Page 1

Version 1.0

Technical Product Training

Phaser

8550/8500/8400

Solid Ink Printers

Page 2

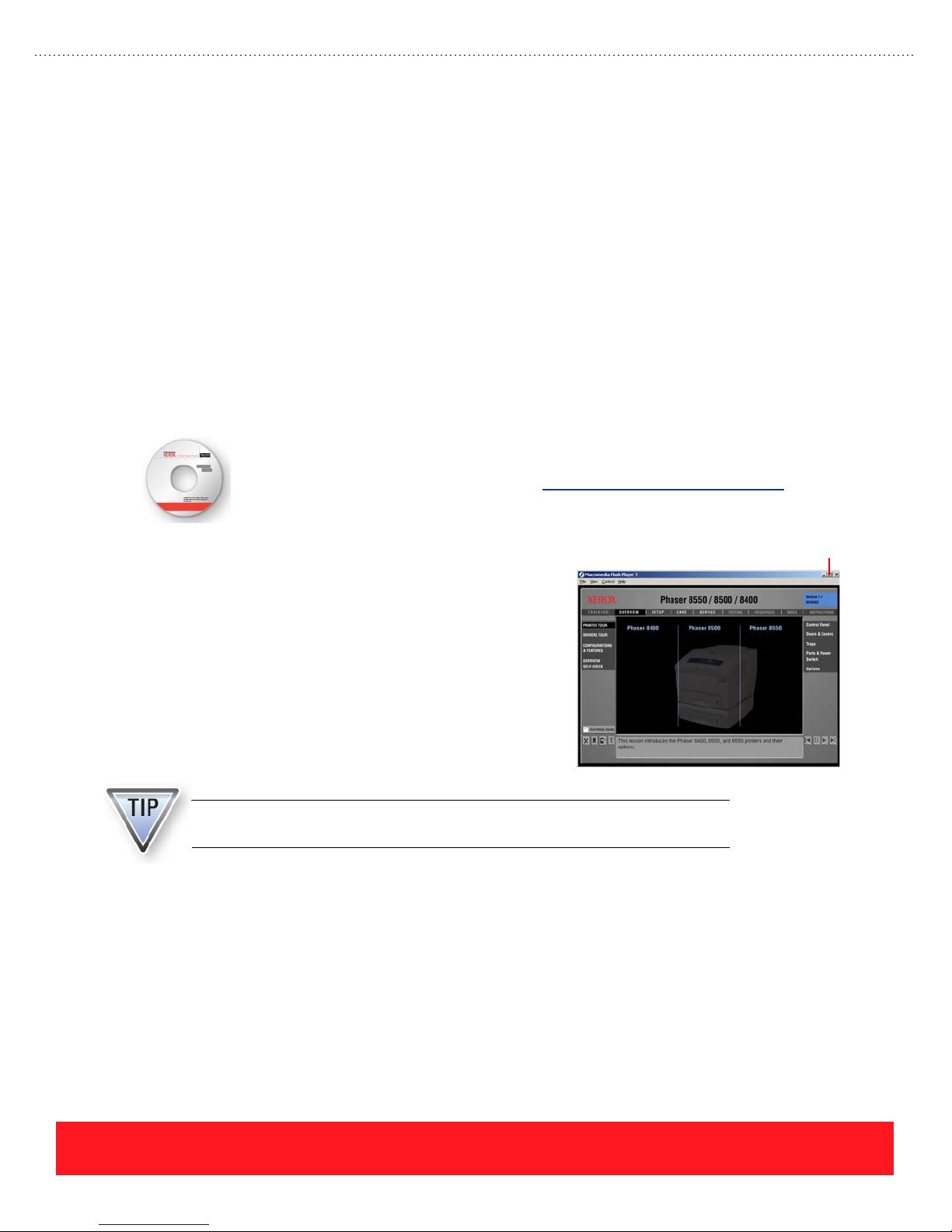

Product Training CD-ROM

The Product Training CD-ROM provides multimedia lessons and videos

for the Phaser 8550, Phaser 8500 and Phaser 8400 printers.

Self-Study Guide

The Self-Study Guide provides key lessons and exercises for product

Overview, Setup, Care, and Service. To complete the training, you must

complete the Self-Study Guide lessons and the multimedia lessons on the

CD-ROM, as well as the prerequisites.

Testing

Prepare for the Online Test by completing the Self-Checks. Then, visit

the Testing Center to complete your training.

< www.xerox.com/office/testing >

Continuing Support

The Resources section of the training CD-ROM contains useful printer

documentation and supplemental training materials. To obtain the most

current updates, tips, and bulletins, visit the knowledge base and the

Partner Resource Site. To check for updates to the training materials,

visit the Training Updates Site.

< www.xerox.com/support >

< www.xerox.com/office/partners >

< www.xerox.com/office/training >

Prerequisites

Printing Basics

(Waived with certification on another Phaser printer)

Solid-ink Basics

(Waived with certification on the Phaser 840, 850, 860, or 8200 printer,

or the WorkCentre C2424 copier-printer)

Contact Product Training & Information

support.training@office.xerox.com

(503) 685-4400 (North America)

Page 3

To start your training:

Refer to the Introduction section of the Self-Study Guide for instructions to complete the training.

1.

2. Insert the CD-ROM into the CD-ROM drive of a PC running Windows® 95, 98, Me, 2000, NT, or XP.

3. If the program does not auto-launch, browse to the Files folder, then run START.exe.

Product Training CD-ROM

Minimum System Requirements:

Pentium II 233 MHz Processor

Pentium II 400 MHz Processor ( Recommended )

Windows® 95, 98, Me, 2000, NT, or XP

64 MB RAM

6x CD-ROM Drive

16-bit Sound Card

800 x 600 Monitor with 16-bit Color

Minimum Software Requirements:

Adobe® Reader® ( Included on training CD-ROM )

Web Browser ( Internet Explorer 5.X or later recommended )

Page 4

Page 5

Phaser 8550, 8500, & 8400 Service Self-Study Guide

TABLE OF CONTENTS

INTRODUCTION

Training Program Overview ............................................... 1

Training CD-ROM........................................................ 1

Self-Study Guide........................................................... 1

Prerequisite Courses ..................................................... 1

Training Kit Contents ......................................................... 2

Running the Training CD-ROM......................................... 2

Adobe® Reader®........................................................... 2

Supported Operating Systems....................................... 3

Completing the Training..................................................... 3

Phaser 8550, 8500, & 8400 Course Map...................... 4

Required Materials.............................................................. 4

Online Testing Center......................................................... 5

If You Need Help................................................................ 6

How to Contact Xerox Product Training & Information.... 6

OVERVIEW SECTION

Overview Objectives........................................................... 7

Configurations .................................................................... 7

Options & Upgrades ......................................................... 12

Features............................................................................. 14

Phaser 8500 and 8550 Printers...................................... 7

Phaser 8400 Printers ..................................................... 9

Primary Differences.................................................... 10

Memory....................................................................... 12

525-Sheet Feeder ........................................................ 13

Hard Drive (Productivity Kit)..................................... 13

Configuration Upgrades.............................................. 13

Speed & Quality.......................................................... 14

Phaser 8500 and 8550 Print-Quality Modes............... 15

Phaser 8400 Print-Quality Modes............................... 15

Factors That Reduce Print Speed................................ 16

Print Grayscale Images ............................................... 16

Run Black Mode ......................................................... 16

Speed & Quality Review Exercise.............................. 17

Walk-Up Features ....................................................... 17

Media Support................................................................... 19

Tray 1 (MPT).............................................................. 19

PHASER 8550, 8500, & 8400 TABLE OF CONTENTS

Version 1.0

page i

Page 6

SETUP SECTION

525-Sheet Tray (Trays 2, 3, & 4) ............................... 20

Media Support Review Exercise................................ 20

Documentation & Software.............................................. 21

User Manuals & Guides ............................................. 22

Videos......................................................................... 22

Embedded Pages ........................................................ 23

Printer Drivers & Utilities.......................................... 23

Color Adjustment Sliders........................................... 25

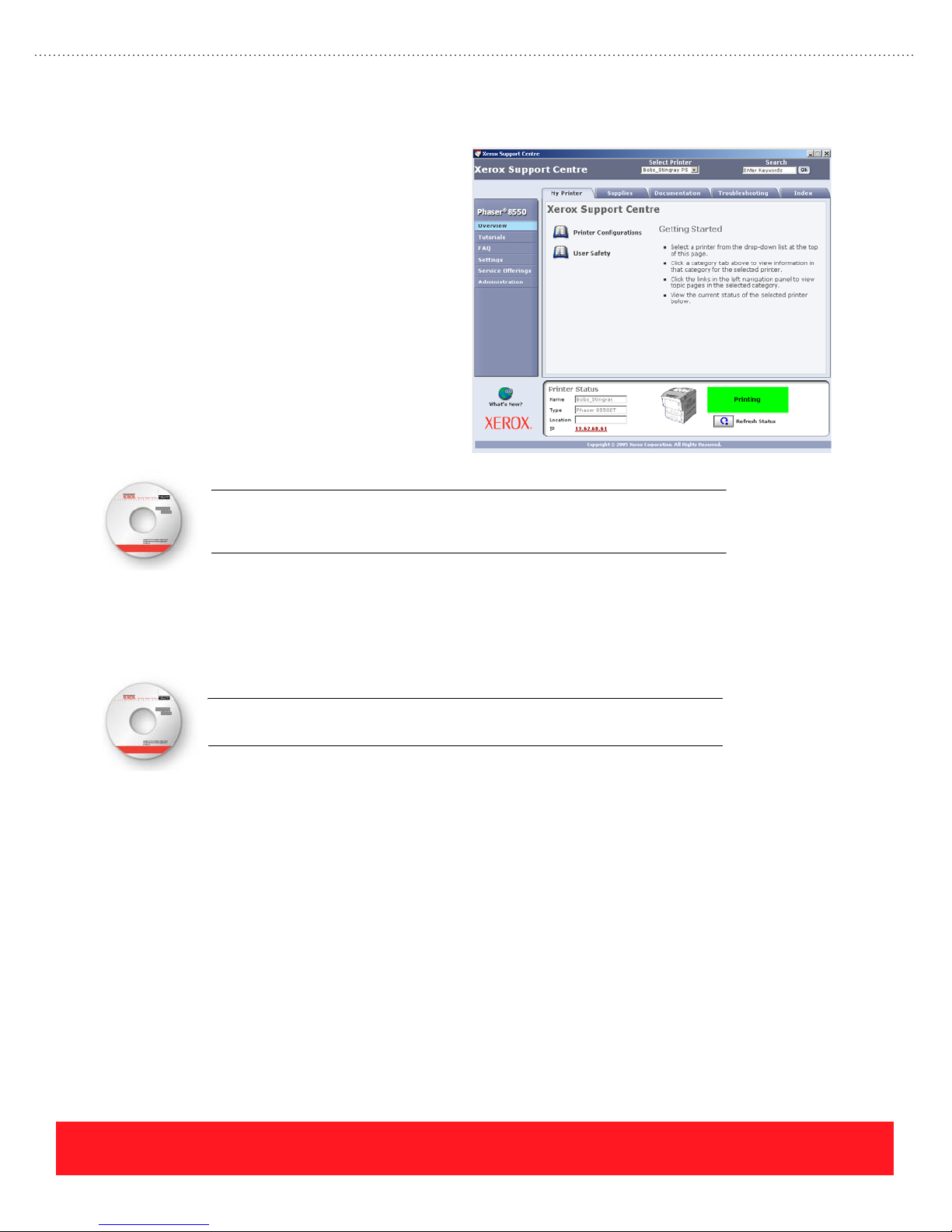

Xerox Support Centre................................................. 26

Your Next Step................................................................. 26

Setup Objectives............................................................... 27

Setting up the Printer........................................................ 27

Setup Review Exercise............................................... 28

Load Paper........................................................................ 28

Guidelines................................................................... 29

Loading Tray 1 (MPT) ............................................... 29

Loading Trays 2, 3, & 4 ............................................. 31

Loading Paper Review Exercise................................. 31

Configure Control Panel................................................... 32

Menus ......................................................................... 32

Shortcuts..................................................................... 32

Control Panel Defaults ............................................... 33

Control Panel Lab....................................................... 33

Test Ports.......................................................................... 33

Network Diagnostics .................................................. 34

Test Windows Ethernet Port (Alternate Procedure)... 34

Test Parallel Port ........................................................ 35

Test Macintosh USB Port........................................... 36

Test Macintosh Ethernet Port..................................... 38

Printing Lab...................................................................... 39

Install Software .......................................................... 39

Print Jobs.................................................................... 40

Use the Xerox Support Centre.................................... 40

Install Upgrades................................................................ 41

General Instructions ................................................... 41

Memory Upgrade ....................................................... 42

Hard Drive (Productivity Kit) Upgrade...................... 42

Configuration Upgrades ............................................. 43

Your Next Step................................................................. 43

page ii

PHASER 8550, 8500, & 8400 TABLE OF CONTENTS

Version 1.0

Page 7

CARE SECTION

Care Objectives................................................................. 45

Paper Jams ........................................................................ 45

Resources.................................................................... 45

General Techniques .................................................... 46

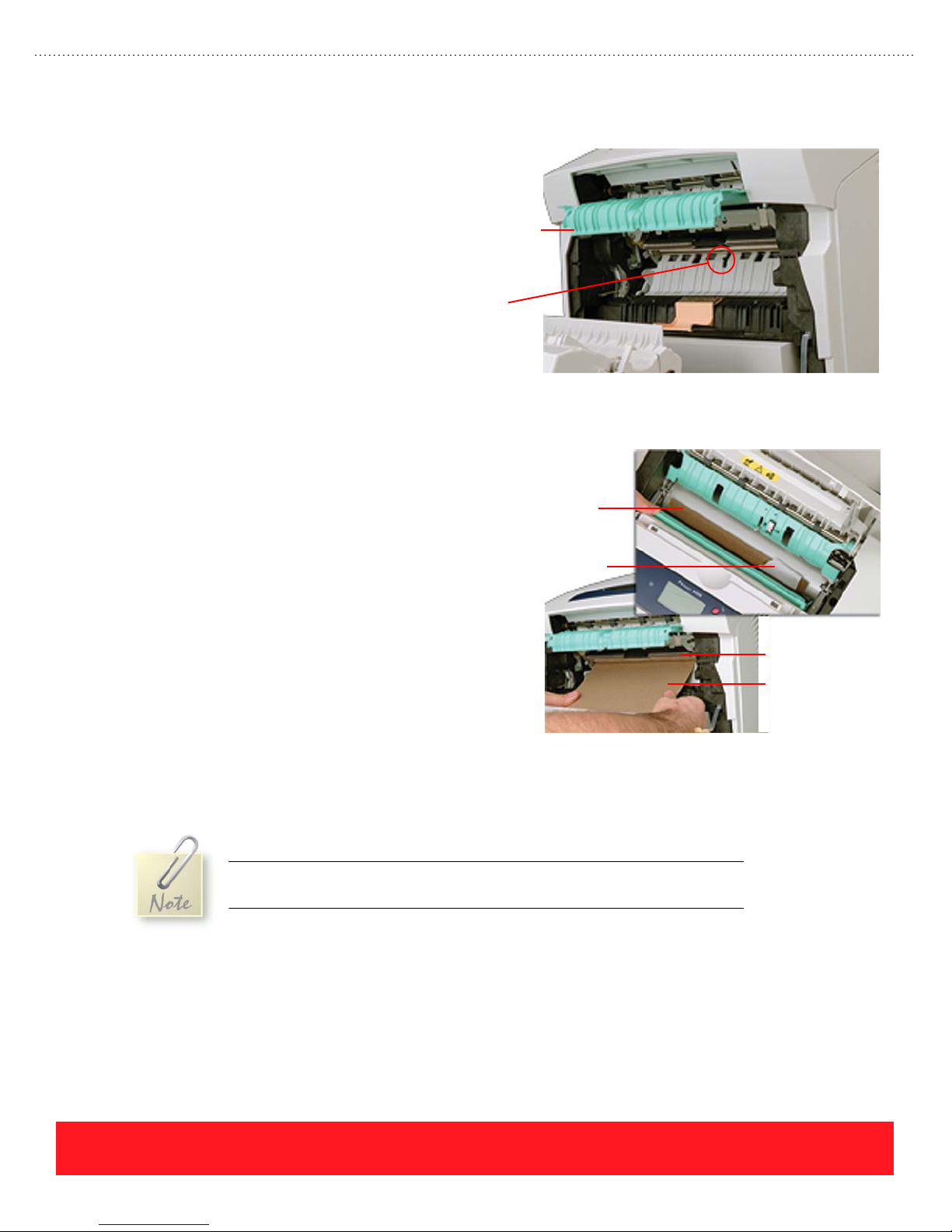

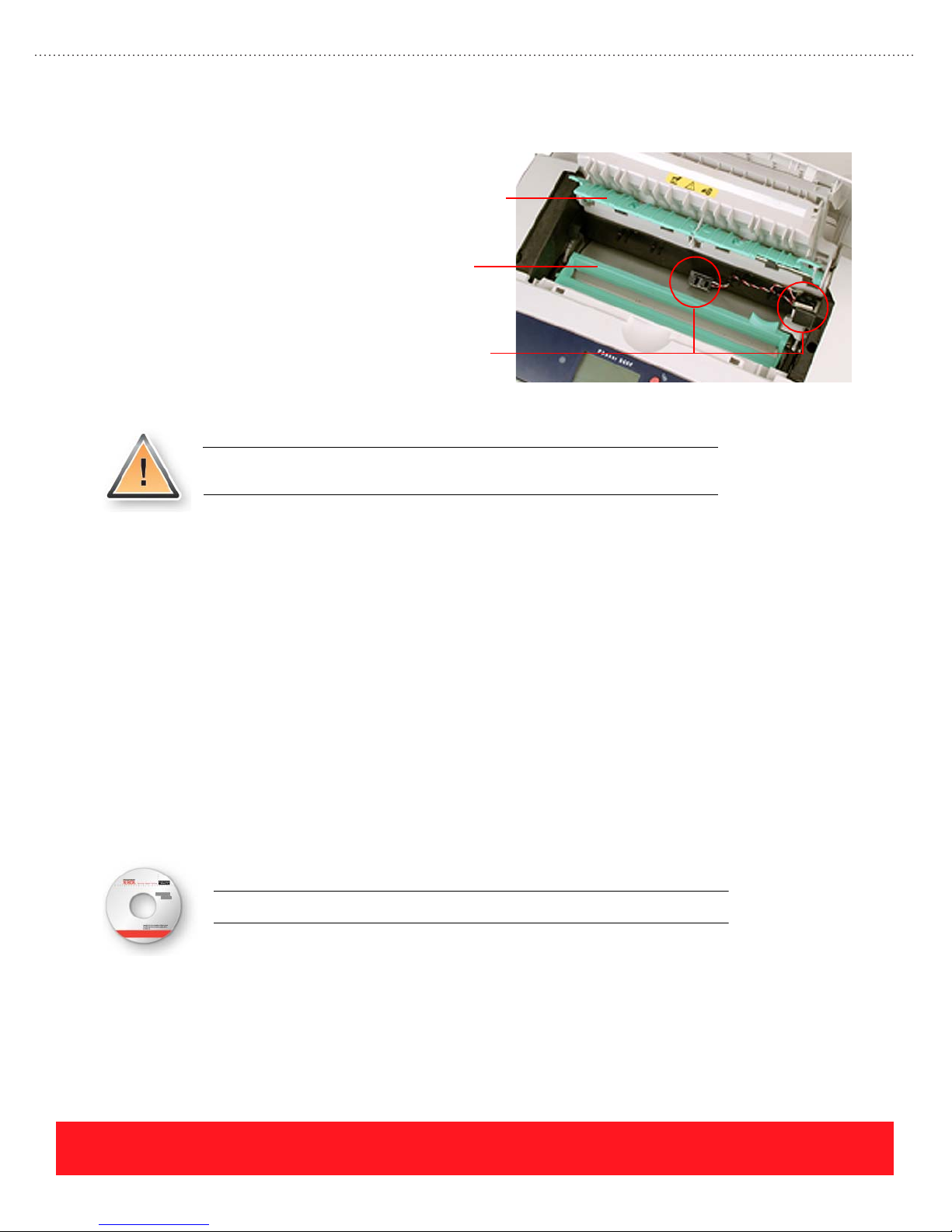

Jams Behind Front Cover ........................................... 47

Jams Inside Preheater.................................................. 47

Exit Jams..................................................................... 48

Jams At Trays ............................................................. 48

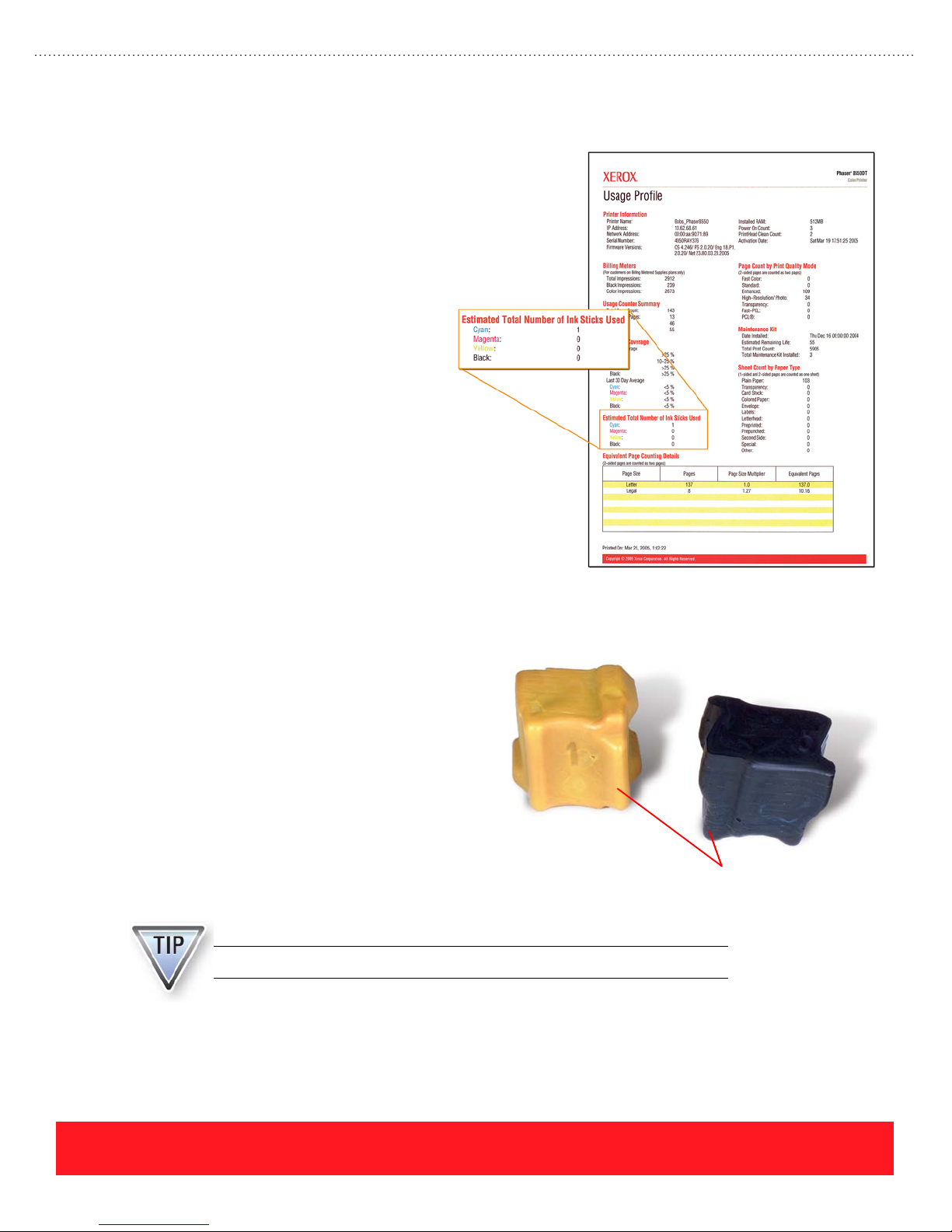

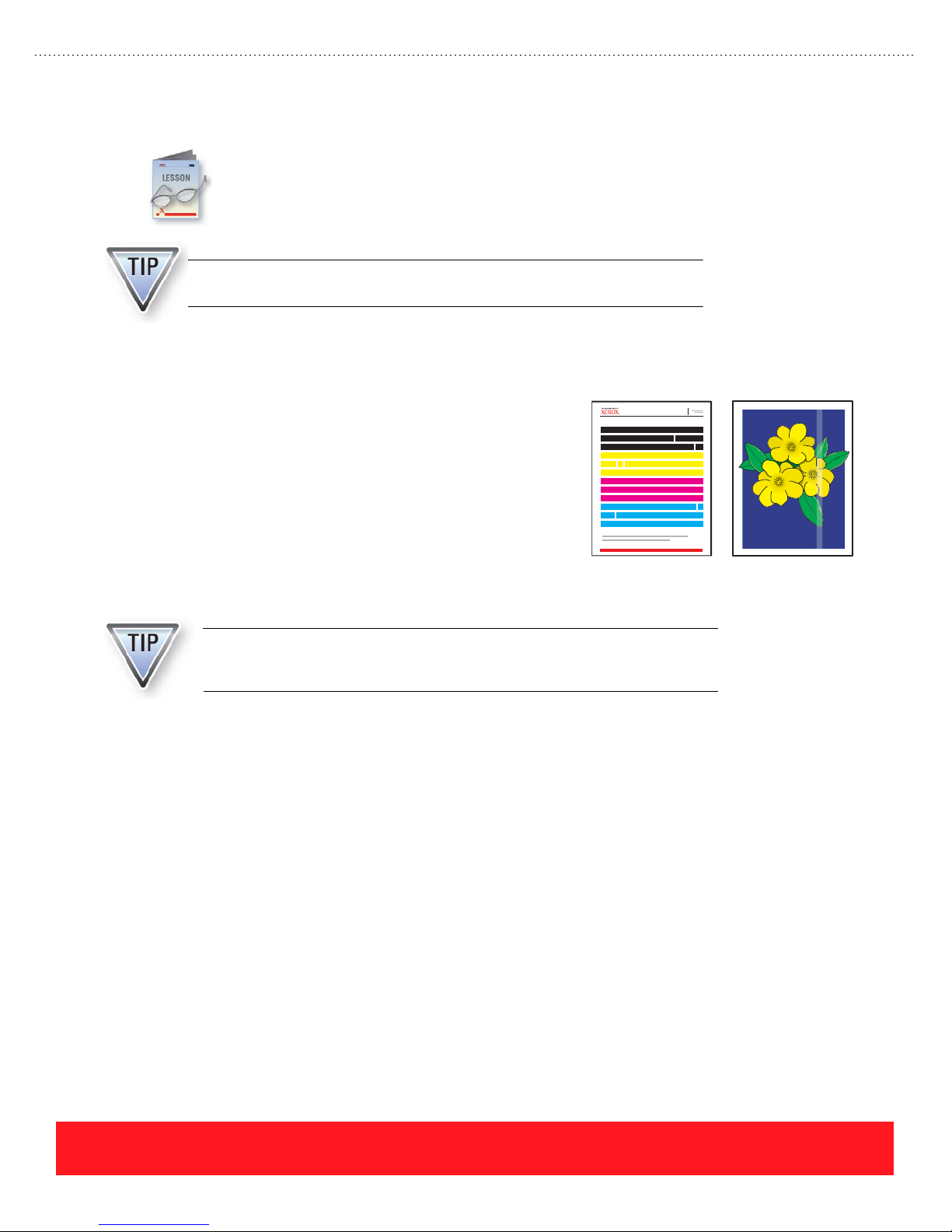

Supplies............................................................................. 49

Ink Sticks .................................................................... 49

Maintenance Kits ........................................................ 52

Troubleshooting Exercise ........................................... 54

Cleaning............................................................................ 56

Eliminate Light Stripes ............................................... 56

Remove Print Smears.................................................. 61

Clean Components Manually...................................... 62

Cleaning Review Exercise.......................................... 63

Replace Parts..................................................................... 64

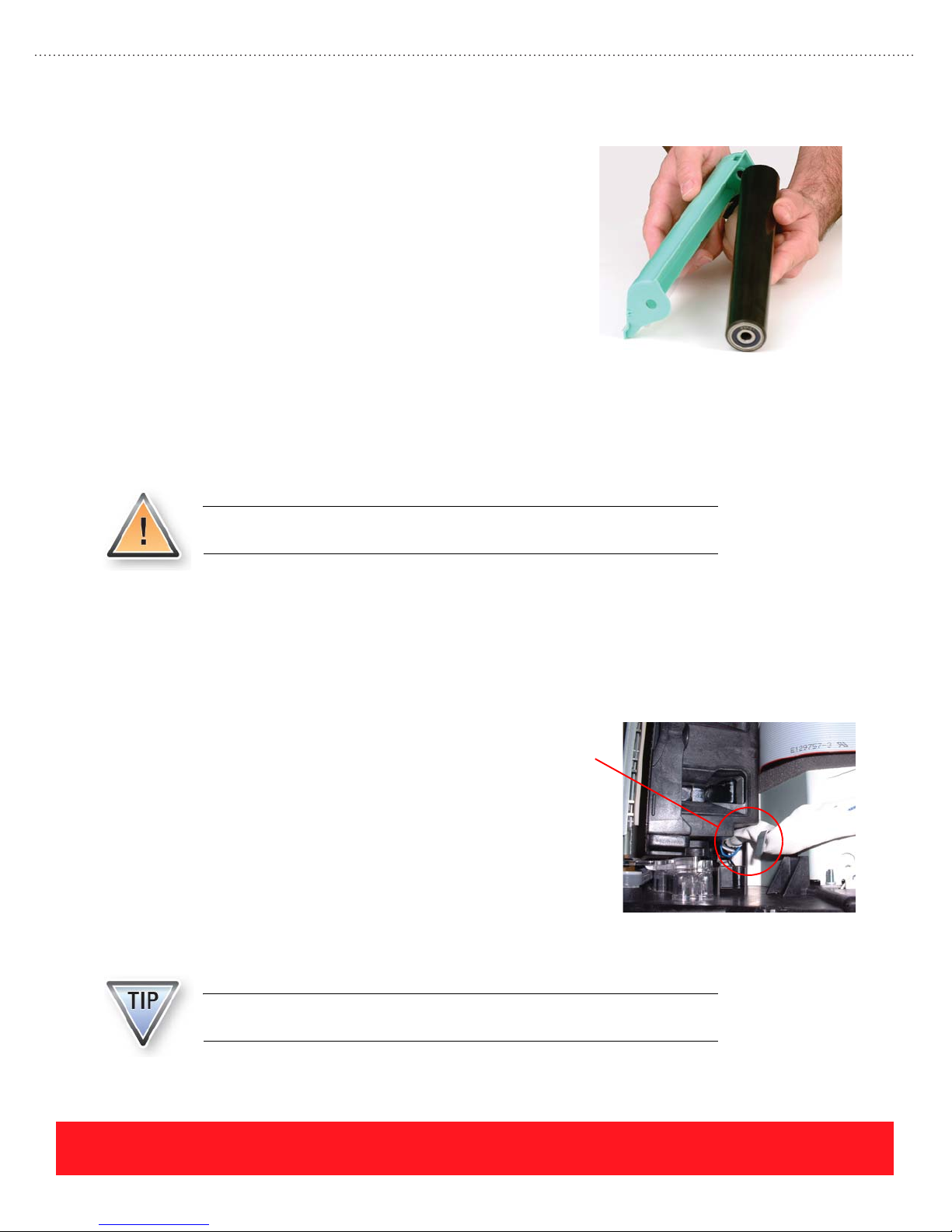

Feed Roller Kit............................................................ 64

Front Door and Tray Kit ............................................. 65

Replace Parts Lab ....................................................... 65

Moving The Printer........................................................... 66

Moving and Shipment Review Exercise..................... 66

Your Next Step ................................................................. 66

SERVICE SECTION

Service Objectives ............................................................ 67

Troubleshooting................................................................ 68

Service Tools .............................................................. 68

Error Codes................................................................. 68

Print Quality................................................................ 71

Electronics Troubleshooting....................................... 73

Printhead Troubleshooting Checklist Exercise........... 74

Service Precautions........................................................... 75

Hazards ....................................................................... 75

Customer Environment............................................... 76

Handling Parts............................................................. 76

Grounding ................................................................... 77

Homing Components .................................................. 78

PHASER 8550, 8500, & 8400 TABLE OF CONTENTS

Version 1.0

page iii

Page 8

APPENDIX

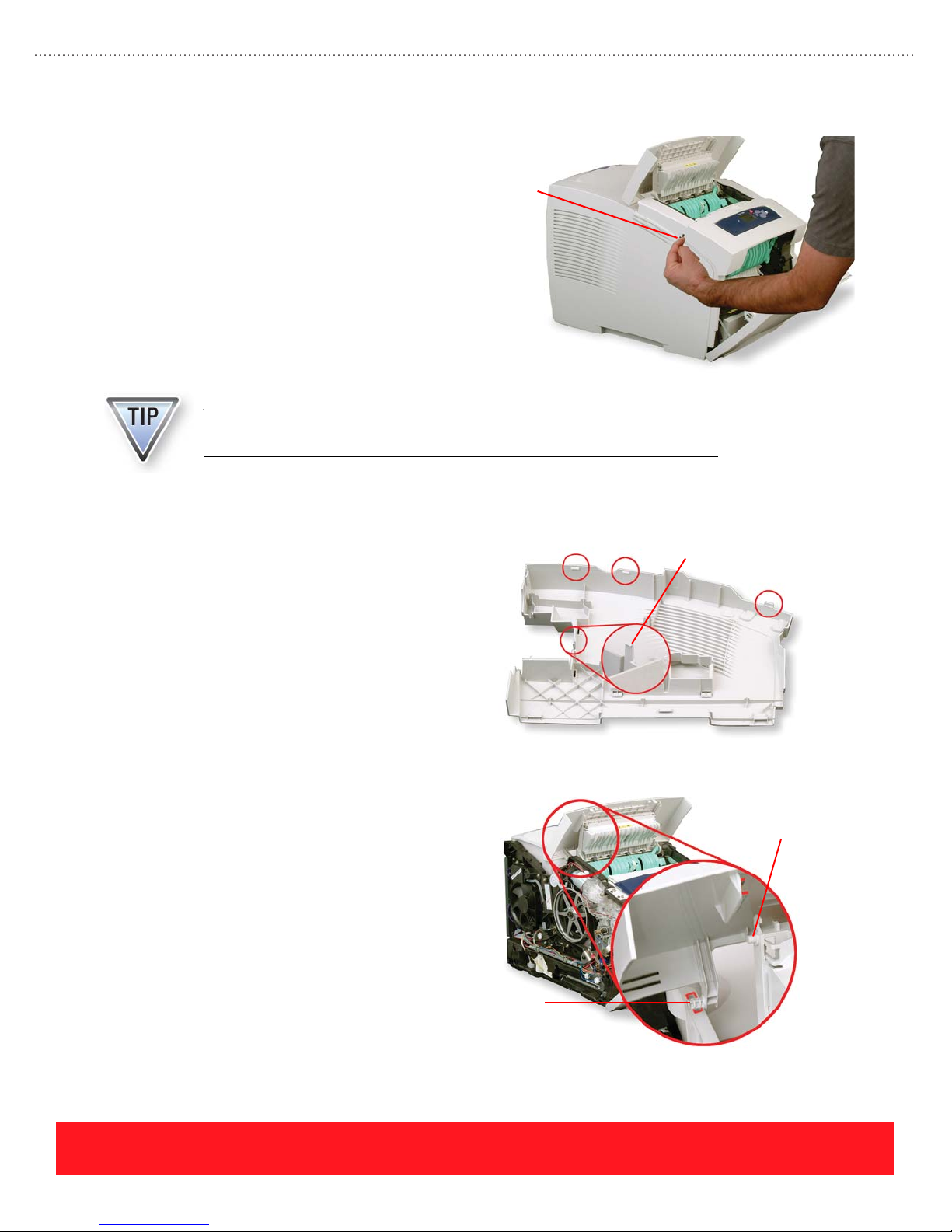

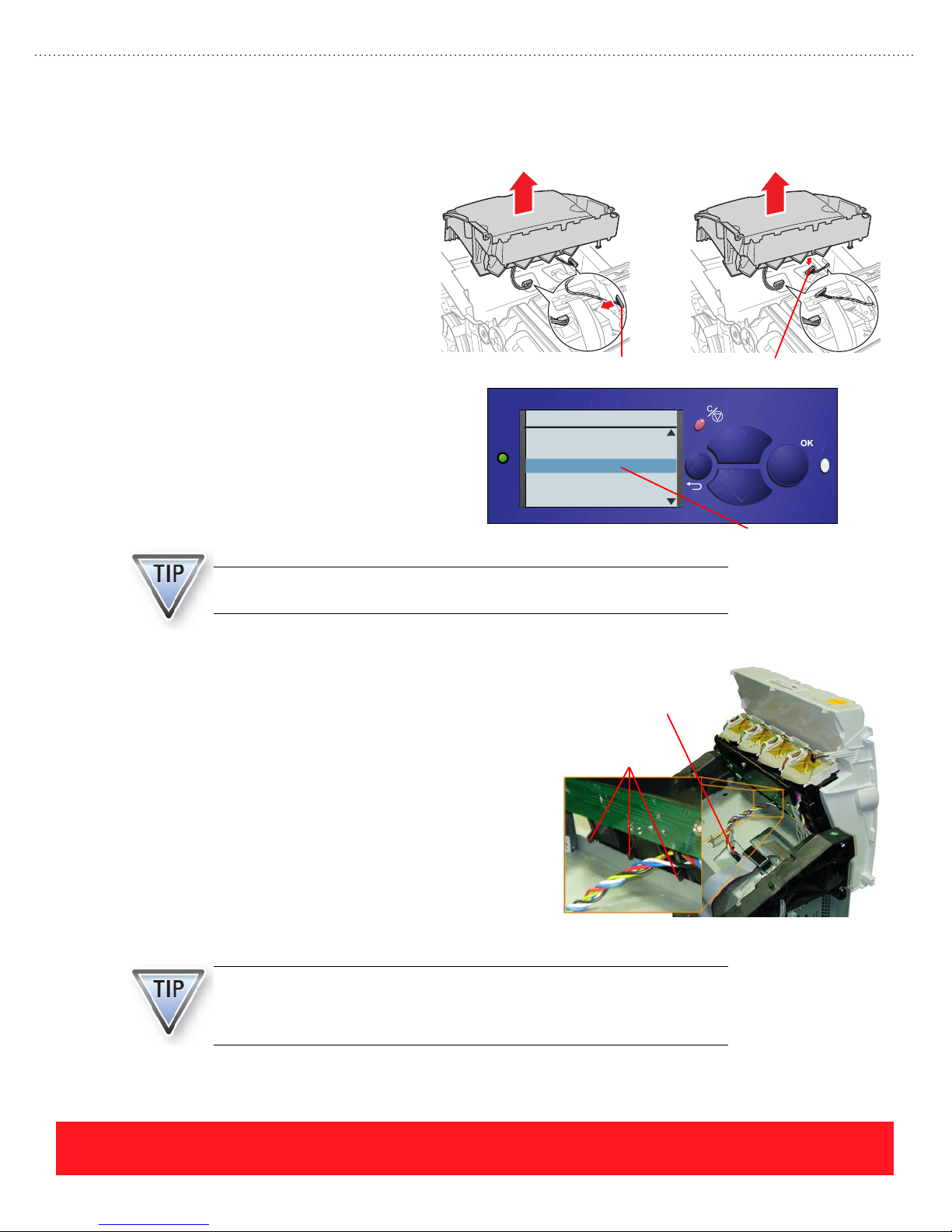

Parts Replacement Tips.................................................... 79

Exterior Covers .......................................................... 79

Ink Loader Assembly ................................................. 81

Stripper Carriage Assembly ....................................... 82

Printhead..................................................................... 82

Electronics Module .................................................... 84

X-Axis Motor Assembly ............................................ 84

Y-Axis Drive Motor Assembly .................................. 84

Exit Assembly ............................................................ 85

Printhead Wiper Assembly......................................... 85

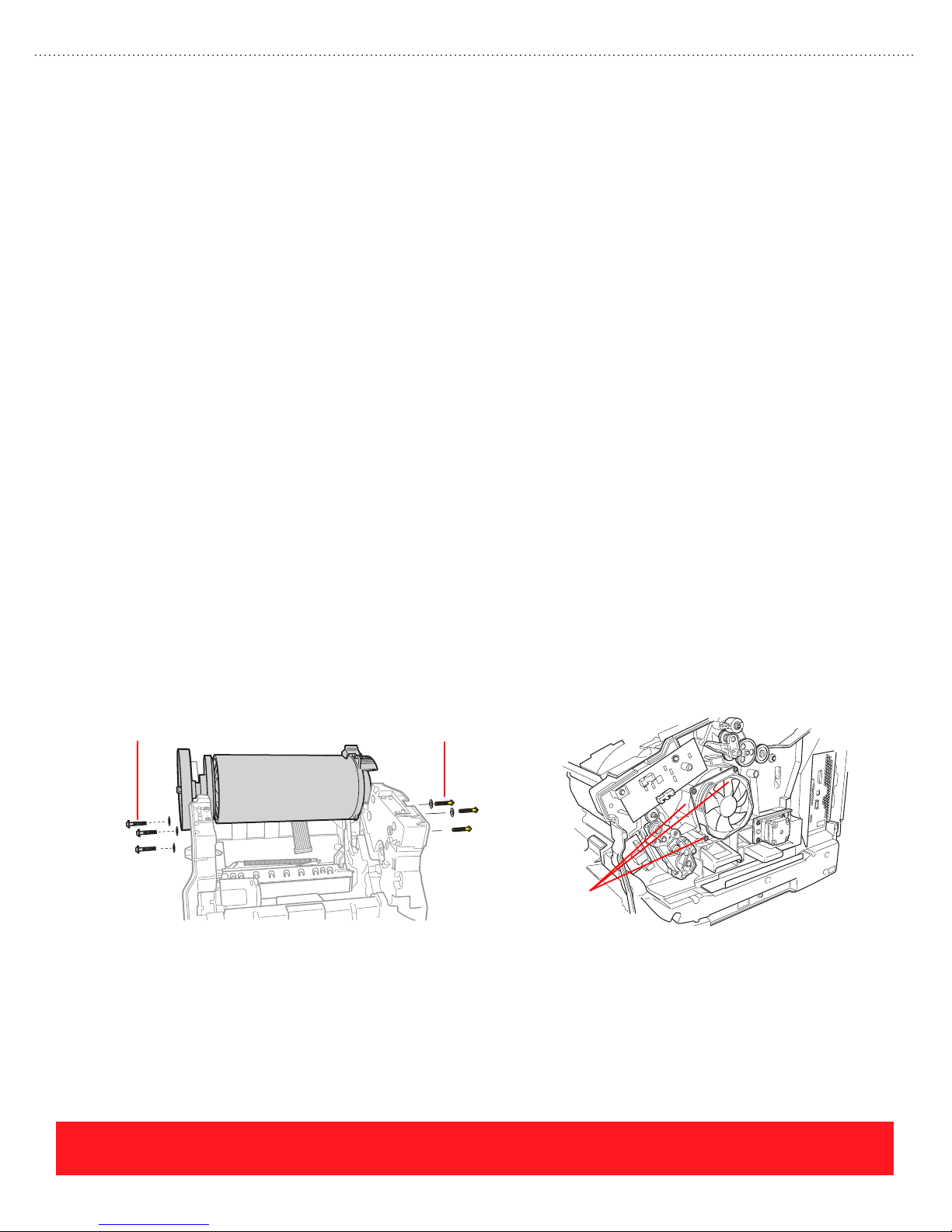

Drum Assembly.......................................................... 86

Lubrication ................................................................. 87

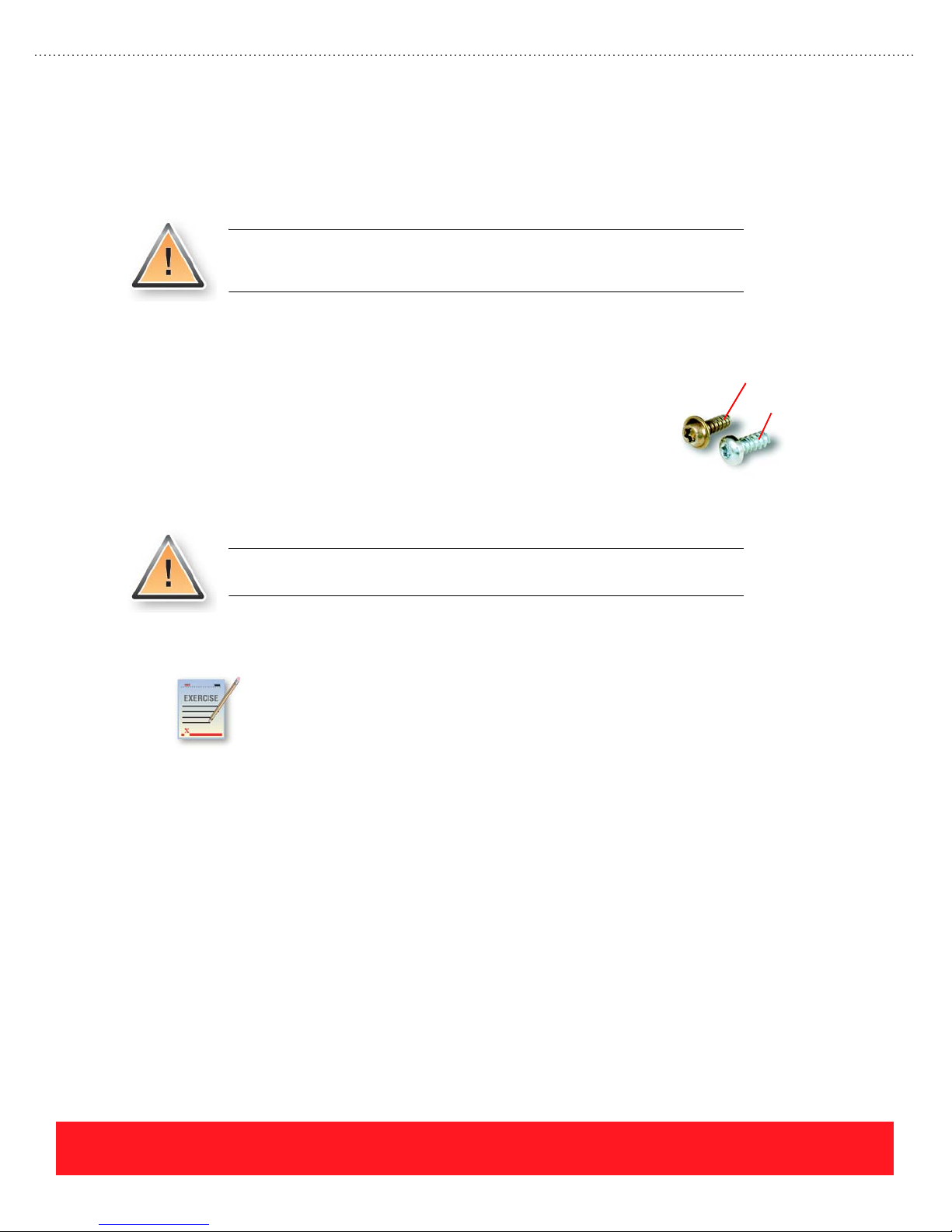

Tightening Screws...................................................... 87

Disassembly Lab ........................................................ 88

Your Next Step................................................................. 88

Answers to Overview Exercises....................................... 89

Speed & Quality Review Exercise............................. 89

Media Support Review Exercise................................ 89

Answers to Setup Exercises ............................................. 90

Setup Review Exercise............................................... 90

Loading Paper Review Exercise................................. 90

Answers to Care Exercises............................................... 90

Troubleshooting Exercise........................................... 90

Cleaning Review Exercise.......................................... 91

Moving and Shipment Review Exercise .................... 91

Answers to Service Exercises........................................... 92

Error Codes Review Exercise..................................... 92

Print Quality Review Exercise ................................... 92

Printhead Troubleshooting Checklist Exercise .......... 92

Homing Components Exercise................................... 93

Tightening Screws Review Exercise.......................... 93

Resources.......................................................................... 94

Links........................................................................... 94

Contact Information ................................................... 94

Glossary of Acronyms................................................ 94

page iv

PHASER 8550, 8500, & 8400 TABLE OF CONTENTS

Version 1.0

Page 9

Phaser 8550, 8500, & 8400 Service Self-Study Guide

INTRODUCTION

Prerequisites

❑ Printing Basics

❑ Solid-ink Basics

Printer Requirements

❑ A Phaser 8550, 8500, or

8400 printer is optional

for this training

Time To Complete

❑ Reading: 2.5 hours

❑ Video run time: 3 hours

❑ Exercises: 2 hours

❑ Optional labs: 5 hours

❑ Self-Checks: 45 min.

❑ Online test: 45 min.

Online Tests

An online test must be taken

to complete the Phaser 8550,

8500, & 8400 Service

Training. Refer to “Online

Testing Center” on page 5 for

details.

Resources

❑ Phaser 8550, 8500, &

8400 Product Training

CD-ROM

❑ Phaser 8400/8500/8550

Service Manual

❑ Testing Center:

www.xerox.com/

office/testing

❑ Partner Resource Site:

www.xerox.com/

office/partners

❑ Knowledge Base:

www.xerox.com/support

❑ Training Update Site:

See “If You Need Help”

on page 6.

Training Program Overview

The Phaser 8550, 8500, & 8400 training program is a self-paced course for service

technicians. It is divided into four sections called Overview, Setup, Care, and Service.

The course consists of the Phaser 8550, 8500, & 8400 Self-Study Guide, the

Phaser 8550, 8500, & 8400 Product Training CD-ROM, and two prerequisite courses.

Complete this course for certification on the Phaser 8550, 8500, and

8400 printers.

Training CD-ROM

The training CD-ROM provides multimedia training lessons and self-checks to

prepare for the certification test. The Resources section of the training CD-ROM

contains electronic versions of the printer documentation including manuals,

instruction sheets, and examples of the most important embedded pages. Web links on

the CD-ROM provide access to support information and the online testing center.

Self-Study Guide

The Self-Study Guide provides instructions for completing the training and many of

the lessons you will need to pass the certification test. It also provides exercises that

can be completed if you do not have access to the printer, and hands-on labs for use

when a printer is available. A PDF version of this Self-Study Guide is available from

the training CD-ROM’s Resources section.

Prerequisite Courses

The Printing Basics and Solid-ink Basics prerequisite courses must be completed

before you begin the Phaser 8550, 8500, and 8400 training program. The prerequisites

are waived if you have previously been certified on other Xerox Phaser printers, as

shown below:

■ Printing Basics

Waived with certification on another Phaser printer

■ Solid-ink Basics

Waived with certification on the Phaser 840, 850, 860, or 8200 printer, or

the WorkCentre C2424 copier-printer

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

If you are already certified on the Phaser 840, 850, 860, or 8200

color printer, or the WorkCentre C2424 copier-printer, you are

ready to begin this training.

page 1

Page 10

Training Kit Contents

The following items are provided in the Phaser 8550, 8500, & 8400 Service Training Kit:

■ Phaser 8550, 8500, & 8400 Self-Study Guide

■ Phaser 8550, 8500, & 8400 Product Training CD-ROM

■ Phaser 8500/8550 Software and Documentation CD-ROM

■ Phaser 8500 and 8550 Network Connectivity Sheet

■ Phaser 8400/8500/8550 Service Manual (not included in Help Desk kits)

Use the Self-Study Guide, training CD-ROM, and Service Manual to complete this training. Use the

Software and Documentation CD-ROM to install printer drivers and other system software. Refer to the

Network Connectivity Sheet for the supported operating systems, network topologies, and protocols.

Running the Training CD-ROM

The Phaser 8550, 8500, & 8400 Training CD-ROM was created using Macromedia Flash. If

the training program fails to run as expected, you may need to download and install the latest

version of the Macromedia Flash Player. Use www.macromedia.com/downloads/

the player.

to access

Adobe

The training CD-ROM is designed to auto-launch. If

your computer does not automatically start the training

Restore Down Button

CD-ROM, follow the steps below:

1. Insert the Phaser 8550, 8500, & 8400 Product

Training CD-ROM into your computer.

2. Navigate the contents of the CD-ROM and

double-click Start.exe.

The training launches in full-screen view. Press <Esc>

on your keyboard to view it in a smaller window, or use

the “Restore Down” button shown to the right.

Viewing the program in a smaller window allows you to view reference

documents or switch between the training and other programs on your computer.

®

Reader

®

Adobe Reader is required to view the PDF documents contained in the Resources section. If Adobe Reader is

not installed, use the following procedure to install it on your computer:

1. Insert the Phaser 8550, 8500, & 8400 Product Training CD-ROM.

2. Browse to the Files/Installers folder.

3. Open the file “AdbeRdr70_enu_full.exe” and follow the instructions to install Adobe

page 2

®

Reader®.

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

Page 11

Supported Operating Systems

The following operating systems may be used to run the training program:

■ Windows

■ Windows

®

95, Windows 98, Windows Millennium Edition (Me)

®

NT 4.0, Windows 2000, Windows XP, Windows Server 2003

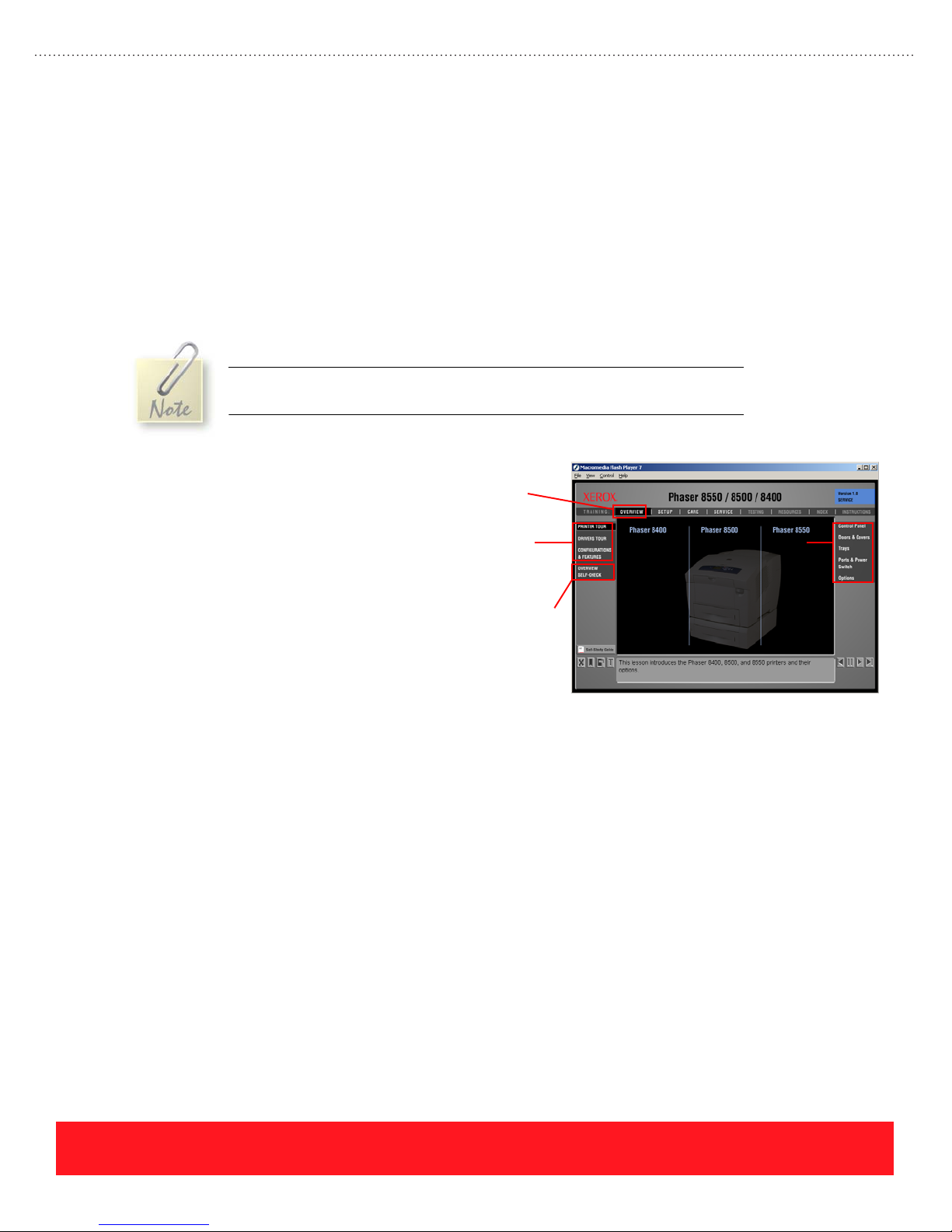

Completing the Training

Complete the following tasks to become certified on the Phaser 8550, 8500, and 8400 printers. Refer to the

“Phaser 8550, 8500, & 8400 Course Map” on page 4 for a visual guide of the training topics.

You will be tested on material located on the training CD-ROM and in the

Self-Study Guide.

1. Insert the training CD-ROM to

launch the training program.

2. Select “Overview” and complete

each training lesson on the left

side of the screen. Many lessons

also have subtopics that are listed

on the right side of the screen.

3. Turn to “Overview Objectives” on

page 7 of the Self-Study Guide (SSG)

and complete the Overview section.

Overview

Section

Training

Lessons

Self-Check

Subtopics

4. Complete the Overview Self-Check

located on the training CD-ROM.

5. Complete the Setup section of the training course:

a. Complete the Setup multimedia lessons located on the training CD-ROM.

b. Turn to “Setup Objectives” on page 27 and complete the Setup section of the SSG.

c. Return to the training CD-ROM and complete the Setup Self-Check.

6. Complete the Care section of the training course:

a. Complete the Care multimedia lessons located on the training CD-ROM.

b. Turn to “Care Objectives” on page 45 and complete the Care section of the SSG.

c. Return to the training CD-ROM and complete the Care Self-Check.

7. Complete the Service section of the training course:

a. Complete the Service multimedia lessons located on the training CD-ROM.

b. Turn to “Service Objectives” on page 67 and complete the Service section of the SSG.

c. Return to the training CD-ROM and complete the Service Self-Check.

8. Complete the Phaser 8400/8500/8550 online test.

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

page 3

Page 12

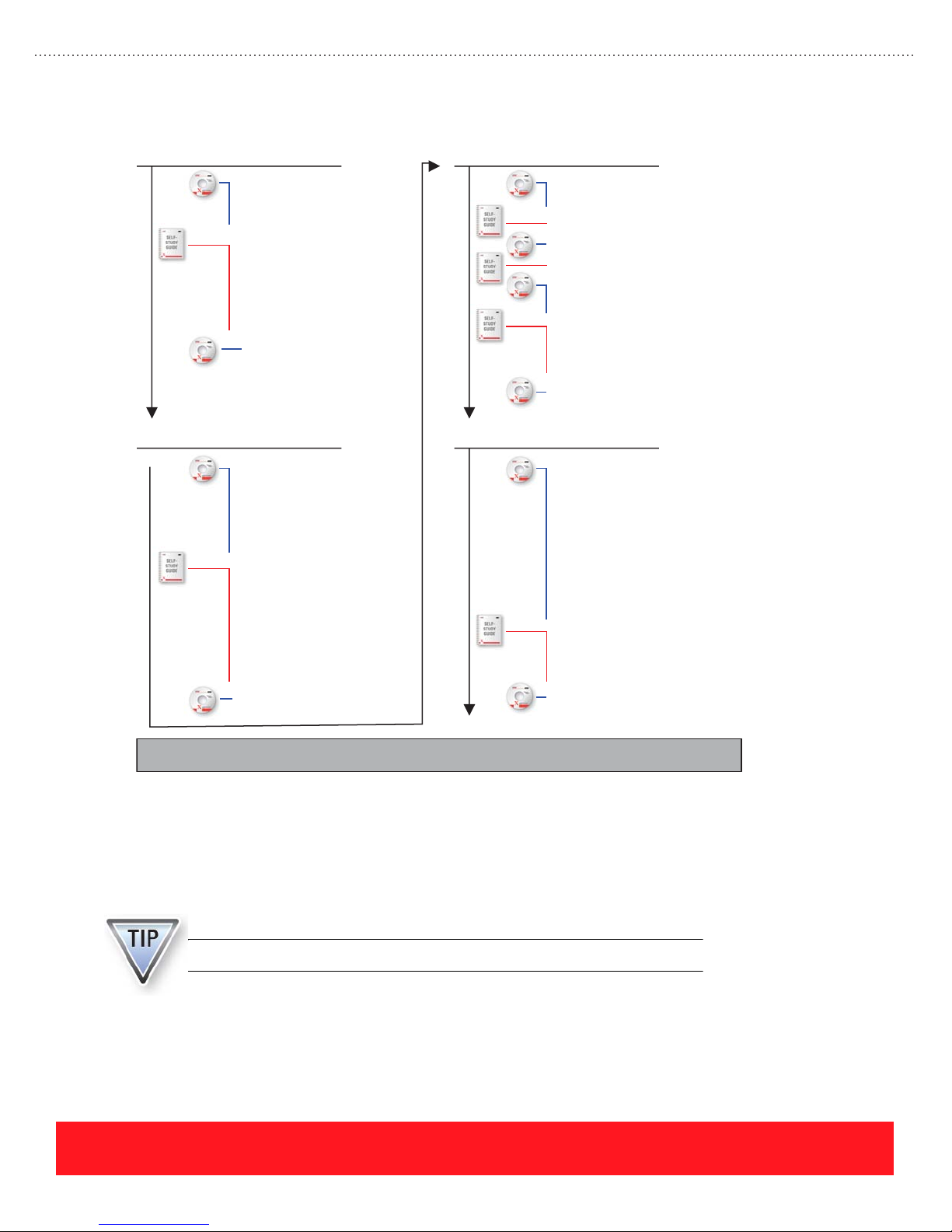

Phaser 8550, 8500, & 8400 Course Map

Overview

Setup

Printer Tour

1.

Drivers Tour

2.

Configurations & Features

3.

Configurations

4.

Options & Upgrades

5.

Features

6.

Media Support

7.

Documentation & Software

8.

Overview Self-Check

9.

Printer Installation

1.

Power-On Process

2.

Test Ports

3.

Custom Size Jobs

4.

Advanced Setup Procedures

5.

Setup the Printer

6.

Load Paper

7.

Configure Control Panel

8.

Test Ports

9.

Printing Lab

10.

Install Upgrades

11.

Setup Self-Check

12.

Care

Service

Print Process

1.

Paper Jams

2.

3.

Paper Jams

Supplies

4.

5.

Supplies

Troubleshooting

6.

User Maintenance

7.

8.

Cleaning

9.

Replace Parts

10.

Moving the Printer

Care Self-Check

11.

Theory Of Operation

1.

Printhead Procedures

2.

Media Drive Procedures

3.

Process Drive Procedures

4.

Transfix Load Module Procedures

5.

Replacement Videos

6.

Troubleshooting

7.

Precautions & Tips

8.

Troubleshooting

9.

Service Precautions

10.

Parts Replacement Tips

11.

Service Self-Check

12.

Required Materials

A printer is not required to complete the certification process. However, this Self-Study Guide includes labs

that provide hands-on activities to enhance understanding when a printer is available. Use the following

manuals, software, and equipment to complete this training course:

A printer is not required to complete the certification process.

page 4

Online Test

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

Page 13

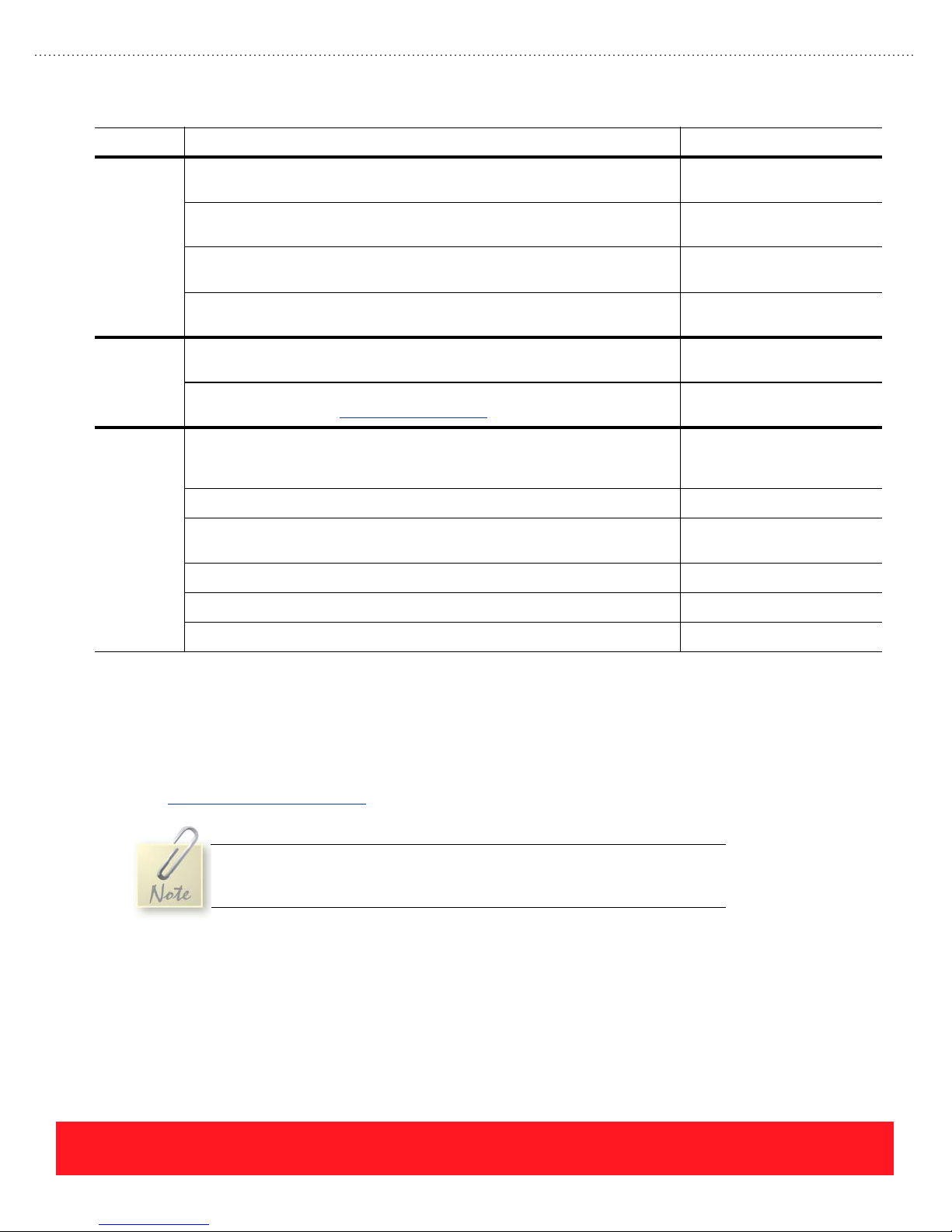

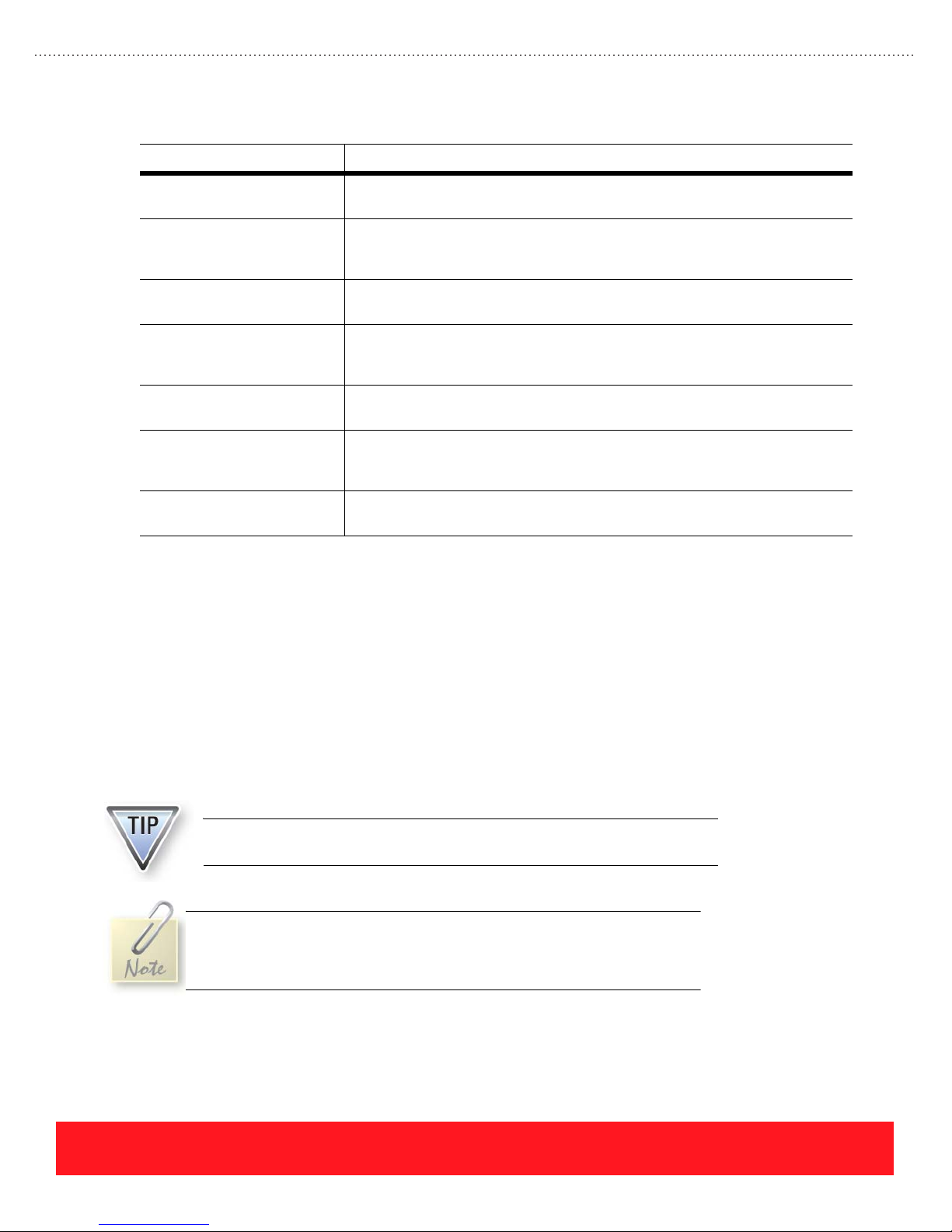

Item Minimum Requirements Example

Manuals Xerox Phaser 8500/8550 User Guide (available from the Resources section

Software Internet Explorer

Equipment Minimum workstation requirements: Pentium II 233 MHz CPU, Windows

of the training CD-ROM)

Xerox Phaser 8500/8550 Quick Reference Guide (available from the

Resources section of the training CD-ROM)

Xerox Phaser 8500/8550 Setup Guide (available from the Resources section

of the training CD-ROM)

Xerox Phaser 8400/8500/8550 Service Manual (available from the Resources

section of the training CD-ROM)

®

5.5, Macromedia Flash 6.0® ActiveX Control/Plug-in,

Adobe Reader

Phaser 8500/8550 Software and Documentation CD-ROM

(download drivers from www.xerox.com/support

9x/Me/NT/2000/XP, 64 MB RAM, 6x CD-ROM drive, 16-bit sound card, 800 x

600 monitor with 16-bit color

Xerox Phaser 8550, 8500, or 8400 printer (optional) Xerox Phaser 8550DP

DB25-to-Centronics parallel cable (for Phaser 8400 printers only),

USB 2.0 cable, or Category 5 UTP Ethernet cable (optional)

Grease, Reolube 768 (optional) Xerox P/N 006799700

Torque Screwdriver (optional) Xerox P/N 003082700

®

)

®

Xerox P/N 721P58550

Xerox P/N 063347500

Desktop or laptop PC with

400 MHz Pentium II Processor (or faster) recommended

Standard bench tools (optional)

Online Testing Center

The last step in the training process is an online test. Use the Self-Checks provided on the training CD-ROM

to prepare for the online test. You should take the online test immediately after completing the Self-Study

Guide, multimedia lessons, and the Self-Checks to complete your training. To access the Testing Center,

launch a web browser such as Microsoft

www.xerox.com/office/testing

An account name and password are required to access the Testing Center. If

you do not already have these, they are included in your welcome letter,

which is mailed separately from this training package.

®

Internet Explorer® and enter the following URL:

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

page 5

Page 14

During the test, only one question appears on the screen. You cannot jump ahead to see other questions, or

scroll back to change answers. Certain questions that cover key information may trigger an automatic test

failure if you answer them incorrectly. Manuals that are normally available (for example, the Service Manual)

may be used as resources when taking the test. Test results are provided immediately. When a test failure

occurs, review topics are suggested based on the questions missed. If you fail a test three times, you must

contact a Xerox Product Training & Information representative at (503) 685-4400 (North America only).

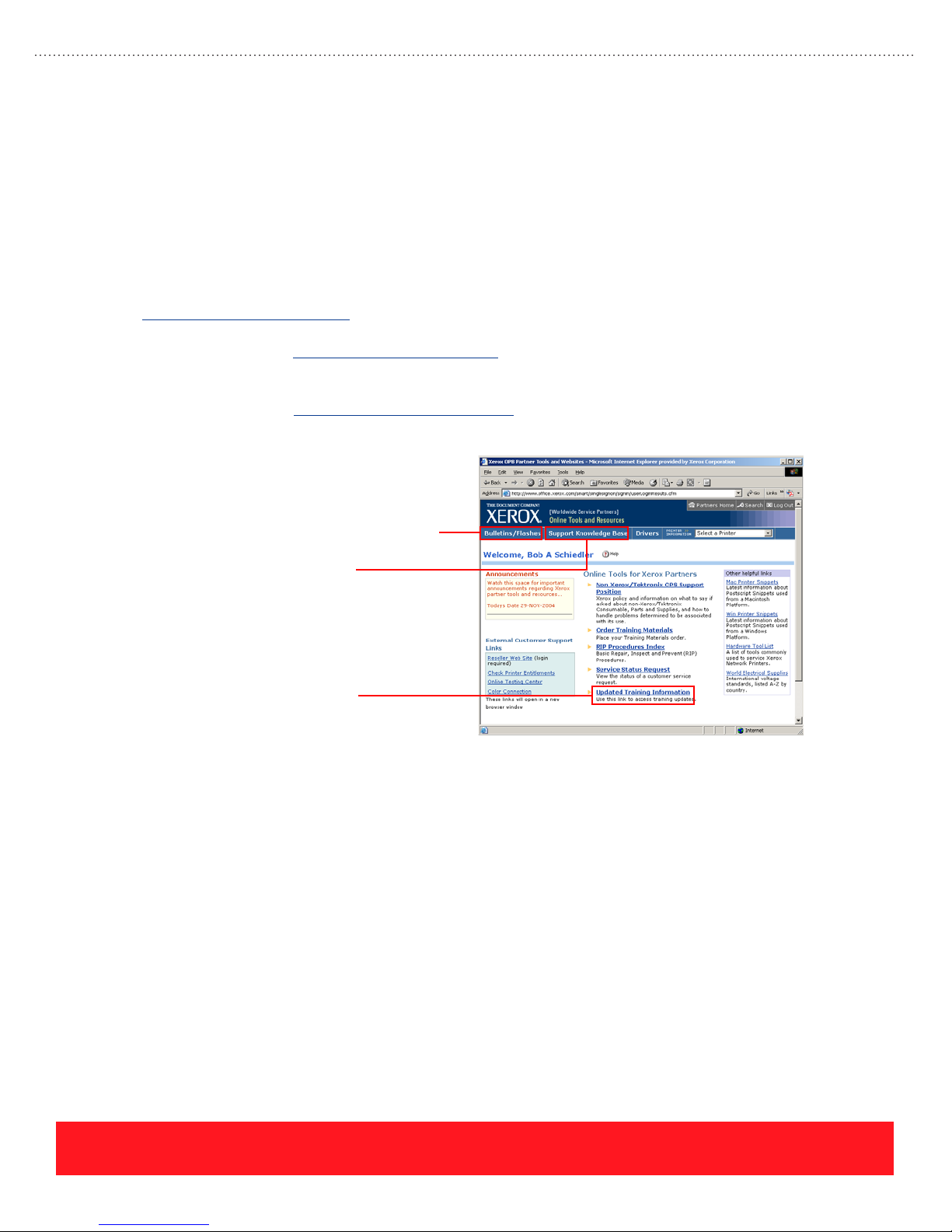

If You Need Help

To obtain the most current updates, tips, and bulletins, visit the Partner Resources site at

www.xerox.com/office/partners, or the training update site at one of these locations:

Internet Access: www.xerox.com/office/training

■ Requires login (user name and password)

Intranet Access: cpidserv.opbu.xerox.com/training

■ Requires intranet access, located behind Xerox firewall

Service Bulletins & Flashes

Knowledge Base

Training Updates

Certified technicians should use the Updated Training Information link to access updated training and

general reference material. The site includes links to Frequently Asked Questions for training. It also includes

Certification Checklists for all training programs.

How to Contact Xerox Product Training & Information

Xerox wants to help you successfully complete this training course. If you need assistance with any part of

the training, please contact us through the Contact Us link located on the Testing Center web page, or by

using the following email address and telephone number:

■ E-mail: support.training@office.xerox.com

■ Phone: (503) 685-4400 (North America only)

page 6

PHASER 8550, 8500, & 8400 INTRODUCTION

Version 1.0

Page 15

Phaser 8550, 8500, & 8400 Service Self-Study Guide

OVERVIEW SECTION

Prerequisites

❑ Overview section of the

Phaser 8550, 8500, &

8400 Product Training

CD-ROM

Time To Complete

❑ Reading: 30 min.

❑ Video run time: 30 min.

❑ Exercises: 20 min.

Equipment Checklist

❑ Phaser 8500/8550 User

Guide (available from

the Resources section

of the training CD-ROM

❑ Adobe

®

Reader

®

Reference Manuals

Electronic copies of the

product manuals, guides,

and instruction sheets are

located on the training

CD-ROM.

Use the training CD-ROM’s

Resources section to access

the manuals and other

documentation.

Overview Objectives

■ Describe the printer configurations, specifications, and features

■ Identify the supported media types, sizes, and capacities

■ Locate sources of information, such as user documentation and software

Before you begin this section of the Self-Study Guide, you should have already

completed the Overview section of the Phaser 8550, 8500, & 8400 Product Training

CD-ROM. The multimedia topic “Configurations & Features” indicates when to

begin the lessons in the Self-Study Guide.

Complete the Overview multimedia lessons on the training

CD-ROM before you begin this section of the Self-Study Guide.

Configurations

This lesson presents the configurations available for the Phaser 8550,

8500, and 8400 printers. A summary of the primary differences between

the printer models is also included.

Phaser 8500 and 8550 Printers

The Phaser 8500 and 8550 printers are the next generation of solid ink technology,

exclusively from Xerox. The Phaser 8500 and 8550 are actually two printer families

targeting two distinctly separate markets.

■ Phaser 8500 - Phaser 8500 printers are for cost-conscious customers who

require the lowest acquisition costs. There are two configurations in the

Phaser 8500 family, each capable of printing up to 24 pages-per-minute.

The base Phaser 8500N configuration is network-ready and the Phaser

8500DN configuration features automatic two-sided (duplex) printing as

well as networking. Both models are network-ready, but only the Phaser

8500DN model features automatic two-sided printing.

■ Phaser 8550 - The Phaser 8550 family prints up to 30 pages-per-minute. Entry

level Phaser 8550DP printers support networking and automatic two-sided

printing. The Phaser 8550DT configuration includes an additional 525-Sheet

Feeder. The fully-featured Phaser 8550DX configuration includes 512 MB of

RAM, two 525-Sheet Feeders, and the advanced printing features associated

with the hard drive.

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 7

Page 16

All Phaser 8500 and 8550 printers include the following standard features:

■ 600 MHz processor ■ USB 2.0 and Ethernet ports

■ First page out time as low as 5 seconds ■ Automatic color corrections

■ 139 PS and 81 PCL resident fonts ■ Standard 1-year, on-site service warranty

■ Support for PostScript 3 and PCL5c ■ PrintingScout, CentreWare IS,

PhaserSMART, & CentreWare Web

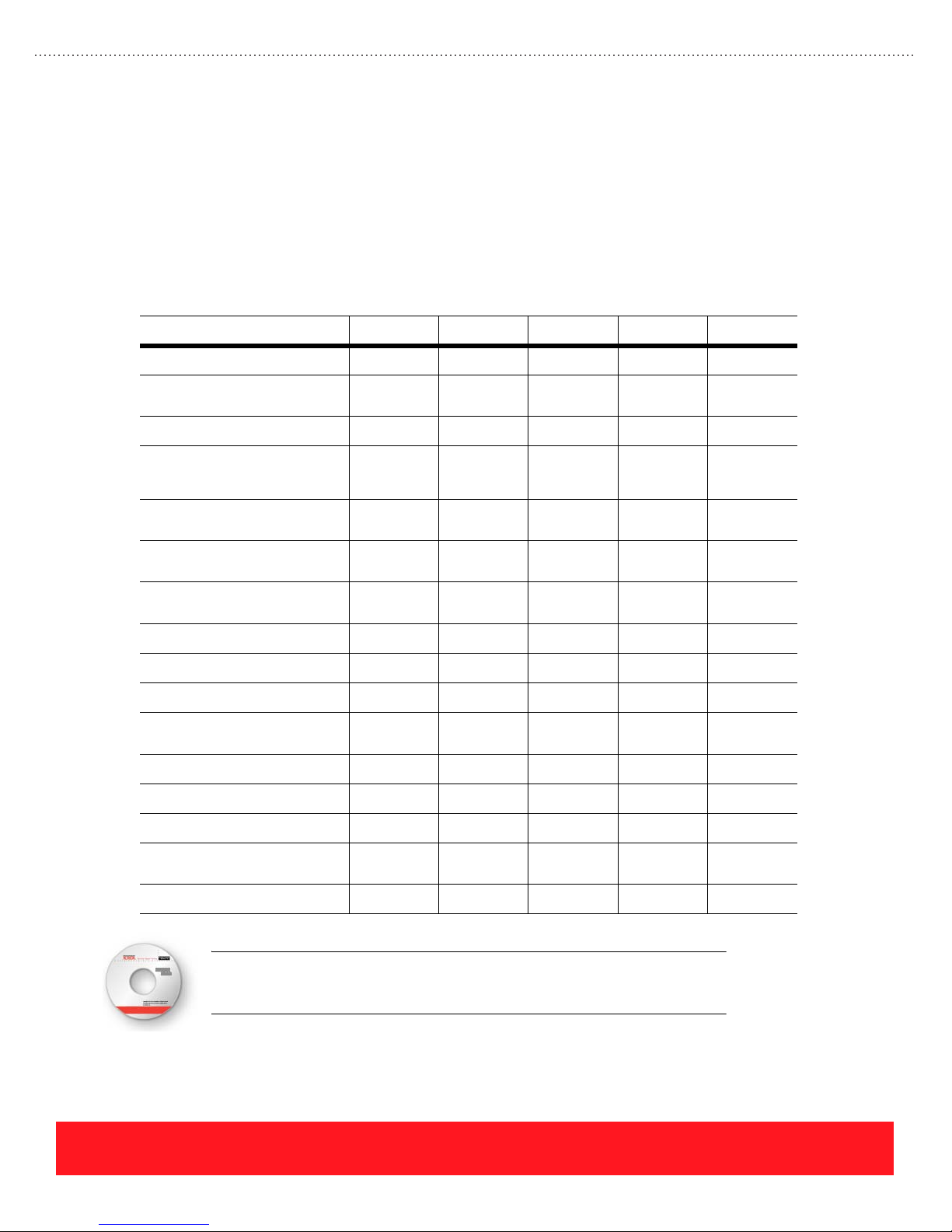

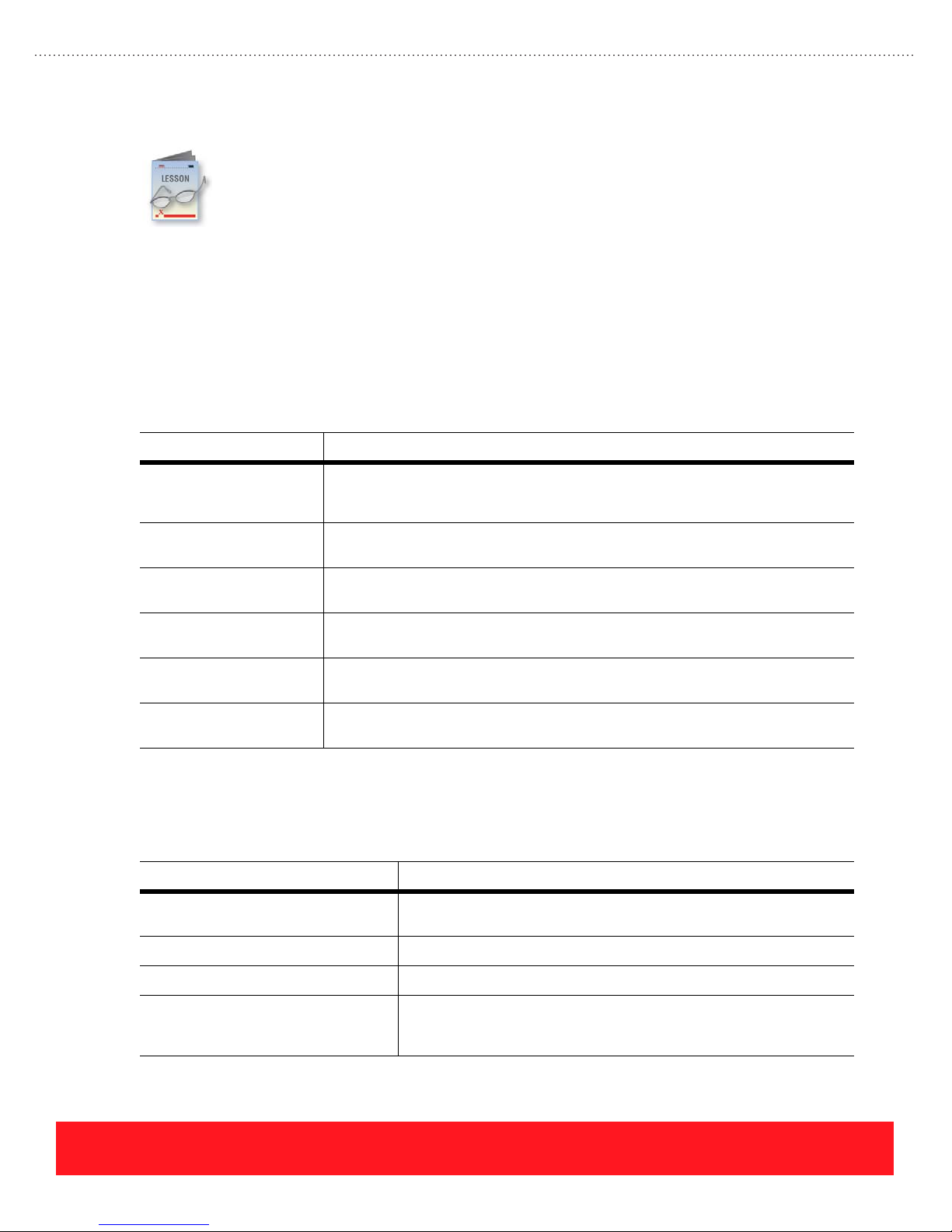

Use the following table to compare the features of each Phaser 8500 and 8550 printer configuration.

Feature 8500N 8500DN 8550DP 8550DT 8550DX

Maximum Print Speed

Minimum First Print Out

Time (FPOT)

Controller

Standard Memory

Maximum

Fast Color & Enhanced Print

Quality Modes

Standard & High Res/Photo

Print Quality Modes

PCL Print Quality Modes

Productivity Kit (Hard Drive)

Automatic 2-Sided Printing

Legal Printing

Connectivity

Pipelining

RAM Collation

24 ppm 24 ppm 30 ppm 30 ppm 30 ppm

6 seconds 6 seconds 5 seconds 5 seconds 5 seconds

600 MHz 600 MHz 600 MHz 600 MHz 600 MHz

128 MB

------------1 GB

128 MB

------------1 GB

256 MB

------------1 GB

256 MB

------------1 GB

512 MB

------------1 GB

33333

No No 333

600 x 300 600 x 300 600 x 300

600 x 600

600 x 300

600 x 600

600 x 300

600 x 600

No Support No Support Optional Optional 3

No 3333

33333

USB &

Ethernet

USB &

Ethernet

USB &

Ethernet

USB &

Ethernet

USB &

Ethernet

No No 333

No No 33No

Disk Collation

Proof/Saved/Secure/

Personal Print

525-Sheet Feeder(s)

An optional multimedia lesson called “Phaser 8500 and 8550 Product Tour” is

available on the training CD-ROM. To access the lesson, select the Resources

section of the training CD-ROM and choose “User Videos”.

page 8

No No Optional Optional 3

No No Optional Optional 3

Optional Optional Optional 1 2

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 17

Phaser 8400 Printers

The Phaser 8400 can be ordered in four configurations: B, N, DP, and DX. A fifth configuration, the BD, is

available by installing an upgrade to Phaser 8400B printers. Each printer has a common set of standard

features, which include the following:

■ 500 MHz processor ■ Support for PostScript 3 and PCL5c

■ Up to 24 full color pages per minute ■ USB 2.0 and bi-directional parallel ports

■ First page out time as low as 6 seconds ■ Automatic color corrections

■ 137 PS and 81 PCL resident fonts ■ Standard 1-year, depot service warranty

■ Fast Color, Standard, Enhanced, and

High Res/Photo Print Quality Modes

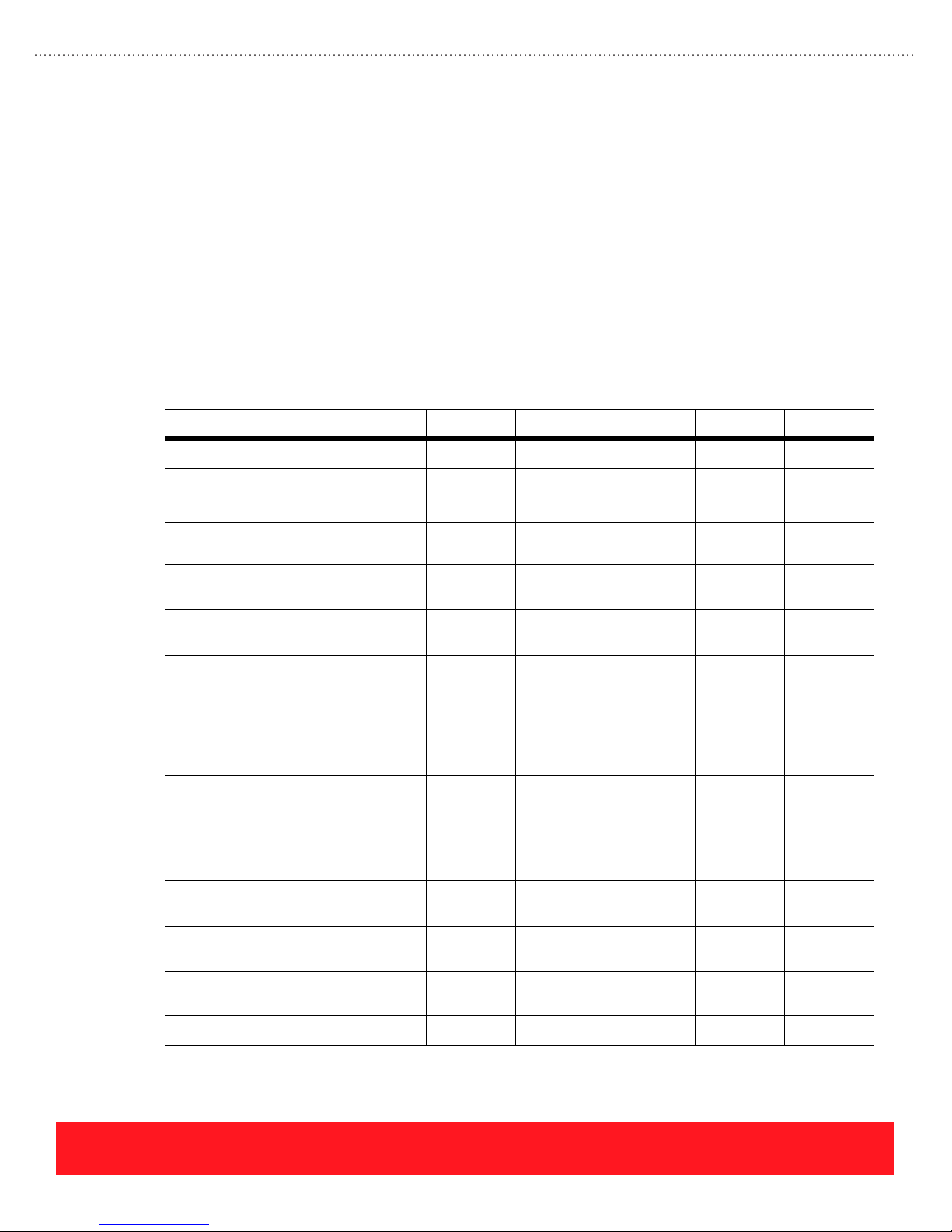

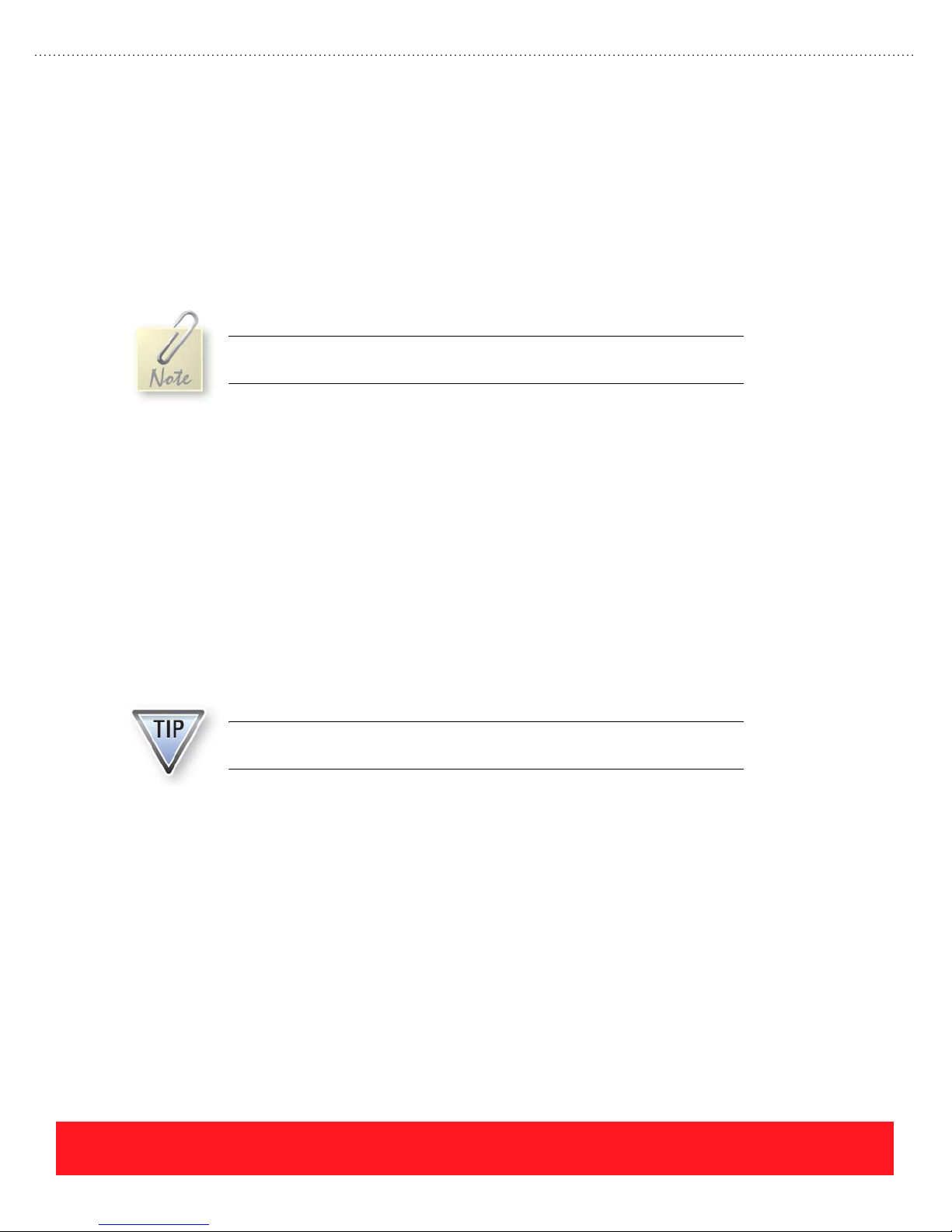

Use the following table to compare the features of each Phaser 8400 printer configuration.

Feature 8400B 8400BD 8400N 8400DP 8400DX

Maximum Print Speed

Standard Memory

Maximum

Fast Color, Standard, Enhanced, &

High Res/Photo Print Quality Modes

PCL Print Quality Modes

Hard Drive

Automatic 2-Sided Printing

Job Pipelining

Legal Printing

Connectivity

PrintingScout, PhaserSMART,

CentreWare IS, & CentreWare Web

Disk Collation

24 ppm 24 ppm 24 ppm 24 ppm 24 ppm

128 MB

------------512 MB

256 MB

------------512 MB

128 MB

------------512 MB

256 MB

------------512 MB

256 MB

------------512 MB

33333

600 x 300

600 x 600

Upgrade

required

Upgrade

required

Upgrade

required

600 x 300

600 x 600

Upgrade

required

3 Upgrade

3 Upgrade

600 x 300

600 x 600

600 x 300

600 x 600

600 x 300

600 x 600

Optional Optional 3

33

required

33

required

33333

Parallel &

USB

Upgrade

required

Upgrade

required

Parallel &

USB

Upgrade

required

Upgrade

required

Parallel,

USB, &

Ethernet

Parallel,

USB, &

Ethernet

Parallel,

USB, &

Ethernet

333

Upgrade

required

Upgrade

required

3

Job Accounting

Proof/Saved/Secure Print

525-Sheet Feeders

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Upgrade

required

Upgrade

required

Upgrade

required

Upgrade

required

50 records 500

records

Upgrade

required

Upgrade

required

5000

records

Optional Optional Optional Optional 1

3

page 9

Page 18

Primary Differences

Phaser 8500 and 8550 printers look and function much like Phaser 8400 printers, but physical differences can

be used to identify the Phaser 8500/8550 print engine, supplies, manuals, and printer software CD-ROM.

There are also differences in the network connectivity and hard drive features.

Print Engine

Key differences between the Phaser 8500/8550 and Phaser 8400 print engines include the Control Panel

menus, communication ports, and customer touch points.

■ Control Panel Menus - The Control Panel menus include several new features and usability

improvements. Use the training CD-ROM’s Resources section to view or print Menu Maps for the

Phaser 8400 and Phaser 8500/8550 printers.

■ Communications Ports - Ethernet and USB ports are standard on all Phaser 8500 and 8550

models. A parallel port is not provided. In comparison, all Phaser 8400 printers include parallel

and USB ports. Only the Phaser 8400N, DP, and DX configurations provide an Ethernet port.

■ Customer Touch Points - Most customer touch points are green plastic on Phaser 8400 printers.

On Phaser 8500 and 8550 printers, the same parts are white with green labels. Customers use the

touch points to perform maintenance functions such as clearing jams and replacing supplies.

Printer Supplies

Phaser 8500/8550 supplies are similar to Phaser 8400 supplies but are not interchangeable. Refer to

“Supplies” on page 49 for more information on the ink sticks and Maintenance Kits.

■ Ink Sticks - Phaser 8500/8550 ink sticks have unique shapes and are not interchangeable with

other printers. The same inks are used in Phaser 8500 and 8550 models.

■ Ink Status - When Phaser 8500 and 8550 printers run out of ink, the Control Panel display

indicates which color must be loaded. Phaser 8400 printers indicate when ink is low, but the user

must open the ink loader to visually determine which color is low.

■ Maintenance Kit - Customers can tell

the difference between Phaser 8400 and

Phaser 8500/8550 Maintenance Kits by

Phaser 8500/8550

Printer Model

checking the label on the bottom of the

kit as shown to the right. The label for

Phaser 8500/8550 Maintenance Kits

includes the product type. Phaser 8400

Maintenance Kit labels have no product

identification.

Software & Documentation

Phaser 8400 printers include a User Documentation CD-ROM and a Printer Installer & Utilities CD-ROM.

The Phaser 8500 and 8550 printer software and user documentation is provided on a single Software and

Documentation CD-ROM. Installing the Phaser 8500 and 8550 software also loads a utility called the Xerox

Support Centre. This utility provides access to the user documentation and printer driver settings, online

documentation, and troubleshooting tools. See “Xerox Support Centre” on page 26 for details.

page 10

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 19

Network Connectivity

Network connectivity is standard for the Phaser 8400N, DP, and DX printers and all Phaser 8500 and 8550

configurations. Each model supports PhaserSMART, PrintingScout, MaiLinX, and the Usage Analysis Tool,

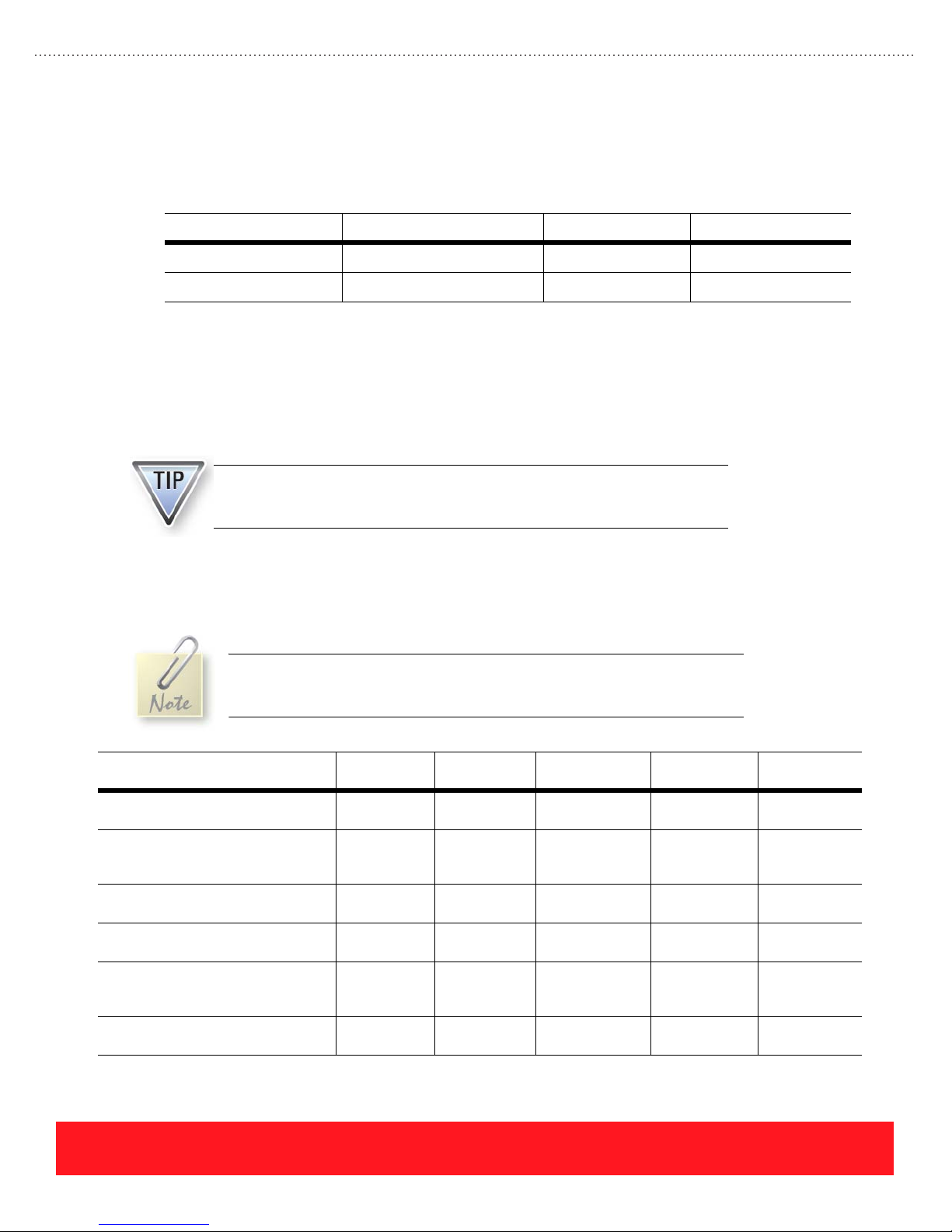

but there are differences in support for network protocols and CentreWare as shown below:

Network Connectivity 8400N, DP, & DX 8500N & DN 8550DP, DT, & DX

Network Protocols TCP/IP, IPX/SPX, & EtherTalk TCP/IP & EtherTalk TCP/IP & EtherTalk

CentreWare Web, IS, DP, & MC Web, IS, & MC Web, IS, & MC

Hard Drive Features

The hard drive for Phaser 8550 printers is called the “Productivity Kit”. It is standard on the Phaser 8550DX

configuration and is available as an upgrade for Phaser 8550DP and DT configurations. The Productivity Kit

disables RAM collation because it provides disk space for the collation process. It also enables Personal

Print, a Walk-Up Feature that is not available in Phaser 8400 printers.

Although disk collation and Proof, Saved, Secure, and Personal Print are

available after installing the Productivity Kit into Phaser 8500 printers, these

features are not supported or tested.

The Phaser 8400DX configuration includes the hard drive. When Phaser 8400 printers have the DX feature

set, the hard drive provides the most complete set of features. Installing a hard drive into the Phaser 8400N

and DP configurations provides a limited set of features as shown in the following table.

A hard drive can be installed into Phaser 8400N and 8400DP printers, but

features including Collation and Proof/Saved/Secure Print will not be

supported unless the feature set is also upgraded to DX.

Features After Upgrade 8400N & DP

(Upgrade)

Disk Collation DX upgrade

Walk-Up Features DX upgrade

Support for Print-Ready Document

Manager Via CentreWare IS

Storage for CentreWare IS

Context-Sensitive Help

Increased Storage for Fonts,

Macros, Systart Jobs, & Job

Accounting Records

User Manuals, Videos, & Drivers 33Not supported

required

required

DX upgrade

required

DX upgrade

required

33Not supported

8400DX

(Standard)

3 Not supported

Proof,

Saved,

Secure

3 Not supported

3 Not supported

8500N & DN

(Unsupported)

or tested

Not supported

or tested

or tested

or tested

or tested

or tested

8550DP & DT

(Upgrade)

33

Proof, Saved,

Secure,

Personal

33

33

33

33

8550DX

(Standard)

Proof, Saved,

Secure,

Personal

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 11

Page 20

Options & Upgrades

The Phaser 8400, 8500, and 8550 options and upgrade kits include extra memory, the 525-Sheet

Feeder, the hard drive (Productivity Kit), and configuration upgrades.

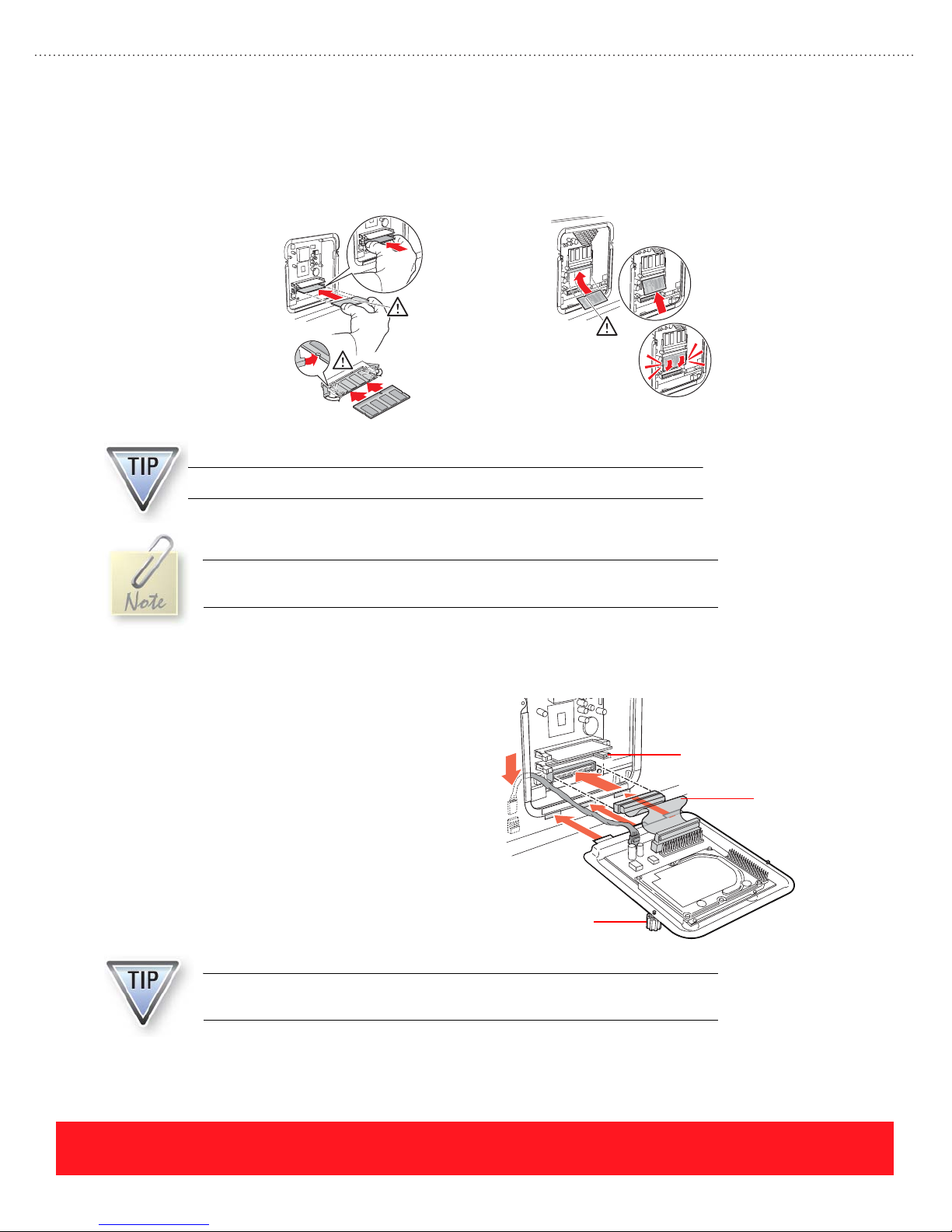

Memory

The Phaser 8400, 8500, and 8550 printers each provide two memory slots. Phaser 8500/8550 memory

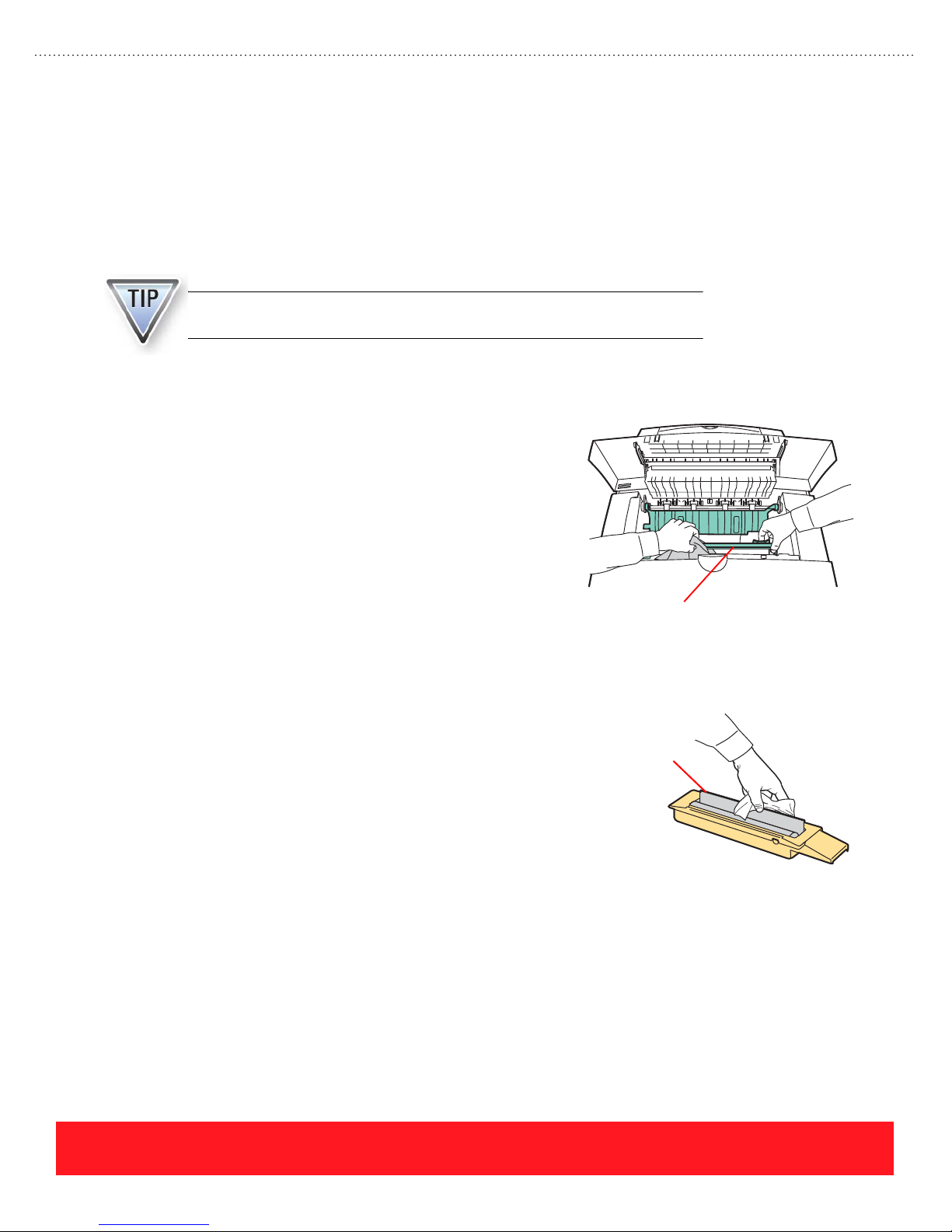

modules are physically different than Phaser 8400 modules and are not interchangeable. Memory is located

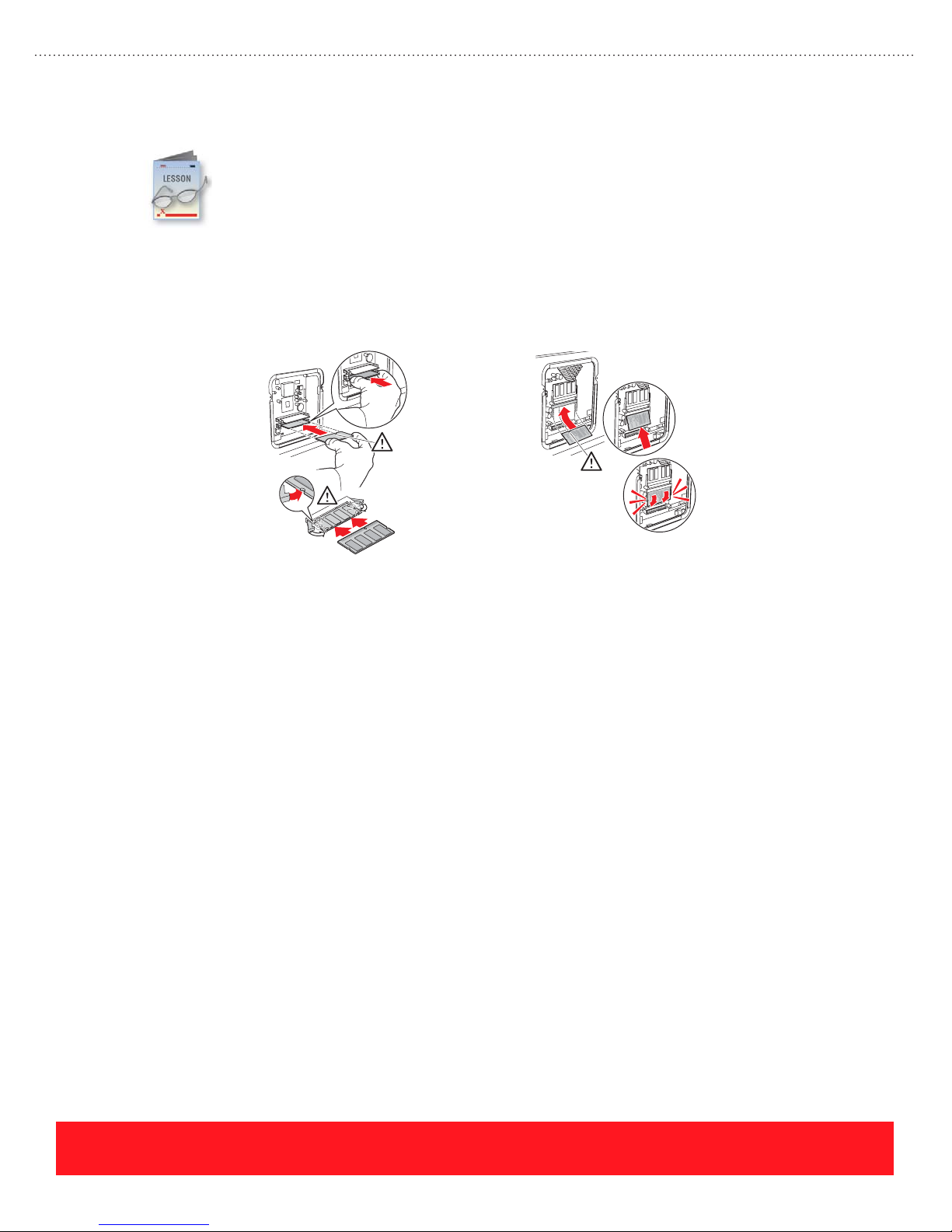

behind the option cover on both models, but a different installation procedure is required as shown below.

4

Installing Phaser 8400 Memory Installing Phaser 8500/8550 Memory

Phaser 8400 Memory

Phaser 8400 printers include either 128 or 256 MB of memory, so customers will rarely need to install more

RAM. The benefits of adding memory include the following:

■ Increased frame buffer size can improve printing throughput for complex jobs

■ On Phaser 8400N printers with 128 MB of RAM and no hard drive, additional memory increases

the job accounting record capacity from 50 to 500

■ At least 256 MB of memory is required for automatic two-sided printing

The printer supports PC133-compliant, 128 and 256 MB DIMMs. One or two memory DIMMs may be

installed. The supported memory configurations are 128, 256, 384, and 512 MB (any combination of 128 and

256 MB DIMMs).

Phaser 8500 and 8550 Memory

Phaser 8500/8550 printers support more memory than Phaser 8400 printers (1 GB vs. 512 MB) using 128,

256, and 512 MB memory modules. The printers support combinations of 128, 256, and 512 MB modules

(supported configurations are 256, 384, 512, 640, 768 MB, and 1 GB). Adding memory provides more space

for RAM collation, which is supported by Phaser 8550 models with no hard drive. Larger files will

“chunk-collate” when the printer runs short on memory space. Adding memory improves collation and also

increases the frame buffer size to improve printing throughput for complex jobs.

page 12

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 21

525-Sheet Feeder

The 525-Sheet Feeder adds an extra media tray that is interchangeable with Tray 2. Up to two assemblies can

be installed for a total of three 525-sheet trays plus Tray 1 (MPT). For the supported media types and sizes,

refer to the embedded Paper Tips Page, the Quick Reference Guide, or the User Guide. For Phaser 8500 and

8550 printers, also refer to the Recommended Media List at www.xerox.com/office/8500_8550support

The 525-Sheet Feeder for Phaser 8500/8550 and Phaser 8400 printers is

interchangeable.

Hard Drive (Productivity Kit)

The benefits of adding a hard drive depend on the printer’s model and feature set. Installing the Productivity

Kit into Phaser 8550 DP and DT printers adds all the features of the Phaser 8550DX configuration.

Phaser 8500 printers can be upgraded with full functionality, but the features are not tested or supported.

Upgrading Phaser 8400 N and DP printers adds a limited feature set, while Phaser 8400 B and BD printers do

not recognize the hard drive after installation. Refer to “Hard Drive Features” on page 11 for a summary.

Configuration Upgrades

There are no configuration upgrade kits available for Phaser 8500 or 8550 printers. However, customers can

purchase the components needed to upgrade their Phaser 8550 printer. Use the following table as a guide.

.

Configuration Upgrade Parts Required Benefits

Phaser 8550DP to DT 525-Sheet Feeder Increases paper capacity by 525 sheets

Phaser 8550DP to DX Productivity Kit (hard drive)

256 MB memory module

Two 525-Sheet Feeders

Phaser 8550DT to DX Productivity Kit (hard drive)

256 MB memory module

525-Sheet Feeder

NEVER attempt to convert Phaser 8400 printers to Phaser 8500 models or to

convert Phaser 8500 models to Phaser 8550 printers.

Increases paper capacity by 1050 sheets

Adds Proof, Saved, Secure, and Personal Print

features, disk collation, expanded storage for fonts,

and other hard disk features

Increases paper capacity by 525 sheets

Adds Proof, Saved, Secure, and Personal Print

features, disk collation, expanded storage for fonts,

and other hard disk features

Five upgrade kits are available to change the feature set and add functionality to Phaser 8400 printers. Each

kit provides a Configuration Card, which controls the printer’s feature set regardless of the installed options

or total memory. Users can determine their printer’s feature set by selecting the Printer Identification menu

on the Control Panel.

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 13

Page 22

Use the following table to determine the components required to upgrade Phaser 8400 printers. Each kit that

adds automatic two-sided printing includes a 128 MB memory DIMM, because the printer requires 256 MB

of total memory to process duplex pages.

Phaser 8400 Upgrade Upgrade Components New Features

Features

B to N

B to BD

N to DP

N to DX

DP to DX

A 525-Sheet Feeder is not included in the Phaser 8400DX upgrade kits.

Configuration Card

Instructions to access

Ethernet port

Configuration Card

128 MB memory DIMM

Configuration Card

128 MB memory DIMM

Configuration Card

128 MB memory DIMM

Hard drive

Configuration Card

Hard drive

Network connectivity

CentreWare IS, PrintingScout,

troubleshooting via PhaserSMART

Automatic two-sided printing

Job pipelining

Automatic two-sided printing

Job pipelining

Automatic two-sided printing

Job pipelining

All hard drive features including Collation and

Proof/Saved/Secure Printing

All hard drive features including Collation and

Proof/Saved/Secure Printing

Phaser 8400, 8500, and 8550 printers include a variety of features that are common to Xerox

Phaser printers. Refer to the User Guide or Reference Guide for a list of features that may be

selected using the printer driver, Control Panel, and CentreWare IS. This section describes the

Print-Quality Modes, factors that can reduce print speed, printing grayscale images, the “run

black” mode, and the Walk-Up Features.

Speed & Quality

The printer’s Print-Quality Mode establishes the maximum print speed and resolution.This topic describes

the two PCL Print-Quality Modes and four PostScript Print-Quality Modes for Phaser 8400, 8500, and 8550

printers. Recommended uses for each of the PostScript Print-Quality Modes are provided below:

■ Fast Color - Fastest full-color mode, useful for many images, rapidly producing review

documents, previewing work, and rush jobs.

■ Standard - General-purpose mode for full-color printing. Produces crisp, bright prints at high

speed. Recommended for vibrant, saturated color prints.

■ Enhanced - Best mode for business presentations. Produces superior text resolution and smooth

color transitions. Enhanced is the factory default.

page 14

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 23

■ High Resolution/Photo (2400 FinePoint™) - Highest quality mode for color prints. Provides the

best detail and smoothness for photographic images. Produces highest-quality color prints with the

best text resolution and smoothest light colors.

The High Resolution/Photo mode uses image enhancement technology to

produce photo-quality images.

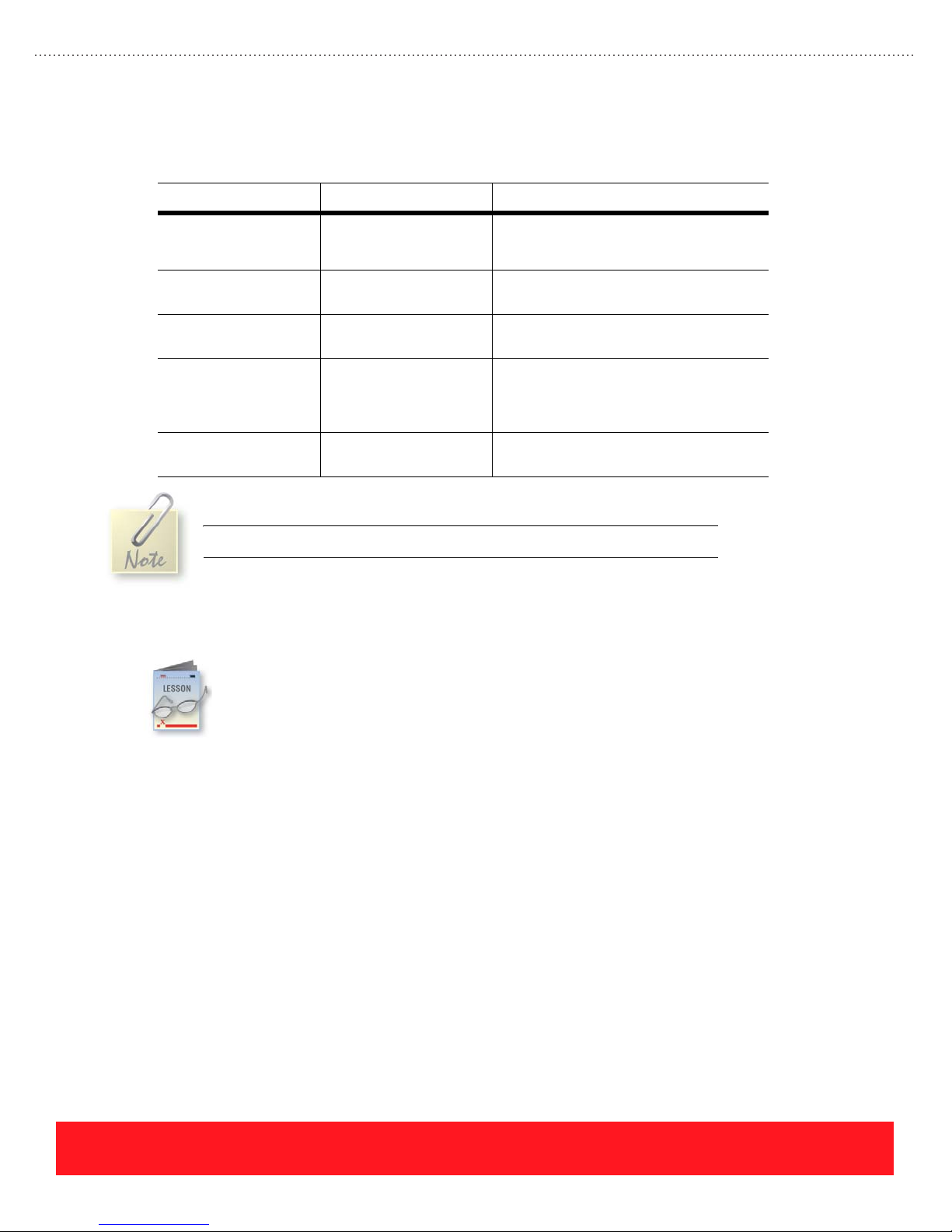

Phaser 8500 and 8550 Print-Quality Modes

The Print-Quality Modes and maximum print speeds are different for the Phaser 8500 and 8550 printers. Use

the chart below to determine the available Print-Quality Modes as well as the maximum print speeds. The

term “ppm” means pages per minute and “spm” means sides per minute for two-sided pages.

Printer

Phaser 8500N

Phaser 8500DN

Trays 2, 3, & 4

Phaser 8550DP

Phaser 8550DT

Phaser 8550DX

Trays 2, 3, & 4

All Models

Tray 1 Only

Fast Color

225 x 400 dpi

24 ppm

30 ppm

20 spm

15 ppm 12 ppm 8 ppm 5 ppm 10 ppm 7 ppm

Standard

300 x 450 dpi

N/A 12 ppm N/A 11 ppm N/A

24 ppm

18 spm

Phaser 8400 Print-Quality Modes

The Print-Quality Modes and maximum print speeds are the same for all Phaser 8400 printers, as shown in

the following chart.

Printer

All Phaser 8400

Configurations

Trays 2, 3, & 4

Fast Color

300 x 300 dpi

24 ppm

17 spm

Standard

300 x 450 dpi

18 ppm

14 spm

Enhanced

(1200 FinePoint™)

16 ppm

13 spm

Enhanced

563 x 400 dpi

12 ppm

10 spm

HighRes/Photo

(2400 FinePoint™)

10 ppm

8 spm

HighRes/Photo

(2400 FinePoint™)

7 ppm

6 spm

PCL 600x300 PCL 600x600

11 ppm 8 ppm

PCL 600x300 PCL 600x600

13 ppm 6 ppm

All Phaser 8400

Configurations

Tray 1 Only

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

12 ppm

10 spm

9 ppm

7 spm

6 ppm

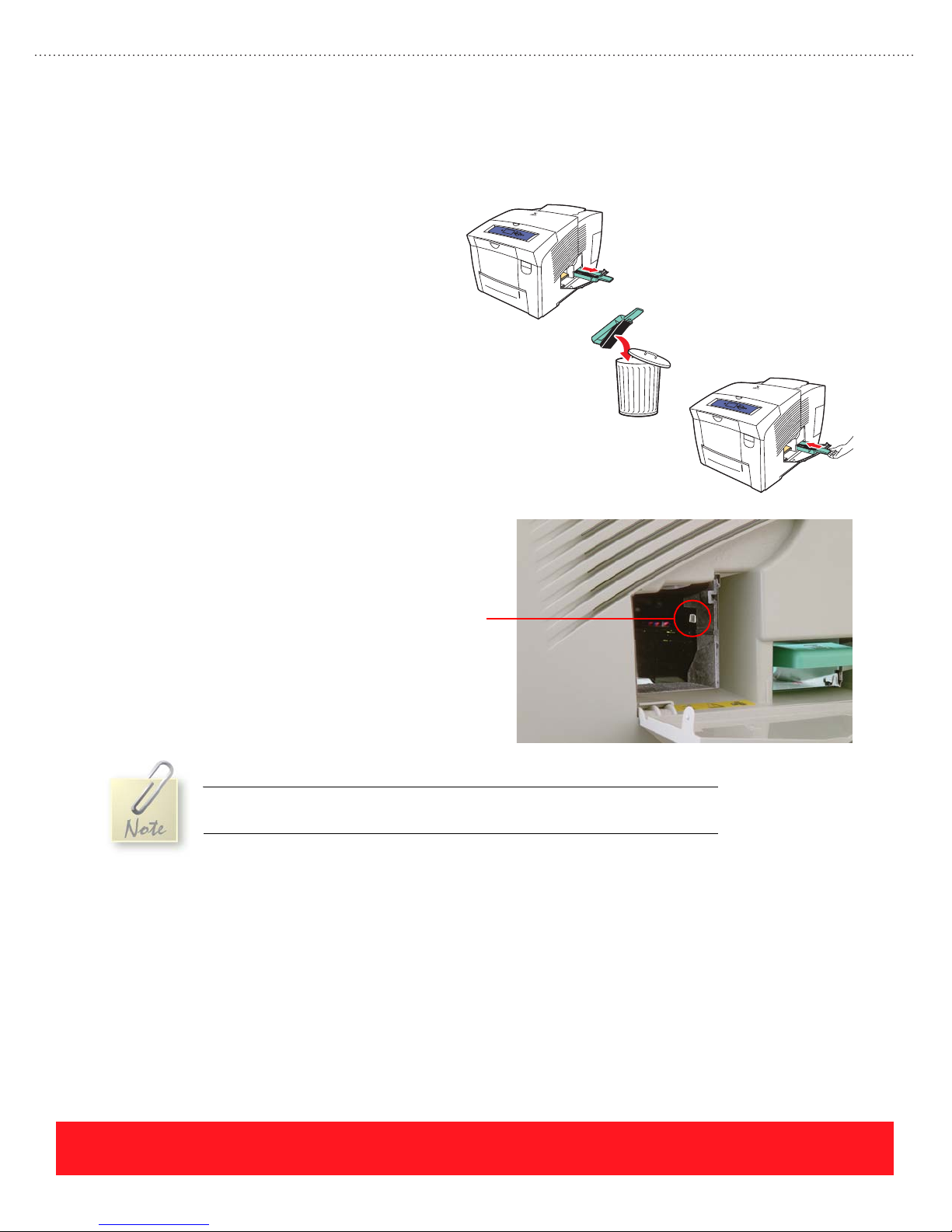

5 spm

3.5 ppm

3 spm

6.5 ppm 3 ppm

page 15

Page 24

Factors That Reduce Print Speed

Many factors, in addition to the Print-Quality Mode and duplex printing, can reduce the print speed:

■ Transparency Jobs - These jobs require a slower transfix speed than printing on paper. A two-pass

printing process is used in the Enhanced and High Resolution/Photo Print-Quality Modes.

■ Legal-Size Jobs - These jobs require a slower transfix speed than printing on A/A4-size sheets.

■ Tray 1 Jobs - Printing from the Tray 1 (MPT) reduces maximum print speeds by approximately

50% when compared to the 525-Sheet Trays.

■ PCL Jobs - The maximum print speed using a PCL driver is slower than printing the same file

using a PostScript driver. To achieve maximum print speeds, use the PostScript printer driver.

■ Jet Substitution Mode - The printer’s Jet Substitution Mode may require more imaging time and

reduce the print speed. Jet Substitution Mode for Phaser 8500 and 8550 printers has less impact on

printer performance and may be used as an end solution for print-quality problems, while the

Phaser 8400 Jet Substitution Mode provides a temporary solution only. Refer to “Jet Substitution”

on page 59 for more information.

Print Grayscale Images

The printer mixes cyan, magenta, and yellow

(CMY) ink with black to improve gradient

fills and gray tones. The combinations of

black and CMY inks vary depending on the

Print-Quality Mode and color correction

setting. Customers can print using only black

ink by selecting the “Black & White” mode,

as shown to the right. Using this mode

avoids color tinting that can occur when

printing composite blacks using CMY and K

inks.

Select “Black

& White” to

Print Using

Black Ink Only

Run Black Mode

When Phaser 8500 and 8550 printers run out of cyan, magenta, or yellow ink, the user is given the choice to

continue printing using black ink only. This capability is known as “run black” mode. Although many other

Phaser printers have the “run black” capability, Phaser 8500 and 8550 printers are the first solid ink models to

include this feature. For example, when Phaser 8400 printers run out of any color of ink, the Control Panel

status LED turns red and the “out of ink” message is displayed. The user must replenish the missing color in

order to continue printing.

If a Phaser 8500 or 8550 printer runs out of CMY ink, users can select the Black & White Color Correction to

continue printing using “run black” mode. Black & White is available on the TekColor driver properties

window shown above. If the printer runs out of cyan, magenta, or yellow ink and no more ink sticks are

available, cancel the current job. To print in “run black” mode, select Black & White and resend the job.

page 16

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 25

Speed & Quality Review Exercise

Use the information provided in this section to recommend solutions for the following customer

examples.

The answers for this exercise are located in the Appendix on page page 89.

1. If a customer indicates that his printer is too slow when printing transparencies, what solution

could you recommend? __________________________________________________________

2. A customer is printing letterhead from Tray 1 using the High Resolution/Photo Print-Quality

Mode. What are two suggestions you can give her to increase the print speed? ______________

_____________________________________________________________________________

3. What advice would you give a customer who has ordered more cyan ink because her printer ran

out of cyan, but she has an immediate need to print a draft copy of her document? ___________

_____________________________________________________________________________

Walk-Up Features

A range of features involving the printer drivers, Control Panel menu, and hard drive are bundled together as

the Walk-Up features. This topic provides an overview of the Walk-Up Printing technology followed by

descriptions of the Walk-Up installation process, Walk-Up features, and the special Walk-Up printer driver.

Walk-Up Printing/Technology

The Phaser 8400, 8500, and 8550 Control Panel

contains the Walk-Up Features menu shown to the

right. This menu provides access to the Walk-Up

Printing menu and the Select for Installation

feature.

■ Walk-Up Printing Menu - Select this

menu to search the printer’s hard drive

for any Proof, Saved, Secure, or Personal

print jobs and to select them for printing.

Only Phaser 8550 printers support

Personal print jobs.

Ph ase r 8400 Ph ase r 8400

Ready to Print

Information

Walk-Up Features

Printer Setup

Troubleshooting

Shut Down

Walk-Up Printing

Select for Installation

Exit

Walk-Up Features

■ Select for Installation - When installing the printer driver, use this feature to identify the printer

for installation over the network (see “Walk-Up Driver Installation” for details).

Walk-Up Driver Installation

The printer’s Walk-Up Installation capability simplifies the printer driver installation process. When

installing a Windows driver, if the installer detects more than one Phaser 8400, 8500, or 8550 printer

connected to an Ethernet network, the option “Use Walk-Up Technology” will appear.

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 17

Page 26

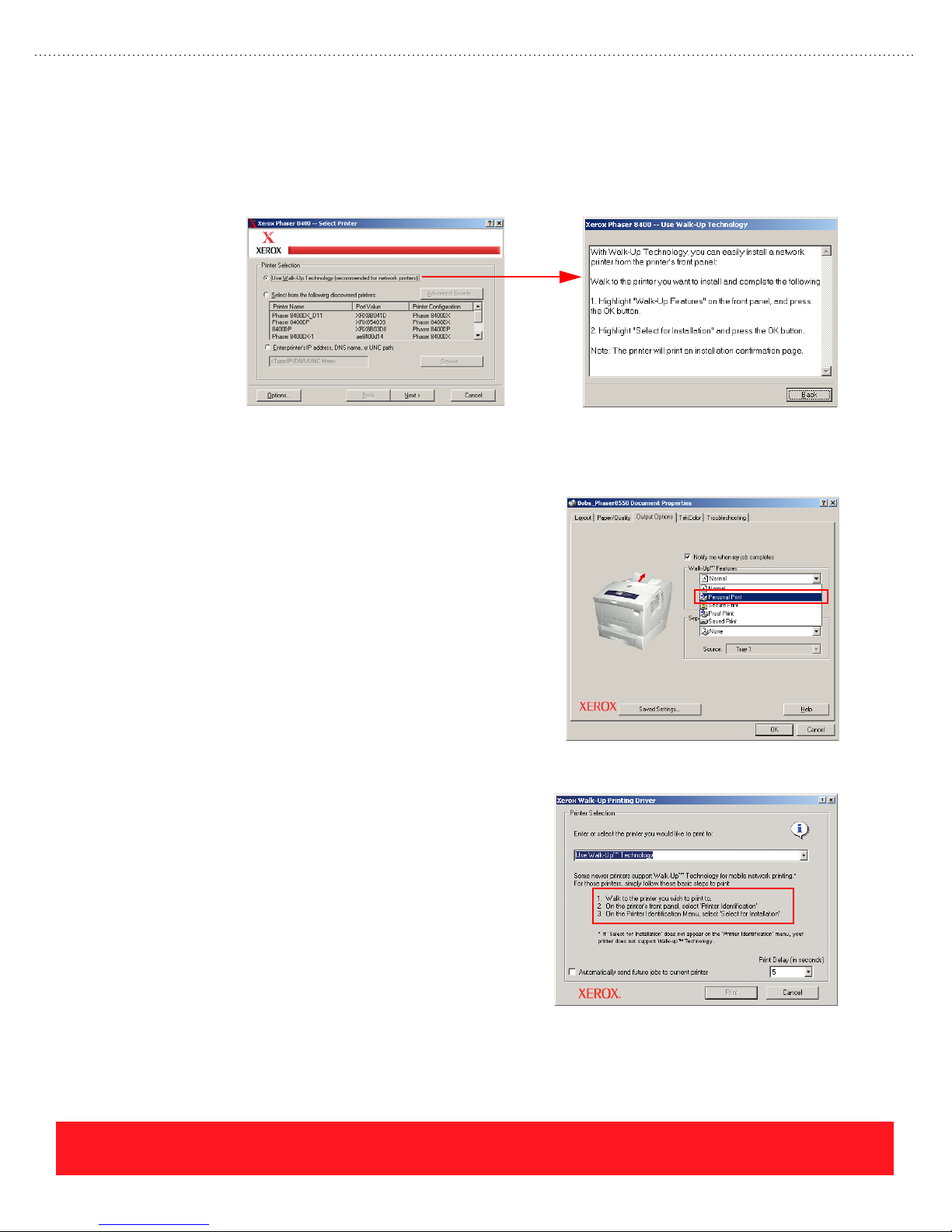

As shown to the left below, the installer provides an option to “Use Walk-Up Technology” for the driver

installation. The installer displays instructions, as shown to the right, which prompt the user to navigate the

Control Panel menus and choose “Select for Installation.” After the user presses the Control Panel’s OK

button, the printer sends its information to the computer. After the printer’s information arrives, the installer

automatically loads the driver for that printer with no more user interaction.

Selecting Walk-Up Driver Installation “Select for Installation” Instructions

Walk-Up Features

When Phaser 8400DX printers and all

Phaser 8550 printers are equipped with a hard

drive or Productivity Kit, users can designate a

job as Proof, Saved, or Secure. These choices are

available in the printer driver’s Walk-Up Features

pull-down menu, shown to the right.

Phaser 8550 printers offer an additional feature

called Personal Print. It provides a virtual mailbox

feature, allowing users to send a job and then print

at their convenience using the printer’s Control

Panel or CentreWare IS.

Walk-Up Driver

The Walk-Up Driver shown to the right is designed for

people who travel frequently, and may have a variety of

different Xerox PostScript office printers available

depending on the user’s current location. Instead of

reinstalling and configuring printer drivers every time they

need to print, the user installs one driver that works with

many Xerox printers. When the user connects to a network

with a Phaser 8400, 8500, or 8550 printer installed, they

can select the Walk-Up Driver, choose “Use Walk-Up

Technology,” and print a job. The computer holds the job

until the user chooses Walk-Up Printing on the printer’s

Control Panel. After the computer receives a signal from

that printer, it sends the job for printing.

page 18

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 27

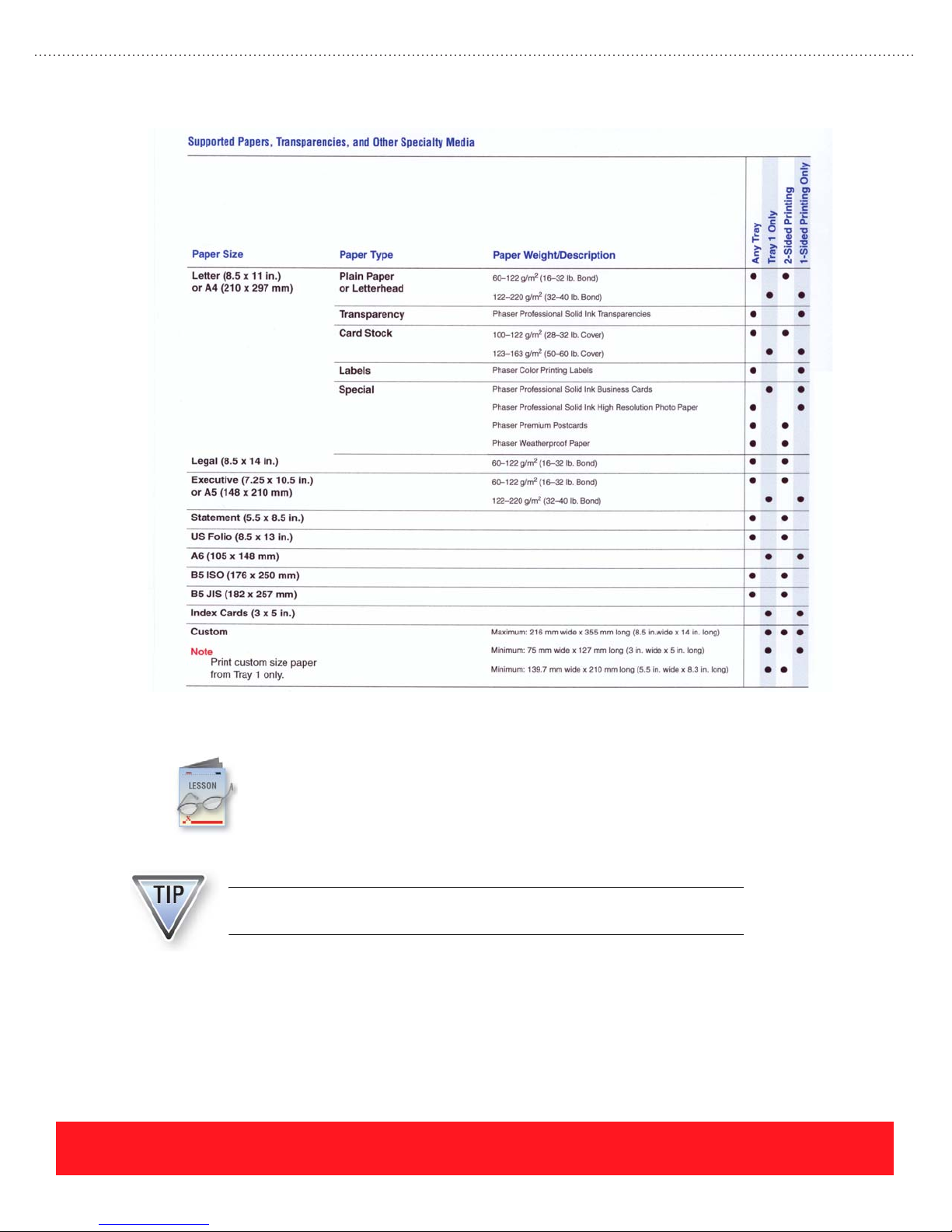

Media Support

based on 20 lb. bond paper (75 g/m

525-Sheet Feeders may be installed to increase the

total paper capacity to 1675 sheets (525 sheets x 3

trays + 100 sheets for Tray 1).

The Recommended Media List for Phaser 8500 and 8550 printers is located online at

www.xerox.com/office/8500_8550support

media available from Xerox. Additional sources for media support include the embedded Paper Tips Page,

the Quick Reference Guide, and the User Guide. These documents provide general information about the

supported media sizes, weights, and types, but they do not provide ordering information.

Phaser 8400 printers do not support Phaser 860 and 8200 Glossy Paper. Some

types of glossy paper will stick to the Transfix Roller, possibly resulting in a

service call. A new Transfix Roller is used in Phaser 8500 and 8550 printers to

correct this problem.

Each Phaser 8400, 8500, and 8550

printer includes a 100-sheet

Multi-Purpose Tray called Tray 1 and a

525-sheet standard media tray called

Tray 2. The capacities of each tray are

2

). Up to two

. This website provides up-to-date information about the current

Tray 1 (MPT)

Tray 2

Tray 3 (Optional)

Tray 4 (Optional)

Tray 1 (MPT)

The Tray 1 (MPT) is optimized for printing on paper that is at least 90 g/m2 (24 lb. bond), although lighter

weights are supported. It handles the widest variety of media types and sizes, including the following:

■ Standard paper sizes:

■ Plain paper up to 220 g/m

■ Card stock up to 163 g/m

■ Phaser Professional Solid Ink Business Cards

■ 10 sizes of envelopes

■ Custom size paper:

Use only the Tray 1 (MPT) for printing on custom sizes, A6 paper, 3 x 5 inch

Index Cards, and Phaser Professional Solid Ink Business Cards.

■ Largest size – Legal (8.5 x 14 in)

■ Smallest sizes – A6 and 3 x 5 inch Index Cards

2

2

■ Minimum dimensions – 75 mm wide x 127 mm long (3 x 5 in)

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 19

Page 28

■ Maximum dimensions – 216 mm wide x 355 mm long (8.5 x 14 in.)

Phaser 8500/8550 printers allow 5 mm margins on all sides of custom size

pages. When printing custom sizes on Phaser 8400 printers, the minimum

page margin is 12.5 mm.

525-Sheet Tray (Trays 2, 3, & 4)

The 525-Sheet Trays have adjustable guides with clearly marked positions that allow the tray to support the

following media sizes and types:

■ Supported sizes – Letter, A4, Legal, Executive, A5, Statement, US Folio, B5 ISO, B5 JIS

■ Supported types:

■ Plain paper from 16 – 32 lb. bond (60 – 120 g/m

2

)

■ Light card stock from 100 – 120 g/m

■ Phaser Professional Solid Ink Transparencies

■ Phaser Professional Solid Ink High Resolution Photo Paper

■ Phaser Premium Postcards

■ Phaser Weatherproof Paper

■ Phaser Trifold Brochures

■ #10 Commercial, DL, and C5 envelopes

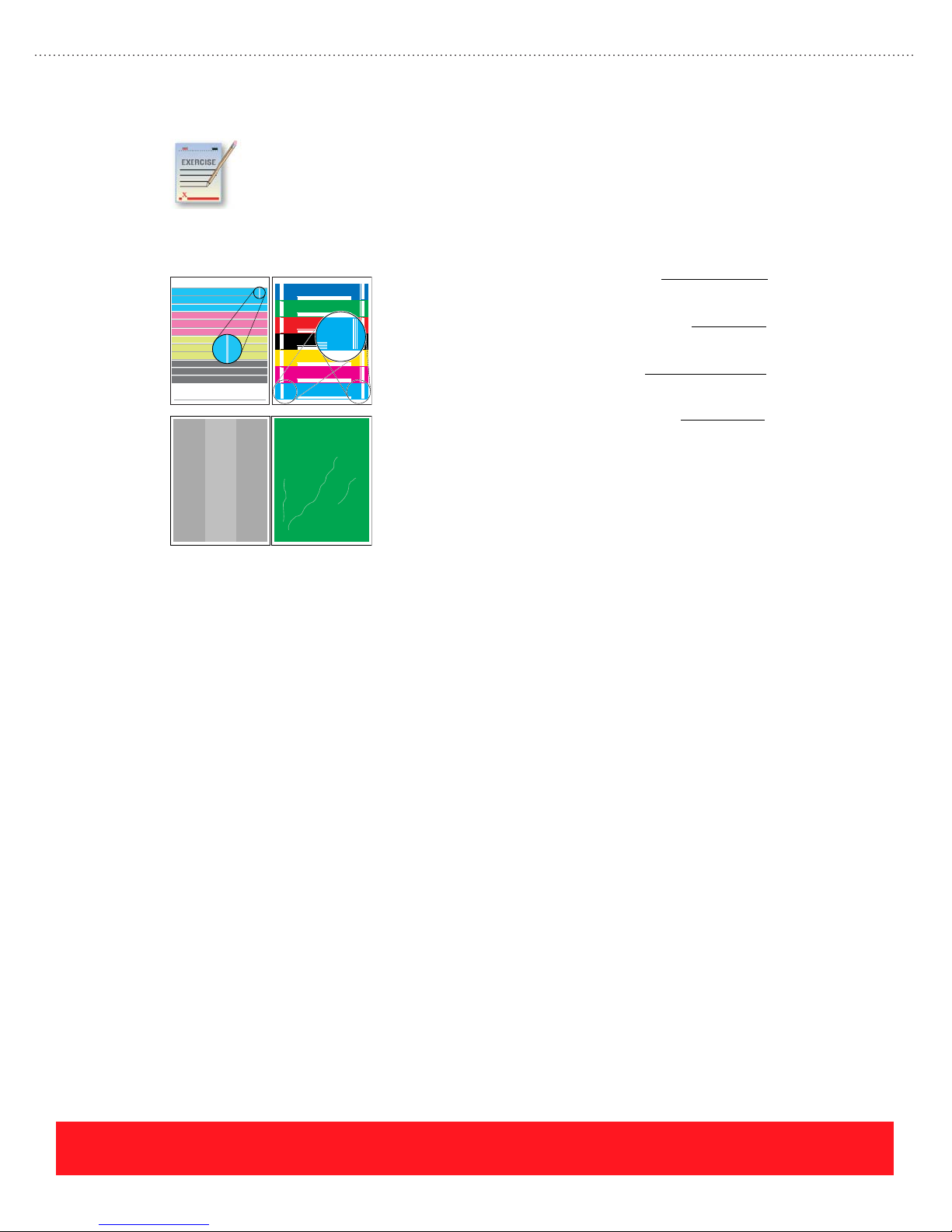

Media Support Review Exercise

Use the chart from the Phaser 8400 Paper Tips Page to determine which of the following

media must be printed using Tray 1.

The answers for this exercise are located in the Appendix on page page 89.

1. 8.5 x 11 inch sheets of 32 lb. bond: ________________________________________________

2. A6-size sheets of 20 lb. plain paper: _______________________________________________

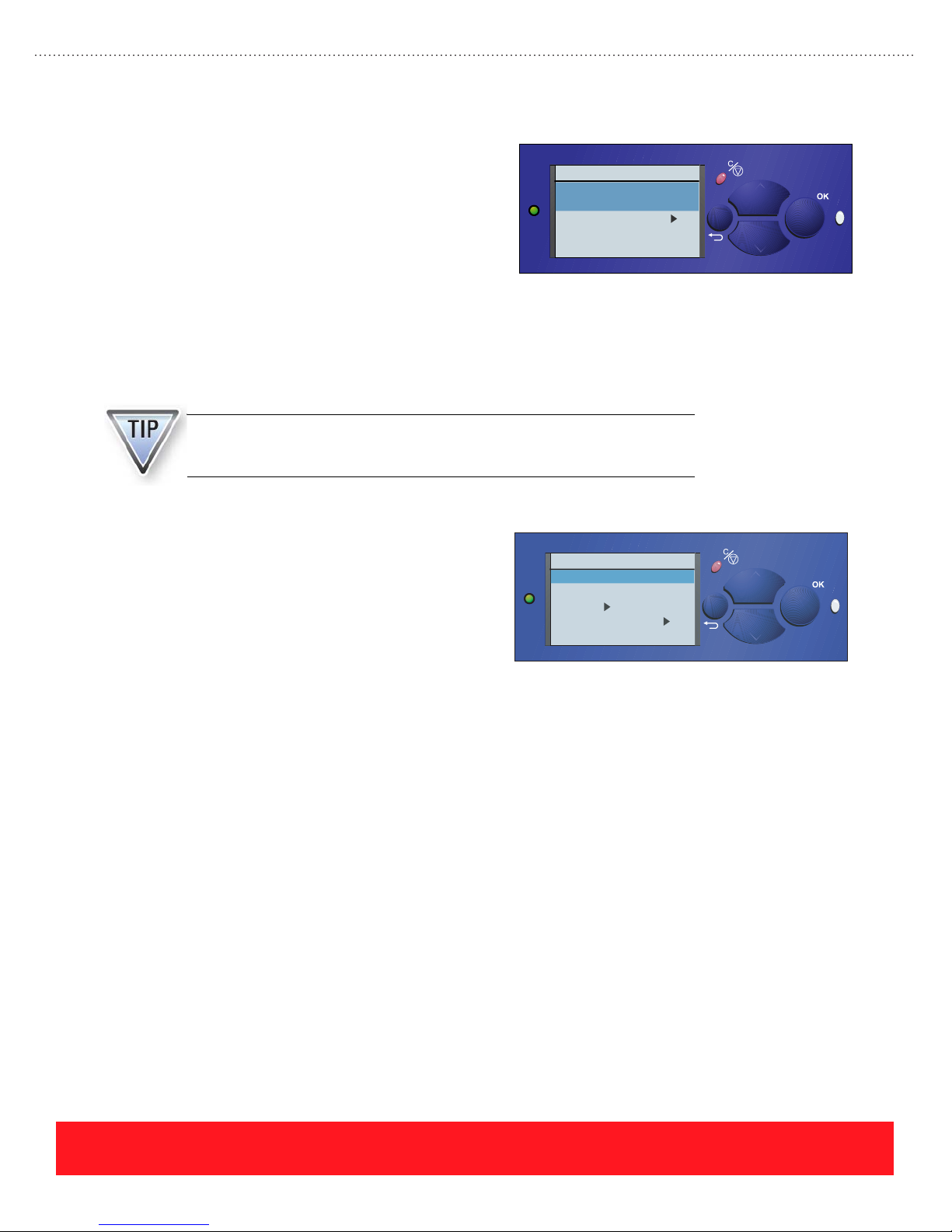

2

3. Phaser Color Printing Labels: _____________________________________________________

4. 100 mm x 200 mm custom-size sheets of 32 lb. plain paper: ____________________________

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 20

Page 29

Documentation & Software

The printers ship with a complete set of user documentation and software. Phaser 8400 printers

have a separate User Documentation CD-ROM and Printer Installer & Utilities CD-ROM. The

Phaser 8500 and 8550 printer drivers and user documentation are delivered on a single Software

and Documentation CD-ROM. This section provides a quick overview of the printed user

documentation, electronic manuals, videos, embedded pages, and drivers & utilities.

Use the Resources section on the training CD-ROM to view or print copies of

the user documentation.

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 21

Page 30

User Manuals & Guides

The following user documentation is available for the printers:

Document Format Content Description

Videos

Setup Guide Printed poster

(standard accessory)

Quick Reference

Guide

User Guide

(Phaser 8500/8550)

Reference Guide

(Phaser 8400)

Advanced Features

Guide

(Phaser 8500/8550

only)

Printed manual

(standard accessory)

Soft copy This manual provides detailed descriptions of the printer

Soft copy

(Internet access

required for viewing)

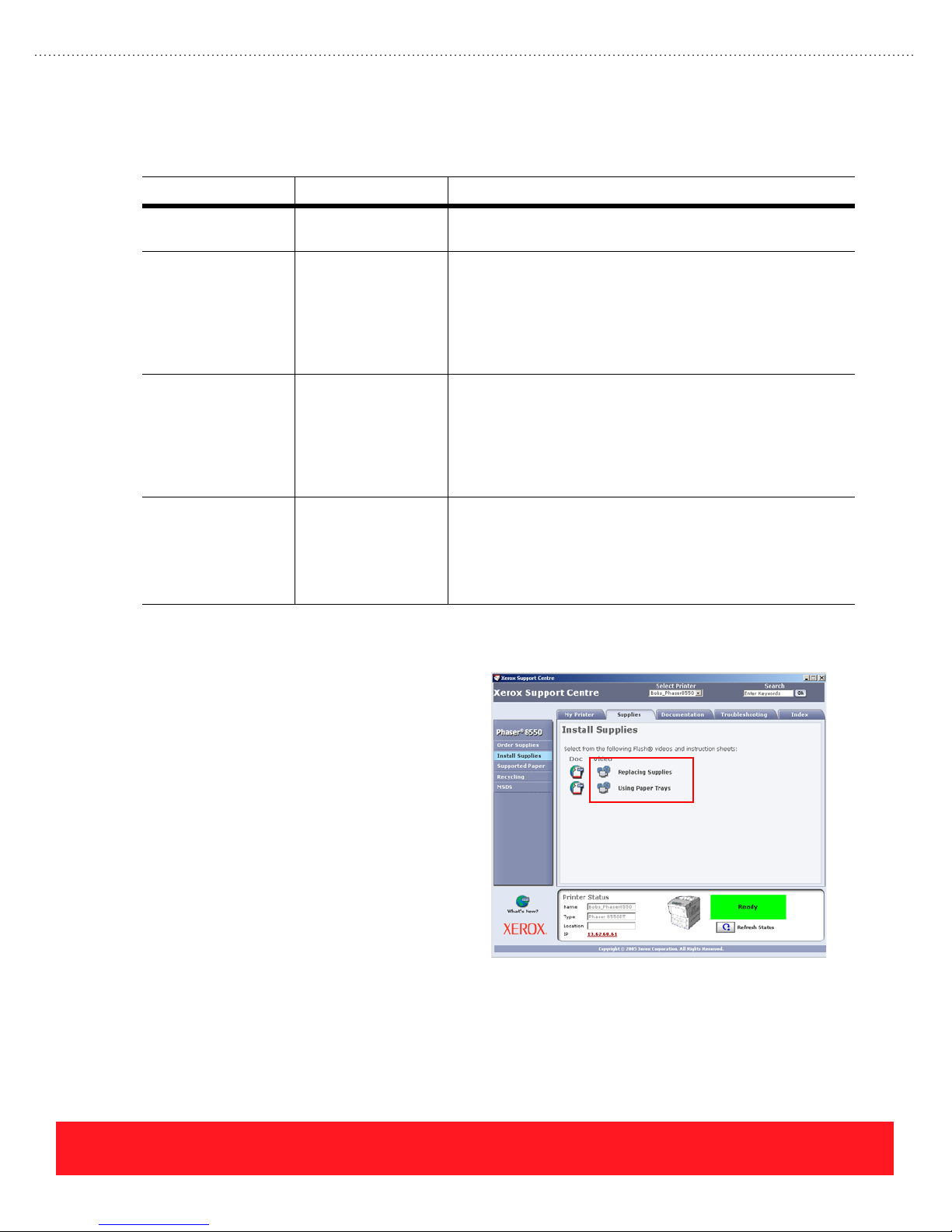

Videos are available to demonstrate the

procedures for installation, printing, and user

maintenance. The videos can be accessed

using CentreWare IS, the Phaser 8400 User

Documentation CD-ROM, or the Phaser

8500/8550 printers’ Xerox Support Centre

shown to the right. Many videos are also

available from the Resources section of the

training CD-ROM.

This printed poster provides visual instructions for installation.

This printed guide should be stored in the printer’s

documentation pocket. It provides the most commonly-needed

user information including tours of the printer and Control

Panel, supported papers, and instructions for basic printing.

Also provided are troubleshooting instructions for print quality

and paper jams. The Phaser 8500/8550 Quick Reference

Guide includes an overview of the Xerox Support Centre.

features, instructions for basic network installation, and

procedures for printing. Additional topics include print quality,

printer maintenance, and troubleshooting. When loading the

Phaser 8500/8550 printer software, a .pdf version of the User

Guide is installed on the user’s computer for access using the

Xerox Support Centre.

An Internet connection is required to access this manual using

the Xerox Support Centre. The guide contains instructions for

using advanced features such as printing in black & white,

booklets, or custom sizes. Instructions are provided for using

Proof, Saved, Secure, or Personal Print, managing fonts,

printing on specialty media, and for networking.

Accessing Videos Using

Xerox Support Centre

page 22

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 31

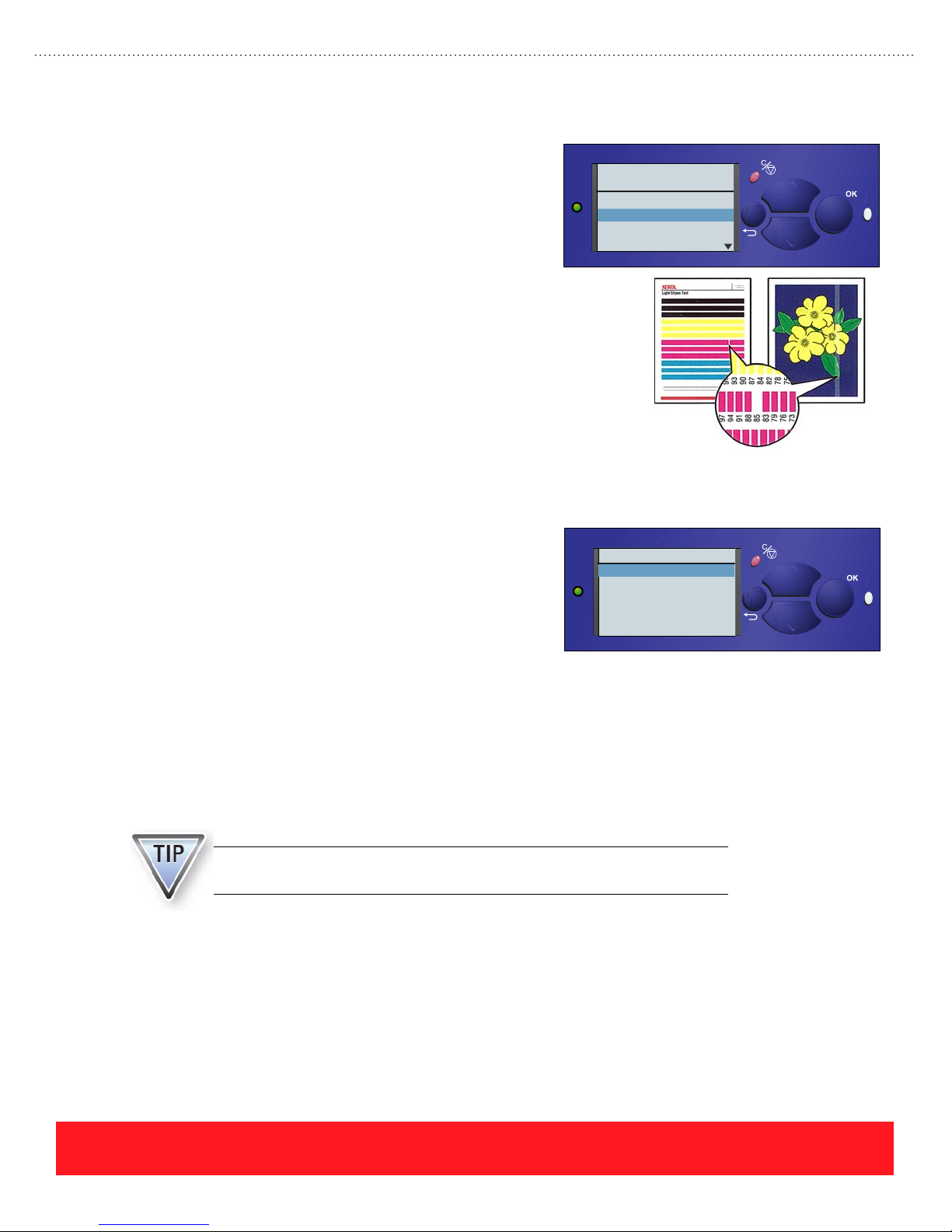

Embedded Pages

The Control Panel provides access to embedded pages for setting up, using, and troubleshooting the printer.

Embedded pages can be located in more than one menu. Study the chart to learn about the most

commonly-used pages.

Embedded Page Menu Location Description

Configuration Page Information

Pages Menu

Connection Setup

Page

Help Guide

(Phaser 8400 only)

Moving Guide

(Phaser 8400 only)

Paper Tips Page Information

Troubleshooti ng Print

Quality Page

Usage Profile Information

Information Menu

Connection Setup

Menu

Information

Pages Menu

Information

Pages Menu

Pages Menu

Troubleshooting

Menu

Print Quality

Menu

Troubleshooting

Menu

Pages Menu

Prints a summary of information that identifies the printer, its

installed options, and settings.

Describes how to connect the printer using the parallel, USB,

and Ethernet ports.

Provides hints and tips for solving printing problems by

directing users to sources of information on a variety of topics.

Provides cautions that apply when moving the printer, and

specific instructions for moving within the office and preparing

the printer for shipment.

Summarizes the supported media types and sizes for each

tray and provides tips for loading the trays to achieve the most

reliable operation.

Helps users get the best colors and print quality by providing

information about media, troubleshooting instructions for the

most common print-quality problems, and color settings such

as Print-Quality Modes and TekColor Color Correction

settings.

Provides usage information such as the average percent

coverage, paper sizes used, and number of color versus black

& white prints.

PDF versions of many embedded pages are available from the Resources

section of the training CD-ROM.

Printer Drivers & Utilities

The drivers and utilities are available from the Xerox website, the Phaser 8400 Printer Installer & Utilities

CD-ROM, the Phaser 8500/8550 Software and Documentation CD-ROM, and the printer’s hard drive (when

installed). The website contains the most up-to-date and comprehensive list of printer drivers.

Always use www.office.xerox.com to access the most current software.

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 23

Page 32

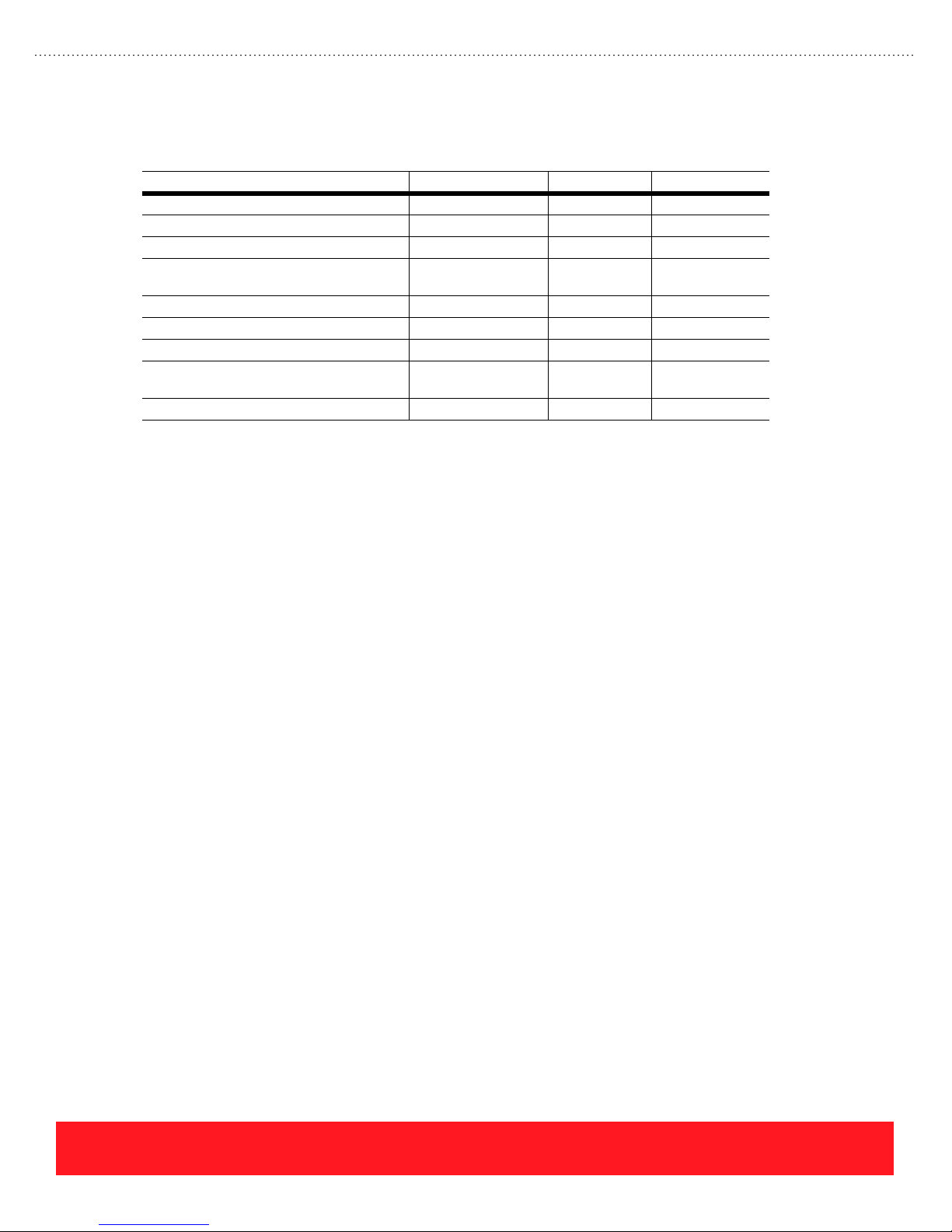

Printer Drivers

Study the chart to determine where to access the supported printer drivers.

Drivers Software CD-ROM Hard Drive Xerox Website

Windows XP/2003 PS Driver Yes Yes Yes

Windows 2000 PS Driver Yes Yes Yes

Windows 98/Me PS Driver Yes Yes Yes

Windows NT PS Driver

(Phaser 8400 only)

Mac OS 10.x Driver Yes Yes Yes

Mac OS 9.x Driver Yes Yes Yes

Windows 2000/XP PCL Drivers No No Yes

Xerox Walk-Up Printer Driver & Installer

for Windows 2000/XP

UNIX Drivers No No Yes

Ye s Ye s Ye s

No No Yes

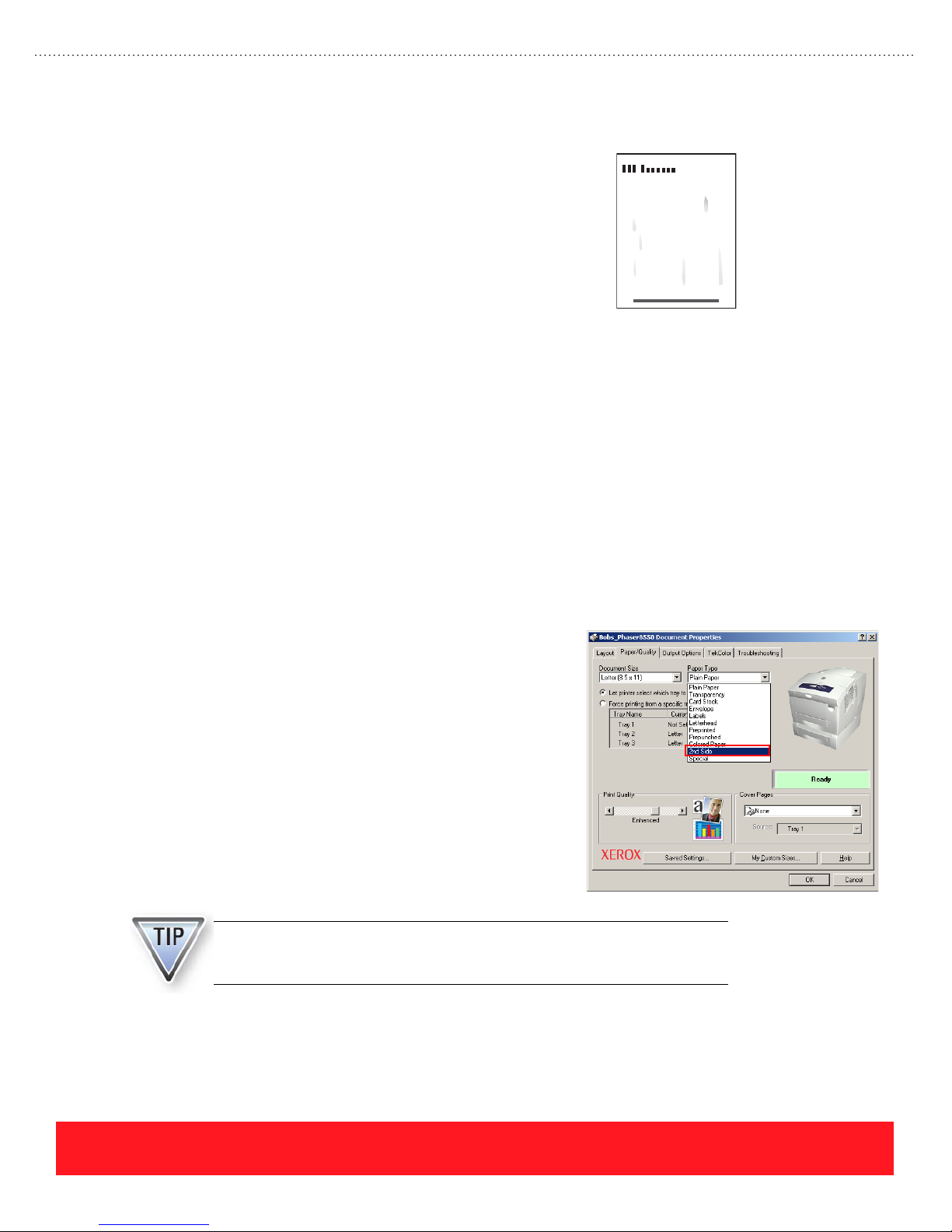

The Phaser 8400, 8500, and 8550 printer drivers are similar, but not identical. Three features that are unique

to the Phaser 8500/8550 printer drivers include Personal Print, the 2nd Side Paper Type, and the Color

Adjustment Sliders:

■ Personal Print - Personal Print provides a virtual mailbox feature, allowing users to send jobs and

then print at their convenience using the printer’s Control Panel or CentreWare IS.

■ 2nd Side - This paper type option provides a workaround to avoid smearing when manually

duplexing preprinted solid-ink pages. Phaser 8500/8550 printers achieve faster print speeds than

Phaser 8400 printers by increasing the preheater temperature. This choice compensates for the

increased temperature.

■ Color Adjustment Sliders - This feature allows advanced users to customize the TekColor Color

Corrections. See “Color Adjustment Sliders” on page 25 for details.

Utilities

The printer utilities listed below are available from the Xerox website to support Phaser 8400, 8500, and

8550 printers. The Usage Analysis Tool enables system administrators to collect, organize, and analyze Job

Accounting data from multiple printers. It is often used to roll up usage statistics by individual users or

groups in order to calculate charge-back billing or to plan for optimized printer deployment.

■ Usage Analysis Tool & Installer

■ MaiLinX Client & Installer

■ Font Management Utility

■ CentreWare Web/MC & Installers (Phaser 8400 also supports CentreWare DP)

■ NDPS Gateway & Installer

page 24

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 33

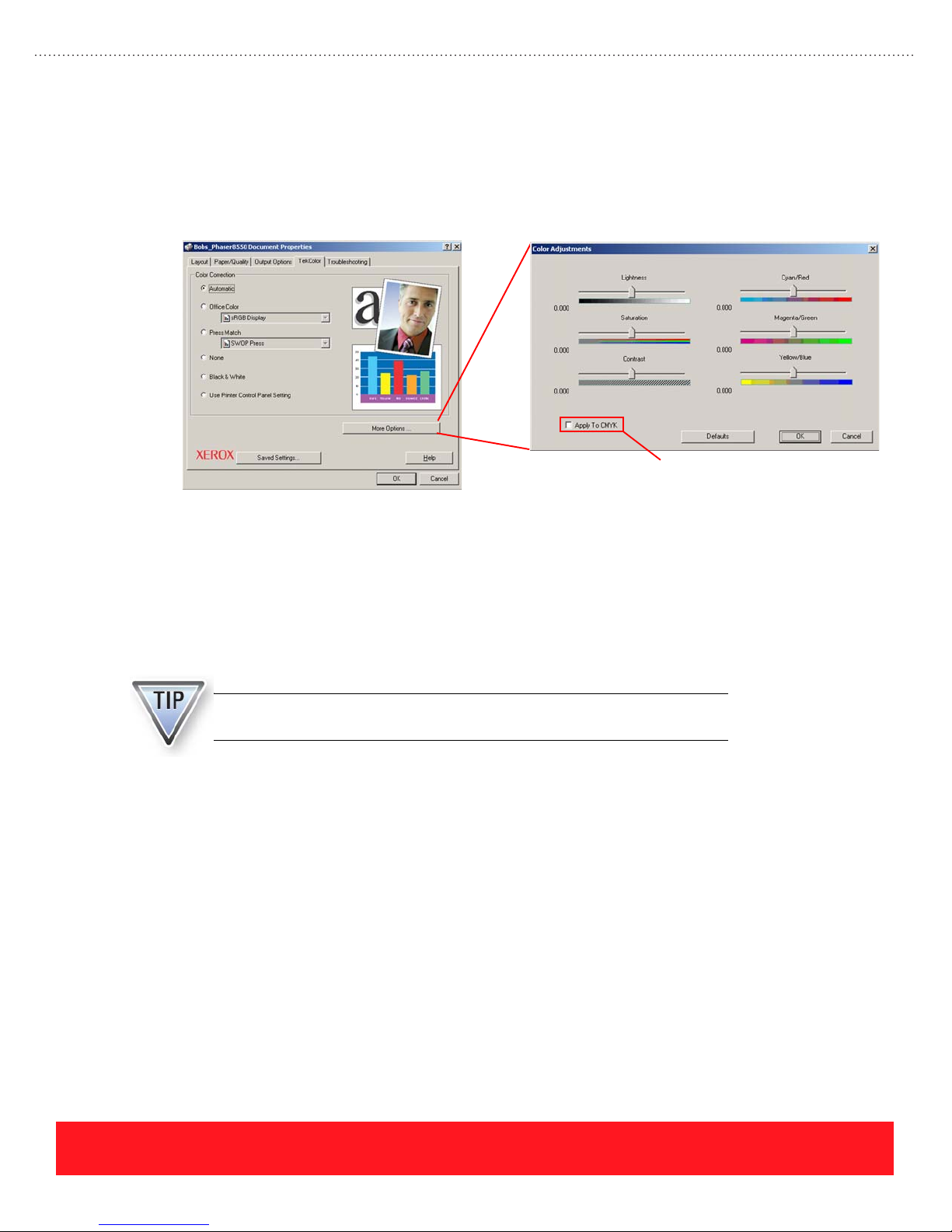

Color Adjustment Sliders

The Phaser 8500 and 8550 TekColor driver properties page contains the standard Color Correction settings in

addition to a “More Options” button. Advanced users can choose this feature to adjust colors for the current

Color Correction setting. If one of the “Press Match” settings are selected, the “Apply to CMYK” checkbox

must also be selected in order to implement the slider settings, as shown in the example below.

Customers who are having color problems should begin the troubleshooting process by defaulting the Color

Adjustments (all sliders set to 0.000). They must also be aware that the adjustments always apply to the

active Color Correction setting. For example, a customer may select the Color Correction “None” and then

adjust the sliders to customize the printed output. If the customer changes the Color Correction to

“Automatic”, the sliders will not default to 0.000. Instead, the Color Adjustments previously selected for

“None” will be applied to the “Automatic” setting. Prints generated in this mode will have different colors

when compared to prints that use the “Automatic” Color Correction and no Color Adjustment.

Select to customize

the “Press Match” settings

When troubleshooting color issues on Phaser 8500 and 8550 printers,

always begin by resetting the Color Adjustment sliders to 0.000 (default).

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

page 25

Page 34

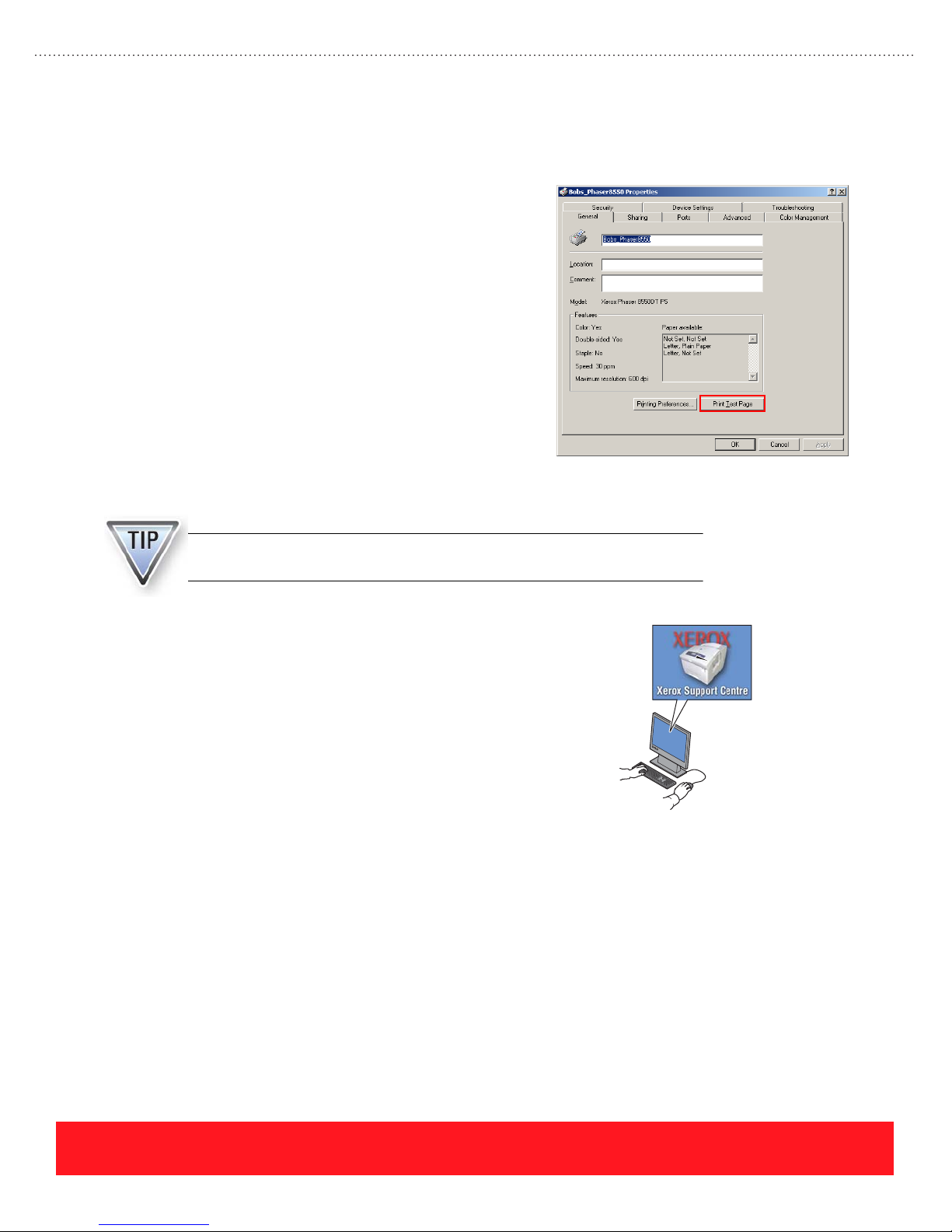

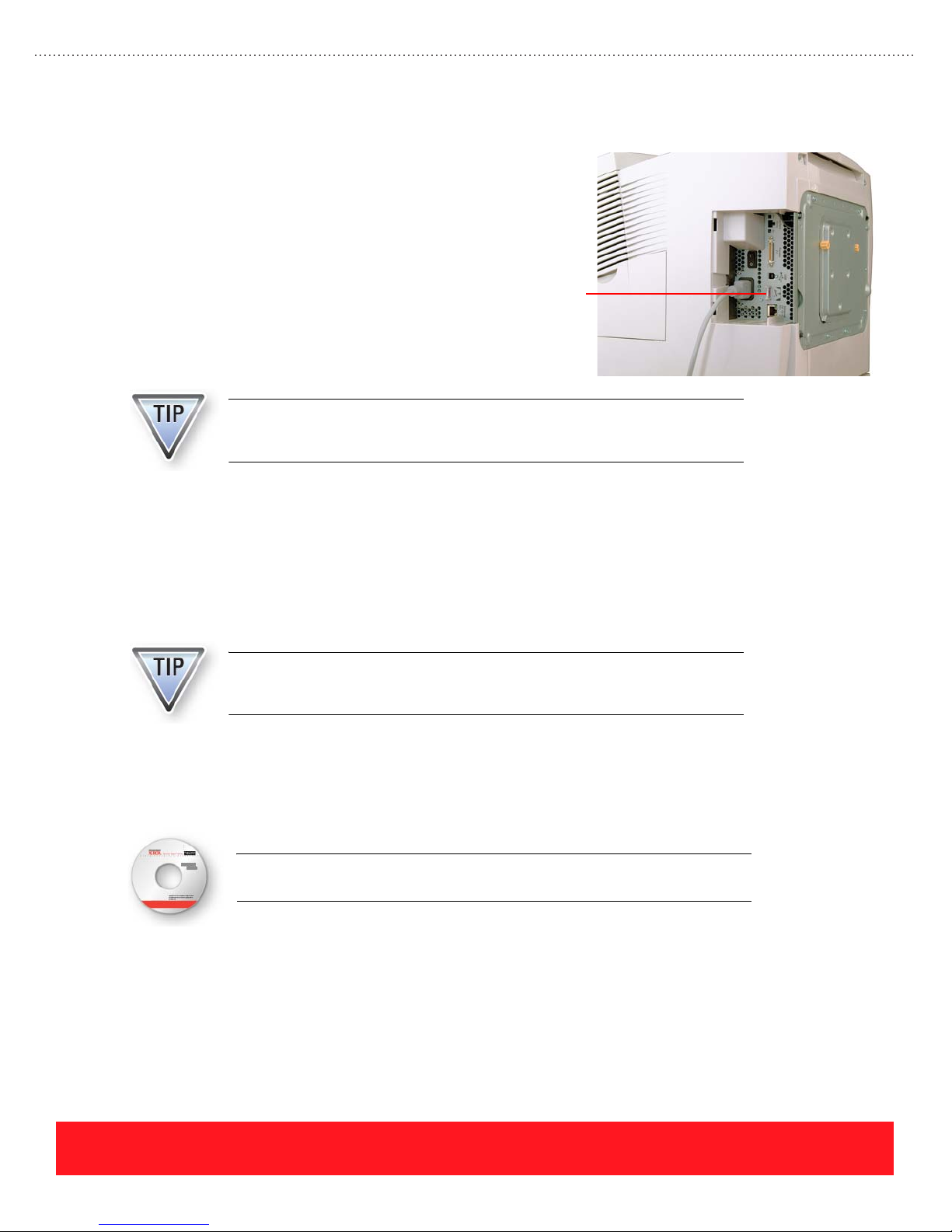

Xerox Support Centre

Loading the Phaser 8500/8550 printer

software installs the Xerox Support Centre in

addition to the printer driver. This utility

provides a single location for accessing user

documentation, setting printer driver

properties, and going online to access features

such as CentreWare IS, support websites, the

knowledge base, and PhaserSMART.

During the software installation, the Installer

creates a shortcut to the Xerox Support Centre

and saves it on the computer desktop. After

the installation completes, the Xerox Support

Centre automatically opens to provide

immediate access to its features.

An optional multimedia lesson called “Xerox Support Centre” is available on

the training CD-ROM. To access the lesson, select the Resources section of

the training CD-ROM and choose “User Videos”.

Your Next Step

You have completed the Overview section of the Self-Study Guide.

Return to the training CD-ROM and complete the Overview Self-Check. Then,

select the Setup section on the CD-ROM to continue.

page 26

PHASER 8550, 8500, & 8400 OVERVIEW SECTION

Version 1.0

Page 35

Phaser 8550, 8500, & 8400 Service Self-Study Guide

SETUP SECTION

Prerequisites

❑ Setup section of the

Phaser 8550, 8500, &

8400 Product Training

CD-ROM

Time To Complete

❑ Reading: 35 min.

❑ Video run time: 20 min.

❑ Exercises: 20 min.

❑ Optional labs: 60 min.

Equipment Checklist

❑ Adobe

❑ Phaser 8500 & 8550

❑ Phaser 8400 Installer &

❑ Phaser 8550, 8500, or

®

Software and

Documentation

CD-ROM (optional)

Utilities CD-ROM

(optional)

8400 printer (optional)

Reader

®

Reference Manuals

Electronic copies of the

product manuals, guides,

and instruction sheets are

located on the training

CD-ROM.

Use the training CD-ROM’s

Resources section to access

the manuals and other

documentation.

Setup Objectives

■ Setup the printer (if printer available)

■ Load paper and specialty media correctly into the trays

■ Navigate the Control Panel menus

■ Test the communication ports

■ Print documents (if printer is available)

■ Install upgrades

Complete the Setup multimedia lessons on the training

CD-ROM before you begin this section of the Self-Study Guide.

This section of the Self-Study Guide contains a lab for setting up the printer (if

available). It also presents information on loading paper and specialty media,

changing Control Panel settings, testing the communication ports, printing

documents, and installing hardware upgrades.

Refer to the Setup Guide and Phaser 8400 Reference Guide or Phaser 8500/8550

User Guide to complete the exercises and optional labs in this section. Electronic

versions are available from the training CD-ROM’s Resources section.

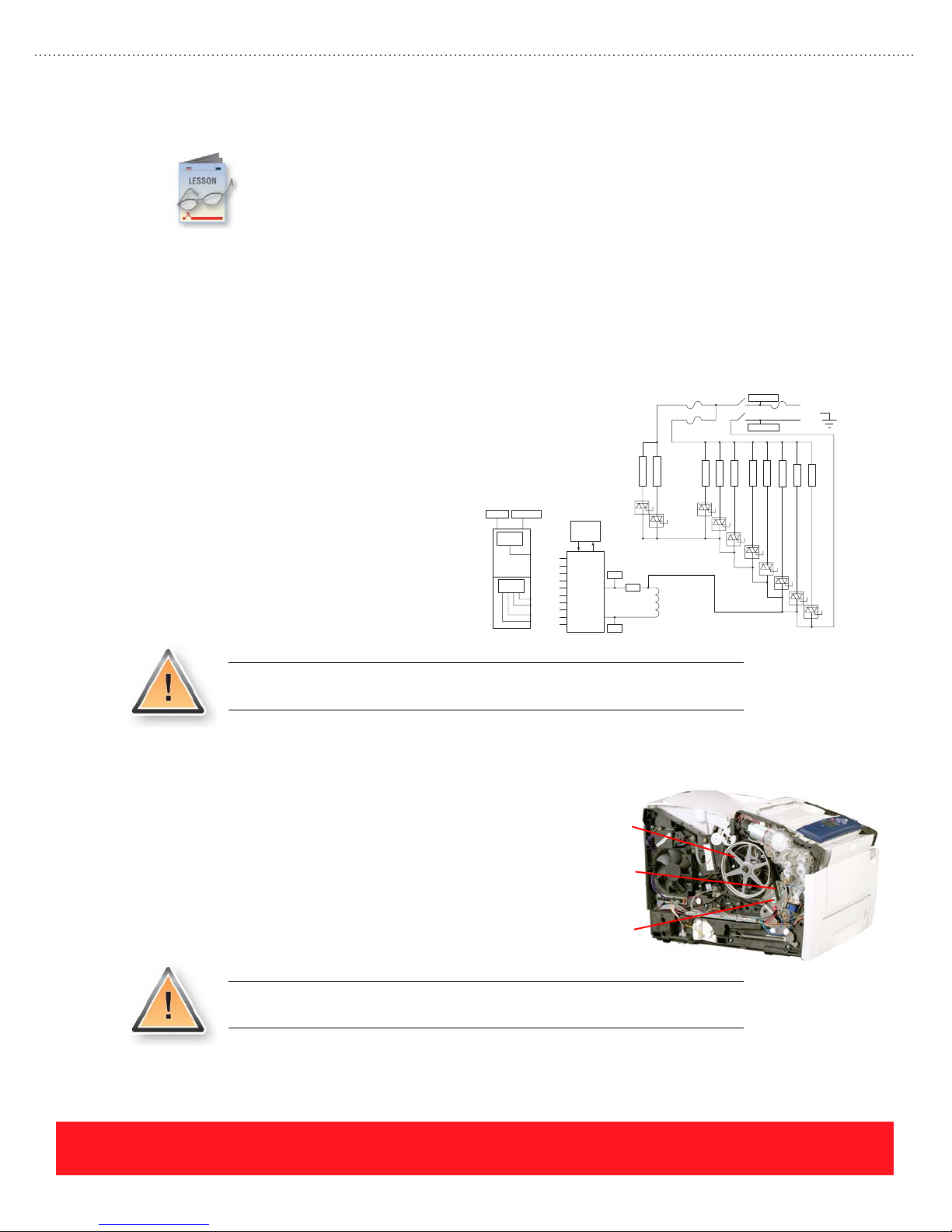

Setting up the Printer

If you have a Phaser 8550, 8500, or 8400 printer, follow the Setup Guide

to unpack and install it now. Use the steps below as a guide to setup and

power on the printer.

PHASER 8550, 8500, & 8400 SETUP SECTION

Version 1.0

1. If necessary, unpack the printer.

2. Choose the printer location and install the 525-Sheet Feeder (if

available) and the printer.

3. Connect the communications and power cables.

4. Turn on the power switch so the printer begins to warm up.

5. If necessary, load ink.

When you reach the steps for loading paper, changing Control

Panel settings, and loading drivers, read the corresponding

lessons and then perform those installation steps on your printer.

page 27

Page 36

Setup Review Exercise

The answers for this exercise are located in the Appendix on page 90.

1. According to the Setup Guide, what is the first step of the installation process? ______________

_____________________________________________________________________________

2. How many people are required to lift the printer? _____________________________________

3. Which sides of the printer can be within 10 cm (4 in) of the wall? ________________________

4. The surface on which the printer is placed must be level from side-to-side within how many

inches? ______________________________________________________________________

Load Paper

This lesson provides general guidelines for loading paper and specialty media. Tips and hints for

loading the trays are also provided. Use the Phaser 8400 Reference Guide, the Phaser 8500/8550

User Guide, or the embedded Paper Tips Page when completing this lesson. Electronic versions

are available from the training CD-ROM’s Resources section.

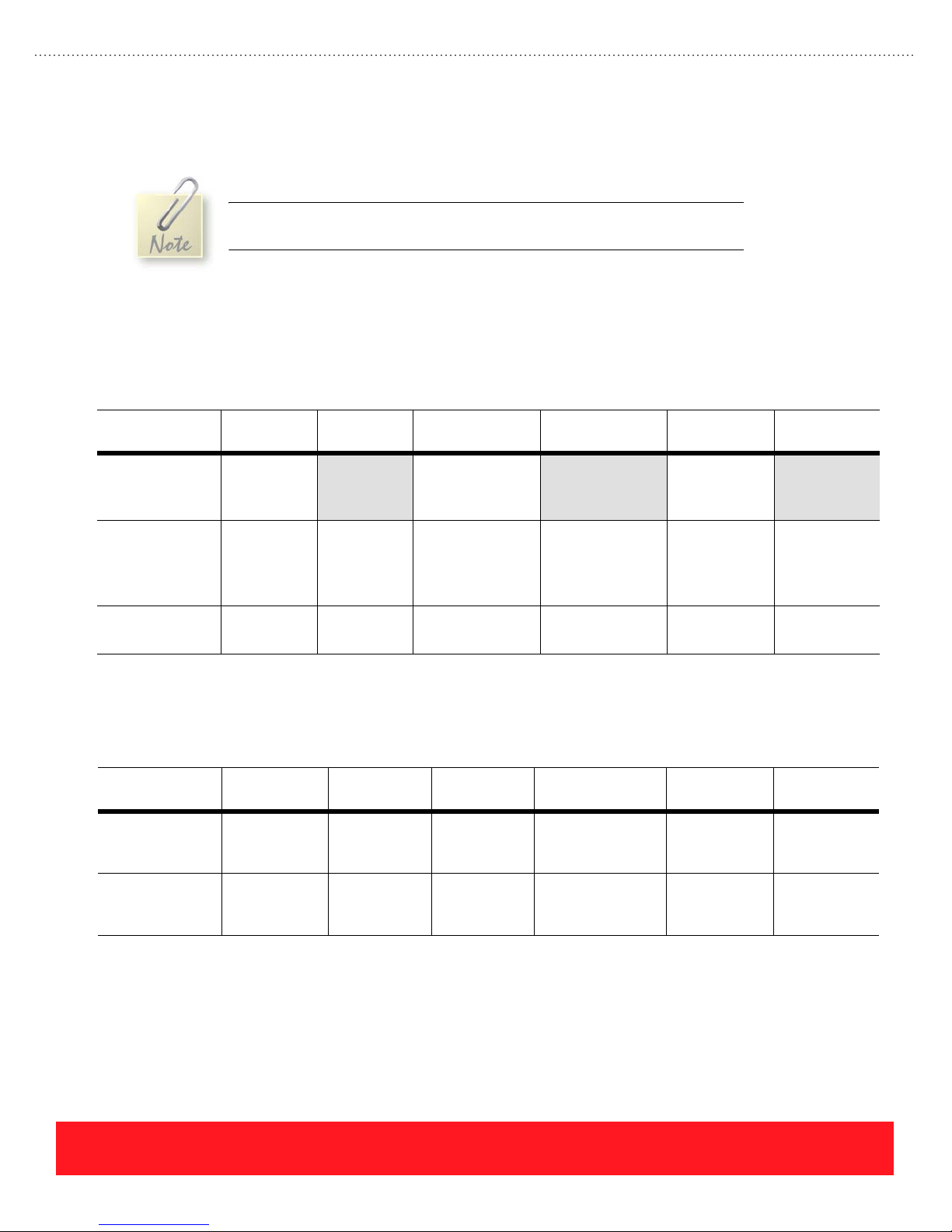

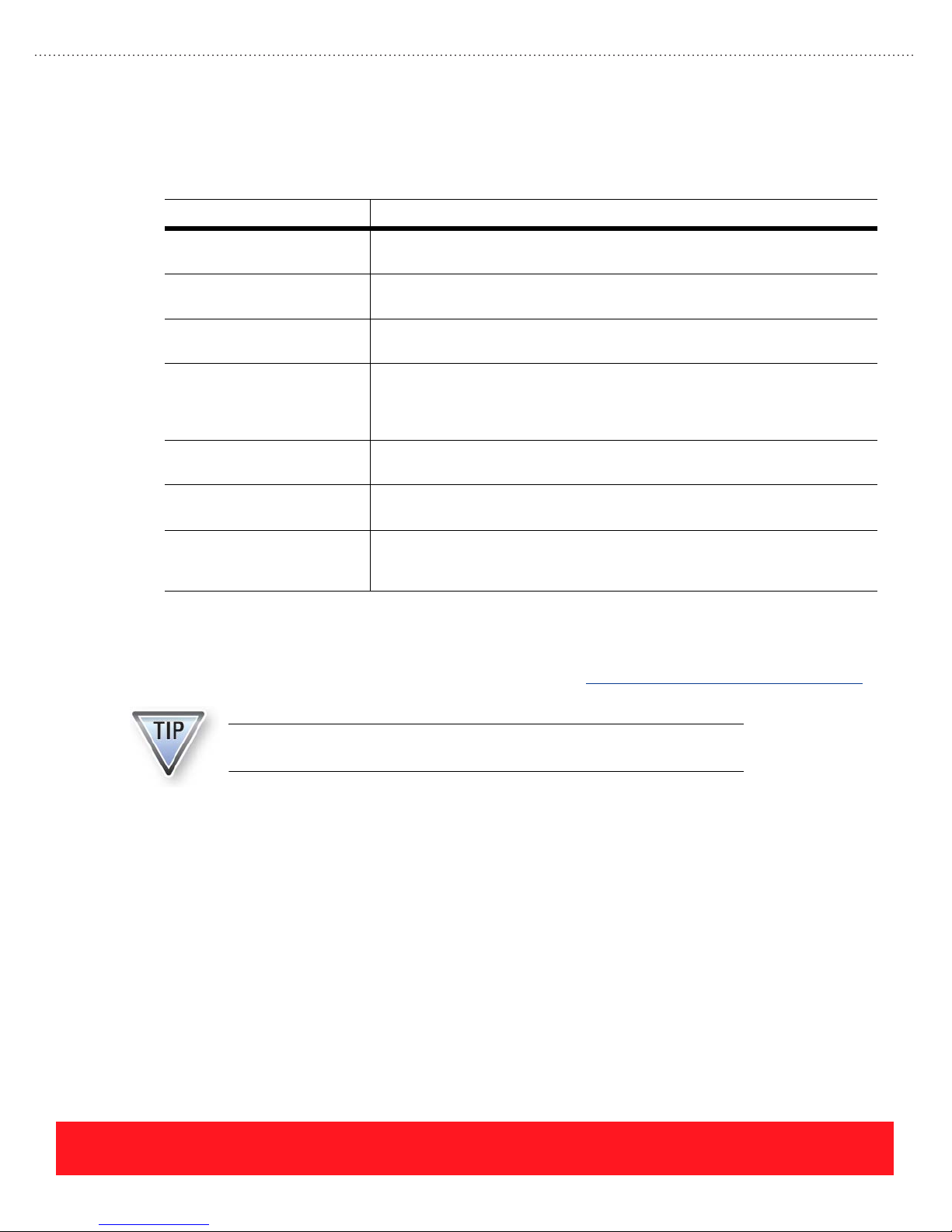

Users can refer to the printer driver and, on Phaser 8500 and 8550 printers, the CentreWare IS page to

determine the current media type and size settings as shown in the examples below.

If you do not have a printer, refer to the Setup Guide and complete this exercise. Then, read the

following lessons for loading paper, configuring the Control Panel, testing ports, printing

documents, and installing upgrades.

CentreWare IS Paper Tray Settings Printer Driver Paper Tray Settings

(Phaser 8500 and 8550 only)

page 28