Page 1

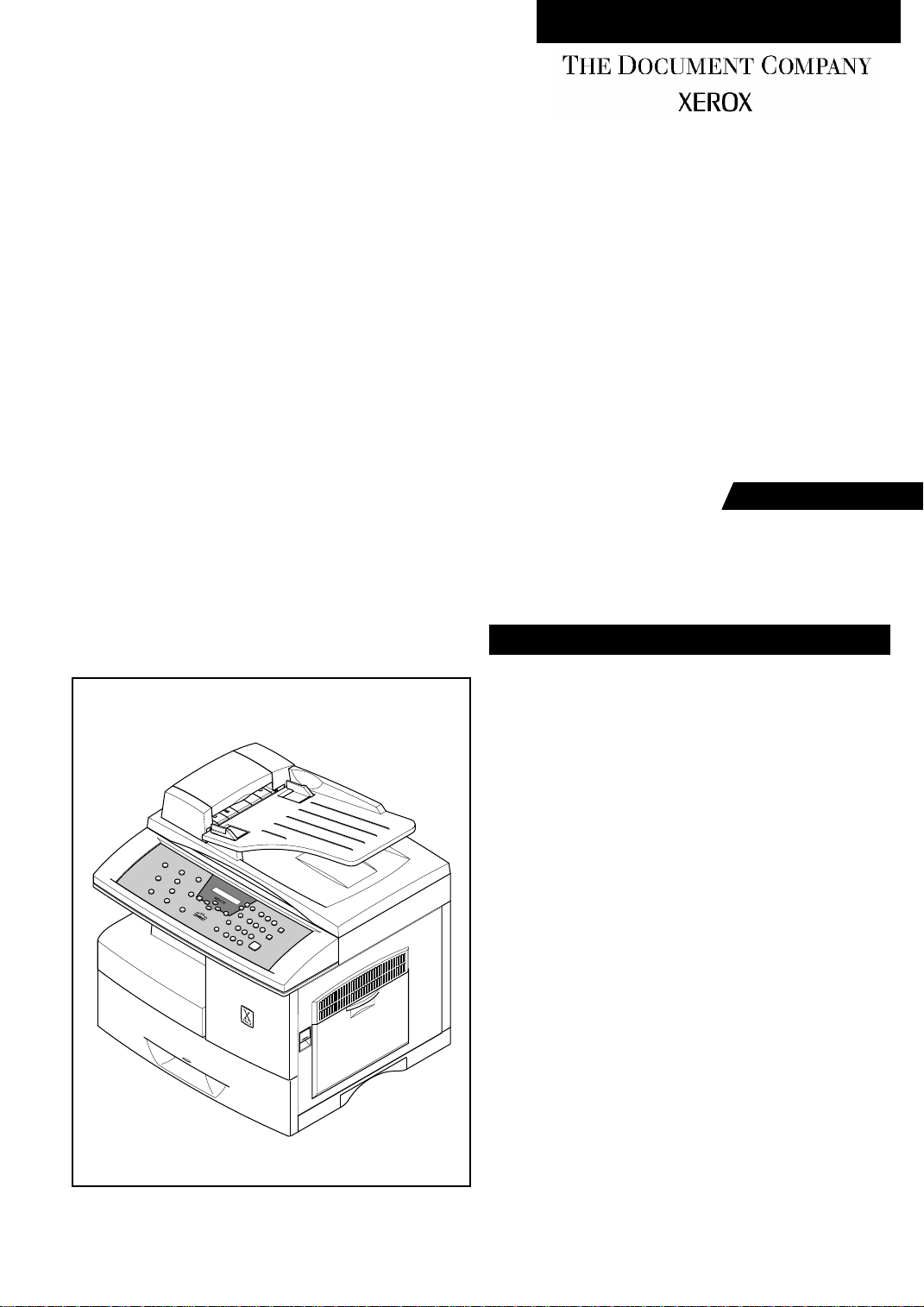

WorkCentre Pro 412

Launch Issue

SERVICE

1. Introduction

2. Service Call Procedures

MANUAL

Contents

3. Precautions

4. Specifications

5. Circuit Description

6. Disassembly

7. Maintenance & Troubleshooting

8. Exploded Views and Parts List

9. Electrical Parts List

10. Block Diagram

11. Connection Diagram

12. Schematic Diagrams

Part Number 708P86391

Page 2

WorkCentre Pro 412.

Service Documentation.

WorkCentre Pro 412 Service Manual.

August 2001.

Prepared by:

Xerox Europe

Global Knowledge & Language Services

Enterprise Centre

P. O. Box 17

Bessemer Road

Welwyn Garden City

Hertfordshire AL7 1HE

England.

© Copyright 2001 by Xerox Europe

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes only. Xerox

service documentation is intended for use by certified, product trained service personnel only. Xerox does

not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or modules, components or parts of such equipment

may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with

respect to such eq uipment. You should co ns ult the applicable warranty for its te rms re gard ing customer or

third-party provided service.

While every care has been taken in the preparation of this manual, no liability will be accepted by Xerox

Europe arising out of any inaccuracies or omissions.

Xerox Europe, Xerox ® and all identifying n umb ers us ed in co nne cti on with the Xerox prod uct s mentioned

in this publication are trademarks of Xerox Europe.

Printed in the United Kingdom.

Adobe and PostScript are trademarks of Adobe Systems Incorporated.

PCL, PCL5e, and PCLXL2.0 are trademark s of Hew le tt-Packa rd C om pan y. IBM is a tr ade mark of Inte rna-

tional Business Machines Corporation. Microsoft, Microsoft Windows, Windows3.1, Windows3.11,

Windows95/98, WindowsNT, Windows2000, Microsoft Word, MS, and MS-DOS are trademarks of

Microsoft Corporation. All other product names are trademarks/trade names of their respective owners.

Page 3

Table of Contents

1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Organisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Warnings, Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Safety Procedures and Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-4 Heath and Safety Incident Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5 Translation of Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . 1-6

2. Service Call Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SCP 1 Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SCP 2 First Call Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SCP 3 Normal Call Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SCP 4 Fault Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SCP 5 Final Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3. Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

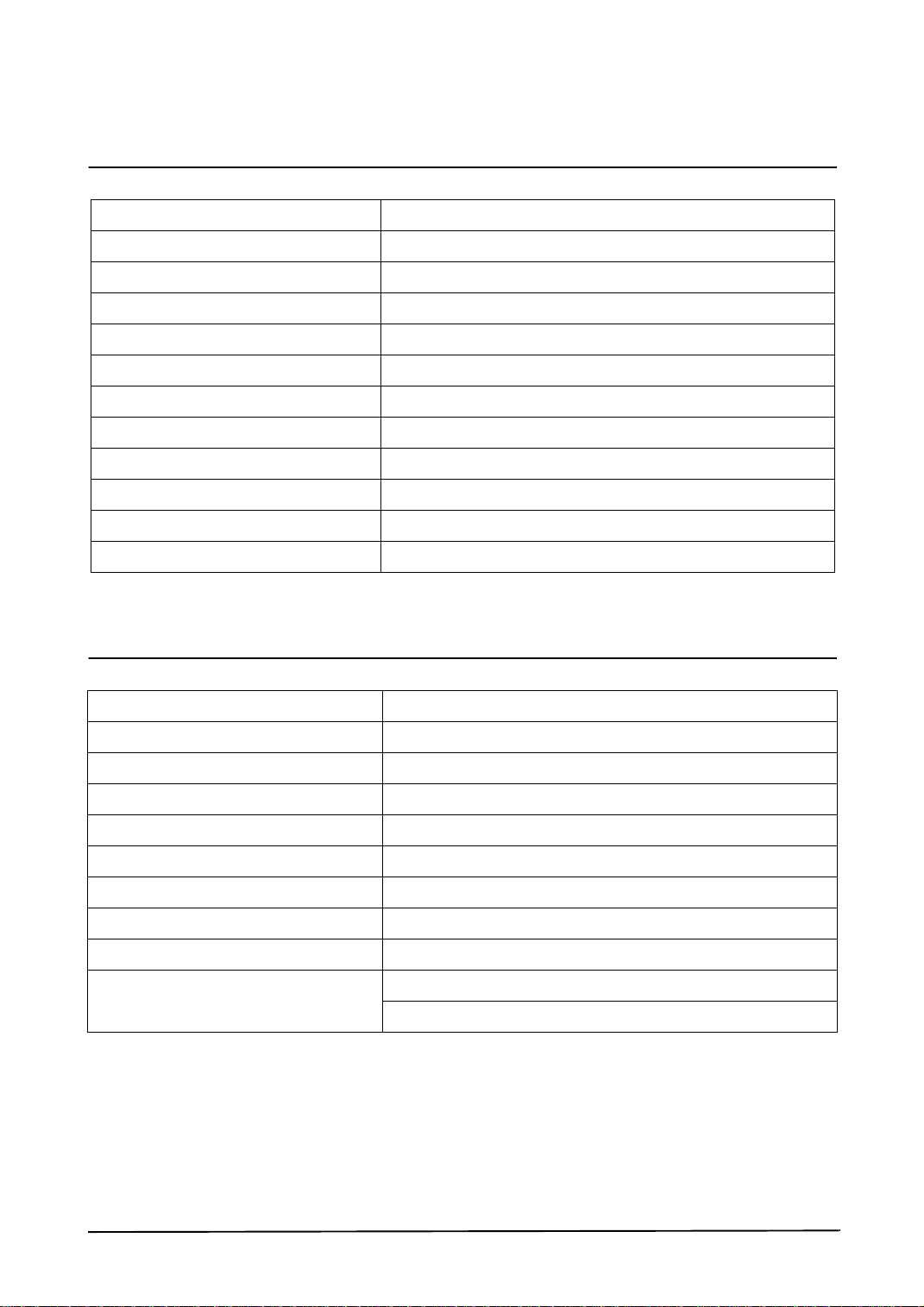

4. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Facsimile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3 Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-4 Copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-6 Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-7 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-8 Environmental Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-9 Machine Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Table of Contents

5. Circuit Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 Main PBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Circuit Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-4 Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5-5 Engine Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5-6 OPE PBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5-7 LIU PBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

5-8 SMPS (Switching Mode Power Supply) Unit. . . . . . . . . . . . . . . . . . . . . 5-36

6. Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1 General Precautions on Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3 Scanner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4 ADF Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-5 OPE Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-6 Side Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-7 Fuser Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-8 Exit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-9 Cover Paper Exit Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-10 Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-11 SMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-12 LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-13 Main Frame Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-14 Cover Exit Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-15 MP Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-16 Feed Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-17 Pick Up Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-18 Main PBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

WorkCentre Pro 412

Launch Issue

August 2001

TOC-1

Page 4

Table of Contents

7. Maintenance & Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1 Preventative Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-3 Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7-4 FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7-5 Print Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7-6 Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

8. Exploded View & Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-1. Main Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2. Platen Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . 8-4

8-3. ADF ASS’Y Exploded View & Parts List. . . . . . . . . . . . . . . . . . . . . . . . 8-6

8-4. Side Cover Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . 8-10

8-5. Cassette Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . 8-14

8-6. Exit Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8-7. Feeder Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . 8-18

8-8. MP Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8-9. Base Frame Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . 8-22

8-10. Pick- up Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . 8-24

8-11. Drive Ass’y Exploded View & Parts List. . . . . . . . . . . . . . . . . . . . . . . 8-26

8-12. Main Frame Ass’y Exploded View & Parts List . . . . . . . . . . . . . . . . . 8-28

8-13. FuserA ss’y Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . 8-30

9. Electrical Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1 Main PBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

10. Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

11. Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12. Schematic Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12-1 Main Circuit Diagram (1 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12-2 Main Circuit Diagram (2 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

12-3 Main Circuit Diagram (3 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

12-4 Main Circuit Diagram (4 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12-5 Main Circuit Diagram (5 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

12-6 Main Circuit Diagram (6 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

12-7 Main Circuit Diagram (7 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12-8 Main Circuit Diagram (8 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12-9 Main Circuit diagram (9 of 14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

12-10 Main Circuit Diagram (10 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

12-11 Main Circuit Diagram (11 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

12-12 Main Circuit Diagram (12 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-12

12-13 Main Circuit Diagram (13 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

12-14 Main Circuit Diagram (14 of 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

12-15 LIU Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

12-16 OPE Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

12-17 HVPS Circuit Diagram (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12-18 HVPS Circuit Diagram (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

12-19 SMPS (110) Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-19

12-20 SMPS (220) Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-20

12-21 ADF Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

12-22 Flat Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

12-23 PTL Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-23

12-24 Sensor Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-24

12-25 Toner RX Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-25

12-26 Toner TX Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-26

WorkCentre Pro 412

Launch Issue

August 2001

TOC-2

Page 5

Introduction

1. Introduction

This service manual is part of a multinational service documentation system, but is not structured in the standard Xerox service manual format.

1-1 Organisation

Section 1 Introduction

This section describes the contents of the service manual, describes the Heath & Safety Incident Reporting

and gives translations of all warnings within the service manual in French, Italian, German and Spanish languages.

Section 2 Service Call Procedures

This section is used to start and complete a service call. This section will either direct you to the Maintenance

and Troubleshooting section, or identify a faulty component or sub-assembly.

Section 3 Precautions

This section contains ESD precautions.

Section 4 Specifications

This section contains the specifications for the various modules of the machine.

Section 5 Circuit Description

This section describes the control system of the machine.

Section 6 Disassembly and Reassembly

This section gives instructions for dismantling and assembling the machine.

Section 7 Maintenance & Troubleshooting

This section contains instructions for preventative maintenance and diagnosis of machine fault

Section 8 Exploded Views and Parts Lists

This section shows all parts of the machine in exploded views with lists of spared parts.

Section 9 Electrical Parts Lists.

This section lists all of the spared electrical components.

Section 10 Block Diagram

This section contains a block diagram of the machine functions.

Section 11 Connection Diagram

This section contains an electrical connection diagram for the whole machine.

Section 12 Schematic Diagrams

This section contains the schematic diagrams for the machine.

1-2 Warnings, Cautions and Notes

Translated versions of all warnings are in Translation of Warnings at the end of this section.

WorkCentre Pro 412 August 2001 1-1

Launch Issue

Page 6

Introduction

WARNING

A warning is used whenever an operating or maintenanc e procedure, prac tice, condi tion or statement,

if not strictly observed, could result in personal injury.

CAUTION

A caution is used whenever an operation or maintenance procedure, practice, condition or statement, if not

strictly observed, could result in damage to the equipment

NOTE: A note is used where it is essential to highlight a procedure, practice, condition or statement

1-3 Safety Procedures and Information

The Xerox WorkCentre Pro 412 product and supplies are manufactured, tested and certified to strict safety

regulations, electromagnetic regulations and established environmental standards.

WARNING

Any unauthorised alteration, which may include the addition of new fun ction s, th e c onne ction of exte rnal devices or the use of components not specified by Xerox may impact the products certification,

safety performance or compliance with legislation.

Warning markings

All warning instructions marked on or supplied with the product should be followed.

WARNING

A warning is used whenever an operating, service or maintenance procedure, practice, condition or

statement, if not strictly observed could result in personal injury

.

WARNING

Alerts to areas of the product where there are heated surfaces which must be avoided during service

or maintenance operations.

WARNING

The following are general warning statements which apply in various service or maintenance situations.

WorkCentre Pro 412 August 2001 1-2

Launch Issue

Page 7

Introduction

General Safety Warning

Switch off the po w er to th e m achin e an d disconnect the power cord fro m t he o utl et w h ile pe rform ing tas ks th at

do not need the electricity on. Contact with electricity can cause death or injury.

Power Supply

This product must be operated from the type of power supply indicated on the product’s data plate label.

This product must be connected to a protective earth circuit.

Safe Working

Throughout this pro cedure prior to working on a ny electrical circui t or any m ec han ic al driv e com po nen t di sc onnect all electrical power to the product. The disconnect device is the power cord. Remove the plug from the

power outlet.

Ventilation

This product should not be placed in a built-in installation unless proper ventilation is provided.

Operator Accessible Areas

This product has been designed to restrict operator access to safe areas only. Operator access to hazardous

areas is restricted with covers or guards, which require a tool to remove. Ensure that these covers or guards

are correctly replaced after every service or maintenance task.

Maintenance/Service

Do not to carry out any maintenance or service on the product, which is not described this service documentation.

Cleaning

Before cleaning this product, unplug the product from the power outlet. Always use materials specifically designated for this product, the use of other materials may result in poor performance and may create a hazardous situation. Do not use aerosol cleaners, they may become flammable under certain circumstances.

Precautions

1. Be sure that all built-in protective devices are in place. Restore any missing protective covers.

2. When re-installing chassis and assemblies, be sure to restore all protective devices, including control

knobs and compartment covers.

3. Design Alteration Warning: Never alter or add to the mechanical or electrical design of this equipment,

such as auxiliary c onn ect ors, etc. Such alterations a nd m odi fic ati ons will void the manufacturer’s warranty.

4. Components, parts, and wiring that appear to have overheated or are otherwise damaged should be

replaced with Xerox spare parts. Always determine the cause of damage or overheating, and correct any

potential hazards.

5. Observe the original harness routing, especially near sharp edges, AC, and high voltage power supplies.

Always inspect for pinched, out-of-place, or frayed wiring. Do not change the spacing between components and the printed circuit board.

6. Product Safety Notice: Some electrical and mechanical parts have special safety-related characteristics

which might not be obvious from visual inspection. These safety features and the protection they provide

could be lost if a replacement component differs from the original. This holds true, even though the

replacement may be rated for higher voltage, wattage, etc.

Lithium battery precautions

The Main PWBA is provided with a lithium Cell designated BAT1. Observe the following precautions:

•There could be a danger of explosion if the battery is subject to forced discharge or reverse voltage.

•The battery must only be replaced with the same type.

•The battery should only be replaced at a service centre not at a customer location

•The replacement battery must be the same type and manufacturer as the original.

•Lithium batteries contain substances which are subject to control and should not be opened, crushed or

burned during disposal.

WorkCentre Pro 412 August 2001 1-3

Launch Issue

Page 8

Introduction

Laser Safety

WARNING

Invisible laser radiation. avoid exposure to beam.

Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

This product contains laser warning labels. These labels are intended for use by Service and Maintenance Representatives an d are placed on the top surfa ce of the La ser U ni t. D o not a ttemp t to o pen the

laser unit. There are no serviceable components or areas inside the unit. Operation of the laser unit

with machine or laser covers removed could cause e ye damage if the laser beam is viewed directly.

Electrostatic Damage Caution

The following is an example of the terminology and symbols used in this manual for an electrostatic damage

caution:

Caution

Certain components in this product are susceptible to damage from electrostatic discharge. Observe all ESD

procedures to avoid component damage.

1-4 Heath and Safety Incident Reporting

I. Summary

This standard defines requirements for notification of health and safety incidents involving Xerox products

(equipment and materials) at customer locations.

II. Scope

Xerox Corporation and subsidiaries worldwide.

WorkCentre Pro 412 August 2001 1-4

Launch Issue

Page 9

Introduction

III. Objective

To enable promp t reso luti on of health and safety incidents invo lvi ng Xerox products and to ensure Xerox regulatory compliance.

IV. Definitions

Incident:

An event or condition occurring in a customer account that has resulted in injury, illness or property damage.

Examples of incidents incl ude mach ine fires, sm oke generati on, physi cal inju ry to an oper ator or service representative. Alleged events and product conditions are included in this definition.

V. Requirements

Initial Report:

1. Xerox organisations shall establish a process for individuals to report product incidents to EH&S within 24

hours of becoming aware of the event.

2. The information to be provided at the time of reporting is contained in Appendix A (Health and Safety Incident Report involving a Xerox product).

3. The initial notification may be made by any of the following methods:

• For incidents in North America and Developing Markets West (Brazil, Mexico, Latin American North

and Latin American South):

Phone* EH&S at: 1-800-828-6571.

• Electronic mail EH&S at: Doris.Bush@usa.xerox.com.

• Fax EH&S at: 1-716-422-7734 [intelnet 8*222 7734].

• For incident s i n Euro pe and Developing Mar ket s Eas t (M idd le East , Afric a, India, China and Hong

Kong):

• Phone* EH&S at: +44 (0) 1707 35343.

• Electronic mail EH&S at: Elaine.Grange@GBR.xerox.com.

• Fax EH&S at: +44 (0) 1707 353914 [intelnet 8*668 3914].

*Initial notification m ade by phon e must be fol lowe d within 24 hou rs by a com pleted in cident report and sen t to

the indicated electronic mail address or fax number.

NOTE: If sending a fax, please also send the original via internal mail.

Responsibilities for resolution:

1. Business Groups/Product Design Teams responsible for the product involved in the incident shall:

a. Manage field bulletins, customer correspondence, product recalls, safety retrofits.

b. Fund all field retrofits.

2. Field Service Operations shall:

a. Preserve the Xerox product involved and the scene of the incident inclusive of any associated equipment located in the vicinity of the incident.

b. Return any affe cte d equip ment/par t(s) to th e loca tion de signat ed by EH&S a nd/or the Bus iness D ivisi on.

c. Implement all safety retrofits.

3. EH&S shall:

a. Manage and report all incident investigation activities.

b. Review and approve proposed product corrective actions and retrofits, if necessary.

c. Manage all communications and correspondence with government agencies.

d. Define actions to correct confirmed incidents.

VI. Appendices

The Health and Safety Incid ent Report invol ving a Xerox Pro duct (For m # EH&S-70 0) is a vailable at the end of

this Service Manual.

WorkCentre Pro 412 August 2001 1-5

Launch Issue

Page 10

Introduction

1-5 Translation of Warnings and Precautions

WARNING

A warning is used whenever an operating or maintenanc e procedure, prac tice, condi tion or statement,

if not strictly observed, could result in personal injury.

AVERTISSEMENT

Un avertissement est utilisé chaq ue fois qu'une procédure d'utilisation ou de ma inten ance peu t provo-

quer des blessures si elle n'est pas strictement respectée.

AVVERTENZA

Un’ avvertenza viene utilizzata per segnalare pro cedu re, operazion i, condizi oni o istruzion i operative e

di manutenzione, la cui mancata osservanza può causare infortuni.

VORSICHT

Warnhinweise dieser Art gelten für Anweisungen und Situationen, bei deren Nichtbeachtung bzw.

Auftreten Verletzungsgefahr besteht.

AVISO

Los avisos se utilizan cuan do un procedimiento, ejerci cio, condic ión o declara ción de funcionam iento

o mantenimiento puede producir lesiones personales, si no se sigue estrictamente.

WARNING

Any unauthorised alteration, which may include the addition of new fun ction s, th e c onne ction of exte rnal devices or the use of components not specified by Xerox may impact the products certification,

safety performance or compliance with legislation.

AVERTISSEMENT

Toute modification non autorisée, qu'il s'agisse de l'ajout de nouvelles fonctions, de la connexion de

dispositifs externes ou de l'utilisation de composants non recommandés par Xerox, peut entraîner

l'annulation de la garantie.

AVVERTENZA

Qualunque modifica che implich i l’ aggiungi mento di nuove funzioni , il collegamento ad un dispositivo

esterno o l’ utilizzo di componenti non autorizzati da Xerox può invalidare la certificazione e le dichiarazioni di conformità del prodotto, nonché compromettere la sicurezza operativa di questo.

VORSICHT

Warnhinweise dieser Art gelten für Anweisungen und Situationen, bei deren Nichtbeachtung bzw.

Auftreten Verletzungsgefahr besteht.

AVISO

Cualquier modificación no autorizada, que puede incluir la adición de nuevas funciones, la conexión

de dispositivos externos o el uso de componentes no especificados por Xerox, puede afectar a la certificación del producto, el funcionamiento seguro o el cumplimiento de la legislación.

WARNING

A warning is used whenever an operating, service or maintenance procedure, practice, condition or

statement, if not strictly observed could result in personal injury

AVERTISSEMENT

WorkCentre Pro 412 August 2001 1-6

Launch Issue

Page 11

Introduction

Un avertissement est utilisé à chaque fois q u'une procédure de maintenance ou qu'une manipulation

présente un risque de blessure si elle n'a pas été strictement observée.

AVVERTENZA

Un’ avvertenza viene utilizzata per segnalare pro cedu re, operazion i, condizi oni o istruzion i operative e

di manutenzione, la cui mancata osservanza può causare infortuni.

VORSICHT

Warnhinweise dieser Art gelten für Anweisungen und Situationen, bei deren Nichtbeachtung bzw.

Auftreten Verletzungsgefahr besteht.

AVISO

Los avisos se utilizan cuando un procedimiento, eje rcicio, condición o declara ción de funcionamien to,

servicio o mantenimiento puede producir lesiones personales, si no se sigue estrictamente.

WARNING

Alerts to areas of the product where there are heated surfaces which must be avoided during service

or maintenance operations.

AVERTISSEMENT

Prévient des risques encourus lors d'une intervent ion dans des zones chaudes qui peuve nt provoquer

des blessures.

AVVERTENZA

Evitare le superfici calde del prodotto, indicate da etichette di avvertenza, durante le operazioni di

manutenzione o di assistenza.

VORSICHT

Weist auf heiße Gerätebereiche hin, die bei der Wartung und Pflege nicht angefasst werden dürfen.

AVISO

Llama la at ención sobre áreas del producto donde hay superficies calientes que deben evitarse

durante las tareas de servicio o mantenimiento.

WARNING

The following are general warning statements which apply in various service or maintenance situations.

General safety warning

Switch off the po w er to th e m achin e an d disconnect the power cord fro m t he o utl et w h ile pe rform ing tas ks th at

do not need the electricity on. Contact with electricity can cause death or injury.

Power Supply

This product must be operated from the type of power supply indicated on the product’s data plate label.

This product must be connected to a protective earth circuit.

Safe Working

Throughout this pro cedure prior to working on a ny electrical circui t or any m ec han ic al driv e com po nen t di sc onnect all electrical power to the product. The disconnect device is the power cord. Remove the plug from the

power outlet.

Ventilation

This product should not be placed in a built-in installation unless proper ventilation is provided.

WorkCentre Pro 412 August 2001 1-7

Launch Issue

Page 12

Introduction

Operator Accessible Areas

This product has been designed to restrict operator access to safe areas only. Operator access to hazardous

areas is restricted with covers or guards, which require a tool to remove. Ensure that these covers or guards

are correctly replaced after every service or maintenance task.

Maintenance/Service

Do not to carry out any maintenance or service on the product, which is not described this service documentation.

Cleaning

Before cleaning this product, unplug the product from the power outlet. Always use materials specifically designated for this product, the use of other materials may result in poor performance and may create a hazardous situation. Do not use aerosol cleaners, they may become flammable under certain circumstances.

AVERTISSEMENT

Cette mention indique des informations relatives à différentes situations de maintenance.

Sécurité générale - Avertissement

Mettre la machine hors tension et débrancher le cordon d'alimentation de la prise murale lors d'interventions

qui ne nécessitent pas que l'alimentation soit maintenue. Un contact avec une zone sous tension peut mettre

en danger la sécurité des personnes.

Alimentation

Ce produit doit être utilisé avec l'alimentation indiqué sur la plaque de la machine.

Ce produit doit être connecté à un circuit avec mise à la terre.

Sécurité

Pendant toute cette procédure d'intervention dans de s ci rcuits électriques ou des en traîn em ents mécaniques,

débranchez la machine. Le système de déconnexion est le cordon d'alimentation. Retirer le connecteur de la

prise murale.

Aération

Cet équipement ne doit pas être encastré, sans une ventilation appropriée.

Zones accessibles aux utilisateurs

Ce produit a été conçu de façon à ce que les zones accessibles par les utilisateurs soient sans danger. Les

zones qui peuvent être dangereuses sont protégées par des panneaux ou des sécurités qui nécessitent l'utilisation d'un outil pour être retirer. Veiller à ce que ces pann eau x et sécurités sont correctement remis en place

après toute intervention technique ou de maintenance.

Maintenance

N'effectuez aucune procédure de maintenance non décrite dans la documentation.

Nettoyage

Avant toute procédure d e nettoya ge, débranchez l' équipemen t de la prise m urale. Util isez toujours l es produ its

d'entretien conçus spécifiquement pour l'appareil. L'utilisation d'autres produits risque de nuire au bon fonctionnement de l'appareil et peut s'avérer dangereuse. N'utilisez jamais d'aérosols, ils p euvent s'enflammer

sous certaines circonstances.

AVVERTENZA

Le seguenti avvertenze sono applicabili a svariate situationi di manutenzione o di assistenza.

WorkCentre Pro 412 August 2001 1-8

Launch Issue

Page 13

Introduction

Avvertenza sicurezza generale

Spegnere l’ apparecchio e scollegare il cavo di alimentazione dalla presa durante l’ esecu zio ne di opera zi oni

che non richiedono l’ utilizzo di elettricità. Scosse elettriche accidentali posso no caus are lesio ni pers onali o

morte.

Alimentazione

Utilizzare il prodotto esclusivamente con il tipo di energia indicato e collegarlo a un circuito protettivo con

messa a terra.

Sicurezza elettrica

Accertarsi che il prod otto non ri ceva elet tricità dura nte le ope razioni di intervent o sui cir cuiti elet trici o su lle parti

meccaniche. Il dispositivo di disattivazione del prodotto è costituito dal cavo di alimentazione, il quale deve

essere scollegato dalla presa.

Ventilazione

Non installare l’ apparecchio in un alloggiamento a incasso, a meno che non sia garantita una ventilazione

adeguata.

Aree accessibili per l’ operatore

Questo prodotto è stato progettato in modo da impedire l’ accesso dell’ operatore ad aree non sicure; queste

sono protette da coperture o schermi che richiedono l’ utilizzo di attrezzi per la rimozione. Accertarsi che le

coperture o gli scherm i siano reinseriti in seguito a qualunque op eraz ion e d i m anu ten zio ne o di assistenza del

prodotto.

Manutenzione e assistenza

Non effettuare alcuna operazione di manutenzione o di assistenza non descritta nella documentazione del

prodotto.

Pulizia del prodotto

Prima di eseguire operazioni di pulizia, scollegare il cavo di alimentazione dalla presa a muro. Utilizzare sempre prodotti specifici per questo apparecchio: l’ utilizzo di prodotti diversi da quelli consigliati può comportare

un deterioramento delle prestazioni e causare situazioni di pericolo. Non utilizzare detergenti aerosol, che in

alcune circostanze possono risultare infiammabili.

VORSICHT

Die folgenden Warnhinweise gelten für diverse Wartungs- und Pflegearbeiten.

Allgemeine Sicherheitshinweise

Bei Arbeiten, bei denen kein Strom erforderlich ist, das Gerät ausschalten und den Netzstecker abziehen.

Netzanschluss

Das Gerät muss an eine einwandfrei funkt ionierende Steckdose an geschlos sen sein. Das Gerät muss geerde t

sein.

Arbeitssicherheit

Vor jeg lichen Arbei ten an einem Stro mkreis ode r einem mech anischen Antrieb ist immer de r Netzanschl uss zu

trennen. Das Gerät wird durch Abziehen des Netzsteckers abgeschaltet.

Belüftung

Das Gerät darf nur dann in einer Einbau pos iti on installiert werden, we nn f ür au sre ich end e -Lüftung gesorgt ist.

WorkCentre Pro 412 August 2001 1-9

Launch Issue

Page 14

Introduction

Gefahrenbereiche im Gerät

Der Zugang zum Gerät ist durch Abdeckungen und mechanische Verriegelungen auf sichere Bereiche

eingegrenzt. Gefahrenbereiche sind mit Abdeckungen versehen, die nur mit Werkzeug entfernt werden kön-

nen. Diese Abdeckungen müssen nach Reparaturarbeiten durch den Kundendienst wieder ordnungsgemäß

eingebaut werden.

Wartung/Kundendienst

Keine Wartungsarbeiten, die nicht in der Dokumentation beschrieben sind, ausführen.

Reinigung

Vor der R einigung de s Geräts den Netzstecke r abziehen. Nur di e speziell für das Gerät em pfohlenen Teile und

Verbrauchsmaterialien benutzen, da im anderen Fall schlechte Laufleistung und Sicherheitsrisiken möglich

sind. Keine Reinigungssprays verwenden, da diese sich ggf. entzünden können.

AVISO

Los siguientes son declaraciones generales de aviso aplicables en varias situaciones de servicio o

mantenimiento.

Aviso de seguridad general

Apague la máquina y de se nchufe el cable de alimentación de la tom a d e c orri ente pa ra r eal izar tareas que no

necesiten que se tenga corriente eléctrica en la máquina. El contacto con la corriente eléctrica puede causar

lesiones e incluso la muerte.

Fuente de alimentación eléctrica

Este producto debe utilizarse con el tipo de alimentación eléctrica que se indique en la etiqueta o placa de

datos técnicos del producto. Este producto debe conectarse a un circuito con puesta a tierra de protección.

Seguridad en el trabajo

Durante este procedimiento antes de trabajar en algún circuito eléctrico o componente impulsor mecánico

desconecte el producto de la corriente eléctrica. El dispositivo de desconexión es el cable de alimentación.

Desconecte el enchufe de la toma de corriente.

Ventilación

Este producto no debe colocarse en un lugar empotrado al menos que se tenga la ventilación apropiada.

Áreas accesibles por el operador

Este producto está diseñado para limitar el acceso del operador solamente a áreas seguras. El acceso del

operador a áreas de peligro se li mi ta m edi ante cub ierta s y pr otec tore s qu e para quit arlo s es nec es ario utilizar

alguna her ramienta. Asegúrese de volver a colocar las cubiertas y los protectores correctamente después de

cada tarea de servicio o mantenimiento.

Mantenimiento/Servicio

No realice ninguna operación de mantenimiento o servicio en este producto si no está descrita en esta documentación de servicio.

Limpieza

Antes de limpiar este producto, desenchúfelo de la toma de corriente. Utilice siempre materiales designados

específicamente para este producto ; el us o d e ot ros materiales puede pro duc ir u n fu ncionamiento defectuos o

o crear situaciones de peligro. No utilice limpiadores de aeros ol; en cie r t as circ uns t a nci as puede n lle gar a ser

inflamables.

WorkCentre Pro 412 August 2001 1-10

Launch Issue

Page 15

Introduction

Precautions

1. Be sure that all built-in protective devices are in place. Restore any missing protective covers.

2. When re-installing chassis and assemblies, be sure to restore all protective devices, including control

knobs and compartment covers.

3. Design Alteration Warning: Never alter or add to the mechanical or electrical design of this equipment,

such as auxiliary c onn ect ors, etc. Such alterations a nd m odi fic ati ons will void the manufacturer’s warranty.

4. Components, parts, and wiring that appear to have overheated or are otherwise damaged should be

replaced with Xerox spare parts. Always determine the cause of damage or overheating, and correct any

potential hazards.

5. Observe the original harness routing, especially near sharp edges, AC, and high voltage power supplies.

Always inspect for pinched, out-of-place, or frayed wiring. Do not change the spacing between components and the printed circuit board.

6. Product Safety Notice: Some electrical and mechanical parts have special safety-related characteristics

which might not be obvious from visual inspection. These safety features and the protection they provide

could be lost if a replacement component differs from the original. This holds true, even though the

replacement may be rated for higher voltage, wattage, etc.

7. Components critical for safety are indicated in the parts list with symbols shown below. Use only replacement components that have the same ratings, especially for flame resistance and dielectric specifications.

A replacement part that does not have the same safety characteristics as the original may create shock,

fire, or other safety hazards.

Lithium battery precautions

The Main PWBA is provided with a lithium Cell designated BAT1. Observe the following precautions:

There could be a danger of explosion if the battery is subject to forced discharge or reverse voltage.

The battery must only be replaced with the same type.

The battery should only be replaced at a service centre not at a customer location

The replacement battery must be the same type and manufacturer as the original.

Lithium batteries contain substances which are subject to control and should not be opened, crushed or

burned during disposal.

Précautions

1. Vérifier que tous les dispositifs de protection intégrés sont en place. Replacer les panneaux de protection

manquants.

2. Lors de la réinstallation du châssis et des différentes pièces, veiller à bien replacer tous les dispositifs de

protection, y compris les boutons de contrôle et les couvercles de compartiment.

3. Avertissemen t rela tif a ux m odi fic ati ons de c onc ep tion : Ne jam ai s m odi fier l a st ructure mécanique ou élec-

trique de cet équipement (en ajoutant, par exemple, des connecteurs auxiliaires, etc.). De telles transformations et modifications annuleraient la garantie du constructeur.

4. Tout compos ant, pièce o u câblage ayant été exposé à une surchauffe ou endommagé d’une quelconque

autre façon doit être remplacé par une pièce Xerox. Toujours déterminer la cause du dommage ou de la

surchauffe et élim in er les risq ue pote ntie ls .

5. Examin er le câblage initial, aux abords notamment des arêtes coupantes, de l’alimentation en courant

alternatif et haute tension et toujours s’assurer qu’aucun fil n’est coincé, déplacé ou endommagé. Ne pas

modifier l’espacement des composants et de la carte de circuit imprimé.

6. Sécurité produit : Certaines pièces mécaniques et électriques présentent des caractéristiques de sécurité

particulières qui peuvent ne pas être évidentes à l’oeil nu. Ces caractéristiques de sécurité et la protection

qu’elles assurent risquent de disparaître si un composant de rechange différent du composant d’origine

est utilis é. Ceci est vrai même dans le cas où la pièce de rechange serait destinée à un voltage, à un

ampérage, etc., supérieur.

7. Les composant s es sen tiels pour la sécurité sont indiqués dans la lis t e de s pièces par les symbol es décrits

ci-dessous. Utiliser uniquement des composants de rechange présentant les mêmes caractéristiques

assignées, surtout en matière de tenue à la flamme et de spécifications diélectriques. Une pièce de

rechange ne présentant pas les mêmes caractéristiques de sécurité que la pièce d’origine peut provoquer

des accidents : électrocution, incendie, et autres dangers pour la sécurité.

WorkCentre Pro 412 August 2001 1-11

Launch Issue

Page 16

Introduction

Précautions relatives aux piles au Lithium

La carte PWBA est équipée d'une pile au lithium identifiée BAT 1. Observez les précauti ons suivantes :

Il existe un risque d'explosion si la pile est l'objet d'une alimentation forcée ou d'un voltage inversé.

Une pile ne doit être remp lac ée que par une de même type.

La pile ne doit être remplacée que dans un Centre de maintenance et non chez le client.

Les piles de remplacement doive nt être de même type et fabrication que celles d'origine.

Les piles au Lithium contiennent des substances qui nécessitent des contrôles et ne doivent pas

être ouvertes, écrasées ou brûlées.

Precauzioni

1. Accertari che non manchino dispositivi di protezione. Rimettere in sede eventuali coperture di protezione

mancanti.

2. Duran te l’installazione di coperture e gruppi, accertarsi che siano presenti tutti i dispositivi di protezione,

comprese manopole di controllo e coperture nelle diverse aree.

3. Avvertenza: no n modi ficare la stru ttura me ccani ca o e lettric a dell a macc hina, quali connet tori aus iliari , ecc.

Eventuali modifiche o alterazioni renderanno nullo il certificato di garanzia del produttore.

4. Componenti, parti e cab laggio che app aiono s urrisca ldati o d annegg iati va nno sos tituiti da parti di ricamb io

Xerox. Stabilire la causa del problema e intervenire in modo adeguato per evitare che si ripresenti.

5. Mantenere il percorso originale del cablaggio, in particolare in prossimità di bordi, per CA e alimentazione

elettrica ad alta tensione. Verificare che il cablaggio non sia strozzato, fuori sede o consumato. Non

alterare lo spazio tra i componenti e la scheda del circuito stampato.

6. Avviso sulla sicurezza del prodotto: alcuni componenti elettrici e meccanici possiedono delle funzioni di

sicurezza non sempre ovvie durante l’ispezione visiva. Queste funzioni possono non essere più attive se

un componente viene sostituito con uno diverso dall’originale. Questo vale anche se le parti di ricambio

hanno specifiche più elevate, ad esempio, di alta tensione, potenza nominale, ecc.

7. I componenti per la sicurezza più importanti sono riportati nell’elenco delle parti di ricambio con i simboli

illustrati qui di seguito. Utilizzare solo componenti con gli stessi valori, in particolare per quanto riguarda i

valori di resistenza al calore e le specifiche dielettriche. Una parte di ricambio con funzioni di sicurezza

diverse dalla parte originale può causare condizioni di pericolo quali scosse elettriche e incendi.

Precauzioni della batteria al litio

La PWBA (scheda a circuito stampato) principale è fornita di una batteria al litio (BAT1).

Osservare le precauzioni riportate di seguito.

La batteria può esplodere se soggetta ad una forzata discarica o tensione inversa.

Sostituire la batteria ESCLUSIVAMENTE con una dello stesso tipo.

Sostituire la batteria pr esso un centro di assi stenz a tecnic a e accert arsi che la batteria di sostit uzione sia dello

stesso tipo e marca dell’ originale.

Le batterie al litio contengono sostanze soggette a controllo e non devono essere aperte, frantumate o bruciate durante l’ eliminazione.

Vorsichtsmaßnahmen

1. Darauf achten, dass alle Sicherheitsvorrichtungen vorhanden sind. Evtl. fehlende Sicherheitsabdeckungen einbauen.

2. Beim Zusammenbau von Komponenten und Gehäuse alle Sicherheitsvorrichtungen sowie Steuerknöpfe

und Abdeckungen installieren.

3. Bauartänderungen: keinerlei Änderung an der mechanischen oder elektrischen Bauart des Geräts, z. B.

durch Installation von Zusatzanschlüssen, durchführen. Bei solchen Änderungen wird die Garantie des

Herstellers ungültig.

4. Komponenten oder Kabel/Drähte, die überhitzt oder anderweitig beschädigt sind, müss en durc h Ersatz teile von Xerox ersetzt werden. Die Ursache einer Überhitzung mus s immer ges uc ht und ents prec hen de

Gefahrenquellen beseitigt werden.

WorkCentre Pro 412 August 2001 1-12

Launch Issue

Page 17

Introduction

5. Kabelbaum, Netzkabel und Hochspannungskabel besonders in der Nähe scharfer Kanten auf Schäden

und Positionsänderungen überprüfen. Der Absta nd zwisc hen Kompon enten und der Leite rpla tte darf ni cht

geändert werden.

6. Gerätesicherheit: Einige elektrische und mechanische Komponenten verfügen über bestimmte, nicht sichtbare, Sicherheitsmerkm ale. W erde n Kompo nenten d urch solc he ande rer Bauart e rsetzt, bieten die se ggf.

nicht denselben Gefahrenschutz wie die Originalkomponenten. Das gilt auch dann, wenn die Ersatzteile

für eine höhere Spannung ausgelegt sind, o. Ä.

7. Für die Betriebssicherheit wichtige Komponenten sind in der Teileliste mit dem unten gezeigten Symbol

gekennzeichnet. Es dürfen nur Ersatzteile mit der gleichen Sicherheitsauslegung, insbesondere mit den

gleichen dielektrischen und flammhemmenden Spezifikationen, verwendet werden. Bei Einbau einer

Komponente mit ei ner and eren Sic herhei tsausl egung als d er des O riginal s bes tehen St romsc hlag-/Bran dund weitere Sicherheitsrisiken.

Lithiumbatterie

Das Haupt-PWBA enthält eine Lithiumbatterie (BAT1). Folgende Hinweise beachten:

Bei Rückspannung oder erzwungener Entladung besteht Explosionsgefahr.

Die Batterie darf nur durch eine Batterie gleichen Typs ersetzt werden.

Die Batterie darf nur im Kundendienstzentrum, nicht aber im Haus des Kunden, ersetzt werden.

Die Ersatzbatterie muss vom gleichen Typ und Hersteller sein, wie das Original.

Lithiumbatterien müssen den vorschriftmäßig entsorgt werden.

Precauciones

1. Asegúrese de que todos los dispositivos de protección incorporados están en su sitio. Restaure las cubi-

ertas protectoras que falten.

2. Al reinstalar el chasis y los ensamblajes, asegúrese de restaurar todos los dispositivos de protección,

incluyendo mandos de control y cubiertas de compartimientos.

3. Aviso de alteración del diseño: Nunca altere o agregue nada al diseño mecánico o eléctrico de este

equipo, como conectores auxiliares, etc. Tales alteraciones y modificaciones anularán la garantía del fabricante.

4. Los componentes, piezas y cables que parezcan haber sufrido sobrecalentamiento o daños de otro tipo

deben reemplazarse por piezas de repuesto de Xerox. Siempre determine la causa del daño o sobrecalentamiento y corrija cualquier tipo de riesgo potencial.

5. Observe la ruta original de los mazos de cables, especialmente cerca de bordes afilados, CA y alimentaciones eléctricas de alto voltaje. Siempre inspeccione si los cables están pellizcados, fuera de lugar o pelados. No cambie el espacio entre los componentes y la tarjeta de circuito impreso.

6. Aviso de seguridad del producto: Algunas piezas eléctricas y mecánicas tienen características especiales

relacionadas con la seg uridad que pueden pasar desape rci bid as a una in sp ecc ión visual. Estas funciones

de seguri dad y la prot ecci ón que proporcionan podría perderse si un componente de repuesto difiere del

original. Esto es verdadero, aunque la pieza de repuesto admita un voltaje o vatios más altos, etc.

7. Los componentes críticos para la seguridad se indican en la lista de piezas con símbolos mostrados

debajo. Use sólo compo nentes d e repues to que te ngan lo s mism os va lores, s obre todo en cua nto a resi stencia al fuego y es pecifica ciones dieléctricas. Una pieza de r eca mbio q ue no ten ga las mism as cara cter ís-

ticas de seguridad que la original puede producir una descarga, fuego u otros riesgos de seguridad.

Precauciones con la batería de litio.

El PWBA principal tiene una batería de litio denominada BAT1. Observe las precauciones siguientes:

Podría producirse peligro de explosión si la batería se ve sometida a descarga forzada o tensión inversa.

La batería solamente debe cambiarse por otra del mismo tipo.

La batería debe cambiarse solamente en un centro de servicio y no donde el cliente.

Las baterías de litio contienen substancias sujetas a control y no deben abrirse, aplastarse ni

quemarse para deshacerse de ellas.

WorkCentre Pro 412 August 2001 1-13

Launch Issue

Page 18

This page intentionally blank

Introduction

WorkCentre Pro 412 August 2001 1-14

Launch Issue

Page 19

Service Call Procedures

2. Service Call Procedures

SCP 1 Initial Actions

The Service Call Procedures section is used to identify a suspected problem with the machine.

Start a service call with Initial Actions and end with SCP 6 Final Actions.

Initial Actions are used to gather information of the machine performance.

Procedure

Warning

Switch off the power to the machine and disconnect the power cord from the outlet while performing

tasks that do not need the electricity on. Electricity can cause death or injury.

NOTE: Ignore any references in this manual to options not installed on the machine.

NOTE: If the machine is equipp ed w i th FAX, do not service or interrupt power u ntil the j obs in th e FAX Queue

are completed, or the FAXs in the queue may be lost.

1. Take note of symptoms, error messages or error codes.

2. Ask the operator to describe or demonstrate the problem.

3. If the problem is the result of incorrect operator action, refer the operator to the user documentation.

4. Make sure that:

a. The power cord is connected to the wall outlet and to the machine.

b. Documents are not loaded.

c. Paper is loaded correctly and all paper trays and covers are closed.

d. The telephone line cable is connected correctly between the line socket and the wall jack.

e. The telephone line is good.

f. Connection cable between the machine and any computer or computer network is correctly connected

and in good condition.

5. Check the machine service log book for any previous actions that may be relevant to the call.

6. Either perform SCP 2 First Call Actions or SCP 3 Normal Call Actions.

SCP 2 First Call Actions

First Call Actions are used for the first service call.

Procedure

Perform the following:

1. Check the machine configuration with the customer. Check that all required hardware and software is

installed and / or enabled.

2. Check that all the relevant machine settings are correctly entered.

3. If a fault is present, go to SCP 3 Normal Call Actions. If there is no fault present, go to SCP 6 Final

Actions.

WorkCentre Pro 412 August 2001 2-1

Launch Issue

Page 20

Service Call Procedures

SCP 3 Normal Call Actions

Normal Call Actions are used to determine the reason for the service call.

Procedure

NOTE: If an error message appears at any time. Refer directly to the error code tables in 1-1 Error Codes

RAP, and perform the procedure.

Perform the Following:

1. Review any defective print or copy samples.

2. If the LCD is completely blank, switch off the machine. Wait 10 seconds. Switch on the machine. If the

LCD is still blank, go to 7-6 Malfunction, No Power (LCD or LED).

3. If connected to a network, verify with the customer, that it is permissible to disconnect the machine from

the network.

4. Check and record the total number of images made by the machine.

5. Make a note of any parts requiring cleaning or replacement, refer to 7-1 Preventative Maintenance.

6. Go to SCP4 Fault Analysis.

SCP 4 Fault Analysis

Fault Analysis is used to identify a fault.

Procedure

Exercise the machine in all modes until the fault is determined.

Perform the following:

• If an error message is displayed, go to 7-2 Diagnostics.

• If an image defect is evident, go to 7-3 Scanner.

• If there are problems in sending or receiving FAXs, go to 7-4 FAX.

• If a print defect is evident, go to 7-5 Print Quality.

• If the machine is malfunctioning, go to 7-6 Malfunction.

• When the fault is corrected, go to SCP 5 Final Actions.

SCP 5 Final Actions

Final Actions are used to evaluate the total operation of the system and to identify the actions required to

complete the service call.

Procedure

Complete the following:

• Perform any remaining cleaning or replacement actions, referred to in SCP 3.

• Exercise the machine in all modes, making copies and / or prints from all trays, utilising the ADF and

the document glass.

• If necessary, make a proof copy of a customer document.

• Remove and destroy any copies of test patterns.

• Provide customer training if required.

• If any of the customers selections were changed, return them to the customers preferred settings.

• Complete all administrative tasks.

Ensure the machine and service area are clean before leaving the customer premises.

2-2 August 2001 WorkCentre Pro 412

Launch Issue

Page 21

3. Precautions

Follow these ESD precautions to prevent equipment damage.

Precautions

1. Certain semiconductor devices can be easily

damaged by static electricity. Such components

are commonly called “Electrostatically Sensitive

(ES) Devices”, or ESDs. Examples of typical

ESDs are: integrated circuits, some field effect

transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduc e the incid ence of com ponent

damage caused by static electrici ty.

CAUTION

•Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

2. Before handling a semiconductor component or

semiconductor-equi pped a ssembly, drain off any

electrostatic charge on your body by using the

standard Xerox ESD protection kit, which sho uld

be removed for your personal safety reasons

prior to applying power to the machine.

3. After removing an electrical assembly equipped

with ESDs, place the assembly on the conductive mat of the ESD kit, to prevent electrostatic

charge buildup in the vicinity of the assembly.

4. Use only a grounded tip soldering iron to solder

or de-solder ESDs.

Use only an “anti-static” solder removal device .

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before

installing it. Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective

shorting material from the leads o f a replacement

ESD, touch the protective mat erial to the ch assis

or circuit assembly into which the device will be

installed.

8. Maintain continuous elec tric al con tac t between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling unpacked replacement ESDs. Normal motions,

such as the brushing together of clothing fabric

and lifting one’s foot from a carpeted floor, can

generate static electricity sufficien t to damage an

ESD.

WorkCentre Pro 412

Launch Issue

August 2001

3-1

Page 22

Precautions

This page intentionally blank

3-2

August 2001

WorkCentre Pro 412

Launch Issue

Page 23

4. Specifications

4-1 Printer

Printing method Laser scanning unit + electro photography

Print speed 12 PPM (Letter size, 5% area coverage)

Resolution True 600 X 600 DPI

Emulation PCL6

Operation system Windows 95/98/2000/NT 4.0/Win-ME

Interface IEEE1284 (Nibble/ECP)

USB (Windows 98/2000 only, without HUB mode)

Source of Light Laser diode (LSU)

Feed method Cassette type and multi-purpose tray

Feed direction FISO (front-in side-out)

Paper Size

Specifications

Normal paper: A4,letter,legal,B5,

Executive, A5

Envelope: normal envelope

Length: 149 to 356mm (5.87 to 14 inches)

Width: 100 to 216mm (3.94 to 8.5 inches)

Weight: For MPF, 60 to 90gsm (16 to 24 bond/xerographic)

For cassette, 60-163 gsm (16 to 40 bond/xerographic)

Paper capacity MPF: 100 sheets (based on 75gsm, 20 lb.)

Cassette: 550 sheet (based on 75gsm, 20 lb.)

Paper stacker capacity Face Down: 250 Sheets (75gsm, 20 lb.)

Warming up time Stand-by: 20 seconds

First printing time Power save mode: 30 seconds

Minimum PC spec Pentium II 300 MHz, 64MB RAM

Duplex printing Yes

WorkCentre Pro 412

Launch Issue

August 2001

4-1

Page 24

Specifications

4-2 Facsimile

Machine type Desk top

Applicable line G3 PSTN

Compatibility ITU Group 3

Data coding MH/MR/MMR/JPEG (colour FAX transfer)

FAX Mode Standard, fine, super fine, halftone

Modem speed 33,600 bps

Transmission speed Approx. 3 sec.

Effective scanning width 208 mm (8.2 inches)

Memory 4 M Byte

Halftone 256 levels

Automatic document feeder 30 pages (75gsm)

LCD 16 characters x 2 lines

4-3 Scanner

Operation System Windows 95/98/2000/NT 4.0/Win-ME

Interface IEEE 1284 (ECP Support), USB (without HUB Mode)

Compatibility TWAIN standard, WIA

Device Color CCD (charge coupled device) module

Scan width Max.: 216 mm (8.5 inches), effective: 208 mm (8.2 inches)

Color depth Internal 36 bit, external 24 bit

Optical resolution (H x V) 600 x 600 dpi

Interpolation resolution Max. 4800 dpi

Pre-scan mode: Yes, 75 dpi

Scan speed Mono: 1.25 msec/line, Color: 5 msec/line

(Pentium II 300MHz, 64MB Memory)

4-2

August 2001

WorkCentre Pro 412

Launch Issue

Page 25

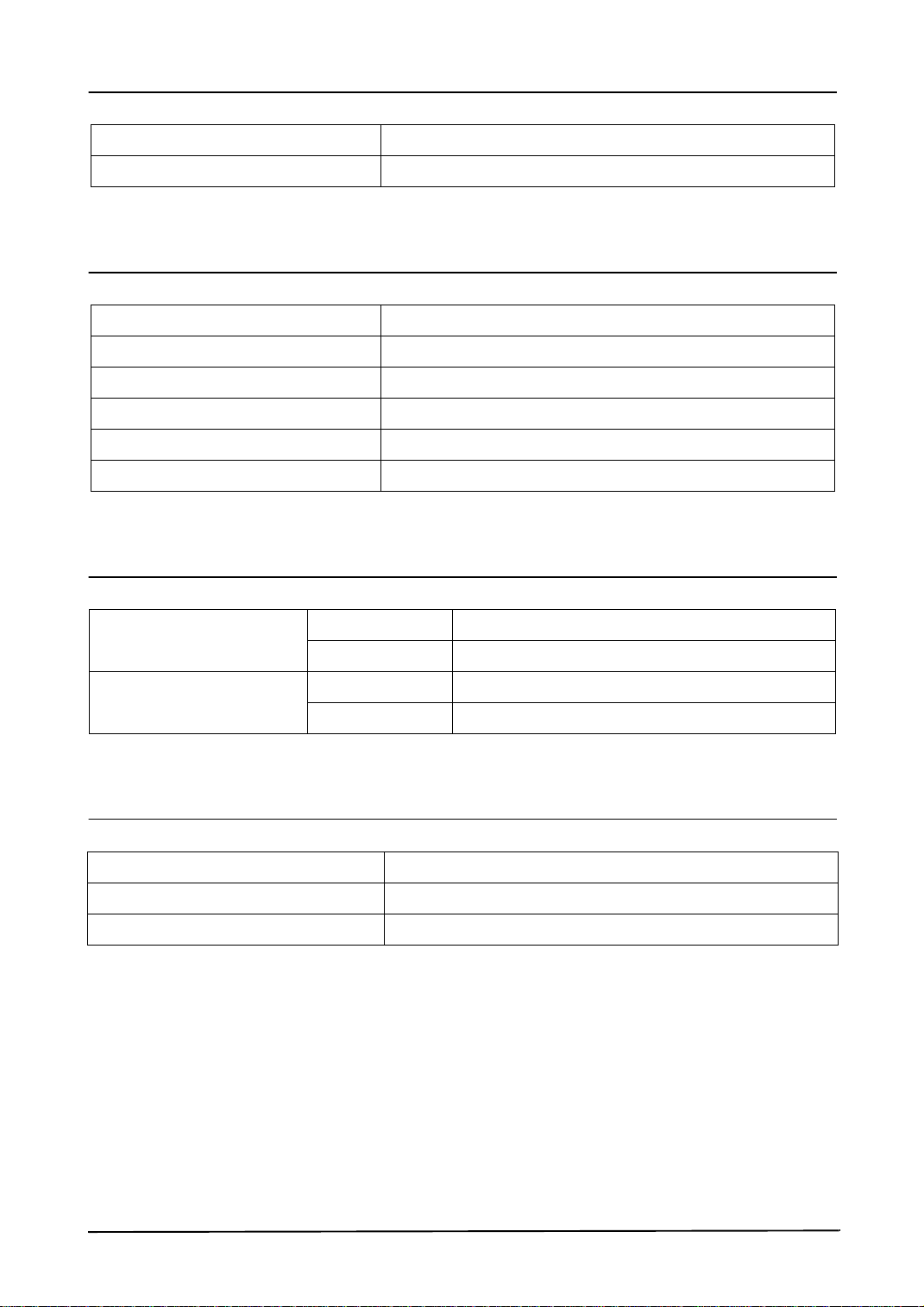

4-4 Copier

Copy mode B/W

Scanner type CCD, Flat-bed with automatic document feeder

Maximum original size A4/letter

Maximum paper size A4/letter/legal

Maximum scan width 216 mm (8.5 inches)

Optical resolution 600 x 600 dpi

Copy quality Text/photo/mixed

Paper type selection Plain, label, card stock, index, transparency

Mono copy speed (Note 1) Platen (SDMP): 12 cpm

ADF (SDMP): 12 cpm

ADF (MDPS): text/mixed:6.6 cpm, photo: 3.3cpm

Effective print-edge margin Top: 4mm, bottom: 4mm, each side: 4mm (0.16 inches)

Multi copy 999 pages (memory multi copy: mono fast mode only)

Specifications

Zoom Rate Platen: 25% ~ 400% (1% step)

ADF: 25% ~ 100% (1% step)

Fixed reduction/enlargement settings 100%, autofit, clone

Contrast control 5 steps

FCOT (platen/ADF) 9.8sec(300 dpi), 18sec(600dpi)

Note 1:

Speed claims based on the test chart: Printed spdtst.sam(mono)/letter size.

SDMP = single document multiple printout

MDSP = multiple document single printout

4-5 Power Supply

Power rating AC 110V to 127V ± 15% 50/60Hz ± 3Hz,

AC 220V to 240V ± 15% 50/60Hz ± 3Hz

Power consumption Average. 300W

Power saving consumption Average. 30W

WorkCentre Pro 412

Launch Issue

August 2001

4-3

Page 26

Specifications

4-6 Dimension

Machine size (W x D x H) 554.5x 433.9 x 459.1 mm (21.8 x 17 x 18 inches)

Machine weight About 23 Kg (50.6 pounds) with CRU

4-7 Packaging

Power cord 1ea (USA standard, ivory)

IEEE 1284 cable No

USB cable 1ea

CD-ROM 1ea

Cartridge Drum CRU 1EA, toner CRU 1EA

Manual 1vol.

4-8 Environmental Condition

Absolute storage Temperature- 20 to 40 degrees C (68 to 104 degrees F)

Humidity 10% RH to 95% RH

Recommended operating

condition

Temperature 6 to 30 degrees C (43 to 86 degrees F)

Humidity 30% RH to 70% RH

4-9 Machine Life

Product life 5 years

Product life in pages 150,000 printing pages (A4 size, 5% area coverage)

Maximum monthly duty cycle 2,500 printing pages (A4 size, 5% area coverage)

4-4

August 2001

WorkCentre Pro 412

Launch Issue

Page 27

Circuit Description

5. Circuit Description

5-1 Main PBA

5-1-1 Summary

The main circuit that co nsi st s of CPU , MF P con troll er (bu ilt-i n 32bit RISC processor core: ARM7 TD MI) i ncl uding various I/O device drivers, system memory, scanner, printer, motor driver, PC I/F, and FAX transceiver

controls the whole system. The entire structure of the main circuit is as follows:

OSC

20 MHz

POWER

ON RESET

MODEM

CIP3

OSC.(Video)

45.3928 MHz

LIU

IMCS

/MIR0,

/RD,/WR

D0~D7

A0~A4

RST_OUT

/RST_OUT

/XDACK

/XDREQ

/SDIP CS

/RD,/WR

D0~D15

A0~A5

IOCS

PLL

Reset & WDT

Generation

ROM/SRAM/

FLASH ROM

Control

(4 Bank)

I/O

Control

(5 Bank)

GPIO

Interrupt

Control

(4 External)

Timer

(3 CH)

Tone

Generator

VIS

Engine

Comm. I/F

ADC

RAM : 512B

A/D BUS

ARM7TDMI

Cache 8KB

CPU BUS

Interface Block

SYSTEM BUS

Interface Block

[Arbiter]

UART

(3 CH)

JBIG

LRAM:1296B

CXRAM:256B

EDO/FPM

DRAM

Control

(4 Bank)

GEU

PVC

PPI

DMAC

(2 CH)

HCT

HPVC

RAM

512B+512B

/CS,/RD,/WR

MA

MD

PROGRAM

ROM

1MB x 4EA

RAS

CAS

OSC.

48 MHz

SRAM

256K

USB

INTERFACE IC

(UNICON)

DATA RAM

(DRAM)

8MB x 2EA

RTC

PARALLEL

INTERFACE

OPE PANEL

INTERFACE

USB

WorkCentre Pro 412

Launch Issue

Block Diagram

August 2001

5-1

Page 28

Circuit Description

5-2 Circuit Operation

5-2-1 Clock

1) System Clock

Device Oscillator

Frequency 20MHz

• KS32C61200 RISC PROCESSOR: drives PLL internally and uses 60MHz.

2) Video Clock

Device Oscillator

Frequency 45.3928 MHz

• Fvd = ((PAPER 1SCAN LINE sending time * SCAN effective late /1SCAN LINE DOT #)*4

=(600dpi*600dpi*58.208mm/s*216mm*4)/(25.4mm*25.4mm*76.1%) = 28.697MHz.

•PAPER 1SCAN LINE sending time = SCAN LINE interval/DOCUMENT SPEED (58.208mm/S)

•1SCAN LINE DOT # = MAZ SCAN distance (216mm) *DOT # per 1mm.

3)USB Clock

Device Oscillator

Frequency 48MHz

5-2-2 Power on/off Reset

1) Signal Operation

Input Signal +5V Power Line (VCC)

Output Signal KS32C61200 nRESET 29F800B nRESET

• Power on/off detect VCC RISING/FALLING 4.5°¦4.6V

Reset time (Td) 1.48 to1.52ms

• Td = (Ct*V sensing)/I charge (...Ct = 33µF, Is = 100µA)

2) Timing Chart

V

and SENSE

CC

Threahold Voltage

V

3.6V

CC

Output

Undefined

RESET

t

d

t

d

V

CC

Output

Undefined

2V

5-2

August 2001

WorkCentre Pro 412

Launch Issue

Page 29

Circuit Description

5-2-3 Risc Microprocessor

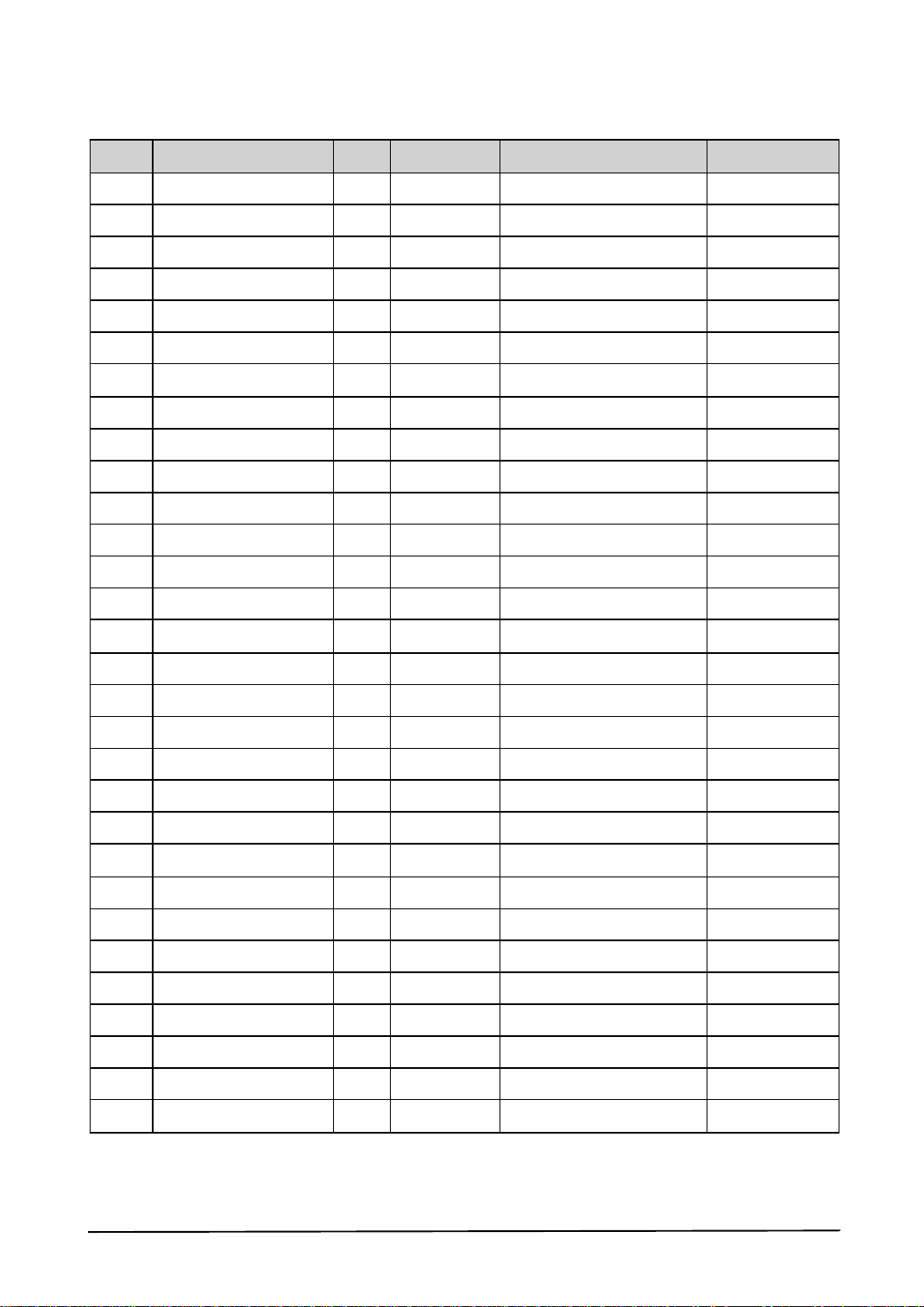

1) RISC microprocessor pin & interface

No Pin Name I/O Reset Value Description PAD

1 DATA0 I/O Input CPU Data Bus 0 PHBTT8, 8 mA

2 DATA1 I/O " CPU Data Bus 1 "

3 DATA2 I/O " CPU Data Bus 2 "

4 DATA3 I/O " CPU Data Bus 3 "

5 Vsso Vss - 5VGnd

6 DATA4 I/O Input CPU Data Bus 4 PHBTT8, 8 mA

7 Vddo Vdd - 5V

8 DATA5 I/O Input CPU Data Bus 5 PHBTT8, 8 mA

9 DATA6 I/O " CPU Data Bus 6 "

10 DATA7 I/O " CPU Data Bus 7 "

11 DATA8 I/O " CPU Data Bus 8 "

12 Vssi Vss - 3.3 V Gnd

13 DATA9 I/O Input CPU Data Bus 9 PHBTT8, 8 mA

14 Vddi Vdd 3.3 V

15 DATA10 I/O Input CPU Data Bus 10 PHBTT8, 8 mA

16 DATA11 I/O " CPU Data Bus 11 "

17 DATA12 I/O " CPU Data Bus 12 "

18 DATA13 I/O " CPU Data Bus 13 "

19 Vsso Vss - 5VGnd

20 DATA14 I/O Input CPU Data Bus 14 PHBTT8, 8 mA

21 DATA15 I/O " CPU Data Bus 15 "

22 DATA16 I/O " CPU Data Bus 16 "

23 DATA17 I/O " CPU Data Bus 17 "

24 Vsso Vss - 5VGnd

25 DATA18 I/O Input CPU Data Bus 18 PHBTT8, 8 mA

26 DATA19 I/O " CPU Data Bus 19 "

27 DATA20 I/O " CPU Data Bus 20 "

28 DATA21 I/O " CPU Data Bus 21 "

29 Vddi Vdd - 3.3 V

30 DATA22 I/O Input CPU Data Bus 22 PHBTT8, 8 mA

WorkCentre Pro 412

Launch Issue

August 2001

5-3

Page 30

Circuit Description

No Pin Name I/O Reset Value Description PAD

31 Vssi Vss - 3.3 V Gnd

32 DATA23 I/O Input CPU Dat a Bus 23 PHBTT8, 8 mA

33 DATA24 I/O " CPU Data Bus 23 "

34 Vddp Vdd - 5V

35 DATA25 I/O Input CPU Dat a Bus 23 PHBTT8, 8 mA

36 Vssp Vss - 5VGnd

37 DATA26 I/O Input CPU Dat a Bus 23 PHBTT8, 8 mA

38 DATA27 I/O " CPU Data Bus 23 "

39 Vddo Vdd - 5V

40 DATA28 I/O Input CPU Dat a Bus 23 PHBTT8, 8 mA

41 Vsso Vss - 5VGnd

42 DATA29 I/O Input CPU Dat a Bus 23 PHBTT8, 8 mA

43 DATA30 I/O " CPU Data Bus 23 "

44 DATA31 I/O " CPU Data Bus 23 "

45 Vssi Vss - 3.3 V Gnd

46 LFIA0 / OP4 O H Line Feed Mot or Phase A PHOB4, 4mA

47 Vddi Vdd - 3.3 V

48 LFIA1 / OP5 O H Line Feed Motor Phase /A PHOB4, 4mA

49 LFIB0 / OP6 O " Line Feed Mot or Phase B "

50 LFIB1 / OP7 O " Line Feed Motor Phase /B "

51 TnRST I TAP Controller Reset PHIT

52 TMS I TAP Controller Mode Sel PHIT

53 TDI I TAP Controller Data In "

54 TCK I TAP Controller Clock "

55 TDO O TAP Cont roller Data Out PHOB4

56 AVdd Vcca - Analog 3.3 V

57 AVin[0] I - Analog Input 0 PICA

58 AVin[1] I - Analog Input 1 "

59 AVss Vssa - Analog Gnd

60 AVssAVin[2] I - Analog Input 2 PICA

5-4

August 2001

WorkCentre Pro 412

Launch Issue

Page 31

Circuit Description

No Pin Name I/O Reset Value Description PAD

61 AVref I - Analog Positve Reference PICA

62 nIO CS0 O H IO Chipselect 0 PHOB4, 4 mA

63 nIOCS2/ToneOut O " IO Chipselect 2 / ToneOut "

64 nIOCS3/BufferSel O " IO Chipselect 2 / BufferSel "

65 Vssi Vss - 3.3 V Gnd

66 nSELECTIN I - Select Input PHIL, ST

67 nFAULT O H Fault for Error Condition PHOB8, 8 mA

68 nAUTOFD I - Auto Feed PHIL, ST

69 nINIT I - Initialization "

70 SELECT O L Parallel Port Select PHOB8, 8 mA

71 Vddp Vdd - 5V

72 PERROR O L Paper Error PHOB8, 8 mA

73 BUSY O " Parallel Port Busy PHOB8, 8 mA

74 nACK O H Parallel Port Acknowledge PHOB8, 8 mA

75 Vssp Vss - 5VGnd

76 PD0 I/O Input Parallel Port Data 0 PHBTT8, 8 mA

77 PD1 I/O " Parallel Port Data "

78 Vddi Vcca - 3.3 V f or Ring OSC

79 PD2 I/O Input Parallel Port Dat a PHBTT8, 8 mA

80 PD3 I/O " Parallel Port Data "

81 Vssi Vssa - 3.3 V Gnd for Ring OSC

82 PD4 I/O Input Parallel Port Dat a PHBTT8, 8 mA

83 PD5 I/O " Parallel Port Data "

84 Vddo Vdd - 5V

85 PD6 I/O Input Parallel Port Dat a PHBTT8, 8 mA

86 PD7 I/O " Parallel Port Data "

87 nSTROBE I - Data Strobe PHIL, ST

88 Vsso Vss - 5VGnd

89 RxD1 / CTin[2] I - Uart 1 Rx Dat a PHIL, ST

90 TxD1 O H Uart 1 Tx Data PHOB4, 4 mA

WorkCentre Pro 412

Launch Issue

August 2001

5-5

Page 32

Circuit Description

No Pin Name I/O Reset Value Description PAD

91 nDREQ1/RxD2/CTin[1] I - DMA Request1/Uart 2 RxD PHIL, ST

92 nDMACK1 / TxD2 O H DMA Ack1/Uart 2 TxD PHOB4, 4 mA

93 nIOCS1 / nIOCS5 O " IO CS1 / DMA IO1 CS "

94 Vddi Vdd - 3.3 V

95 nDREQ0 /IP1/CTin[0] I - DMA Request0 / Input Port PHIL, ST

96 nDMACK0 / OP1 O H DMA Ack1 / Out Port PHOB4, 4 mA

97 nIOCS4 / OP2 O " DMA IO0 CS / Out Port "

98 EIRQ0 I - External Interrupt 0 PHILU50, ST

99 EIRQ1 I - External Interrupt 1 "

100 EIRQ2 I - Externa l Interrupt 2 "

101 nWait/EIRQ3 I - Wait Request / Ex. IRQ 3 "

102 Vssi Vss - 3.3 V Gnd

103 VCLK I - Video Clock Input PHIC

104 Vddi Vdd - 3.3 V

105 IP[7] / nFSYNC I - Input Port / Frame Sync PHIL, ST

106 nLSYNC I - Line Sync "

107 OP[8 ] / nPRIN T O H OutPort/PrintStart PHOB4, 4 mA

108 Vssi Vss - 3.3 V Gnd

109 VDO O H Vi deo Data Output PHOB16, 16mA

110 Vsso Vss - 5VGnd

111 CCLK / PWM[0] O H Com. Clock / PWM [0] PHOB4, 4 mA

112 nEPRDY / RxD0 I -

Engine Power Ready

PHIL, ST

/Uart0RxData

Command Busy

113 nCBSY / TxD0 O H

PHOB4, 4 mA

/Uart0TxData

114 nEMSG / PWM[1] I/O Input Eng. Message / PWM [1] PHBLT4,ST,4mA

115 nEBSY / nLsuReady I - Eng. Busy / LSU Ready PHIL, ST

116 nCMSG / PWM[ 2] O H Com. Busy / PWM [2] PHOB4, 4 mA

117 Vddo Vdd - 5V

118 nDRAMCAS0 O L DRAM Cas Strobe 0 PHOB8, 8 mA

119 nDRAMCAS1 O " DRAM Cas Strobe 1 "

120 nDRAMCAS2 O " DRAM Cas Strobe 2 "

5-6

August 2001

WorkCentre Pro 412

Launch Issue

Page 33

Circuit Description

No Pin Name I/O Reset Value Description PAD

121 nDRAMCAS3 O L DRAM Cas Strobe 3 PHOB8, 8 mA

122 Vsso Vss - 5VGnd

123 nDRAMOE O H DRAM Data Out Enable "

124 nDRAMWE O H DRAM Data Write Enable "

125 Vssi Vss - 3.3 V Gnd

126 nDRAMRAS0 O L DRAM Ras Strobe 0 PHOB8, 8 mA

127 Vddi Vdd - 3.3 V

128 nDRAMRAS1 O L DRAM Ras Strobe 1 PHOB8, 8 mA

129 nDRAMRAS2 O " DRAM Ras Strobe 2 "

130 nDRAMRAS3 O " DRAM Ras Strobe 3 "

131 Vsso Vss - 5VGnd

132 DRAMD0 I/O Input DRAM Data Bus 0 PHBTT12, 12mA

133 Vddo Vdd - 5V

134 DRAMD1 I/O Input DRAM Data Bus 1 PHBTT12, 12mA

135 DRAMD2 I/O " DRAM Data Bus 2 "

136 DRAMD3 I/O " DRAM Data Bus 3 "

137 DRAMD4 I/O " DRAM Data Bus 4 "

138 Vsso Vss - 5VGnd

139 DRAMD5 I/O Input DRAM Data Bus 5 PHBTT12, 12mA

140 DRAMD6 I/O " DRAM Data Bus 6 "

141 DRAMD7 I/O " DRAM Data Bus 7 "

142 Vssi Vss - 3.3 V Gnd

143 DRAMD8 I/O Input DRAM Data Bus 8 PHBTT12, 12mA

144 Vddi Vdd - 3.3 V

145 DRAMD9 I/O Input DRAM Data Bus 9 PHBTT12, 12mA

146 DRAMD10 I/O " DRAM Data Bus 10 "

147 DRAMD11 I/O " DRAM Data Bus 11 "

148 Vssp Vss - 5VGnd

149 DRAMD12 I/O Input DRAM Data Bus 12 PHBTT12, 12mA

150 Vddp Vdd - 5V

WorkCentre Pro 412

Launch Issue

August 2001

5-7

Page 34

Circuit Description

No Pin Name I/O Reset Value Description PAD

151 DRAMD13 I/O Input DRAM Data Bus 13 PHBTT12, 12mA

152 DRAMD14 I/O " DRAM Data Bus 14 "

153 DRAMD15 I/O " DRAM Data Bus 15 "

154 DRAMD16 I/O " DRAM Data Bus 16 "

155 Vsso Vss - 5VGnd

156 DRAMD17 I/O Input DRAM Data Bus 17 PHBTT12, 12mA

157 Vddo Vdd - 5V

158 DRAMD18 I/O Input DRAM Data Bus 18 PHBTT12, 12mA

159 DRAMD19 I/O " DRAM Data Bus 19 "

160 DRAMD20 I/O " DRAM Data Bus 20 "

161 DRAMD21 I/O " DRAM Data Bus 21 "

162 Vssi Vss - 3.3 V Gnd

163 DRAMD22 I/O Input DRAM Data Bus 22 PHBTT12, 12mA

164 Vddi Vdd - 3.3 V

165 DRAMD23 I/O Input DRAM Data Bus 23 PHBTT12, 12mA

166 DRAMD24 I/O " DRAM Data Bus 24 "

167 DRAMD25 I/O " DRAM Data Bus 25 "

168 DRAMD26 I/O " DRAM Data Bus 26 "

169 Vsso Vss - 5VGnd

170 DRAMD27 I/O Input DRAM Data Bus 27 PHBTT12, 12mA

171 Vddo Vdd - 5V

172 DRAMD28 I/O Input DRAM Data Bus 28 PHBTT12, 12mA

173 DRAMD29 I/O " DRAM Data Bus 29 "

174 DRAMD30 I/O " DRAM Data Bus 30 "

175 DRAMD31 I/O " DRAM Data Bus 31 "

176 Vsso Vss - 5VGnd

177 DRAMA0 O L DRAM Address Bus 0 PHOB8, 8 mA

178 DRAMA1 O " DRAM Address Bus 1 "

179 DRAMA2 O " DRAM Address Bus 2 "

180 DRAMA3 O " DRAM Address Bus 3 "

5-8

August 2001

WorkCentre Pro 412

Launch Issue

Page 35

Circuit Description

No Pin Name I/O Reset Value Description PAD

181 DRAMA4 O L DRAM Address Bus 4 PHOB8, 8 mA

182 Vsso Vss - 5VGnd

183 DRAMA5 O " DRAM Address Bus 5 "

184 DRAMA6 O " DRAM Address Bus 6 "

185 DRAMA7 O " DRAM Address Bus 7 "

186 Vddo Vdd - 5V

187 DRAMA8 O L DRAM Address Bus 8 PHOB8, 8 mA

188 Vsso Vss - 5VGnd

189 DRAMA9 O L DRAM Address Bus 9 PHOB8, 8 mA

190 DRAMA10 O " DRAM Address Bus 10 "

191 DRAMA11 O " DRAM Address Bus 11 "

192 Vssi Vss - 3.3 V Gnd

193 nROMCS0 O H ROM Chip Select 0 PHOB4, 4 mA

194 Vddi Vdd - 3.3 V

195 nROMCS1 O H ROM Chip Select 1 PHOB4, 4 mA

196 nROMCS2 O " ROM Chip Select 2 "

197 nROMCS3 O " ROM Chip Select 3 "

198 nROMRD O " ROMorIORead PHOB8, 8 mA

199 Vssp Vss - 5VGnd

200 nROMWR O H ROMorIOWrite PHOB8, 8 mA

201 Vddp Vdd - 5V

202 ADDR2 O L Address Bus 2 for ROM PHOB8, 8 mA

203 ADDR3 O " Address Bus 3 for ROM "

204 ADDR4 O " Address Bus 4 for ROM "

205 Vsso Vss - 5VGnd

206 ADDR5 O L Address Bus 5 for ROM PHOB8, 8 mA

207 ADDR6 O " Address Bus 6 for ROM "

208 ADDR7 O " Address Bus 7 for ROM "

209 Vssi Vss - 3.3 V Gnd

210 ADDR8 O L Address Bus 8 for ROM PHOB8, 8 mA

WorkCentre Pro 412

Launch Issue

August 2001

5-9

Page 36

Circuit Description

No Pin Name I/O Reset Value Description PAD

211 ADDR9 O L Address Bus 9 for ROM PHOB8, 8 mA

212 Vddo Vdd - 5V

213 ADDR10 O L Address Bus 10 for ROM PHOB8, 8 mA

214 Vsso Vss - 5VGnd

215 ADDR11 O L Address Bus 11 for ROM PHOB8, 8 mA

216 ADDR12 O " Address Bus 12 for ROM "

217 ADDR13 O " Address Bus 13 for ROM "