Page 1

7017 / 7017SF Technical Reference

Manual

Table of Contents

Section 1 Service Call Procedures

Section 2 Status Indicator Repair Analysis Procedures

Section 3 Image Quality

Section 4 Repair / Adjustment

Section 5 Parts List

Section 6 General Procedures / Information

Section 7 Wiring Data

Section 8 Store and Forward Option

7010 / 7017SF Technical Reference Manual

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/7017stoc.htm [28/09/1999 11:33:51]

Page 2

1. Service Call Procedures

Introduction 1-2●

Call flow 1-2●

Procedures

1.1 Initial Actions 1-2●

1.2 System Checks 1-2●

1.2.1 Prepare for System Checks 1-3

1.2.2 Off-Line System Check 1-3

1.2.3 On-Line System Check 1-5

1.3 Additional System Checks 1-6●

1.3.1 G2 On-Line Check 1-6

1.3.2 Store and Forward Check 1-6

1.3.3 Automatic Document Feeder Check 1-7

1.4 Final Actions 1-7●

1.4.1 Call Completion 1-7

1. Service Call Procedures

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section1.htm [28/09/1999 11:33:53]

Page 3

Section Introduction

www.printcopy.info

www.printcopy.info

The Service Call Procedures section is used to

identify a suspected problem. This section

contains, Initial Actions, System Check,

Additional Systems Check and Final Actions.

Initial Action is used to gather information

regarding the performance of the terminal.

Initial Action is usually the first step performed

on a service call. System Check is used to verify

the normal operation of the terminal.

Additional System Check contains mechanical

RAPs (Repair Analysis Procedures) and various

built-in electrical tests that can be initiated by

the service representative. Refer to Additional

System Check when directed by System Check.

Final Actions is used to complete the service

call after the problem has been repaired.

Call Flow

The Call Flow diagram illustrates the normal

sequence of events used on each service call.

Service Call Procedures

Status Indicator RAPs

Procedures

1.1 Initial Action

Initial Action is used to gather information

from the operator concerning problems at the

local terminal. Question the operator and

make note of symptoms and error codes or

other information concerning the error. This

information may help you to identify a

problem in the case of an intermittent or

unusual machine error. Once all information is

gathered, prepare for System Check. If the

operator is not available, go directly to the

System Check.

1.2 System Checks

Begin each procedure in System Check with

Step 1. It is important to follow the sequence

outlined in the Off-Line and On-Line

procedures since each step assumes the

previous steps to be correct. Each step is the

normal operational event of the terminal and

can be confirmed by answering Y (yes) to the

statement. A Y response leads to the next

step. A N (No) response will lead to a RAP

(Section 2.0) or a component replacement.

Replace the components listed after N in the

order given.

Perform the System Check to verify repair after

completing each corrective action (replacing

or adjusting a part, or reseating a connector,

etc.).

If an error code is displayed, go to Section 2.0.

Turn to the Table of Contents and locate the

Error Code List. Locate the error code that was

displayed and follow the Corrective Action

indicated.

If an operator function and error code are

displayed, write down the error code and

perform the operator function. In the event

the operator function does not repair the

problem, go to Section 2. Locate the error

code in the Error Code List and follow the

actions indicated.

Introduction, Call Flow, Procedures 1-2 Telecopier 7017 / 7017SF

Image Quality RAPs

Repair

Spare Parts List

Figure 1 Call Flow

In the event Service Call Procedures do not

isolate the problem call for assistance.

7017-104

6/88

Page 4

1.2.1 Prepare for System Checks

www.printcopy.info

www.printcopy.info

1. Check for any obvious problems such as a

recording paper jam, original jam,

telephone or data cable connections

loose at the terminal jacks or wall jack.

2. Ensure that handset is on handset cradle

and that power cord is connected to

terminal and to wall outlet.

3. If unable to perform any of the following

steps, go to 1.2.2 Off-Line System Check.

4. Enter service mode.

a. Press Menu.

b. Press

c. Press Stop.

d. Upper line of display blinks to

indicate terminal is in service mode.

5. Print the service option report (save for

Final Actions).

a. Press Menu.

b. On the keypad, press 2 then 2.

c. Press Start.

6. Set listen to dial to on.

RX NOTE: Perform this step only if listen to

dial is permitted in your country.

a. Press Menu.

b. On the keypad, press 4 then 5.

Display indicates:

on the key pad three times.

*

7. Set key tone to on.

a. Press Menu.

b. On the keypad, press 5 then 2.

Display indicates:

52 PANEL KEY TONE

PRESS [ENTER] OR [SCROLL]

c. Press Enter.

d. If panel key tone is on, go to next

step. If panel key tone is off, press

Select to change to on.

e. Press Enter.

8. Go to 1.2.2 Off-Line System Check.

1.2.2 Off-Line System Check

NOTE: If an error code (COXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

1. Ensure that handset is on handset cradle.

continue. Refer to Section 2 for the

Disconnect power cord from terminal,

wait five seconds, then reconnect power

cord to terminal. Observe red LED and

green LED of power supply come on.

(LEDs are visible through fan vent at rear

of terminal.)

YN

| RAP 2.3.1

2. Power supply fan comes on.

YN

| Replace fan.

3. Within 3 seconds display indicates:

Please WAIT

Telecopier 7017

YN

| Replace A2, A6, A10.

4. Approximately 15 seconds after terminal

powers up, power supply fan and red LED

go off.

YN

| RAP 2.3.12

5. ADF feed belt and nudger are stationary.

YN

| Replace A2.

45 LISTEN TO DIAL

Telecopier 7017 / 7017SF 1-3

PRESS [ENTER] OR [SCROLL]

c. Press Enter.

d. If listen to dial is on, go to next step.

If listen to dial is off, press Select to

change to on.

e. Press Enter.

8/88

Prepare for System Checks, Off-Line System Check

Page 5

6. Look upward into document output area

www.printcopy.info

www.printcopy.info

(between upper and lower scan covers).

LED array on A1 (video assembly) is off.

(Ignore the momentary flash.)

YN

| Replace A2.

7. Approximately 15 seconds after terminal

powers up, following message appears:

LOAD ORIGINALS FACE DOWN IN INPUT TRAY

TIME DATE

YN

| Check document sensor (RAP 2.3.8);

replace A2, A10

8. Error Correct LED is off.

YN

| Press Comm Mode key one time,

then go to next step.

9. Only one Original LED, only one

Resolution LED, and only one Comm

Mode LED are on.

YN

| Replace A2, A6.

10. Control panel LEDs on steady (not

flashing).

YN

| Replace A2, A6.

NOTE: If keys do not function properly at any

time during remainder of test, replace A2, A6.

11. Tone is heard when Stop key is pressed.

YN

| Replace A2, A6, speaker.

12. Run Auto Diagnostics.

a. Press Menu.

b. On the key pad, press 2 then 4.

c. Press Start. The display indicates:

24 DIAGNOSTICS

YN

| Perform the operator action

indicated. Go to Section 2. for the

Error Code List.

13. Printer operates without excessive motor

noise during the print operation.

YN

| Check printer belt (RAP 2.3.11);

replace A2, print motor.

14.Printer completely feeds approximately

14 inches (35.5 cm) of recording paper

out of the terminal.

YN

| RAP 2.3.6; replace A2.

15. Recording paper is cut.

YN

| RAP 2.3.6; replace A2, cutter

solenoid.

16. The diagnostic test pattern is acceptable

(compare to test pattern in Section 3).

YN

| RAP 2.3.3

NOTE: If extended operation of printer is

RAP

desired, perform

2.3.7 Paper Feed Test.

17. Set document guides for 8.5 inches (21.6

cm).

18. Place original (test pattern 82P151) into

the ADF face down. The display

indicates:

DIAL TELEPHONE NUMBER

PRESS [COPY] TO MAKE A COPY

YN

| Check document sensor (RAP 2.3.8);

replace A2.

19. Press Copy, then press Start. Nudger

cycles only once as original is fed into

scanner.

YN

| Replace A2, nudger solenoid.

20. Scanner motor noise is normal (no

excessive noise).

YN

| Replace A2; check scan input drive

belt (RAP 2.3.11); replace scan motor.

21. Original is fed through scanner.

YN

| Replace video assembly, A2.

22. Recording paper is cut, and original feeds

out.

YN

| Check scan position sensor (RAP

2.3.8), scan output drive belt (RAP

2.3.11); replace A2.

23. Original is unwrinkled.

YN

| Check platen belt (RAP 2.3.11);

replace A2, scan motor.

Off-Line System Check 1-4 Telecopier 7017 / 7017SF

12/88

Page 6

24. Image is full size (not reduced).

www.printcopy.info

www.printcopy.info

YN

| Check wide original sensor (RAP

2.3.8); replace A2.

25. Image is parallel with paper edges (not

skewed).

YN

| Check platen belt (RAP 2.3.11).

26. Image quality is acceptable (compare to

test pattern sample in Section 3).

YN

| Clean platen glass; replace A2, video

assembly.

27. Set document guides for 11 inches (28

cm).

28. Place test pattern 82P151 into the ADF

face down. Reduction LED comes on.

YN

| Check wide original sensor (RAP

2.3.8); replace A2.

29. Press Copy, then press Start. The original

is fed into the Scanner.

YN

| Replace A2.

30. Image quality is acceptable (compare to

Wide Original sample test pattern in

Section 3).

YN

| Clean platen glass; replace A2, video

assembly.

31. Perform 1.2.3 On-Line System Check.

1.2.3 On-Line System Check

NOTE: Perform this check only after 1.2.2 OffLine System Check has been performed.

NOTE: If an error code (COXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

RX NOTE: If listen to dial is not permitted in

your country, go to step 3.

continue. Refer to Section 2. for the

1. Perform a send operation to a known

good G3 facsimile terminal.

2. Dial tone is heard when terminal goes On

Line.

YN

| RAP 2.3.4.

3. Dialing is completed successfully.

YN

| Replace A10, A2.

4. Terminal transmitted in G3 mode at 9600.

YN

| Replace A5, A2.

5. After completion of the send operation,

the display indicates:

SEND OPERATION COMPLETE #1

TIME DATE

YN

| Replace A2, A5, A10.

6. Image quality received at the remote

terminal is acceptable. (Image quality

acceptance is determined by the remote

operator’s perception of quality.)

YN

| RAP 2.3.13.

7. Call the terminal from another

telephone. The terminal answers with a

ready tone and the following is displayed

for approximately 3 seconds.

INCOMING CALL

TIME DATE

YN

| RAP 2.3.5.

8. Perform a receive operation. Terminal

receives normally at 9600 bps.

YN

| Replace A10, A2.

9. Image quality is acceptable (refer to

Image Quality Section 3).

YN

| RAP 2.3.13.

10. All suspect options and features have

been checked.

YN

| Refer to Table 1 to select the

appropriate Additional System

Checks (1.3).

11. Go to Final Actions.

Table 1. Additional System Checks

Suspect Option or Feature Check

G2 mode in send or receive 1.3.1

Store and forward option 1.3.2

Automatic Document Feeder

(multiple originals)

1.3.3

Telecopier 7017 / 7017SF 1-5

12/88

Off-Line System Check, On-Line System Check

Page 7

24. Image is full size (not reduced).

www.printcopy.info

www.printcopy.info

YN

| Check wide original sensor (RAP

2.3.8); replace A2.

25. Image is parallel with paper edges (not

skewed).

YN

| Check platen belt (RAP 2.3.11).

26. Image quality is acceptable (compare to

test pattern sample in Section 3).

YN

| Clean platen glass; replace A2, video

assembly.

27. Set document guides for 11 inches (28

cm).

28. Place test pattern 82P151 into the ADF

face down. Reduction LED comes on.

YN

| Check wide original sensor (RAP

2.3.8); replace A2.

29. Press Copy, then press Start. The original

is fed into the Scanner.

YN

| Replace A2.

30. Image quality is acceptable (compare to

Wide Original sample test pattern in

Section 3).

YN

| Clean platen glass; replace A2, video

assembly.

31. Perform 1.2.3 On-Line System Check.

1.2.3 On-Line System Check

NOTE: Perform this check only after 1.2.2 OffLine System Check has been performed.

NOTE: If an error code (COXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

RX NOTE: If listen to dial is not permitted in

your country, go to step 3.

continue. Refer to Section 2. for the

1. Perform a send operation to a known

good G3 facsimile terminal.

2. Dial tone is heard when terminal goes On

Line.

YN

| RAP 2.3.4.

3. Dialing is completed successfully.

YN

| Replace A10, A2.

4. Terminal transmitted in G3 mode at 9600.

YN

| Replace A5, A2.

5. After completion of the send operation,

the display indicates:

SEND OPERATION COMPLETE #1

TIME DATE

YN

| Replace A2, A5, A10.

6. Image quality received at the remote

terminal is acceptable. (Image quality

acceptance is determined by the remote

operator’s perception of quality.)

YN

| RAP 2.3.13.

7. Call the terminal from another

telephone. The terminal answers with a

ready tone and the following is displayed

for approximately 3 seconds.

INCOMING CALL

TIME DATE

YN

| RAP 2.3.5.

8. Perform a receive operation. Terminal

receives normally at 9600 bps.

YN

| Replace A10, A2.

9. Image quality is acceptable (refer to

Image Quality Section 3).

YN

| RAP 2.3.13.

10. All suspect options and features have

been checked.

YN

| Refer to Table 1 to select the

appropriate Additional System

Checks (1.3).

11. Go to Final Actions.

Table 1. Additional System Checks

Suspect Option or Feature Check

G2 mode in send or receive 1.3.1

Store and forward option 1.3.2

Automatic Document Feeder

(multiple originals)

1.3.3

Telecopier 7017 / 7017SF 1-5

12/88

Off-Line System Check, On-Line System Check

Page 8

1.3 Additional System Checks

www.printcopy.info

www.printcopy.info

1.3.1 G2 On-Line Check

NOTE: Perform this check only after 1.2.2 OffLine System Check and 1.2.3 On-Line System

Check have been performed. Transmit and

receive to/from a known good terminal

capable of G2 operation.

NOTE: If an error code (COXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

continue. Refer to Section 2 for the

1. Ensure power has been on for 15 seconds,

then enter service mode.

2. Press Menu.

3. Press 9 then 3 on the key pad.

9. Perform a transmit operation and then a

receive operation. Terminal transmits

and receives normally for CCITT G2.

YN

| Replace A5, A2,

10. Press Menu.

11. Press 9 then 3 on the key pad.

12. Press Start.

13. Press Select until display indicates

communications mode customer had

selected (AUTO, G3STD, or G2) as noted

in Step 9.

14. Return to procedure which directed you

to this check or go to Final Actions.

1.3.2 Store and Forward Check

NOTE: Perform this check only after 1.2.2 OffLine System Check and 1.2.3 On-Line System

Check have been performed.

NOTE: If an error code (COXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

continue. Refer to Section 2. for the

1. Visually check that store and forward

A8 PWB is installed.

2. Ensure power has been on for 15

seconds, then enter service mode.

3. Press Menu.

4. Press 1 then 8 on key pad. Display

indicates:

4. Press Start.

5. Display indicates:

93 COMMUNICATIONS MODE >XXX

PRESS [START] OR [SCROLL]

6. Note which communications mode

customer has selected (AUTO, G3STD, or

G2).

7. If G2 not selected, select G2 by pressing

Select until display indicates:

93 COMMUNICATIONS MODE >G2

PRESS [START] OR [SCROLL]

8. Press Enter.

18 CONFIDENTIAL SEND >OFF

PRESS [SELECT] TO CHANGE THEN [ENTER]

YN

| Replace A8, A2.

5. Exit service mode.

6. Ask customer to perform store and

forward operation.

7. Store and forward completes normally.

YN

| Replace A8, A2.

8. Return to procedure which directed you

to this check or go to Final Actions.

G2 On-Line, Store & Forward Checks 1-6 Telecopier 7017 / 7017SF

12/88

Page 9

1.3.3 Automatic Document Feeder

www.printcopy.info

www.printcopy.info

Check

NOTE: Perform this check only after 1.2.2 OffLine System Check and 1.2.3 On-Line System

Check have been performed.

NOTE: If an error code (CXXX, FPXX, EXXX, or

OPXX) appears at any time during this check,

do not

Error Code List and perform the actions

indicated.

continue. Refer to Section 2 for the

1. Enter Service Mode.

2. Place at least three sheets of paper

(multiple originals) into input tray.

3. Enter Original Feed Test.

a. Press Menu.

b. On the key pad, press 7 then 2. The

display indicates:

72 ORIGINAL FEED

PRESS [START] OR [SCROLL]

4. Press Start.

5. Originals feed one sheet at a time.

YN

| RAP 2.3.10.

6. Press Stop to end test.

7. Go to Final Actions.

1.4 Final Action

1.4.1 Call Completion

1. Clean the platen glass.

a. Open and secure the upper scan

cover.

b. Moisten a soft, lint-free cloth or

paper towel with Xerox Lens and

Mirror Cleaner and clean the platen

glass.

2. Cheat upper scan cover interlock switch.

3. Enter Service Mode.

NOTE: Use Xerox CLEAN-UPS to perform the

following cleaning functions (it may be

necessary to use several CLEAN-UPS).

4. Enter the Scan Motor Test.

a. Press Menu.

b. On the key pad, press 7 then 4.

c. Press Start. (Scan motor operates.)

d. Hold the CLEAN-UP against the ADF

belt. Apply enough pressure to clean

the ADF belt but not stall the scan

motor.

5. Clean the ADF belt.

6. Press Stop to end test.

7. Clean the following:

a. Clean the retard pad.

b. Clean the lower scan drive rollers.

c. Clean the platen roller.

8. Clean the pressure roller.

a. Open printer.

b. Clean the exposed area of the

pressure roller and rotate the roller

clockwise to clean the complete roller

surface.

9. Make a Service Options Report for future

reference.

a. Press Menu.

b. On the key pad, press 2 then 2.

c. Press Start.

10. Refer to Service Options Report printed

during Prepare For System Check (if

available) and ensure present

configuration agrees with original

customer configuration.

11. Fold as necessary and place the Service

Options Report behind the Operator

Guide in the output tray.

NOTE: The Service Options Report is retained

as a record of the system data configuration

and all option settings configured by the

Customer. This is useful in case such

information is lost due to Main A2 PWB

replacement or inadvertent erasure.

12. Perform System Check to verify

operation.

13. Replace and clean all covers removed

during the service call.

14. Complete all required administrative

tasks.

Telecopier 7017 / 7017SF 1-7

d. Clean the upper scan idler rollers.

12/88

ADF Check, Call Completion

Page 10

2. Status Indicator Repair Analysis Procedures

Introduction 2-2●

PWB Designations 2-2●

Error Code List

COXX Error Codes 2-3●

FPXX Error Codes 2-3●

EXXX Error Codes 2-3●

FCXX Error Codes 2-4●

OPXX Error Codes 2-5●

Status Indicator RAPs

RAP 2.3.1 One or Both LEDs of Power Supply are Off 2-7●

RAP 2.3.2 Load Isolation 2-9●

RAP 2.3.3 Diagnostic Pattern is Unacceptable 2-10●

RAP 2.3.4 Dial Tone is Not Heard 2-10●

RAP 2.3.5 The Terminal Does Not Answer 2-11●

RAP 2.3.6 Mechanical Checkout 2-11●

RAP 2.3.7 Paper Feed Test 2-12●

RAP 2.3.8 Sensor Test 2-12●

RAP 2.3.9 Scanner Test 2-14●

RAP 2.3.10 Automatic Document Feeder Test 2-14●

RAP 2.3.11 Belt Checkout 2-16●

RAP 2.3.12 Both LEDs Remain On 2-16●

RAP 2.3.13 Received Image Quality is Unacceptable 2-16●

2. Status Indicator RAPs

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section2.htm [28/09/1999 11:34:11]

Page 11

Section Introduction

www.printcopy.info

www.printcopy.info

The Status Indicator Repair Analysis

Procedures section is used to isolate an

identified problem to a faulty component or

subassembly. It contains this Introduction, an

Error code list and RAPs (Repair Analysis

Procedures).

RAPs have been written for most defects that

require the replacement of four or more

components or subassemblies.

The Error Code List includes all error codes

generated by the terminal and displayed in

the Control Panel Display Window. The Action

column of the Error Code List identifies a

component(s), subassembly, or RAP that

correspond to the error code.

Use the Error Code List to identify the action

required for error codes displayed in the

Display Window.

RAPs, when followed step-by-step, will isolate

a problem to a specific component or

subassembly.

2.1.1 Status Indicator Repair Analysis

Procedures

Begin Repair Analysis Procedures with Step 1.

A Y (yes) response will lead you to the next

step. An N (no) response will indicate a

component replacement. Replace in

sequence, the components listed under the

Action column. Run System Check to verify

that each component replaced has resolved

the problem.

In the case of OPXX codes, the terminal will

display a message and an error code. The

Display Message column indicates an operator

function that the service representative can

perform to affect the performance of the

terminal. In the event the function does not

correct the problem and the error code

continues to be displayed, refer to the Action

column.

Reinstall good parts that may have been

removed during troubleshooting after the

repair is verified.

2.1.2 Printed Wiring Board (PWB)

Designations

A0 - CNC

A1 - Video assembly

A2 - Main

A3 - Telephone line filter assembly

A5 - Modem

A6 - Control panel assembly

A8 - Store and forward

A10 - Coupler

Note: All meter ranges and readings are

referenced to the Xerox Digital Meter

(600T1616). These ranges and readings may

be valid with other meters.

not

For example, Error Code CO42 identifies A2

PWB and A5 PWB as replacement parts.

Replace the A2 PWB first. Then run System

Check to verify that replacing A2 has resolved

the problem. If not, replace A5 PWB and

reinstall the original A2 PWB. Then run System

Check again to verify that replacing A5 PWB

has resolved the problem. If the problem is

still not resolved, call for assistance. If the

problem is resolved, go to Final Actions.

Introduction 2-2 Telecopier 7017 / 7017SF

8/88

Page 12

2.2 Error Code List

www.printcopy.info

www.printcopy.info

2.2.1 CXXX Error Codes

Code Corrective Action

CO32 Replace A2, A8

CO42 Replace A2, A5

CO43 Replace A2, A5, perform RAP 2.3.1

CO52 Replace A2, A10

CO53 Replace A2, A10

CO54 Replace A2, A10

CO55 Replace A2, A5, A10

CO60 Replace A2, video assembly

CO61 Replace video assembly, A2

CO70 Replace A2, A8

CO71 Replace A2, A8

CO72 Replace A2, A8

CO80 Replace A2

CO81 Replace A2

CO82 Replace A2

CO83 Replace A2

2.2.2 FPXX Error Codes

Code Corrective Action

FP01 Replace A2

FP02 Replace A2

FP03 Replace A2

FP04 Replace A2

FP05 Replace A2

FP09 Replace A2, A6

FP10 Replace A2, power supply

assembly

FP11 Replace A2

FP12 Replace A2

FP13 Replace A2

FP14 Replace A2, A5

FP15 Replace A2

FP16 Replace A2, A10

FP20 Replace A2, A5, A8

2.2.3 EXXX Error Codes

Code Corrective Action

E001 Replace A2, A5, A8

E003 Replace A2

E004 Replace A2

E006 Replace A2

E007 Replace A2

E009 Replace A2

E011 Replace A2

E012 Replace A2

E013 Replace A2

E021 Replace A2

E022 Replace A2

E032 Replace A2, A5

E033 Replace A2, A5

E034 Replace A2, A5

E035 Replace A2, A10

E036 Replace A2, A10

E038 Replace A2, A10

E040 Replace A2

E041 Replace A2, A5

E050 Replace A2, A8

E051 Replace A2, A8

E052 Replace A2, A8

E200 Replace A2, A5, A10

E201 Replace A2, A5, A10

E203 Replace A2, A5, A10

E204 Replace A2, A5, A10

E205 Replace A2, A5, A10

E210 Replace A2, A5, A10

E211 Replace A2, A5, A10

E212 Replace A2, A5, A10

E220 Replace A2, A5, A10

E221 Replace A2, A5, A10

E222 Replace A2, A5, A10

E223 Replace A2, A5, A10

E231 Replace A2, A5

E240 Replace A2, A5, A10

E241 Replace A5, A5, A10

E242 Replace A2, A5, A10

E243 Replace A2, A5, A10

E244 Replace A2, A5, A10

E245 Replace A2, A5, A10

E246 Replace A2, A5, A10

E248 Replace A2, A5, A10

Telecopier 7017 / 7017SF 2-3

12/88

CXXX, FPXX, EXXX Error Codes

Page 13

Code Corrective Action

www.printcopy.info

www.printcopy.info

E250 Replace A2, A5, A10

E251 Replace A2, A5, A10

E252 Replace A2, A5, A10

E253 Replace A2, A5, A10

E254 Replace A2, A5, A10

E255 Replace A2, A5, A10

E256 Replace A2, A5, A10

E257 Replace A2, A5, A10

E260 Replace A2, A5, A10

E261 Replace A2, A5, A10

E262 Replace A2, A5, A10

E263 Replace A2, A5, A10

E264 Replace A2, A5, A10

E265 Replace A2, A5, A10

E400 Replace A2

E401 Replace A2

E402 Replace A2

E600 Replace video assembly, A2

E601 Replace video assembly, A2

E602 Replace video assembly, A2

E800 Replace A2, Print Motor

E803 Replace A2

E804 Replace A2

E805 Replace A2

2.2.4 FCXX Error Codes

Code Corrective Action

FC02 Replace A2, A6

FC03 Replace A2

FC04 Replace A2

FC06 Replace A2, A5

FC07 Replace A2

FC08 Replace A2

FC09 Replace A2

FC10 Replace A2

FC11 Replace A2

FC12 Replace A2, A5

FC14 Replace A2

FC15 Replace A2

FC16 Replace A2

FC17 Replace A2

FC18 Replace A2

FC19 Replace A2

FC20 Replace A2

FC21 Replace A2

FC22 Replace A2

FC23 Replace A2

FC24 Replace A2

FC25 Replace A2

FC26 Replace A2

FC27 Replace A2

FC28 Replace A2

FC29 Replace A2

FC30 Replace A2

FC31 Replace A2

FC32 Replace A2

FC33 Replace A2

FC34 Replace A2

FC37 Replace A8

Code

FC50 Replace A2, A10, perform RAP 2.3.1

FC60 Replace A2, video assembly

FC70 Replace A8

FC71 Replace A2

FC72 Replace A8

FC73 Replace A2

FC74 Replace A2

FC75 Replace A2

FC81 Replace A2

FC83 Replace A2

FC85 Replace A2

FC87 Replace A2

Corrective Action

EXXX, FCXX Error Codes 2-4 Telecopier 7017 / 7017SF

12/88

Page 14

Code Corrective Action

www.printcopy.info

www.printcopy.info

E250 Replace A2, A5, A10

E251 Replace A2, A5, A10

E252 Replace A2, A5, A10

E253 Replace A2, A5, A10

E254 Replace A2, A5, A10

E255 Replace A2, A5, A10

E256 Replace A2, A5, A10

E257 Replace A2, A5, A10

E260 Replace A2, A5, A10

E261 Replace A2, A5, A10

E262 Replace A2, A5, A10

E263 Replace A2, A5, A10

E264 Replace A2, A5, A10

E265 Replace A2, A5, A10

E400 Replace A2

E401 Replace A2

E402 Replace A2

E600 Replace video assembly, A2

E601 Replace video assembly, A2

E602 Replace video assembly, A2

E800 Replace A2, Print Motor

E803 Replace A2

E804 Replace A2

E805 Replace A2

2.2.4 FCXX Error Codes

Code Corrective Action

FC02 Replace A2, A6

FC03 Replace A2

FC04 Replace A2

FC06 Replace A2, A5

FC07 Replace A2

FC08 Replace A2

FC09 Replace A2

FC10 Replace A2

FC11 Replace A2

FC12 Replace A2, A5

FC14 Replace A2

FC15 Replace A2

FC16 Replace A2

FC17 Replace A2

FC18 Replace A2

FC19 Replace A2

FC20 Replace A2

FC21 Replace A2

FC22 Replace A2

FC23 Replace A2

FC24 Replace A2

FC25 Replace A2

FC26 Replace A2

FC27 Replace A2

FC28 Replace A2

FC29 Replace A2

FC30 Replace A2

FC31 Replace A2

FC32 Replace A2

FC33 Replace A2

FC34 Replace A2

FC37 Replace A8

Code

FC50 Replace A2, A10, perform RAP 2.3.1

FC60 Replace A2, video assembly

FC70 Replace A8

FC71 Replace A2

FC72 Replace A8

FC73 Replace A2

FC74 Replace A2

FC75 Replace A2

FC81 Replace A2

FC83 Replace A2

FC85 Replace A2

FC87 Replace A2

Corrective Action

EXXX, FCXX Error Codes 2-4 Telecopier 7017 / 7017SF

12/88

Page 15

2.2.5 OPXX Error Codes

www.printcopy.info

www.printcopy.info

Code Meaning Display message Corrective Action (after performing message)

OP03 Invalid telephone number detected TELEPHONE NUMBER ENTERED INCORRECTLY Perform System Check

during pulse dial (#,

OP05 Store memory full detected. MEMORY CAPACITY EXCEEDED-PLEASE DIVIDE Perform System Check

OP06 Communication data memory empty THERE IS NO INFORMATION AVAILABLE TO Perform System Check

(Service mode only) REPORT OP06

OP10 Job card not detected in job reserve JOB CARD NOT DETECTED-PLEASE RELOAD JOB Perform System Check

mode. IN INPUT TRAY

OP12 Unauthorized Job Card detected. JOB CARD NUMBER DETECTED DOES NOT MATCH Perform System Check

OP13 Start hole/information hole is too long. JOB CARD IS WORN-PLEASE REPLACE WITH NEW Perform System Check

OP14 Bottom interval is too short. JOB CARD IS WORN-PLEASE REPLACE WITH NEW Perform System Check

OP15 Hole interval is too long. LONG ORIGINAL OR JAM DETECTED IN Perform System Check

OP22 No document detected in ADF. NO ORIGINALS DETECTED-PLEASE RELOAD Perform System Check

OP23 Document is sensed by scan position ORIGINAL DETECTED IN SCANNER-PLEASE Check scan output drive belt (RAP 2.3.11),

sensor. REMOVE ORIGINAL FROM SCANNER OP23 scan position sensor (RAP 2.3.8); replace A2

OP24 Misfeed in ADF. ORIGINALS OR JOB CARD DID NOT FEED Check scan input drive belt (RAP 2.3.11),

OP25 Document is too long or jammed. LONG ORIGINAL OR JAM DETECTED IN Perform System Check

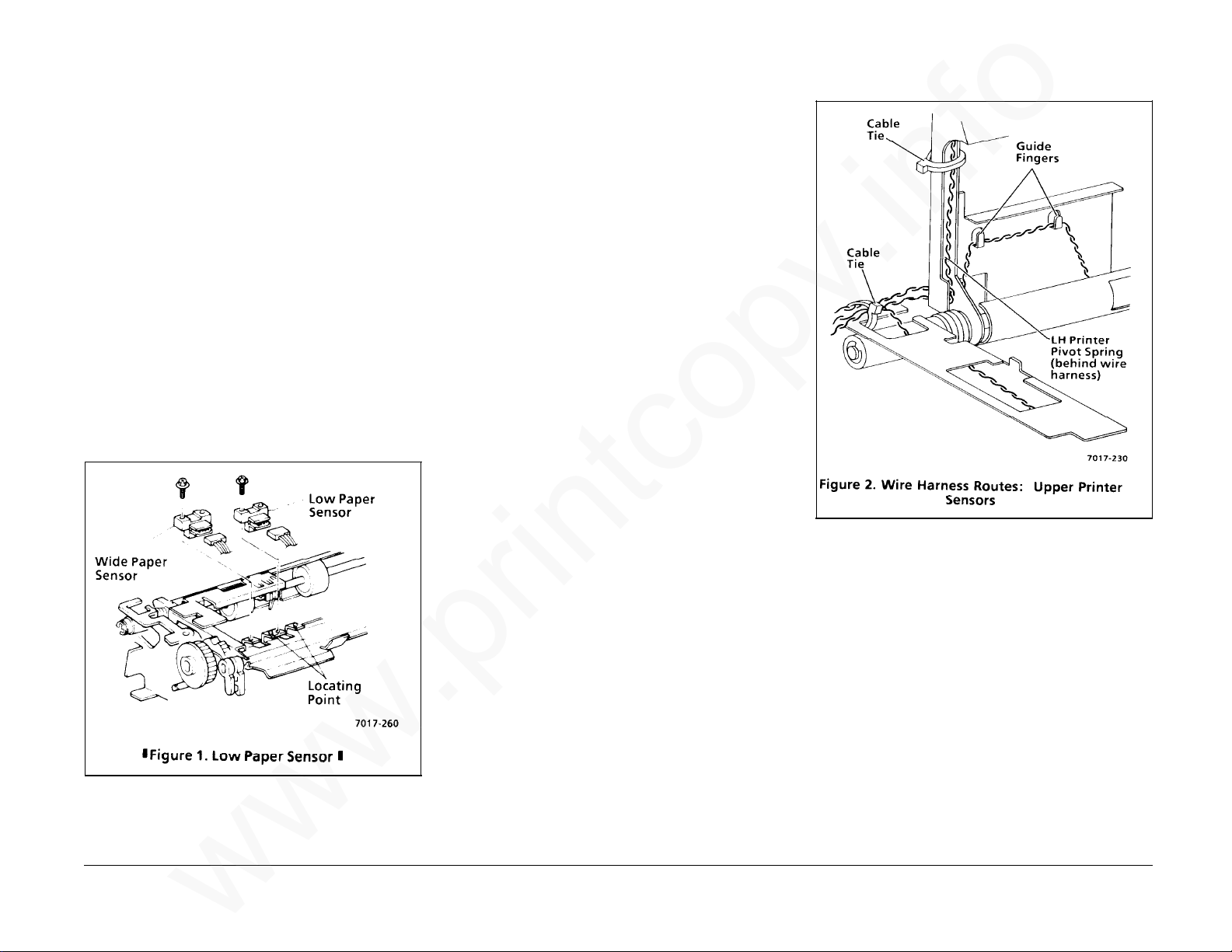

OP32 Recording paper is low or empty. Check low paper sensor (RAP 2.3.8);

(Normal case) RECORDING PAPER LOW-PLEASE REPLACE OP32 replace A2

OP32 Recording paper is low or empty. RECEIVED DOCUMENT IN MEMORY Check low paper sensor (RAP 2.3.8);

(Special case) RECORDING PAPER LOW-PLEASE REPLACE OP32 replace A2

OP36 Recording paper remained by the Perform System Check

jam sensor. (Normal case) RECORDING JAM-CLEAR PAPER PATH OP36

OP36 Recording paper remained by the RECEIVED DOCUMENT IN MEMORY Check printer jam sensor (RAP 2.3.8),

jam sensor. (Special case) RECORDING JAM-CLEAR PAPER PATH OP36 replace A2

*) PLEASE REMOVE ANY # or * -TRY AGAIN OP03

JOB AND RESEND OP05

NUMBER IN JOB MEMORY-PLEASE MATCH OP12

JOB CARD OP13

JOB CARD OP14

SCANNER-PLEASE REFER TO MANUAL. OP15

ORIGINALS AND TRY OPERATION AGAIN OP22

PLEASE CLEAN FEED BELT & TRY AGAIN OP24 scan position sensor (RAP 2.3.8); replace A2

SCANNER-PLEASE REFER TO MANUAL OP25

Telecopier 7017 / 7017SF 2-5

8/88

OPXX Error Codes

Page 16

Code Meaning Display message Corrective Action (after performing message)

www.printcopy.info

www.printcopy.info

OP37 Recording paper did not reach the Check printer belt (RAP 2.3.11),

jam sensor. (Normal case) RECORDING JAM-CLEAR PAPER PATH. OP37 printer jam sensor (RAP 2.3.8),

cutter switch (RAP 2.3.8); replace A2

OP38 Recording paper did not pass the Perform System Check

jam sensor. (Normal case) RECORDING JAM-CLEAR PAPER PATH. OP38

OP64 DT (dial tone) not detected. DIAL TONE NOT DETECTED-PLEASE CHECK RAP 2.3.4

TELEPHONE/LINE CONNECTORS-TRY AGAINOP64

OP66 No answer from remote unit. NO ANSWER-PLEASE CHECK NUMBER-TRY AGAIN Perform System Check

OR CALL REMOTE OPERATOR OP66

OP67 Line busy through N times redial REDIALS COMPLETED-REMOTE STILL BUSY PLEASE Perform System Check

attempted. TRY AGAIN-CHECK WITH REMOTE OPERATOR OP67

OP68 Off-hook detected during auto dial. TELEPHONE HANDSET IS OFF HOOK-PLEASE Perform System Check

RESEAT HANDSET-REFER TO MANUAL OP68

OP70 Security I.D. not matched. UNABLE TO COMPLETE OPERATION SECURE ID Perform System Check

MISMATCH OR STOP PRESSED AT REMOTE OP70

OP71 Remote unit unable to transmit. (No UNABLE TO RECEIVE-REMOTE NOT READY Perform System Check

document in ADF or polled mode is off) PLEASE CHECK WITH REMOTE OPERATOR OP71

OP73 Remote unit unable to receive. REMOTE CANNOT RECEIVE-PLEASE CHECK WITH Perform System Check

(No record paper or paper jam) REMOTE OPERATOR OR TRY AGAIN OP73

OP74 Operator did not respond to recall REMOTE NOT RESPONDING TO VOICE REQUEST Perform System Check

(configuration 6 only) PLEASE CALL REMOTE OPERATOR OP74

OP77 (G3 TX/RCV) Remote terminal sent DCN. UNABLE TO COMPLETE OPERATION-SECURE ID Perform System Check

MISMATCH OR STOP PRESSED AT REMOTE OP77

OP78 Operator did not respond to voice REMOTE NOT RESPONDING TO VOICE REQUEST Perform System Check

request. (PIP/PIN with a DCN) PLEASE CALL REMOTE OPERATOR OP78

OP80 Scanner cover open. SCANNER COVER IS OPEN-PLEASE CLOSE COVER Check scan interlock switch (RAP 2.3.8);

OP80 replace A2

OP81 Printer cover open. PRINTER COVER IS OPEN-PLEASE CLOSE COVER Check printer interlock switch (RAP 2.3.8);

OP81 replace A2

OPXX Error Codes 2-6 Telecopier 7017 / 7017SF

8/88

Page 17

2.3 Status Indicator RAPS

www.printcopy.info

www.printcopy.info

RAP 2.3.1One Or Both LEDs of Power

Supply Are Off.

1. At least one LED is on.

YN

| Go to Step 9.

2. Disconnect power cord from terminal.

Remove LH cover. Reconnect power cord

to terminal. Remove black plastic

fastener in upper left corner of EME

shield. Pull EME shield away from CNC

A0 PWB. Connect jumper from TP-LG to

TP41 on CNC A0 PWB (Figure 1). Both

LEDs of power supply come on.

YN

| RAP 2.3.2.

TP41

3. Replace A2. Problem resolved.

YN

| Go to Step 5.

TP-LG

Figure 1.

7017-107

5. Replace A6. Problem resolved.

YN

| Go to Step 7.

6. Go to Final Actions.

7. Replace A10. Problem resolved.

YN

| Call for assistance.

8. Go to Final Actions.

9. Fuse F1 has been replaced (on this call).

YN

| Go to Step 13.

10. Remove the power supply fuse F1. Check

fuse resistance. Meter reads less than 10

ohms.

YN

| Replace power supply assembly.

11. Perform Load Isolation RAP 2.3.2.

Problem resolved.

YN

| Call for assistance.

12. Go to Final Actions.

WARNING

Improper connection of the grounding

conductor can result in the risk of electrical

shock. The following must be observed:

• Never use a ground adapter plug to

connect the terminal to a power source

which does not have a ground

connection.

• Never attempt any maintenance function

which is not specifically called out in the

service procedures.

• Never remove any covers which are

fastened with screws, unless so

instructed in the service procedures.

CAUTION

If any of the voltage measurements are not as

specified in the following steps, the cause

must be corrected. Caution the customer not

to connect the terminal to the wall outlet.

Advise the customer that a licensed electrician

must correct the wiring. Do not attempt to

correct the wiring yourself. If you later find

the condition has not been corrected, inform

your manager in writing of the improper

wiring.

4. Go to Final Actions.

Telecopier 7017 / 7017SF 2-7

8/88

RAP 2.3.1

Page 18

13. Perform the following line voltage check.

www.printcopy.info

www.printcopy.info

a. Disconnect power cord from the wall

outlet.

b. USO: Measure the AC voltage

between AC Hot and Neutral. Meter

= 107 to 127 VAC (Figure 2).

RX UK Only: Measure the AC voltage

between live and neutral and

between live and earth. Meter = 196

to 264 VAC (Figure 3).

RX Europe Only: Measure the AC

voltage between pin. Meter = 200

to 240 VAC (Figure 4).

c. USO: Measure the AC voltage

between the AC Neutral and GND.

Meter = less than 3 VAC (Figure 2).

RX, UK Only: Measure the AC voltage

between Neutral and Earth. Meter

= less than 3 VAC (Figure 3).

RX, Europe Only: Measure the AC

voltage between supply pin and

earth. Meter = 200 to 240 VAC

(Figure 4).

YN

| Inform customer of insufficient

voltage (or improper wiring).

USO

AC Neutral

(ACN)

GND

Figure 2. USO Wall Outlet

RX Only

Neutral

Figure 3. RX UK Wall Outlet

RX Only

Supply

Figure 4. RX Europe Wall Outlet

AC Hot

(ACH)

Earth

Live

Earth

7017-108

7017-109

7017-110

14. Remove the power cord from terminal.

Place the black and red meter leads at the

corresponding female and male

connectors of each wire within the power

cord. Meter reads less than 10 ohms.

YN

| Replace power cord.

15. Remove the power supply fuse F1. Check

fuse resistance. Meter reads less than 10

ohms.

YN

| Replace fuse.

16. Reinstall fuse. Ensure power cord is

disconnected from terminal. Remove

power supply from terminal. Place

power supply on insulated surface.

Connect jumper across pins of J3 (Figure

5). Connect power cord from wall outlet

to power supply. Both LEDs of power

supply come on.

YN

| Replace power supply assembly.

Fuse F1

J3

RAP 2.3.1 2-8 Telecopier 7017 / 7017SF

AC Power Connector

Figure 5.

7017-111

17 Remove jumper from J3 and reinstall

power supply. Perform Load Isolation

RAP 2.3.2. Problem resolved.

YN

| Call for assistance.

18. Go to Final Actions.

8/88

Page 19

RAP 2.3.2 Load Isolation

www.printcopy.info

www.printcopy.info

Note: Perform this procedure to isolate a

power loading problem.

1. Ensure power cord is disconnected from

power supply. Remove A2 from terminal

with A5, and A10, and (if applicable) A8

attached. Connect power cord from wall

outlet to terminal. Remove black plastic

fastener in upper left corner of EME

shield. Pull EME shield away from A0

CNC PWB. Connect jumper from TP-LG to

TP41 on A0 CNC PWB (Figure 1). Both

LEDs of power supply come on.

YN

| Go to Step 6.

2. Disconnect power cord from terminal.

Remove all PWBs from A2. Reinstall A2.

Connect power cord from wall outlet to

terminal. Both LEDs of power supply

come on.

YN

| Replace A2.

TP41

TP-LG

3. Disconnect power cord from terminal.

Reinstall one of the PWBs removed in

Step 2. Connect power cord to terminal.

Both LEDs of power supply come on.

YN

| Replace last PWB reinstalled.

4. All PWBs removed in Step 2 reinstalled.

YN

| Repeat step 3.

5. Go to Final Actions.

6. Disconnect power cord from terminal.

Reinstall A2 with A5, and A10, and (if

applicable) A8 attached. Disconnect P/J

123. Connect power cord from wall

outlet to terminal. Both LEDs of power

supply come on.

YN

| Go to Step 8.

7. Replace video assembly.

8. Disconnect power cord from terminal.

Disconnect P/J 120. Connect power cord

from wall outlet to terminal. Both LEDs

of power supply come on.

YN

| Go to Step 10.

10. Disconnect power cord from terminal.

Disconnect P/J 111. Connect jumper from

TP-LG to TP41 on CNC A0 PWB (Figure 1).

Connect power cord from wall outlet to

terminal. Both LEDs of power supply

come on.

YN

| Go to Step 12.

1 1. Replace A6 (control panel assembly).

12. Disconnect all other connectors on CNC

A0 PWB one at a time. (Disconnect

power cord before disconnecting each

connector, then reconnect the power

cord.) When both LEDs of power supply

come on, refer to wiring data to trace last

connector disconnected to a replaceable

part. Replace the part, reconnect all

connectors disconnected in this

procedure, and perform System Check to

verify the repair.

Note: Ignore any display fault codes which

may appear during this procedure.

Telecopier 7017 / 7017SF 2-9

9. Replace thermal head.

Figure 1.

7017-112

12/88

RAP 2.3.2

Page 20

RAP 2.3.3 Diagnostic Pattern Is

www.printcopy.info

www.printcopy.info

Unacceptable

Note: If possible, obtain from Customer any

copies of unacceptable quality related to this

call.

1. Copy (from Customer or from System

Check) shows damage from excessive

thermal head heat (holes in paper, odor,

discoloration on reverse side, etc.).

YN

| Go to Step 12.

2. Disconnect power cord from terminal.

Remove LH cover.

3. Remove black plastic fastener in upper

left corner of EME shield. Pull EME shield

away from A0 CNC PWB.

4. Disconnect P/J121 from A0 CNC PWB

(Figure 1).

8. Perform auto diagnostics.

a. Press Menu.

b. Press 2 on keypad.

b. Press 4 on keypad.

9. Meter reads greater than 3.5 VDC during

printing.

10. Repeat Step 6 through 8 until all test

points listed in Figure 1 have been

checked. All test point voltages are

correct.

YN

| Replace both A2 AND

assembly.

11. Replace thermal head.

12. Perform RAP 2.3.6. Problem resolved.

YN

thermal head

| Replace A2, thermal head

assembly.

RAP 2.3.4 Dial Tone Is Not Heard

1. Display indicates:

DIAL TONE NOT DETECTED-PLEASE CHECK

TELEPHONE /LINE CONNECTORS-TRY AGAIN OP64

YN

| Go to Step 4.

2. Disconnect the handset from terminal.

Disconnect the data cable from the

telephone wall jack. Plug the handset

into the telephone wall jack. Dial tone is

heard.

YN

| Inform Customer of telephone line

problem.

3. Reseat connectors, then replace data

cable, A10.

4. Replace A10, A2.

P/J121

5. Connect the black meter lead to TP-LG

(Figure 1).

6. Connect power cord to terminal.

7. Connect the red meter lead to one of the

test points listed in Figure 1 (TP12, TP13,

TP14, TP15).

TP12, TP13, TP14, TP15

TP-LG

Figure 1.

7017-113

13. Return to procedure which directed you

to this RAP or go to Final Actions.

8/88

RAPS 2.3.3, 2.3.4 2-10 Telecopier 7017 / 7017SF

Page 21

RAP 2.3.5 The Terminal Does Not

www.printcopy.info

www.printcopy.info

Answer.

1. Phone rings (but does not answer).

YN

| Go to Step 3.

RX NOTE: Check manual receive is not

selected. Check all Autodialer and System Data

parameters are set correctly (switches, links

and System Data) for your particular country.

2. Replace A10, A2.

3. Disconnect the handset from the

terminal. Disconnect the data cable from

the telephone wall jack. Plug the

handset into the telephone wall jack.

Dial tone is heard.

YN

| Inform Customer of telephone line

problem.

4. Reseat connectors, then replace data

cable, A10.

RAP 2.3.6 Mechanical Checkout.

NOTE: The following checks apply to all belts,

gears, pulleys, springs and bearings in these

areas:

• Front and Rear Frames.

• Upper and Lower Scanner.

• Upper and Lower Printer.

1. Remove LH cover.

2. Inspect all drive belts. Belts are in good

condition (not broken, frayed and do not

have surface cracks).

YN

| Replace belt.

3. Inspect all shafts. Shafts turn freely.

YN

| Replace shaft and bearings.

4. Inspect all bearings. Bearings are secure

on shafts and positioned properly in

frame cutouts.

YN

| Position bearings in frame cutouts,

replace bearings.

8. Inspect hold down springs on scanner

shaft bearings. Springs are secure on

bearings and shafts turn freely.

YN

| Replace springs.

9. Inspect gears. Gears are secure on shafts

and are not broken. Gears mesh

properly.

YN

| Tighten set screw in gear or replace

gear or E-rings.

10. Return to procedure which directed you

to this RAP or go to Final Actions.

Telecopier 7017 / 7017SF 2-11

5. Inspect pulleys. Pulleys are secure on

shafts and are not broken.

YN

| Replace pulley or E-ring.

6. Inspect upper scanner. Upper scanner

closes and latches.

YN

| Replace latch spring, latches.

7. Inspect upper printer. Upper printer

closes and latches.

YN

| Replace latch spring, latches or

printer frame.

12/88

RAPS 2.3.5, 2.3.6

Page 22

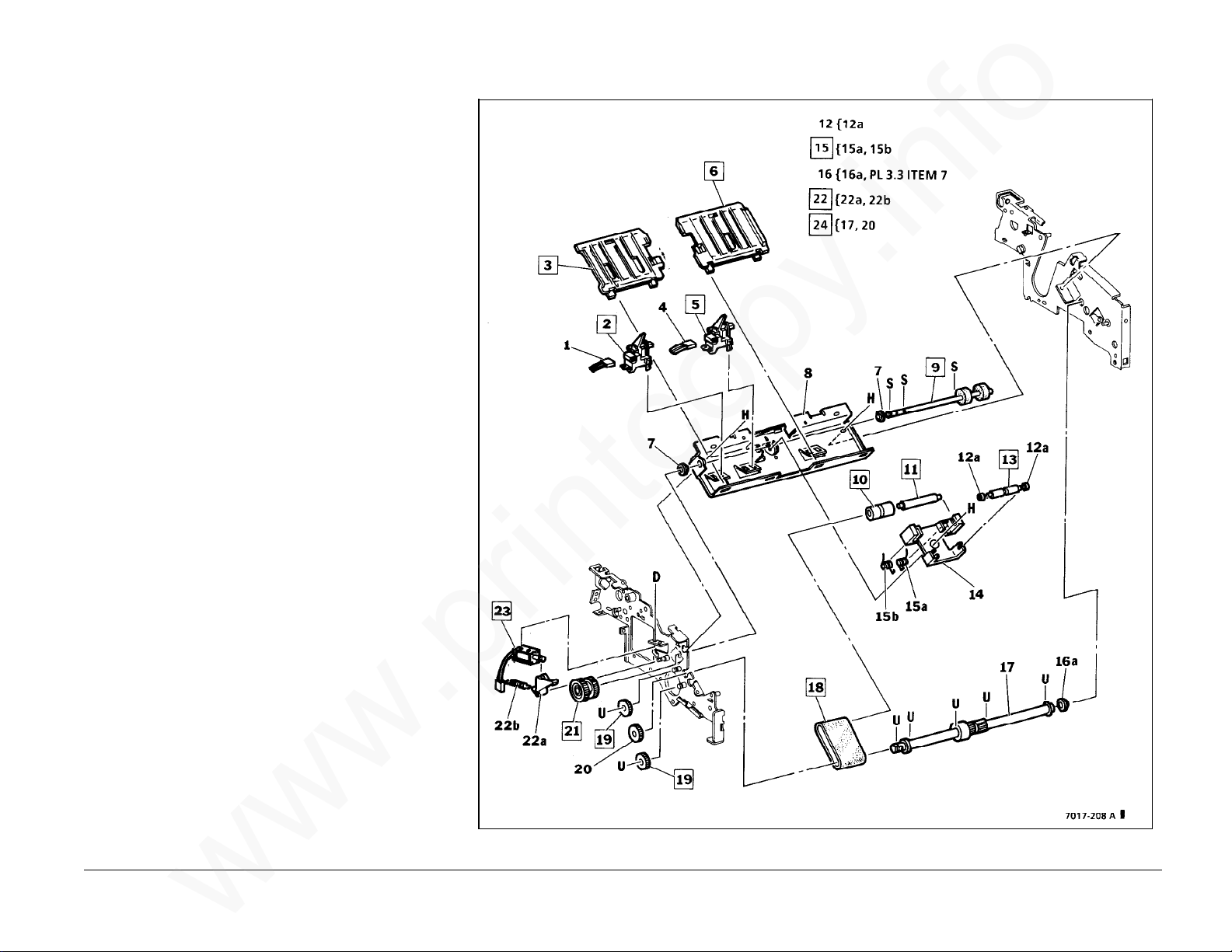

RAP 2.3.7 Paper Feed Test

www.printcopy.info

www.printcopy.info

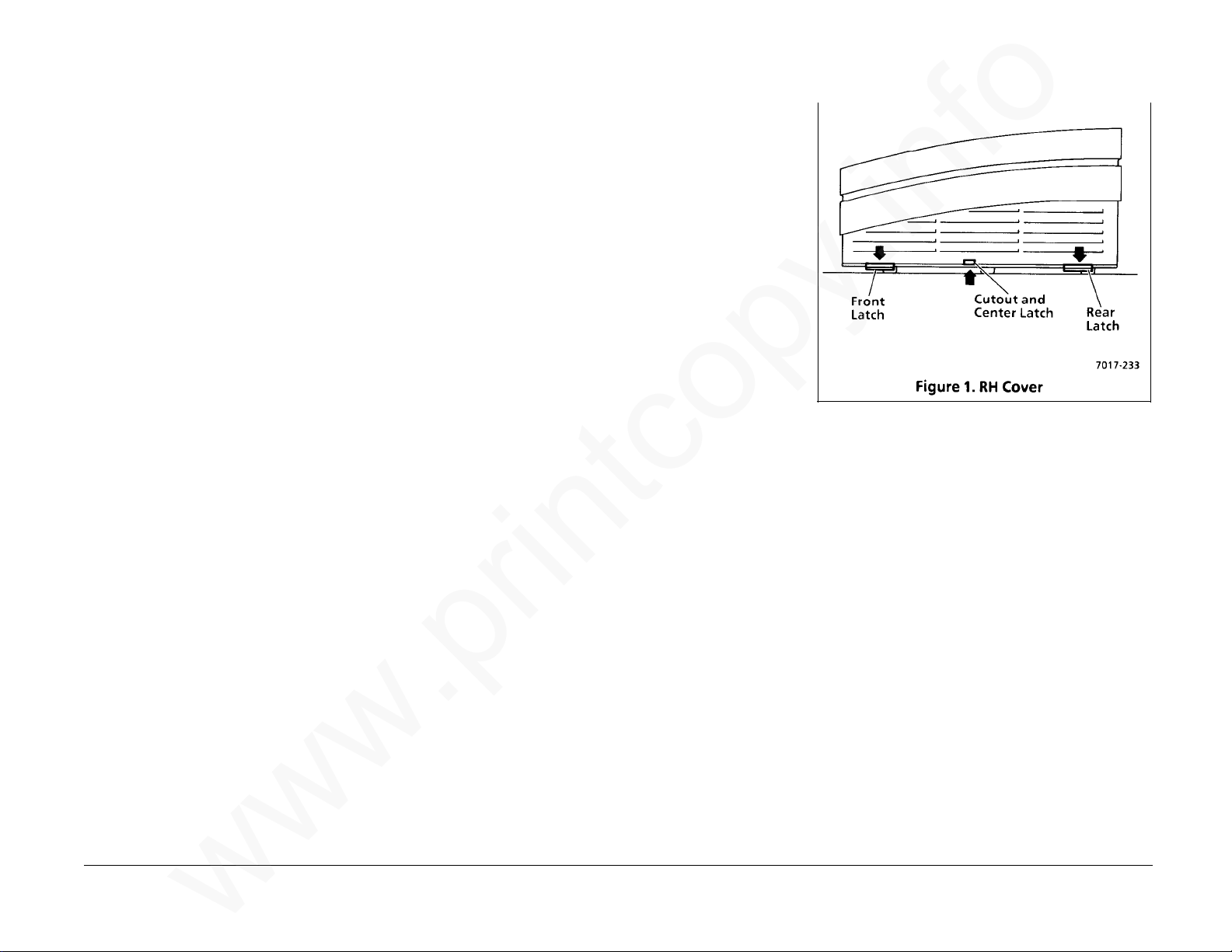

NOTE: Refer to Figure 1 on the next page for a

diagram of the print drive system.

1. Enter Service Mode.

2. Perform the Paper Feed Test.

a. Press Menu.

b. On the key pad, press 7 then 1. The

display indicates:

71 RECORD PAPER FEED TEST

PRESS [START] OR [SCROLL]

CAUTION

To prevent possible damage to the thermal

head, do not perform this test without paper.

(Test will not start if low paper condition has

been detected.)

d. Press Start.

3. Paper feeds without a paper jam.

YN

| RAP 2.3.6.

4. Press Stop to end test.

5. Return to procedure which directed you

to this test or go to Final Actions.

RAP 2.3.8 Sensor Test

1. Enter Service Mode.

NOTE: OP32, OP36, and OP38 do not display

a flashing top line if A8 PWB is not installed.

2. Perform Sensor Test.

a. Press Menu.

b. On the key pad, press 7 then 6. The

display indicates:

76 SENSOR TEST

PRESS [START] OR [SCROLL]

c. Press Start. The display indicates

(sample):

SC PC DS B4 A4 PJ CP SP LP 4P R H F

LLLLHLHHHL H H

3. Perform a copy operation or manually

actuate suspect sensor. Observe display.

Displayed code for suspect sensor

changes state (from H to L or L to H).

Refer to Table 1.

Table 1. Sensor Code

SC Scan interlock switch

PC Printer interlock switch

DS Document sensor

B4 Wide Original sensor

A4 A4 document sensor (FX only)

PJ Printer Jam Sensor

CP Cutter switch

SP Scan position sensor

LP Low paper sensor

4P Wide paper sensor (FX, RX only)

4. End test.

a. Enter diagnostics mode (Section 6).

b. Exit diagnostics mode (Section 6).

5. Return to procedure which directed you

to this test or go to Final Actions.

RAPS 2.3.7, 2.3.8 2-12 Telecopier 7017 / 7017SF

R Ring Indicator

H Hook Signal

F Fax Net Ring Indicator (FX only)

YN

| Replace applicable sensor.

12/88

Page 23

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaaaaaaaaaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

Printer

aaaaaaaaaaaaa

a

a

a

a

a

a

a

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

www.printcopy.info

www.printcopy.info

output

drive roller

(Friction

driven)

Printer

output idler

roller

Cutter

belt

Cutter

(Gears)

(Idler gears)

Thumb

wheel

(Note 1)

NOTE 1: Thumb wheel manually driven.

NOTE 2: When cutter solenoid is not

energized,

motion is applied to pressure roller (and not to

cutter). When cutter solenoid is energized, motion

is applied to cutter (and not to pressure roller).

Gear on right side

of pressure roller

Gear on left side

of pressure roller

(Gears)

Paper roll

Telecopier 7017 / 7017SF 2-13

Cutter crank

arm

Cutter crank

pulley

Figure 1. Print Drive System (Viewed from Left Side)

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

Cutter

solenoid

(Note 2)

Printer

belt

Print

motor

Cutter clutch,

Planet gears,

and pulley

7017-105

6/88

Print Drive System

Page 24

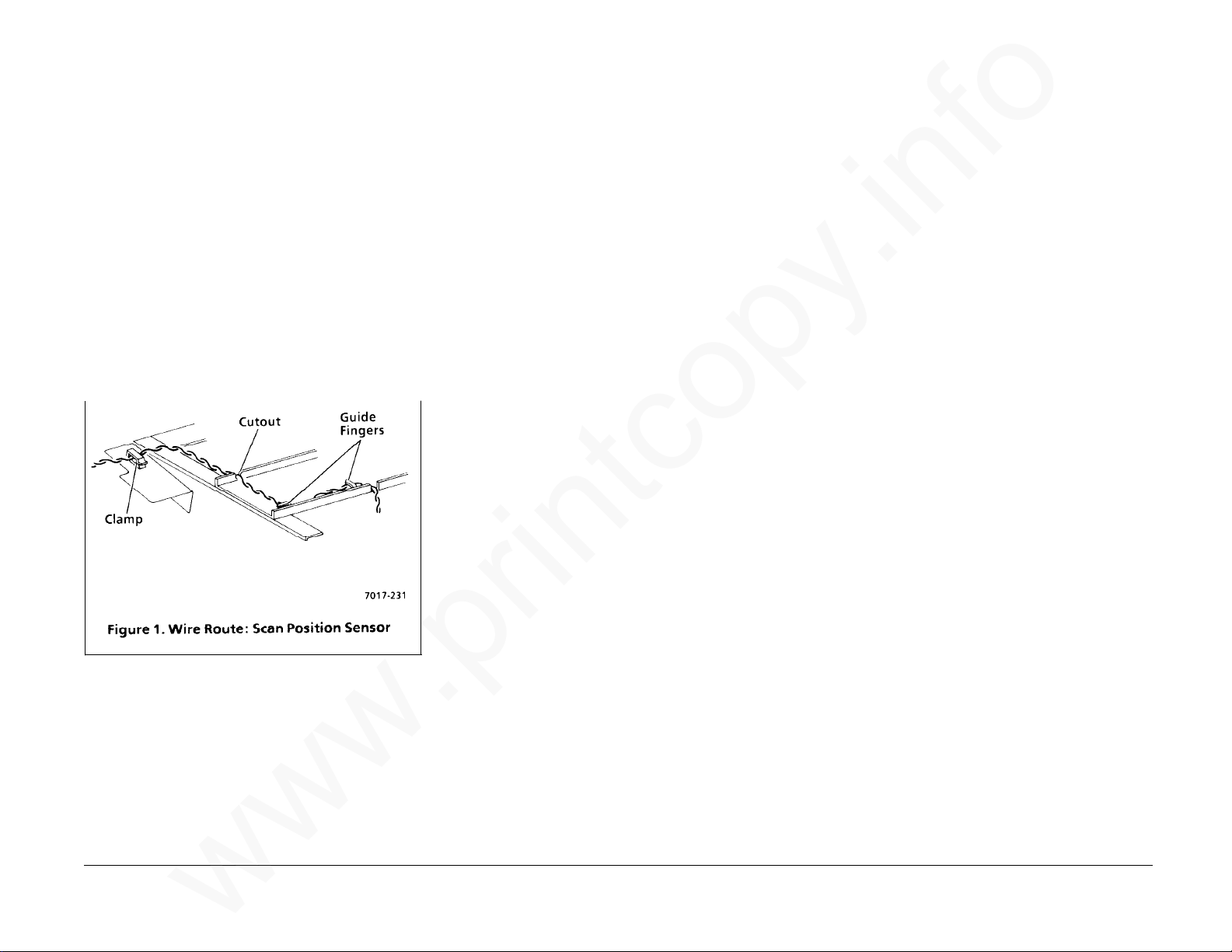

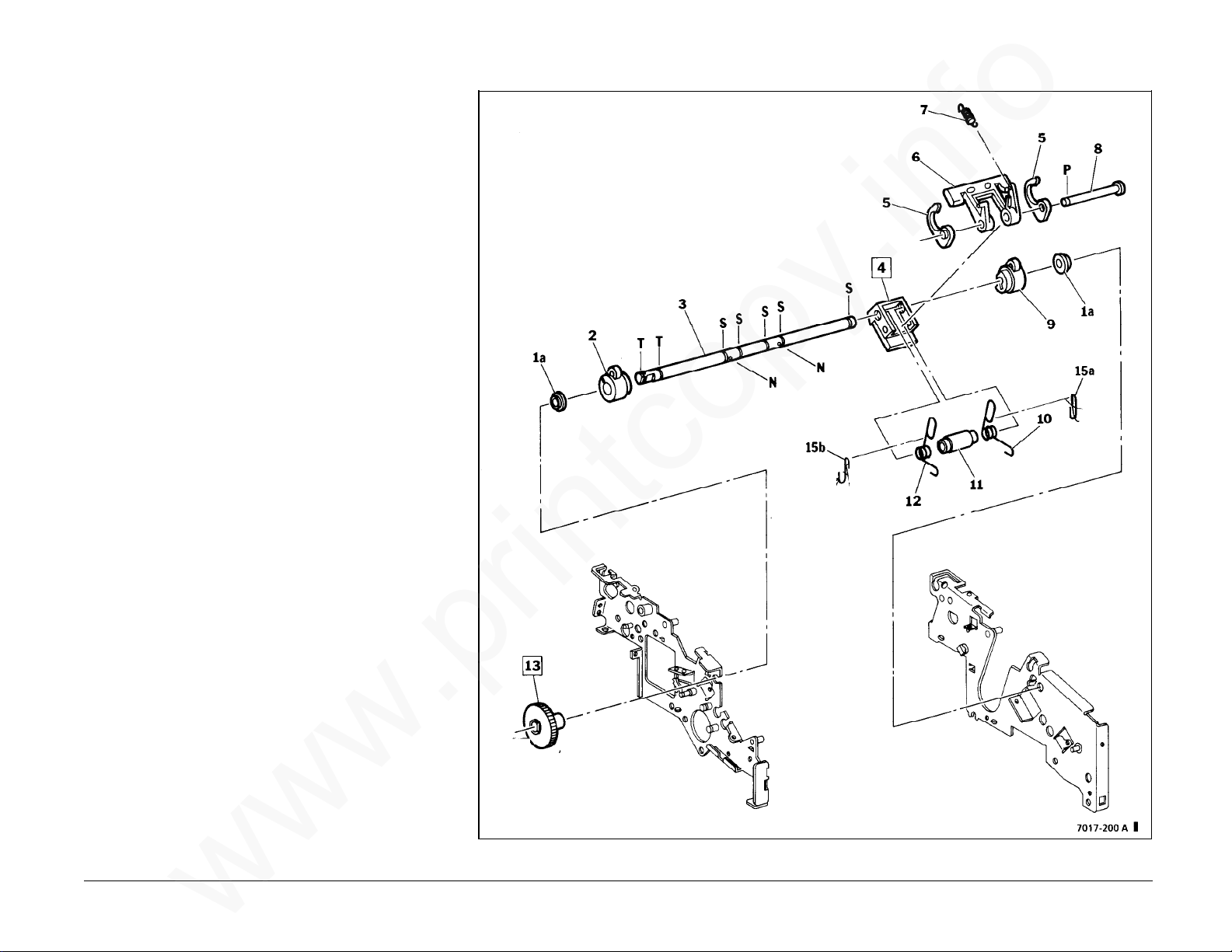

RAP 2.3.9 Scanner Test

www.printcopy.info

www.printcopy.info

NOTE: Refer to Figure 1 on the next page for a

diagram of the scan drive system.

1. Open scanner.

2. Clean platen roller, scan idler and scan

drive rollers, and retard pad. (Refer to

1.4.1 Call Completion in Section 1 for

cleaning procedure.)

3. Inspect tension on scan idler rollers and

the platen roller.

a. Press the end of each roller at the

front and rear.

b. The tension should feel the same at

the left and right.

YN

| Replace springs.

4. Problem resolved:

YN

| RAP 2.3.6.

5. Return to procedure which directed you

to this test or go to Final Actions.

RAP 2.3.10 Automatic Document

Feeder Test

1. Open Scanner.

2. Inspect ADF Belt. Belt is clean and

undamaged.

YN

| Clean or replace belt.

3. Inspect one way clutch by pushing the

ADF belt toward the front. Clutch allows

belt to rotate freely.

YN

| Replace clutch.

4. Rotate belt toward the rear. Clutch does

not allow belt to rotate.

YN

| Replace clutch.

5. Inspect document guides by extending

guides to maximum and minimum width.

Guides move freely and are parallel.

YN

| Replace Input Tray.

6. Enter Service Mode.

9. Press Start.

10. Originals feed one sheet at a time.

YN

| RAP 2.3.6.

11. Press Stop to end test.

12. Return to procedure which directed you

to this check or go to Final Actions.

RAPS 2.3.9, 2.3.10 2-14 Telecopier 7017 / 7017SF

7. Place at least three sheets of paper

(multiple originals) into input tray.

8. Enter Original Feed Test.

a. Press Menu.

b. On the key pad, press 7 then 2. The

display indicates:

72 ORIGINAL FEED

PRESS [START] OR [SCROLL]

12/88

Page 25

Original document

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

www.printcopy.info

www.printcopy.info

ADF Tension

shaft

Retard shaft

(with nudger and

retard pad)

ADF Belt

Scan input

idler roller

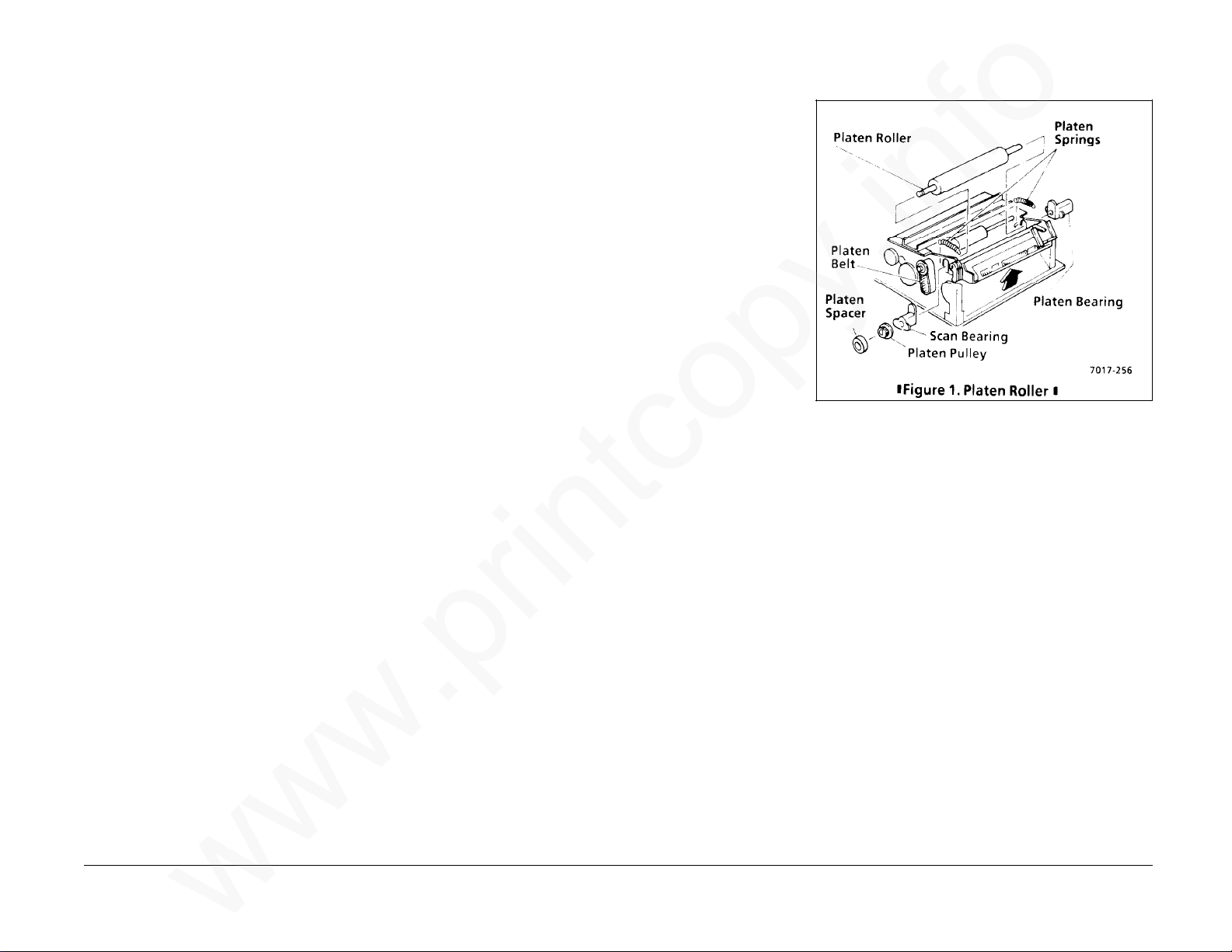

Platen roller

Platen belt

Scan output

idler roller

(Friction drive)

(Gears)

(Friction drive)

Telecopier 7017 / 7017SF 2-15

ADF Drive

shaft

(Gears)

Scan input

drive belt

Figure 1. Scan Drive System (Viewed from Left Side)

Scan input

drive roller

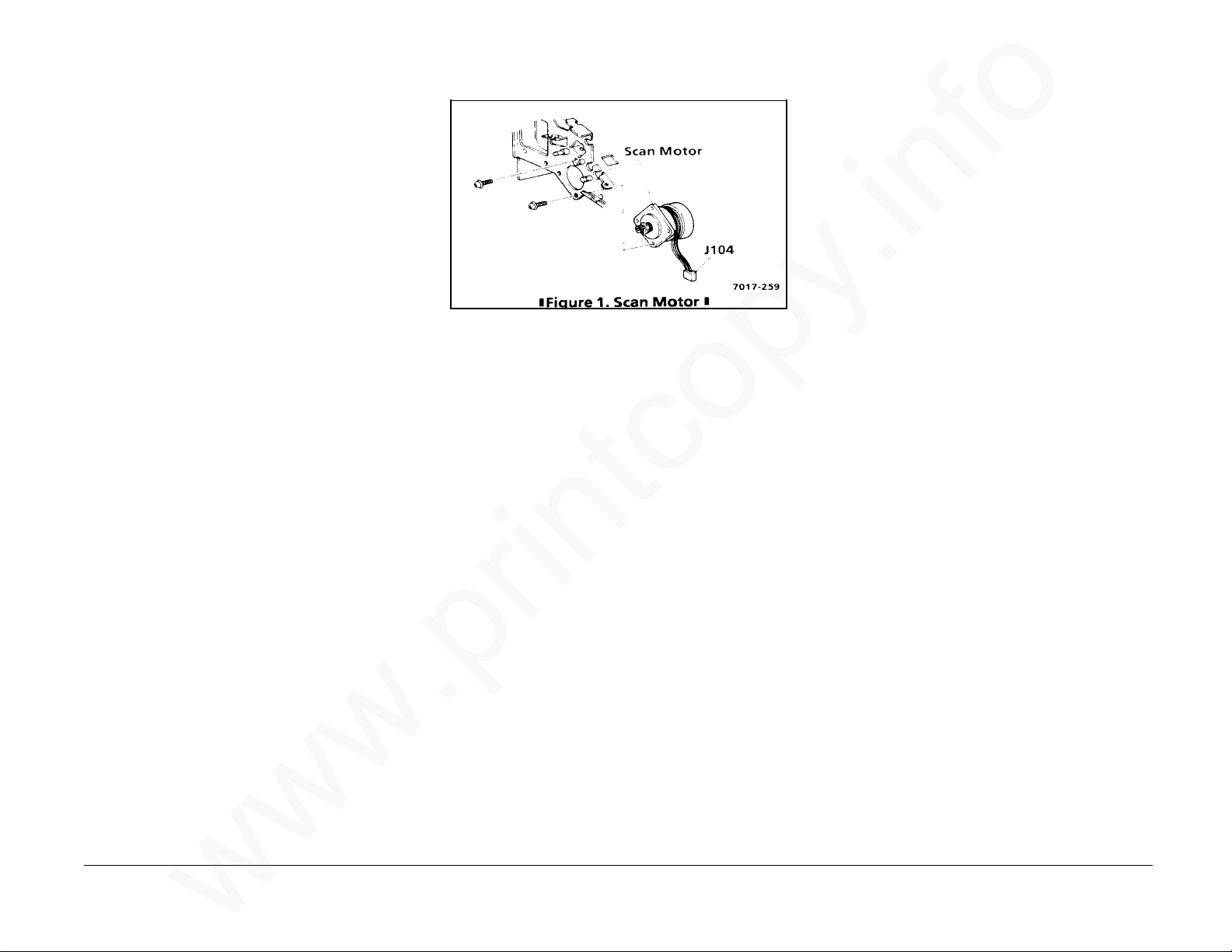

Scan motor

6/88

Scan output

drive belt

Scan output

drive roller

7017-106

Scan Drive System

Page 26

RAP 2.3.11 Belt Checkout.

www.printcopy.info

www.printcopy.info

NOTE: The following check applies to all belts.

1. Remove covers and parts as necessary to

access the belt. (Refer to Section 4 and

Section 5.)

2. Inspect the belt. Belt is in good condition

(not broken, frayed and does not have

surface cracks).

YN

| Replace belt.

3. Return to procedure which directed you

to this test or go to Final Actions.

RAP 2.3.12 Both LEDs remain on.

1. The display indicates:

DIAL TELEPHONE NUMBER OR

WHEN READY - PRESS [MANUAL RCV]

YN

| Replace A2, power supply

assembly.

2. Lift handset from handset cradle. Press

switch on handset. Handset is silent (no

dial tone).

YN

| Replace handset.

3. Replace A2, A10.

RAP 2.3.13 Received Image Quality is

Unacceptable.

NOTE: This procedure applies to image quality

problems either:

• Received at the local terminal and sent by a

remote terminal, or

• Received at a remote terminal and sent by

the local terminal.

1. Replace A10. Problem resolved.

YN

| Go to Step 3.

2. Go to Final Actions.

3. Replace A2. Problem resolved.

YN

| Go to Step 5.

4. Go to Final Actions.

5. Call the Facsimile Technical Support

Center (TSC). Request to receive (not in

Error Correct mode) from their terminal.

Image quality is acceptable. (Refer to

Section 3 for image quality.)

YN

| Inform Customer of telephone line

problem.

RAPS 2.3.11, 2.3.12 2-16 Telecopier 7017 / 7017SF

6. Go to Final Actions.

8/88

Page 27

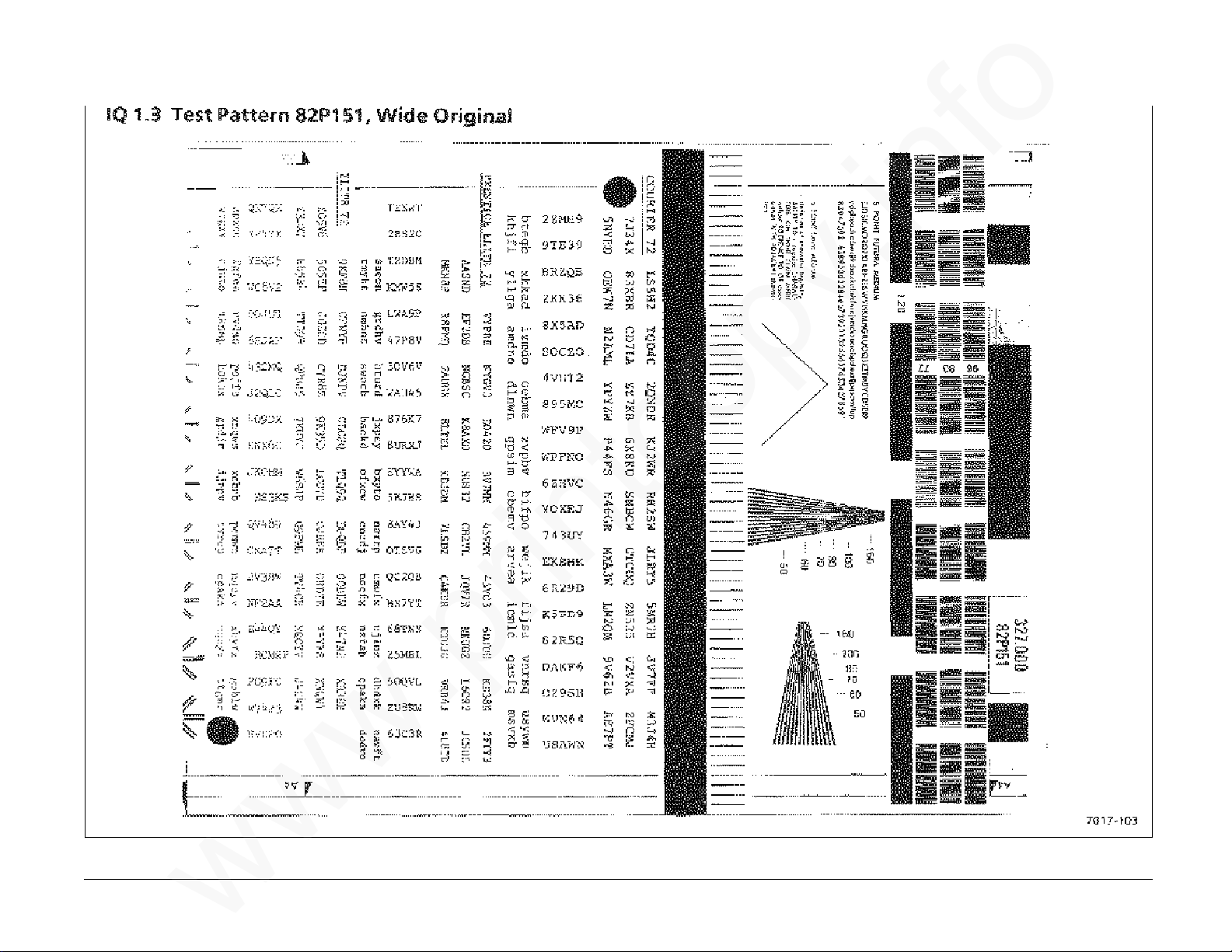

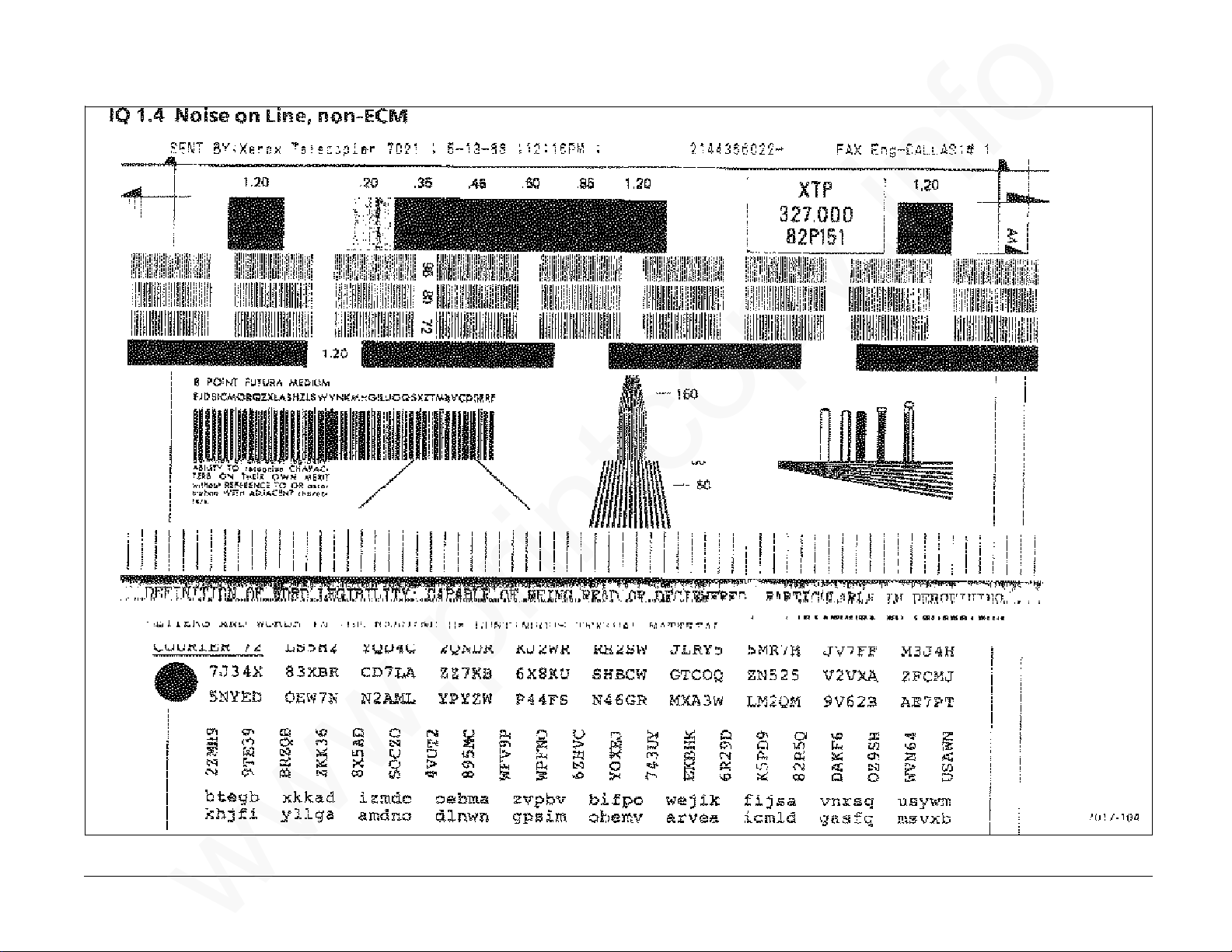

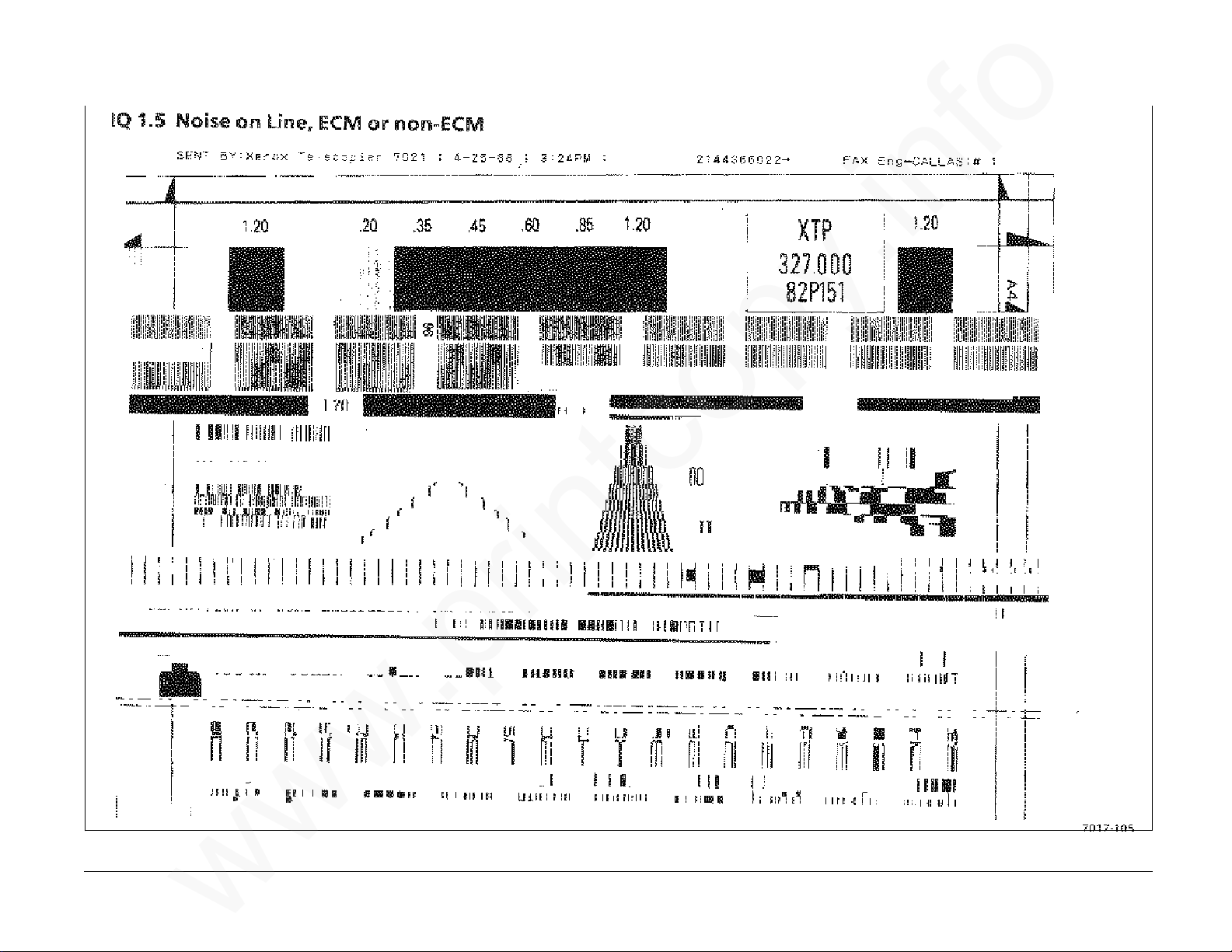

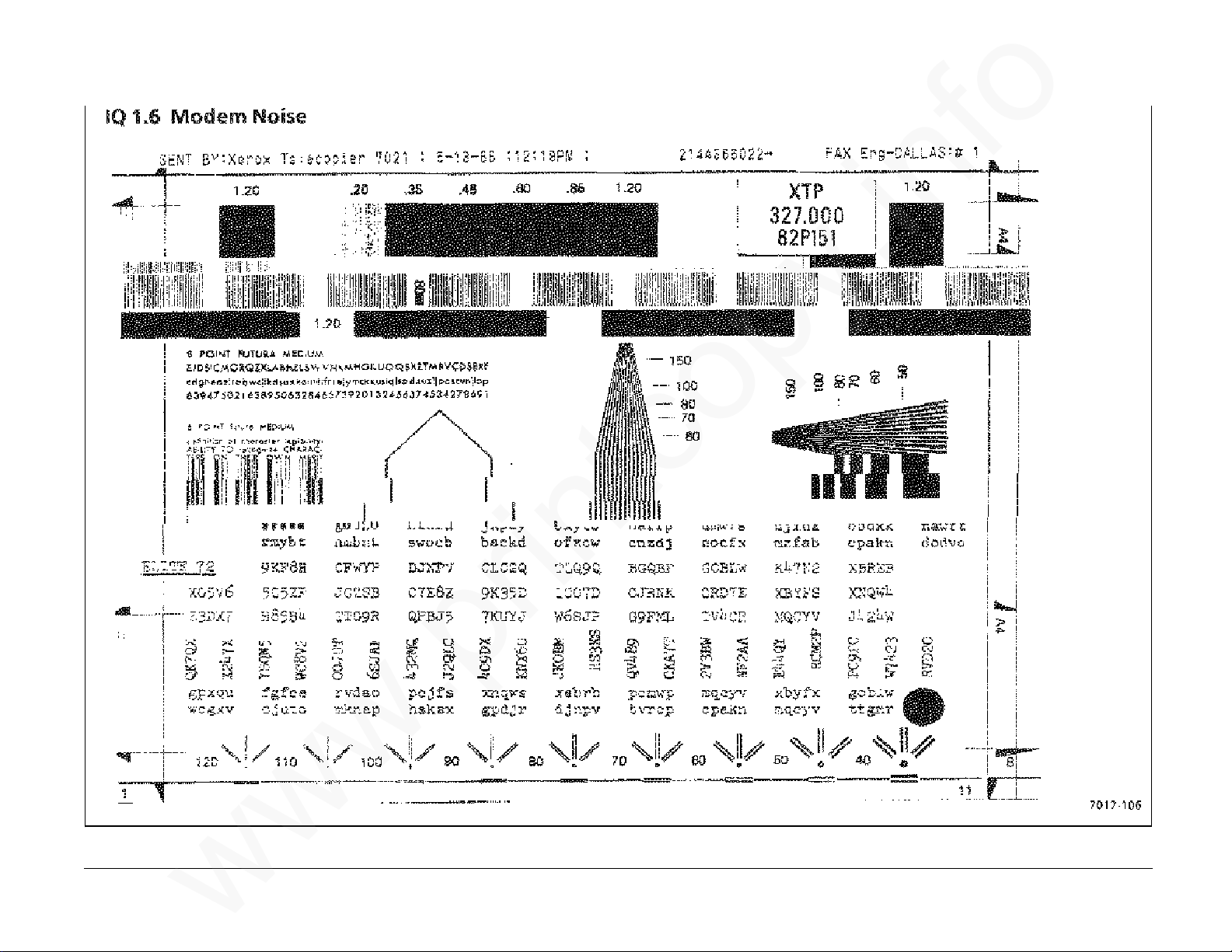

3. Image Quality

Introduction 3-2●

Image Quality Samples

IQ 1.1a Diagnostic Test Pattern (Upper Half) 3-3●

IQ 1.1b Diagnostic Test Pattern (Lower Half) 3-4●

IQ 1.2 Test Pattern 82P151 3-5●

IQ 1.3 Test Pattern 82P151 (Wide Original) 3-6●

IQ 1.4 Noise on Line, non-ECM 3-7●

IQ 1.5 Noise on Line, ECM or non-ECM 3-8●

IQ 1.6 Modem Noise 3-9●

3. Image Quality

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section3.htm [28/09/1999 11:34:48]

Page 28

Section Introduction

www.printcopy.info

www.printcopy.info

The Image Quality (IQ) section is used to

identify an image quality problem. It contains

this Introduction and Image Quality samples.

These samples are reproductions of

acceptable image quality of the Diagnostic

Test Pattern (generated by the terminal) and

Test Pattern 82P151 (copied on the terminal).

Samples of telephone line noise and modem

noise are also included.

Use the Image Quality Samples as a

comparison to identify any image quality

defects which may have been produced during

System Check.

Introduction 3-2 Telecopier 7017 / 7017SF

12/88

Page 29

IQ 1.1a Diagnostic Test Pattern (Upper Half)

www.printcopy.info

www.printcopy.info

7017-100

Telecopier 7017 / 7017SF 3-3

6/88

IQ 1.1a

Page 30

IQ 1.1b Diagnostic Test Pattern (Lower Half)

www.printcopy.info

www.printcopy.info

IQ 1.1b 3-4 Telecopier 7017 / 7017SF

6/88

Page 31

IQ 1.2 Test Pattern 82P151

www.printcopy.info

www.printcopy.info

Telecopier 7017 / 7017SF 3-5

6/88

IQ 1.2

Page 32

IQ 1.3 Test Pattern 82P151, Wide Original

www.printcopy.info

www.printcopy.info

IQ 1.3 3-6 Telecopier 7017 / 7017SF

6/88

Page 33

IQ 1.4 Noise on Line, non-ECM

www.printcopy.info

www.printcopy.info

Telecopier 7017 / 7017SF 3-7

12/88

IQ 1.4

Page 34

IQ 1.5 Noise on Line, ECM or non-ECM

www.printcopy.info

www.printcopy.info

IQ 1.5 3-8 Telecopier 7017 / 7017SF

12/88

Page 35

IQ 1.6 Modem Noise

www.printcopy.info

www.printcopy.info

Telecopier 7017 / 7017SF 3-9

12/88

IQ 1.6

Page 36

4. Repair / Adjustment

Introduction 4-2●

Covers and Panels

REP 1.1 Document Catch Tray Assembly 4-3●

REP 1.2 RH Cover 4-3●

REP 1.3 Coupler Cover 4-4●

REP 1.4 LH Cover 4-4●

REP 1.5 Output Tray Assembly 4-4●

REP 1.6 Rear Cover 4-5●

REP 1.7 Upper Scan Cover 4-5●

REP 1.8 Lower Scan Cover 4-5●

REP 1.9 Input Tray / Printer Cover Assembly 4-6●

REP 1.10 Input Tray Extension 4-6●

REP 1.11 Paper Side Plates 4-6●

ADF

REP 2.1 Retard Assembly 4-7●

REP 2.2 Nudger Timing Gear 4-7●

REP 2.3 Pad Assembly 4-8●

REP 2.13 Nudger Solenoid Assembly 4-14●

REP 2.14 Nudger Pawl and Nudger Pawl Spring 4-15●

Scanner

REP 3.1 Scan Position Sensor 4-15●

REP 3.2 Scan Interlock Switch 4-16●

REP 3.3 Scan Input Idler Roller 4-17●

REP 3.4 Platen Roller 4-17●

REP 3.5 Scan Output Idler Roller 4-18●

REP 3.6 Upper Scan Assembly 4-18●

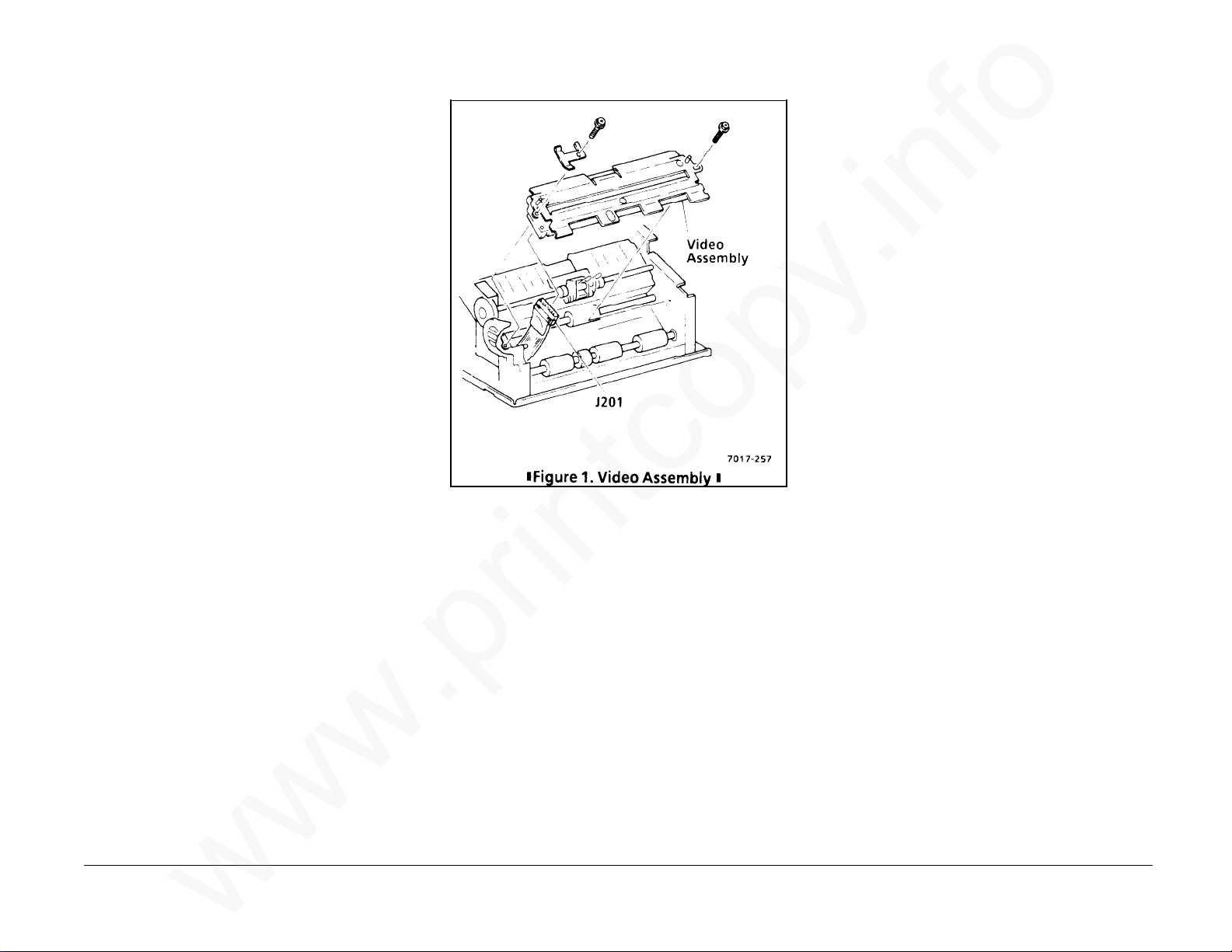

REP 3.7 Video Assembly 4-19●

REP 3.8 Scan Pulley / Gear 4-20●

REP 3.9 Scan Input Drive Roller 4-20●

REP 3.10 Scan Output Drive Roller 4-21●

REP 3.11 Scan Output Drive Pulley 4-21●

REP 3.12 Scan Motor 4-22●

4. Repair / Adjustment

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section4.htm (1 of 3) [28/09/1999 11:36:44]

Page 37

Printer

REP 4.1 Low Paper Sensor and RX: Wide Paper Sensor 4-23●

REP 4.2 Printer Jam Sensor 4-24●

REP 4.3 Printer Interlock Switch 4-24●

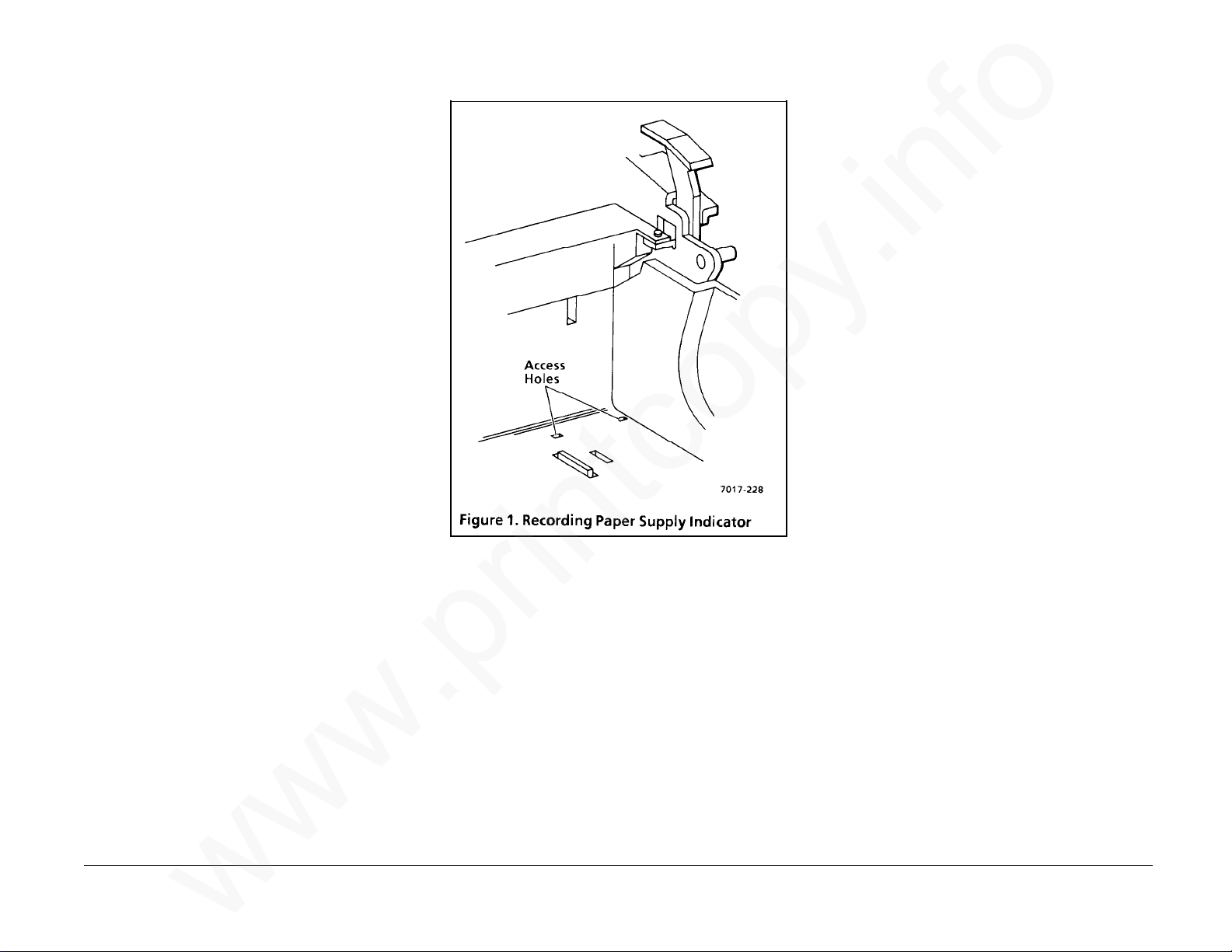

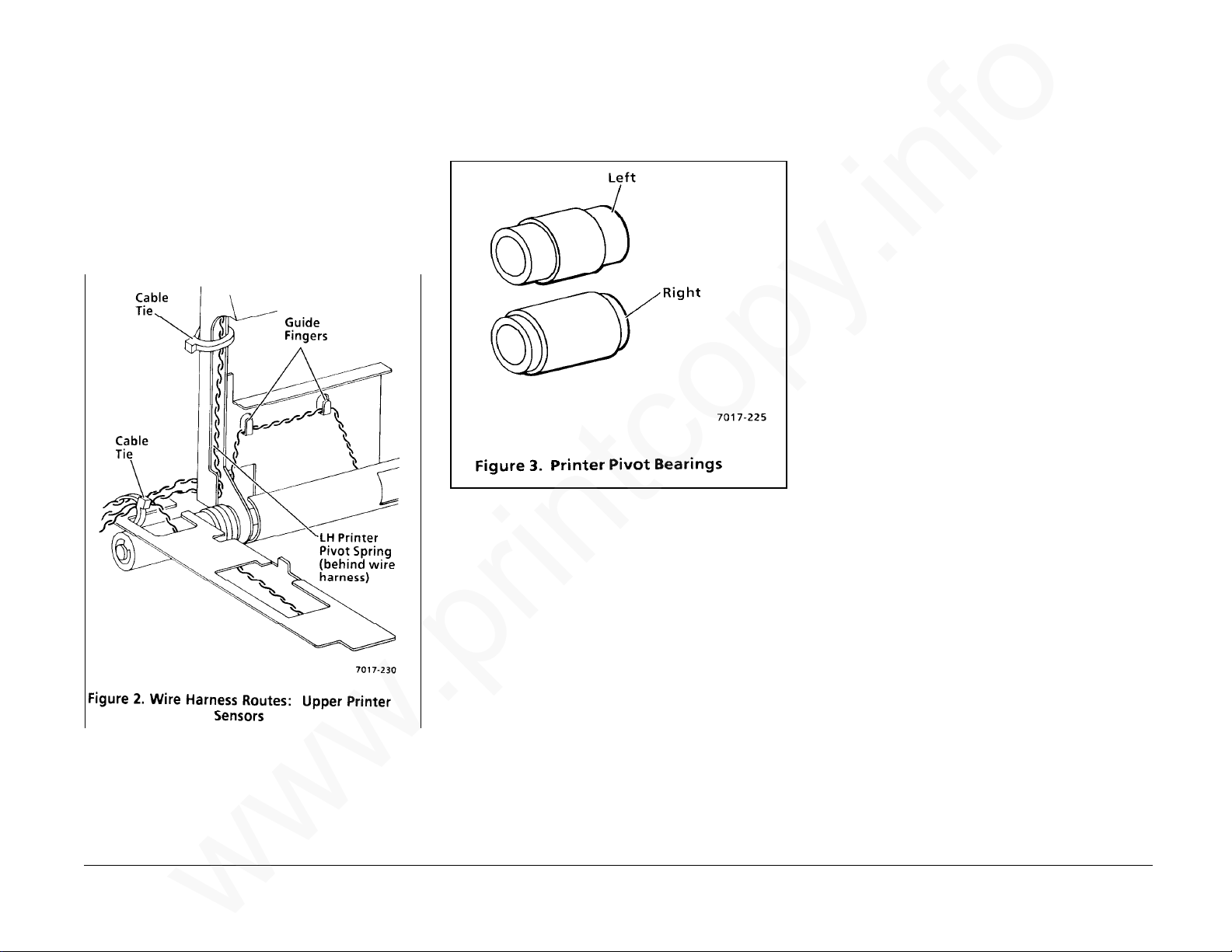

REP 4.4 Recording Paper Supply Indicator 4-25●

REP 4.5 Lower Paper Guide Assembly 4-26●

REP 4.6 Printer Motor Cover 4-26●

REP 4.7 Upper Printer Assembly 4-27●

REP 4.8 Printer Output Idler Rollers 4-28●

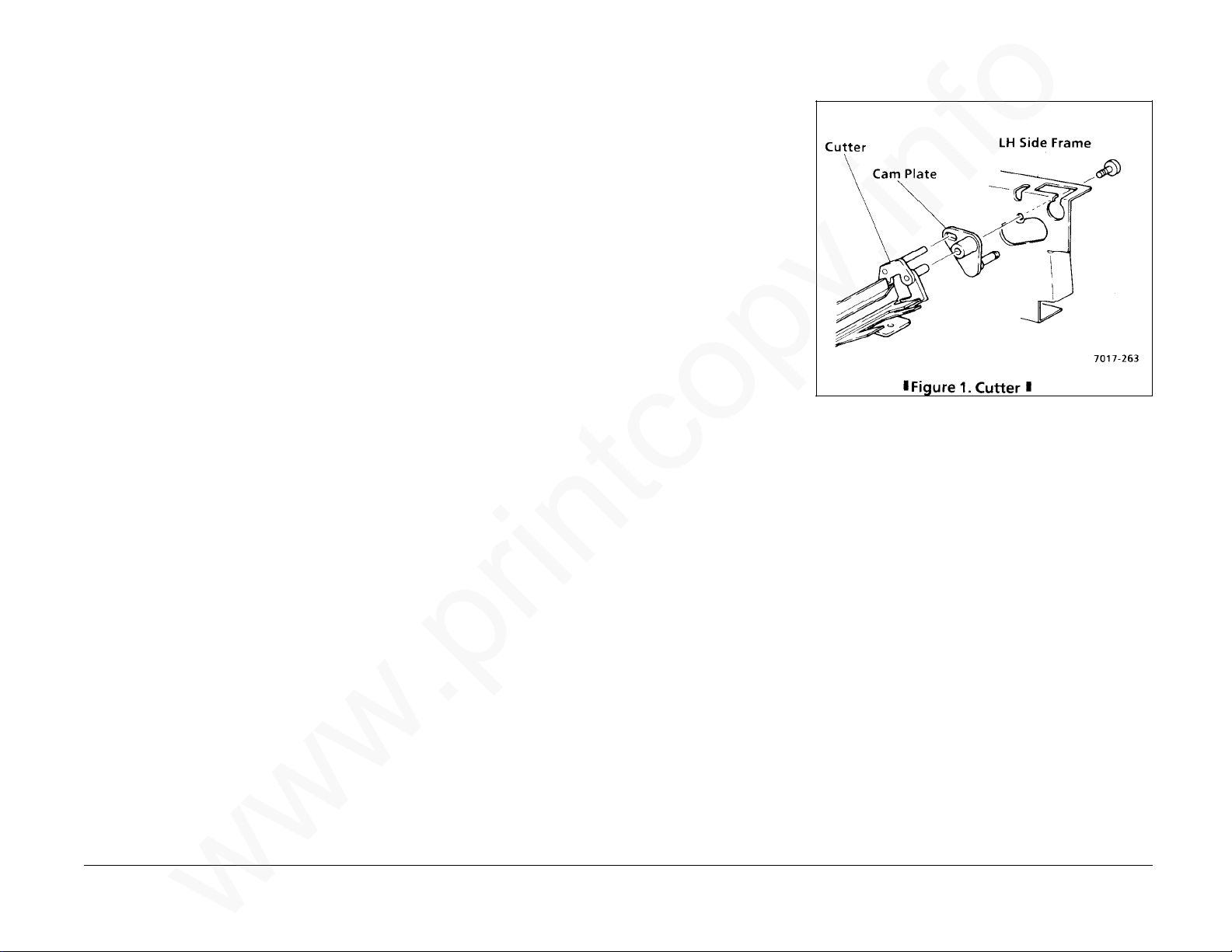

REP 4.9 Cutter 4-29●

REP 4.10 Printer Output Drive Roller 4-30●

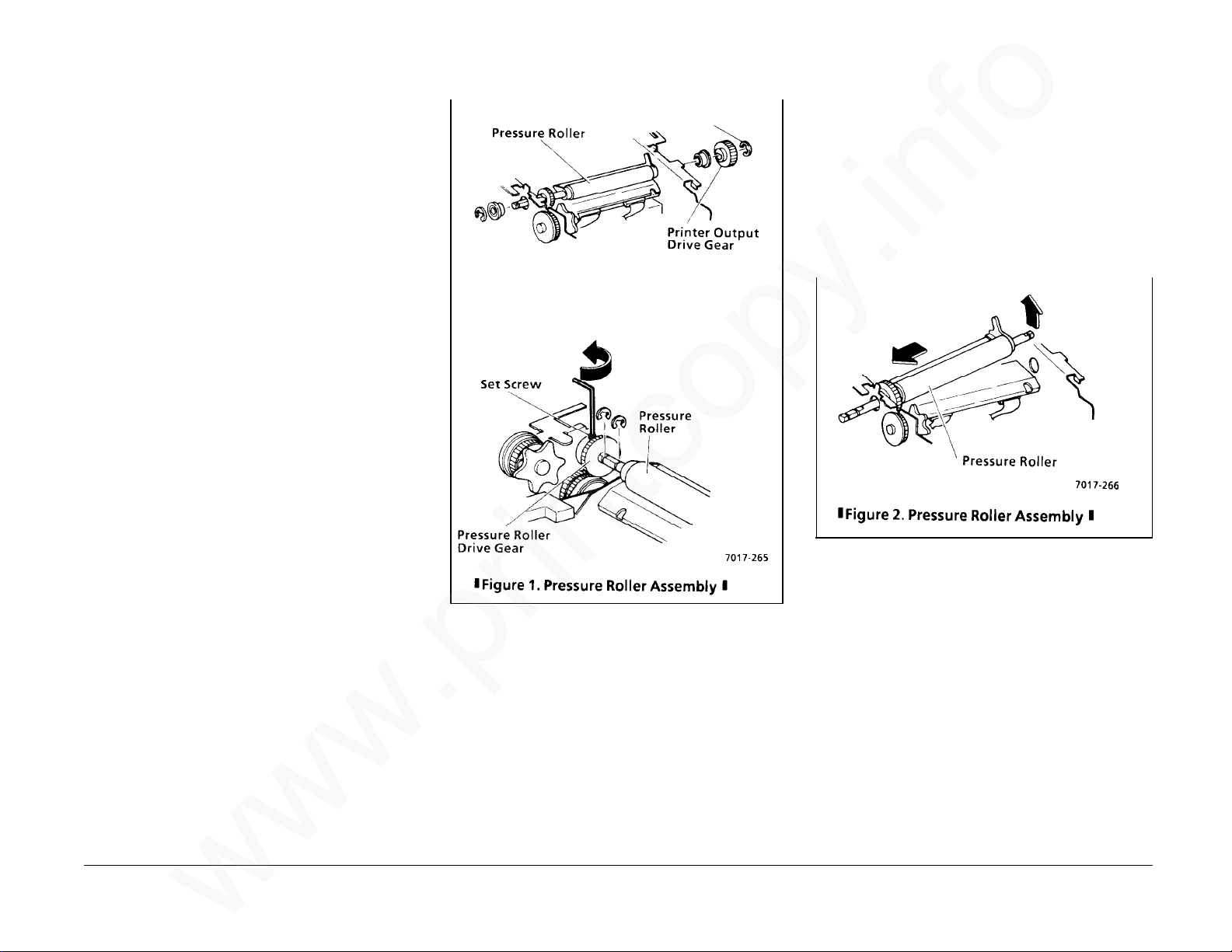

REP 4.11 Pressure Roller Assembly 4-31●

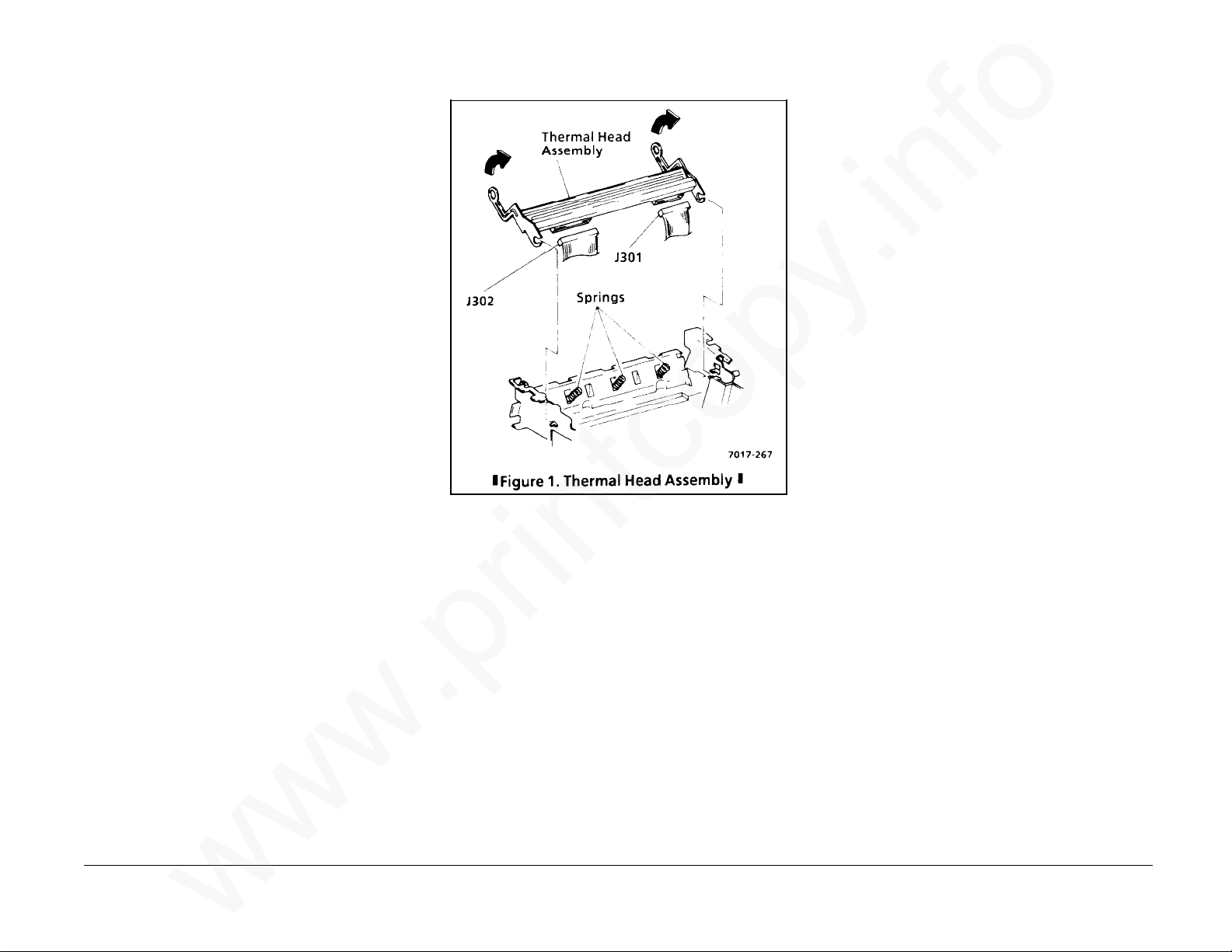

REP 4.12 Thermal Head Assembly 4-32●

REP 4.13 Cutter Crank Arm 4-33●

REP 4.14 Cutter Cam 4-33●

REP 4.15 Printer Motor 4-34●

REP 4.16 Cutter Belt 4-35●

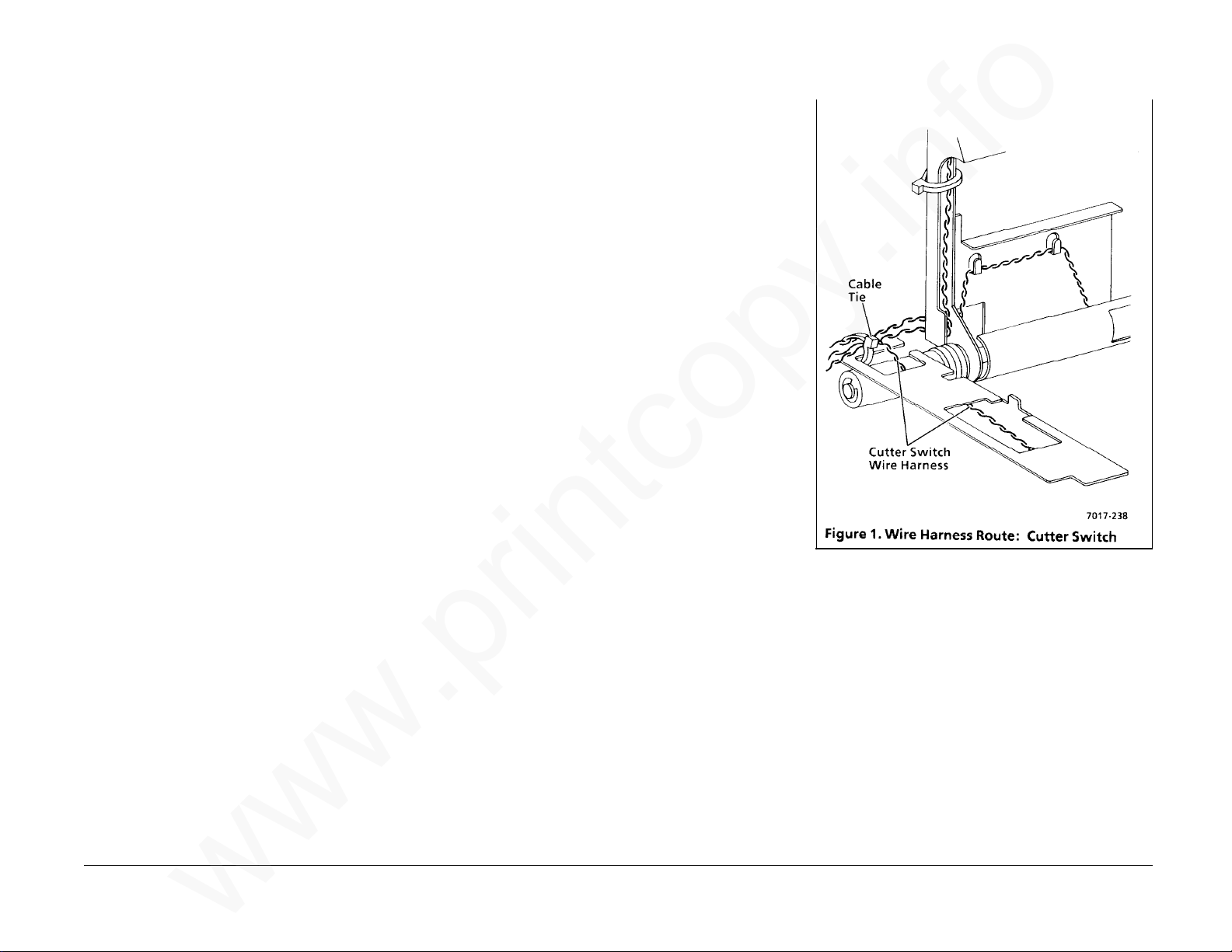

REP 4.17 Cutter Switch 4-35●

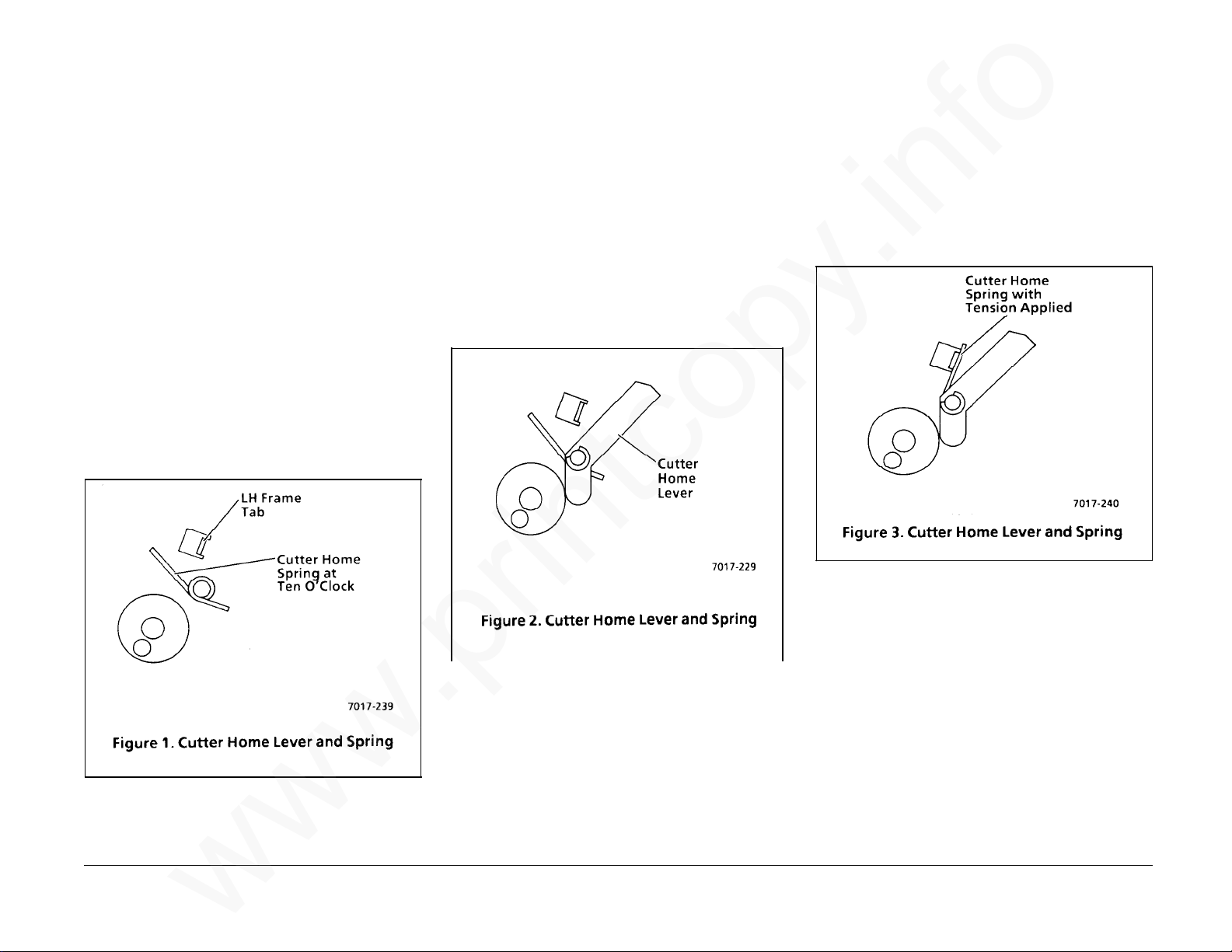

REP 4.18 Cutter Home Lever and / or Cutter Home Spring 4-36●

REP 4.19 Planetary Assembly 4-37●

REP 4.20 Cutter Crank Pulley 4-38●

REP 4.21 Cutter Clutch 4-38●

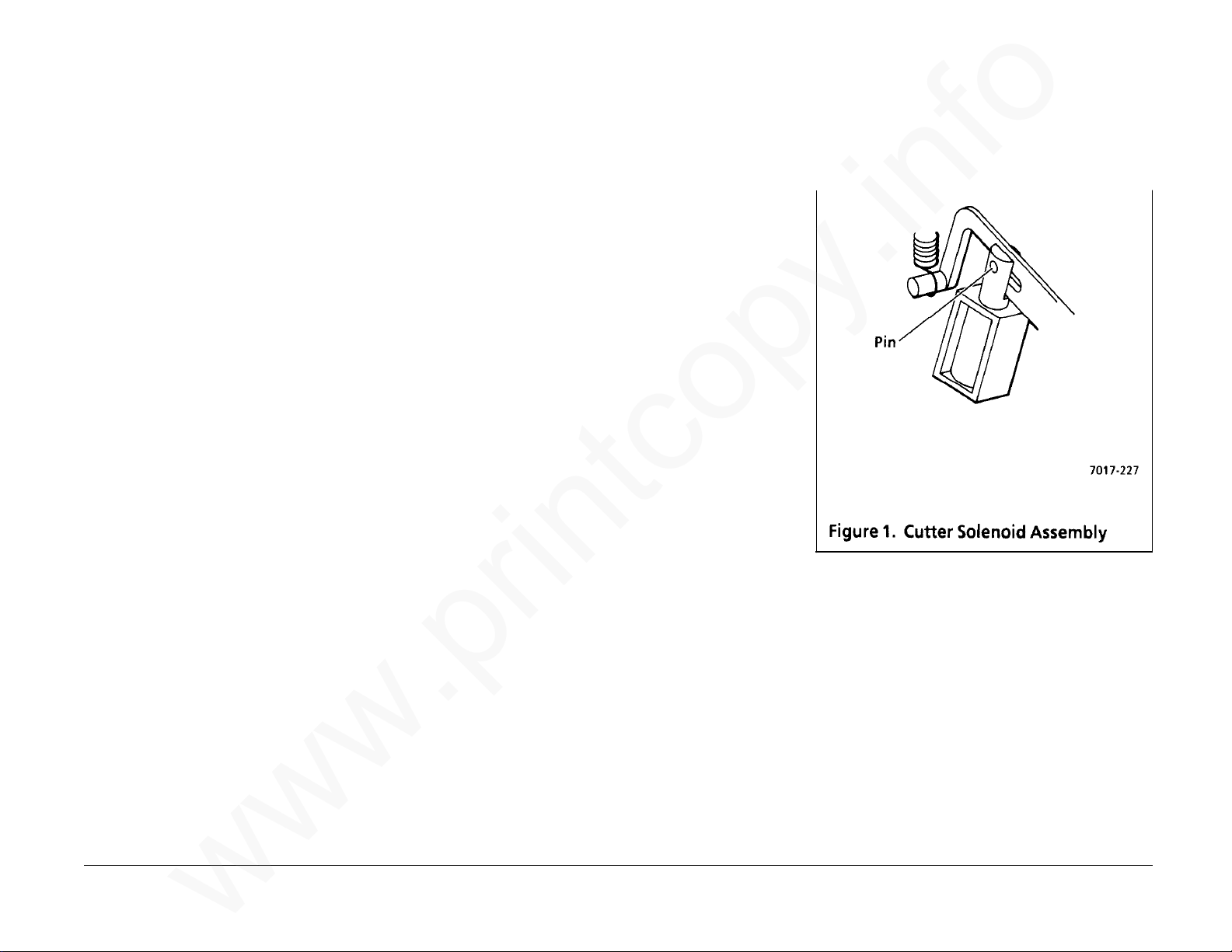

REP 4.22 Cutter Solenoid Assembly 4-39●

REP 4.23 Cutter Solenoid Lever 4-40●

REP 4.24 Printer Belt 4-41●

Electronics

REP 5.1 A6 Control Panel and / or Control Panel Assembly 4-42●

REP 5.2 Speaker Assembly 4-43●

REP 5.3 Fan 4-43●

REP 5.4 A8 Store & Forward PWB 4-44●

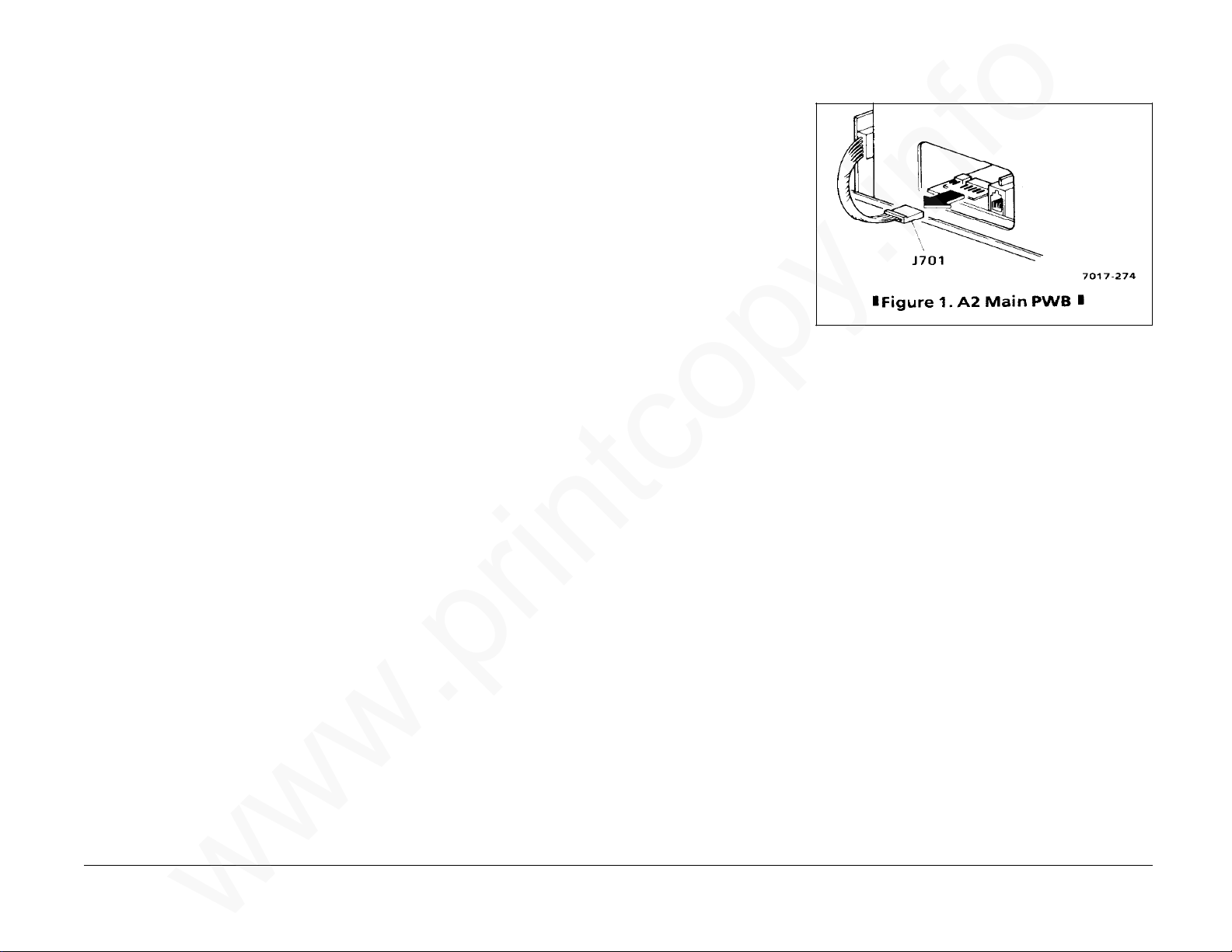

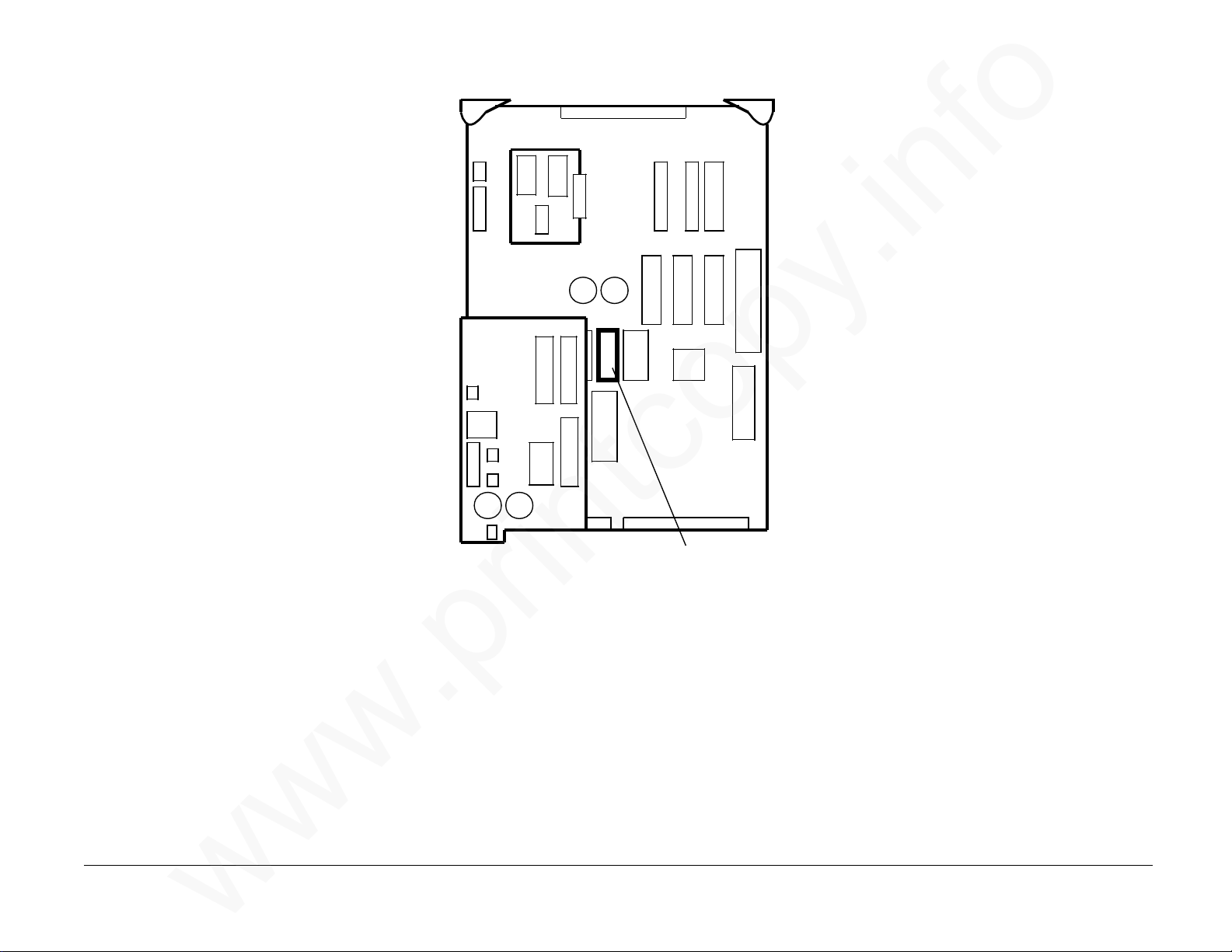

REP 5.5 A2 Main PWB 4-44●

REP 5.6 Power Supply Assembly 4-45●

REP 5.7 A3 Telephone Line Filter PWB 4-46●

4. Repair / Adjustment

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section4.htm (2 of 3) [28/09/1999 11:36:44]

Page 38

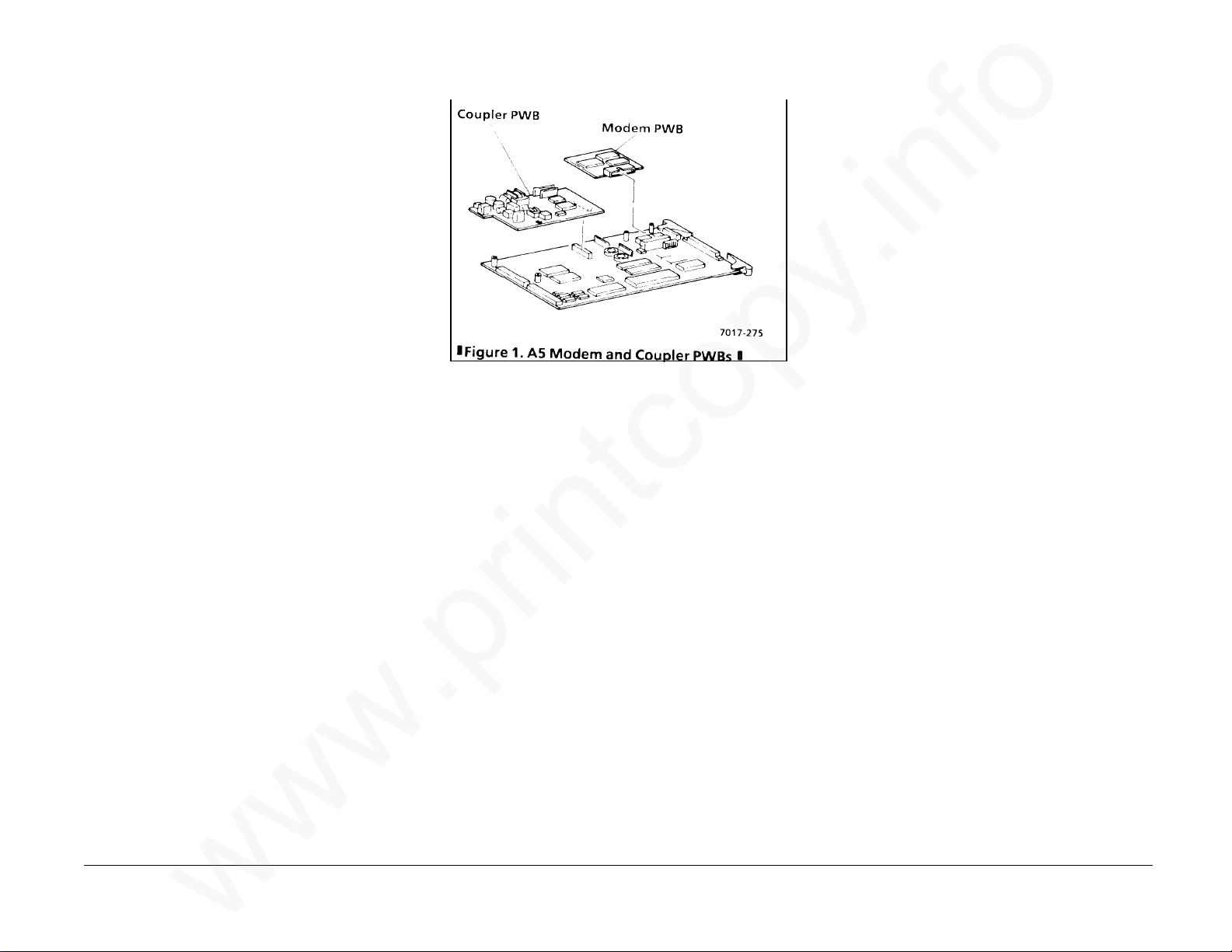

REP 5.8 A5 Modem PWB 4-46●

REP 5.9 A10 Coupler PWB 4-47●

REP 5.10 CNC PWB Assembly 4-47●

Electronics

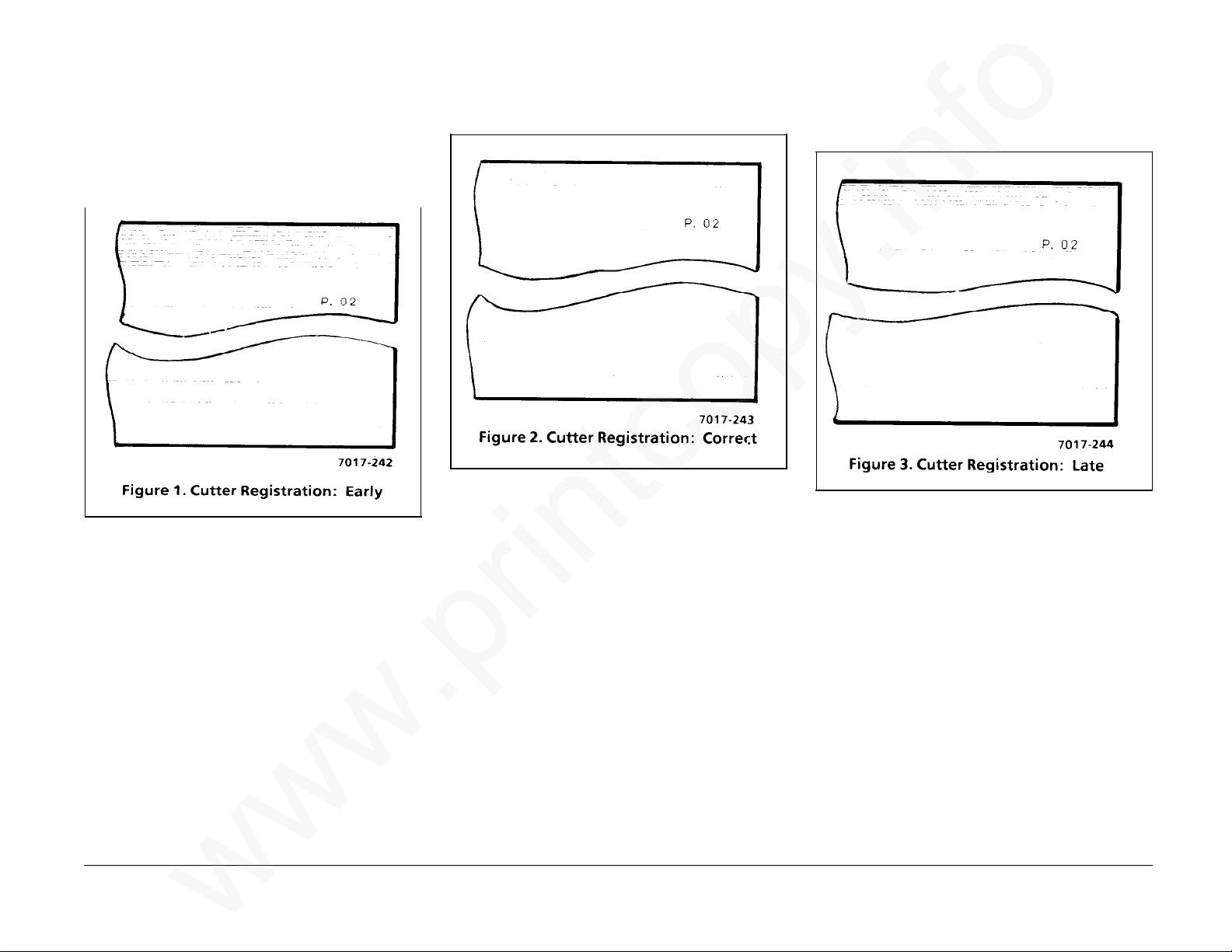

ADJ 5.1 Cutter Registration 4-48●

ADJ 5.2 Scan Registration 4-52●

4. Repair / Adjustment

www.printcopy.info

www.printcopy.info

http://xww.xedoc.world.xerox.com/data/XEDOC/Central/Fax/7017/TECH/section4.htm (3 of 3) [28/09/1999 11:36:44]

Page 39

Introduction

www.printcopy.info

www.printcopy.info

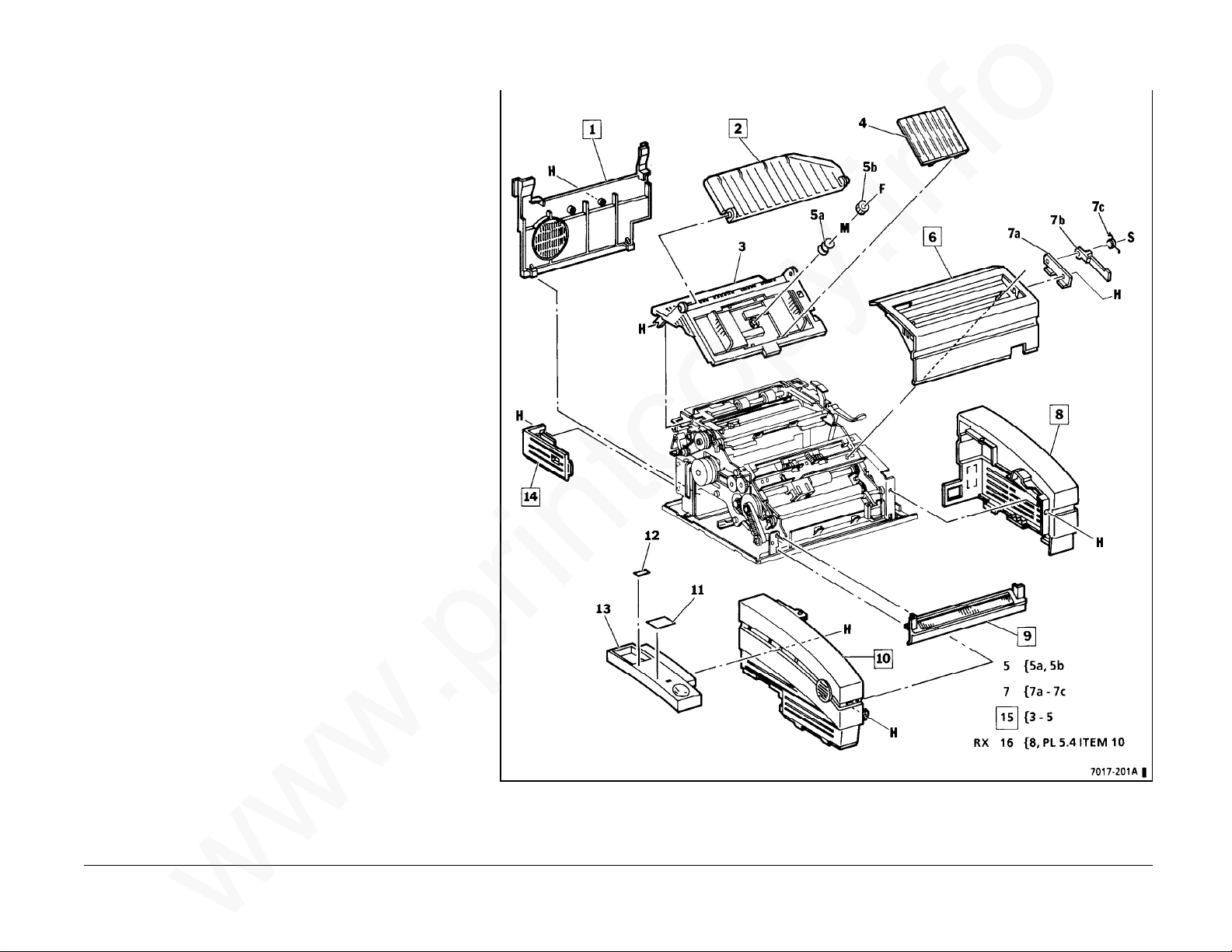

Overview

The Repair / Adjustment section contains the

removal, replacement, and adjustment

procedures for most components and

assemblies.

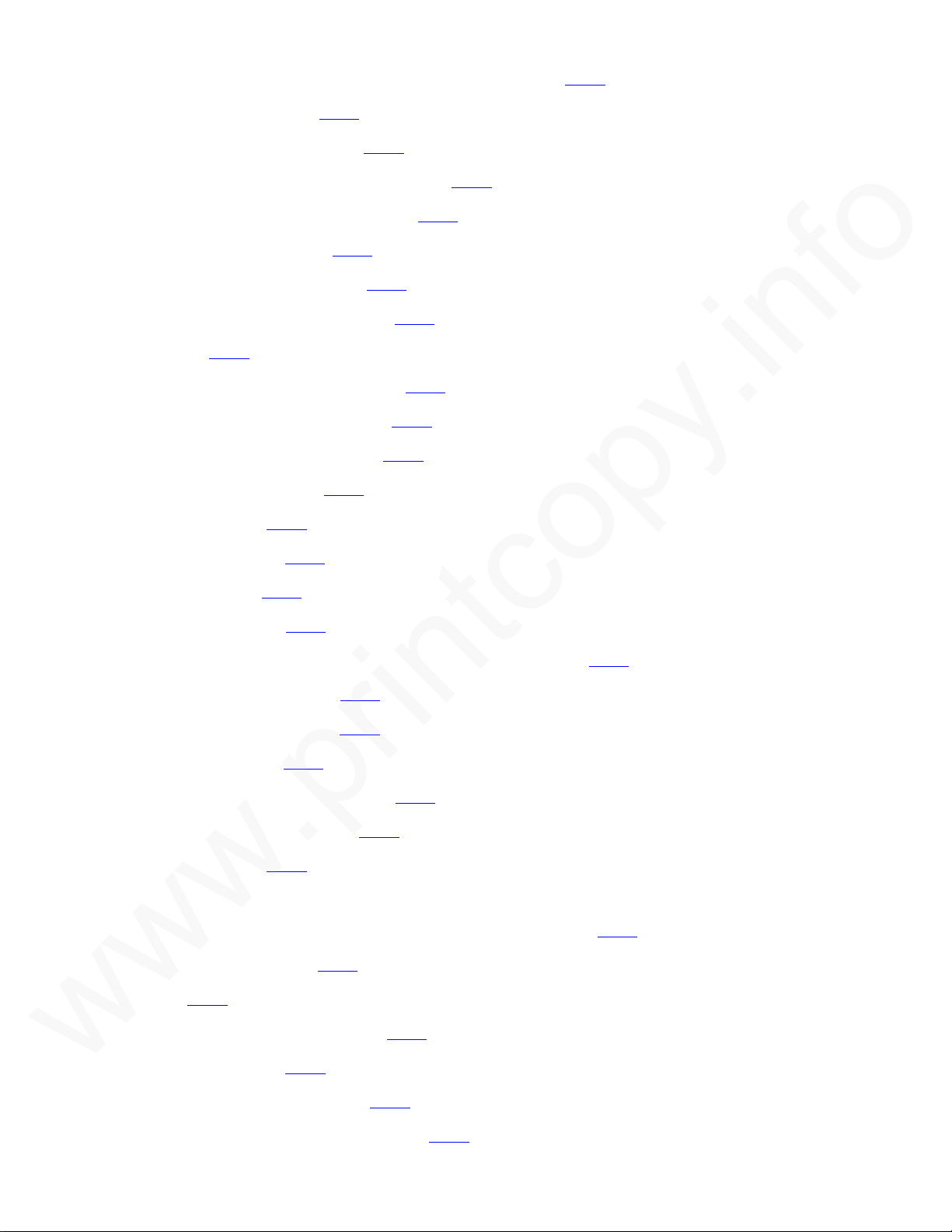

Refer to Figure 1 below in order to assist you

with references to left, right, front, and rear in

the procedures.

Organization

Section contents gives page references for all

procedures in the repair / adjustment section.

Repair contains the removal and replacement

procedures for many parts shown in the Parts

List. If a component procedure cannot be

found in this section, it usually means that

Removal or Replacement procedures are

obvious; the part or assembly is not spared

and cannot be ordered; or the part does not

need to be removed, replaced, or adjusted.

All removal replacement procedures are listed

first. They are then followed by all the

adjustment procedures.

Removal

Removal contains step-by-step removal

procedures for a specific component part or

assembly.

Illustrations are provided in some adjustments

in order to assist you with the procedures. You

should refer to the specific parts list

illustration (listed under the repair title) for

locating most components within a procedure.

Replacement

Replacement contains procedures to reinstall

or replace a component part or assembly and

those components or assemblies removed

during the removal process.

If a replacement procedure should be

completed in the exact reverse order of

removal, a generic replacement statement is

provided.

If you are in one replacement procedure and

are directed to go to another procedure to

reinstall a component, reinstall that

component then return to the original

procedure that directed you there. Do not

continue through and reinstall every

component listed in the procedure that you

referenced. The best sequence for replacing

each component removed in the original

procedure is listed in the original procedure.

Adjustment

Adjustment contains the adjustment

procedures for component parts or assemblies.

It also contains a functional check of the

component part or assembly.

Repair / Adjustment Introduction 4-2 Telecopier 7017 / 7017SF

6/88

Page 40

REP 1.1 Document Catch Tray

www.printcopy.info

www.printcopy.info

Assembly

Parts List on PL 1.1

Removal

Pull document catch tray assembly straight

forward to remove.

Replacement

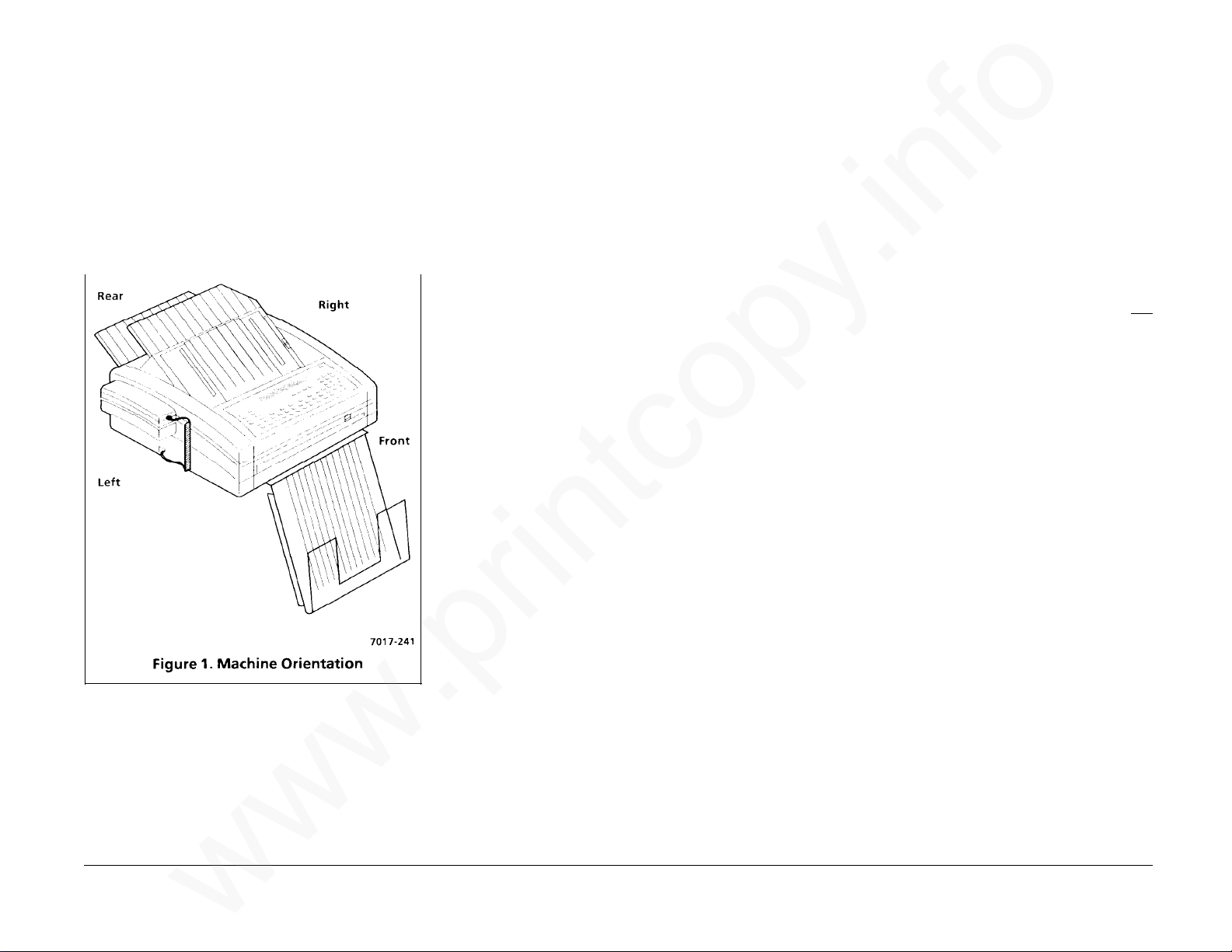

REP 1.2 RH Cover

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. Open printer.

1. Align positioning slots on document

catch tray assembly with the two

channels on base plate.

2. Press firmly towards the rear to secure.

4. Open and secure scanner.

WARNING

Do not bump the scanner after it is secured.

The scan support assembly will release and

cause the upper scan assembly to pinch you.

5. Remove RH cover.

NOTE: Use the cutout in the RH cover to

access and release the center latch.

a. Release the three latches (Figure 1)

from the base plate.

NOTE: Machines with serial numbers

(TBD) and above do not have the

center latch.

b. Remove the two screws securing the

RH cover to the RH frame.

c. Slide RH cover towards the right to

clear the upper scan cover and the

base plate, then pull it up and

towards the rear to clear the A8 store

& forward PWB, if installed.

Replacement

Reinstall in reverse order.

Telecopier 7017 / 7017SF 4-3

12/88

REP 1.1, 1.2

Page 41

4

www.printcopy.info

www.printcopy.info

REP 1.3 Coupler Cover

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. USO: Remove coupler cover.

a. Disconnect handset cord from the left

side of terminal.

b. Disconnect telephone line cord from

the rear of terminal.

c. Remove the screw securing coupler

cover.

d. Slide coupler cover towards the rear

until it stops, then rotate bottom

edge towards the left and down to

remove.

Replacement

1. Align upper locking tab on coupler cover

with the rear of cutout on LH cover.

2. Reinstall in reverse order.

REP 1.4 LH Cover

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. Remove coupler cover (REP 1.3).

4. Open printer.

5. Open and secure scanner.

WARNING

Do not bump the scanner after it is secured.

The scan support assembly will release and

cause the upper scan assembly to pinch you.

6. Remove LH cover.

a. Release two latches from the base

plate.

b. Remove the two screws securing the

LH cover to the LH frame.

c. Pull LH cover towards the left to clear

the upper scan cover and the base

plate, then pull it straight up to clear

speaker assembly.

Replacement

Reinstall in reverse order.

REP 1.5 Output Tray Assembly

Parts List on PL 1.1

Removal

1. Remove document catch tray assembly

(REP 1.1).

2. Remove output tray assembly.

a. Lift output tray assembly straight up

until top front ridge touches base

frame.

b. Rotate rear of output tray assembly

forward, then slide output tray

assembly backward to remove.

Replacement

1. Align front lip of output tray assembly

with opening in rear of base frame.

2. Position output tray assembly parallel to

input tray extension.

3. Insert front of output tray assembly fully

into opening.

4. Rotate rear of output tray assembly

forward while pressing down on front of

output tray assembly until output tray

assembly slips into a secured position.

5. Press output tray assembly down to

ensure it is fully seated.

6. Reinstall document catch tray assembly

(REP 1.1).

REP 1.3, 1.4, 1.5 4-4 Telecopier 7017 / 7017SF

6/88

Page 42

REP 1.6 Rear Cover

www.printcopy.info

www.printcopy.info

REP 1.7 Upper Scan Cover

REP 1.8 Lower Scan Cover

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. Remove output tray assembly (REP 1.5).

4. Remove rear cover.

a. Remove the two screws securing rear

cover to the power supply housing.

b. Rotate the top edge of rear cover

towards the rear to clear printer

output drive roller.

c. Lift rear cover up and out of cutouts

in power supply housing.

Replacement

Reinstall in reverse order.

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. Remove coupler cover (REP 1.3).

4. Remove LH cover (REP 1.4).

5. Remove scan support assembly.

6. Remove control panel assembly (REP 5.1).

7. Remove upper scan cover.

a. Remove the two screws securing

upper scan cover.

b. Remove upper scan cover.

Replacement

1. Position the two locating pegs on upper

scan cover into the two locating holes.

2. Ensure W4 wire harness is not pinched by

the upper scan cover.

3. Reinstall in reverse order.

Parts List on PL 1.2

Removal

1. Remove power cord.

2. Remove document catch tray assembly

(REP 1.1).

3. Open and secure scanner.

WARNING

Do not bump the scanner after it is secured.

The scan support assembly will release and

cause the upper scan assembly to pinch you.

4. Remove lower scan cover.

a. Release the latch securing lower scan

cover to LH frame.

b. Release the latch securing lower scan

cover to RH frame.

c. Pull lower scan cover gently forward

to clear video assembly, then raise it

to clear lip of base plate.

Replacement

Reinstall in reverse order.

Telecopier 7017 / 7017SF 4-5

6/88

REP 1.6, 1.7, 1.8