Page 1

Phaser

Laser Printer

Service

Manual

™

4400

Page 2

Page 3

PHASER™ 4400

LASER PRINTER

Service Manual

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in the

operating instructions, unless you are qualified

to do so.

First Printing: June 2002

071-0861-00

Page 4

Service Terms

Manual Terms

Various terms are used throughout this manual to either provide additional

information on a specific topic or to warn of possible danger that might be present

during a procedure or action. Be aware of all symbols and terms when they are used,

and always read NOTE, CAUTION and WARNING messages.

Note: A NOTE may indicate an operating or maintenance

procedure, practice or condition that is necessary to

efficiently accomplish a task.

A NOTE may also provide additional information related to a

specific subject or add a comment on the results achieved

through a previous action.

Caution: A CAUTION indicates an operating or maintenance

procedure, practice or condition that, if not strictly

observed, could result in damage to, or destruction of,

equipment.

Warning: A WARNING indicates an operating, or maintenance

procedure, practice or condition that, if not strictly

observed, could result in injury or loss of life.

PL: Corresponds to the FRU Parts List.

RRP: Corresponds to the FRU Disassembly Removal and Replacement Procedures.

Product Terms

Caution: A personal injury hazard exists that may not be apparent. For

example, a panel may cover the hazardous area.

Danger:

Phaser 4400 Laser Printer Service Manual iii

A personal injury hazard exists in the area where you see the sign.

Page 5

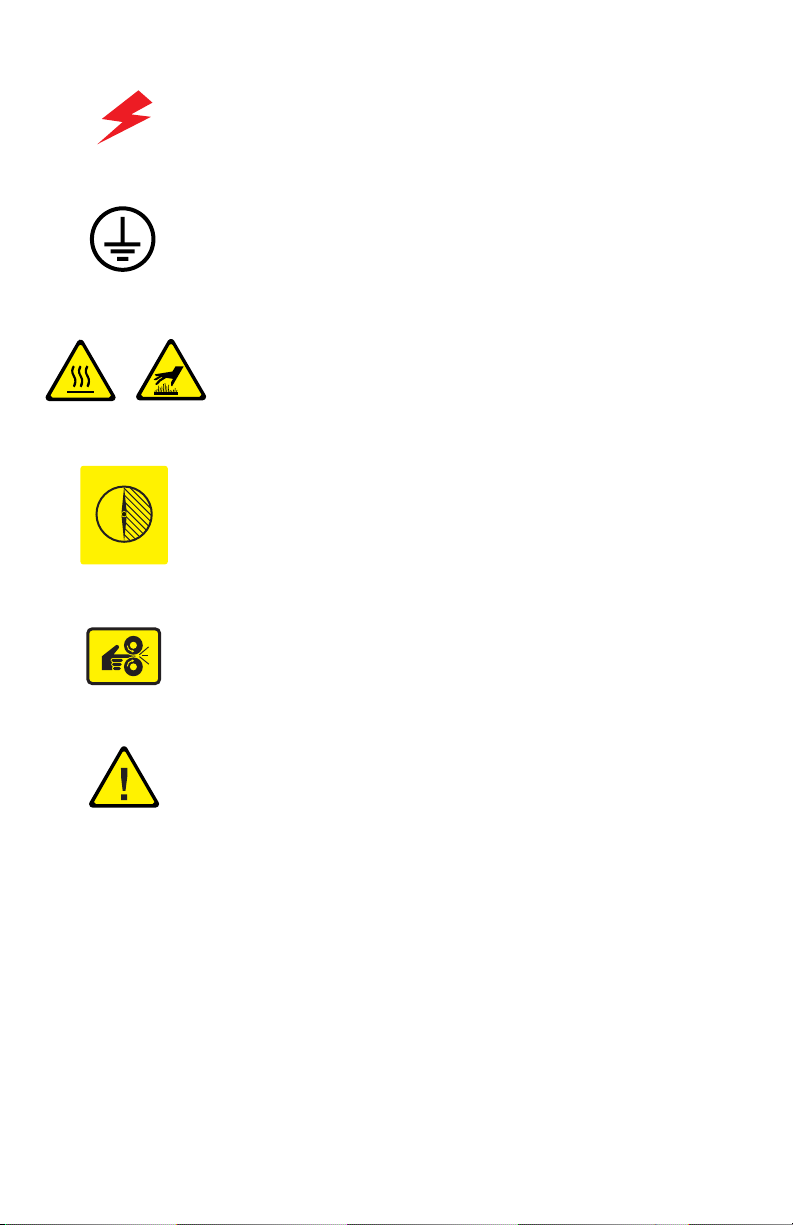

Symbols Marked on the Product

DANGER high voltage.

Protective ground (earth) symbol.

Hot surface on or in the printer. Use caution to avoid

personal injury.

0

30 min.

The surface is hot while the printer is running. After

turning off the power, wait 30 minutes.

Avoid pinching fingers in the printer. Use caution to

avoid personal injury.

Use caution (or draws attention to a particular

component). Refer to the manual(s) for information.

iv Phaser 4400 Laser Printer Service Manual

Page 6

Power Safety Precautions

Power source

For 110 VAC printers, do not apply more than 140 volts RMS between the supply

conductors or between either supply conductor and ground. Use only the specified

power cord and connector. For 220 VAC printers, do not apply more than 264 volts

RMS between the supply conductors or between either supply conductor and ground.

Use only the specified power cord. This manual assumes that the reader is a qualified

service technician.

Warning: Plug the three-wire power cord (with grounding prong)

into a grounded AC outlet only. If necessary, contact a

licensed electrician to install a properly grounded outlet. If

the product loses its ground connection, contact with

conductive parts may cause an electrical shock.

Disconnecting Power

Warning: Turning the power OFF using the On/Off switch does not

completely de-energize the printer. You must also

disconnect the printer power cord from the AC outlet.

Position the power cord so that it is easily accessible during

servicing so that you may power down the printer during

an emergency.

Disconnect the power plug by pulling the plug, not the cord. Disconnect the power

cord in the following cases:

■ If the power cord or plug is frayed or otherwise damaged

■ If any liquid or foreign material is spilled into the case

■ If the printer is exposed to any excess moisture

■ If the printer is dropped or damaged

■ If you suspect that the product needs servicing or repair

■ Whenever you clean the product

Phaser 4400 Laser Printer Service Manual v

Page 7

Electrostatic Discharge (ESD) Precautions

Some semiconductor components, and the respective sub-assemblies that contain

them, are vulnerable to damage by Electrostatic discharge (ESD). These components

include Integrated Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect

transistors and other semiconductor chip components. The following techniques will

reduce the occurrence of component damage caused by static electricity.

Caution: Be sure the power is off to the chassis or circuit board, and

observe all other safety precautions.

■ Immediately before handling any semiconductor components assemblies,

drain the electrostatic charge from your body. This can be accomplished by

touching an earth ground source or by wearing a wrist strap device

connected to an earth ground source. Wearing a wrist strap will also prevent

accumulation of additional bodily static charges. (Be sure to remove the

wrist strap before applying power to the unit under test to avoid potential

shock.)

■ After removing a static sensitive assembly from its anti-static bag, place it

on a grounded conductive surface. If the anti-static bag is conductive, you

may ground the bag and use it as a conductive surface.

■ Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage some devices.

■ Do not remove a replacement component or electrical sub-assembly from its

protective package until you are ready to install it.

■ Immediately before removing the protective material from the leads of a

replacement device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

■ Minimize body motions when handling unpackaged replacement devices.

Motion such as your clothes brushing together, or lifting a foot from a

carpeted floor can generate enough static electricity to damage an

electro-statically sensitive device

■ Handle ICs and EPROM’s carefully to avoid bending pins.

■ Pay attention to the direction of parts when mounting or inserting them on

Printed Circuit Boards (PCB’s).

vi Phaser 4400 Laser Printer Service Manual

Page 8

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the preceding Power Safety

Precautions.

Avoid servicing alone: Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several

points in this product. To avoid personal injury, do not touch exposed connections and

components while power is on. Disconnect power before removing the power supply

shield or replacing components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other

metallic objects could come into contact with dangerous voltages and currents.

Power source: This product is intended to operate from a power source that will not

apply more then 264 volts rms for a 220 volt AC outlet or 140 volts rms for a 110 volt

AC outlet between the supply conductors or between either supply conductor and

ground. A protective ground connection by way of the grounding conductor in the

power cord is essential for safe operation.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are

displayed on potentially dangerous components. As you service the printer, check to

make certain that all warning labels remain in place.

Safety Interlocks

Make sure covers and panel are in place and that all interlock switches are functioning

correctly after you have completed a printer service call. If you bypass an interlock

switch during a service call, use extreme caution when working on or around the

printer.

CLASS 1 LASER PRODUCT

The Phaser 4400 laser printer is certified to comply with Laser Product Performance

Standards set by the U.S. Department of Health and Human Services as a Class 1

Laser Product. This means that this is a class of laser product that does not emit

hazardous laser radiation; this is possible only because the laser beam is totally

enclosed during all modes of customer operation. When servicing the printer or laser

unit, follow the procedures specified in this manual and there will be no hazards from

the laser.

Phaser 4400 Laser Printer Service Manual vii

Page 9

Servicing Electrical Components

Before starting any service procedure, switch off the printer power and unplug the

power cord from the wall outlet. If you must service the printer with power applied,

be aware of the potential for electrical shock.

Warning: Turning the power OFF using the On/Off switch does not

completely de-energize the printer. You must also

disconnect the printer power cord from the AC outlet.

Position the power cord so that it is easily accessible during

servicing so that you may power down the printer during

an emergency.

Warning: Do not touch any electrical component unless you are

instructed to do so by a service procedure.

S7300-02

Servicing Mechanical Components

Manually rotate drive assemblies to inspect drive gears.

Warning: Do not try to manually rotate or manually stop the drive

assemblies while any printer motor is running.

S7300-03

Servicing Fuser Components

This printer uses heat to fuse the toner image to a sheet of paper. The Fuser Assembly

is very hot. Turn the printer power OFF and wait at least 5 minutes for the Fuser to

cool before you attempt to service the Fuser Assembly or adjacent components.

viii Phaser 4400 Laser Printer Service Manual

Page 10

Regulatory Specifications

Federal Communications Commission Compliance

The equipment described in this manual generates and uses radio frequency energy. If

it is not installed properly in strict accordance with Xerox instructions, it may cause

interference with radio and television reception or may not function properly due to

interference from another device. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

■ Reorient or relocate the receiver (device being interfered with).

■ Increase the separation between the printer and the receiver.

■ Connect the printer into an outlet on a circuit different from that which the

receiver is connected.

■ Route the interface cables on the printer away from the receiver

■ Consult the dealer, Xerox service, or an experienced radio/television

technician for help.

Changes or modifications not expressly approved by Xerox can affect the emission

and immunity compliance and could void the user's authority to operate this product.

To ensure compliance, use shielded interface cables. A shielded parallel cable can be

purchased directly from Xerox at www.xerox.com/officeprinting/6200supplies

Xerox has tested this product to internationally accepted electromagnetic emission

and immunity standards. These standards are designed to mitigate interference caused

or received by this product in a normal office environment. This product is also

suitable for use in a residential environment based on the levels tested.

.

In the United States this product complies with the requirements of an unintentional

radiator in part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference; (2) this device must

accept any interference received, including interference that may cause undesired

operation.

This digital apparatus does not exceed the Class B limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications, ICES-003.

Le présent appareil numérique n'émet pas de bruits radioélectrique dépassant les

limits applicables aux appareils numériques de la classe B prescrites dans le

Réglement sur le brouillage radioélectrique édicté par le ministere des

Communications du Canada, NMB-003.

Declaration of Conformity

Xerox Corporation, declares, under our sole responsibility that the printer to which

this declaration relates, is in conformity with the following standards and other

normative documents:

Phaser 4400 Laser Printer Service Manual ix

Page 11

In the European Union

following the provisions of the Low Voltage Directive 73/23/EEC and its

amendments:

EN 60950 (IEC 950) “Safety of Information Technology Equipment including Electrical

Business Equipment”

following the provisions of the Electromagnetic Compatibility Directive 89/336/EEC

and its amendments:

EN55022:1998

(CISPR 22)

EN61000-3-2:1995

+A1:1998+A2:1998.

(IEC61000-3-2)

EN61000-3-3:1995

(IEC61000-3-3)

EN55024:1998

(CISPR 24)

CISPR 24 Immunity

Phenomena

Electrostatic Discharge IEC61000-4-2:1995 6kV Contact, 10kV Air

Radio-Frequency

Electromagnetic Field

(radiated)

Fast Burst Transients IEC61000-4-4:1995 5/50 Tr/Th ns, 5kHz Rep. Freq

Line Surge IEC61000-4-5:1995 Combination wave

Radio-Frequency

Electromagnetic Field

(Conducted)

Line voltage dips IEC61000-4-11:1994 >95% dip for ½ cycle @ 50 Hz

Line voltage drop-out IEC61000-4-11:1994 >95% dropout for 250 cycles @ 50 Hz

“Limits and Methods of measurement of radio interference

characteristics of Information Technology Equipment.” Class B.

“Part 3: Limits - Section 2: Limits for harmonic current emissions

(equipment input current less than or equal to 16A per phase).”

“Part 3: Limits - Section 3: Limitation of voltage fluctuations and

flicker in low-voltage supply systems for equipment with rated

current less than or equal to 16A.”

“Information technology equipment - Immunity characteristics Limits and methods of measurement. “

Basic Standard Test Specification

IEC61000-4-3:1995 80-1000 MHz, 3V/m, 80% AM @

1KHz

0.5kV on Signal Lines

1kV on AC Mains

2.0kV Common mode

2.0kV Differential mode

IEC61000-4-6:1996 0.15 - 80 MHz, 3V, 80% AM @ 1kHz

30% dip for 25 cycles @ 50 Hz

This product, if used properly in accordance with the user's instructions is neither

dangerous for the consumer nor for the environment. A signed copy of the

Declaration of Conformity for this product can be obtained from Xerox.

x Phaser 4400 Laser Printer Service Manual

Page 12

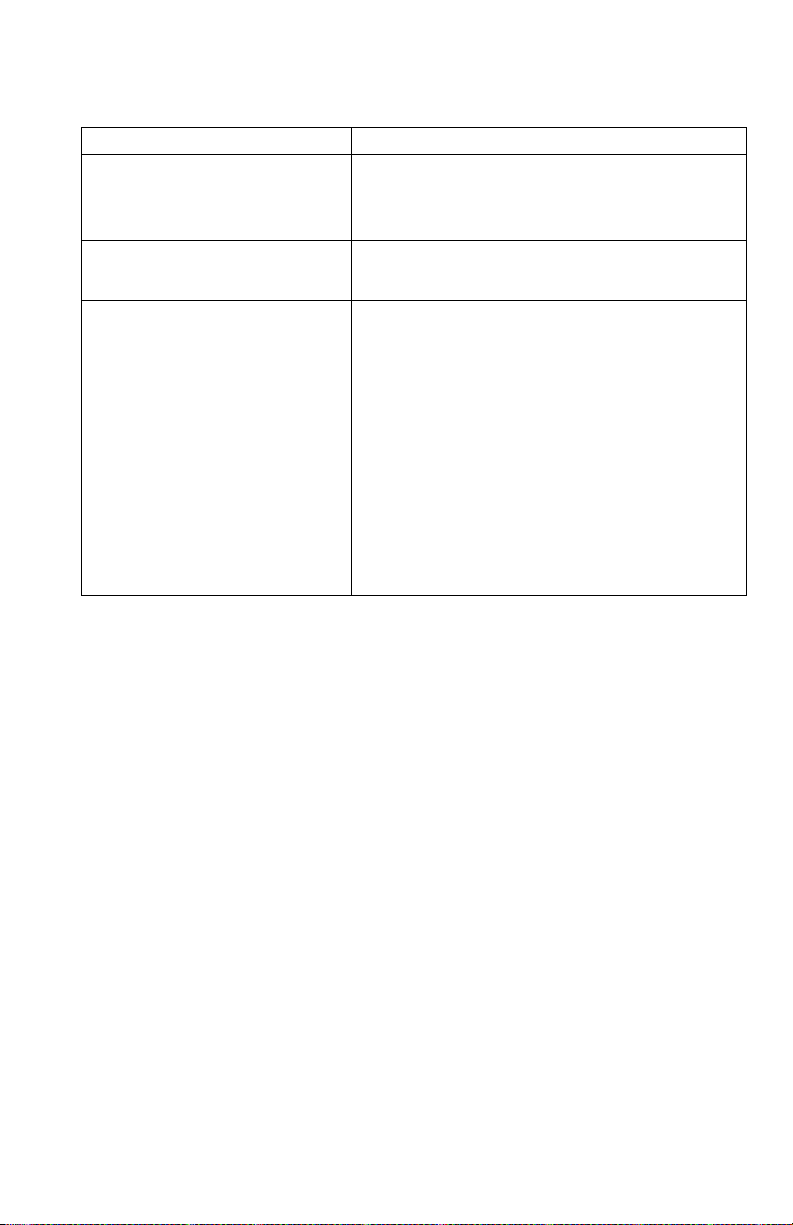

Safety Standards

Phaser 4400 satisfies the following safety standards:

Category Standard Satisfied

Laser Safety 100 V/120 V type is submitted to FDA 21 CFR

Ozone Density Does not exceed 0.02 ppm of ozone density TWA

Other standards 100 V/120 V type satisfies:

(Chapter 1, Subchapter J, Section 1010/1040).

220 V/240 V type is submitted to IEC 825 Class 1

Laser Product.

(Time Weight Average), measured according to ECMA

129 standard

UL 1950 3rd Edition, CSA C22.2 no. 950-M95 or

equivalent, NOM

200 V/220 V satisfies:

IEC 950 including amendments 1,2,3 and 4, CE

Directive 1, Nordic and other Agency Approval 2, CCIB

Notes:

1. When the controller is installed, the OEM customer

shall be responsible for the submittal of CE and CCIB.

2. The OEM customer shall be responsible for the

Nordic agency approvals including NEMKO, SEMKO,

SETI and DEMKO.

Phaser 4400 Laser Printer Service Manual xi

Page 13

xii Phaser 4400 Laser Printer Service Manual

Page 14

Contents

General Information 1-1

Section Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Phaser 4400 Laser Printer Overview . . . . . . . . . . . . . . . . . . . . 1-2

Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Machine Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Error Messages and Codes 2-1

Section Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Service Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Printer Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Image Processor POST Error Codes . . . . . . . . . . . . . . . . . . . 2-58

Troubleshooting 3-1

Section Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Image-Quality Checkout Procedures . . . . . . . . . . . . . . . . . . . 3-41

Image-Quality Troubleshooting Procedures . . . . . . . . . . . . . . 3-53

Tests Prints, Adjustments, and NVRAM Reset 4-1

Section Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Service Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Resetting NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Phaser 4400 Laser Printer Service Manual xiii

Page 15

Cleaning and Maintenance 5-1

Service Preventive Maintenance Procedure . . . . . . . . . . . . . . . 5-1

FRU Disassembly 6-1

List of Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Covers and Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Paper Feed (Tray 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Paper Feed (MPT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

Paper Transportation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Exit Assembly and Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-65

Xerographics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-79

Main Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-84

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-87

Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-101

Optional Paper Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-120

Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-141

Envelope Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-157

Parts Lists 7-1

Parts List Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Using the Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Theory of Operation 8-1

Section Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Print Process Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Print Process Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

The Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Drive Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Engine Logic Board and Front Panel Functions . . . . . . . . . . . 8-22

Image Processor Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

xiv Phaser 4400 Laser Printer Service Manual

Page 16

Laser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Fuser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Erase Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Duplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Envelope Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Option Feeder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

Wiring Data 9-1

Section Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Base Engine Wiring Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

550-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Envelope Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

Phaser 4400 Laser Printer Service Manual xv

Page 17

xvi Phaser 4400 Laser Printer Service Manual

Page 18

General Information

The Xerox Phaser™ 4400 Laser Printer Service Manual is the primary document

used for repairing, maintaining and troubleshooting.

To ensure complete understanding of the product, participation in Xerox Phaser 4400

Service Training is recommended.

Section Contents

Phaser 4400 Laser Printer Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Monitoring Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Repackaging Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Base Configuration Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Image Processor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

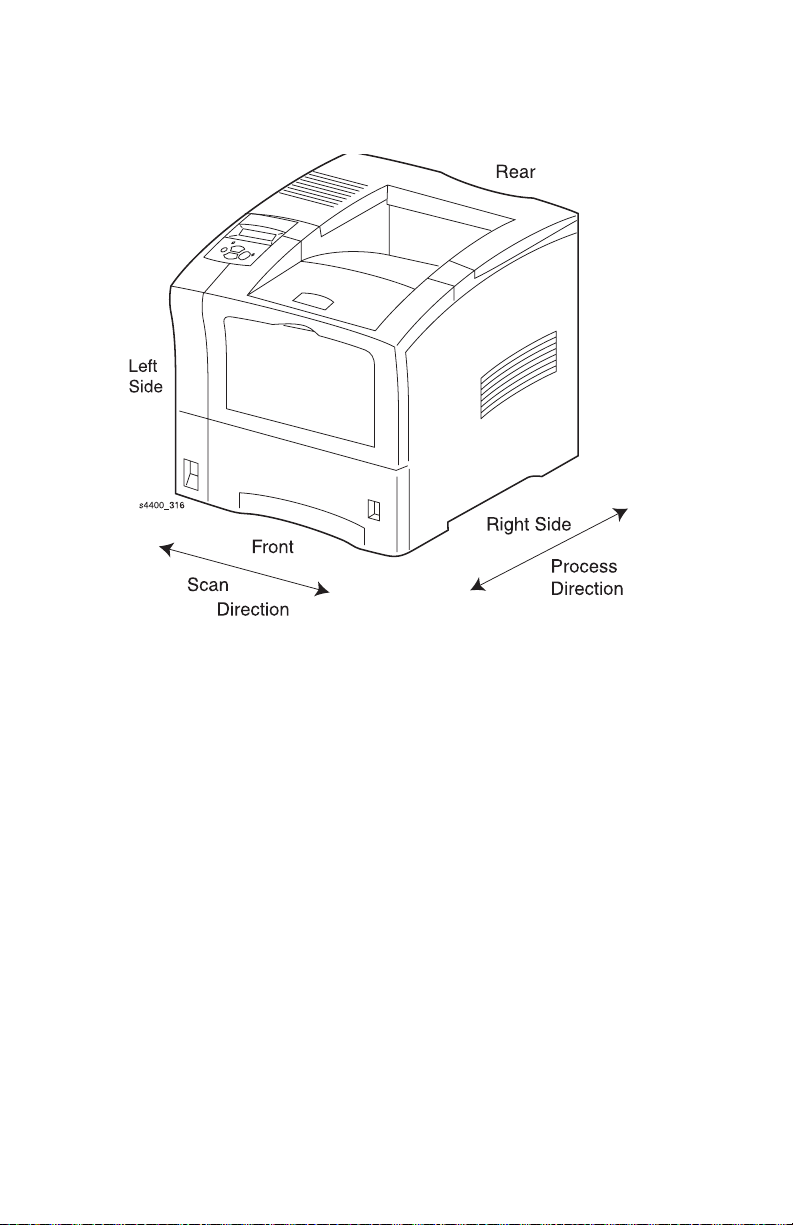

Machine Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

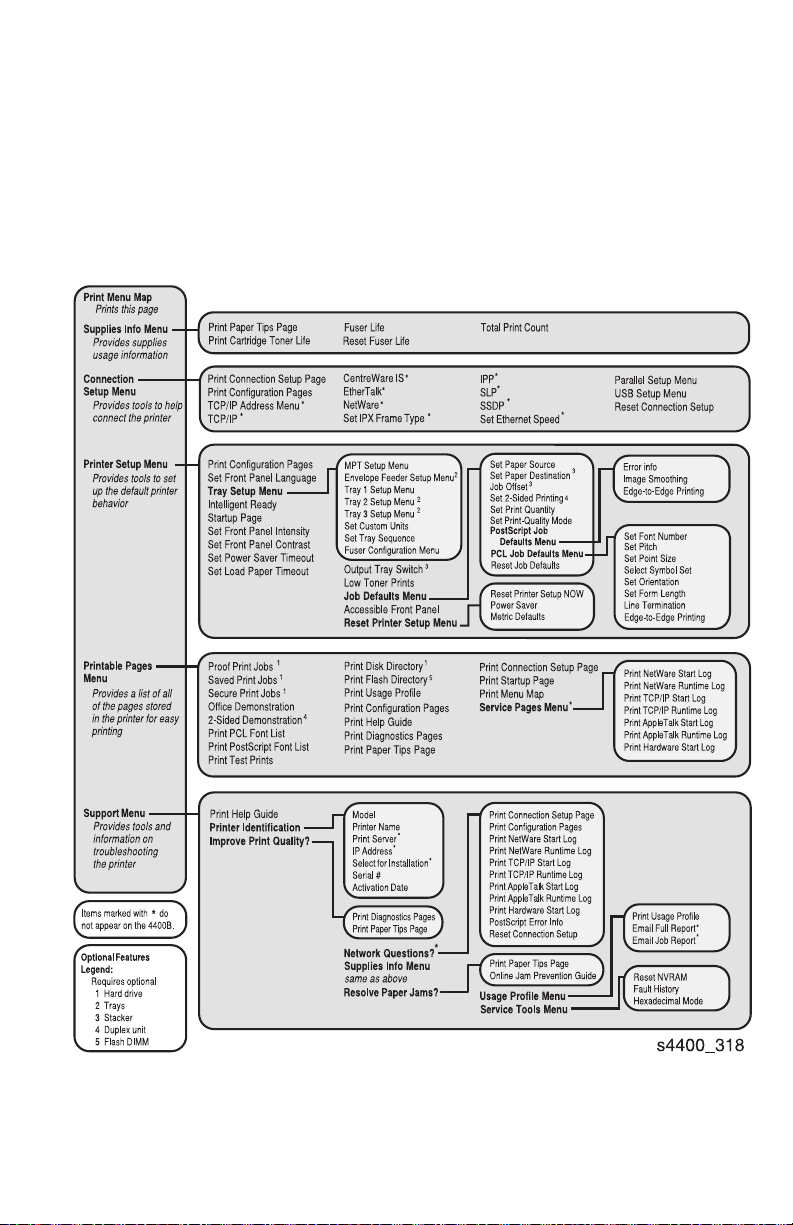

Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Media and Tray Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Phaser 4400 Laser Printer Service Manual 1-1

Page 19

Phaser 4400 Laser Printer Overview

The Phaser 4400 Laser Printer combines a monochrome print engine with an image

processor supporting PostScript 3 and PCL5e/6. The Phaser 4400 is a high

performance, 26 ppm desktop laser printer with a resolution up to 1200 x 1200 dpi.

Configurations

The Phaser 4400 is available in four configurations. A replaceable “Configuration

Upgrade Chip” holds configuration information that enables or disables built-in

features as described here.

Phaser 4400B The Phaser 4400B is the base configuration laser printer. The printer

comes standard with 32 Mbytes of memory, 600 x 600 dpi resolution, USB and

Parallel support, a built in Multi-Purpose Tray, and a 550-sheet universal paper tray.

Note: The Phaser 4400B reports 32 Mbytes of memory even though

Phaser 4400N The Phaser 4400N is the networking configuration. This

configuration includes all the features of the 4400B, but comes with 64 Mbytes of

memory, built-in 10/100 Ethernet networking capabilities, and a resolution up to 1200

x 1200 dpi.

Phaser 4400DT The Phaser 4400DT includes all the features of the 4400N but

comes standard with built in auto-duplexing, and one added 550-sheet feeder.

Phaser 4400DXThe Phaser 4400DX includes all the features of the 4400DT, along

with a 20-Gbyte hard drive and a Stacker with offset.

it has a 64-Mbyte DIMM installed. In order to get the full

64 Mbytes of memory to be reported as well as activate other

features, users need to upgrade to the N-configuration with a

Configuration Upgrade Kit, part number 098S04703.

Page Description Languages (PDL)

■ PCL5e/6

■ Adobe PostScript 3

■ PDF

Resident Fonts

■ 39 PostScript Roman fonts available on all models, plus an additional 97

Roman fonts available with the optional Hard Drive.

■ 81 PCL fonts (more fonts are available with the optional internal Hard

Drive.)

1-2 Phaser 4400 Laser Printer Service Manual

Page 20

Printer Memory Configuration

The printer features two slots which accept 32-, 64-, and 128-Mbyte SDRAM

DIMMs. All combinations except 32 Mbytes alone are allowed to a maximum of 256

Mbytes.

The Phaser 4400B reports 32 Mbytes of memory, even though it has a 64-Mbyte

DIMM installed. In order to get the full 64 Mbytes of memory to be reported as well

as activate other features, users must upgrade to the N-model with a Configuration

Upgrade Kit, part number 098S04703.

The Startup page and the Configuration pages list the amount of RAM installed in the

printer.

If the memory does not meet the following specifications, it is ignored by the printer.

■ PC133 DRAM Standard

■ 144-Pin SODIMM

■ Serial Presence Detect

■ 3.3 Volt

Monitoring Consumables

The status of printer consumables is available through the Supplies Info Menu.

Replaceable Items Print Life

Print Cartridge (rated at 5% image

coverage of letter-size paper)

Maintenance Kit (includes Fuser,

Transfer Roller, and nine rollers for Feed,

Retard, and Nudger Roller assemblies).

High-Capacity 15,000

Toner wt. 620 g (1.36 lbs.)

Standard-Capacity 10,000

Toner wt. 420 g. (.9 lbs.)

up to 200,000

Repackaging Information

If the printer must be returned to Xerox and the customer has not saved the shipping

box and all internal packaging, a repackaging kit is available for order from the local

Customer Support Center.

Repackaging Kit: part number 065-0606-00

Phaser 4400 Laser Printer Service Manual 1-3

Page 21

Parts of the Printer

The parts of the printer are covered here in three groups:

■ Base configuration components

■ Internal components

■ Printer options

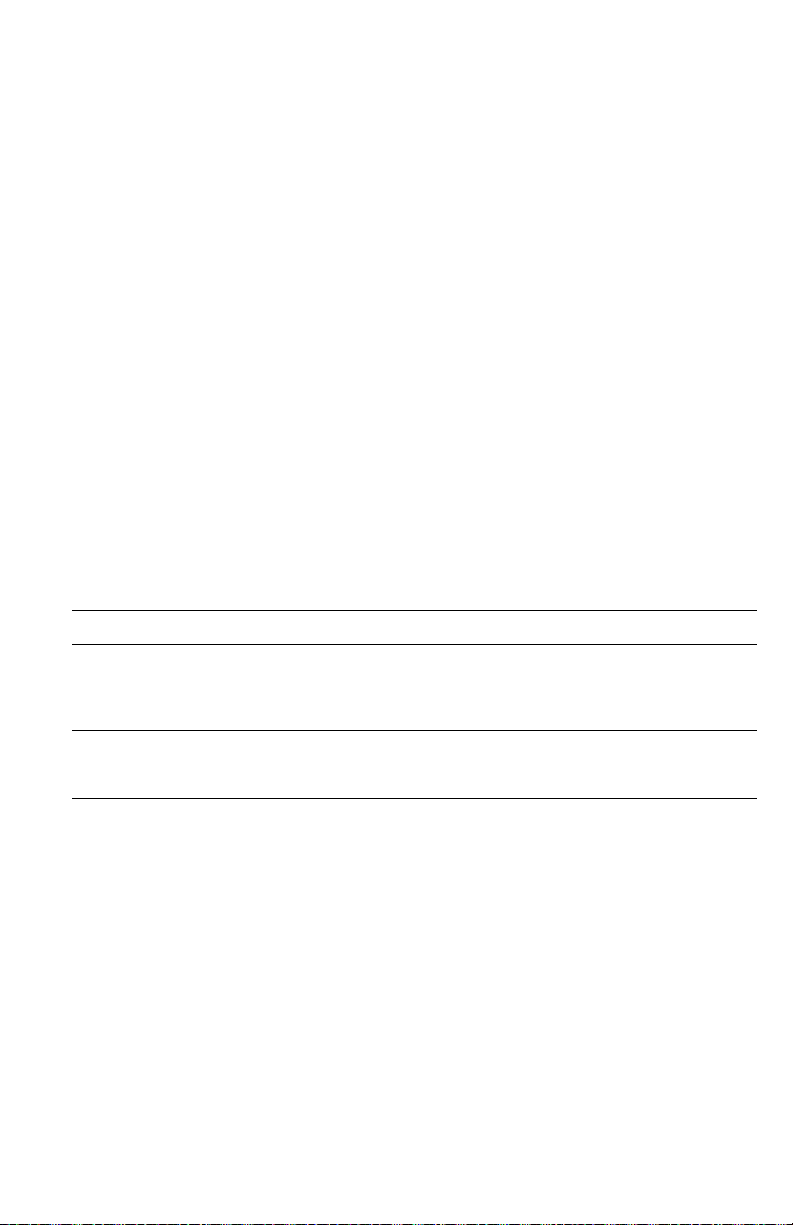

Base Configuration Components

3

4

5

6

7

2

1

8

Front view of base configuration

No. Description

1. Paper exit slot

2. Standard Output Tray

3. Front panel

4. Front cover (shown closed)

5. Multi-Purpose Tray (MPT)

6. Multi-Purpose Tray extension

7. Power switch

8. Tray 1

9. Paper level gauge

9

1-4 Phaser 4400 Laser Printer Service Manual

Page 22

1

2

3

4

5

6

Rear view of base configuration

No. Description

1. Option Cover

2. Rear cover release

3. Rear cover (shown closed)

4. Parallel connector

5. USB connector

6. Ethernet connector

7. Power cord receptacle

8. Left cover

9. Ventilation slots

9

7

8

Phaser 4400 Laser Printer Service Manual 1-5

Page 23

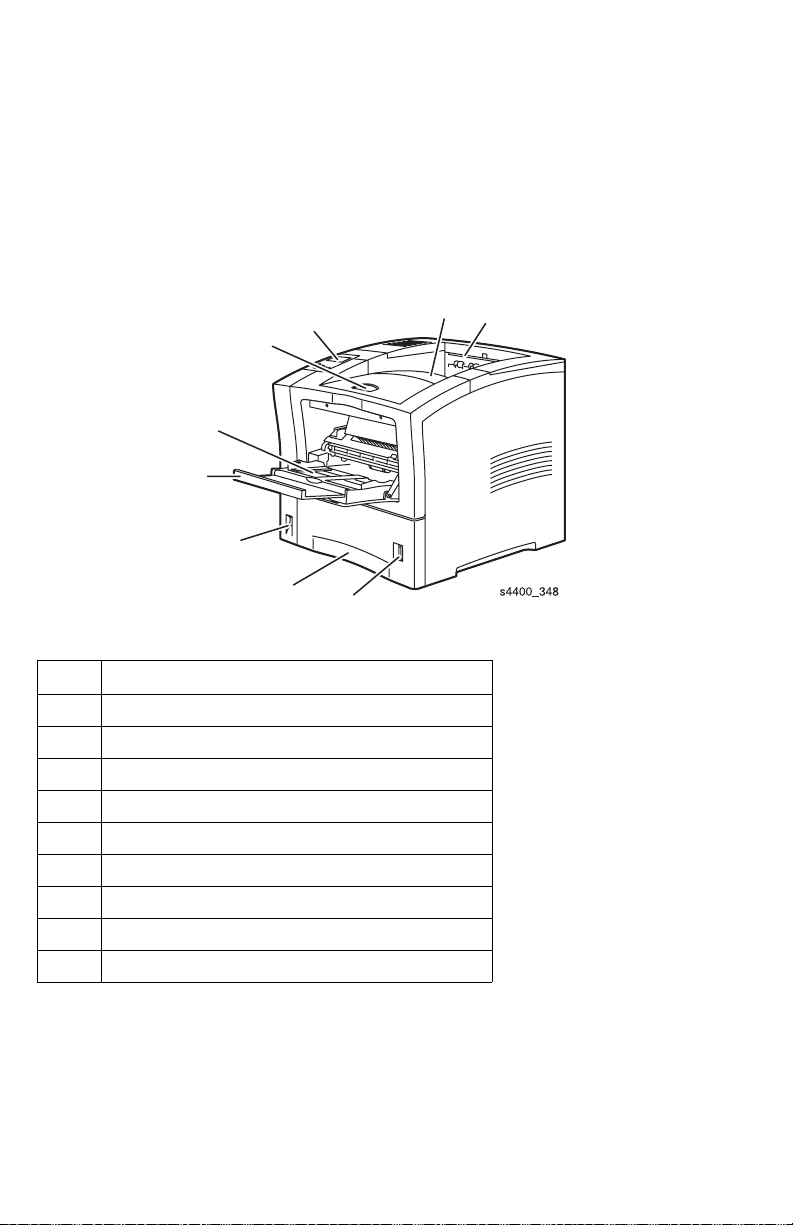

Internal Components

1

2

3

4

Front and rear views with covers open

No. Description

1. Print Cartridge

2. Front cover (shown open)

3. Fuser

4. Rear door (shown open)

Printer Options

The following customer-installed options are available for the Phaser 4400 printer.

Option Customer

Description

Order Number

32-Mbyte DIMM 97S02923 32-Mbyte Memory

64-Mbyte DIMM 97S02912 64-Mbyte Memory

128-Mbyte DIMM 97S02913 128-Mbyte Memory

16-Mbyte Flash DIMM 97S02914 16-Mbyte Flash ROM for storage of fonts, forms, etc.

4400 Network

Upgrade Kit

20+ Gbyte Hard Drive 97S02917 Adds hard disk capability to the printer:

550-Sheet Feeder 97S02878 Provides 550-sheet additional input capacity when

550-Sheet Paper Tray 109R00448 Used with the 550-Sheet Feeder. The Tray holds 550

Duplex Unit 97S02880 Provides duplex (two sided) printing capability.

Stacker 97S02881 Adds 500 sheet output capacity with offset capability.

Envelope Feeder 97S02879 Provides dedicated envelope feed.

98S04703 Configuration Upgrade Chip upgrades a Base printer

to a Network printer.

■ Stores fonts, forms, etc.

■ Enables collation, proof, secure and save jobs.

■ Provides user documentation, setup and care

videos, and printer drivers.

used in conjunction with the 550-sheet Paper Tray.

You can install one or two 550-Sheet Feeders.

sheets of paper.

1-6 Phaser 4400 Laser Printer Service Manual

Page 24

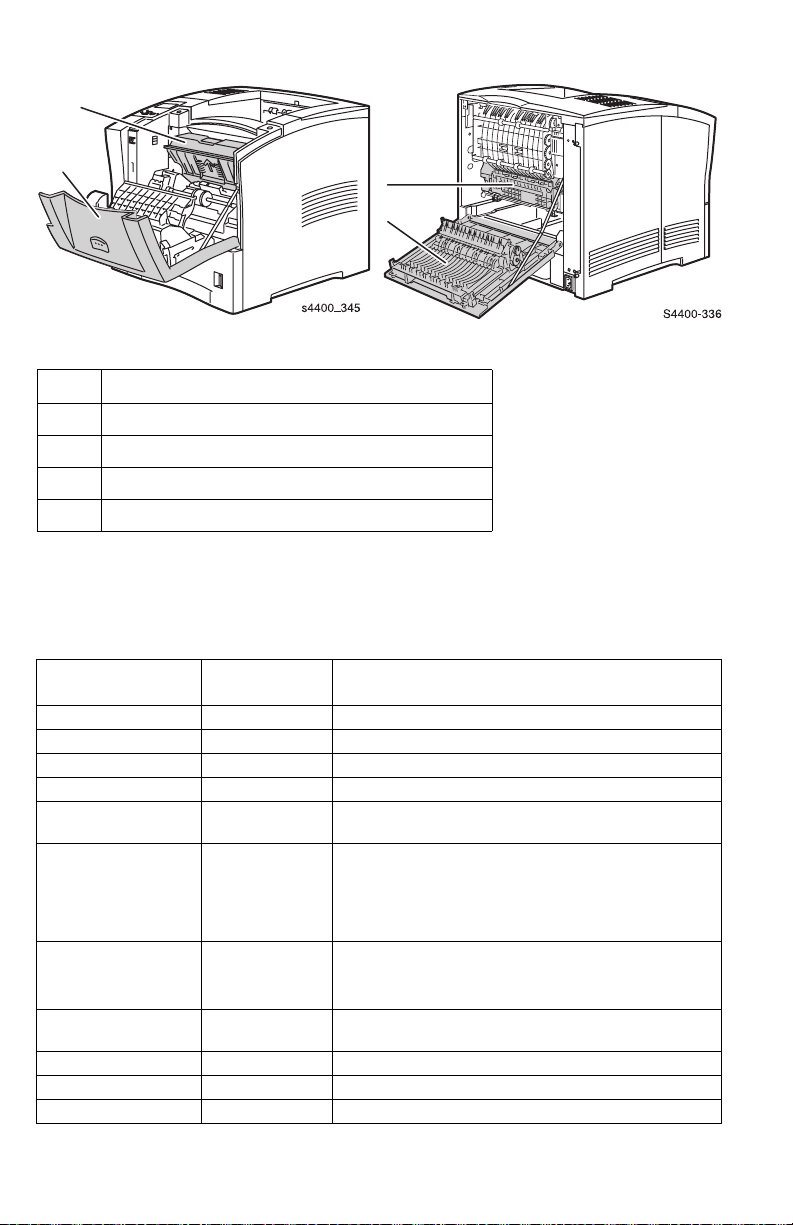

1

2

5

3

4

Printer options

No. Description

1. 500-Sheet Stacker

2. Envelope feeder

3. 550-sheet feeder with tray 2

4. 550-sheet feeder with tray 3

5. Automatic duplex unit

s4400-346

Phaser 4400 Laser Printer Service Manual 1-7

Page 25

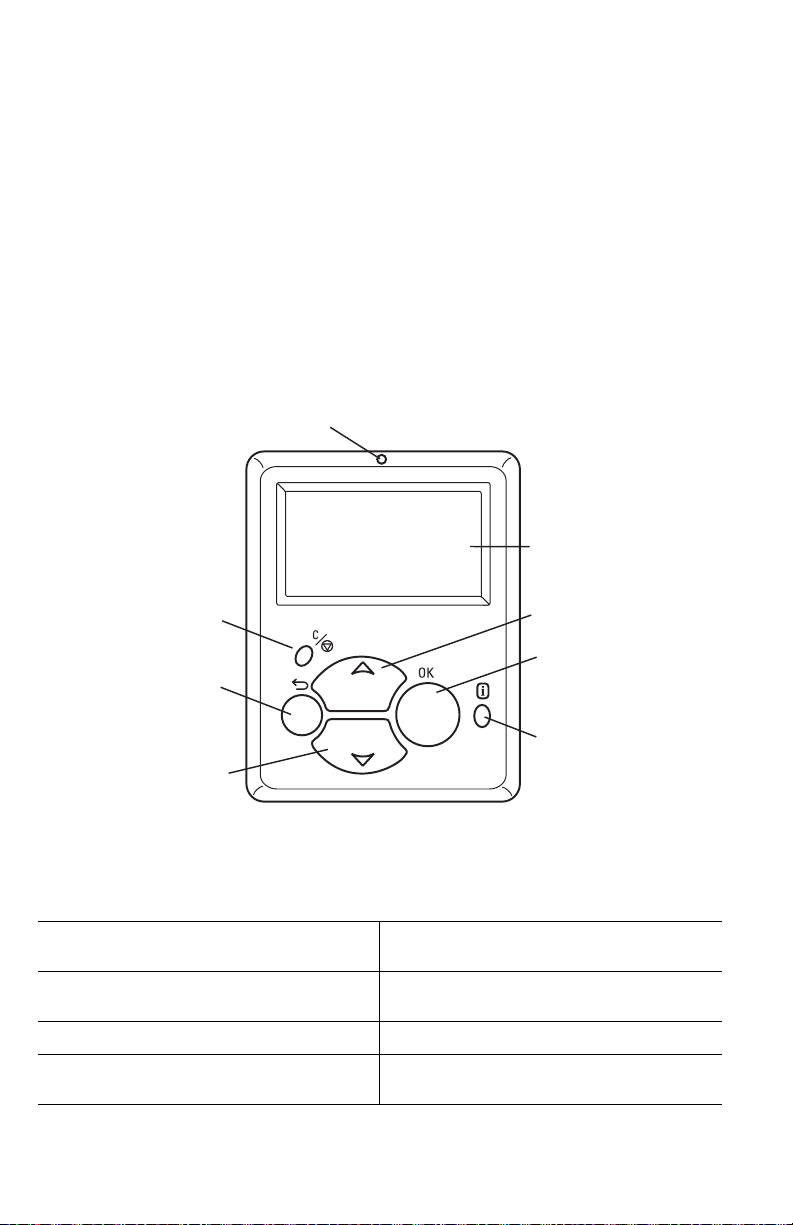

Front Panel Configuration

The Front Panel consists of one tricolor LED, a display window and six functional

keys. These keys navigate the menu system, perform functions and select modes of

operation for the printer.

The LED (light emitting diode) above the Graphics Display can be green, yellow or

red, and can be off, blinking or steady.

LED indications:

Green — Ready to Print

Flashing Green — Receiving, Processing Data or Printing

Flashing Yellow — Warning

Flashing Red — Error (blinks in unison with Image Processor Health LED)

1

2

3

5

7

4

8

6

s4400_006

Phaser 4400 Front Panel Configuration

Front Panel Key Descriptions

Status LED

1

Graphic front panel display

2

Cancel Key

3

Back Key

4

Up Arrow Key - scrolls up the menu

5

system

Down Arrow Key - scrolls down the menu

6

system

OK (select) Key

7

INFO Key - for additional explanation or

8

help

1-8 Phaser 4400 Laser Printer Service Manual

Page 26

Front Panel Shortcuts

Mode Press this selection at power-on

Skip execution of POST diagnostics OK

Print Service Menu Map INFO

Reset PostScript NVRAM BACK+OK

When “Password” appears, press UP +

DOWN keys within 2 seconds

Enter Service Diagnostics BACK+INFO

Phaser 4400 Laser Printer Service Manual 1-9

Page 27

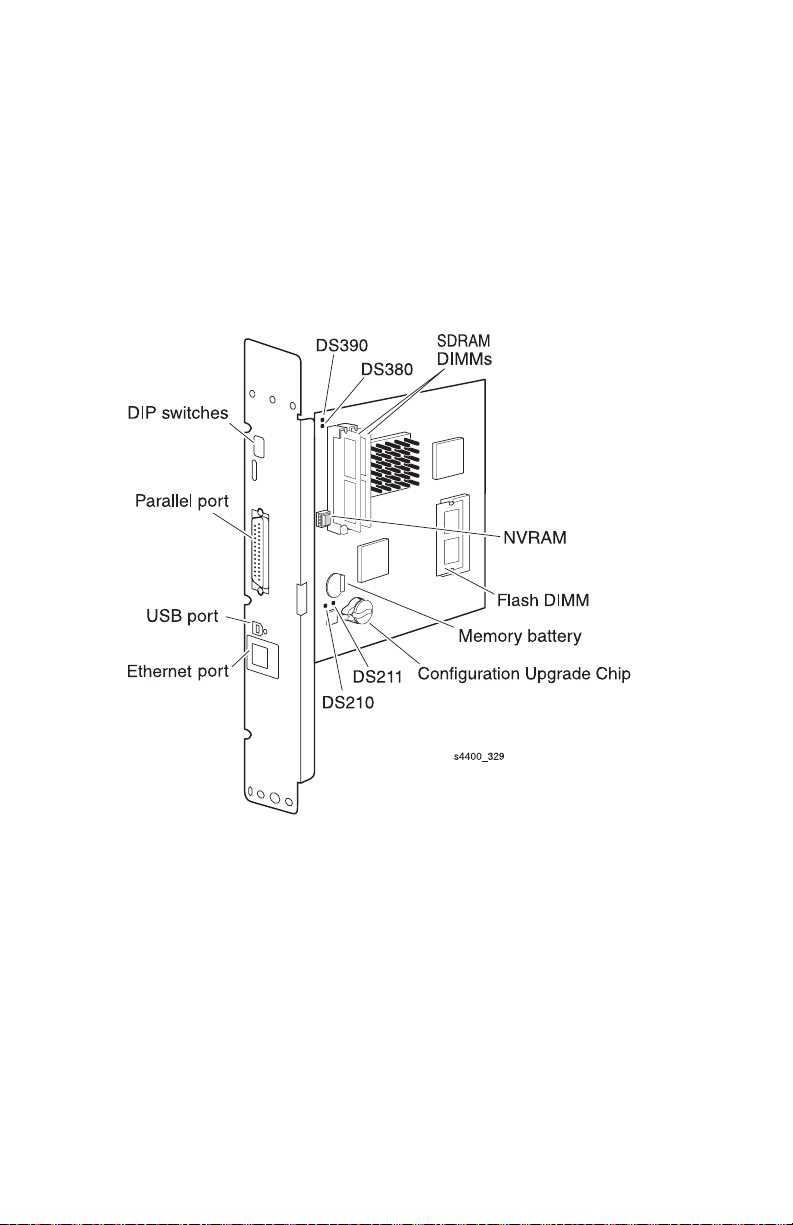

Image Processor Board

The following components must be transferred from the old board when installing a

new Image Processor Board in the printer:

■ SDRAM DIMMs (Slot 1 on the left, slot 2 on the right)

■ NVRAM

■ Configuration Upgrade Chip

■ Flash DIMM

See RRP 9.2 Image Processor Board on page 6-88 for information on replacing the

Image Processor Board.

Inside the printer on the Image Processor board are four LEDs shown in the figure.

DS210 illuminates when the e-net rate is set to 10 Mbits/sec (off indicates

100 Mbits/sec).

DS211 illuminates when a link is established.

DS380 is the HEALTH LED. The CPU flashes this LED to indicate that it is “alive”,

or in the case of a failure, the CPU flashes this LED (and the Front Panel LED, also)

with a code to help diagnose the problem.

DS390 is the CHECK STOP indicator, which illuminates when various fatal errors

occur in the CPU.

1-10 Phaser 4400 Laser Printer Service Manual

Page 28

Rear Panel Configuration Interfaces

■ IEEE 1284 parallel

■ Ethernet 10/100BaseTx

■ USB

On the Ethernet port, the green LED is a RECEIVE DATA indicator and the yellow

LED is a TRANSMIT DATA indicator.

Rear Panel DIP Switch Settings

Note: The DIP switch setting information presented here is meant

to provide a means of returning to as-shipped status in case

the switches have been inadvertently changed. Except in

extreme circumstances, the DIP switches should be left in the

Normal operating mode.

The DIP switches are defined as follows:

■ Switches 1-2 select the modes of operation, as follows:

DIP Switch Settings

Mode of Operation SW1 SW2 SW3 SW4

Normal (or Customer) Open Open Open Open

Manufacturing Open Closed Open Open

Developer (no POST) Closed Closed Open Open

Disaster Recovery (vxWorks only) Closed Open Open Open

■ Switch 3 selects whether the rear panel serial port presents PostScript or

vxWorks backchannel messages. OPEN presents PostScript; Closed presents

vxWorks.

■ Switch 4 is an IP board Reset switch (normally OPEN).

Processor Information

The processor used on the Image Processor board is a 266 MHz PowerPC processor.

Phaser 4400 Laser Printer Service Manual 1-11

Page 29

Machine Orientation

For servicing the Phaser 4400 Laser Printer, all references to machine orientation are

as illustrated below.

Machine Orientation

1-12 Phaser 4400 Laser Printer Service Manual

Page 30

Menu Map

The menu map shown here lists the choices available when you select Menus, and is

printed when you select

of menus, items, and values found in the Menu Map is the order in which the menus,

items, and values are displayed when scrolling through the menu items.

Menus and items in this map marked with a numbered footnote do not appear on the

front panel display unless the associated option is installed in the printer. Items in this

map marked with an asterisk (*) do not appear on the base configuration 4400B.

Print Menu Map from the top level of Menus. The order

Phaser 4400 Laser Printer Service Manual 1-13

Page 31

Printer Specifications

Physical Specifications

Physical Dimensions - Printer

Dimensions Value

Size and weight (not

including the Print

Cartridge, Image

Processor Board or any

options)

Printer clearances

Clearances Value

Top (to closest

overhead object):

Left: Minimum 12” or 300 mm

Right: 300 mm (12 in.)

Front: Minimum 600 mm (24 in.)

Rear: Minimum 600 mm (24 in.)

Mounting surface

flatness:

Width: 422 mm x Depth 439 mm x Height 413 mm (16.5 in. x

17.25 in. x 16.25 in.)

Weight: 25 Kg (55 lbs.)

Packaged Weight: 32.7 kg (72 lbs.)

With Stacker 102 mm (4.0")

Without Stacker 292 mm (11.5")

Horizontal bias within 5° of level

Media and Tray Specifications

Refer to the “Paper Tips” pages shown beginning on page 1-15. You can print the

Paper Tips pages from the Front Panel by selecting

Menu | Print Paper Tips Page

.

The following table lists the total paper capacities available with the three paper deck

combinations:

Maximum Paper Stack Capacity

Combination MBF

(standard)

1 100 sheets 550 sheets — — 650 sheets

2 100 sheets 550 sheets 550 sheets — 1200 sheets

3 100 sheets 550 sheets 550 sheets 550 sheets 1750 sheets

Note: Paper stack capacity applies to baseline paper:

Xerox 4200/4024 20 lb. Letter and RX 80 A4 (3R91720).

1-14 Phaser 4400 Laser Printer Service Manual

1st deck

(standard)

Menus | Supplies Info

2nd deck

(option)

3rd deck

(option)

Tota l

Capacity

Page 32

The Paper Tips Pages shown here list the supported paper and paper sizes, and

provide the paper specifications for the printer.

Refer to the following tables to ensure the best print-quality and to avoid paper jams. For best results, use Xerox-branded paper as it is

guaranteed to produce excellent results on your Xerox Phaser

vary depending on vendor and type of paper used.

Note: If you change the type of paper or transparencies, you must specify the type on the front panel of the printer. For the Multi-Purpose Tray

or envelope feeder only: if you change the size of paper, also specify the size on the front panel.

TM

4400 Laser Printer. Print-quality and paper handling performance may

Supported paper and paper sizes

Input Output

Paper Type

550-Sheet Tray

Multi-Purpose

Tray

A4 (210 x 297 mm)

A5 (148 x 210 mm)

A6 (105 x 148 mm)

ISO B5 (176 x 250 mm)

(1) (1)

(1)

custom

(1)

custom

B5 JIS (182 x 257 mm)

Index Card (3 x 5 in.)

Statement (5.5 x 8.5 in.)

---

custom

(1)

Executive (7.25 x 10.5 in.)

Letter (8.5 x 11 in.)

US Folio (8.5 x 13 in.)

Legal (8.5 x 14 in.)

Envelopes

#10 Commercial (4.12 x 9.5 in.)

Monarch (3.87 x 7.5 in.)

DL (110 x 220 mm)

C5 (162 x 229 mm)

B5 (176 x 250 mm)

custom

custom

custom

custom

custom

(1)

(1)

(1)

(1)

(1)

Transparencies

A4 (210 x 297 mm)

Letter (8.5 x 11 in.)

(1)

(1)

Labels

A4 (210 x 297 mm)

Letter (8.5 x 11 in.)

(2)

Capacity

= Short-edge feed (1) Simplex (one-sided) printing only. (2) Maximum capacity at 75 g/m (20 lb.) paper stock. Capacity is reduced for heavier/thicker stock.

(1)

(1)

550 100 75 500 500

2

Envelope

Feeder

---

---

(1)

(1)

---

---

(1)

(1)

---

---

---

---

---

---

(1)

(1)

(1)

(1)

(1)

custom

(1)

(1)

(1)

(1)

---

---

---

---

Standard

Tray

(1)

500-Sheet

Stacker

---

(1)

(1)

(1)

(1)

(1)

s4400_351

Paper Tips Page 1 of 3

Phaser 4400 Laser Printer Service Manual 1-15

Page 33

Custom paper sizes

550-Sheet Tray

(one-sided)

Simplex

Width

Length

Duplex

Width

Length

98 - 216 mm 76 - 216 mm 98 - 178 mm 76 - 216 mm 98 - 216 mm

3.87 - 8.5 in. 3.0 - 8.5 in. 3.87 - 7.0 in. 3.0 - 8.5 in. 3.87 - 8.5 in.

148 - 356 mm 127 - 356 mm

5.83 - 14.0 in. 5.0 - 14.0 in. 5.83 - 10.0 in. 5.0 - 14.0 in. 5.83 - 14.0 in.

(two-sided)

182 - 216 mm

7.16 - 8.5 in.

257 - 356 mm

10.12 - 14.0 in.

Input Output

Multi-Purpose Tray

182 - 216 mm

7.16 - 8.5 in.

257 - 356 mm

10.12 - 14.0 in.

Envelope Feeder Standard Tray 500-Sheet Stacker

148 - 254 mm

---

---

127 - 356 mm 148 - 356 mm

Same as Input

Same as Input

Paper weights

The Phaser 4400 Laser Printer supports paper weights as follows:

• 16 - 130 lbs. (60 - 216 g/m ) simplex/one-sided

• 16 - 28 lbs. (60 - 105 g/m ) duplex/two-sided

Plain Paper: (60 - 120 g/m ) (16 - 32 lb.)

Card Stock: (120 - 216 g/m ) (32 - 130 lb.)

TM

2

2

2

2

Paper tips

• If excessive jams occur, flip the paper in the tray or install fresh paper from a newly opened ream.

• Transparencies should be fanned prior to loading.

• Other size envelopes may be printed as custom paper sizes.

• Use only paper envelopes. Do not use envelopes with windows or metal clasps.

• Label media should be fanned prior to loading.

• Do not print to label stock once a label has been removed.

s4400_352

Paper Tips Page 2 of 3

1-16 Phaser 4400 Laser Printer Service Manual

Page 34

Ordering supplies

See

www.xerox.com/officeprinting/4400supplies

Xerox Branded Paper

Item Paper Size Part Number

Plain Paper

Xerox Premier 80 A4 (210 x 297 mm) 3R91720

Xerox Premier 80 A5 (148 x 210 mm) 3R91832

Xerox 4024 DP statement Statement (5.5 x 8.5 in.) 3R2072

Xerox 4024 DP Letter (8.5 x 11 in.) 3R721

Xerox 4024 DP folio Folio (8.5 x 13 in.) 3R725

Xerox 4024 DP legal Legal (8.5 x 14 in.) 3R727

Transparencies

Xerox 3M Type L transparencies A4 (210 x 297 mm) 3R91334

Xerox Clear transparencies Letter (8.5 x 11 in.) 3R4446

Labels

Xerox A4 24-up label A4 (210 x 297 mm) 3R96178

Xerox Multi-purpose 30-up label Letter (8.5 x 11 in.) 3R12051

for information on ordering supplies.

Replaceable Items

Item Part Number

Standard-Capacity Print Cartridge 113R00627

High-Capacity Print Cartridge 113R00628

Maintenance Kit

Contains: a Fuser Cartridge,

1 Transfer Roll, and 9 Feed Rollers.

s4400_353

108R00497

108R00498

for 110 V (60 Hz)

for 220 V (50 Hz)

Paper Tips Page 3 of 3

Phaser 4400 Laser Printer Service Manual 1-17

Page 35

Functional Specifications

Characteristic Specification

Printing process Recording System - Electro-photographic system (roller charging,

Resolution /

Addressability

Operating Modes Ready Mode: Ready to receive data.

Continuous Operating

Printing Speed

Fuser Configuration

Temperature

First Print Out

(Engine speed only)

Warm-up time From a cold start (22° C / 71.6° F ambient temperature) to READY

single component magnetic toner development)

Exposure System - Infrared Laser Diode Beam Scanning

Class 1 Laser Product

Class 3B Laser, rated at 5 mW output @ 780 nm

Fusing System - Heat and pressure

600/1200 dots per inch (dpi), switchable at full engine speed.

Power Saver Mode: entered after a user-specified period of Print

Engine inactivity since completion of the last print to minimize

energy consumption.

Paper Size Fuser Setting Duplex

Low Medium High Extra High (ipm)

Letter SEF 18 26 22 8 19

A4 SEF 18 25 22 8 18

Legal 14” SEF 18 21.5 18 7.5 16

Legal 13” SEF 18 21.5 18 7.5 16

Executive 18 26 22 8 19

B5 (JIS) SEF 18 26 22 8 19

Low - Medium setting High - Extra High setting

Range: 194-209°C/ Range: 197-212°C/

381-408°F 387-414°F

Tray 1 (t sec) Tray 2 (sec) Tray 3 (sec) MPT (sec)

Paper Size Simp Dup Simp Dup Simp Dup Simp Dup

Letter 7.5 13.8/ 8.3 14.6/ 9.2 15.5/ 7.7 14.0/

14.6 15.4 16.3 14.8

A4 7.6 14.0/ 8.4 14.8/ 9.3 15.7/ 7.8 15.9/

15.4 16.2 17.1 17.3

TO PRINT within 70 seconds.

1-18 Phaser 4400 Laser Printer Service Manual

Page 36

Electrical Specifications

Characteristic Specification

Power supply 120 VAC (98–140 VAC) 50/60 Hz (47 Hz – 63 Hz)

220/240 VAC (198–264 VAC) 50/60 Hz (47 Hz – 63 Hz)

Power consumption Maximum - 600 Watts

Printing - 525 Watts/hour or 1792 Btus/hour

Standby - 110 Watts/hour or 375 Btus/hour

Power Saver - 20 Watts/hour or 68 Btus/hour

Note: No electrical power is supplied to the Fuser assembly in

Power Saver Mode.

Environmental Specifications

Characteristic Specification

Operating environment 5–35° C / 41–95° F @ 15% to 85% Relative Humidity (operating)

0 - 3100 meter (10171 ft.) above sea level

Storage environment

with a packed Print

Cartridge

Storage environment

without a packed Print

Cartridge

Heat Emission Maximum - 2730 BTU; Average - 1603; 102 (sleep mode)

Acoustic Noise (MPT

closed; options are

Duplex Unit, two

additional feeders,

Envelope Feeder,

Stacker)

Dust Emission No more than 0.075 mg/m3 concentration.

Ozone Emission No more than 0.02 mg/m3 concentration, measured in accordance

Normal condition:12 months maximum at 0–35° C/32–95° F

@ 15–80% Relative Humidity with no condensation present

Severe condition: 1 month maximum at -20° to 0° C / -4° to 32° F or

35° to 40° C / 95 to104° F

@ 5–15 or 80–95% Relative Humidity with no condensation present

Normal condition: 12 months maximum at -20 to -50° C / -4 to -58° F

@ 5-85% Relative Humidity with no condensation present

Severe condition: 48 hours maximum at 50–60° C / 122–140 ° F

@ 85-95% Relative Humidity with no condensation present

Standby: 4.9 B (35.0 dB(A))

Power Saver: 0 dB above background noise

Printing (without options): 6.8 B (52.0 dB(A))

Printing (with options): 7.1 B (55.5 dB(A))

with BAM Standard.

Phaser 4400 Laser Printer Service Manual 1-19

Page 37

1-20 Phaser 4400 Laser Printer Service Manual

Page 38

Error Messages and Codes

Section Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Service Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Service Technician Cautionary Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Voltage Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using Fault History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Entering Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Service Diagnostics Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Using the Front Panel with Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Engine Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Engine NVRAM Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Printer Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Index of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Error Message Summaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Image Processor POST Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

Fault Reporting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Introduction

This section covers troubleshooting procedures for the Phaser 4400 Laser Printer’s

front panel error messages. Only jams and fatal errors will produce an associated

numeric code. Error messages and codes are usually specific, making it important that

service personnel and users record errors exactly when reporting problems with the

printer.

Any error code associated with an error message or jam can be viewed by pressing the

INFO key. Jam error are displayed at the beginning of the info menu, while engine

errors are display at the end.

Some procedures require running Service Diagnostics tests to verify a specific printer

assembly is operating correctly. Refer to Service Diagnostics on page 2-7.

To troubleshoot problems not associated with a front panel error message or code

such as ac power, or problems related to print-quality, refer to the section

Troubleshooting on page 3-1.

Phaser 4400 Laser Printer Service Manual 2-1

Page 39

Service Flowchart

The Service Flowchart outlines one possible approach to troubleshooting and repair

of the printer. The Service Flowchart is an overview of the path a service technician

could

take, using this technical manual, to service the printer and options.

If you choose not to use the Service Flowchart, it is recommended that you start at the

appropriate troubleshooting table and proceed from there.

Step 1: Identify the Problem:

1. Verify the reported problem does exist.

2. Check for any error codes and write them down.

3. Print Test Prints.

4. Make note of any print-quality problems in the Test Prints.

5. Make note of any mechanical or electrical abnormalities present.

6. Make note of any unusual noise or smell coming from the printer.

7. Print a Usage Profile Report, if the printer is able to print.

8. View the fault history under the Service Tools Menu

9. Verify the AC input power supply is within proper specifications.

Step 2: Inspect and Clean the Printer:

1. Switch OFF printer power.

2. Disconnect the AC power cord from the wall outlet.

3. Verify the power cord is free from damage or short circuit and is connected properly.

4. Remove the Print Cartridge and protect it from light.

5. Inspect the printer interior and remove any foreign matter such as paper clips,

staples, pieces of paper, dust or toner.

6. Clean the printer interior with a lint-free cloth, dampened slightly with cold water and

mild detergent.

■ Do not use solvents or chemical cleaners to clean the printer interior.

■ Do not use any type of oil or lubricant on printer parts.

■ Use only an approved toner vacuum.

7. Clean all rubber rollers with a lint-free cloth, dampened slightly with cold water and

mild detergent.

8. Inspect the interior of the printer for damaged wires, loose connections, toner

leakage, and damaged or obviously worn parts.

9. If a Print Cartridge appears obviously damaged, replace with a new one.

Step 3: Find the Cause of the Problem:

1. Use the Print Engine Error Messages table (page 2-11) or POST Error Code table

(page 2-58) to find the cause of the problem.

2. Use Diagnostics to check printer and optional components.

3. Use the Wiring Diagrams and Plug/Jack Locator to locate test points.

4. Take voltage readings at various test points as instructed in the appropriate

troubleshooting procedure.

5. Use the Engine Logic Board Test Print on page 3-49, to isolate print capability

problems between the print engine the Image Processor Board.

Step 4: Correct the Problem:

1. Use the Parts List to locate a part number

2. Use the Removal and Replacement Procedures to replace the part.

Step 5: Final Checkout:

1. Test the printer to be sure you have corrected the initial problem and there are no

additional problems present.

2-2 Phaser 4400 Laser Printer Service Manual

Page 40

Service Technician Cautionary Statements

■ Always turn off the printer and remove the AC power cord, unless instructed

to do otherwise in a procedure. This is particularly important when checking

continuity between wiring.

■ If the printer is kept ON, never touch the conductive parts.

■ Wear an electrostatic discharge wrist strap to help prevent damage to the

sensitive electronics on the printer circuit boards.

■ Wait at least 5 minutes after you have switched OFF the printer power for

the Fuser to cool before you work on or around the Fuser.

■ If checking a specific part with the covers removed and the interlocks, safety

and power switches ON, laser beams may be irradiated from the Laser Unit

causing a health hazard. Observe proper precautions at all times.

■ When using service diagnostics to turn motors, drives and/or gears, never

touch or interrupt the moving parts as damage to the printer will result.

Procedures

Using the Troubleshooting Procedures

1. Each Step in a Troubleshooting Procedure instructs you to perform a certain action

or procedure. The steps are to be followed sequentially in the order given until the

problem is fixed or resolved.

2. The Actions and Questions box contains additional information and/or additional

procedures you must follow to isolate the problem.

3. When a procedure instructs you test a component using service diagnostics, see

Service Diagnostics on page 2-7 for the detailed steps and functions for testing

parts of the printer.

4. The action is followed by a question. If your response to the question is “Ye s” ,

then follow the instructions for a “Ye s ” reply. If your response to the question is

“No”, then follow the instructions for a “No” reply.

5. Troubleshooting Procedures may ask you to take voltage readings or test for

continuity at certain test points within the printer. For detailed diagrams, refer to

the section Wiring Data on page 9-1 for complete information on test point

locations and signal names.

6. Troubleshooting Procedures often ask you to replace a printer component. The

section FRU Disassembly on page 6-1 provides detailed steps for removing and

replacing all major parts of the printer. The section Parts Lists on page 7-1 details

the location, quantity and part number for all spared parts of the printer.

Phaser 4400 Laser Printer Service Manual 2-3

Page 41

General Notes on Troubleshooting

1. Unless indicated otherwise, the instruction “switch ON printer main power” means

for you to switch ON printer power and let the printer proceed through POST.

2. When instructed to take voltage, continuity or resistance readings on wiring

harness, proceed as follows: check P/J 232–1 to P/J 210–5 by placing the red probe

(+) of your meter on pin 1 of P/J 232, and place the black probe (–) of your meter

on pin 5 of P/J 210.

3. When you are instructed to take voltage readings between “P/J 232 P/J 210”

(without specified pin numbers), check all pins. Refer to the section Wiring Data

on page 9-1 for the location of all wiring harnesses and pins.

4. When you are instructed to take a voltage reading, the black probe (–) is generally

connected to a pin that is either RTN (Return) or SG (Signal Ground). You can

substitute any RTN pin or test point in the printer, and you can use FG (frame

ground) in place of any SG pin or test point.

5. Unless a troubleshooting procedure instructs otherwise; before measuring voltages

make sure the printer is switched ON, the Imaging Unit and the paper trays are in

place, and the interlock switches are actuated.

6. All voltage values given in the troubleshooting procedures are approximate values.

The main purpose of voltage readings is to determine whether or not a component

is receiving the correct voltage value from the power supply and if gating (a

voltage drop) occurs during component actuation. Gating signals may be nothing

more than a pulse, resulting in a momentary drop in voltage that may be difficult or

impossible to read on the average multi-meter.

7. When a Troubleshooting Procedure instructs you to replace a non-spared

component and that component is part of a parent assembly, you should replace the

entire parent assembly.

Voltage Measurements

Power and signal grounds are connected to frame ground. You can perform all circuit

troubleshooting using the metal frame (chassis) as the grounding point. If you need

more information to locate connectors or test points, refer to Wiring Data on page 9-1.

Unless otherwise specified, the following voltage tolerances are used within this

section.

Voltage Measurements

Stated Measured Stated Measured

+3.3 VDC +3.0 to 3.6 VDC +24.0 VDC +21.6 to +26.4 VDC

+5.0 VDC +4.8 to +5.2 VDC 0.0 VDC Less than +0.5 VDC

2-4 Phaser 4400 Laser Printer Service Manual

Page 42

Using Fault History

The printer keeps a record of engine errors and jams. You can access Fault History for

either engine errors or jams in one of three ways:

■ View the Fault History at the Front Panel.

■ Print the printer’s Usage Profile.

■ View or print the Usage Profile from the printer’s web page, if the printer is

connected to a network.

The errors are presented as a series of one- or two-digit numeric codes. Use the tables

in “Interpreting Fault History” to decipher the codes.

When an error first occurs, record the error message and code, then cycle power to the

printer to see if the error recurs.

Accessing Fault History

1. View the printer’s fault history on the front panel.

a. Enter Menus, then select Support Menu | Service Tools

Menu | Fault History

b. Select

Engine Errors or Jam Errors to display the errors.

2. Print (if possible) the Usage Profile from the printer’s front panel Support

Menu

. Fault history information for Engine Errors and Jams is detailed in this

report log.

3. If the printer is connected to a network and has a TCP/IP address, view the

printer’s web page using a web browser.

a. Open a web browser.

b. Enter the printer’s IP address as the URL.

c. Select the “Jobs” tab and click the Usage Profile link. You can then

click a link to view or to print the Usage Profile.

.

Phaser 4400 Laser Printer Service Manual 2-5

Page 43

Interpreting Fault History Error Codes

The following tables provide a cross-reference of the numeric fault history codes to

the Diagnostic Message and code found in Printer Error Messages on page 2-11.

These numeric codes are displayed on the Front Panel for both Engine Errors and

Jams; in the Usage Profile, the numeric codes are used only in the Engine Error Log

(Item 262).

Fault History Codes for Engine Errors

Fault

History

Code

0 Fan Failure (U5) 6 Tray 2/3 Failure (E11)

1 Fuser Failure (U4) 7 Tray 1 Failure (C3)

2 Motor Failure (U1) 8 Tray 2 Failure (C3)

3 IOT NVM Failure (U6) 9 Tray 3 Failure (C3)

4 Stacker Failure (E9) 10 Tray 2 Failure (E11)

5 Laser failure (U2) — —

Error Fault

History

Code

Error

Fault History Codes for Jams

Fault

History

Code

1 E7-1 12 E2-12

2 E7-2 13 E2-03

3 E7-3 14 E2-13

4 E4-0 15 E2-0E

Jam Code Fault

History

Code

Jam Code

5 E4-2 16 E2-1E

6 E4-3 17 E6-1

7 E2-0M 18 E6-2

8 E2-1M 19 PSE-1

9 E2-01 20 E3-1

10 E2-11 21 E3-2

11 E2-02 22 E7-0

2-6 Phaser 4400 Laser Printer Service Manual

Page 44

Service Diagnostics

The printer’s Service Diagnostics provide the ability to:

■ Print the Service Diagnostics Menu Map.

■ Check the current print engine status.

■ Start the Engine Test Print after selecting the print quantity, the source tray,

output tray, and simplex or duplex printing.

■ Test the functionality of printer motors and fans, solenoids, and clutches.

■ Test some portions of drive trains by engaging combinations of motors and

clutches or solenoids.

■ Test the functionality of sensors, switches, and options by manually toggling

each sensor or installing an option.

■ Perform NVRAM adjustments essential to the performance of the printer.

■ Check eight different print engine components.

■ Reset the PS NVRAM locations to factory defaults (see Resetting NVRAM

on page 4-7).

Entering Service Diagnostics

To enter Service Diagnostics:

While turning on power, press and hold Back + Info until the message “Entering

Service Diagnostics” appears on the display, then release the keys. The Service

Diagnostics Menu appears.

The Service Diagnostic menu has the following selections:

General Status — Provides current print engine status.

Engine Test Print — Starts the test print.

Motors/Fans Tests — Tests the functionality of the printer Motors/Fan.

Main Motor + Clutches/Sol Tests — Tests the functionality of the main

motor plus clutches or Solenoid at the same time.

Sensor Tests — Tests the functionality of sensors, switches, or the presence of

options by manually toggling each sensor or installing an option. Some of the sensor

tests require cheating the front and/or rear door interlocks.

Note: The Service Diagnostics Sensor Tests do not include a check

of the Tray Stack Height Sensor. Refer to the Stack Height

Sensor Checkout on page 3-23.

Solenoid Tests — Tests the functionality of printer solenoids.

Clutch Tests — Tests the functionality of printer clutches.

Engine NVRAM Adjustments — Perform NVRAM adjustments essential to

the performance of the printer.

Phaser 4400 Laser Printer Service Manual 2-7

Page 45

Component Checks — Tests print engine component functions.

NVRAM Access — Lets you reset the PS NVRAM locations to factory defaults.

Exit — Reboots the Printer out of Diagnostics.

Service Diagnostics Menu Map

The Service Diagnostics Menu Map lists the tests available for testing print engine

parts and functions while diagnosing printer problems. When you enter Service

Diagnostics, the menu items shown in bold type appear on the front panel. When you

select one of these items, the list of individual tests appear.

Print Service Menu Map:

General Status:

Engine ROM Version

Engine Print Counter

Engine Configuration

Print Resolution

Read Fuser Temperature

Read Fuser Set Temperature

Engine Test Print: Starts the test print.

Print Test pattern

Input tray

Output tray

Duplex

Print Quantity

Motors/Fan Test:

Duplex Motor High

Duplex Motor Low

Exit Motor Forward

Exit Motor Reverse High

Exit Motor Reverse Low

Main Motor

Fan Motor High Speed

Laser Scan Motor

Stacker Motor

Stacker Offset Motor

Main Motor + Clutch/Sol Tests: * Runs main drive motor with each

individual clutch and MPT solenoid.

Sensor Tests:

manually toggling each sensor or installing an option.

Front Cover Switch

Rear Cover Switch

Paper Tray Size Read (display paper size, for trays)

Print Cartridge Switch

Toner Sensor

Registration Sensor

Exit Sensor (Fuser)

Duplex Sensor

Stacker Sensor

Stacker Full Sensor

Output Tray Full Sensor (Printer)

Tray 1 Low Paper Sensor

Tray 2 L

Tray 3 Low Paper Sensor

Tray 1 No Paper Sensor

Tray 2 No Paper Sensor

Tray 3 No Paper Sensor

MPT No Paper Sensor

Envelope Feeder No Paper Sensor

Envelope Feeder Presence

Duplex Unit Presence

Stacker Unit Presence

Provides current print engine status.

Test the functionality for motors/fan.

Tests the functionality of sensors/switches/options by

ow Paper Sensor

Prints this page

Solenoid Tests:

*MPT Solenoid

Stacker Direction Solenoid

Clutch tests:

*Registration Clutch

*Tray 1 Feed Clutch

*Tray 2 Feed Clutch

*Tray 3 Feed Clutch

*Tray 1 Turn Roll Clutch

*Tray 2 Turn Roll Clutch

*Tray 3 Turn Roll Clutch

*Envelope Feeder Clutch

Engine NVRAM Adjustments:

the performance of the printer.

Laser Power Setting

MPT Paper Size Adjustment

Envelope Paper Size Adjustment

Tray 1 Process Direction

Tray 2 Process Direction

Tray 3 Process Direction

Envelope Feeder Process Direction

MPT Process Direction

Tray 1 Scan Direction

Tray 2 Scan Direction

Tray 3 Scan Direction

Envelope Feeder Scan Direction

MPT Scan Direction

Duplex Process Direction

Duplex Scan Direction

Component Checks:

Laser Diode

Detack Saw Output

Transfer Roll +

Transfer Roll ñ

Developer Bias AC

Developer Bias DC

Charge Roll AC

Charge Roll DC

NVRAM Access: This menu lets you reset the PS NVRAM locations to

factory defaults.

PostScript NVRAM Reset

Exit:

For Service Use Only:

The Service menu functions are to be used by Xerox service personnel

and authorized service providers. The p

improper use of the built-in service tests.

Test the functionality of printer solenoids

Test the functionality of printer clutches.

Reboots Printer out of Diagnostics.

Perform NVRAM adjustments essential to

rinter can be damaged by

2-8 Phaser 4400 Laser Printer Service Manual

Page 46

Using the Front Panel with Service Diagnostics

The keys on the Front Panel provide the user interface for Service Diagnostics. The

keys and their functions are shown in Front Panel Configuration on page 1-8. After

you enter Service Diagnostics, the Up and Down keys allow you to move or scroll the

highlight up and down through a menu. When you have highlighted the item you

want to select, press OK to enter the selection.

When you are selecting a page quantity in the Engine Test Print menu use the

OK key to move the highlight to the right. then use the Up or Down key to change the

value of the selected digit. when you have entered the desired quantity, use the Back

key to enter the selection.

Note: If you moved past the digit you want to change, keep pressing

the OK key until the highlight wraps to the desired digit.

In most of the Service Diagnostics menus, use the Back key to exit a menu to the

level just above. In most cases, scrolling to the end of a menu and selecting Exit takes

you back to the Service Diagnostics Main Menu.

When you select Read Fuser Temperature from the General Status

menu, the temperature is presented in hex values. The following table lists the

temperatures that correspond to the hex values displayed.

Fuser Temperature Cross Reference Table

Hex value Tem p e ra t u re (°C / °F) Hex value Te m pe r a ture ( °C / °F)

EE 0°C / 32°F CA 140°C / 284F

FE 10°C / 50°F C6 145°C / 293°F

FD 20°C / 68°F C1 150°C / 302°F

FC 30°C / 86°F BD 155°C / 311°F

FB 40°C / 104°F B8 160°C / 320°F

F9 50°C / 122°F B3 165°C / 329°F

F7 60°C / 140°F AE 170°C / 338°F

F4 70°C / 158°F A9 175°C / 347°F

F0 80°C / 176°F A4 180°C / 356°F

EC 90°C / 194°F 99 190°C / 374°F

E7 100°C / 212°F 8F 200°C / 392°F

E1 110°C / 230°F 85 210°C / 410°F

DA 120°C / 248°F 7C 220°C / 428°F

D3 130°C / 266°F 72 230°C / 446°F

Phaser 4400 Laser Printer Service Manual 2-9

Page 47

Engine Test Print

The Engine Test Print test pattern (shown on page 4-4) is stored in the Engine Logic

Board and is accessible through Service Diagnostics. You can use the Engine Test

Print to identify, repair, and validate the operability of printer xerographics and paper

handling from all paper sources, options, and output destinations. When you select

Engine Test Print from the main Service Diagnostics menu, the following selections

are available:

Print Test Pattern — Starts the print

Input Tray — Allows you to select the paper source

Output Tray — Allows you to select the test print destination

Duplex — Turns duplexing on or off if the Duplex Unit is installed

Print Quantity — Allows you to select the number of test prints to run

Error and Jam Recovery

If the printer encounters a problem while printing the Engine Test Print, it halts

printing and displays an error message on the Front Panel. Refer to the Diagnostic

Messages in the Print Engine Error Messages table that follows. (The Diagnostic

Messages also appear as secondary headings in the Troubleshooting Procedures.)

Printing resumes after the problem has been fixed.

Engine NVRAM Default Settings

The following table lists the defaults for each of the Engine NVRAM Adjustments

except the paper size adjustments, which have no default settings.

NVRAM Default Table

Engine NVRAM

Adjustment

Laser Power 10 0 - 15 Tray 2 Scan Direction 3 0 - 8

Tray 1 Process

Direction

Tray 2 Process

Direction

Tray 3 Process

Direction

Envelope Process

Direction

MPT Process

Direction

Tray 1 Scan

Direction

Default

Value

8 0 - 15 Tray 3 Scan Direction 2 0 - 8

8 0 - 15 Envelope Scan Direction 4 0 - 8

8 0 - 15 MPT Scan Direction 6 0 - 8

8 0 - 15 Duplex Process

8 0 - 15 Duplex Scan Direction 4 0 - 8

4 0 - 8

Range Engine NVRAM

Adjustments

Direction

Default

Value

8 0 - 15

Range

2-10 Phaser 4400 Laser Printer Service Manual

Page 48

Printer Error Messages

Index of Errors

Front Panel Message Page

Jam Errors

Jam at Tray [#]. Open Tray [#] and Front Cover. Code: Jam E2-## 2-18

Jam at Envelope Feeder; Remove Feeder and Open Front Cover.

Code: Jam E2-#E

Jam at MPT; Open Front Cover to Clear. Code: Jam E2-0M

Code: Jam E2-1M

Jam at Front; Open Front Cover to Clear. Code: Jam E3-# 2-23

Jam At Exit; Open Rear Cover To Clear. Code: Jam E4-0

Code: Jam E4-2

Code: Jam E4-3

Jam at Stacker; Open Both Rear Covers to Clear. Code: Jam E6-# 2-27

Jam at Front/Rear; Open Front/Rear Cover to Clear. Code: Jam E7-1

Code: Jam E7-2

Code: Jam E7-3

Paper Size Jam; Check Size and Open Rear Cover to Clear. (PSE-1)

Code: Jam PSE-1

Door and Cover Errors

Close Front Cover/Close Rear Cover. 2-31

Consumable Errors

Install or Reseat Print Cartridge. 2-33

Replace Print Cartridge. 2-34

Toner is Low. 2-35

Maintenance Kit is Near End of Life. 2-36

Printer Option Errors

Install or Reseat the Duplex Unit. Code: E9-1 2-36

Stacker Failure. Code: E9-2 2-37

Install or Reseat the Envelope Feeder. Code: E9-E 2-37

Tray and Media Errors

Standard Output Tray is Full. Unload Paper. 2-38

Tray [#] Failure. Open and Close Tray [#]. C3-[#]E 2-43

Tray [#] Paper is Low. 2-39

Tray 2 (or Tray 3) Paper is Low. 2-40

Load MPT with [paper size] [paper type]. 2-51

No Paper in Tray [#]. 2-41

Media Mismatch Errors

Load Tray [#] with [paper size] [paper type]. 2-42

Front Panel Fatal Error Messages and Codes

Tray 2 or 3 Failure. Code: E11 2-52

Main Motor Failure. Code: U1 2-45

Laser Unit Failure. Code: U2 2-48

Fuser Failure. Code: U4 2-49

2-21

2-22

2-25

2-29

2-30

Phaser 4400 Laser Printer Service Manual 2-11

Page 49

Index of Errors (cont'd.)

Front Panel Message Page

Fan Failure; Power Off Now. Code: U5 2-49

Engine Logic Board NVRAM Failure. Code: U6 2-50

Image Processor POST Error Codes 2-58

Error Message Summaries

Note: The messages listed in the “Diagnostic Message” column

appear only in Service Diagnostics while printing Engine

Test Prints. The code numbers in these messages also

appear as part of the Help information displayed when you

press i.

Front Panel

Message

Jam At Tray [#];

Open Tray [#]

and Front Cover

to Clear.

Press i.

Jam At

Envelope

Feeder;

Remove Feeder

and Open Front

Cover to Clear.

Press i.

Jam At MPT;

Open Front

Cover To Clear.

Press i.

Diagnostic

Error Description Troubleshooting

Message

E2-01: Feed Jam

E2-02

E2-03

E2-11: Feed Jam

E2-12

E2-13

E2-0E: Feed Jam Paper arrives at

E2-1E: Feed Jam Paper does not

E2-0M: Feed Jam Paper arrives at

E2-1M: Feed Jam Paper does not

Paper arrives at

Registration Sensor

too early.

Paper does not

arrive at Registration

Sensor position

within the specified

time.

Registration Sensor

too early.

arrive at Registration

Sensor position

within the specified

time.

Registration Sensor

too early.

arrive at REG

Sensor position

within the specified

time.

Procedure

Open Tray [#].

Open Front Cover.

Clear Paper Path.

Go to Jam at Tray [#]. Open

Tray [#] and Front Cover.

on page 2-18.

Remove Envelope Feeder.

Open Front Cover.

Clear Paper Path.

Go to Jam at Envelope

Feeder; Remove Feeder

and Open Front Cover. on

page 2-21.

Open Front Cover and

remove paper.

Go to Jam at MPT; Open

Front Cover to Clear. on

page 2-22.

2-12 Phaser 4400 Laser Printer Service Manual

Page 50

Error Message Summaries (cont'd.)

Note: The messages listed in the “Diagnostic Message” column

appear only in Service Diagnostics while printing Engine

Test Prints. The code numbers in these messages also

appear as part of the Help information displayed when you

press i.

Front Panel

Message

Jam at Front;

Open Front

Cover to Clear.

Press i.

Jam At Exit;

Open Rear

Cover To Clear.

Press i.

Jam At Stacker;

Open Both Rear

Covers to Clear.

Press i.

Diagnostic

Error Description Troubleshooting

Message

E3-1: Registration

Jam

E3-2: Registration

Jam

E4-0: Exit Jam Paper leaves Exit

E4-2: Exit Jam 1. Paper late off Exit

E4-3: Exit Jam Custom Paper late

E6-1: Stacker Jam 1. Paper late to

E6-2: Stacker Jam 1. Paper late off

Paper Late to Fuser

sensor after arrival at

Registration Sensor.

Exit Sensor did not

actuate within time

after the Registration

clutch is actuated.

1. Registration

Sensor did not

deactuate within time

after actuation of

Registration sensor.

2. Registration

Sensor is actuated at

power-on.

Sensor early.

Sensor.

2. Exit Sensor on at

power-on.

off Exit Sensor,

exceeding the

specified time from

Registration Sensor.

Stacker Sensor.

Stacker Sensor.

2. Stacker Sensor on

at power-on.

Procedure

Open Front Cover.

Remove Print Cartridge.

Clear Paper Path.

Go to Jam at Front; Open

Front Cover to Clear. on

page 2-23.

Open Rear Cover.

Clear Paper Path.

Go to Jam At Exit; Open

Rear Cover To Clear. on

page 2-25.

Open Rear Cover.

Clear Paper Path.

Change Paper Setting in

Custom Mode to correct

size.

Go to Jam At Exit; Open

Rear Cover To Clear. on