Page 1

Phaser® 3600

Laser Printer

Service Manual

Page 2

Phaser

Service Manual

®

3600 Printer

First Printing: September 2008

Warning

The following servicing instructions are for use by qualified service personnel

only. To avoid personal injury, do not perform any servicing other than that

contained in the operating instructions, unless you are qualified to do so.

Page 3

Prepared By:

Xerox Corporation

XOG Worldwide Product Training and Information

26600 SW Parkway

Wilsonville, OR 97070

Unpublished rights reserved under the copyright laws of the United States. Contents of this publication may not be reproduced in any form

without permission of Xerox Corporation.

Copyright protection claimed includes all forms and matters of copyrightable materials and information now allowed by statutory or judicial law

or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen such as

styles, templates, icons, screen displays, looks, etc.

Xerox technical training materials and service manuals are intended for use by authorized Xerox service technicians and service partners only

and are not for resale. These materials may not be distributed, copied, or otherwise reproduced without prior written consent from Xerox

Corporation.

XEROX®, CentreWare®, Phaser®, PrintingScout®, and Walk-Up® are trademarks of Xerox Corporation in the United States and/or other

countries.

Adobe® and PostScript® are trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Apple®, Bonjour®, ColorSync®, EtherTalk®, Macintosh®, and Mac OS® are trademarks of Apple Computer, Inc. in the United States and/or

other countries.

PCL® is a trademark of Hewlett-Packard Corporation in the United States and/or other countries.

Microsoft®, Windows®, Windows Server®, and Windows Vista® are trademarks of Microsoft Corporation in the United States and/or other

countries.

Novell®, NetWare®, and IPX/SPX™ are trademarks of Novell, Incorporated in the United States and/or other countries.

SM

Sun

, Sun Microsystems™, and Solaris™ are trademarks of Sun Microsystems, Incorporated in the United States and/or other countries.

UNIX® is a registered trademark in the US and other countries, licensed exclusiv ely through X/Open Company Limited.

As an ENERGY STAR® partner, Xero x Corporation has determined that this product meets the ENERGY ST AR guidelines for energ y efficiency.

The ENERGY STAR name and logo are registered U.S. marks.

Page 4

Service Terms

Not

Manual Terms

Various terms are used throughout this manual to either provide additional

information on a specific topic or to warn of possible danger present during a

procedure or action. Be aware of all symbols and terms when they are used,

and always read Note, Caution, and Warning statements.

e

A note indicates an operating or maintenance procedure, practice or

condition that is necessary to efficiently accomplish a task.

A note can provide additional information related to a specific subject or

add a c

Caution

A caution indicates an operating or mainte nance pr oc edure, practice or

condition that, if not strictly observed, results in damage to, or destruction of,

equipment.

omment on the results achieved through a previous action.

Product Terms

Warning

A warning indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, results in injury or loss of life.

Caution: A personal injury hazard exists that may not be apparent. For

example, a panel may cover the hazardous area.

Danger: A personal injury hazard exists in the area where you see the sign.

Phaser 3600 Printer Service Manual iii

Page 5

Symbols Marked on the Product

Warning. Danger invisible laser radiation when open. Avoid

direct exposure to beam.

Hot surface on or in the printer. Use caution to avoid personal

injury.

Warning. Use caution to avoid personal injury.

Use caution (or draws attention to a particular component).

Refer to the manual(s) for information.

0°C

32°F

Do not touch the OPC Drum.

Do not expose the item to sunlight.

Do not tilt the Print Cartridge.

35°C

Do not expose item to extreme temperature.

95°F

Recycle the item.

iv Phaser 3600 Printer Service Manual

Page 6

Power Safety Precautions

Power Source

Disconnecting Power

For 115 VAC printers, do not apply more than 127 volts RMS between the

supply conductors or between either supply conductor and ground. For 230

VAC printers, do not apply more than 254 volts RMS between the supply

conductors or between either supply conductor and ground. Use only the

specified power cord and connector. This manual assumes that the reader is

a qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC

outlet only. If necessary, contact a licensed electrician to install a properly

grounded outlet. If the product loses its ground connection, contact with

conductive parts may cause an electrical shock. A protective ground

connection by way of the grounding conductor in the power cord is essential

for safe operation.

Warning

Turning the power Off using the power switch does not completely deenergize the printer. You must also disconnect the power cord from the

printer’s Alternating Current (AC) inlet. Disconnect the power cord by pulling

the plug, not the cord.

Disconnect the power cord in the following cases:

■ if the power cord or plug is frayed or otherwise damaged,

■ if any liquid or foreign material is spilled into the product,

■ if the printer is exposed to any excess moisture,

■ if the printer is dropped or damaged,

■ if you suspect that the product needs ser vi cing or repa ir,

■ whenever you clean the product.

Phaser 3600 Printer Service Manual v

Page 7

Electrostatic Discharge Precautions

Some semiconductor components, and the respective sub-assemblies that

contain them, are vulnerable to damage by Electrostatic Discharge (ESD).

These components include Integrated Circuits (ICs), Large-Scale Integrated

circuits (LSIs), field-effect transistors, and other semiconductor chip

components. The following techniques will reduce the occurrence of

component damage caused by static electricity.

Be sure the power is Off to the chassis or circuit board, and observe all other

safety precautions.

■ Immediately before handling any semiconductor components assemblies,

drain the electrostatic charge from your body. This can be accomplished

by touching an earth ground source or by wearing a wrist strap device

connected to an earth ground source. Wearing a wrist strap will also

prevent accumulation of additional bodily static charges. Be sure to

remove the wrist strap before applying power to the unit under test to

avoid potential shock.

■ After removing a static sensitive assembly from its anti-static bag, place it

on a grounded conductive surface. If the anti-static bag is conductive, you

may ground the bag and use it as a conductive surface.

■ Do not use freon-propelled chemicals. These can generate electrical

charges sufficient to damage some devices.

■ Do not remove a replacement component or electrical sub-assembly from

its protective package until you are ready to install it.

■ Immediately before removing the protective material from the leads of a

replacement device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

■ Minimize body motions when handling unpacked replacement devices.

Motion such as your clothes brushing together, or lifting a foot from a

carpeted floor can generate enough static electricity to damage an

electro-statically sensitive device.

■ Handle IC’s and Erasable Programmable Read-Only Memories

(EPROM’s) carefully to avoid bending pins.

■ Pay attention to the direction of parts when mounting or inserting them on

Printed Circuit Boards (PCB’s).

vi Phaser 3600 Printer Service Manual

Page 8

Service Safety Summary

General Guidelines and Safety precautions:

Warning Labels

For qualified service personnel only: Refer also to the preceding “Power Safety

Precautions” on page v.

Avoid servicing alone: Do not perform internal service or adjustment of this

product unless another person capable of rendering first aid or resuscitation is

present.

Use care when servicing with power: Dangerous voltages may exist at several

points in this product. To avoid personal injury, do not touch exposed

connections and components while power is On. Disconnect power before

removing the power supply shield or replacing components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces, and

other metallic objects could come into contact with dangerous voltages and

currents.

Read and obey all posted warning labels. Throughout the printer, warning

labels are displayed on potentially dangerous components. As you service the

printer, check to make certain that all warning labels remain in place.

Safety Interlocks

Make sure all covers are in place and all Interlock Switches are functioning

correctly after you have completed a printer service call. If you bypass an

Interlock Switch during a service call, use extreme caution when working on

or around the printer.

Class 1 Laser Product

The Phaser 3600 is certified to comply with Laser Product Performance

Standards set by the U.S. Department of Health and Human Services as a

Class 1 Laser Product. This means that this product does not emit hazardous

laser radiation; which is possible only because the laser beam is totally

enclosed during all modes of customer operation. When servicing the printer

or laser unit, follow the procedures specified in this manual and there will be

no hazards from the laser.

Phaser 3600 Printer Service Manual vii

Page 9

Servicing Electrical Components

Before starting any service procedure, switch the printer power Off and

unplug the power cord from the wall outlet. If you must service the printer with

power applied, be aware of the potential for electrical shock.

Warning

Do not touch any electrical component unless you are instructed to do so by a

service proc edure.

Servicing Mechanical Components

When servicing mechanical components within the printer, manually rotate

the Drive Assemblies, Rollers, and Gears.

Warning

Do not try to manually rotate or manually stop the drive assemblies while any

printer motor is running.

Servicing Fuser Components

Warning

This printer uses heat to fuse the toner image to paper. The Fuser is VERY

HOT. Turn the printer power Off and wait at least 5 minutes for the Fuser to

cool before attempting to service the Fuse r or adjacent compo nen ts.

viii Phaser 3600 Printer Service Manual

Page 10

Regulatory Information

United States (FCC Regulations)

Xerox has tested this product to electromagnetic emission and immunity

standards. These standards are designed to mitigate interference caused or

received by this product in a typical office environment.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the Federal Communications

Commission (FCC) Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy. If it is not

installed and used in accordance with these instructions, it may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be

determined by turning the equipment Off and On, the user is encouraged to

try to correct the interference by one or more of the following measures:

■ Reorient or relocate the receiver (device being interfered with).

■ Increase the separation between the printer and the receiver.

■ Connect the equipment into an outlet on a circuit different from that which

■ Consult the dealer or an experienced radio/television technician for help.

Any changes or modifications not expressly approved by Xerox could void the

user's authority to operate the equipment. To ensure compliance with Part 15

of the FCC rules, use shielded interface cables.

Canada (Regulations)

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada

the receiver is connected.

.

Phaser 3600 Printer Service Manual ix

Page 11

European Union

The CE mark applied to this product symbolizes Xerox’s

declaration of conformit y with the following applicable

Directives of the European Union as of the dates indicated:

December 12, 2006: Council Directive 2006/95/EC as amended. Approximation of

the laws of the member states related to low voltage equipment.

December 15, 2004: Council Directive 2004/108/EC as amended. Approximation of

the laws of the member states related to electromagnetic compability.

This product, if used properly in accordance with the user's instructions, is

neither dangerous for the consumer nor for the environment.

To ensure compliance with European Union regulations, use shielded

interface cables.

A full declaration of conformity , defining the relevant directives and referenced

standards, can be obtained from your Xerox Limited representative.

x Phaser 3600 Printer Service Manual

Page 12

Manual Organization

The Phaser 3600 Printer Service Manual is the primary document used for

repairing, maintaining, and troubleshooting the printer. Use this manual as

your primary resource for understanding the operational characteristics of the

printer and all available options. This manual describes specifications, theory,

and the diagnosis and repair of problems occurring in the print engine and

attached options. Also included are detailed replacement procedures, parts

lists, and wiring diagrams.

The Phaser 3600 Printer Service Manual contains these chapters:

Introductory, Safety, and Regulatory Information: This section contains important

safety information and regulatory requirements.

Chapter 1 - General Information: This chapter contains an overview of the

printer’s operation, configuration, specifications, and consumables.

Chapter 2 - Theory of Operation: This chapter contains detailed functional

information on the printer components.

Chapter 3 - Error Messages: This chapter provides detailed troubleshooting

procedures for error messages generated by resident diagnostics.

Chapter 4 - General Troubleshooting: This chapter contains general information

on troubleshooting the printer. In addition, this chapter includes

troubleshooting methods for situations where error indicators are not

available.

Chapter 5 - Print-Quality Troubleshooting: Th is chapter f ocuses on t echniques to

correct image quality problems associated with the printer output.

Chapter 6- Cleaning and Maintenance: This chapter provides periodic cleaning

procedures for the printer.

Chapter 7- Service Parts Disassembly:

procedures for spare parts listed in the Parts List. A replacement procedure is

included when necessary.

Chapter 8- Parts List: Th

and optional Field Replaceable Units (FRUs), as well as part numbers for

orderable parts.

Chapter 9- Plug/Jack and Wiring Diagrams: This chapter contains the plug/jack

locations and the wiri ng dia grams for the printer.

Reference: This section provides a list of acronyms and abbreviations

is chapter contains exploded views of the print engine

This chapter contains removal

Phaser 3600 Printer Service Manual xi

Page 13

Service Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Symbols Marked on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Power Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Electrostatic Discharge Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 General Information

Printer Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer Options and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Consumable and Service Part Life Expectancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Parts of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Printer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer Location and Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Environmental Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Media and Tray Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table Of Contents

Table Of Contents

2 Theory of Operation

Phaser 3600 Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Summary of the Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Print Cartridge and Print Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Printer Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Paper Path Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Duplex Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Print Engine Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Image Processing Assembly and Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Laser Scan Unit (LSU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Motor Drive Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Feed Assembly Process and Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Transfer Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Duplex and Tray Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Duplex Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Tray 2 and Optional Tray 3 Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Printer Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Paper Size Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Automatic Paper Pick Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Laser Scan Unit (LSU) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Laser Light Intensity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Toner Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Fuser Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Phaser 3600 Color Laser Printer Service Manual 1

Page 14

Sensor Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sensor Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sensors in the Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

High Voltage Power Supply (HVPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Switching Mode Power Supply (SMPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3 Error Messages

Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using the Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Service Diagnostics Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Entering Service Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Service Diagnostic Control Panel Button Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Diagnostic Test Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Troubleshooting Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Jam At Tray [1] [2] [3] (Jam 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Jam At Top (Jam 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Jam At Exit (Jam 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Jam At Rear (Duplex Jam 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Jam At Duplex (Duplex Jam 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Check Cartridge, Invalid Print Cartridge, Non-Xerox Cartridge, Replace Print Cartridge . . . . . . . . . . . . . . . 3-18

Close Fuser Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Close Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Fuser Failure, Engine Fuser Low Heat Error, or Engine Fuser Over Heat Error. . . . . . . . . . . . . . . . . . . . . . . 3-20

Laser Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Output Tray is Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

4 General Troubleshooting

Servicing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Preventive Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control Panel Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

No Control Panel Display after Power Is Turned ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Control Panel LED is On, Control Panel Display Is Blank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Power Supply Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Taking Voltage Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5 Print-Quality Troubleshooting

Print-Quality Problems Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Repeating Defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Repeating Defects Measurement Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Control Panel (Internal) Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2 Phaser 3600 Printer Service Manual

Page 15

Image-Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Blank Print (No Print) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Light or Undertone Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Black Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Background Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Residual Image or Ghosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Faded or Missing Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Random Spots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Repeating Bands, Lines, Marks, or Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Unfused Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Horizontal Band, Voids, or Streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

6 Cleaning and Maintenance

Service Maintenance Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Cleaning the Laser Scan Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Cleaning the Print Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Control Panel Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Cleaning the Drum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Cleaning the Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Table Of Contents

7 Service Parts Disassembly

Service Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

General Notes on Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Fastener Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Notations in the Disassembly Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Standard Orientation of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Covers and Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Right Cover (PL 1.2.3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Left Cover (PL 1.2.2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Rear Cover (PL 1.2.6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Rear Cover Fan (PL1.2.6.10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Top Cover (PL 1.2.1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Access Door (PL 1.2.1.1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Control Panel (PL 1.2.9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Tray 1 (MPT) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Inner Cover (PL 1.2.5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Tray 1 (MPT) Knock-Up Plate Only (PL 1.1.3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Tray 1 (MPT) Pick-Up Rack (PL 1.3.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Retard Assembly (PL 1.3.49) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Tray 1 (MPT) Separator Pad Assembly (PL 1.3.4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Tray 1 (MPT) Feed Sensor (PL1.3.97). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Paper Tray Empty Sensor (PL1.3.95) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Paper Tray Empty Actuator (PL1.3.58) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Sub Toner Low Sensor Board (PL1.3.47) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Pick Roller and Shaft (PL 1.3.2.5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Tray 1 (MPT) Pick Roller Only (PL 1.3.2.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Tray 1 (MPT) Solenoid (PL 1.1.26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Phaser 3600 Color Laser Printer Service Manual 3

Page 16

Tray 2 Pick-Up Assembly and Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Pick-Up Gear and Bearing (PL 1.1.21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Tray 2 Feed Roller (PL1.3.59.5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Tray 2 Pick Roller (PL1.3.59.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Tray 2 (PL2.1.0) and Optional Tray 3 (PL2.2.0) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Duplex Unit (PL2.3.0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Main Drive and Registration Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Main Drive Assembly (PL 1.1.18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Main Board (PL 1.1.19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Main Solenoid (PL 1.1.25). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Registration Assembly (PL 1.1.12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Transfer Roller (PL 1.1.7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Exit Roller (PL 1.3.6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Exit Gear (PL 1.3.9). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Outbin Full Actuator (PL 1.3.8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Outbin Full Sensor (PL1.3.21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Duplex Roller (PL 1.3.11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

Exit Solenoid (PL 1.1.16). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Feed Idle Unit (PL 1.3.50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Pre-transfer Lamp (PTL) Board (PL 1.3.71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Developer Drive Assembly (PL 1.1.17) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

Joint Board (PL 1.3.61). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Paper Size Sensor (PL 1.3.14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

Fuser Assembly (1.3.80) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Fuser Interlock Switch (PL 1.3.77) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Fuser Exit Sensor (PL 1.3.76) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Fuser Thermostat (PL 1.4.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

Fuser Thermistor (PL 1.4.40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

Heat Roller (PL 1.4.53) and Bushing (PL 1.4.44) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

Dual-lamp (PL 1.4.56). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

Pressure Roller (PL 1.4.66) and Bushing (PL 1.4.50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

Laser Scan Unit (PL 1.1.15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

LSU Lower Cover (PL 1.3.48) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Left Side Cooling Supply Fan and Duct (PL 1.1.31). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-73

Cover Open Board and Sensor (PL 1.3.47) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-74

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-75

High Voltage Power Supply (HVPS) (PL 1.1.29.1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-75

Switched Mode Power Supply (PL 1.1.29.2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-76

8 Parts List

Serial Number Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Serial Number Label Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Using the Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

PL 1.1 Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

PL 1.2 Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

PL 1.3 Frame Assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

PL 1.3 Frame Assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

PL 1.4 Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

PL 2.1 Tray 2 Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

PL 2.2 Tray 3 Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

PL 2.3 Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

4 Phaser 3600 Printer Service Manual

Page 17

9 Plug/Jack and Wiring Diagrams

Plug/Jack Diagrams and Designators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Plug/Jack and Connector Locators and Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Printer Plug/Jack/Connector Designators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Map 1- LSU and Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Map 2- Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Map 3- SMPS Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Map 4 - HVPS Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Notations Used in the Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

General Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

HVPS/SMPS to Main Board Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Sensor to Main Board Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Main Drive/Joint Board and Optional Tray Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-15

LSU and Main Motor to Main Board Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

Controller Unit and Duplex Board to Main Board Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

A Reference

Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table Of Contents

Index

Phaser 3600 Color Laser Printer Service Manual 5

Page 18

General Information

In this chapter...

■ Printer Configuratio ns

■ Consumable and Service Part Life Expectancy

■ Parts of the Printer

■ Control Panel

■ Printer Specifications

■ Media and Tray Specifications

Chapter

1

Page 19

General Information

Printer Configurations

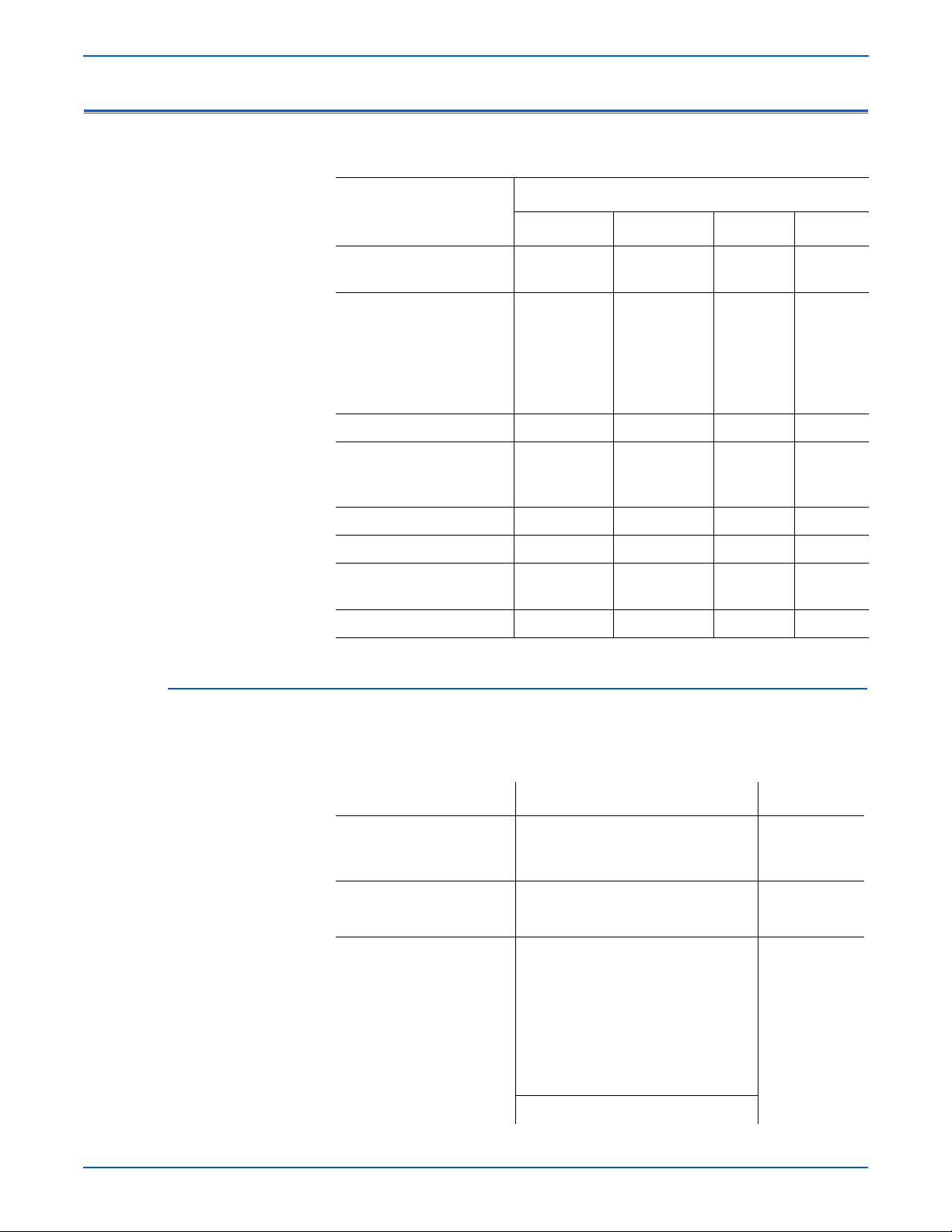

Print Features and Configurations

Printer Configurations

Features

Maximum Print Speed

tter

Le

Memory (Optional)

Up to 512 MB Optional if

e original DIMM is

th

replaced with 256MB RAM

DIMM and the second slot

has a 256MB RAM DIMM

PostScript and PCL Fonts Yes Yes Yes

Default Resolution

Maximum Resolution

500-Sheet Feeder (Tray 3) Optional Optional Optional Optional

Network Interface Not Optional Not Optional Standard Standard

Automatic 2-Sided Printing

(Separate Duplex

USB, Parallel Interface Yes Yes Yes Yes

Printer Options and Supplies

Unit)

3600_B 3600V_B 3600_N 3600V_N

40 ppm 40 ppm 40 ppm 40 ppm

64 MB 64 MB 128 MB 128 MB

600 x 600 dpi

1200 x 1200

dpi

Optional Optional Optional Standard

x 600 dpi

600

1200 x 1200

dpi

Options and Supplies

Printer Option Item Part Number

Memory 64 MB additional RAM memory

128 MB additional RAM memory

256 MB additional RAM memory

Optional Units Duplex Unit

500-Sheet Feeder

Cartridges Standard-Capacity Print Cartridge

00 pages)

(7,0

gh-Capacity Print Cartridge (14,000

Hi

pages)

Extra High-Capacity Print Cartridge

,

000 pages)

(20

Metered/Pagepack Print cartridge

000 pages)

(20,

Gear Lubricant Xerox lubricant Plastislip grease 043E00550

1-2 Phaser 3600 Printer Service Manual

097S03759

097S03760

097S03761

097S03387

097S03385

106R01370

106R01371

106R01372

106R01369

Page 20

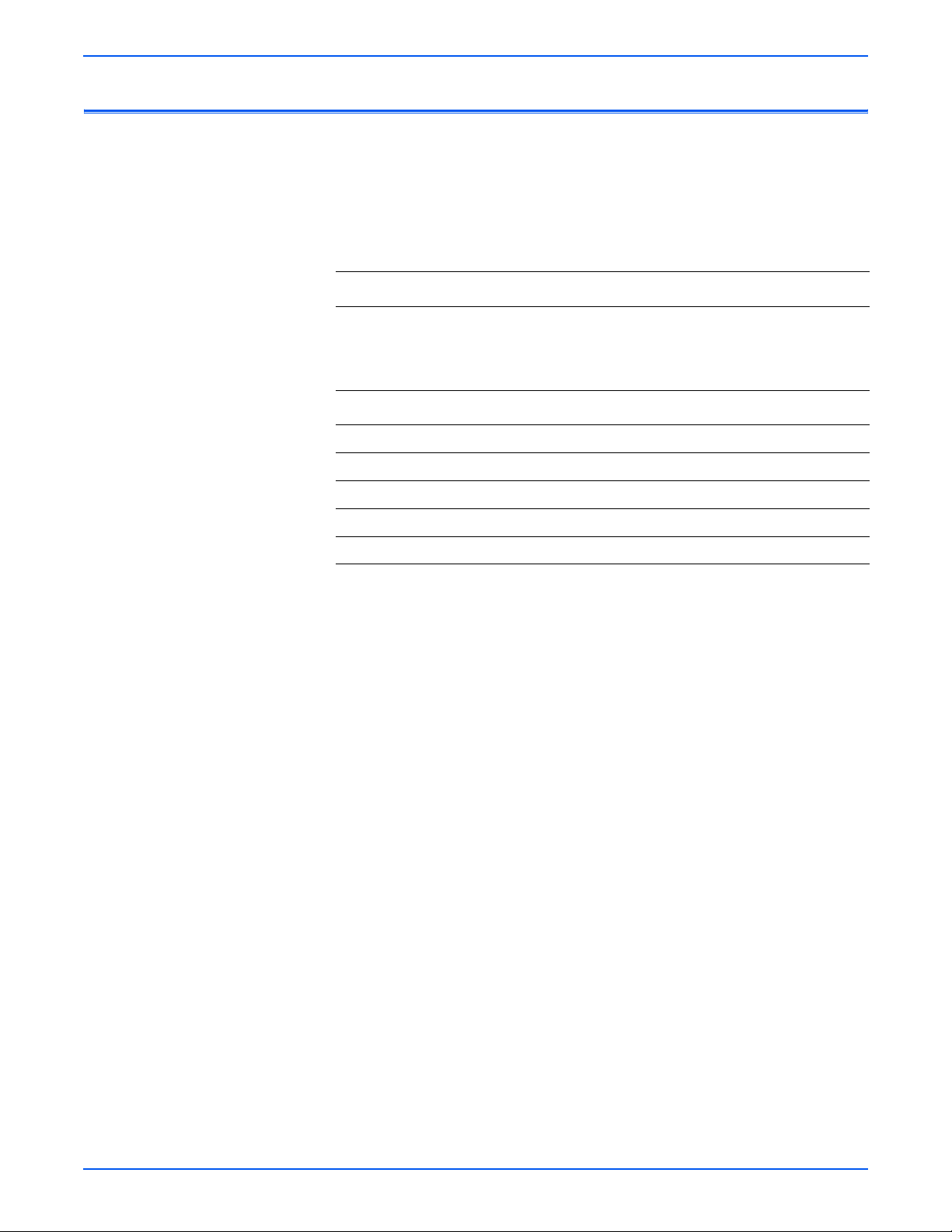

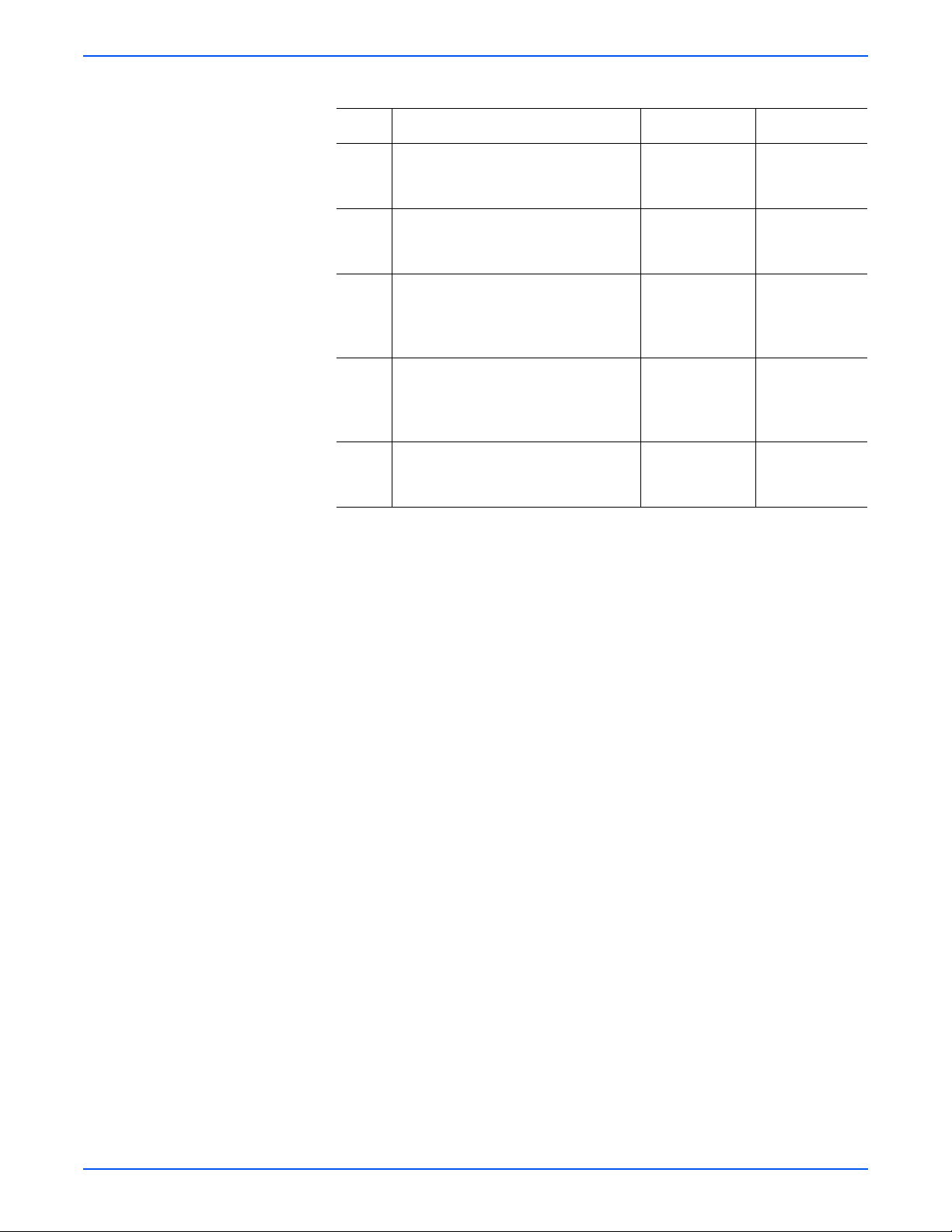

Consumable and Service Part Life Expectancy

Not

Consumable (toner/print cartridge) usage is tracked by the CRUM and

monitored by the Main Board in order to display the near end-of-life and endof-life messages. Life ratings are based on 5% coverage and an average 4

page job length.

Consumables Print Life

Print Cartridge Standard Capacity 7,000 pages

Service Parts

Fuser Assembly 150,000 pages

Transfer Roller 150,000 pages

Feed Roller Kit 150,000 pages

General Information

High Capacity 14,000 pages

Extra High Capacity 20,000 pages

Metered/Pagepack 20,000 pages

Retard Roller 150,000 pages

Separator Pad 150,000 pages

e

The service parts are not tracked with an NVRAM counter and there is no

replace or low warnings associated with these service parts.

Phaser 3600 Printer Service Manual 1-3

Page 21

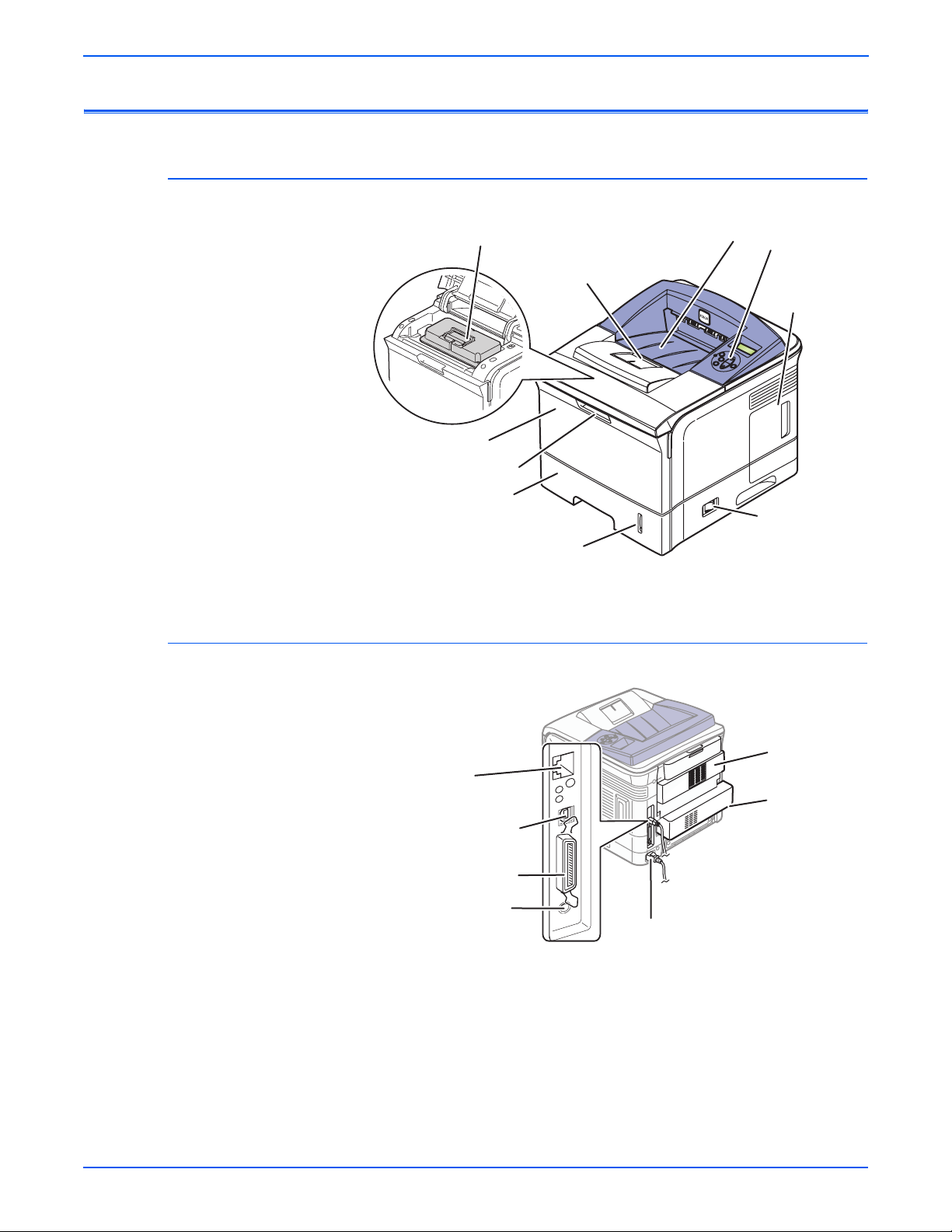

General Information

Parts of the Printer

Front View

Rear View

Print Cartridge

Paper Output Support

Tray 1 (MPT)

Tray 1 (MPT) Release

Tray 2

Paper Gauge

Output Tray

Control Panel

Control Board

Cover

On/Off Switch

s3600-001

Network Port

(optional for 3500B)

IEEE 1284 Parallel Port

Tray 3 Optional

Cable Connector

1-4 Phaser 3600 Printer Service Manual

USB Port

Power Cord Receptacle

Rear Door

Duplex Unit

(optional)

s3600-112

Page 22

Control Panel

The Control Panel has three components:

■ Multi-colored Light Emitting Diode (LED) light

■ Alphanumeric disp lay

■ Six-button cluster

Control Panel Buttons

Button Function

Return Returns to the prior higher level menu structure, if

able.

l

avai

CANCEL Terminates the current action.

MENU Cycles through all of the top level menu items.

UP Scrolls up one menu item within a menu list. If you

con

inually press this control, the menu items will ‘wrap’.

t

General Information

DOWN Scrolls up one menu item within a menu list. If you

OK Executes the highlighted menu item.

Menu Map

The Menu Map is a visual representation of the Control Panel settings and

information pages. All Menu Map settings are documented in the User Guide.

Error and Warning Messages

When there is a problem with the printer, the Control Panel LED (3) blinks red

for an error and a warning. An error or warning message is displayed in the

Alphanumeric Display (5).

cont

inually press this control, the menu items will ‘wrap’.

Phaser 3600 Printer Service Manual 1-5

Page 23

General Information

Printer Specifications

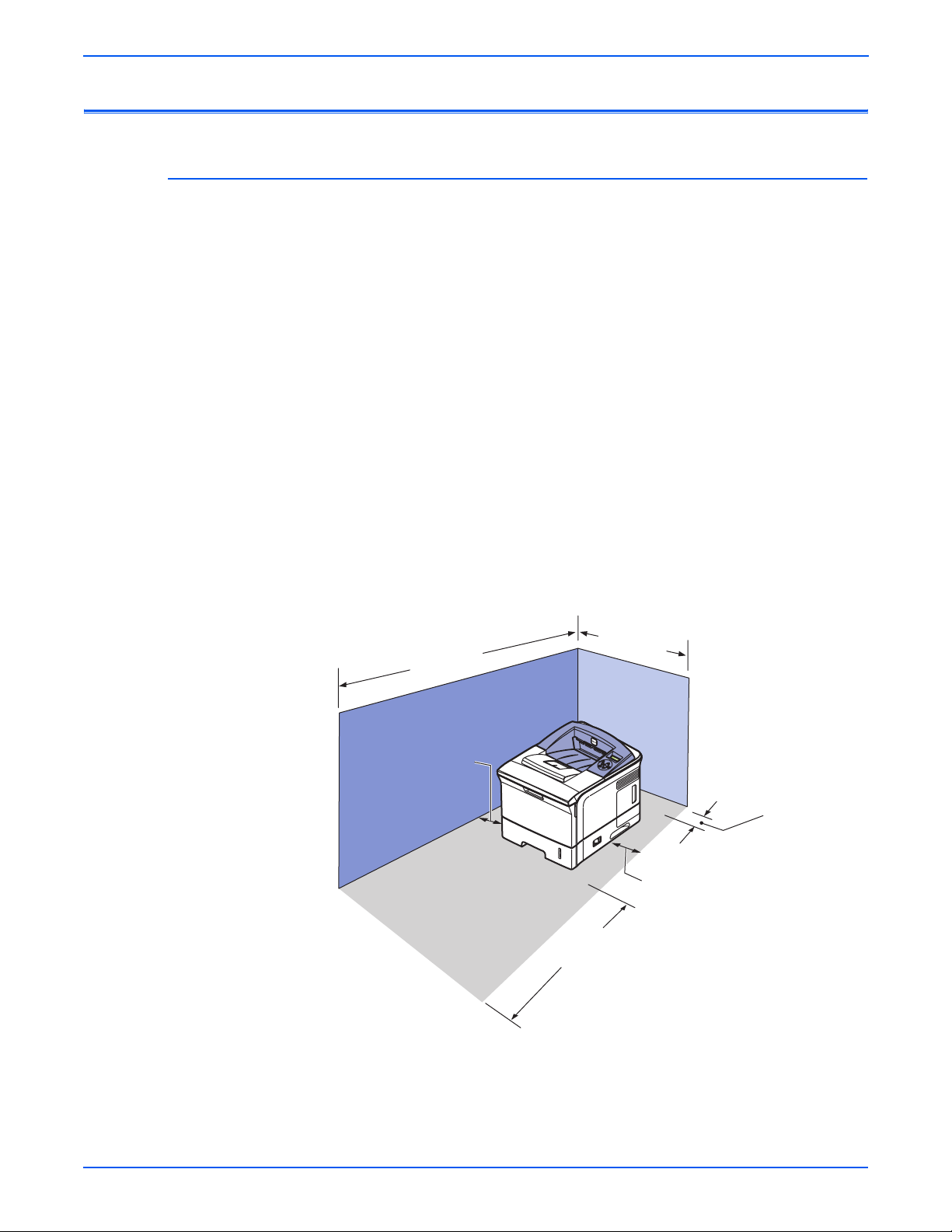

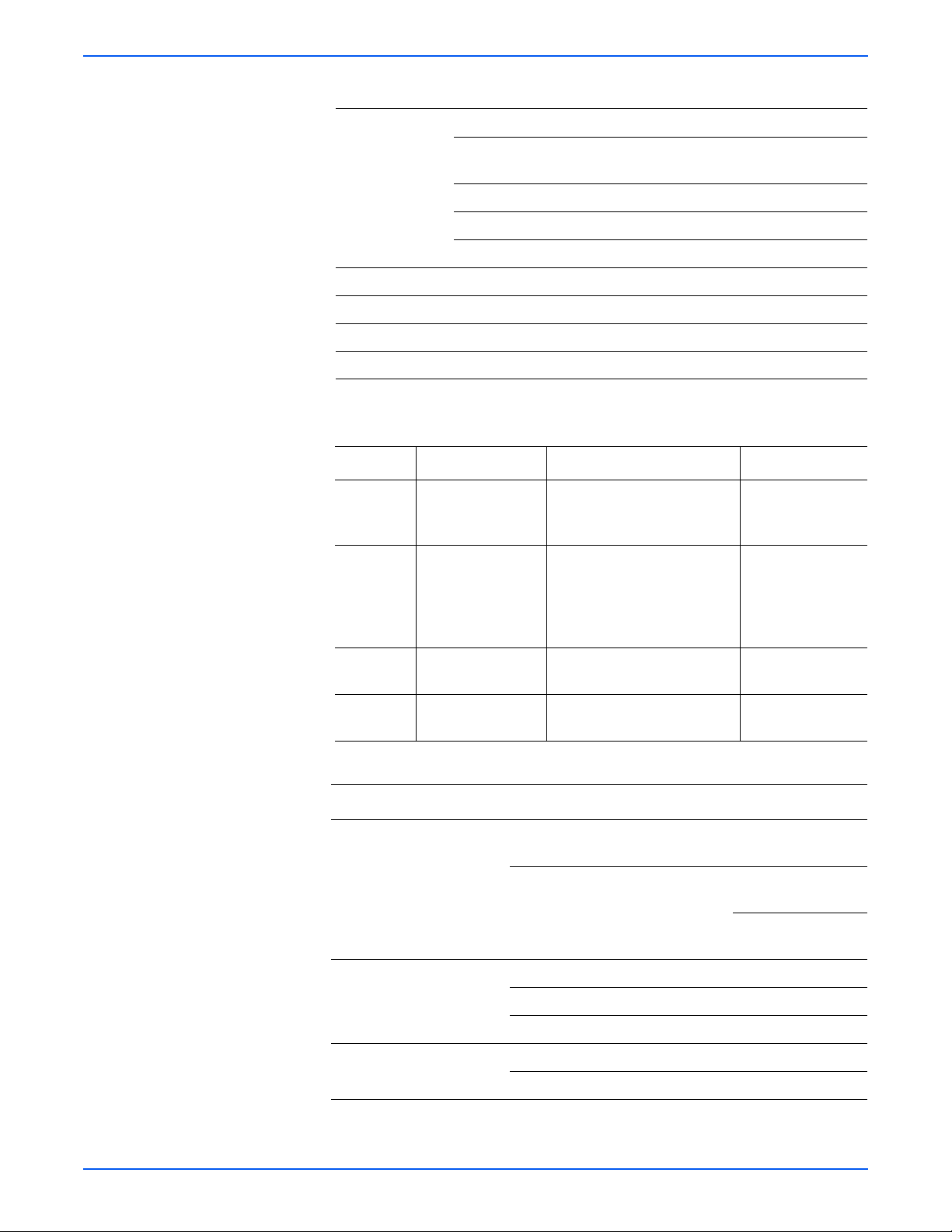

Printer Location and Clearance

Place the printer in a dust-free area where the temperature range is 50

degrees F to 89 degrees F (10 degrees C to 32 degrees C) and the relative

humidity range is between 20% to 80%.

■ Place the printer in an area where there is adequate space for ventilation,

operation, and servicing. See the clearance graphic below.

■ Do not block or cover the slots and openings on the printer. The printer

can overheat without adequate ventilation.

■ For altitudes under 2,050 meters (6,726 feet), use the Low Altitude

setting. For altitudes over 2,050 meters (6,726 feet), use the High Altitude

setting.

■ Do not place the printer near a heat source.

■ Do not place the printer in direct sunlight.

■ Do not place the printer in line with the cold air flow from an air

conditioning system.

■ Place the printer on a level, solid surface with adequate strength for the

weight of the printer.

596 mm

1255.6 mm

(24.6 in.)

(49.2 in.)

100 mm

(4 in.)

320 mm

(12.6 in.)

100 mm

(4 in.)

482.6 mm

(18.8 in.)

s3600-003

1-6 Phaser 3600 Printer Service Manual

Page 24

Printer Physical Specifications

Physical Dimensions and Weight

General Information

Item Specification

Packaging

Dimen

(W*D*H)

Net Dimension

(W*D*H)

Toner Dime n s ion

(W*D*H)

Weight SET with 10K toner

Functional Specifications

sion

Packing Dimension w/o

option tray

Net Dimension w/o Option

y

Tra

Net Dimension with Option

Tra

y

Toner 314 x 225 x 116 mm

Toner Packing 368 x 286 x 169 mm

cartri

ge

d

SET w/o toner cartridge 15.46kg (34.06lb)

Consumable toner

cartrid

ge

Set + Consumables 19.15 kg (42.2lb) with 10K toner

Packing Weight 22.46kg (49.50lb)

518*566*568mm

(20.4"*22.3"*22.4")

396*453*353mm

(15.6"*17.8"*13.9")

396*453*501mm

(15.6"*17.8"*19.7")

17.30kg (38.14lb)

10K : 1.85kg (4.08lbs) 20K :

2.06kg (4.54 lbs)

cart.

Print Operability

Characteristic Specification

Printing process Non-Impact Electrophotography

Color medium Monochrome

Resolution / Addressability True 600 x 600 dpi

Addressable 1200 x 1200 dpi

Operating Modes Standby Mode: Pr

prints in less than 9 seconds.

Sleep/ Low Power/ Power Saver Mode: 31

nds from completion of a print.

seco

Continuous Operating Printing

Sp

eed (ppm = pages per

minute)

First Print-Out

(in seconds)

Warm-Up Time Power-on Boot: 40 seconds or less

Letter:

Up to 40 ppm

A4:

Up to 38 ppm

10 seconds or less

int engine capable of making

Phaser 3600 Printer Service Manual 1-7

Page 25

General Information

Print Quality

Property Characteristic Specification

Resolution Normal Up to 1200 x 1200 dpi effective output

Line Width @ 600dpi

Line Width @ 1200dpi

Dot Diameter @ 600dpi

Dot Diameter @ 1200dpi

RET Yes

Halftone (Gray Scale) 256 levels

Blackness >1.20

Homogeneity of Halftone at five points on page must be 0.1

Halftone 20 % = 0.17 50 % = 0.49 80 % = 0.91

Printable Area Letter 208 x 271 mm

A4 200 x 289 mm

Non-Printable Area Envelope 10mm(0.4") from edge(Top/Bottom/Left/Right)

Other Media 4mm(0.16") from edge(Top/Bottom/Left/Right)

Toner Fixing Black (100% Solid) 80%

Halftone 70%

Magnification Horizontal (applied to

17

m length)

7.8m

Vertical (applied to

241.3m

m length)

Printing Skew Tray 1 (MPT)

Tray 2

< 1.0 mm (0.04 ) ( 0.5 % )

< 3.0 mm (0.12 ) ( 1.2 % )

< 1.5 mm (0.06 ) Simplex & Horizontal

< 2.0 mm (0.08 ) Duplex & Horizontal

< 2.0 mm (0.08 ) Simplex & Vertical

< 2.5 mm (0.10 ) Duplex & Vertical

< 1.5 mm (0.06 ) Simplex & Horizontal

< 2.0 mm (0.08 ) Duplex & Horizontal

< 2.0 mm (0.08 ) Simplex & Vertical

< 2.5 mm (0.10 ) Duplex & Vertical

Optional Tray 3

1-8 Phaser 3600 Printer Service Manual

< 2.0 mm (0.08 ) Simplex & Horizontal

< 2.5 mm (0.1 ) Duplex & Horizontal

< 2.5 mm (0.10 ) Simplex & Vertical

< 3.0 mm (0.12 ) Duplex & Vertical

Page 26

Electrical Specifications

Power Rating and Line Voltages

Characteristic Specification

Primary line voltages 110 - 127 V Printer - (100 - 135 V) 13 amp circuit

General Information

220 - 240 V Printer - (180 - 264 V) 7-8 amp circuit

Primary line voltage

ncy range

freque

Power consumption Printing: 550 Watts (average)

Environmental Specification

Operating Environment

Characteristic Specification

Optimal Temperature 10 - 30 degrees C (50-60 degrees F)

Optimal Humidity 20% - 80% Relative Humidity

Altitude

Operating

Low Altitude Setting

High Altitude Setting

Transportation

Acoustic Noise

Idle

Printing

100 - 135 V Printer - 50/60 Hz + 3 Hz

220 - 240 V Printer - 50/60 Hz

Sleep: under 10 Watts

0 - 2,500 meters (8,200 ft.)

0 - 2,050 meters (6,726 ft.)

2,050 - 2,500 meters (6,726 - 8,200 ft.)

0 - 6,092 meters (20,000 ft.)

35.0db or less

49.0db or less

+ 3 Hz

Acoustic Characteristic Mode Specification

Printing Simplex from Tray1 Less than 56.0 dBA

Simplex from MP Less than 56.0 dBA

Simplex from SCF Less than 59.0 dBA

Duplex from Tray1 Less than 59.0 dBA

Measurement Standby Less than 35.0 dBA

Warm up Less than 50.0 dBA

Maximum Less than 60.0 dBA

Phaser 3600 Printer Service Manual 1-9

Page 27

General Information

Media and Tray Specifications

Media Tray Capacity

Property Media Specification

Input Size Max Custom Paper (W*H) 216 x 356 mm (8.5" x 14")

Min Custom Paper

(W*H)

Input Capacity Standard 500-sheet Cassette Tray/100-sheet Multi

Maximum 1 to 100 sheets

Output Capacity Face-Down Capacity 250 sheets

Face-Up Capacity 100 sheets

Output Full sensing Yes (Paper Outbin Full Sensor)

Output path change Face Up/Down controlled manually by

Multi-Purpose

Tra

y

Plain Paper Capacity 100 sheets

Envelope Capacity 10 sheets

Card Stork Capacity 10 sheets

Labels Capacity 25 sheets

Transparencies

Capaci

ty

Media sizes A4/A5/A6/Letter/Legal/Oficio/Folio/

76

x 127 mm (3.0" x 5.0") (>105g)

Purpose T

op

50

Executi

No.10/DL/C5/C6

ray @75g

ng rear cover

eni

sheets

ve/ISO B5/JIS B5/3"x5"/Monarch/

Media type Transparencies/Envelopes/Labels/Card

stock

Media weight 16~43lb (60 to 163g

Sensing Paper Empty Sensor

Standard

Cassette Tr

1-10 Phaser 3600 Printer Service Manual

ay

Capacity 500 sheets

Media sizes A4/A5/Letter/Legal/Executive/Folio/

Ofic

io/ISO B5/JIS B5

Media types Plain paper

Media weight 16~28lb (60 to 105g)

Sensing Paper Empty Sensor and Paper Size

S

nsor

e

Page 28

Media Tray Capacity

General Information

Optional Cassette

Tray

Duplex Supporting Optional

Media Input Size/Weight

Source Media Types Media Sizes Media Weights

Tray 1 Paper, Envelope,

Tray 2 Paper, Cardstock

Capacity 500 sheets@75g

Media sizes A4/A5/Letter/Legal/Executive/Folio/

Oficio

/ISO B5/JIS B5

Media types Plain paper

Media weight 16~28lb (60 to 105g/)

Sensing Paper Empty Sensor

Media sizes A4/Letter/Legal/Folio/Oficio

Media types Plain paper

Media weight 20~24lb (75 to 90g )

A4, Letter, Legal, Folio,

P

per Labels,

a

Transparency.

Min: 76 mm x 127

mm

(3 in. x 5 in.)

Max: Legal

Executive, ISO and JISB5, A5

A4, Letter, Legal, Folio,

O and JISB5, A5,

ve, IS

Executi

A6, Statement Monarch, COM

10, C5, DL, 3” x 5”

16 lb. ~ 28 lb.

(60 ~ 176 gsm)

16 lb. ~ 43 lb.

(60 ~ 105 gsm)

65# Cover

Tray 3 Paper A4, Letter, Legal, Folio,

ve, ISO and

Executi

Duplex Paper A4, Letter, Legal, Folio 20 lb. ~ 24 lb.

Media Print Speed

Property Mode Specification

Speed Simplex Up to 38 ppm in A4

Duplex

First-Page Output Time

(FPOT)

Warm Up Time from sleep/power save mode Less than 31 sec

from standby Less than 9 sec

from sleep/power save mode Less than 40 sec

from cold status Less than 49 sec

from cold status Less than 40 sec

JISB5, A5

16 lb. ~ 28 lb.

(60 ~ 105 gsm)

(75 ~ 90 gsm)

(40 pp

m in Letter)

26 ipm in A4 (27

ip

m in Letter)

(Letter A4 Folio

Of

icio Legal)

Phaser 3600 Printer Service Manual 1-11

Page 29

General Information

Media Print Speed

Toner save setting unit SWS Support

PSU Support (30%)

LUI(Local UI) Support(UI2.0)

Duplex Print Simplex Support

Manual Duplex N/A

Duplex Optional

1-12 Phaser 3600 Printer Service Manual

Page 30

Theory of Operation

In this chapter...

■ Phaser 3600 Operational Overview

■ Printer Paper Path

■ Printer Controls

■ Sensor Functions

■ Printer Controls

Chapter

2

Page 31

Theory of Operation

Phaser 3600 Operational Overview

Summary of the Printing Process

The Phaser 3600 Laser Printer is a desktop monochrome laser printer,

applying the principals of an electrophotographic system to place a

monochrome image onto the print media. The system contains a drum and

developing unit which places the toner image onto print media producing

monochrome prints through the transfer unit.

The printing process is composed of the following:

Charging: T

VDC by the high voltage power supply (HVPS). The charge roller is kept in

contact with the drum surface to provide a uniform negative charge of

approximately -800 VDC on the drum surface as it rotates at a constant

speed.

Exposure: T

image data from the Main board. The laser beams are directed onto the drum

surface through a system of mirrors and lenses. A rotating polygonal mirror

causes the laser beams to scan the drum surface from end to end (axially) as

it rotates. The beams are turned on to print a pixel and off when no printing is

required. The negative charge on the drum surface is reduced to

approximately -250 VDC at each point where the energized laser beam

strikes, to form an invisible electrostatic latent image on the drum surface.

Development: N

applied to the supply roller and are then applied to the developer roller in a

even lay er controlled by the metering blade. The developer roller turns against

the drum and the toner particles are attracted to the relatively positive latent

image. The toner forms a visible image on the drum surface.

Pre-Clean: T

drum lowering the surface potential and thereby providing enhanced transfer

efficiency.

Transfer: Th

media using the voltage supplied by the Transfer Roller. The conductive

Transfer Roller receives a high positive voltage (approximately +1000 VDC)

from the HVPS that puts it at a higher potential than the drum. Since the

Transfer Roller is located behind the print media, the toner image is attracted

to the high potential and deposits on the surface of the print media.

Fixing: T

the

image, the print media goes through the Fuser where it passes between a

pressure roller and the Heat Roller. The toner is fused onto the print media by

the combination of heat and pressure.

The Heat Roller is heated by a heat element. The roller surface temperature is

ec

ted by a Thermistor. The information is fed back to the heater control to

det

maintain a surface temperature of 185º C during printing and 145º C during

standby. If the thermostats detect a Fuser overheat condition, it disconnects

AC power to the Fuser.

Cleaning: A

inside the cartridge removes any remaining toner particles from the drum.

h

he finished toner image is impermanent and easily smeared. To fix

fte

e charge roller is negatively charged at approximately -1400

h

e Laser Scan Unit (LSU) emits laser beams in response to

tively charged toner particles from the toner hopper are

ega

h

e pre-transfer Lamp exposes the developed surface of the

e finished toner image on the drum is transferred onto the print

r the image is transferred to the print media, a cleaning blade

2-2 Phaser 3600 Printer Service Manual

Page 32

Print Cartridge and Print Modes

Print Cartridge

The Print Cartridge receives image data in the form of pulsed laser light from

the Laser Scan Unit (LSU) and creates the image via the xerographic

process. The Print Cartridge contains the following components:

■ Charge Roller

■ Drum

■ Developer Roller (D/R)

■ Supply Roller (S/R)

■ Metering Blade

■ Cleaning Blade

Theory of Operation

Print Modes

Cleaning Roller

-1.5 ~ -1.30KV

Charging Roller

Cleaning Blade

LSU

0.20 mW

Zener Diode

-100V

-400 ~ -500±20V

V

: -680V

0

V

: -620V

L

OPC Drum

Transfer Roller

Doctor Blade

Developing

Roller

Max. +4.2kV

-500 ~

-600±20V

Supply Roller

PTL

s3600-004

The Phaser 3600 Laser Printer provides two print modes:

1. Draft mode: Uses a combination of reduced toner output and the lowest

resolution (300 x 300 dpi) to extend print cartridge life.

2. Enhanced mode: Used for printing on plain paper with an addressable

resolution of 1200 x 1200 dpi.

Phaser 3600 Printer Service Manual 2-3

Page 33

Theory of Operation

Printer Paper Path

Paper Path Components

The diagram below shows the paper path and identifies the major

components of the printer. The simplex paper path is shown in red and the

duplex path is shown in light red.

Registration Sensor

Tray 1 Pick Roller

Tray 1

No Paper

Sensor

Feed 2 Idler

Feed 2 Roller

Retard Roller

Feed 1 Roller

Tray 2

Pick Roller

Retard Roller

Tray 3 Feed Roller

Imaging Drum (OPC)

Idler

Registration Roller

Tray 3 No Paper Sensor

Tray 3 Pick Roller

Exit Roller

Heat Roller

Tray 2 No Paper Sensor

Exit/Duplex Roller

Idler

Fuser Exit Roller

Fuser Exit Sensor

Pressure Roller

Transfer

Roller

Duplex

Rollers

Duplex Sensor

s3600-085

Media that meets printer specifications can be fed from Tray1 (MPT) and Tray

2, or the Optional Tray 3. If you use thick paper with a weight of more than 105

gsm (60 lbs), you must insert the paper into T ra y 1 (MPT) and select the paper

type. Paper will exit the printer to the face down top tray. A door at the rear of

the printer provides access for jam clearance.

All major components of the printer are explained in greater detail under

i

nter Controls on page 2-10.

Pr

2-4 Phaser 3600 Printer Service Manual

Page 34

Duplex Paper Path

Paper Feed Sequence

Paper Transport

Theory of Operation

When 2-sided printing is selected, side two is printed first, the image being

printed is the first image. After the first image prints, the paper is reversed and

is fed through the duplexer and back up to the feed roller with side one

positioned for printing with the second image.

When the Main Board is ready to feed paper, it energizes the paper feed

solenoid. The solenoid armature releases the clutch and the Pick-Up Roller

makes one revolution. This drives the paper to the Feed Roller and the Retard

Roller. The Feed Roller and Retard Roller drive the paper to the Registration

Assembly, which in turn drives the paper towards the transfer area. Before

arriving at the transfer area, the paper actuates the Feed Sensor.

The Registration Assembly continues to drive the paper into the transfer area,

where the image is transferred from the drum to the paper.

After the image transfers, the paper continues to the Fuser Assembly for the

ng the process. In the Fuser Assembly, the Heat Roller is heated by a heat

fusi

element and the paper passes in between the Heat Roller and the pressure

roller, where toner melts onto the paper to form a permanent image. The

temperature of the heat roller is monitored by a Thermistor that sends signals

to the Main Board.

The Fuser Assembly drives the paper into the Exit Rollers, which drive the

er

into the output tray . When printing the first side of a duplex print job, the

pap

drive direction is reversed when the Exit Sensor is actuated. Paper is then

directed into the Duplex Unit for printing on the second side.

Paper Feed Drive

The drive for all rollers is provided by the Main Drive Motor and a series of

drive gears. The Main Motor is used for paper feed, fusing, and the duplex/exit

roller reversal for 2-sided printing. When the main motor turns, all the paper

path components also turn except the Pick-Up Roller. The Pick-Up Roller

assembly moves the paper along the path with the Feed Solenoid. There is a

separate Developer Motor for the Print Cartridge.

Phaser 3600 Printer Service Manual 2-5

Page 35

Theory of Operation

C

Print Engine Assemblies

The print engine assemblies include the following:

■ Image Processing and the Main Board

■ Laser Scan Unit

■ Main Drive Assembly

■ Feed assembly Process and Components

■ Transfer Roller Assembly

■ Fuser Assembly

Image Processing Assembly and Main Board

The Main Board receives image data from the host computer, converts it to a

bitmap image, and then transfers the image to the Laser Scan Unit (LSU).

The Main Board combines the Image Processor and Engine Control

tions. It contains a 32 bit RISC processor and comes with a standard

func

memory capacity of 64 Mbytes of RAM and 4 Mbytes of flash memory. The

board provides one expansion slot that allows available memory to be

expanded up to 512 Mbytes with two 256Mbyte RAM DIMM.

ontrol Panel (CN16)

Cover Open (CN26)

Duplex Solenoid (CN11)

Laser Unit (CN9)

Developer

Thermistor (CN8)

Motor (CN20)

PTL (CN21)

Toner Sensor Board (CN6)

Rear Fan (CN4)

LVPS (CN19)

Ethernet (CN1)

Power (CN22)

USB (CN2)

Duplex (CN17)

Main Motor

(CN18)

Exit Sensor

Parallel Port

(CN3)

(CN23)

Joint Board

(CN24)

Optional

3rd Tray

(CN25)

RAM DIMM 1 (CN14)

RAM DIMM 0 (CN12)

s3600-077

2-6 Phaser 3600 Printer Service Manual

Page 36

Laser Scan Unit (LSU)

The Laser Scan Unit (LSU) is the core element of the image production

process. The LSU receives video data from the controller on the Main Board

and converts the data to an electrostatic latent image on the OPC (Organic

Photo Conductor) drum. The laser beam exposes the OPC drum under

direction of the controller. The controller also turns the drum synchronously

with a polygon mirror within the LSU. The OPC drum also turns in relation to

the speed of the paper feed process. An /HSYNC signal is created when the

laser beam from LSU reaches the end of a polygon mirror, and the signal is

sent to the controller.

The controller detects the /HSYNC signal to adjust the vertical line of the

age

im

image data is sent to the LSU to adjust the left margin of the media.

Motor Drive Assemblies

The Motor Drive Assemblies include the Main Motor and the Developing

Motor. Under control of the Main Board, the Main Motor Drive is a power

delivery unit. Through a series of gears, it supplies the power to the paper

feed components, the fusing unit, and the distributing unit. For the duplex

process, the Main Motor energizes a solenoid to change paper direction.

By gearing, the main motor drives the rollers such as Feed Roller, developing

oll

er, fuser roller, and Exit Roller. In addition, a step motor controls the

r

acceleration of the drive gearing.

The Developing motor also drives gears that, in turn, drive components used

in the

Theory of Operation

on paper. That is, after the controller detects the /HSYNC signal, the

image development process.

Feed Assembly Process and Components

The Feed assembly process and components consists of:

1. Separation process

parates the paper from the friction pad mounted to the center of the

Se

cassette and applies a Retard Roller which uses a spring clutch. A

separate Feed Roller then uses an electronic clutch to control driving

power.

2. Center Loading Process

A center loading method applies 'friction pad separation’, which means

that a software process first detects paper (even though there is a paper

sensor). After the initial detection, the Paper Size Sensor determines

paper size (see “Paper Size Sensor” on page 2-16).

Both the side guide and the rear guide can be adjusted for various types

of papers from A5 to legal size paper. The process also includes a paper

arranging function and a display function displays the amount of paper

remaining. In the front side of the tray, there is a paper level indicator.

3. Paper Pick-up Process

Functions include a paper pickup function, paper feeding function, and the

removal of electronic static.

Phaser 3600 Printer Service Manual 2-7

Page 37

Theory of Operation

Transfer Roller Assembly

4. Miscellaneous Paper Functions

A paper arrangement function uses a stopper roller and a weight without

an electric actuator. It also includes an additional paper separating

function, a driving control function, and a multi feeding prevention

function. The Feed Roller transfers paper along the paper path and is also

part of jam detection.

The transfer subsystem consists of the Pre-transfer Lamp (PTL) and the

Transfer Roller . The PTL exposes the drum surface after the latent image has

been developed to lower surface potential of the drum. This provides

enhanced transfer efficiency.

The Transfer Roller provides a high positive potential on the back of the print

. This potential attracts the negatively charged toner image from the

media

drum and deposits it on the surface of the print media.

The transfer voltage is controlled by PWM (Pulse Width Modulation). When

the pap

er enters the Transfer Roller, the resistance value of the Transfer

Roller will change due to the surrounding temperature of the printer. If the

temperature changes, a new voltage level is created through an AD converter.

Fuser Assembly

The Fuser Assembly contains the entire Fuser Subsystem and is a field

replaceable unit. The Fuser Assembly contains the following components:

■ Heat Element and Heat Roller :Two quartz lamps operate as the heating

elements, which generate the heat inside the Heat Roller. The Heat Roller

melts the toner so it adheres to the paper.

■ Pressure Roller: Provides pressure on the opposite side of the print

media so the Heat Roller can embed the melted toner in the media.

■ Thermistor: Monitors the surface temperature of the He at Roller. This