Page 1

WorkCentre Pro 420

Service Manual

Septemper 2002

Fuji Xerox of Shanghai Limited

Page 2

NOTICE:

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product trained service personnel only. Xerox does not warrant or represent that such documentation is complete, nor

does Xerox represent or warrant that it will notify or provide to such customer any future

changes to this documentation. Customer performed service of equipment, or modules, components or parts of such equipment may affect the warranty offered by Xerox with respect to

such equipment. You should consult the applicable warranty for its terms regarding customer or

third party provided service. If the customer services such equipment, modules, components

or parts thereof, the customer releases Xerox from any and all liability for the customer actions,

and the customer agrees to indemnify, defend and hold Xerox harmless from any third party

claims which arise directly or indirectly from such service.

Xerox Corporation

Global Knowledge & Language Services

800 Phillips Road - Bldg. 845-17S

Webster, New York 14580-9791

USA

©2001 Xerox Corporation. All rights reserved.

Printed in the United States of America

XEROX®, The Document Company®,

the stylized X and the identifying product

names and numbers herein are trademarks

of XEROX CORPORATION.

701Pxxxxx

Page 3

About This Documentation .............................................................................................. iii

Organization.................................................................................................................... iii

How to Use This Documentation..................................................................................... iv

Other Information ............................................................................................................ v

Reference Symbology..................................................................................................... vi

Introduction

WorkCentre Pro 420

9/02

i

Introduction

Page 4

Introduction

9/02

ii

WorkCentre Pro 420

Page 5

About This Documentation

Documentation Design and Purpose

This Service Documentation contains diagnostic, repair, and maintenance information, which

has been designed to assist the Service Representative in the isolation and repair of faults as

well as maintenance of the Printer/Copier.

This documentation assumes that the user is familiar with the electrical and mechanical standards that are commonly used throughout industry, as well as certain Xerox design and documentation conventions. This documentation also assumes that the user has successfully

completed any required training and is familiar with the use of any special tools that are

required to service this product.

Applicability

The diagnostic, repair, and adjustment procedures found in this documentation apply equally to

all 50 Hz and 60 Hz machine versions. Some procedures, however, may be identified as being

applicable to a specific version or machine configuration.

Organization

This documentation is divided into six sections. In addition to the Introduction, the following

sections are contained within this documentation.

Section 1 - Service Call Procedures

Section 2 - Status Indicator RAPs

Section 3 - Image Quality RAPs

Section 4 - Repair/Adjustment Procedures

Section 5 - Parts List

Section 6 - General Procedures/Information

Section 7 - BSD

Limitations

This service documentation does not support specific electrical, mechanical, or operational

considerations of any accessory device or machine modification not authorized by Xerox Corporation for this product.

Service Documentation Revisions

This service documentation may be subject to periodic revision in order to reflect any changes

in electrical or mechanical hardware, as well as any possible additions or corrections necessary to ensure the technical accuracy of the documentation.

Service Information (Yellow Pages - hardcopy only)

When appropriate, service information in the form of yellow pages (for those with hard copy

only) will be distributed and should be incorporated into their service documentation. Service

information may include bulletin information, Tag and Kit information, page revisions, or current

top problems relative to the repair and maintenance of the machine.

Field Service Bulletins

Field service information specifically applicable to the machine may occasionally be issued in

the form of electronic or critical bulletins. Because bulletins contain important information, they

should always be retained within this service documentation for quick reference.

A detailed description of the information contained within each section of the service documentation will be found in the following subsection.

WorkCentre Pro 420

9/02

iii

Introduction

About This Documentation, Organization

Page 6

How to Use This Documentation

Introduction

This section provides the Service Representative with information pertaining to the organization and use of this service documentation, and includes the following supportive reference

data:

Reference Symbology

Signal Nomenclature

DC Voltage Range Specifications

AC Voltage Range and Current Specifications

Section 1: Service Call Procedures

This section is used by the Service Representative as a structured process for determining the

type and sequence of actions that are performed during a service call. The Service Call Procedures section is designed to assist in the effective recognition of machine symptoms and problems, as well as to provide instructions for the maintenance and corrective actions that are

required to return the machine to the full operating condition.

Section 1 of this service documentation is the entry level for all service calls. The Service Representative should begin each service call with the Initial Action procedure found in Section 1.

The Service Call Procedures section is composed of five integral elements: Initial Action, System Checks, Subsystem Maintenance, Preventive Maintenance, and Final Action. The maintenance and diagnostic activities in this section may direct the Service representative to perform

additional service activities found elsewhere in the documentation, such as RAPs, removal and

replacement procedures, and adjustment procedures.

The Initial Action procedure identifies certain required actions that are necessary to obtain a

basic appraisal of machine operation at the start of the service call.

The System Checks subsection is used to test the machine in order to confirm and define the

problem areas. This subsection is used to assist the Service Representative in diagnosing the

not readily apparent machine problems, or when there are conflicting or ambiguous symptoms

present. It is important that this procedure be used in order to ensure that the correct symptom

is being diagnosed.

The Subsystem Maintenance subsection contains a specific activity procedure that must be

performed on the service call.

Section 2: Status Indicator RAPs

Section 2 of this documentation contains the Repair Analysis Procedures (RAPs) necessary to

repair all faults other than the image quality faults. The Service Representative will be referred

to this section from some other section of this documentation during the service call. When a

machine defect or fault has been resolved by using a RAP, the Service Representative should

immediately return to the point in the service call from which section 2 was entered.

There are two types of RAPs found in section 2. The first type is a RAP that is associated with

the display of a status code or fault code in the RAP title. The second type is the Other Fault

RAP. Other Fault RAPs are diagnostic procedures that are designed to address symptoms or

problems that are not identified by, or associated with, a displayed status or fault code.

Section 3: Image Quality RAPs

Contains the Image Quality Repair Analysis Procedures (IQ RAPs) that are used to diagnose

image quality defect problems. The RAPs that are associated with image quality defect symptoms will contain the prefix “IQ” to differentiate them from other types of machine failure symptoms.

Section 4: Repairs / Adjustment Procedures

Contains all repair and adjustment procedures for the machine. Repairs (REPs) and adjustments (ADJ’s) are identified by the use of a standard chain prefix number.

Section 5: Parts List

Contains a list of spare parts for the machine. All parts list page reference numbers begin with

the letters “PL”, followed by a prefix number, a decimal point, and a sequential number used

within the subsystem.

Section 6: General Procedures / Information

Contains procedures and information of a general nature that apply to the machine. This section is divided into two basic parts.: General Procedures and General Information.

The General Procedures subsection contains frequently used procedures that relate to the

diagnosis, the setup, or the operation of the machine.

The General Information subsection contains specific information that is pertinent to the operation of the machine, but will not be found in any other part of the service documentation. This

information may include product codes, environmental operating data, installation space

requirements, and paper and electrical specifications. This subsection may also contain information regarding supplemental tools and supplies, general service notes, a glossary of commonly used terms, and a Change Tag Index of authorized machine modifications and retrofits.

The Preventative Maintenance procedure contains a list of the cleaning and lubrication activities that are designed to extend and enhance the reliability and performance of the machine.

The Final Action subsection is used to identify the actions necessary to clear the call with the

Customer and to complete any administrative tasks that are associated with completing the

service activity.

Introduction

How to Use This Documentation

Section 7: Wiring Data (Optional)

Contains support information to assjst in the electrical diagnosis of machine problems.

9/02

iv

WorkCentre Pro 420

Page 7

Other Information

The Use of Caution, Warning, and Note statements

Information relative to the completion of a task in a safe or thorough manner will be supplied in

the form of a Caution, a Warning, or a Note statement. These statements are found throughout

the service documentation.

Cautions, Warnings, and Note statements appear before the steps to which they apply. These

statements should be read before continuing to the next step in a procedure.

The definition of a Caution, Warning, or Note is as follows:

Caution - A Caution statement indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to, or destruction of, equipment.

Warning - A Warning statement indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in personal injury or loss of life.

Note - A Note statement indicates an operating or maintenance problem, practice, or condition

that is necessary to accomplish a task efficiently.

The Use of Acronyms, Abbreviations, Specific or Unique Terms, and Conventions

A list of acronyms and abbreviations used in this service documentation will be found in the

Reference Symbology subsection, contained elsewhere in this section.

Specific Terms

Test Pattern 82P524 (inch) and 82P523 (metric) will be referred to in this documentation as the

Standard Test Pattern.

Conventions

The following bolding convention is used in this service documentation:

Bolded numbers or words following the words “Press the” represent the actual keypad button

on the Control Console.

The terms “dry ink” and “toner” are interchangeable.

WorkCentre Pro 420

9/02

v

Introduction

Other Information

Page 8

Reference Symbology

Introduction to Reference Symbology

This section describes and defines the various acronyms, abbreviations, reference symbols,

Signal Nomenclature, and AC and DC power specifications. The following is a description of

some of the terms found in this section:

Acronyms

Acronyms are used throughout this service documentation to denote common terminology.

Although some acronyms may be unique to this product, most acronyms used in this document

are known throughout the service industry. Table 1 lists the acronyms that are found in this service documentation that enable use of the documentation. A complete list of all acronyms is in

Section 6

Reference Symbols

Reference symbols consist of various icons used in this documentation to denote supportive

data that can be found in other sections of this documentation. The purpose of these symbols

is to inform the Service Representative of procedures, adjustments, or other information that is

important for successful diagnosis and repair.

Schematic Symbols

These symbols represent various electrical and mechanical components or devices that are

commonly found in Xerox equipment. These symbols are included as an aid to understanding

the representations used in the Circuit Diagrams (CD’s).

Table 1 General Acronyms

Acronym Definition

AC Alternating Current

ACH Alternating Current High

ACN Alternating Current Neutral

AMP Ampere

BSD Block Schematic Diagram

BTU British Thermal Unit

CD Circuit Diagram

IQ Image Quality

DC Direct Current

ESD Electrostatic Discharge

HFSI High Frequency Service Item

LED Light Emitting Diode

PL Parts List

PWB Printed Wiring Board

RAP Repair Analysis Procedure

VAC Volts Alternating Current

VDC Volts Direct Current

AC and DC Voltage References

The expected AC and DC voltage levels found in this machine are defined in this section.

These specifications represent the expected range for AC (machine input power source) and

DC (machine internal power supplies) voltages that are encountered during normal operation.

Abbreviations

Table 2 lists the electrical wire colors that are identified in this service documentation and

reflects the use of standardized abbreviations.

Introduction

Reference Symbology

Table 2 Wire Color Abbreviations

Abbreviation Wire Color

BLK black

BLU blue

BRN brown

GRAY gray

GRN green

G/Y green/yellow

ORN orange

PINK pink

RED red

VIO violet

WHT white

YEL yellow

Y/G yellow/green

9/02

vi

WorkCentre Pro 420

Page 9

REFERENCE SYMBOLOGY

Notes, adjustments, and parts lists, support the checklists and the RAP information. The symbols that refer to this supportive data are shown below.

Flag Symbol

Indicates part of circuit referred to in RAP.

Figure 1 Flag Symbol

Figure 5 Ground Symbol

Connector

Plug / Jack Connector number and pin number

Parts List

The terminology in the figure below refers to the parts list that is located in section 5 of this Service Documentation. The PL designation is Parts List. The number refers to the 8.5 parts list.

Figure 2 PL Symbol

Note

Refers to notes, usually on same page.

Figure 3 Note Symbol

Miscellaneous Symbols

Descriptions of all commonly used graphic symbols are included to assist in diagnostics.

Feed Back

Feedback signal.

Figure 4 Feedback Symbol

Figure 6 Connector Symbol

LED / Photo transistor Sensor

Symbol identifies sensor used in document and paper path. Blocked and unblocked light

switches sensor off and on.

Figure 7 LED Photo transistor Symbol

Tria c

Triac switches AC power via Low Voltage Input.

Figure 8 Triac Symbol

LED

Light Emitting Diode (LED)

Ground

Machine ground symbol

WorkCentre Pro 420

Motor

Motor provides motive force

9/02

vii

Figure 9 LED Symbol

Introduction

Reference Symbology

Page 10

Without Tag Change

Symbol indicates that the area to which the triangle points has not been modified by the tag

number in the circle.

Figure 10 Motor Symbol

Thermistor

Thermistor Bead, used to sense temperature

Figure 11 Thermistor Symbol

Driver

Driver controls DC components.

Figure 12 Driver Symbol

Solenoid

Relay, Clutch, or Solenoid.

Symbol indicates that the entire page has not been modified by the tag number in the circle.

Figure 14 Without Tag Symbol

With Tag Change

Symbol indicates that the area to which the triangle points has been modified by the tag number in the circle.

Symbol indicates that the entire page has been modified by the tag number in the circle.

Figure 15 With Tag Symbol

Laser Warning

WARNING

Symbol is used to warn of possible eye damage from a laser beam if service procedures

are not followed exactly as written.

Figure 16 Laser Warning Symbol

Figure 13 Relay, Clutch, or Solenoid Symbol

Introduction

Reference Symbology

ESD Warning

CAUTION

Symbol is used when components in the copier are susceptible to damage from electrostatic

discharge. Observe ESD procedures to avoid component damage.

Figure 17 ESD Caution Symbol

9/02

viii

WorkCentre Pro 420

Page 11

Warning

WARNING

A warning is used to alert the personnel to an operating or maintenance procedure,

practice, or condition that, if not strictly observed could result in injury or loss of life.

Caution

CAUTION

A caution is used to alert the personnel to an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to, or destruction of equipment.

Signal Nomenclature

The signal is named to imply the condition of the machine when the signal is available. For

example:

MAIN MOTOR ON (L) +5 VDC

1. MAIN MOTOR ON= Signal Name

2. (L) = Logic State when the signal is available in it’s named state. In this case the signal is

Lo when the Main Motor is energized.

3. +5 VDC= Logic level when the signal is Hi.

DC Voltage Levels

DC Voltages should be measured between the test point and the machine frame, unless

instructed otherwise. Table 3 shows the value of the voltages.

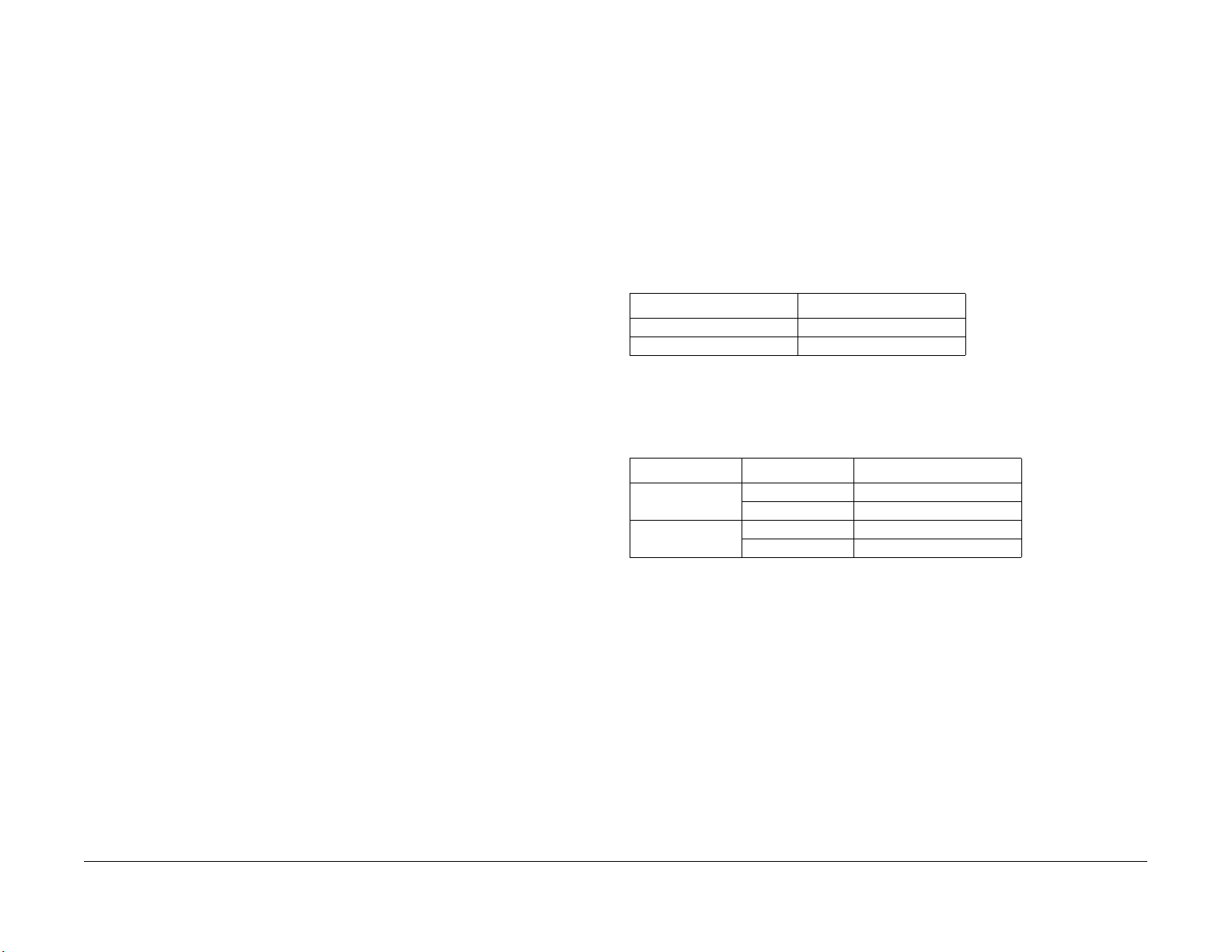

Table 3 DC Voltage Levels

Voltage Specification

+5 VDC +4.75 to +5.25 VDC

+24 VDC +21.6 to +26.4 VDC

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified ground point,

unless some other point is referenced in a diagnostic procedure.

Table 4 Logic Voltage Levels

Nominal Voltage Logic State Actual Voltage Ranges

+5 VDC Hi +2.4 VDC to +5.2 VDC

Lo 0.0 VDC to +0.45 VDC

+24 VDC Hi +22.0 VDC to +25.7 VDC

Lo 0.0 VDC to +3.0 VDC

WorkCentre Pro 420

9/02

ix

Introduction

Reference Symbology

Page 12

Introduction

Reference Symbology

9/02

x

WorkCentre Pro 420

Page 13

Introduction

Service Call Procedures.................................................................................................. 1-3

Call Flow

Call Flow Procedure ........................................................................................................ 1-5

Status Codes / Other Faults Listing

Status Codes / Other Faults Listing................................................................................. 1-7

Subsystem Maintenance

Periodic Maintenance...................................................................................................... 1-9

Maintenance Procedures ................................................................................................ 1-9

1 Service Call Procedures

Initial Issue

WorkCentre Pro 420

9/02

1-1

Service Call Procedures

Page 14

Service Call Procedures

9/02

1-2

Initial Issue

WorkCentre Pro 420

Page 15

Service Call Procedures

Use Service Call Procedures as a maintenance guide when performing any service on printer/

copier. This is designed to be used with printer/copier Service Documentation and is starting

point for all service calls.

Call Flow Procedure

Identifies and classifies machine problems and refers to appropriate RAP for repair. When all

problems are repaired, perform Final Actions.

• Initial Actions

Steps to diagnose faults.

• Corrective Actions

Steps to repair faults. Choices made based on machine symptom.

– Status Codes / Other Faults Listing

List of status codes and other faults with descriptions.

– Corrective Actions

Schedule of periodic maintenance to do when copy count reaches specific quantity.

Maintenance Procedures

Tables of subsystem components to be maintained with suggested materials

and procedures when that subsystem is repaired by direction from a RAP.

• Final Actions

Steps to verify machine operation and image quality.

Initial Issue

WorkCentre Pro 420

9/02

1-3

Service Call Procedures

Service Call Procedures

Page 16

Service Call Procedures

Service Call Procedures

9/02

1-4

Initial Issue

WorkCentre Pro 420

Page 17

Call Flow Procedure

Initial Actions

On Telephone

1. Call Customer and attempt to correct problem over telephone.

2. If problem cannot be resolved over telephone, give Customer your estimated time of

arrival.

3. Ask Customer to save copies or prints made when problem occurred.

At Account

1. Check that space requirements and power requirements for machine are met.

2. Ask Operator or Customer to describe problem. If possible, ask Customer to demonstrate

problem. Also ask for any additional problems encountered with machine.

3. Make a record of copy meter and Status Code.

4. Enter Diagnostic Mode. Enter [3–2] (GP 7 Status Code History ) and record most recent

status code. Continue with R/E button to display all most recent status codes. Press 0

button to display secondary codes.

5. The Service Log and Change Tag Matrix (behind front door) may contain information

related to machine problem. Check Service Log and Tag Matrix.

6. Inspect sample copies provided by Customer.

7. Switch off power, wait 5 seconds, and then switch on power.

8. Clear any jammed paper from machine. Make copies (if possible) using Tray 1 (and Tray

2 if present).

• Select a tray.

• Load the document(s).

– ADF Only: Load two (2) 8.5 x 11 inch (A4) documents into the ADF.

– Without ADF: Place Standard test pattern on the Document Glass.

• Make copies.

9. ADF Only: Using the copies from the first run, put 10 documents in the ADF.

10. Proceed to Corrective Actions.

Corrective Actions

1. Read following 6 items and respond as required. Go to step 2 after responding to one or

more of following items.

• If a status code is displayed on Control Panel, and any jammed paper is removed, go

to Table 1 in this section.

• If Fault History contains several faults with same status code, service this status

code.

• If an image defect occurs only in printing mode, go to OF 14-1 PRINTER RAP.

• If an image defect occurs in copying mode (printing mode not relevant at this point),

go to Image Quality Diagnostics Overview in Image Quality Section.

• If an obvious problem occurs, repair as required and refer to Parts List as required

for Removal, Reinstallation or Replacement information

• For other problems not listed above, go to Tab l e 2 in this section.

2. After responding to one or more of previous items in step 1, read following 2 items and

respond as required.

• If more than 2000 copies have been made since last service call, or if 20 days have

elapsed since last service call, go to Periodic Maintenance in this section and perform actions listed after making repairs required in step 1. Then go to Final Actions

• If less than 2000 copies have been made or if 20 days have not elapsed since last

service call, go directly to Final Actions to complete service call.

Final Actions

In this section you will make sure that machine is feeding paper correctly, making copies free of

defects, and operating to specification. You will also make sure that machine appearance is

satisfactory and that administrative tasks necessary to close out a service call are performed.

If machine will not feed paper from all of paper trays, or if machine makes blank or unfused

copies, or if a status code is displayed, return to Corrective Actions and make necessary

repairs.

1. Load the document(s).

• ADF Only: Load two (2) 8.5 x 11 inch (A4) documents into the ADF.

• Without ADF: Place Standard test pattern on the Document Glass.

2. Make copies (if possible) using Tray 1, Bypass Tray, and Tray 2 if present.

3. Perform GP 2 Main PWB Generated Image [1–1] to generate ROS Test Pattern. Exit

Diagnostic Mode and make 4 copies of standard test pattern. Examine copies for obvious

image quality defects. Ensure image quality meets specifications in Section 3.

4. Perform GP3 Main PWB [3–11] to generate Printer Test Pattern. If defects are present,

go to OF 14-1 PRINTER RAP in Section 2.

5. If machine is used as a printer perform following:

• Verify that connections at rear of machine are secure. printer cable must be securely

connected.

• If used as a network printer, check network connection.

• Ask customer to run a print job to verify print operation.

6. If a new Drum Cartridge was installed in machine and problem continues, reinstall old

Drum Cartridge in machine. Put new Drum Cartridge in packaging, and ask Customer to

store cartridge.

7. Clean machine covers and area around machine.

8. Make 2 copies. Show copies to operator or Customer.

9. Provide operator training if required.

10. Place remaining copy with Service Log.

11. Update Change Tag Matrix as required.

12. Give appropriate copy credits to Customer.

13. Make a record of copy count meter in Service Log. Make a record in Service Log of all

necessary actions performed during service call. Also record any changes that were

made to NVM.

Initial Issue

WorkCentre Pro 420

9/02

1-5

Service Call Procedures

Call Flow Procedure

Page 18

Service Call Procedures

Call Flow Procedure

9/02

1-6

Initial Issue

WorkCentre Pro 420

Page 19

Status Codes / Other Faults Listing

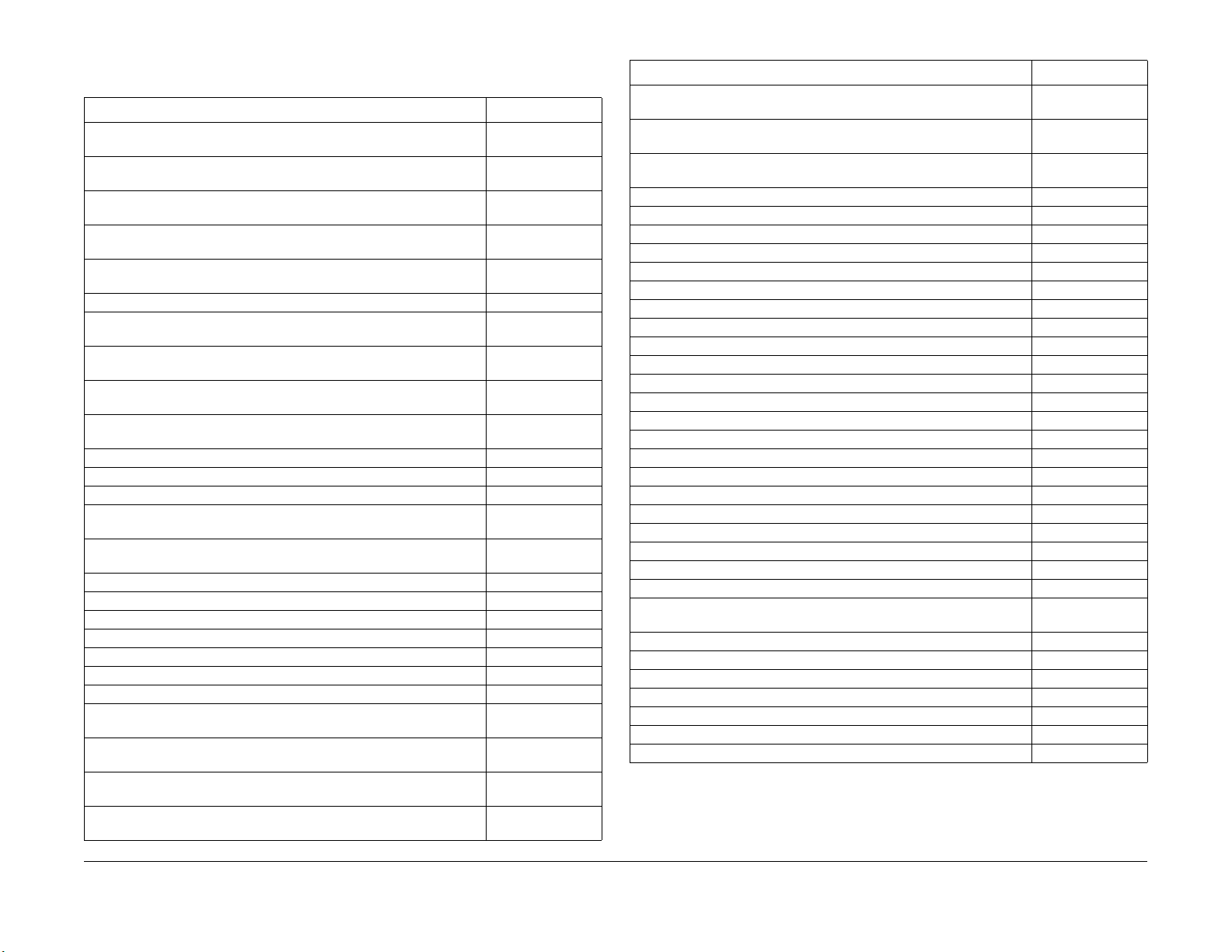

Table 1 Status Codes Entry Chart

Status Code / Description Corrective Action

A1–1: Document can not actuate Pre Regi. Sensor after Document

Solenoid is energized

A2–0: Document can not actuate Document Registration Sensor after

actuating Document Presence Sensor

A2–1: After constant-speed feed motor is energized, Document can not

deactivate in time Document Registration Sensor

A2–2: After constant-speed feed motor is energized, document can not

actuate in time Document Exit Switch

A2–3: Document can not deactivate in time Document Exit Switch after

deactivating Document Registration Sensor

A5–0: ADF Cover is open A5 RAP

C1–0: Tray 1 fed paper did not actuate Tray 1 Takeaway Sensor in time

after Tray 1 Feed Motor energized

C2–0: Tray 2 fed paper did not actuate Tray 2 Takeaway Sensor in time

after Tray 2 Feed Motor energized

C3–0: Bypass fed paper did not actuate Registration Sensor in time after

Bypass Feed Solenoid energized

C3–1: Bypass fed paper actuated Registration Sensor too early after

Bypass Feed Solenoid energized

C4–0: Tray 1 fed paper did not deactuate Tray 1 Feed Sensor in time C4-0 RAP

C4–1: Tray 1 fed paper did not actuate Registration Sensor in time C4-1 RAP

C4–2: Tray 2 fed paper did not actuate Registration Sensor in time C4-2 RAP

C4–3: Tray 1 fed paper actuated Registration Sensor too early after Tray

1 Takeaway Motor energized

C4–4: Tray 2 fed paper actuated Registration Sensor too early after Tray

2 Takeaway Motor energized

C4–5: Two-side fed paper did not actuate Registration Sensor in time C4-5 RAP

C4–6: Two-side fed paper actuated Registration Sensor too early C4-6 RAP

C5–0: The Tray 1 Paper Sensor not actuated C5 RAP

C6–0: The Tray 2 Paper Sensor not actuated C6 RAP

C7–0: The Tray 1 Interlock Switch not actuated C7 RAP

C8–0: The Tray 2 Interlock Switch not actuated C8 RAP

C9–0: Tray 1 fed paper did not actuate Tray 1 Feed Sensor in time C9 RAP

E1–1: Paper did not actuate Fuser Switch in time after Registration

Clutch energized

E1–2: The paper did not de-actuate Registration Sensor in time after

actuating Fuser Switch

E1–3: The paper did not de-actuate Fuser Switch in time after deactuat-

ing Registration Sensor

E1–4: The paper did not actuate Exit Sensor in time after actuating

Fuser Switch

A1-1 RAP

A2 RAP

A2-1 RAP

A2-2 RAP

A2-3 RAP

C1 RAP

C2 RAP

C3 RAP

C3 RAP

C4-3 RAP

C4-4 RAP

E1 RAP

E1 RAP

E1 RAP

E1 RAP

Table 1 Status Codes Entry Chart

Status Code / Description Corrective Action

E1–5: The paper did not de-actuate Exit Sensor in time after de-actuat-

ing Fuser Switch

E2–1: Paper can not actuate in time OCT Exit Sensor after leaving

Fuser Exit Switch

E2–2: Paper can not deactuate in time OCT Exit Sensor after leaving

Fuser Exit Switch

E5–0: Front Door or Side Door is open E5 RAP

E6–1: Tray 1 Door interlock is open E6 RAP

E6–2: Tray 2 Door interlock is open E6 RAP

J1–0: Toner level is low J1 RAP

J3–0: Drum Cartridge not installed or incorrectly installed J3 RAP

J4–1: Billing Counter missing or not installed correctly J4-1 RAP

J4–2: Billing Counter is not a FXSL uniqueware J4-2 RAP

J4–3: Billing Counter unit type Error J4-3 RAP

J6–1: CRUM Communication Error J6-1 RAP

J6–3: Billing Counter Communication Error J6-3 RAP

J7–0: Drum Cartridge reached end of service life J7 RAP

J8–0: Drum Cartridge not correct J8 RAP

J9–1: CRUM is not a FXSL uniqueware J9-1 RAP

L9–1: Current login account has no credits L9-1 RAP

U1–0: Drive Module speed signal failure U1 RAP

U2–1: Scan Home Sensor circuit, Scan Drive Motor, or carriages failure U2 RAP

U2–2: The Exposure Lamp not lit or black white strip not sensed U2 RAP

U3–0: Laser not detected U3 RAP

U4–0: Previous U4 Status Code not cleared U4 RAP

U4–1: Fuser overtemperature condition (425° F) is sensed U4 RAP

U4–2: Fuser warm up failure occurred U4 RAP

U4–3: Fuser warm up time exceeded U4 RAP

U5–0: The Fuser temperature dropped below minimum temperature for

more than 5 seconds

U5–1: AC input power problem U5 RAP

U6–0: Printer control communication failure U6 RAP

U6–1: Drum Cartridge, or Tray 1, or Tray 2 communication failure U6 RAP

U6–4: NVM signal failure U6 RAP

U7: Control Panel communication from Main PWB failure U7 RAP

U8: Control Panel communication to Main PWB failure U8 RAP

U9–0: A HVPS output is shorted or overloaded, or intermittent U9 RAP

E1 RAP

E2-1 RAP

E2-2 RAP

U5 RAP

Initial Issue

WorkCentre Pro 420

9/02

1-7

Service Call Procedures

Status Codes / Other Faults Listing

Page 20

Table 2 Other Faults Entry Chart

Other Fault Description Corrective Action

Cooling Fan not operating OF 1-3 COOLING FAN RAP

Control Panel is blank OF 2-1 BLANK DISPLAY RAP

Scanning problem U2 RAP

Paper Tray problem OF 7-1 PAPER TRAY RAP

Audible Noise / Odor problem OF 16-1 NOISE or ODOR RAP

Print problems OF 14-1 PRINTER RAP

Copies/prints exit machine in non-standard or dam-

aged condition

Intermittent copier/printer operation OF 16-2 GROUND RAP

Ground Checkout OF 16-2 GROUND RAP

Diagnostics not available U2 RAP

OF 8-1 PAPER DAMAGE or STACKING RAP

Service Call Procedures

Status Codes / Other Faults Listing

9/02

1-8

Initial Issue

WorkCentre Pro 420

Page 21

Periodic Maintenance

Activities to perform if 2K copies or 20 days elapsed since last service call.

NOTE: While performing a repair in a RAP, you may be directed to perform one or more following activities. When returning here after a repair, skip what is already serviced.

Procedure

1. Make a copy to run Cooling Fan. If fan is not operating go to OF 1-3 Cooling Fan RAP.

2. Do Paper Feed and Registration Maintenance Procedures (Ta ble 2 ).

3. Do Xerographic maintenance (Table 3).

4. Do Copy Transportation and Fusing Maintenance Procedures (Ta b l e 4 ).

5. Do Document Feeder maintenance procedures (Ta b l e 5 ).

6. Clean top of Document Glass with Lens and Mirror cleaner and a Lint–Free Cloth.

7. Clean Document Cover Pad with Lens and Mirror Cleaner and a Lint–Free Cloth.

8. Every 125K copies:

a. Replace Fuser Module (PL 1.4) (REP 10.1).

b. Replace Bypass Feed Roll (PL 6.3) (REP 8.11) and Bypass Retard Pad (PL 6.2)

(REP 8.12).

c. Go to OF 16-2 Ground RAP and perform Ground Check.

Maintenance Procedures

This section contains a list of machine subsystem components to be maintained and suggested materials and procedures to be used. You will be referred here from Periodic Maintenance, a Status Code, an Other Fault, or an Image Quality RAP.

Procedure

Service following components as directed. Clean any component that appears contaminated

with dirt, paper dust, or dry imager, whenever component is made accessible during repair of

machine.

Table 1 Optics Subsystem Maintenance Procedures

Perform this activity

whenever Document Glass

(REP 6.5) is completely

removed. Materials

Perform GP 9 R.

CAUTION

If bottom of Document Glass

is cleaned, Image Quality

defects will occur if RIS Module is not vacuumed before

reinstalling Document Glass.

Table 2 Paper Feed and Registration Subsystem

Maintenance Procedures

Perform this activity when

given direction in Call Flow. Materials

Clean Bypass Feed Roll

CAUTION

Do not clean Retard Pad.

Clean Registration Roll and

Idler Roll

• Lens and Mirror Cleaner

• Lint–Free Cloth

• Vacuum Cleaner

• Film Remover/General

Cleaning Solvent

• Lint–Free Cloth

• Film Remover/General

Cleaning Solvent

• Lint–Free Cloth

Initial Issue

WorkCentre Pro 420

9/02

1-9

Service Call Procedures

Periodic Maintenance, Maintenance Procedures

Page 22

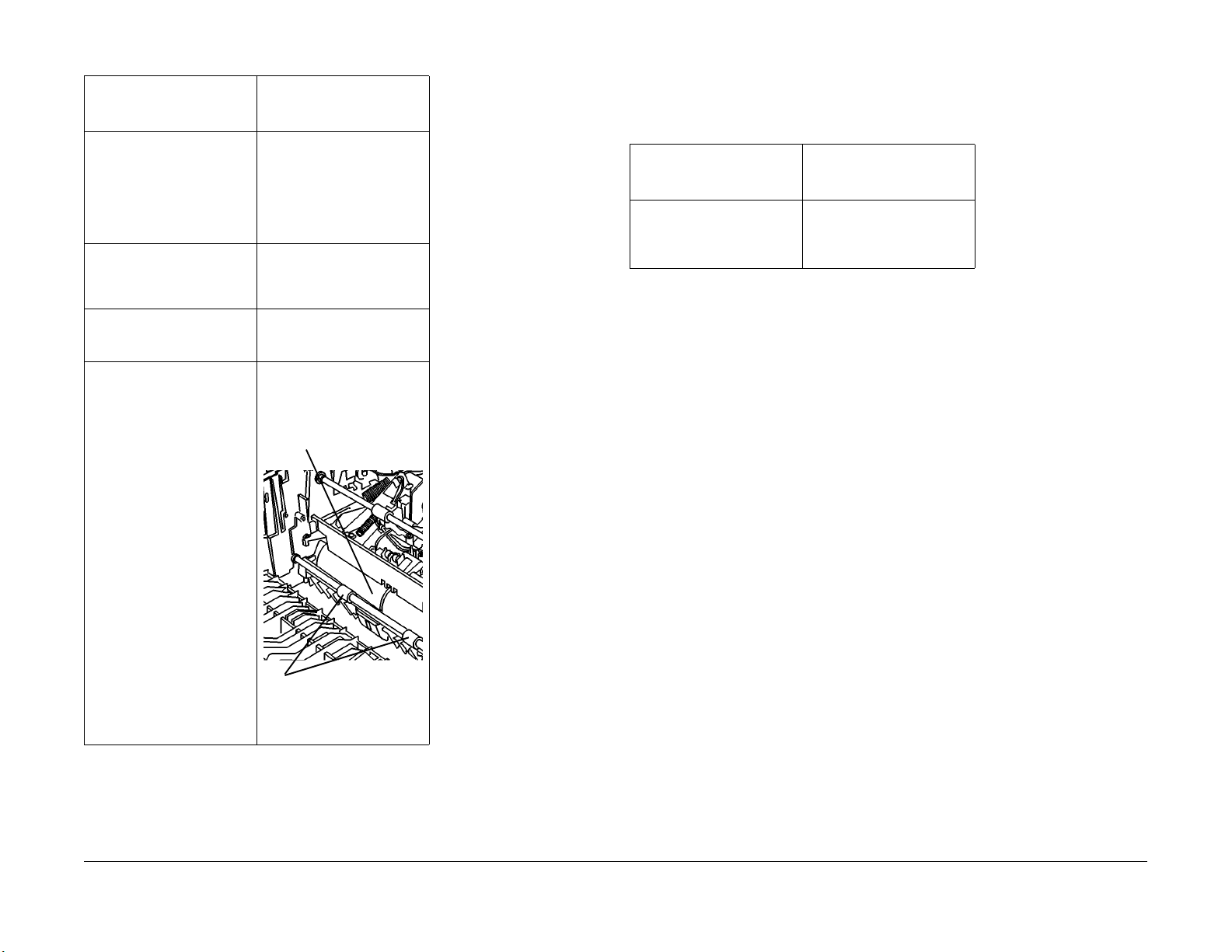

Table 2 Paper Feed and Registration Subsystem

Maintenance Procedures

Perform this activity when

given direction in Call Flow. Materials

Clean Registration Roll and

Idler Roll.

Clean Registration Roll Contacts

• Film Remover/General

Cleaning Solvent

• Lint–Free Cloth

Reg Roll

Reg Roll

Contacts

Figure 1 Registration

Table 3 Xerographics Subsystem Maintenance Procedures

Perform this activity when

given direction in Call Flow. Materials

• Clean Transfer/Detack

Corotron wire with a cotton swab to remove

Toner.

• Clean Transfer/Detack

Corotron housing with a

soft brush.

• Clean Transfer Detack

contacts and corresponding contacts on

HVPS with a Lint–Free

Cloth and Film Remover/

General Cleaning Solvent.

• Clean Transfer Roll Contact with a Lint–Free

Cloth and Film Remover/

General Cleaning Solvent.

• Remove Drum Cartridge

(REP 9.1).

• Clean any toner from

Drum Cartridge.

Clean Drum Cartridge contacts

• Cotton Swab

• Soft Brush

• Film Remover/General

Cleaning Solvent

• Lint–Free Cloth

Reg Roll

Reg Roll

Contacts

• Vacuum Cleaner

• Lint–Free Cloth

• Film Remover/General

Transfer

Corotron

Figure 2 Transfer

Cleaning Solvent

Detack

Corotron

Service Call Procedures

Maintenance Procedures

Table 4 Copy Transportation and Fusing Subsystem

Maintenance Procedures

Perform this activity when

given direction in Call Flow

or RAP’s Materials

Clean Fuser Roll Make 10 copies of a white

document.

Clean Exit Rollers. • Film Remover/General

Cleaning Solvent

• Heavy Duty Towel/Cleaning Cloth.

9/02

1-10

Initial Issue

WorkCentre Pro 420

Page 23

Table 5 Document Feeder (ADF)

Subsystem Maintenance Procedures

Perform this activity when

given direction in Call Flow

or RAP’s Materials

Clean Feed Roll, gentle push

Roll, Output Roll, Output

Pressure Roll, Exit Roll and

CVT Roll. Remove offset

Receiving Tray (REP 5.3) to

approach Feed Roll and gentle push Roll.

Clean CVT glass pad. If the

bottom of CVT glass is contanimated, do GP9 RIS/Mirror

cleaning.

Clean CVT Roll • Film Remover/General

Clean Exit Roll/Idler Roll • Film Remover/General

• Film Remover/General

Cleaning Solvent

• Lint-Free Cloth.

• Film Remover/General

Cleaning Solvent

• Lint-Free Cloth.

Cleaning Solvent

• Lint-Free Cloth.

Cleaning Solvent

• Lint-Free Cloth.

CVT Roll

CAUTION

Image Quality defects will occur if machine is on and cleaning solutions are used on covers.

Cooling Fan may draw cleaning solution vapor into machine. Switch off machine before clean-

ing so that Cooling Fan is off.

Table 6 Covers Subsystem Maintenance Procedures

Perform this activity when

given direction in Call Flow

or RAP’s Materials

Clean covers as necessary. • Formula A/All Purpose

Cleaner

• Heavy Duty Towel/Cleaning Cloth

Initial Issue

WorkCentre Pro 420

Exit Roll/Idler Roll

Figure 3 Registration

9/02

1-11

Service Call Procedures

Maintenance Procedures

Page 24

Service Call Procedures

Maintenance Procedures

9/02

1-12

Initial Issue

WorkCentre Pro 420

Page 25

Status Indicator RAPs

+5VDC POWER RAP...................................................................................................... 2-3

+24VDC POWER RAP.................................................................................................... 2-3

A1 RAP ........................................................................................................................... 2-4

A2 RAP ........................................................................................................................... 2-8

C1 RAP ........................................................................................................................... 2-11

C2 RAP ........................................................................................................................... 2-12

C3 RAP ........................................................................................................................... 2-14

C4 RAP ........................................................................................................................... 2-16

C5 RAP ........................................................................................................................... 2-18

C6 RAP ........................................................................................................................... 2-19

C7 RAP ........................................................................................................................... 2-20

C8 RAP ........................................................................................................................... 2-21

C9 RAP ........................................................................................................................... 2-22

E1 RAP ........................................................................................................................... 2-23

E2 RAP ........................................................................................................................... 2-27

J1 RAP............................................................................................................................ 2-31

J4 RAP............................................................................................................................ 2-32

J6 RAP............................................................................................................................ 2-32

J3 RAP............................................................................................................................ 2-33

J6 RAP............................................................................................................................ 2-33

J8 RAP............................................................................................................................ 2-33

J9 RAP............................................................................................................................ 2-33

J7 RAP............................................................................................................................ 2-34

U1 RAP ........................................................................................................................... 2-35

U2 RAP ........................................................................................................................... 2-36

U3 RAP ........................................................................................................................... 2-38

U4 RAP ........................................................................................................................... 2-40

U5 RAP ........................................................................................................................... 2-42

U6 RAP ........................................................................................................................... 2-43

U7, U8 RAP..................................................................................................................... 2-44

U9 RAP ........................................................................................................................... 2-46

Other Faults

OF 1-1 CONTROL PANEL RAP..................................................................................... 2-47

OF 1-2 MACHINE RUN RAP.......................................................................................... 2-48

OF 1-3 COOLING FAN RAP........................................................................................... 2-51

OF 2-1 BLANK DISPLAY RAP........................................................................................ 2-54

OF 7-1 PAPER TRAY RAP............................................................................................. 2-58

OF 8-1 PAPER DAMAGE or STACKING RAP............................................................... 2-60

OF 14-1 PRINTER RAP.................................................................................................. 2-62

OF 16-1 NOISE or ODOR RAP ...................................................................................... 2-64

OF 16-2 GROUND RAP.................................................................................................. 2-66

2 Status Indicator RAP/Other Faults

Initial Issue

WorkCentre Pro 420

9/02

2-1

Status Indicator RAP/Other Faults

Page 26

Status Indicator RAP/Other Faults

9/02

2-2

Initial Issue

WorkCentre Pro 420

Page 27

+5VDC POWER RAP

CR2 on MAIN PWB is turned on.

YN

Turn OFF the power.

Check the connection between P/J 109 on MAIN PWB and LVPS.

This connection is in good condition.

YN

Reconnect MAIN PWB and LVPS.

+24VDC POWER RAP

The voltage between P/J102-(+) and GND(-) on MAIN PWB has +24VDC.

YN

Turn OFF the power.

Check the Connection between P/J 109 on MAIN PWB and LVPS.

This connection is in good condition.

YN

Reconnect MAIN PWB and LVPS.

Turn ON the power.

Check the voltage between P109-C9(+) and GND(-) on MAIN PWB.

Approximately +5VDC is measured.

YN

The voltage between P/J205-2 and P/J205-3 on LVPS has approximately 110/

220VAC.

YN

Check the voltage between ACN and ACH on POWER CORD.

Approximately 110/220VAC are measured.

YN

Check the power cord.

If no problems are found, check the customer's power supply.

Replace POWER SUPPLY PWB

Replace LVPS.

Replace MAIN PWB.

Check the wire between MAIN PWB and the applicable component for an open circuit or poor

contact by referring to BSD CHI.

Turn ON the power.

Check the Voltage between P109-A31(+) and GND(-) on MAIN PWB.

Approximately +24VDC is measured.

YN

The voltage between P/J205-2 and P/J205-3 on LVPS has approximately 110/

220VAC.

YN

Check the Voltage between ACN and ACH on POWER CORD.

Approximately 110/220VAC are measured.

YN

Check the power cord.

If no problems are found, check the customer's power supply.

Replace POWER SUPPLY PWB

Replace LVPS.

Replace MAIN PWB.

Check the wire between MAIN PWB and the applicable component for an open circuit or poor

contact by referring to BSD CHI.

Initial Issue

WorkCentre Pro 420

9/02

2-3

Status Indicator RAP/Other Faults

A1

Page 28

A1 RAP

A1–1: Document can not actuate Pre Regi Sensor after Document Solenoid is energized.

Initial Actions

• Ensure ADF hinges firmly lean against Top Cover.

• Ensure ADF is securely closed. Repair as required.

• Ensure offset catch tray is correctly installed if it was removed recently.

Procedure

Remove ADF drive cover and offset catch tray. Observe the gentle push roll when switching on

or off power source of machine.

The gentle push roll must rapidly moves down and up.

YN

Remove ADF Rear Cover.

Enter [5-5] and turned ON.

The voltage between P/J605-4(+) and GND(-) on ADF PWB has +24VDC.

YN

The voltage between Pin 2(+) and GND(-) on Nudger Solenoid has +24VDC.

YN

The voltage between Pin 1(+) and GND(-) on Nudger Solenoid has 0VDC.

YN

Status Indicator RAP/Other Faults

A1

9/02

2-4

Initial Issue

WorkCentre Pro 420

Page 29

B

CVT Motor rotates.

YN

When [5-1] is turned ON, the voltage between P/J603-1(+) and GND(-) on ADF PWB

has approximately +1.3VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-1(+) and GND(-) on MAIN

PWB has approximately +1.3VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-1 on MAIN PWB and P/J603-1 on ADF PWB for an

open circuit or poor contact.

C

Document Feed Clutch is energized.

YN

When [5-7] is turned ON, the voltage between P/J605-1(+) and GND(-) on ADF PWB

has +24VDC.

YN

The voltage between Pin 2(+) and GND(-) on Document Feed Clutch has

+24VDC.

YN

The voltage between Pin 1(+) and GND(-) on Document Feed Clutch has

0VDC.

YN

Replace Nudger Solenoid.

When [5-1] is turned ON, the voltage between P/J603-2(+) and GND(-) on ADF PWB

has approximately +10VDC.

YN

When [5-1] is turned ON, the voltage between P/J603-3(+) and GND(-) on ADF

PWB has approximately +5VDC.

YN

Replace MAIN PWB.

Check the wire between P/J103-2 on MAIN PWB and P/J603-21 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J603-3(+) and GND(-) on ADF PWB

has approximately +5VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-3(+) and GND(-) on MAIN

PWB has approximately +10VDC.

YN

Replace MAIN PWB.

Check the wire between P/J103-3 on MAIN PWB and P/J603-3 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J601-2(+) and GND(-) on ADF PWB

has approximately +10VDC.

YN

The Voltage between P/J602-1(+) and GND(-) on ADF PWB has +24VDC.

Replace CVT MOTOR.

Enter[5-7] and press START button.

The voltage between P/J605-5(+) and GND(-) on ADF PWB has +24VDC

YN

GO TO +24VDC Power FIP.

Check the wire between P/J605-5 on ADF PWB and Pin 1 on Document Feed

Clutch for an open circuit or poor contact.

Check the wire between P/J605-1 on ADF PWB and Pin 2 on Document Feed Clutch

for an open circuit or poor contact.

The voltage between P/J603-10(+) and GND(-) on ADF PWB has +5VDC.

YN

The voltage between P/J103-10(+) and GND(-) on MAIN PWB has +5VDC.

YN

Replace MAIN PWB.

Check the wire between P/J103-10 on MAIN PWB and P/J603-10 on ADF PWB for

an open circuit or poor contact.

Replace ADF PWB.

Enter [5-9].

C

Initial Issue

WorkCentre Pro 420

9/02

2-5

D

Status Indicator RAP/Other Faults

A1

Page 30

D

Use hand or paper to actuate or deactuate Document Presence Sensor, display should

change between "0" and "1".

YN

Block the Document Presence Sensor with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 2(+) and GND(-) on Document Presence Sensor has

+5VDC.

YN

Check the wire between Pin 2 on Document Presence Sensor and P/J103-18

on MAIN PWB for an open circuit or poor contact. If no problems are found,

replace MAIN PWB.

The voltage between Pin 1(+) and Pin 3(-) on Document Presence Sensor has

+5VDC.

YN

The voltage between P/J605-10(+) and P/J605-12(-) on ADF PWB has

+5VDC.

YN

Go to +5VDC Power FIP.

Check wire of the following:

• Between P/J605-10 on ADF PWB and Pin 1 on Document Presence Sensor for an open circuit or poor contact.

• Between P/J605-12 on ADF PWB and Pin 3 on Document Presence Sensor for an open circuit or poor contact.

Check for contamination and improper installation of the Sensor. If no problems are

found, replace the Document Presence Sensor.

E

Document Feed Clutch is energized, and Document Feed Roll is rotated.

YN

Check the mechanical load of Document Feed Roll.

• Check CVT feed area for obstruction.

• Close ADF feed door, put in a sheet of document in Document Feed Tray. Enter [5-14] and

press START button. Document should be fed and reach Document Exit Tray. If document

is stopped or blocked, repeat the test while observing document and drive.

• If pre-input appears slow, clean or replace Feed Roll/Gentle push Roll.

• Enter [5-7], Document Feed Clutch is energized. Manually rotate counter-clockwise CVT

Roll ( opposite to normal direction) to check the rotation of Feed Rolls. Repair as required.

• If the failure of A1 status code continues, replace Document Feed Clutch.

Remove the blank sheet of paper from the Sensor.

"0"(High) is displayed.

YN

Remove the connector of Document Presence Sensor.

The display should change to "0" (High).

YN

Check the circuit between Pin 2 on Document Presence Sensor and P/J103-18

on MAIN PWB for a short circuit. If no problems are found, replace MAIN PWB.

Check installation of the Sensor and the extraneous light diffraction. If no problems

are found, replace Document Presence Sensor.

Check installation of the Sensor.

If the failure of A1-1 Status Code continues, replace Document Presence Sensor.

Enter [5-1] and press START button.

When CVT MOTOR rotates, enter [7] and press START button.

E

Status Indicator RAP/Other Faults

A1

9/02

2-6

Initial Issue

WorkCentre Pro 420

Page 31

Initial Issue

WorkCentre Pro 420

9/02

2-7

Status Indicator RAP/Other Faults

A1

Page 32

A2 RAP

A2–0: Document can not actuate Document Registration Sensor after actuating Document

Presence Sensor.

A2–1: After constant-speed feed motor is energized, document can not deactivate in time Document Registration Sensor.

Initial Actions

Ensure CVT glass is faced steadily to the registration edge. If top cover is removed, clean GP9

RIS /reflector.

Ensure ADF hinges lean steadily against top cover.

Ensure ADF feed door is securely closed.

Procedure

Enter [5-11].

Use hand or paper to actuate or deactuate Document Registration Sensor, display should

change between "0" and "1".

YN

Block the Document Registration Sensor with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 2(+) and GND(-) on Document Registration Sensor

has +5VDC.

YN

Check wire between Pin 2 on Document Registration Sensor and P/J103-17 on

MAIN PWB for an open circuit or poor contact. If no problems are found,

replace MAIN PWB.

The voltage between Pin 1(+) and Pin 3(-) on Document Registration Sensor

has +5VDC.

YN

The voltage between P/J609-1(+) and P/J609-3(-) on ADF PWB has +5VDC.

YN

Go to +5VDC Power FIP

Check wire of the following:

• Between P/J609-1 on ADF PWB and Pin 1 on Document Registration

Sensor for an open circuit or poor contact.

• Between P/J609-3 on ADF PWB and Pin 3 on Document Registration

Check for contamination and improper installation of the Sensor. If no problems are

found, replace Document Registration Sensor.

Remove the blank sheet of paper from the Sensor.

"0"(High) is displayed.

YN

Remove the connector of Document Registration Sensor.

The display should change to "0"(High).

YN

AB

AB

Status Indicator RAP/Other Faults

C

Sensor for an open circuit or poor contact.

Check the circuit between Pin 2 on Document Registration Sensor and P/J10317 on MAIN PWB for a short circuit. If no problems are found, replace MAIN

PWB.

A2

AB

Enter [5-1] and press START button

CVT Motor rotates.

YN

• Check CVT document transport area for obstruction.

• Close ADF feed door, put in a sheet of document in Document Feed Tray. Enter [5-14] and

9/02

2-8

C

Check installation of the Sensor and the extraneous light diffraction. If no problems

are found, replace Document Registration Sensor.

Check installation of the Sensor.

If the failure of either A2-0 or A2-1 Status Code continues, replace Document Registration

Sensor.

When [5-1] is turned ON, the voltage between P/J603-1(+) and GND(-) on ADF PWB

has approximately +1.3VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-1(+) and GND(-) on MAIN

PWB has approximately +1.3VDC.

YN

Replace MAIN PWB.

Check the wire between P/J103-1 on MAIN PWB and P/J603-1 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J603-2(+) and GND(-) on ADF PWB

has approximately +10VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-2(+) and GND(-) MAIN

PWB has approximately +10VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-2 on MAIN PWB and P/J603-2 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J603-3(+) and GND(-) on ADF PWB

has approximately +5VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-3(+) and GND(-) on MAIN

PWB has approximately +10VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-3 on MAIN PW and P/J603-3 on ADF PWB for an open

circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J601-2(+) and GND(-) on ADF PWB

has approximately +10VDC.

YN

The voltage between P/J602-1(+) and GND(-) on ADF PWB has +24VDC.

Replace CVT MOTOR.

press START button. Document should be fed and reach Document Exit Tray. If document

is stopped or blocked, repeat the test while observing document and drive.

Initial Issue

WorkCentre Pro 420

Page 33

A2–2: After constant-speed feed motor is energized, document can not actuate in time Docu-

ment Exit Switch.

A2–3: Document can not deactivate in time Document Exit Switch after deactivating Document

Registration Sensor.

Initial Actions

Ensure CVT glass is faced steadily to the registration edge. If top cover is removed, clean GP9

RIS /reflector.

Ensure ADF hinges lean steadily against top cover.

Ensure ADF feed door is securely closed.

Procedure

Enter [5-12].

Turned ON/OFF the Document Exit Switch with a blank sheet of paper.

Display should change between "0" and "1".

YN

Block the Document Exit Switch with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 1(+) and GND(-) on Document Exit Switch has +5VDC.

YN

Check wire between Pin 1 of Switch and P/J103-19 on MAIN PWB for an open

circuit or a poor contact. If no problems are found, replace MAIN PWB.

The voltage between Pin 2(+) and GND(-) on Document Exit Switch has +5VDC.

YN

Replace Document Exit Switch.

Check wire between Pin 2 on Document Exit Switch and P/J609-5 on ADF PWB for

an open circuit or poor contact. If no problems are found, replace ADF PWB.

Remove the blank sheet of paper from the Sensor.

The display should change to "0"(High).

YN

Remove the connector of Document Exit Switch.

The display should change to "0"(High).

YN

Check the circuit between Pin 1 on Document Exit Switch and P/J103-19 on

MAIN PWB for a short circuit. If no problems are found, replace MAIN PWB.

Replace Document Exit Switch.

Check Actuator for damage or breakage. Check attachment of SWITCH. If the failure of

either A2-2 or A2-3 Status Code continues, replace Document Exit Switch.

Enter [5-1] and press START button.

A

CVT Motor rotates.

YN

When [5-1] is turned ON, the voltage between P/J603-1(+) and GND(-) on ADF PWB

has approximately +1.3VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-1(+) and GND(-) on MAIN

PWB has approximately +1.3VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-1 on MAIN PWB and P/J603-1 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between J603-2(+) and GND(-) on ADF PWB

has approximately +10VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-2(+) and GND(-) on MAIN

PWB has approximately +10VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-2 on MAIN PWB and P/J603-21 on ADF PWB for an

open circuit or poor contact.

When [5-1] is turned ON, the voltage between P/J603-3(+) and GND(-) on ADF PWB

has approximately +5VDC.

YN

When [5-1] is turned ON, the voltage between P/J103-3(+) and GND(-) on MAIN

PWB has approximately +10VDC.

YN

Replace MAIN PWB.

Check wire between P/J103-3 on MAIN PWB and J603-3 on ADF PWB for an open

circuit or poor contact.

When [5-1] is turned ON, voltage between P/J601-2(+) and GND(-) on ADF PWB has

approximately +10VDC.

YN

The voltage between P/J602-1(+) and GND(-) on ADF PWB has +24VDC.

Replace CVT MOTOR.

• Check CVT document transport area for obstruction.

• Close ADF feed door, put in a sheet of document in Document Feed Tray. Enter [5-14] and

press START button. Document should be fed and reach Document Exit Tray. If document

is stopped or blocked, repeat the test while observing document and drive.

A

Initial Issue

WorkCentre Pro 420

9/02

2-9

Status Indicator RAP/Other Faults

A2

Page 34

A5–0: ADF Cover is open.

Procedure

ADF Cover Interlock Switch is turned ON by hand.

A5-0 is gone off.

YN

Close ADF Cover.

The voltage between P/J605-2(+) and GND(-) on ADF PWB has +24VDC.

YN

Close ADF Cover.

The voltage P/J605-1(+) and GND(-) on ADF PWB has +24VDC.

YN

The voltage between P/J602-1(+) and GND(-) on ADF PWB has +24VDC.

YN

Go to +24VDC Power FIP.

Replace ADF PWB.

Check the wire between P/J605 on ADF PWB and ADF Cover Interlock Switch for an

open circuit or poor contact. If no problems are found, replace ADF Cover Interlock

Switch.

The voltage between P/J103-15(+) and GND(-) on MAIN PWB has +5VDC.

YN

Replace MAIN PWB.

The voltage between P/J603-15(+) and GND(-) on ADF PWB has +5VDC.

YN

Check wire between P/J603-15 on ADF PWB and P/J103-15 on MAIN PWB for an

open circuit or poor contact.

Replace ADF PWB.

Adjustment with ADF Cover and ADF Interlock Switch is poor.

Check damage of ADF Interlock Switch Actuator and attachment of ADF Cover.

Status Indicator RAP/Other Faults

A2

9/02

2-10

Initial Issue

WorkCentre Pro 420

Page 35

C1 RAP

C1–0: Tray 1 fed paper did not actuate Tray 1 Takeaway Sensor in time after Tray 1 feed motor

is energized.

Initial Actions

• Remove paper from tray and fan it to ensure edges are separated. Refer to label on paper

tray and reinstall paper.

• Check Paper Guides are adjusted to the set paper size and properly laid.

Procedure

Clear C1 status code. Make a copy. After C1, remove rear cover, and open Tray 1 Access

Door. Paper is at the Takeaway roll.

YN

Make machine enter diagnostic state. Enter [7-13], press START button and check

Feed rolls. Feed rolls rotate.

YN

The operating sound of the Tray 1 Feed Motor is audible.

YN

When [7-13] is turned ON, the voltage between P/J403-1(+) and GND(-) on

Tray 1 Control PWB has approximately +16VDC.

YN

The voltage between P/J402-1(+) and GND(-) on Tray 1 Control PWB

has +24VDC.

YN

Go to +24VDC Power RAP.

Replace Tray 1 Control PWB.

Replace Tray 1 Feed Motor.

Enter [7-11] and ON.

Tray 1 Feed Clutch is in good condition.

YN

When [7-11] is turned ON, the voltage between P/J408-2(+) and GND(-) on

Tray 1 Control PWB has +24VDC.

YN

The voltage between P/J408-1(+) and GND(-) on Tray 1 Control PWB

has +24VDC.

YN

The voltage between P/J402-1(+) and GND(-) on Tray 1 Control

PWB has +24VDC.

YN

Go to +24VDC Power RAP.

A

Enter [7-7]. Use hand or paper to actuate or deactuate Tray 1 Takeaway Sensor, display

should change between "0" and "1".

YN

Block Tray 1 Takeaway Sensor with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 1(+) and GND(-) on Tray 1 Takeaway Sensor has

+5VDC.

YN

Check the voltage between Pin 1 on Tray 1 Takeaway Sensor and PWB P/J4052 on Tray 1 Control. If no problems are found replace Tray 1 Control PWB.

The voltage between Pin 3(+) and Pin 2(-) on Tray 1 Takeaway Sensor has

+5VDC.

YN

The voltage between P/J405-1 (+) and P/J405-3(-) on Tray 1 Control PWB

has +5VDC.

YN

Go to +5VDC Power FIP.

Check the following:

• Between P/J405-1 on Tray 1 Control PWB and Pin 3 on Tray 1 Takeaway

Sensor for an open circuit or poor contact.

• Between P/J405-3 on Tray 1 Control PWB and Pin 2 on Tray 1 Takeaway

Sensor for an open circuit or poor contact

Check for contamination and improper installation of the Sensor. If no problems are

found, replace Tray 1 Takeaway Sensor.

Remove the blank sheet of paper.

"0"(High) is displayed.

YN

Remove connector of Tray 1 Takeaway Sensor.

The display should change to "0"(High).

YN

Check circuit between Pin 1 on Tray 1 Takeaway Sensor and P/J405-2 on Tray

1 Control PWB for a short circuit. If no problems are found, replace Tray 1 Con-

trol PWB.

Check installation of the Sensor and the extraneous light diffraction. If no problems

are found, replace Tray 1 Takeaway Sensor.

Check installation of the Sensor.

If the failure of C1-0 Status Code continues, replace Tray 1 Takeaway Sensor.

Check Tray 1 Takeaway Sensor for mechanical failure. Repair as required.

Replace Tray 1 Control PWB.

Replace Tray 1 Feed Clutch.

Replace Tray 1 Control PWB.

Eliminate mechanical failure. If Feed Rolls can not operate, replace Clutch.

Remove Tray 1, check and clean Feed Roll and Retard Roll to see if they are aging.

YN

Clear paper path and ensure no mechanical resistance.

Replace Feed Roll and Retard Roll.

A

Initial Issue

WorkCentre Pro 420

9/02

2-11

Status Indicator RAP/Other Faults

C1

Page 36

C2 RAP

C2–0: Tray 2 fed paper did not actuate Tray 2 Takeaway Sensor in time after Tray 2 Feed Motor

energized.

Initial Actions

• Make a copy using Tray 1. If a status code is displayed, to RAP Takeaway Tray 1 status

code.

• Remove paper from tray and fan it to ensure edges are separated. Refer to label on paper

tray. Reinstall paper.

• Check Paper Guides are adjusted to the set paper size and properly laid.

Procedure

Clear C2 status code. Make a copy. After C2, remove Rear Cover and Rear Cover of Tray 2,

and open Tray 2 Access Door and Tray 1 Access Door. A sheet of paper is in Tray 2 Access

Door.

YN

Make machine enter diagnostic state. Enter [7-14], press START button and check

Feed rolls. Feed rolls rotate.

YN

The operating sound of the Tray 2 Feed Motor is audible.

YN

When [7-14] is turned ON, the voltage between P/J403-1(+) and GND(-) on

Tray 2 Control PWB has approximately +16VDC.

YN

The voltage between P/J402-1(+) and GND(-) on Tray 2 Control PWB

has +24VDC.

YN

Go to +24VDC Power RAP.

Replace Tray 2 Control PWB.

Replace Tray 2 Feed Motor.

Enter [7-12] and ON.

Tray 2 Feed Clutch is in good condition.

YN

When [7-12] is turned ON, the voltage between P/J408-2(+) and GND(-) on

Tray 2 Control PWB has +24VDC.

YN

The voltage between P/J408-1(+) and GND(-) on Tray 2 Control PWB

has +24VDC.

YN

The voltage between P/J402-1(+) and GND(-) on Tray 2 Control

PWB has +24VDC.

YN

Go to +24VDC Power RAP.

AB

YN

Clear paper path and ensure no mechanical resistance.

Replace Feed Roll and Retard Roll.

Enter [7-8]. Use hand or paper to actuate or deactuate Tray 2 Takeaway Sensor, display

should change between "0" and "1".

YN

Block Tray 2 Takeaway Sensor with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 1(+) and GND(-) on Tray 2 Takeaway Sensor has

+5VDC.

YN

Check the voltage between Pin 1 on Tray 2 Takeaway Sensor and PWB P/J4052 on Tray 2 Control. If no problems are found replace Tray 2 Control PWB.

The voltage between Pin 3(+) and Pin 2(-) on Tray 2 Takeaway Sensor has

+5VDC.

YN

The voltage between P/J405-1 (+) and P/J405-3(-) on Tray 2 Control PWB

has +5VDC.

YN

Go to +5VDC Power FIP.

Check the following:

• Between P/J405-1 on Tray 1 Control PWB and Pin 3 on Tray 2 Takeaway

Sensor for an open circuit or poor contact.

• Between P/J405-3 on Tray 1 Control PWB and Pin 2 on Tray 2 Takeaway

Sensor for an open circuit or poor contact.

Check for contamination and improper installation of the Sensor. If no problems are

found, replace Tray 2 Takeaway Sensor.

Remove the blank sheet of paper.

"0"(High) is displayed.

YN

Remove connector of Tray 2 Takeaway Sensor.

The display should change to "0"(High)

YN

Check circuit between Pin 1 on Tray 2 Takeaway Sensor and P/J405-2 on Tray

2 Control PWB for a short circuit. If no problems are found, replace Tray 2 Con-

trol PWB.

Check installation of the Sensor and the extraneous light diffraction. If no problems

are found, replace Tray 2 Takeaway Sensor.

Check installation of the Sensor.

If the failure of C1-0 Status Code continues, replace Tray 2 Takeaway Sensor.

Check Tray 2 Takeaway Sensor for mechanical failure. Repair as required.

Replace Tray 2 Control PWB.

Replace Tray 2 Feed Clutch.

Replace Tray 2 Control PWB.

Eliminate mechanical failure. If Feed Rolls can not operate, replace Clutch.

Remove Tray 2, check and clean Feed Roll and Retard Roll to see if they are aging.

AB

Status Indicator RAP/Other Faults

C2

9/02

2-12

Initial Issue

WorkCentre Pro 420

Page 37

Initial Issue

WorkCentre Pro 420

9/02

2-13

Status Indicator RAP/Other Faults

C2

Page 38

C3 RAP

C3–0: Bypass fed paper did not actuate IOT Registration Sensor in time after Bypass Feed

Solenoid energized.

C3–1: Bypass fed paper actuated IOT Registration Sensor too early after Bypass Feed Solenoid energized.

Initial Actions

• Turn paper so that topside faces down. Exchanging lead edge for trail edge will not be

effective.

• Check Paper Guides are adjusted to paper without pinching or squeezing paper.

Procedure

Select Bypass Tray and make a copy. Copy is delivered and machine is ready.

YN

Go to corresponding status code RAP.

Check position of Paper Lift Plate. There must be a gap between Bypass Feed Rolls and Pad

on Paper Lift Plate. Gap should be enough for 50 sheets of 80 g/m

Check that 50 sheets fit under Bypass Feed Roll. 50 sheets of paper fit.

YN

Lift Plate Cam is out of position. Lift Plate Cam Follower should be on high part of Lift

Plate Cam. Perform or Check the following.

• Open Door Module.

• Check Sector Gear for damage or breakage. Ensure Slot is present. If Sector Gear

goes wrong, replace Sector Gear.

• Manually rotate Sector Gear counterclockwise, while holding Lift Plate Cam Follower

away from Lift Plate Cam until cam follower is at position shown in figure 2.

• Sector Gear Spring should be in position shown. In this position Sector Gear cannot

be rotated clockwise (direction of normal rotation), unless Bypass Solenoid energized. Replace failed component if Sector Gear can be rotated clockwise without

stopping.

Load 10 sheets of paper in Bypass Tray. Select Bypass Tray. Observe Paper Lift Plate and

make 10 copies. Paper Lift Plate must lift lead edge of paper to Bypass Feed Roll to feed.

Paper Lift Plate lifts lead edge of paper up to Bypass Feed Roll before a C3 occurs.

YN

Problem is either Sector Gear, Sector Gear Spring, Bypass Feed Solenoid or Door Module.

• Open Door Module.

• Check Sector Gear for damage or breakage. Ensure slot is present. If there is problem with Sector Gear, replace Door Module.

Sector Gear is free of damage.

YN

Replace Door Module.

2

.

AB

YN

Reinstall Sector Gear Spring or replace Door Module.

Check Bypass Feed Solenoid.

• Open Door Module.

• Enter [8-5], observe Bypass Feed Solenoid and press START button. Bypass Feed

Solenoid should be energized.

Bypass Feed Solenoid energizes.

YN

Disconnect Bypass Feed Solenoid plug from P308 on PCM interface PWB.

Measure resistance (ohms) between two wires of Bypass Feed Solenoid plugs.

Resistance should be approximately 41 ohms or less.

Bypass Solenoid measures approximately 41 ohms or less.

YN

Replace Bypass Feed Solenoid.

Go into diagnostic mode and enter [8-5]. Measure voltage at P211-10 on

PCM PWB and press START button.

Voltage should change from +0.1VDC to +6VDC.

YN

Replace LVPS first, if no effects, replace MAIN PWB then.

Connect Bypass Feed Solenoid plug to P308 on PCM interface PWB.

Measure voltage at J311-10 on PCM interface PWB.

Approximately +24 VDC is measured.

YN

Replace PCM interface PWB.

Replace LVPS.

Enter [8-6]

Actuator of IOT Regi Sensor is turned ON/OFF by hand.

C

Check Sector Gear Spring condition and installation. Sector Gear Spring should be connected as shown and be free of damage. Bypass feed sequence depends on Sector Gear

Spring being in position shown. In this position, Sector Gear cannot be rotated clockwise

(direction of normal operation), unless Bypass Solenoid energizes.

Sector Gear Spring is connected as shown and is free of damage.

AB

Status Indicator RAP/Other Faults

C3

9/02

2-14

Initial Issue

WorkCentre Pro 420

Page 39

C

The display should change between "0" and "1".

YN

Block Sensor with a blank sheet of paper.

"1"(Low) is displayed.

YN

The voltage between Pin 1(+) and GND(-) on IOT Regi Sensor has +5VDC.

YN

Check the wire Pin 1 on IOT Regi Sensor and P/J211-3 on LVPS for an open

circuit or poor contact. (Including PCM PWB)

If no problems are found, check the connection between MAIN PWB and LVPS.

If the problem persists, replace LVPS, MAIN PWB in sequence.

The voltage between Pin 2(+)and Pin 3(-) on IOT Regi Sensor has +5VDC.

YN

The voltage between J306-2(+) and J306-3(-) on PCM PWB has +5VDC.

YN

Go to +5VDC Power RAP.

Check wire of the following:

• Between J306-2 on PCM PWB and Pin 2 on IOT Regi Sensor for an open

circuit or poor contact.

• Between J306-3 on PCM PWB and Pin 3 on IOT Regi Sensor for an open

circuit or poor contact

Check for contamination and improper installation of the Sensor. Check Actuator for

damage. If no problems are found, replace IOT Regi Sensor.

Remove the blank sheet of paper from the Sensor.

The display should change to "0"(High).

YN

Remove the connector of IOT Regi Sensor.

The display should change to "0"(High)

YN

Check the circuit between Pin 2 on IOT Regi Sensor and P/J211-3 on LVPS for

a short circuit. (Including PCM PWB).

If no problems are found, check the connection between MAIN PWB and LVPS.

If the problem persists, replace LVPS, MAIN PWB in sequence.

Check installation of the Sensor and the extraneous light diffraction. If no problems

are found, replace IOT Regi Sensor.

Check installation of the Sensor.

If the failure of either C3-0 or C3-1 Status Code continues, replace IOT Regi Sensor.

Replace Bypass Drives Kit. Paper Lift Plate failed to lift stack in a previous check.

Check machine operation after doing each item.

• Ensure Retard Pad Spring pushes Retard pad up against bottom of Bypass Feed Roll as

required .A problem here may also result in an E1 status code.

• Check for obstructions in Bypass Exit Guides.

• Check gear on Bypass Takeaway Roll Shaft. Check idlers that are driven by Bypass Take-

away Roll Shaft.

• Clean or replace Bypass Feed Roll.

Initial Issue

WorkCentre Pro 420

9/02

2-15

Status Indicator RAP/Other Faults

C3

Page 40

C4 RAP

C4-0: Tray 1 fed paper did not deactuate in time.

C4-1: Tray 1 fed paper did not actuate Registration Sensor in time.

C4-2: Tray 2 fed paper did not actuate Registration Sensor in time.

C4-3: Tray 1 fed paper actuated Registration Sensor too early after Tray 1 Feed Motor is ener-

gized.