Page 1

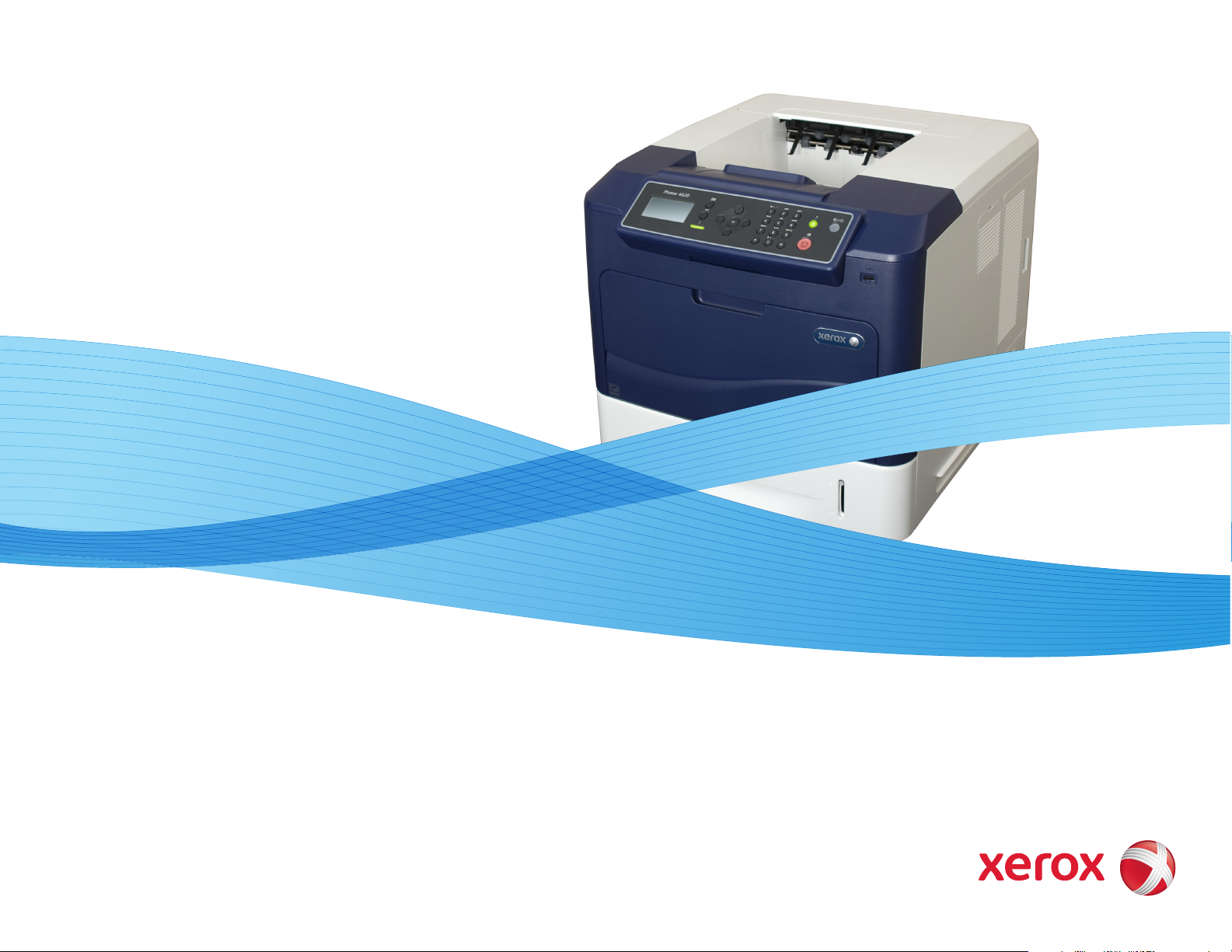

Phaser® 4600/4620

Laser Printer

Phaser® 4600/4620

Service Manual

Xerox Internal-Use Only

Page 2

Phaser 4600/4620 Printer Service Manual

Service Documentation

Phaser 4600/4620 Printer Service Manual

705P01287

Revision - Xerox Internal Use Only

5/2011

Acrobat®, Adobe® Reader®, Adobe Type Manager®, ATM™, Illustrator® PageMaker®, Photoshop®, PostScript®, Adobe Brilliant® Screens, Adobe Garamond®, Adobe Jenson™,

Birch®, Carta®, IntelliSelect®, Mythos®, Quake®, and Tekton® are trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Apple®, AppleTalk®, Bonjour®, EtherTalk®, LaserWriter®, LocalTalk®, Macintosh®, Mac

OS®, TrueType®, Apple Chancery®, Chicago®, Geneva®, Monaco®, New York® , and QuickDraw® are trademarks of Apple Computer, Inc. in the United States and/or other countries.

HP-GL®, HP-UX®, and PCL® are trademarks of Hewlett-Packard Corporation in the United

States and/or other countries.

Xerox Corporation

Customer and Service Training and Information

26600 Parkway - Bldg. 60

P.O. Box 1000, M/S 7060-776

Wilsonville, OR 97070-1000

NOTICE: All service documentation is supplied to Xerox external cu stomers for informational

purposes only. Xerox service documentation is intended for use by certified, product trained

service personnel only. Xerox does not warrant or represent that such documentation is complete, nor does Xerox represent or warrant that it will notify or provide to such customer any

future changes to this documentation. Customer performed service of equipment, or modules,

components or parts of such equipment may affect the warranty offered by Xerox with respect

to such equipment. You should consult the applicable warranty for its terms regarding customer or third party provided service. If the customer services such equipment , modules, com ponents or parts thereof, the customer releases Xerox from any and all liability for the customer

actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third

party claims which arise directly or indirectly from such service.

Unpublished rights reserved under the copyright laws of the United States. Contents of this

publication may not be reproduced in any form without permission of Xerox Corporation.

Copyright protection claimed includes all forms of matters of copyrightable materials and information now allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen such

as styles, templates, icons, screen displays, looks, etc.

IBM® and AIX® are trademarks of International Business Machines Corporation in the U nited

States and/or other countries.

Windows®, Vista™, Windows Server™, and Wingdings® are trademarks of Microsoft Corporation in the United States and/or other countries.

Novell®, NetWare®, NDPS®, NDS®, Novell Directory Services®, IPX™, and Novell Distributed Print Services™ are trademarks of Novell, Incorporated in the United States and/or other

countries.

SunSM, Sun Microsystems™, an d Solaris™ are trademarks of Sun Microsystems, Incorporated in the United States and/or other countries.

SWOP® is a trademark of SWOP, Inc.

UNIX® is a trademark in the United States and other countries, licensed exclusively through X/

Open Company Limited.

As an ENERGY STAR® partner , Xerox Corporation has determined that this product meets the

ENERGY STAR guidelines for energy efficiency. The ENERGY STAR name and logo are registered U.S. marks.

PANTONE® Colors generated may not match PANTONE-identified standards. Consult current

PANTONE Publications for ac curate color. PANTONE® and other Pantone, Inc. trademarks

are the property of Pantone, Inc. © Pantone, Inc., 2000.

Xerox technical training materials and service manuals are intended for use by authorized

Xerox service technicians and service partners only and are not for resale. These materials

may not be distributed, copied or otherwise reproduced without prior written consent from

Xerox Corporation.

© 2010 Xerox Corporation. All rights reserved. XEROX® and XEROX and design®, P haser®,

PhaserSMART®, DocuCard®, DocuSP®, FreeFlow® CentreWare®, infoSMART®, Made For

Each Other®, PagePack™, ColorCube®, ProfitAccelertor™, and Walk-Up™ are trademarks of

Xerox Corporation in the United States and/or other countries.

Page 3

About This Manual .............................................................................. ......... .... .... .... ....... iii

How To Use This Manual................................................................................................ iii

Service Safety Summary......................................................... ........................................ iv

Symbols Used On The Product....................................................................................... v

Voltage Measurement and Specifications....................................................................... vi

Health and Safety Incident reporting ............................................................................... vi

Regulatory Specifications................................................................................................ vii

Translation of Warnings .................................................................................................. viii

Phaser 4600/4620 Overview........................................................................................... x

Printer Options................................................................................................................ xi

Control Panel Layout........................................................... ................................... ......... xiii

Routine Maintenance Items ............................................................................................ xiv

Consumables.................................................................................................................. xiv

Introduction

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

i

Introduction

Page 4

About This Manual

The Phaser 4600/4620 Printer Service Manual is part of a multinational service documentation

system organized in the standard Xerox EDOC serv ice manual format. This manual is the primary document used for diagnosing, repairing, maintaining, and troubleshooting these sys tems. The Service Manual is the controlling publication for a service call. Information on using

this document is found in the Introduction section. To ensure understanding of this product,

complete the Xerox Service Training Program for this particular printer.

Organization

Section titles and the information contained in each is presented in the following paragraphs:

Section 1 Service Call Procedures

This section is used to start and complete a service call. The procedures in this section will

either direct you to a Repair Analysis Procedure (RAP), or identify a faulty component or subassembly.

Section 2 Status Indicator Repair Analysis Procedures

This section contains the Repair Analysis Procedures (RAPs) and checkouts necessary to

diagnose, isolate and repair faults other than image quality faults.

Section 3 Image Quality

This section contains the Image Quality Repair Analysis Procedures (IQ RAPs), checkouts and

setup procedures necessary to diagnose, isolate and repair image quality faults.

Section 4 Repairs/Adjustments

This section contains the instructions for removal, replacement, and adjus tm ent of parts within

the machine.

How To Use This Manual

Always start with the Service Call Procedures, Section 1. Perform Initial Actions and verify the

problem, then follow the directions given.

How to Differentiate Between Machine Variants

The machine will be identified in this manual by the model identifier 4600/4620.

When a procedure, parts list description or other reference is unique amongst different models

of machine, the appropriate model designator is indicated. Any artwork is also specific.

NOTE: This manual services all configurations of the machine. Ignore references to options

not installed on the machine.

Warnings, Cautions and Notes

WARNING

A warning is used whenever an operating or main tenance procedure, practice, condition or statement, if not strictly observed, could result in personal injury.

A translated version of all warnings is in Translation of Warnings.

CAUTION

A caution is used whenever an operation or maintenance procedure, practice, condition or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A note is used where it is essential to highlight a procedure, practice, condition or statement.

Section 5 Parts List

This section contains the detailed and illustrated spare parts list. Any part that is spared or that

must be removed to access a spared part is illustrated.

Section 6 General Procedures / Information

This section contains all other procedures, product specifications and general information.

Section 7 Wiring Data

This section contains the wiring diagrams.

Section 8 Accessories

This section contains details of any accessories that the machine may have.

Publication Comments Sheet

A Publication Comment Sheet is provided at the rear of the hardcopy manual.

Component Names

Names of parts that appear in the disassembly procedures may not be exactly the same as the

names that appear on the part or listed in the Parts List. For example; a part called the Registration Chute Assembly may appear on the Parts List as Assembly, Chute REGI.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

iii

Introduction

About This Manual, How To Use This Manual

Page 5

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the preceding Electrical Safety.

Avoid servicing alone: Do not perform internal service or adjustment of this product unless

another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power applied: Dangerous voltages may exist at several points in

this product. To avoid personal injury, do not touch exposed connections and components

while power is on. Disconnect power before removing the power supply shield or replacing

components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other metallic

objects could come into contact with dangerous voltages and currents.

Electrical Safety

• Use the Power Cord supplied with the printer.

• Plug the Power Cord directly into a properly grounded electrical outlet.

• Do not use a ground adapter plug to connect the printer to an electrical outlet that does

not have a ground connection terminal.

• Do not use an extension cord or power strip.

• Do not place the system in an area where people might step on the power cord.

• Do not place objects on the power cord.

• Do not block the ventilation openings. These openings are provided to prevent overheat ing of the printer.

• Do not drop paper clips or staples into the printer.

Operational Safety

The printer and supplies were designed and tested to meet strict safety requirements. These

include safety agency examination, approval, and compliance with established environmental

standards.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are displayed

on potentially dangerous components. As you service the printer, check to make certain that all

warning labels remain in place.

Safety Interlocks

Make sure all covers are in place an d all interlock switches are functioning correc tly after you

have completed a printer service call. If you bypass an interlock switch during a service call,

use extreme caution when working on or around the printer.

Pay attention to these safety guidelines to ensure the continued, safe operation of the printer.

• Use the supplies specifically designed for your system. The use of unsuitable materials

may cause poor performance and a possible safety hazard.

• Follow all warnings and instructions marked on, or supplied with, the system, options and

supplies.

NOTE: The Total Satisfaction Guarantee is available in the United States and Canada. Coverage may vary outside these areas; please contact your local representative for details.

Maintenance Safety

• Do not attempt any maintenance procedure that is not specifically described in the doc umentation supplied with the printer.

• Do not use aerosol cleaners. The use of supplies that are not approved may cause poor

performance and could create a hazardous condition.

• Do not burn any consumables or routine maintenance items. For inform ation on Xerox

supplies recycling programs, go to www.xerox.com/gwa.

Introduction

Service Safety Summary

5/2011

iv

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 6

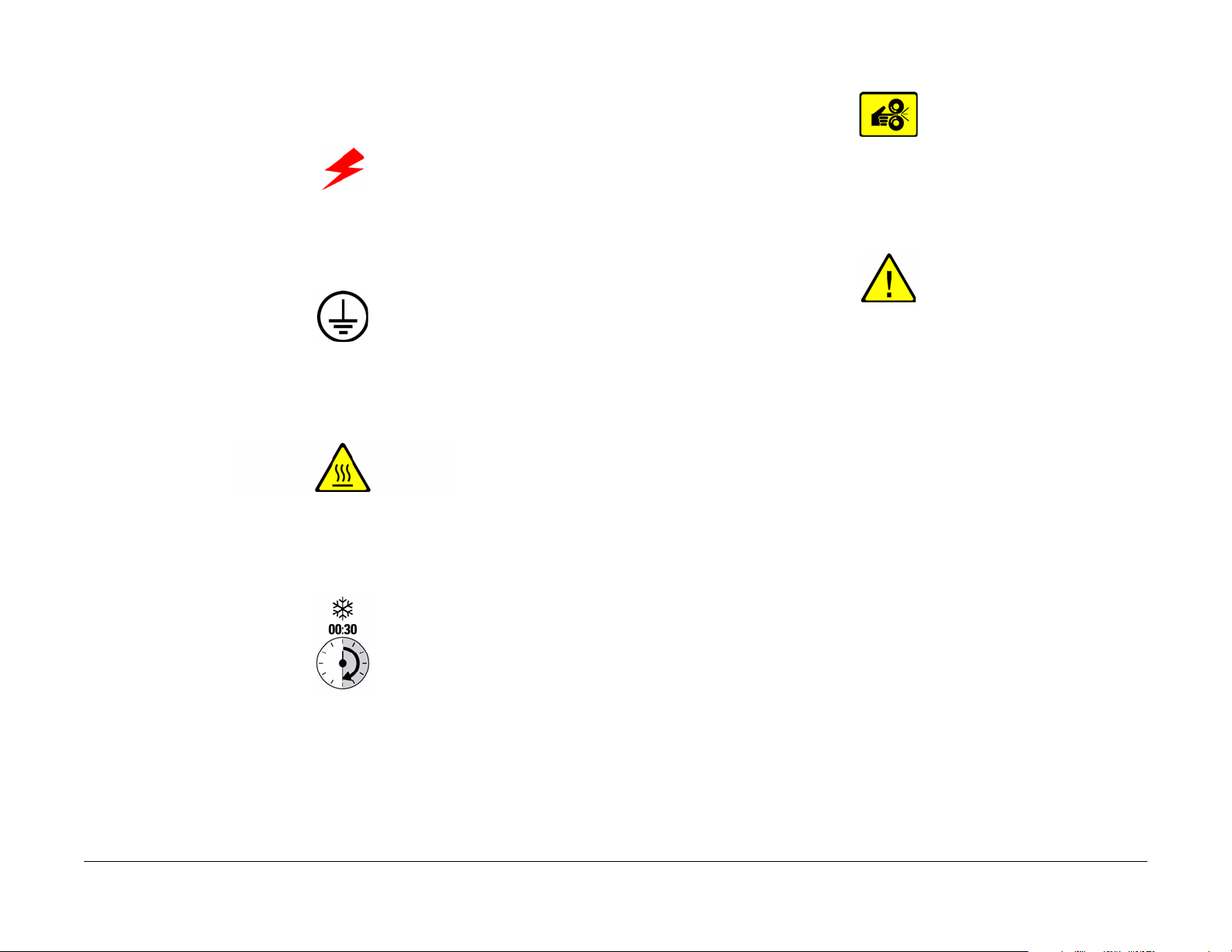

Symbols Used On The Product

The following precautionary symbols may appear on the machine.

This symbol indicates Danger High Voltage.

Figure 1 High Voltage Symbol

Protective Ground (Earth) symbol.

Figure 2 Protective Ground (Earth) Symbol

This symbol indicates hot surface. Use caution to avoid personal injury.

Avoid pinching fingers in the printer. Use caution to avoid personal injury.

Figure 5 Pinch Injury Symbol

Use caution (or draws attention to a particular component). Refer to the manual(s) for information.

Figure 6 Use Caution Symbol

Figure 3 Hot Surface Symbol

The surface is hot while the printer is running. After turning off the power, wait 30 minutes.

Figure 4 Wait 30 Minutes Symbol

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

v

Introduction

Symbols Used On The Product

Page 7

Voltage Measureme n t and S pec if ica t ions

Measurements of DC voltage must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure. All measurements of AC voltage should be made with respect to the adjacent return or ACN wire.

Table 1 Voltage Measurement and Specifications

Voltage Specification

Input Power 220 V 198 VAC TO 254 VAC

Input Power 100 V 90 VAC TO 135 VAC

Input Power 120 V 90 VAC TO 135 VAC

+5 VDC +4.75 VDC TO +5.25 VDC

+24 VDC +23.37 VDC TO +27.06 VDC

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure.

Table 2 Logic Levels

Voltag e H/L Specification

+5 VDC H = +3.00 V or greater

L = below 0 .8 V

+3.3V H = +2 V or greater

L =below 0.8 V

DC Voltage Measurement in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found in a RAP.

There is +5 VDC from P/J7 to P/J68.

In this example, the red meter lead would be placed on P/J7 and the black lead on P/J68.

If a second test point is not given, it is assumed that the black meter lead may be attached to

chassis ground.

Health and Safety Incident reporting

I. Summary

This section defines requirements for notification of health and safety incidents involving Xerox

products (equipment and materials) at customer locations.

II. Scope

Xerox Corporation and subsidiaries worldwide.

III. Objective

To enable prompt resolution of health and safety incidents involving Xerox products and to

ensure Xerox regulatory compliance.

IV. Definitions

Incident:

An event or condition occurring in a customer acco unt that has resulted in injury, illness or

property damage. Examples of incidents include machine fires, smoke generation, physical

injury to an operator or service representative. Alleged events and product conditions are

included in this definition.

V. Requirements

Initial Report:

1. Xerox organizations shall establish a process for individuals to report product incidents to

Xerox Environment Health & Safety within 24 hours of becoming aware of the event.

2. The information to be provided at the time of reporting is contained in Appendix A (Health

and Safety Incident Report involving a Xerox product).

3. The initial notification may be made by any of the following methods:

• For incidents in North America and Developing Markets West (Brazil, Mexico, Latin

American North and Latin American South):

– Phone* Xerox EH&S at: 1-800-828-6571.

– Electronic mail Xerox EH&S at: Doris.Bush@xerox.com.

– Fax Xerox EH&S at: 1-585-422-6449 [intelnet 8*222 6449].

• For incidents in Europe and Developing Markets East (Middle East, Af rica, India,

China and Hong Kong):

– Phone* Xerox EH&S at: +44 (0) 1707 353434.

– Electronic mail Xerox EH&S at: Elaine.Grange@xerox.com.

– Fax Xerox EH&S at: +44 (0) 1707 353914 [intelnet 8*668 3914].

*Initial notification made by phone must be followed within 24 hours by a completed incident report and sent to the indicated electronic mail address or fax number.

NOTE: If sending a fax, please also send the original via internal mail.

Introduction

Voltage Measurement and Spec ifications, Health and

5/2011

vi

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 8

Responsibilities for resolution:

1. Business Groups/Product Design Teams responsible for the product involved in the incident shall:

a. Manage field bulletins, customer correspondence, product recalls, safety retrofits.

b. Fund all field retrofits.

2. Field Service Operations shall:

a. Preserve the Xerox product involved and the scene of the incident inclusive of any

associated equipment located in the vicinity of the incident.

b. Return any affected equipment/part(s) to the location designated by Xerox EH&S

and/or the Business Division.

c. Implement all safety retrofits.

3. Xerox EH&S shall:

a. Manage and report all incident investigation activities.

b. Review and approve proposed product corrective actions and retrofits, if necessary.

c. Manage all communications and correspondence with government agencies.

d. Define actions to correct confirmed incidents.

Regulatory Specifications

Xerox has tested this product to elec tromagnetic emission and immunity standards. These

standards are designed to mitigate interference caused or receiv ed by this product in a typical

office environment.

United States (FCC Regulations)

The Phaser 4600/4620 has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial installation. This equipment generates,

uses, and can radiate radio frequency energy. If it is not installed and used in accordance with

these instructions, it may cause harmful interference to radio communications. Operation of

Class A equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense. There is no guarantee

that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment Off and O n, the user is encou raged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiver.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/television technician for help.

Any changes or modifications not expressly approved by Xerox could void the user's authority

to operate the equipment. To ensure compliance with Part 15 of the FCC rules, use shielded

interface cables.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Canada (Regulations)

This Class A digital apparatus (4600/4620) complies with Canadian ICES-003.

Cet appareil numérique (4600/4620) de la classe A est conforme

Canada.

5/2011

vii

Health and Safety Incident reporting, Regulatory

à la norme NMB-003 du

Introduction

Page 9

European Union

CE Mark

The CE mark applied to this product symbolizes Xerox’s

declaration of conformity with the following applicable Directives of the European Union as of the dates indicated:

Figure 1 CE Symbol

December 12, 2006: Low Voltage Directive 2006/95/EC

December 15, 2004: Electromagnetic Compatibility Directive 2004/108/EC

This product, if used properly in accordance with the user's instructions, is neither dangerous

for the consumer nor for the environment.

To ensure compliance with European Union regulations, use shielded interface cables.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

Translation of Warnings

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury . Moving parts can cause injury.

DANGER : Mettez la machine hors tension. Déconnectez le cordon d'alimentation de

l'alimentation du client lorsque vous réalisez des tâches qui ne nécessitent pas d'électricité. L'électricité peut être à l'origine de blessures, voire d'un accident mortel. Les

pièces amovibles peuvent être à l'origine de blessures.

AVVERTENZA: Spegnere la macchina. Scollegare il cavo di alimentazione dall'alimentatore quando si eseguono attività che non richiedono elettricità. L'elettricità può causare

morte o lesioni personali. Le parti in movimento possono causare lesioni personali.

VORSICHT: Schalten Sie die Stromversorgung der Maschine ab. Ziehen Sie das Stromkabel ab, wenn Sie Aufgaben ausführen, für die keine Stromversorgung benötigt wird.

Stromschläge können Todesfällen oder Verletzungen verursachen. Bewegliche Teile

können zu Verletzungen führen .

AVISO: Apague la electricidad de la máquina. Desconecte el cable de alimentación eléctrica de la toma de pared mientras esté realizando tareas que no necesiten corriente. La

electricidad puede causar daños o la muerte. Las partes móviles pueden causar daños.

WARNING

Do not work in a confined space. 1 m (39 inches) space is needed for safe working.

DANGER : Ne pas travailler dans un espace restreint. 1 mètre d'espace est nécessaire

pour un dépannage en toute sécurité.

AVVERTENZA: Non lavorare in uno spazio limitato; è necessario uno spazio di almeno

un metro attorno alla macchina per la sicurezza dell'operatore.

VORSICHT: Nur mit ausreichendem Bewegungsspielraum (1 m) arbeiten.

AVISO: No trabaje en un espacio reducido. Se necesita 1 metro de espacio para trabajar

con seguridad.

WARNING

Use safe handling procedures when removing the module. Re fer to GP 16. The module

is heavy.

DANGER: Conformez-vous aux procédures de manipulation de sécurité p our le retrait

du module. Reportez-vous à GP 16. Le module est lourd.

AVVERTENZA: Utilizzare procedure di gestione sicure durante la rimozione del modulo.

Vedere GP 16. Il modulo è pesante.

VORSICHT: Verwenden Sie sichere Vorgehensweisen zum Entfernen des Moduls. Siehe

auch GP 16. Das Modul ist sehr schwer.

AVISO: Utilice los procedimientos de seguridad cuando elimine el módulo. Consulte el

GP 16. El módulo es pesado.

Introduction

Regulatory Specifications, Translation of Warnings

5/2011

viii

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 10

WARNING

Follow the service procedure exactly as written. Use of controls or adjustments other

than those specified in this manual, may result in an exposure to invisible laser radiation. During servicing, the invisible laser radiation can cause eye damage if looked at

directly.

DANGER : Les procédures de dépannage doivent être suivies à la lettre. Si les réglages

ou vérifications ne sont pas effectués suivant les instructions de ce manuel, il peut y

avoir un risque d'exposition dangereuse au faisceau laser. Celui-ci peut provoquer des

lésions oculaires s'il est observé directement.

AVVERTENZA: Eseguire le procedure di servizio esattamente come descritto. L'utilizzo

di dispositivi di controllo o di registrazione diversi da quelli riportati in questo manuale

potrebbe comportare un'esposizione a radiazioni laser invisibili. Tali radiazioni possono

danneggiare gli occhi se si guarda direttamente il fascio laser durante gli interventi di

servizio.

VORSICHT: Die Wartungsarbeiten genau den Anweisungen entsprechend durchführen.

Der Umgang mit Steuer- oder Bedienelementen, deren Verwendung nicht ausdrücklich

in diesem Handbuch angewiesen wurde, kann dazu führen, dass unsichtbare Laserstrahlung frei gesetzt wird. Direkter Blickkontakt mit dem Laserstrahl kann bleibende

Augenschäden verursachen.

AVISO: Siga los procedimientos de mantenimiento tal como están descritos. El uso de

controles o ajustes no especificados en este manual puede tener como resultado la

exposición a radiación láser invisible. Durante las operaciones de mantenimiento, la

radiación de láser invisible puede causar daños en los ojos si se mira directamente a

ella.

WARNING

USA and Canada. Do not install this machine in a hallway or exit route that does not

have 1.12 m (44 inches) of space additional to the normal space requirements in front of

the machine. To conform with fire reg ulations this additional 1.12 m (44 inches) of space

is needed in front of the machine in hallway and exit routes.

DANGER : États-Unis et Canada. Si cette machine est installée dans un couloir ou une

voie de sortie, 1,12 m (44 pouces) d'espace supplémentaire à l'espace normal doit être

disponible devant la machine conformément aux normes de sécurité d'incendie.

A VVERTENZA: N/A

VORSICHT: N/A

AVISO: Estados Unidos y Canadá. No instale esta máquina en un corredor o ruta de sal-

ida que no tenga 1.12 m (44 pulgadas) de ancho delante de la máquina, sin incluir el

espacio que ocupe la máquina. Este espacio adicional de 1.12 m (44 pulgadas) delante

de la máquina en corredores y rutas de salida es necesario para cumplir los requisitos

de las normas sobre incendios.

WARNING

Use only Xerox materials and components. This product is safety certified using Xerox

materials and components. The use of non Xerox materials and components may invalidate the safety certificate.

DANGER : N'utilisez que des matières premières et des composants Xerox. La sécurité

du produit est assurée dans le cadre de son utilisation avec des matières premières et

des composants Xerox. L'utilisation de matières premières et de composants autres

que ceux de Xerox risque d'invalider le certificat de sécurité.

AVVERTENZA: Utilizzare solo materiali e componenti Xerox per avvalersi della certificazione di protezione. L'utilizzo di materiali e componenti non Xerox può rendere nulla

la certificazione di pr otezione.

VORSICHT: Verwenden Sie nur Materialien und Komponenten von Xerox. Dieses

Produkt besitzt die Sicherheitszertifizierung bei Verwendung von Xerox-Materialien und

-Komponenten. Die Verwendung von Materialien und Komponenten anderer Hersteller

setzt möglicherweise das Sicherheitszertifikat außer Kraft.

AVISO: Utilice solo los materiales y componentes Xerox. Este producto dispone de un

certificado de seguridad si se utilizan los materiales y componentes Xerox. Este certificado de seguridad no será válido si se utilizan materiales y componentes que no sean

de Xerox.

WARNING

Do not touch the fuser while it is hot.

DANGER : Ne pas toucher au four pendant qu'il est encore chaud.

AVVERTENZA: Non toccare il fonditore quando è caldo.

VORSICHT: Fixierbereich erst berühren, wenn dieser abgekühlt ist.

AVISO: No toque el fusor mientras está caliente.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

ix

Introduction

Translation of Warnings

Page 11

Phaser 4600/4620 Overvi ew

The Phaser 4600/4620 combines a monochrome laser print engine with a multi-purpose Tray 1

(bypass) and universal media tray, Tray 2. The Output Tray holds 500 20lb. sheets facedown.

Phaser 4600/4620 options add memory, media capacity, and functionality . For models not originally equipped, a 160 GB Hard Drive is available. A memory upgrade raises the installed RAM

to the 768 MB maximum. Configurations of up to four 520-Sheet Feeders, or an additional 2

520-sheet feeders and the high-capacity 2000-sheet feeder. On the output side, 500 sheet stapler/stacker or 4-bin, 400-sheet Mailbox are available, Figure 1.

Front View

Rear View

Figure 2 shows features located at the rear of the system.

Figure 1 Front View

Table 1 Front View

1. Finisher (Stacker & Stapler) 10. Tray 2

2. Mailbox 11. Front Door

3. Staple Cartridge Door 12. Top Door

4. IP Board Cover 13. Control Panel

5. Filter Cover 14. Top Cover

6. Printer Stand 15. Toner Cartridge

7. 2000-Sheet Feeder 16. Drum Cartridge

8. Media level Indicator 17. Tray 1 (bypass)

9. 520-Sheet Feeder(s) 18. Tray 1 Media Extension

Introduction

Phaser 4600/4620 Overview

Figure 2 Rear view

Table 2 Rear View

1. Finisher Rear Door 6. Power Switch

2. Rear Door 7. Ethernet Connection

3. Mailbox Rear Door 8. Configuration Card Slot

4. Waste Toner Cartridge Door 9. USB Port

5. AC Input 10. Wireless Network Adaptor Slot

5/2011

x

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 12

Printer Options

Phaser 4600/4620 options include:

• Additional Memory (512 MB)

• Hard Disk

• Wireless network adaptor

• Printer stand

• 520-sheet Feeder

• 2000-sheet Feeder with casters

• Finisher with stapler, 500-sheet stacker .

• Mailbox, 4-bin, 400-sheets

Table 1 lists both Service and Sales part numbers for available options and accessories.

Table 1 Option and Accessory Part Numbers

Item Service Part Number Sales Part Number

520-Sheet Feeder 050K74180 097N01874

2000-Sheet Feeder 059K77920 097N01875

Finisher (500-sheet) 059K77910 097N01876

Mailbox (400-sheet) 050K74190 097N01877

Duplex Unit 022N02484 097N01923

Memory Upgrade 128K01770 097N01878

160MB Hard Disk 007N01651 097N01879

Wireless Network Adaptor 120K03640 097N01880

Stand 078K00870 097N01916

Figure 1 Optional memory

520-Sheet Feeder

The 520-sheet Feeder increases the input capacity of the printer and is attached to the printer

underneath Tray 2. These additional tray combinations are supported:

• One 520-Sheet Feeder (Tray 3)

• Up to 4, 520-Sheet Feeders (Trays 3, 4, 5, and 6)

Hard Disk Drive

The Phaser 4600/4620 supports an internal 160 GB Hard Disk Drive mounted to the IP Board.

Features enabled by Hard Drive installation include:

• Secure Print

•Proof Print

• Save Print

• Disk Collation

Additional Memory

The Phaser 4600/4620 IP Board includes 1 slot for a 512 MB DDR2 DIMM, Figure 1. Memory

must meet these characteristics:

• 200 Pin DDR2 SODIMM

• Unbuffered, Non-parity

The printer’s Configuration page lists the amount of RAM installed in the printer.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

xi

Figure 2 520-Sheet Feeder

Introduction

Printer Options

Page 13

2000-Sheet Feeder

The 2000-sheet Feeder increases the input capacity of the printer and is attached to the printer

underneath Tray 2 or installed 520-sheet Feeders. These additional tray combinations are supported:

• One 2000-Sheet Feeder (Tray 3)

• Up to 2 520-Sheet Feeders (Trays 3, 4) and 1 2000-Sheet Feeder (Tray 5).

Mailbox

The Mailbox provides four 100-sheet output trays.

Introduction

Printer Options

Figure 3 2000-Sheet Feeder

5/2011

xii

Figure 4 Optional Mailbox

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 14

Finisher

The finisher provides a 500-sheet, offset Stacker Tray and includes a fixed-head stapler.

Control Panel Layout

The Control Panel consists of one LED, a display window, a keypad, and several buttons.

These buttons are used to navigate the menu system, perform functions, and select modes of

operation for the printer. Table 1 lists the function of each control.

Figure 1 Control Panel

Figure 5 Finisher

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

T able 1 Control Panel Features

1. Display Displays printer settings, status, messages and menus.

2. Menu Enters Menu Mode and scrolls through the available

3. Back Sends you back one level in the menu.

4. Status LED • Green: Printer is ready to print.

5. OK Accepts the selected settings.

6. Keypad Use to enter alphanumeric characters.

7. Help (?) Additional information.

8. Energy Saver Illuminates when the printer is in Power Saver mode. Press

9. Stop Press to cancel the current activity.

5/2011

xiii

menus.

• Yellow: Startup sequence or error condition.

• Flashing:

– Yellow: Error Condition

– Green: Warming up or Receiving data

to enter or exit from Power Saver mode.

Printer Options, Control Panel Layout

Introduction

Page 15

Routine Maintenance Items

Table 1 Routine Maintenance Items

Item Description Print Life

1. Pick and nudger Rollers 200,000 pages

2. Separator Roller 100,000 pages

3. Transfer Roller 100,000 images

4. Fuser 200,000 images

5. Feed Roller 100,000 pages

Consumables

The rated life expectancy of 4600/4620 consumables is listed in Table 1.

T able 1 Consumable Life Expectancy

Item Description Print Life

1. Standard Toner Cartridge 20,000 cycles

High Capacity Toner Cartridge 30,000 cycles

Starter Toner Cartridge 10,000 cycles

2. Drum Cartridge 60,000 cycles

3. Waste Toner Cartridge Provided with new Toner Cartridge

4. Staple Cartridge 15,000

5. Maintenance Kit (Fuser, Feed Rollers, T ransfer

Roller)

200,000 cycles

Introduction

Routine Maintenance Items

5/2011

xiv

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 16

Service Call Procedures.................................................................................................. 1-3

SCP 1 Initial Actions........................................................................................................ 1-4

SCP 2 First Call Actions .................................................................................................. 1-4

SCP 3 Normal Call Actions.................................... .................................................... ..... 1-5

SCP 4 Fault Analysis ...................................................................................................... 1-5

SCP 5 Subsystem Maintenance ..................................................................................... 1-6

SCP 6 Final Actions ........................................................................................................ 1-7

SCP 7 Configurations and Options................................................................................. 1-8

1 Service Call Proced ur es

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

1-1

Service Call Procedures

Page 17

Service Call Procedures

This section provides an overview of the steps a service technician should take to service the

printer and attached options. The printer’s diagnostic routines report problems using error messages and fault codes displayed on the Control Panel, logged in the Serv ice Usage Pr ofile, or

by flashing LEDs. These error indications serve as the entry point into the troubleshooting process. System problems not directly indicated by or associated with an error message or fault

code are covered in Section 6, General Procedures. Print-quality problems are covered in Section 3, Image Quality.

The steps listed here are a guide for performing any service on this printer. If you choose not to

use these steps, it is recommended that you start at the appropriate troubleshooting procedure

and proceed from there. When servicing the printer, follow the safety measures detailed in the

Service Safety Summary section.

1. Identify the problem.

• Verify the reported problem does exist.

• Check for any error codes and write them down.

• Print normal customer prints and service test prints.

• Make note of any print-quality problems in the test prints.

• Make note of any mechanical or electrical abnormalities present.

• Make note of any unusual noise or smell coming from the printer.

• Print a Usage Profile, if the printer is able to print.

• View the Engine Error and Jam Histories under the Tools menu.

• Verify the AC input from the wall outlet is within specifications.

2. Inspect and clean the printer.

• Follow the cleaning instructions.

• Verify that the power cord is in serviceable condition.

• Restart the printer to check if the error reoccurs.

3. Find the cause of the problem.

• Use the troubleshooting procedures to find the root cause of the problem.

• Use Service Diagnostics to check the printer and optional components.

• Use the Wiring Diagrams and Plug/Jack Locator to locate test points.

• Take voltage readings as instructed in the troubleshooting procedure.

4. Correct the problem.

• Use the Parts List to locate a part number.

• Use the Repair procedures to replace the part.

5. Final Checkout

• Test the printer to verify the problem is corrected and no new problems arose.

Accessing Engine Fault History

Listed below are three ways in which you can access fault history records.

1. Print (if possible) the Error Message report from the Troubleshooting menu. The error history is listed on the report.

NOTE: Error and fault code definitions of the codes appear in Section 2.

2. If the printer is connected to a network and has a TCP/IP address, view the printer’s web page using a web browser.

a. Open a web browser. b. Enter the printer’s IP address as the URL. c. Selec t Support --> Troubleshooting --> Diagnostics Logs and the fault history

displays.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

1-3

Service Call Procedures

Service Call Procedures

Page 18

SCP 1 Initial Actions

Initial Actions are used to gather information on the machine performance

SCP 2 First Call Actions

First Call Actions are used for the first service call.

Start a service call with SCP 1 and end with SCP6 Final Actions.

Also refer to SCP 7 Configurations and Options.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

WARNING

Do not work in a confined space. 1m (39 inches) space is needed for safe working.

NOTE: Ignore any references in this manual to options not installed on the machine.

1. Take note of symptoms or error messages.

2. Ask the operator to describe or demonstrate the problem.

3. Make sure that: a. The power cord is connected to the wall outlet and to the machine. b. Paper is loaded correctly and all paper trays and covers are closed c. If installed, the USB cable or network connection is installed correctly.

4. If available, check the machine service log book for any previous actions that m a y be relevant to the call.

5. If this is the first service call t o this machine perform SCP 2 First Call Actions, otherwise go to SCP 3 Normal Call Actions.

Procedure

1. Check the machine configuration with the customer, refer to SCP 7 Machine Configurations and Options. Check that all required hardware and software is installed and/or enabled.

2. Check that all the relevant machine settings are correctly entered, refer to GP 4 System Administration Tools.

3. If a fault is present, go to SCP 3 Normal Call Actions. If there is no fault present, go to

SCP 6 Final Actions.

4. Enter the machine details and the customer details in the service log.

Service Call Procedures

SCP 1, SCP 2

5/2011

1-4

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 19

SCP 3 Normal Call Actions

Normal Call Actions are used to determine the reason for the service call.

SCP 4 Fault Analysis

Fault Analysis is used to identify a fault.

Procedure

NOTE: If a fault message appears at any time. Refer directly to the RAP for the fault message and perform the procedure.

If possible, perform the following:

1. Review any defective print samples.

2. Determine that the user accessible settings are correct. If necessary refer to the user documentation.

3. Check all job queues and verify with the customer any requirement to print the documents in memory, before switching off the power or clearing memory.

4. Print the Customer Assistance Report (Call for Assistance), then record the total print count.

5. Go to SCP 4 Fault Analysis.

Procedure

When diagnosing or repairing a fault in a particular subsystem, exercise the machine in all

modes until the fault is determined. In the instance of finding more than one fault or failure, correct one fault before going to the next fault. If no fault is found, go to SCP 5 Subsystem Maintenance.

Fault Codes

If a fault code is displayed, go to the relevant RAP.

UI Faults

If the machine is on but the UI is blank, test the UI with dC330.

Stapler Faults

If the machine has a stapler fault, test the Stapler with dC330.

Image Quality Defects

If the image quality is defective, go to the IQ1 Image Quality Entry RAP.

For image quality specifications, refer to the following:

• IQS 1 Solid Area Density.

• IQS 2 Skew.

• IQS 3 Registration.

Additional Information

If necessary, refer to the following general procedures and information:

• GP 1 Diagnostics Entry

• GP 2 Fault Codes and History Files

• GP 3 System Administration Tools

• GP 4 Reports

• GP 5 Firmware Upgrade

• GP 6 Electrostatic Discharge Prevention

• GP 7 Machine Specifications

• GP 8 General Disassembly Precautions

• GP 9 Service Menu Map

• GP 10 How to Check a Motor

• GP 11 How to Check a Sensor

• GP 12 How to Check a Solenoid or Clutch

• GP 13 How to Check a Switch

• GP 14 Separate System Modules

• GP 15 How to Safely Move heavy Modules

• GP 16 Machine Lubrication

• GP 17 Installation Space Requirements

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

1-5

Service Call Procedures

SCP 3, SCP 4

Page 20

• GP 18 Glossary of Terms

• GP 19 Restriction of Hazardous Substances (RoHS)

• GP 20 First Print Output Time

• GP 21 Media Specifications

• GP 22 Environmental Data

SCP 5 Subsystem Maintenance

Subsystem Maintenance contains information regarding the component life of the machine.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

1. Clean the Pick Rollers on every call.

2. Use the Control Panel to check maintenance item counters.

3. Compare the counter values to those listed in Consumables.

4. Advise the customer of any routine maintenance items that are approaching or over the service limit.

Inspection

Rollers

Replace the Rollers when you see any of the following defects:

• Flat spots

• Out of roundness

• Cracked rubber

• Loss of traction (tackiness) causing pick or feed failures

Gears

Replace Gears that show any signs of wear or damage. Look for these problems:

• Thinned gear teeth

• Bent or missing gear teeth; check especially where a metal gear drives a plastic gear.

• Fractured or cracked Gears (oil or incorrect grease on a plastic Gear can cause t he Gear

to crack).

Belts

There are rubber belts in the printer. Inspect the belts for wear. Look for these problems:

Service Call Procedures

SCP 4, SCP 5

• Loose rubber particles below the belts indicate a worn belt.

• Missing teeth in the belts.

• Cracking or moderate fraying; a small amount of fraying is inevitable, so look for other

signs of wear before replacing the belt.

Lubrication

The printer is lubricated during assembly at the factory and does not require periodic lubrication. Some parts require lubrication following replacement. These parts are identified in the

replacement procedures. When lubricating during replacement, use the grease approved for

all Phaser printers.

CAUTION

Plastic parts will deteriorate when unspecified grease and chemicals are used. To avoid damage to the printer, use only Rheolube 768 grease.

• Rheolube 768 Grease: Part Number 070E00890

5/2011

1-6

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 21

Component Life

The design life of the major components are shown in Table 1. Environmental conditions and actual use will vary these factors. The component life shown in Table 1 is for reference only.

SCP 6 Final Actions

Final Actions are used to evaluate the total operation of the system and to identify the actions required to complete the service call.

Table 1 Component Life Expectancies

Item Description Print Life

1. Pick and nudger Rollers 200,000 pages

2. Separator Roller 100,000 pages

3. Transfer Roller 100,000 images

4. Fuser 200,000 images

5. Feed Roller 100,000 pages

HFSI

The High Frequency Service Items are shown in Table 2.

Table 2 High frequency service items

Item Description

Drum Cartridge The total sides of copies and prints

after the last HFSI reset.

Tray 1 Pick Roller Sheets fed from Tray 1 after last

HFSI reset.

Tray 2 Pick Rollers Sheets fed from Tray 2 after last

HFSI reset.

Transfer Roller Total prints after the last HFSI

reset.

Fuser Total prints after the last HFSI

reset.

Recommended life Reference

10k impressions PL 9.10 Item 1

150k feeds PL 8.10 Item 3

200k feeds PL 8.15 Item 10

100k impressions PL 9.10 Item 2

200k impressions PL 10.10 Item 1

Procedure

Complete the following, if a fault is identified, return to SCP 4 Fault Analysis:

• Perform the end of call subsystem maintenance actions, SCP 5 Subsystem Maintenance.

• Exercise the machine in all modes, printing from all trays. If a fault message is displayed

or some other problem is evident, go to SCP 4 Fault Analysis.

• Make a print of a customer document.

• If any of the customers selections were changed, return t hem to the cu stomers preferred

settings. R e fe r t o GP 4 System Administration Tools.

• At the first service and at any subsequent service where changes are made or options are

added, print the configuration report and store it with machine log book. Discard any previous versions of the configuration report.

• Remove and destroy any copies of test patterns.

• Ensure the machine and service area are clean before leaving the customer premises.

• Provide customer training if required.

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

1-7

Service Call Procedures

SCP 5, SCP 6

Page 22

SCP 7 Configurations and Options

Configurations and Options

Refer to Table 1 for basic configurations and options. This service manual covers all configurations. Within this manual ignore any references to options that are not installed.

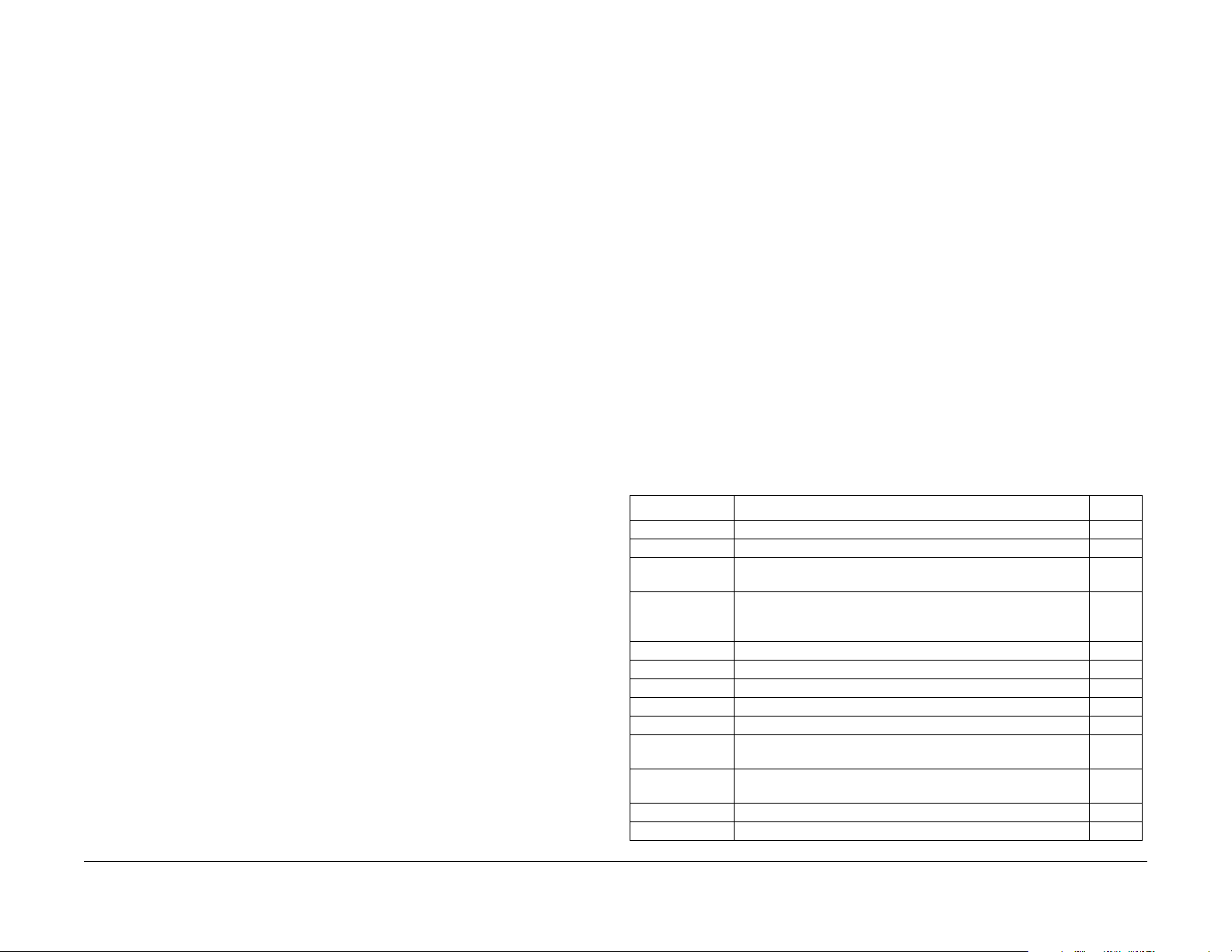

Table 1 Phaser 4600/4620 Configurations

Features 4600N 4600DN 4600DT 4620DN 4620DT

Processor Speed 700 MHz 700 MHz 700 MHz 700 MHz 700 MHz Memory* 256 MB 256 MB 256 MB 256 MB 256 MB Print Speed 55 ppm, Letter

52 ppm A4 PS3 Fonts (136) Standard Standard Standard Standard Standard PCL6 Fonts (80 Scalable, 9 Bitmap) Standard Standard Standard Standard Standard USB 2.0 Standard Standard Standard Standard Standard Ethernet Interface 10/100 Base-TX 10/100 Base-TX 10/ 100 Base-TX 10/100 Base-TX 10/100 Base-TX Tray 1 (100 sheet) Standard Standard Standard Standard Standard Tray 2 (520 sheet) Standard Standard Standard Standard Standard Tray 3 (520 sheet) Optional Standard Standard Optional Standard Tray 4 (520 sheet) Optional Optional Optional Optional Optional Tray 5 (2000 / 520-sheet) Optional Optional Optional Optional Optional Tray 6 (520-sheet) Optional Optional Optional Optional Optional Duplex Not available Standard Standard Standard Standard Mailbox (4-bin) Optional Optional Optional Optional Optional Finisher Optional Optional Optional Optional Optional Hard Disk Drive Optional Optional Optional Optional Optional Printer Stand Optional Optional Optional Optional Optional Wireless LAN Optional Opti onal Optional Optional Optional Printer Resolution 600 x 600 dpi

1200 Class * All configurations have one memory slot supporting a 512 MB DDR2 DIMM, to a maximum 768 MB total.

55 ppm, Letter 52 ppm, A4

600 x 600 dpi 1200 Class

55 ppm, Letter 52 ppm, A4

600 x 600 dpi 1200 Class

65 ppm, Letter 62 ppm, A4

600 x 600 dpi 1200 Class

65 ppm, Letter 62 ppm, A4

600 x 600 dpi 1200 Class

Service Call Procedures

SCP 7

5/2011

1-8

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 23

01-100-00 Top Door Open RAP....................................................................... .... .... .. ..... 2-3

01-102-00 Rear Door Open RAP.................................................................................... 2-3

01-500-00 Finisher Door Open RAP ............................................................................... 2-4

01-700-00 Stapler Door Open RAP ................................................................................ 2-4

01-900-00 Mailbox Rear Door Open RAP....................................................................... 2-5

03-100-00, 03-110-00 Finisher Interface Error RAP ....................................................... 2-5

03-115-00 Mailbox Interface Error RAP. ......................................................................... 2-6

03-120-00, 03-940-00 Tray 3 Communications Fault RAP............................................. 2-6

03-130-00, 03-950-00 Tray 4 Communications Fault RAP............................................. 2-7

03-140-00, 03-960-00 Tray 5 Communications Fault RAP............................................. 2-7

03-150-00, 03-965-00 Tray 6 Communications Fault RAP............................................. 2-8

03-160-00, 03-990-00 HCF Communications Fault RAP................................................ 2-8

03-305-00 Configuration Card Not Present RAP............................................................ 2-9

03-315-00, 03-325-00 Manufacturer ID RAP .................................................................. 2-9

03-335-00 Configuration Card Not Configured RAP....................................................... 2-10

03-410-00 Tray 2 Paper Mismatch RAP ......................................................................... 2-10

03-420-00 Tray 3 Paper Mismatch RAP ......................................................................... 2-11

03-430-00 Tray 4 Paper Mismatch RAP ......................................................................... 2-11

03-440-00 Tray 5 Paper Mismatch RAP ......................................................................... 2-12

03-450-00 Tray 1 Paper Mismatch RAP ......................................................................... 2-12

03-470-00 Tray 6 Paper Mismatch RAP ......................................................................... 2-13

03-480-00 HCF Paper Mismatch RAP............................................................................ 2-13

03-600-00 Memory Failure RAP ..................................................................................... 2-14

03-800-00 Hard Disk Drive Failure RAP......................................................................... 2-15

03-970-00 Software Lock Up RAP.................................................................................. 2-15

04-100-00 Tray 2 Lift Error RAP ..................................................................................... 2-16

04-110-00 Tray 6 Lift Error RAP ..................................................................................... 2-16

04-200-00 Tray 3 Lift Error RAP ..................................................................................... 2-17

04-300-00 Tray 4 Lift Error RAP ..................................................................................... 2-18

04-400-00 Tray 5 Lift Error RAP ..................................................................................... 2-19

04-500-00 Main Motor Failure RAP ................................................................................ 2-20

04-730-00 HCF Lift Error RAP ........................................................................................ 2-21

04-810-00 Rear Fan Failure RAP ................................................................................... 2-22

04-930-00 Main Fan Failure RAP ................................................................................... 2-22

06-100-00, 06-200-00 LSU Error RAP............................................................................ 2-23

07-110-00 Paper Empty at Tray 2 RAP .......................................................................... 2-23

07-120-00 Tray 2 is Open RAP....................................................................................... 2-24

07-130-00 Jam 0 in Tray 2 RAP...................................................................................... 2-24

07-210-00 Paper Empty at Tray 3 RAP .......................................................................... 2-25

07-220-00 Tray 3 is Open RAP....................................................................................... 2-25

07-230-00, 07-231-00 Jam in Tray 3 RAP...................................................................... 2-26

07-310-00 Paper Empty at Tray 4................................................................................... 2-26

07-320-00 Tray 4 is Open RAP....................................................................................... 2-27

07-330-00, 07-331-00 Jam in Tray 4 RAP...................................................................... 2-27

07-410-00 Paper Empty at Tray 5................................................................................... 2-28

07-420-00 Tray 5 is Open RAP....................................................................................... 2-29

07-430-00, 07-431-00 Jam in Tray 5 RAP...................................................................... 2-29

07-500-00 Paper Empty in Tray 1 RAP........................................................................... 2-30

2 Status Indicator RAPS

07-510-00, 07-700-00 Paper Empty at Tray 6................................................................. 2-31

07-520-00 Tray 6 is Open RAP................... .. .... .... ....... .... .... .. .... ....... .... .... .. .... ......... .. .... . 2-31

07-530-00 Jam 0 in Tray 1 RAP...................................................................................... 2-32

07-531-00, 07-630-00 Jam in Tray 6 RAP ...................................................................... 2-32

07-710-00 HCF Out of Paper.......................................................................................... 2-33

07-720-00 HCF Door is Open RAP.............................. .... .. .... .. ....... .... .. .... .. .... ....... .. .... .. . 2-34

07-730-00, 07-731-00 Jam in HCF RAP......................................................................... 2-35

08-100-00 Jam 1 in Registration RAP............................................................................. 2-36

08-110-00 Feed Motor Failure RAP ................................................................................ 2-37

08-200-00 Jam in Tray 2 RAP......................................................................................... 2-37

08-300-00 Jam in Tray 3 RAP......................................................................................... 2-38

08-400-00 Jam in Tray 4 RAP......................................................................................... 2-39

08-450-00 Jam in Tray 5 RAP......................................................................................... 2-40

08-500-00 Jam 2 in Fuser Exit RAP................................................................................ 2-41

08-600-00 Jam 0 in Duplex Unit RAP ............................................................................. 2-42

08-610-00 Jam 1 in Duplex Unit RAP ............................................................................. 2-43

08-650-00 Duplex Unit Not Installed RAP....................................................................... 2-43

08-800-00 Jam in Tray 6 RAP......................................................................................... 2-44

08-850-00 Jam in HCF RAP............................................................................................ 2-45

09-003-00 Developer Motor Failure RAP.......... .... ....... .. .... .. .... ....... .... .. .... .... .. ....... .... .... . 2-46

09-100-00 Toner Low RAP.............................................................................................. 2-46

09-200-00, 09-220-00 Toner Empty RAP........................................................................ 2-47

09-210-00, 09-270-00 Toner (ADC) Sensor Error RAP .................................................. 2-47

09-230-00, 09-250-00 Toner Cartridge CRUM Write/Read Error RAP....... .................... 2-48

09-240-00 Toner Cartridge Communications Error RAP................................................. 2-48

09-271-00 Clean ID (ADC) Sensor RAP......... .... ......... .... .... .... ........... .... .... .... ......... .... ... 2-49

09-290-00 Adjusting Image Quality RAP......................................................................... 2-49

09-300-00 Drum Warning RAP .................................................................................... .. . 2-50

09-400-00 Replace Drum Cartridge RAP........................................................................ 2-50

09-500-00 Toner Cartridge Not Installed RAP ................................................................ 2-51

09-508-00 Waste Toner Cartridge Near Full RAP........................................................... 2-51

09-589-00 Waste Toner Cartridge Full RAP ................................................................... 2-52

09-590-00 Waste Toner Cartridge Not Installed RAP ..................................................... 2-52

09-591-00 Waste Toner Full Sensor Error RAP.............................................................. 2-53

09-600-00 Drum Cartridge Not Installed RAP....................................... .... .... ......... .... ..... 2-53

09-700-00 Toner Supply Error RAP................................................................................ 2-54

09-800-00, 09-810-00 Invalid Toner Cartridge RAP........................................................ 2-54

09-900-00, 09-910-00 Invalid Drum Cartridge RAP........................................................ 2-55

09-920-00 Transfer Unit Error RAP. ................................................................................ 2-55

10-100-00, 10-200-00, 10-300-00 Fuser Thermal Errors RAP........................................ 2-56

10-308-00 Fuser Motor Error RAP.................................................................................. 2-56

10-500-00, 10-510-00 Fuser End of Life RAP................................................................. 2-57

10-700-00, 10-710-00 Fuser Initial Fuse Error RAP........................................................ 2-57

12-100-00, 12-487-00 Jam at Finisher Entrance RAP................................................. ... 2-58

12-200-00 Jam 1 in Finisher RAP ................................................................................... 2-58

12-300-00, 12-488-00, 12-489-00 Jam in Finisher Exit RAP .......................................... 2-59

12-500-00 Full Stack RAP............................................................................................... 2-59

12-605-00 Staples Low RAP........................................................................................... 2-60

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

2-1

Status Indicator RAPS

Page 24

12-610-00, 12-855-00 Out of Staples RAP ..................................................................... 2-60

12-715-00, 12-716-00 Front Jogger Home Fault RAP.................................................... 2-61

12-725-00, 12-726-00 Rear Jogger Home Fault RAP..................................................... 2-61

12-735-00, 12-736-00 Support Finger Home Fault RAP................................................. 2-62

12-750-00, 12-755-00 Stapler Fault RAP........................................................................ 2-62

12-760-00, 12-770-00 Stacker Fault RAP....................................................................... 2-63

12-870-00 Stapler Safety Not Detected RAP.................................................................. 2-63

12-906-00, 12-907-00 Jam in Mailbox Entrance RAP..................................................... 2-64

12-910-00, 12-920-00, 12-930-00, 12-940-00 Mailbox Bin Full ...................................... 2-64

12-911-00, 12-921-00, 12-931-00, 12-941-00 Mailbox Bin Jam ..................................... 2-65

12-912-00, 12-922-00, 12-932-00, 12-942-00 Mailbox Bin Jam ..................................... 2-65

12-913-00, 12-923-00, 12-933-00, 12-943-00 Mailbox Bin Jam ..................................... 2-66

12-915-00 Diverter Fault RAP......................................................................................... 2-66

12-925-00, 12-935-00 Upper Diverter Fault Home RAP................................................. 2-67

12-945-00, 12-955-00 Lower Diverter Fault Home RAP................................................. 2-67

15-110-00 Email Send Failed RAP ........................................................................ .. ....... 2-68

15-120-00 Invalid Recipient Email Address RAP............................................................ 2-68

15-300-00 Network Connection Failure RAP.................................................................. 2-69

15-310-00, 15-600-00 Authentication Failure RAP......................................................... 2-69

15-320-00, 15-330-00 Mail Server Connection Failure RAP........................................... 2-70

15-700-00 DNS Error RAP.............................................................................................. 2-70

17-100-00 IP Address Conflict RAP................................................................................ 2-71

17-110-00 Connection Error RAP ................................................................................... 2-71

17-120-00 Server Not Found RAP.................................................................................. 2-72

17-200-00 Network Cable Disconnected RAP................................................................ 2-72

17-700-00, 17-710-00 BOOTP Server Error RAP........................................................... 2-73

17-800-00, 17-810-00 DHCP Server Error RAP............................................................. 2-73

17-900-00 802.1X Authentication Error RAP .................................................................. 2-74

17-910-00 Firmware Upgrade Fault RAP........................................................................ 2-74

Status Indicator RAPS

5/2011

2-2

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 25

01-100-00 Top Door Open RAP

01-100-00 The Top Door is not latched.

01-102-00 Rear Door Open RAP

01-102-00 The Rear Door is not latched.

BSD-Reference: WD 1

Initial Actions

• Close the Top Door.

• Check for obstructions blocking the latch.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Reseat the Toner Cartridge and close the Top Door. The error message is displayed.

YN

Complete.

Check the Top Door interlock actuators. The interlock actuators are undamaged.

YN

Replace the Top Door, REP 28.5.

Select dC330 code 01-100. The switch is operational (open/closed).

YN

Replace the Top Door Interlock Switch, REP 1.6.

Remove the Left Cover (REP 28.3) and check P/J45 and CN9 on the MCU Board. The con-

nections are secure.

YN

Secure the connections.

BSD-Reference: WD 1

Initial Actions

• Close the Rear Door.

• Check for obstructions or bent pins in P/J61.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Close the Rear Door. The error message is displayed.

YN

Complete.

Check the Rear Door connection P/J63. The connector is undamaged.

YN

Repair or replace the Rear Door, REP 28.6.

Select dC330 code 01-300. The connection is operational (open/closed).

YN

Repair or replace the Rear Door, REP 28.6.

Remove the Right Cover (REP 28.2) and check CN4 on the Joint Board. The connection is

secure.

YN

Secure the connections.

Replace these components in order until the error is corrected.

1. Top Door Interlock Switch, PL 28.15 Item 2

2. MCU Board, PL 3.10 Item 3

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Replace these components in order until the error is corrected.

1. Rear Door, PL 28.25 Item 1

2. Joint Board, PL 9.15 Item 7

3. Exit Assembly, PL 10.30 Item 25

5/2011

2-3

Status Indicator RAPS

01-100-00, 01-102-00

Page 26

01-500-00 Finisher Door Open RAP

01-500-00 The Finisher Rear Door is not latched.

01-700-00 Stapler Door Open RAP

01-700-00 The Staple Cartridge Door is not latched securely.

BSD-Reference: WD 17

Initial Actions

• Close the Finisher Rear Door.

• Check for obstructions blocking the sensor.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Check the Rear Door sensor actuator. The actuator is undamaged.

YN

Repair or replace the Finisher Rear Door, REP 12.17.

Select dC330 code 12-895. The sensor is operational (high/low).

YN

Remove the Finisher Top Cover (REP 12.18) and check the Finisher Rear Door Open Sensor (PL 12.35 Item 14). The sensor connection is secure.

YN

Secure the Finisher Rear Door Open Sensor connection.

Check the Finisher option harness in the Finisher right cover. The harness is undam-

aged.

YN

Repair or replace the Finisher option harness.

Replace the Finisher Rear Door Open Sensor, REP 12.20.

BSD-Reference: WD 17

Initial Actions

• Close and latch the Staple Cartridge Door.

• Check for obstructions blocking the interlock switch.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Check the Staple Cartridge Door interlock actuator. The actuator is undamaged.

YN

Repair or replace the Finisher right cover, REP 12.11.

Select dC330 code 12-870. The switch is operational (high/low).

YN

Replace the Staple Cartridge Door Interlock Switch, REP 12.13.

Remove the Finisher Right Cover (REP 12.11) and check the Staple Cartridge Door Interlock Switch (PL 12.45 Item 4). The switch connections are secure.

YN

Secure the Staple Cartridge Door Interlock Switch connections.

Check the Finisher option harness in the Finisher right cover. The harness is undamaged.

YN

Repair or replace the Finisher option harness.

Replace these components in order until the error is corrected.

1. Finisher Rear Door Open Sensor, PL 12.35 Item 14

2. Finisher Control Board, PL 12.15 Item 2

3. IOT Upper Option Harness, PL 10.30 Item 24

4. MCU Board, PL 3.10 Item 3

Status Indicator RAPS

01-500-00, 01-700-00

Replace these components in order until the error is corrected.

1. Staple Cartridge Door Interlock Switch (PL 12.45 Item 4)

2. Finisher Control Board, PL 12.15 Item 2

3. IOT Upper Option Harness, PL 10.30 Item 24

4. MCU Board, PL 3.10 Item 3

5/2011

2-4

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

Page 27

01-900-00 Mailbox Re ar Door Open RAP

01-900-00 The Mailbox Rear Door is not latched securely.

03-100-00, 03-110-00 Finisher Interface Error RAP

03-100-00 Communications between the Finisher and IOT has failed.

BSD-Reference: WD 18

Initial Actions

• Close the Mailbox Rear Door.

• Check for obstructions blocking the interlock switch.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Check the Mailbox Rear Door interlock actuator. The actuator is undamaged.

YN

Repair or replace the Mailbox rear door, REP 11.4.

Select dC330 code 12-915. The switch is operational (high/low).

YN

Replace the Mailbox Rear Door Interlock Switch, REP 11.13.

Remove the Mailbox top cover (REP 11.12, step 5) and check the Rear Door Interlock Switch (PL 11.30 Item 4). The switch connections are secure.

YN

Secure the Mailbox Rear Door Interlock Switch connections.

Check the Mailbox option harness in the Mailbox right cover. The harness is undamaged.

YN

Repair or replace the Mailbox option harness, PL 11.15 Item 4.

03-110-00 Communications between the Finisher and IOT has failed.

BSD-Reference: WD 17

Initial Actions

• Reseat the Finisher on the IOT connection.

• Check for obstructions or damage to the interface connection.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Remove the Finisher right cover (REP 12.11) and check the option harness. The harness is

undamaged.

YN

Repair or replace the Finisher option harness.

Check the IOT Upper Option Harness. The harness is undamaged.

YN

Repair or replace the Upper Option Harness, REP 10.4.

Replace these components in order until the error is corrected.

1. Finisher Control Board, PL 12.15 Item 2

2. MCU Board, PL 3.10 Item 3

Replace these components in order until the error is corrected.

1. Mailbox Rear Door Interlock Switch, PL 11.30 Item 4

2. Mailbox Control Board, PL 11.15 Item 1

3. IOT Upper Option Harness, PL 10.30 Item 24

4. MCU Board, PL 3.10 Item 3

Revision - Xerox Internal Use Only

Phaser 4600/4620 Printer Service Manual

5/2011

2-5

Status Indicator RAPS

01-900-00, 03-100-00, 03-110-00

Page 28

03-115-00 Mailbox Interface Error RAP

03-115-00 Communications between the Mailbox and IOT has failed.

03-120-00, 03-940-00 Tray 3 Communications Fault RAP

03-120-00 A communication error has occurred between the MCU Board and Tray 3.

BSD-Reference: WD 18

Initial Actions

• Reseat the Mailbox on the IOT connection.

• Check for obstructions or damage to the interface connection.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Remove the Mailbox right cover (REP 11.3) and check the option harness. The harness is

undamaged.

YN

Repair or replace the Mailbox option harness, PL 11.15 Item 4.

Check the IOT Upper Option Harness. The harness is undamaged.

YN

Replace the Upper Option Harness, REP 10.4.

Replace these components in order until the error is corrected.

1. Mailbox Control Board, PL 11.15 Item 1

2. MCU Board, PL 3.10 Item 3

03-940-00 A communication error has occurred between the MCU Board and Tray 3.

BSD-Reference: WD 15

Initial Actions

• Lock the feeder to the IOT.

• Reseat the IOT on the Feeder.

• Check for obstructions blocking the option harness.

Procedure

WARNING

Use safe handling procedures when removing the module. Re fer to GP 15. The module is heavy.

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer supply while performing tasks that do not need electricity. Electricity can cause death or injury . Moving parts can cause injury.

Cycle system power. The error message is displayed. YN

Complete.

Remove the IOT from the Feeder and check the Feeder Option Connector. The connector is

undamaged.

YN

Replace the Feeder Upper Option Harness, REP 7.31.