Xerox DocuPrint 100 EPS, DocuPrint 135, DocuPrint 115 EPS, DocuPrint 135 EPS, DocuPrint 155 EPS Installation Planning Manual

...Page 1

Xerox DocuPrint 100/115/135/155/180 EPS

installation

planning

701P24750

April, 2005

guide

Page 2

Prepared by:

Xerox Corporation

Global Knowledge and Language Services

800 Philips Road Bldg. 845-17S

Webster, New York 14580

USA

©2005 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and information

now allowed by statutory judicial law or hereinafter granted, i ncluding without limitation, material generated

from the software programs di splayed on the screen such as ic ons, screen displays, or look s.

Printed in the United States of America.

XEROX® and all Xerox product names mentioned in this publicat i on are trademarks of XEROX CORPORATION.

Other company trademark s are al so acknowledged.

Changes are periodically made to thi s document. Changes, tec hni cal inaccuracies, and

typographic errors will be corrected

in subsequent editions.

Page 3

Safety

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Radio and telecommunications equipment directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Introduction

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Table of contents

1 Product overview

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Client workstations and system software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Supported hardware and operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Client networking software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

MICR printing features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

MICR fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Unsupported features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Host connectivity options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Remote Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2 Controller components and options

Controller overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Sun workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Controller interface options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Online interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Tape drive option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3 Printer components and options

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation Planning Guide

i

Page 4

Table of contents

Printer configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Bypass transport option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Roll feeder support (DP155 and DP180 EPS only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4 Preparing for installation

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Xerox responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Customer responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installation planning checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Connectivity requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Ethernet specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Token Ring specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Channel-attached specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5 Controller requirements and specifications

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Controller placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Guidelines for controller placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Controller hardware specifications and requirements summary . . . . . . . . . . . . . . . . . . . . . . . . 5-4

6 Printer requirements and specifications

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

60 Hz printer outlet voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

50 Hz printer outlet voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Printer configurations available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printer configuration diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Bypass transport specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Bypass transport dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Configuration diagrams with bypass transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Space planning guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Clearance space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Shared space between components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Shared space configuration diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Floor leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Delivery access requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Turning radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Printer hardware specifications and requirements summary . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Space planning templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

7 System connections

Cable lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Cable locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Channel attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8 Installation

ii Installation Planning Guide

Page 5

Installation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Your responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Defining the printer to the host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Software licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Ongoing maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Meter reading and reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

A Supplies

Paper and other throughput stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Selecting paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Paper sizing and print speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Paper care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Other supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Dry ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Fuser agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Cartridge tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Stacker containers and pallets (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Consumable supplies tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Paper and special stocks tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Complete supplies list for the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Ordering supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

Table of contents

Paper width and throughput speed (LCDS printing only) . . . . . . . . . . . . . . . . . A-3

Paper size and pitch mode minimum and maximum . . . . . . . . . . . . . . . . . . . . A-5

Feed direction for standard paper sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

B Xerox support services

Xerox Customer Service Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Xerox Printing Systems Customer Support Center (U. S.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Xerox Documentation and Software Services (U. S.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Xerox Customer Education . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B -3

Xerox Font Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

C Related publications

DocuPrint 100/115/135/155/180 EPS documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

NPS/IPS publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Index

Installation Planning Guide iii

Page 6

Table of contents

iv Inst allation Planning Guide

Page 7

Laser safety

Safety

WARNING: Adjustments, use of controls, or performance of

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certifi ed to comply with the

performance standards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or sh ields that must be

removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

Ozone information: U. S. only

Installation Planning Guide v

This product produces ozone during normal operati on. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental p a rameters specified in the

Xerox installation i nstructi ons ensure th at concent ration l evels are

within safe limits. If you need additional information concerning

ozone, call 1-800-828-6571 to request the Xerox publication

Facts About OZONE.

Page 8

Safety

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with environment al

standards. Please observe the following precautions to ensure

your continued safety.

WARNING: Improper connection of the equipment grounding

conductor may result in risk of electrical shock.

• Always connect equipment to a properly grounded elect ri cal

• Never use a ground adapter plug to connect equipment to an

• Always place equipment on a solid support surface with

• Always use materials and supplies specifically designed for

outlet. If in doubt, have the outlet checked by a qualified

electrician.

electrical outlet that lacks a ground connection terminal.

adequate strength for its weigh t.

your Xerox equipment. Use of unsuit able materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the controller without first

contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord f rom the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United St ates:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

vi Installation Planning Guide

Page 9

Operation safety: Europe

This Xerox product and supplies are manufactured, tested and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised alteration, whic h may include the addition of

new functions or connection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Wa rning markings

All warning instructions marked on or suppli ed with the product

should be followed.

This WARNING alerts users to areas of the produc t where there is

the possibility of personal damage.

Safety

Electrical supply

This WARNING alerts users to areas of the product where there

are heated surfaces, which should not be touched.

This product shall be operated from the type of elec trical supply

indicated on the product’s data plate label . If you are not sure that

your electrical supply meets the req uirements, please consul t your

local power company for advice.

WARNING

This product must be connected to a protective eart h cir cuit. This

product is supplied with a plug that has a protectiv e earth pi n. This

plug will fit only into an earthed electrical outlet. This is a safety

feature. Always connect equipment to a properly grounded

electrical outlet. If in doubt, have the outlet checked by a qualified

electrician.

Installation Planning Guide vii

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Page 10

Safety

Ventilation

Slots and opening in the enclosure of the product are provided for

ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheati ng.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to rest rict operator access to safe

areas only. Operator access to hazardous areas is restricted with

covers or guards, which would require a tool to remove. Never

remove these covers or guards.

Maintenance

Before cleaning your product

CE mark: Europe only

Any operator product maintenanc e procedures will be descr ibed in

the user documentation supplied with the product. Do not carry

out any maintenance on the product, which is not descr ibed in t he

customer documentation.

Before cleaning this pro duct, unplug the product from the el ectrical

outlet. Always use materials specifi cally designated for this

product, the use of other materi als may result in po or performance

and may create a hazardous situation. Do not use aerosol

cleaners, they may be flammable under certain circumstances.

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336/EEC, appr oximation of

the laws of the member states related to electromagnetic

compatibility.

viii Installation Planning Guide

Page 11

March 9, 1999: Council Directi ve 99/5/EC, on radio equipment and

telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives and

referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment thi s product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Dir ective 89/36/EEC.

Radio and telecommunications equipment directive

Safety

Europe only

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog publi c switched

telephone network (PSTN) in accordance with Directive 1

999/5/EC.

The product has been designed to work with the national PSTNs

and compatible PBXs of the following countries:

• Austria • Germany • Luxembourg • Sweden

• Belgium • Greece • Netherlands • Switzerland

• Denmark • Iceland • Norway • United Kingdom

• Finland • Ireland • Portugal

• France • Italy • Spain

In the event of problems, contact your local Xerox representative

in the first instance.

Installation Planning Guide ix

This product has been tested to, and is compliant wit h, TBR21, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

Page 12

Safety

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no user-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliabl e and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, inval idat es its

certification.

For further information

For more information on Environment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

x Installation Planning Gu ide

Page 13

About this guide

Introduction

This document helps you prepare for delivery and installation of

your new Xerox DocuPrint printing system.

This guide is intended for the person responsible for coordinating

the installation of the Xerox DocuPrint 100/115/135/155/180

Enterprise Printing System at your site. It lists the tasks you must

complete before installation can begin, as well as your

responsibilities during the installation. This guide i s a companion

to the Getting Ready for Installation manual.

NOTE: All information in this guide, unless otherwise stated,

pertains to the Xerox DocuPrint 100/ 115/135/155/180 EPS

printers.

Contents

The Inst allat ion Planning Gui de is one of several manuals that are

available for your new printing system. You receive it in advance

of hardware delivery to help you prepare your site for the delivery

and installation of the system. A set of user material will be

delivered with the system.

Before using this guide, become familiar with its contents and

conventions.

This guide contains the following:

• Chapter 1, “Product overview,” provides an overview of the

Xerox DocuPrint 100/115/135/155/180 Enterprise Printing

System.

• Chapter 2, “Controller components and options,” describes

controller hardware, software, and options.

• Chapter 3, “Printer components and options,” describes

printer components, configurations, and options.

• Chapter 4, “Preparing for installation,” provides a checklist of

tasks that must be accomplished before the in stallat ion. It also

explains connectivity requirements for submitting documents

from the host or client to the printing system.

Installation Planning Guide xi

• Chapter 5, “Controller requirements and specifications,”

Page 14

Introduction

describes power, environmental, and space requirements for

the controller.

• Chapter 6, “Printer requirements and specifications,”

describes power, environmental, and space requirements for

the printer. Space planning guidelines and diagrams are

provided to help you set up the work area.

• Chapter 7, “System connections,” provides cable requirement s

for the printing system.

• Chapter 8, “Installation,” describes the activities that occur

during installation. It also describes ongoing maintenance

activities.

• Appendix A, “Supplies,” describes how to sel e ct, store, and

use supplies for the printing system. It also provides a list of

consumable supplies you can order.

• Appendix B, “Xerox support services,” explains how to utilize

available Xerox support services.

• Appendix C, “Related publications, ” lists other Xerox

documents that are part of this publication set.

Conventions

• An index is provided at the end of this document.

This guide uses the following conventions :

• Initial capita l and an gle brackets: Within procedures, the

names of keys are shown with an initial capital and within

angle brackets (for example, pr ess <Enter>).

• Angle brackets: Variable information, or the position of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <pattern>).

• Fixed pitch font: Within procedures, text and numbers that

you enter are shown in a bold, fixed pit ch (“computer”) font (for

example, enter privilege operator).

Messages that appear on the controller screen are shown in

the medium weight fixed pitch font (for example, Online

Gateway disabled).

• The word “enter” within procedures: The two-step process

of keying in data and pressing <Enter> (for example, enter y).

xii Installation Planning Gu ide

• Italics: Document and li brary names are shown in italics (for

example, the Xerox DocuPrint NPS/IPS Guide to Managing

Print Jobs).

Variable elements in a command or directory path are also

shown in italics (for example, var/spool/XRXnps/ filename).

Vertical bars: Alternatives to specified arguments are

separated by vertical bars (f or example, Set Time <Time |

Page 15

Notice

Introduction

Remote Host Name | IP Address>).

NOTE: Notes are hints that help you perform a task or under stand

the text.

CAUTION: Cautions alert you to an action that could damage

hardware or software.

WARNING: Warnings alert you to conditions that may affect the

safety of people.

This publication may contain descriptions of concepts and

features not currently available for your Xerox printing system.

Consult your Xerox sales represent ativ e or your operat in g system

software program descripti on for additional information.

Installation Planning Guide xiii

Page 16

Introduction

xiv Installation Planning Guide

Page 17

System overview

1 Product overview

This chapter provides an overview of the features and functions of

the Xerox DocuPrint 100/115/135/155/180 Enterprise Printing

System (EPS).

The Xerox DocuPrint 100/115/135/155/180 EPS prints high

quality, high resolution monochrome documents in simplex (onesided) or duplex (two-sided) at high production speeds from

LCDS, PostScript, PCL, IPDS, and other data streams.

The printer supports:

• Duplex printing

• Offline printing of data from 9-track and 18/36-track tape

drives

• Media handling of multiple weights, sizes, and types

• Optional modules for enhanced finishing and output to third

party devices

• Optional high capacity feeder stacker modules, which provide

additional feeder trays and output bins

• High resolution printing of supported data streams (shown in

the following table)

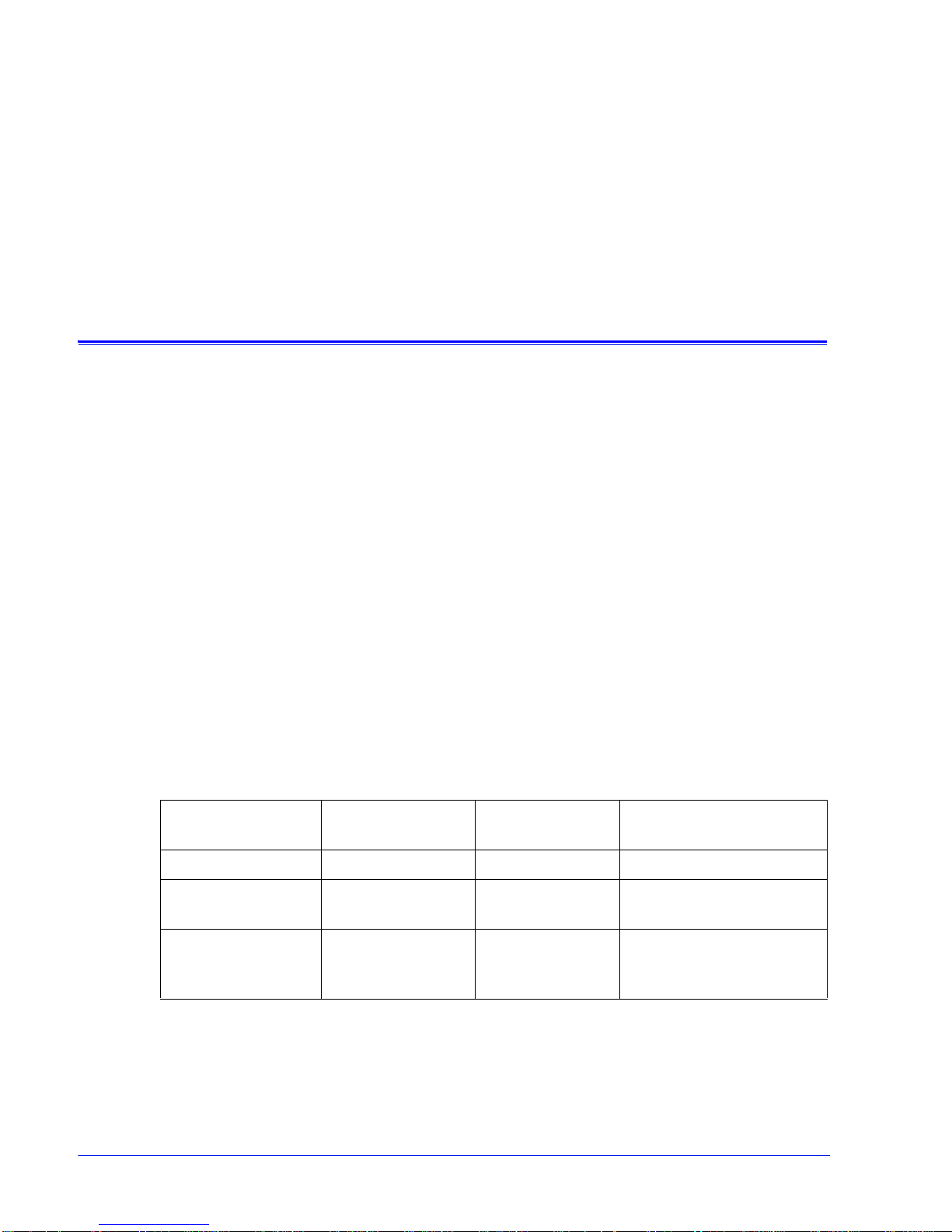

Table 1-1 Data stream resolution

Data stream Input resolution Print resolution:

DP155 and DP180

LCDS 300 by 300 dpi 600 x 2400 dpi 600 by 600 dpi

PostScript and PCL 300 by 300 dpi or

600 by 600 dpi

IPDS* 240 by 240 dpi* or

300 by 300 dpi or

600 by 600 dpi**

600 x 2400 dpi 600 by 600 dpi

600 x 2400 dpi 600 by 600 dpi

Print resolution:

DP100, DP115, and DP135

Installation Planning Guide 1-1

*Requires additional equipment to enable.

**600 by 600 dpi input resolution support ed for f u ll page IOCA

only

Page 18

Product overview

System components

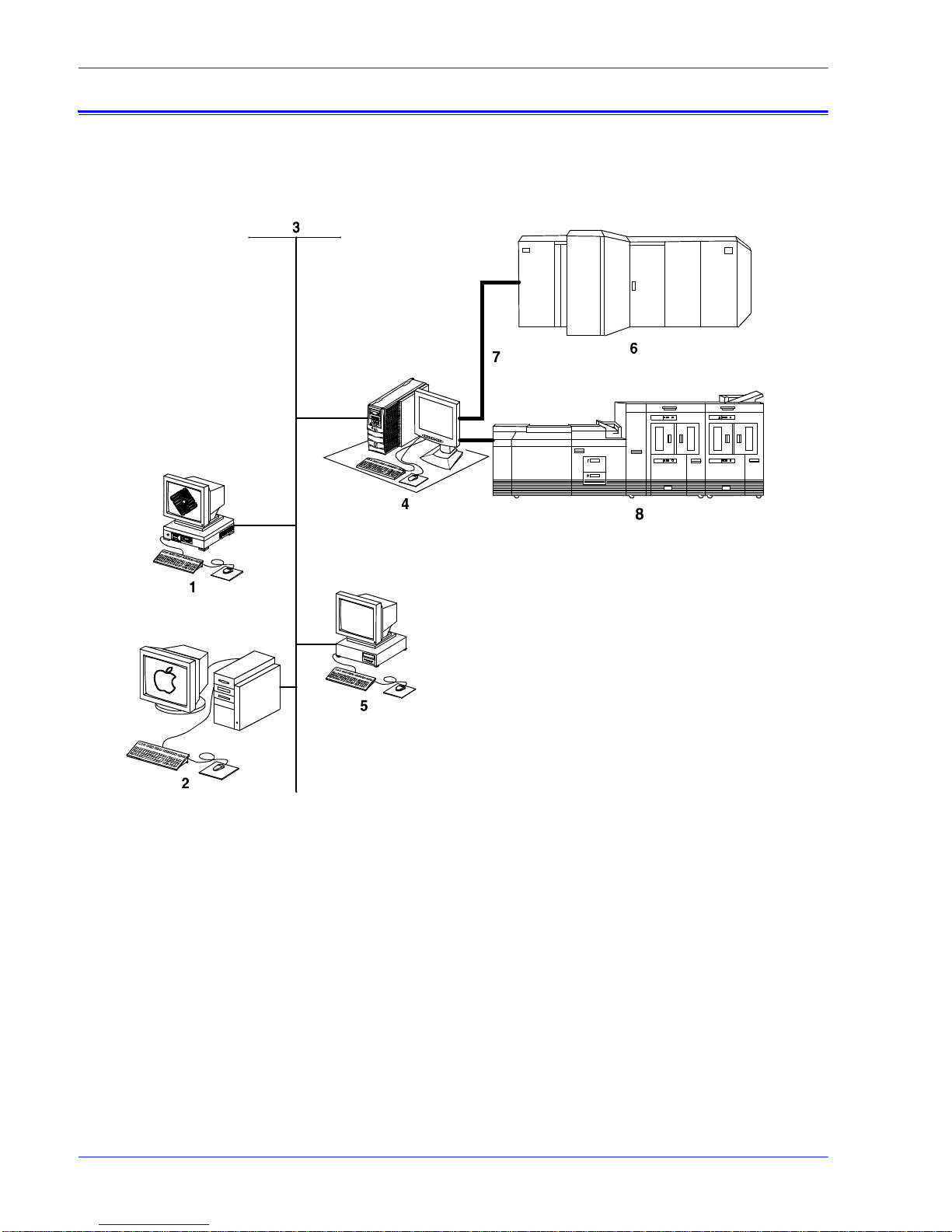

The following figure shows the configurations supported for the

Xerox DocuPrint 100/115/135/155/180 EPS.

1-2 Installat ion Planning Guide

QTC0702A-SOR

Figure 1-1 Configurations supported by Xerox DocuPrint

100/115/135/155/180 EPS

1. Sun UNIX client workstation

2. Apple Macintosh client workstation

3. Network connection

4. Controller

5. PC client workstation

6. Mainframe host computer

7. Bus and tag cables (channel connection)

8. Print engine

The following sections briefly describe the functionality of each

system component.

Page 19

Product overview

DocuPrint 100/115/

135/155/180 EPS

Customer-supplied

client workstation

The DocuPrint 100/115/135/155/180 EPS includes the controller,

printer and all appropriat e sof tware. “DocuPri nt printe r” or “pr inter”

refers to the base printer engine (IOT) only.

NOTE: Some printer configurations may include a control console

(not shown).

A host mainframe computer or network-connected PC, Apple

Macintosh, or Sun UNIX client workstati on submits print jobs to

the printing system. The print job may be in any of the following

data formats:

• PostScript levels 2 and 3

• HP PCL5c, PCL5e, and PCL6: Hewlett-Packard Print Control

Language

• LCDS: Line Conditioned Data Stream

• IPDS: Intelligent Printer Data Stream

• ASCII: American Standard Code for Information Interchange

• PDF: Portable Document Format

• TIFF: Tagged Image File Format

• VIPP: Variable Data Int elligent PostScript Print Ware

Customer-supplied

network and

channel connection

Xerox-supplied

controller

NOTE: Enablement of IPDS data format may require additional

equipment. Contact your local Xerox representative for more

information.

The customer needs to supply one or more of the following

communication connections:

• Ethernet local area network (LAN) running TCP/IP, AppleTalk,

or Novell NetWare network protocol software.

• Online (channel-attached): Bus and tag cables supporting the

IBM 3211/4245 interface.

• Token ring LAN running TCP/IP, Novell 3.x, or AppleTalk

network protocol software.

NOTE: Enablement of channel-attached and Token Ring

communication connection requires additiona l equipment. Contact

your local Xerox represent ative for more information.

The controller (monitor, processor, DVD drive, keyboard, mouse,

diskette drive, and cartridge tape drive) accepts the print job from

the host mainframe computer or network-connected client

workstation, converts the files into page images, and sends the

page images to the print engine. External 9-track and 18/36-track

tape drives can be used for resource loading and for offline

printing.

Xerox-supplied

printer

Installation Planning Guide 1- 3

The printer (also known as t he image output termina l [IOT] or pr int

engine) accepts page image dat a from the controller and prints

the document according to the print options specified by the user.

The printer also handles paper stacking, collating, and optional

finishing.

Page 20

Product overview

NOTE: It is the responsibility of the customer to supply , ins tall, and

maintain hardware and software on any PC, Sun workstation, or

Macintosh workstation that is used to generate documents for

printing on the DocuPrint 100/115/135/155/180 EPS. You are also

responsible for obtaining, installing, and maintaining the required

Ethernet local area network , transceivers, b us and tag cables, and

any other connecting cables.

The Xerox DocuPrint 100/115/135/155/180 EPS prints LCDS data

from a mainframe host computer, emulating an IBM 4245 or 3211

line printer. The printing system can receive data over a channel

through bus and tag cables and throug h the Socket Gateway or lpr

using TCP/IP protocol.

Table 1-2 Throughput speed

Printing

system

Maximum

throughput

speed

Maximum throughput

speed with 7 by 10 inch/

178 by 254 mm paper

DP100 EPS 100 ppm 100 ppm

DP115 EPS 115 ppm 115 ppm

DP135 EPS 135 ppm 154 ppm

DP155 EPS 155 ppm 155 ppm

DP180 EPS 180 ppm 206 ppm

NOTE: Maximum throughput speed with 7 by 10 inch / 178 by 254

mm paper requires the 7 by 10 inch enablement kit.

Xerox is responsible for the phys ical inst alla tion and ser vice of the

printer and controller hardware and software components. You

have the general responsibility for the site of ensuring that the

correct personnel, supplies, and network hardware and software

are available. Refer to the “Pr ep ari ng for ins t all ation” chapt er for a

detailed description of the shared responsibilities of the customer

and of Xerox.

Client workstations and system software

1-4 Installat ion Planning Guide

To submit print jobs to the printing system, the customer needs to

provide the proper client hardware as well as operating system

and network software.

Page 21

Supported hardware and operating systems

The Xerox DocuPrint 100/115/135/155/180 EPS supports the

following types of networked client wo rkstations and operating

systems:

• Sun Workstation r unning Solaris 2.3 or higher

• PC running MS-DOS 5.0 or higher , using Ethernet with TCP/IP

or Novell NetWare 3.11 or higher, Windows 95/98, Windows

NT 4.0, Windows Millennium, Windows 2000, or Windows XP

• PC running MS-DOS 5.0 or higher, with one or more of the

following TCP/IP packages:

– PC/TCP Network Software by FTP Software, Inc.

– Pathway Access by Wollongong Group, Inc.

– PC-NFS by Sun Select

• Apple Macintosh running 8.6 through 9.x, or 10.1 or higher in

Classic mode, using AppleTalk through Ethernet

• Any system that supports RFC-1179 lpr/lpd

The printing system software may be compatible with workstation

models and software versions other than those l ist ed above.

Product overview

Client networking software

Xerox client software, a third-party TCP/IP lpr networking

software, Novell, or Apple/Macintosh Printer Access Protocol

(PAP) networking softw are must be installed on your client

workstations or downloaded from the controller. This software

provides an interface with the contro ller, which allows you to

submit print jobs and check job status.

NOTE: The printing options that are available to a client user vary

according to the networking software loaded on the client

workstation.

Additional information on submitting j obs from a cli ent workstation

is specified in othe r documents that are p art of this publicati on set.

MICR printing features

The DocuPrint 100/115/135/155/180 MX systems produc e a

Magnetic Ink Character Recognition (MICR) line on negotiable

and turnaround documents such as checks and bills. The MICR

printing system prints documents using magnetic ink and special

fonts to create machine readable information that allows for quick

document processing.

Installation Planning Guide 1- 5

Page 22

Product overview

In general, MICR is used to print accounting and routing

information on blank checks and ot her negotiable document s. The

magnetic encoding capabil iti es can be used f or any pri nted out put.

The following illustrates a check printed with a MICR line in U.S.

format. The entire MICR line, which consist s of numbers and

characters (called symbols), is printed using magnetic ink.

ERA

PAY ROLL ACCOUNT

PAYTOTHE ORDER OF

ERA CORP O R ATION P.O.BOX 9968 KENAN,N.Y.146008

JEAN L.MAGNIN

484 NORTH PROSPECT

CARUBA BEACH, CA 80297

PAYABLE IF DESIRED AT SOUTHERN PACIFIC

NATIONALTRUST AND SAVINGS ASSOC.

OMAHA, NEBRASKA

SECURITYTRUST COMPANY OF KENEAN,N.Y.

Figure 1-2 Example of a check printed with MICR line (U. S.)

The DocuPrint 100/115/135/155/180 MX systems meet ABA

standards and ANSI and ISO specifications for automatic check

handling. They print the variable data and the MICR line at the

same time. This single-p ass printing c apability reduc es processing

time and costs.

06-29-84

VOID AFTER 90 DAY S

NOT NEGOTIABLE

$* * * *980 28

12-35/9290

DOLLARS CENTS

MICR Line

1962721

$980.28

50-16

223

MICR fonts

MICR fonts The MICR fonts include the following .

1-6 Installat ion Planning Guide

Xerox provides a set of 300 and 600 dpi E13B and CMC7 MICR

fonts for use with your DocuPrint 100/115/135/155/180 MX

system. To receive the high print qu ality gua ranteed by Xerox, yo u

must use these MICR fonts.

CMC7 fonts have been adopted in vari ous countr ies out side of the

U.S., and are the official standard in France. Like the E13B font,

they are magnetically readable, but wit h a different character

design and recognition criteria. (Currently, CMC7 is available only

through Xerox Europe.)

E13B fonts:

• E13B

• E13B Landscape

Page 23

Product overview

• E13B Test

• E13B Test Landscape.

CMC7 fonts:

•CMC7

• CMC7 Landscape

•CMC7 Test

• CMC7 Test Landscape

The “Test” fonts are non-readable MICR hollow bitmap (or outline)

fonts, provided for testing MICR applications and printing nonnegotiable documents.

LCDS MICR fonts The MICR fonts that are used for printing an LCDS data stream

include the following.

E13B4 fonts:

• E13B4 Portrait

• E13B4 Landscape

• E13B4 Inverse Portrait

• E13B4J

CMC7 fonts:

• CMC74 Portrait

• CMC74 Landscape

• CMC74 Inverse Portrait

• CMC74J

Unsupported features

The DocuPrint 100/115/135/155/180 EPS does not support the

security and audit feature or bar code reading. In addition,

although the Line Thickening selection and the Virtual Printer

Imaging parameters are available when you use MICR, using

these features when printing MICR documents is not

recommended, as they corrupt the MICR line.

In general, all print quali ty adj ustm ent s and enhance ment sett ing s

should be set at the nominal settings when printing MICR output.

Host connectivity options

Installation Planning Guide 1- 7

The Xerox DocuPrint 100/115/135/155/180 EPS can receive data

in the following w a y s:

• Over a channel through a bus and tag cable connection

• Through a network interface, using Novell, TCP/IP, or

Page 24

Product overview

Remote Services

AppleTalk protocols

Your system may have one or both of these configurations.

Remote Services is a web based application that enables direct

communication between DocuSP and Xerox support. This service

enables:

• Quick resolution of First Call issues

• Automated workflow monitoring

• Real-time trouble-shooting and analysis of print jobs

• Live demonstrations of new product features

For additional information, contact your local Xerox

representative.

1-8 Installat ion Planning Guide

Page 25

2 Controller component s and

Controller overview

options

This chapter describes the components and options available for

the Xerox DocuPrint 100/115/135/155/180 EPS controller.

The controller receives dat a from a mainframe host or a

workstation client, processes the data, and sends it to the printer.

The controller also provides the printer with print data and

commands, and receives status information from the printer.

The controller consists of a high performance Sun workstation

processor running Solaris s oftware. Al so resident on th e controller

is the DocuSP software, which manages all printing, diagnostic,

and administrative functions on the pr inting system.

The DocuSP software includes a full colo r graphical user interface

(GUI). Using the GUI, you set up and configure the system, set up

and implement system options, and manage print jobs.

DocuSP remote access

(Remote Workflow)

Remote Workflow, a remote graphical user interface, is available

for installation from a CD. The remote GUI allows you to manage

your DocuSP-based printers from a single PC or Sun work stati on.

You may set your preferences from the remote client to disable or

enable some or all connections.

Remote Workflow allows you to configure the printers that you

want to manage, and provides real t ime status of the printer s. You

may switch between the printers that you are managing, but you

can display only one printer GUI at a time.

The Remote Workflow GUI looks and functions the same as the

local DocuSP GUI on the controller.

Controller components

The controller consists of a specially-configured Sun workstation

and uses proprietary Xerox hardware, firmware, and software.

Your controller has one of two possible configurations, described

in the following sections.

NOTE: Controller hardware configurations are subject to change,

to keep up with technology advances.

Installation Planning Guide 2-1

Page 26

Sun workstation

Sun Blade 1000/2000

configuration

The controller is based on either the Sun Blade 1000/2000, Sun

Blade 2500, or the Sun W1100z workstations with highperformance architecture for complex processing tasks.

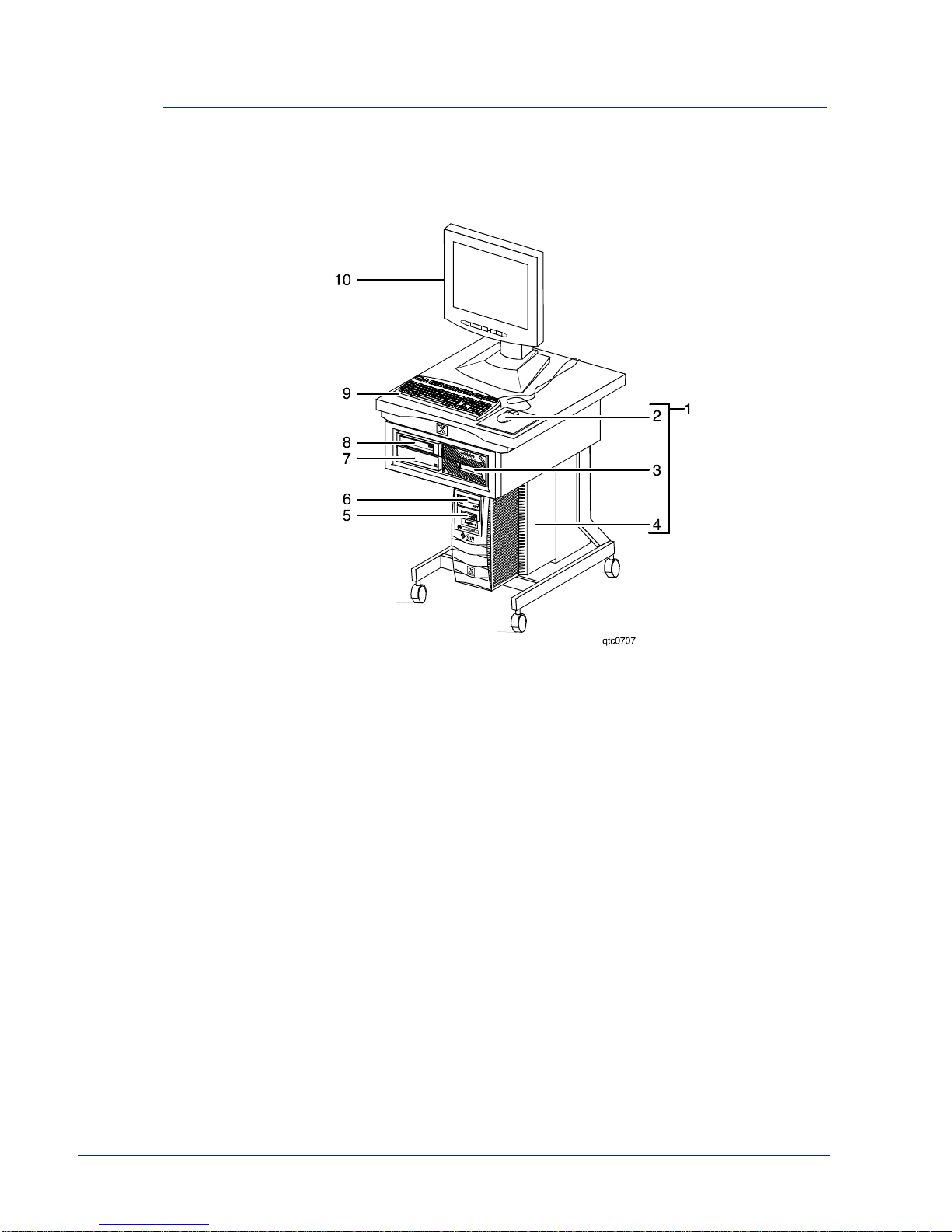

Figure 2-1 Sun Blade 1000/2000 controller

1. Controller stand

2. Mouse

3. 18/36-track cartridge tape drive (optional)

4. Processor

5. Diskette drive

6. CD drive

7. Quarter-inch cartridge (QIC) tape drive

8. External fixed disk drive (optional)

9. Keyboard

10. Display monitor

The Sun Blade 1000/2000 contains the following hardware

components:

• Processor (system unit) containing the following:

– One or two UltraSPARC III high-speed central processing

unit (CPU) modules

• DP 100, 115, and 135: 1 CPU

• DP 155 and 180: 2 CPUs

Installation Planning Guide 2-2

Page 27

NOTE: In XE, all printers use a dual CPU configuration.

– 1 or 2 GB of memory (one or two 1-GB Dual In-line

Memory Modules, or DIMMs)

• DP 100, 115, and 135: 1 GB

• DP 155 and 180: 1 or 2 GB

NOTE: In XE, all printers use a 2 GB memory

configuration.

– Hard disk drive

• Sun Blade 1000: 36 GB

• Sun Blade 2000: 73 GB

– CD drive

– Diskette drive: uses 3.5 inch, 1. 44 MB, double-sided, high-

density diskettes

– Ethernet

– Two Printer Controller Interface (PCI ) boards to interface

with the printer

– PGx64 video graphics board

• Universal Serial Bus (USB) keyboard and three-button mous e

• 17-inch flat panel monitor

Installation Planning Guide 2-3

Page 28

Sun Blade 2500 and

Sun W1100z

configuration

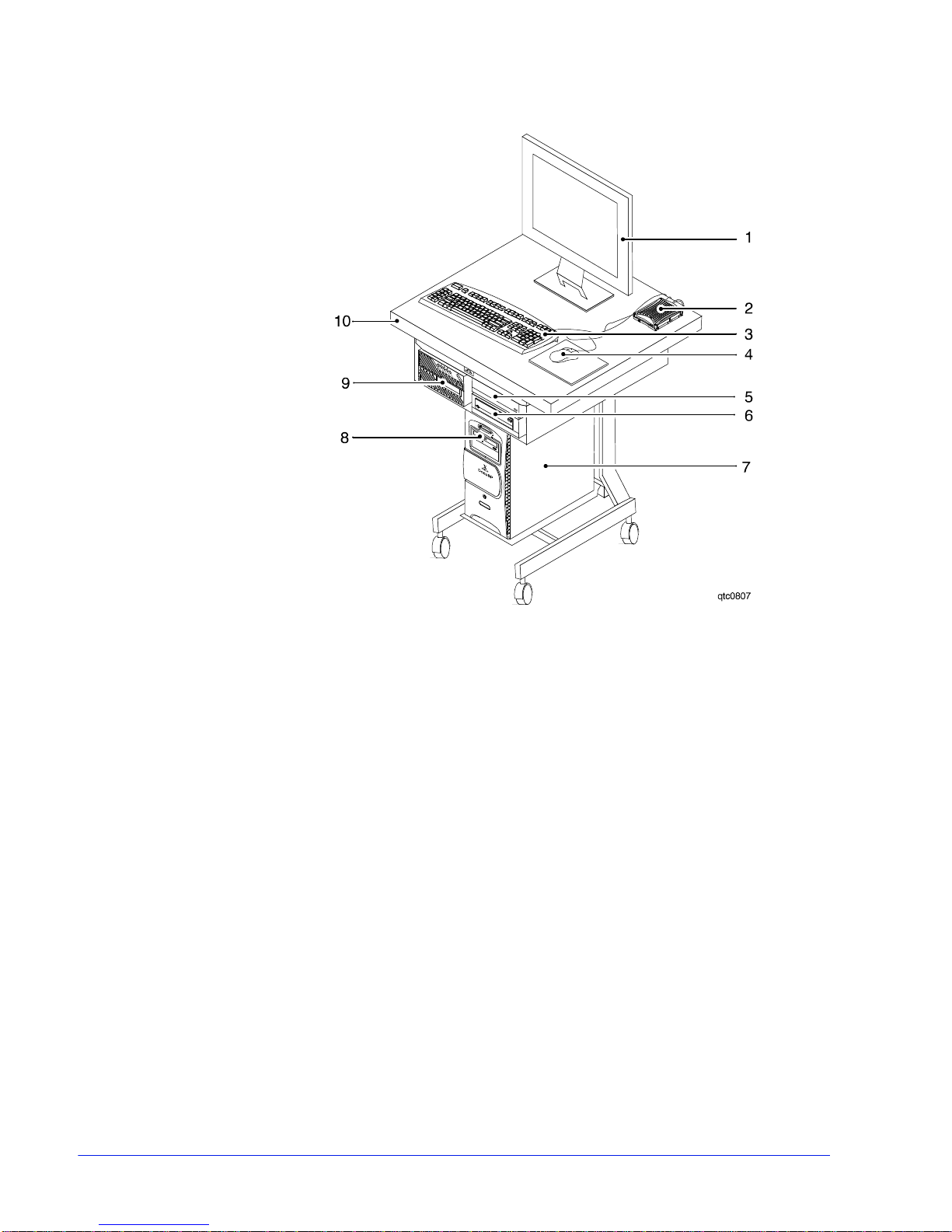

Figure 2-2 Sun Blade 2500 and Sun W1100z controller

1. Display monitor

2. External diskette drive

3. Keyboard

4. Mouse

5. External fixed disk drive (optional)

6. Quarter-inch cartridge (QIC) tape drive

7. Processor

8. DVD/CD-RW drive

9. 18/36-track cartridge tape drive (optional)

10. Controller stand

The Sun workstation contain s the following hardware

components:

• Processor (system unit) containing the following:

– One UltraSPARC IIIi high-speed processing unit (CPU)

module

– 1 or 2 GB of memory (one or two 1-GB Dual In-line

Memory Modules, or DIMMs)

• DP 100, 115, and 135: 1GB

Installation Planning Guide 2-4

• DP 155 and 180: 2 GB

Page 29

NOTE: In Xerox Europe, all printers use a 2 GB memory

configuration.

– 36 GB hard disk drive

– High-density, read-only DVD-ROM drive

– Ethernet

– One or two Printer Controller Interf ace (PCI) boards to

interface with the printer

• DP 100, 115, and 135: 1 board

• DP 155 and 180: 2 boards

– XVR-100 video graphics board

• Universal Serial Bus (USB) keyboard and three-button mous e

• 17-inch flat panel monitor

• Diskette drive (external)

Processor The central processing unit contains the memory, internal disk

drive, a graphics board, a DVD/CD-RW drive, a diskette drive,

power receptacle and outlet, connectors and ports.

• Memory: T wo 1 GB Dual In-line Memory Modules, or DIMMs,

are provided as a standard feature of the processor.

• Hard disk drive: A 36 or 73 GB primary dis k drive is provided

as a standard feature of the processor. The operating system,

the NPS/IPS application, and any queued print jobs are stored

on the internal disk. This disk cannot be used to st ore other

applications or data except as directed by your service

representative.

• CD drive: The CD drive is a high density, read-only, optical

laser storage device used for loading the NPS/IPS operating

system and other files. The CD-ROM drive is located in the

processor above the diskette drive.

Installation Planning Guide 2-5

Page 30

Controller components and option s

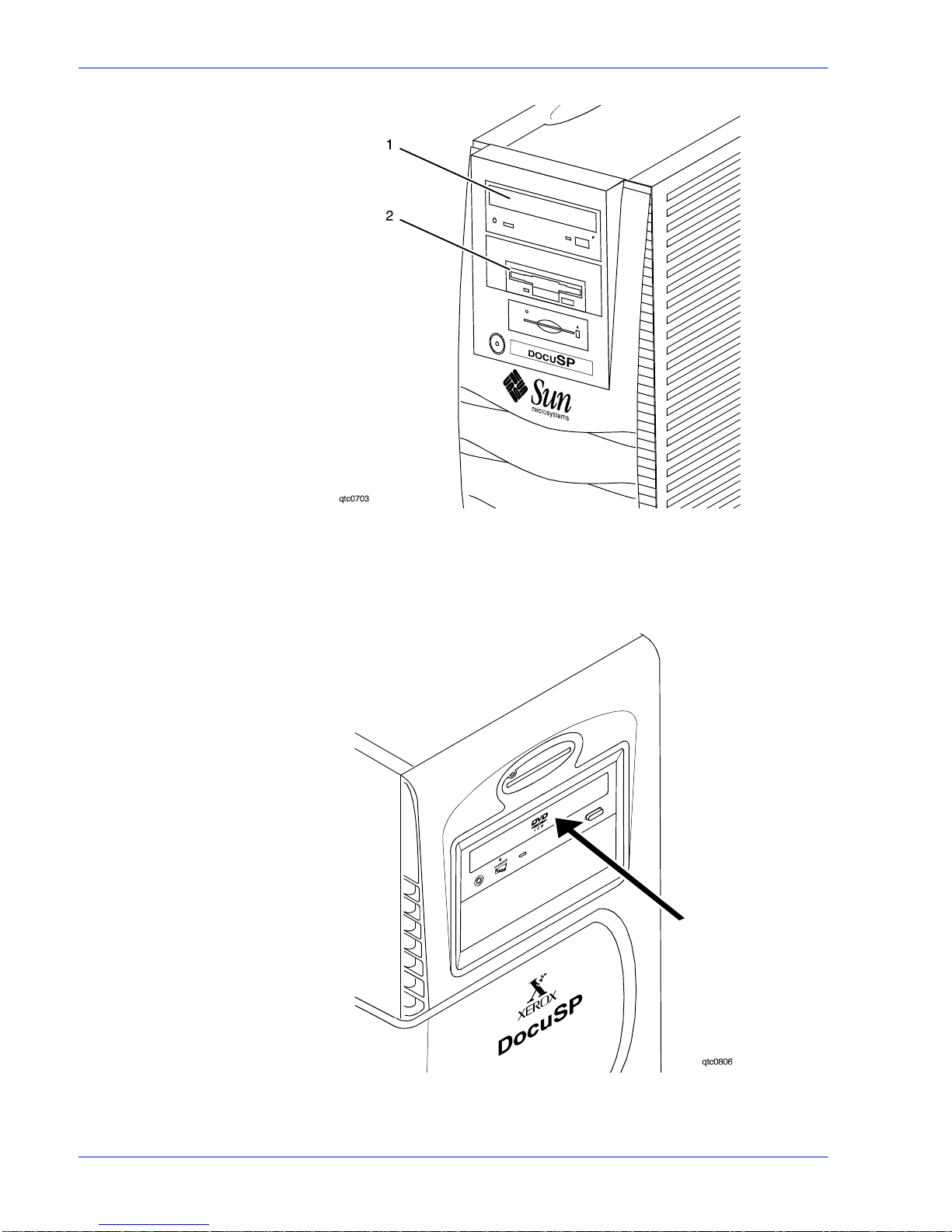

Figure 2-3 Drive locations on the Sun Blade 1000/2000 processor

1. CD drive

2. Diskette drive

2-6 Installat ion Planning Guide

Figure 2-4 DVD/CD-RW drive location on Sun Blade 2500 and Sun

W1100z processor

Page 31

Controller components and options

• Back panel: The back panel of the processor has a power

receptacle and outlet, connectors, connector openings, and

ports. The following figure shows the back panel of the

controller.

Installation Planning Guide 2- 7

Figure 2-5 Back panel of the Sun Blade 1000/2000 controller

1. Access panel lock block

2. Serial connectors A and B, DB-25

3. Parallel connector

4. SCSI connector

5. Universal serial bus (USB) connectors

(for keyboard and for mouse)

6. Twisted-pair Ethernet (TPE) connector

7. IEEE 1394 connectors

8. Fibre Channel-Arbitrated Loop (FC-AL) connector

9. Audio module headphones, line-in, line-out, and

microphone connectors

10. Graphics card / video connector (frame buffer 0)

11. PCI card slot 4

12. Graphics card / video connector (frame buffer not used)

13. PCI card slots 3 and 2

14. Power connector

15. PCI card slot 1

Page 32

Controller components and option s

Figure 2-6 Common back panel of Sun Blade 2500 and Sun W1100z

1. Parallel connector

2. Audio module headphones, line-in, line-out, and

microphone connectors

3. PCI card slots 4 and 5

4. Graphics accelerator

5. PCI card slots 0, 1, and 2

6. External UltraSCSI connector

7. Twisted-pair Ethernet

8. Serial connector

9. USB connectors (The diskette drive may be plugged into

any one of these.)

10. Power connector

Keyboard The keyboard consists of alphanumeric keys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. The keyboard is one of your

main methods of communicating with the printer. You can use the

keyboard to make selections, and to enter commands that control

functions such as requesting sample prints, or shutting down the

system.

2-8 Installat ion Planning Guide

Page 33

Controller components and options

Mouse The mouse is another main method of communicating with the

printer.

Display monitor The 17-inch LCD monitor allows you to interact with the printer

and to monitor it s interaction with the various components. During

a print job, printer er ror messages may displa y to notify you of any

unexpected conditions.

Diskette drive The external diskette drive plugs into the back panel of the

processor. Diskettes inserted into a diskette drive are used to

install font s and to load files to, and back up files f rom, the inter nal

disk drive. The diskette drive uses industry st andard 3.5 inch, 1.44

MB, double-sided, high-density diskettes.

Optional processor

components

The controller may be configured with any of the followi ng optional

components:

• Connectivity board to enable Token Ring

• Channel interface board for channel connection to a host for

online LCDS printing

• One SCSI board to connect to an external tape drive

• Graphics board:

– PGx64 (Sun Blade 1000/2000)

– XVR-100 (Sun Blade 2500)

– Creator-3D series 3 graphics board

NOTE: The PGX64 graphics board is provided as a standard

feature of the processor. If more than one connectivity option is

installed, the PGx64 board is repl aced by the Creator3D graphics

board.

Controller interface options

Online interface

Installation Planning Guide 2- 9

Your printing system may be configured for either the online

interface, the offline interface, or both.

The online (channel-attached) interface receives input directly

from any environment that supports the IBM 3211 and 4245 host

systems.

Page 34

Controller components and option s

Tape driv e option

The 36-track cartridge tape drive i s an option. Your printing

system supports the followin g tape drives for offline prin ting and

importing and exporting of resources:

• 9-track open reel tapes

• 36-track cartridge tapes

Figure 2-7 Peripheral cabinet with tape drives

1. 9-track open reel tape drive

2. 18/36-track cartridge tape drive

If you have other Xerox printing systems, you may alread y have a

peripheral cabinet that houses a 9-track open reel and an 18/36track cartridge tape drive. The DocuPrint 100/115/135/155/180

EPS supports existing peripheral cabinets, but the peripheral

cabinet option is not available with new systems.

The following 18-track tape drives are not supported:

• STK 4220 MOD 1 tape drive (3480)

• STK 4220 MOD 2 tape drive (3490)

2-10 Installation Planning Guide

Page 35

3 Printer components and

Printer components

options

The printer processes the page images received from the

controller and produce s the pri nted output. Thi s chap ter descr ibes

the components and options available for the Xerox DocuPrint

100/115/135/155/180 EPS printer.

The standard printer components are the sample tray, the purge

tray, the two processor feeder trays, and the feeder/stacker

module or modules.

The base configuration for the printer includes an inverter feeder/

stacker and one additional feeder/stacker module.

Installation Planning Guide 3-1

Figure 3-1 Printer base components

1. Processor feeder trays

2. Sample tray

3. Attention light

4. Purge tray

5. Feeder/stacker module

6. Inverter feeder/stacker module

NOTE: Some printer configurations may include a control

console (not shown).

The printer provides control buttons and displays for basic printer

functions and status information. Where available, the printer

control console displays messages and graphics that assist you

with jam clearance and printer maintenance. Labels are located

Page 36

Printer components and options

Printer configurations

throughout the printer to assist you with a variety of tasks such as

clearing a paper jam.

Refer to the Xerox DocuPrint 100/115/135/155/180 Enterprise

Printing System Operator Guide for detailed description of the

features and operation of the printer components.

The Xerox DocuPrint 100/115/135/155/180 EPS is available in

several different conf igurations, which allow you to customize the

printing system for increased e fficiency and for specialized

applications.

• Inverter feeder/stacker + 1 feeder/stacker

• Inverter feeder/stacker + 2 feeder/stackers

• Inverter feeder/stacker + 3 feeder/stackers

These configurations are illustrated below.

Figure 3-2 Printer with inverter feeder/stacker and

one feeder/stacker

Figure 3-3 Printer with inverter feeder/stacker and

two feeder/stackers

3-2 Installat ion Planning Guide

Page 37

Figure 3-4 Printer with inverter feeder/stacker and

Bypass transport option

The bypass transport option provides an interface between the

DocuPrint 100/115/135/155/180 EPS and your finishing

accessories. However, finishing devices require separate power

sources that are independent of the printing system.

The bypass transport optio n enables third party finishing devi ces

to interface directly with t he pr inti ng system. The bypass transport

allows you to customize your printer for increased efficiency and

specialized applications i n volving finishing.

Printer components and opti ons

three feeder/stackers

Function of the

bypass transport

Paper stocks

supported on

bypass transport

Bypass transport

printer

configurations

NOTE: A bypass transport must be installed for the printing

system to support a third party finishing device.

Connected to the last feeder/st acker module, the bypass transport

moves paper from the stacker to a third party finisher such as a

stitcher, booklet maker, tape binder, and so on. By making

selections on the user interface windows, you can program the

printer to send output to the byp a ss transport, which direct s the

output to the finishing equipment.

The bypass transport a ccepts all paper stocks on which the prin ter

can print, and it accommodates simplex and duplex printing.

The following printer configurations may have the bypass

transport, illustrated below:

• Printer with inverter feeder/stacker and 1 feeder/stacker

• Printer with inverter feeder/stacker and 2 feeder/stacker s

Installation Planning Guide 3- 3

Page 38

Printer components and options

Figure 3-5 Printer with inverter feeder/stacker,

one feeder/stacker, and bypass transport

Figure 3-6 Printer with inverter feeder/stacker,

two feeder/stackers, and bypass transport

Roll feeder support (DP155 and DP180 EPS only)

The roll feeder option may be installed in the inverter feeder/

stacker module, replacing the feeder tray. This option does not

require DFA or input enablement software, or any additional

hardware.

The maximum number of feeder/stacker modules supported for

this configuration is four, including the inverter module with the roll

feeder. With the two processor feeder trays, this makes a total of

six input trays possible.

3-4 Installat ion Planning Guide

Page 39

4 Prep aring for installation

This chapter assists you in preparing for the installation of your

Xerox DocuPrint 100/115/135/155/180 EPS. Use this chapter in

conjunction with the Getting Ready for Installation manual.

Preparing for inst alla tion is a responsibi lity shar ed by perso nnel at

your site and Xerox. Your Xerox representatives are available to

discuss installation issues and to assist you in completing the site

installation tasks.

Before installation, you must select and prepare an appropriate

location for the printing syst em and order supplies. This chapter

helps you accomplish these tasks by providing the following

information:

• A summary of your responsibilities and those of your Xerox

service representative

• A checklist of installation planning activities.

For information on contr oller power and spa ce requirement s, r efer

to the “Controller specific ations and requirements” chapter of thi s

guide. For facts about printer power and space requirements,

refer to the “Printer specifications and requirements” chapter of

this guide.

Responsibilities

This section describes your site responsibilities and the

responsibilities of your service representatives. Some joint

responsibilities are included.

Installation Planning Guide 4-1

Page 40

Preparing for installation

Xerox responsibilities

This section list s the respon sibili ties of t he service r epresent atives

and systems analysts before, duri ng, and after installati on:

• Site selection

– Assist in site selection

– Inspect and approve the site

• Installation

– Schedule the delivery of the hardware

– Monitor installation activities

– Assist you in ordering any supplies requi red

– Install the printing system

– Install LCDS system resource files, if applicable

•Training

– Provide initial operator training

– Provide information an d assist ance in regi stering for Xe rox

Customer Education classes

• Service

– Review preventive maintenance schedules and service

call procedures

– Provide ongoing maintenance

– Assist in resolving hardware and software problems

– Obtain software licenses as appropriate

Customer responsibilities

Your responsibilities before, during, and after inst allation of the

DocuPrint printing system are to schedule and monitor your

installation activities. Refer to the installation planning checklist in

this chapter for a complete list of responsibilities.

Refer to the “Xerox support services” appendix for information on

services designed to support you before, during, and after your

installation.

NOTE: Operating system software is not the same for all printing

systems. Therefore, make sure that your system specialists are

familiar with the operating syst em software that is specifi c to your

DocuPrint system. If your system specialists are familiar with one

operating systems and you are converting to, or adding another,

they should be familiar with the differences.

Site personnel Identify the person (or persons) at your site who will be the

4-2 Installat ion Planning Guide

primary interface with Xerox.

Page 41

Preparing for inst allation

After the installation of the printing system, there are a few

ongoing tasks that must be performed. These tasks may include

all or some of the following:

• Meter reading and reporting

• Overseeing routine maintenance

• Placing service calls for hardware problems

• Ordering additional documentation, software, or fonts

• Arranging additional operator training

• Maintaining an adequate inventory of consumable supplies.

It is your responsibility to designate a person (or persons) to

perform these tasks.

Operator and

systems training

Site preparation Select and prepare the site for system installation (including

Network install ation Install the necessary network components required to connect

Channel-attached

printing

Client workstations Make sure all client workstations that will be submitting print jobs

Applications Work with your Xerox systems analyst to determine requi rements

Select personnel for operator and systems training and set up a

training schedule.

proper power, air conditioning, and work space). If connecting to

other equipment, obtain the necessary interfaces, cables,

transceivers, phone lines, and so forth.

client workstations to the printing system. Refer to the Getting

Ready for Installation manual for details.

Obtain and install fully populated bus and tag cables required to

connect the host to the printing system. Refer to the Getting

Ready for Installation manual for details.

have the proper hardware, operating system, and networking

software required by the print ing system as client platforms.

for initial applications.

Installation planning checklist

Installation Planning Guide 4- 3

To aid you in planning for printer installation, the following

checklist contains the tasks that you and your service

representative must complete before installation. If you have

questions about any of these activities, contact your sales or

service representative.

Use the time frames in this checklist as guidelines. It is best to

consult your suppliers to determine the required lead times.

Page 42

Preparing for installation

Table 4-1 Installation planning checklist

Week Activity Responsibility

Date

completed

-4 • Select location for the printing system.

• Order additional sets of documentation, as

necessary.

• Register for Xerox Customer Education classes

and order tutorials, as necessary.

• Schedule printer delivery.

-3 • Schedu le har dwa re deliver y.

• Prepare site:

• Ensure proper electrical outlets are installed.

• Install network to system location, if applicable.

• Install channel to system location, if applicable.

Cables must be fully populated.

• Ensure proper operating environment.

-2 • Inspect and approve site.

• Order consumable supplies. Minimum supplies

needed for installation:

• Pa per (2 cartons )

• Developer (1 carton)

• Fuser agent (2 boxes)

• Dry ink (1 carton)

• After installation, you will need to establish a

procedure for ordering supplies according to

your ongoing production requirements.

Customer

Customer

Customer and Xerox

Xerox

Customer and Xerox

Customer

Xerox

Customer and Xerox

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

-1 • Schedu le oper a tor trainin g. Customer and Xerox _________

Install Ensure supplies are available.

Ensure system administrators are available during

Customer

Customer

_________

_________

software installation.

Provide applicable completed worksheets from the

Customer

_________

Getting Ready for Installation document.

If the NPS/IPS Extension option is being installed,

provide applicable information as directed in the 96/

4635/180 NPS/IPS Installation Pl ann ing Guid e.

Install printing system hardware and software.

Have operators available for training.

Check documentation and software kits for

completeness.

Xerox

Customer

Customer

_________

_________

_________

Have test jobs ready to run.

Provide stocks needed fo r default input

configuration.

Customer

Customer

_________

_________

Obtain and enable software license.

Customer

_________

4-4 Installat ion Planning Guide

Page 43

Preparing for inst allation

Week Activity Responsibility

Date

completed

Post-install Become familiar with support services available.

Establish supplies maintenance procedure.

Provide ongoing system maintenance.

Adjust the printer alignment and magnification.

Order additional documentation, as necessary.

.

Connectivity requirements

An Ethernet local area network (LAN) running Transmission

Control Protocol/Internet Protocol (TCP/IP), AppleTalk, or Novell

NetWare software is the network communication system used to

transport documents from the client workstation to the printing

system.

Ethernet specifications

Customer

Customer

Customer and

Xerox

Xerox

Customer

_________

_________

_________

_________

_________

The Ethernet connection to the controller processor must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

The Ethernet interface on the controlle r processor is a 10 Mb/sec

twisted pair standard (10BaseT, 100BaseT, and 1000BaseT).

Attachment Unit Interface (AUI) Coax Ethernet is enabled with an

adapter cable.

Work with your system administrator to assess what type of

network you have and what modifications need to be made to

supply an Ethernet connector to the controller processor.

Token Ring specifications

Users of network client workstations may send print jobs to the

printer using TCP/IP, Novell 3.x, or Apple Talk network protocol.

The Token Ring connection to the controller processor must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

The controller processor has a 4 MB or 16 MB Token Ring Auto

interface (16 MB is preferred).

Installation Planning Guide 4- 5

Page 44

Preparing for installation

Channel-attached specifica tions

For an online configuration with an I BM host system, t he foll owing

cables must be available:

• Bus and tag cables (bus in, bus out, t ag in, tag out)

• Terminators (as necessary, due to location on channel).

For your convenience, you may be able to order the bus and tag

cables through Xerox on a purchase-only basis. Cont act your

Xerox sales representative for availability, current pricing, and

order information.

4-6 Installat ion Planning Guide

Page 45

5 Controller requirements

Power requirements

and specifications

This chapter provides power and space requirements for the

controller. It also provides controller environmental specificati ons.

For facts about pri nter power and s pace requirement s, refer to the

“Printer specifications and requi rements” chapter of this guide.

Your controller has important power requirements that must be

accommodated. These requirements are summarized in the table

below.

For details on printer power requirements, refer to the “Printer

specifications and requirements” chapter of this guide.

Table 5-1 Controller electrical requirements

Sun and

Sun Blade

controller

60 HZ 100 to 240

50 HZ 100 to 240

Table 5-2

Agency certification: UL 1950, IEC 950, CSA 22.2 #950-1950,

FCC (Class A), and EN 55022: 1998 (Clas s A), and EN 61000-3 -2

(or EN 61000-4-2,3,4,5,6,8,11): 1995 + A1-1998 + AZ 1998,

EN6100-3-3: 1995 and EN 55024: 1998.

Outlet configurations

Voltage Amp service KVA rating NEMA

15 amp 0.4 KVA 5-15R

VAC

15 amp 0.4 KVA N/A

VAC

Installation Planning Guide 5-1

This section discusses specific ations for system outlets and the

required wall outlet configurations f or the USA / Canada and

internationally.

Page 46

Controller requirements and specifications

N

USA/Canada

Supply

NOTE: All power outlets must be dedicated to this equipment.

When determining the electrical connections for printing system,

make sure that:

-Each power cord has a separate circuit.

-The printer power cord configurati ons match your receptacle.

-Your electrical outlets are within the required specifications.

50 Hz systems: Ensure that power connections are per local

codes/regulations.

The following figure shows American, Canadian, and European

wall outlets in which to plug the controller.

NOTE: The optional 9 track and 18/36 track tape drives each

require an outlet identical to the one that is shown for the

controller.

AC Neutral

(ACN)

eutral

AC Hot (ACH)

Earth Ground (GND)

United Kingdom

Europe

Earth

Earth

Live

Figure 5-1 Multinational wall outlet c onfigurations

The required wall outlet voltages for USA / Canada, United

Kingdom, and the rest of Europe are as follows:

5-2 Installat ion Planning Guide

• USA / Canada: The voltage at the wall outl et is 100 to 120

VAC between AC hot and neutral, and between AC hot and

GND. The voltage is less than three VAC between GND and

neutral.

• United Kingdom: The voltage at the wall receptacle is 200 to

240 VAC between live and neutral, and between live and

earth. The voltage is less than three VAC between earth and

neutral.

• Europe: The voltage at the wall recept acle is 200 to 240 VAC

between supply pins. The volt age be tween one suppl y pin and

Page 47

earth is 200 to 240 VAC. The voltage between the other

supply pin and earth is less than 3 VAC.

Refer to the controller electrical requirements table earlier in this

chapter for a description of the power specifications for the

controller.

WARNING: To reduce the risk of electrical shock, do not plug

components into any other type of power system. Contact your

facilities manager or a qual ified el ectrician i f you are not sure what

type of power is supplied to your work area.

Environmental specifications

The controller is a sturdy piece of equipment; however, like any

piece of electronic equipment, it must be treated properly. Avoid

extremes in temperature and other environmental hazards. Place

the controller in a rel ativel y du st-fr ee ar ea that i s well -venti lated t o

avoid overheating.

Controller requirements and specifications

Space requirements

Controller placement

In general, if your wor king envi ronment i s comfor t abl e fo r yo u, it is

suitable for your controller. The following sections define the

acceptable environmental ranges for the controller models with

which your system may be configured.

For recommended environmental ran ges for the pri nter work area,

refer to the “Printer specifications and requirements” chapter of

this guide.

This section provides recommendations for placement of

controller hardware components.

For printer component space requirements, refer to the “Printer

specifications and requirements” chapter of this guide. Cont act

your service representative if you have questions not specificall y

addressed in this guide.

Installation Planning Guide 5- 3

WARNING: The controller must be positioned within the line-ofsight of the printer for safety purposes while servicing the

equipment.

The controller components are place d in the accompanying

controller stand. You should consider the following factors when

deciding where to place the controller and stand:

• There should be at least 36 inches / 15.2 cm of clearance on

Page 48

Controller requirements and specifications

all sides of the controller stand.

• Adequate work space and service clearance around the

equipment

• Proximity to electrical and network connectors

• Security of the work area. You may need to place the system

in an area where you can restrict access to it.

Guidelines for controller placement

To ensure consistent performance and avoid any damage to

equipment, follow these rules for placi ng the components of the

controller.

Do:

• Use the controller stand that comes with your printing system

equipment.

• Allow at least 6 inches / 152 mm of unobstructed space at the

front and rear of the processor, so the fan and vents are not

blocked.

The following illustration shows fa n and vent locations on the

front and back of the processor.

Do not:

• Place the monitor and processor on a desk or table top.

• Do not place the monitor on top of the processor.

• Do not allow any piece of equipment to blow warm air into the

air intake vents of the pr ocessor.

• Do not place the processor on its side, or i n any other posit ion

but the upright, vertical position achieved by using the

controller stand.

• Do not place the processor or monitor on top of the printer.

Controller hardware specifications and requirements summary

For a summary of printer hardware specifications and

requirements, refer to the “Printer specifications and

requirements” chapter of this guide. Contact your local Xerox