Xerox Phaser Color 8400, Phaser Color 8500, Phaser Color 8550, Phaser Color 8560 Service Manual

Page 1

Версия 22.05.2009

Руководство по техническому

обслуживанию

PHASER 8400/8500/8550/8560

Документация изменена и дополнена:

1. Добавлены технические бюллетени для аппаратов Phaser 8400/8500/8550/8560.

Page 2

Xerox

Office

Group

Service Bulletin

2-Feb-2004

Phaser 8400

SB 607

Washer On The Drum Assembly’s Lower Right

Mounting Screw May Cause Dog-earing On Prints

Phaser Xerox Office Group Service Bulletin SB 607

2. Retighten the rear screw to 25 in-lbs.

3. Tighten the lower screw (without washer) and torque to 25 inlbs.

4. Tighten the front screw to 25 in-lbs.

When troubleshooting a persistent dog-ear print problem, ensure

the Stripper Carriage Assembly works correctly and the stripper

blade is not damaged. Also ensure an appropriate paper is being

used.

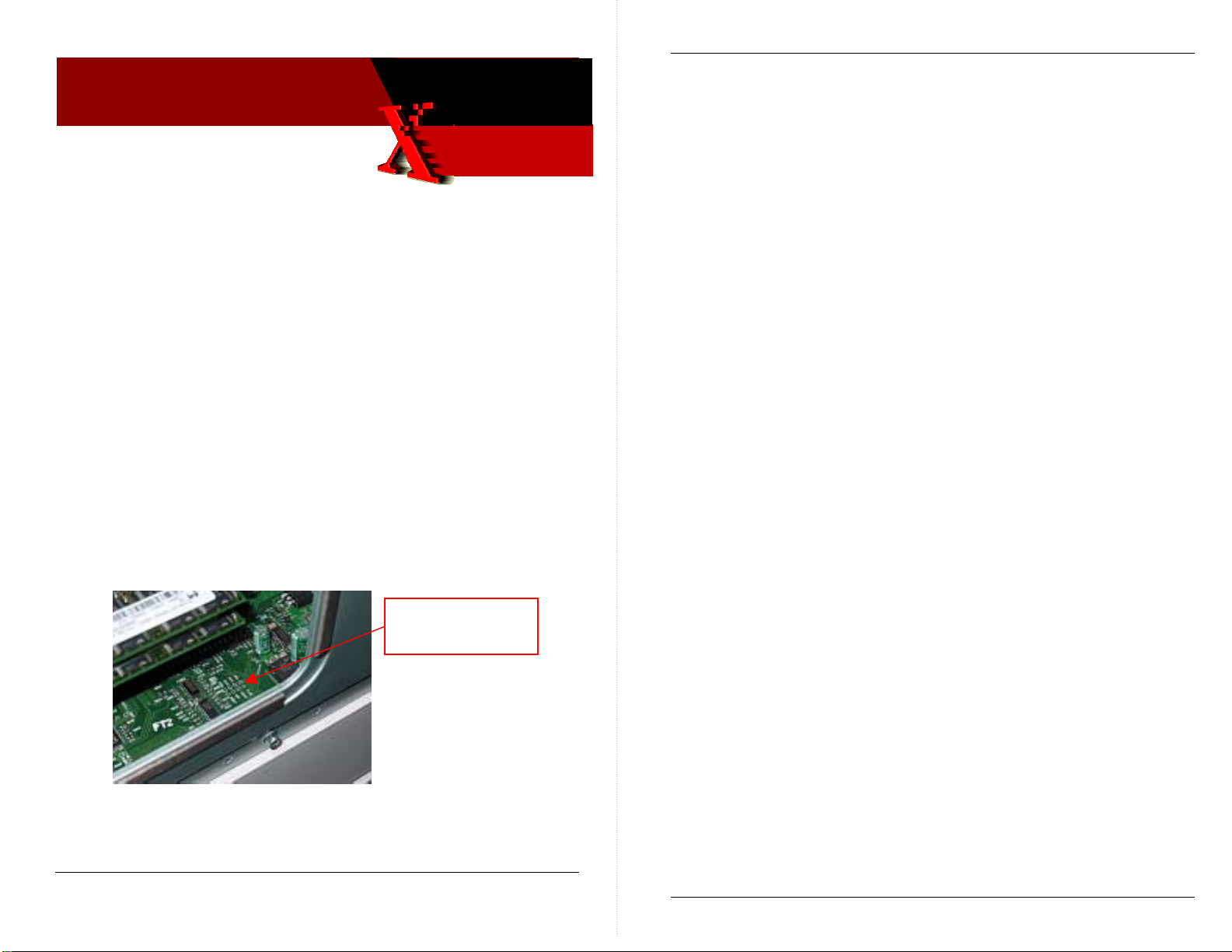

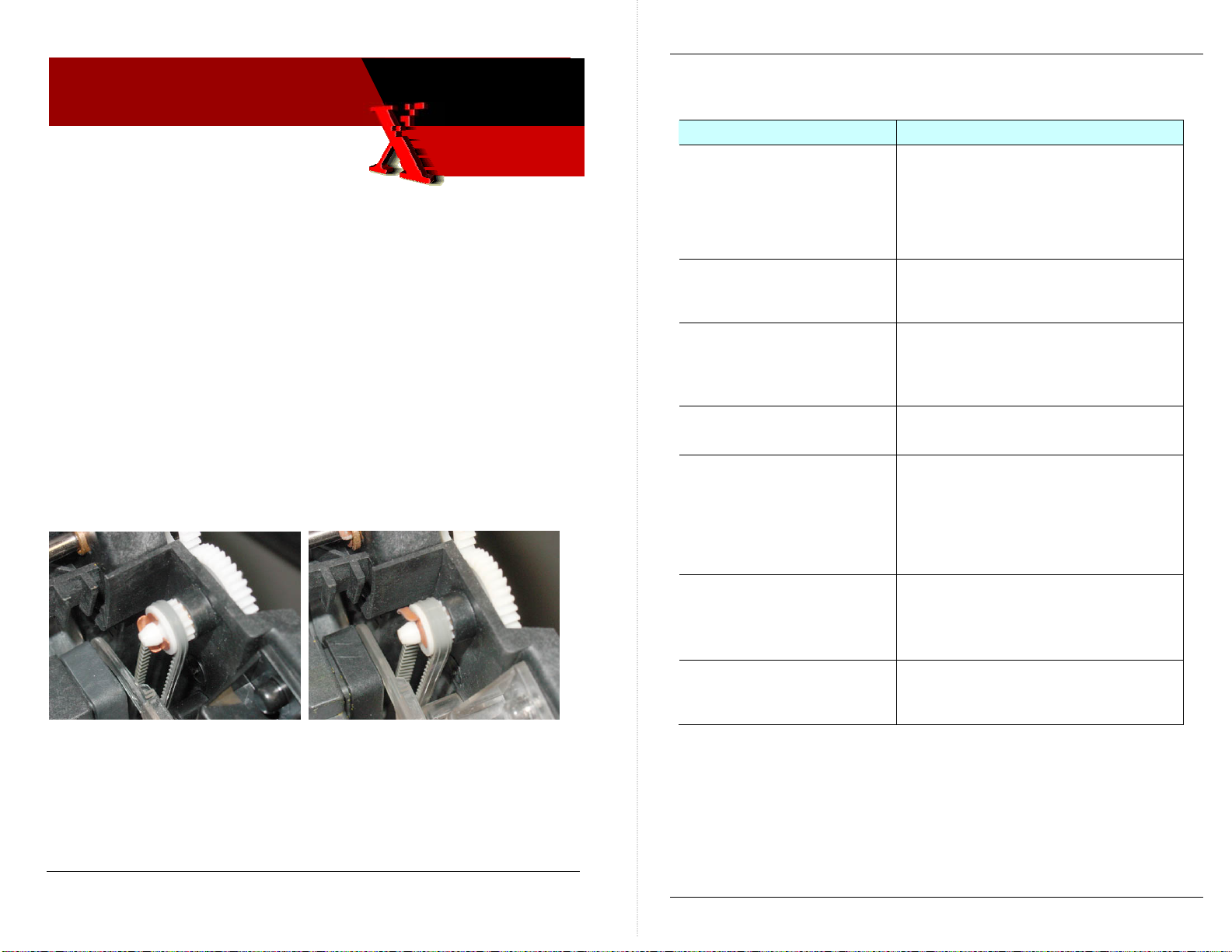

LOWER RIGHT DRUM SCREW USES NO WASHER

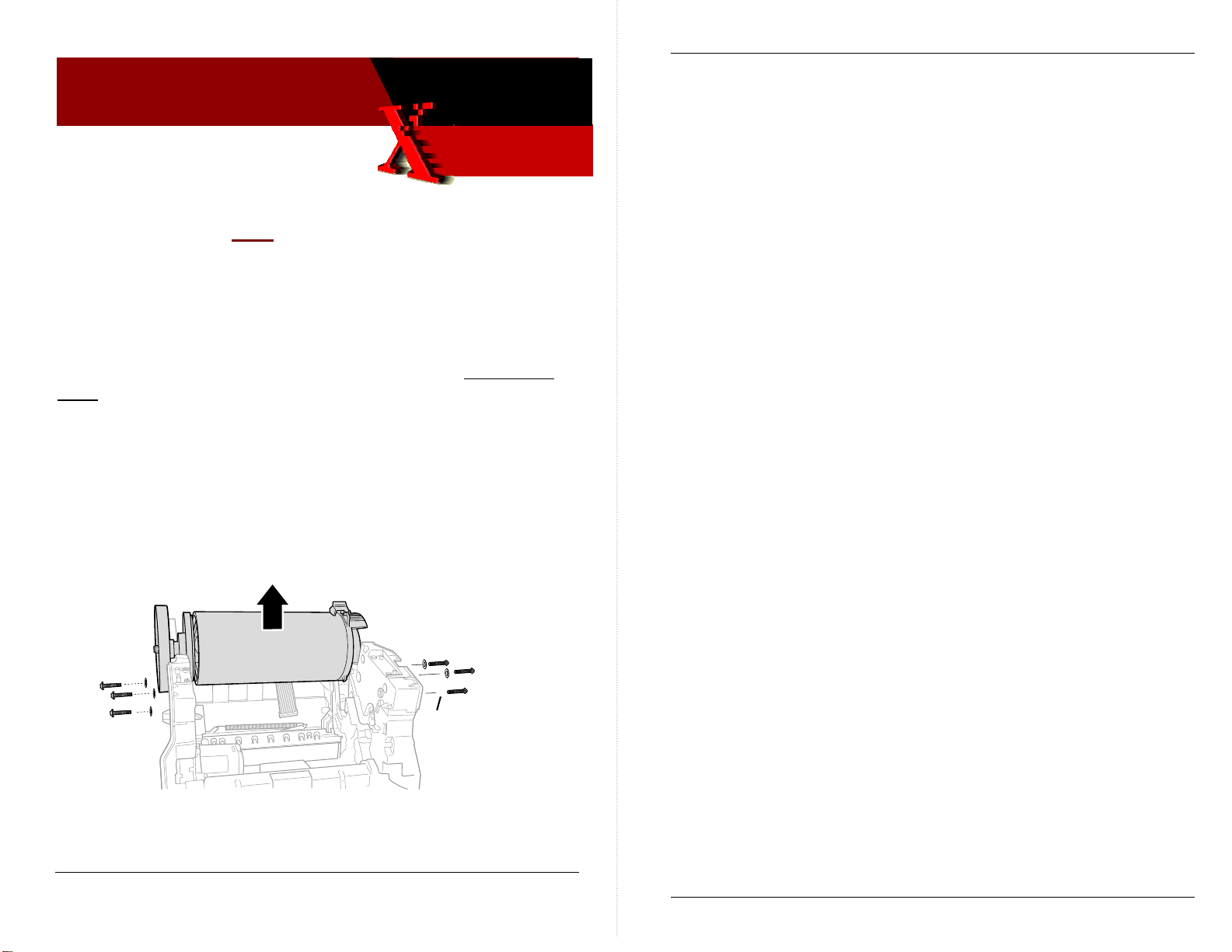

A washer added to the lower right screw that holds the Drum

Assembly to the Chassis on the right side prevents the right

Labyrinth Seal from seating in its proper location. This can cause

the Stripper Carriage to also not be properly located. In very rare

cases this results in prints on lighter-weight papers having one

corner folded over on the leading edge (dog-ear) as they are

stripped from the Drum. Occasional dog-earing is normal.

WHAT TO DO

When servicing a drum assembly ensure there is no washer on the

lower right drum mounting screw. Update your service manual’s

Drum Disassembly/Assembly Procedure indicating all the drummounting screws use washers except the lower right screw.

No washer

PARTS STRATEGY

Do not replace the Drum Assembly to correct a dog-ear print

problem. Remount the assembly and ensure the screws are

correctly installed and tightened.

TE

s8400-160a

The proper sequence for tightening the right-side drum screws is:

1. Loosen the three drum screws.

Service Manual Update SB607 SB 607 Error! Reference source not found. SB 607 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

Page 2 of 2

Page 3

Xerox

Office

Group

Service Bulletin

16-Aug-2004

Phaser 8400 SB608Rev1 Sb 608 Rev 1

SB 608, Rev 1

Some FRU part numbers are not orderable

SERVICE MANUAL LISTS FRU PART NUMBERS THAT

CANNOT BE ORDERED BY THE FIELD ORGANIZATION

Four part numbers listed in the service manual cannot be ordered by

the field organization. Alternate 650- part numbers have been set

up to use instead.

FRU Part Old (unusable)

part number

525-Sheet Feeder

(HCF) with Tray

Main Tray 097S03195 650-4332-00

097S03174 650-4331-00

New part number you

should order with

Hard Drive Assy 097S03172 650-4299-00

Hard Drive Assy with

Japanese Fonts

097S03173 650-4330-00

WHAT TO DO

Update your service manual with the new, replacement part

numbers. Do not use the old part numbers to order an FRU.

PART INVENTORY STRATEGY

Do not stock these parts. Order them only when needed for a

printer repair.

TME

Service Manual Update Error! Reference source not found. SB 608, Rev 1 Page 1 of 1

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 4

Xerox

Office

Group

Service Bulletin

6-August-2004

Phaser 8400 SB624Rev2 SB 624 Rev3

SB 624 Rev 2

Printhead Exhibits Random Missing Jets

INFORMATION: SERIAL-NUMBERED PRINTERS RPC030017 TO

RPC044425 REQUIRE PRINTHEAD FIRMWARE CODE UPDATE

Printhead engineering has developed new drift compensation alg orithms

that improve reliability of the Phaser 8400 printer’s printhead. All printers

serial-numbered below RPC044426 need to have their printhead’s firmware

updated via a downloadable snippet file. Printers RPC044426 and above

already have the new algorithm built in.

The snippet file and a readme file are packaged as files 8400_fw_update.exe

(PC) or 8400_fw_update.dmg (Mac). They are available at:

http://www.office.xerox.com/cgi-bin/formeng.pl?form=8400printheadfirmware

Follow the readme instructions to download the snippet to a printer.

About a year or so after the printer was manufactured, a printhead that is

not updated will exhibit numerous, random missing jets. The missing jets

may clear with a cleaning cycle but other jets drop out. Downloadi ng the

update file to the printer resolves this problem. There is no means to

determine the printhead’s firmware version. Only downloading the snippet

to the printer will tell you if the printhead firmware is up-to-date or not.

Following the download, the printer prints a download status print.

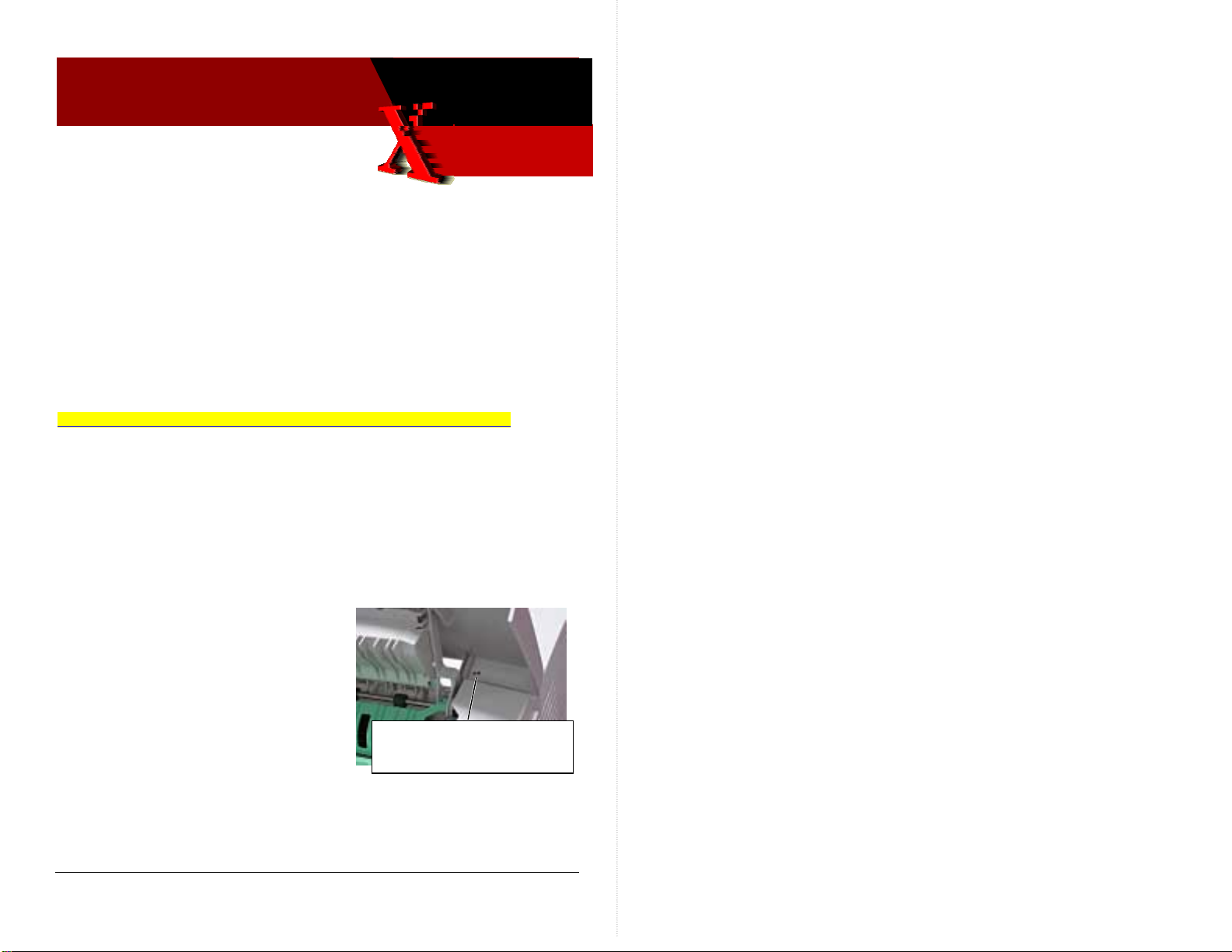

WHAT TO DO

As you service a Phaser 8400 printer,

check its serial number. If it is between

RPC030017 to RPC044425, download the

printhead firmware update snippet to

the printer. For update tracking

purposes, indicate in your Tech Notes

when you have updated a printer. Also

mark the underside of the exit door with

a “PH” to indicate the printer has been updated.

With an indelible marker,

mark the underside of the exit

door with a “PH”

PART INVENTORY STRATEGY

None. TME

Firmware Issue Page 1 of 1

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

Page 5

Xerox

Office

Group

Phaser 8400

Service Bulletin

21-July-2004

SB 633

Phaser Xerox Office Group Service Bulletin SB 633

WHAT TO DO

Ensure these EMI countermeasures are correctly re-installed when

you service printers featuring these parts.

Older printers that do not feature these EMI countermeasures do

not need to be updated.

EMI Suppression Changes SB633 633

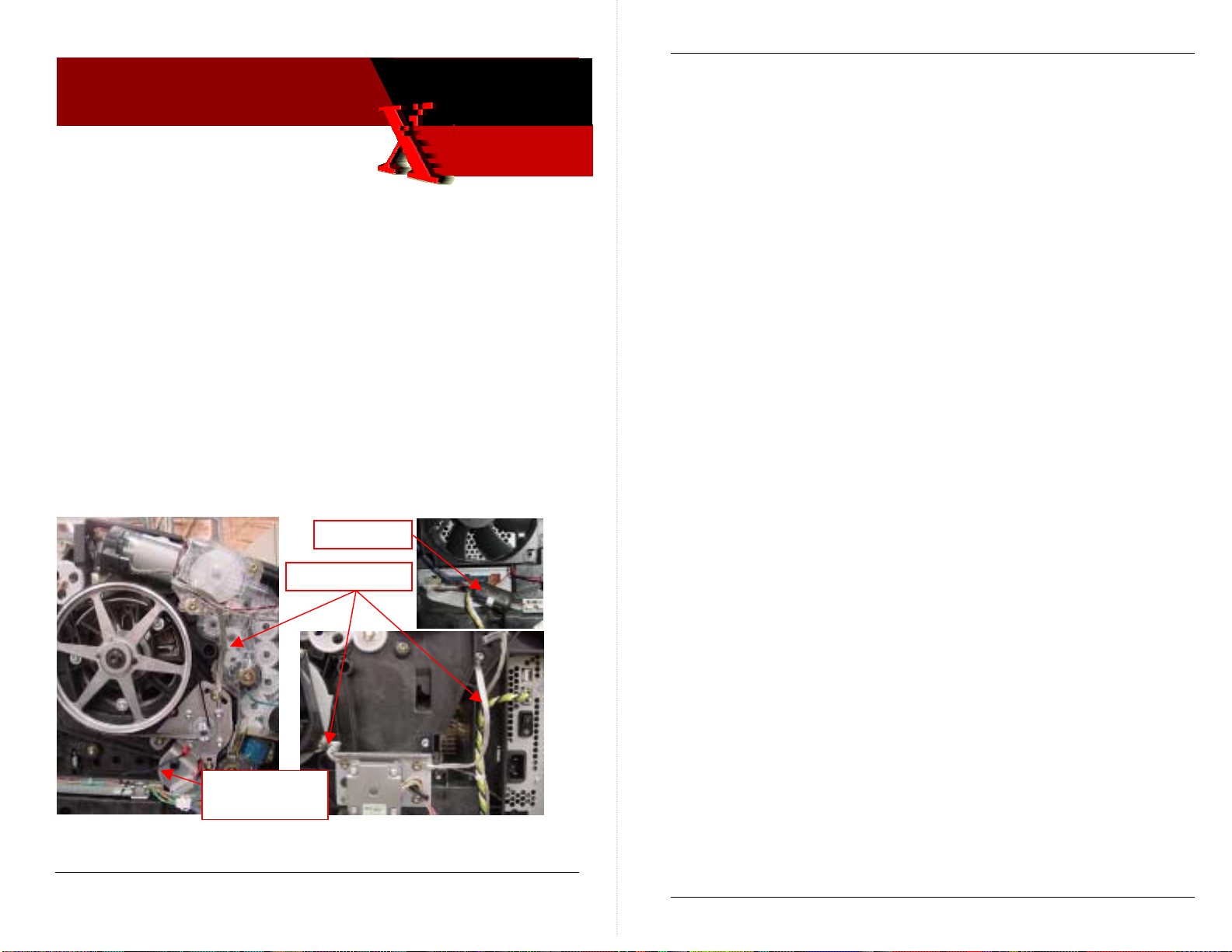

NEWER PRINTERS FEATURE NEW EMI SUPPRESSION

DEVICES

Newer printers may include new EMI countermeasures. These

include:

• Choke coil on the left umbilical wiring harness

• Media path motor-to-drum motor bracket ground strap

• X-axis motor bracket-to-drum fan bracket ground strap

• X-axis motor bracket-to-chassis ground strap

• 0-ohm Y-axis motor ground wire (replaces 100k ohm ground

wire)

Choke coil

Braided cables

Update your service manual with this information.

PART INVENTORY STRATEGY

None

TME

O-ohm ground

wire

Service Manual Update Error! Reference source not found. SB 633 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

Page 2 of 2

Page 6

Date Issued: 10 Oct 2006

SB 634 Rev 1

Product: Phaser 8400, 8500, 8550, C2424

Operational Groups: OPB, NADC

INSUFFICIENT AC POWER CAN CAUSE 37,002 THRU 37,013

PEST FAULT CODES

AC power supplied by power sources such as uninterruptible power

supplies (UPSs) or DC-to-AC inverter systems may not supply correct

voltage to properly power up the printer. Likewise, other devices

sharing the same AC circuit can cause AC voltage sags that cause the

printer to fail its AC heater PEST tests (Print Engine Self Test).

In both cases the printer may produce any of the following disconnected

heater errors:

• Printhead jet-stack 37,002.47 or 37,003.48

• Reservoir heater, 37,004.40 or 37,005.41

• Drum heater error 37,006.42

• Preheater error 37,008.44

• Ink melters errors 37,009.45 thru 37,013.40

SOLUTION

Verify the AC power source when you troubleshoot a printer exhibiting

any of these errors. Try powering up the printer on a different AC circuit

on a different breaker. Turn off other devices, such as laser printers and

coffee makers on the same circuit.

PART INVENTORY STRATEGY

None.

TME

Pub. No.:

CAUSE

The printer features several heaters controlled by printer electronics and

powered by AC electricity. The printer itself can power up despite

insufficient or irregular AC voltage but it may fail its AC heater tests.

This is due the test not measuring sufficient current flowing through the

heater at the moment the test runs.

Devices sharing the AC circuit shared with the printer, such as a laser

printer pulse-heating its fuser, a coffee maker heating its warming plate

via a thermo-breaker, or a space heater turning on, may be placing heavy

intermittent demand on the AC circuit. This sudden inductive demand

creates momentary AC voltage sag that causes the PEST test to fail.

Copyright © 2006 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

1 of 1

Page 7

Xerox

Office

Group

Phaser 8400

Service Bulletin

21-July-2004

SB 635

SB635 635

Undocumented Error Codes 11,001 thru 11,100

UNDOCUMENTED/CORRECTED ERROR CODES

11,001.47 -

ECM_UHCF_SER_LINK_

BROKEN

11,002.41 -

ECM_LHCF_SER_LINK_

BROKEN

11,003.42 -

ECM_FP_SER_LINK_

BROKEN

11,004.43 -

ECM_IO_SER_LINK_

BROKEN

11,005.44 -

ECM_PCTL_SER_LINK_

BROKEN

11,006.45 -

ECM_HEAD_SER_LINK_

BROKEN

11,007.44 ECM_PCI_ERROR

11,008.45 -

ECM_DMA_TRANSFER_

FAILURE

11,009.46 -

Service Manual Update Error! Reference source not found. SB 635 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

Upper feeder –Tray 2 – broken serial communication timeout

failure detected. Seven consecutive frames occurred with

errors. Ensure the ground integrity of the printer. Inspect

and reseat all connectors. Reset NVRAM and retest.

Lower feeder –Tray 3 – broken serial communication timeout

failure detected. Seven consecutive frames occurred with

errors. Ensure the ground integrity of the printer. Inspect

and reseat all connectors. Reset NVRAM and retest.

Replace the Tray 3 feeder assembly.

Front panel broken serial communication timeout failure

detected. Seven consecutive frames occurred with errors.

Ensure the ground integrity of the printer. Inspect and reseat

all connectors. Reset NVRAM and retest. Replace the front

panel.

I/O board broken serial communication timeout failure

detected. Seven consecutive frames occurred with errors.

Ensure the ground integrity of the printer. Inspect and reseat

all connectors. Reset NVRAM and retest. Replace the I/O

board.

Power control board broken serial communication timeout

failure detected. Seven consecutive frames occurred with

errors. Ensure the ground integrity of the printer. Inspect

and reseat all connectors. Reset NVRAM and retest.

Replace the electronics module.

Printhead broken serial communication timeout failure

detected. Seven consecutive frames occurred with errors.

Ensure the ground integrity of the printer. Inspect and reseat

all connectors. Reset NVRAM and retest. Replace the

printhead

A PCI anomaly or PCI core bit error occurred. Ensure the

ground integrity of the printer. Inspect and reseat all

connectors. Reset NVRAM and retest. Replace the

electronics module

A DMA transfer error was detected. Ensure the ground

integrity of the printer. Inspect and reseat all connectors.

Reset NVRAM and retest. Replace the electronics module.

PostScript communication timeout failure detected. This

indicates the PS microcontroller received no response for

Phaser Xerox Office Group Service Bulletin SB 635

ECM_PS_COM_FAILURE 800ms. Ensure the ground integrity of the printer. Inspect

11,010.48 -

ECM_PS_HW_VERSION_

MISMATCH

11,011.48 -

ECM_PS_SW_VERSION_

MISMATCH

11,010.47 -

ECM_PS_HW_VERSION_

MISMATCH

11,012.49 -

ECM_PCTL_PLD_

VERSION_MISMATCH

11,013.41 -

ECM_IO_PLD_VERSION_

MISMATCH

11,014.42 -

ECM_FP_PLD_VERSION

MISMATCH

11,015.43 -

ECM_HEAD_PLD_

VERSION_MISMATCH

11,016.44 -

ECM_BTM_HCF_PLD_

VERSION_MISMATCH

11,017.45 -

ECM_TOP_HCF_PLD_

VERSION_MISMATCH

11,018.46 -

ECM_TITAN_VERSION_

MISMATCH

11,100.60 -

ECM: PS UC FOUND A

PARITY ERROR WITH

THE LAST ECM XMIT

and reseat all connectors. Reset NVRAM and retest.

Replace the electronics module.

PS hardware version mismatch. This indicates that the PS

hardware does not match the expected version. Replace the

electronics module.

PS software version mismatch. This indicates that the PS

software does not match the expected version. Replace the

electronics module.

PS hardware version mismatch. This indicates that the

PostScript hardware does not match the expected version.

Replace the electronics module.

Power Control PLD version mismatch. This indicates that the

power control programmable logic device does not match the

expected version. Replace the electronics module.

I/O PLD version mismatch. This indicates that the I/O

programmable logic device does not match the expected

version. Replace the I/O board.

Front panel version mismatch. This indicates that the front

panel programmable logic device does not match the

expected version. Replace the front panel.

Head PLD version mismatch. This indicates that the Head

programmable logic device does not match the expected

version. Replace the printhead.

Bottom HCF programmable logic device version mismatch.

This indicates that the bottom HCF programmable logic

device does not match the expected version. Replace the

Tray 3 feeder assembly.

Top HCF PLD version mismatch. This indicates that the top

HCF programmable logic device does not match the

expected version. Replace the Tray 2 feeder assembly

Titan version mismatch. This indicates that Titan chip does

not match the expected version. Replace the electronics

module.

Generally, the root problem for this error is temperature

sensitivity with the power-supply’s opto-isolat or chi ps.

Replace the electronics module.

WHAT TO DO

Update your service manual with this information.

PART INVENTORY STRATEGY

None

TME

Page 2 of 2

Page 8

Xerox

Office

Group

Phaser 8400

Service Bulletin

27-July-2004

SB 636

Troubleshooting the 37,016 Error Code SB636 636

TECHNIQUES FOR TROUBLESHOOTING THE 50V POWER

SUPPLY FAULT ERROR CODE

37,016.4x - PEST_FAULT_HM_CLUTCH_DISCONNECT

Despite the “clutch disconnect” message, thi s error code indicates that the

50V power supply failed its PEST test. (The 5 0V supply is loaded with the

head maintenance wipe r clutch in order to test; hence the message when

the test fails.) Follow these steps in the order listed to find a short that is

causing the 50v supply to fail:

1. Checking for a short in electronics module. Turn off the printer and

wait 30 seconds for power supply capacitors to

circuits within the electronics module may occur if the

capacitors are not allowed to fully discharge.

NOTE: It is possible that the power supply is not shorted but instead is

out of spec, which lead s to an error conditio n. You can measure the

50V power supply output. The test point is located o n the Power

Control board below the main board’s RAM DIMMs.

discharge. Damage to

power supply

50v power supply

test point

Phaser 8400 Xerox Office Group Service Bulletin SB 636

2. Unplug the following electronics module connectors. This step

disconnects all other ex ternal circuits so the e lectronics module c an be

tested alone:

• Power Control to I/O board (J800 - gray ribbon cable on right side)

• Power Control right (J400 – 16 wire, multi-color)

• Printhead data interface (J130 – gray ribbon cable on top side)

• Wave amp signal (J790) short gray ribbon cable located on left side)

• Power Control left (J390 – 34 wire, multi-color)

• Y-Axis motor (J280)

3.

Turn on power to the printer.

4. If the PE and PS indicators do not flash, the short is in side the

electronics module. Replace the electronics module and retest the

printer. If PE and PS indicators flash, continue with the next step.

5. Checking for short on the I/O board. Turn off the printer and wait 30

seconds for power supply capacitors to discharge.

6. Unplug the front panel connector (J220) on the I/O board. This

removes the front panel from the I/O board.

7. Plug in the Power Control to I/O board connector (J800). This step

adds the I/O board back to the working electronics module - nothing

else is connected.

8. Turn on power to the printer. If the PE and PS indicators do not flash,

the short is on the I/O board or related cabling.

If the 50V PS LED (viewed thru the cooling grill below the power cord

receptacle) illuminates, the short is on one of the external devices you

unplugged earlier. In this case, systematically tur n off the printer,

plug a wiring harness back in, and turn the printer on until the 50V

supply fails.

Typically, the power supply should measure 50v (47 to 52v).

Service Manual Update Error! Reference source not found. SB 636 Page 1 of 4

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

9. Turn off the printer. Verify the short is on the I/O board by using an

ohmmeter to check the resistance on I/O board J270, pin 1 to ground.

Resistance of less than 1K ohm indicates a problem.

10. To isolate the problem to the I/O board or its related cabling, unplug

the I/O board connectors. Leave the control panel (J220) plugged in:

• Umbilical Right J1

• Waste Tray Sense J110

• Stripper Solenoid J250

• Paper Tray Sense J610

Page 2 of 4

Page 9

Phaser 8400 Xerox Office Group Service Bulletin SB 636

Phaser 8400 Xerox Office Group Service Bulletin SB 636

• Front Door Sense J600

• Ink load Signal J910

• DMU Sense J860

• Drum Thermistor J870

• Exit Module J680

• Heater Relay Control J950

11. Retest the resistance of the I/O board. If the resistance is still less than

1K ohm, replace the I/O board, reinstall all cables and retest printer.

If the I/O board resistance is not shorted, plug in the I/O board

connectors one at a time and retest the resistance. Replac e the

component that creates a short at J270.

12. Turn on the printer.

13. If the PE and PS indicators do not flash, the short is on the front panel.

Replace the front panel and retest the printer.

14. Checking for a short circuit on 50V within the printhead. Turn off

printer and wait 30 seconds for power supply capacitors to discharge.

15. Plug in the printhead interface connector (J130) to the electronics

module. This step adds the printhead back to a working electronics

module and I/O board.

16. Turn on power to the printer.

WHAT TO DO

Update your service manual with this information.

PART INVENTORY STRATEGY

None

TME

17. If the PE and PS indicators do not flash, the short is on the printhead.

Replace the printhead and retest the printer. Test the printer to ensure

damage to the electronics module did not occur due to the shorted

printhead.

18. Run the Head Maintenance Clutch test.

19. Check the Head Maintenance Clutch wiring.

20. Connect the Wave Amp signal cable (J790) at the left side of the

Electronics Module.

21. Turn on power to the printer. If the PE and PS indicators do not flash,

the short is on the wave amp. Replace the wave amp.

22. Reinstall all printer cables.

23. Test the printer.

Page 3 of 4

Page 4 of 4

Page 10

Xerox

Office

Group

Service Bulletin

3-Aug-2004

Phaser 8400

SB 637

Troubleshooting Dead or Hung Printers SB637 637

Phaser 8400 Xerox Office Group Service Bulletin SB 637

1. Turn off the printer. Wait for it to completely shut down. Unplug

the printer’s AC power cord.

2. After at least 30 se c onds, reconnect the power c or d and turn on the

printer.

• If the printer powers-up correctly, try printing the

Configuration Page or Startup Page (or any embedded page).

If the embedded pages print normally, the problem has been

solved.

Techniques For Troubleshooting Printers That Are Hung

At Power-Up Or Appear Dead

Dead or hung printers can fail to power-up for a variety of reasons

ranging from improper AC power source to defective components.

The following steps can help resolve dead or hung printers:

1. Verify the printer is in a hung conditi on

2. Eliminate corrupted data in the printer’s mem ory

3. Isolate the printer from the network

4. Isolate the hard drive (if installed )

5. Verify the power source

Verify The Printer Is Hung

The printer can take several minutes to reach its operating temperature.

Cold environments require more time. If the printer appears to be hung

(unable to respond), ope n the front cover.

• If the front panel message changes from “Warming Up ” to “Close

Front Cover to Continue”, the printer is not hung. Instead, it may

be in the process of warming up, canceling a large job, or even

processing a job.

• If the printer does not power-up correctly, go to the next

procedure.

Isolating Network Issues

Corrupted network traffic, print files, or printer drivers ca n cause the

printer to hang. Use the following procedure to isolate the printer from the

network:

1. Disconnect all communication cables from the printer, power

down the printer for 30 seconds, and then turn on t he printer.

• If the printer does power-up, try printing an embedded page

such as the Configuration page or Startup.

• If the embedded pages do not print, there may be

corrupted data in the printer’s RAM. Complete the

procedure “Eliminate Corrupted Data from RAM”.

• If the embedded pages print normally, go to Step 2.

• If the printer does not power-up correctly, proceed to the

“Isolate the Hard Drive” topic.

2. Try printing an embedded page when the printer is connected to

the network.

• If the embedded pages print normally, go to Step 3.

• If the front panel message does not change after opening the front

cover, the printer is hung (unable to respond).

Eliminate Corrupted Data From Memory

If there is corrupted data in the printer’s memory, the printer may be

unable to generate embedded pages. Use the following procedure to

eliminate the corrupted data:

Service Manual Update Error! Reference source not found. SB 637 Page 1 of 4

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

• If the printer stops responding while connected to the network,

there may be corrupt network information getting to the

printer.

3. Send a print job to the printer using the network connection. If the

printer stops responding only after sendi ng the print job, the file or

printer driver may be corrupted. Try to isolate the file and/or

reinstall the printer driver. Reviewing the printer's Network Logs

(front panel Troubleshooting menu > Network Log Pa ges) can

offer clues to a network event that might be confusing the printer.

Page 2 of 4

Page 11

Phaser 8400 Xerox Office Group Service Bulletin SB 637

Phaser 8400 Xerox Office Group Service Bulletin SB 637

Isolate the Hard Drive (if installed)

If the printer is a DX model equipped with a hard drive, corrupted files on

the hard drive may prevent the printer from completing its start-up

sequence. Use the following procedure to isolate problems to the hard

drive. Observe ESD precautions:

1. Turn the printer off.

2. At the rear of the printer, open the access panel (held in place with

two thumbscrews). The hard drive mounts to the access panel.

3. Disconnect the wide, gray data cable from the Hard Drive

Assembly.

4. Turn on the printer.

• If the printer powers on normally, the hard drive must be

replaced.

• If the printer fails to power on go on to the next procedure.

Verify the Power Source

Verify the printer is plugged into a stable power so urce that can supply

enough current for the printer’s initial warm-up. Always plug the printer

directly into a known-to-be- good outlet. If other devices are plugged into

the same circuit, there may not be enough power available for the printer.

The printer can tolerate AC power level fluxuations (brown-outs) . But it

cannot tolerate loss of A C cycles (blips, interruptions) or AC fre que nc y

changes. Also, the printer power must be a standard sinewave waveform.

Note: Many DC-to-AC inverter systems, gas-powered AC generators, and

uninterruptible power supply devices do not output proper

sinewave-shaped AC power. This makes them unsuitable as power

sources for the printer. Likewise, many of those devices cannot

output the current necessary to power the printer.

If the printer is unable to power on, use the following procedure to verify

the power source:

1. Disconnect the printer from the suspect outlet.

2. Plug the printer directly into a stable, known- to-be-good wall

outlet. If possible, monitor the line voltage. For testing purposes,

do not use any of the following:

• Circuits that connect to several other devices.

If the power-up problem only occurs when the printer is plugged

into a surge protector, power strip, UPS, or one specific outlet, then

the problem is with that device or outlet.

3. Verify that both ends of the power cord are firmly plugged in.

4. Turn on the printer.

• If the printer powers on normally, the problem has been

solved.

• If the printer does not power on, go to Step 5.

5. Did the printer start power cycling (turning off and on) after a

power surge from an electr ical storm or power outage?

• If yes, turn the printer off and unplug it. After waiting at least

2 hours, plug the printer into a stable, known-to-be-good wall

outlet and turn it on.

• If no, complete the next procedures found in the printer

Service Manual.

6. Check for illuminated LEDs on the printer’s power supply. Refer

to Service Manual topic “Verifying Power Supply Operation” for

locations of the LEDs. Refer to Service Ma nua l topic "Printer Fails

to Power-Up: PS, PE and the 3.3 V Indicator LEDs are Not

Illuminated" for troubleshooting instructions.

WHAT TO DO

Update your service manual with this information.

PART INVENTORY STRATEGY

None

TME

• Power strip/surge protector

• Uninterruptible power supply (UPS)

Page 3 of 4

Page 4 of 4

Page 12

Xerox

Office

Group

Service Bulletin

Phaser 8400, 8200, 860, 850 SB640 SB 640

20-Aug-2004

SB 640

JetFix Snippets Available To

Correct Weak And Missing Jets SB640 640

DOWNLOADABLE SNIPPETS EFFECTIVE FOR CLEARING

WEAK OR MISSING PRINTHEAD JETS

A technique, referred to as JetFix, has been developed that is

effective in clearing stubborn weak or missing jets that a printer’s

regular printhead purge cycle cannot clear. The technique consists

of raising the printhead drive voltage to 255, printing several solid

fills of the missing jet color, returning the drive setting to its default

128 setting, and then performing a printhead clean/purge cycle.

The technique is effective about 50% of the time in clearing a

stubborn weak or missing jet.

This technique has been encapsulated into two sets of downloadable

snippet files to simplify performing the technique. One set of files is

for the Phaser 8400. The other set is for the 8200, 860 and 850. (The

technique is not very effective in the Phaser 840 because of the age

of the printheads).

Each set consists of four snippets; one for each ink color. When a

printer receives a JetFix snippet it will print five double-coverage

solid fills and then perform a printhead clean/purge cycle.

Note: It is normal for the solid-fill prints to show many light

stripes; this will clear with the purge cycle.

If process should be interrupted by a power glitch or a hang, powerdown the printer, wait 30 seconds, and turn on the printer. The 255

Head Adjust setting automatically will be overwritten by the 128

value retrieved from the printer’s NVRAM on power-up.

Phaser 850, 860, 8200, 8400 Xerox Office Group Service Bulletin SB 640

WHAT TO DO

Before replacing a printhead for a weak or missing jet issue (not

caused by non-Xerox ink) upload the appropriate JetFix snippet to

the printer. Use the snippet that corresponds to the jet’s missing

color. JetFix is effective in clearing printheads with one or two

missing jets that cannot be cleared using the printer’s “Eliminate

Light Stripes” cleaning cycles.

Obtain the snippets from the Customer Support Resources website:

http://www.office.xerox.com/partners

pulldown to retrieve the 8400’s snippets. Select 8200 or 860 from the

Printer Info pulldown for the 8200/860/850 snippets.

A readme file is included with instructions on different methods of

uploading a snippet to a printer.

Important Note: Always follow and complete the latest version of the

Troubleshooting Printhead Checklist. Be sure to

include sample prints as noted in the checklist. Also be

sure to correctly complete the green card.

. Select 8400 from the Printer Info

PART INVENTORY STRATEGY

None

TME

Information 20-Aug-2004 SB 640 Page 1 of 2

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corpo rati on i n the Unit e d States an d/o r oth er c ou ntri es.

Page 2 of 2

Page 13

Xerox

Office

Group

Service Bulletin

Phaser 8400, WorkCentre C2424,

Phaser 8500/8550

29 June 2005

SB 647 Rev 1

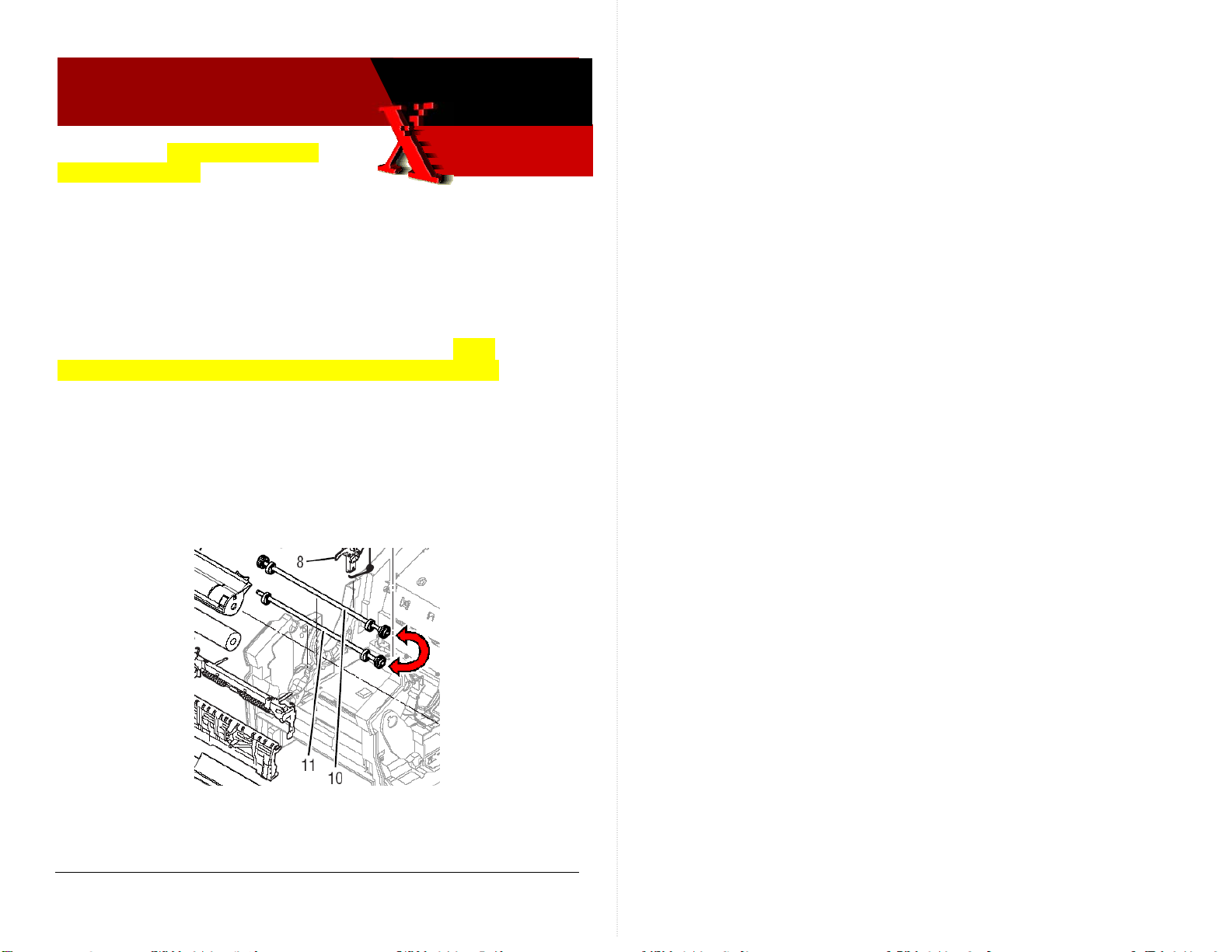

Camshafts Incorrectly Illustrated

In Service Manual

INFORMATION

The illustration on page 9-6 of the Service Manuals incorrectly

shows the Drum Maintenance Camshaft and Transfix Camshaft

assemblies. The camshaft drawings are transposed. Items

highlighted in yellow indicate updates to original bulletin.

WHAT TO DO

Item 11 should point to the Drum Maintenance Camshaft (which

has a gear at each end of the shaft). Item 10 should point to the

Transfix Camshaft (it has no gear on its left end). The Drum

Maintenance Camshaft should be located below the Transfix

Camshaft. Modify your Service Manual similar to the following

illustration.

PART INVENTORY STRATEGY

N/A JMK

Service Manual Update 29 June 200 SB Page 1 of 1

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 14

Xerox

Office

Group

Service Bulletin

Phaser 8400 SB655 SB 655 sb655 sb 655

8-Dec 2004

SB 655

Paper Path Motor Cooling Fan deleted,

Left Side Power Control Harness and

Exit Module Assembly modified

INFORMATION

The Paper Path Motor Cooling Fan is no longer installed on printers

serial-numbered RCP148641 and above. The Left Side Power

Control Wiring Harness has been modified to remove the fan’s

receptacle and to include a resistor to simulate the presence of the

fan to the printer’s boot up firmware. The exit module assembly has

been modified to remove the motor cooling fan.

Ongoing reliability testing has determined that the motor cooling

fan is not necessary. Therefore it is being removed for the remaining

printers being built.

Phaser 8400 Xerox Office Group Service Bulletin SB 655

Service tips:

If a motor cooling fan has failed, remove it and replace the Left

Side Power Control Wiring Harness with the new -81 version

harness.

If you replace the exit module assembly, move the motor cooling

fan from the old exit module assembly to the new assembly.

If you replace an old Left Side Power Control Wiring Harness

(which does not have a paper path cooling fan plug receptacle),

remove the paper path motor cooling fan.

The printer will produce the power-on error code 37,015.42

FAULT MP MOTOR DISCONNECT if the printer boots up with

an old Left Side Power Control Wiring Harness but no Paper

Path Cooling Fan.

PART INVENTORY STRATEGY

Do not stock these parts. Order them only when needed for a

printer repair.

TME

WHAT TO DO

Update you service manual with these new part numbers:

Paper Path Motor Cooling Fan

Exit Module Assembly 441-2239-81

Cable, Power Control Left Side 174-4494-81

Parts Issue/Service Manual Update 8-Dec 2004 SB 655 Page 1 of 2

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

No longer available

Page 2 of 2

Page 15

D

Xerox

Office

Group

Phaser 8400

Service Bulletin

06 Sept 2005

SB 657 Rev 2

Ripping sound during transfixing; prints show

poor transfix print quality

PIVOT PLATES CRACKING RESULTS IN INSUFFICIENT

DRUM OILING

Cracking of the drum maintenance pivot plate results in the pivot

plate not pushing the drum maintenance unit forward enough to

provide sufficient oiling of the imaging drum during a print cycle.

The result is poor ink transfixing and poor print quality.

The pivot plate may crack at either the left end or the right end or

both. This results in a print quality defect, such as dropout or smear,

at the corresponding left or right sides of the prints.

WHAT TO DO

Replace the

original (white)

pivot plate with

the new (black)

pivot plate.

Phaser 8400 Xerox Office Group Service Bulletin SB 657 Rev 2

To replace the pivot plate:

1. Power-down the printer.

2. Remove the drum maintenance kit.

3. Remove the left and right side covers.

4. Unplug the pivot plate wiring harness from I/O board J860.

5. Remove the ground clip (lower-left corner of drum fan) from

the right end of the drum maintenance shaft.

6. Remove the KL-clips securing each end of the drum

maintenance shaft. Slide the shaft out of the printer frame.

7. Remove the pivot plate thru the drum maintenance kit cavity.

Wiring harness

routes thru hole

Shaft

Pivot Plate

Observe standard ES

precautions

Lightly grease the metal plates on which the drum maintenance

cams ride, using a small amount of Rheolube 768 grease (P/N 0067997-00). Also fill the pocket under the shaft ground with grease.

Reverse the removal steps to install the new pivot plate.

Tip

It you have difficulty seating the left end of the shaft thru the left

side frame; remove the paper preheater for better access to the

left end of the shaft and the pivot plate. Use needle-nose pliers to

fish the wiring harness thru the right-side frame hole.

Hardware Issue SB 657 Rev 2 Page 1 of 2

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

PART INVENTORY STRATEGY

Order this part as needed, and keep no more than one in trunk

stock.

TME

Page 2 of 2

Page 16

)

Xerox

Office

Group

Service Bulletin

Phaser 8550/8500

21 Sept 2005

SB 700

Service Manual Corrections

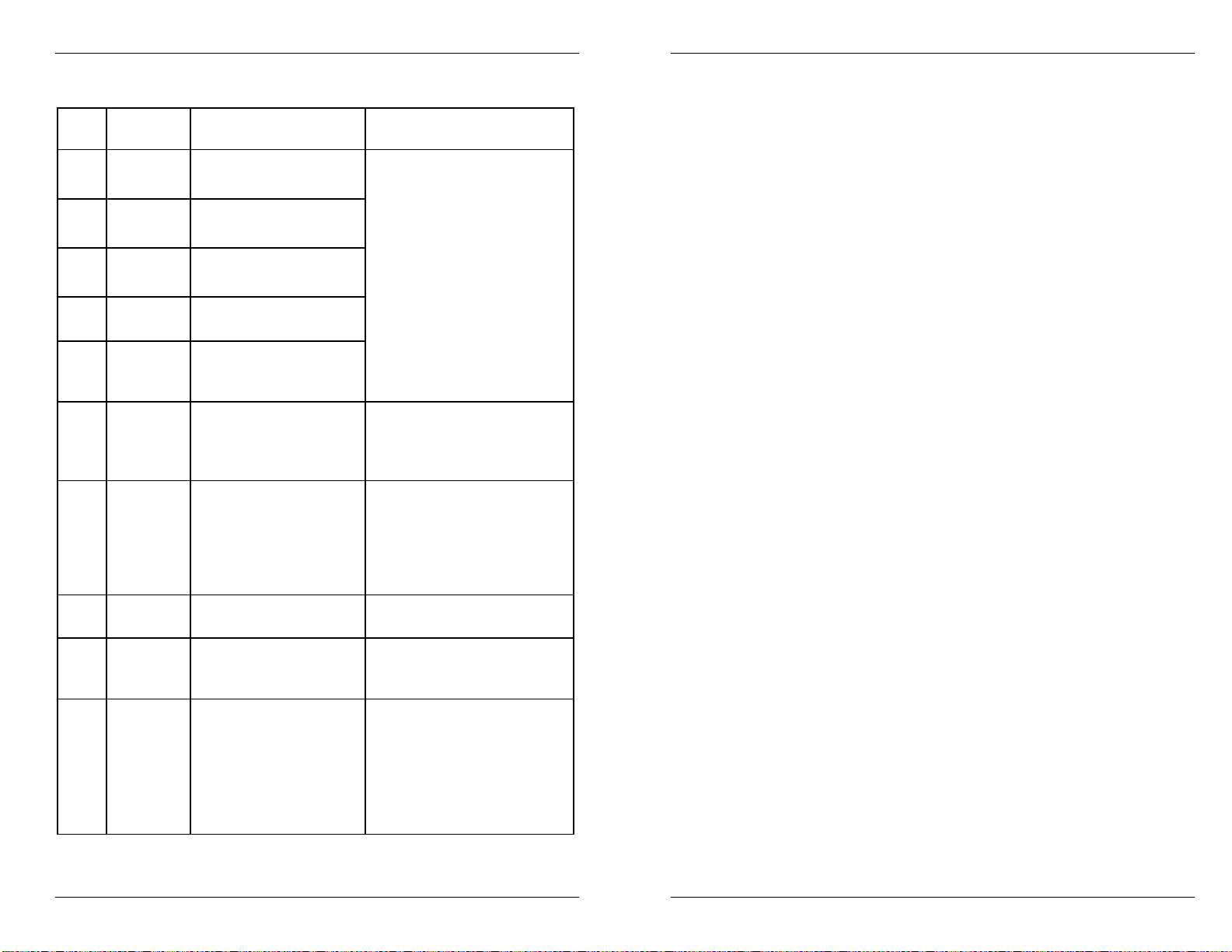

INFORMATION

The tables below list errors, corrections and omissions in the

Phaser 8400/8500/8550 Service Manual.

Table 1 Replaceable Parts List Changes

Page

#

9-5 Drum Maintenance Door

9-6 Illustrations of items 10 and

9-7 Ink Loader Assy and Door

9-7 Printhead Wiper Assembly

9-7 Belt, Wiper Drive

9-7 Purge Pressure Pump

9-7 Transfix Camshaft Assy

9-7 Transfix Roller

9-7 Drum Maintenance Pivot

Service Manual Update SB Page 1 of 4

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Item or Wording was: Correction or Change is:

Drum Maintenance Door (Side)

(Side) 802K93870

11 are swapped.

133K25030

8500/8550 require ver. 4.302

firmware

8500/8550 require ver. 4.302

firmware

604K31120

068K02160

401102780 (8400)

022E32280 (8500/8550)

Plate Assy 367053180

802E93870

Item 11has a gear on each end

of the camshaft. Item 10 only

has a gear on the right end

Ink Loader Assy and Door

133K25031 (8500/8550)

Ink Loader Assy and Door,

PagePack 133K25660 (8550M)

367053480 (8400/8500/8550)

033E05080 (8500/8550)

214501280 (8400/8500/8550)

023E30660 (8500/8550)

Purge Pressure Pump

119641180

Transfix Camshaft Assy

008K02160

Transfix Roller

401102780 (8400)

022E32290 (8400/8500/8550)

Drum Maintenance Pivot Plate

Assy 367053181

Phaser 8500-8550 Xerox Office Group Service Bulletin SB 700

9-9 Outer Duplex Paper Guide

with Sensors 351113681

9-9 525-Sheet Feeder and Tray

059K50030

9-11 Gearbox Media Drive with 2

Clutches 807K16050

9-13

9-13

9-15 Safety Interlock Switch (Mech

9-16 Mechanical Kit (Hardware)

9-16 Frame Replacement Screw

9-16 Repackaging Kit (8500/8550)

9-17 Memory (8500)

9-17 Memory (8550)

9-18

128 MB SDRAM 156486100

(8400)

256 MB SDRAM 156466300

(8400)

128 MB SDRAM 537E66480

(8500/8550)

256 MB SDRAM 537E66490

(8500/8550)

512 MB SDRAM 537E66500

(8500/8550)

Config Card-N 069E00360

(8500/8550)

Config Card-DN 069E00370

(8500/8550)

119645581

650429700

(silver tint)

695K22810

128 MB, SDRAM ZMD128

256 MB, SDRAM ZMD256

256 MB, SDRAM ZMD256

512 MB, SDRAM ZMD512

Not listed

not listed

Outer Duplex Paper Guide with

Sensors 351113680

525-Sheet Feeder and Tray

650-4331-00

Gearbox Media Drive with 2

Clutches 807E16050

128 MB SDRAM 156483700 (8400)

256 MB SDRAM 156466300 (8400)

128 MB SDRAM 856000200

(8500/8550)

256 MB SDRAM 856000300

(8500/8550)

512 MB SDRAM 856000400

/8550)

(8500

Config Card-N 069E00360

(8500/

8550)

Config Card-DN 069E00370

(8500/8550)

Safety Interlock Switch (Mech)

119645580

Mechanical Kit (Hardware)

604K31780

Frame Replacement Screw

(red tint)

Repackaging Kit (8500/8550)

659K22810

Memory (8500)

128 MB, SDRAM 097S03380

256 MB, SDRAM 097S03381

Memory (8500)

256 MB, SDRAM 097S03381

512 MB, SDRAM 097S03382

Metered Solid Ink Cyan

(6 sticks) 108R00706 (8550M)

Metered Solid Ink Magenta

(6 sticks) 108R00707 (8550M)

Metered Solid Ink Yellow

(6 sticks) 108R00708 (8550M)

Metered Solid Ink Black

(6 sticks) 108R00709 (8550M)

Rainbow Pack (1 each color)

108R00612 (8400)

058K00200 (8500/8550)

Page 2 of 4

Page 17

Phaser 8500-8550 Xerox Office Group Service Bulletin SB 700

Phaser 8500-8550 Xerox Office Group Service Bulletin SB 700

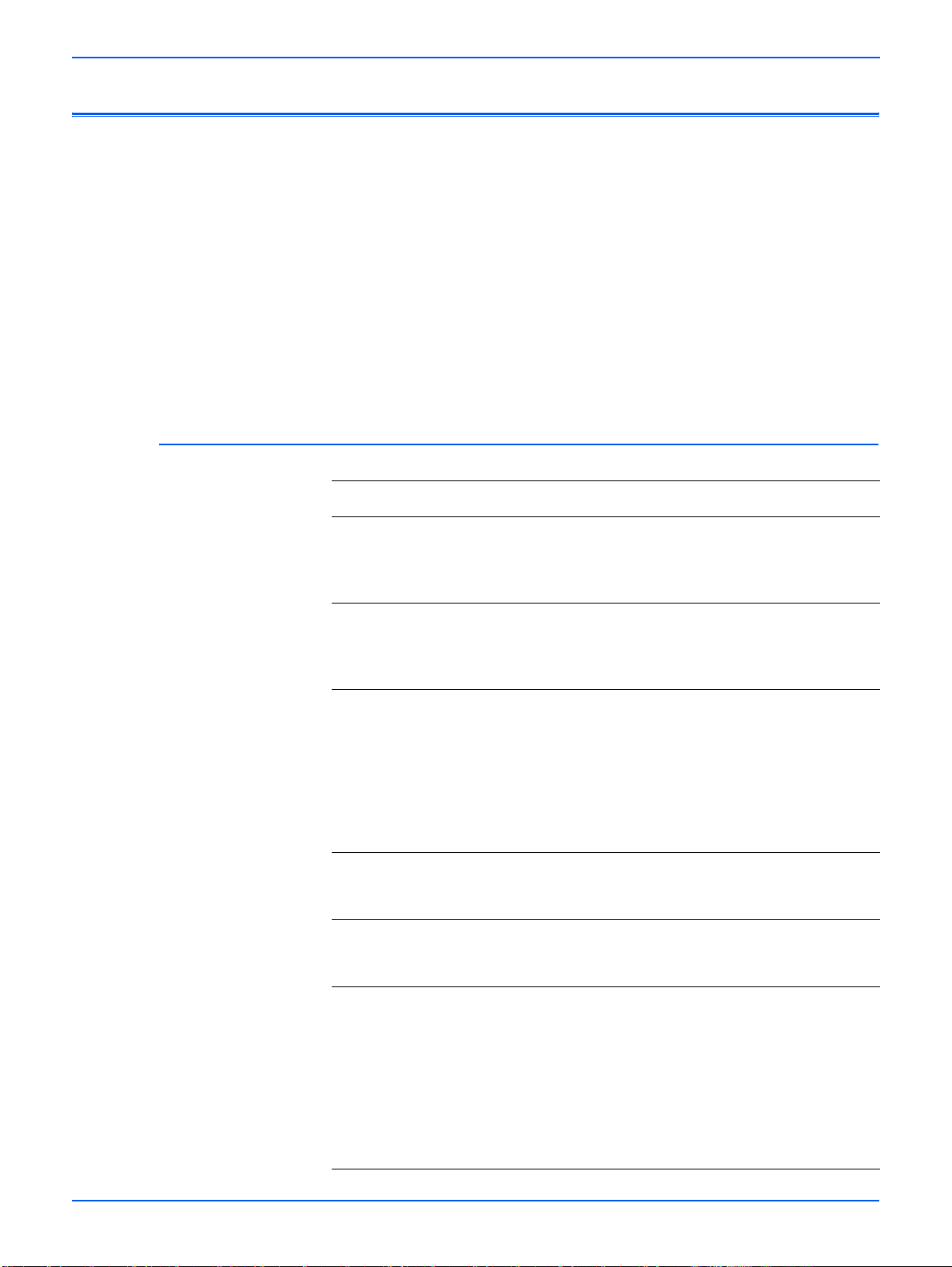

Table 2 Fault Codes Corrections and Updates

Page

#

3-10 2,008.67 Configuration Card is

2,009.68 Configuration Card is

2,010.69 Configuration Card is

2,011.61 Configuration Card is

2,012.62 Configuration Card is

3-14 5,004.44 Y-axis General

3-23 9,035.43

3-32 19,005.63 Wave Amp

3-32 26,962.64 “Fall out” code Check the previous error is

3-35 36,002.44 Printer can’t write to

Error

code

thru

9,038.46

Description Action

1. Turn off printer

missing.

bad.

blank.

for the wrong product.

an invalid model.

Failure

Ink Stick Count Fault The clear ISC Fault menu

overcurrent

Drum Maintenance

Unit

2. Verify that config card is

correct card for printer

3. Insert or replace config

card.

4. Turn on printer.

5. If problem continues,

replace the electronics

module.

There is a problem with the

Y-axis motion sub-system.

Troubleshoot the same as

for a 5,003.43 error code.

item is located in the

internal diagnostics

Functions Menu. This must

be performed following an

ink loader replacement.

This error can occur in toolow humidity conditions

the fault history and

troubleshoot that code.

1. Ensure the DMU seats

correctly in the pivot

plate.

2. Replace the DMU.

3. Replace the drum

maintenance pivot plate

assy.

WHAT TO DO

Note these corrections in the hard copy of your Service Manual.

PART INVENTORY STRATEGY

Not applicable.

TME

Page 3 of 4

Page 4 of 4

Page 18

Xerox

Office

Group

Service Bulletin

21 Sept 2005

Phaser 8500 8550

SB 701

Updated Firmware Code and Wiper Belts Now

Shipping with Phaser 8500/8550 Printers

INFORMATION

Firmware. Printers manufactured since September 12, 2005 contain

a new version of firmware code. Its code version is

Engine: 18.P1.4.8.0; NW: 25.28.08.19.2005; PS: 4.8.0

.

Wiper Belts. Printers manufactured since September 12 are also

being built with wide-style wiper drive belts. The narrow wiper

drive belts shipped on the earlier printers are prone to a

phenomenon called “wiper chatter.” Wiper chatter can lead to jet

color mixing following a printhead cleaning cycle. The color

mixing usually clears after a few prints. Using wide belts requires

that firmware code Ver 4.302 be installed on the printer.

vxWorks: 4.302;

Phaser 8500 8550 Xerox Office Group Service Bulletin SB 701

New Version 4.302 Firmware Features

Description Comments

Adds support for wide-style

wiper drive belts (same belts

used on Phaser 8400)

Implements support for

metered ink.

Correct incrementing Usage

Profile Token #1041 for

HQ/Photo mode

Implements Direct PDF

printing

Implements scalable

Protected jobs

By default, printers running version

4.302 require wide-style wiper belts

installed in the printer. Alternately, the

snippet 8500-8550useThinBelts.ps can

be sent to the printer to enable support

for narrow-wiper belts instead.

Enabling metered ink mode allows the

printer to be used in the Pack

Pack/eClick supplies program.

The Usage Profile was incorrectly

scaling down the resolution for the

High Resolution/Photo mode tally. It

value was 1/4th what it should be.

Requires a Phaser HD hard drive be

installed on the printer.

Increases the current limit of 200

PRDM (Print Ready Document

Management) jobs to 2,000 jobs.

These jobs are only viewable to print

from CWIS and do not show up within

the printer's control panel.

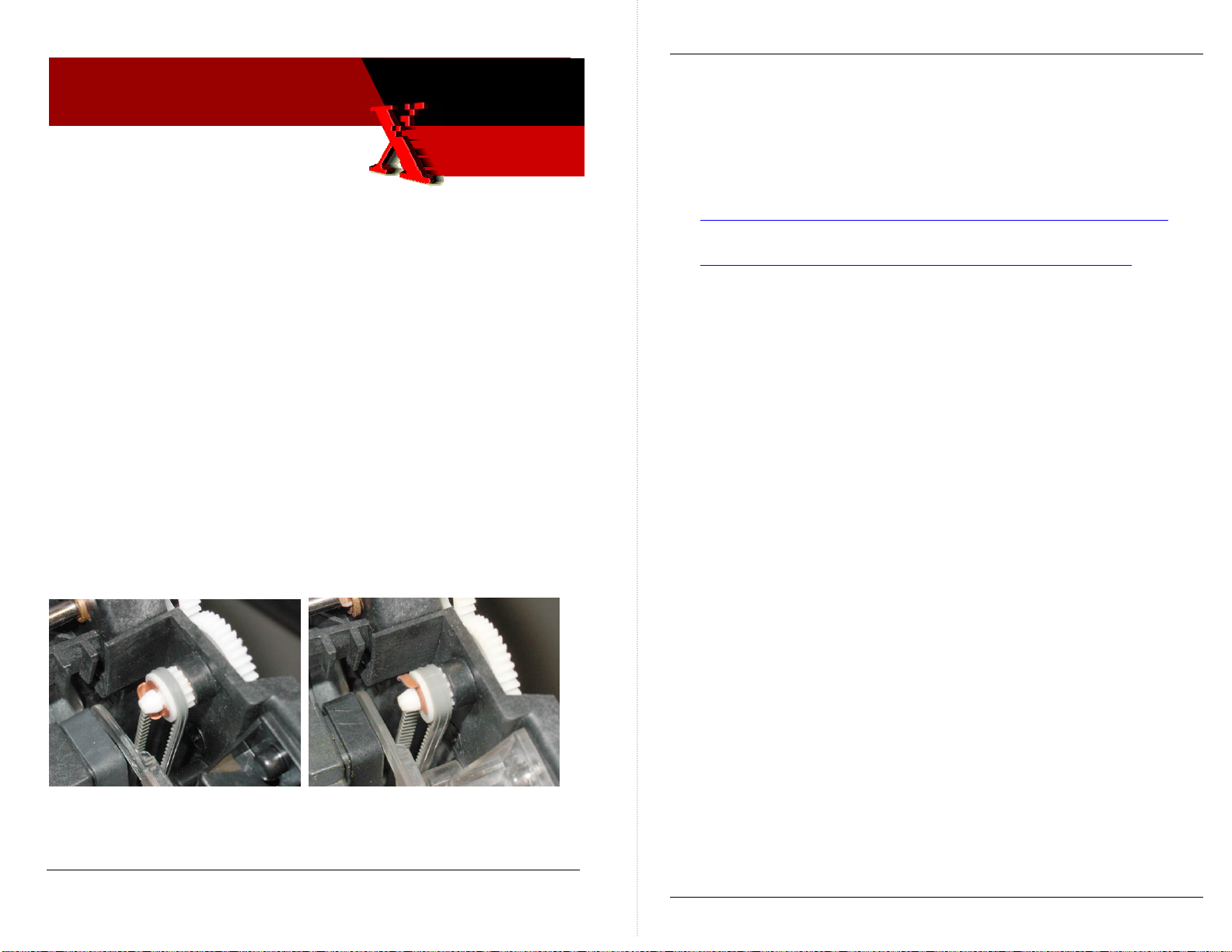

Narrow wiper drive belt Wide wiper drive belt

Printers manufactured with the new version code and the wide

wiper belts are serial numbered WYP1xxxxx (8550) and

WYN1xxxxx (8500).

Repair Notes Rev 0 Page 1 of 4

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Implement support for an

extended Power Saver mode

timeout.

Corrects a SNMP status flag

for the Low Ink condition

while in Power Saver Mode.

Allow the Power Saver mode timeout

to be changed to any value longer than

240 minutes by sending a properly

coded PostScript snippet to the printer.

SNMP for hrDeviceStatus with Ink Low

condition is incorrect while in Power

Saver mode.

Page 2 of 4

Page 19

Phaser 8500 8550 Xerox Office Group Service Bulletin SB 701

Phaser 8500 8550 Xerox Office Group Service Bulletin SB 701

WHAT TO DO

Update a printer’s firmware only if the update is needed to support

one of the issues noted in the Version 4.302 Firmware Features list.

The new version firmware is available for download at:

Service Partners

http://www.office.xerox.com/partners/products/Phaser8500/Phaser8500Series.html

Internal Support

http://cpidserv.opbu.xerox.com/products/Phaser8500/Phaser8500Series.html

Ordinarily, a replacement FRU electronics module will contain the

latest version firmware. If it does not, download the new printer

firmware code and upload it to the printer.

Wiper Belts. Old printer code (ver 4.278) only supports narrow

wiper drive belts. Using older-version firmware code with wide

wiper belts can result in 08,xxx.4x Wiper Faults.

Printers with the new firmware code can support either narrow or

wide wiper belts. By default, the code is set to support wide belts.

Uploading the snippet 8500-8550useThinBelts.ps will set the code to

use narrow wiper belts.

PART INVENTORY STRATEGY

The Electronics Module part number (p.n. 137E14020) remains the

same for all printer models.

Only use the 8400 Printhead Wiper Assembly p.n. 367-0534-80 and

the wide-style wiper belts p.n. 214-5012-80. The 8500/8550 wiper and

narrow belts are discontinued.

TE

Only the new-version code has dual wiper belt capability. Uploading the

snippet 8500-8550useThickBelts.ps will set the printer to use wide

wiper belts. The belt snippets are available at the support websites

listed above.

Uploading the new-version firmware code to an older printer with

narrow wiper belts, without also uploading the thinbelt snippet to

the printer, can result in 08,xxx.4x Wiper Faults.

To avoid issues with wiper chatter and color mixing, when you

replace a wiper assembly use the 8400 wiper assembly p.n. 3670534-80 and belts. Be sure to upload the new firmware code to the

printer as well.

Page 3 of 4

Page 4 of 4

Page 20

Xerox

Office

Group

Service Bulletin

9 Jan 2007

Phaser 8400

SB 705 R1

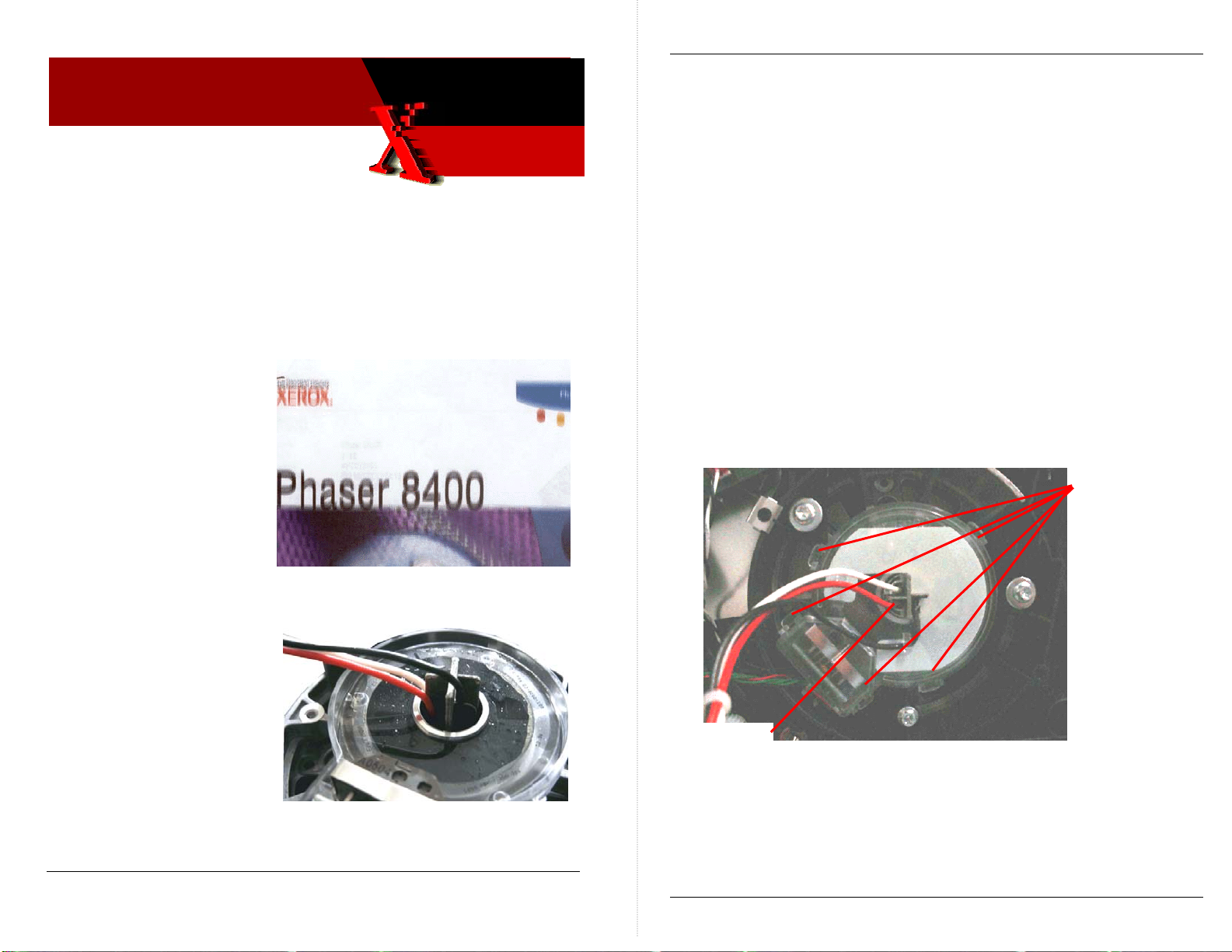

Blurry Prints Caused by Oil-Contaminated Drum

Encoder

OIL ON THE ENCODER WHEEL CAUSES DRUM

ROTATION POSITION PROBLEMS

Oil on the drum encoder’s disk produces erroneous positioning

signals to the electronics

module. This results in the

drum rotating at the wrong

speed during imaging. The

resulting prints appear

blurry, with the image

distorted in the Y-axis,

vertical direction. Figure 1

illustrates the problem.

Horizontal, X-axis printhead

movement is not affected.

Figure 1

The problem is caused by oil

migrating from the drum

assembly’s bearing and

contaminating the encoder

disk as shown in Figure 2.

By design the encoder disk

is immune to some

contamination, but too much

contamination overwhelms

the system.

Figure 2

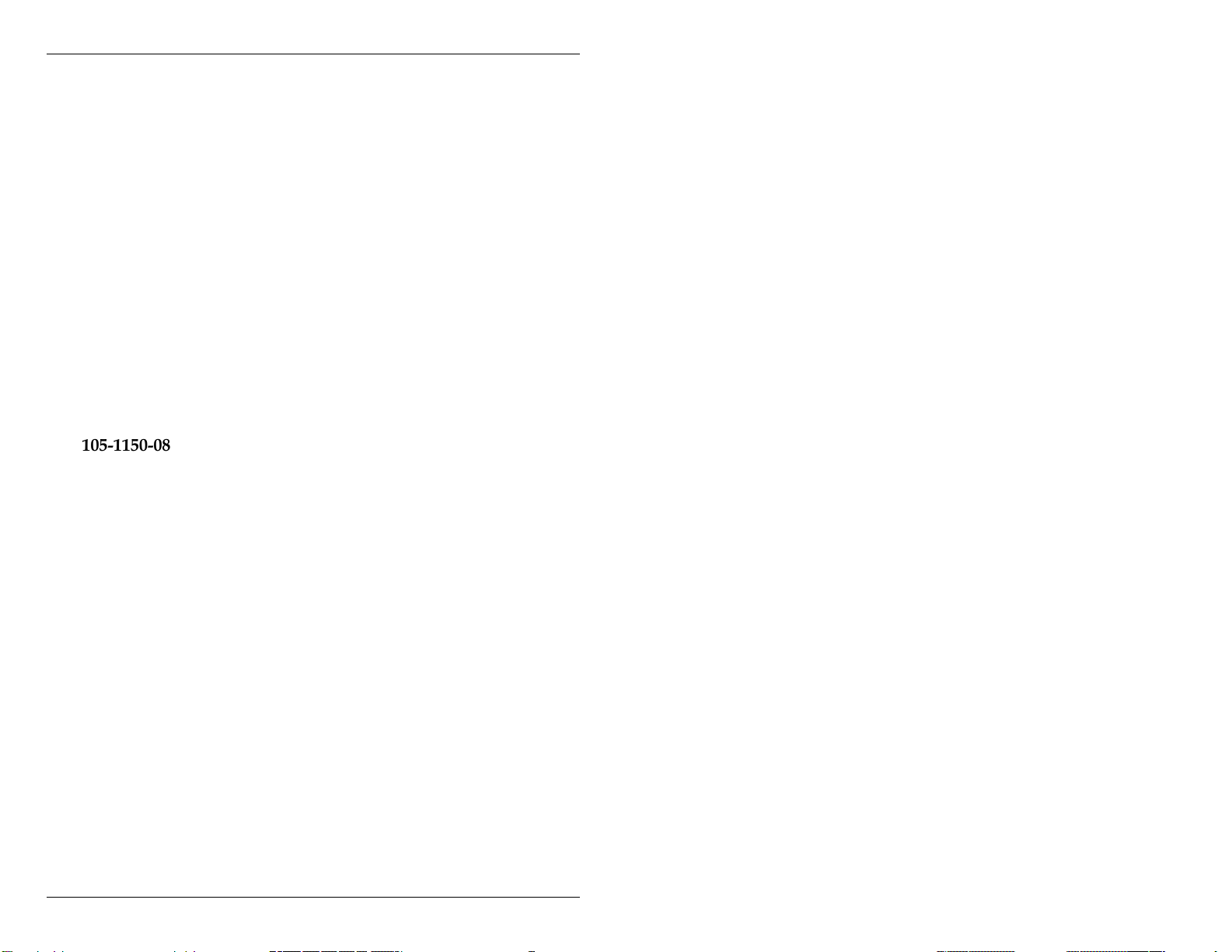

Phaser 8400 Xerox Office Group Service Bulletin SB 705

WHAT TO DO

Carefully disassemble the drum encoder’s cover to access the

encoder disk and then clean the disk.

1. Turn off the printer.

2. Remove the right side cover.

3. Remove the drum fan.

4. Disconnect the drum assembly’s encoder wiring harness from

the I/O board. Disconnect the drum heater wiring harness

from the drum relay board.

NOTE: Observe for reassembly how the AC wiring harness

routes thru the encoder disk cover and the heater

frame.

5. Free the encoder wiring from the encoder cover.

6. Carefully pry off the transparent encoder cover by releasing its

five snap-fit latches.

Snap-fit

latches

Note wire

routing

Figure 3

Hardware Issue Rev 0 Page 1 of 3

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 2 of 3

Page 21

Phaser 8400 Xerox Office Group Service Bulletin SB 705

7. Gently feed the AC wiring thru the encoder cover to move the

cover out of the way.

8. With a cleaning swab, gently clean the oil off the encoder disk.

If available, use Xerox cleaning fluid (p.n. 008R90176) to “cut”

the oil.

9. Carefully reassembly the drum encoder. Be sure to correctly

route the drum heater AC wiring thru the encoder disk cover

and the heater frame.

10. Print some test prints.

PART INVENTORY STRATEGY

If cleaning repairs are not effective, replace the drum assembly,

p.n. 105-1150-08

TE

Page 3 of 3

Page 22

Xerox

Office

Group

Service Bulletin

01 Dec 2005

Phaser 8400/8500/8550

SB 709

Revised Service Manual Available

INFORMATION

An updated version of the Phaser 8400/8500/8550 Color Printer

Service Manual is available in PDF format. The files are available

on the in the Phaser 8400 and the Phaser 8500/8550 pages of the

Service Support website http://cpidserv.opbu.xerox.com/

same files are also accessible thru the Service Partner website

www.officeprinting.xerox.com/partners

The single-file version of the service manual is a change-bar

marked manual that indicates which topics are updated.

The individual chapter files do not contain the change bars.

The updated manual can be identified by the revision date

Oct 24, 2005 on the title page.

.

. The

WHAT TO DO

Download the manual files of your choice.

PART INVENTORY STRATEGY

Printed copies of the updated service manual will be available to

order in January 2006 using part number 721P58550.

TE

Service Manual Rev 0 Page 1 of 1

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 23

p

Xerox

Office

Group

Service Bulletin

14 Dec 2005

Phaser 8500/8550

SB 711

Clarifications regarding using Jet Substitution and

the Light Stripes Test Page

INFORMATION

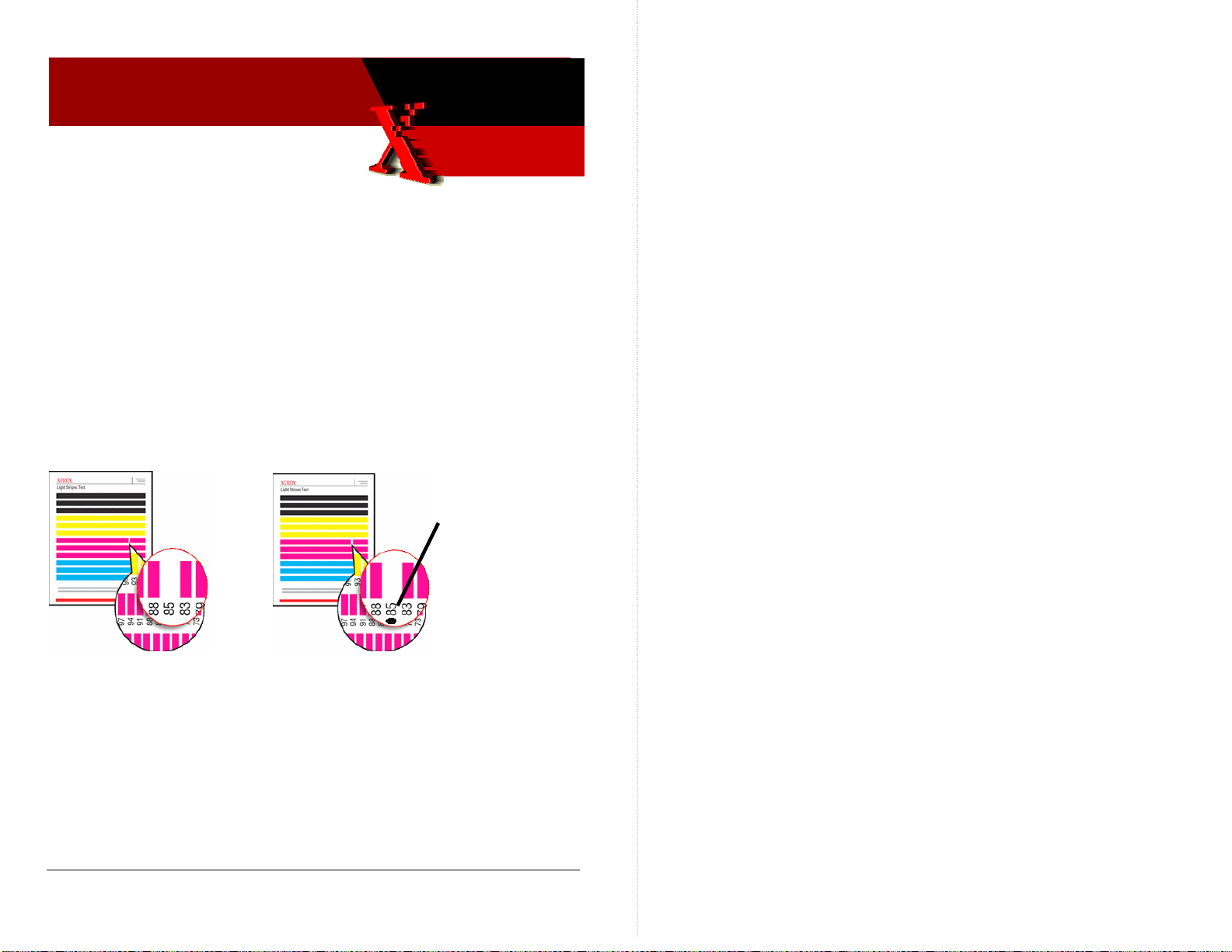

Use the Light Stripes Test Page to determine the jet number of an

unrecoverable weak or missing jet that you will want to fix using

jet substitution. A weak or missing jet will always appear weak or

missing on the Light Stripes Test print even when Jet Substitution

is being used. Once jet substation is activated, a small, black dot is

printed next to the jet number of a jet that will be substituted

during normal printing.

Jet Substitution

dot A sub’ed jet

will still show as

missing on Light

Stri

es print

Missing Jet Missing jet that will be substituted

during regular printing

WHAT TO DO

Note that Jet Substitution mode is enabled during normal printing

but is not used when printing the Light Stripes Test page.

PART INVENTORY STRATEGY

None TE

Repair Notes Rev 0 Page 1 of 1

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 24

Xerox

Office

Group

Service Bulletin

14 Dec 2005

Phaser 8500/8550

SB 712

Only Newest Firmware-Version Electronics Module

(p.n. 137E14021) is Available; Uploading NarrowStyle Wiper Belt Snippet May Be Necessary

8,XXX.4X WIPER MOVEMENT ERROR CODES MAY OCCUR

IF PRINTER FIRMWARE AND WIPER DRIVE BELTS DO

NOT MATCH

Only replacement FRU electronic modules which contain the latest

version firmware are now orderable. These electronic modules

contain engine code version:

25.28.08.19.2005; PS: 4.8.0

. As detailed in Service Bulletin 701, this

firmware level implements metered printing capability as well as

support for wide-style wiper drive belts.

WHAT TO DO

When you install a replacement electronics module in a printer you

must verify what style of wiper drive belts are used in the printer.

vxWorks: 4.302; Engine: 18.P1.4.8.0; NW:

Phaser 8500/8550 Xerox Office Group Service Bulletin SB 712

If the printer uses narrow-style belt, you must upload the snippet

8500-8550useThinBelts.ps to set the firmware code to use narrow

wiper belts.

Snippets to set the electronics module’s firmware to work with

either narrow- or wide-style belts are available at:

Service Partners

http://www.office.xerox.com/partners/products/Phaser8500/Phaser8500Series.html

Internal Support

http://cpidserv.opbu.xerox.com/products/Phaser8500/Phaser8500Series.html

By default, the electronics module is set to work with wide-style

belts.

Be sure that the style of wiper drive belts matches the firmware

version of the electronics module.

Refer to Service Bulletin 701. Be sure that the firmware version of the

electronics module is correct for the style of wiper drive belts used.

FW Version 4.302 Default supp ort for wide wiper belts

Can be set to support narrow wiper belts

FW Version 4.278 Only support narrow wiper belts

Wiper movement error codes 08,xxx.4x may result if the firmware

does not match the wiper belts.

Narrow wiper drive belt Wide wiper drive belt

Repair Notes Rev 0 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

PART INVENTORY STRATEGY

Order electronics modules only as needed.

Electronics Module 137E14021

Wiper Assembly – wide style 367053480

Wiper Drive Belts – wide style 214501280

8400/8500/8550

TE

Page 2 of 2

Page 25

e

Xerox

Office

Group

Service Bulletin

04 Jan 2006

Phaser 8400/8500/8550

SB 714

Jam Open Front Cover (C3T) after Replacing or

Reinstalling the Process Drive Assembly

PROCESS DRIVE ASSEMBLY ALIGNMENT PROBLEM

After replacing the process drive assembly, pivot plate or the drum

maintenance camshaft (or any other procedure requiring the removal

of the process drive assembly), the printer may experience jams from

Tray 2. The jam occurs with paper in the preheater and C3T jam errors

(strip flag timeout during transfix) recorded in the Jam History. In

many cases, Tray 1 (MPT) prints with no jams.

These symptoms indicate that the transfix load module is incorrectly

timed and is therefore not advancing the paper to the strip flag within

the correct timeframe. Therefore the printer reports a front cover jam

and records the C3T jam error.

WHAT TO DO

The majority of the time, the problem is that the drum maintenance

camshaft is out of position by one or two teeth. Correct by:

1. Rotate the drum

maintenance camshaft

clockwise to tilt the

printhead forward to its

home position. (This

disengages the

printhead and its tilt

gear from the camshaft.)

2. Pin the process drive

assembly to keep its two

missing tooth gears in their disengaged positions.

Repair Notes Rev 0 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Pin the process drive to

secure its missing tooth

gears

Drum maintenance

Phaser 8400/8500/8550 Xerox Office Group Service Bulletin SB 714

3. Remove the process drive assembly.

4. Press against the

drum maintenance

kit to force it (and

the pivot plate)

against the drum

maintenance cams.

This forces the

drum maintenance

shaft end gear to it

home position. The

camshaft’s homed

position is indicated by the hole in the drum maintenance

camshaft gear aligning with the embossed arrow on the metal

plate below the gear.

Note: When properly aligned, the hole in the camshaft gear points to the

6:00 or 5:30 position. If the hole does not point at the arrow, while the

DMU is being pressed against the cams, a cam may be broken on the

drum maintenance camshaft.

5. With the drum

maintenance

camshaft held in its

home position,

install the pinned

process drive.

6. Once the process

drive assembly is

secured in place,

remove the lock

pins.

Pivot Plat

Cams

Press and maintain

pressure against

DMU to force the DM

cams to their upright

home position

DMU horizontal

Camshaft gear

alignment hole should

be in this position

PART INVENTORY STRATEGY

None

TE

Page 2 of 2

Page 26

p

Xerox

Office

Group

Service Bulletin

20 Mar 2006

Phaser 8500/8550

SB 716 Rev 1

Installing Pick Clutch Ground Clip Prevents

19,005.4 Error Codes, Printer Hangs During

Printing, and some Jams Behind Front Cover

Phaser 8500/8550 Xerox Office Group Service Bulletin SB 716

2. Loosely install the ground

clip and then the washer

with the screw you just

removed. The other end

of the ground clip should

contact the end of the

paper pick clutch.

Loosely install ground

cli

and washer

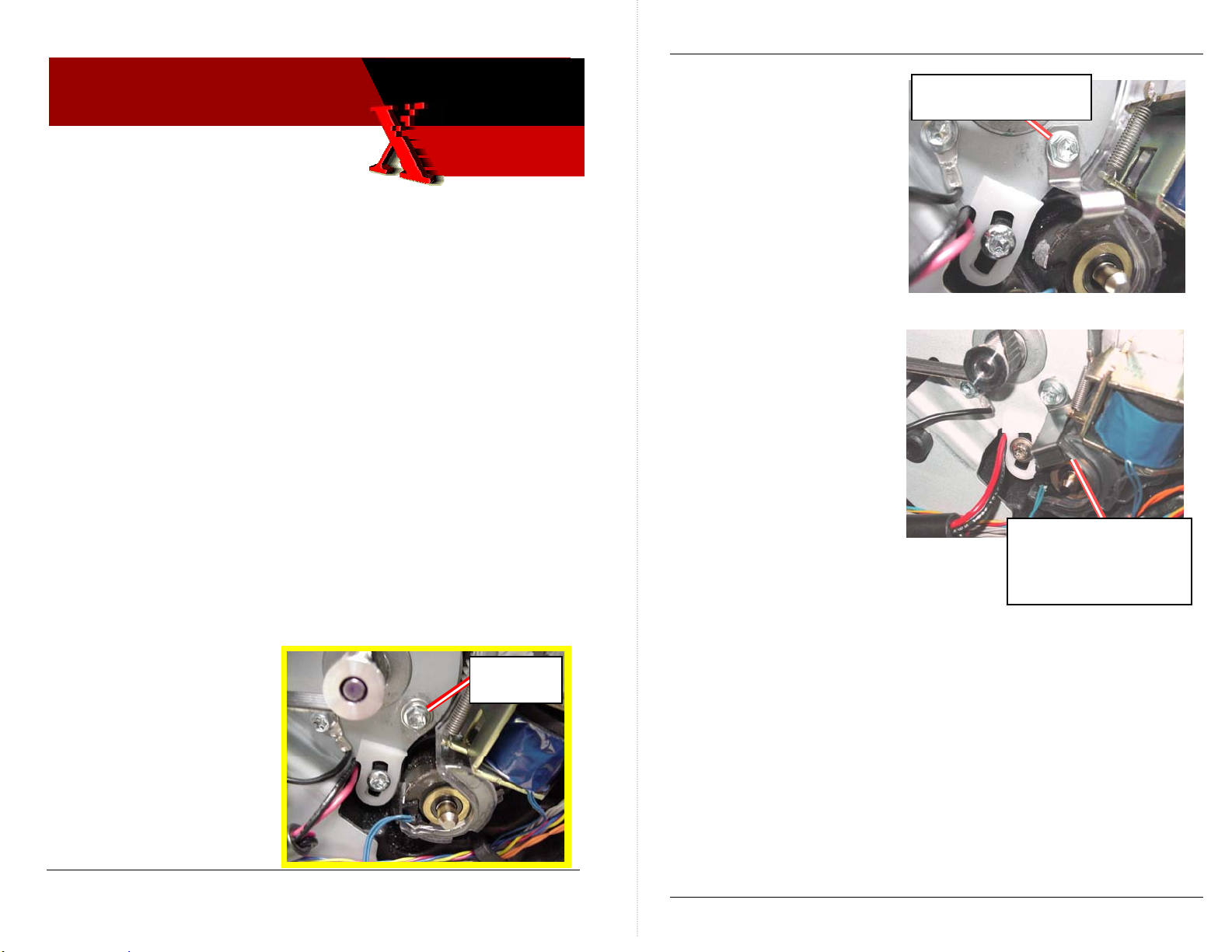

GROUND CLIP PREVENTS STATIC CHARGE BUILD-UP

Static build up at the pick roller during printing can lead to a static

discharge thru the pick roller clutch into the electronics module. This

results in either:

• A 19,005.41 error code displayed on the front panel.

• The printer hanging while printing with the electronics fan

on full.

• Occasional Jams Behind the Front Cover messages. This jam is

usually accompanied by error 19,005.41 in Fault History.

The static buildup occurs while printing in very low-humidity

environments.

WHAT TO DO

Install a ground clip from the Y-axis motor bracket to the pick clutch.

1. Remove the lower-right

Y-axis motor mounting

screw. It is the screw

closest to the paper pick

clutch.

Remove

screw

3. Position the ground clip

so its end rests against the

face of the pick clutch

body. The corner of the

ground clip end should

contact the plastic frame

of the media path drive

module.

4. Tighten the screw to

secure the ground clip in

position.

Position the clip so its

edge contacts the clutch

face and the plastic

housing

PART INVENTORY STRATEGY

Update any Phaser 8500 or 8550 you service with a static ground clip

as needed to solve 19,005.43 errors, some printer hangs during

printing, and random jamming behind the front cover.

Pick Clutch Ground Clip Kit - Part Number 650-4427-00

TE

Repair Notes Rev 0 Page 1 of 2

Copyright © 2003 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 2 of 2

Page 27

Xerox

Office

Group

Service Bulletin

Phaser 8500/8550

09-April-2006

SB 719

New Locking-Style ZIF Connector Being Used for

Printhead Flex Cable

INFORMATION: THREE TYPES OF PRINTHEAD FLEX CABLE

CONNECTORS ARE USED; ONE OF THEM IS A LOCKING ZIF

CONNECTOR

Until recently, the Phaser 8500/8550 printers used two different non-locking

style flex cable connectors. In order to meet new Reduction of Hazardous

Substances (RoHS) standards, a third locking-style ZIF connector will be

used. It replaces the use of the previous two connectors. Only the new

locking-style ZIF connector meets electrical specifications and the RoHS

standards.

Non-locking style connectors

(white or black)

Locking style ZIF connector

Phaser Xerox Office Group Service Bulletin SB 719

WHAT TO DO

As you service a Phaser 8500 or 8550 printer, be aware that you may need to

unlock and lock the flex cable when disconnecting and reconnecting the

cable.

• Use care when locking and unlocking the connector.

• Failing to unlock a ZIF connector, before removing the cable, may

damage the connector.

• Ensure the cable is fully inserted into the connector before locking

the connector.

PART INVENTORY STRATEGY

None.

TME

Part Issue Error! Reference source not found. SB 719 Page 1 of 2

Copyright © 2006 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Lift up on small tabs on

each end of the connector

to release the lock

Page 2 of 2

Page 28

Xerox

Office

Group

Service Bulletin

11-April-2006

Phaser 8500/8550

SB 720

Printer Produces Gradually Lighter Prints

INFORMATION: PRINTERS BELOW SERIAL-NUMBER

WYP142312 AND WYN142344 BENEFIT FROM PRINTHEAD

FIRMWARE UPDATE

Printhead engineering has developed new drift compensation algorithms

that maintain the print quality/density of the Phaser 85xx printer’s printhead.

All printers serial-numbered below WYN142344 (Phaser 8550) and

WYP142312 (Phaser 8500) benefit from having their printhead’s firmware

constants updated via a downloadable snippet file. Printers above the serial

number break already have the new algorithm built in.

The snippet file and a readme file are contained in file 8500-8550_phfw-

update.zip. The file is available at:

http://www.office.xerox.com/perl-bin/product.pl?page=sprt&product=8500_8550

Follow the readme instructions to upload the snippet to a printer.

As the printhead ages over the years, the prints it produces will gradually

become lighter and lighter. There is no means to determine the printhead’s

firmware constants settings. Only downloading the snippet to the printer will

tell you if the printhead is up-to-date or not. Following the download, the

printer prints a download status print.

WHAT TO DO

As you service a Phaser 8500 or 8550 printer, check its serial number. If it

is below WYP142312 or WYN142344, download the printhead u pdate

snippet to the printer. For update tracking purposes, indicate in your call

closure details or notes that you have updated a printer with the printhead

snippet.

PART INVENTORY STRATEGY

None.

TME

Firmware Issue Error! Reference source not found. SB 720 Page 1 of 1

Copyright © 2006 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 29

Xerox

Office

Group

Phaser 850/860/8200/8400/8500/

8550/C2424

Service Bulletin

8 May 2006

SB 723

Back Channel Trace and Diagnostics using a

USB-to-Serial Adapter

USING A USB-TO-SERIAL PORT ADAPTER TO OBTAIN A

BACK CHANNEL TRACE OR TO RUN PHASER 850

DIAGNOSTICS

Many newer Laptops or PC’s do not have serial ports available. An

alternate method of communicating with the printers is available by

using a USB-to-Serial Port Adapter and its software to communicate

in a serial manner.

WHAT TO DO

Obtain a USB-to-Serial Port Adapter and software for your Laptop

or PC and Load the software as per the instructions provided.

An example of how to load and operate the Port Adapter is

provided below.

Obtaining a VX Works Trace using a USB Adapter – This method

was tested with a Phaser 850. You can also use the adaptor for

running external Diagnostics after modifying the Diags.INI file.

NOTE The instructions contained in this service bulletin were

developed using a Belkin USB/Serial Adapter, P/N F5U109

and the Windows XP O/S. Other USB-to-Serial adapters are

available; however software installation procedures may vary

by brand.

NOTE Xerox is not responsible for any changes made to your laptop

or PC setup to make the adapter software function properly.

Solid Ink Printers Xerox Office Group Service Bulletin SB 723

1. Load the software from the CD and reboot the PC. Follow

the instructions included with your adapter to install the

necessary software.

2. Connect the USB/Serial adapter to an available USB port on

your PC. Attach the port adapter to the 9 pin Serial cable

(012-1535-00) and the diagnostic pig tail (012-1543-00), and

plug it into the service port on the back of the printer

3. Configure the USB port for diagnostics. For Windows XP, go

to [My Computer] - [Control Panel] - [System], select the

[Hardware] tab, and then select [Device Manager]. Click on

the “+” next to [Ports (COM & LPT)], then right click on the

USB-to-Serial Port device and select [Properties]. Make a

note of the port number (usually COM3 or COM4)

NOTE Check the USB/Serial adapter instructions for

acceptable COM ports. Some adapters may require

that the adapter use COM3 or COM4.

4. Click on the [Port Settings] tab. Set “Bits per second” to 19200,

and set “Flow control” to Hardware, then click [OK].

5. Set up a Hyper Terminal port on the PC. Click [Start] -

[Programs] - [Accessories] - [Communications] - [Hyper

Terminal].

6. Name the new connection with the model number of the

printer. Configure the new connection using the COM port

configured in step 3, then click [OK]. Set “Bits per second” to

19200, and set “Flow control” to Hardware, then click [OK].

7. From the Hyper Terminal tool bar, click on [Transfer] and

select [Capture Text]. Click on [Browse], and in the browse

window, navigate to the desktop (or another file where you

wish to save your diagnostic results). Enter a file name for

your trace and click [Save].

8. For the Phaser 850, 860, and 8200 put rear panel DIP-switch 3

in the down position and turn on the printer. For the Phaser

8400/8500/8550 & C2424, no switch is needed. Follow the

Testing Issue Page 1 of 3

Copyright © 2004 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

Page 2 of 3

Page 30

Solid Ink Printers Xerox Office Group Service Bulletin SB 723

instructions in the service manual for performing a

backchannel trace.

9. The backchannel trace should be displayed in the Hyper

Terminal window. When you have captured the necessary

trace data, click [Transfer] – [Capture Text] – [Stop] to end

data capture. This data will be saved as a text file to the

location specified in step #7, and may now be faxed or emailed to EHS for help with troubleshooting problems on

power up or other out of the ordinary problems where

normal diagnostics may not run.

PHASER 850 DIAGNOSTICS

To run diagnostics using a USB-to-serial adapter you must edit the

DIAGS.INI file to launch the correct baud rate and COM port. Edit

the file with a program such as WordPad. You will also need to

verify that your USB/Serial adapter software supports the COM

port you want to use. Some manufacturers may require that the

adapter is used on COM1 through COM4.

It is recommended that the NO-Floppy diagnostics from the

Partners Web site be used for easy diagnostic operation. Always

place switch 1 only in the down position on the Phaser 850 printer to

run diagnostics.

The following are the settings that need to be changed in the

DIAGS.INI file. Set the Port for the Com port you wish to use. The

baud rate is normally set at 19200. Save the file and launch

diagnostics.

PORT0 = COM1 baud: 0 = 9600

PORT1 = COM2 baud: 1 = 19200

PORT2 = COM3 baud: 2 = 38400

PORT3 = COM4

NOTE Beginning with the Phaser 860, all printers have

built-in diagnostics capabilities and do not require the

use of external diagnostics.

Page 3 of 3

Page 31

Date Issued: 16 Oct 2006

SB 733

Product: Phaser 8400, 8500, 8550, C2424

For the Phaser 8500/8550, obtain the file “setFreezeTemp92_85008550v2.ps” from:

http://download.support.xerox.com/pub/drivers/8500_8550/utils/wins2003/en/

setFreezeTemp92_8500‐8550v2.ps

For the Phaser 8400 and Workstation C2424:

Operational Groups: OPB, NADC

1. Print the Service Usage Profile (scroll to Troubleshooting: Service

PRINTER CONSUMES TOO MUCH INK DUE TO EXCESSIVE

AUTO-PURGES

When the printer transitions from its PowerSaver mode to its Ready

state, it unexpectantly performs an automatic cleaning cycle. This is

evidenced by a Cleaning Page (sometimes referred to as a mud page) in

the output bin.

Tools: Service Usage Profile).

2. Examine Token 281 Printhead Clean Count. Determine if the

item Manual shows a significant number of cleanings that do not

coincide with Token 287 PPC -- WP (warm purge). If instead,

Manual cleanings are being tallied under Token 287 PPC – CP

(cold purge), then abnormal auto-purges are taking place.

Additionally, the abnormal number of Manual cleanings (cold

purges) shown on Token 281 should correlate to the number of

CAUSE

auto-purges and mud pages experienced by the customer.

3. If the Manual clean count is high and cleanings are being tallied

Certain printhead conditions can cause the printer to incorrectly think

that the printhead is too cold while in the PowerSaver state. The printer

responds with a cleaning cycle when it reaches its Ready state. The

cleaning cycle is meant to purge any air bubbles that would have

formed in the ink when it was too cold.

as PPC CPs, then upload the appropriate “setFreezeTemp”

snippet file to the printer.

• For the Phaser 8400, obtain the file “8400-setFreezeTemp92.ps”

• For the Workstation C2424, obtain the file

“setFreezeTemp92_C2424.ps”

The snippets reprogram the printer’s printhead to make it more

SOLUTION

Determine if the printer has been performing too many auto-purges.

For the Phaser 8500/8550:

1. Print the Service Usage Profile (scroll to Troubleshooting: Service

Tools: Service Usage Profile).

2. Examine Token 281 to see if item CAP (Cold Abnormal Purge)

shows a more than 5 cleanings. The abnormal number of CAP

cleanings shown on Token 281 should correlate to the number of

auto-purges and mud pages experienced by the customer.

3. If the CAP count is high, then upload the “setFreezeTemp92_8500-

8550v2.ps” snippet file to the printer. The snippet reprograms

the printer’s printhead to make it more immune to the

conditions that cause the false printhead temperature reading.

Copyright © 2006 Xerox Corporation. All rights reserved. XEROX®, the stylized X®, and Phaser®

trademarks of Xerox Corporation in the United States and/or other countries.

immune to the conditions that cause the false printhead temperature

reading.

For the Phaser 8400, obtain the file “8400-setFreezeTemp92.ps” from:

http://download.support.xerox.com/pub/drivers/8400/utils/wins2003/en/8400‐

setFreezeTemp92.ps

For the Workstation C2424, obtain the file “setFreezeTemp92_C2424.ps”

from:

http://download.support.xerox.com/pub/drivers/C2424/utils/wins2003/en/setFreezeTem

p92_C2424.ps

Resolve a “too many auto-cleans” problem by uploading the

“setFreezeTemp” snippet to the printer. Only replace the printhead if

the snippet fails to correct the problem.

1 of 2

Page 32

PART INVENTORY STRATEGY

None

TME

Pub. No.:

Page 2 of 2

Page 33

Date Issued: 10 Oct 2006

SB 740

Product: Phaser 8500, 8550

Operational Groups: OPB, NADC

9,035.43 THRU 9,038.46 INK STICK COUNT FAULTS AND

FALSE INK OUT MESSAGES. SOME INK STICKS MAY NOT

RELIABLY ACTUATE INK OUT SENSORS

Features on the bottom of genuine Xerox Phaser 8500/8550 brand ink

sticks actuate the Ink Out Sensor located at the forward end of each ink

stick channel of the printer’s ink loader. The printer reads each sensor

to determine if an ink stick is present and also to count each stick as it

passes by the sensor.

Some ink sticks may not reliably depress an Ink Out Sensor’s flag. This

can lead to false Ink Out messages as well as Ink Stick Count faults.

Using Phaser 8400 ink sticks in a Phaser 8500 or 8550 will also cause

9,03x.4x ink stick count faults. The Phaser 8400 ink sticks do not have

the features required to actuate the ink out flags.

WHAT TO DO

When you service a Phaser 8500 or 8550 printer for:

• a persistent Ink Out message

• 9,035.43 Cyan Ink Stick Count Fault

• 9,036.44 Magenta Ink Stick Count Fault

• 9,037.45 Yellow Ink Stick Count Fault

• 9,038.46 Black Ink Stick Count Fault

Test the Ink Out Sensors for proper operation.

Inspect the Ink Sticks.

TESTING THE INK OUT SENSORS

Use this procedure to test if an Ink Out Sensor’s flag works correctly.

1. Remove ink sticks from the ink loader’s channels.

2. Place the printer in Diagnostics Mode by:

Service method

a. Turning on the printer and as

XEROX appears on the

screen, press and hold the

Back and Help button until

Beginning Service Mode

Initialization appears.

b. Scroll to and execute test

Monitor: Sensors

3. Insert the clean eraser end of a pencil thru the lowermost oval slot.

(The eraser end of a pencil closely simulates the bottom rail shape of

a Xerox ink stick.)

4. Slide the pencil down the white channel guide until the sensor is

tripped. A sensor change is displayed on the control panel. When

the flag is depressed, the front panel will read <color> Ink Present

H. When released, the reading will change to L. The test will only

display a reading when a sensor change occurs. If a flag is stuck, no

sensor reading will be displayed on the front panel.

Ink Out flag

Customer method

a. While error code displayed,