Page 1

Electric Chain Hoist

Series CPE

Mod. CPE/F

Capacity 1600 kg - 5000 kg

Yale

electric

Operating and Maintenance Manual

Spare Parts Catalog

Yale Industrial Products GmbH

P. O. Box 10 13 24 • D-42513 Velbert, Germany

Am Lindenkamp 31 • D-42549 Velbert, Germany

Tel. 2051-600-0 • Fax 2051-600-127

Ident.-No. 09900069 / 10.02

Page 2

Yale

electric

Yale Electric Chain Hoist CPE

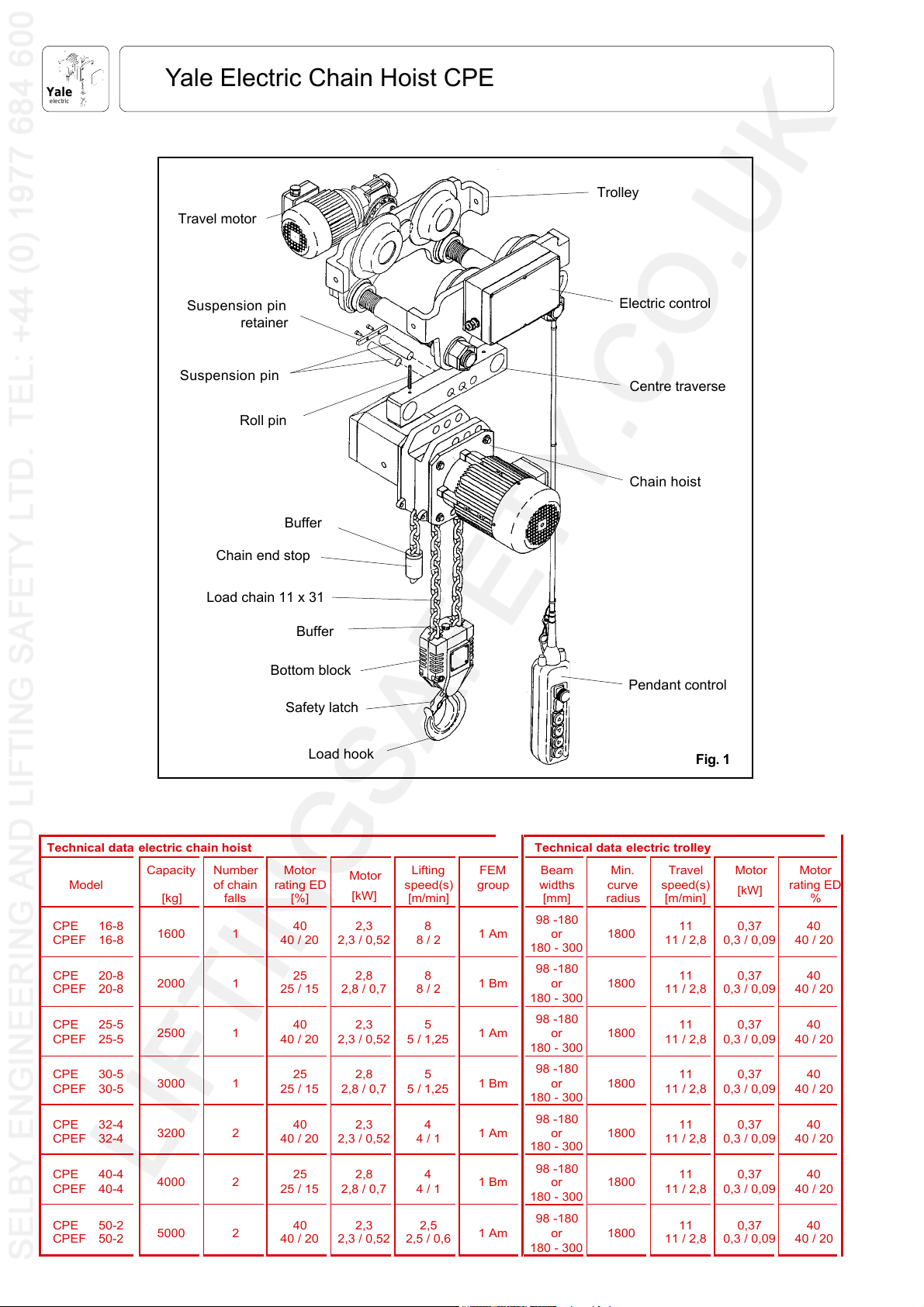

Trolley

Travel motor

Suspension pin

retainer

Suspension pin

Roll pin

Chain end stop

Load chain 11 x 31

Electric control

Centre traverse

Chain hoist

Buffer

Buffer

Bottom block

Pendant control

Safety latch

Load hook

Technical data electric chain hoist Technical data electric trolley

Model

CPE 16-8

CPEF 16-8

CPE 20-8

CPEF 20-8

CPE 25-5

CPEF 25-5

CPE 30-5

CPEF 30-5

CPE 32-4

CPEF 32-4

CPE 40-4

CPEF 40-4

CPE 50-2

CPEF 50-2

Capacity

[kg]

1600 1

2000 1

2500 1

3000 1

3200 2

4000 2

5000 2

Number

of chain

falls

Motor

rating ED

[%]

40

40 / 20

25

25 / 15

40

40 / 20

25

25 / 15

40

40 / 20

25

25 / 15

40

40 / 20

Motor

[kW]

2,3

2,3 / 0,5288 / 2

2,8

2,8 / 0,7

2,3

2,3 / 0,5255 / 1,25

2,8

2,8 / 0,755 / 1,25

2,3

2,3 / 0,5244 / 1

2,8

2,8 / 0,7

2,3

2,3 / 0,52

Lifting

speed(s)

[m/min]

8

8 / 2

4

4 / 1

2,5

2,5 / 0,6

FEM

group

1 Am

1 Bm

1 Am

1 Bm

1 Am

1 Bm

1 Am

Beam

widths

[mm]

98 -180

or

180 - 300

98 -180

or

180 - 300

98 -180

or

180 - 300

98 -180

or

180 - 300

98 -180

or

180 - 300

98 -180

or

180 - 300

98 -180

or

180 - 300

Min.

curve

radius

1800

1800

1800

1800

1800

1800

1800

Travel

speed(s)

[m/min]

11

11 / 2,8

11

11 / 2,8

11

11 / 2,8

11

11 / 2,8

11

11 / 2,8

11

11 / 2,8

11

11 / 2,8

Fig. 1

Motor

[kW]

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

0,37

0,3 / 0,094040 / 20

Motor

rating ED

%

2

Page 3

Yale Electric Chain Hoist CPE

Yale

electric

TABLE OF CONTENTS PAGE

1. GENERAL INFORMATION 3

2. OPERATING INSTRUCTIONS 3

2.1 Correct operation 3

Maximum capacity 3

Danger zones 3

Attaching the hoist / trolley 3

Temperature range 4

Regulations 4

Maintenance / repair 4

2.2 Incorrect operation 4

2.3 Initial operation 4

Inspection before initial operation 4

Inspection before starting work 4

Inspection of load chain 4

Inspection of chain end stop 4

Inspection of chain reeving 4

Inspection of suspension and load hooks 5

Attaching the load 5

Inspect the traverse (for trolleys) 5

Check adjustment of trolley width 5

3. ASSEMBLY 5

3.1 Inspection before assembly 5

3.2 Electric chain hoist with hook suspension

(Standard version) 5

3.3 Electric chain hoist with trolley 5

Assembly of the trolley 6

2.4 Electrical connection 6

Preparation 6

Mains supply connection 6

1. GENERAL INFORMATION

Attention: All users must read these operating instructions

carefully prior to the initial operation. These instructions

are intended to acquaint the user with the hoist / trolley and

enable hime to use it to the full extent of its intended

capabilities.

The operating instructions contain important information

on how to handle the hoist / trolley in a safe, correct and

economic way. Acting in accordance with these instructions

helps to avoid dangers, reduce repair costs and downtime

and to increase the reliability and lifetime of the hoist / trolley.

Anyone involved in doing any of the following work with the

hoist / trolley must read the operating instructions and act

accordingly:

• operation, including preparation, trouble shooting and

cleaning

• maintenance, inspection, repair

• transport

Apart from the operating instructions and the accident

prevention act valid for the respective country and area where

the hoist / trolley is used, also the commonly accepted

regulations for safe and professional work must be adhered

to.

Every unit leaving the factory is furnished with a test certificate

that shows the serial number of the hoist / trolley . This

certificate has to be filed together with the inspection

manual (see page 30).

The continuous sound level at the place of work is equal to

73 dB. The measurements were taken at a distance of 1 m

from the hoist at 9 positions in accordance with DIN 45635,

precision class 2.

4. FUNTIONAL TEST AFTER ASSEMBLY 6

5. OPERATION 7

Installation, service, operation 7

Traversing the trolley 7

Attaching the load 7

Lifting / lowering the load 7

Emergency stop 7

6. SERVICE 8

6.1 Daily checks 8

6.2 Regular inspections, service and testing 8

6.3 Load chain 9

Lubricating the load chain 9

Inspecting the load chain for wear 9

Replace the load chain 9

1-strand design 9

2-strand design 9

6.4 Load and suspension hooks 10

6.5 Trolleys 10

6.6 Electric chain hoist in general 10

6.7 Overload protection device 10

6.8 Gearbox 10

Check oil level 10

Oil change 10

Disassembly and reassambly 11

6.9 Maintenance of the motor 11

Motor 11

Disc brake 11

2. OPERATING INSTRUCTIONS

2.1 Correct operation

Maximum capacity

• The Yale electric chain hoist model CPE is designed to lift

and lower loads up to the rated capacity. The lifting capacity

indicated on the hoist / trolley is the maximum safe working

load which must not be exceeded.

Danger zones

• Do not lift or transport loads

while personnel are in the

danger zone.

• Do not allow personnel to pass

under a suspended load (see

Fig. 2)

• After lifting or tensioning, a load

must not be left unattended for

a longer period of time.

• Start moving the load only after

Fig. 2

Attaching the hoist / trolley

• The operator must ensure that the hoist / trolley is attached

in a manner that does not expose himself or other

personnel to danger by the hoist, trolley , chain(s) or the

load.

it has been attached correctly

and all personnel are clear of

the danger zone.

3

Page 4

Yale

electric

Yale Electric Chain Hoist CPE

Temperature range

• The hoist / trolley can be operated in ambient temperatures

between -10

O

C und +50O C. Consult the manufacturer in

case of extreme working conditions.

Note: At ambient temperatures below 0

O

C check the brake

is not frozen.

Regulations

• The accident prevention act and/or safety regulations of

the respective country for using manual and electric hoists

must be strictly adhered to. In Germany these are VBG 8,

VBG 9, VBG 9a, ZH 1/25, ZH 1/27, and VDE 0100 resp.

VDE 0130.

Maintenance / Repair

• In order to ensure correct operation, not only the operating

instructions, but also the conditions for inspection and

maintenance must be complied with. If defects are found

stop using the hoist / trolley immediately.

Attention: Before starting work on electrical components

switch OFF the main current switch and secure it against

unintentionally being switched back on.

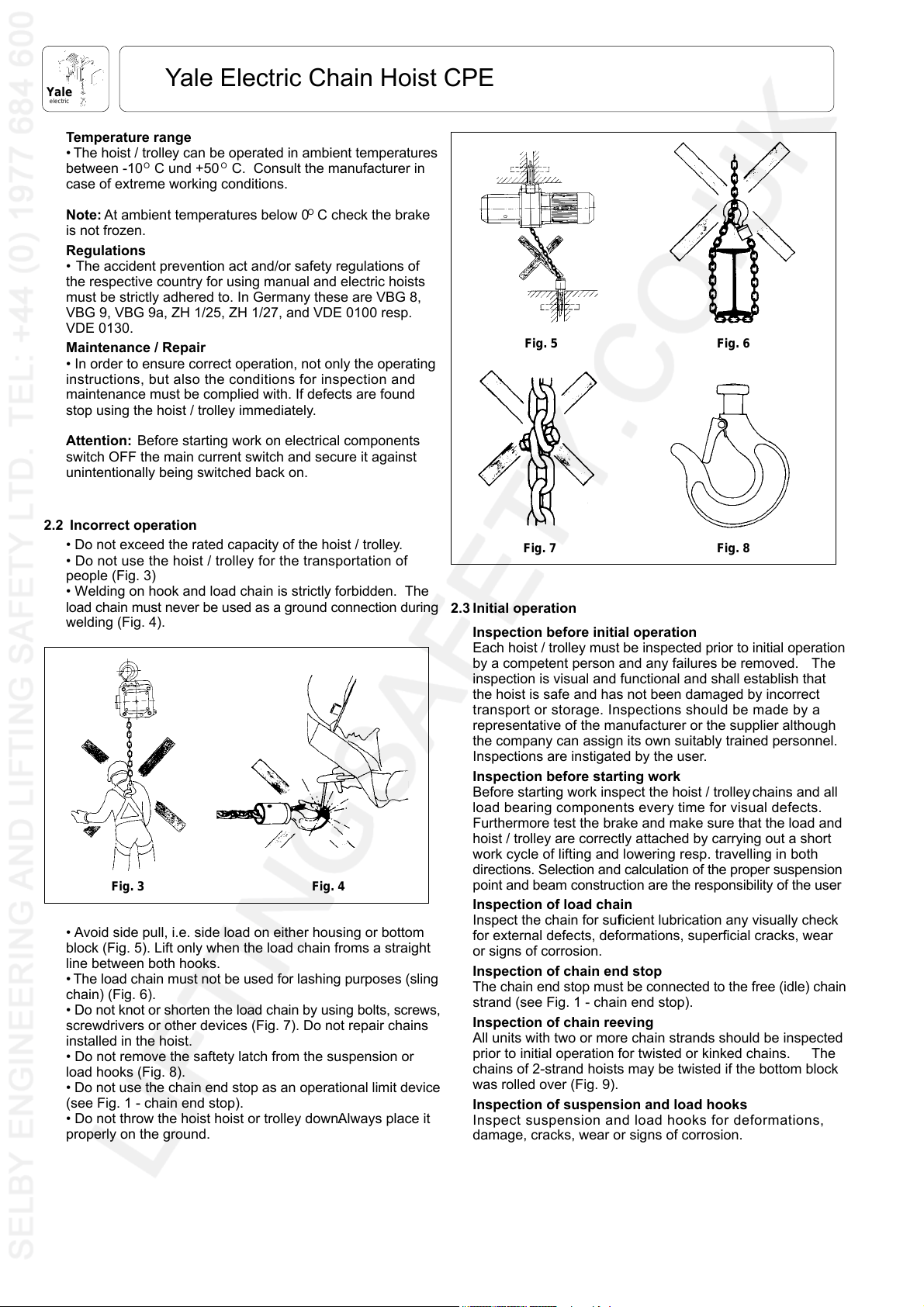

2.2 Incorrect operation

• Do not exceed the rated capacity of the hoist / trolley.

• Do not use the hoist / trolley for the transportation of

people (Fig. 3)

• Welding on hook and load chain is strictly forbidden. The

load chain must never be used as a ground connection during

welding (Fig. 4).

Fig. 3

Fig. 4

• Avoid side pull, i.e. side load on either housing or bottom

block (Fig. 5). Lift only when the load chain froms a straight

line between both hooks.

• The load chain must not be used for lashing purposes (sling

chain) (Fig. 6).

• Do not knot or shorten the load chain by using bolts, screws,

screwdrivers or other devices (Fig. 7). Do not repair chains

installed in the hoist.

• Do not remove the saftety latch from the suspension or

load hooks (Fig. 8).

• Do not use the chain end stop as an operational limit device

(see Fig. 1 - chain end stop).

• Do not throw the hoist hoist or trolley down. Always place it

properly on the ground.

Fig. 5

Fig. 6

Fig. 8Fig. 7

2.3 Initial operation

Inspection before initial operation

Each hoist / trolley must be inspected prior to initial operation

by a competent person and any failures be removed. The

inspection is visual and functional and shall establish that

the hoist is safe and has not been damaged by incorrect

transport or storage. Inspections should be made by a

representative of the manufacturer or the supplier although

the company can assign its own suitably trained personnel.

Inspections are instigated by the user.

Inspection before starting work

Before starting work inspect the hoist / trolley, chains and all

load bearing components every time for visual defects.

Furthermore test the brake and make sure that the load and

hoist / trolley are correctly attached by carrying out a short

work cycle of lifting and lowering resp. travelling in both

directions. Selection and calculation of the proper suspension

point and beam construction are the responsibility of the user.

Inspection of load chain

Inspect the chain for sufficient lubrication any visually check

for external defects, deformations, superficial cracks, wear

or signs of corrosion.

Inspection of chain end stop

The chain end stop must be connected to the free (idle) chain

strand (see Fig. 1 - chain end stop).

Inspection of chain reeving

All units with two or more chain strands should be inspected

prior to initial operation for twisted or kinked chains. The

chains of 2-strand hoists may be twisted if the bottom block

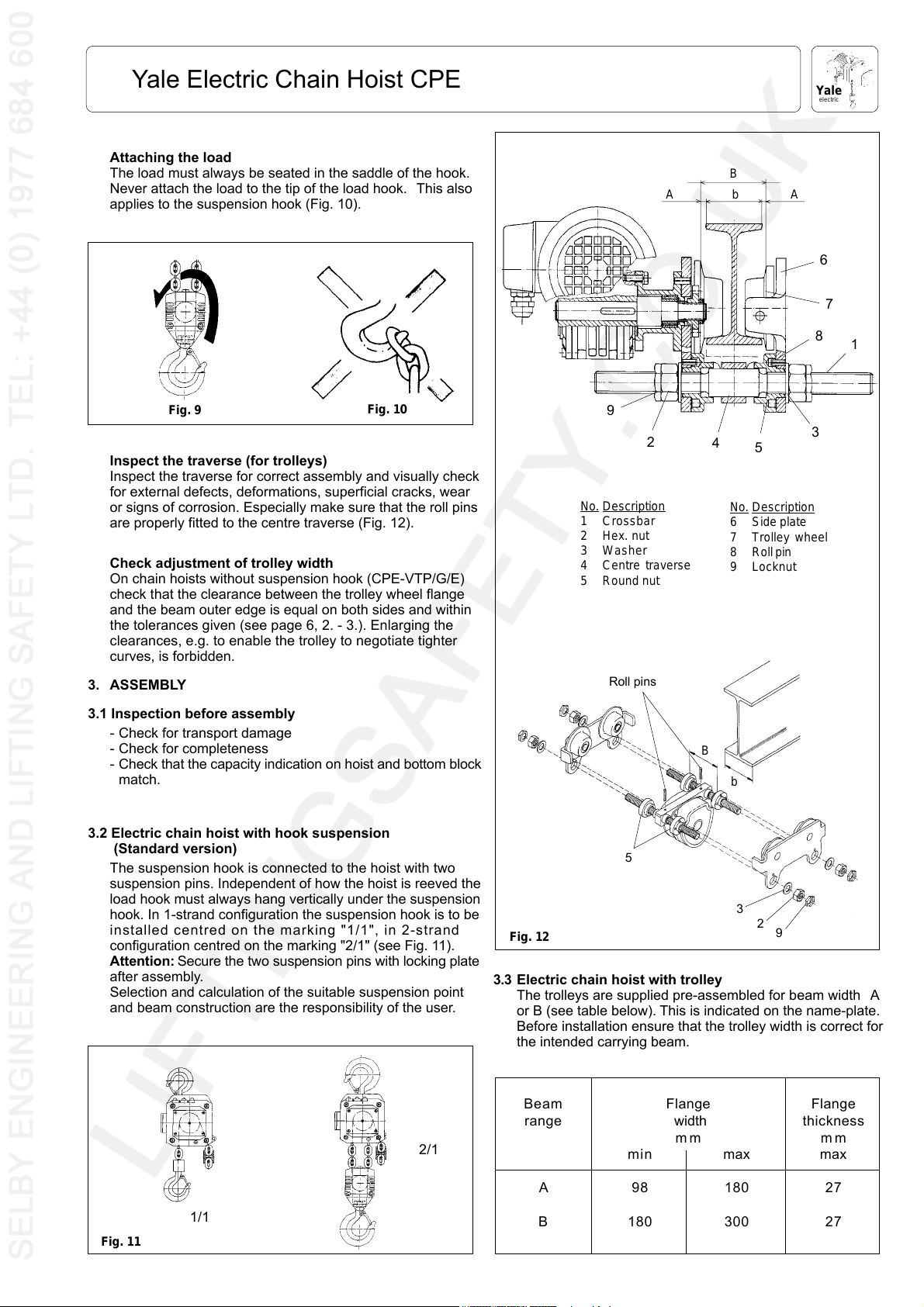

was rolled over (Fig. 9).

Inspection of suspension and load hooks

Inspect suspension and load hooks for deformations,

damage, cracks, wear or signs of corrosion.

4

Page 5

Yale Electric Chain Hoist CPE

Yale

electric

Attaching the load

The load must always be seated in the saddle of the hook.

Never attach the load to the tip of the load hook. This also

applies to the suspension hook (Fig. 10).

Fig. 9

Fig. 10

Inspect the traverse (for trolleys)

Inspect the traverse for correct assembly and visually check

for external defects, deformations, superficial cracks, wear

or signs of corrosion. Especially make sure that the roll pins

are properly fitted to the centre traverse (Fig. 12).

Check adjustment of trolley width

On chain hoists without suspension hook (CPE-VTP/G/E)

check that the clearance between the trolley wheel flange

and the beam outer edge is equal on both sides and within

the tolerances given (see page 6, 2. - 3.). Enlarging the

clearances, e.g. to enable the trolley to negotiate tighter

curves, is forbidden.

3. ASSEMBLY

A

9

2

No. Description

1Crossbar

2 Hex. nut

3 Washer

4Centre traverse

5 Round nut

Roll pins

B

bA

4

5

No. Description

6Side plate

7Trolley wheel

8Roll pin

9 Locknut

6

7

8

1

3

3.1 Inspection before assembly

- Check for transport damage

- Check for completeness

- Check that the capacity indication on hoist and bottom block

match.

3.2 Electric chain hoist with hook suspension

(Standard version)

The suspension hook is connected to the hoist with two

suspension pins. Independent of how the hoist is reeved the

load hook must always hang vertically under the suspension

hook. In 1-strand configuration the suspension hook is to be

installed centred on the marking "1/1", in 2-strand

configuration centred on the marking "2/1" (see Fig. 11).

Attention: Secure the two suspension pins with locking plate

after assembly.

Selection and calculation of the suitable suspension point

and beam construction are the responsibility of the user.

2/1

B

b

5

3

2

Fig. 12

3.3

Electric chain hoist with trolley

9

The trolleys are supplied pre-assembled for beam width A

or B (see table below). This is indicated on the name-plate.

Before installation ensure that the trolley width is correct for

the intended carrying beam.

Beam Flange Flange

range width thickness

mm mm

min max max

Fig. 11

1/1

A98180 27

B 180 300 27

5

Page 6

Yale

electric

Yale Electric Chain Hoist CPE

Assembly of the trolley (see Fig. 12)

1.) Unscrew the locking nuts (item 9) and hex. nuts (item 2)

from the crossbars (item 1) and remove both side plates

(item 6) from the trolley.

2.) Measure the flange width of the beam (see Fig. 1 1 -

measurement "b").

3.) Adjust measurement "B" between the shoulders of the

round nuts (item 5) on the threaded crossbars (item 1).

Ensure that the 4 bores in the round nuts face towards the

outside. Adjust the measurement "B" to equal measure-

ment "b" plus 4 mm. Measurement "A" must be 2 mm on

either side and the suspension traverse (item 4) must be

centred between the round nuts.

4.) Replace one side plate (item 6):

Replace one side plate ensuring that the roll pins (item 8)

engage into one of the bores in the round nuts. To achieve

this it may be necessary to rotate the round nuts slightly .

5.) Replace the washers (item 3) and tighten the hex. nuts

(item 2). Screw on the locknuts (item 9) fingertight and

tighten a further 1/4 to 1/2 turn.

Attention: The locknuts must always be fitted.

6.) Loosely replace the second side plate (item 6) on the

crossbars (item 1). The washers (item 3), hex. nuts (item2)

and locknuts (item 9) can be fitted loosely .

7.) Raise the complete pre-assembled trolley to the carrying

beam.

3.4 Electrical connection

Attention

Work at electrical installations may be carried out by

electrical experts only. The local regulations have to be

strictly observed, in Germany DIN 7100 / VDE 0100 and

DIN 57113 / VDE 0113.

Preparation

• Before beginning work on electrical components the

mains current switch must be switched OFF and secured

against unintentionally being switched back on.

• Before connecting the chain hoist ensure that the

electrical data on the nameplate match the local supply

specifications.

• The mains supply cable must be an insulated cable with

4 flexible leads. The ground (earth) lead must be longer

than the live leads. For wire cross-section and fusing see

table on page 7.

• The length of the pendant control cable is determined by

working conditions. Attach the tension relief wire in a manner

that the pendant control cable hangs load-free.

• Wiring and terminal connecting diagrams are included

with the hoist.

Mains supply connection

1.) The mains supply cable must be connected to the

electric chain hoist before it is connected to the mains

supply.

2.) On chain hoists with an electric trolley (CPE-VTE) the

three phases of the mains supply are to be connected to

the terminal strip within the terminal box on the trolley. The

ground/earth wire is to be connected to the special ground/

earth connection within the terminal box of the chain hoist.

8.) Engage the second side plate (item 6) ensuring that the

roll pins (item 8) engage into one of the bores in the round

nuts (item 5). To achieve this it may be necessary to rotate

the round nuts slightly .

9.) Tighten the hex. nuts (item 2) on the second side plate.

Tighten the locknuts (item 9) fingertight and then a further

1/4 to 1/2 turn.

Attention: The locknuts must always be fitted.

10.) By traversing the trolley check the following:

• that a clearance of 2 mm is maintained on each side

between the trolley wheel flanges and the beam outer edge.

• that the suspension traverse is centred below the beam.

• that all 4 locknuts (item 9) are fitted.

11.) Model CPE-VTG only:

To fit the hand chain position the slot on the outer edge of

the hand chain wheel below the chain guide. Place any

one link of the endless hand chain vertically into the slot

and turn the hand chain wheel until the link has passed

the chain guides on both sides.

Attention: Do not twist the hand chain when fitting.

Geared trolleys are moved by pulling the hand chain.

3.) On chain hoists without electric trolley the mains supply

and the ground/earth wire are to be connected to the

terminal strip within the terminal box of the chain hoist.

4.) After removing the terminal box cover, connect the wiring

as shown on the wiring diagram label inside the terminal

box cover.

Attention: On hoists with direct control the ground/earth

wire should always be connected according to the wiring

diagram. Should the mains supply source not provide a

ground (earth) connection please consult the manufacturer.

5.) After replacing the terminal box cover, connect the other

end of the supply cable to the mains supply .

6.) Check the motor's direction of rotation.

The wiring diagram included has been drawn for a normal,

clockwise rotating installation.Should the user's mains

supply not fulfil these requirements, e.g. the hoist lowers

when lift is selected (or vice versa) switch the unit OFF

immediately and exchange two of the three phase

connections in the mains connection.

Attention:

Under no circumstances may the wiring in the pendant

control be tampered with.

6

Page 7

Yale Electric Chain Hoist CPE

Yale

electric

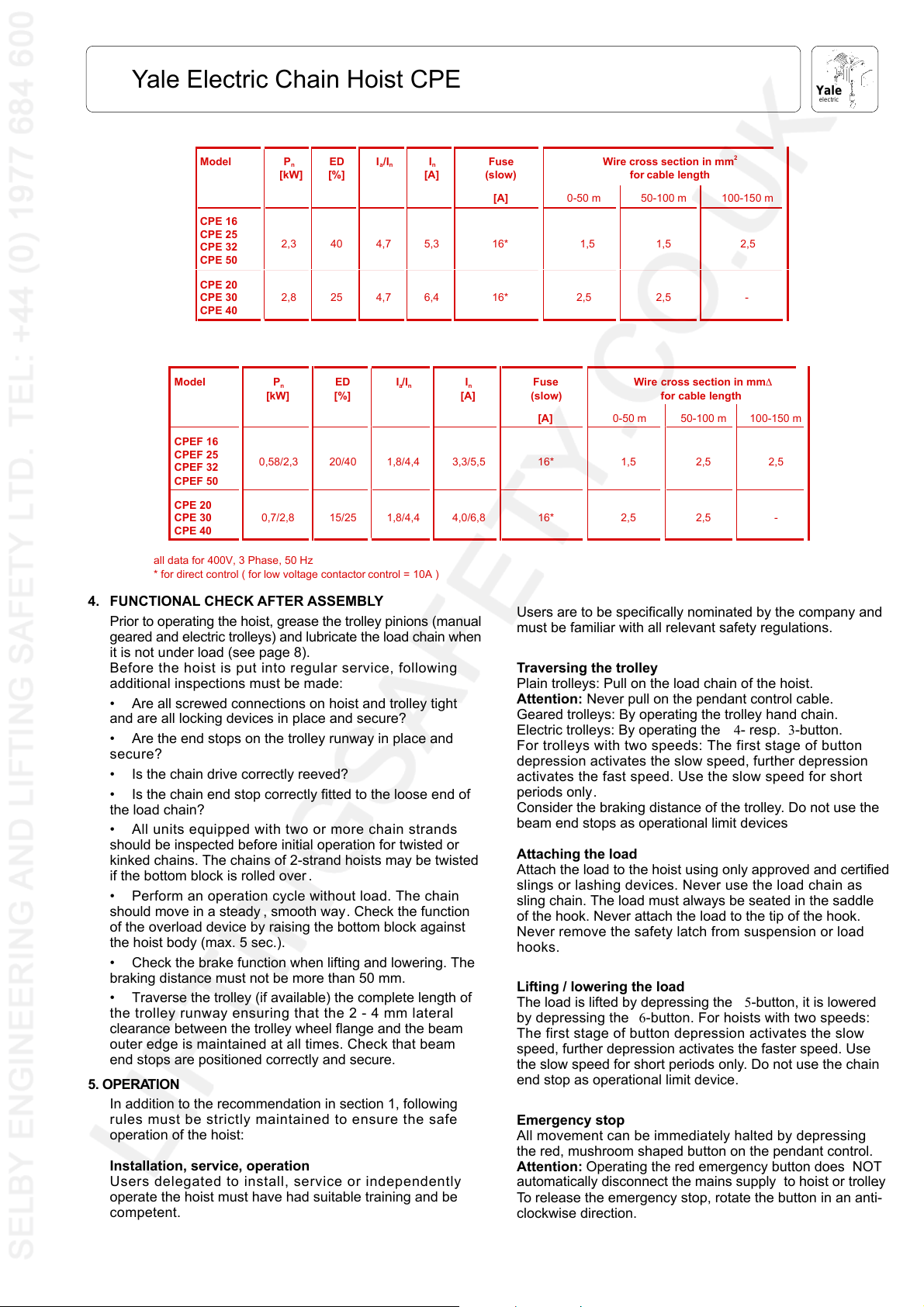

Model P

CPE 16

CPE 25

CPE 32

CPE 50

CPE 20

CPE 30

CPE 40

Model P

CPEF 16

CPEF 25

CPEF 32

CPEF 50

CPE 20

CPE 30

CPE 40

all data for 400V, 3 Phase, 50 Hz

* for direct control ( for low voltage contactor control = 10A )

n

[kW]ED[%]

2,3 40 4,7 5,3 16* 1,5 1,5 2,5

2,8 25 4,7 6,4 16* 2,5 2,5 -

n

[kW]

0,58/2,3 20/40 1,8/4,4 3,3/5,5 16* 1,5 2,5 2,5

0,7/2,8 15/25 1,8/4,4 4,0/6,8 16* 2,5 2,5 -

ED

[%]

I

a/In

[A]

I

a/In

4. FUNCTIONAL CHECK AFTER ASSEMBLY

Prior to operating the hoist, grease the trolley pinions (manual

geared and electric trolleys) and lubricate the load chain when

it is not under load (see page 8).

Before the hoist is put into regular service, following

additional inspections must be made:

• Are all screwed connections on hoist and trolley tight

and are all locking devices in place and secure?

• Are the end stops on the trolley runway in place and

secure?

• Is the chain drive correctly reeved?

• Is the chain end stop correctly fitted to the loose end of

the load chain?

• All units equipped with two or more chain strands

should be inspected before initial operation for twisted or

kinked chains. The chains of 2-strand hoists may be twisted

if the bottom block is rolled over.

• Perform an operation cycle without load. The chain

should move in a steady , smooth way. Check the function

of the overload device by raising the bottom block against

the hoist body (max. 5 sec.).

• Check the brake function when lifting and lowering. The

braking distance must not be more than 50 mm.

• Traverse the trolley (if available) the complete length of

the trolley runway ensuring that the 2 - 4 mm lateral

clearance between the trolley wheel flange and the beam

outer edge is maintained at all times. Check that beam

end stops are positioned correctly and secure.

5. OPERATION

In addition to the recommendation in section 1, following

rules must be strictly maintained to ensure the safe

operation of the hoist:

Installation, service, operation

Users delegated to install, service or independently

operate the hoist must have had suitable training and be

competent.

I

n

Fuse

(slow)

[A] 0-50 m 50-100 m 100-150 m

[A]

I

n

Fuse

(slow)

[A] 0-50 m 50-100 m 100-150 m

Wire cross section in mm

for cable length

Wire cross section in mm∆

for cable length

2

Users are to be specifically nominated by the company and

must be familiar with all relevant safety regulations.

Traversing the trolley

Plain trolleys: Pull on the load chain of the hoist.

Attention: Never pull on the pendant control cable.

Geared trolleys: By operating the trolley hand chain.

Electric trolleys: By operating the 4- resp. 3-button.

For trolleys with two speeds: The first stage of button

depression activates the slow speed, further depression

activates the fast speed. Use the slow speed for short

periods only.

Consider the braking distance of the trolley. Do not use the

beam end stops as operational limit devices

Attaching the load

Attach the load to the hoist using only approved and certified

slings or lashing devices. Never use the load chain as

sling chain. The load must always be seated in the saddle

of the hook. Never attach the load to the tip of the hook.

Never remove the safety latch from suspension or load

hooks.

Lifting / lowering the load

The load is lifted by depressing the 5-button, it is lowered

by depressing the 6-button. For hoists with two speeds:

The first stage of button depression activates the slow

speed, further depression activates the faster speed. Use

the slow speed for short periods only. Do not use the chain

end stop as operational limit device.

Emergency stop

All movement can be immediately halted by depressing

the red, mushroom shaped button on the pendant control.

Attention: Operating the red emergency button does NOT

automatically disconnect the mains supply to hoist or trolley.

To release the emergency stop, rotate the button in an anti-

clockwise direction.

7

Page 8

Yale

electric

Yale Electric Chain Hoist CPE

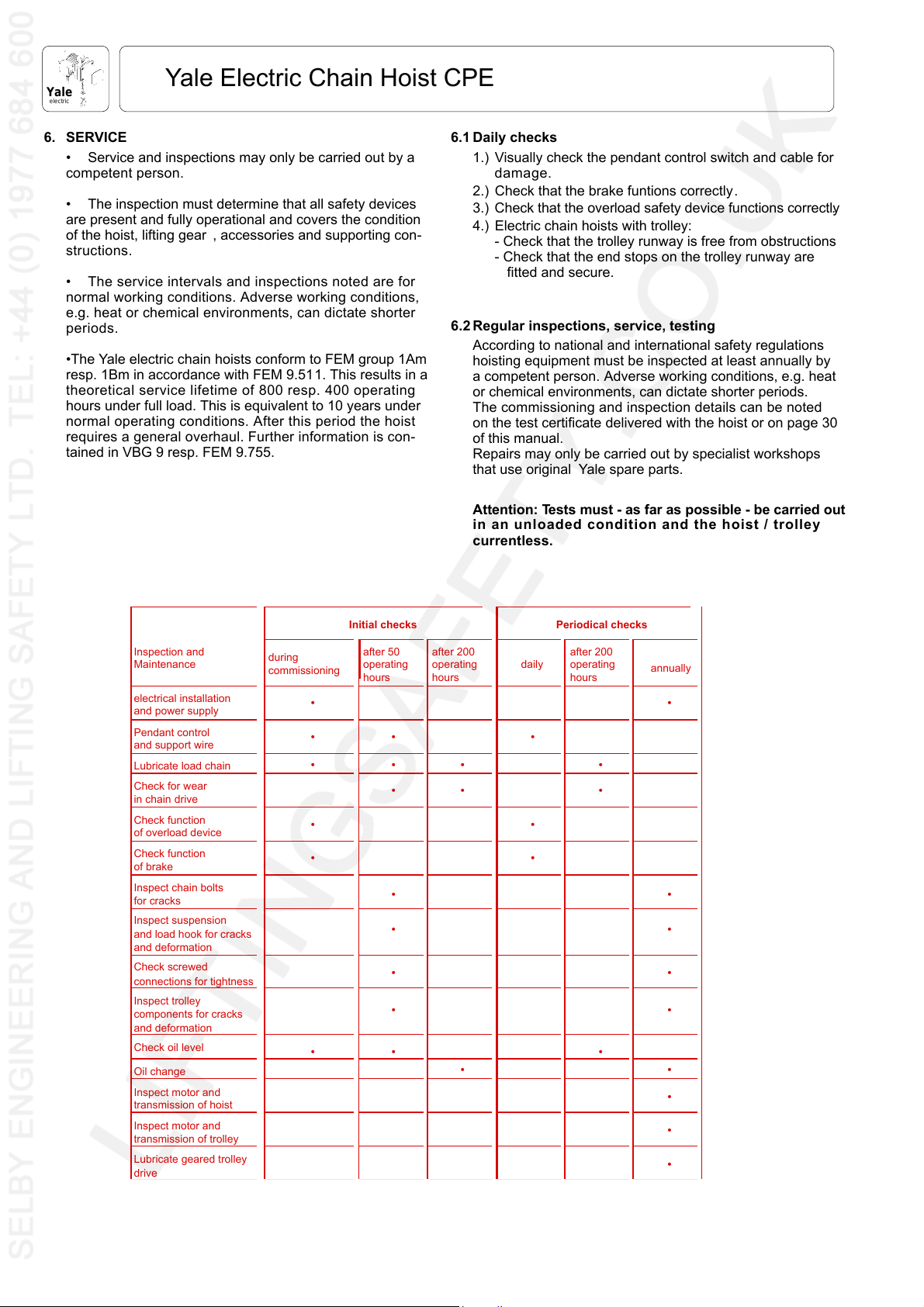

6. SERVICE

• Service and inspections may only be carried out by a

competent person.

• The inspection must determine that all safety devices

are present and fully operational and covers the condition

of the hoist, lifting gear , accessories and supporting con-

structions.

• The service intervals and inspections noted are for

normal working conditions. Adverse working conditions,

e.g. heat or chemical environments, can dictate shorter

periods.

•The Yale electric chain hoists conform to FEM group 1Am

resp. 1Bm in accordance with FEM 9.511. This results in a

theoretical service lifetime of 800 resp. 400 operating

hours under full load. This is equivalent to 10 years under

normal operating conditions. After this period the hoist

requires a general overhaul. Further information is con-

tained in VBG 9 resp. FEM 9.755.

6.1 Daily checks

1.) Visually check the pendant control switch and cable for

damage.

2.) Check that the brake funtions correctly.

3.) Check that the overload safety device functions correctly.

4.) Electric chain hoists with trolley:

- Check that the trolley runway is free from obstructions

- Check that the end stops on the trolley runway are

fitted and secure.

6.2 Regular inspections, service, testing

According to national and international safety regulations

hoisting equipment must be inspected at least annually by

a competent person. Adverse working conditions, e.g. heat

or chemical environments, can dictate shorter periods.

The commissioning and inspection details can be noted

on the test certificate delivered with the hoist or on page 30

of this manual.

Repairs may only be carried out by specialist workshops

that use original Yale spare parts.

Attention: Tests must - as far as possible - be carried out

in an unloaded condition and the hoist / trolley

currentless.

Inspection and

Maintenance

electrical installation

and power supply

Pendant control

and support wire

Lubricate load chain

Check for wear

in chain drive

Check function

of overload device

Check function

of brake

Inspect chain bolts

for cracks

Inspect suspension

and load hook for cracks

and deformation

Check screwed

connections for tightness

Inspect trolley

components for cracks

and deformation

Check oil level

Oil change

Inspect motor and

transmission of hoist

Inspect motor and

transmission of trolley

Lubricate geared trolley

drive

Initial checks Periodical checks

during

commissioning

• •

•• •

••• •

••

••

•• •

after 50

operating

hours

after 200

operating

hours

•• •

••

••

••

••

••

daily

after 200

operating

hours

annually

•

•

•

8

Page 9

Yale Electric Chain Hoist CPE

Yale

electric

6.3 LOAD CHAIN

The Yale load chain is grade 80 chain with the dimensions

11 x 31 mm. The CPE electric hoists are specially designed

to use this type of chain. For this reason only chains that

have been approved by the manufacturer may be used in

these hoists.

Lubricating the load chain

The load chain is to be lubricated before initial operation

and every 3 months but the latest after 200 operating hours.

Adverse working conditions, e.g. excessive dust or con-

tinued heavy duty can dictate shorter periods between

lubrication.

• Before the chain is lubricated it must be cleaned. Flame

cleaning is forbidden. Use only cleansing methods and

agents that do not corrode the chain material. Avoid

cleansing methods that can lead to hydrogen brittleness,

e.g. spraying or dipping chain in caustic solvents. Also avoid

surface treatments that can hide cracks and flaws or other

surface damage.

• The chain must be lubricated in a no-load condition so

that lubricant can enter between the links, e.g. by dipping in

oil.

• Motor oil of the voscosity 100, e.g. Shell Tonna T68 can

be used to lubricate the chain. For very dusty applications

use a dry lubricant.

Inspecting the load chain for wear

Load chains must be inspected every 3 months or the latest

after 200 operating hours (see VBG 8 § 27 or local regu-

lations).

Visually inspect the chain over its full length for defor-

mation, cracks, flaws, elongation, wear or corrosive pitting.

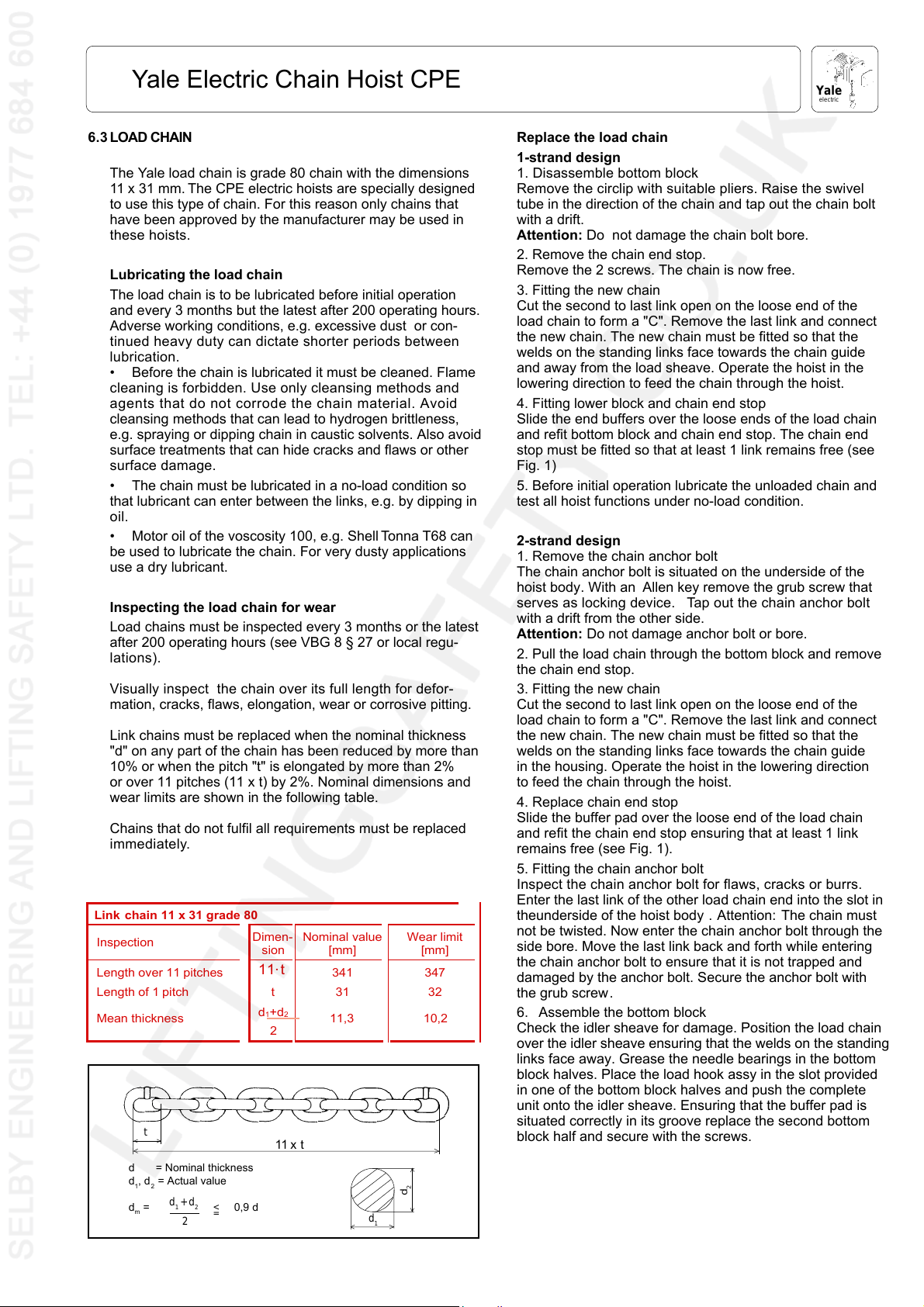

Link chains must be replaced when the nominal thickness

"d" on any part of the chain has been reduced by more than

10% or when the pitch "t" is elongated by more than 2%

or over 11 pitches (11 x t) by 2%. Nominal dimensions and

wear limits are shown in the following table.

Chains that do not fulfil all requirements must be replaced

immediately.

Link chain 11 x 31 grade 80

Inspection

Length over 11 pitches

Length of 1 pitch t 31 32

Mean thickness

t

d = Nominal thickness

d1, d2 = Actual value

d1 + d

dm = 0,9 d

2

2

Dimen-

<

=

sion

11⋅t

d

1+d2

2

11 x t

Nominal value

[mm]

341 347

11,3 10,2

d

1

Wear limit

[mm]

2

d

Replace the load chain

1-strand design

1. Disassemble bottom block

Remove the circlip with suitable pliers. Raise the swivel

tube in the direction of the chain and tap out the chain bolt

with a drift.

Attention: Do not damage the chain bolt bore.

2. Remove the chain end stop.

Remove the 2 screws. The chain is now free.

3. Fitting the new chain

Cut the second to last link open on the loose end of the

load chain to form a "C". Remove the last link and connect

the new chain. The new chain must be fitted so that the

welds on the standing links face towards the chain guide

and away from the load sheave. Operate the hoist in the

lowering direction to feed the chain through the hoist.

4. Fitting lower block and chain end stop

Slide the end buffers over the loose ends of the load chain

and refit bottom block and chain end stop. The chain end

stop must be fitted so that at least 1 link remains free (see

Fig. 1)

5. Before initial operation lubricate the unloaded chain and

test all hoist functions under no-load condition.

2-strand design

1. Remove the chain anchor bolt

The chain anchor bolt is situated on the underside of the

hoist body. With an Allen key remove the grub screw that

serves as locking device. Tap out the chain anchor bolt

with a drift from the other side.

Attention: Do not damage anchor bolt or bore.

2. Pull the load chain through the bottom block and remove

the chain end stop.

3. Fitting the new chain

Cut the second to last link open on the loose end of the

load chain to form a "C". Remove the last link and connect

the new chain. The new chain must be fitted so that the

welds on the standing links face towards the chain guide

in the housing. Operate the hoist in the lowering direction

to feed the chain through the hoist.

4. Replace chain end stop

Slide the buffer pad over the loose end of the load chain

and refit the chain end stop ensuring that at least 1 link

remains free (see Fig. 1).

5. Fitting the chain anchor bolt

Inspect the chain anchor bolt for flaws, cracks or burrs.

Enter the last link of the other load chain end into the slot in

theunderside of the hoist body . Attention: The chain must

not be twisted. Now enter the chain anchor bolt through the

side bore. Move the last link back and forth while entering

the chain anchor bolt to ensure that it is not trapped and

damaged by the anchor bolt. Secure the anchor bolt with

the grub screw.

6. Assemble the bottom block

Check the idler sheave for damage. Position the load chain

over the idler sheave ensuring that the welds on the standing

links face away. Grease the needle bearings in the bottom

block halves. Place the load hook assy in the slot provided

in one of the bottom block halves and push the complete

unit onto the idler sheave. Ensuring that the buffer pad is

situated correctly in its groove replace the second bottom

block half and secure with the screws.

9

Page 10

Yale

electric

Yale Electric Chain Hoist CPE

7. Functional test

All units with two or more chain strands must be inspected

before every operation for twisted or kinked chains. Chains

on 2-strand units may become twisted if the bottom block

is rolled over. If a strand is twisted disconnect it from the

hoist and re-thread it correctly . In some cases it may be

necessary to remove the last link.

8. Before initial operation lubricate the unloaded chain and

test all hoist functions under a no-load condition.

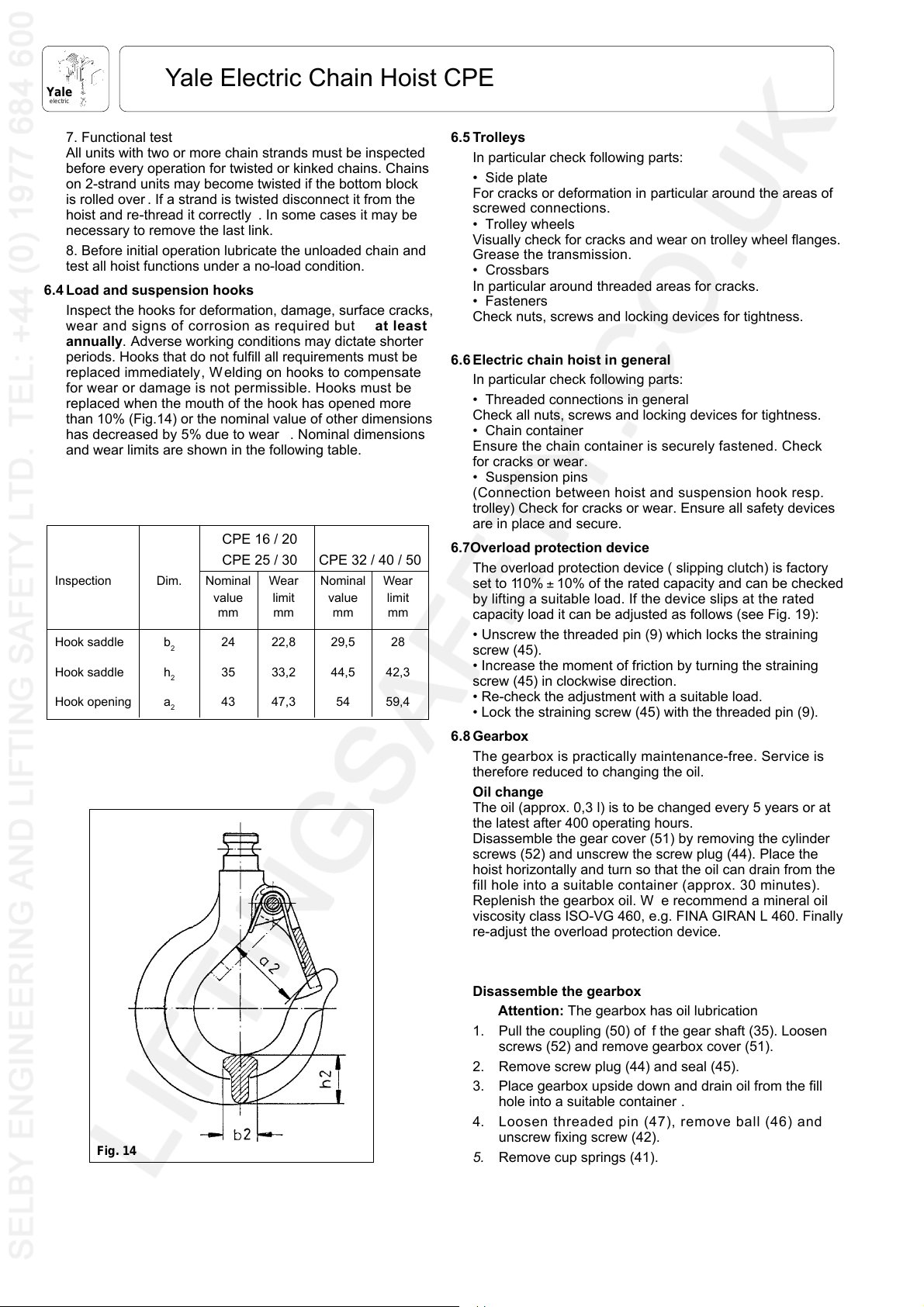

6.4 Load and suspension hooks

Inspect the hooks for deformation, damage, surface cracks,

wear and signs of corrosion as required but at least

annually. Adverse working conditions may dictate shorter

periods. Hooks that do not fulfill all requirements must be

replaced immediately, W elding on hooks to compensate

for wear or damage is not permissible. Hooks must be

replaced when the mouth of the hook has opened more

than 10% (Fig.14) or the nominal value of other dimensions

has decreased by 5% due to wear . Nominal dimensions

and wear limits are shown in the following table.

CPE 16 / 20

CPE 25 / 30 CPE 32 / 40 / 50

Inspection Dim. Nominal Wear Nominal Wear

value limit value limit

mm mm mm mm

Hook saddle b

Hook saddle h

Hook opening a

2

2

2

24 22,8 29,5 28

35 33,2 44,5 42,3

43 47,3 54 59,4

6.5 Trolleys

In particular check following parts:

• Side plate

For cracks or deformation in particular around the areas of

screwed connections.

• Trolley wheels

Visually check for cracks and wear on trolley wheel flanges.

Grease the transmission.

• Crossbars

In particular around threaded areas for cracks.

• Fasteners

Check nuts, screws and locking devices for tightness.

6.6 Electric chain hoist in general

In particular check following parts:

• Threaded connections in general

Check all nuts, screws and locking devices for tightness.

• Chain container

Ensure the chain container is securely fastened. Check

for cracks or wear.

• Suspension pins

(Connection between hoist and suspension hook resp.

trolley) Check for cracks or wear. Ensure all safety devices

are in place and secure.

6.7Overload protection device

The overload protection device ( slipping clutch) is factory

set to 110% ± 10% of the rated capacity and can be checked

by lifting a suitable load. If the device slips at the rated

capacity load it can be adjusted as follows (see Fig. 19):

• Unscrew the threaded pin (9) which locks the straining

screw (45).

• Increase the moment of friction by turning the straining

screw (45) in clockwise direction.

• Re-check the adjustment with a suitable load.

• Lock the straining screw (45) with the threaded pin (9).

6.8 Gearbox

The gearbox is practically maintenance-free. Service is

therefore reduced to changing the oil.

Oil change

The oil (approx. 0,3 l) is to be changed every 5 years or at

the latest after 400 operating hours.

Disassemble the gear cover (51) by removing the cylinder

screws (52) and unscrew the screw plug (44). Place the

hoist horizontally and turn so that the oil can drain from the

fill hole into a suitable container (approx. 30 minutes).

Replenish the gearbox oil. W e recommend a mineral oil

viscosity class ISO-VG 460, e.g. FINA GIRAN L 460. Finally

re-adjust the overload protection device.

Fig. 14

Disassemble the gearbox

Attention: The gearbox has oil lubrication

1. Pull the coupling (50) of f the gear shaft (35). Loosen

screws (52) and remove gearbox cover (51).

2. Remove screw plug (44) and seal (45).

3. Place gearbox upside down and drain oil from the fill

hole into a suitable container .

4. Loosen threaded pin (47), remove ball (46) and

unscrew fixing screw (42).

5. Remove cup springs (41).

10

Page 11

Yale Electric Chain Hoist CPE

Yale

electric

6. Loosen locking screw (38) and remove locking bolt (39).

7. Loosen snap ring (37), remove bearing plate (33) and

ball bearing (36). Remove snap ring (34) and press

ball bearing (36) out of bearing plate (33). Remoove

snap ring (37) from gear shaft (35).

8. Remove friction discs (28) and ring gear (29).

9. Remove planet gears (32), needle bearings (31), stop

washers (30) as well as planet gear carrier assy (27)

and pinion (26). Pull out gear shaft (35).

10. Remove threaded pin (17).

11. Press out remaining gears in the housing (1) in

direction of the flange. Light blows with a rubber

hammer in axial direction onto the rim of the housing

(flange side) may be helpful to loosen the bearing race

(15).

12. Remove planet gears (25), needle bearings (24) and

stop washers (23) from planet gear carrier (22).

13. Pull planet gear carrier (22) and pinion (21) out of planet

gear carrier (3).

14. Remove ball bearing (20) and bearing race (15) from

planet gear carrier (3).

15. Remove snap ring (11) from planet gear carrier (3) and

press out planet gear shaft (10).

16. Remove planet gears (7), needle bearings (8), stop

washers (6) and spacer rings (9).

15. Remove bearing (5) and packing rings (4).

After cleaning, inspection and replacement of all worn parts

re-assembly can be started.

Parts subject to wear are: stop washers (6, 23, 30), needle

bearings (8, 24, 31), O-rings and packing rings (4, 16, 18,

43) as well as the seal (45).

Reassemble the gearbox

Reassemble the gearbox in the reverse order strictly in

accordance with the sectional drawing.

Special care should be taken for clean and correct instal-

lation of planet gears (7) with needle bearings (8) in equal

sorting and stop washers (6) as well as spacer rings (9) in

the planet gear carrier (3).

The friction discs (28) on either side of the ring gear (29)

must be installed oil-soaked (leave in oil for 1 hour before

installation).

The exact adjustment of the overload device is only

possible when the hoist is completely reassembled. Pre-

adjustment of the cup spring (41) is made with the fixing

screw (42).

After the exact adjustment has been made, the fixing screw

(42) is secured by means of the ball (46) and the threaded

pin (47).

6.9 MOTOR

Motor

Under normal conditions the motor is practically main-

tenance-free. Every 2.1/2 years the bearings are to be

inspected, cleaned and repacked half-full with grease. We

recommend K 3 N / KL 3 N DIN 51825 / DIN 51502.

Disc brake

Service to the disc brake is reduced to checking and adjust-

ing the brake air gap. The disc brake air gap should be

between 0,2 and 0,6 mm (this guarantees a short reaction

time and low noise emission). When the wear and tear of

the brake lining comes down to the point where the max.

possible air gap has finally been reached, it is indispen-

sible to carry out a re-adjustment of the brake (the max.

permissible air gaps are shown in the table below).

3.1 Remove fan guard M14.

3.2 Loosen binding screws B14.

3.3 Remove O-ring B62 , insert spacer blocks B40 between

armature disc B42 und adhesive plate B16 (thickness

of the spacer blocks is to be found in the table below).

3.4 Tighten screws B31, or - in case of two shaft extensions

- nut B35 to an extent as to permit the removal of the

spacer blocks B40.

3.5 Evenly tighten the binding screws B14. Please tighten

first screw placed opposite of the fitting key (for the

permissible torque consult the table below).

3.6 Tighten screw B31 once more.

3.7 Remove spacer blocks B40.

3.8 Put on fan guard M14.

3.9 Make a test run for checking the brake funtion.

Attention: Do not allow the brake friction pads to come

into contact with lubricant or similar.

Fig. 15

1234567 891011

Type Nominal Fan B43 Spacer Air gap Pressure Tightening Tightening Adhesive Threaded Quantity

brake with brake block max. spring B9 torque torque plate pin of fitting

torque lining B40 (mm) (mm) colour for B14 for B6 B16 B71 plate B11

EBF 20,2 Nm WS 5907 - 0,6 no colour 7 - 9 Nm 7 + 0,5 Nm no M 5x80 0

11

Page 12

Yale

electric

Yale Electric Chain Hoist CPE

12

14

23

15

9

11

14

1

10

3

7

8

7

6

5

4

11

19

26

22

2

13

16

17

29

14

18

20

25

14

Fig. 16: Hoist body

12

Page 13

Yale Electric Chain Hoist CPE

Yale

electric

Yale Part No.

No. 16 20 25 30 32 40 50

Item Description Qty. CPE / F CPE / F CPE / F CPE / F CPE / F CPE / F CPE / F

1 Housing half - motor side 1 0608972 0608972 0608972 0608972 0608972 0608972 0608972

2 - gearbox side 1 0608974 0608974 0608974 0608974 0608974 0608974 0608974

1-11 Main frame assy.10609449 0609449 0609449 0609449 0609449 0609449 0609449

3 Chain guide 1 0608976 0608976 0608976 0608976 0608976 0608976 0608976

4 Chain stripper 1 0608978 0608978 0608978 0608978 0608978 0608978 0608978

5 Load sheave 1 0609374 0609374 0609374 0609374 0609374 0609374 0609374

6 Roll pin 2 9134001 9134001 9134001 9134001 9134001 9134001 9134001

7 Straight pin 2 9124169 9124169 9124169 9124169 9124169 9124169 9124169

- 2 speeds 1 0600117 0600117 0600117 0600117 0600117 0600117 0600117

8 Straight pin 2 9124111 9124111 9124111 9124111 9124111 9124111 9124111

9 Ball bearing 1 9151106 9151106 9151106 9151106 9151106 9151106 9151106

11 Cyl. screw 2 9102254 9102254 9102254 9102254 9102254 9102254 9102254

12 Brake motor - 1 speed 1 0600116 0600116 0600116 0600116 0600116 0600116 0600116

10 Cyl. screw 1 9102253 9102253 9102253 9102253 9102253 9102253 9102253

13

13 Planetary gear 1 0609678 0609678 0608814 0608814 0609678 0609678 0608814

14 Hex. screw 8 9101660 9101660 9101660 9101660 9101660 9101660 9101660

15 Suspension bolt 2 0609388 0609388 0609388 0609388 0609388 0609388 0609388

16 Bolt locking device 1 0609448 0609448 0609448 0609448 0609448 0609448 0609448

17 Cyl. screw 2 9102150 9102150 9102150 9102150 9102150 9102150 9102150

18 Screw plug 2 9110007 9110007 9110007 9110007 9110007 9110007 9110007

19 Screw plug 1 9192000 9192000 9192000 9192000 9192000 9192000 9192000

20 Screw plug 1 9192003 9192003 9192003 9192003 9192003 9192003 9192003

21 Screw plug 1 9192002 9192002 9192002 9192002 9192002 9192002 9192002

23 Safety latch kit 1 0408671 0408671 0408671 0408671 0408672 0408672 0408672

22-23 Suspension hook assy .10609393 0609393 0609393 0609393 0609517 0609517 0609517

- 2 speeds 1 0609615 0609998 0609457 0609745 0609615 0609999 0609457

25 Identity plate - 1 speed 1 0609614 0609996 0609456 0609744 0609614 0609997 0609456

26 Grooved nail 2 9128004 9128004 9128004 9128004 9128004 9128004 9128004

- Capacity decal 1 0609694 0600002 0609695 0609696 0609682 06000001 0609511

- Nameplate 2 0609692 0609692 0609692 0609692 0609692 0609692 0609692

29 Chain anchor bolt 1 ----0608855 0608855 0608855

Page 14

Yale

electric

Yale Electric Chain Hoist CPE

11

29

14

10

15

21

22

23

16

23

12

13

9

20

7

4

26

22

17

15

20

8

3

2

6

25

27

28

5

21

1

24

18

19

1- strand

Fig. 17: Bottom blocks

CPE / F 16

CPE / F 20

Item D escription Qty. CPE / F 25

No. CPE / F 30

1-8 Bottom block assy. 1600 kg 1 0609684

Bottom block assy. 2000 kg 1 0609993

Bottom block assy. 2500 kg 1 0609677

Bottom block assy. 3000 kg 1 0609909

1-2 Load hook assy.10408430

2 Safety latch kit10408671

3 Load hook coupling 1 0608851

4 Swivel tube 1600 kg 1 0609683

Swivel tube 2000 kg 1 0600003

Swivel tube 2500 kg 1 0609399

Swivel tube 3000 kg 1 0609908

5 Ball set (15 pcs. Ø 5) 1 0404767

6 Threaded pin 1 9114030

7 Snap ring 1 9139020

8 Chain bolt 1 0608855

9 Buffer 1 0609734

10-14 Chain end st op assy.10609995

10 Chain end stop half20608867

11 Cyl. screw 1 9102019

12 Lockwasher 1 9122032

13 Hex. nut 1 9115014

14 Buffer 1 0609734

2- strand

CPE / F 32

Item D escription Qty. CPE / F 40

No. CPE / F 50

15-23 Bottom block assy. 3200 kg 1 0609681

Bottom block assy. 4000 kg 1 0609994

Bottom block assy. 5000 kg 1 0609510

15 Swivel half 2 0609495

16 Idler sheave 1 0609505

17 Buffer 1 0601704

18 Capacity plate 3200 kg 2 0609682

Capacity plate 4000 kg 2 0600001

Capacity plate 5000 kg 2 0609511

19 Grooved nail Ø 3 x 4 8 9128004

20 Cyl. screw 2 9102053

21 Hex. nut 2 9115118

22 Needle bearing 2 9153083

23 Spacer 2 9121218

24-28 Load hook assy.10408434

25 Safety latch kit10408672

26-28 Crosshead assy. 1 0404850

27 Ball set (16 pcs. Ø 6) 1 0404799

28 Threaded pin 1 9114184

29 Load chain (specify length) 6109488

14

Page 15

Yale Electric Chain Hoist CPE

2

Yale

electric

3

1

Fig. 18: Chain Container

Item Description Qty. Yale Part No.

No. all models

1 Chain container assy

1 Chain container assy

2 Cyl. screw 1 9102255

3 Hex. nut 1 9115098

for 13 m linear chain length 1 6109467

for 21 m linear chain length 1 6109468

15

Page 16

Yale

electric

Fitted with Loctite 243

Yale Electric Chain Hoist CPE

Prior to assembly soak in oil for 1 hour

5900-6000 N

Pre-tension

of cup spring

Secure with Loctite 243

(after completion of clutch adjustment)

Transmission oil

0,3 kg

Fina Geran L460

16

Fig. 19: Gearbox

Page 17

Yale Electric Chain Hoist CPE

Yale

electric

Item Description Qty. Model

No. CPE 30-5

- Planet gearbox assy. 1 0600230

1 Gearbox housing 1 0600237

2 Ring 1 0600238

3 Planet gear carrier 1 0600239

4 Packing ring 1 9172110

5 Bearing 1 9150043

6 Stop washer 6 9153043

7 Planet gear 3 0600240

8 Needle bearing 6 9153090

9 Spacer ring 3 0600241

10 Planet gear shaft 3 0600242

11 Snap ring 1 9129070

13 Ring 1 0600243

14 Snap ring 1 9129071

15 Bearing race 1 0600244

16 O-ring 1 9171352

17 Threaded pin 1 9114134

18 Packing ring 1 9172112

19 Washer 1 9121234

20 Ball bearing 1 9151101

Item Description Qty. Model

No. CPE 30-5

27.2 Planet gear shaft 3 0600253

28 Friction disc 2 0600254

29 Ring gear 1 0600255

30 Stop washer 3 9153043

31 Needle bearing 3 9153090

32 Planet gear 3 0600171

33 Bearing plate 1 0600256

34 Snap ring 2 9130034

35 Gear shaft 1 0600257

36 Ball bearing 1 9150043

37 Snap ring 2 9129029

38 Locking screw 1 0600258

39 Locking bolt 1 0600259

40 O-ring 1 9171169

41 Cup spring 4 9120041

42 Fixing screw 1 0600260

43 O-ring 1 9171170

44 Screw plug 1 9110052

45 Seal 1 9179004

46 Ball 1 9159011

21 Pinion 1 0600245

22 Planet gear carrier assy. 1 0600246

22.1 Carrier disc 1 0600247

22.2 Planet gear shaft 3 0600248

23 Stop washer 3 9153043

24 Needle bearing 3 9153090

25 Planet gear 3 0600249

26 Pinion 1 0600250

27 Planet gear carrier assy. 1 0600251

27.1 Carrier disc 1 0600252

Attention: When ordering spare parts always indicate serial number and mfg. year of hoist

47 Threaded pin 1 9114136

48 Fitting plate 1 9121056

50 Coupling 1 0608879

51 Gear box cover 1 0600262

52 Screw 4 9102019

17

Page 18

Yale

electric

Yale Electric Chain Hoist CPE

Fig. 20: Motor

Item Description Qty.

No. 1-speed 2-speed

- Motor assy. 1 0600116 0600117

1 .. Stator 1 0600185 0600196

2 .. Rotor 1 0600186 0600197

3 .. Bearing plate, A-side 1 0600187 0600187

4 .. Bearing plate, B-side 1 0600188 0600188

7 .. Fan cover 1 0600189 0600189

8 .. Terminal box assy. 1 0600190 0600190

(board, box, box cover

box seal)

9 .. Rectifier 1 0600110 0600110

16 .. Armature disc 1 0600113 0600113

17 .. Brake fan 1 0600112 0600112

18 .. Fitting parts set for mounting1 0600194 0600194

the brake ( brake spring, O-ring,

cap screw , washers, fitting key)

CPE CPEF

19 .. Manual brake release system

(optional) 1 0600195 0600195

Attention: When ordering spare parts always indicate serial number and mfg. year of hoist

18

Page 19

Yale Electric Chain Hoist CPE

30

32

24

15 + 18

29

17

29

22

24

21

16

19

18

1

15

Yale

electric

2

9

10

11

12

12

3

5

28

1

7

4

6

8

Fig. 22: Contactor control

Item Description Qty. Yale Part No.

No. all models

1 Housing 1 0609810

2 Mounting plate 1 0609792

3 Screw 4 9108018

4Reversing starter 1 0609558

5 Screw 4/8* 9107005

6 Transformer 1 0719737

7 Fine-wire fuse 1 9190126

8 Screw 4 9107032

9 Fuse carrier 2 0609808

10 Fine-wire fuse 2 9190128

11 Terminal 6/7* 0609811

12 PE conductor terminal 2 0609812

Name tag 110609813

Name tag 210609814

Name tag 310609815

27

Item Description Qty. Yale Part No.

No. all models

15 Screw fitting 3 9184082

16 Screw fitting 1 9184081

17 Counter-nut 1 9184085

18 Counter-nut 3 9184086

19 Plate 1 0609788

20 Screw 2 9103013

21 Washer29121001

22 Cyl. screw 4 9107023

23 Connecting cable (CPE only) 1* 0609828

Connecting cable (CPEF only) 1* 0609829

24 Rope clamp20605355

25 Tension relief wire 1 0609561

26 Control cable (CPE only) 1 0606562

Control cable (CPEF only) 1* 0609563

27 Control switch (CPE only) 1 0609566

Name tag 410609816

Name tag L1 1 0609817

Name tag L2 1 0609818

Name tag L3 1 0609819

Name tag PE 1 0609820

Name tag 3 0609821

Name tag F5 1 0609822

Name tag F6 1 0609823

Control switch (CPEF only) 1 0609567

28 Wiring diagram (CPE only) 1 0609571

Wiring diagram (CPEF only) 1 0609572

29 Tape 5 9181113

30 Fastener 1 0608882

31 Hex. Screw 1 9101661

32 Washer19121006

33 Contactor 1* 0609574

19

Page 20

Yale

electric

Yale Electric Chain Hoist CPE

5

6

8

7

Fig. 23: Direct control

4

9

10

2

1

Item Description Qty.

No. 1-speed 2-speed

1 Pendant control assy

with emergency stop 1 0609454 0609455

2 Control cable (specify length) - 9062407 9062407

3Wiring diagram 1 0609631 0609632

4 Clamp 2 0605355 0605355

5Screw fitting 1 9184082 9184082

6Screw fitting 1 9184084 9184084

7Fastener 1 0608882 0608882

8 Hex. screw 1 9101661 9101661

9 Washer19121006 9121006

10 Strain relief (specify length) - 9093001 9093001

CPE CPEF

20

Page 21

Yale Electric Chain Hoist CPE

Yale

electric

7

6

5

3

10

9

Fig. 24: Pendant switch for direct control

8

2

4

11

1

tem Description Qty.

I

No. 1-speed 2-speed

- Pendant control assy .

with emergency stop 1 0609454 0609455

1 Contact element 1 0609686 0609687

2 Carrier for contact element 1 0609965 0609965

3 Lowering button DN 1 0609966 0609967

Lifting button UP 1 0609968 0609969

4 Contact element emerg. stop 1 0609978 0609978

5 Emergency stop button 1 0609977 0609977

6 Rubber bushing 1 0609970 0609970

7 Loop for tension re lief device 1 0609971 0609971

8 Clamping piece 1 0609972 0609972

9Interlocking lever 1 0609973 0609973

10 Front housing 1 0609974 0609974

11 Rear housing 1 0609975 0609975

CPE CPEF

21

Page 22

Yale

electric

Yale Electric Chain Hoist CPE

2

4

1

3

Fig. 25: Pendant switch for contactor control

I

tem Description Qty.

No. 1-speed 2-speed

- Pendant control assy .

with emergency stop 1 0609566 0609567

1 Contact element 1 0609980 0609981

2 Emergency stop button 1 0609984 0609984

3 Lowering button DN 1 0609985 0609986

Lifting button UP 1 0609987 0609988

4 Contact element emerg. stop 1 0609982 0609983

CPE CPEF

22

Page 23

Yale Electric Chain Hoist CPE

Yale

electric

13

12

8

7

6

2

10

9

8

5

6

7

10

11

9

5

15

15

4

5

9

11

10

1

4

14

5

7

6

8

9

11

3

Fig. 26: Plain Trolley

I

tem Description Qty. Yale Part No.

No. all models

1Side plate10559163

2Side plate10559167

3Roll pin 4 9134120

4Crossbar - beam range A 2 0559169

Crossbar - beam range B 2 0559170

5 Round nut 4 0559168

6Washer 4 9121213

7 Hex. nut 4 9115156

6

10

7

8

Item Description Qty. Yale Part No.

No. all models

8 Locking nut 4 9115155

9Trolley wheel 4 0508210

10 Ball bearing 8 9151079

11 Snap ring 4 9129003

12 Identity plate 1 0559869

13 Grooved nail49128004

14 Centre traverse 1 0559353

15 Roll pin 2 9134002

23

Page 24

Yale

electric

Yale Electric Chain Hoist CPE

1

3

2

18

14

6

13

4

5

Fig. 27: Geared trolley drive (for other parts see Fig. 26)

12

6

7

8

9

15

10

11

17

16

tem Description Qty. Yale Part No.

I

No. all models

1 Geared trolley wheel 2 0508214

2 Ball bearing 8 9151079

3 Snap ring 4 9129003

4 Support 1 0508229

5 Spacer tube 1 0719111

6 Lockwasher 4 9122016

7 Hex. screw 2 9101050

8 Bushing 1 0102503

9 Spacer 4 9121205

Item Description Qty. Yale Part No.

No. all models

10 Hand chain guide 1 0558062

11 Hex. screw 2 9101014

12 Hex. nut 2 9115148

13 Drive shaft 1 0719671

14 Roll pin 1 9134052

15 Hand chain wheel 1 0558061

16 Hand chain (specify length) 4307654

17 Connecting link 1 0404733

18 Side plate 1 0559165

24

Page 25

Yale Electric Chain Hoist CPE

22

20

Yale

electric

1

2

21

15

3

17

16

23

14

10

13

Fig. 28: Electric trolley drive (for other parts see Fig. 26)

11

4

5

18

12

19

8

7

6

9

I

tem Description Qty. Yale Part No.

No. all models

1 Geared trolley wheel 2 0508214

2 Ball bearing 8 9151079

3 Snap ring 4 9129003

4 Worm gear 1 0719764

5 Flange 1 0719371

6Drive shaft 1 0719372

7Fitting key 1 9131072

8 Needle bearing 1 9153077

9 Snap ring 1 9129016

10 Hex screw 4 9101170

11 Lockwasher 4 9122003

12 Roll pin 1 9134080

Item Description Qty. Yale Part No.

No. all models

13 Hex. nut 2 9101014

14 Lockwasher 2 9122004

15 Spacer 7 9121215

16 Pinion 1 0719373

17 Snap ring 1 9123038

18 Screw fitting 1 9184082

19 Brake motor - 1 speed 1 0609586

- 2 speeds 1 0609587

20 Reducing sleeve 1 0719868

21 Bushing 1 0719870

22 Hex. screw 4 9101439

23 Side plate 1 0559165

25

Page 26

Yale

electric

Yale Electric Chain Hoist CPE

11

12

15

7

16

1

13

14

2

4

3

6

10

9

5

8

Fig. 29: Pendant switch for electric hoist with electric trolley (direct and contactor control)

Pendant switch for direct control Pendant switch for contactor control

Item Description Qty. Hoist 1G Hoist 2G Hoist 2G Hoist 1G Hoist 1G Hoist 2G Hoist 2G Hoist 1G

No. Trolley 1G Trolley 2G Trolley 1G Trolley 2G Trolley 1G Trolley 2G Trolley 1G Trolley 2G

1-18 Control switch assy . 1 0609610 0609611 0609832 0609833 0609612 0609613 0609806 0609807

1 Contact element hoist 1 0609686 0609687 0609687 0609686 0600032 0600034 0600034 0600032

Contact element hoist 1 - - - - 0600033 - - 0600033

2 Contact element trolley 1 0600022 0600029 0600022 0600029 0600032 0600034 0600032 0600034

Contact element trolley1 ----0600033 - 0600033 -

3 -button DN, hoist 1 0600023 0600030 0600030 0600023 0600023 0600030 0600030 0600023

4 -button UP, hoist 1 0600024 0600031 0600031 0600024 0600024 0600031 0600031 0600024

5 -button LEFT, trolley 1 0600023 0600030 0600023 0600030 0600023 0600030 0600023 0600030

6 -button RIGHT, trolley 1 0600024 0600031 0600024 0600031 0600024 0600031 0600024 0600031

7 Contact element em. stop 1/2* 0609978 0600032

8-10 Housing assy. without

contacts and buttons 1 0600028 0600035

8 Front housing 1 on request

9 Housing centre part 1 on request

10 Rear housing 1 on request

11 Rubber bushing 1 0600025

12 Clamping piece 1 0609972

13 Interlocking lever 2 0609973

14 Dust cap 1 0600026

15 Rubber bushing support 1 0600027

16 Emergency stop bu tton 1 0609977

* for contactor control only 1G = 1 speed; 2G = 2 speeds

26

Page 27

Yale Electric Chain Hoist CPE

1

Yale

electric

33

Zuleitung

31

12

11

6

10

13

17

26

28

27

3

7

14

23

2

6

6

8

32

18

24

22

16

24

29

30

trolley

Cable conductor

Cable conductor

15

hoist

9

16

32

23

20

19

Fig. 30: Contactor control CPE/F with VTE/F

Item Description Qty. Yale Part No.

No. all models

1Plate 1 0719732

2 Screw 2 9103005

3 Housing 1 0719722

4 Mounting plate 1 0719721

5 Screw 4 9108018

6Screw fitting 4 9184082

7 Counter-nut 4 9184086

8Contactor 2 0609558

9 Screw 8 9107005

10 Transformer 1 0719760

11 Screw 4 9107011

12 Fine-wire fuse 1 9190129

13 Fuse terminal 2 0609808

14 Fine-wire fuse 2 9190130

15 Terminal 8 0609811

16 Ground terminal 2 0609812

17 Name tag 110609813

Name tag 210609814

Name tag 310609815

Name tag 510609848

Item Description Qty. Yale Part No.

No. all models

Name tag 3 0609821

Name tag F5 1 0609822

Name tag F6 1 0609823

18 Wiring diagram CPE+VTE 1 0609854

Wiring diagram CPEF+VTE 1 0609856

Wiring diagram CPE+VTEF 1 0609855

Wiring diagram CPEF+VTEF 1 0609853

19 Identity plate 1 0719680

20 Control switch CPE+VTE 1 0609612

Control switch CPEF+VTE 1 0609806

Control switch CPE+VTEF 1 0609807

Control switch CPEF+VTEF10609613

21 Control cable (for 3 m lift) 1 0609899

22 Strain relief cord (2,4 m) 1 9093001

23 Rope clamp20605355

24 Tape (specify length) 9181113

25 S-hook 1 0717029

26 Support 1 0719742

27 Cyl. screw 1 9102026

28 Lockwasher 1 9122031

Name tag 610609849

Name tag L1 1 0609817

Name tag L2 1 0609818

Name tag L3 1 0609819

Name tag PE 1 0609820

* only CPEF + VTEF

29 Cable conductor trolley10609898

30 Cable conductor hoist 1 0609897

31 Screw 4 9107023

32 Contactor (2nd speed only) 1/2* 0609574

33 Power supply cable 1 -

27

Page 28

Yale

electric

Yale Electric Chain Hoist CPE

1

3

4

23

28

Zuleitung

5

6

2

12

25

24

22

20

7

21

12

26

9

11

27

13

16

19

18

21

20

15

17

Cable conductor trolley

Cable conductor hoist

Fig. 31: Direct control CPE/F with VTE/F

Item D escription Qty. Yale Part No.

No. all models

1Plate 1 0719741

2 Screw 2 9103005

3 Housing 1 0609878

4 Screw 4 9107023

5Carrier 1 0609877

6 Screw 2 9108018

7Screwed fitting 3 9184082

8 Counter-nut 3 9184086

9Screwed fitting 1 9184088

10 Counter-nut 1 9184087

11 Terminal 11 0609811

12 Ground terminal 2 0609812

13 Name tag 110609813

Name tag 210609814

Name tag 310609815

Name tag 410609816

Name tag 510609848

Name tag 910609872

Name tag 10 1 0609873

Name tag 11 1 0609874

Item D escription Qty. Yale Part No.

No. all models

15 Wiring diagram CPE + VTE 1 0609882

Wiring diagram CPEF + VTE 1 0609883

Wiring diagram CPE + VTEF 1 0609884

Wiring diagram CPEF + VTEF 1 0609885

15 Name plate 1 0719680

17 Control switch CPE + VTE 1 0609610

Control switch CPEF + VTE 1 0609832

Control switch CPE + VTEF 1 0609833

Control switch CPEF + VTEF 1 0609611

18 Control cable for 3 m lift 1 0609890

19 Strain relief cord (2,4 m) 1 9093001

20 Clamp 2 0605355

21 Tape (specify length) 9181113

22 S-hook 1 0717029

23 Support 1 0719742

24 Cyl. screw 1 9102026

25 Lockwasher 1 9122031

26 Cable conductor trolley 1 0609879

27 Cable conductor hoist 1 0609888

28 Power supply cable 1 ---

Name tag L1 1 0609817

Name tag L2 1 0609818

Name tag PE 1 0609819

Name tag 3 0609821

Control cable (m) CPE+VTE 1 9062403

Control cable (m) CPEF+VTEF 1 9062403

Strain relief cord (specify length) 9093001

28

Page 29

Yale Electric Chain Hoist CPE

Yale

electric

29

Page 30

Yale

electric

Yale Electric Chain Hoist CPE

Inspection Chart

Inspection before initial operation:

by:

Date of initial operation:

Regular Inspections

Date Findings Repair Test

Date by *

* competent person

30

Page 31

Yale Electric Chain Hoist CPE

EC DECLARATION OF CONFORMITY

Yale

electric

in accordance with Machinery Directive 98/37/EEC (Appendix II A)

We,

Yale Industrial Products GmbH

D-42549 Velbert, Am Lindenkamp 31

hereby declare, that the design, construction and commercialized execution of the below mentioned machine complies

with the essential health and safety requirements of the EC Machinery Directive. The validity of this declaration will

cease in case of any modification or supplement not being agreed with us previously.

Furthermore, validity of this declaration will cease in case that the machine will not be operated correctly and in

accordance with the operating instructions and/or not be inspected regularly.

Machine description: Electric chain hoist CPE/ F

Mod. CPE/F 16-8, Mod. CPE/F 20-8, Mod. CPE/F 25-5,

Mod. CPE/F 30-5, Mod. CPE/F 32-4, Mod. CPE/F 40-4,

Mod. CPE/F 50-2

Capacity 1600 - 5000 kg

Machine type: Electric chain hoist

Serial number: from manufacturing year 1/95

(Serial numbers for the individual capacities/models are registered

in the production book with the remark CE-sign)

Relevant

EC Directives: EC Machinery Directive 98/ 37/EEC

Transposed harmonised

standards in particular: EN 292, part 1 (safety of machines)

EN 292, part 2 (safety of machines)

EN 349 (safety of machines)

EN 818, part 1 (round link chain)

EN 818, part 4 (round link chain)

Transposed (either complete FEM 9.671; DIN 5684 (Lastketten)

or in extracts) national FEM 9.681 (Fahrmotoren)

standards and technical FEM 9.682 (Hubmotoren)

specifications in particular: FEM 9.755 (Betriebsdauer)

FEM 9.511 (Triebwerkseinstufung)

DIN 15018 (Krane)

DIN 15400 (Lasthaken für Hebezeuge)

DIN 15404 (Lasthaken für Hebezeuge)

VDE 0100 / Teil 726; VDE 0113 / EN 60204

BGV D6 (Krane)

BGV D8 (Winden, Hub- und Zuggeräte)

VBG 9.a (Lastaufnahmemittel)

ZH 1/27 (Prüfung von Kranen)

ZH1/25 (Prüfung von Hubgeräten)

Quality assurance: DIN EN ISO 9001 (Certificate Registration No.: 151)

Date / Manufacturer’s

authorized signature: 20.09.2002 ________________________

Identification of the signee: Dipl.-Ing. Andreas Oelmann

Manager Quality Assurance

31

Page 32

Yale

electric

Yale Electric Chain Hoist CPE

Quality engineered

and performance tested -

recognisably

32

Loading...

Loading...