Page 1

®

P H A S E R

2 1 3 5

C O L O R PR I N T E R

Service Quick Reference Guide

Page 2

PHASER® 2135

COLOR PRINTER

Service Quick Reference Guide

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in

operating instructions unless you are qualified

to do so.

This printing: January 2001

071-0725-00

Page 3

Copyright © Xerox Corporation. Unpublished rights reserved under the copyright laws of

the United States. Contents of this publication may not be reproduced in any form without

permission of Xerox Corporation.

Phaser®, PhaserShare®, ColorStix®, the T ekColor® icon, Made For Each Other®, DocuPrint®,

WorkSet®, Ethernet®, the stylized X, and XEROX® are registered trademarks of Xerox

Corporation. PhaserLink™, PhaserPort™, PhaserPrint™, PhaserSym™, PhaserTools™,

InfoSMART™, and the TekColor™ name are trademarks of Xerox Corporation. TekColor

SM

and RealSUPPORTSM are service marks of Xerox Corporation.

Care

®

FTP

Software is a registered trademark of FTP Software, Incorporated.

PCL® and HP-GL

®

are registered trademarks of Hewlett-Packard Corporation.

Novell® and NetWare® are registered trademarks of Novell, Incorporated.

Sun®, Sun Microsystems®, and Sun Microsystems Computer Corporation® are registered

trademarks of Sun Microsystems, Incorporated.Other marks are trademarks or registered

trademarks of the companies with which they are associated.

All trademarks noted herein are either the property of Xerox Corporation, Pantone, Inc., or

their respective companies.

© Pantone, Inc., 1988.

TE/sn

Page 4

Users safety summary

Terms in

manual:

Power source:

between the supply conductors or between either supply conductor and ground.

Use only the specified power cord and connector. For 220 VAC printers, do not

apply more than 260 volts RMS between the supply conductors or between either

supply conductor and ground. Use only the specified power cord and connector.

Refer to a qualified service technician for changes to the cord or connector.

Operation of product:

technician to replace fuses inside the product. Do not operate without the covers

and panels properly installed. Do not operate in an atmosphere of explosive

gases.

Safety instructions:

product into a power source.

Terms on

product:

Care of product:

Disconnect the power plug if the power cord or plug is frayed or otherwise

damaged, if you spill anything into the case, if product is exposed to any excess

moisture, if product is dropped or damaged, if you suspect that the pr oduct needs

servicing or repair, and whenever you clean the product.

CAUTION Conditions that can result in damage to the product.

WARNING Conditions that can result in personal injury

or loss of life.

For 110 VAC printers, Do not apply more than 140 volts RMS

Avoid electric shock by contacting a qualified service

Read all installation instructions carefully before you plug the

CAUTION A personal injury hazard exists that may not be

apparent. For example, a panel may cover the hazardous area.

Also applies to a hazard to property including the product itself.

DANGER A personal injury hazard exists in the area where

you see the sign.

Disconnect the power plug by pulling the plug, not the cord.

Ground the product:

grounded AC outlets only. If necessary, contact a licensed electrician to install a

properly grounded outlet.

Lifting the printer:

lift the printer.

Plug the three-wire power cord (with grounding prong) into

To avoid injury or damage to the printer, use three people to

Page 5

Symbols as marked on product:

DANGER high voltage:

Protective ground (earth) terminal:

Use caution. Refer to the manual(s) for information:

!

WARNING:

controls (and other conductive parts) can cause an electrical shock. Electrical

product may be hazardous if misused.

If the product loses the ground connection, usage of knobs and

Service safety summary

For qualified service personnel only:

Summary.

Do not service alone:

product unless another person capable of rendering first aid or resuscitation is

present.

Use care when servicing with power on:

points in this product. To avoid personal injury, do not touch exposed

connections and components while power is on.

Disconnect power before removing the power supply shield, soldering, or

replacing components.

Do not wear jewelry:

other metallic objects could come into contact with dangerous voltages and

currents.

Power source:

not apply more than 120 or 250 volts AC RMS (depending on printer model)

between the supply conductors or between either supply conductor and ground.

A pr otective ground connection by way of the gr ounding conductor in the power

cord is essential for safe operation.

Do not perform internal service or adjustment of this

Remove jewelry prior to servicing. Rings, necklaces, and

This product is intended to operate from a power source that will

Refer also to the preceding Users Safety

Dangerous voltages may exist at several

Page 6

Contents

General Information 1

The Phaser 2135 Color Printer 2

Printer RAM and printer capabilities 4

CRC life counter behavior 4

Print engine assemblies 5

The image processor board 8

The control panel 9

On Line LED 9

! Fault 9

Rear panel 10

Accessing special operating modes 11

System controller board LEDs 11

Paper tray size sensing 12

Specifications 13

Regulatory specifications 16

Error Codes and Messages 17

Error messages 17

Troubleshooting 29

Fault History Log 29

Power on self-diagnostic test 30

Print engine troubleshooting 31

Testing the print engine controller board 31

Verifying printer operation by using its self-test print 32

Verifying power supply operation 32

Measuring power supply voltages 32

Inspecting the low-voltage power supply fuse 34

Safety interlocks 34

Ensuring the +5 VDC loop is complete 35

Testing for a shorted motor 36

Motor and fuser roller resistances 37

Media jams and the paper path 38

Media-based problems 38

Media problems 38

Multiple-sheet pick 38

The media skews passing through the paper path 39

The paper tray indicates it is empty when it is not 39

Service Guide

v

Page 7

Jams 40

Wrong media 40

Paper jams at the paper tray 40

Manual bypass feeder feed jams 41

Paper jams at the registration rollers 41

Paper jams at the transfer belt 41

Fuser jams 42

Eject jams 42

Jams in the duplex unit 43

No imaging drum installed 43

Imaging drum up/down error 43

Fan error 44

Fuser unit error 44

Other problems 45

The printer continuously displays “Booting” or “Initializing.” 45

False “No toner cartridge installed” message 45

False “No fuser unit installed” message 45

Right-side door indicated being open when it is closed 46

High temperature error 46

Low temperature error 46

Invalid memory DIMM 46

Printing and print quality problems 47

Light or blurred images 47

Dark, stained background 48

Blank print 49

Black stripe in direction of paper travel 50

White stripe in direction of paper travel 51

Poor fusing, toner offsetting 52

Repeating defect or voids on print 53

Missing characters or voids in print 54

Color misalignments 55

Unexpected colors 56

Image is skewed on the paper 57

Image is not centered on the print 57

The print is wrinkled 57

Macintosh printing problems 58

Image never prints 58

Image is rotated 90 degrees 58

Image prints in black-and-white 58

Printer isn’t in the Chooser 59

Windows printing problems 59

Image never prints 59

vi

Phaser 2135 Color Printer

Page 8

Service Tests and Adjustments 61

Starting the diagnostics mode 61

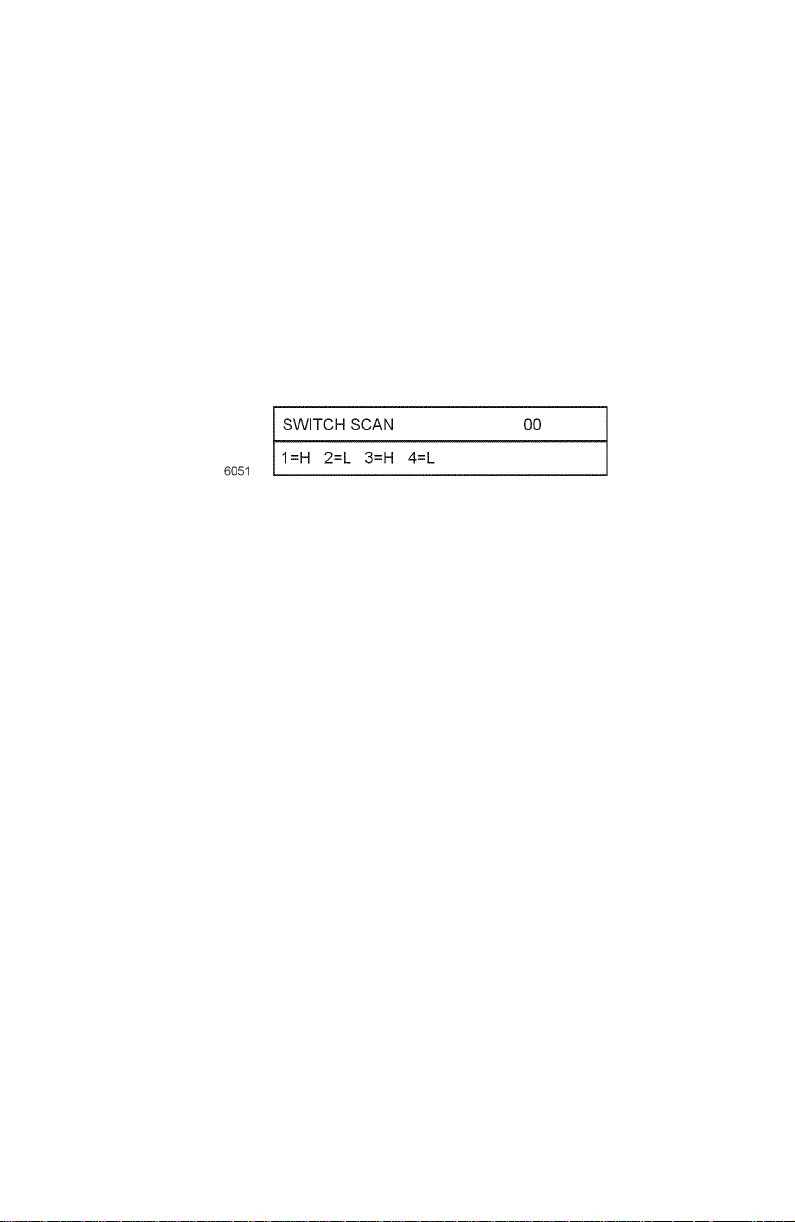

Switch scan test 63

Motor and clutch tests 69

Test printing 72

Consumable count initialization 74

Consumable counter display 75

Consumable continuation counter display 76

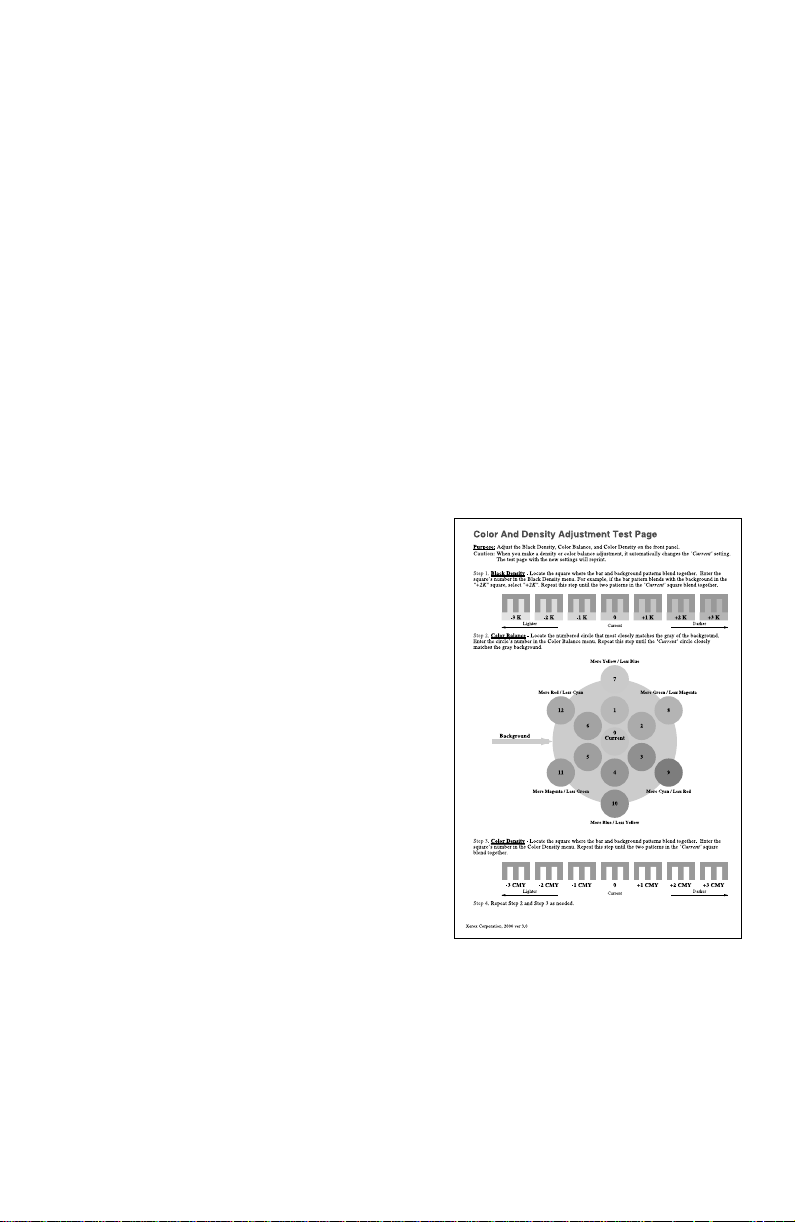

Adjusting color density and balance 77

Printing a Test Page 77

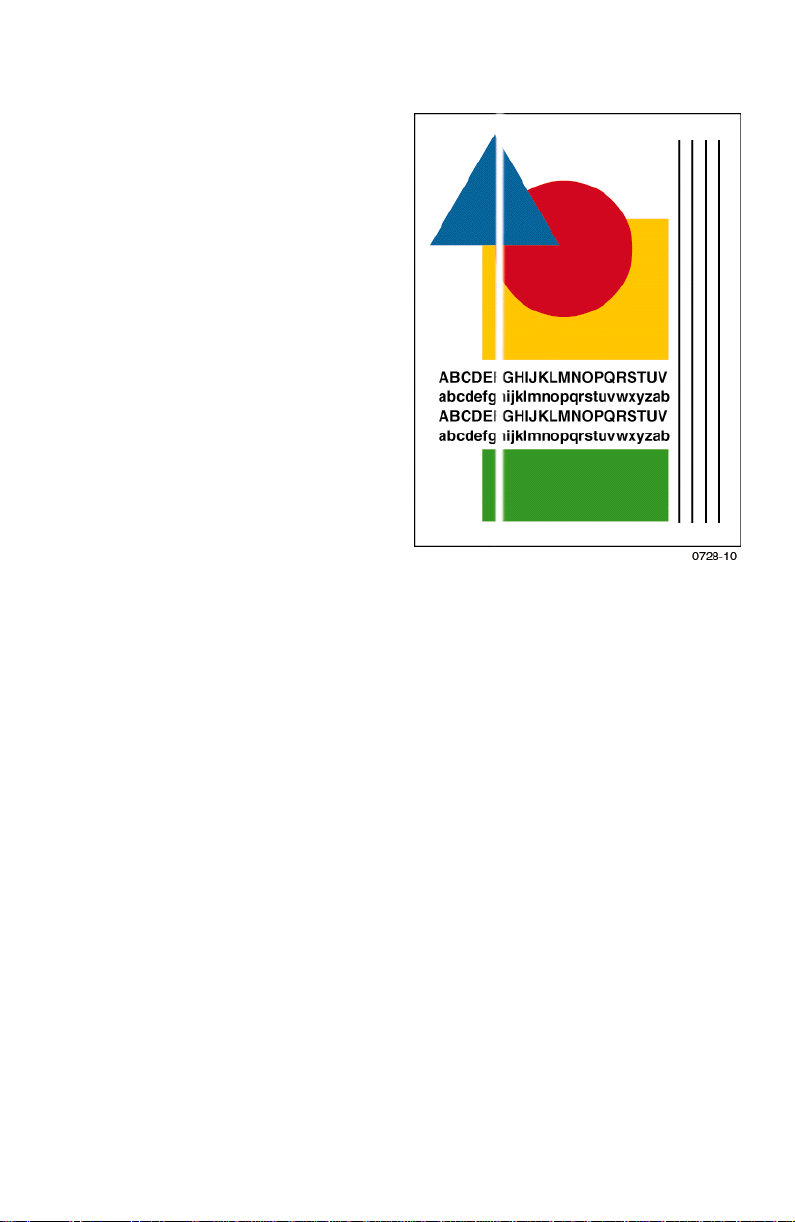

Interpreting the Color Balance test print 77

What to look for 78

Making adjustments 78

Adjustment recovery 79

Cleaning and Maintenance 81

Service preventive maintenance procedure 81

Recommended tools 82

Periodically replaced parts 82

Cleaning 83

Cleaning the LED bar 83

Cleaning the pickup roller 83

Resetting NVRAM 85

FRU Disassembly 87

About screw colors 87

Cabinet panels 88

Top cover 88

Rear cover 89

Front cover 90

Left-side cover 91

Face-up tray 92

Right door 93

Frame components 94

Electrical card cage cooling fan 94

Front power supply fan 95

Rear power supply fan 96

Rear shield plate 97

Electrical card cage 98

Printer unit chassis 100

Top cover inner frame and front/rear top cover spring assembly 102

Front plate assembly 104

Service Guide

vii

Page 9

Electronic boards 105

System controller board 105

RAM DIMMs 106

Hard drive 107

Print engine controller board 108

Toner sensor board 109

Entrance sensor board 111

High voltage power supply 112

Low voltage power supply 114

Control panel 115

Paper feed components 116

Tray 1 feed roller and nudger roller 116

Paper-size sensing board 117

Main feeder assembly 118

Paper tray lift motor 118

Multi-sheet bypass feeder components 119

Multi-sheet bypass feeder 119

Drive gear 119

Multi-sheet bypass feeder sensors 119

Temperature/humidity sensor board 119

Paper transport components 121

Tray 1 entrance sensor actuator 121

Belt entrance and multi-sheet bypass feed sensor actuators 122

Duplex solenoid and exit solenoid 123

Transfer belt unit 124

Registration components 125

Registration clutch 125

Registration motor assembly 126

Registration roller assembly A and drive gear 127

Registration roller assembly B 129

Exit assembly and fuser components 130

Duplex guide assembly 130

Fuser latching handle (front) 132

Fuser latching handle (rear) 134

Fuser exit roller 135

Exit sensor assembly 137

Eject guide assembly 138

Stack full sensor 139

viii

Phaser 2135 Color Printer

Page 10

Drive assembly components 141

Main motor assembly 141

Imaging drum motor 142

Fuser motor and transfer belt drive motor assembly 143

Xerographic components 144

Shutter plate 144

Color registration sensor assembly 145

Color registration solenoid 146

LED assembly 147

Drum contact assembly 148

Toner sensor actuators 149

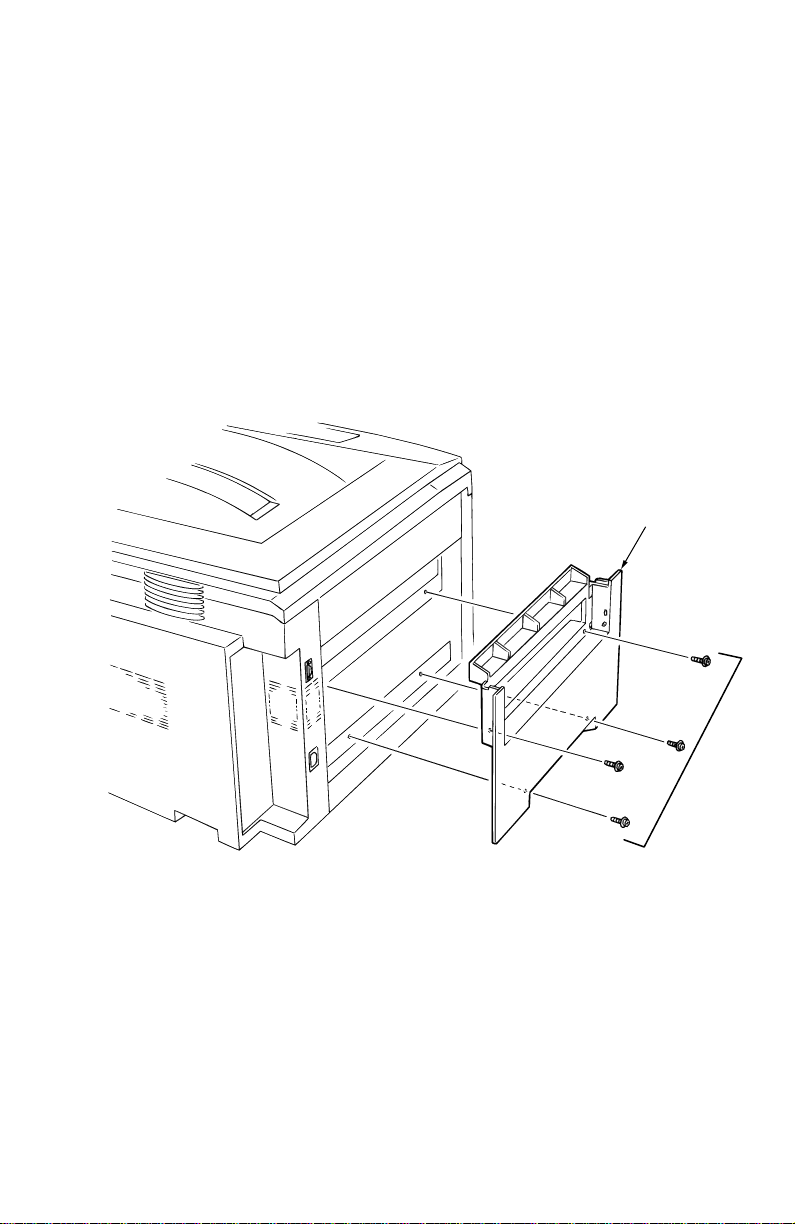

Duplex unit 151

FRU List 153

Using the parts list 153

Test Prints 173

Wiring Diagram 177

Service Guide

ix

Page 11

Figures

The Phaser 2135 Color Printer with lower tray assembly and lower tray deck 1

Print engine circuit boards 5

Print engine sensor and switch locations 6

Print engine motors, clutches and solenoids 7

Features of the controller board 8

The control panel 9

The printer rear panel 10

Tray switch sensors and actuators 12

Door safety interlock switches 35

Print problem caused by dirty LED lens 83

Removing the top cover 88

Removing the rear cover 89

Removing the front cover 90

Removing the left-side cover 91

Removing the face-up tray 92

Removing the right door. 93

Removing the electrical card cage cooling fan 94

Removing the front power supply fan 95

Removing the rear power supply fan 96

Removing the rear shield plate 97

Removing the electrical card cage 99

Disconnecting the registration motor in-line connector (HOPFF) 100

Removing the printer unit chassis 101

Removing the top shield plate 103

Removing the left plate assembly 104

Removing the system controller board 105

Removing the RAM DIMMs 106

Removing the hard drive 107

Removing the print engine controller 108

Removing the toner sensor board 110

Removing the entrance sensor board 111

Removing the high voltage power supply 113

Removing the low voltage power supply 114

Removing the control panel 115

Removing the feed rollers and nudger roller 116

Removing the feed roller and nudger roller 117

Removing the main feeder assembly 118

Removing the multi-sheet bypass feeder 120

x

Phaser 2135 Color Printer

Page 12

Removing the tray 1 entrance sensor actuator 121

Removing the belt entrance sensor actuator 122

Removing the duplex solenoid and the exit solenoid 123

Removing the transfer belt unit 124

Removing the registration clutch 125

Removing the registration motor assembly 126

Removing the registration roller assembly A and drive gear 128

Removing the registration roller assembly B 129

Removing the duplex guide assembly 131

Fuser latching handle (left) 133

Fuser latching handle (left) 134

Removing the fuser exit roller 136

Removing the exit sensor assembly 137

Removing the eject guide assembly 138

Removing the stack full sensor 140

Removing the main motor assembly 142

Removing the fuser motor and transfer belt drive motor assembly 143

Removing the shutter plate 144

Removing the color registration sensor assembly 145

Removing the color registration solenoid 146

Removing an LED assembly 147

Removing the drum contact assembly 148

Removing the toner sensor actuators 150

Removing the duplex unit 151

Cabinet and top cover FRUs 155

Top cover FRUs 157

Printer chassis FRUs (1 of 2) 159

Printer chassis FRUs (2 of 2) 161

Paper tray and paper tray guides FRUs 163

Electrical components FRUs 164

Duplexer unit 165

Lower Tray Assembly FRUs 167

Wiring diagram 177

Wire routing at the engine controller board 178

Details of wiring passthru 179

Wiring under the top shield plate 180

Wiring harnesses route by the imaging drum motors 181

Wire routing by the fuser and transfer belt motor unit. 181

Ribbon cable routing under the toner sensor board 182

Service Guide

xi

Page 13

Tables

Entering special operating modes 11

Paper size detection 12

Physical dimensions 13

Printer clearances 13

Functional specifications 14

Electrical specifications 15

Environmental specifications 15

Printer fault messages 17

System controller board diagnostic error codes 27

System controller board fatal error codes 28

POWER connector pinout 33

Motor and fuser roller resistances 37

Engine maintenance mode menu 62

Switch scans and the sensor and switches test 64

Motor and clutch test constraints 70

Test Print menu 72

Table 1: Initialization items - consumables 74

Consumable counter menu items 75

Consumable life-cycle counts 76

Periodically replaced parts 82

FRU parts list of the printer cabinet and top cover 154

FRU part list of the top cover inner frame 156

FRU part list of the printer chassis (1 of 2) 158

FRU of the printer chassis (2 of 2) 160

FRU of the paper tray and paper tray guides 162

Electrical components FRUs 164

FRUs of the duplexer unit 165

FRUs of the Lower Tray Assembly 166

Hardware kit 168

Gear kit 168

Harness kit 169

Sensor flag kit 170

Customer supplies and accessories 170

xii

Phaser 2135 Color Printer

Page 14

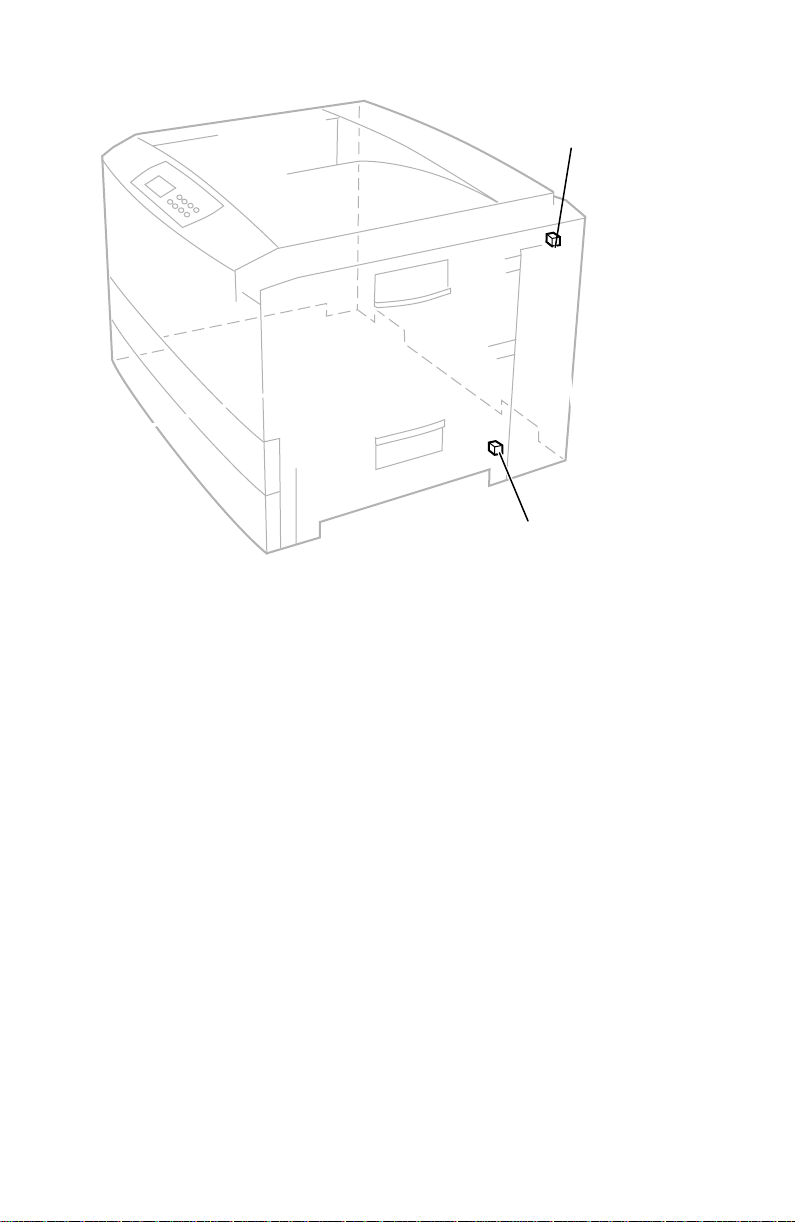

General Information

This service guide contains information useful for troubleshooting, repairing,

adjusting, and maintaining the Xerox Phaser

includes troubleshooting guides, adjustment procedures and a field replaceable

units (FRU) list.

Topics such as printer theory of operation and required service tools are located

on the companion

To ensure a complete understanding of the product, Xerox recommends

participation in Phaser 2135 printer service training.

Color Printer Service & Support Resources CD-ROM

®

2135 Color Printer. This manual

.

0725-56

The Phaser 2135 Color Printer with lower tray assembly and lower tray deck

Service Guide

1

Page 15

The Phaser 2135 Color Printer

The Phaser 2135 Color Printer combines a 4-color, LED-based, tandem-design

Tabloid print engine with an EFI image processing controller board supporting

Adobe’s PostScript Level 3 page description language. The controller features a

bi-directional parallel interface and an Ethernet port for host communication. The

Ethernet port supports EtherTalk 10/100baseT, Novell and TCP/IP. All printer

versions support the color PCL5C printer language.

The printer is available in three configurations:

The

■

Phaser 2135N

Additional 64-, 128- and 256-Mbyte RAM DIMMs can be added with a

maximum usable capacity is 512 Mbytes. The printer contains

136 standard, built-in fonts. The Phaser 2135N prints at a color

resolutions of 600 x 600 dots-per-inch and 600 x 1200 dots-per-inch.

The

■

Phaser 2135DT

192 Mbytes of memory, an auto-duplexer, an internal hard drive and a

lower feeder tray assembly. With the hard drive the 2135DT supports a

print collation mode, a “First Page Preview” mode and a secure print

job “password” mode.

The

■

Phaser 2135DX

Phaser 2135DT printers but includes 256 MBytes of RAM and a

three-tray lower tray deck.

The printer supports the following resolutions:

600 x 600 dpi (Normal)

■

comes standard with 128 Mbytes of RAM.

is the same as the Phaser 2135N except it includes

has all the features and capabilities of the

600 x 1200 dpi (High-quality)

■

The printer also accepts 300 x 300 dpi files from PCL legacy drivers, PCL bit map

fonts, PCL bit map images, although these are imaged at 600 x 600 dpi. The

resolution supported is a function of the PDL used and the feature being selected,

such as Fax Friendly Black and Draft Mode. Both PostScript and PCL allow full

selection of all paper sources, paper sizes, paper types and output trays.

The auto-duplexer unit (optional on the Phaser 2135N) allows the printer to

automatically create two-sided prints.

Print speeds depend on the chosen resolution and selected media. For r esolutions

of 600 x 600 (standard), in color, the printer prints at 21 pages-per-minute (ppm)

on paper. Monochrome printing is at 26 ppm on paper. Transparency film

printing is always 6.5 ppm. For 600 x 1200 dpi (enhanced) color printing, the

printer prints color at the same speeds as standard mode.

The printer support printing on paper sizes such as A-, A4- , Legal-, B-, A3-size

and 12 x 18 in. paper and transparency film from an adjustable tray. The printer

supports up to 5 trays. The printer also features a built-in multi-sheet bypass

feeder from which specialty media, cardstock and envelopes can be fed.

2

Phaser 2135 Color Printer

Page 16

If the printer is equipped with multiple trays loaded with the same-size paper, the

printer will switch to an alternate tray as a paper source when a tray runs out of

paper.

The printer support these tray combination:

One lower tray assembly

■

Two lower tray assemblies

■

One three-tray lower tray-desk

■

One lower tray assembly and a three-tray lower tray deck

■

After being idle for the selected amount of time the printer switches into its

Energy Star mode where it consumes less than 45 watts of power. It “awakens”

upon receiving data at any of its ports.

Proof Jobs.

A proof job is a specific case of a multiple-copy job. With a proof job,

the customer assigns a password and copy account at the client workstation

before printing. The first set of prints are printed immediately. The original

number of requested sets are printed after the customer enters the matching

password on the printer’s control panel. The customer has the option of printing

the original number of requested sets or deleting the job. Since more than one job

may be associated with the same password, the customer can print all the jobs,

delete all the jobs or select or delete individual jobs. A proof job that has not been

printed is retained on hard disk thr ough power cycles. Pr oof jobs sent to a printer

without the hard disk option are not printed and are discarded.

Secure Jobs.

Secure printing allows the customer to defer printing of a job until a

matching password is entered from the control panel. The customer assigns the

password at the client workstation before printing. The job is stor ed, and printing

is delayed until the password is entered on the printer’s control panel. Since more

than one job can have the same password, all secure jobs with the same password

are printed. A secure job that has not been printed or released is retained on disk

through power cycles. The internal hard drive is required for this function.

TIFF Direct Printing.

TIFF files consist of compressed binary images. The TIFF

format itself has no capability to select printing options such as orientation, paper

size, or duplexing. All TIFF files downloaded to the printer are processed using

the default PostScript parameters stored in the printer. Auto sensing of TIFF files

are included in the emulation sensing and switching logic when the TIFF option is

enabled. TIFF direct printing requires the internal hard drive.

PDF Direct Printing

. The printer supports a native PDF image processing.

Processing PDF files directly requir es a hard disk. PDF printing uses the printer’s

currently defined imaging settings. Auto sensing of PDF files are included in the

emulation sensing and switching logic when the PDF option is installed. PDF

direct printing requires the internal hard drive.

Service Guide

3

Page 17

Printer RAM and printer capabilities

The printer features three DIMM connectors which accept 64-, 128-, and

256-Mbytes RAM DIMMs. The printer can use off-the-shelf RAM meeting these

specifications:

168-pin DIMM

■

Synchronous DRAM

■

3.3 volt

■

9 nsec speed

■

Valid on-board Serial Presence Detect ROM.

■

The Startup page and the Configuration Page list the amount of RAM installed in

the printer.

If the DIMM does not meets the system controller board’s specifications, then the

printer reports an “Invalid Memory DIMM Configuration” message and stops the

booting process.

If the power-up self-test diagnostics detect a DIMM with defective memory cells

the printer declares “Diagnostics Failed - Press Enter to Continue.” After the

enter key is pressed the boot process continues and the defective RAM DIMM is

ignored. Note that a seriously defective RAM DIMMs (with grounded address

lines, for example) can keep the system controller board from booting up at all.

With more memory the printer gains the capabilities of printing without having

to use image compression (which trades less installed RAM for longer image

processing time) and dual frame buffers for printing one image while processing

a second image (which gives greater printing throughput).

The printer features three slots each of which can contain a 64-, 128-, or

256-Mbytes SDRAM DIMM. Any slot may be used for any size DIMM. DRAM

memory totalling beyond 512 Mbytes will be ignored.

512 Mbytes, 256-Mbyte DRAM DIMMs cannot be mixed with 128-Mbyte RAM

DIMMs.

non-volatile memory (NVRAM), to store all for the necessary values that can be

set on the printer.

The image-processing controller board also contains 16-kbytes of

For a capacity of

CRC life counter behavior

Internal counters track customer replaceable consumable (CRC) life usage and

store the values in NVRAM. The controller monitors these counters in order to

display the near end-of-use and end-of-use messages.

The toner states displayed are OK, Low, and Empty, where the engine senses and

automatically reports the Low and Empty states. When the empty state is

reached for toner, the printer terminates printing at the end of current page and

displays the appropriate message on the control panel. No further jobs are

accepted from any input port. All printer CRCs wait for the current print job to

finish before declaring a Low or Empty state.

4

Phaser 2135 Color Printer

Page 18

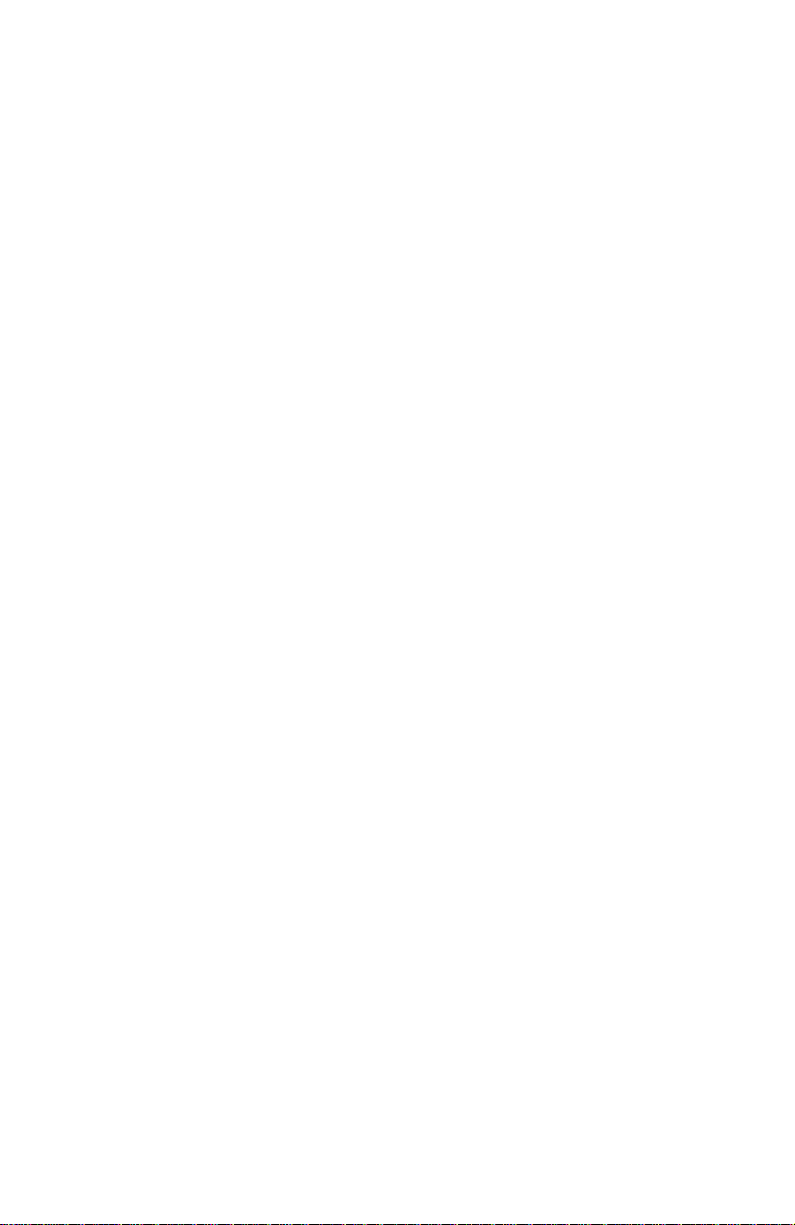

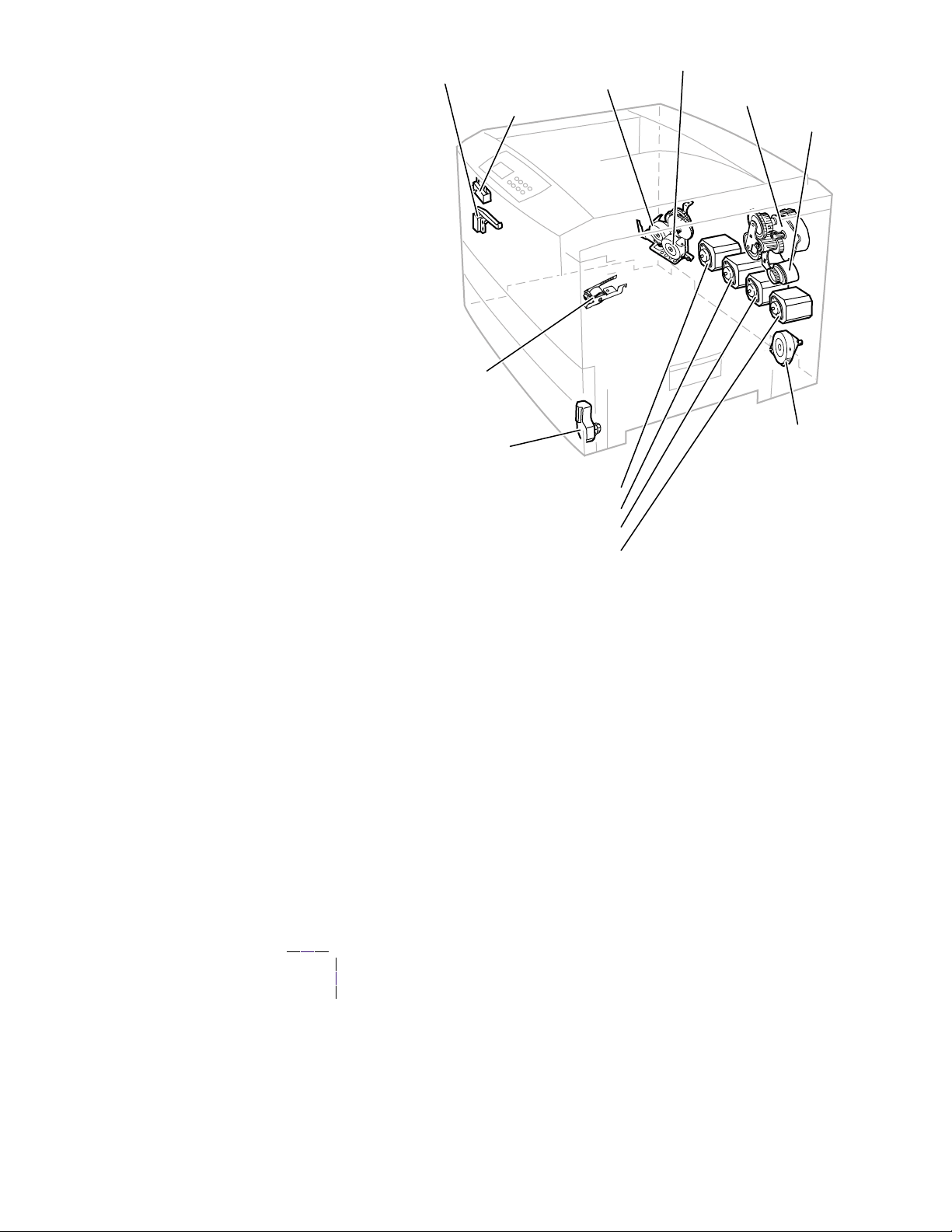

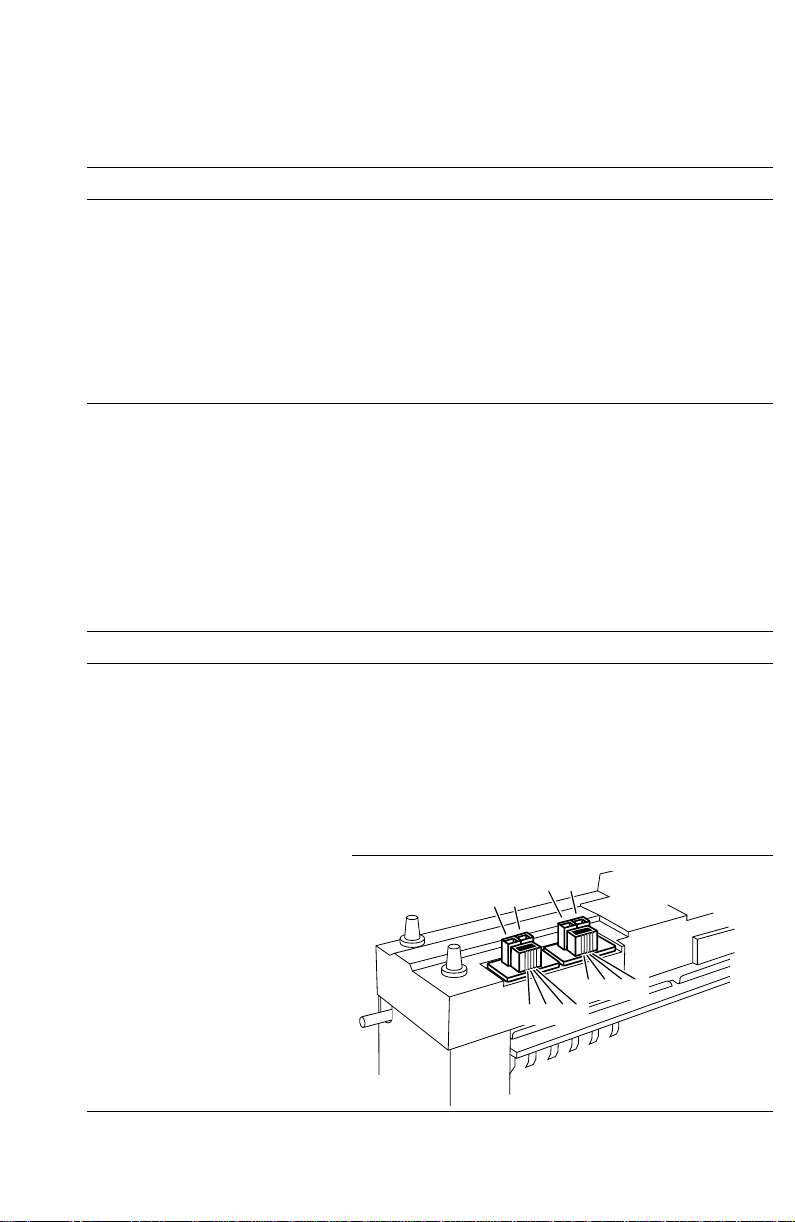

Print engine assemblies

Toner Sensor Board

Control Panel Board

Low Voltage

Power Supply

Board

System Controller Board

Engine Controller Board

High Voltage

Power Supply Board

Print engine circuit boards

Paper Size Sensor Board

Entrance Sensor Board

Service Guide

0725-64

5

Page 19

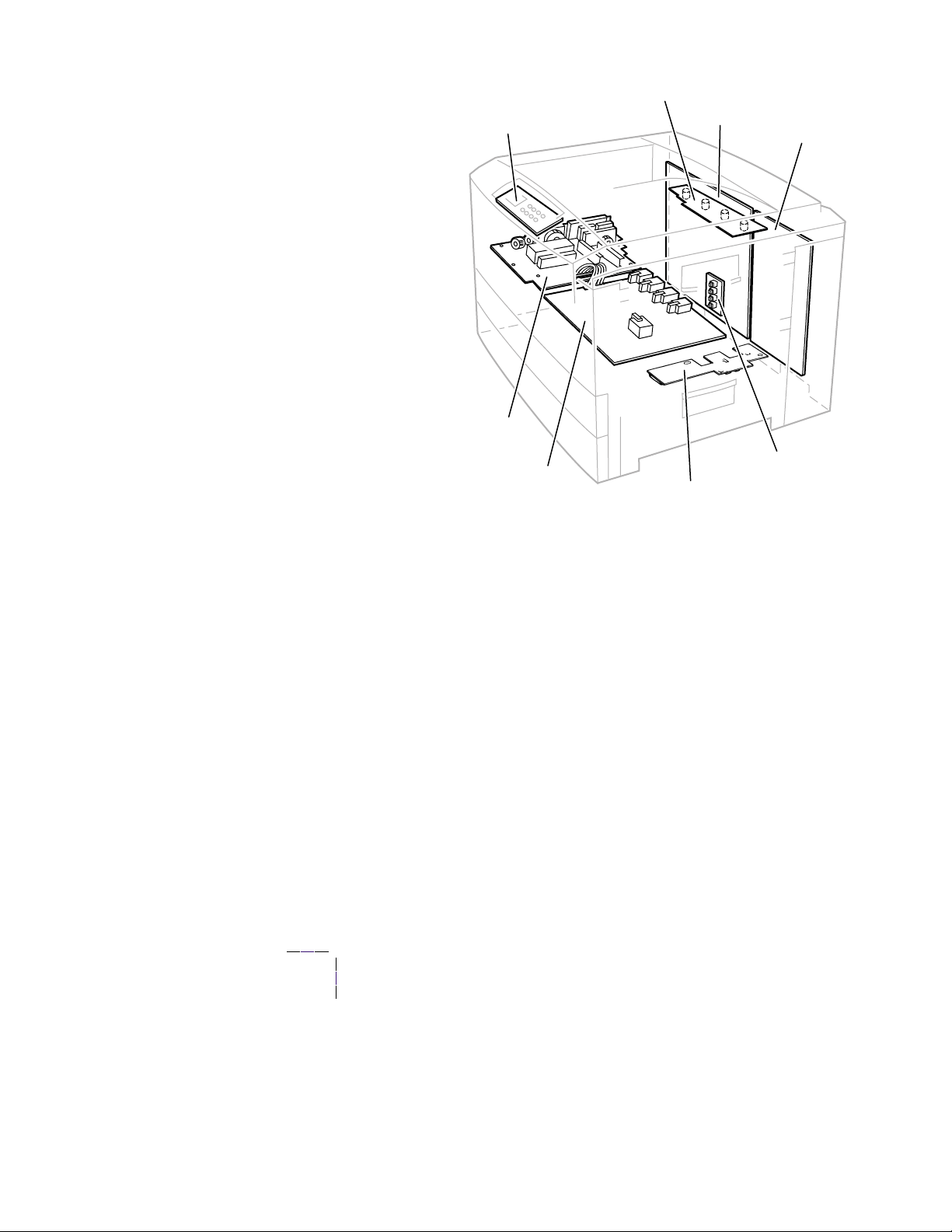

Face-up Tray Open Sensor

Stack Full Sensor

Exit Sensor

Color Registration

Sensor Assembly

Temperature/

Humidity

Sensor Board

Belt Entrance

Sensor

Cyan Toner Cartridge Sensor

Magenta Toner Cartridge Sensor

Yellow Toner Cartridge Sensor

Black Toner Cartridge Sensor

MBF Home Position

Sensor

MBFTransparency

Sensor

MPT Empty Sensor

Top Door

Open Switch

Right-side Door

Open Switch

Tray 1 Low Paper Sensor

Tray 1 Paper Out Sensor

Entrance Sensor

Registration Sensor

Print engine sensor and switch locations

6

Phaser 2135 Color Printer

Waste Toner Sensor

0725-63

Page 20

Duplex Solenoid

Fuser Motor

Exit Solenoid

Color Registration

Shutter Solenoid

Tray Lift Motor

Cyan Imaging Drum Motor

Magenta Imaging Drum Motor

Yellow Imaging Drum Motor

Black Imaging Drum Motor

Transfer Belt Drive Motor

Registration Motor

Registration Clutch

Paper Feed Motor

0725-62

Print engine motors, clutches and solenoids

Service Guide

7

Page 21

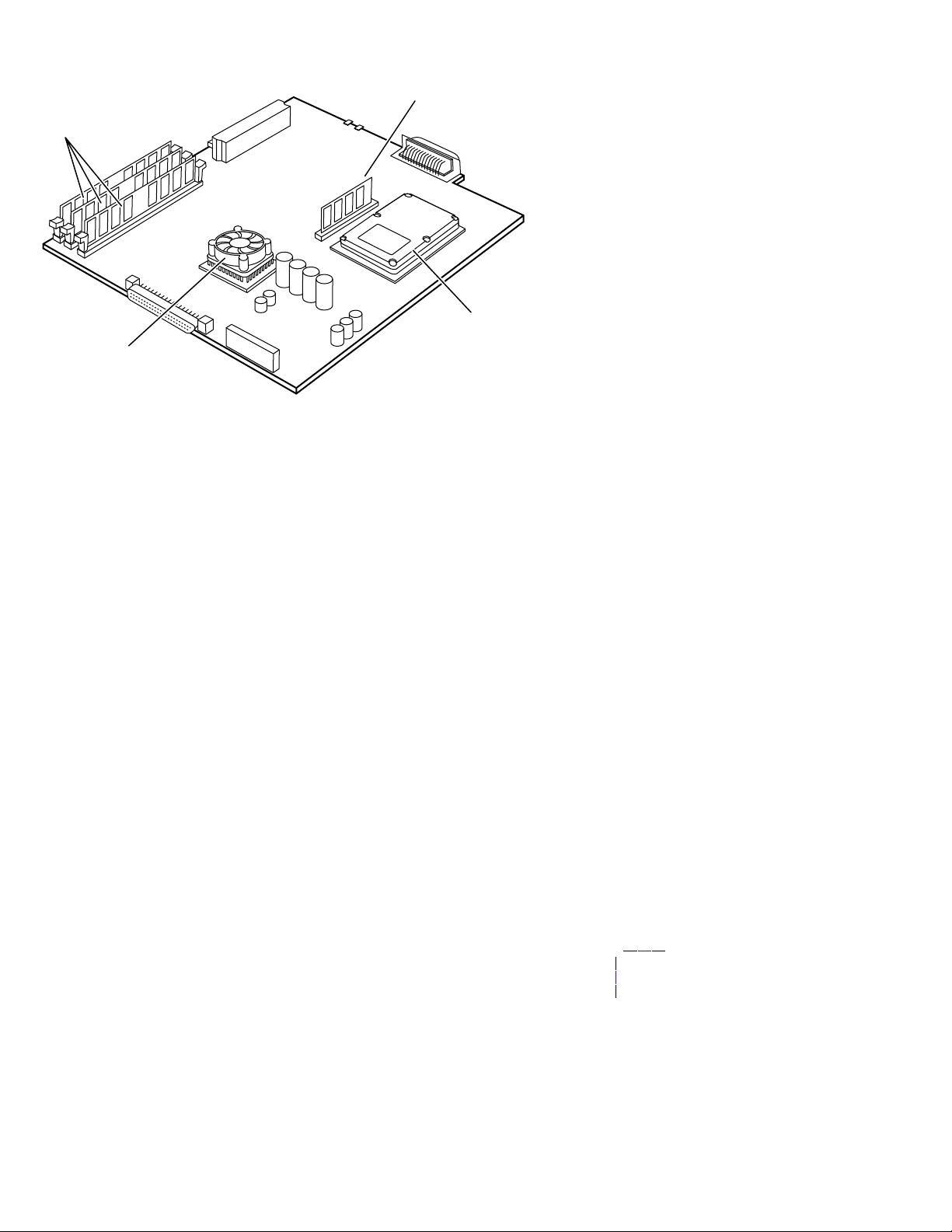

The image processor board

SDRAM

Fan cooled processor

Features of the controller board

ROM DIMM

Hard drive

0728-05

8

Phaser 2135 Color Printer

Page 22

The control panel

The control panel consists of eight labeled keys. These keys navigate the menu

system for printer operations. Two LEDs on the display indicate On Line and

active faults. The LCD display is two lines by twenty-four characters wide.

Menu up/down

Item up/down

Value up/down

C/

The control panel

Key 0 places the printer off-line or on-line. Key 4 is an Enter key. The pairs of

keys 1 and 5 are used to scroll through the main menu. Keys 2 and 6 navigate the

sub menus, and Keys 3 and 7 scroll sub-menu values. Key 6 cancels print jobs.

On Line LED

Green in color, this LED indicates when the printer is “On Line” and ready to

process data. When transitioning from “On Line” to “Off Line”, the LED flashes

at a rate of two times per second. When data is being received and processed, the

LED flashes at a rate of once per second.

! Fault

Red in color, this LED illuminates whenever operator intervention is required,

such as a paper jam in the printer.

Service Guide

9

Page 23

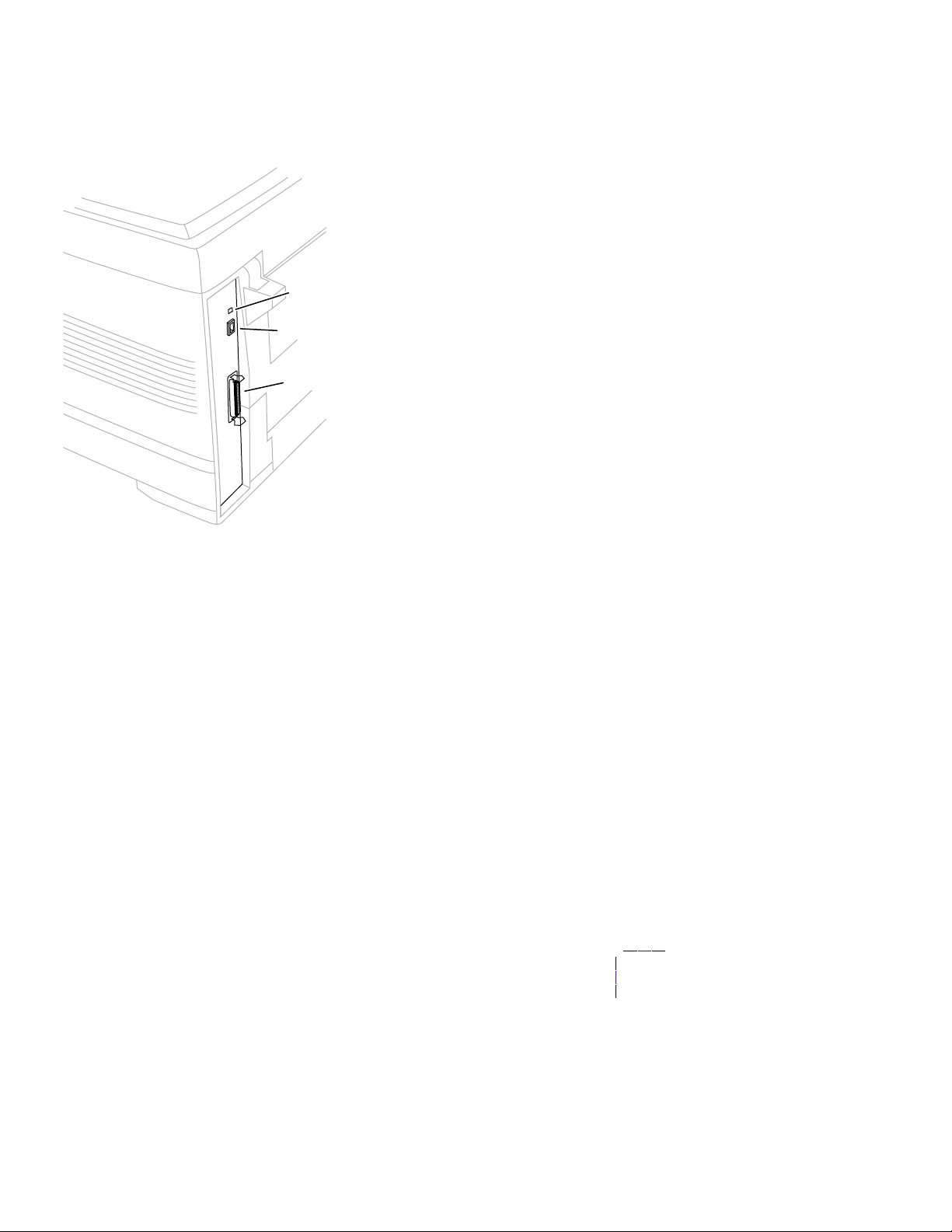

Rear panel

The rear panel of the printer features the host interface connectors:

Bi-directional parallel IEEE 1284-B connector.

■

Twisted Pair 10/100baseT Ethernet connector.

■

LEDs

Ethernet port

Parallel port

The printer rear panel

off

The LED LNK is

blinks

while data is transmitted to the host.

The LED SPD is

when the card is set for 16 MBPS.

10

Phaser 2135 Color Printer

when the printer is not installed on an Ethernet network, it

off

when the card is set for 4 megabits-per-second (MBPS), on

0728-03

Page 24

Accessing special operating modes

The printer can be placed in diagnostics or other operation modes by

simultaneously holding the

Menu Up (1)

the printer.

Entering special operating modes

Key Combination Mode

On Line (0) and

Enter (4)

Menu Up (1) and

Menu Down (5)

Menu Up (1) and

Enter (4)

Enter (4) and

Value Down (7)

This enables the

The Reset Menu is not normally available to the customer, as it contains

the ability to format devices and perform a factory reset of all items.

The control panel displays

To exit, switch the printer power off, then on.

This forces the

The Control Panel will display

Mode

on the second line. This indicates that the printer is ready to be

have its flash firmware updated.

To exit, switch the printer power off, then on.

Forces the printer into the

controller.

The control panel displays

that the printer is ready to enter diagnostics.

To exit, switch the printer power off, then on.

This reinitiates the NVRAM to factory defaults for all values except copy

counts and consumable counts.

The control panel displays

Reset Menu

Software Update Mode

and the

Ready

Engine Diagnostics Mode

Diag Mode 1?

Ready

Enter (4)

to become available at the control panel.

when completed.

Entering...

when complete.

keys as you turn on

on the parallel port.

on the first line

in the first line. This indicates

and Download

, bypassing the

System controller board LEDs

A power LED (PWR), when illuminated, indicates +5V is being supplied to the

system controller board.

The LED HDD, illuminates to flashes to indicate hard drive read/write activity.

LED GIO2 flashes to indicate proper CPU operation.

LED GIO3; off indicates 10baseT connection, on indicates 100baseT.

Service Guide

11

Page 25

Paper tray size sensing

The position of a multi-slotted plate, at the rear of the paper tray, is set according

to the position of the tray’s paper guides. Upon insertion of the tray in the printer,

the plate’s four rows of slots activate four switches. The combinations of the slot

positions indicate the size of the paper in the tray.

Paper size detection

State of Microswitch Paper Size

SW1

(top)

0000No tray installed

0001B4

0010A4 (landscape)

0011A3-Nobi

0100Legal 13 in.

0101Legal 14 in.

0110A5

0111A6

1000B5 (landscape)

1001A3

1010A/Letter (landscape)

1011B/Tabloid

1100B5 (portrait)

1101Executive

1110A4 (portrait)

1111A/Letter (portrait)

SW2 SW3 SW4

(bottom)

Back of paper tray

Tray switch sensors and actuators

12

Phaser 2135 Color Printer

Paper tray

sensor board

0725-67

Page 26

Specifications

Physical dimensions

Dimensions Specification

Height: 46.0 cm (18.1 in.)

Width: 66.6 cm (26.2 in.)

Depth: 62.6.0 cm (24.6 in.)

Weight: About 72 kgs (158 lbs.)

Printer clearances

Clearances Specification

Top: 91.5 cm (36 in.)

Left: 30.5 cm (12 in.)

Right: 30.5 cm (12 in.)

Front: Unlimited for removal of consumables

Rear: 15.3 cm (6 in.) for connecting computer cable and power cord

Mounting surface

flatness:

Each additional lower tray adds 12.7 cm (5 ins.)

The lower tray deck adds 48 cm (19 ins.)

Each additional lower tray adds 16.8 kgs (37 lbs.). The lower tray

deck weights 57.7 kbs (127 lbs)

Maximum deviation of 50 mm (2 in.) from horizontal, side-to-side,

with all four feet in contact with the table surface.

Service Guide

13

Page 27

Functional specifications

Characteristic Specification

Printing process Electro-photographic, four color (CMYK) tandem transfer printing

Color medium Four toner cartridges each contain one of four colors: cyan, magenta,

Addressability Selectable 600 x 600 and 600 x 1200 dpi, text and graphics

Printing speed

pages per minute

(ppm)

yellow or black. The toner is a nonmagnetic, monocomponent

contact medium.

Time from paper-load to paper-eject for continuous printing:

Single-sided

A-size A4 B-size A3

Four-color: 20 21 11 11

Monochrome: 25 26 14.5 14.8

OHP: 6.6 6.4 na na

Cover/specialty: 10 10 6 5.8

Two-sided

Four-color: 10 10 5 5

Monochrome: 12 12 7 7

OHP: na na na na

Cover/specialty: na na na na

Print times do not include image processing time, which can vary

depending on image complexity.

Minimum printing

margins

Usable paper Tray: A-size (Letter), Legal, Executive (7.25 x 10.5 in.),

All sides 5 mm (0.2 in.),

A4-size (metric letter), SRA3, 12 x 18 in. B4, 8 x 13 in, A5

Tabloid (11 x 17 in.), A6, JIS B5, US Folio.

Use only premium bond laser printer or copier paper, transparency

film, card stock and glossy paper in Tray 1

Tray feed paper weight: 60 to 163 g/m2 (16 to 43 lb.)

Minimum paper size: 148 mm x 210 mm (5.83 x 8.27 in.)

Multi-sheet bypass feeder: A-size (Letter), Legal, Executive

(7.25 x 10.5 in.), 8 x 10 in., 12 x 18 in., A 4-size (metric letter),

SRA3, B4,

8 x 13 in, Tabloid (11 x 17 in.), A6, JIS B5, US Folio, A5. SP Folio,

, Statement,

Multi-sheet Bypass Feeder paper weight:

16 lb. to 54 lb. (60g/m2 to 203 g/m2)

Only

Xerox-brand Phaser 35-series A- and A4-size transparency film

is supported.

Automatic two-sided printing: 75 to 120 g/m2 (20 to 32 lb.)

A6 paper, transparency film, heavy card stock, and glossy paper are

not supported by Trays 2 thru 5

A-size A4 B-size A3

14

Phaser 2135 Color Printer

Page 28

Functional specifications

Characteristic Specification

Paper tray capacity Tray 1: 550 sheets of 20 lb. paper, 250 standard transparencies,

200 premium transparencies.

Tray 2 and Tray 5: 550 sheets of paper.

Multi-sheet Bypass Feeder: single sheet to 100 sheets of standard

paper. Varying number of envelopes and other special stock. The

Multi-sheet Bypass Feeder can use media in the 20 to 203 gm2

range.

Electrical specifications

Characteristic Specification

Primary line voltages 99 to 140 VAC (115 VAC nominal)

Primary voltage frequency

range

Power consumption 150 Watts during standby state, (1300 Watts max)

Primary voltage fusing 110 VAC configuration – 20 Amp

Secondary DC voltages Low Voltage Power Supply High Voltage Power Supply

RF emissions Both 110 and 220 VAC-configured instruments pass these

198 to 264 VAC (220 VAC nominal)

50 (48 to 52) or 60 (58 to 62) Hz

1400 Watts during warm-up

550 Watts operation average reference value

42 Watts during Energy Star state

220 VA C configuration – 15 Amp

+3.3 VDC (CH) -900 to -1.4 kV

+ 5 V (DB) -10 to 400/+300 V

+12 V (SB) -100 to -700 V

+ 32 V (TB) +1k to +7 kV

+3.8 V (FIX) 0 to 7 kV

standards: FCC Part 15 Class B

VDE Class B

EN60555-2 Class A

VCCI (CISPR 22:1997) Class B

Environmental specifications

Characteristic Specification

Temperature

Operating

Non-operating

Storage

Humidity

Operating

Non-operating

10o to 32o C (50oto 90oF)

0o to 32o C (32o to 90o F)

-10o to 43o C (-14 to 109o F) (with supplies)

Media should be acclimated 24 hours before using in the printer.

10 to 80% relative humidity, non-condensing

10 to 90% relative humidity, non-condensing

Media should be acclimated 24 hours before using in the printer.

Service Guide

15

Page 29

Environmental specifications

Characteristic Specification

Altitude

Operating

Non-operating

Vibration/shock

Operating

Non-Operating (vibration)

Non-operating (shock)

Acoustic Noise (operating) Standby: 45 dBa, Running: 54 dBa, Impulse: 57 dBa

0 to 2500 m (8,000 ft.) at 25oC

0 to 6000 m (20,000 ft.)

May drop any side or corner 50 mm (2 in.) without impairment of

subsequent operation.

On five mutually perpendicular axes: 0.5 g, 25-minute sweep, 5

to 200 to 5 Hz, 100 to 200 sec./sweep cycle. No resonant

frequencies below 50 Hz.

15 g, trapezoidal flared pulse, 20 msec each axis.

Regulatory specifications

The printer is a recognized component in conformance with the following

regulatory standards:

The packaged product meets ASTM D4169-93 and ASTM D4728-91

■

Transportation Standards.

Listed UL 1950 Information Processing and Business Equipment.

■

Certified CSA C22.2 No. 950 Safety of Information Technology

■

Equipment, Including Electrical Business Equipment.

GS licensed IEC 950 (1991) Second Edition; EN60950 Information

■

Processing and Business Equipment.

EN50022 (CISPR 22) Class B

■

EN61000-3-2

EN61000-3-3

VCCI (CISPR 22) Class B

FCC Class B (for 115 VAC equipment) pursuant to Sub-part J of Part 15.

■

ICES 03 Class B

16

Phaser 2135 Color Printer

Page 30

Error Codes and Messages

Error messages

The front panel displays error codes when it encounters certain system failures.

These error codes are discussed in the next topic. Except for media jams and other

such errors, when an error code first occurs, cycle power on the printer to see if

the error re-occurs.

Printer fault messages

Code Front panel message Service message

A6 Jam Inside Top Cover, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the feeder. Also

ensure the paper is loaded correctly in the feeder.

2.

Clean the bypass feeder’s pick roller.

3.

Test the main feed motor as described in “Motor and clutch tests” on

page 69.

4.

Replace the main feed motor.

5.

Replace the engine controller board.

A7 Jam Inside Top Cover, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the duplex unit’s rollers.

3.

Test the duplex motor and clutch as described in “Motor and clutch tests”

on page 69.

4.

Replace the duplex unit.

5.

Replace the engine controller board.

A10 Jam Inside Top Cover, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the exit rollers.

3.

Ensure the exit rolls rotate freely when the exit roller gear train is rotated.

4.

At the rear of the printer, inspect the gate which directs the print to the

face-up output bin or the face-down output bin.

5.

Test the fuser motor (which drives the exit gear train) using the test

described in “Motor and clutch tests” on page 69.

6.

Replace the engine controller board.

A6-Bypass Feeder Jam

A7-Duplex Entry Jam

A10-Paper Output Jam

Service Guide

17

Page 31

Printer fault messages

Code Front panel message Service message

A11 Jam Inside Top Cover, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the pick and registration rollers.

3.

Ensure there are no obstructions in the paper path.

4.

Test the registration motor and clutch as described in “Motor and clutch

tests” on page 69. Replace the motor or clutch if necessary.

5.

Inspect the wiring for the registration clutch and registration motor.

6.

Replace the engine controller board.

A22 Jam Inside Top cover, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the pick and registration rollers.

3.

Ensure there are no obstructions in the paper path.

4.

Test the registration motor and clutch as described in “Motor and clutch

tests” on page 69. Replace the motor or clutch if necessary.

5.

Inspect the wiring for the registration clutch and registration motor.

6.

Replace the engine controller board.

B8 Jam Inside Duplex Unit, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the duplex unit’s rollers.

3.

Test the duplex motor and clutch as described in “Motor and clutch tests”

on page 69.

4.

Replace the duplex unit.

5.

Replace the engine controller board.

B13 Jam Inside Duplex Unit, Open Cover, See

Labels

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Inspect and clean the eject rollers behind the fuser unit.

3.

Ensure the paper path leading to the duplex unit and the duplex unit’ s paper

path are both clear of obstructions.

4.

Inspect the operation of the solenoid activated separator gate the direct the

print into the duplex unit. Test the exit solenoid with the “Motor and clutch

tests” on page 69.

5.

Replace the duplex unit.

6.

Replace the engine controller board.

A11-Paper Feed Jam

A22-Feed Path Jam

B8-Duplex Jam

B13-Duplex Inverter Jam

18

Phaser 2135 Color Printer

Page 32

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

1.

2.

3.

3.

4.

4.

5.

1.

2.

Printer fault messages

Code Front panel message Service message

B21 Jam Inside Right Door A, Open Right Door A B21-Duplex Area Jam

1.

Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2.

Clean the duplex unit’s rollers.

3.

Test the duplex motor and clutch as described in “Motor and clutch tests”

on page 69.

4.

Replace the duplex unit.

5.

Replace the engine controller board.

C1 Close Tray 1, Tray 1 Not Detected C1-Check Tray 1

C2 Close Tray 2, Tray 2 Not Detected C2-Check Tray 2

C3 Close Tray 3, Tray 3 Not Detected C3-Check Tray 3

C4 Close Tray 4, Tray 4 Not Detected C3-Check Tray 4

C5 Close Tray 5, Tray 5 Not Detected C3-Check Tray 5

Ensure the tray is installed correctly.

Inspect and test the paper size sensors and the tray’s corresponding

sensor flags.

Replace the paper tray sensor board

Replace the paper tray.

Replace the engine controller board.

E1 Tray 1 Misfeed, Open Rt Door A and Tray 1 E1-Tray 1 Misfeed

E2 Tray 2 Misfeed, Open Rt Door B and Tray 2 E1-Tray 2 Misfeed

E3 Tray 3 Misfeed, Open Rt Door C and Tray 3 E1-Tray 3 Misfeed

E4 Tray 4 Misfeed, Open Rt Door D and Tray 4 E1-Tray 4 Misfeed

E5 Tray 5 Misfeed, Open Rt Door E and Tray 5 E1-Tray 5 Misfeed

Ensure the correct weight and type of paper is loaded in the tray. Also

ensure the paper is loaded correctly in the tray.

Clean the pick rollers.

Test the main feed motor as described in “Motor and clutch tests” on

page 69.

Replace the main feed motor.

Replace the engine controller board.

E9 Top Cover Open, Close Top Cover A E9-Top Cover A Open

Close the cover.

Inspect the switch and ensure the switch’s actuator is not broken.

Test the top cover open switch using the sensor test described in “Switch

scan test” on page 63.

Inspect the switch’s wiring harness.

Replace the engine controller board.

E12 Top Output Tray Full Remove Output E12-Output Bin Full, Top

Ensure the output bin full sensor flag operates freely.

T est the output bin full sensor using the test described in “Switch scan test”

on page 63.

Inspect the sensor and its wiring harness.

Replace the engine controller board.

Service Guide

19

Page 33

Printer fault messages

Code Front panel message Service message

E14 Close Duplex Unit, Duplex Unit Not Detected E14-Duplex Unit Not

1.

Ensure the duplexer is installed correctly.

2.

Inspect the connector at the rear end of the

duplexer unit.

3.

Inspect the wiring harness leading from the

duplexer unit interface connector to the

engine controller board.

4.

Replace the duplexer unit.

5.

Replace the engine controller board.

E18 Right Door A Open, Close Right Door A E18-Right Door A Open

E20 Right Door B Open, Close Right Door B E20-Right Door B Open

E21 Right Door C Open, Close Right Door C E21-Right Door C Open

E22 Right Door D Open, Close Right Door D E22-Right Door D Open

E23 Right Door E Open, Close Right Door E E23-Right Door E Open

1.

Ensure the cover’s sensor flag operates

freely.

2.

Test the output bin full sensor using the test

described in “Switch scan test” on page 63.

3.

Inspect the sensor and its wiring harness.

4.

Replace the engine controller board.

EA Black Imaging Drum Missing, Reseat Drum EA-Black Imaging Drum

EB Cyan Imaging Drum Missing, Reseat Drum EA-Cyan Imaging Drum

EC Magenta Imaging Drum Missing, Reseat Drum EA-Magenta Imaging Drum

ED Yellow Imaging Drum Missing, Reseat Drum EA-Yellow Imaging Drum

1.

Remove and install the drum unit.

2.

Inspect the spring-loaded drum contact assembly. Ensure they are clean

and move up and down freely. Remove the assembly and reseat it, if

necessary.

3.

Replace the engine controller board.

4.

Replace the printer unit chassis

Detected

Missing

Missing

Missing

Missing

20

Phaser 2135 Color Printer

Page 34

1.

2.

3.

4.

5.

3.

1.

2.

3.

1.

2.

Printer fault messages

Code Front panel message Service message

EE Transfer Belt Missing, Reseat Belt EE-Transfer Belt Unit

1.

Remove and re-install the transfer belt unit.

2.

Clean the transfer belt unit’s contact on the front-left side of the engine

chassis. Clean the corresponding contacts on the transfer belt unit.

3.

Install a new transfer belt unit.

4.

Replace the engine controller board.

5.

Replace the printer unit chassis.

EF Fuser Missing, Reseat Fuser EF-Fuser Unit Missing

1.

Remove and reinstall the fuser.

2.

install a new fuser.

3.

Replace the low-voltage power supply.

4.

Replace the engine controller board.

H1 Disk Read Error, Press Enter to Clear

A hard disk error was detected that prevented

data from being read from the disk.

H2 Disk Write Error, Press Enter to Clear

A hard disk error was detected that prevented

data from being written to the disk.

H3 Disk Full Error, Press Enter to Clear

A hard disk full error occurred that prevented

data from being written to the disk

Turn the printer off and on again.

Ensure the hard drive is properly installed.

Re initialize the hard drive. by scrolling to the Reset Menu and selecting

the submenu item Disk Init .

Replace the hard drive.

Replace the system controller board.

J3 Replace Fuser J3-Replace Fuser

Install a new fuser.

If a new fuser has been installed but the print engine continues to ask for a

new fuser, reset the fuser life count using the topic “Consumable count

initialization” on page 73.

Replace the engine controller board.

J4 Replace Tr ansfer Belt J4-Replace T r ansfer Belt

Install a new transfer belt.

If a new transfer belt has been installed but the print engine continues to

ask for a new transf er belt, reset the tr ansf er belt life count using the topic

“Consumable count initialization” on page 73.

Replace the engine controller board.

Missing

H1-Disk Read Error

H2-Disk Write Error

H3-Hard Disk Full

Service Guide

21

Page 35

Printer fault messages

Code Front panel message Service message

J5 Replace Yellow Imaging Drum J5-Replace Yellow Imaging

J6 Replace Magenta Imaging Drum J6-Replace Magenta

J7 Replace Cyan Imaging Drum J7-Replace Cyan Imaging

J8 Replace Black Imaging Drum J8-Replace Black Imaging

1.

Install a new drum unit.

2.

If a new drum unit has been installed but the print engine continues to ask

for a new drum unit, reset the drum unit life count using the topic

“Consumable count initialization” on page 73.

3.

Inspect the spring-loaded drum unit contacts (in a set of three). Ensure

they are clean and move up and down freely. Remove and reseat them, if

necessary.

4.

Replace the engine controller board.

J9 Y ellow Toner Empty Replace Yellow Toner J9-Yellow T oner Empty

J10 Magenta Toner Empty Replace Magenta Toner J10-Magenta Toner Empty

J11 Cyan Toner Empty Replace Cyan Toner J11-Cyan Toner Empty

J12 Black Toner Empty Replace Black Toner J12-Black Toner Empty

1.

Install a new toner cartridge.

2.

If a new cartridge has been installed but the print engine continues to ask

for a new cartridge, reset the toner cartridge life count using the topic

“Consumable count initialization” on page 73.

3.

Replace the drum unit.

4.

Replace the engine controller board.

L0 Load Tray # 1 Size 2 Type 3 Load Tray #, Size Type

1. Load the requested size and type of paper in the tray.

2. Ensure the tray is installed correctly.

3. Inspect and test the paper size sensors and the tray’s corresponding

sensor flags.

4. Replace the paper tray sensor board.

5. Replace the paper tray.

6. Replace the engine controller board.

Drum

Imaging Drum

Drum

Drum

22

Phaser 2135 Color Printer

Page 36

Printer fault messages

Code Front panel message Service message

T1 Fuser Upper Error T1 Power Off/On T1-Fuser Upper Error

T2 Fuser Lower Error T2 Power Off/On T2-Fuser Lower error

1. Remove and install the fuser.

2. Test the thermistors inside the fuser using the test described in “Switch

scan test” on page 63.

3. Replace the fuser.

4. Replace the low-voltage power supply.

5. Replace the engine controller board.

T29 Temp Sensor Error T29, Power Off/On T29-Temp Sensor Error

T30 RH Sensor Error T30, Power Off/On T30-RH Sensor Error

1. Test the temperature sensor or the relative humidity sensor using the

sensor test described in “Switch scan test” on page 63.

2. Inspect the wiring harness leading to the entrance sensor board.

3. Replace the temperature/humidity sensor board.

4. Replace the engine controller board.

T31 Roller Over Temp T31, Power Off/On T31-Roller Over Error

1. Inspect the fuser cooling fan. Ensure it is running correctly and is not

blocked.

2. Remove and install the fuser.

3. T est the thermistor inside the fuser using the test described in “Switch scan

test” on page 63.

4. Replace the fuser.

5. Replace the low-voltage power supply.

6. Replace the engine controller board.

T32 LED Over Temperature T32, Power Off/On T32-LED Over Temp Error

1. Ensure all the chassis cooling fan is operating and is not blocked.

2. Ensure the printer is operating in the correct temperature environment; the

printer’s Service Menu : Print Diag Summary test page lists the ambient

temperature sensed by the printer.

3. Replace the LED heads.

4. Replace the engine controller board.

Service Guide 23

Page 37

Printer fault messages

Code Front panel message Service message

U0 Engine ROM Error U0, Power Off/On U0-Engine ROM Error

U1 Engine RAM Error U1, Power Off/On U1-Engine RAM Error

U2 Engine EPROM Error U2, Power Off/On U2-Engine EPROM Error

U3 Engine EPROM Missing U3, Power Off/On U3-Engine EPROM Missing

U4 Engine SRAM Error U4, Power, Off/On U4-Engine SRAM Error

U5 Engine Control Error U5, Power, Off/On U5-Engine Control Error

1. Turn the printer off and then on

2. Reset the printer NVRAM using the procedure “Resetting NVRAM” on

page 85.

3. Replace the engine controller board.

U6 Power Supply Error U6, Power Off/On U6-Power Supply Error

1. Inspect the front and rear power supply fans. Ensure they is running

correctly and are not blocked. The front fan blows into the chassis. The

rear fan blows out from the chassis.

2. Turn the printer off and then on.

3. Replace the low-voltage power supply.

4. Replace the engine controller board.

U7 Feeder Home Error U7, Power Off/On U7-Feeder Home Error

1. Test the manual bypass feeder home sensor using the test described in

“Switch scan test” on page 63.

2. Inspect the sensor and its wiring harness.

3. Replace the engine controller board.

U8 Controller Fan Error U8, Power Off/On U8-Controller Fan Error

1. Inspect the electrical chassis fan to see if it is running and not blocked.

2. Inspect the fan’s wiring harness.

3. Replace the fan.

4. Replace the engine controller board.

U9 Supply Fan Error U9, Power Off/On U9-Supply Fan Error

1. Inspect the main cooling fan to see if it is running and not blocked.

2. Inspect the fan’s wiring harness.

3. Replace the fan.

4. Replace the engine controller board.

U10 Roller Position Error U10, Power Off/On U10-Roller Position Error

1. Ensure the correct weight and type of paper is loaded in the currently used

tray. Also ensure the paper is loaded correctly in the tray.

2. Clean the pick and registration rollers.

3. Ensure there are no obstructions in the paper path.

4. Test the registration motor and clutch as described in “Motor and clutch

tests” on page 69. Replace the motor or clutch if necessary.

5. Inspect the wiring for the registration clutch and registration motor.

6. Replace the engine controller board.

24 Phaser 2135 Color Printer

Page 38

Printer fault messages

Code Front panel message Service message

U12 Duplex I/F Error U12, Power Off/On U12-Duplex I/F Error

1. Turn the printer off and on.

2. Pull out the duplexer and inspect its connector at the right front corner (the

connector faces rearward). Inspect the printer’s corresponding connector

on the printer chassis (covered by a flexible metal plate).

3. Inspect the wiring harness leading from the engine control board to the

duplex unit connector.

4. Replace the duplex unit.

5. Replace the engine controller board.

U13 Tray 3 I/F Error U13, Power Off/On U13-Tray 3 I/F Error

U14 Tray 2 I/F Error U14, Power Off/On U14-Tray 2 I/F Error

U16 Tray 4 I/F Error U13, Power Off/On U13-Tray 4 I/F Error

U17 Tray 5 I/F Error U14, Power Off/On U14-Tray 5 I/F Error

1. Turn the printer off and then on.

2. Inspect the interface connector connecting the tray unit to the print engine.

Inspect the printer’s corresponding connector on the underside of the

printer. Inspect the wiring harness leading from the connector to the

engine control board.

3. Replace the engine controller board.

U15 Control Panel Error U15, Power Off/On U15-Control Panel Error

1. Turn the printer off and then on.

2. Reset the printer NVRAM using the procedure “Resetting NVRAM” on

page 85.

3. Replace the engine controller board.

U18 Yellow LED Error U18, Power Off/On U18-Yellow LED Bar

U19 Magenta LED Error U19, Power Off/On U19-Magenta LED Bar

U20 Cyan LED Error U20, Power Off/On U20-Cyan LED Bar Missing

U21 Black LED Error U21, Power Off/On U21-Black LED Bar Missing

1. Ensure the LED assembly is correctly installed.

2. Inspect the wiring harnesses leading to the LED assembly.

3. Replace the engine controller board.

U22 Yellow Toner Missing, Reseat Toner U22-Yellow Toner Missing

U23 Magenta Toner Missing, Reseat Toner U23-Magenta Toner Missing

U24 Cyan Toner Missing, Reseat Toner U24-Cyan Toner Missing

U25 Black Toner Missing, Reseat Toner U25-Black Toner Missing

1. Inspect the toner cartridge sensor flag. Ensure to moves properly and is

not broken.

2. T est the sensor using the test described in “Switch scan test” on page 63.

3. Inspect he toner sensor boards wiring harness.

4. Replace the toner sensor board.

5. Replace the engine control board.

U26 Yellow Drum Error U26, Power Off/On U26-Yellow Drum Error

Missing

Missing

Service Guide 25

Page 39

Printer fault messages

Code Front panel message Service message

U27 Magenta Drum Error U27, Power Off/On U27-Magenta Drum Error

U28 Cyan Drum Error U28, Power Off/On U28-Cyan Drum Error

U29 Black Drum Error U29 Power Off/On U29-Black Drum Error

1. Remove and install the drum unit.

2. Inspect the spring-loaded drum unit contacts (in a set of three). Ensure

they are clean and move up and down freely. Remove the assembly and

reseat it, if necessary.

3. Test the drum unit contacts using the Drum contact switch test listed in

“Switch scan test” on page 63.

4. Install a new drum unit.

5. Replace the engine controller board.

6. Replace the print unit chassis.

W16 Fuse Cut Error W16 - Fuse Cut Error

For the new Customer Replaceable

Consumable (imaging drums, transfer belt or

fuser) just installed, the printer did not detect

the CRC’s “new/used” fuse blow. An internal

fuse of a new CRC ordinarily blows a few

seconds after the CRC is installed. If the fuse

cannot be blown, then the consumable’s

counter can't be reset and the “consumable

expired / replace” messages will not go away.

1. Remove the CRC.

2. Cycle the printer’s power.

3. Install the CRC again. If the error still

occurs, try a different CRC.

4. If error reoccurs with a different CRC,

replace the engine controller board.

5. Replace the print unit chassis.

26 Phaser 2135 Color Printer

Page 40

System controller board diagnostic error codes

Code Test Possible Cause

1 Memory Bad memory DIMMs

2 Memory Speed Bad DIMMs or system controller board

3 CPU Tick Bad system controller board

4 System Timer Bad system controller board

5 BX Host Bridge Bad system controller board

6 PIIX4 PCI-ISA Bridge Bad system controller board

7 21152 PCI-ISA Bridge Bad system controller board

8 PCI-PCI Bridge Bad system controller board

9 IX Bad system controller board

10 Parameter Flash R/W not implemented

11 Strata Flash R/W not implemented

12 Strata Flash Boot Block

Integrity

13 Strata Flash File System

Integrity

14 STE100 Bad system controller board

15 VX2b-0 Bad system controller board

16 VX2b-1 Bad system controller board

17 VX2b-2 Bad system controller board

18 VX2b-3 Bad system controller board

19 Disk Identify Bad hard disk drive

20 Disk Read/Write Bad hard disk drive

21 Disk Read Capability Bad hard disk drive

22 Disk Write Capability Bad hard disk drive

23 Disk Data Format Check Bad hard disk drive

Bad system controller board

Bad system controller board

Service Guide 27

Page 41

These are error codes returned by the system controller board. In the event that

one of these errors occurs:

1. Cycle printer power to see if the error reoccurs.

2. Reseat the system controller board.

3. Replace the system controller board.

These errors can also be caused by the board’s hard drive or the RAM DIMMs.

System controller board fatal error codes

Code Description

00 Unknown. Replace the hard drive before replacing the controller board.

04 Video T ask

08 Serial Task

10 System Display Task

14 System Status Task

18 Startup, Key Press Processing, Menus Task

1C Parallel Port Read Buffer Manager

20 Parallel Port Write Buffer Manager

24 NVEE Manager

28 Scheduler

2C Job Log

30 Print File Task

34 Video Cleanup Task

3C Collation T ask

40 Parallel Port Hear Task

48 PostScript Task 1. Replace the hard drive before replacing the controller

board.

4C PostScript Task 2

50 PostScript_Wrapper Task

54 PCL Task. Replace the hard drive before replacing the controller board.

58 PJL T ask

78 Dequeue T ask

84 In-menu Print File Task

8C Alert Recovery Task

90 Sweeper T ask

94 SNMP Alert Task

98 SNMP Main Task

9C SNMP UDP Task

A0 SNMP DDP Task

A4 SNMP IPX Task

A8 Notification Manager

B4 Image Handler

C4 Job Manager

D0 PowerSa ver Task

D4 TIFF T ask

28 Phaser 2135 Color Printer

Page 42

Troubleshooting

This topic discusses troubleshooting the printer. Troubleshooting is discussed

with two approaches:

A step-by-step verification procedure that systematically confirms that

■

particular components of the printer are properly functioning until a

problem is found.

A symptom/cause scheme that lists particular printer failures or error

■

codes and their possible causes.

Fault History Log

The printer maintains a log file of the last 50 errors that have occurred. The most

recent error is displayed first.

To view the log:

1.

Turn on the printer.

2.

Press the

3.

Press the

4.

Press the

most recent error. Press the

Menu (5)

Item(6)

Value (7)

key to scroll to the

key to scroll to the menu item

key to scroll down the list of errors. The first item is the

Value (3)

Support Menu.

Show Fault History

key to scroll back up the list.

.

Service Guide

29

Page 43

Power on self-diagnostic test

Initial test. The following checks are automatically performed when the printer is

powered on:

1.

ROM check (loader). Checks ROM by comparing the sum of bits in the

received data unit by the number of bits in the transferred data unit.

2.

RAM check. Checks RAM by writing a preset data pattern in RAM, reading

the contents of RAM, and comparing the data read from RAM by the data

written in RAM.

3.

EEPROM check. Checks ID numbers stored in the fixed addresses of

EEPROM. Checks the content of the menu area by control firmwar e and the

engine area by engine firmware.

4.

Flash ROM check. Checks Flash ROM by writing a present data pattern in

Flash ROM, reading the contents of Flash ROM, and comparing the data

read from Flash ROM by the data written in Flash ROM.

5.

Mechanical check.

All the engine fans turned on and are checked to ensure they run

■

properly.

The fuser heaters activate to heat up the heated rollers.

■

■

The print engine checks to see that the imaging drums are installed.

■

The engine motors rotate to ensure that their rotation sensors are

detected.

■

A sensor check is made to determine if any paper is jammed in the

printer.

■

The print engine checks the presence of each toner cartridge.

■

Option unit check. Checks whether the optional units (such as the paper

tray 2, paper tray 3, duplex unit) have been installed before entering the

operation mode.

The print engine performs a color misalignment detection check by

■

laying down patches of toner on the transfer belt and reading their

relative positions to each other with the color registration sensor

assembly.

■

After the fuser reaches its idle temperature the printer is placed on line in

its READY state.

The print engine is initialized. If the startup page feature has not been disabled

and no error occurred with the printer, the printer prints a startup page.

30

Phaser 2135 Color Printer

Page 44

Print engine troubleshooting

This topic is a step-by-step procedure for systematically verifying particular

aspects of the printer's operation. Following this procedure should lead to the

cause of a printer's failure.

Testing the print engine controller board

1.

If the printer does not power up, or does not initialize, or the printer

initializes but the motors do not run properly, go to the later topic,

“Verifying power supply operation” on page 32.

2.

Observe that the

go to the later topic “Verifying power supply operation” on page 32.

3.

To ensure the print engine operates correctly, print one of its internal test

pages from its diagnostic menu as explained in the topic “Test printing” on

page 71.

If the printer prints a test print, then the printer's print engine is working

correctly. Proceed with the next topic, “Verifying printer operation by using its

self-test print” on page 32.

If the printer does not make the test print, then a problem exists with the print

engine. Proceed with the topic, “Verifying power supply operation” on page 32.

Ready

message is displayed on the front panel. If it is not,

Service Guide

31

Page 45

Verifying printer operation by using its self-test print

1.

If not already on, turn on the printer. If the printer does not power up, or

does not initialize, or the printer initializes but the motors do not run

properly, go to the next topic “Verifying power supply operation.”

2.

Verify that the system controller board’s health LED is flashing. The health

LED is viewable through the rear panel. If the health LED is not flashing,

then the system controller board is not working.

3.

When the

Ready

message is displayed, press the

Menu (1, 5)

buttons to

enter the menu.

4.

Press the

Item (2, 6

Menu (1, 5)

buttons to navigate to the

Print Menu

item. Press the

) keys to scroll through the list of available test prints. Select any

test print.

5.

Press

Enter

to print a test prints. The printer should print a test page from

the system controller board.

If the printer prints a test pattern, then the print engine controller board and the

system controller board are working correctly and the printer's problem resides

with the network or host interface.

Verifying power supply operation

Required tools

#1 Phillips screwdriver

■

■

Digital multimeter (DMM)

Verifying the power supply involves four steps:

Measuring the input and output voltages.

■

Checking the power supply fuse.

■

Checking the safety interlocks.

■

Ensuring the +5 VDC loop is complete.

■

Testing for a shorted motor which would shut down the power supply

■

or damage the engine controller board.

Measuring power supply voltages

1.

Turn off the printer and unplug it from its power outlet.

2.

AC Input:

being supplied to the printer. It should measure between 87 to 128 VAC

(115 VAC nominal) or 174 to 250 VAC (220 VAC nominal).

32

With the DMM set to measure AC voltages, measure for power

Phaser 2135 Color Printer

Page 46

3.

Power supply fans

: With the power switch on, ar e the fr ont and rear power

supply fans running? (Access the fans by removing the front and rear

covers.) If not, check the fans’ wiring harnesses (CN2 and CN5) to the

low-voltage power supply board; each fan’s voltage should measure 32 to

38VDC (the voltage drops to zero when you disconnect a fan). If the

voltage is not correct, replace the low-voltage power supply. Otherwise,

replace the non-functioning power supply fan.

DC Output:

With the DMM set to measure DC voltages, measure the voltages at

the POWER connector on the bottom of the print engine controller board for

+3.3VDC, +5 VDC, +12 VDC and +32 VDC. (You must remove the rear cover and

rear shield plate to access the engine controller board.)

If the voltages are not correct, inspect the wiring harness connecting the POWER

connector of the engine controller board to the CN1 connector of the low-voltage

power supply. If the harness is undamaged, replace the power supply.

POWER connector pinout

Pin Voltage/Signal Level Pin Voltage/Signal Level

1 +12 VDC 16 +3.3 VDC

2 No connection 17 +3.3 VDC

3 Ground 18 +3.3 VDC

4 Ground 19 No connection

5 Ground 20 Signal

6 Ground 21 Signal

7 +32 VDC 22 Signal

8 +32 VDC 23 Signal

9 +32 VDC 24 Signal

10 +32 VDC 25 Ground

11 +5 VDC 26 Ground

12 +5 VDC 27 Ground

13 +5 VDC 28 Ground

14 +5 VDC 29 Signal

15 +3.3 VDC 30 Signal

If DC voltages are not being output by the power supply, proceed to the next step,

“Inspecting the low-voltage power supply fuse” on page 34.

If the +5 and +32 VDC voltages measure correctly, but the printer does not operate

correctly, then proceed to the topic, “Safety interlocks” on page 34.

Service Guide

33

Page 47

Inspecting the low-voltage power supply fuse

The 115 VAC power supply features a 20 A fuse. The 220 V AC power supply fuse

uses a 15 A fuse.

1.

Turn off the printer.

2.

Disconnect the power cord from the printer.

3.

Remove the front cover as described in “Front cover” on page 90.

4.

Remove the AC power switch (1 screw) and the front power supply fan as

described in “Front power supply fan” on page 95. The fuse is now

accessible.

If the fuse is good, but the printer's power supply does not output DC voltages,

replace the low-voltage power supply. Check the +% v loop circuit as described

earlier in “Ensuring the +5 VDC loop is complete” on page 35.

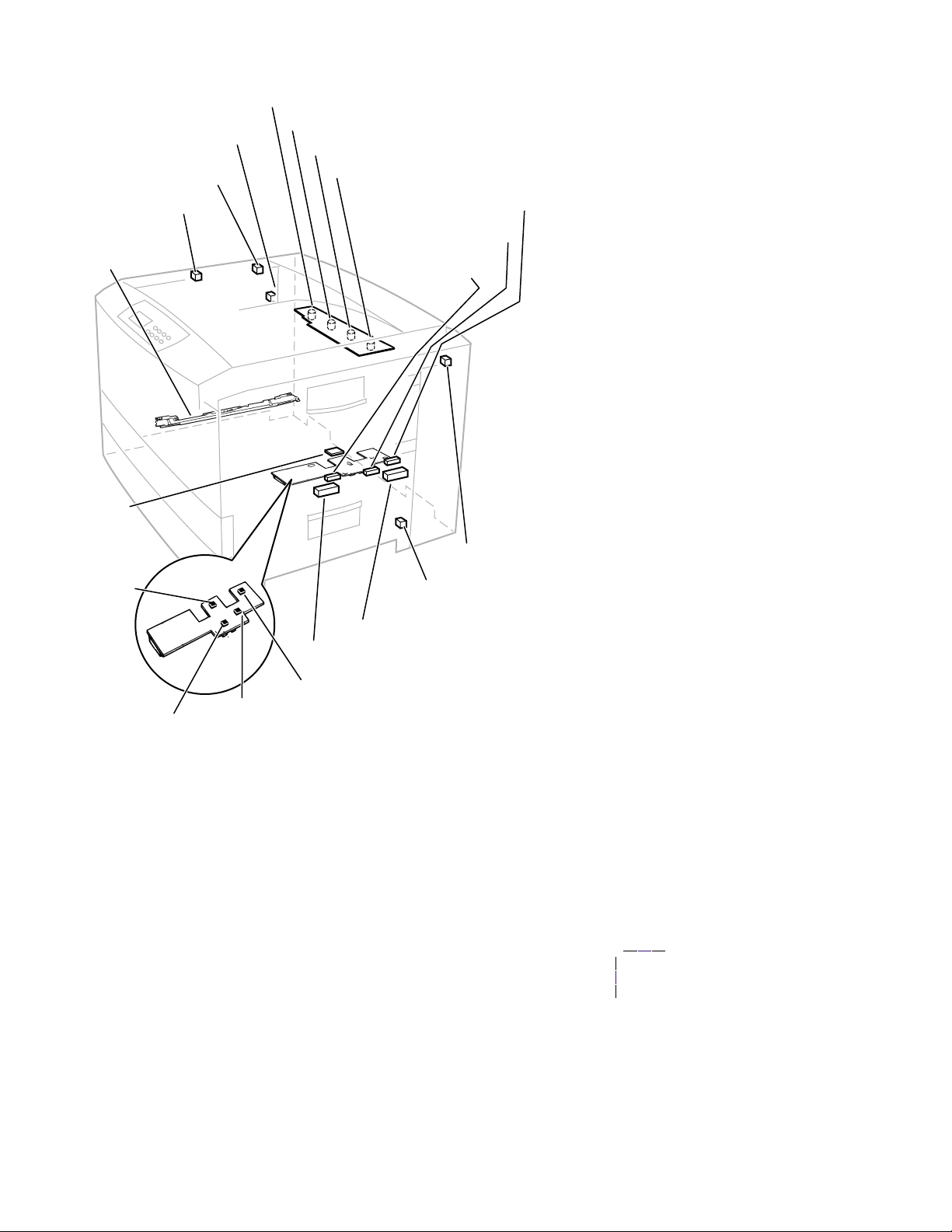

Safety interlocks

The printer features two safety interlock switches:

Top door-opened switch.

■

Right door-opened switch.

■

When the top cover switch is opened, the +32 VDC supply to the motors is shut

down, as well as the high-voltage power supply and an error message is

displayed on the front panel. When the right cover door is opened, the +32 VDC

supply to the duplex unit and high-voltage power supply is disabled.

1.

Turn off the printer.

2.

With a DMM set to measure resistance, test each switch when it is opened

and closed.

3.

Inspect each switch’s wiring harness for pinches, nicks or open connections.

If you find a switch that is defective, replace it. If no motors appear to be at fault,

replace the engine controller board.

34

Phaser 2135 Color Printer

Page 48

Door safety interlock switches

Top Cover

Open Switch

Front Cover

Open Switch

0725-63

Ensuring the +5 VDC loop is complete

The +5 voltage from low-voltage power supply is routed out of the power supply

connector CN1, via a wiring harness, to the POWER connector the engine

controller board, through surface-mount fuse F6, out the engine controller board

via the ribbon cable OPTN to the toner sensor board. The +5V is then routed back

out the toner sensor board through its power supply harness to the low-voltage

power supply connector CN 2.

Upon power-up, if the low-voltage power supply does not detect the return of the

+5 VDC, then the power supply will immediately shut-down. You may see the

CPU fan “bump” or the engine board LED (LED2) flash. To troubleshoot the loop:

1.

Test surface-mount fuse F6 for continuity. It is located on the upper-right

corner of the engine controller board next to the REG connector. If the fuse

is opened, replace the engine controller board.

2.

Inspect the two power wiring harnesses and the ribbon cable that carry the

+5 VDC loop. Ensure they are properly connected. The wiring harness

leading form the toner sensor board to the power supply features an

interconnect next to the rear hinge. Ensure it is properly connected.

Service Guide

35

Page 49

3.

Disconnect the POWER wiring harness (red wire bundle) from the engine

controller board. Also, disconnect the power wiring harness interconnect

connecting the toner sensor board’s white wire harness to the low-voltage

power supply board’s dark-gray wire harness. The interconnect is located

by the rear hinge.

Run a jumper wire from the +5V pins of the first wiring harness (pins 11 14, red wire bundle) to the +5V pin (pin 9, dark-gray wire bundle) of the

second power wiring harness. (With the jumper wire, you are bypassing

the engine controller board, the OPTN ribbon cable and the toner sensor

board).

Turn the printer on. If the jumper connection is correct, the low-voltage

power supply will start and the power supply fans will run. This indicates

the problem lies with the engine controller board or the toner sensor board

or their wiring. If the low-voltage power supply does not turn on, it is

probably bad. (Ensure your jumper connection is correct.)

Testing for a shorted motor

1.

Remove the top and rear covers.

2.

Disconnect the motor harnesses and verify motor resistances (see the

following topic).

3.

Refer to the topic “Wiring Diagram” on page 215 for a diagram that locates

each connector.

4.

Turn on the printer again to see if it overloads now that the motors are

disconnected from the engine driver board.

If the power supply still does not function, replace it.

36

Phaser 2135 Color Printer

Page 50

Motor and fuser roller resistances

1.

Turn off the printer and disconnect the power cord.

2.

With a DMM set for measuring resistance, test each motor's windings for

correct resistance (disconnected from the printer).

Motor and fuser roller resistances

Motor Measure between ... Resistance

~3

Yellow drum unit motor

Magenta drum unit motor

Cyan drum unit motor

Black drum unit motor

Between motor Pins 1 and 2

Between motor Pins 3 and 4

All the drum motors connect to

connector ID at the top of the

engine controller board

Black Pins 1 thru 4

Yellow Pins 5 thru 8

magenta Pins 9 thru 12

Cyan Pins 13 thru 16

Transfer belt motor

Registration motor

Fuser motor

Main feed drive motor

Between motor Pins 1 and 2