Page 1

Service

Phaser® 3500

laser printer

Manual

Page 2

Service Terms

Cautions, Notes, and Warnings

Note: A note indicates an operating or maintenance procedure, practice or condition that

is neccessary to efficiently accomplish a task. A note can provide additional information

related to a specific subject or add a comment on the results achieved through a previous

action.

Caution: A caution statement indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in damage to, or destruction of,

equipment.

Warning: A warning statement indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in injury or loss of life.

Product Terms

Caution: A personal injury hazard exists that may not be apparent. For example, a panel

may cover the hazardous area.

Warning: A personal injury hazard exists in the area where you see the sign.

Phaser® 3500 Laser Printer Service Manual

ii

Page 3

Symbols Marked on the Product

DANGER high voltage.

Protective ground (earth) symbol.

Hot surface on or in the printer. Use caution to avoid personal

injury.

0

30 min.

The surface is hot while the printer is running. After turning off

the power, wait 30 minutes.

Avoid pinching fingers in the printer. Use caution to avoid

personal injury.

Use caution (or draws attention to a particular component). Refer

to the manual(s) for information.

Phaser® 3500 Laser Printer Service Manual

iii

Page 4

Power Safety Precautions

Power Source

For 110 VAC printers, do not apply more than 140 volts RMS between the supply conductors

or between either supply conductor and ground. Use only the specified power cord and

connector. For 220 VAC printers, do not apply more than 264 volts RMS between the supply

conductors or between either supply conductor and ground. Use only the specified power

cord. This manual assumes that the reader is a qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet only. If

necessary, contact a licensed electrician to install a properly grounded outlet. If the product

loses its ground connection, contact with conductive parts may cause an electrical shock.

Disconnecting Power

Turning the power off using the On/Off switch does not completely de-engergize the printer.

You must also disconnect the printer power cord from the AC outlet. Position the power cord

so that it is easily accessible during servicing so that you may power down the printer during

an emergency.

Disconnect the power plug by pulling the plug, not the cord.

Disconnect the power cord in the following cases:

■ if the power cord or plug is frayed or otherwise damaged,

■ if any liquid or foreign material is spilled into the case,

■ if the printer is exposed to any excess moisture,

■ if the printer is dropped or damaged,

■ if you suspect that the product needs servicing or repair,

■ whenever you clean the product.

Phaser® 3500 Laser Printer Service Manual

iv

Page 5

Electrostatic Discharge (ESD) Precautions

Some semiconductor components, and the respective sub-assemblies that contain them, are

vulnerable to damage by Electrostatic Discharge (ESD). These components include Integrated

Circuits (ICs), Large-Scale Integrated Circuits (LSIs), field-effect transistors and other

semiconductor chip components. The following techniques will reduce the occurrence of

component damage caused by static electricity.

Be sure the power to the chassis or circuit board is off, and observe all other safety

precautions.

■ Before handling any semiconductor components assemblies, drain the electrostatic

charge from your body. This can be accomplished by touching an earth ground source

or by wearing a wrist strap device connected to an earth ground source. Wearing a

wrist strap will also prevent accumulation of additional bodily static charges. Be sure

to remove the wrist strap before applying power to the unit to avoid potential shock.

■ After removing a static sensitive assembly from its anti-static bag, place it on a

grounded conductive surface. If the anti-static bag is conductive, you may ground the

bag and use it as a conductive surface.

■ Do not use freon-propelled chemicals, as they can generate electrical charges that may

damage some devices.

■ Do not remove a static sensitive replacement component or electrical sub-assembly

from its protective package until you are ready to install it.

■ Before removing the protective material from the leads of a replacement device, touch

the protective material to the chassis or circuit assembly into which the device will be

installed.

■ Minimize body motions when handling unpackaged replacement devices. Simple

motions such as your clothes brushing together or lifting a foot from a carpeted floor

can generate enough static electricity to damage a static sensitive device

■ Handle IC’s and EPROM’s carefully to avoid bending pins.

■ Pay attention to the direction of parts when mounting or inserting them on Printed

Circuit Boards (PCB’s).

Phaser® 3500 Laser Printer Service Manual

v

Page 6

Service Safety Summary

General Guidelines

Note: The material presented here is intended as a safety reminder for qualified service

personnel. Refer also to the preceding Power Safety Precautions.

Avoid servicing alone

Do not perform internal service or adjustment of this product unless another person capable of

rendering first aid or resuscitation is present.

Use care when servicing with power

Dangerous voltages may exist at several points in this product. To avoid personal injury, do not

touch exposed connections and components while power is on. Disconnect power before

removing the power supply shield or replacing components.

Do not wear jewelry

Remove jewelry prior to servicing. Rings, necklaces and other metallic objects could come

into contact with dangerous voltages and currents.

Power Source

This product is intended to operate from a power source that will not apply more then 264

volts rms for a 220 volt AC outlet or 140 volts rms for a 110 volt AC outlet between the supply

conductors or between either supply conductor and ground. A protective ground connection by

way of the grounding conductor in the power cord is essential for safe operation.

Warning Labels

Read and obey all posted warning labels. Warning labels are displayed on potentially dangerous printer

components. As you service the printer, check to make certain that all warning labels remain in place.

Safety Interlocks

Make sure all covers and the printer’s control panel are in place and all interlock switches are

functioning correctly after you have completed a printer service call. If you bypass an interlock

switch during a service call, use extreme caution when working on or around the printer.

CLASS 1 LASER PRODUCT

The Phaser 3500 Laser Printer is certified to comply with Laser Product Performance

Standards set by the U.S. Department of Health and Human Services as a Class 1 Laser

Product. This means that this is a class of laser product that does not emit hazardous laser

radiation; this is possible only because the laser beam is totally enclosed during all modes of

customer operation. The laser is not hazardous during servicing if you follow the procedures

specified in the manual.

Phaser® 3500 Laser Printer Service Manual

vi

Page 7

Servicing Electrical Components

Before starting any service procedure, switch off the printer power and unplug the power cord

from the wall outlet. If you must service the printer with power applied, be aware of the

potential for electrical shock.

Warning: Turning the power off by using the On/Off switch does not completely de-energize

the printer. You must also disconnect the printer power cord from the AC outlet. Position the

power cord so that it is easily accessible during servicing.

Warning: Do not touch any electrical component unless you are instructed to do so by a

service procedure.Servicing Mechanical Components

Caution: When servicing mechanical components within the printer, manually rotate drive

assemblies, rollers, and gears.

Warning: Do not try to manually rotate or manually stop the drive assemblies while any

printer motor is running.

Warning: This printer uses heat to fuse the toner image to media. The Fuser Assembly is

VERY HOT. Turn the printer power off and wait at least 5 minutes for the Fuser to cool before

you attempt to service the Fuser Assembly or adjacent components.

Regulatory Specifications

Regulatory Specifications for this printer can be found in the User Guide and on the Xerox

Website.

Phaser® 3500 Laser Printer Service Manual

vii

Page 8

Contents

Service Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Cautions, Notes, and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Product Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Symbols Marked on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Power Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Disconnecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

CLASS 1 LASER PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Servicing Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 Service Call Procedures

Servicing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Preventive Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 Repair Analysis Procedures

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Accessing Fault History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Using the Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Entering Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Service Diagnostics Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Service Diagnostic Control Panel Button Descriptions . . . . . . . . . . . . . . . . . 2-5

Troubleshooting Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Jam At Tray [1] [2] [3] (Jam 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Jam At Top (Jam 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Jam At Exit (Jam 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Jam At Rear (Duplex Jam 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Jam At Duplex (Duplex Jam 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Check Cartridge, Invalid Print Cartridge, Non-Xerox Cartridge,

Replace Print Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Close Fuser Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Close Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Fuser Failure, Engine Fuser Low Heat Error, or Engine Fuser Over Heat Error . . . 2-15

Laser Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Output Tray Is Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Phaser® 3500 Laser Printer Service Manual

viii

Page 9

Contents

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Control Panel Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

No Control Panel Display after Power Is Turned ON . . . . . . . . . . . . . . . . . 2-17

Control Panel LED is On, Control Panel Display Is Blank . . . . . . . . . . . . . 2-17

Power Supply Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Taking Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3 Image-Quality Troubleshooting

Image-Quality Problems Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Repeating Defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Print Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Transfer Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Repeating Defects Measurement Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Control Panel (Internal) Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Deletions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Registration and Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Skips or Smears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Image-Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

No Image/Blank Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Light Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Black Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Dark Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Background Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Ghosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Non-Uniform Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Black Spots/Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Spot or Vertical Deletions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Horizontal Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Character Defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Unfused Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Skewed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Skips/Smears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

OHP Print Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4 Repairs and Adjustments

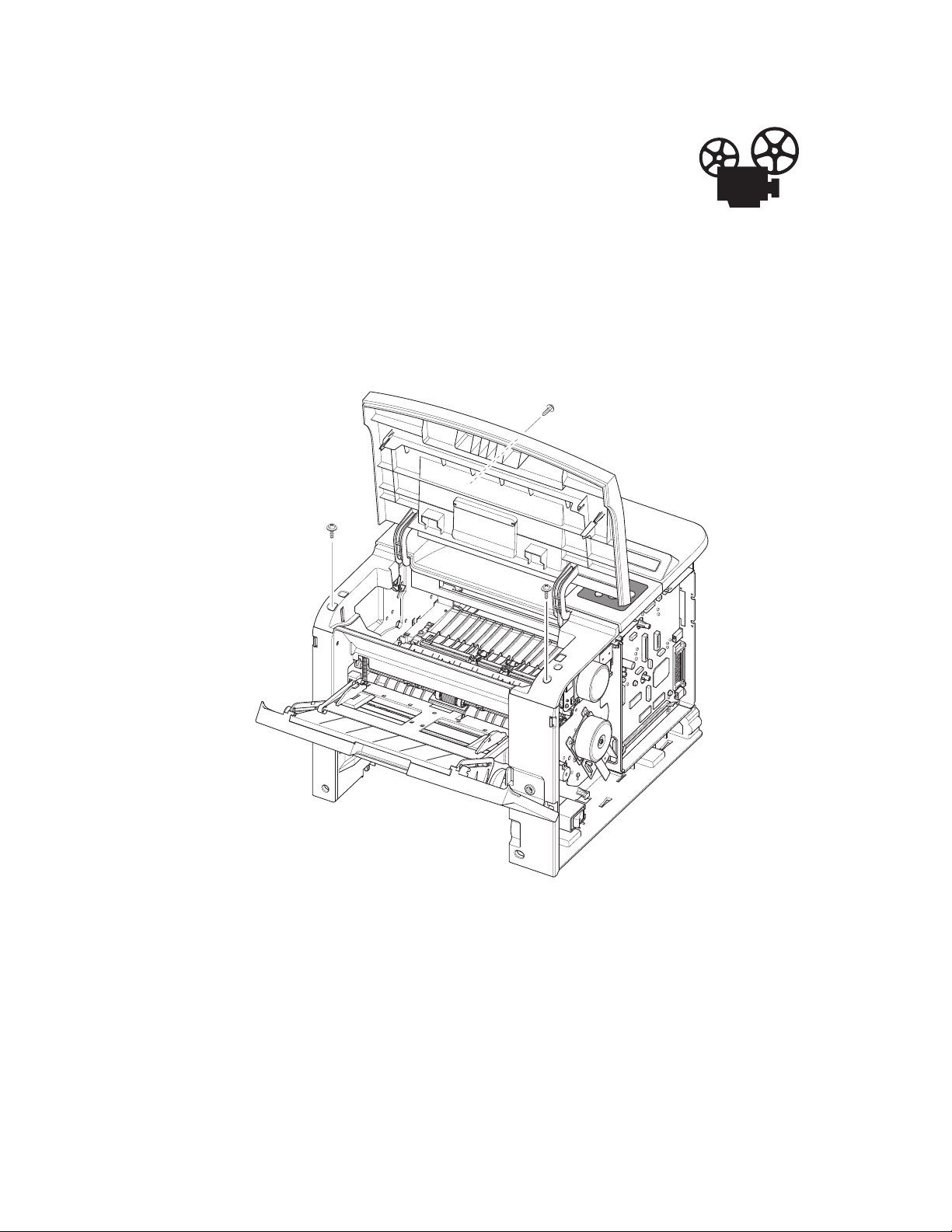

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

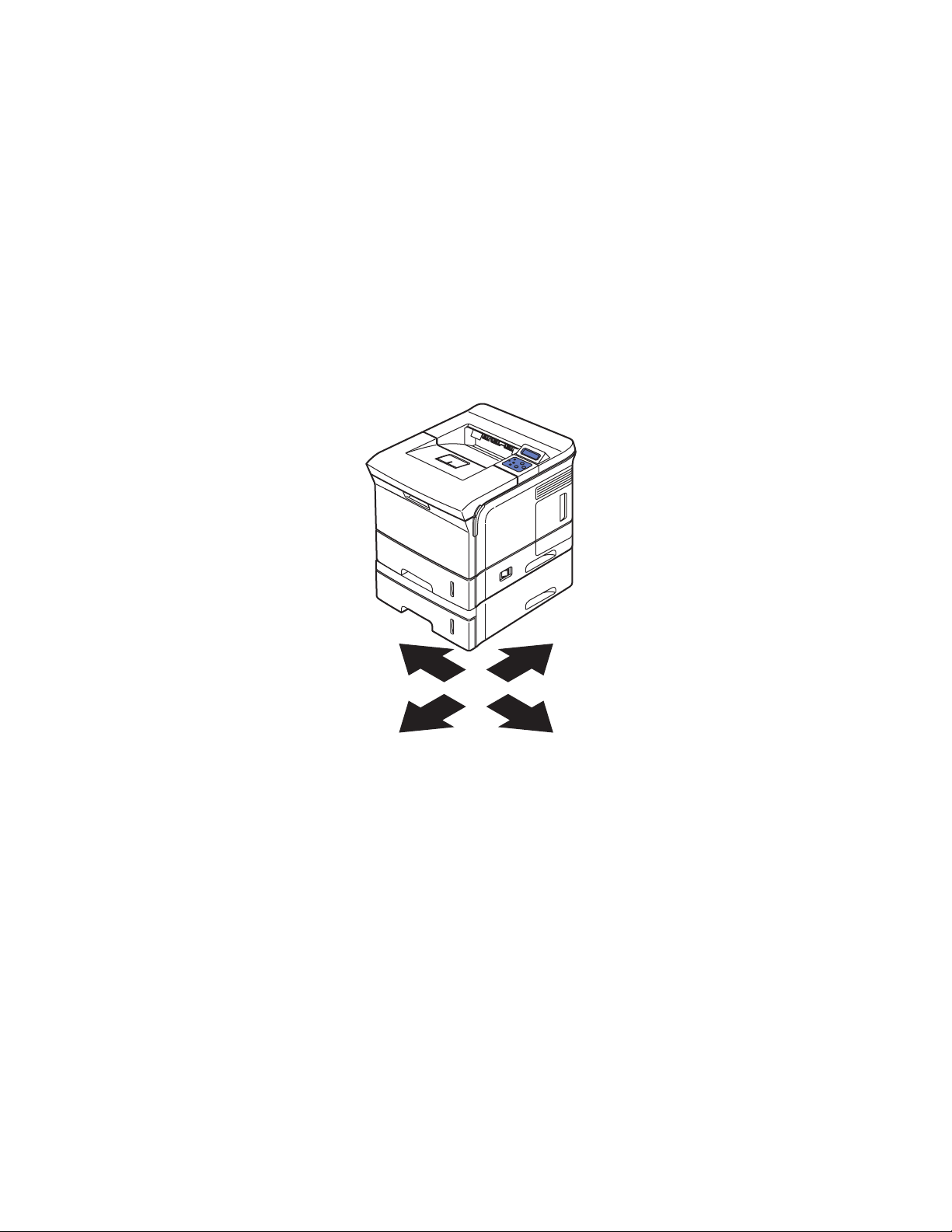

Standard Orientation of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

General Notes on Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Notations in the Disassembly Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Phaser® 3500 Laser Printer Service Manual

ix

Page 10

Contents

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Control Panel and LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Open Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Tray 1 (MPT) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Tray 1 Knock-Up Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Tray 1 Pick-Up Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Transfer Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Retard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Tray 1 Separator (Holder) Pad Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Feed2 Idle Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Registration Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

PTL Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

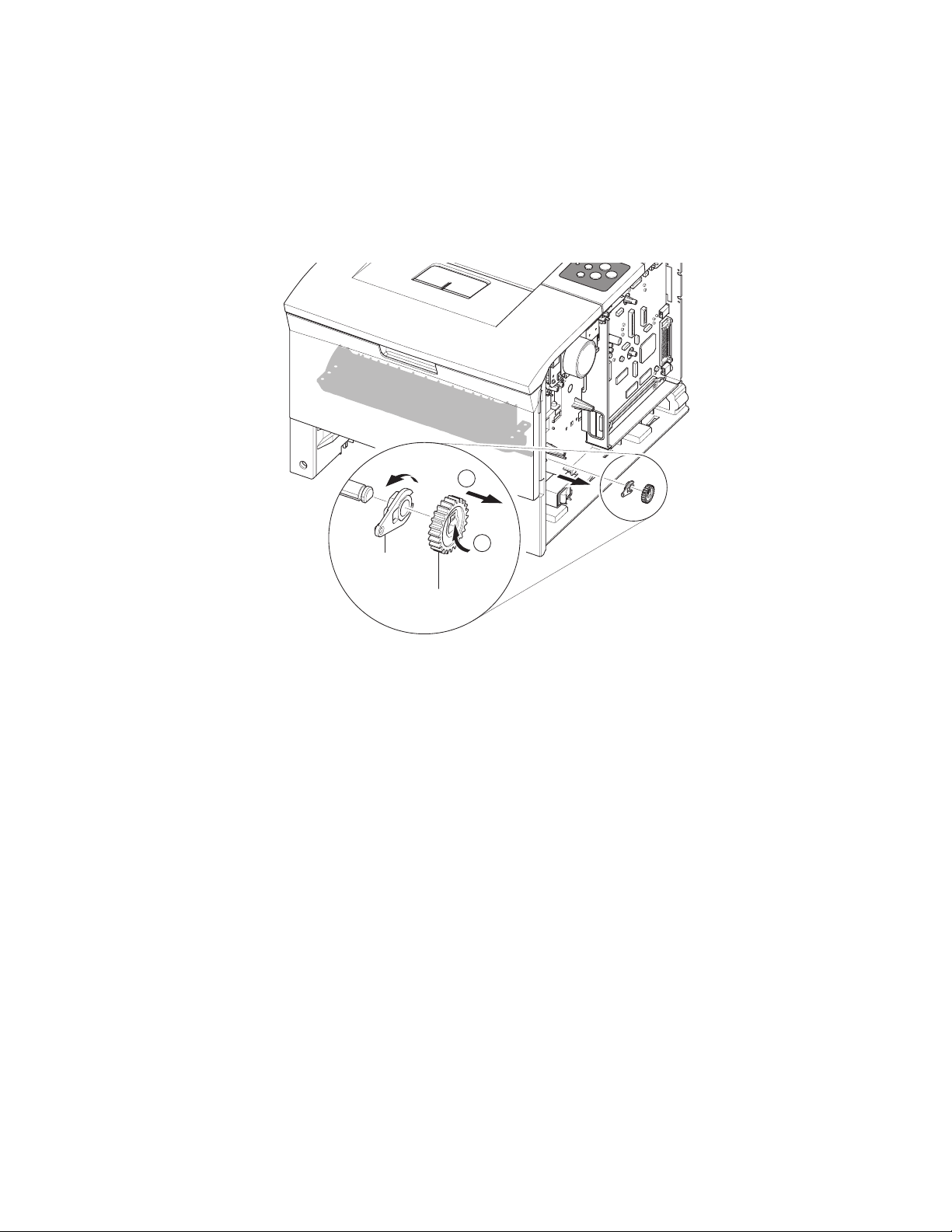

Main Drive Assembly and Registration (Feed) Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Feed Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Main Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Tray 1 Pick-Up Assembly and Pick Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Tray 1 Pick Roller Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Pick Roller and Shaft Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Tray 2 Pick-Up Assembly and Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Feed 2 Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Developer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Connector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Tray 1 (MPT) Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Main Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Exit Solenoid Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Exit and Duplex Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Exit Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Tray Full Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Duplex Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Laser (LSU) Assembly and Lower Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

LSU Lower Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Left Side Cooling Supply Fan and Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Toner Sensor Board and CRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Cover Open Board and Harness Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Main Board and Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Power Supply and Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Fuser Gear Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Paper Size Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Phaser® 3500 Laser Printer Service Manual

x

Page 11

Contents

5Parts List

Using the Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

PL 8.1 Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

PL 8.1 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

PL 8.2 Cover Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

PL 8.2 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

PL 8.3 Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

PL 8.3 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

PL 8.4 Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

PL 8.4 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

PL 8.9 Tray 2 Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

PL 8.9 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

PL 8.10 Tray 3 Cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

PL 8.10 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

PL 8.11 Duplex Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

PL 8.11 Parts List Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

6 General Information and Specifications

Printer Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Printer Options and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Consumable and Service Part Life Expectancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Printer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printer Location and Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printer Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Media and Tray Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

7 Wiring Data

Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Phaser® 3500 Laser Printer Service Manual

xi

Page 12

Contents

8 Theory of Operation

Overview of the Phaser 3500 Laser Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Summary of the Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Print Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Printer Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Duplex Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Paper Feed Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Paper Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Paper Feed Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Major Assemblies and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Imaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Print Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Laser Scan Unit (LSU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Transfer Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Sensor Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Paper Empty Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Tray 1 Paper Empty Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Registration Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Fuser Exit Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Cover Open Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Duplex Unit Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Printer Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Image Processor Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Print Engine Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Paper Size Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Paper Pick Auto-Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Toner Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Laser Light Intensity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Fuser Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Phaser® 3500 Laser Printer Service Manual

xii

Page 13

Service Call Procedures

This section includes the following:

■ Servicing Instructions on page 1-2

■ Service Preventive Maintenance Procedure on page 1-3

Phaser® 3500 Laser Printer Service Manual

2-1

Page 14

Service Call Procedures

Servicing Instructions

The service flowchart is an overview of the path a service technician should take, using this

manual, to service the print engine and options.

Step 1: Identify the Problem

1. Verify the problem reported and check for any error codes and write them down.

2. Print normal customer prints and service test prints and look for any of the following:

■ any image quality problems in the test prints.

■ any mechanical or electrical abnormalities present.

■ any unusual noise or smell coming from the printer.

3. View the fault and jam histories and look at the total print count for the printer.

4. Verify the AC input power supply is within proper specifications by measuring the

voltage at the electric outlet while the printer is running.

Step 2: Inspect and Clean the Printer

5. Switch OFF printer power and disconnect the AC power cord from the wall outlet.

6. Verify the power cord is free from damage or short circuit and is connected properly.

7. Remove the Print Cartridge and protect it from light, then inspect the printer interior

and remove any foreign matter, obstructions, or loose toner.

8. Inspect the interior of the printer for damaged wires, loose connections, toner leakage,

and damaged or obviously worn parts.

■ Do not use solvents or chemical cleaners to clean the printer interior.

■ Do not use any type of oil or lubricant on printer parts.

■ Use only an approved toner vacuum.

9. Clean all rubber rollers with a lint-free cloth, dampened slightly with cold water.

10. Replace any service items that have reached their 150,000 end-of-life.

Step 3: Find the Cause of the Problem

11. Use the Repair Analysis Procedures to find the cause of the problem.

12. Use Diagnostics to check printer and optional components.

13. Use the Wiring Diagrams to locate test points.

14. Take voltage readings at various test points as instructed in the appropriate

troubleshooting procedure.

Step 4: Correct the Problem

15. Use the Parts List to locate a part number.

16. Use the Repair and Adjustments Procedures to replace the part.

Step 5: Final Checkout

17. Test the printer to be sure you have corrected the initial problem and there are no

additional problems present.

Phaser® 3500 Laser Printer Service Manual

1-2

Page 15

Service Call Procedures

Service Preventive Maintenance Procedure

Perform the following procedures whenever you check, service, or repair a printer. Cleaning

the printer, as outlined in the following steps, assures proper operation of the printer and

reduces the probability of having to service the printer in the future.

The frequency of use and the type of paper a customer prints on determines how critical and

how often cleaning the machine is necessary. Record the number of sheets printed.

Recommended Tools

■ Toner vacuum cleaner

■ Clean water

■ Clean, dry, lint-free cloth

■ Black light protective bag

Cleaning

■ Never apply alcohol to any parts in the printer.

■ Never use a damp cloth to clean up toner.

■ If you remove the Print Cartridge, place it in a light protective bag. Exposure to light

can degrade its performance and result in early failure.

1. Record number of sheets printed.

2. Print several sheets of paper to check for problems or defects.

3. Print several cleaning sheets to clear up image-quality problems.

4. Turn off the printer.

5. Remove any debris or foreign objects.

6. Remove any loose toner from the interior of the printer using a Type II toner vacuum only.

7. Remove and clean the paper trays.

8. Clean pick rollers with a slightly damp, lint-free cloth.

Phaser® 3500 Laser Printer Service Manual

1-3

Page 16

Repair Analysis Procedures

This section includes the following:

■ Introduction on page 2-2

■ Service Diagnostics on page 2-4

■ Troubleshooting Error Messages on page 2-10

■ General Troubleshooting on page 2-17

■ Power Supply Troubleshooting on page 2-18

Phaser® 3500 Laser Printer Service Manual

2-1

Page 17

Repair Analysis Procedures

Introduction

This section covers troubleshooting procedures for the Phaser 3500 Laser Printer. When an

error first occurs, record the error message and code and then cycle power to the printer to see

if the error recurs. Be sure to follow the Service Call Procedures on page 1-1 before servicing

the printer.

To troubleshoot image-quality problems, see image-quality Troubleshooting on page 3-1.

Accessing Fault History

Any code associated with an error message or jam can be viewed by displaying the Fault

History or Jam History on the Control Panel.

1. View the printer’s fault history on the Control Panel.

a. Go to Troubleshooting --> Service Tools --> Fault History or Jam History.

If the printer is connected to a network and has a TCP/IP address, you can view the

printer’s web page using a web browser.

b. Open a web browser.

c. Enter the printer’s IP address as the URL.

d. Select the Troubleshoot link and the fault history will be displayed.

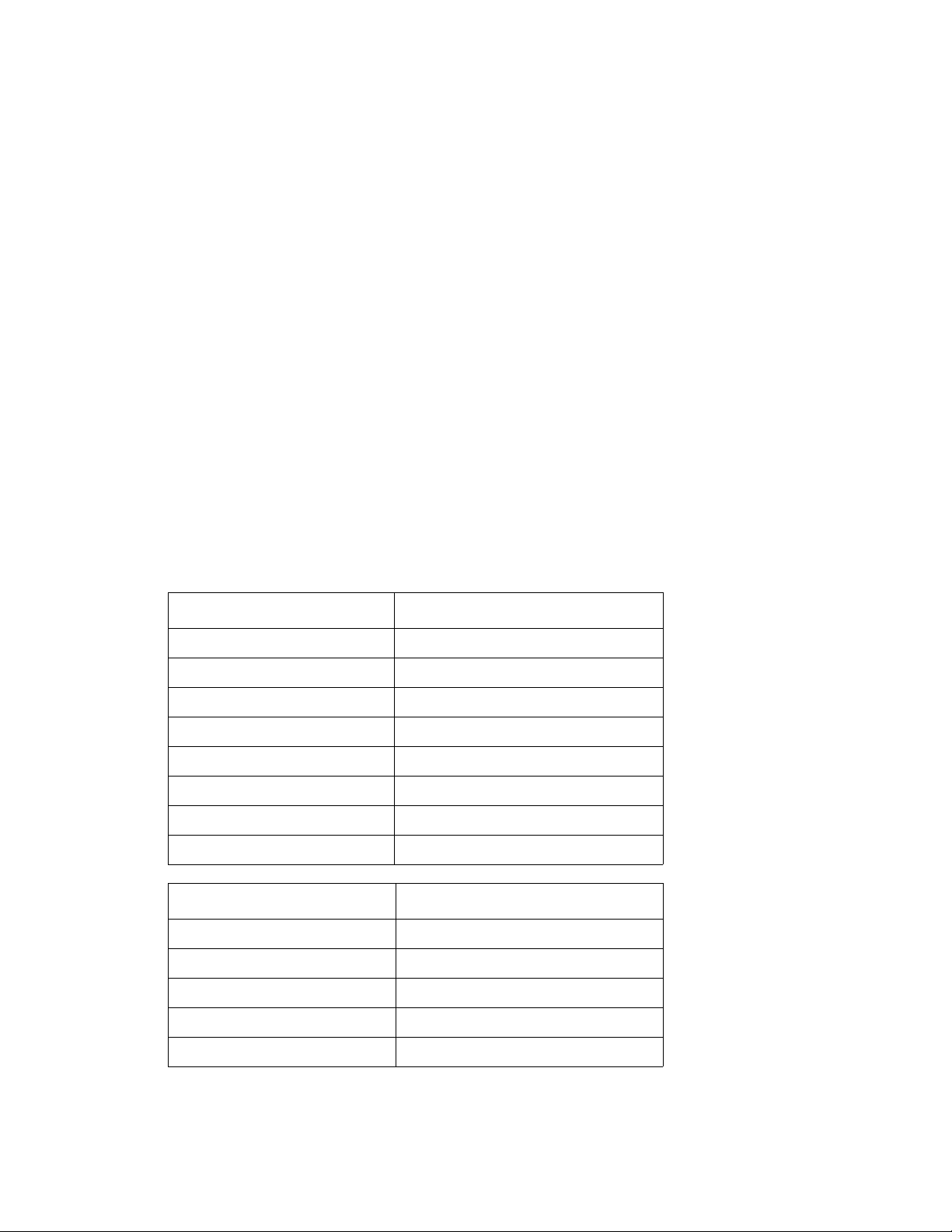

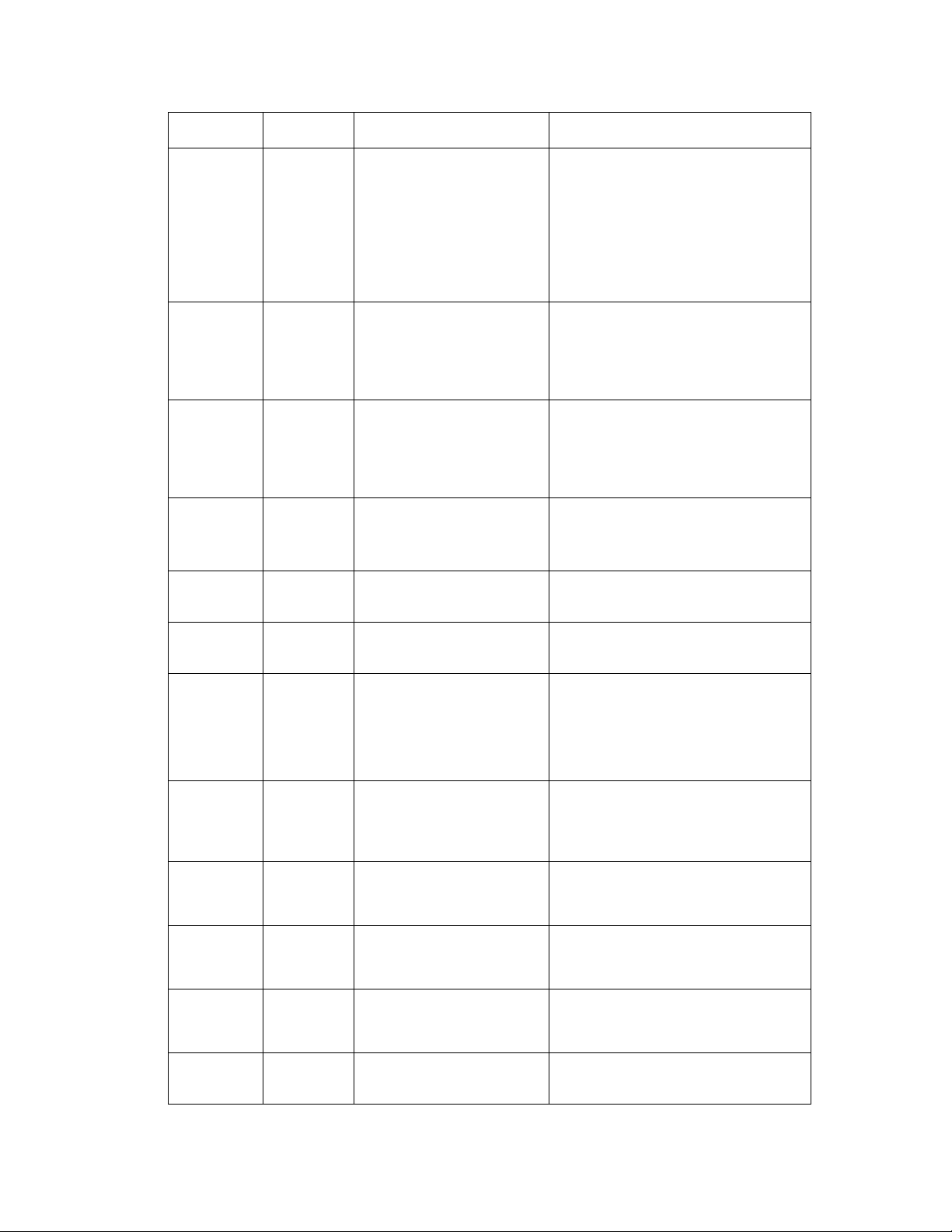

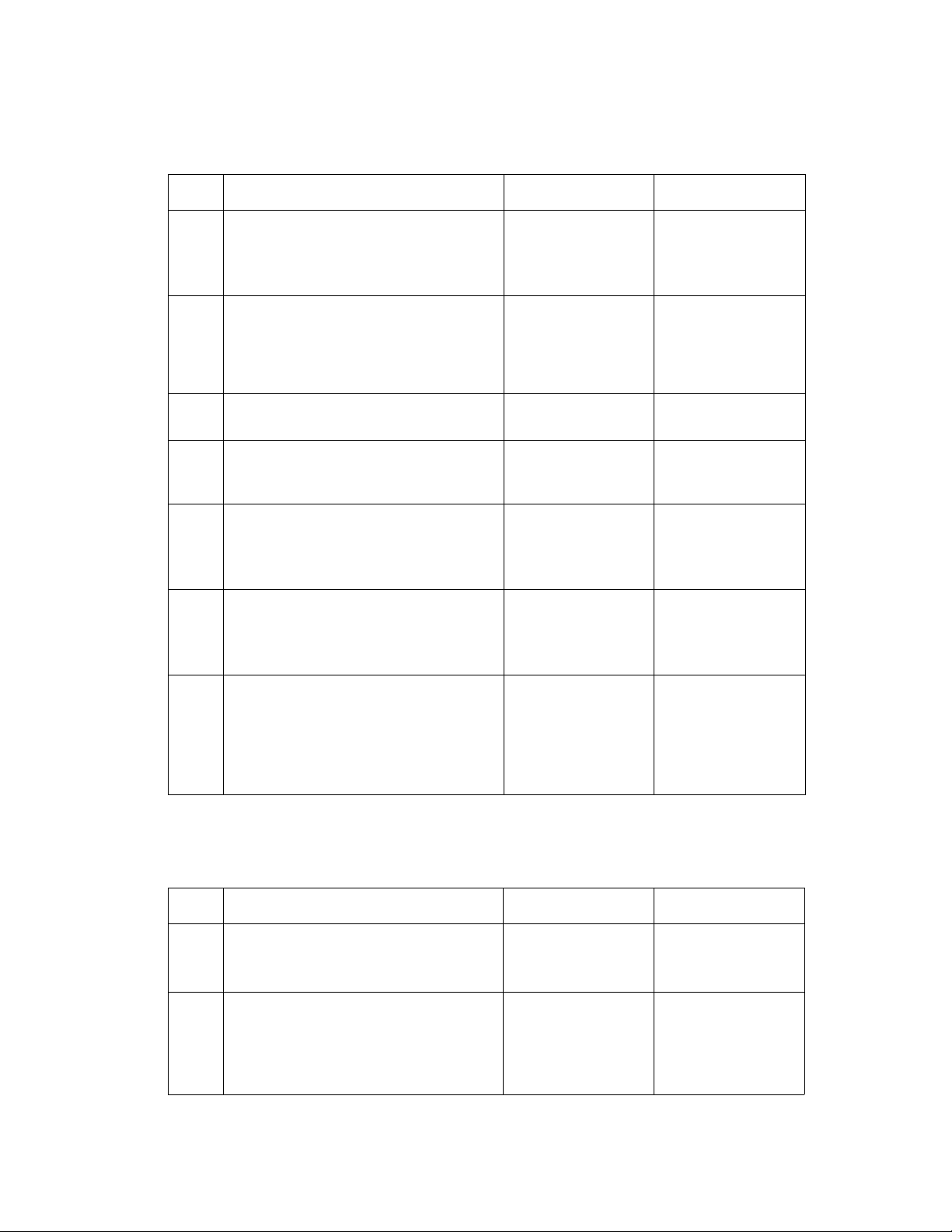

Fault History Code Printer Error Message

41 Insufficient Memory

44 Output Tray Is Full

5A Laser Failure

53 Replace Print Cartridge

55 Invalid Print Cartridge

56 Fuser Failure/Open Fuser Error

57 Fuser Failure/Low Heat Error

58 Fuser Failure/Over Heat Error

Jam History Code Jam Error Message

01 Jam At Tray 1, 2, or 3 (Jam 0)

02 Jam At Top (Jam 1)

03 Jam At Exit (Jam 2)

04 Jam At Rear (Duplex Jam 1)

05 Jam At Duplex (Duplex Jam 2)

Phaser® 3500 Laser Printer Service Manual

2-2

Page 18

Repair Analysis Procedures

Using the Troubleshooting Procedures

1. Each Step in a Troubleshooting Procedure instructs you to perform a certain action or

procedure. The steps are to be followed sequentially until the problem is fixed or resolved.

2. The Actions and Questions box contains additional information and/or additional

procedures you must follow to isolate the problem.

3. When a procedure instructs you to test a component using service diagnostics, see the

Service Diagnostics Menu Map on page 2-5 for the detailed steps and functions for testing

parts of the printer.

4. The action is followed by a question. If your response to the question is “Ye s”, then follow

the instructions for a “Ye s ” reply. If your response to the question is “No”, then follow the

instructions for a “No” reply.

5. Troubleshooting Procedures may ask you to take voltage readings or test for continuity at

certain test points within the printer. For detailed diagrams, see Section 7, Wiring Data on

page 7-1 for complete information on test point locations and signal names.

6. Troubleshooting Procedures often ask you to replace a printer component, see Repairs and

Adjustments on page 4-1 for detailed steps in removing and replacing all major

components of the printer. Section 5, Parts List on page 5-1, details the location, quantity,

and part number for all spared printer components.

Phaser® 3500 Laser Printer Service Manual

2-3

Page 19

Repair Analysis Procedures

Service Diagnostics

The printer has built-in diagnostics to aid in troubleshooting problems. The Service

Diagnostics Menu provides a means to test sensors, motors, switches, clutches, fans and

solenoids. Diagnostics also contain built-in test prints, cleaning procedures, printer status and

some NVRAM access.

Service diagnostics are to be executed through the control panel by a certified service

technician only. The printer must be rebooted to enter Service Diagnostics.

Entering Service Diagnostics

1. Turn the printer power OFF.

2. Hold down the OK button and turn the printer back ON.

3. Continue to hold the button until the following mesage is displayed on the Control Panel:

“Diagnostic Mode” / “Press Menu Key”, and then release the OK button.

4. Press the Menu button and use the Arrow buttons to scroll through the available functions

(see the following Service Diagnostic Menu Map Table).

Phaser® 3500 Laser Printer Service Manual

2-4

Page 20

Repair Analysis Procedures

Service Diagnostics Menu Map

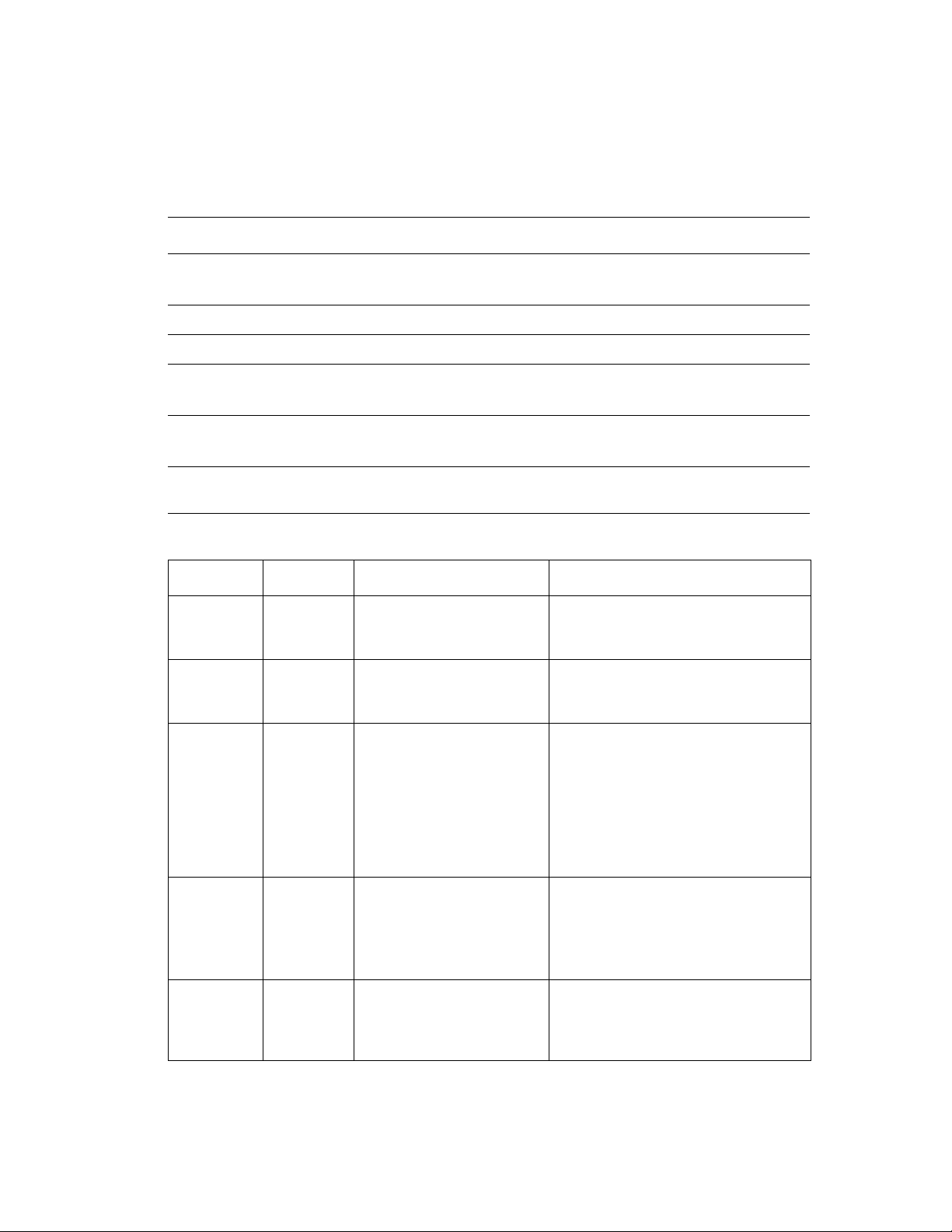

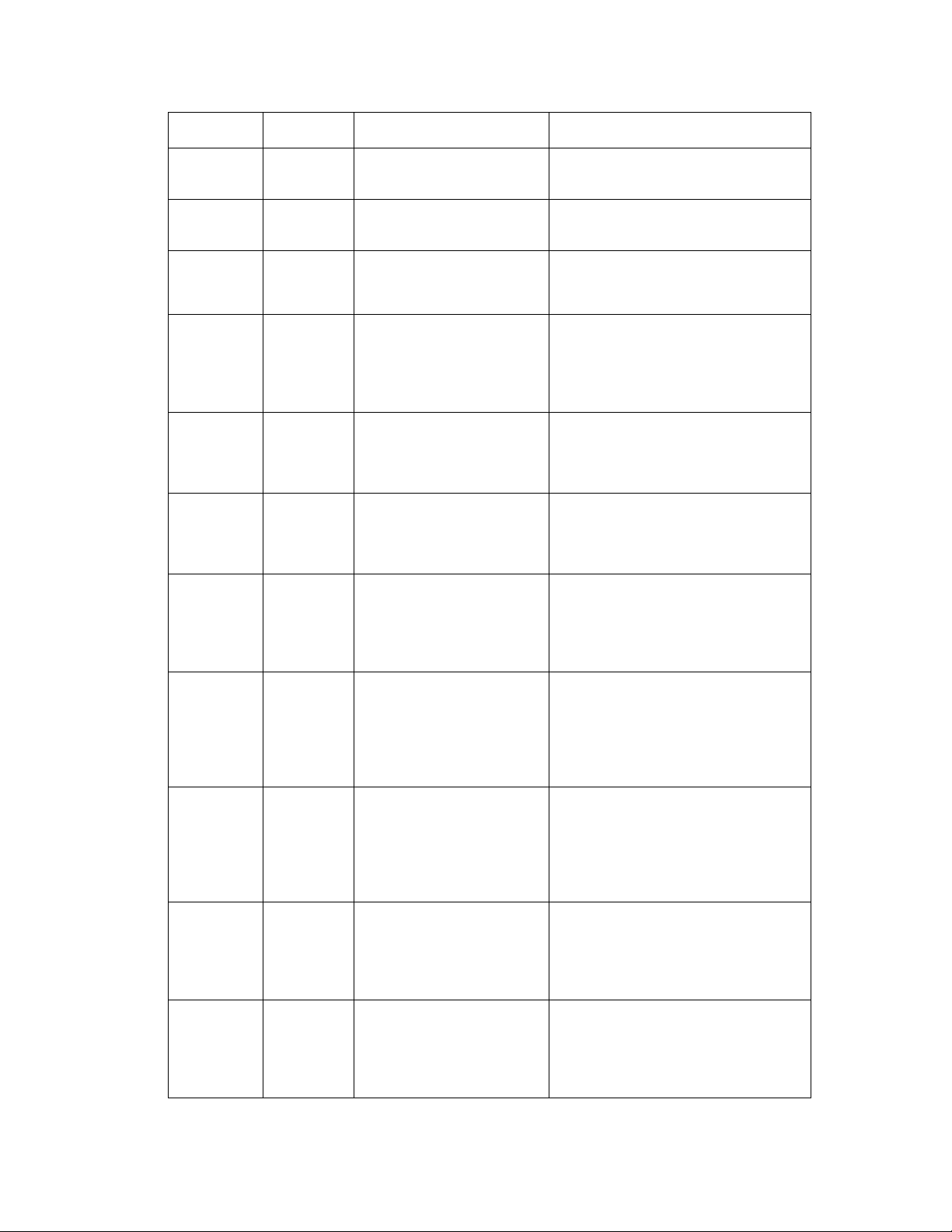

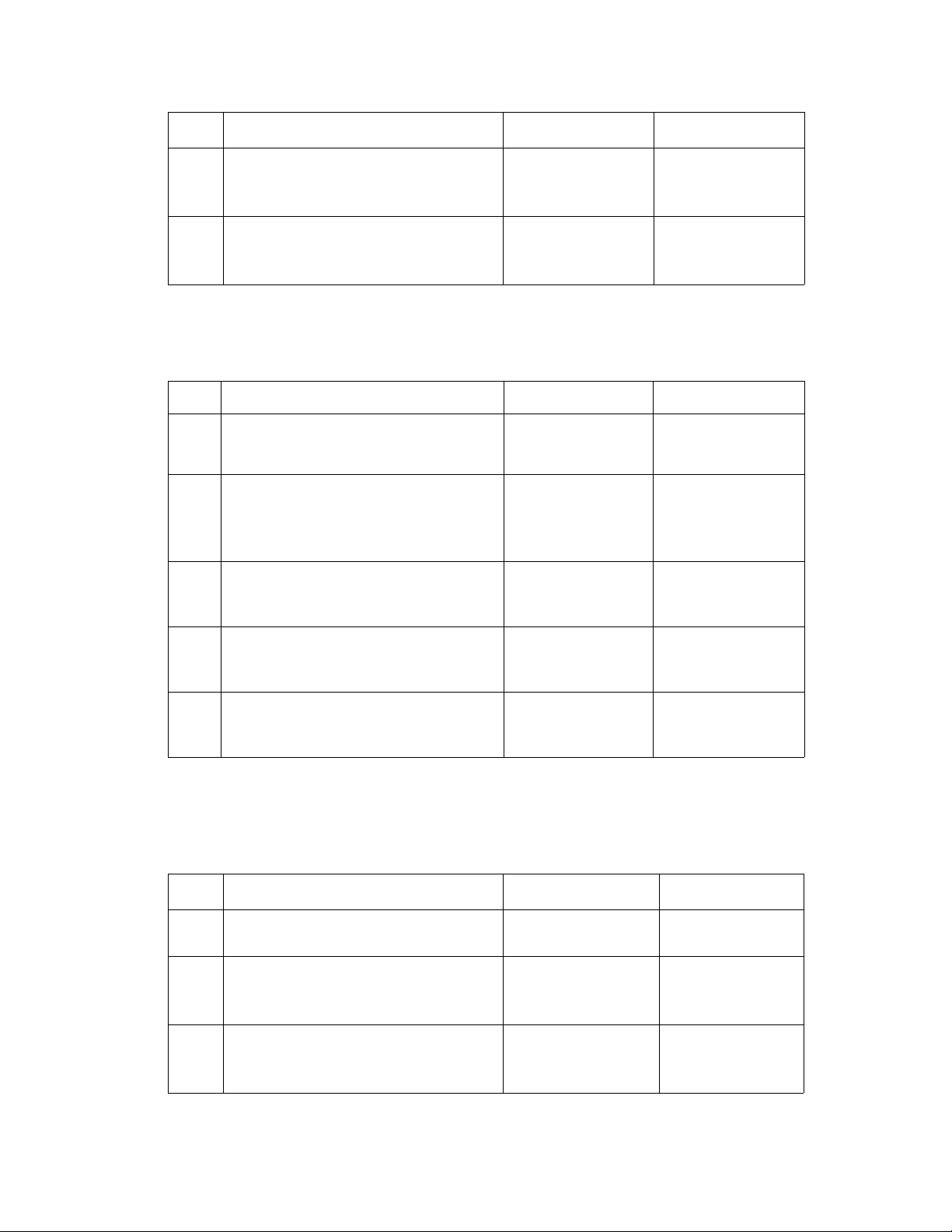

Service Diagnostic Control Panel Button Descriptions

Button Function

BACK Returns to the prior higher level menu structure, if available.

Stops the actively running test.

CANCEL Terminates the current test.

MENU Cycles through all of the top level menu items.

UP Scrolls up one menu item within a menu list. This control does not ‘wrap’.

Used to increment values in tests requiring user input.

DOWN Scrolls up one menu item within a menu list. This control does not ‘wrap’.

Used to increment values in tests requiring user input.

OK Enters the highlighted menu. Executes the current test item.

Used to select the value entered by the user.

Main Menu Sub Menu Description/Function Control Panel Display

Optins

Interface

Tes t

Pattern

Motor/Fan Main Motor Main drive motor runs when

Tr ay 3

Interface

Duplex

Interface

Simplex Prints the test print page in

Duplex Prints the test print page in

Tests the interface between

the main controller and the

Tray 3 interface board.

Tests the interface between

the main controller and the

duplex interface board.

simplex mode. The Control

Panel will display the papers

location during the print

process.

This process will print

continuosly until stopped by

the user.

2-sided or duplex mode.

This process will print

continuosly until stopped by

the user.

the OK button is pressed

and stops when the Cancel

button is pressed.

Tray 3 Interface:

Pass /Fail :x.x.x

Duplex Interface

Pass/Fail :x.x.x

Simplex Print

Start -> Feed On -> Exit On

Duplex Print

Start -> Feed On -> Exit On -> Duplex

On

Main Motor

Running Test

ON/OFF

Phaser® 3500 Laser Printer Service Manual

2-5

Page 21

Repair Analysis Procedures

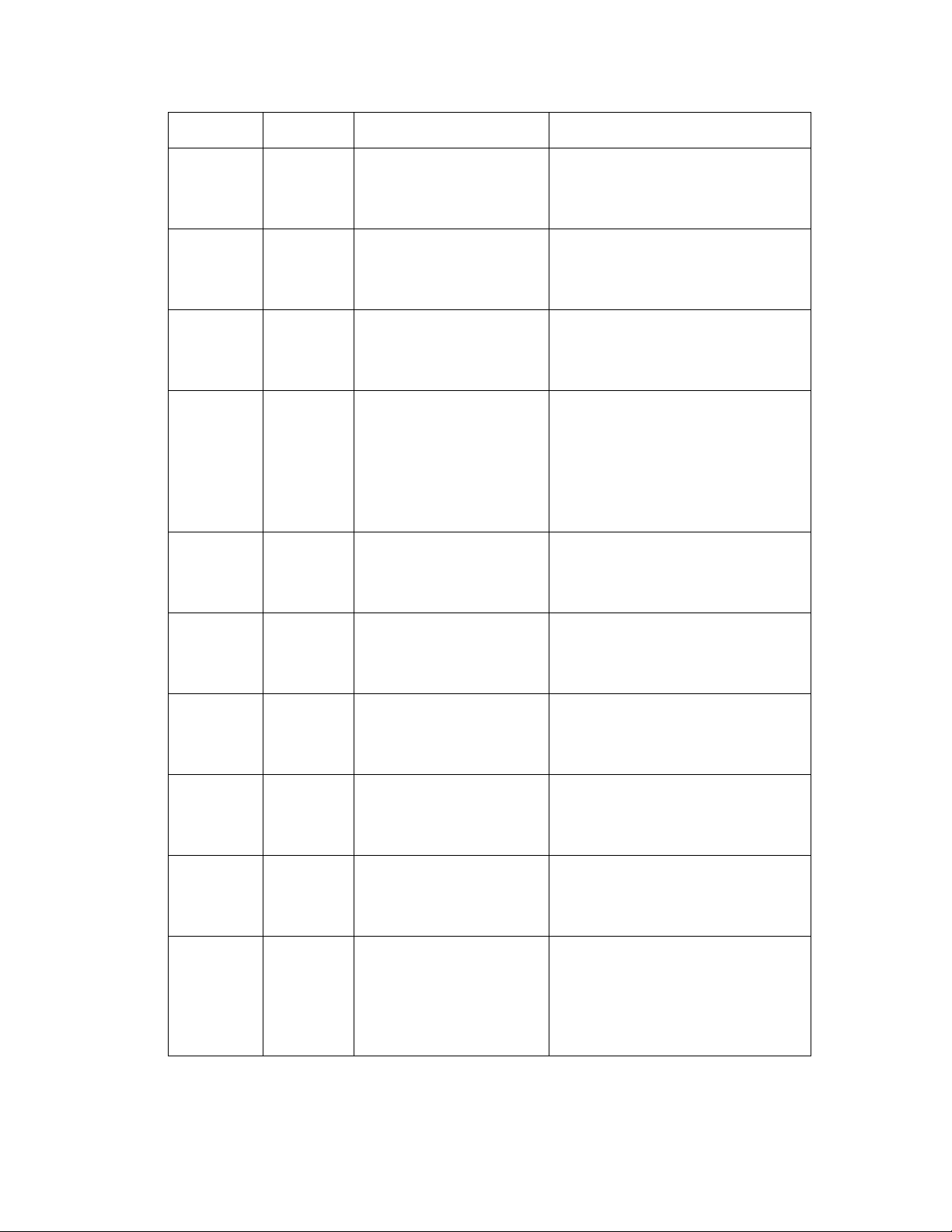

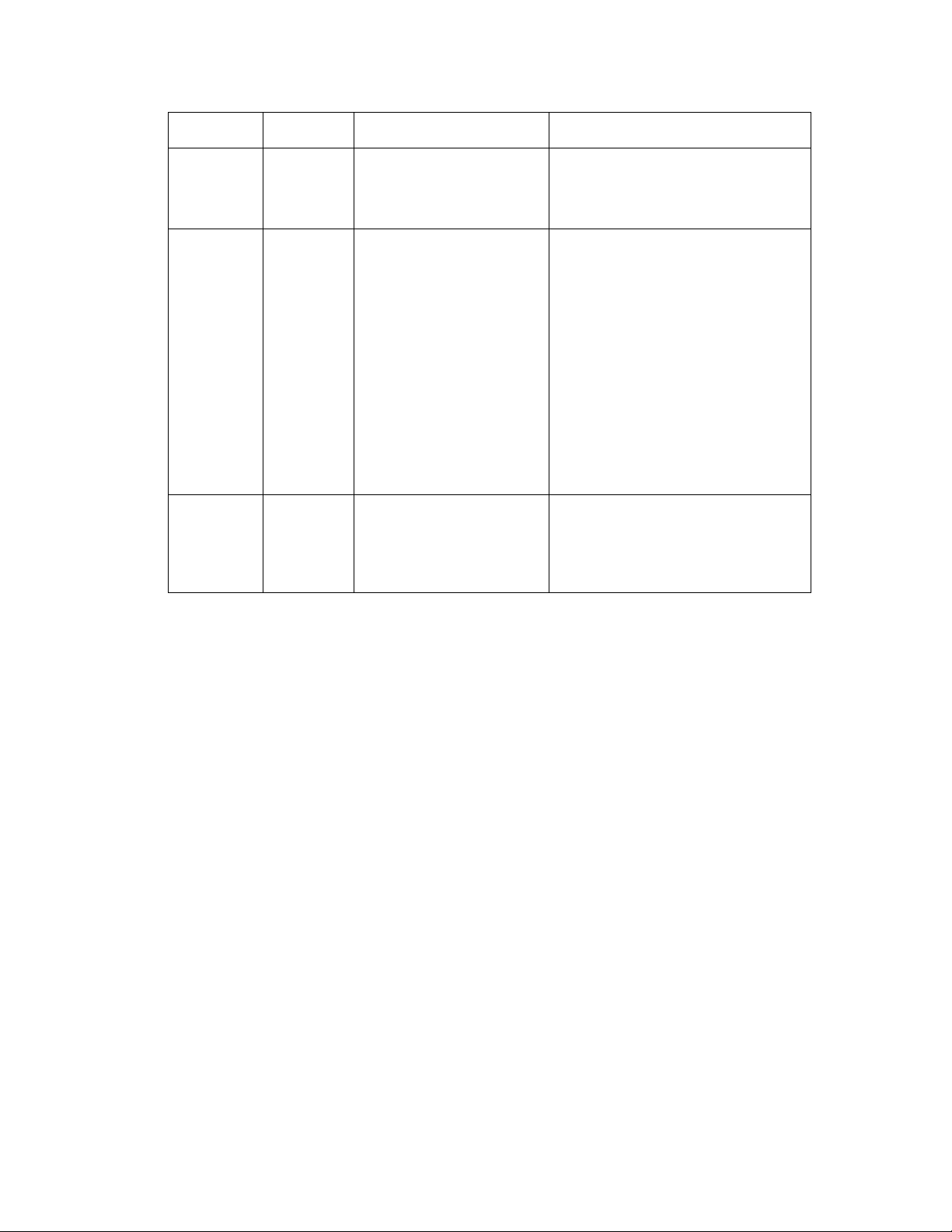

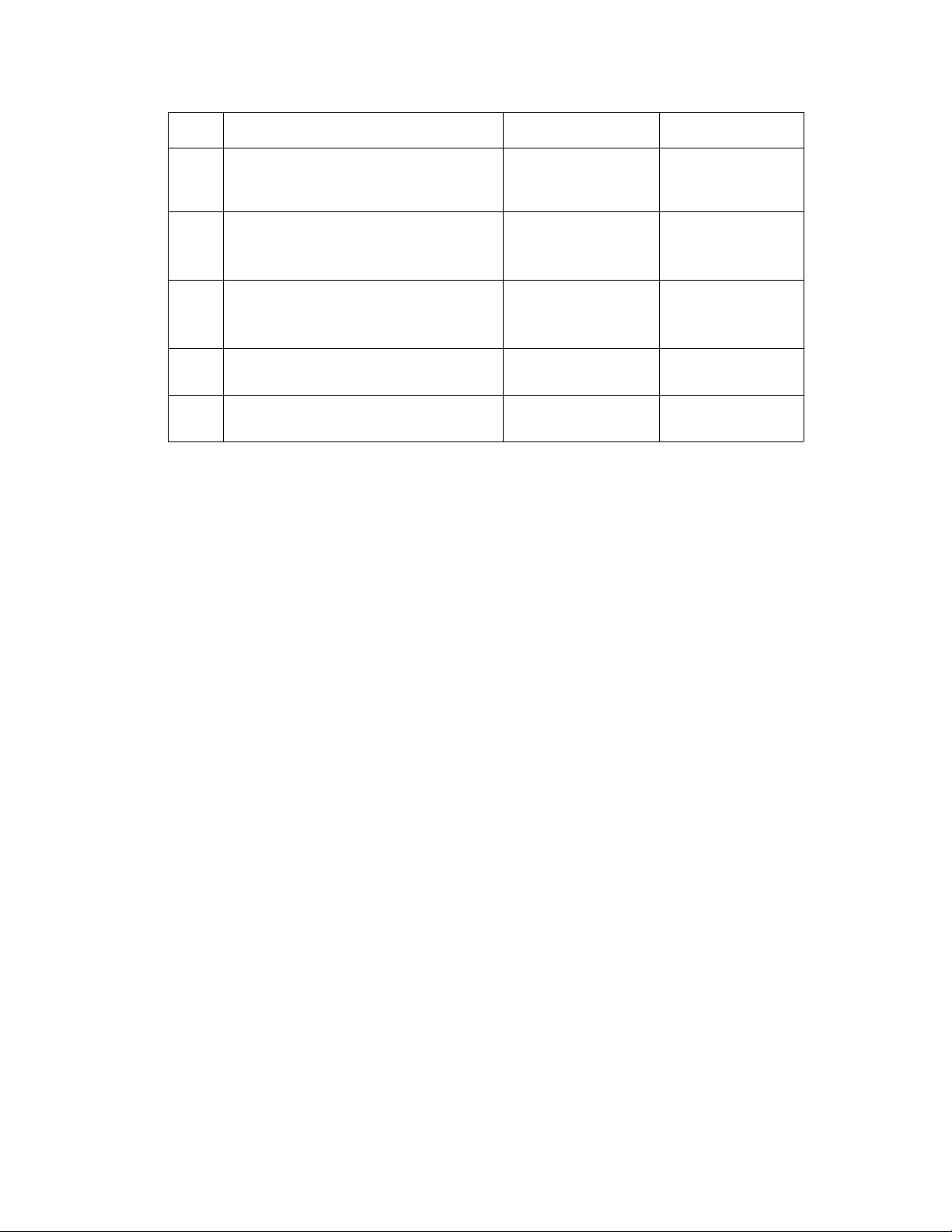

Main Menu Sub Menu Description/Function Control Panel Display

DEV Motor Developer motor runs when

the OK button is pressed

and stops when the Cancel

button is pressed.

Laser

Motor

Duplex

Motor

Tra y 3

Motor

(If installed)

Main Fan Main fan runs when the OK

Laser motor runs when the

OK button is pressed and

stops when the Cancel

button is pressed.

Duplex motor runs when the

OK button is pressed and

stops when the Cancel

button is pressed.

Tray 3 motor runs when the

OK button is pressed and

stops when the Cancel

button is pressed.

If Tray 3 is not installed, test

does not run.

button is pressed and stops

when the Cancel button is

pressed.

DEV Motor

Running Test

ON/OFF

Laser Motor

Running Test

ON/OFF

Duplex Motor

Running Test

ON/OFF

Tray 3 Motor

Running Test

ON/OFF

Tray 3 Not Installed

Main Fan

Running Test

ON/OFF

Solenoid/

Clutch

SMPS Fan SMPS fan runs when the

OK button is pressed and

stops when the Cancel

button is pressed.

Duplex Fan Duplex fan runs when the

OK button is pressed and

stops when the Cancel

button is pressed

Tra y 1

Solenoid

Tra y 2

Solenoid

Tra y 3

Solenoid

When the OK button is

pressed the Tray 1 solenoid

is turned on for 200ms, and

then it automatically stops.

When the OK button is

pressed the Tray 2 solenoid

is turned on for 200ms, and

then it automatically stops.

When the OK button is

pressed the Tray 3 solenoid

is turned on for 200ms, and

then it automatically stops.

When Tray 3 is not installed,

this function does not work.

SMPS Main

Running Test

ON/OFF

Duplex Fan

Running Test

ON/OFF

Tray 1 Solenoid

ON/OFF

Tray 2 Solenoid

ON/OFF

Tray 3 Solenoid

ON/OFF

Tray 3 Not Installed

Phaser® 3500 Laser Printer Service Manual

2-6

Page 22

Repair Analysis Procedures

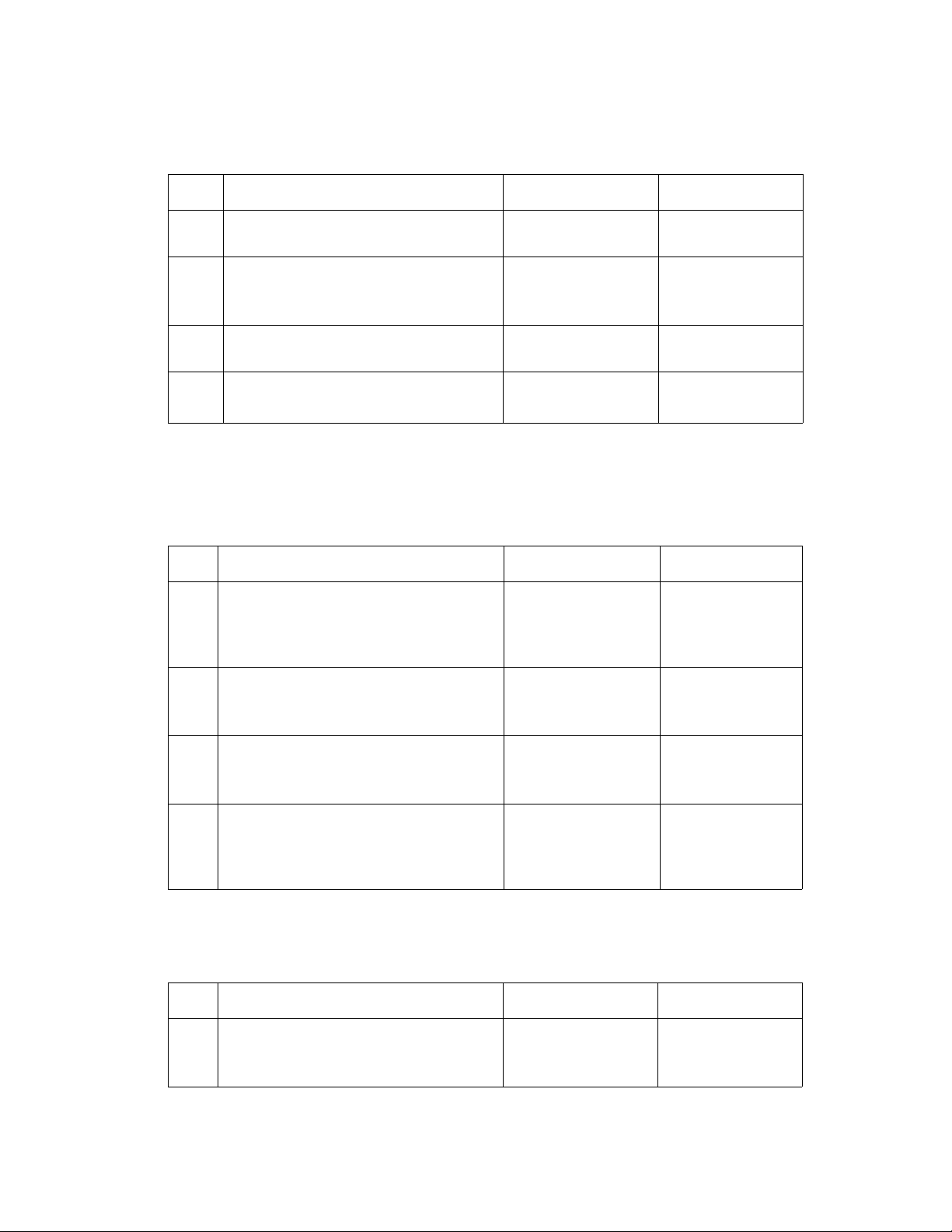

Main Menu Sub Menu Description/Function Control Panel Display

Reg Clutch When the OK button is

Duplex

Solenoid

Tr ay 3

Clutch

Sensors Paper Size

Sensor

T1 NP

Sensor

pressed, the registration

clutch and main motor turn

on for 200ms, and then they

automatically stop.

You can visually observe

this test by removing the Top

Cover and Print Cartridge.

When the OK button is

pressed, the duplex

solenoid is turned on for

200ms, and then it

automatically stops.

When the OK button is

pressed, the Tray 3 clutch

and motor turn on for

200ms, and then they

automatically stop.

Place paper in the tray and

compare the size with the

control panel display.

Pull out Tray 1 and manually

toggle the actuator.

Reg Clutch

ON/OFF

Duplex Solenoid

ON/OFF

Tray 3 Clutch

ON/OFF

Example:

Tray2: Legal

Tray3: Letter

Tr ay 1

W/Out Paper or With Paper

T2 NP

Sensor

T3 NP

Sensor

Duplex

Sensor

Cover

Open

Sensor

Feed

Sensor

Exit Sensor Open the rear cover, and

Out Bin

Sensor

Pull out Tray 2 and manually

toggle the actuator.

Pull out Tray 3 and manually

toggle the actuator.

When Tray 3 is not installed,

this function does not work.

With the rear cover open,

push a piece of paper into

the duplex path and watch

the control panel display.

Open the top cover and

toggle the actuator.

Open the top cover, remove

the print cartridge, and then

actuate the sensor

insert paper into the exit

path.

Actuate the output sensor. Out Bin Sensor

Tr ay 2

W/Out Paper or With Paper

Tr ay 3

W/Out Paper or With Paper

Tray 3 Not Installed

Duplex Sensor

W/Out Paper or With Paper

Cover

Open/Closed

Feed Sensor

W/Out Paper or With Paper

Exit Sensor

W/Out Paper or With Paper

Not Full/Full

Phaser® 3500 Laser Printer Service Manual

2-7

Page 23

Repair Analysis Procedures

Main Menu Sub Menu Description/Function Control Panel Display

Tray 2 Out

Sensor

Tray 3 Out

Sensor

Fuser Door

Sensor

HVPS Dev Bias

DC

Dev Bias

AC

Charge

Roll

Voltage

Transfer

Roll (+)

Remove Tray 2 from the

printer.

Remove Tray 3 from the

printer.

Open the rear cover and

actuate the fuser door

sensor.

Developer Bias DC is

applied when the OK button

is pressed, and then goes

off when the Cancel button

is pressed.

Developer Bias AC is

applied when OK is pressed

and goes off when Cancel is

pressed.

Charge Roller Voltage

(+1200V) is supplied when

OK is pressed and goes off

when Cancel is pressed.

Positive Transfer Voltage

(+1200V) is supplied when

OK is pressed and goes off

when Cancel is pressed.

[%d] is the value of the ADC.

Tray 2

IN/OUT

Tray 3

IN/OUT

Fuser Door Sensor

Closed/Opened

Dev Bias DC

ON/OFF

Dev Bias AC

ON/OFF

Charge Roll

ON/OFF

Transfer Roll (+)

[%d]

ON/OFF

Laser Scan

Unit

Transfer

Roll (-)

Pretransfer

Lamp

(PTL)

Laser

Diode_0

Laser

Diode_1

Negative Transfer Voltage

(-800V) is supplied when

OK is pressed and goes off

when Cancel is pressed.

Measure voltage with a

DMM, if required.

PTL turns on when OK is

pressed and goes off when

Cancel is pressed. Visual

confirmation is possible with

the cover open and the Print

Cartridge removed.

Laser Diode0 On is

displayed when the laser

diode is on. In the other

case Laser Diode0 Off is

displayed.

Laser Diode1 On is

displayed when the laser

diode is on. In the other

case Laser Diode0 Off is

displayed.

Transfer Roll (-)

ON/OFF

Pre-transfer Lamp

ON/OFF

Laser Diode0

ON/OFF

Laser Diode1

ON/OFF

Phaser® 3500 Laser Printer Service Manual

2-8

Page 24

Repair Analysis Procedures

Main Menu Sub Menu Description/Function Control Panel Display

L Motor

Ready

Fuser Fuser

Te m p.

Read OPC

Cycle

This tests if the laser unit is

ready and capable of

printing, or at a stable

polygon motor speed.

When the Target Temp is

displayed, INput the

temperature you would like

to set with the arrow buttons.

Press the OK button.

The target temperature and

the real temperature will be

displayed on the bottom line.

Default is T:190

Note: You can adjust the

temperature value while in

diagnostics, however, once

you exit the temperature will

return to the default.

The total rotating number of

the OPC drum is displayed

on the bottom line of the

control panel display when

the process is on.

Laser Ready Test

Pass/Fail

Target/Current

T: 190, C: XX

Total OPC-Cycle

XXXX

Phaser® 3500 Laser Printer Service Manual

2-9

Page 25

Repair Analysis Procedures

Troubleshooting Error Messages

Error Description Page

Jam At Tray [1|2|3] (JAM 0)

The leading edge of the paper doesn’t pass the registration sensor or the sensor does

not turn ON.

■ After paper pick, paper is not fed.

■ After paper pick, paper enters the printer but does not reach the registration sensor

in the specified time.

■ After paper pick, the registration sensor turns ON and tries to pick again but the

paper does not reach the registration senor in the specified time.

Jam At Top (JAM 1)

The paper is between the registration sensor and the exit sensor.

■ The leading edge of the paper passes the registration sensor but the trailing edge

does not pass through the registration sensor in the specified time. (The registration

sensor cannot be OFF).

■ The leading edge of the paper passes the registration sensor, but the paper cannot

reach the exit sensor in the specified time. (The exit sensor cannot be ON).

Jam At Exit (JAM 2)

■ The trailing edge of the paper passes the registration sensor, but the paper does not

pass the exit sensor in the specified time.

Jam at Rear (Duplex JAM 1)

■ The trailing edge of the paper passes the exit sensor, but does not reach the duplex

sensor in the specified amount of time.

page 2-11

page 2-11

page 2-12

page 2-12

Jam at Duplex (Duplex JAM 2)

■ The leading edge of the paper passes the duplex sensor, but the leading edge of the

paper does not reach the registration sensor in the specified time.

Check Cartridge, Invalid Print Cartridge, Non-Xerox Cartridge

■ A print cartridge is not detected.

■ A non-Xerox print cartridge is installed.

■ The toner sensor board is malfunctioning.

Close Fuser Door

■ The fuser door sensor or actuator is malfunctioning or damaged.

Close Top Cover.

■ Top cover is damaged

■ Sensor or actuator is damaged.

Fuser Failure, Engine Fuser Low Heat Error, Engine Overheat Error

■ Fuser is damaged or malfunctioning.

Laser Failure

■ The laser unit is malfunctioning or damaged.

Output Tray is Full

■ The outbin full sensor or actuator is malfunctioning or damaged.

page 2-14

page 2-14

page 2-14

page 2-15

page 2-15

page 2-15

page 2-16

Phaser® 3500 Laser Printer Service Manual

2-10

Page 26

Repair Analysis Procedures

Jam At Tray [1] [2] [3] (Jam 0)

Step Actions and Questions Yes No

1.

2.

3.

4.

5.

6.

1. Check the side guides for the

inoperative tray for damage or

improper seating.

2. Are guides damaged or loose?

1. Check the surface of the pick-up rollers

for dirt or damage.

2. Are the rollers dirty or damaged?

1. Do the Registration Rollers turn freely? Go to Step 4. Replace Registration

1. Is the Registration/Feed Sensor

Actuator damaged or binding?

1. Use service diagnostics to checkthe

operation of the tray solenoids.

2. Do the tray solenoids operate

correctly?

1. Use service diagnostics to check the

operation of the Regi Clutch and Feed

Clutch.

2. Do the clutches operate correctly?

Replace the Tray. Go to Step 2.

Clean rollers with a

soft cloth very

slightly dampened

with water or replace

if damaged.

Repair or replace the

actuator and/or

sensor.

Go to Step 6. Replace the

Go to Step 7. Replace the

Go to Step 3.

Assembly.

Go to Step 5.

inoperative solenoid.

defective clutch.

7.

1. If paper feeds into the printer and the

Jam error message appears, use

service diagnostics to check the feed

sensor operation.

2. Does the feed sensor operate

correctly?

Replace the Main

Board

Jam At Top (Jam 1)

Step Actions and Questions Yes No

1.

2.

1. Clean the paper path of any

obstructions, dirt or debris.

2. Did this correct the problem

1. Use service diagnostics to test the

operation of the Registration roller and

clutch.

2. Does the registration roller and clutch

operate correctly?

Complete. Go to Step 2.

Go to Step 3. Replace the

Replace the

defective sensor or

actuator.

Registration

Assembly.

Phaser® 3500 Laser Printer Service Manual

2-11

Page 27

Repair Analysis Procedures

Step Actions and Questions Yes No

3.

4.

1. Use service diagnostics to test the exit

sensor.

2. Does the sensor operate correctly?

1. Replace the Fuser Assembly and

retest.

2. Did this correct the problem?

Go to Step 4. Replace the exit

Complete. Replace the SMPS.

Jam At Exit (Jam 2)

Step Action and Questions Yes No

1.

2.

3.

4.

5.

1. Is the Exit Sensor Actuator damaged or

binding?

1. Inspect the Exit Roller Assembly.

2. Use service diagnostics to test the main

drive to exit.

3. Is the exit roller damaged or binding?

1. Visually inspect the Fuser.

2. Is there paper wrapped around the

Fuser rollers?

1. Is the Fuser Assembly operational.

2. Do the Fuser gears rotates when the

Main motor is on?

1. Use the embedded diagnostics to check

the Exit Sensor.

2. Is the sensor operational?

Repair or replace the

actuator and/or

sensor.

Replace the Exit

Roller Assembly.

Remove obstruction

and clean Fuser

rollers.

Go to Step 5. Replace the Fuser

Replace Main Board. Replace SMPS.

sensor.

Go to Step 2.

Go to Step 3.

Go to Step 4.

Assembly.

Jam At Rear (Duplex Jam 1)

Step Actions and Questions Yes No

1.

2.

3.

1. Does paper jam after reversal but

before reaching duplex sensor?

1. Replace Transport Roller Shaft

Assembly.

2. Does problem recur?

1. Use service diagnostics to check the

operation of the Duplex Sensor.

2. Does the sensor operate correctly?

Phaser® 3500 Laser Printer Service Manual

Go to Step 2. Go to Step 3.

Replace Duplex

Assembly.

Go to Step 4. Replace the Duplex

2-12

Complete

Sensor and/or

Actuator.

Page 28

Repair Analysis Procedures

Step Actions and Questions Yes No

4.

5.

6.

7.

8.

1. Inspect the Duplex Assembly. Is any

paper wrapped around the Duplex

rollers?

1. Use service diagnostics to check the

exit sensor.

2. Does the sensor operate correctly?

1. Inspect the exit and duplex roller

assemblies.

2. Are the rollers damaged or binding?

1. Inspect the duplex assembly for

damage.

1. Does the Feed Roller Assembly

operate properly without binding?

Remove obstruction

and clean rollers.

Go to Step 6. Replace the exit

Replace the exit or

duplex roller as

necessary.

Replace the duplex

assembly.

Replace Main Board. Replace the Feed

Go to Step 5.

sensor and/or

actuator.

Go to Step 7.

Go to Step 8.

Roller Assembly.

Phaser® 3500 Laser Printer Service Manual

2-13

Page 29

Repair Analysis Procedures

Jam At Duplex (Duplex Jam 2)

Step Actions and Questions Yes No

1.

2.

3.

4.

1. Does the paper jam after reversal but

before reaching the duplex sensor?

1. Use service diagnostics to test the

duplex sensor.

2. Does the sensor operate correctly?

1. Inspect the exit and duplex rollers for

any signs of damage or binding.

1. Replace the Duplex Assembly.

2. Does the problem still occur?

Replace the transport

roller shaft.

Go to Step 3. Replace the duplex

Replace the problem

roller.

Replace the Main

Board.

Go to Step 2.

sensor.

Go to Step 4.

Replace the Power

Supply Board.

Check Cartridge, Invalid Print Cartridge, Non-Xerox Cartridge, Replace Print Cartridge

Step Action and Questions Yes No

1.

1. Open the top cover and ensure that the

Print Cartridge is properly seated.

2. Does the error clear after reseating the

cartridge?

Complete Go to Step 2.

2.

3.

4.

1. Check the Print Cartridge for damage.

2. Does the cartridge contain toner and

appear to be operating properly?

1. Reseat all harness connections to the

Toner Sensor (CRUM) Board.

2. Does the error clear?

1. Check continuity between the Toner

Sensor (CRUM) Board and CN6 on the

Main Board.

2. Does the harness show continuity?

Go to Step 3. Replace Print

Complete Go to Step 4.

Replace the Toner

Sensor Board.

Close Fuser Door

Step Action and Questions Yes No

1.

1. Visually inspect the fuser door close tab

for damage.

2. Is the tab broken?

Replace the Fuser. Go to Step 2.

Cartridge.

Replace Harness.

Phaser® 3500 Laser Printer Service Manual

2-14

Page 30

Repair Analysis Procedures

Step Action and Questions Yes No

2.

1. Verify the sensor and actuator on the

Fuser is operating correctly.

Replace the Main

Board.

Replace the Fuser.

Replace the SMPS.

Close Top Cover

Step Action and Questions Yes No

1.

2.

1. Visually inspec the top cover and the

top cover actuator.

2. Is the top cover or actuator damaged?

1. Use diagnostics to test the cover open

sensor.

2. Does the sensor function properly?

Replace the Top

Cover.

Replace the Main

Board.

Go to Step 2.

Replace the Sensor.

Fuser Failure, Engine Fuser Low Heat Error, or Engine Fuser Over Heat Error

Step Action and Questions Yes No

1.

2.

3.

4.

1. Does the error report Fuser Failure? Go to Step 2. Go to Step 3.

1. Check the thermistor.

2. Is the circuit open?

1. Check the line voltages across the

thermostats.

2. Are they open?

1. Is the Fuser getting power? Replace the Fuser. Replace the SMPS.

Replace the Fuser. Replace the Main

Replace the Fuser. Go to Step 4.

Laser Failure

Step Actions and Questions Yes No

1.

1. Reseat the connections to the laser

and visually inspect the laser unit for

damage.

2. Did this correct the problem?

Complete Go to Step 2.

Board.

Replace the Main

Board.

Phaser® 3500 Laser Printer Service Manual

2-15

Page 31

Repair Analysis Procedures

Step Actions and Questions Yes No

2.

1. Use diagnostics to check the laser

motor function.

2. Did the laser motor fail?

Replace the Laser

Unit.

Output Tray Is Full

Step Actions and Questions Yes No

1.

2.

1. Check the Output Tray sensor and

actuator for obvious damage.

2. Is the actuator damaged?

1. Use diagnostics to test the output tray

sensor.

2. Does the sensor operate correctly?

Replace the actuator. Go to Step 2.

Replace the Main

Board.

Replace the Main

Board.

Replace the Output

Tray S e n s o r .

Phaser® 3500 Laser Printer Service Manual

2-16

Page 32

Repair Analysis Procedures

General Troubleshooting

The following procedures cover Control Panel and Start-up problems with the printer when no

specific error code or Control Panel message is displayed.

Control Panel Troubleshooting

No Control Panel Display after Power Is Turned ON

1. Verify that power cord is securely plugged into both the printer and the grounded, three

prong AC outlet with the appropriate power available.

2. Ensure that all covers are securely closed.

3. Verify the Top Cover, Print Cartridge, and Fuser interlocks are functional.

4. Verify voltages at the Main Board, see Power Supply Troubleshooting on page 2-18.

5. Replace the Power Supply Board.

6. Replace the Main Board.

7. Replace the Control Panel.

Control Panel LED is On, Control Panel Display Is Blank

1. Remove and reseat the Control Panel wiring to the Main Board.

2. Replace the Control Panel.

3. Replace the Main Board.

Phaser® 3500 Laser Printer Service Manual

2-17

Page 33

Repair Analysis Procedures

Power Supply Troubleshooting

1. Check the voltage at the AC wall outlet, there should be approximately 110 VAC (or 220

VAC if the printer is a 220 V model) at the AC wall outlet?

2. Check the power cord for defects, damage, or a loose connection.

3. Check the AC switch harness for continuity.

4. Verify the Power Supply is operating correctly.

Taking Voltage Measurements

To locate connectors or test points, refer to Wiring Data on page 7-1 for more information.

Unless otherwise specified, the following voltage tolerances are used within this section

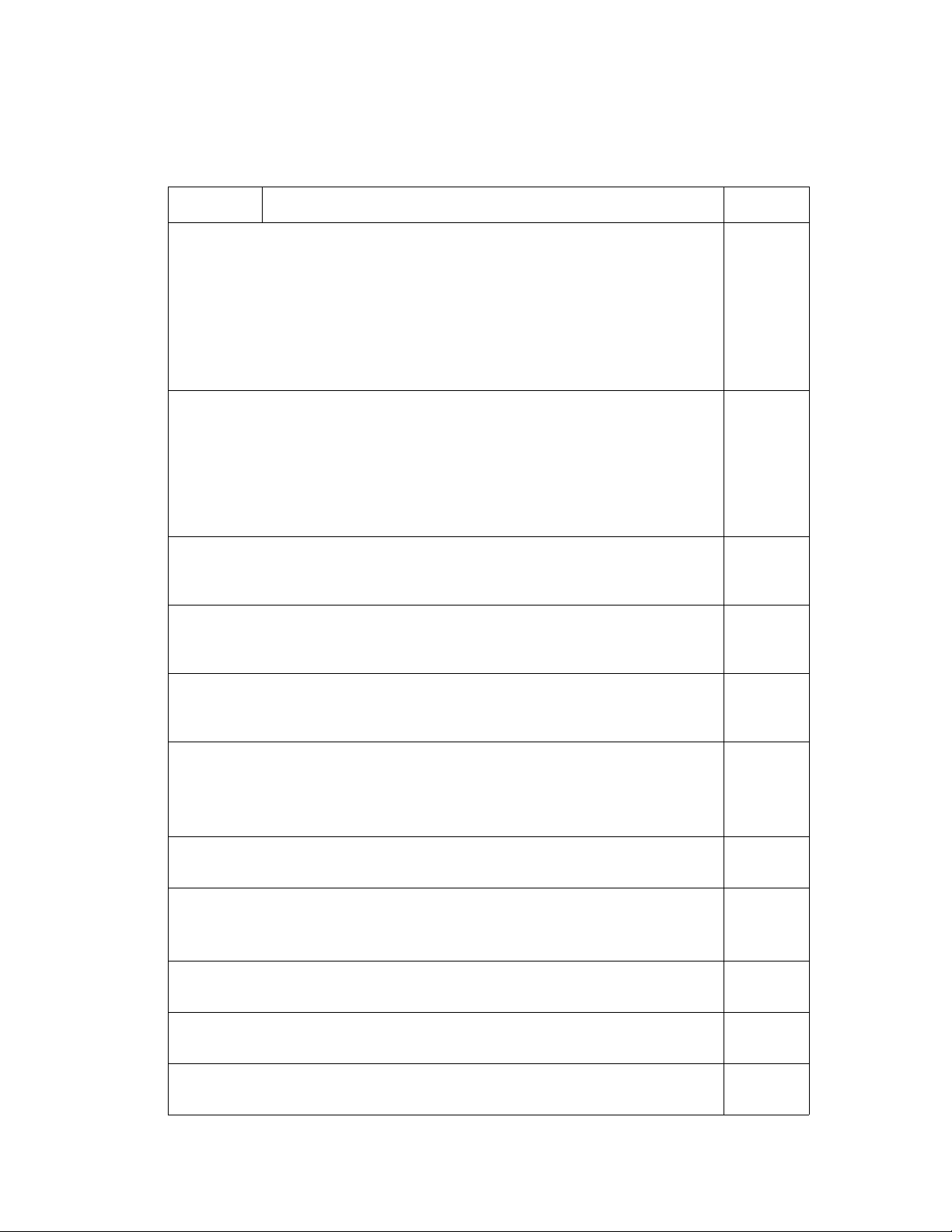

Stated Measured

+3.3 VDC +3.135 to +3.465 VDC

+5.0 VDC +4.75 to +5.25 VDC

+24.0 VDC +21.6 to +26.4 VDC

0.0 VDC Less than +0.5 VDC

Phaser® 3500 Laser Printer Service Manual

2-18

Page 34

Image-Quality

Troubleshooting

This section covers the following:

■ Image-Quality Problems Overview on page 3-2

■ Control Panel (Internal) Test Print on page 3-4

■ Image-Quality Troubleshooting on page 3-7

Phaser® 3500 Laser Printer Service Manual

3-1

Page 35

image-quality Troubleshooting

Image-Quality Problems Overview

Image-quality defects can be attributed to printer components, consumables, media, internal

software, external software applications, and environmental conditions. To successfully

troubleshoot image-quality problems, as many variables as possible must be eliminated.

The following guidelines should be used before troubleshooting an image-quality problem:

■ Use an unopened ream of approved media for evaluating image-quality problems

Note: See the approved media list, Media and Tray Specifications on page 6-9, for media

that has been tested and approved for use with the Phaser 3500 Laser Printer.

■ Generate the Control Panel (Internal) Test Print on page 3-4, and see if the image-

quality problem still exists

■ When analyzing a image-quality defect, first determine if the defect is repeating or

random. Repeating defects can often be associated with a particular component.

■ Inspect the surfaces of all rollers in the paper path for obvious defects.

Phaser® 3500 Laser Printer Service Manual

3-2

Page 36

image-quality Troubleshooting

Repeating Defects

Some image-quality problems can be associated with specific assemblies, the most common

problems and the associated assemblies are listed below. Also, see the specific image-quality

troubleshooting procedure for more information.

Print Cartridge

■ Streaks

■ Fine Lines

■ Banding in Process Direction

■ Uneven Density

■ Vo i d s

■ Repeating Defects

Transfer Roller

■ Toner on the back side of the printed page (simplex mode)

■ Light Prints

■ Repeating Defects

■ Spots on Image

Fuser

■ Hot or Cold Offsetting

■ Repeating Defects

■ Vo i d s

Repeating Defects Measurement Table

Distance between

Assembly Component

Print Cartridge Developer Roller 50 mm (1.97 in.) Horizontal image band

Drum 94 mm (3.70 in.) White spots on black image

Drum Charge Rollers 38 mm (1.50 in.) Black spots

Supply Roller 42 mm (1.65 in.) Light or dark horizontal

Transfer Roller Transfer Roller 56 mm (2.20 in.) Image ghost

Fuser Assembly Heat Roller 126 mm (4.96 in.) Black spots and image

Pressure Roller 126 mm (4.96 in.) Black spots on back

Defects Typical Defect

or black spots on white

image bands

ghost

Phaser® 3500 Laser Printer Service Manual

3-3

Page 37

image-quality Troubleshooting

Control Panel (Internal) Test Print

A test print is available to aid in determining the quality of output from the printer and to assist

in troubleshooting image-quality problems. Each area of the test print is used for a imagequality parameter. The following pages explain each of the areas and the image-quality

parameters. Follow these guidelines when generating the test print:

■ Use supported paper from a fresh, unopened ream

■ Print five copies of the test print.

■ Discard the first two prints and retain the remaining prints for image-quality analysis.

Deletions

Inspect the test print for the presence of deletions or unprinted spots. If these are found, see

Spot or Vertical Deletions on page 3-10.

Fusing

Rub the image three times at the indicated points with a soft cloth or tissue. The toner should

not lift off of the surface of the print. If the image smears or toner lifts off the image onto the

cloth, see Unfused Image on page 3-11.

s3500-039

Phaser® 3500 Laser Printer Service Manual

3-4

Page 38

image-quality Troubleshooting

Resolution

Observe the three resolution check points on several test prints.

■ Ensure that the 2 pixel horizontal, vertical, and diagonal lines are clear and

continuous. The diagonal lines might appear to be narrower than the others.

■ Characters in the text paragraphs should be uniform and equal in density.

■ The halftone patches should be uniform in appearance.

If the image does not meet the criteria, see Non-Uniform Image on page 3-9 or Character

Defects on page 3-10.

Registration and Skew

Fold the paper from two consecutive test prints in half (first side edge to side edge and then top

edge to bottom edge). Observe the fold lines with reference to the crosshairs of the printed

target. The fold line should be aligned perpendicular to the target crosshairs and should be

within ±2.0 mm of the target crosshairs (each line on the target is 1.0 mm). If the image does

not meet the criteria, see Skewed Image on page 3-11.

Phaser® 3500 Laser Printer Service Manual

3-5

Page 39

image-quality Troubleshooting

Skips or Smears

Check the test print in the indicated areas for loss, stretching, or distortion of the image in

bands across the process direction that make the image seem distorted, blurred, or compressed.

If these faults are observed, see Skips/Smears on page 3-11.

Phaser® 3500 Laser Printer Service Manual

3-6

Page 40

image-quality Troubleshooting

Image-Quality Troubleshooting

The following table provides examples and descriptions, possible causes, and the solutions for

troubleshooting various image or printing defects that may be observed in the Phaser 3500

Laser Printer.

Image Defect Possible Causes Solutions

No Image/Blank Prints

Prints have no visible image.

s3500-043

Light Prints

All areas of the print are light with

no ghosting.

■ Sealing tape or shipping

restraint was not removed

from the cartridge.

■ Low or no toner

■ Defective ground to the

Print Cartridge or OPC

Drum

■ Malfunctioning solenoid or

drive.

■ Main Board

■ Incorrect high-voltage

output from the Power

Supply Board.

■ Multiple sheet feeding

■ Unsupported Media (paper)

■ Seal tape or shipping

restraint was not removed

from the cartridge.

■ Incorrect Control Panel

settings

■ Low toner

■ Transfer Roller

■ Laser contamination or

obstruction

■ Incorrect high-voltage

output

■ Low ambient temperature

(<10º C)

1. Ensure that sealing tape and

shipping restraint have been

removed.

2. Verify Print Cartridge ground.

3. Verify continuity between the

cartridge ground and frame.

4. Ensure the feed solenoid is

functioning properly.

5. Replace in the following

order:

■ Print Cartridge

■ Main Board

■ Power Supply Board

■ Laser Assembly

1. Verify paper meets printer

specifications. Print 20 to

30 pages using the

recommended paper.

2. Verify image-quality menu is

not set to “draft.”

3. Ensure that the sealing tape

and the shipping restraint

have been removed.

4. Verify low toner warning is not

displayed on control panel.

Remove the Print Cartridge

and shake, reinstall or

replace.

5. Inspect the Transfer Roller for

contamination and verify highvoltage contacts. Replace as

required.

6. Inspect the Laser assembly

for any obstructions; clean the

laser exit window.

7. Replace the Power Supply

Board.

Phaser® 3500 Laser Printer Service Manual

3-7

Page 41

image-quality Troubleshooting

Image Defect Possible Causes Solutions

Black Prints

The prints are completely black,

has no visible image.

s3500-045

Dark Image

All areas of the print are too

dark.

Background Contamination

Uniform toner contamination in

non-image area.

s3500-046

■ No charge voltage

■ Power Supply Board

■ Print Cartridge

■ Main board

■ Laser is always ON

■ Incorrect Control Panel

settings

■ Print Cartridge

■ Incorrect high-voltage

outputs (Developer Bias

voltage)

■ Laser assembly

■ Media (paper)

■ Operating environment

■ Print Cartridge

■ Transfer Roller

■ Incorrect High Voltage

outputs

1. Verify the high-voltage

contacts are operational and

make good contact with the

print cartridge.

2. Replace in the following

order:

■ Print Cartridge

■ Power Supply Board

■ Main Board

■ Laser Assembly

1. Verify Remote Control Panel

setting for the Print Density

menu is not set to "dark.”

2. Verify that the high-voltage

contacts are operational and

make good contact with the

print cartridge.

3. Replace the following in

order:

■ Print Cartridge

■ Power Supply Board

■ Laser assembly

1. Verify that paper meets

printer specifications. Print 20

to 30 pages using

recommended paper. If using

recycled paper, try nonrecycled paper.

2. Printer is installed in specified

environment.

3. Replace Print Cartridge.

4. Inspect Transfer Roller for

contamination and good

electrical contact, replace if

required.

5. Clean the Pre-transfer Lamp.

6. Replace Power Supply Board.

Phaser® 3500 Laser Printer Service Manual

3-8

Page 42

image-quality Troubleshooting

8

Image Defect Possible Causes Solutions

Ghosting

Image from the previous page

prints on consecutive pages.

.

s3500-047

Non-Uniform Image

The Line darkness and solidarea density image vary across

the print.

.

s3500-04

■ Operating environment

■ Media (paper)

■ Print Cartridge

■ Transfer Roller

■ Fuser assembly

■ Incorrect high-voltage

outputs.

■ Print Cartridge

■ Print Cartridge grounding

■ Unstable high voltage

output

■ Transfer Roller

contamination

■ Laser Window or optic

contamination

1. Printer is installed in specified

environment?

2. Verify that paper meets

printer specifications. Print 20

to 30 pages using

recommended paper.

3. Determine ghosting pitch and

replace the corresponding

assembly.

NOTE: See Repeating

Defects on page 3-3 for defect

pitch.

4. Replace Power Supply Board.

1. Ensure that Cartridge is not

out of toner. Inspect Drum for

deterioration or

contamination.

2. If defective, replace the Print

Cartridge.

3. Verify Print Cartridge ground.

Check continuity between

cartridge ground contact and

frame ground. Ensure that

drum contact is clean and

undamaged.

4. Inspect the Transfer Roller

spring tension and bearing

contacts.

5. Remove Laser assembly,

clean window, or replace

assembly as necessary.

6. Replace Power Supply Board.

Phaser® 3500 Laser Printer Service Manual

3-9

Page 43

image-quality Troubleshooting

2

Image Defect Possible Causes Solutions

Black Spots/Marks

There are spots and/or marks of

toner on the printed side of the

page.

s3500-051

Spot or Vertical Deletions

Solid areas are marked with

irregular white spots.

.

■ Print Cartridge

■ Fuser Assembly

■ Paper transports

■ Transfer Roller

■ Damp paper

■ Foreign matter

contamination of printer

components

■ Print Cartridge

■ Transfer Roller

1. Replace the Print Cartridge.

NOTE: See Repeating

Defects on page 3-3 for defect

pitch.

2. Inspect /clean/replace Fuser

Assembly as necessary.

3. Clean contamination from

paper transports and exit

rollers.

4. Clean or replace the Transfer

Roller.

1. Replace paper.

2. Check printer components for

surface contamination or

paper scraps. Clean as

required.

3. If deletions repeat every 94

mm, replace Print Cartridge.

s3500-05

Horizontal Bands

Dark bands appearing in the

horizontal direction.