Page 1

Phaser® 3320 and WorkCentre® 3315/3325

Service Manual

Product Photo

Phaser® 3320 and

®

WorkCentre

3315/3325

Service Manual

Xerox Internal-Use Only

Page 2

Phaser 3320

WorkCentre 3315/3325

Service Manual

WARNING: The following servicing instructions are for use by qualified service

personnel only. To avoid personal injury, do not perform any servicing other than

that contained in the operating instructions, unless you are qualified to do so.

First Printing: June 2012 Xerox Internal Use Only

Page 3

Prepared By:

Xerox Corporation

Content Development and Language Services

26600 SW Parkway

Wilsonville, OR 97070

© 2012 by Xerox Corporation. All rights reserved. XEROX® and XEROX and Design®, Phaser®, CentreWare®, PrintingScout®, Walk-Up®,

WorkCentre®, FreeFlow®, SMARTsend®, Scan to PC Desktop®, ColorQube, Global Print Driver®, and Mobile Express Driver are trademarks of

Xerox Corporation in the United States and/or other countries

Unpublished rights reserved under the copyright laws of the United States. Contents of this publication may not be reproduced in any form

without permission of Xerox Corporation.

Copyright protection claimed includes all forms and matters of copyrightable materials and information now allowed by statutory or judicial

law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen

such as styles, templates, icons, screen displays, looks, etc.

Xerox technical training materials and service manuals are intended for use by authorized Xerox service technicians and service partners only

and are not for resale. These materials may not be distributed, copied, or otherwise reproduced without prior written consent from Xerox

Corporation.

Adobe Reader®, Adobe Type Manager®, ATM™, and PostScript® are trademarks of Adobe Systems Incorporated in the United States and/or

other countries.

Apple®, AppleTalk®, Bonjour®, EtherTalk®, LaserWriter®, LocalTalk®, Macintosh®, Mac OS®, and TrueType® are trademarks of Apple

Computer, Inc. in the United States and/or other countries.

HP-GL®, HP-UX®, and PCL® are trademarks of Hewlett-Packard Corporation in the United States and/or other countries.

Windows®, Vista™, and Windows Server™ are trademarks of Microsoft Corporation in the United States and/or other countries.

Novell®, NetWare®, NDPS®, NDS®, Novell Directory Services®, IPX™, and Novell Distributed Print Services™ are trademarks of Novell,

Incorporated in the United States and/or other countries.

SM

Sun

, Sun Microsystems™, and Solaris™ are trademarks of Sun Microsystems, Incorporated in the United States and/or other countries.

SWOP® is a trademark of SWOP, Inc.

UNIX® is a registered trademark in the US and other countries, licensed exclusively through X/Open Company Limited.

As an ENERGY STAR® partner, Xerox Corporation has determined that this product meets the ENERGY STAR guidelines for energy efficiency.

The ENERGY STAR name and logo are registered U.S. marks.

PANTONE® Colors generated may not match PANTONE-identified standards. Consult current PANTONE Publications for accurate color.

PANTONE® and other Pantone, Inc. trademarks are the property of Pantone, Inc. © Pantone, Inc., 2000.

Page 4

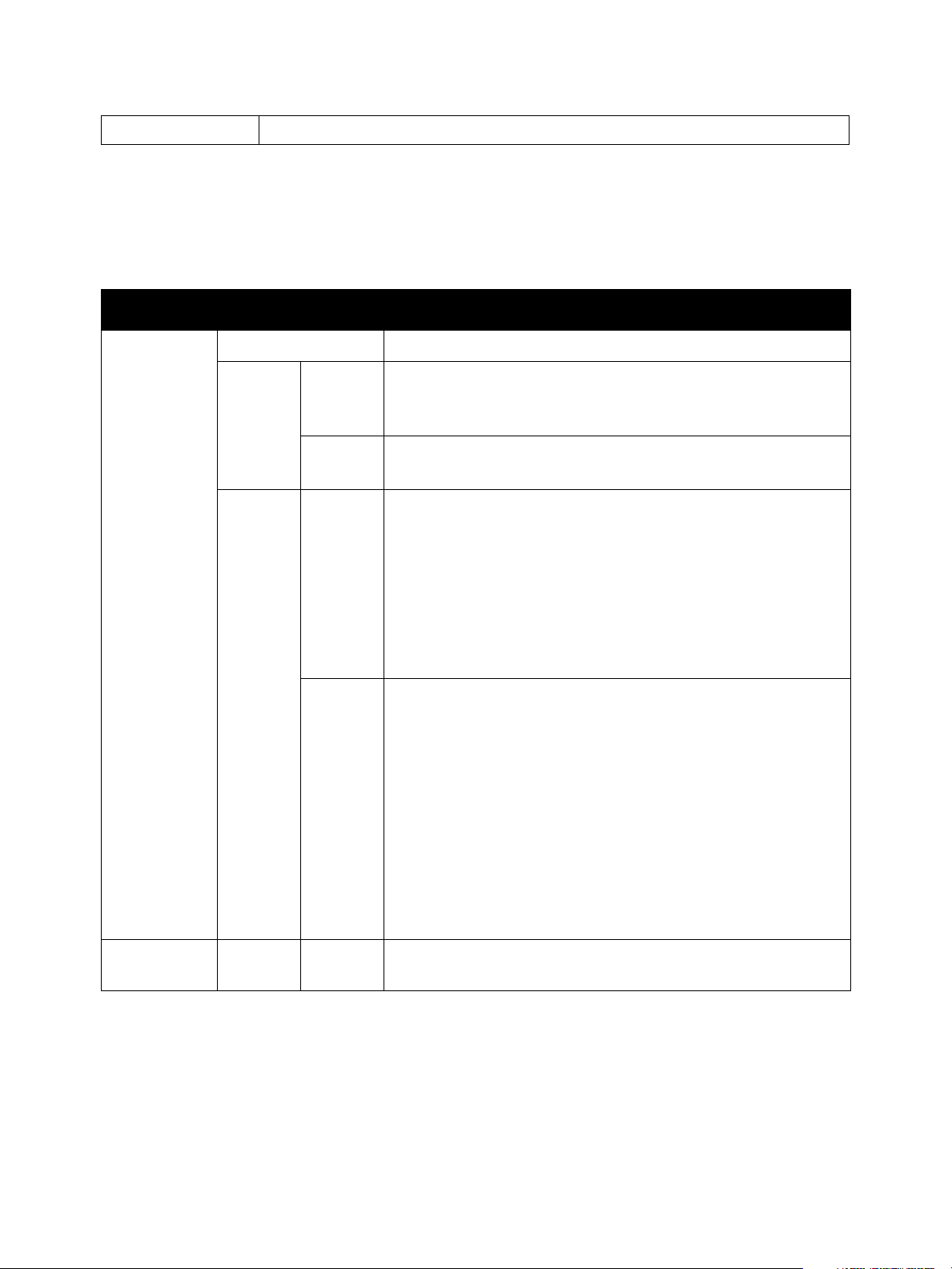

Contents

1 General Information

About this Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Power Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Health and Safety Incident Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Printer Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Introduction and Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Technical Support Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Parts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Phaser 3320 Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Phaser 3320 Rear and Side Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

WorkCentre 3315/3320 Front Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

WorkCentre 3315/3320 Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Phaser 3320DN/I Control Panel Button Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

WorkCentre 3315DN Control Panel Button Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

WorkCentre 3325DN/DNI Control Panel Button Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Understanding the Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Media Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Pick Up / Retard Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Registration Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Bypass Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

Print Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

Print Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

Laser Scanning Unit (LSU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

Maintenance Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

iii

Page 5

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

Paper Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-35

Scanning Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-36

Copy Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-37

Fax Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-38

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-39

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-40

Physical Dimensions and Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-41

Mounting Surface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

2 Error Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Monitoring Supplies Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Display Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Printing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Copy/Scan Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

ADF Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Fax Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Media-Based Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Servicing Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Phaser 3320 Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Entering Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Phaser 3320 Service Mode Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Service Mode Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

WorkCentre 3315/3325 Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Entering Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

WorkCentre 3315/3325 Service Mode Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Error Messages and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Troubleshooting Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Tray and Media Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Print Cartridge Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Fuser Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

Motor Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

Laser Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

Fax Communication and Configuration Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

Network Configuration Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

Scan to Email Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

Scanner Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

Other Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

Multi Sheet Picks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

iv

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 6

3 Image Quality

Image Quality Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Defects Associated with Specific Printer Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Print-Quality Defect Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Vertical Blank Line or Band. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Vertical White Lines or Bands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Horizontal Black Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Black or White Spots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Light or Undertone Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Black Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Uneven Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Background Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Ghosting or Residual Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Stains on Printed Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Stains on Back of Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Blank Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Toner Smears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Unfused Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

ADF/DADF Lines or Streaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Spots from ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Printing the Test Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Image Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Guaranteed Print Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Contents

4 Service Parts Disassembly

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Standard Orientation of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Notations in the Disassembly Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Fastener Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Print Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Phaser 3320 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Rear Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

v

Page 7

Contents

WorkCentre 3315/3325 Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Rear Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Middle Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Base Plate Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Tray 1 Retard Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Bypass Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Bypass Tray Retard Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Bypass Tray Pick Up Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Feed Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Feed Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

Pick Up, Registration, and Bypass Tray Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

20 Feed Gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

44-29 Feed Gear/19 Idle Gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Pick Up Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Xerographics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

Transfer Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

Laser Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Thermistor Assembly 43

Rear Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Exit Roller Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Exit Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

Main Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Main Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Main Drive Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

RDCN 23/23 Gear and DR 19 Swing Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Wireless Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

Control Panel Board (Phaser 3320) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

Control Panel Assembly and Board (WorkCentre 3315/3325). . . . . . . . . . . . . . . . . . . . . . . . . .4-59

LCD (WorkCentre 3325). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-61

LVPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

HVPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

Fax Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

Modem Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-65

DADF Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-66

ADF Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

Upper and Lower CRUM Holders and CRUM Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

Middle Cover Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

LVPS Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-73

Exhaust Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-75

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-76

vi

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 8

Contents

Sensors and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

Out-bin Full Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

Registration Sensor and Feed Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

Feed Actuator Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-80

Paper Empty Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-81

Exit Sensor and Exit Sensor Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

Coupler Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-85

WorkCentre 3315/3325 Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

Scanner Assembly (WorkCentre 3315/3325) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

Upper Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-88

Lower Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-88

A4 Middle Platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-89

A4 Middle Platen Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-89

Scanner Contact Image Sensor (WorkCentre 3315/3325) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-91

Scanner Scan Motor (WorkCentre 3315/3325) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-93

Home Position Sensor (WorkCentre 3315/3325) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-94

Timing Gear Belt (WorkCentre 3315/3325). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-95

WorkCentre 3325 DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-97

DADF Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-97

DADF Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-98

DADF Pick Up Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-99

DADF Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

DADF Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

DADF White Bar Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

DADF Registration Sensor, DADF Feed Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-109

DADF Feed Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114

DADF Lifting Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

DADF Separator Pad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-123

WorkCentre 3315 ADF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-124

ADF Assembly (WorkCentre 3315). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-124

ADF Pick Up Assembly (WorkCentre 3315) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-126

ADF Paper Path Assembly (WorkCentre 3315) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-127

White Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-128

ADF Drive (WorkCentre 3315) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-129

ADF Input Tray (WorkCentre 3315). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-130

ADF Front/Rear Cover (WorkCentre 3315). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-131

Optional Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-133

Optional Tray Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-133

Optional Tray Left Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-134

Optional Tray Right Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-135

Optional Tray Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-136

Optional Tray Dummy Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-136

Optional Tray Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-137

Optional Tray Registration/Feed Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-139

Optional Tray Feeder Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-142

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

vii

Page 9

Contents

5Parts Lists

Serial Number Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Using the Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Parts List 1.0 Phaser 3320 Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Parts List 1.1 Phaser 3320 Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Parts List 1.2 Phaser 3320 Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Parts List 1.3 Phaser 3320 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Parts List 1.4 WorkCentre 3315/3325 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Parts List 1.5 WorkCentre 3315/3325 Middle Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Parts List 2.1 Phaser 3320 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Parts List 3.1 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Parts List 3.2 Bypass Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Parts List 3.3 Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Parts List 3.4 Rear Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Parts List 3.5 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

Parts List 3.6 Feed Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Parts List 4.1 Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Parts List 5.1 Tray 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Parts List 6.1 WorkCentre 3315/3325 Main. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

Parts List 7.1 WorkCentre 3315 ADF (1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Parts List 7.1 WorkCentre 3315 ADF (2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

Parts List 8.1 WorkCentre 3325 DADF Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Parts List 8.2 WorkCentre 3325 Lower DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

Parts List 8.3 WorkCentre 3325 Upper DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-48

Parts List 8.4 WorkCentre 3325 Platen DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

Parts List 9.1 WorkCentre 3315 Scanner and ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Parts List 9.2 WorkCentre 3315 Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

Parts List 10.1 WorkCentre 3325 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

Parts List 10.2 WorkCentre 3325 Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-58

Parts List 11.1 WorkCentre 3315/3325 Middle Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-60

Parts List 12.1 Optional Cassette Tray 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-62

Xerox Supplies and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Consumables and Maintenance Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

6 Maintenance

Service Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Recommended Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Cleaning the Laser Unit Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Cleaning the Feed Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Cleaning the Platen and Document Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Cleaning the Interior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Moving the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Adjusting Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

viii

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 10

Firmware Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Remote Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Local Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

7 Wiring

Printer Plug/Jack Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Phaser 3320 Plug/Jack Designators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Phaser 3320 Plug/Jack Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

WorkCentre 3315/3325 Plug/Jack Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Notations Used in the Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Phaser 3320 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Phaser 3320 System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Phaser 3320 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

Phaser 3320 HVPS, LVPS, Laser, and Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Phaser 3320 Sensors and Wireless Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Phaser 3320 Control Panel and Optional Tray Feeder Board . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

WorkCentre 3315 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

WorkCentre 3315 System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

WorkCentre 3315 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26

WorkCentre 3315 HVPS, LVPS, Laser Unit, and Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27

WorkCentre 3315 Control Panel and Optional Tray Feeder Board . . . . . . . . . . . . . . . . . . . . . .7-28

WorkCentre 3315 Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

WorkCentre 3315 Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-30

WorkCentre 3325 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-31

WorkCentre 3325 System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-31

WorkCentre 3325 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

WorkCentre 3325 HVPS, LVPS, Laser Unit, and Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-33

WorkCentre 3325 Control Panel and Optional Tray Feeder Board . . . . . . . . . . . . . . . . . . . . . .7-34

WorkCentre 3325 Modem Board and CIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35

WorkCentre 3325 Scanner and DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-36

WorkCentre 3325 DADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-37

Contents

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

ix

Page 11

General Information

This chapter includes...

• About this Service Manual

• Manual Organization

• Safety

• Introduction and Overview

• Configurations

• Parts of the Printer

• Control Panel

• Media Path

• Feeder

• Print Process

• Drive

• Electrical

• Maintenance Items

• Consumables

• Specifications

1

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-1

Page 12

General Information

About this Service Manual

The Phaser 3320 and WorkCentre 3315/3325 Service Manual is the primary document used for

repairing, maintaining, and troubleshooting the printer. Use this manual as your primary resource for

understanding the operational characteristics of the printer and all available options. This manual

describes specifications and the diagnosis and repair of problems occurring in the printer and attached

options. Also included are detailed replacement procedures, parts lists, and wiring diagrams.

Manual Terms

Various terms are used throughout this manual to either provide additional information on a specific

topic or to warn of possible danger present during a procedure or action. Be aware of all symbols and

terms when they are used, and always read Note, Caution, and Warning statements.

WARNING: A warning indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, results in injury or loss of life.

CAUTION: A caution indicates an operating or maintenance procedure, practice or condition that,

if not strictly observed, results in damage to, or destruction of, equipment.

Replacement Note: A replacement note provides important information related to parts

replacement. When needed, replacement notes appear at the end of the disassembly procedure.

Note: A note indicates an operating or maintenance procedure, practice or condition that is

necessary to efficiently accomplish a task. A note can provide additional information related to a

specific subject or add a comment on the results achieved through a previous action.

1-2

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 13

General Information

Manual Organization

The Phaser 3320 and WorkCentre 3315/3325 Service Manual contains these sections:

Introductory, Safety, and Regulatory Information

This chapter contains important safety information and regulatory requirements.

Chapter 1 - General Information

This chapter describes the printer’s operation, configuration, specifications, and consumables.

Chapter 2 - Error Troubleshooting

This chapter provides detailed troubleshooting procedures for error messages and codes displayed

on the Control Panel. Troubleshooting covers the operation of Service Diagnostics. In addition, this

section includes troubleshooting methods for situations where an error indicator is not available.

Chapter 3 - Image Quality

This chapter focuses on techniques to correct image quality problems in printer output.

Chapter 4 - Service Parts Disassembly

This chapter contains removal procedures for spare parts listed in the Parts List. A replacement

procedure is included when necessary.

Chapter 5 - Parts List

This chapter contains exploded views of the print engine and optional Field Replaceable Units

(FRUs), as well as part numbers for orderable parts.

Chapter 6 - Maintenance

This chapter provides periodic cleaning procedures for the printer. This section also provides

procedures for the adjustment of print engine components.

Chapter 7 - Wiring

This chapter contains printer plug/jack locations and wiring diagrams.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-3

Page 14

General Information

Safety

Power Safety Precautions

Power Source

For 115 VAC printers, do not apply more than 127 volts RMS between the supply conductors or

between either supply conductor and ground. For 230 VAC printers, do not apply more than 254 volts

RMS between the supply conductors or between either supply conductor and ground. Use only the

specified power cord and connector. This manual assumes that the reader is a qualified service

technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet only. If necessary,

contact a licensed electrician to install a properly grounded outlet. If the product loses its ground

connection, contact with conductive parts may cause an electrical shock. A protective ground

connection by way of the grounding conductor in the power cord is essential for safe operation.

Disconnecting Power

WARNING: Turning the power Off using the power switch does not completely de-energize the

printer. You must also disconnect the Power Cord from the printer’s Alternating Current (AC) inlet.

Disconnect the Power Cord by pulling the plug, not the cord.

Disconnect the Power Cord in the following cases:

• if the power cord or plug is frayed or otherwise damaged,

• if any liquid or foreign material is spilled into the product,

• if the printer is exposed to any excess moisture,

• if the printer is dropped or damaged,

• if you suspect that the product needs cleaning, servicing or repair,

Electrostatic Discharge (ESD) Precautions

Some semiconductor components, and the respective sub-assemblies that contain them, are

vulnerable to damage by Electrostatic Discharge (ESD). These components include Integrated Circuits

(ICs), Large-Scale Integrated circuits (LSIs), field-effect transistors, and other semiconductor chip

components. The following techniques will reduce the occurrence of component damage caused by

static electricity.

Be sure the power is Off and observe these other safety precautions.

• Immediately before handling any semiconductor component assemblies, drain the electrostatic

charge from your body. This can be accomplished by touching an earth ground source or by

wearing a wrist strap device connected to an earth ground source. Wearing a wrist strap will also

prevent accumulation of additional bodily static charges. Be sure to remove the wrist strap before

applying power to the unit under test to avoid potential shock.

1-4

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 15

General Information

• After removing a static sensitive assembly from its anti-static bag, place it on a grounded

conductive surface. If the anti-static bag is conductive, you may ground the bag and use it as a

conductive surface.

• Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage

some devices.

• Do not remove a replacement component or electrical sub-assembly from its protective package

until you are ready to install it.

• Immediately before removing the protective material from the leads of a replacement device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

• Minimize body motions when handling and unpacked replacement devices. Motion such as your

clothes brushing together, or lifting a foot from a carpeted floor can generate enough static

electricity to damage an electro-statically sensitive device.

• Handle ICs and Erasable Programmable Read-Only Memories (EPROM’s) carefully to avoid

bending pins.

• Pay attention to the direction of parts when mounting or inserting them on circuit boards.

Service Safety Summary

General Guidelines

For qualified service personnel only:

Refer also to the preceding Power Safety Precautions on page 1-4.

Avoid servicing alone:

Do not perform internal service or adjustment of this product unless another person capable of

rendering first aid or resuscitation is present.

Use care when servicing with power:

Dangerous voltages may exist at several points in this product. To avoid personal injury, do not

touch exposed connections and components while power is On. Disconnect power before

removing the power supply shield or replacing components.

Do not wear jewelry:

Remove jewelry prior to servicing. Rings, necklaces and other metallic objects could come into

contact with dangerous voltages and currents.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are displayed on

potentially dangerous components. As you service the printer, check to make certain that all warning

labels remain in place.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-5

Page 16

General Information

Safety Interlocks

Make sure all covers are in place and all Interlock Switches are functioning correctly after you have

completed a printer service call. If you bypass an Interlock Switch during a service call, use extreme

caution when working on or around the printer.

Servicing Electrical Components

Before starting any service procedure, switch the printer power Off and unplug the power cord from the

wall outlet. If you must service the printer with power applied, be aware of the potential for electrical

shock.

WARNING: Do not touch any electrical component unless you are instructed to do so by a service

procedure

.

Servicing Mechanical Components

When servicing mechanical components within the printer, manually rotate the Drive Assemblies,

Rollers, and Gears.

WARNING: Do not try to manually rotate or manually stop the drive assemblies while any motor

is running.

Servicing Fuser Components

WARNING: This printer uses heat to fuse the image to the media. During operating, the Fuser is

very hot. Allow the Fuser to cool before you attempt to service the Fuser or adjacent components.

1-6

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 17

General Information

Health and Safety Incident Reporting

This section defines requirements for notification of health and safety incidents involving Xerox

products (equipment and materials) at customer locations worldwide. These requirements apply to

Xerox Corporation and its subsidiaries worldwide.

Objective

To enable prompt resolution of health and safety incidents involving Xerox products and to ensure

Xerox regulatory compliance.

Definitions

Incident:

An event or condition occurring in a customer account that has resulted in injury, illness or

property damage. Examples of incidents include machine fires, smoke generation, physical injury

to an operator or service representative. Alleged events and product conditions are included in this

definition.

Requirements

Initial Report:

1. Xerox organizations have established a process for individuals to report product incidents to Xerox

Environment Health & Safety within 24 hours of becoming aware of the event.

2. The information to be provided at the time of reporting is outlined in the Health and Safety

Incident Report form.

The Health and Safety Incident Report form used to report incidents involving Xerox products is

available on Xerox Global Service Net at https://www.xrxgsn.com/secure/main.pl?CatId=1789. If

you are unable to download the form, request a form when reporting the incident by phone,

electronic mail or Fax.

3. The initial notification may be made by any of the methods that follow:

– For incidents in North America and Developing Markets West (Brazil, Mexico, Latin American

North and Latin American South):

• Phone* Xerox EH&S at: +1-800-828-6571.

• Electronic mail Xerox EH&S at: usa.xerox.ehs@xerox.com.

• Fax Xerox EH&S at: +1-585-216-8817 [intelnet 8-219-8817].

– For incidents in Europe and Developing Markets East (Middle East, Africa, India, China and

Hong Kong):

• Phone* Xerox EH&S at: +44 (0) 1707 353434.

• Electronic mail Xerox EH&S at: ehs-europe@xerox.com.

• Fax Xerox EH&S at: +44 (0) 1707 353914 [intelnet 8 668 3914].

Note: Initial notification made by phone must be followed within 24 hours by a completed Health

and Safety Incident Report form sent to the indicated electronic mail address or fax number. If

sending a fax, please also send the original form by internal mail.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-7

Page 18

General Information

Responsibilities for resolution:

1. Business Groups / Product Design Teams responsible for the product involved in the incident shall:

a. Manage field bulletins, customer correspondence, product recalls, safety retrofits.

b. Fund all field retrofits.

2. Field Service Operations shall:

a. Preserve the Xerox product involved and the scene of the incident inclusive of any associated

equipment located in the vicinity of the incident.

b. Return any affected equipment/part(s) to the location designated by Xerox EH&S and/or the

Business Division.

c. Implement all safety retrofits.

3. Xerox EH&S shall:

a. Manage and report all incident investigation activities.

b. Review and approve proposed product corrective actions and retrofits, if necessary.

c. Manage all communications and correspondence with government agencies.

d. Define actions to correct confirmed incidents.

1-8

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 19

Printer Symbols

Symbol Description

Warning or Caution:

Ignoring this warning could cause serious injury or even death.

Ignoring this caution could cause injury or damage to the property.

Hot surface on or in the printer. Use caution to avoid personal injury.

Caution: Electrostatic sensitive devices

Verify that you are properly grounded before making contact with the printer.

Ignoring this caution could cause damage to the property.

Do not touch components with this symbol as personal injury could result.

General Information

Do not burn the item.

It may take 40 minutes for the fuser to cool down.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-9

Page 20

General Information

Regulatory

Xerox has tested this product to electromagnetic emission and immunity standards. These standards

are designed to mitigate interference caused or received by this product in a typical office

environment.

European Union

The CE mark applied to this product symbolizes Xerox’s declaration of conformity with the following

applicable Directives of the European Union as of the dates indicated:

December 12, 2006: Low Voltage Directive 2006/95/EC

December 15, 2004: Electromagnetic Compatibility Directive 2004/108/EC

March 9, 1999: Electromagnetic Compatibility Directive 99/5/EC

This product, if used properly in accordance with the user's instructions, is neither dangerous for the

consumer nor for the environment.

To ensure compliance with European Union regulations, use shielded interface cables.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

1-10

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 21

General Information

Introduction and Overview

The Phaser 3320 and WorkCentre 3315/3325 use a single-pass laser design, offering mono print

speeds of 33 to 37 ppm, and resolutions up to 1200 x 1200 dots-per-inch (dpi).

The Tray 1 is a 250-sheet multi purpose tray. The Bypass Tray is a 50 sheet tray that supports specialty

media, card stock, and envelopes. The Output Tray holds 150 sheets facedown.

The WorkCentre 3315/3325 combines a 1200 dpi scanner with the laser printer to provide copy, scan,

and print functions. Both models have a G3 Fax modem, Ethernet interface, and wireless capability to

provide networked copy, scan, and Fax functions.The WorkCentre 3315 model has an Automatic

Document Feeder (ADF), and the WorkCentre 3325 has a Duplex Automatic Document Feeder (DADF).

Technical Support Information

The Xerox Service Manual is the primary document used for repairing, maintaining, and

troubleshooting the printer. To ensure complete understanding of this product, participation in Xerox

Service Training is strongly recommended. To service this product, certification for this product is

required.

For updates to the Service Manual, Service Bulletins, knowledge base, etc., go to:

• Xerox Global Service Net - https://www.xrxgsn.com/secure/main.p

For further technical support, contact your assigned Xerox Technical Support for this product.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-11

Page 22

General Information

Parts of the Printer

Phaser 3320 Front View

1

2

8

3

7

4

6

5

9

11

No. Description No. Description

1. Output Tray 7. Tray 1

10

s3320-036

2. Control Panel 8. Bypass Tray

3. Control Board Cover 9. Bypass Tray Paper Extension

4. Front Cover 10. Bypass Tray Paper Width Guides

5. Paper Level Indicator 11. Output Support

6. Optional Tray 2

1-12

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 23

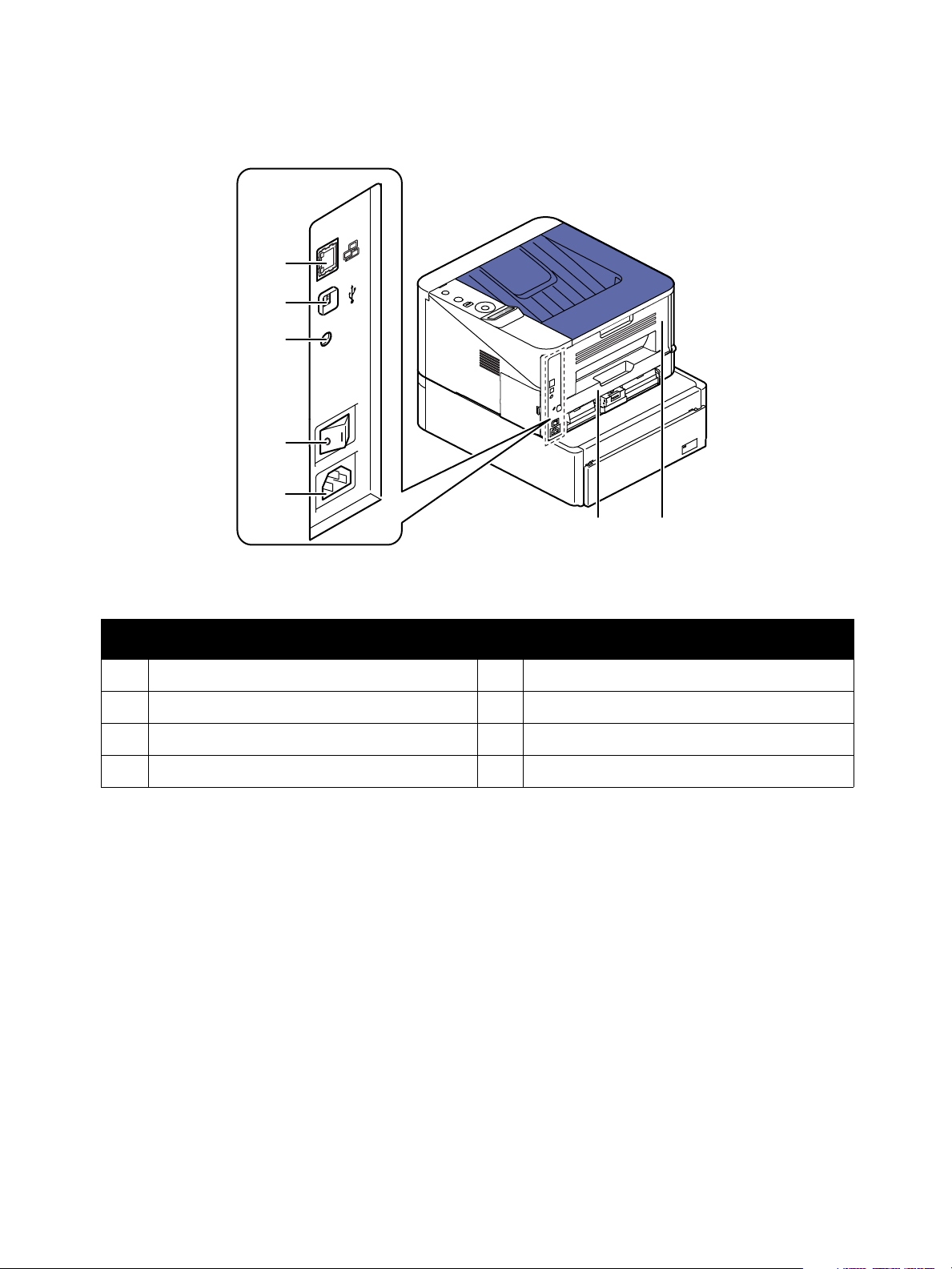

Phaser 3320 Rear and Side Views

1

2

3

4

5

General Information

6

No. Description No. Description

1. Network Port 5. Power Receptacle

2. USB Port 6. Duplex Unit

3. 5V Output 7. Rear Door

4. Power Switch

7

s3320-037

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-13

Page 24

General Information

14

15

16

s3320-038

16

13

12

11

8

10

9

1

4

2

5

3

7

6

18

19

17

14

15

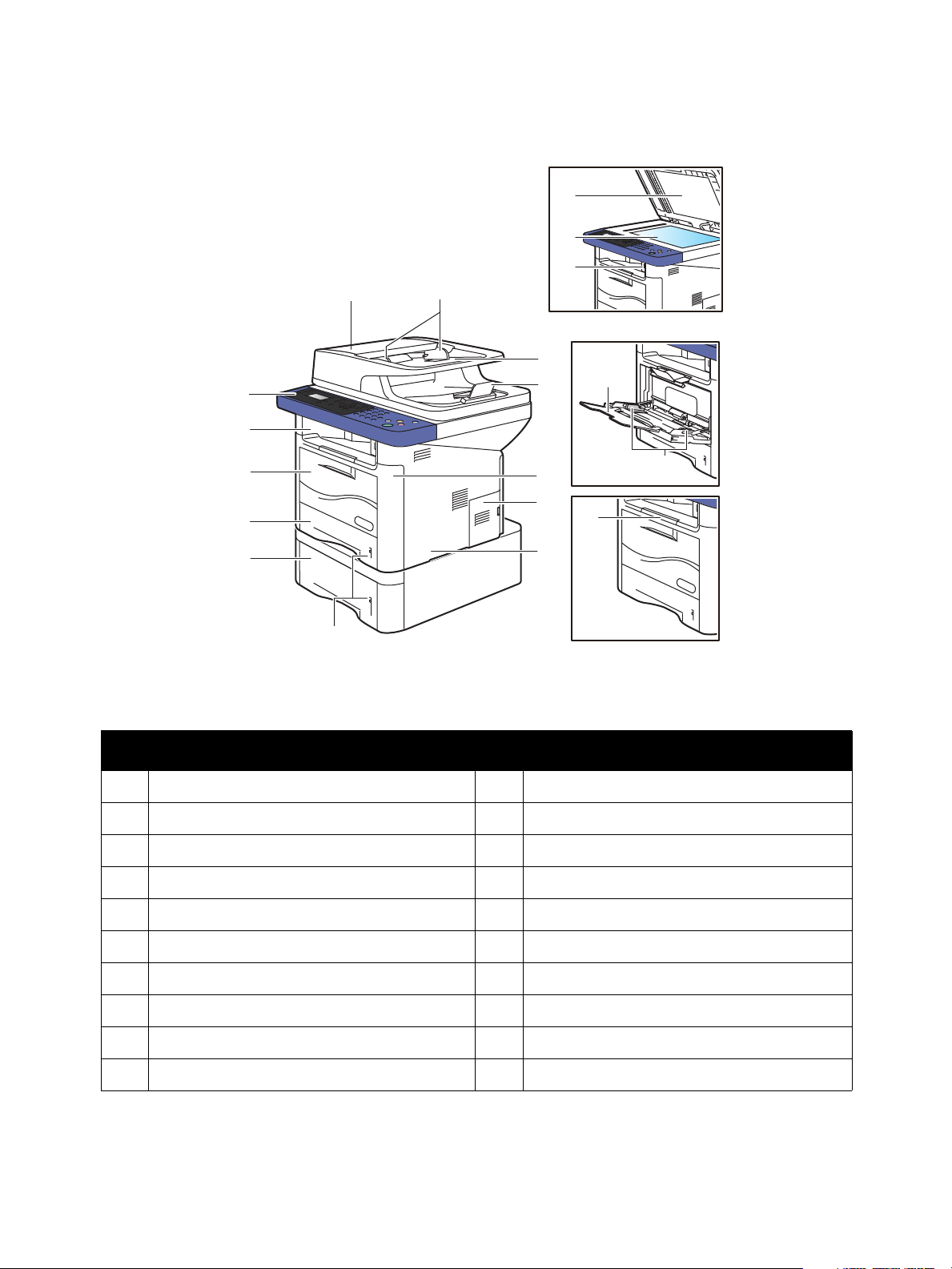

WorkCentre 3315/3320 Front Views

No. Description No. Description

1. Document Feeder Cover 11. Bypass Tray

2. Document Feeder Width Guide 12. Output Tray

3. Document Feeder Input Tray 13. Control Panel

4. Document Feeder Output Tray 14. Bypass Tray Extension

5. Front Cover 15. Bypass Tray Paper Width Guides

6. Control Board Cover 16. Output Tray Extension

7. Right Side Cover 17. Scanner Cover

8. Paper Level Indicators 18. Platen

9. Tray 2 (optional) 19. USB Thumbdrive Connector

10. Tray 1

1-14

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 25

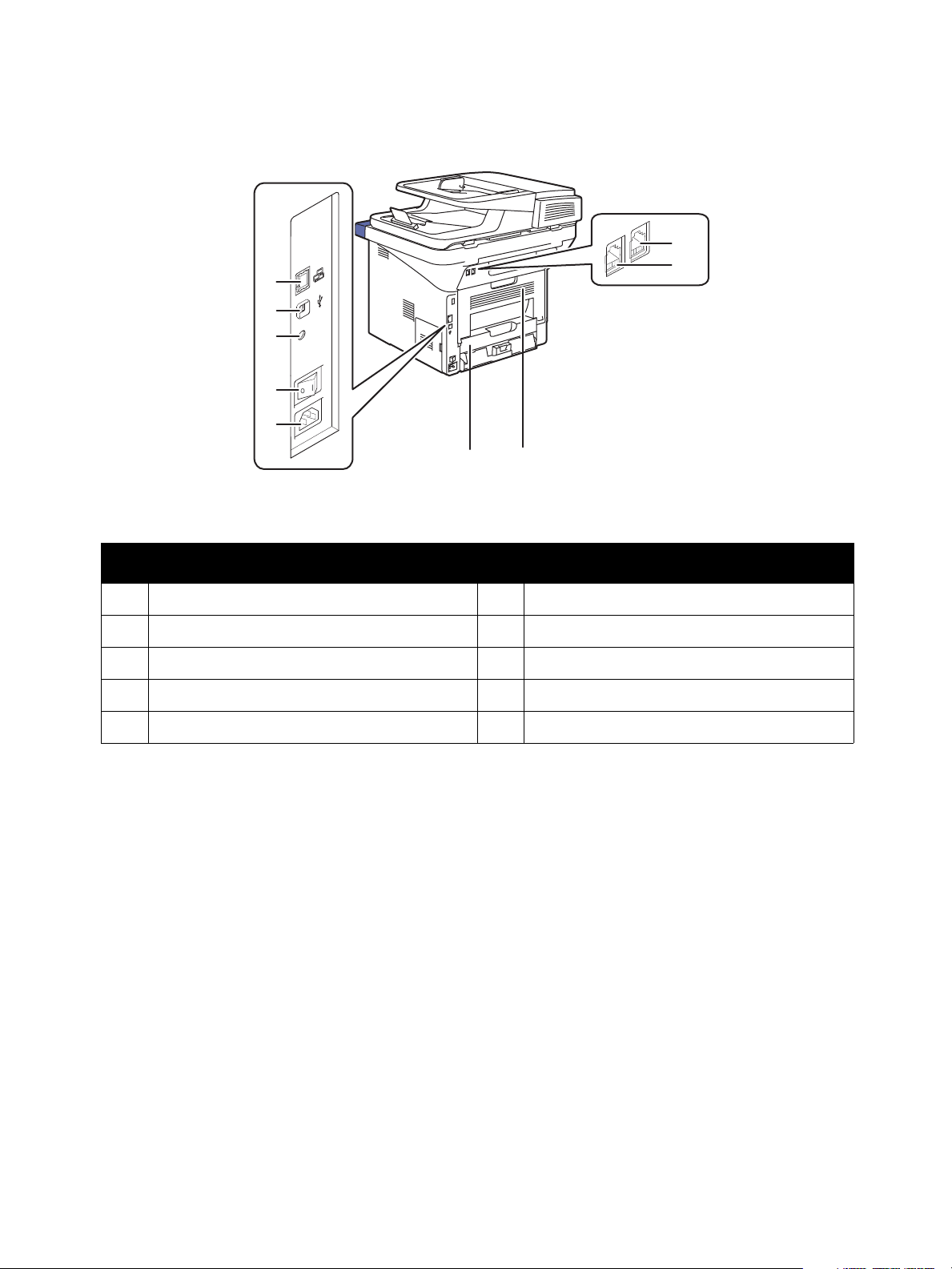

WorkCentre 3315/3320 Rear View

1

2

3

4

5

General Information

9

8

67

s3320-039

No. Description No. Description

1. Network Port 6. Duplex Assembly

2. USB Port 7. Rear Door

3. 5V Output 8. Telephone Line Socket

4. Power Switch 9. Telephone Extension Socket (EXT)

5. Power Receptacle

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-15

Page 26

General Information

Control Panel

The Control Panel consists of multiple LEDs, a display, and several function buttons. These buttons are

used to navigate the menu system, perform functions, and select modes of operation.

Phaser 3320DN/I Control Panel Button Descriptions

Display

Screen

OK

Menu

Power

Save

3320

Arrows

Back

Stop

Status/Wireless LED

s3320-042

Item Description

Display Shows the current status and prompts during an operation.

Menu Enters menu mode and scrolls through the available menus.

OK Confirms the selection on the display.

Arrows Navigates available values by moving to the next or previous options.

Back Sends you back to the upper menu level.

Cancel Stops the current job.

Power Turn the power on and off with this button.

Status/Wireless LED Shows printer status and wireless network connection.

1-16

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 27

WorkCentre 3315DN Control Panel Button Descriptions

3315

Copy

Scan

Display

Screen

Arrows

Arrows

Address

Book

OK Keypad

Pause/

Redial

Machine

Status

Job

Status

Menu

2-Sided

Email

Fax

Paper

Supply

Status/Wireless

LED

Clear All

Stop

Start

Cancel EntryManual Dial

Back

Power

Save

s3320-236

General Information

Item Description

Copy, Scan,

E-mail,and Fax

Display Screen Shows current status and prompts during operations.

Paper Supply Use to select the paper tray for a copy job.

Job Status Indicates the status of the printer – power and ready-to-print.

Machine Status Accesses machine information, status information, the machine serial number and

Arrow / OK (5) Navigate menus and useOK to set or confirm the current selection.

Address Book Store or search frequently used fax numbers and email addresses.

Manual Dial In Fax mode, opens the fax line. In E-mail mode, accesses commonly used e-mail

Keypad (14) Input and delete alphanumeric characters.

Power Saver When illuminated, indicates Low Power Mode. Press to return to Ready mode.

CA (Clear All) Clears all text, numbers or instructions.

Stop Stops the current job.

Start Starts the current job.

Back Move back to previous screen.

Menu Enters Menu mode and scrolls through the available menus.

System Switches the display to the System menus.

2 Sided Puts the printer in Manual Duplex mode.

Status/Wireless LED Shows printer status and wireless network connection.

Use these buttons to move to the top of each menu.

various reports to print.

addresses.The text available can be customized using CentreWare Internet Services.

When the user is making changes to a function (Copy, Scan, Print, or Fax), pressing the

Clear All button restores the previous settings and returns the menu to the top level of

that function.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-17

Page 28

General Information

3325

Copy

Scan

Display

Screen

Arrows

Arrows

Address

Book

OK Keypad

Pause/

Redial

Machine

Status

Job

Status

Menu

2-Sided

Email

Fax

Paper

Supply

Status/Wireless

LED

Interrupt

Printing

Clear All

Stop

Start

Cancel EntryManual Dial

Back

Power

Save

s3320-237

WorkCentre 3325DN/DNI Control Panel Button Descriptions

Item Description

Copy, Scan,

E-mail,and Fax

Display Screen Shows current status and prompts during operations.

Paper Supply Use to select the paper tray for a copy job.

Job Status Indicates the status of the printer – power and ready-to-print.

Machine Status Accesses machine information, status information, the machine serial number and

Arrow / OK (5) Navigate menus and useOK to set or confirm the current selection.

Address Book Store or search frequently used fax numbers and email addresses.

Manual Dial In Fax mode, opens the fax line. In E-mail mode, accesses commonly used e-mail

Keypad (14) Input and delete letters and numbers.

Interrupt Printing Interrupts the current job to run a more urgent job.

CA (Clear All) Clears all text, numbers or instructions.

Power Saver When illuminated, indicates Low Power Mode.

Stop Stops the current job.

Start Starts the current job.

Use these buttons to move to the top of each menu.

various reports to print.

addresses.The text available can be customized using CentreWare Internet Services.

Press to move to Ready from Energy Saver mode.

Back Move back to previous screen.

Menu Enters Menu mode and scrolls through the available menus.

2 Sided Puts the printer in Manual Duplex mode.

1-18

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 29

Status/Wireless LED Indicates the wireless status of the printer.

Understanding the Status LED

The color of the Status LED indicates the machine’s current status.

Status Description

Status LED Off The machine is off-line.

Green Blinking • When the backlight slowly blinks, the machine is receiving data

from the computer.

• When the backlight blinks rapidly, the machine is printing data.

On • The machine is on-line and can be used.

• The machine is in power saver mode.

Red Blinking • A minor error has occurred and the machine is waiting for the

error to be cleared. Check the display message. When the

problem is cleared, the machine resumes. For some models that

do not support the display screen on the control panel, this

feature is not applicable.

• Small amount of toner is left in the cartridge. The estimated

cartridge life of toner is close. Prepare a new cartridge for

replacement. You may temporarily increase the printing quality

by redistributing the toner.

General Information

On • A minor error has occurred and the machine is waiting for the

error to be cleared. Check the display message. When the

problem is cleared, the machine resumes. For some models that

do not support the display screen on the control panel, this

feature is not applicable.

• Small amount of toner is left in the cartridge. The estimated

cartridge life of toner is close.

replacement. You may temporarily increase the printing quality

by redistributing the toner.

• The cover is opened. Close the cover.

• There is no paper in the tray. Load paper in the tray.

• The machine has stopped due to a major error.

a

Wireless LED

a. Wireless model only.

b. Estimated cartridge life means the expected or estimated Print Cartridge life, which indicates the average

capacity of print-outs and is designed pursuant to ISO/IEC 19752. The number of pages may be affected

by operating environment, printing interval, graphics, media type and media size. Some amount of toner

may remain in the cartridge even when red LED is on and the printer stops printing.

Blue On When the printer is connected to a wireless network, the Wireless

LED is illuminated.

b

Prepare a new cartridge for

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

Service Manual

1-19

Page 30

General Information

s3320-044

Main Paper Path

Duplex Paper Path

Bypass Paper Path

Laser Unit

Developer

Tray 1

Duplex

Media Path

The media path throught the print engine is the same for all models

.

1-20

Phaser 3320 and WorkCentre 3315/3325 Xerox Internal Use Only

Service Manual

Page 31

General Information

Pick Up Roller

Retard Roller

Lift Pad

s3320-235

Feeder

Tray 1

The basic tray is located on front side of the machine and allows feeding of common paper. Paper size

is set using the Size Guides in each tray. Adjust the Paper length/width guides to match the paper size.

Paper Width Guide

Paper Length Guide

s3320-045

Pick Up / Retard Roller

When pickup takes place, the Pick Up Roller rotates to separate and transport the paper. The Pick Up

Roller rotates when the Pick Up Clutch is activated. The Retard Roller ensures that a single sheet of

paper is moved to the paper path, and the paper is moved as far as the Registration Roller by the Feed

Roller.

Registration Roller

When a sheet is fed from the tray to the toner transfer section, the registration of the sheet may not be

correctly maintained due to misalignment of lead edges in the tray. To avoid this problem, the lead

edge position needs to be aligned at the Registration Rollers before the sheet is fed in front of the

Transfer Belt, or in front of the BTRs.

By pressing the edge of the sheet fed out of the Tray 1 or Bypass Tray against the Registration Roller

that is locked, the lead edge position of the sheet is corrected.

Xerox Internal Use Only Phaser 3320 and WorkCentre 3315/3325

1-21

Service Manual

Page 32

General Information

Before the Registration Rollers are energized, the paper is advanced from the tray to the rollers. This

process aligns the leading edge of the page. By pushing the edge of the sheet against the Registration

Roller that is not turning, the lead edge of the sheet is registered.

Bypass Tray

The Bypass Tray can hold special sizes and types of print material, such as postcards, note cards, and

envelopes. It is useful for single page printing on letterhead or colored paper. It uses a 3 roller feeding

method to feed 50 sheets of general papers.

The media path from Tray 1 and Bypass Tray are the same. The sheets loaded in the Bypass Tray are