRM 1767 12/14

FUEL SYSTEM PSI 2.4L................................................................................................ 550108892 0900 YRM 1757 12/14

SINGLE SPEED PS CHAIN DRIVE PTO........................................................................ 550108495 1300 YRM 1740 12/14

DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 550109112 1400 YRM 1768 12/14

STEERING AXLE REPAIR............................................................................................. 550109113 1600 YRM 1769 12/14

BRAKE SYSTEM............................................................................................................ 550108498 1800 YRM 1743 12/14

HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14

HYDRAULIC GEAR PUMPS.......................................................................................... 550108499 1900 YRM 1744 12/14

MAIN CONTROL VALVE................................................................................................ 550108500 2000 YRM 1745 12/14

CYLINDER REPAIR (MAST S/N A698 AND A699)....................................................... 550109114 2100 YRM 1770 12/14

WIRE HARNESS REPAIR.............................................................................................. 524223769 2200 YRM 1128 12/14

ELECTRICAL SYSTEM.................................................................................................. 550109115 2200 YRM 1771 12/14

ENGINE ELECTRICAL SYSTEM, PSI 2.4L ENGINE..................................................... 550109116 2200 YRM 1772 12/14

MAST REPAIR (S/N A698 AND A699)........................................................................... 550109117 4000 YRM 1773 12/14

METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13

PERIODIC MAINTENANCE............................................................................................ 550109197 8000 YRM 1774 12/14

CAPACITIES AND SPECIFICATIONS........................................................................... 550109119 8000 YRM 1775 12/14

DIAGRAMS AND SCHEMATICS.................................................................................... 550109120 8000 YRM 1776 12/14

DIAGNOSTIC TROUBLESHOOTING MANUAL............................................................ 550022929 9000 YRM 1434 12/14

NUMBER

YRM

NUMBER

REV

DATE

PART NO. 550109188 (12/14)

0100 YRM 1766 General

General

The surface must be solid, even, and level when

WARNING

The lift truck must be put on blocks for some

types of maintenance and repairs. The removal of

the following assemblies will cause large changes

in the center of gravity: mast, drive axle, engine

and transmission, and counterweight. When the

lift truck is put on blocks, put additional blocks in

the following positions to maintain stability:

• Before removing the mast and drive axle,

put blocks under the counterweight so the

lift truck cannot fall backward.

• Before removing the counterweight, put

blocks under the mast assembly so the lift

truck cannot fall forward.

the lift truck is put on blocks. Make sure that any

blocks used to support the lift truck are solid,

one-piece units. See the Operating Manual or the

Periodic Maintenance 8000YRM1774.

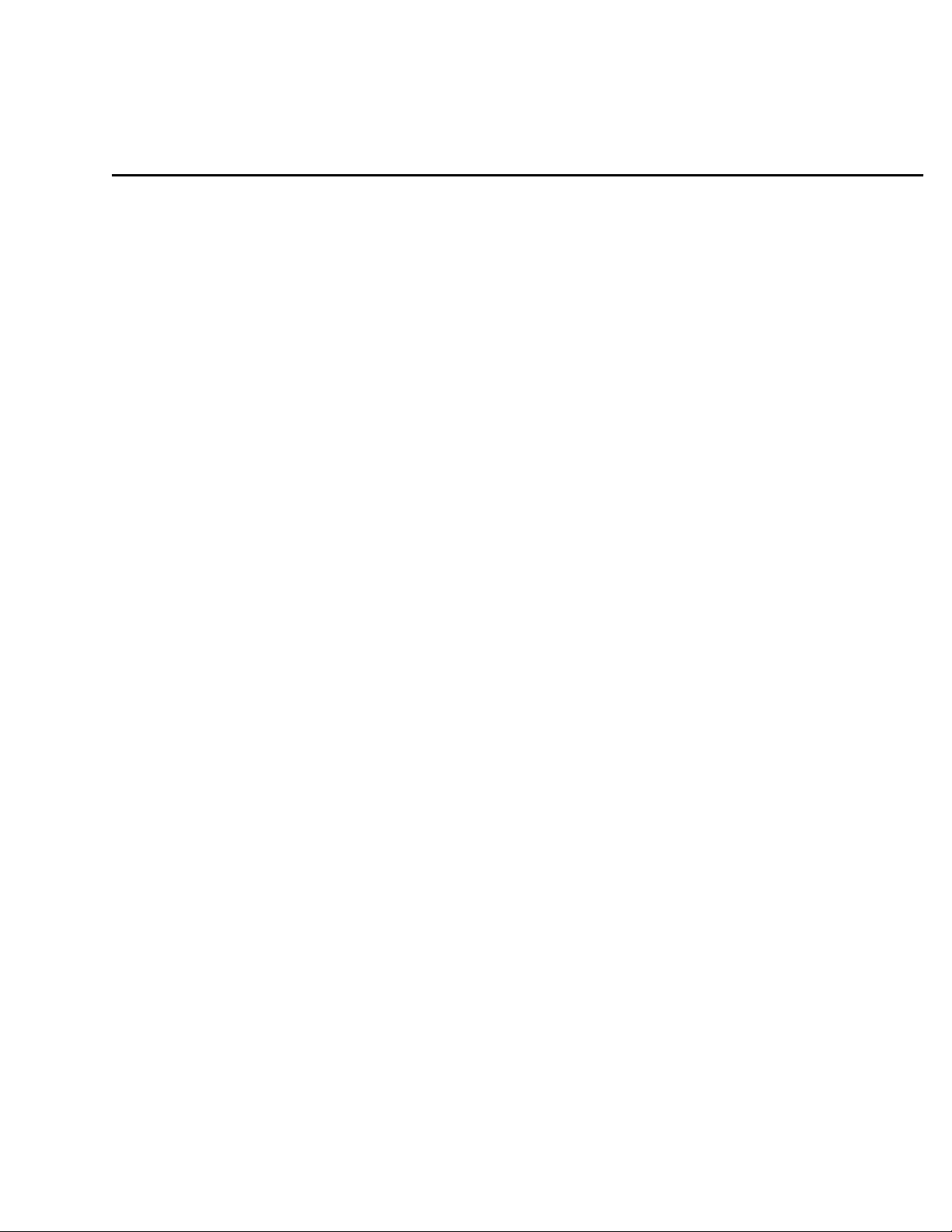

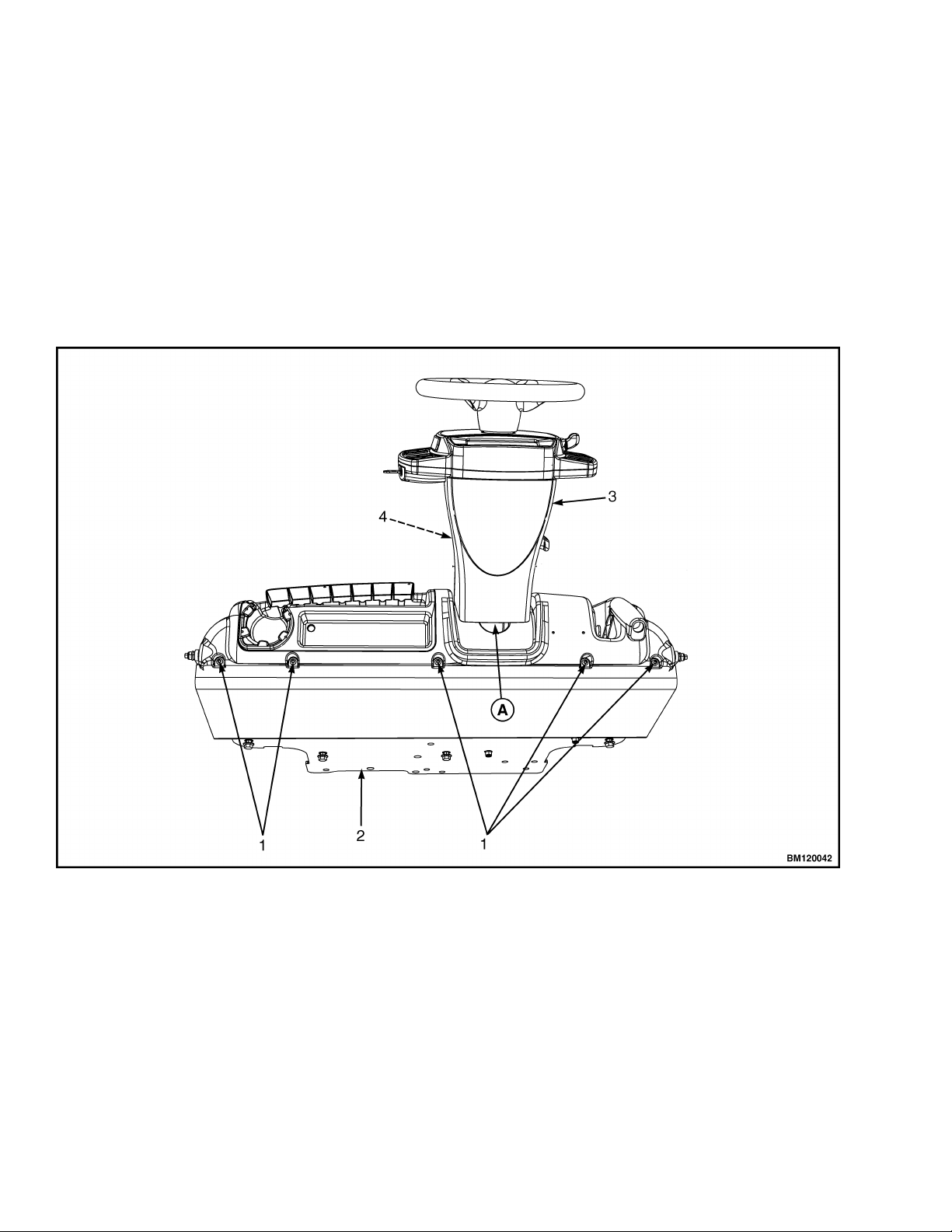

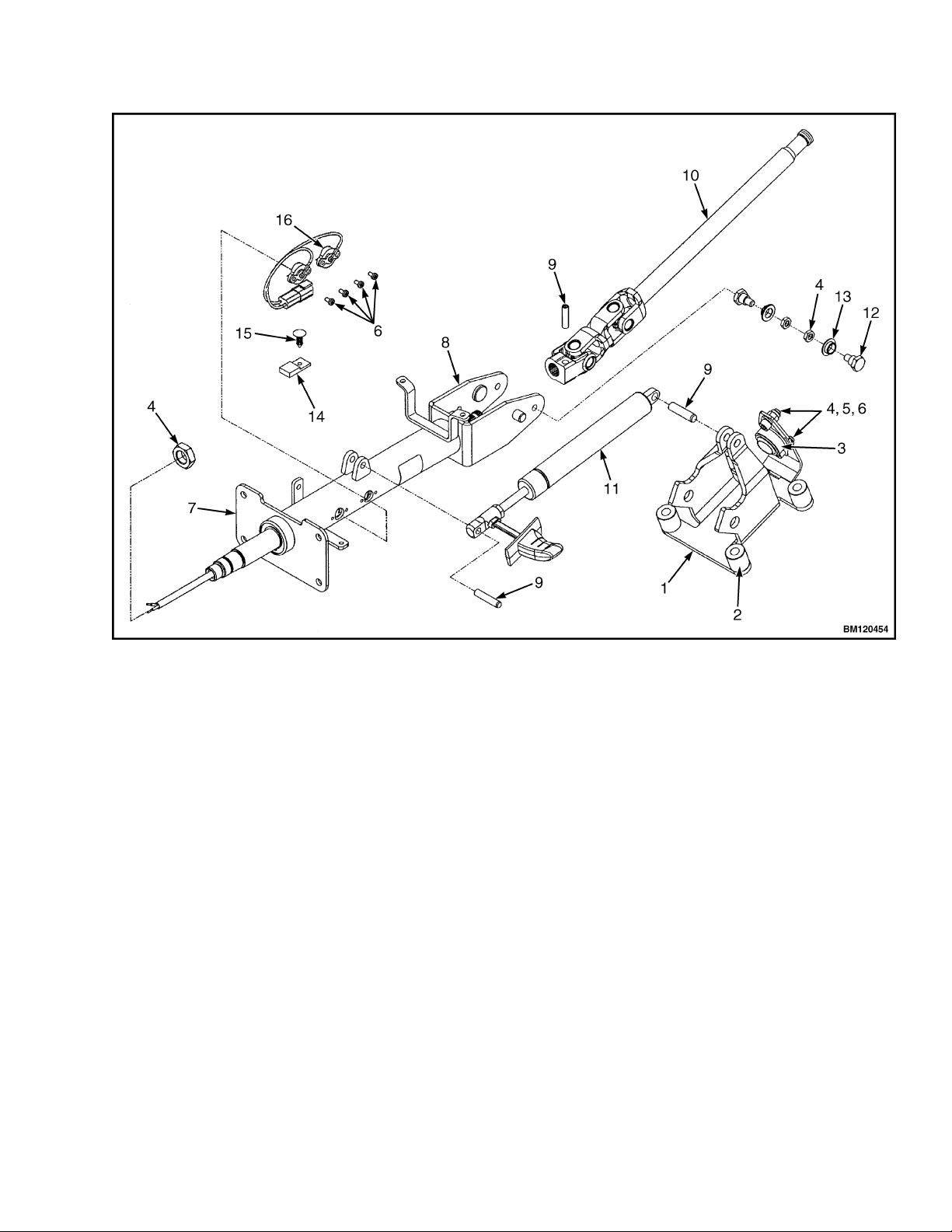

This section contains the description of the frame (see

Figure 1 and Figure 2) and connected parts.

Procedures for removing and installing the

counterweight, hood, overhead guard, engine, and

cooling system are found in this section. Checks for

the operator restraint system, adjustments for the

throttle pedal stop, and procedures for the repair of

tanks and installation of safety labels are also

included.

1. COWL PLATE

2. FENDER

3. FRAME

4. HOOD MOUNT

5. COUNTERWEIGHT SUPPORT

6. LEFT-HAND FRAME WELDMENT

7. HYDRAULIC TANK

Figure 1. Frame, LPG

1

General 0100 YRM 1766

1. COWL PLATE

2. FENDER

3. FRAME

4. HOOD MOUNT

5. COUNTERWIEGHT SUPPORT

6. FUEL TANK

7. HYDRAULIC TANK

Figure 2. Frame, Dual Fuel or Diesel

2

0100 YRM 1766 Hood, Seat, and Side Covers Replacement

Hood, Seat, and Side Covers Replacement

REMOVE

1. Slide the seat to the closest position to the steer-

ing column.

2. Fully tilt the steering column forward.

NOTE: Perform Step 3 for lift trucks equipped with

LPG.

3. Swing LPG tank off to side. See Fuel System PSI

2.4L 0900YRM1757 for procedures.

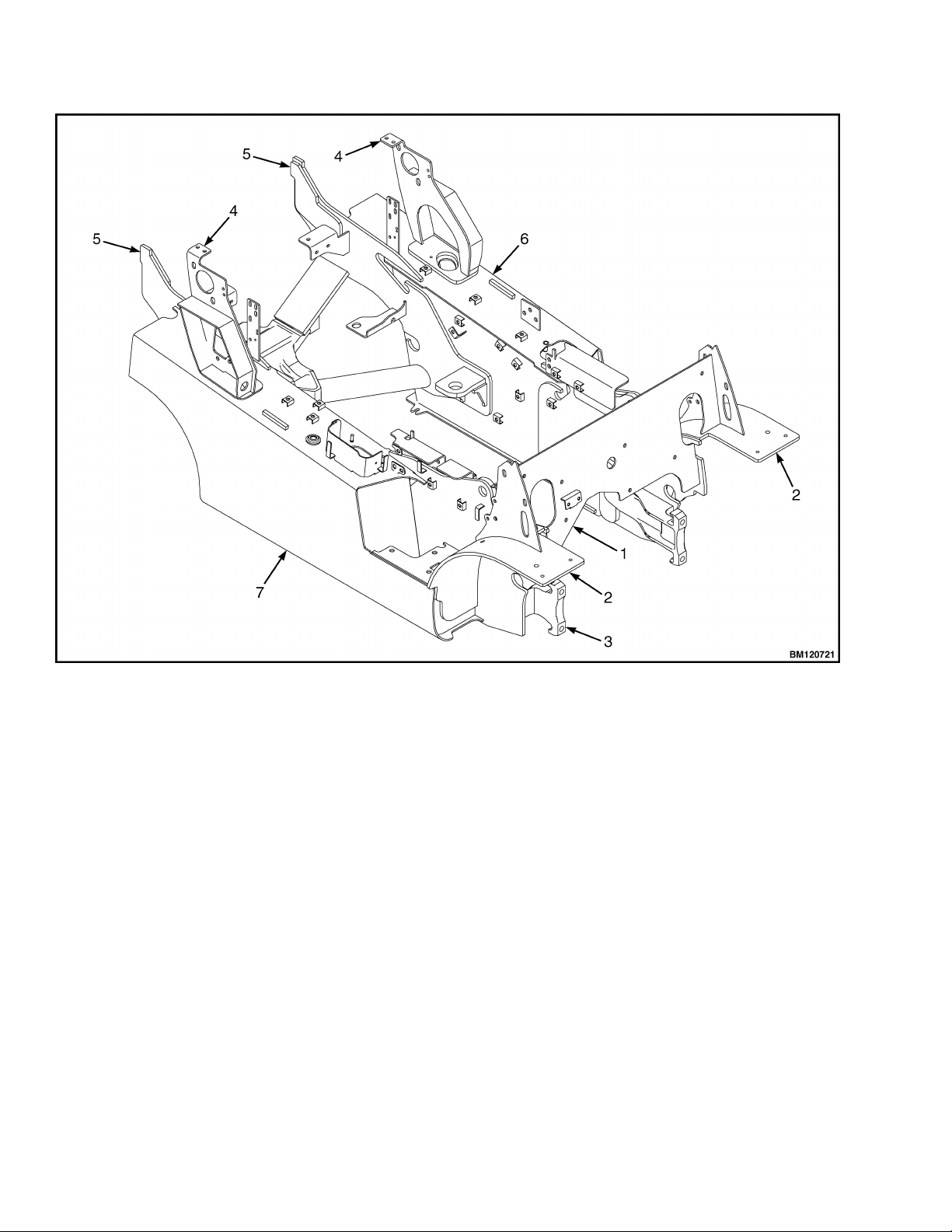

4. Raise the hood latch on the left, front corner of

the hood to unlatch and lift up the hood. See Figure 3.

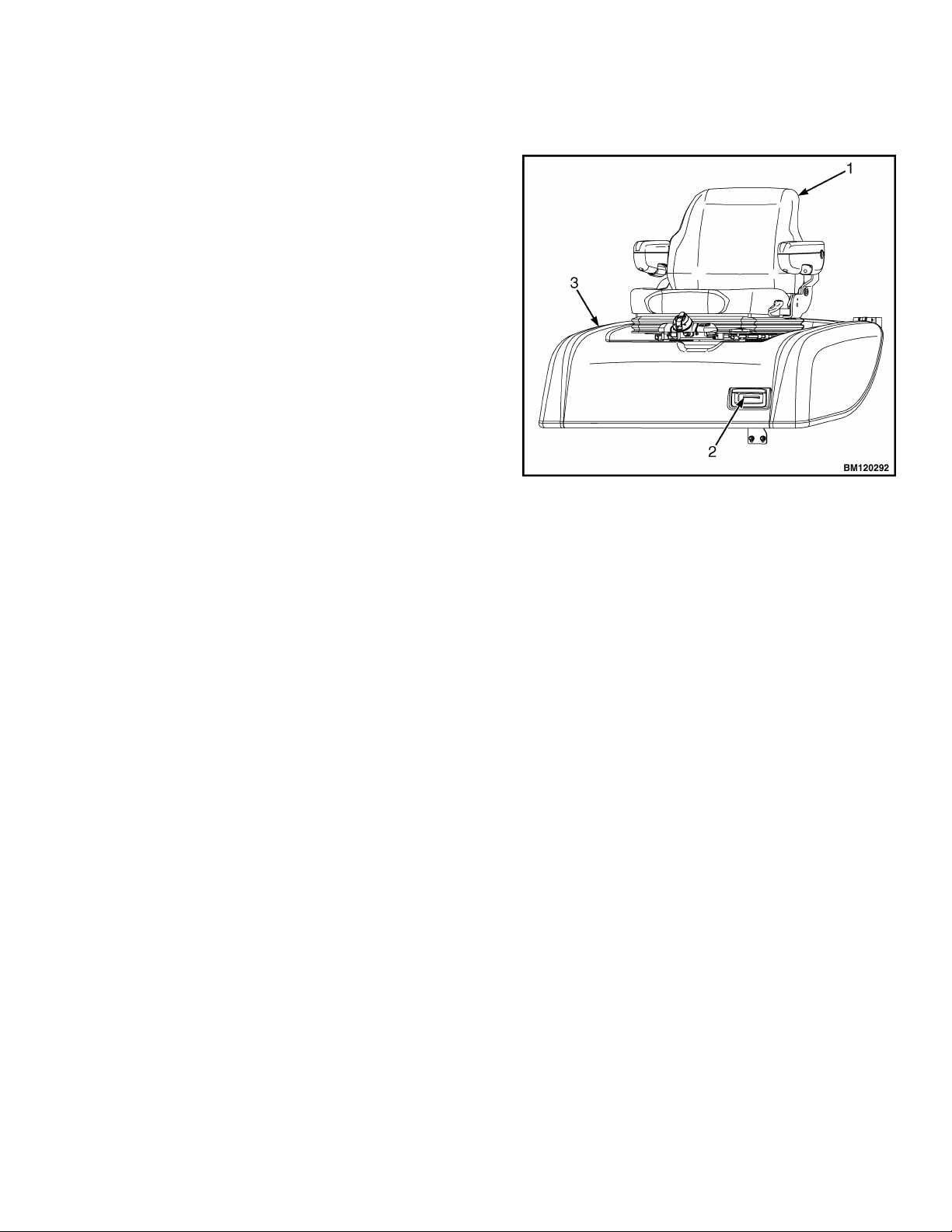

5. Remove the floor mat and floor plate. See Figure 4.

6. Remove the two capscrews holding the left and

right rear side covers to the frame. Remove the

rear side covers from the frame. See Figure 4.

1. HOOD LATCH

2. SEAT

Figure 3. Hood Latch

3. HOOD

3

Hood, Seat, and Side Covers Replacement 0100 YRM 1766

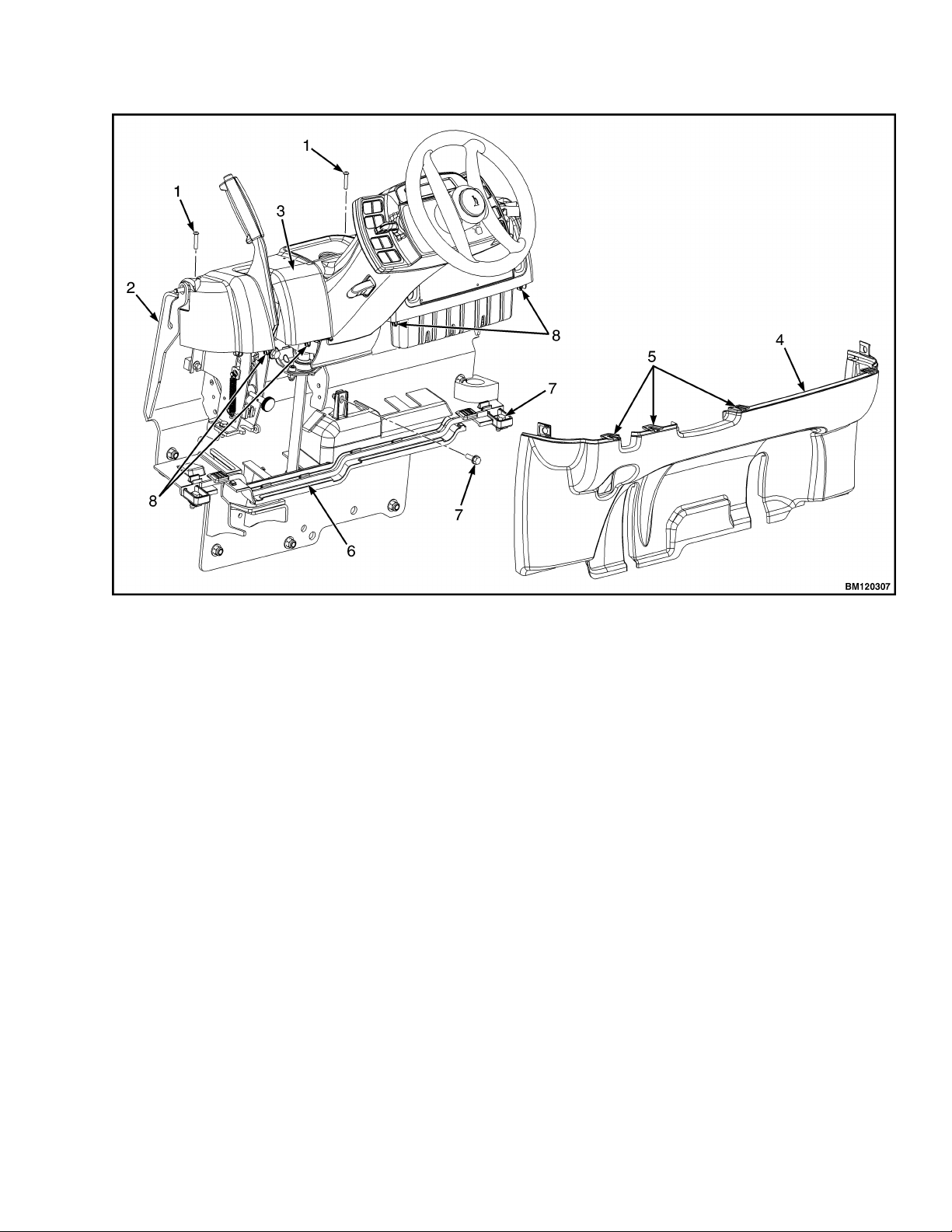

Figure 4. Side Cover, Floor Plate, and Cowl Components

4

0100 YRM 1766 Hood, Seat, and Side Covers Replacement

Legend for Figure 4

1. DASH ASSEMBLY

2. UPPER STEERING COLUMN COVER

3. LOWER STEERING COLUMN COVER

4. KICK PANEL

5. PLATE ASSEMBLY

6. GROMMET

7. LEFT FRONT SIDE COVER

8. RIGHT FRONT SIDE COVER

9. LEFT STEP PANEL

10. RIGHT STEP PANEL

11. LEFT STEP PLATE

12. RIGHT STEP PLATE

13. LEFT REAR SIDE COVER

14. RIGHT REAR SIDE COVER

15. FLOOR MAT

16. FLOOR PLATE

17. RADIATOR COVER

18. SEALS

19. CAPSCREW

20. CLIP NUT

21. INSERT

22. PLATE ASSEMBLY SEAL

23. LEFT COWL PLATE

24. RIGHT COWL PLATE

5

Hood, Seat, and Side Covers Replacement 0100 YRM 1766

7. Remove the four capscrews and clip nuts holding

the left and right front side covers and left and

right cowl plates to the frame. Remove front side

covers and cowl plates.

8. Fully lower the steering column.

9. Remove upper steering column cover by pulling

up on the base of the upper steering column

cover to release the latches (one on either side),

and pulling cover away from steering column. See

Figure 5.

10. Remove the five Allen Head screws (see Figure 5) securing the dash to top of cowl.

11. Pull kick panel up from bottom and out to remove

kick panel from seal plate and clips on dash

panel.

12. Remove dash panel from cowl. See Figure 6.

13. Remove three capscrews holding the seal plate.

Remove seal plate. See Figure 6.

NOTE: TOP VIEW OF DASH PANEL SHOWN

A. INDICATES TO PULL UP TO UNLATCH

1. ALLEN HEAD SCREWS

2. COWL

Figure 5. Dash Panel and Upper Steering Column Cover Removal

6

3. UPPER STEERING COLUMN COVER

4. LOWER STEERING COLUMN COVER

0100 YRM 1766 Hood, Seat, and Side Covers Replacement

1. ALLEN HEAD SCREWS

2. COWL

3. DASH PANEL

4. KICK PANEL

Figure 6. Dash Panel, Kick Panel, and Seal Plate Removal

5. KICK PANEL NOTCHES

6. SEAL PLATE

7. CAPSCREWS

8. CLIPS

7

Hood, Seat, and Side Covers Replacement 0100 YRM 1766

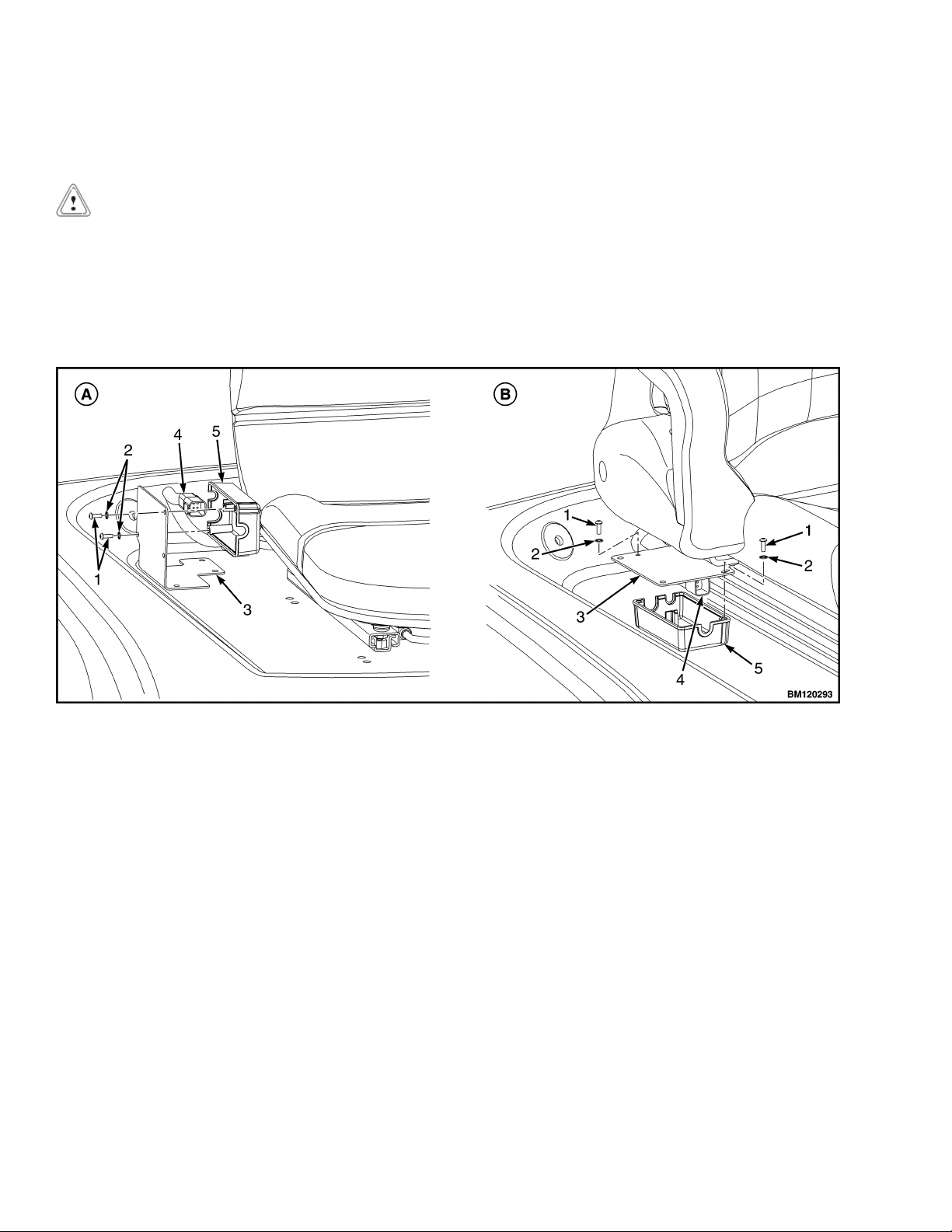

14. Remove two capscrews and washers from cover

plate and remove electrical cover. Disconnect

seat harness from chassis harness. See Figure 7.

CAUTION

When removing the seat from the hood, do not

use an impact wrench to remove the capscrews.

Damage can be caused to the threads on the capscrews and in the holes.

15. Open hood and pull chassis harness through hole

in hood. See Figure 8.

Remove the four capscrews and nuts holding the

seat to the hood. Lift the seat off the hood. See

Figure 8. Close hood.

16. Remove the nuts from ball studs on gas springs.

Remove gas springs from the hood. See Figure 9.

17. Remove the hinge capscrews and nuts, located in

the rear of the hood. See Figure 9.

18. Lift the hood from the truck.

A. NON-SUSPENSION SEAT B. FULL SUSPENSION SEAT

1. CAPSCREWS

2. WASHER

3. COVER PLATE

Figure 7. Disconnect Seat Wire Harness

8

4. ELECTRICAL CONNECTOR (SEAT HARNESS)

5. ELECTRICAL COVER

0100 YRM 1766 Hood, Seat, and Side Covers Replacement

Legend for Figure 8

NOTE: MOUNTING HOLES FOR FULL SUSPENSION SEAT SHOWN. MOUNTING HOLES FOR

NON-SUSPENSION SEAT ARE THE SAME.

1. CAPSCREW

2. NUT

3. HOLE FOR CHASSIS HARNESS

4. HOOD LINER

Figure 8. Remove Seat From Hood

A. HOOD HINGE ARRANGEMENT B. GAS SPRING ARRANGEMENT (LEFT SIDE

SHOWN)

1. NUT

2. CAPSCREW

3. HOOD HINGE MOUNT

4. HOOD HINGE ARM

5. HOOD

Figure 9. Gas Spring and Hood Removal

6. BALL STUD

7. GAS SPRING MOUNTING BRACKET

8. HOOD MOUNT

9. GAS SPRING

9

Hood, Seat, and Side Covers Replacement 0100 YRM 1766

INSTALL

1. Place the hood onto the lift truck frame.

2. Install the hood hinge mount screws and nuts, lo-

cated in the rear of the hood, and tighten to

38 N•m (28 lbf ft). See Figure 9.

3. Align the ball studs in the gas springs with holes

in the gas spring mounting bracket and hood

mount. See Figure 10 for holes to use depending

on type of seat being installed. Install nuts on ball

studs to attach gas springs to the hood. Tighten

nuts to 19.2 N•m (170 lbf in).

4. Install latch striker in highest slot position. Check

that latch striker is in center of jaws of hood latch

when hood closes. Open and close the hood to

ensure that the center pin strikes the hood latch

properly and that the stop screw contacts the

frame. A properly closed hood MUST click twice

on the hood latch. If the hood latch does not close

properly, loosen the capscrews on the back of the

center pin and adjust the center pin up or down as

required for correct alignment. See Figure 11.

5. Push down until hood just touches rubber

bumper. Make sure latch striker is still in center of

hood latch. Open hood and tighten capscrews for

latch.

6. Check operation of hood latch. Have an operator

sit in the seat. Make sure hood is fully closed (two

clicks). Also check that hood touches rubber

bumper. If necessary, repeat Step 4 and Step 5.

A. LEFT SIDE B. RIGHT SIDE

1. FULL SUSPENSION SEAT

2. NON-SUSPENSION SEAT

Figure 10. Gas Spring and Seat Hole Alignment

10

3. GAS SPRING MOUNTING BRACKET

4. HOOD MOUNT

0100 YRM 1766 Hood, Seat, and Side Covers Replacement

8. Align the holes in the seat with the holes in the

hood. See Figure 8. Insert capscrews and nuts.

Tighten capscrews to 18 N•m (159 lbf in).

9. Connect seat harness to chassis harness. Install

cover plate to electrical cover using two capscrews and washers. See Figure 7.

10. Using three capscrews, install seal plate. See Figure 6. Tighten capscrews to

10.8 N•m (95.6 lbf in).

11. Place dash panel on cowl and secure dash panel

to cowl using five Allen Head screws. Tighten Allen Head screws to 3.5 N•m (31 lbf in). See Figure 5.

12. Align notches on kick panel to clips on dash panel

and push kick panel into place on seal plate. See

Figure 6.

13. Raise steering column to highest position and install upper steering column cover by aligning the

two latches and pushing down until latched. See

Figure 5.

1. HOOD

2. HOOD LATCH

3. CENTER PIN

4. CAPSCREW

Figure 11. Hood Latch Adjustment

CAUTION

When installing the seat to the hood, do not use

an impact wrench to install the capscrews. Damage can be caused to the threads on the screws

and in the holes.

7. Place the seat on the hood and thread the chas-

sis harness through the holes in the hood. See

Figure 8.

14. Using four capscrews and clip nuts, install the left

and right front side covers and left and right cowl

plates to the frame. See Figure 4.

15. Using two capscrews, install the left and right rear

side covers to the frame. See Figure 4.

16. Install the floor mat and floor plate.

NOTE: Perform Step 17 for lift trucks equipped with

LPG.

17. Swing the LPG tank into position on back of counterweight. See Fuel System PSI 2.4L

0900YRM1757 for procedures.

18. Adjust the steering column and seat positions.

11

Steering Column 0100 YRM 1766

Steering Column

DESCRIPTION

CAUTION

This section describes the repair procedures for the

steering column. The Steering Column Assembly

mounts to the cowl inside the operator compartment

and is the mechanical connection between the steering wheel and the steering control unit. The steering

column includes the steering wheel, housing, bracket

and lower shaft. For lift trucks with gas and LPG engines, bolts and bushings attach the steering column

to the cowl standoffs. For lift trucks with diesel engines, bolts, bushings and isolators attach the steering column to the cowl standoffs See Figure 12.

Disconnect the negative battery cable on internal

combustion trucks. Disconnect the battery before

removing any covers.

2. Attach a tag on the battery connector or negative

battery cable stating, DO NOT CONNECT BATTERY. Move the steering column to the most

FORWARD position.

CAUTION

If a puller tool is used to remove steering wheel

from steering column, be careful not to damage

horn wires.

NOTE: This procedure is for the removal of all com-

ponents of the steering column assembly. All components are not often removed for a repair procedure.

Do only those steps of the procedure necessary to remove the required component.

NOTE: DIESEL SHOWN, LPG AND BI-FUEL SIMILAR.

1. STEERING WHEEL

2. STEERING COLUMN

3. COWL

Figure 12. Steering Column and Cowl

STEERING COLUMN REPAIR

Remove

1. Put blocks on each side (front and back) of tires

to prevent lift truck from moving.

NOTE: Tag wires prior to disconnect

3. Remove the horn button assembly and discon-

nect electrical wires. Remove large hex nut and

steering wheel from steering column. See Figure 13.

1. HORN BUTTON

2. HEX NUT

3. STEERING WHEEL

4. STEERING COLUMN

12

Figure 13. Steering Wheel Remove/Install

0100 YRM 1766 Steering Column

4. Remove steering column covers. Remove floor

mats and floor plate. See section Hood, Seat, and

Side Covers Replacement.

NOTE: Perform Step 5 for lift trucks equipped with bifuel or LPG engines.

5. Remove four capscrews, four bushings and steering column from cowl standoffs. See Figure 14.

NOTE: Perform Step 6 for lift trucks equipped with

diesel engines.

6. Remove four capscrews, four bushings, four isolators, steering column and four isolators from

cowl standoffs. See Figure 14.

Disassemble

NOTE: Remove and discard snap rings if installed.

1. Remove two pins and gas spring from housing.

See Figure 15.

2. Remove two pivot bolts, two bushings, two nuts

and bracket from housing.

3. Remove split pin and lower shaft from upper

shaft.

4. Remove connector from connector bracket. Remove connector bracket, fastener, four screws

and two horn contacts from housing.

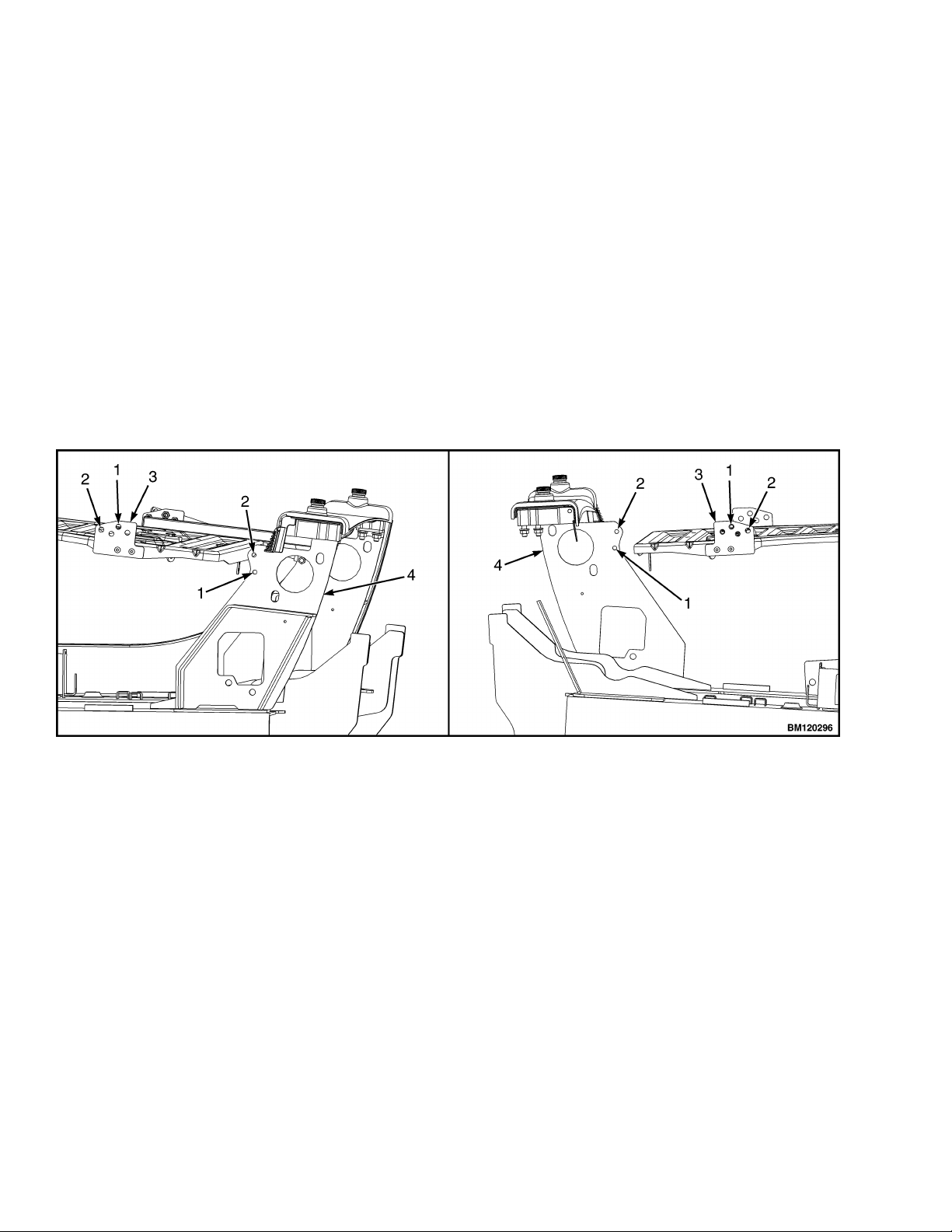

NOTE: DIESEL SHOWN, LPG AND GAS SIMILAR.

1. CAPSCREW

2. BUSHING

3. ISOLATOR

Figure 14. Steering Column Remove/Install

4. STEERING COLUMN

5. COWL STANDOFF

13

Steering Column 0100 YRM 1766

Clean

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer's recommended safety precautions.

WARNING

Compressed air is used for cleaning and drying

purposes, or for cleaning restrictions. wear protective clothing (goggles/shields, gloves, etc.).

Make sure the path of the compressed air is away

from all personnel to avoid injury.

1. Clean metal parts in solvent. Remove all traces of

old lubricant and dirt. Clean nonmetal parts with

warm soapy water and a lint free cloth.

2. After cleaning dry parts with compressed air. DO

NOT dry parts with a cloth.

Inspect

1. Inspect for loose, burned, missing, cracked or

damaged hardware.

2. Inspect all parts for dents, holes, bends, burrs,

rust, corrosion or marred finishes.

3. Replace all defective or damaged parts.

2. Install fastener, connector bracket and connector,

two horn contacts and four screws.

3. Assemble lower shaft and upper shaft, secure

with spit pin.

4. Install two pivot bolts, two bushings, two nuts and

bracket onto housing.

5. Install gas spring and two pins on housing.

Install

NOTE: Lubricate spline end of lower shaft with multi

purpose grease, see Periodic Maintenance Manual

for your lift truck.

NOTE: Perform Step 1 for lift trucks equipped with

gas or LPG engines.

1. Install steering column, four bushings and four

bolts on cowl standoffs. Tighten bolts to

38 N•m (28 lbf ft). See Figure 14.

NOTE: Perform Step 2 for lift trucks equipped with

diesel engines.

2. Install four isolators, steering column four isolators, four bushings and four bolts standoffs on

cowl. Tighten bolts to 38 N•m (28 lbf ft). See Figure 14.

3. Install floor plate, floor mats and steering column

covers. See section Hood, Seat, and Side Covers

Replacement.

Assemble

NOTE: This procedure is for the installation of all

components of the steering column assembly. All

components are not often removed for a repair procedure. Do only those steps of the procedure necessary

to install the required component.

NOTE: Perform Step 1 only for lift trucks manufactured before January, 2012.

1. Lubricate the horn contact slip rings with a small

amount of conductive grease Yale P/N

582014302. See Figure 15.

14

4. Install steering wheel and hex nut on steering col-

umn. Tighten hex nut to 40 to 54 N•m (30 to

40 lbf ft). Connect electrical wiring and install horn

button. See Figure 13.

5. Remove tag from negative battery connector and

connect to battery. Adjust steering column to neutral position.

6. Remove blocks from each side of tires.

0100 YRM 1766 Steering Column

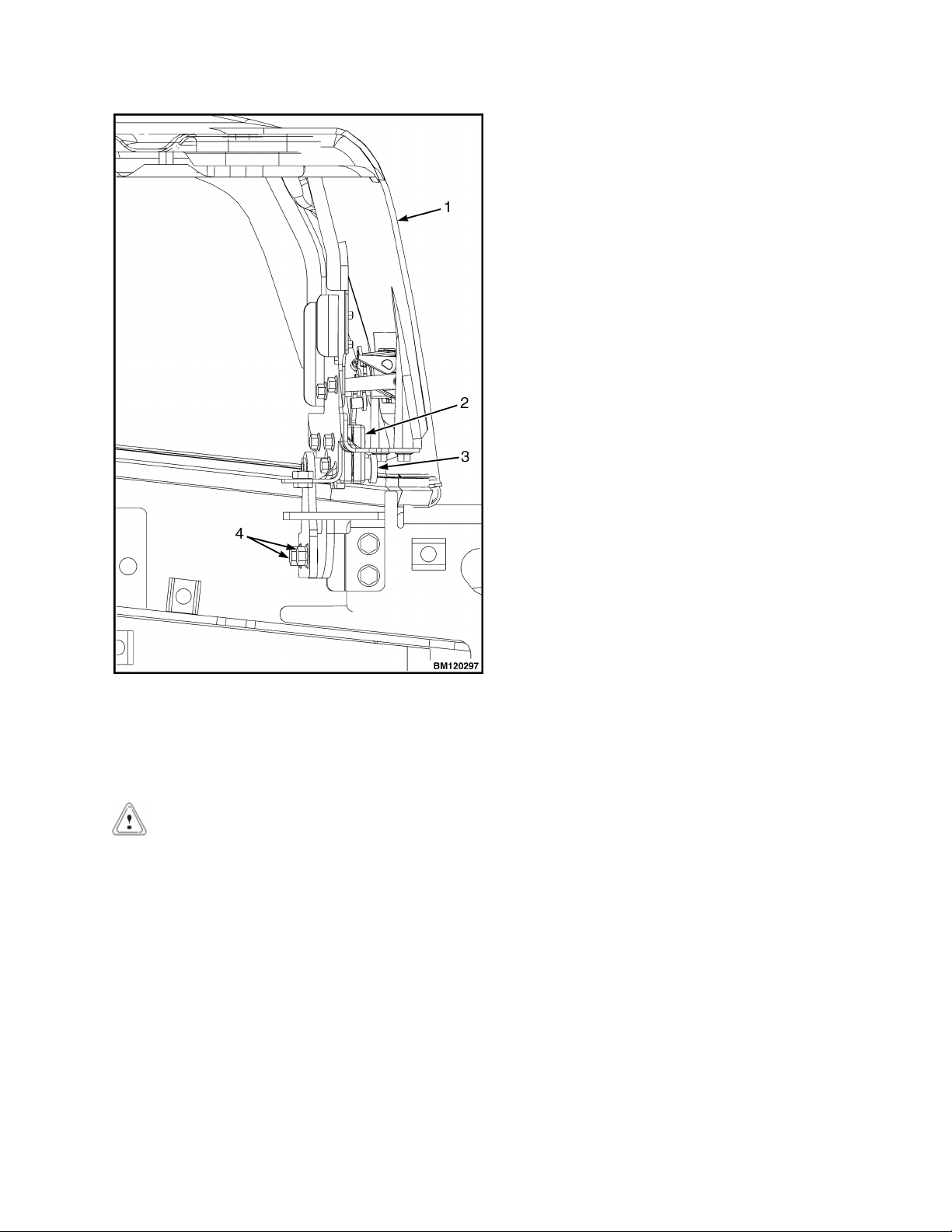

1. BRACKET

2. SPACER

3. JOINT

4. NUT

5. WASHER

6. SCREW

7. UPPER SHAFT

8. HOUSING

9. PIN

10. LOWER SHAFT

11. GAS SPRING

12. BOLT

13. BUSHING

14. CONNECTOR

15. FASTENER

16. HORN CONTACT

Figure 15. Steering Column Assembly

15

Counterweight Replacement 0100 YRM 1766

Counterweight Replacement

REMOVE

WARNING

The lift truck must be put on blocks for some

types of maintenance and repair. The removal of

the following assemblies will cause large changes

in the center of gravity: mast, drive axle, engine

and transmission, and counterweight. When the

lift truck is put on blocks, put additional blocks in

the following positions to maintain stability:

• Before removing the mast and drive axle,

put blocks under the counterweight so the

lift truck cannot fall backward.

• Before removing the counterweight, put

blocks under the mast assembly so the lift

truck cannot fall forward.

The surface must be solid, even, and level when

the lift truck is put on blocks. Make sure that any

blocks used to support the lift truck are solid,

one-piece units. See the Operating Manual or Periodic Maintenance 8000YRM1774.

WARNING

DO NOT operate the lift truck if the capscrew for

the counterweight is not installed. When the capscrew is removed, the counterweight can fall from

the lift truck.

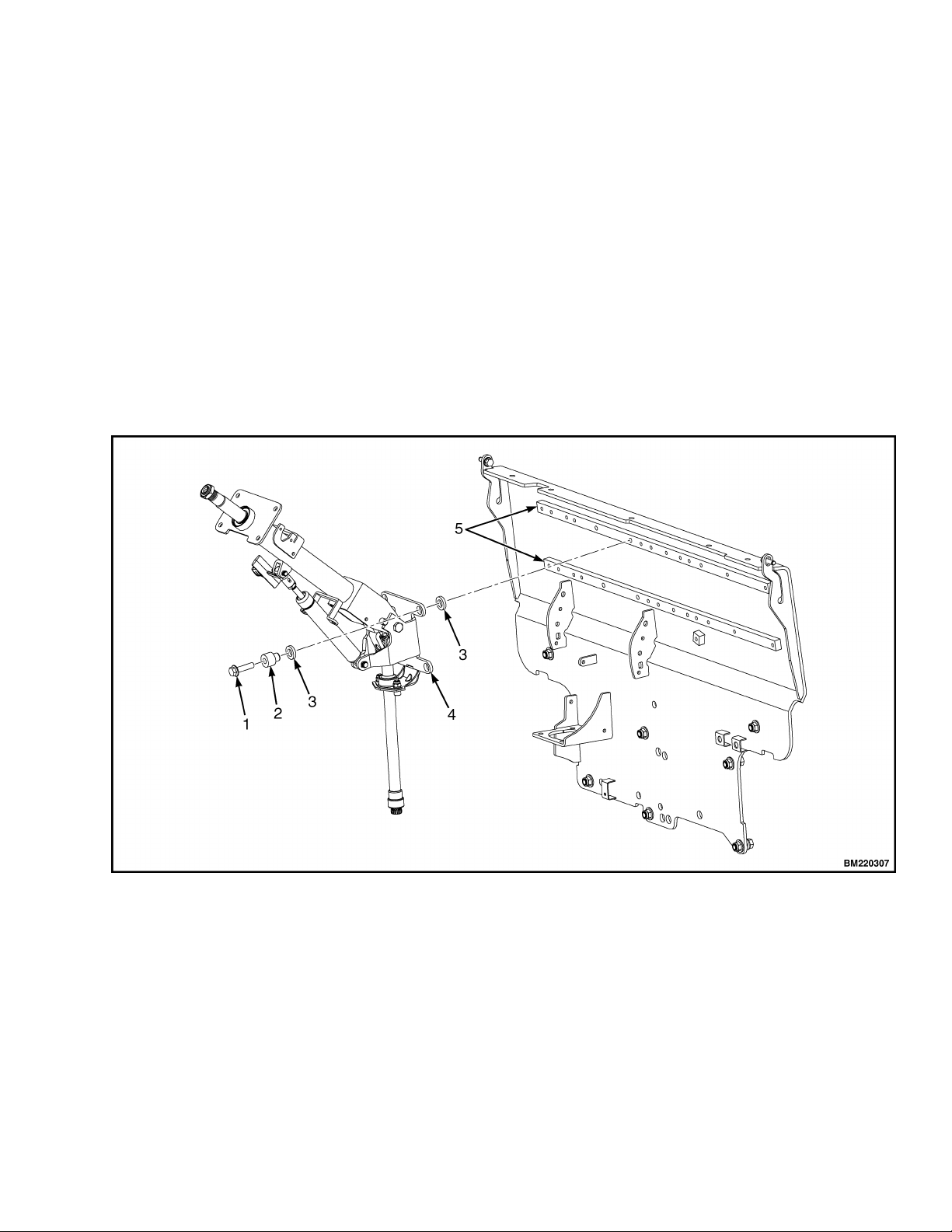

NOTE: The counterweight is held in position on the

frame by two hooks that are part of the frame. One

M24 × 3 × 110 capscrew holds the counterweight to

the lower part of the frame on lift truck models See

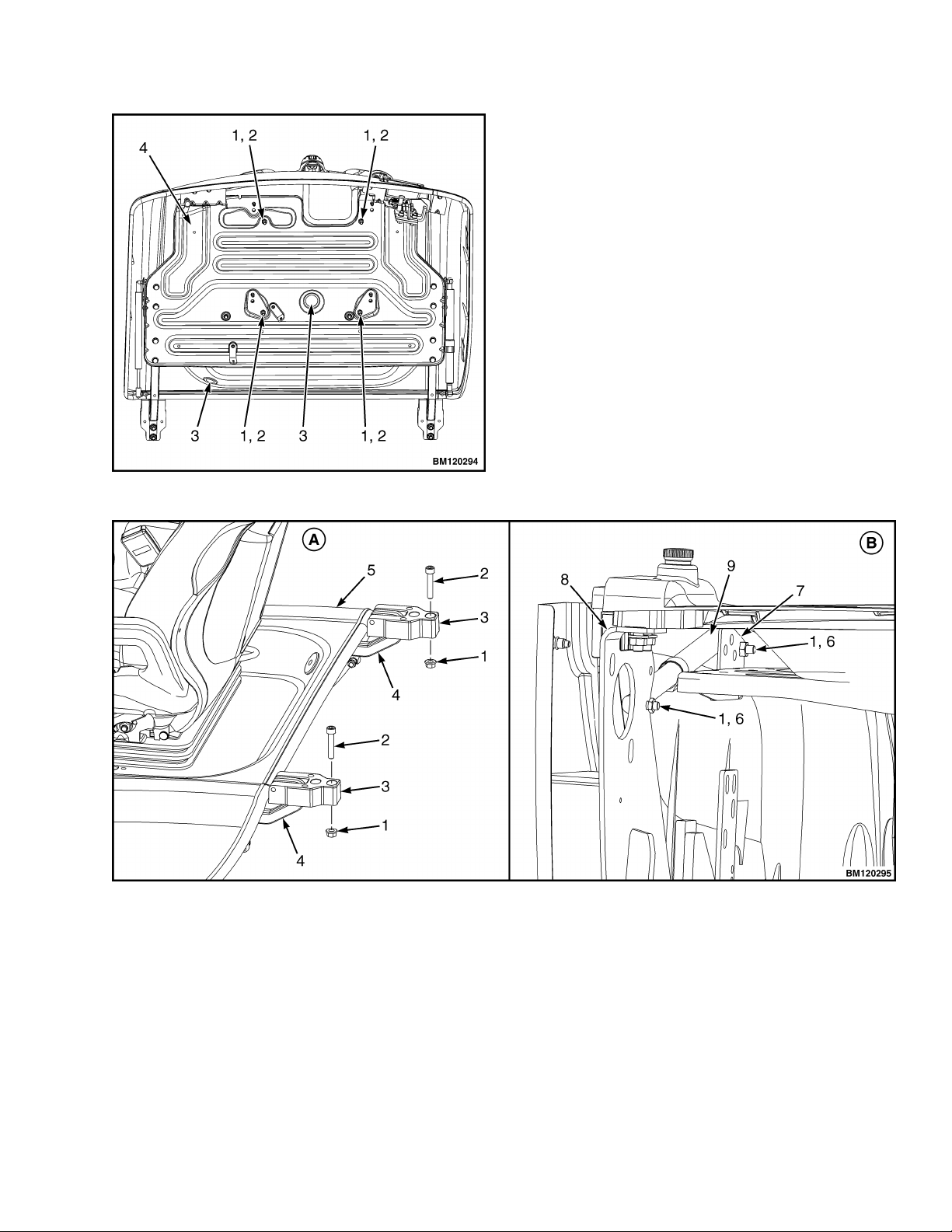

Figure 16.

NOTE: Perform Step 1 for lift trucks equipped with

LPG.

1. Use the procedures in Fuel System PSI 2.4L

0900YRM1757 to remove the LPG tank and

bracket so that the counterweight can be removed.

Additional information on the LPG fuel system can

be found in Fuel System PSI 2.4L 0900YRM1757.

WARNING

The counterweight is heavy. Make sure that the

eyebolts and lifting devices have enough capacity

to lift the weight. The approximate weights of the

counterweight castings are shown in Table 1.

2. Install washers, lifting eyebolts, and nuts into lift

holes of the counterweight. See Figure 17. Connect a crane to the lifting eyebolts and raise the

crane until it holds part of the weight of the counterweight.

3. Remove the tow pin from counterweight.

WARNING

LPG can cause an explosion. DO NOT cause

sparks or permit flammable material near the LPG

system. LPG fuel systems can be disconnected

indoors only if the lift truck is at least 8 m (26 ft)

from any open flame, motor vehicles, electrical

equipment, or ignition source.

Close the shutoff valve on the LPG tank before

any part of the engine fuel system is disconnected. Run the engine until the fuel in the system is

used and the engine stops.

If the engine will not run, close the shutoff valve

on the LPG tank. Loosen the fitting on the supply

hose from the LPG tank where it enters the filter

unit. Permit the pressure in the fuel system to decrease slowly. Fuel leaving the fitting removes

heat. Use a cloth to protect your hands from the

cold fitting.

16

4. Remove the capscrew from counterweight and

frame. See Figure 16 and Figure 17. Use the

crane to lift the counterweight from the lift truck.

Put counterweight on the floor so that it has stability and will not fall over. Take care not to damage

exhaust or cooling system components.

Table 1. Weight of Counterweights

Model kg lb

GLC050LX (B967) 1401 3088

GLP/GDP20LX (B974) 950 2094

GLP/GDP25LX (GLP/

GDP050LX) (B974)

GLP/GDP25LX (GLP/

GDP050LX) (B974)

1230 2712

1335 2943

0100 YRM 1766 Counterweight Replacement

INSTALL

1. Make sure the seals are on the counterweight. If

lifting eyebolts were removed from counterweight,

install washers, lifting eyebolts, and nuts into lift

holes on counterweight. See Figure 17.

2. Connect a crane to the lifting eyebolts and place

counterweight in position on lift truck frame. Make

sure hooks on frame fully engage counterweight

so it is aligned with the frame.

3. Install capscrew onto counterweight and frame.

See Figure 16 and Figure 17. Tighten capscrew

to 555 N•m (409 lbf ft).

4. Install tow pin onto counterweight.

NOTE: Perform Step 5 for lift trucks equipped with

LPG.

5. Use the procedures in Fuel System PSI 2.4L

0900YRM1757 to install the LPG tank and

bracket after the counterweight has been installed.

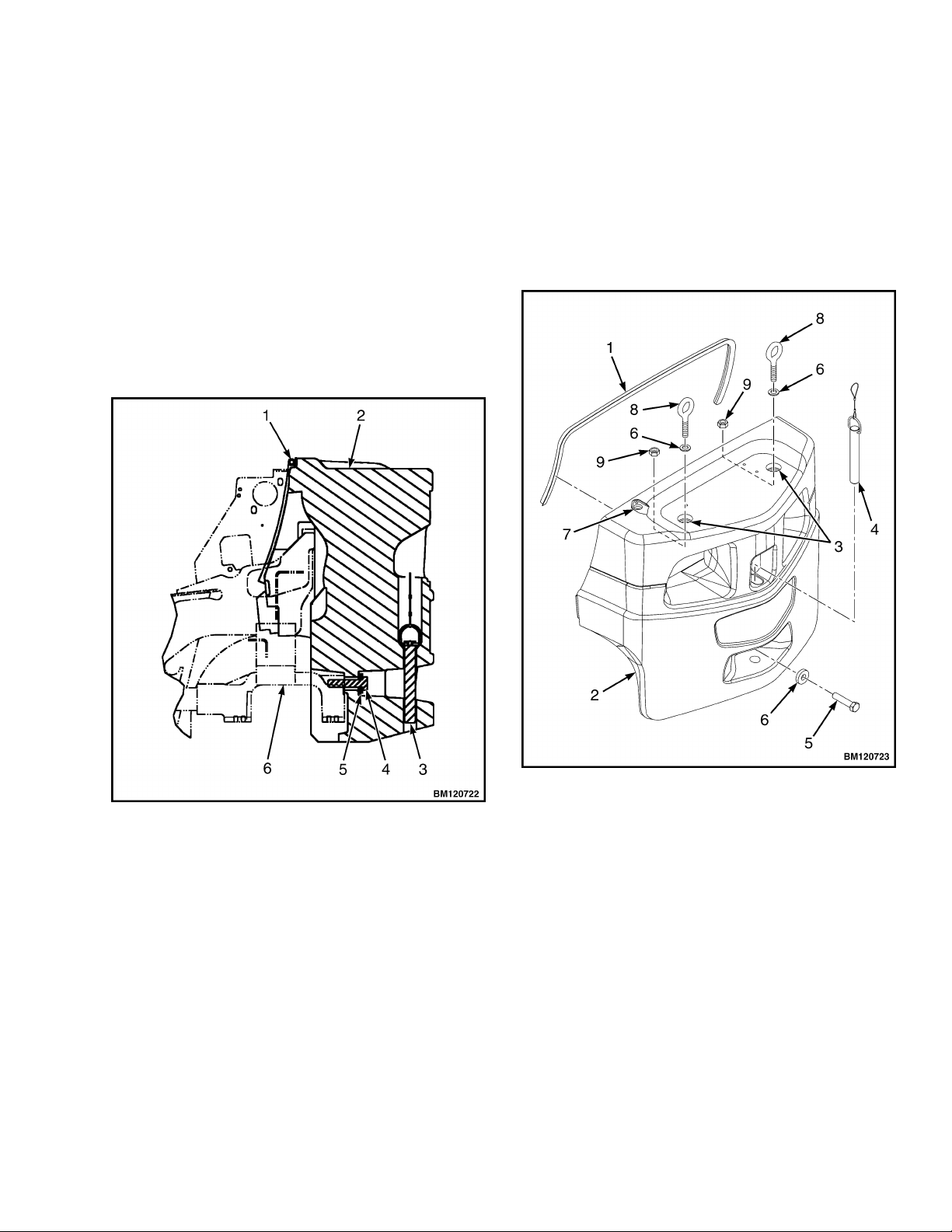

1. SEAL

2. COUNTERWEIGHT

3. TOW PIN

4. CAPSCREW

5. WASHER

6. FRAME

Figure 16. Counterweight Installation

1. SEAL

2. COUNTERWEIGHT

3. LIFT HOLE

4. TOW PIN

5. CAPSCREW

6. WASHER

7. LPG ACCESS HOLE

8. LIFTING EYEBOLT

9. NUT

Figure 17. Counterweight With Lifting Eyebolts

17

Overhead Guard Replacement 0100 YRM 1766

Overhead Guard Replacement

REMOVE

WARNING

DO NOT operate the lift truck without the overhead guard correctly fastened to the lift truck.

WARNING

DO NOT weld mounts for lights or accessories to

legs of the overhead guard. Changes that are

made by welding, or by drilling holes that are too

big or in the wrong location, can reduce the

strength of the overhead guard.

See your dealer for Yale lift trucks BEFORE performing any changes to the overhead guard.

NOTE: The lifting device can be connected to any

number of positions on the overhead guard depending upon the lifting device available. The ideal choices

are a four point sling connected to all four corners on

the top of the overhead guard, or a two point sling

connected to two opposite corners of the overhead

guard. If a single point hoist is used, make sure that

the lift point is as close to the center of the overhead

guard as possible. If during the initial start of the lift,

the overhead guard is off balance, lower immediately

and move the hoist to a more centered point.

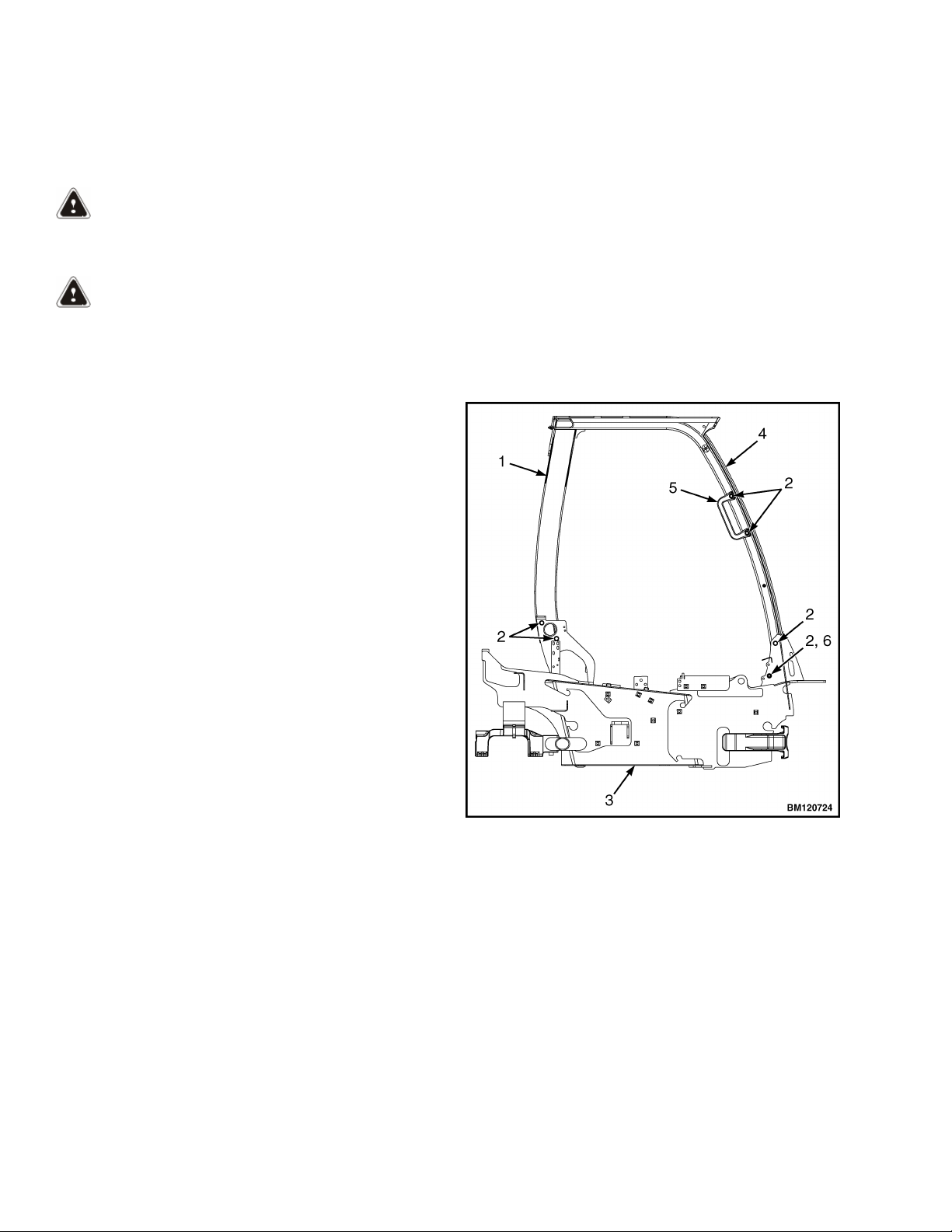

5. Remove capscrews from overhead guard front

legs and frame. See Figure 18.

NOTE: When overhead guard is lifted from the

frame, make sure that any electrical wires are moved

through the holes in the frame so that they are not

damaged.

6. Using lifting device, remove overhead guard from

frame. See Figure 18.

7. Remove capscrews and handle from overhead

guard. See Figure 18.

No welding or drilling on legs of overhead guard is

permitted as per previous WARNING.

1. Connect a lifting device to overhead guard.

NOTE: Note routing of electrical wires prior to discon-

necting. Tag electrical connectors during removal to

aid in installation.

2. Disconnect wires between frame and overhead

guard.

3. Remove capscrews from overhead guard rear

legs and frame. See Figure 18.

4. Remove dash and kick panel from cowl. See section Hood, Seat, and Side Covers Replacement

for removal procedures.

1. OVERHEAD GUARD REAR LEG

2. CAPSCREW

3. FRAME

4. OVERHEAD GUARD FRONT LEG

5. HANDLE

6. NUT

Figure 18. Overhead Guard

18

0100 YRM 1766 Overhead Guard Replacement

INSTALL

NOTE: Make sure electrical wires are routed as no-

ted during removal to ensure that wires do not get

pinched.

1. Using lifting device, install overhead guard onto

frame.

2. Install capscrews onto overhead guard front legs

and frame. See Figure 18. Tighten capscrews to

66 N•m (49 lbf ft).

3. Install kick panel and dash onto cowl. See section

Hood, Seat, and Side Covers Replacement for install procedures.

4. Install capscrews onto overhead guard rear legs

and frame. See Figure 18. Tighten capscrews to

66 N•m (49 lbf ft).

5. Connect electrical wires as tagged during removal.

6. Install handle and capscrews onto overhead

guard. See Figure 18.

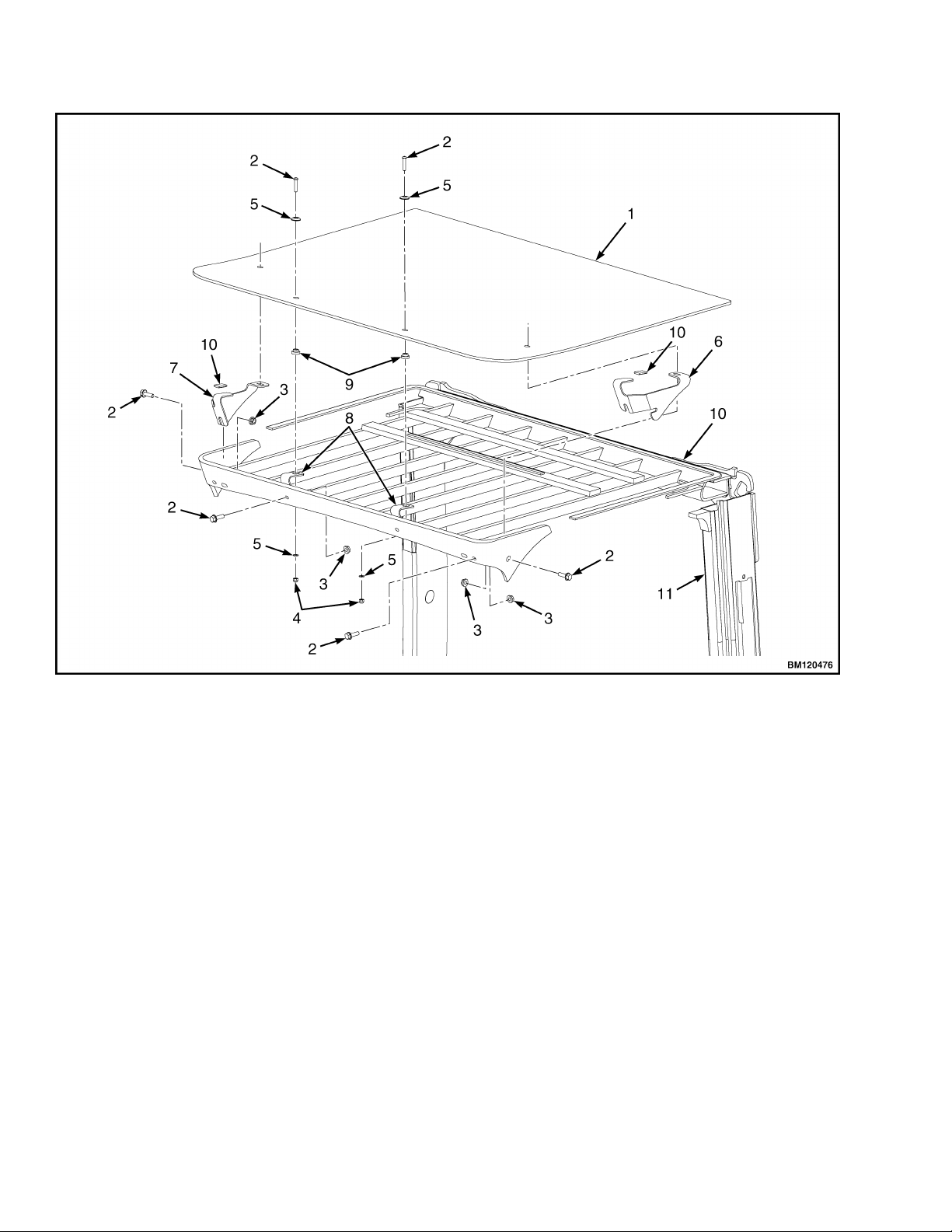

Rain Top (Optional)

Remove

1. Remove two capscrews, two locknuts, two bushings and two washers from bracket and rain top at

front center of overhead guard. See Figure 19.

2. Remove two capscrews, two locknuts, two bushings and two washers from bracket and rain top at

front corners of overhead guard. See Figure 19.

3. Remove two capscrews, two wheel nuts and two

brackets from front center of overhead guard. See

Figure 19.

NOTE: Note position of rain top on overhead guard

before removal.

5. Remove rain top from overhead guard. See Figure 19.

Clean and Inspect

1. Clean all remaining sealer residue from rain top

and overhead guard surfaces.

2. Inspect rain top and brackets for cracks. Replace

if necessary.

Install

1. Apply a continuous bead of sealer to back corners

of overhead guard. See (item 10) Figure 19.

NOTE: Apply even pressure to rain top to squeeze

down sealer to a thickness of 3 to 5 mm (0.118 to

0.197 in.).

2. Install rain top onto overhead guard as noted during removal.

3. Install right bracket, left bracket two capscrews,

two wheel nuts, onto front corner of overhead

guard. See Figure 19.

4. Install two brackets, two capscrews, and two

wheel nuts to front center of overhead guard. See

Figure 19.

5. Install two capscrews, two bushings, two washers

and two locknuts onto bracket and rain top at front

corners of overhead guard. See Figure 19.

6. Install two capscrews, two bushings, two washers

and two locknuts onto bracket and rain top at front

center of overhead guard. See Figure 19.

4. Remove two capscrews, two wheel nuts, right

bracket and left bracket from front corner of overhead guard. See Figure 19.

19

Overhead Guard Replacement 0100 YRM 1766

1. RAIN TOP

2. CAPSCREW

3. WHEEL NUT

4. LOCKNUT

5. WASHER

6. LEFT BRACKET

7. RIGHT BRACKET

8. CENTER BRACKET

9. BUSHING

10. SEALER

11. OVERHEAD GUARD

Figure 19. Overhead Guard Rain Top

20

Loading...

Loading...